Patents

Literature

264 results about "Waste production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste production implies the use of material and energy and the depletion of the Earth's renewable and non-renewable resources (see Chapter 13). Waste issues and their solutions are inevitably linked to production and consumption throughout all stages of the life-cycle of materials and the use of energy (see Chapter 12).

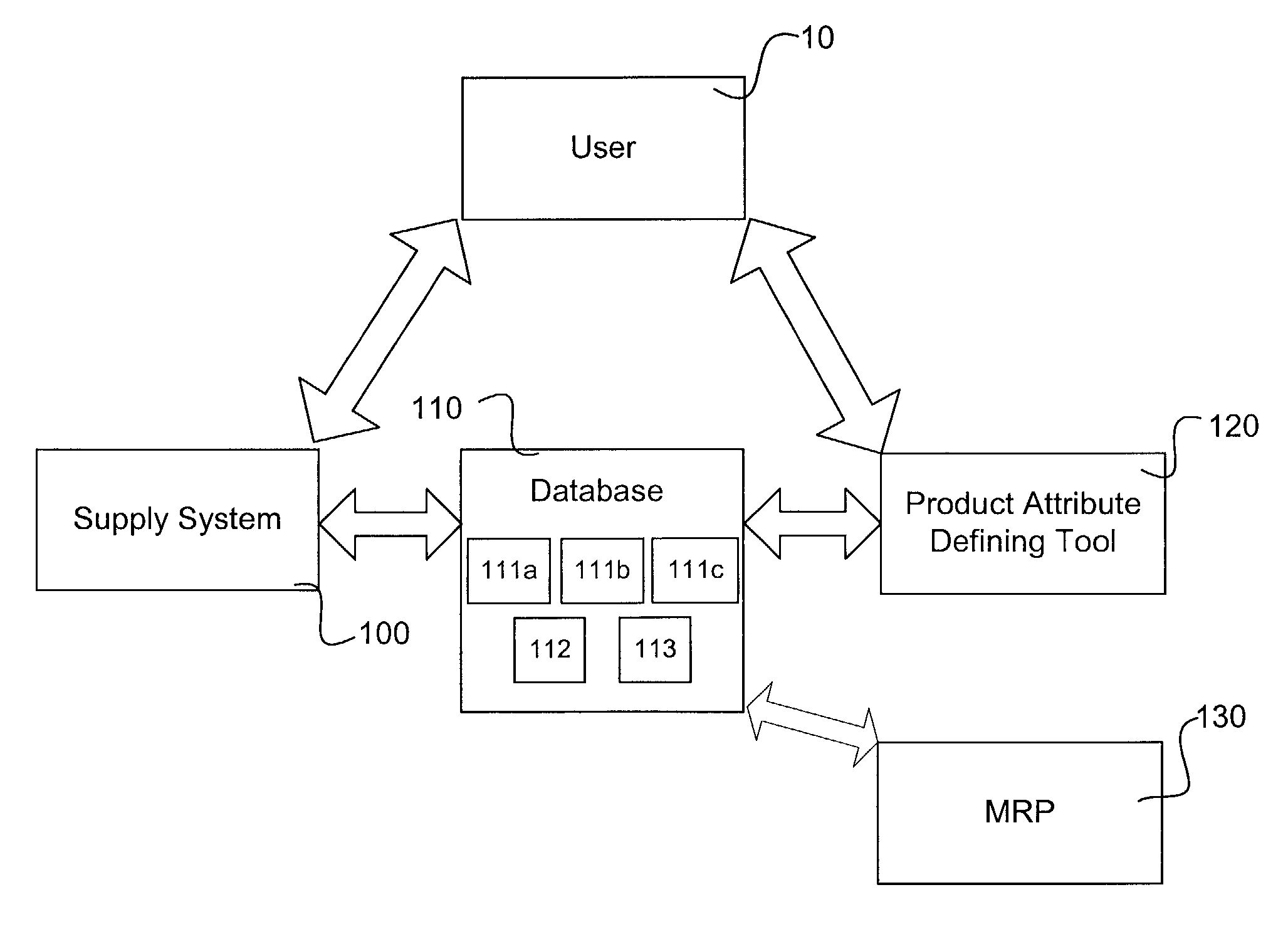

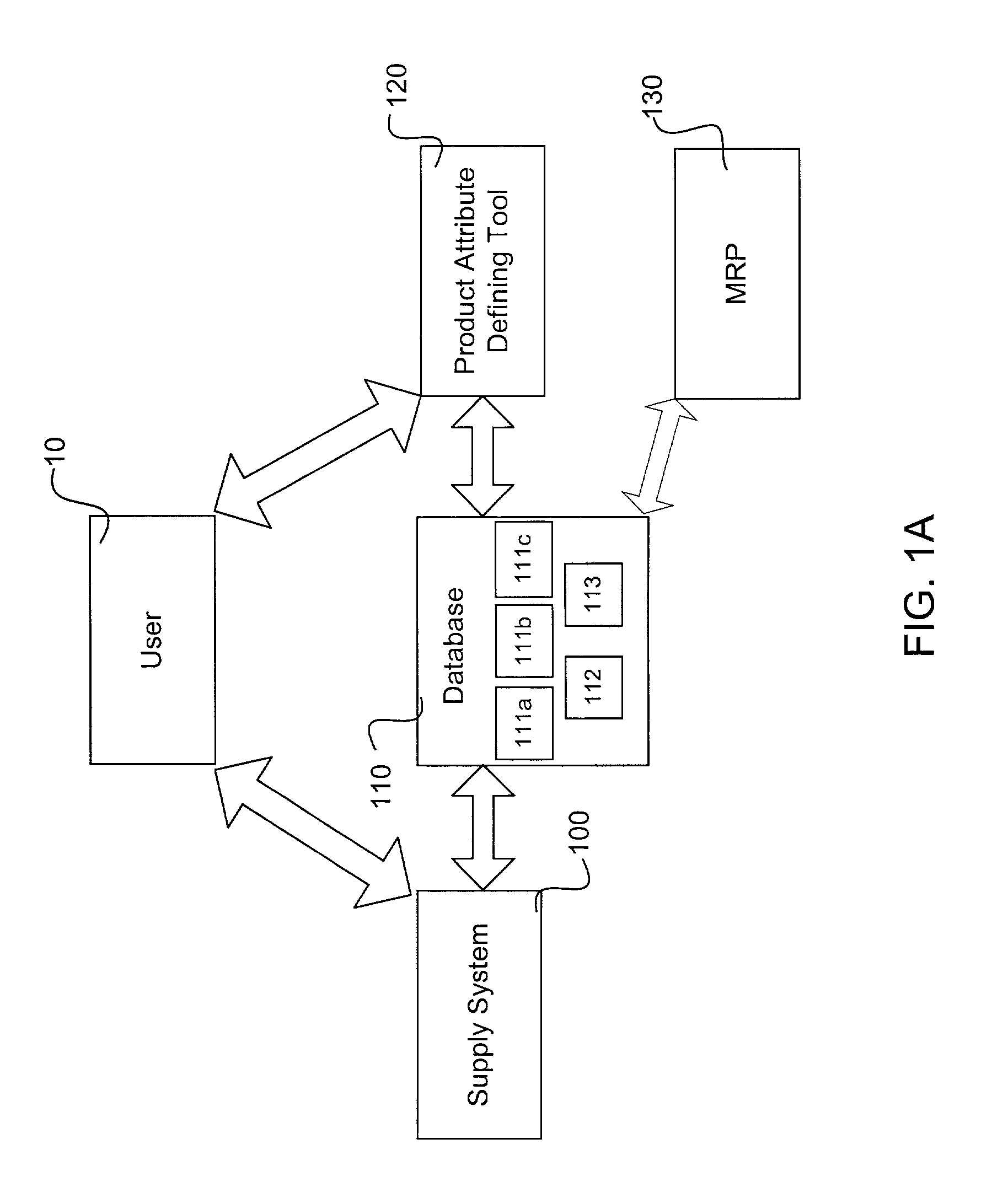

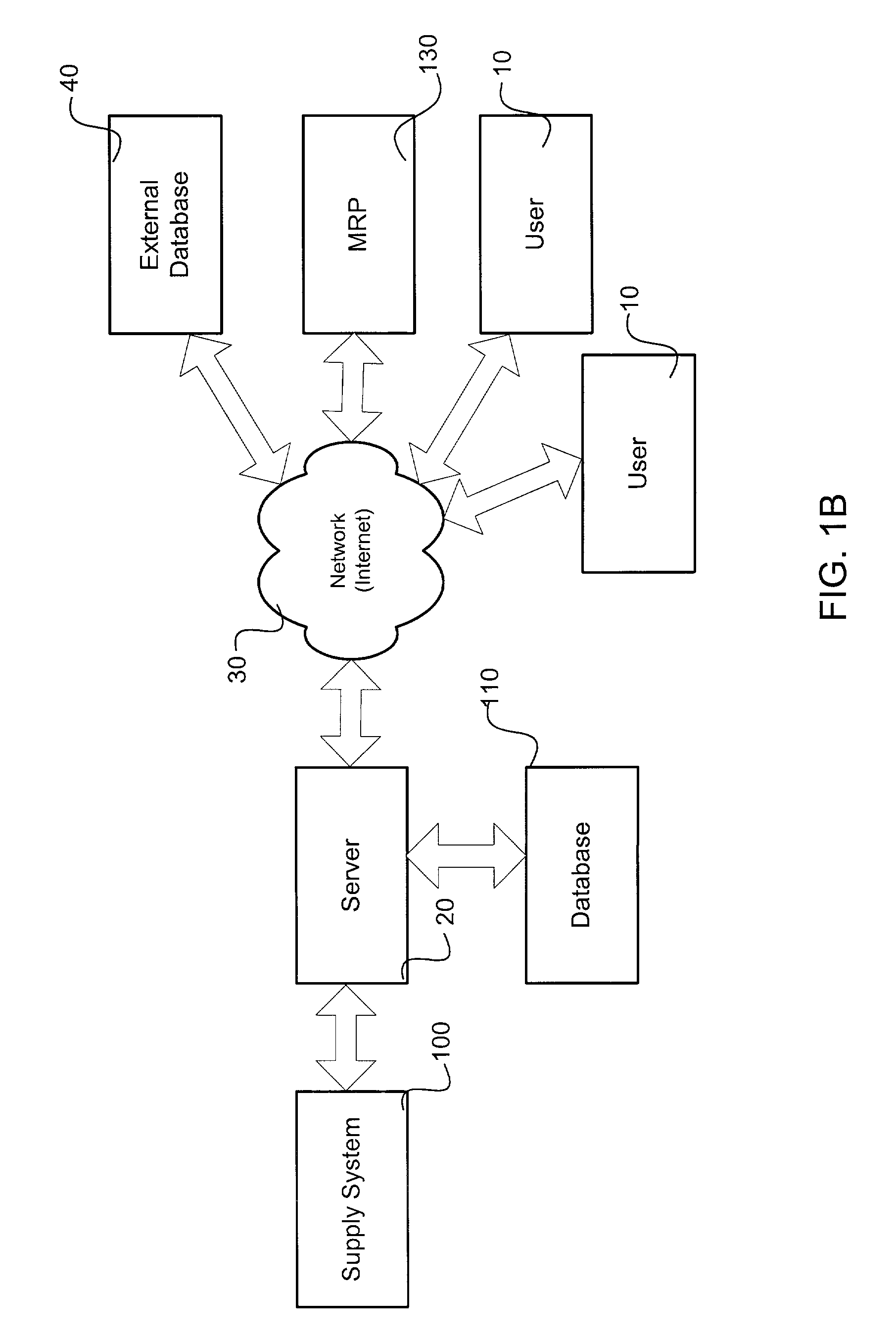

System and method for allocating the supply of critical material components and manufacturing capacity

InactiveUS7058587B1Improve responsivenessMaximize inventory useResourcesSpecific program execution arrangementsProgram planningChange analysis

The present invention allocates the supply of critical components and manufacturing capacity by optimizing critical material planning decisions and dynamically allocating constrained materials using advanced substitution logic that considers alternate suppliers and supports product life cycle from design through end-of-life. The present invention may utilize unique synchronized allocations and matched sets logic. The synchronized allocations ensure that all materials necessary for production are available in the appropriate time-phased allocation before beginning production to minimize wasted production capacity and materials. The supply system may include various combination of components, including a Supply Planner, a Resource Optimizer, a Constraint Based Master Planner, a Product Change Analyzer, a Comparer, a Resource Requirements Planner, a Finite Resource Planner, a Customer Promiser, and an Interactive Master Scheduler. Another embodiment of the supply system includes a tool that allows users to define products using engineering specifications.

