Patents

Literature

288results about How to "Lower protein content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for preparing thin slice of tobacco and prepared thin slice of tobacco

InactiveCN101438852ARich aromaImprove combustion qualityTobacco preparationTobacco treatmentPectinaseChemistry

The invention provides a technique for preparing tobacco sheets and the tobacco sheets. The technique comprises the following steps: soaking tobacco materials in water to obtain extract liquid and a water-insoluble solid; carry out enzymatic hydrolysis on the extract liquid by pectinase and / or protease so as to obtain a first water-soluble extract; degrading the protein in the water-insoluble solid by the protease so as to obtain an enzyme-hydrolyzed water-insoluble solid and a second water-soluble extract; placing the enzyme-hydrolyzed water-insoluble solid in acidic alcohol solution so as to acid-degrade lignose, then preparing the separated solid into tobacco sheet bases; and carrying out vacuum concentration on the first and the second water-soluble extracts and applying the first and the second water-soluble extracts to the tobacco sheet bases to prepare the tobacco sheets. The technique can effectively reduce the content of water-soluble pectin and water-insoluble protease, and reduce the unique lignin flavor in the tobacco sheets by the chemical degradation of the lignose.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD +1

Processing process for rapeseed oil

ActiveCN103666749ALow in phospholipidsReduce crude fiber contentFatty-oils/fats refiningFatty-oils/fats productionFlavorFood safety

The invention discloses a processing process for rapeseed oil. The process comprises the following steps of (1) carefully selecting rapeseeds of the year, drying the rapeseeds in the sun until the water content is 9 to 11 percent, and removing impurities, wherein the oil content of the rapeseeds is 36 to 39 percent; (2) crushing the rapeseeds, and performing flasking to obtain rapeseed flakes; (3) steam-roasting the rapeseed flasks for 70 to 80 minutes by utilizing the natural water of the flasks; (4) placing the steam-roasted rapeseeds in an oil press, and pressing the rapeseeds to extract crude oil at low temperature of 60 to 70 DEG C; (5) filtering the crude oil by using a conventional method, and performing refining to obtain a rapeseed oil finished product. According to the process, the rapeseeds with the oil content of 36 to 39 percent are taken as raw materials, and are subjected to the steps of drying in the sun, steam-roasting, low-temperature pressing and the like, the obtained rapeseed oil is a non-transgenic product, the intrinsic flavor, aroma and nutrient substances of the rapeseed oil are maximally maintained, the oil yield is over 35 percent, the requirements of green processing are met, and the food safety is ensured.

Owner:贵州侗乡生态农业科技发展有限公司

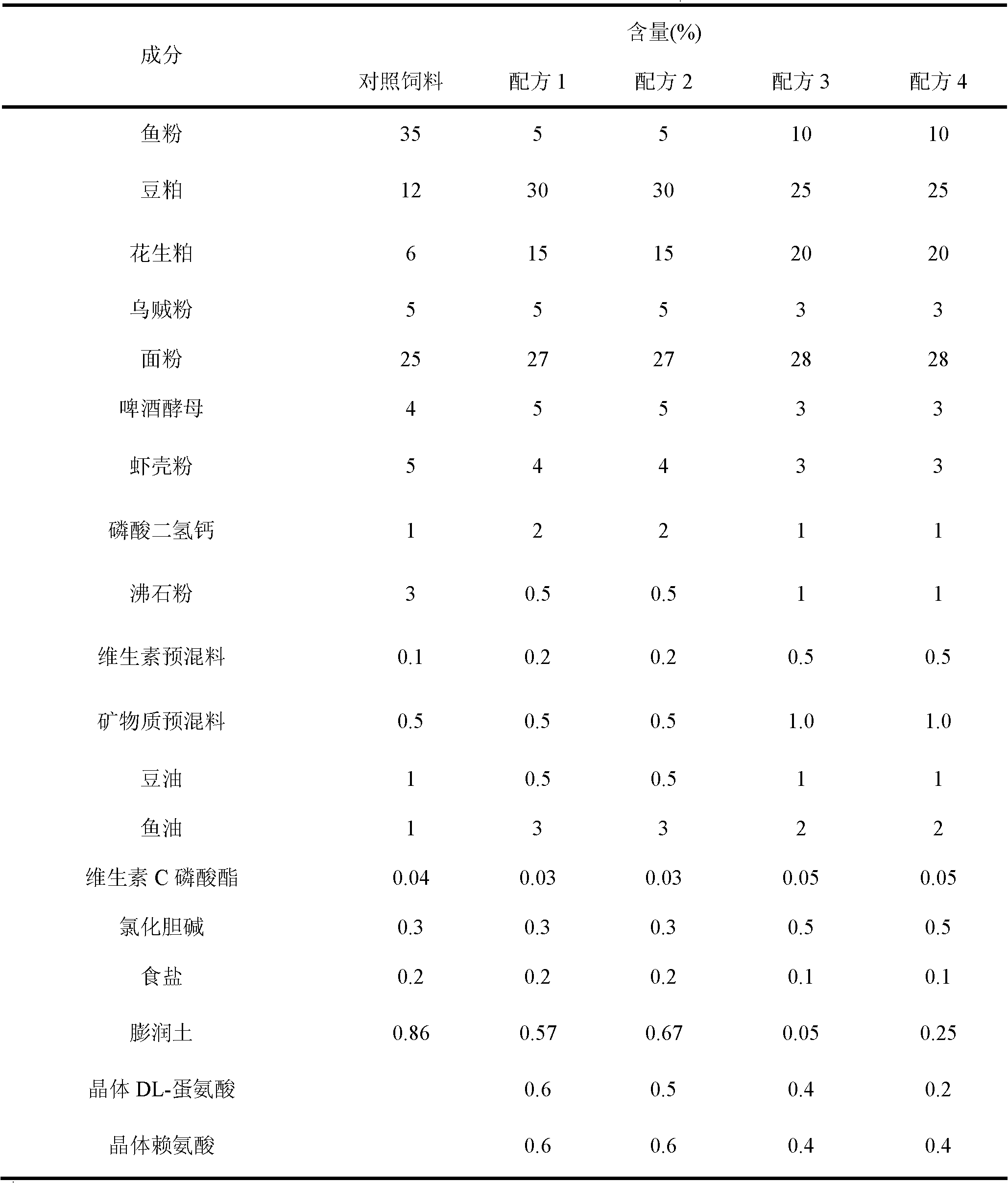

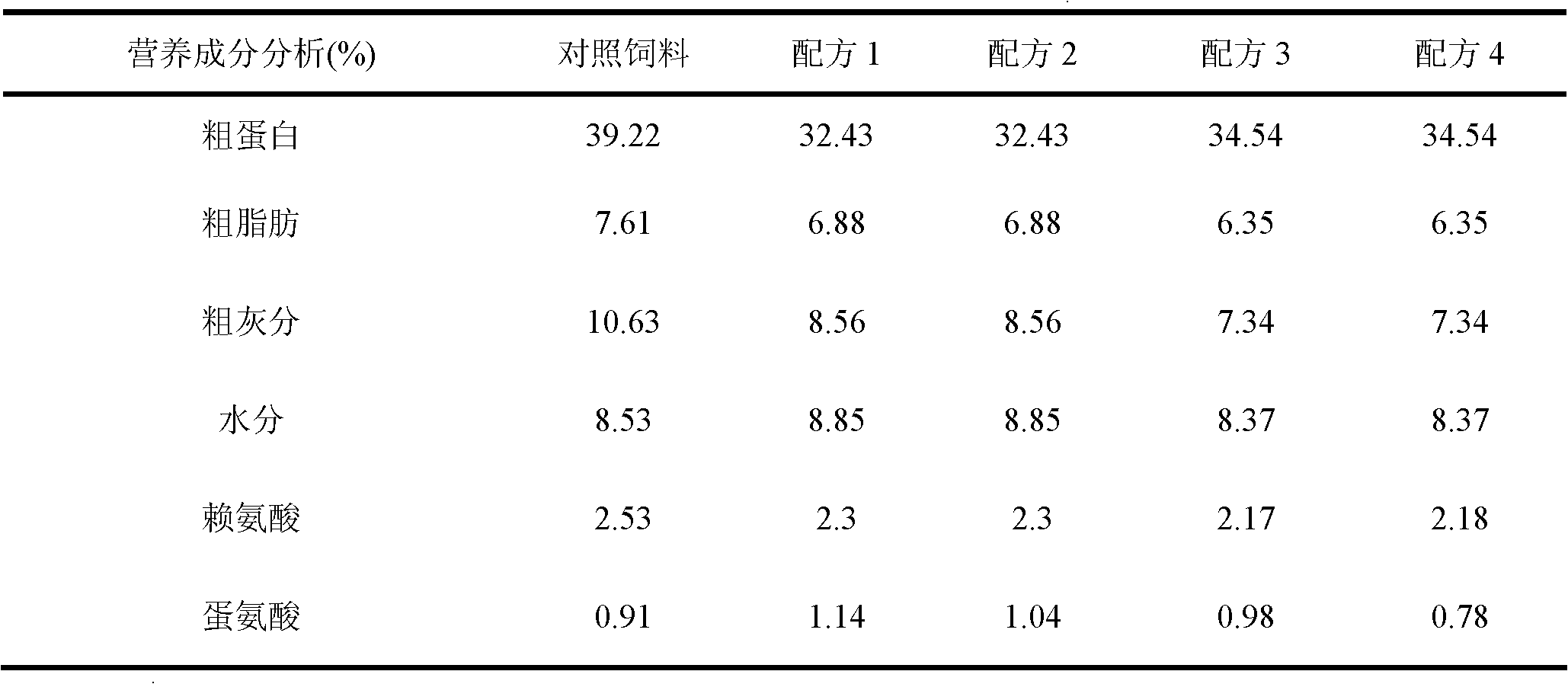

Low-protein low-fish meal feed for Litopenaeus vannamei

InactiveCN102217741ALower protein contentReduce excretionClimate change adaptationAnimal feeding stuffBiotechnologyPeanut meal

The invention discloses a low-protein low-fish meal feed for Litopenaeus vannamei. The content of proteins in a Litopenaeus vannamei feed is reduced by supplementing exogenous methionine, the content of fish meal in the feed is reduced by utilizing bean pulp with plant protein sources and peanut meal, and then the exogenous methionine, the bean pulp and plant protein sources and other raw materials are mixed according to a reasonable proportion to form the low-protein low-fish meal feed for the Litopenaeus vannamei. The using amount of the fish meal in the feed is reduced to be less than 10 percent to the maximum extent, and the problem that amino acid is unbalanced in a single protein source is solved by adding a plurality of kinds of plant protein sources. The content of the fish meal and the content of the proteins in the Litopenaeus vannamei feed are remarkably reduced, and the feed is favorable for reducing the cost, improves the utilization rate of the feed, and reduces the discharge of nitrogen and phosphorus in the aquaculture process so as to reduce environmental pollution. Through feeding experiments for a long time, the results show that when the Litopenaeus vannamei is fed by using the low-protein low-fish meal feed for the Litopenaeus vannamei, the feed has no adverse effect on the growth performance and feed coefficient of the Litopenaeus vannamei, and the discharge amount of nitrogen and phosphorus in water bodies can also be reduced.

Owner:广东省农业科学院畜牧研究所 +1

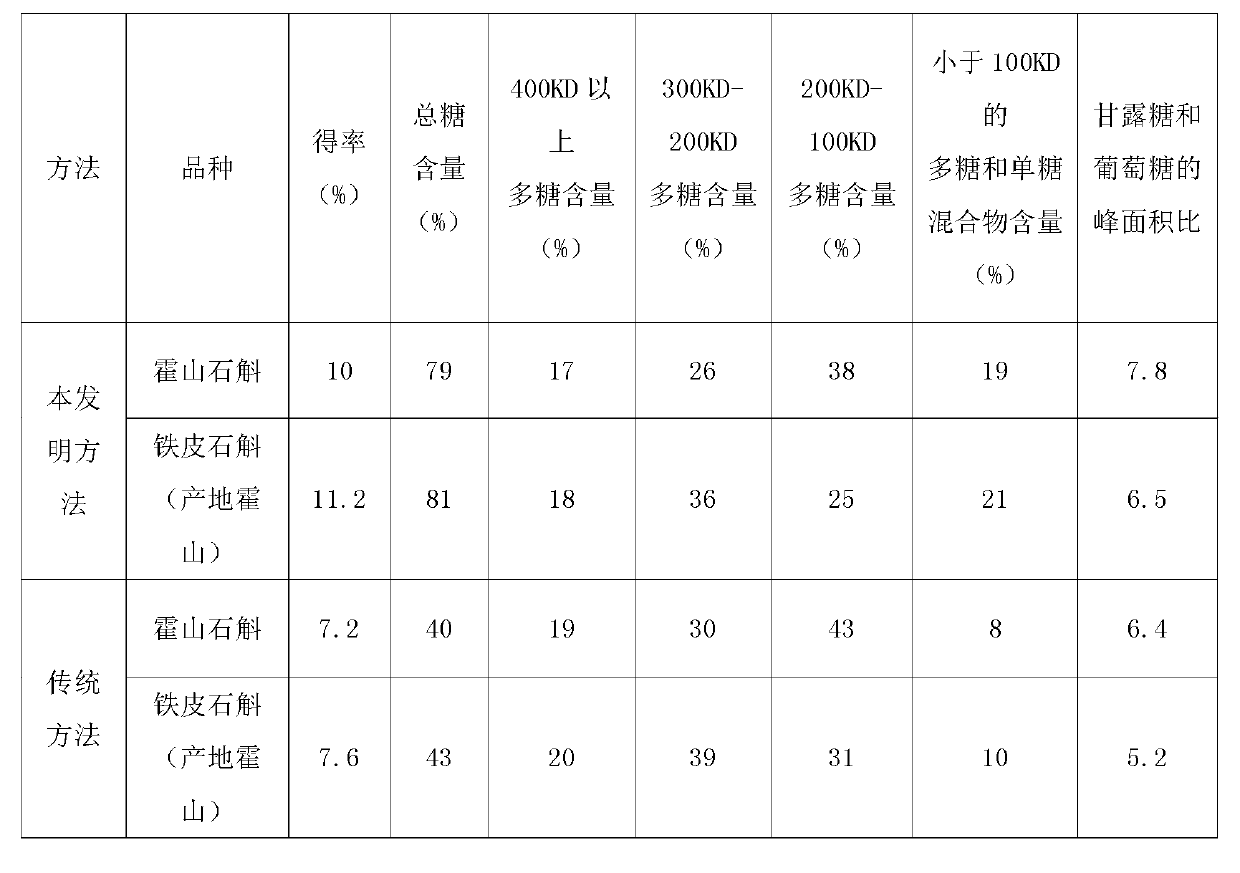

Auxiliary extraction method of biological enzyme for improving dissolution rate of dendrobe bioactive polysaccharide

ActiveCN102964461AImprove dissolution rateLower protein contentAntinoxious agentsImmunological disordersChemistryEnvironmental resistance

The invention discloses an auxiliary extraction method of biological enzyme for improving the dissolution rate of dendrobe bioactive polysaccharide, which is used for auxiliary extracting of the dendrobe polysaccharide by various biological enzymes of which the most proper pH is close to be neutral in a compounding way step by step. The auxiliary extraction method comprises the following steps of: firstly selecting cellulose, xylanase and pectinase to decompose substances of dendrobe cell wall, i.e. cellulose, hemicellulose, pectin substance, decomposing protein and polypeptide in cells by proteasem, so that the polysaccharide can be sufficiently dissolved in water, and carrying out HPSEC (high performance size exclusion chromatography) separation, parallax and refraction detector detection, and a phenol-sulfuric acid method on a final product to detect the content of reducing sugar. According to the auxiliary extraction method, the dissolution rate of dendrobe bioactive polysaccharide can be effectively improved, the protein content can be obviously reduced, the product quality and the yield can be greatly improved, and the use and the discharge of the acid-base solution and the toxic organic reagent and the generation of the microwave radiation can be avoided in the production technology, so that the auxiliary extraction method is more energy-saving and environment-friendly.

