Preparation method of anti-dezincification lead-free bismuth arsenic brass pipe

A zinc-lead-free bismuth-arsenic brass and copper tube technology is applied in the field of preparation of dezincification-resistant lead-free bismuth-arsenic brass tubes, which can solve the problems of weakening the dezincification corrosion resistance of duplex brass, and improve the dezincification resistance. The effect of zinc corrosion performance, improving element absorption rate and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of anti-dezincification lead-free bismuth arsenic brass is characterized in that: be made up of the raw material of following mass percent:

[0028] Cu61%, Bi0.5%, As0.07%, Al0.5%, Sn0.08%, Pb0.06%, Zn37.75% and total 0.04% impurities.

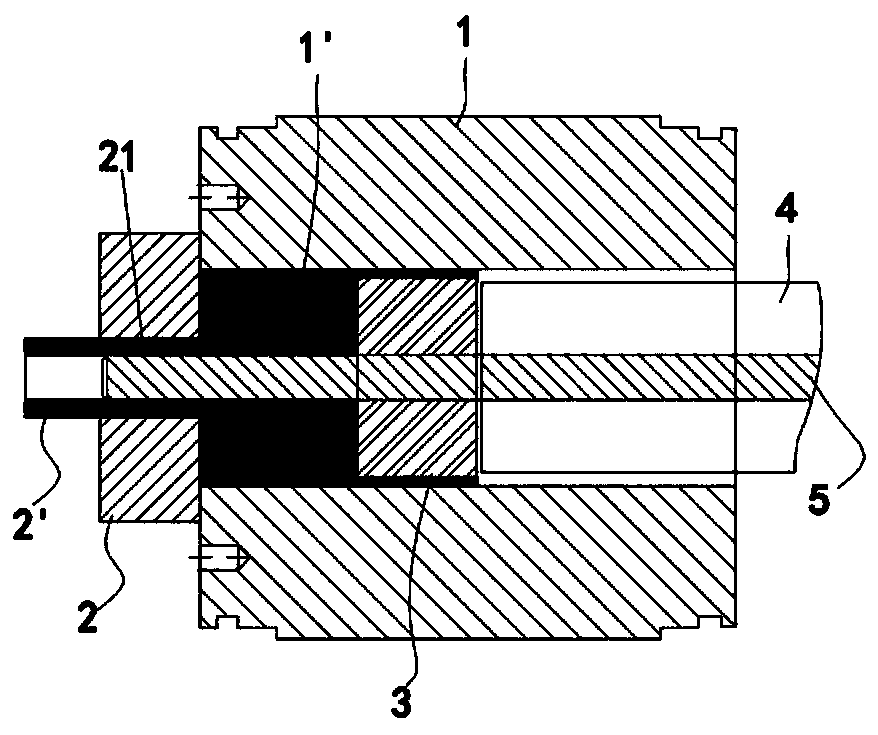

[0029] A method for preparing a dezincification-resistant lead-free bismuth-arsenic brass tube, including casting the brass liquid with the above mass percentage into a copper ingot → extruding into a copper tube billet → stretching → annealing → inspection of the finished copper tube → finished product The step of copper pipe warehousing; Wherein, the step of introducing and casting copper ingots includes:

[0030] 1) First add 150kg of pure copper rice into the cored power frequency furnace. The total amount of pure copper rice in the power frequency furnace is 7.5% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.08% tin ingot, 0.5% bismuth ingot and 0.5% aluminum ingot accounted fo...

Embodiment 2

[0047] A kind of anti-dezincification lead-free bismuth-arsenic brass is made up of the following raw materials in mass percentage: Cu62%, Bi0.7%, As0.1%, Al0.7%, Sn0.15%, Pb0.09%, Zn36 .12% and total 0.14% impurities.

[0048] A method for preparing a dezincification-resistant lead-free bismuth-arsenic brass tube, including casting the brass liquid with the above mass percentage into a copper ingot → extruding into a copper tube billet → stretching → annealing → inspection of the finished copper tube → finished product The step of copper pipe warehousing; Wherein, the step of introducing and casting copper ingots includes:

[0049] 1) First add 200kg of pure red copper rice into the cored power frequency furnace. The total amount of pure red copper rice in the power frequency furnace is 10% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.15% tin ingot, 0.7% bismuth ingot and 0.7% aluminum ingot accounted for the total raw material...

Embodiment 3

[0061] A dezincification-resistant lead-free bismuth-arsenic brass, consisting of the following raw materials in mass percentage: Cu63%, Bi0.9%, As0.12%, Al0.8%, Sn0.24%, Pb0.02%, Zn34 .84% and a total of 0.08% impurities.

[0062]A method for preparing a dezincification-resistant lead-free bismuth-arsenic brass tube, including casting the brass liquid with the above mass percentage into a copper ingot → extruding into a copper tube billet → stretching → annealing → inspection of the finished copper tube → finished product The step of copper pipe warehousing; Wherein, the step of introducing and casting copper ingots includes:

[0063] 1) First add 300kg of pure copper rice into the cored power frequency furnace. The total amount of pure copper rice in the power frequency furnace is 15% of the total raw materials. When it is in a semi-molten state, press it into the preheated 0.24% tin ingot, 0.9% bismuth ingot and 0.8% aluminum ingot accounted for the total raw material, ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com