Patents

Literature

717 results about "Acid proteinase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

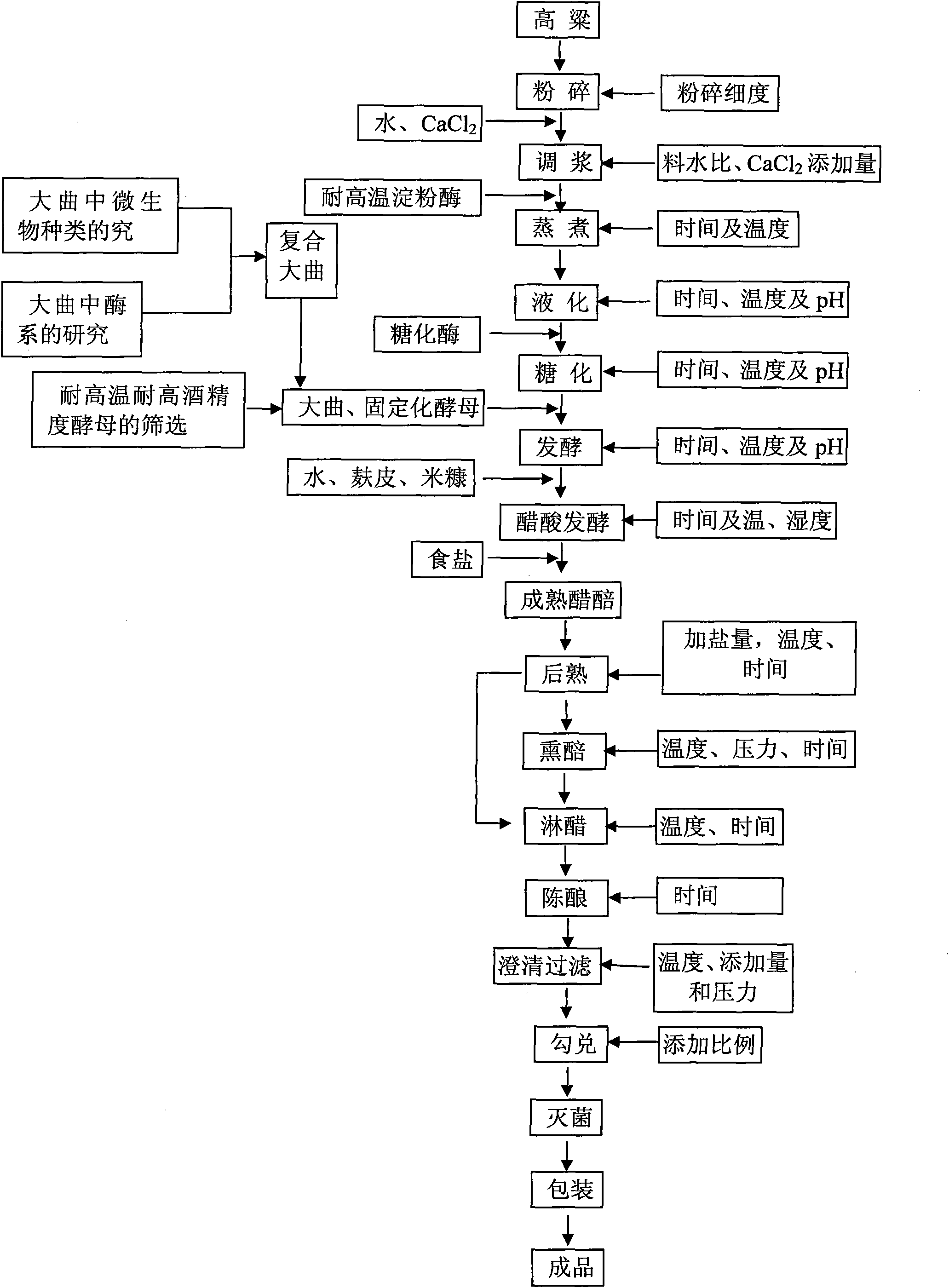

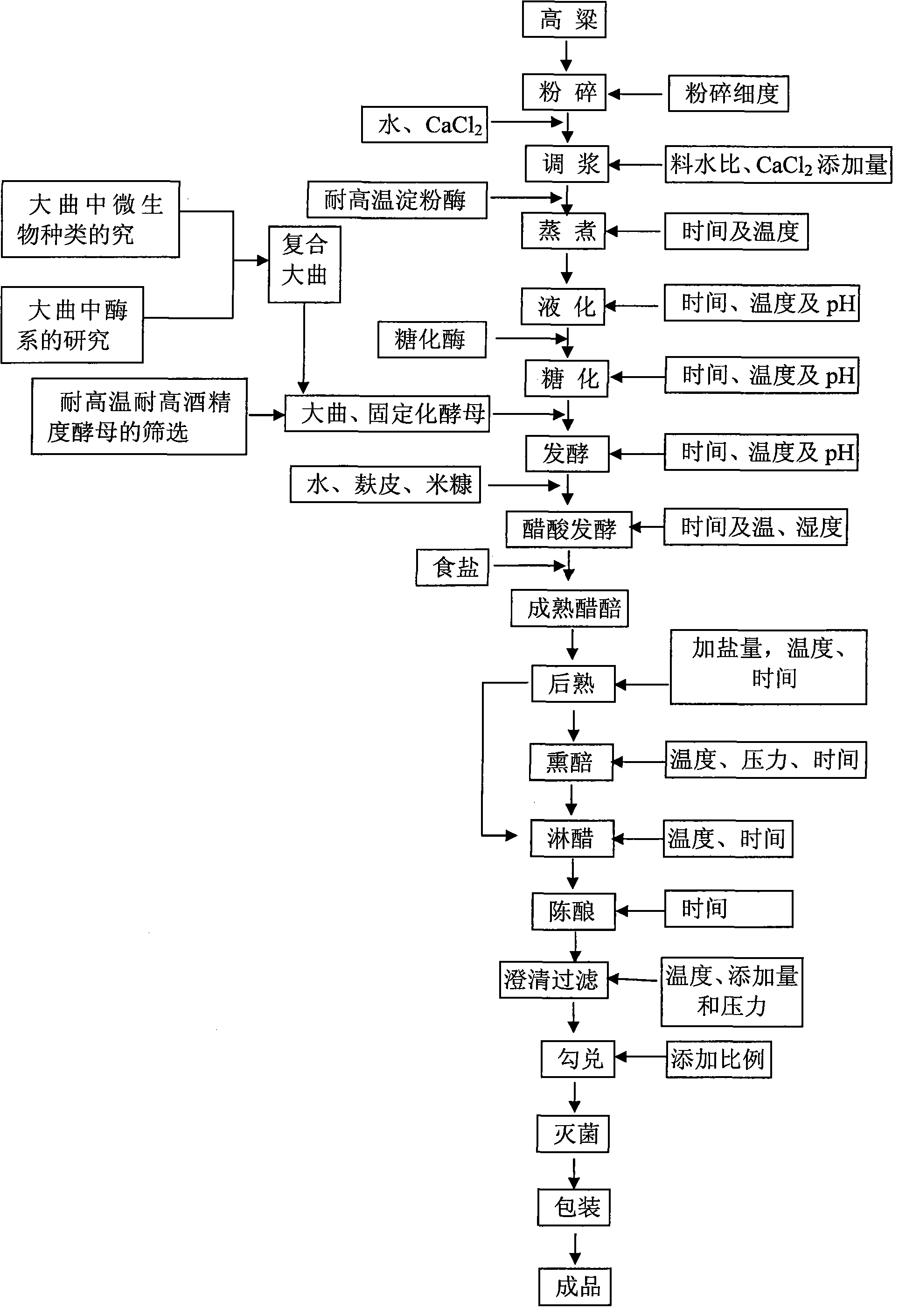

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

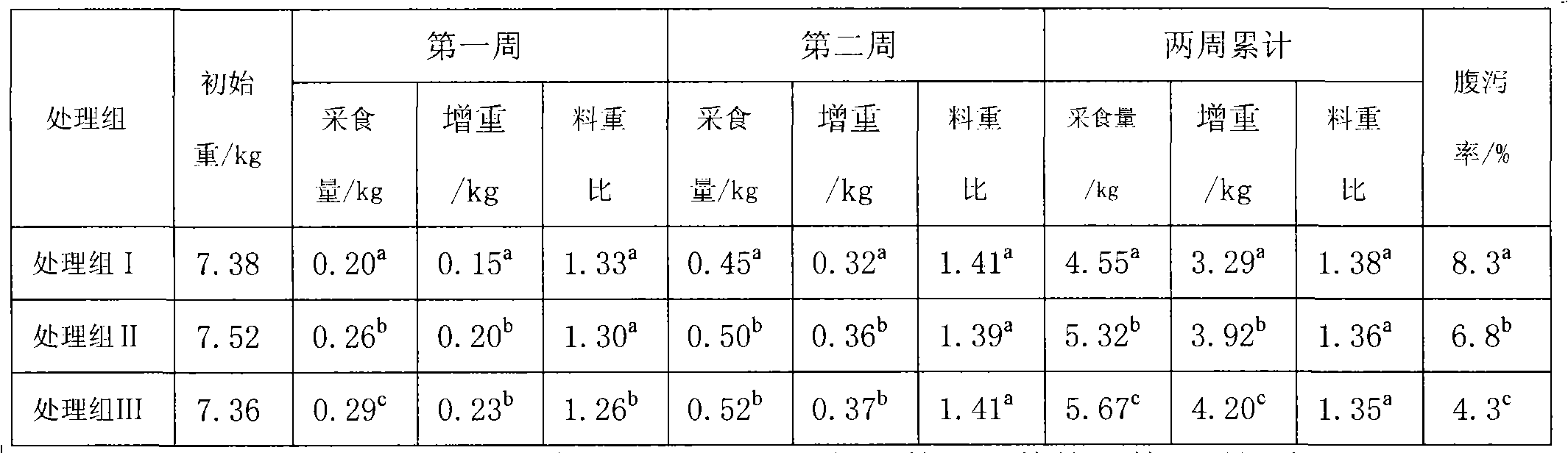

Complex enzyme preparation for feeding piglets

InactiveCN102119768AImprove metabolic energyReduce chyme viscosityAnimal feeding stuffAccessory food factorsPectinaseDisease