Owner:BLUE YONDER GRP INC

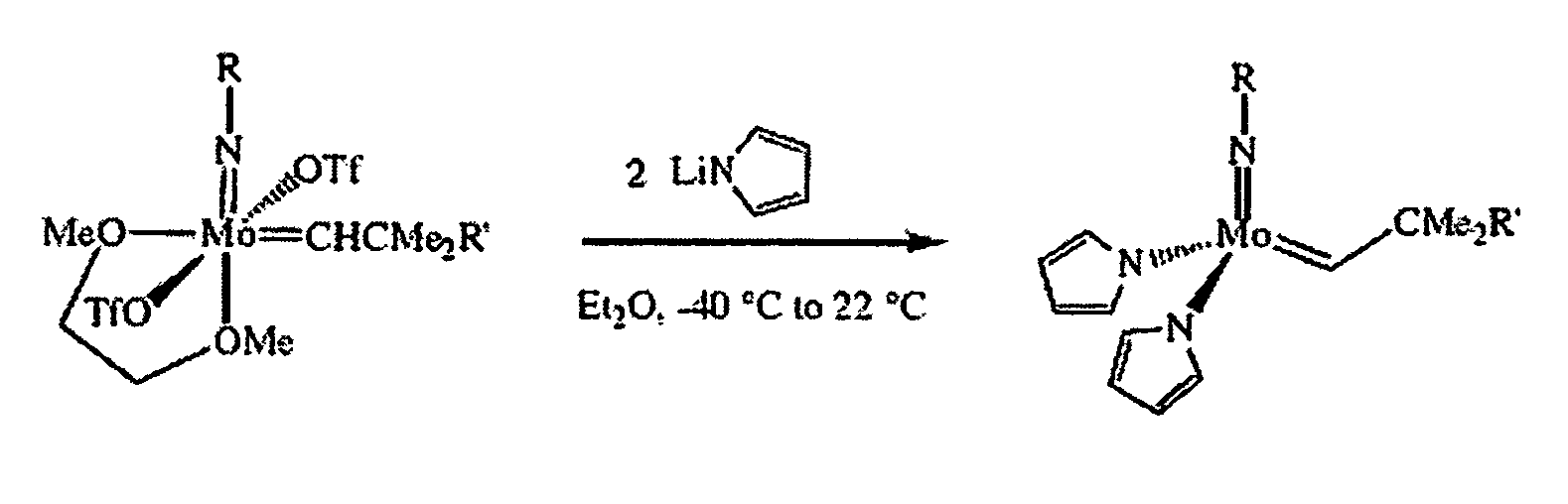

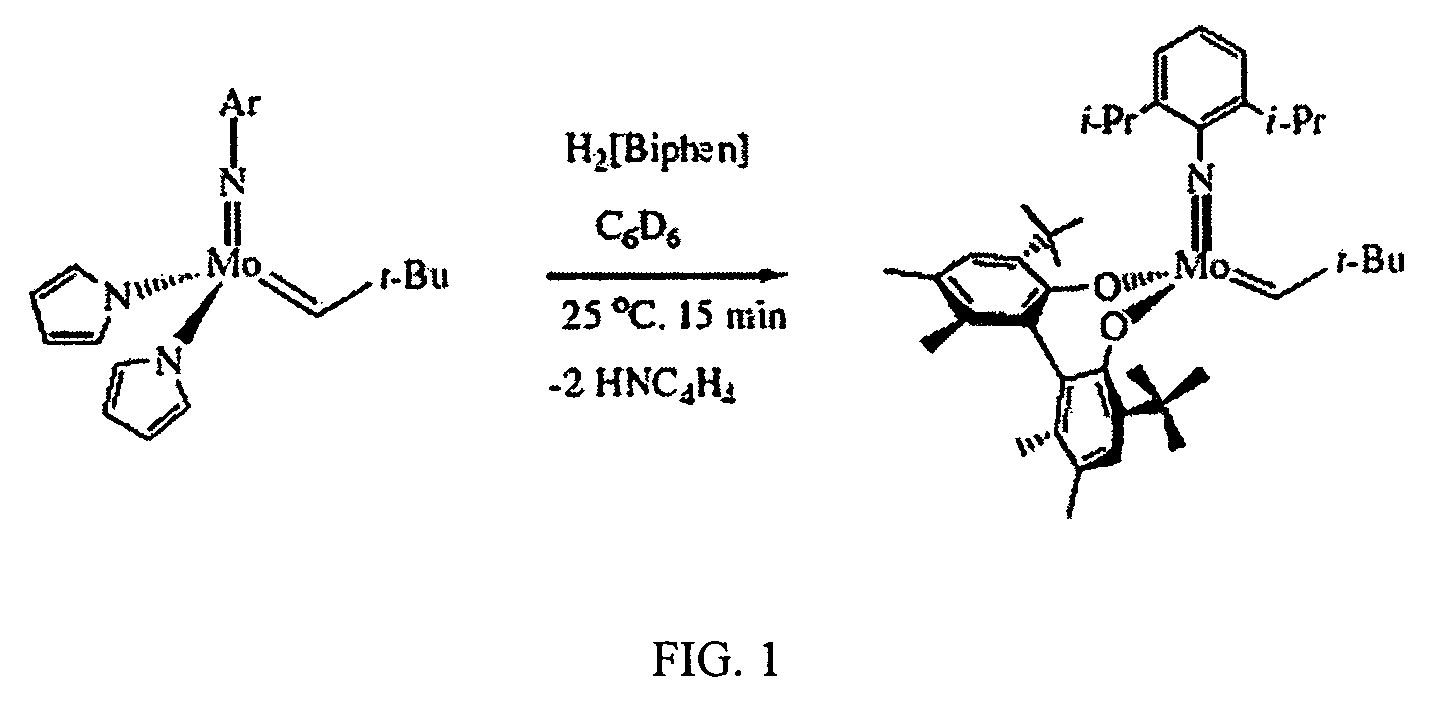

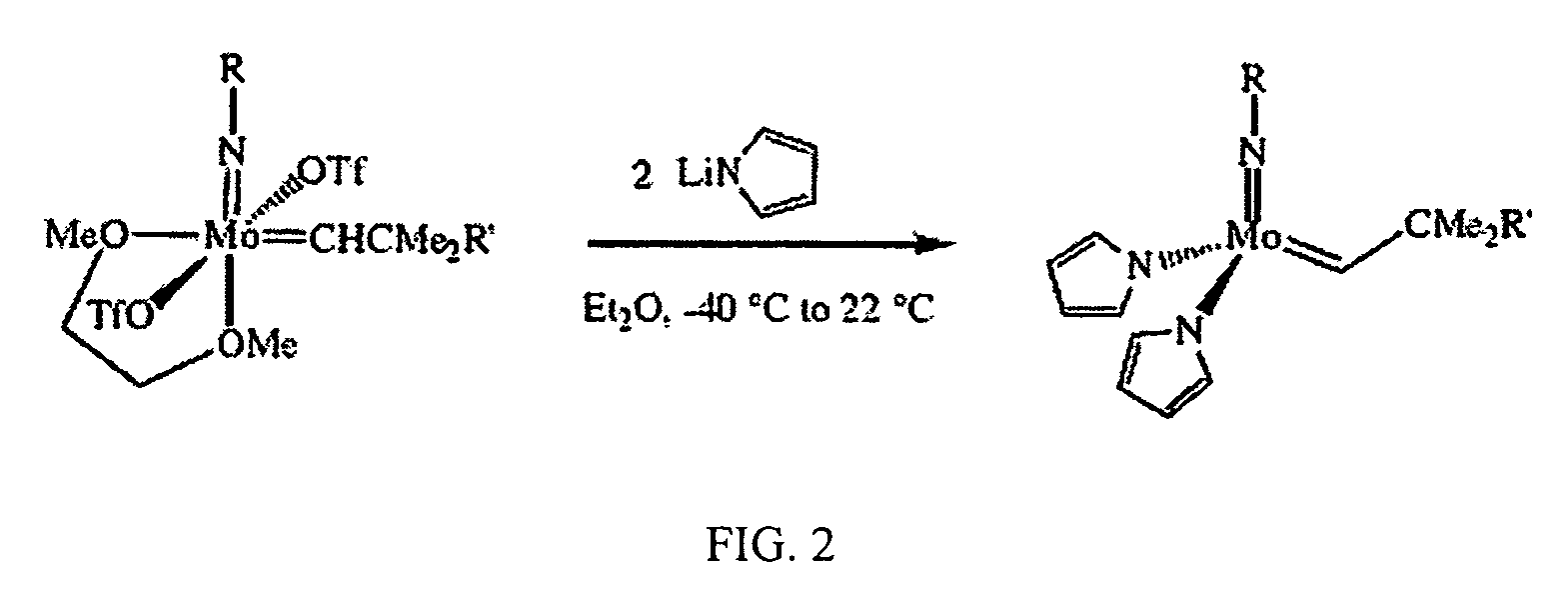

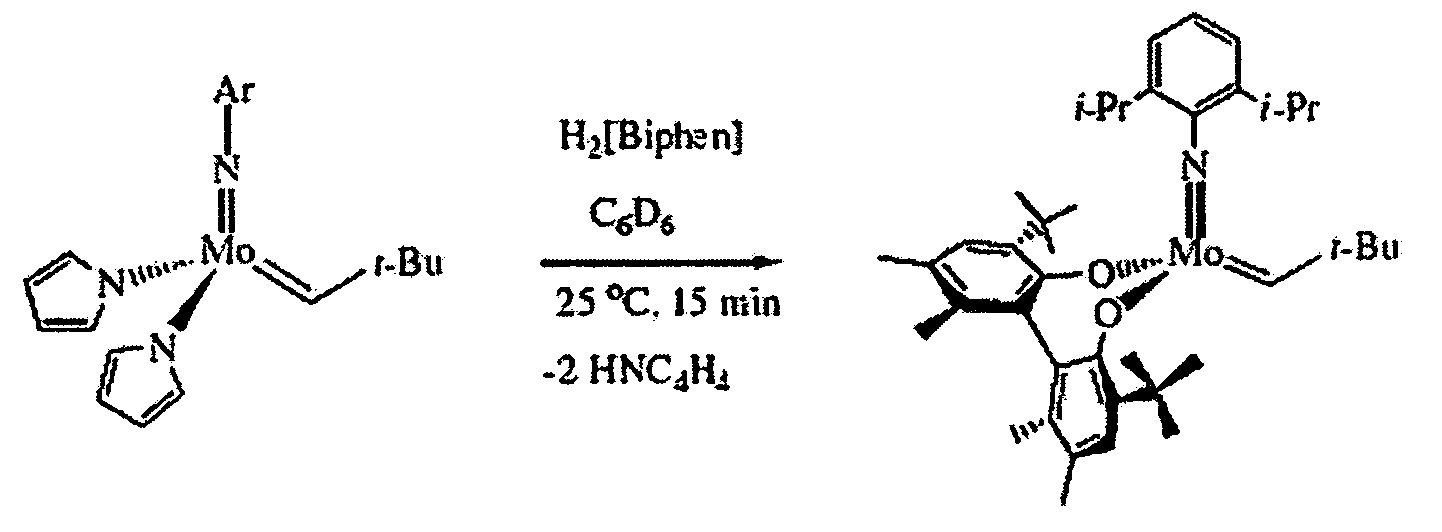

Olefin metathesis catalysts and related methods

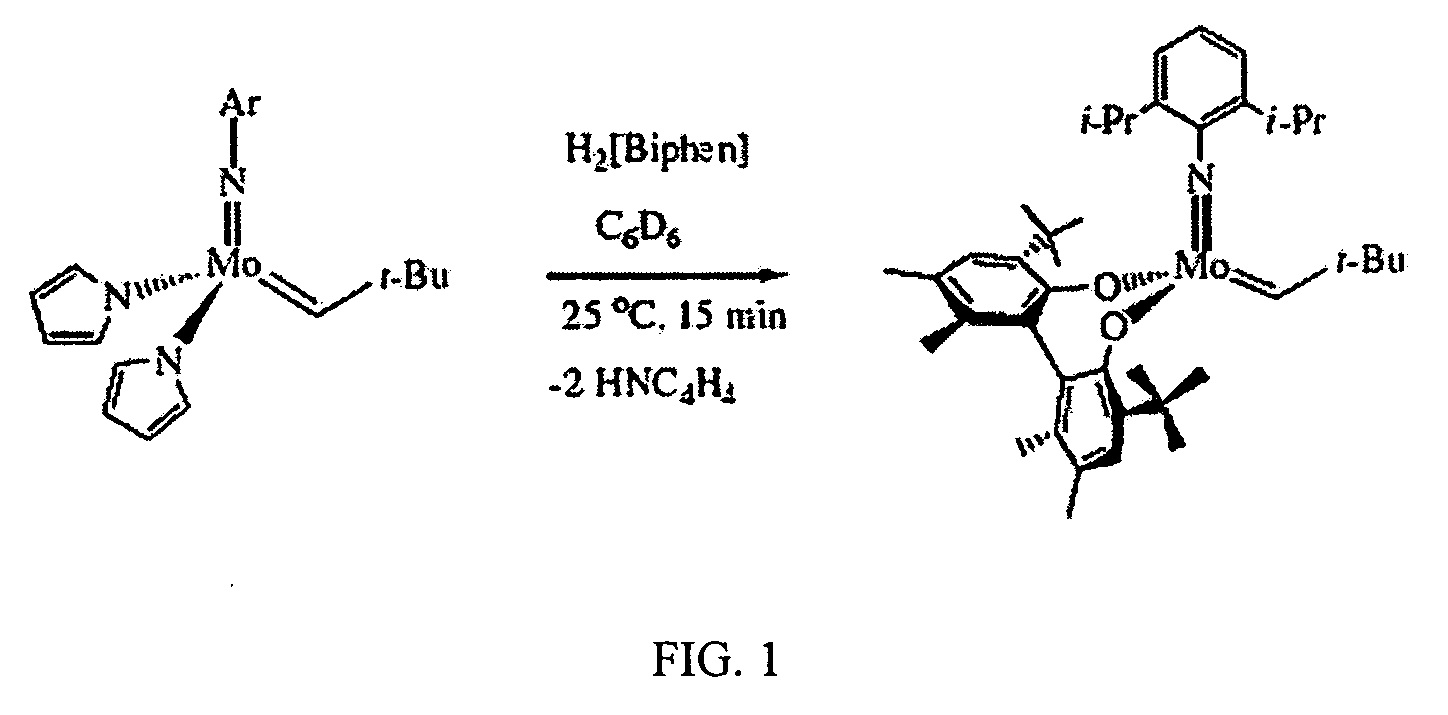

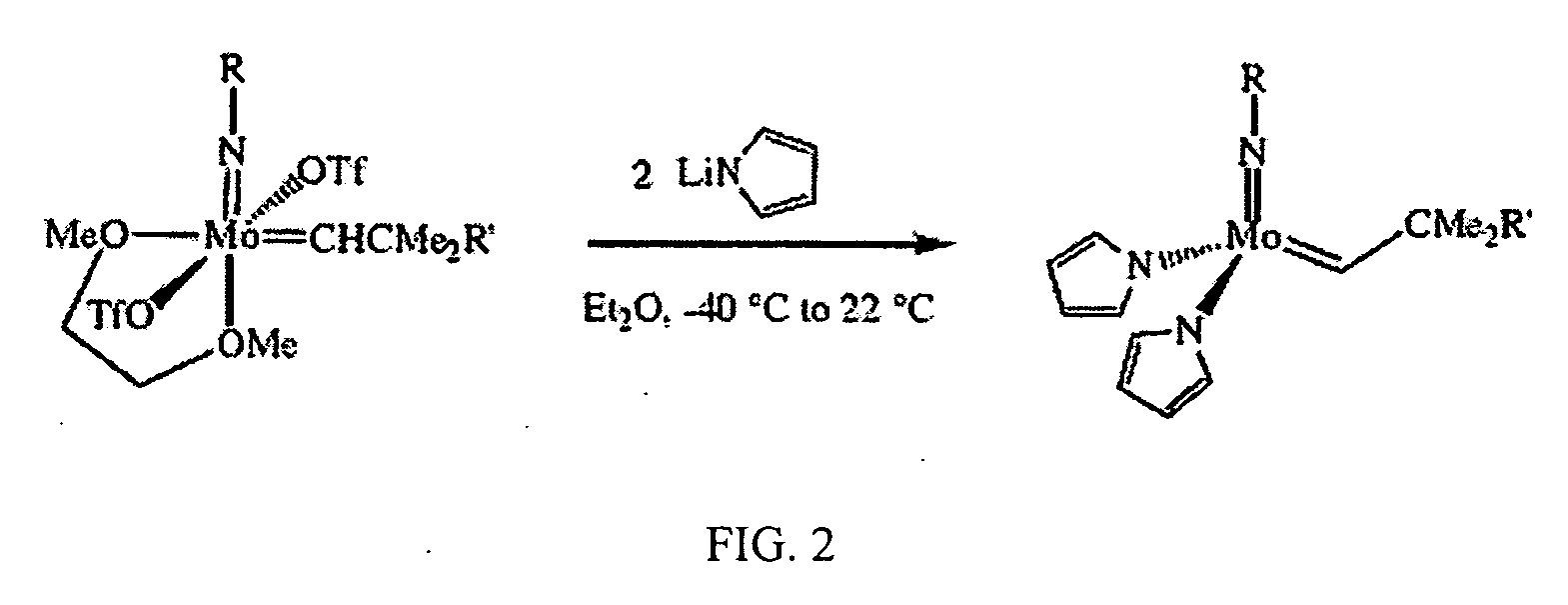

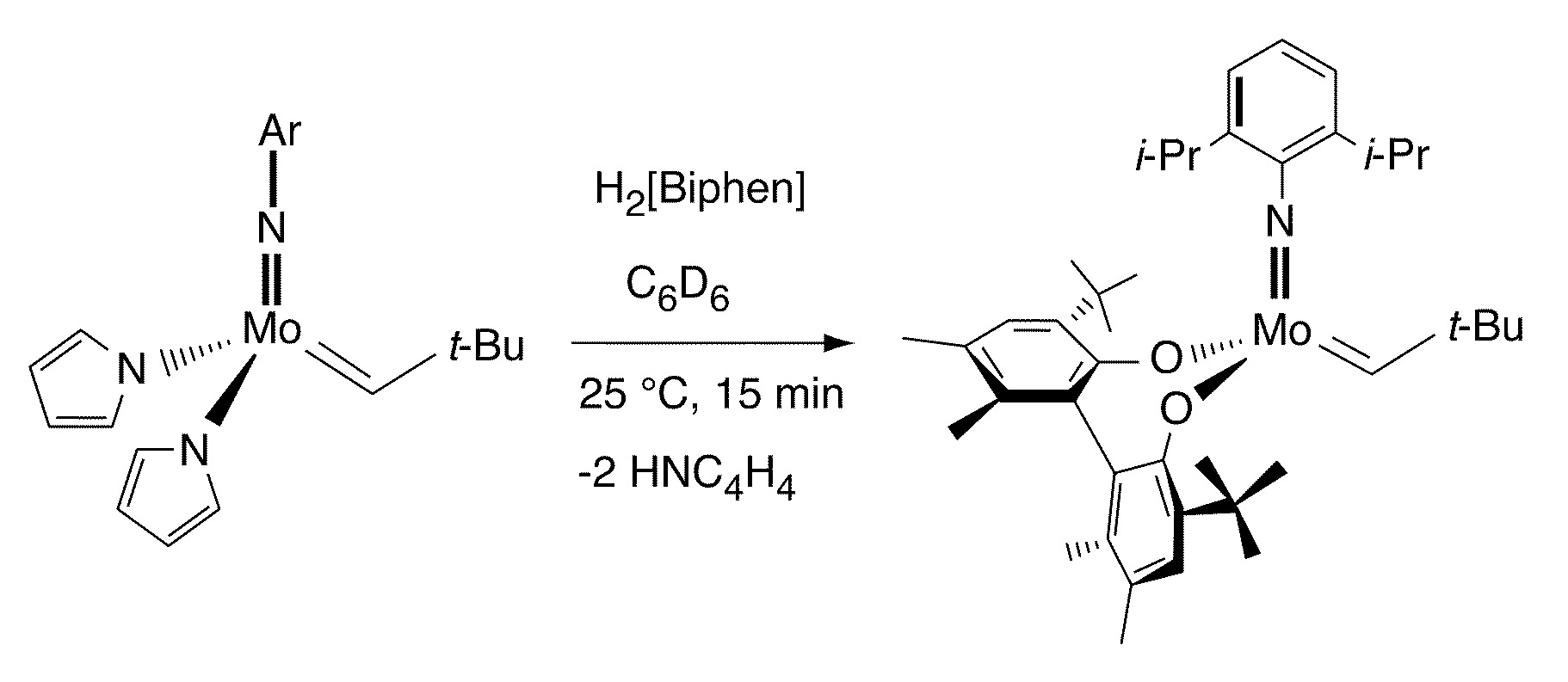

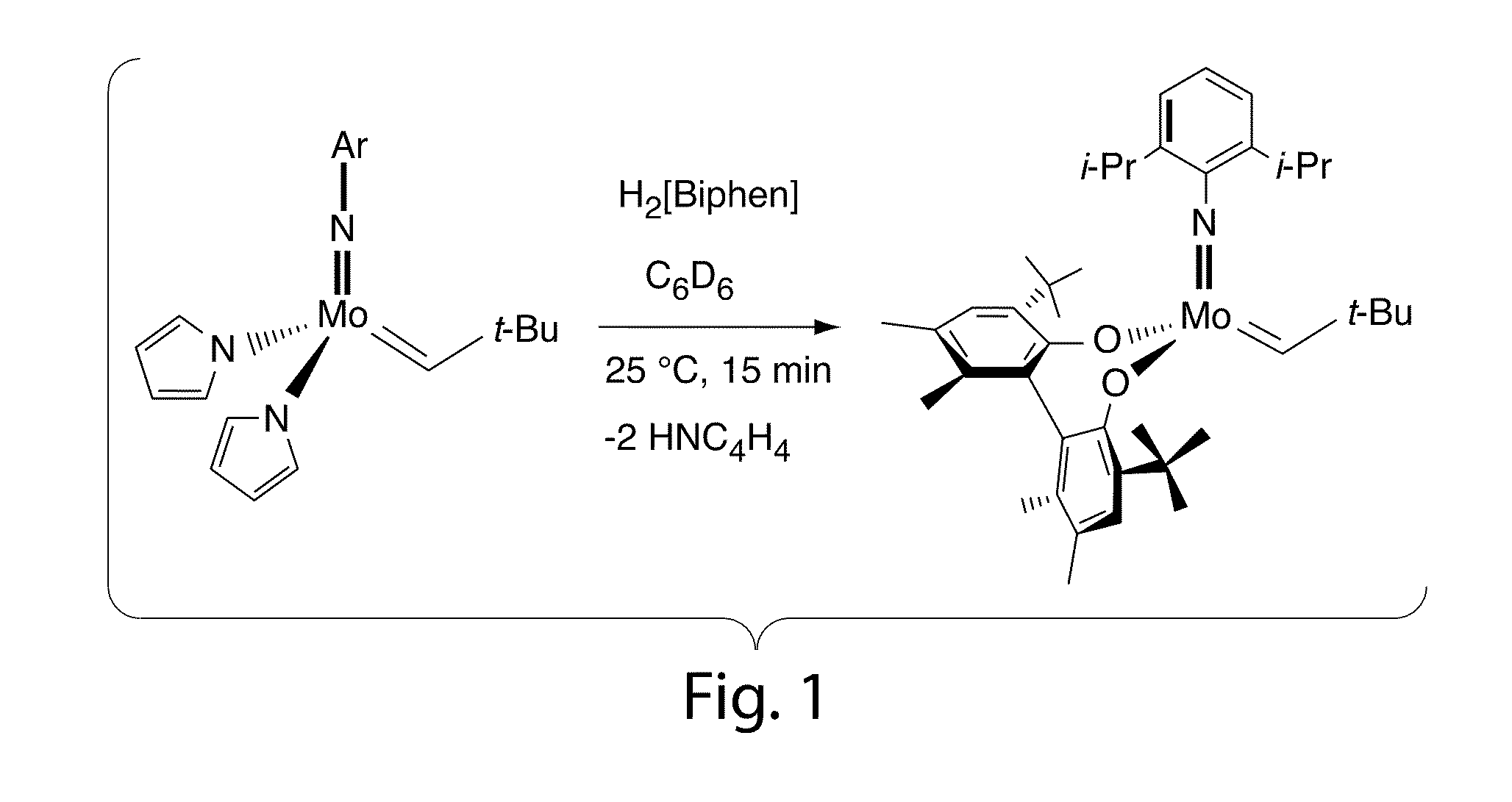

ActiveUS7932397B2Group 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsChemical reactionAlkene

The present invention provides methods for the synthesis of catalysts and precursors thereof. Methods of the invention may comprise combining a catalyst precursor and at least one ligand to generate a catalytically active species, often under mild conditions and in high yields. In some cases, a wide variety of catalysts may be synthesized from a single catalyst precursor. Methods of the invention may also include the preparation of catalysts which, under reaction conditions known in the art, may have been difficult or impossible to prepare and / or isolate due to, for example, steric crowding at the metal center. The present invention also provides catalyst compositions, and precursors thereof, which may be useful in various chemical reactions including olefin metathesis. In some cases, methods of the invention may reduce the number of synthetic and purification steps required to produce catalysts and / or other reaction products, as well as reducing time, cost, and waste production.