Owner:安徽同济生生物科技有限公司

Ecoalimental macrobrachium rosenbergii feed and production method thereof

InactiveCN101444266ALower protein contentImprove stabilityFood processingClimate change adaptationMacrobrachiumCompounded preparations

The invention discloses an ecoalimental macrobrachium rosenbergii feed and a production method thereof, belonging to an animal feed production method. The macrobrachium rosenbergii feed comprises fish meal, bean pulp, fermented bean pulp, wheat middling, cuttlefish paste, oil bran, various mineral salt, lycine, fish oil, various vitamins, eclosion hormone, bond, antioxidant, mildew preventive, compound enzyme preparation, microecological preparation 'quick-healing hormone', a Chinese herb sophora flavescens alkaloid compound preparation, and the like. The yield of per mu is 310kg and can be improved by 44kg by using the ecoalimental the macrobrachium rosenbergii feed than common feeds. The effective utilization of the protein and amino acid in the feed by the macrobrachium rosenbergii is improved; the coefficient of the macrobrachium rosenbergii feed bait is 1.57 which is lower by 0.2 than the common feed. The ecoalimental macrobrachium feed reduces the pollution to a breeding environment. The produced matching feed of the macrobrachium rosenbergii can induce the macrobrachium rosenbergii to eat, the growing speed of the macrobrachium rosenbergii is quick, and feed coefficient is low.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

Processing method of deproteinized rice

ActiveCN103211163APromote dissolutionImprove removal effectFood preparationFlavorReaction temperature

The invention provides a processing method of deproteinized rice. The processing method comprises the following steps of: (1) washing and removing impurities; (2) carrying out enzymolysis and fermentation: in a reaction tank, adding processed rice, purified water, proteolytic enzyme and lactic acid bacteria according to proportion, wherein the weight proportion of rice to purified water is 1:(5-20), the reaction temperature is 10-60 DEG C, the reaction time is 3-20 hours, the initial pH of reaction liquid is between 4.5 and 9.5, the using amount of proteolytic enzyme accounts for 0.1% to 5% of total weight of rice, and the dropping amount of lactic acid bacteria is as follows: 109-1014 bacteria is added in every ton of reaction liquid; and (3) after enzymolysis and fermentation, leaching, washing and drying to obtain the deproteinized rice. According to the method, the technology is simple, the cost is low, the appearance, the color, the flavor and the taste of the deproteinized rice processed by adopting the technology are the same as those of ordinary rice; and the protein removal ratio can be more than 95% at most.

