Patents

Literature

63results about How to "Increase ethanol concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xylitol synthesis mutant of xylose-utilizing zymomonas for ethanol production

InactiveUS7741119B2Reduce productionIncreased ethanol productionBacteriaUnicellular algaeFructoseOxidoreductase Gene

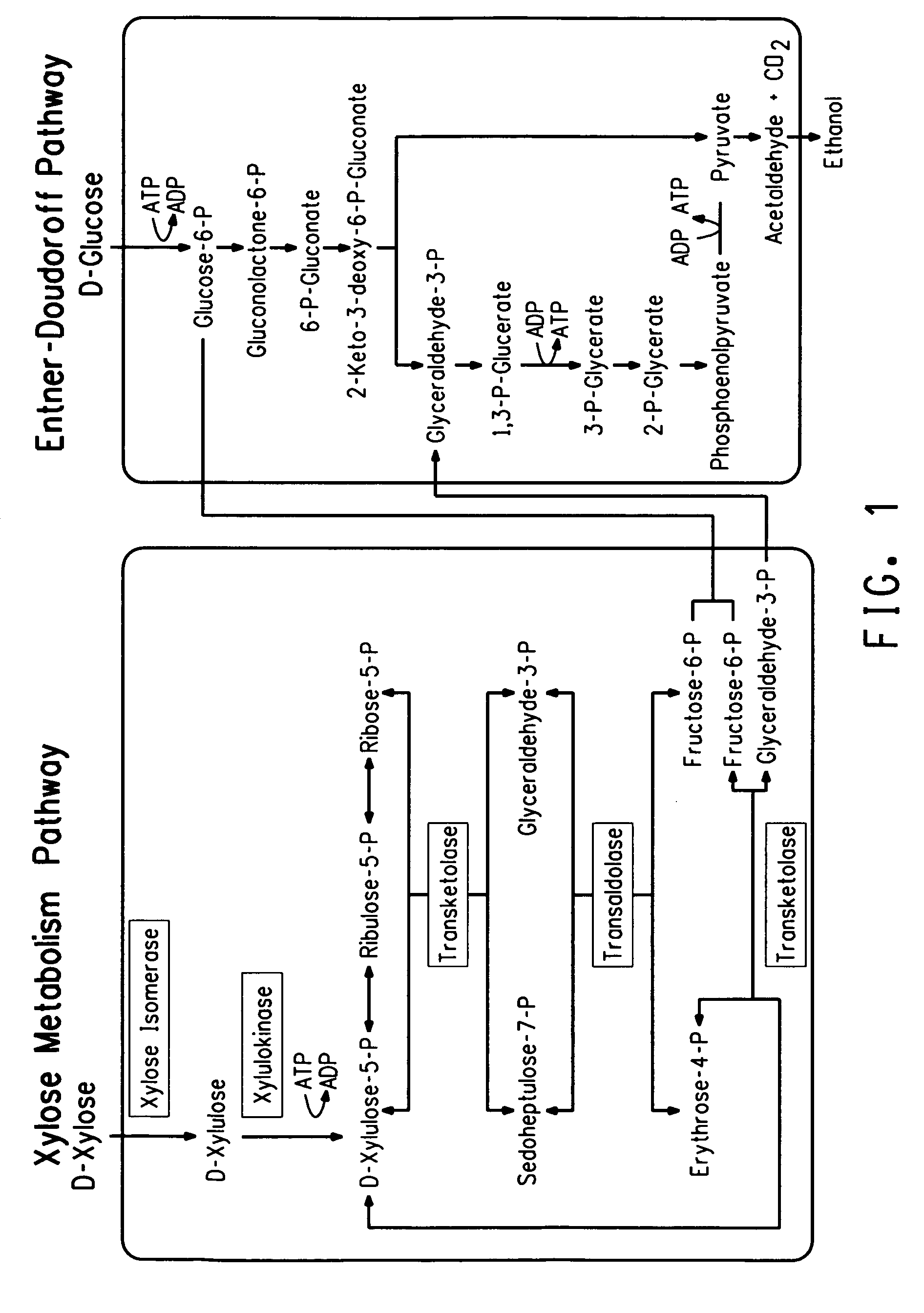

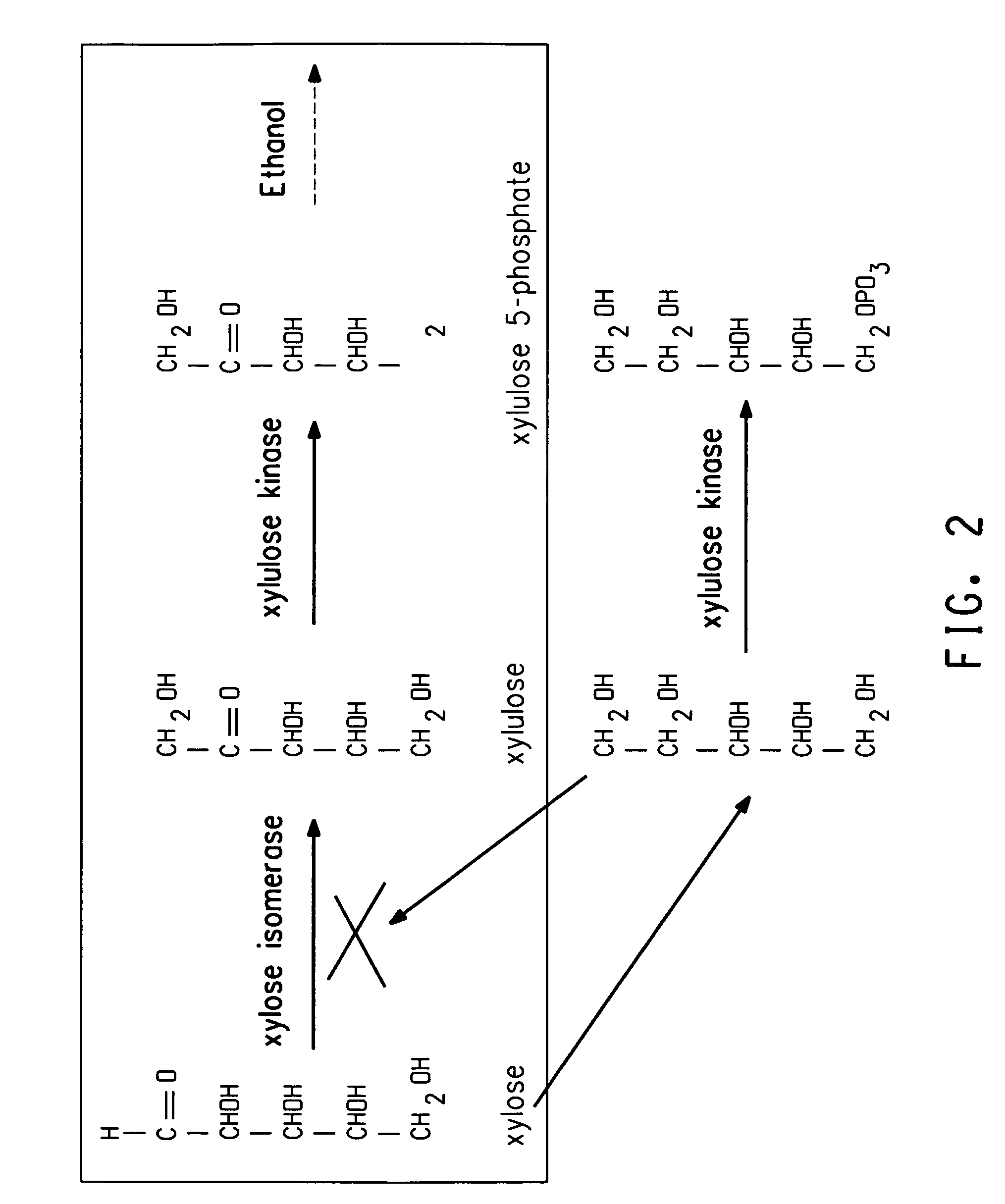

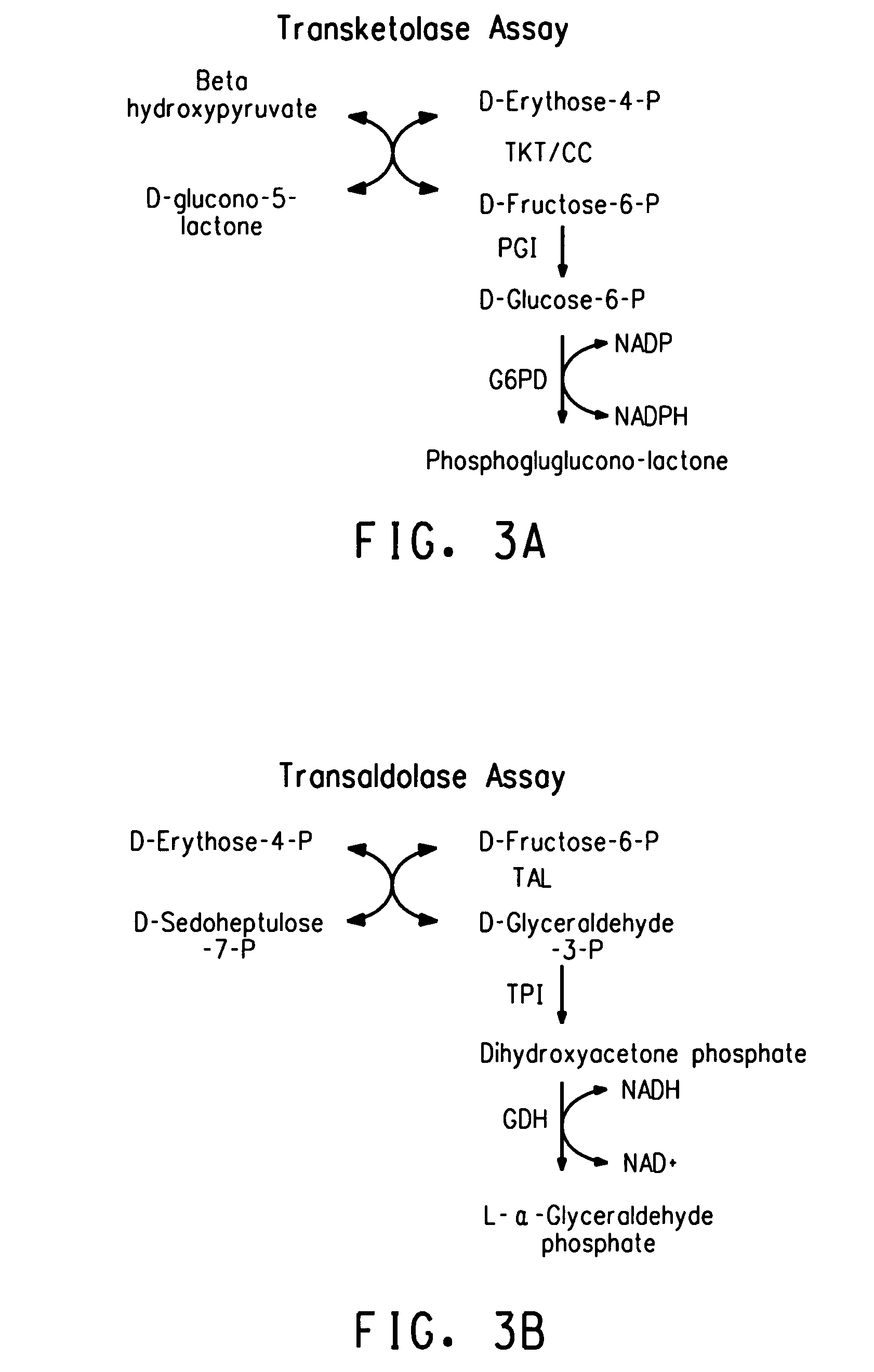

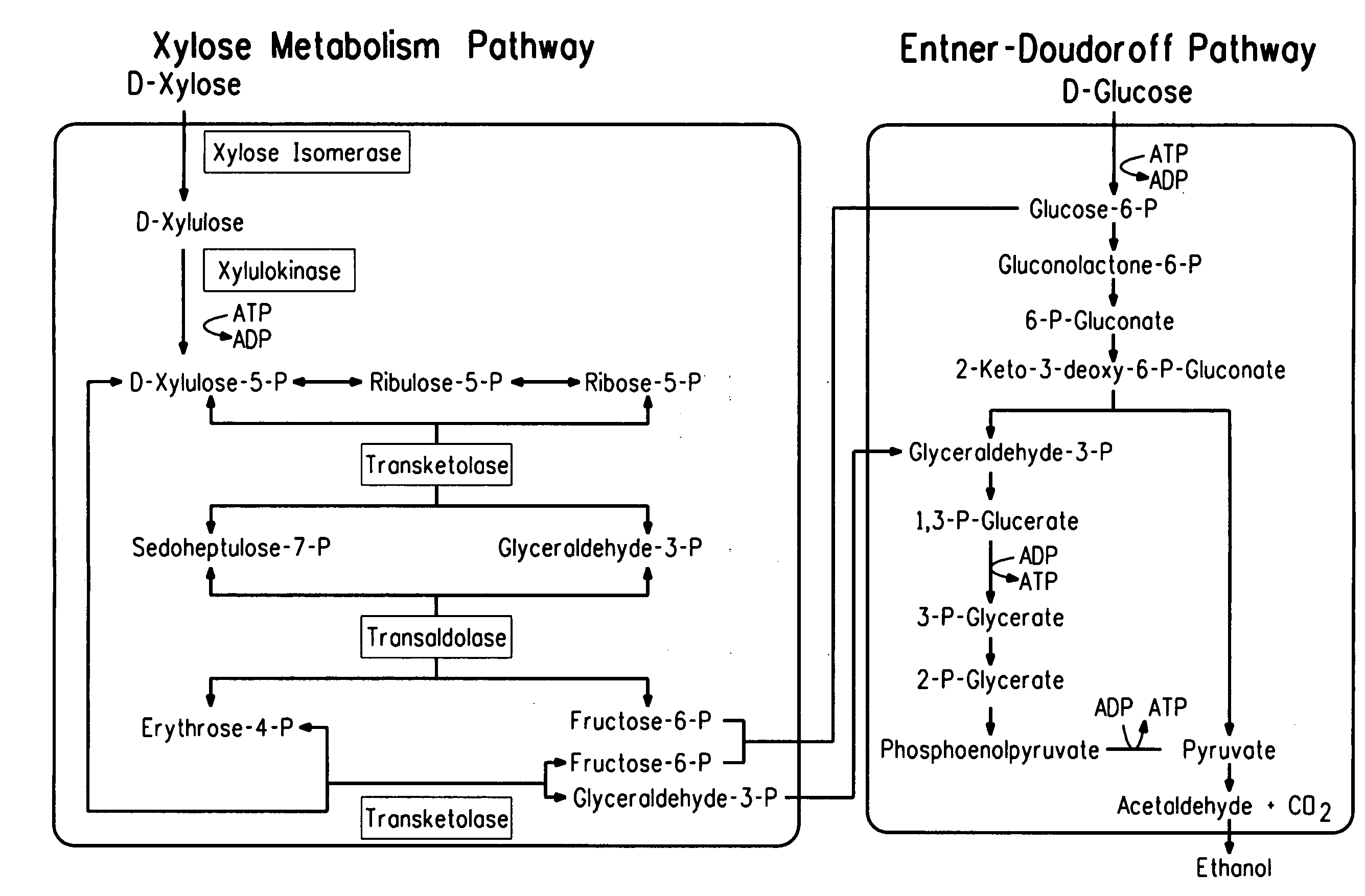

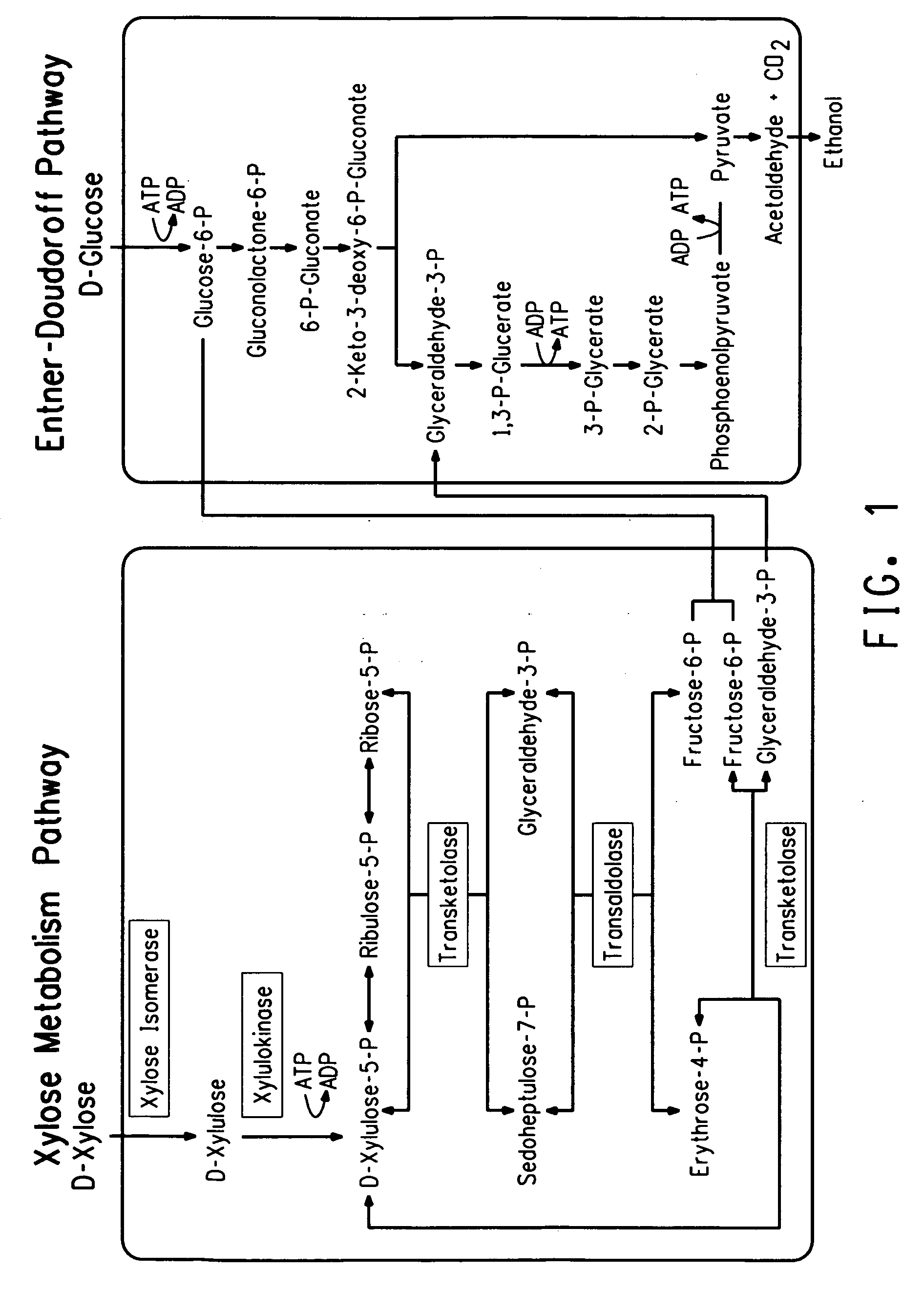

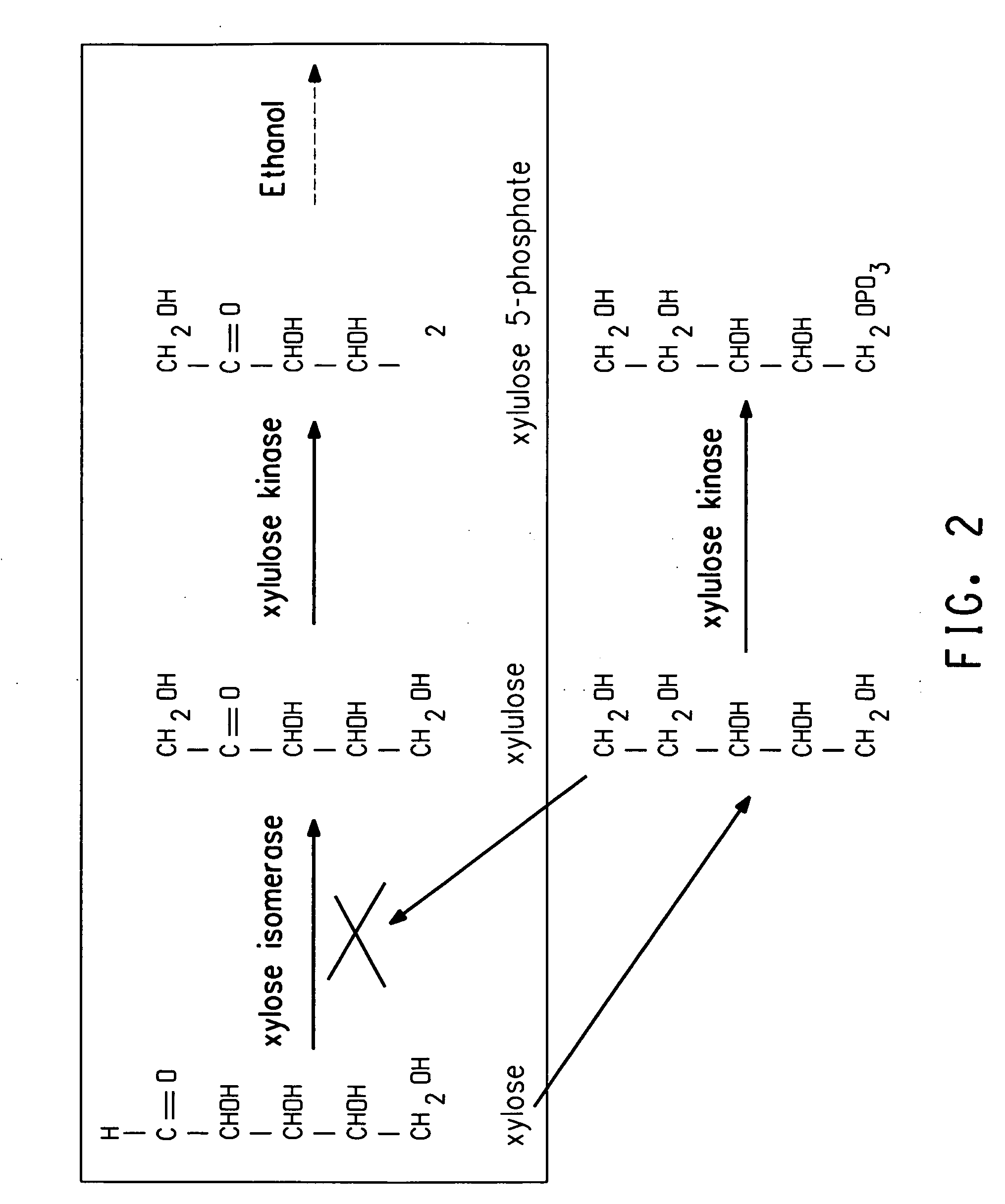

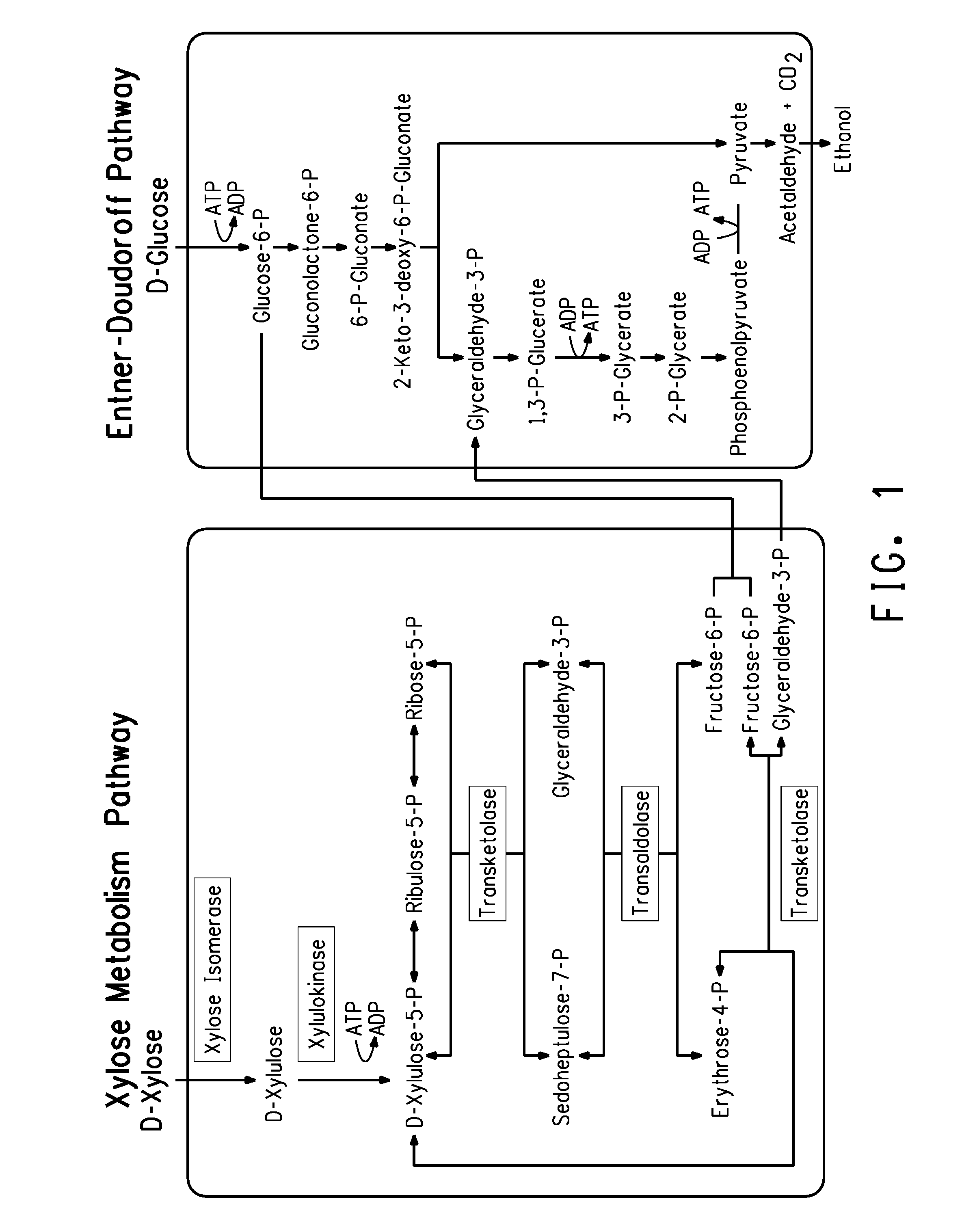

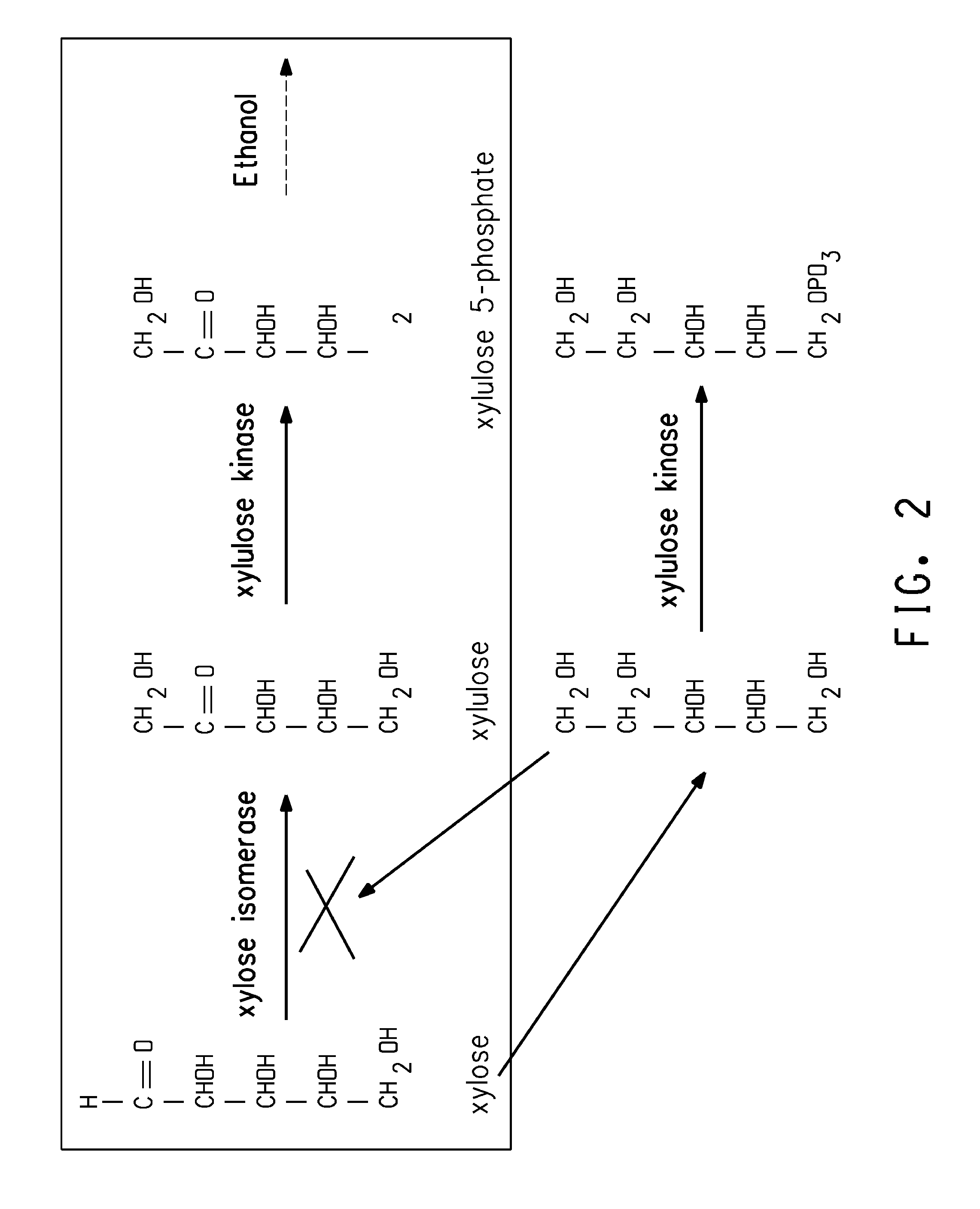

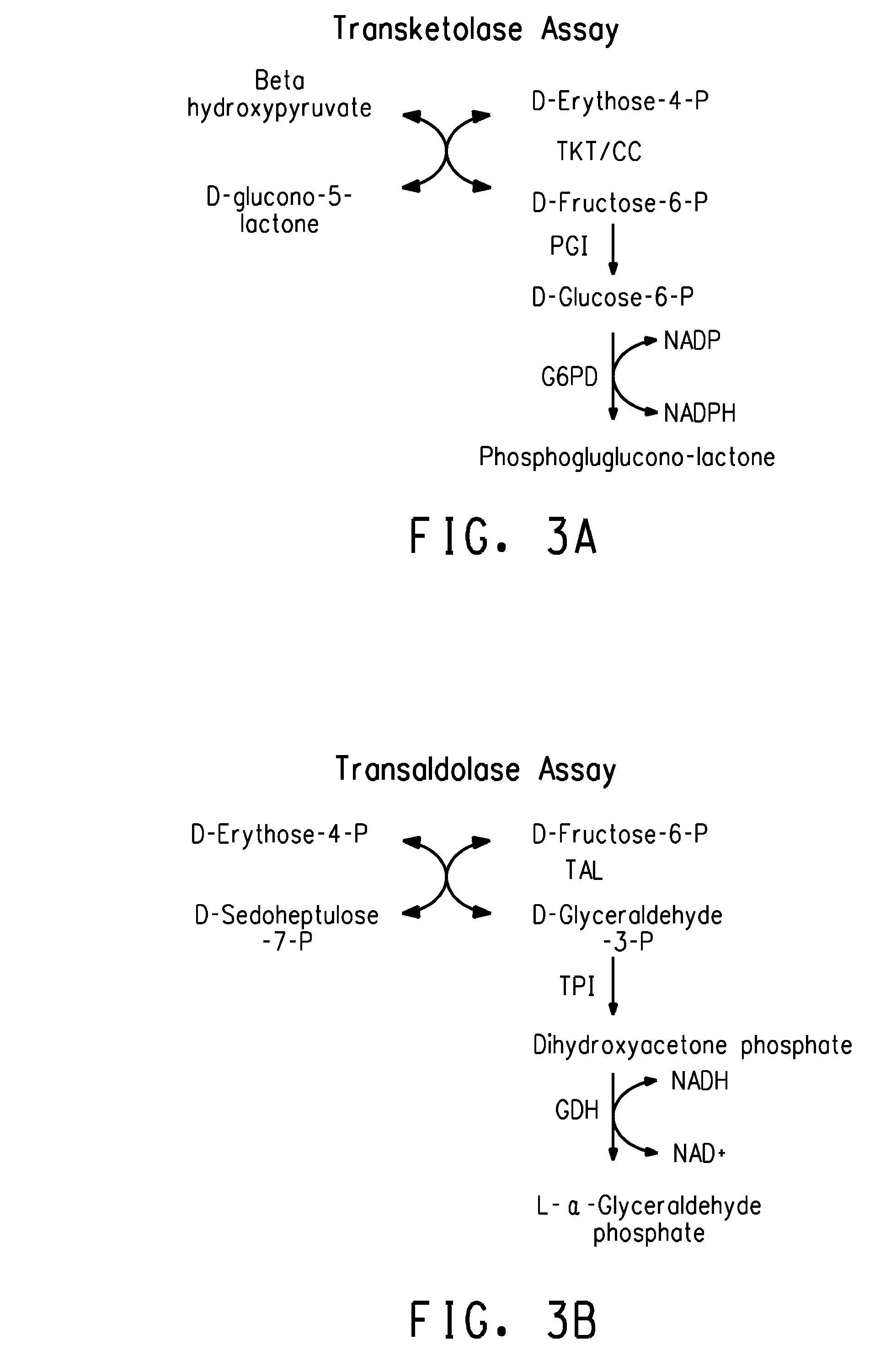

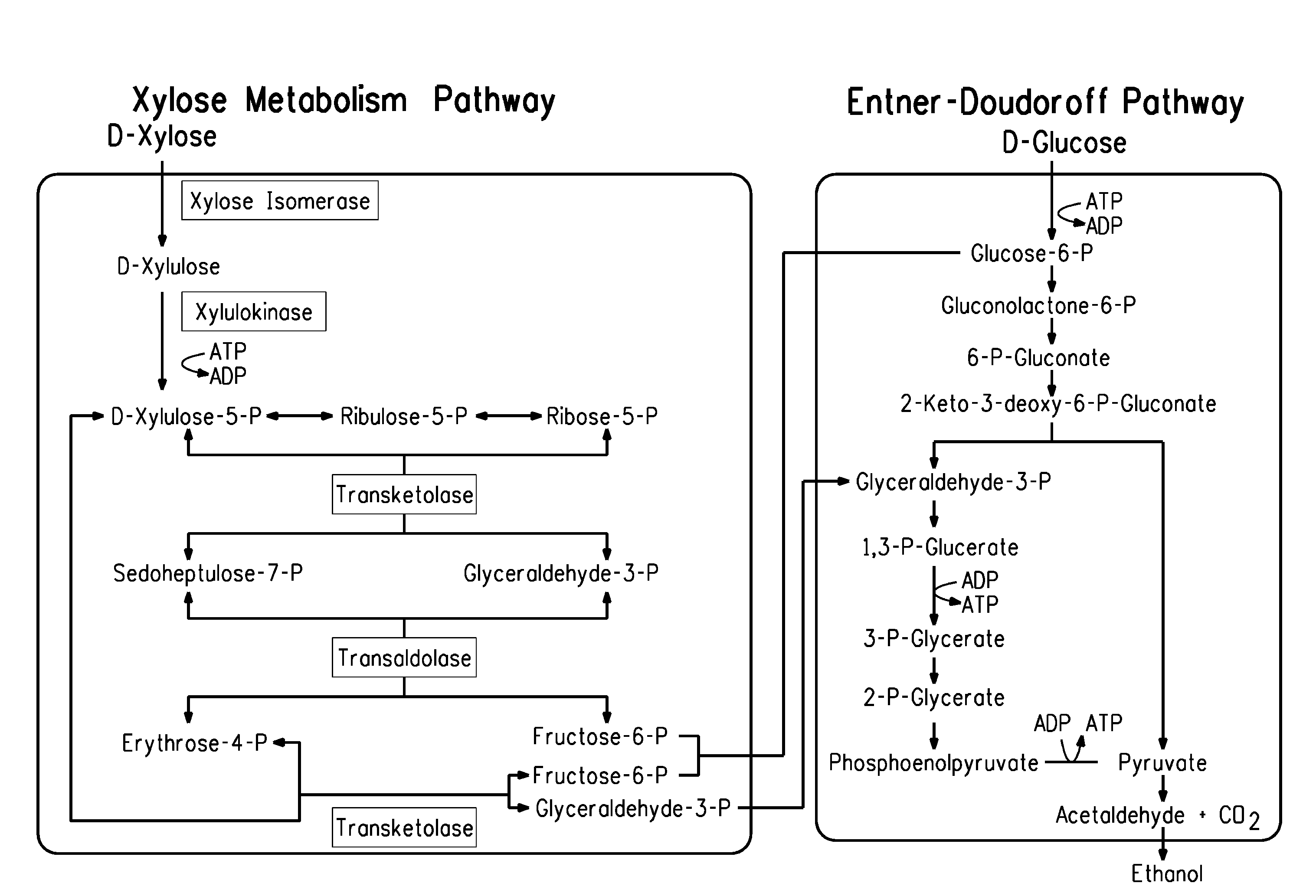

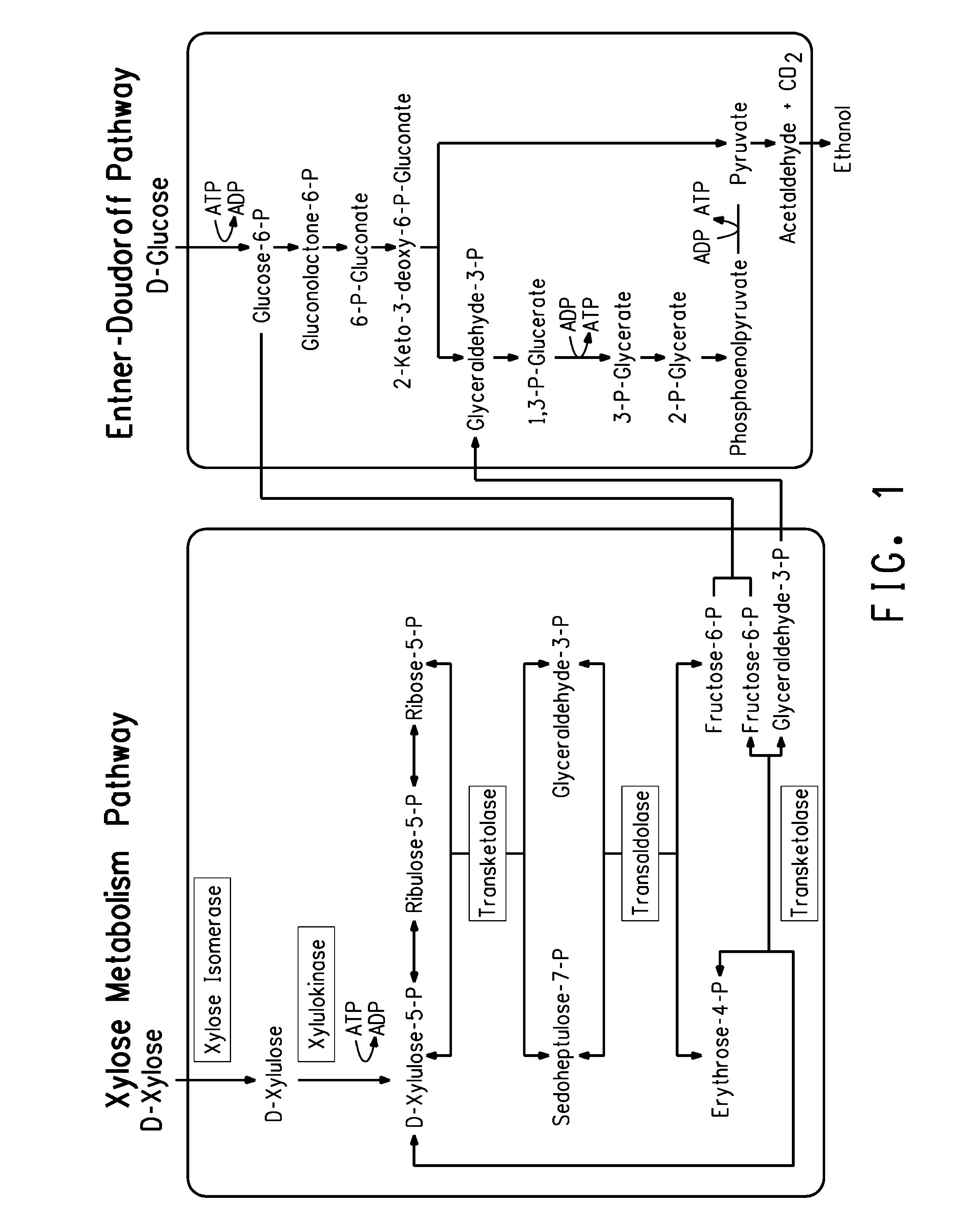

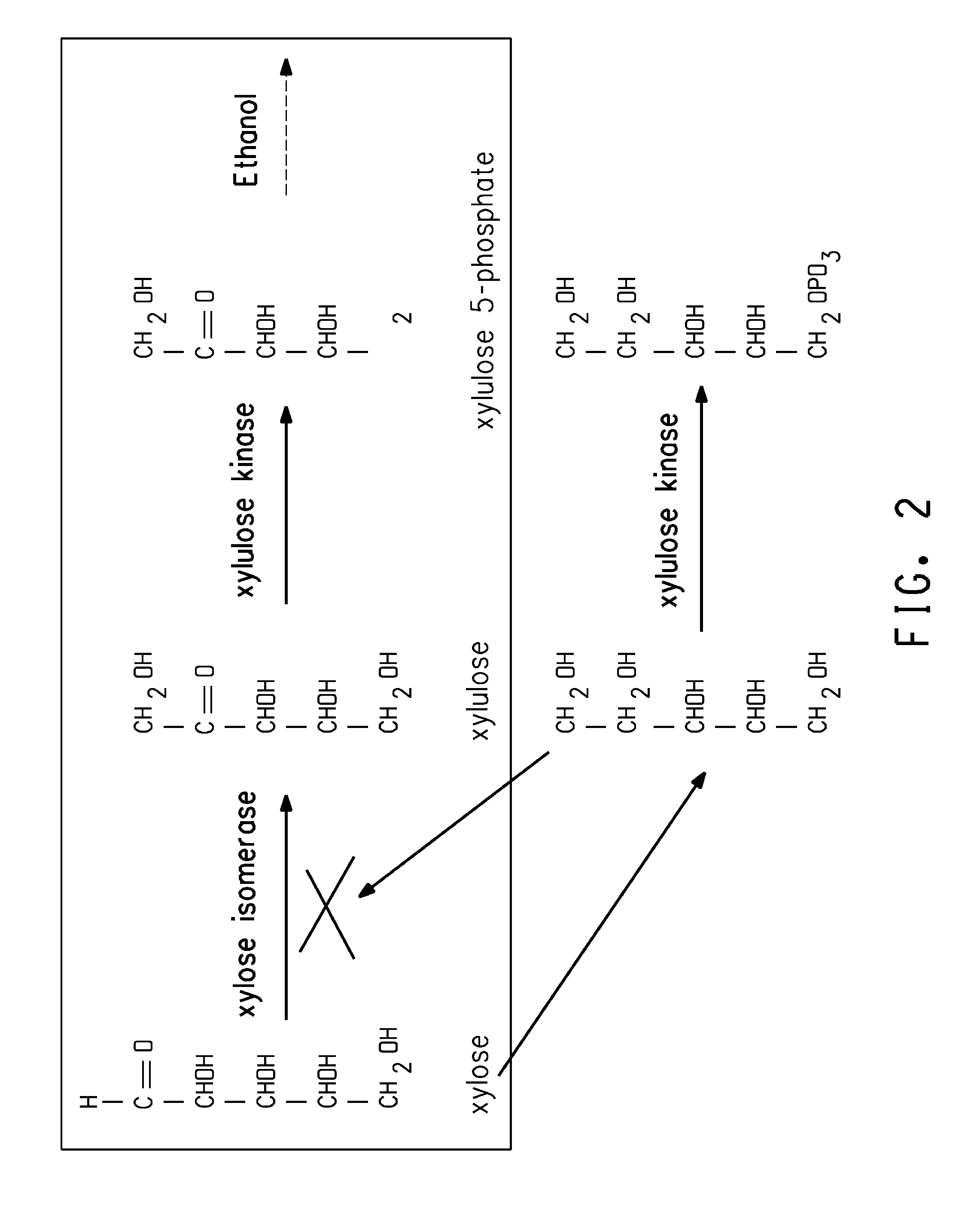

A strain of xylose-utilizing Zymomonas was engineered with a genetic modification to the glucose-fructose oxidoreductase gene resulting in reduced expression of GFOR enzyme activity. The engineered strain exhibits reduced production of xylitol, a detrimental by-product of xylose metabolism. It also consumes more xylose and produces more ethanol during mixed sugar fermentation under process-relevant conditions.

Owner:SUSTAINABLE TECH CORP +1

Xylitol synthesis mutant of xylose-utilizing zymomonas for ethanol production

InactiveUS20080286870A1Reduce productionIncreased ethanol productionBacteriaUnicellular algaeSugarGlucose-fructose oxidoreductase

A strain of xylose-utilizing Zymomonas was engineered with a genetic modification to the glucose-fructose oxidoreductase gene resulting in reduced expression of GFOR enzyme activity. The engineered strain exhibits reduced production of xylitol, a detrimental by-product of xylose metabolism. It also consumes more xylose and produces more ethanol during mixed sugar fermentation under process-relevant conditions.

Owner:SUSTAINABLE TECH CORP +1

Ethanol production using xylitol synthesis mutant of xylose-utilizing zymomonas

InactiveUS7741084B2Reduce productionIncreased ethanol productionBacteriaBiofuelsFructoseMicrobiology

Production of ethanol using a strain of xylose-utilizing Zymomonas with a genetic modification of the glucose-fructose oxidoreductase gene was found to be improved due to greatly reduced production of xylitol, a detrimental by-product of xylose metabolism synthesized during fermentation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Treatment Systems and Processes for Lignocellulosic Substrates that Contain Soluble Carbohydrates

InactiveUS20090061495A1Lowering capital cost per unit of ethanol producedImprove throughputBiofuelsFermentationDistillationPolymer

