Wire harness protector

A technology of protectors and wire harnesses, applied in the direction of electrical components, circuits or fluid pipelines, connecting end caps, etc., can solve problems such as not easy to ensure, and achieve the effect of effectively accommodating and maintaining insulation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

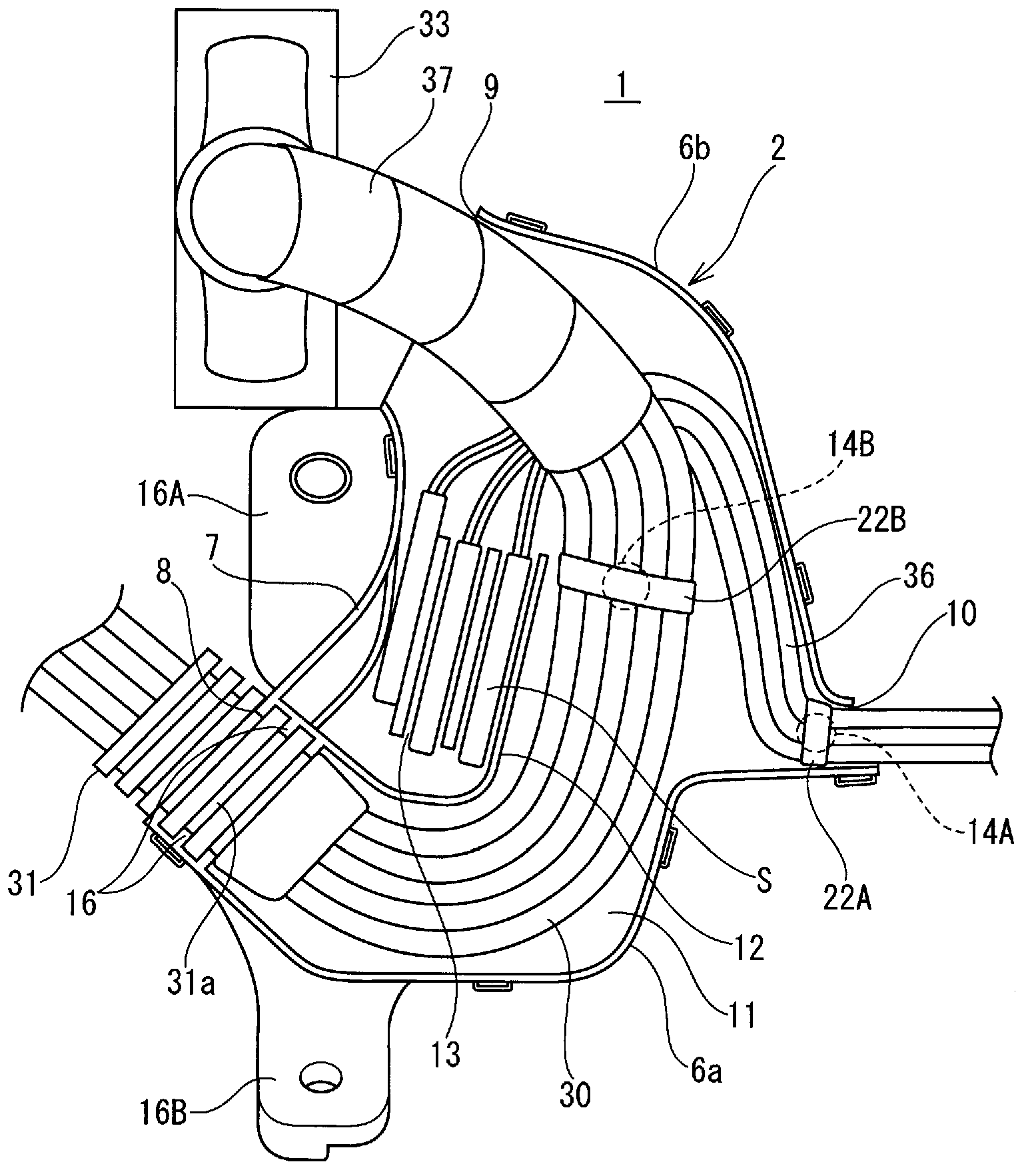

[0042] Hereinafter, embodiment of the protector of this invention is demonstrated based on drawing.

