Patents

Literature

556results about How to "Reduce fluid loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement compositions with improved fluid loss characteristics and methods of cementing in surface and subterranean applications

InactiveUS20050034864A1Reduce fluid lossReducing fluid lossDrilling compositionSealing/packingAcrylic acidMaterials science

An improved fluid loss control additive and methods of using such compositions in surface and subterranean applications are provided. A method of cementing in a subterranean formation, that comprises providing a cement composition that comprises a cement, water, and a fluid loss control additive, the fluid loss control additive comprising an acrylic acid copolymer derivative, an iron compound, and at least one of a hydratable polymer or a dispersant, placing the cement composition into the subterranean formation, and permitting the cement composition to set therein, is provided. Also provided are methods of reducing the fluid loss from a cement composition, cement compositions, and fluid loss control additives.

Owner:HALLIBURTON ENERGY SERVICES INC

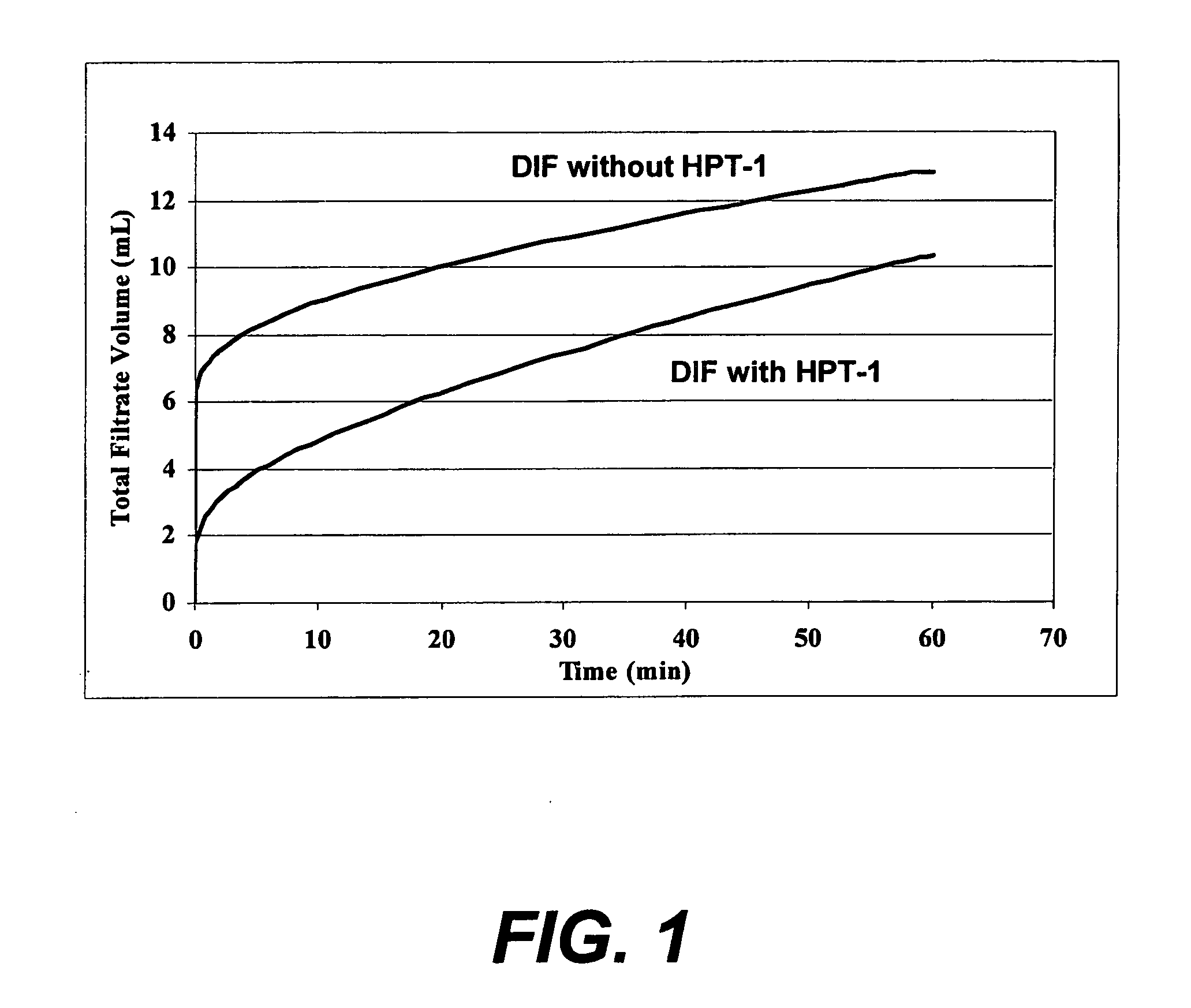

Drill-in fluids and associated methods

InactiveUS20080070805A1Reduce fluid lossIrreversible degradationLiquid/gas jet drillingDrilling compositionChemistryFilter cake

Of the many methods provided herein, the present invention provides a method comprising: providing a drill-in fluid that comprises an aqueous base fluid, a viscosifier, a relative permeability modifier fluid loss control additive, and a degradable bridging agent comprising a degradable material capable of undergoing an irreversible degradation downhole; placing the drill-in fluid in a subterranean formation; and allowing the relative permeability modifier fluid loss control additive to reduce fluid loss from the drill-in fluid to the subterranean formation. Another example is a method of degrading a filter cake in a subterranean formation comprising: providing a filter cake produced by a drill-in fluid that comprises an aqueous base fluid, a viscosifier, a relative permeability modifier fluid loss control additive, and a degradable bridging agent comprising a degradable material capable of undergoing an irreversible degradation downhole; and allowing the degradable bridging agent to degrade.

Owner:HALLIBURTON ENERGY SERVICES INC

Strong-inhibition anticaving drilling fluid and application thereof

InactiveCN105038737AReduce fluid lossAdjust the flow patternDrilling compositionOrganic chemistryPetroleum engineering

The invention discloses a strong-inhibition anticaving drilling fluid and application thereof. The strong-inhibition anticaving drilling fluid consists of 1000 parts of water, 20 to 60 parts of bentonite for drilling fluid, 5 to 20 parts of sodium carbonate, 5 to 20 parts of alkali, 10 to 20 parts of coating agent, 5 to 20 parts of flow pattern regulator, 5 to 20 parts of shale inhibitor, 10 to 30 parts of borehole stabilizer, 10 to 30 parts of plugging agent, 5 to 30 parts of lubricating agent, 5 to 40 parts of filtrate reducer, 1 to 10 parts of pH regulator, and a proper amount of salts and barite added according to the requirement. The strong-inhibition anticaving drilling fluid has the remarkable characteristics of properties of stabilizing a borehole, protecting an oil layer, improving the drilling speed, and preventing a balled bit and the like from approaching to oil-based drilling fluid.

Owner:北京中科天启油气技术有限公司

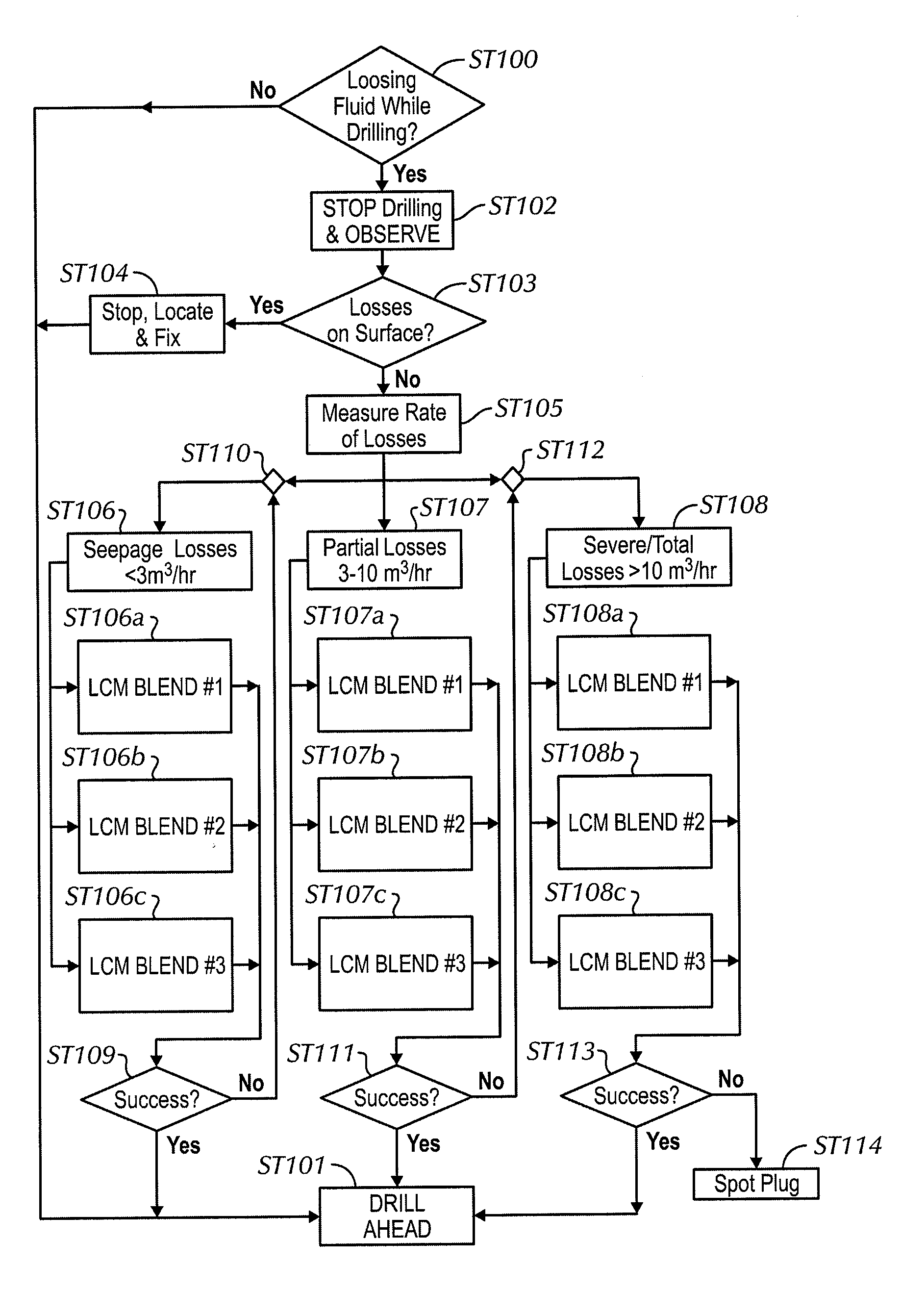

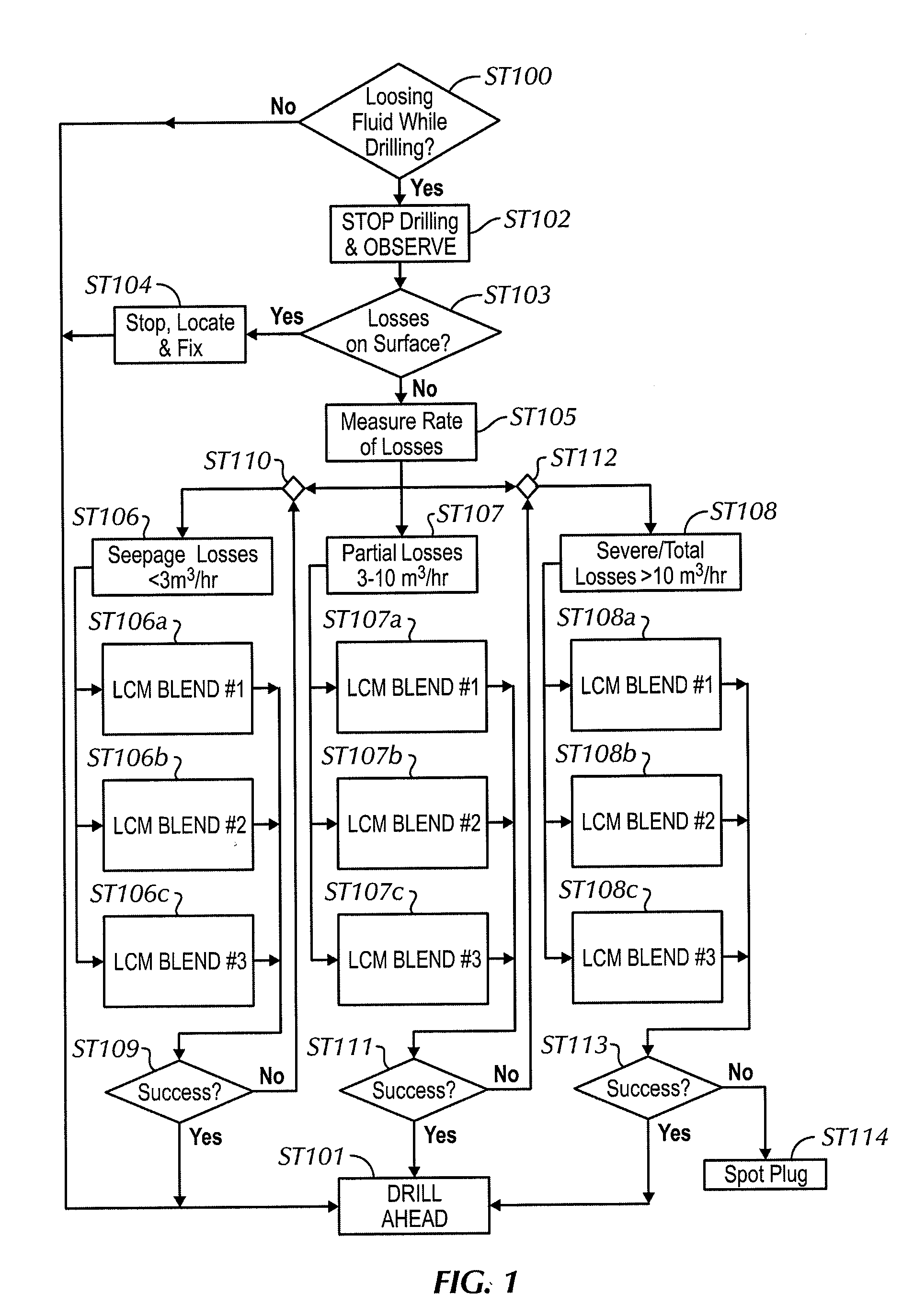

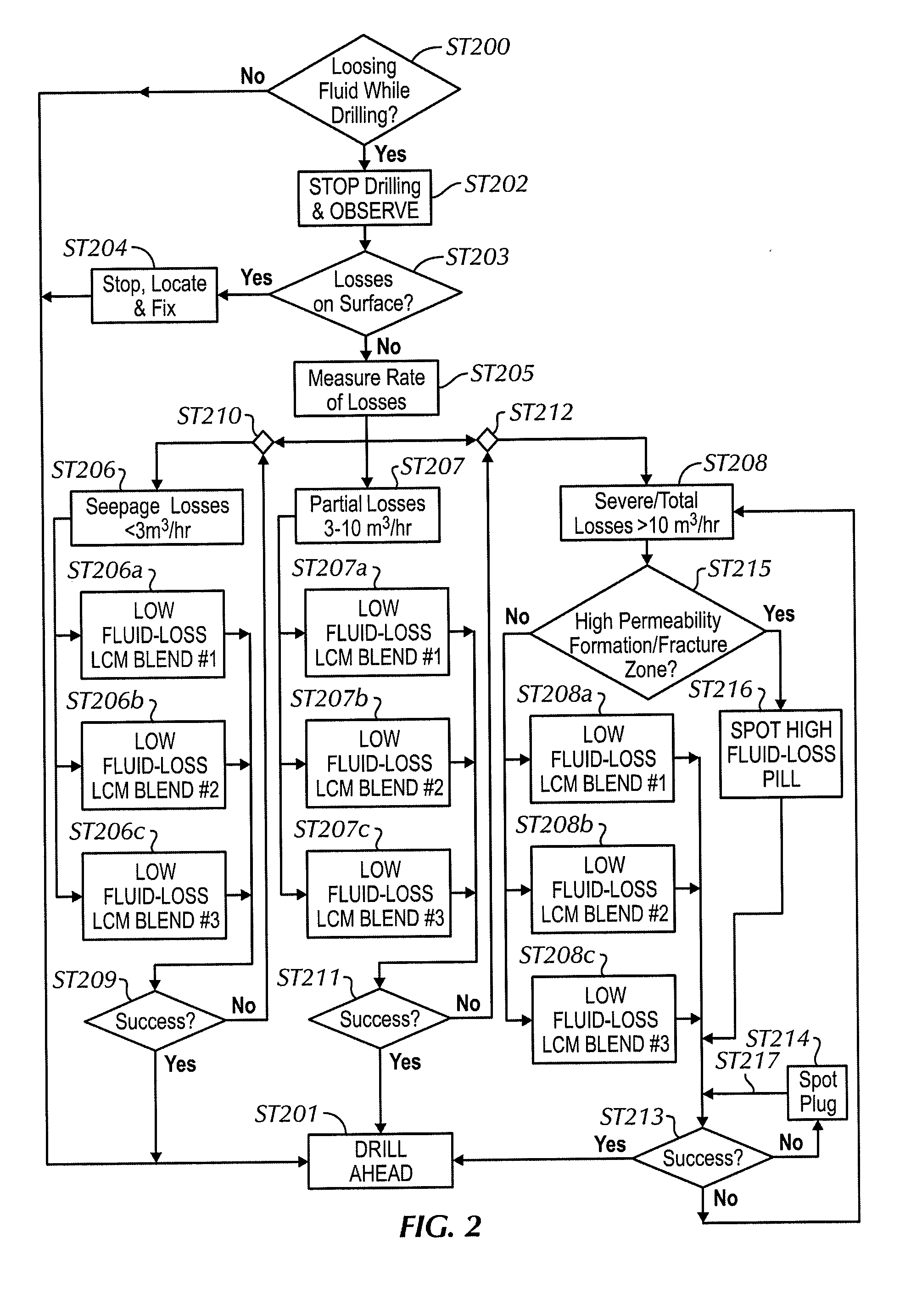

Methods of detecting, preventing, and remediating lost circulation

ActiveUS20090188718A1Reduce fluid lossElectric/magnetic detection for well-loggingSurveyLoss rateWell drilling

A method for planning a wellbore, the method including defining drilling data for drilling a segment of a planned wellbore and identifying a risk zone in the segment. Additionally, the method including determining an expected fluid loss for the risk zone and selecting a solution to reduce fluid loss in the risk zone. Furthermore, a method for treating drilling fluid loss at a drilling location, the method including calculating a drilling fluid loss rate at the drilling location, classifying the drilling fluid loss based on the drilling fluid loss rate, and selecting a solution based at least in part on the classifying.