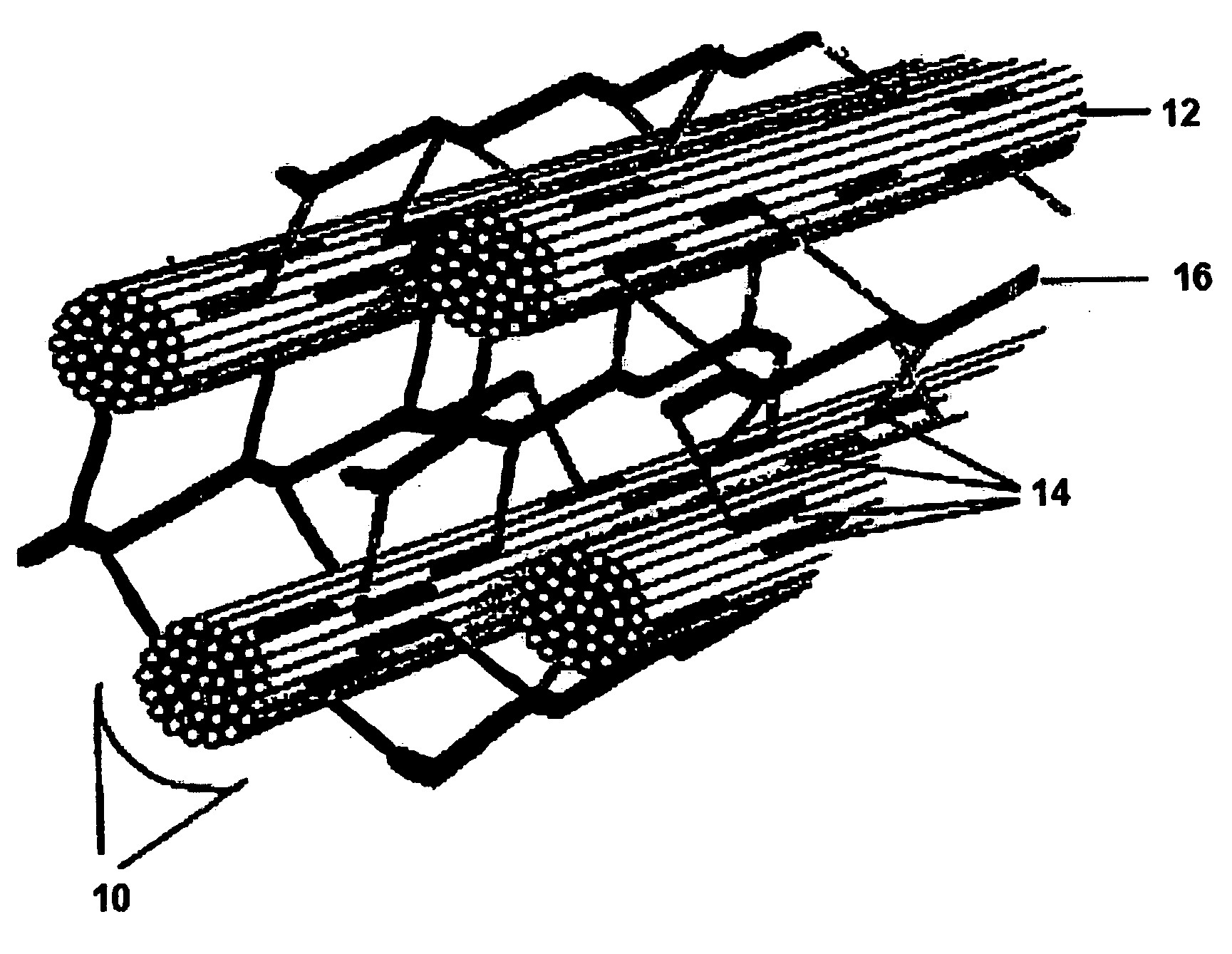

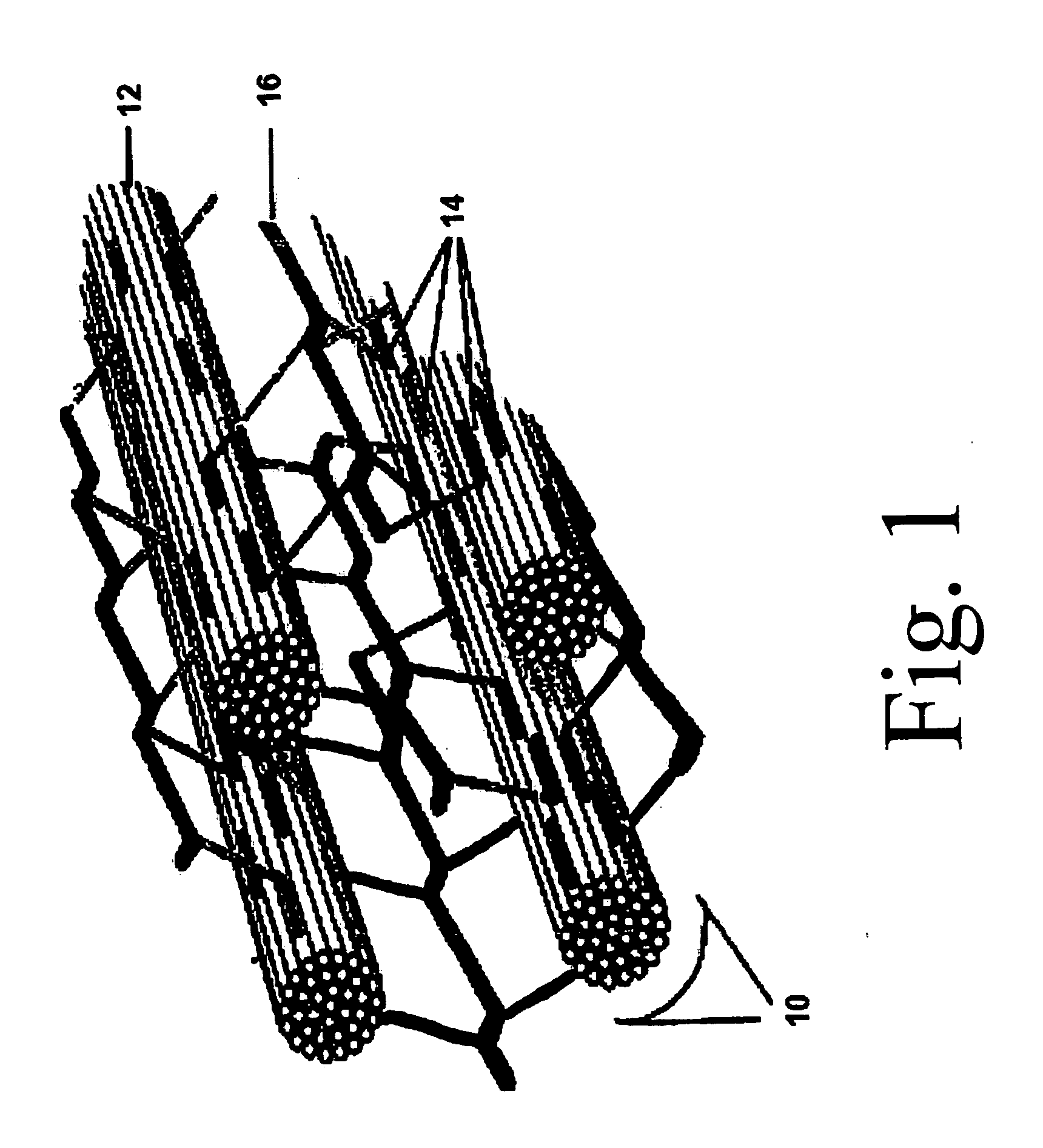

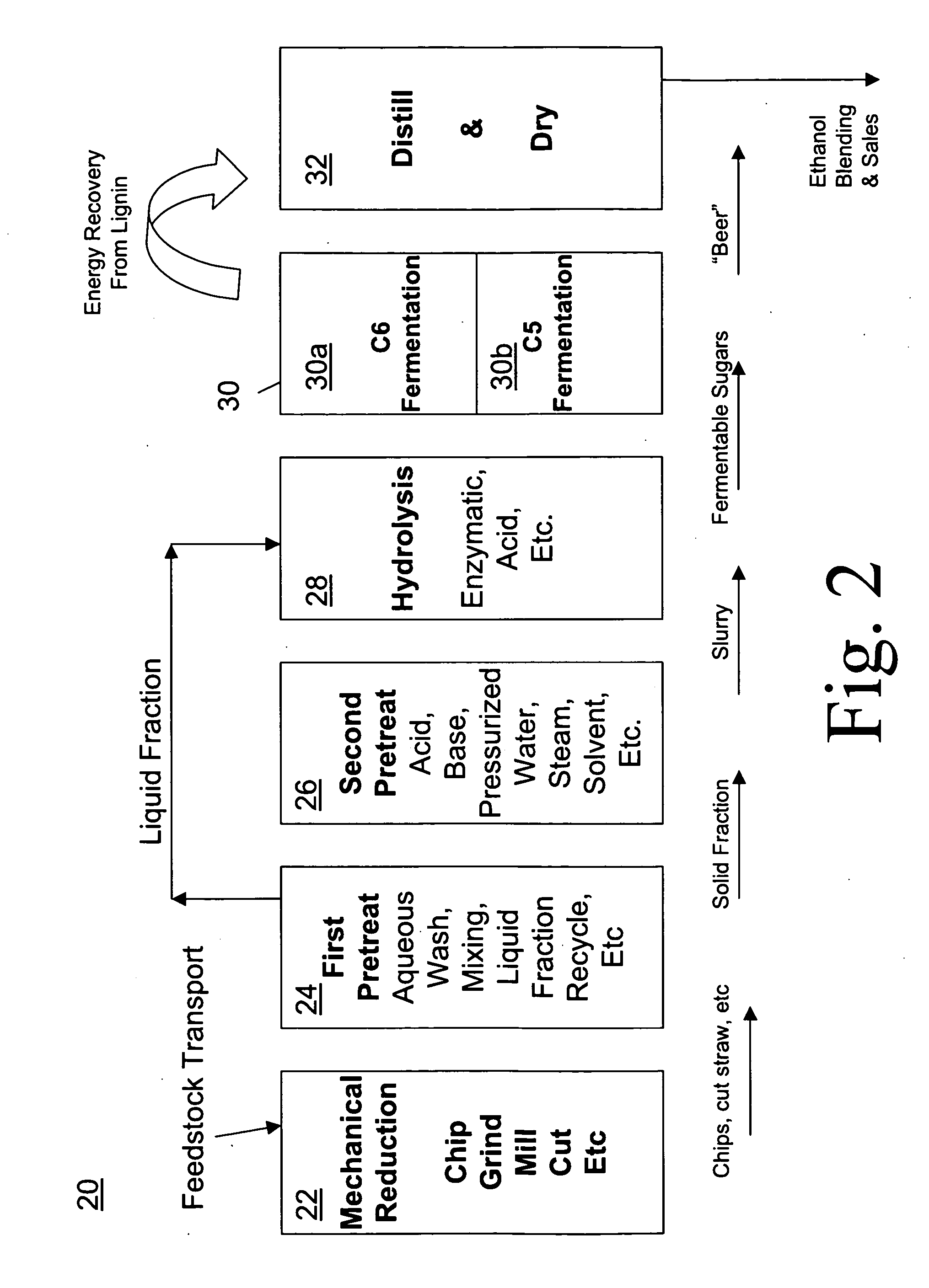

A biorefining process used to convert lignocellulosic biomass into ethanol via a fermentation pathway. In a first pretreatment process step, the biomass is mixed with an aqueous wash solution to remove soluble carbohydrates from the biomass structure. Next, the solid fraction is separated from a liquid fraction. In a second pretreatment process, the solid fraction is pre-treated to make the fiber bundles and complex polysaccharides more amenable to enzymatic hydrolysis. Following the second pretreatment process, the pre-treated biomass is subjected to one or more enzymes in a hydrolysis process. The liquid fraction isolated from the first pretreatment process is diverted past the second pretreatment process and is recombined with the solid fraction in the hydrolysis process. The enzyme cocktail in the hydrolysis process breaks down the alpha- and hemicellulose polymers into fermentable sugars. Finally, a fermentation process produces a “beer” that is further processed in a distillation and dehydration process.

Owner:BEATTY CHRIS +2

Ethanol production using xylitol synthesis mutant of xylose-utilizing zymomonas

InactiveUS20080187973A1Speed up the conversion processReduces glucose-fructose oxidoreductase activityBacteriaBiofuelsMutantZymomonas

Production of ethanol using a strain of xylose-utilizing Zymomonas with a genetic modification of the glucose-fructose oxidoreductase gene was found to be improved due to greatly reduced production of xylitol, a detrimental by-product of xylose metabolism synthesized during fermentation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