Owner:成都东洋百信制药有限公司

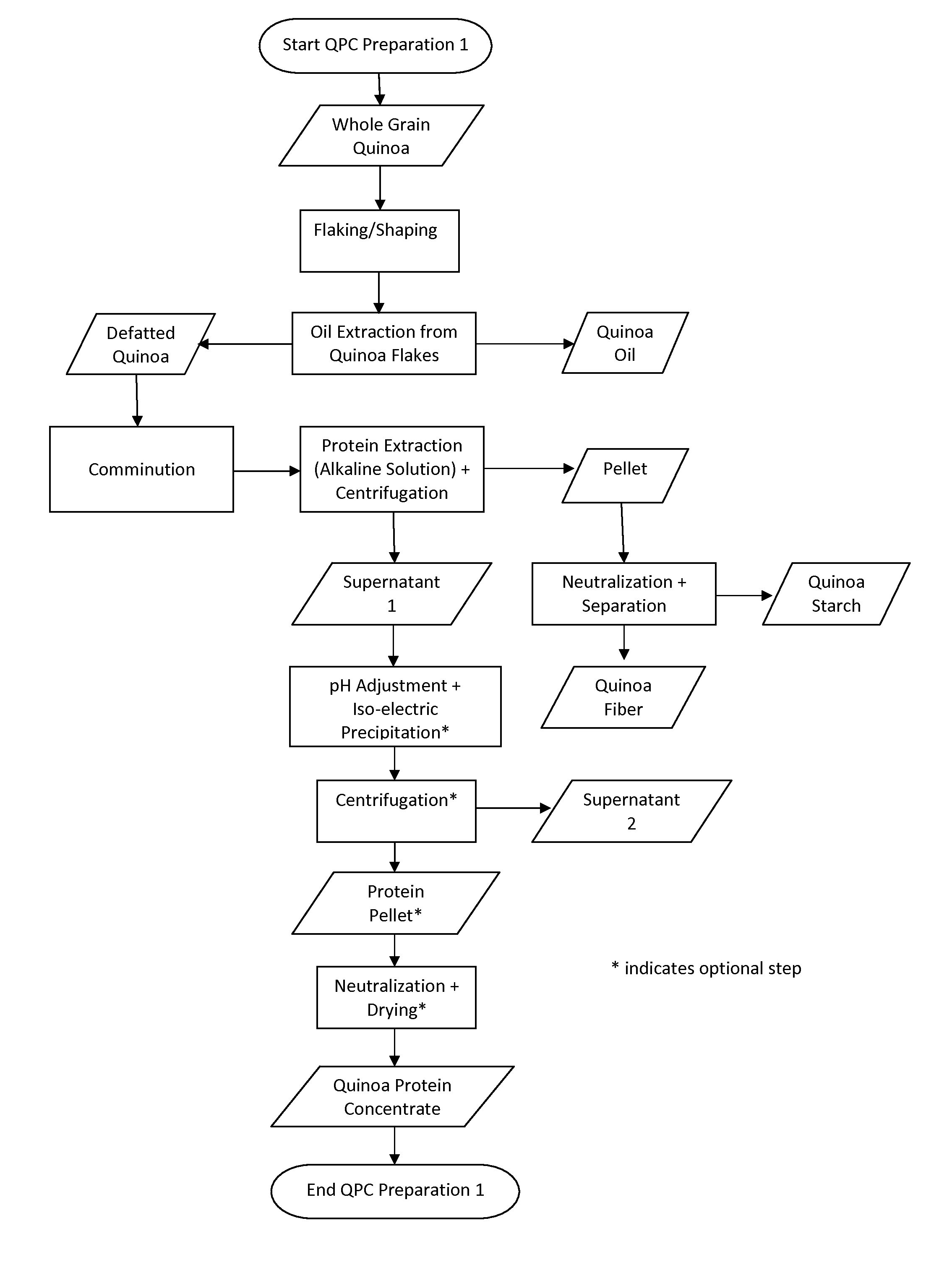

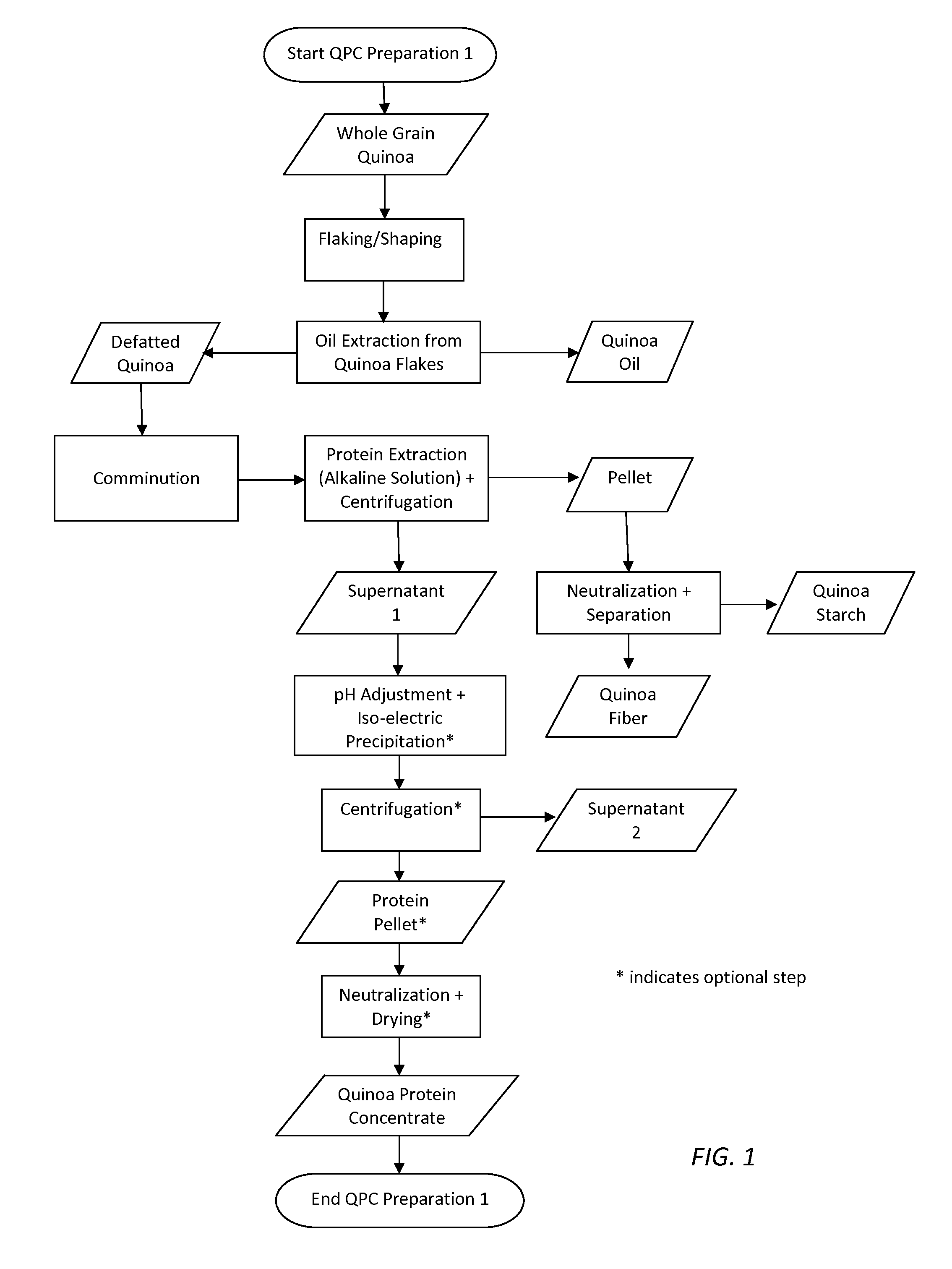

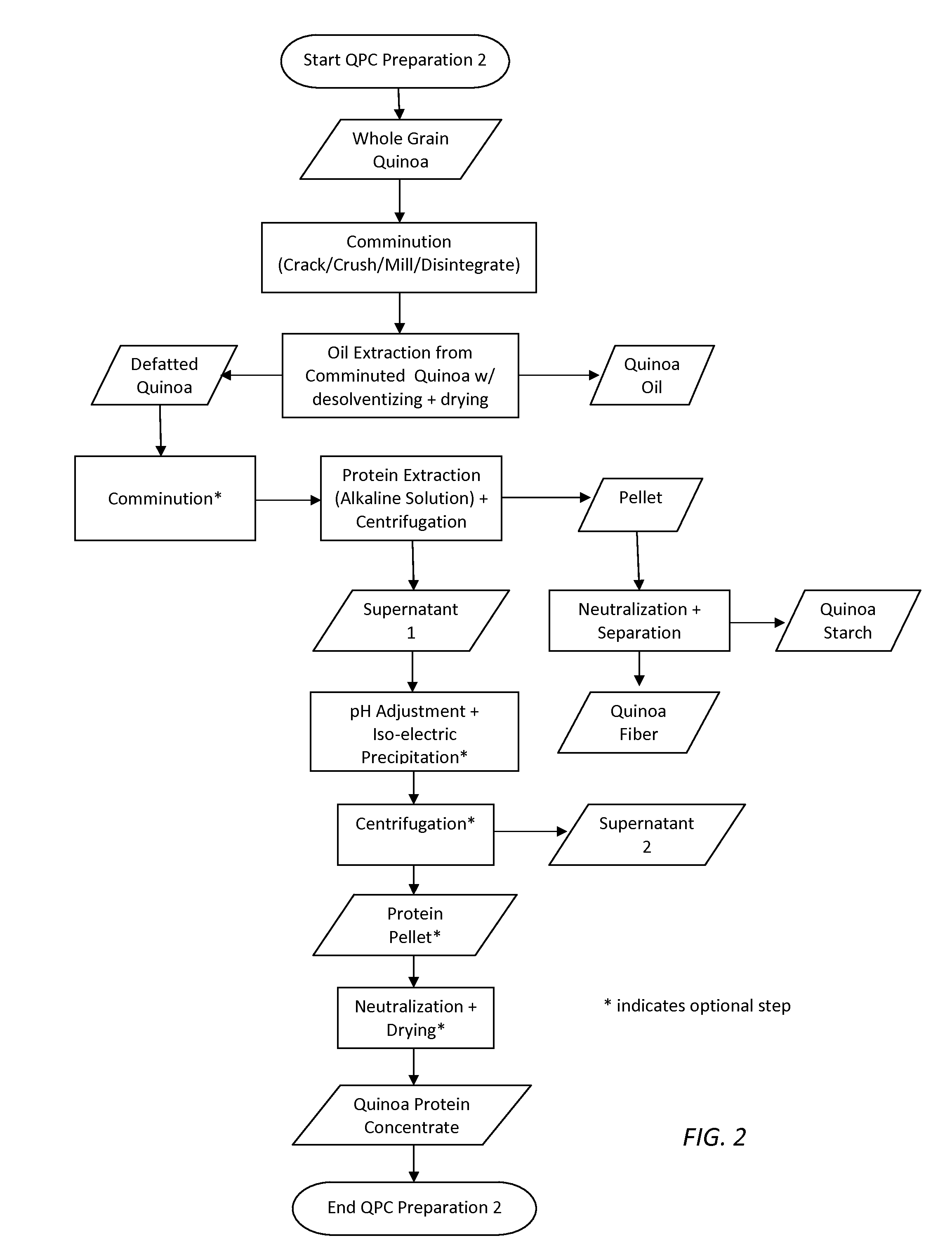

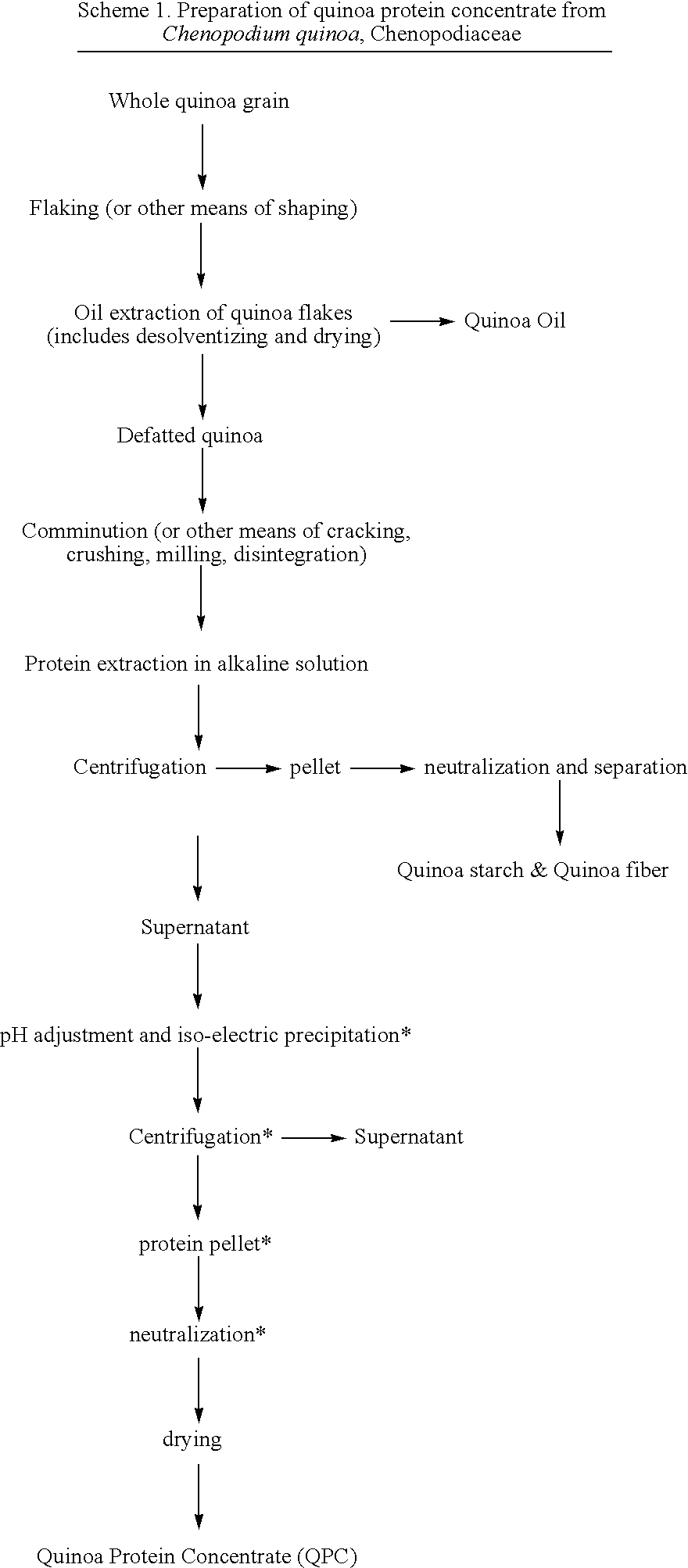

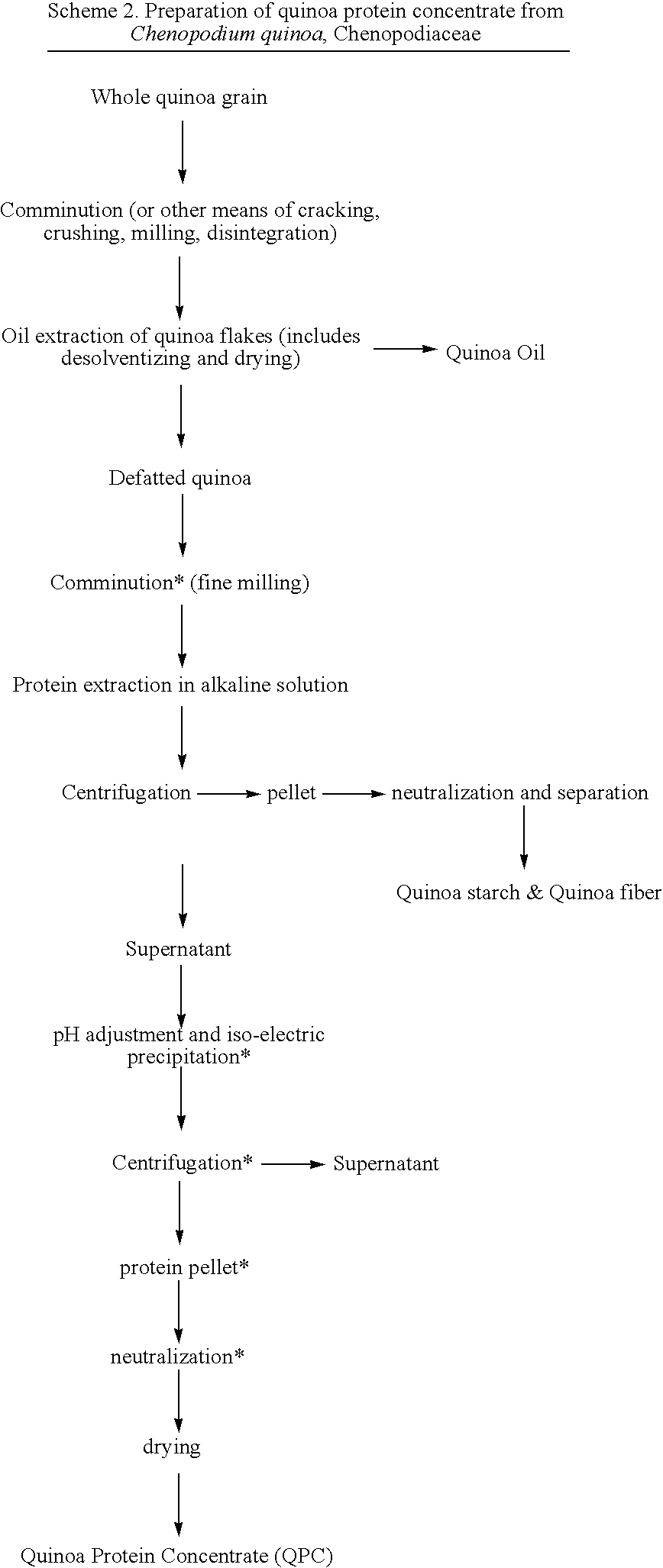

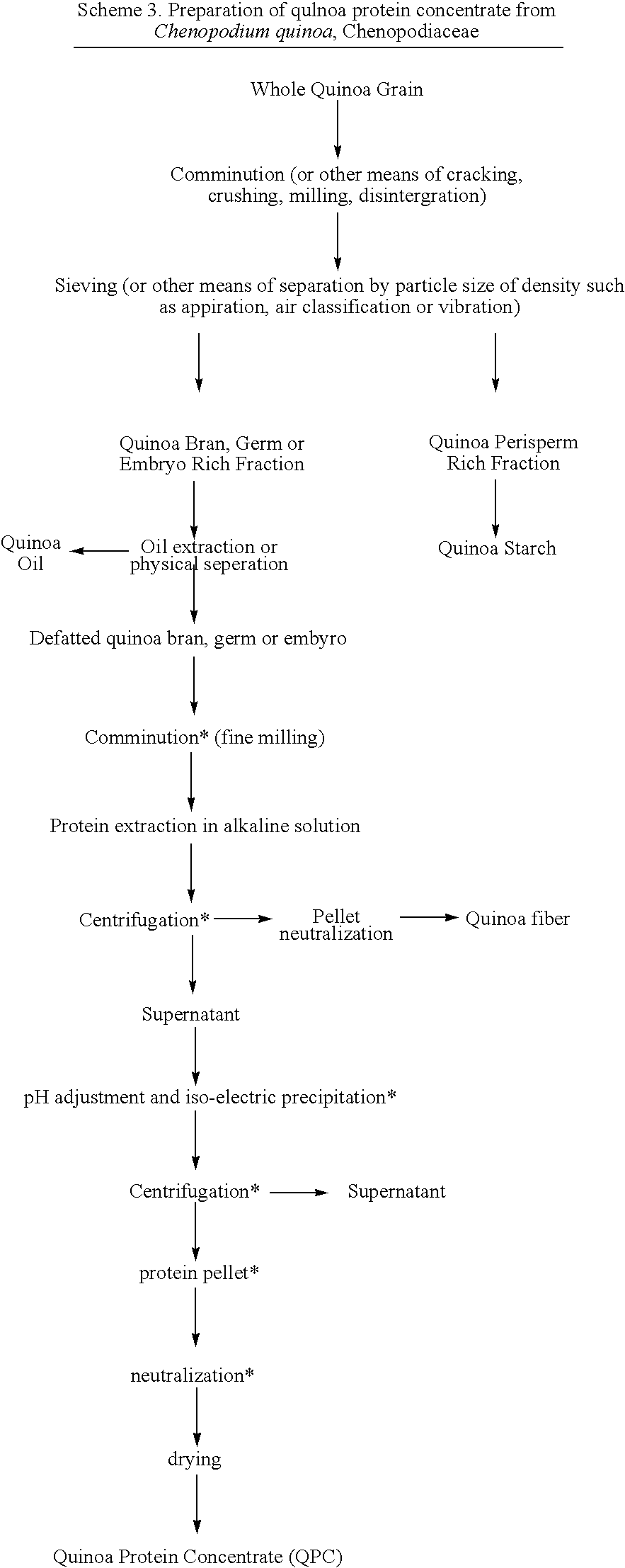

Quinoa protein concentrate, production and functionality

InactiveUS20100184963A1Reduced activityReduce fatDough treatmentAccessory food factorsFiberFood grade

The present invention relates to a new source of high quality plant protein, termed, “quinoa protein concentrate” or “QPC”, which contains at least about 50 wt % protein which is food-grade and / or pharmaceutical-grade and methods of preparing such protein concentrates as well as starch, oil, and fiber from quinoa grain. The quinoa protein concentrate of the invention is useful as food ingredients, infant formula ingredients, cosmetic ingredients, pet food ingredients, and animal feed supplements.

Owner:KEEN INGREDIENTS

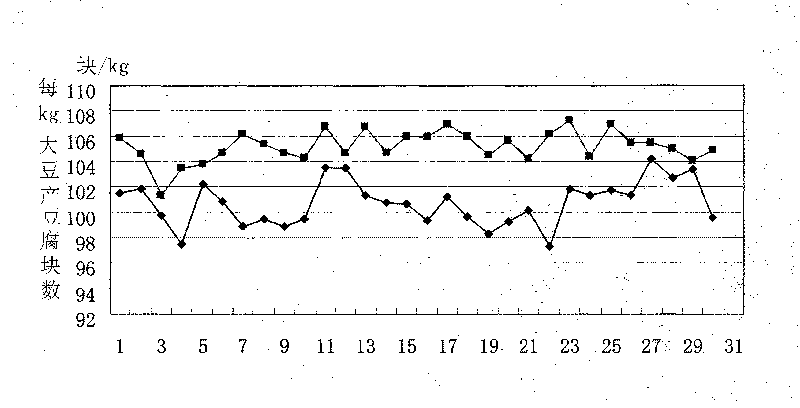

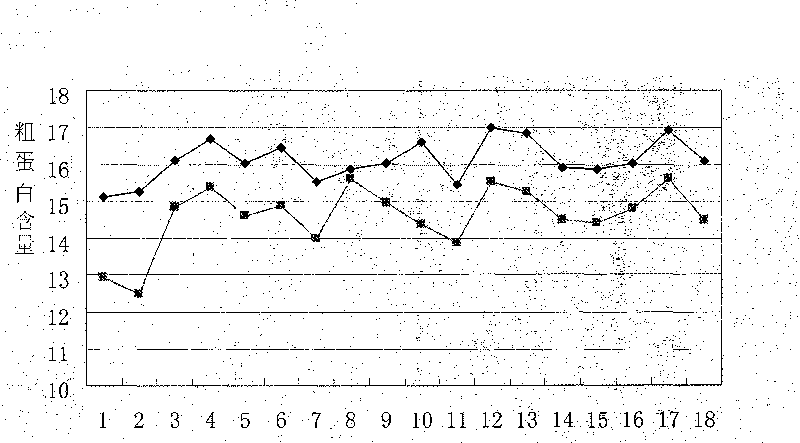

Process for preparing fermented bean curd

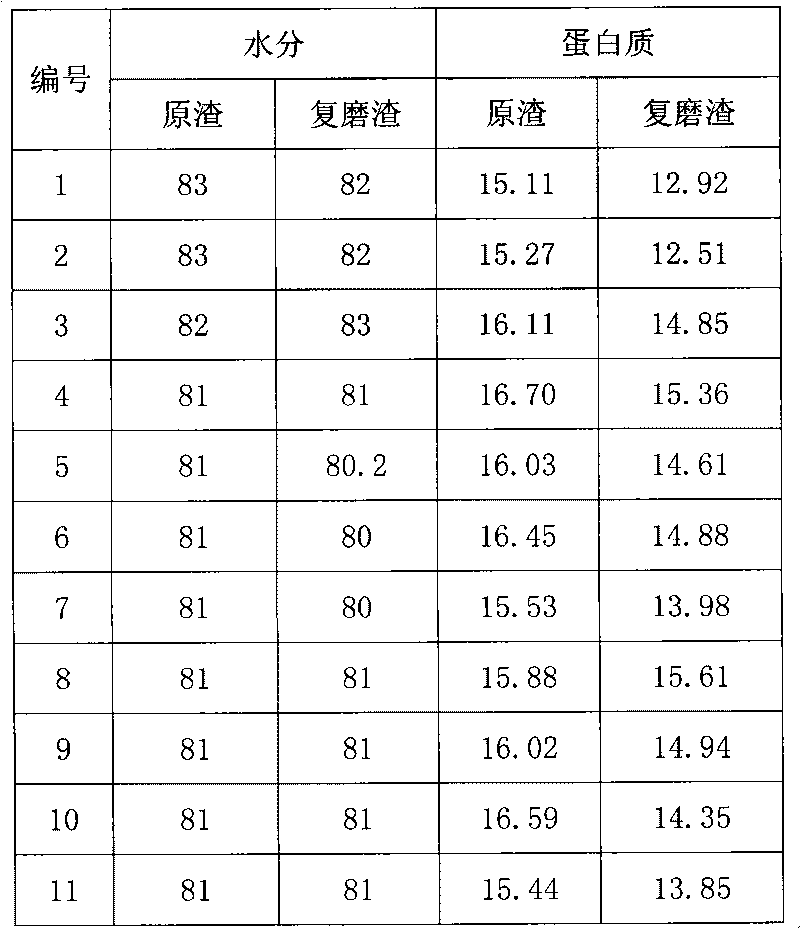

The invention discloses a process for preparing fermented bean curd, which comprises the following steps of: decontaminating soybeans; soaking the soybeans; grinding the soybeans; separating the soybeans; regrinding the soybeans; putting first soybean dregs obtained by the step C into a stirring pool; adding proper amount of three kinds of seriflux, and stirring the mixture into a paste; delivering the paste into a regrinder for regrinding; delivering the paste into a centrifuge for secondary centrifugation, and merging the milk and the first milk into fresh soybean milk; boiling the soybean milk; pointing the soybean milk; blanking; early fermenting; salting blanks; filling; later fermenting; and obtaining finished products. The process has the advantages of reducing residual protein in the bean dregs and having high product yield.

