Patents

Literature

409 results about "Fluid filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

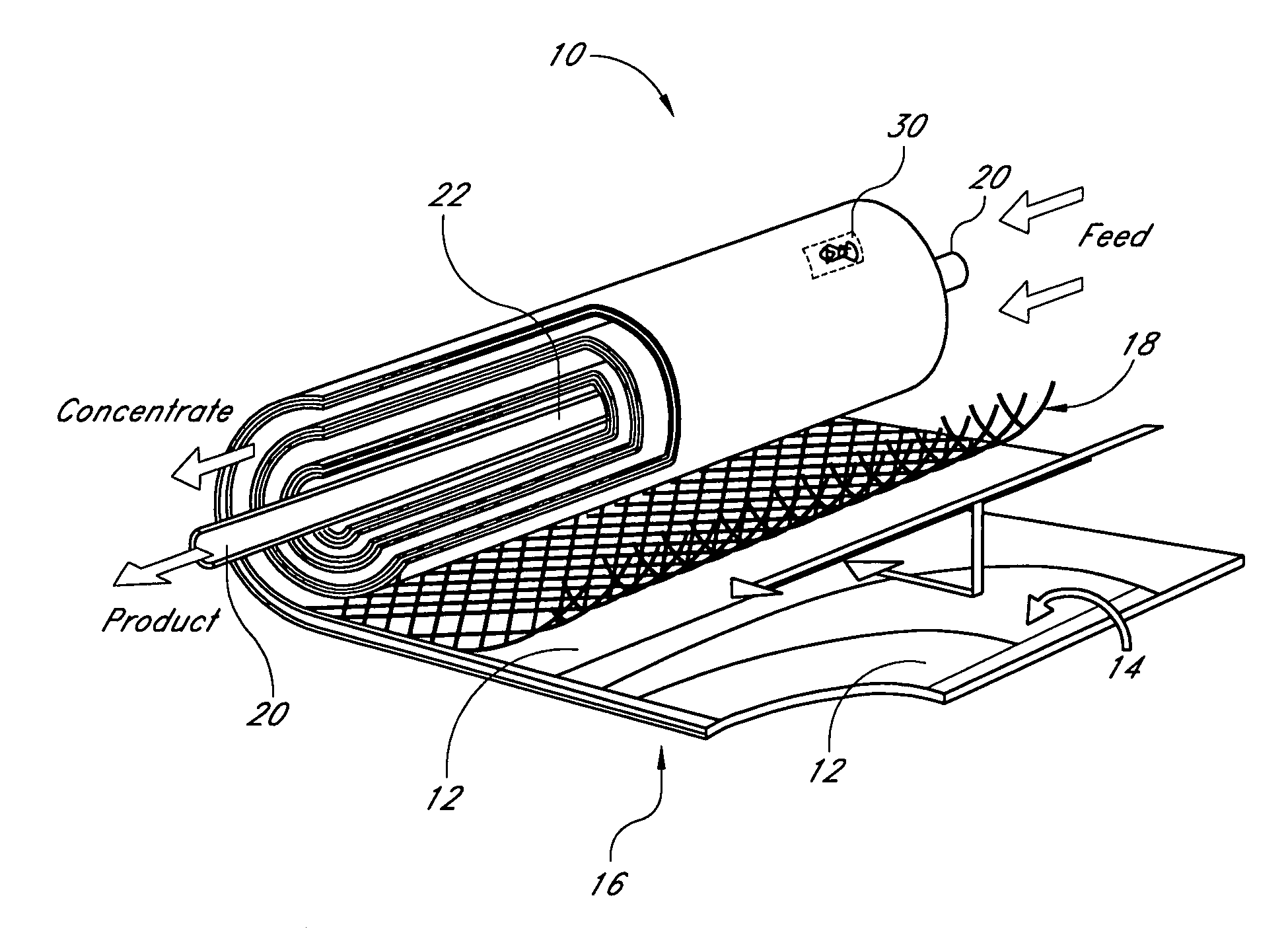

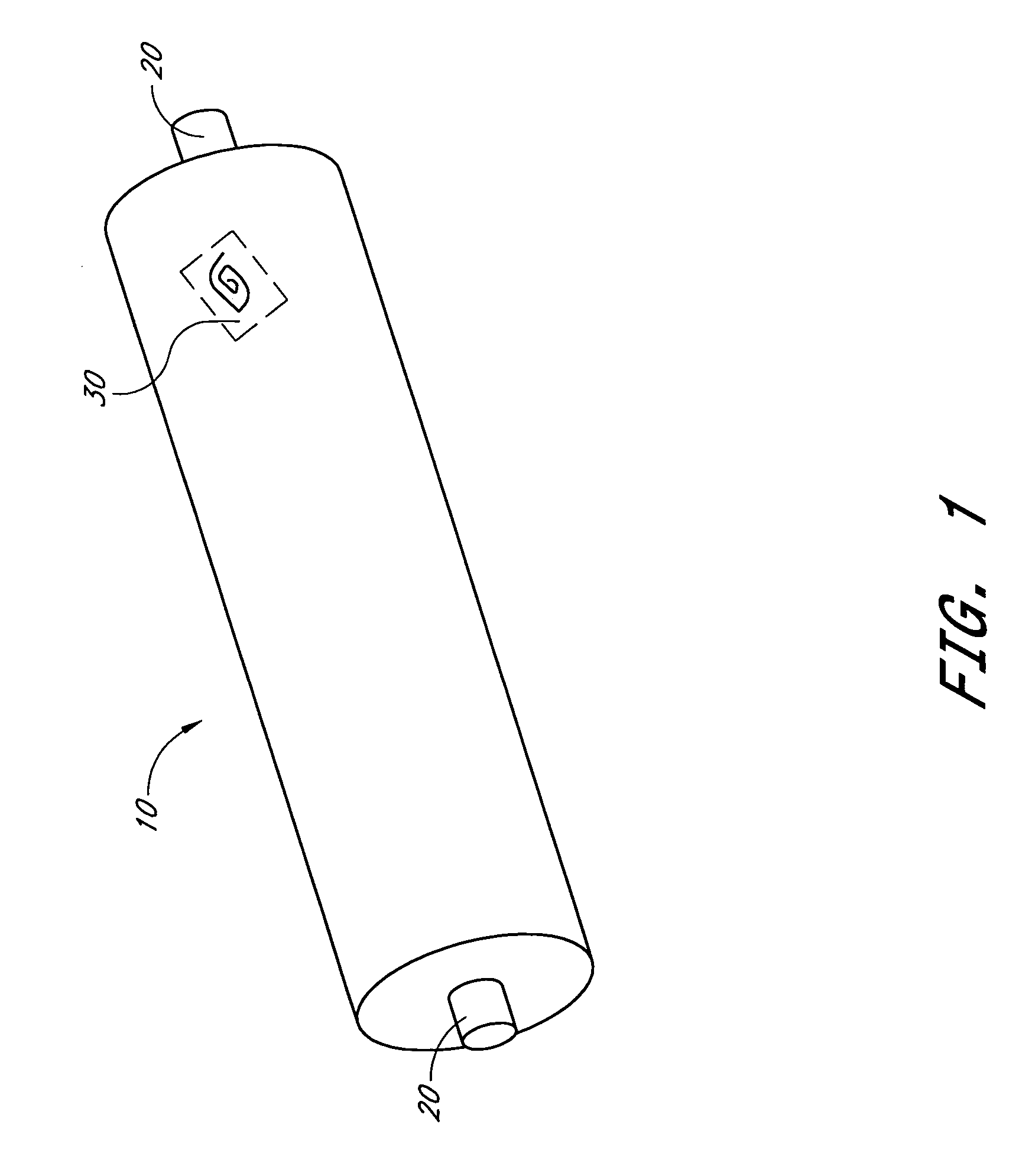

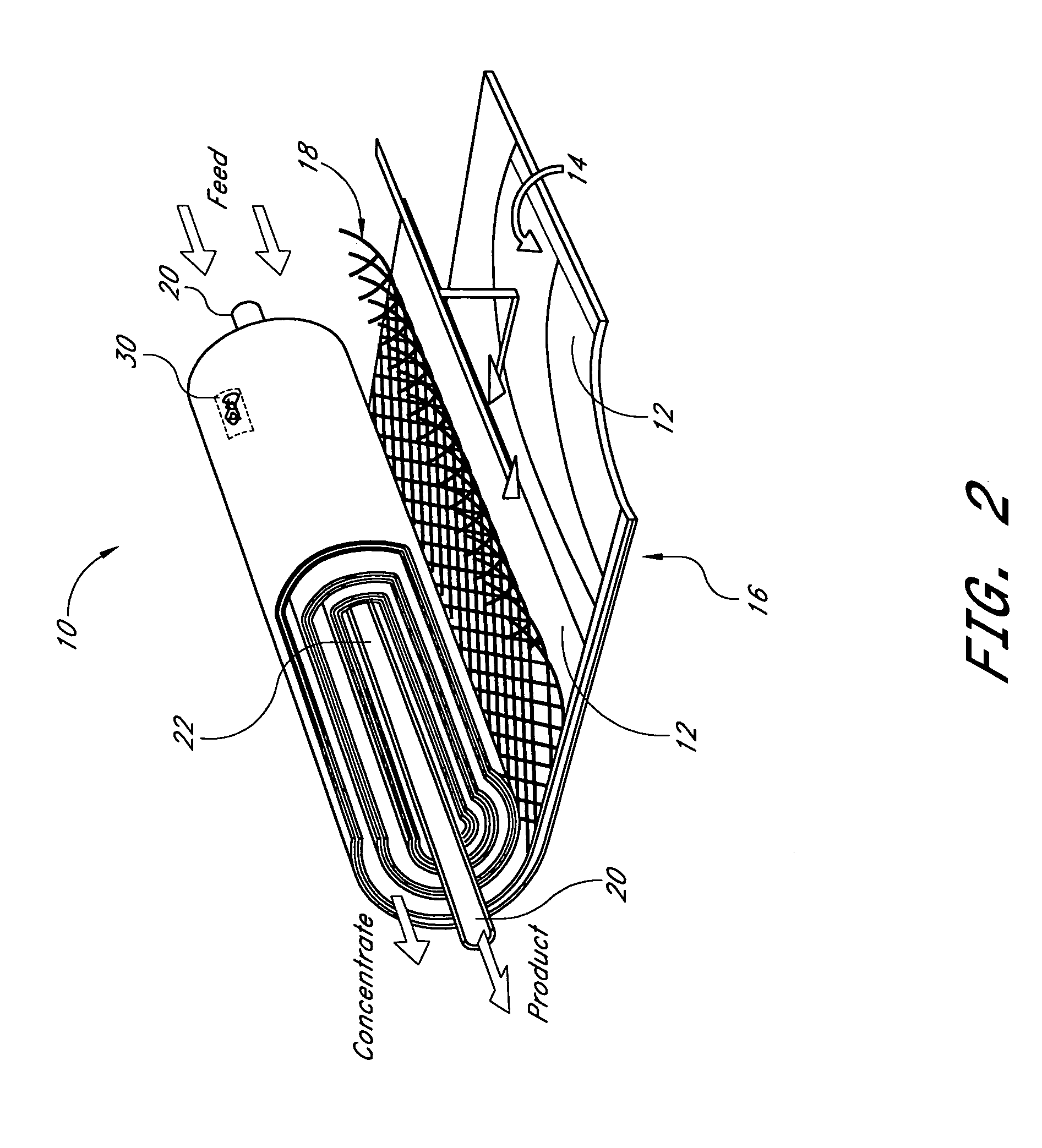

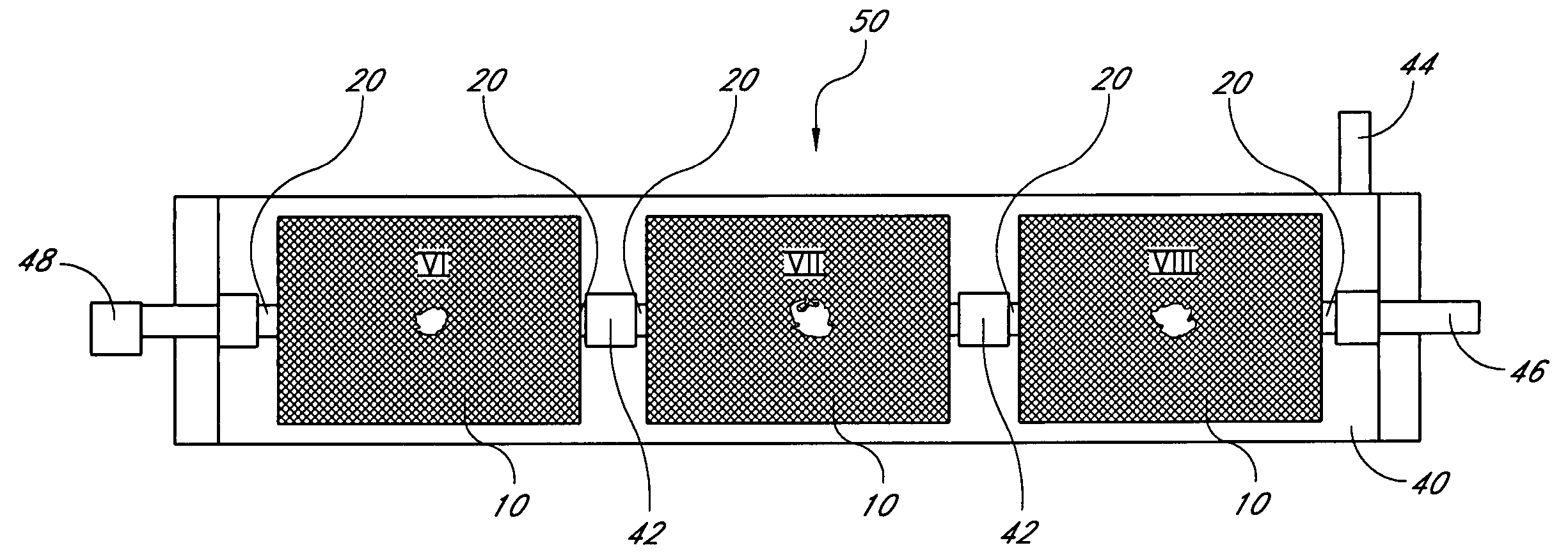

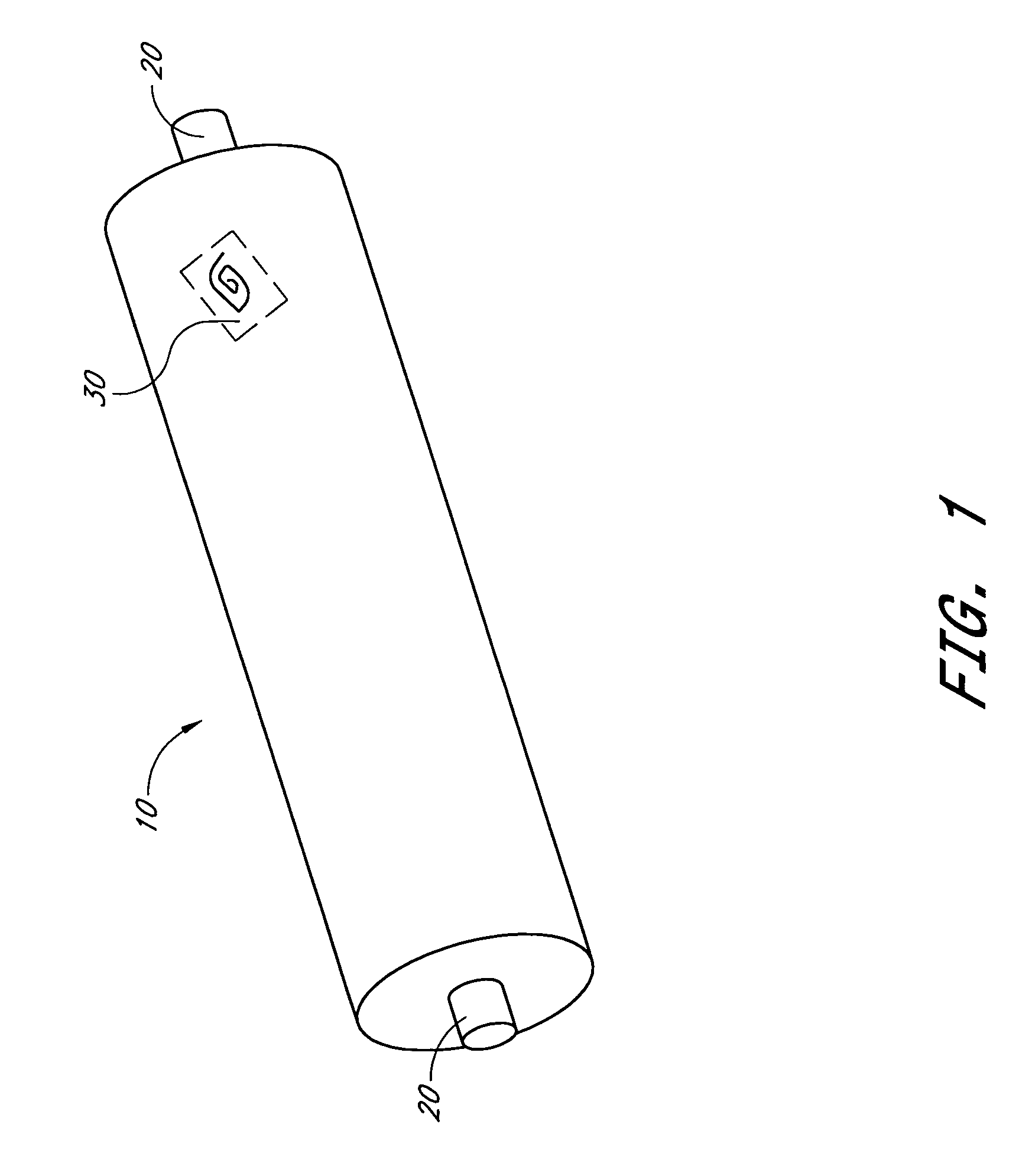

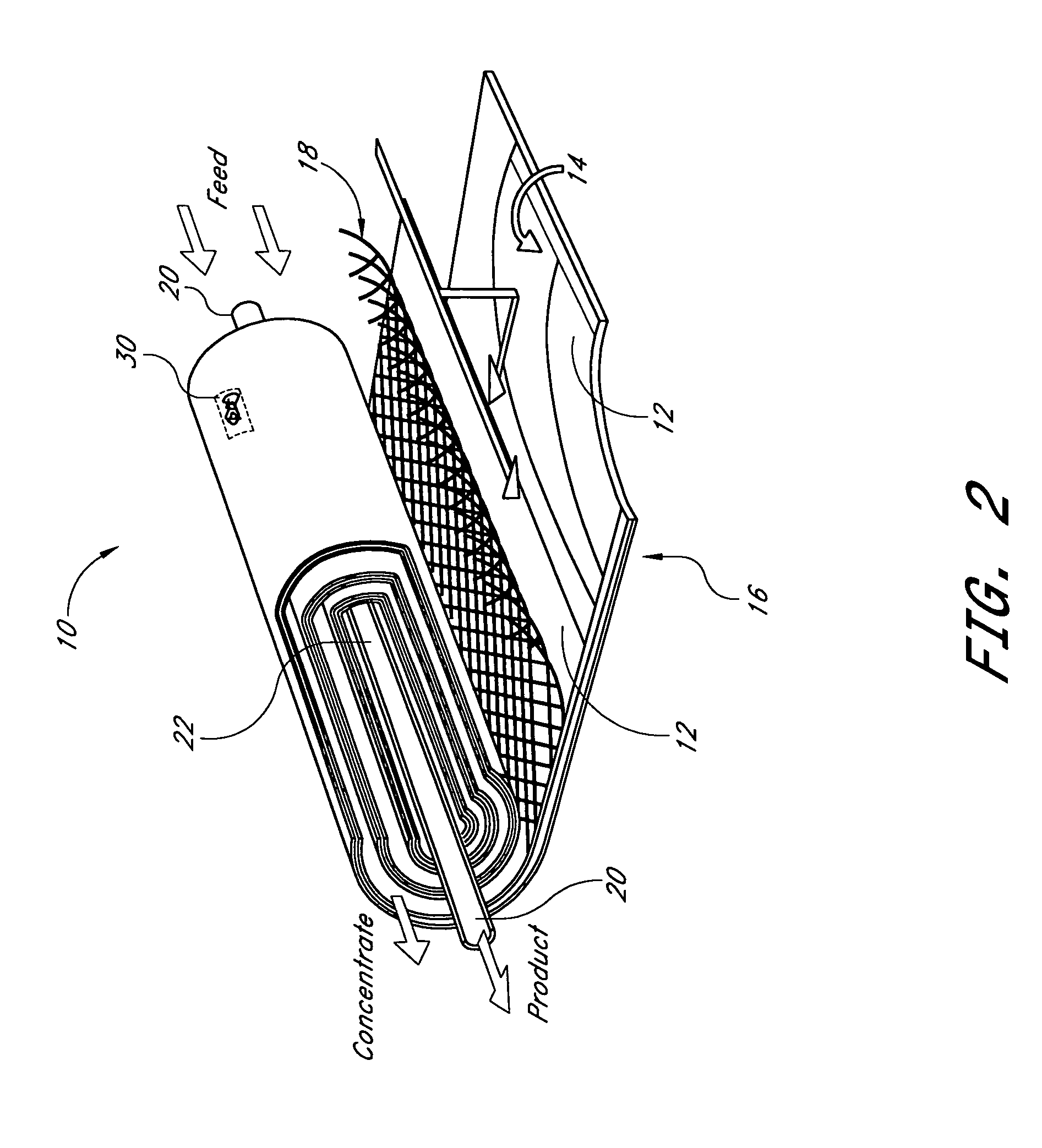

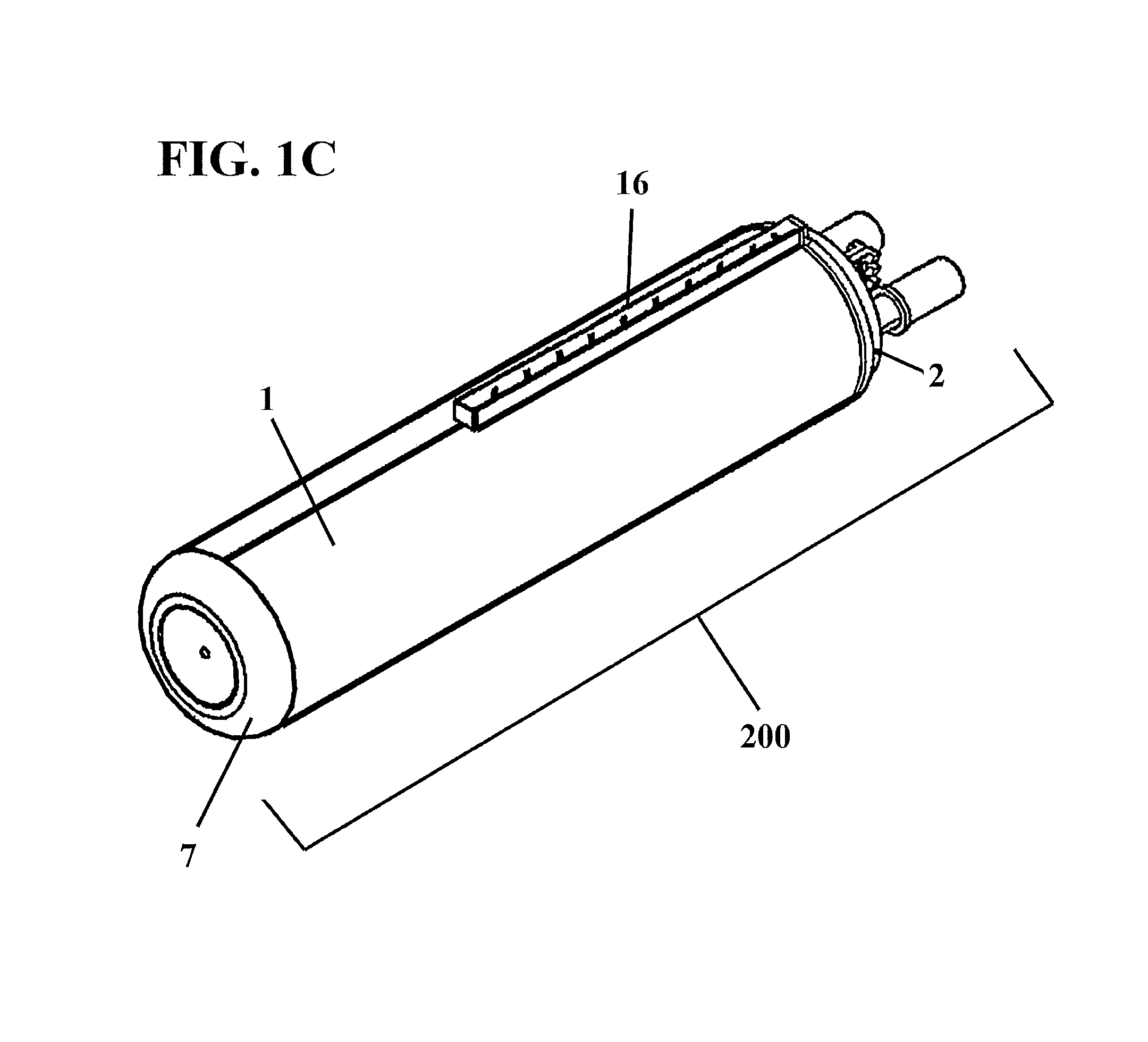

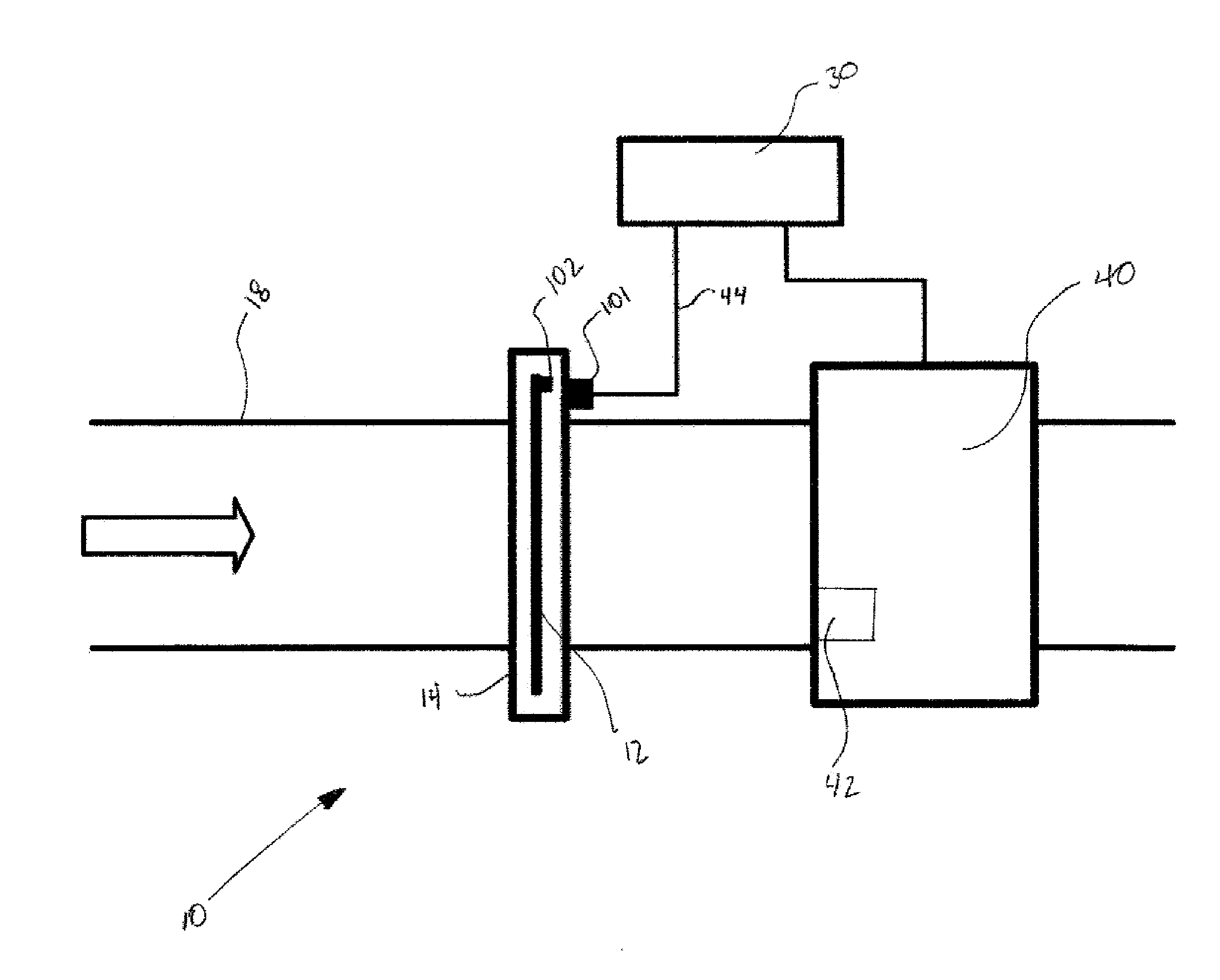

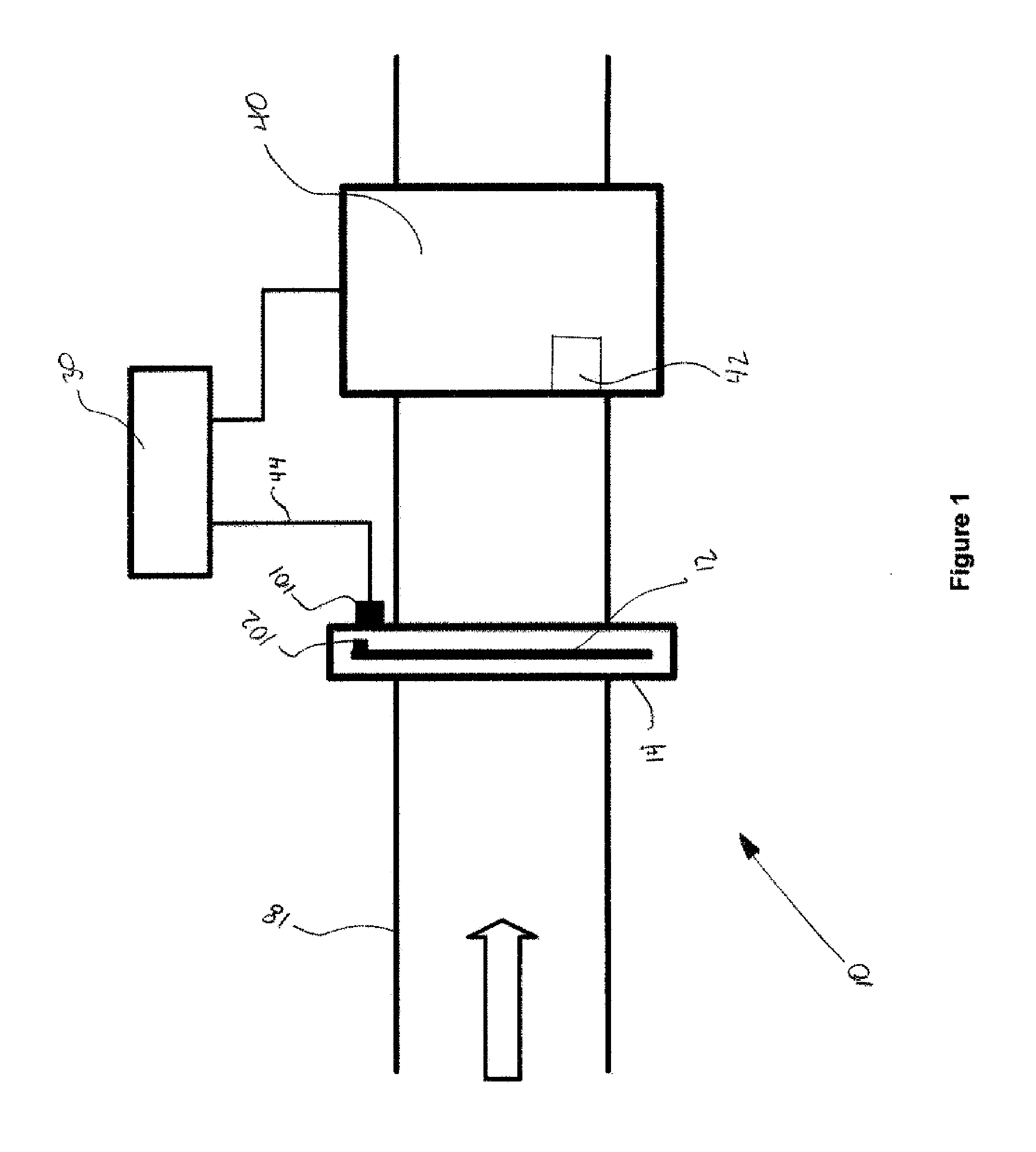

Filtration devices with embedded radio frequency identification (RFID) tags

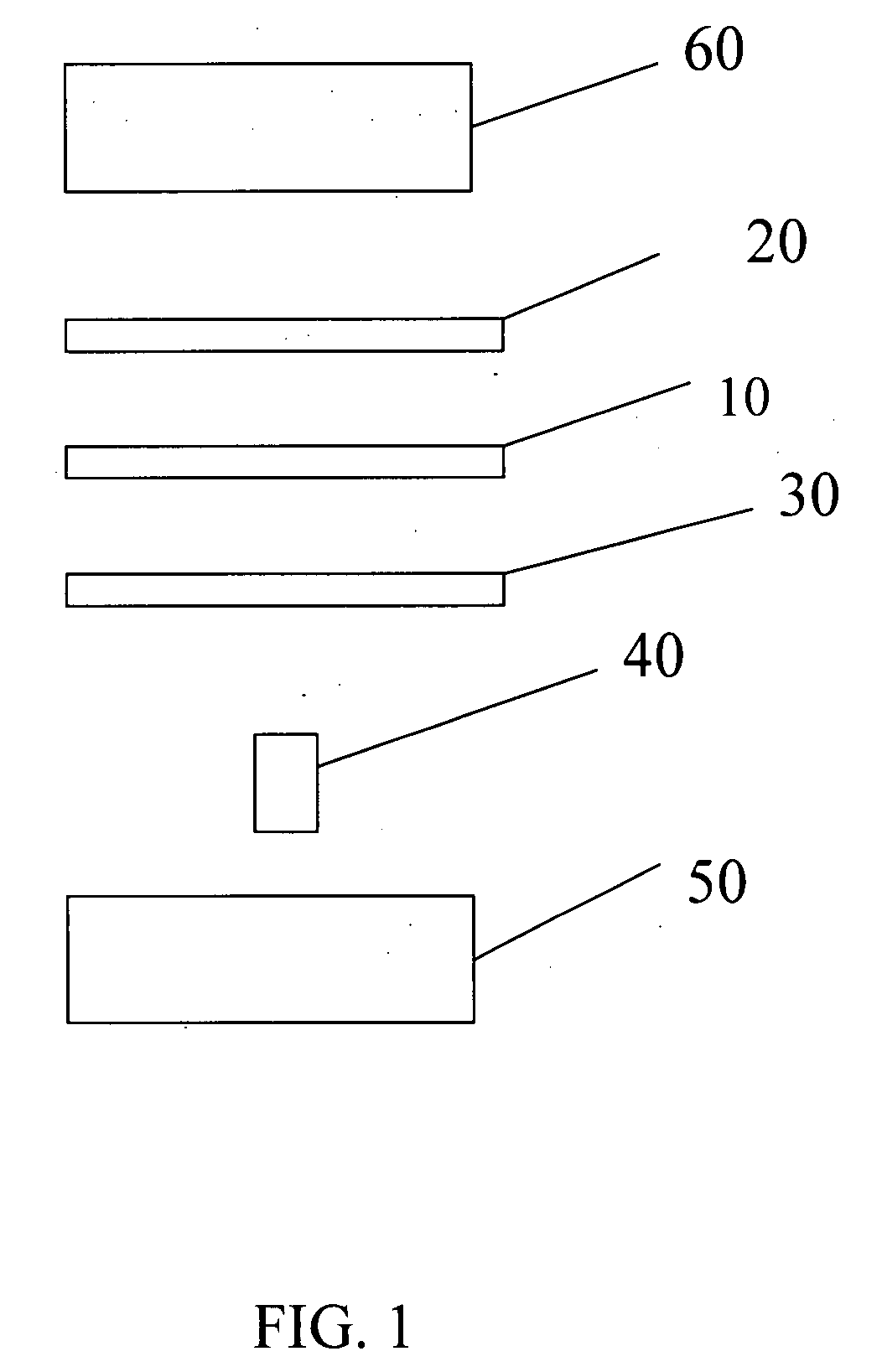

ActiveUS20050194317A1Easily store and retrieve dataEasy loadingWater/sewage treatment bu osmosis/dialysisReverse osmosisReverse osmosisFluid filtration

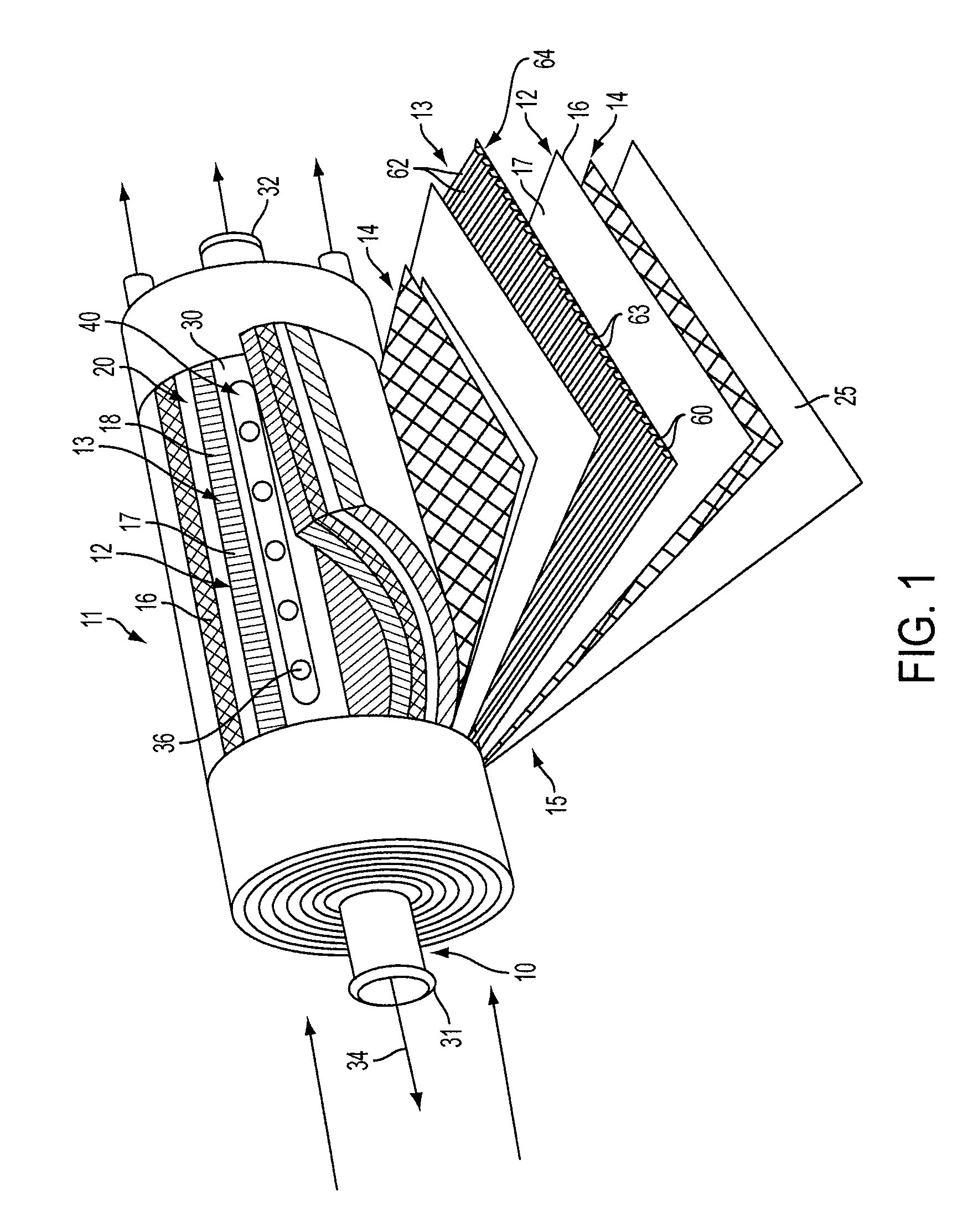

Embodiments of the present invention comprise reverse osmosis filters and systems comprising embedded radio frequency identification (RFID) tags for storing and retrieving data. The RFID tags can be preferably embedded under a filtration device's protective outer shell. Information can be easily stored onto and retrieved from the embedded RFID tags. The ability to easily store and retrieve data from the embedded RFID devices facilitates the creation of loading maps, monitoring, addition, and replacement of fluid filtration devices.