Owner:MI

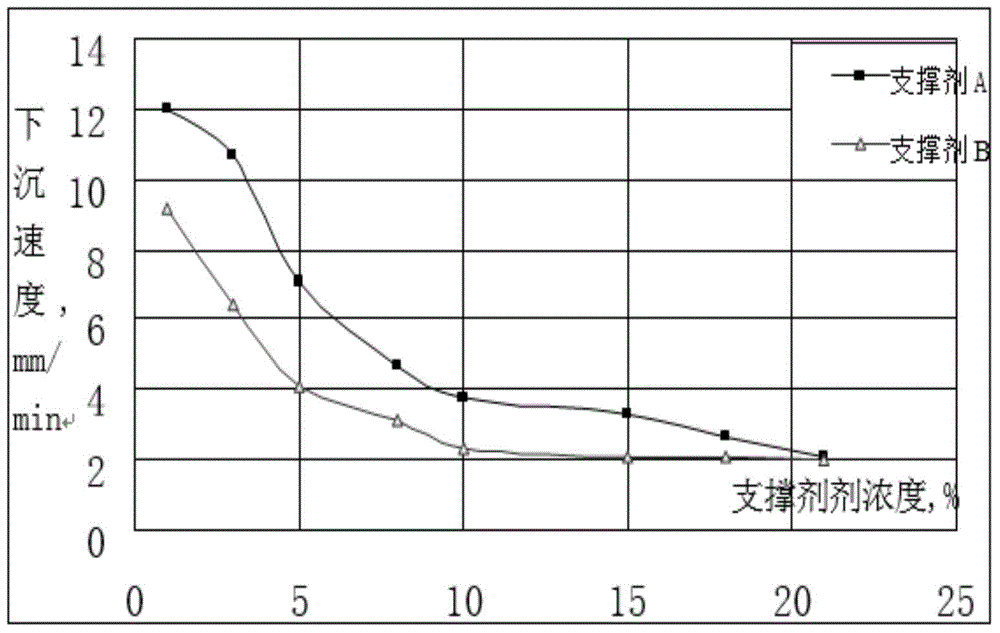

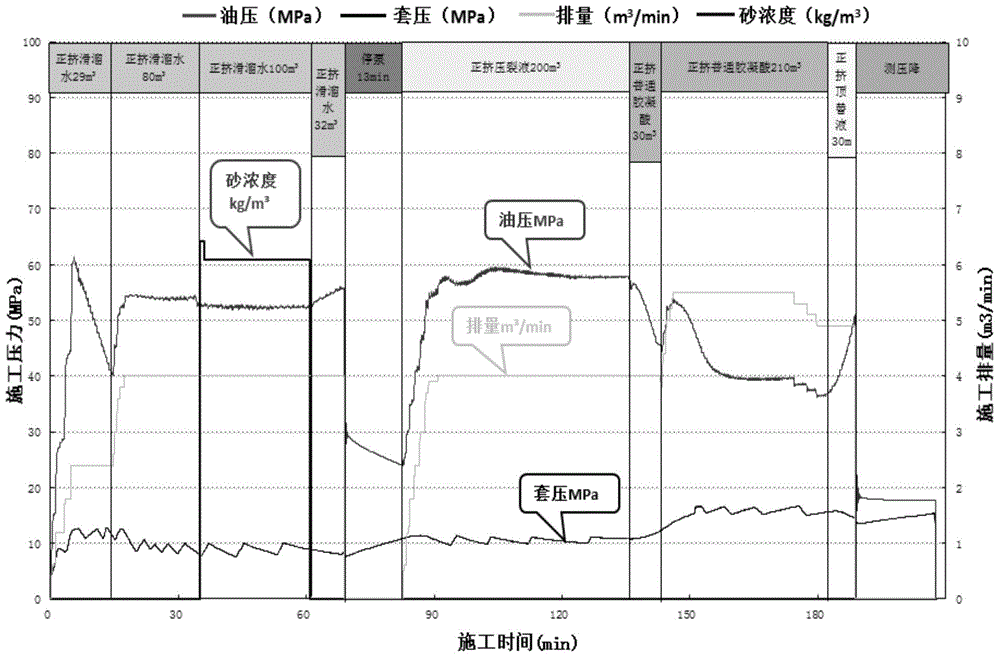

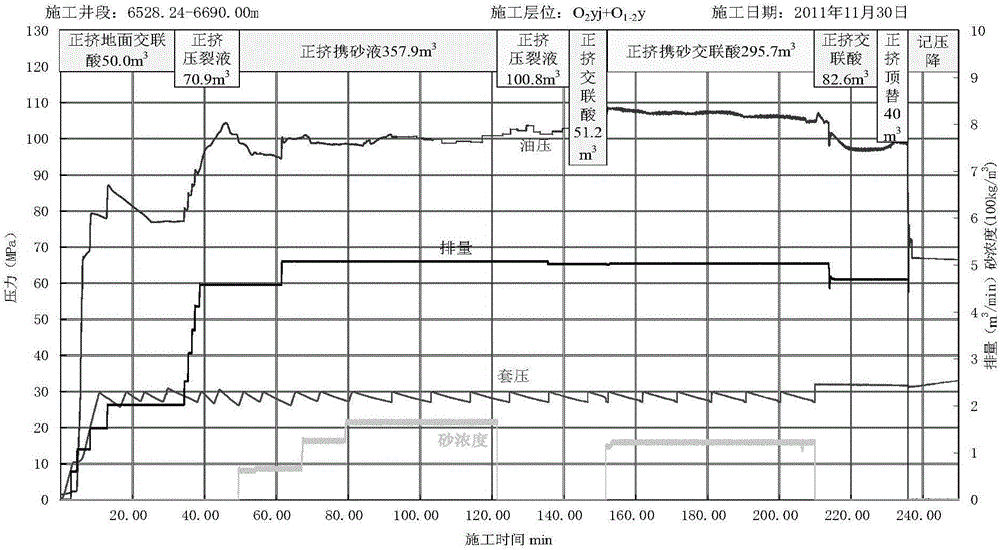

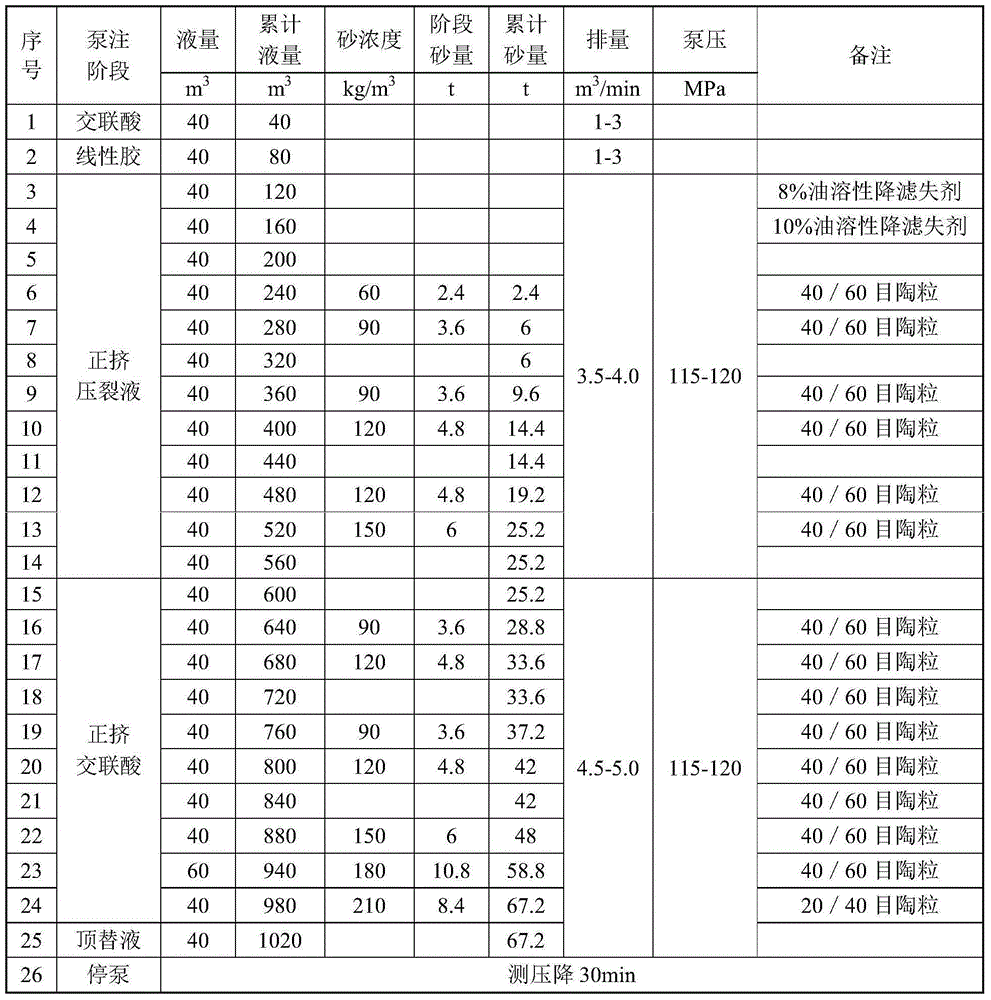

Pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to carbonate reservoir

InactiveCN104564002AReduce fluid lossIncrease the lengthFluid removalAcid fracturingFracturing fluid

The invention relates to a pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to a carbonate reservoir. The method comprises the following work procedures that before the normal fracturing, low-viscosity slickwater is adopted for fracture making, and the initial fracture height is controlled; then, after the slickwater enters the stratum in a way of carrying support agent sand, the pumping stop is adopted for prompting the support agent sand to be settled near a fracture opening, so that each stage of support agent sand shields the back section in advance, a high-intensity artificial separation layer is formed, the stress state is changed, and the goal of effectively controlling the lower fracture height extending to prevent the communication with the lower part water body is achieved; low-viscosity fracturing fluid is injected for fracture making at a stable discharge capacity; after the fracturing fluid enters the stratum, acid liquid is injected for etching the stratum, and high-flow-guide capability artificial fractures are formed; after the acid liquid is extruded into the stratum, the pumping is stopped for measuring the pressure drop, and the construction is completed. The process has the advantages that the artificial separation layer can be formed, the fracture height vertical direction extending can be controlled, the stress state is changed, and the goals of effectively controlling the lower fracture height extending and preventing the communication with the lower part water body are achieved.

Owner:CHINA PETROLEUM & CHEM CORP

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

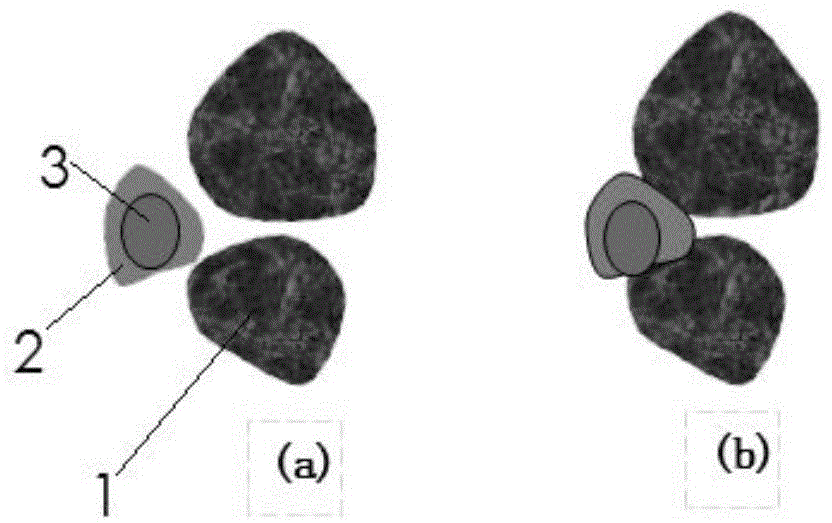

Elastic plugging agent

ActiveCN104559973AGood deformabilityImprove the blocking effectDrilling compositionSolid particleMonomer

The invention relates to an elastic plugging agent which comprises the following components in parts by weight: 1 part of elastic temporary plugging particles and 0.1-10 parts of a bridging agent, wherein the elastic temporary plugging particles are prepared in such a way that a monomer, an initiating agent, a dispersing agent, rigid solid particles and elastic gel are added into water, stirred uniformly, heated to 60-150 DEG C, and dried after reaction is finished. The elastic plugging agent provided by the invention plays a unidirectional plugging effect, and has favorable adaptability to holes with inlets in different shapes owing to the characteristic of variable elasticity.

Owner:东营市大用石油助剂有限责任公司

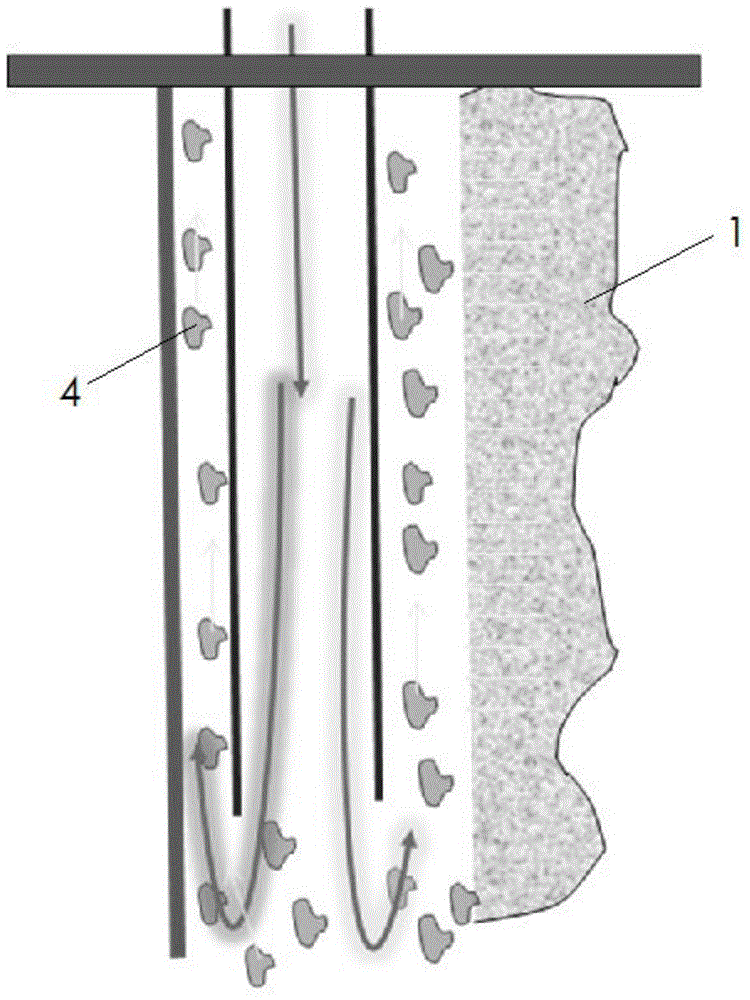

Follow-drilling plugging agent and its preparation method and use

The invention provides a leak preventer along with drilling and the method for its preparation, relating to the field of additive of boring fluid. Such leak preventer along with drilling contains: a) plant fiber without colloid or lignin, 100 weight shares; b) lime carbonate with calcium carbonate for at least 90 weight percent, 10-60 weight shares; c) oil-soluble resin of oil-soluble ratio no less than 95 weight percent and softening point 50-250 Deg. C, 3-30 weight shares. The leak preventer along with drilling is prepared by equably mixing the disintegrated ingredients which contains there substances above. It has a remarkable effect of leak prevention, which can be mixed with boring fluid to prevent leak while drilling, needing not stop drilling or stop laboratory sifter, improving the drilling speed and saving the drilling cost. And it also can release stoppage in acid solvent, oil solvent and negative pressure, and protect the reservoir. The leak preventer along with drilling is easy to spread, extensive sources of the material, low cost, and convenient technique.

