Patents

Literature

33results about How to "Improve dezincification corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin-brass alloy containing rare earth

The invention relates to a rare earth stannum copper alloy, belonging to the technical field of the alloying of metal material and the anti-corrosion; the invention comprises copper, zinc, stannum, aluminum, nickel, manganese, antimony, boron, mischmetal containing mainly light rare earth elements such as lanthanum and cerium, each component element takes up the weight proportion as: copper 69-71%, stannum 0.5-1%, aluminum 0.1-0.5%, nickel 0.1-0.5%, manganese 0.1-0.6%, antimony 0.01-0.05%, boron 0.002-0.02%, mischmetal containing mainly light rare earth elements such as lanthanum and cerium 0.02-0.2%, the rest is taken by zinc and impurity with the total volume of no greater than 0.05%, the sum up of each component element is 100%. The invention aiming at the high corrosion resistance requirements by a condenser tube for heat exchange, via optimized design and multiple test, is finished to improve the anti-stress corrosion rupture performance, and level up the anti high C1-, NH4+, S2- ion density corrosion performance of polluted water.

Owner:ZHEJIANG HAILIANG

Low-lead brass alloy and preparation method thereof

InactiveCN104087782AExcellent machinabilityImprove dezincification corrosion resistanceManganeseAlloy

The invention discloses a low-lead brass alloy. The low-lead brass alloy comprises 61.5-63.5% of copper and 0.02-0.15% of arsenic and also comprises less than or equal to 0.3% of nickel, less than or equal to 0.1% of aluminum, less than or equal to 0.2% of lead, less than or equal to 0.1% of manganese, iron and tin and the balance Fe and unavoidable impurities, wherein the content of the unavoidable impurities is less than or equal to 0.2%. The low-lead brass alloy reduces an alloy manufacturing cost, improves cutting ability and improves dezincification resistance.

Owner:NINGBO IDC INT TRADE +1

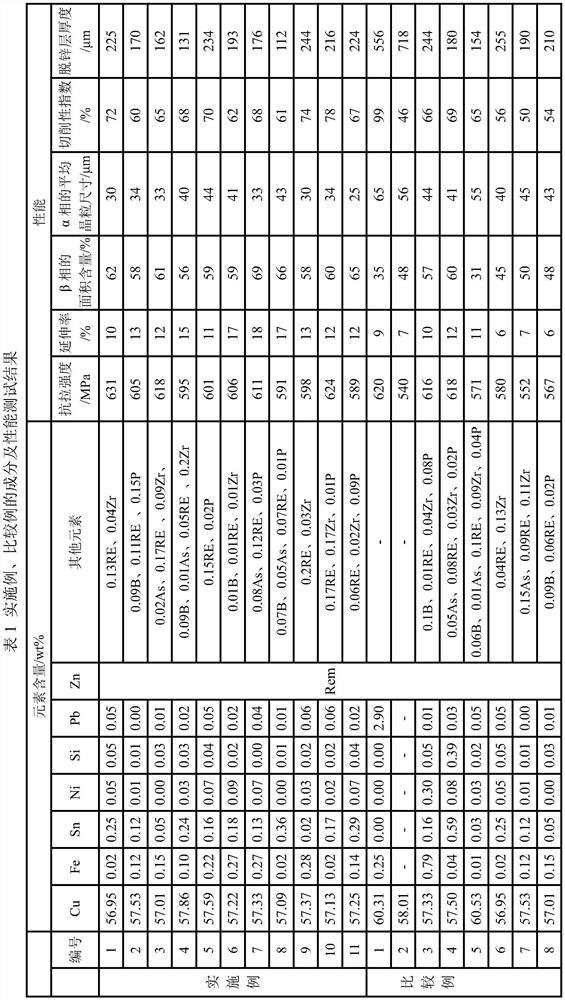

Free-cutting brass alloy and preparation method and application thereof

ActiveCN111235427AImprove dezincification corrosion resistanceReduce wearHome applianceMachinability

