Patents

Literature

39results about How to "Guaranteed insulation reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

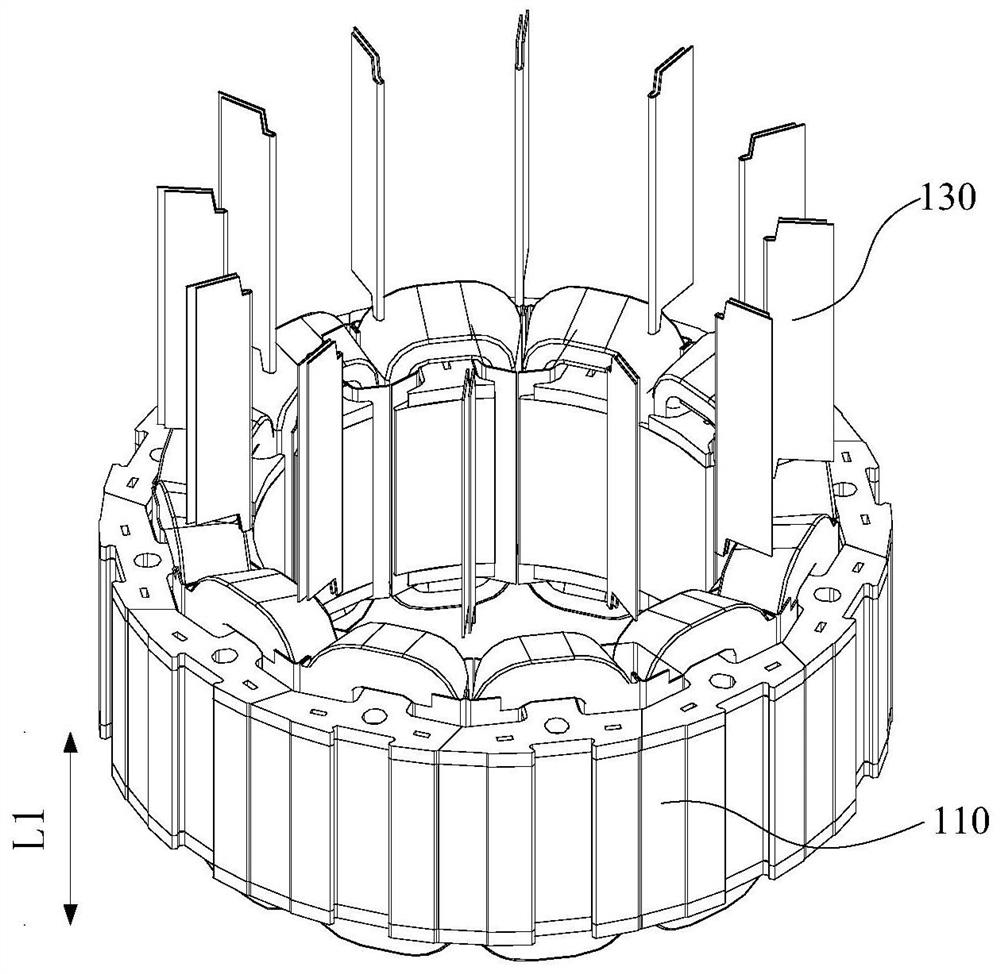

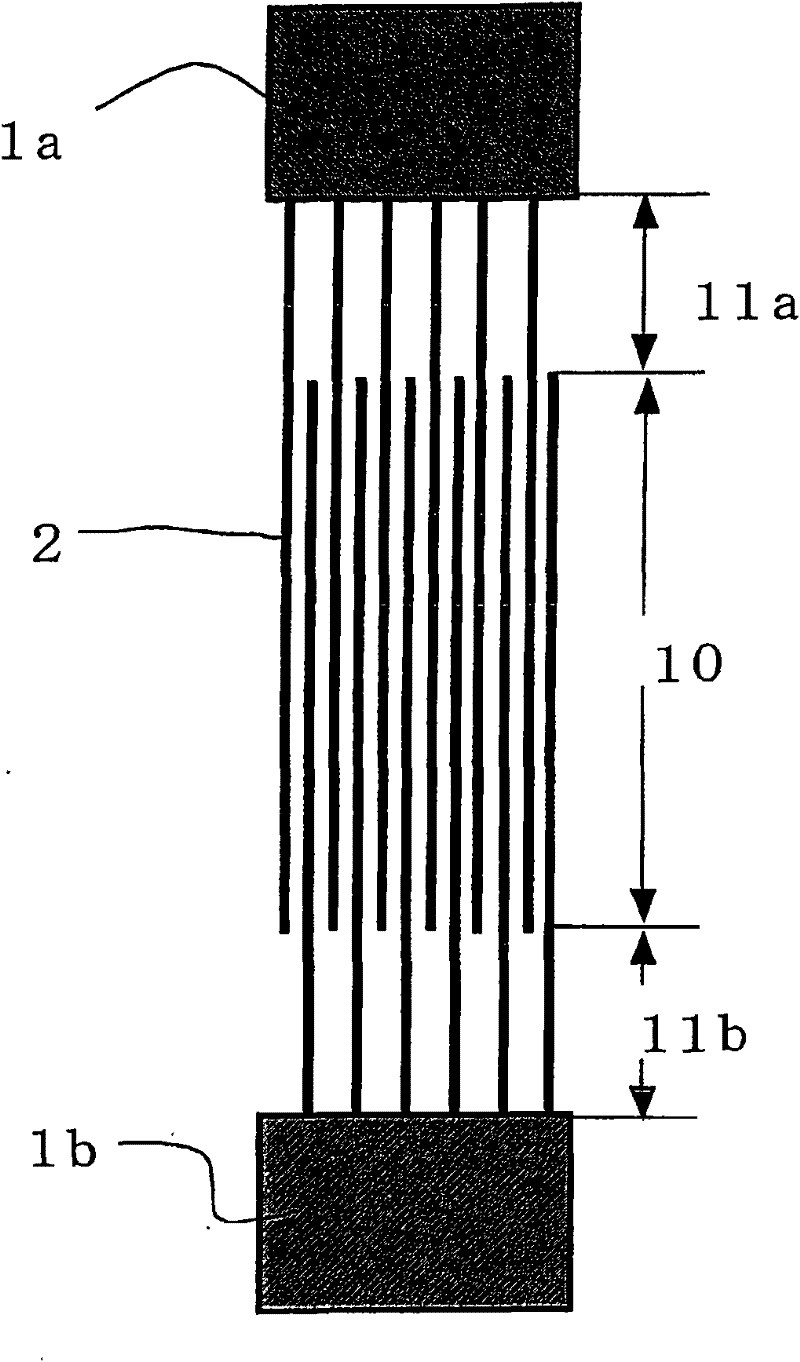

Direct drive permanent magnet wind generator, direct drive permanent magnet wind generator system and stator of direct drive permanent magnet wind generator

ActiveCN104600886AReduce risk of erosionGuaranteed insulation reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringTurbine

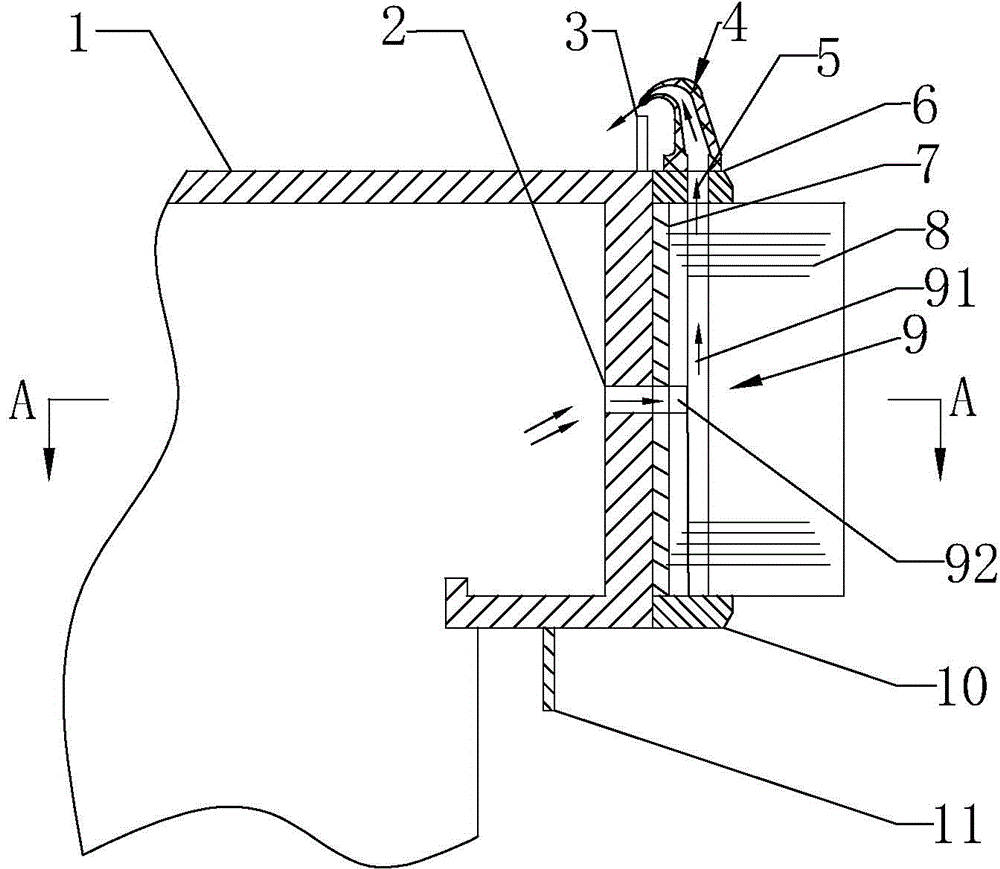

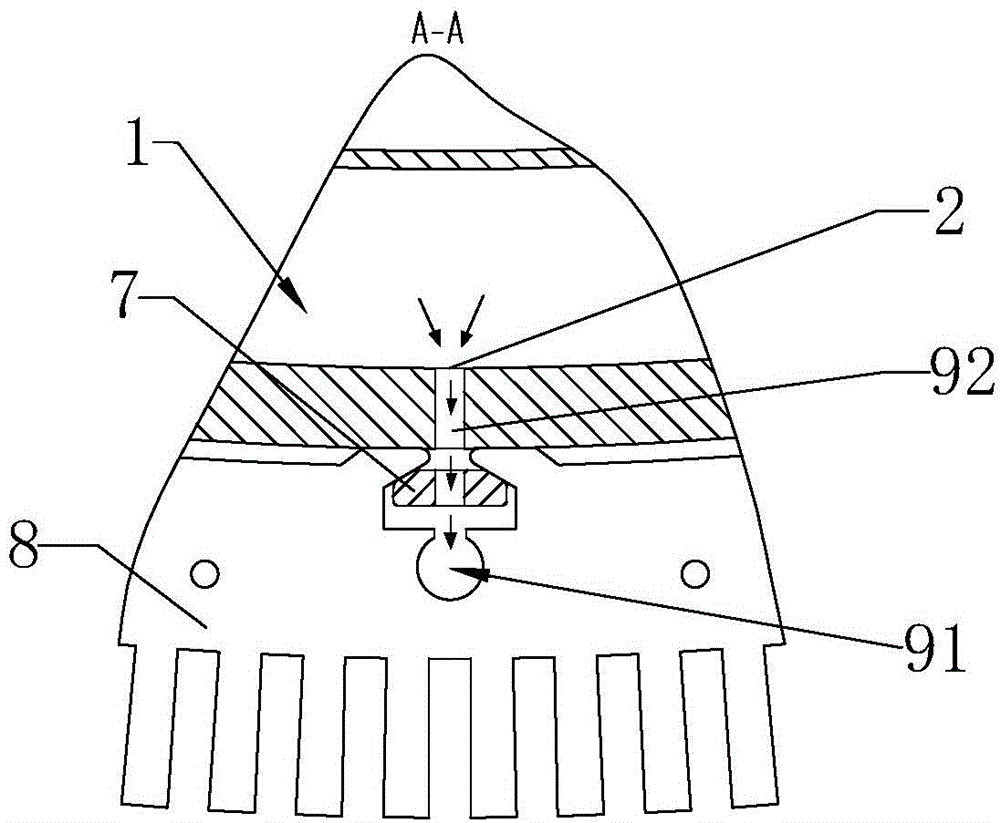

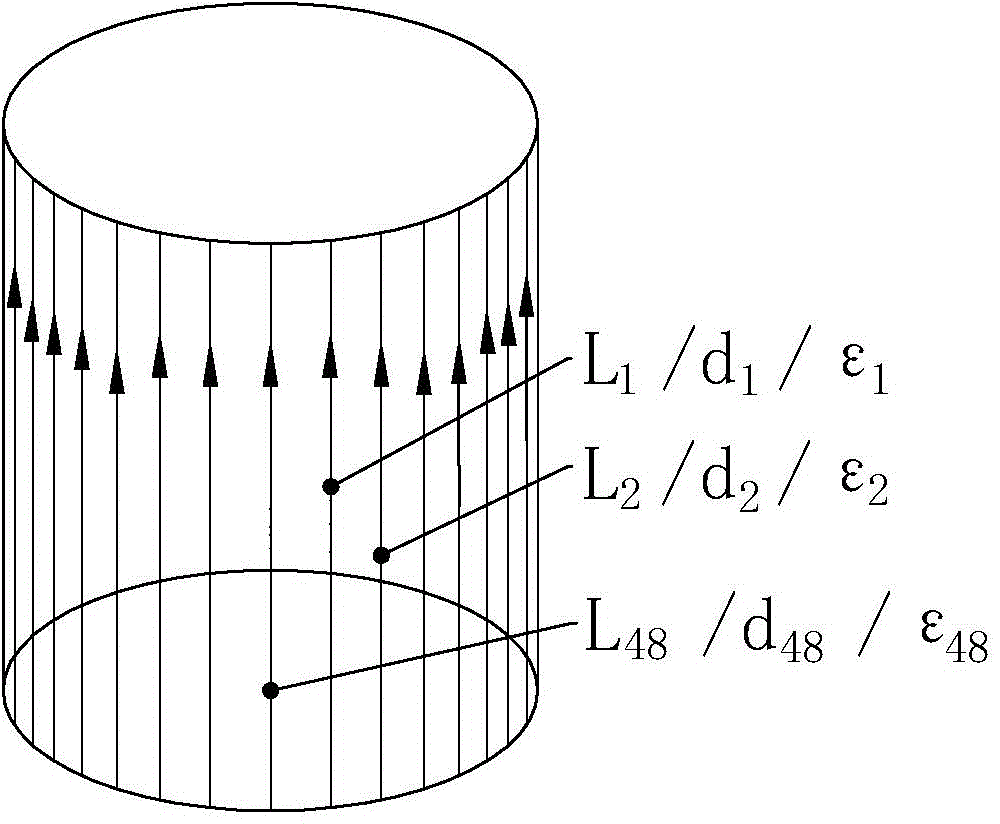

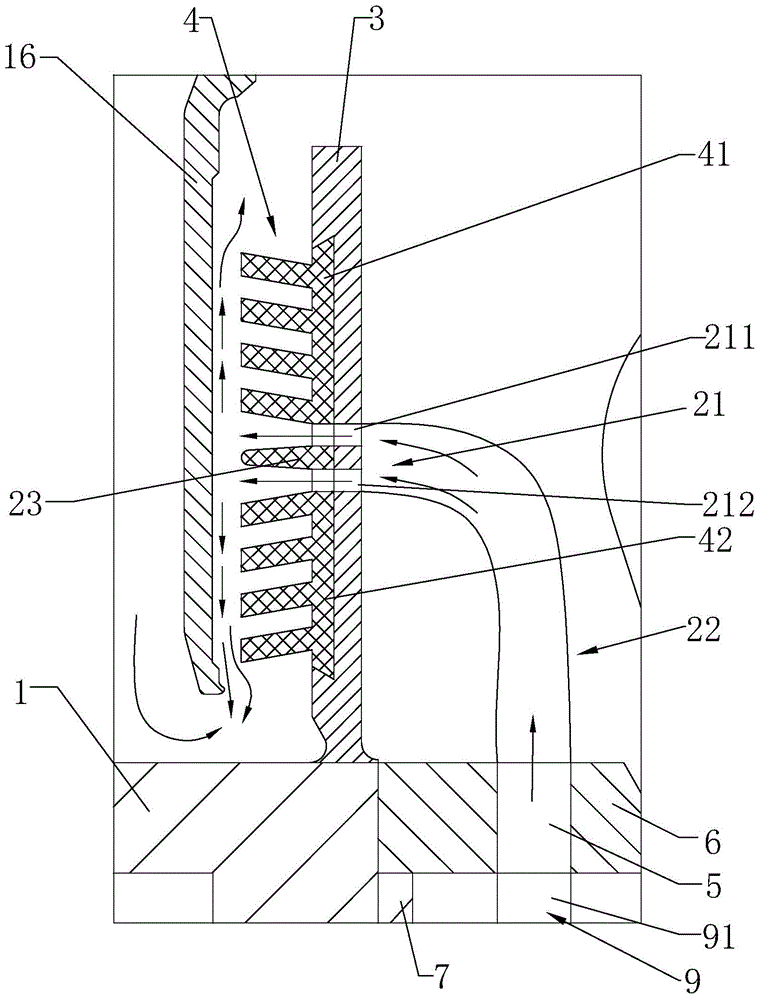

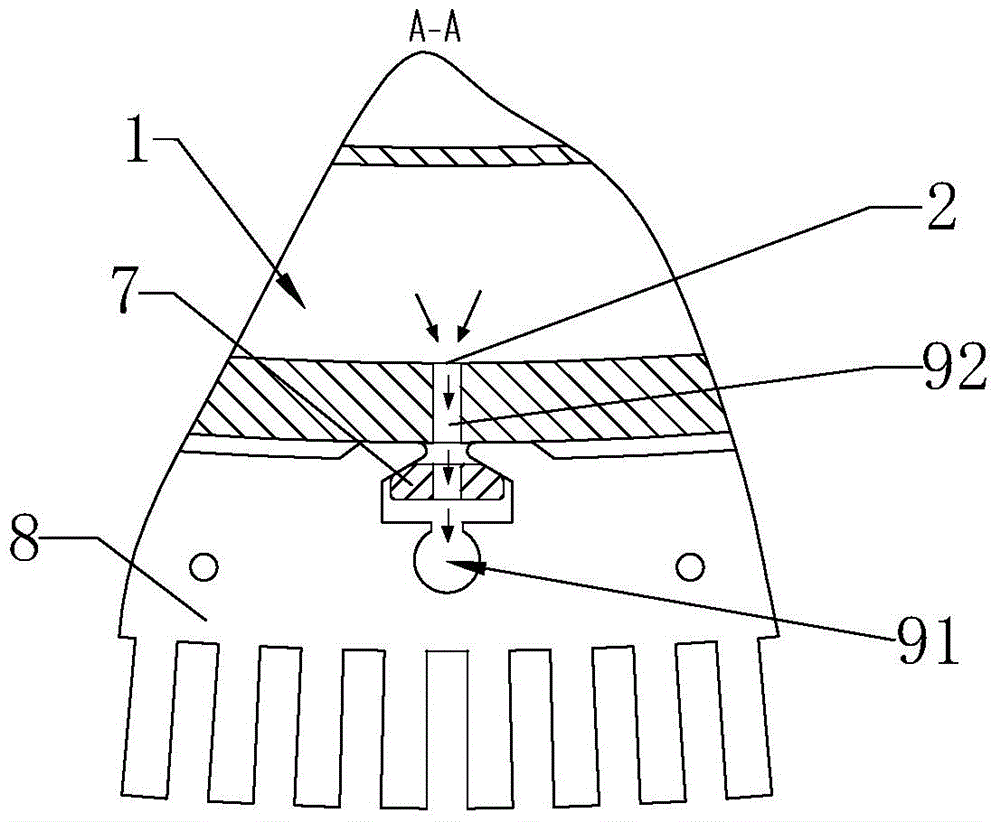

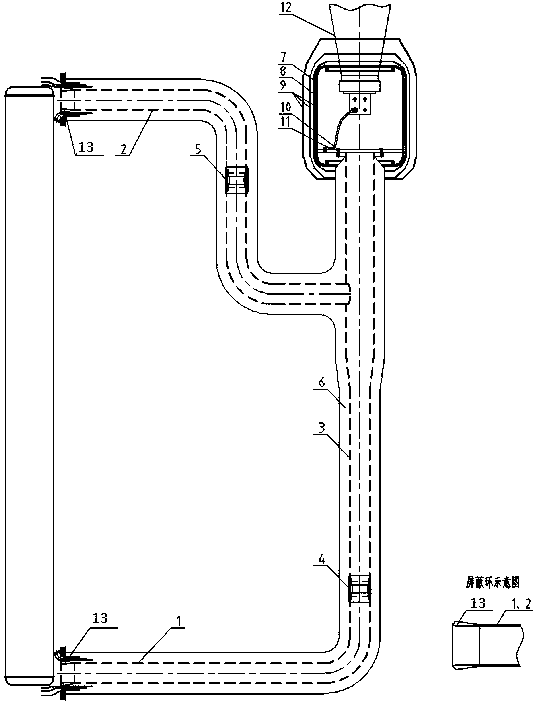

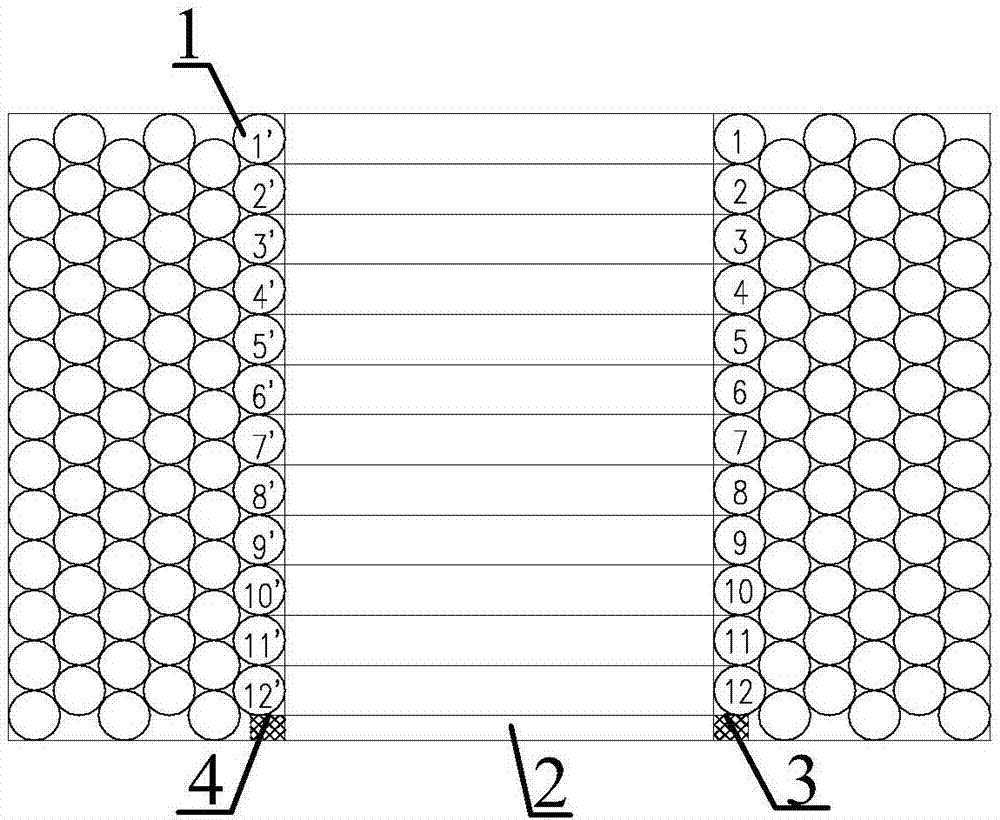

The invention provides a direct drive permanent magnet wind generator, a direct drive permanent magnet wind generator system and a stator of the direct drive permanent magnet wind generator. The stator comprises a stator support, a stator iron core arranged on the peripheral wall of the stator support, and a paddle side tooth support, wherein the paddle side tooth support is arranged on the paddle side axial end face of the stator iron core, at least one air hole is formed in the peripheral wall of the stator support, and at least one second air hole is formed in the paddle side tooth support. The stator further comprises at least one air flow passageway used for communicating the first air holes with the second air holes, wherein the air flow passageways penetrate through the stator iron core. The micro-positive pressure technology is used in the stator and a rotor of the airborne wind turbine, and therefore a motor can dry itself in a self-adaption mode, external severe air flow is prevented from entering the motor, the service life of permanent magnet poles is prolonged, the insulation level reduction of devices inside the motor is prevented, the risk that the motor is corroded by severe air flow is lowered, and the insulation reliability is improved.