Owner:CHINA PETROLEUM & CHEM CORP +1

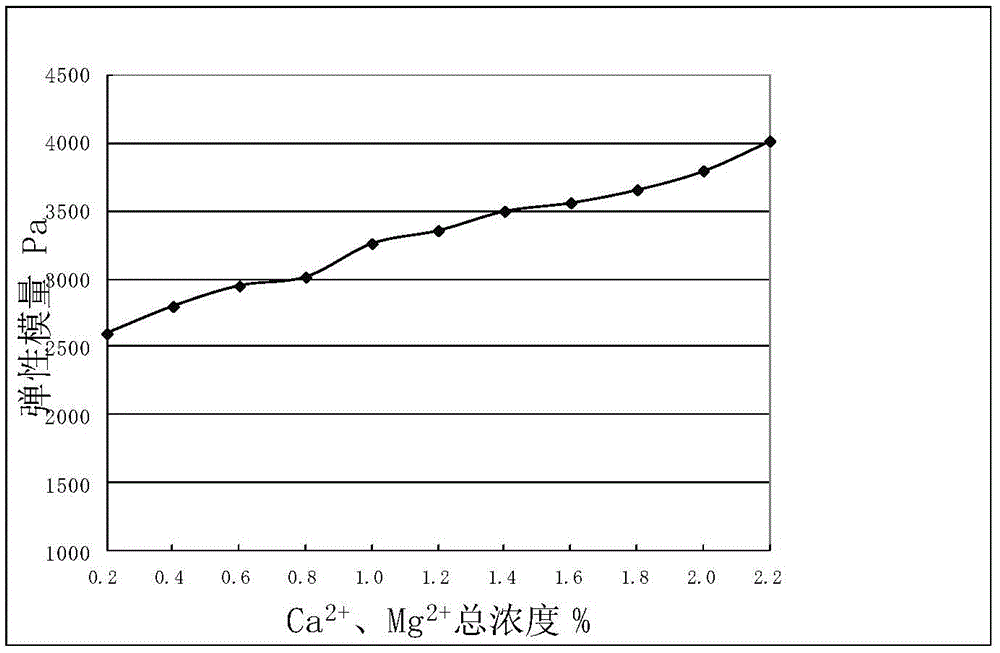

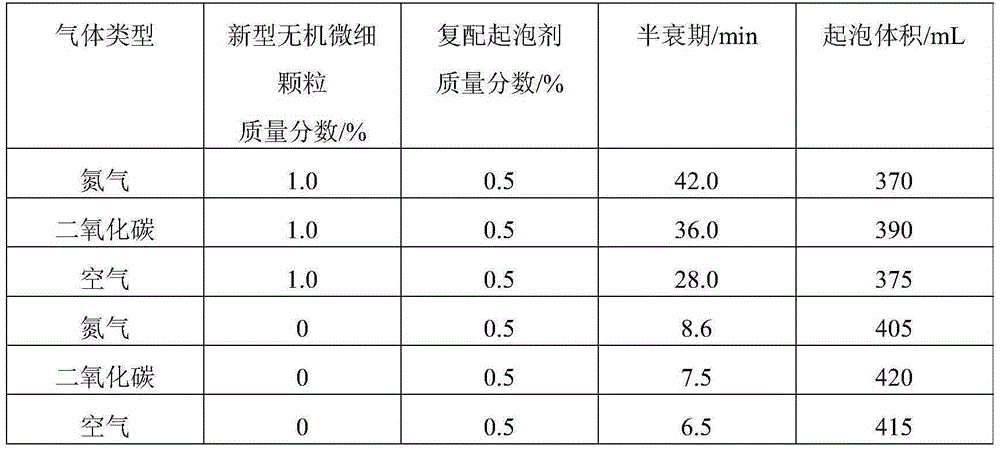

Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

ActiveCN105238380AFormation damage is smallImprove performanceDrilling compositionFoaming agentGas phase

The invention relates to a novel inorganic fine particle enhanced foam system for oil and gas fields, and a preparation method thereof. The enhanced foam system comprises a gas phase and a liquid phase; the gas phase is nitrogen, carbon dioxide or air; the liquid phase comprises 0.2-0.8wt% of a foaming agent, 0.5-2.0wt% of novel inorganic fine particles, and the balance of water; and the novel inorganic fine particles are fine particles with the particle size being not greater than 2.5[mu]m, trapped and screened from air. The invention also provides the preparation method of the foam system. The enhanced foam system can be used to benefit efficient exploitation of oil and gas resources, can change the novel inorganic fine particles into valuables, reduces pollution of the novel inorganic fine particles to air environment, and has the advantages of low cost of the raw materials, simple preparation process, low operation cost, good oil and gas yield increasing effect, and high economic benefit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

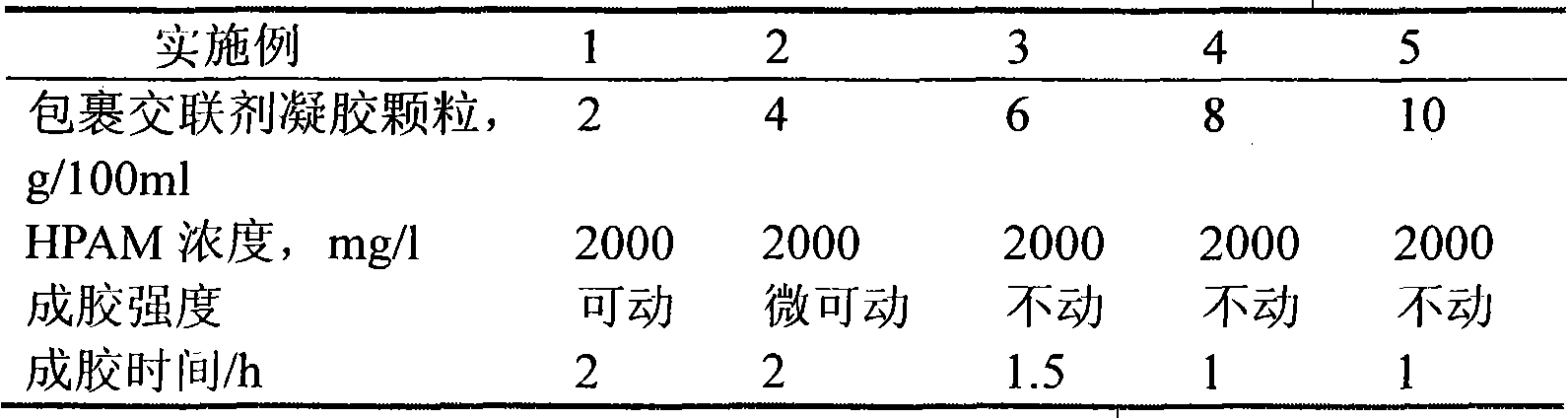

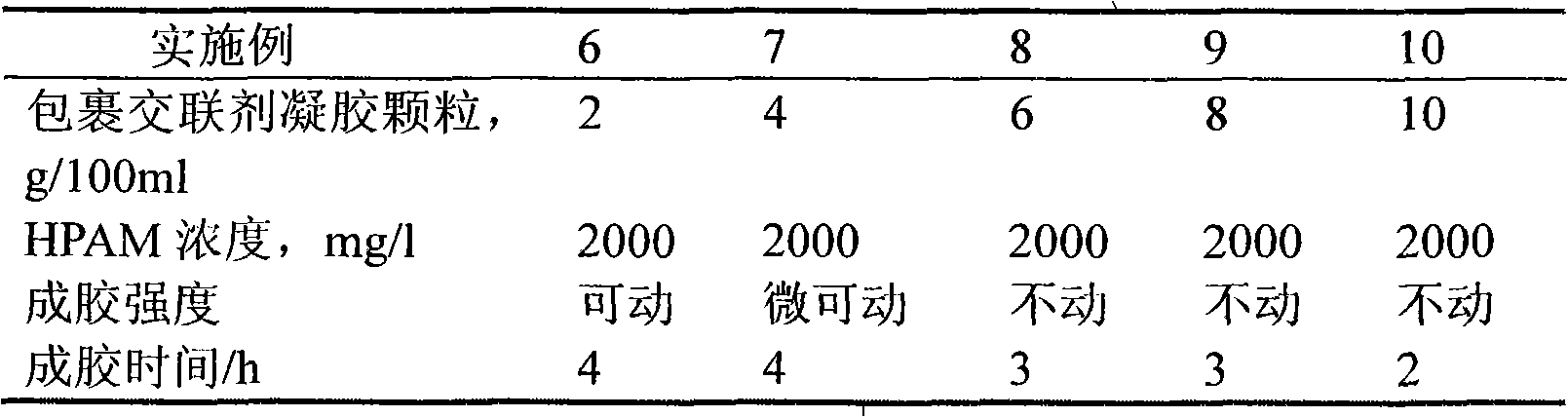

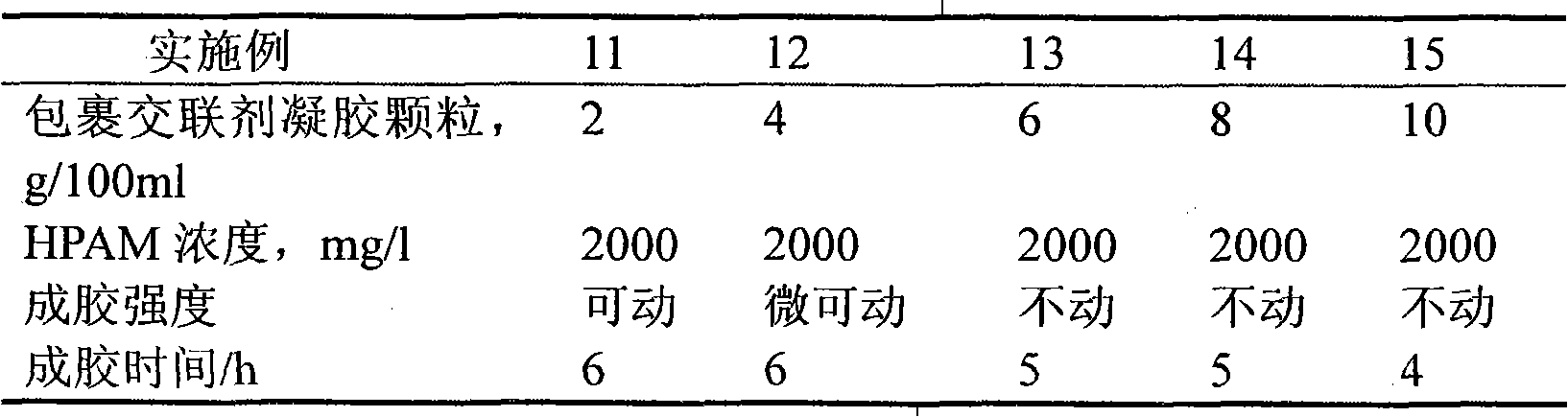

Controllable cross linked gel water blockage plugging material

InactiveCN101353569AImprove sealingSimple production processDrilling compositionCross-linkPolymer science

The invention relates to a controllable cross linking gel water shutoff and lost circulation material used for oil-gas fields, which can block off a fractured, vuggy or malignant leaking formation and increase the strength and stability of gel. The technical proposal is as follows: acrylamide of certain amount is added into a breaker containing deionized water, after the acrylamide dissolved, N, N-methylene-bisacrylamide and initiating agent are added, the mixture stands still for 1h at room temperature after 0.5h of gelation, therefore, lump gel product is obtained and finally becomes gel particles after granulation, parching and sieving; the gel particles are then soaked in the solution of chromium trichloride, cross linker is fully absorbed in the gel particles, and the obtained material is dried for spare; the product is then added into the solution of polyvinyl alcohol and the packaged gel particles are obtained after packaging 1-3 times and drying; finally the packaged gel particles containing the cross linker are added into the solution of the water soluble polymer HPAM for slow cross linking reaction, thus obtaining quiescent strong gel. The material is characterized by simple manufacturing process, low cost, little filtration loss and good leak tightness and stability.

Owner:SOUTHWEST PETROLEUM UNIV

Production-increasing method by water-plugging and fracturing

ActiveCN102134986AControl altitudePrevent upwardsFluid removalSealing/packingReservoir typeFracturing fluid

The invention discloses a production-increasing method by water-plugging and fracture, comprising the following steps: mixing 5 to 7 proportions of crack shielding agents with 100 proportions of clean water; injecting a mixture a into pressed cracks of a well layer under the temperature of 0 to 45 DEG C; shielding an aperture in a storage layer; mixing 5 to 10 proportions of bottom water oil reservoir plugging agent with 100 proportions of low-viscosity fracturing fluid; injecting the mixture generated in step c into cracks pressed in oil layer or gas layer under the temperature of 0 to 45 DEG C; plugging lower water layer after deposition of the mixture; carrying out sand-adding and fracturing operation on the oil layer or the gas layer at the upper part of the storage layer; closing a well and waiting for condensation then fishing the construction. In the method, the bottom water oil reservoir type or the bottom water gas reservoir type gas well bottom is plugged, the jumping-up of bottom water is prevented, simultaneously the crack height is controlled effectively, the extending-down of the crack is prevented, therefore, the aims of plugging the water layer is achieved and the single-well output of an oil well or a gas well is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

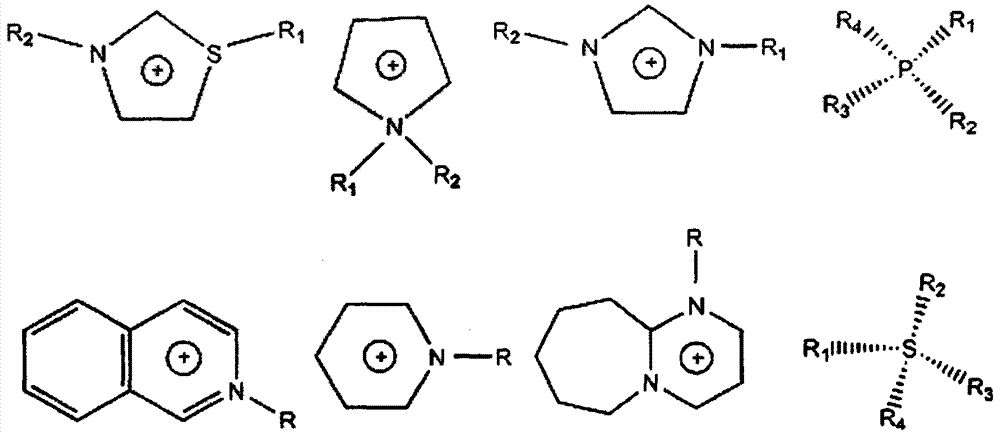

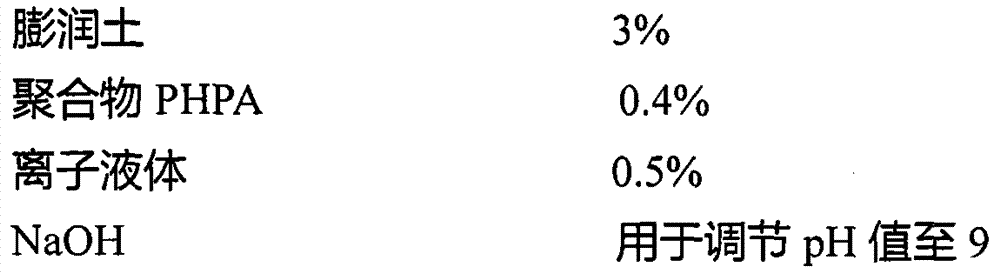

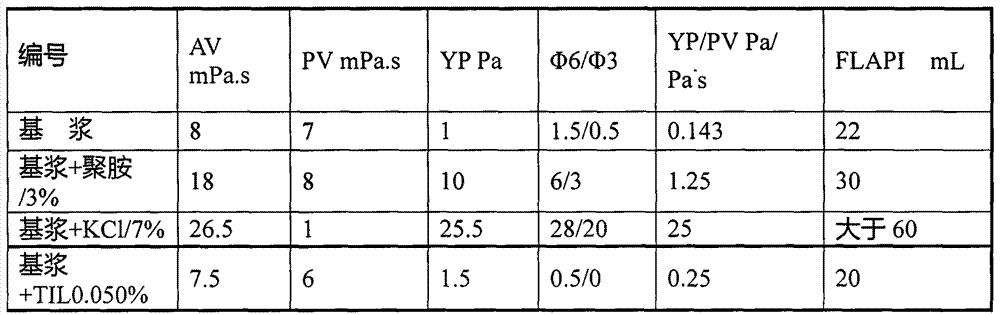

Drilling fluid and application of ionic liquid in drilling fluid

InactiveCN104497994AImprove high temperature inhibitionReduce fluid lossDrilling compositionWell drillingFiltration

The invention relates to a drilling fluid, which comprises heterocycle-containing ionic liquid. Compared with the current drilling fluid, the drilling fluid containing the ionic liquid can increase high temperature inhibition performance, and filtration rate is reduced, and system rheological property is not influenced.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High density fracturing liquid

The invention offers high density fracturing fluid formula used inorganic salt to improve water-base fracturing fluid density. Its feature is that its weight ratio is as follows: weight additive 4-50%, vegetable gum thickener 0.3-1.0%, cross linking agent 0.1-2.0%, pH value regulator 0.5-1.0%, cracking agent 0.002-0.3%, cleanup additive 0.05-0.5%, fungicide 0.03-0.2%, and water 30-73%. The density of the high density fracturing fluid is adjustable and can exceed 1.51g / cm3. It has good high temperature resistant, shearing resistant, and so on. Thus it can supply reliable assurance for abnormal high pressure and ultra-deep well exploration test oil and exploitation.

