Patents

Literature

38 results about "Risk zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Risk Zone involves adapting to new circumstances, and it is the most fertile place for learning. It is where most people are willing to take some risks, to not know everything, or sometimes, to not know anything at all; where people clearly know they want to learn and will take the risks necessary to do so.

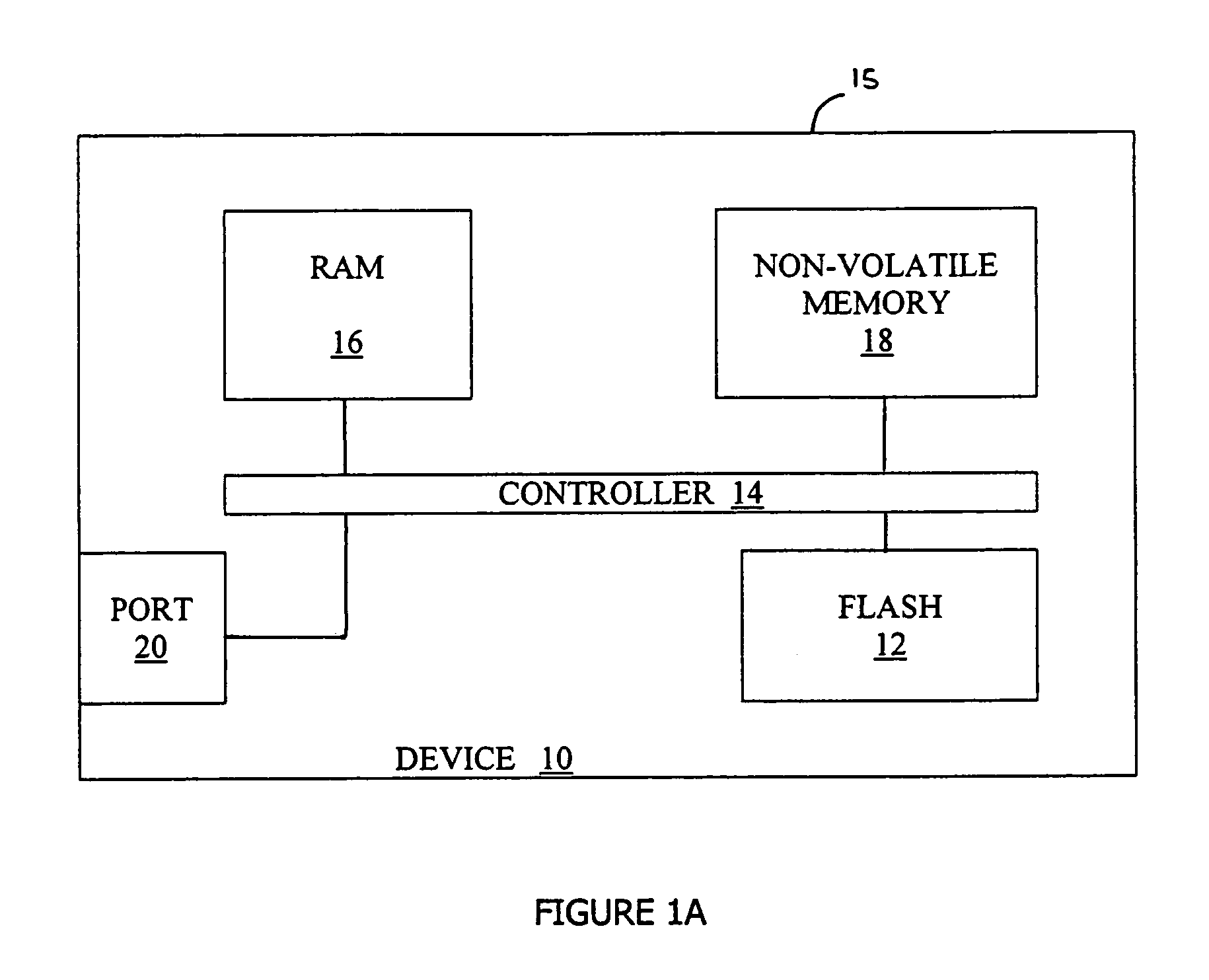

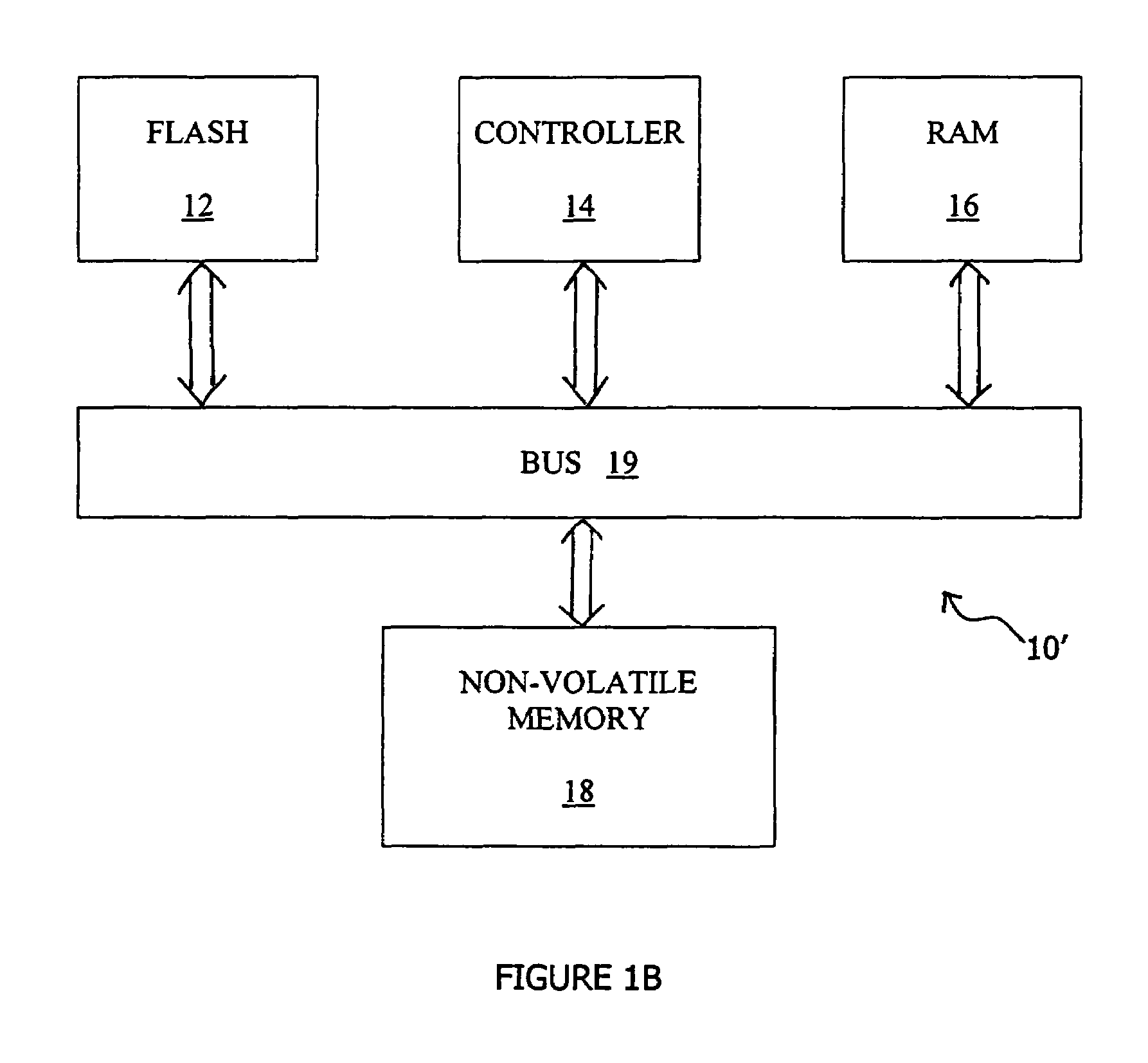

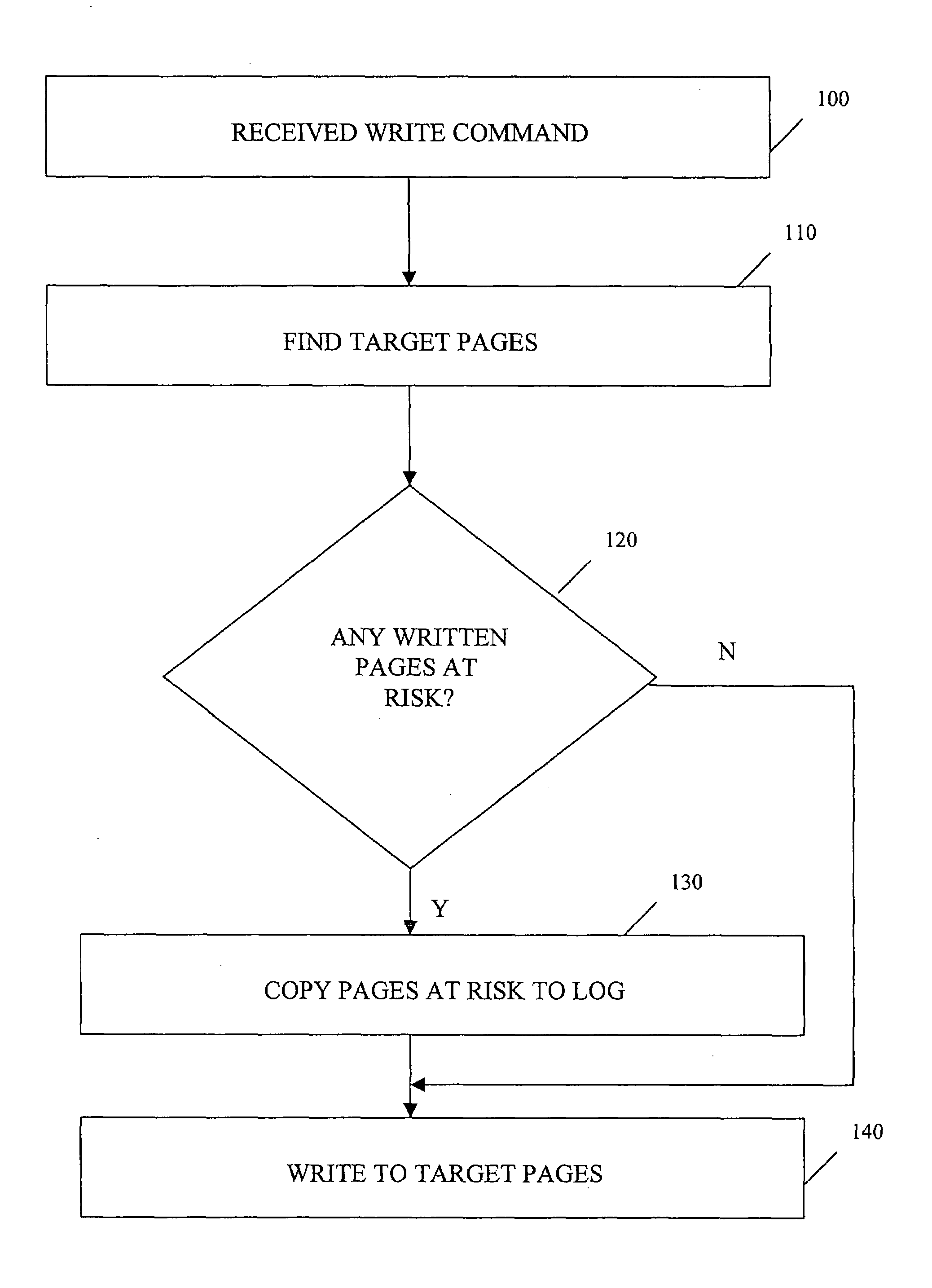

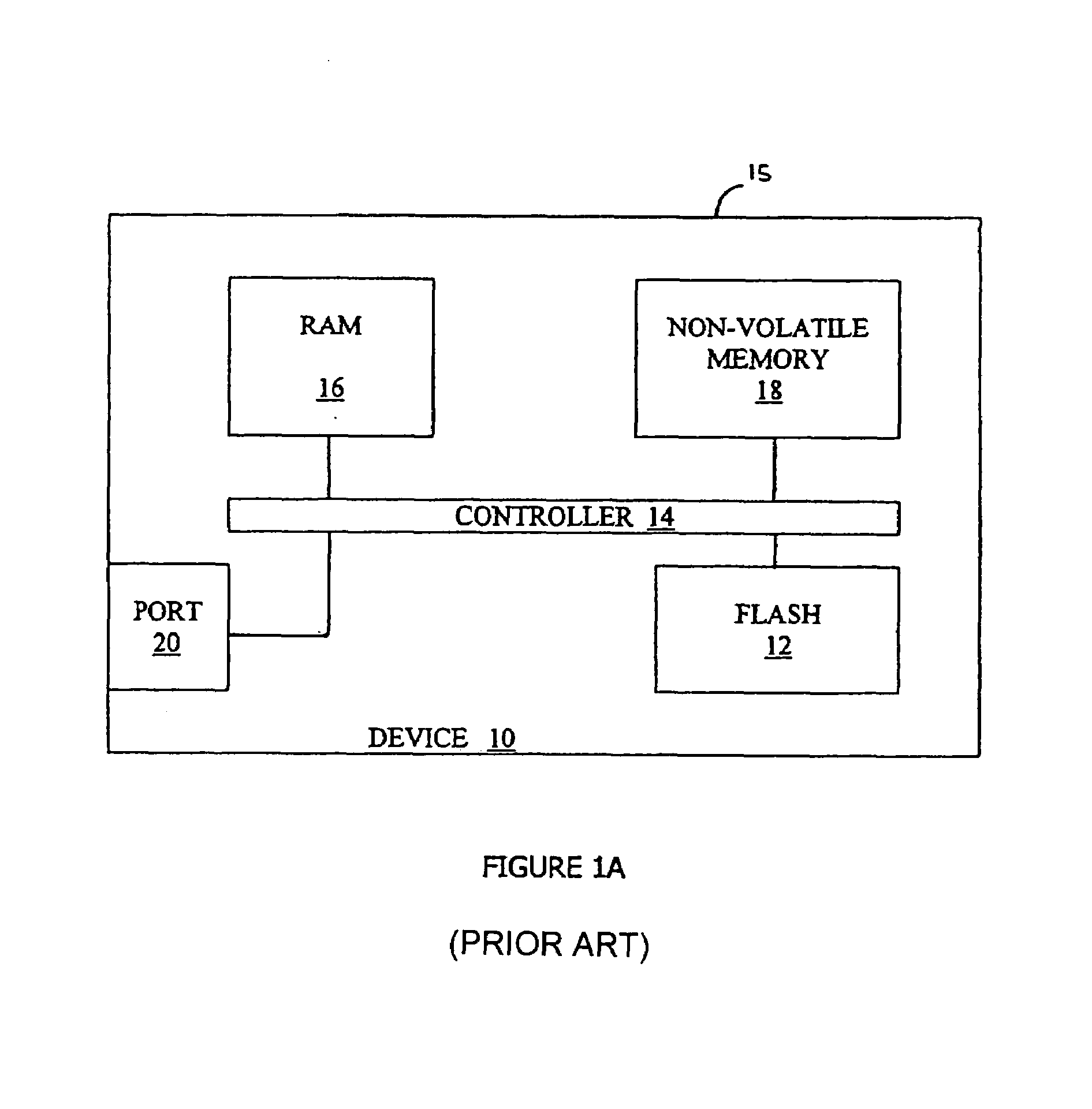

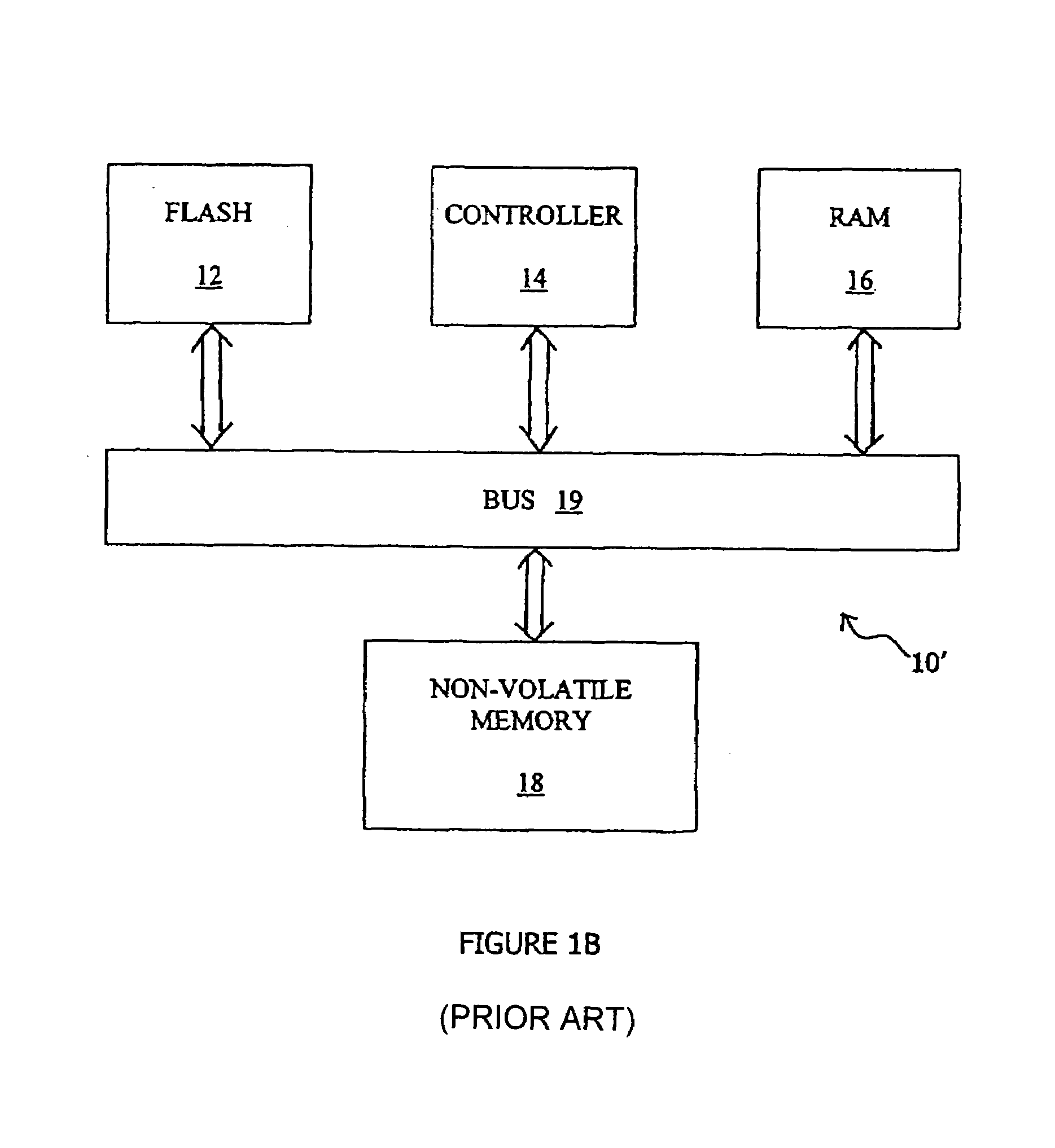

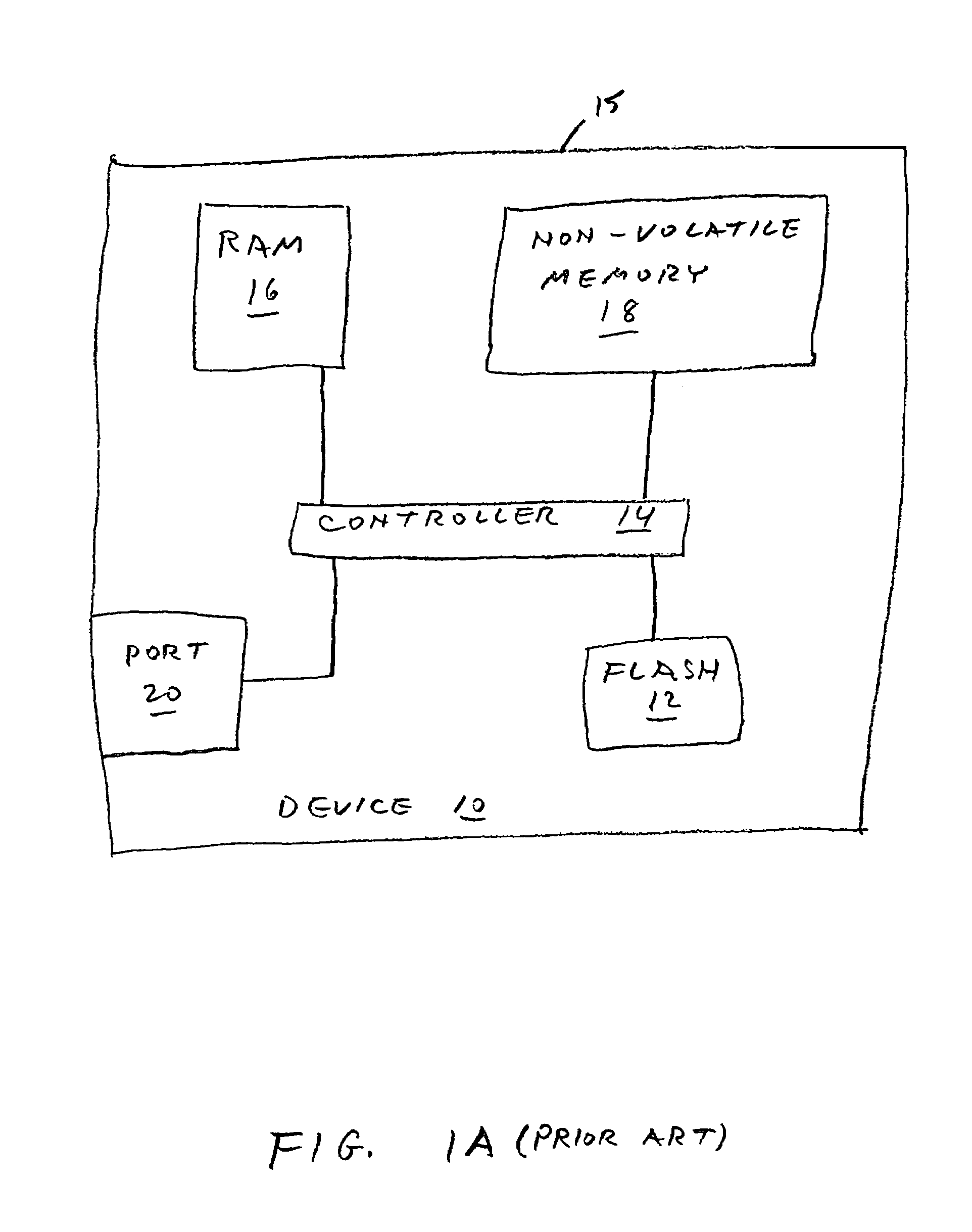

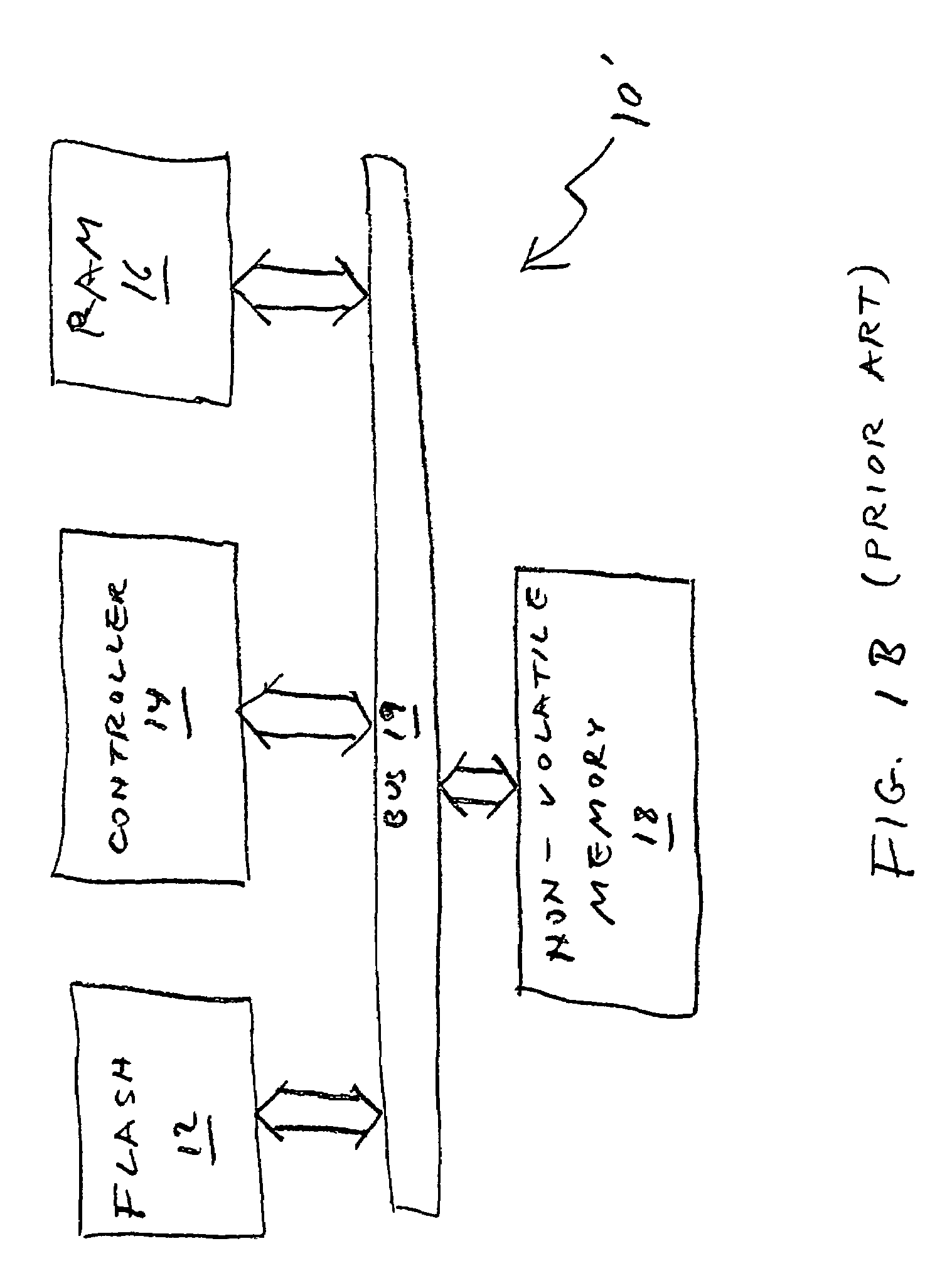

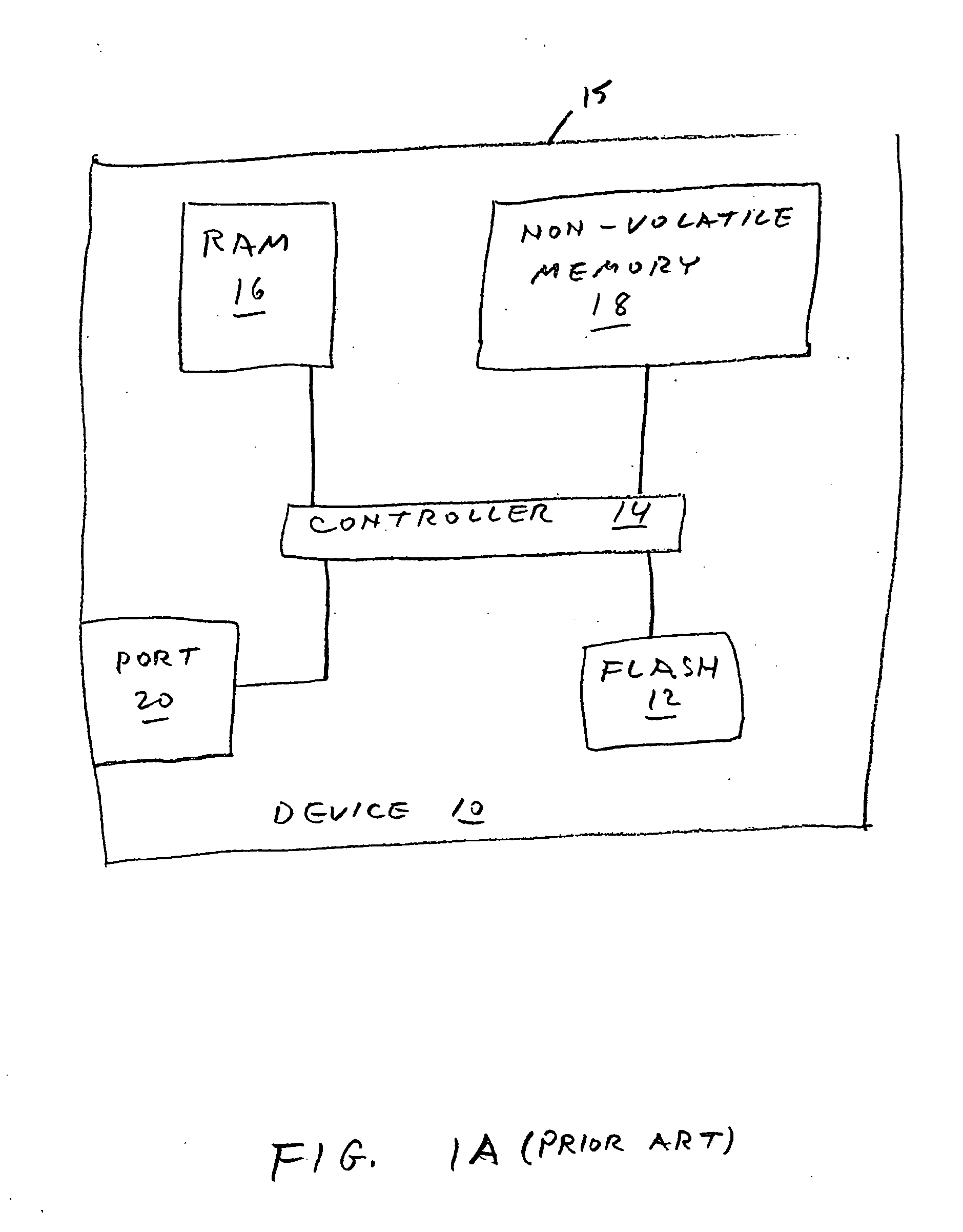

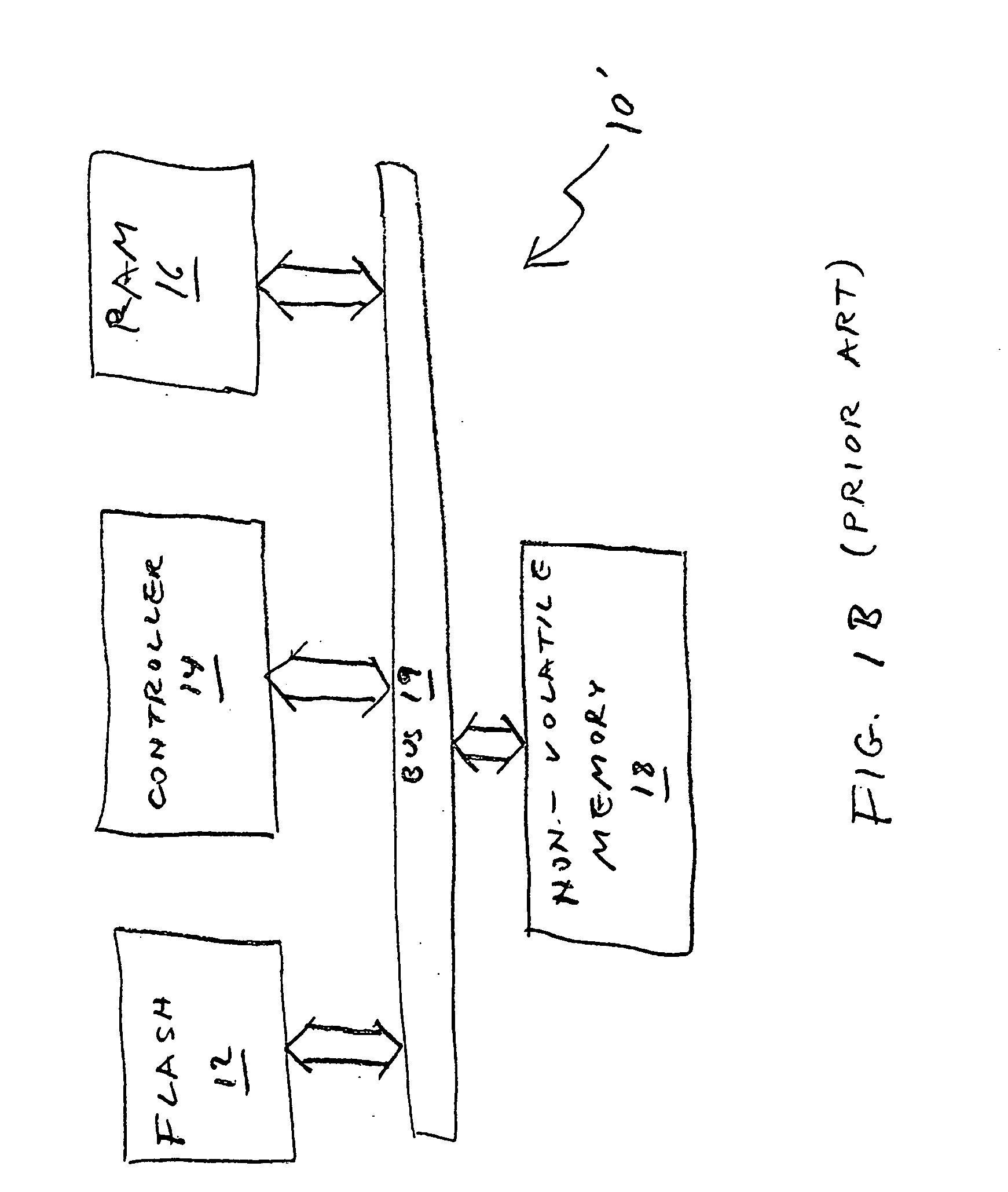

Flash memory management method that is resistant to data corruption by power loss