Owner:XINJIANG GOLDWIND SCI & TECH

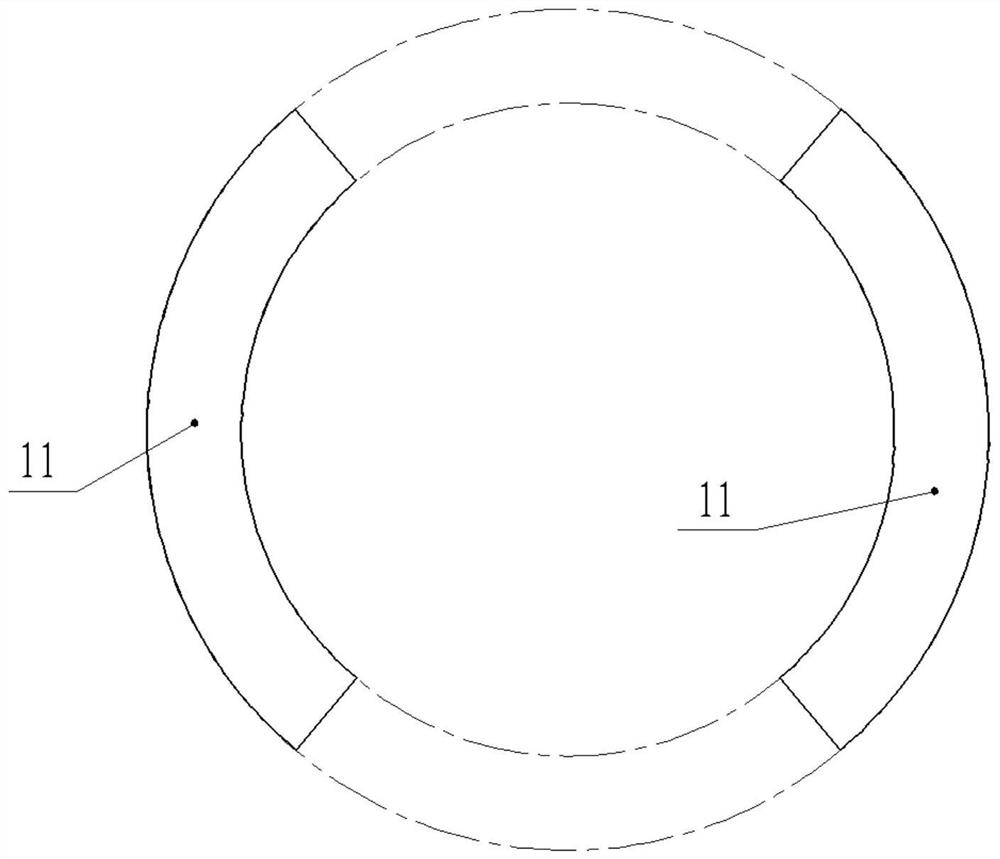

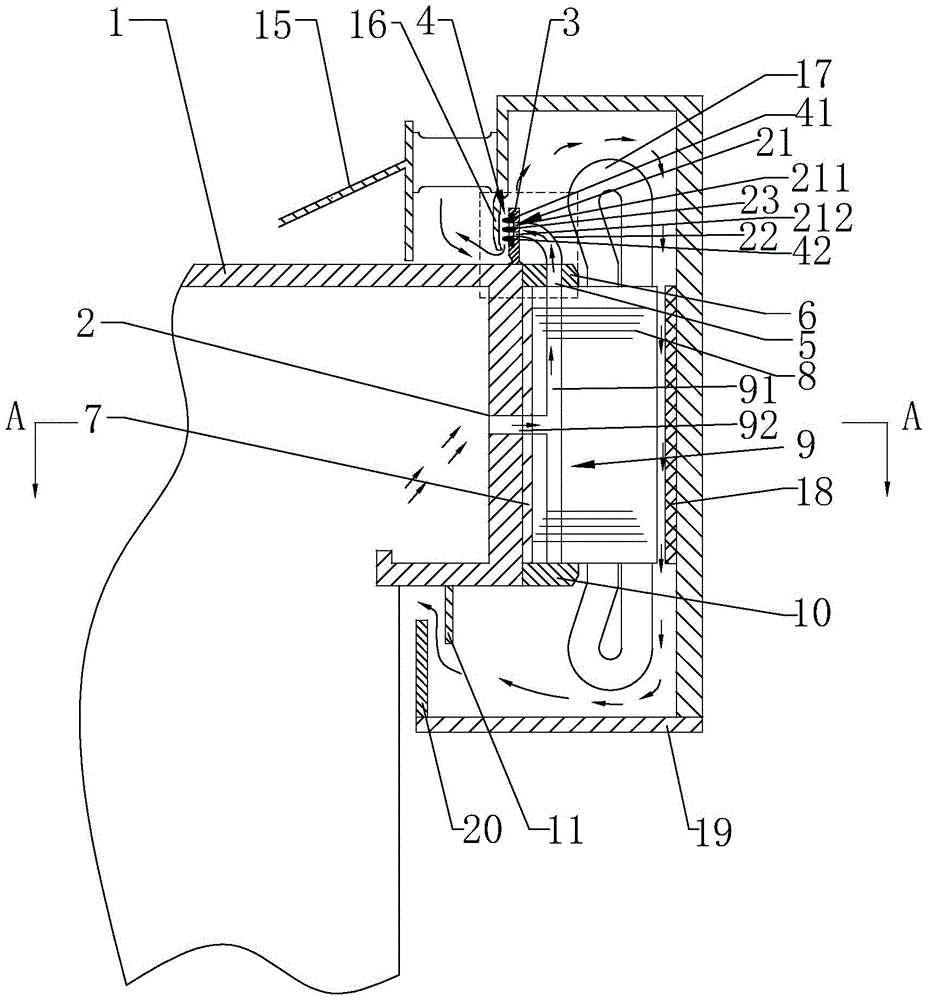

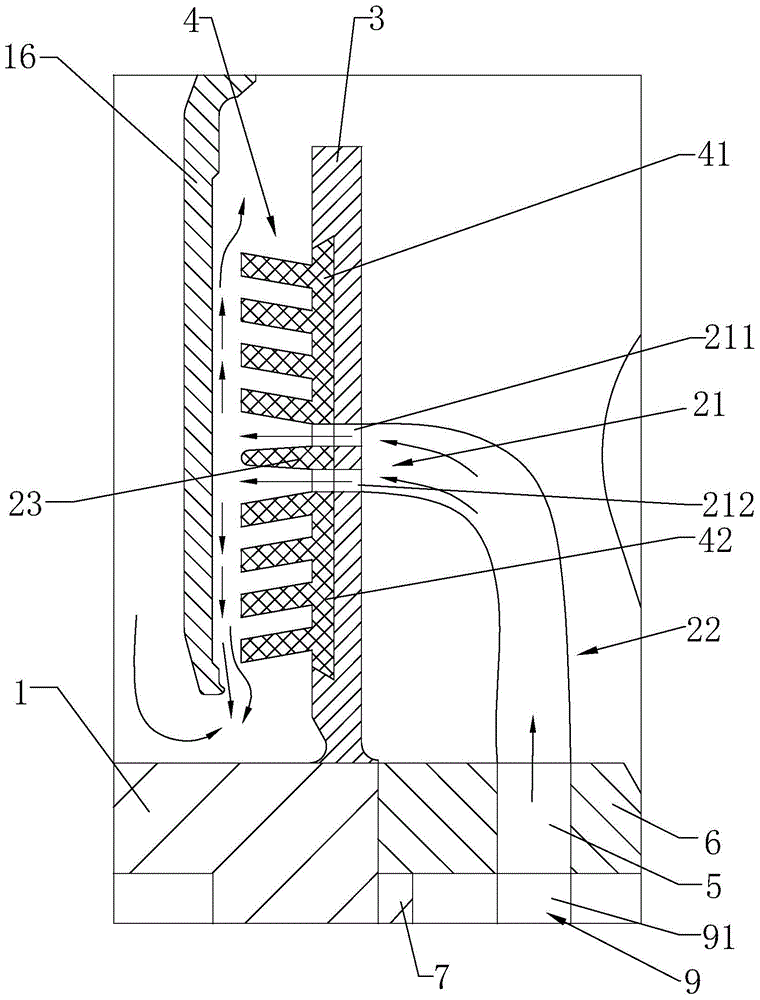

Permanent magnet direct-drive wind-powered generator, system and stator thereof

ActiveCN104810942AReduce risk of erosionGuaranteed insulation reliabilityEngine sealsMagnetic circuit stationary partsPropellerEngineering

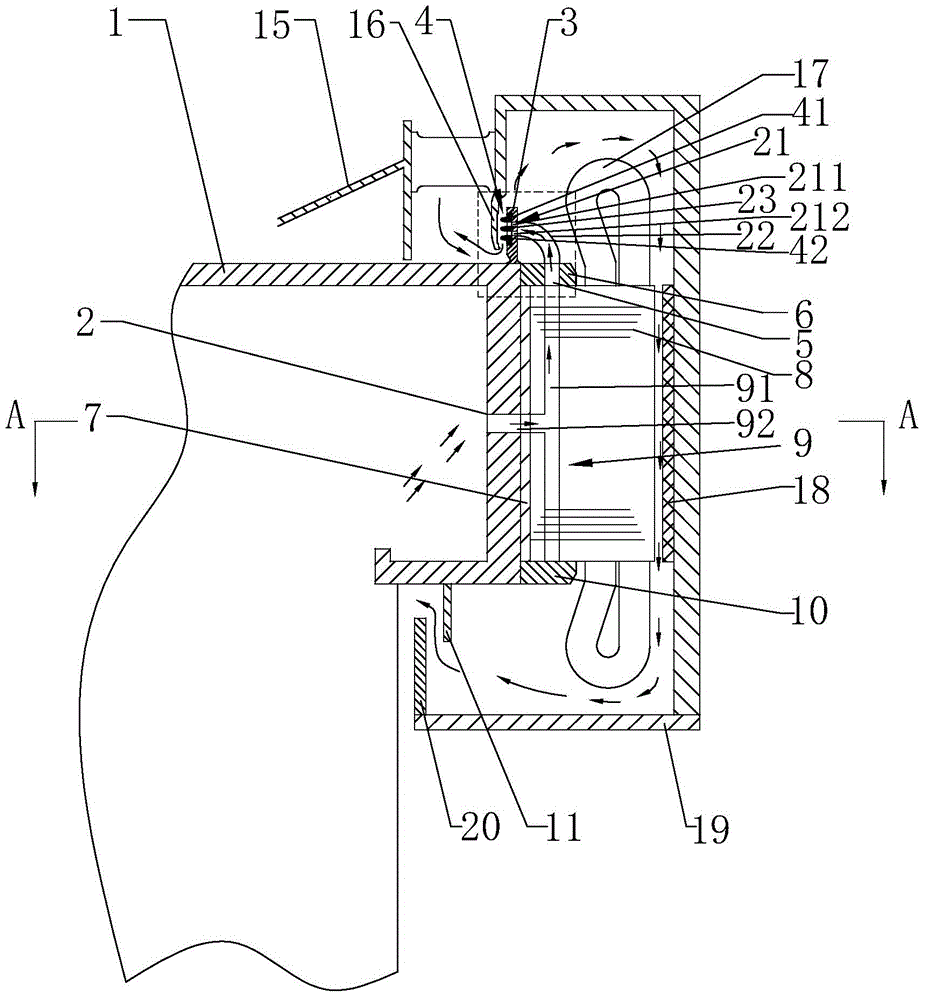

The invention provides a permanent magnet direct-drive wind-powered generator, system and stator thereof. The stator comprises a stator bracket, a stator iron core, a propeller side gear pressing plate and a propeller side enclosing plate; the propeller side gear pressing plate is arranged on the axial end surface of propeller side of the stator iron core; a first air hole is formed in the peripheral wall of the stator bracket; a second air hole is formed in the propeller side gear pressing plate; the stator further comprises an air channel for communicating the first air hole with the second air hole; the air channel passes through the inner part of the stator iron core; a comb teeth air feeding hole is formed in the propeller side enclosing plate and is connected with the second air hole through an air guide tube; a first spiral comb teeth structure is annular in the whole appearance and is communicated with the comb teeth air feeding hole is arranged on the propeller side enclosing plate; first spiral comb teeth are positioned in annular gaps formed by the propeller side enclosing plate and a rotor sealing ring. According to the technical scheme, the rotor has the advantage that the multi-phase airflow sealing can be performed for the annular gap between the propeller side enclosing plate and the rotor sealing ring.

Owner:XINJIANG GOLDWIND SCI & TECH

Epoxy resin composite insulating material and preparation method thereof

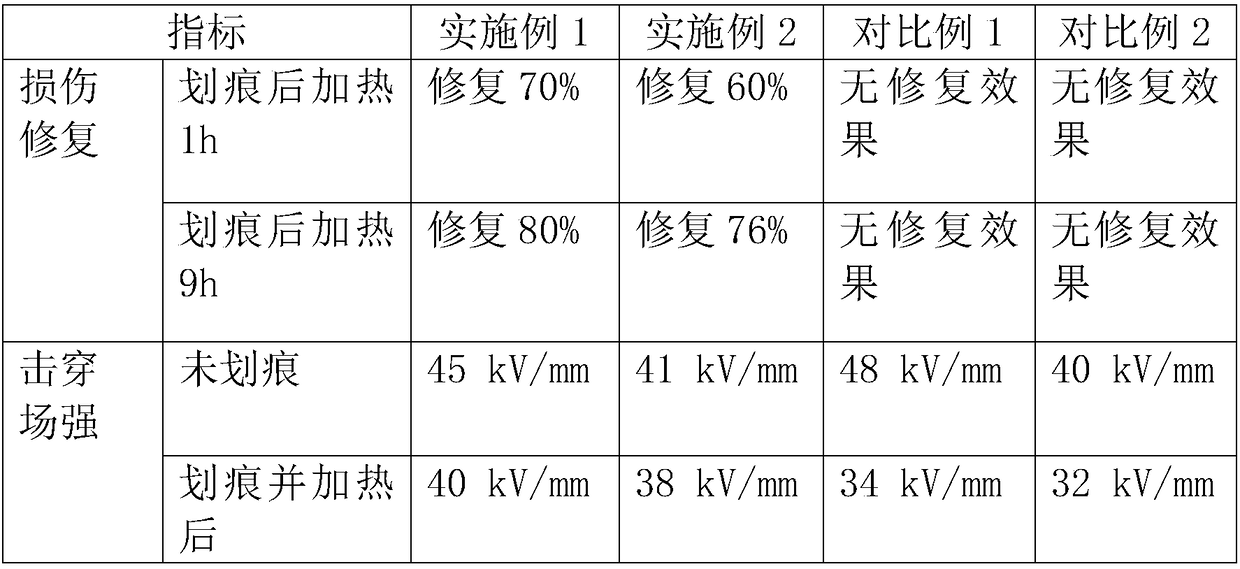

InactiveCN109294166AStable electrical insulationExtend your lifeMicroballoon preparationMicrocapsule preparationChemical compositionRuthenium

The invention provides an epoxy resin composite insulating material and a preparation method thereof. The epoxy resin composite insulating material is formed by preparing microcapsules, a ruthenium carbene complex catalyst, and a component including at least a bisphenol A type epoxy resin, a first curing agent, a curing accelerator, and a toughening agent. The microcapsules are formed by preparinga urea-formaldehyde resin performed polymer composition and a core material composition in the presence of a second curing agent and a modifier, the urea-formaldehyde resin performed polymer composition is formed by stirring and heating urea, formaldehyde and deionized water under alkaline conditions, and the core material composition is formed by stirring an emulsifier, dicyclopentadiene and deionized water under heating condition. The epoxy resin composite insulating material has the ability to self-repair when damaged.

Owner:CHONGQING UNIV

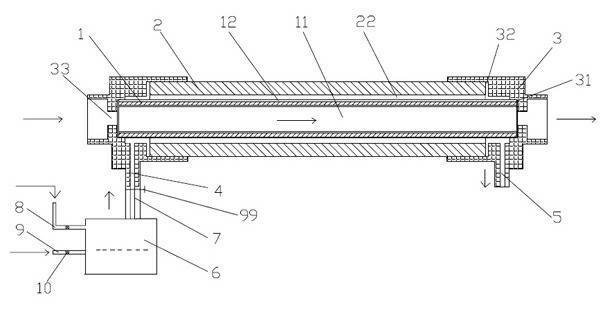

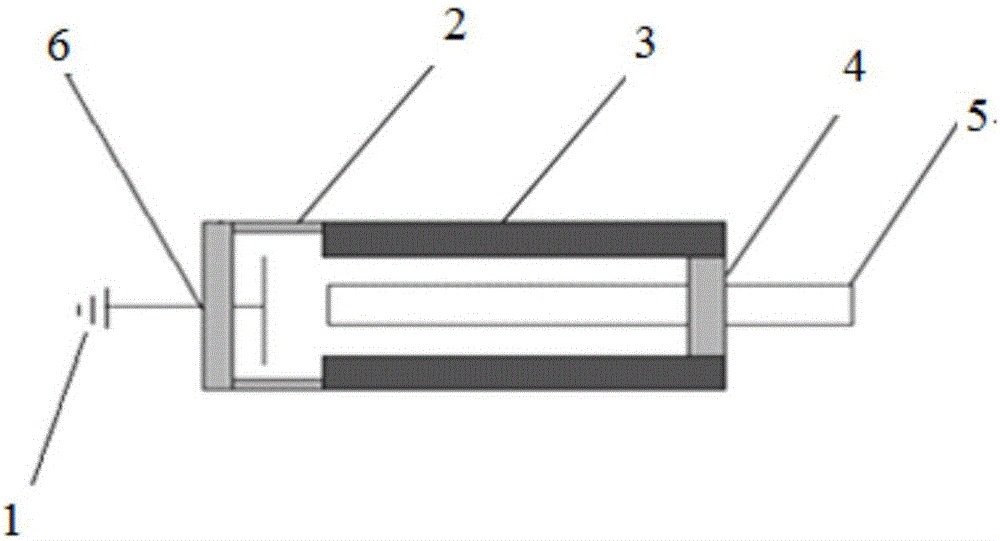

High-energy multi-state low-temperature ionizer

InactiveCN102333412AAvoid burningGuaranteed insulation performancePlasma techniqueIonizationHigh energy

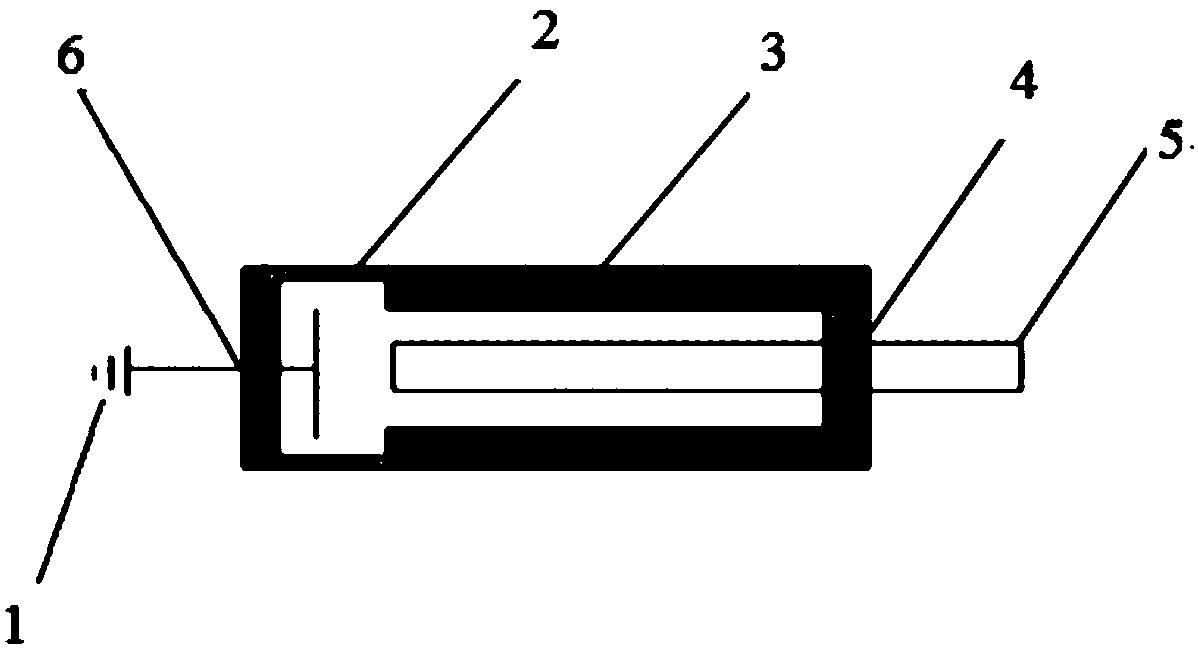

The invention discloses a high-energy multi-state low-temperature ionizer, comprising an internal electrode and an external electrode, wherein the internal electrode and the external electrode are respectively connected with a power supply. The internal electrode and the external electrode are both tubular structures, and a hollow cavity of the internal electrode is a cooling channel; two ends of the internal electrode and two ends of the external electrode are respectively provided with an electrode support, and the two ends of the internal electrode and the two ends of the external electrode are respectively fixed on the electrode support; the internal electrode is sleeved in the external electrode, and an ionization channel is formed between the external surface of the internal electrode and the internal surface of the external electrode; two ends of the ionization channel are respectively provided with an aerial fog input port and an aerial fog output port, and the aerial fog input port and the aerial fog output port are respectively communicated with the ionization channel. The ionizer provided by the invention is simple in structure and convenient to use, the cooling channel is formed at the center of the internal electrode, when working, the cooling channel can cool the ionization channel so as to generate a large amount of low-temperature plasmas, the cooling effect is better, and the generated plasmas have high energy charge.

