Patents

Literature

30 results about "Entry pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

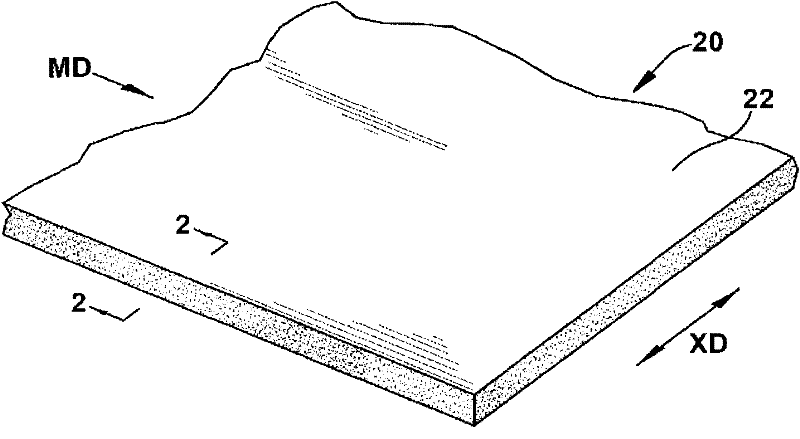

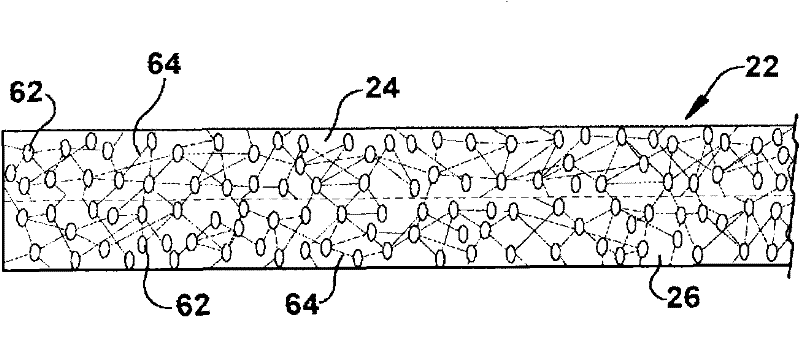

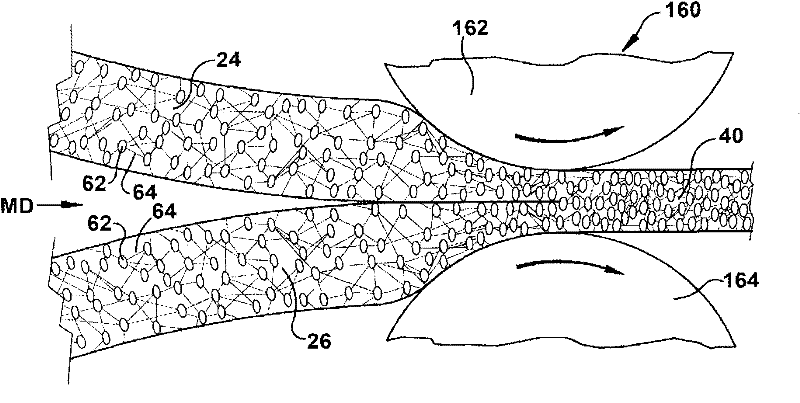

Porous membrane

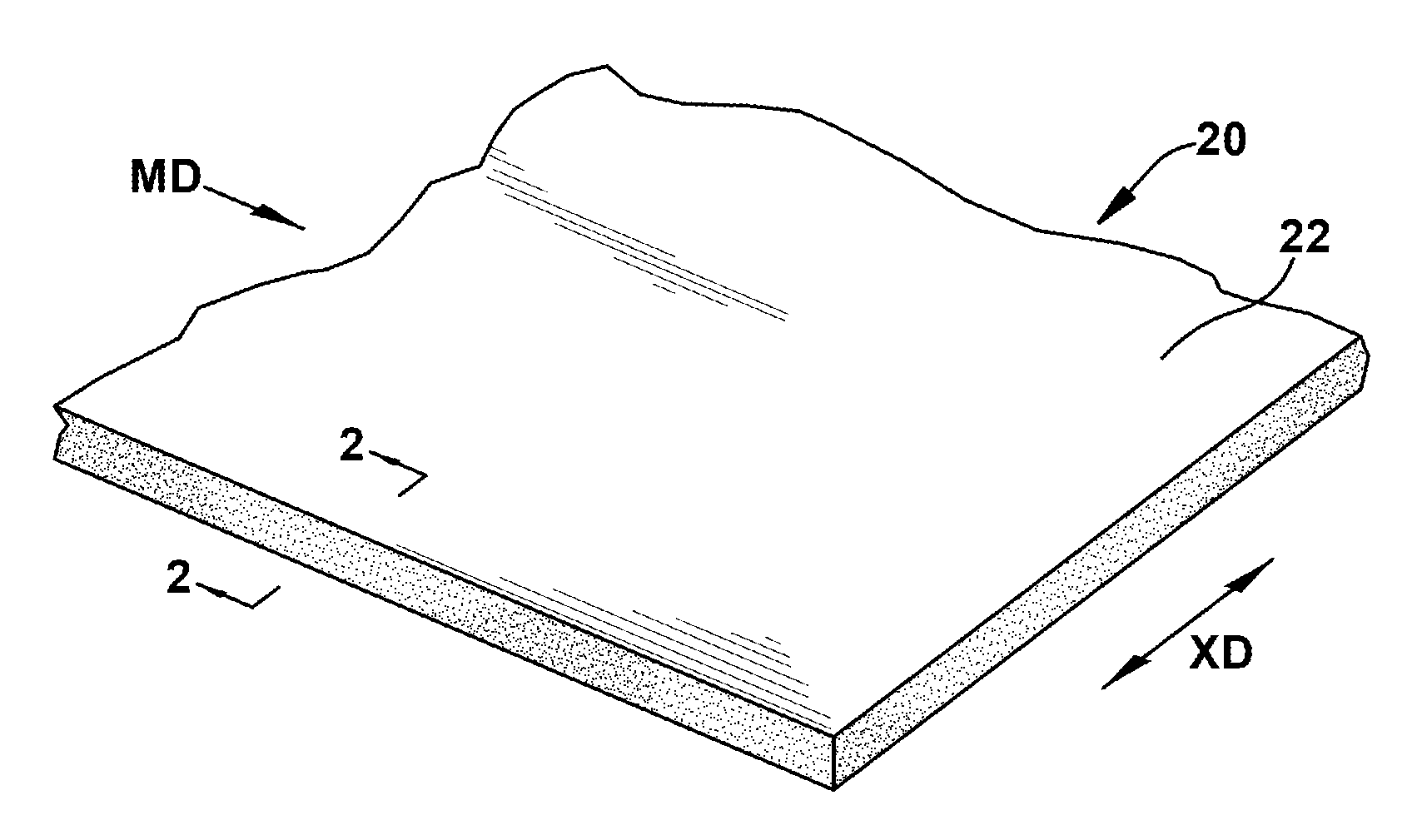

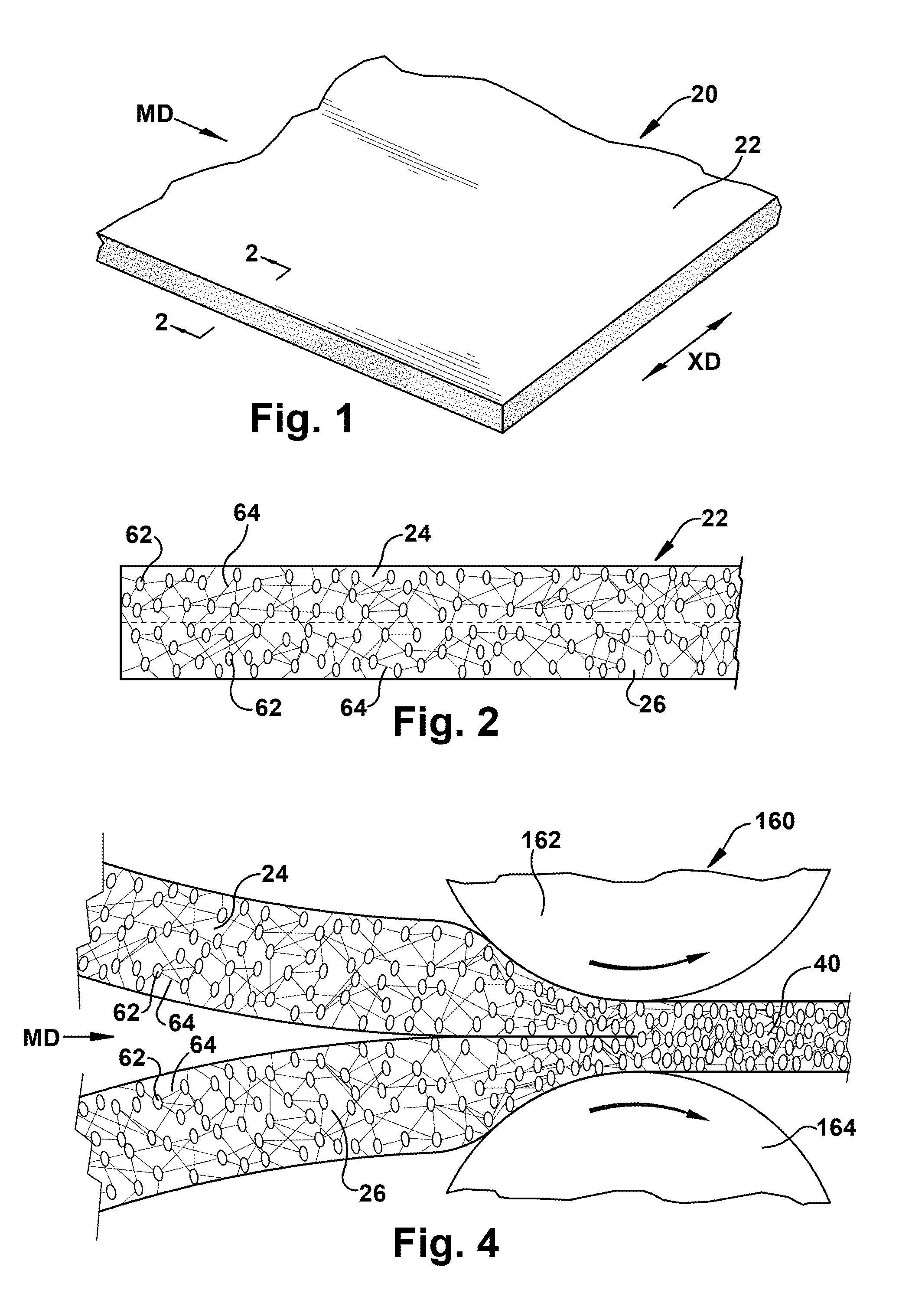

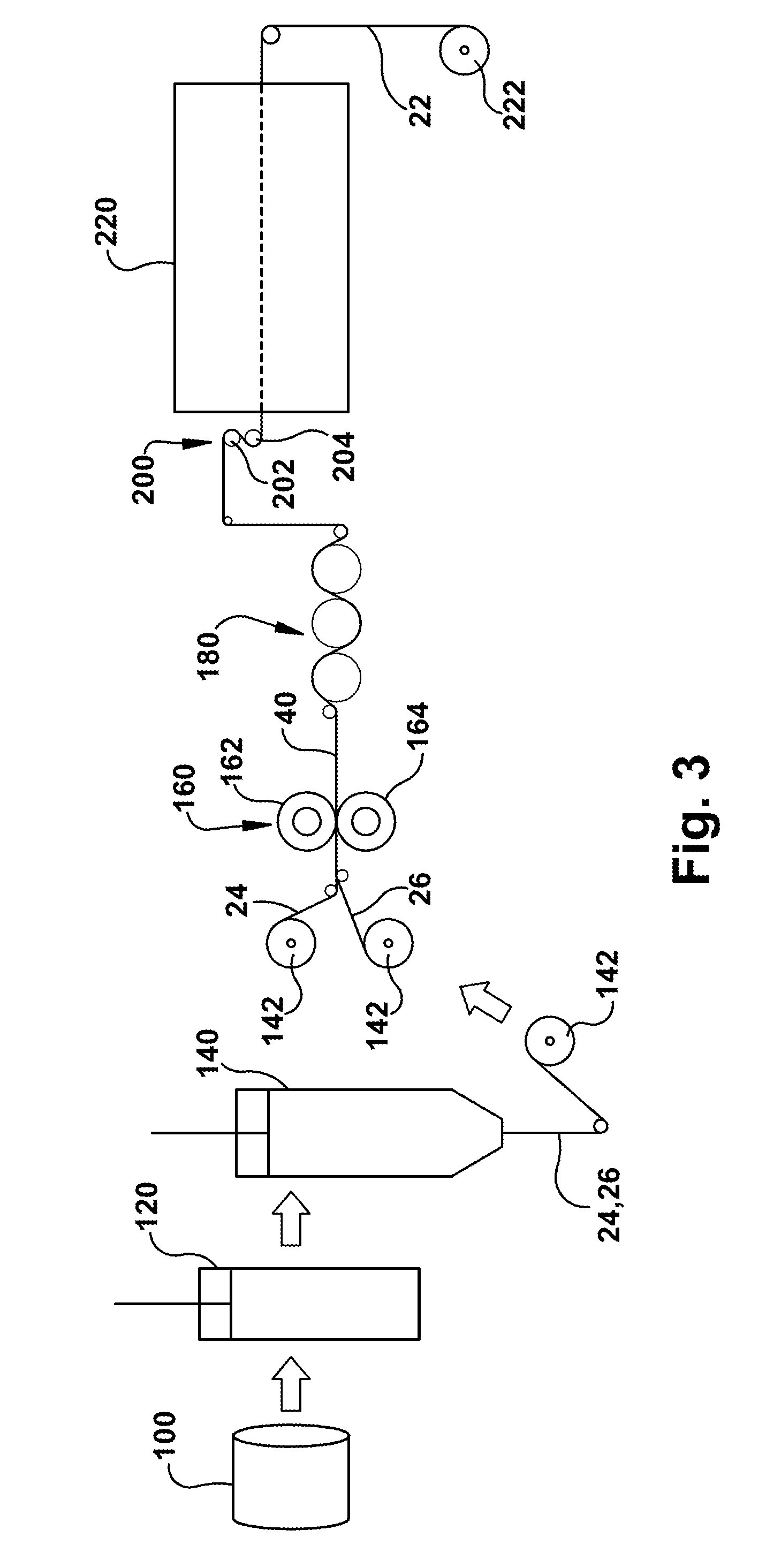

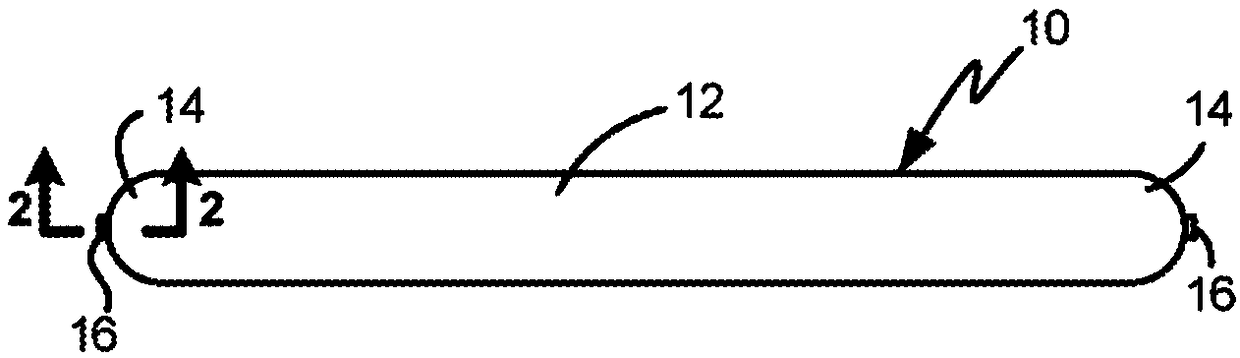

InactiveUS20110268959A1Improve stabilityHigh strengthSemi-permeable membranesMembranesPorous membraneEntry pressure

A membrane including a sheet of expanded polytetrafluoroethylene. The sheet is porous and has a gas permeability of at least 0.2 CFM according to ASTM D737 testing. The gas permeability of the membrane changes by less than 30% when the membrane is exposed to a temperature of 180° C. for a time of one hour. The sheet also has an average Mullen Hydrostatic Entry pressure of at least 135 psi according to ASTM D751 testing. The average Mullen Hydrostatic Entry pressure is substantially unchanged after exposure to a temperature of 180° C. for a time of one hour. The membrane has a bubble point value that changes by less than 20% when the membrane is exposed to a temperature of 180° C. for a time of one hour.