Owner:JIANGSU XINZHONG BREWING

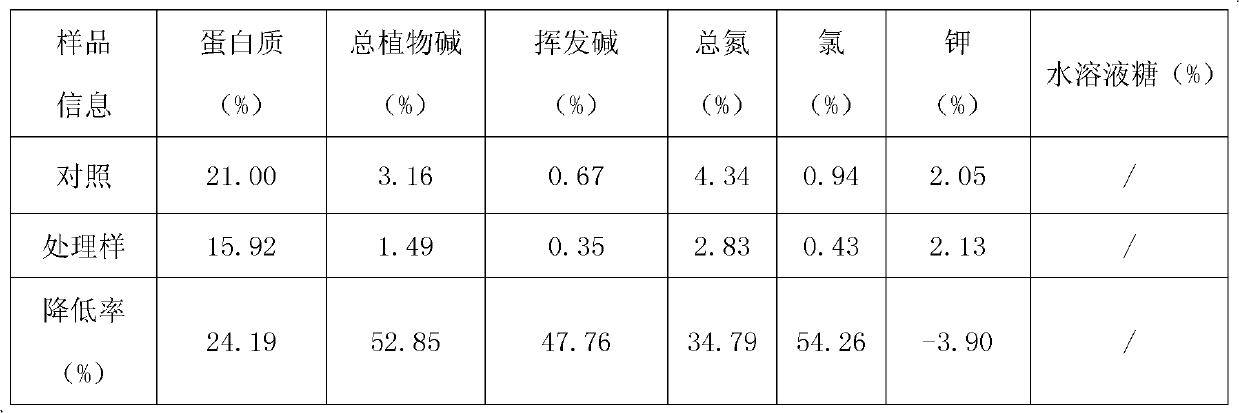

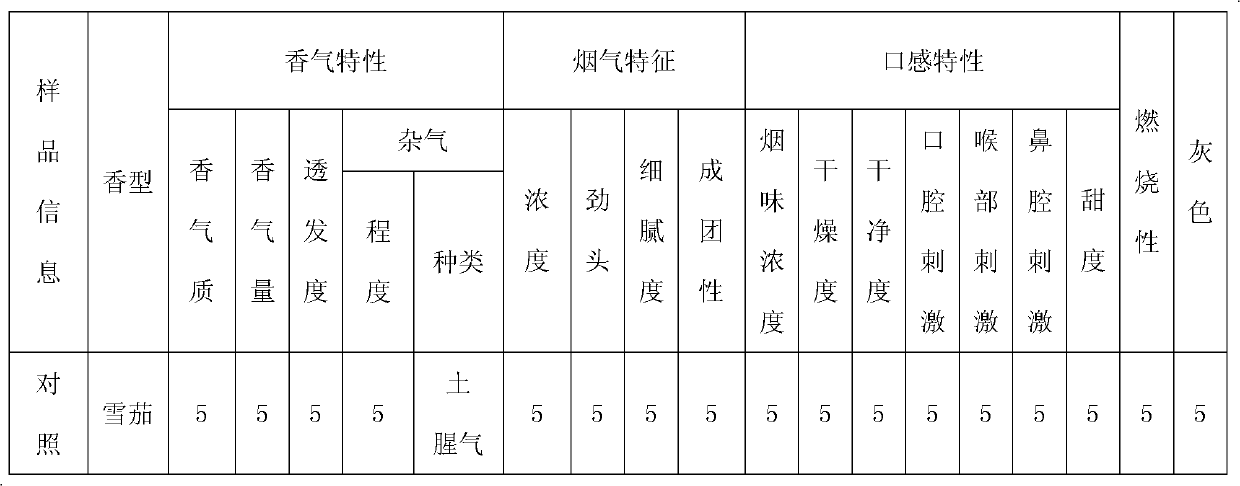

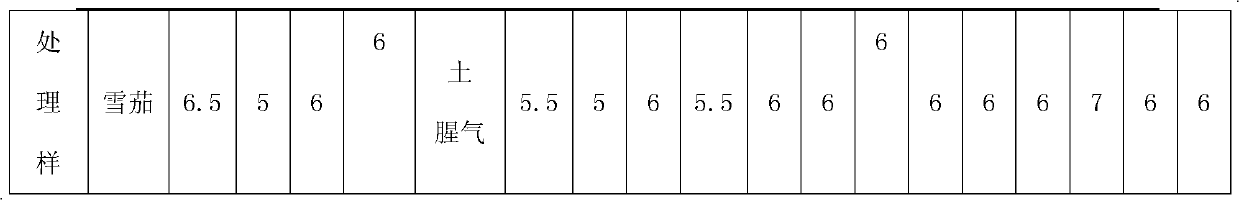

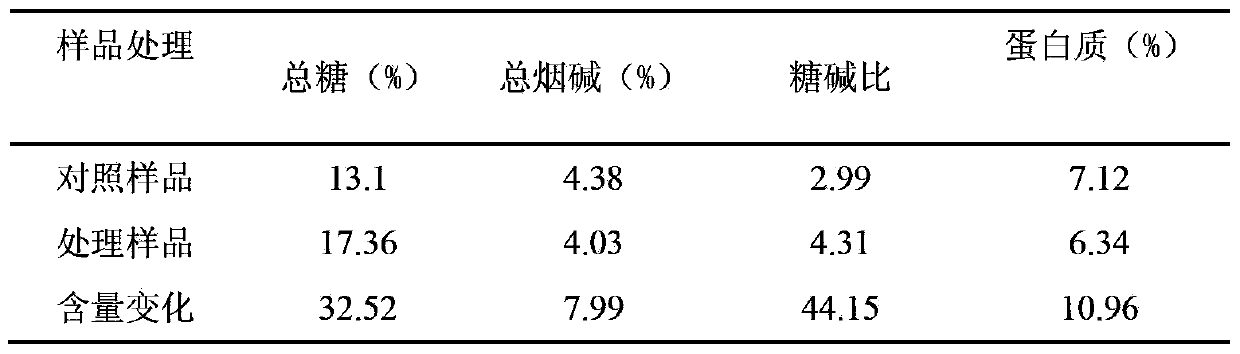

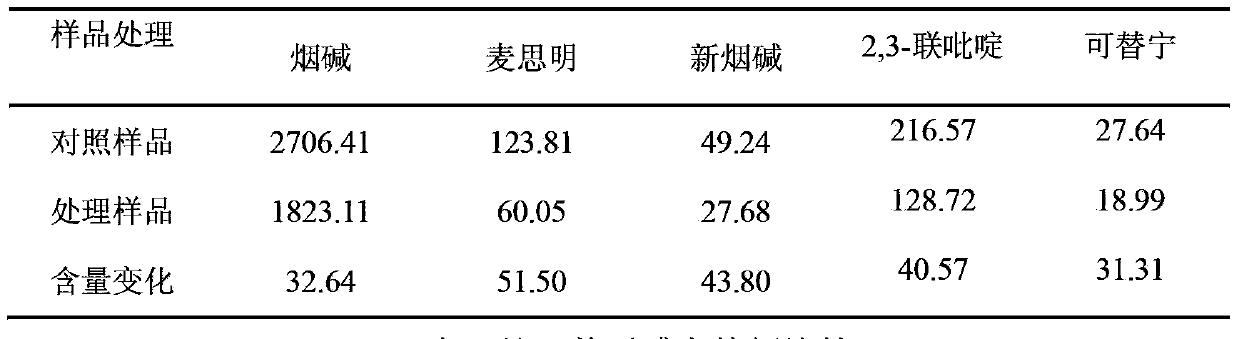

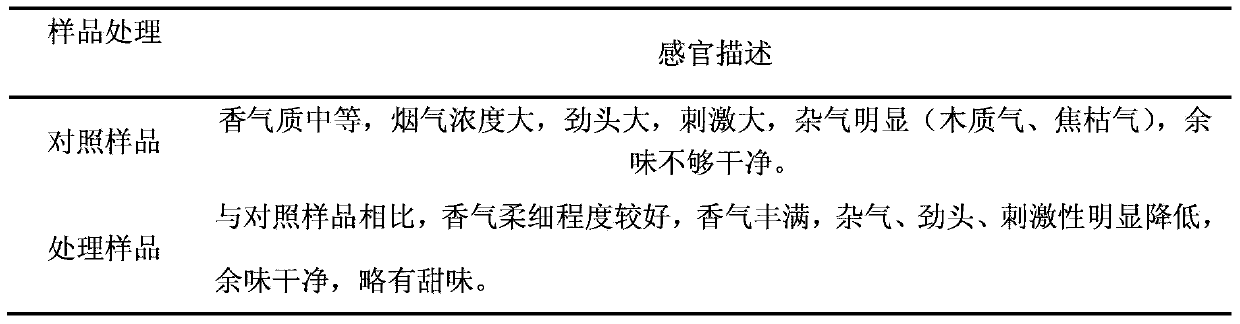

Method for reducing protein of cigar core leaves

ActiveCN102178344ALower protein contentReduce bitternessTobacco treatmentProtease preparationRepeatability

The invention relates to a method for reducing protein of cigar core leaves, in particular to a method for degrading the protein of core leaves by utilizing a protease preparation before the aired core leaves are produced by a formula to improve the quality of the core leaves. In the method, the core leaves which are watered for conditioning are fermented artificially by utilizing a combination preparation of one or more of proteases according to the optimum fermentation parameters, and are subjected to enzyme cutoff to obtain the core leaves of which the quality is improved. In the processed core leaves, the protein content is reduced, bitter and astringent tastes are reduced, the fragrant and sweet feeling is increased, the irritation is reduced, foreign flavors are removed substantially, and the agreeable aftertaste is improved. The method adopts a simple process, has high repeatability and is low in cost.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