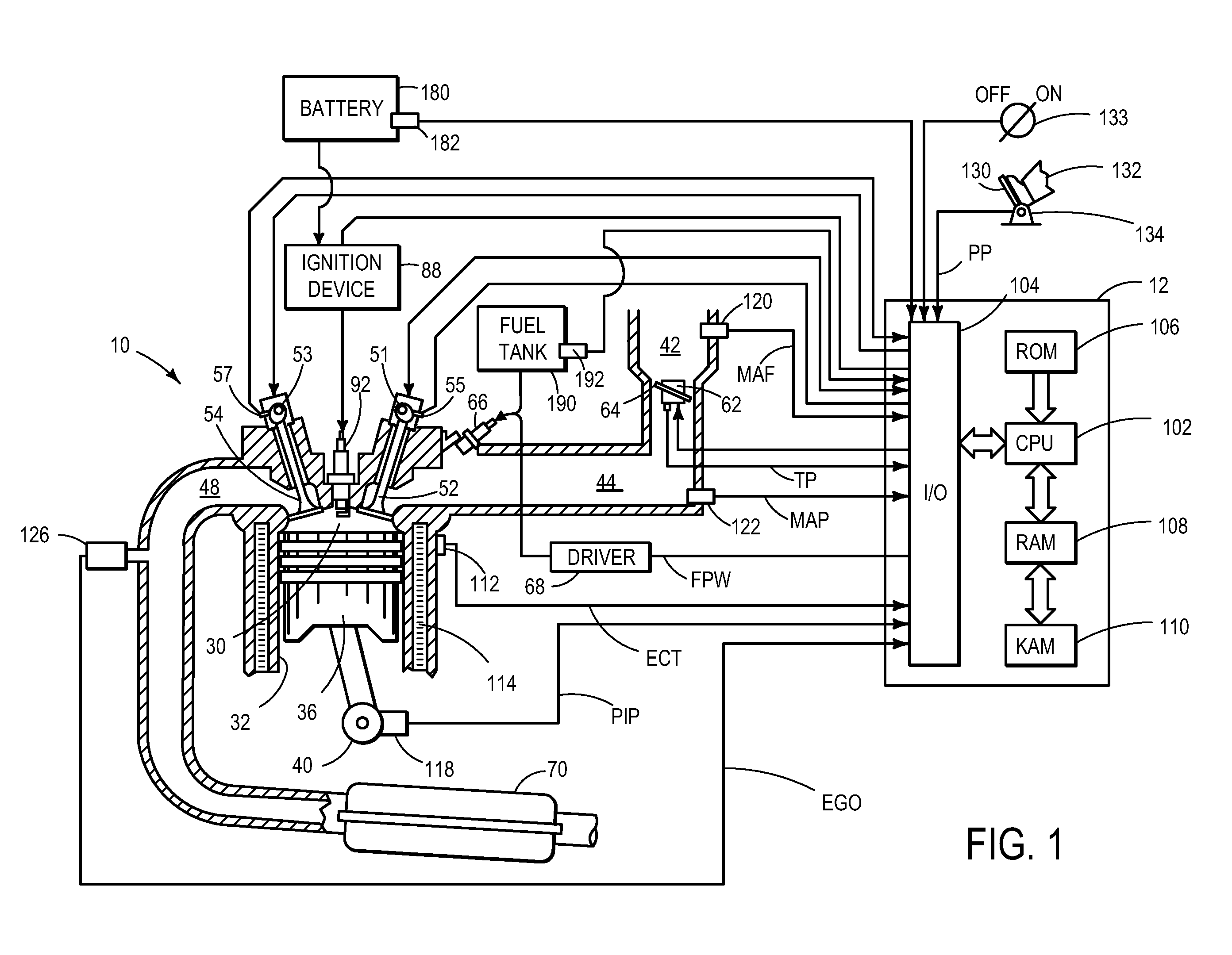

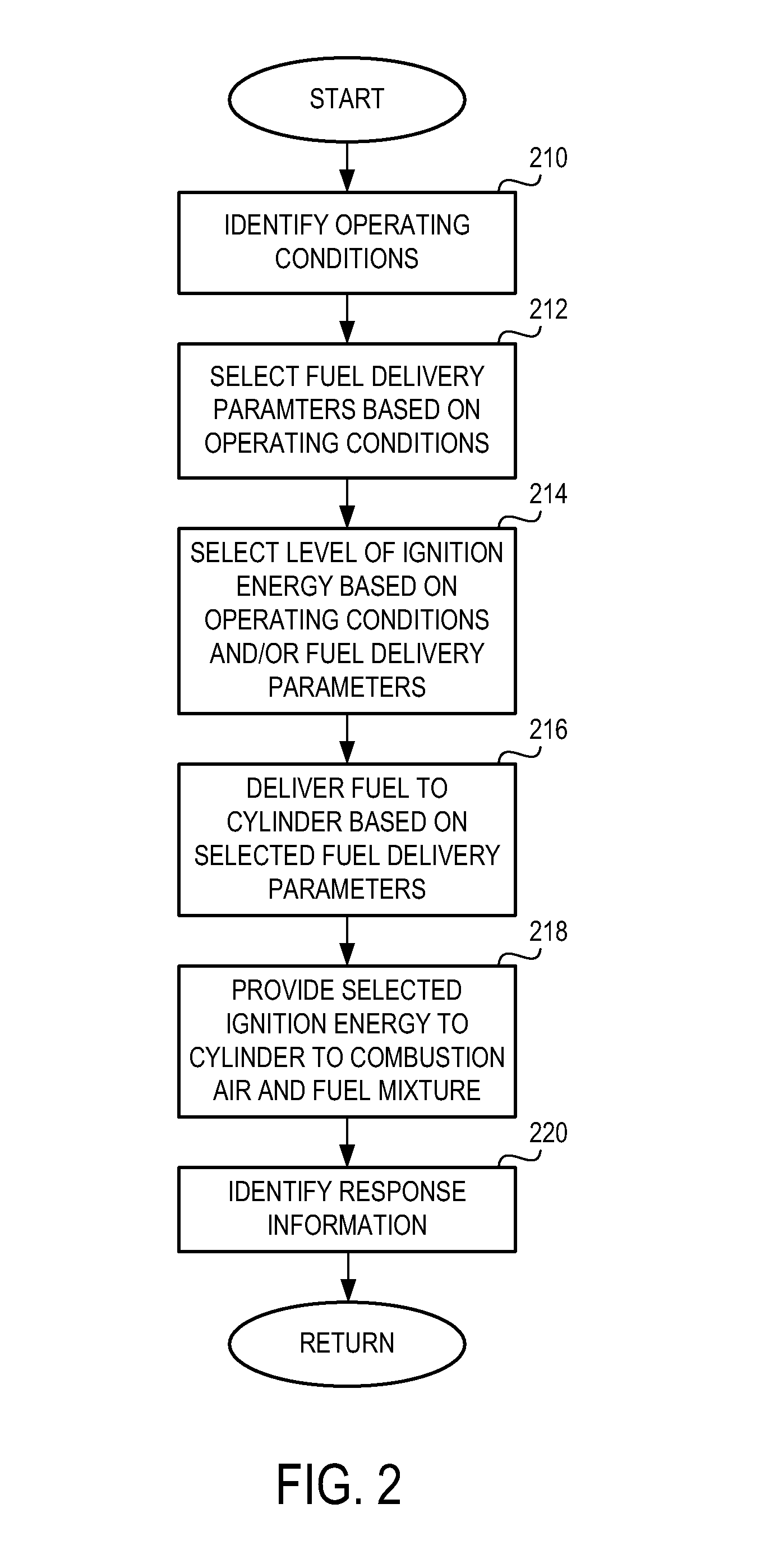

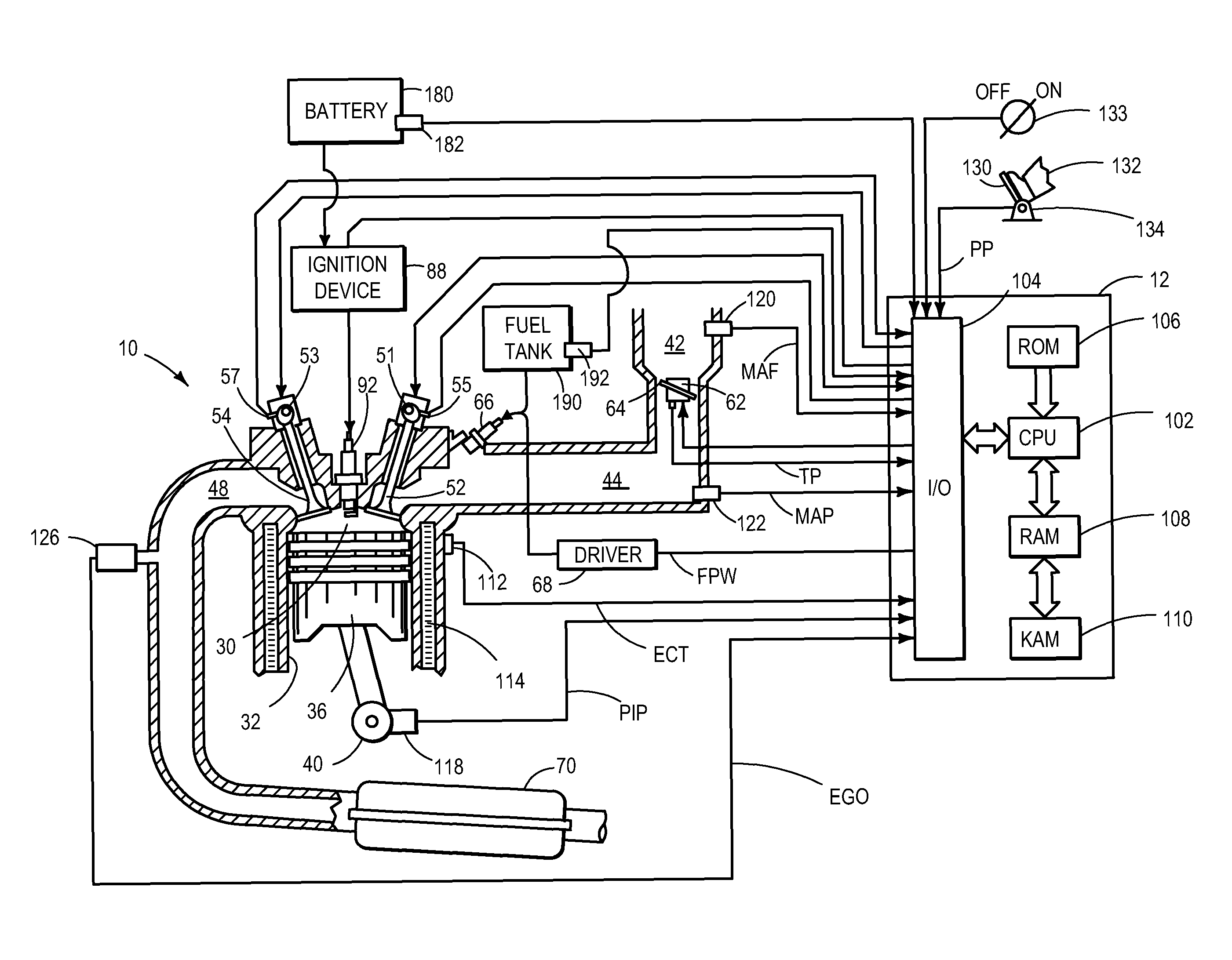

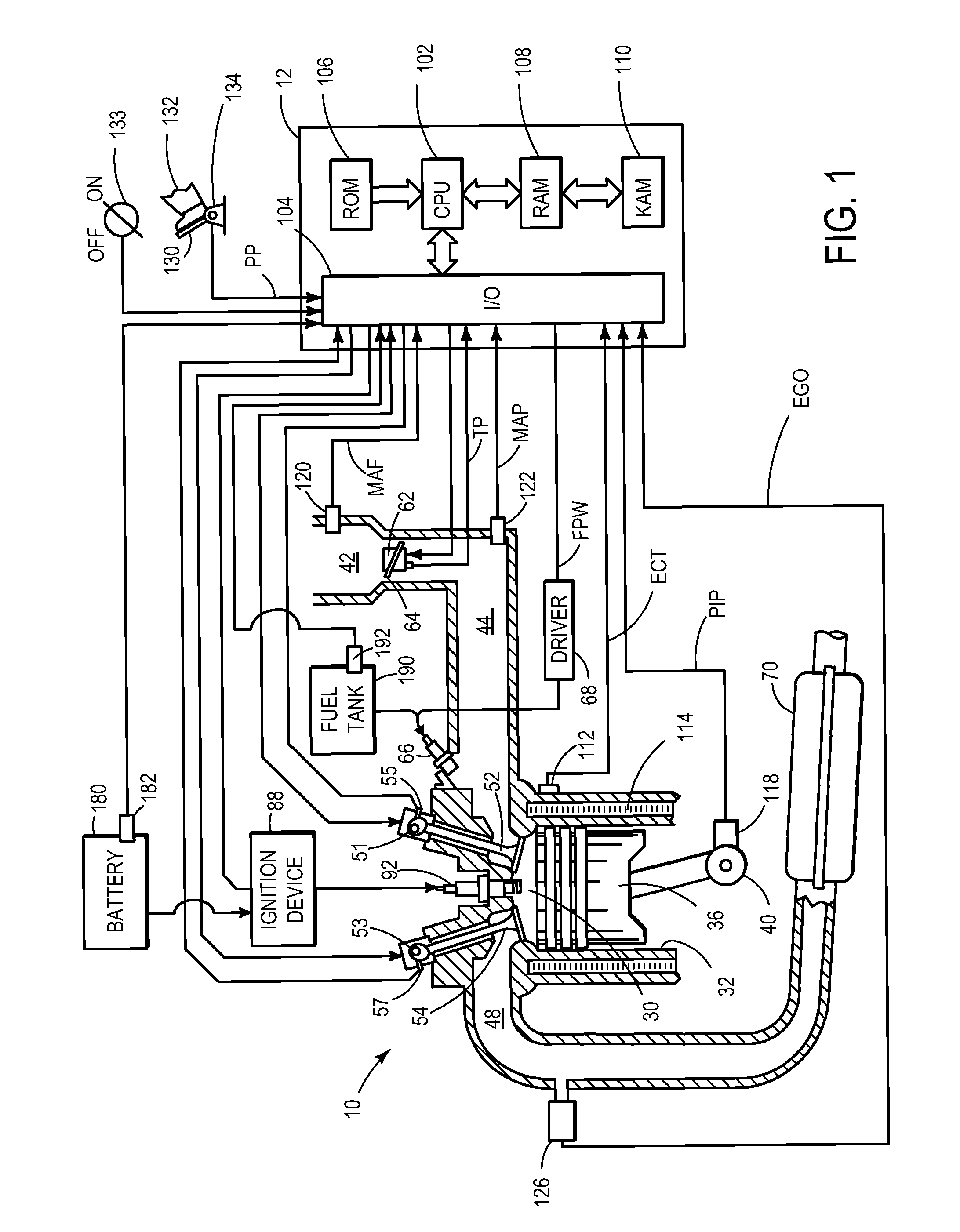

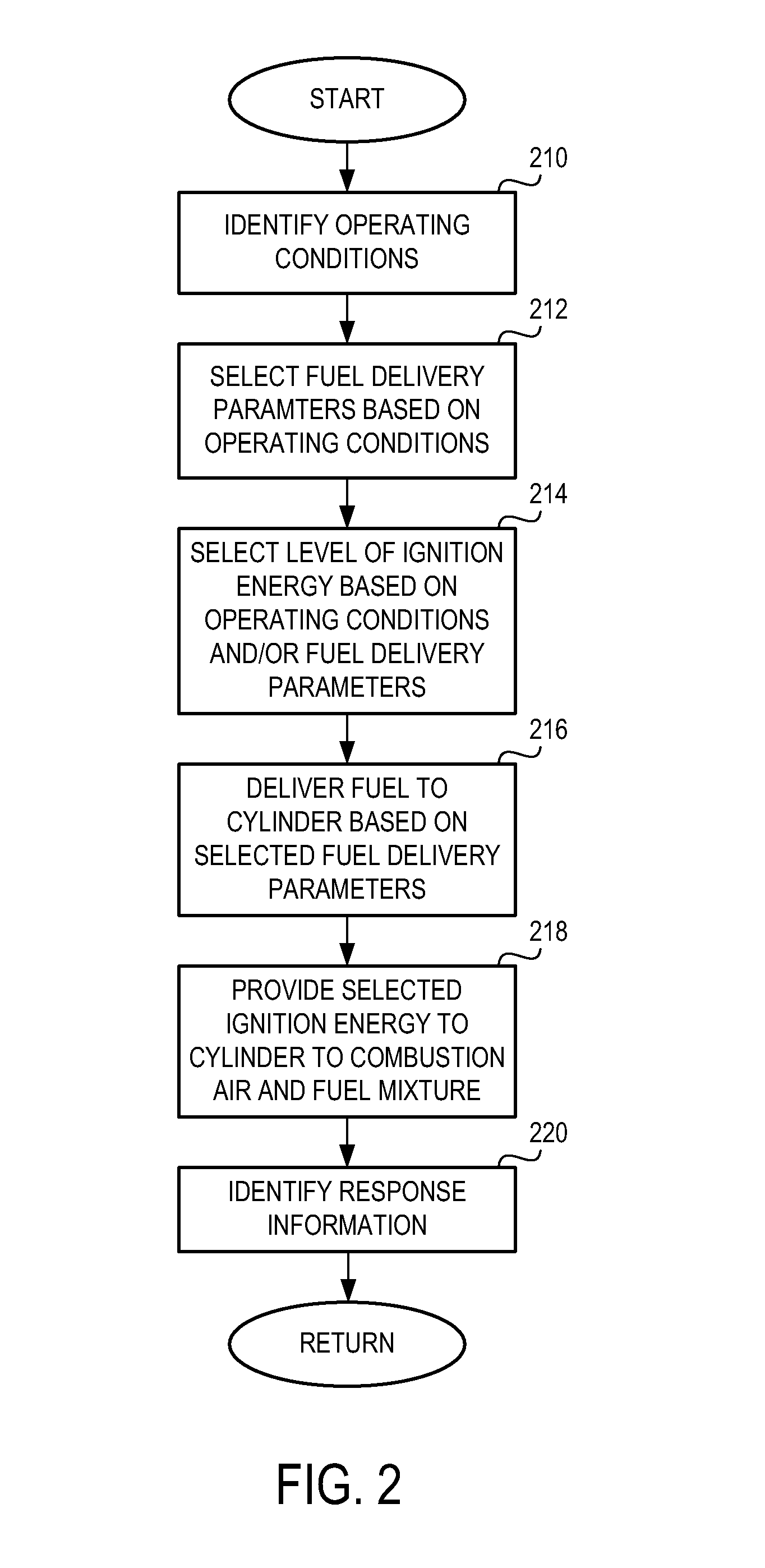

Ignition Energy Control for Mixed Fuel Engine

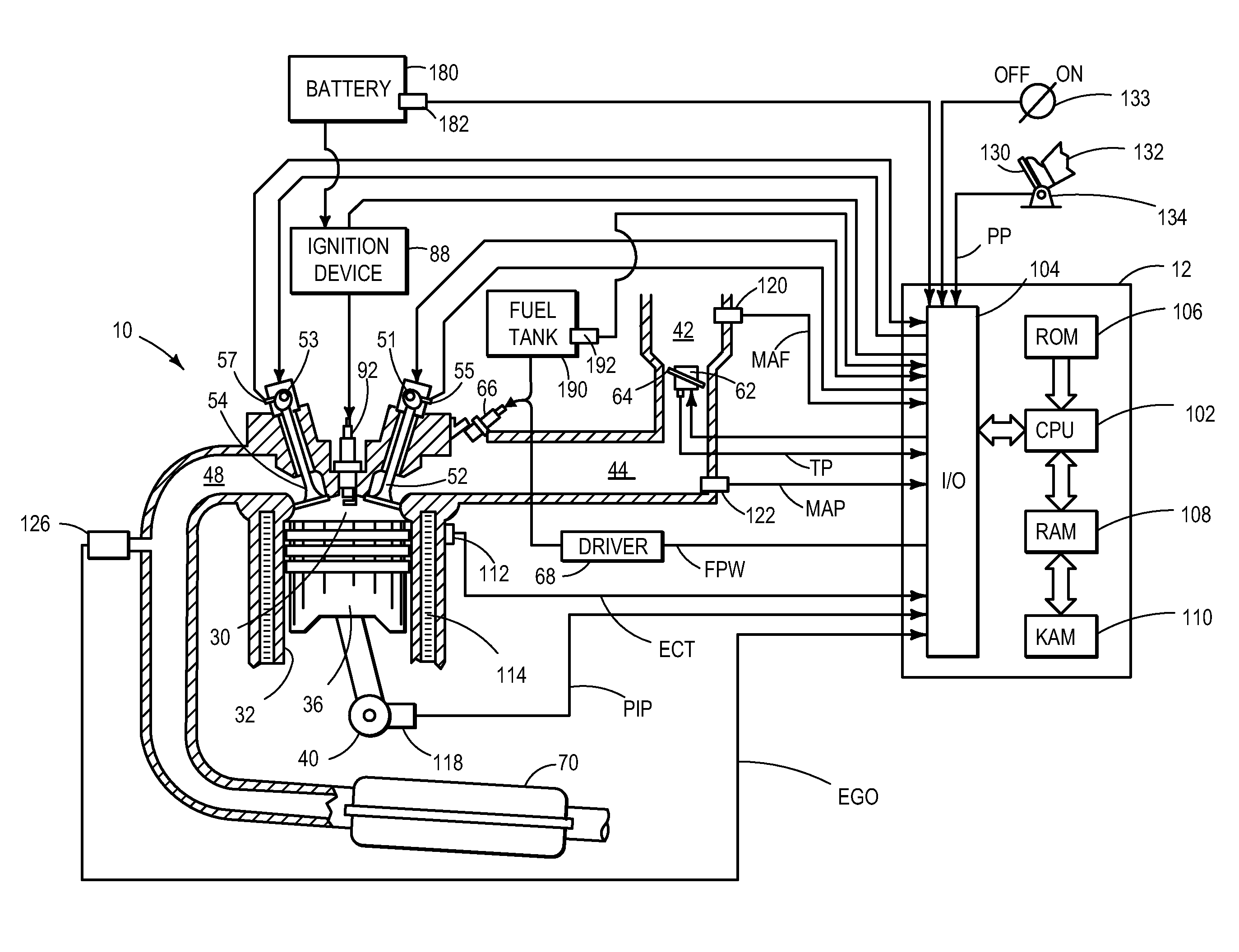

InactiveUS20090114188A1Improve combustion qualityImprove the level ofElectrical controlOther installationsEnergy controlControl system

As one example, an engine system for a vehicle is provided, including an internal combustion engine having at least one cylinder; a fuel system configured to provide a fuel to the cylinder; an ignition system including at least a spark plug; a control system configured to vary a level of ignition energy provided to the cylinder via the spark plug in response to a composition of the fuel provided to the cylinder by the fuel system. A method of operating the engine system by varying a level of ignition energy provided to the engine after a start-up is also provided.

Owner:FORD GLOBAL TECH LLC

Method of preparing high concentration ethanol fermentation liquid by paddy rice raw material fermentation

InactiveCN1442483ALow costIncrease ethanol concentrationBiofuelsFermentationAmylaseHigh concentration

A process for preparing fermented high-concentration alcohol liquid from raw rice grains includes such steps as pulverizing, sieving by more than 40 meshes, dissolving in water at 34-36 deg.C, addingcomposite enzyme prepared from beta-amylase, alpha-emylase, acidic proteinase, cellulose, xylanase, pectase, phytase and dry yeast, and fermenting at 30-40 deg.C for 60-95 hr. Its advantages are simple process, low cost and high concentration.

Owner:TIANJIN UNIV

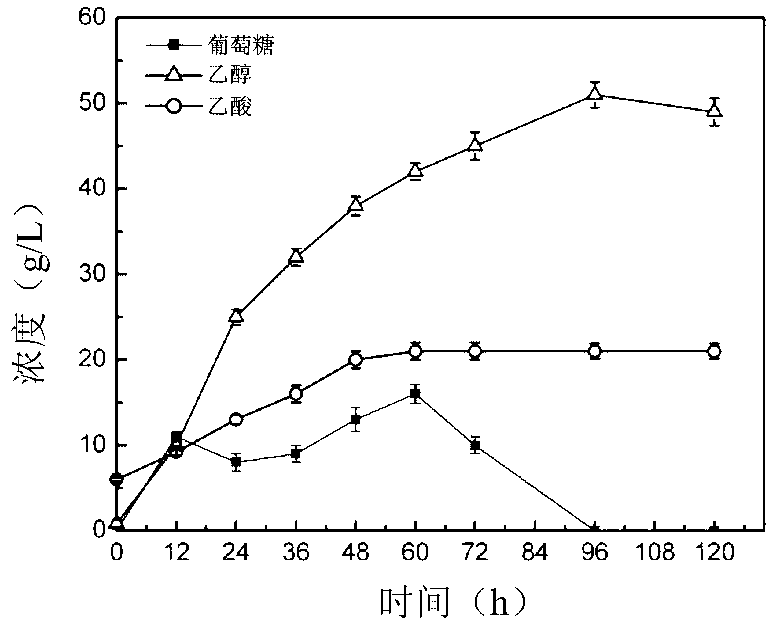

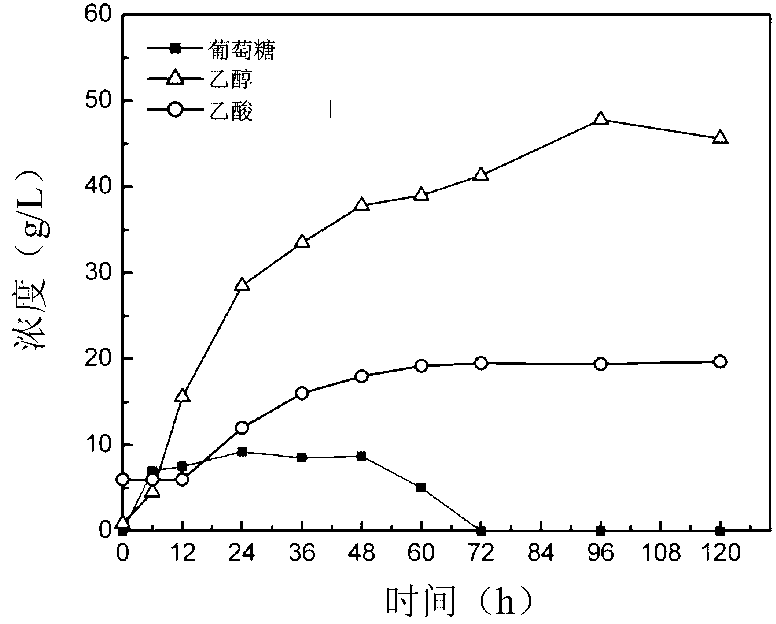

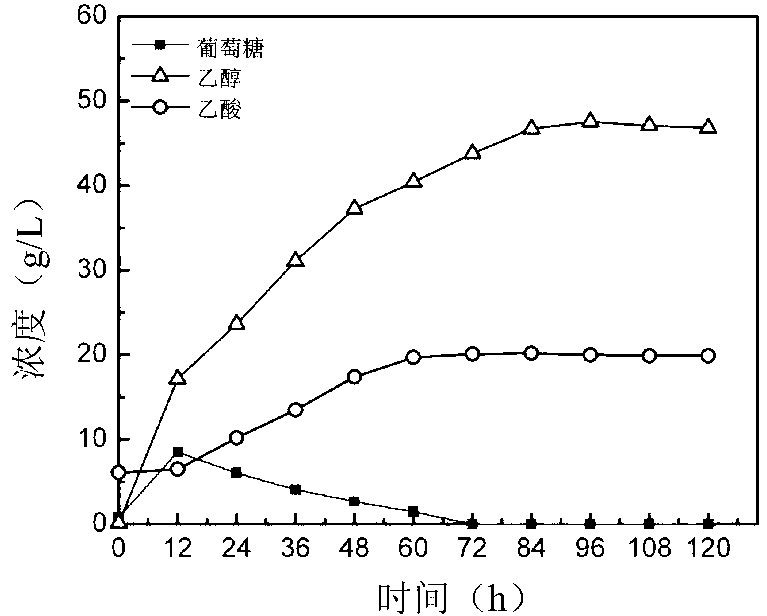

Synchronous saccharification and ethanol fermentation method with lignocelluloses treated by steam explosion method as raw material

InactiveCN103103220AReduce consumptionIncrease ethanol concentrationBiofuelsMicroorganism based processesHigh concentrationBeta-glucosidase

The invention provides a synchronous saccharification and ethanol fermentation method with lignocelluloses treated by a steam explosion method as raw material. The method comprises the following steps of taking the lignocelluloses treated by the steam explosion method as raw material and directly as a substrate without detoxification, adding mixed enzyme comprising cellulase and beta-glucosaccharase, simultaneously inoculating (Saccharomyces cerevisiae) Y5 with CGMCC (China General Microbiological Culture Collection Center) NO. 2660, adding a nitrogen source, and carrying out ethanol fermentation production. According to the method, the step of detoxification by washing the lignocelluloses (such as maize straw) pre-treated by steam explosion is omitted, and the final fermented product of ethanol of high concentration is obtained. For example, the concentration for steam explosion of the maize straw is 30%, synchronous saccharification and fermentation time is 96 hours, and the ethanol concentration of a reactor of 100ml, a reactor of 3000ml and a fermentation tank of 5L respectively reaches 50g / L, 47.8g / L and 47.5g / L. The production technology is greatly simplified, the equipment investment is lowered, water consumption is reduced, and the production cost is lowered.

Owner:CAPITAL NORMAL UNIVERSITY

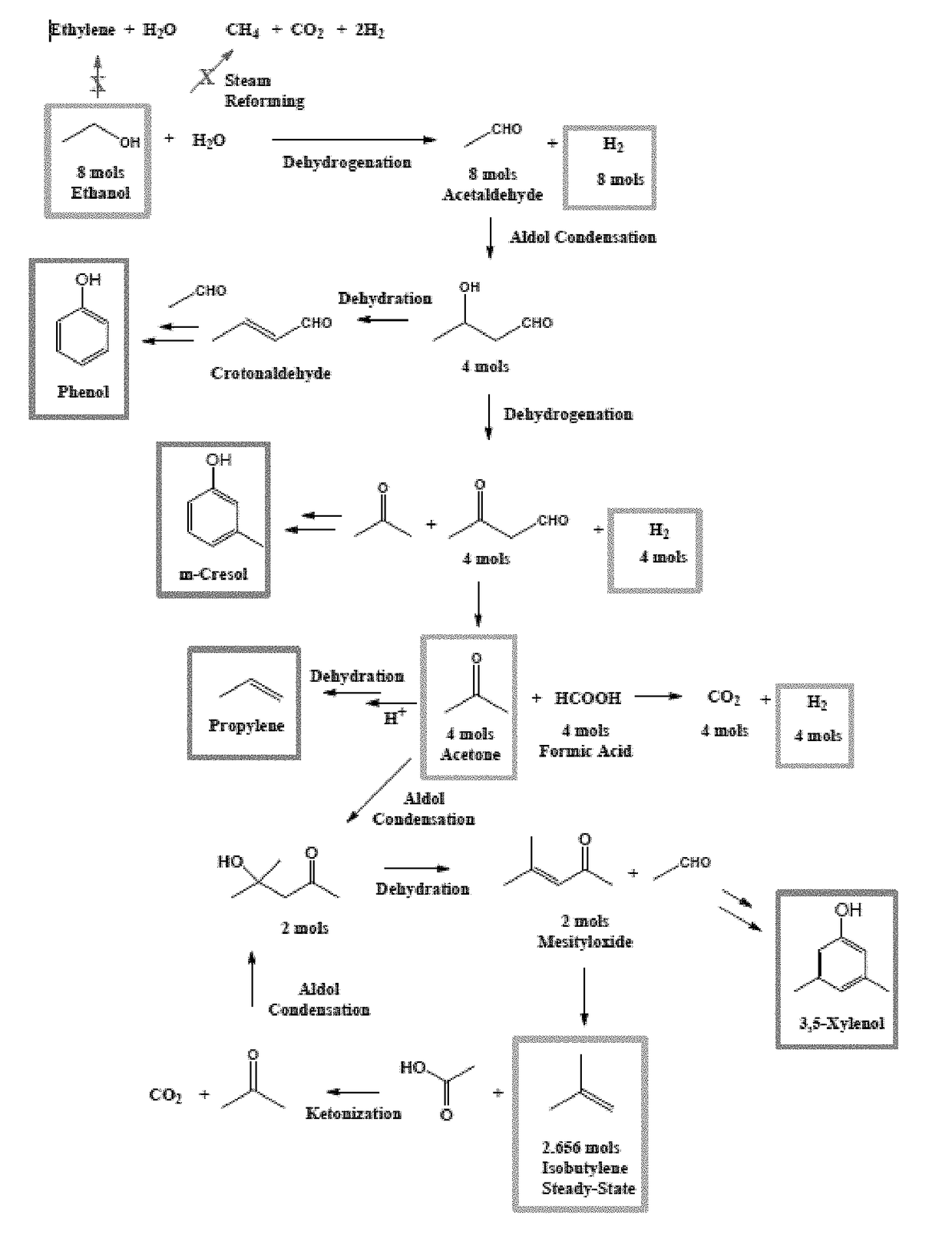

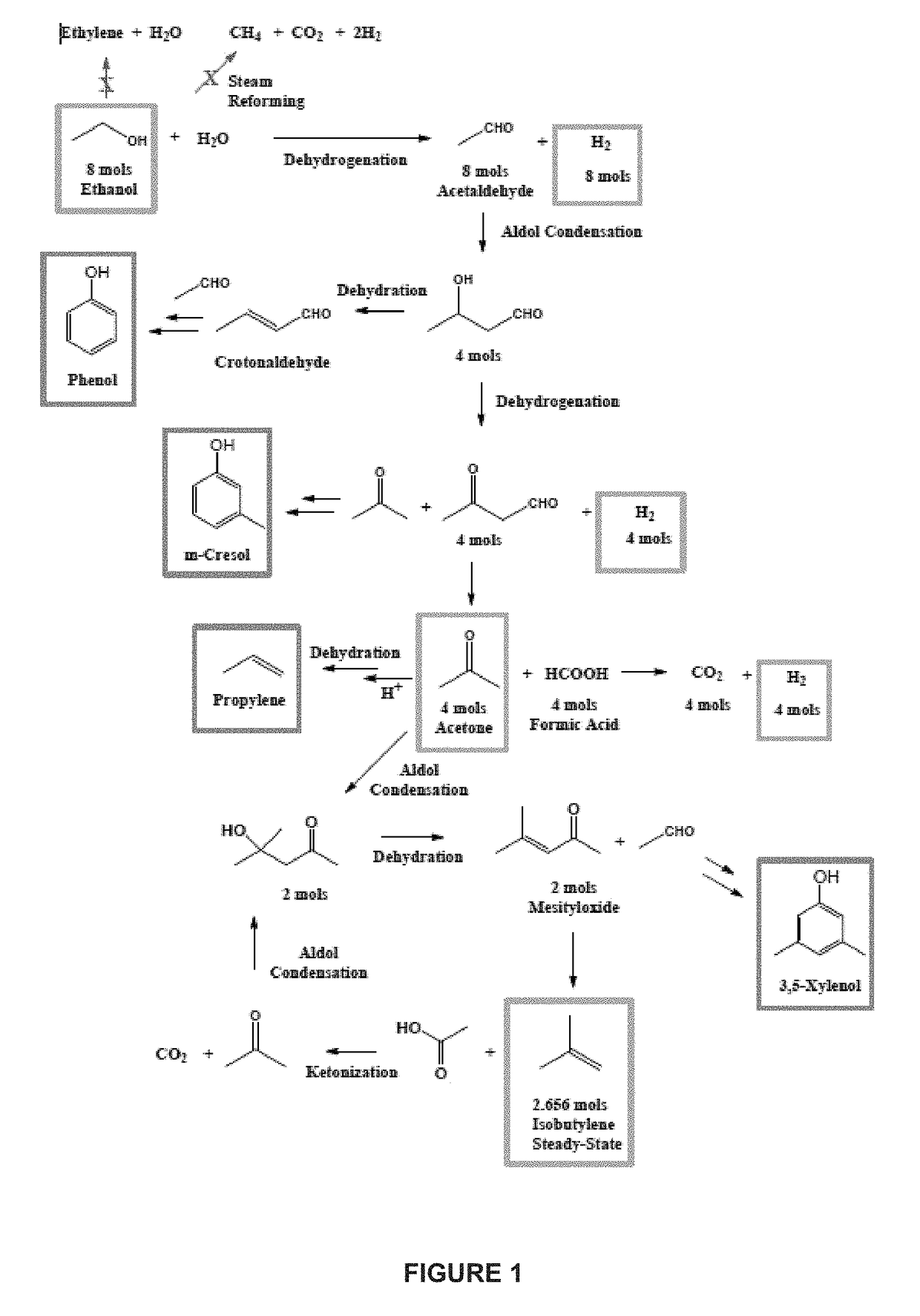

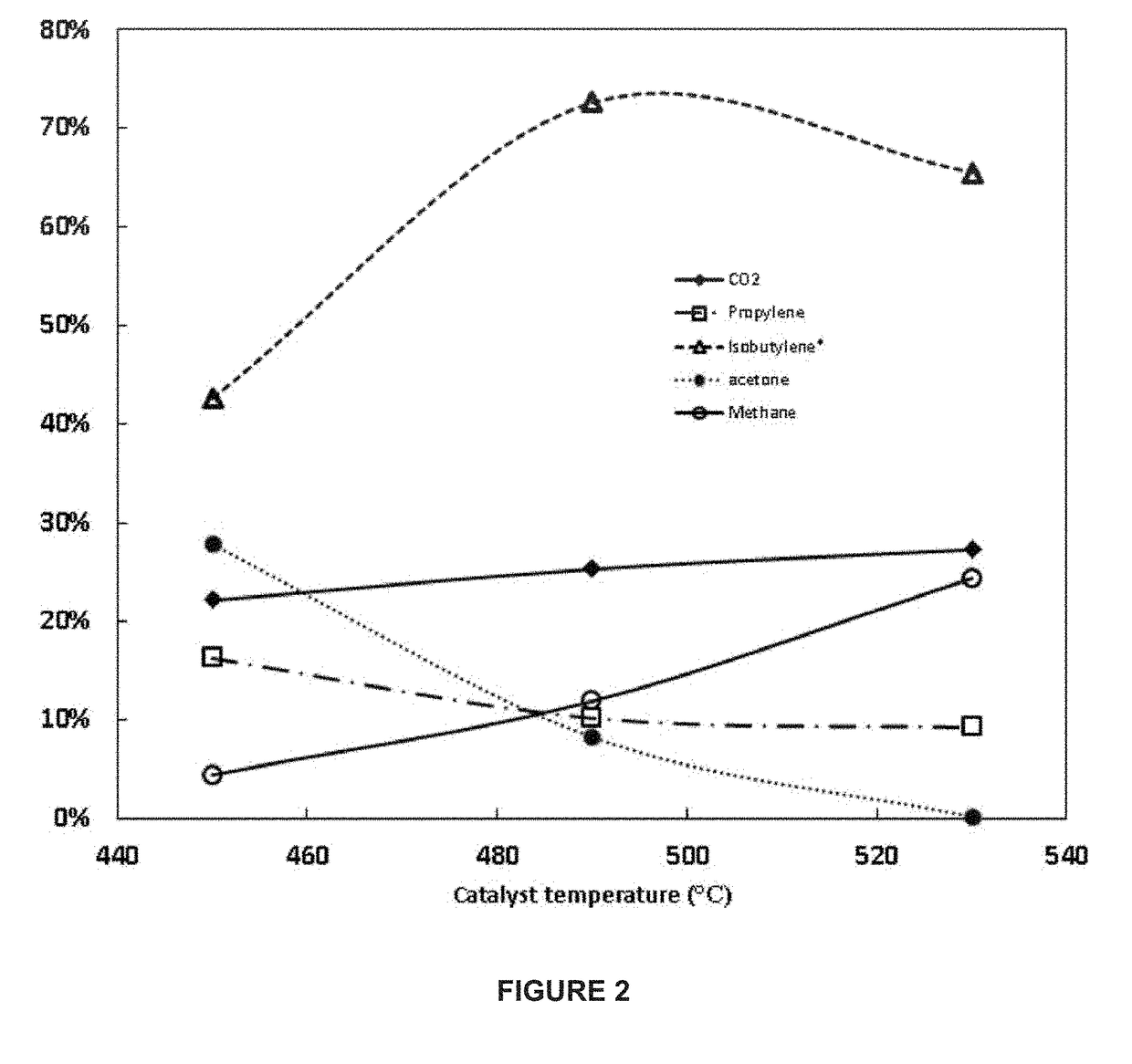

Methods for conversion of ethanol to functionalized lower hydrocarbons and downstream hydrocarbons

ActiveUS20170226028A1High selectivityEconomically beneficialBiofuelsBulk chemical productionMixed oxideHomogeneous catalysis

This application relates to the production of functionalized lower hydrocarbons and more particularly to the process of converting ethanol to functionalized lower hydrocarbons. In particular embodiments, the ethanol to functionalized lower hydrocarbon conversion is catalyzed by a ZnxZryAvQsMnwOz mixed oxide catalyst or a bifunctional heterogeneous catalyst. In particular embodiments, the ethanol to be converted is present at molar concentrations in the reactor feed equal to or exceeding 14%.