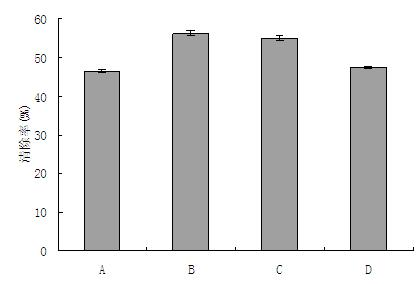

The invention discloses a complex enzyme preparation for feeding piglets. The complex enzyme preparation for feeding piglets comprises the following seven enzymes: acid protease, amylase, xylanase, beta-glucanase, cellulase, pectinase and phytase; and the enzymatic activity ratio of the seven enzymes is 1: 1: (8-10): (3.3-4): 1: (0.5-0.55): (0-0.02). By applying the complex enzyme preparation disclosed by the invention, various anti-nutritional factors in feed can be degraded, the viscosity of chyme in an intestinal tract can be reduced, and the metabolic energy of the feed can be improved; the protein and starch digestibility of the piglets can be improved; excessive reproduction of harmful microorganisms in the intestinal tract can be reduced, damage to the intestinal wall can be reduced, and the microecological balance of the intestinal tract can be regulated; the survival rate and disease resistance of the piglets can be improved, the diarrhea rate can be reduced, and the overall uniformity is improved; and the weight gaining of the piglets can be promoted, and the cultivation cost is reduced.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

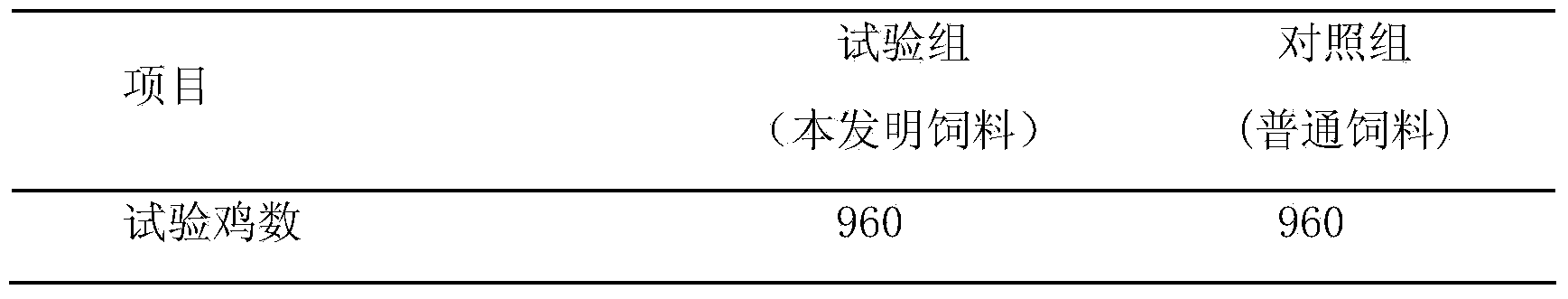

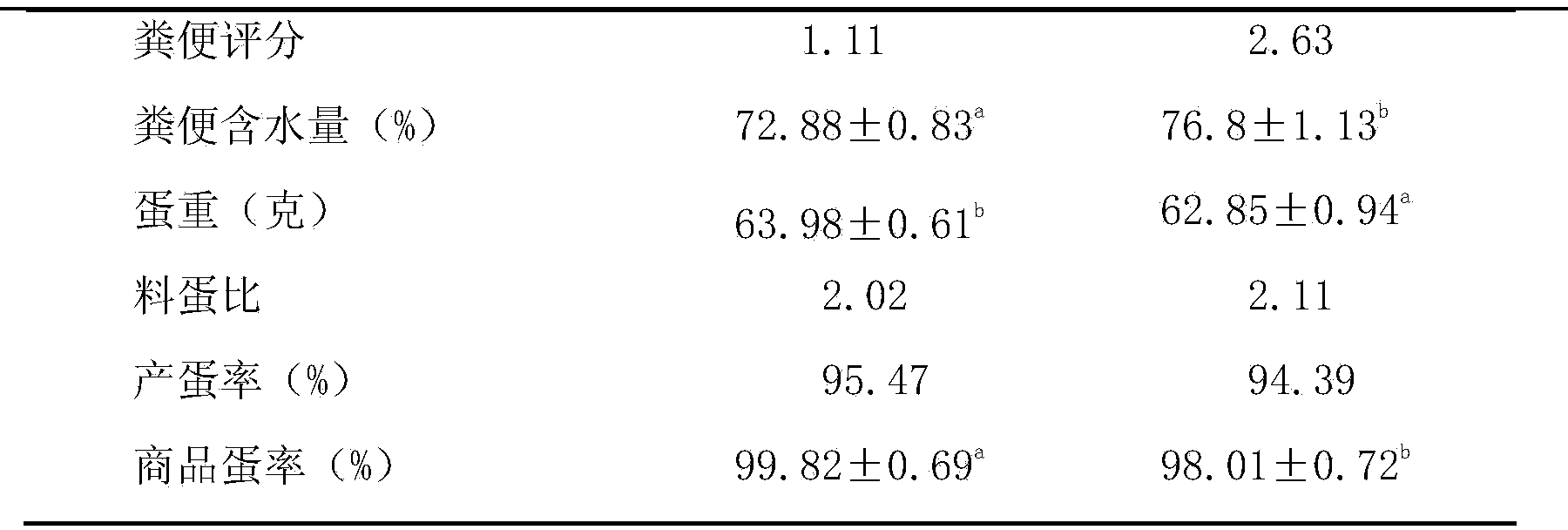

Laying hen composite premix

InactiveCN104106731AEffective pH adjustmentSoft textureFood processingAnimal feeding stuffFiberAnti nutrients

The invention discloses a laying hen composite premix, and belongs to the technical field of feed composition. A composite enzyme preparation containing beta-mannase, beta-glucanase, acidic proteinase, phytase, pectinase, and amylase is adopted to eliminate the anti-nutrient factors in soybean meal. Yeast cell wall type mycotoxin absorbent is used to effectively eliminate the hazardous factors that may affect the intestine health and are caused by using a large amount of corns. A stomach fortifying acid is used to effectively adjust the pH value of intestines. The used wood chips in the premix are soft and high in fiber content, do not hurt the intestines, do not pollute the environment, can effectively strengthen the digesting and absorbing abilities of laying hens, and have a stronger bearing and water-absorbing performance. The materials mentioned above are systematically and scientifically used to guarantee that the intestines of the laying hens be in the best state. The premix can improve the immunity and disease resistant performance of laying hens, and makes the laying hens exert the maximal laying ability. Moreover, the water content of manure is reduced, and the economic profit of farms that use the premix is prominently improved.

Owner:邵素英

Method for producing tobacco sheets by paper making method

ActiveCN101695407AIncrease the content of reaction intermediatesPromotes Maillard reactionTobacco preparationMaillard reactionPhosphate

The invention relates to a method for producing tobacco sheets by a paper making method, which is characterized by using acidic proteinase, pectase and amylase to carry out biological degradation on sheet materials, improving the content of Maillard reactants in a tobacco extraction liquid, utilizing Maillard reaction catalysts, namely phosphate, phosphate, dibasic alkaliine, dihydric phosphate, propanediol and the like, and regulating and controlling the condition of reaction medium, on-line promoting the Maillard reaction in a tobacco aqueous solution, and improving the content of Maillard reaction intermediates and products in concentrated solution. The method for producing the tobacco sheets by the paper making method can reduce acrimony and offensive taste of the sheets, coordinate smell, improve after taste and improve comfort level of sheet suction.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Compound enzyme preparation for fermentation of pu'er tea and application

InactiveCN102492665APromote decompositionImprove the unique quality of connotationHydrolasesPre-extraction tea treatmentBiotechnologyPhytase

The invention relates to a compound enzyme preparation for fermentation of pu'er tea, which is formed by compounding 10% to 20% of cellulase, 10% to 20% of pectinase, 5% to 15% of polyphenol oxidase, 5% to 10% of glucose oxidase, 5% to 10% glucoamylase, 5% to 10% xylanase, 5% to 10% of beta-glucanase, 5% to 10% of beta-mannase, 5% to 10% of tannase, 5% to 10% of acidic protease, 5% to 10% of lipase, 1% to 5% of alpha-amylase and 1% to 5% of phytase. By the aid of coordination of the enzyme system, polysaccharide and other substances in tea including cellulose and hemicellulose can be effectively decomposed, so that various physiochemical substances in cells can be dissolved. Meanwhile, oxidation and condensation of tea polyphenol, decomposition of protein, amino acid and carbonhydrate, a series of reactions of various products including polymerization and condensation and the like are accelerated and promoted.

Owner:YUNNAN NORMAL UNIV

Feed additive containing compound enzyme

InactiveCN102771627AImprove digestibilityIncrease production capacityAnimal feeding stuffBacillus licheniformisBiotechnology

The invention relates to an animal feed additive containing compound enzyme. The additive is a microecological compound enzyme preparation mainly composed of xylanase, mannanase, beta-glucanase, cellulase, acid protease, alpha-amylase, phytase, Bacillus subtilis, Bacillus licheniformis and the like. The product of the additive containing compound enzyme in the invention can be used as a novel feed additive, has no drug residue, no pollution and no generation of drug resistance, drug residues and drug-resistant strains, can be extensively applied to livestock feeds and ruminant feeds and has effects on improving the digestion and utilization rate of feeds, enhancing production performance of animals, strengthening immunity of animals, etc.