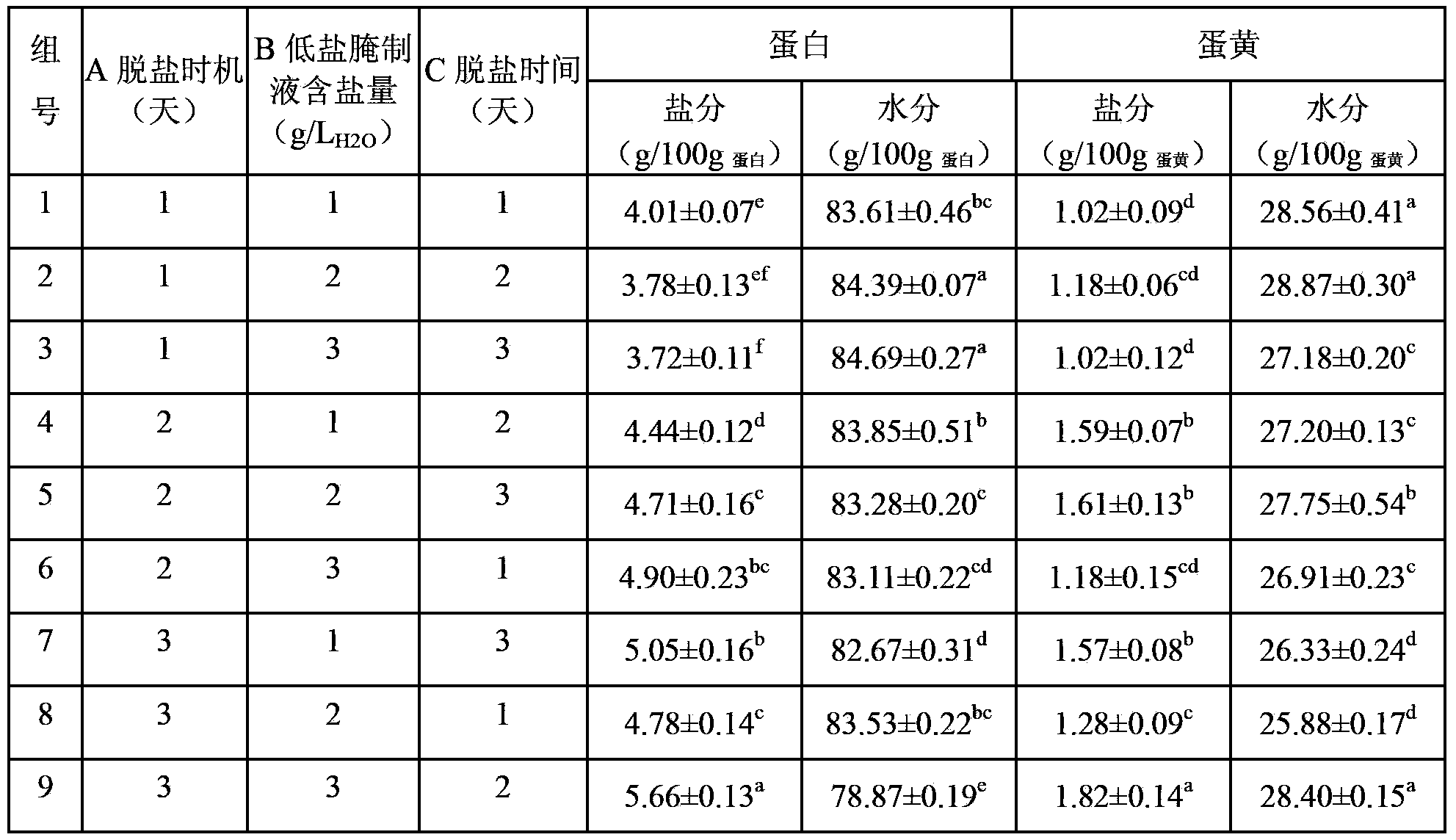

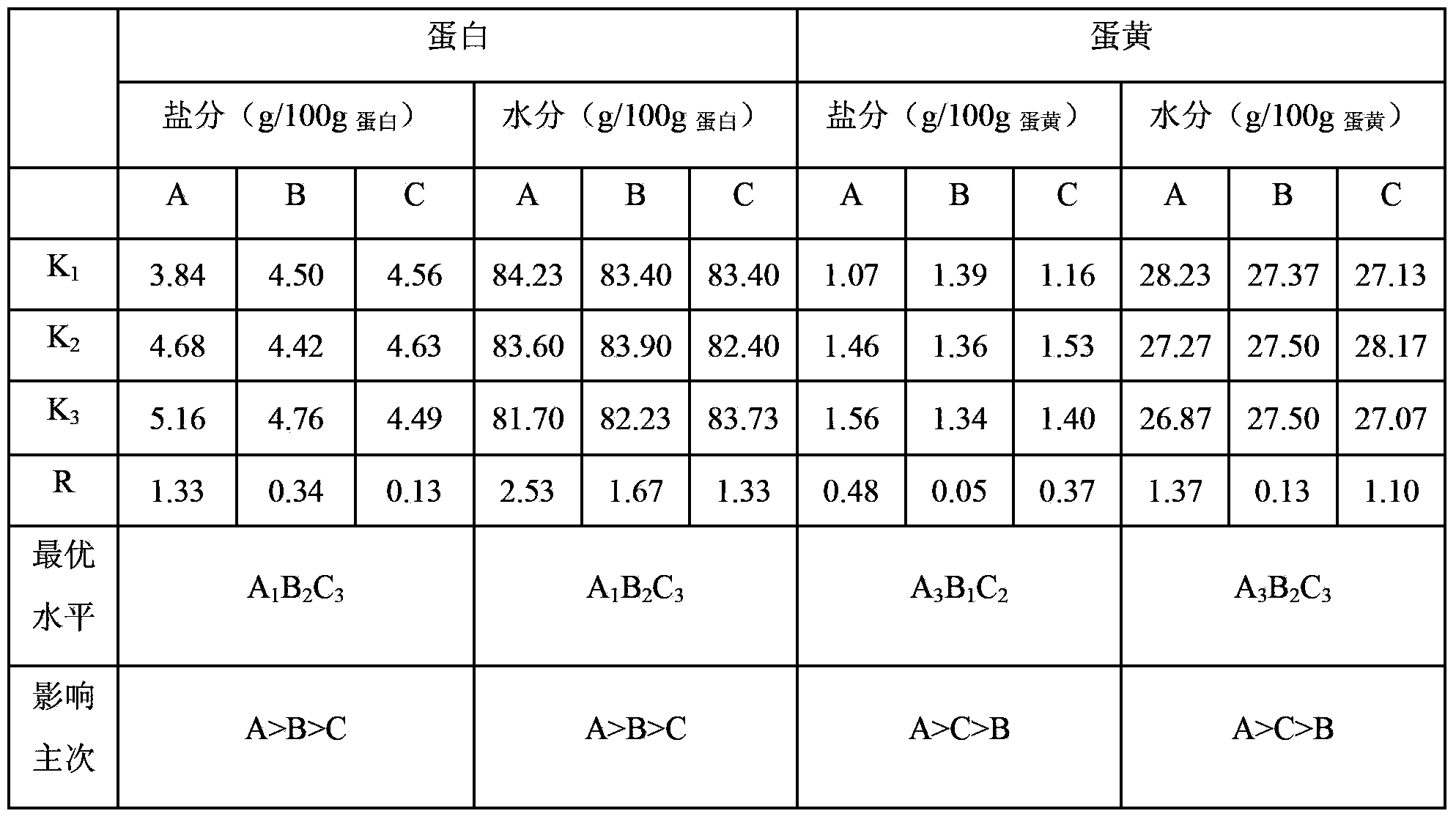

Low-salt salted duck egg dynamic sousing salinity regulation and control method

The invention relates to a low-salt salted duck egg dynamic sousing salinity regulation and control method and belongs to the technical field of deep processing of animal products. The method comprises the steps as follows: firstly, dynamically sousing egg stuff in a high-salt sousing liquid for 2-3 hours by cooperating ultrasound with bubbles; secondly, continuously dynamically sousing the egg stuff in the high-slat sousing liquid under the condition of bubbling of a gas pump for 25-35 days; lastly, transferring the egg stuff to a low-salt sousing liquid for dynamic sousing under the condition of bubbling for 4.5-13.5 days, taking out the egg stuff from a tank, and cleaning, drying and packing the egg stuff to obtain the finished product. According to the invention, salt in the sousing liquid can be uniformly distributed by cooperating the ultrasound with the bubbles for dynamic souring; with the adoption of bubbling dynamic souring, the souring liquid and the egg stuff can be agitated, the salt more quickly infiltrates into egg whites and yolks from the sousing liquid, so as to shorten the processing cycle; the high-salt reverse infiltration of the egg whites can be achieved by adopting low-salt bubbling dynamic souring, the salinity of the egg whites of the finished product of the salted duck eggs is effectively lowered, and the moisture is improved, as a result, the product quality is improved, and a modern processing method for mass production of low-salt salted duck eggs is supplied.

Owner:NANJING AGRICULTURAL UNIVERSITY

High-fiber high-protein noodles for diabetics and people needing to control body weight

ActiveCN104431770ASave energyLower protein contentVitamin food ingredientsFood ingredient functionsBiotechnologyLow glucose

The invention relates to high-fiber high-protein noodles for diabetics and people needing to control body weight. The high-fiber high-protein noodles are made from the following raw materials in parts by weight: 0-10 parts of tartary buckwheat flour, 0-20 parts of oat flour, 18-70 parts of wheat flour, 0-15 parts of whole wheat flour, 2-15 parts of puerarin powder, 0-6 parts of Chinese yam flour, 0-8 parts of ultra-fine black rice flour, 5-15 parts of wheat protein, 0-10 parts of soybean protein, 0-10 parts of whey protein, 0-10 parts of dietary fiber and 0-0.55 part of vitamins and microelements. The noodles can ensure that the diabetics and overweight people fully ingest protein, dietary fiber and vitamin B to maintain normal nutrient requirements under the condition of controlling energy intake, and is popular food which has low energy, high fiber, high protein and low glycemic index and can be eaten as staple food.

Owner:蒋博

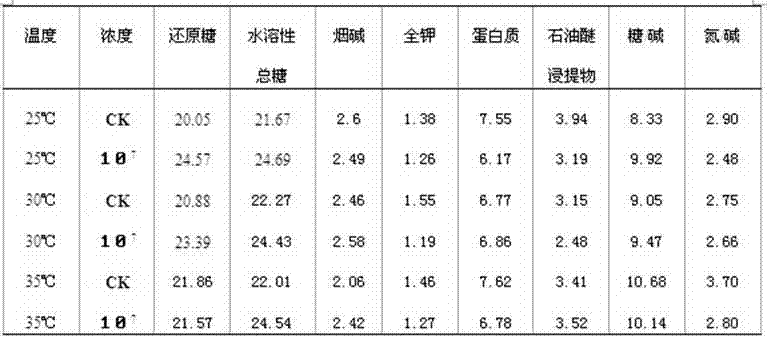

Early-flue-cured tobacco quality improving method with eurotium cristatum

The invention discloses an early-flue-cured tobacco quality improving method with eurotium cristatum. The method comprises the steps that (1) the eurotium cristatum is cultured in an activation mode; (2) conidium bacterial colony culturing is carried out, a conidium bacterial colony culture medium is prepared and is formed into a flat plate, bacterial colonies of bacterial strain slopes from the step (1) are planted on the flat plate in a point mode and are cultured for 5-7 days in an inverting mode until the bacterial colonies overgrow on the flat plate; (3) spore suspension is prepared, conidium generated according to the step (2) is inoculated and is washed off with asepsis water and then is prepared to be the spore suspension which is used as inoculant to be evenly sprayed on early-flue-cured tobacco. When processing conditions are that culturing temperature is 30 DEG C and spore concentration is 106 and 107, aroma of the early-flue-cured tobacco becomes good, impurity odor and irritation are relieved, smoke sweet feeling is improved and is fine, pure and mild, after taste is pure and comfortable, nicotine is lowered, and whole tobacco quality is improved.

Owner:GUIZHOU UNIV +1

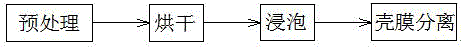

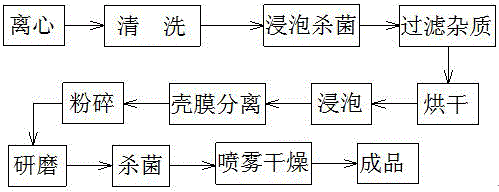

Method and device for processing egg shell meal

The invention discloses a simple and economical method for separating a shell and a membrane so as to further obtain high-purity egg shell meal and the membrane, and a processing device. The method for processing the egg shell meal comprises the following steps of: removing residue egg liquid and impurities in the egg shell, drying and soaking the egg shell, and separating the shell with the membrane. The processing device comprises a drying device, a soaking device, a shell and the membrane separation device, a membrane collector, a shell collector and a circulation loop. Compared with the prior art, the method and the device enable the purity of the separated egg shell meal and membrane to be higher and the membrane to be more complete, and are lower in production cost.

Owner:北京二商健力食品科技有限公司

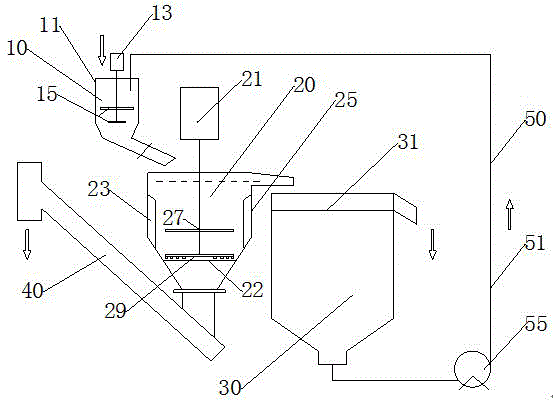

Bletilla striata polysaccharide extract and preparation method thereof

The invention relates to the field of pharmacy, and discloses a Bletilla striata polysaccharide extract and a preparation method thereof. The preparation method comprises the following steps: crushingand sieving a Bletilla striata medicinal material to prepare Bletilla striata powder; adding the Bletilla striata powder to water, and carrying out ultrasonic extraction, centrifuging and filtering to prepare Bletilla striata water extract; concentrating the Bletilla striata water extract, adding ethanol to precipitate, taking the obtained precipitate, and washing and drying the precipitate to obtain crude Bletilla striata polysaccharides; and adding distilled water to dissolve the crude Bletilla striata polysaccharides, centrifuging the obtained solution, taking the obtained supernatant, sequentially carrying out microfiltration and ultrafiltration, concentrating the filtered supernatant, precipitating the obtained concentrate with alcohol, and taking, washing and drying the obtained precipitate in order to obtain the Bletilla striata polysaccharide extract. The ultrasonic extraction process used to destroy cell walls of the Bletilla striata powder facilitates the full dissolving ofthe Bletilla striata polysaccharides, and microfiltration-ultrafiltration combined purification is carried out based on the preparation of the crude Bletilla striata polysaccharides through an ultrasonic water extraction and alcohol precipitation technology to prepare the Bletilla striata polysaccharide extract, so the method can effectively remove proteins, starch and other impurities, and the prepared Bletilla striata polysaccharide extract has a high purity and a low protein content, and is free from starch and inactive polysaccharides.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Fermented product based on an oat suspension

InactiveUS20040219261A1Low in proteinReduce fiber contentMilk preparationTea extractionProduct baseSoured cream

A fermented product selected from yogurt, yogurt drink, smothie, crème fraiche, sour cream, and spread is disclosed. The fermented product is based on an oat suspension essentially free from soy and dairy milk. Also disclosed is a process for preparing the product, and a starter culture useful in the process.

Owner:OATLY AB

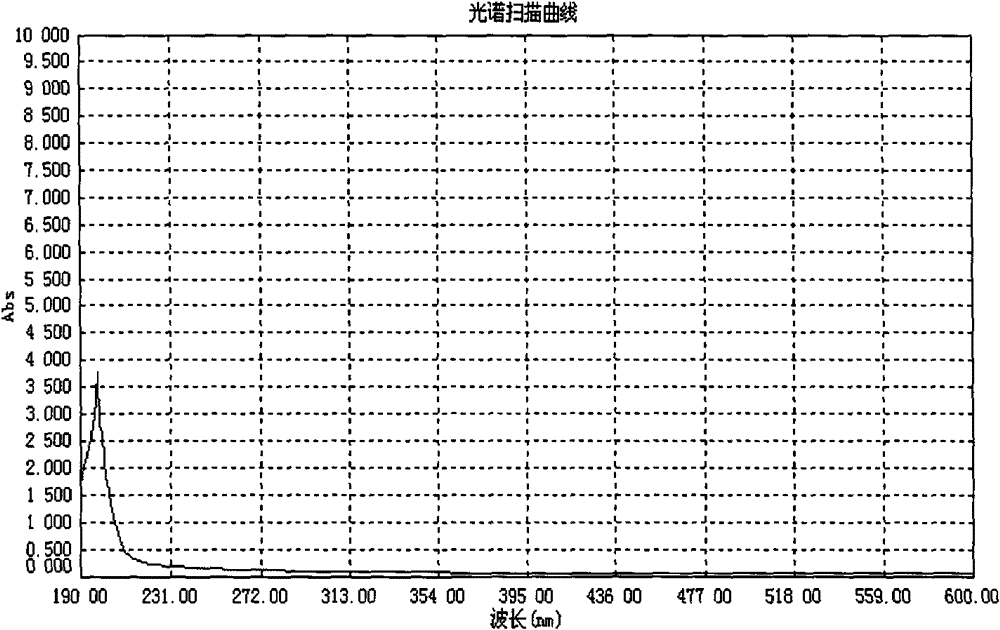

Preparing method of cocoa powder spice and application thereof

ActiveCN104804872ALower protein contentRich aromaTobacco preparationEssential-oils/perfumesFlavorCocoa Powders

The invention discloses a preparing method of cocoa powder spice. According to the method, biological compound enzymes are firstly used for carrying out biological fermentation processing on natural cocoa powder, then, fermentation liquid is used as a natural nitrogen source to take Maillard flavor enhancing reaction with a carbohydrate source, the cocoa powder spice with richer fragrance and higher flavor enhancing ingredient content is obtained, and the cocoa powder spice is applied to recombined tobacco leaves. Compared with the cocoa powder which is not subjected to enzymolysis fermentation and Maillard flavor enhancement, the cocoa powder has the advantages that the fragrance of the cigarettes is richer, the baking fragrance is enhanced, the smoke gas stimulation is reduced, and offensive odor is reduced, so that the smoking flavor defects of great stimulation and poor mouthfeel of the recombined tobacco leaves are overcome.