Owner:MASSACHUSETTS INST OF TECH

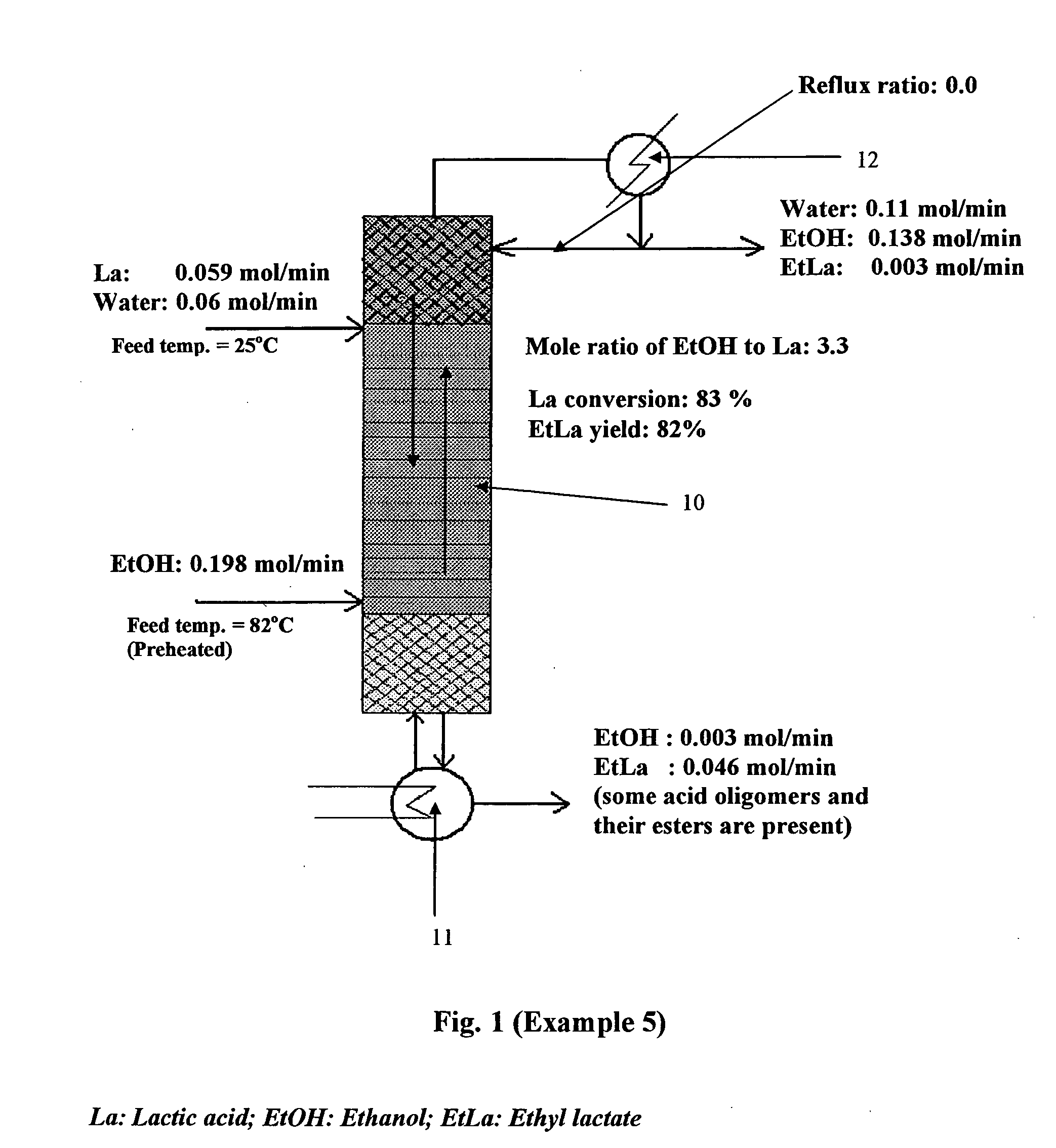

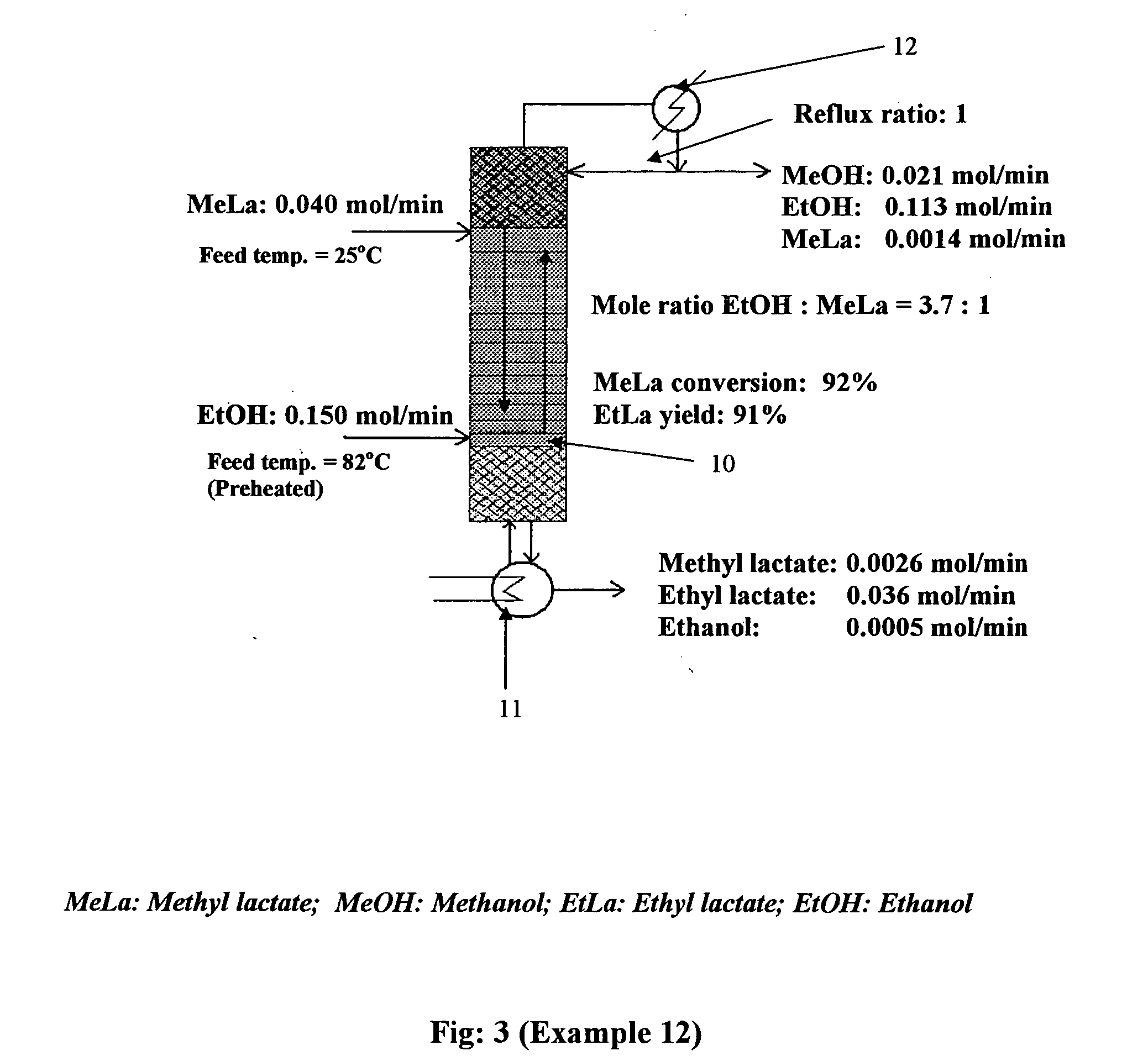

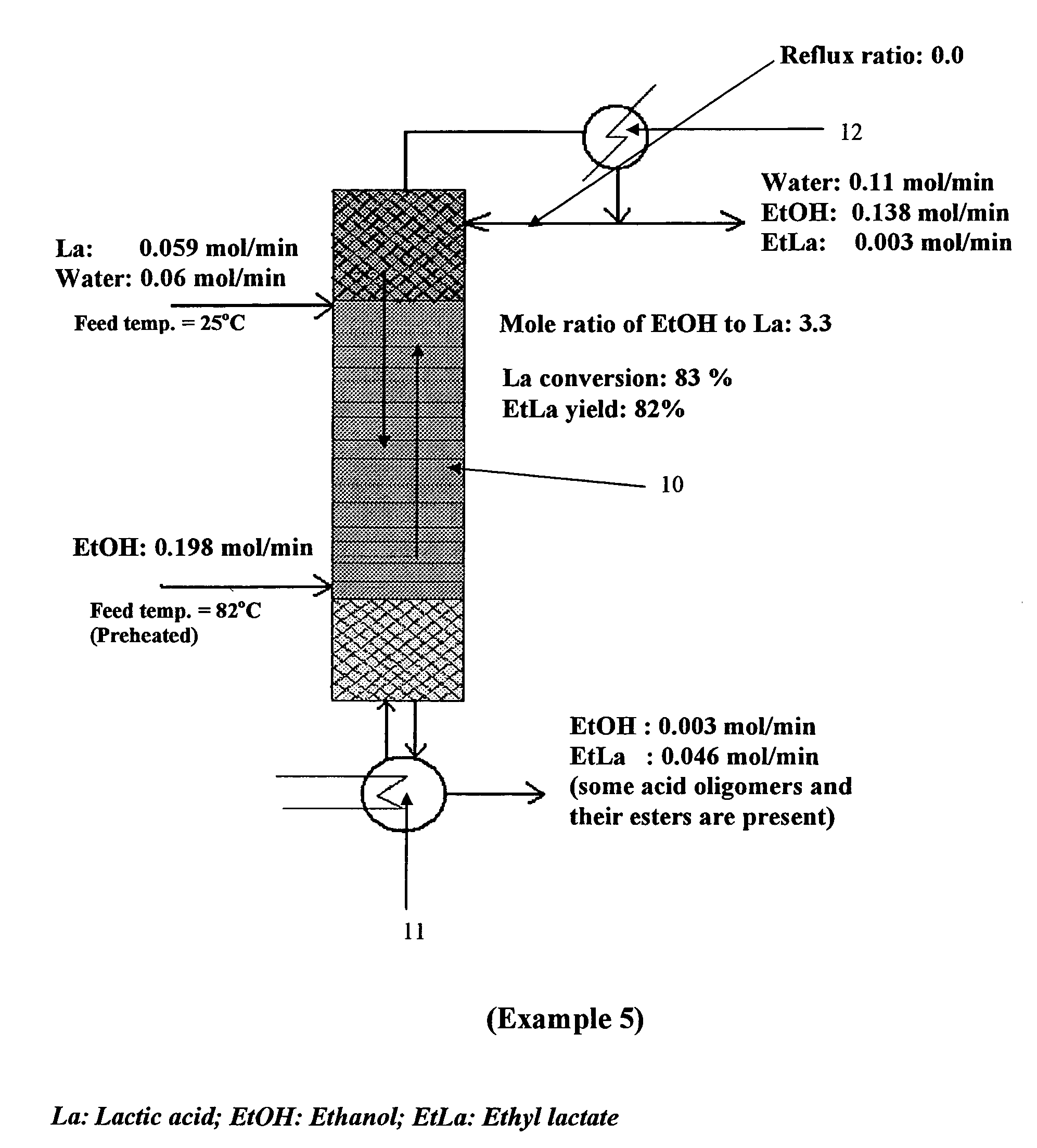

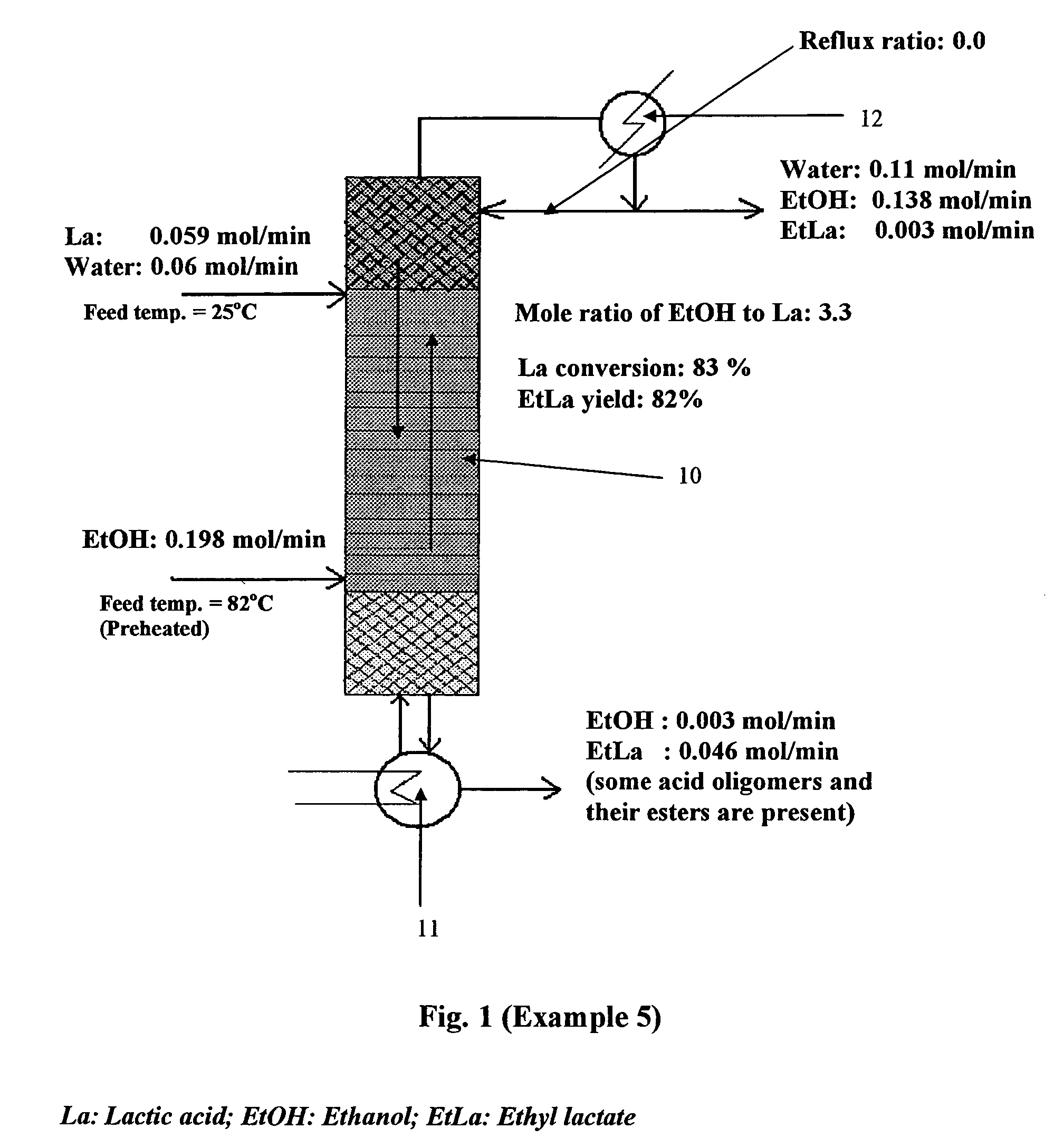

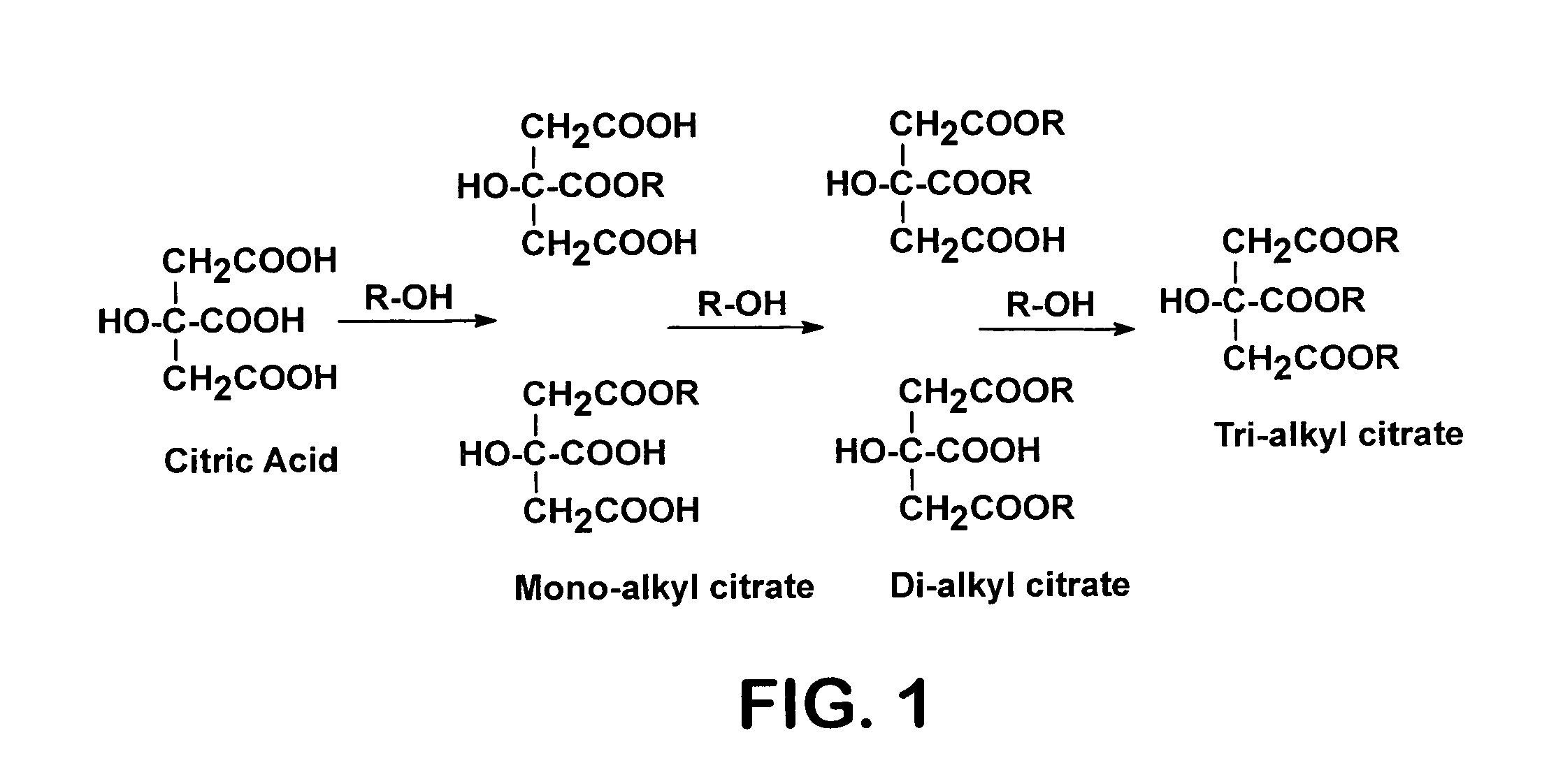

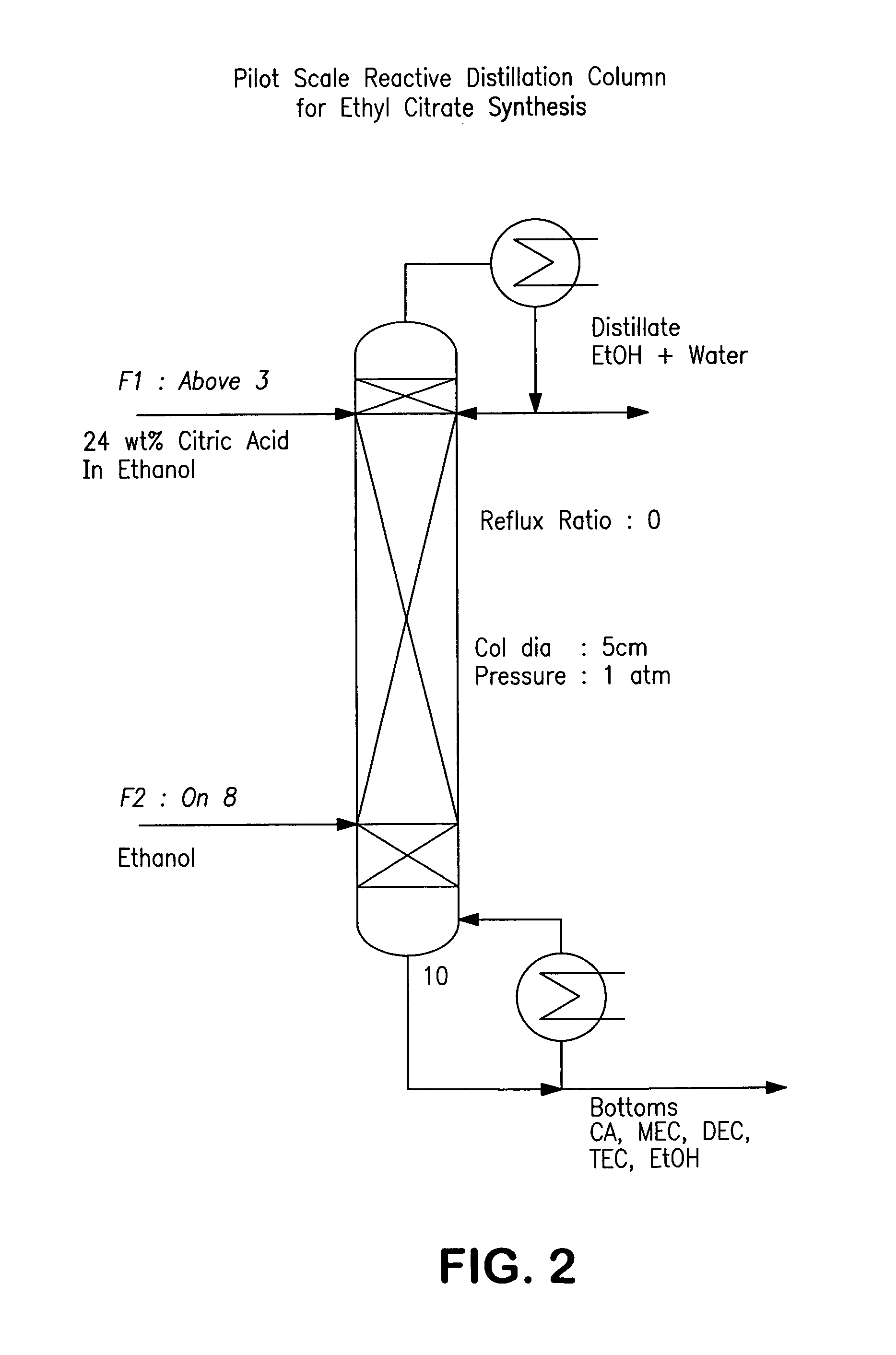

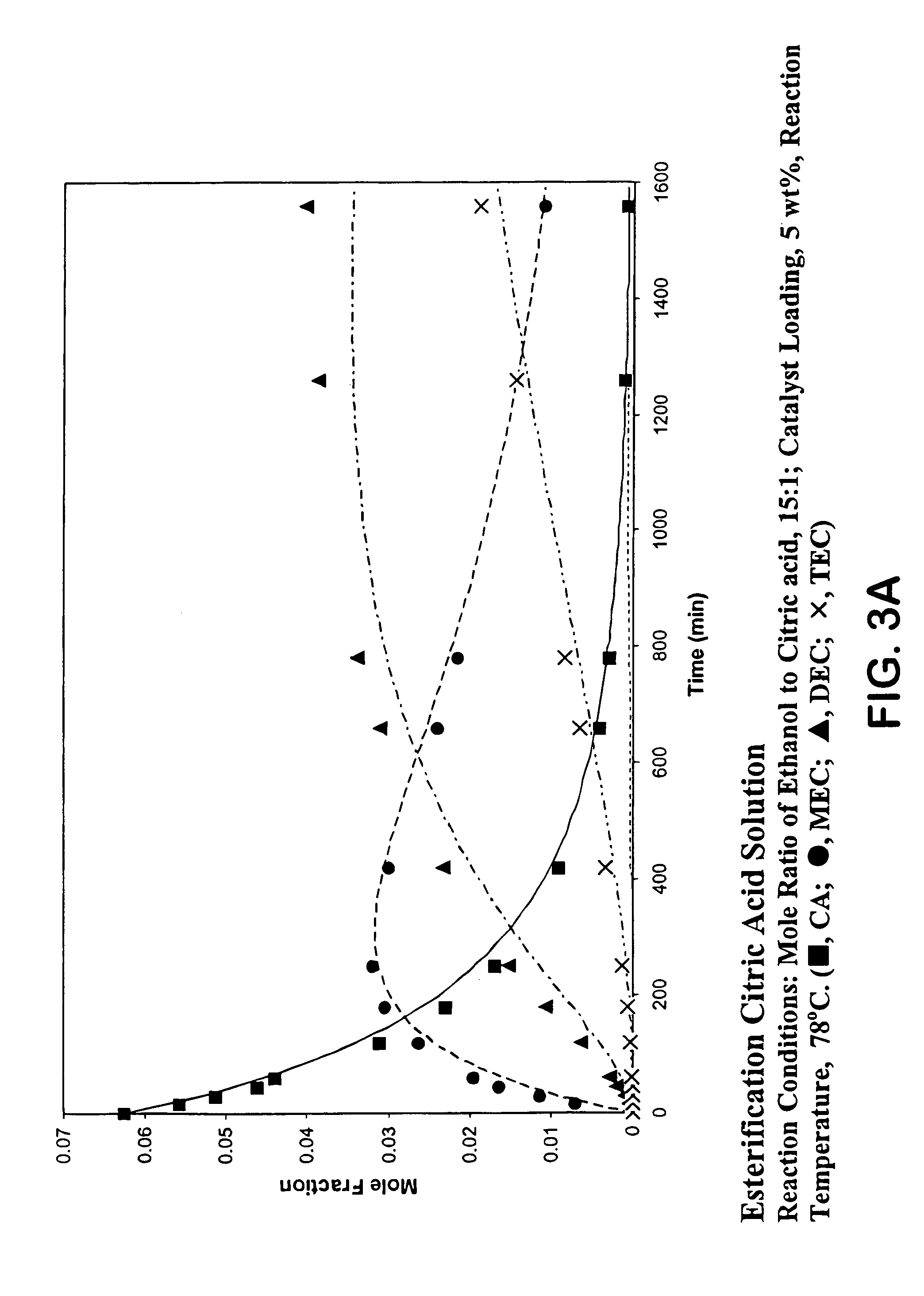

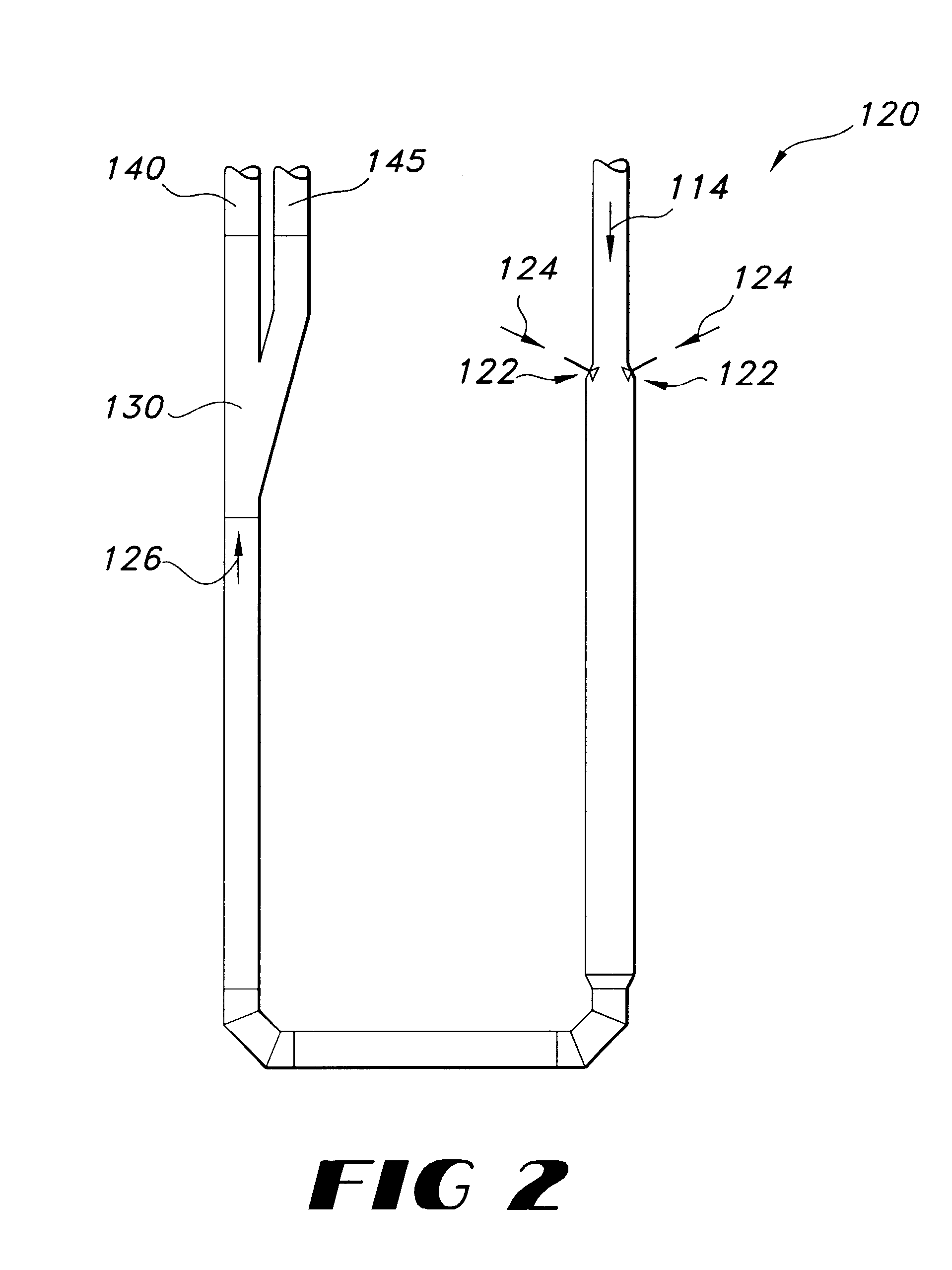

Process for production of organic acid esters

InactiveUS20060014977A1Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

A process for producing organic acid esters using continuous countercurrent reactive distillation using acid catalysts in a structured packing in a single column (10) is described. In the reactive distillation an organic acid ester is formed by chemical reaction and can be purified to its final state within the single column. Organic acid esters are produced at relatively low cost, with less waste production, and in a less complicated manner than prior processes. Organic acid ester have uses as solvents, as intermediate chemicals, and in consumer products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