Owner:NITTO DENKO CORP +1

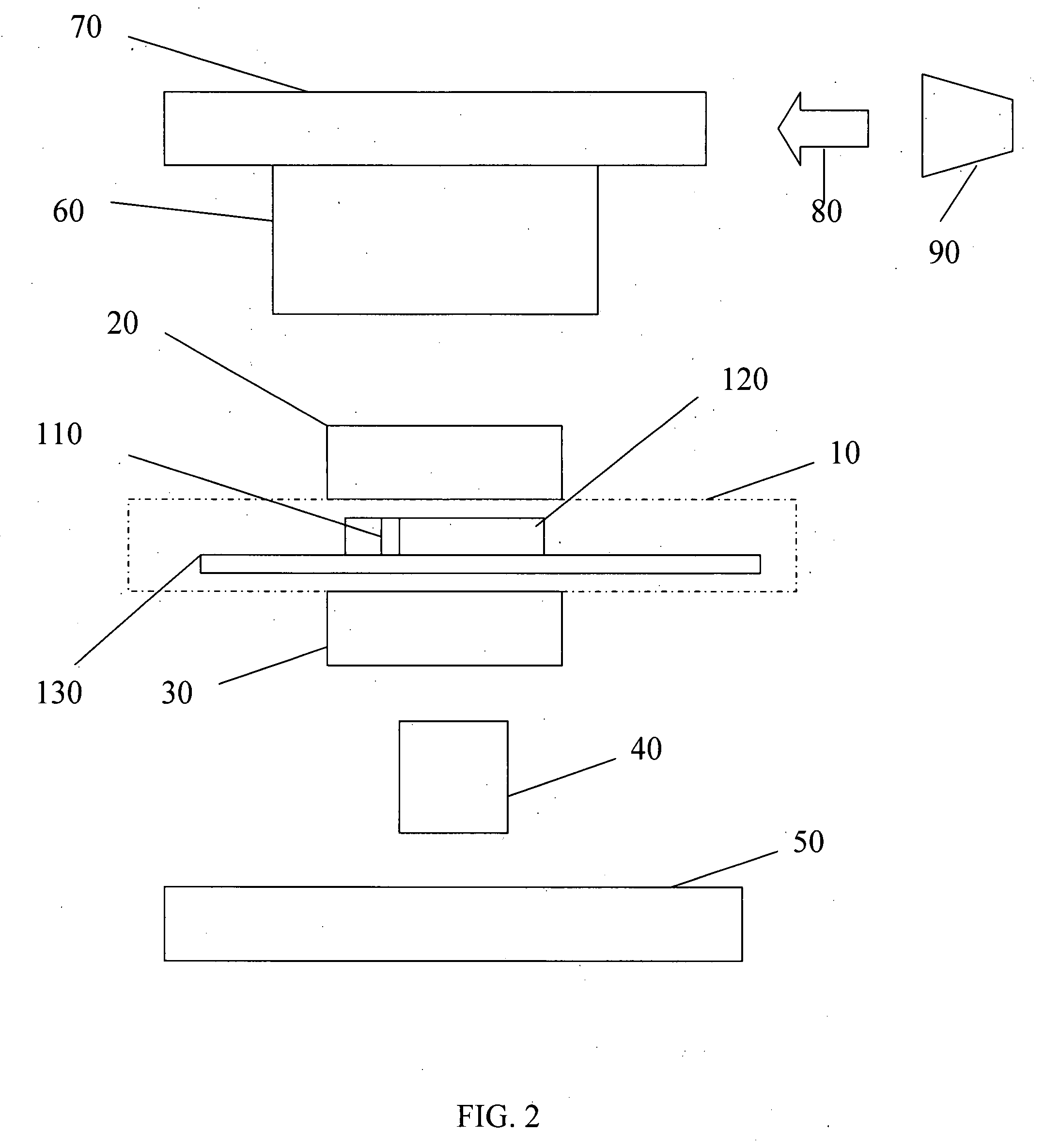

Fluorescence detector, filter device and related methods

ActiveUS20080013092A1Small sizeIncrease costSemi-permeable membranesDischarging arrangementAntigenFluorescent light

Microfluidic assay detectors and microfluidic assay detection methods are disclosed. A microfluidic chip is coupled to a light emitting device, emission filters and excitation filters. Excited fluorescent light is detected by a camera and a lens. The correspondent reading allows parallel detection of features such as antigens and biomarkers. A microfluidic filter and related methods are also disclosed. The filter can be used with on-chip fluid filtration such as whole blood filtration for microfluidic blood analysis. The filter is able to filter the necessary volume of fluid and in particular blood in an acceptable time frame.

Owner:CALIFORNIA INST OF TECH

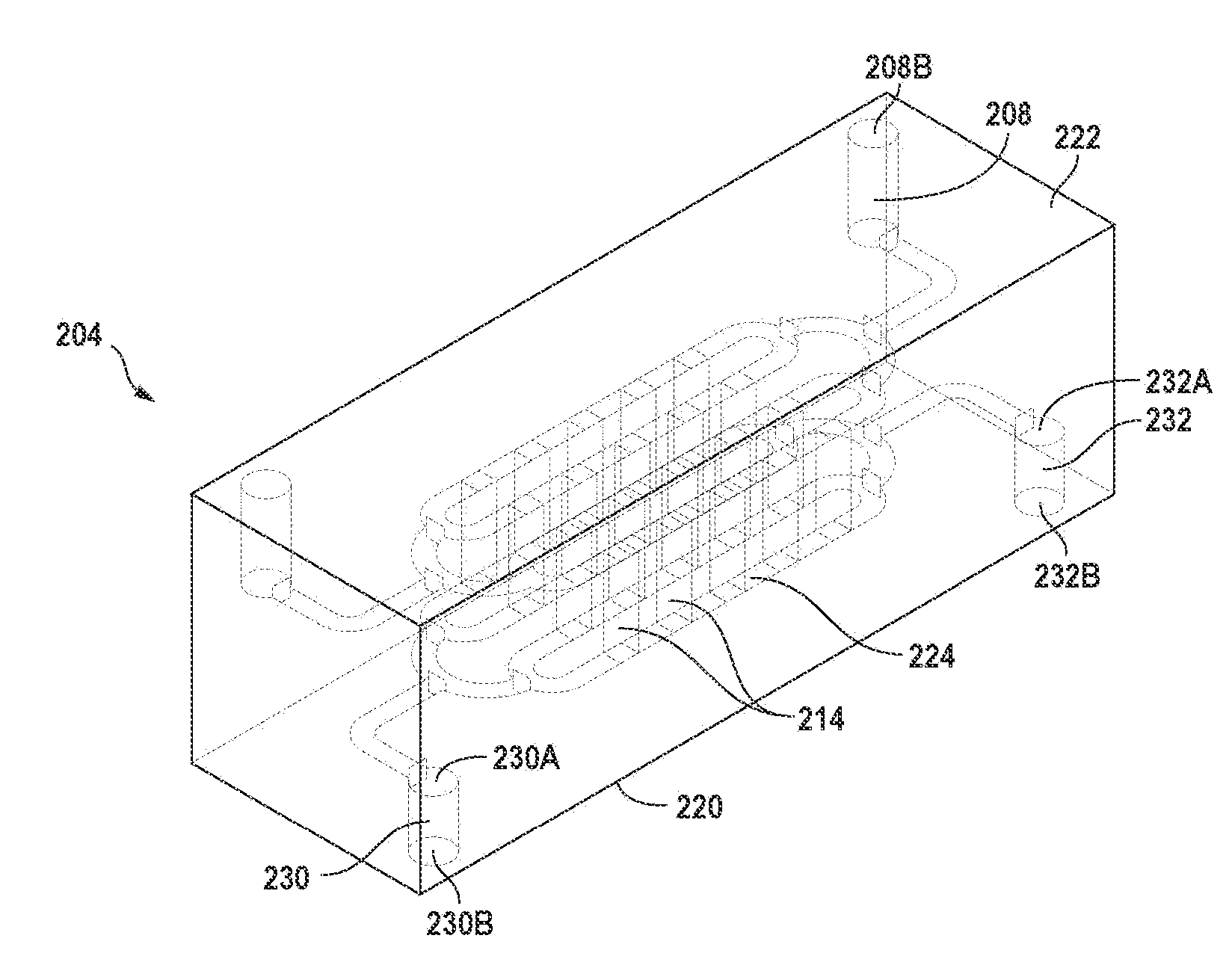

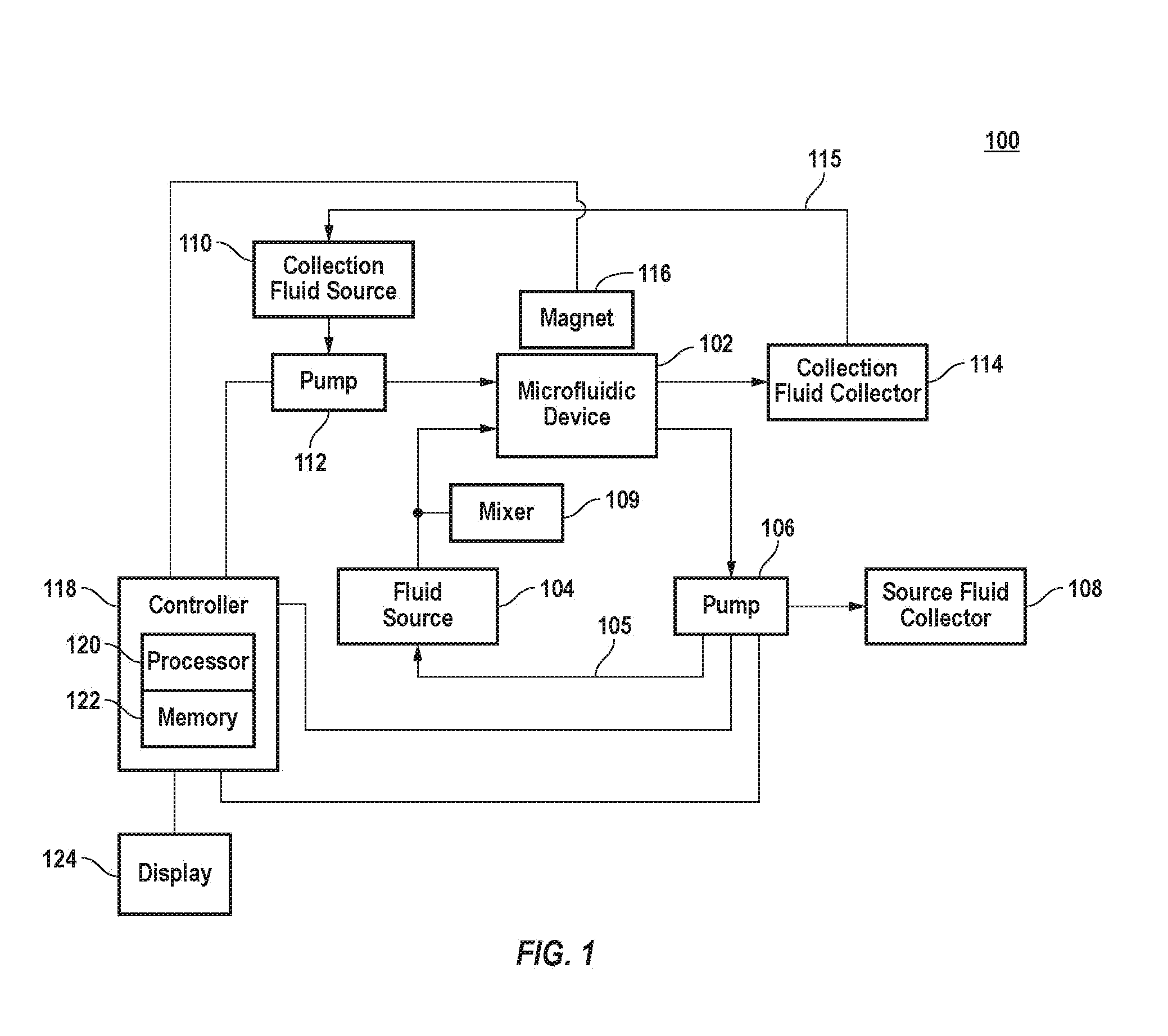

Device for Filtration of Fluids Therethrough and Accompanying Method

ActiveUS20120149021A1Easy to separateEasy to removeBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic field gradientFluid filtration

A microfluidic device for separating target components from a source fluid includes one or more source channels connected to one or more collection channels by one or more transfer channels. The target components of the source fluid can be magnetic or bound to magnetic particles using a know binding agent. A source fluid containing magnetically bound target components can be pumped through the source channel of the microfluidic device. A magnetic field gradient can be applied to the source fluid in the source channel causing the magnetically bound target components to migrate through the transfer channel into the collection channel. The collection channel can include a collection fluid that is stagnant until a predefined volume of source fluid is processed or a predefined volume of target components accumulate in the collection channel, at which point collection fluid can be pumped into the collection channel to flush the target components out of the collection channel. The target components can be subsequently analyzed for detection and diagnosis.

Owner:CHARLES STARK DRAPER LABORATORY +1

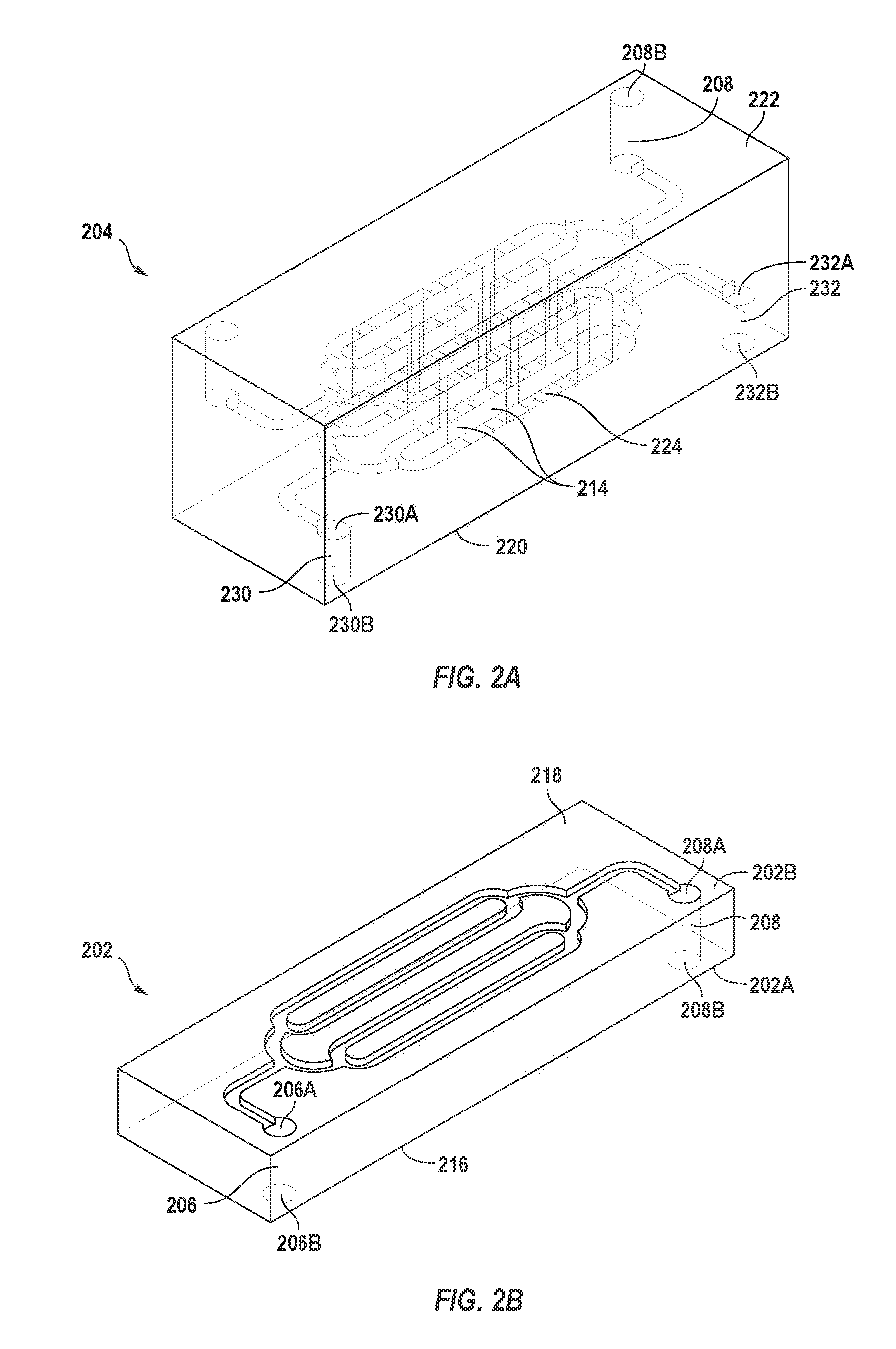

Fluid filtration and particle concentration device and methods

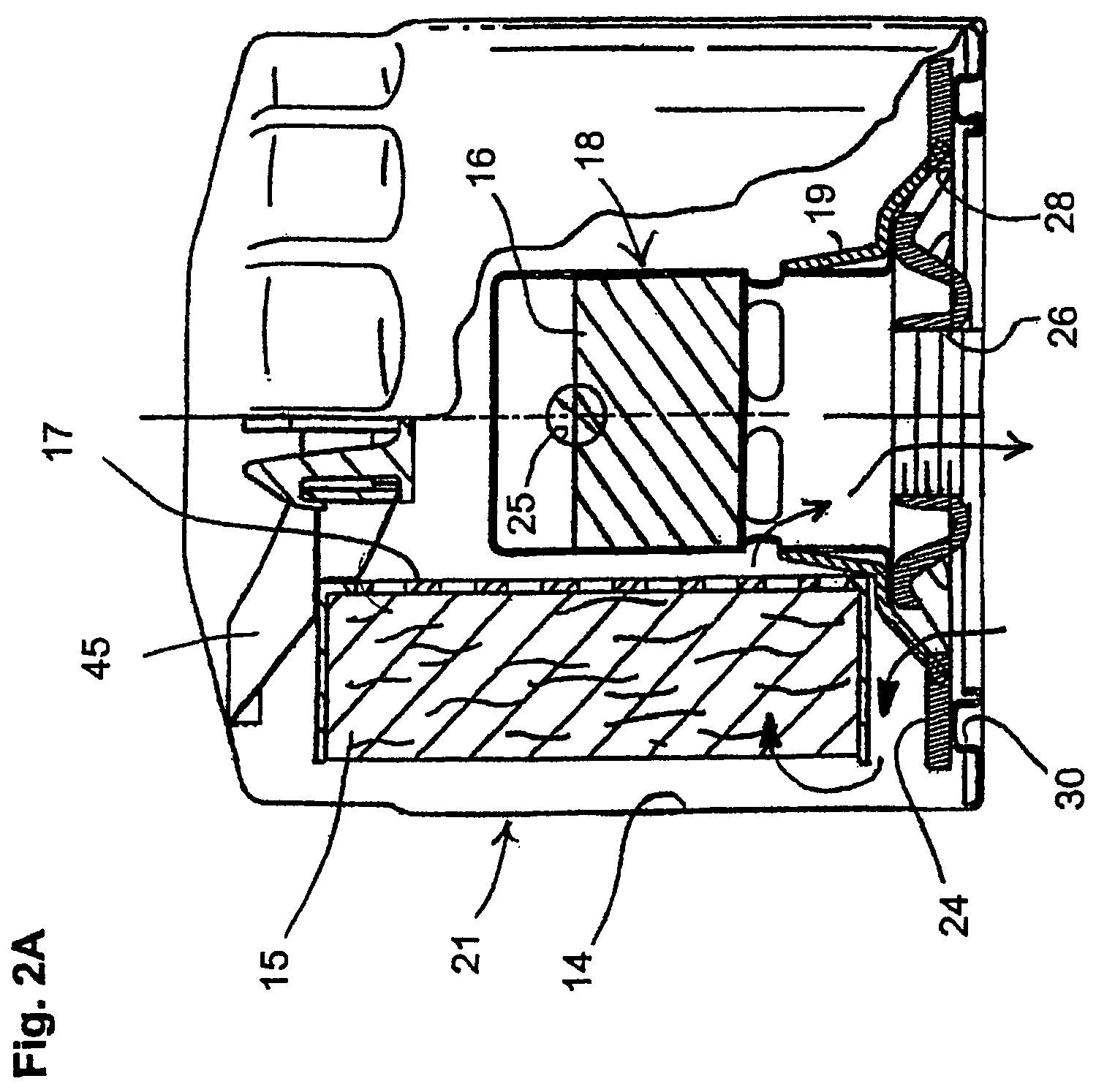

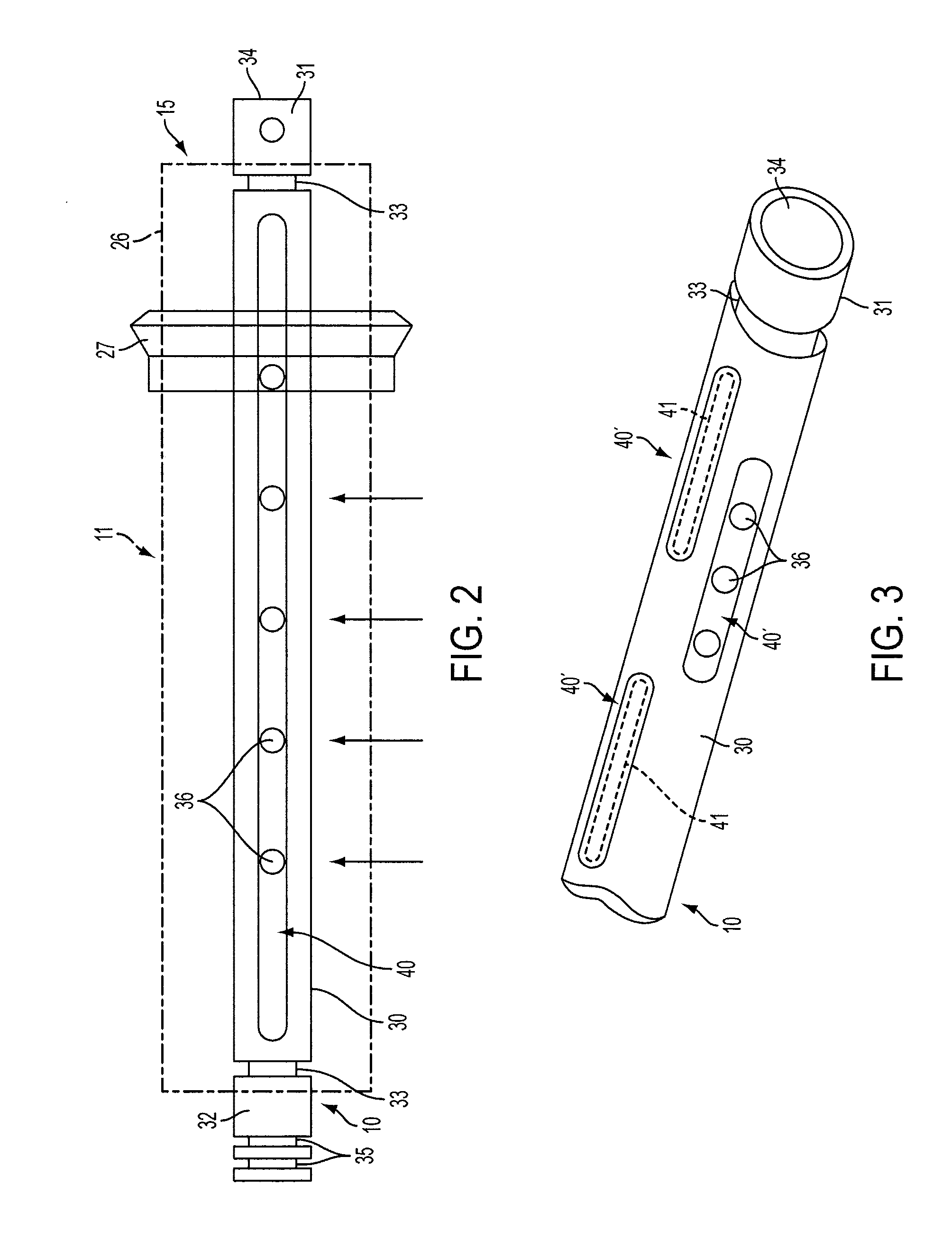

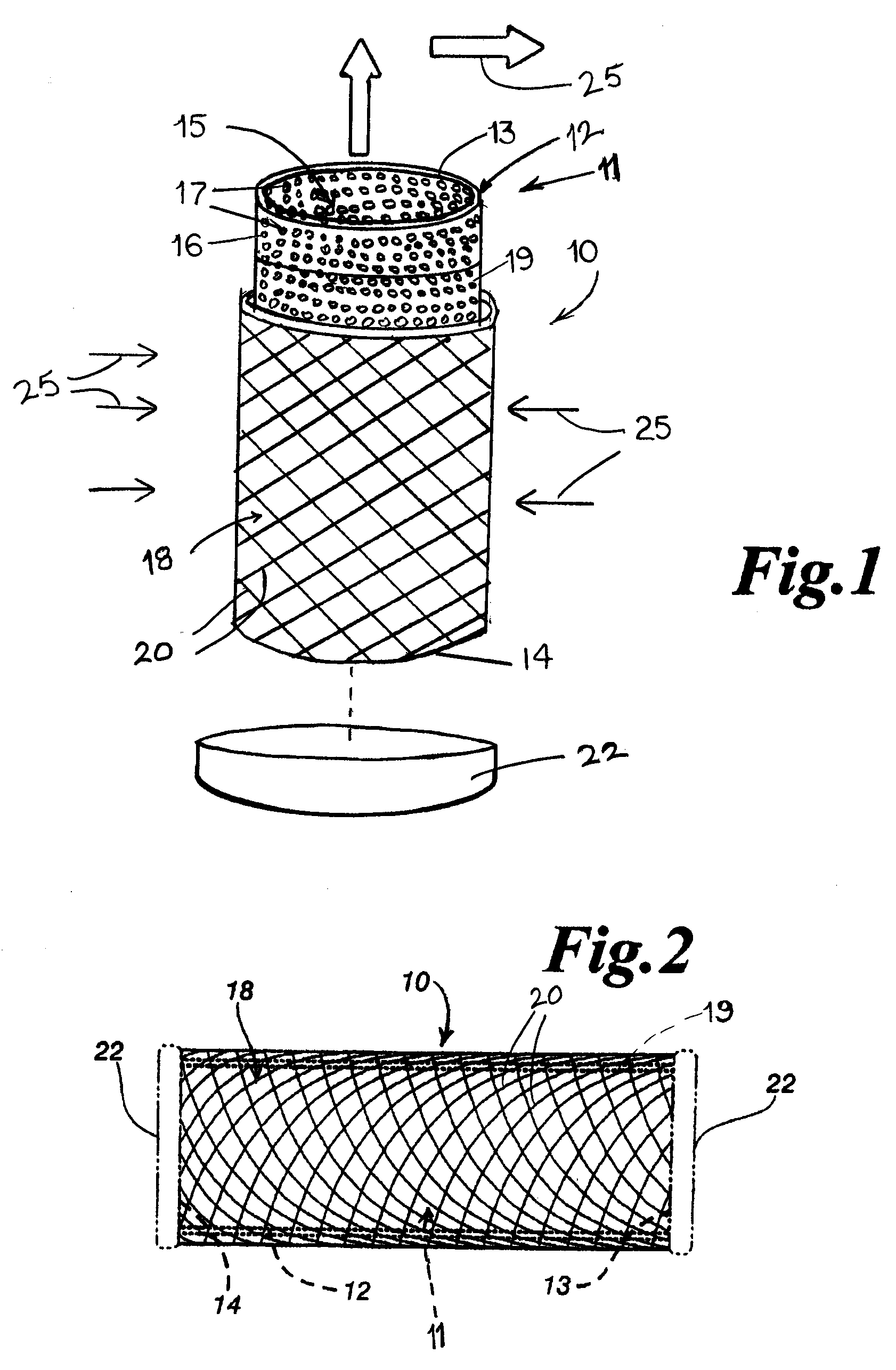

Fluid filtration devices and methods of filtering fluids are described. The devices generally include a housing and an annular filter assembly, wherein the filter assembly is located inside the housing and comprises a filter material. The filter material may be, for example, an electroformed nickel screen having a smooth working surface and expanding pores. A rotating cleaning assembly comprising a distributor and wipers may be located inside the filter assembly.