Owner:HUBEI CHINA TOBACCO IND

Quinoa protein concentrate, production and functionality

ActiveUS7563473B2Easy to useReduced activityCosmetic preparationsToilet preparationsFood gradeAdditive ingredient

The present invention relates to a new source of high quality plant protein, termed, “quinoa protein concentrate (QPC)”, which contains at least about 50 wt % protein which is food-grade and / or pharmaceutical-grade and methods of preparing such protein concentrates as well as starch, oil, and fiber from quinoa grain. The quinoa protein concentrate of the invention is useful as food ingredients, infant formula ingredients, cosmetic ingredients, pet food ingredients, and animal feed supplements.

Owner:COLORADO STATE UNIVERSITY

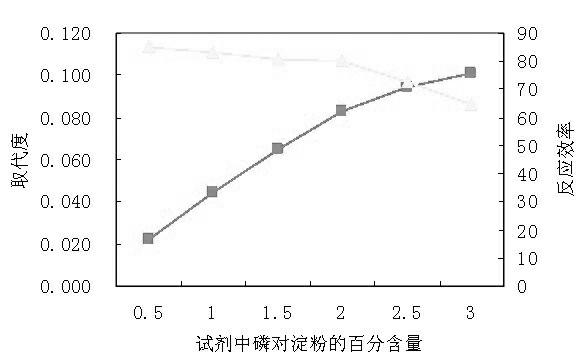

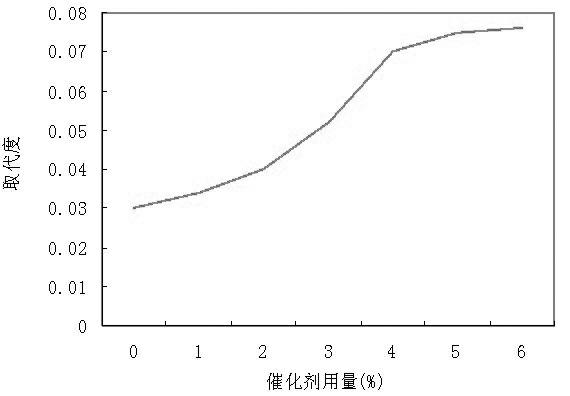

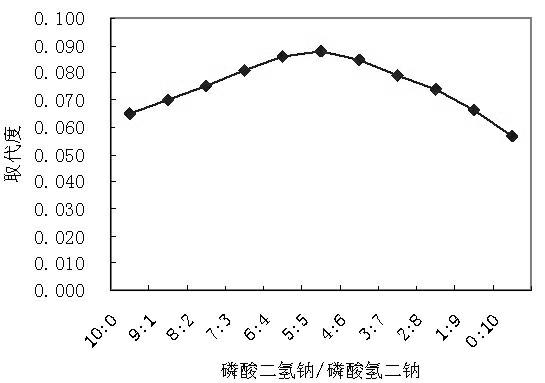

Phosphate starch printing paste and preparation method thereof

InactiveCN102154851AHigh viscosityGood viscosity stabilityDyeing processSODIUM METAPHOSPHATEPhosphoric Acid Esters

The invention discloses a phosphate starch printing paste and a preparation method thereof. Cassava starch is utilized to be reacted with sodium dihydrogen phosphate and sodium hydrogen phosphate in hot air, and urea is adopted as a catalyst to produce phosphate starch. The sodium dihydrogen phosphate and the sodium hydrogen phosphate generate micro sodium metaphosphate at high temperature, and the sodium metaphosphate is crosslinked with the starch, thus the viscosity of the starch is improved. Simultaneously, the urea is used as the catalyst and in esterification with the starch so as to generate hydrophilic carbamic acid ester starch. The phosphate starch produced by adopting the method can be dissolved in cold water; the paste is transparent and has clean color and luster; the sodium metaphosphate is corsslinked with the starch, thus the viscosity and the viscosity stability of the starch are improved, the PVI (polyvinyl isobutyl ether) value is increased, and the preparation method is more suitable for being applied to the printing paste.

Owner:JIANGXI BODA CHEM

Method for improving quality of tobacco leaves by adding enzyme preparation, glucose and citric acid

The invention provides a method for improving quality of tobacco leaves by adding enzyme preparation, glucose and citric acid and belongs to the field of tobacco processing. The method includes: spraying, by weight of that of treated tobacco leaves, 0.05%-0.1% of xylanase solution (pH=8.0) onto surfaces of the tobacco leaves prior to placing the tobacco leaves at the temperature ranging from 55 DEG C to 60 DEG C and the humidity of 50-60% in an enclosed environment for 4-10 hours; then spraying, by weight of that of the treated tobacco leaves, 0.1%-0.4% of acid protease solution (pH=3.5) onto the surfaces of the tobacco leaves and subjecting the tobacco leaves to stored-leaves enzymolysis for 3-6 hours at the temperature ranging from 20 DEG C to 30 DEG C and the humidity of 50-60%; adding, by weight of that of the treated tobacco leaves, 2.0%-4.0% of the glucose and 0.5%-1.0% of the citric acid for leaves storage for 5-8 hours in an environment at the temperature ranging from 20 DEG C to 30 DEG C and the humidity of 50-60%, drying the tobacco leaves for 3-10 minutes at the temperature ranging from 110 DEG C to 150 DEG C, and keeping flowing of air and turning of the tobacco leaves to further remove offensive odor and stimulus in the low-grade raw tobacco leaves; placing the well-treated tobacco leaves in an environment of a constant temperature and humidity chamber 22 DEG C in temperature and 60% in humidity for balancing for more than 48 hours till moisture content is equilibrium to 12%, and shredding prior to packing the tobacco leaves. By the method, tobacco smoke strength, the stimulus and the offensive odor can be lowered, pureness and mildness can be enhanced, and aroma can be harmonized.

Owner:CHINA TOBACCO GUANGXI IND

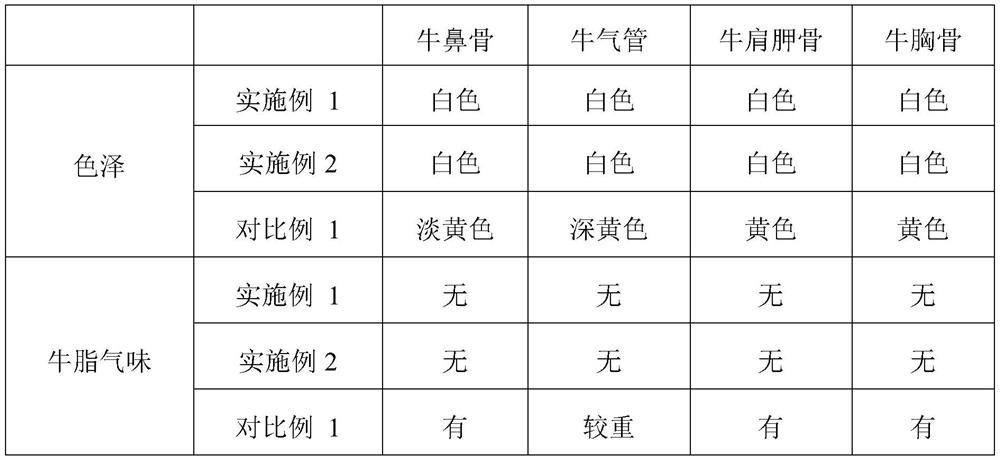

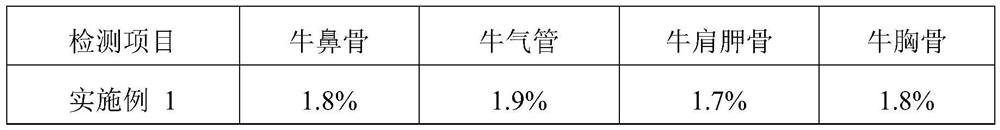

Process for improving quality and yield of collagen peptide coproduced from sodium chondroitin sulfate

PendingCN111793145AHigh extraction process requirementsReduce dosageConnective tissue peptidesPeptide preparation methodsUltrafiltrationIon exchange

A process for improving quality and yield of collagen peptide coproduced from sodium chondroitin sulfate comprises the following steps: (1) degreasing bovine cartilage by supercritical / subcritical extraction; (2) hydrolyzing, flocculating and separating endonuclease; (3) carrying out ultrafiltration to separate chondroitin sulfate sodium and collagen peptide; (4) refining the sodium chondroitin sulfate; and (5) refining the collagen peptide. The process is used for extracting the dried bovine cartilage chondroitin sulfate sodium and collagen peptide, meanwhile, the product yield and quality are improved, and the obtained product is white in color and luster and free of beef tallow smell. According to the process, the dried bovine bones are adopted, so that the problems that domestic bovinefeeding and slaughtering are scattered, and fresh bovine cartilage is high in storage, collection and transportation cost and high in difficulty are solved; and the process is simple in technologicalprocess, easy to filter, short in production time, capable of saving energy and reducing emission, low in production cost and remarkable in economic benefit and social benefit, and processes such asresin decoloration and ion exchange are not needed.

Owner:HUNAN WUXING BIOLOGICAL TECH CO LTD

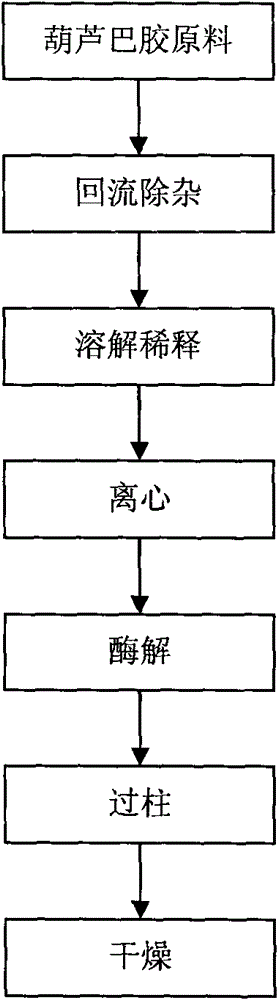

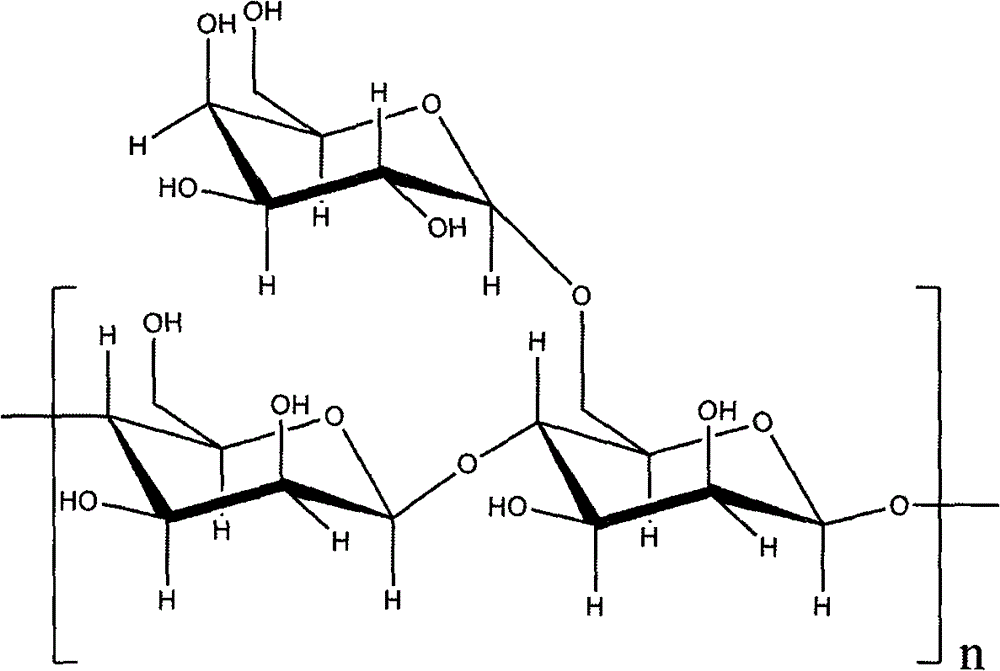

Method for preparing high-content fenugreek gum

The invention relates to a method of preparing high-content fenugreek gum from industrial grade fenugreek gum. The method is characterized in that through reflux purification, high speed centrifugation, enzymolysis, resin adsorption and drying, the high-content fenugreek gum which has a pure white color, no taste and no smell, is a transparent solution and has mannogalactan content great than or equal to 95%, protein content less than or equal to 1.0% and viscosity great than or equal to 5600mPaS is obtained.

Owner:CHENGDU WAGOTT PHARMA

Method for treating waste water containing sericin protein

InactiveCN101182062ALower protein contentLow costWater contaminantsWater/sewage treatment by flocculation/precipitationSocial benefitsChemical oxygen demand

The invention discloses a treatment method for wastewater containing sericin, which utilizes sericin itself to undergo a coordination reaction with metals to synthesize a sericin metal complex, and uses the complex as a flocculant to agglomerate and precipitate silk factory wastewater sericin, so as to effectively treat the wastewater, and finally recover the sericin protein at low cost by dilute acid washing. The method not only solves the environmental pollution problem caused by the high chemical oxygen demand of the waste water, but also effectively protects the water quality; at the same time, it realizes low-cost and effective recovery of the sericin in the waste water, turning waste into treasure. The development and implementation of this new process will bring not only good social benefits but also considerable economic benefits to silk enterprises in terms of wastewater treatment, so it has broad industrial application prospects.