Owner:GEVO INC

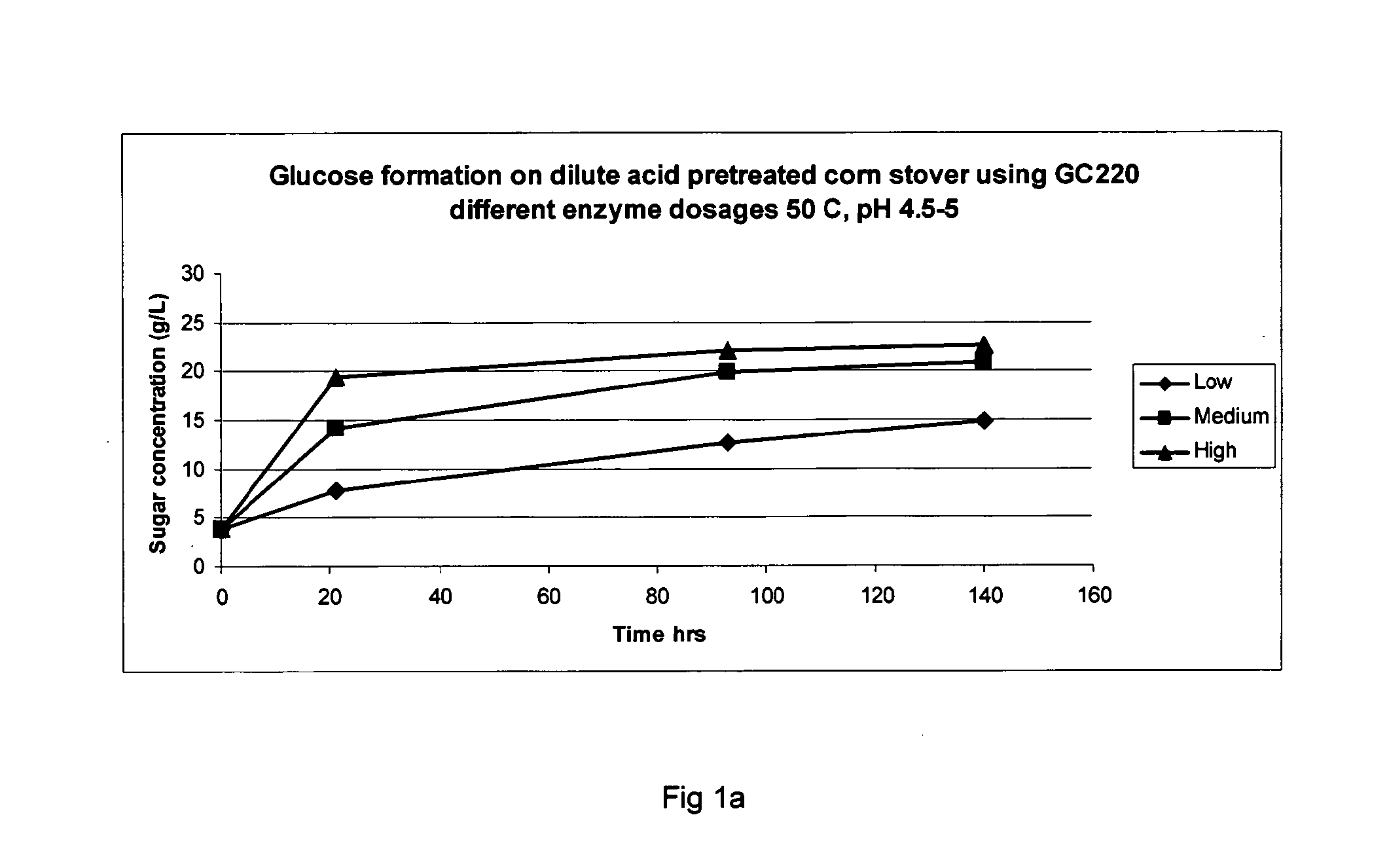

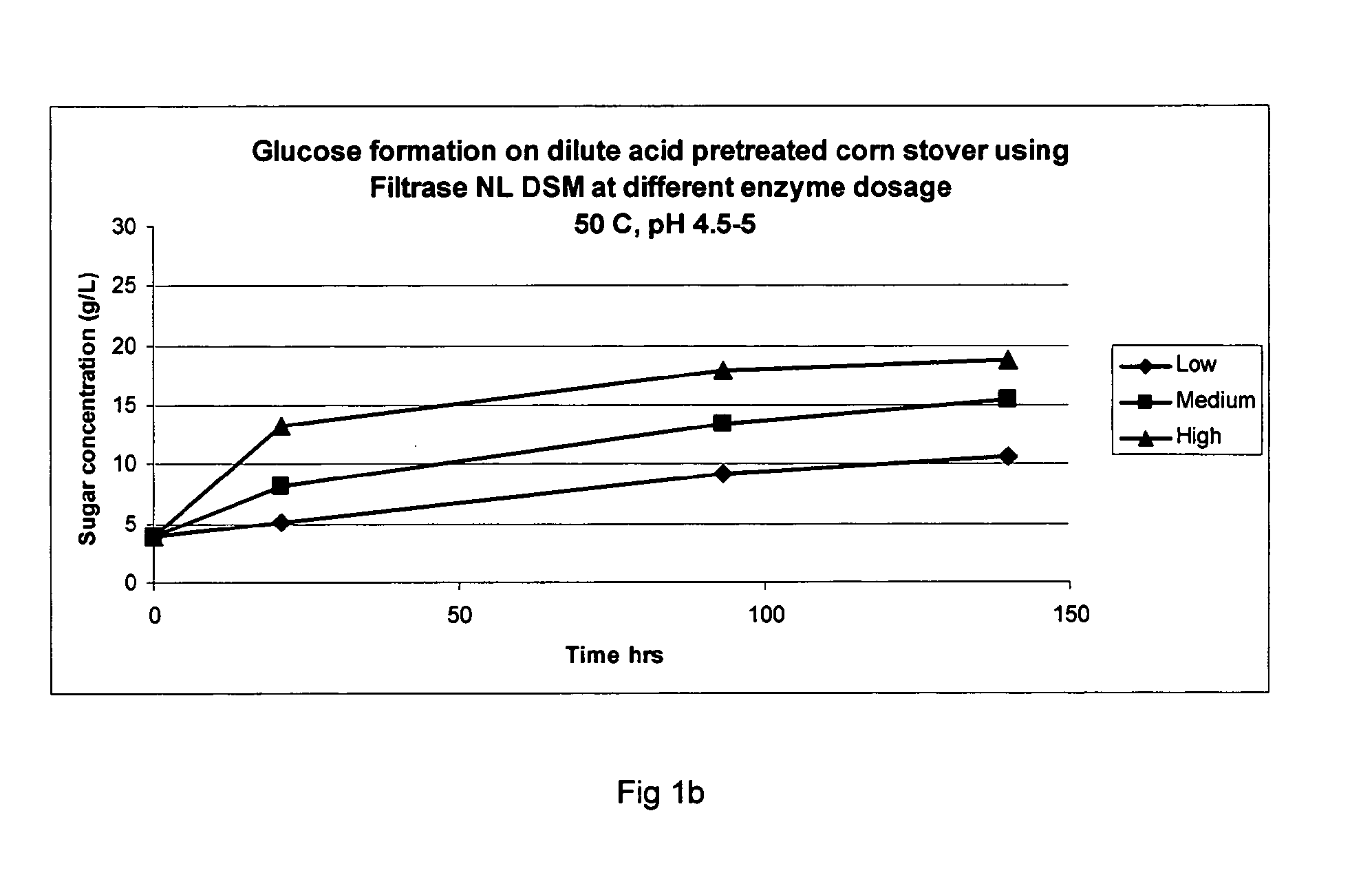

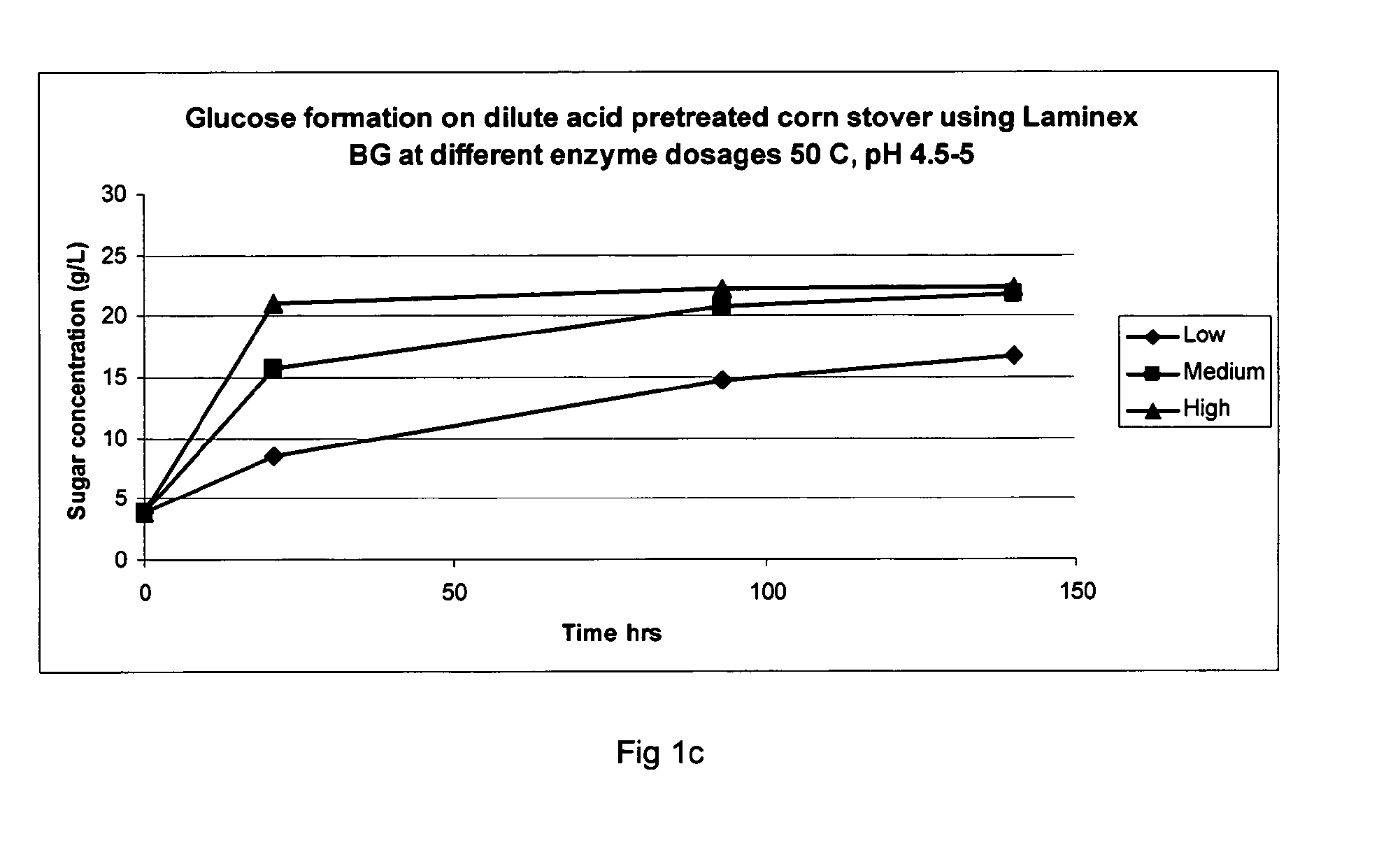

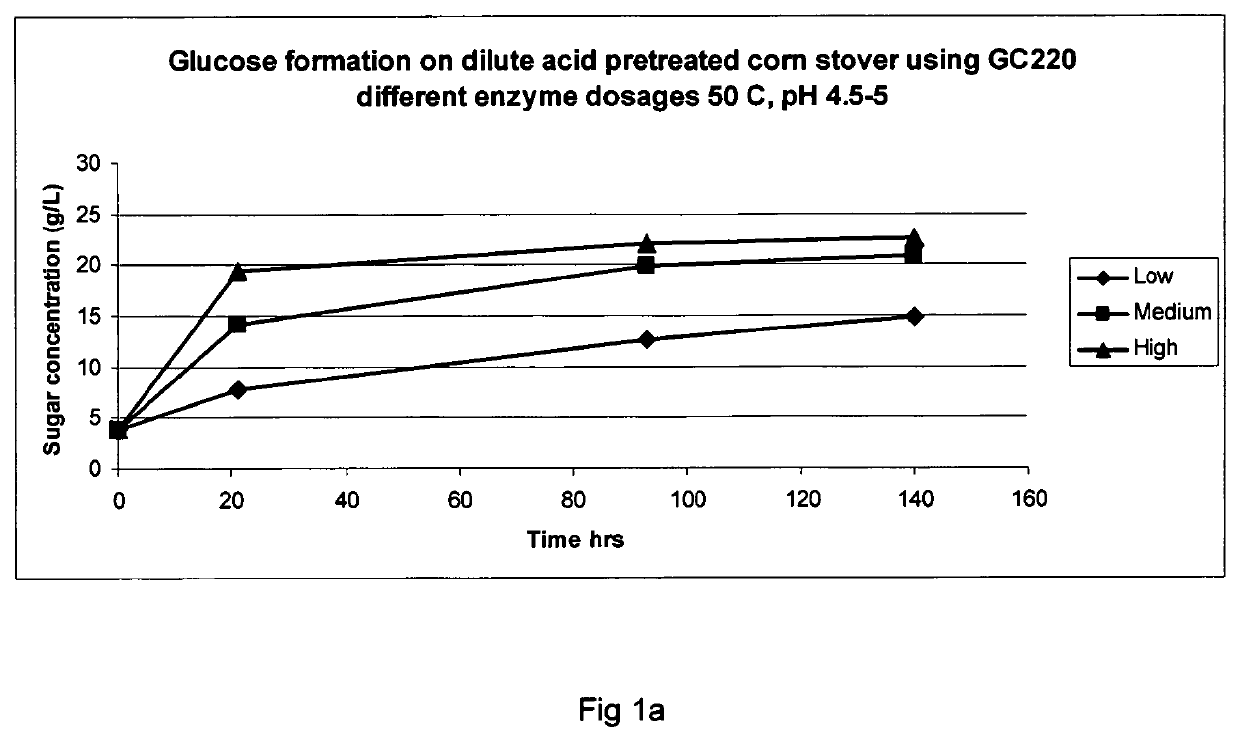

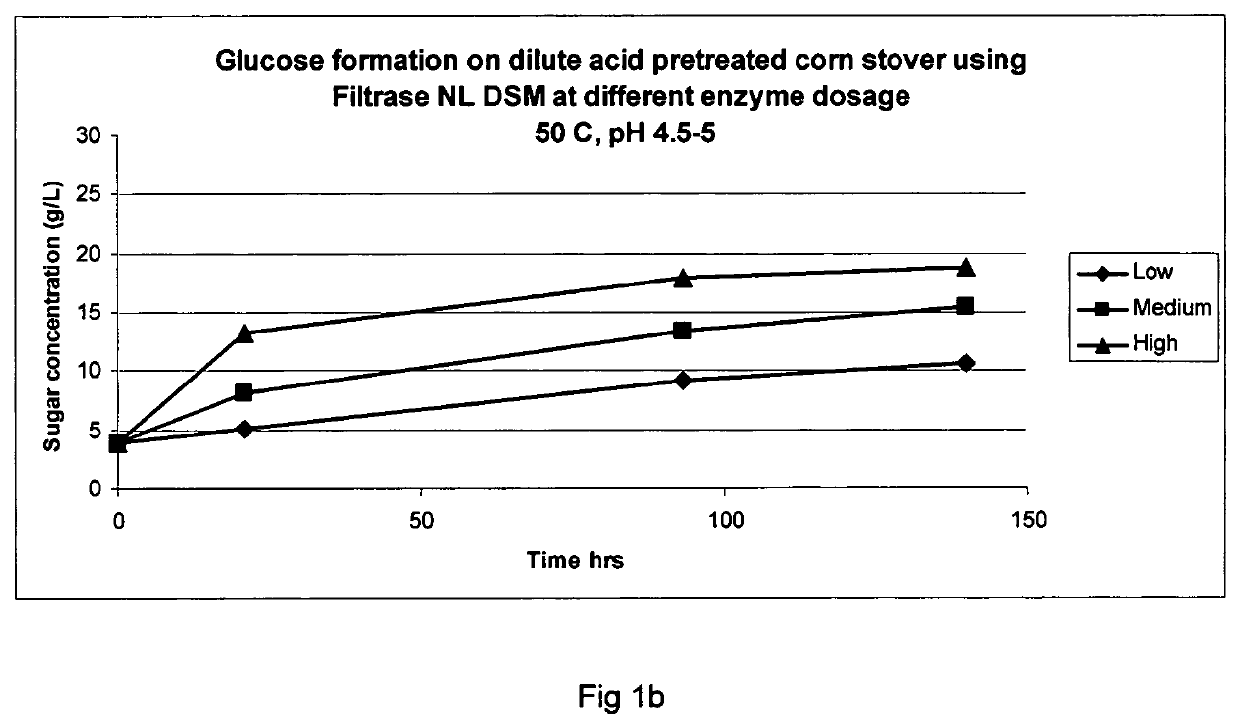

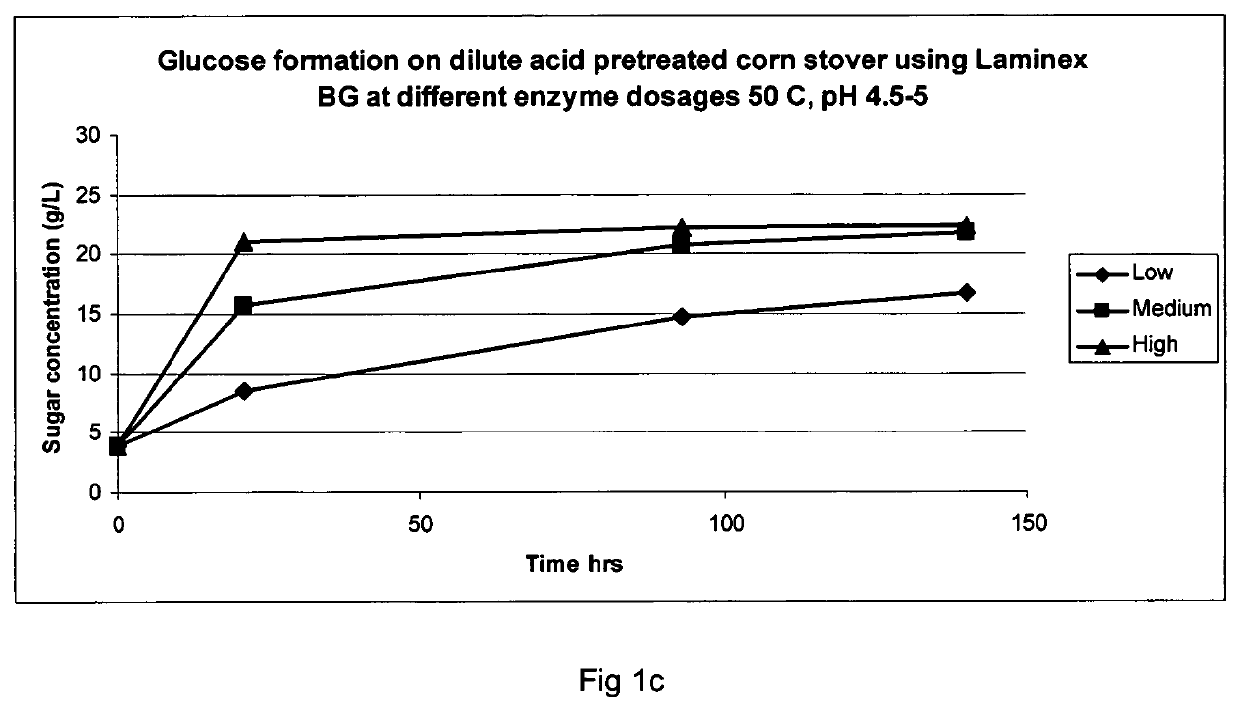

Degradation of lignocellulosic material

ActiveUS20110143402A1Efficient hydrolysisHigh specific activityBiofuelsEnzymesCellulaseHemicellulose

The present invention describes a method for the treatment of lignocellulosic material which method comprises contacting said lignocellulosic material with a composition comprising two or more enzyme activities, said enzyme activities being cellulase and / or hemicellulase activities, wherein the pH during the treatment is about 4.5 or lower, and the treatment is carried out at a dry matter content of 15% or more.

Owner:DSM IP ASSETS BV

Method for improving yield of simultaneous saccharification and fermentation lignocellulose ethanol

InactiveCN103290067AImprove enzymatic hydrolysis efficiencyImprove filtration efficiencyBiofuelsFermentationYeastWater resources

The invention discloses a method for improving the yield of simultaneous saccharification and fermentation lignocellulose ethanol. The method comprises the following steps of: heating straws in a steam explosion reactor by using steam, releasing the pressure instantaneously so as to obtain a solid-liquid mixture; separating the solid from the liquid; sterilizing the obtained solid by using high-temperature steam; mixing the sterilized solid, cellulase and sterile water, adjusting the pH value and enzymolyzing; introducing high-temperature resisting yeast so as to ferment; separating the solid from the liquid so as to obtain a liquid, namely, a fermented liquid which is rich in ethanol. By utilizing the method, the efficiency of enzymolysis and fermentation is improved; the diastatic fermented solid content is high; the obtained fermented liquid is high in ethanol concentration; the water resource is saved.

Owner:TIANJIN UNIV

Method for producing high-concentration ethanol by mixed fermentation of starch and molasses

InactiveCN102080105AIncrease profitIncrease total sugar concentrationBiofuelsFermentationHigh concentrationDistillation

The invention discloses a method for producing high-concentration ethanol by the mixed fermentation of starch and molasses which are used as raw materials. The method comprises the following steps of: adding water to the raw material of starch and stirring to constant volume, liquefying at low temperature and simultaneously fermenting and saccharifying, and then adding the raw material of molasses for mixed fermentation through the batch or continuous flow feeding supplement way. The mixing ratio of the raw materials of starch and molasses is 1:2-8:1 (W / V), the temperature of fermentation is 30-37 DEG C, the time of fermentation lasts for 40-48h, the percentage of ethanol yield is 12.43-16.67% (V / V). The invention changes the traditional single raw material fermentation way, and not only improves the total sugar concentration of the fermented mash, but also reduces the viscosity of starch raw mash and improves the liquidity, so the concentration of ethanol in the fermentation mash is increased, and the raw material utilization rate is improved, and ethanol distillation energy consumption and production cost are decreased, the amount of sewage discharge is reduced, the load of sewage treatment is lowered and the ethanol production process is more economical and environmentally friendly.