InactiveUS6988175B2Avoid dataMemory architecture accessing/allocationError detection/correctionElectricityRisk zone

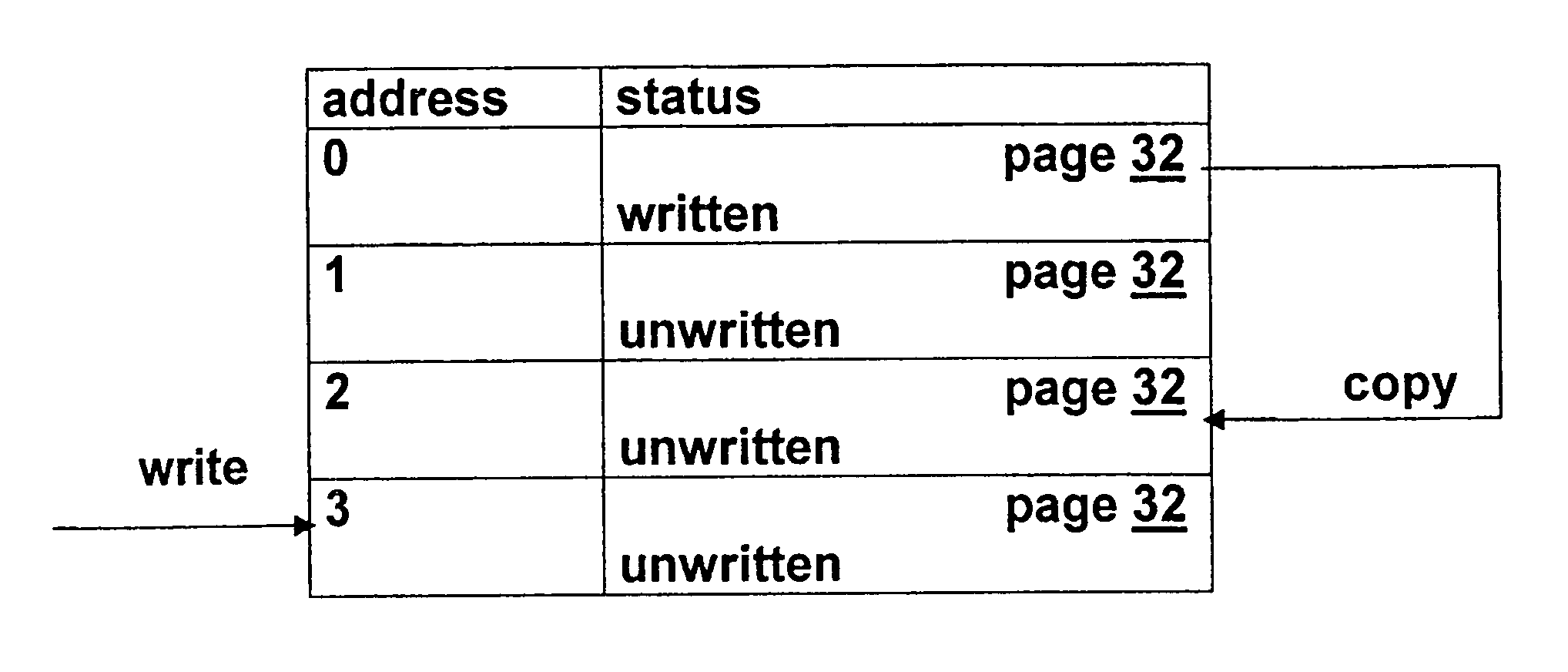

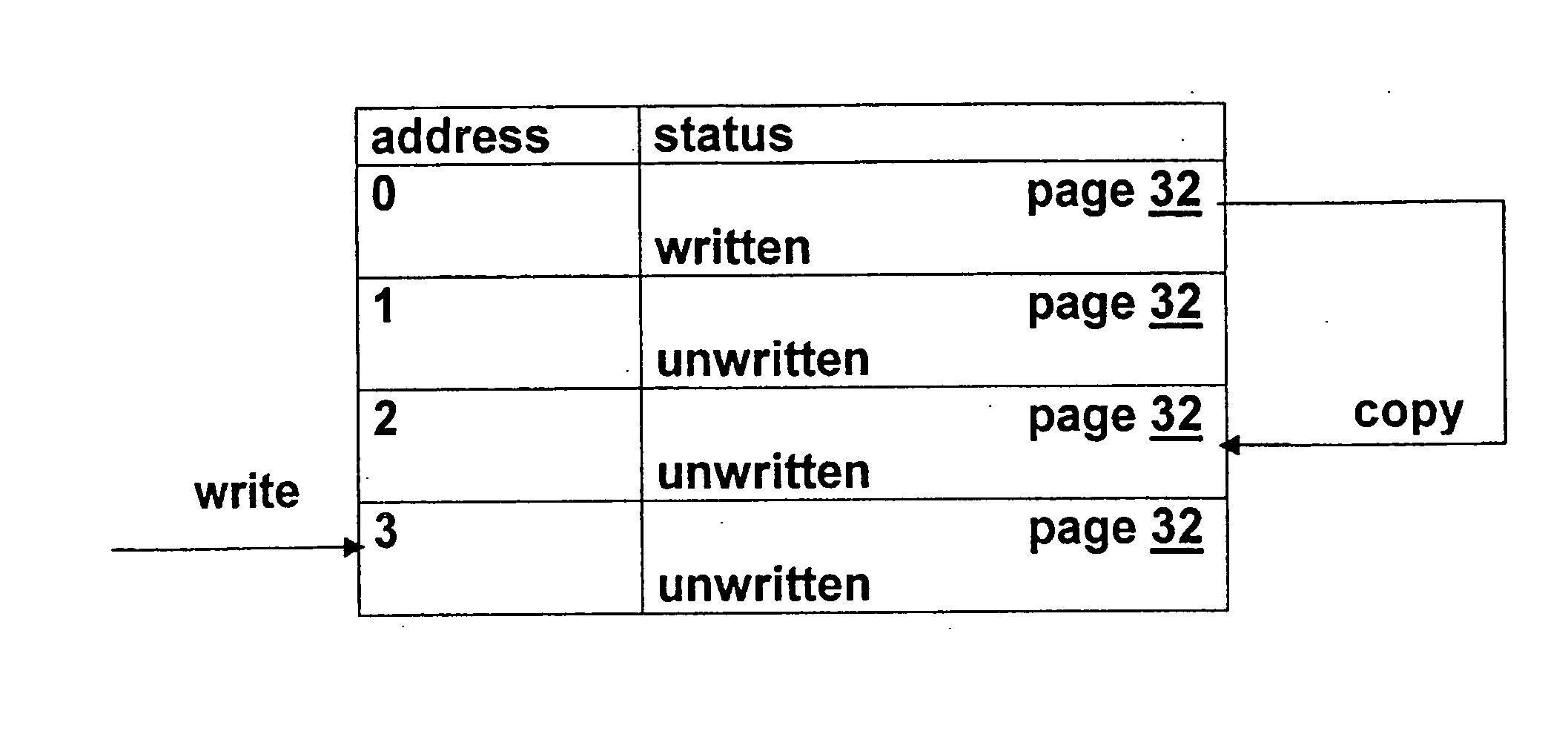

A method for managing page-based data storage media such as flash media, a system that uses that method, and a computer-readable storage medium bearing code for implementing the method. New data are written to the storage medium in a manner that precludes corruption of old data if the writing of the new data is interrupted. Specifically, risk zones are defined, by identifying, for each page, the other pages whose data are put at risk of corruption if writing to the page is interrupted. A page, that otherwise would be the target of a write operation, is not written if any of the pages in its risk zone contain data that could be corrupted if the write operation is interrupted.

Owner:WESTERN DIGITAL ISRAEL LTD

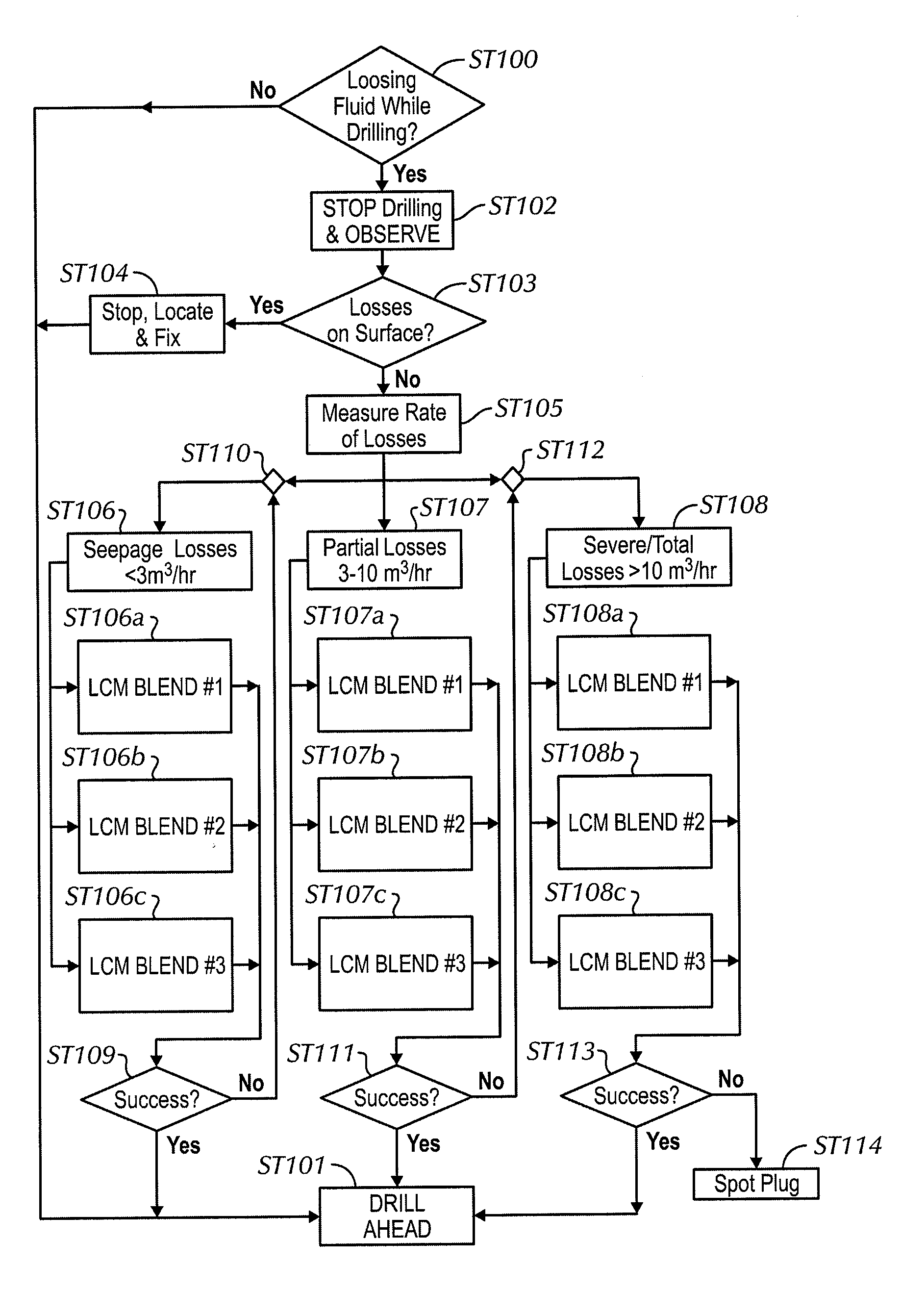

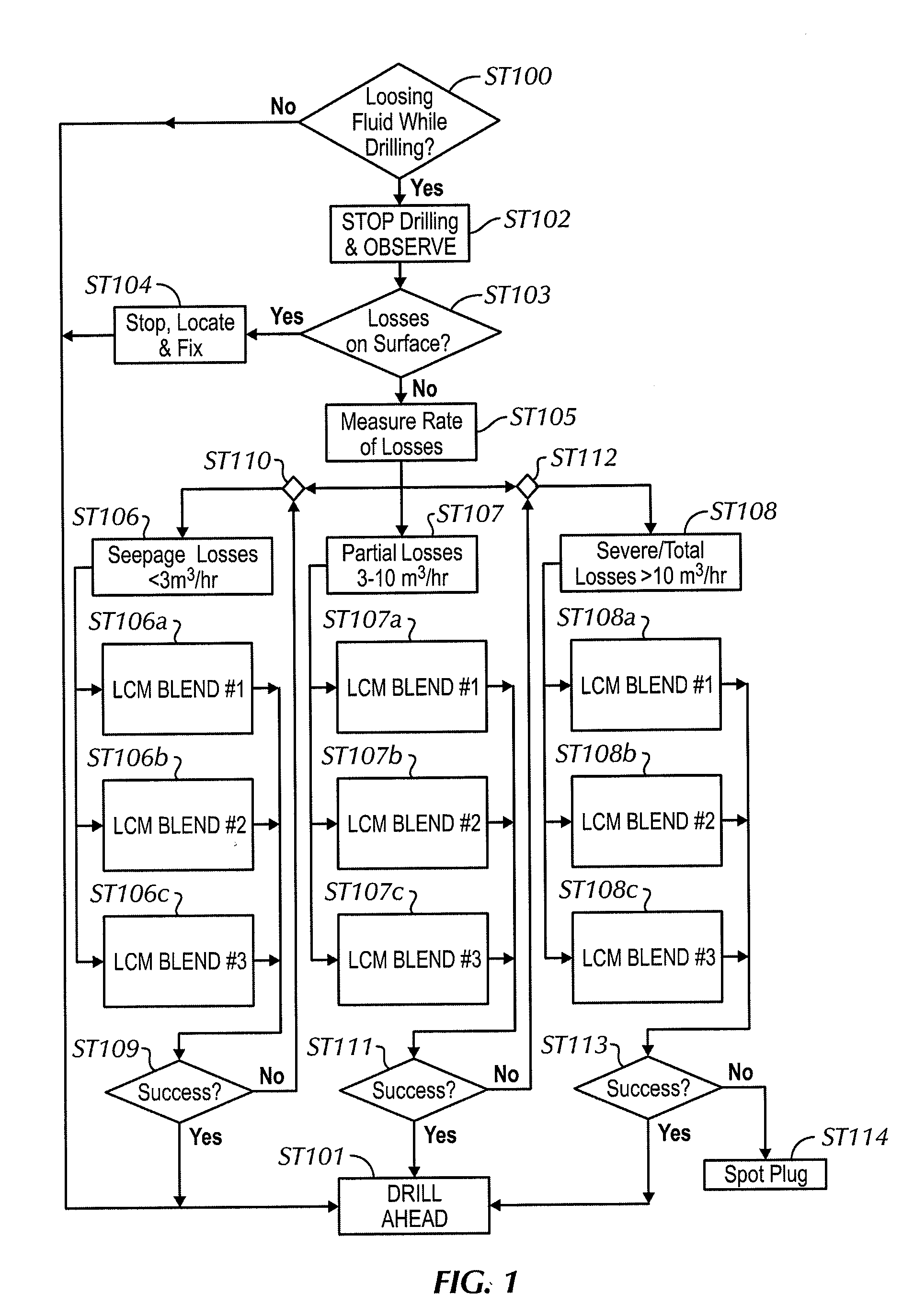

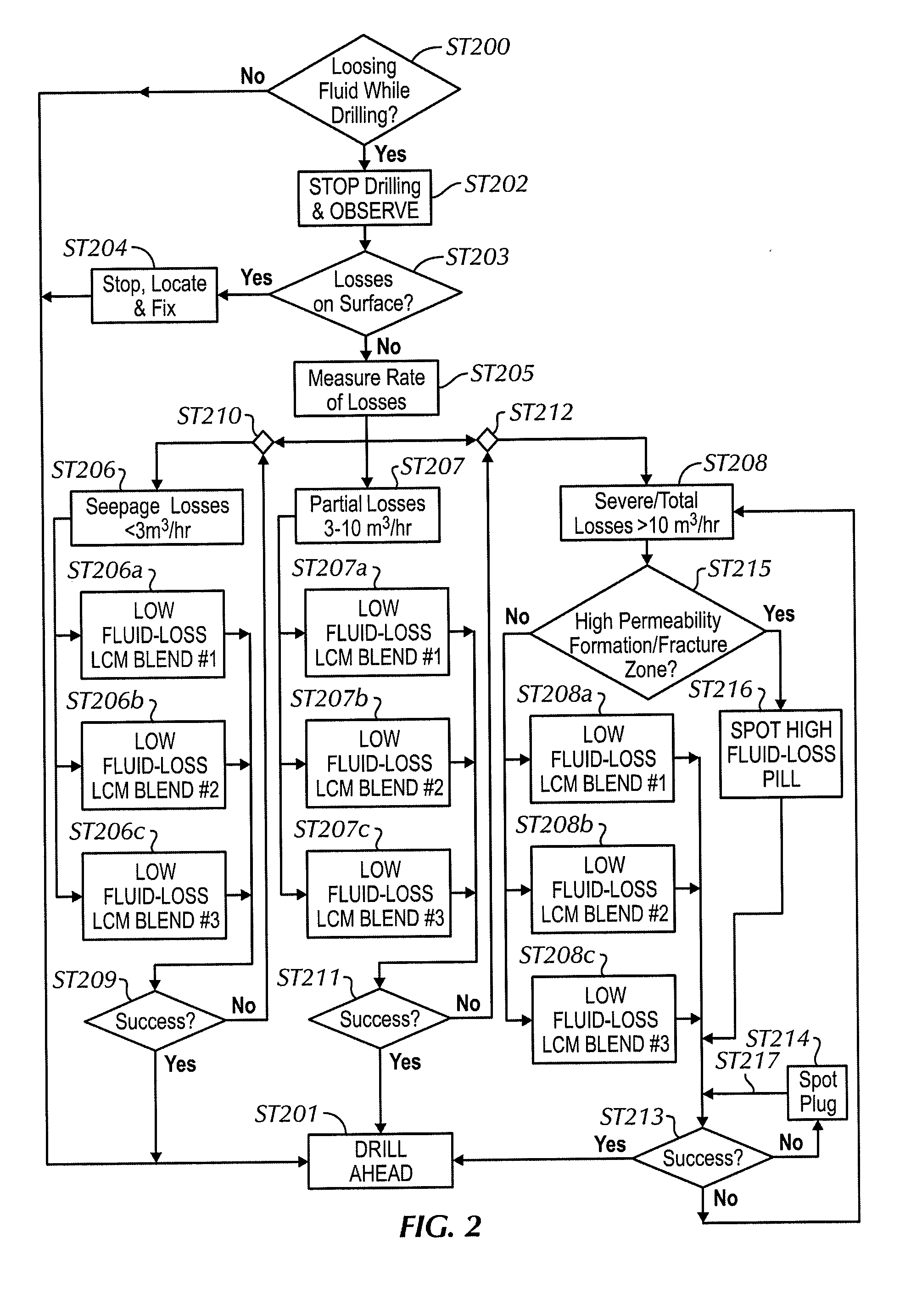

Methods of detecting, preventing, and remediating lost circulation

ActiveUS20090188718A1Reduce fluid lossElectric/magnetic detection for well-loggingSurveyLoss rateWell drilling

A method for planning a wellbore, the method including defining drilling data for drilling a segment of a planned wellbore and identifying a risk zone in the segment. Additionally, the method including determining an expected fluid loss for the risk zone and selecting a solution to reduce fluid loss in the risk zone. Furthermore, a method for treating drilling fluid loss at a drilling location, the method including calculating a drilling fluid loss rate at the drilling location, classifying the drilling fluid loss based on the drilling fluid loss rate, and selecting a solution based at least in part on the classifying.

Owner:MI

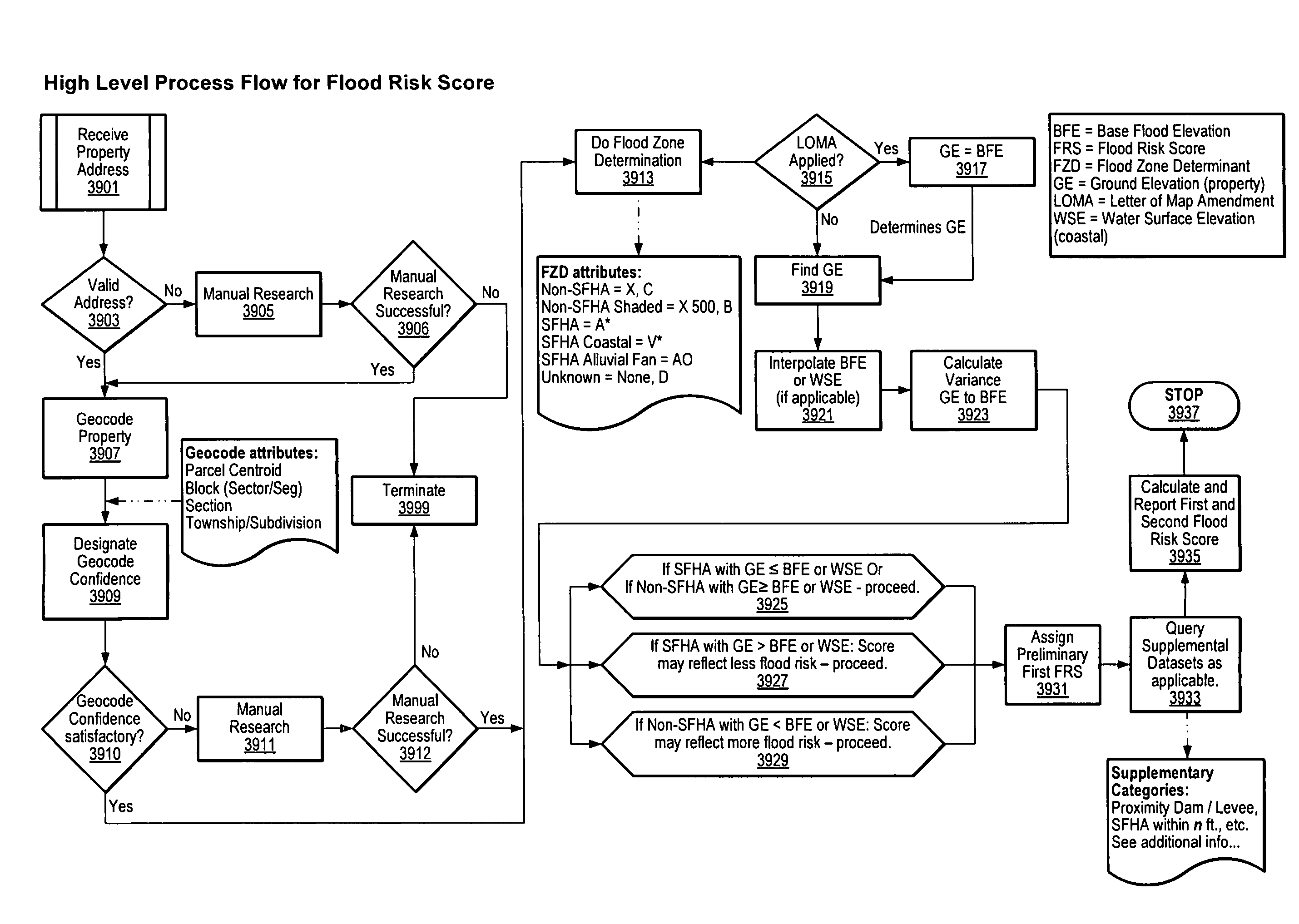

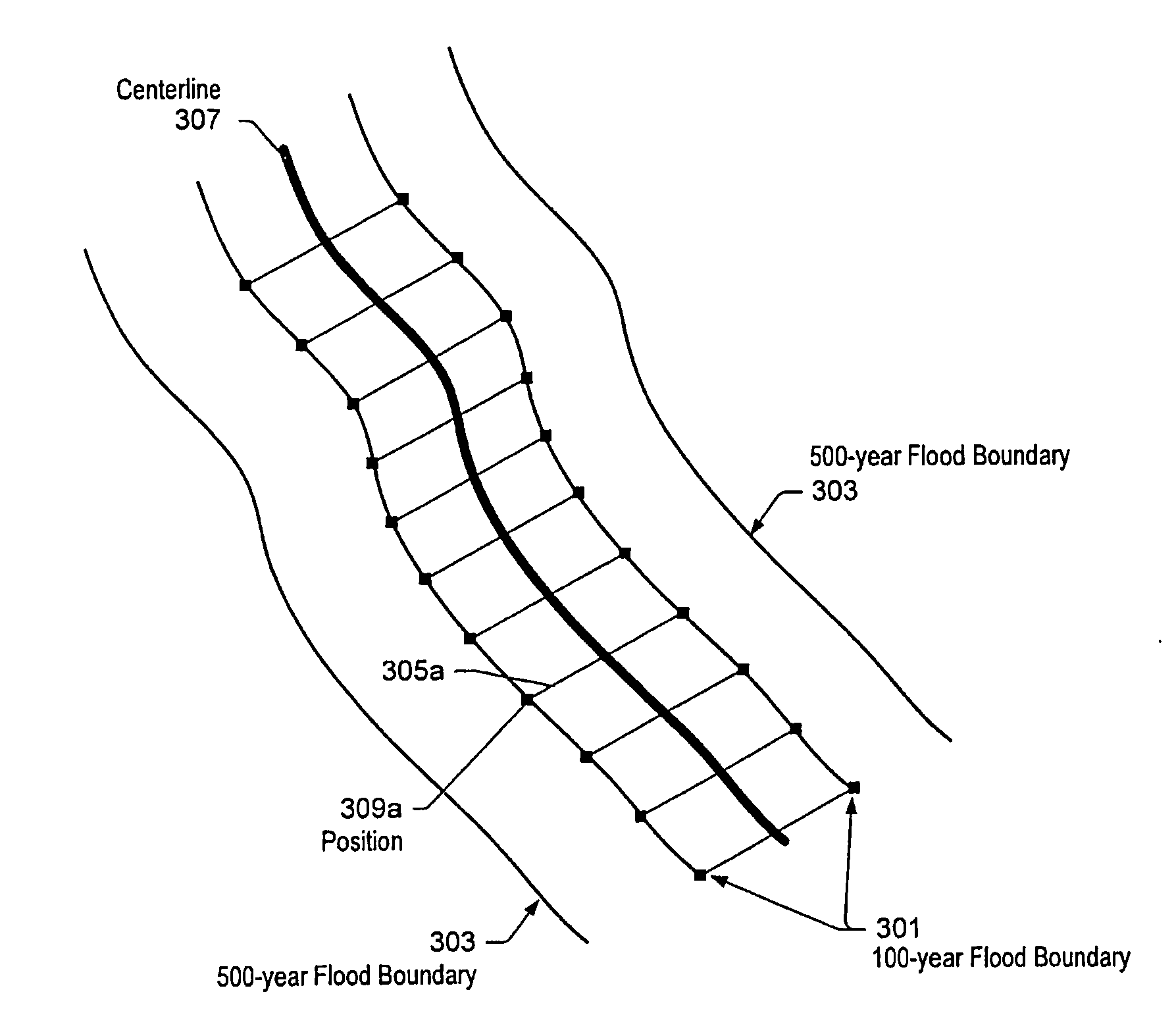

Systems and methods for quantifying flood risk

In various embodiments, a flood risk score may be determined for a property point that provides a comprehensive assessment of the property point's risk of flooding. Determining the flood risk score may include determining a flood risk characteristic for the property point and assigning a flood risk score that corresponds to the flood risk characteristic. In some embodiments, flood risk characteristics may include a difference in elevation between the elevation of the property point and an elevation of a calculated point (e.g., on a known flood risk zone boundary). Flood risk characteristics may also include a flood zone determination for the property point and / or proximity of the property point to a known flood risk zone boundary or a flood source. In some embodiments, flood risk scores may be provided on flood risk score reports.