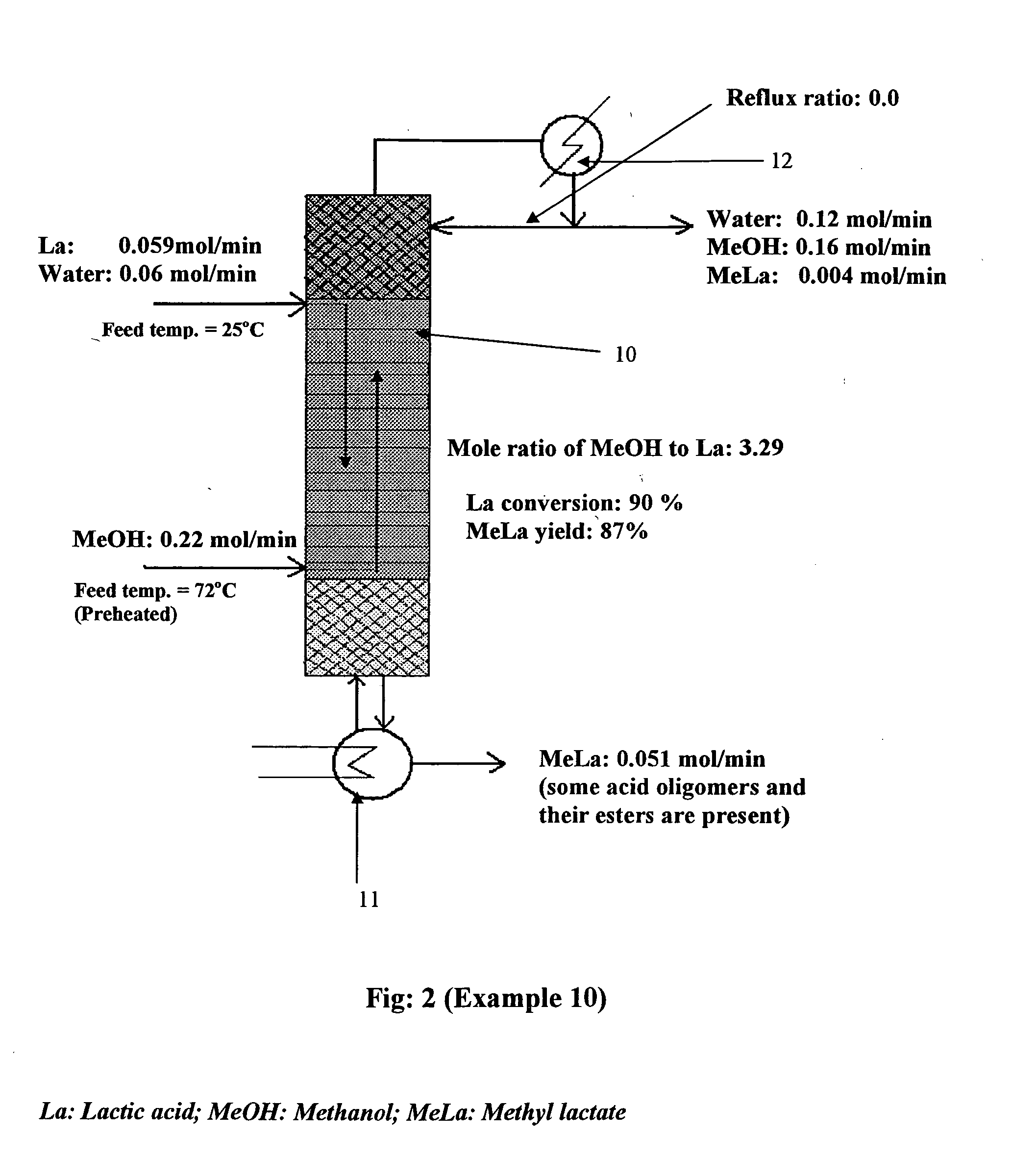

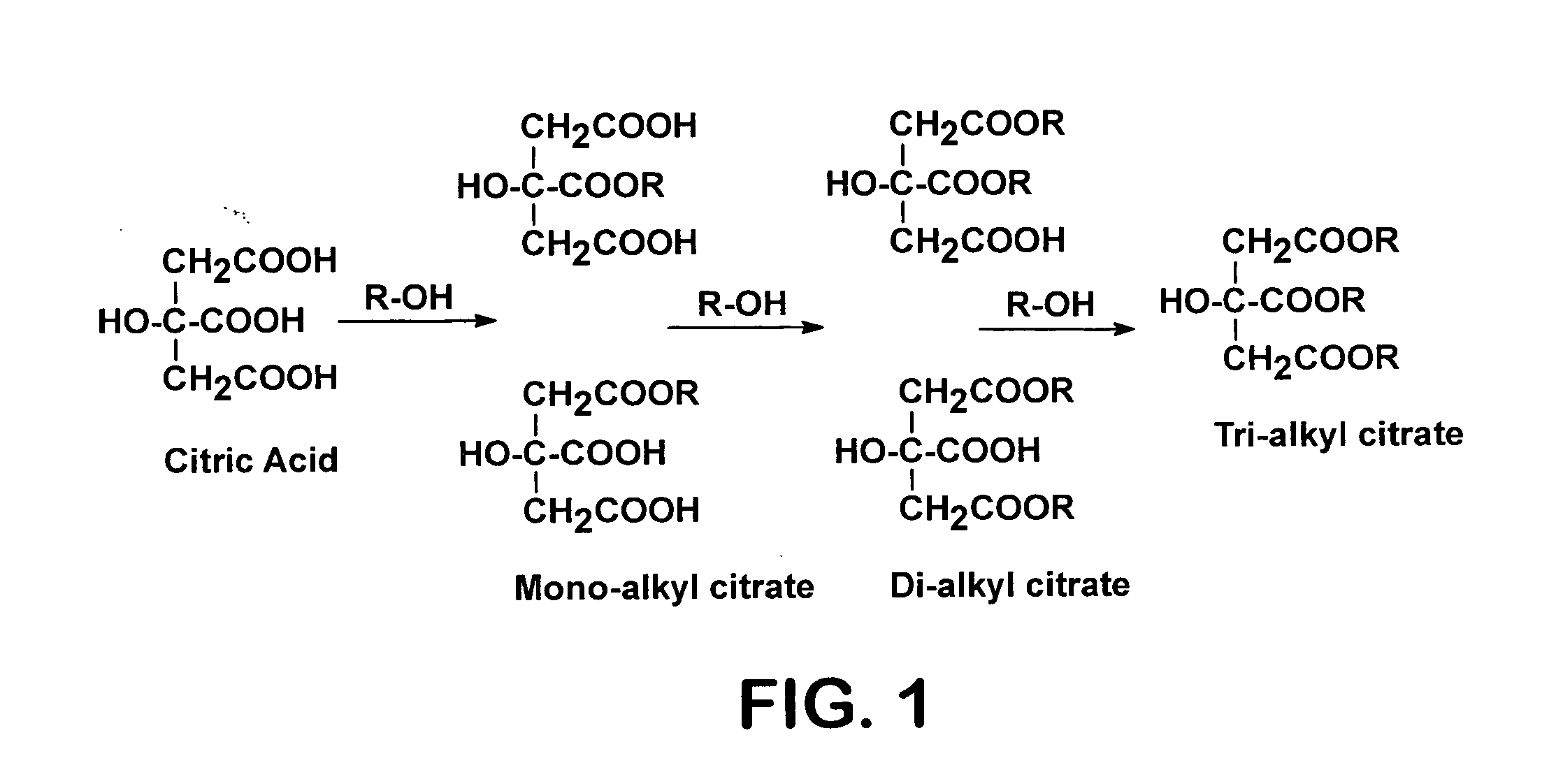

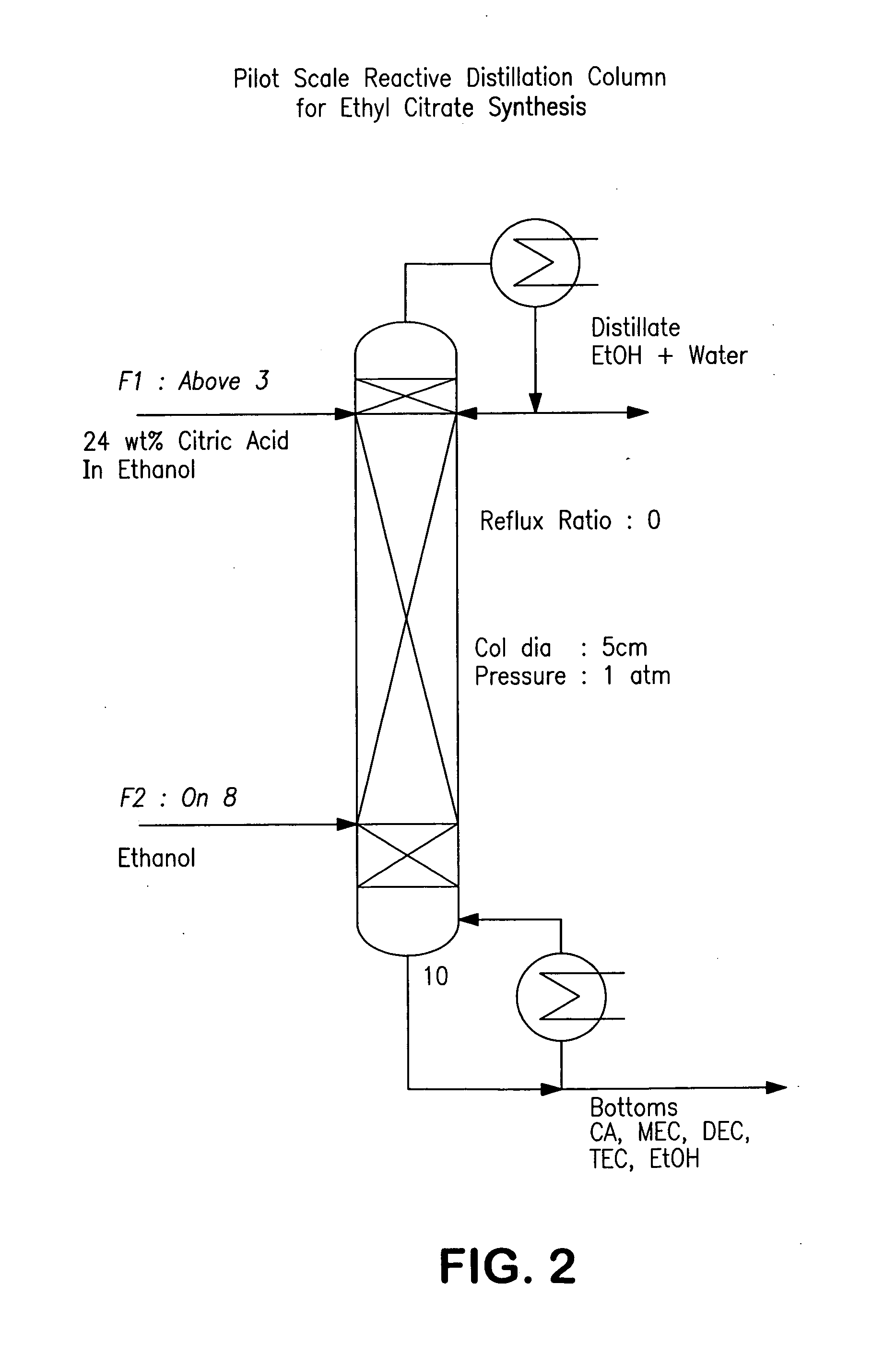

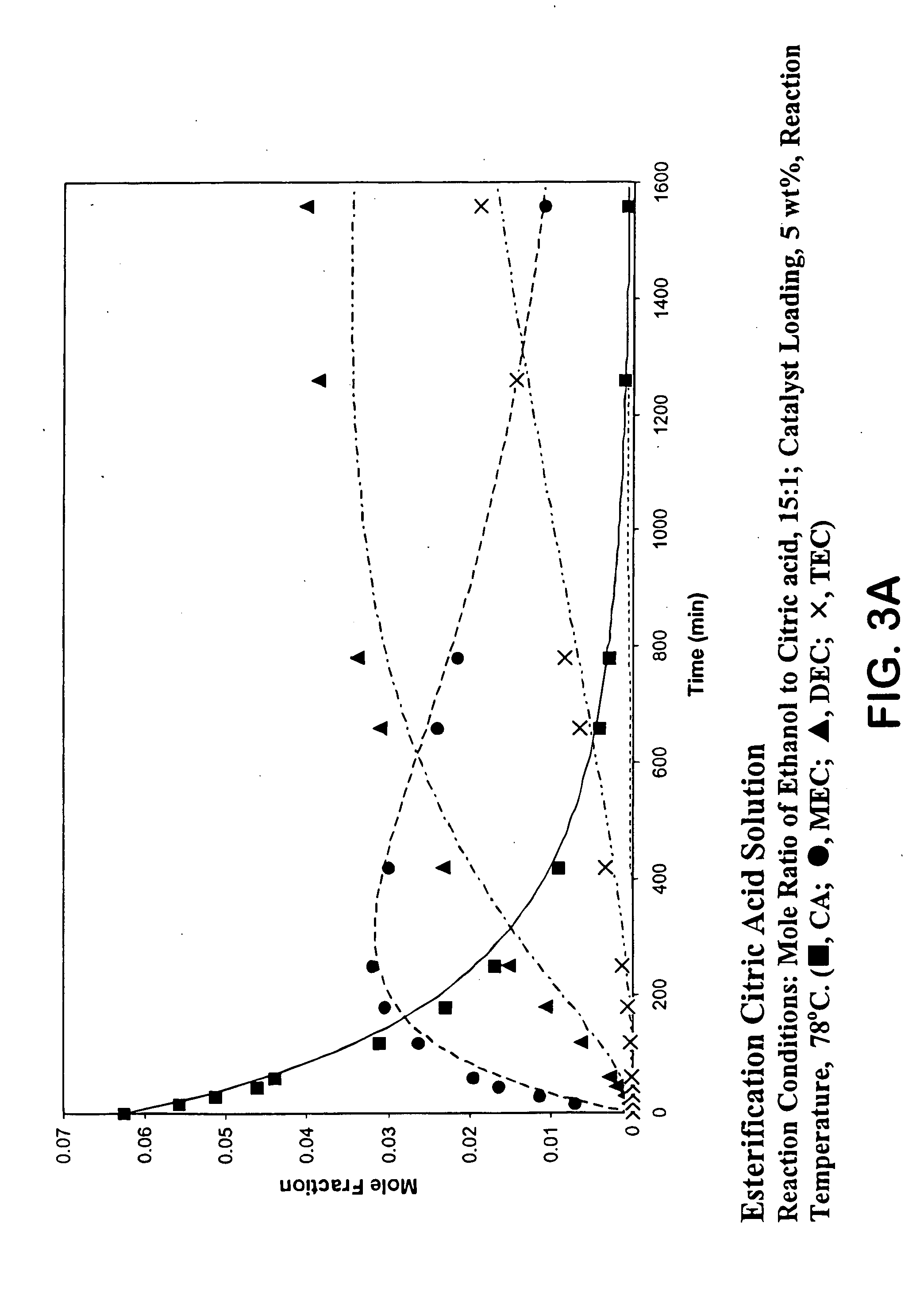

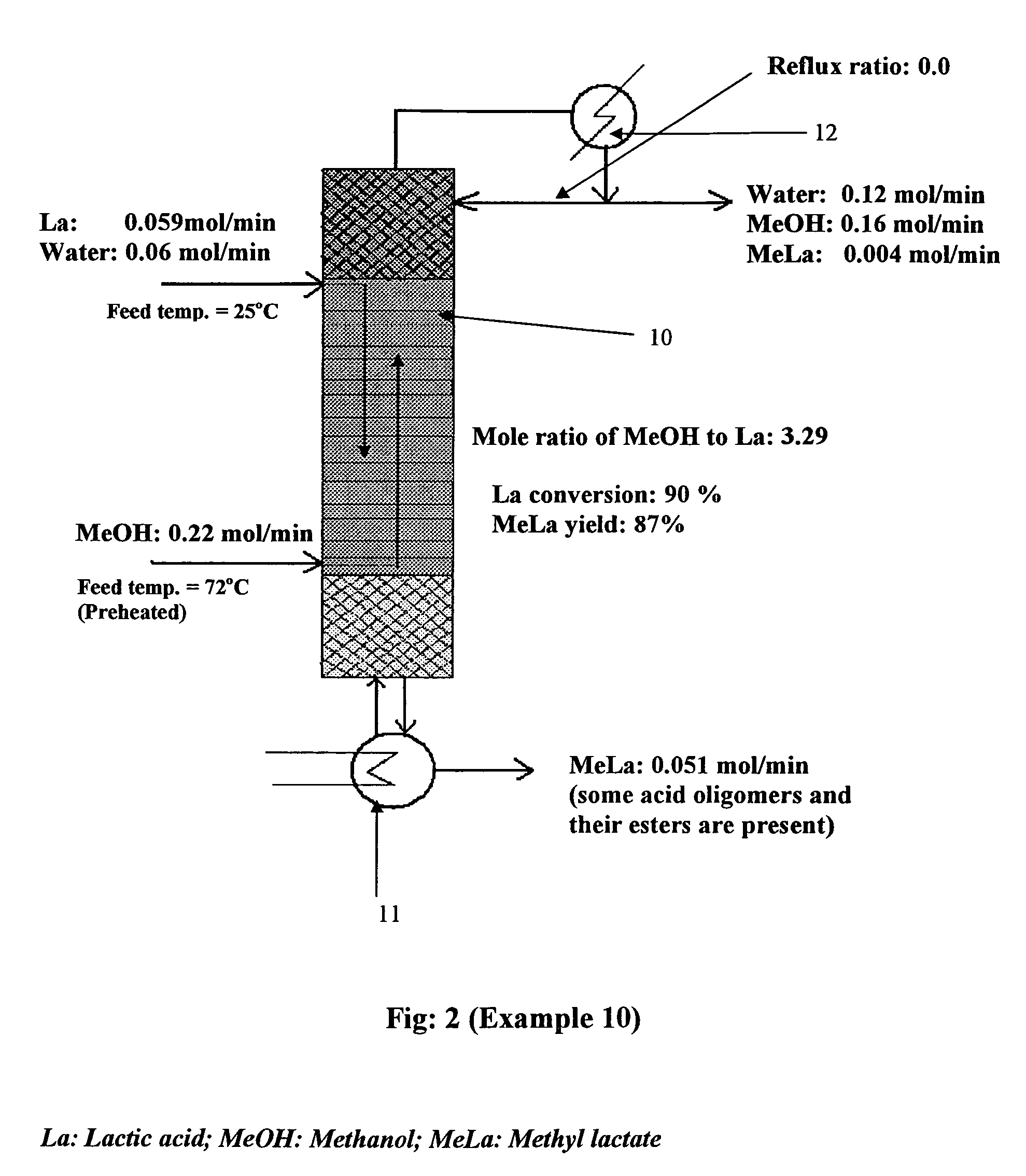

Process for reactive esterification distillation

ActiveUS20060252956A1Preparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

A process for producing organic acid di- or tri-esters, particularly citric acid tri-esters, with the available acid groups esterified using countercurrent reactive distillation using acid catalysts in a structured packing is described. In the reactive distillation an organic acid di- or tri-ester is formed by chemical reaction and purified to its final state within the single column. Organic acid di- or tri-esters are produced at relatively low cost, with less waste production in by-products of the reaction, and in a less complicated manner than prior processes. Organic acid di- and tri-esters have uses as solvents, as plasticizers and in conversion products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Process for production of organic acid esters

InactiveUS7652167B2Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Olefin metathesis catalysts and related methods

ActiveUS20080119678A1Group 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsChemical reactionAlkene

The present invention provides methods for the synthesis of catalysts and precursors thereof. Methods of the invention may comprise combining a catalyst precursor and at least one ligand to generate a catalytically active species, often under mild conditions and in high yields. In some cases, a wide variety of catalysts may be synthesized from a single catalyst precursor. Methods of the invention may also include the preparation of catalysts which, under reaction conditions known in the art, may have been difficult or impossible to prepare and / or isolate due to, for example, steric crowding at the metal center. The present invention also provides catalyst compositions, and precursors thereof, which may be useful in various chemical reactions including olefin metathesis. In some cases, methods of the invention may reduce the number of synthetic and purification steps required to produce catalysts and / or other reaction products, as well as reducing time, cost, and waste production.

Owner:MASSACHUSETTS INST OF TECH

Process for reactive esterification distillation

ActiveUS7667068B2Organic compound preparationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