Owner:SPIRAL WATER TECH

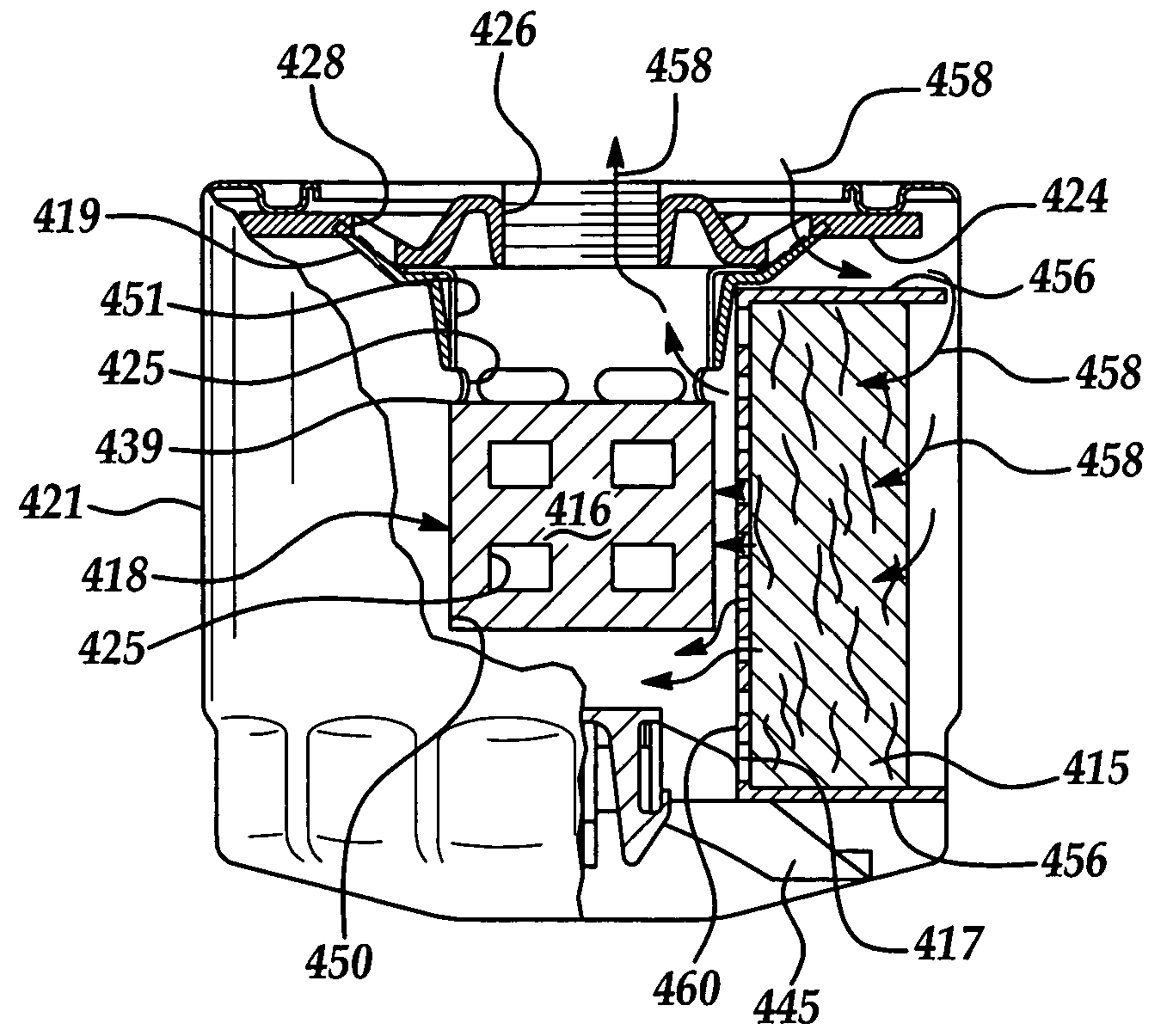

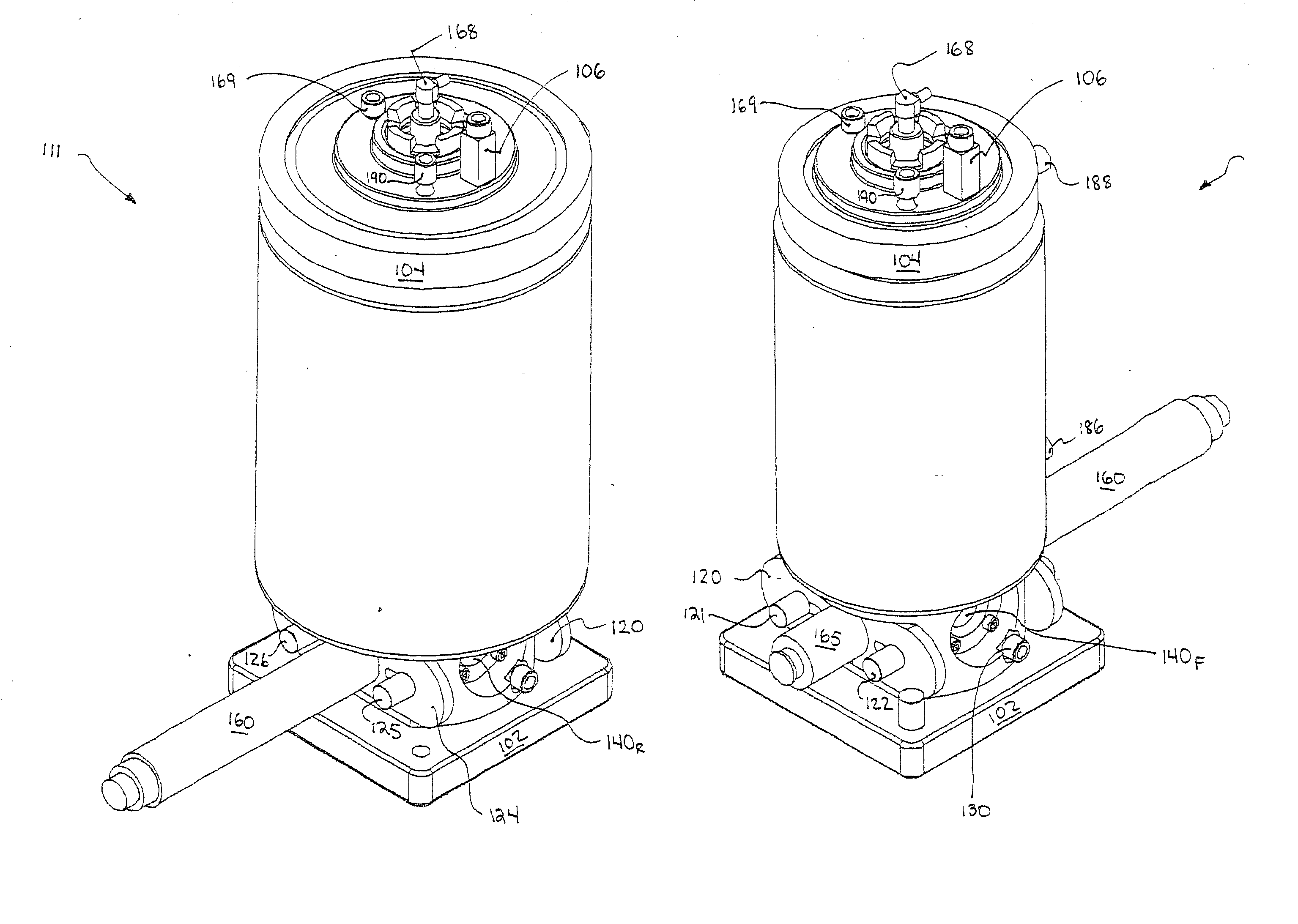

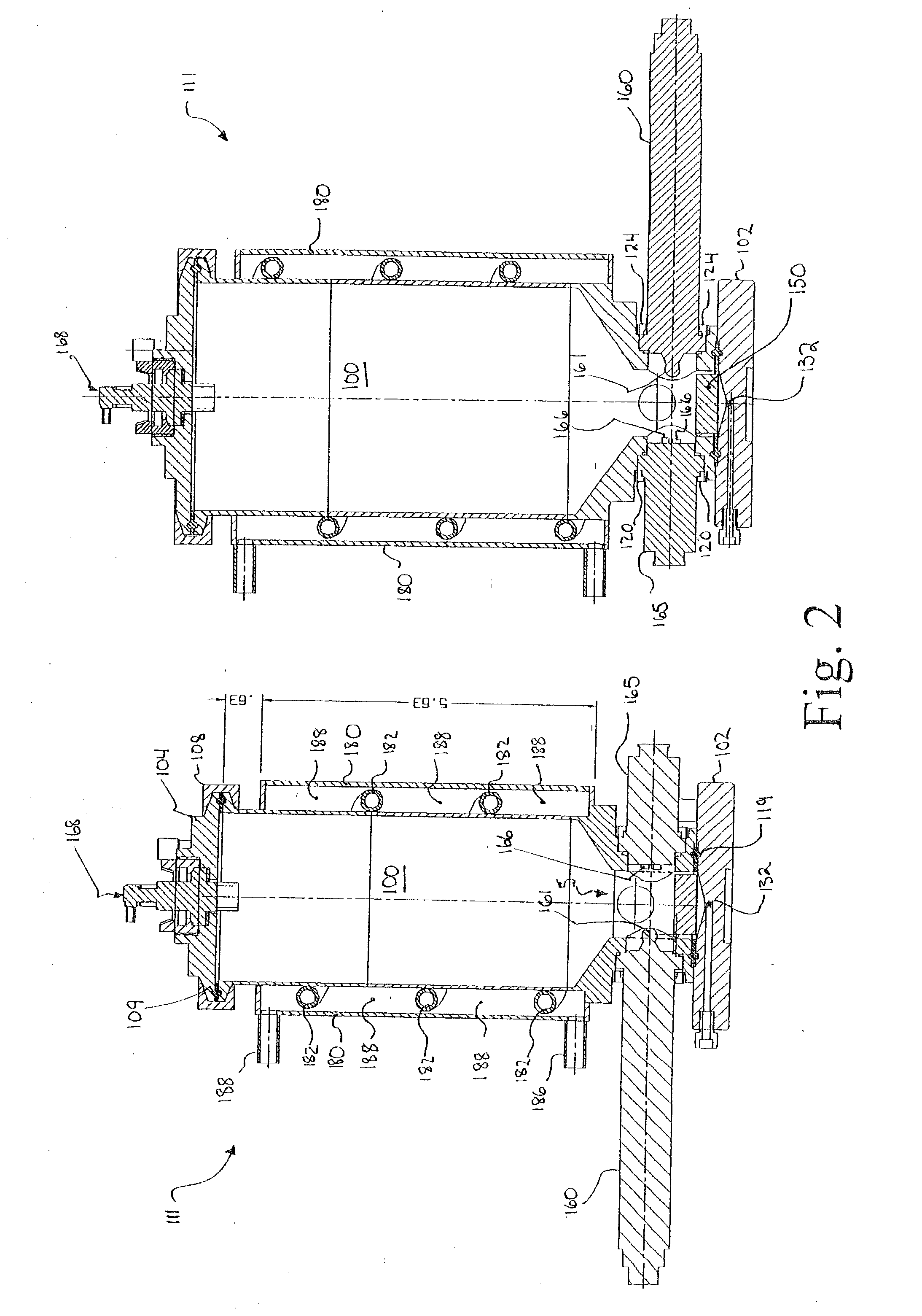

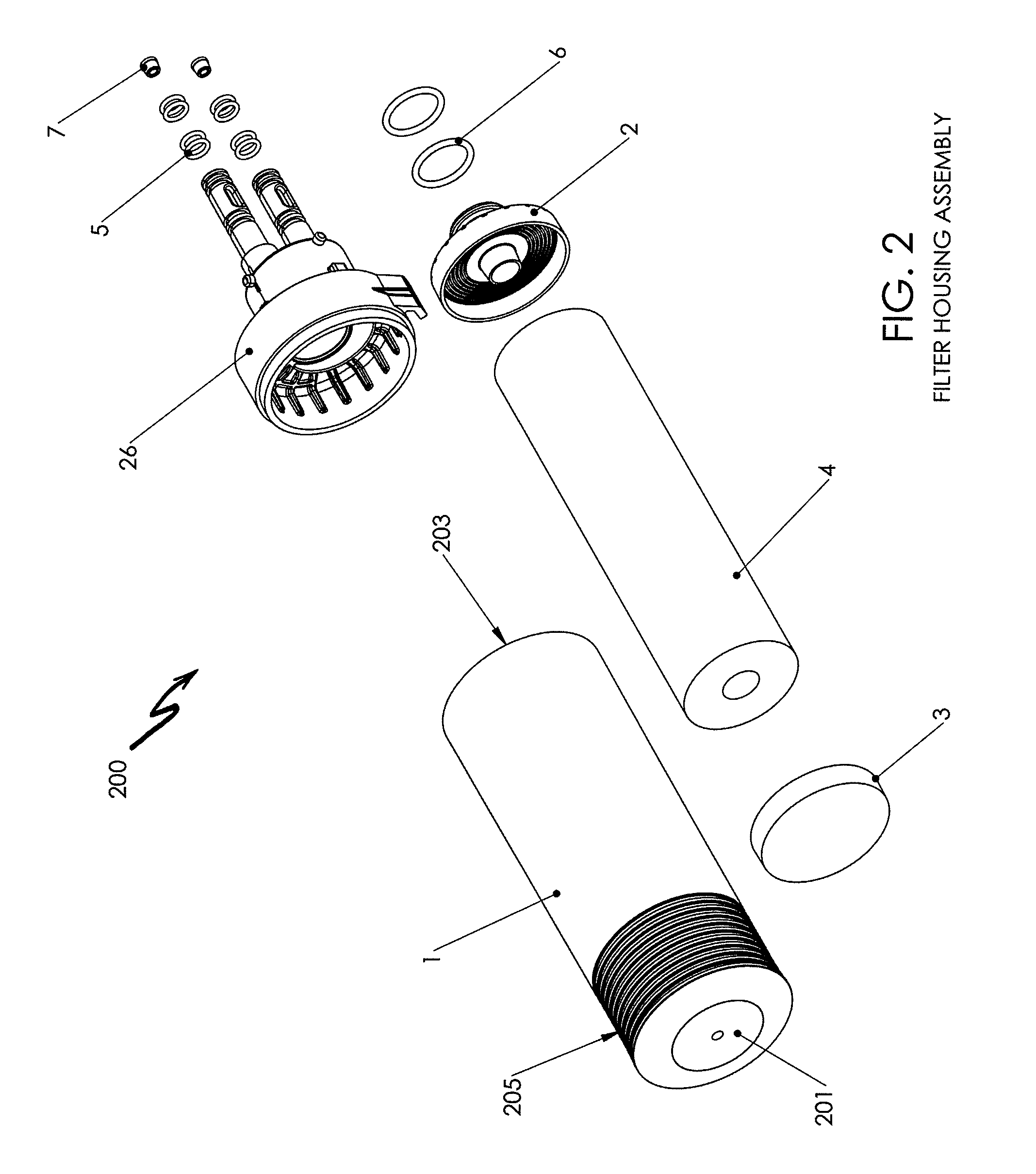

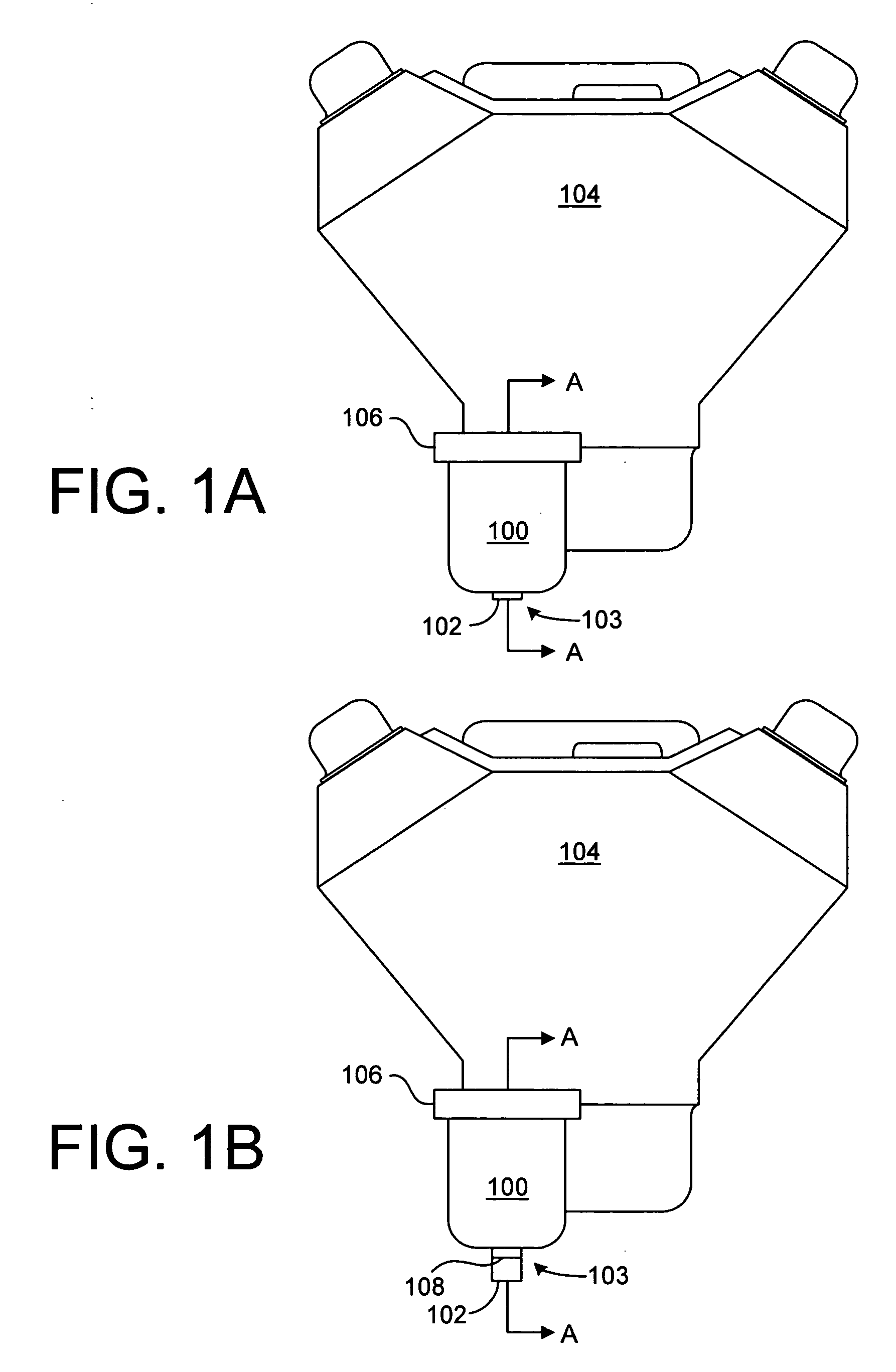

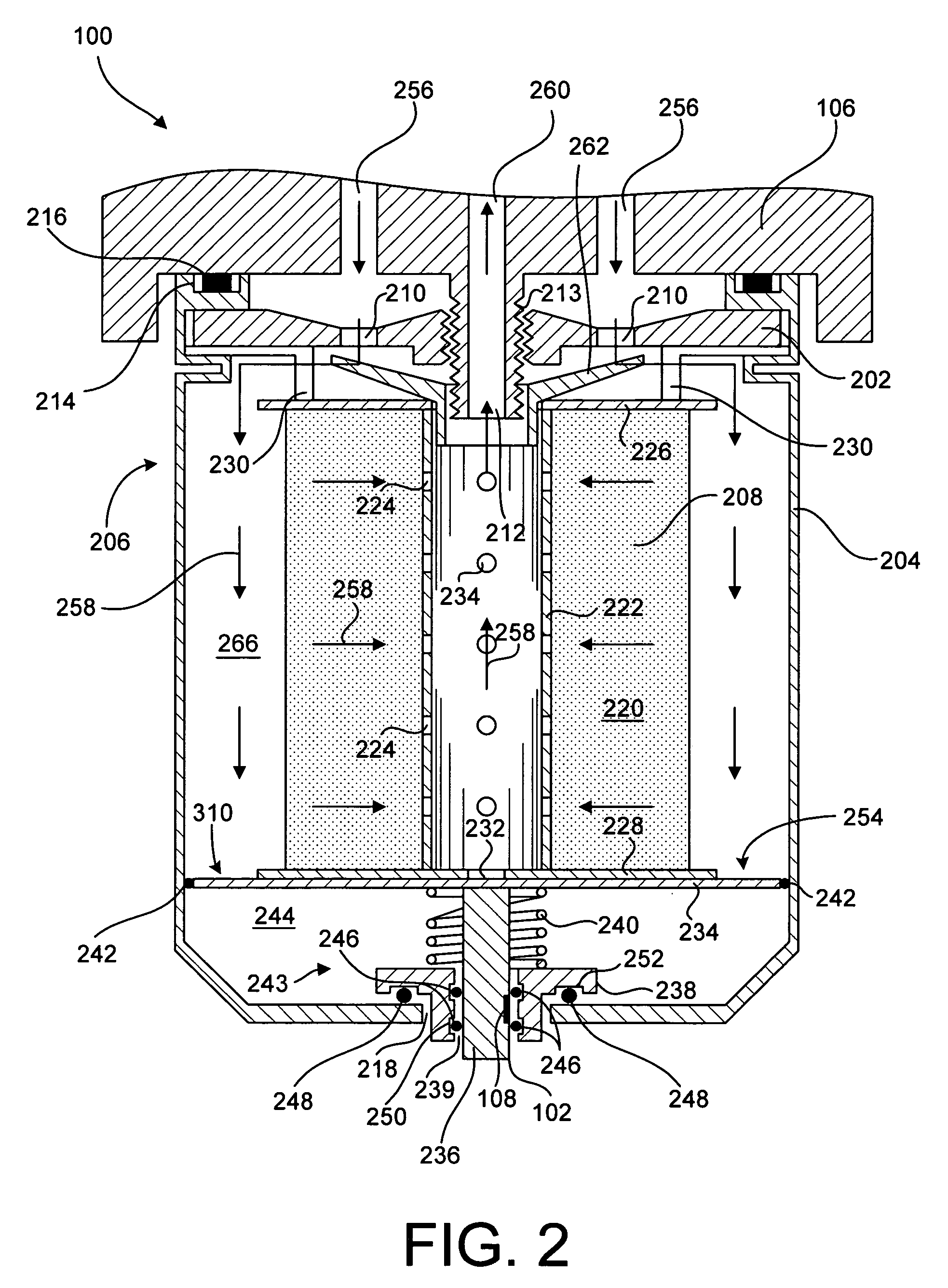

Filter housing apparatus with roatating filter replacement mechanism

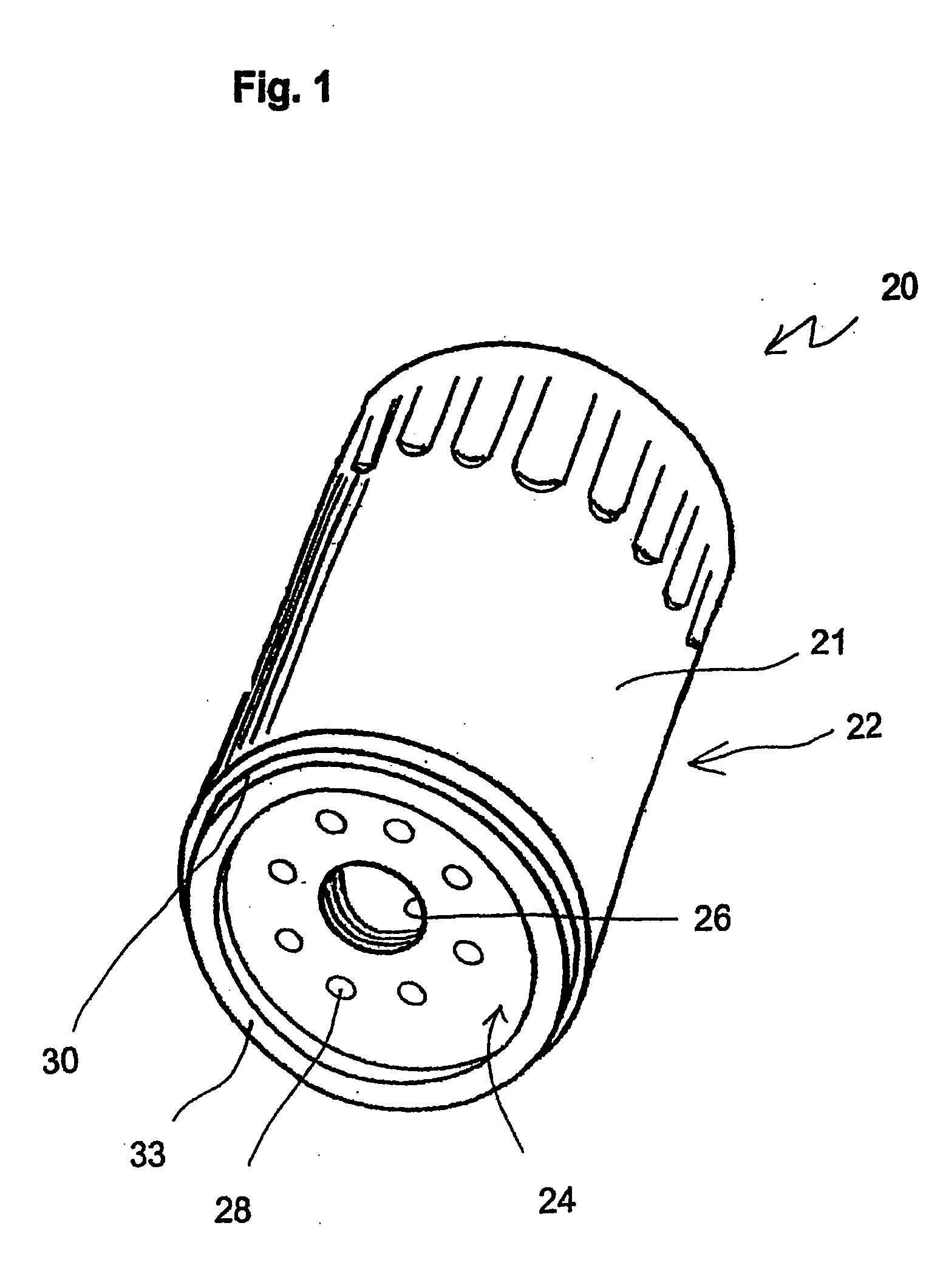

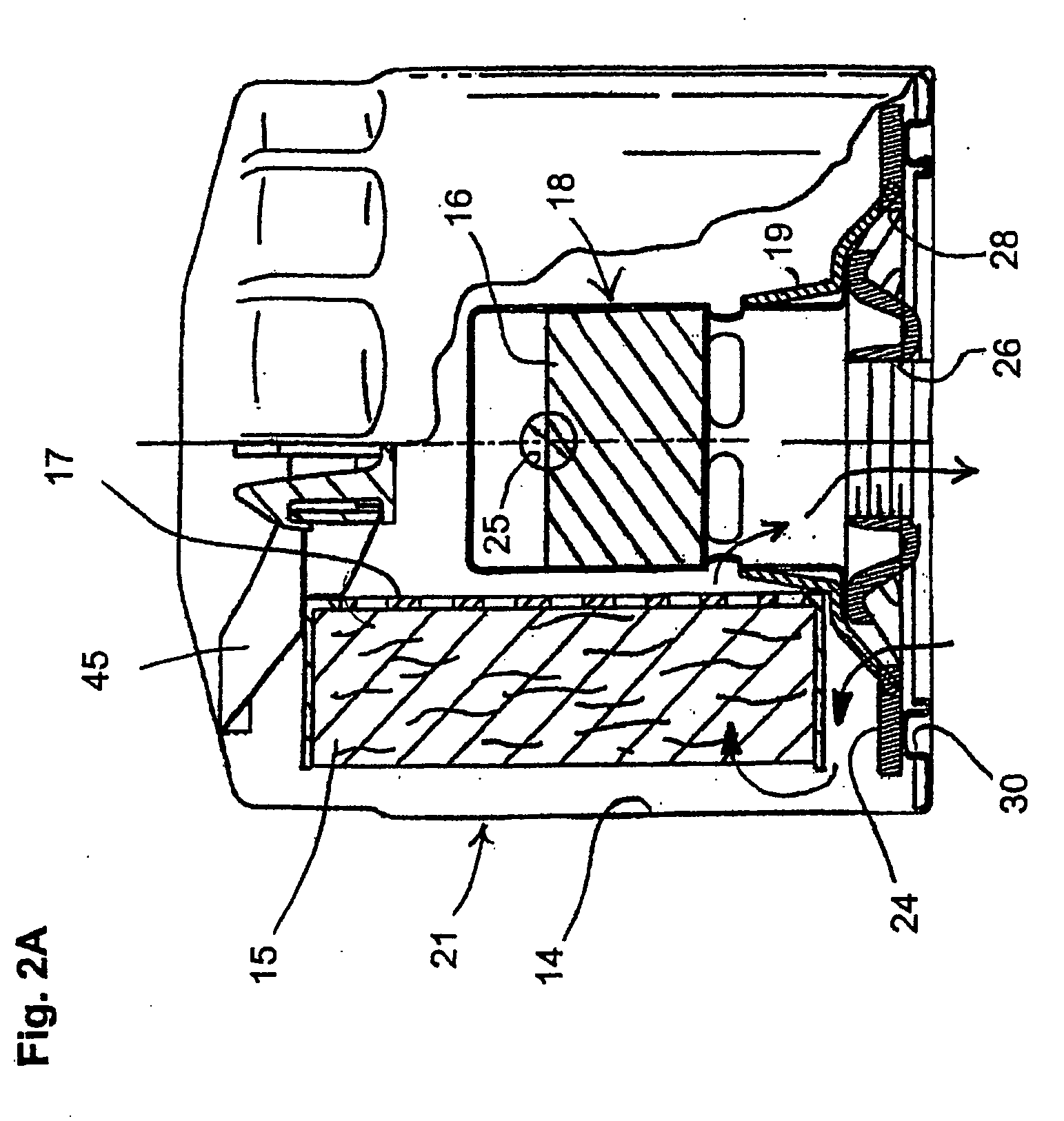

InactiveUS20080047889A1Easy to disassembleSimple replacement and removalDomestic cooling apparatusSettling tanks feed/dischargeFilter mediaFluid filtration

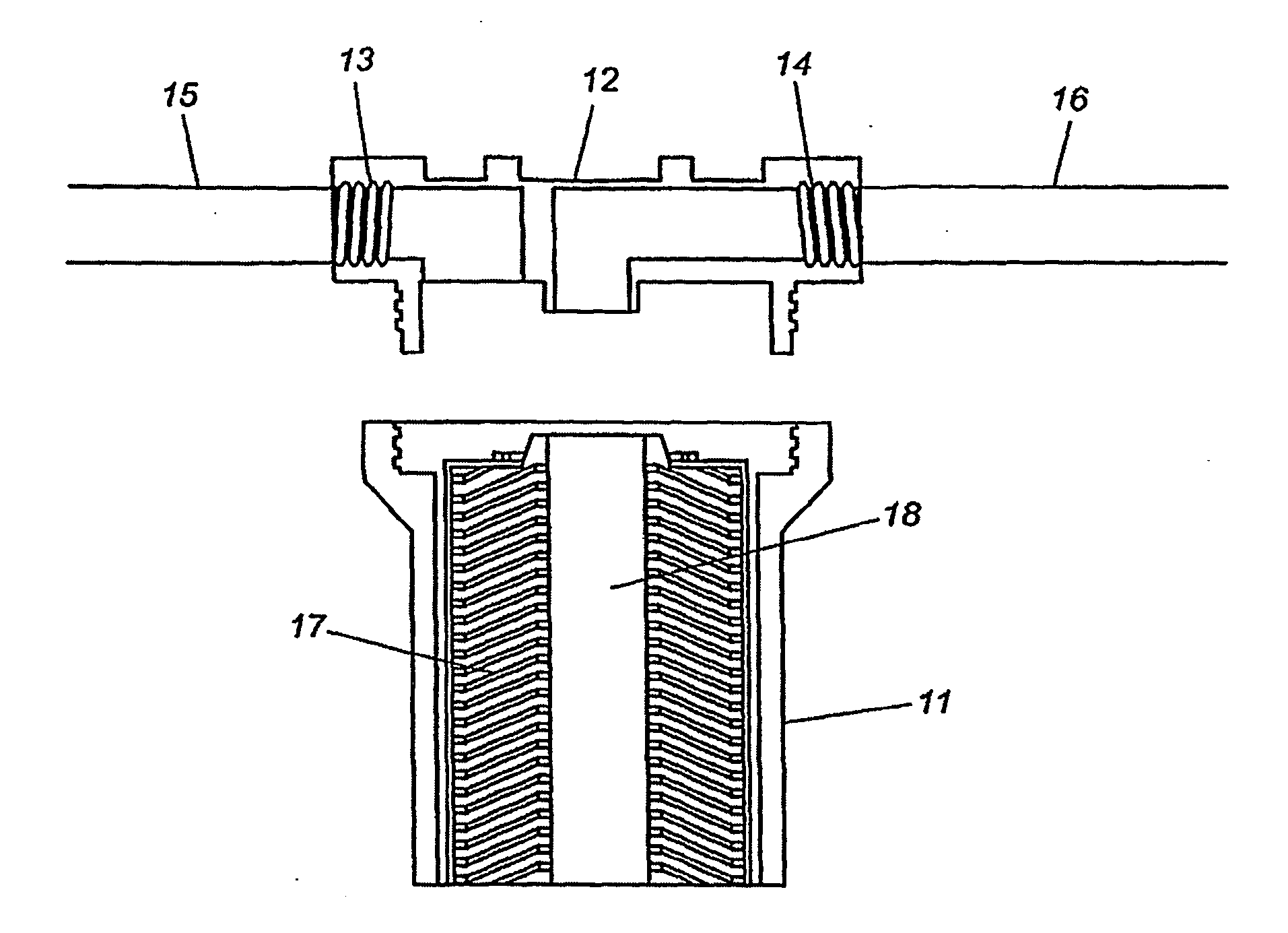

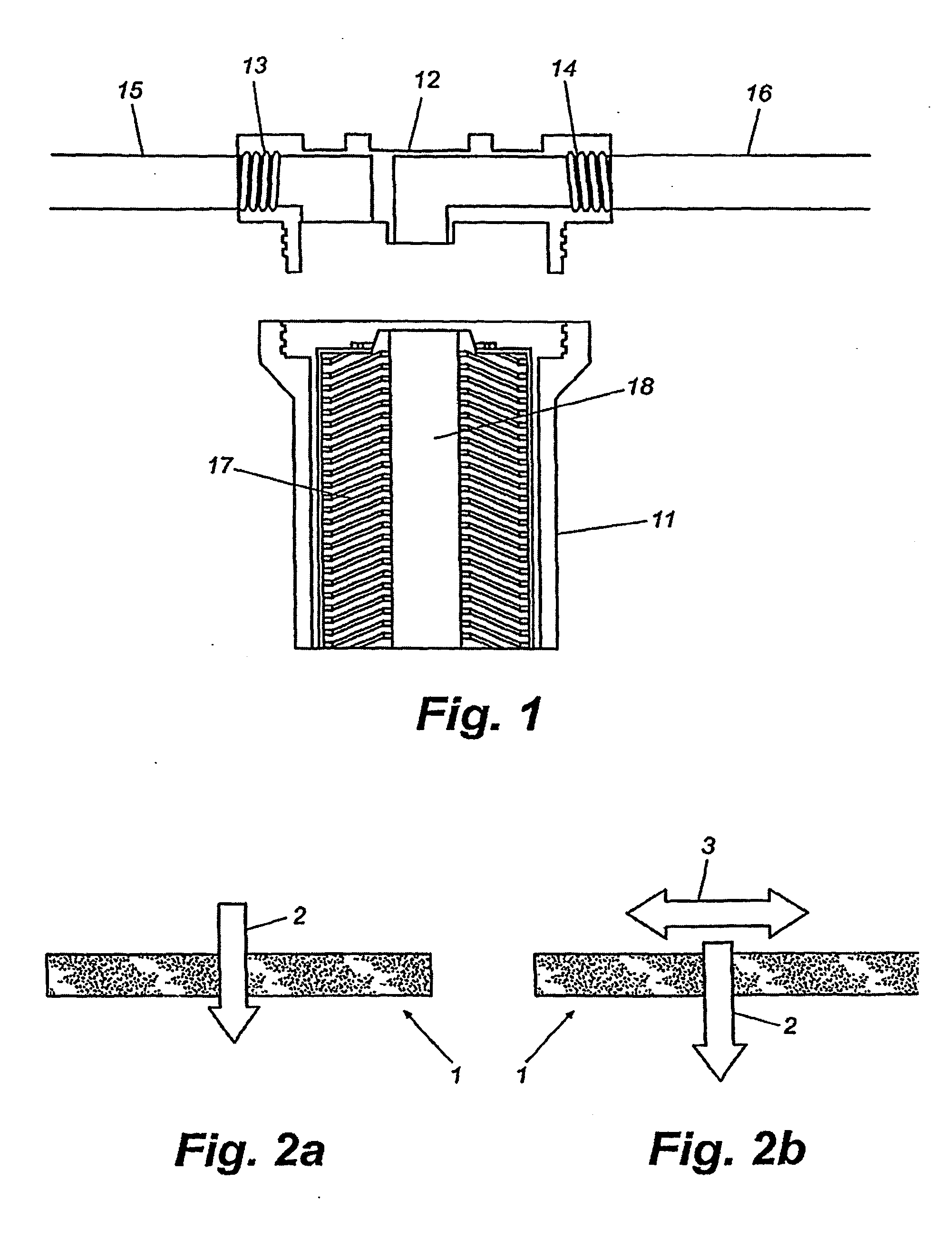

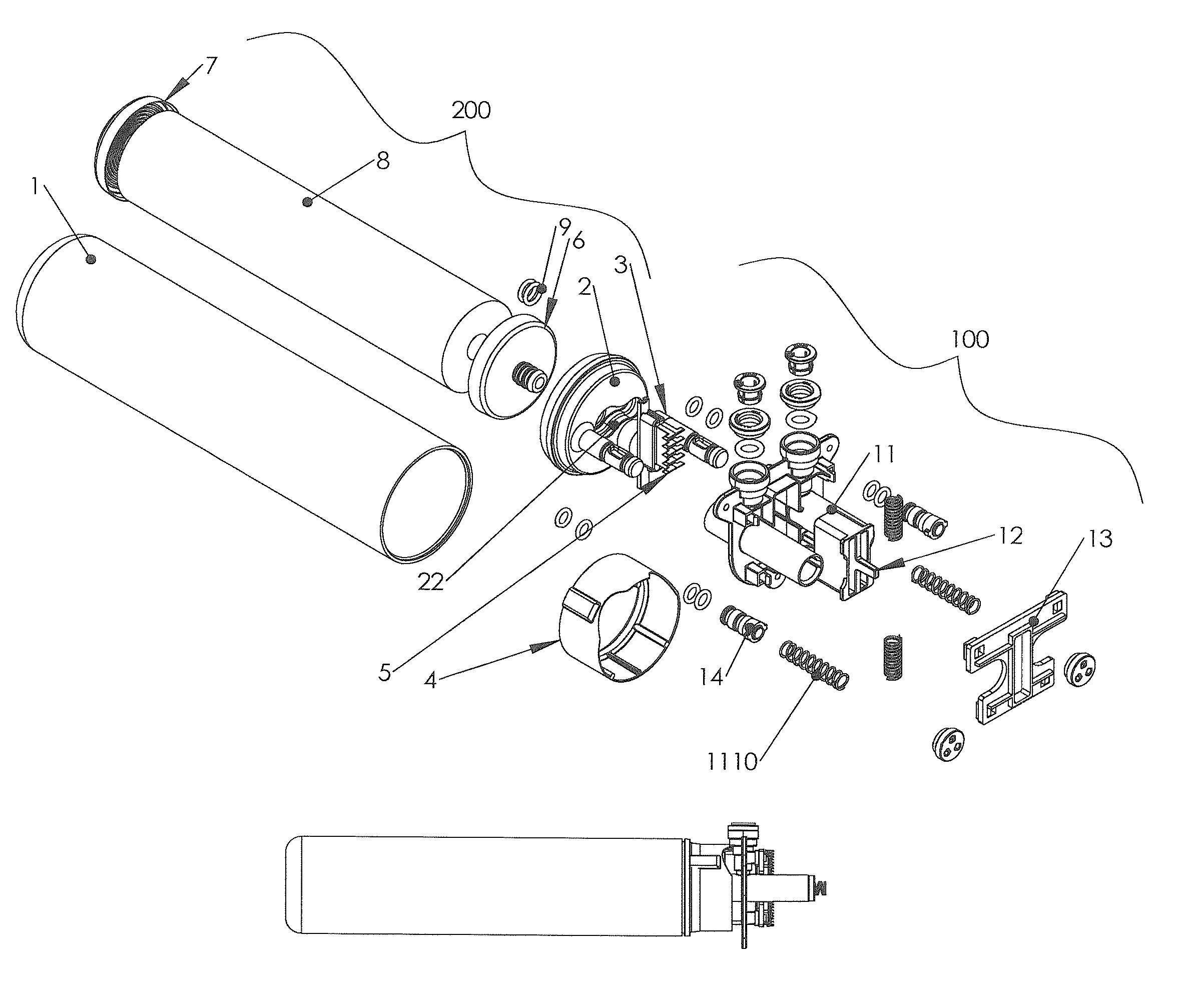

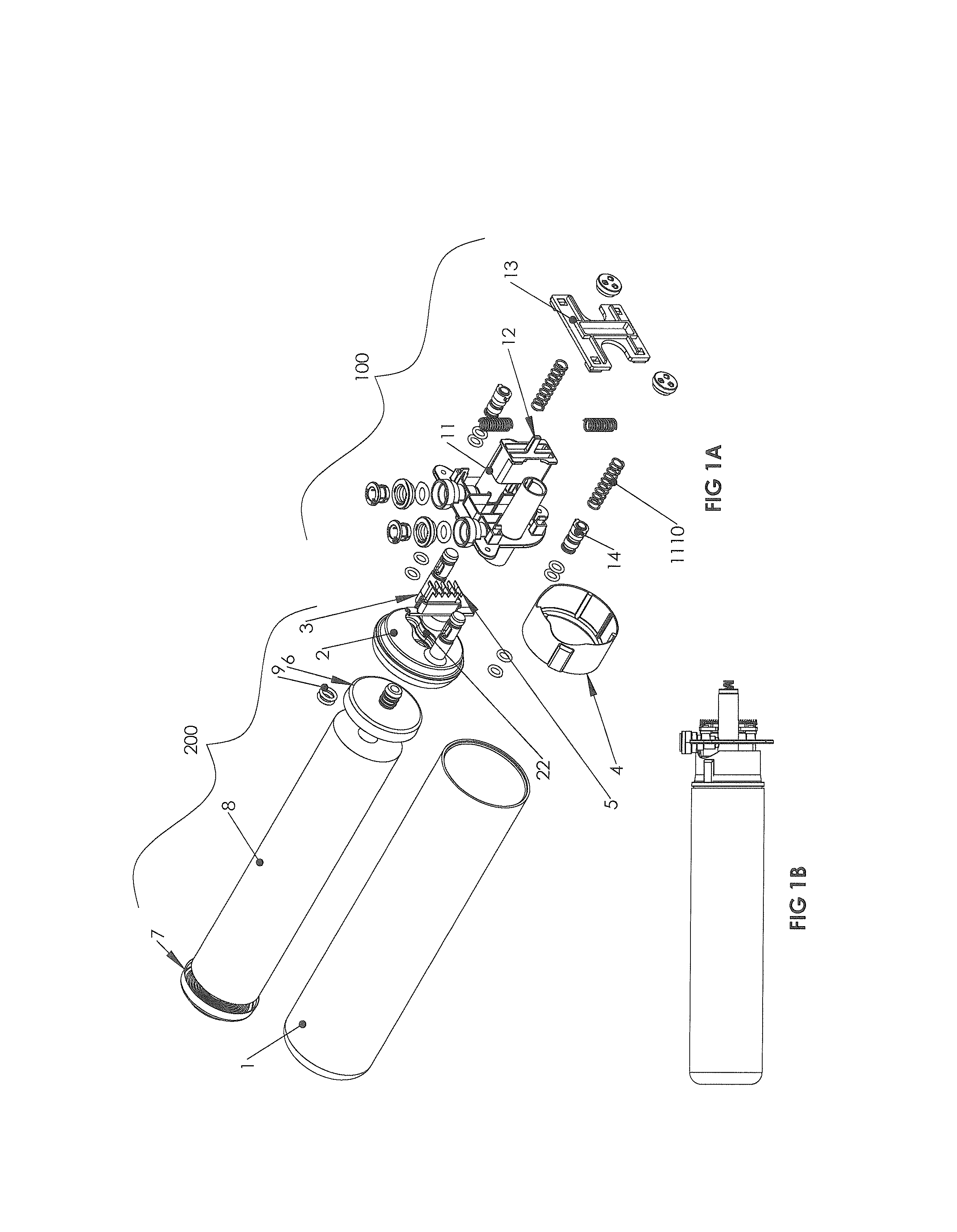

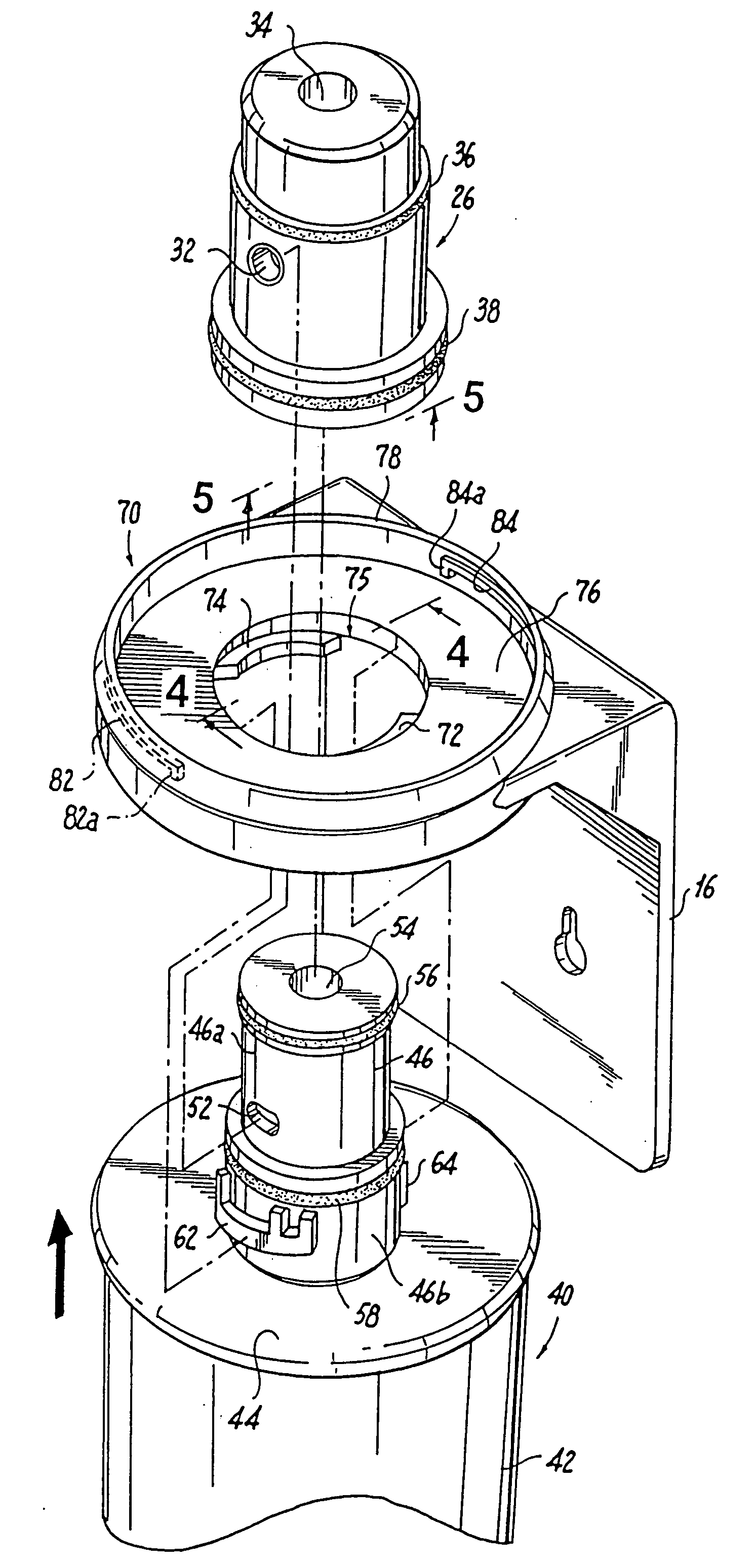

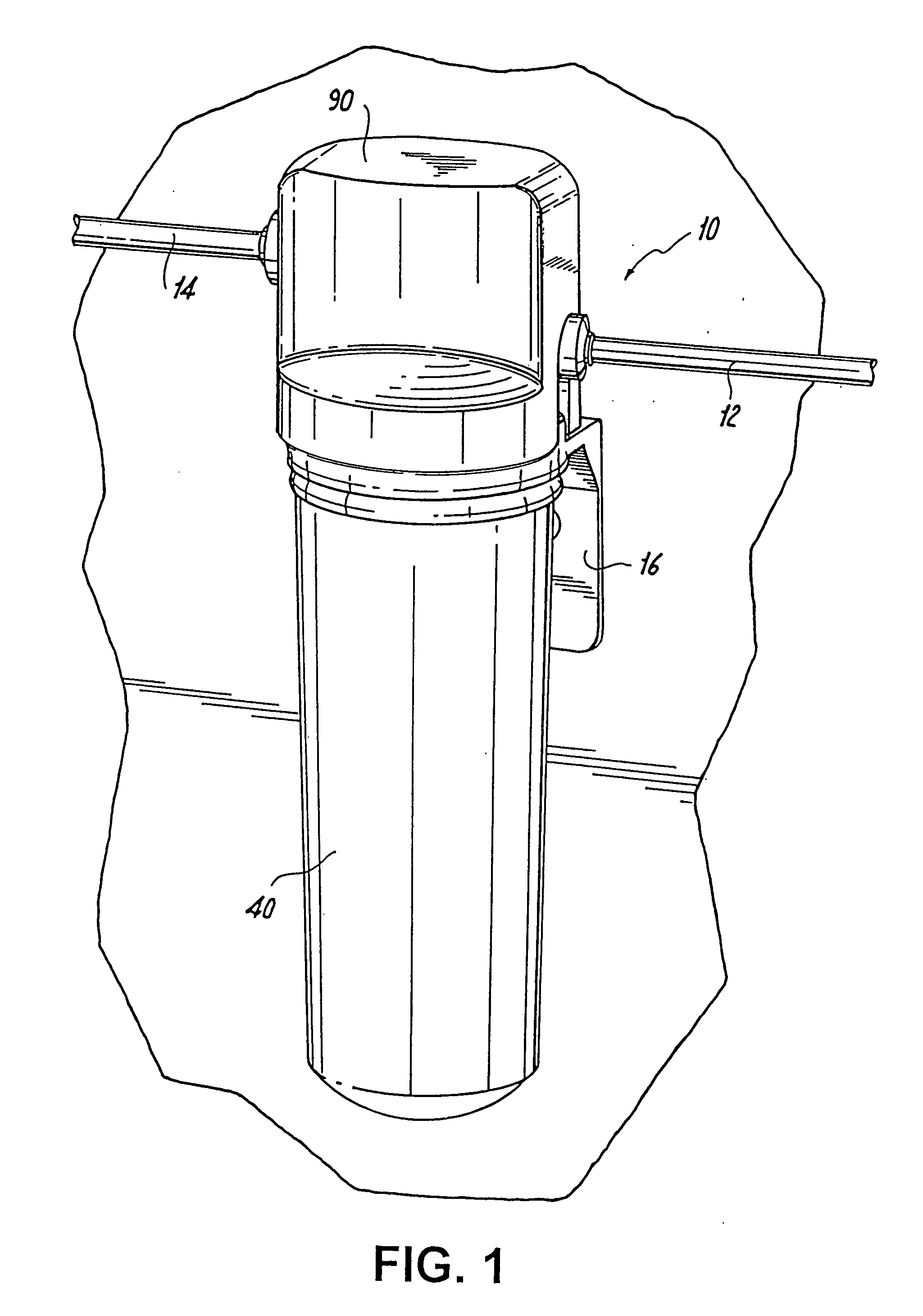

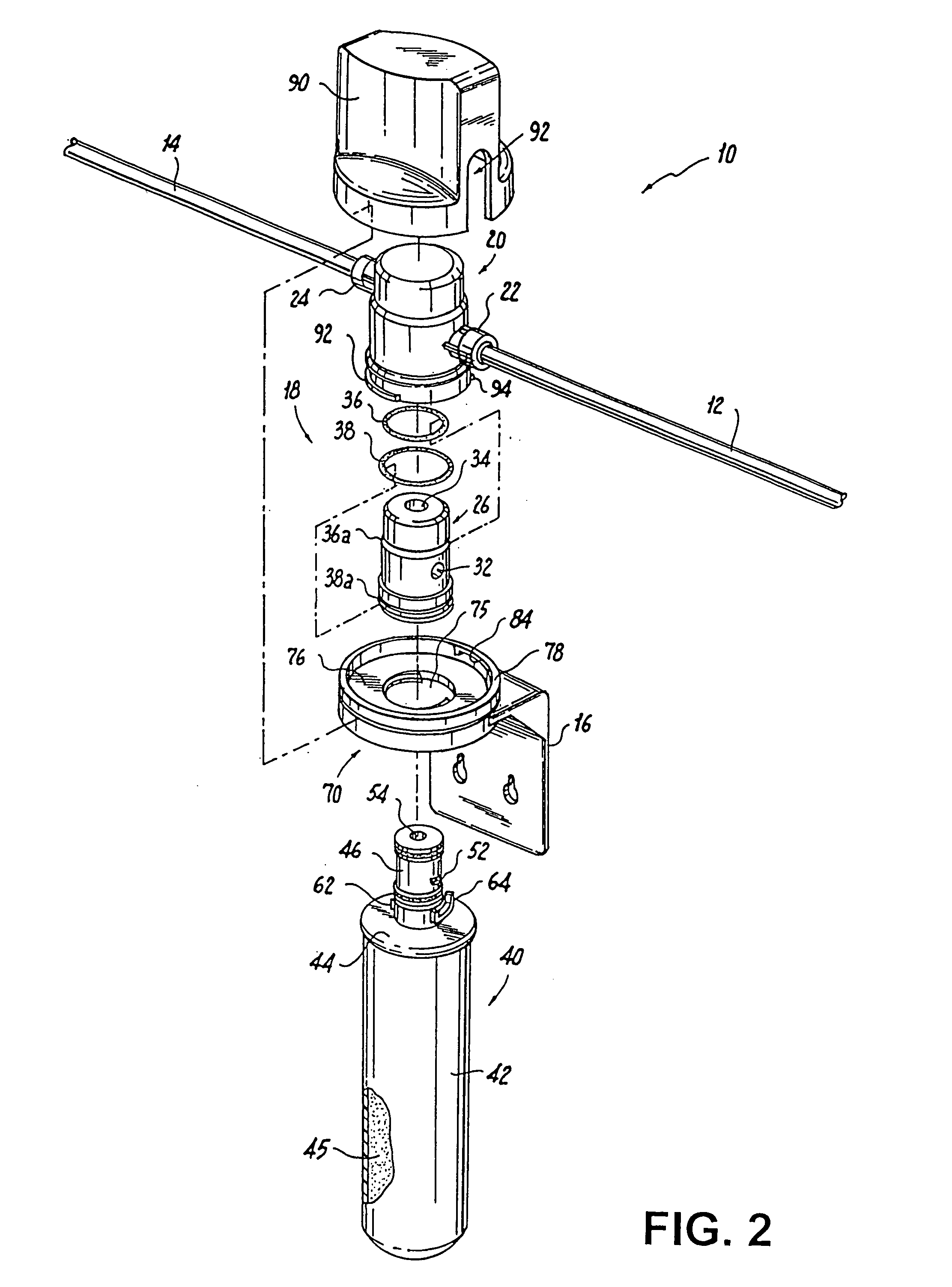

A filter assembly for fluid filtration having a push-activated lock and release mechanism. The filter housing has a sump for enclosing the filter media, a filter head, and at least one standoff protruding outwards for use in securing the filter head to a filter manifold. The filter manifold supports the filter housing with a filter locator. A filter guide having a rotator actuating mechanism secures and holds the filter head in place when the filter head is axially inserted. The rotator actuating mechanism has tabs and slots that rotate upon a transverse axial force from the standoff and from tabs on an internal shutoff. The internal shutoff has an inlet extension and an outlet extension with apertures for fluid ingress and egress. The internal shutoff tabs slidably contact and align the rotator actuating mechanism to secure and remove the filter head.