Owner:PETROCHINA CO LTD

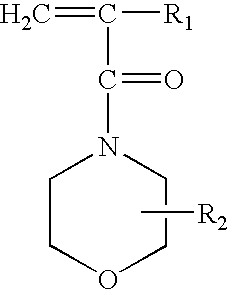

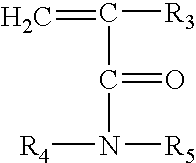

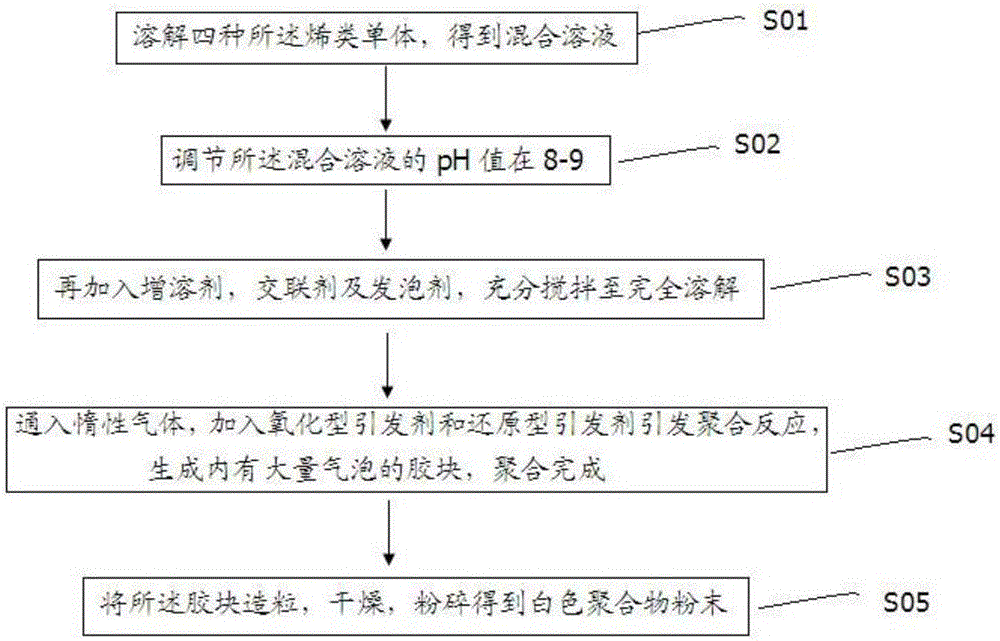

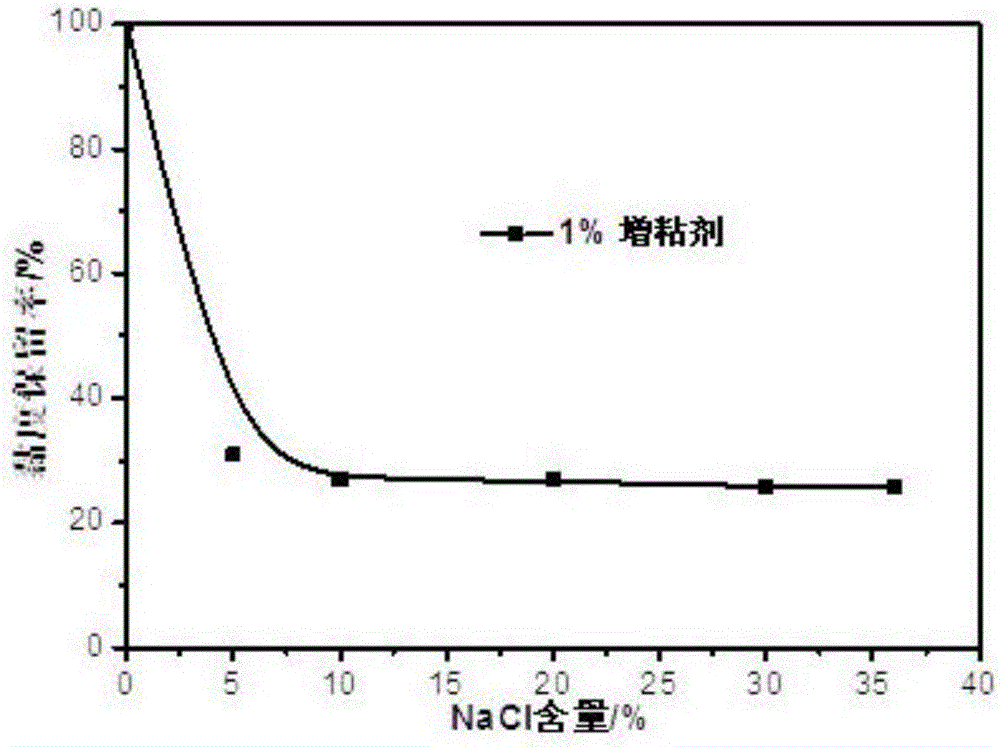

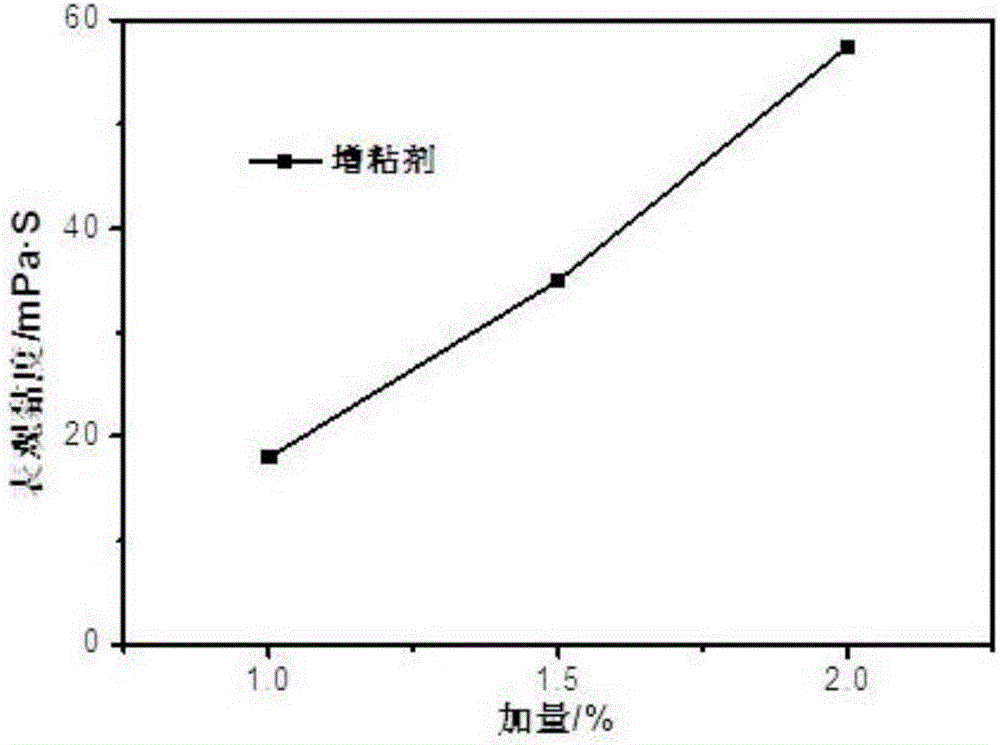

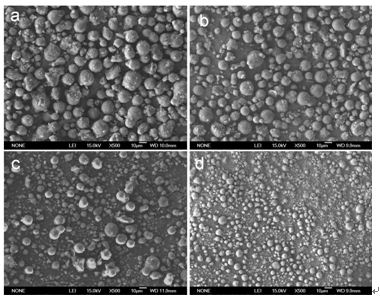

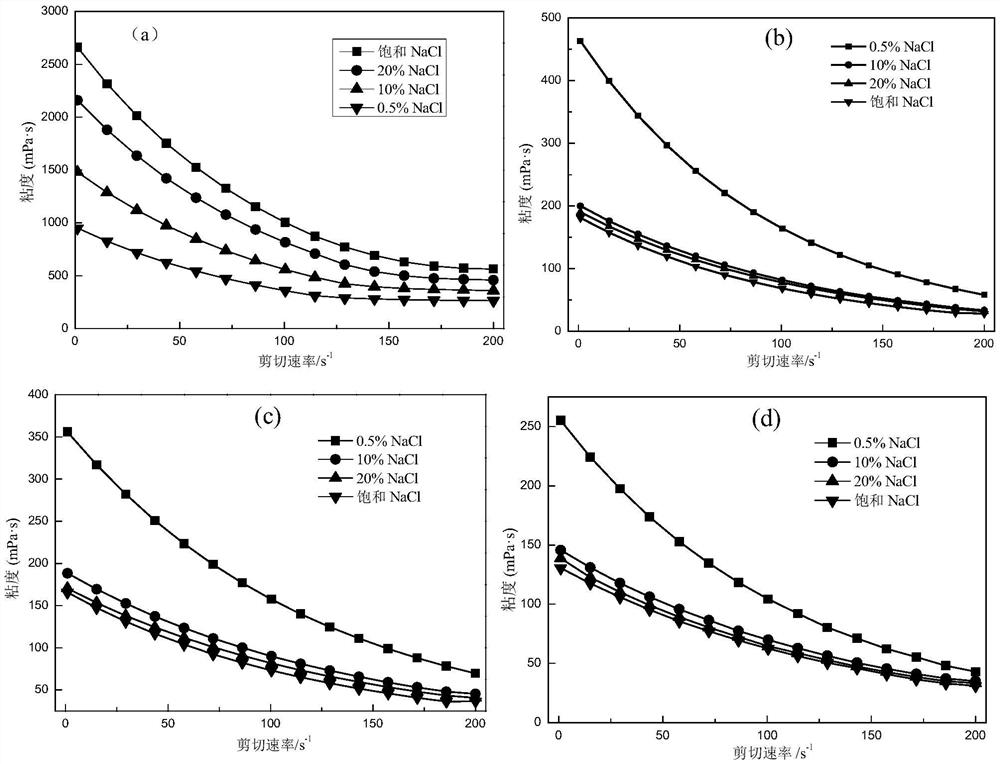

Tackifier for drilling fluid, and preparation method and application thereof

ActiveCN106243266AGood temperature and salt resistancePromote hydrationDrilling compositionAlkaneDouble bond

The invention provides a tackifier for a drilling fluid, and a preparation method and application thereof. The tackifier is a quadripolymer formed by polymerization of four alkene monomers, wherein the four alkene monomers are selected from a temperature-resistant salt-tolerant monomer, a hydrated monomer and an adsorptive monomer; the temperature-resistant salt-tolerant monomer is selected from an alkenyl sulfonic acid monomer; the hydrated monomer is selected from alkenyl carboxylic acid, alkenyl alkane ketone and double-bond-containing quaternary ammonium salt compounds; and the adsorptive monomer is selected from an alkenyl amide monomer. The tackifier provided by the invention can resist a high temperature of no less than 180 DEG C, is resistant to saturated salt, has remarkable tackifying effect, is low in toxicity and environmentally friendly, and can obviously improve the dehydration and wall building capability of the drilling fluid, thereby effectively reducing the dehydration. The invention solves the downhole complexity possibly caused by the fact that the drilling fluid system can not carry and suspend rock debris and thus can not clear boreholes in time due to reduced viscosity shearing force as a result of poor temperature resistance and salt tolerance of the tackifier in deep well, ultradeep well, horizontal well and extended reach well operations.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

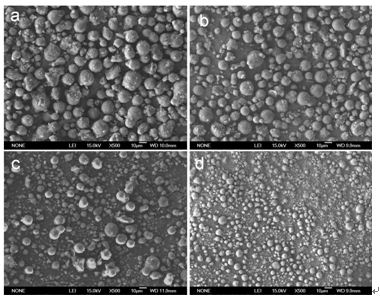

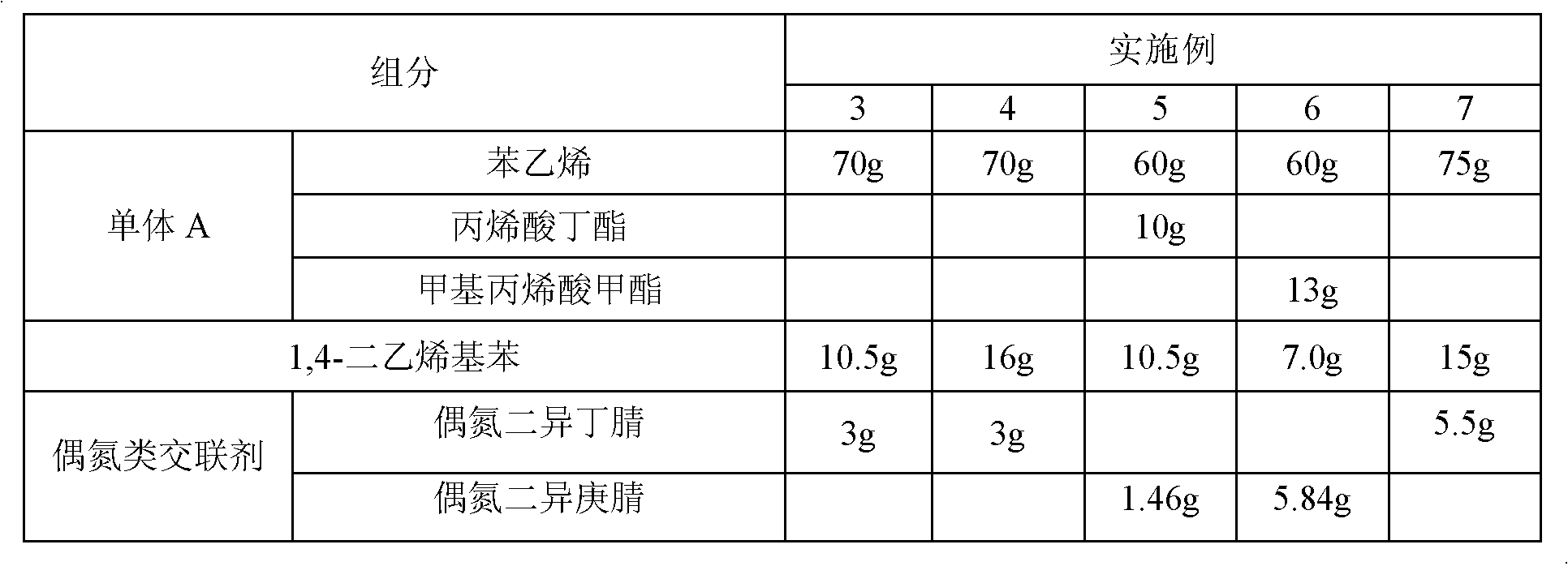

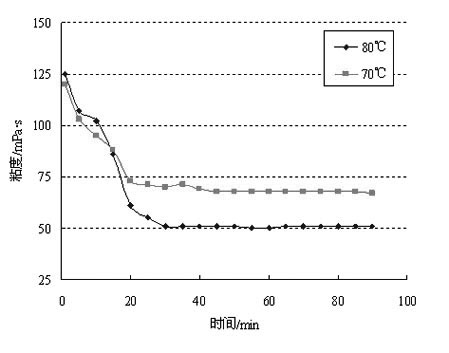

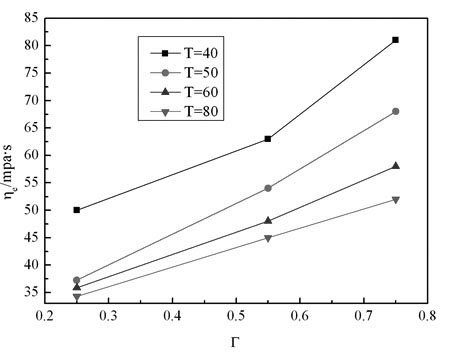

High-temperature-resistant while-drilling plugging agent and preparation method thereof