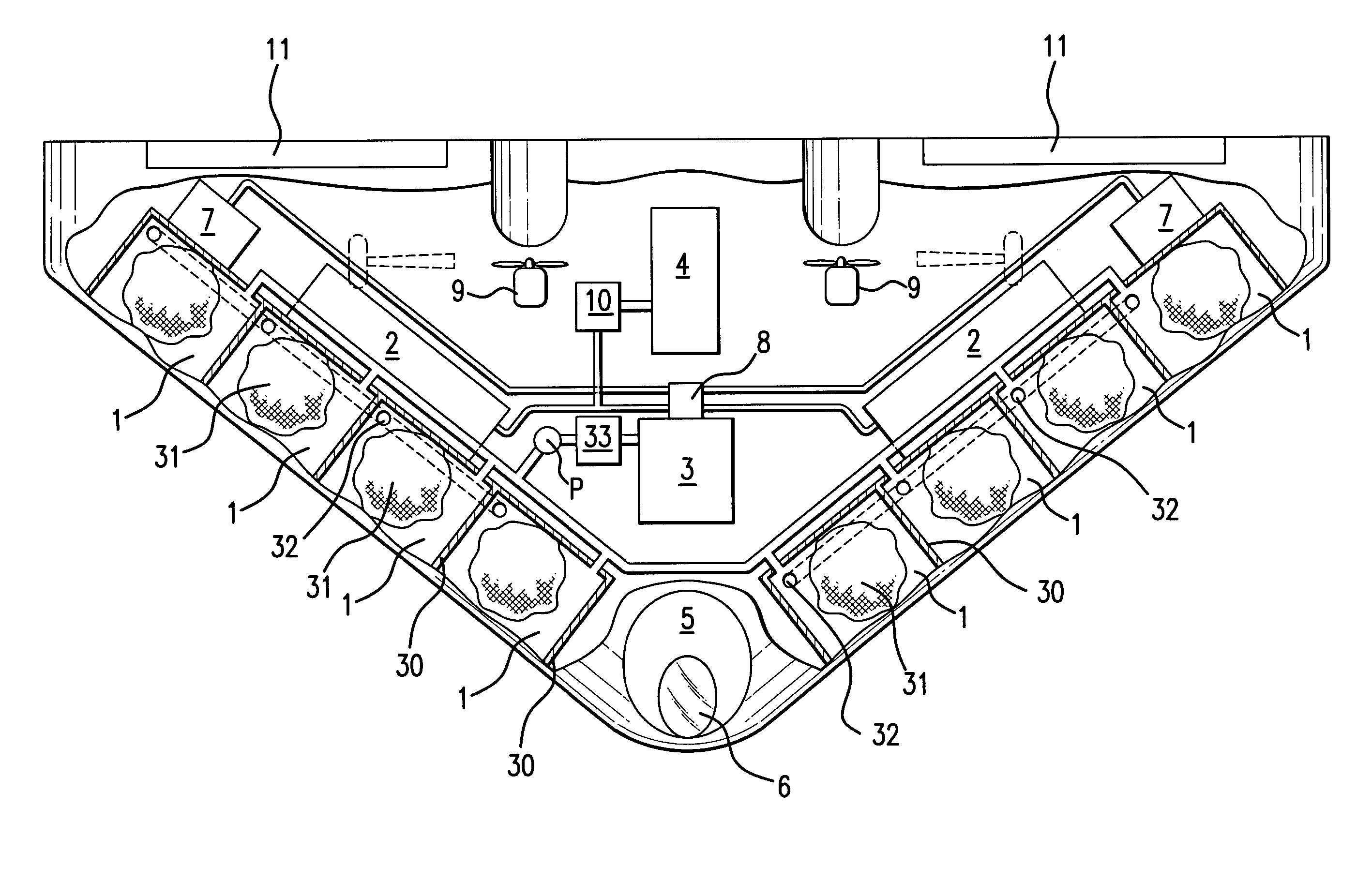

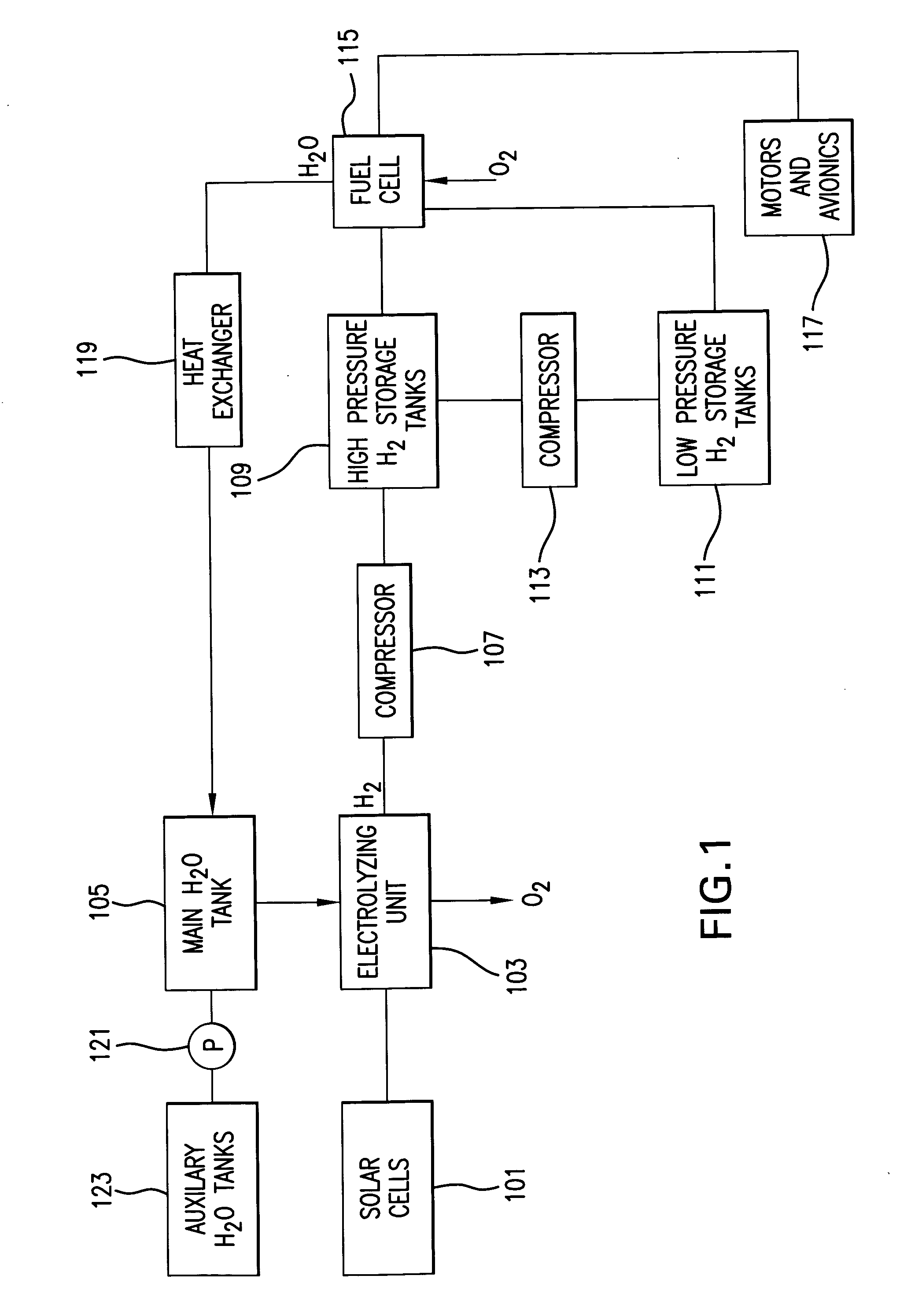

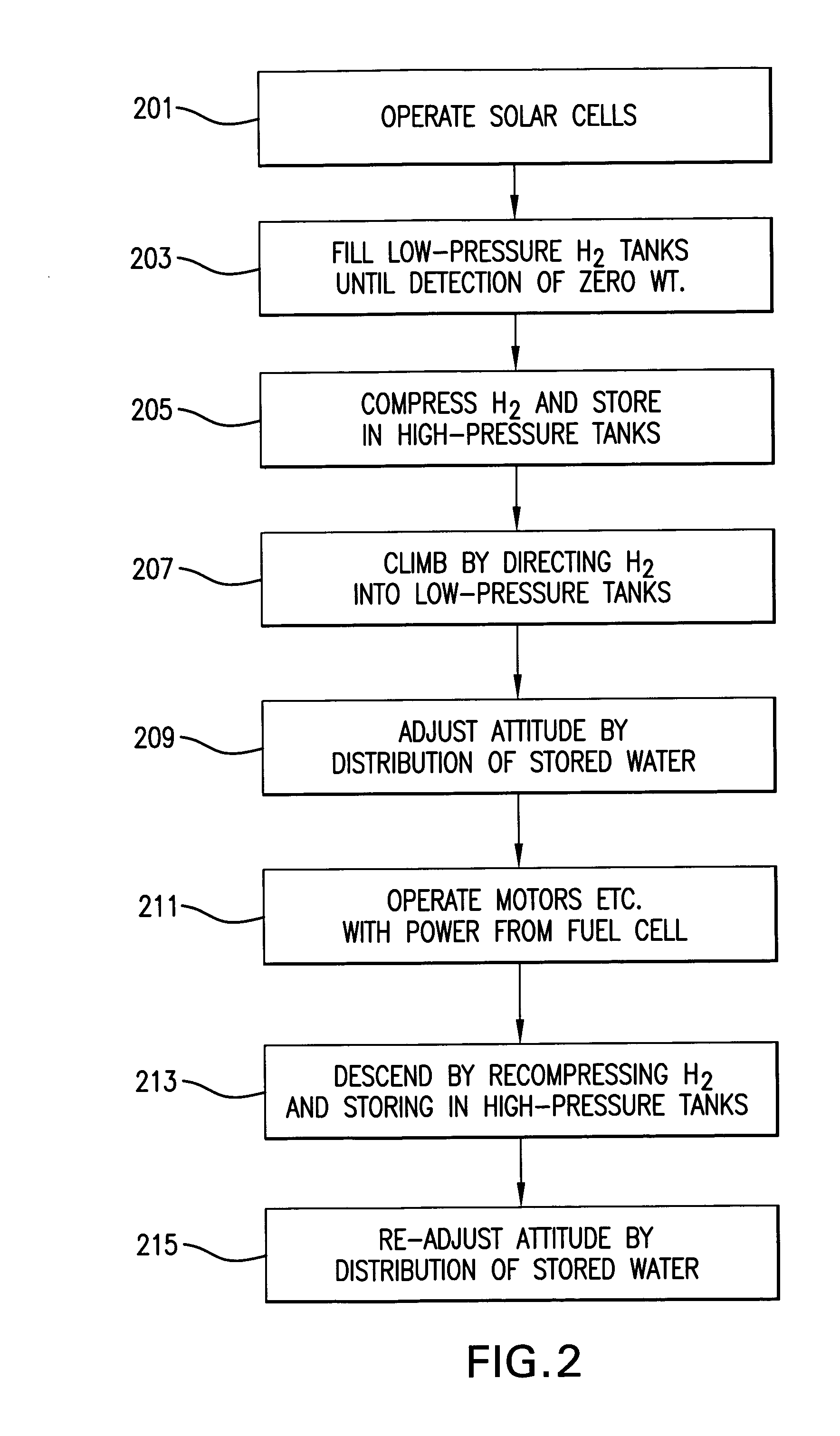

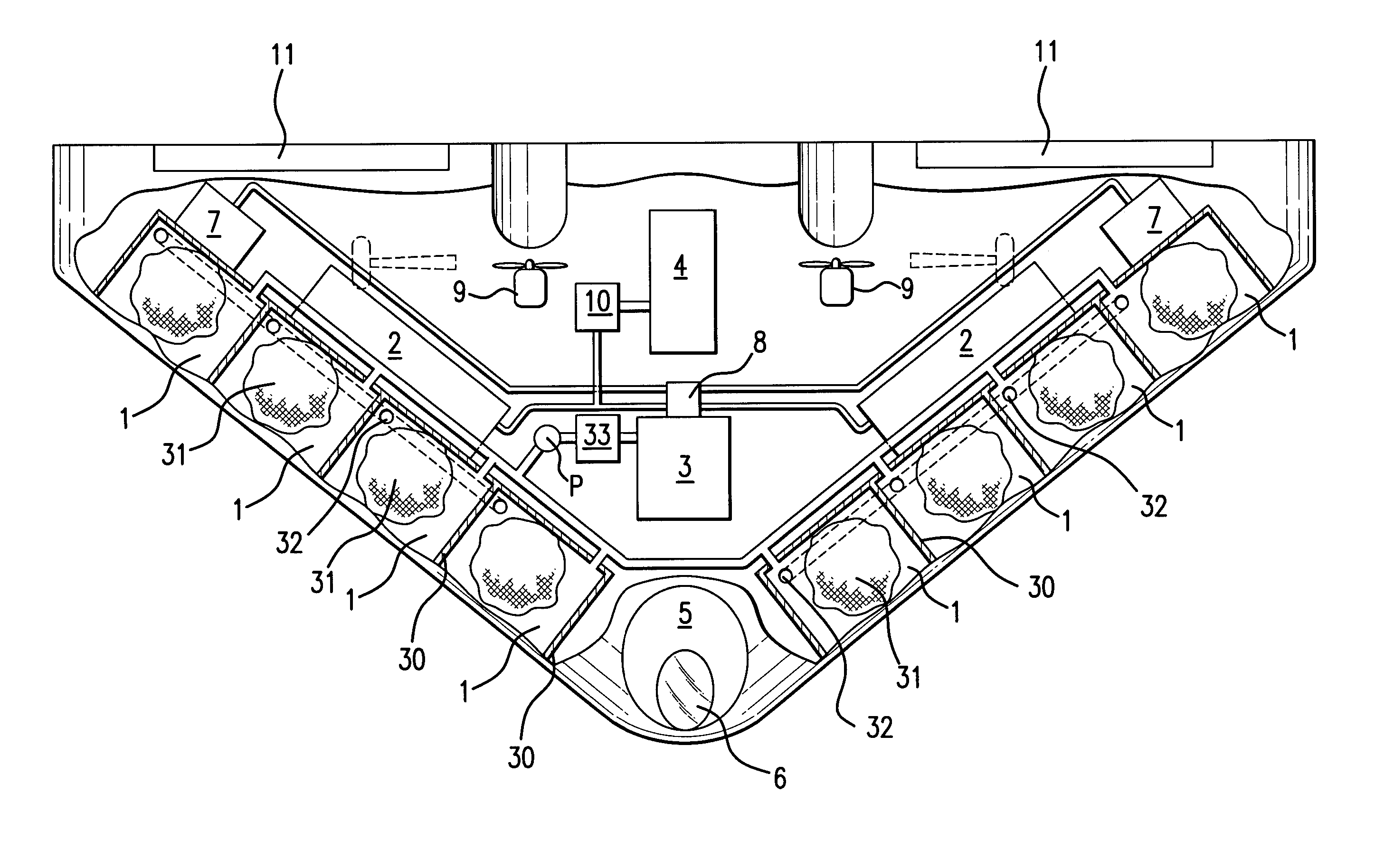

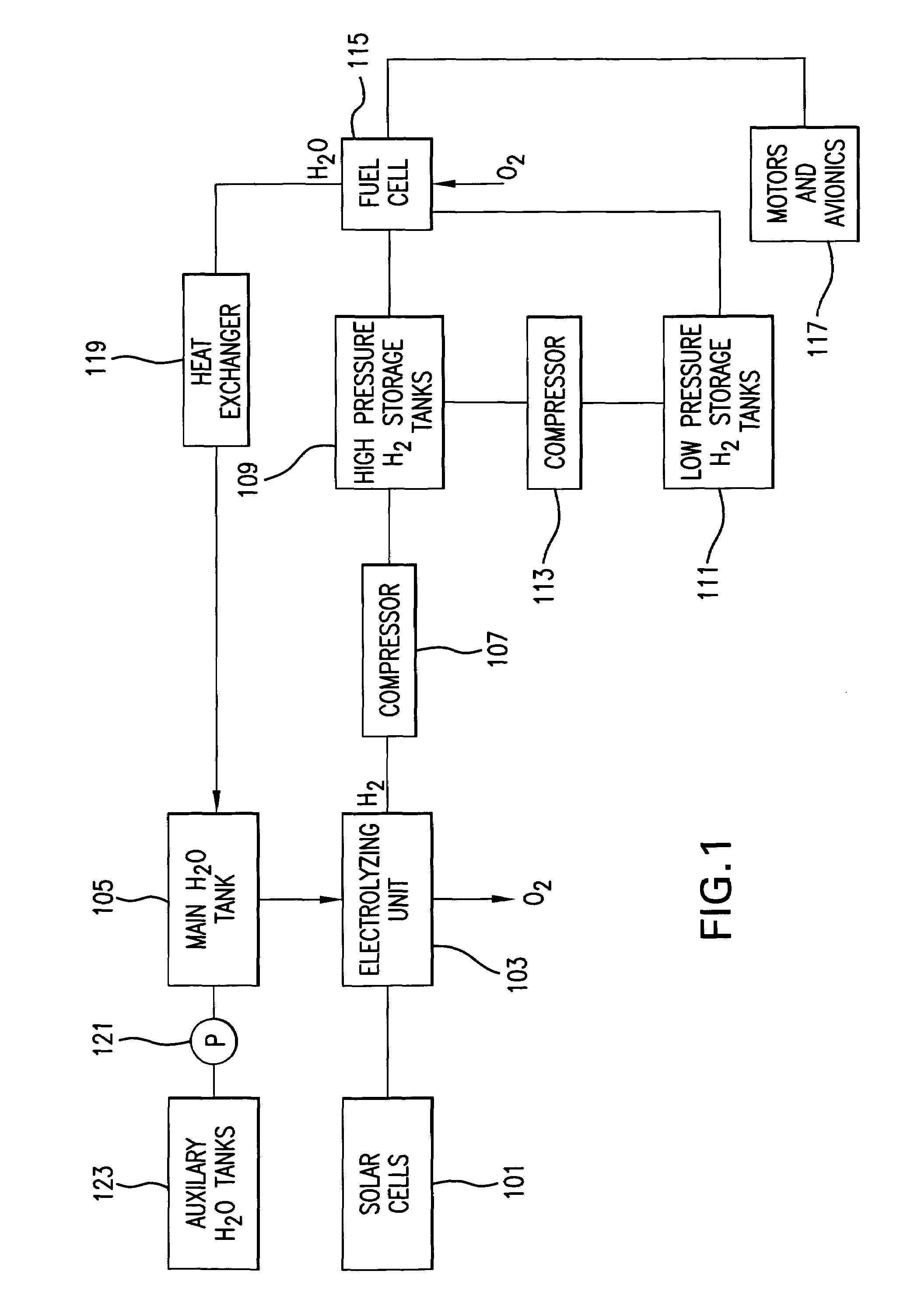

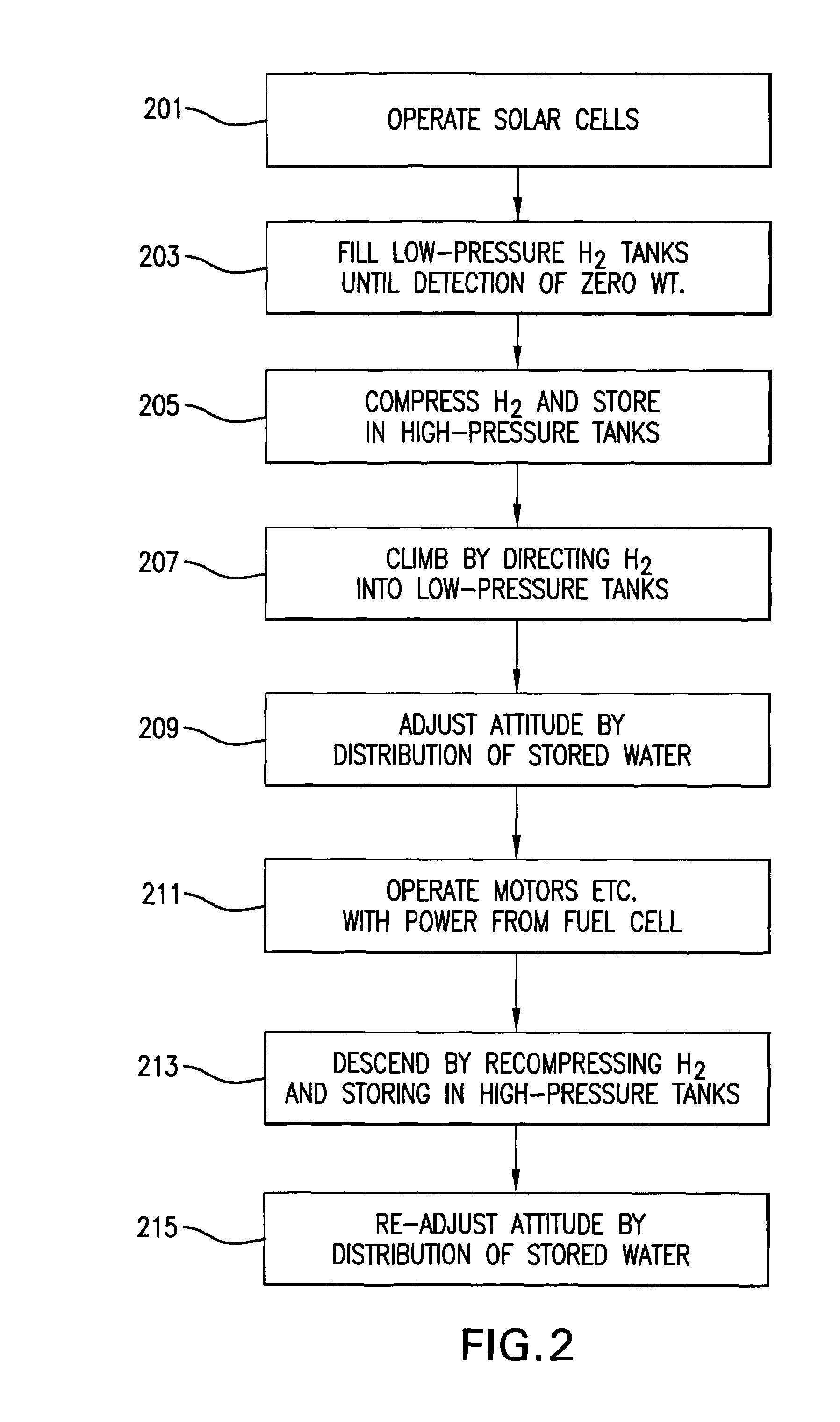

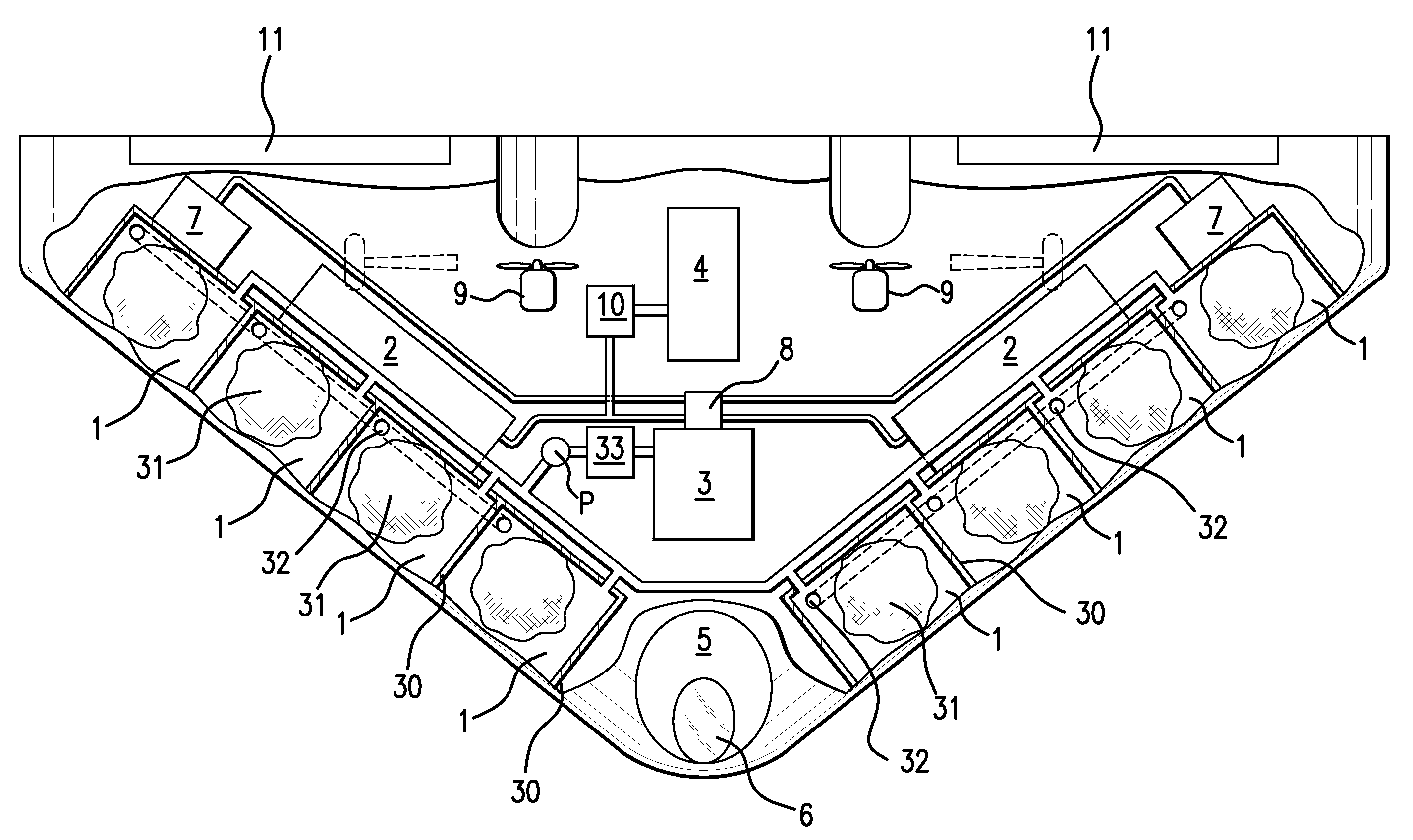

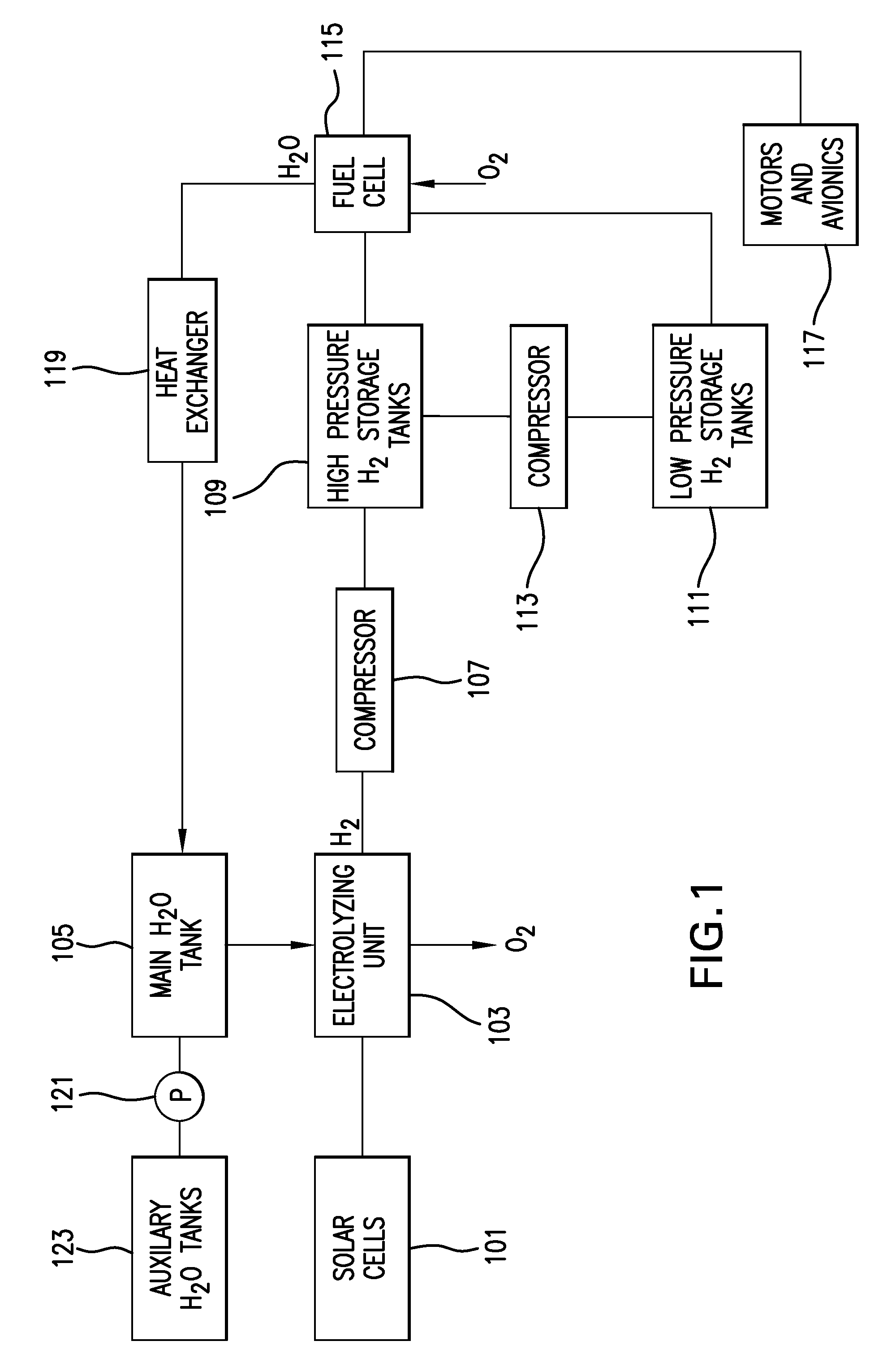

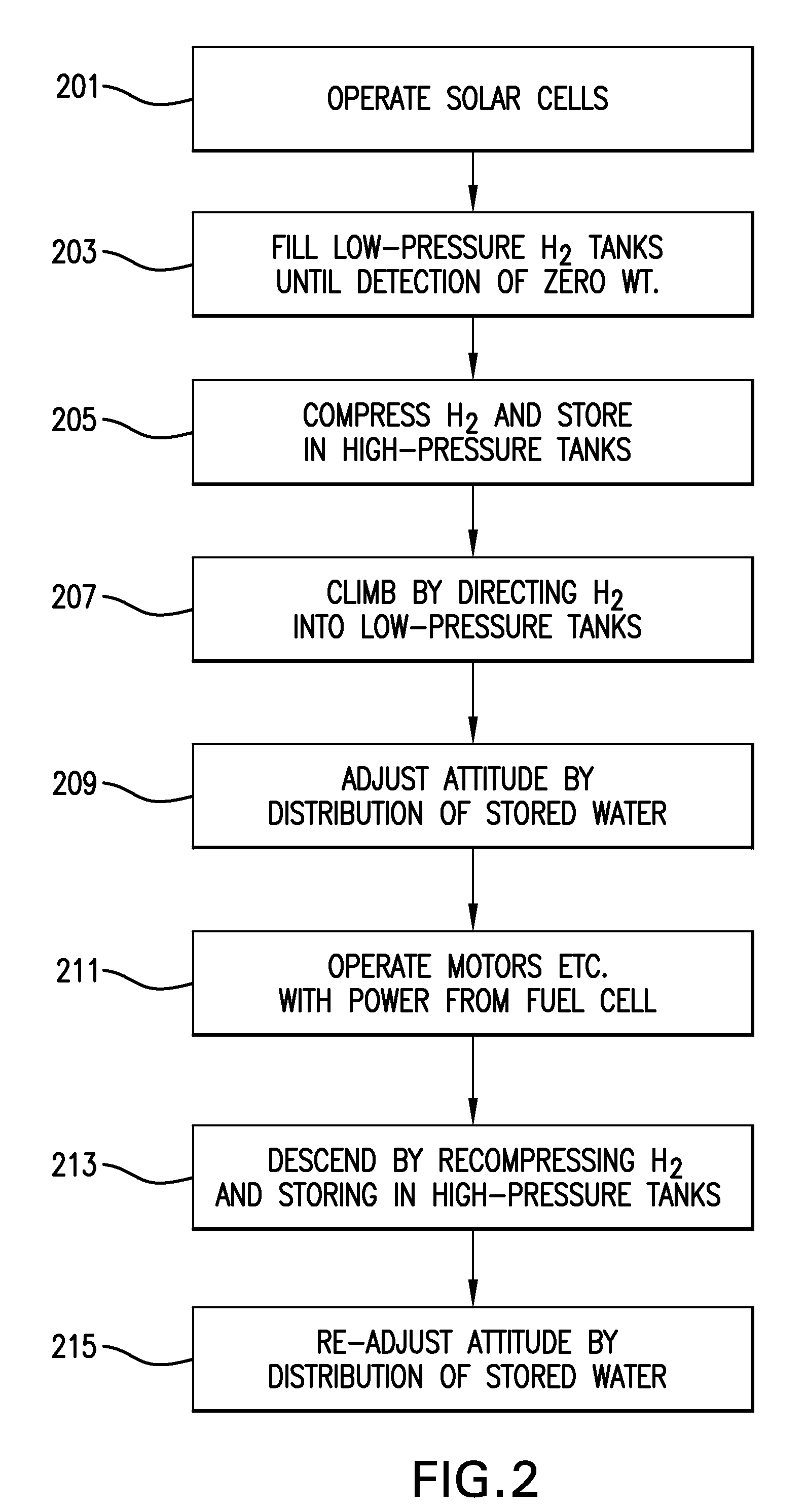

Solar-powered aircraft

InactiveUS20070034741A1Weight of to shiftPower installationsEnergy efficient board measuresHydrogenFuel cells

A solar-powered aircraft uses solar energy to electrolyze on-board water to produce hydrogen. The hydrogen fills various on-board tanks, causing the aircraft to become lighter than air. The hydrogen is also used to operate a fuel cell which provides power for electrical equipment, including a motor for turning a propeller. Water produced as waste by the fuel cell is recycled for use in the production of hydrogen. When hydrogen is removed from the tanks, either because it is consumed by the fuel cell or because it is compressed and pumped out of the tanks, air returns to the tanks, and the aircraft becomes heavier than air. The aircraft can thus be made to climb and descend by making it lighter than air, or heavier than air. The aircraft emits no harmful substances into the environment. The aircraft can remain aloft indefinitely, limited only by an insignificant amount of leakage of hydrogen and water.

Owner:FULLER HOWARD J

Olefin metathesis catalysts and related methods

ActiveUS20110237815A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChemical reactionAlkene

The present invention provides methods for the synthesis of catalysts and precursors thereof. Methods of the invention may comprise combining a catalyst precursor and at least one ligand to generate a catalytically active species, often under mild conditions and in high yields. In some cases, a wide variety of catalysts may be synthesized from a single catalyst precursor. Methods of the invention may also include the preparation of catalysts which, under reaction conditions known in the art, may have been difficult or impossible to prepare and / or isolate due to, for example, steric crowding at the metal center. The present invention also provides catalyst compositions, and precursors thereof, which may be useful in various chemical reactions including olefin metathesis. In some cases, methods of the invention may reduce the number of synthetic and purification steps required to produce catalysts and / or other reaction products, as well as reducing time, cost, and waste production.

Owner:MASSACHUSETTS INST OF TECH

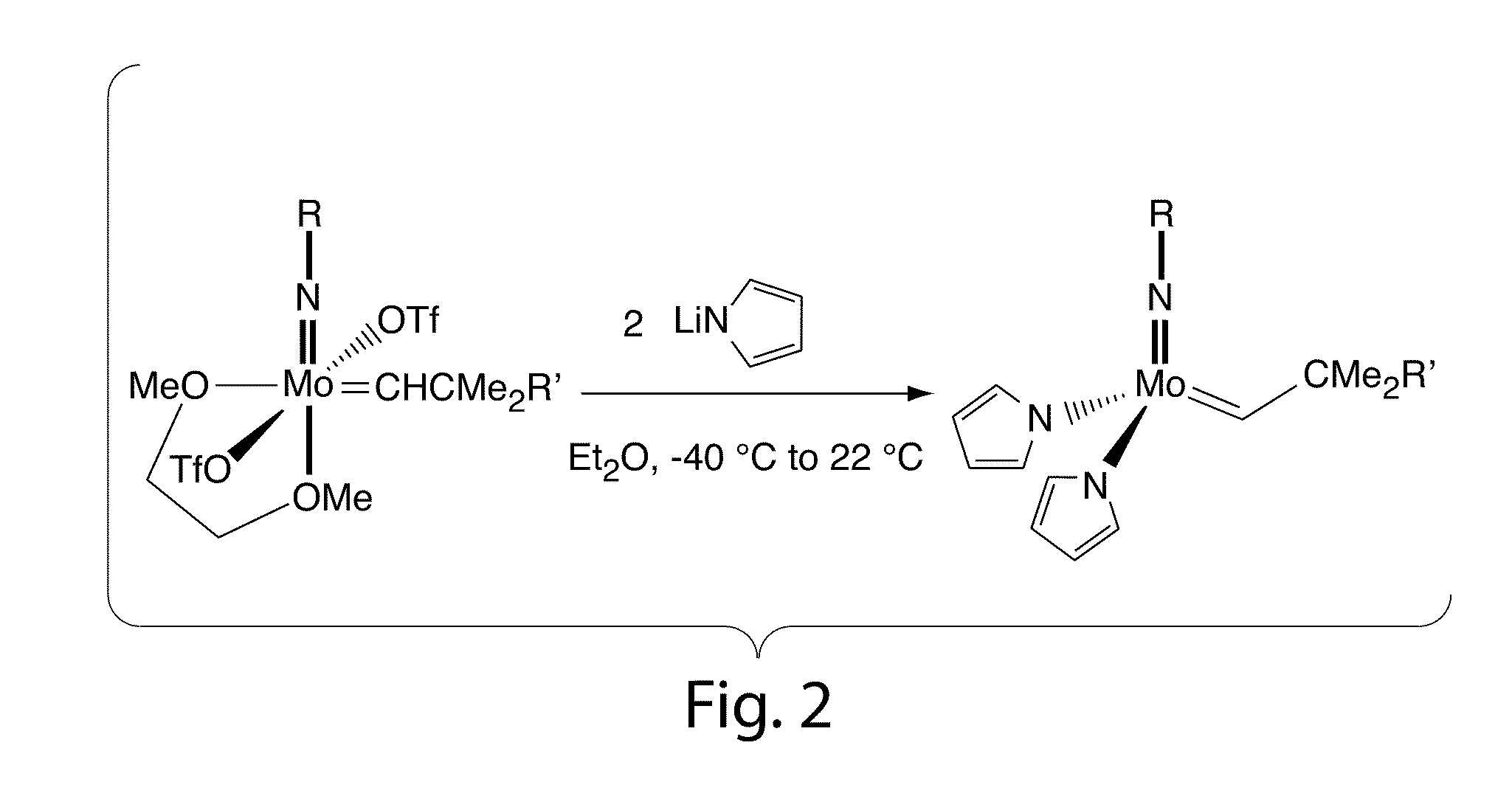

Efficient magnetic separation method for quartz sand

InactiveCN102626668AIncrease production capacityReduce unit energy consumptionWet separationPurification methodsNo production

The invention discloses an efficient purification method for quartz sand. In the method, two-section smashing (rough smashing and fine smashing) and ore milling with a rod mill are adopted, so that the production capacity is increased greatly, unit energy consumption is lowered, and the method is suitable for large-scale production. A method for removing weakly-magnetic minerals and intergrowth quartz with high iron content from quartz sand through advanced ore washing and weakly magnetic-high gradient strongly magnetic combined magnetic separation before ore milling is adopted, so that the purity of quartz sand is increased greatly. The method has the advantages of simple process flow, easiness for operating, low cost, high purification efficiency, stable performance and environmental friendliness of a produced product, no use of any chemical substance in an entire production process, no production of any waste water, waste residues and waste gas, true realization of zero emission, no production of waste and prevention of pollution. The method is not limited by the production scale, various quartz sand products of low, medium and high grades can be produced, the enterprise profit can be maximized, and the method has a wide application prospect on the aspect of purification of quartz sand.