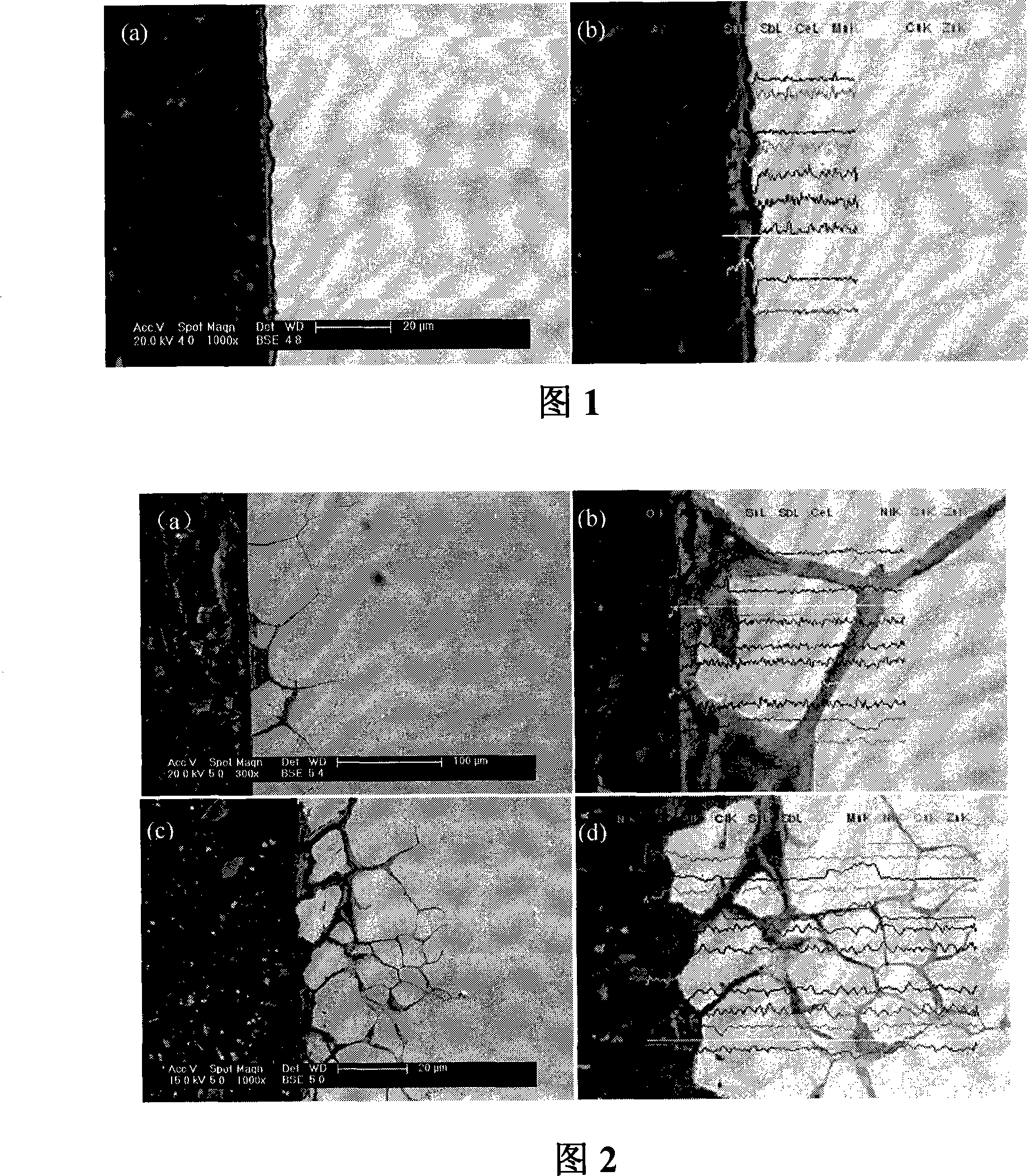

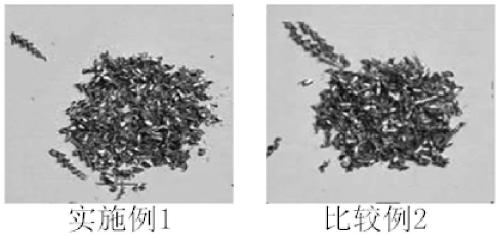

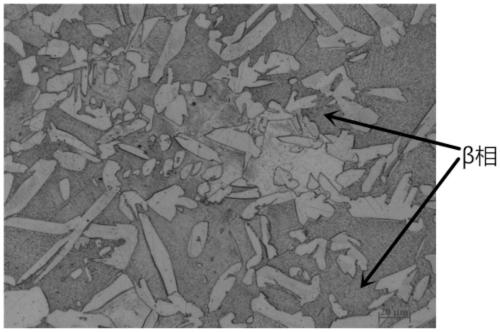

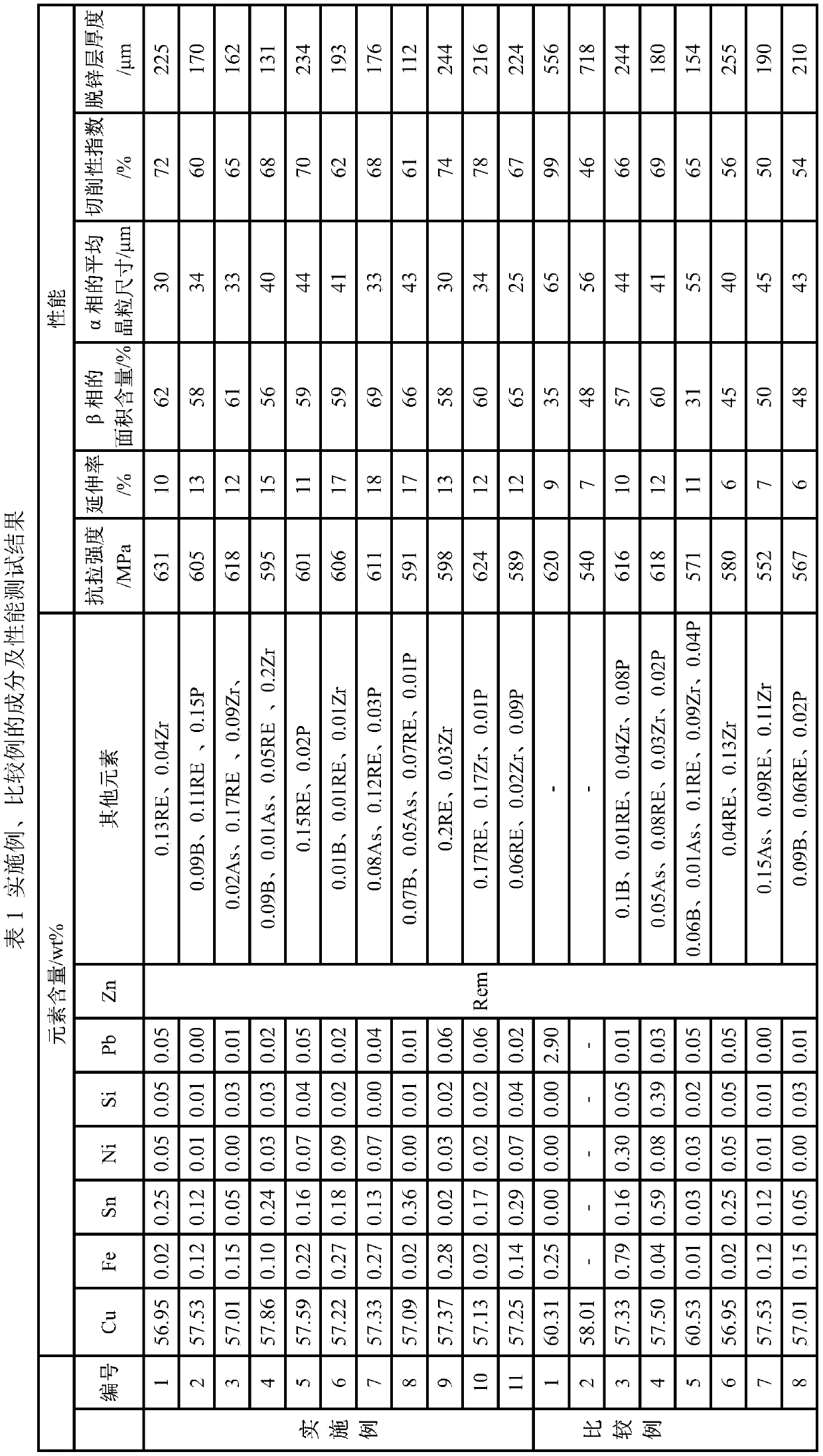

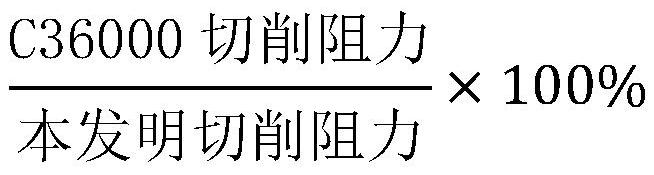

The invention discloses a free-cutting brass alloy. The brass alloy comprises the following components in percentage by mass: 56.8-58.0% of Cu, Fe+Sn less than 0.5%, Ni less than 0.1%, Si less than 0.05%, Pb less than 0.07%, 0.0005-0.2% of element X, 0.001-0.2% of element M, and the balance of Zn and inevitable impurities, wherein the element X is at least one element of B, As and RE, and the element M is at least one element of Zr and P. The brass alloy is free of pollution and excellent in cutting and processing performance, acid removing corrosion resistance and mechanical performance, reaches the tensile strength of not less than 550 MPa, the ductility of more than 9%, the cutting performance of more than 60% of that of C36000, the longest chip length of less than 20% compared with C28500 and the zinc removing layer thickness of less than 250 microns, and can meet the demands of household appliances, communication equipment, detecting and control instruments and water heating industry.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Elastic alloy brass with high strength

The invention provides elastic alloy brass with high strength, relating to the field of copper alloys. The elastic alloy brass with the high strength is characterized in that the strength and elasticity of the alloy are improved through adding elements of tin and phosphorus on the basis of a copper-zinc binary alloy; the alloy brass comprises the following components in percentage by weight: 59.0-65.0 % of copper, 0.2-1.5 % of tin and 0.015-0.15 % of phosphorus as well as the balance of zinc and not more than 0.05 % of inevitable impurities; and the alloy is prepared by smelting and rolling. The elastic alloy brass with the high strength, provided by the invention, has the advantages of reasonable mixing ratio design and higher performance cost; compared with the copper content of 93.0 % in the tin-phosphorus brass, the copper content in the alloy brass is reduced by 28.0 % and domestic scarce resource copper metal is saved. The elastic alloy brass with the high strength, provided by the invention, is mainly used for manufacturing electronic appliance connectors, springs, connectors, switches, contacts and the like as well as various copper alloy parts used under the marine environment; hardness and elastic modulus which are equivalent to those of the tin-phosphorus brass are obtained; and good dezincification corrosion resistance is also obtained; and the tin-phosphorus brass can be partially replaced with the elastic alloy brass.

Owner:菏泽广源铜带有限公司

Alloy brass

The invention provides alloy brass relating to the field of copper alloys. The alloy brass is characterized by comprising the following components in percentage by weight: 65.0-69.0 % of copper, 0.3-1.8 % of tin and 0.015-0.15 % of phosphorus as well as the balance of zinc and not more than 0.3% of inevitable impurities; and the alloy brass is prepared by smelting and rolling. In the invention, the strength and elasticity of the alloy are improved by adding elements of tin and phosphorus on the basis of a common Cu-Zn brass; after being machined, the alloy brass obtains equivalent mechanical property and chemical property with the tin-phosphorus brass; a finished product also obtains more excellent elongation and dezincification corrosion resistance under a marine environment so that copper resources are saved and higher cost performance is obtained. The alloy brass provided by the invention is widely used for electronic appliance connectors, springs, connectors, switches, contacts and the like as well as various copper alloy parts used under the marine environment.

