Blocking removing solution applied to blocking removal of sandstones of water injection well and preparation method of blocking removing solution

A technology for well sandstone and plug removal, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy stripping, migration of solid phase particles, fast reaction rate of acid solution, damage to rock skeleton, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

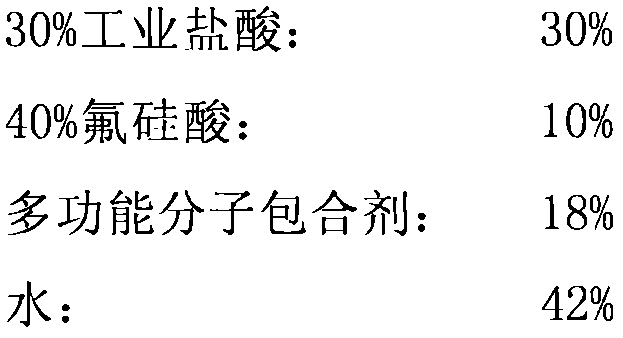

[0016] The present invention is applied to the plugging removal fluid for sandstone plugging removal of water injection wells, and its components and weight percentages are as follows:

[0017]

[0018] The multifunctional molecular inclusion agent is a mixture of β-cyclodextrin derivatives, cationic quaternary ammonium salts, sodium erythorbate, EDTA, citric acid, Mannich bases, and fluorocarbon surfactants.

[0019] Its preparation method is:

[0020] Water, industrial hydrochloric acid with a mass concentration of 30%, fluosilicic acid with a mass concentration of 40%, and a multifunctional molecular inclusion agent were mixed and stirred in sequence for 20 minutes to prepare a blockage-removing liquid with a retarding effect.

[0021] This product was applied to a water injection well of Sinopec. After the plugging removal measures, the daily water injection volume of the well was reduced from 15.2m 3 / d increased to 32.1m 3 / d, the injection pressure is reduced from ...

Embodiment 2

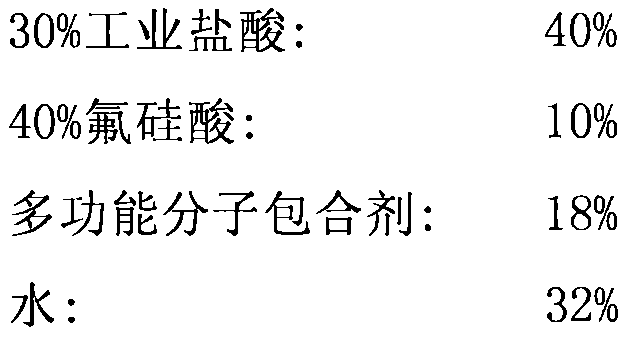

[0023] The present invention is applied to the plugging removal fluid for sandstone plugging removal of water injection wells, and its components and weight percentages are as follows:

[0024]

[0025] The multifunctional molecular inclusion agent is a mixture of β-cyclodextrin derivatives, cationic quaternary ammonium salts, sodium erythorbate, EDTA, citric acid, Mannich bases, and fluorocarbon surfactants.

[0026] Its preparation method is:

[0027] Water, industrial hydrochloric acid with a mass concentration of 30%, fluosilicic acid with a mass concentration of 40%, and a multifunctional molecular inclusion agent were mixed and stirred in sequence for 20 minutes to prepare a blockage-removing liquid with a retarding effect.

[0028] This product was applied to a water injection well of Sinopec. After the plugging removal measures, the daily water injection volume of the well was reduced from 5.6m 3 / d increased to 34.7m 3 / d, the injection pressure is reduced from 1...

Embodiment 3

[0030] The present invention is applied to the plugging removal fluid for sandstone plugging removal of water injection wells, and its components and weight percentages are as follows:

[0031]

[0032]

[0033] The multifunctional molecular inclusion agent is a mixture of β-cyclodextrin derivatives, cationic quaternary ammonium salts, sodium erythorbate, EDTA, citric acid, Mannich bases, and fluorocarbon surfactants.

[0034] Its preparation method is:

[0035] Water, industrial hydrochloric acid with a mass concentration of 30%, fluosilicic acid with a mass concentration of 40%, and a multifunctional molecular inclusion agent were mixed and stirred in sequence for 20 minutes to prepare a blockage-removing liquid with a retarding effect.

[0036] This product was applied to a water injection well of CNOOC. After the plugging removal measures, the daily water injection volume of the well increased from 109.3m3 / d to 586.1m3 / d, and the injection pressure decreased from 9MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com