Owner:赣州金环磁选科技装备股份有限公司

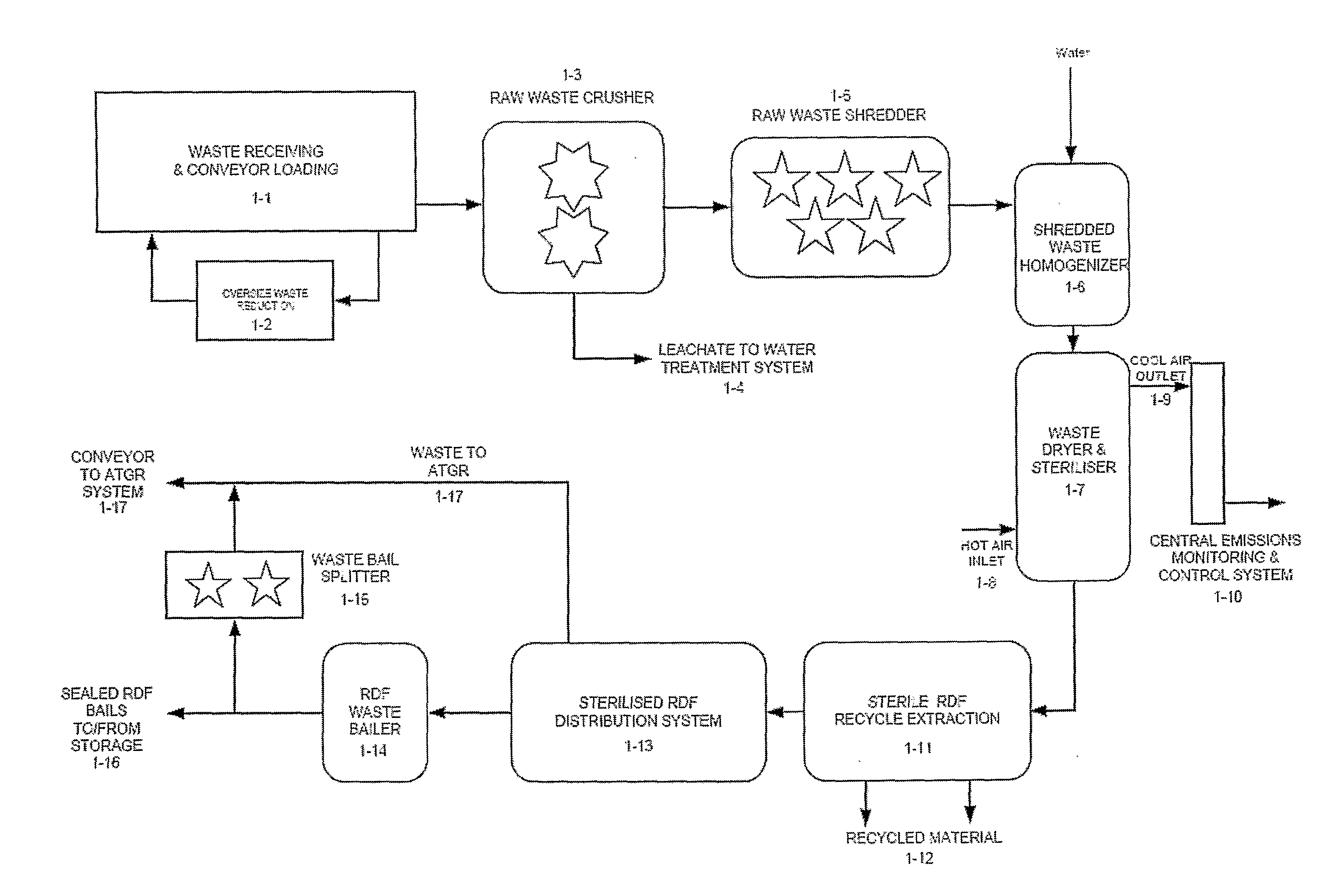

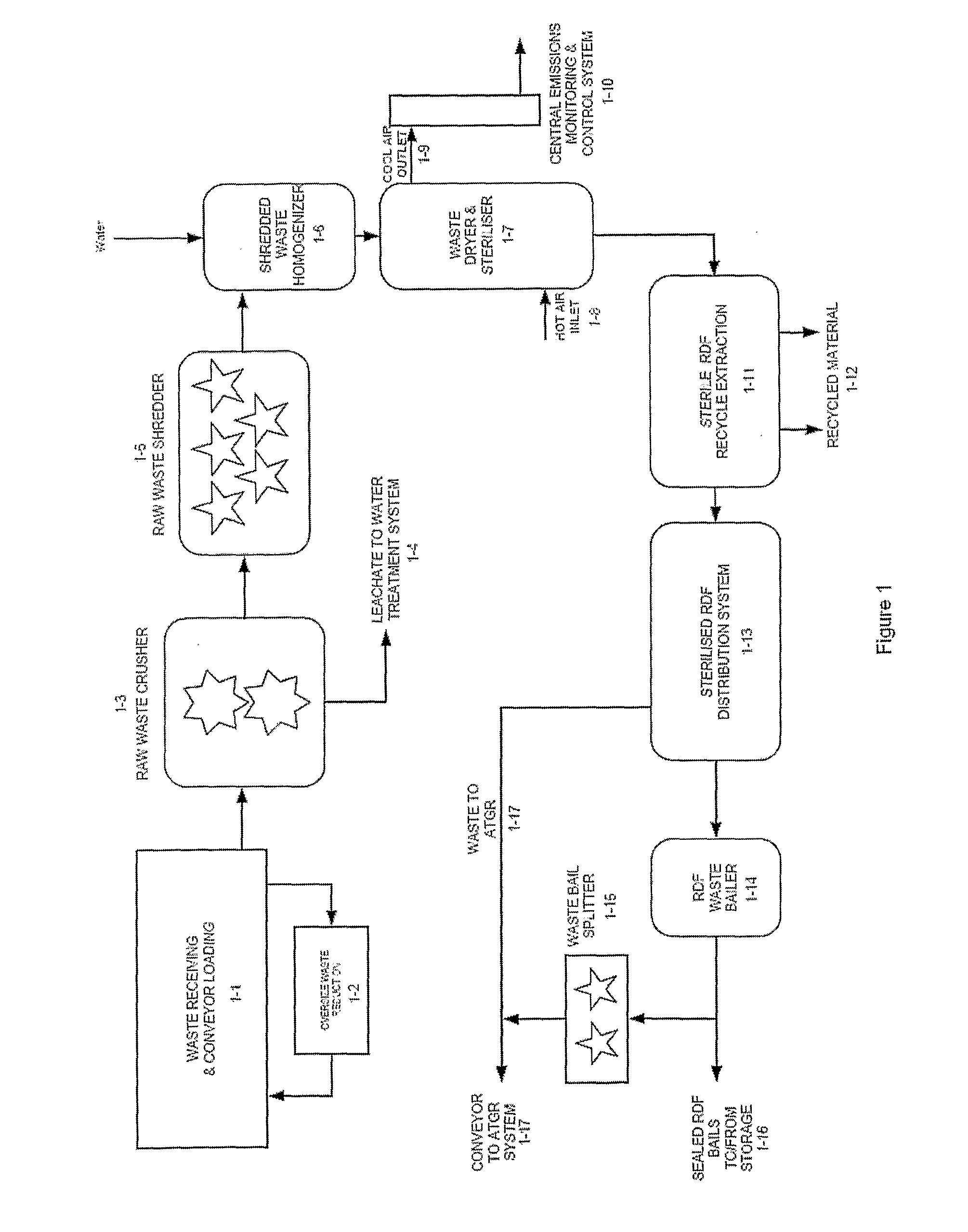

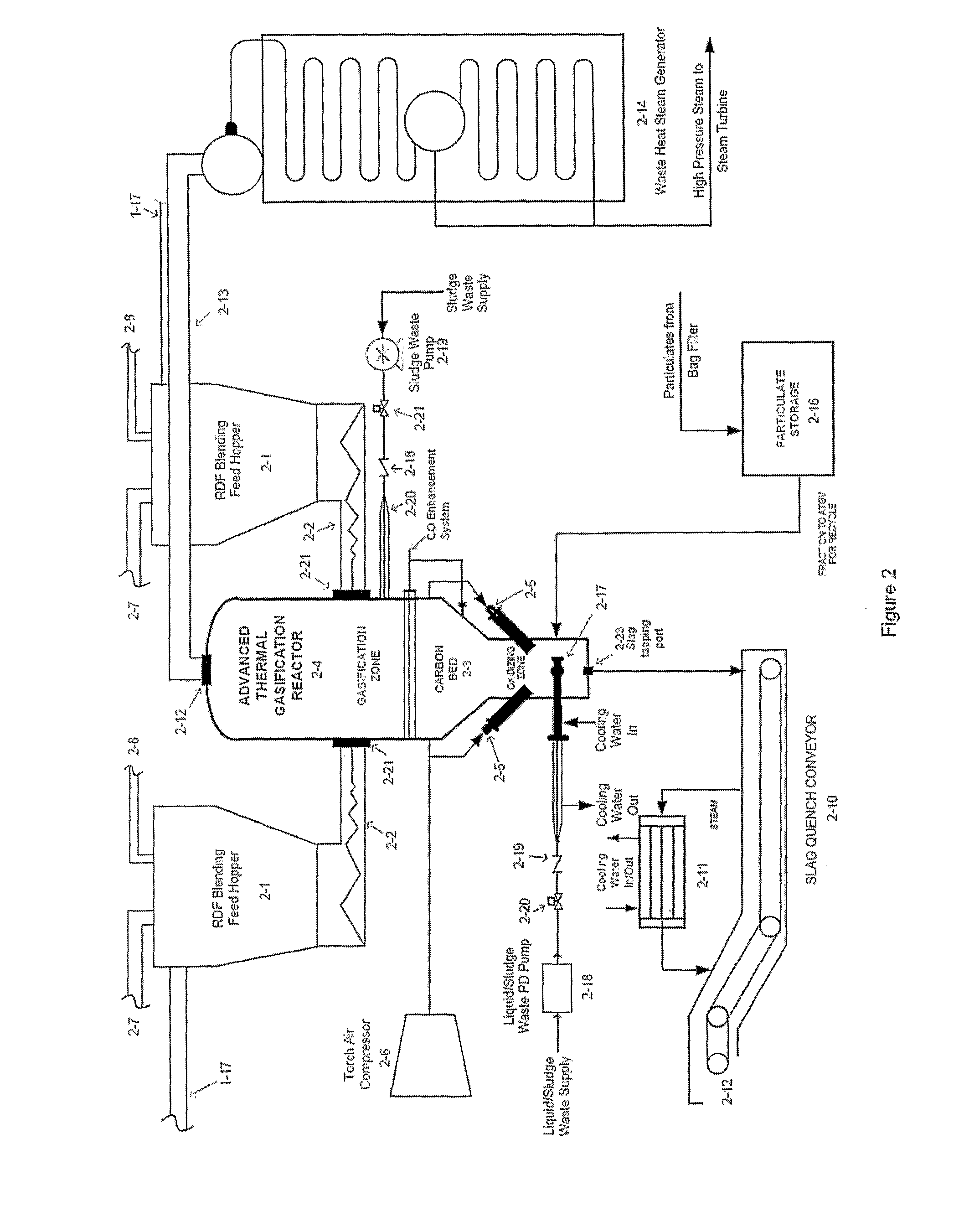

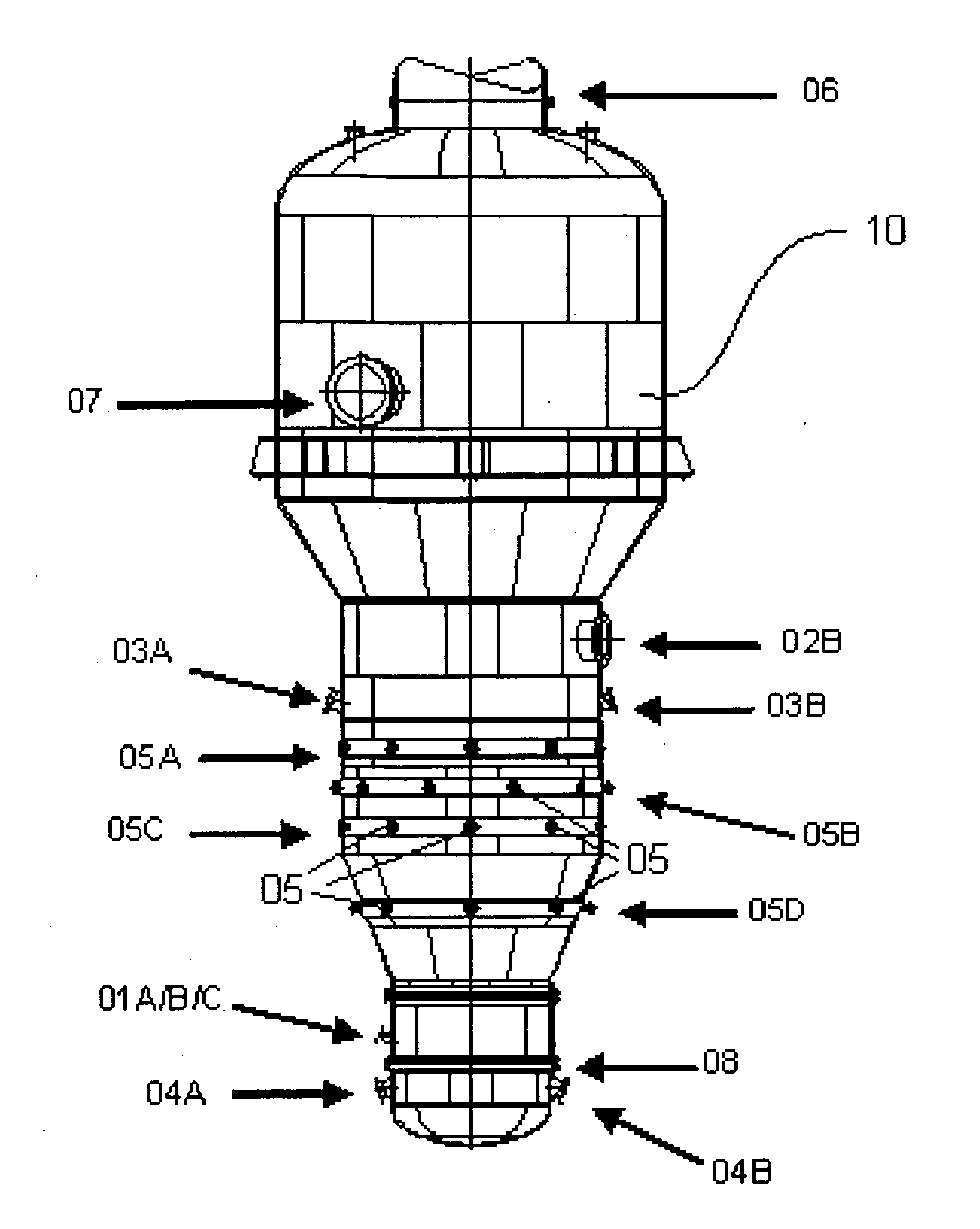

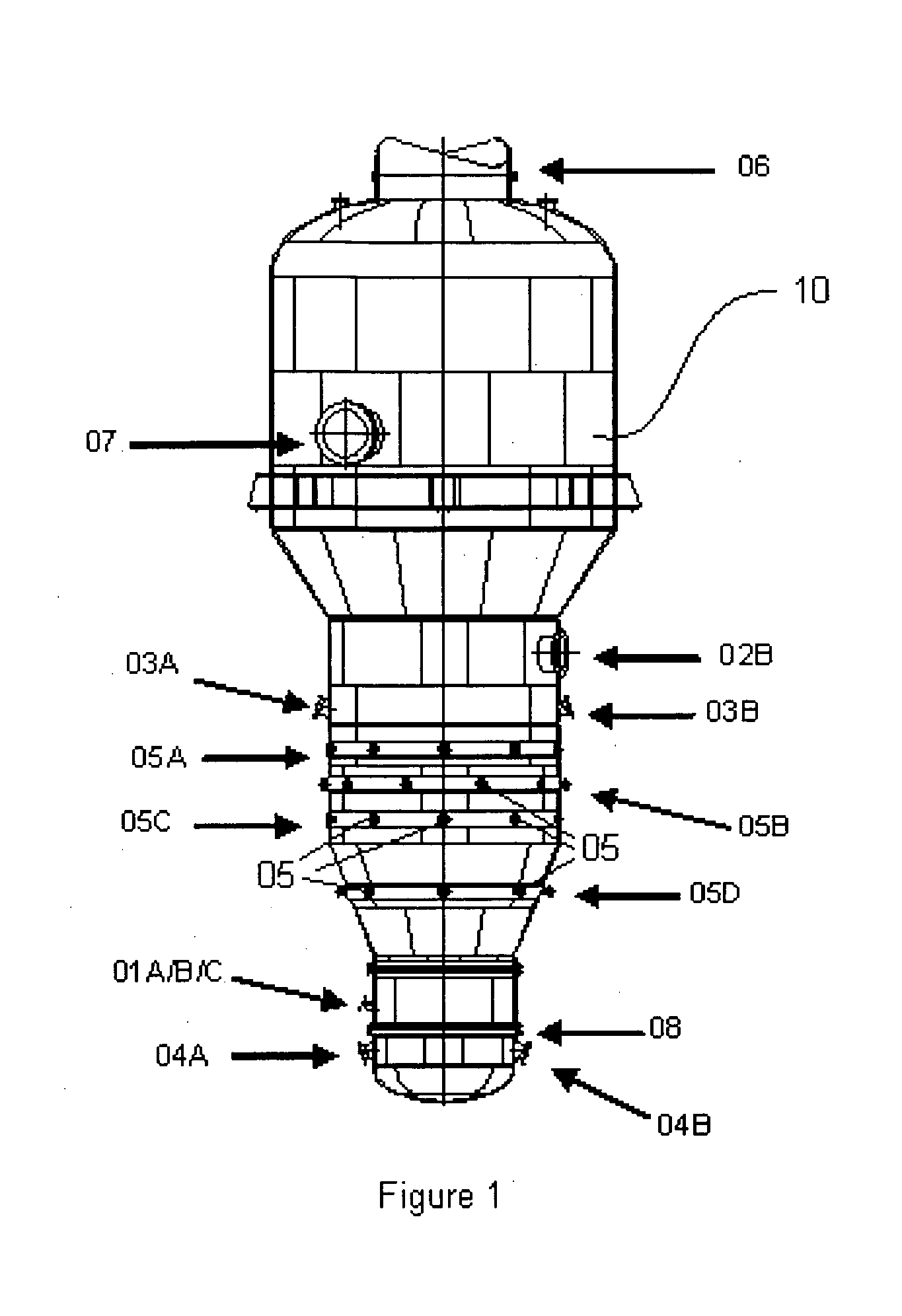

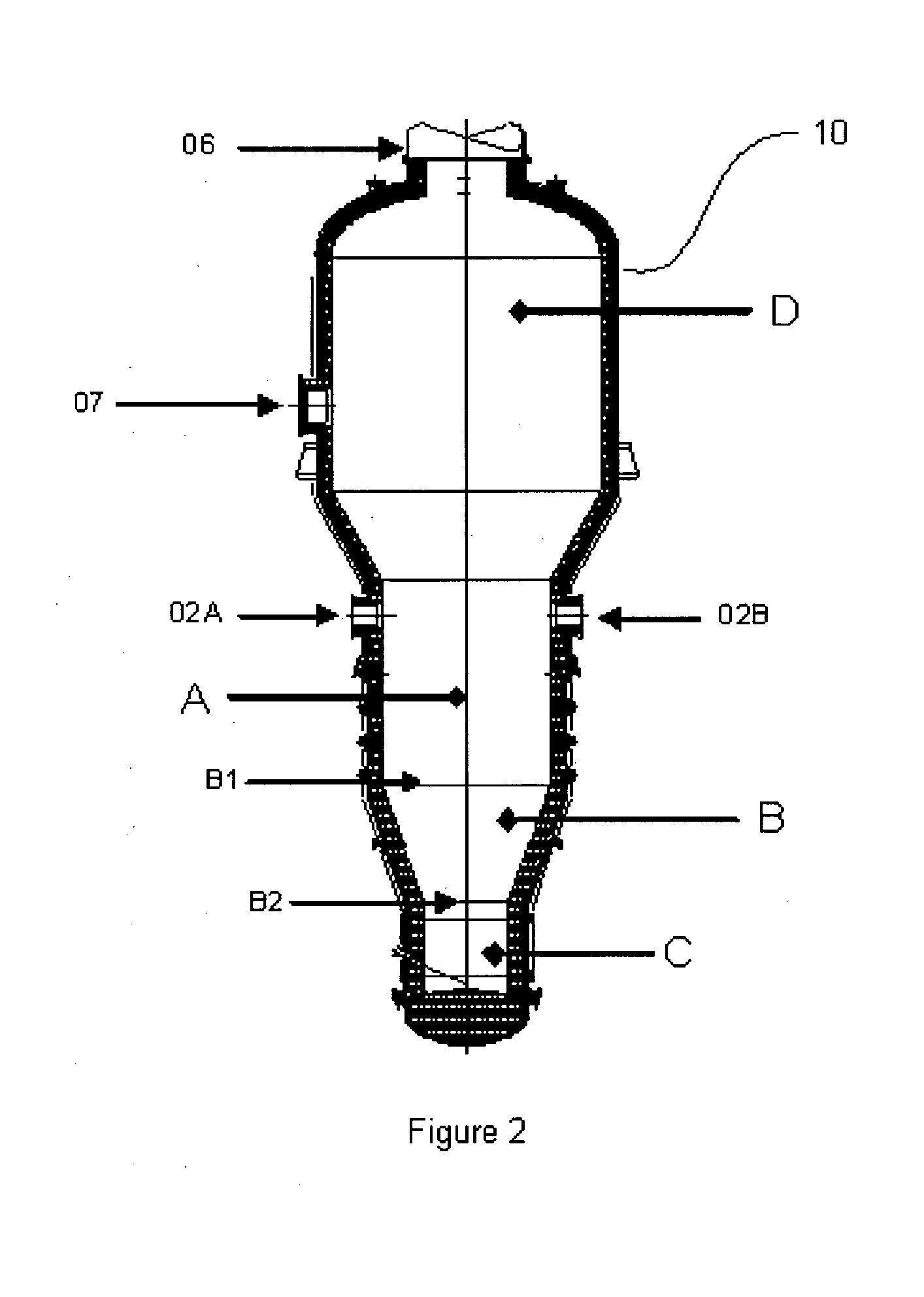

Method and system for producing energy from waste

A method and system for the conversion of waste into energy in a sealed system where combustion does not take place and the operating pressure prior to the inlet of the steam or power generating equipment is maintained below atmospheric pressure. Destruction of the RDF (refuse derived fuel) is accomplished by subjecting the RDF to a high temperature environment under controlled conditions in a purpose designed and built reactor. The high temperature environment, <5000° C., is achieved through the use of one or more non-transferred plasma torches for generation of plasma gas. The plasma gas exiting the torch and provides the thermal energy for the continual gasification of metallurgic coke configured as a carbon bed in the lower part of the reactor, which acts as a thermal catalyst and this provides the thermal energy for the gasification process.

Owner:GREEN ENERGY & TECH

Environment-friendly separation and recovery method of fluorine in fluorine-containing waste liquid

InactiveCN105948083AAchieve separationAchieve recyclingMagnesium fluoridesHydrogen fluorideRecovery methodEnvironmental resistance

The invention discloses an environment-friendly separation and recovery method of fluorine in a fluorine-containing waste liquid. According to the invention, a magnesium-containing compound is added into the fluorine-containing waste liquid as a precipitation agent, such that fluorine in the waste liquid is selectively precipitated; filtering is carried out, and fluorine-removed liquid and magnesium fluoride precipitate are obtained; the fluorine-removed liquid is used in waste water recycling; the magnesium fluoride precipitate is decomposed with sulfuric acid, such that a series of compounds of fluorine are obtained; decomposition residue is subjected to a dissolution-crystallization treatment, such that magnesium sulfate crystals are obtained; the obtained magnesium sulfate crystals are returned and recycled in the fluorine selective precipitation process; the crystallization mother liquor of magnesium sulfate is returned to the dissolution-crystallization process or the magnesium fluoride precipitation decomposition process. The method has the advantages of simple process, simple operation, low production cost, and good fluorine-removing effect. With the method, fluorine resource utilization is realized. The method also has the advantages of no fluorine-containing waste production and no three-waste emission.

Owner:CENT SOUTH UNIV

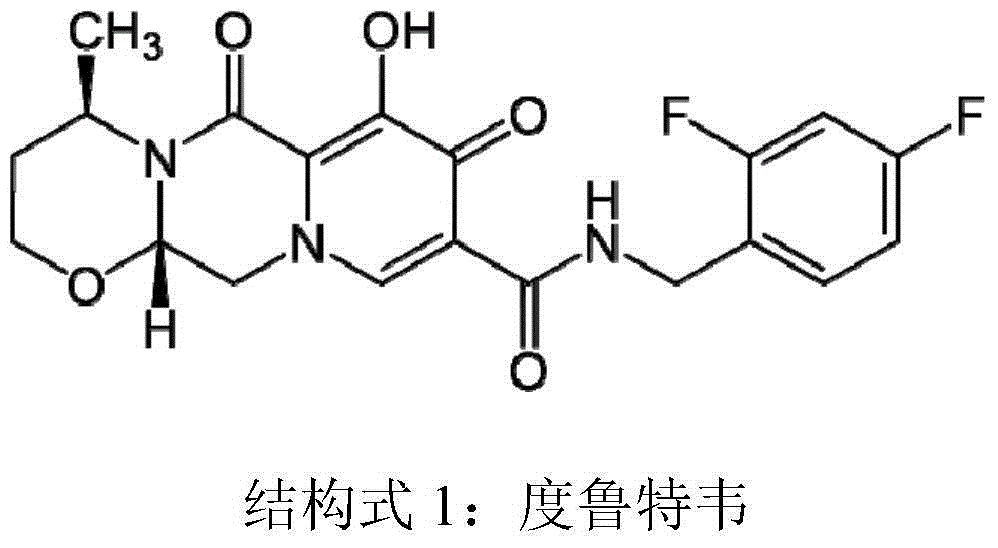

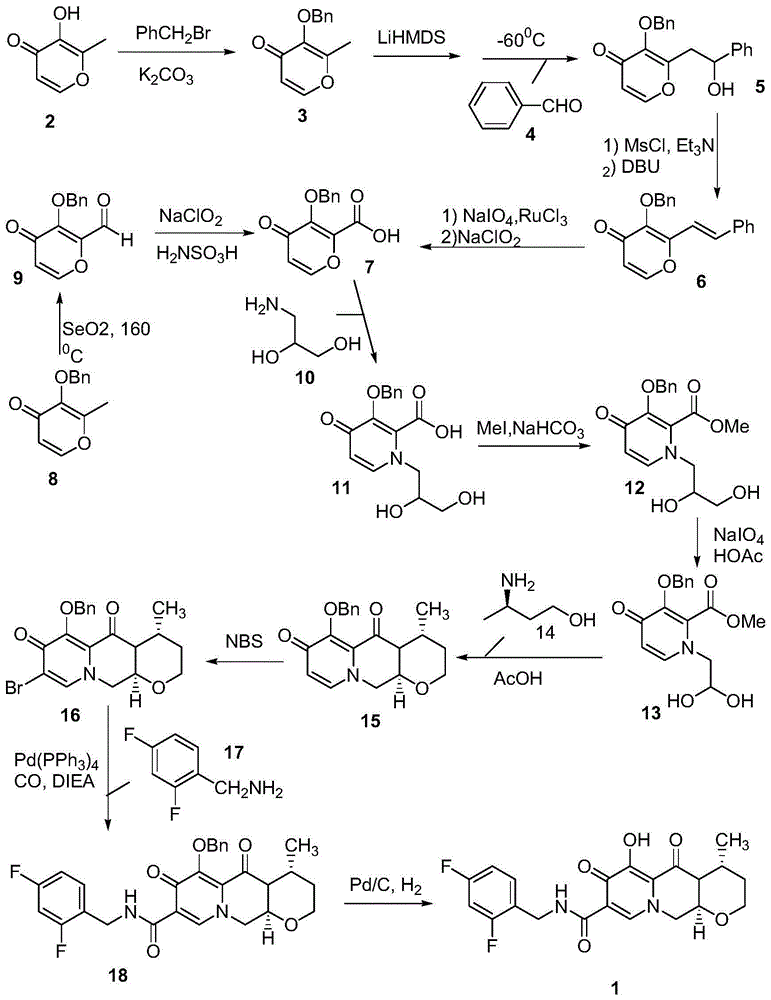

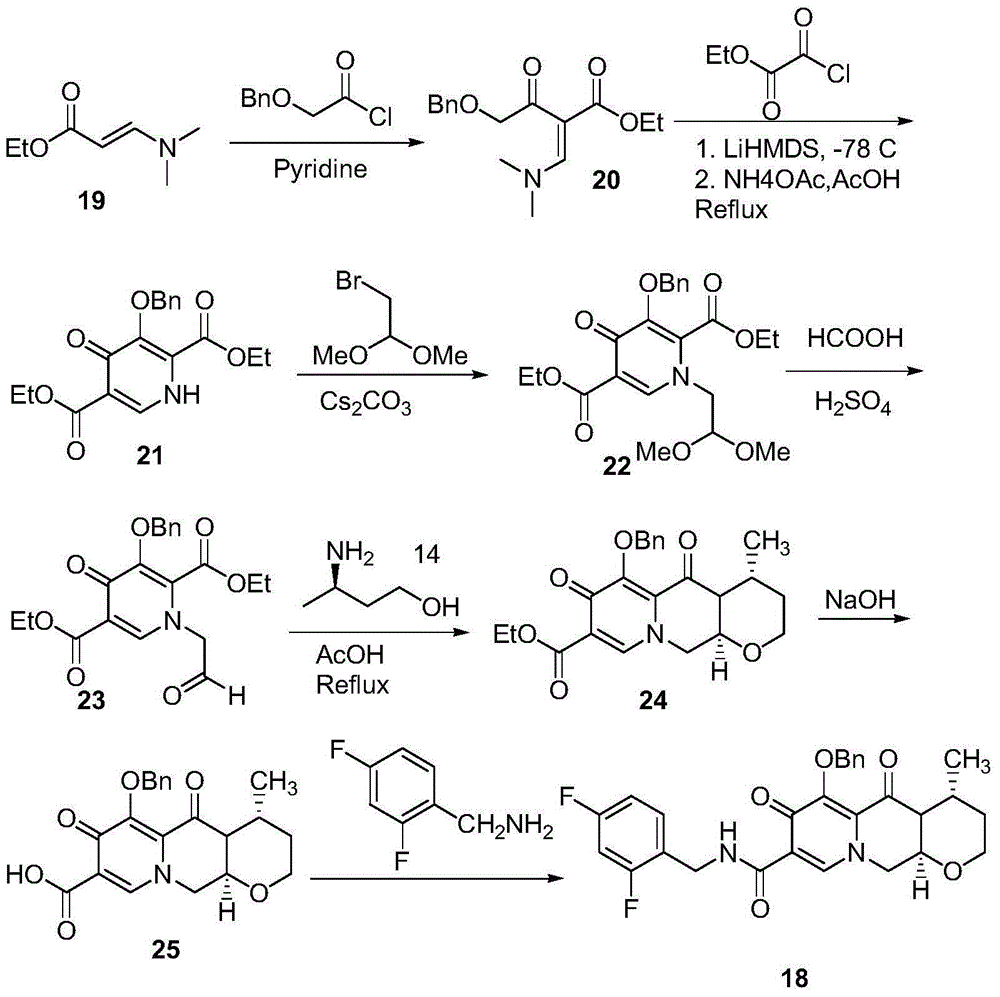

Preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid

ActiveCN104370755ANon-hazardousImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationSolventHydrolysis

The present invention discloses a preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid. The optical activity active 3-amino butanol preparation method comprises: in a solvent, under effects of a hydroboration reduction agent and a Lewis acid, carrying out a reduction reaction on a compound represented by a formlu 65 to produce a compound represented by a formlu 14. The optical activity active 3-amino butyric acid preparation method comprises: carrying out a hydrolysis reaction on a compound represented by a formlu 64 to produce a compound represented by a formlu 65. According to the present invention, the preparation method has characteristics of cheap and easily-available raw materials, simple operation, short process route, no hazard of raw materials, high yield, little waste production, environment protection, high raw material conversion rate, high product chemical purity and high product optical purity, and the industrialization is easily achieved. The formulas 64, 65 and 14 are defined in the instruction.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

Solar-powered aircraft

InactiveUS7278607B2Weight of to shiftPower installationsEnergy efficient board measuresFuel cellsHydrogen

Owner:FULLER HOWARD J

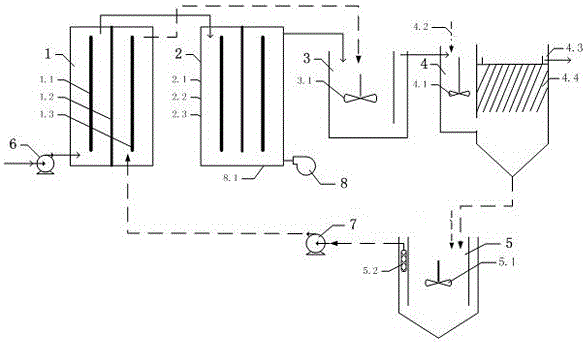

Wastewater treatment device with coupled Electro-Fenton and electrocatalytic oxidation without solid waste generation

ActiveCN105884091AAchieve recyclingOvercome the disadvantages of polluting the environmentWater contaminantsMultistage water/sewage treatmentFenton reactionAcid dissolution

The invention relates to a wastewater treatment device with coupled Electro-Fenton and electrocatalytic oxidation without solid waste generation. The wastewater treatment device comprises a raw water pump, a first diaphragm electrolytic cell, a second diaphragm electrolytic cell, a Fenton reaction tank, a coagulating sedimentation tank and an iron cement dissolving tank which are connected in sequence, wherein the anode chambers of the first diaphragm electrolytic cell and the second diaphragm electrolytic cell are adopted for electrocatalytic oxidation reaction to dissolve organic pollutants; Fe<+3> generated after Fenton reaction is reduced into Fe<+2> in the cathode chamber of the first diaphragm electrolytic cell; H2O2 is generated through electrochemical synthesis in the cathode chamber of the second diaphragm electrolytic cell; the reduced Fe<+2>, the newly generated H2O2 and wastewater are fed into the reaction tank for Fenton reaction; the effluent is subjected to iron cement separation in the coagulating sedimentation tank; treated water is discharged; the sedimentary iron cement is Fe<+3> which is fed into the iron cement dissolving tank; after acid dissolution, the sedimentary iron cement is fed into the cathode chamber of the first diaphragm electrolytic cell and is circulated after electrochemical reduction; and therefore, solid waste production and emission are avoided.

