Method for preparing ethanol from wood fiber raw material

A technology for lignocellulosic raw materials and ethanol, which is applied in the directions of biofuel and fermentation, can solve the problems of inoperable continuous processing, high equipment material requirements, serious environmental pollution, etc., and achieves increased effective specific surface area, low corrosion resistance requirements, and improved The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

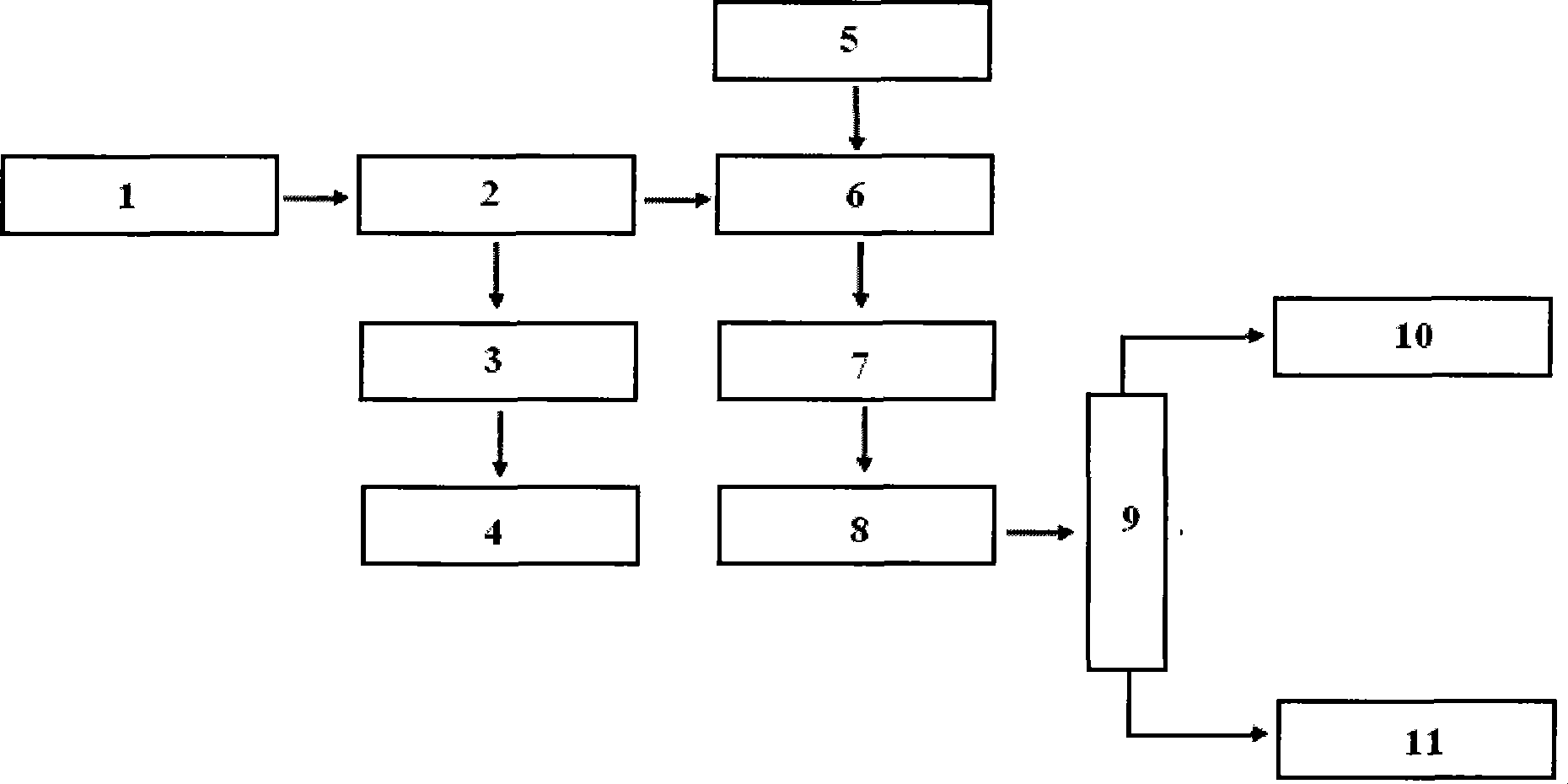

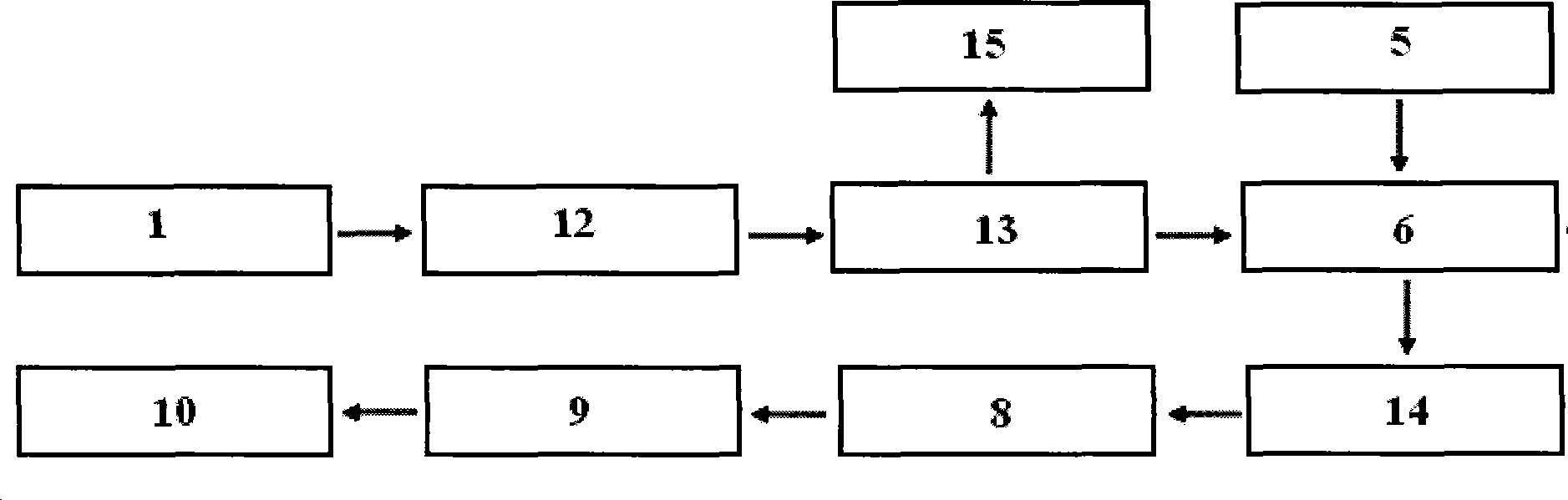

Method used

Image

Examples

Embodiment 1

[0023] 400 grams of corn stalks are pressurized by a screw at 100°C and 2.5MPa, and instantly decompressed and puffed to obtain a porous fluffy material; The solution is washed to separate and remove lignin; the lignin-removed material is hydrolyzed with 10 FPIU / gram of cellulose niger at 43°C and pH=5 to obtain a sugar-containing solution with a concentration of 3.5% by weight; the above-mentioned sugar-containing The solution was fermented by 8 g / L Saccharomyces cerevisiae at 35°C under anaerobic conditions to obtain an ethanol solution with a concentration of 40 g / L; finally, the ethanol solution was rectified and concentrated to obtain ethanol with a purity of 95%.

[0024] The yields of each step are as follows: the yield of cellulose hydrolysis is 81.5%, the sugar utilization rate of sugar fermentation is 85.6%, the ethanol yield is 881.2%, the total sugar utilization rate is 45.2%, and the ethanol yield is 10.4%.

Embodiment 2