Owner:陈固明 +1

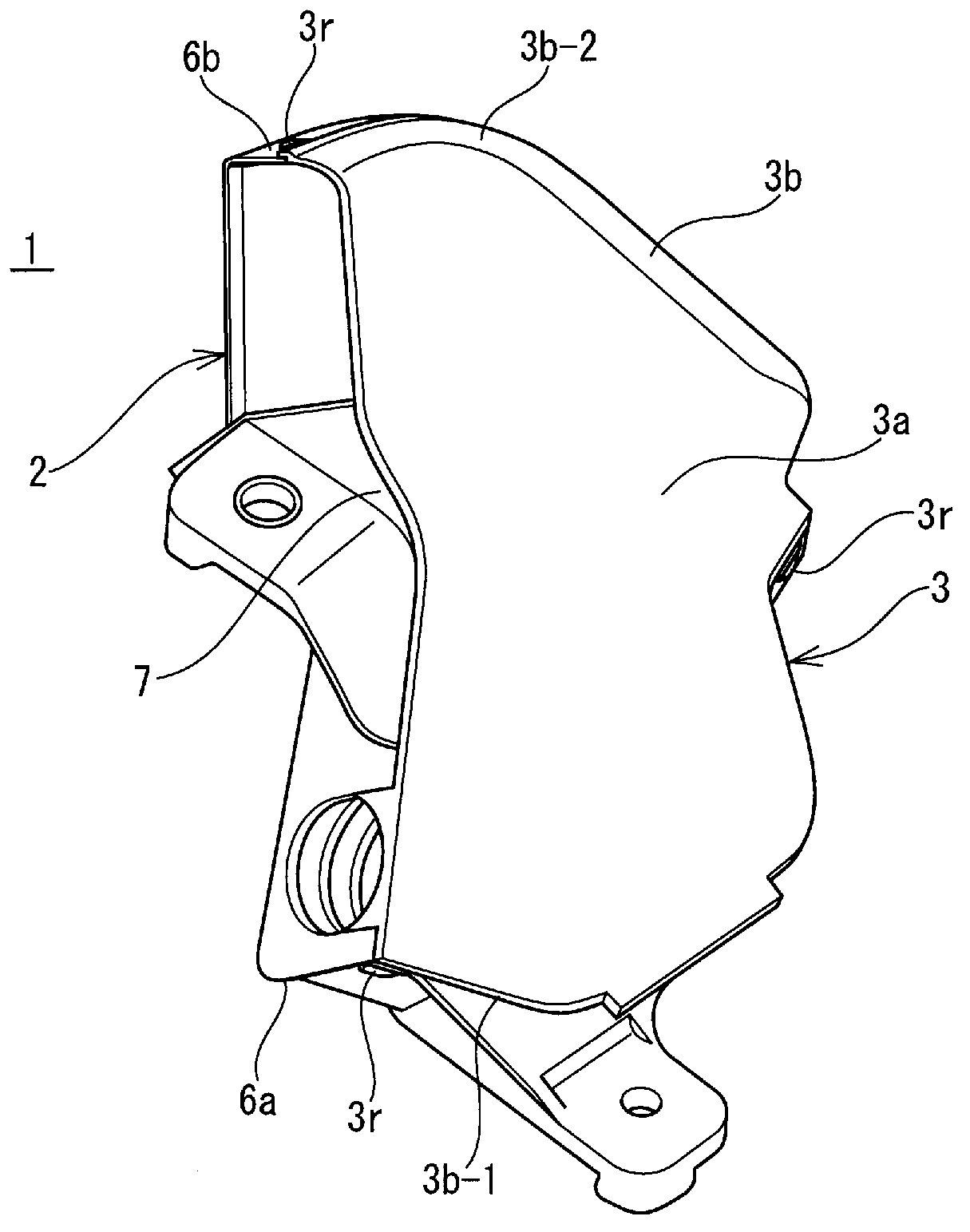

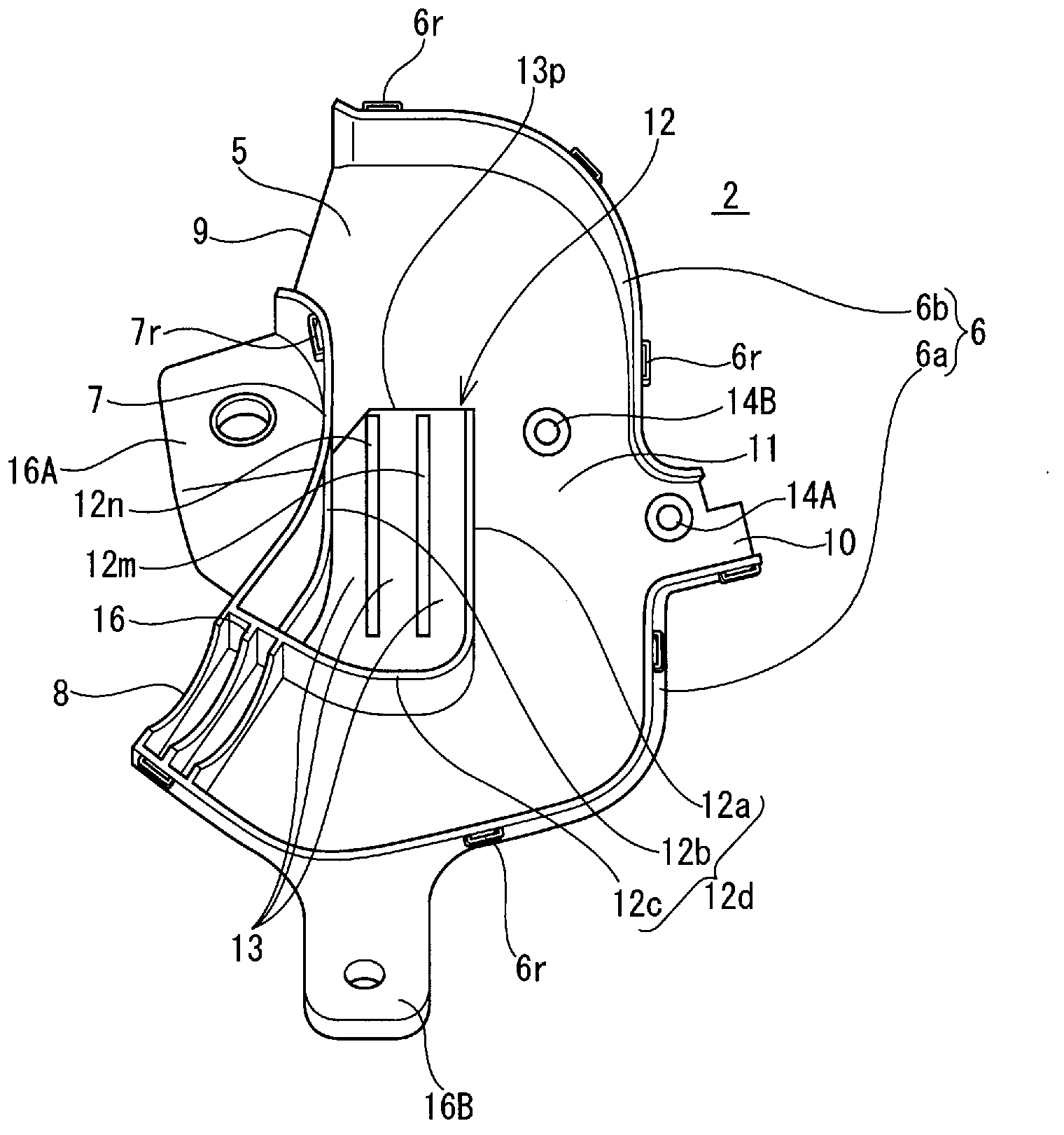

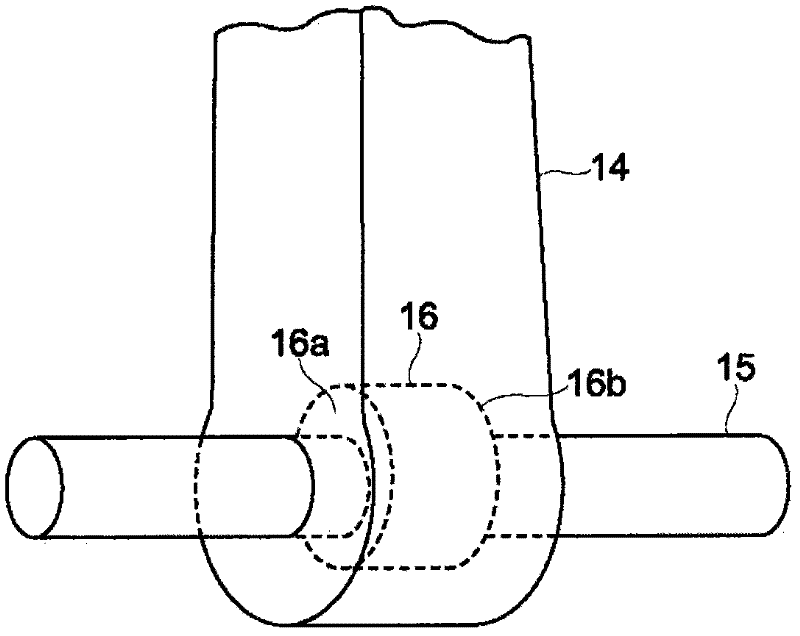

Wire harness protector

InactiveCN103329377AGuaranteed insulation reliabilityAccommodate effectivelyConnection end capsElectric/fluid circuitEngineeringOverwrap

The present invention enables many splices to be housed inside a protector provided on the outside of a wire harness. A splice housing part protrudes from a bottom wall into a side space of a main wire harness passage enclosed by the bottom wall and peripheral walls of the body of the protector. The splice housing part is provided with partition walls erected at regular intervals, and a blocking wall on one side of the partition walls. A plurality of splice chambers, which are sandwiched by the partition walls, are provided in a row, and the side facing the blocking wall of each splice chamber serves as an insertion opening. Each splice chamber: is set at a height that enables splices to be housed in at least two vertical tiers; and, among the splices that branch from the wire harness, houses, in a vertically adjacent manner, a splice wrapped with a splice sheet on the outer peripheral surface, and a splice covered with a cap made of an insulating resin.

Owner:SUMITOMO WIRING SYST LTD

Traction motor junction box suitable for high voltage class and manufacture method of traction motor junction box

ActiveCN103855849AImprove sealingImprove insulation performanceManufacturing dynamo-electric machinesSupports/enclosures/casingsThree-phaseEngineering

The invention discloses a traction motor junction box suitable for a high voltage class and a manufacture method of the traction motor junction box. The traction motor junction box comprises a box body, a junction box cover plate, a three-phase outgoing line, a three-phase cable wire and pouring sealant, wherein the junction box cover plate covers the box body, both the three-phase outgoing line and the three-phase cable wire enter the box body from the outside and are connected in the box body, and the pouring sealant is poured inside the box body. A three-phase outgoing line outlet through which the three-phase outgoing line passes, a three-phase cable wire outlet through which the three-phase cable wire passes, and a screwing member used for screwing the three-phase cable wire are arranged on the box body. The manufacture method of the junction box comprises the following steps: casting the box body; connecting the three-phase outgoing line with the three-phase cable wire; insulation-wrapping; and pouring and sealing. The junction box disclosed by the invention brings the convenience for sealing and mass production, and is low in cost, reliable in sealing and insulation, and capable of meeting the requirements of high voltage class and small space size during the operation of a traction motor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

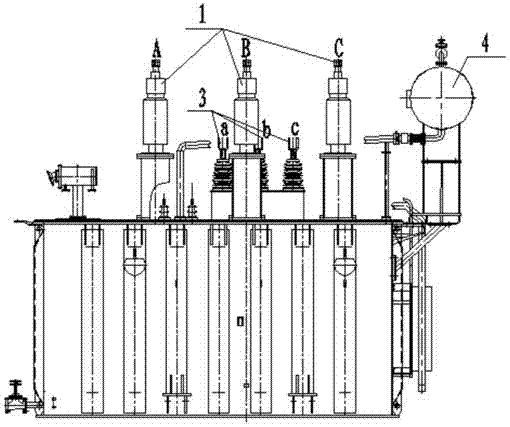

66kV burst short circuit transformer

ActiveCN103500632ASimple insulation structureImproved ampere-turn balanceTransformers/inductances coils/windings/connectionsLow voltageStress level

The invention relates to a 66kV burst short circuit transformer. A three-phase three-limb iron core is arranged in a lower fuel-saving box of the transformer. The iron core is sleeved with a low-voltage coil and a high-voltage coil. Wires are led out from the head end of the high-voltage coil and the head end and tail end of the low-voltage coil in the axial direction, and are led into a sleeve through cables. The high-voltage coil is of a fully continuous structure, wherein every two of three composite conductors are wound in parallel in the radial direction. A subsidiary pressing plate on the high voltage side and a subsidiary pressing plate on the low voltage side are respectively of a fan shape as a whole, and the fan-shaped subsidiary pressing plate on the high voltage side and the fan-shaped subsidiary pressing plate on the low voltage side share the same center of a circle and are placed in a symmetric mode. The subsidiary pressing plates and a pressing plate are provided with positioning holes and are connected through an insulating screw rod. According to the 66kV burst short circuit transformer, the insulation structures of the coils are optimized, ampere-turn balance of the coils is improved, horizontal eddy current loss of the coils is lowered on the premise that insulation reliability is guaranteed, the stress level of the coils is lowered substantially at the time of a short circuit, the capability in resistance to the short circuit of a product is enhanced, and a basis is provided for further optimization of a product design.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

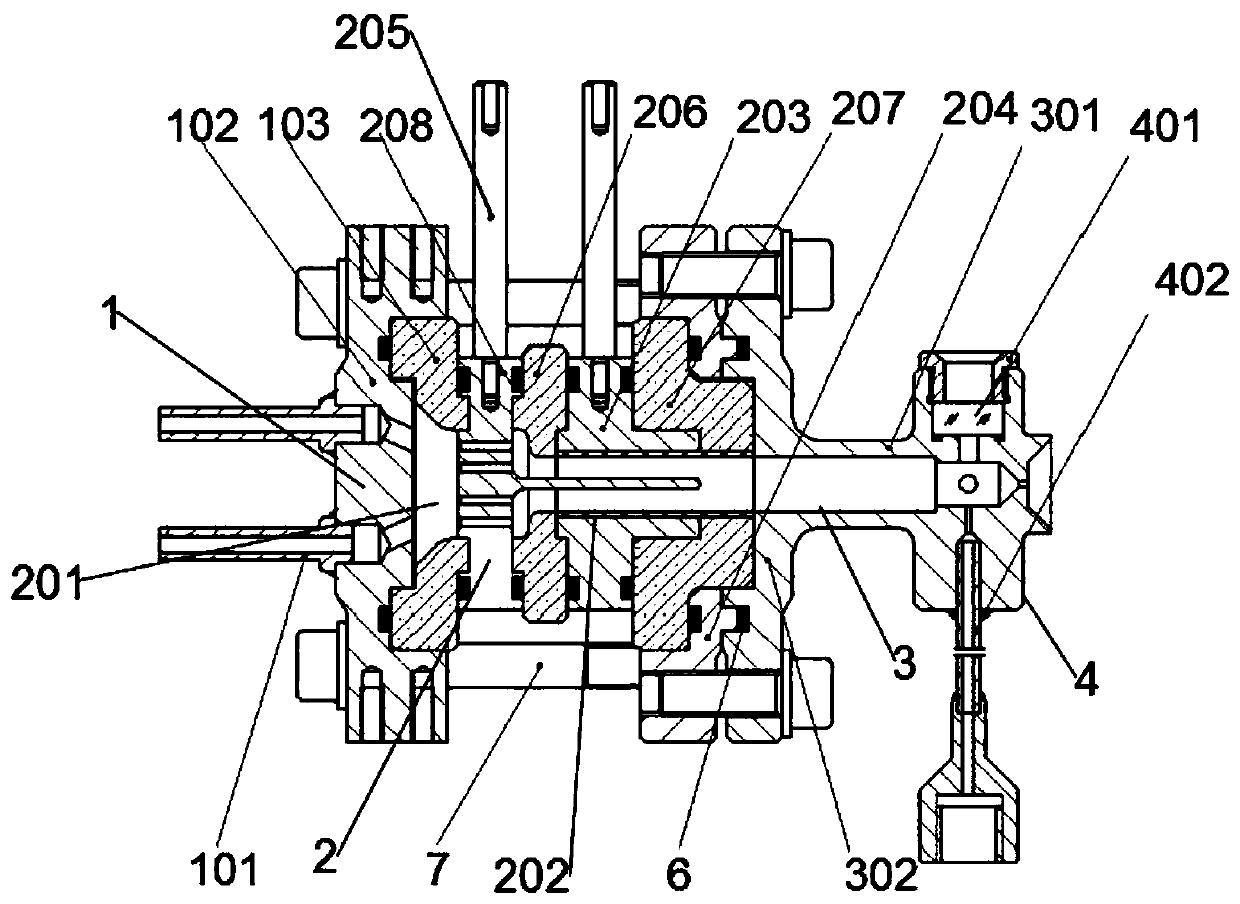

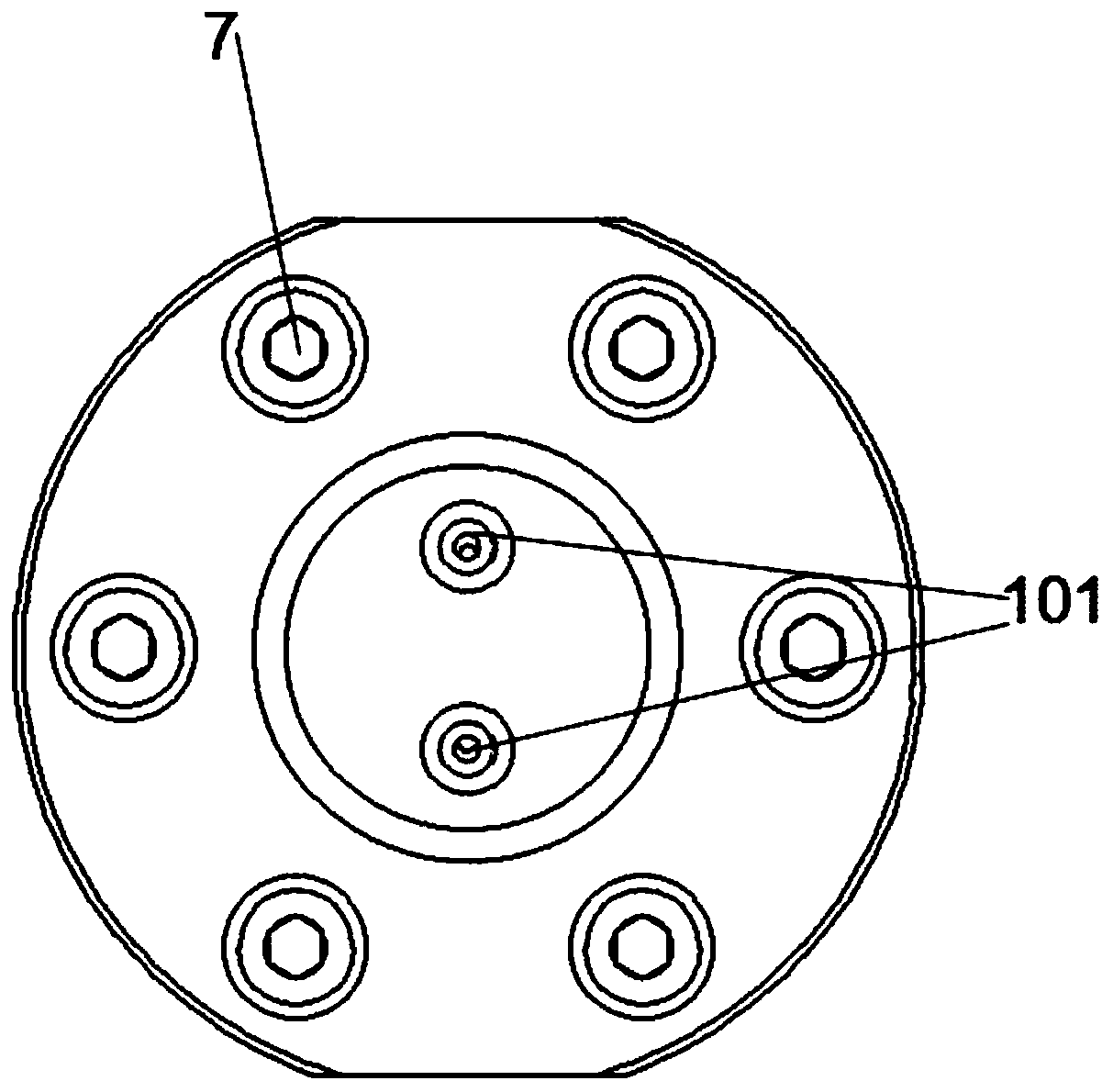

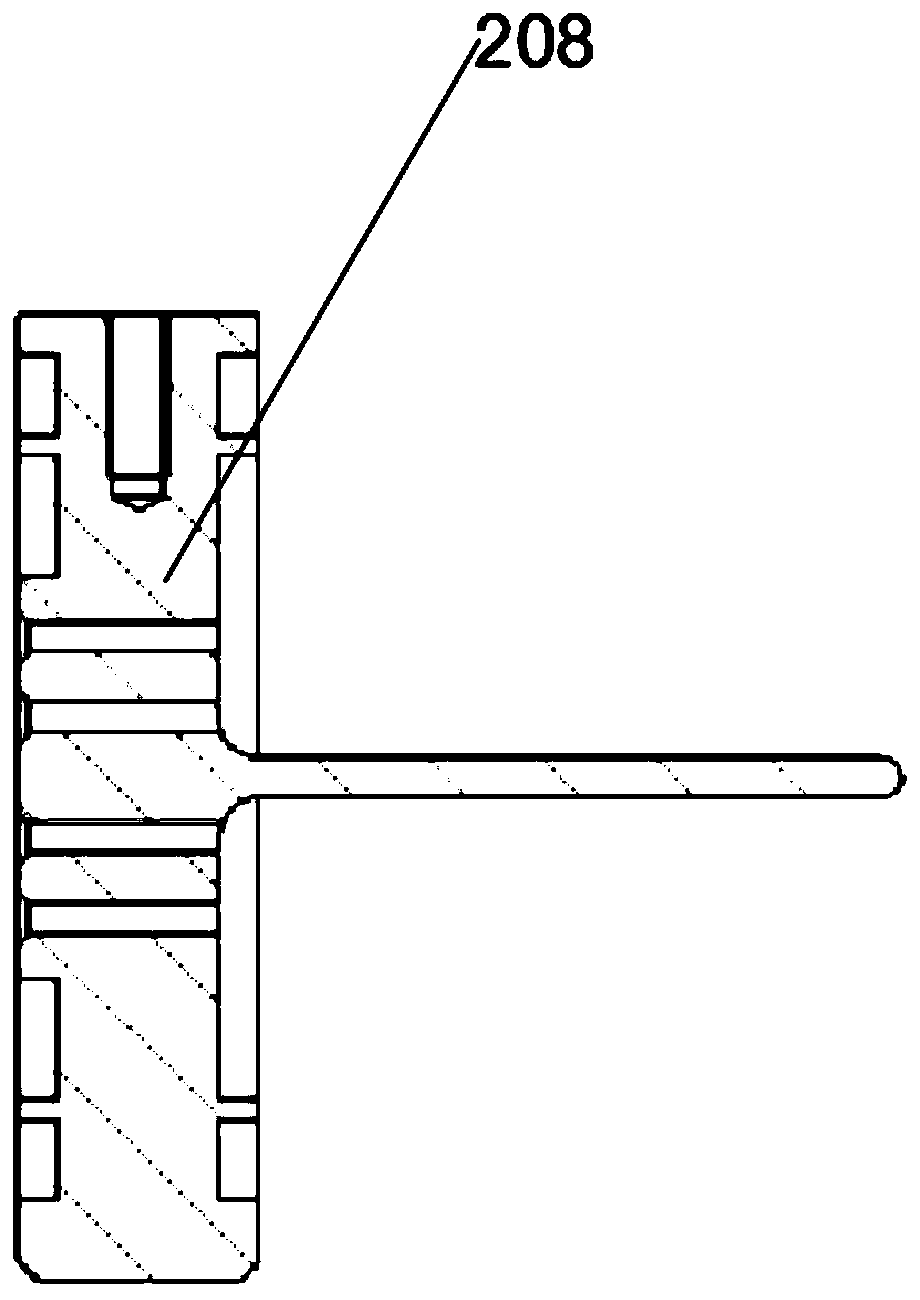

ADN based single-component thruster adopting low-temperature plasma concerted catalysis

