Tin-brass alloy containing rare earth

A tin-brass and alloy technology, applied in the field of rare-earth-containing tin-brass alloys, can solve problems such as inevitable toxic and side effects, and achieve the effects of wide application range and improved corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

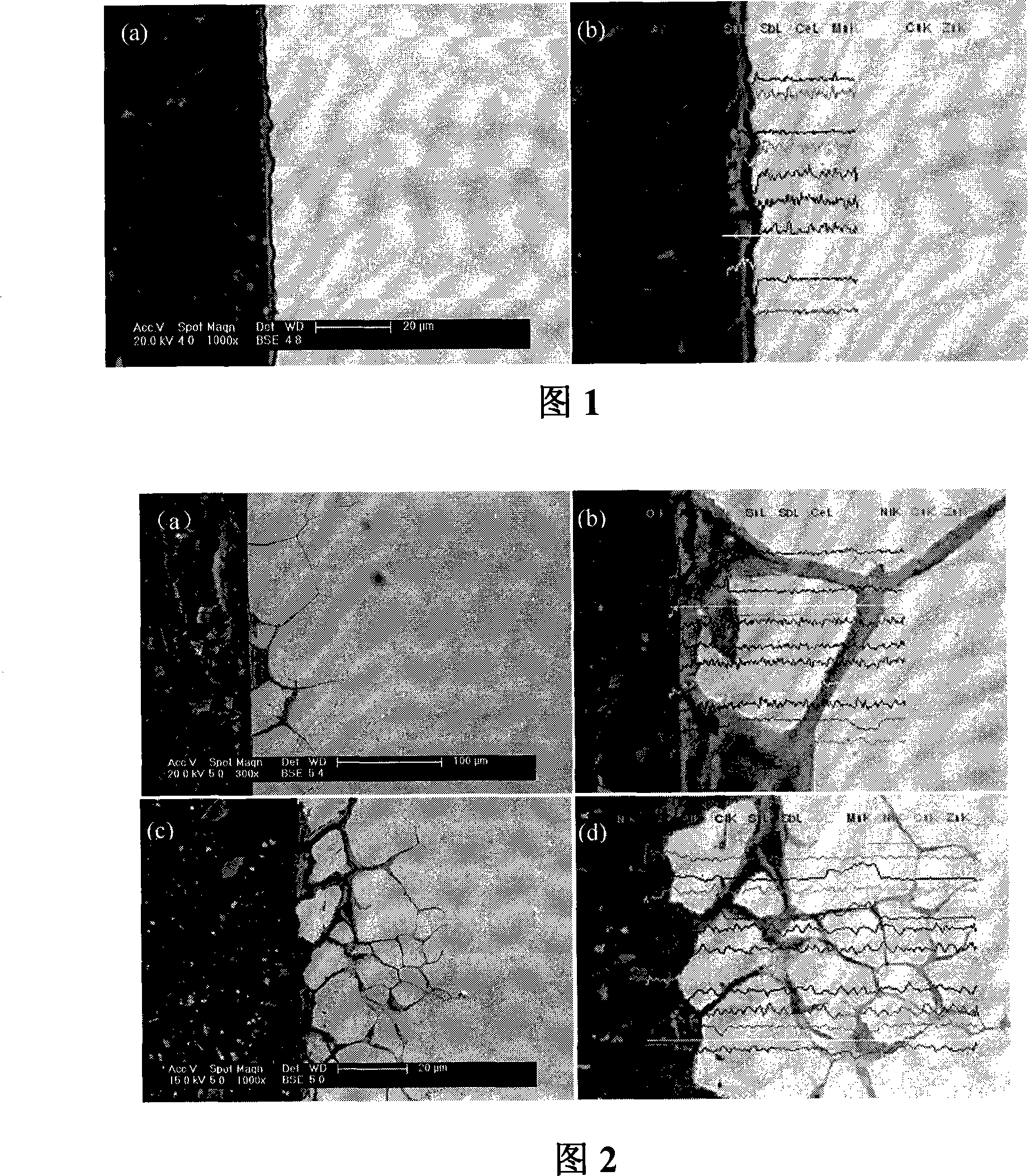

Image

Examples

Embodiment Construction

[0019] Below with 2 embodiments of the present invention and the conventional product HSn70-1A on the market (being comparative example 1) and HSn70-1B (being comparative example 2) the composition (seeing table 1) of each component of two comparative examples and in different The comparative list of corrosion resistance performance index in corrosive medium is as follows (see table 2), to further illustrate the excellent performance of the present invention.

[0020] The chemical composition of table 1 embodiment and comparative example

[0021] Chemical composition (wt%)

[0022] The static corrosion rate (mm / a) of table 2 embodiment and comparative example in different media

[0023] NaCl (3.5%)

[0024] It can be seen from Table 2 that the rare earth tin-containing brass prepared in Examples 1 and 2 has better corrosion resistance than the common arsenic-containing tin brass HSn70-1A and HSn70-1B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com