No-waste production method for peeled sweet potato starch

A sweet potato and starch technology, applied in food science, application, food preparation, etc., can solve the problems of low concentration, difficult to handle, and low quality, and achieve the effect of reducing protein content, reducing browning degree, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the waste-free deep processing method of sweet potato and product analysis thereof

[0054] Sweet potato varieties in this example: Mixuan No. 1, the yellow variety Jiangsu 55-1 with obvious anti-browning ability, and the orange variety Xinong 431 sweet potato with high carotene content.

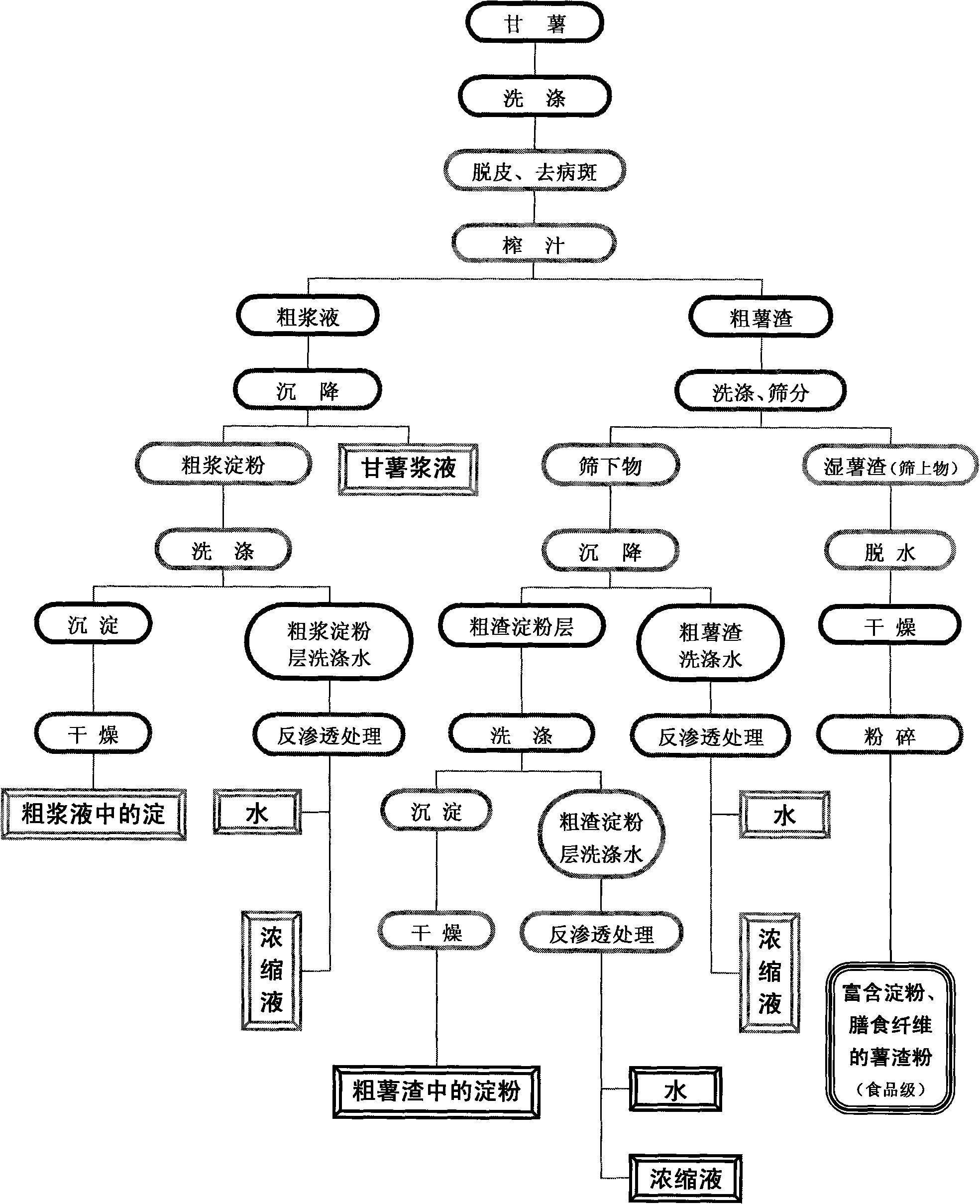

[0055] The waste-free deep processing flow chart of sweet potato is shown in figure 1 .

[0056] 1. After washing the sweet potatoes, remove the skin and lesions with a paring knife, cut them into pieces, and then process them with a household juicer (Shanghai Langbofei) to obtain two parts: coarse slurry and coarse potato residue.

[0057] 2. After the coarse slurry is placed in a beaker to settle for 4 hours, the coarse starch layer and the first by-product sweet potato slurry above the starch layer are obtained.

[0058] Sweet Potato Syrup See figure 2 , the sweet potato slurry is bright in color, the sweet potato slurry of Sinonong 431 is orange, the sweet potato...

Embodiment 2

[0109] Embodiment 2, the application of sweet potato slurry

[0110] Method 1: Centrifuge the coarse slurry of Jiangsu 55-1 at 800rpm for 10 minutes, put the supernatant, i.e. sweet potato slurry, into a sterilized bottle, cover the bottle cap, put it in a sterilized pot, and store it at 121°C , treated for 15 minutes, and placed at room temperature. see results Figure 11 , it can be seen from the figure that the sweet potato slurry after heating has a partial precipitation, the supernatant is rich in soluble sugar, and the precipitation contains a certain amount of protein, starch, ash and other substances. The color of the supernatant was orange-yellow, and no browning phenomenon was observed after being stored at room temperature for 3 months. It can be seen that the sweet potato slurry can completely suppress the browning phenomenon in the process of processing through proper processing. Therefore, it can be inferred that it is feasible to process sweet potato juice, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com