Owner:北京奕农生物技术有限公司

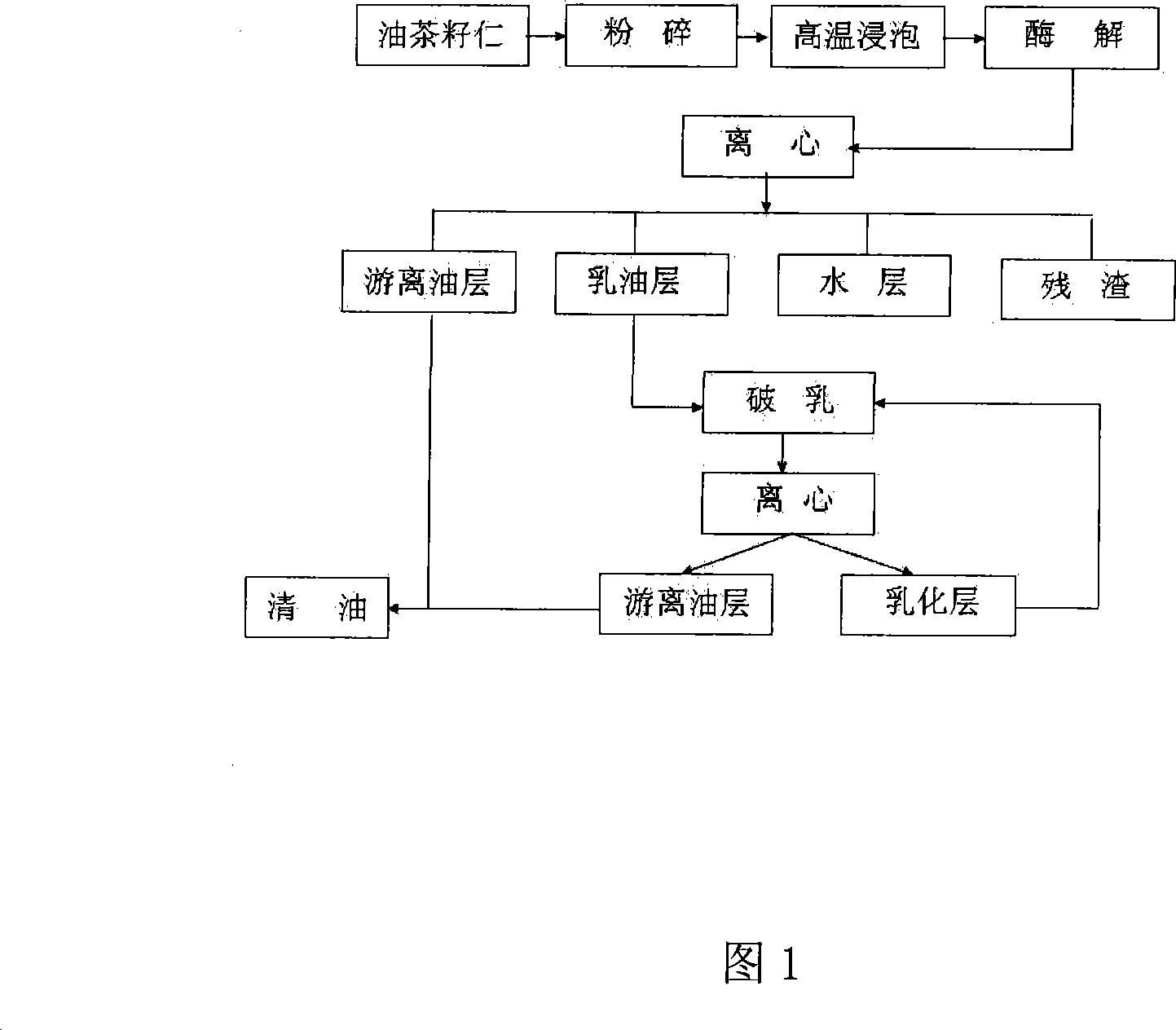

Technique for extracting grease from oil-tea camellia seed by enzyme method

InactiveCN101235399AReduce emulsificationReduce foaming and other problemsFermentationCamellia oleiferaDry weight

The invention relates to an enzymatical extraction process of oil in tea seed oil kernel, which comprises the following steps: firstly, utilizing dried tea seed oil kernel to be raw material, immersing in water in high temperature after disintegrating, stirring in uniform speed under 70-100 DEG C, secondly, enzyme hydrolyzing, adding acid protease which is 0.02-1% dry weight of disintegration samples or mixed enzyme of acid protease / cellulose in 45-55 DEG C to stir in uniform speed, and enzymatic hydrolysis for 2-4 hours, thirdly, separation emulsion breaking processing, directly separating out primary free boiled oil after enzymolysis liquid is centrifuged, getting secondary free boiled oil through centrifuging after missible oil demulsifies, combining the primary free boiled oil and the secondary free boiled oil, and getting the total boiled oil. The invention has the advantages that first, the invention reduces the problem of emulsification, foaming and the like which are faced when a grinding method is utilized to destroy cell structures, second, the invention prevents various enzymes in cells from degrading oil, which has high oil extraction rate to a further disintegrated function to tea seed oil kernel cell, third, the invention increases the treatment to missible oil, which increases free boiled oil yield through demulsifying, centrifuging, stewing to layer and the other modes.

Owner:江西春源绿色食品有限公司

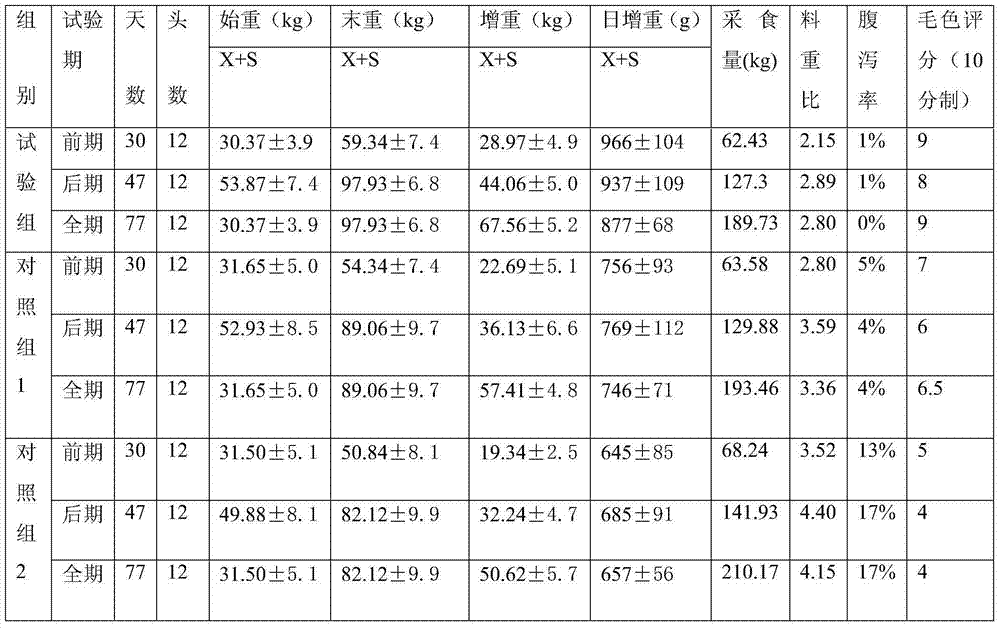

Complex enzyme preparation for growing and fattening pig feed

InactiveCN102106477AImprove metabolic energyReduce chyme viscosityAnimal feeding stuffAccessory food factorsPectinaseAnimal science

The invention discloses a complex enzyme preparation for a growing and fattening pig feed. The complex enzyme preparation for the growing and fattening pig feed comprises the following eight enzymes: acid protease, amylase, beta-mannase, xylanase, beta-dextranase, cellulase, pectinase and phytase; and the enzyme activity ratio of the eight enzymes is sequentially 1: (0.8-14.5): (0.19-0.3): (33.7-35): (25-30): (3.2-3.5): (0.19-2.0): (0-0.025). The complex enzyme preparation can degrade various anti-nutritional factors in the feed, reduce the chime viscosity of the intestinal tract, improve the metabolic energy of the feed, improve the digestion rate of growing and fattening pigs on protein and starch, reduce the nutrient content of the chime entering the intestinal tract, effectively inhibit the reproduction of harmful microbes in the intestinal tract, reconcile the micro-ecological balance of the intestinal tract, promote the health of the pigs, improve the average daily gain of the growing and fattening pigs, reduce the feed-meat ratio, shorten the maintenance period and improve the economic benefit.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

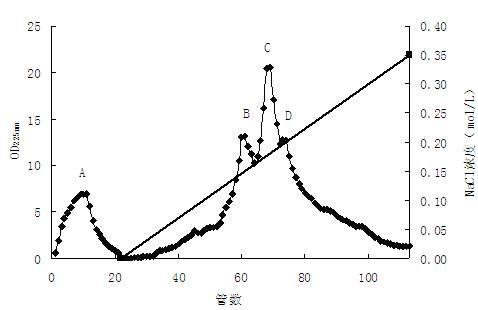

Method for producing soybean polypeptide powder

InactiveCN102511648AAdvanced technologyIncrease productivityProtein foodstuffs working-upSolubilityNeutral protease

The invention relates to a method for processing soybean isolated protein by utilizing a biological enzyme technology. The method comprises the following steps of: during preparation, selecting high-quality soy protein isolate, and dissolving; performing thermal denaturation; adjusting the pH value to 8.0 to 9.0; adding composite hydrolase of alkali protease, neutral protease, papain and trypsin, and reacting for 2 to 3 hours; adjusting the pH value to 4.0 to 6.0; inactivating enzyme; when cooling to a temperature below 50 DEG C, adding filter aid enzyme; collecting filtrate to dissolve filter residues; adding composite hydrolase of acidic protease, neutral protease, papain and trypsin, and reacting for 1 to 2 hours; inactivating the enzyme; when cooling to temperature of below 50 DEG C, adding the filter aid enzyme; filtering by a paperboard; performing ultrafiltration; drying by microwaves under vacuum; and crushing and sieving. The soybean polypeptide powder prepared by the method can improve the solubility of albumen powder to a maximum limit and keep the color and luster of appearance, mouthfeel, flavors and the bioactivity of active ingredients, offers a good mouthfeel, is easy to absorb and can be widely applied to industry of dairy products, drinks and health-care products.