Owner:菏泽广源铜带有限公司

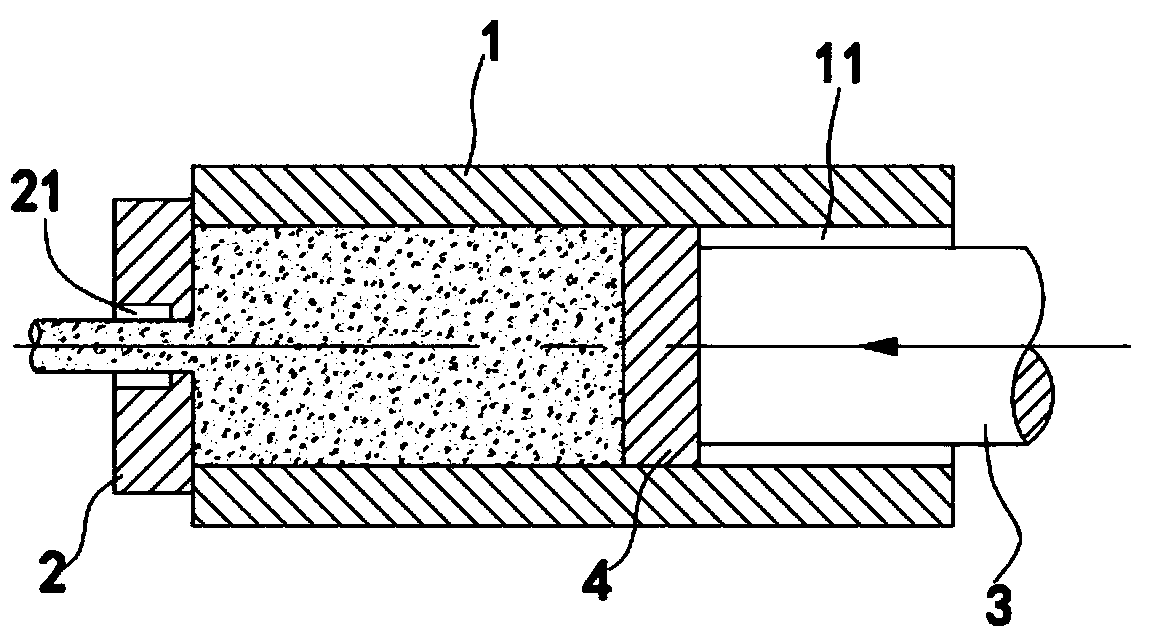

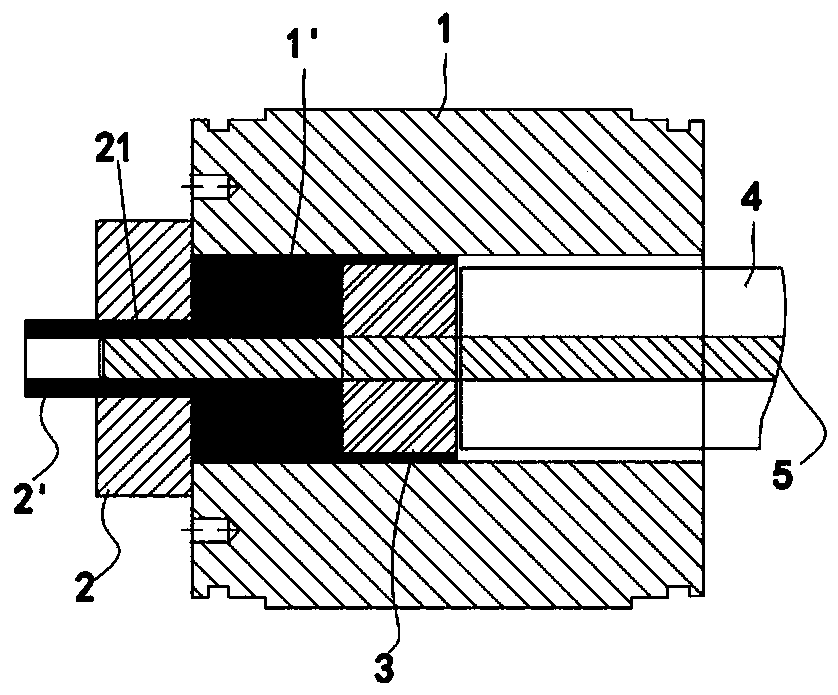

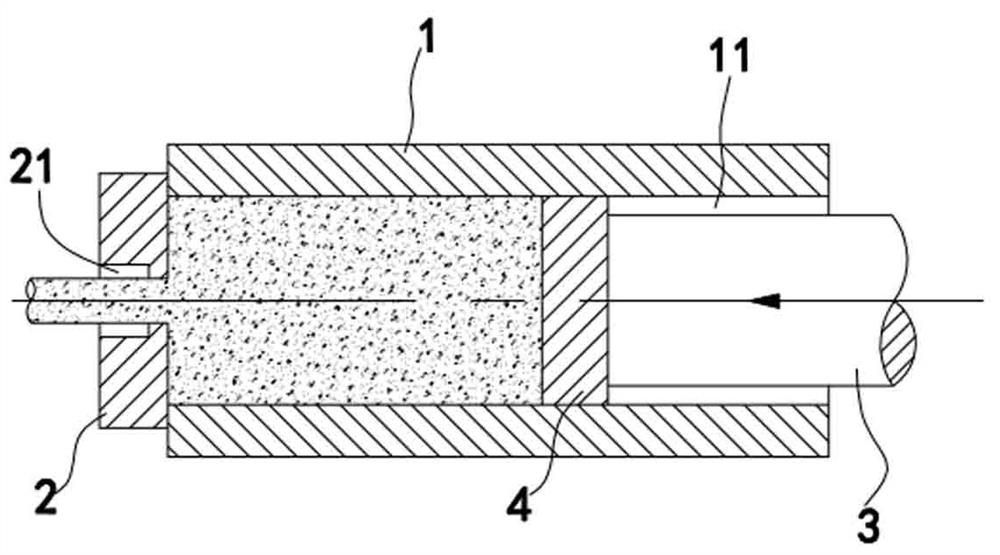

Copper alloy material and manufacturing method for lead-free brass ball valve component

