Corrosion-resistant brass material and preparation method thereof

A corrosion-resistant, brass technology, applied in the field of material anti-corrosion technology and metal smelting, can solve the problems of severe toxicity, health damage, etc., and achieve the effect of good corrosion resistance and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

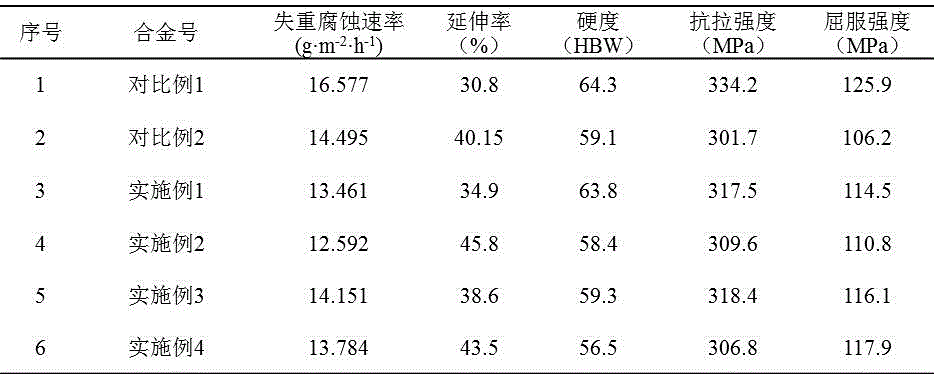

Examples

Embodiment 1

[0018] The composition weight ratio (wt%) of the embodiment material of the present invention is: 62% Cu, all the other are Zn and unavoidable impurity, lanthanum oxide (La 2 o 3 ) processing capacity is 0.2%.

[0019] Take the following steps to make:

[0020] (1) Copper powder and La 2 o 3 Mix evenly according to the mass ratio of 1:1, and then press it into a block with a hydraulic press, the pressure used is 50MPa, and the pressure holding time is 1 minute;

[0021] (2) Put the copper block into the graphite crucible, heat and melt it with a medium-frequency induction furnace, add broken glass as a covering agent before the copper is about to melt, heat up to melt and overheat to 1150 ℃, add the preheated zinc block, and stir with a carbon rod Let the zinc melt completely;

[0022] (3) Continue to raise the temperature of the alloy liquid to 1330°C, add the mixture of massive lanthanum oxide and copper powder, stir with a carbon rod, and let it stand for 10 minutes. T...

Embodiment 2

[0024] The composition weight ratio (wt%) of the material of the embodiment of the present invention is: 62% Cu, the rest is Zn and unavoidable impurities. Lanthanum oxide (La 2 o 3 ) processing capacity is 0.8%.

[0025] Take the following steps to make:

[0026] (1) Copper powder and La 2 o 3 Mix evenly according to the mass ratio of 1:1, and then press it into a block with a hydraulic press, the pressure used is 60MPa, and the holding time is 3 minutes;

[0027] (2) Put the copper block into the graphite crucible, heat and melt it with a medium-frequency induction furnace, add broken glass as a covering agent before the copper is melted, heat up to melt and overheat to 1170°C, add the preheated zinc block, and stir with a carbon rod Let the zinc melt completely;

[0028] (3) Continue to raise the temperature of the alloy liquid to 1370°C, add the mixture of massive lanthanum oxide and copper powder, stir with a carbon rod, and let it stand for 8 minutes. The alloy liq...

Embodiment 3

[0030] The composition weight ratio (wt%) of the embodiment material of the present invention is: 62% Cu, all the other are Zn and unavoidable impurity, lanthanum oxide (La 2 o 3 ) processing capacity is 1.4%.

[0031] Take the following steps to make:

[0032] (1) Copper powder and La 2 o 3 Mix evenly according to the mass ratio of 1:1, and then press it into a block with a hydraulic press, the pressure used is 70MPa, and the pressure holding time is 5 minutes;

[0033] (2) Put the copper block into the graphite crucible, heat and melt it with a medium-frequency induction furnace, add broken glass as a covering agent before the copper is about to melt, raise the temperature to melt and overheat to 1180°C, add the preheated zinc block, and stir with a carbon rod Let the zinc melt completely;

[0034] (3) Continue to raise the temperature of the alloy liquid to 1380°C, add the mixture of massive lanthanum oxide and copper powder, stir with a carbon rod, and let it stand fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com