Owner:BHA ALTAIR

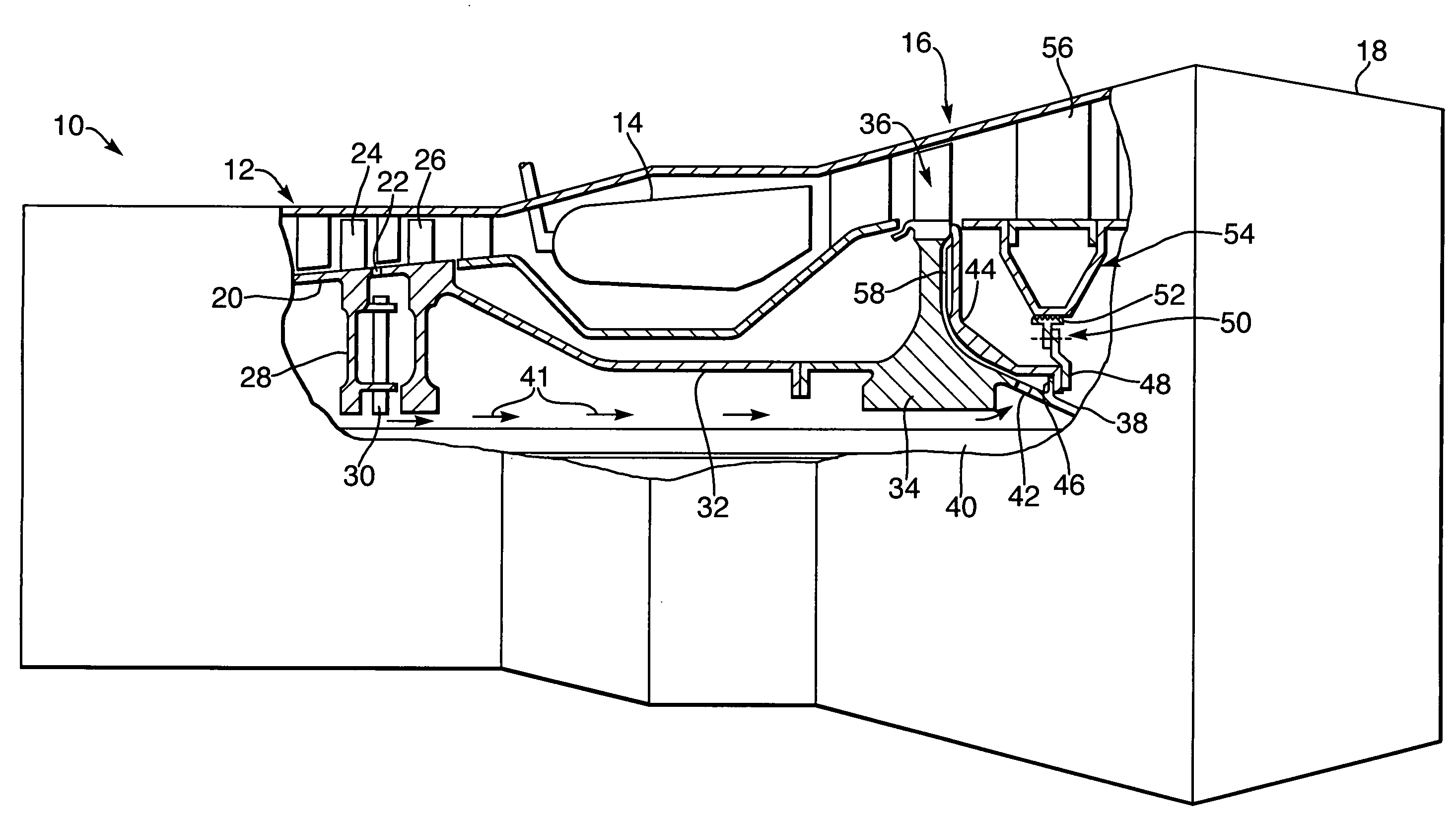

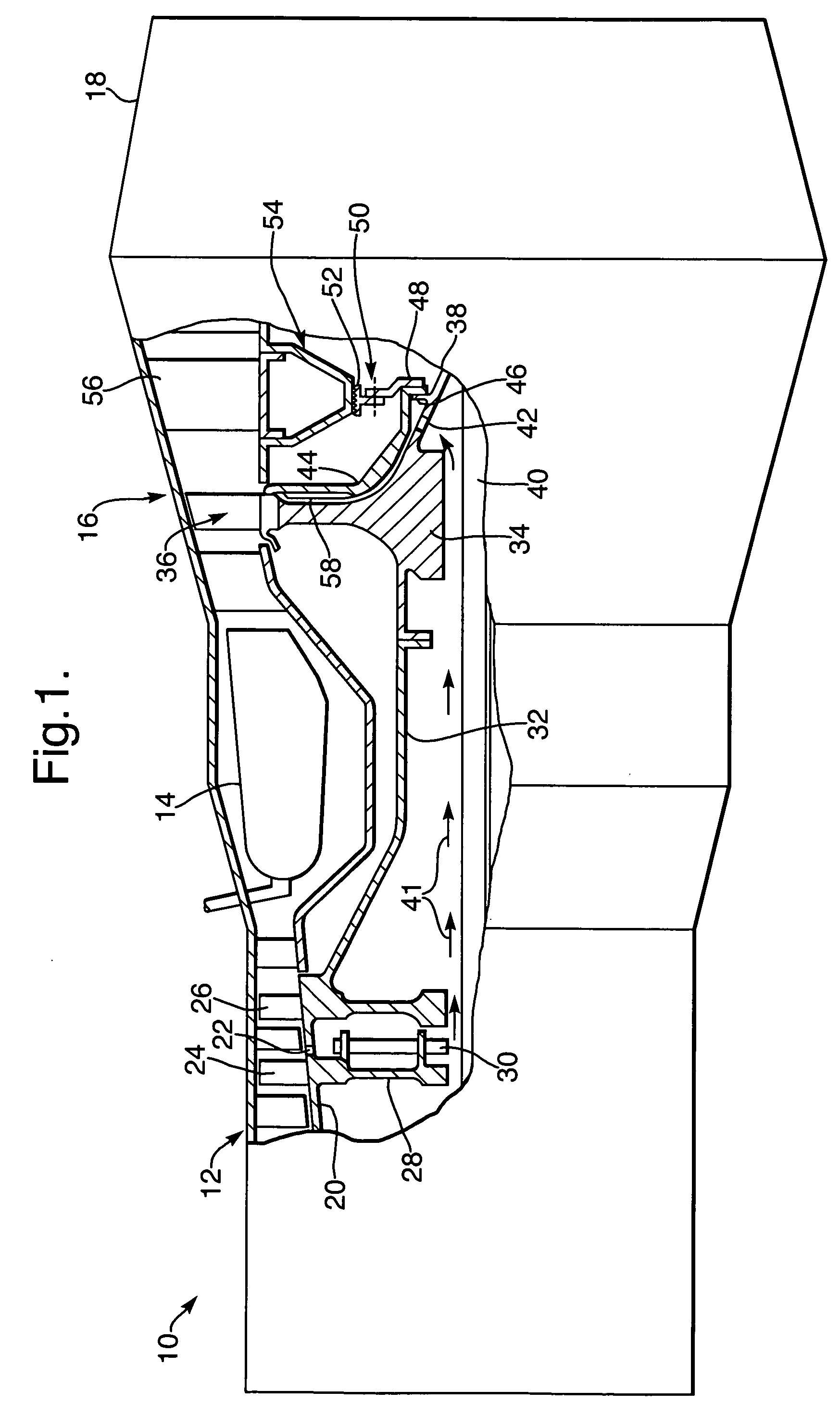

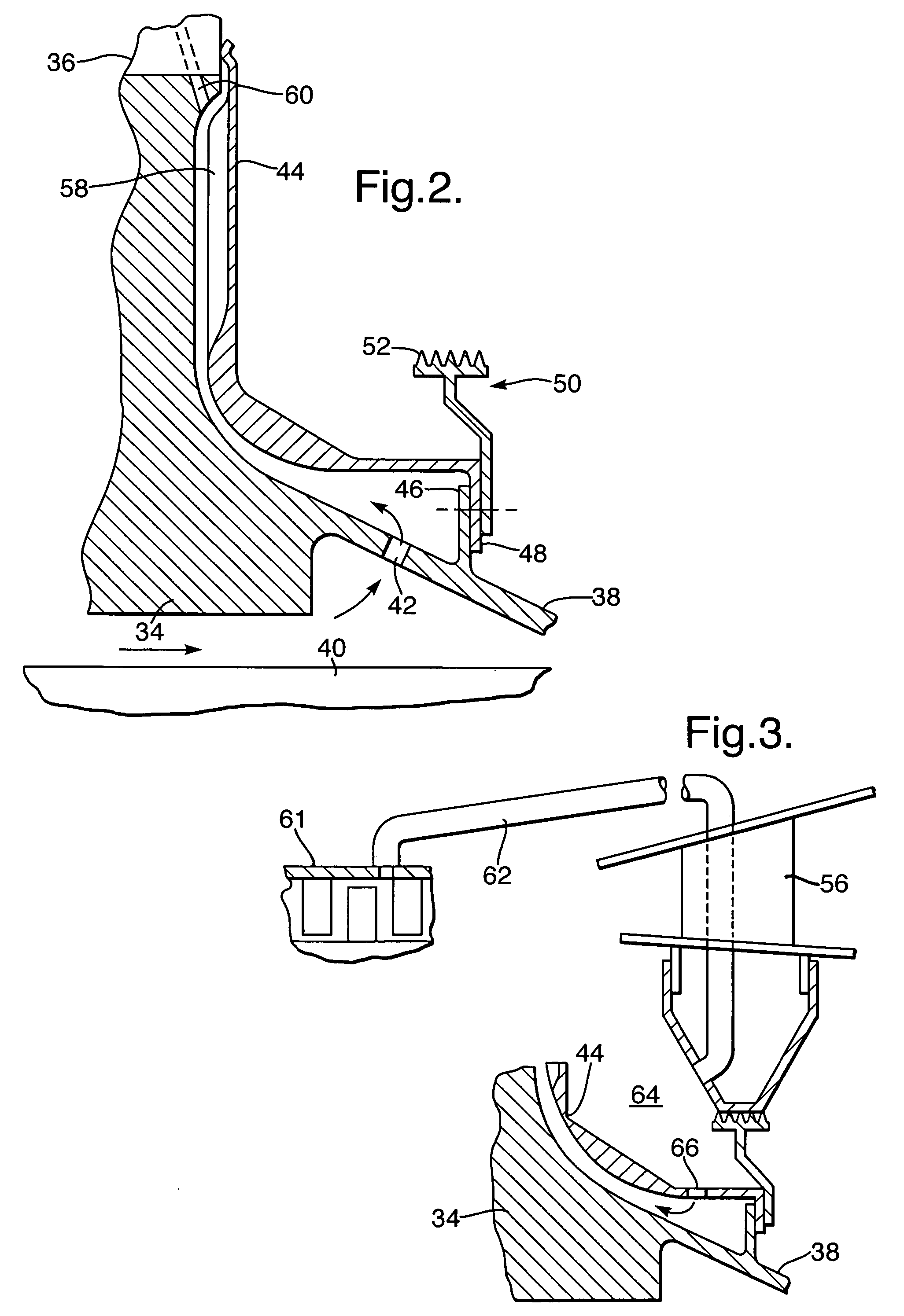

Turbine blade cooling system

Efficient cooling of a stage of gas turbine engine turbine blades (36) is achieved by first reducing the pressure of the cooling air after it has been bled from the annulus of the compressor (12) by passing it through a diffuser (30), to a pressure magnitude lower than is required at entry to the turbine blades, then re-pressurizing the bled air up to the required entry pressure, by passing it through a radial compressor defined by a cowl (44) positioned in close spaced, co-rotational relationship with the downstream face of the associated turbine disk (34).

Owner:ROLLS ROYCE PLC

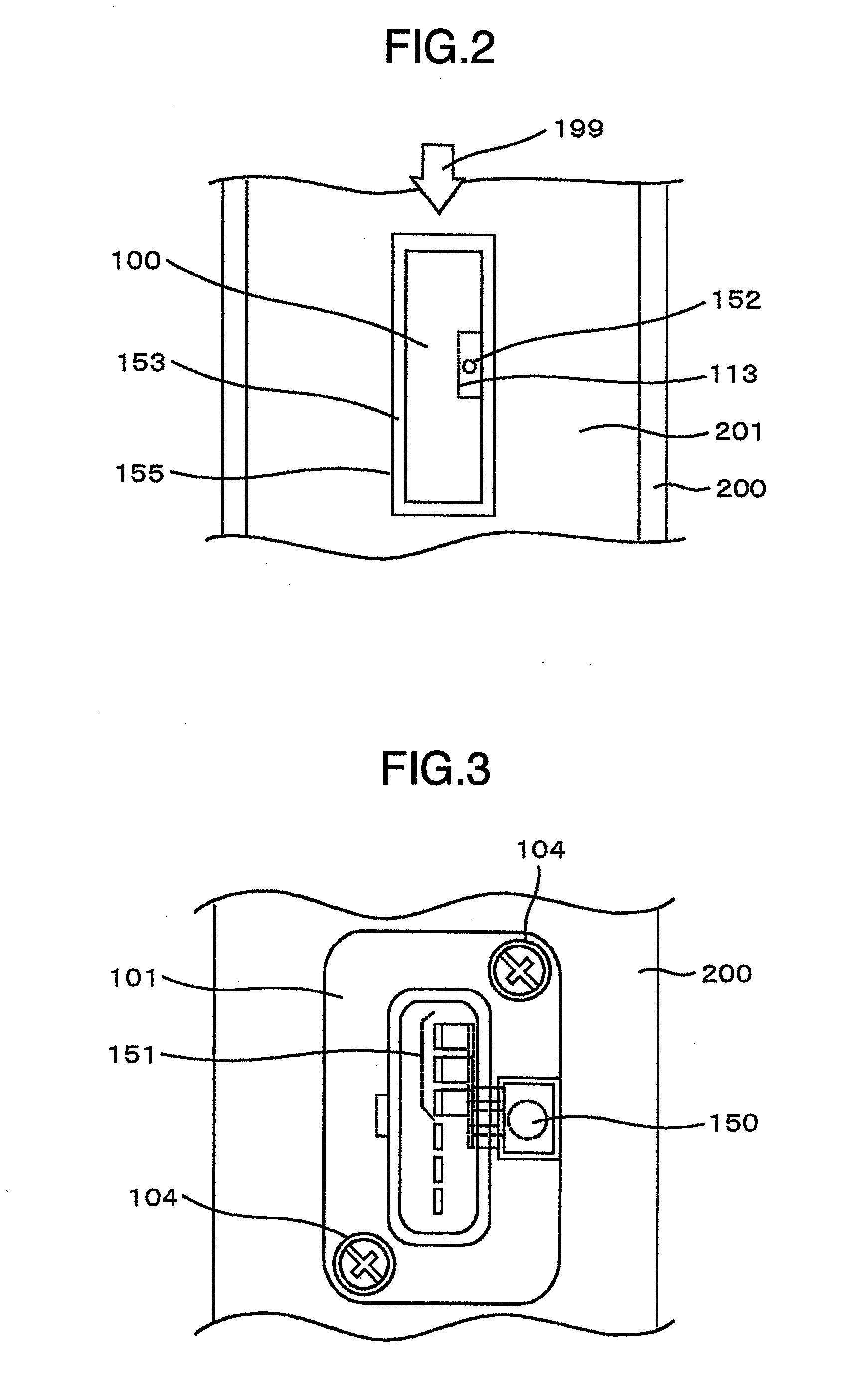

Intake air mass flow measurement device

ActiveUS20080302173A1Save natural resourcesReduce the amount requiredEngine testingVolume flow proportion measurementMeasurement devicePressure sense

In an intake air mass flow measurement device, for preventing clogging in a pressure intake tube due to water or the like entering the pressure intake tube in a device measuring a pressure in the intake air tube, the intake air mass flow measurement device includes a mass air flow measurement device for measuring an intake air mass flow in an intake air tube; and a pressure sensing device for sensing pressure in the intake air tube, the pressure sensing device being integrated with the mass air flow measurement device, and an aperture plane opened to the inside of a main air flow passage for detection of the pressure takes in pressure by using a gap generated between a main air flow passage constituting member and an insertion part of the mass air flow measurement device when a measurement part of the mass air flow measurement device is inserted into the main air flow passage. With this construction, it is possible to provide a structure in which water or the like can hardly clog the pressure intake port.