Owner:天津诺奥酶生产力促进有限公司

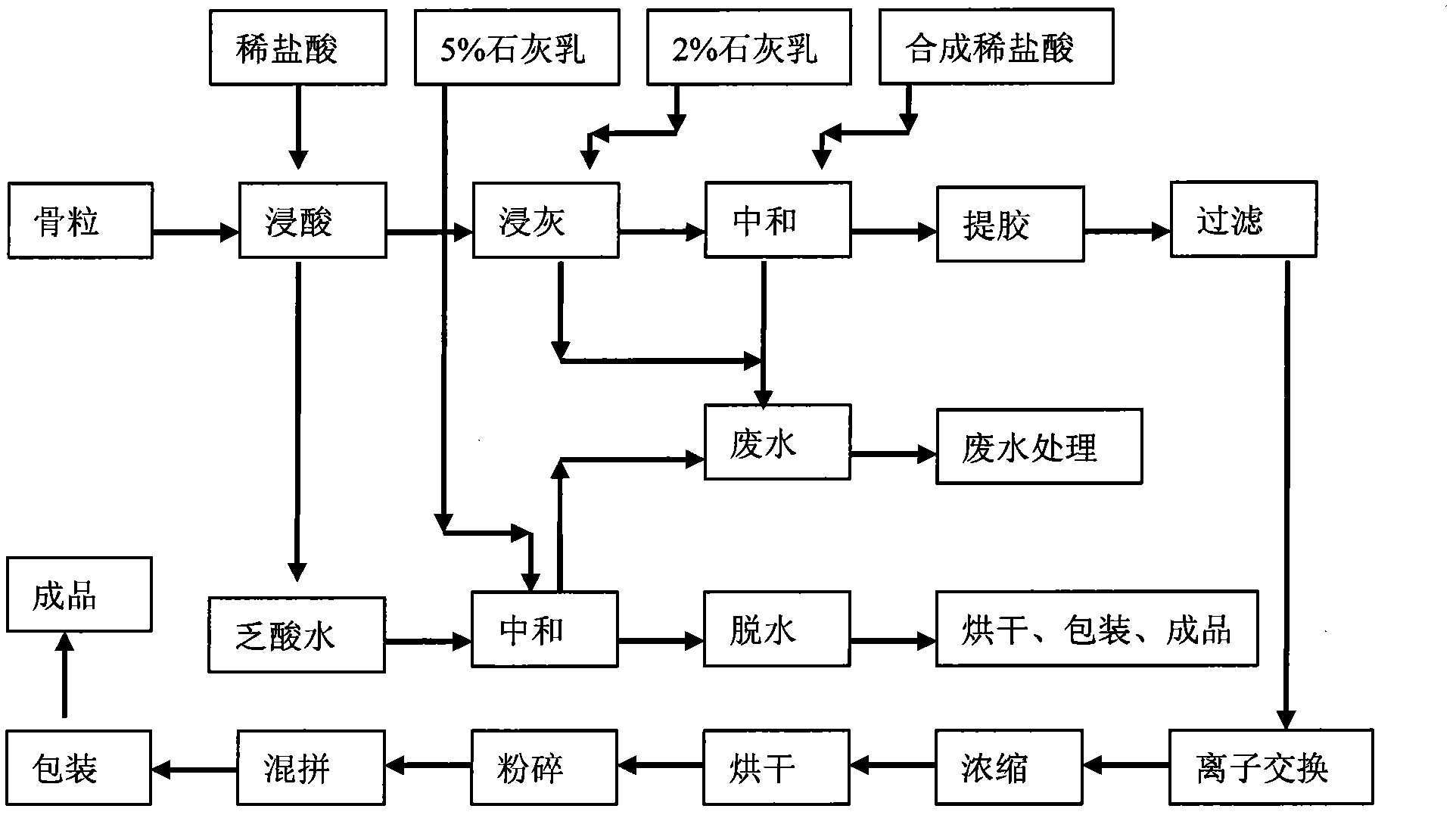

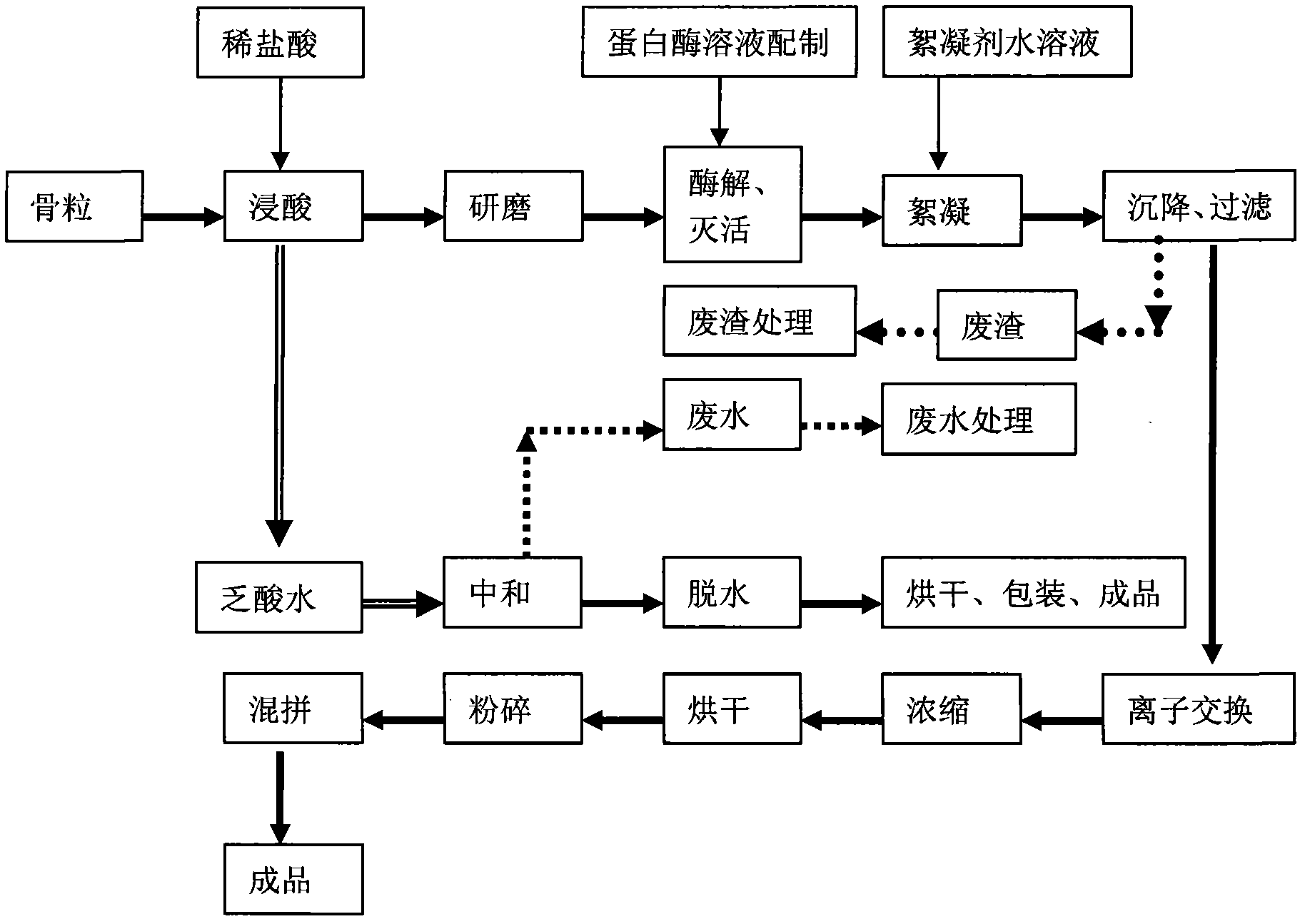

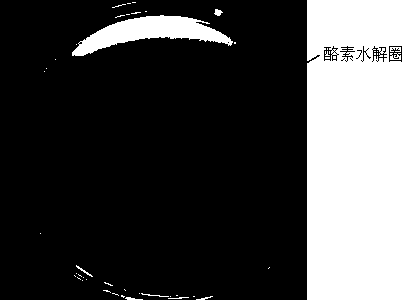

Enzyme method for preparing gelatin

ActiveCN102329843ALarge specific surface areaTake advantage ofGlue/gelatin preparationFermentationCalcium hydroxideProteinase activity

The invention relates to an enzyme method for preparing gelatin, which comprises the following steps of: pulverizing bone grains into bone meal, acidifying the bone meal by using phosphoric acid, and adding acid protease to hydrolyze; then, decoloring the solution by using hydrogen peroxide, and adjusting the pH value by using calcium hydroxide; and finally adding a flocculating agent. In the method provided by the invention, phosphoric acid is adopted for acidification, because a great amount of soluble calcium salts is formed, the enzymolysis reaction is mild. The defect that the enzymolysis end point of the finely ground collagen (ossein) enzymolysis method is difficult to control is overcome by controlling the end point of the enzymolysis reaction, so that the enzymolysis method for preparing gelatin is more practical.

Owner:安徽丰原集团有限公司

Method of two-step united multi-strain fermented feed

ActiveCN104996722AHigh activityConducive to vigorous growth and reproductionAnimal feeding stuffFeed techniqueBiotechnology