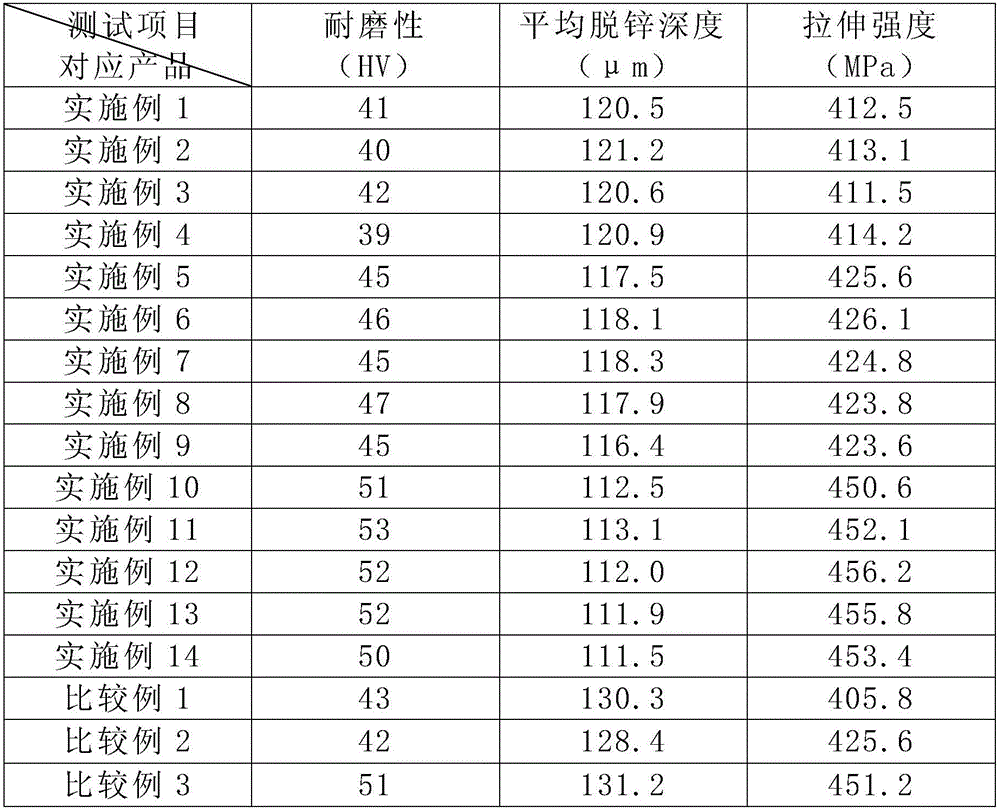

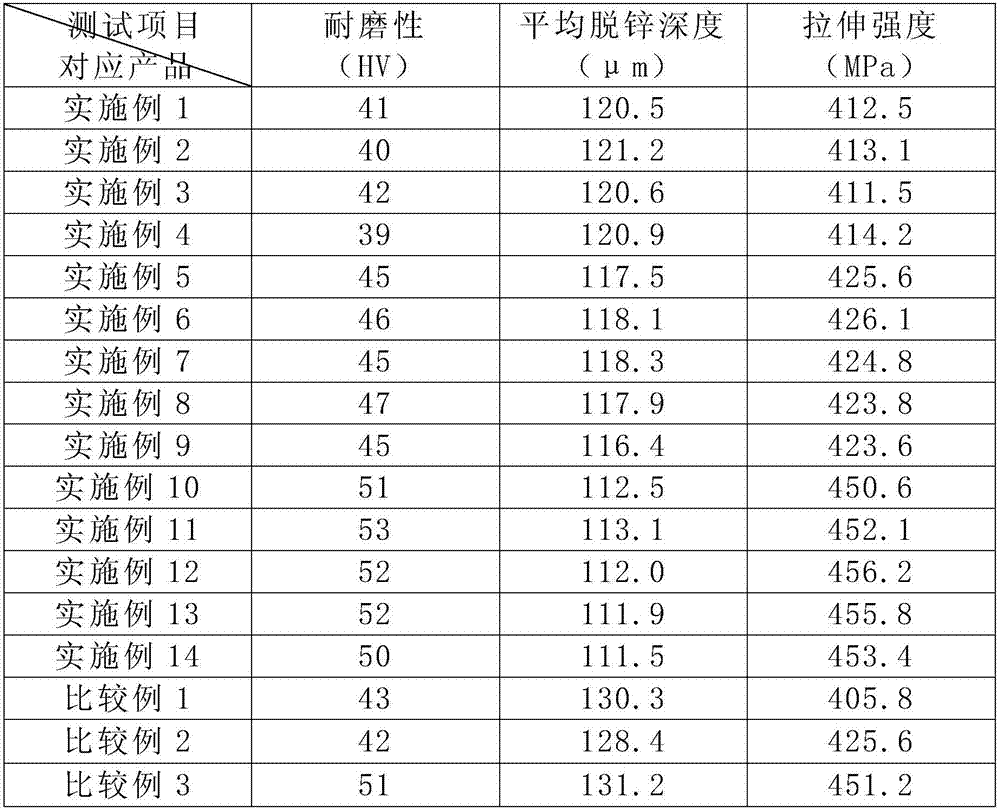

ActiveCN105821243AImprove dezincification corrosion resistanceImprove wear resistanceWear resistanceUltimate tensile strength

The invention relates to a copper alloy material and a manufacturing method for a lead-free brass ball valve component, belongs to the technical field of alloy materials and aims to solve the problem that existing dezincification resistance and corrosion resistance are poor. The copper alloy material mainly includes, by weight percentage, 58-63% of copper, 0.6-1.0% of tin, 0.02-0.06% of arsenic, less than or equal to 0.1% of lead and the balance zinc and inevitable impurities. The method includes the steps that a corresponding copper rod is selected to be cut and segmented, the temperature is raised to 700-800 DEG C for hot forging forming, and the lead-free brass ball valve component is obtained; then isothermal annealing treatment is conducted at the temperature of 550-600 DEG C, cooling is conducted, and the corresponding lead-free brass ball valve component is obtained. Zinc and tin are added, and the copper alloy material can have the advantages of being high in dezincification resistance, corrosion resistance, wear resistance and strength.

Owner:TAIZHOU BADA VALVE

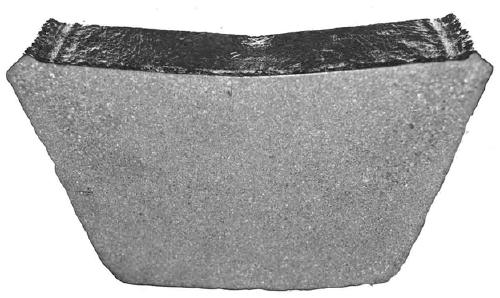

Preparation method of anti-dezincification lead-free bismuth arsenic brass pipe

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Production method of anti-dezincification and unleaded lead-cast brass ingot

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

Low-cost lead-free dezincification-resistant brass alloy for casting

A low-cost lead-free dezincification corrosion-resistant brass alloy for casting. The brass alloy contains: 60-65 wt. % of Cu, 0.05-0.25 wt. % of Pb, 0.05-0.8 wt. % of Al, 0-0.1 wt. % of Sn, and 0.05-0.16 wt. % of As, with the balance being Zn and inevitable impurities. Moreover, the equivalent weight of zinc X meets the requirements of the following formula: 35%<X<39.5%, and X=(B+ΣCiKi / (A+B+ΣCiKi); in the formula, X is the equivalent weight of zinc in the complex brass, A is the copper content (%), B is the actual zinc content (%), Ci is the content (%) of the other alloy elements, and CiKi is the corresponding equivalent weight of zinc of various elements.

Owner:XIAMEN LOTA INT CO LTD

Free-cutting lead-free anticorrosive brass alloy with low boron and bismuth

ActiveCN100463987CImprove cutting performanceImprove dezincification corrosion resistanceManganeseAlloy