Owner:HITACHI ASTEMO LTD

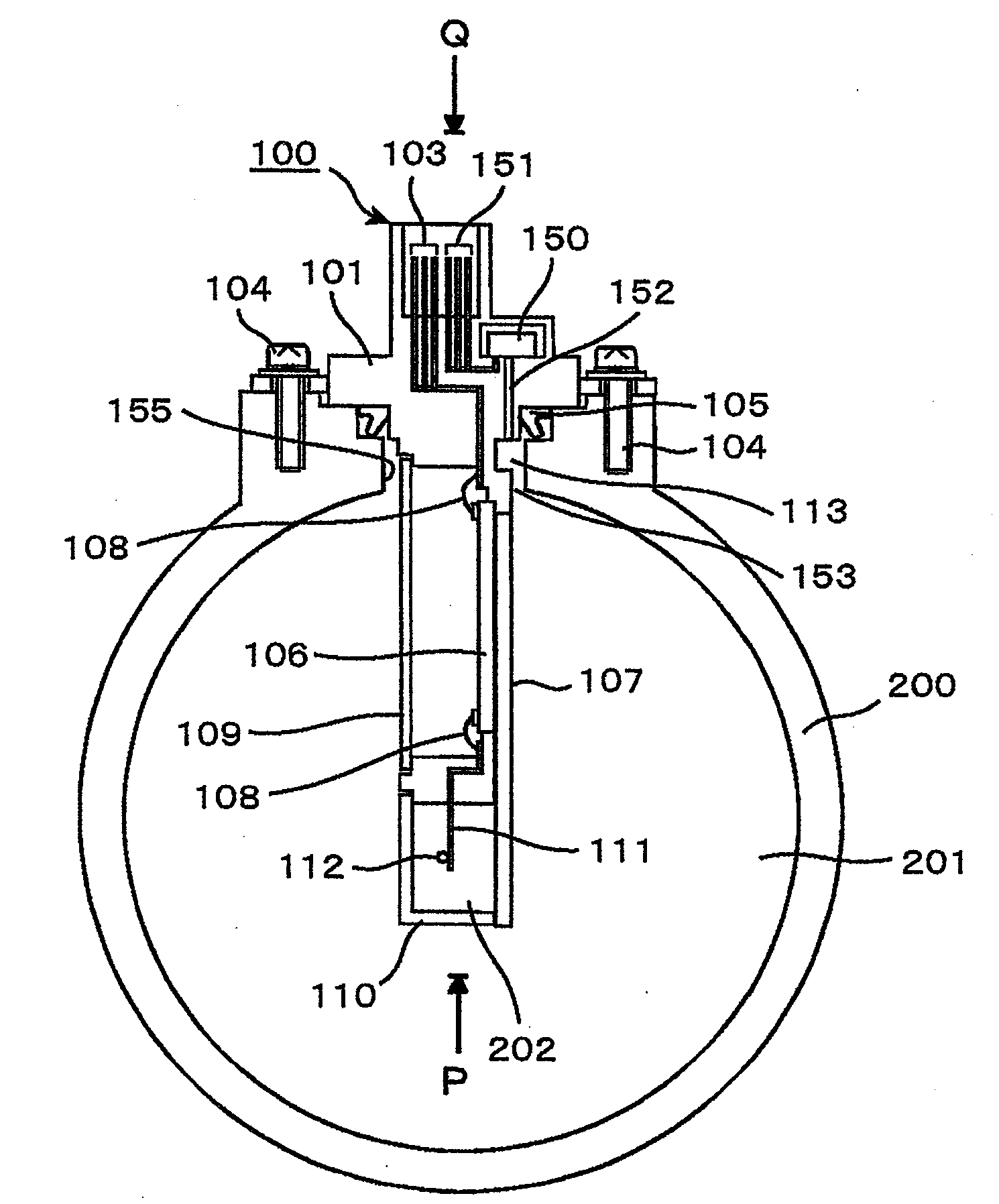

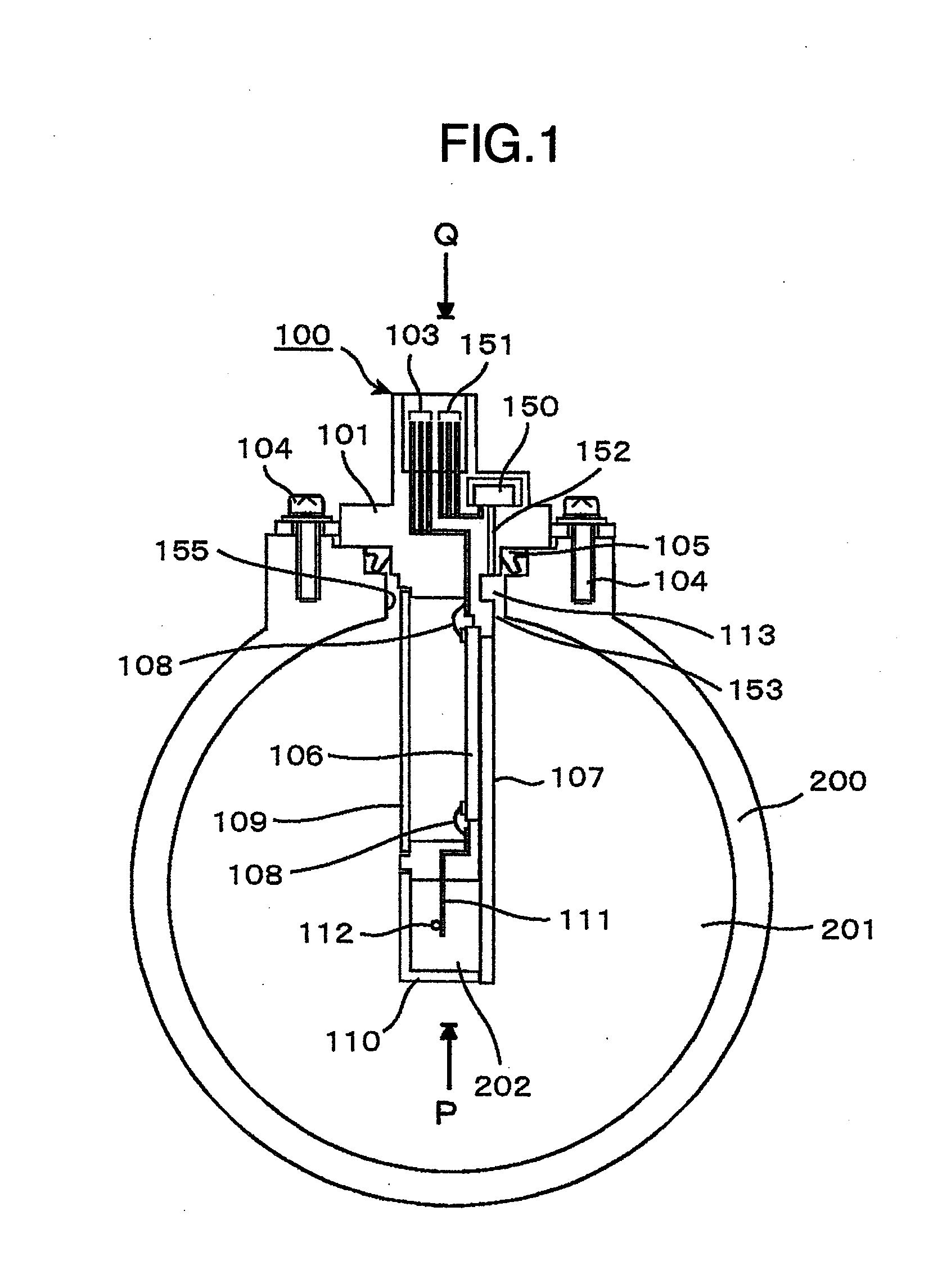

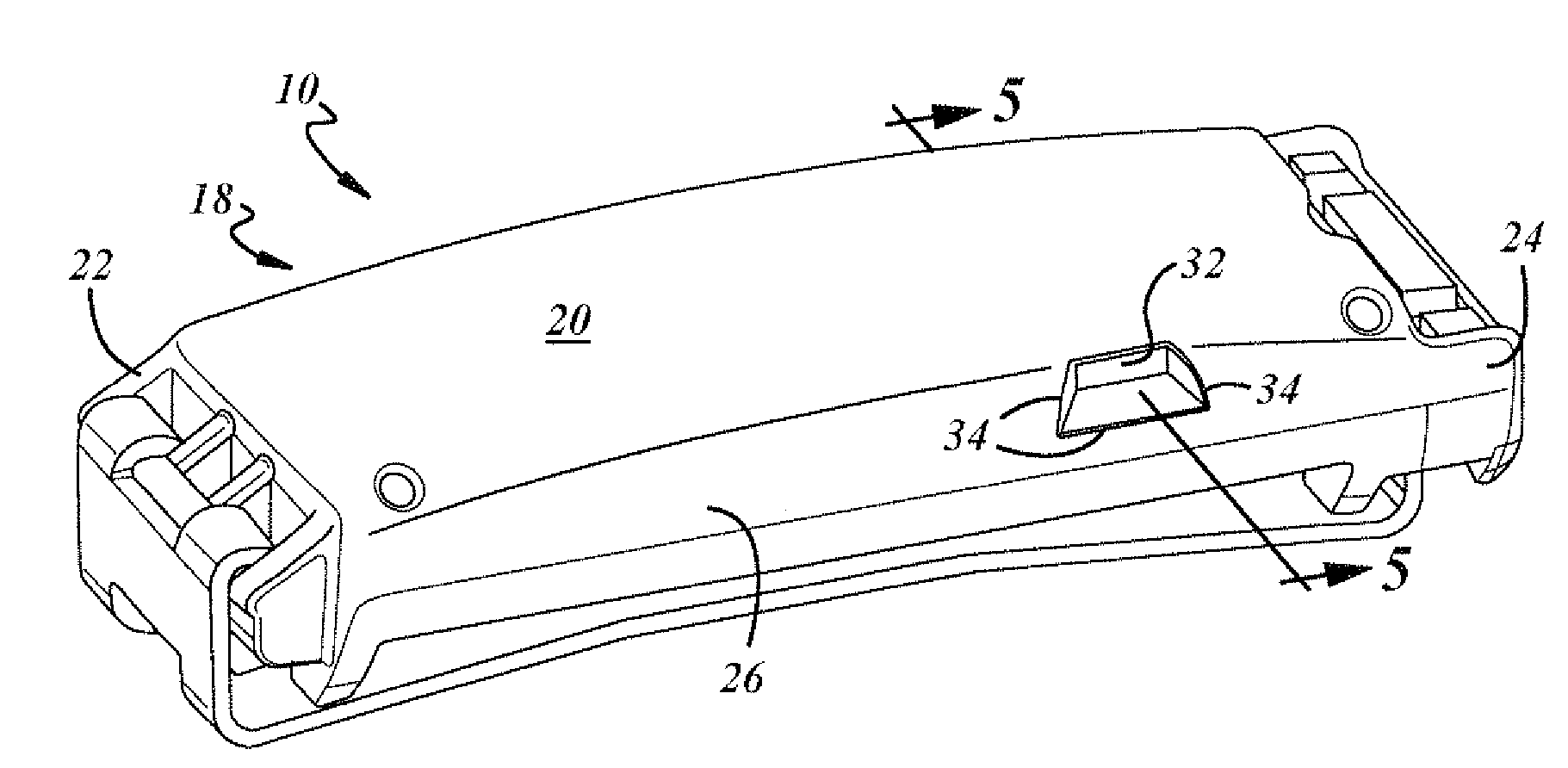

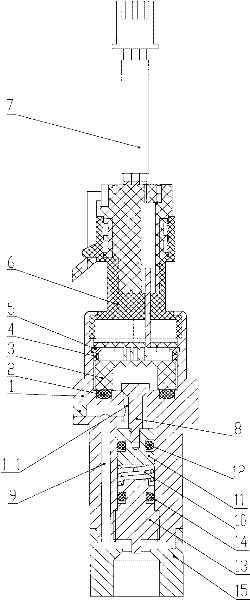

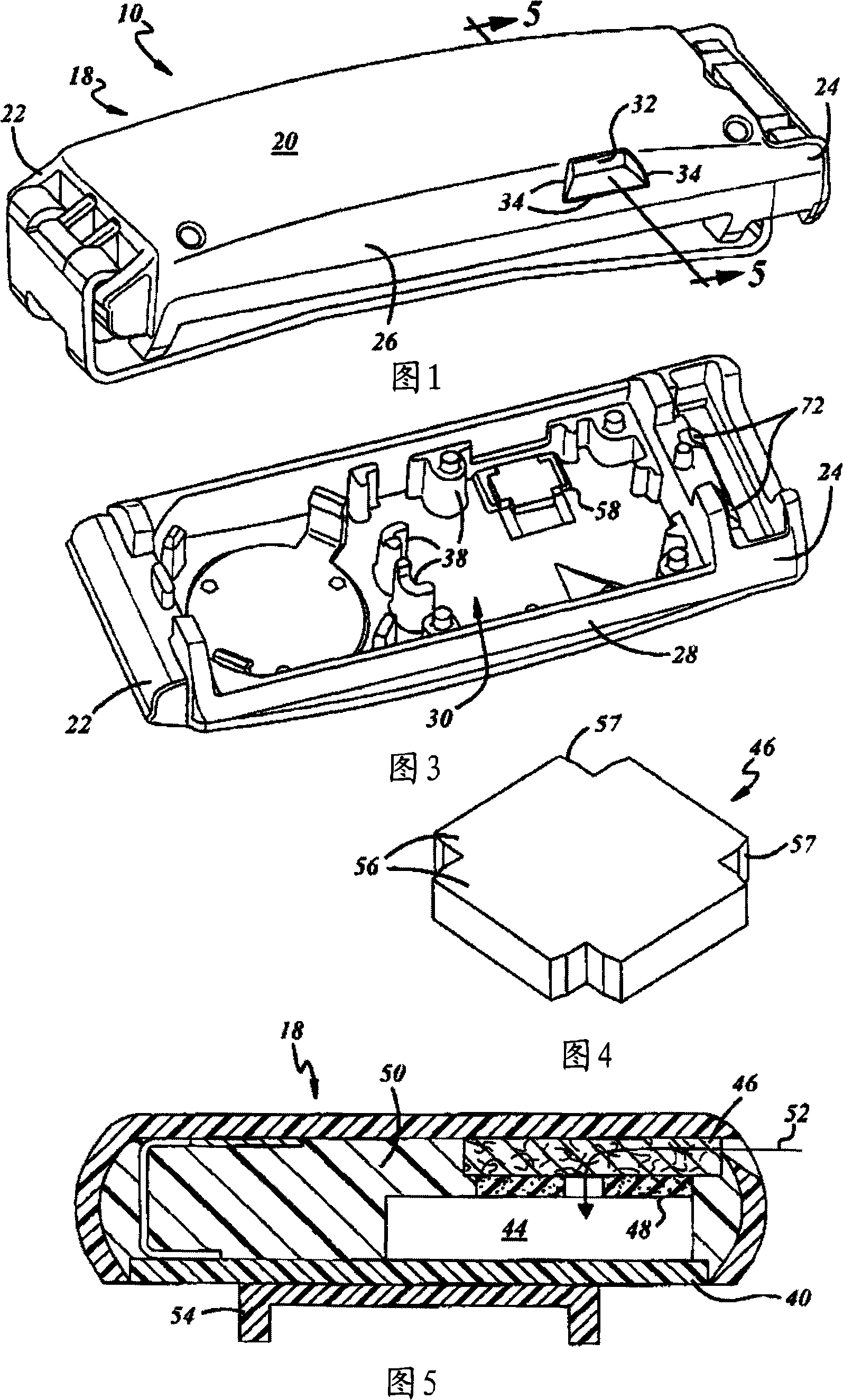

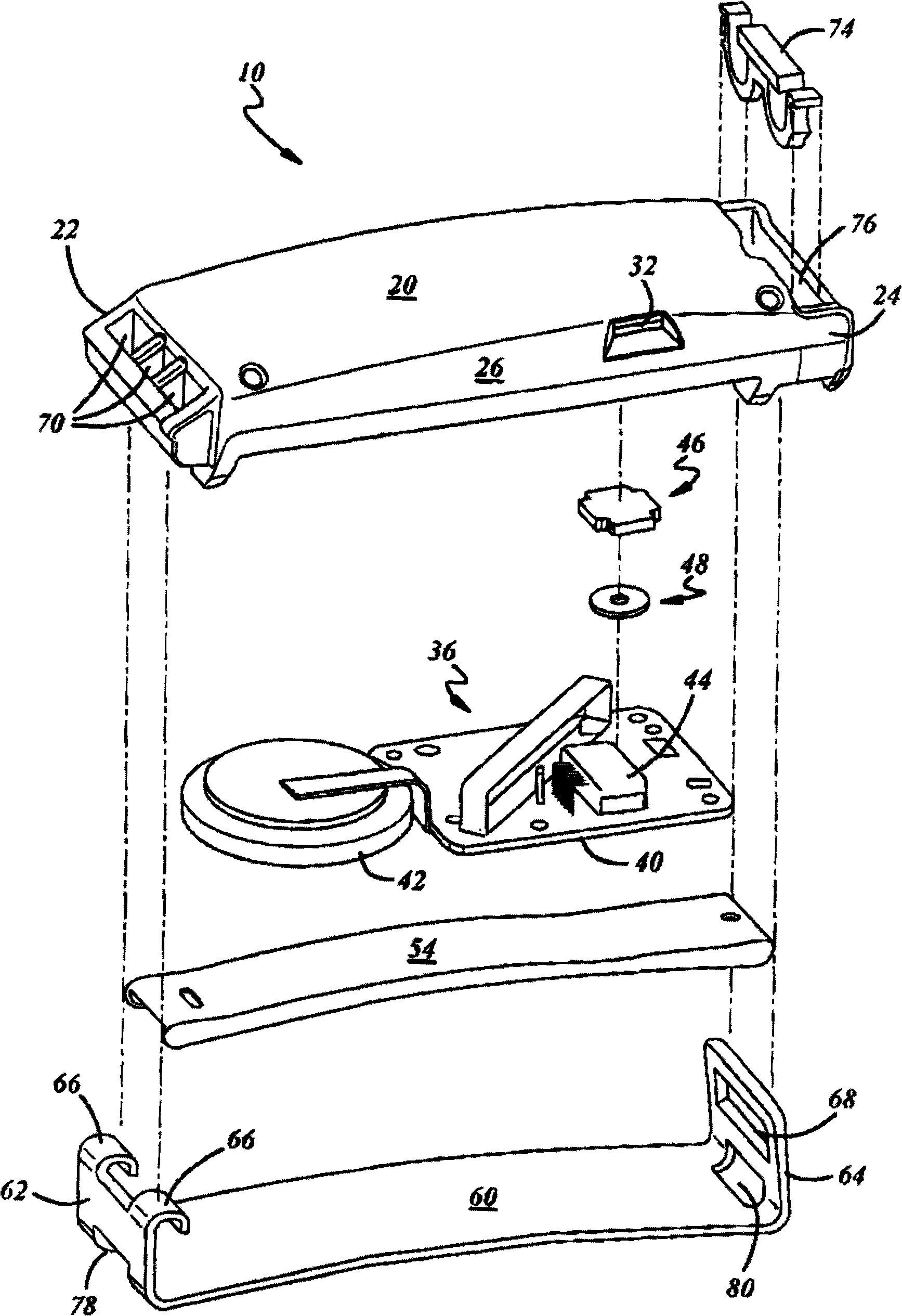

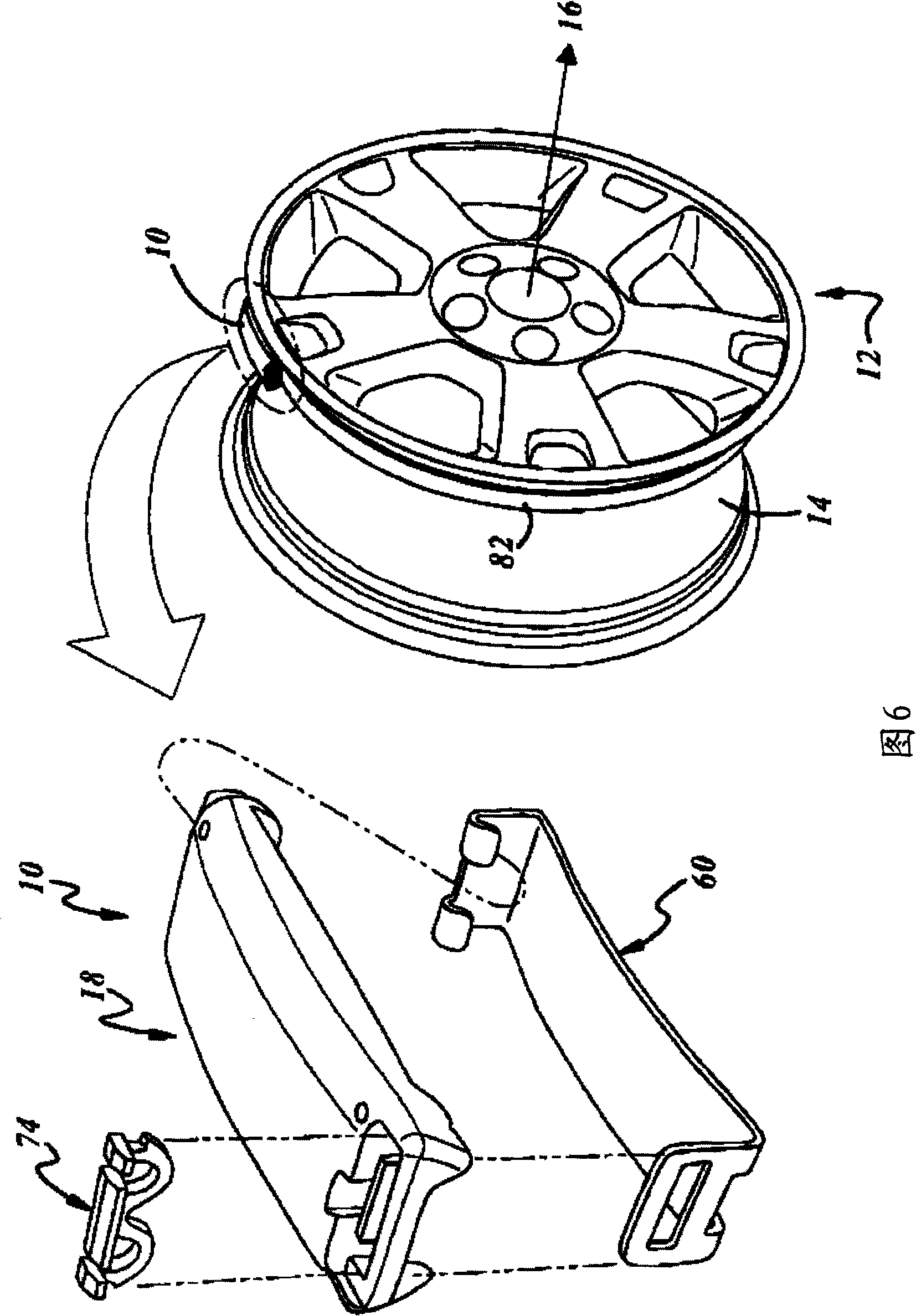

Tire pressure monitor system with side entry pressure port

A tire pressure monitor system is provided including a sensor housing forming an internal housing mount chamber. An air inlet port is formed on a housing side surface and is orientated parallel to the wheel rim rotational axis. A sensor assembly including an air pressure sensor element is mounted within the internal housing mount chamber. A filter element and a gasket element are positioned between the air pressure sensor element and the air inlet port. A potting material fills the internal housing mount chamber. The filter element and the gasket element creating an air pressure flow path from the air inlet port to the air pressure sensor element.