Owner:CORELOGIC SOLUTIONS

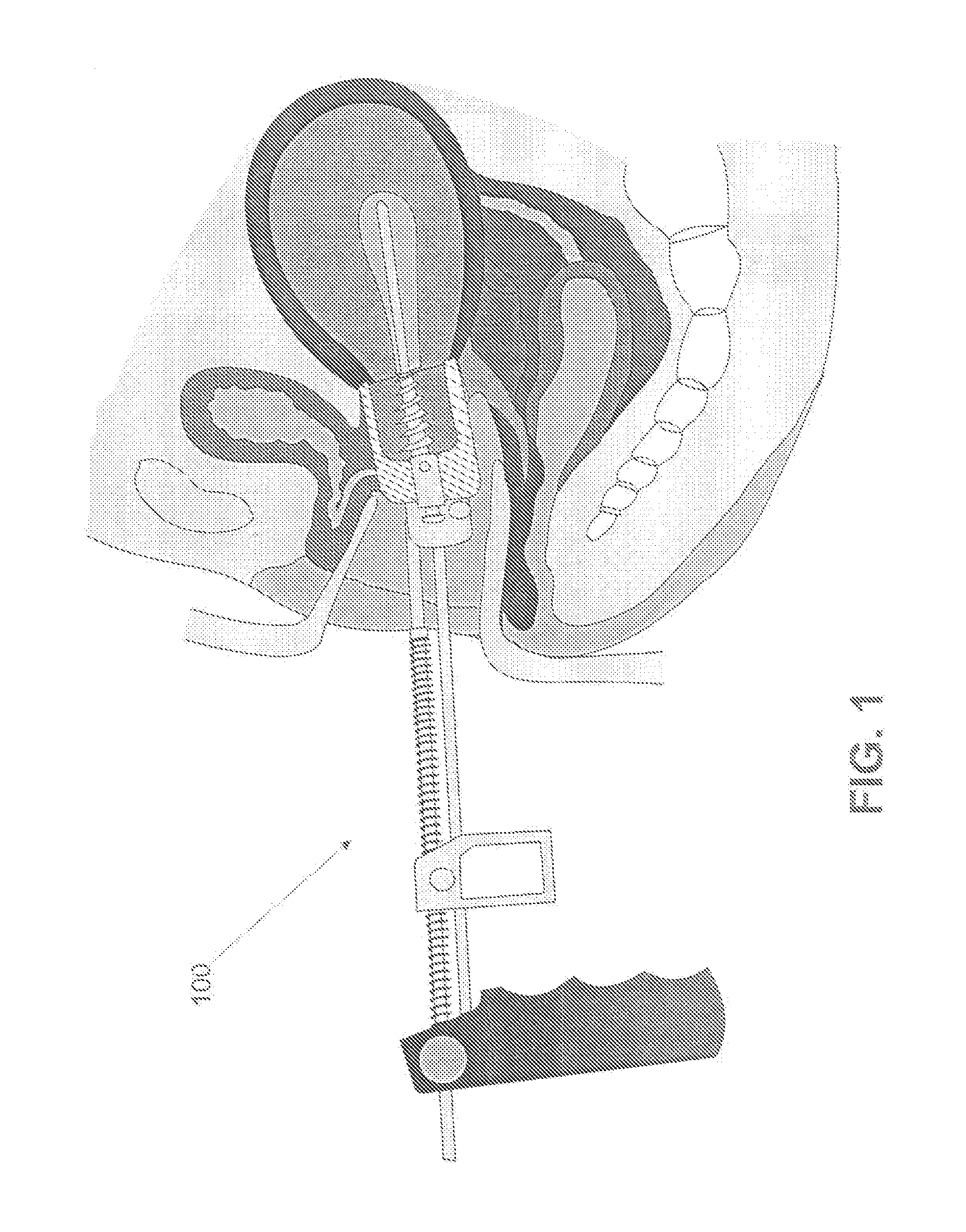

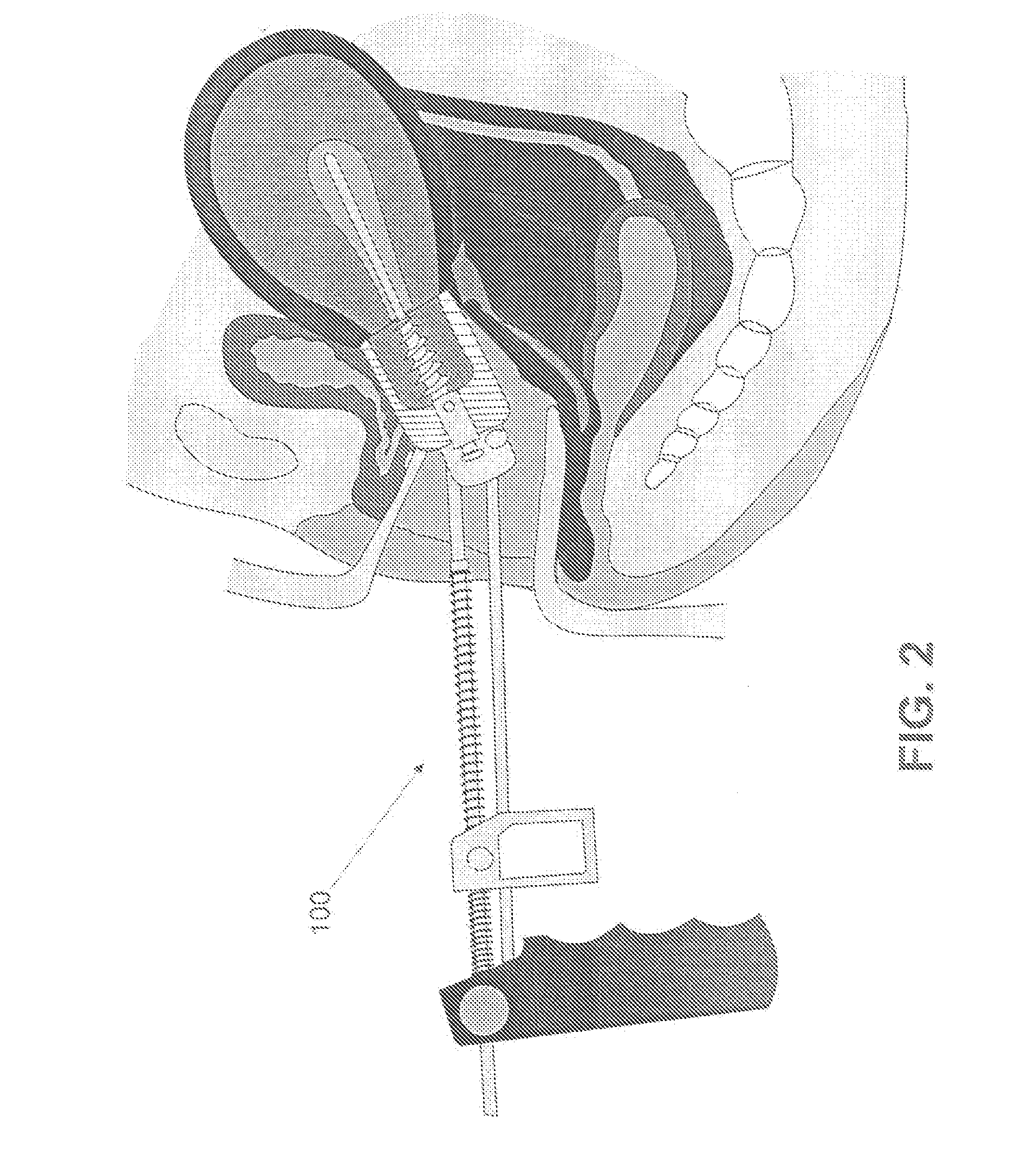

Uterine Manipulator for Complete Removal of Human Uteri

A uterine manipulator designed to perform a total laparoscopic hysterectomy in an easy, safe and effective manner, which simplifies the surgical procedure by improving the anatomical angle of access to round ligaments, salpinges, utero-ovarian ligaments, broad ligaments, uterine vessels, anterior endopelvic fascia, lateral endopelvic fascia, but very especially to the posterior endopelvic fascia due to innovative design of said manipulator that allows the anteversoflexion movement of uterus. In addition, the invention moves ureters away from the risk zone when tying the uterine vessels, and protects and prevents the mobilization of the bladder and rectum, as a result of improving the angle of access. Additionally, the manipulator has the advantage of being easily manageable because of the anatomical design of its handle and its strong design allows for total hysterectomy uterus, still too big and heavy uteri.

Owner:LOPEZ ZEPEDA MARCO ANTONIO

Flash memory management method that is resistant to data corruption by power loss

The present invention includes a method of managing page-based data storage media such as flash media, a system that uses the method, and a computer-readable storage medium bearing code for implementing the method. For each page, a corresponding risk zone, of other pages whose data are put at risk of corruption if writing to the page is interrupted, is identified. When a page is selected for writing new data, the written pages in its risk zone are copied to a log. As necessary, corrupt data are replaced with corresponding data from the log.

Owner:WESTERN DIGITAL ISRAEL LTD

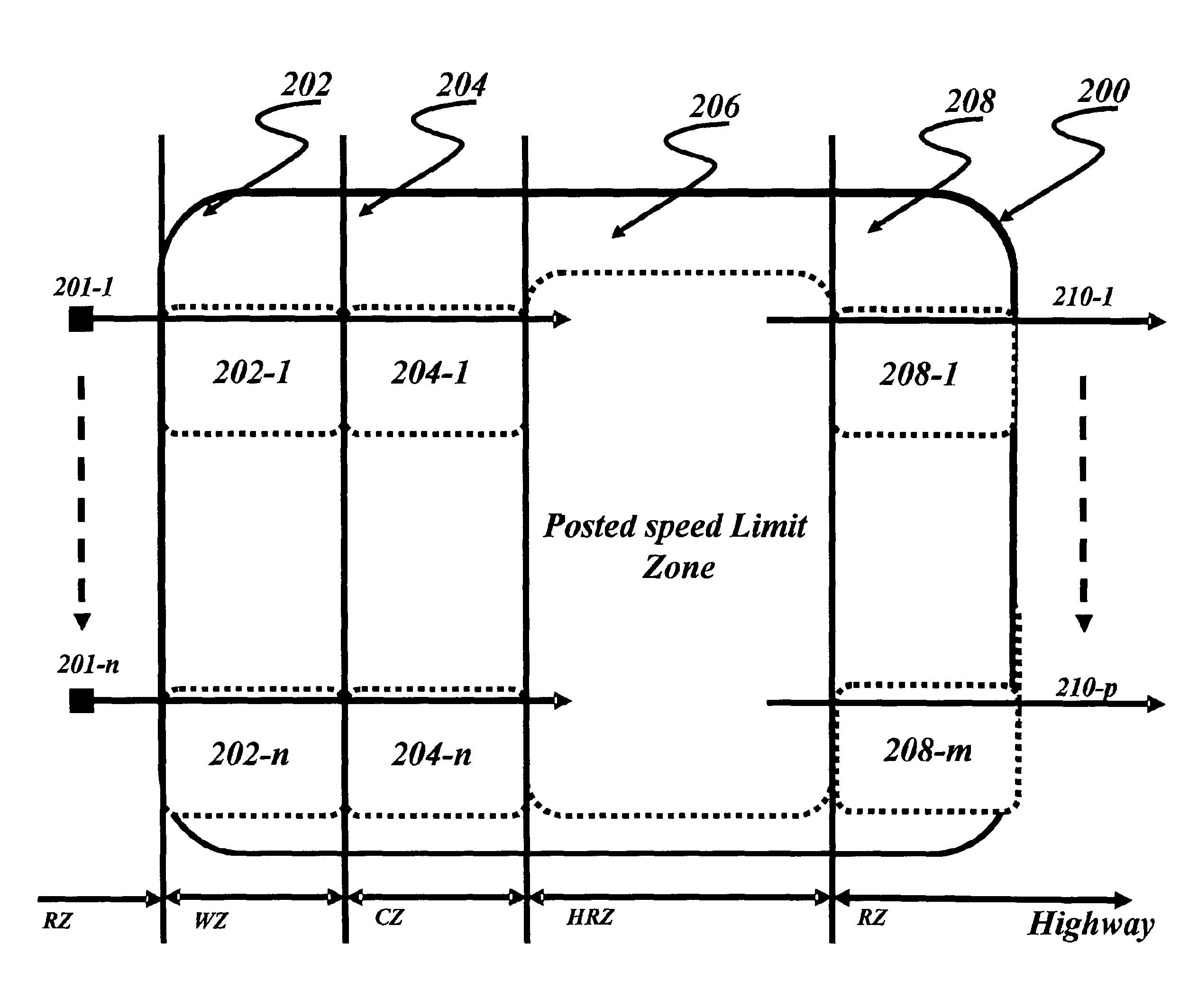

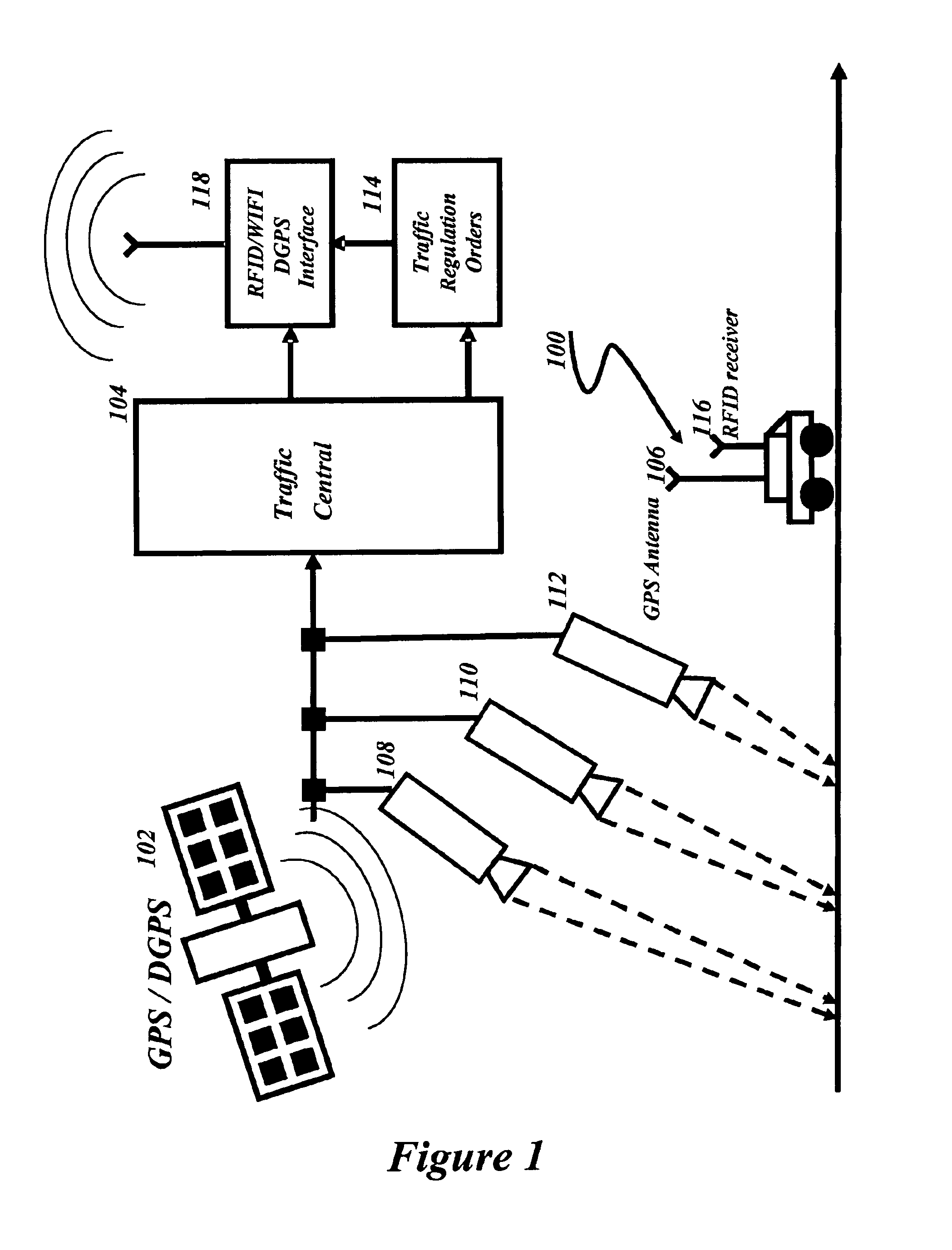

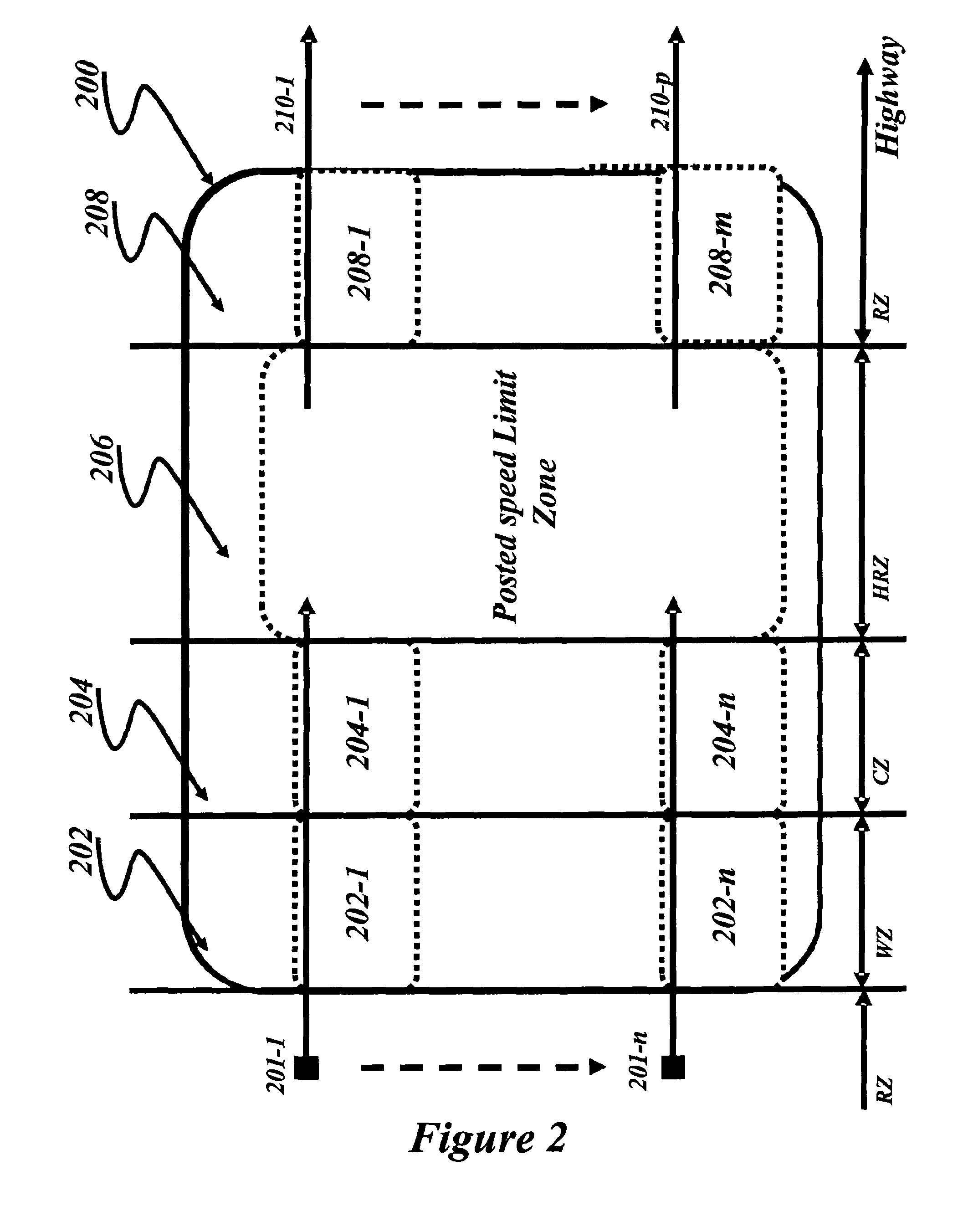

Method and system for monitoring speed of a vehicle

Owner:KYNDRYL INC

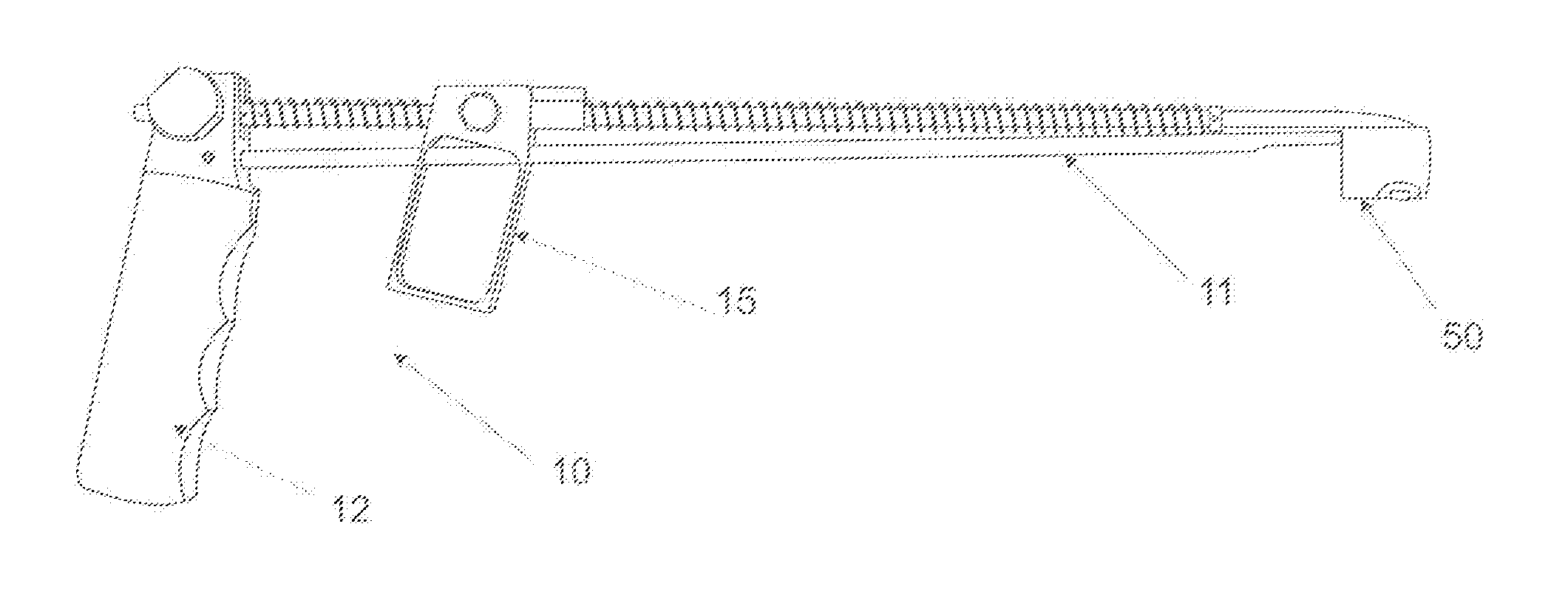

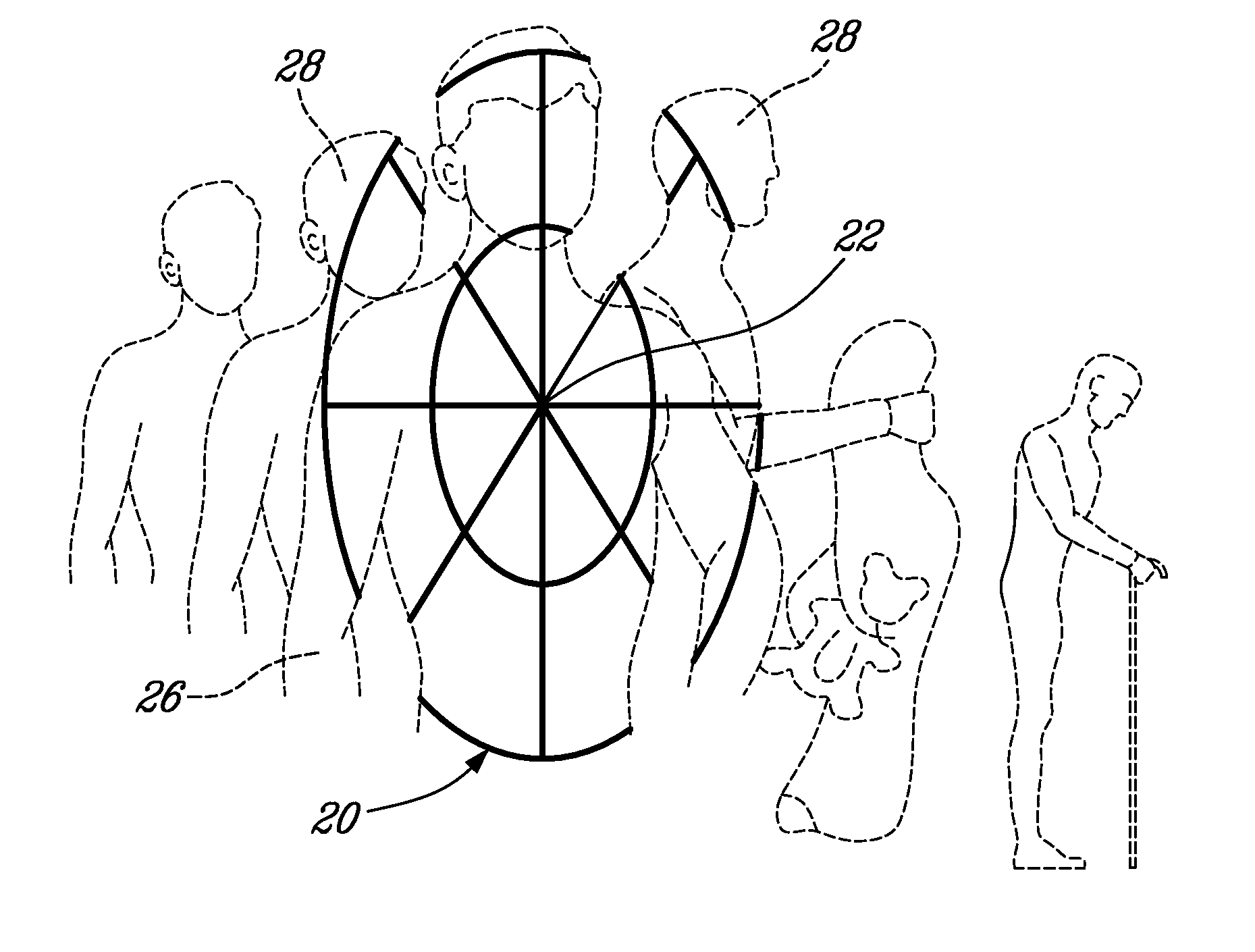

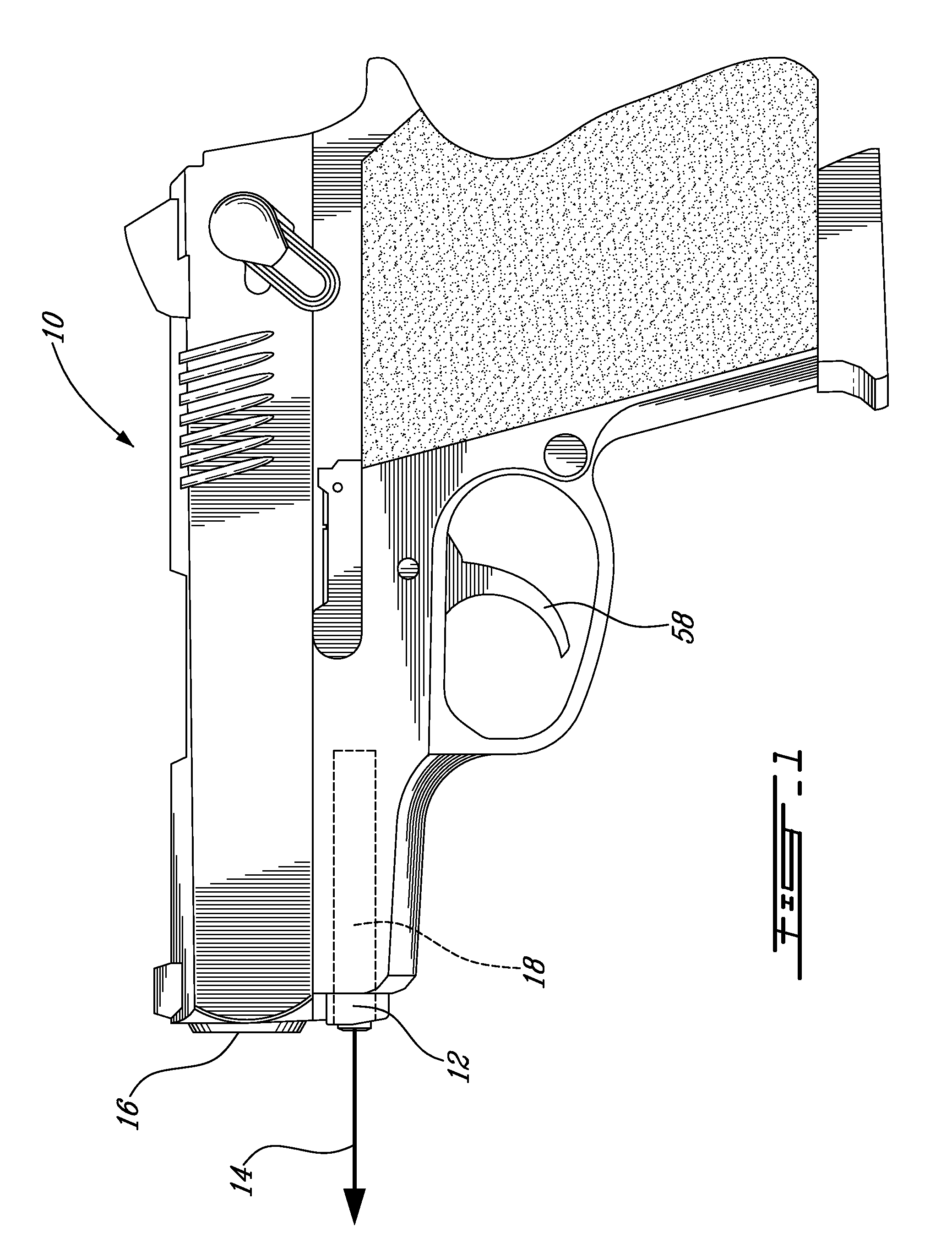

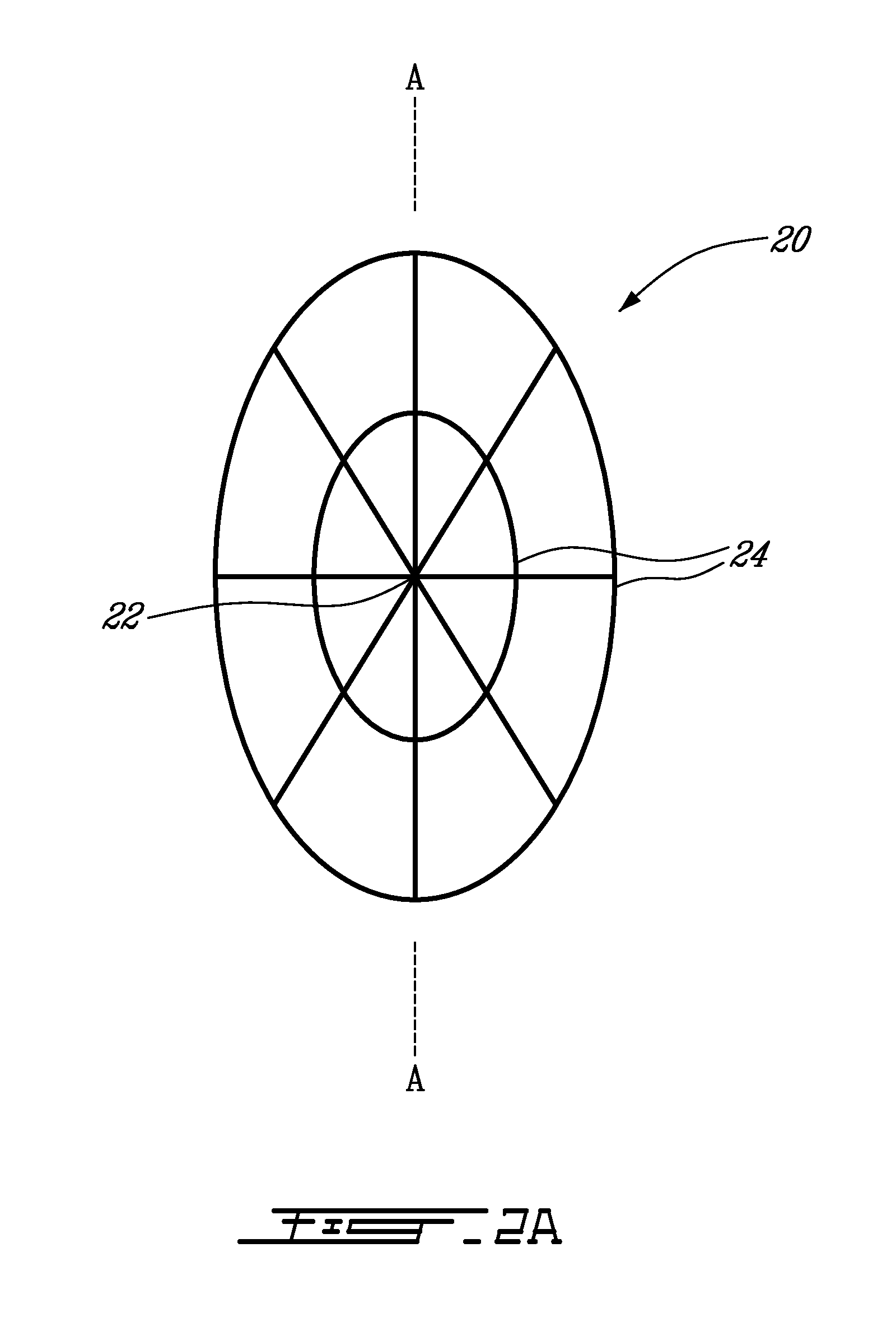

Splatter indicator sight for firearms

A splatter indicator sight for use with a firearm taking one or more variables affecting the bullet trajectory under consideration to create a risk zone map of the different zones which can be hit after the user has aimed the firearm at a target. In embodiments of the invention, the boundaries of the most probable hit zones can be quickly indicated to the user by the risk zone map. The risk zone map is illustratively created by projecting a laser beam directly on the target.

Owner:9609385 CANADA INC

Systems and methods for quantifying flood risk

In various embodiments, a flood risk score may be determined for a property point that provides a comprehensive assessment of the property point's risk of flooding. Determining the flood risk score may include determining a flood risk characteristic for the property point and assigning a flood risk score that corresponds to the flood risk characteristic. In some embodiments, flood risk characteristics may include a difference in elevation between the elevation of the property point and an elevation of a calculated point (e.g., on a known flood risk zone boundary). Flood risk characteristics may also include a flood zone determination for the property point and / or proximity of the property point to a known flood risk zone boundary or a flood source. In some embodiments, flood risk scores may be provided on flood risk score reports.