InactiveCN102603985AImprove temperature resistanceEnsure stabilityDrilling compositionTemperature resistancePollution

The invention relates to a high-temperature-resistant while-drilling plugging agent and a preparation method thereof and belongs to the technical field of oil field chemical drilling fluid treating agents. The method comprises the following steps: preparing a stable emulsion from an oil soluble monomer A, an oil soluble crosslinking agent B, an azo-type initiator, an organic hydroperoxide and water in the presence of an emulsifier, and polymerizing the stable emulsion to obtain a powder M; and swelling the powder M by use of a swelling agent, adding a water soluble monomer C, a water soluble crosslinking agent D and a reductive initiator into the swelled powder M, and polymerizing the mixture at the room temperature to obtain the high-temperature-resistant while-drilling plugging agent. The high-temperature-resistant while-drilling plugging agent is in a powder shape, has relatively high temperature resistance, can resist the temperature up to 180 DEG C, and can be used for performing while-drilling plugging on deep wells and supper deep wells. The while-drilling plugging agent can be used for quickly effectively plugging the permeability leak, the micro order crack and gap leak, avoiding the repeated leak, participating in the formation of a filter cake, keeping the stability of a well wall and obviously reducing the drilling filler loss and the pollution to a reservoir, has no influence on the rheological property of the drilling fluid and has the advantages of good compatibility with various drilling fluid systems and relatively good combination property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing fluid system of CO2 cleaning foam

The invention relates to a fracturing fluid system used in an oil and gas field, in particular to a fracturing fluid system of CO2 cleaning foam. The fracturing fluid system comprises the following components in percentage by weight: 0.3-0.8 percent of water-soluble hydrophobic association polymer, 0.25-0.55 percent of rheological auxiliary agent, 0.5-3.0 percent of clay stabilizer, 0.1-0.5 percent of foaming agent, 0.01-0.2 percent of gel breaker, 30.0-80.0 percent of liquid CO2 and the balance of water. Compared with the prior art, in the fracturing fluid system of the CO2 cleaning foam, a cross-linking agent is not needed, the foamability is good, the foam stability is high, the sand-carrying capability is strong, gel breaking is easy to control, no residue is generated after gel breaking, the superficial / interfacial tension of gel-breaking liquid is low, and the damage to the formation is less, and therefore, the fracturing fluid system can be used for fracturing modification of hypoisotonic, low-pressure and water-sensitive storage layers at the temperature of 60-140 DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

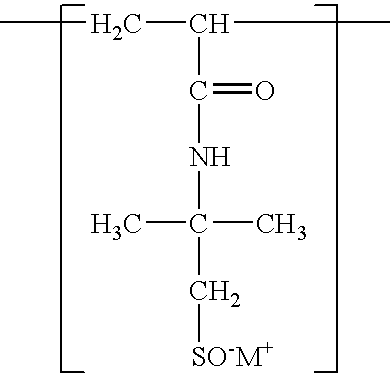

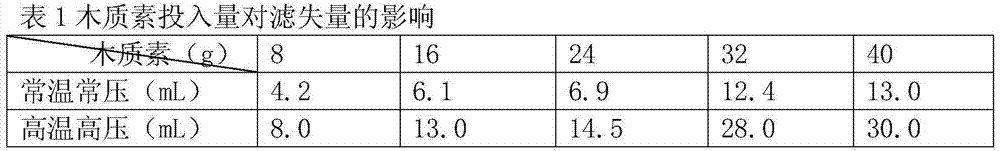

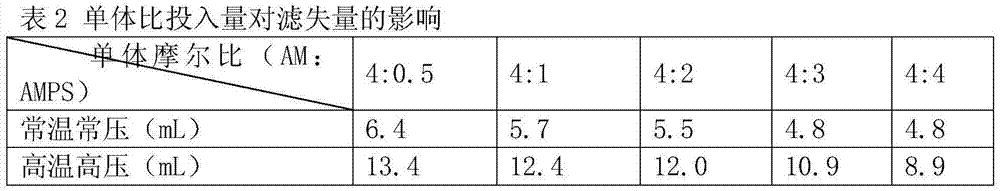

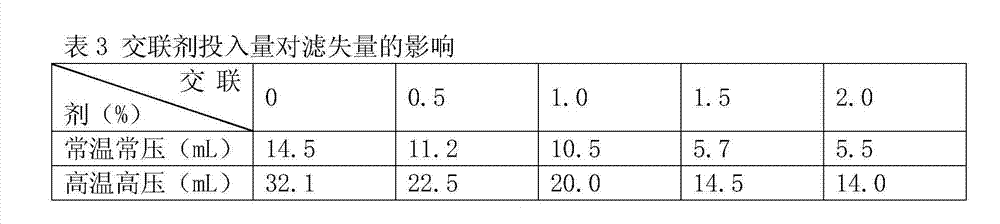

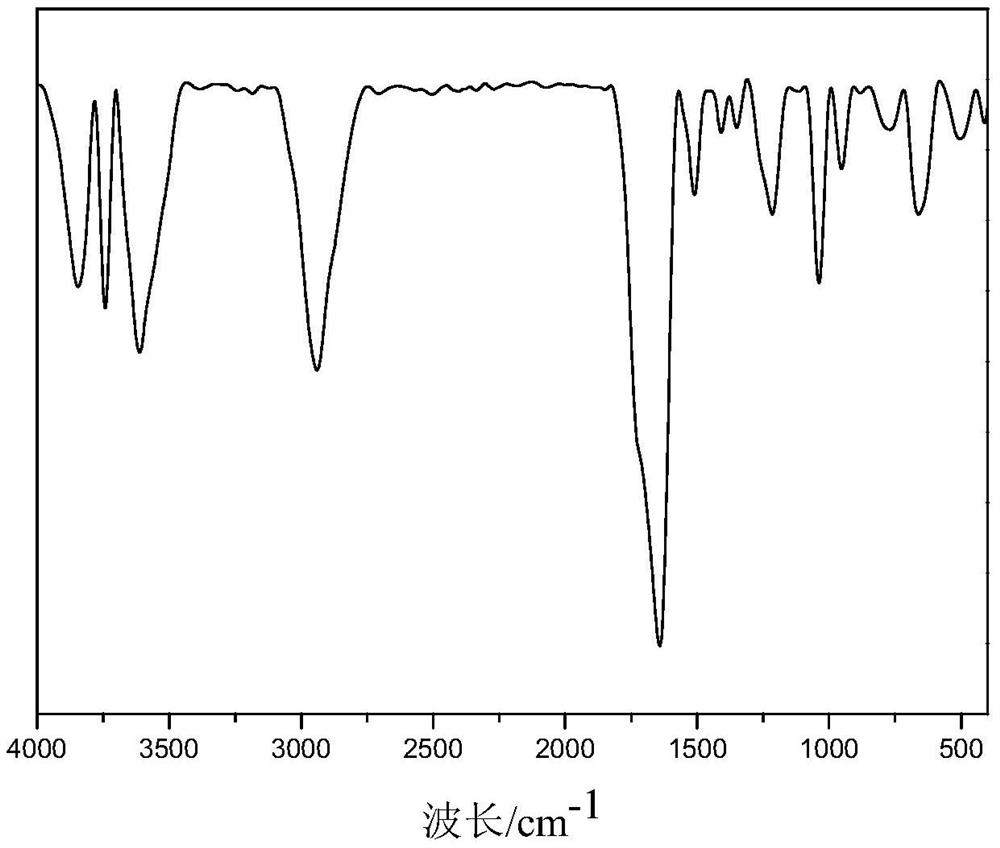

Filtrate loss reducer for high-temperature-resistant oil field drilling fluid and preparation method thereof

InactiveCN104119845AWide variety of sourcesLow costDrilling compositionSynthetic monomerPotassium peroxodisulfate

The invention relates to a filtrate loss reducer for high-temperature-resistant oil field drilling fluid, a preparation method of the filtrate loss reducer, and application of a treatment agent. A novel high-temperature-resistant filtrate loss reducer is synthesized by implementing the following steps: adopting lignin, acrylamide and 2-acrylamide-2-methyl propanesulfonate as synthetic monomers; enabling the synthetic monomers to perform graft copolymerization under the initiation of potassium peroxodisulfate, ammonium ferrous sulfate hexahydrate and hydrogen peroxide respectively; adding a crosslinking agent, namely N,N-methylene bisacrylamide to enhance the stabilizing force of the synthetic monomers under high temperature condition. The filtrate loss reducer disclosed by the invention adopts waste materials of a paper-making factory, is extensive in source and low in cost, and can be used for absorbing the excellent viscosity reduction capacity of lignin; the introduced acrylamide and 2-acrylamide-2-methyl propanesulfonate can be used for improving the precipitation capacity at a high temperature; N,N-methylene bisacrylamide is added as the crosslinking agent to ensure that a network structure is formed, the high temperature resistance can be improved, an oil and gas layer can be protected from collapsing, and the service life of an oil well can be prolonged. A product disclosed by the invention is applied to the oil field drilling fluid.