[0043] The protector 1 of the embodiment is a protector for a wire harness arranged in an automobile, and the protector 1 of the present embodiment is arranged in an engine room in a submerged area.

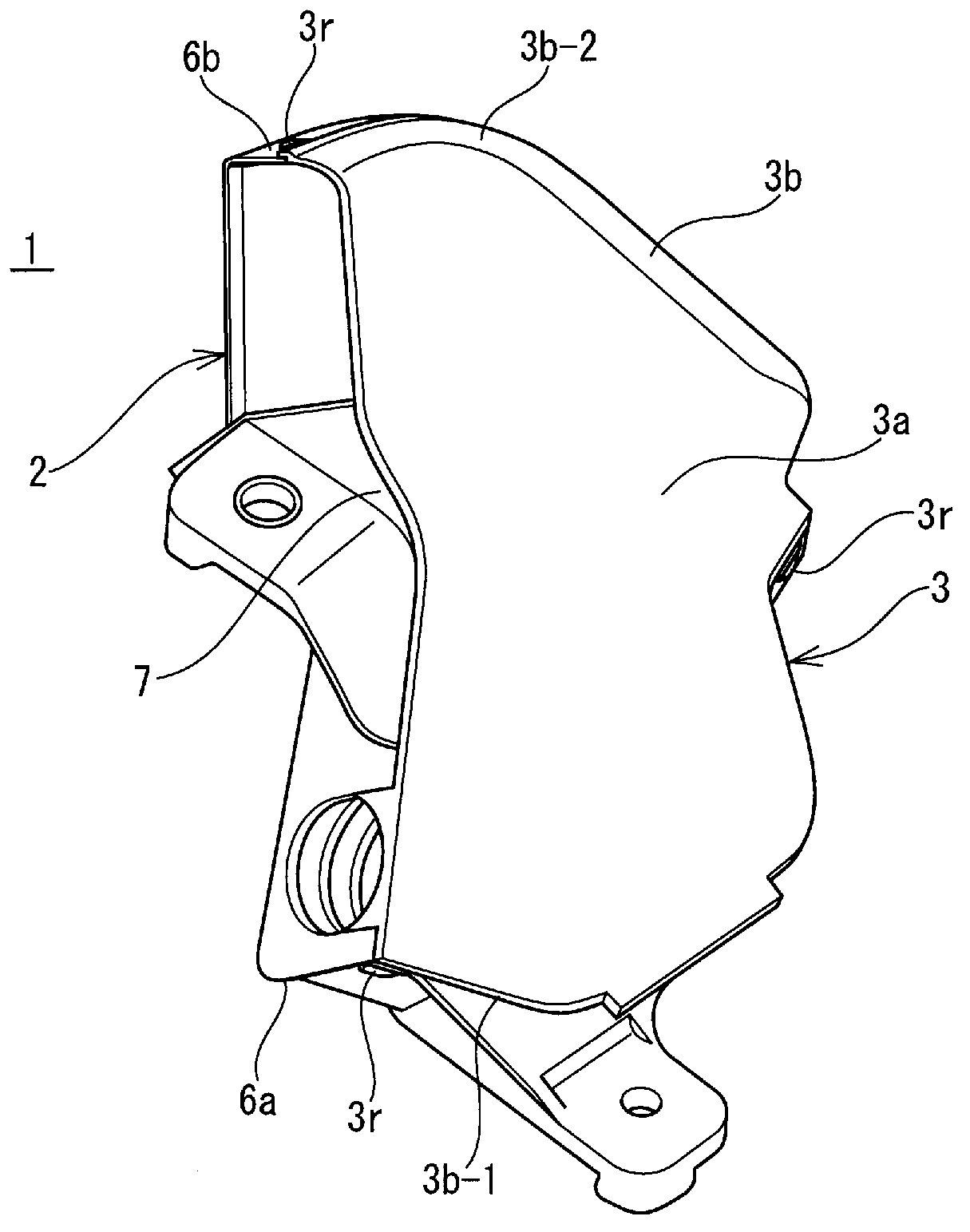

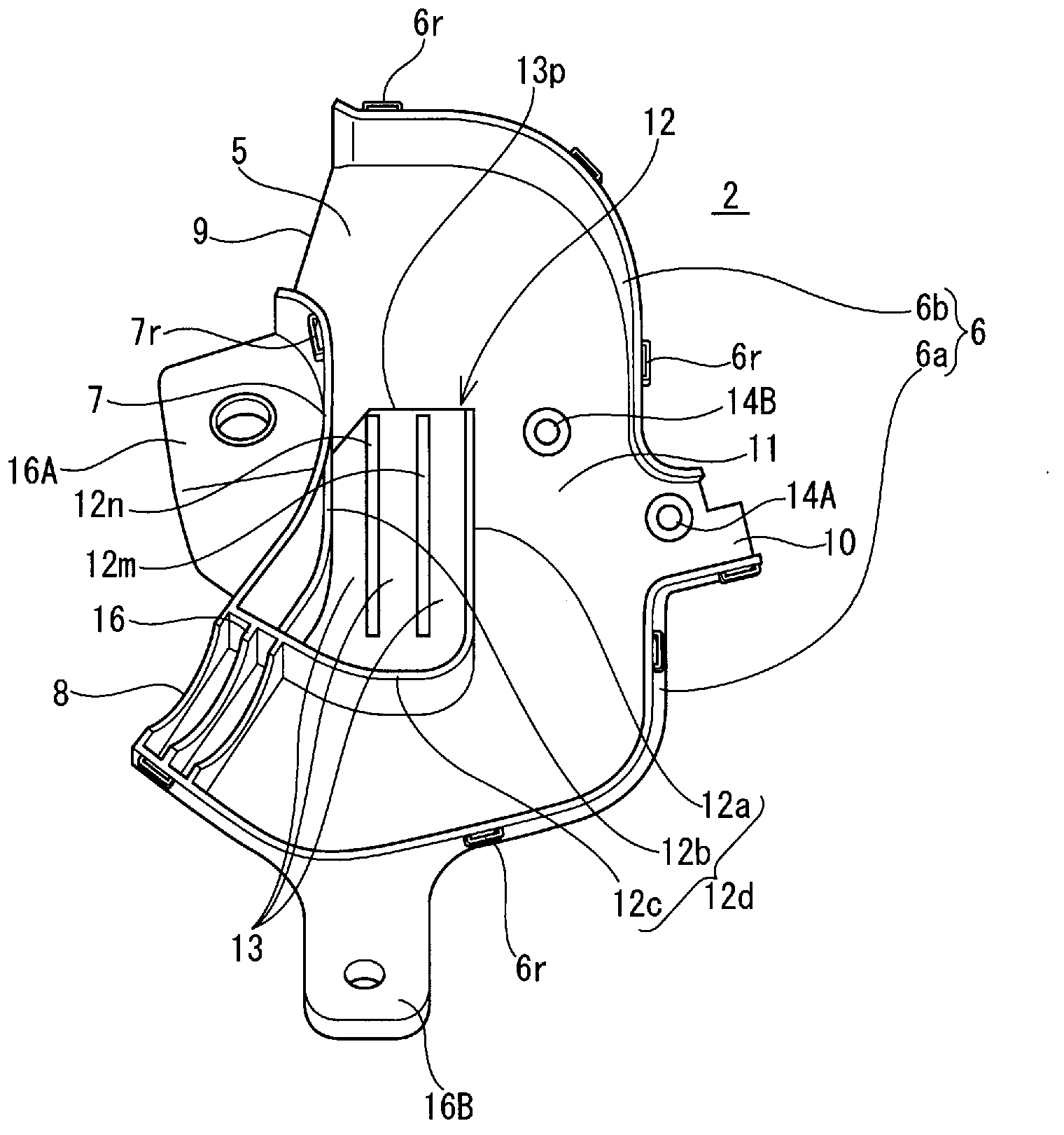

[0044] The protector 1 is composed of a main body 2 and a cover 3 covering an opening on the upper surface of the main body 2, and both the main body 2 and the cover 3 are resin molded products.

[0045] Such as figure 2, 3 As shown, the main body 2 has a bottom wall 5 and a peripheral wall composed of an outer side wall 6 and an inner side wall 7 protruding from both sides of the bottom wall 5 in the width direction. The outer wall 6 is bent in a substantially C shape with a large arc as a whole, and an inlet 8 and an outlet 9 for the harness opening in the same direction are provided between the inner wall 7 and both ends in the longitudinal direction of the outer wall 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com