Owner:CORELOGIC SOLUTIONS

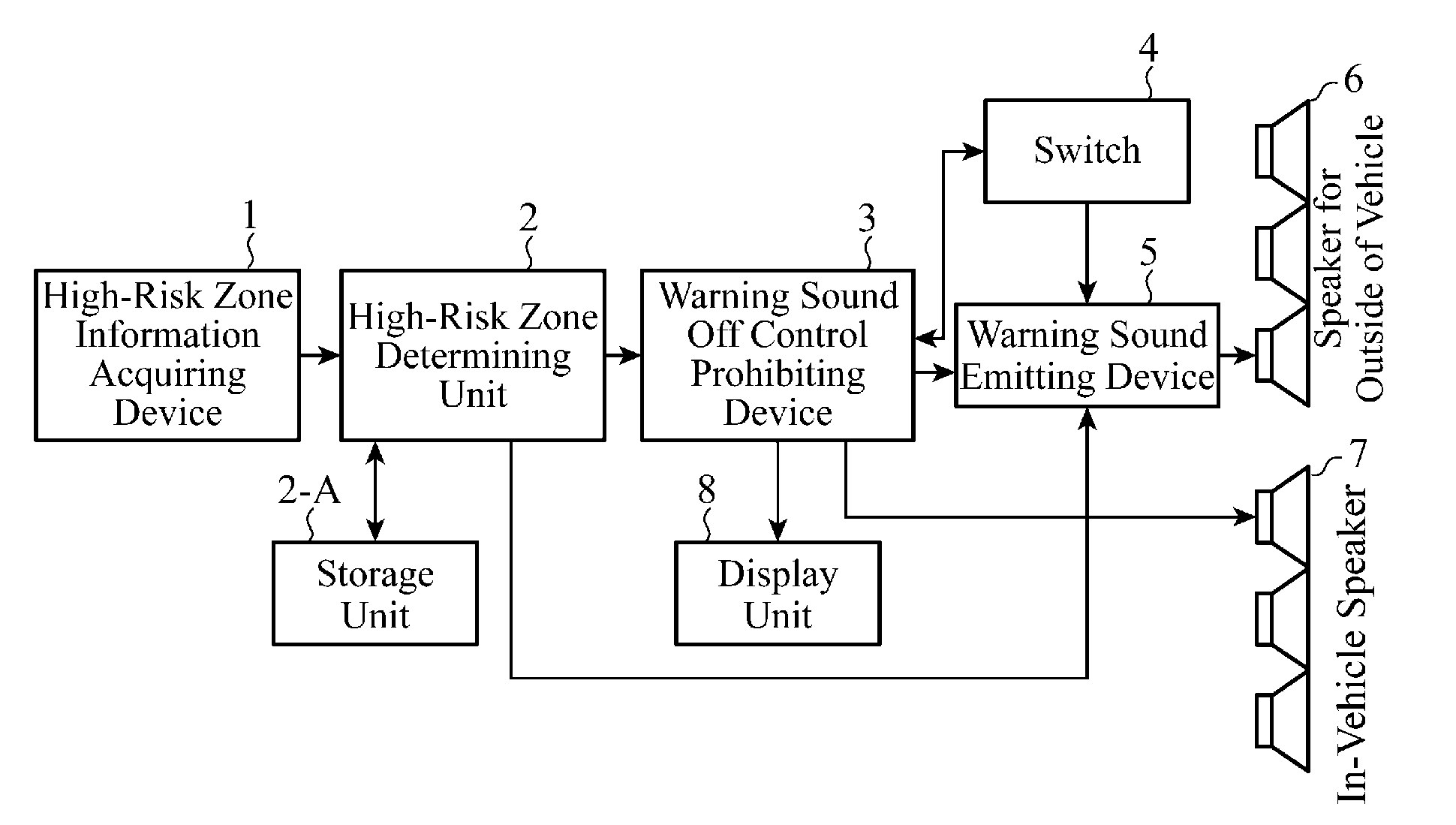

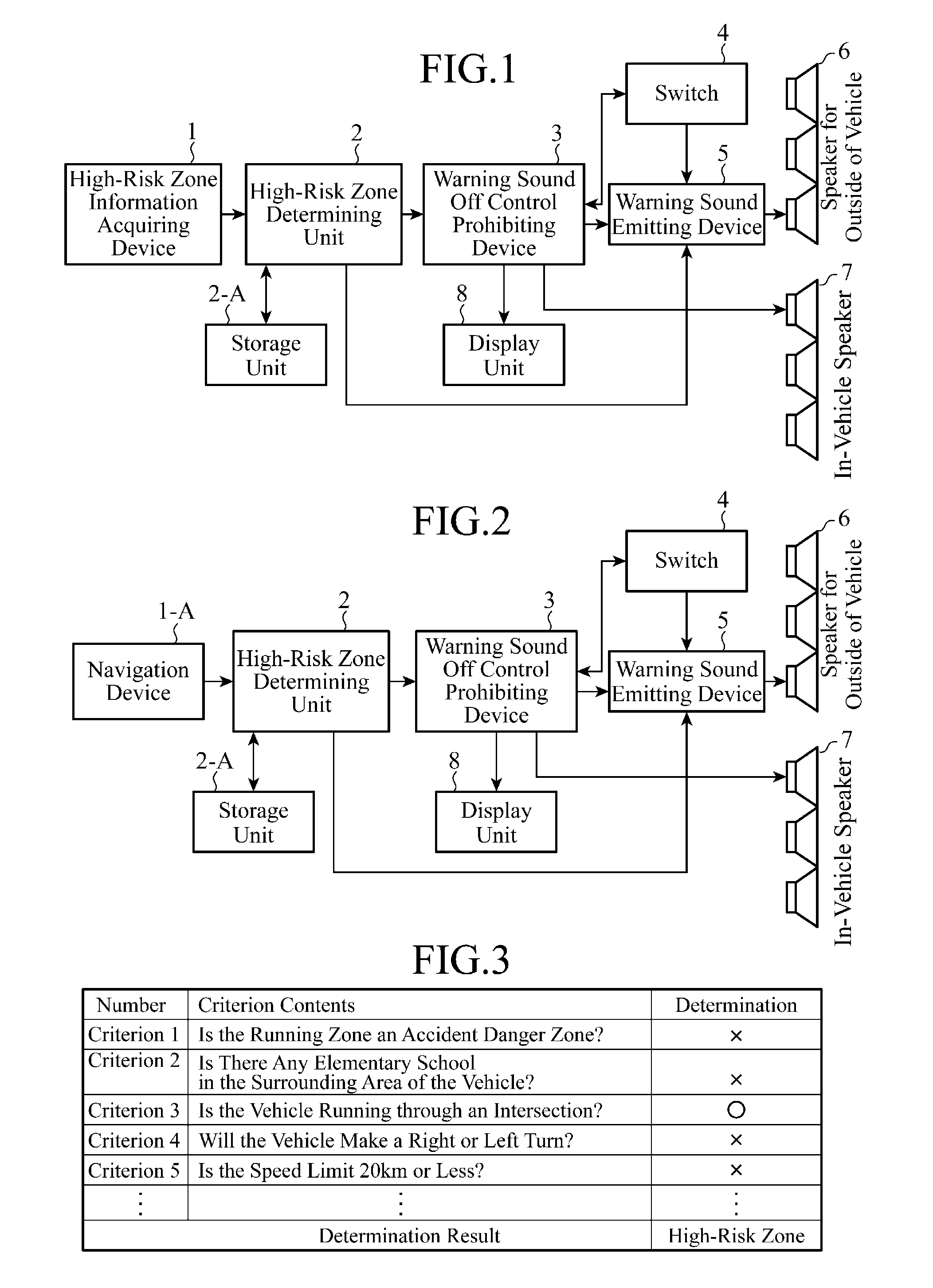

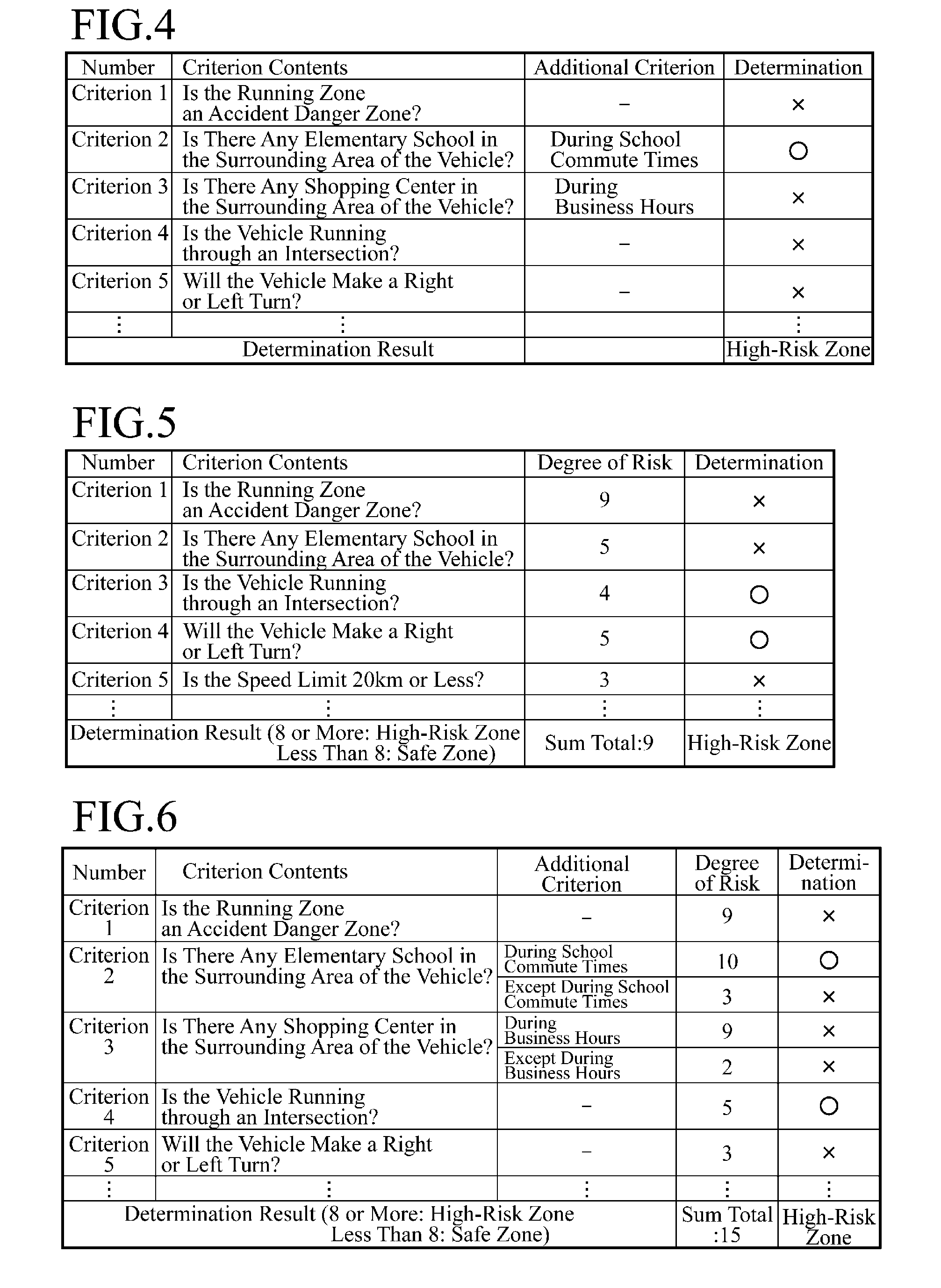

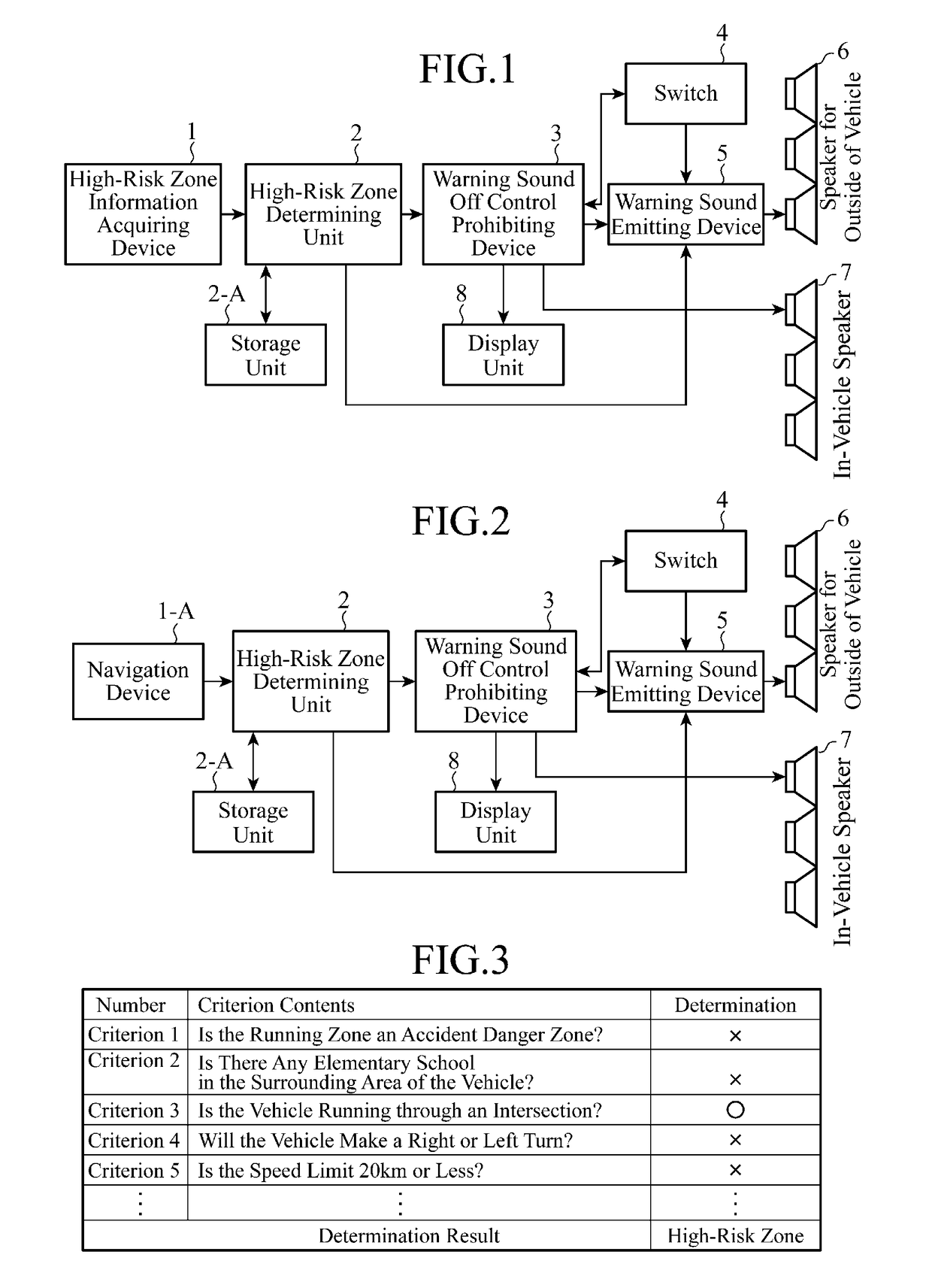

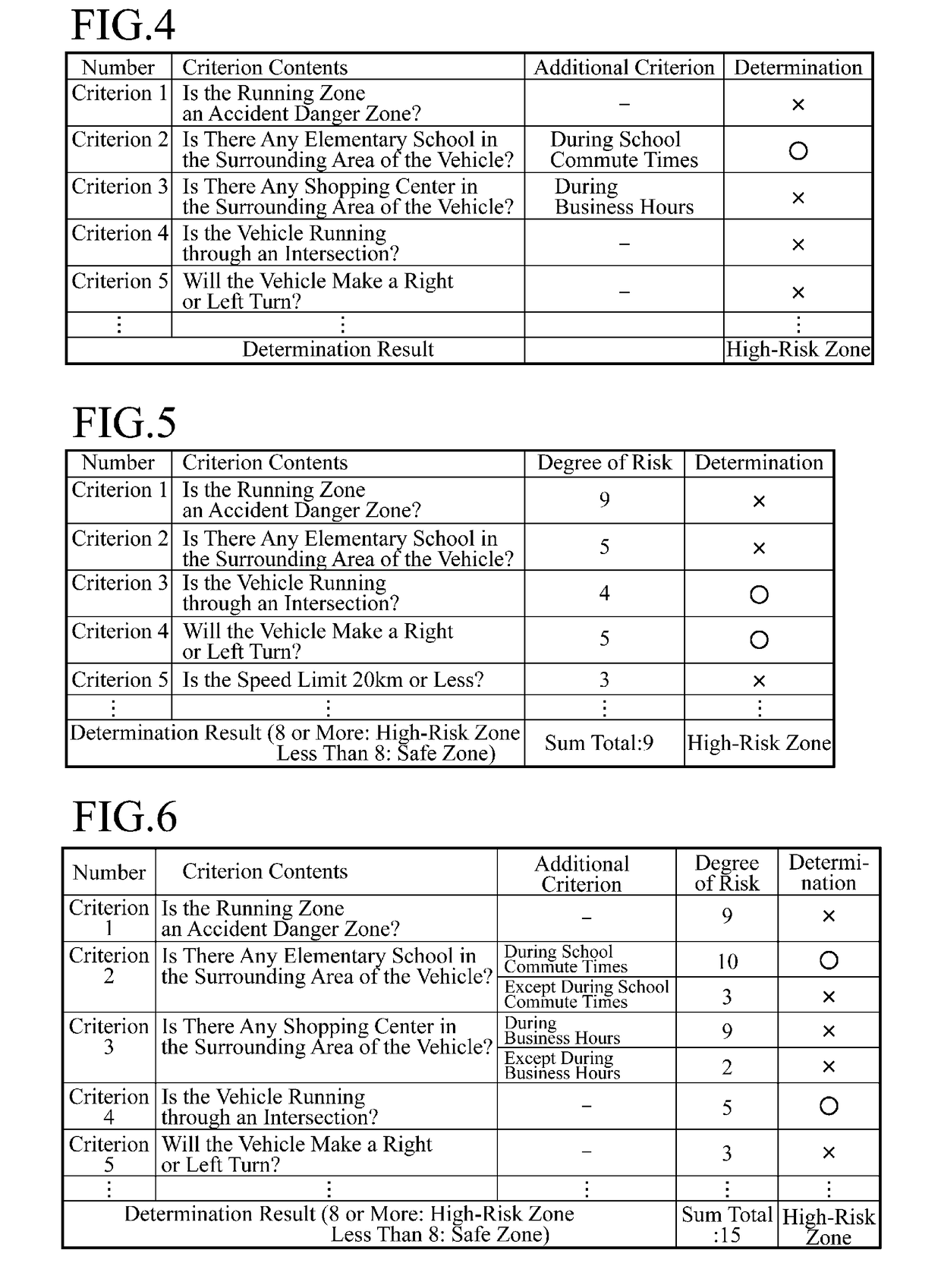

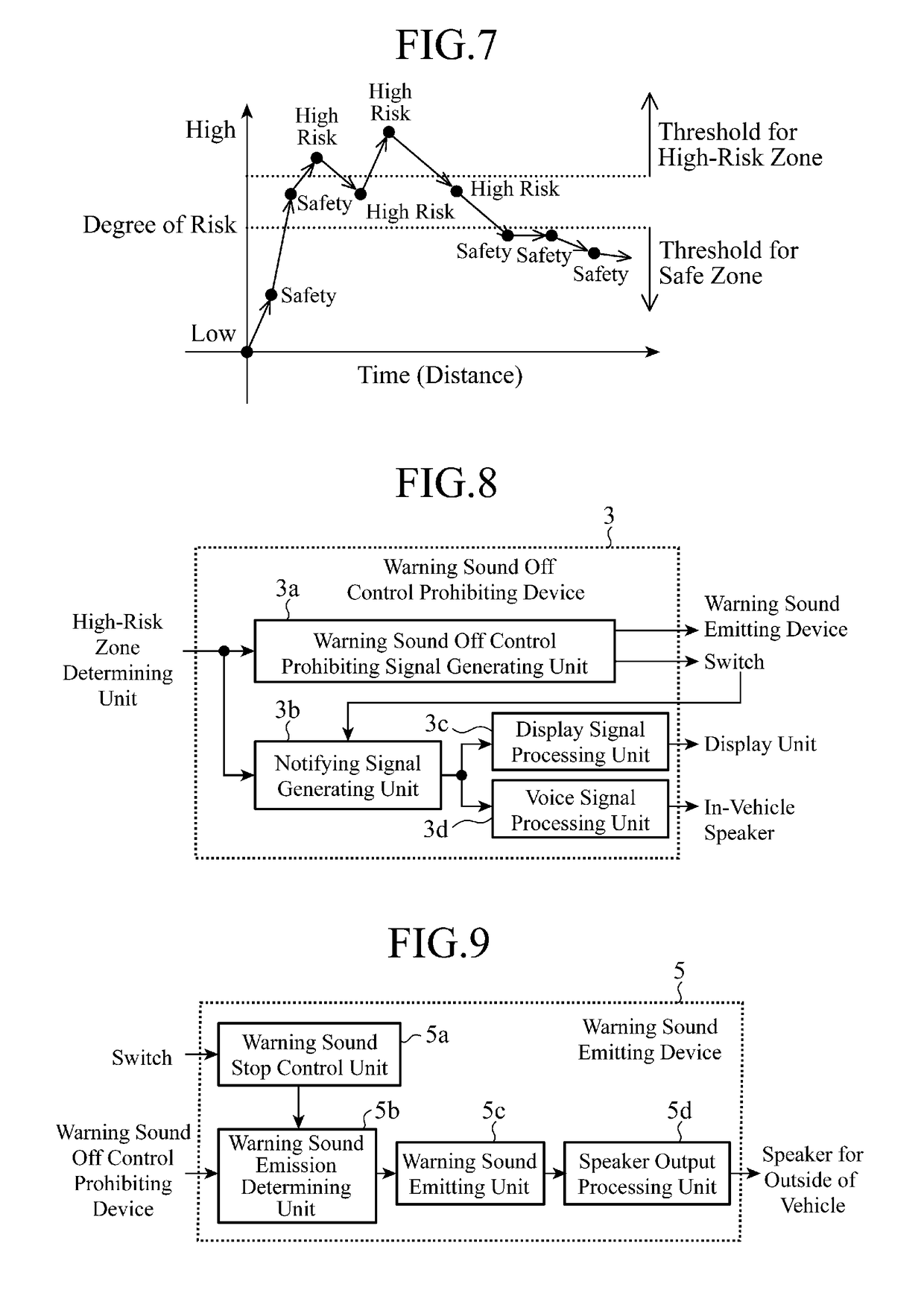

Sound-directed-outside-vehicle emitting device

ActiveUS20110313617A1Improve securityAcoustic signal devicesDigital data processing detailsEngineeringRisk zone

A sound-directed-outside-vehicle emitting device includes a storage unit 2-A for storing criteria by each of which to determine whether or not a running zone is a high-risk zone, each of the criteria describing a status of the vehicle, and a navigation device 1-A for acquiring information showing a status of the vehicle. The sound-directed-outside-vehicle emitting device compares the information acquired by the navigation device 1-A with the criteria stored in the storage unit 2-A to determine whether the above-mentioned vehicle is running through a high-risk zone, and does not stop the output of a warning sound when determining that the vehicle is running through a high-risk zone even if a switch 4 for commanding a stop of the output of the warning sound is operated.

Owner:MITSUBISHI ELECTRIC CORP

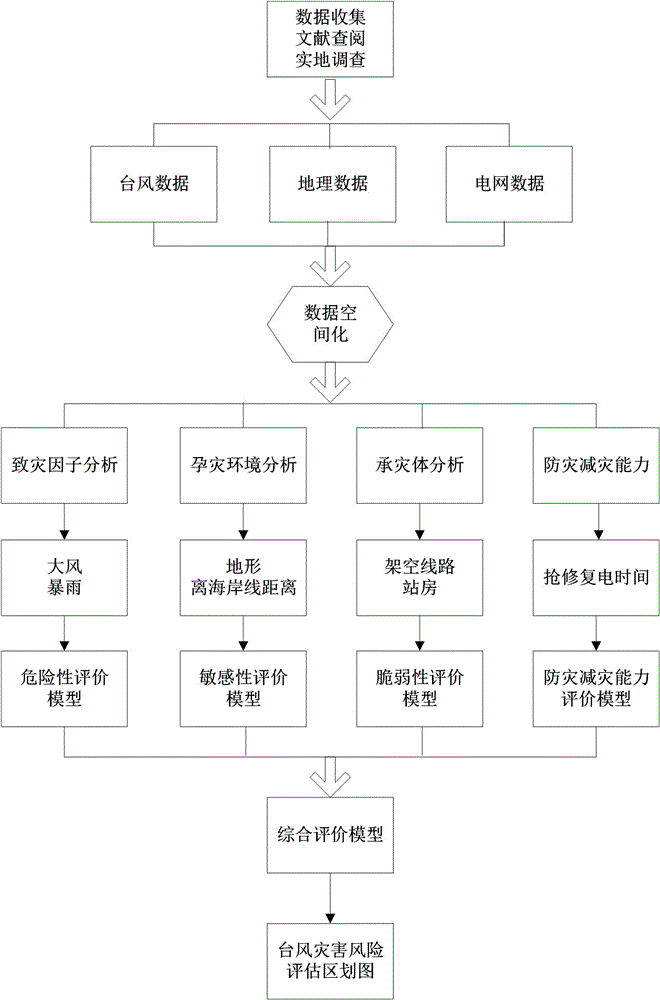

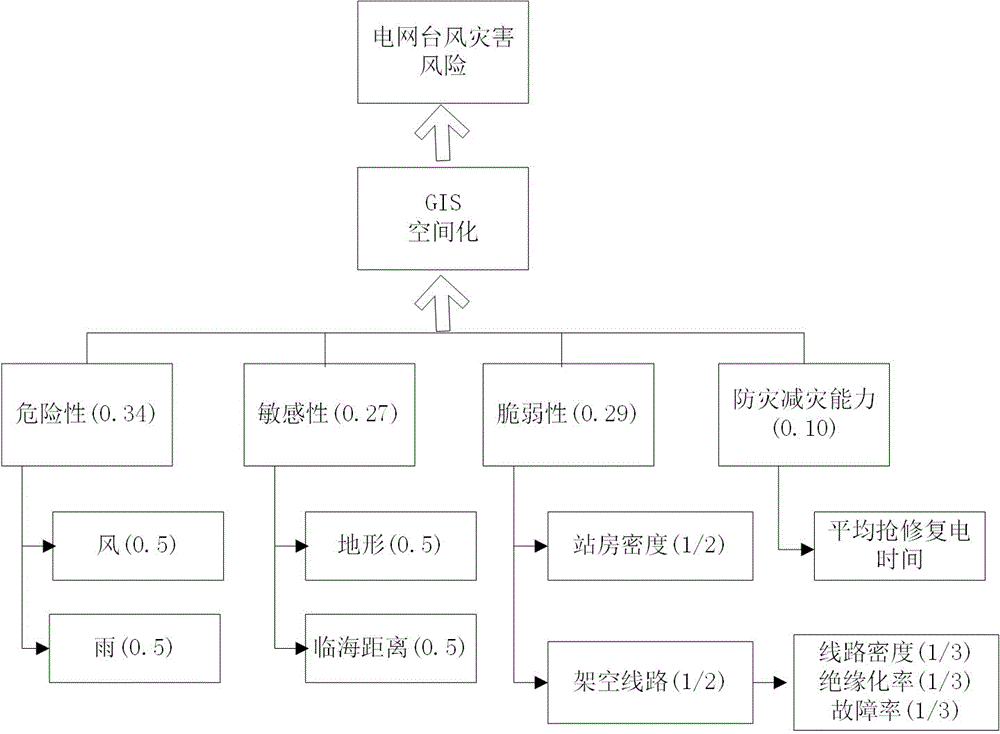

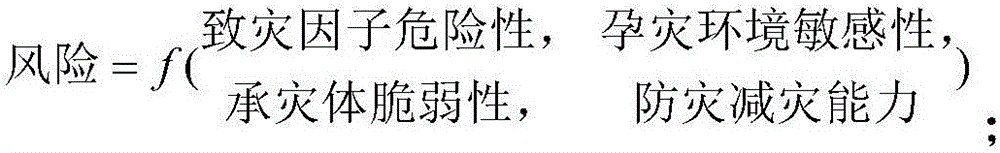

GIS-based typhoon disaster risk assessment method for power grid

The invention relates to a GIS-based typhoon disaster risk assessment method for a power grid. Through analysis and assessment of risk of typhoon, topographical sensitivity, fragility of the power grid and disaster prevention and mitigation capabilities, the typhoon disaster risk assessment method for the power grid is created. On one hand, compiling of a typhoon disaster risk zoning map for the power grid can be realized, and on the other hand, systematization and integrity of disaster risk division can be perfected to provide technical support for making a countermeasure for regional disaster prevention and mitigation.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

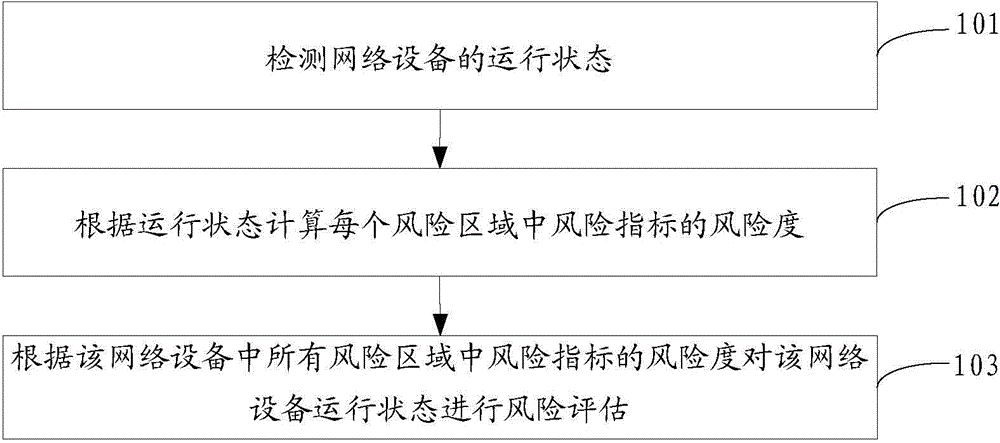

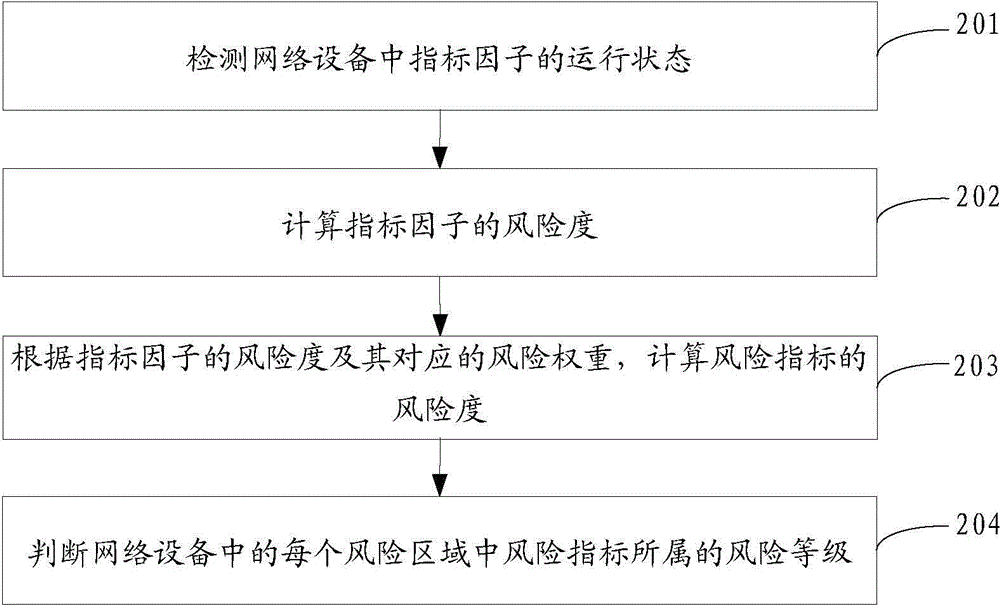

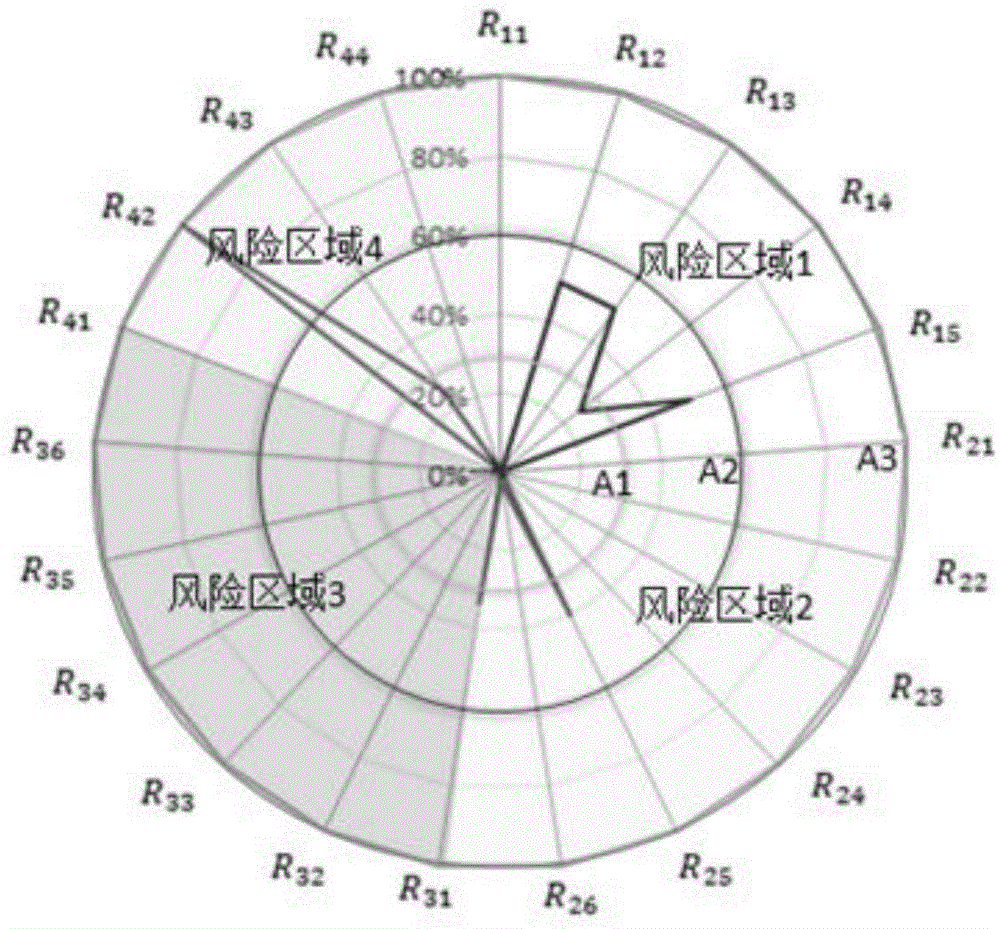

Data network device risk assessment method and device

InactiveCN106203666AComprehensive risk indicatorsThe evaluation method is reliableForecastingRisk indicatorNetwork management

The invention provides a data network device risk assessment method and device. The method is applied to a network management device, a risk zone is set for each network device in an electric power communication data network by the network management device, and each risk zone comprises one or more risk indicators; the method comprises the following steps: an operation state of the network device is detected, risk degrees of risk indicators in each risk zone are calculated according to the operation state, and the operation state of the network device is subjected to risk assessment operation according to risk degrees of risk indicators in all risk zones of the network device. Compared with technologies of the prior art, the data network device risk assessment method and device are advantaged by comprehensive risk indicators, reliable assessment method and accurate risk assessment results.