Owner:LEAR CORP

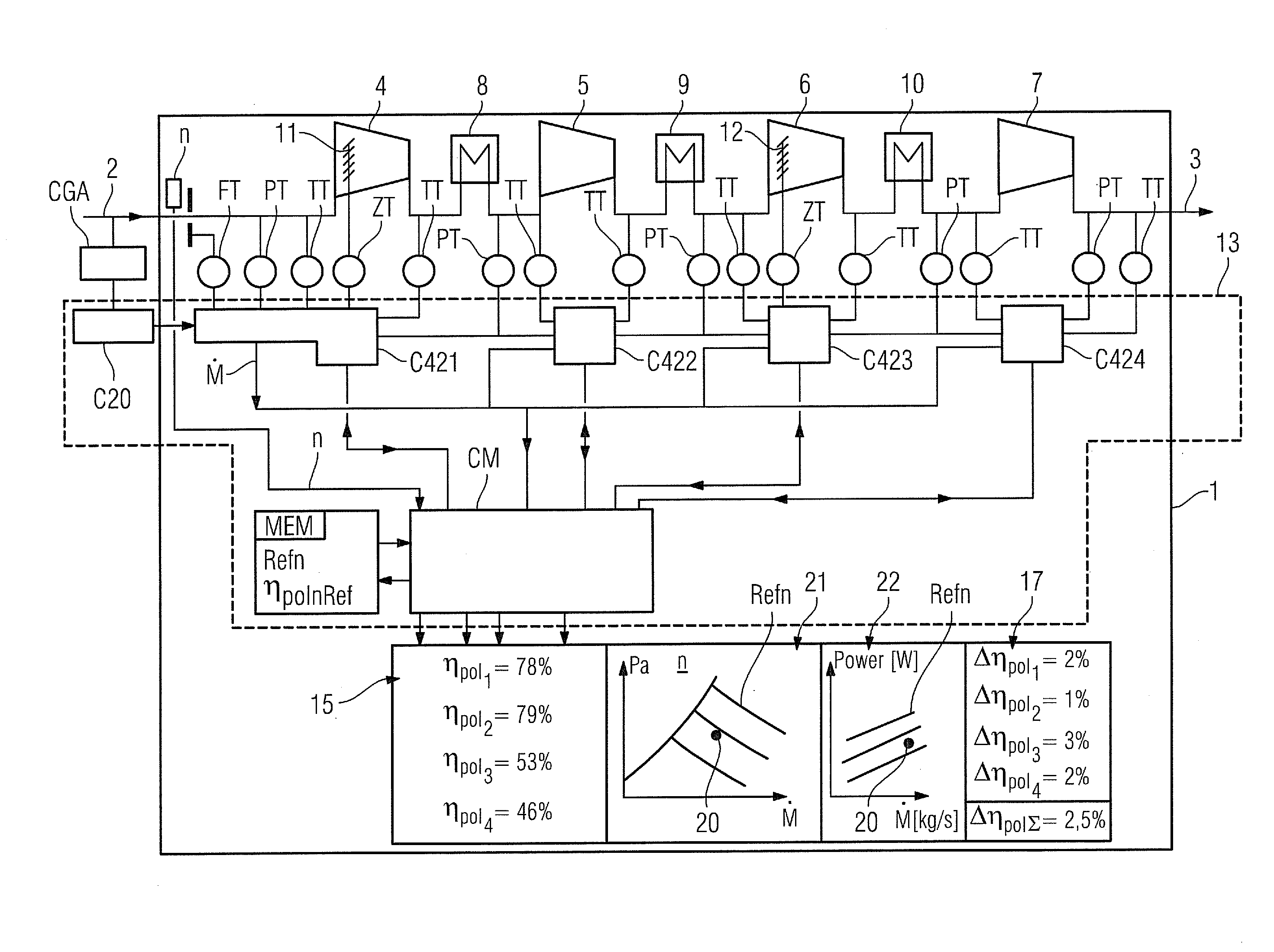

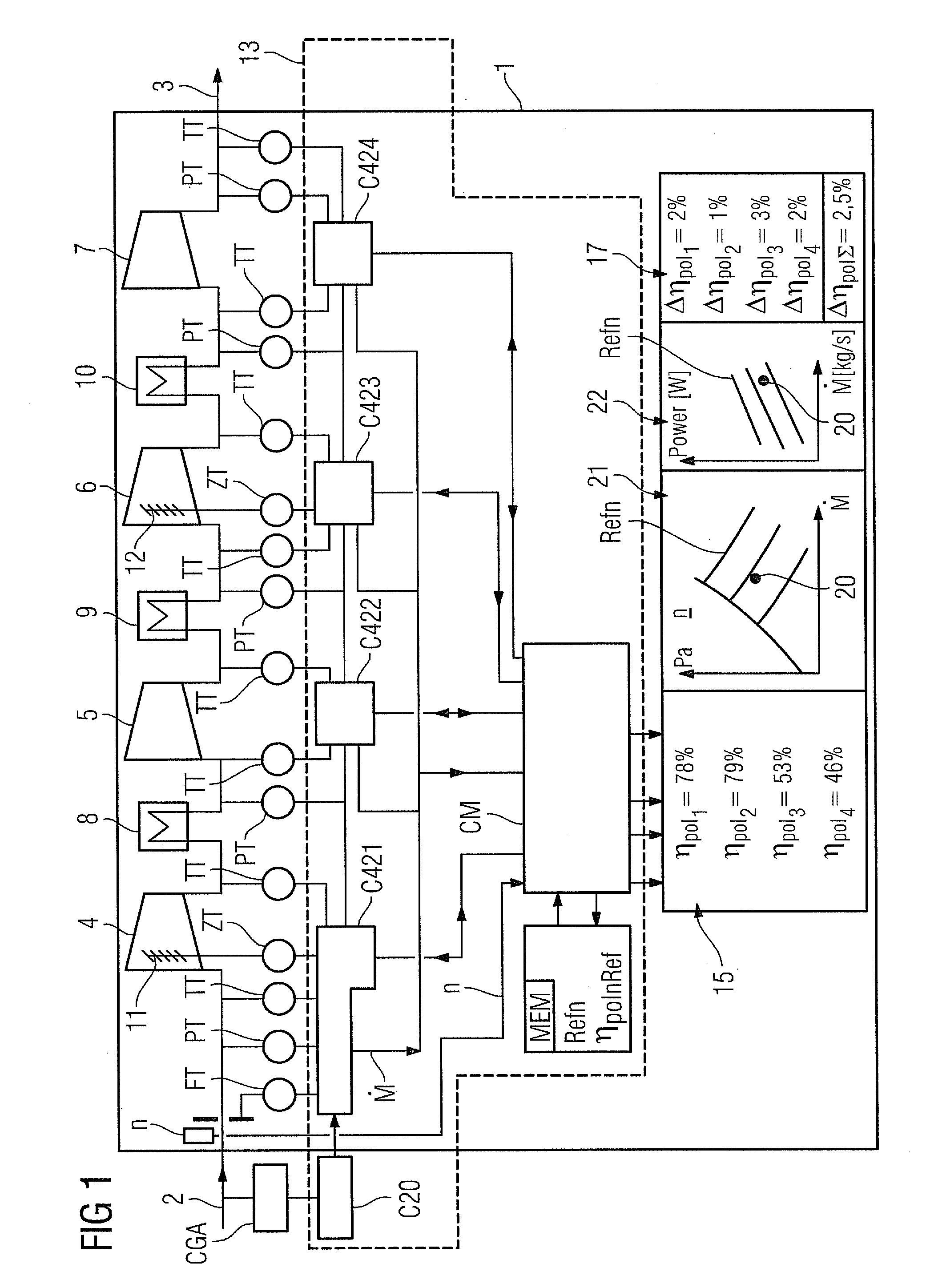

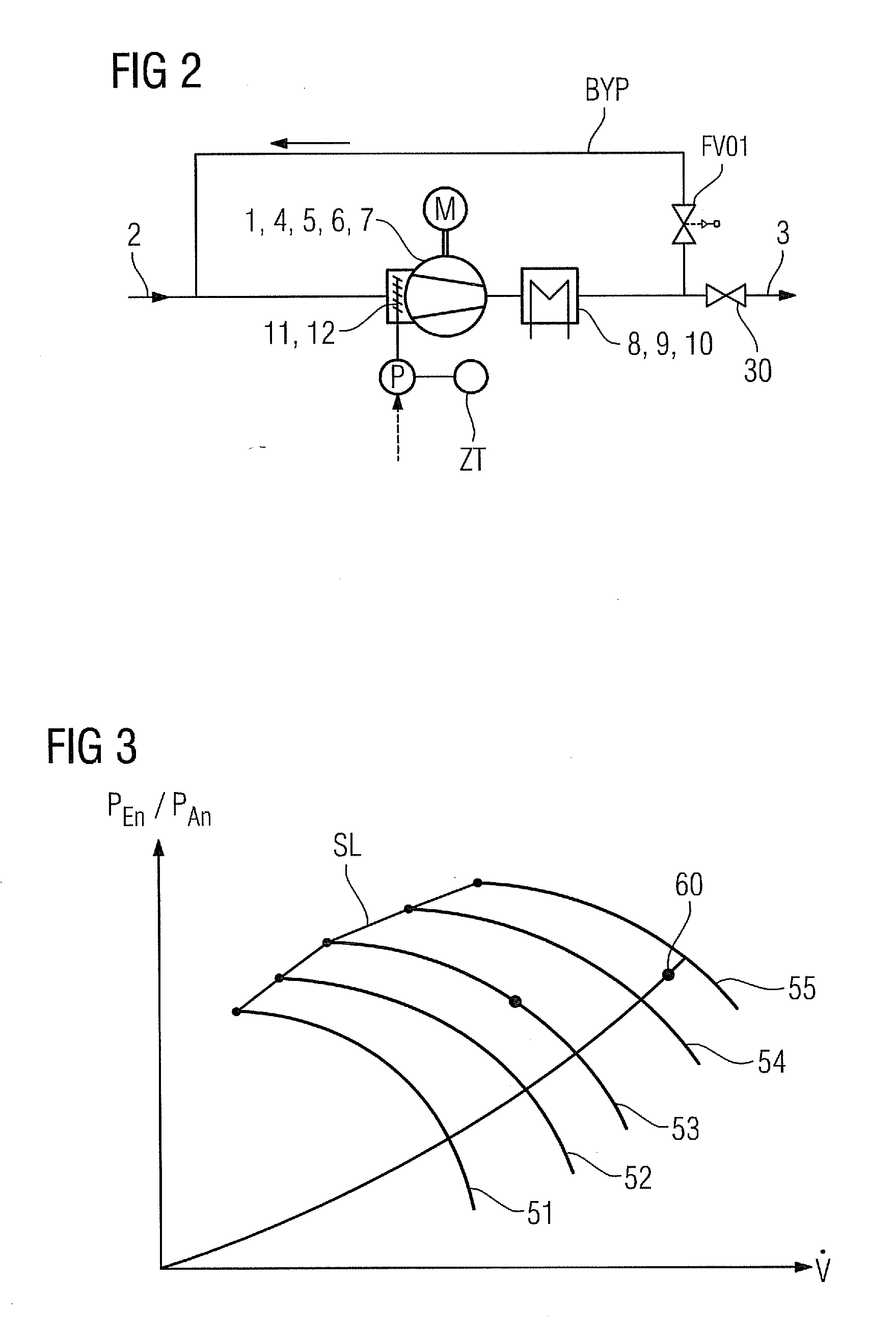

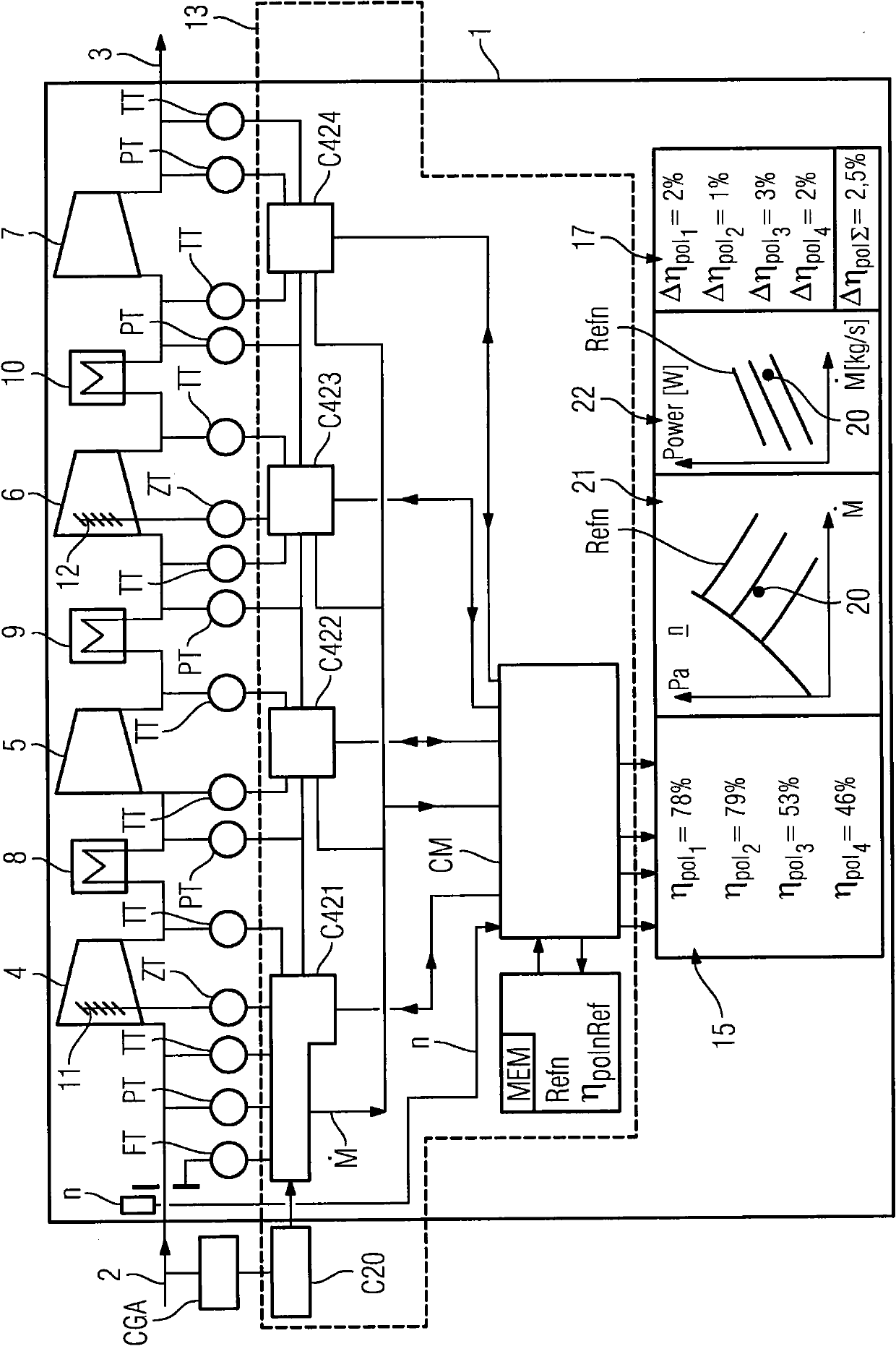

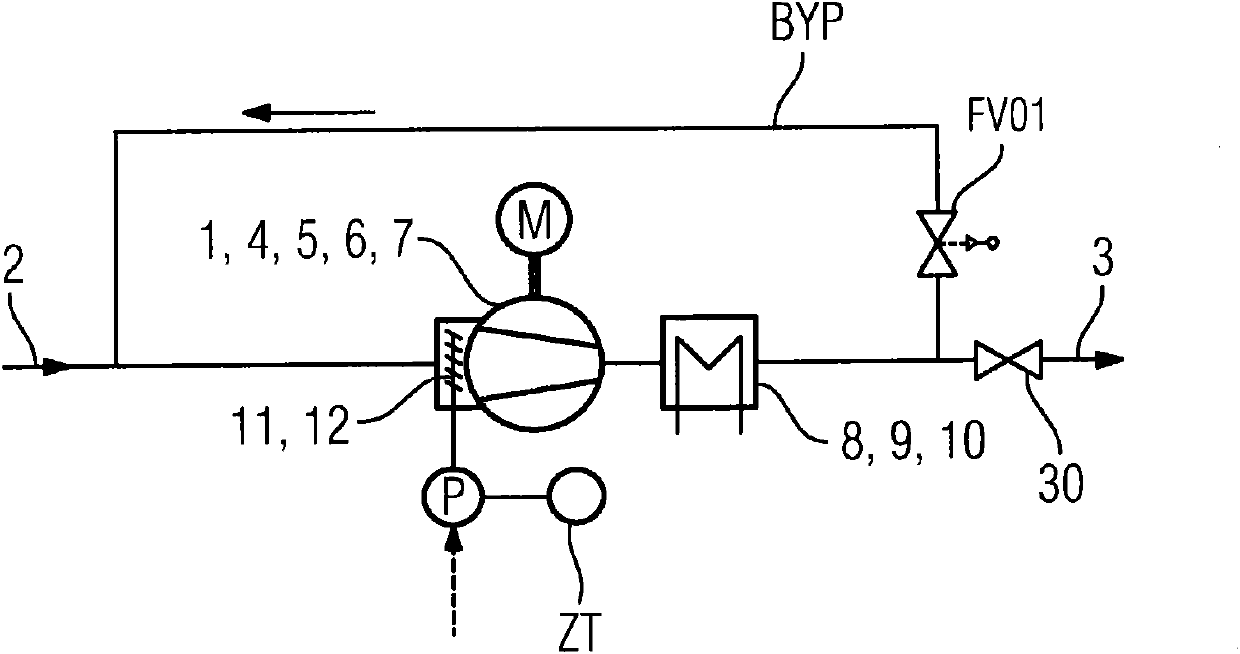

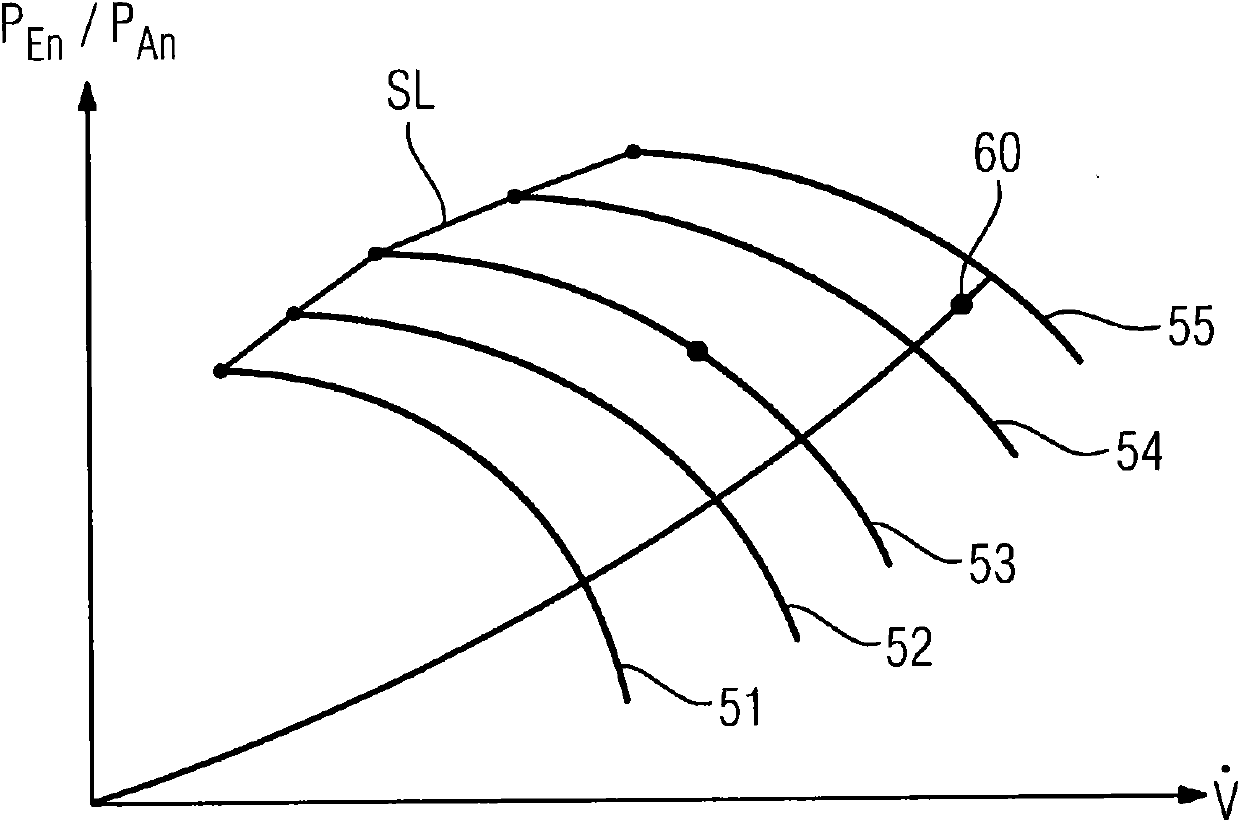

Efficiency monitoring of a compressor

InactiveUS20110112797A1Loss in efficiencyImprove accuracyGas-turbine engine testingNuclear monitoringProcess engineeringEntry pressure

A method for monitoring the efficiency of a compressor is provided. A mass flow, an entry pressure, an exit pressure, an entry temperature, and an exit temperature of the process medium are all determined and a performance factor is ascertained. At the inlet of each stage, a stage entry temperature and a stage entry pressure are directly or indirectly measured as measurement parameters. At the outlet of each stage, a stage exit temperature and a stage exit pressure are directly or indirectly measured as measurement parameters. Each stage is assigned a module which calculates a stage efficiency as a performance factor from the measurement parameters using a calculation means.

Owner:SIEMENS AG

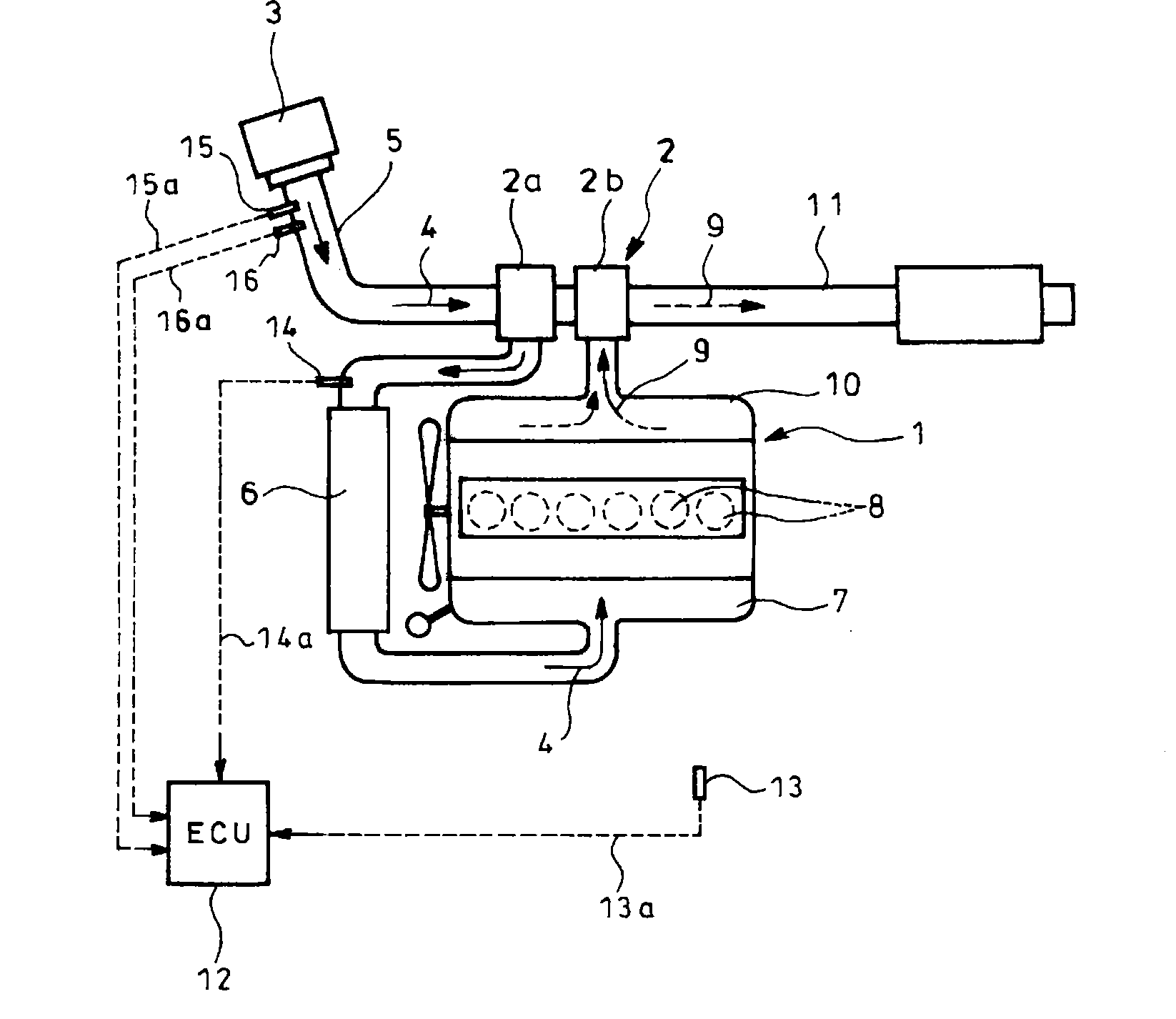

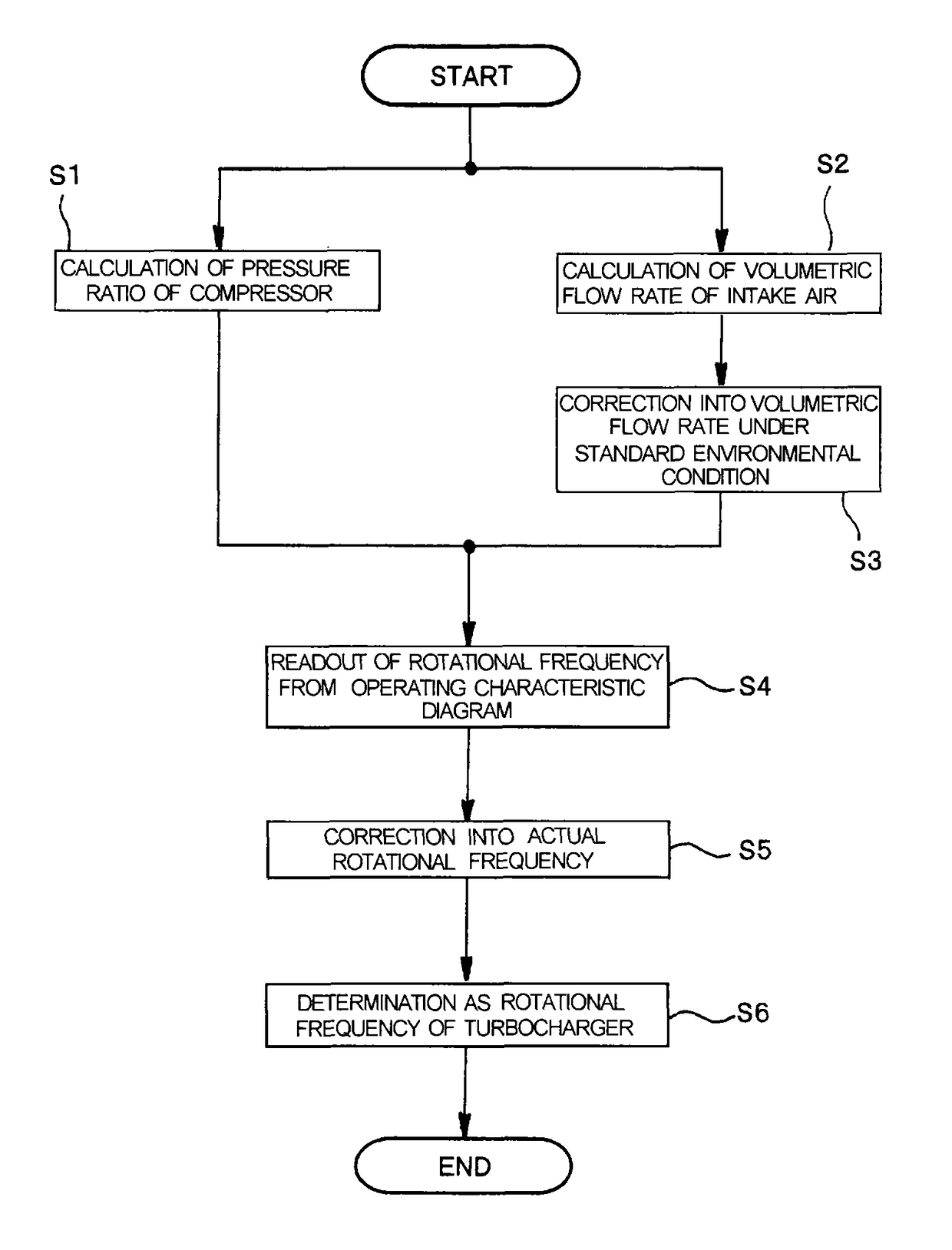

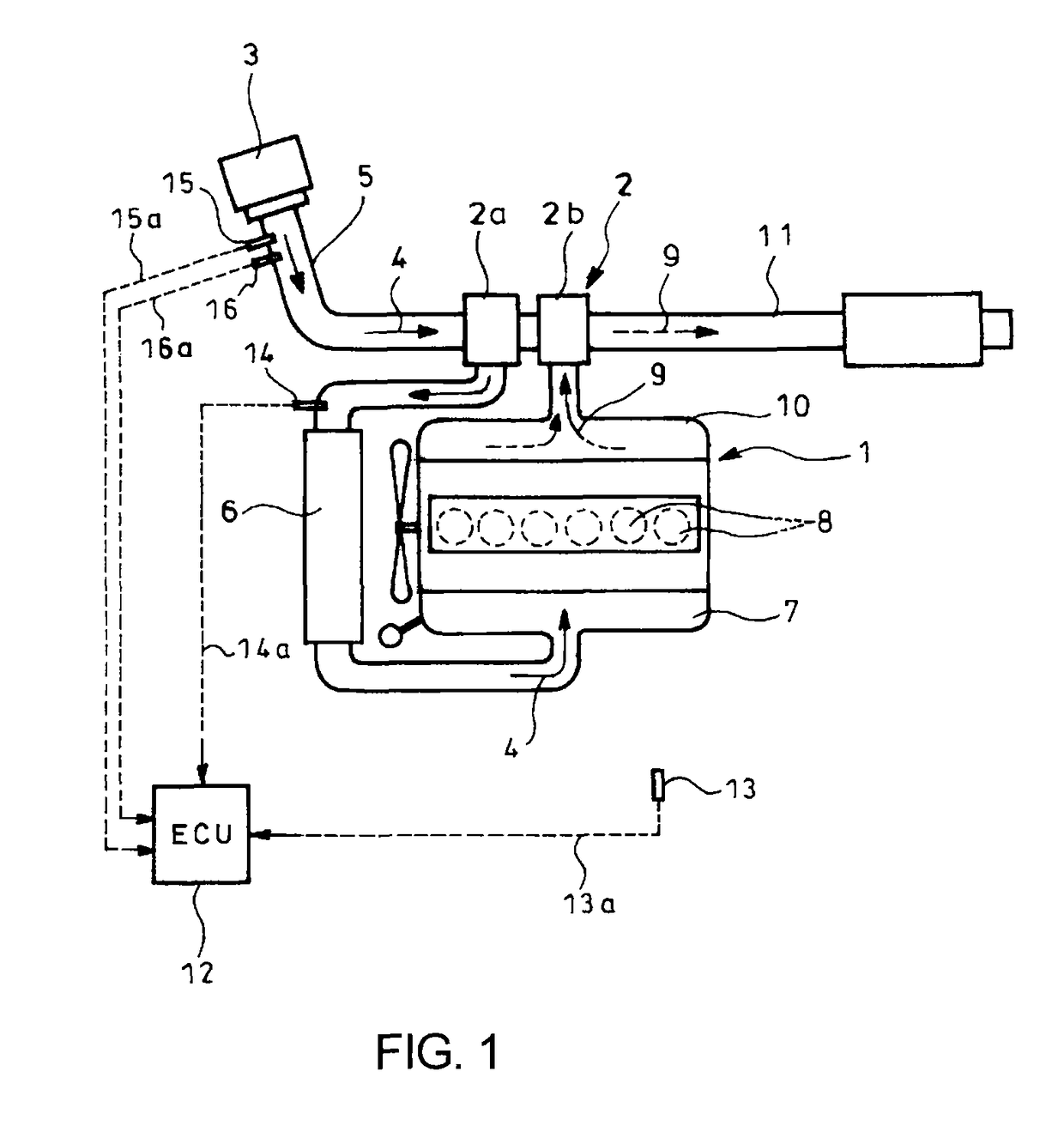

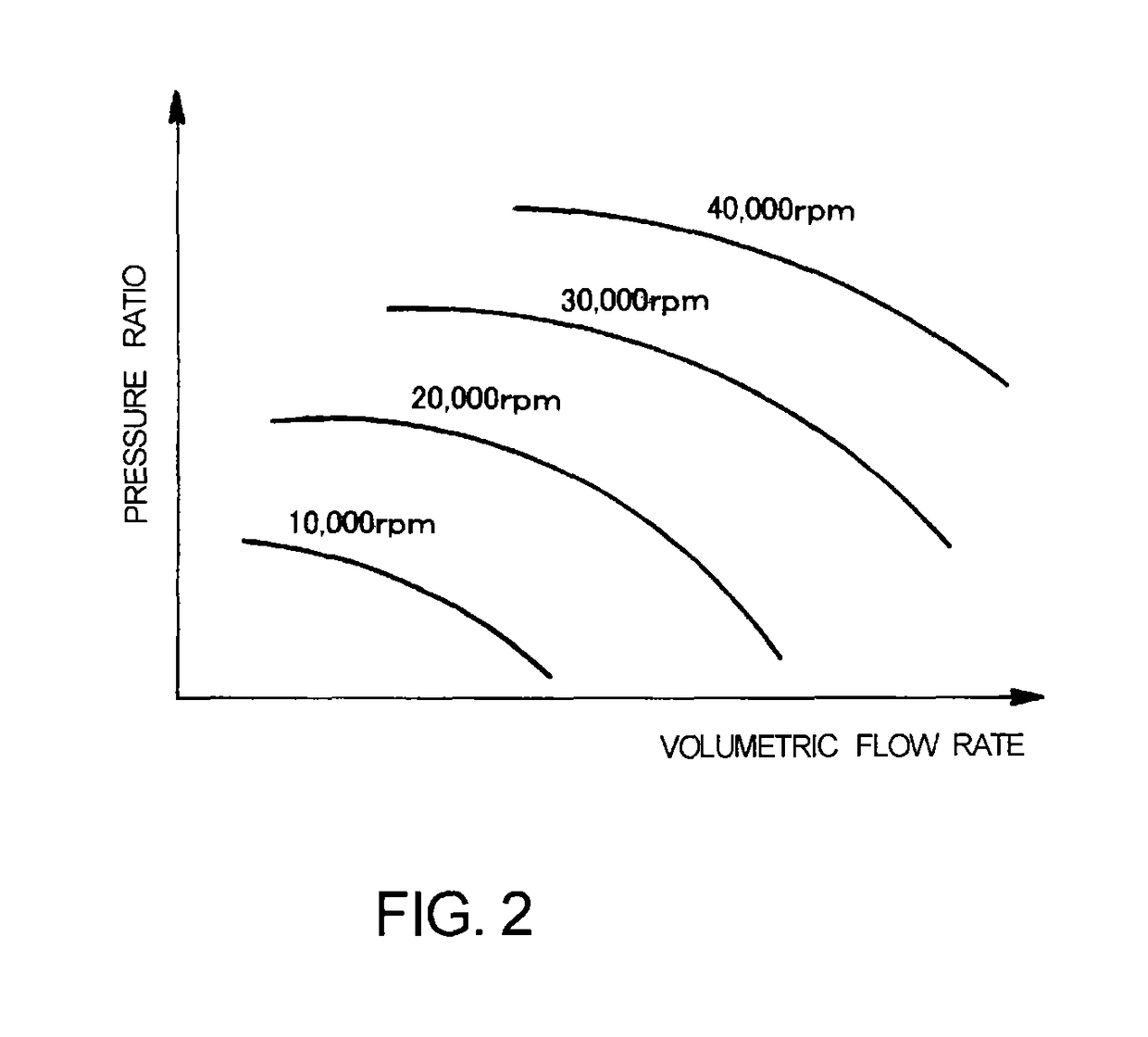

Turbo rotational frequency detection device

InactiveUS20150143882A1Low costGood effectElectrical controlGas-turbine engine testingTurbochargerEngineering