Owner:GUANGXI ACAD OF SCI

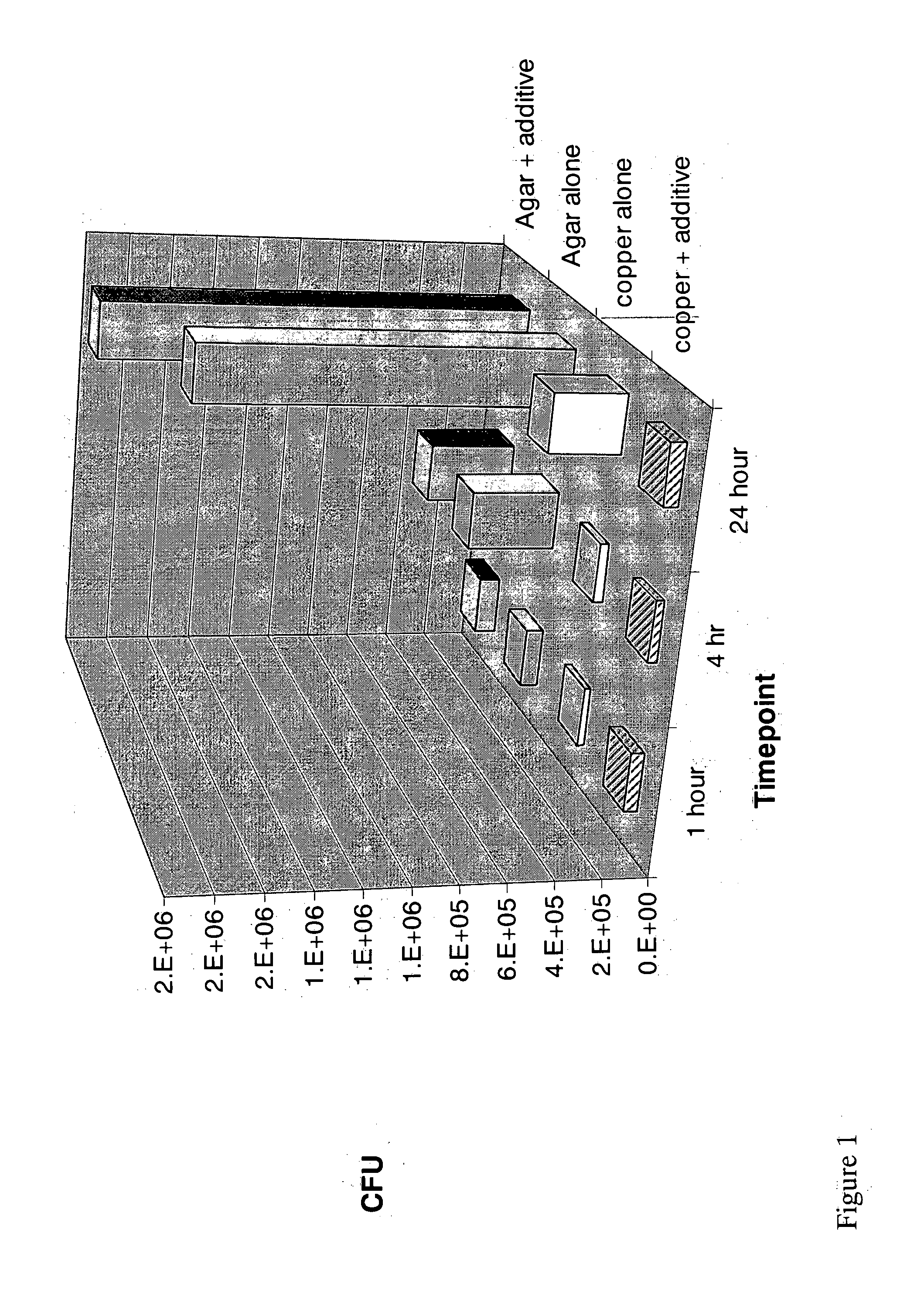

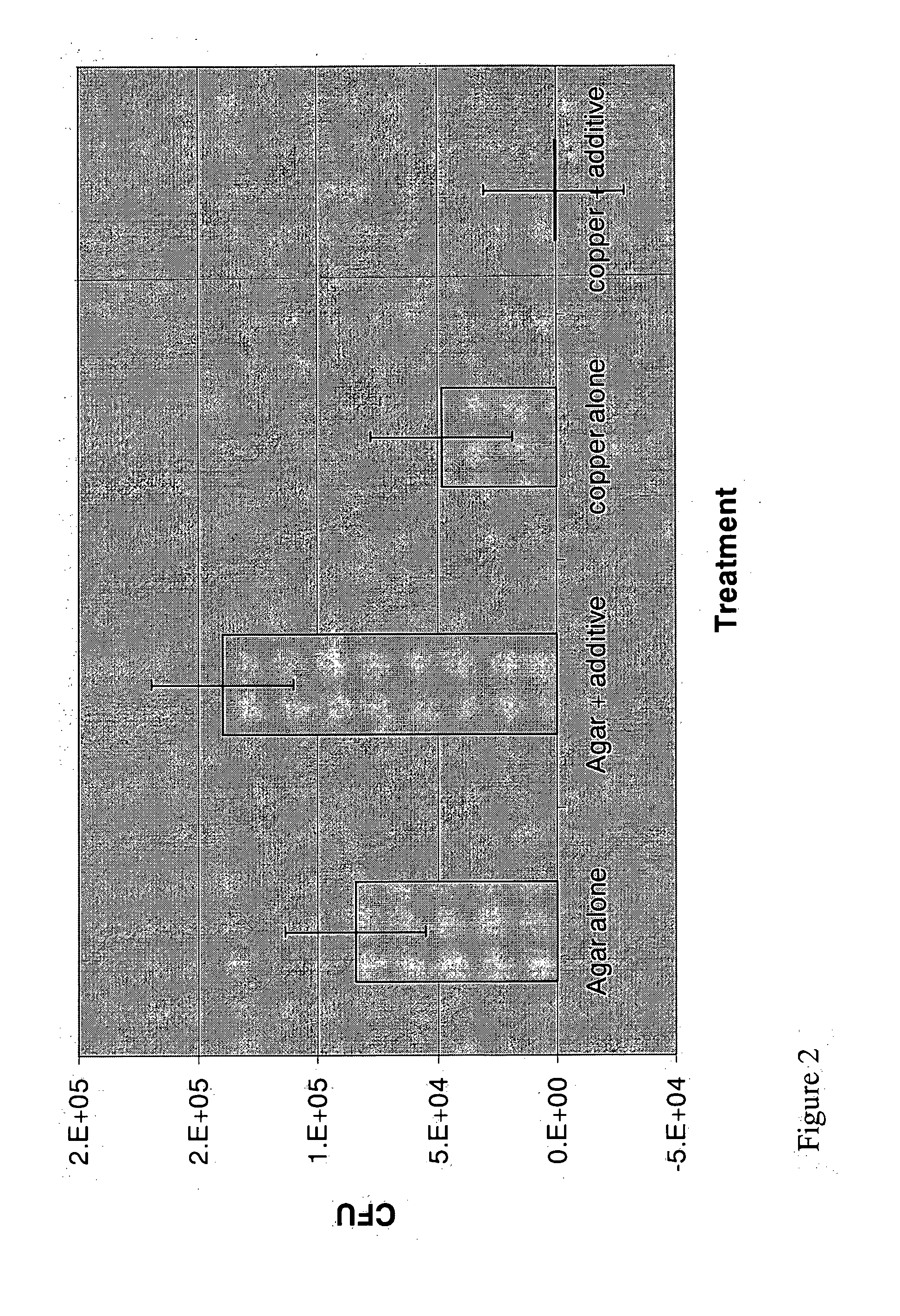

Biofilm resistant materials

InactiveUS20130195841A1Decreased cfuIncrease ethanol concentrationBiocideInorganic active ingredientsBiological membraneMaterials science

This invention provides a biofilm resistant material comprising an active agent, which active agent consists essentially of an insoluble copper oxide at a concentration of between 3 and 10% w / w of said biofilm resistant material and uses thereof.

Owner:THE CUPRON

Method for solid state fermentation of ethanol through steam explosion of cassava and comprehensive utilization of cassava

InactiveCN101768606ASolve the need to consume a lot of energy for cassava crushingSolve the cooking of starchClimate change adaptationBiofuelsNutritive valuesDistillation

The invention discloses a method for solid state fermentation of ethanol through steam explosion of cassava and comprehensive utilization of the cassava. In the method, the steam explosion technology is applied to the pretreatment of the cassava. On one hand, under the action of high-temperature water vapor of the steam explosion pretreatment, cyanogenetic glycoside in the cassava raw material is converted into volatile hydrocyanic acid for volatilization, the toxic action of the cyanide in the cassava product is removed, and the utilization ratio of the follow-up resource is improved; on the other hand, the cassava after the steam explosion pretreatment can be directly fermented to produce the ethanol, and the energy consumption for crushing the cassava and stewing and liquefying the starch is greatly reduced. The cassava is subjected to solid fermentation, so that the water content in the fermenting mash is greatly reduced. Therefore, the ethanol concentration in the fermenting mash is increased, the distillation energy consumption is reduced, subsequent wastewater treatment is reduced, the problems that the alcohol dregs obtained by the traditional fermentation process have large water content, low nutritive value and difficult utilization are solved, the production cost is reduced, and the method is favorable for the comprehensive utilization of the cassava.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

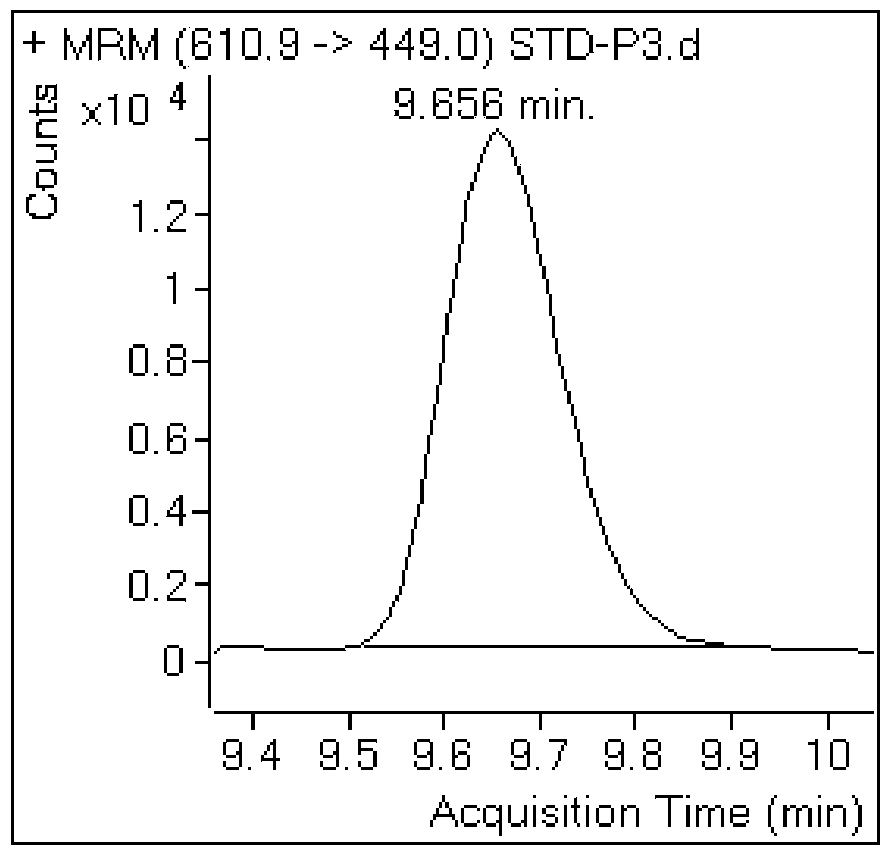

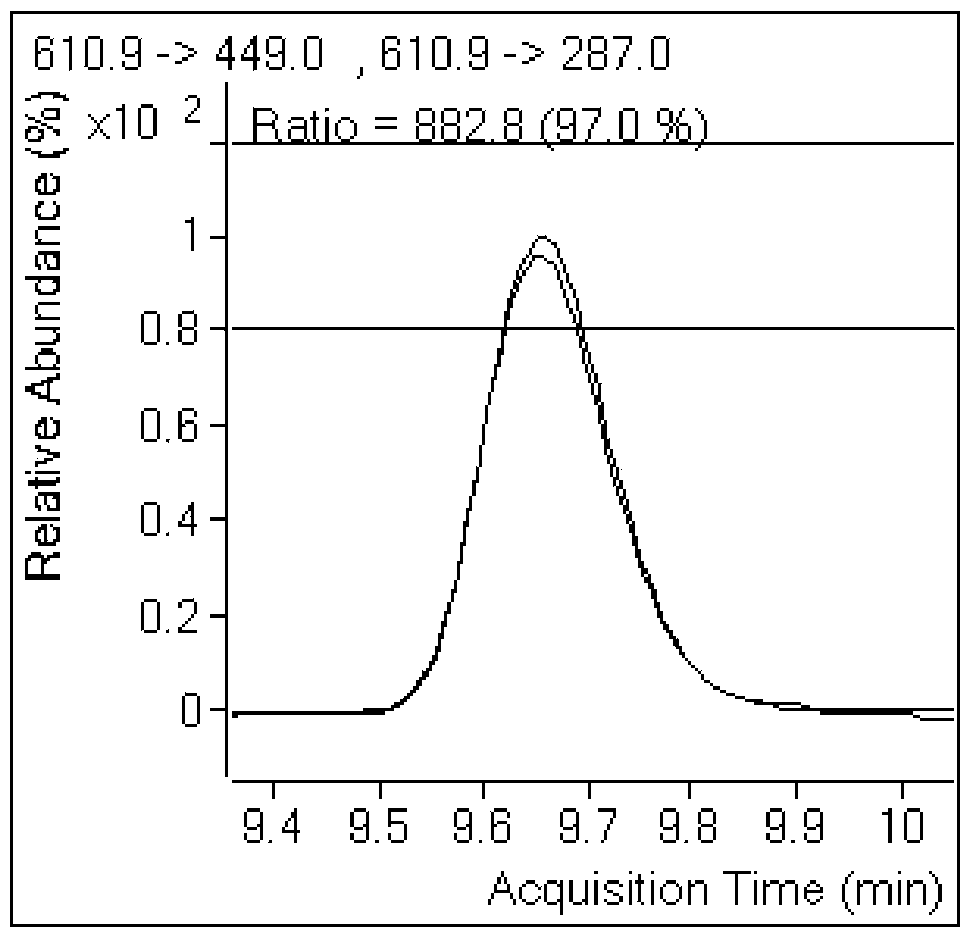

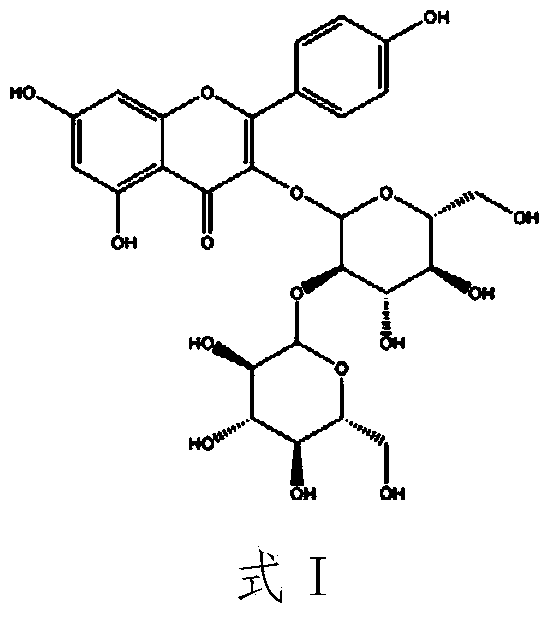

Method for identifying bee pollen based on kaempferol 3-O-beta-D-glucose-(2-1)-beta-D-glucoside

ActiveCN104181269AGood repeatabilityStrengthen species identificationComponent separationTandem mass spectrometryStandard curve

The invention relates to a method for identifying bee pollen based on kaempferol 3-O-beta-D-glucose-(2-1)-beta-D-glucoside. The method comprises the following steps: preparing a standard stock solution and a standard working solution, pretreating bee pollen, and detecting by using a liquid chromatogram-tandem mass spectrometry method. The detection result of the method shows that the standard curve relevance coefficient is greater than 0.9990, the addition recycling rate ranges from 73.1 percent to 98.4 percent, the relative standard error is less than 6.1 percent, the detection limit is 0.1mu g / g, and the quantitation limit is 0.3mu g / g. The result shows that the established extraction method and an instrument analysis method are accurate and stable and applicable to qualitative and quantitative analysis on kaempferol 3-O-beta-D-glucose-(2-1)-beta-D-glucoside.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Persimmon vinegar and preparation method thereof

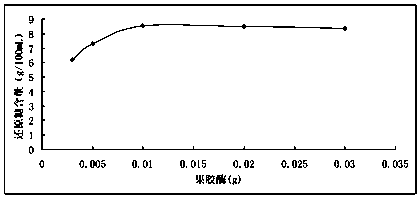

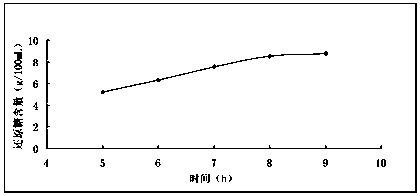

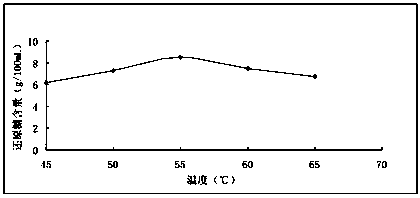

ActiveCN108641883ASimple process equipmentShorten fermentation timeBiofuelsMicroorganism based processesChemistryPectin

The invention discloses persimmon vinegar and a preparation method thereof. The preparation method comprises the steps that persimmons are collected and are cleaned, and then diced for later use; pectase being 0.01 to 0.03 percent of the content of the persimmons is added for mixing, after the heating to 55 to 60 DEG C, saccharification liquid is added for saccharification reaction for 6 to 10h, through saccharification influencing factor experiments, the content of reducing sugar in saccharification liquid is tested so as to determine the optimum saccharification process conditions, and a persimmon saccharification solution is obtained; mixed fermentation is performed, namely activated yeasts and acetic bacteria are respectively added into the persimmon saccharification solution accordingto the volume ratio, and mixed fermentation is performed for 72 to 80 hours under the condition of 32 and 35 DEG C to obtain a fermentation solution; and persimmon vinegar is prepared, namely the fermentation solution is subjected to centrifugation, filtration, sterilization and packaging to obtain the persimmon vinegar. The yeasts and the acetic bacteria are mixed and fermented; the alcoholic fermentation and the acetic fermentation are performed at the same time; the process equipment is simplified; the fermentation time is shortened; the energy consumption is reduced; and the adverse influence caused by too high ethanol concentration of an intermediate product on the acetic fermentation can be avoided.

Owner:HUBEI SHIWEITIAN PHARMA TECH

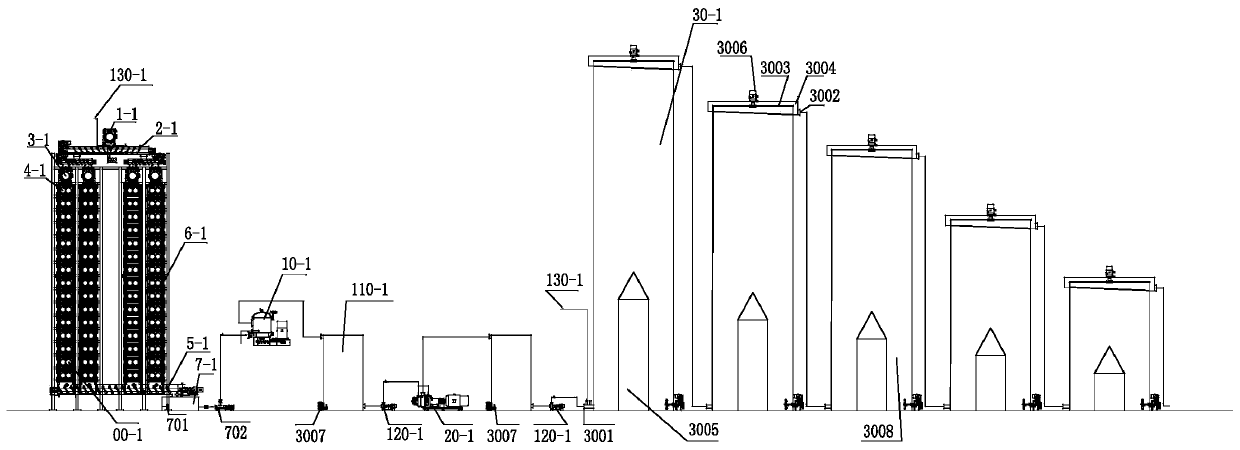

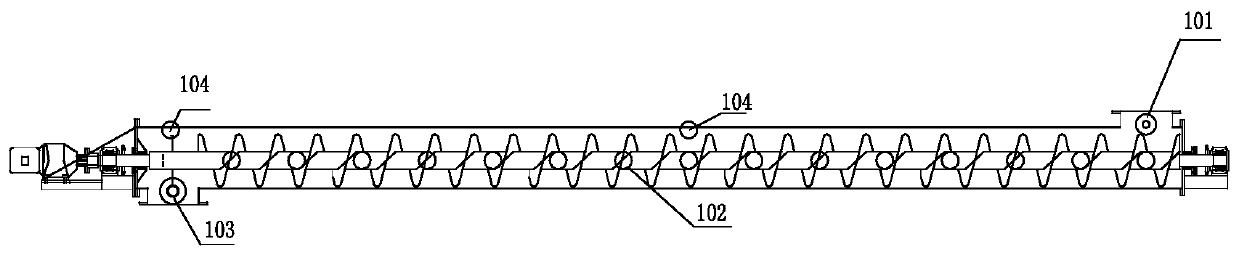

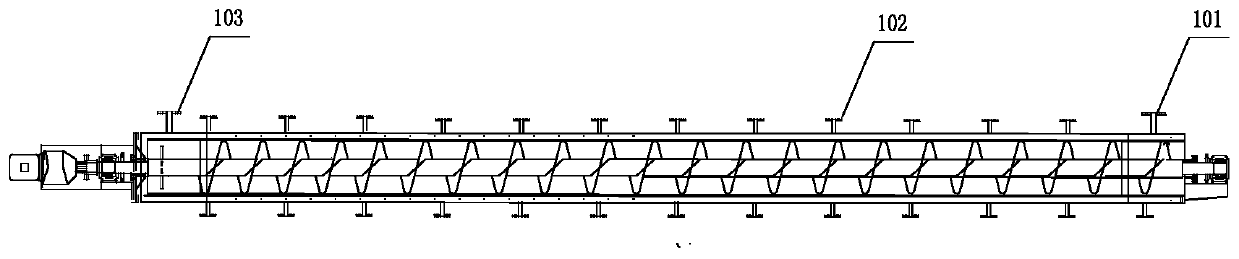

Method and system for high-solid content continuous enzymolysis of biomass raw materials

InactiveCN110343727AWell mixedIncrease contentBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationEngineering

The invention discloses a method and system for high-solid content continuous enzymolysis of biomass raw materials. The system comprises a high-concentration pre-enzymolysis system, a screening device, a high-shear force device, and a continuous enzymolysis system, wherein pretreated straw materials enter the high-concentration pre-enzymolysis system to be subjected to enzymolysis, so that thick liquid having fluidity is obtained; then the thick liquid having fluidity enters the screening device, and non-biomass impurities are removed; and after being treated by the high-shear force device, the screened thick liquid having fluidity enters a continuous enzymolysis jar until the enzymolysis process is completed. According to the method and the system disclosed by the invention, the solid content of the enzymolysis materials is high, so that the enzymolysis efficiency is high, the enzyme preparation dosage is also reduced, the energy consumption is low, the process is continuous, water issaved, and automation control is convenient; and the system is especially suitable for industrialization large-scale production, and can promote the popularization and the application of a biologicalenergy source technique.

Owner:吴学军 +4

High-concentration alcoholic fermentation method

InactiveCN101177695AEnough dissolved oxygenDoes not cause overgrowthBiofuelsMicroorganism based processesHigh concentrationTO-18

The invention pertains to the bio-engineering technical field, disclosing a fermentation method of alcohol with high concentration. The invention overcomes the shortages of low fermentation efficiency and long fermentation time, etc., of the existing alcohol fermentation technique. The invention adopts the steps that: bacteria-free air is introduced at the first stage; after 8 to 30 hours fermentation, material and fermentation agent are added under the temperature of 25 to 35 DEG C, oscillated or stirred with a rotation speed of 10-500r / min for 50 to 66 hours; the high concentration alcohol is made, and the volume concentration of the alcohol in the fermentation liquid is up to 16 to 18 percent. The invention can fast and effectively produce the high concentration alcohol.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Ignition energy control for mixed fuel engine

InactiveUS8584650B2Increase temperatureReduce vaporizationElectrical controlOther installationsEnergy controlEngineering

A method of operating an engine including varying a level of ignition energy provided to the engine during an engine start is provided. For example, the ignition energy level may be varied responsive to the amount of alcohol in fuel delivered to the engine in order to improve cold engine starting with higher alcohol fuels.

Owner:FORD GLOBAL TECH LLC

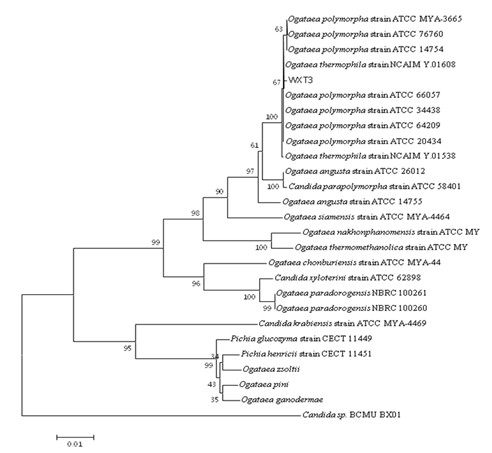

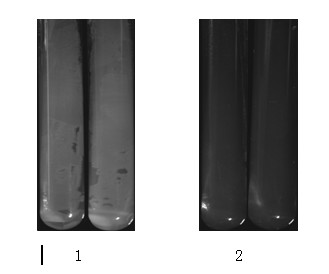

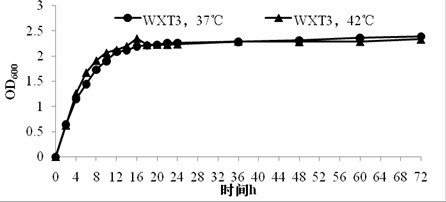

High-temperature resistant yeast and application thereof

InactiveCN102492634AIncrease temperatureWide pH range for growthFungiBiofuelsBiotechnologyFermentation

The invention discloses high-temperature resistant yeast and application thereof. The high-temperature resistant yeast Ogataeasp.WXT3 is preserved in China Center for Type Culture Collection with the preservation number of CCTCC NO:M2011108; the yeast disclosed by the invention is screened out from soil, the strain can be fermented at the temperature of 25-48 DEG C to produce ethanol; and ethanolyield is high, carbon sources which can be used for fermentation are wide, the strain is especially applicable to an ethanol preparation process by virtue of a lignocelulose simultaneous saccharification and fermentation (SSF) process, and usage amount of cellulose can be effectively reduced, thus production cost of cellulosic ethanol is reduced.