Owner:CHINA SOUTHERN POWER GRID COMPANY

Flash memory management method that is resistant to data corruption by power loss

InactiveUS7603525B2Avoid dataMemory architecture accessing/allocationRead-only memoriesElectricityRisk zone

A method for managing page-based data storage media such as flash media, a system that uses that method, and a computer-readable storage medium bearing code for implementing the method. New data are written to the storage medium in a manner that precludes corruption of old data if the writing of the new data is interrupted. Specifically, risk zones are defined, by identifying, for each page, the other pages whose data are put at risk of corruption if writing to the page is interrupted. A page, that otherwise would be the target of a write operation, is not written if any of the pages in its risk zone contain data that could be corrupted if the write operation is interrupted.

Owner:WESTERN DIGITAL ISRAEL LTD

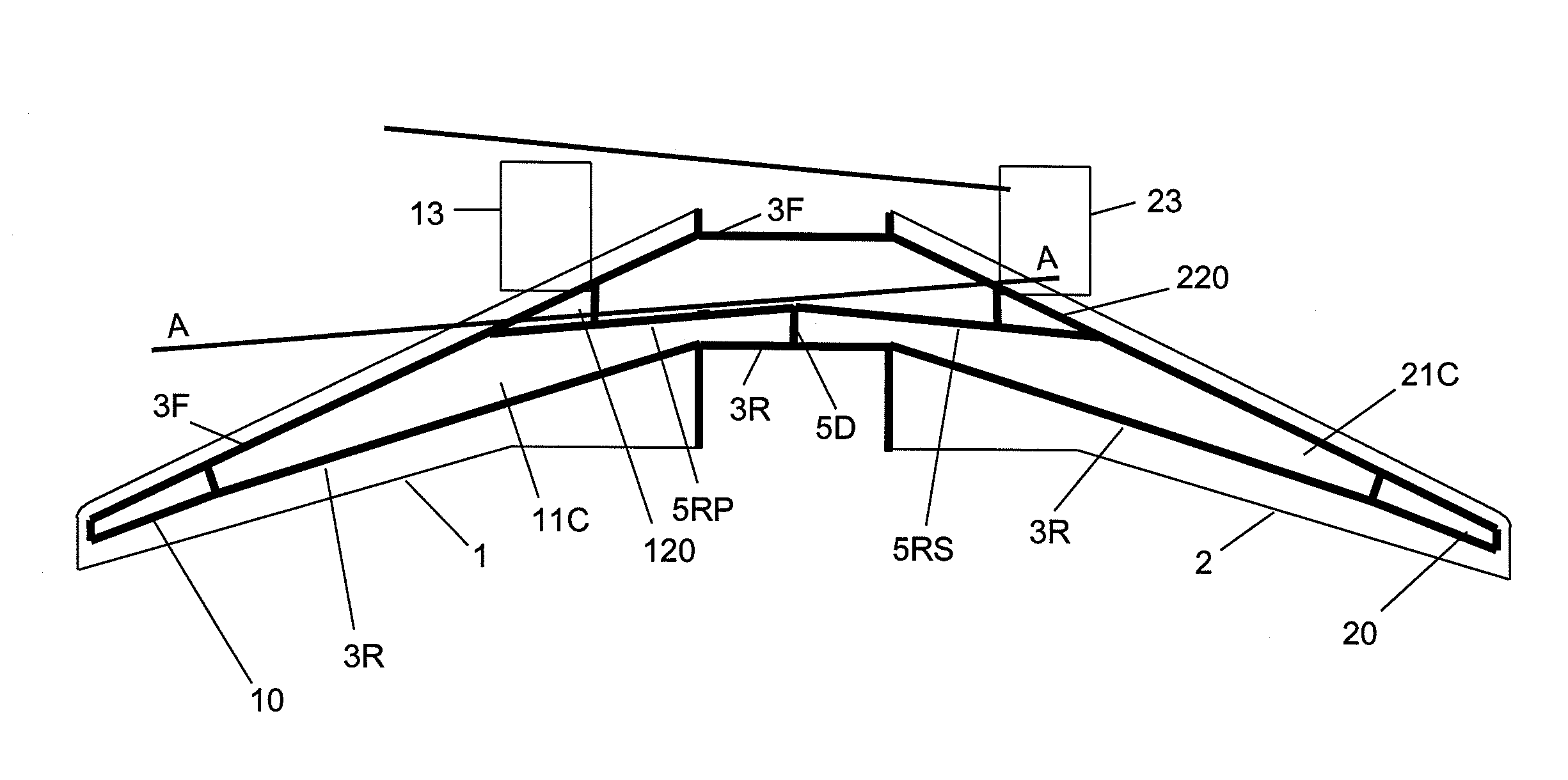

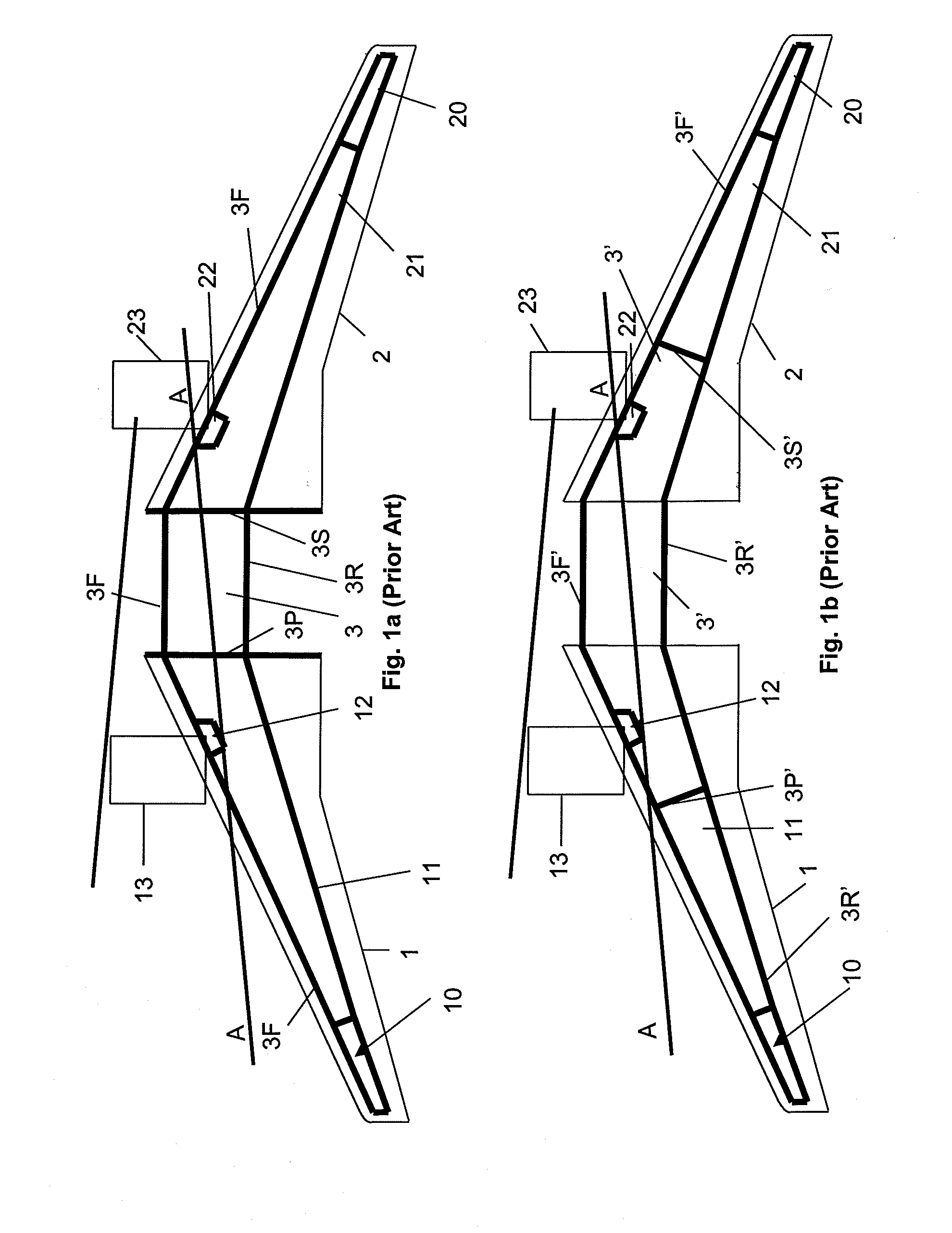

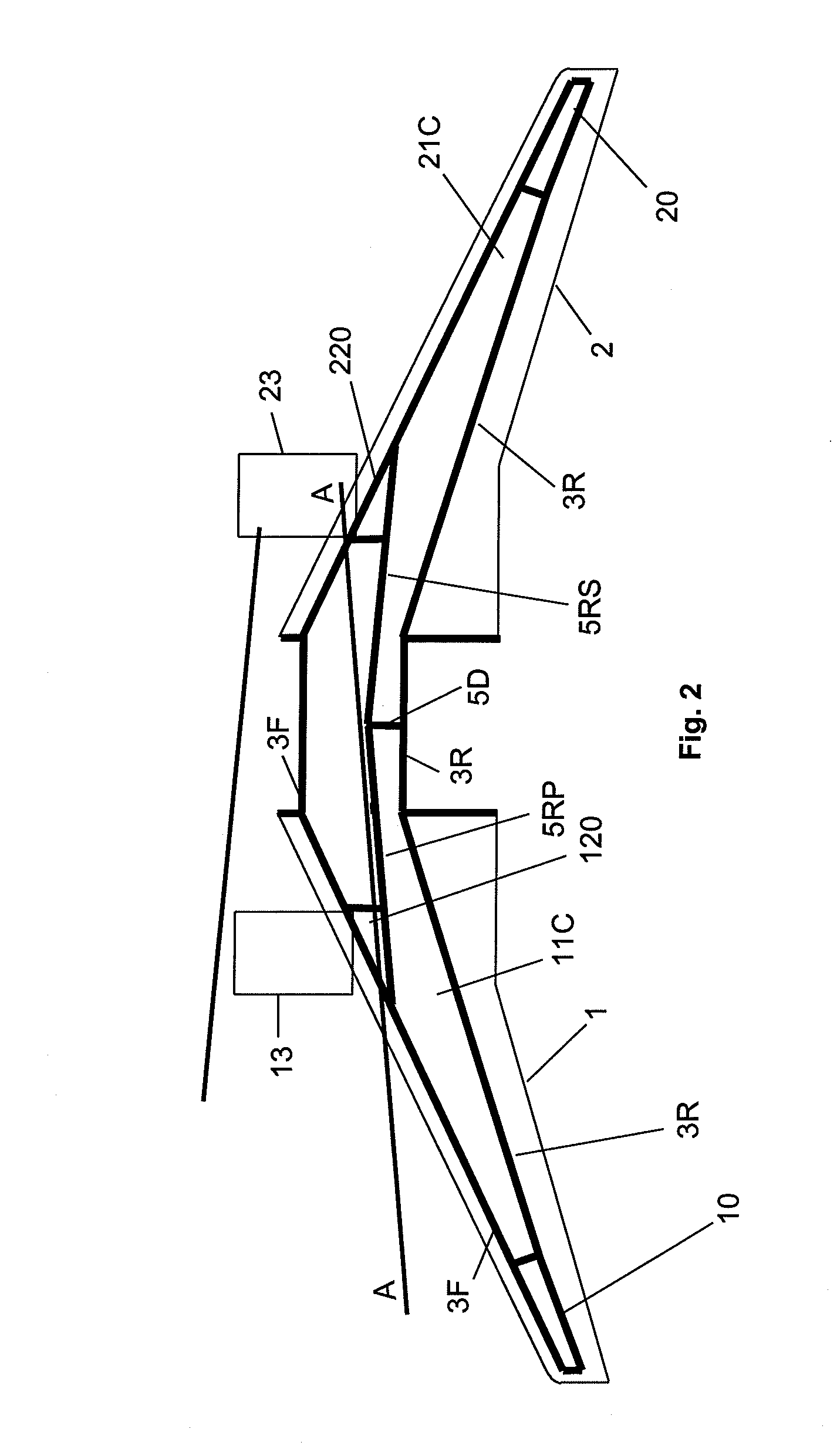

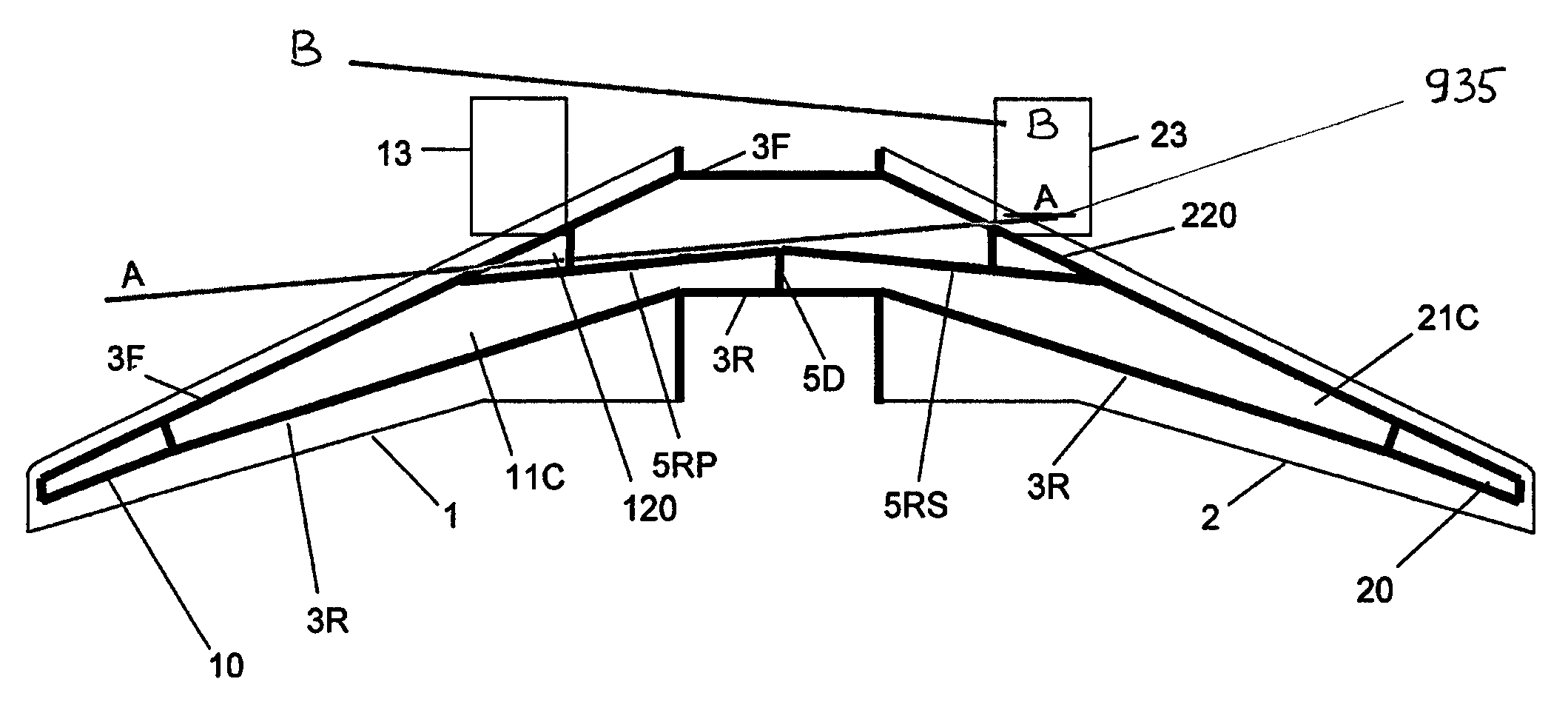

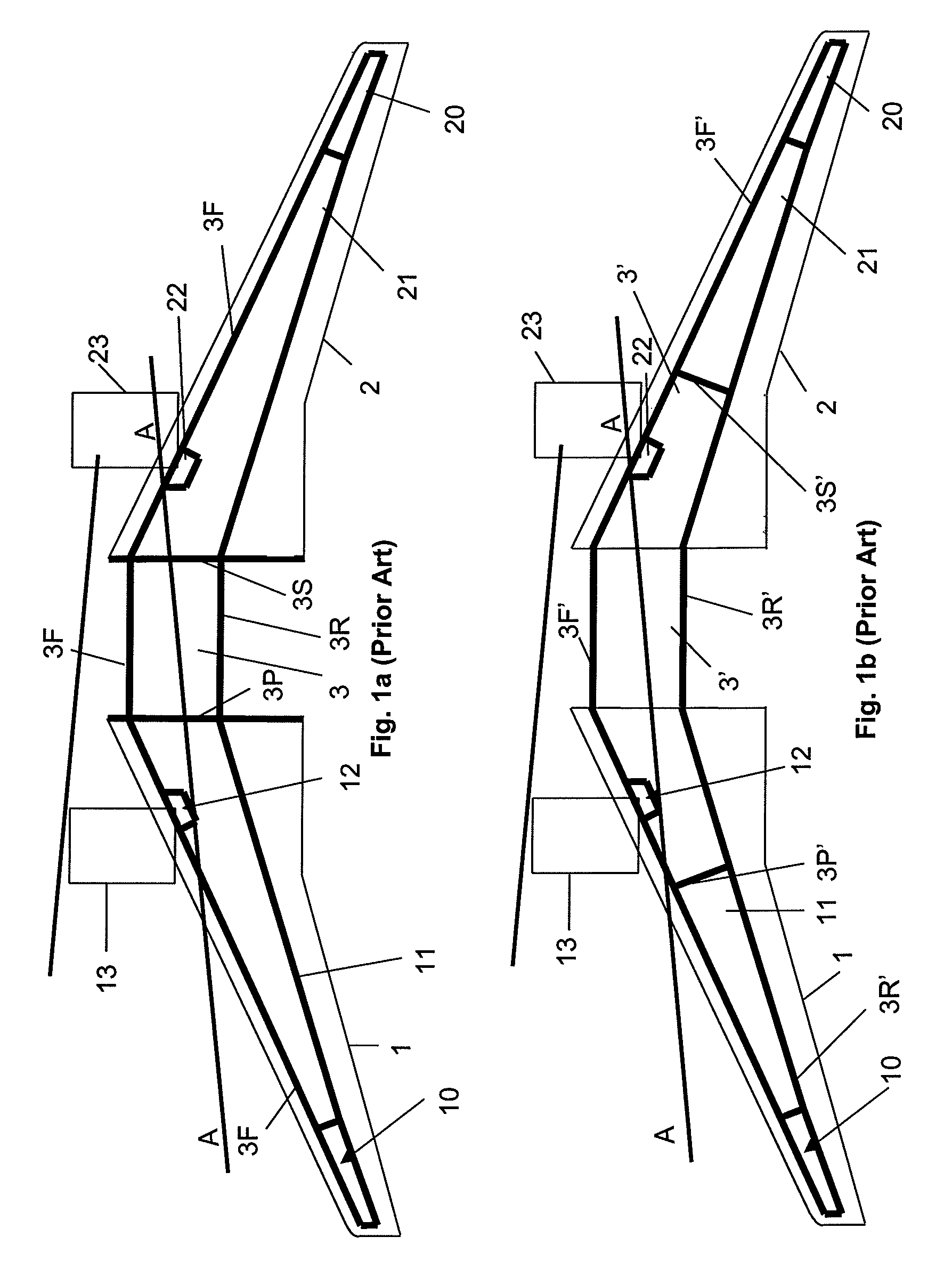

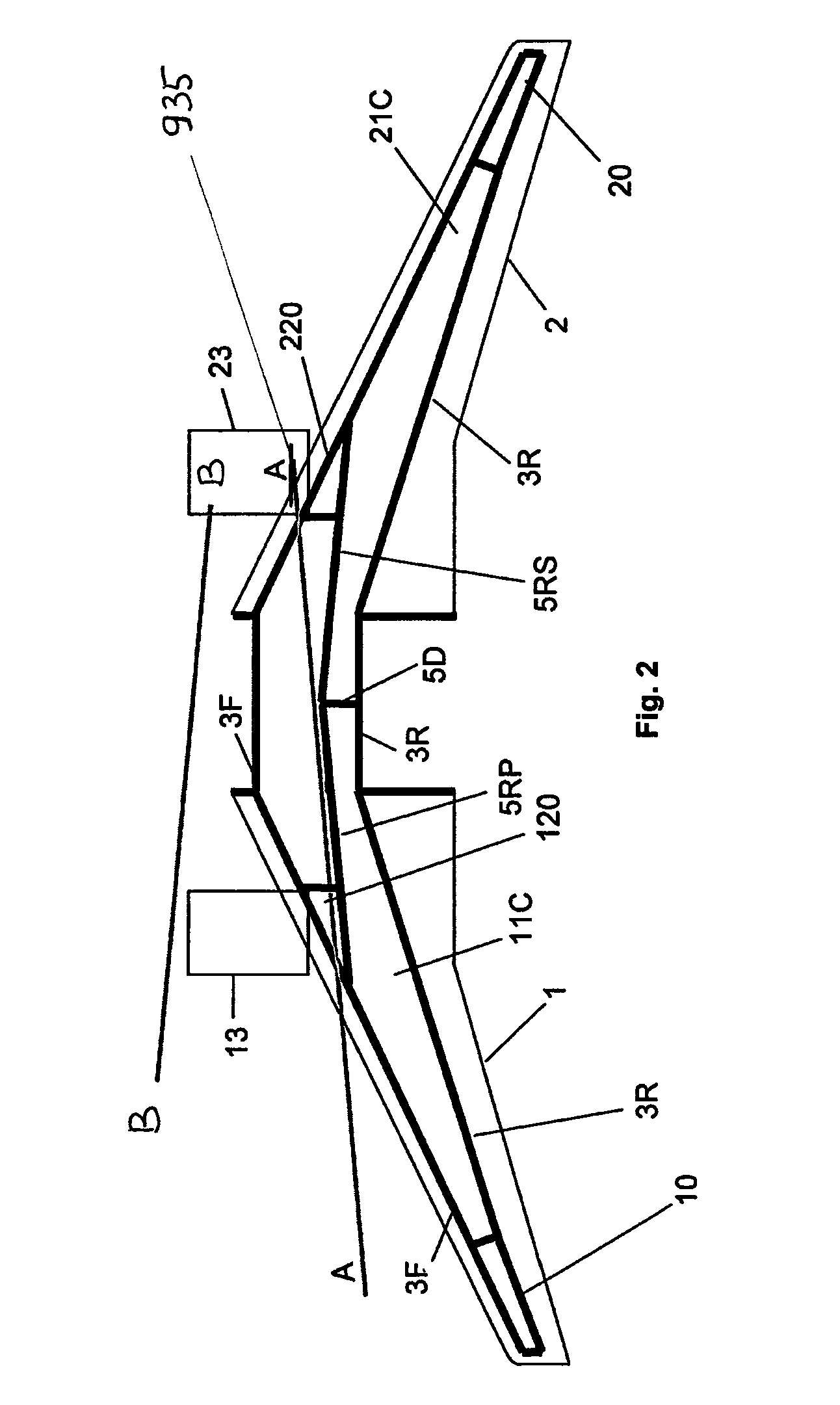

Aircraft wings and fuel tanks

InactiveUS20090212162A1Volume maximizationPower plant fuel tanksAircraft stabilisationVertical planeFuel tank

On failure, a burst rotor of a wing-mounted engine (13, 23) can penetrate fuel tank walls in the wing of a conventional aircraft. There exists a zone that is at risk of such damage. Thus, the layout of fuel tanks (3, 11C, 21C) in the wing of an aircraft in accordance with embodiments includes port and starboard inner fuel tanks (11C, 21C) that are positioned adjacent to a central fuel tank (3) in the central wing section, but outside of the at-risk zone. Each of the port and starboard inner fuel tanks (11C, 21C) is defined in part by a respective inner boundary member (5RP, 5RS) that when viewed in plan extends, at least in part, in a direction at an angle of less than 20° to the adjacent vertical plane (A-A) defining the at-risk zone. Thus the amount of fuel stored in fuel tanks (11C, 21C) in the wing assembly that cover a region outside of the at-risk zone and that do not extend into the at-risk zone may be increased.

Owner:AIRBUS OPERATIONS LTD

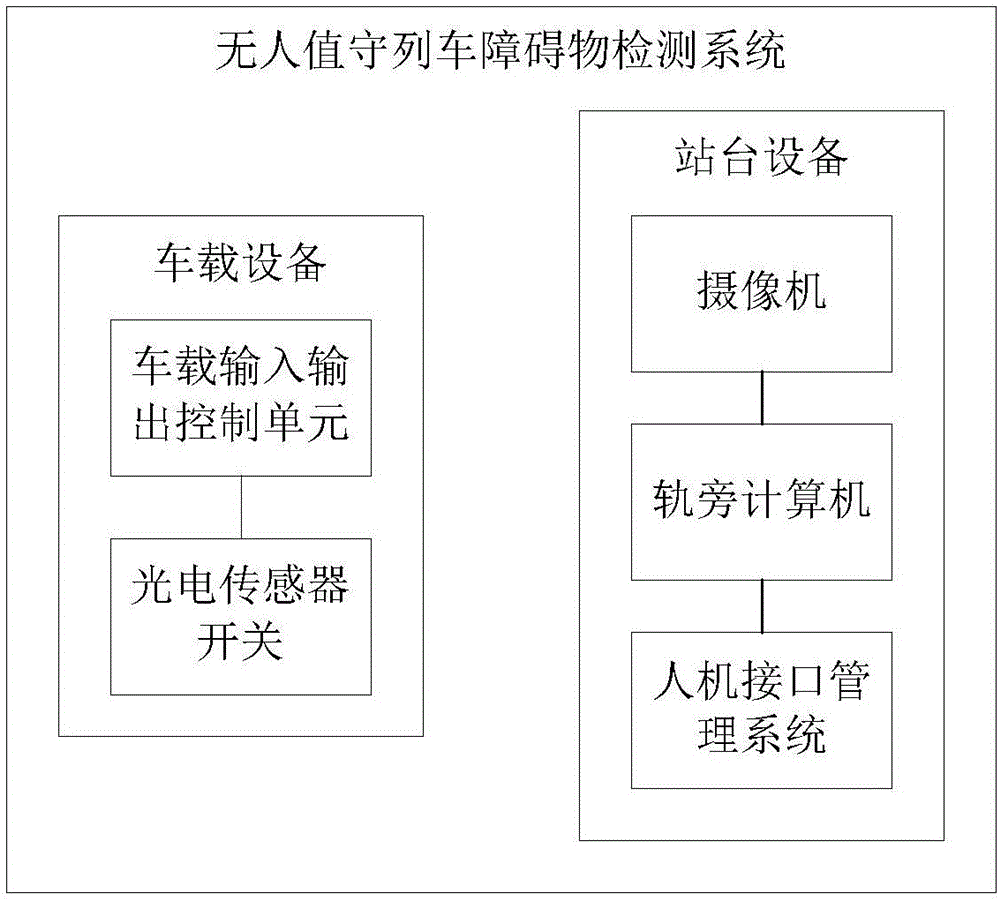

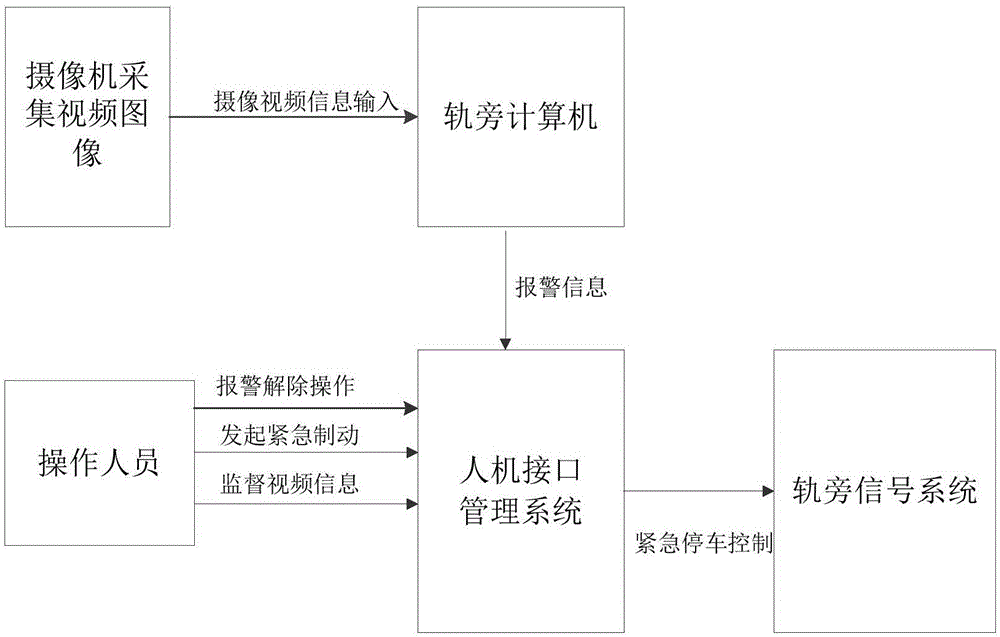

Unmanned on duty train barrier detection system

InactiveCN106572333ASolving Obstacles JudgmentHigh degree of automationClosed circuit television systemsBurglar alarmLow speedEngineering

The invention discloses an unmanned on duty train barrier detection system comprising platform equipment and vehicle equipment; the platform equipment is used for collecting video information on the head and tail of a railing zone platform with no safety door or a half-height safety door, detecting barriers according to object sizes in the video information, and sending alarms when a barrier is detected; the vehicle equipment is used for using a plurality of sensor switches to detect barriers in front of a train in a non-contact manner, and sending alarms when any sensor senses a barrier. The system allows the unmanned train to determine barriers in a low speed non-contact condition and in high risk zones like the platform, thus greatly improving the automation level and safety of the unmanned train signal system; in addition, the detection system is designed by using general relay or analog quantity interfaces, and can be directly connected into rail side or vehicle signal equipment.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

Flash memory management method that is resistant to data corruption by power loss

InactiveUS20050240721A1Avoid dataMemory architecture accessing/allocationRead-only memoriesElectricityData Corruption

A method for managing page-based data storage media such as flash media, a system that uses that method, and a computer-readable storage medium bearing code for implementing the method. New data are written to the storage medium in a manner that precludes corruption of old data if the writing of the new data is interrupted. Specifically, risk zones are defined, by identifying, for each page, the other pages whose data are put at risk of corruption if writing to the page is interrupted. A page, that otherwise would be the target of a write operation, is not written if any of the pages in its risk zone contain data that could be corrupted if the write operation is interrupted.