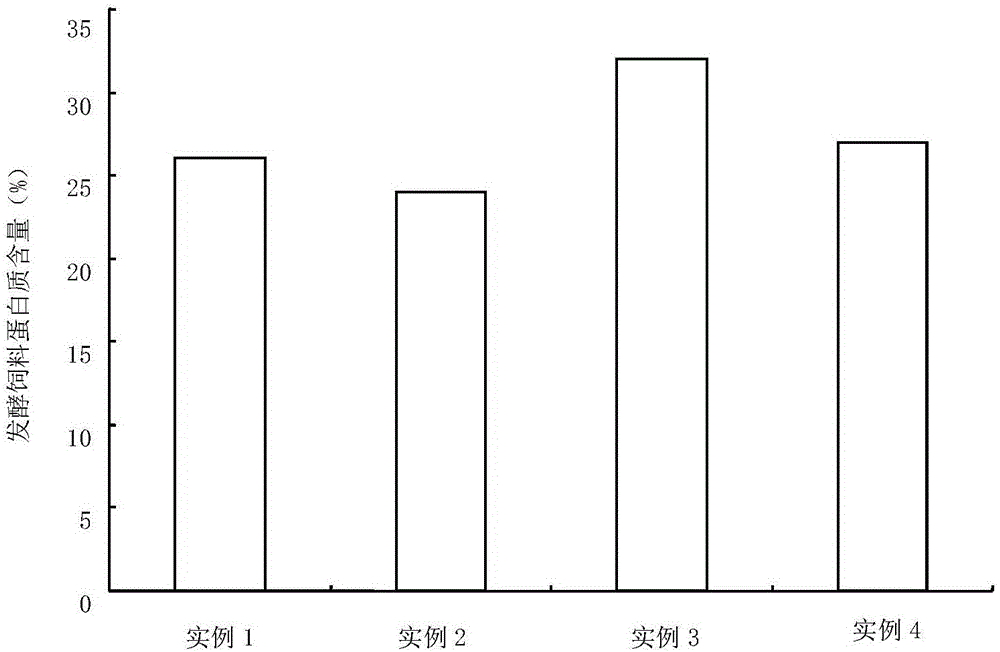

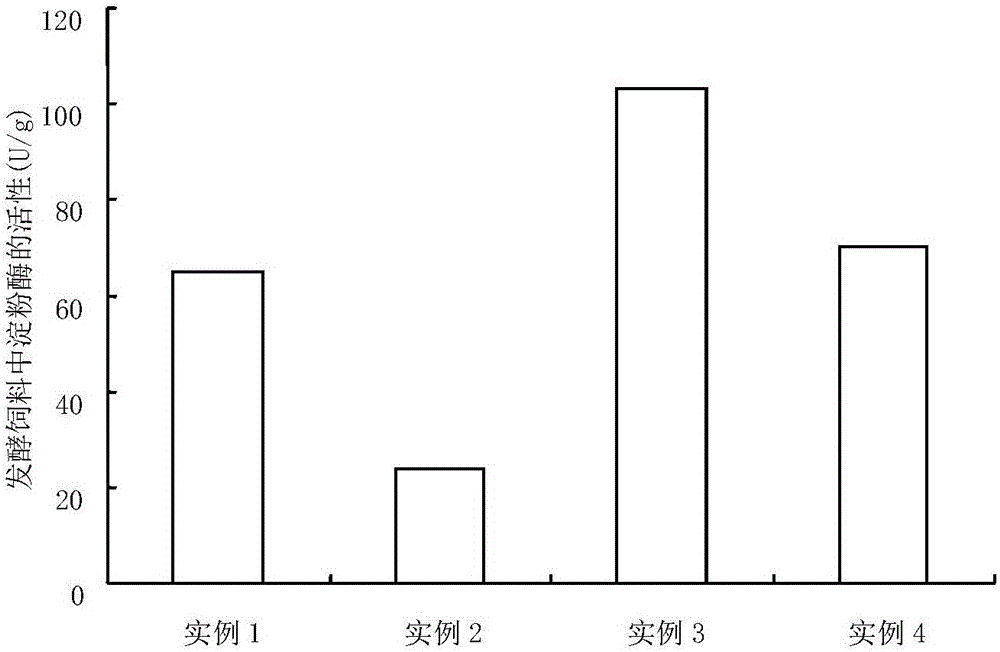

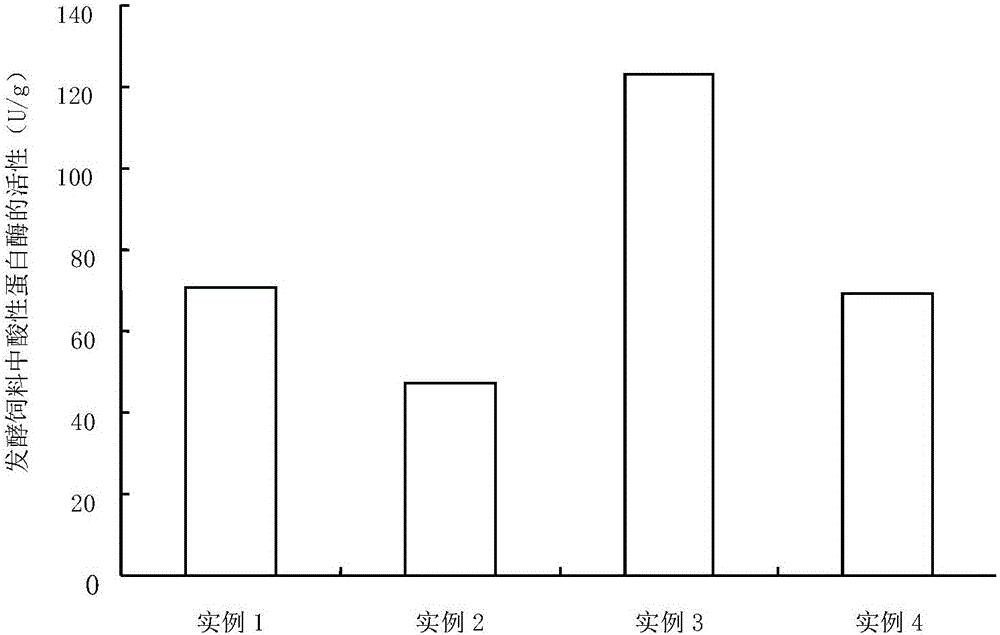

The invention discloses a method of a two-step united multi-strain fermented feed, and belongs to the technical field of feeds. The fermented feed disclosed by the invention is obtained through two steps of aerobic fermentation and anaerobic fermentation by using maize flour, palm dregs, soybean meal, bran and middling as raw materials and by using rhizopus nigricans, aspergillus oryzae, bacillus subtilis, lactobacillus plantarum and beer yeast as fermenting strains. The feed fermented through the method disclosed by the invention has the advantages that the protein content is as high as 30-34% which is increased by 45-62% than that of raw materials, the content of alpha-amylase is as high as 90-110U / g, the enzyme activity of acidic protein is as high as 110-130U / g, and the feed is rich in protein, rich in probiotics and high in enzymic activity. The method disclosed by the invention has the characteristics of high maneuverability, being suitable for large-scale industrial production and the like, and has favorable market prospects.

Owner:JIANGNAN UNIV

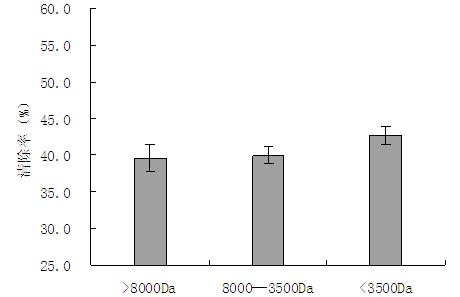

Oxidation resisting polypeptide and preparation method thereof

ActiveCN102219830AResolve concernsImprove the low utilization rate of collagenPeptide preparation methodsFermentationEngineeringCollagenan

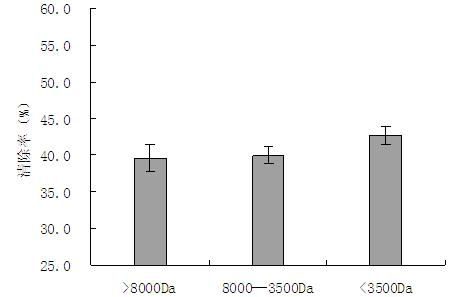

The invention provides an oxidation resisting polypeptide and a preparation method thereof. The method takes sharkskin collagen as the raw material. By means of enzymolysis of acidic protease, separation and purification, a specific oxidation resisting polypeptide can be obtained, with a molecular weight of 902Da and a complete amino acid sequence as Gly-Thr-Met-Gly-Ala-Val-Gly-Pro-Arg-Gly. The oxidation resisting polypeptide of the invention eliminates the defects of natural antioxidants and relieves the public from their anxiety about synthetic antioxidant, thus establishing the theoretical foundation for developing oxidation resisting polypeptide based on food sources and exploring the wide application of the oxidation resisting polypeptide in food and medical science.

Owner:FUZHOU UNIV

Antioxidation polypeptide prepared from sharkskin collagen

ActiveCN102219828AResolve concernsImprove the low utilization rate of collagenPeptide preparation methodsFermentationCollagenanAnti oxidant

The invention provides an antioxidation polypeptide prepared from sharkskin collagen. In the method, the sharkskin collagen is adopted as a raw material; and acid protease is broken down by enzymes and separated and purified to obtain specific antioxidation polypeptide, wherein the molecular weight of the specific antioxidation polypeptide is 866 Da; and the complete sequence of the amino acid ofthe specific antioxidation polypeptide is Gly-Ala-Ile-Gly-Pro-Ala-Gly-Pro-Arg-Ala. According to the invention, the defects of a natural antioxidant are eliminated, the worries of the public about artificial antioxidant are eliminated, and theoretical basis is laid for developing the antioxidation polypeptide based on a food source and exploring wide application of the antioxidation polypeptide infoods and medical science.

Owner:FUZHOU UNIV

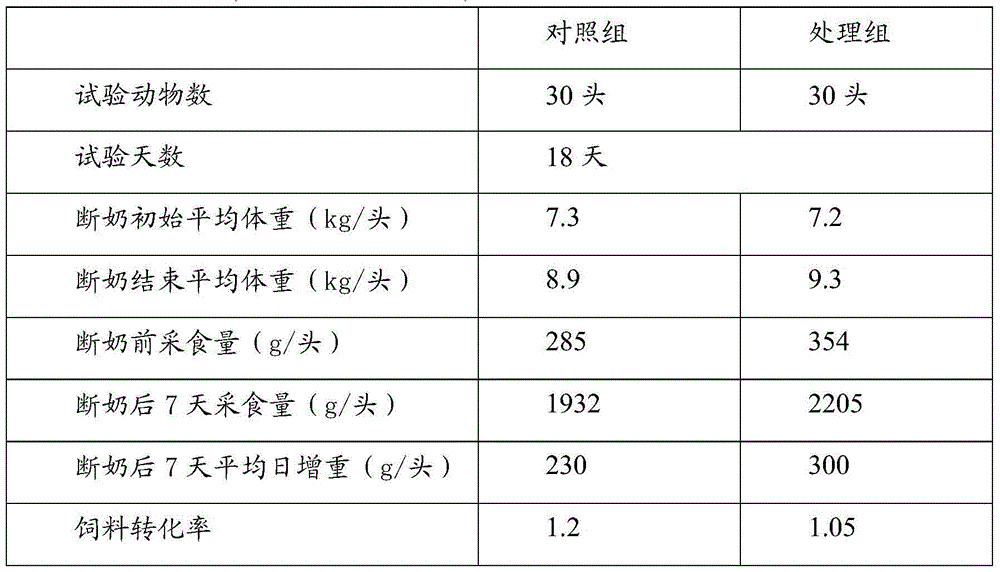

Non-resistance piglet milk replacer and application thereof

The invention discloses a non-resistance piglet milk replacer and an application thereof. The non-resistance piglet milk replacer is prepared from the following raw materials in parts by weight: 30-45 parts of extruded corn, 15-20 parts of extruded soybean, 2-5 parts of plasma protein powder, 2-5 parts of dried porcine soluble, 8-15 parts of whey powder, 3-5 parts of excellent white fish meal, 5-8 parts of lactose, 2-4 parts of calcium hydrophosphate, 0.5-1 part of zeolite powder, 2-4 parts of lysine, 0.1-0.3 part of methionine, 0.1-0.3 part of threonine, 0.1-0.15 part of tryptophan, 0.1-0.3 part of acid proteinase, 0.1-0.3 part of trace elements for piglets, 0.1-0.3 part of vitamin for piglets, 0.1-0.3 part of lactic acid bacteria fermented powder, 0.1-0.4 part of glutamine dipeptide, 0.6-1.2 parts of an acidity regulator, 1.5-2.4 parts of an antioxidant, 0.1-0.3 part of allicin and 0.1-0.3 part of carvacrol. According to the milk replacer disclosed by the invention, weaned piglet diarrhea is reduced, and / or the survival rate of the piglets is improved.