Owner:南京赛佳环保实业有限公司

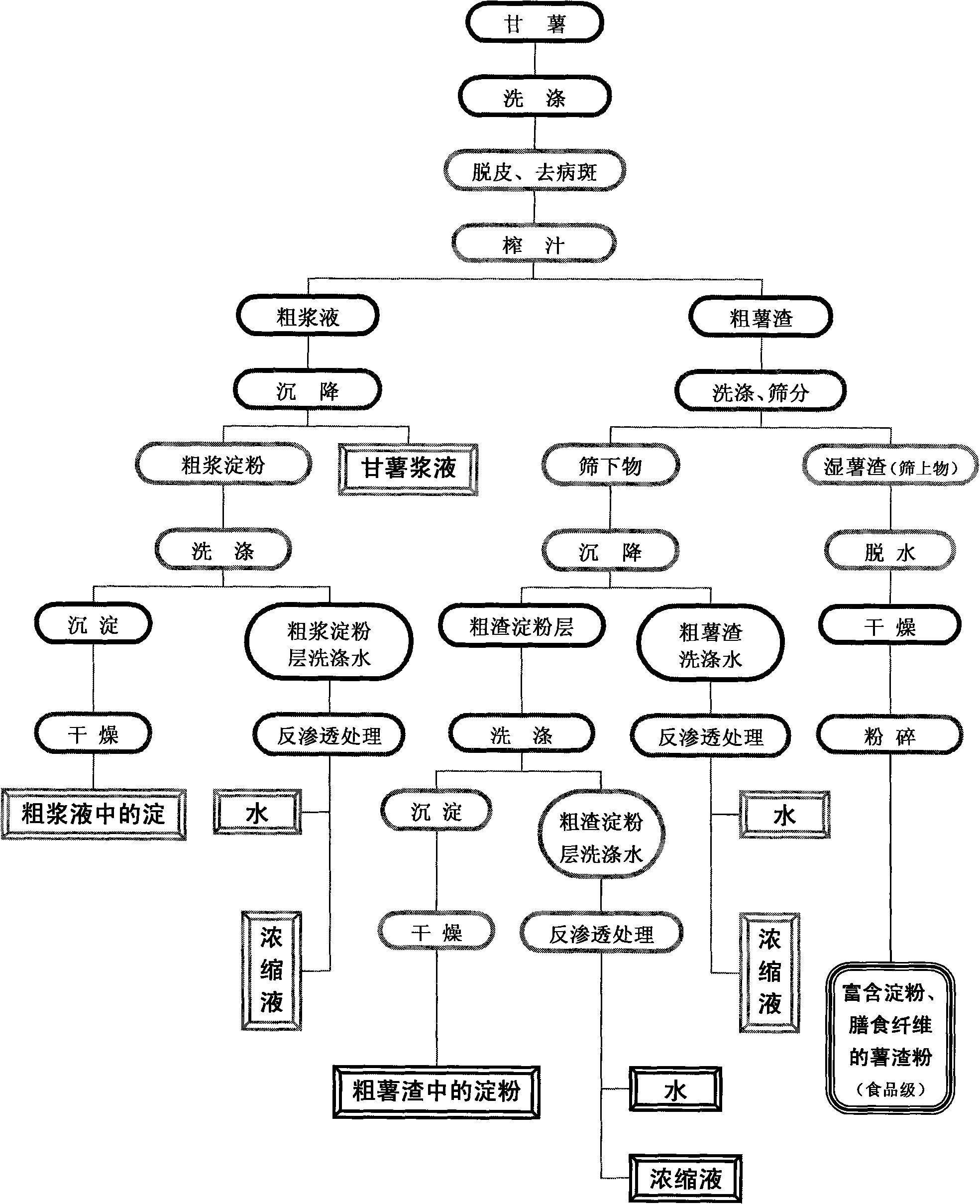

No-waste production method for peeled sweet potato starch

The invention discloses a no-waste production method for peeled sweet potato starch. The provided method comprises the following steps: step 1. the sweep potato is peeled and / or the speck is removed; step 2. the sweep potato obtained in the step 1 is squeezed to obtain coarse size and coarse potato residue; and step 3. the coarse size obtained in the step 2 is treated to obtain starch in the coarse size and a first by-product, i.e., sweet potato size; the coarse potato residue obtained in the step 2 is treated to obtain starch in the coarse potato residue and a second by-product, i.e., potato powdered residue; and the coarse size and the washing water obtained during the coarse potato residue treatment are treated to obtain a third by-product containing polysaccharide and protein and water, and the water can be further taken as the washing water for the sweet potato, the starch and the coarse potato residue. The method can utilize all the nutritious substances in the sweet potato and is free from the influence of reduction of the starch content during the storage process of the sweet potato, and the application of the sweet potato size and the concentrated solution of the washing water provides a possibility of prolonging the processing cycle of the sweet potato starch.

Owner:孙艳丽

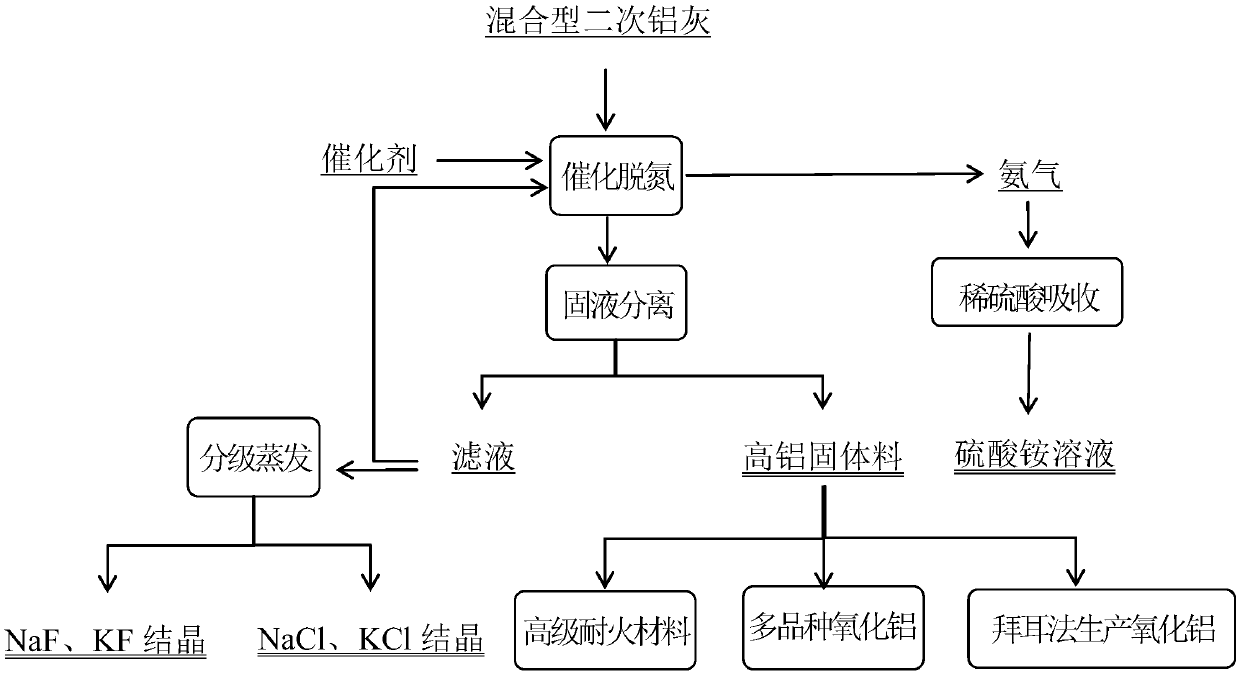

Method for comprehensively recycling mixed secondary aluminum dross

InactiveCN109678180AAchieve recyclingAvoid pollutionAlkali metal chloridesAmmonia compoundsEvaporationNitride

The invention relates to a method for comprehensively recycling mixed secondary aluminum dross. The method comprises the following recycling processes: step (1) adding water into mixed secondary aluminum dross for catalytic deamination reaction, decomposing aluminum nitride to generate ammonia gas to overflow, performing solid-liquid separation to obtain filtrate and high aluminum solids after reaction; step (2) completely decomposing aluminum nitride in secondary aluminum dross to generate ammonia gas, feeding the overflowed ammonia gas into a sulfuric acid solution, collecting the overflowedammonia gas to obtain an ammonium sulfate solution; and step (3) performing staged evaporation and crystallization on the filtrate obtained by solid-liquid separation by using an evaporation crystallizer, performing first-stage evaporation crystallization to obtain a mixture of NaF and KF, performing second-stage evaporation crystallization to obtain a mixture of NaCl and KCl. The method providedby the invention not only fully recycles elements Al, N, F and Cl in the secondary aluminum dross, but also does not generate any secondary wastes in the whole process, and realizes green recycling of secondary resources of aluminum.

Owner:平罗县中兴碳素有限公司 +1

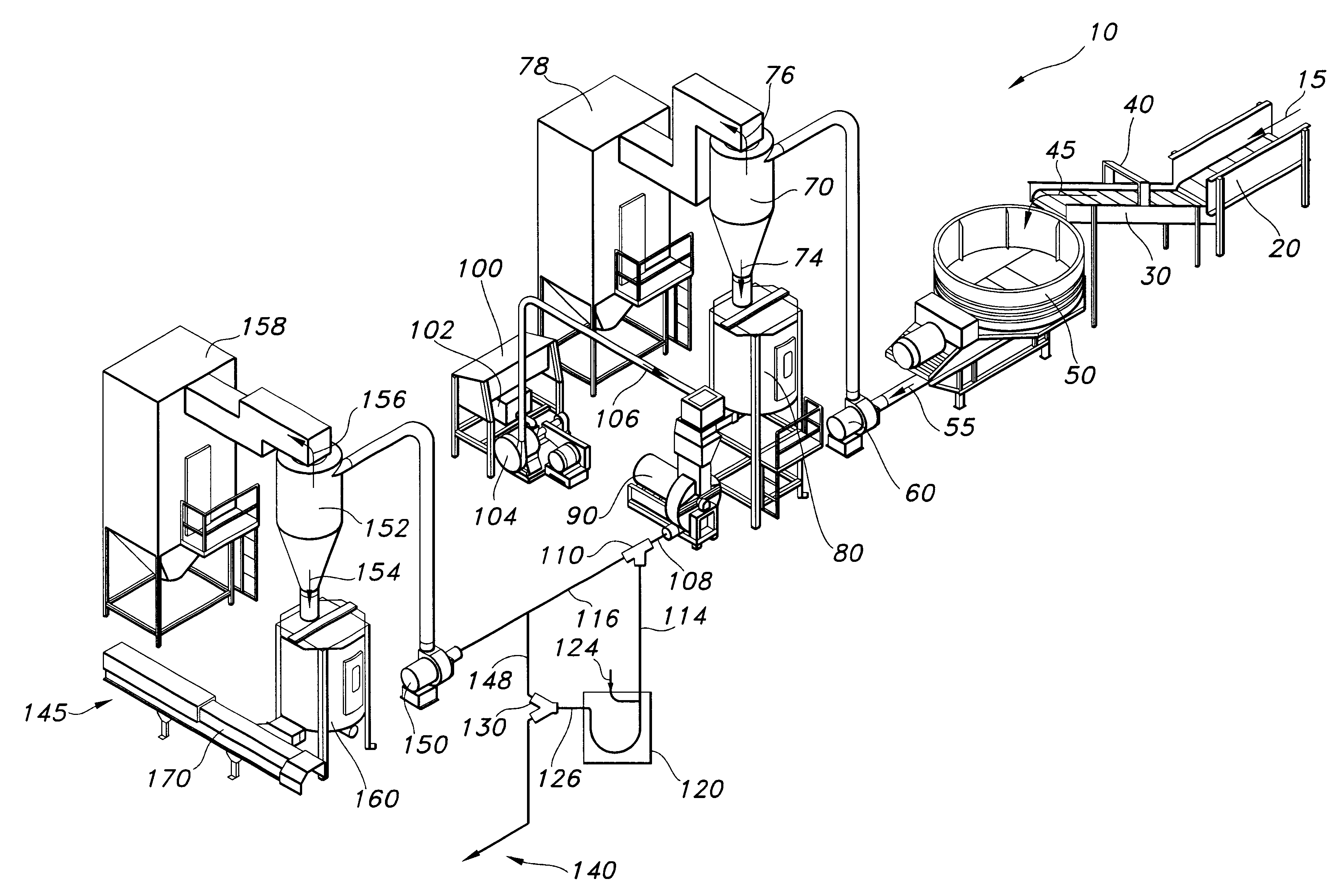

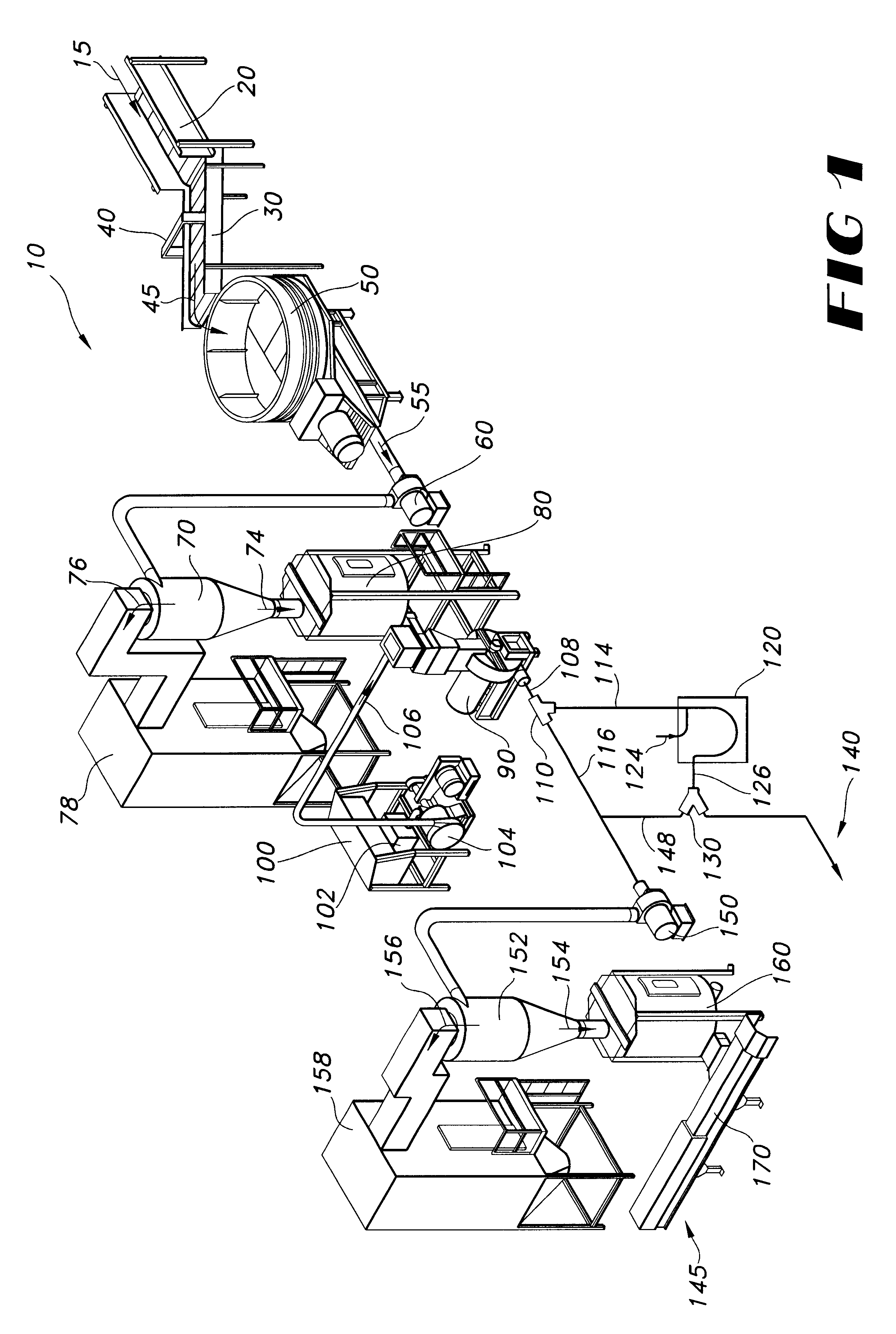

Method and system for producing prescription animal bedding from recycled paper waste products

A method and system for producing an animal bedding material from recycled waste paper, and including one or more chemical additives. The base material is fiberized, and the chemical additives may include: pesticides, disease immune additives (medicines), ammonia inhibitors, fire retardants, or other additives, depending on the characteristics desired of the final product. At least one of the additives is applied as a liquid.

Owner:CELLULOSE TECH GROUP

Thermal gasification reactor for producing heat energy from waste

ActiveUS20120121477A1Ameliorate aforementioned disadvantageDestroy wasteSolid waste disposalBiofuelsSyngasElectricity

A thermal reactor for producing usable heat energy by destroying waste including a vessel wherein organic waste upon entering said vessel gasifies as it falls onto a carbon bed and is transformed into a synthesis gas with high heat and kinetic energy that can be harnessed to produce electricity. Inorganic waste upon entering melts as it falls onto the carbon bed and exits via slag ports to form an inert slag. Because there is no oxygen present in the gasification zone, the waste is not combusted and neither furan or dioxin are formed. The waste includes either prepared refuse derived fuel (RDF) or unprepared raw waste or a combination thereof.

Owner:GREEN ENERGY & TECH

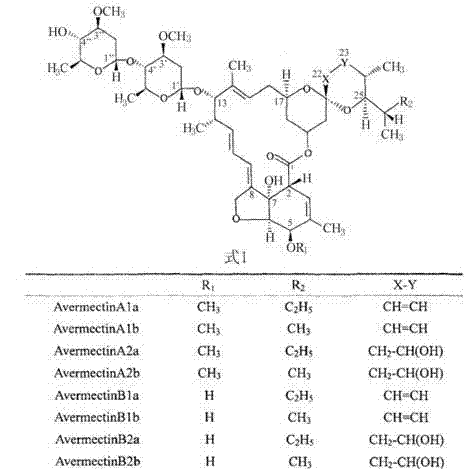

Process of extracting abamectin components B1 and B2 step by step by utilizing crystallization method

ActiveCN103030675AReduce wasteReduce generationSugar derivativesSugar derivatives preparationSolventFermentation

The invention relates to a process of extracting abamectin components B1 and B2 step by step by utilizing a crystallization method, comprising the steps of leaching abamectin mycelia by using ethanol (or methanol), subjecting the leachate to preliminary concentration, adding active carbon to decolorize the leachate, converting the solvent into toluene after the decolorization is completed, carrying out cooling crystallization to obtain a mixture of the abamectin components B1 and B2, converting the solvent of the crystallization mother liquor into methanol, carrying out cooling crystallization on the mixture of the abamectin components B1 and B2, obtained in the first crystallization, to obtain crystals i.e. the abamectin component B1, converting the solvent of the mother liquor into toluene and obtaining the components B2 through crystallization. According to the invention, on the premise of not increasing the fermentation cost, the components B1 and B2 are extracted from the mycelia step by step, so that the economic benefit of enterprises is increased, and the resource waste and the waste production are reduced at the same time.

Owner:内蒙新威远生物化工有限公司

Fluorocarbon rubber with easy demoulding and tear resistance and preparation method thereof

The invention provides a fluorocarbon rubber with easy demoulding and tear resistance and banburying method thereof, comprising the following components: 100 parts of crude fluororubber; 4-6 parts of high activity magnesium oxide; 2-4 parts of calcium hydroxide; 1.5-6 parts of iron oxide red; 0.4-1.0 part of rubber ingredient WS280; 0-1.0 part of rhine 54; 0-1.0 part of brazil carnauba wax; 1.2-2.4 parts of bisphenol AF; 0.4-1.0 part of benzyltriphenylphosphonium chloride; and appropriate calcium silicate or barium sulphate added according to hard requirement. The invention also provides two banuring methods of fluorocarbon rubber with easy demoudling and tear resistance. The product of the invention has good demoulding performance, and the produced trimming after vulcanization can be taken down along with the product, thus reducing clearing time of operators and avoiding waste production caused by reduction of mould temperature. By the improvement of banburying method of fluorocarbon rubber, dispersion performance of fluorocarbon rubber can be improved, thus improving demoulding performance thereof in vulcanization and reducing tear of product, so that scrap rate of product in one specification caused by tear is reduced to 0.15% from 0.36% (reduced by near 60%).

Owner:QINGDAO TKS SEALING IND

Solar-powered aircraft

InactiveUS20080185475A1Weight of to shiftPower installationsAircraft stabilisationHydrogenFuel cells

A solar-powered aircraft uses solar energy to electrolyze on-board water to produce hydrogen. The hydrogen fills various on-board tanks, causing the aircraft to become lighter than air. The hydrogen is also used to operate a fuel cell which provides power for electrical equipment, including a motor for turning a propeller. Water produced as waste by the fuel cell is recycled for use in the production of hydrogen. When hydrogen is removed from the tanks, either because it is consumed by the fuel cell or because it is compressed and pumped out of the tanks, air returns to the tanks, and the aircraft becomes heavier than air. The aircraft can thus be made to climb and descend by making it lighter than air, or heavier than air. The aircraft emits no harmful substances into the environment. The aircraft can remain aloft indefinitely, limited only by an insignificant amount of leakage of hydrogen and water.

Owner:FULLER HOWARD J

Heating control method of steel rolling heating furnace applicable to pipeline steel

InactiveCN105420486AGuaranteed continuityGuaranteed process requirementsFurnace typesHeat treatment process controlHeating timeHeat control

The invention relates to a heating control method of a steel rolling heating furnace applicable to pipeline steel. A four-stage heating mode is adopted. The temperature at the preheating stage is 1100+ / -50 DEG C, and the preheating time is more than or equal to 105 min; the temperature at the first heating stage is 1200+ / -30 DEG C, and the heating time is more than or equal to 30 min and less than or equal to 60 min; the temperature at the second heating stage is 1220+ / -20 DEG C, and the heating time is more than or equal to 35 min and less than or equal to 60 min; the temperature at the uniform heating stage is 1180+ / -20 DEG C, and the heating time is more than or equal to 40 min; the temperature of a flue inlet is 750+ / -50 DEG C; the heating speed before the temperature of a plate blank is lower than or equal to 600 DEG C is controlled not to be higher than 7 DEG C / min, and the difference between the adjacent lowest temperature and the highest temperature in the length direction of the plate blank is controlled to be lower than or equal to 8 DEG C. By means of the heating control method, the continuity of the plate blank heating process is guaranteed, and plate blank cracks caused by improper heating speed are avoided; the performance stability of the whole plate is effectively guaranteed in the pipeline steel rolling process, and steel wasting production accidents and plate blank black print defects caused by squatting and bending of an intermediate billet are avoided.