Owner:KX TECH LLC (DW US)

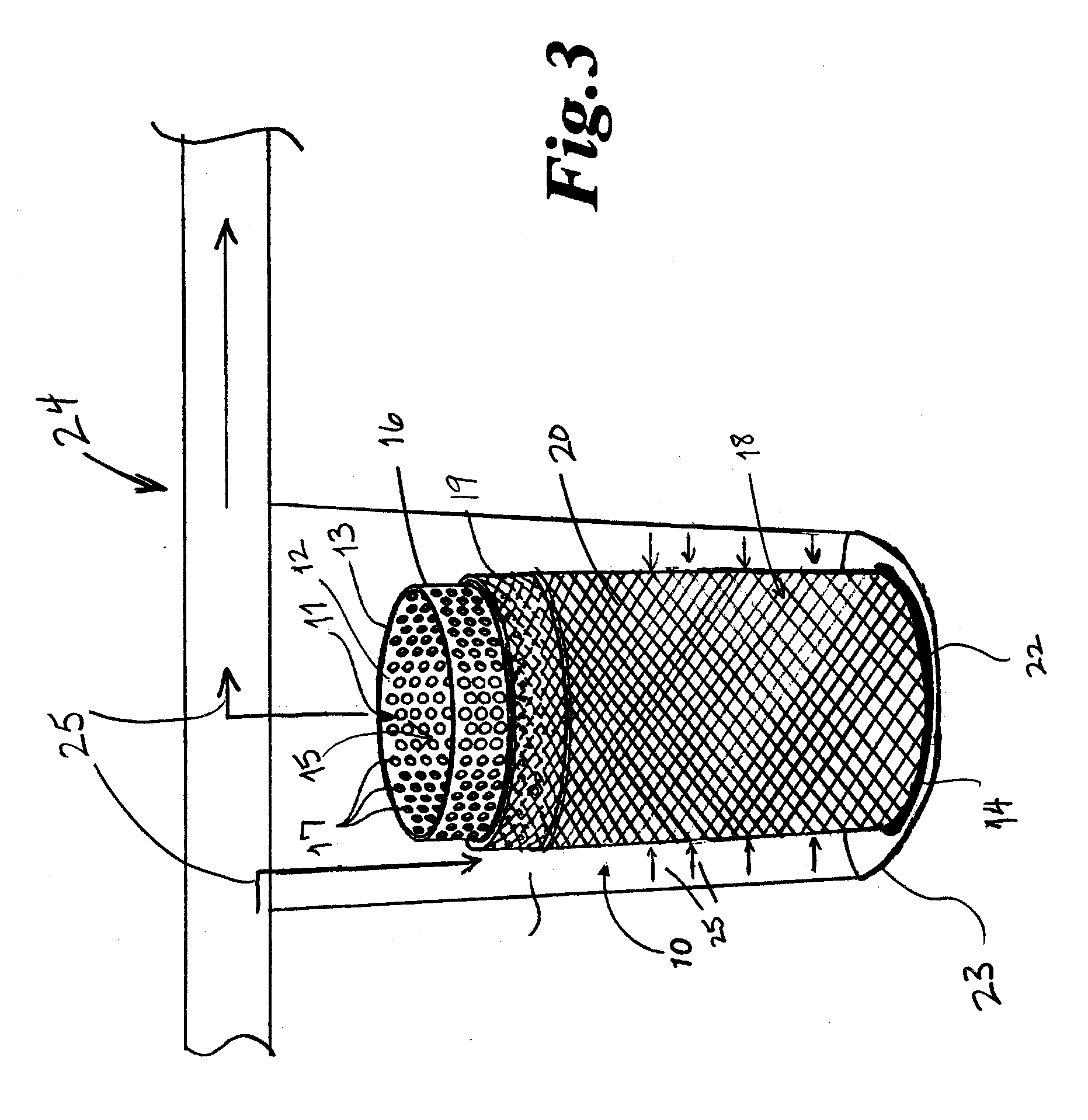

Rotary valve assembly for fluid filtration system

A valve assembly is disclosed for use in conjunction with a replaceable filter cartridge system. The valve assembly includes a head member having an interior valve chamber defining a central axis, and inlet and outlet passages extending parallel to and communicating with the interior valve chamber. The valve assembly further includes a valve member having an inlet path and an outlet path, adapted for rotation within the interior valve chamber of the head member between a filter position wherein the inlet path of the valve member is in communication with the inlet passage of the head member and a bypass position wherein the inlet path of the valve member is out of communication with the inlet passage of the head member. The valve assembly further includes a seal member seated in an upper surface of the valve member and positioned to seal against an opposing surface of the interior valve chamber. The seal member sealingly isolates untreated and treated fluid streams flowing through the inlet and outlet paths of the valve member, respectively, when the valve member is in the filter position, and sealingly isolates the inlet and outlet passages of the head member from the atmosphere when the valve member is in the bypass position to permit fluid to flow therebetween.

Owner:3M INNOVATIVE PROPERTIES CO

Additive dispersing filter and method of making

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

Purification materials and method of filtering using the same

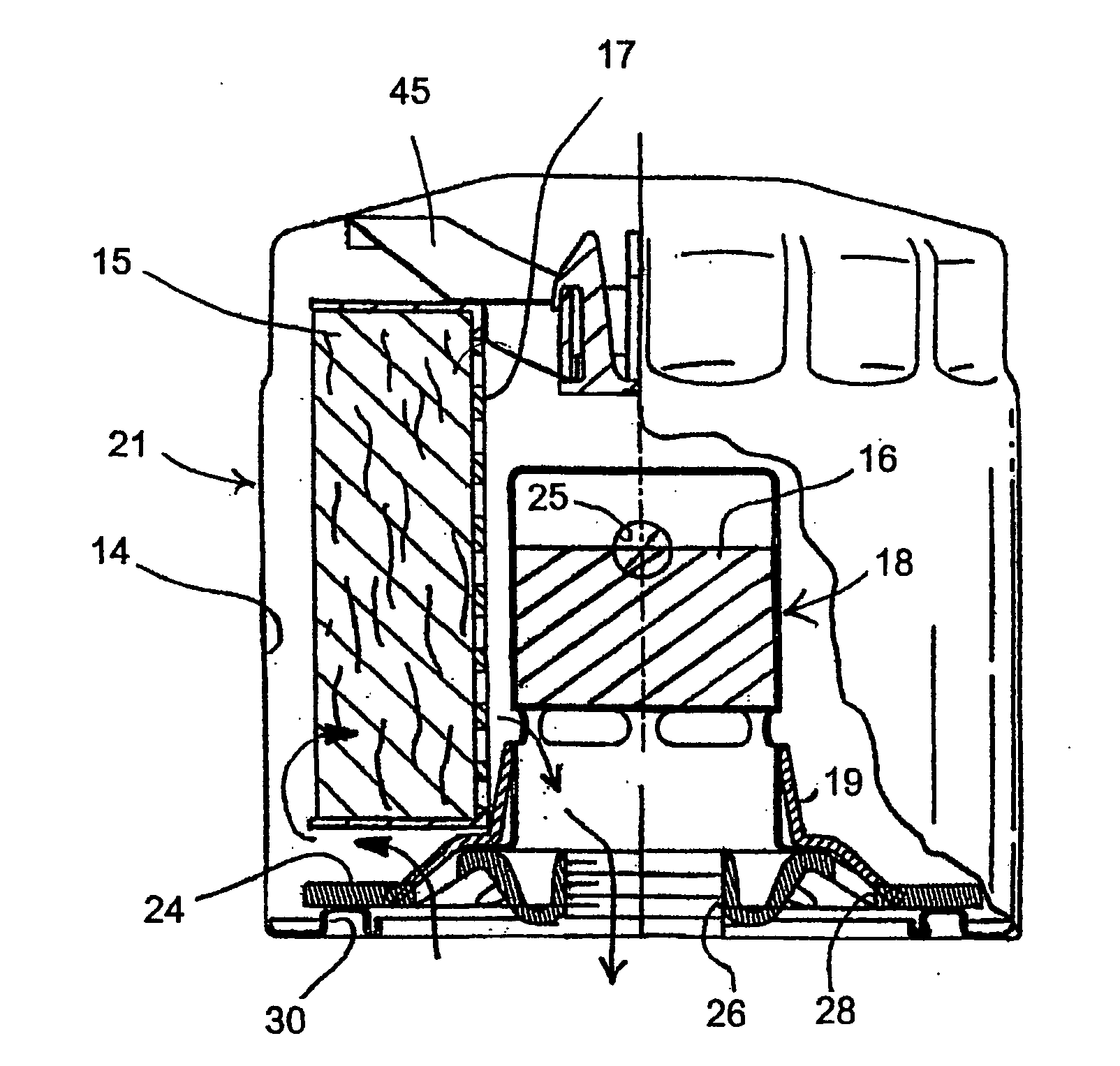

InactiveUS20050098495A1Reduce recordsRule out the possibilityMembrane filtersLoose filtering material filtersParticulatesCyst

The invention relates to a purification material (1) comprising filtration particulate matter aggregated with a first binder and further processed with a second binder to generate a porous fluid filtration material or a non-pourous coating, a filtering device comprising a housing (11) and the purification material (1), and a method of filtering and / or purifying a fluid including water or other solutions containing chemical and microbiological contaminants, such as fluids containing heavy metals, pesticides, by products of oxidation chemicals and including cysts, bacteria and / or viruses, where the fluid is passed through ot made to contact a surface of the purification material (1).

Owner:HUGHES KENNETH D

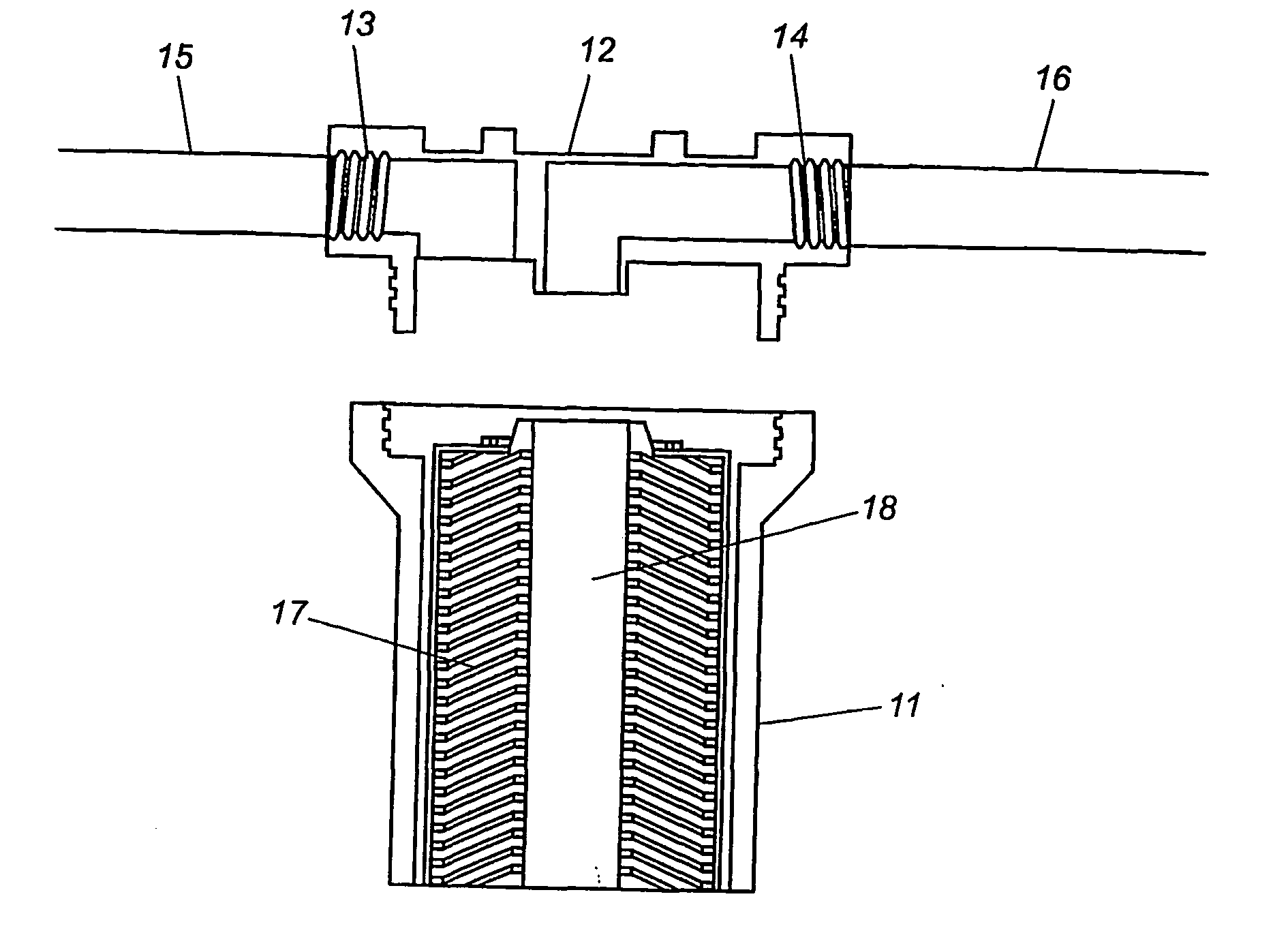

Filter element for fluid filtration system

InactiveUS20120261333A1Improve configurationEasy to controlSemi-permeable membranesMembranesYarnMembrane bioreactor

A filter element for use in a reverse osmosis, nano-filtration, membranes and spacers membrane-bioreactor, forward osmosis, or other filtration system, includes a permeate carrier substrate having a wrapped core tube. The permeate carrier includes a series of spaced ribs. The ribs are formed by application of yarns, strings or resinous or polymeric materials to a membrane substrate. The ribs define channels for passage of a liquid or gas permeate therealong. The permeate is received at the core tube which has one or more elongated flow recesses therealong to facilitate collection of the permeate.

Owner:GFD FABRICS

Compositions of insoluble magnesium containing minerals for use in fluid filtration

InactiveUS20040159605A1Rule out the possibilityReadily availableSpecific water treatment objectivesWater/sewage treatmentPhosphateFluid filtration

A method and device for the filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing cysts, bacteria and / or viruses, and heavy metals and / or pesticides, where the fluid is passed through a purification material composed of magnesium containing mineral and more preferably silicates containing magnesium, oxides containing magnesium, hydroxides containing magnesium, and phosphates containing magnesium and absorption media in a fixed binder matrix.

Owner:HUGHES KENNETH D

Transfer device with fluid filter

A vial access device is described comprising an upper housing having a fluid connecter in fluid communication with the upper housing; a vial access spike projecting from the upper housing; a fluid filter body within the upper housing or connectable thereto, the fluid filter body in fluid communication with the vial access spike and the fluid connector. Methods of reducing or eliminating particulate matter from medicament solutions are also provided.

Owner:YUKON MEDICAL

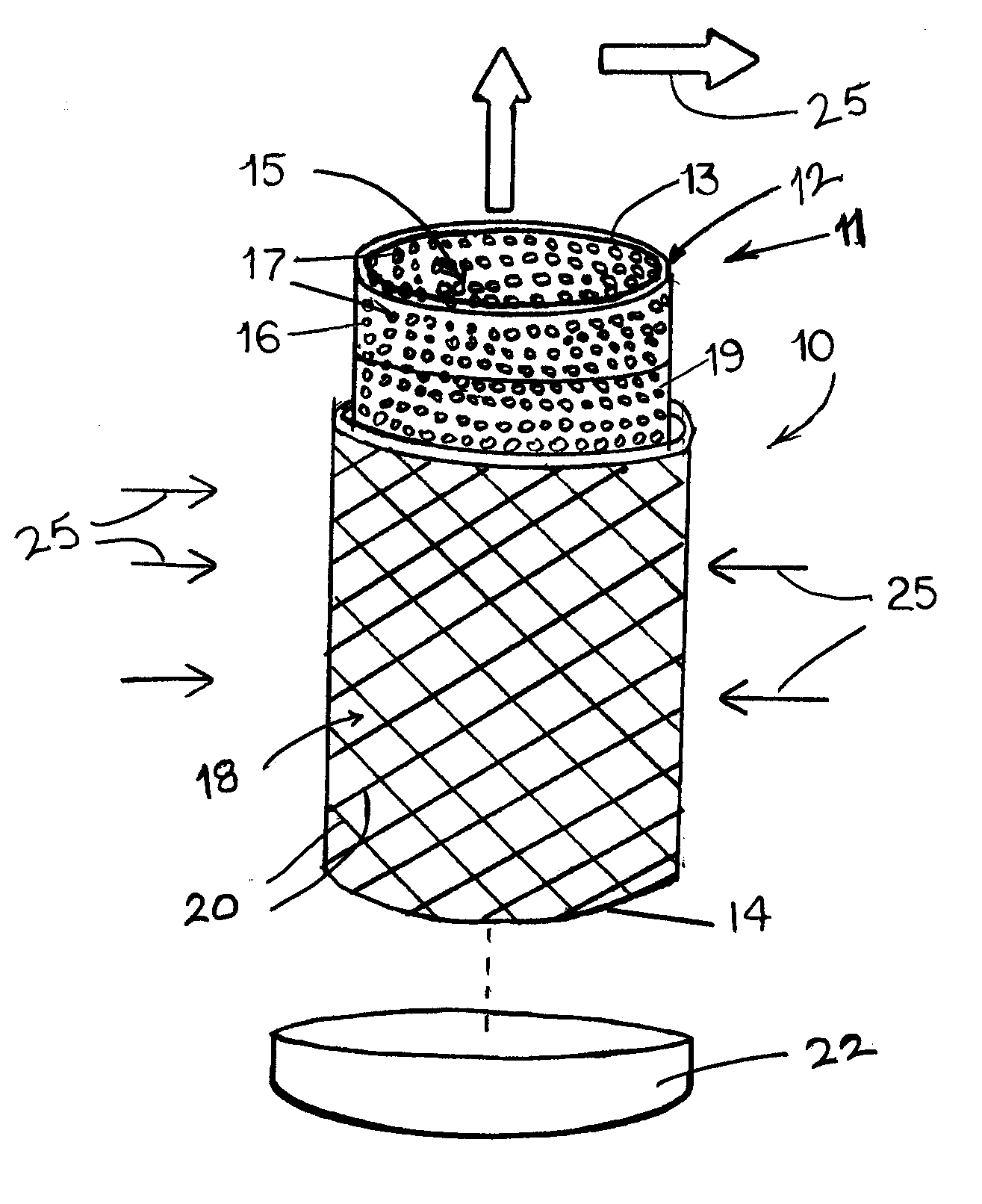

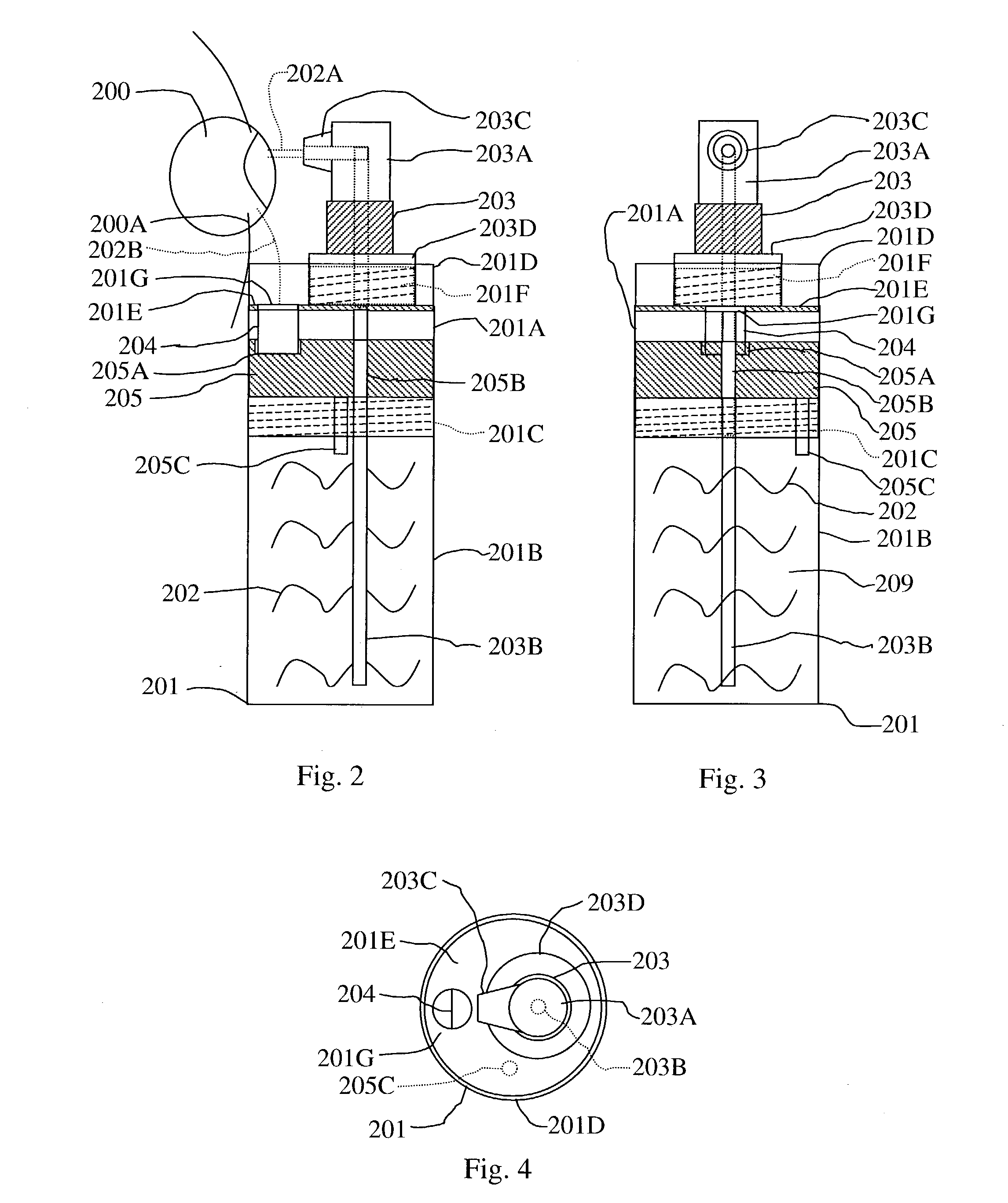

Cleaning assembly for use in fluid filtration systems

ActiveUS20120010063A1Easy to useEasy to disassembleWater/sewage treatment by centrifugal separationSemi-permeable membranesFluid filtrationFluid bearing

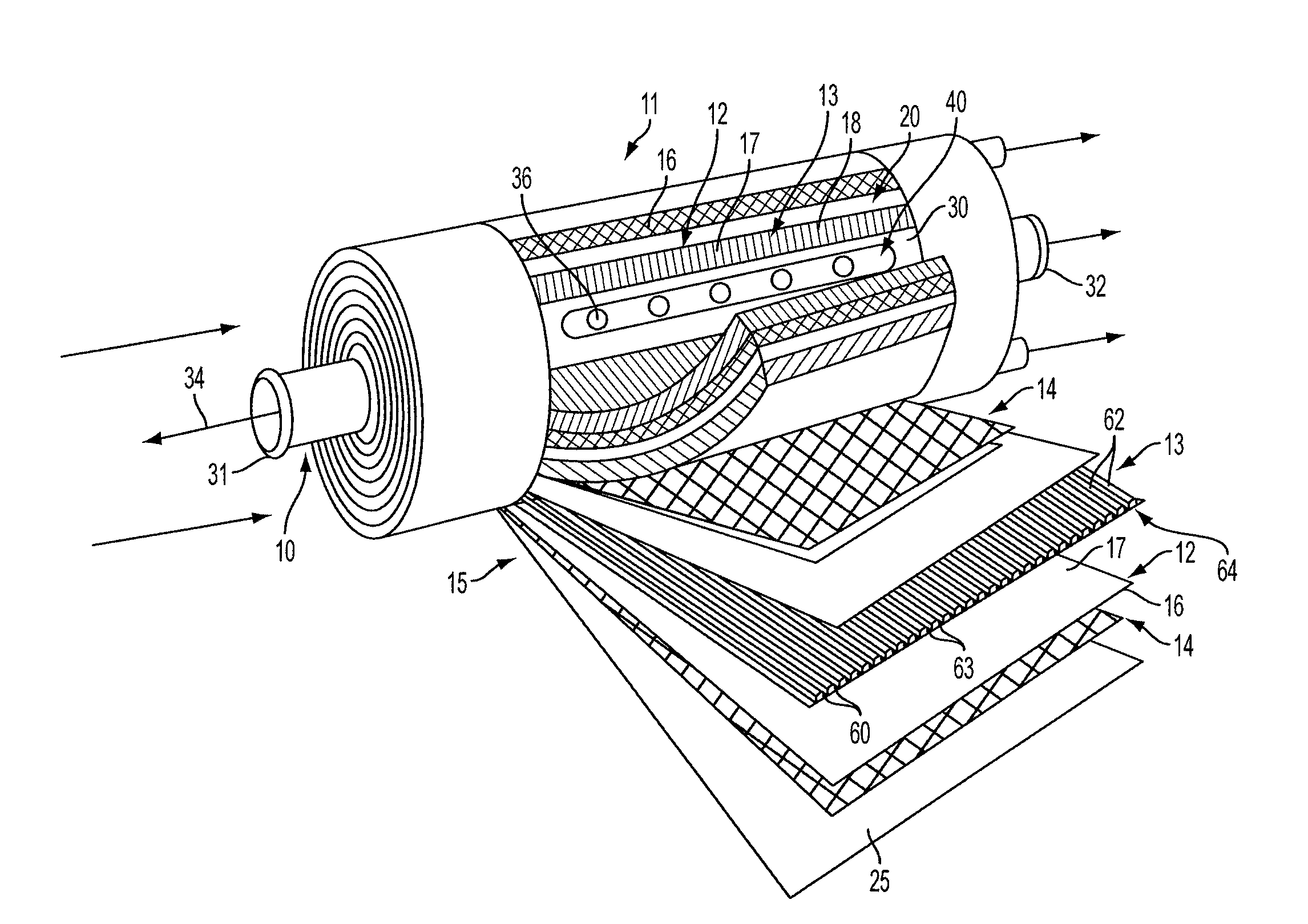

Cleaning assemblies and particulate tolerant fluid bearings that are particularly well suited for use in centrifugal separation enhanced filtration devices are described. In one aspect of the invention, at least one bearing is arranged to carry a circulating cleaning assembly such that the cleaning assembly can rotate around a filter membrane during filtering operation of the filtration device. The bearing is preferably arranged to maintain the circulating cleaning assembly in a substantially coaxial alignment with the filter membrane and in a substantially stable longitudinal position relative to the filter membrane as the circulating cleaning assembly is rotated around the filter membrane. In another aspect of the invention a variety of particulate tolerant bearings are described.

Owner:ACCELERATED FILTRATION INC

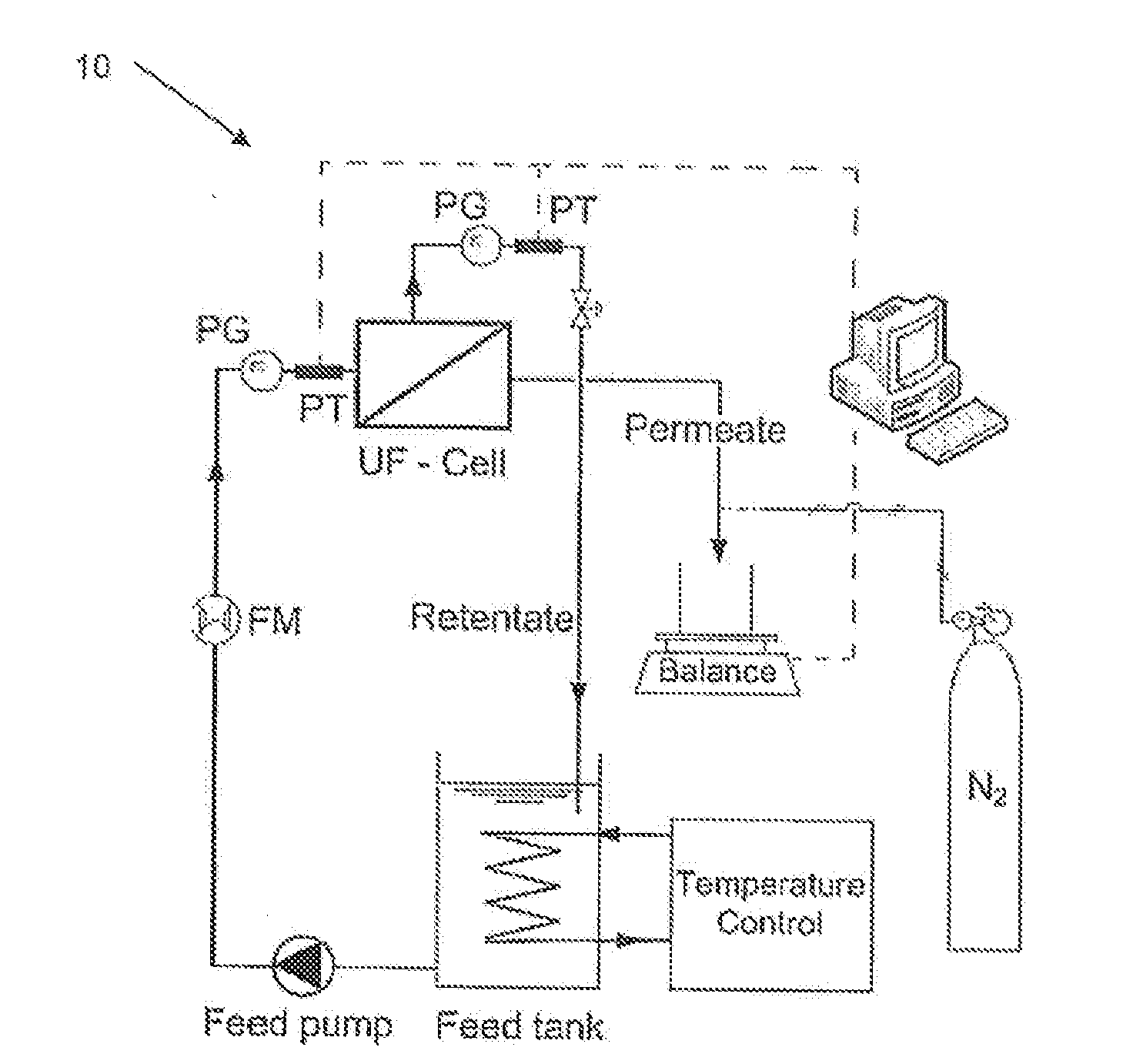

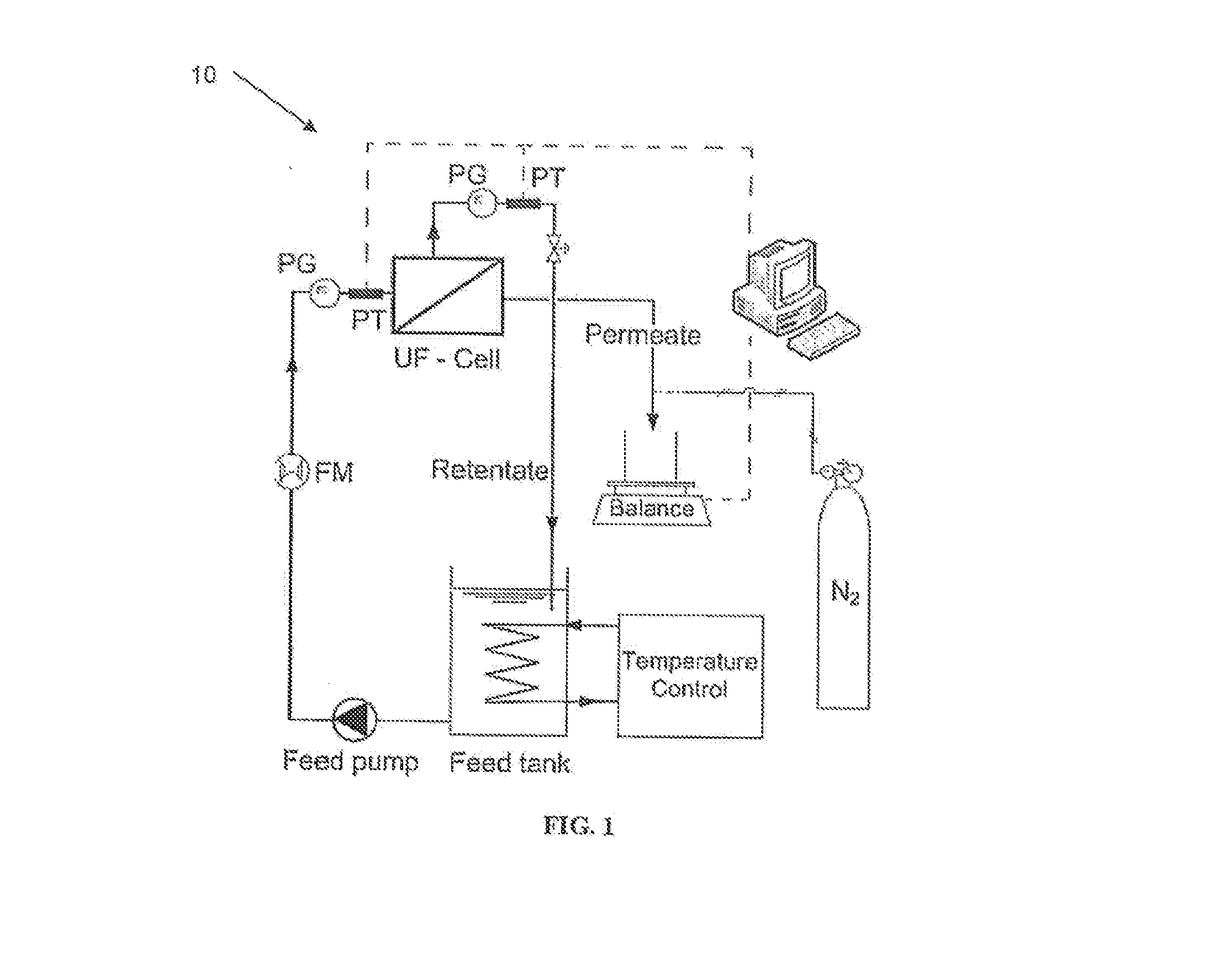

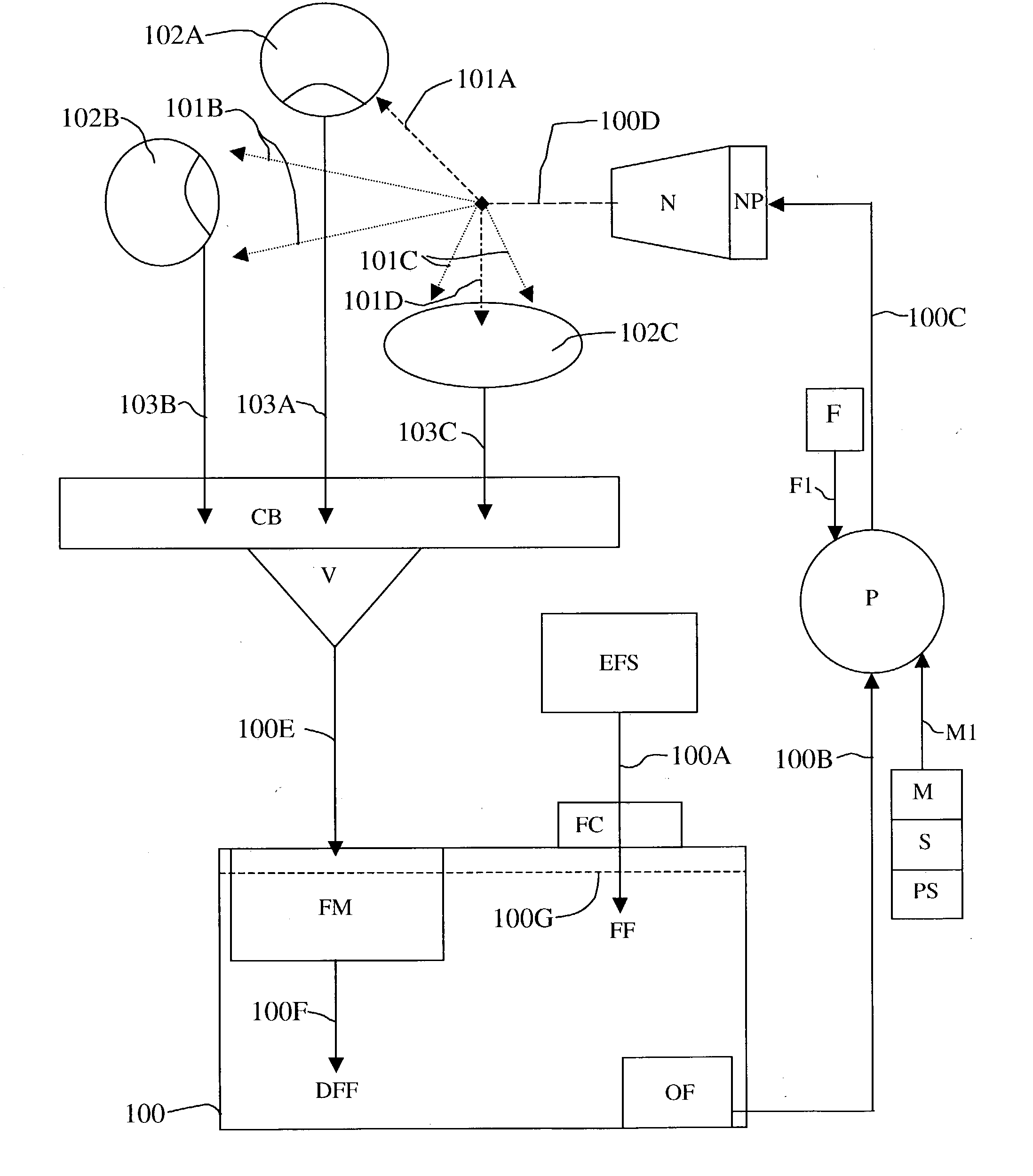

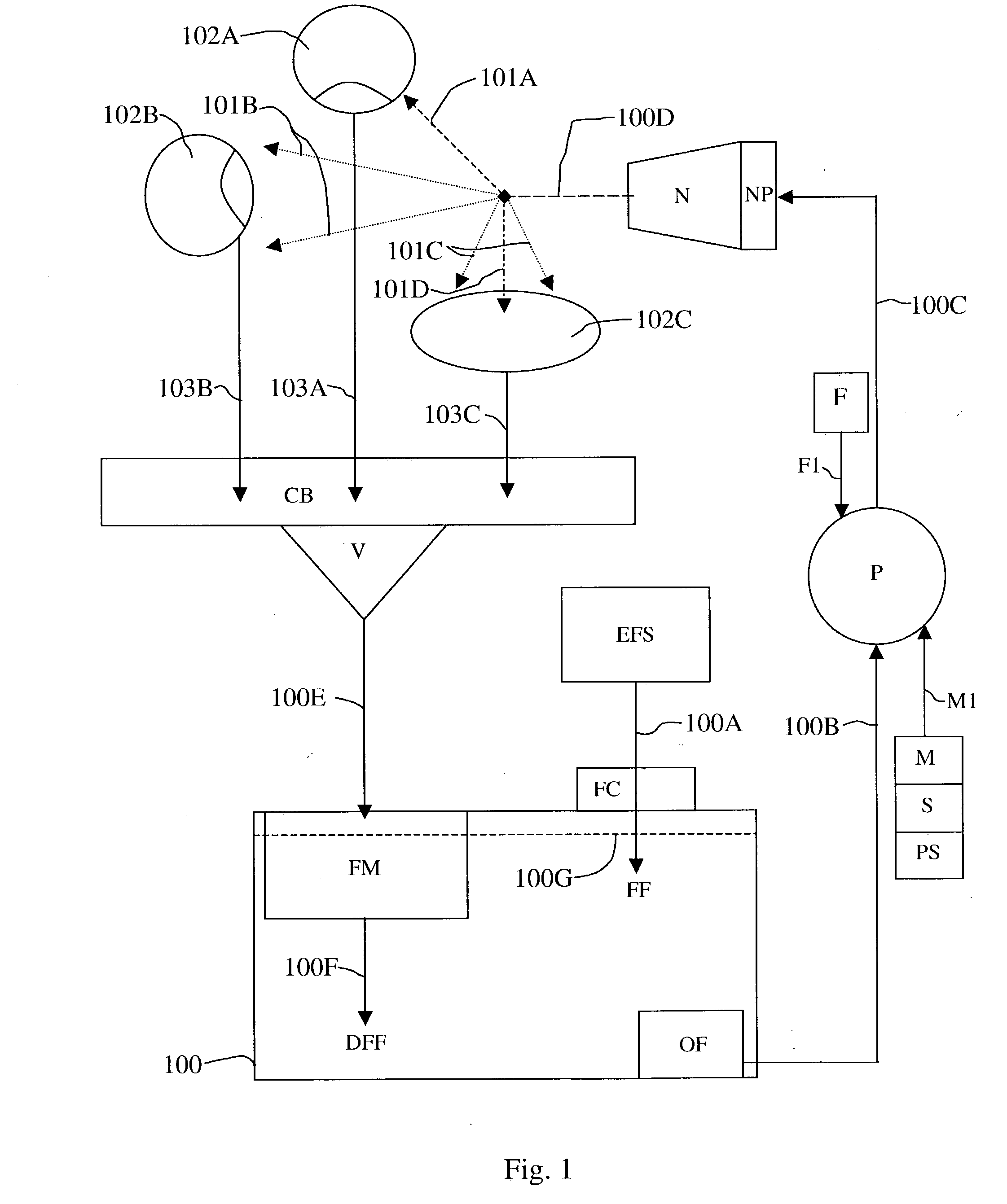

Automated fluid filtration system for conducting separation processes, and for acquiring and recording data thereabout