Owner:FUJIAN AONONG BIOLOGICAL TECH GRP CO LTD

Antioxidant polypeptide prepared by enzymatic hydrolysis of sharkskin collagen with acid protease

ActiveCN102219829AResolve concernsImprove the low utilization rate of collagenPeptide preparation methodsFermentationEnzymatic hydrolysisCollagenan

The invention provides an antioxidant polypeptide prepared by enzymatic hydrolysis of sharkskin collagen with acid protease. According to the invention, sharkskin collagen is used as the raw material; after enzymatic hydrolysis with acid protease, the sharkskin collagen is subjected to isolation and purification so as to obtain a specific antioxidant polypeptide, the complete amino acid sequence of which is as follows: Gly-Pro-Ala-Gly-Pro-Ala-Gly-Ala-Ala-Gly. The invention enables the elimination of shortcomings of natural anti-oxidants and of public worry about synthetic anti-oxidants and lays a theoretical basis for the development of food derived antioxidant polypeptides and for the exploration of their application in foodstuff and medical science.

Owner:FUZHOU UNIV

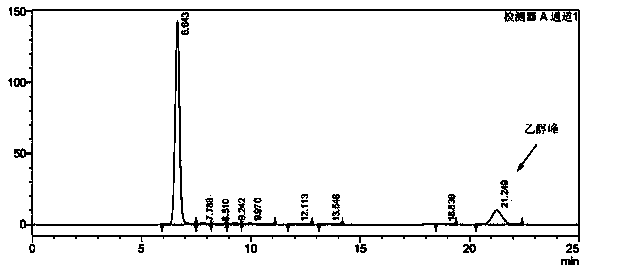

Method of preparing high concentration ethanol fermentation liquid by paddy rice raw material fermentation

InactiveCN1442483ALow costIncrease ethanol concentrationBiofuelsFermentationAmylaseHigh concentration

A process for preparing fermented high-concentration alcohol liquid from raw rice grains includes such steps as pulverizing, sieving by more than 40 meshes, dissolving in water at 34-36 deg.C, addingcomposite enzyme prepared from beta-amylase, alpha-emylase, acidic proteinase, cellulose, xylanase, pectase, phytase and dry yeast, and fermenting at 30-40 deg.C for 60-95 hr. Its advantages are simple process, low cost and high concentration.

Owner:TIANJIN UNIV

Method for improving enzymolysis efficiency of crude heparin sodium extraction technology

The invention relates to a method for improving enzymolysis efficiency of a crude heparin sodium extraction technology. The method can effectively improve enzymolysis efficiency, decompose impurity proteins, improve crude product quality, improve a yield and increase economic benefits. The method comprises the following steps of 1, dissolution: preparing mucous membrane water, 2, acid protease catalysis: heating the mucous membrane water, adding acid protease into the mucous membrane water based on the number of small intestines of the pig, adjusting a pH, adding metal ions into the mixed solution based on the number of small intestines of the pig, adjusting salinity by sodium chloride, and carrying out a thermal insulation reaction process, 3, alkaline protease catalysis: carrying out heating, adding two alkaline proteases into the reaction produce based on the number of small intestines of the pig, adding a pH value and salinity, carrying out a thermal insulation reaction process, carrying out heating and carrying out a thermal insulation reaction process, and 4, filtration on the enzymolysis mother liquor by a combined filter cloth, introduction of the filtered enzymolysis mother liquor into an adsorption tank, and follow-up processes.

Owner:杭州惠顺生物科技有限公司

Method for extracting maize germ oil and recovering protein by water enzyme method

A process for extracting corn embyro oil and recovering protein includes immersing corn embryo in hot solution of citric acid, dripdrying, adding water, grinidng, and acidic proteinase and cellulase, enzymolyzing, centrifugal separating to obtain corn embryo oil, mixing the immersing liquid with separated liquid, nano-filter, vacuum concentrating, and spray drying to obtain protein.

Owner:JIANGNAN UNIV

Soya protein oligopeptides production

InactiveCN1439720AReduce manufacturing costSimplify downstream processingFermentationAlkaline proteinaseNeutral proteinase

A process for preparing soybean protein oligopeptide from concentrated soybean protein, separated soybean protein, defatted soybean powder, soybean dregs, or soybean cake features the cooperative hydrolysis with alkaline proteinase, acidic proteinase and / or neutral proteinase at 30-70 deg.C for 2-24 hr. Its advantages are simple downstream steps and low cost.

Owner:DALIAN UNIV OF TECH

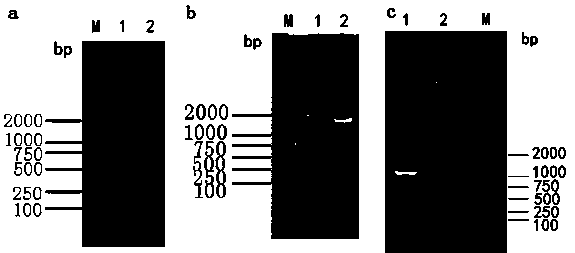

Genetic recombinant saccharomyces cerevisiae capable of degrading and utilizing kitchen wastes

The invention relates to the field of genetic engineering and fermentation engineering and in particular discloses genetic recombinant saccharomyces cerevisiae capable of degrading and utilizing kitchen wastes. The genetic recombinant saccharomyces cerevisiae is constructed by transferring alpha-amylase (alpha-amylase) genes, glucoamylase (glucoamylase) genes and acid protease (acid protease) genes through a multi-gene coexpression vector of the saccharomyces cerevisiae and obtaining accurate secretory expression. The previous three enzyme genes are simultaneously transferred into the saccharomyces cerevisiae for realizing the secretory expression, so that the saccharomyces cerevisiae can simultaneously secrete the alpha-amylase, glucoamylase and acid protease. Therefore, main nutritional ingredients such as starch and proteins in the kitchen wastes can be efficiently degraded and become carbon sources and nitrogen sources needed by growth and fermentation of recombinant yeasts, and high-efficiency conversion between the kitchen wastes and ethanol is realized.

Owner:GUANGDONG RECYCLEAN LOW CARBON TECH CO LTD

Feed compound enzyme-containing dedicated enzyme for growing pigs and preparation method of feed compound enzyme-containing dedicated enzyme

ActiveCN103667222AGrowth inhibitionInhibition of reproductionAnimal feeding stuffAccessory food factorsESCHERICHIA COLI ANTIGENAmylase

The invention discloses a feed compound enzyme-containing dedicated enzyme for growing pigs and a preparation method of the feed compound enzyme-containing dedicated enzyme, and belongs to the technical field of preparation of enzyme preparations. The dedicated enzyme for the growing pigs is prepared by scientifically compounding aspergillus niger cultures, acidic xylanase, phytase, beta-dextranase, cellulase, amylase, acid proteinase, Chinese herb extracts, a protective agent and an activating agent, wherein the aspergillus niger cells in the aspergillus niger cultures can inhibit the growth of pathogenic escherichia coli, inhibit the growth and breeding of aspergillus flavus, disintegrate the aspergillus flavus, promote the growth of animals, adjust gastrointestinal tract flora to be balanced, and enhance whole immunity during the processes of growth and fermentation, in addition, the fermentation liquid crude enzyme liquid of the aspergillus niger cultures contains different enzyme activity such as protease activity, mannase activity, alpha-galactase activity and pectinase activity, and the dedicated enzyme is specially suitable for being added in the feed for the growing pigs.

Owner:SHANXI DAYU BIOLOGICAL ENG CO LTD

High-solubility soybean peptide as well as preparation technology and application thereof

ActiveCN108157583AImprove solubilityGuaranteed enzymatic effectVegetable proteins working-upSolubilityNeutral protease

The invention provides high-solubility soybean peptide as well as a preparation technology and application thereof, and relates to the field of a processing technology of soybean protein. The preparation technology of the high-solubility soybean peptide comprises the following steps of uniformly mixing and stirring soy protein isolate with distilled water; warming soy protein isolate slurry to 50-55 DEG C, adding alkali protease under natural pH condition for enzymolysis, then adding neutral protease for enzymolysis, then adding organic acid for regulating the pH to 5.4-6.2, and adding acid protease for enzymolysis so as to obtain enzymatic hydrolysate; performing enzyme deactivation on the enzymatic hydrolysate; and lowering the temperature to 60-70 DEG C, performing physical bitterness removing treatment, performing concentration, and performing spray drying. According to the preparation technology, the organic acid is used for regulating the pH during acidic enzymolysis, so that theenzymolysis effect is guaranteed, besides, the labor cost is saved, and the preparation technology is simple and convenient to operate, and is suitable for scaled production. The prepared high-solubility soybean peptide is high in solubility under the acidic and high-temperature high-pressure condition, and is free from bitterness. The high-solubility soybean peptide can be made into health-carefoods, functional foods and foods.

