Hydrophobic associated matter and preparation method thereof, and clean diverting acid for fracturing acidizing of heterogeneous carbonate reservoir, and preparation method thereof

A technology of hydrophobic association and diverting acid, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting the effect of deep reformation of acid fracturing, high mass transfer rate, poor retardation performance of acid solution, etc. Achieve the effects of uniform transformation, low emulsification, and low reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

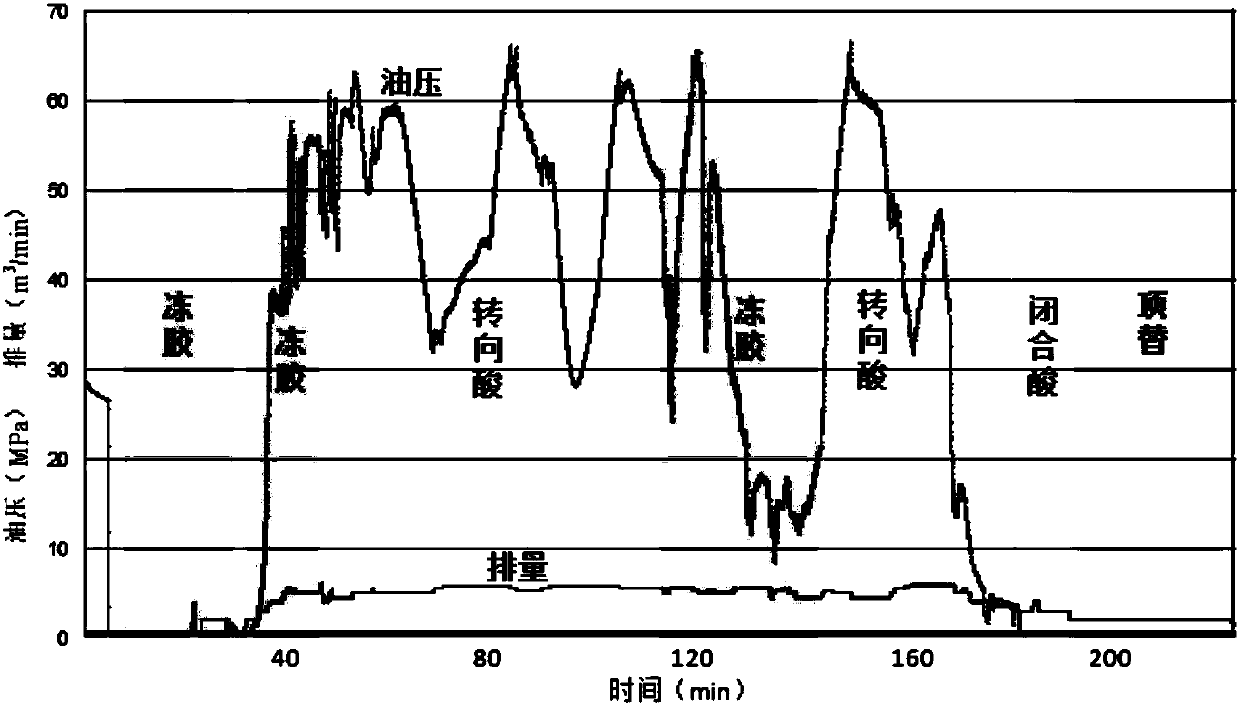

Method used

Image

Examples

Embodiment 1

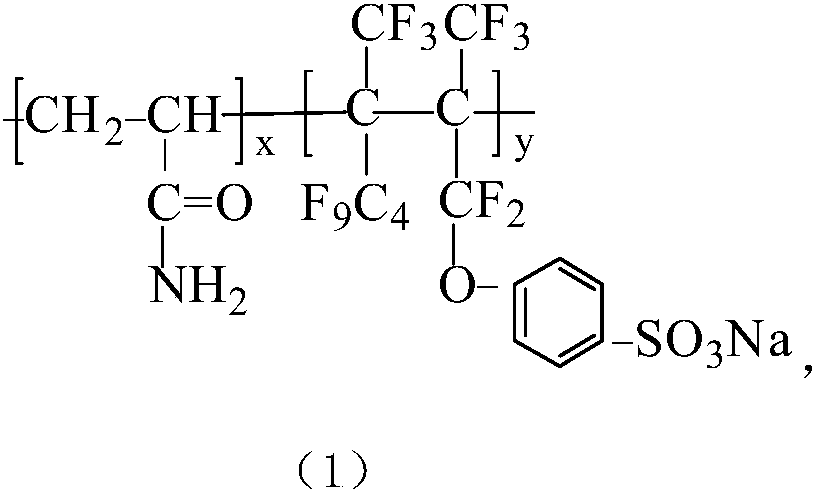

[0044] The hydrophobic association compound of this embodiment has a structure shown in the following formula:

[0045]

[0046] Where x:y=90:10, the number average molecular weight of the hydrophobic association is 1.1-1.2 million.

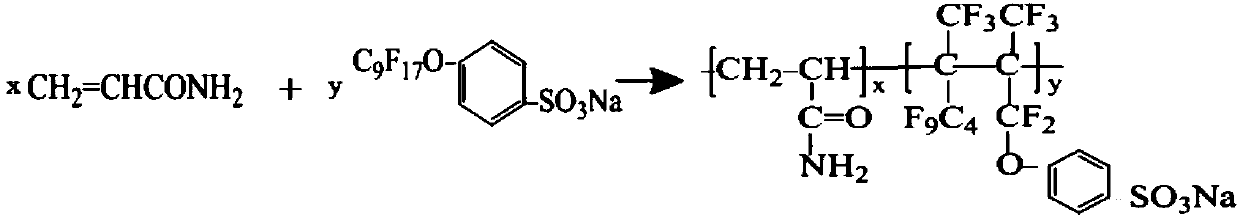

[0047] The preparation method of the hydrophobic association compound of this embodiment includes the following steps:

[0048] 1) Add 13.75g of acrylamide, 6.25g of 4-[(heptadefluorononenyl)oxy]benzenesulfonate sodium, 80g of deionized water into the reactor, stir to fully dissolve the raw materials, add an appropriate amount The pH of the NaOH solution adjustment system is 6;

[0049] 2) Then pour nitrogen into the reactor for 30 minutes to remove the oxygen in the reactor, then add 0.034g ammonium persulfate and 0.017g sodium bisulfite to the reactor, stir to fully dissolve it, and place the reactor at 30℃ In the constant temperature water bath, react for 5 hours under the protection of nitrogen atmosphere. After the reaction is completed, filter, pu...

Embodiment 2

[0053] The hydrophobic association compound of this embodiment has a structure shown in the following formula:

[0054]

[0055] Where x:y=95:5, the number average molecular weight of the hydrophobic association compound is 800-900,000.

[0056] The preparation method of the hydrophobic association compound of this embodiment includes the following steps:

[0057] 1) Add 17.19g of acrylamide, 7.81g of 4-[(heptafluorononenyl)oxy]benzenesulfonate sodium, 75g of deionized water into the reactor, stir to fully dissolve the raw materials, add an appropriate amount The pH of the NaOH solution adjustment system is 6;

[0058] 2) Then pour nitrogen into the reactor for 30 minutes to remove the oxygen in the reactor, then add 0.034g ammonium persulfate and 0.017g sodium bisulfite to the reactor, stir to fully dissolve it, and place the reactor at 30℃ In a constant temperature water bath, react for 5 hours under the protection of a nitrogen atmosphere. After the reaction is completed, filter, ...

Embodiment 3

[0062] The hydrophobic association compound of this embodiment has a structure shown in the following formula:

[0063]

[0064] Where x:y=92:8, the number average molecular weight of the hydrophobic association compound is 1 to 1.05 million.

[0065] The preparation method of the hydrophobic association compound of this embodiment includes the following steps:

[0066] 1) Add 15.25g of acrylamide, 7.5g of 4-[(heptafluorononenyl)oxy]benzenesulfonate sodium, 77.25g of deionized water into the reactor, stir to fully dissolve the raw materials, and add an appropriate amount Adjust the pH of the system with the NaOH solution to 6;

[0067] 2) Then pour nitrogen into the reactor for 30 minutes to remove oxygen in the reactor, then add 0.04g ammonium persulfate and 0.02g sodium bisulfite to the reactor, stir to fully dissolve it, and place the reactor at 30°C In the constant temperature water bath, react for 5 hours under the protection of nitrogen atmosphere. After the reaction is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com