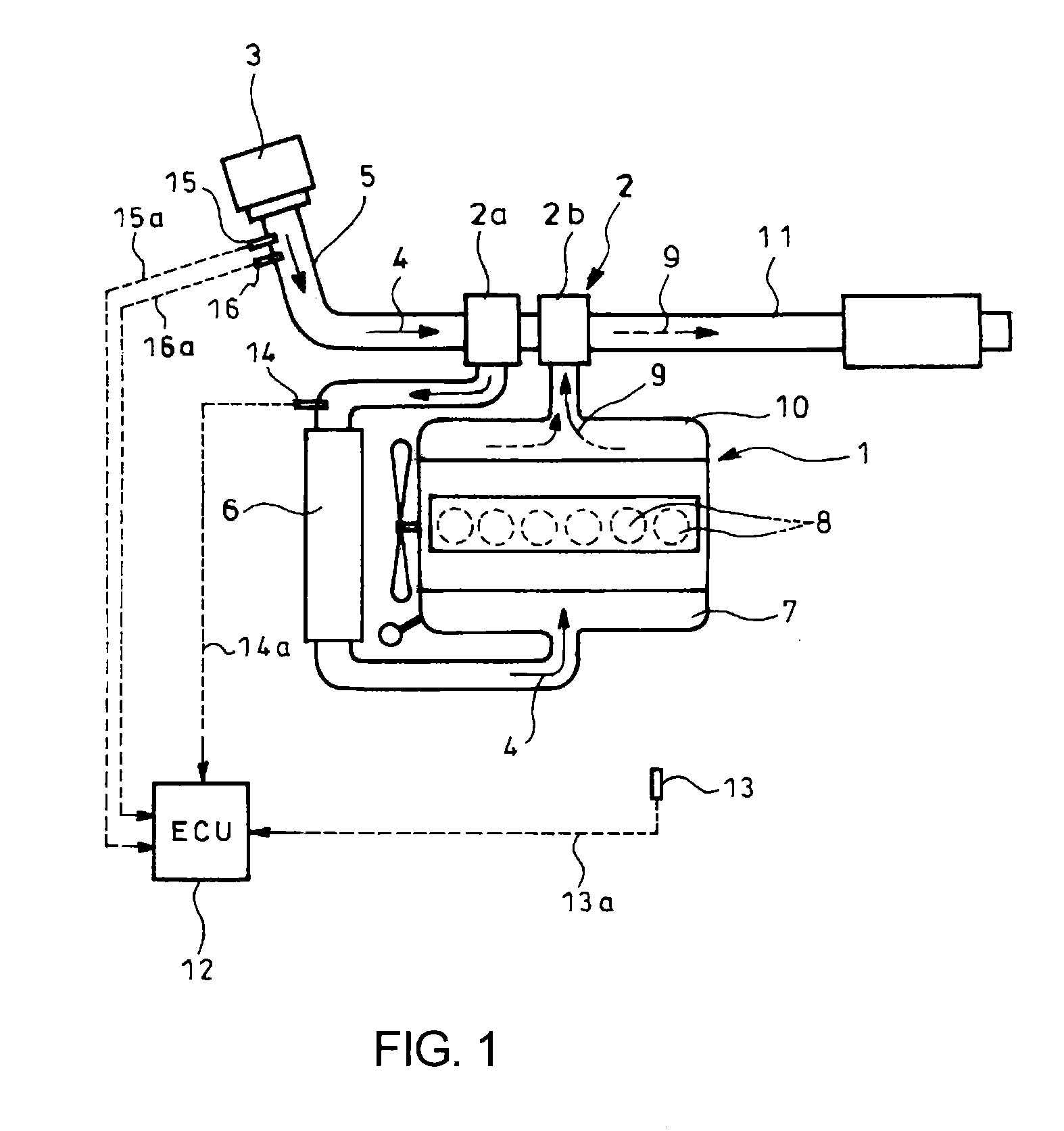

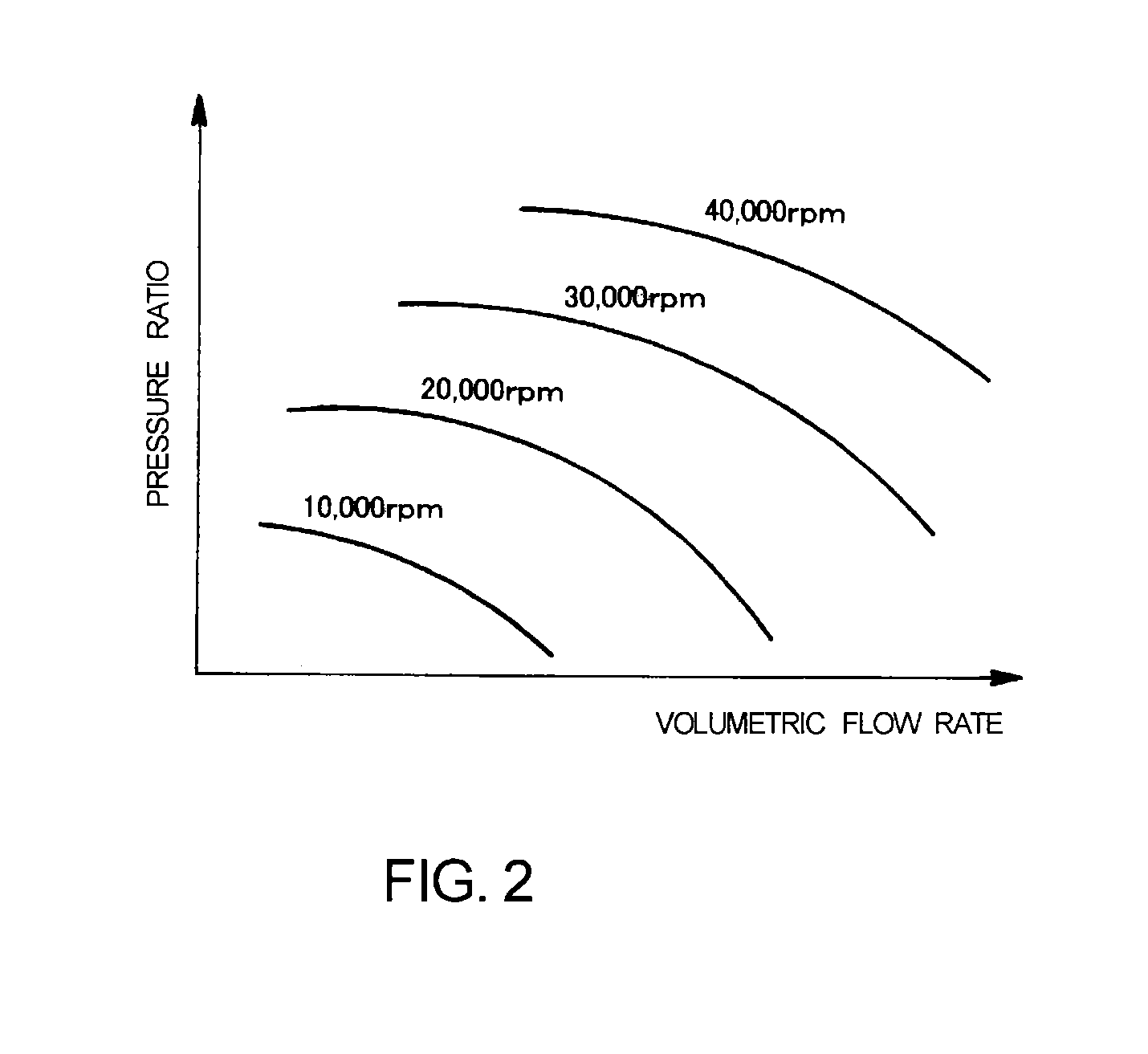

Based on entry / exit pressures of compressor 2a detected by atmospheric / boost pressure sensors 13 and 14, pressure ratio of compressor is calculated. Based on mass flow rate and entry temperature of intake air 4 detected by intake air flow-rate / temperature sensors 15 and 16 and entry pressure, volumetric flow rate of intake air is calculated in environmental condition at detection time using gas state equation, and is corrected into volumetric flow rate under standard environmental condition thorough multiplication by corrective coefficient based on entry temperature of intake air. Based on corrected value and calculated pressure ratio, rotational frequency of compressor under standard environmental condition is read out in light of operating characteristic diagram for compressor. Read-out rotational frequency is corrected into actual rotational frequency of compressor through multiplication by corrective coefficient based on entry temperature of intake air, which is determined as rotational frequency of turbocharger 2.

Owner:HINO MOTORS LTD

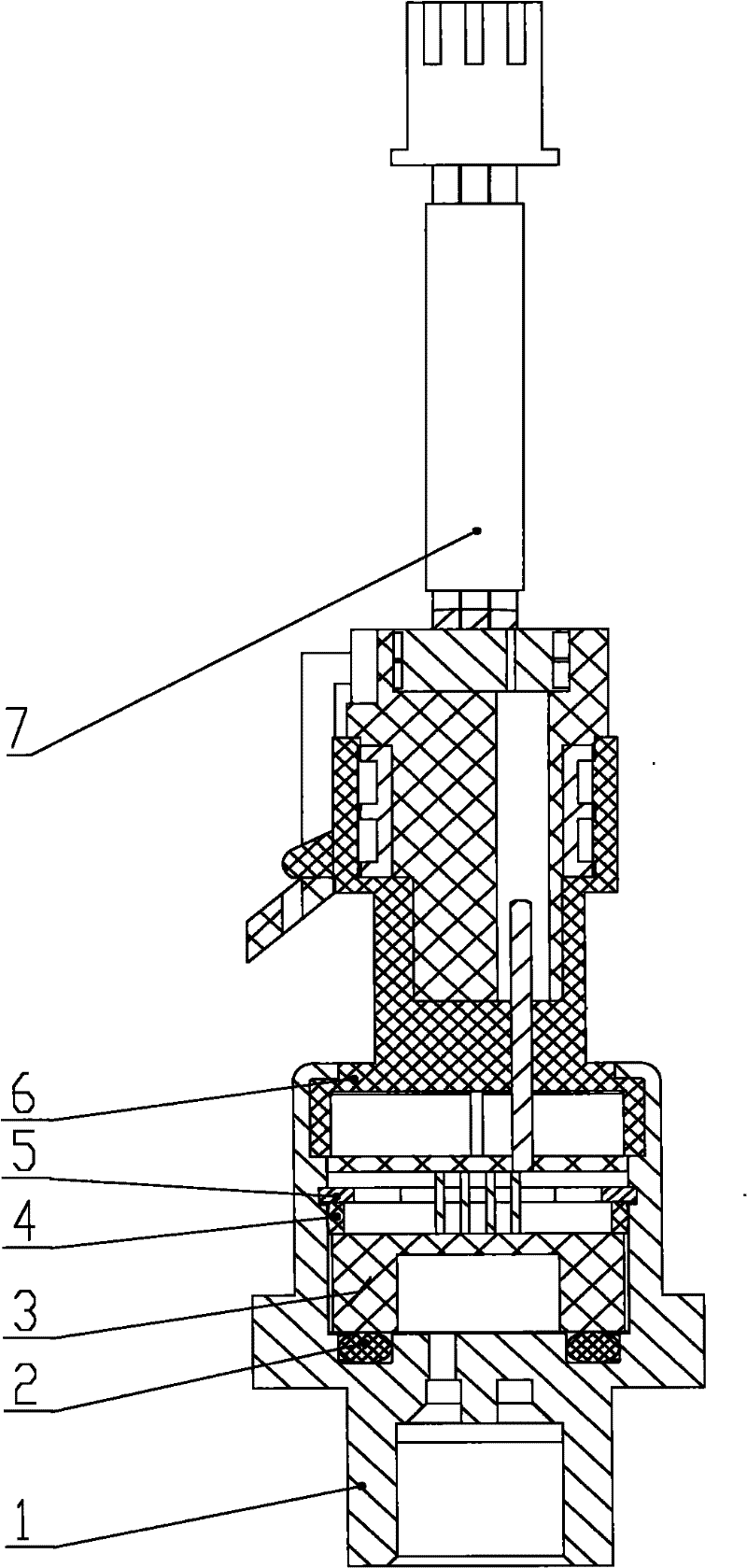

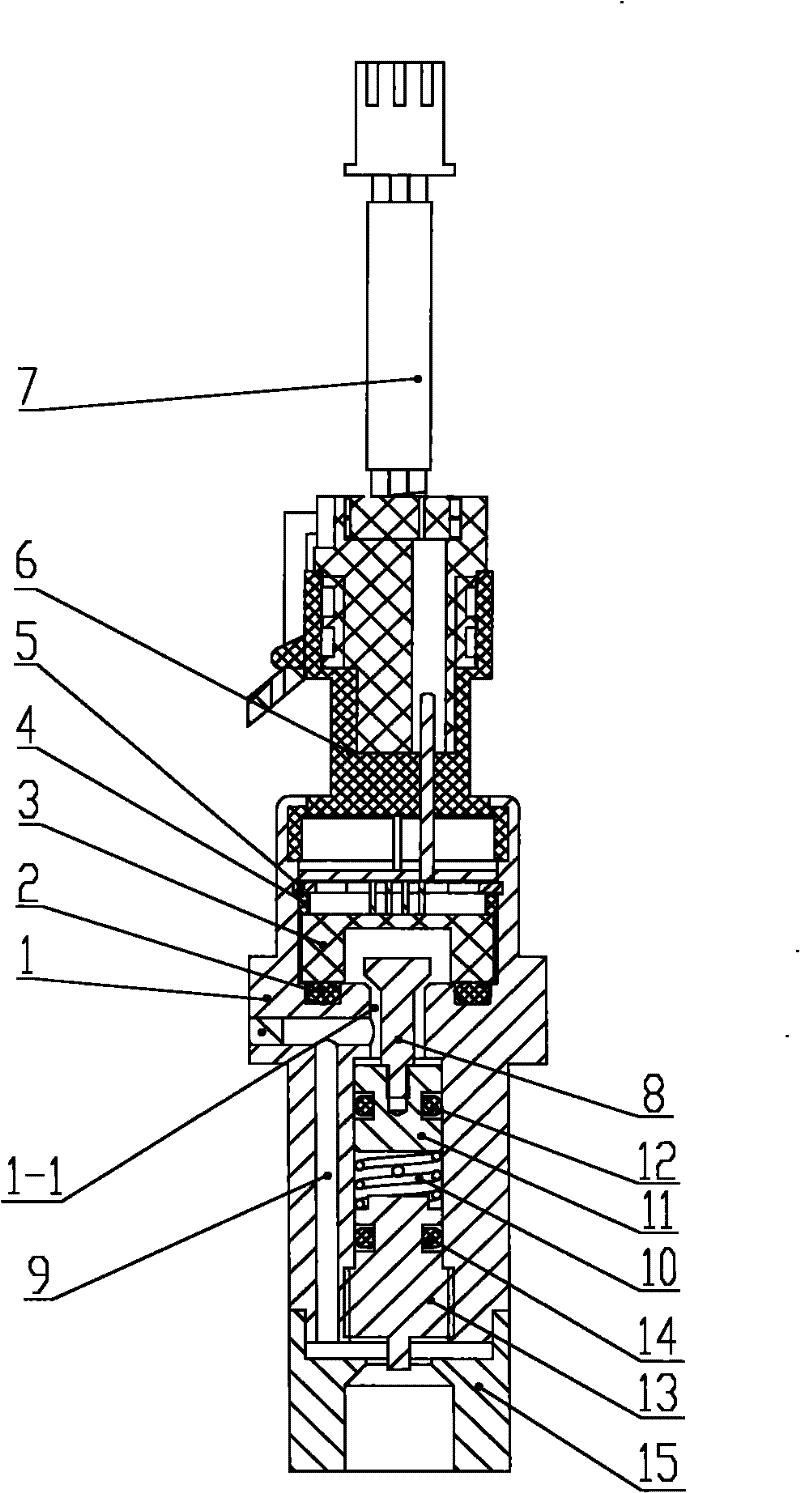

Pressure sensor

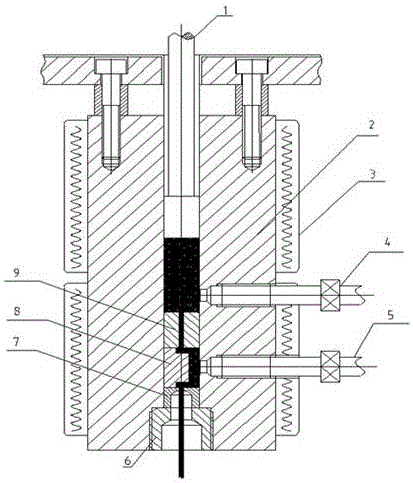

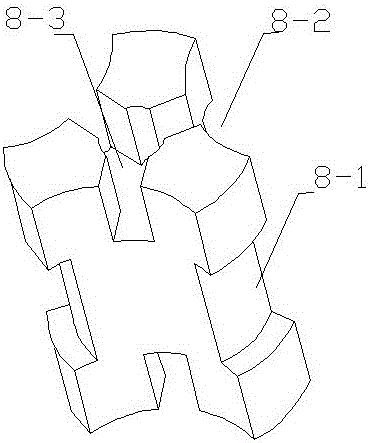

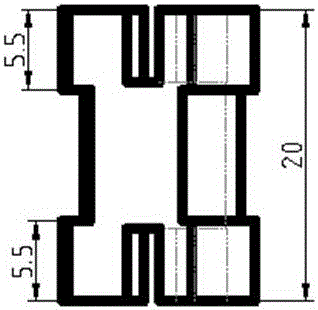

InactiveCN102445302AEffective protectionWon't breakFluid pressure measurement by electric/magnetic elementsSystem pressureEngineering

The invention relates to the technical field of sensors and particularly discloses a pressure sensor. The pressure sensor comprises a pressure core body and a sensor base, wherein the pressure core body and the sensor base form a pressure cavity; the sensor base is provided with a pressure inlet communicated with the pressure cavity; and the tested system pressure is communicated with the pressure inlet. The pressure sensor also comprises a pressure protector, the pressure protector is arranged at the pressure inlet; and when the tested system pressure is greater than a preset value, the pressure protector closes the pressure inlet. In the pressure sensor provided by the invention, the pressure protector is arranged at the pressure inlet of the pressure cavity, and when the tested system pressure is greater than the preset value, the pressure protector closes the pressure inlet, so that the test system pressure cannot enter into the pressure cavity, thus the pressure core body is effective protected; and the pressure sensor has the advantages of better durability, better reliability and loner service life.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

Efficiency monitoring of a compressor

InactiveCN102027348AFind reference level efficiency with exactAccurate reference dataGas-turbine engine testingPump controlProcess engineeringPerformance factor

The invention relates to a method for monitoring the efficiency (Eta pol n) of a compressor (1), in which a mass flow, an entry pressure (Pe n), an exit pressure (Pa n), an entry temperature (Te n), an exit temperature (Ta n) of the process medium are determined and a performance factor is ascertained. In order to improve the accuracy it is suggested that - at the inlet of each stage (4, 5, 6, 7), a stage entry temperature (Ten) and a stage entry pressure (Pen) are directly or indirectly measured as measurement parameters, - at the outlet of each stage, a stage exit temperature (Tan) and a stage exit pressure (Pan) are directly or indirectly measured as measurement parameters, and each stage (4, 5, 6, 7) is assigned a module (C421 to C424) which calculates a stage efficiency (Eta pol n), for example as polytropic stage efficiency, as performance factor from the measurement parameters using the calculation means.

Owner:SIEMENS AG

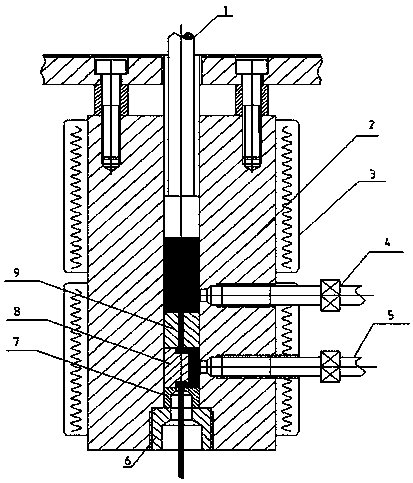

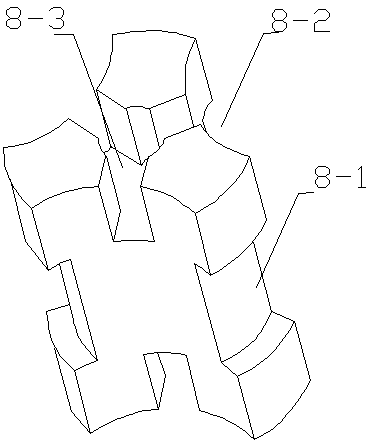

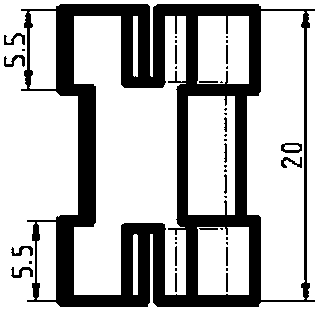

Single-feed-cylinder capillary rheometer

InactiveCN105675443AEliminate pressure dropHigh precisionDirect flow property measurementEngineeringShear flow

The invention discloses a single-feed-cylinder capillary rheometer. A feed cylinder of the capillary rheometer is a single feed cylinder; the front end of the feed cylinder is provided with a plunger, the rear end of the feed cylinder is provided with a traveling nut, an electric heater is arranged around the feed cylinder, a long capillary die, a support part and a zero-length capillary die / short capillary die are arranged in the feed cylinder, and the outer diameter of the long capillary die, the outer diameter of the zero-length capillary die / short capillary die and the outer diameter of the support part all are matched with the inner diameter of the feed cylinder. The single-feed-cylinder capillary rheometer can be used for measuring extensional flow and shear flow parameters of polymer melt simultaneously, can eliminate entry pressure drop well, has the same function as a double-feed-cylinder capillary rheometer, and also has the advantages of saving raw materials, facilitating dismounting, purging easily, reducing artificial influences, realizing higher precision, and the like.

Owner:TAIYUAN INST OF TECH

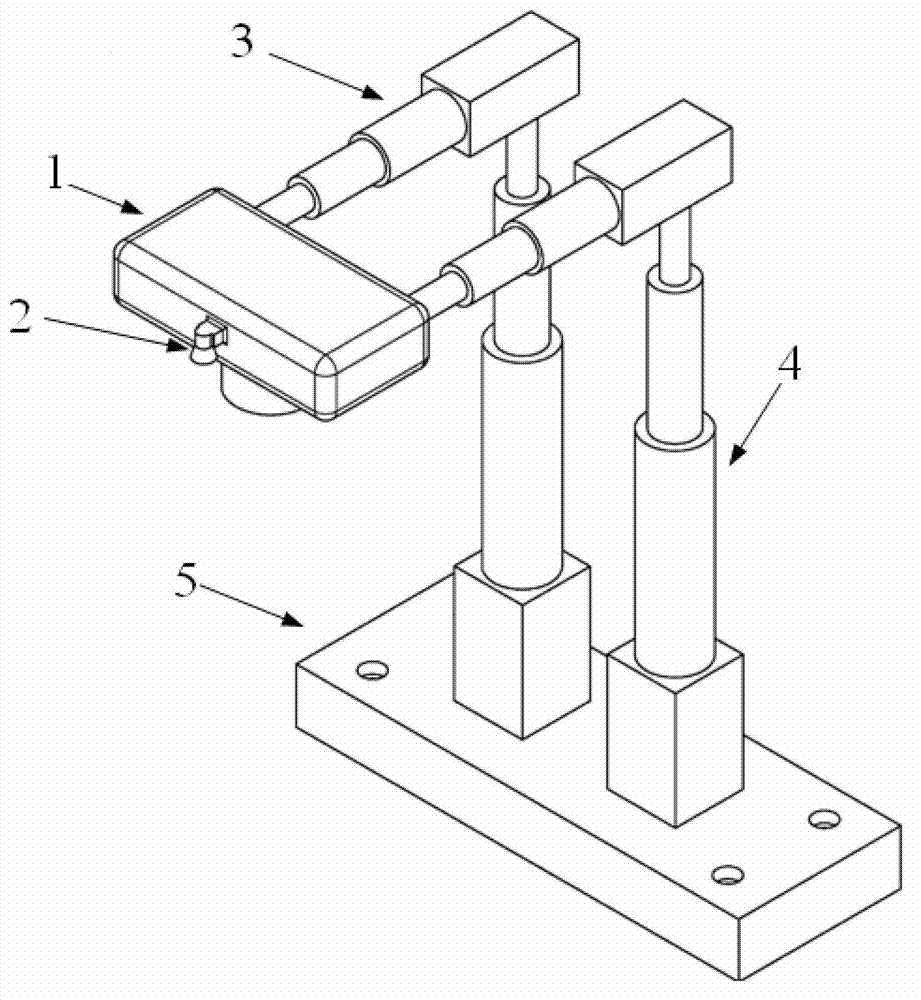

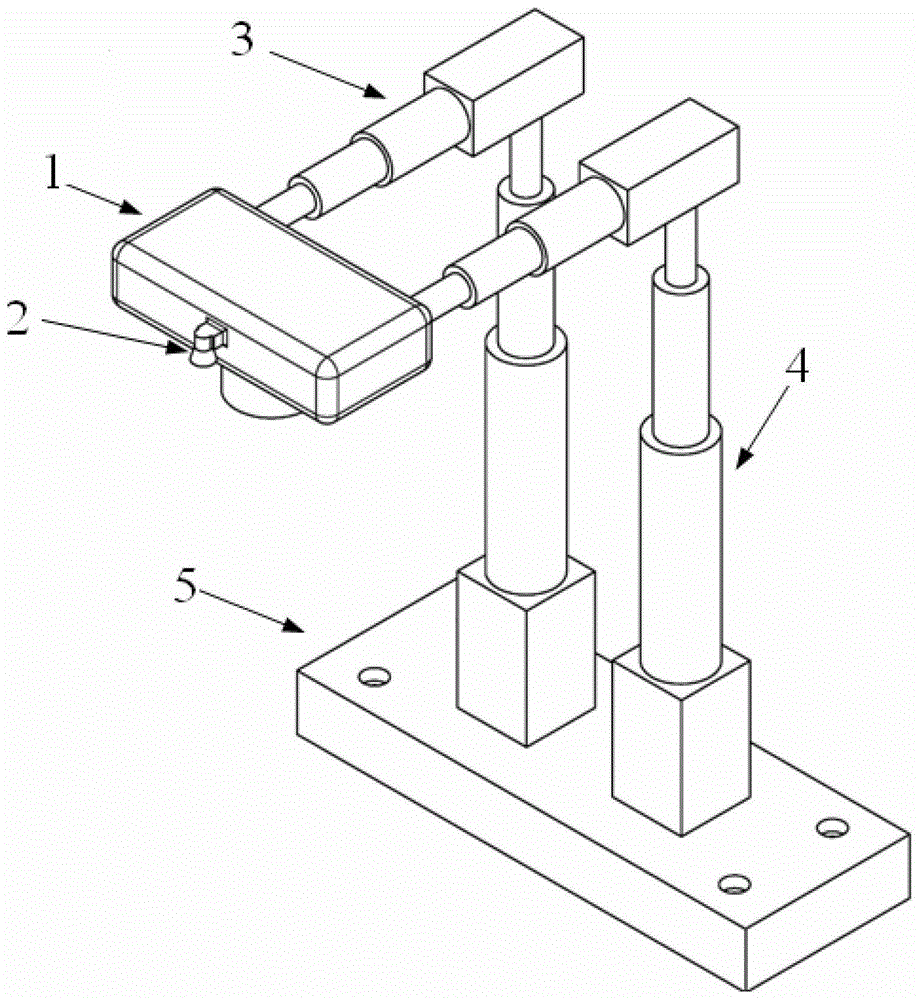

Automatic measuring device for assembly clearance of radial support key

ActiveCN103925884AAvoid the pitfalls of manual measurementUsing optical meansMeasurement devicePressurized water reactor