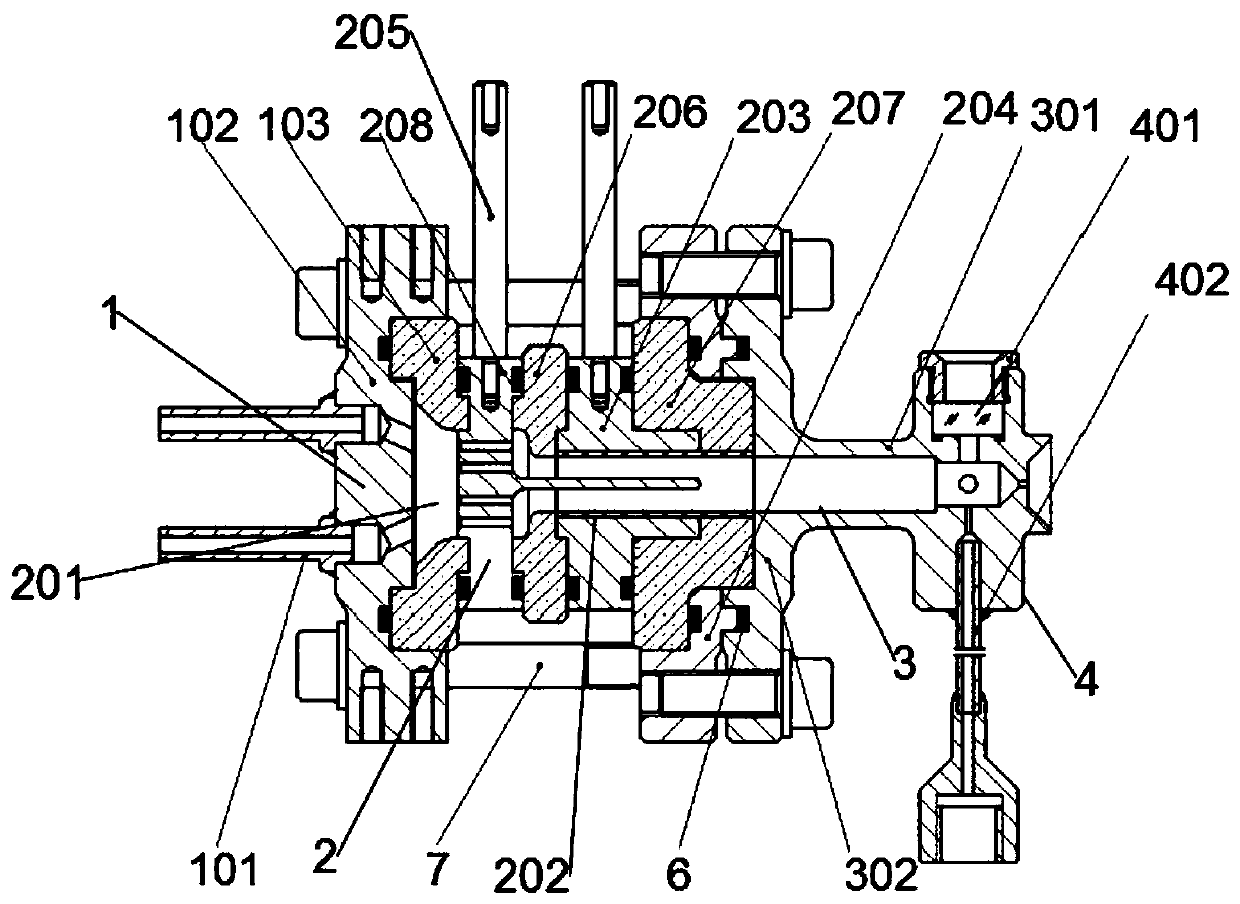

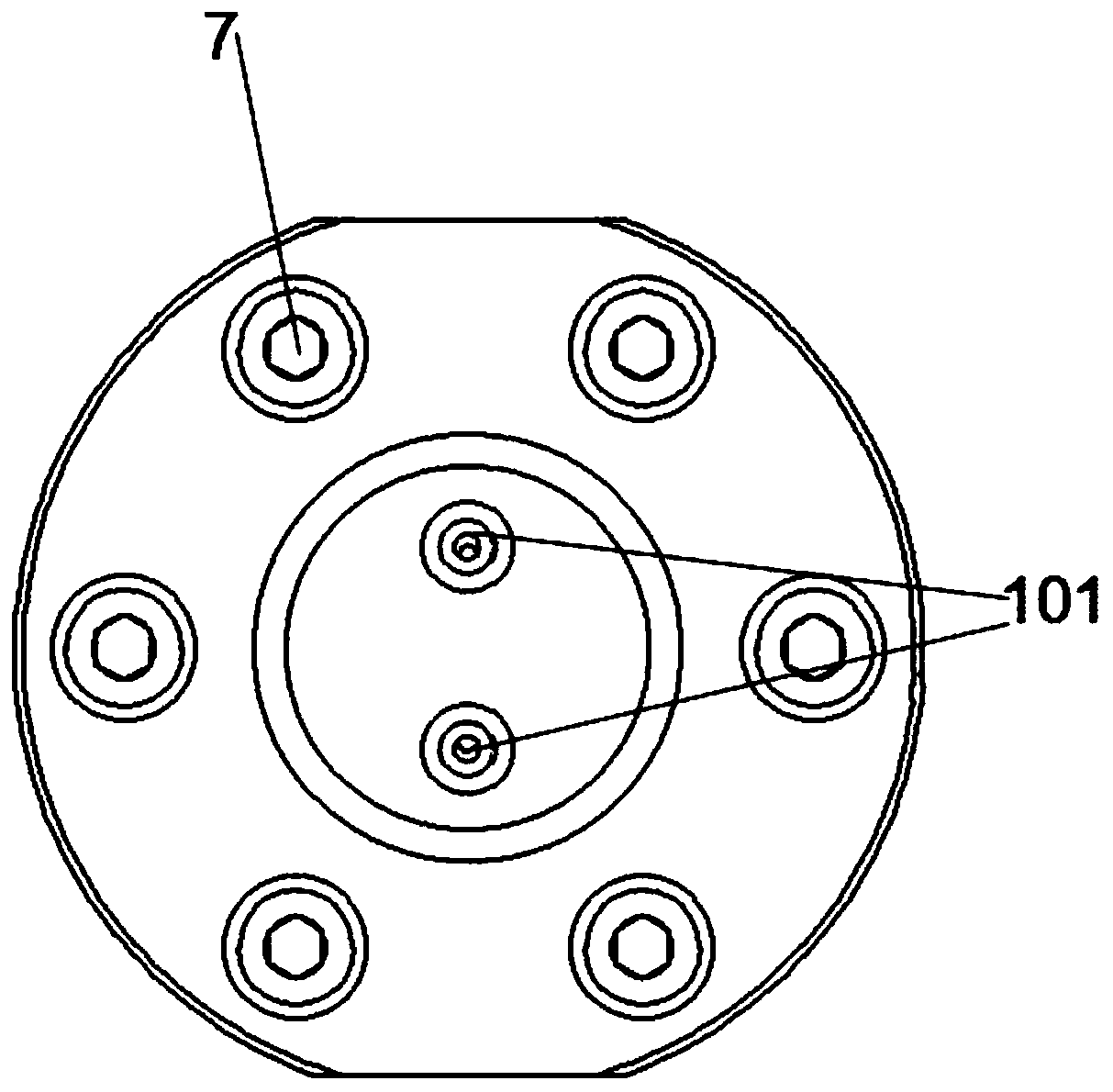

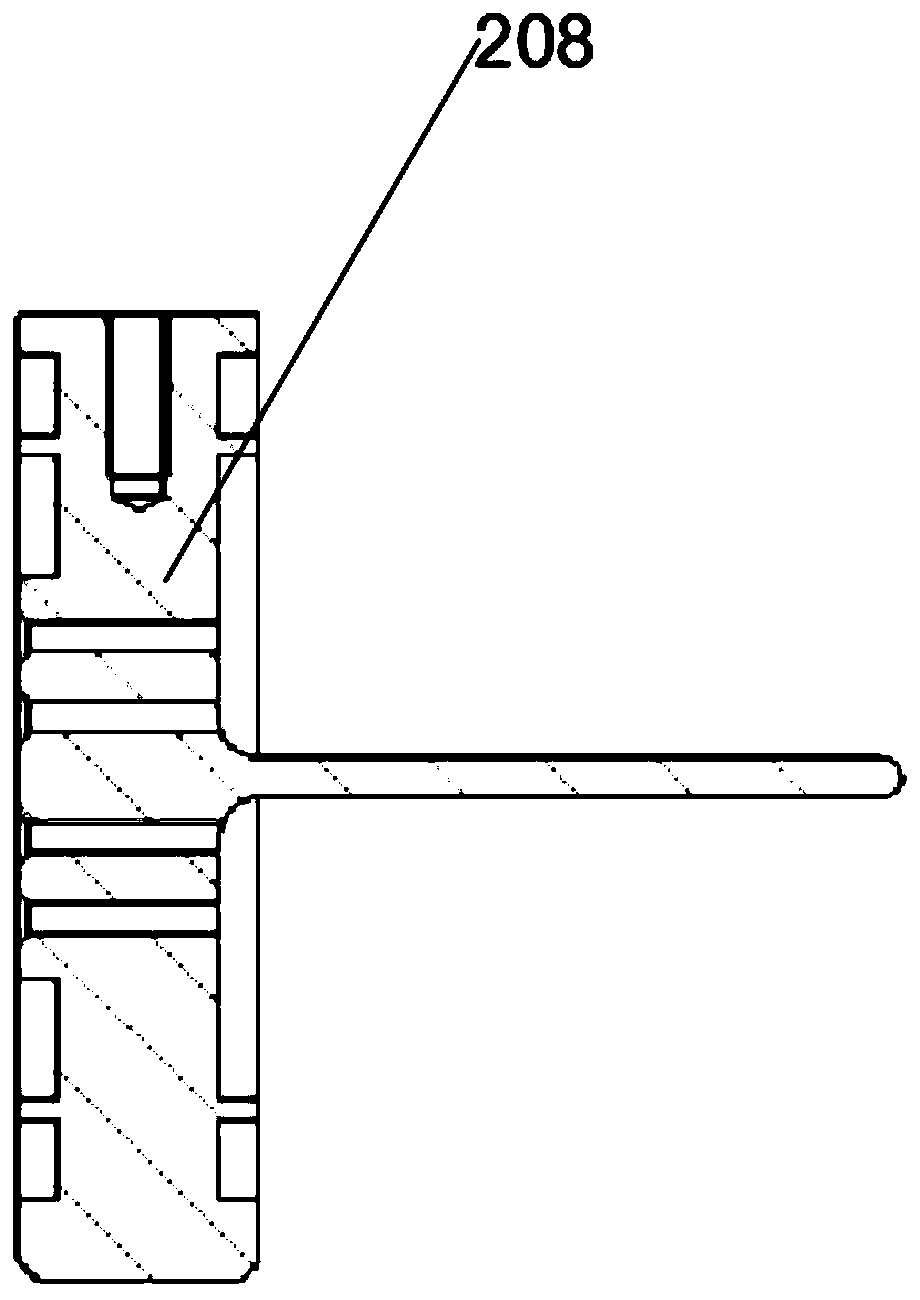

ActiveCN110259605AIndependently observe the ionization effectPlays the role of removing residual propellantRocket engine plantsCombustion chamberOptical testing

The embodiment of the invention discloses an ADN based single-component thruster adopting low-temperature plasma concerted catalysis. The ADN based single-component thruster comprises a spouting section, an ionization section, a catalysis section and a combustion chamber which are coaxially connected sequentially, wherein the two ends of the spouting section and the two ends of the ionization section are pressed by a front flange plate and a middle flange plate; an integrated structure formed by the catalysis section and the combustion chamber and the ionization section are pressed by the middle flange plate and a rear flange plate; the spouting section comprises the front flange plate, a front insulator and an anode chassis as well as gas and liquid supply tubes separately used for providing an ADN liquid propellant and gas; the ionization section comprises a cylindrical anode, a middle insulator, a barrel-shaped cathode, a rear insulator and the middle flange plate which are sequentially connected to the anode chassis; the middle flange plate and the front flange plate are matched and pressed through a locking bolt; the catalysis section comprises a rear flange plate and a catalysis bed; and the combustion chamber comprises an optical test window and a reserved sensor jointing base. The AND based single-component thruster has various ignition ways, and is of great significance in completely converting an existing catalysis dissociation ignition way.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

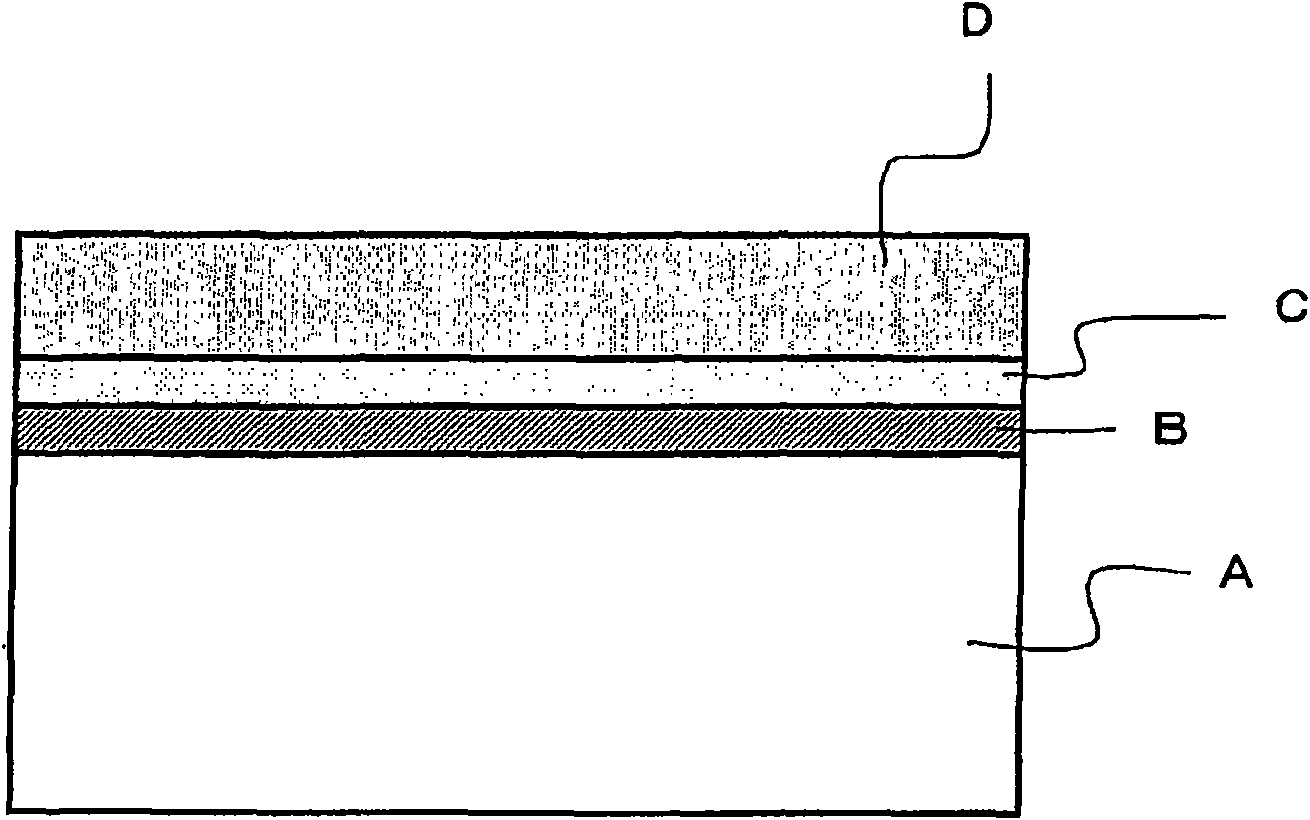

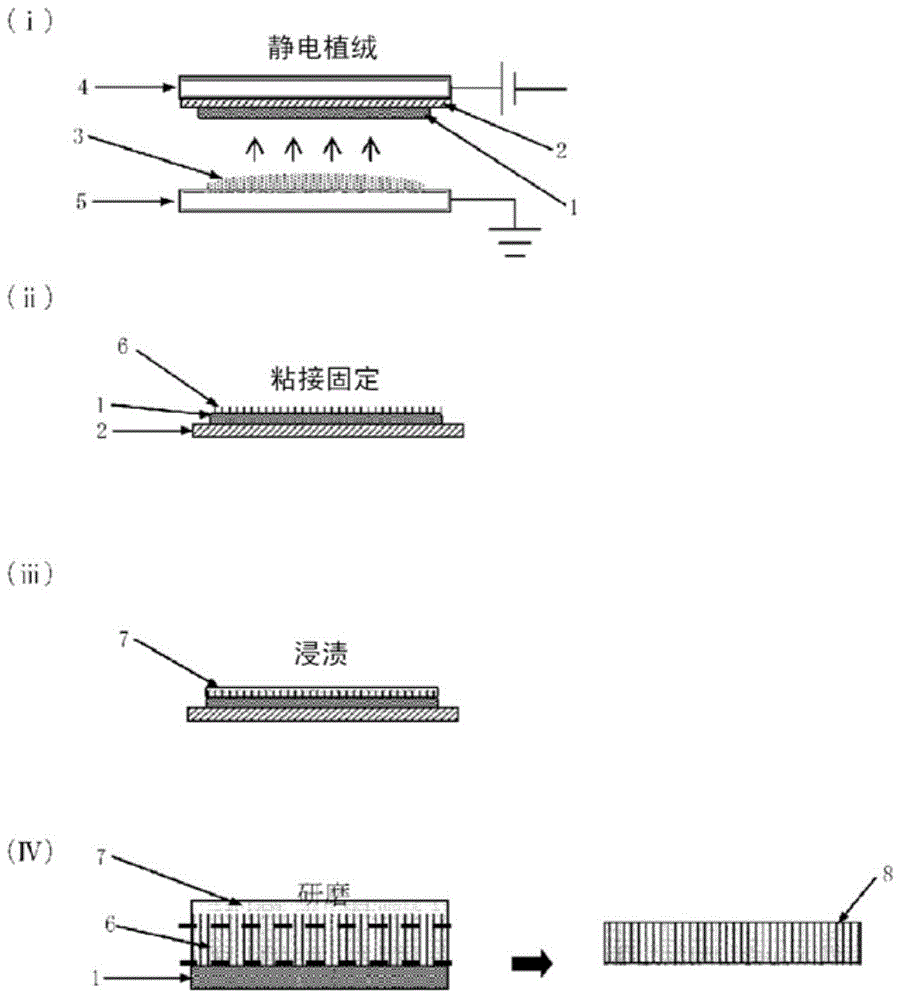

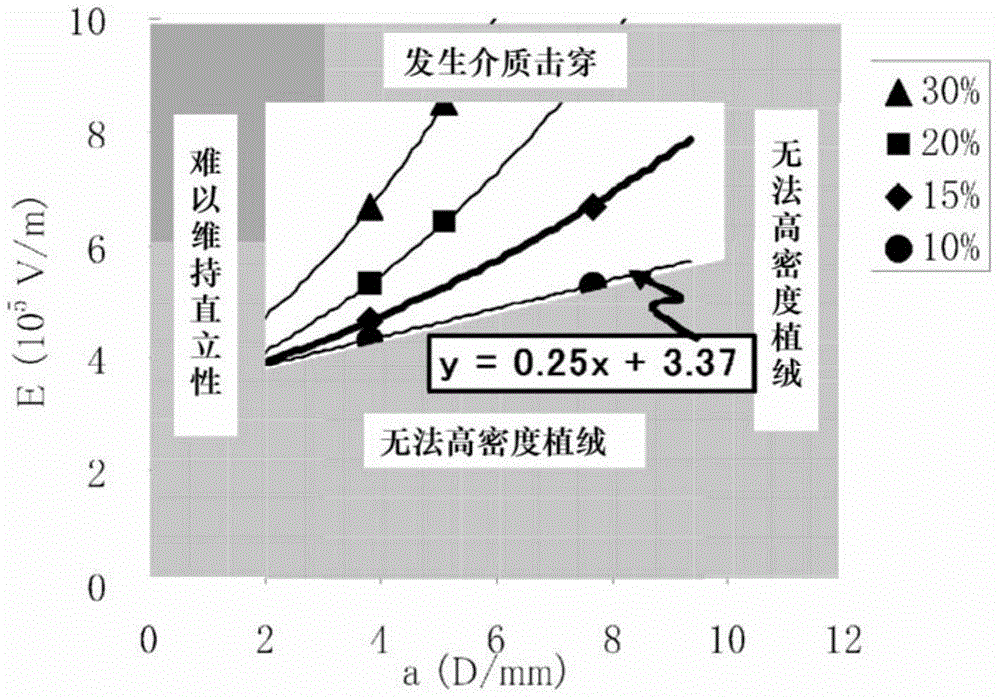

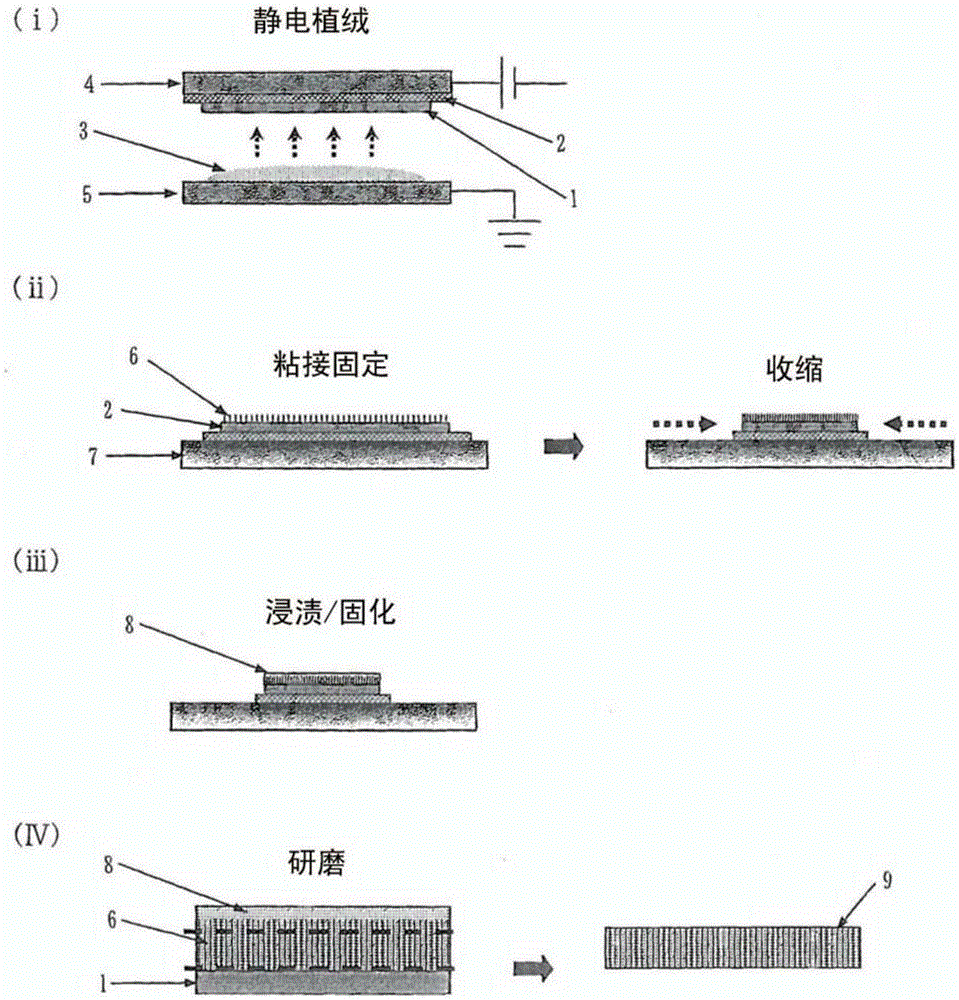

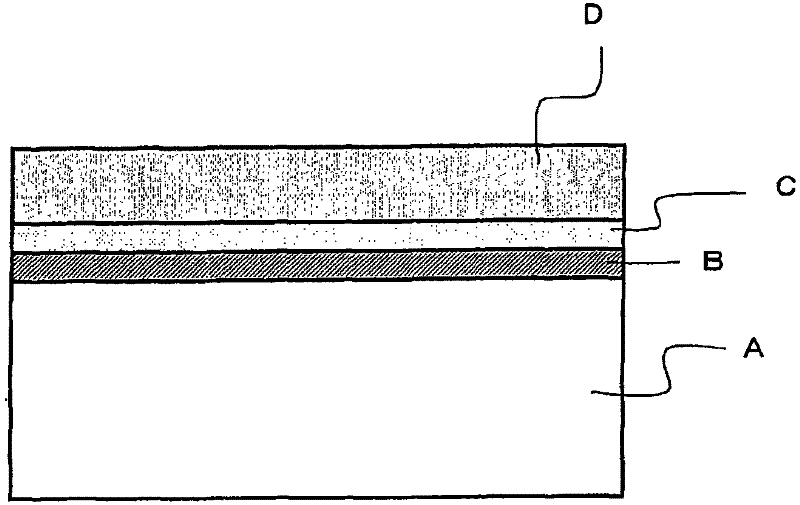

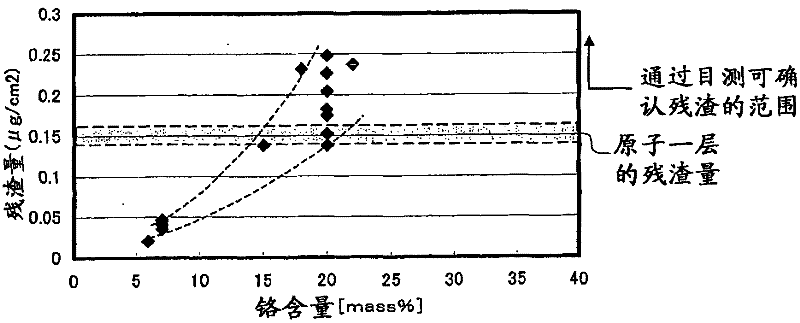

Printing wiring cardinal plate and method for producing the same

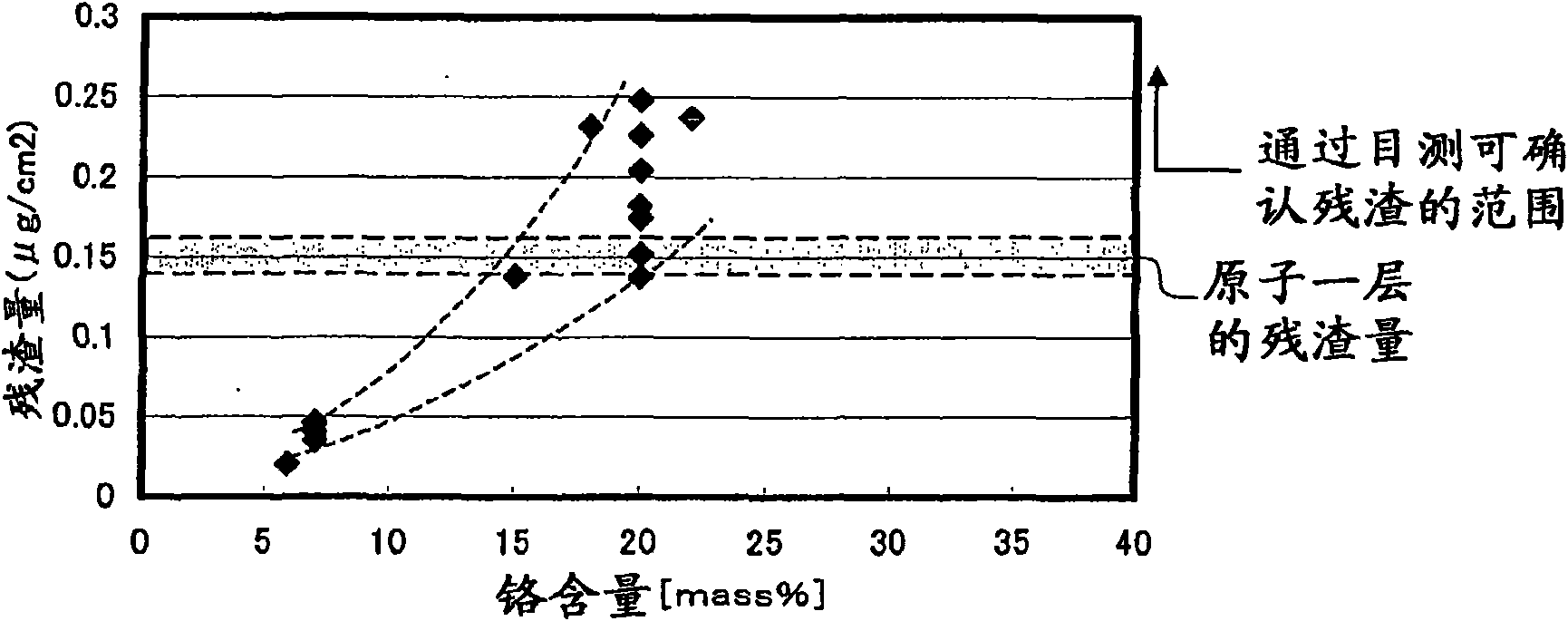

ActiveCN101594737AGuaranteed insulation reliabilityImprove corrosion resistanceConductive material chemical/electrolytical removalMetallic pattern materialsEtchingElectrical conductor

The invention provides a printing wiring cardinal plate with high insulation reliability and corrosion resistance and method for producing the same, namely the conductor wiring is formed with high etching, when etching is performed by ferric chloride solution or hydrochloric acid solution of copper chloride, residual etching draff with ingredients of the base metal layer between the conductor wirings are few, when high voltage is exerted among the conductor wirings. On at least one surface of the insulating resin film A, a metallic layer B with nickel, or nickel-chromium alloy containing nickel above 70 quality percentage and chromium below 15 quality percentage is stacked in series without an adhesive agent; a metallic layer C made of alloy containing chromium over 15 weight percentage, unnecessary part of a metal membrane composed by copper tunica layer D with thickness 10 nm to 35 Mum, chemical etching processing is adopted for selective removal, and then the printing wiring cardinal plate of conductor wirings is formed.