Owner:WESTERN DIGITAL ISRAEL LTD

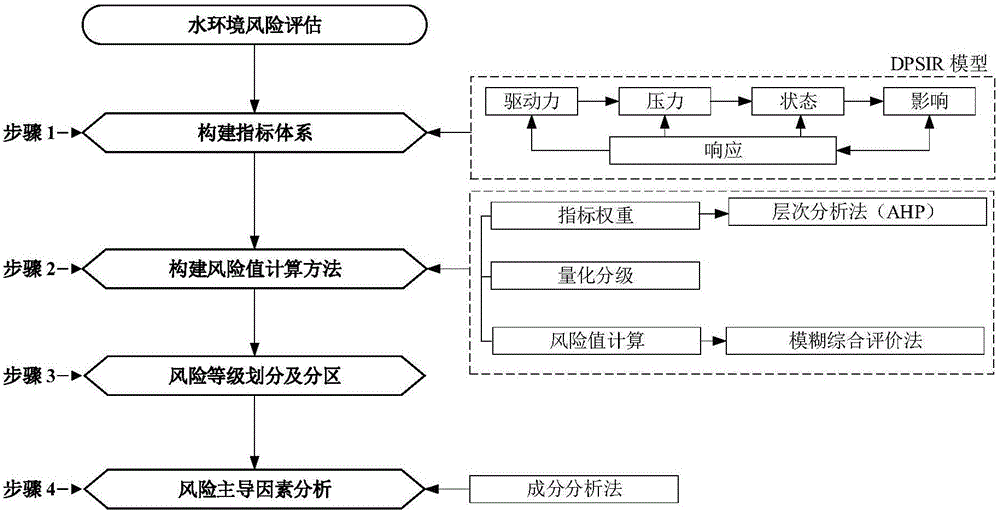

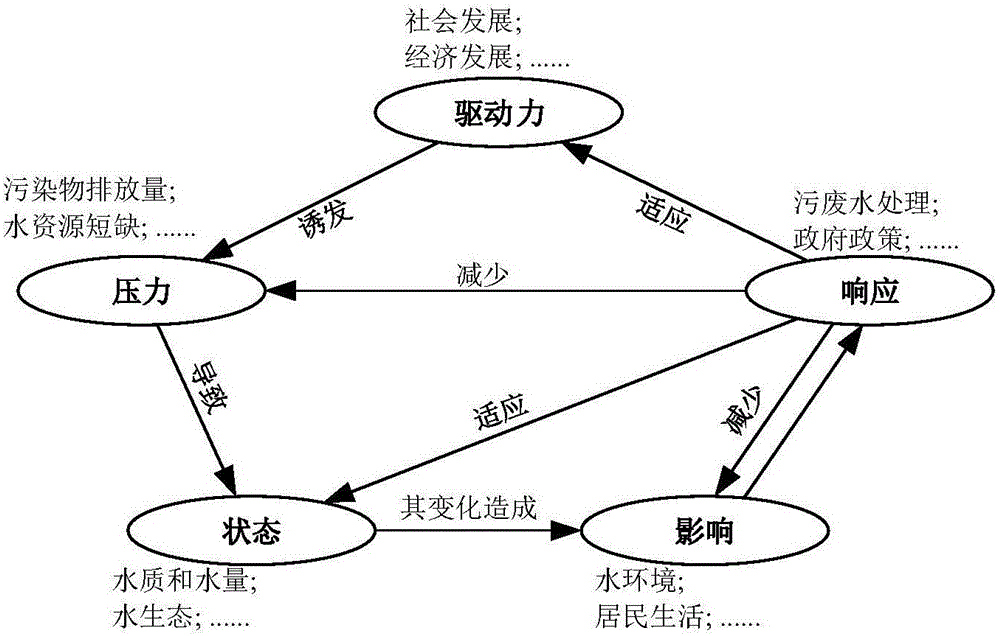

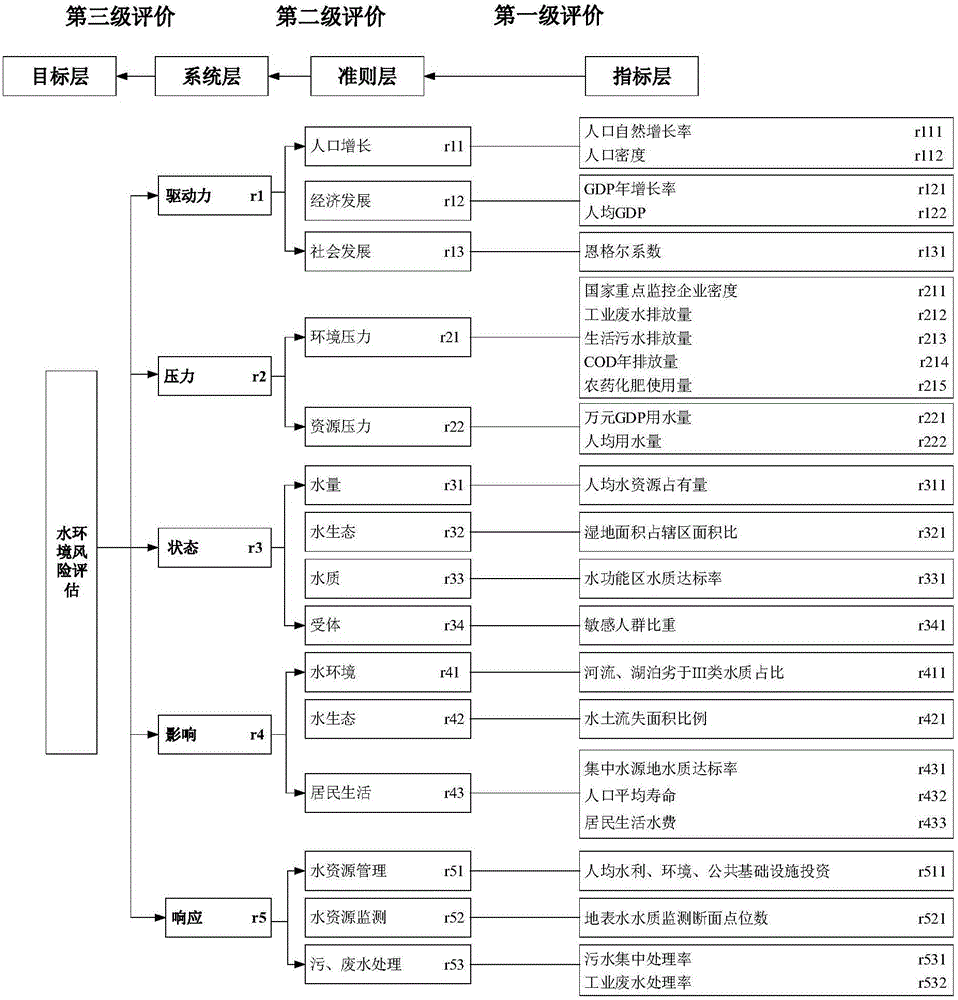

Regional water environment risk zoning method

The invention provides a regional water environment risk zoning method comprising the steps that a driving force factor, a pressure factor, a state factor, an impact factor and a response factor of a DPSIR module are determined; a regional water environment risk assessment index system is constructed, and the constructed regional water environment risk assessment index system comprises a target layer, a system layer, a criterion layer and an index layer which reflect the regional water environment risk from different angles; the weight of each index is calculated by using the analytic hierarchy process and value assignment is performed, and then all the index systems are quantitatively graded; then the regional water environment risk value is calculated through a fuzzy comprehensive evaluation method; and the regions are divided into a high-risk region, a medium-risk region, a low-risk region and a no-risk region in a decreasing order according to the risk with ArcGIS acting as an auxiliary tool. According to the scheme, the regional water environment can be more accurately assessed so as to provide accurate basis for decision.

Owner:BEIJING NORMAL UNIVERSITY

Aircraft wings and fuel tanks

InactiveUS7600717B2Volume maximizationPower plant fuel tanksAircraft stabilisationVertical planeFuel tank

On failure, a burst rotor of a wing-mounted engine (13, 23) can penetrate fuel tank walls in the wing of a conventional aircraft. There exists a zone that is at risk of such damage. Thus, the layout of fuel tanks (3, 11C, 21C) in the wing of an aircraft in accordance with embodiments includes port and starboard inner fuel tanks (11C, 21C) that are positioned adjacent to a central fuel tank (3) in the central wing section, but outside of the at-risk zone. Each of the port and starboard inner fuel tanks (11C, 21C) is defined in part by a respective inner boundary member (5RP, 5RS) that when viewed in plan extends, at least in part, in a direction at an angle of less than 20° to the adjacent vertical plane (A-A) defining the at-risk zone. Thus the amount of fuel stored in fuel tanks (11C, 21C) in the wing assembly that cover a region outside of the at-risk zone and that do not extend into the at-risk zone may be increased.

Owner:AIRBUS OPERATIONS LTD

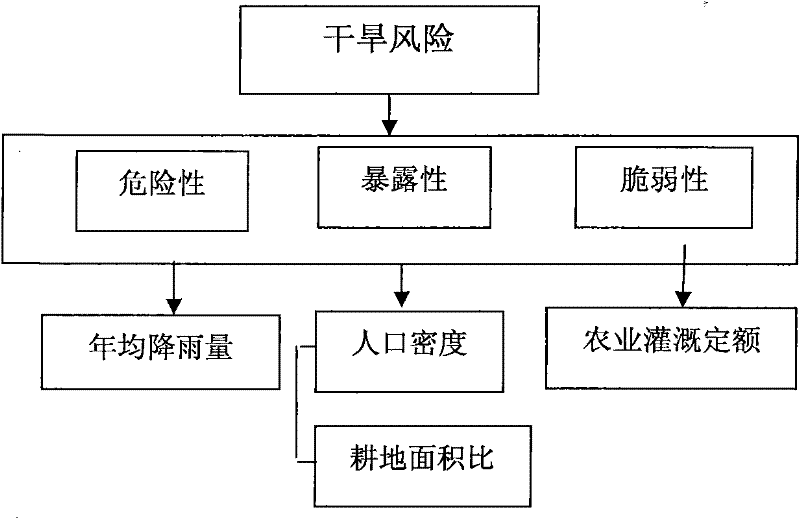

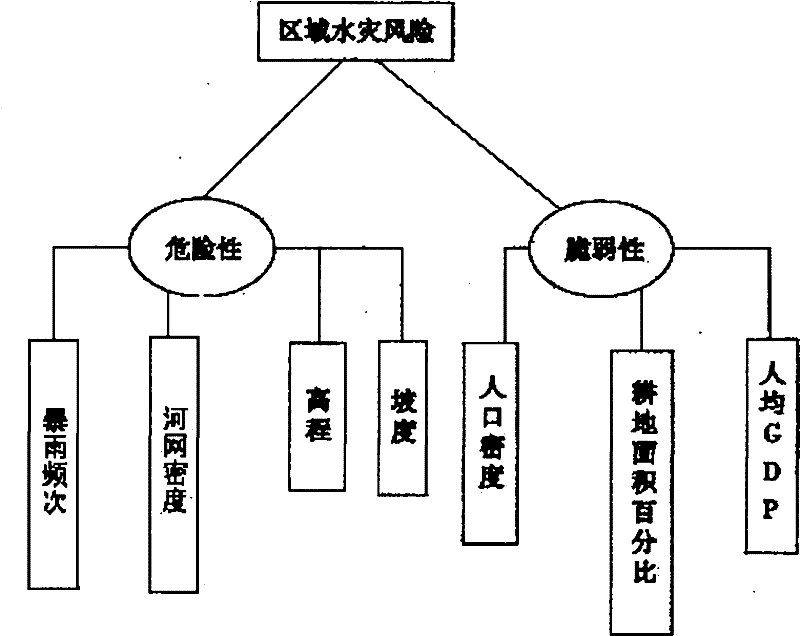

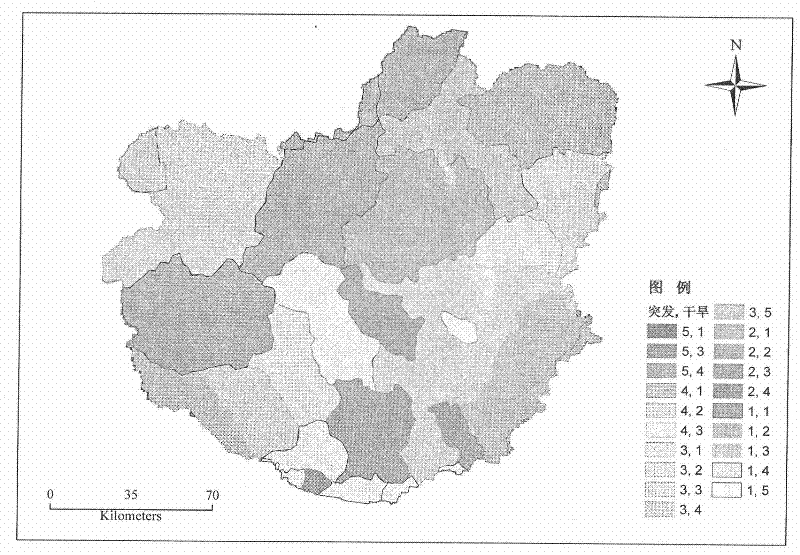

Method for sudden accident risk zoning of river basin based on change of water resource

InactiveCN102364503AImprove the level of scienceImprove accuracyClimate change adaptationInstrumentsWater resourcesEngineering

The invention relates to a method for sudden accident risk zoning of a river basin based on changes of water resources, which comprises the following steps: 1) carrying out drought risk zoning within a selected zone scope according to drought risk indexes; 2) carrying out flood disaster zoning within the selected zone scope according to flood risk indexes; 3) carrying out sudden accident risk zoning within the selected zone scope according to sudden accident risk indexes; and 4) superimposing zoning results in a GIS (geographic information system) to realize sudden risk zoning under different precipitation conditions. The conditions of the water resources are taken to account for sudden accident risk zoning, the sudden accident risk zoning results of zones are more reasonable and reliable, and the scientific level of regional environmental management can be improved. Moreover, the sudden accident risk zoning results of the zones can be displayed promptly through the GIS technology, and the accuracy of integrated environmental management can be improved. Meanwhile, the method has high operability and a wide scope of application and is suitable for zones of different sizes.

Owner:程红光 +1

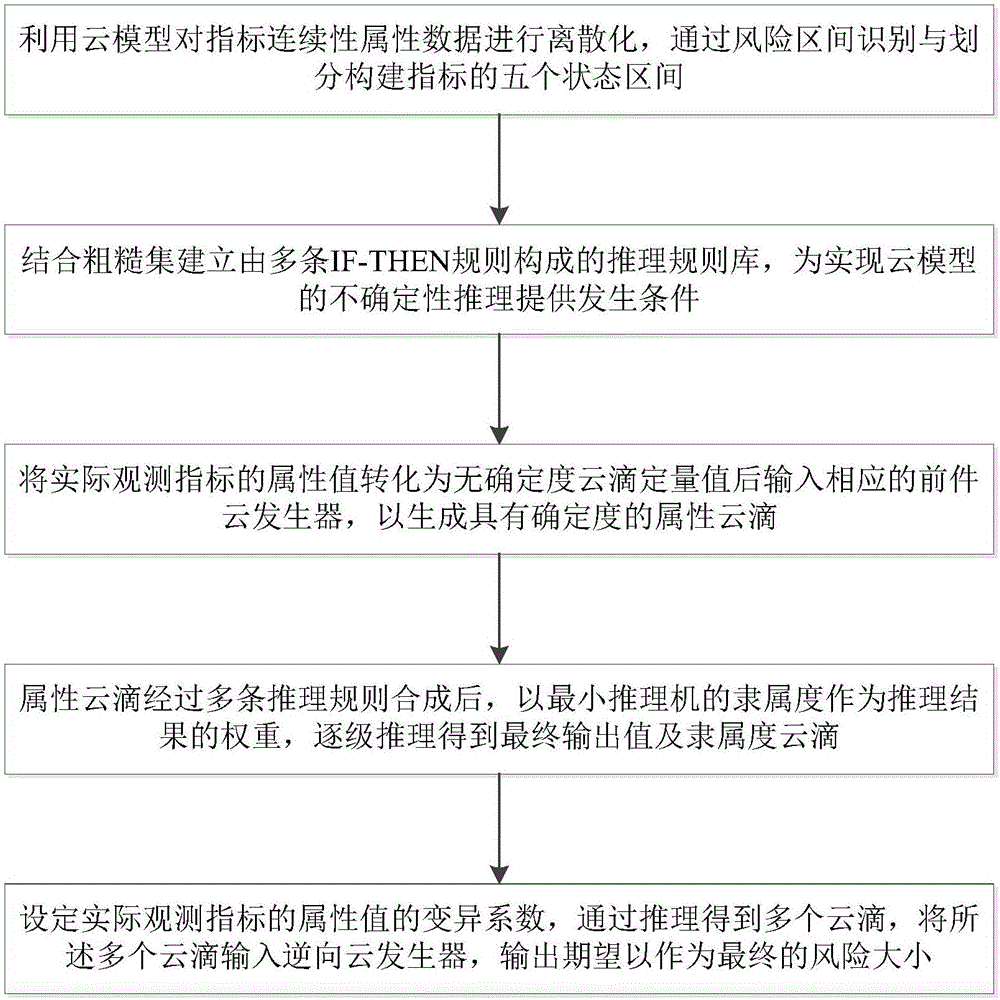

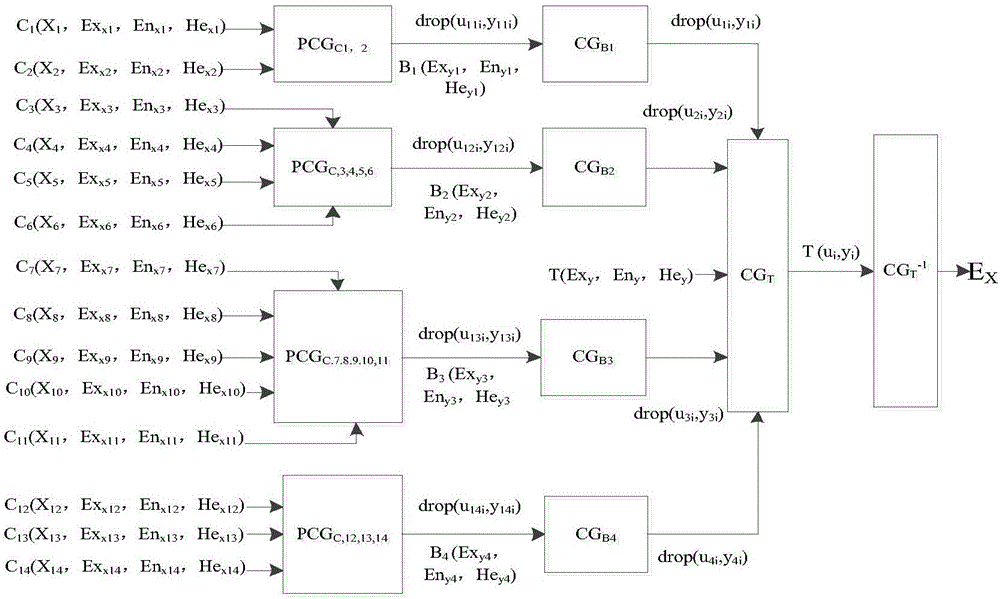

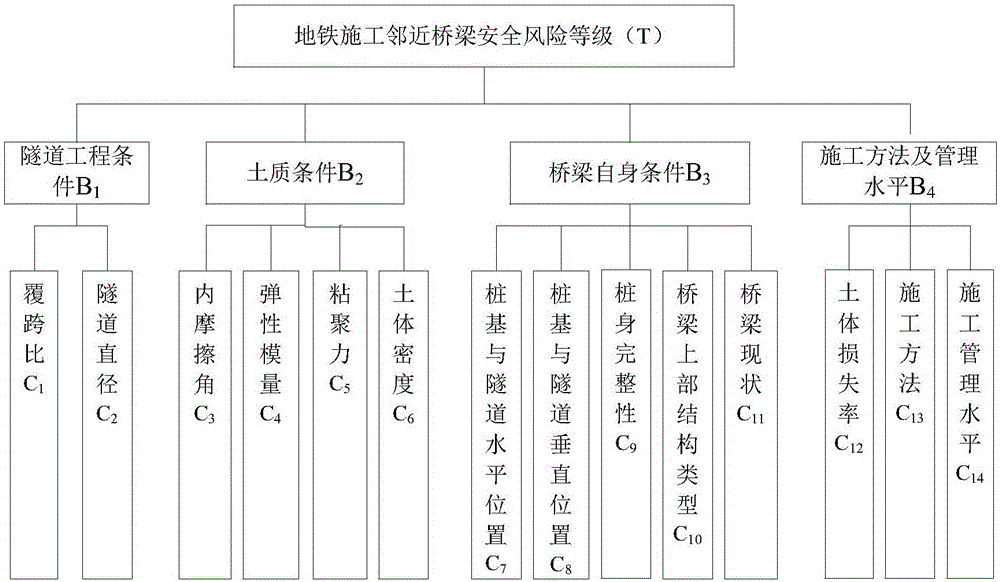

Risk assessment and evaluation method for adjacent bridge damage caused by subway construction

The invention discloses a risk assessment and evaluation method for an adjacent bridge damage caused by subway construction. The method comprises: step one, carrying out discretization on index continuity attribute data by using a cloud model and constructing a five state zones of an index based on risk zone identification and division; step two, establishing an inference rule base piece formed by a plurality of IF-THEN rules by combining a rough set; (3), converting a practical observation index attribute value and then inputting the converted value into a corresponding first piece cloud generator, thereby generating an attribute cloud droplet; (4), after synthesis of a plurality of inference rules, carrying out step-by-step inference processing on the attribute cloud droplet by using a membership degree of a minimum inference engine as a weight of an inference result so as to obtain a final output value and a membership degree cloud droplet; and (5), setting a variable coefficient of the attribute value of the practical observation index, carrying out inference processing to obtain a plurality of cloud droplets, inputting the plurality of cloud droplets into a backward cloud generator, and outputting an expectation value used as a final risk value.

Owner:HUAZHONG UNIV OF SCI & TECH

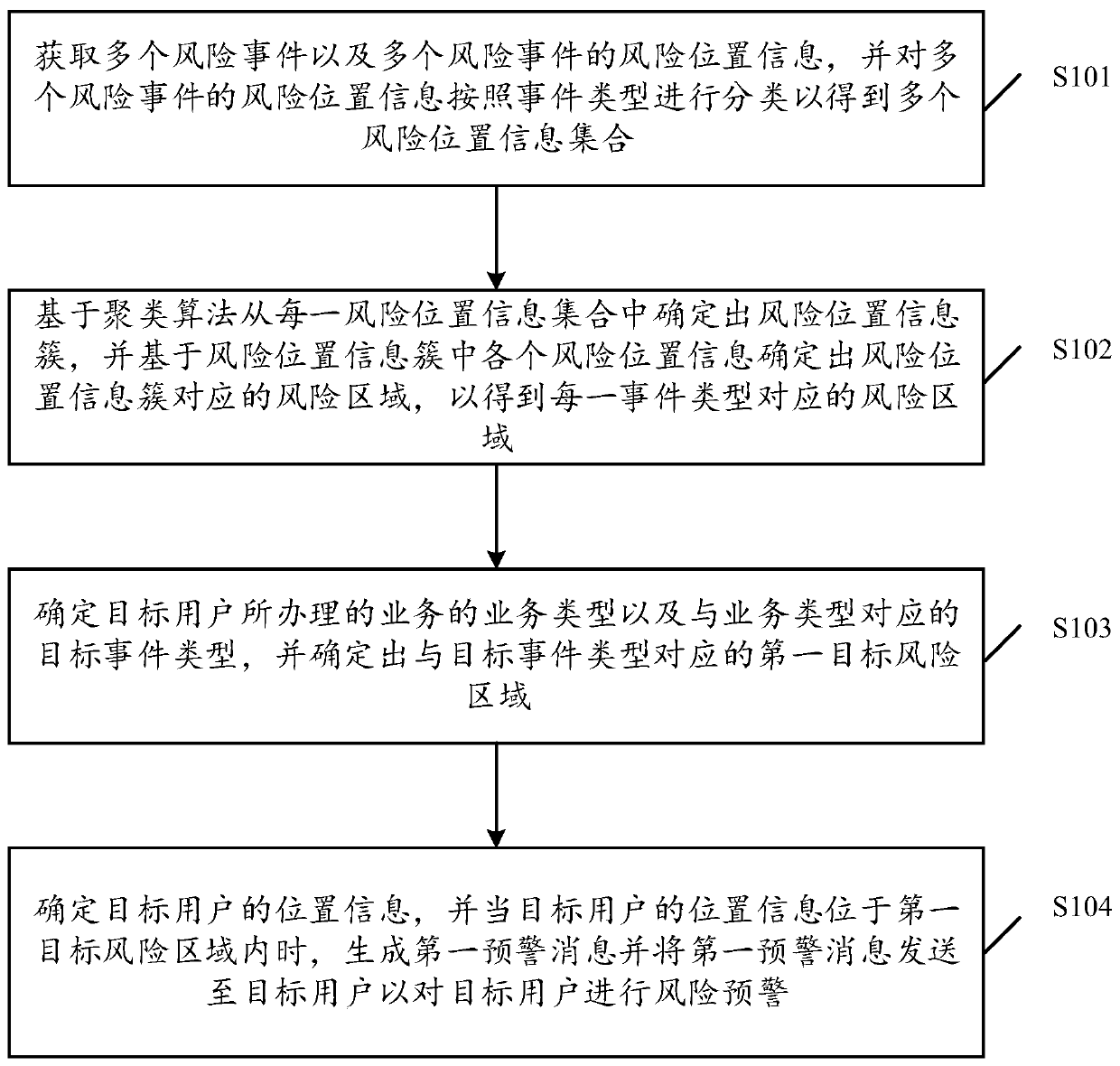

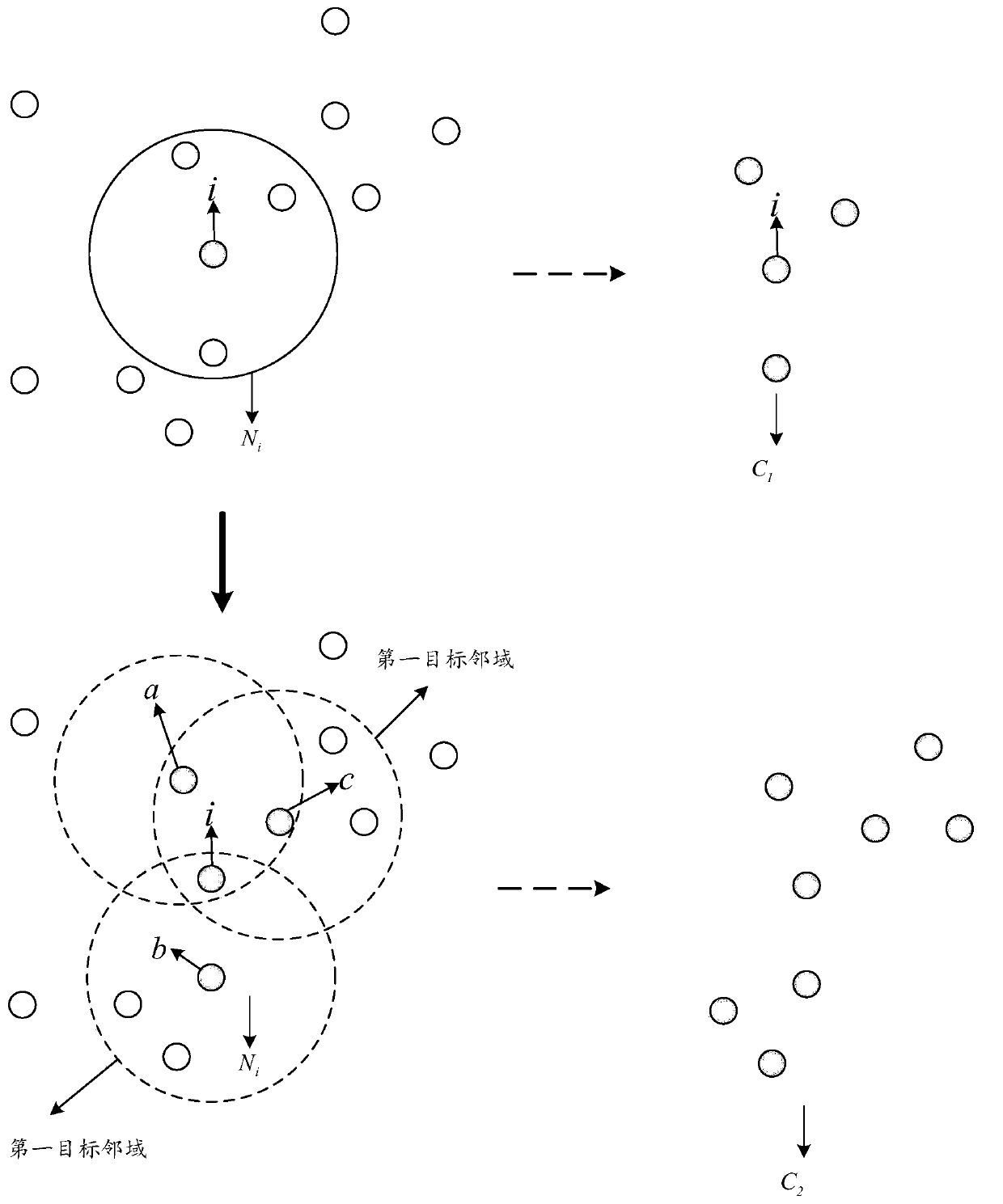

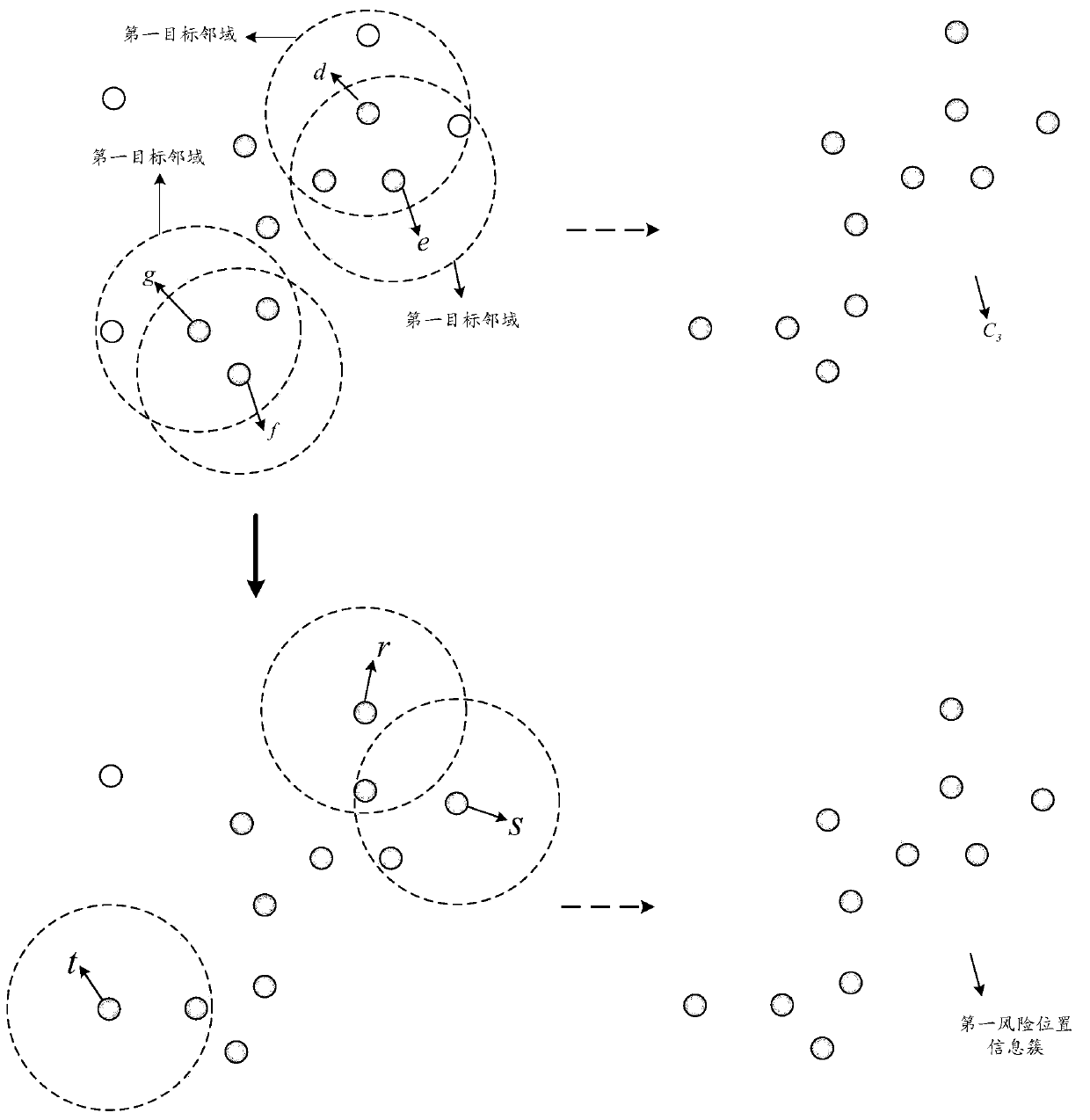

Risk early warning method and related device

ActiveCN111260215AImprove experienceAvoid receivingCharacter and pattern recognitionResourcesCluster algorithmRisk zone