Owner:重庆工学院

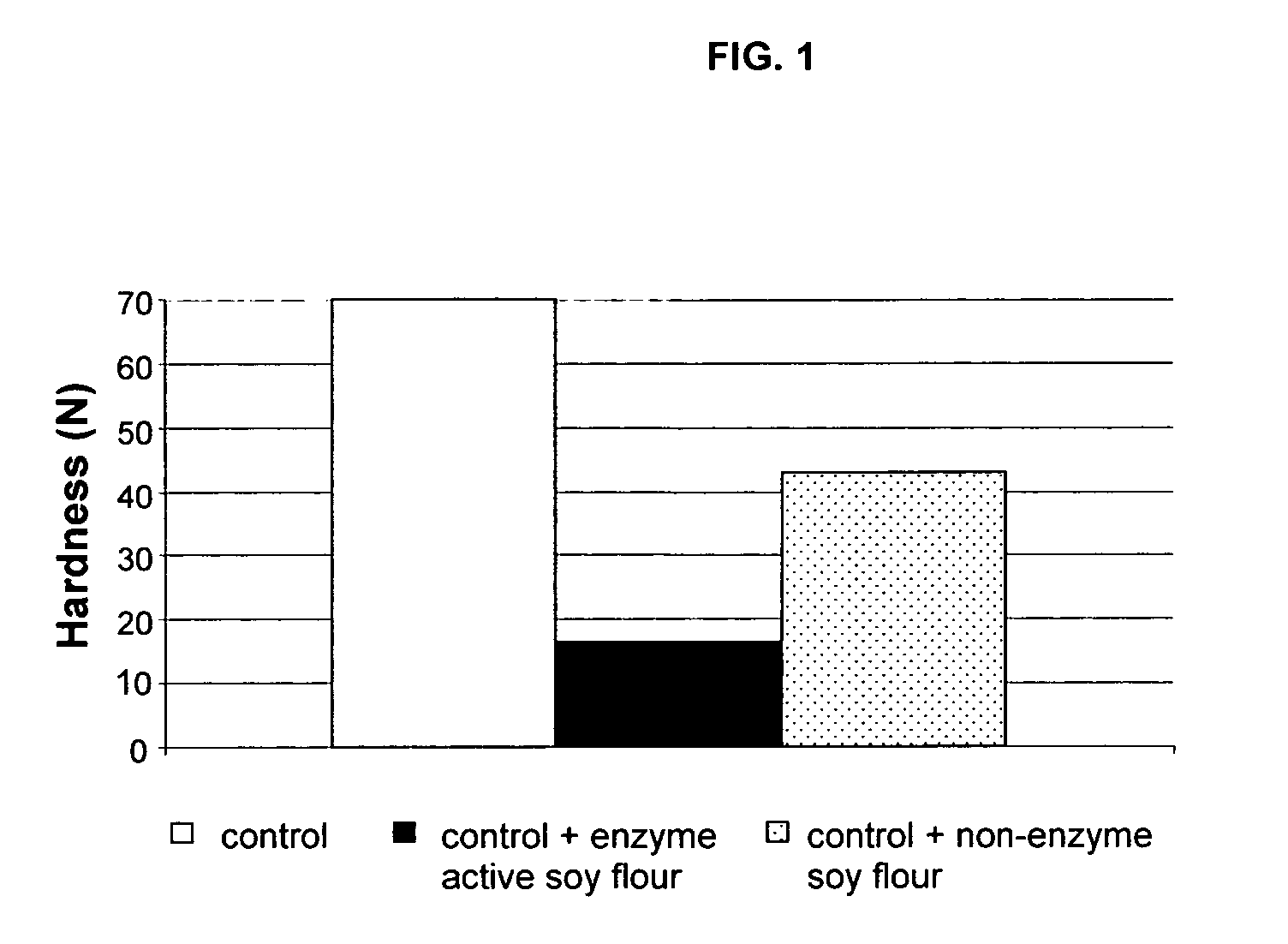

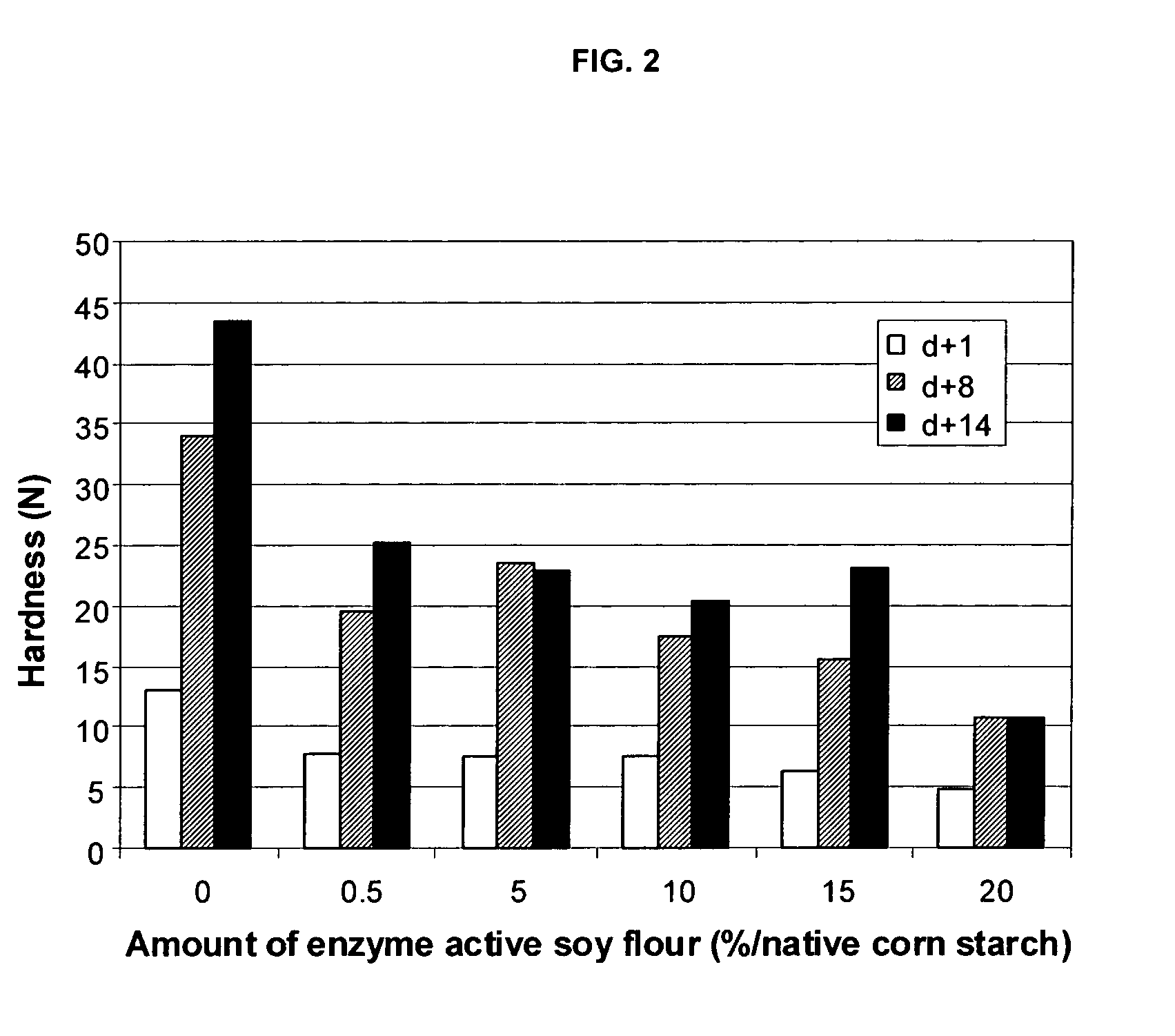

Composition for preparing improved gluten-free or gluten-reduced bakery products

InactiveUS20110117246A1Reduce hardnessOptimal level of useMilk preparationDough treatmentAdditive ingredientSoy flour

The present invention relates to a composition for preparing gluten-free or gluten-reduced bakery products, comprising enzyme active soy flour and at least one hydrocolloid, as well as a kit of a plurality of ingredients for preparing gluten-free or gluten-reduced bakery products, comprising said enzyme active soy flour and said at least one hydrocolloid. The present invention further relates to a dough comprising said composition, and to a gluten-free or gluten-reduced bakery product, in particular bread or a bread product, produced using said composition. In addition, the present invention relates to the use of enzyme active soy flour or a combination of enzyme active soy flour and at least one hydrocolloid in the preparation of a gluten-free or gluten-reduced, preferably gluten-free, bakery product.

Owner:CARGILL INC

Low-protein feed for small broiler chicken and preparation method thereof

The invention discloses a low-protein feed for small broiler chicken and a preparation method thereof. The protein content of the feed is 17.0 to 18.0 percent and is 20 percent lower than that of a common feed for the small broiler chicken, and the feed is suitable for the small broiler chicken at the age of 15 to 35 days. Common bean pulp and mixed meal are prepared into enzymolysis bean pulp and enzymolysis mixed meal by enzymolysis, so that anti-nutritional factors are reduced, small molecular polypeptide content and soluble protein content are increased, and digestion and absorption of nitrogen-derived nutritional substances are facilitated. By reducing the protein content, the cost of the feed is reduced, and excrement discharge and pollution of livestock are reduced; and by enzymolysis, digestion and absorption of proteins for the small broiler chicken are improved, the growth performance, the feed-meat ratio and the chicken quality of the small broiler chicken are ensured, and economic benefits are improved.

Owner:HENAN UNIV OF SCI & TECH

Imitation cheese compsns. and its prepn. method

An imitation cheese composition containing moisture, preferably in an amount that is as least 60 % by weight, a hydrocolloid, a cheese-derived component in an amount less than about 15 % by weight of the composition, cheese flavoring that is natural or artificial and an acidulents in an amount that causes a pH of the composition to be not greater than 4.6. The composition is sufficiently firm such that it can be at least one of sliced, cut, shredded or grated. Preferably, no more than 1 % protein is present, and / or the acidulent is in a total titrateable amount of less than 1.5 % by weight of the composition, resulting in an imitation cheese having a flavor, texture and consistency that was only previously attainable in a pasturized process cheese product.