Owner:SUMITOMO METAL MINING CO LTD

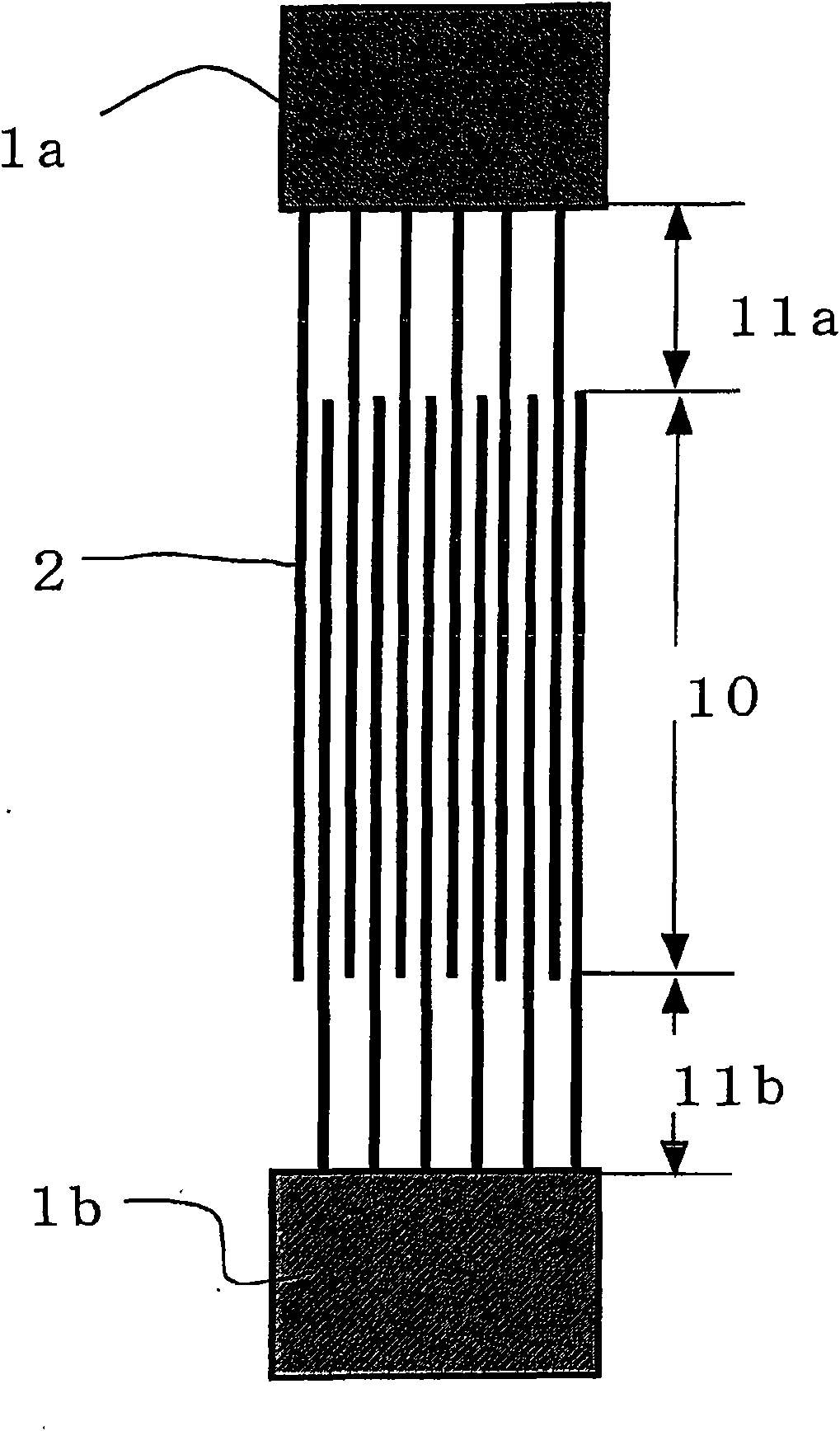

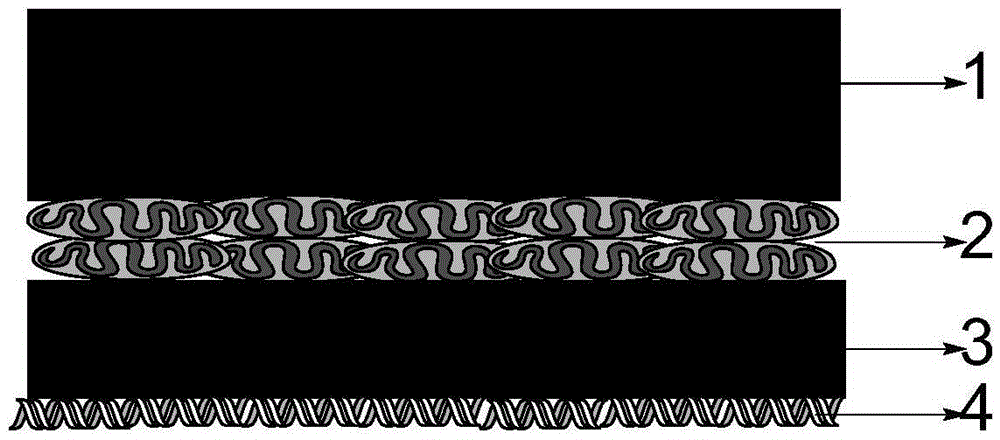

Insulating and thermally conductive sheet

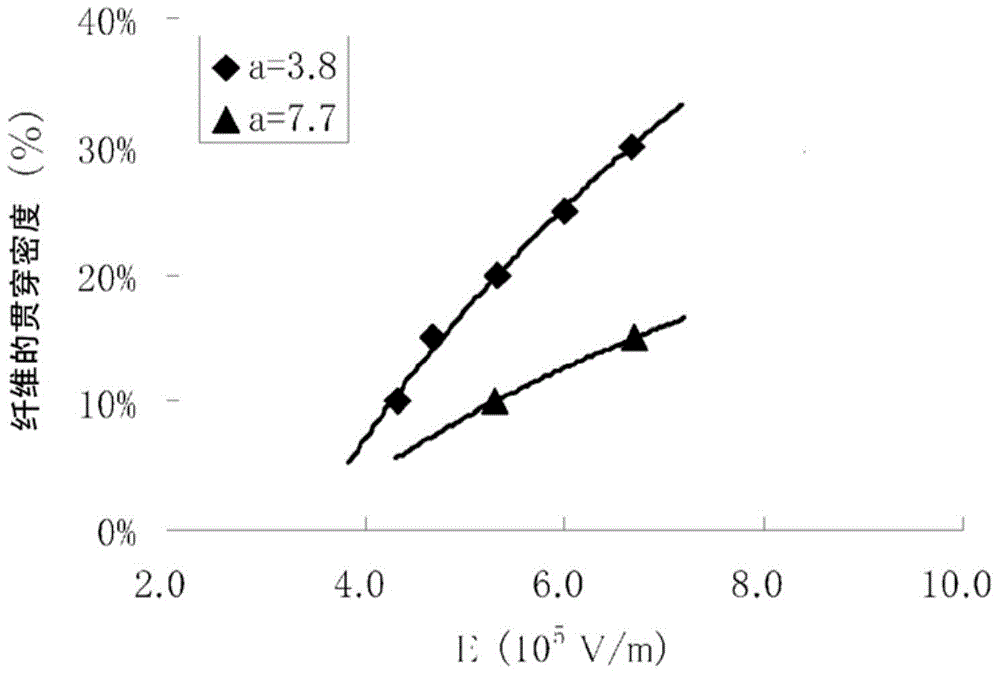

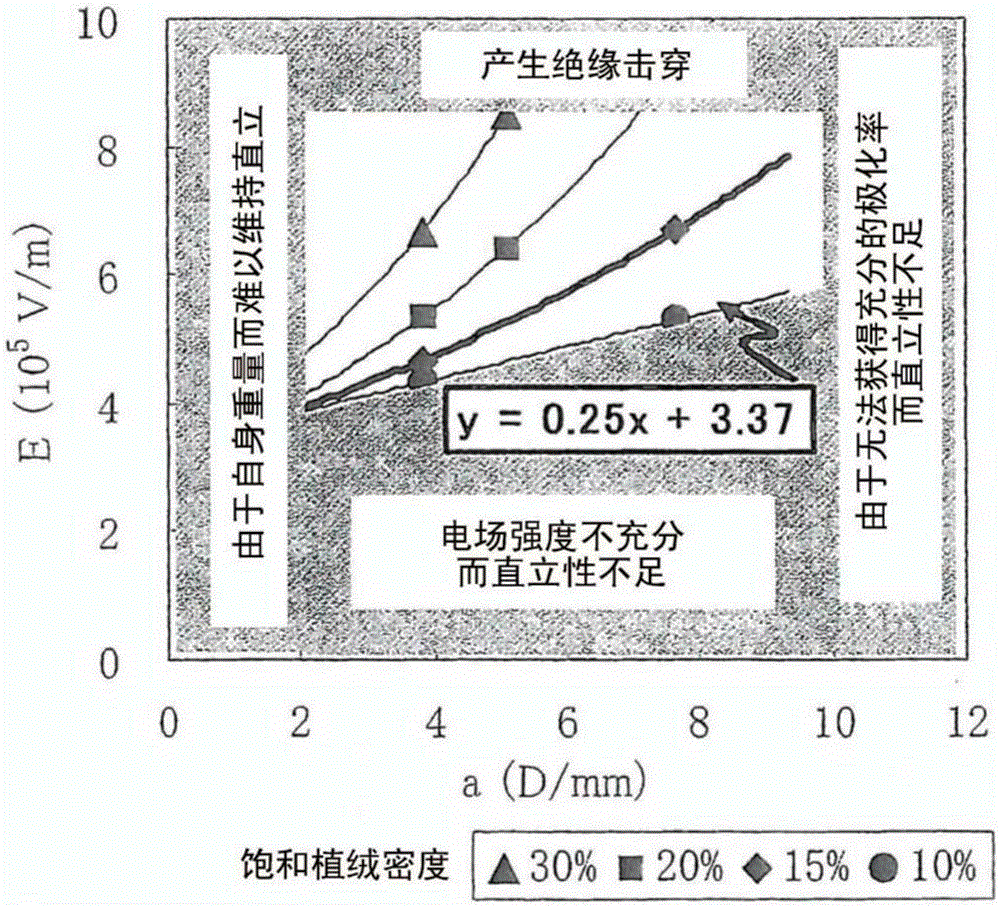

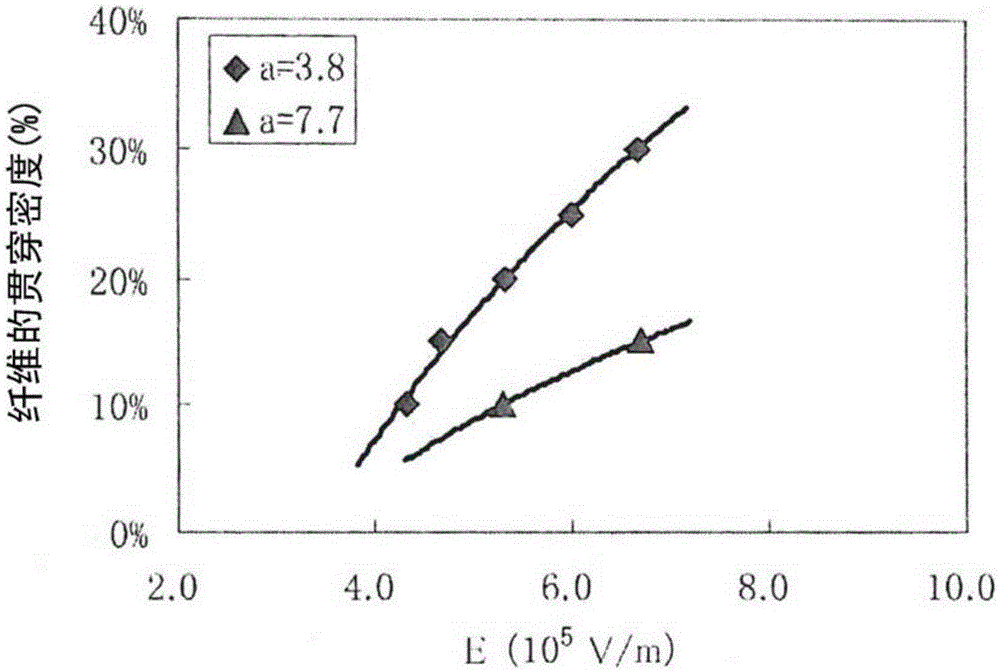

InactiveCN104025290ADissipate quicklyGuaranteed insulation reliabilitySemiconductor/solid-state device detailsSolid-state devicesFiberHigh density

Owner:TOYOBO CO LTD

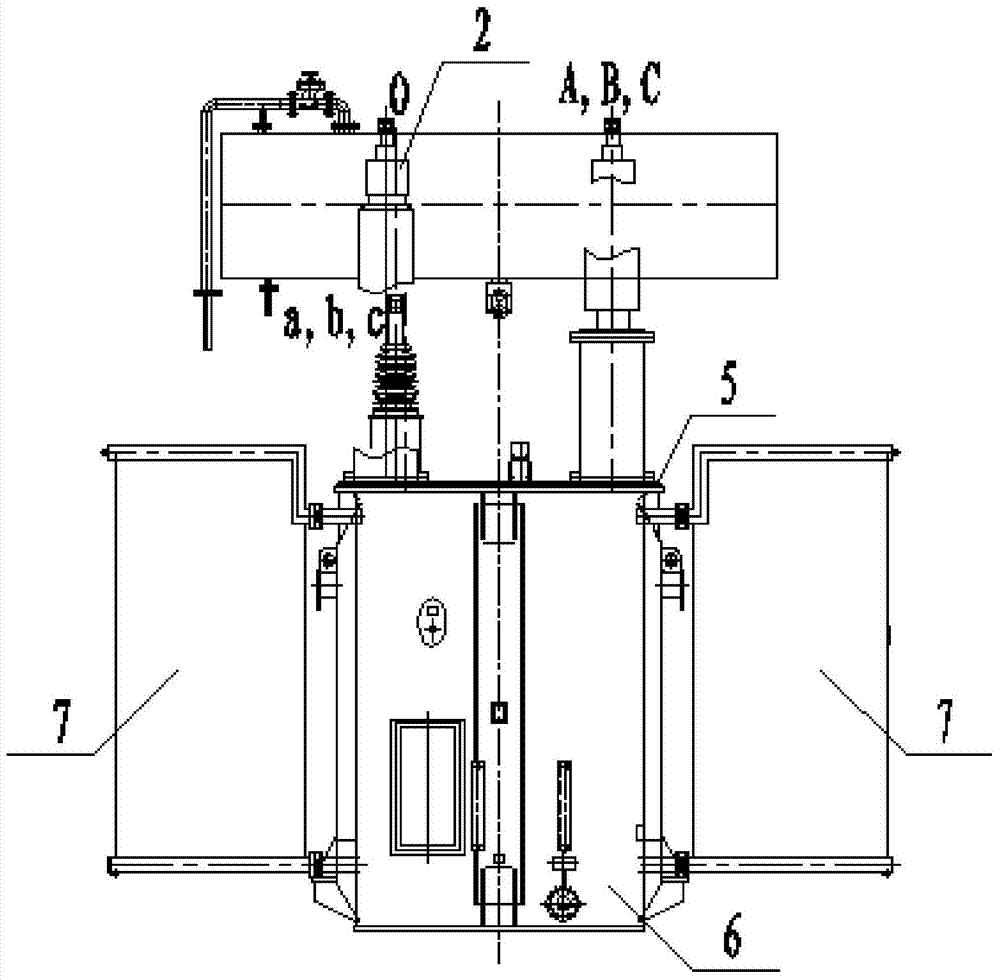

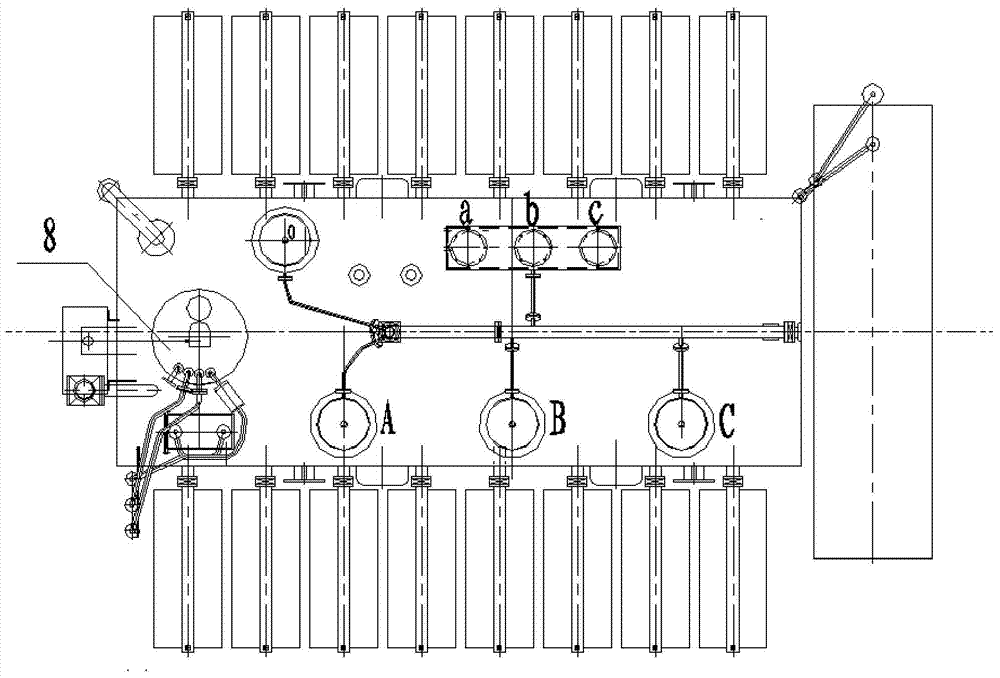

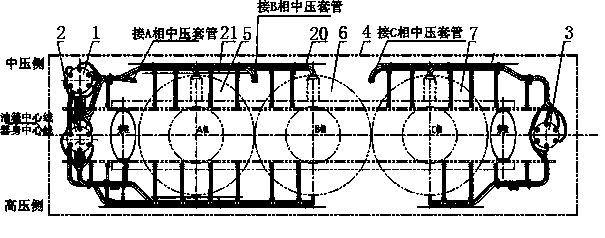

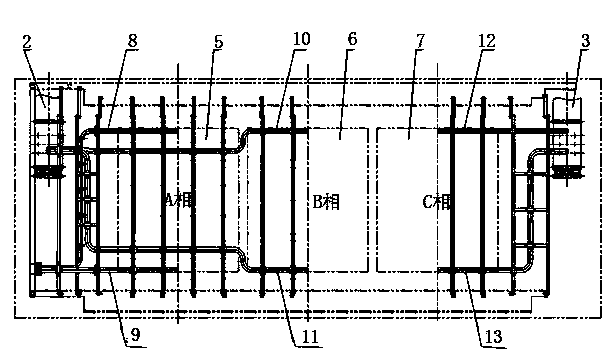

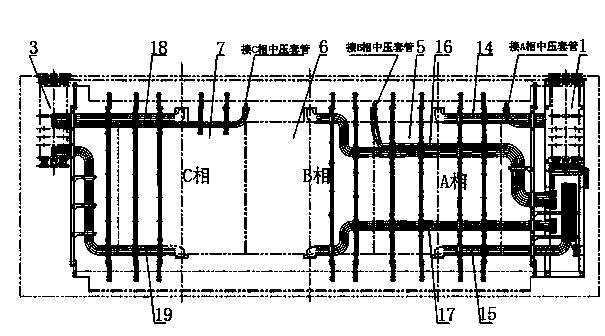

Novel three-phase-integrated autotransformer switch lead arranging method

InactiveCN103730239AMeet the insulation distanceReduce widthElectric component structural associationAutotransformerTransformer

The invention relates to a novel three-phase-integrated autotransformer switch lead arranging method and belongs to the technical field of transformer manufacturing. The method includes arranging an A-phase single-phase voltage adjusting switch and a B-phase single-phase voltage adjusting switch on the left side of a transformer long shaft facing a high voltage side, and arranging a C-phase single-phase voltage adjusting switch on the right side of the transformer long shaft; connecting A, B and C to tap contacts of respective single-phase voltage adjusting switches; arranging leads, connected with a medium-voltage sleeve, of the respectively single-phase voltage adjusting switches on a medium voltage side to be clamped together with a tap wire. By the method, insulation distance between an out-of-phase switch and the tap wire is guaranteed, and width of an oil tank is correspondingly reduced to meet requirements of transport limit; insulating partitions are arranged between the leads and the oil tank as well as an out-of-phase coil to separate electric fields of the leads, so that unde the premise that insulation reliability of the leads is guaranteed, width dimension of the oil tank is further reduced to adapt to more harsh and strict transport conditions.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