The embodiment of the invention discloses a risk early warning method and a related device, which are suitable for risk management and control. The method comprises the steps of obtaining a pluralityof risk events and risk position information of the plurality of risk events, and classifying the risk position information of the plurality of risk events according to event types to obtain a plurality of risk position information sets; determining a risk position information cluster based on a clustering algorithm, and determining a risk area corresponding to the risk position information cluster; determining a service type of a service handled by the target user and a target event type corresponding to the service type, and determining a first target risk area corresponding to the target event type; and when the position information of the target user is located in the first target risk area, generating a first early warning message and sending the first early warning message to the target user so as to carry out risk early warning on the target user. By adopting the method of the invention, the risk event can be subjected to all-around early warning while relatively high early warning accuracy is ensured, and the user experience is improved.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

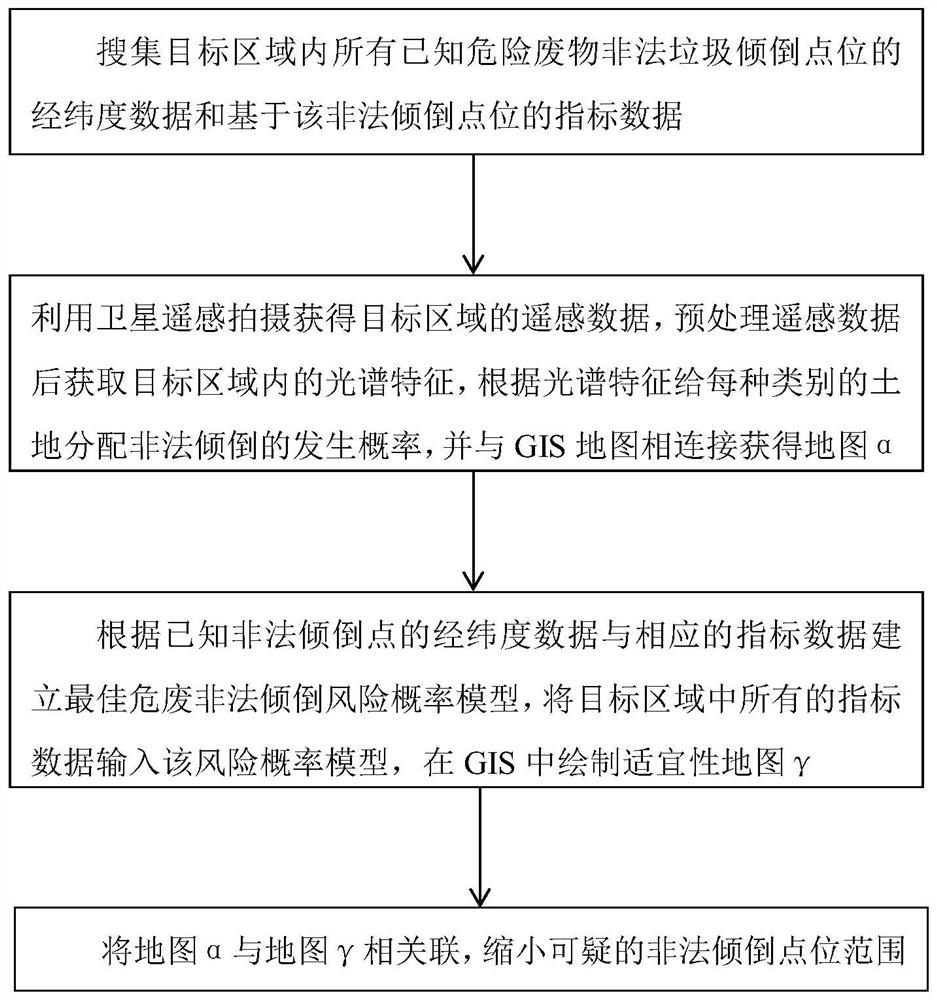

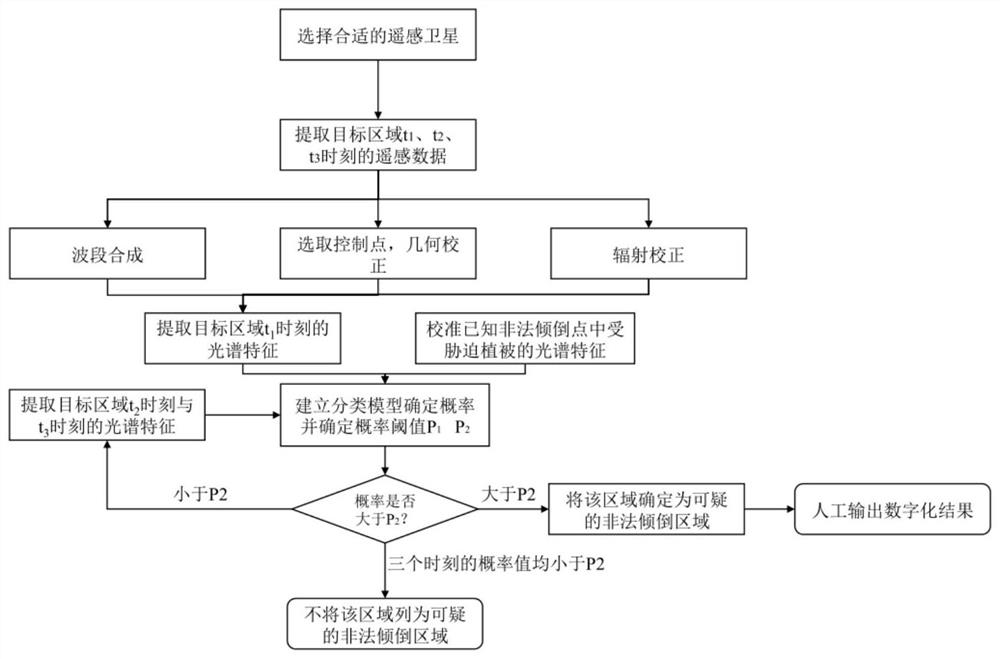

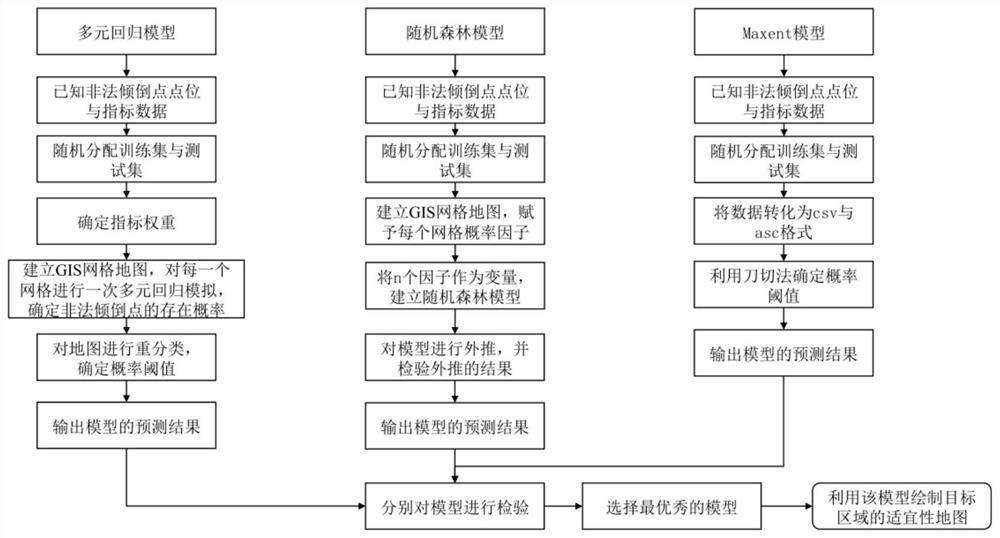

Dangerous waste illegal dumping risk area identification and traceability method based on multi-source data

ActiveCN113077133ANarrow the scope of regulationRealize accurate traceabilityGeographical information databasesResourcesEnvironmental resource managementClassification methods

The invention discloses a dangerous waste illegal dumping risk area identification and traceability method based on multi-source data. According to the method, illegal dumping point locations in an area are determined through remote sensing technology and deep learning; secondary review is performed on the determined medium-high risk area by combining unmanned aerial vehicle shooting and image classification means, dangerous and waste illegal dumping point areas are quickly identified in the determined medium-high risk area, and an illegal dumping risk probability map is constructed; through construction of a hazardous waste database and a classification method based on machine learning, whether or not hazardous waste missing report, wrong report and insufficient report behaviors occur in a waste production unit is judged, and a suspicious waste production unit is determined, so that a supervision range of a supervision department can be narrowed. And meanwhile, the risk probability map is combined with the determined risk probability map, so that a list of waste production units possibly involved in illegal dumping in a certain illegal dumping point can be identified, and accurate traceability of illegal dumping dangerous wastes is realized.

Owner:NANJING UNIV

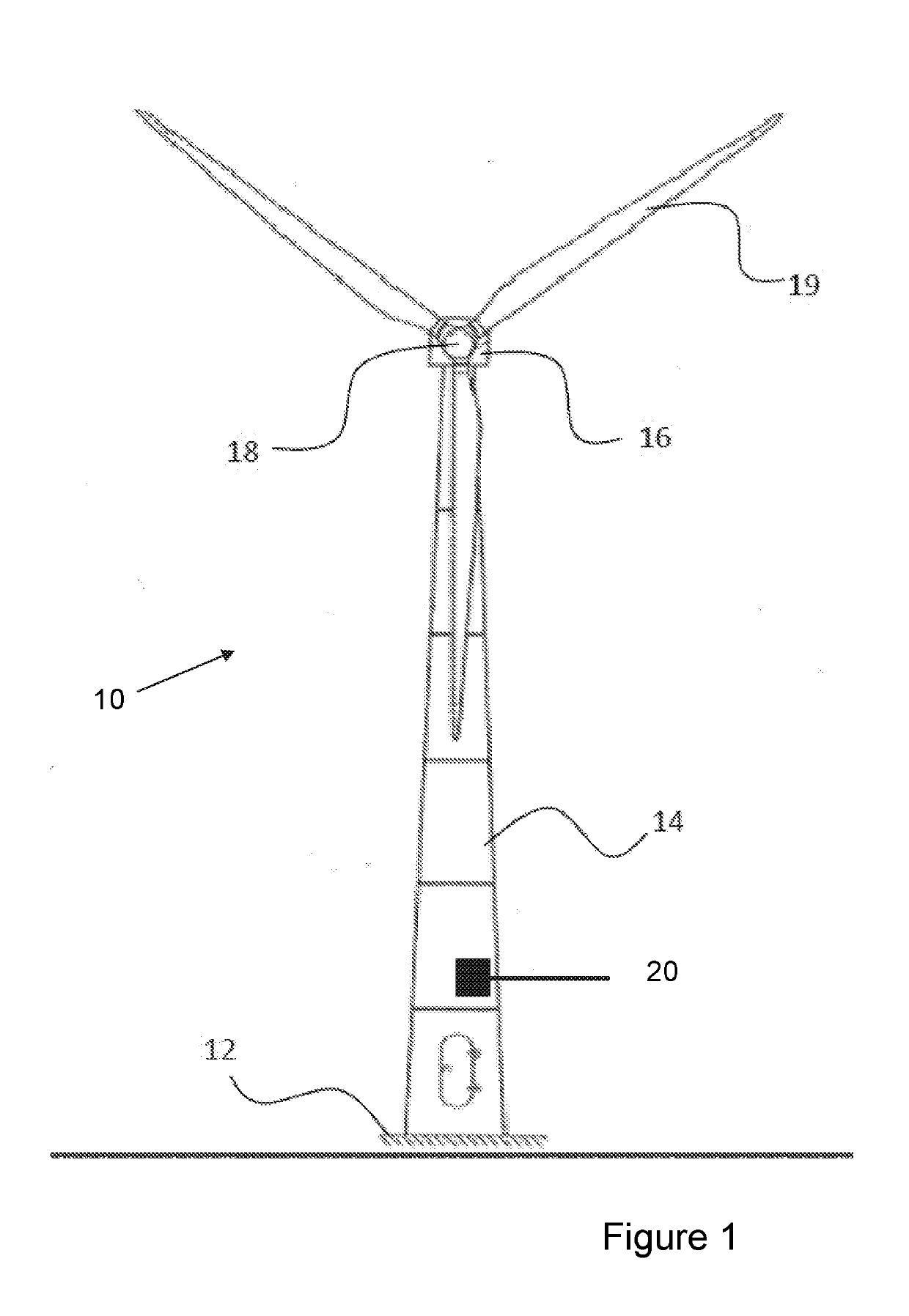

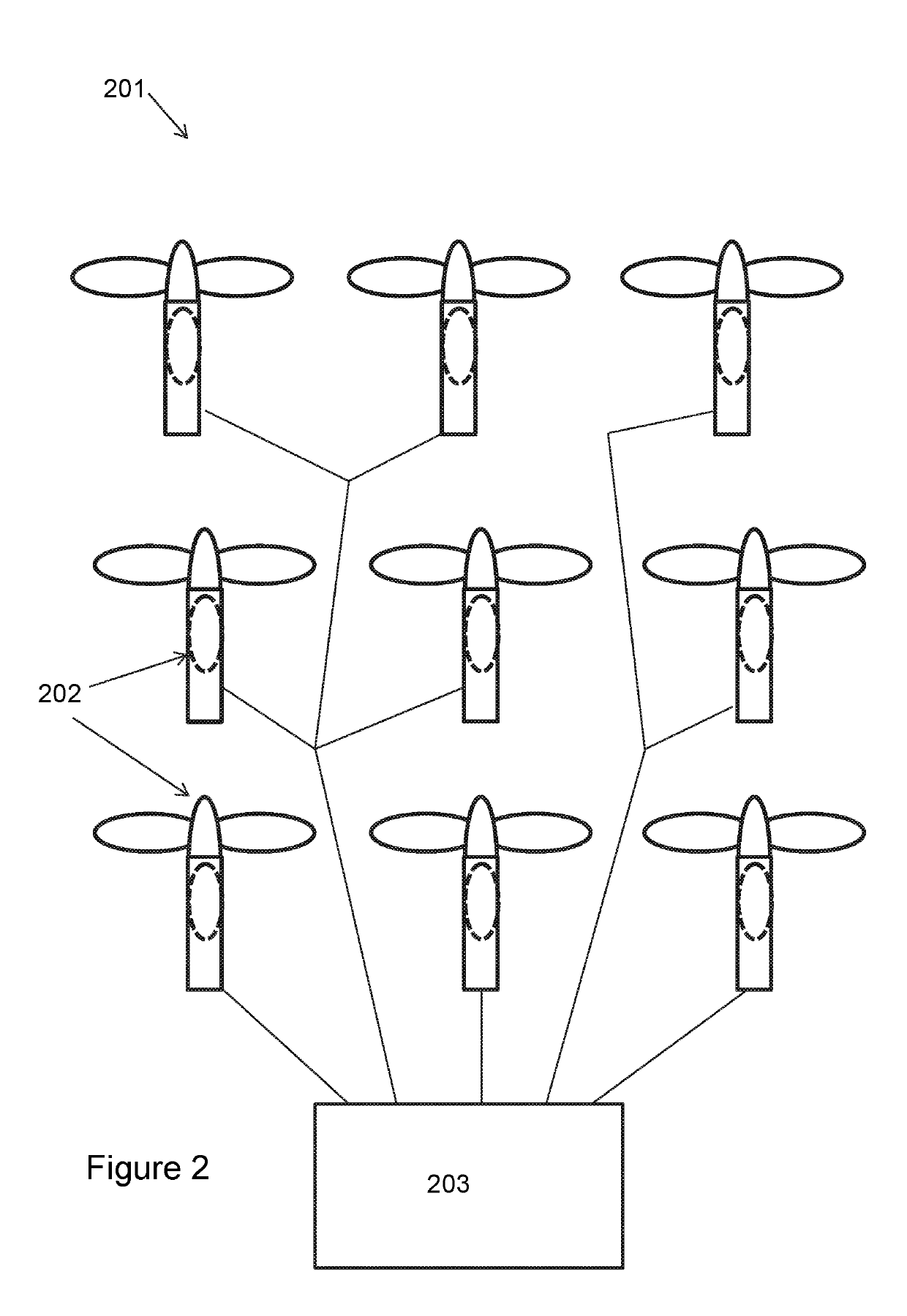

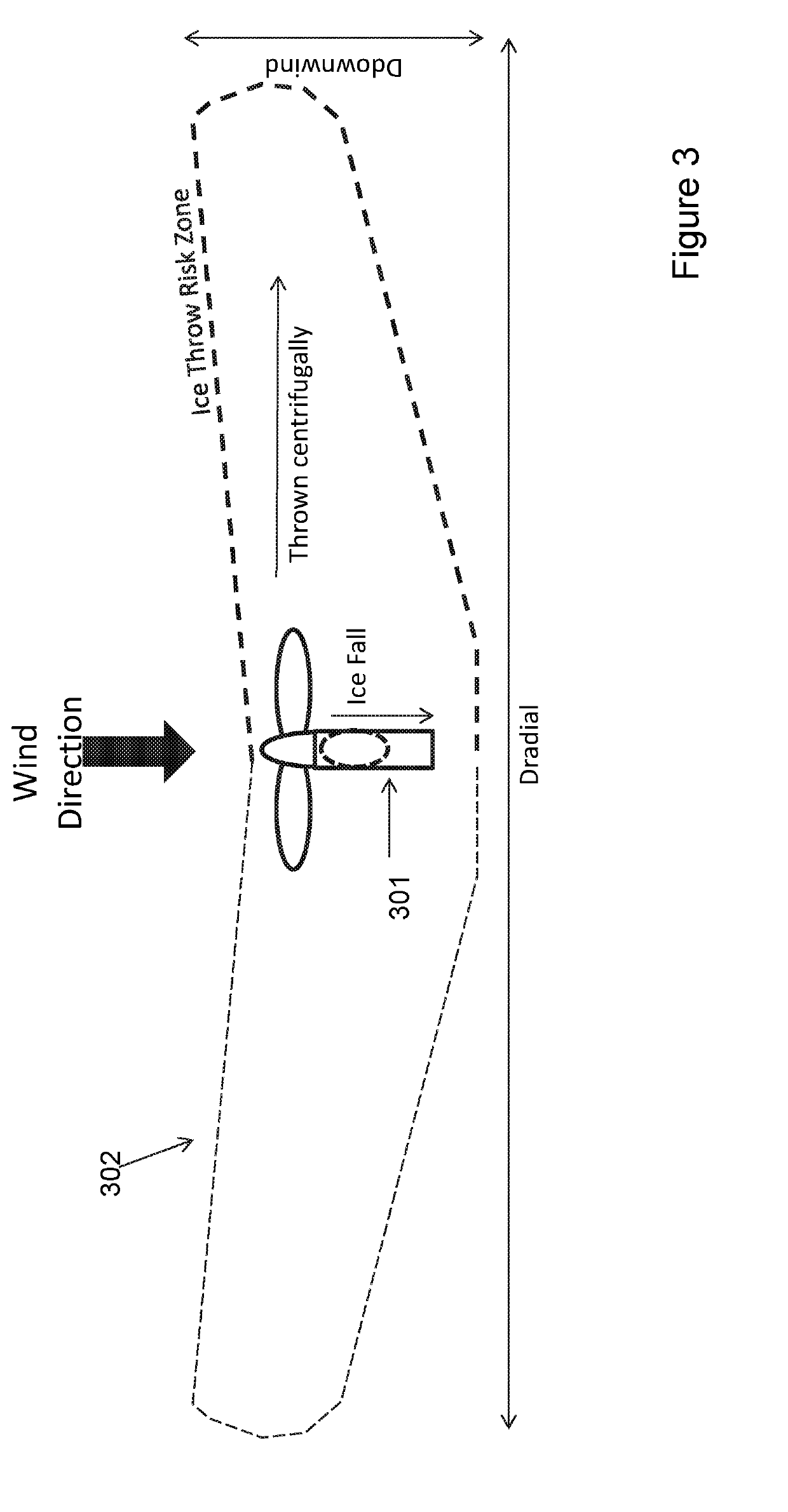

Improved wind turbine safety system

ActiveUS20190323484A1Reduce ice throw risk zoneKeep powerWind motor controlEngine fuctionsRisk zoneTurbine

The present invention relates to a method, controller, wind turbine and wind farm that advantageously determines an ice throw risk zone (302) for a wind turbine (301), wherein the ice throw risk zone (302) defines an area surrounding the wind turbine (301) within which ice can be thrown from one or more blades of the wind turbine (301); determining whether the determined ice throw risk zone (302) impinges one or more exclusion zones; and if the determined ice throw risk zone (302) impinges one or more exclusion zones, determining an alteration to one or more operating parameters of the wind turbine (301) in order to alter the ice throw risk zone (302) such that the determined ice throw risk zone (302) does not impinge the one or more exclusion zones.

Owner:VESTAS WIND SYST AS

Sound-directed-outside-vehicle emitting device

ActiveUS8121755B2Improve securityAcoustic signal devicesDigital data processing detailsEngineeringRisk zone

A sound-directed-outside-vehicle emitting device includes a storage unit 2-A for storing criteria by each of which to determine whether or not a running zone is a high-risk zone, each of the criteria describing a status of the vehicle, and a navigation device 1-A for acquiring information showing a status of the vehicle. The sound-directed-outside-vehicle emitting device compares the information acquired by the navigation device 1-A with the criteria stored in the storage unit 2-A to determine whether the above-mentioned vehicle is running through a high-risk zone, and does not stop the output of a warning sound when determining that the vehicle is running through a high-risk zone even if a switch 4 for commanding a stop of the output of the warning sound is operated.

Owner:MITSUBISHI ELECTRIC CORP

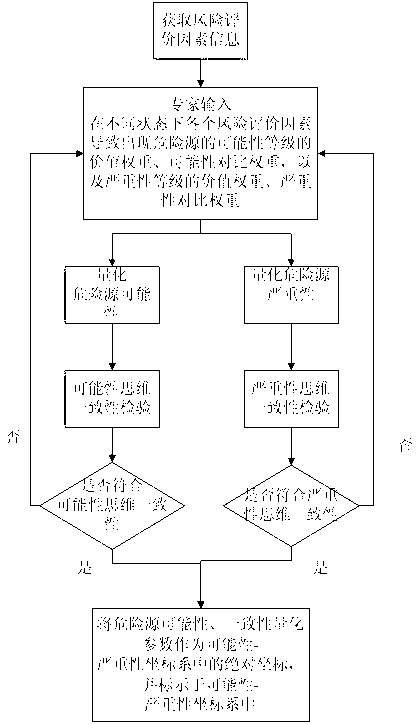

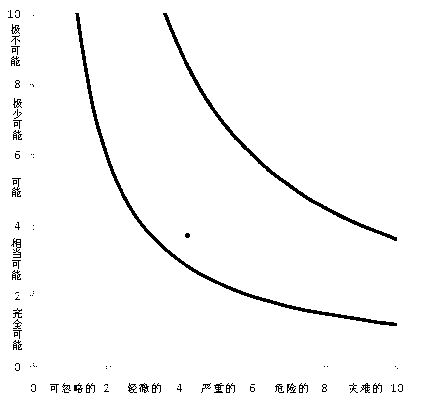

Risk assessment system

InactiveCN103218525AOvercoming discrete problemsSpecial data processing applicationsRisk zoneRisk area

The invention discloses a risk assessment system, which comprises a risk assessment factor information acquisition subsystem, an expert judgment input module, a possibility and severity quantification subsystem and a risk display subsystem. The risk assessment system quantifies the possibility and severity of a risk source to obtain possibility and severity quantification parameters, takes the possibility and severity quantification parameters as an absolute coordinate of a possibility-severity coordinate system, and defines the risk area of the possibility-severity coordinate system, thereby overcoming the discrete problem, and strictly defining the risk value.