Owner:KUNMING UNIV OF SCI & TECH

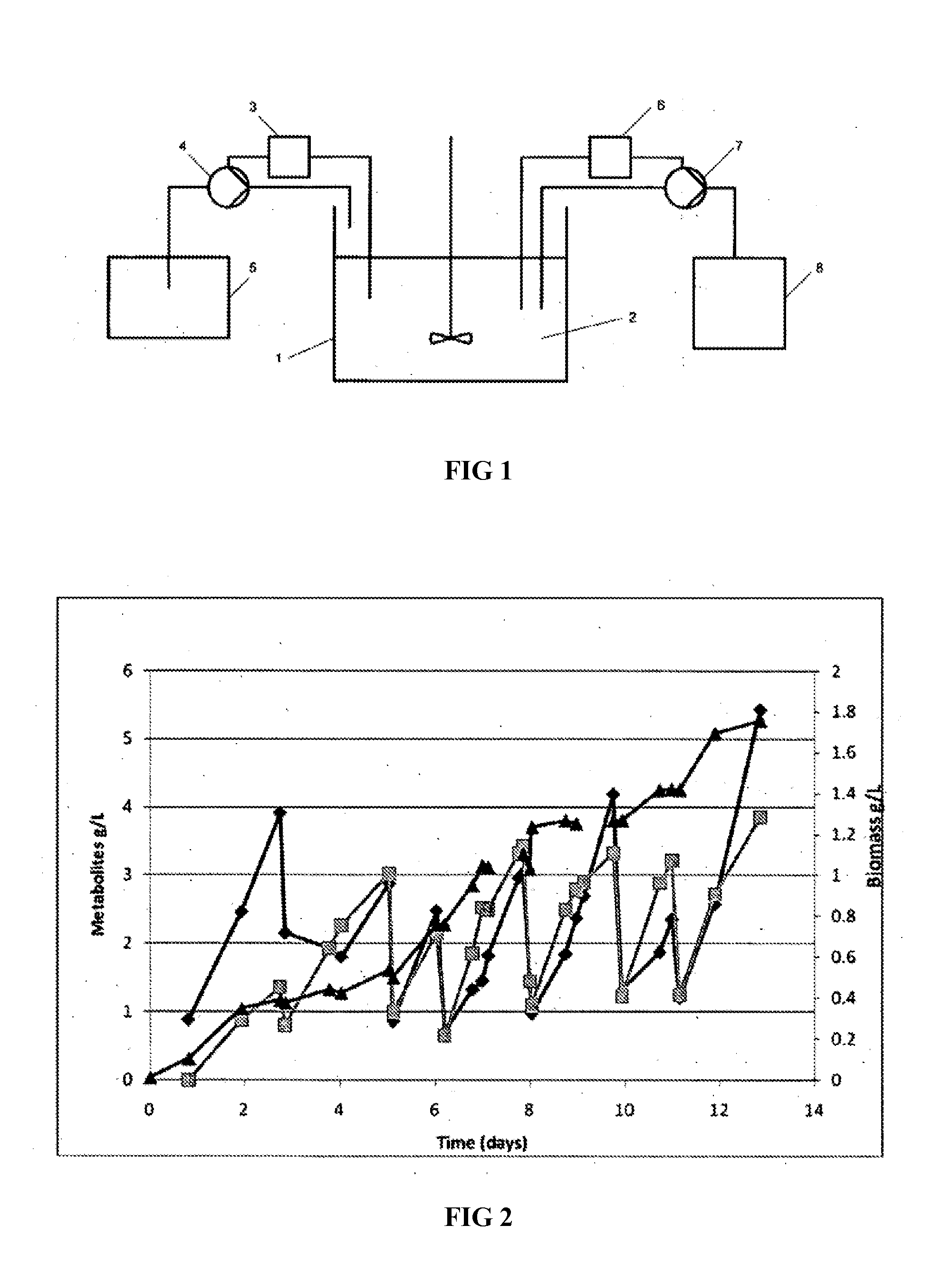

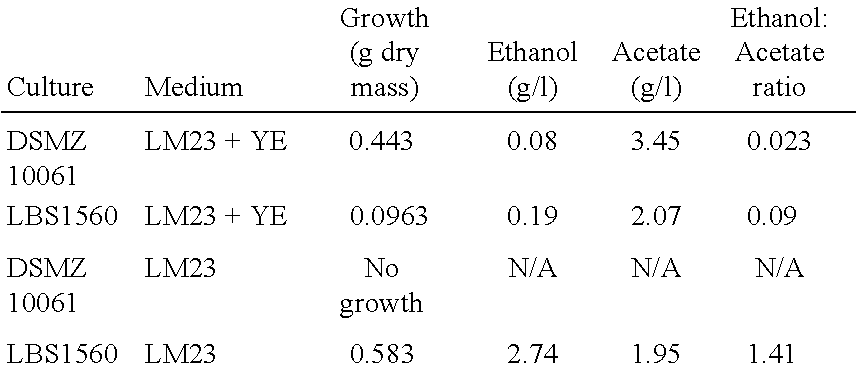

Novel bacteria and methods of use thereof

ActiveUS20100311104A1Constant volumeRaise the ratioBacteriaUnicellular algaeCarbon monoxideFermentation

A novel class of bacteria is described which has improved efficiency in the production of thanol by anaerobic fermentation of substrates containing carbon monoxide.

Owner:LANZATECH NZ INC

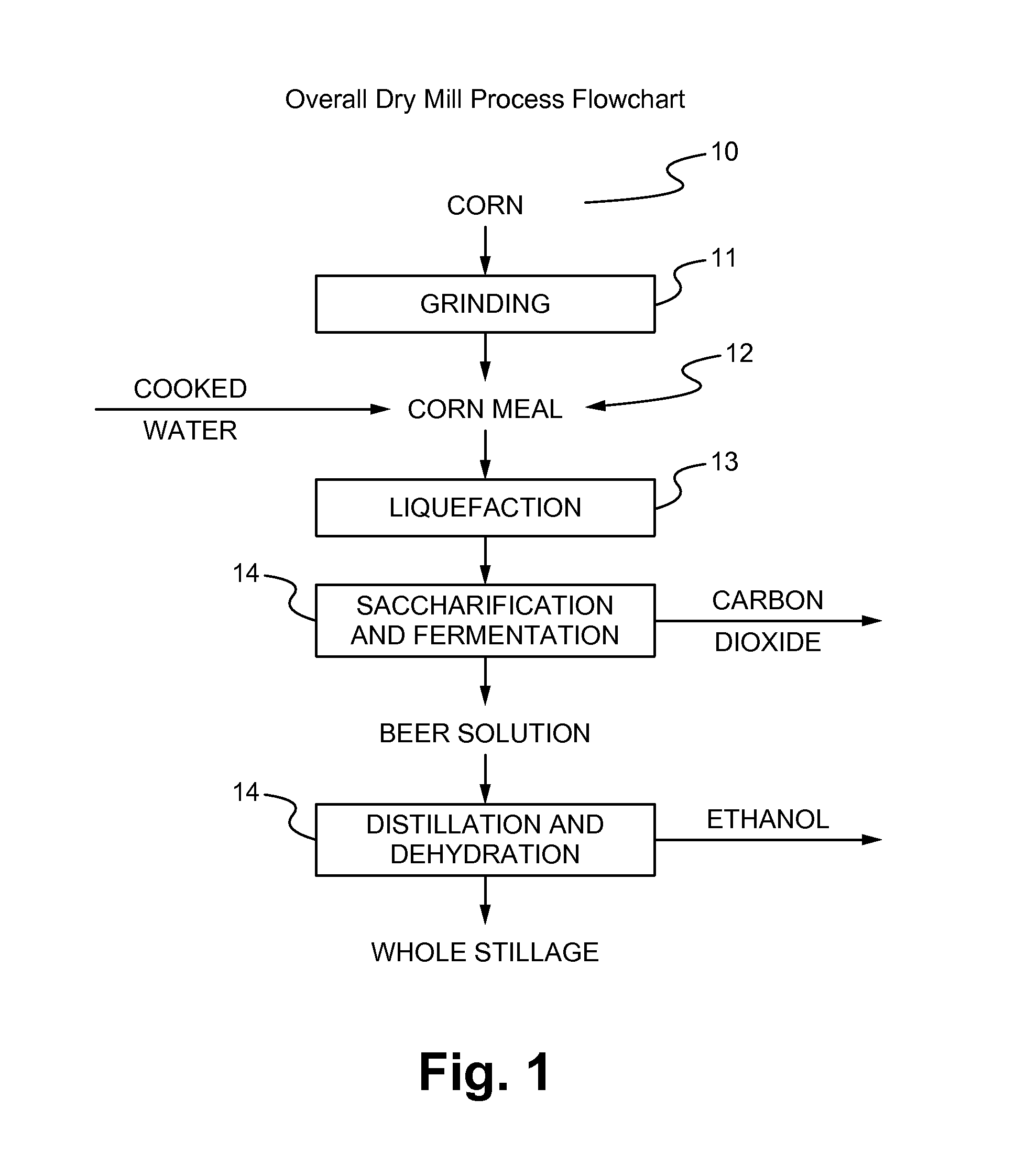

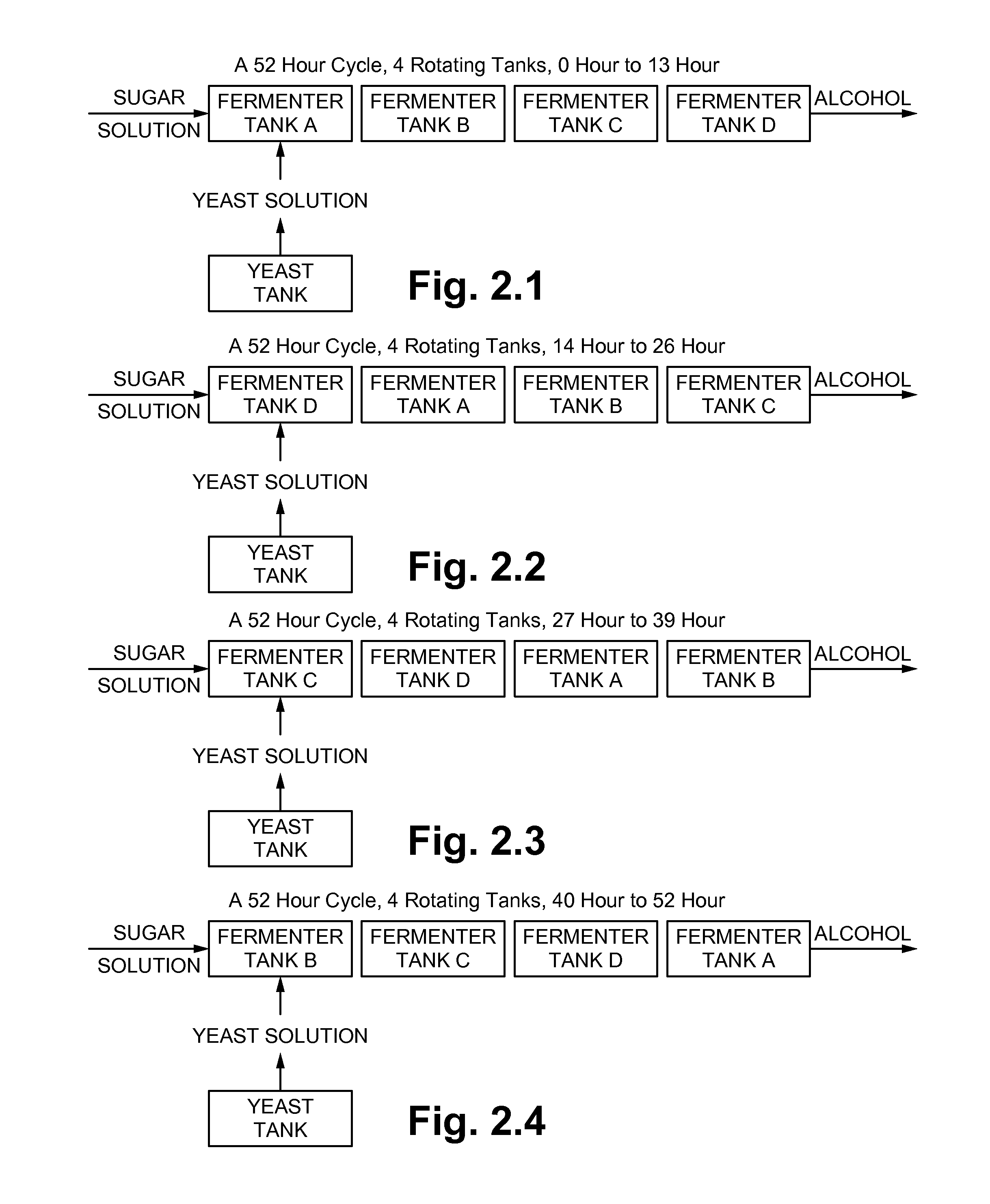

Fermentation system for dry mill processes

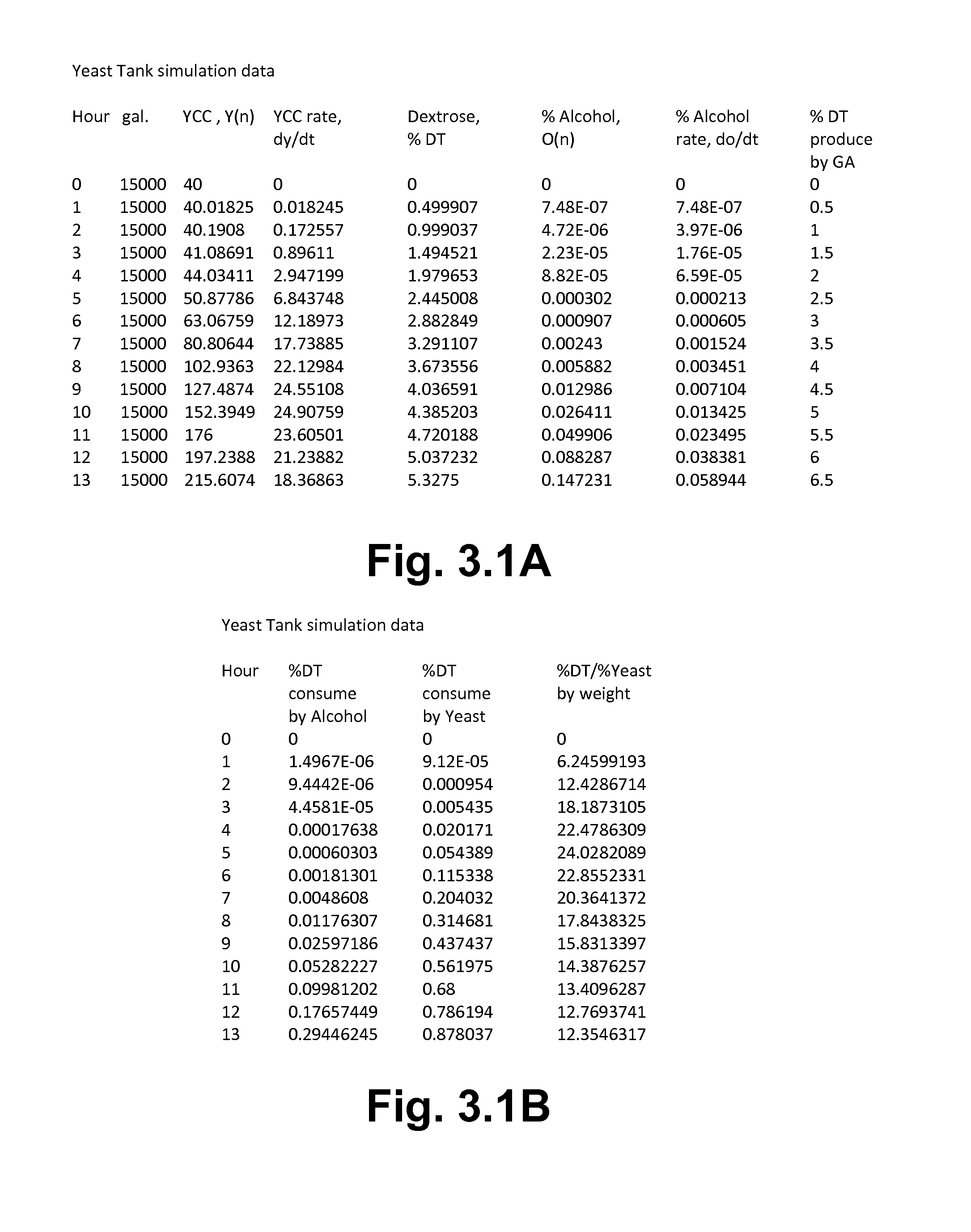

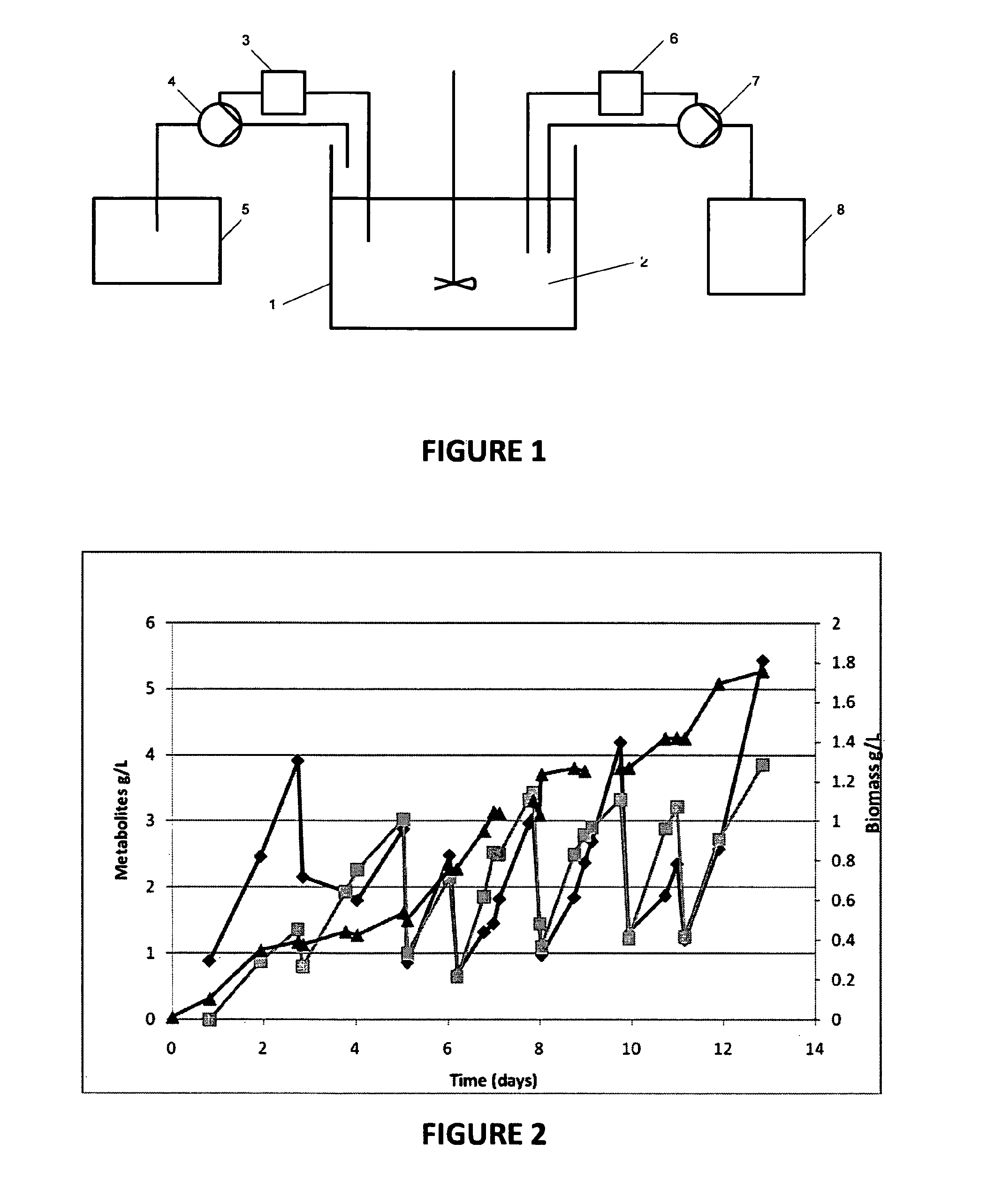

Methods of and system for growing higher and stronger levels of yeast in the Yeast Tank and Fermenter Tank during the fermentation filling cycle are provided. The yeast growth is reconfigured by continuing pumping yeast under the most active conditions while at a lower YCC (yeast cell count) into the Fermenter Tank during a filling period. A measurable and useful parameter, % DT / % Yeast by weight ratio (or “food” to yeast ratio), is introduced (e.g., % DT=glucose), which offers information on the health status of the yeast.

Owner:LEE TECH LLC

Bacteria and methods of use thereof

ActiveUS8222013B2Raise the ratioIncrease ethanol concentrationBacteriaUnicellular algaeFermentationCarbon monoxide

A novel class of bacteria is described which has improved efficiency in the production of thanol by anaerobic fermentation of substrates containing carbon monoxide.

Owner:LANZATECH NZ INC

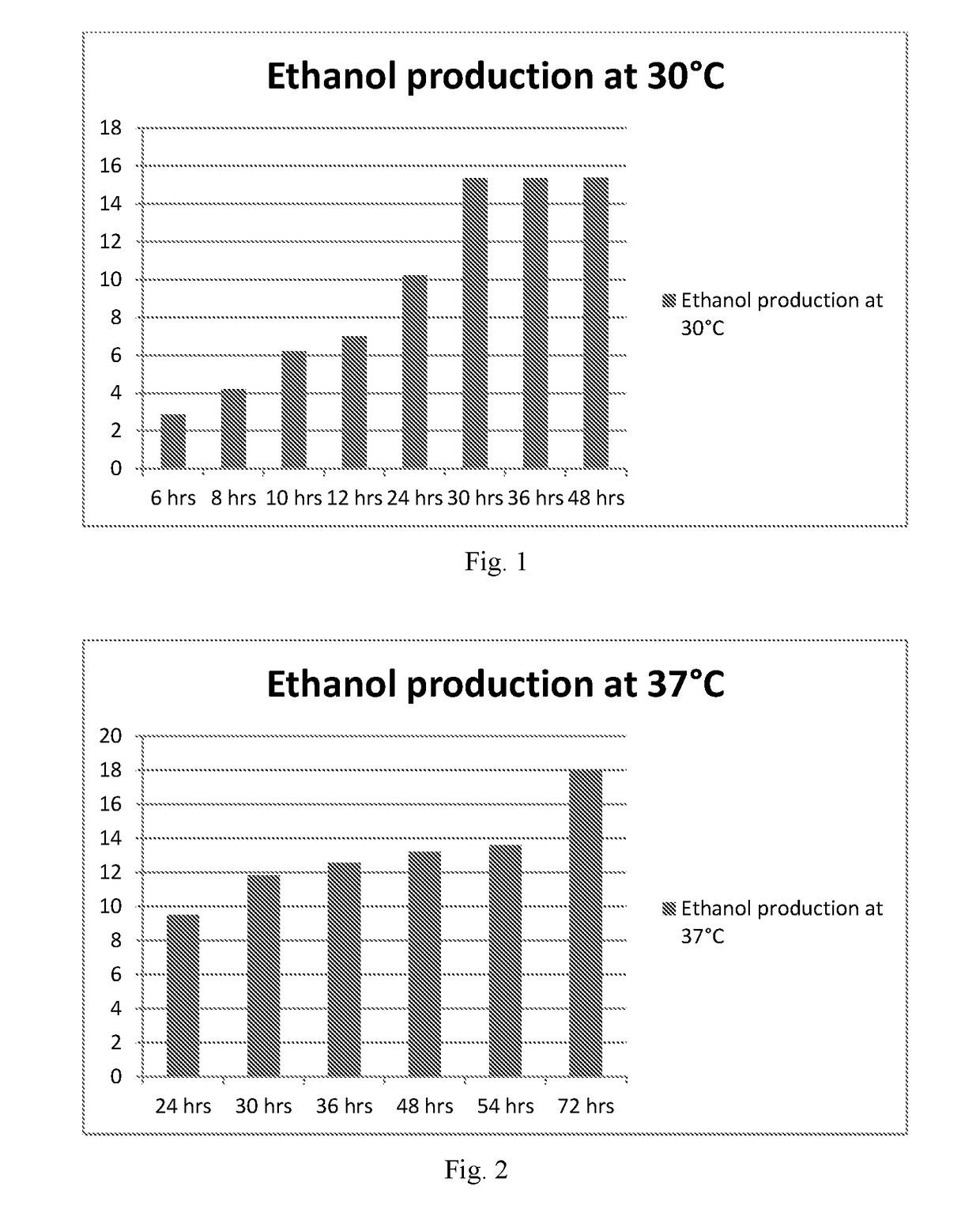

A Method Of Producing High Amount Of Ethanol At High Temperature By Modified Yeast Strain Saccharomyces Cerevisiae