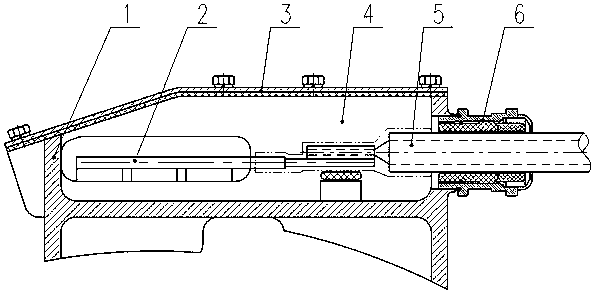

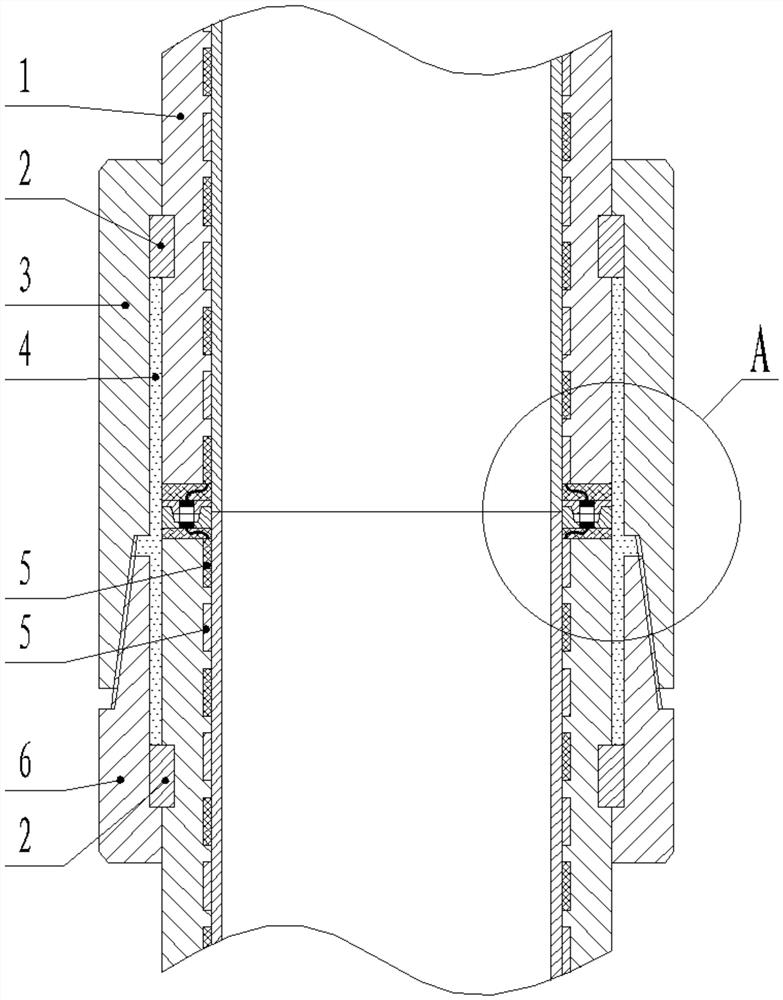

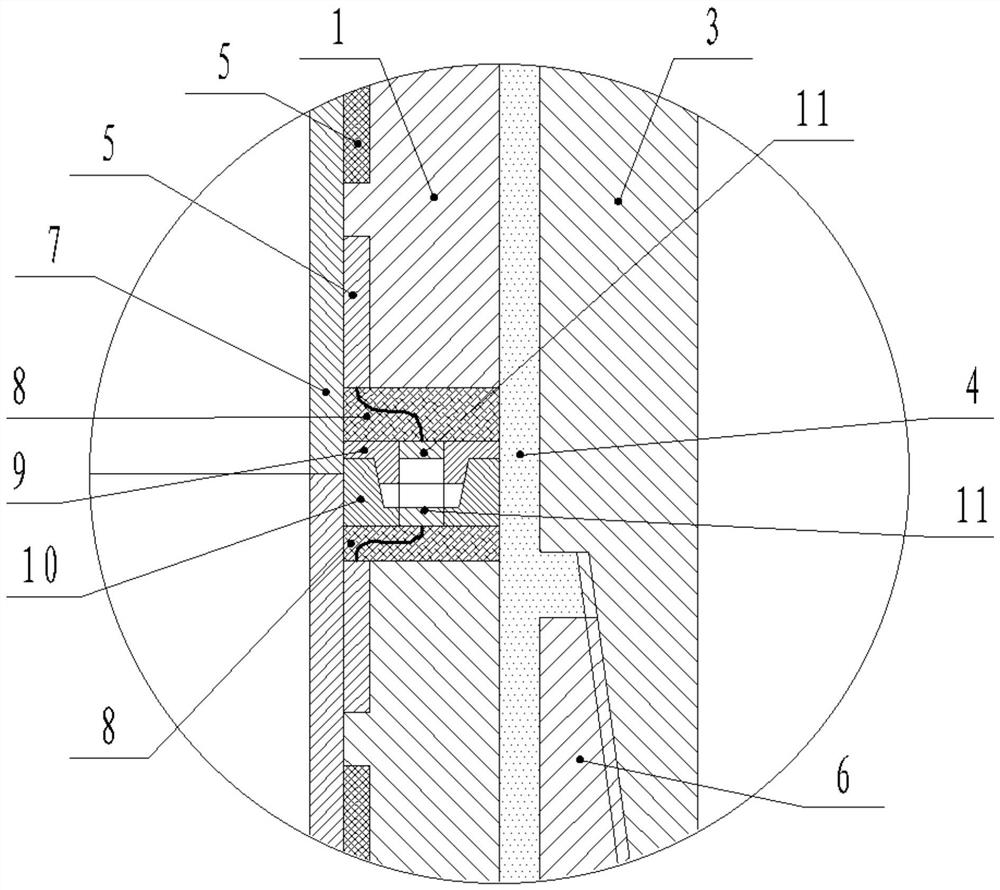

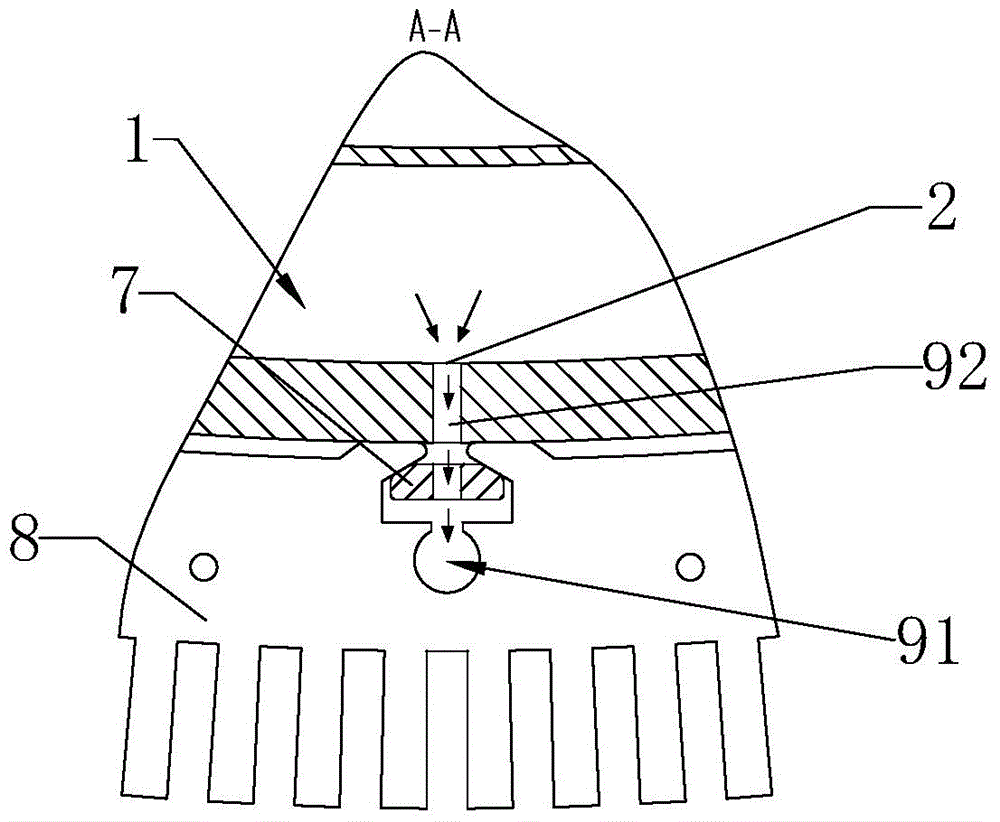

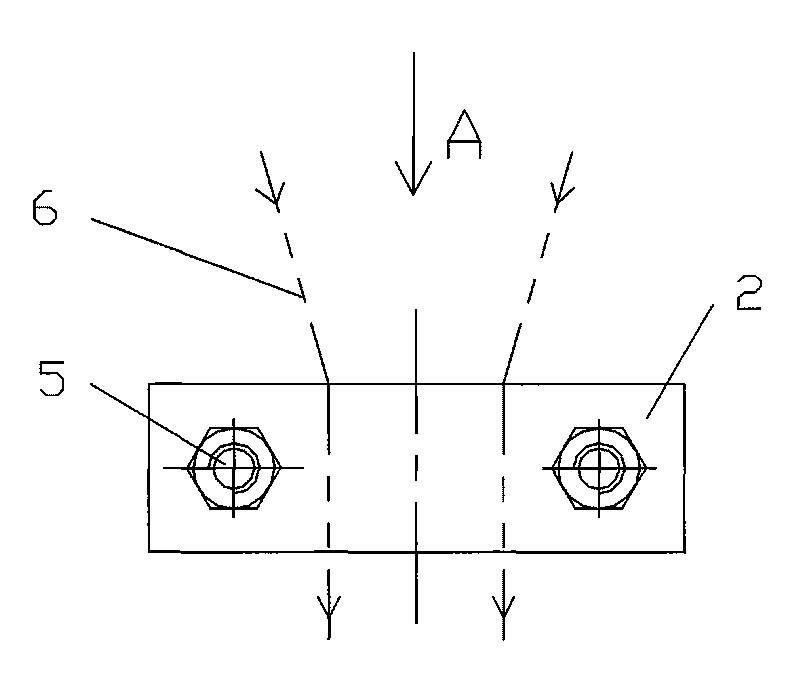

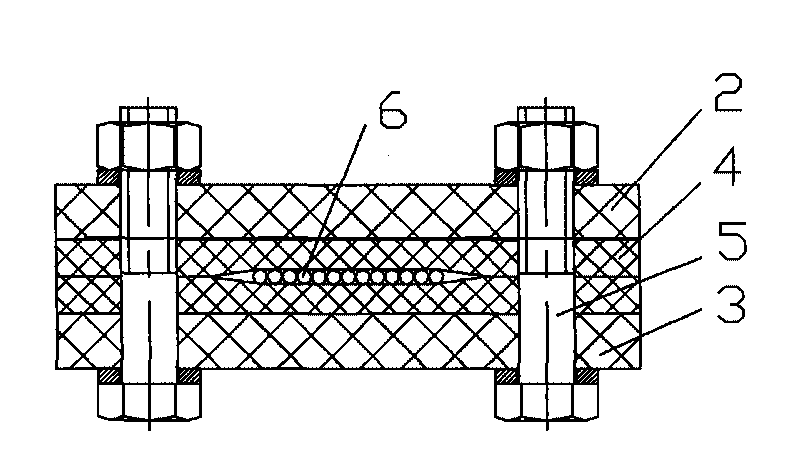

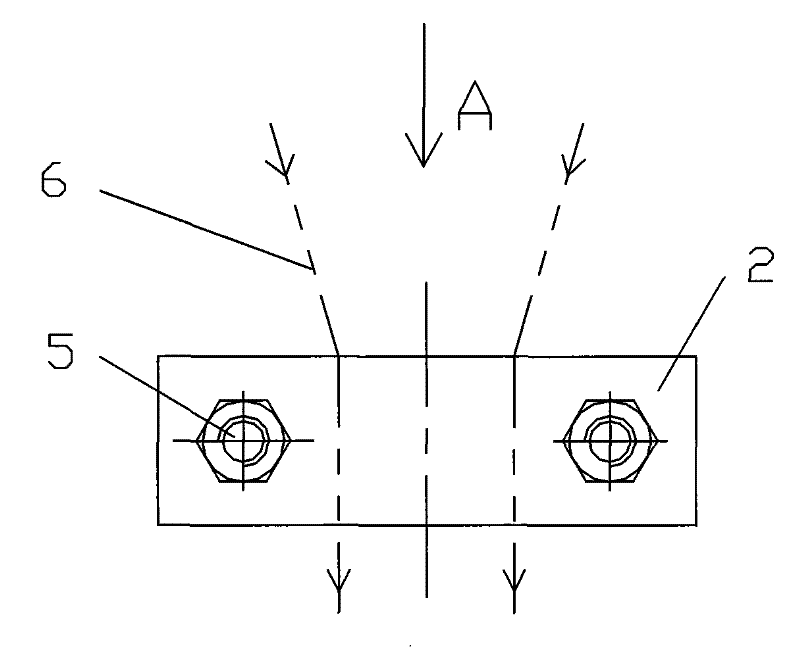

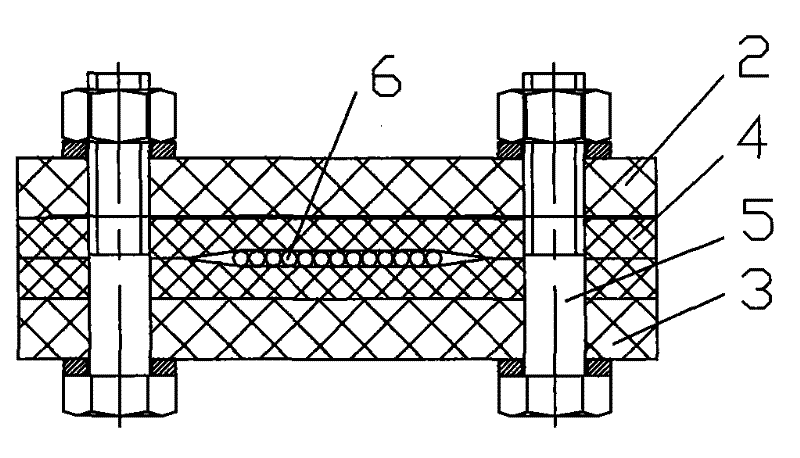

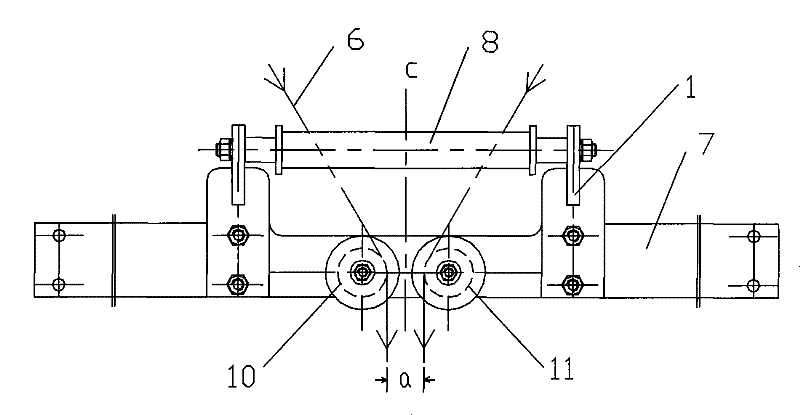

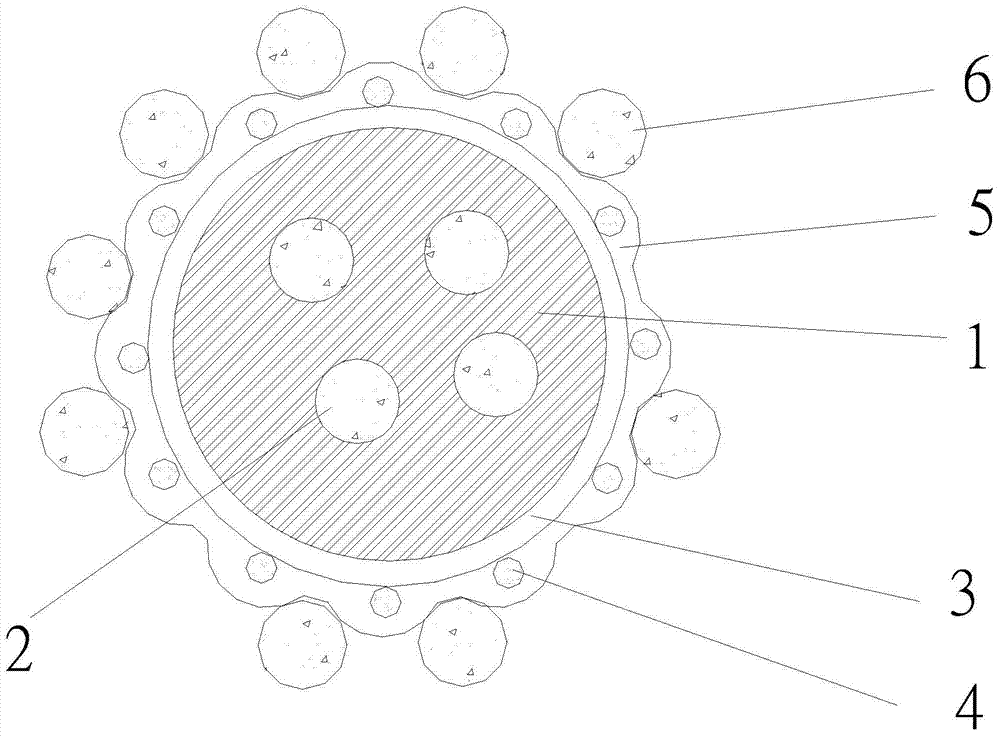

Gas current transformer

InactiveCN102360896AImprove insulation reliabilityGuaranteed insulation reliabilityTransformersTransformers/inductances coils/windings/connectionsState of artElectrical conductor

The invention relates to a gas current transformer, in particular to an inverted SF6 (Sulfur Hexafluoride) gas insulated current transformer with a voltage of 35-500 kV, belonging to the technical field of a transformer. The technical scheme provided by the invention is as follows: the gas current transformer comprises a primary conductor (1), a shielding cover for a secondary winding (2), a disk-type insulator (3), a high-potential shielding cylinder (4), a shielding tube of a lead-out wire of the secondary winding (5), a compound hollow insulator (6), an SF6 gas (7), a base (8) and the like; the upper end of the shielding tube of the lead-out wire of the secondary winding is leveled and parallel to the upper end of the disk-type insulator; an insulating sleeve (9) is sealed and fixed on the upper end of the shielding tube of the lead-out wire of the secondary winding; and a gap is reserved between the insulating sleeve and the disk-type insulator. In the gas current transformer provided by the invention, the insulation reliability between the shielding tube of the lead-out wire of the secondary winding and the disk-type insulator is improved so that the insulation reliability of the transformer is ensured. Compared with the prior art, the gas current transformer provided by the invention has advantages of material saving, simple and novel structure, convenience for manufacture and installation, and safeness and reliability in the insulation performance.

Owner:BAODING TIANWEI GRP CO LTD

Insulating and heat-conductive sheet

InactiveCN105308105AAvoid damageGuaranteed insulation reliabilityLiquid surface applicatorsPlastic/resin/waxes insulatorsFiberVolumetric Mass Density

The present invention addresses the problem of providing a heat-conductive sheet having excellent insulation properties and thermal anisotropy and also having high heat-dissipating properties. An insulating and heat-conductive sheet characterized by comprising insulating and highly heat-conductive fibers that penetrate in the thickness direction and a binder resin, wherein the penetration density of the insulating and highly heat-conductive fibers that penetrate in the thickness direction is 6% or more, the ratio of the thermal resistivity in the thickness direction to the thermal resistivity in the planar direction is 2 or more, and the initial dielectric breakdown strength is 20 kV / mm or more.

