A kind of free-cutting brass alloy and its preparation method and application

A brass alloy, free-cutting technology, used in the field of copper alloys to reduce wear, improve alloy strength, and improve cutting performance

Active Publication Date: 2020-12-29

NINGBO POWERWAY ALLOY MATERIAL

View PDF13 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

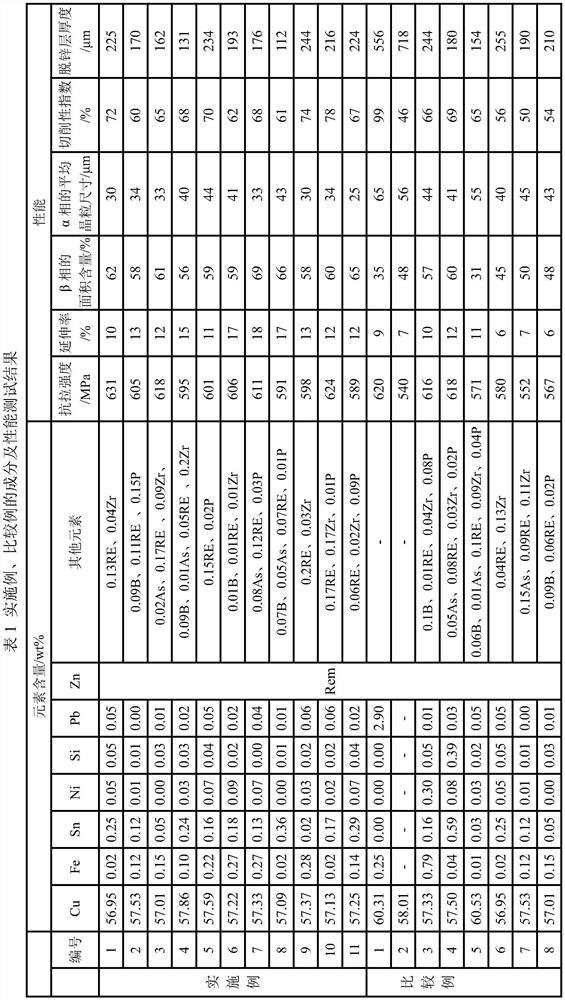

[0006] The technical problem to be solved by the present invention is to provide a non-polluting free-cutting brass alloy with good cutting performance, dezincification corrosion resistance and mechanical properties and its preparation method and application. The tensile strength of the copper alloy is ≥550MPa, the elongation is >9%, the cutting performance is more than 60% of the cutting performance of C36000, the longest chip length is more than 20% lower than that of C28500, and the thickness of the dezincification layer is less than 250μm, which can meet the requirements of household appliances, communication Equipment, detection and control instruments, needs of plumbing industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a free-cutting brass alloy. The brass alloy comprises the following components in percentage by mass: 56.8-58.0% of Cu, Fe+Sn less than 0.5%, Ni less than 0.1%, Si less than 0.05%, Pb less than 0.07%, 0.0005-0.2% of element X, 0.001-0.2% of element M, and the balance of Zn and inevitable impurities, wherein the element X is at least one element of B, As and RE, and the element M is at least one element of Zr and P. The brass alloy is free of pollution and excellent in cutting and processing performance, acid removing corrosion resistance and mechanical performance, reaches the tensile strength of not less than 550 MPa, the ductility of more than 9%, the cutting performance of more than 60% of that of C36000, the longest chip length of less than 20% compared with C28500 and the zinc removing layer thickness of less than 250 microns, and can meet the demands of household appliances, communication equipment, detecting and control instruments and water heating industry.

Description

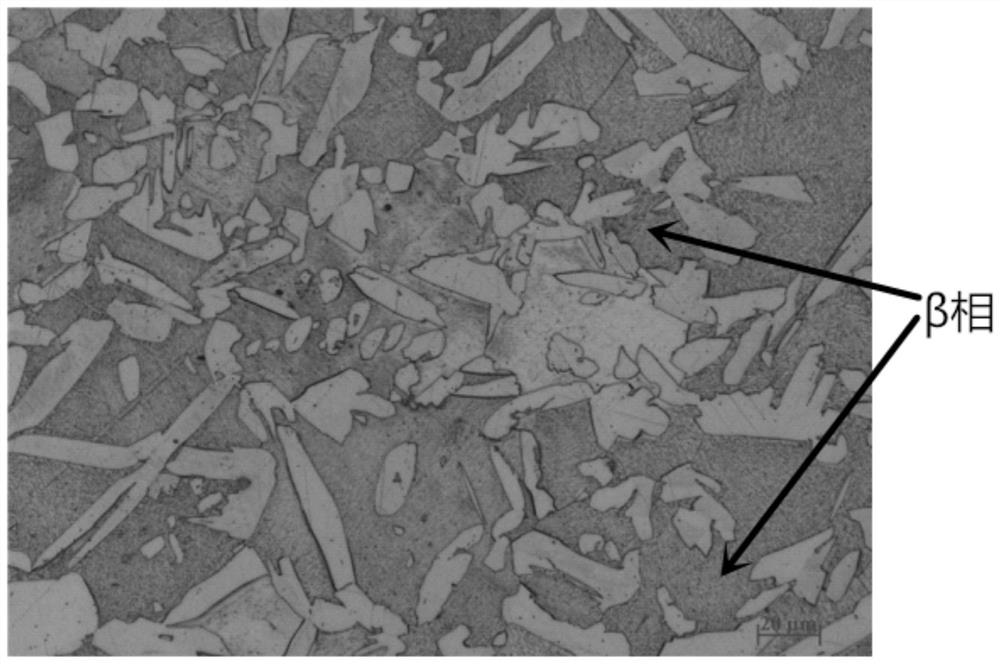

technical field [0001] The invention relates to the technical field of copper alloys, in particular to a free-cutting brass alloy and its preparation method and application. The brass alloy can be applied to industries such as household appliances, communication equipment, detection and control instruments, and plumbing. Background technique [0002] Brass has excellent machinability, mechanical strength, corrosion resistance, and is a commonly used basic material in industrial engineering, such as bolts, nuts, hydraulic parts, valves and connectors, switches, etc. These parts are usually produced by machining brass, and the machinability of brass is a critical indicator of material performance. As a representative of brass, lead brass is widely used in various fields such as electrical, mechanical, and plumbing due to its low cost, good corrosion resistance, and excellent cutting performance. [0003] In leaded brass, lead does not form a solid solution on the matrix, but ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C9/04C22C1/02C22F1/08

CPCC22C1/02C22C9/04C22F1/08

Inventor 张儿裴勇军胡廷务孟祥鹏程治伟张轩

Owner NINGBO POWERWAY ALLOY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com