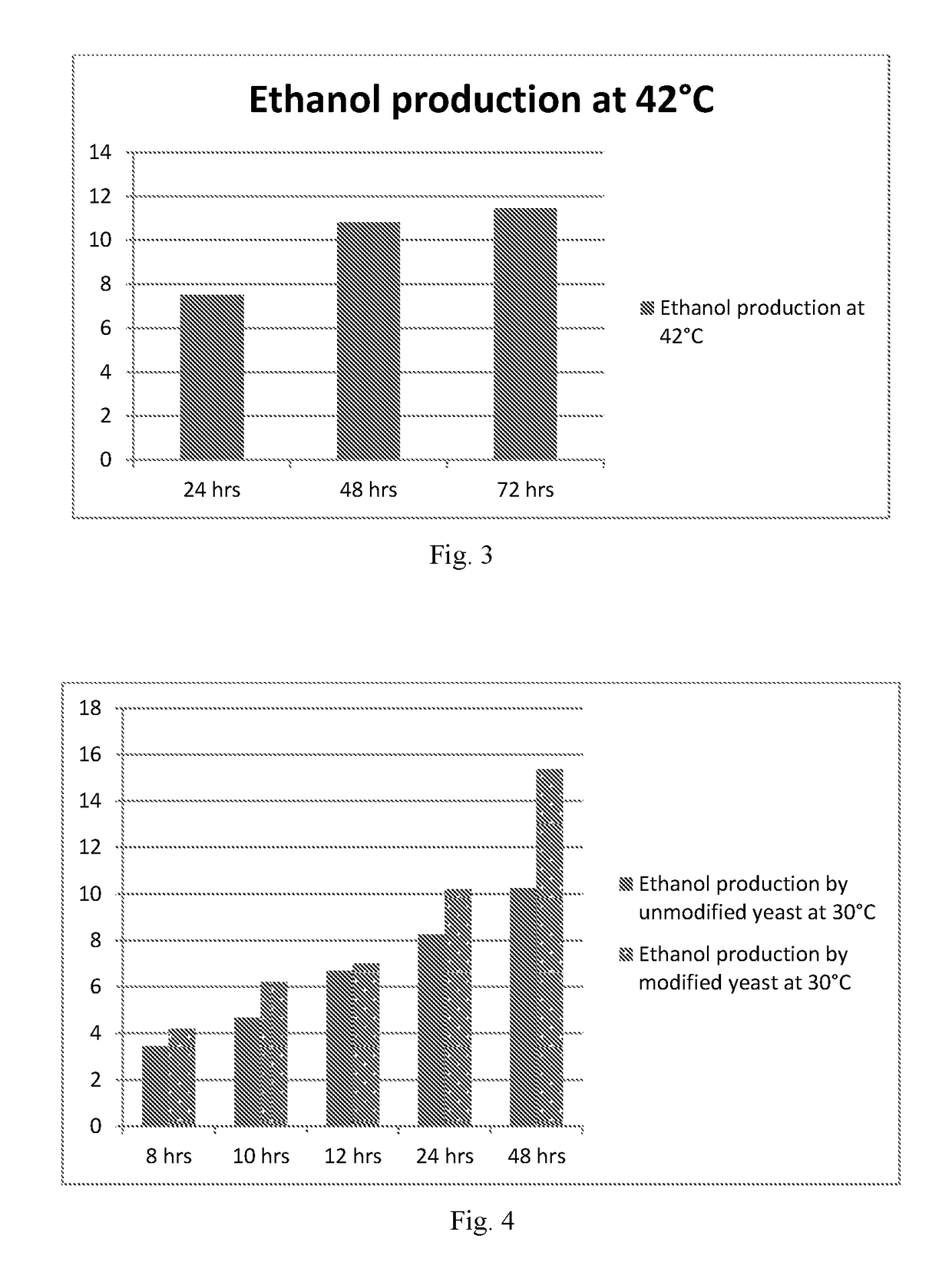

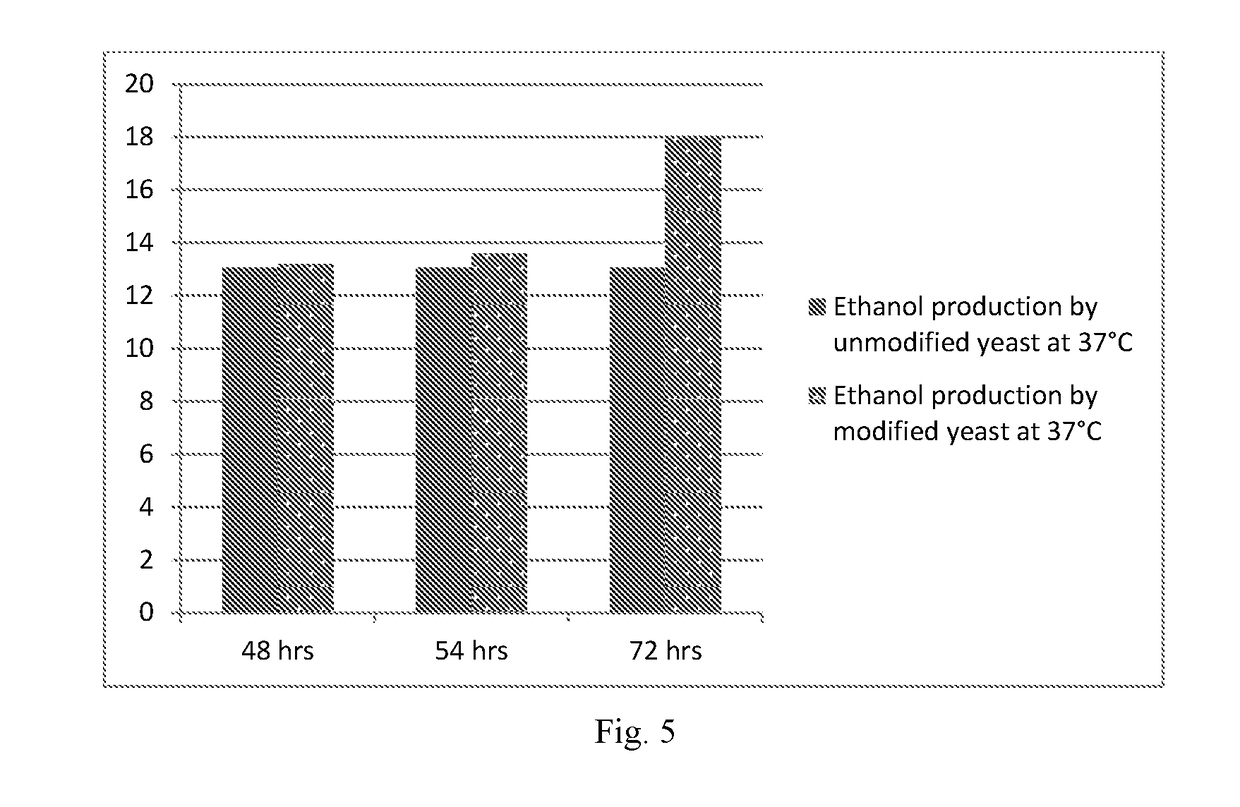

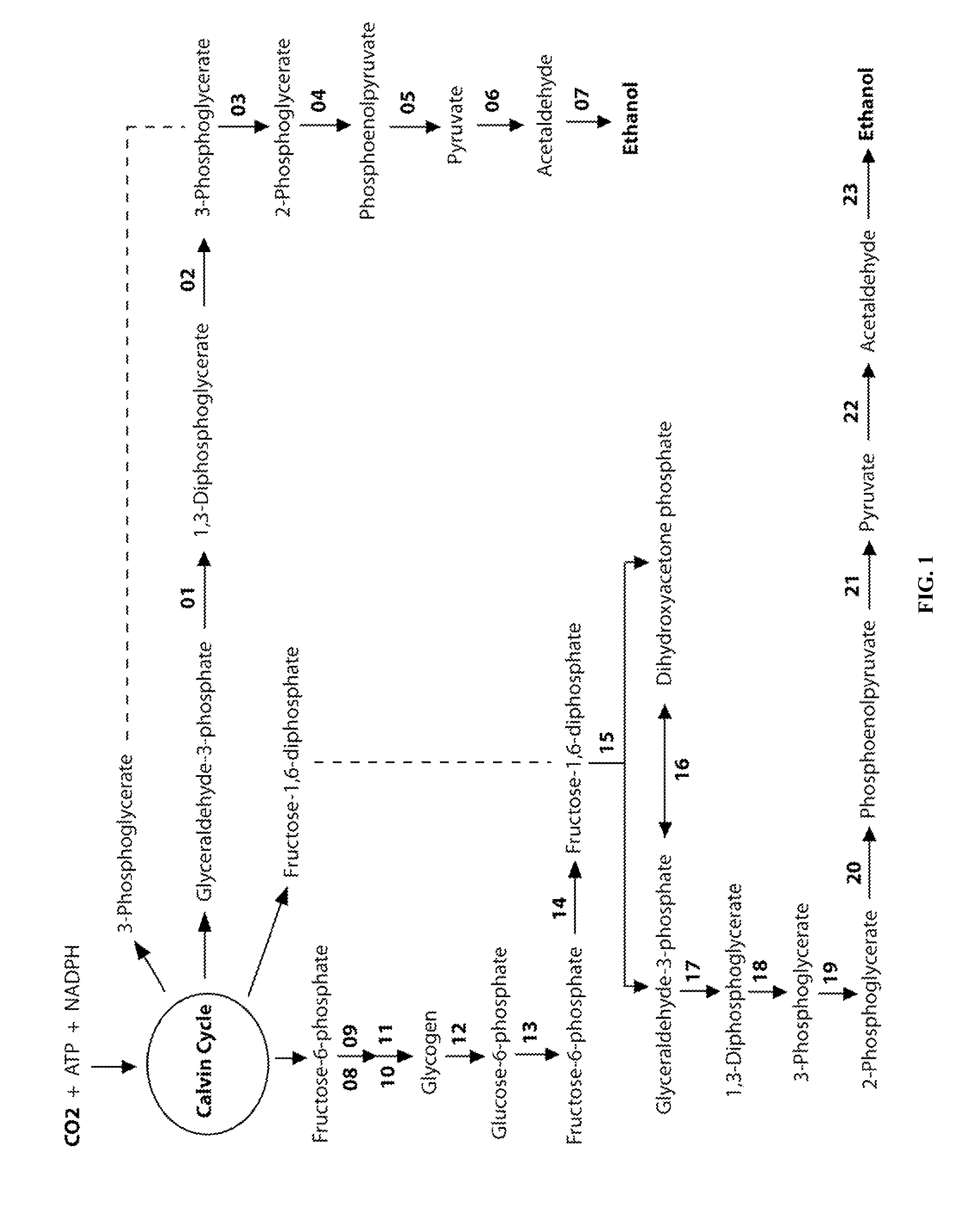

ActiveUS20180327709A1Low input costImprove downstream processingFungiCulture processFlocculationYeast strain

The present invention relates to a modified yeast strain of Saccharomyces cerevisiae having MCC accession number 0069 with osmo-tolerant, thermo-tolerant, ethanol tolerant and self-flocculation properties. Further, the present invention relates to a method for obtaining modified yeast strain. The present invention also relates to a method of production of ethanol at high temperature using said yeast strain. The ethanol produced by the method disclosed in the present invention is used as fuel.

Owner:SURANA RAJENDRA

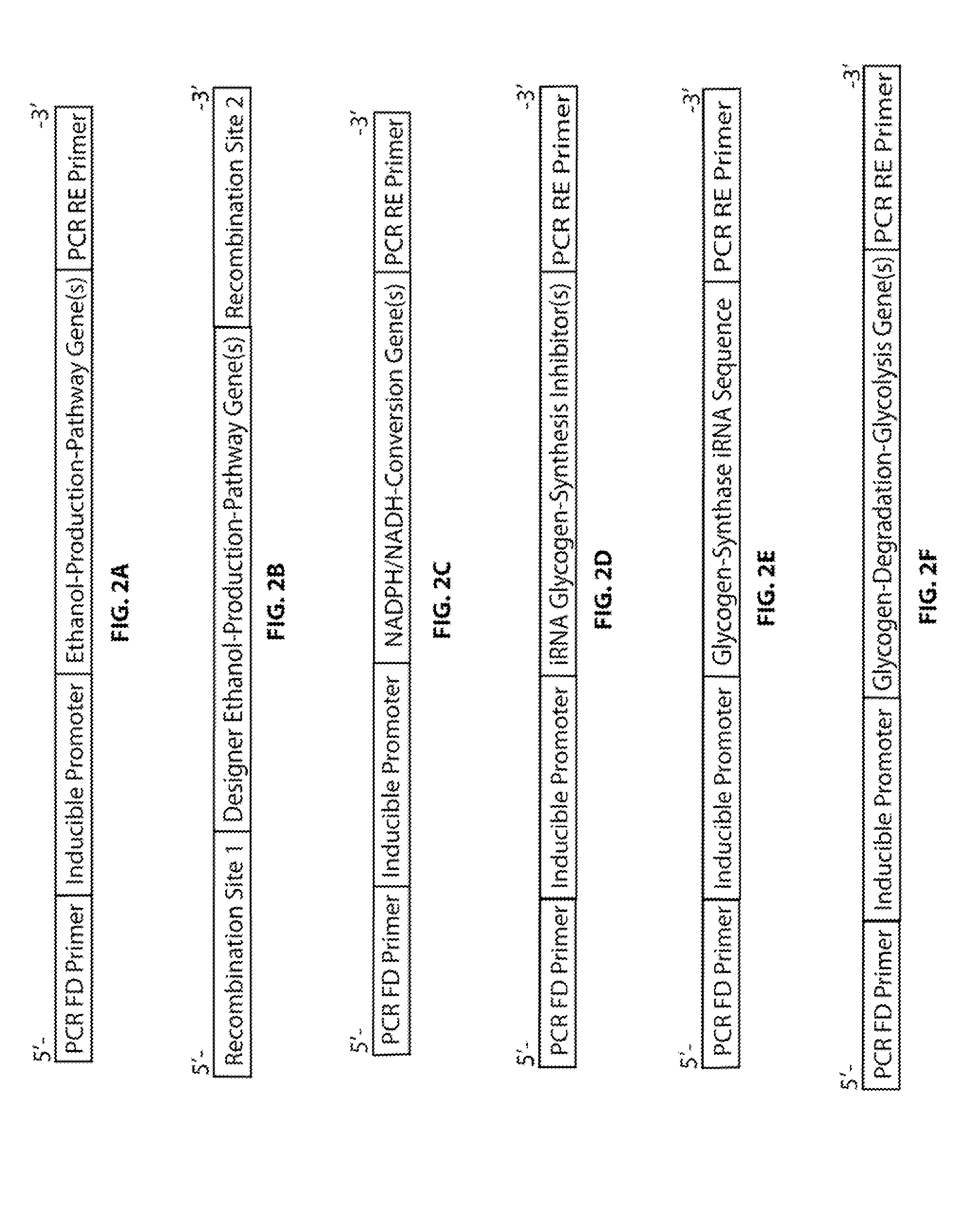

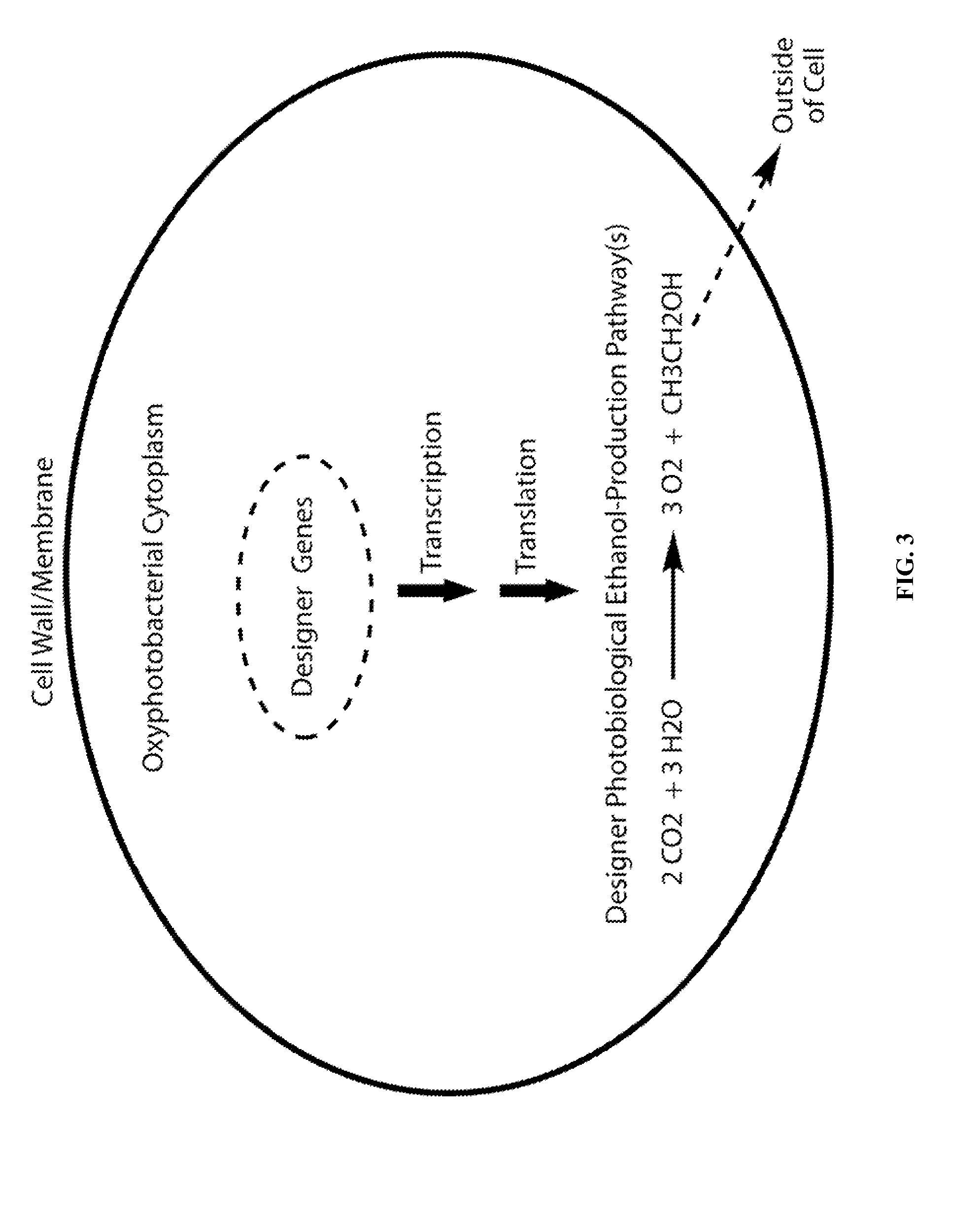

Designer Oxyphotobacteria and greenhouse distillation for photobiological ethanol production from carbon dioxide and water

InactiveUS8753837B2Quality improvementIncrease ethanol concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteDistillation

The present invention provides a photobiological ethanol production and harvesting technology using greenhouse distillation systems with designer photosynthetic organisms, such as designer transgenic oxyphotobacteria. The designer oxyphotobacteria are created such that the endogenous photobiological regulation mechanism is tamed, and the reducing power (NADPH) and energy (ATP) acquired from the photosynthetic process are used for synthesis of ethanol (CH3CH2OH) directly from carbon dioxide (CO2) and water (H2O). The designer use of a pair of NADPH-dependent vs. NAD-dependent glyceraldehyde-3-phosphate dehydrogenases in the pathway designs offers a special cyclic “transhydrogenase” redox-shuttle function to convert NADPH to NADH for enhanced photobiological ethanol production. Through combined use of a designer photosynthetic organism with a greenhouse distillation system, the waste solar heat associated with the photobiological ethanol-production process is utilized in harvesting the produced ethanol. In addition to production and harvesting of ethanol, use of the technology can also produce intermediate metabolites and freshwater from seawater.

Owner:LEE JAMES WEIFU

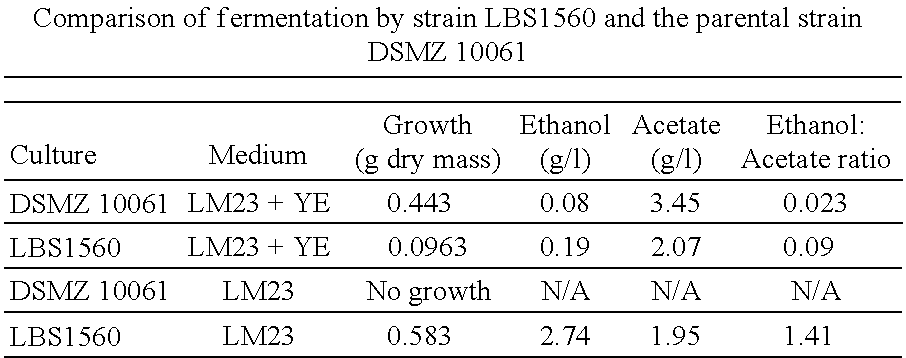

Novel Bacteria and Methods of Use thereof

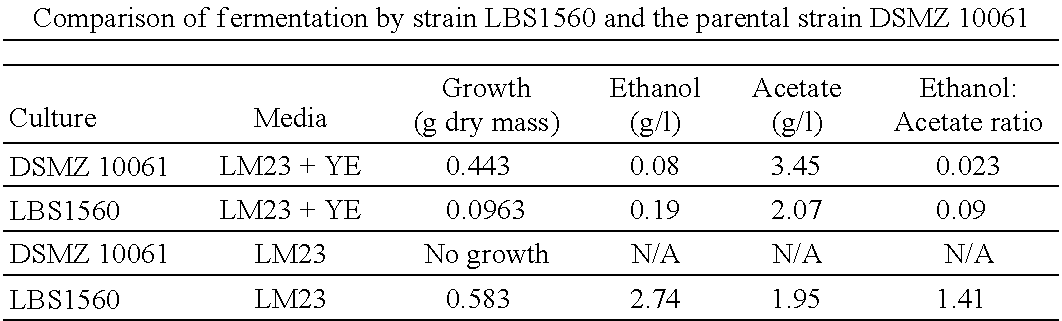

ActiveUS20120309075A1Raise the ratioIncrease ethanol concentrationBacteriaBiofuelsSporeClostridium autoethanogenum

A biologically pure isolate of a selected bacterium derived from Clostridium autoethanogenum is described which has improved efficiency in the production of ethanol by anaerobic fermentation of substrates comprising carbon monoxide. The bacterium can produce ethanol and acetate at an ethanol to acetate ratio of at least 1.0 and has a productivity of at least 1.2 g of ethanol / l of fermentation broth per day. The bacterium is also characterized in that it has substantially no ability to sporulate.

Owner:LANZATECH NZ INC

Degradation of lignocellulosic material

ActiveUS10557153B2Efficient hydrolysisHigh specific activityBiofuelsFermentationEngineeringCellulase

The present invention describes a method for the treatment of lignocellulosic material which method comprises contacting said lignocellulosic material with a composition comprising two or more enzyme activities, said enzyme activities being cellulase and / or hemicellulase activities, wherein the pH during the treatment is about 4.5 or lower, and the treatment is carried out at a dry matter content of 15% or more.

Owner:VERSALIS SPA

Roxatidine acetate pharmaceutical salt sustained-release pellets and preparation method and applications thereof

ActiveCN109833306ASolve the technical problem of low drug loading in the coatingHigh drug loadingAntibacterial agentsOrganic active ingredientsSustained release pelletsPlasticizer

The invention relates to roxatidine acetate pharmaceutical drug-loading salt sustained-release pellets. A coating liquid of a sustained-release layer comprises a sustained-release material, a pore-forming agent, a plasticizer and a coating solvent, wherein the coating solvent is a 70-100% ethanol aqueous solution by mass, and the sustained-release pellets have good dissolution characteristics andquality stability.

Owner:北京轩升制药有限公司

Method for preparing ethanol from wood fiber raw material

ActiveCN101497895AReduce the degree of polymerizationReduce crystallinityBiofuelsFermentationHigh energyDistillation

The invention relates to a method for preparing ethanol by wood fibre raw materials, which mainly solves the problem that the ethanol synthesized by the existing wood fibre raw materials has high energy consumption, high requirements for equipment material and severe environmental pollution, and is incapable of processing continuously. The wood fibre raw materials are pressed by a screw rod and expanded with instant decompression so as to obtain porous fluffy materials; aqueous slkali is added into the porous fluffy materials for washing and realizing the first separation of xylogen; the xylogen-separated materials are hydrolyzed by cellulase so as to obtain sugar-containing solution; ethanol solution is obtained by fermenting the sugar-containing solution; and the ethanol with the purity of 95 percent is obtained by regular distillation and purification. The method can be applied to the industrial production of preparing ethanol by wood fibre raw materials.

Owner:CHINA PETROCHEMICAL CORP +1

Micronized roxatidine acetate pharmaceutical salt pellets and preparation method and applications thereof

ActiveCN109833299ASolve the technical problem of low drug loading in the coatingHigh drug loadingOrganic active ingredientsDigestive systemMedicineBULK ACTIVE INGREDIENT

The invention relates to micronized roxatidine acetate pharmaceutical salt pellets. The pellets comprise a blank pellet core and a drug-loading layer, wherein the drug-loading layer contains micronized rosatidine acetate pharmaceutical salt, the rosatidine acetate pharmaceutical salt can improve the actual content of active ingredients in the drug-loading pellets after micronization treatment, thetechnical problem that the actual drug-loading amount of the drug-loading coating is relatively low, and the content stability of a final product is improved.

Owner:北京轩升制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com