Owner:JILIN UNIV

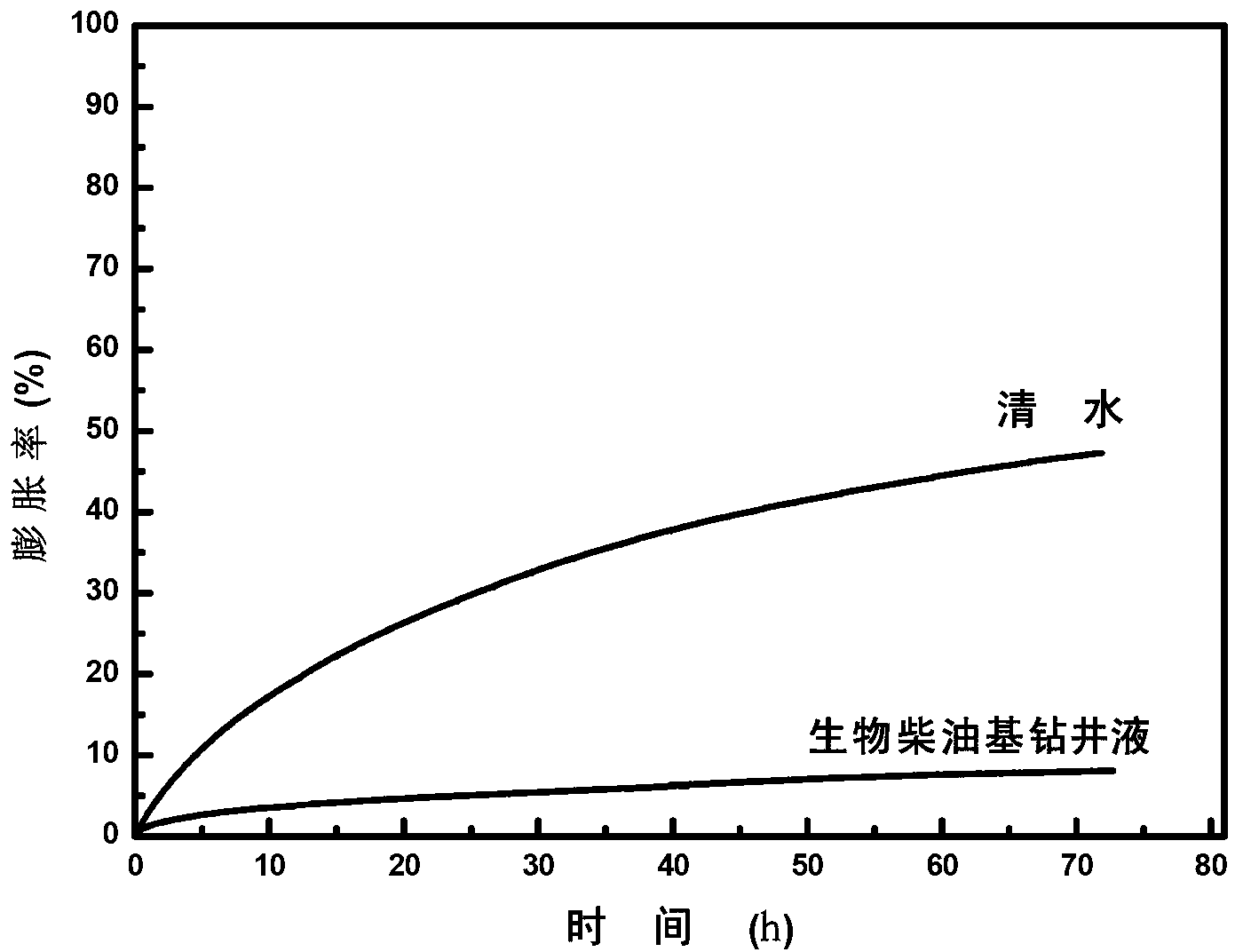

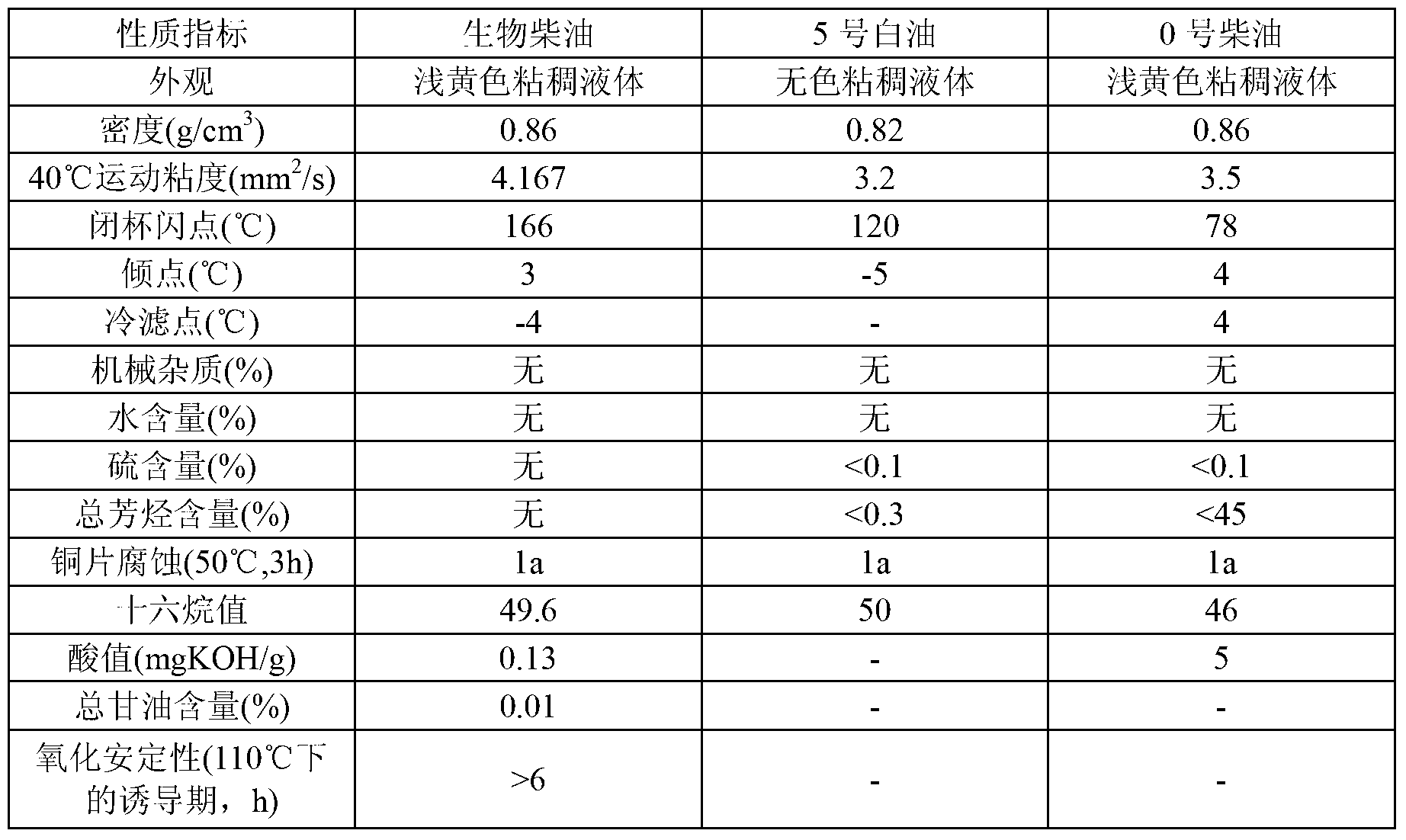

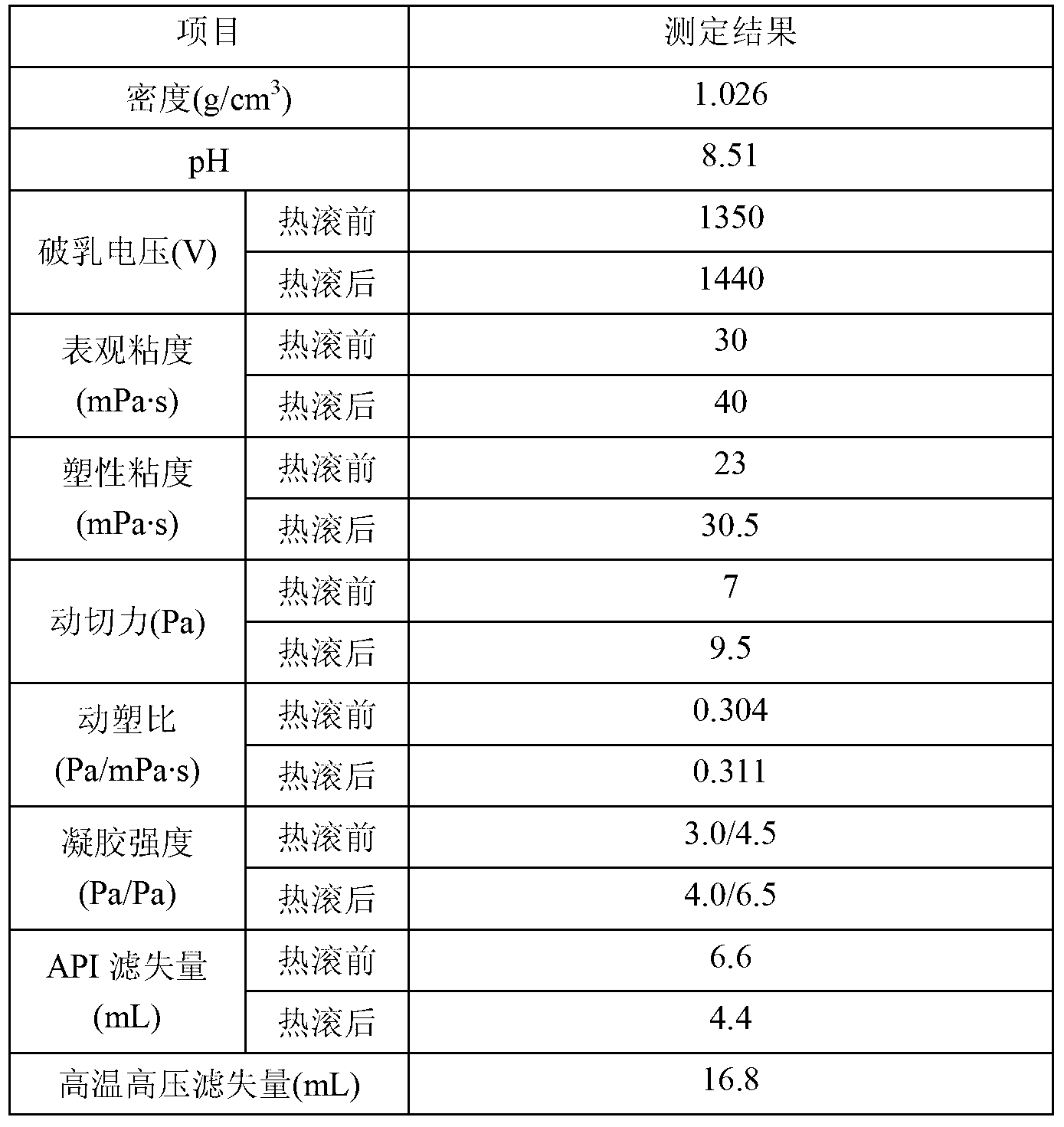

Water-in-oil-type biodiesel-based drilling fluid and preparation method thereof

ActiveCN103320104ASource requirements relaxedInhibit migrationDrilling compositionOil and greaseBiodiesel

The invention discloses a water-in-oil-type biodiesel-based drilling fluid and a preparation method thereof. The drilling fluid comprises the following components in parts by volume: 70 to 90 parts of biodiesel prepared by taking waste oils as a raw material, and 10 to 30 parts of calcium chloride aqueous solution. Based on the total volume of the biodiesel and the calcium chloride aqueous solution, the drilling fluid further comprises the following components in mass-volume ratio: 2% to 6% of calcium oxide, 1% to 6% of organic soil, 2% to 8% of emulsifier, 2% to 8% of wetting agent, 2% to 6% of filtrate reducer and 0% to 200% of weighting material. The drilling fluid disclosed by the invention has the characteristics of good operating performance, low cost, strong collapse-resisting inhibiting performance, excellent lubricating performance and excellent biological degradability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

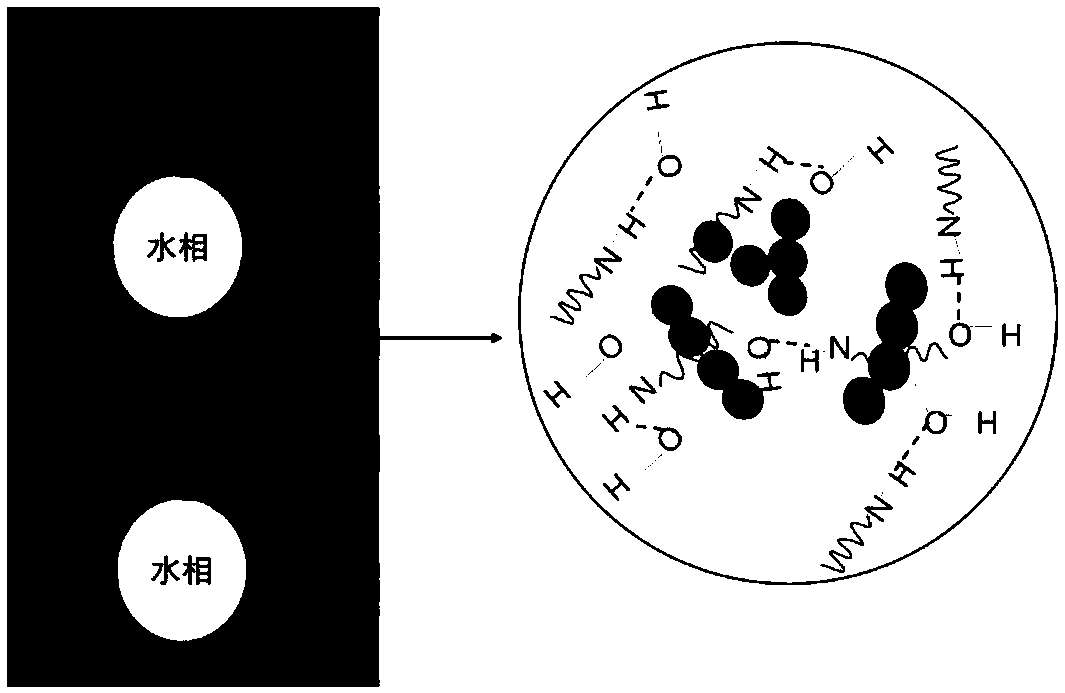

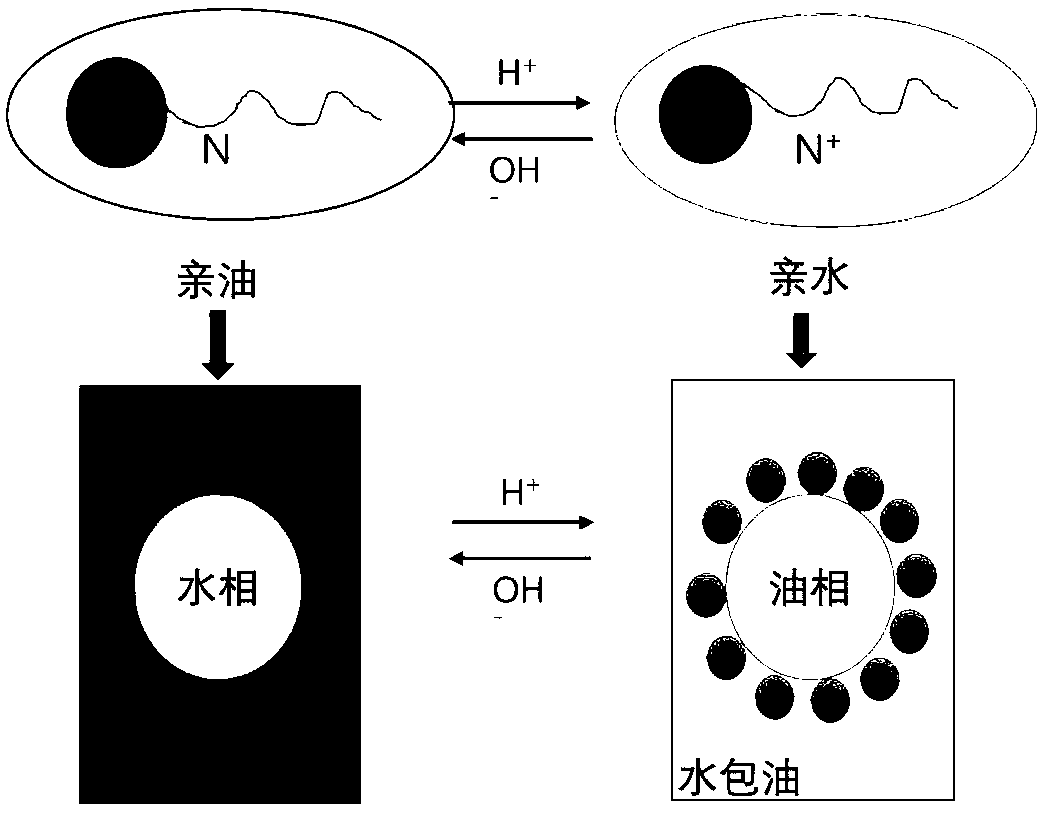

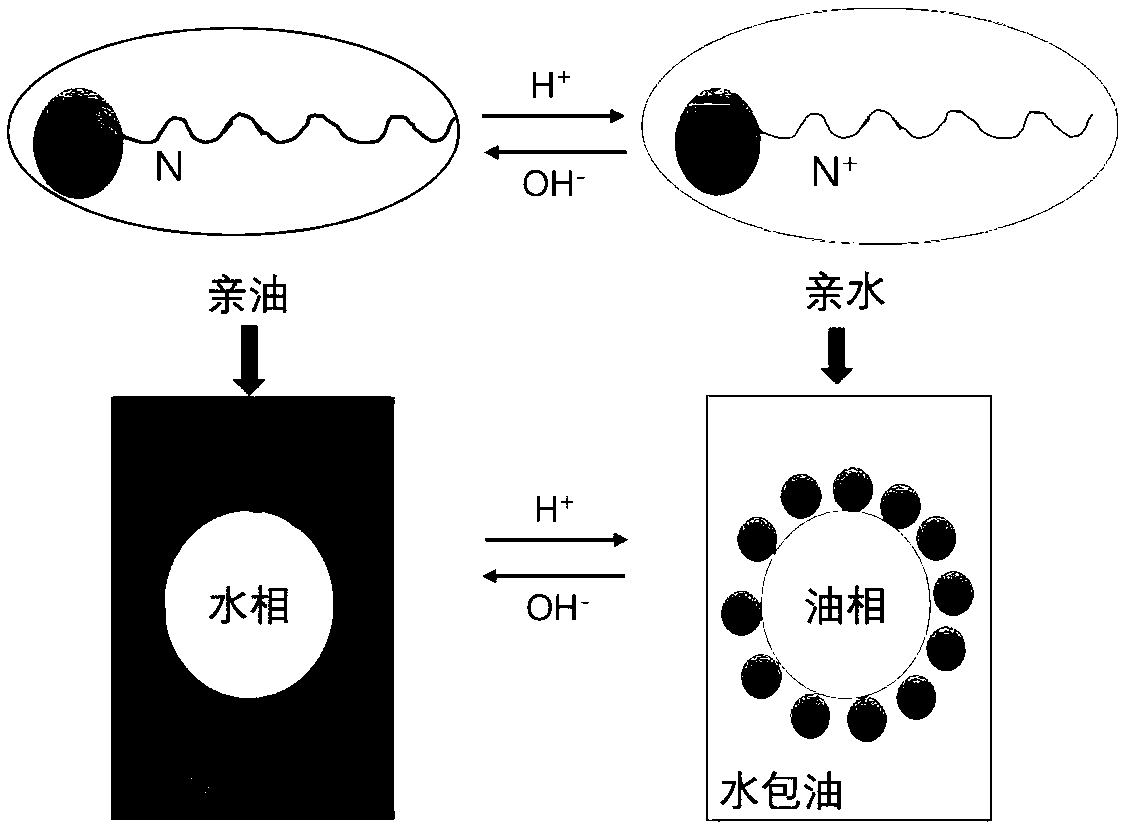

Reversible Pickering emulsion, preparation method of reversible Pickering emulsion, and reversible high-temperature high-density drilling fluid

ActiveCN108841364ADoes not affect smooth reversalStability is not affectedDrilling compositionOil phaseAmine derivatives

The invention provides a reversible Pickering emulsion, and the reversible Pickering emulsion comprises an oil phase, an aqueous phase and a nanoparticle activated in situ by an amine surfactant or anamine derivative surfactant. The nanoparticle is a lipophilic, hydrophilic or amphiphilic nano oxide, and the amine surfactant is primary amine, secondary amine, tertiary amine surfactants or derivatives of the surfactants. The lipophilic nanoparticle is activated in situ by a short chain amine surfactant or a short chain amine derivative surfactant; the hydrophilic or amphiphilic nanoparticle isactivated in situ by a long chain amine surfactant or a long chain amine derivative surfactant. The invention further provides a drilling fluid comprising the emulsion. An enhancer for the drilling fluid is an amphiphilic hyperbranched polymer, the density of the prepared reversible high-temperature high-density drilling fluid is directly adjusted within 1.6g / cm<3> to 2.2g / cm<3>, and has the relatively excellent properties of rheological property, suspension stability, filter cake clearance, filter loss control, environmentally friendliness, and reversibility of a water-in-oil emulsion and anoil-in-water emulsion.