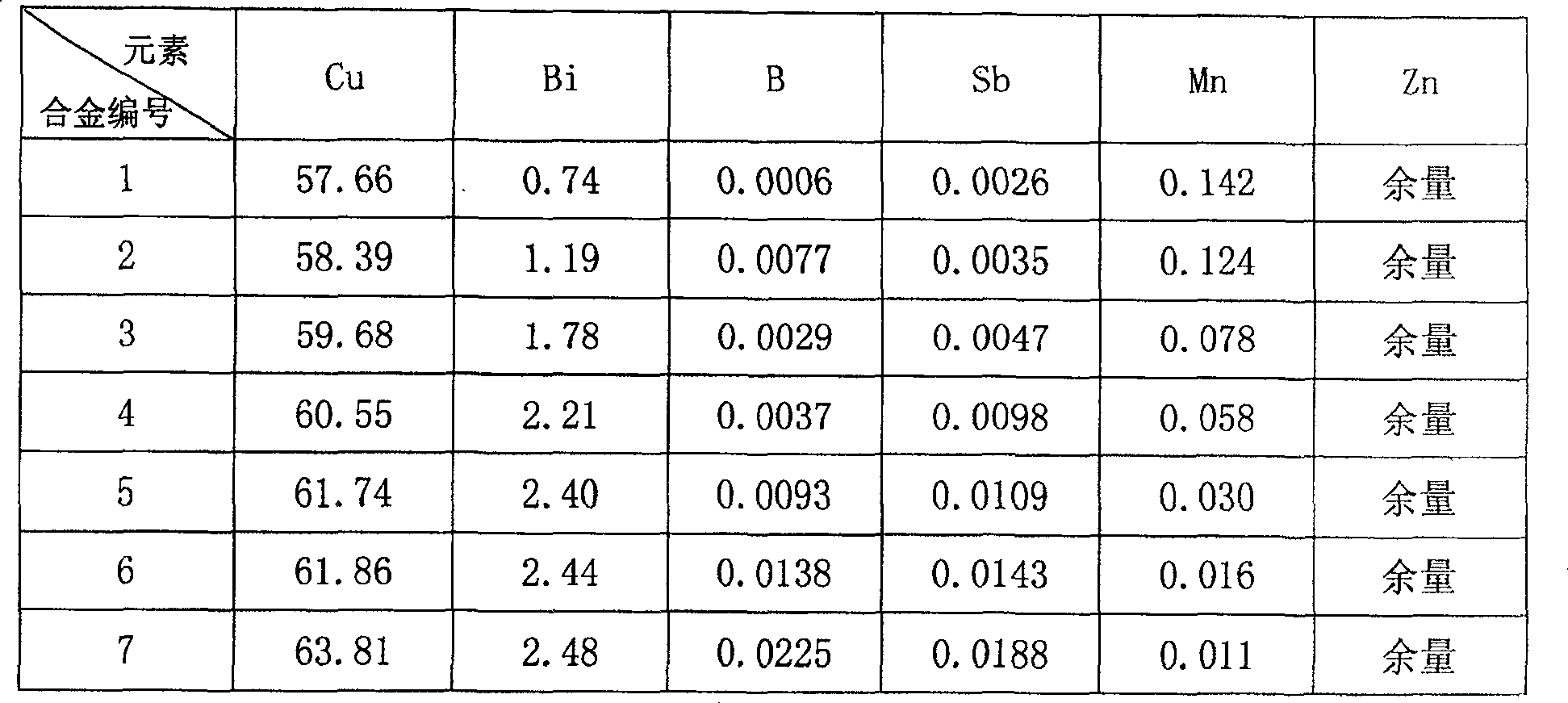

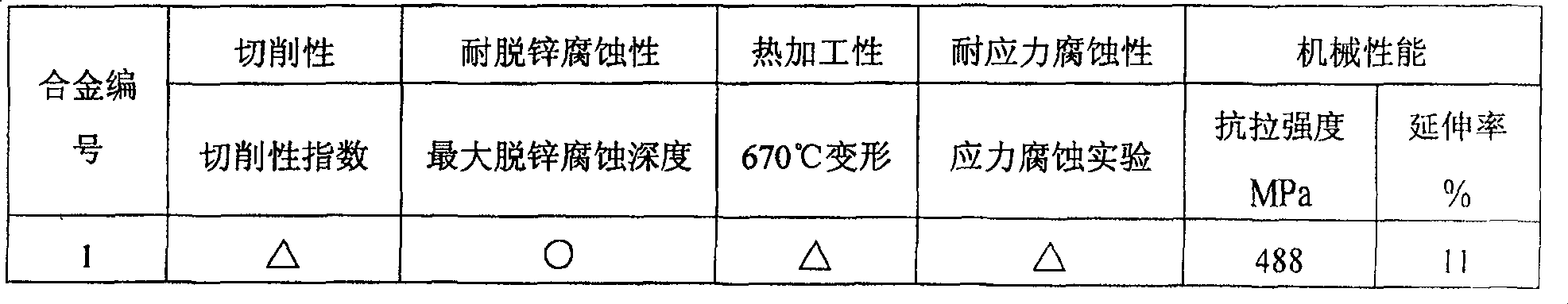

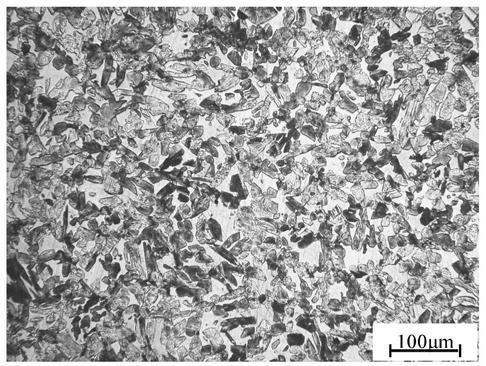

The present invention discloses one kind of free-cutting anticorrosive brass alloy and its preparation process. Chemically, the brass alloy consists of Cu 57-64 wt%, Bi 0.6-2.5 wt%, B 0.0003-0.025 wt%, Mn 0.01-0.2 wt%, Sb 0.002-0.02 wt% and Zn and inevitable impurities for the rest. The inevitable impurities has content within 0.3 wt%, and includes Pb within 0.1 wt% and Cd within 0.001 wt%; and the alloy contains Cu+Zn over 97 wt%. The brass alloy has high anticorrosive performance, excellent cutting performance and good welding performance.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Silicon bismuth lead-free casting brass alloy and preparing method thereof

The invention relates to a silicon bismuth lead-free casting brass alloy and a preparing method thereof. The brass alloy comprises, by mass percent, 61 to 67% of Cu, 0.5 to 1.0% of Bi, 0.8 to 1.25% of Si, 0.3 to 0.7% of Al, 0.05 to 0.3% of Sn, smaller than 0.01% of Pb, not larger than 0.002% of B, not larger than 0.008% of Ti, not larger than 0.01% of a rare earth modifier (at least comprising three of Nd, Eu, Er, Y, Zr and the like) and the balance Zn and smaller than 0.3% of impurities. Bi / Si is larger than or equal to 0.4 and smaller than or equal to 1.1.