Owner:武汉天天好生物制品有限公司

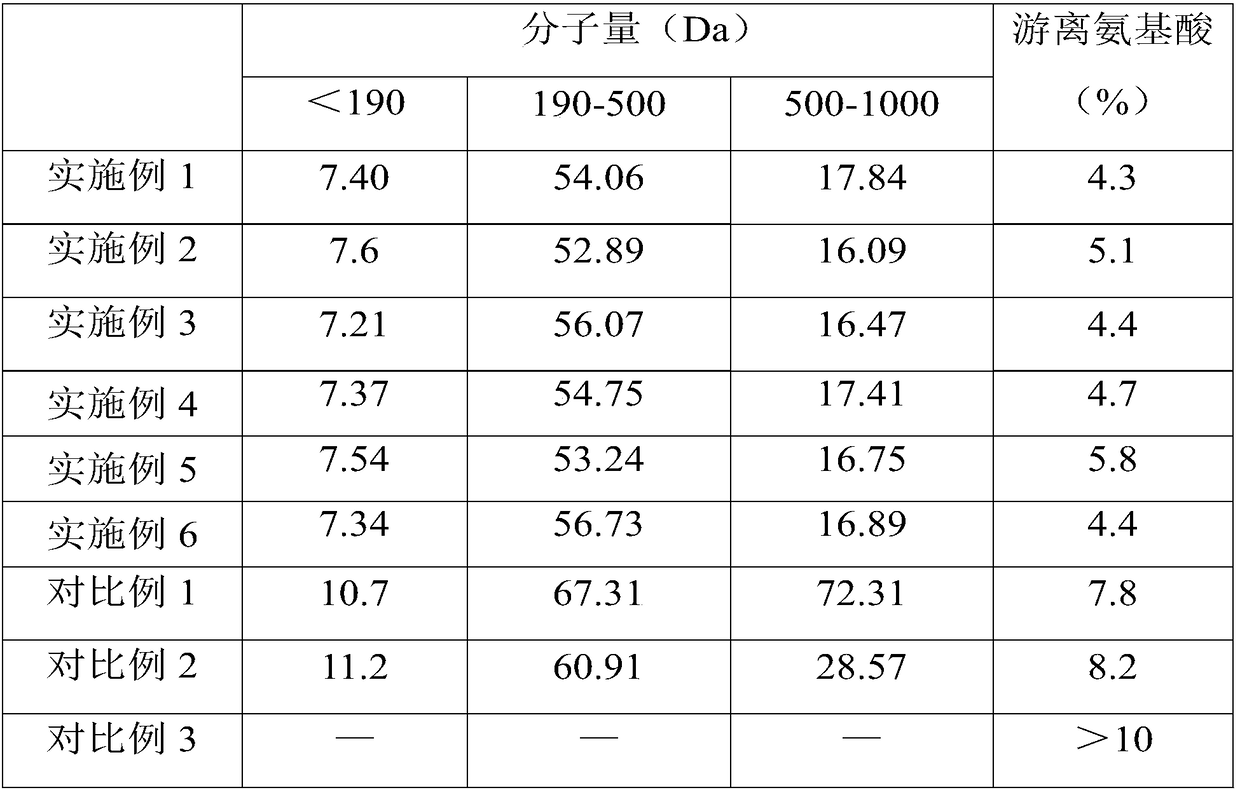

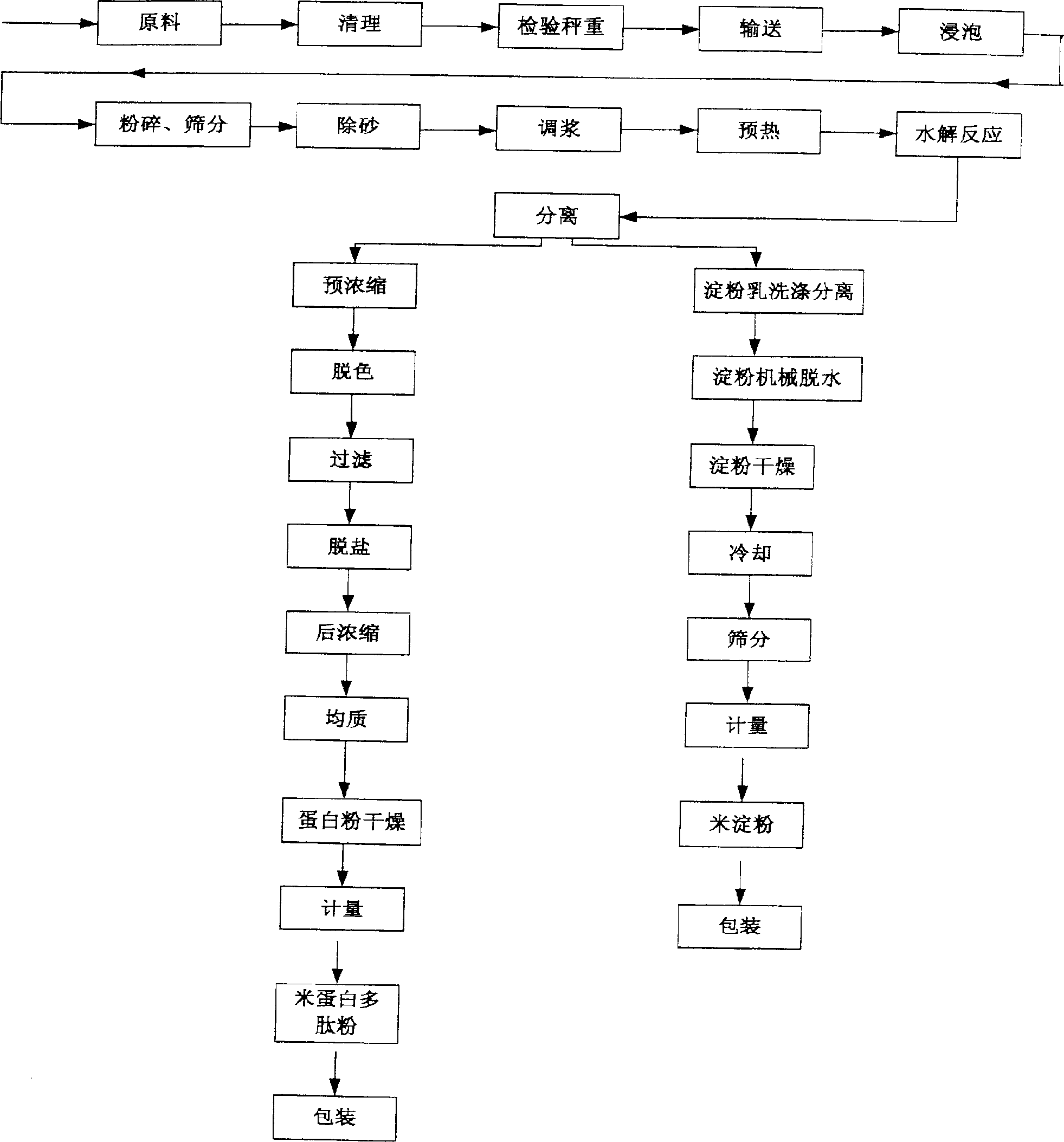

Production of rice-starch and rice-protein polypeptide powder by composite enzyme method

InactiveCN1896261ARelaxed reaction conditionsImprove securityFermentationNeutral proteaseRice protein

This invention is a method to produce rice starch and rice polypeptide powder using compound enzymes. The rice is crushed into rice powder, steeped in water and stirred. Sodium hydroxide is added for regulating the pH value and conditioning. Then 200 thousand activity units of compound enzymes as 4-8%. of the dry basis are added for hydrolysis. The compound enzyme is composed of basic protease, neutral protease, acidic protease and flavor enzyme. Then after centrifugal separation, water is added to the subjacent white sedimentation and homogenized, and after another centrifugal separation, the white sedimentation is dried to produce rice starch. The supernatant and the upper swallow portion are produced into rice polypeptide powder after homogenizing concentrated liquid and drying. This invention shortens the productive period consumedly and decreases the cost. In the productive progress there is no waste water generated. The quality and productive efficiency is also improved compared with other methods.

Owner:普洱永吉生物技术有限责任公司

Method for extracting collagen from fish skin

The invention discloses a method for extracting collagen from fish skin. The method comprises the following steps of: treating raw materials; degreasing the treated raw materials with isopropanol; removing non-collagen protein with sodium chloride; leaching with acetic acid; adding acid protease for enzymolysis; centrifugally concentrating; and drying so as to obtain fish skin collagen. The collagen is extracted by performing acid extraction and enzymolysis simultaneously, so that extraction rate is high and extraction time is shortened. The fish skin is treated repeatedly with the isopropanol and fat and pigments are removed fully, so that product quality is enhanced. The method of the invention has high collagen extraction rate and bright color, and does not have fat residues.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Preparation method of mango condensed thick juice

InactiveCN101543306AIncrease the juice yieldHigh retention rateFood preparationFood industryCellulase

The invention relates to a preparation method for mango condensed thick juice, belonging to the technical field of the application of enzyme engineering technology to the food industry. The method comprises the following steps: using fresh mangos as raw material, blanching, peeling, discarding kernels, protecting colors and pulping to obtain mango pulp; then, carrying out composite enzymolysis treatment of cellulose, glucamylase, pectase and acid protease, degerming and pressure filtering to obtain mango zymolyte juice; and concentrating, packaging, sterilizing and cooling to obtain the mango condensed thick juice product with the dissolvable solid content of 50 to 60 degrees Brix, the beta-renieratene content more than 4000 microgrammes / g and a pH value of 3.6 to 4.0. The invention has the advantages of scientific and reasonable technology, simple and convenient operation, high juice yield rate, high maintenance rate of nutrient contents, such as pulp, and the like, high degree of concentration and good color stability.

Owner:JIANGNAN UNIV

Additive for predigestion fermented feed for piglet

InactiveCN102100311AImprove digestibilityPromote Microecological BalanceAnimal feeding stuffAccessory food factorsCellulosePectinase

The invention discloses an additive for predigestion fermented feed for piglets, relating to pannage additive. The additive for predigestion fermented feed for piglets can stably improve the digestibility of feed and maintain the microecological balance of intestinal tracts. Each ton of perfect compound feed comprises 800-1000g of complex enzyme preparation, 300-500g of probiotic bacteria and 3000-5000g of lactic acid bacteria liquid, wherein 1g of complex enzyme preparation contains 800-1200U of acid protease, 80-120U of amylase, 1800-2200U of saccharifying enzyme, 12000-18000U of xylanase, 4000-5000U of beta-glucanase, 12000-16000U of cellulose, 6000-9000U of pectinase and 400-600U of phytase; 1g of probiotic bacteria contains 1.0*1010-2.0*1010CFU (colony-forming unit) of Bacillus licheniforms endogenous spore and 1.0*1010-2.0*1010CFU of yeast cell; and 1ml of lactic acid bacteria liquid contains 1.0*109-2.0*109CFU of lactic acid bacteria.