Owner:中国民用航空中南地区空中交通管理局

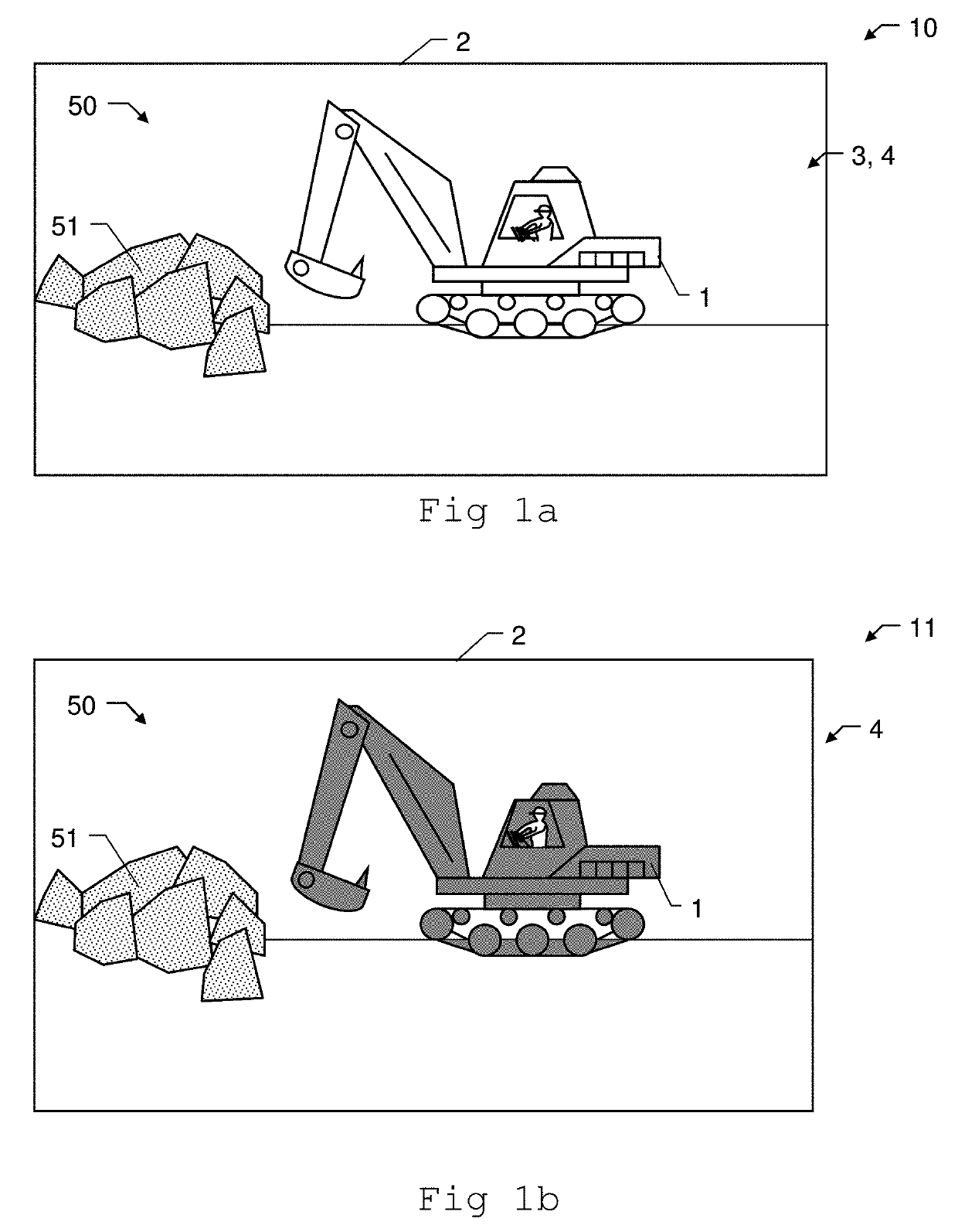

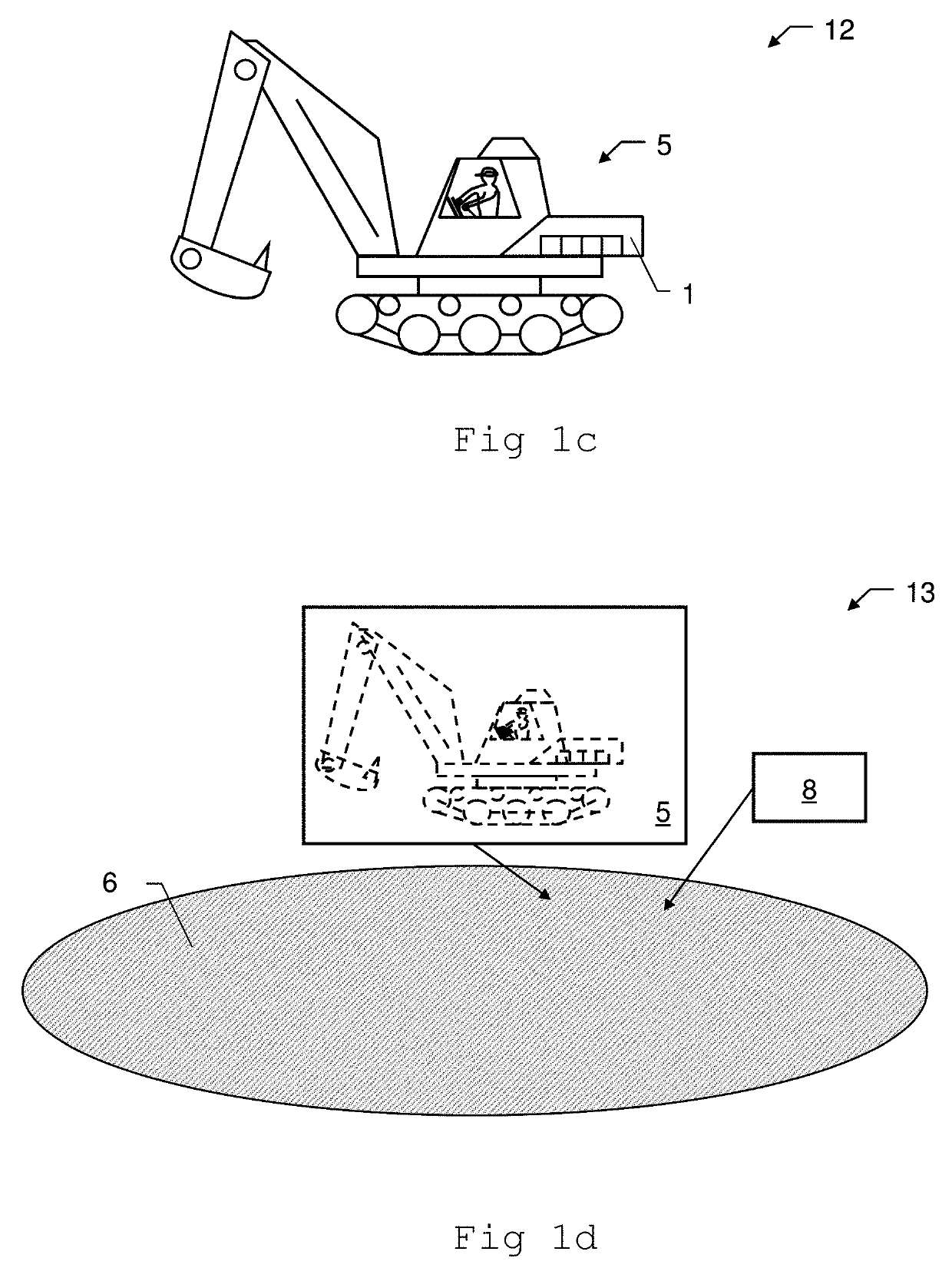

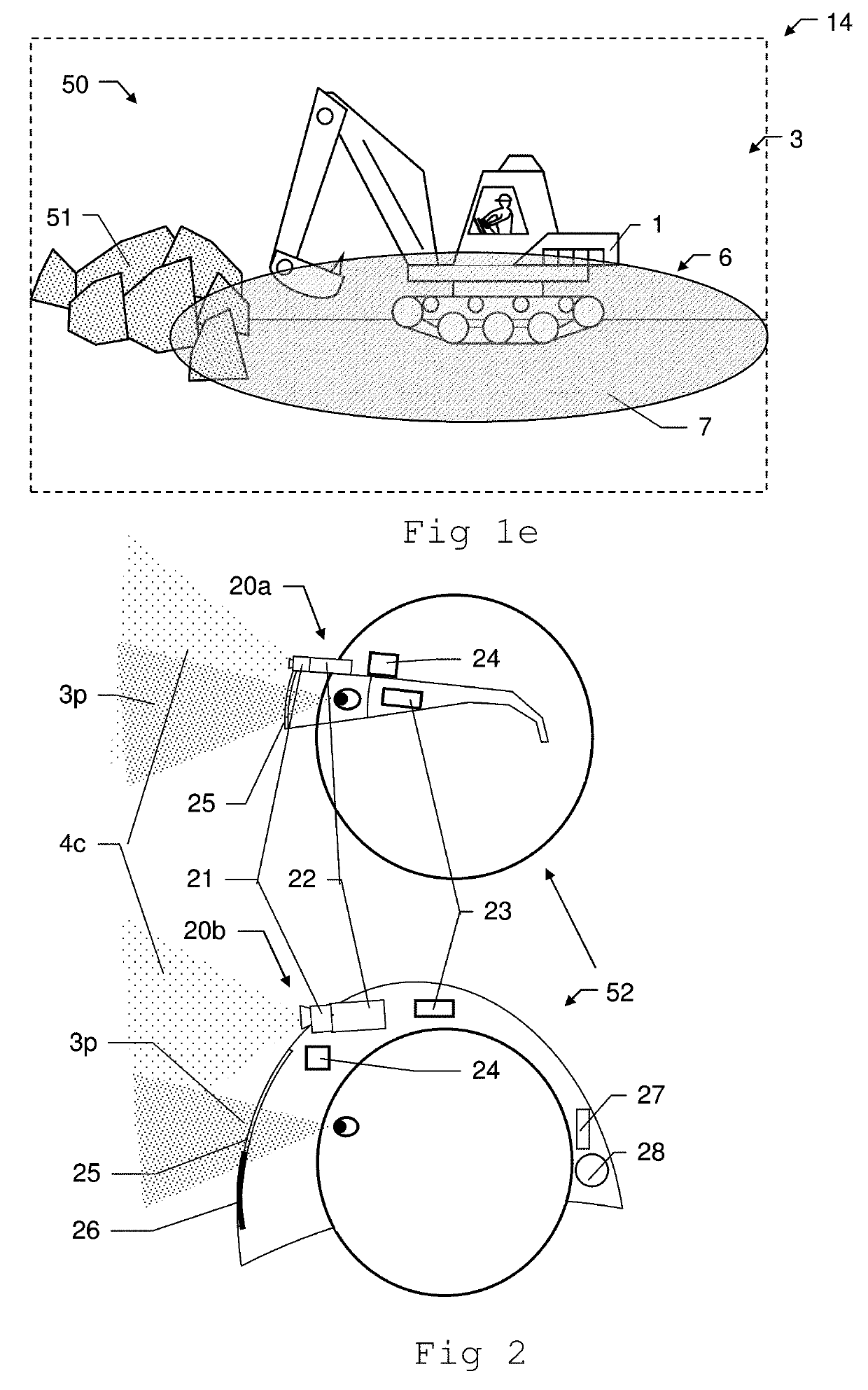

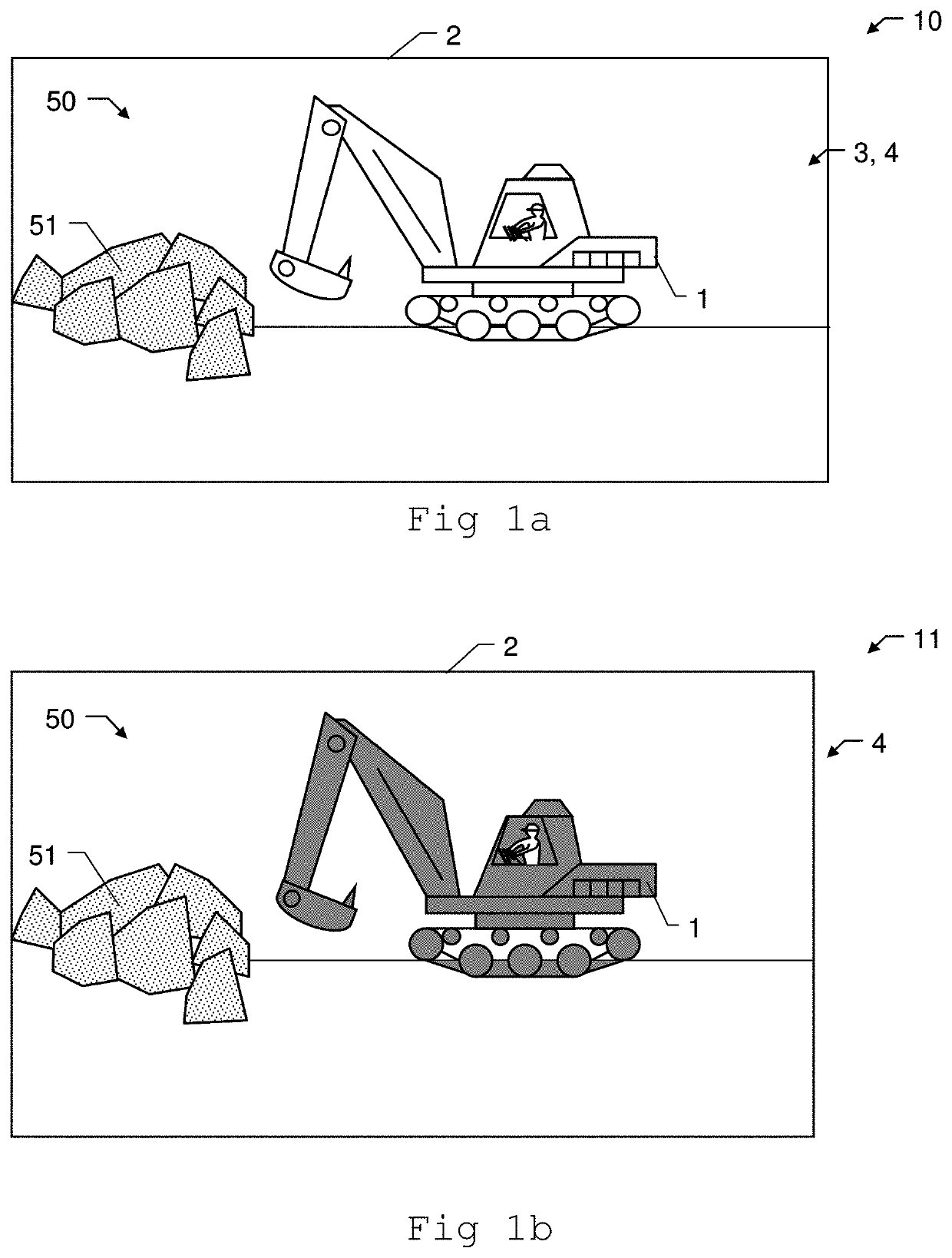

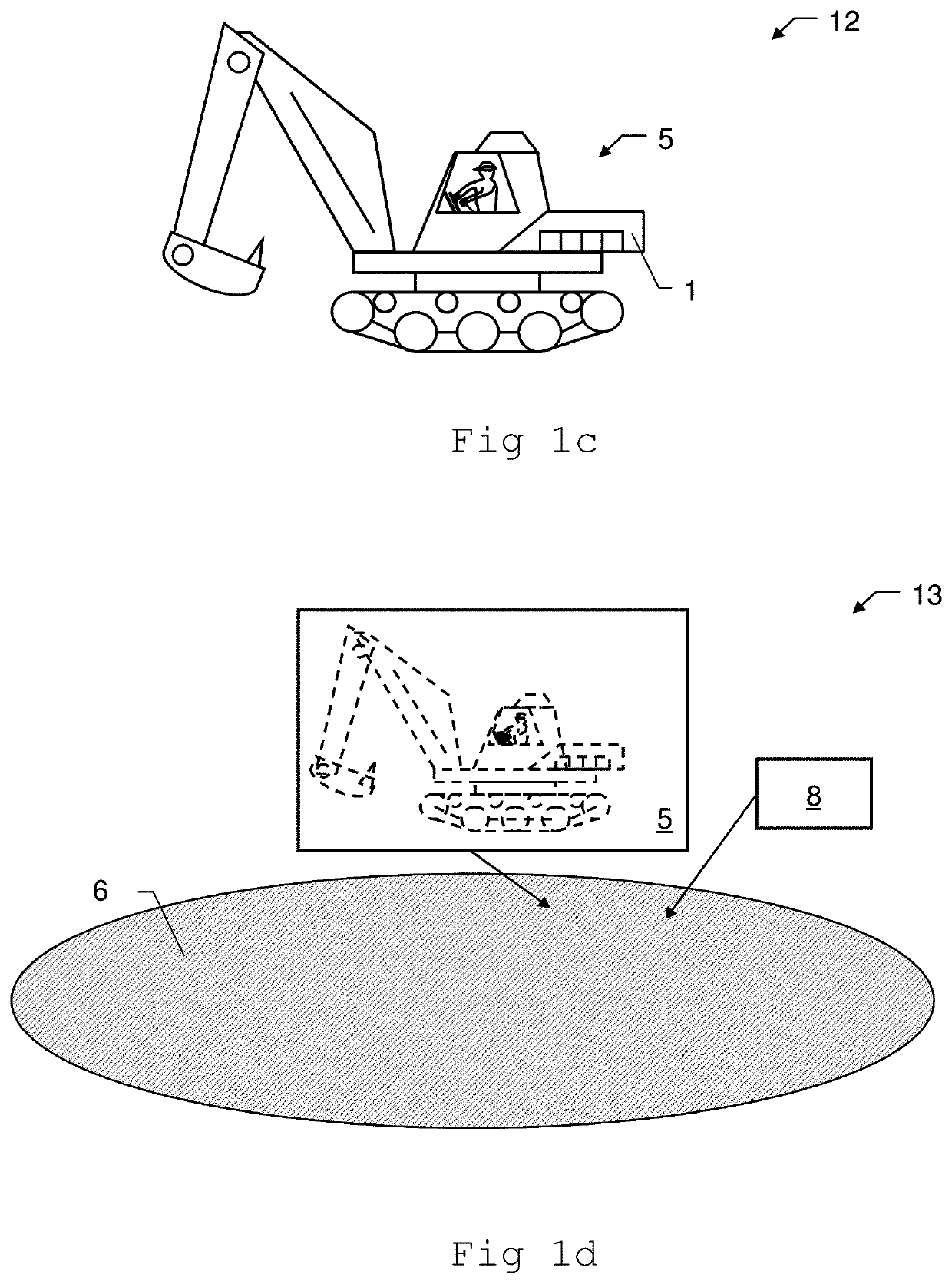

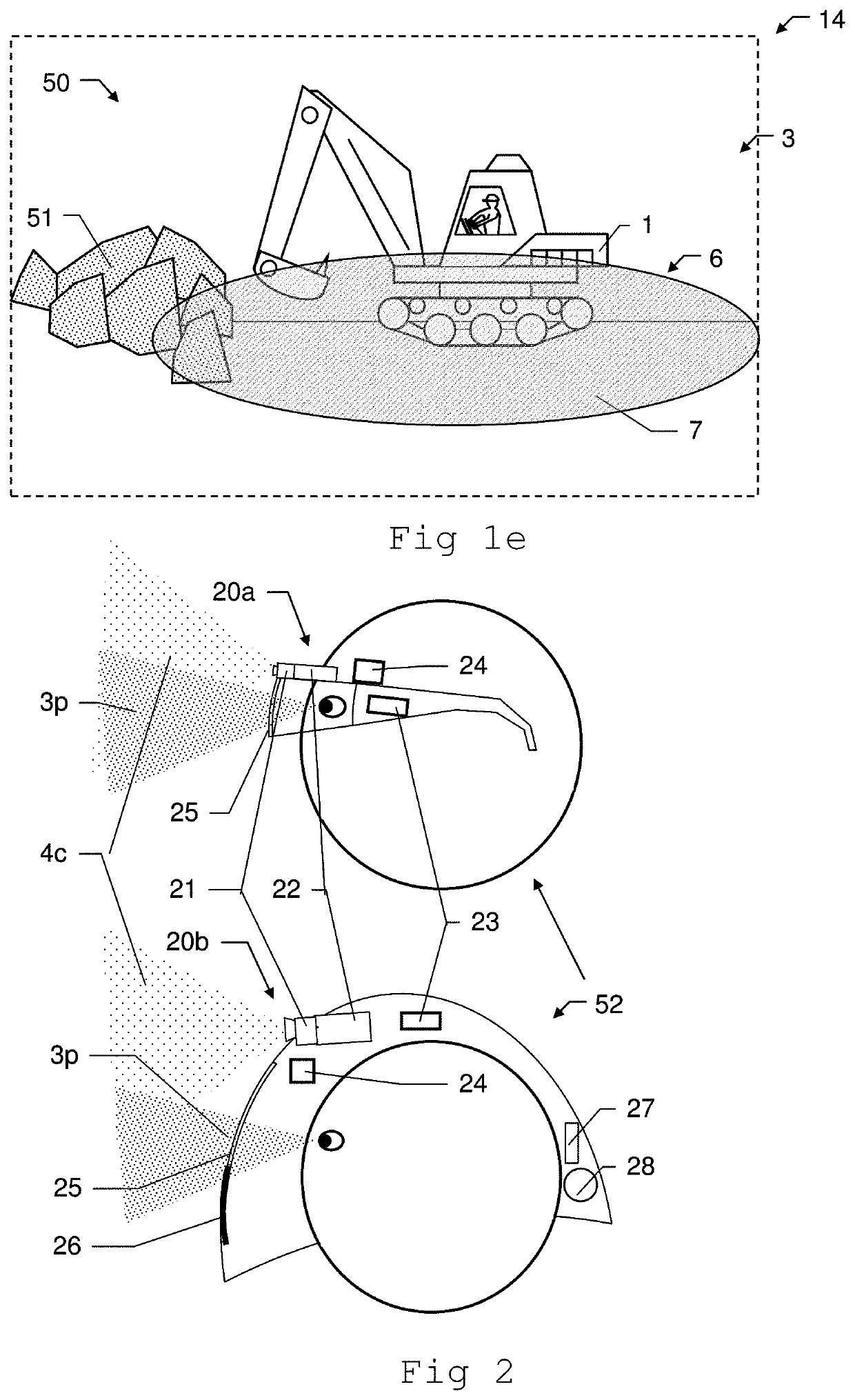

Method and device for augmenting a person's view of a mining vehicle on a mining worksite in real-time

ActiveUS20190244023A1Planning and assessmentImprove discriminationImage enhancementImage analysisImaging processingDisplay device

A method for real-time visualization of a risk zone of a mining vehicle to a person on a mining worksite for augmenting the person's current view of the mining vehicle including capturing with a camera a stream of pictures corresponding at least partly to the person's field of view, recognizing at least one mining vehicle in the picture stream by means of image processing, extracting image data of the mining vehicle from the picture stream, calculating, based on the image data and on preset vehicle risk zone data, at least one risk zone of the mining vehicle adapted to the person's current view of the mining vehicle, and visualizing the risk zone on a person's display such that the person's current view of the mining vehicle is overlayed in real-time with the visualization of the risk zone.

Owner:MY VIRTUAL REALITY SOFTWARE

Expansion type support management method for slope ground partial potential safety hazard section

InactiveCN101487265AHigh strengthStable supportClimate change adaptationExcavationsEngineeringRisk zone

The invention discloses an expansion-style support treatment method used for the local risk zones of slope rock. A plurality of axial parallel expansion-style plain concrete anchor rods are arranged in the risk zones of the slope rock. The invention has the beneficial effects that arranging the expansion-style plain concrete anchor rods can perform the side expansion effect of the anchor rods so as to extrude the risk zones of the rocks, enhance the integral intensity of the rocks in the risk zone and effectively support the local risk zones of the slope rock.

Owner:陈洪凯 +1

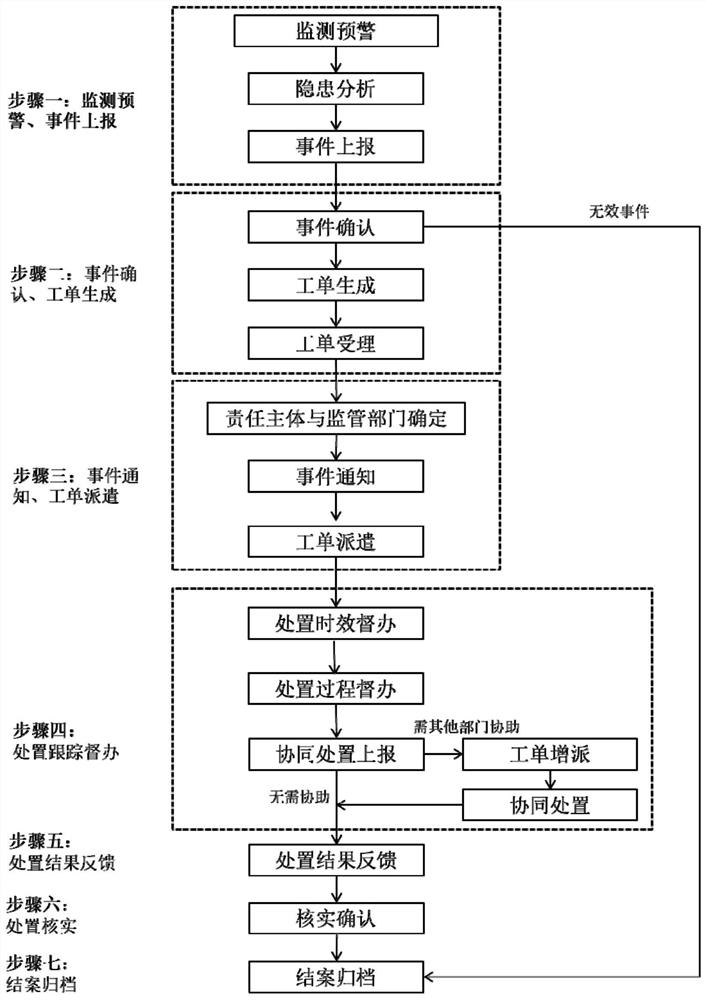

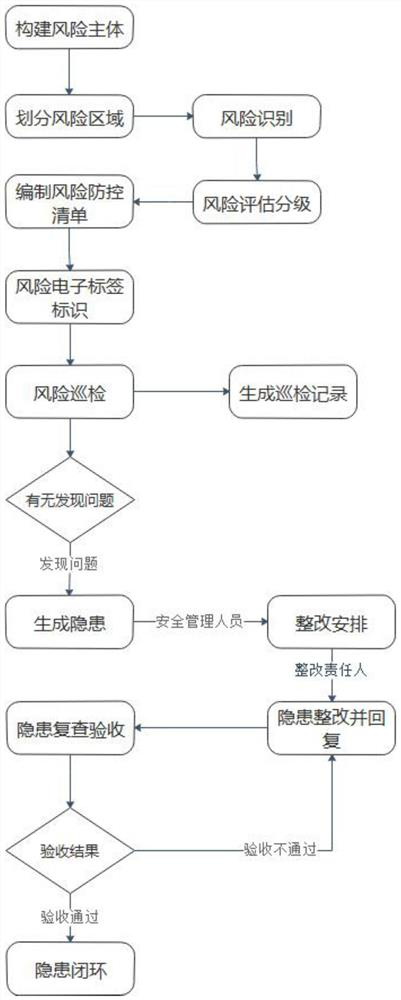

Production potential safety hazard monitoring and closed-loop disposal method

PendingCN112381451AEnsure real-time sensing and monitoringDisposal Efficient DriveOffice automationResourcesHazard monitoringData information

The invention discloses a production potential safety hazard monitoring and closed-loop disposal method which comprises the steps of monitoring, early warning and event reporting, and is characterizedin that front-end risk sensing equipment for monitoring potential safety hazard event information is arranged in a risk area in an enterprise production environment, and is connected with a rear-enddata analyzing, processing and early warning module through a network; the front-end risk sensing equipment pushes the obtained monitoring result data information to the rear-end data analyzing, processing and early warning module, and the rear-end data analyzing, processing and early warning module forms graded early warning information according to comparison of the monitoring result data and arisk threshold value and automatically reports the graded early warning information to a safety management and control module; and the safety management and control module is used for automatically generating a work order after confirming the risk early warning information generated by monitoring discovery, allocating the work order to a corresponding responsibility unit for disposal according tothe responsibility list, and tracking and supervising the rectification disposal process until the event disposal is completed. According to the invention, real-time monitoring and early warning of enterprise production potential safety hazards, automatic reporting and dispatching of events, linkage disposal and timely feedback can be realized.

Owner:SUZHOU IND PARK SURVEYING MAPPING & GEOINFORMATION CO LTD +1

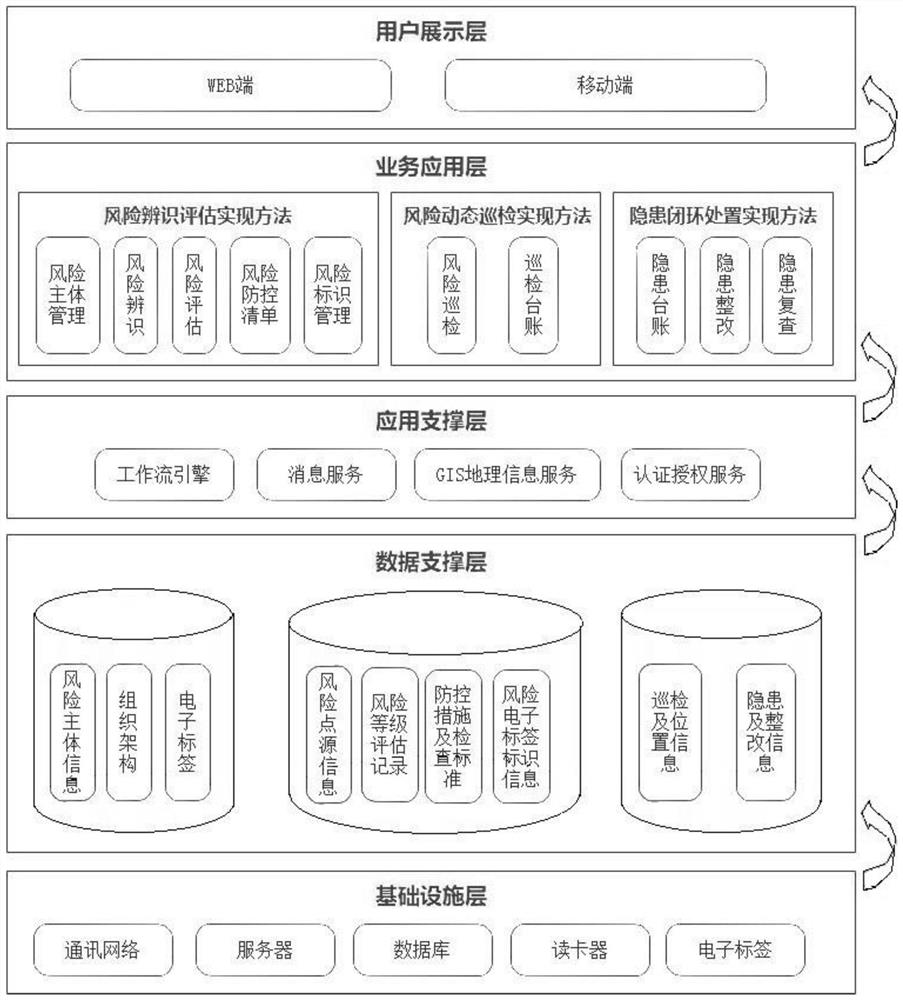

Intelligent risk prevention and control platform and risk identification prevention and control and dynamic inspection implementation method

PendingCN112819339AGuaranteed automaticGuaranteed efficientResourcesTransmissionThe InternetEngineering

The invention discloses an intelligent safety risk prevention and control platform which comprises an infrastructure layer, a data support layer, a business application layer and a display layer. The method comprises the steps of constructing a risk subject; dividing a risk area; carrying out risk identification; risk assessment and grading; compiling a risk prevention and control list; carrying out risk inspection, generating an inspection record, judging whether risks and hidden danger problems are found or not, and if yes, allocating rectification responsible persons to carry out rectification arrangement according to measures set by safety management personnel; and the rectification responsible person carrying out hidden danger rectification, uploading rectification information and uploading electronic tag identification information and geographical location information. According to the method, an accident prevention gateway can be moved forward, risks are controlled before hidden dangers are formed, the hidden dangers are eliminated before accidents, and the automation, high efficiency and visualization of the whole risk management and control process are ensured by means of the Internet and the Internet of Things.

Owner:成都鼎安华智慧物联网股份有限公司

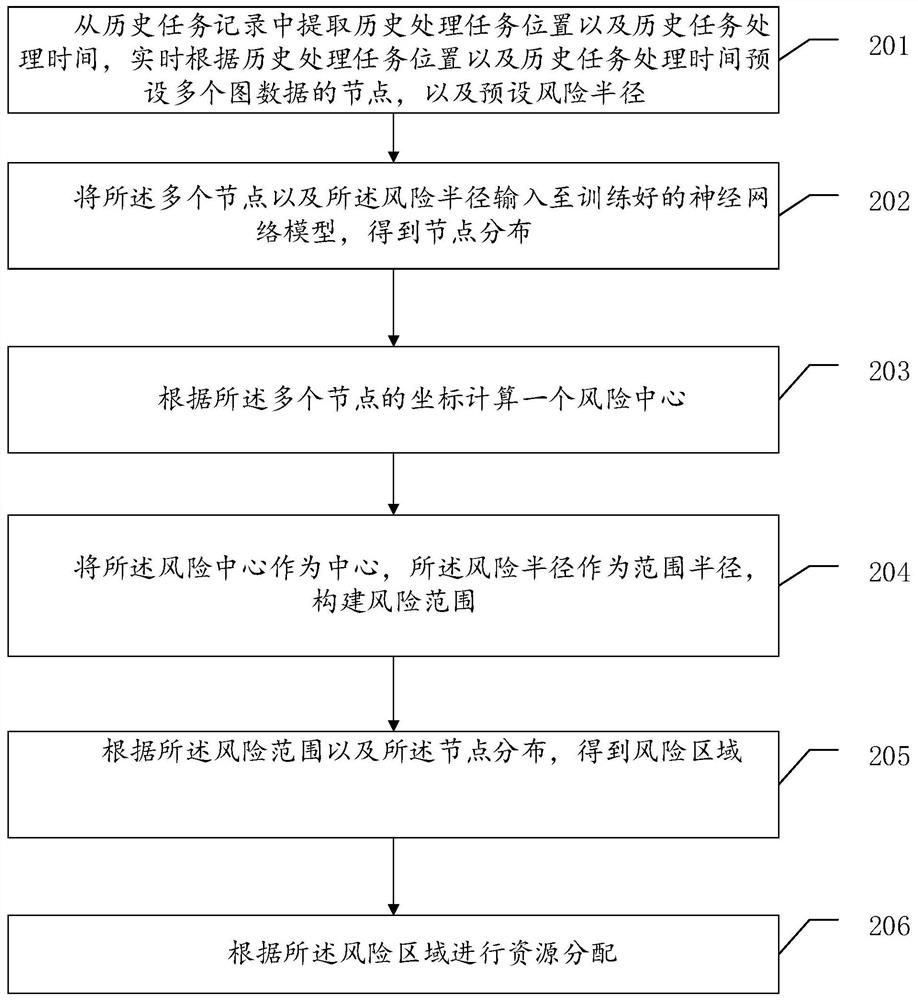

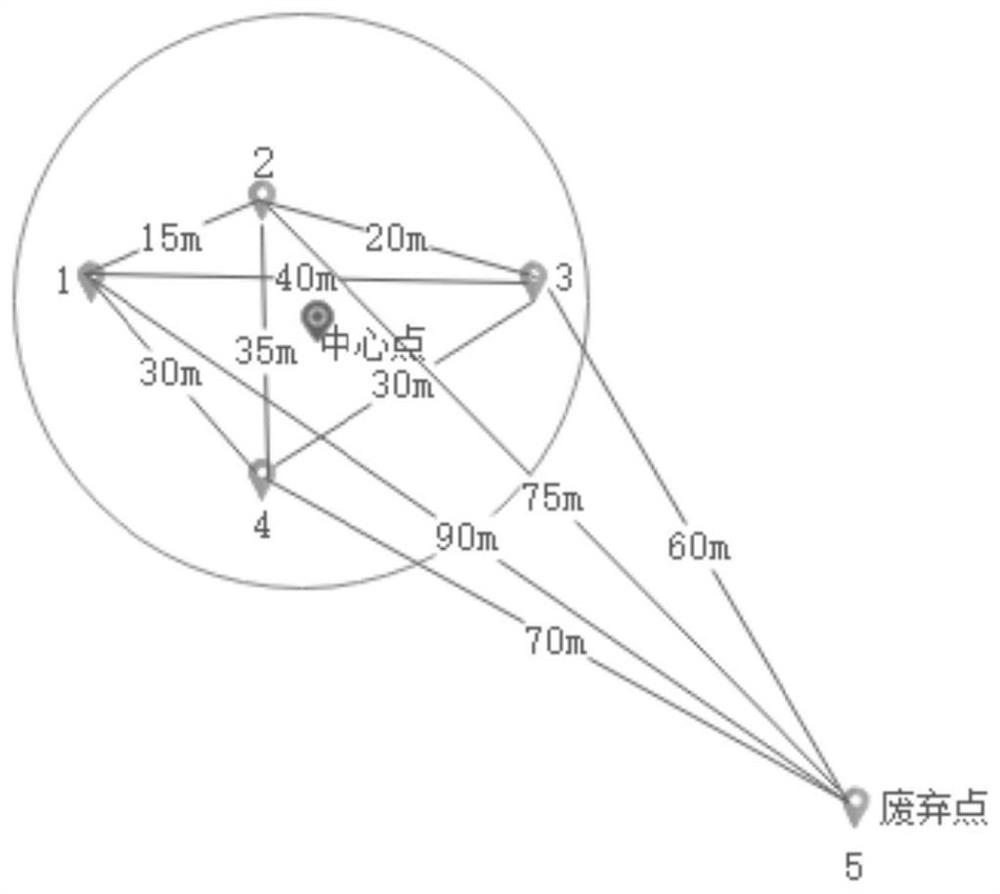

Resources allocation method and device, computer equipment and storage medium

The embodiment of the invention belongs to the field of operation and maintenance, and relates to a resources allocation method, which comprises the following steps of: extracting a historical processing task position and historical task processing time from a historical task record, and presetting nodes of a plurality of graph data and a preset risk radius in real time according to the historicalprocessing task position and the historical task processing time; inputting nodes and the risk radius into a trained neural network model to obtain node distribution; calculating a risk center according to the coordinates of the plurality of nodes; constructing a risk range by taking the risk center as a center and the risk radius as a range radius; obtaining a risk area according to the risk range and the node distribution; and performing resource allocation according to the risk area. In addition, the invention further relates to a blockchain technology, and historical task records can be stored in the blockchain. The invention further provides a resources allocation device, computer equipment and a storage medium. Effective degree of resources allocation is improved.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

Method and device for augmenting a person's view of a mining vehicle on a mining worksite in real-time

ActiveUS20200175272A1Planning and assessmentImprove discriminationImage enhancementImage analysisImaging processingDisplay device

A method for real-time visualization of a risk zone of a mining vehicle to a person on a mining worksite for augmenting the person's current view of the mining vehicle including capturing with a camera a stream of pictures corresponding at least partly to the person's field of view, recognizing at least one mining vehicle in the picture stream by means of image processing, extracting image data of the mining vehicle from the picture stream, calculating, based on the image data and on preset vehicle risk zone data, at least one risk zone of the mining vehicle adapted to the person's current view of the mining vehicle, and visualizing the risk zone on a person's display such that the person's current view of the mining vehicle is overlayed in real-time with the visualization of the risk zone.

Owner:MY VIRTUAL REALITY SOFTWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com