Owner:FUJIAN UNIV OF TECH

Nd reinforced brass alloy and preparation technology thereof

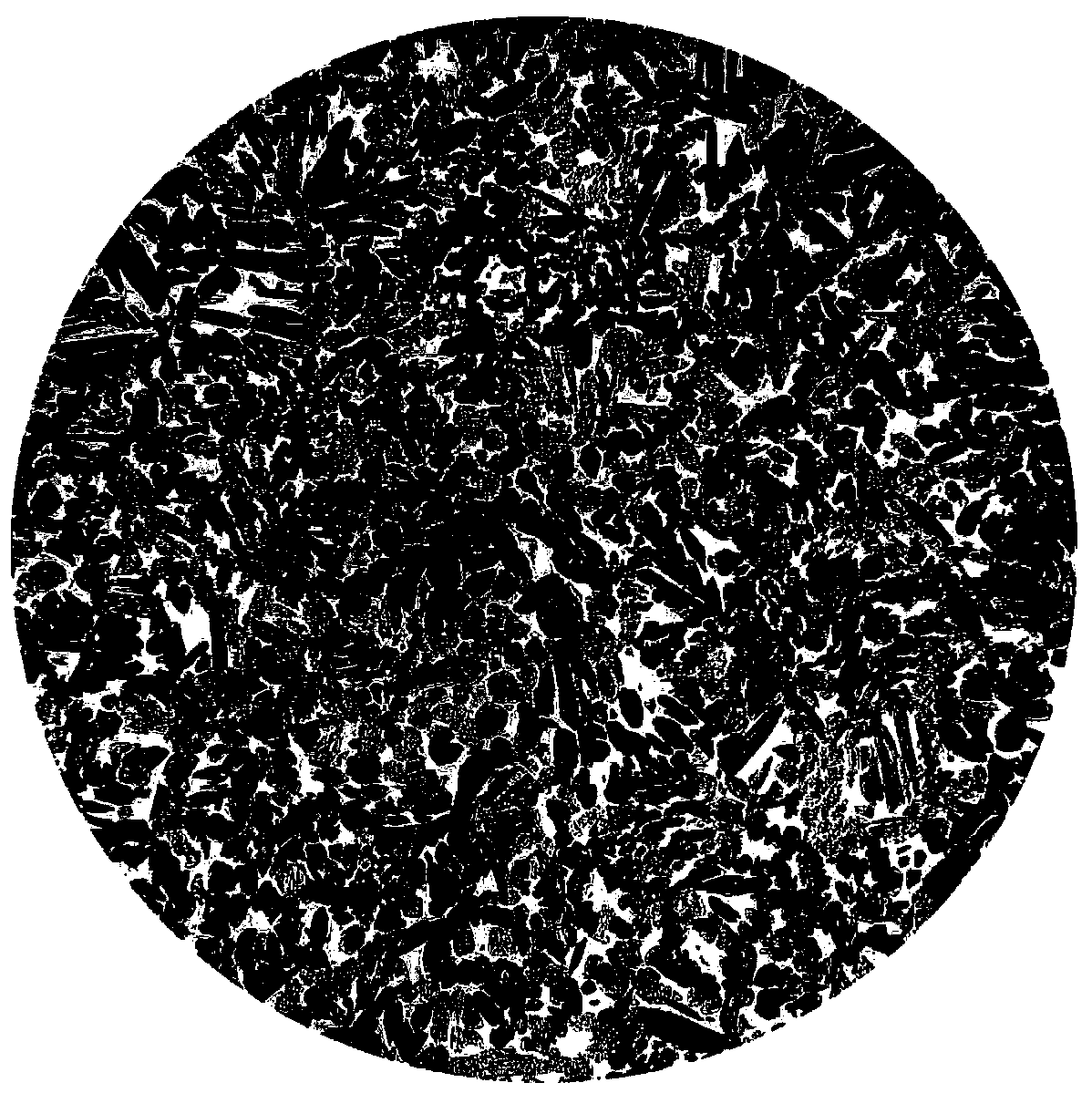

The invention relates to a high-strength corrosion-resistant brass material and a preparation method thereof. The weight percent composition of the alloy material: copper (Cu) 55%~72%, neodymium (Nd) addition 0.06%~2.0%, the rest is zinc (Zn) and unavoidable impurities whose total amount is not more than 0.5% . The invention uses neodymium to treat ordinary brass materials, so that the microstructure of the alloy changes significantly, the structure is purified, and the strength, hardness and corrosion resistance of the alloy material are improved, so that it has good comprehensive performance and is suitable for manufacturing corrosion-resistant Sanitary ware, plumbing equipment, instrumentation condensation pipes and valves with strict requirements.

Owner:UNIV OF JINAN

A kind of free-cutting brass alloy and its preparation method and application

ActiveCN111235427BImprove dezincification corrosion resistanceReduce wearHome applianceMachinability

The invention discloses a free-cutting brass alloy. The brass alloy comprises the following components in percentage by mass: 56.8-58.0% of Cu, Fe+Sn less than 0.5%, Ni less than 0.1%, Si less than 0.05%, Pb less than 0.07%, 0.0005-0.2% of element X, 0.001-0.2% of element M, and the balance of Zn and inevitable impurities, wherein the element X is at least one element of B, As and RE, and the element M is at least one element of Zr and P. The brass alloy is free of pollution and excellent in cutting and processing performance, acid removing corrosion resistance and mechanical performance, reaches the tensile strength of not less than 550 MPa, the ductility of more than 9%, the cutting performance of more than 60% of that of C36000, the longest chip length of less than 20% compared with C28500 and the zinc removing layer thickness of less than 250 microns, and can meet the demands of household appliances, communication equipment, detecting and control instruments and water heating industry.

Owner:NINGBO POWERWAY ALLOY MATERIAL

High-strength corrosion-resistant brass material and preparation and application thereof

The invention relates to a high-strength corrosion-resistant brass material and a preparation method thereof. The alloy material comprises, by weight, 50%-72% of copper (Cu), 0.03%-2.0% of samarium (Sm) and the balance zinc (Zn) and no more than 0.5% of impurities. According to the high-strength corrosion-resistant brass material and the preparation method thereof, the samarium is adopted for treating the ordinary brass material, the alloy microstructure of the brass material is changed obviously, the composition is purified, the strength, hardness and the corrosion resistance of the alloy material are improved, good comprehensive performance is achieved, and the high-strength corrosion-resistant brass material and the preparation method thereof are suitable for manufacturing condenser pipes and valves of sanitary ware, water heating equipment, instruments and meters with a requirement for corrosion resistance.

Owner:UNIV OF JINAN

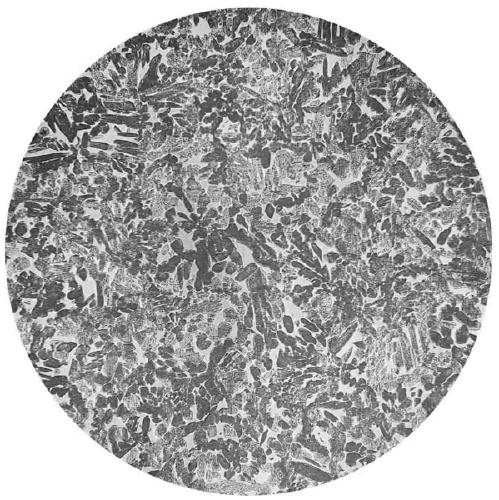

Corrosion-resistant brass material and preparation method thereof

The invention relates to a corrosion-resistant brass material and a preparation method thereof. The alloy material comprises the following components in percentage by weight: 55-74% of copper (Cu) and the balance of zinc (Zn) and not more than 0.5% of unavoidable impurities. The application amount of lanthanum oxide (La2O3) is 0.2-1.5%. The brass material is processed by virtue of La2O3, so that the microstructures of the alloy are obviously changed and purified and thus the corrosion resistance and plasticity of the alloy material are improved, the yield strength of the alloy material is reduced, the alloy material has good comprehensive mechanical performances and is suitable for manufacturing sanitary ware, plumbing devices and materials, instrument condenser pipes, valves and the like having corrosion-resistant requirement. Compared with pure elemental rare earth, rare earth oxides are easily available and inexpensive and high in utilization rate of rare earth.

Owner:UNIV OF JINAN

Method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubes

The invention relates to the field of copper alloys for toilet and kitchen industries and provides a method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubeswhich are good in dezincification corrosion resistance, high in strength and good in processing performance. The method comprises the steps of smelting the following raw materials in percentage by mass: 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, Pb less than 0.1% and the balance of Zn and impurities with the total amount not more than 0.35%, casting to form copper ingots, extruding to form copper tube billets, stretching, annealing, inspecting the finished copper tubes and putting the finished copper tubes into a warehouse.

Owner:龙岩市鸿航金属科技有限公司

A kind of preparation method of anti-dezincification lead-free low-silicon-arsenic brass tube

The invention relates to the field of copper alloys for toilet and kitchen industries and provides a method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubeswhich are good in dezincification corrosion resistance, high in strength and good in processing performance. The method comprises the steps of smelting the following raw materials in percentage by mass: 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, Pb less than 0.1% and the balance of Zn and impurities with the total amount not more than 0.35%, casting to form copper ingots, extruding to form copper tube billets, stretching, annealing, inspecting the finished copper tubes and putting the finished copper tubes into a warehouse.

Owner:龙岩市鸿航金属科技有限公司

A production method of anti-dezincification lead-free low-silicon lead cast arsenic brass ingot

ActiveCN107855481BAvoid burnsImprove dezincification corrosion resistanceIngotUltimate tensile strength

The invention relates to the field of copper alloys used in the toilet and kitchen industry and provides a production method for dezincification-preventing lead-free low-silicon lead casting of an arsenic brass ingot. The production method is good in dezincification corrosion preventing performance, high in strength and good in machining performance. The production method includes the step for melting the raw materials including, by mass percent, 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, smaller than 0.1% of Pb and the balance Zn and impurities withthe total amount not larger than 0.35% and then forming the brass ingot in a lead casting manner.