Owner:TOYOBO CO LTD

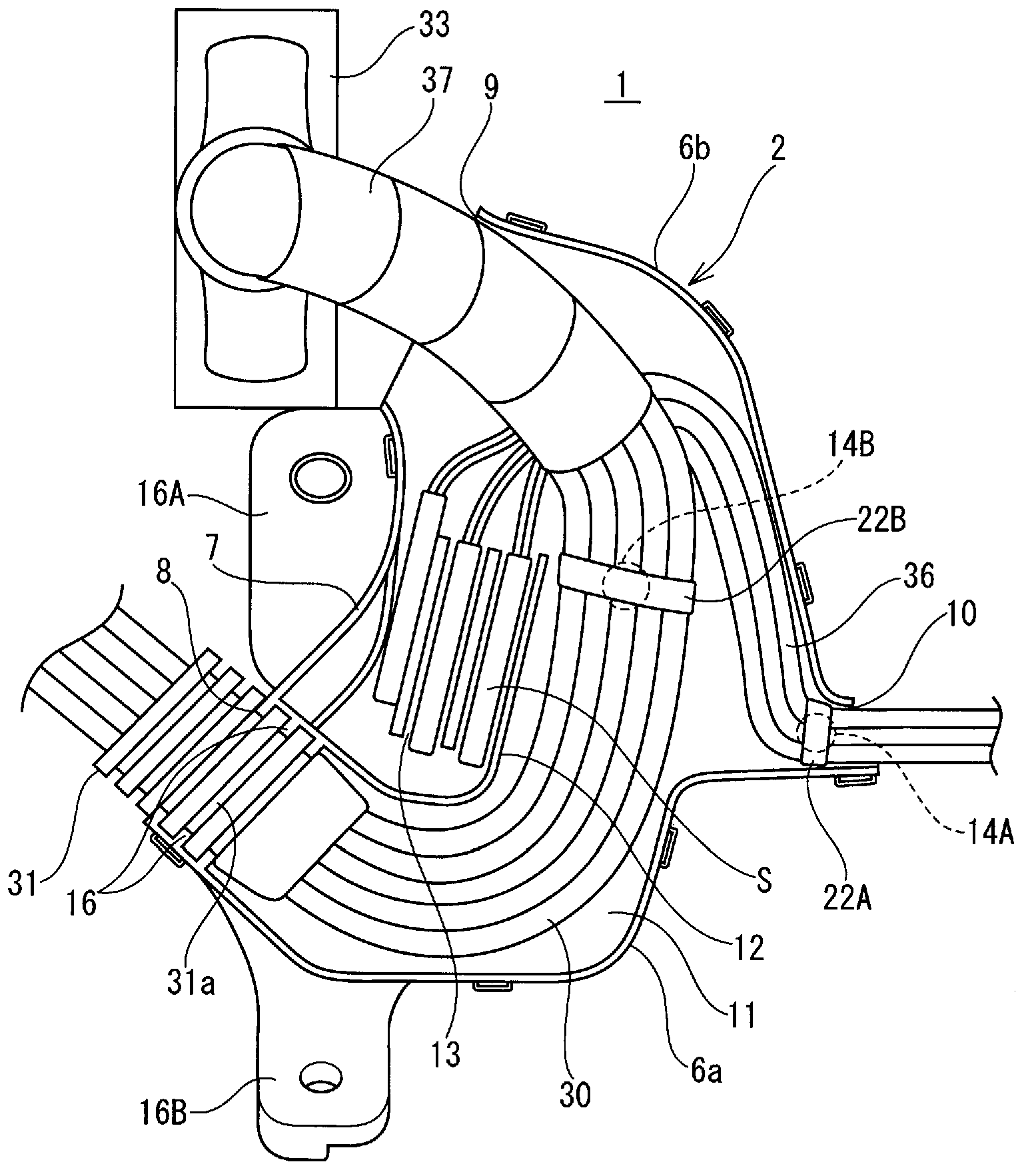

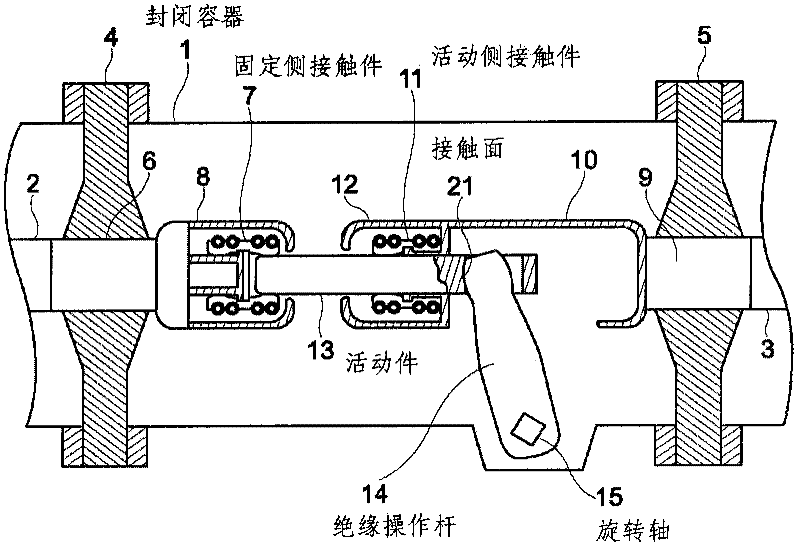

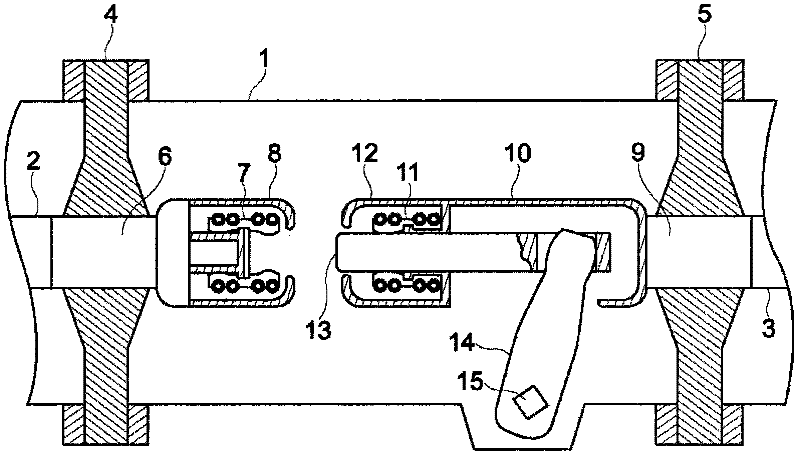

Gas-insulated switching device

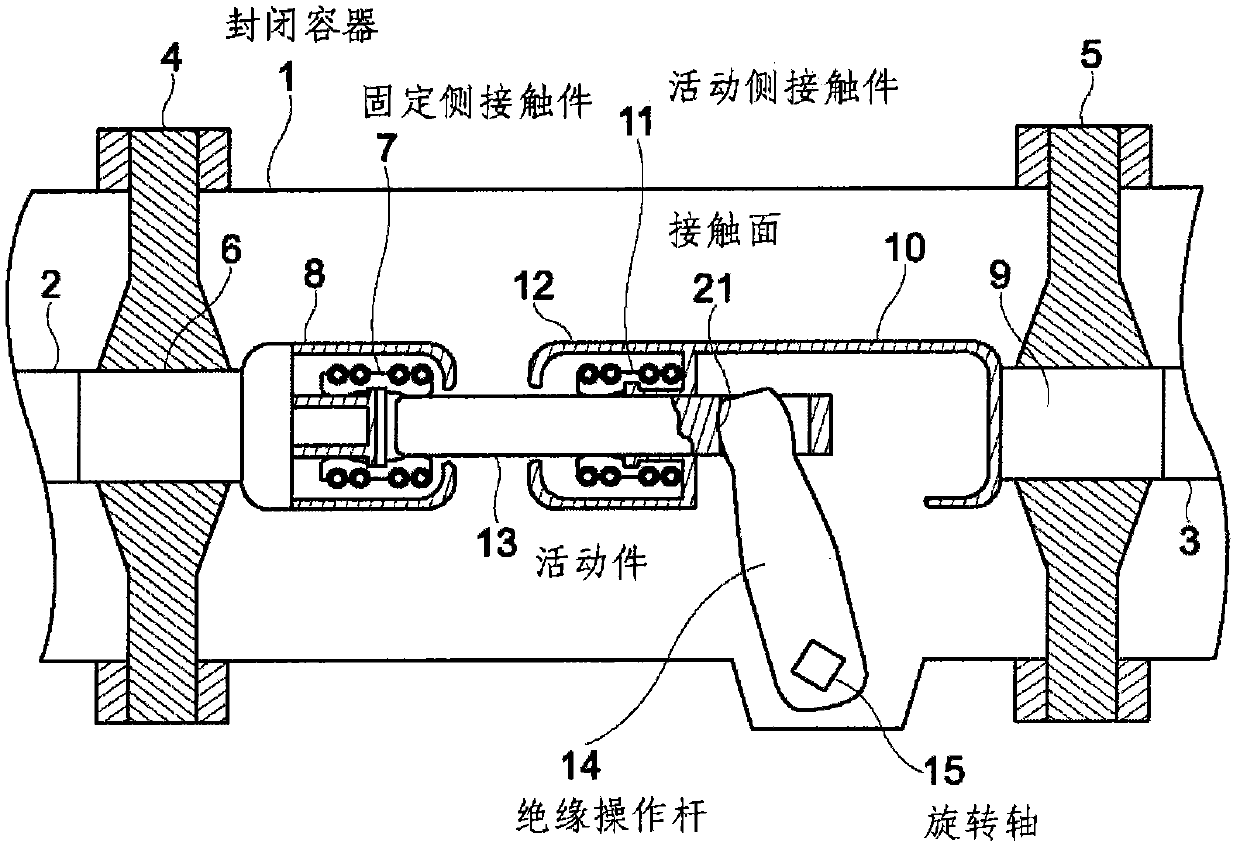

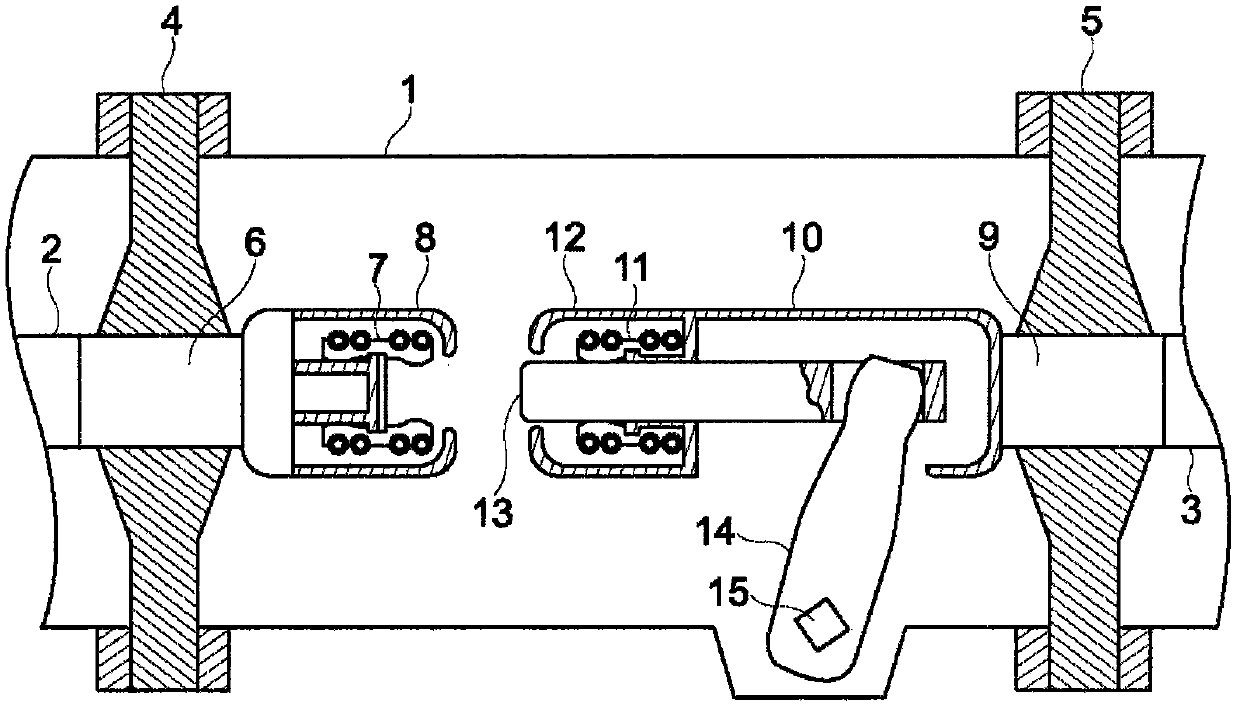

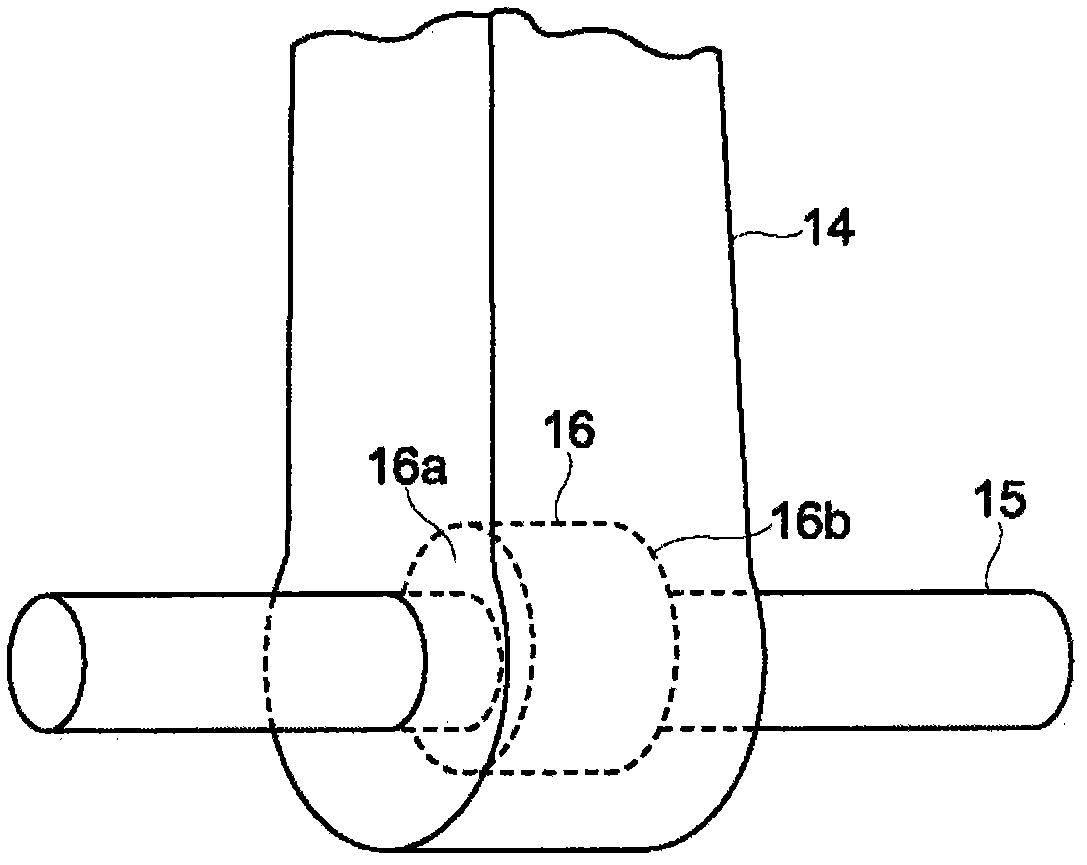

ActiveCN102187537ASmall sizeExcellent abrasion resistanceHigh-tension/heavy-dress switchesAir-break switchesMechanical engineeringGas insulation

Disclosed is a compact gas-insulated switching device with a reduced number of components. A large-diameter part (16) is formed in the central part in the axial direction of a rotary shaft (15) which is driven and rotated by an operating device. An insulated operating rod (14) the other end of which is moved in an arc by the rotation of the rotary shaft (15) is formed by cast molding and encases and is formed integrally with the large-diameter part (16) of the rotary shaft (15) in a filler packed with resin. The contact connection part of the insulated operating rod (14) and a movable element (13) is formed for example on an elliptically shaped contact face (21) to contact at almost one point on the central axial line of the movable element (13) during the switching operation.

Owner:HITACHI LTD

Super-high-voltage vacuum insulation device

InactiveCN105679596AAvoid arcingGuaranteed insulation performanceHigh-tension/heavy-dress switchesAir-break switchesElectricityEngineering

The invention discloses a super-high-voltage vacuum insulation device. A vacuum chamber is divided into a first vacuum chamber and a second vacuum chamber; one end of the first vacuum chamber is communicated with one end of the second vacuum chamber; the other end of the first vacuum chamber is provided with a grounding end interface; the other end of the second vacuum chamber is provided with a high-voltage end interface; a grounding wire is connected into the first vacuum chamber; a high-voltage wire is connected into the second vacuum chamber; the first vacuum chamber, the second vacuum chamber, the grounding end interface, the high-voltage end interface and the high-voltage wire are all made of an insulation material; and in the second vacuum chamber, the high-voltage wire is provided with an insulation coating corresponding to the inner wall of the second vacuum chamber. Thus, high voltage can be effectively prevented from generating electric arcs in the insulation device, and the insulation performance and service life of the insulation device can be effectively ensured.

Owner:CHENGDU CVAC VACUUM TECH CO LTD

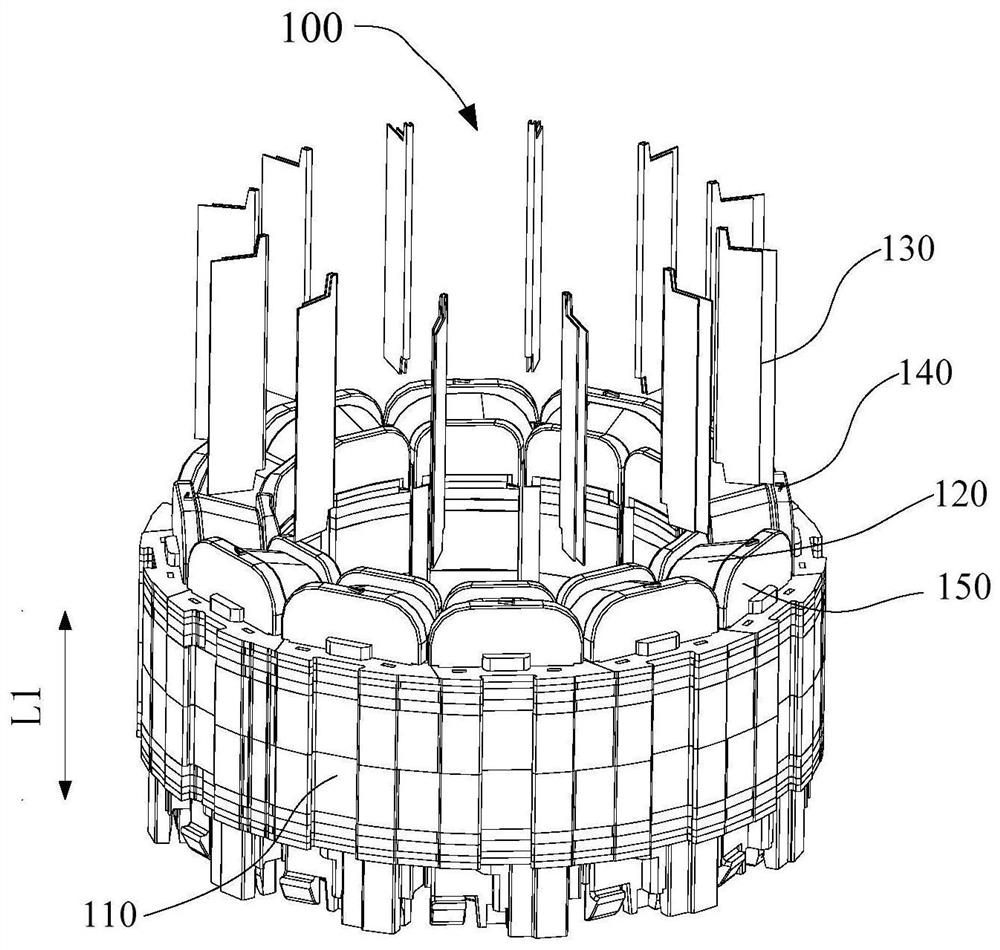

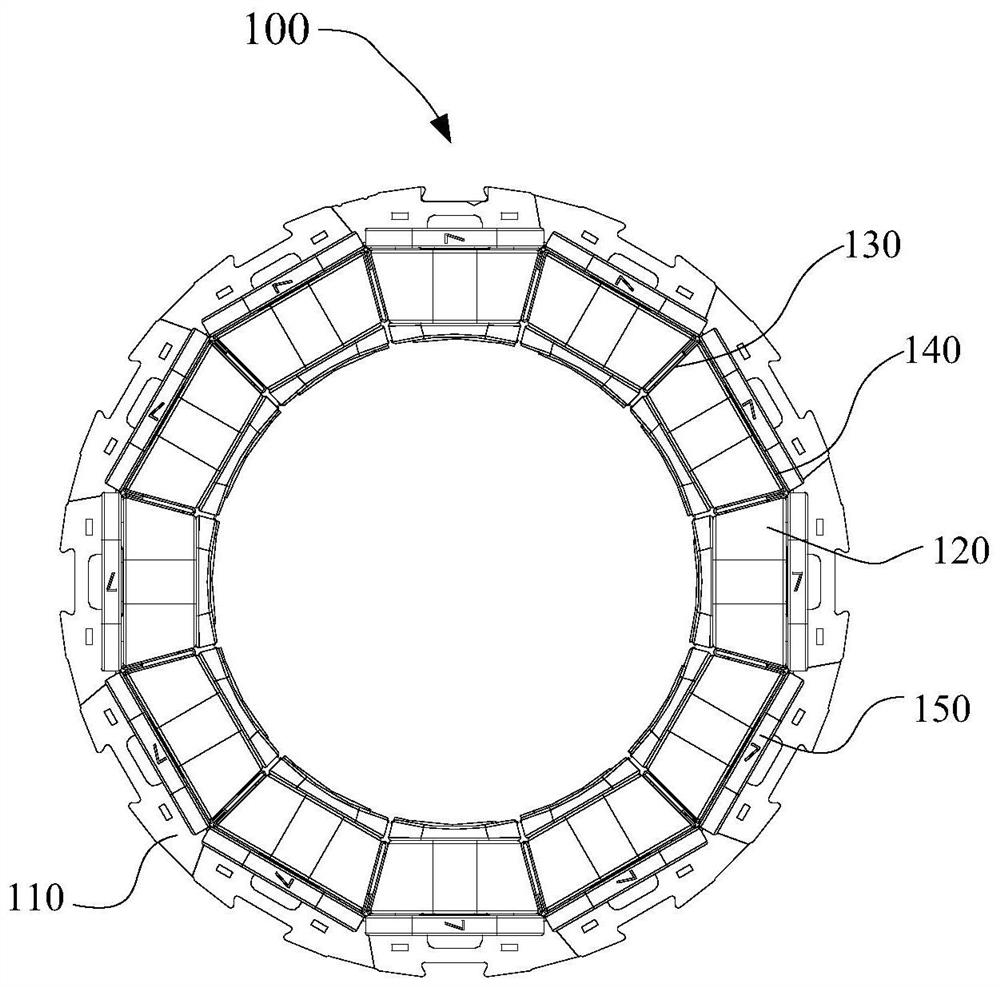

Stator, motor, compressor and vehicle

PendingCN113300503AReduce dosageImprove reliabilityWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineryTooth part

The invention provides a stator, a motor, a compressor and a vehicle, the stator comprises a stator iron core, wherein the stator iron core comprises a plurality of tooth parts, the plurality of tooth parts are distributed along the circumferential direction of the stator iron core, and a stator slot is arranged between two adjacent tooth parts; a winding which is wound on the tooth parts and extends into the stator slots; and a first insulating part, wherein at least part of the first insulating part is located in a gap between the windings on the two adjacent tooth parts, the first insulating part comprises a first insulating part and a second insulating part which are connected, in the same stator groove, the first insulating part is in contact with one winding, the second insulating part is in contact with the other winding, and in a cross section perpendicular to the axis direction of the stator core, the length of the first insulating part is greater than that of the second insulating part. According to the stator provided by the invention, the first insulating part is optimized, that is, the lengths of the first insulating part and the second insulating part are optimized, so that the stator has the characteristics of high insulating reliability, good fixity, easiness in automatic production and low cost.

Owner:ANHUI WELLING AUTO PARTS CO LTD +1

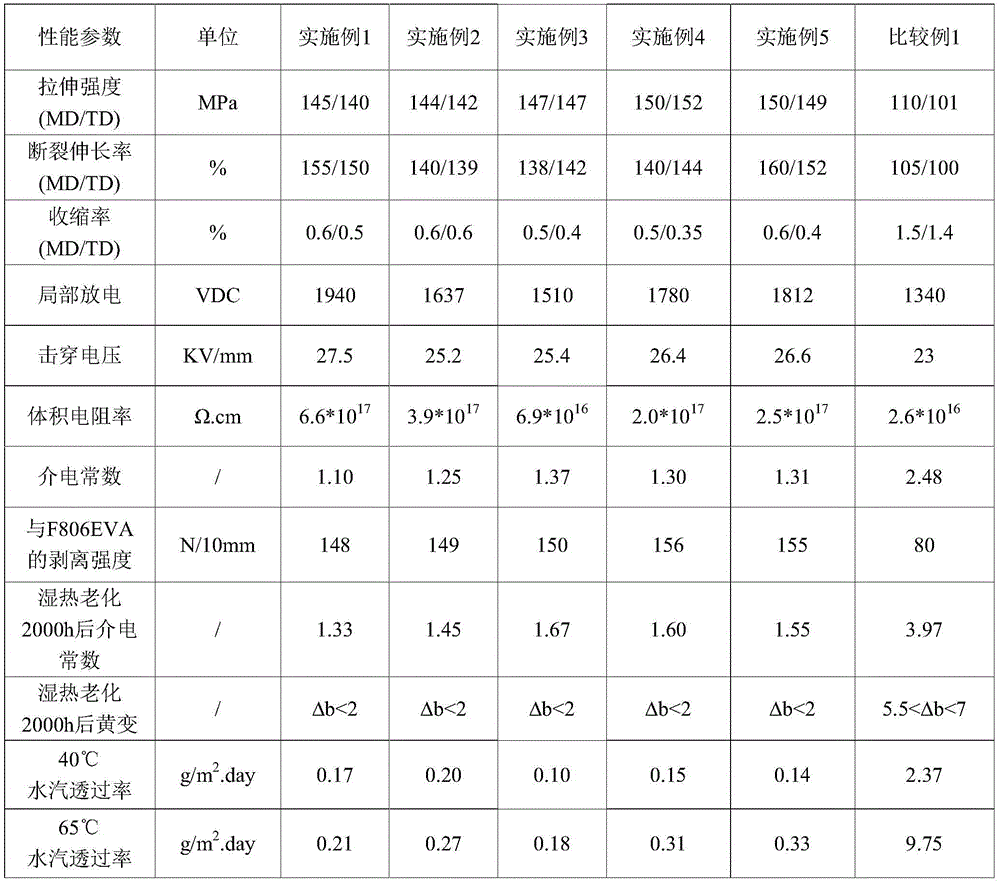

High-insulation moisture-resistant back panel for crystal silicon photovoltaic module packaging

ActiveCN105619980AImprove barrier propertiesGuaranteed insulation reliabilitySynthetic resin layered productsLaminationInsulation layerWater vapor

The invention relates to a high-insulation moisture-resistant back panel for crystal silicon photovoltaic module packaging, and belongs to the field of photovoltaic packaging materials. The back panel is composed of an inner insulation layer, a moisture-resistant layer, a supporting layer and an outer weather-resistant layer in sequence from inside to outside. The manufactured back panel has excellent insulativity and water vapor barrier property, and also has excellent mechanical strength, heat resistance and long-term weather resistance. The back panel is simple in process and stable in product performance, and is an excellent photovoltaic back panel of a crystal silicon photovoltaic module suitable for being mounted in a high-voltage system in a humid area.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

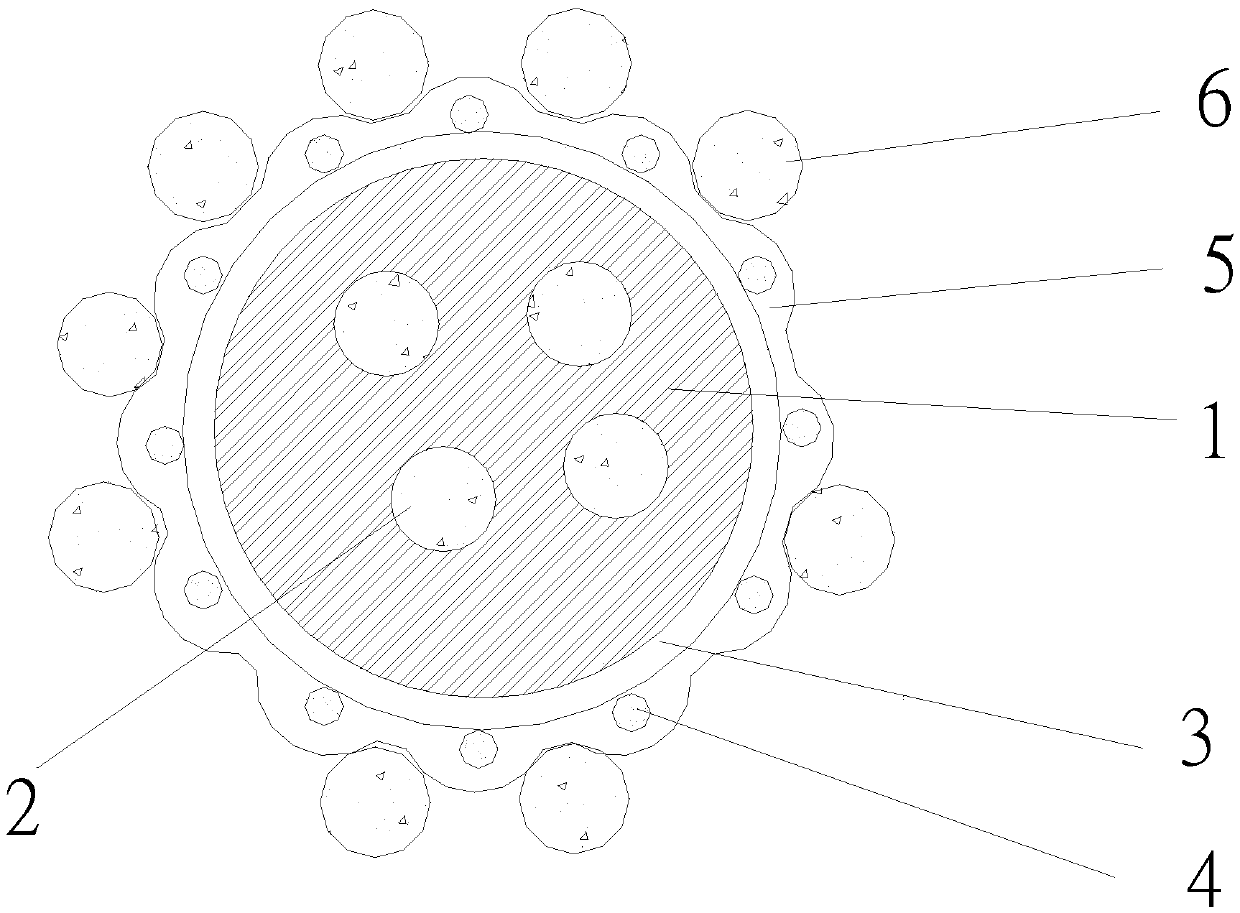

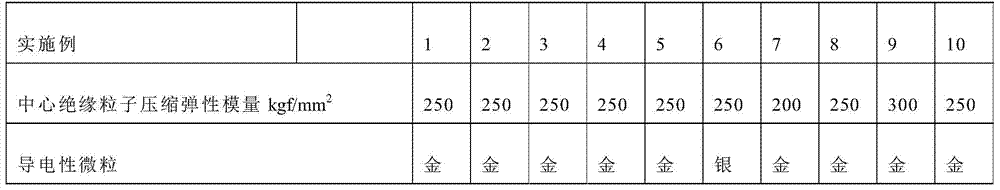

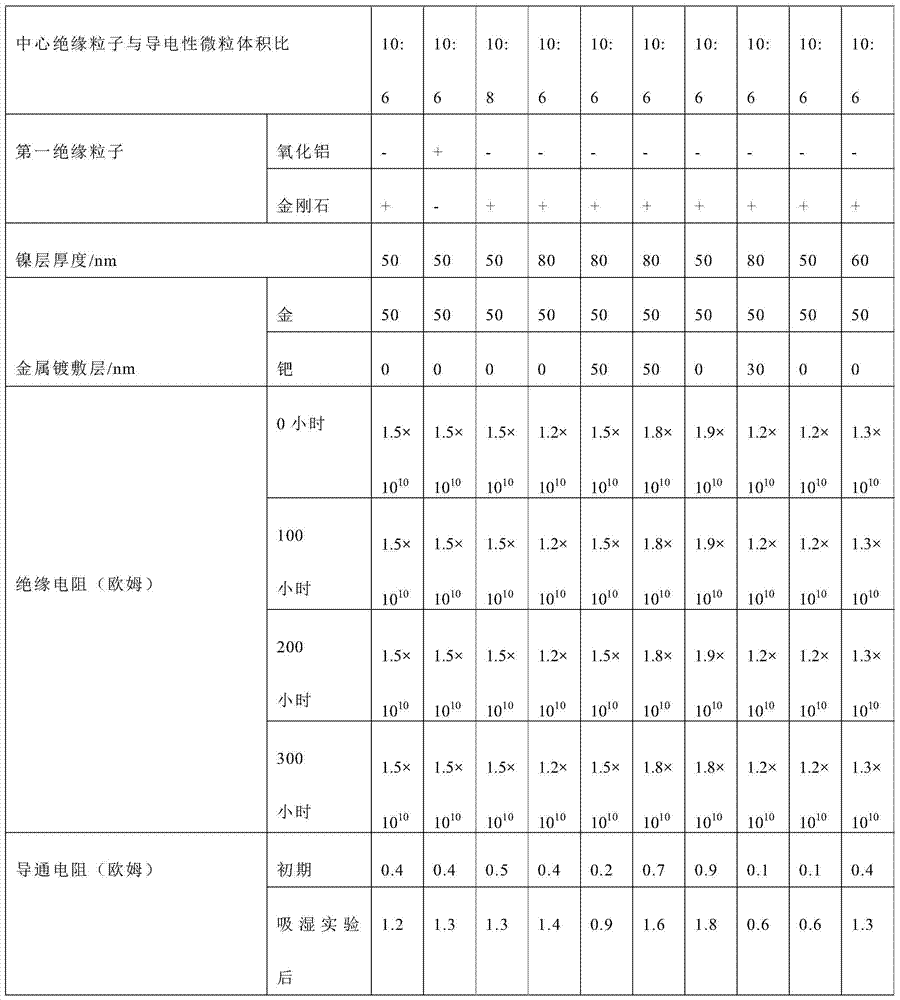

Conducting particle and preparation method thereof

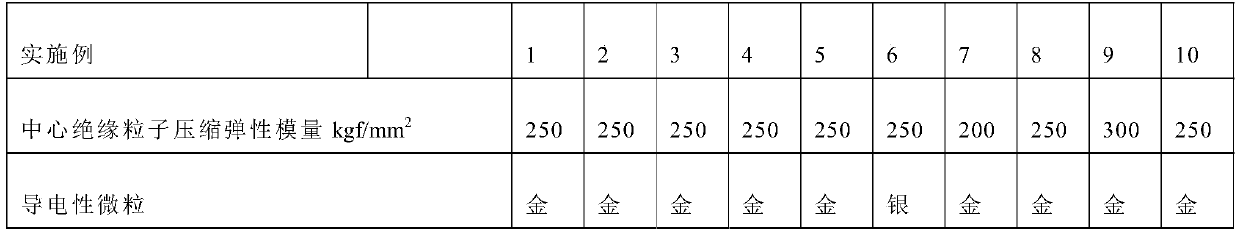

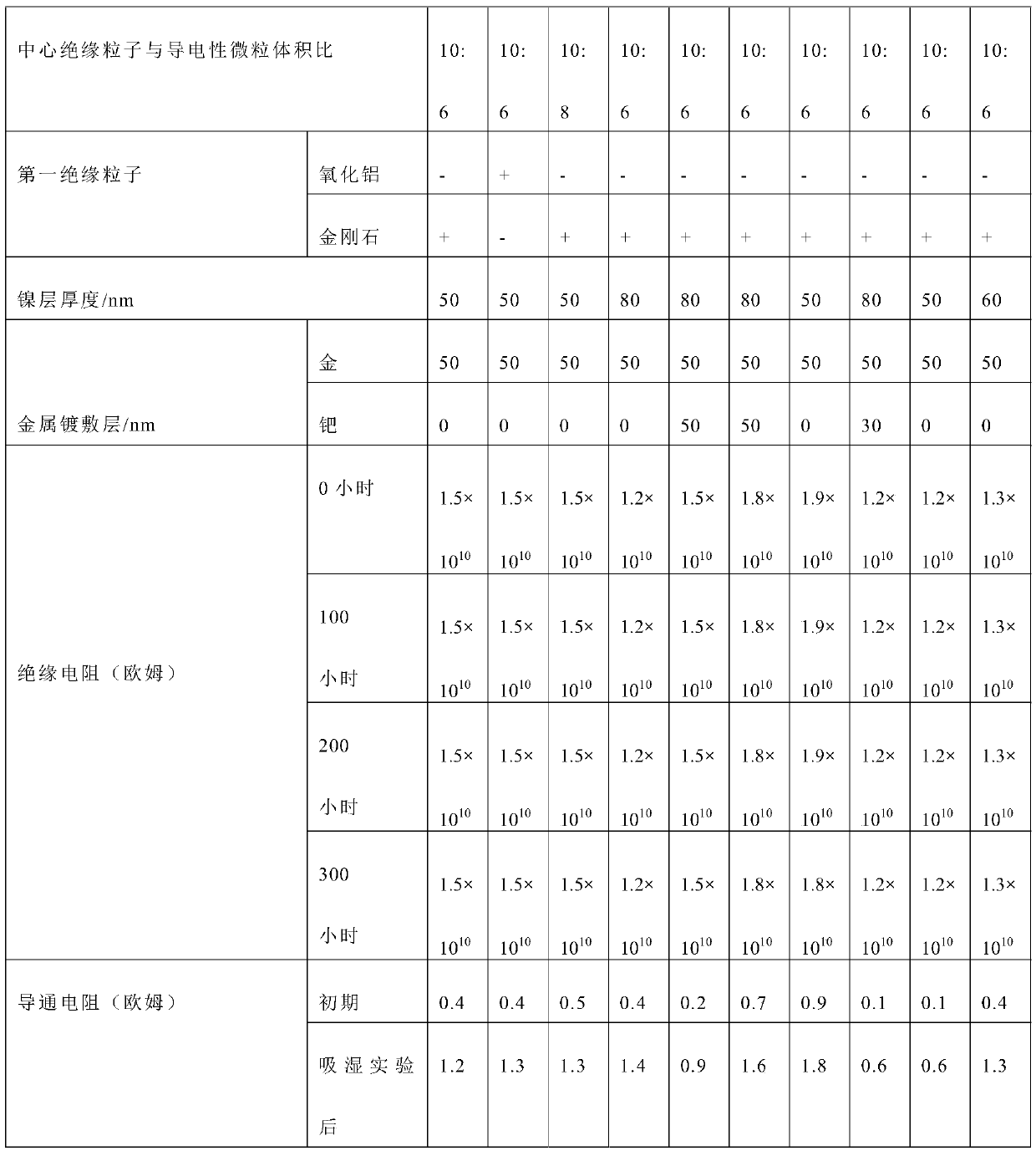

InactiveCN105513673AGood insulation reliabilityAvoid short circuitNon-conductive material with dispersed conductive materialCable/conductor manufactureInsulation resistanceNickel