InactiveUS20030116487A1Economical and fastPreparing sample for investigationUltrafiltrationLaboratory scaleUser input

An automated fluid filtration system is disclosed, the system providing flexibility and accuracy for the investigative development of liquid separation processes. The system can be used for optimizing the protocol parameters of laboratory scale separation processes towards larger, commercial scale processes. The system-operable to an unprecedented minimum reliable recirculation volume of approximately 20 milliliters-comprises: (a) a reservoir; (b) a fluid filtration module; (c) a plurality of conduits defining, together with said reservoir and said fluid filtration module, a fluid process stream through which a liquid sample is conducted; (d) a plurality of pumps positioned along said fluid process stream for driving the flow of said liquid sample therethrough; (e) a plurality of valves positioned along the fluid process stream for regulating the flow of said liquid sample therethrough; (f) a plurality of sensors positioned along said fluid process stream for acquiring data about the liquid sample as it flows therethrough; and (g) an electronic data processing network capable of (i) receiving, processing, and recording data from said pumps, valves, and sensors and from an external source (e.g., user input), and (ii) transmitting signals to the pumps, valves, and sensors to effect the operation thereof.

Owner:MILLIPORE CORP

Fluid filter with localized flow attachment

ActiveUS20090014381A1More serviceThe environment is moreDispersed particle filtrationSettling tanks feed/dischargeEngineeringFluid filtration

Owner:CUMMINS FILTRATION IP INC

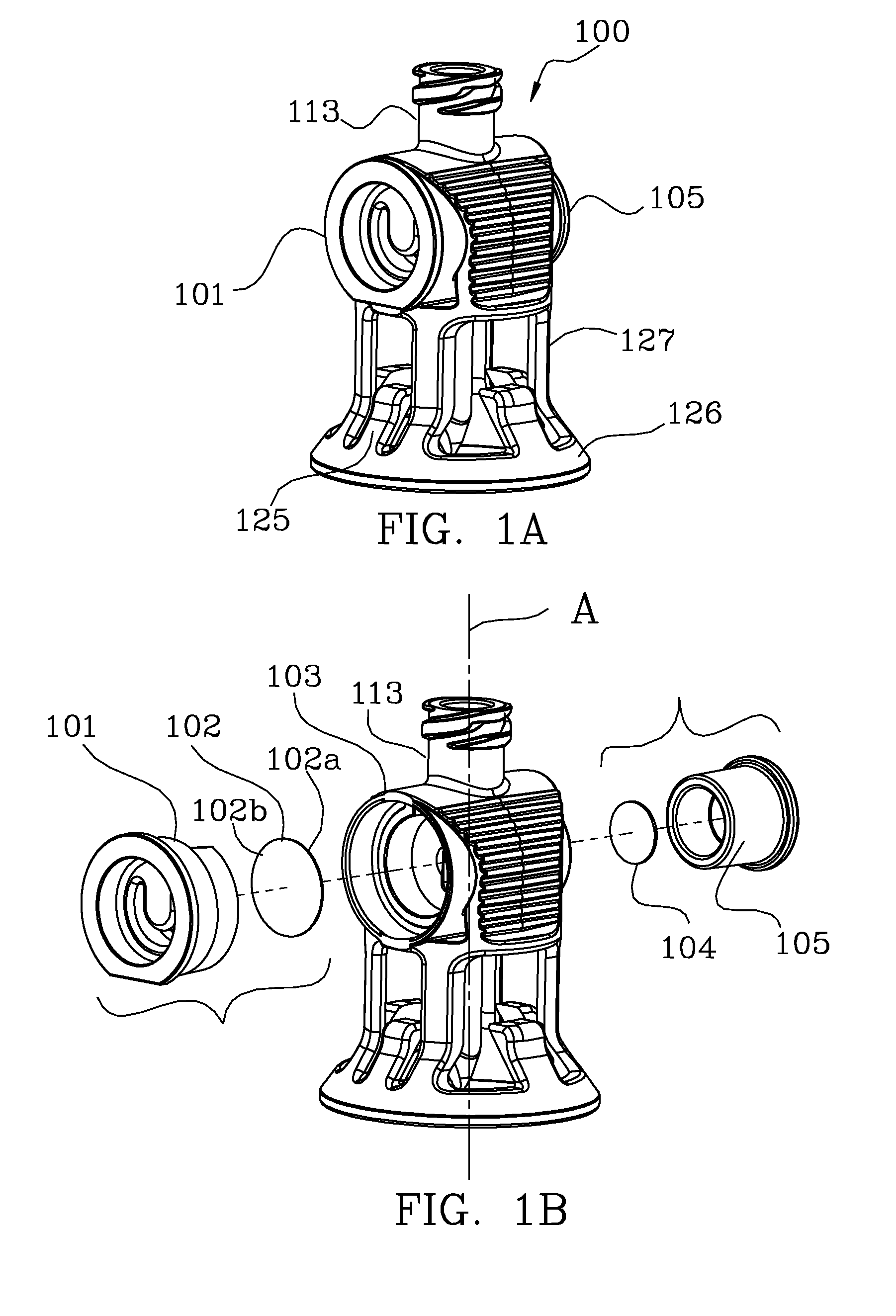

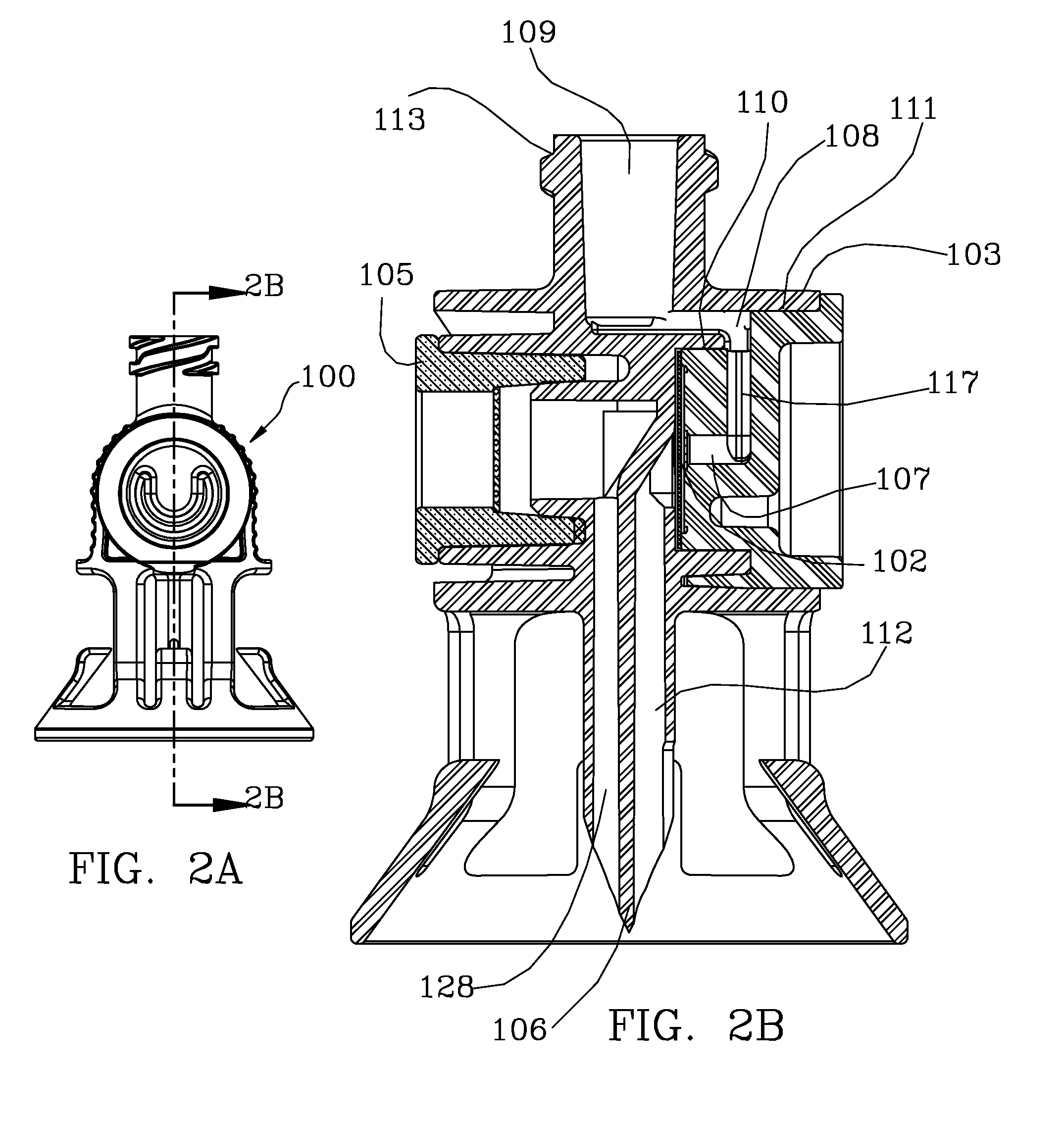

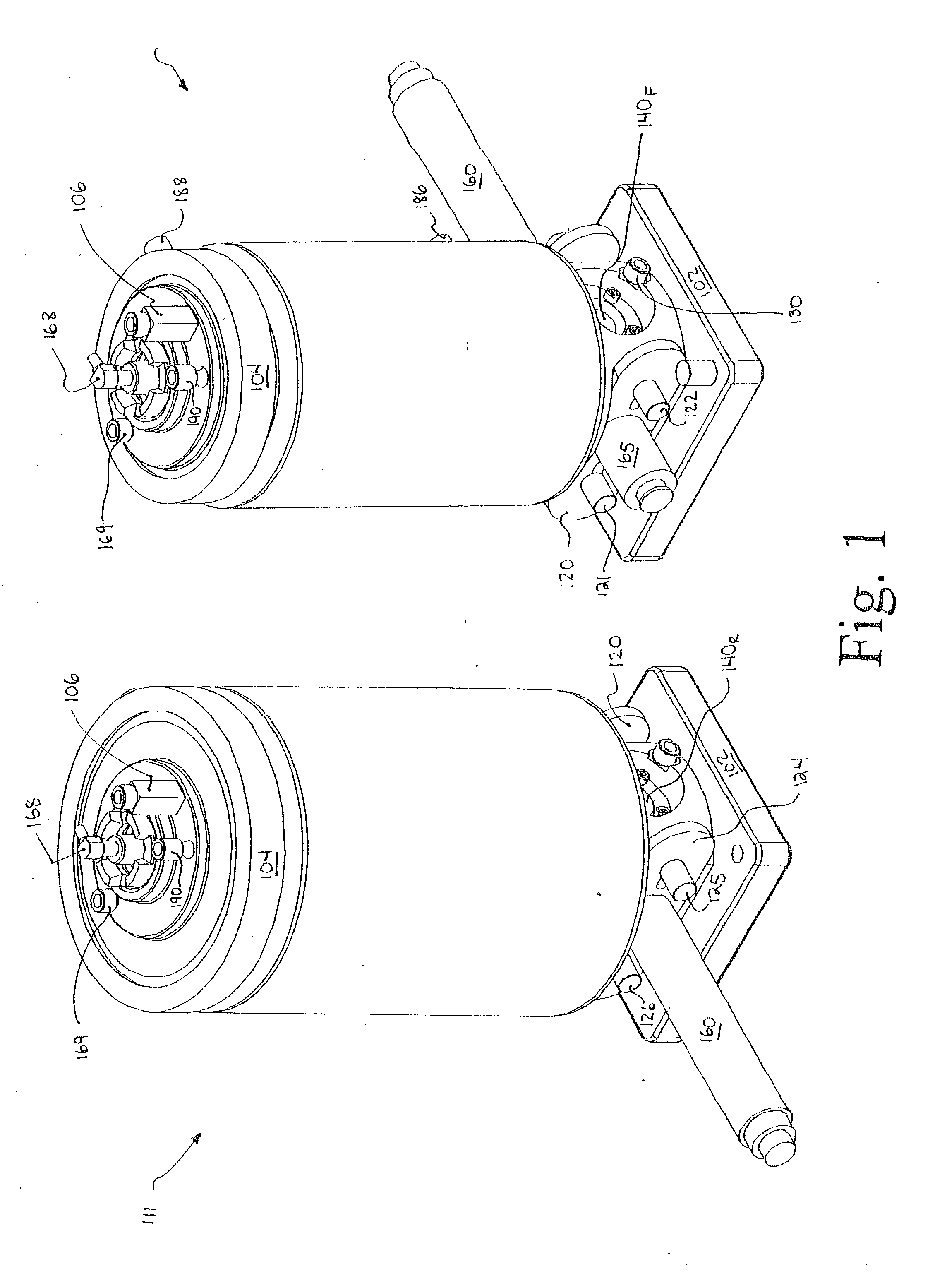

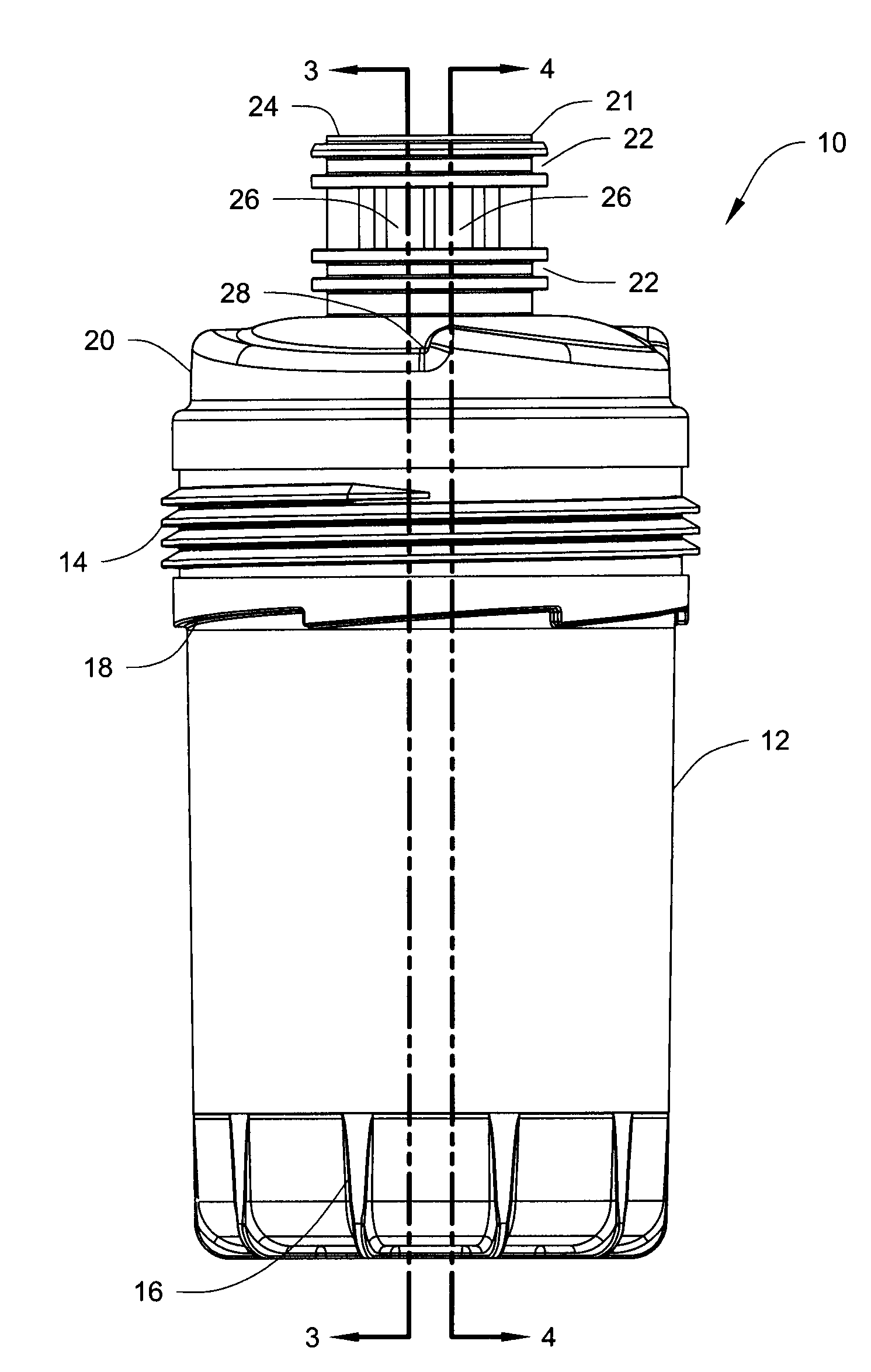

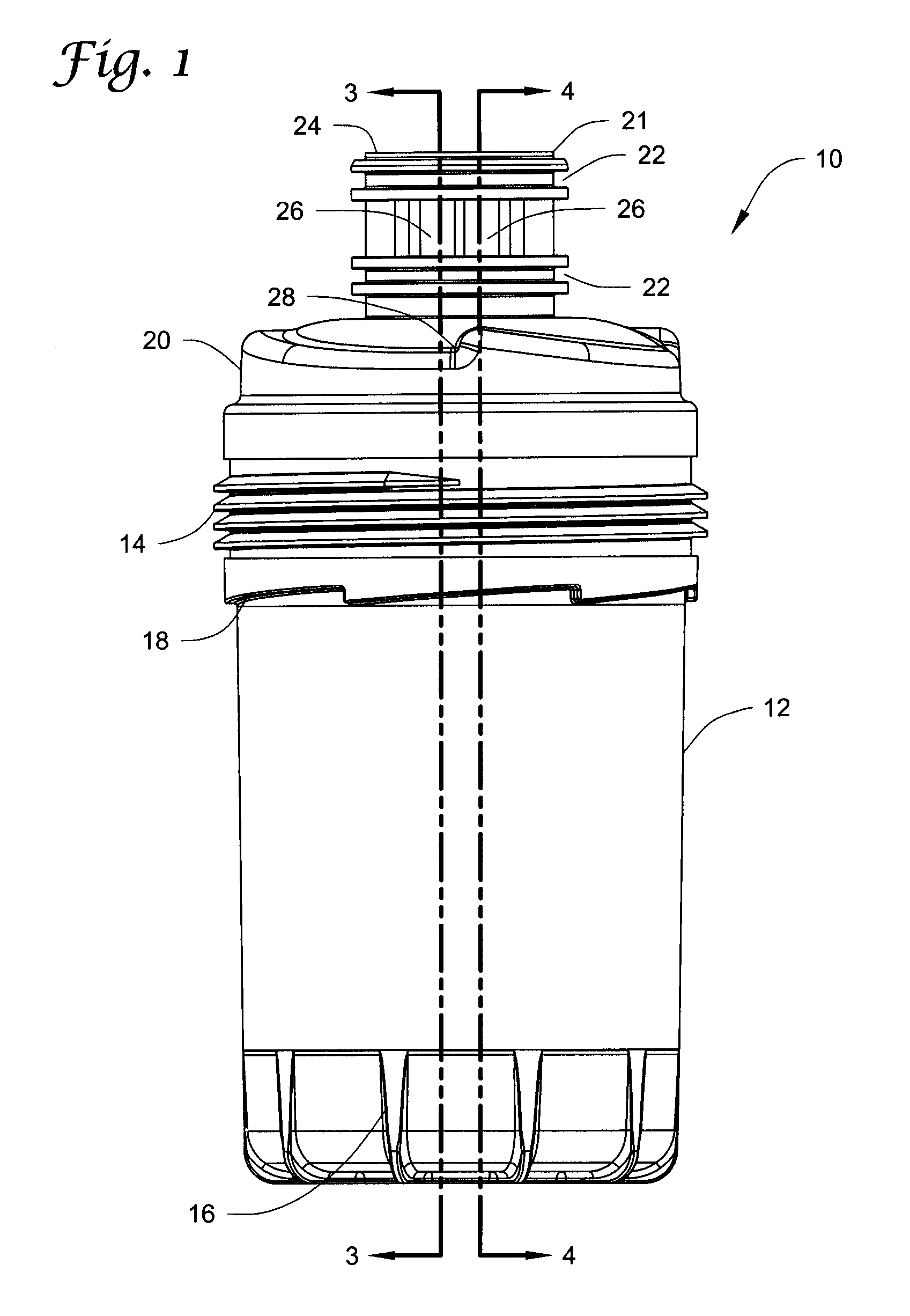

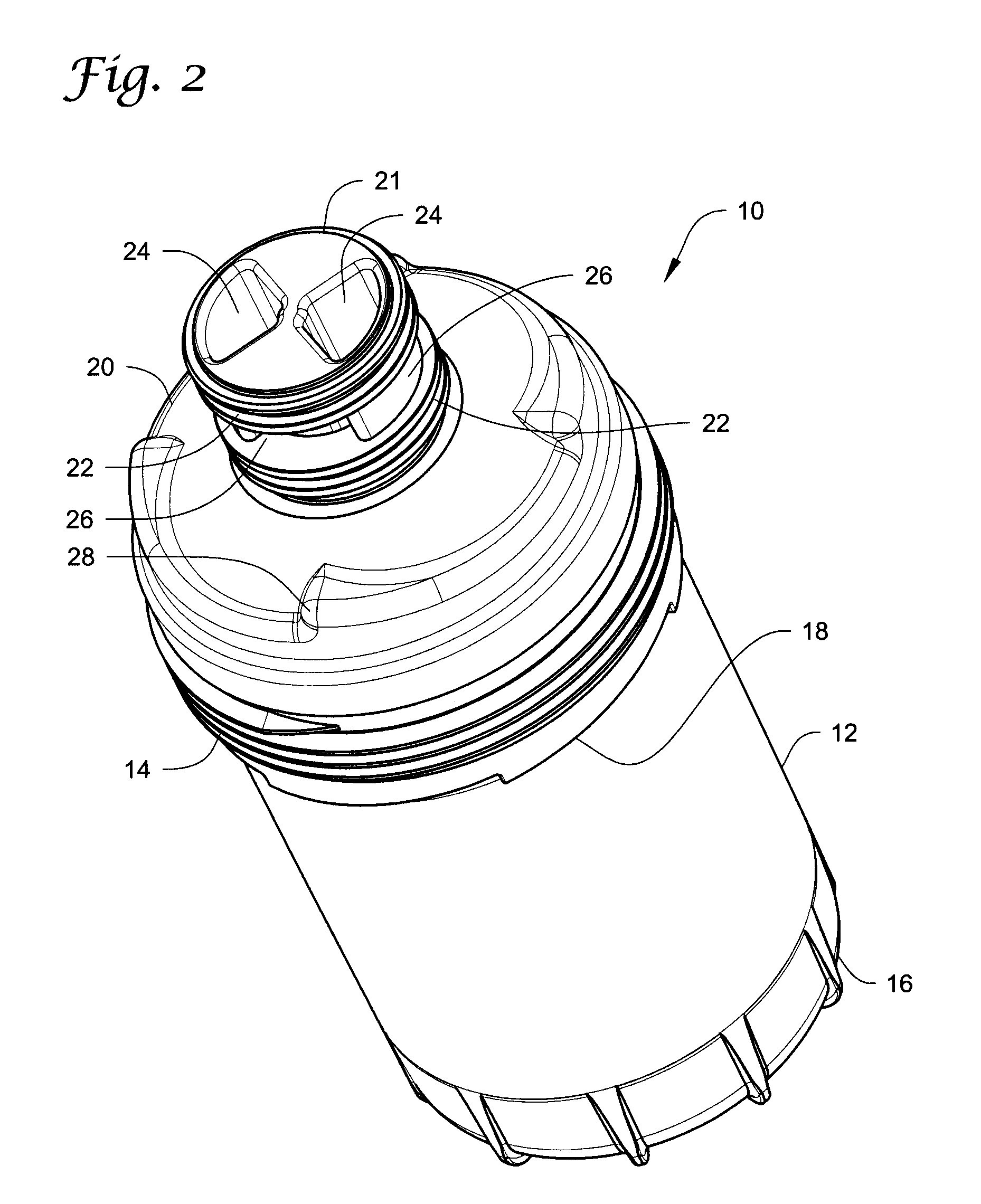

Push filter with floating key lock

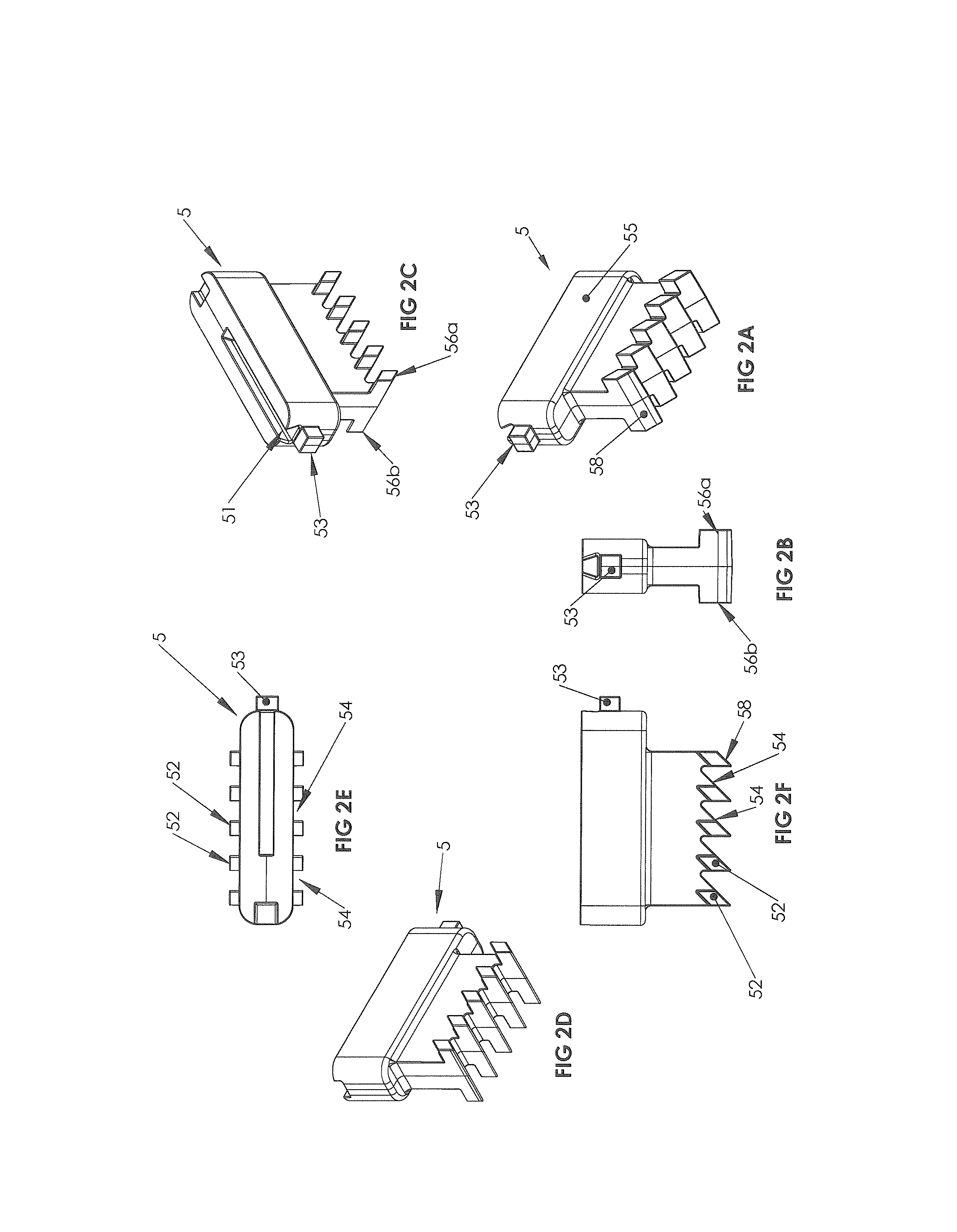

ActiveUS8137551B1Simple replacement and removalMembrane filtersCartridge filtersFluid filtrationRefrigerated temperature

A filter assembly for fluid filtration having a push-activated lock and release mechanism. A push filter design activates a floating key lock upon insertion and extraction, where the filter key may be used simultaneously as a lock and as an identifier for particular filter attributes. The filter base may be situated inline, and in fluid communication, with influent and effluent piping, such as within a refrigerator. The filter housing assembly may be attached to, and removed from, the filter base by a push-actuated release. Upon insertion, the filter key shifts the filter lock longitudinally to receive interlocking segments. Upon extraction, the same axial push shifts the filter lock further to align the interlocking fingers within gaps that allow for easy extraction. The specific key lock design allows a user to identify and match certain filter configurations received by the mechanical support, and reject other filter configurations.

Owner:KX TECH LLC (DW US)

Additive dispersing filter and method of making

InactiveUS20050040092A1Extend life of engine oilExtended time intervalMachines/enginesSolid materialOil additiveEngineering