Owner:龙岩市鸿航金属科技有限公司

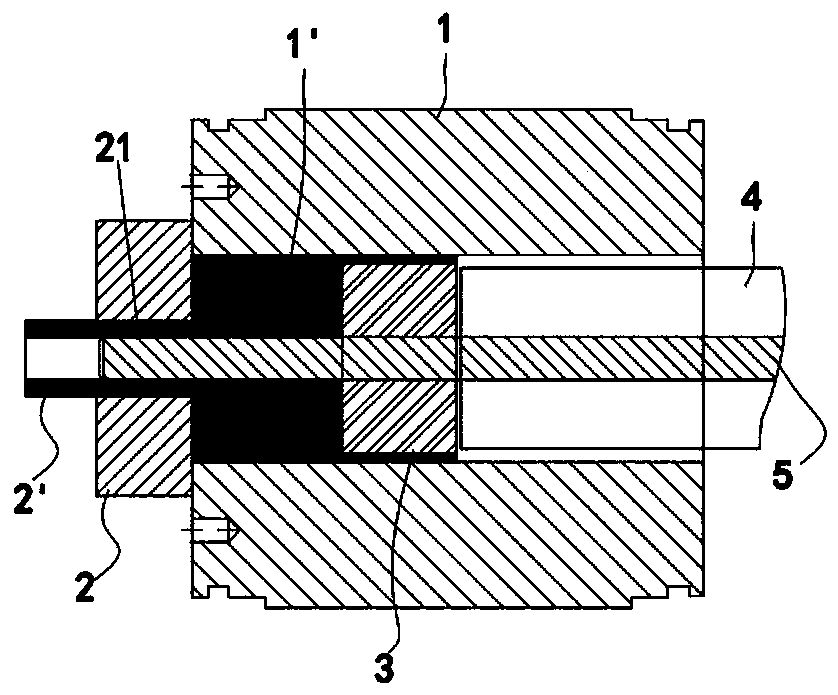

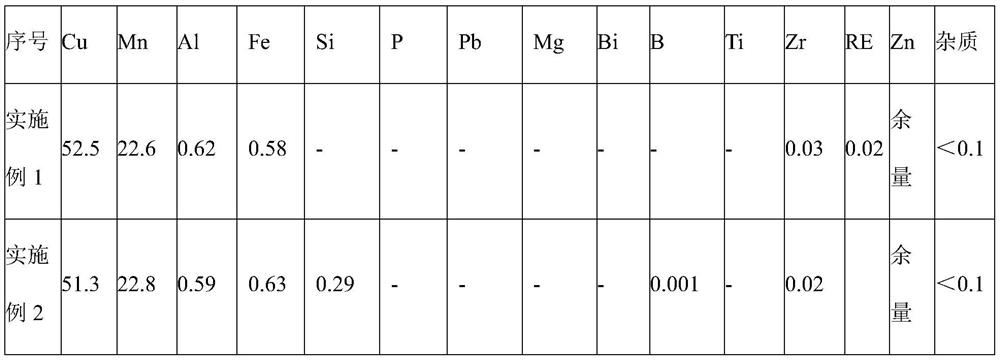

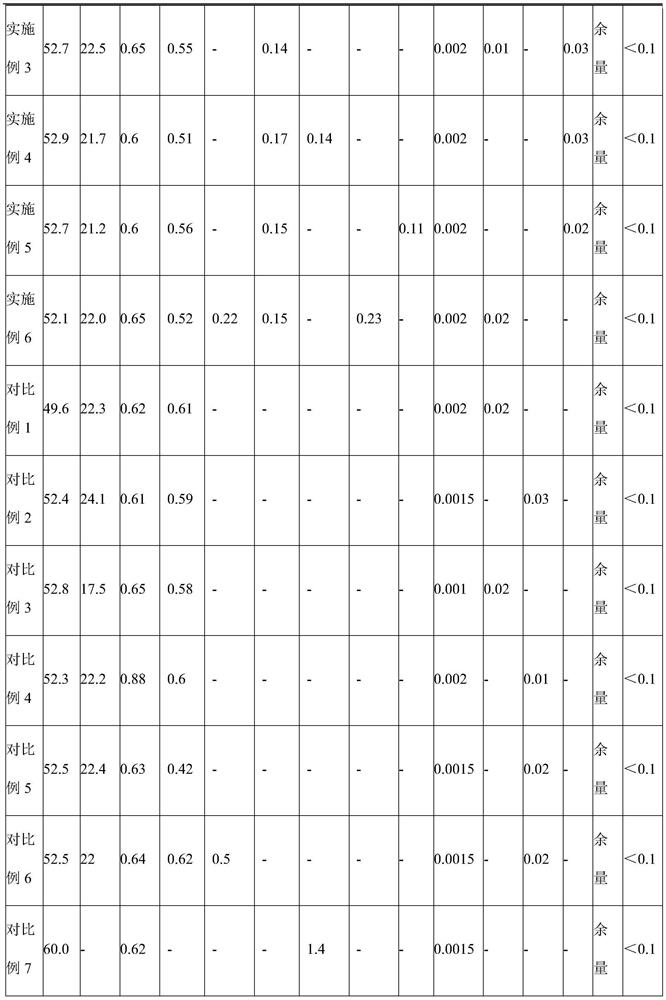

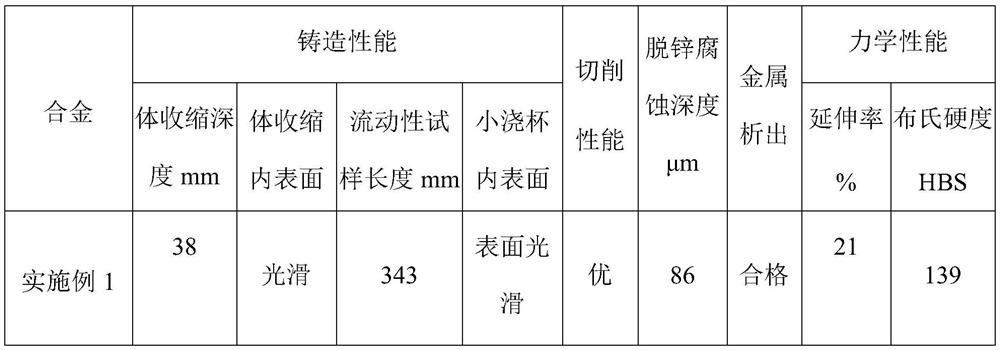

A kind of lead-free copper alloy for casting and preparation method thereof

The invention discloses a lead-free copper alloy for casting, which comprises: 50-54wt% Cu, 18-23wt% Mn, 0.4-0.8wt% Al, 0.5-1.0wt% Fe, 0.001-0.2wt% modified element, the balance includes Zn and unavoidable impurities; wherein the modified element is at least one of B, Ti, Zr and rare earth elements. The invention also discloses a preparation method of the lead-free copper alloy for casting. The lead-free copper alloy for casting of the present invention meets the multi-dimensional comprehensive requirements of sanitary faucets and valves on cost, machining performance, casting performance, corrosion resistance, mechanical properties, etc., and has a good application prospect.

Owner:JOMOO KITCHEN & BATHROOM

Leadless free-cutting bismuth brass alloy

The invention discloses a lead-free free-cutting bismuth-brass alloy, and belongs to the technical field of metallic material manufacture. The alloy comprises the following components by weight percentage: 58.0 to 62.0 percent of Cu, 0.6 to 2.0 percent of Bi, 0.01 to 1.7 percent of Sn and / or Se, 0.05 to 0.6 percent of Al, 0.01 to 0.1 percent of P, 0.03 to 0.08 percent of RE, and the balance beingZn and inevitable impurities, wherein content of lead in the impurities is less than 0.1 percent. The alloy has the advantages of excellent cutting property, mechanical property, corrosion resistanceand plastic forming property, and can be widely applied in the industries such as automobile, clock, electric appliance, lock making, toy, sanitary ware, and the like.

