Dually retarded emulsified self-generated acid and preparation method thereof

A self-generating acid and retarding technology, applied in chemical instruments and methods, earth drilling, mining fluids, etc., can solve the problems of poor temperature resistance, lack of retarding effect, unusable, etc., and achieve high conductivity, good Acidification effect, good retarding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

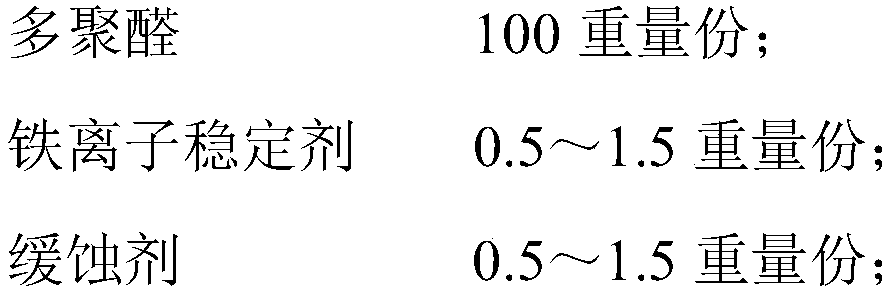

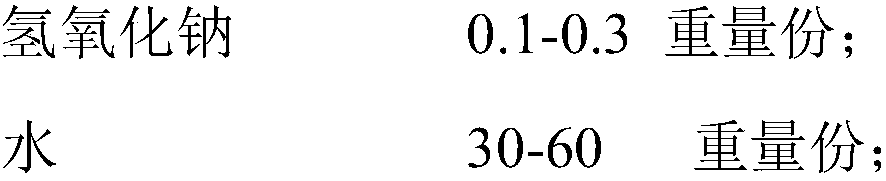

[0047] (1) Prepare autogenous acid A by the following components by weight: 100 parts by weight of paraformaldehyde (commercially available), add 50 parts of water, 0.15 part of sodium hydroxide (commercially available), and then add 0.5 part of iron ion stabilizer (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid (commercially available), stir evenly;

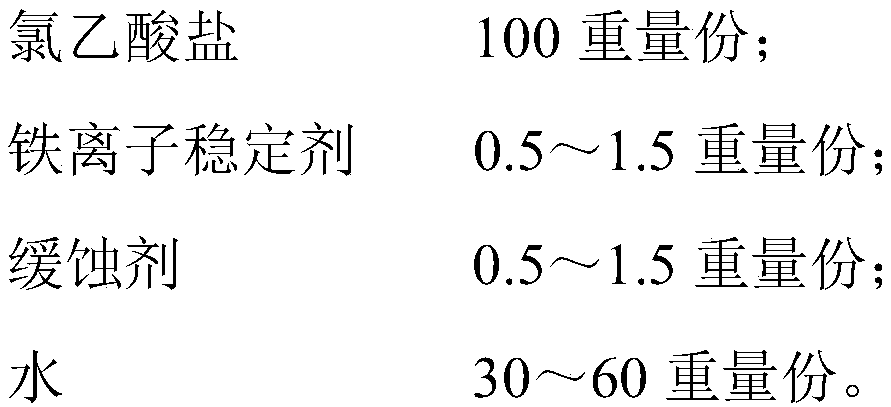

[0048] (2) Prepare autogenic acid matrix B according to the following components by weight: by mass fraction, weigh 100 parts of ammonium chloride (commercially available), measure 50 parts of water, and add ammonium chloride to the water. Stir until dissolved. Add 1 part of iron ion stabilizer (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid (commercially available) to B, and stir well

[0049] (3) Prepare the oil external phase according to the following components by weight: heat and dissolve 3 parts of span80 and 0.5 part of dodecylamine in...

Embodiment 3

[0057] (1) Prepare autogenic acid matrix A according to the following components by weight: 100 parts by weight of paraformaldehyde (commercially available), add 50 parts of water, 0.15 parts of sodium hydroxide (commercially available), and then add 0.5 parts of iron ions to stabilize agent (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid (commercially available), stir evenly;

[0058] (2) Prepare autogenic acid matrix B according to the following components by weight: by mass fraction, weigh 100 parts by weight of ammonium chloride (commercially available), measure 50 parts of water, and add salt into the water. Stir until dissolved. Add 0.5 part of iron ion stabilizer (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid (commercially available) in B, stir well

[0059] (3) Prepare the oil external phase according to the following components by weight: heat and dissolve 3 parts of sorbitan sorbi...

Embodiment 4

[0062] (1) Prepare autogenic acid matrix A according to the following components by weight: 100 parts by weight of paraformaldehyde (commercially available), add 50 parts of water, 0.15 parts of sodium hydroxide (commercially available), and then add 0.5 parts of iron ions to stabilize agent (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid (commercially available), stir evenly;

[0063] (2) Prepare autogenic acid matrix B according to the following components by weight: by mass fraction, weigh 100 parts by weight of ammonium chloride (commercially available), measure 40 parts of water, add the salt into the water, and stir until dissolved. Add 1 part of iron ion stabilizer (commercially available) and 1 part of corrosion inhibitor ethylenediaminetetraacetic acid to B, and stir well

[0064] (3) Prepare the oil external phase according to the following components by weight: heat and dissolve 2 parts of autosorbitan fatty acid ester and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com