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

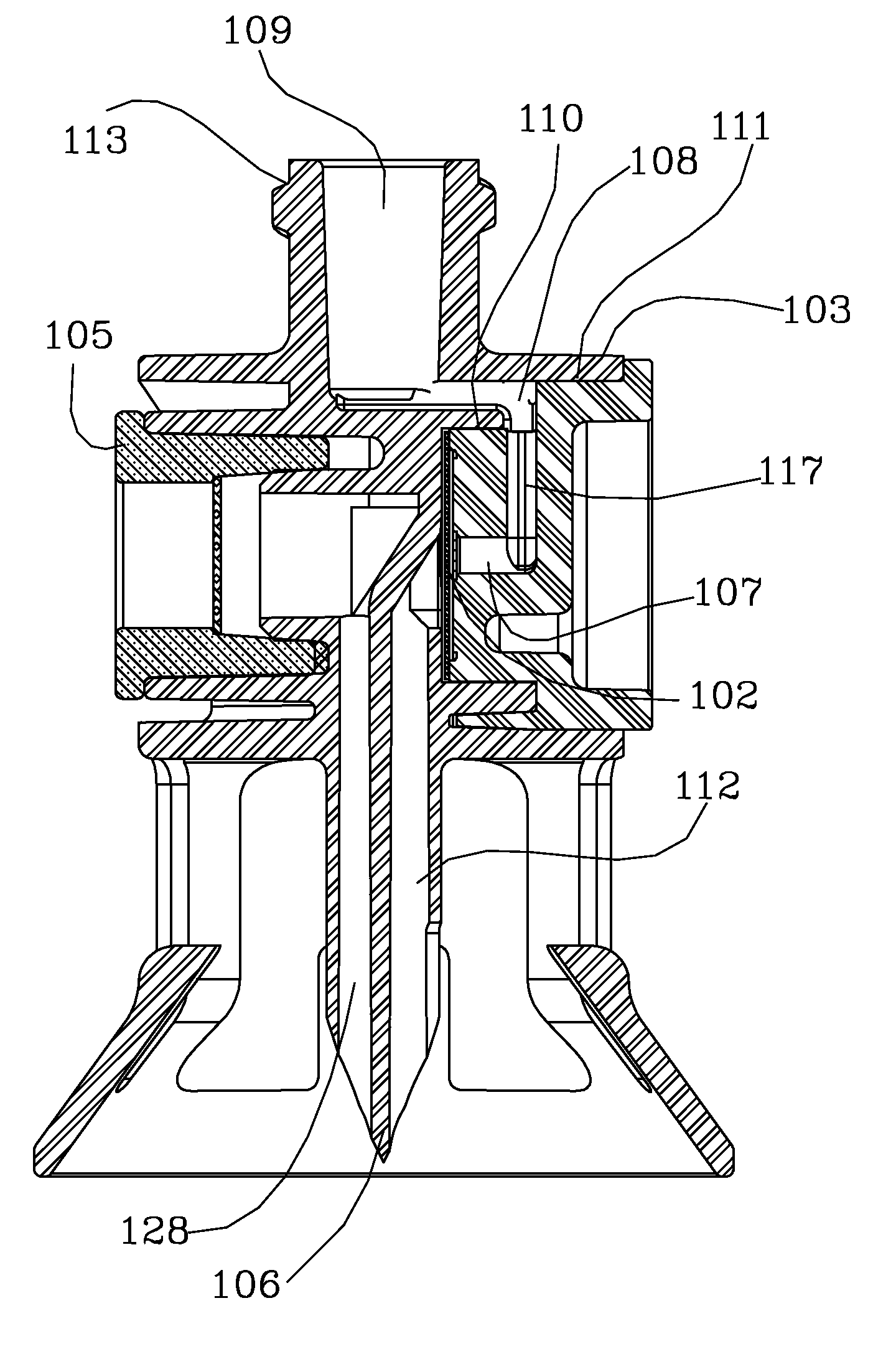

Filter housing apparatus with rotating filter replacement mechanism

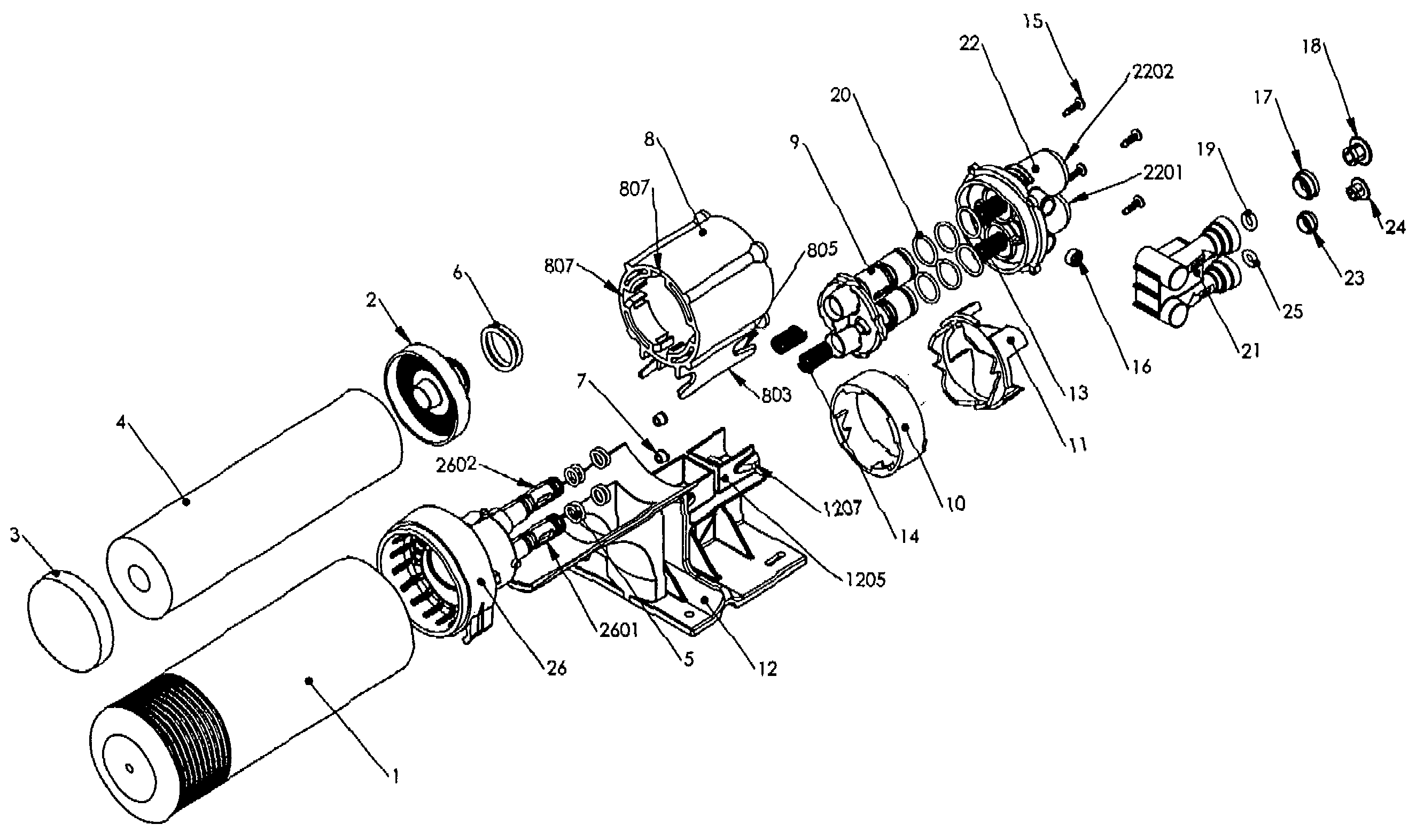

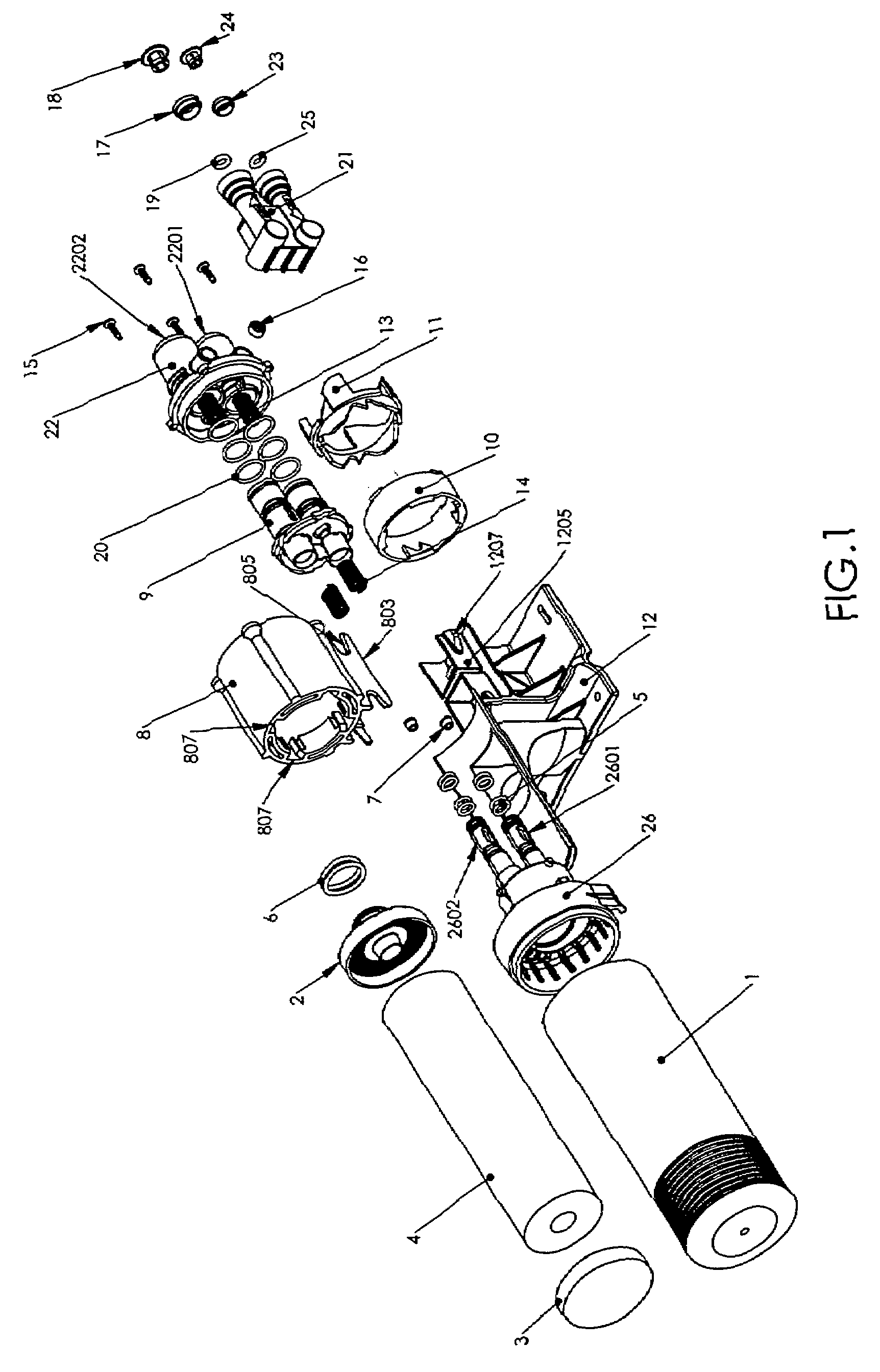

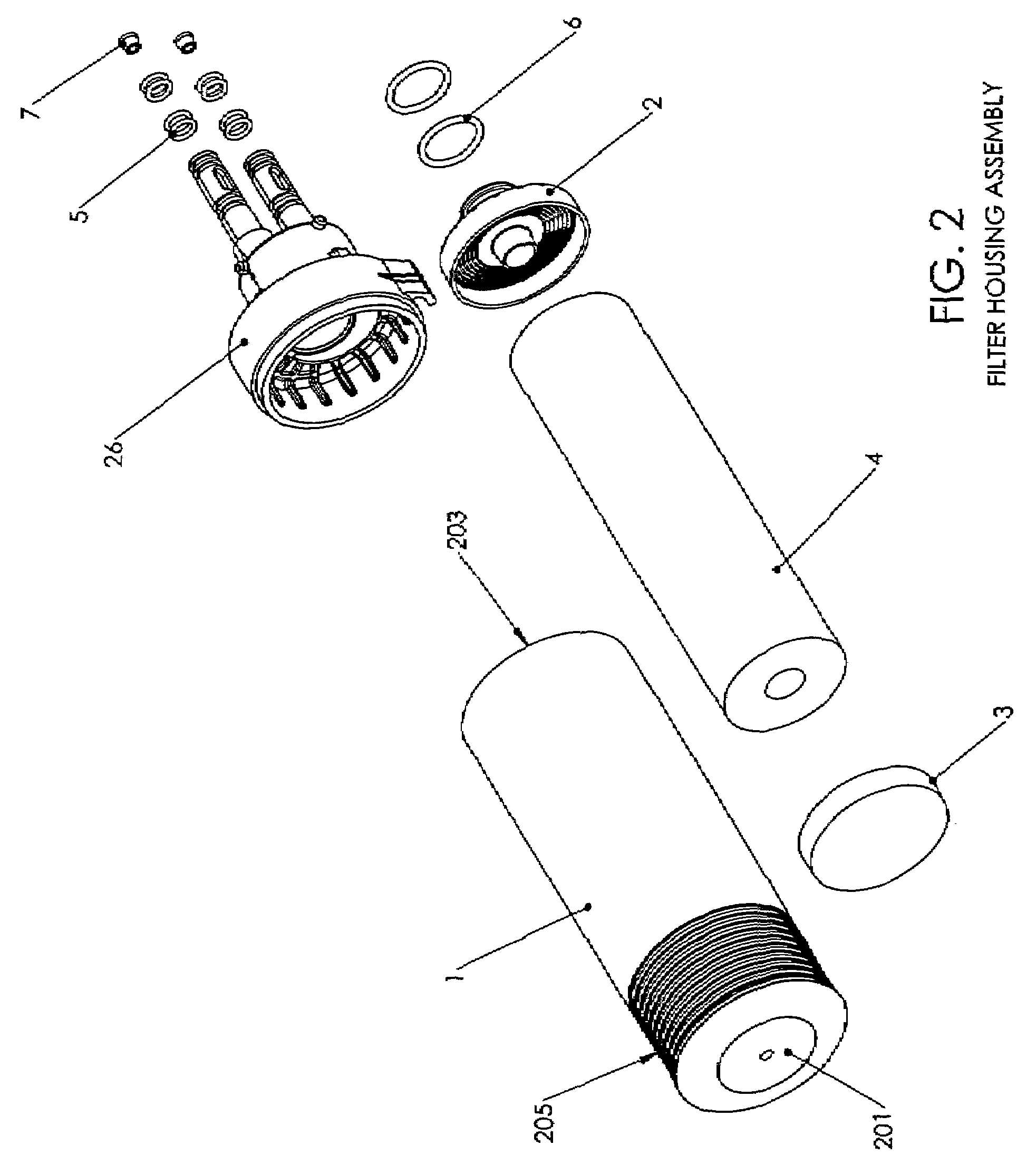

InactiveUS7442301B2Easy to disassembleSimple replacement and removalDomestic cooling apparatusSettling tanks feed/dischargeDetentFilter media

A filter assembly for fluid filtration having a push-activated lock and release mechanism. The filter housing has a sump for enclosing the filter media, a filter head, and at least one standoff protruding outwards for use in securing the filter head to a filter manifold. The filter manifold supports the filter housing with a filter locator. A filter guide having a rotator actuating mechanism secures and holds the filter head in place when the filter head is axially inserted. The rotator actuating mechanism has tabs and slots that rotate upon a transverse axial force from the standoff and from tabs on an internal shutoff. The internal shutoff has an inlet extension and an outlet extension with apertures for fluid ingress and egress. The internal shutoff tabs slidably contact and align the rotator actuating mechanism to secure and remove the filter head.

Owner:KX TECH LLC (DW US)

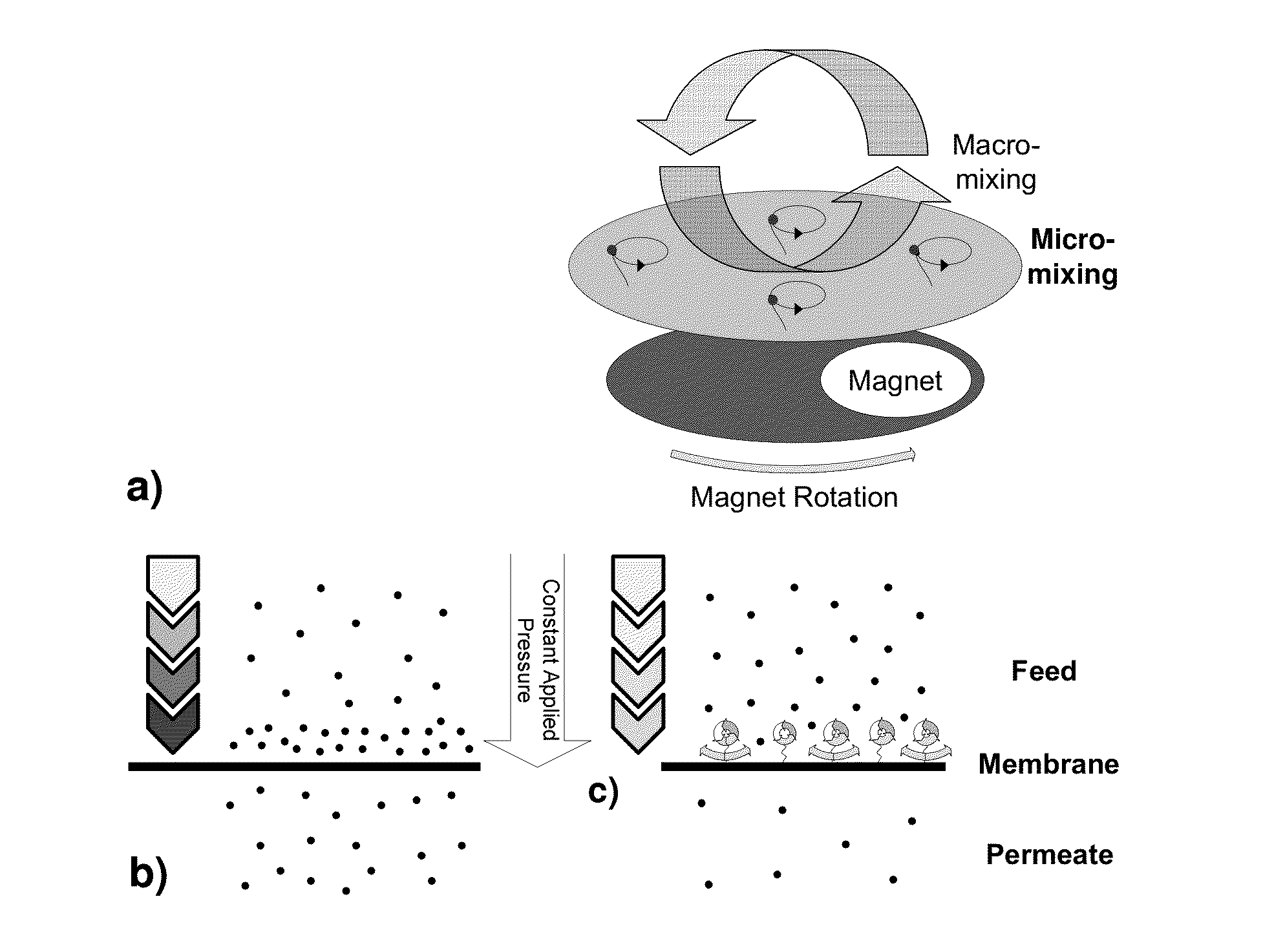

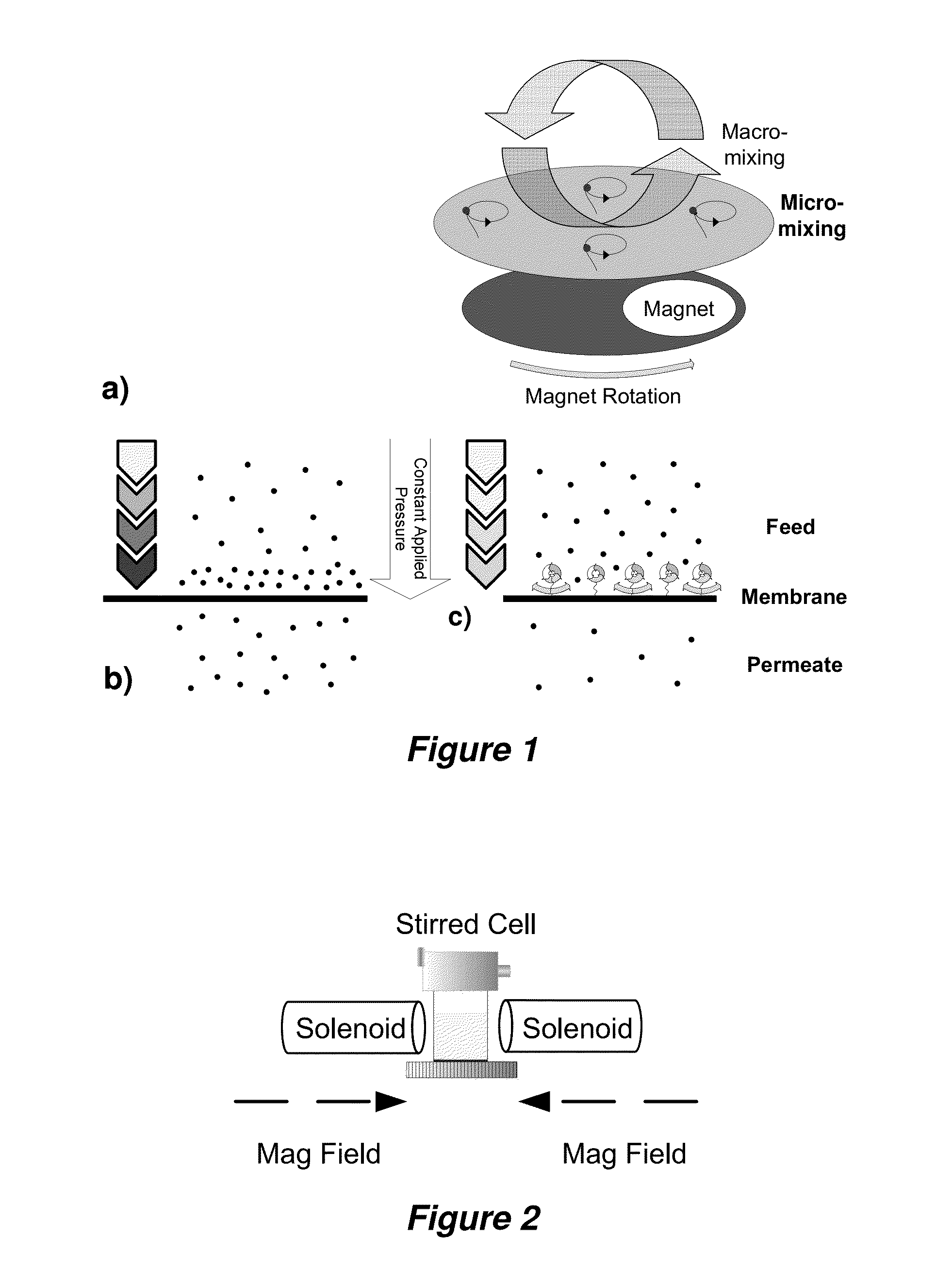

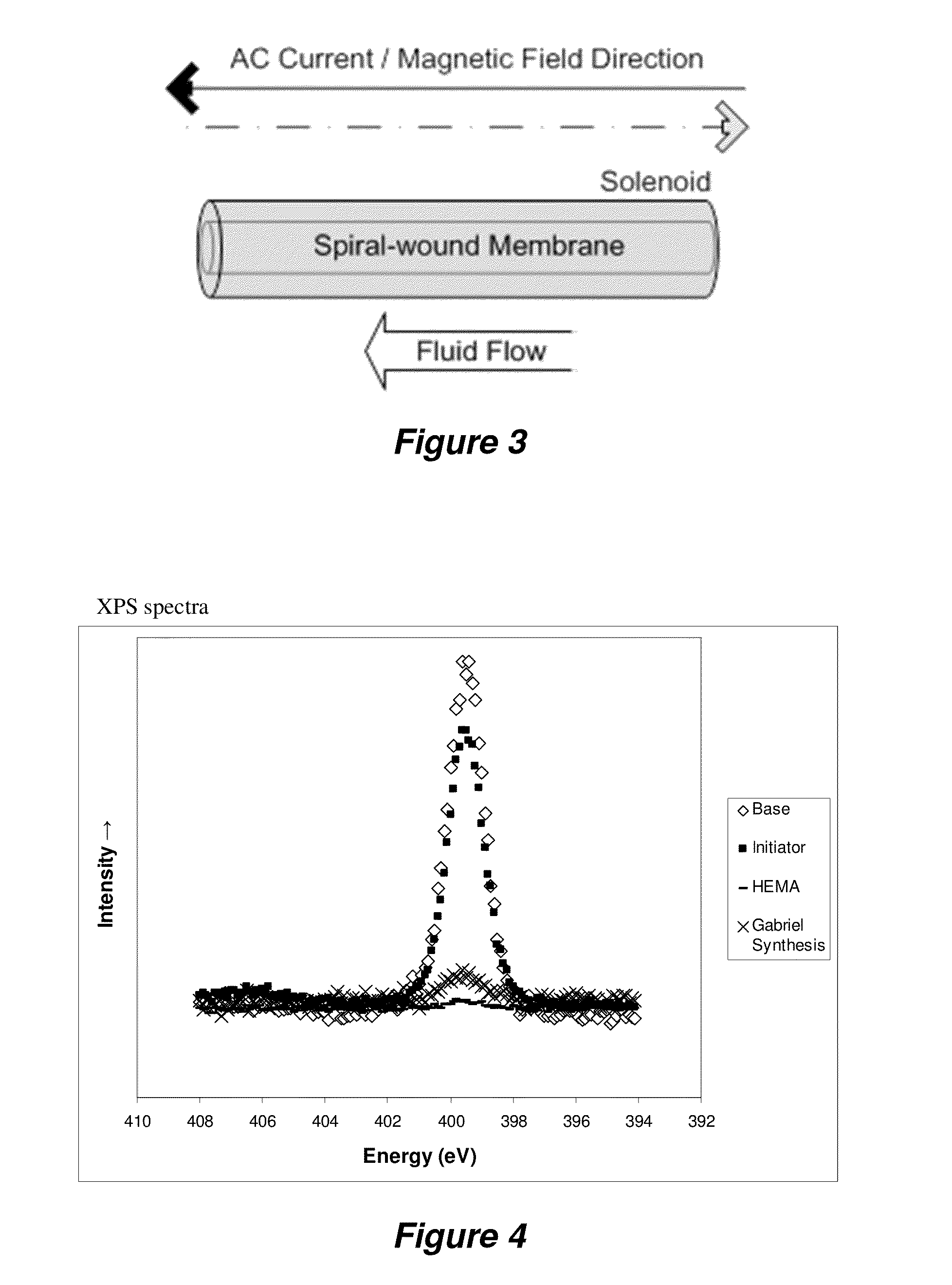

Magnetically responsive membranes

ActiveUS20140231351A1Low purityReduced effectivenessMembranesWater/sewage treatment bu osmosis/dialysisPolymer scienceHydrophilic polymers

The invention provides permeable magnetically responsive filtration membranes that include a filtration membrane polymer base suitable for fluid filtration; hydrophilic polymers conjugated to the surface of the filtration membrane polymer; and magnetic nanoparticles affixed to the ends of a plurality of the hydrophilic polymers, wherein the hydrophilic polymers are movable with respect to the surface of the filtration membrane polymer surface in the presence of an oscillating magnetic field.

Owner:LEHRSTUHL FUR TECHN CHEM II UNIV DUISBURG ESSEN +2

Filtration devices with embedded radio frequency identification (RFID) tags

ActiveUS7481917B2Easily store and retrieve dataEasy loadingWater/sewage treatment bu osmosis/dialysisReverse osmosisReverse osmosisFluid filtration

Embodiments of the present invention comprise reverse osmosis filters and systems comprising embedded radio frequency identification (RFID) tags for storing and retrieving data. The RFID tags can be preferably embedded under a filtration device's protective outer shell. Information can be easily stored onto and retrieved from the embedded RFID tags. The ability to easily store and retrieve data from the embedded RFID devices facilitates the creation of loading maps, monitoring, addition, and replacement of fluid filtration devices.

Owner:NITTO DENKO CORP +1

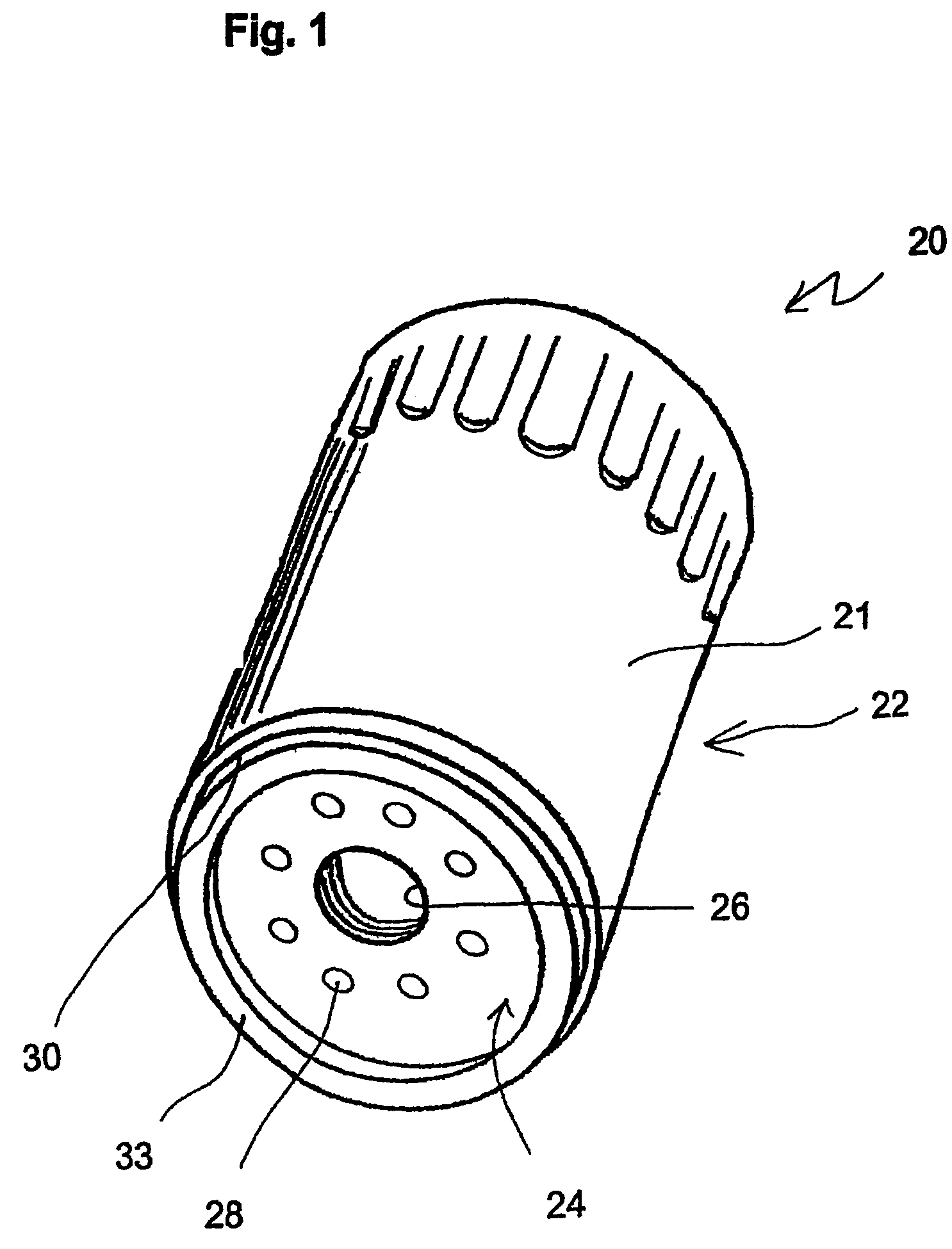

Antimicrobial filter cartridge

An antimicrobial filter cartridge having a microporous core member about which is applied a yam which may be impregnated with a antimicrobial agent. The filter cartridge is sized so as to fit tightly into a cartridge housing of a fluid filtration system. Fluid passing through the cartridge housing will be filtered by the filter cartridge to remove bacteria and other contaminants from the water and which prevents the growth of bacterial and other microorganisms on the filter media.

Owner:PATRICK GILBERT

Push filter with floating key lock

ActiveUS9233322B1Simple replacement and removalMembrane filtersStationary filtering element filtersFluid filtrationRefrigerated temperature

A filter assembly for fluid filtration having a push-activated lock and release mechanism. A push filter design activates a floating key lock upon insertion and extraction, where the filter key may be used simultaneously as a lock and as an identifier for particular filter attributes. The filter base may be situated inline, and in fluid communication, with influent and effluent piping, such as within a refrigerator. The filter housing assembly may be attached to, and removed from, the filter base by a push-actuated release. Upon insertion, the filter key shifts the filter lock longitudinally to receive interlocking segments. Upon extraction, the same axial push shifts the filter lock further to align the interlocking fingers within gaps that allow for easy extraction. The specific key lock design allows a user to identify and match certain filter configurations received by the mechanical support, and reject other filter configurations.

Owner:KX TECH LLC (DW US)