Owner:厦门火炬特种金属材料有限公司

A kind of anti-dezincification lead-free low silicon arsenic brass and preparation method thereof

Owner:龙岩市鸿航金属科技有限公司

Brass material for water heating equipment

The invention discloses a brass material for water heating equipment. The brass material comprises the following components in percentage by mass of 62-63.5% of Cu, 0.27-0.81% of Si, 0.35-0.41% of Bi, 0.11-0.19% of Al, 0.12-0.21% of Mn, 0.025-0.06% of Ce+Nd+Os, 0.004-0.005% of B, 1.21-2.15% of Sn+Ni+Co, 0.42-0.9% of Mg, 0.05-0.08% of Sb, 0.03-0.057% of P and the balance of zinc and inevitable impurities. The brass material for the water heating equipment is easy to cut, high in strength and excellent in corrosion resistance.

Owner:黄山市龙跃铜业有限公司

Copper alloy material for lead-free brass ball valve assembly and manufacturing method thereof

ActiveCN105821243BImprove dezincification corrosion resistanceImprove wear resistanceIsothermal annealingHigh wear resistance

The invention relates to a copper alloy material and a manufacturing method for a lead-free brass ball valve component, belongs to the technical field of alloy materials and aims to solve the problem that existing dezincification resistance and corrosion resistance are poor. The copper alloy material mainly includes, by weight percentage, 58-63% of copper, 0.6-1.0% of tin, 0.02-0.06% of arsenic, less than or equal to 0.1% of lead and the balance zinc and inevitable impurities. The method includes the steps that a corresponding copper rod is selected to be cut and segmented, the temperature is raised to 700-800 DEG C for hot forging forming, and the lead-free brass ball valve component is obtained; then isothermal annealing treatment is conducted at the temperature of 550-600 DEG C, cooling is conducted, and the corresponding lead-free brass ball valve component is obtained. Zinc and tin are added, and the copper alloy material can have the advantages of being high in dezincification resistance, corrosion resistance, wear resistance and strength.

Owner:TAIZHOU BADA VALVE

A kind of preparation method of anti-dezincification lead-free bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Dezincification-resistant lead-free low-silicon arsenic brass and preparation method thereof

The invention relates to the field of copper alloys for kitchen and bathroom industries and provides a dezincification-resistant lead-free low-silicon arsenic brass which is good in dezincification corrosion resistance property and processing property and high in strength and a preparation method of the dezincification-resistant lead-free low-silicon arsenic brass. The method includes the steps that the following raw materials including, by mass, 62-65% of Cu, 0.6-1.0% of Si, 0.07-0.12% of As, 0.5-0.8% of Al, 0.03-0.1% of Fe, less than 0.1% of Pb and the balance Zn and no larger than 0.35% ofimpurities in total amount are smelted, refined and subjected to furnace front detection and casting, and then a low-silicon arsenic brass ingot of which the content of Pb is less than 0.1% is obtained.

Owner:龙岩市鸿航金属科技有限公司

Corrosion-resistant brass material and preparation method thereof

The invention relates to a corrosion-resistant brass material and a preparation method thereof. The alloy material comprises the following components in percentage by weight: 55-74% of copper (Cu) and the balance of zinc (Zn) and not more than 0.5% of unavoidable impurities. The application amount of lanthanum oxide (La2O3) is 0.2-1.5%. The brass material is processed by virtue of La2O3, so that the microstructures of the alloy are obviously changed and purified and thus the corrosion resistance and plasticity of the alloy material are improved, the yield strength of the alloy material is reduced, the alloy material has good comprehensive mechanical performances and is suitable for manufacturing sanitary ware, plumbing devices and materials, instrument condenser pipes, valves and the like having corrosion-resistant requirement. Compared with pure elemental rare earth, rare earth oxides are easily available and inexpensive and high in utilization rate of rare earth.

Owner:UNIV OF JINAN

Easily-cut tin-brass alloy and preparation method thereof

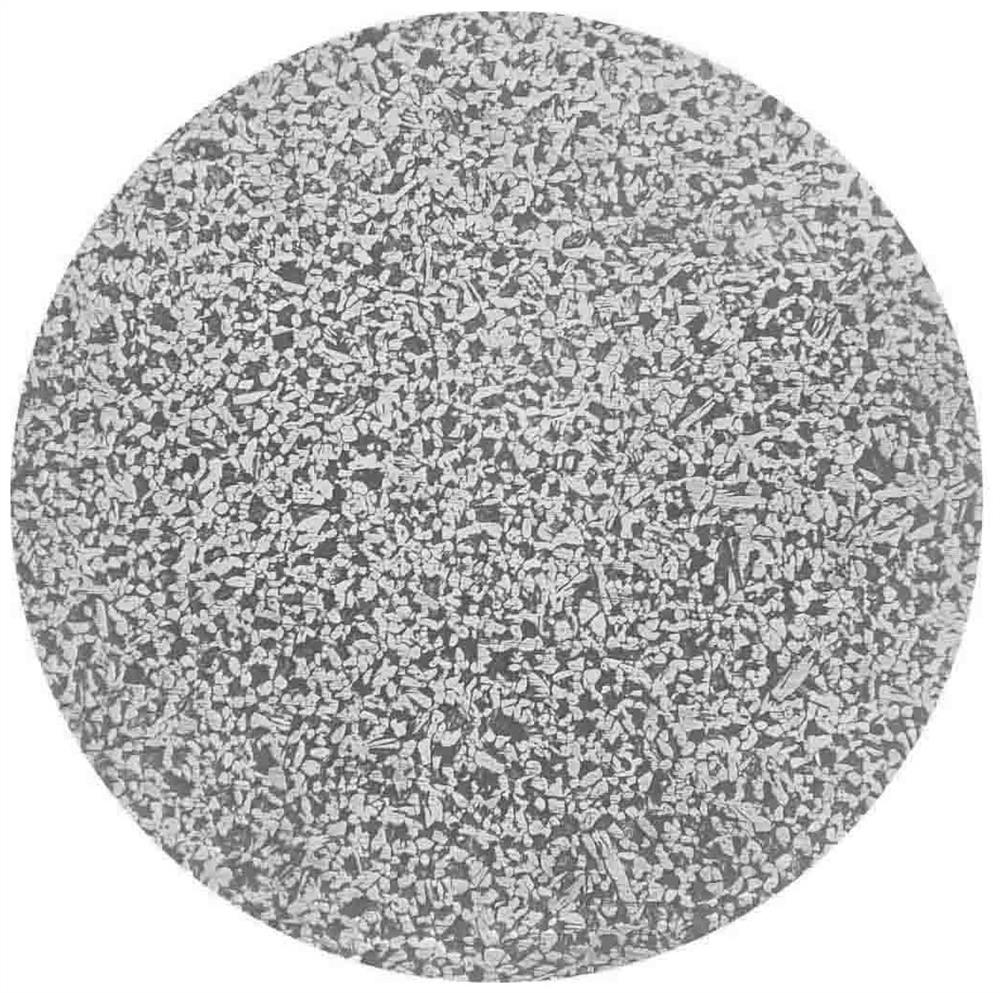

ActiveCN103695700BImprove cutting performanceImprove dezincification corrosion resistanceManganeseAlloy

The invention provides a lead-free easily-cut tin-brass alloy. According to the easily-cut tin-brass alloy, lead is replaced with tin, and the produced easily-cut tin-brass alloy has the advantages of excellent cutting performance, corrosion resistance and good mechanical properties. By adding a proper amount of tin into brass, the mechanical properties and corrosion resistance of the alloy can be improved. According to the method, a variety of other metallic elements, such as manganese, aluminum, antimony, arsenic, lead, nickel and the like, are added while tin is added and are treated by a special process, and then, the brass alloy performance improvement effect of tin can be enhanced, so that the corrosion resistance and cutting performance of the easily-cut tin-brass alloy prepared by the method are improved greatly. The easily-cut tin-brass alloy prepared by the method has excellent cutting performance and corrosion resistance.

Owner:JIANGXI AUDY BRASSWORK

A kind of production method of anti-dezincification lead-free casting brass ingot

ActiveCN107876715BAvoid burnsImprove dezincification corrosion resistanceIngotUltimate tensile strength

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

A kind of preparation method of anti-dezincification lead-free bismuth arsenic brass tube

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com