High-energy multi-state low-temperature ionizer

A low-temperature plasma and generator technology, applied in the direction of plasma, can solve the problems of poor cooling effect, difficult ion control, complex ion generator structure, etc., and achieve the effect of avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

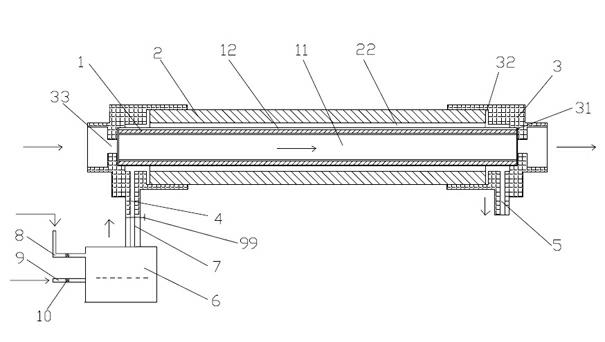

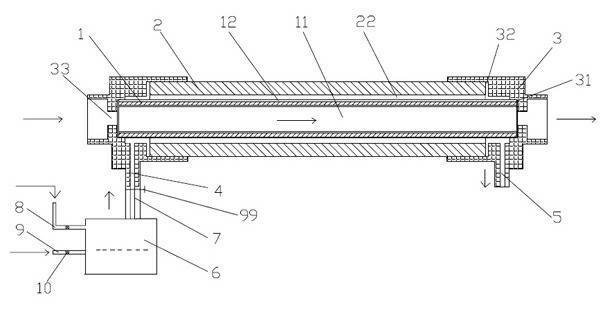

[0017] The structural representation of the high-energy multi-state low-temperature plasma generator of the present invention is as attached figure 1 As shown, the inner electrode 1 and the outer electrode 2 are included, and the inner electrode 1 and the outer electrode 2 are respectively connected to a high-frequency high-voltage power supply. The inner electrode 1 and the outer electrode 2 are tubular structures, and the hollow cavity of the inner electrode 1 is used as a cooling channel 11. The two ends of the inner electrode 1 and the outer electrode 2 are respectively provided with electrode holders 3, and the two ends of the inner electrode 1 and the outer electrode 2 are respectively fixed on the electrode holders 3, the inner electrode 1 is set inside the outer electrode 2, and the outer surface of the inner electrode 1 is in contact with the An ionization channel 22 is formed between the inner surfaces of the outer electrodes 2. The ionization channel 22 is suitable f...

Embodiment 2

[0024] The structure of this embodiment is similar to that of Embodiment 1, and the difference is that an insulating layer 12 is also provided on the inner and outer surfaces of the outer electrode 2 to further ensure the insulation reliability between the inner electrode 1 and the outer electrode 2, wherein the material of the insulating layer 12 Also for ceramics.

[0025] The working process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com