The invention belongs to the technical field of the design of a nuclear reactor of a pressurized water reactor nuclear power plant, and particularly relates to an automatic measuring device for the assembly clearance of a radial support key. The automatic measuring device for the assembly clearance of the radial support key comprises a probe, a camera, a horizontal telescopic support, a vertical telescopic support and an installation platform. The camera is installed on one side of the probe. The other side of the probe is connected with the front end of the horizontal telescopic support. The rear end of the horizontal telescopic support is connected with the upper end of the vertical telescopic support. The lower end of the vertical telescopic support is connected with the installation platform. The automatic measuring device for the assembly clearance of the radial support key has the advantages of automatic measurement and high precision. A data acquisition device is controlled outside a pressure container so that the probe can be moved to measure the assembly clearance between different positions of the radial support key and a reactor core support block and the assembly clearance between the different positions of the radial support key and an insert of the radial support key; in this way, defects of manual measurement conducted by operation personnel in the prior art are overcome, and the limitation that the operation personnel must enter the pressure container to conduct measurement is avoided.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Tire pressure monitor system with side entry pressure port

Owner:LEAR CORP

Improved porous membrane

Owner:BHA ALTAIR

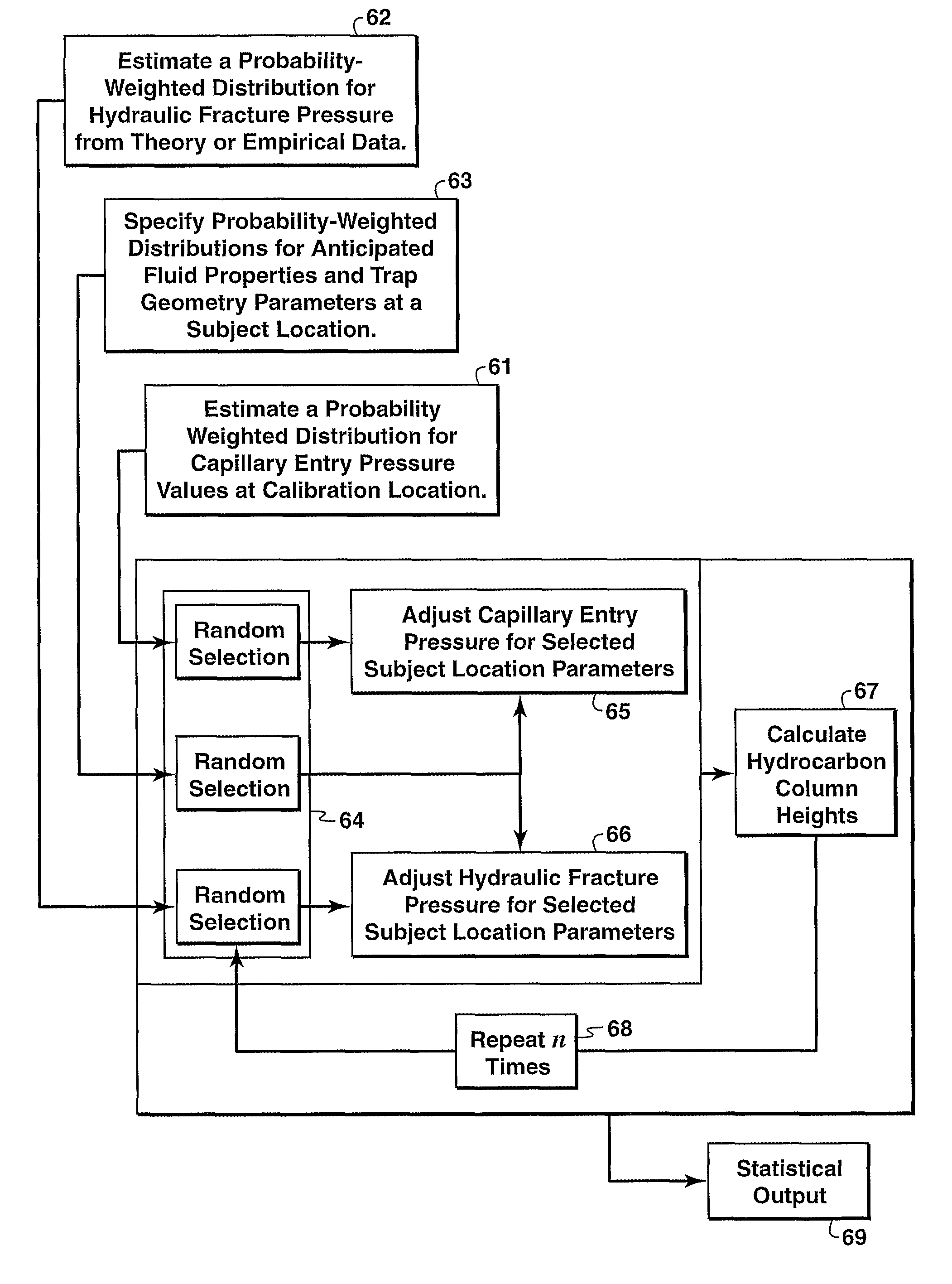

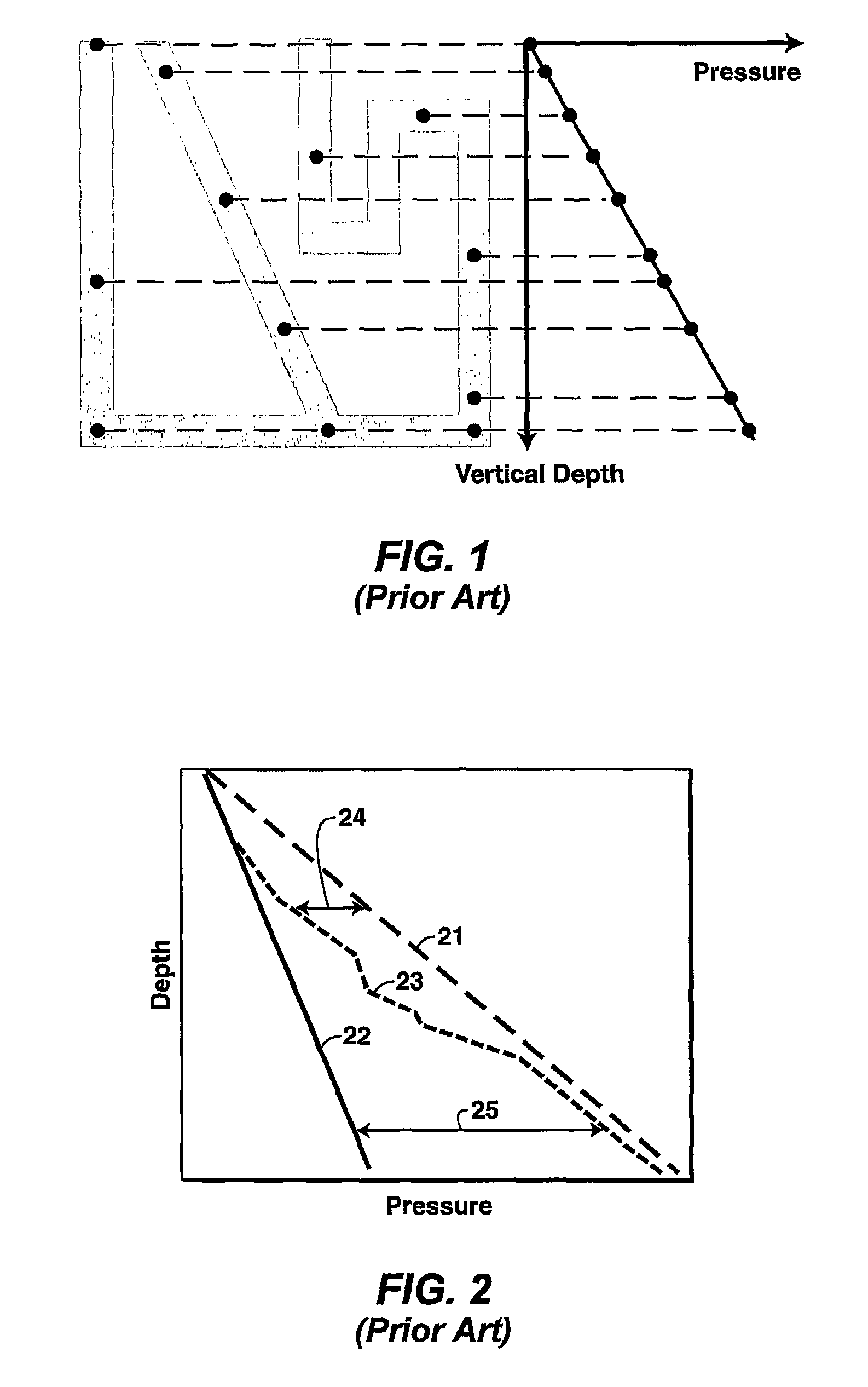

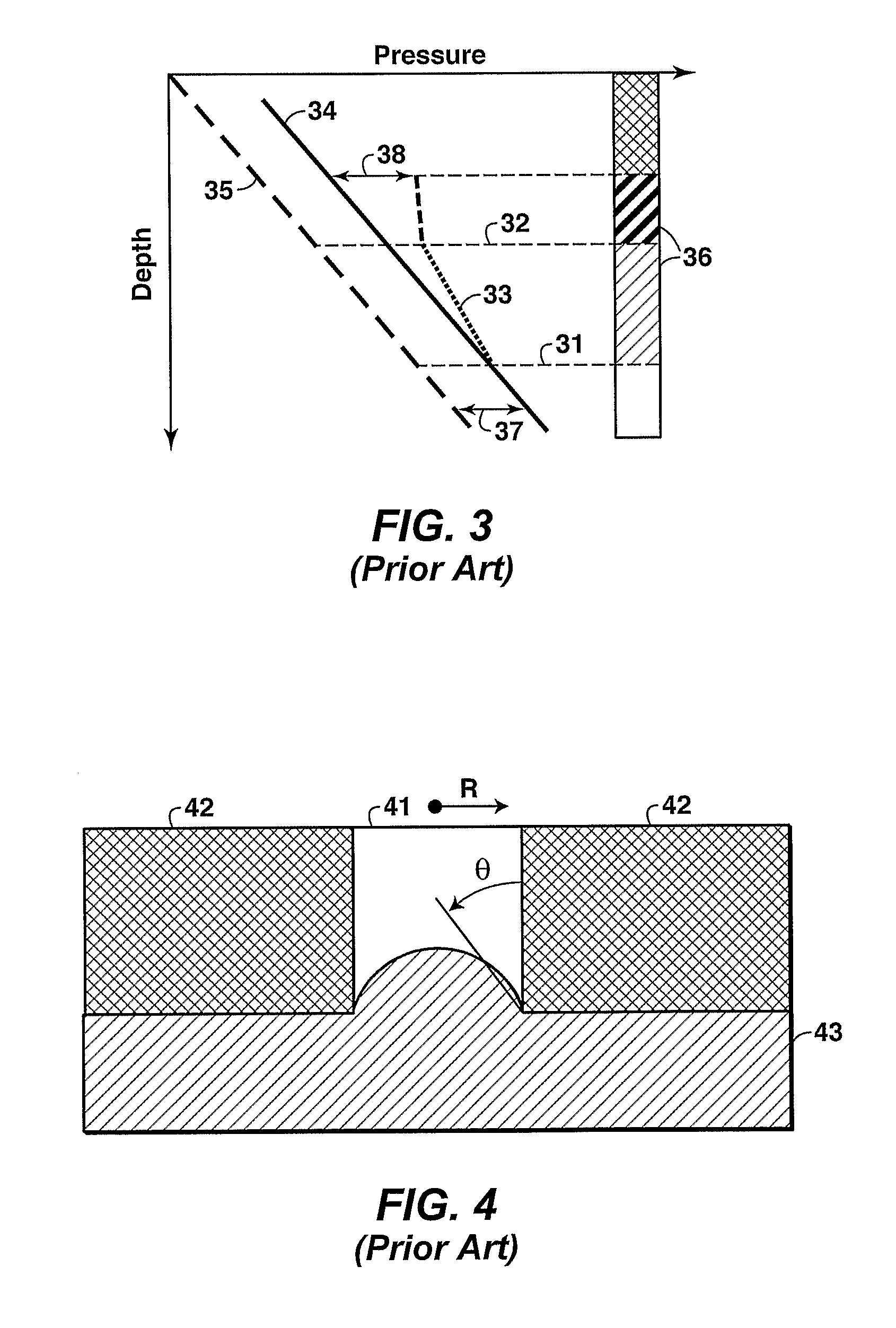

Method for mechanical and capillary seal analysis of a hydrocarbon trap

Method for making a probabilistic determination of total seal capacity for a hydrocarbon trap, simultaneously considering both capillary entry pressure and mechanical seal capacity, and where capillary entry pressure is estimated by relating it directly to the buoyancy pressure applied by the hydrocarbon column to the top seal. The method thus considers the substantial uncertainty associated with input parameters, which uncertainty limits the utility of such analyses for robust hydrocarbon column height and fluid contact predictions. The method disclosed for estimating seal capillary entry pressure, the requisite input parameter for capillary seal capacity analysis, by inverting trap parameters avoids the need for direct measurement by mercury injection capillary capacity tests on small pieces of rock, which test results often are not available for all desired locations nor are they necessarily representative of adjacent rocks in the seal.