Owner:AFP ADVANCED FOOD PROD LLC

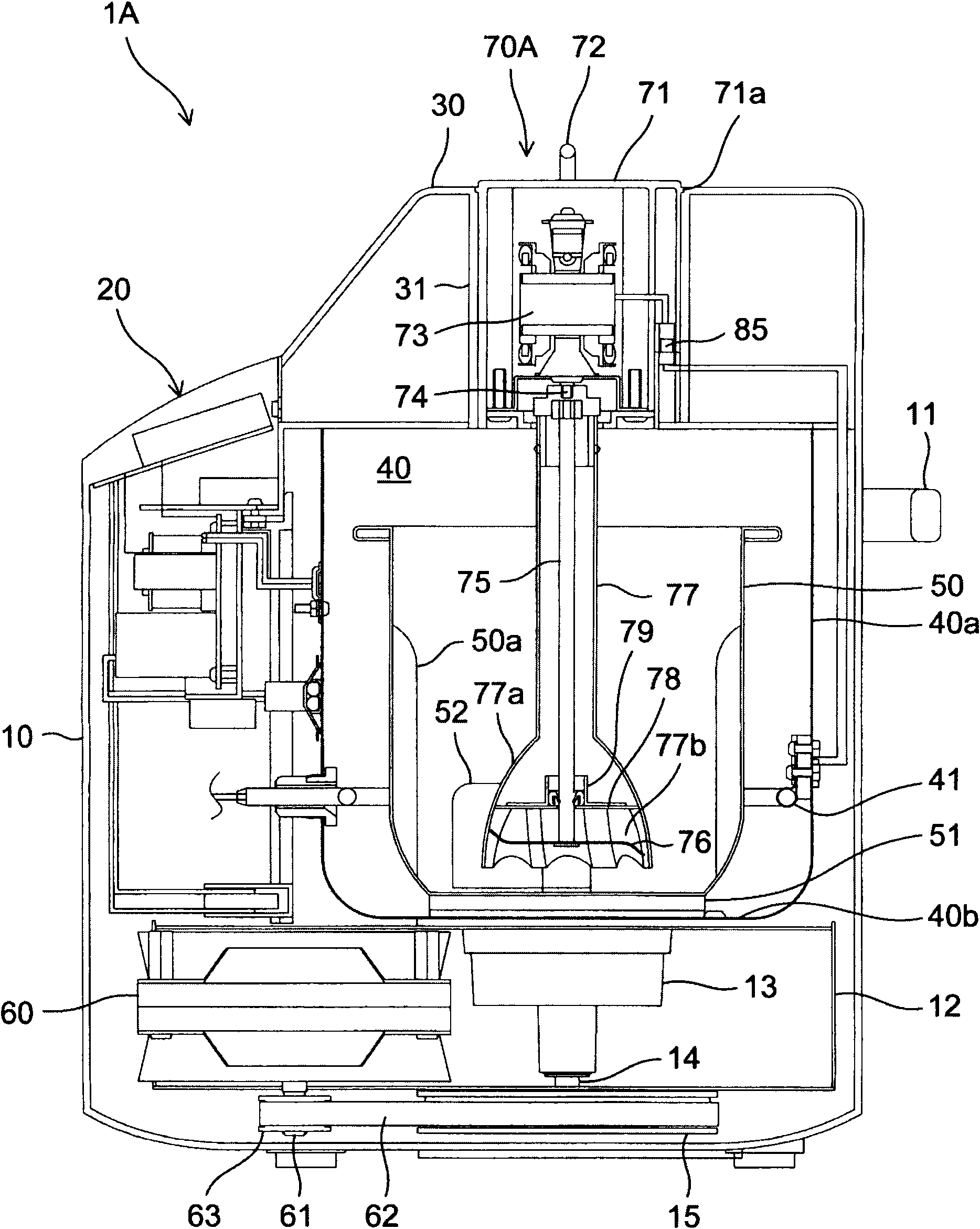

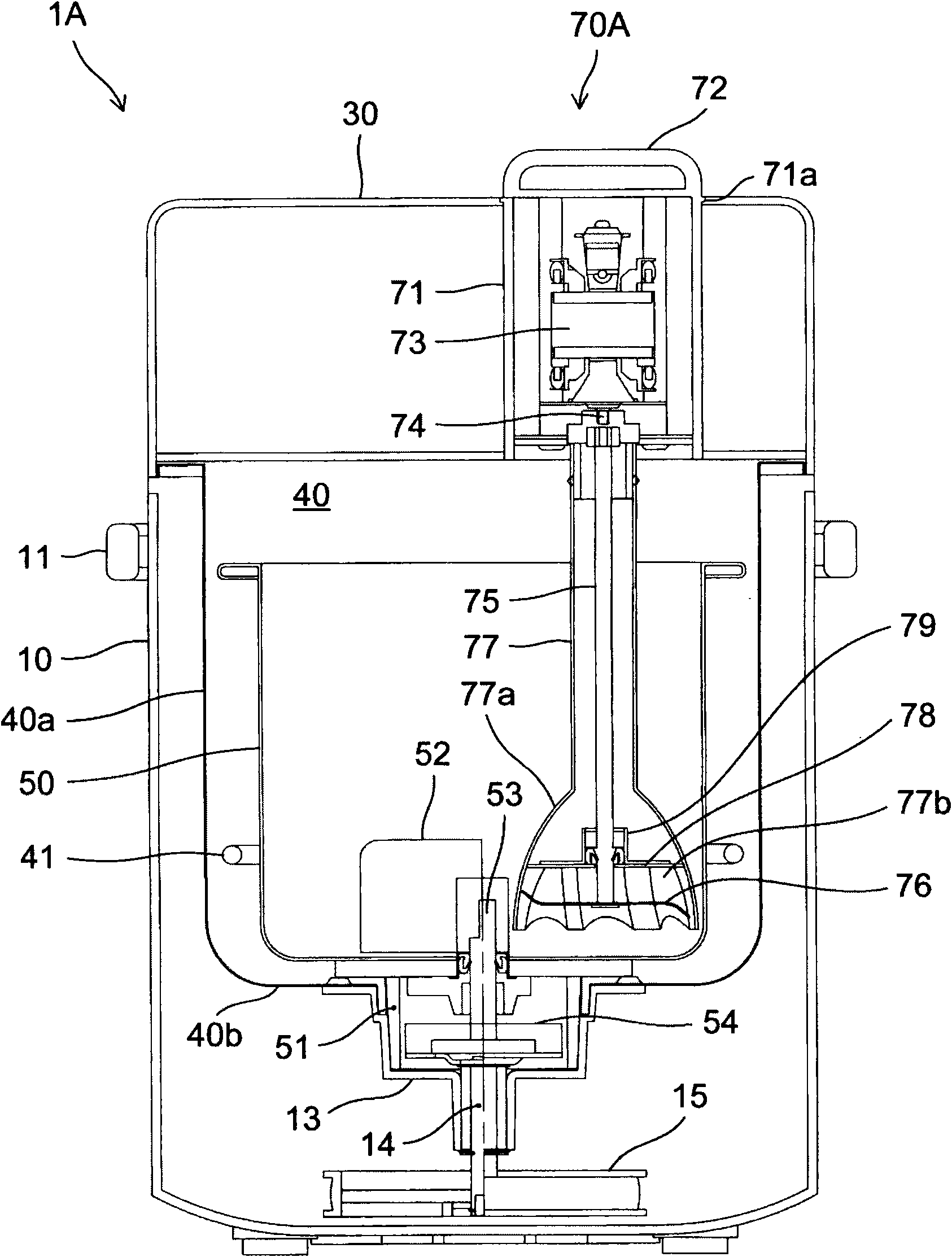

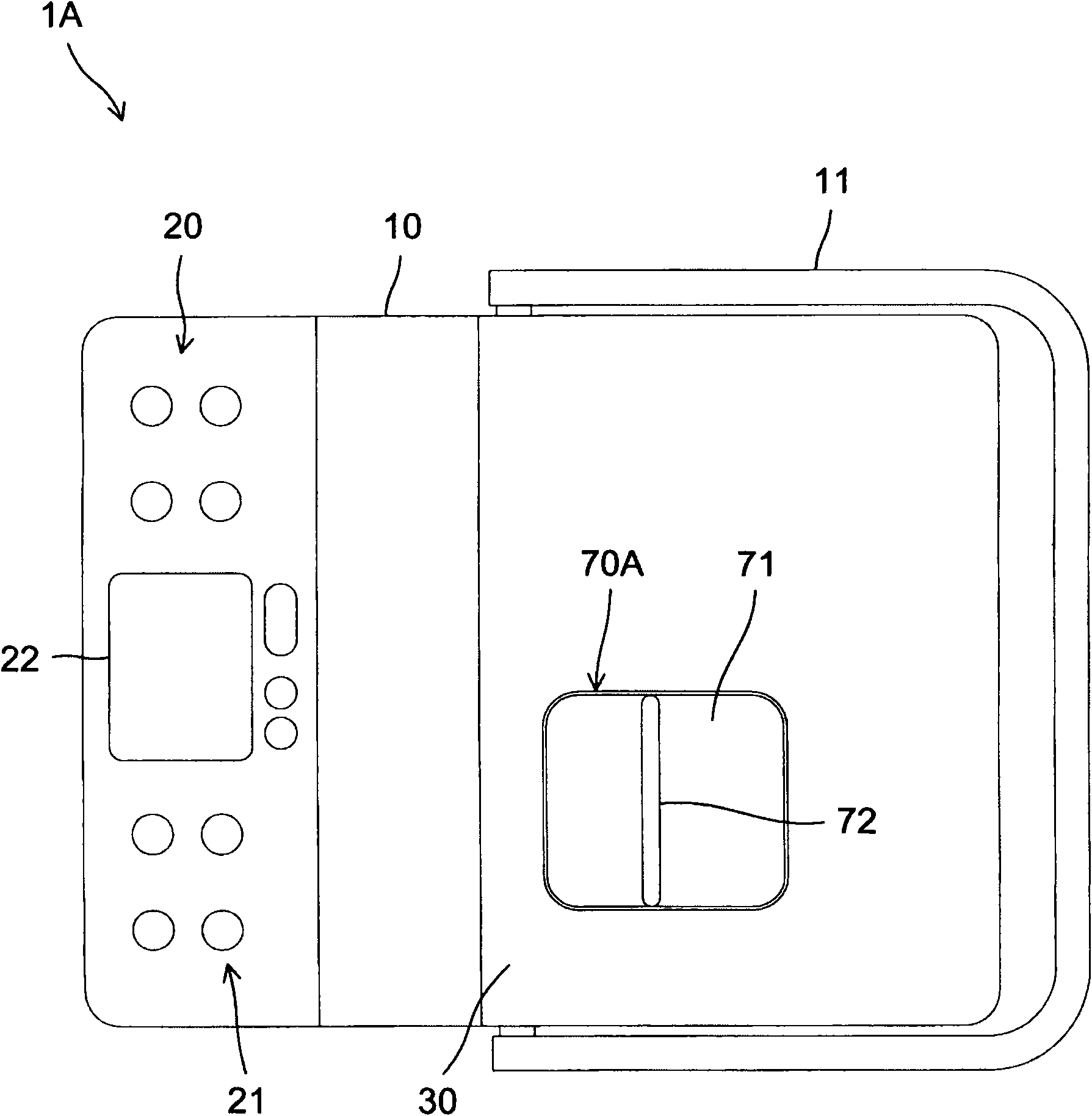

Automatic bread machine

InactiveCN102028008AReduces the risk of mixing into bread doughNo lossBakery productsKitchen equipmentEngineeringFermentation

Provided is an automatic bread maker which sequentially performs a mixing / kneading process, a fermentation process, and a baking process, the automatic bread maker including: a bread container used for accommodating breadmaking materials; a baking chamber which is provided inside a body and receives the bread container; a grinding blade which is capable of being put in and taken out of the bread container in the baking chamber; and a grinding motor provided for rotating the grinding blade.

Owner:SANYO ELECTRIC CO LTD +1

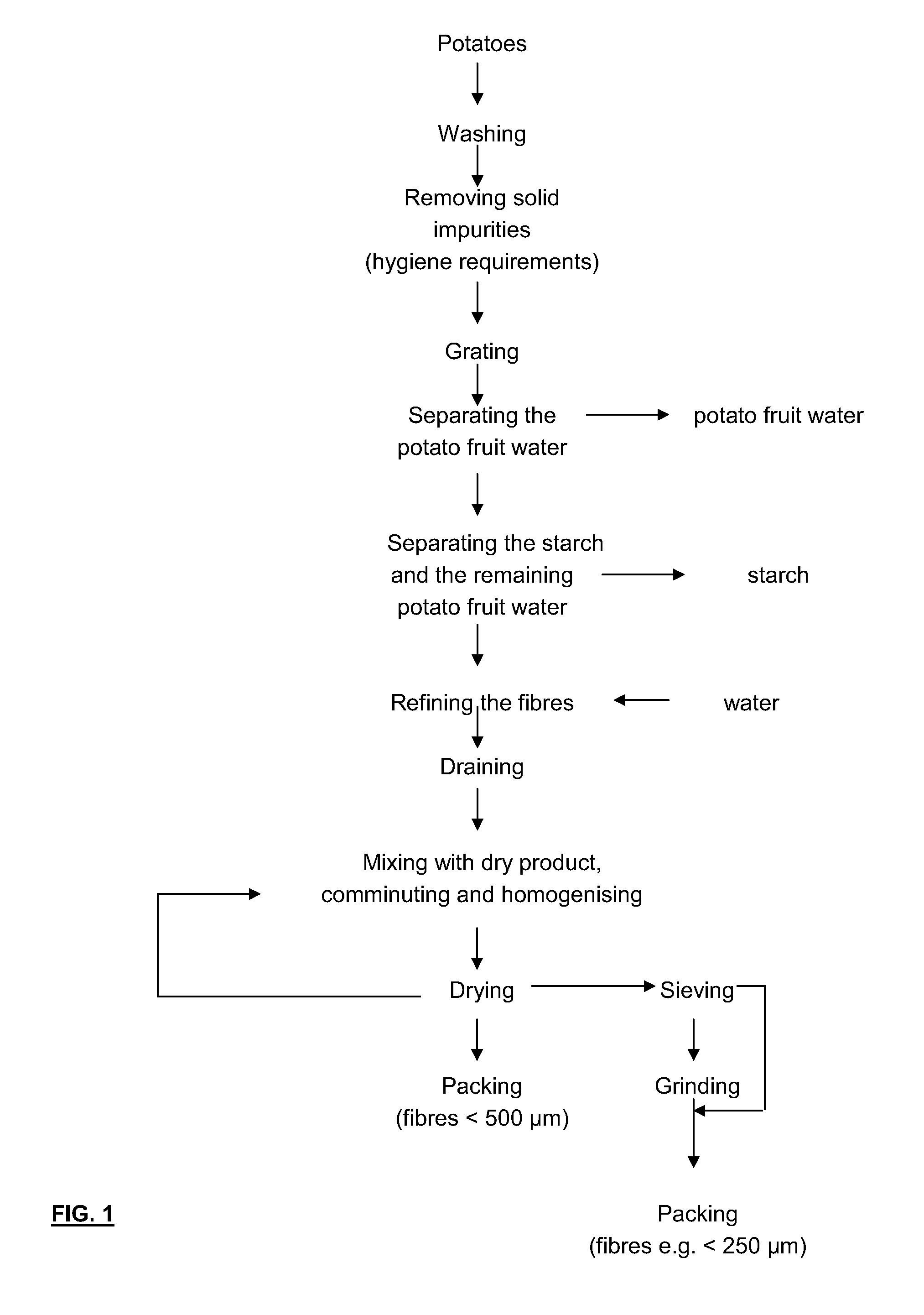

Potato Fibres, Methods of Preparing Them and Their Use

A method of preparing potato fibres includes the steps of: a) washing potatoes; b) optionally removing solid impurities and rinsing water adhering to the potatoes; c) grinding the potatoes into a pulp; d) separating potato fruit water; e) removing starch and optionally residual potato fruit water in order to obtain raw fibres; f) refining the raw fibres; g) mixing in potato fibres which have previously been dried; and h) drying the fibres; as well as potato fibres obtainable by that method and use thereof.

Owner:EMSLAND STARKE GMBH

Mixed fodder

InactiveCN1934984AImprove conversion rateReasonable proportionFood processingAnimal feeding stuffFeed conversion ratioAntioxidant

The present invention relates to a mixed animal feed. Its composition includes (by wt%) 14-60% of conventional protein feed raw material, 5-80% of non-conventional feed raw material, 1.2-4% of amino acid, 0.01-0.05% of antioxidant, 1-25% of fat, 0.01-5% of enzyme preparation and 0.05-0.3% of mould inhibitor.

Owner:周凤山

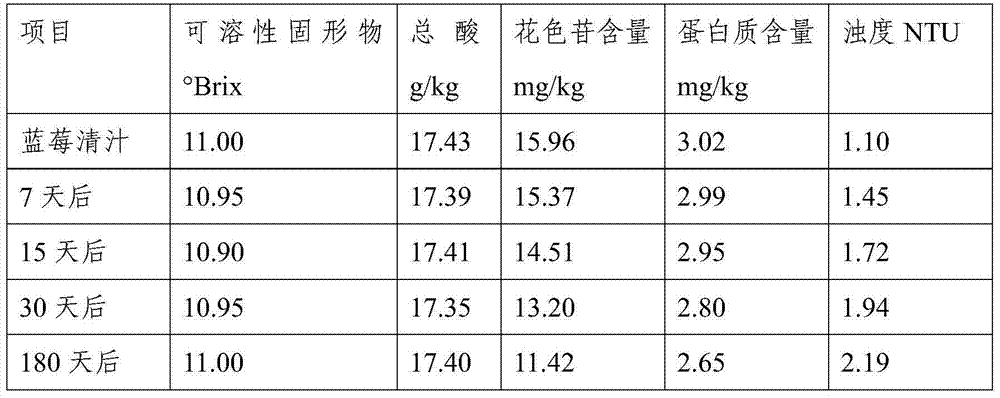

Processing method for preventing secondary muddying of wild blueberry clear juice

ActiveCN103750449AReduce solubilityPromote precipitationFood thermal treatmentFood ingredient functionsPectinaseVitamin C

The invention relates to a processing method for preventing secondary muddying of wild blueberry clear juice. The processing method comprises the following steps of adding vitamin C (VC) into pulped and broken fresh blueberries, adding pectinase to carry out enzymolysis, squeezing blueberry pulp, after being subjected to the enzymolysis, in a squeezing machine to obtain blueberry juice, carrying out high-temperature enzyme deactivation on the blueberry juice, adding the pectinase and amylase to carry out secondary enzymolysis, adding acid proteinase to carry out the enzymolysis, filtering by utilizing a diatomite filtering machine to obtain blueberry clear juice after the enzymolysis, preserving the blueberry clear juice at a low temperature after carrying out high-temperature sterilization on the blueberry clear juice, carrying out chill filtering by utilizing a paperboard filtering machine, and carrying out filling so as to obtain the blueberry clear juice product. According to the blueberry clear juice prepared by utilizing the processing method, a secondary muddying phenomenon of the blueberry clear juice is effectively avoided, and the appearance quality of the product is improved, the processing method is simple, the preparation cost is low, the taste of the product is good, the nutrition is rich, and the blueberry clear juice is beneficial to human bodies.

Owner:江苏伊云贝尔饮料股份有限公司

Fresh cassava dumpling wrappers and preparation method thereof

ActiveCN103859255AImprove flow and adhesionNutritional balanceFood ingredient functionsFood preparationMagnesiumFiber

The invention discloses fresh cassava dumpling wrappers and a preparation method thereof. The preparation method comprises the following steps: cleaning fresh cassava, completely removing the outer skin, and thoroughly steaming; breaking the thoroughly steamed cassava to obtain cassava granules; coldly extruding the cassava granules by using a double-screw bulking machine to obtain hot cassava dough; and finally immediately rolling the hot cassava dough to form round wrappers, namely the fresh cassava dumpling wrappers. The fresh cassava dumpling wrappers are rich in nutritional substances such as edible fibers, various vitamins, amino acids, calcium, potassium, phosphorus and magnesium, uniform in nutrition, high in viscosity, boiling-resistant and good in freezing-thawing stability, and have health effects of preventing obesity, relaxing the bowels and the like.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com