A conducting particle comprises a center insulation particle, conductive microparicles, a nickel layer, a metal coating layer, first insulation particles and second insulation particles. The center insulation particle is made of an organic insulation material. The conductive microparicles are dispersed in the center insulation particle. The center insulation particle is covered with the nickel layer. The nickel layer is covered with the metal coating layer. The first insulation particles are dispersed in the metal coating layer and cover the nickel layer. The second insulation particles are dispersed in the periphery of the metal coating layer. The conducting particle has good conductivity and insulation reliability, and after the conducting particle is used for a period of time, the insulation resistance of all conducting particles is not reduced, and good conductivity is still kept. The conductivity of the conducting particle is not obviously reduced after a moisture absorption experiment.

Owner:ZHENGZHOU TECHN COLLEGE

An electric heating oil pipeline

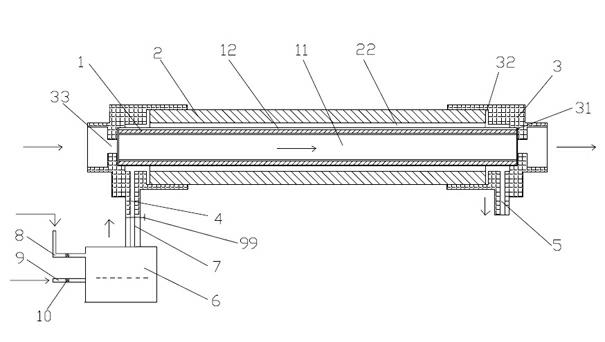

ActiveCN112324359BHeat tracing installation and construction are simpleImprove heating effectDrilling rodsCleaning apparatusThermodynamicsOil field

The invention belongs to the field of oil production equipment in oilfields, and in particular relates to an electrically heated oil delivery pipe. It includes the oil pipe body and the coupling assembly, and two adjacent oil pipe bodies are connected through the coupling assembly; the oil pipe body includes the base layer made of carbon steel and the inner lining layer made of stainless steel, and the inner side of the base layer is processed with two There are two spiral grooves of the same size that do not intersect with each other. Each of the two spiral grooves contains an electric heating cable. The two electric heating cables spirally coil along the inner wall of the base layer and extend to both ends of the base layer. Each end is connected with a connection terminal, and the connection terminal is fixed on the end surface of the base layer. The invention can make the heat tracing installation and construction of the oil pipe simpler by embedding electric heating cables inside the oil pipe, and effectively improve the heat tracing effect at the same time.

Owner:席赫

Permanent magnet direct drive wind turbine, system and its stator

ActiveCN104810942BReduce risk of erosionGuaranteed insulation reliabilityEngine sealsMagnetic circuit stationary partsEngineeringTurbine

The present invention provides a permanent magnet direct drive wind power generator, a system and a stator thereof, wherein the stator includes a stator bracket, a stator core, a paddle side tooth pressure plate and a paddle side shroud, and the paddle side tooth pressure plate is arranged on the paddle side of the stator core On the axial end face, a first air hole is opened on the outer peripheral wall of the stator bracket, and a second air hole is opened on the paddle side tooth pressure plate. The stator also includes an air flow channel connecting the first air hole and the second air hole. The air flow channel passes through the stator Inside the iron core, a comb-toothed air intake hole is provided on the oar side coaming plate, and the comb-teeth air intake hole and the second air hole are connected through an air guide tube. The first helical comb tooth mechanism communicated with the air intake hole of the tooth, and the first helical comb tooth is located in the annular gap formed by the paddle side shroud and the rotor sealing ring. Through the technical proposal of the present invention, the "multi-phase" airflow sealing of the annular gap formed by the paddle side shroud and the rotor sealing ring is realized.

Owner:XINJIANG GOLDWIND SCI & TECH

A low-temperature plasma-cocatalyzed ADN-based monocomponent thruster

ActiveCN110259605BIndependently observe the ionization effectPlays the role of removing residual propellantRocket engine plantsCombustion chamberEngineering

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

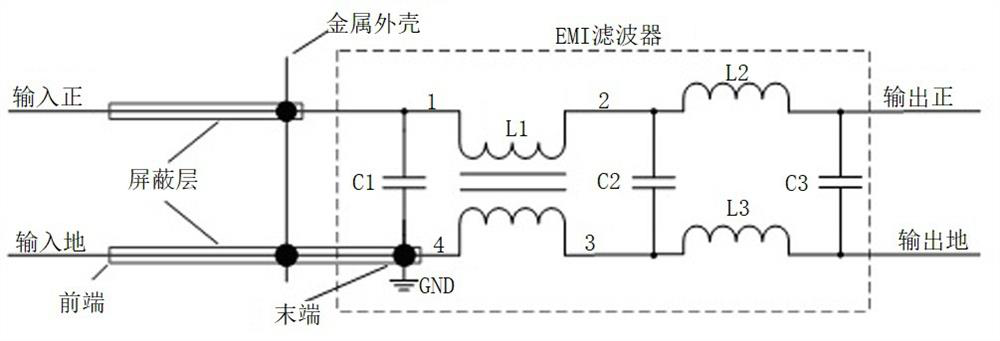

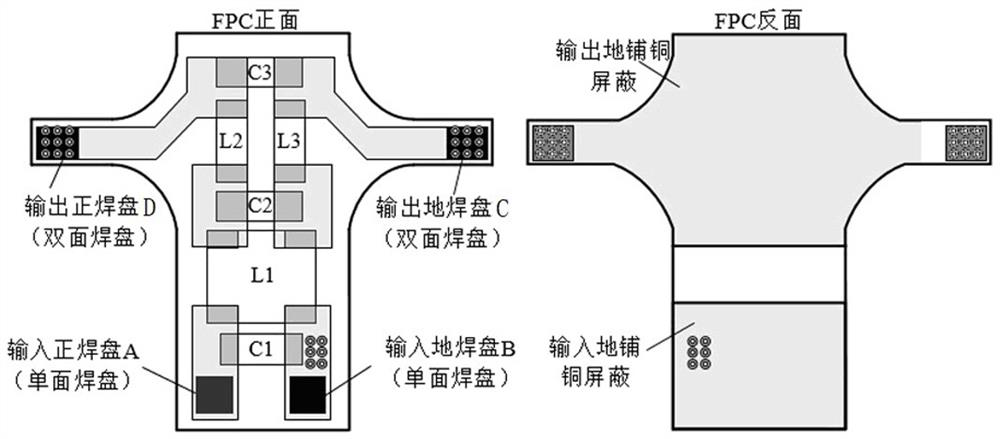

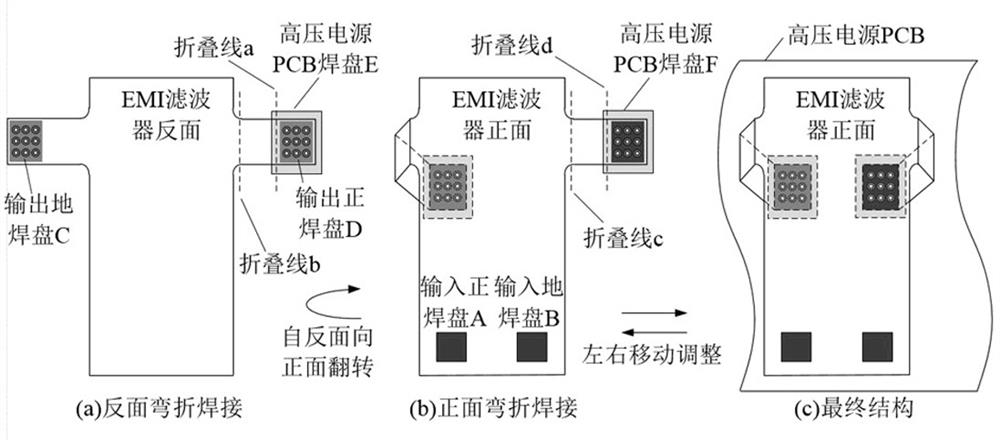

EMI filter for image intensifier and assembling method thereof

PendingCN112117983AThe solution cannot be placed reasonablyImprove electromagnetic compatibilityPrinted circuit assemblingMultiple-port networksCapacitanceMetallic enclosure

The invention belongs to the technical field of image intensifiers, and particularly provides an EMI filter for an image intensifier and an assembling method thereof, the EMI filter is of a two-stagecombined filtering structure, integrates a capacitor, an inductor and a magnetic bead component, adopts a flexible printed board to independently design a layout, and then welds the designed flexibleprinted board on a high-voltage power supply PCB in a laminated mode. The bonding pad on the front side is reinforced, the bonding pad on the back side is insulated, the bonding pad and the high-voltage power supply PCB are bent together, the bonding pad and the high-voltage power supply PCB are put into the metal shell, encapsulating by using silicone rubber to finish integral shaping, and finally welding the shielding wire and the metal shell by 360 degrees. Reasonable placement of the EMI filter is achieved, the problems that a small image intensifier cannot directly use the EMI filter or the placement position and layout design are not ideal are solved, meanwhile, the small image intensifier can be reliably assembled on the image intensifier, the electromagnetic compatibility of the image intensifier is effectively improved, and it is ensured that the image intensifier can meet the requirement of an electromagnetic compatibility test.

Owner:NORTH NIGHT VISION TECH

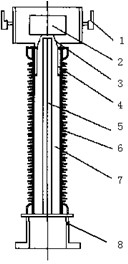

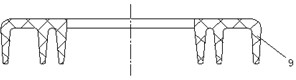

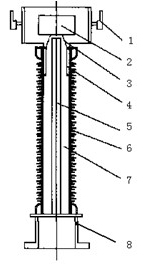

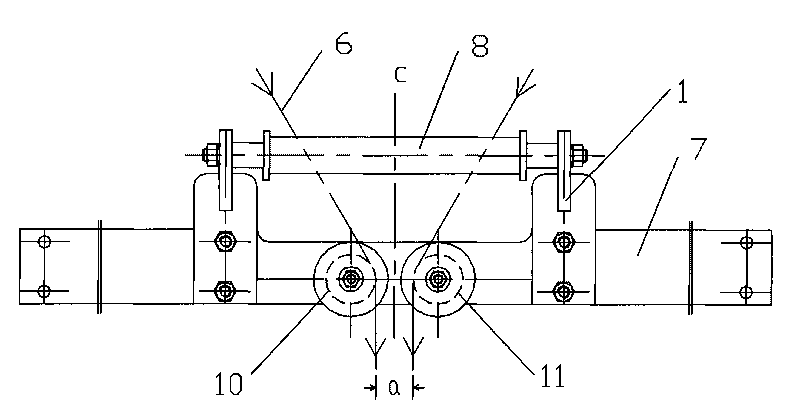

Ultra-multiple parallel-winding wire concentrator for wire winding

InactiveCN101764477AImprove wear resistanceReduce frictionManufacturing dynamo-electric machinesPulp and paper industryConductor Coil

The invention discloses an ultra-multiple parallel-winding wire concentrator for wire winding, comprising a machine frame, supporting plates and rollers. The supporting plates are fixed at the middle part of the machine frame, a first roller and a second roller are arranged in parallel in front of the machine frame, the left and right ends of the first roller and the second roller are crossed on the supporting plates, the first roller is located right above the second roller, the first roller and the second roller form an upper roller set and a lower roller set, and a gap is arranged between the first roller and the second roller; a third roller and a fourth roller are vertically arranged with the machine frame, are located at the rear of the first roller and the second roller after penetrating through the machine frame, and are arranged between the two supporting plates; the third roller is located at the left side of the fourth roller, the third roller and the fourth roller form a left roller set and a right roller set, and a gap is arranged between the third roller and the fourth roller. A plane formed by shaft axes of the third roller and the fourth roller is parallel to that formed by the shaft axes of the first roller and the second roller. With simple structure and convenient installation, the wire concentrator can concentrate a plurality of widely-dispersed lacquered wires into a group of wire bundles without any damage.

Owner:SHANGHAI ELECTRIC XIANFENG ELECTRICAL MACHINERY

500kV wire outlet device for extra-high voltage transformer

PendingCN110911131AImprove electric field distributionElectric Field Distribution RulesTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionControl theoryHigh voltage transformer

The invention relates to a 500kV wire outlet device for an extra-high voltage transformer, which solves the problem of electric field concentration caused by a 500kV lead, improves the electric fielddistribution of the lead, and ensures the insulation reliability of the lead and a 1000kV coil, an oil tank, an iron core and the like. The outgoing line device is simple in structure, does not need to be shielded and bound manually, does not have a complex insulating cylinder matching problem, and has low skill requirements for installation personnel. The wire outlet device can be adjusted, the position of a voltage-sharing ball can be adjusted in a rotating mode with the third shielding cylinder as the axis after the connecting device is loosened, meanwhile, the long circular installation hole in the voltage-sharing ball can be used for adjustment, it is guaranteed that the installed sleeve and the voltage-sharing ball are concentric, electric field distribution is more regular, and insulation reliability is higher.

Owner:WUJIANG TRANSFORMER CO LTD

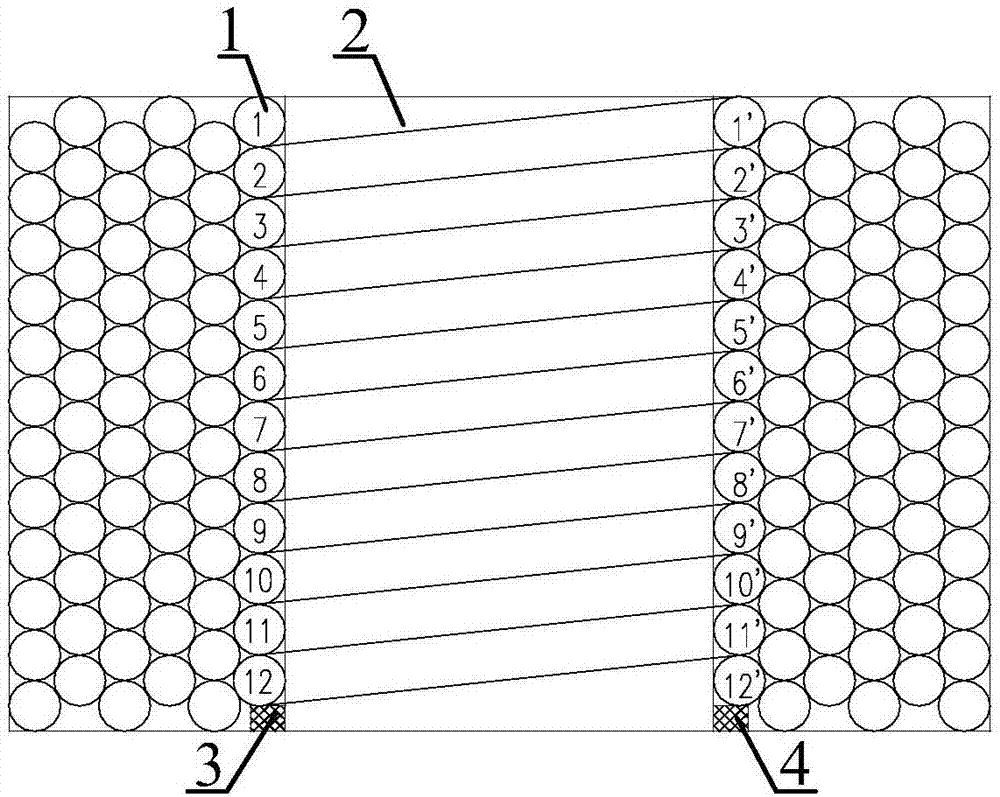

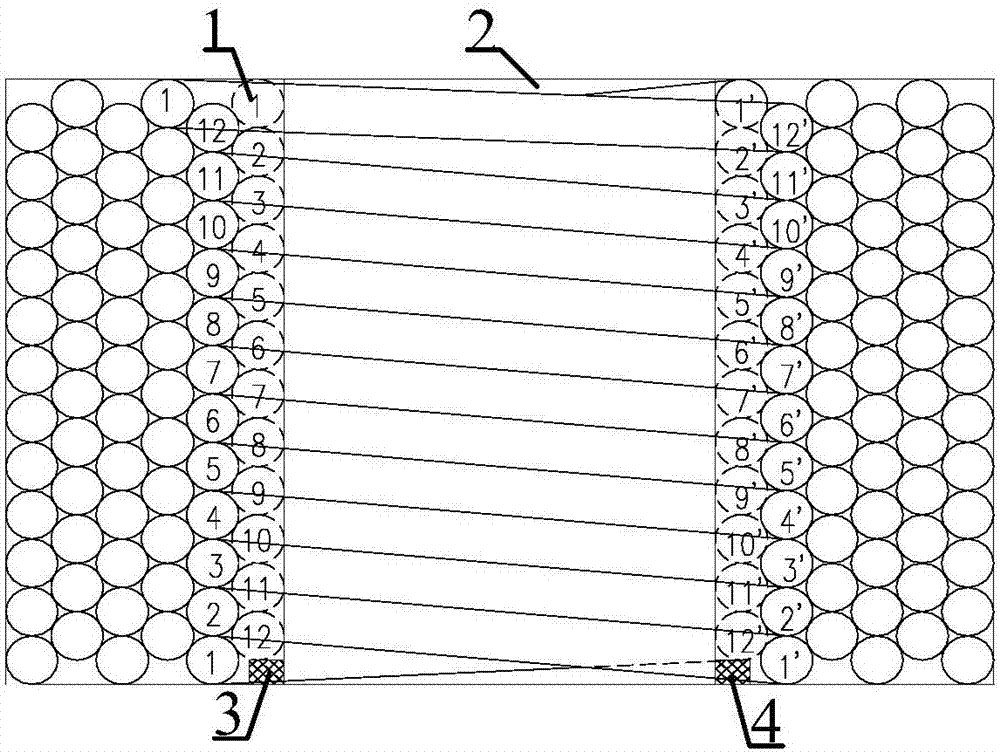

A kind of multi-layer winding and its winding method

ActiveCN106469598BGuaranteed insulation reliabilityArrange neatlyInductances/transformers/magnets manufactureCoilsConductor CoilLine structure

Owner:CSR ZHUZHOU ELECTRIC CO LTD

An ultra-high voltage vacuum insulation device

InactiveCN105679596BAvoid arcingGuaranteed insulation performanceHigh-tension/heavy-dress switchesAir-break switchesUltra high voltageHigh tension line

Owner:CHENGDU CVAC VACUUM TECH CO LTD

Gas-insulated switching device

ActiveCN102187537BSmall sizeExcellent abrasion resistanceHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

Large-diameter part 16 is formed at the axial-middle part of rotary shaft 15 that rotates driven by operating device. Insulated operating rod 14, the distal end of which makes move in the form of a segment of a circle effected by the rotation of rotary shaft 15, is formed integrally using filler-filled resin over large-diameter part 16 of rotary shaft 15 by cast so that the large-diameter part 15 is embedded into one end of insulated operating rod 14. The contact and connection between insulated operating rod 14 and moving rod 13 is given such sliding surface 21 as is formed for example in an elliptical shape so that the contact occur always at almost one-point on the axis line of the moving rod 13.

Owner:HITACHI LTD

Ultra-multiple parallel-winding wire concentrator for wire winding

InactiveCN101764477BImprove wear resistanceReduce frictionManufacturing dynamo-electric machinesMachineWire wrap

The invention discloses a multiple parallel-winding wire concentrator for wire winding, comprising a machine frame, supporting plates and rollers. The supporting plates are fixed at the middle part of the machine frame, a first roller and a second roller are arranged in parallel in front of the machine frame, the left and right ends of the first roller and the second roller are crossed on the supporting plates, the first roller is located right above the second roller, the first roller and the second roller form an upper roller set and a lower roller set, and a gap is arranged between the first roller and the second roller; a third roller and a fourth roller are vertically arranged with the machine frame, are located at the rear of the first roller and the second roller after penetrating through the machine frame, and are arranged between the two supporting plates; the third roller is located at the left side of the fourth roller, the third roller and the fourth roller form a left roller set and a right roller set, and a gap is arranged between the third roller and the fourth roller. A plane formed by shaft axes of the third roller and the fourth roller is parallel to that formed by the shaft axes of the first roller and the second roller. With simple structure and convenient installation, the wire concentrator can concentrate a plurality of widely-dispersed lacquered wires into a group of wire bundles without any damage.

Owner:SHANGHAI ELECTRIC XIANFENG ELECTRICAL MACHINERY

Printing wiring cardinal plate and method for producing the same

ActiveCN101594737BGuaranteed insulation reliabilityImprove corrosion resistanceConductive material chemical/electrolytical removalMetallic pattern materialsElectrical conductorEtching

The invention provides a printing wiring cardinal plate with high insulation reliability and corrosion resistance and method for producing the same, namely the conductor wiring is formed with high etching, when etching is performed by ferric chloride solution or hydrochloric acid solution of copper chloride, residual etching draff with ingredients of the base metal layer between the conductor wirings are few, when high voltage is exerted among the conductor wirings. On at least one surface of the insulating resin film A, a metallic layer B with nickel, or nickel-chromium alloy containing nickel above 70 quality percentage and chromium below 15 quality percentage is stacked in series without an adhesive agent; a metallic layer C made of alloy containing chromium over 15 weight percentage, unnecessary part of a metal membrane composed by copper tunica layer D with thickness 10 nm to 35 Mum, chemical etching processing is adopted for selective removal, and then the printing wiring cardinal plate of conductor wirings is formed.

Owner:SUMITOMO METAL MINING CO LTD

A kind of conductive particle and preparation method thereof

InactiveCN105513673BGuaranteed electrical conductivityGuaranteed insulation reliabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureMetal coatingMoisture absorption

A conducting particle comprises a center insulation particle, conductive microparicles, a nickel layer, a metal coating layer, first insulation particles and second insulation particles. The center insulation particle is made of an organic insulation material. The conductive microparicles are dispersed in the center insulation particle. The center insulation particle is covered with the nickel layer. The nickel layer is covered with the metal coating layer. The first insulation particles are dispersed in the metal coating layer and cover the nickel layer. The second insulation particles are dispersed in the periphery of the metal coating layer. The conducting particle has good conductivity and insulation reliability, and after the conducting particle is used for a period of time, the insulation resistance of all conducting particles is not reduced, and good conductivity is still kept. The conductivity of the conducting particle is not obviously reduced after a moisture absorption experiment.

Owner:ZHENGZHOU TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com