Owner:SOUTHWEST PETROLEUM UNIV

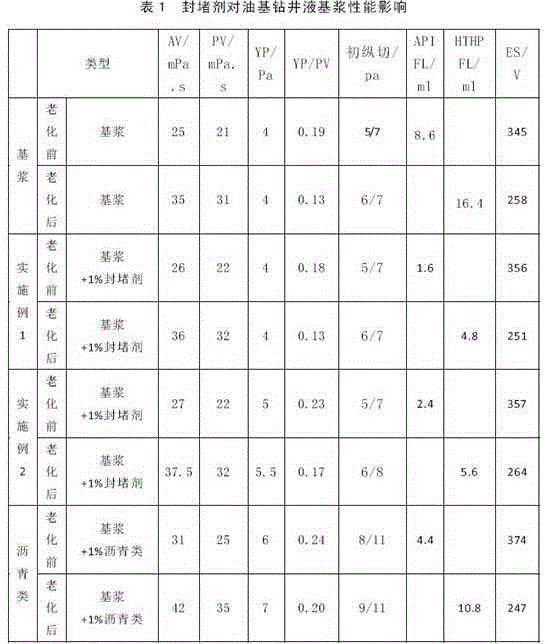

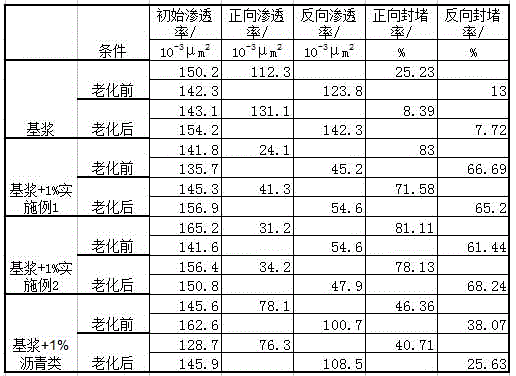

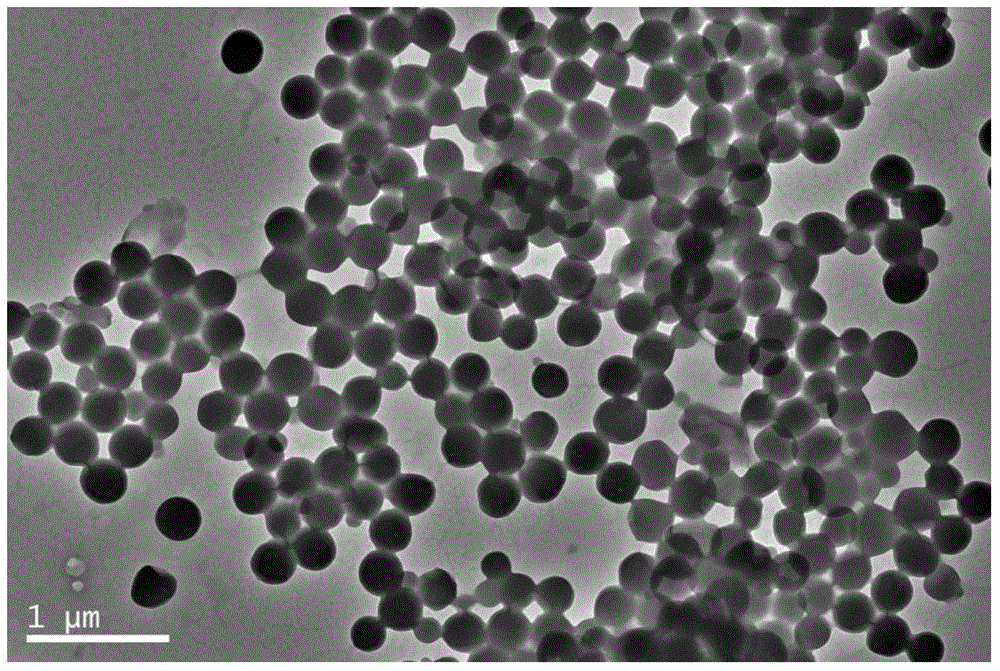

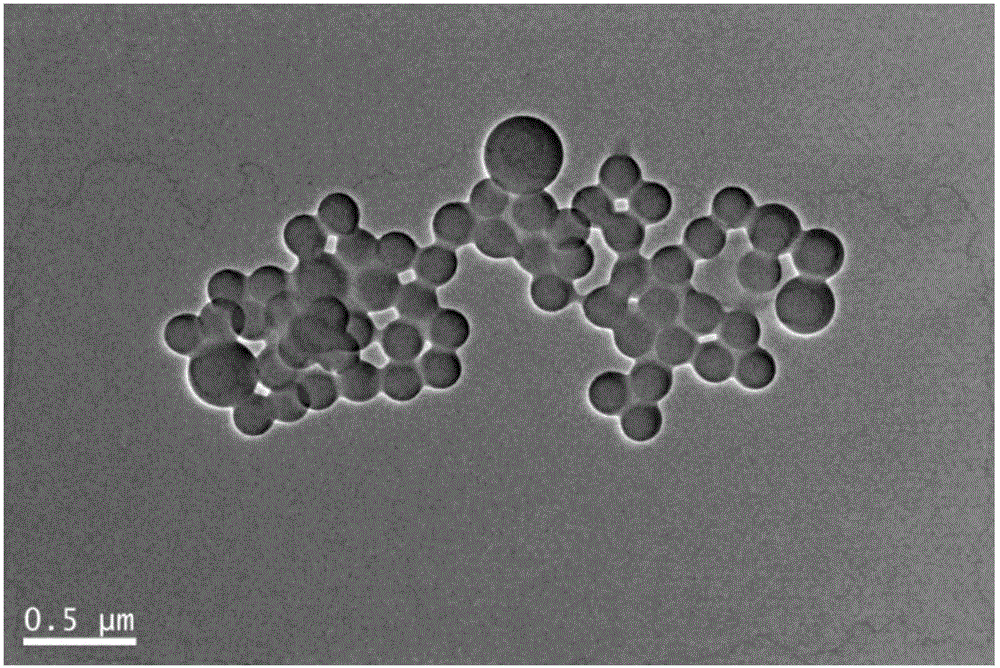

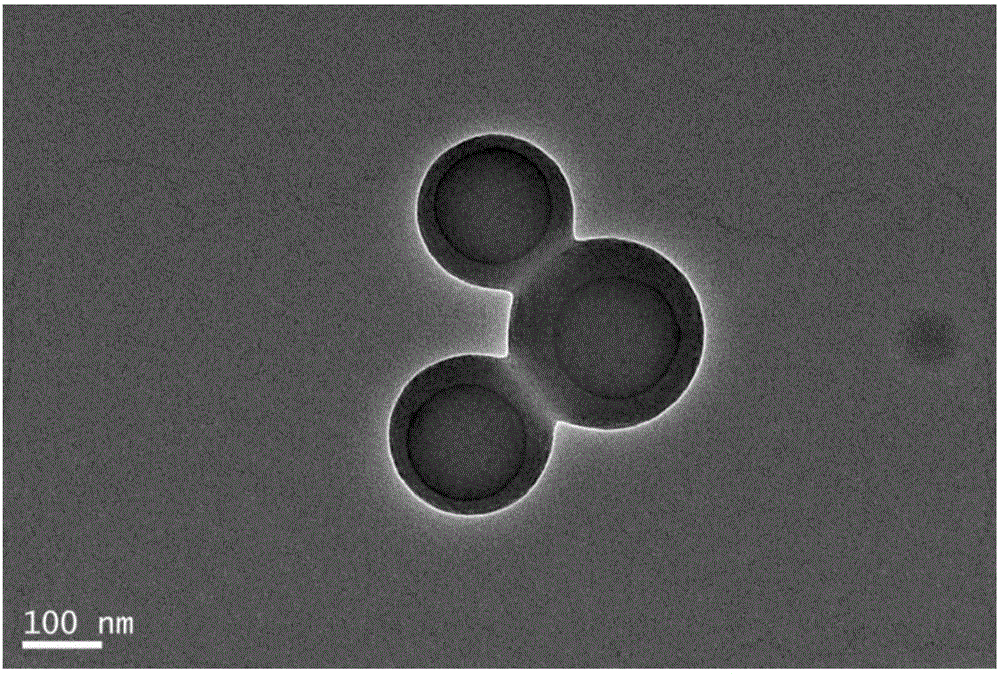

Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

ActiveCN105462568AHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Temperature-sensitive-type intelligent nano particles used in drilling fluid and preparation method thereof

InactiveCN105038728AGood dispersionImprove water resistanceDrilling compositionHydrophilic monomerPressure transmission

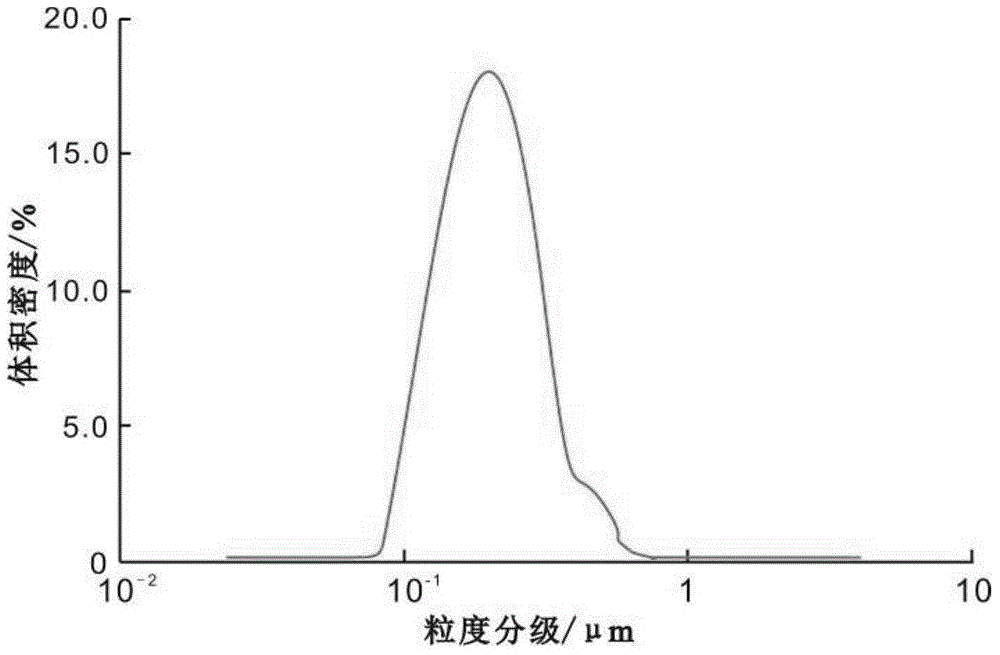

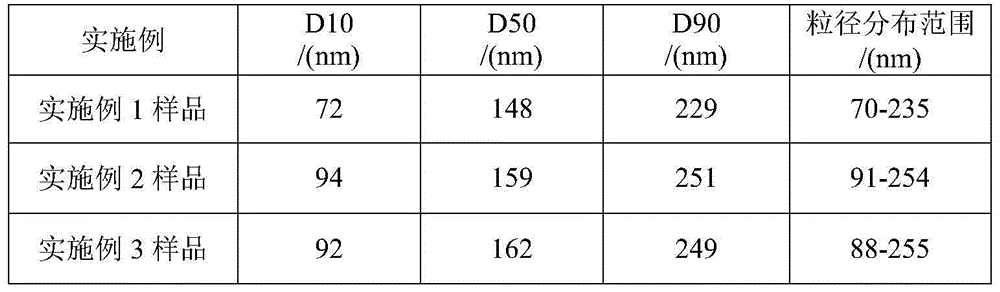

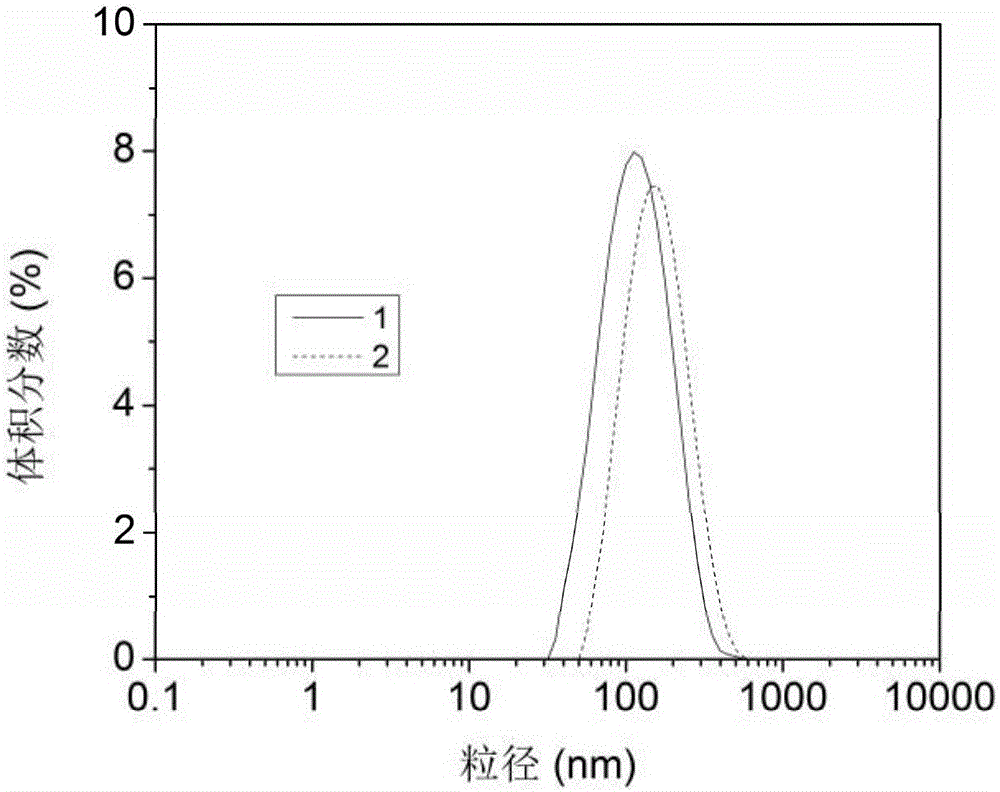

The invention relates to a temperature-sensitive-type intelligent nano particles used in a drilling fluid and a preparation method thereof. In the invention, a silane coupling agent is used for performing ultrasound surface modification to nano SiO2 and a vinyl functional group is introduced. With the surface-modified nano SiO2, a temperature-sensitive-type monomer and a hydrophilic monomer are subjected to a polymerization reaction in a water medium with a co-solvent with addition of an initiator, wherein granularity distribution of the temperature-sensitive-type intelligent nano particles is D10 <= 100 nm, D 50 <= 165 nm and D90 <= 260 nm. When the temperature is higher than a sensitive value, the nano particles achieve double functions of both physical blocking and chemical inhibition, so that a continuous compact hydrophobic blocking layer is formed inside shale, thereby achieving effects of preventing and delaying pressure transmission and filtration invasion, and further enhancing stability of a shale well wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing temperature-resistant anti-salt amphoteric polymer filtrate reducer

The invention relates to a method for preparing a temperature-resistant anti-salt amphoteric polymer filtrate reducer used for drilling fluid. In the filtrate reducer, C6 to C10 paraffin hydrocarbons are used as a continuous phase; Span and Tween are used as a compound non-ionic surface active agent, wherein the mass ratio of the Span to the Tween is 2-4:1-3; three monomers, namely acrylamide(AM), acrylic acid(AA) and styrene sulfonic sodium(SSS), are used as raw materials in a mass ratio of 10:3-6:1-4; and an initiator of ammonium persulphate or redox initiator of ammonium persulphate-sodium bisulphite is added for copolymerization by adopting an opposite micro-emulsion polymerization method to obtain the filtrate reducer. The filtrate reducer provided by the invention has the advantages of higher temperature resistance, salt resistance and filtrate-reducing property, simple preparation method, mild and controllable reaction conditions, high polymerization stability, high reaction speed and high conversion rate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Temperature-resistant and salt-resistant latex blocking agent and preparation method thereof

ActiveCN105884954AImprove temperature resistanceImprove salt toleranceDrilling compositionHydrophilic monomerHigh pressure

The invention provides a temperature-resistant and salt-resistant latex blocking agent. The latex blocking agent is prepared from, by weight, 100 parts of hydrophobic monomers, 0.5-25 parts of hydrophilic monomers, 0.1-10 parts of emulgator, 0.01-5.5 parts of a buffer agent, 0.01-4.5 parts of molecular weight modifier, 0.01-6.9 parts of a protective agent, 0.01-2.3 parts of initiator and 67-172 parts of deionized water. The latex blocking agent has good blocking and water loss reduction effects and is resistant to high pressure and high temperature, and a formed mud cake is dense, thin and tough.