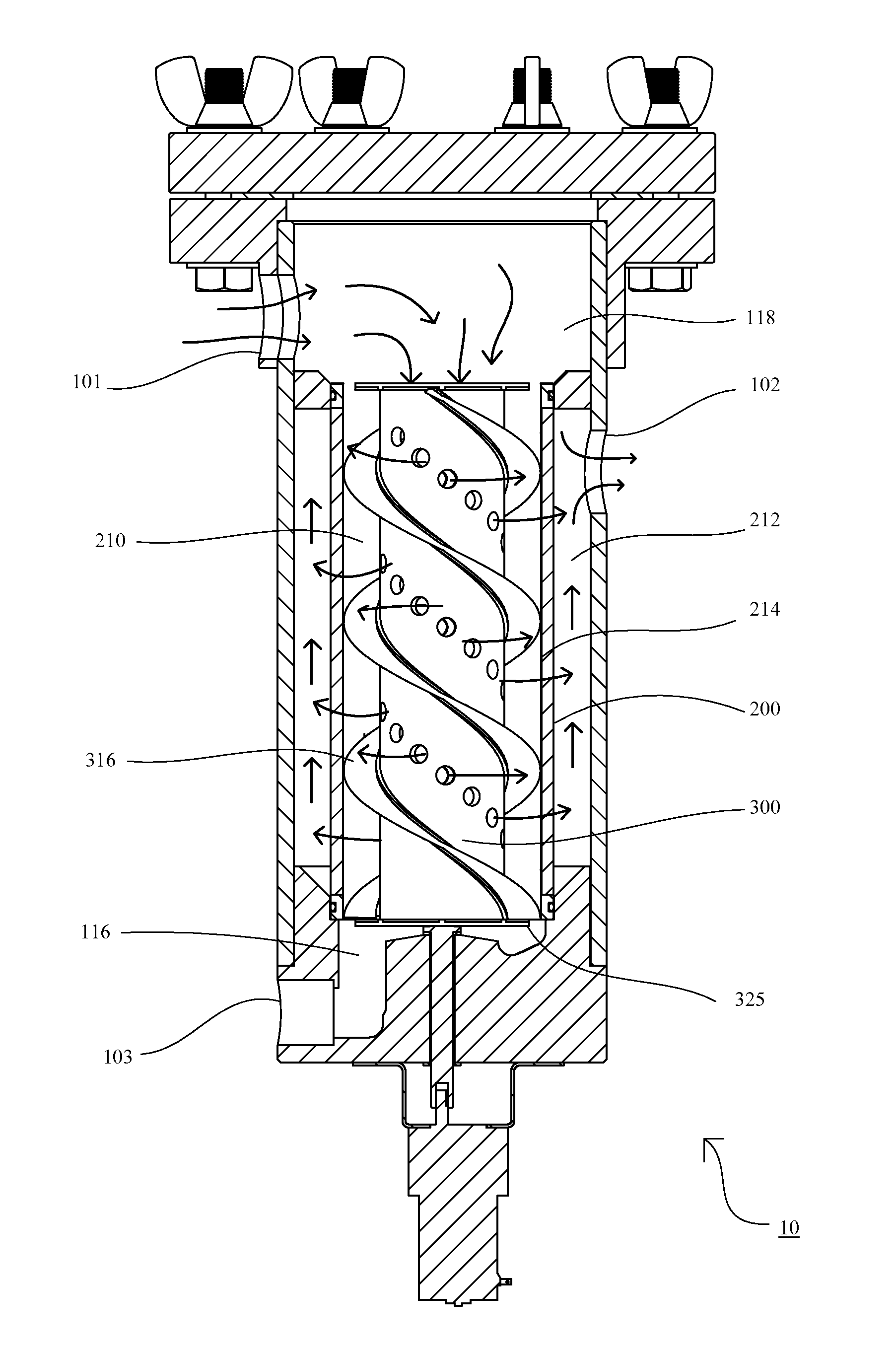

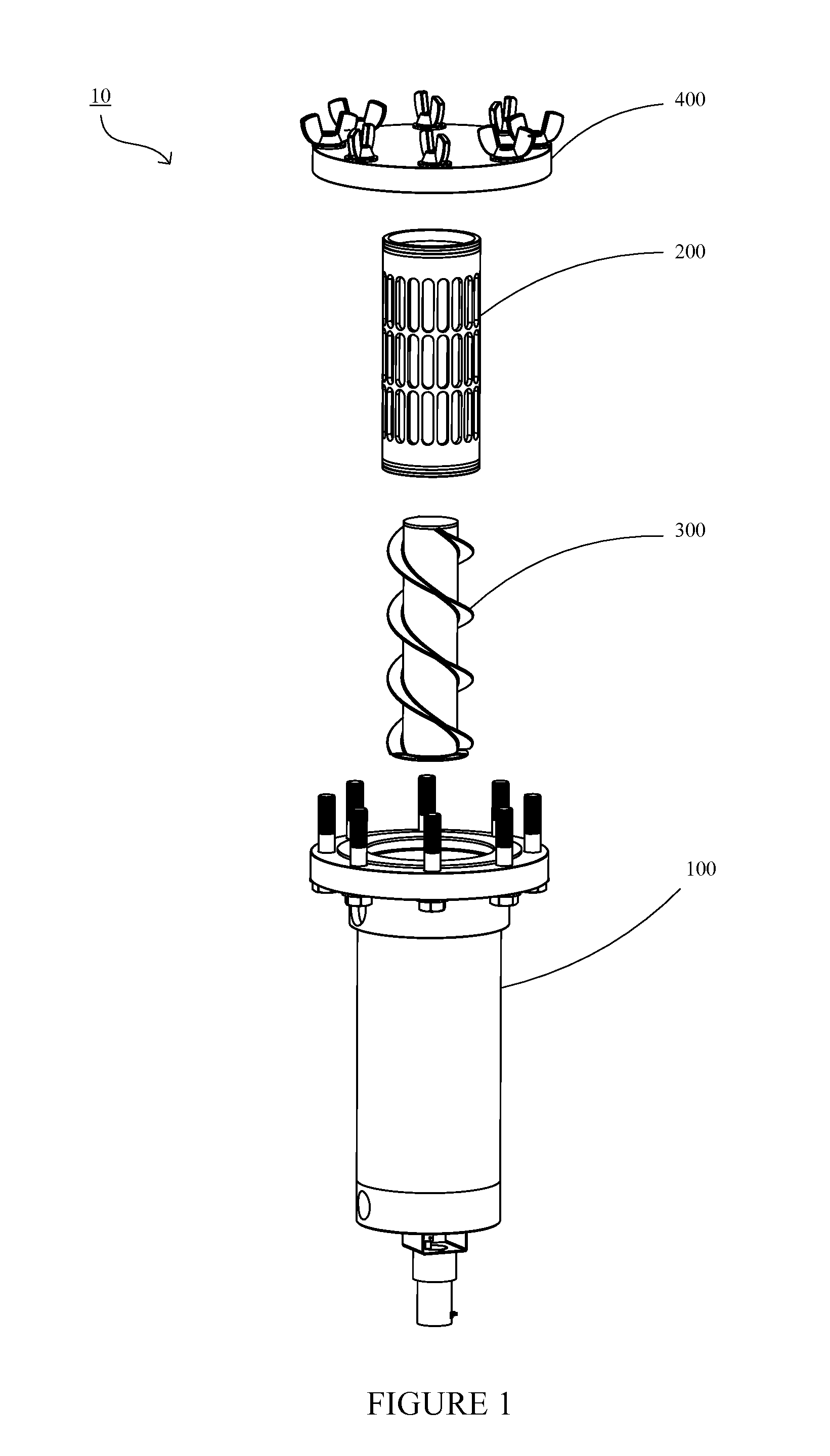

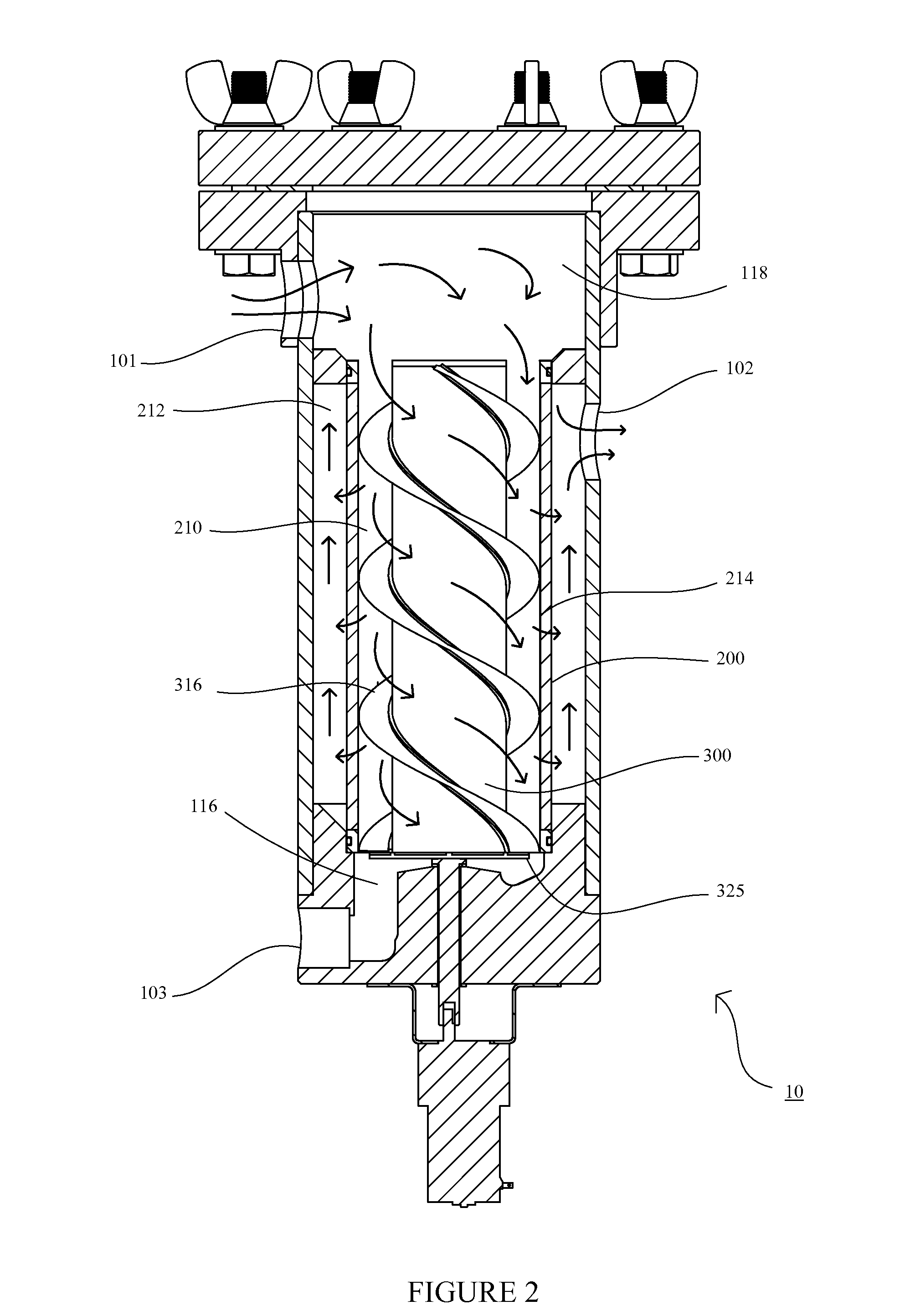

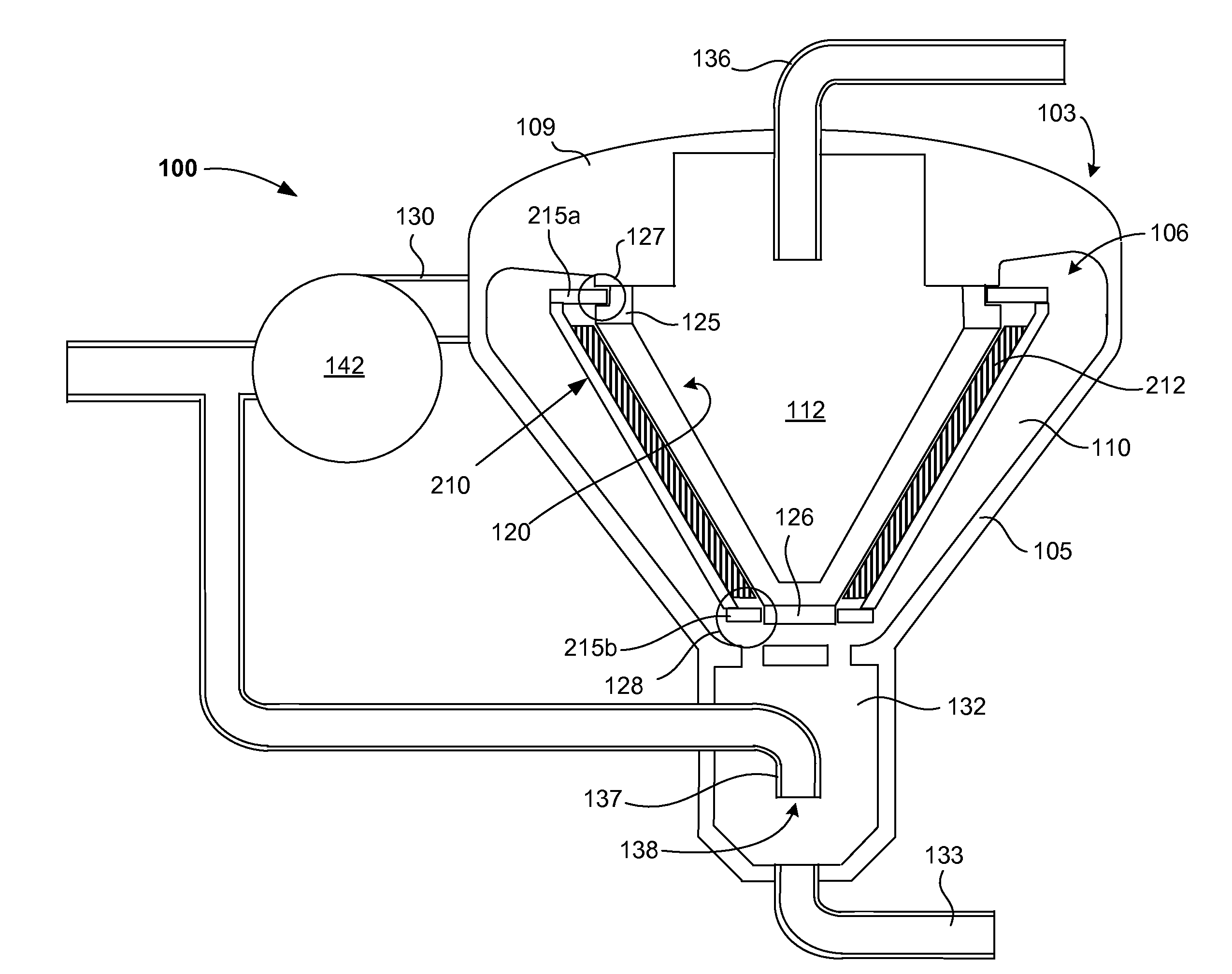

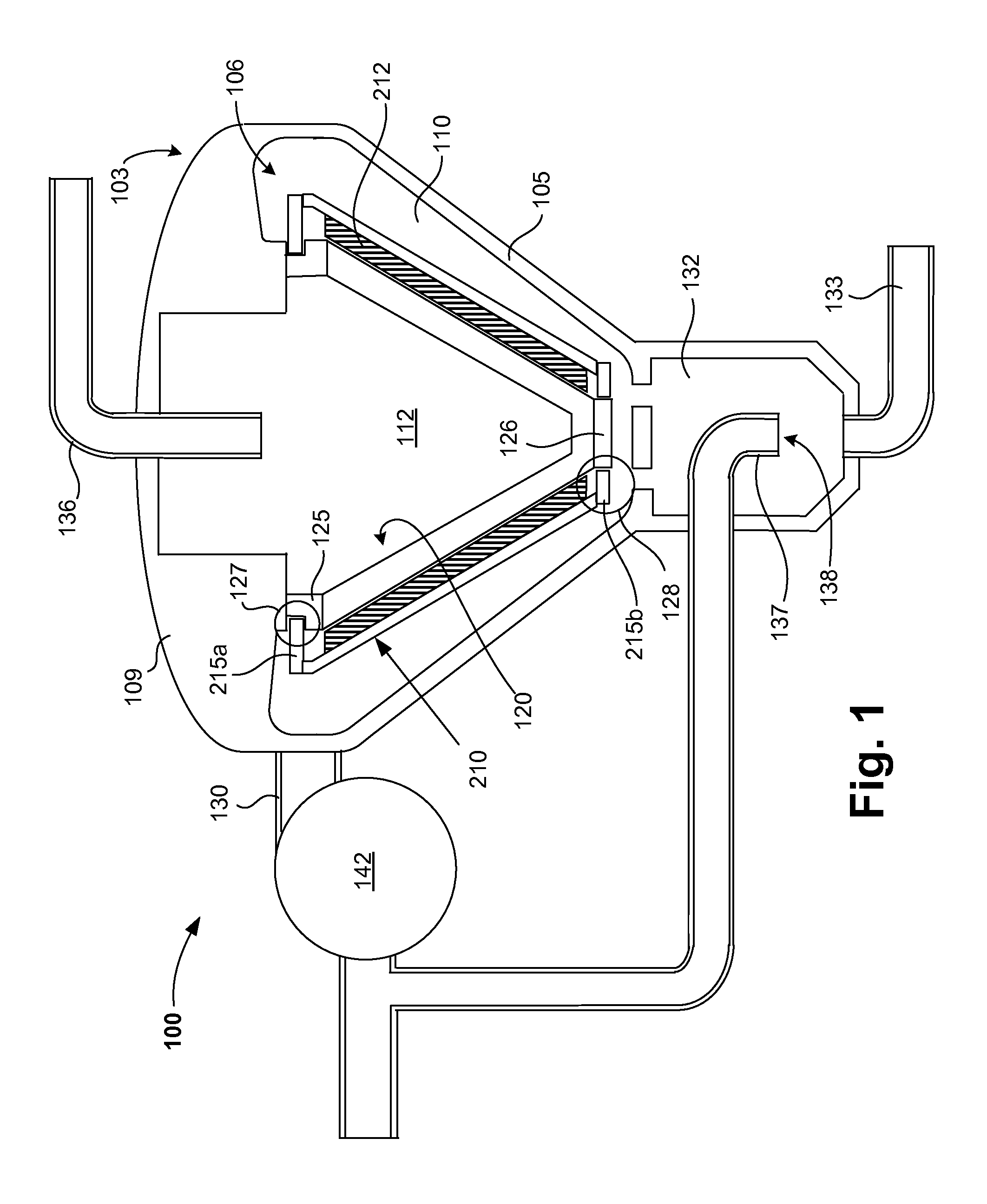

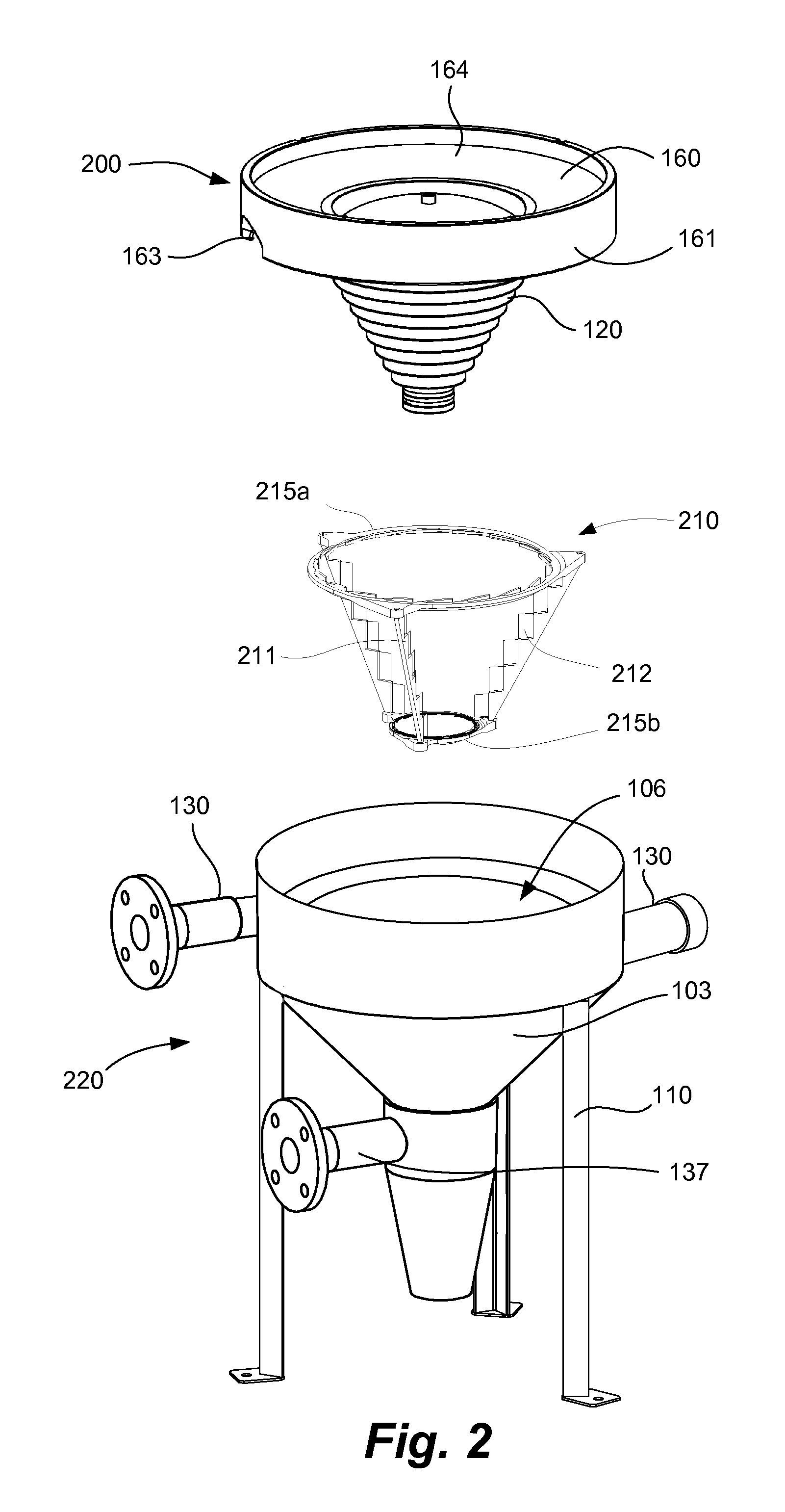

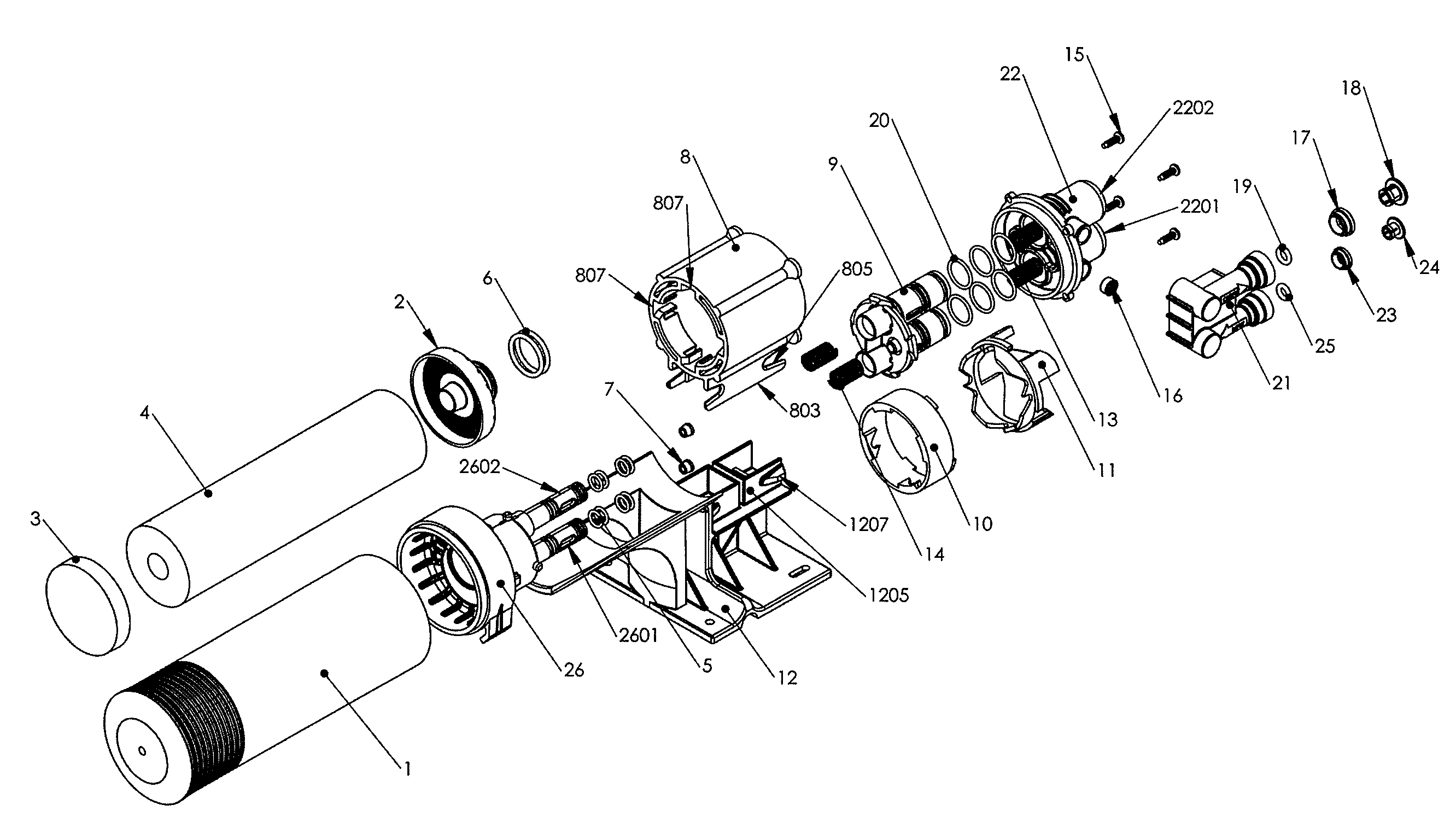

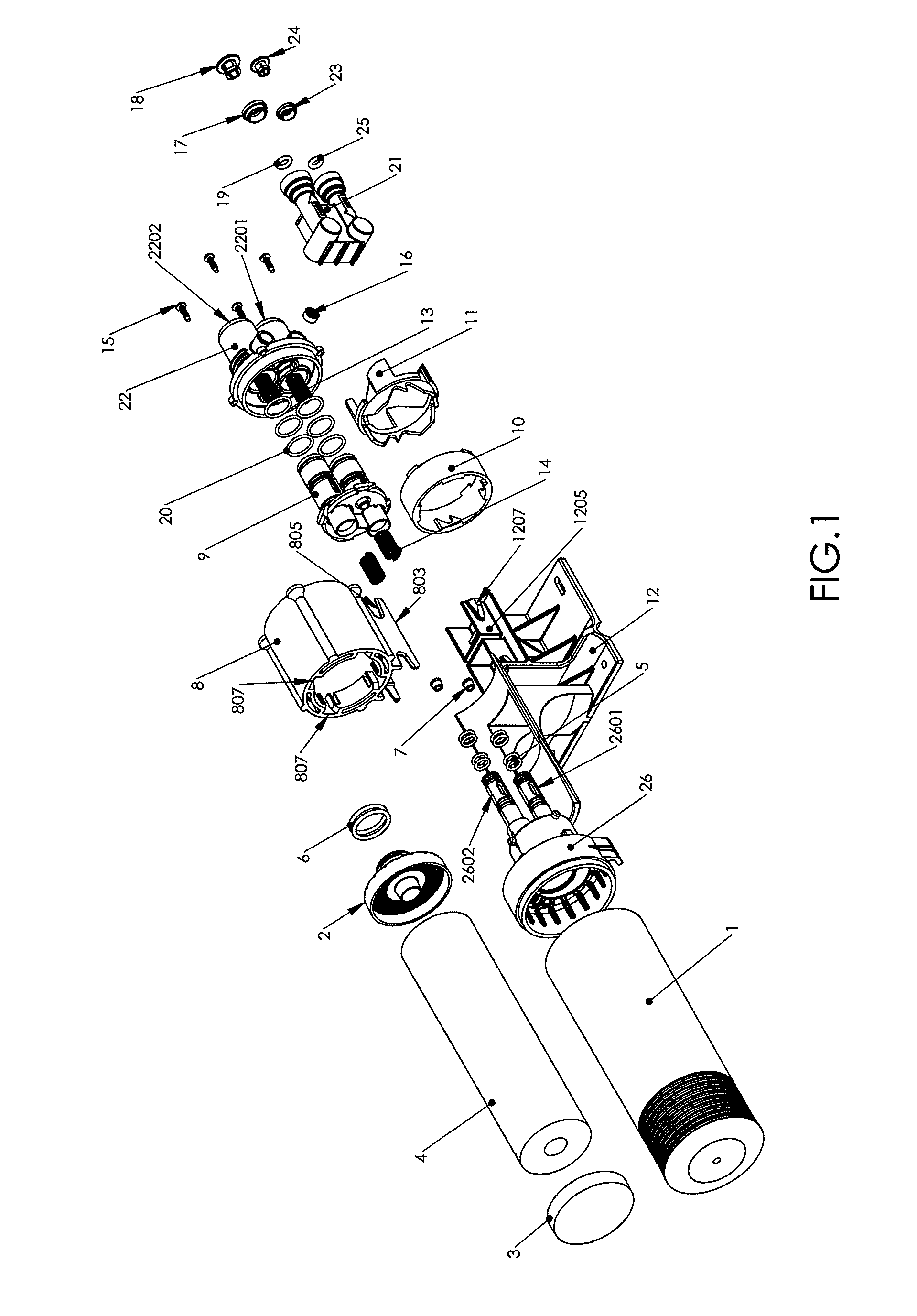

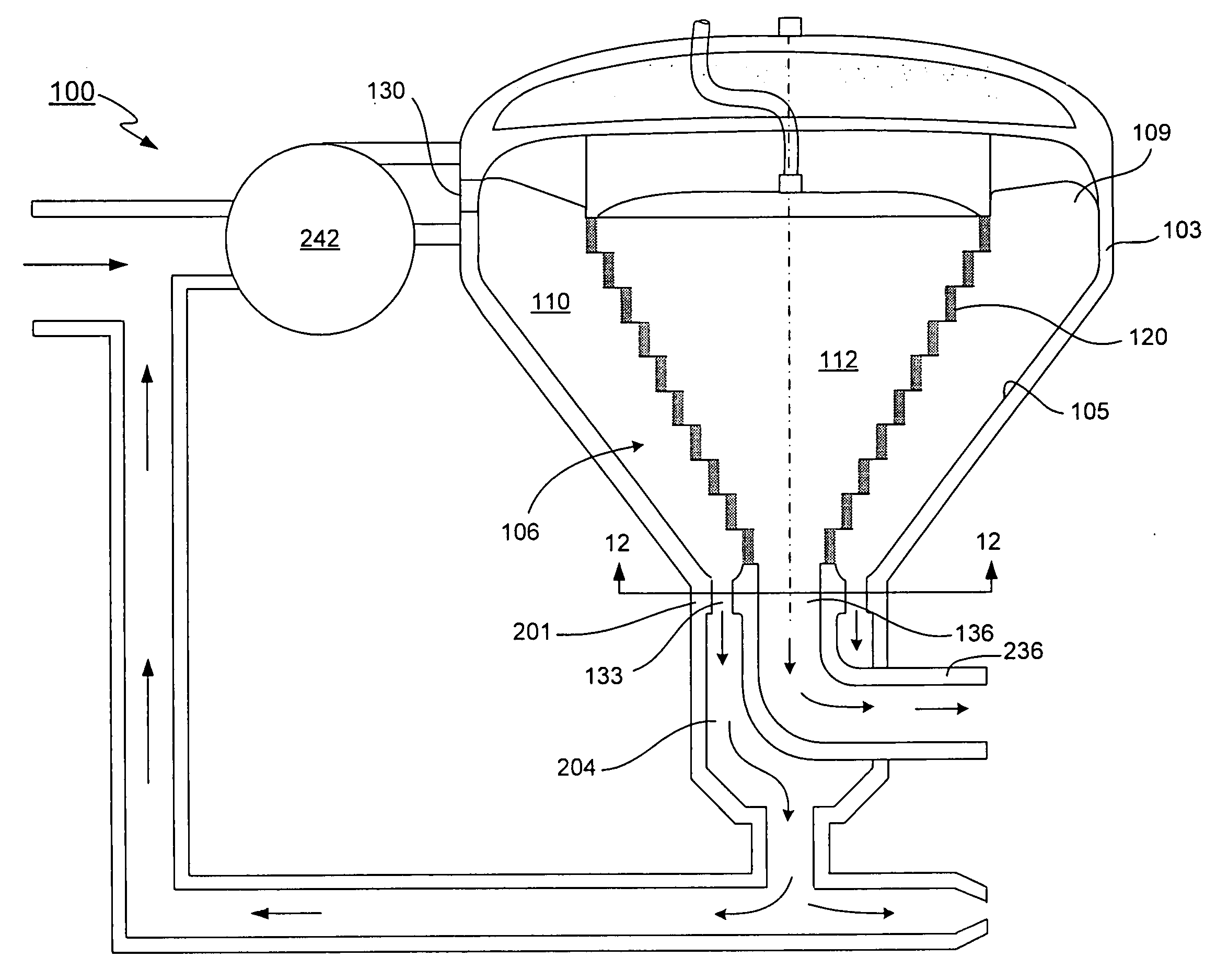

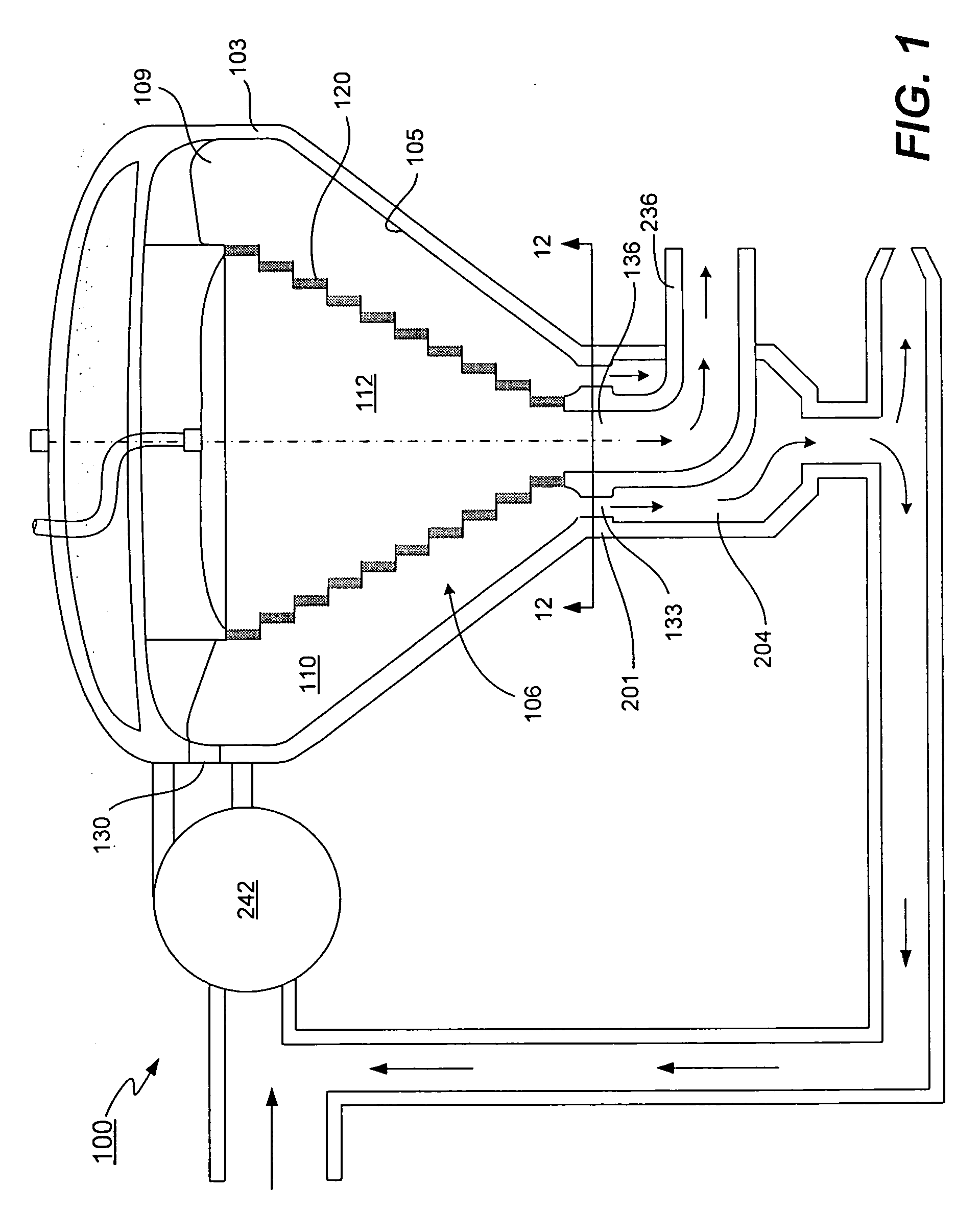

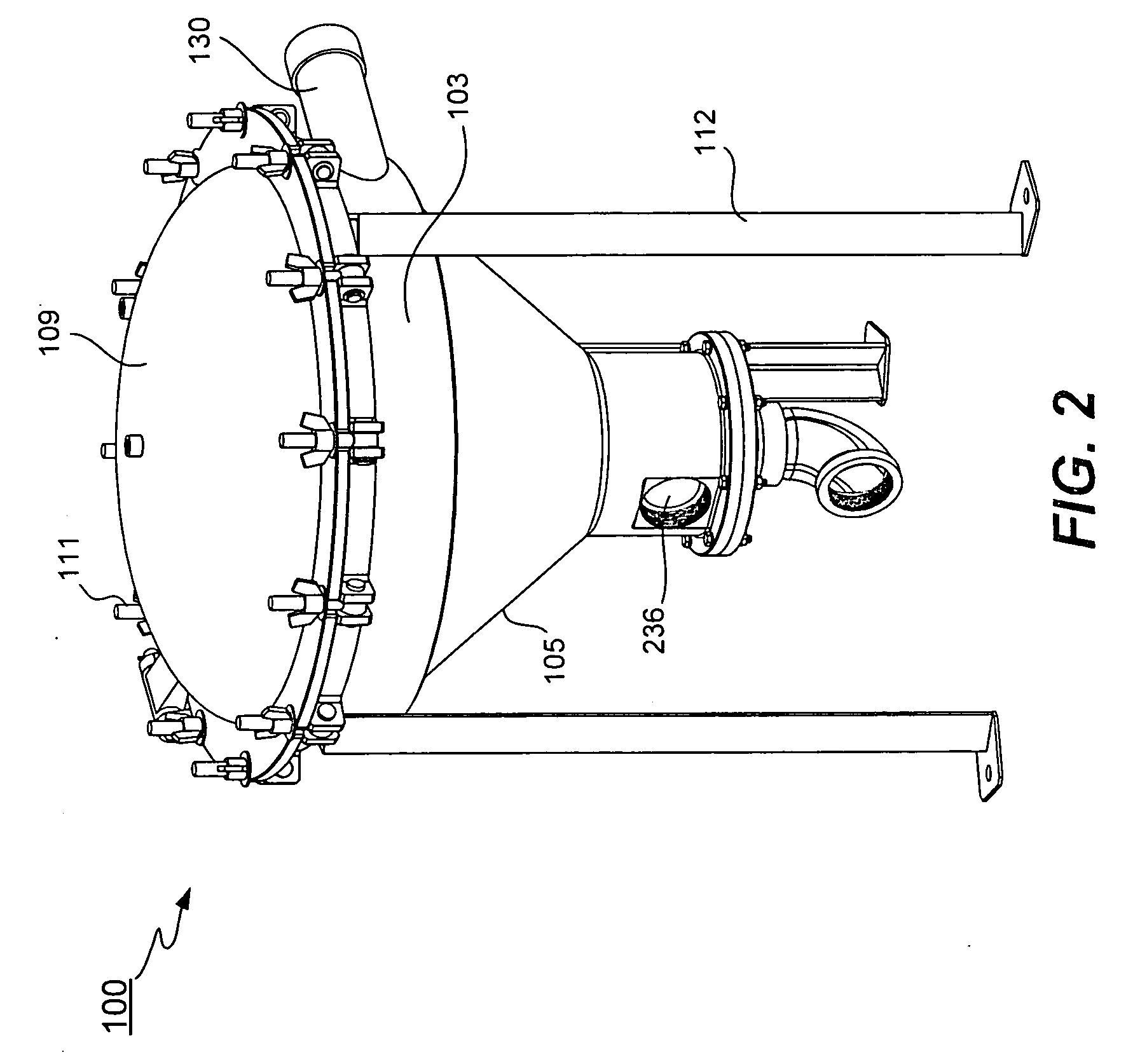

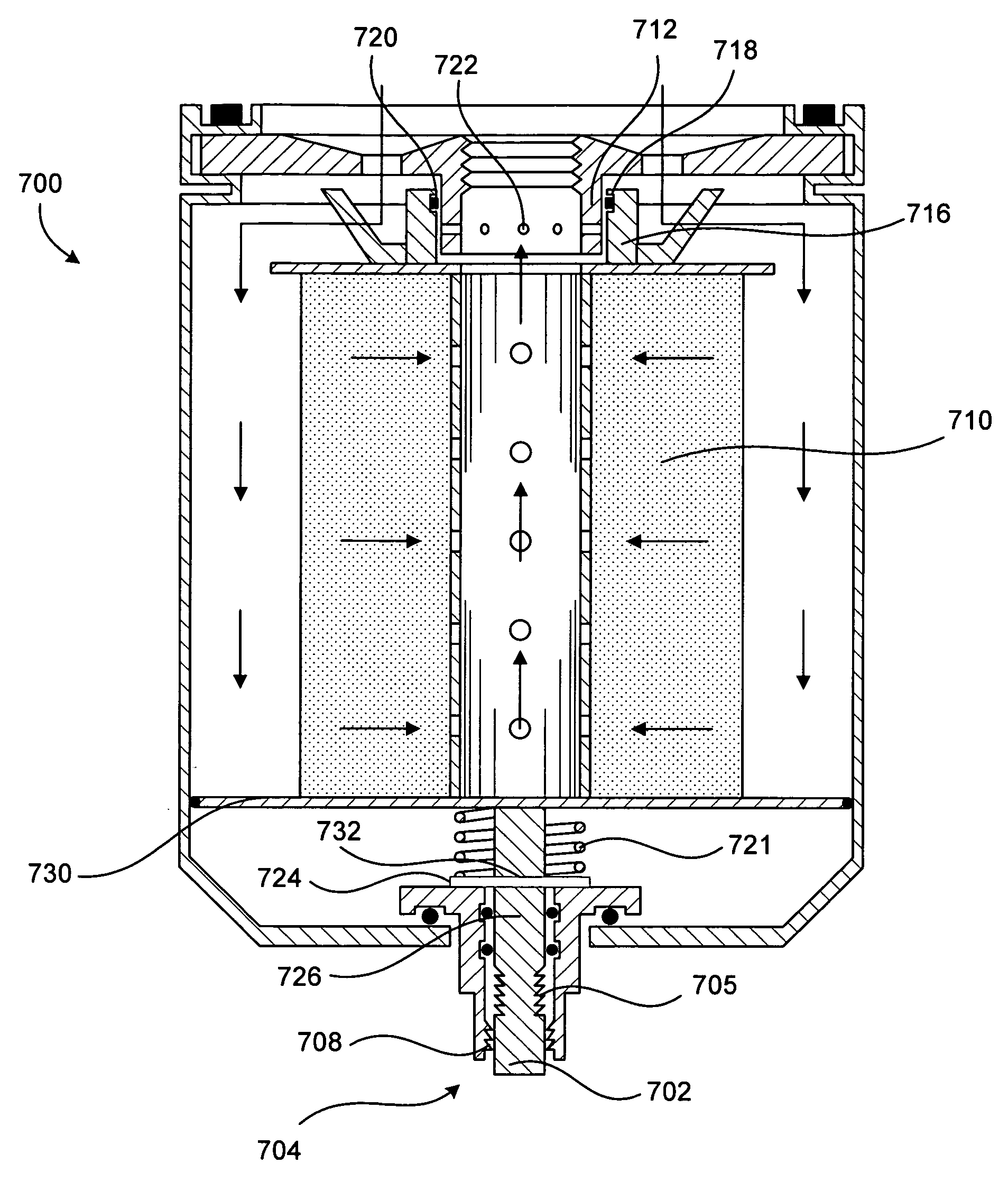

Hydroclone based fluid filtration system

ActiveUS20070039900A1Reduce morbiditySmall diameterLiquid separation auxillary apparatusReversed direction vortexCross-flow filtrationFluid filtration

A variety of improved hydroclone based fluid filtering systems are described. The hydroclones generally include a tank having an internal chamber and a filter (preferably a surface filter) that is positioned within the internal chamber. The filter defines a filtered fluid chamber within the internal chamber of the tank. The hydroclone may be operated such that a vortex of flowing fluid is formed between the chamber wall and the filter with the filter being located in the center of the vortex. With this arrangement, the filter acts as a cross-flow filter. In one aspect of the invention, the filter is a stepped filter. In another aspect of the invention, the filter is an surface filter, as for example, an electroformed metal surface filter. In some preferred embodiments, the openings in the filter are arranged as slots that extend substantially vertically so that they are oriented substantially perpendicular to the flow path of fluid flowing in the adjacent portion of the vortex. In another aspect of the invention, a circulating cleaning assembly is provided in the hydroclone region. The cleaning assembly is arranged to help clean the filter and is driven by the vortex of flowing fluid formed in the hydroclone region of the internal chamber. In yet another aspect of the invention, improved hydroclone intake structures are described. The described hydroclones may be used to filter water and other fluids in a wide variety of applications.

Owner:ACCELERATED FILTRATION INC

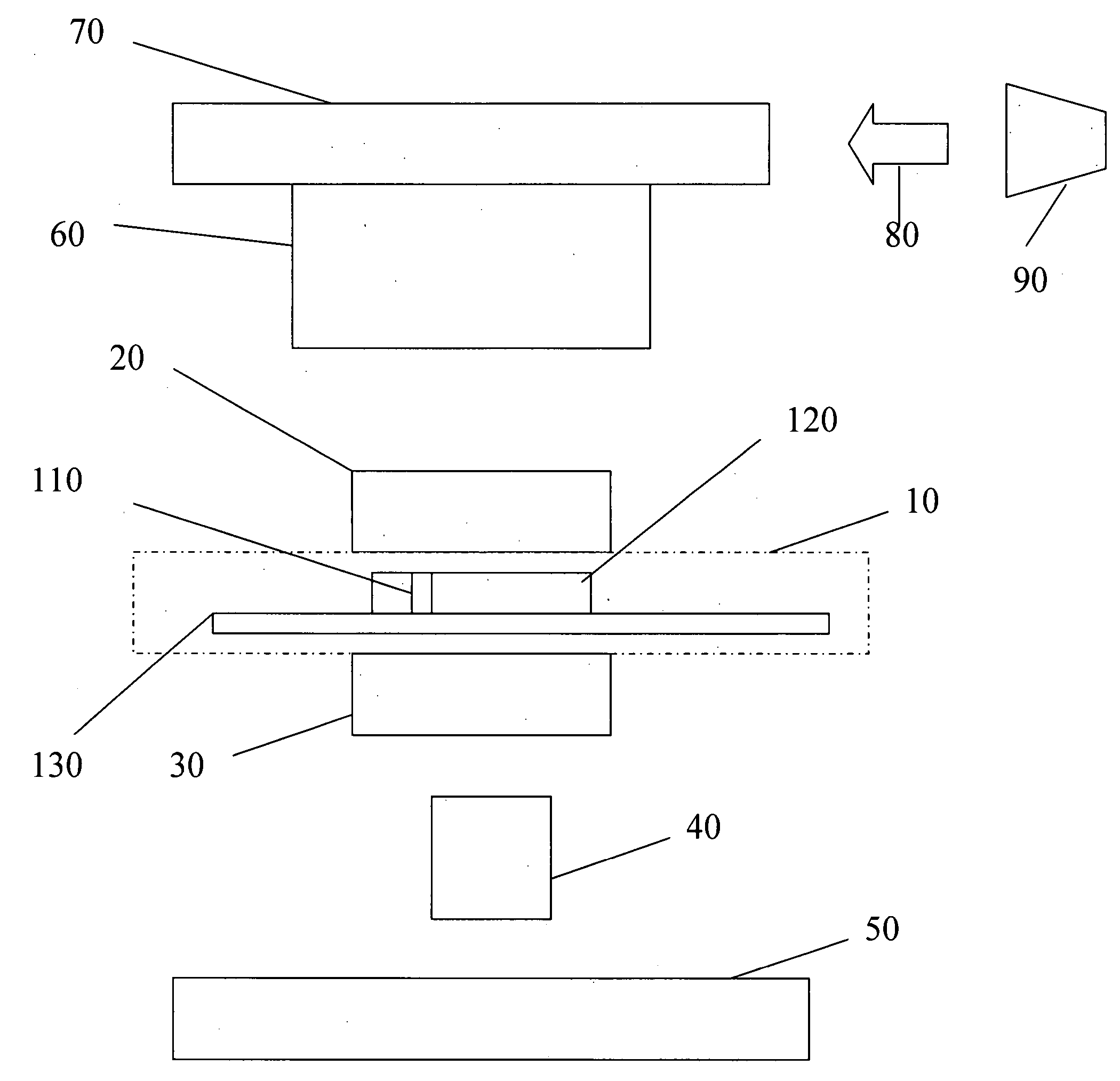

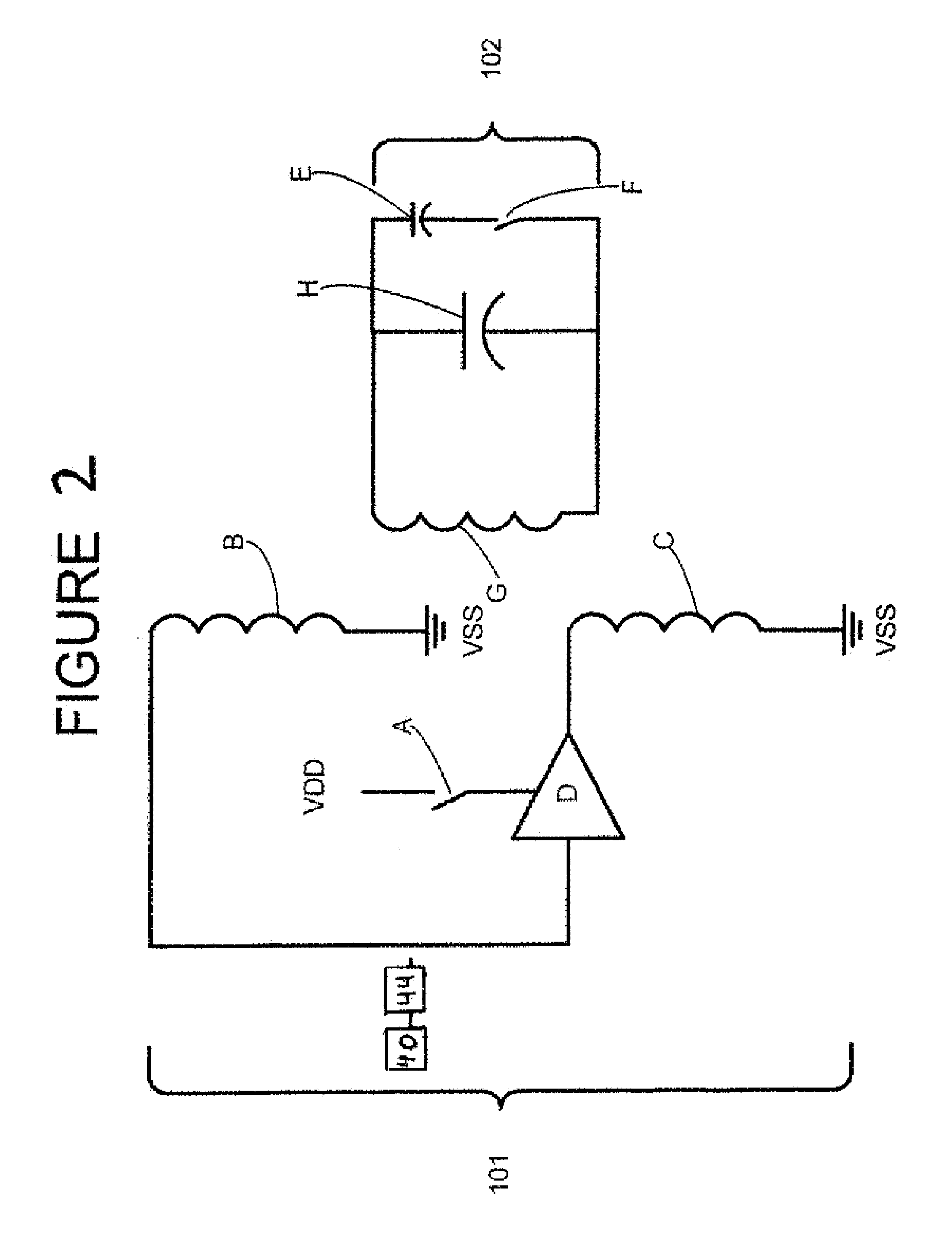

System and method for communication between a fluid filtration apparatus and filter

InactiveUS20110062060A1Semi-permeable membranesSedimentation separationFluid filtrationElectrical and Electronics engineering

A system allowing the wireless transfer of data between a fluid filtering apparatus having a controller and a filter when the filter is positioned within the fluid filtering apparatus is described. The system includes a reader circuit and tag circuit in which the tag circuit includes read-only information and an enable bit responsive to a disable signal from the reader circuit to permanently de-authorize use of the filter with the fluid filtering apparatus. The controller is operatively connected to the reader circuit for interpreting the coded information and may modify or eliminate fluid flow within the fluid filtering apparatus, and / or provide a visible or audible warning to the user on the basis of filter manufacturer specifications such as volume and / or time of filter use.

