High-temperature resistant yeast and application thereof

A technology of high temperature resistance and yeast, applied in the field of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

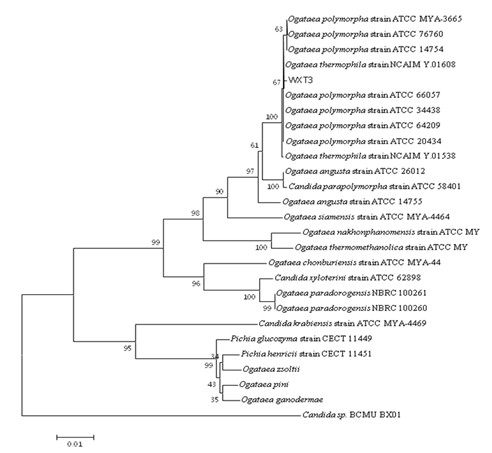

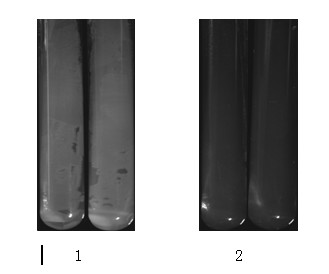

[0058] Embodiment 1: high temperature resistant yeast Ogataea For the screening of sp. WXT3 strain, the specific operation process is as follows:

[0059] Take 5g of soil sample from Xishuangbanna orchard, inoculate it into 100mL YPD liquid medium, add chloramphenicol and tetracycline at a final concentration of 50μg / ml to the medium, and culture it on a shaker at 42°C and 150rpm for 2 days; take the culture 100μl, inoculated into 10ml of fresh YPD liquid medium, 24 days later, take 100μl of the culture and spread it on the YPD agar plate, incubate at 42°C for 24h, pick a single colony and inoculate it on the YPD liquid agar medium, a total of 26 single colonies were selected , cultured at 45°C and 48°C, and the colony with the highest ethanol yield was selected as WXT3, and then identified by molecular biology, physiology and biochemistry, and sent to CCTCC for preservation. The preservation number is: CCTCC NO: M 2011108.

[0060] The culture medium used in this embodimen...

Embodiment 2

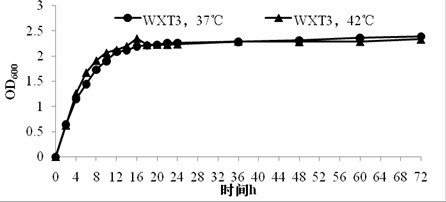

[0064] Embodiment 2: high temperature resistant yeast Ogataea Sp. WXT3 Strain Utilizes Glucose Fermentation to Produce Ethanol at Different Temperatures

[0065] Take a 250ml Erlenmeyer flask, add 100ml of culture medium (medium composition: 5% glucose, 1% yeast extract, 1% peptone), sterilize at 115°C for 20min; prepare YPD liquid medium at the same time, inoculate Ogataea sp. WXT3 yeast strain, cultivated at 42°C for 8 hours, and used as seed culture solution for later use.

[0066] Add 5mL seed culture (5% (V / V) for fermentation inoculum) into a sterilized Erlenmeyer flask, and ferment at 30°C, 37°C, 42°C, 45°C, 150rpm shaking table respectively, and set up three groups in parallel Fermentation, after 72 hours of fermentation, the ethanol concentrations in the system produced by fermentation at 30°C, 37°C, 42°C, and 45°C were 15.41g / L, 13.41g / L, 13.45g / L, and 1.34g / L, respectively. The results See Figure 7 . The ethanol yield when fermented at 42°C was the same as ...

Embodiment 3

[0068] Embodiment 3: high temperature resistant yeast Ogataea Sp. WXT3 strains use different concentrations of glucose to ferment and produce ethanol

[0069] Take a 250ml Erlenmeyer flask, add 100ml medium (medium composition: 10% or 15% glucose, 0.5% yeast extract, 1% peptone), sterilize at 115°C for 20min, prepare YPD liquid medium at the same time, and inoculate WXT3 yeast strain , cultivated at 42°C for 8h, and used as seed culture for later use.

[0070] Add 5mL seed culture into a sterilized Erlenmeyer flask, ferment and culture on a shaker at 42°C and 150rpm, set up three groups of parallel fermentation, the results are shown in Figure 8 , the figure shows that before 72h, the concentration of ethanol increases with the prolongation of fermentation time, and the concentration of ethanol decreases with the increase of glucose concentration. From 72h to 96h, the concentration of ethanol fermented with 10% glucose is lower than the concentration of ethanol fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com