Cross-linked emulsified acid, preparation method and applications thereof

A technology of emulsified acid and cross-linked acid, which is applied in the fields of chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve problems such as limited range of communication reservoirs, poor effect of acid fracturing, difficulty in meeting high-temperature reservoirs, etc. Achieve the effects of improving acidizing and acid fracturing effects, good acid fracturing/acidizing effects, and prolonging the etching distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

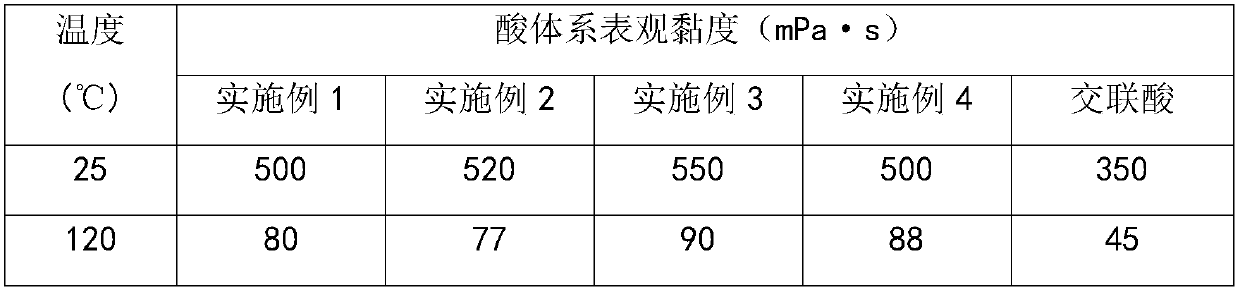

Embodiment 1

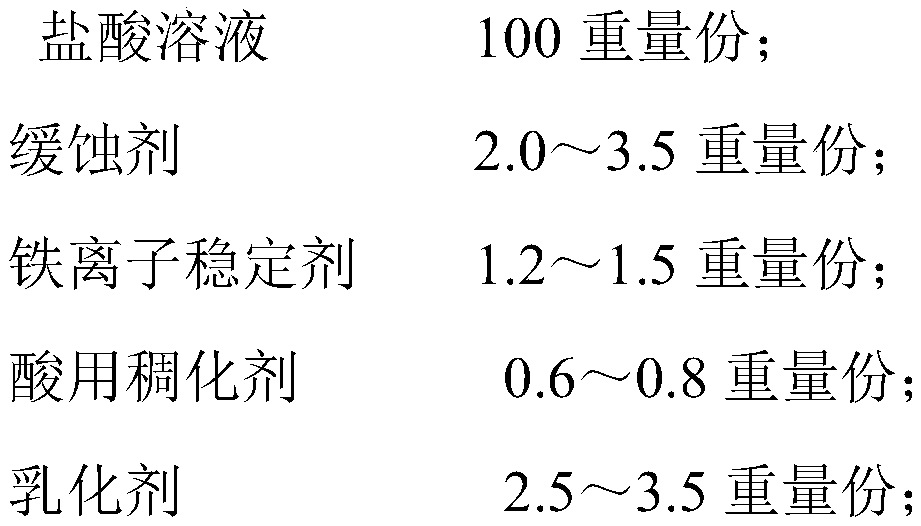

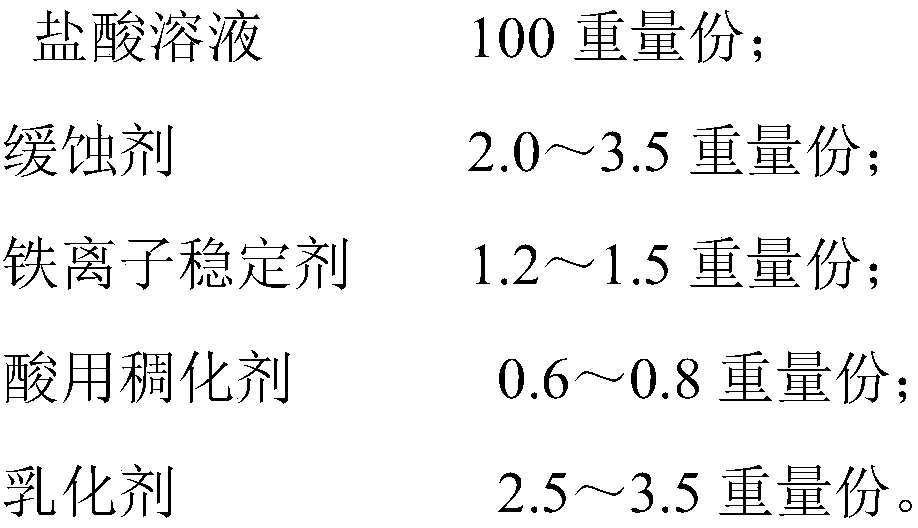

[0048] 1) Prepare the cross-linked acid base solution according to the following components by weight: Take 100 parts of hydrochloric acid solution (concentration: 15% wt), slowly add 0.6 parts of polyacrylamide thickener SRAP for acid at 500r / min -1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, then added 1.2 parts of iron ion stabilizer (ethylenediaminetetraacetic acid, Tianjin Guangfu Chemical Reagent Factory), 2.0 1-part of 1-aminoethyl-2-pentadecyl imidazoline quaternary ammonium salt (commercially available) and 2.5 parts of sorbitan fatty acid ester polyoxyethylene ether (commercially available) emulsifier are stirred evenly, sealed at room temperature Leave it for 4 hours;

[0049] 2) Prepare the emulsion according to the following components by volume: under the condition of a stirring speed of 500r / min, slowly add white oil dropwise to the cross-linked acid base liquid prepared ...

Embodiment 2

[0052] 1) Prepare the cross-linked acid base solution according to the following components by weight: take 100 parts of hydrochloric acid solution (concentration: 20% wt), slowly add 0.7 parts of polyacrylamide thickener SRAP for acid at 500r / min -1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, then added 1.5 parts of iron ion stabilizer citric acid (commercially available), 3.0 parts of 1-aminoethyl -2-Pentadecyl imidazoline quaternary ammonium salt (commercially available) and 3.0 parts of polyoxyethylene polyoxyethylene octylphenol ether-10 (commercially available) emulsifier were stirred evenly, and sealed at room temperature for 5 hours;

[0053] 2) Prepare the emulsion according to the following components by volume: under the condition of a stirring speed of 800r / min, slowly add white oil dropwise to the cross-linked acid base liquid prepared in , and the volume ratio of the two ph...

Embodiment 3

[0056] 1) Prepare the cross-linked acid base solution according to the following components by weight: Take 100 parts of hydrochloric acid solution (concentration: 25% wt), slowly add 0.8 parts of polyacrylamide thickener SRAP for acid at 500r / min -1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, then added 1.5 parts of iron ion stabilizer acetic acid (commercially available), 3.5 parts of Mannich base buffer Etching agent (commercially available) and 3.0 parts of polyoxyethylene polyoxyethylene octylphenol ether-10 and cetyltrimethylammonium bromide mixture (mass ratio 1:1) (commercially available) emulsifier are stirred evenly, Sealed and placed at room temperature for 5 hours;

[0057] 2) Prepare the emulsion according to the following components by volume: under the condition of a stirring speed of 1000r / min, slowly add white oil dropwise to the cross-linked acid base liquid prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com