Owner:CHINA NAT OFFSHORE OIL CORP +1

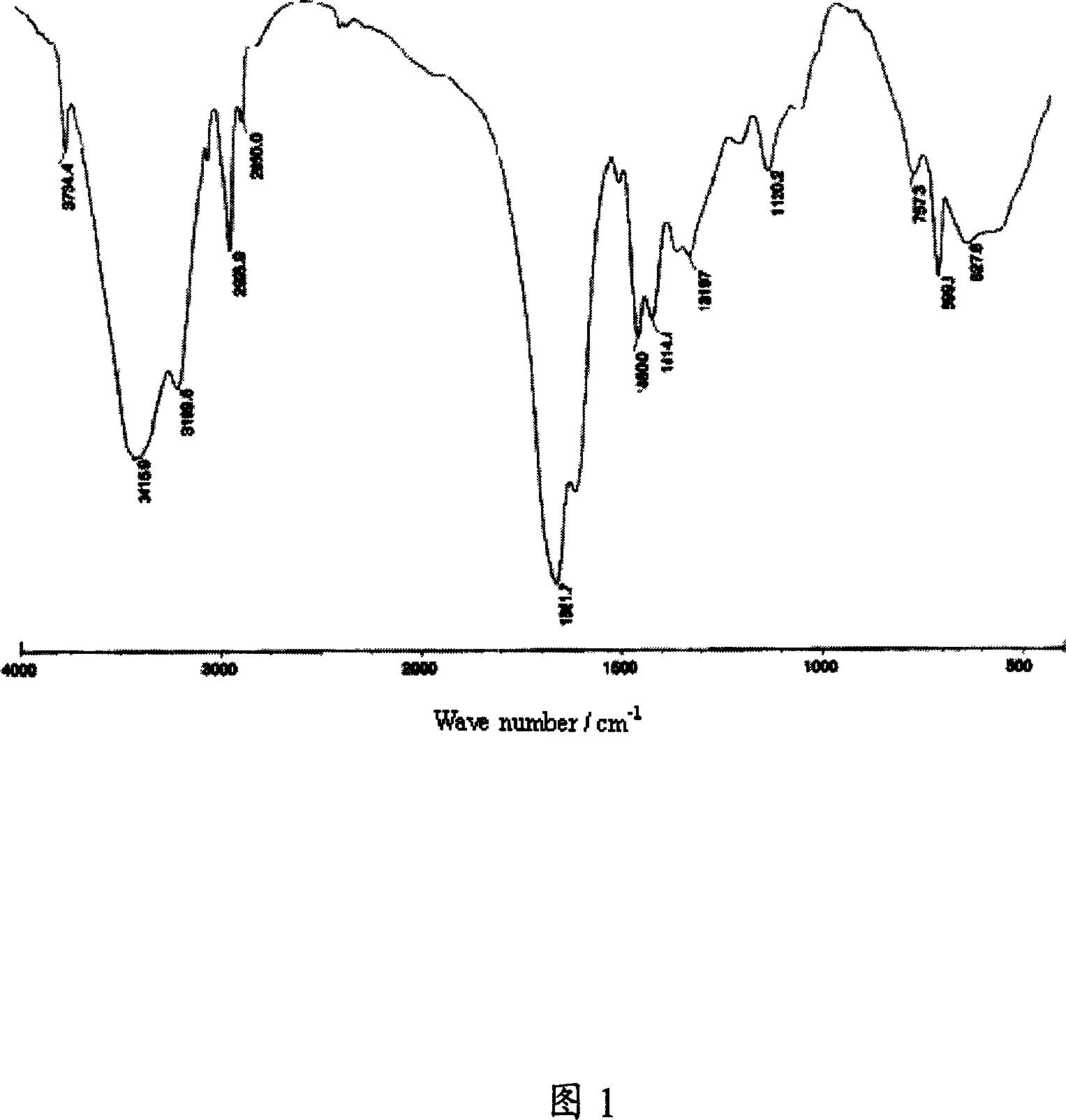

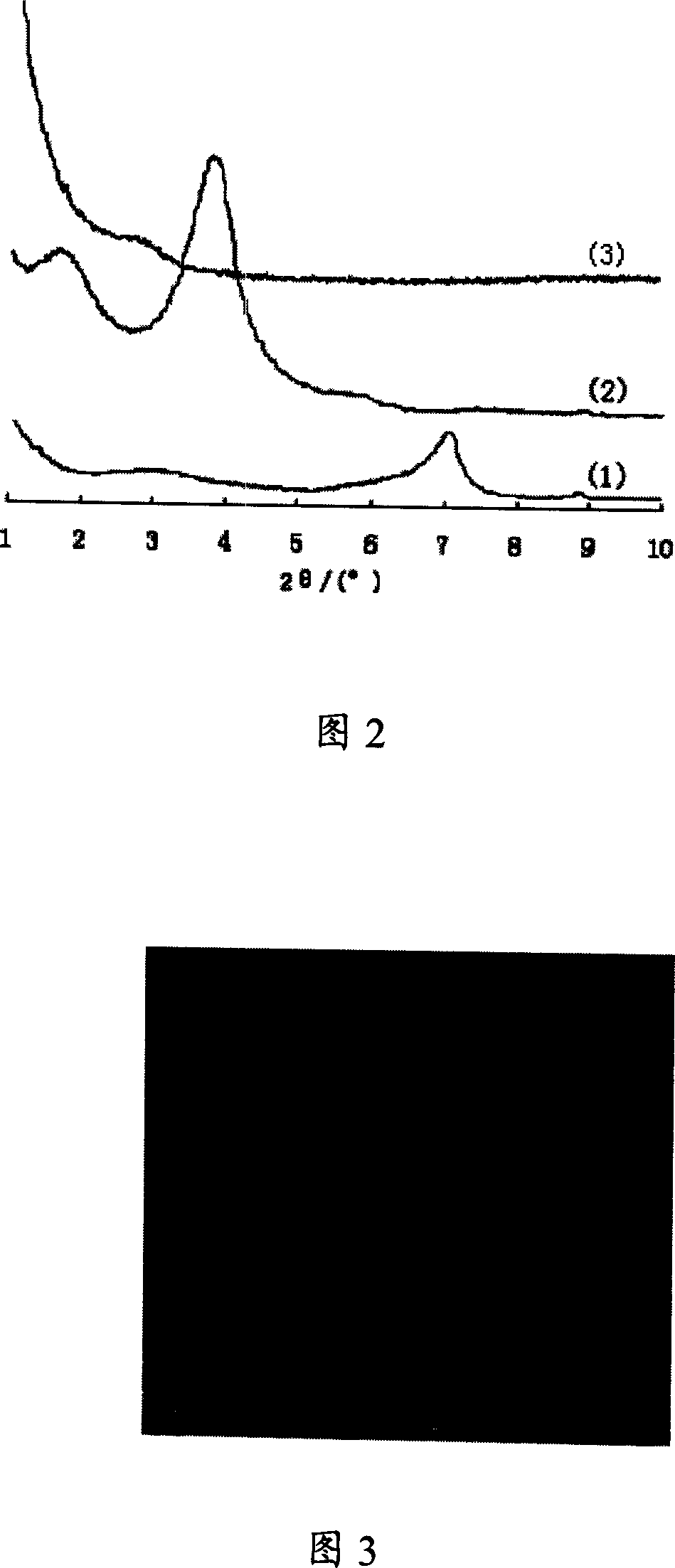

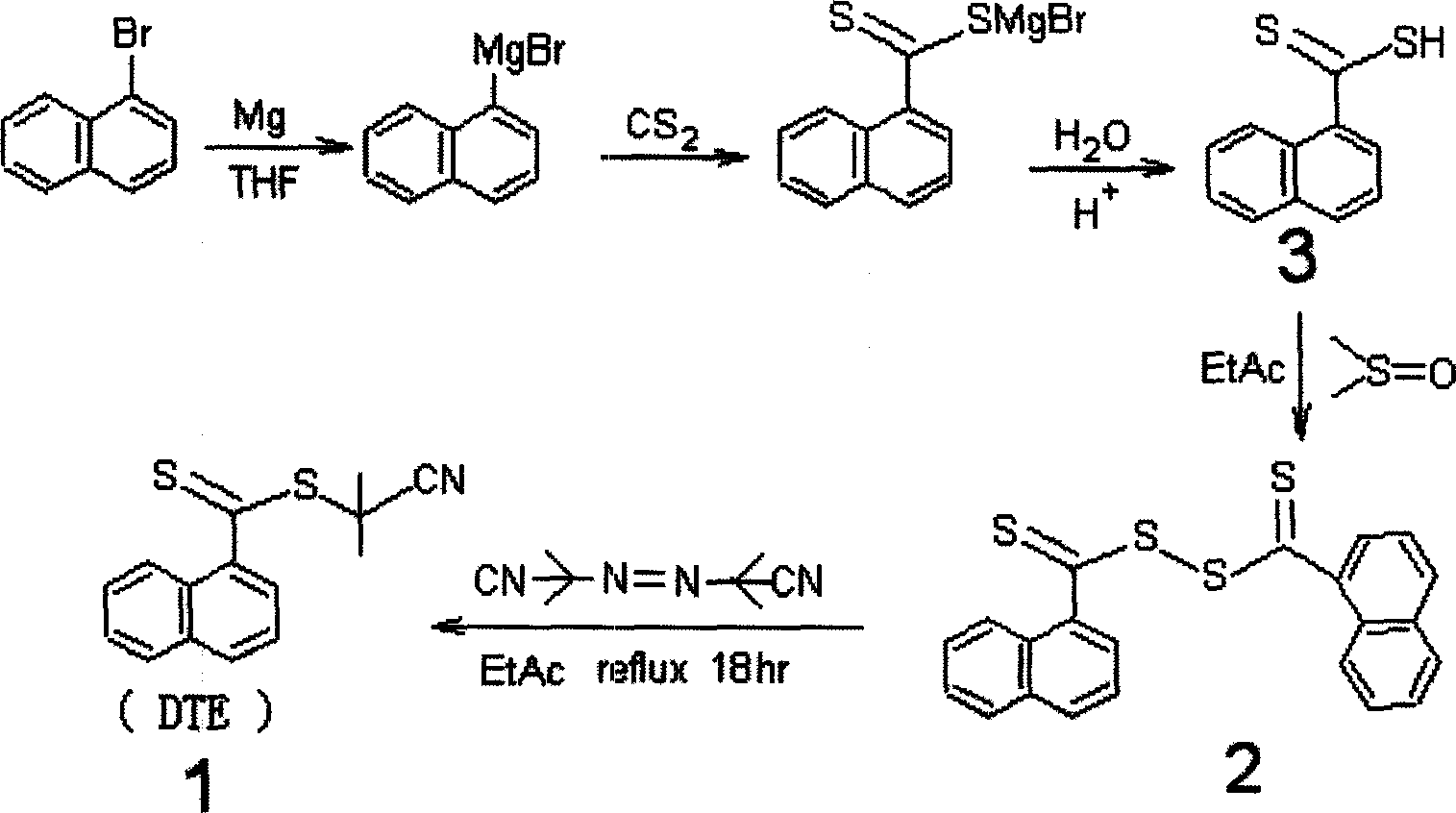

Nanometer composite heat resisting fluid loss reducing agent and its prepn

InactiveCN101020814AImprove thermal stabilityGood physical and mechanical propertiesDrilling compositionPolymer scienceFiltration

The present invention discloses one kind of nanometer composition heat resisting filtration reducing agent and its preparation process. The nanometer composition filtration reducing agent is synthesized through a reverse addition-fracturing chain transferring (RAFT) process, and has nanometer montmorillonite layer dispersed inside amphiphilic block polymer base. The organic combination between rigid and stable montmorillonite and flexible block polymer makes the nanometer composition filtration reducing agent possess high physical and mechanical performance and high heat stability. It is used as drilling fluid treating agent and has obvious filtration reducing effect at high temperature and high pressure.

Owner:CNPC DRILLING RES INST

High-temperature-resistant high-density reversible water-in-oil/oil-in-water drilling fluid and preparation method thereof

ActiveCN109097010AGood reversalComparable performanceOrganic compound preparationCarboxylic acid amides preparationOil phasePolyamine

The invention provides high-temperature-resistant high-density reversible water-in-oil / oil-in-water drilling fluid which is composed of the following raw materials in parts by weight: 30-70 parts of an oil phase, 30-70 parts of an aqueous phase, 2-5 parts of a reversible emulsifier, 1-3 parts of an auxiliary emulsifier, 0-2 parts of organic soil, 1-4 parts of a filtrate reducer, 0-1 part of an alkalinity regulator, 0-0.5 part of a wetting agent, 0-2 parts of an enhancer and 0-800 parts of weighting materials. The reversible emulsifier is fatty acyl polyamines and derivatives thereof, and has astructural general formula of R1(CH2)m(CONH)n(C6H4)x(NH)y(NH2)zR2; the filtrate reducer is an amphiphilic filtrate reducer. The amphiphilic filtrate reducer comprises but is not limited to an amphiphilic polymer filtrate reducer, a hydrophilic modified asphalt filtrate reducer and a hydrophobic modified humic acid filtrate reducer. The compounded auxiliary emulsifier is a high HLB (Hydrophile-Lipophile Balance) value surfactant. The drilling fluid disclosed by the invention has directly adjustable density of 0.8-1.8g / cm<3>, and has excellent properties such as rheological property, suspensionstability, filter cake clearance, filter loss control, environment friendliness and stable reversibility of water-in-oil emulsion and oil-in-water emulsion in a range of 100-180 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

Salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and preparation method and application thereof

ActiveCN112011318AImprove salt toleranceImprove temperature resistanceDrilling compositionPolyelectrolyteMeth-

The invention provides a salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and a preparation method and application thereof. The filtrate reducer is prepared from the following raw materials in parts by mass: 2 to 40 parts of N, N-dimethylacrylamide, 2 to 20 parts of methacryloxyethyl trimethyl ammonium chloride, 2 to 20 parts of 2-acrylamide-2-methylpropanesulfonicacid, 4 to 8 parts of nano oxide, 1.0 to 1.5 parts of silane modifier and 0.3 to 0.4 part of an initiator. The salt-responsive zwitterionic polymer provided by the invention has a special polyelectrolyte resistance effect and positive response to salt, essentially realizes conversion from salt resistance to salt response, and is essentially compatible with salt, the obtained filtrate reducer has excellent salt resistance, temperature resistance and filtrate loss reduction performance, and also has shear dilutability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Proppant-carrying acid fracturing method for high-temperature ultra-deep carbonate reservoir

InactiveCN106321044ASimple processEasy to operateFluid removalDrilling compositionAcid fracturingFracturing fluid

The invention provides a proppant-carrying acid fracturing method for a high-temperature ultra-deep carbonate reservoir. The proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir comprises the following steps that (1) fracture forming is conducted through fracturing fluid; (2) ground crosslinked acid is adopted and is made to react with rock, so that an acid-etched fracture is generated in a formed fracture, and a proppant is carried with the ground crosslinked acid for supporting the acid-etched fracture; and (3) linear glue is used for replacement, and thus acid fracturing is completed. According to the proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir, the technique is simple, operation is convenient, and the construction effect is remarkable; and the proppant-carrying acid fracturing method is suitable for transforming construction of deep well carbonatite at the high temperature of 150-170 DEG C, a supporting fracture which has deep penetration and longer flow conductivity can be formed in a stratum, the productivity is increased and the production time is prolonged after acid fracturing and well fracturing, and the length of the formed fracture is larger than 120 m.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling fluid and preparation method thereof

The invention provides a drilling fluid and a preparation method thereof. The drilling fluid comprises base slurry and additives, wherein the additives include a high-softening point asphalt composition particle, a performance regulator, a stable dispersant and a stable dispersing aid, the addition amount of the high-softening point asphalt composition particle is 2% to 5% of the total mass of the drilling fluid, and the average particle size of the high-softening asphalt composition particle is 10 to 120 mm. The preparation method comprises the following steps: (1) preparing the high-softening point asphalt composition particle; and (2) adding the high-softening point asphalt composition particle into the drilling fluid and then adding proper additives like the performance regulator, a surfactant and a film-forming additive so as to allow the high-softening point asphalt particle to be uniformly and stably dispersed into the drilling fluid. The drilling fluid provided by the invention overcomes the problem that high-softening point asphalt is hard to be crushed into fine particles and has difficulty in stable dispersion in a water-based drilling fluid, and the drilling fluid can be widely used in the process of drilling operation for deep oil and gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature resistant cement mortar

The invention relates to high-temperature-resistance cement slurry, which relates to the cement slurry used by oil drilling and cementing technical field, solving the problem of bad high-temperature-resistance performance of prior cement slurry. Components and proportions of the high-temperature-resistance cement slurry of the invention are as follows by weight portions: 100 portion of cement, 55-65 portion of water, 6-15 portion of filtrate loss reducer, 4.8-7.2 portion of retarder, 20-40 portion of drag reduction agent, 3-5 portion of filler and 1-3 portion of stabilizer; wherein, the filtrate loss reducer is high molecular polymer; the retarder is lignin inorganic salt; the drag reduction agent is sulphonated acetone-formaldehyde polymer; the filler is silicon dioxide with concentration more than 95 percent; the stabilizer is polyester fiber. The high-temperature-resistance cement slurry has the advantages of strong high-temperature resistance, low filtrate loss water, good slurry stability, strong anti-hydrosphere channeling ability and strong compressive strength of cement paste which can improve construction security for cementing high-deep wells, reduce damage of filtrate of the cement slurry to formation, protect oil and gas formation and can be popularized and applied for wells in complex blocks.

Owner:DAQING PETROLEUM ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com