[0026]400 grams of rice straw are pressurized by a screw under the conditions of 120°C and 5MPa, and the porous fluffy material is obtained by instant decompression and puffing; The solution is washed to separate and remove the lignin; the lignin-removed material is hydrolyzed at 15 FPIU / gram of Trichoderma reesei cellulose at 53°C and pH=4.2 to obtain a sugar-containing solution with a concentration of 4.5% by weight; the above-mentioned The sugar solution is concentrated to 10% sugar at a temperature of 100°C; the above sugar solution is fermented by 8 g / L of Saccharomyces cerevisiae at 35°C under anaerobic conditions to obtain an ethanol solution with a concentration of 60 g / L ; Finally, the ethanol solution is rectified and concentrated to obtain ethanol with a purity of 95%.

[0027] The yields of each step are as follows: cellulose hydrolysis yield 83.7%, sugar fermentation sugar utilization rate 88.5%, ethanol yield 81.9%, total sugar utilization rate 47.6%, ethanol yie...

Embodiment 3

[0029] 400 grams of wheat straw are pressurized by a screw under the conditions of 125°C and 5MPa, and the porous fluffy material is obtained by instant decompression and puffing; Carry out washing to separate and remove lignin; the lignin-removed material is hydrolyzed with 15 FPIU / gram of cellulose Trichoderma reesei at 50°C and pH=4.2 to obtain a sugar-containing solution with a concentration of 4.5% by weight; the above-mentioned sugar-containing The solution is concentrated by nanofiltration membrane at room temperature and membrane entry pressure of 2.0 MPa, and concentrated to 10% sugar content; the above sugar solution is fermented by 8 g / L Saccharomyces cerevisiae at 35 °C under anaerobic conditions to obtain ethanol solution, its concentration is 68 g / L; finally the ethanol solution is rectified and concentrated to obtain ethanol with a purity of 95%.

[0030] The yields of each step are as follows: the yield of cellulose hydrolysis is 85.2%, the sugar utilization ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com