Owner:EXXONMOBIL UPSTREAM RES CO

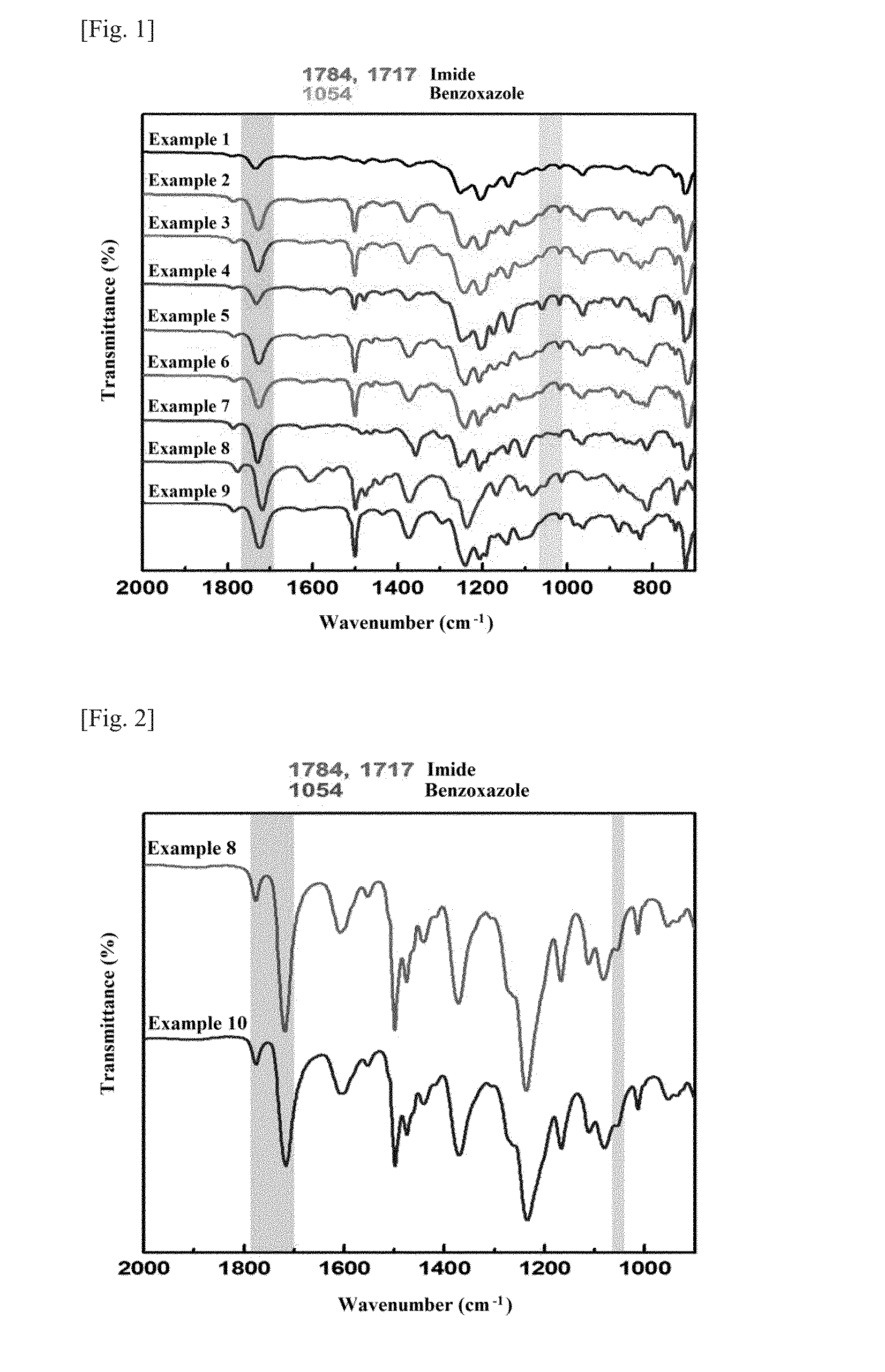

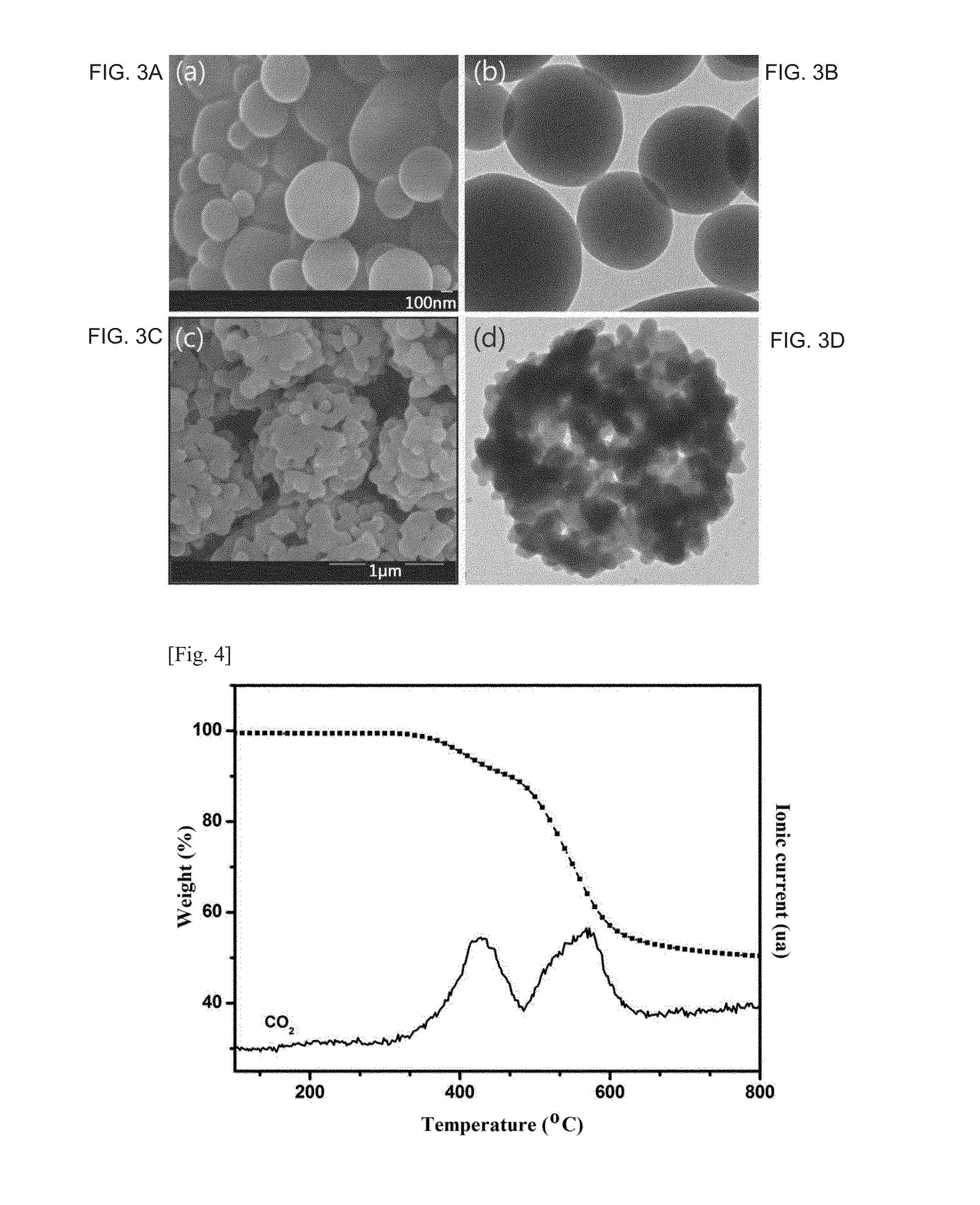

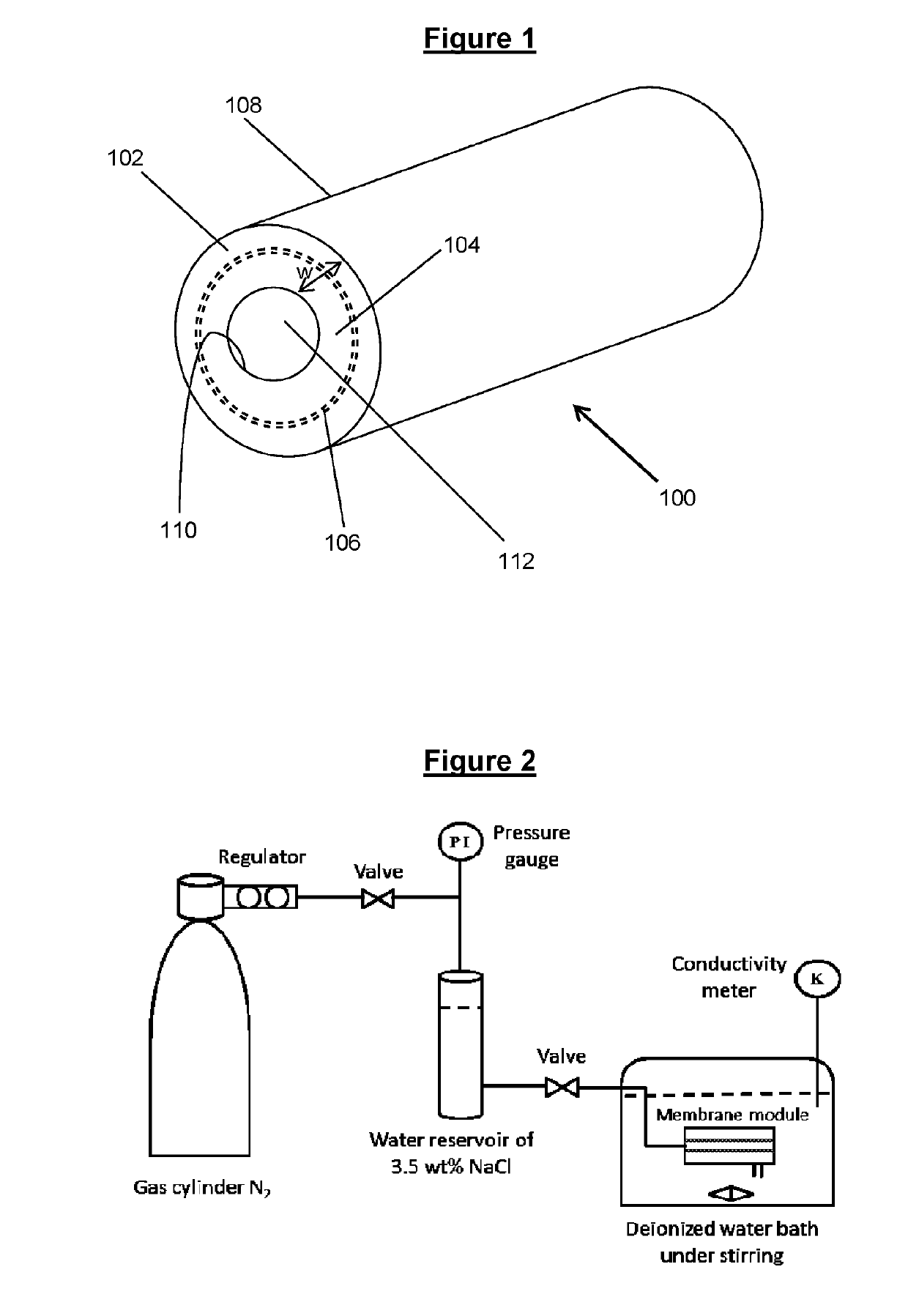

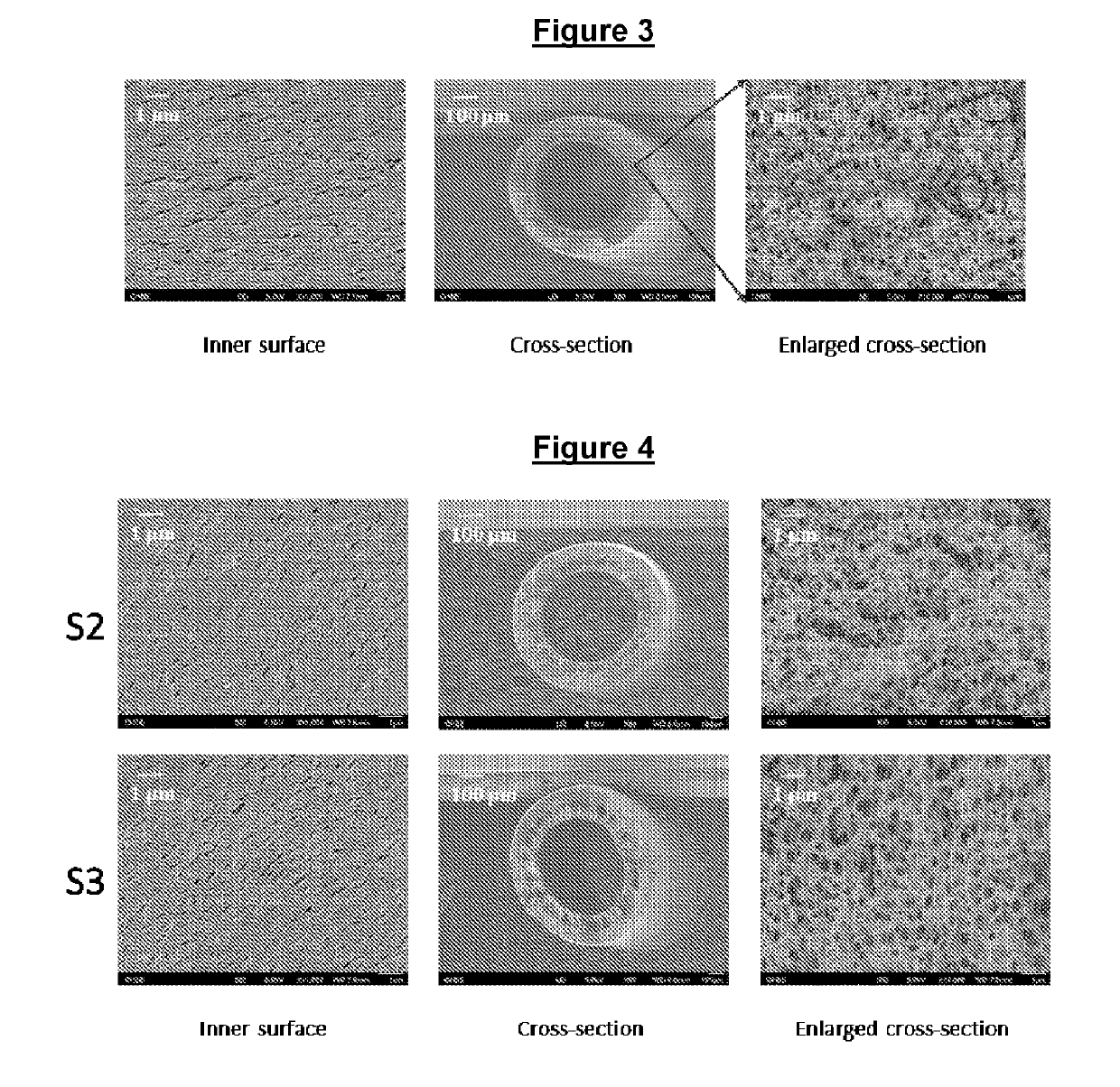

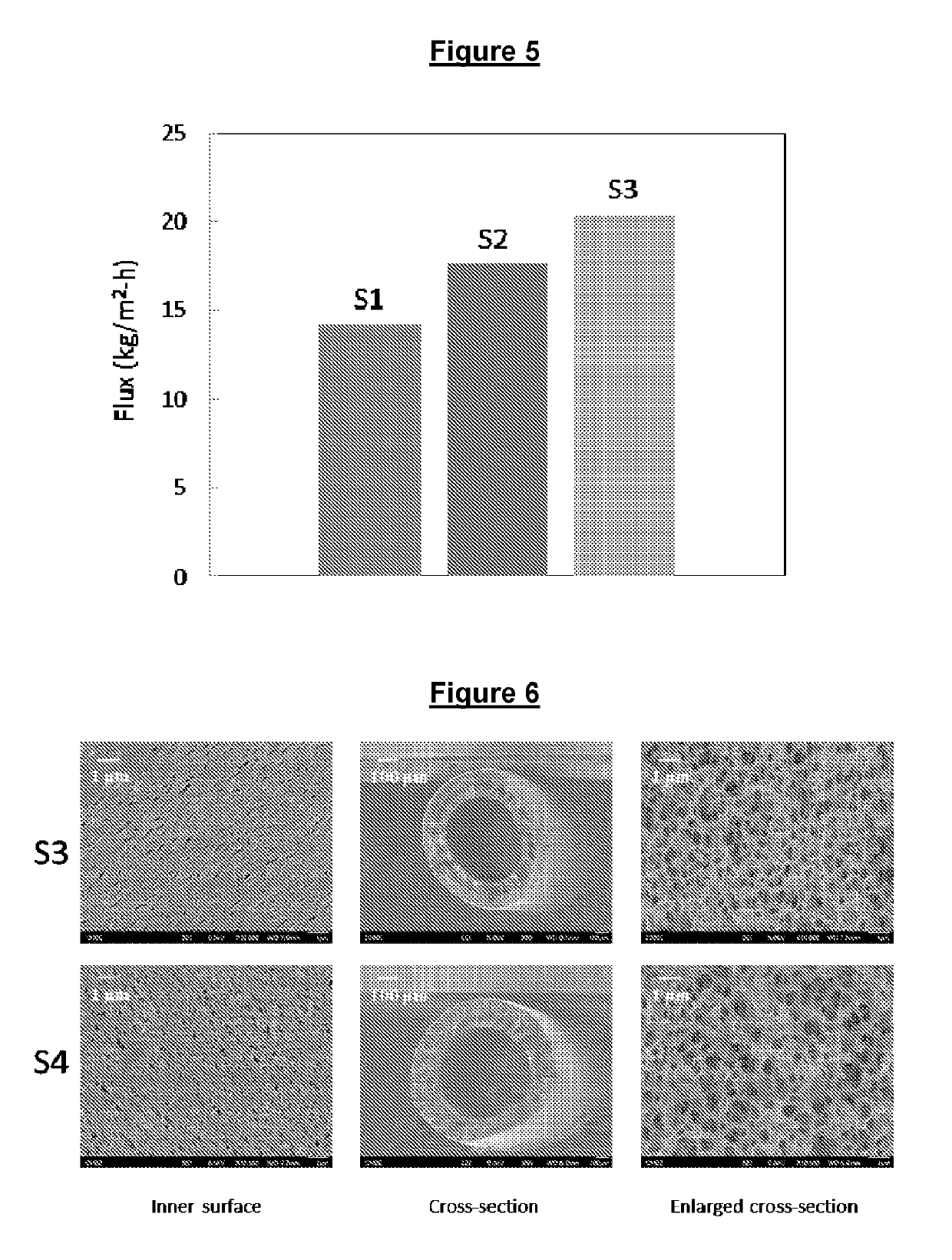

Thermally rearranged poly(benzoxazoleco-imide) separation membrane for membrane distillation and fabrication method thereof

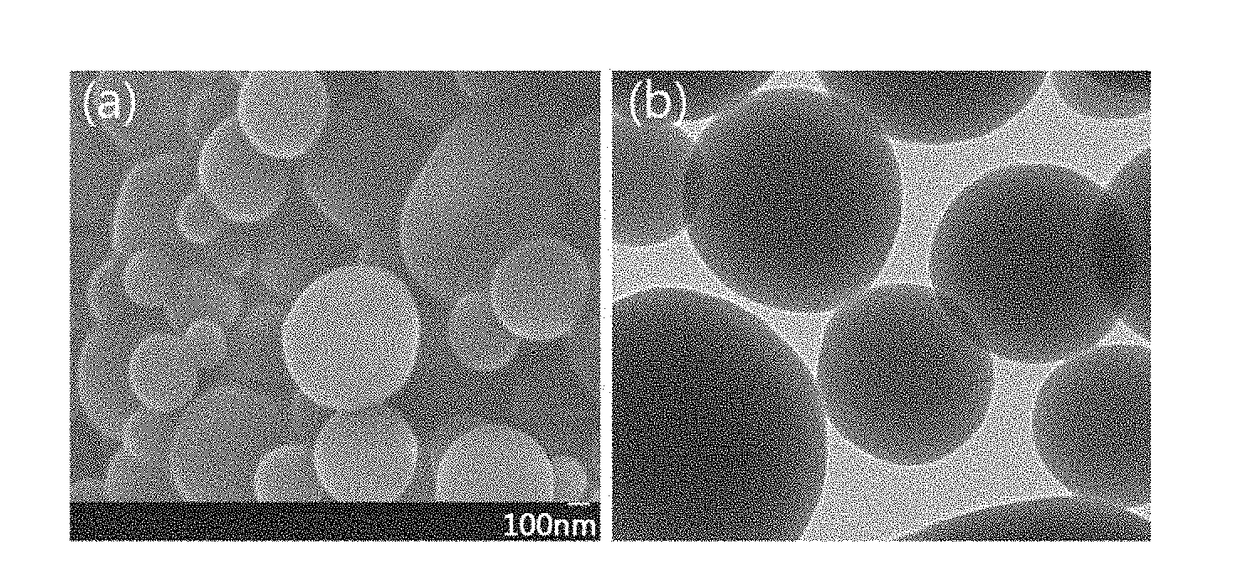

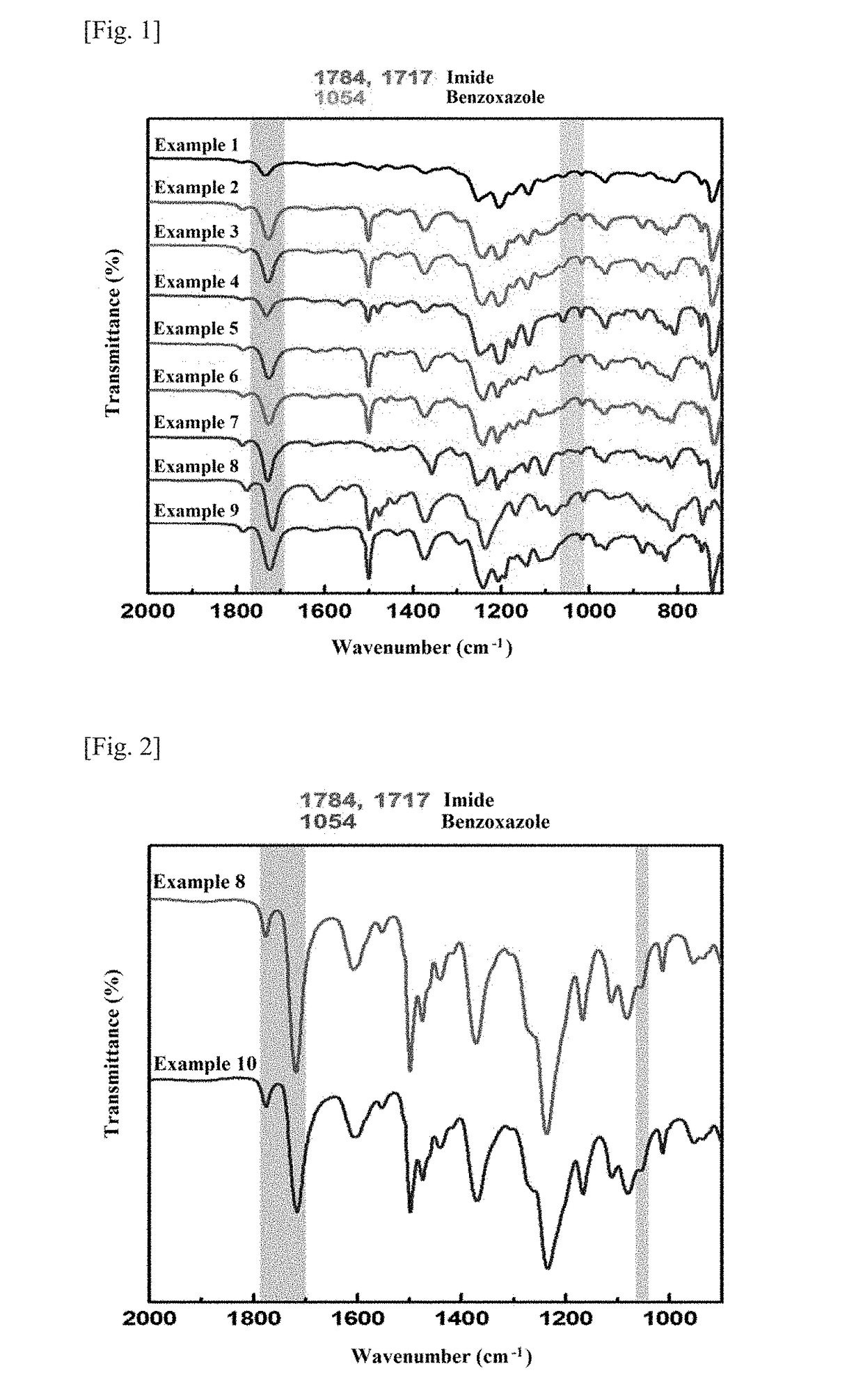

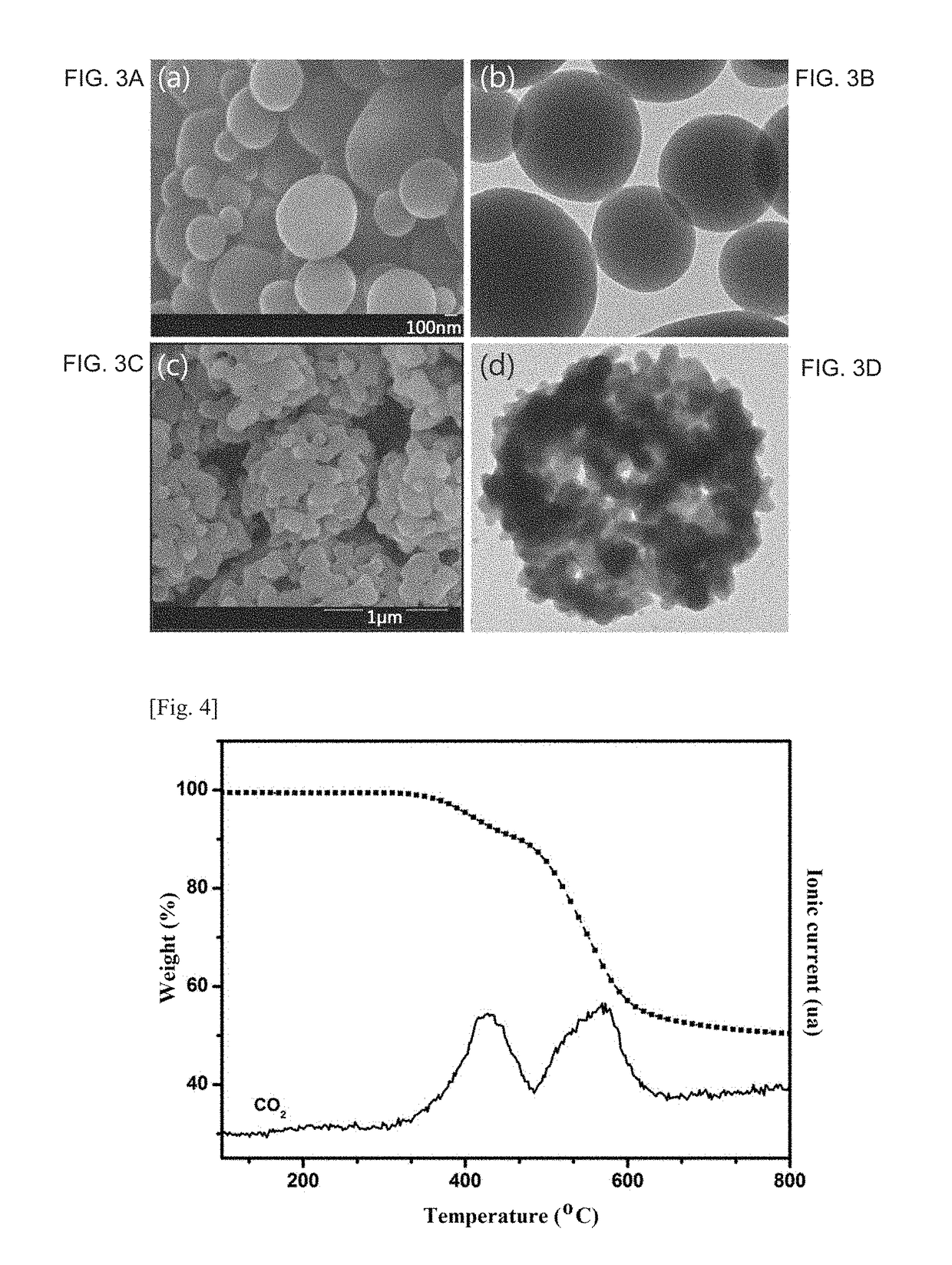

ActiveUS20160214065A1Increase pressureLow thermal conductivityMaterial nanotechnologyDistillationBenzoxazoleImide

The present invention relates to the production of a hydroxyl polyimide-co-polyimide membrane, the fabrication of a thermally rearranged poly(benzoxazole-co-imide) membrane by thermally treating the hydroxyl polyimide-co-polyimide membrane, and the application of the thermally rearranged poly(benzoxazole-co-imide) membrane to membrane distillation. The thermally rearranged poly(benzoxazole-co-imide) separation membrane has high liquid entry pressure, low thermal conductivity, high permeate flux, and good long-term stability, as well as excellent thermal and chemical properties. Due to these advantages, the copolymer separation membrane can be applied to membrane distillation processes.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Thermally rearranged poly(benzoxazoleco-imide) separation membrane for membrane distillation and fabrication method thereof

ActiveUS10071346B2Increase pressureLow thermal conductivityMaterial nanotechnologyDistillationBenzoxazoleImide

The present invention relates to the production of a hydroxyl polyimide-co-polyimide membrane, the fabrication of a thermally rearranged poly(benzoxazole-co-imide) membrane by thermally treating the hydroxyl polyimide-co-polyimide membrane, and the application of the thermally rearranged poly(benzoxazole-co-imide) membrane to membrane distillation. The thermally rearranged poly(benzoxazole-co-imide) separation membrane has high liquid entry pressure, low thermal conductivity, high permeate flux, and good long-term stability, as well as excellent thermal and chemical properties. Due to these advantages, the copolymer separation membrane can be applied to membrane distillation processes.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