Owner:沈阳爱特杰牧业有限公司

Extraction method of the tobacco thin slice production of paper process

InactiveCN101766327AObvious sweetnessImprove taste qualityTobacco preparationTobacco treatmentFlavorCellulose

The present invention discloses an extraction method of the tobacco thin slice production of a paper process, which belongs to a thin slice production technology in the technical field of cigarettes. The following matters are also put into extraction liquid, and the weight percentage accounted by the extraction liquid is: 0.02 to 0.1 % of acid protease, 0.01 to 0.1% of cellulose, 0.01 to 0.1 % of pectase, and 0.1 to 1% of accelerant. The acid protease is made in liquid subsurface fermentation and rear processing, and meanwhile, self-made enzyme activity accelerant is used. The extraction method is used for the production of tobacco thin slices of the paper process. The eating flavor quality of the tobacco thin slices is improved; the miscellaneous QI is reduced; the thrill is reduced, and meanwhile, the sour flavor formed in a process of manufacture paper with pulp of part of thin slices; and the natural tobacco sweet feeling is obvious.

Owner:HUBEI CHINA TOBACCO IND

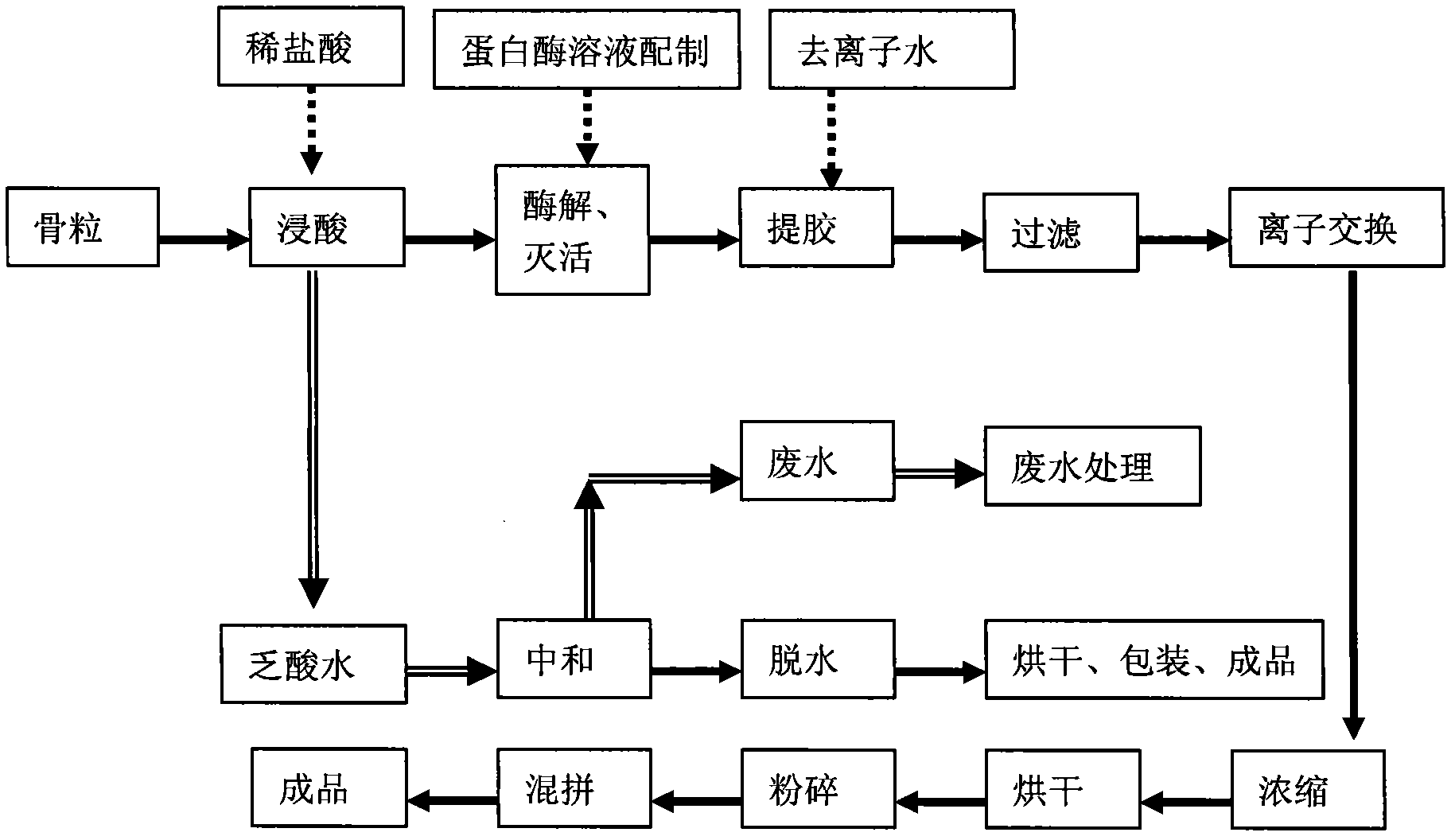

Method of preparing edible gelatin with combined zyme

The invention provides a method using combined degradation ossein adopting prolease of different specificities in sequence for zymolysis to prepare edible gelatine. The detailed procedure is that: marinating the ossein washed by dipping into acid water of the traditional lie wash technics into water for 2h to 3h, adding acid protease with the quality of dry ossein achieves to 1 per mill to 3 per mill after oil removal and conducting the first deterioration 2 to 5 when the temperature is 55 DEG C. to 60 DEG C.; raising mucus, filtering and drying after sterilizing enzyme with high temperature, thus achieving the dry gelatin; then adding water in the remained ossein, adjusting the solution reacted with the PH reaches to 4 to 8 by using alkali; then adding neutral or alkaline protease with the quality of the original dry ossein as 2 to 3 per mill and conducting the second deterioration with the temperature of 55 to 60 DEG C.; then raising mucus, filtering and drying after sterilizing enzyme with high temperature, thus achieving the dry gelatin. The ossein consumption for the first zymohydrolysis of the invention achieves 60 per cent per cent to 80 per cent and the viscosity of the glutin obtained is 2.3 mPa is multiplied by s and the bloom is 139 Bloom g; while the ossein consumption for the second zymohydrolysis of the invention achieves 15 to 30 per cent with the viscosity reaches to 3.4 mPa is multiplied by s and bloom of 101 Bloom g. Only little amoune of soft ossein dregs without viscosity are remained after boiled the remained ossein.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Methods and compositions for reducing the appearance of dynamic facial wrinkles

The present invention relates to methods and compositions for reducing the appearance of dynamic facial wrinkles by administering oral and / or topical compositions comprising therapeutically-effective amounts of extracts of one or more relaxing herbal agents (“RHAs”) alone or in combination with one or more extracts of an edible solanaceous glycoalkaloid-containing plant (“ESGP”) or an edible glycoalkaloid-containing fungus (“EGF”) selected from plant species in the genus Solanum and mushrooms. RHAs are selected from the group consisting of extracts of Q. amara, E. angustifolia, P. oleracea, M. dubia, P. orientalis and A. muscaria and plant species from the genus Valeriana, Passiflora, Verbascum, Scutellaria, Cypripedium, Magnolia, Atriplex and Symphytum. Additionally, the methods of the present invention may comprise exfoliating the skin, preferably with at least one acid protease enzyme.

Owner:LIPOTEC USA INC

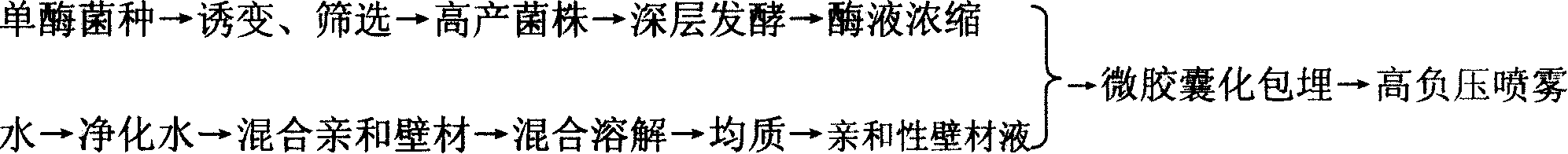

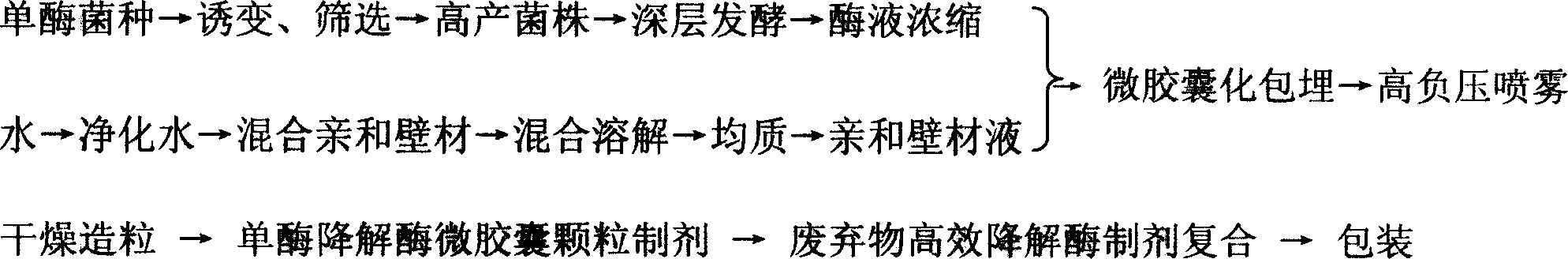

Composite enzyme prepn for degrading agricultural waste effectively and its prepn process

InactiveCN101045919AHigh potencyImprove digestion and absorption rateHydrolasesHeat recovery systemsProteinase activityMethane production

The present invention relates to enzyme preparation, and is especially one kind of composite enzyme preparation for degrading agricultural waste effectively and its preparation process. The composite enzyme preparation includes xylanase with enzyme activity not lower than 100 KU / g, beta-dextranase with enzyme activity not lower than 80 KU / g, cellulose with enzyme activity not lower than 28 KU / g, acid protease with enzyme activity not lower than 56 KU / g, lipase with enzyme activity not lower than 15 KU / g, pectase with enzyme activity not lower than 6 KU / g, and alpha-amylase with enzyme activity not lower than 12 KU / g. Its preparation process includes the steps of spawn preparation, enzyme preparation production, compounding, etc. The present invention may be used in feed production, methane production and other fields.

Owner:唐东升 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com