Owner:SMART WAVE INTEGRATED PRODS

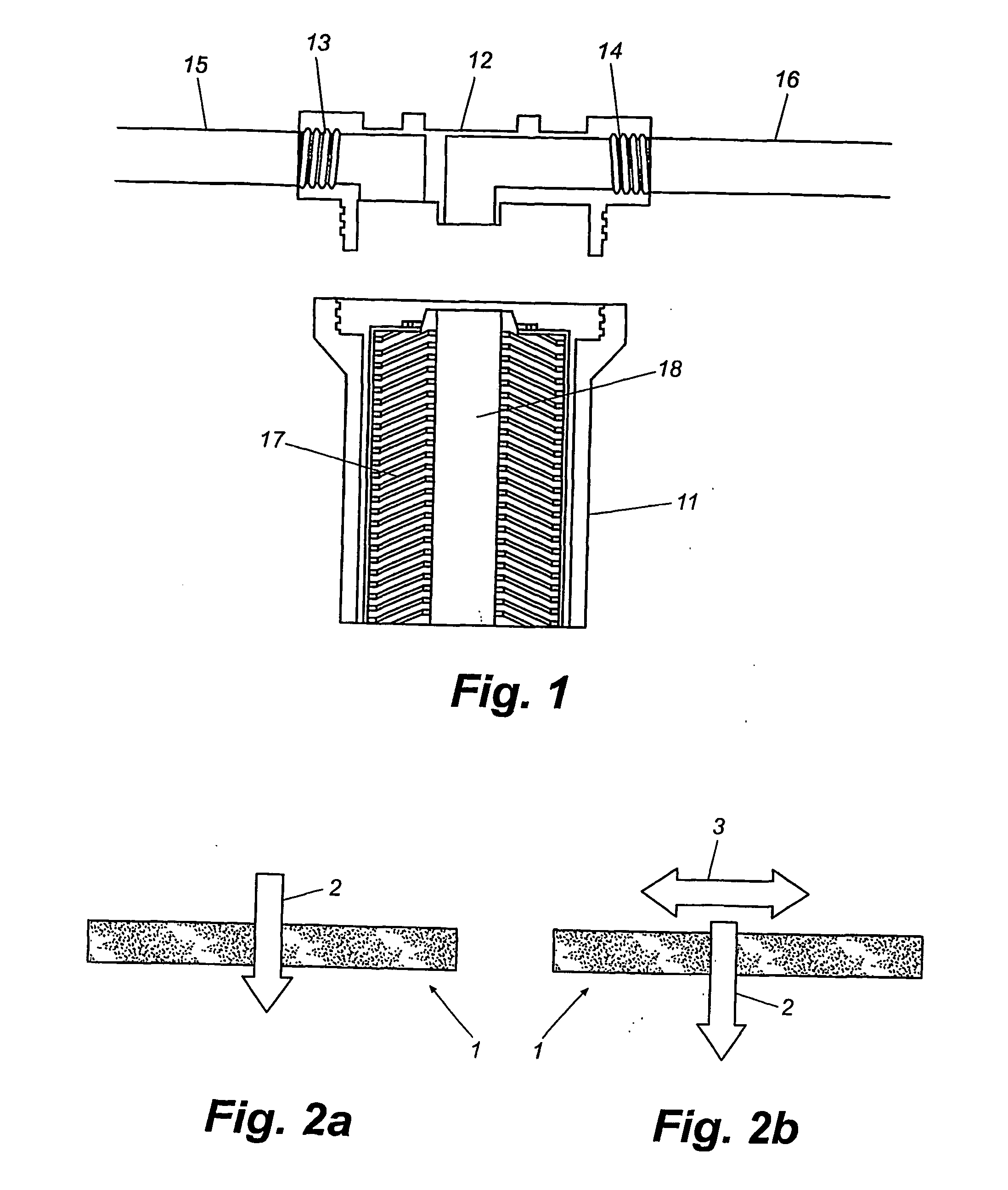

Filter material, method for the production thereof, a filter and filtering method

ActiveUS20080164214A1High propertyLow hydrodynamic resistanceOther chemical processesLayered productsFiberRetention efficiency

The invention concerns the production of filter materials for the purification and disinfection of water, water solutions and other liquids, as well as for sterilizing filtration of injections and other solutions, for concentration of biomolecules in physiological liquids, concentration and extraction of viruses, preparation of apyrogenic water, in biocatalytic diaphragm reactors. The invention solves the problems of a new filter material production, characterized by high sorption properties, high retention efficiency of submicron electronegative particles, microorganisms, submicron non-polar particles and chemical contaminations, and, at the same time, characterized by low hydrodynamic resistance. A base of filter material is the nonwoven organic synthetic polymeric fabric, modified by the aluminum hydroxide particles, fixed to the surface of base fibers for improvement of its sorption properties and for making it positively charged. A method of filter material production comprises: applying the modifying composition onto the fibrous base in the form of organic nonwoven synthetic polymeric fabric, wherein said modifying composition comprises the particles of the aluminum-based material, hydrolysis thereof results to formation and fixation of the aluminum hydroxide particles to the base fibers. A method of fluid filtration is carried out using the filter material as a non-woven organic synthetic polymeric fabric, to the fibers of which the aluminum hydroxide particles are fixed.

Owner:INST OF STRENGTH PHYSICS & MATERIALS SCIENC

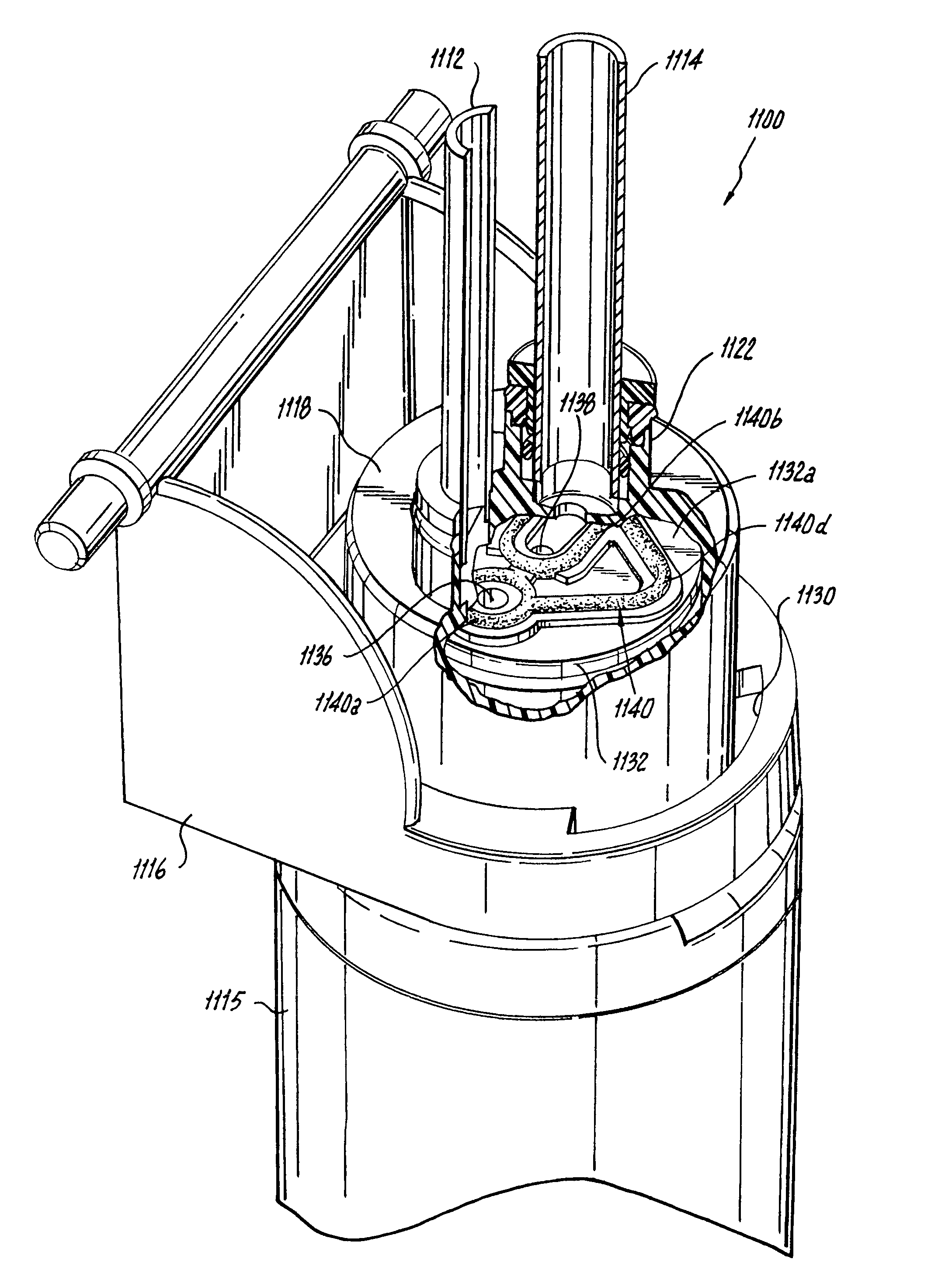

Rotary valve assembly for fluid filtration system

A valve assembly is disclosed for use in conjunction with a replaceable filter cartridge system. The valve assembly includes a head member having an interior valve chamber defining a central axis, and inlet and outlet passages extending parallel to and communicating with the interior valve chamber. The valve assembly further includes a valve member having an inlet path and an outlet path, adapted for rotation within the interior valve chamber of the head member between a filter position wherein the inlet path of the valve member is in communication with the inlet passage of the head member and a bypass position wherein the inlet path of the valve member is out of communication with the inlet passage of the head member. The valve assembly further includes a seal member seated in an upper surface of the valve member and positioned to seal against an opposing surface of the interior valve chamber. The seal member sealingly isolates untreated and treated fluid streams flowing through the inlet and outlet paths of the valve member, respectively, when the valve member is in the filter position, and sealingly isolates the inlet and outlet passages of the head member from the atmosphere when the valve member is in the bypass position to permit fluid to flow therebetween.

Owner:3M INNOVATIVE PROPERTIES CO

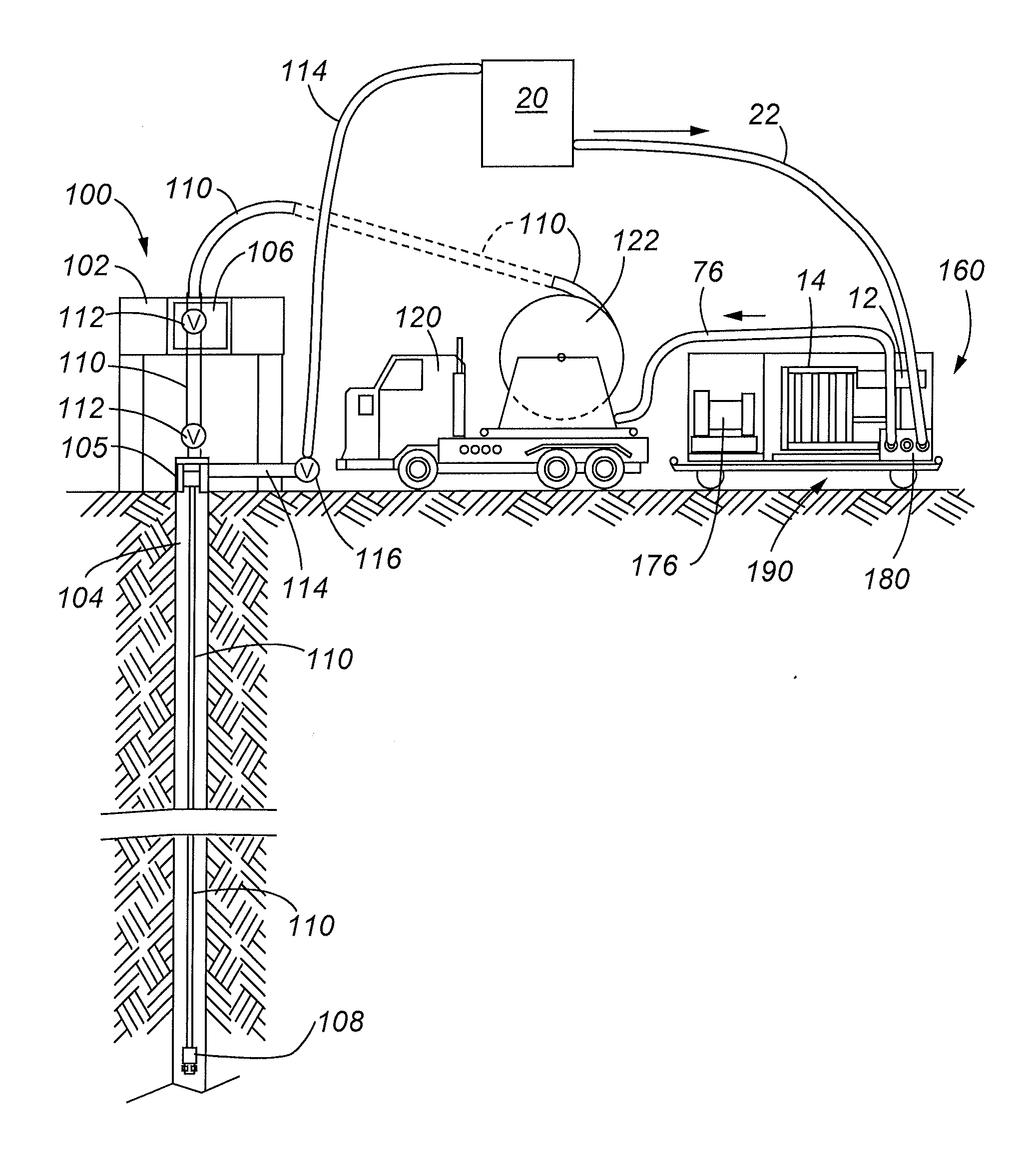

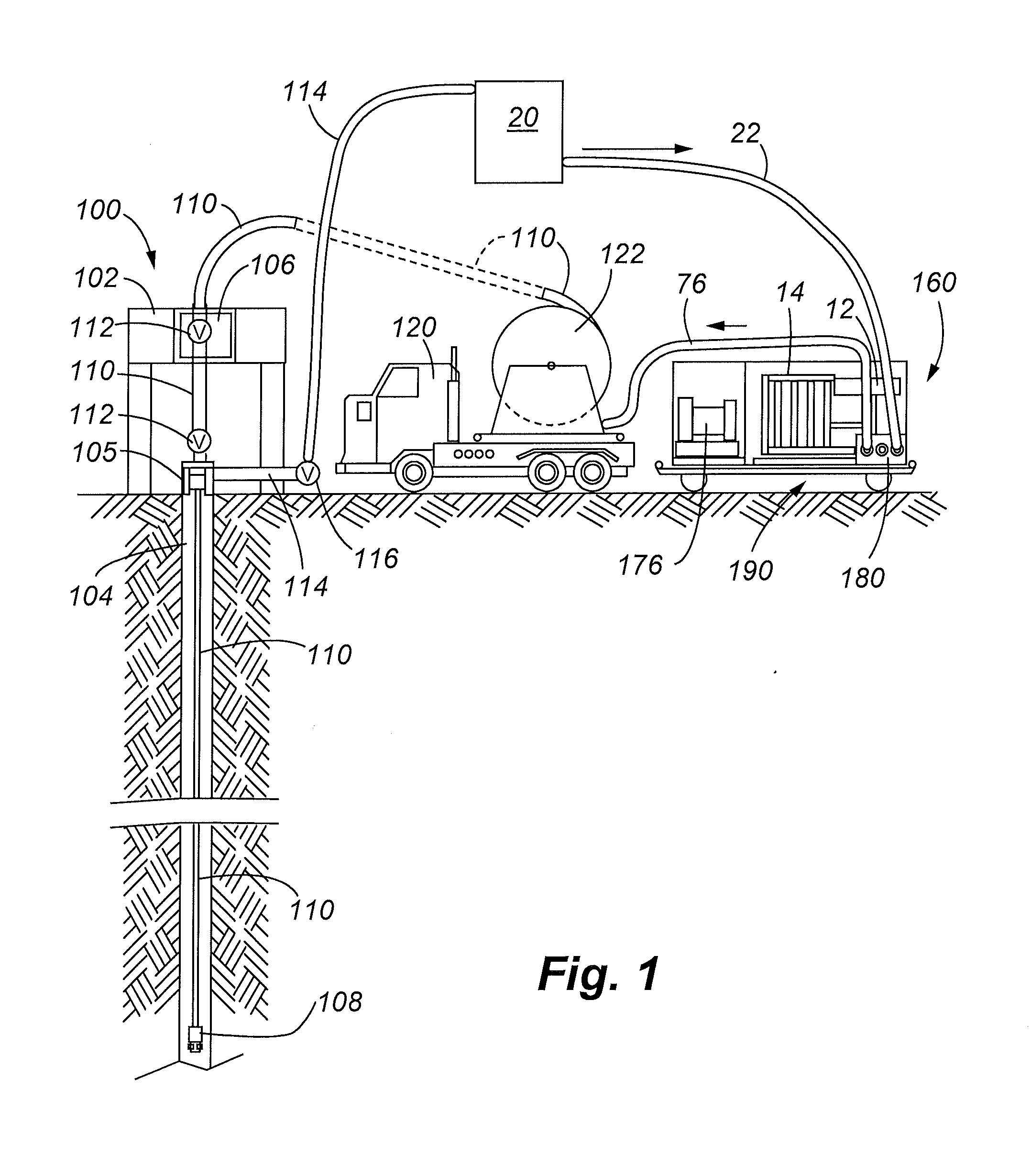

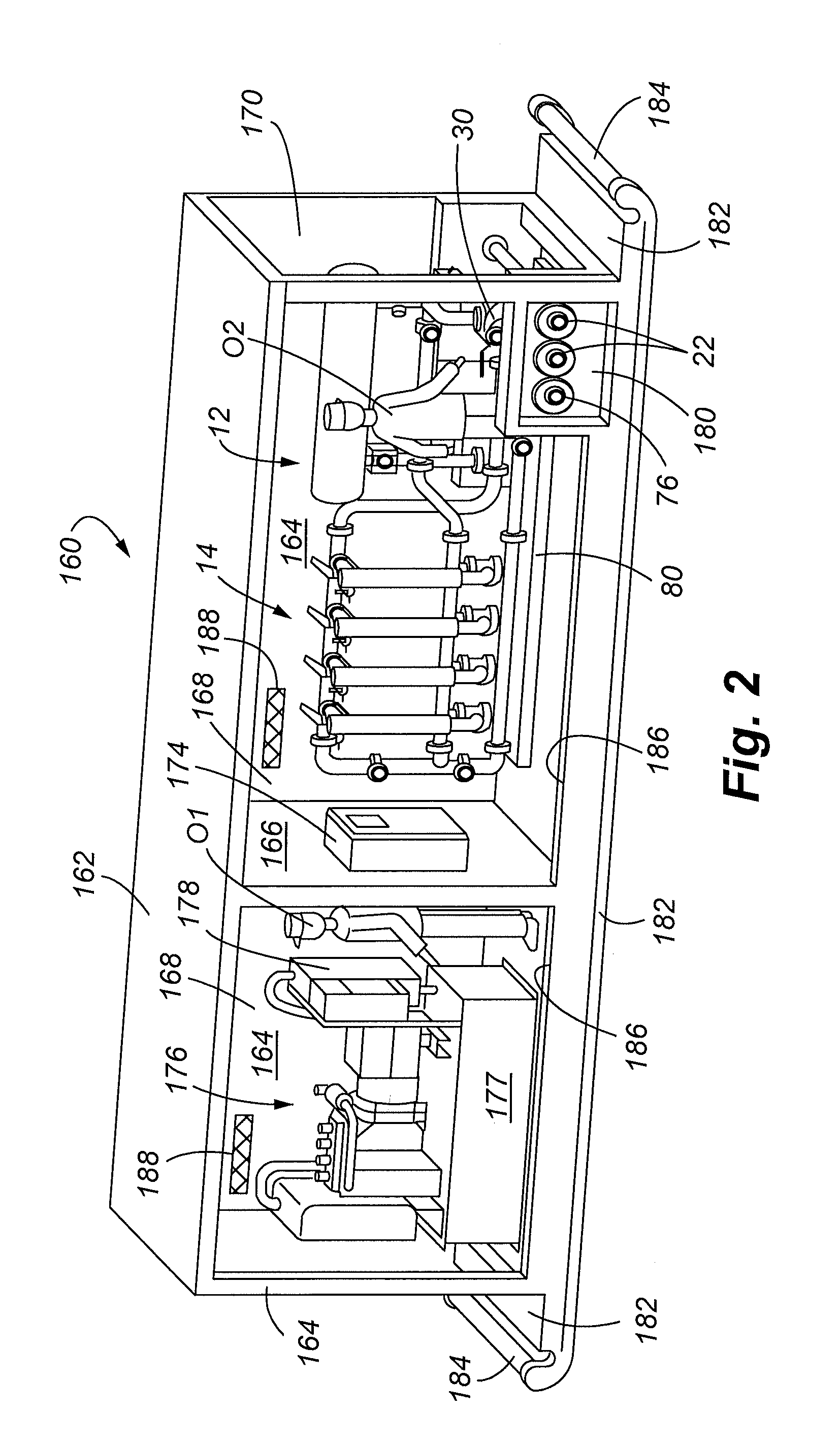

Integrated fluid filtration and recirculation system and method

InactiveUS20110030951A1Save amountImprove economyCleaning apparatusSettling tanks feed/dischargeProcess engineeringFluid filtration

An integrated fluid filtration and recirculation system and method are provided for re-circulating and filtering fluid that is used in well cleaning operations. The system is incorporated within an enclosure, which is transportable, such as on a vehicle trailer. The system has power generation capability, thereby making the system capable of operating as a stand-alone unit. Chemicals may be infused into the filtered fluid from an integral chemical supply allowing the system to also function as a treatment facility for the fluid. The components of the system are arranged in a linear fashion that enables the system to maintain a minimum profile for transport upon a conventional trailer, yet the system provides enough room within the enclosure to allow operators to repair / inspect each of the system components. The enclosure may be climate controlled, and the enclosure may include removable panels for operation of the system in temperate conditions when climate control is unnecessary.

Owner:ENG FLUID SOLUTIONS

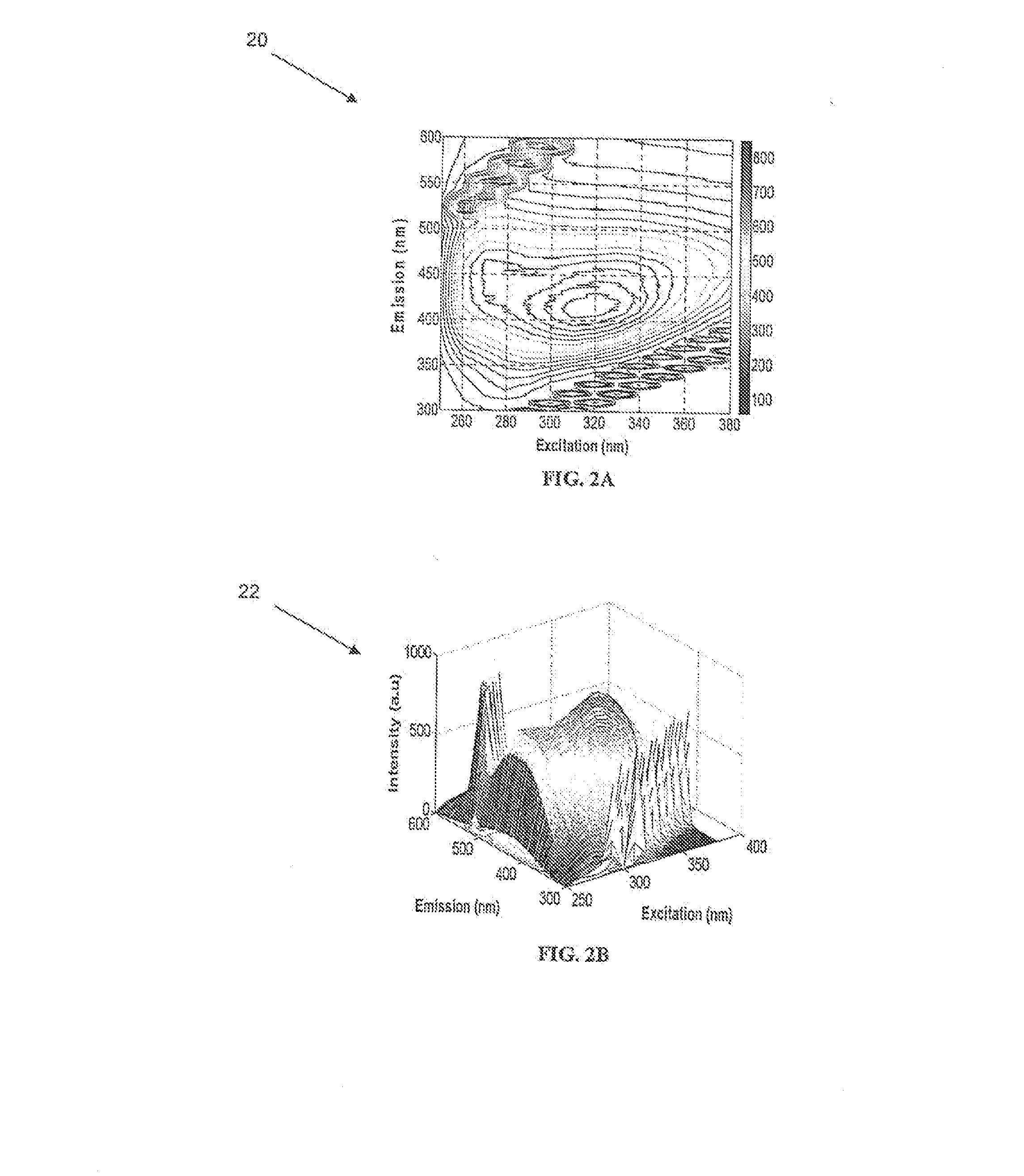

Method for fluorescence-based fouling forecasting and optimization in membrane filtration operations

InactiveUS20130075331A1Improve modeling accuracyImprove forecast accuracyMembranesMathematical modelsFluorescencePrincipal component analysis

The present invention provides a fluorescence-based modeling method that is capable of capturing the dynamic changes of different membrane foulant fractions that occur in fluid filtration operations. Principal component analysis is utilized to de-convolute spectral information captured within fluorescence EEMs into principal component scores that are related to different known foulant groups. The principal component scores are then used as states within a system of differential equations representing approximate mass balances of the main foulant groups to obtain a dynamic forecasting of membrane fouling. Based on the fouling dynamics forecasted by this modeling method, an optimization strategy can be developed for estimating the optimal membrane back-washing scenario for minimizing energy consumption while maximizing clean fluid production.

Owner:PEIRIS RAMILA HISHANTHA +3

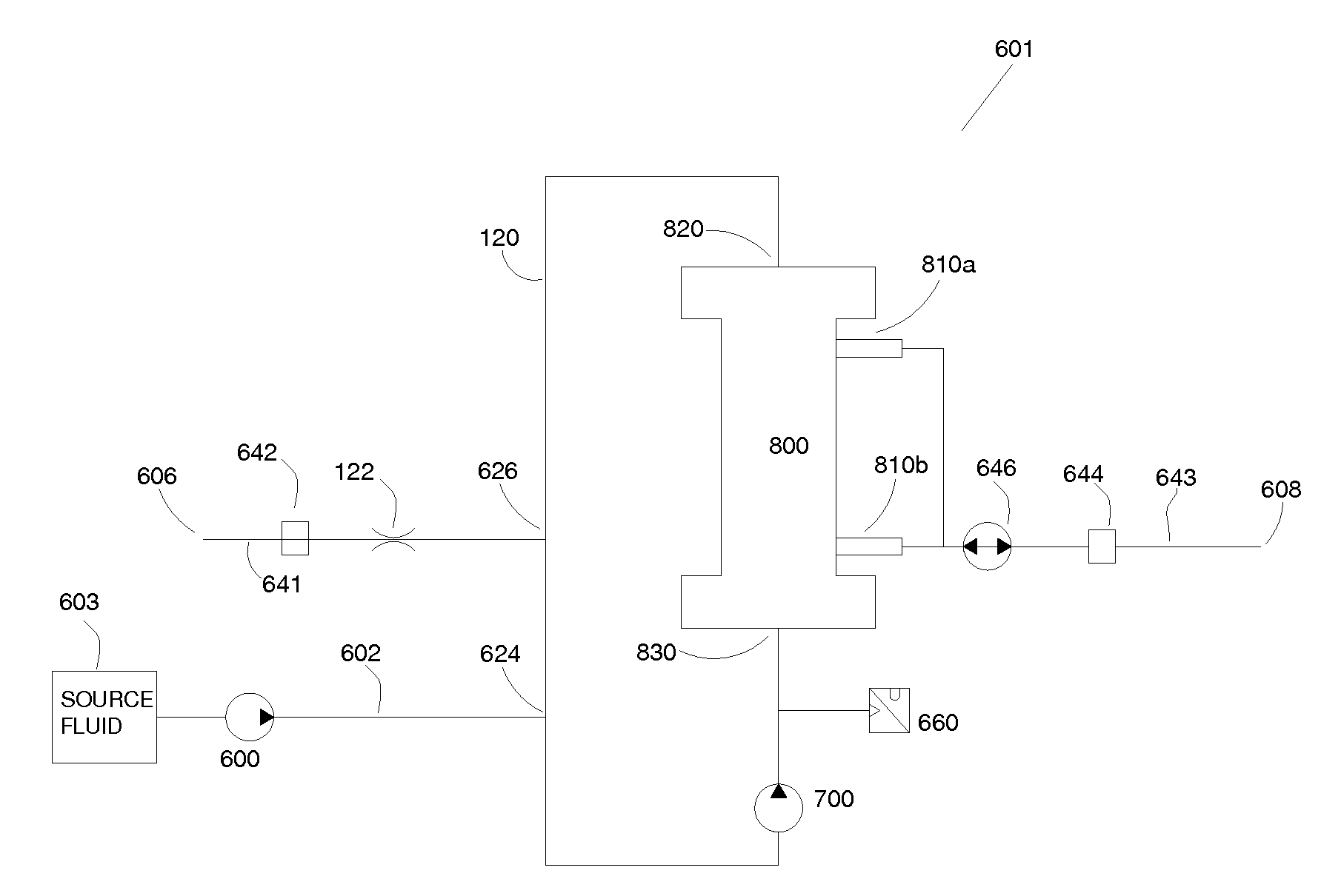

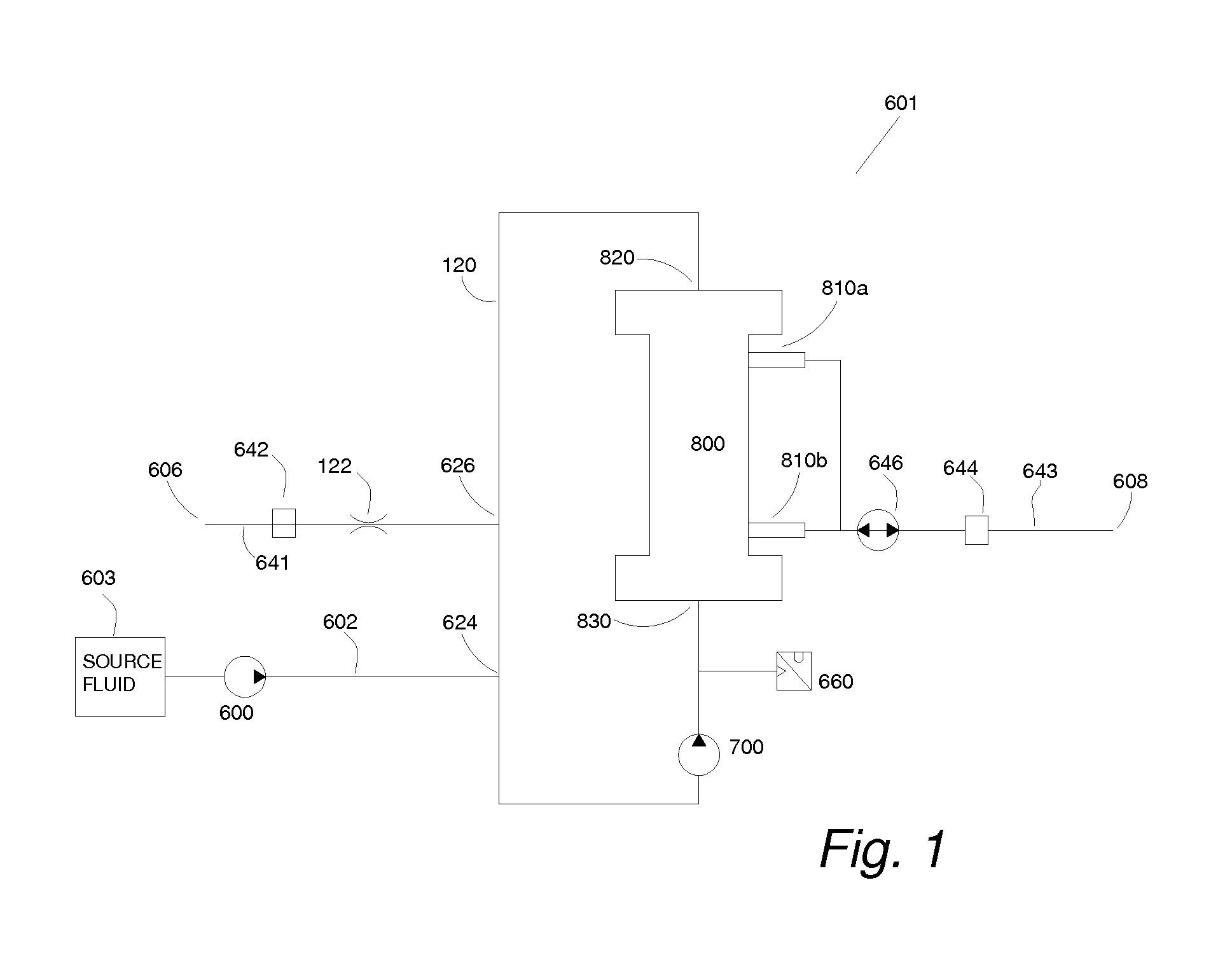

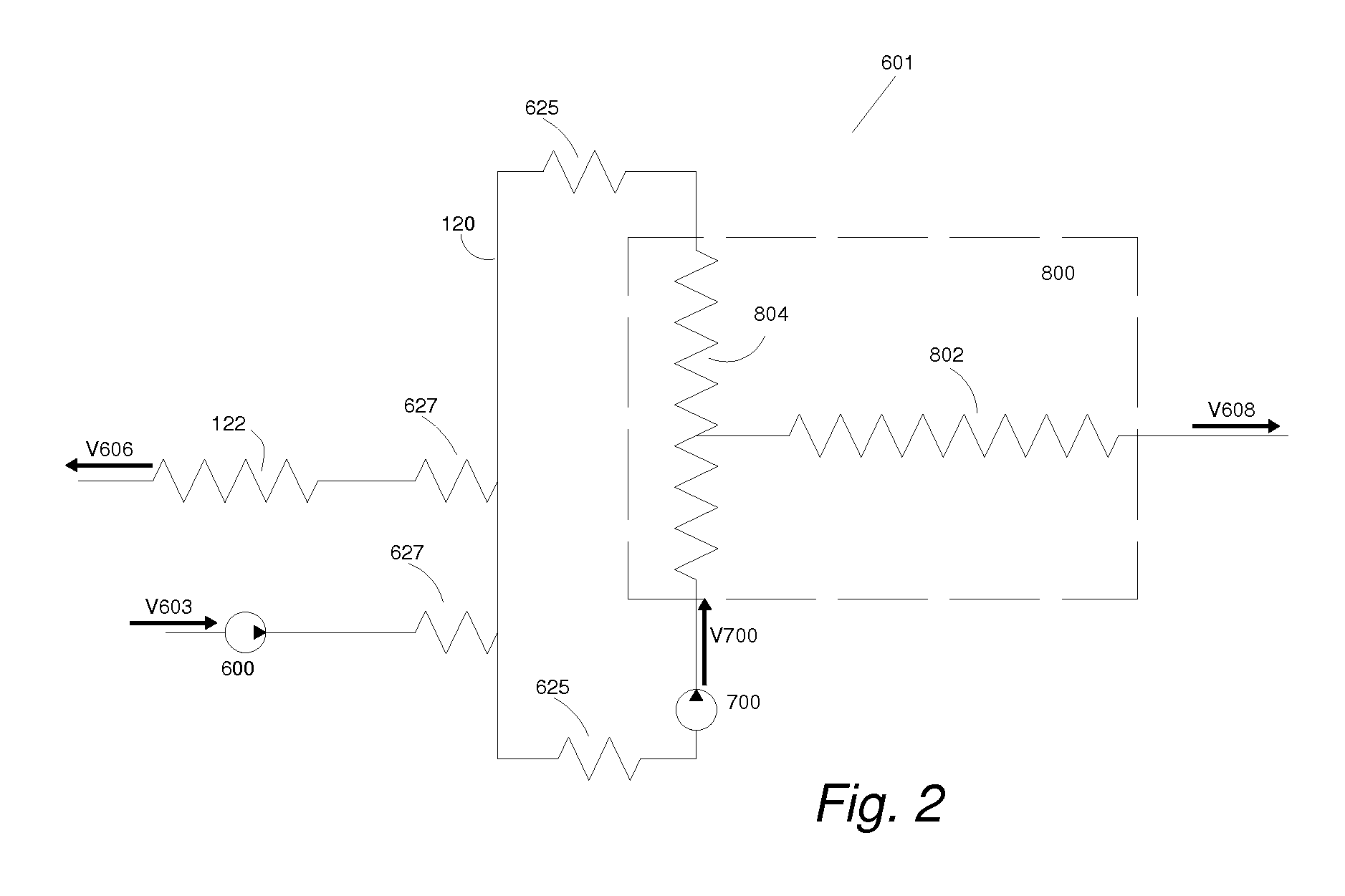

Recirculating fluid filtration system

ActiveUS20130248450A1Easy to operateKeep the pressureSemi-permeable membranesIon-exchanger regenerationHazardous substanceCross-flow filtration

A fluid filtration system comprising a cross-flow filter is arranged to permit a first pump to recirculate part of the retentate of the filter to the inlet of the cross-flow filter and a second pump to return part of the permeate to the inlet of the cross-flow filter. A third pump is configured supply source fluid to the inlet of the filter. The flow path between the second pump and the cross-flow filter inlet may include an adsorption filter that may selectively remove contaminants, toxins, or pathogens in the permeate. A controller may control the first, second and third pumps to provide predetermined flow ratios among the fluid flow paths of the system in order to achieve a desired filtration level. This system may be applicable to the removal of harmful substances from blood, by first separating the plasma from the blood and then removing harmful substances from the plasma.

Owner:DEKA PROD LLP

Filter pressure indicator

InactiveUS20080053879A1Easy to seeInhibit wearMachines/enginesCartridge filtersFilter mediaFluid filtration

A fluid filter having a fluid pressure sensor integral with a canister enclosing a filter medium, such that the fluid filter can be removed and replaced as a unit and further such that a new fluid pressure sensor is provided each time the fluid filter is replaced. The fluid filter can be readily adapted to many different fluid systems. In some embodiments, the fluid filter has two housing sections fastened together to enclose a filter medium. In some embodiments, the sensor includes an indicator that is easily visible outside of the housing. In some embodiments the indicator is responsive to a predetermined fluid pressure within the fluid filter.

Owner:HARRIS INTPROP LP

Portable recyclable fluid flushing method

InactiveUS20040244106A1Sufficiently lightweightSufficiently smallLarge containersBathing devicesEmergency SupplyRe introduction

A small-scale portable recyclable fluid flushing method used for flushing irritants or inflammatory agents from the skin or eyes, or for flushing infectious debris from wounds. The invention is either made reusable or disposable, and typically comprises: a. a single or plurally chambered container with at least one flushing fluid chamber filled with an uncontaminated flushing fluid appropriate for the intended flushing procedure; b. a first outflow fluid conduit, e.g., a channel or tube, which transports uncontaminated fluid from the container flushing fluid chamber to a pump or impeller housing; c. a manual or electrically operated pump or impeller for transporting uncontaminated fluid through to a second outflow fluid conduit to a dispersal outlet or nozzle; d. a fluid runoff collector surrounding the dispersal outlet, or a catch basin situated below the dispersal outlet, either of which acts as a sump to capture the contaminated runoff fluid from the flushing procedure; e. a first drain fluid conduit; f. an optional one-way elastomeric drain valve, e.g., a synthetic polymer duckbill valve, such as silicone rubber, or other form of check valve preceding the first drain fluid conduit to avoid reverse flow spillage; g. an appropriate sealed filter media unit suitably housed in line with the first drain fluid conduit for decontamination of the contaminated fluid run-off from the drain; h. a second drain fluid conduit to re-introduce the reclaimed decontaminated fluid from the sealed filter media back into the flushing fluid chamber for re-introduction to the fluid transport system; i. an optional second outflow fluid filter for final removal of any residual contaminants prior to re-introduction to the first outflow fluid conduit. The portable recyclable fluid flushing method of the invention provides a reliable emergency supply of flushing fluid for continuous flushing dispersal onto an affected body part. Typically, the filtering media used will have visual indicators to warn when the useful life of the media is ending.

Owner:CHESTERS THOMAS PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com