Owner:HANGANG GRP HANBAO IRON & STEEL

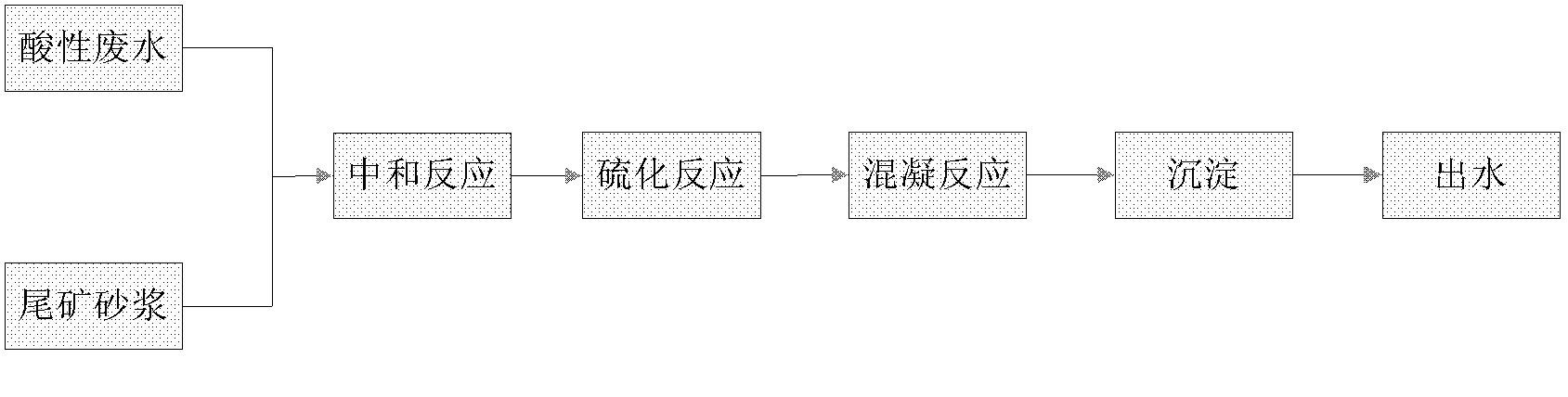

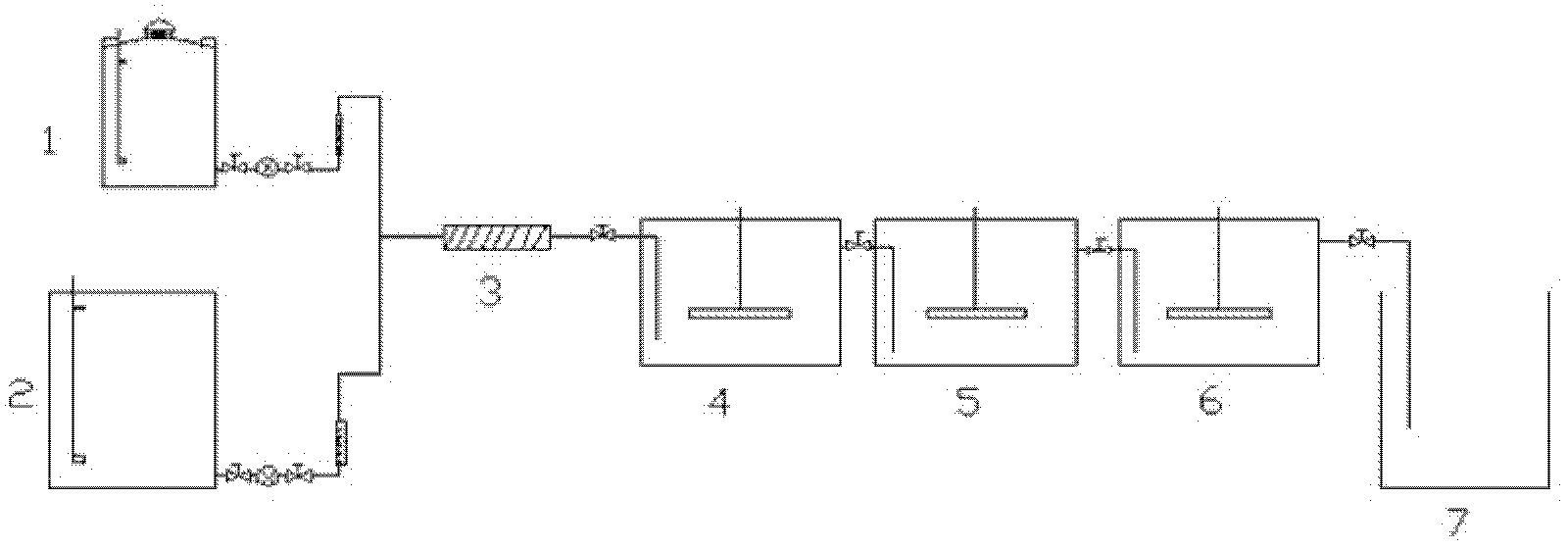

Method for treating heavy metal-containing acidic wastewater in nonferrous metal industry

InactiveCN102795728AReduce usageReduce investmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationVulcanizationNonferrous metal

A method for treating heavy metal-containing acidic wastewater in nonferrous metal industry adopts a tailings mortar neutralization-vulcanization-coagulation combined process, wherein the major flow of the process comprises the following steps of: neutralizing and absorbing the heavy metal-containing acidic wastewater by using tailings mortar at first, and then putting Na2S in a vulcanization reaction with left heavy metals in the acidic wastewater; next, performing coagulation and sedimentation with FeSO4 as a coagulant and polyacrylamide as a coagulant aid so that H+ in the acidic wastewater is neutralized, thereby removing heavy metals in the wastewater. The method reduces capital investment of an enterprise on wastewater disposal to an utmost extent, and simultaneously reduces the solid waste yield of the enterprise by utilizing the tailings mortar produced in mining and milling of ores; besides, the acidity of the wastewater can be effectively neutralized and the heavy metals can be effective removed.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

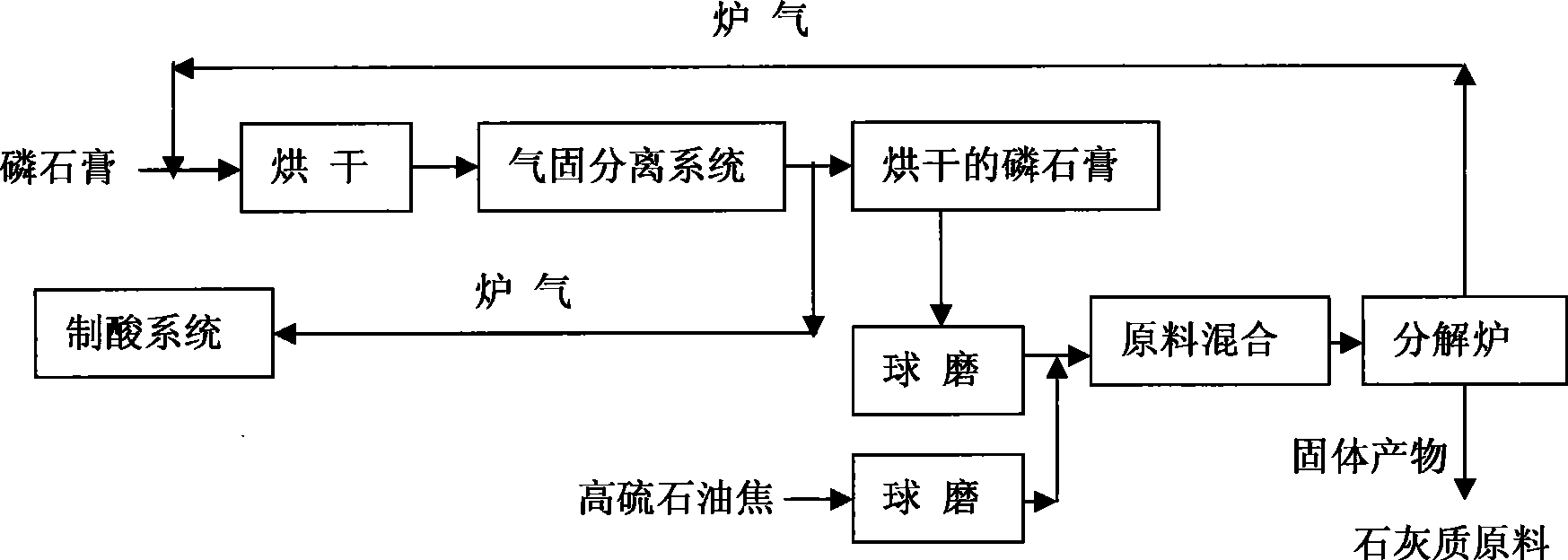

Method for preparing lime raw material and SO2 by decomposing phosphogypsum from high sulphur refinery coke

InactiveCN101486480AStable concentrationIncrease contentSolid waste disposalSulfur compoundsReductive decompositionDecomposition

The invention discloses a method for preparing a calcium carbonate raw material and SO2 by utilizing high-sulfur petroleum coke to decompose phosphogypsum, i.e., the high-sulfur petroleum coke with the carbon mass fraction higher than 80 percent and the sulfur mass fraction higher than 2 percent to 6 percent is used for reducing and decomposing the phosphogypsum to prepare burner gas with the SO2 volume percentage higher than or equal to 15 percent. The burner gas can be directly used as qualified virgin gas for the two-conversion and two-absorption acid-making technology so as to produce the solid product, CaO, with the mass fraction of higher than 50 percent, and can also be directly used as a chemical raw material, for instance, for making cement. No waste is generated in the process, the decomposition rate of the phosphogypsum is higher than or equal to 95 percent, and the desulphurization degree is higher than or equal to 90 percent. By utilizing the technology for decomposing the phosphogypsum, pretreatment is not required and the concentration of SO2 is stable in the burner gas. The content and the thermal value of carbon in the high-sulfur petroleum coke are comparatively high, and the contents of nitrogen and sulfur are higher than that of other fuels, thereby reducing reaction temperature, energy consumption and production cost, simultaneously, environment pollution is not generated and waste is changed into valuable. The utilization of components of the phosphogypsum is maximized during the technical process so as to solve the problem of realizing the harmlessness and sales of the phosphogypsum as 'dangerous waste'.

Owner:KUNMING UNIV OF SCI & TECH

Combining treatment method based on waste incineration

InactiveCN107366913AAvoid damageAvoid instabilityIncinerator apparatusEnvironmental engineeringToxic industrial waste

The invention provides a compatibility treatment method based on waste incineration, which belongs to the technical field of industrial waste treatment. The invention makes reasonable compatibility before waste incineration, so as to ensure a high incineration removal rate, and at the same time make the waste produced in the furnace more efficient. The calorific value is relatively uniform, the incineration system is relatively stable, and it will not cause excessive burden to the incineration equipment, so as to prolong the service life of the equipment.

Owner:NANJING FUCHANG ENVIRONMENTAL PROTECTION

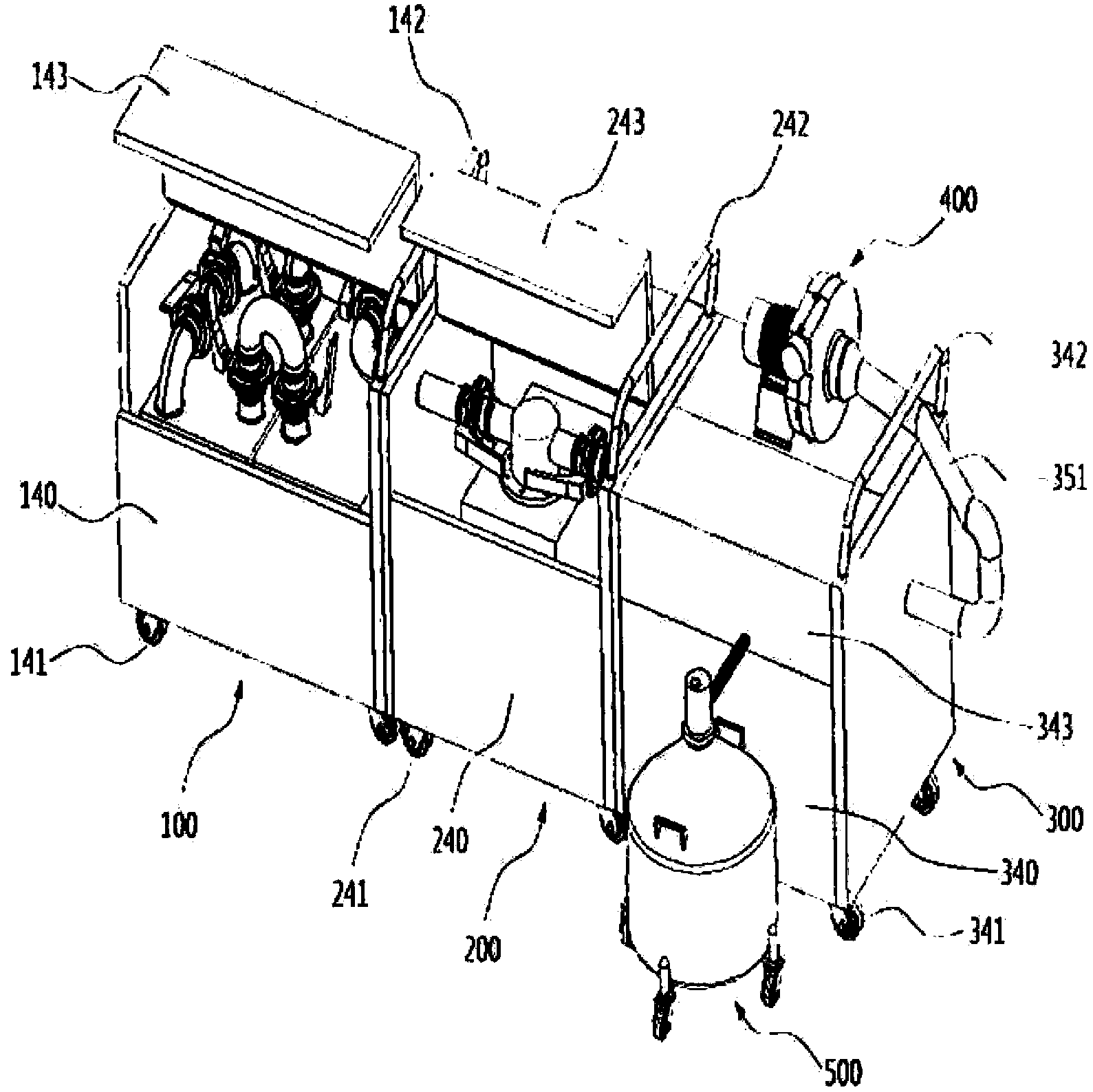

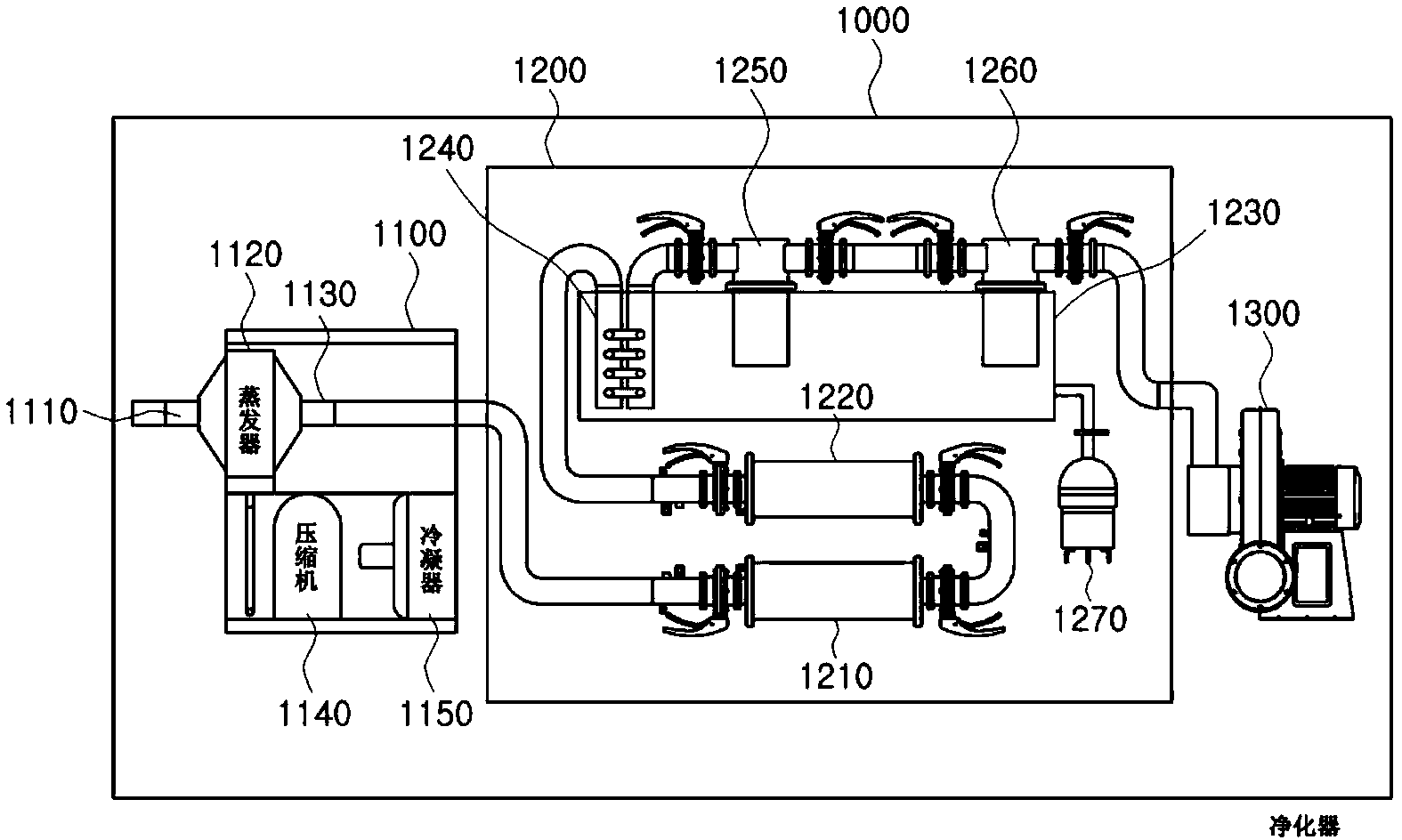

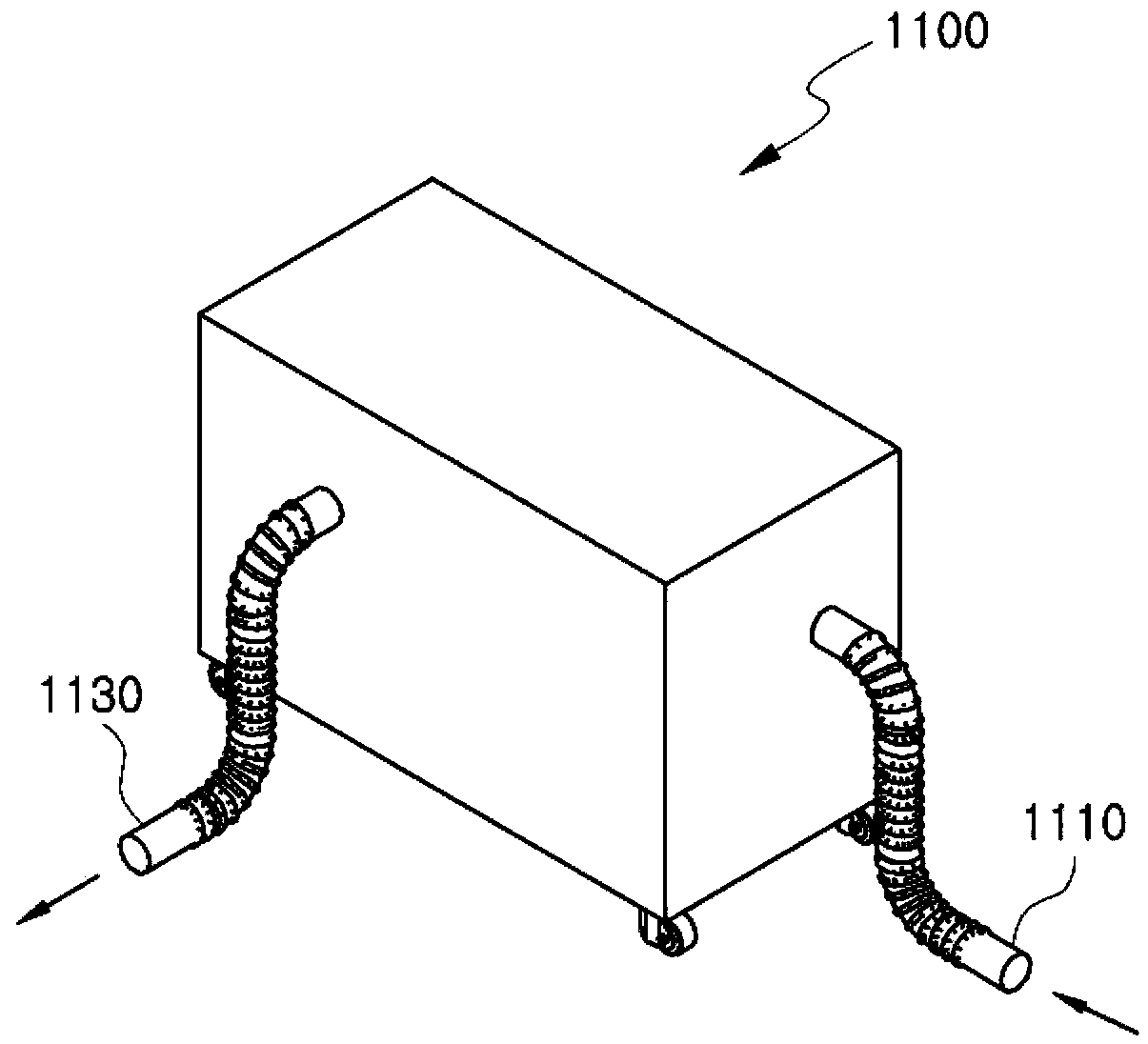

Movable radioactivity inert gas purifier

InactiveCN104143367AReduce dosageReduce generationDispersed particle filtrationRadioactive decontaminationKryptonMolecular sieve

The invention discloses a movable radioactivity inert gas purifier, specifically a movable radioactivity inert gas purifier that is small-sized and convenient to move, dehumidification is implemented for two times by using a molecular sieve as a cooling circulation and absorber, and carbon dioxide and inert gases (argon (Ar), krypton (Kr), radon (Rn), xenon (Xe), etc.) can be effectively eliminated in a cooling state with the absorber and a cold trap. Compared with original developed equipment, continuous dehumidification can be carried out under the condition that hot and humid suction air is feed, use of the absorber is obviously reduced and therefore radioactivity waste production is reduced, and the purifier is capable of effectively eliminating and purifying inert gases and carbon dioxide.

Owner:DS SCI

Flocculation adsorption treatment method of waste liquid of nuclear power plant and flocculating agent

ActiveCN102915783AImprove decontamination abilityEfficient removalRadioactive decontaminationLiquid wastePotassium

The invention provides a flocculation adsorption treatment method of waste liquid of a nuclear power plant and a flocculating agent. The flocculation adsorption treatment method includes the steps of adding flocculating agent into the waste liquid of the nuclear power plant, keeping a pH (potential of hydrogen) value within 7-9, performing mixed reaction to obtain colloid flocculation; and subjecting the colloid flocculation to activated carbon adsorption column for adsorption, wherein Fe, Co, Mn and Ag nuclides are absorbed and intercepted by the activated carbon adsorption column. The flocculating agent comprises a component A including NaOH or KOH, a component B which is polyacrylamide, a component C which is sodium polyacrylate or potassium polyacrylate. Coagulation capacity of corrosion product colloids is improved by adding the flocculating agent, and decontamination factor of activated carbon to Fe, Co, Mn, Ag is increased by 5 times. The flocculation adsorption treatment method is stable in eliminating effect, good in repeatability, low in running energy consumption and less in secondary pollution output.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Preparation method of 5-methyl-2-mercapto-1,3,4-thiadiazole

The invention provides a preparation method of 5-methyl-2-mercapto-1,3,4-thiadiazole. The preparation method comprises the following steps of adding ethyl acetate and hydrazine hydrate into a reaction flask having a volume of 500ml, keeping backflow for 2 hours, cooling to obtain an acethydrazide solution, dropwisely adding carbon disulfide into the acethydrazide solution, then feeding NH3 into the acethydrazide solution containing carbon disulfide at a temperature of 40 DEG C, adding a crude thiadiazole product into deionized water, carrying out elution of filter cake several times by distilled water, and carrying out vacuum-drying to obtain a thiadiazole finished product. The preparation method has that advantages that ethanol is not used in synthesis so that solvent-free reactions are realized; under solvent-free conditions, high reactant concentration is conducive to reaction development; solvent-free reactions are easy to operate, saves energy and prevents waste production; and NH3 replaces potassium hydroxide and thus it is avoided that potassium N-acetylhydrazinodithioformate produced in synthesis is dissolved in methanol and dissolution of potassium hydroxide needs a large amount of methanol and thus the part of potassium N-acetylhydrazinodithioformate dissolved in methanol is lost.

Owner:HEILONGJIANG HAOYUN FINE CHEM

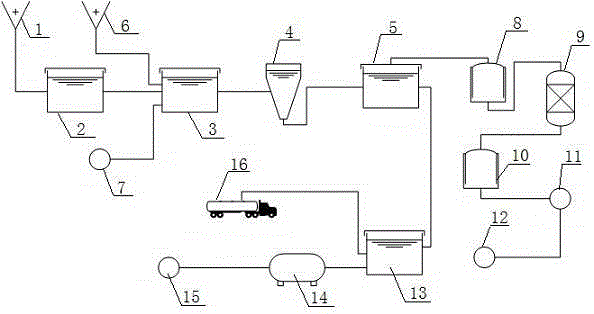

Community organic matter in-place digestion degradation biogas preparation electrical power generating system, and applications thereof

InactiveCN105296337AShort processReduce processing costsBioreactor/fermenter combinationsInternal combustion piston enginesHigh concentrationNew energy

The invention provides a community organic matter in-place digestion degradation biogas preparation electrical power generating system. According to the community organic matter in-place digestion degradation biogas preparation electrical power generating system, kitchen waste of each household in a community is smashed into small particle organic waste, and is mixed with toilet wastewater of each household and community green garbage, and high concentration waste water is obtained via concentration; the high concentration waste water is subjected to anaerobic digestion so as to obtain biogas and a digestion liquid; biogas is subjected to desulfuration purifying so as to obtain pure biogas, the biogas is used for generating electric energy via combustion in an internal combustion engine, and electric energy is recycled back to users in the community; the digestion liquid is treated so as to obtain a fertilizer and terminal waste water; and terminal waste water is subjected to simple treatment in septic tanks, and then is discharged into municipal sewage pipe networks. The community organic matter in-place digestion degradation biogas preparation electrical power generating system is capable of realizing pretreatment of waste sources, and in-place anaerobic digestion, so that technological process is short, treatment cost is low; kitchen waste is not stacked or transported, environment pollution is not caused, and transportation cost is reduced; and at the same time, electric energy generated by the community organic matter in-place digestion degradation biogas preparation electrical power generating system can be used, new energy policy subsidies from the government can be obtained, and economic efficiency maximization is realized.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com