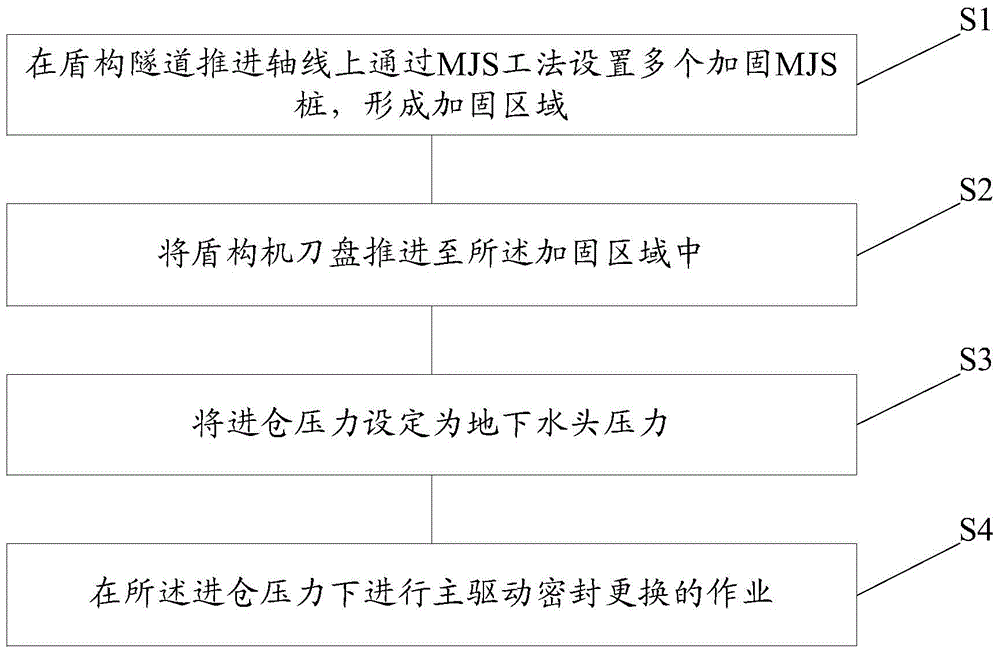

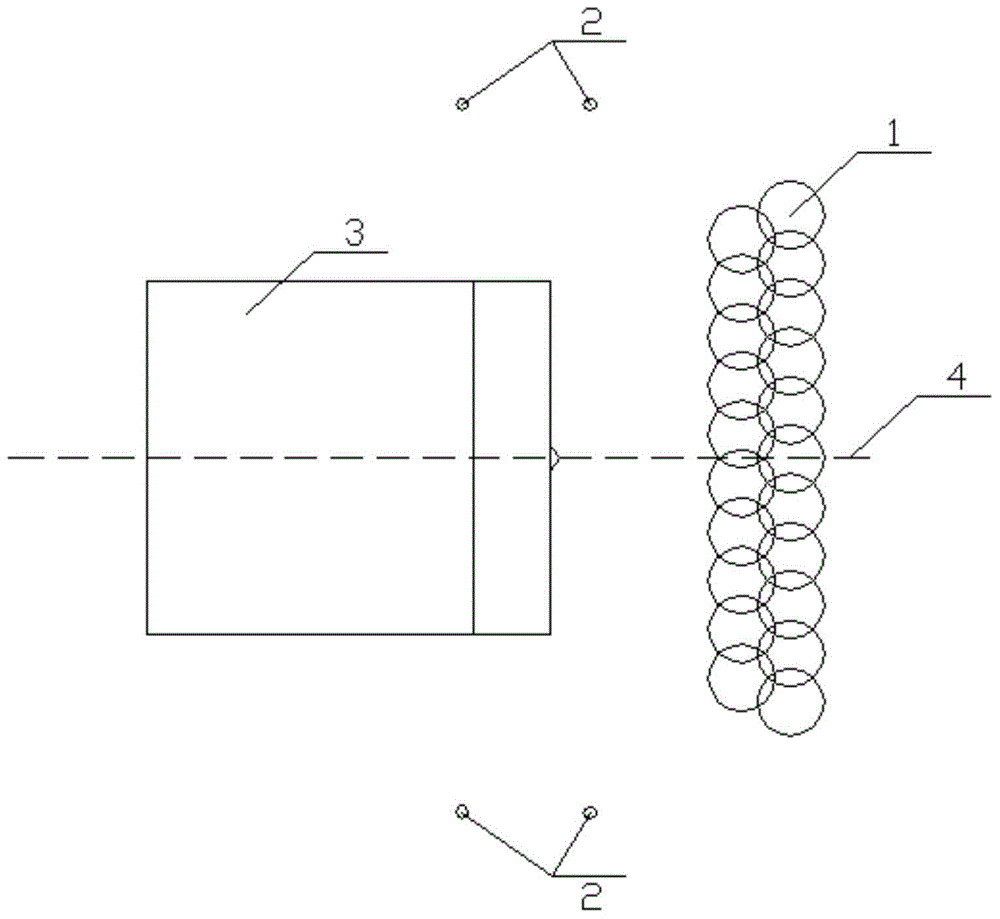

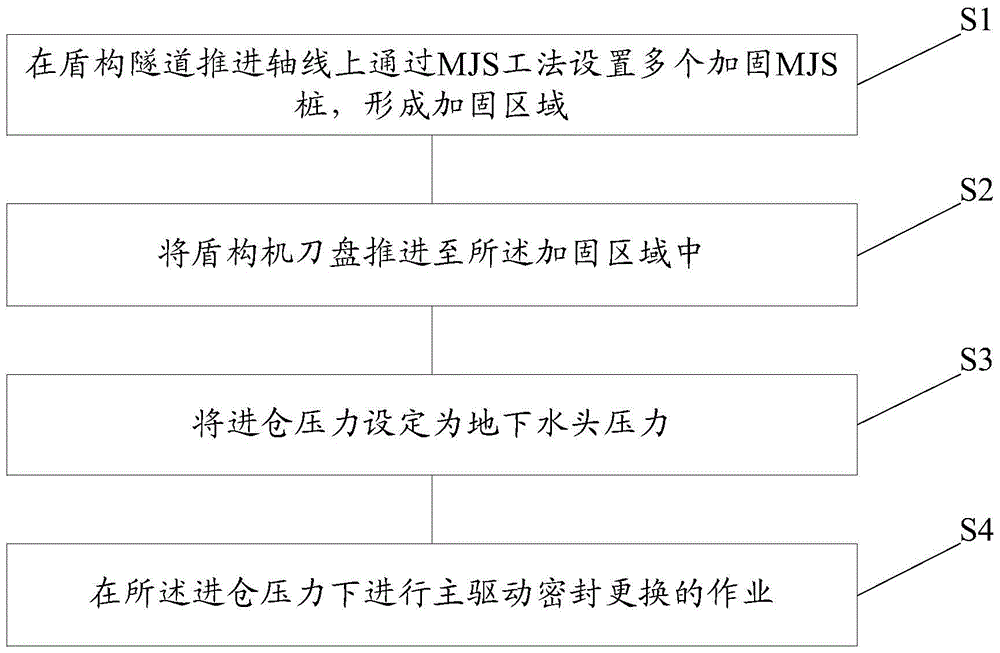

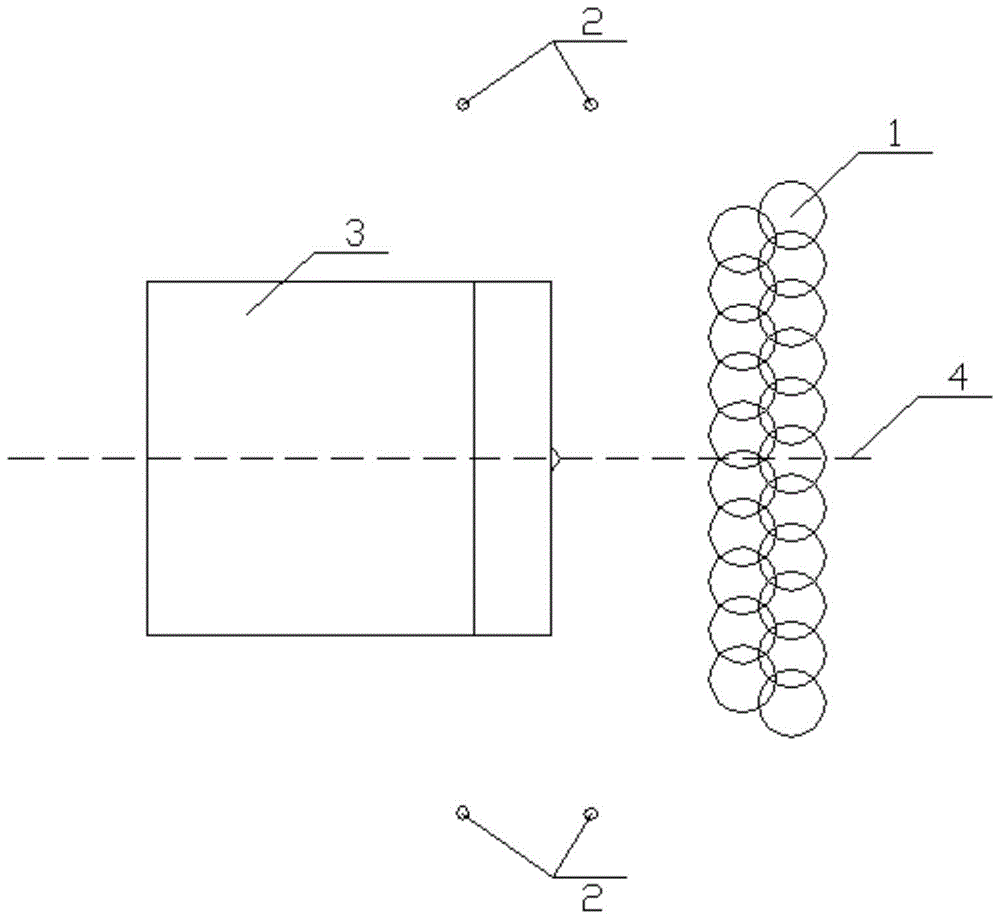

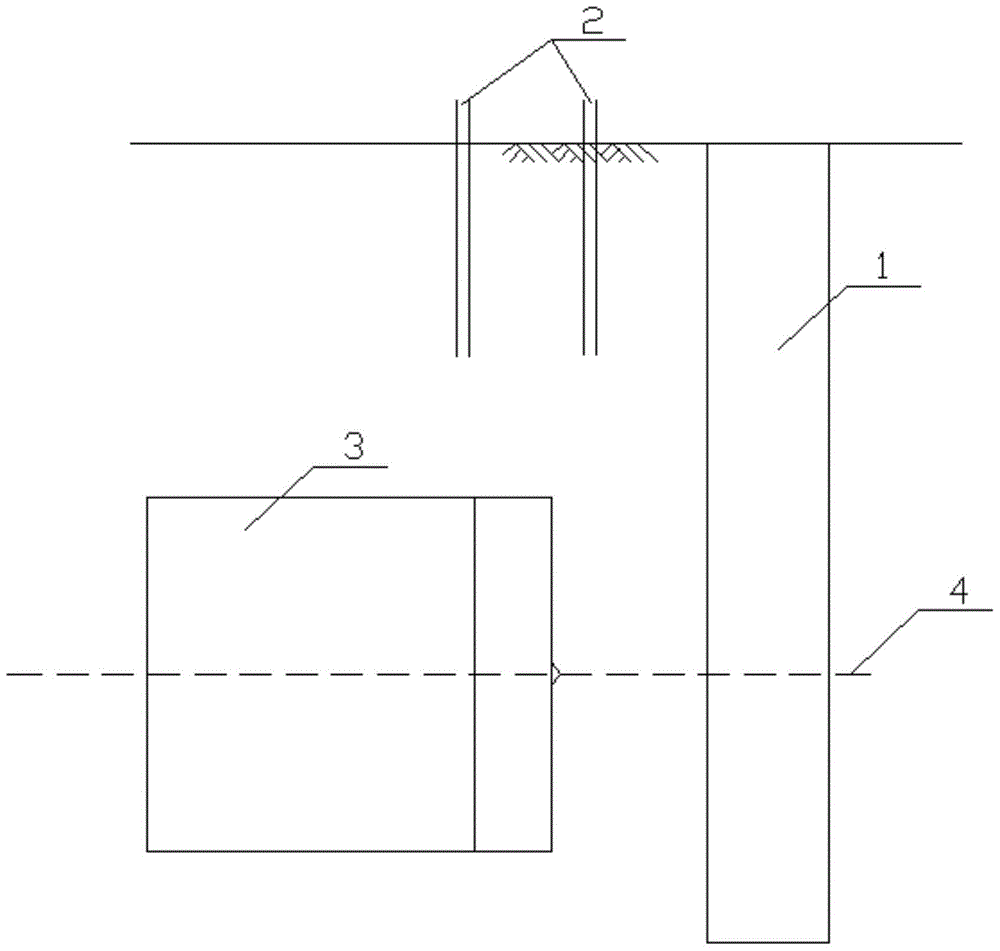

Method for replacing main drive seal of slurry shield in complex stratum

The invention provides a method for replacing the main drive seal of a slurry shield in a complex stratum. The method comprises the following steps: arranging a plurality of reinforced MJS (Metro Jet System) piles on the propelling axis of a shield tunnel to form a reinforced area; propelling a cutter head of a shield machine into the reinforced area; setting the storehouse entry pressure as the underground head pressure; replacing the main drive seal under the storehouse entry pressure. By adopting the method, the problem of lack of replacement of the main drive seal in the complex stratum in the existing technical scheme is solved, the replacement risk of the main drive seal is lowered greatly, and the safety and efficiency of main drive seal replacement construction are improved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

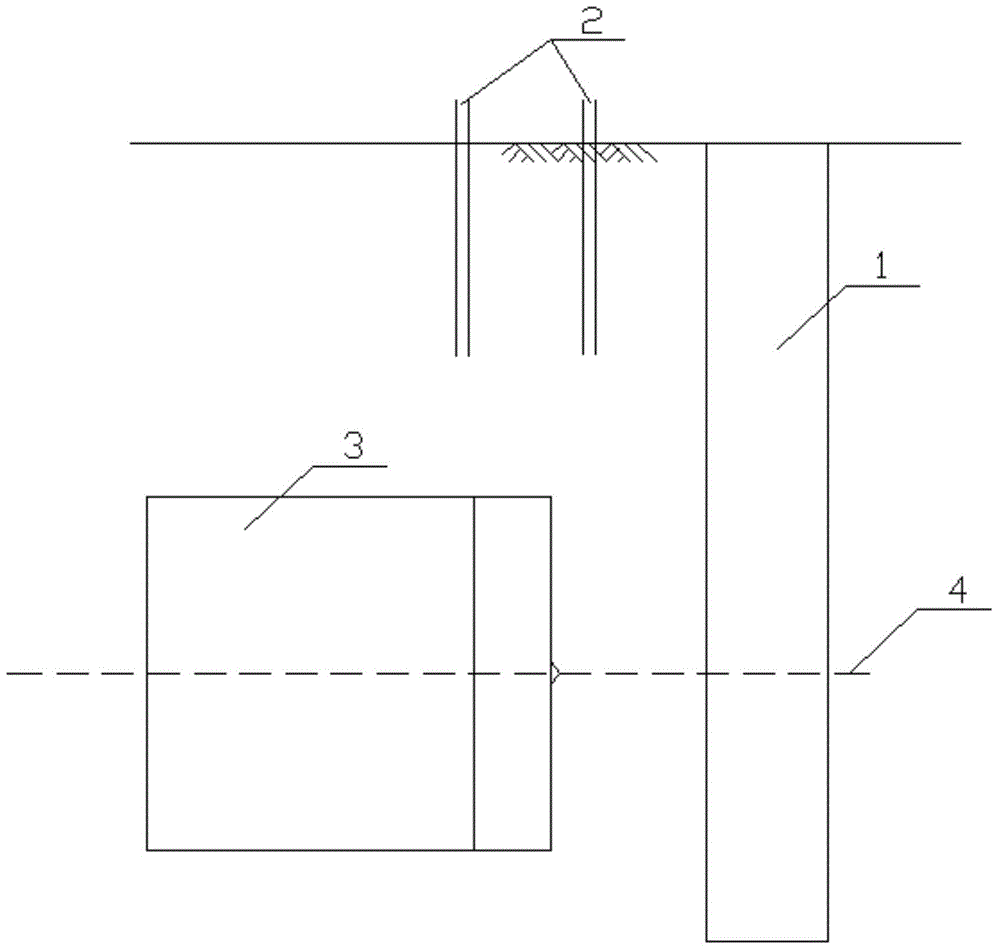

Waste magnetic suspension liquid processing method and device

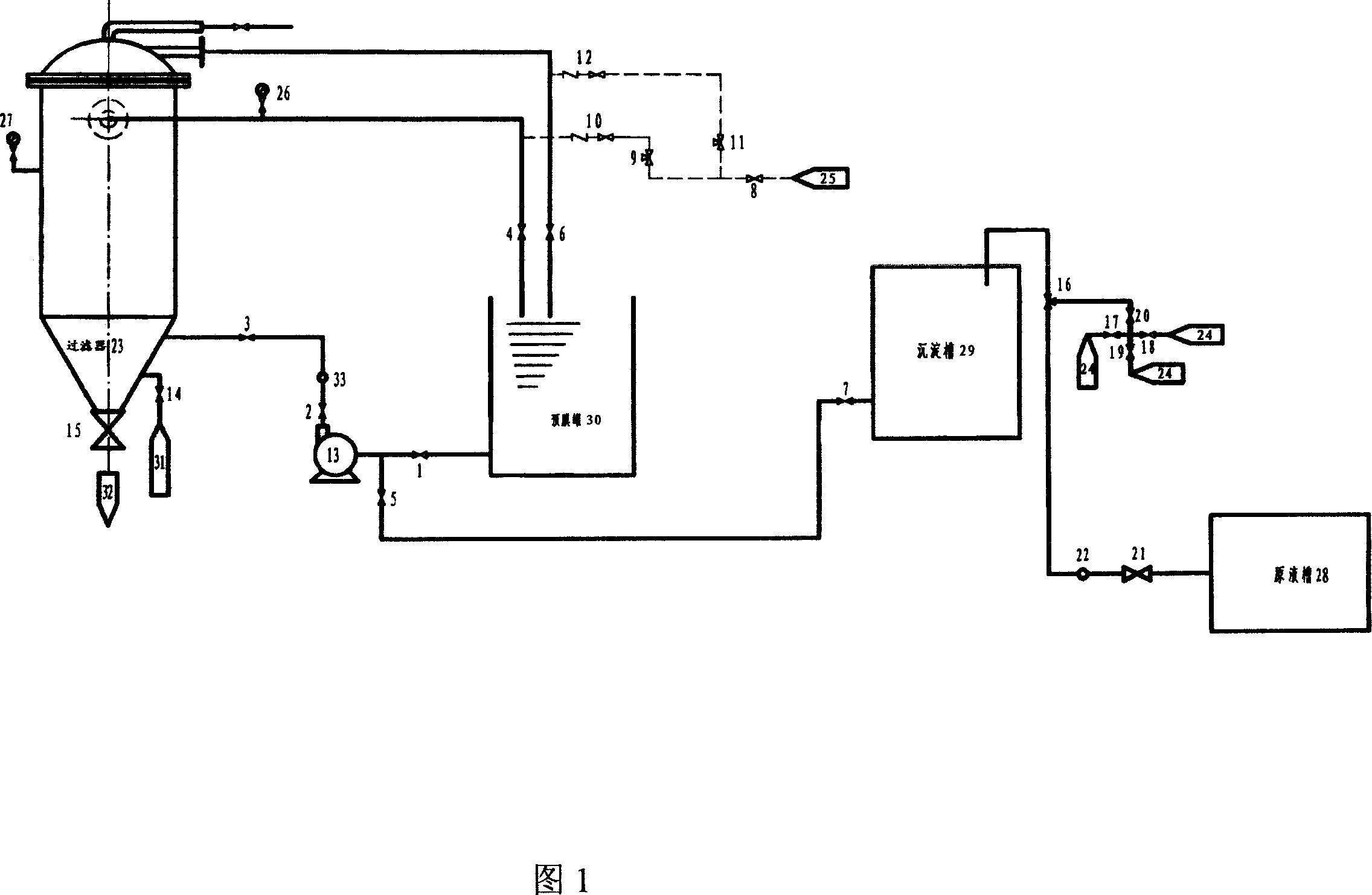

InactiveCN1565996AEasy to handleSolve the emission problemMultistage water/sewage treatmentStationary filtering element filtersWater qualitySewage

The invention discloses a waste magnetic suspension liquid processing method and device, wherein the method comprises four steps of coagulation, pre-filming, filtering and backwashing. The device comprises a raw liquid tank, a coagulating bath in conduct connection with the raw liquid tank through a sewage water pump and valves, a pre-filming tank in conduct connection with the coagulating bath through valves, a filter in conduct connection with the pre-filming bath through clean pumps and valves, and a pressure control apparatus for controlling the pressure difference between the entry pressure and outlet pressure of the filter.

Owner:BAOSHAN IRON & STEEL CO LTD

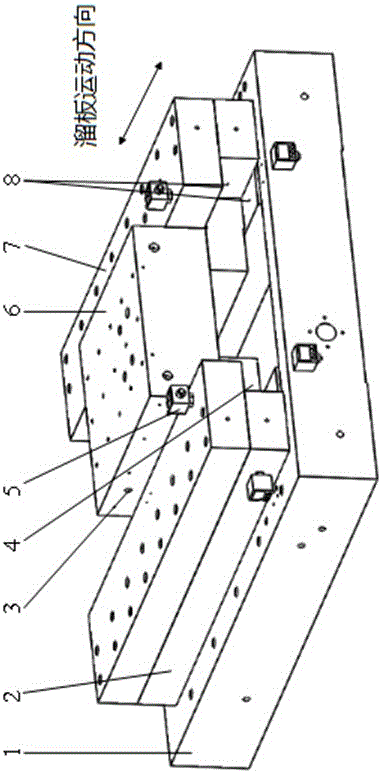

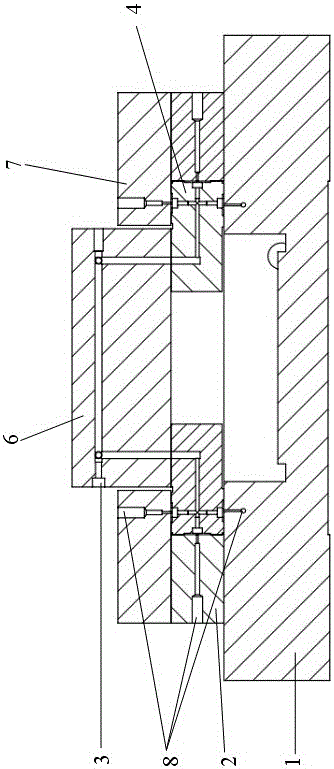

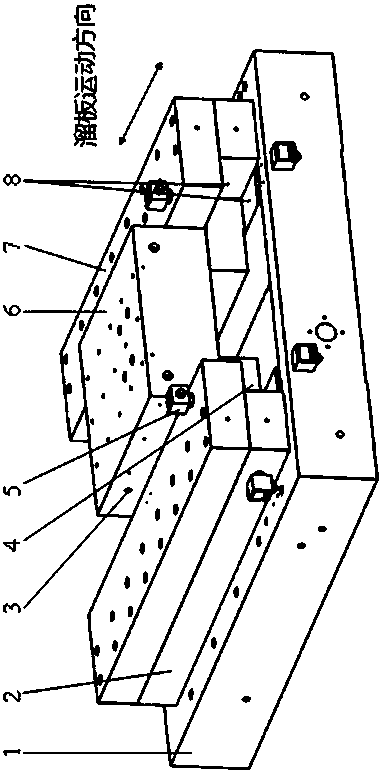

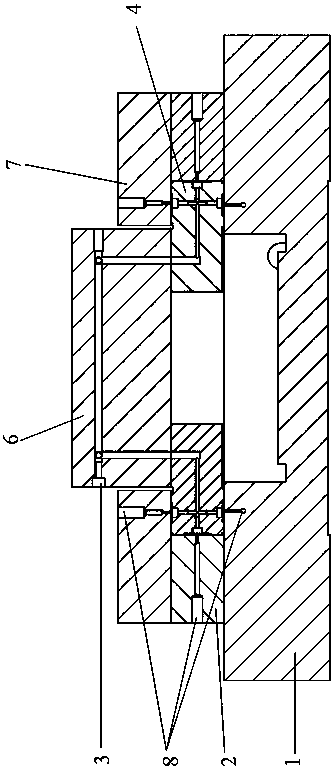

Method for detecting pressure distribution in oil cavity of hydrostatic guideway

ActiveCN106563970AShorten the lengthQuick measurementMeasurement/indication equipmentsInlet channelCavity pressure

The invention discloses a method for detecting the pressure distribution in an oil cavity of a hydrostatic guideway. The method comprises the following steps: 1, hydraulic oil is sent by a hydraulic station into each oil cavity through an oil inlet channel and a throttling device, so that a guideway moving part can be floated; 2, the guideway moving part is moved to an oil cavity pressure measuring station, pressure oil in the oil cavity enters a pressure measuring channel, a pressure sensor takes a signal pressure signal as the input and begins to read the pressure value at a certain positon in the oil cavity, and the signal processing and the real-time display are performed; 3, after that, the oil cavity pressure of a corresponding position is recorded each time after the guideway moving part is moved by a small displacement, so that a curve of the pressure distribution in the oil cavity of the hydrostatic guideway can be obtained; and 4, according to the obtained curve of the pressure distribution, the impact of the pressure distribution in the oil cavity on the performance of the hydrostatic guideway is researched. According to the method disclosed by the invention, an oil cavity pressure testing point is arranged on the hydrostatic guideway, thereby effectively solving the problem about how to detect the pressure distribution in the oil cavity of the hydrostatic guideway.

Owner:HARBIN INST OF TECH

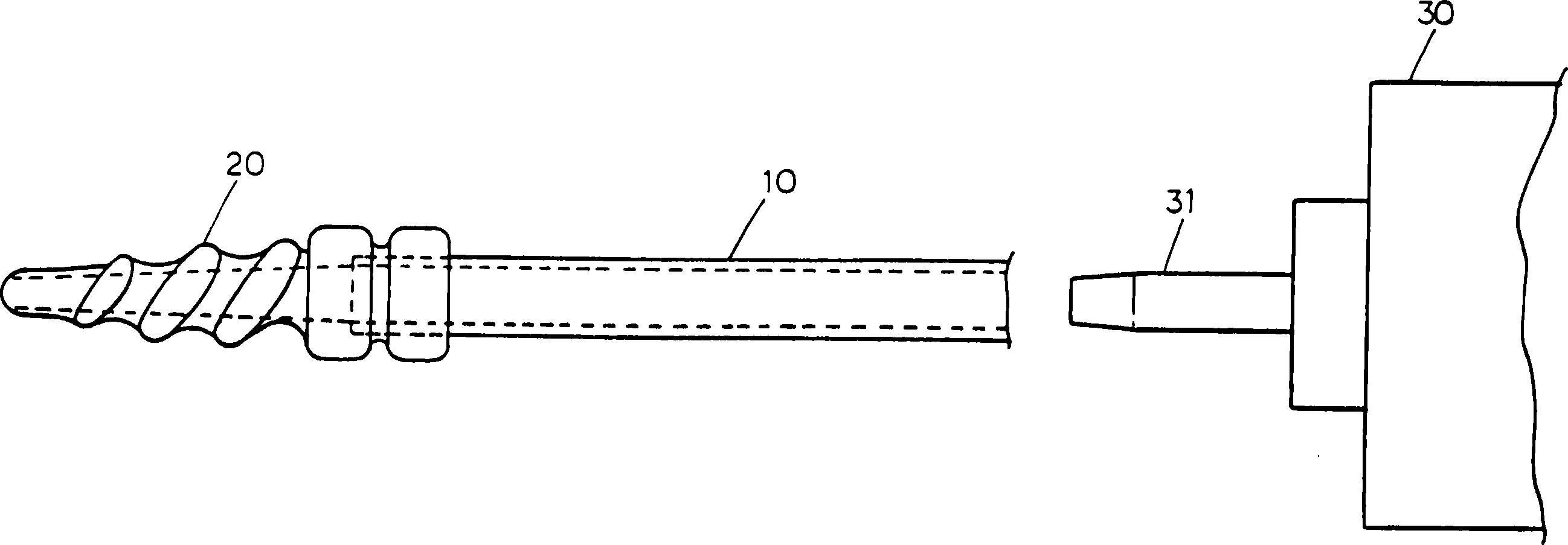

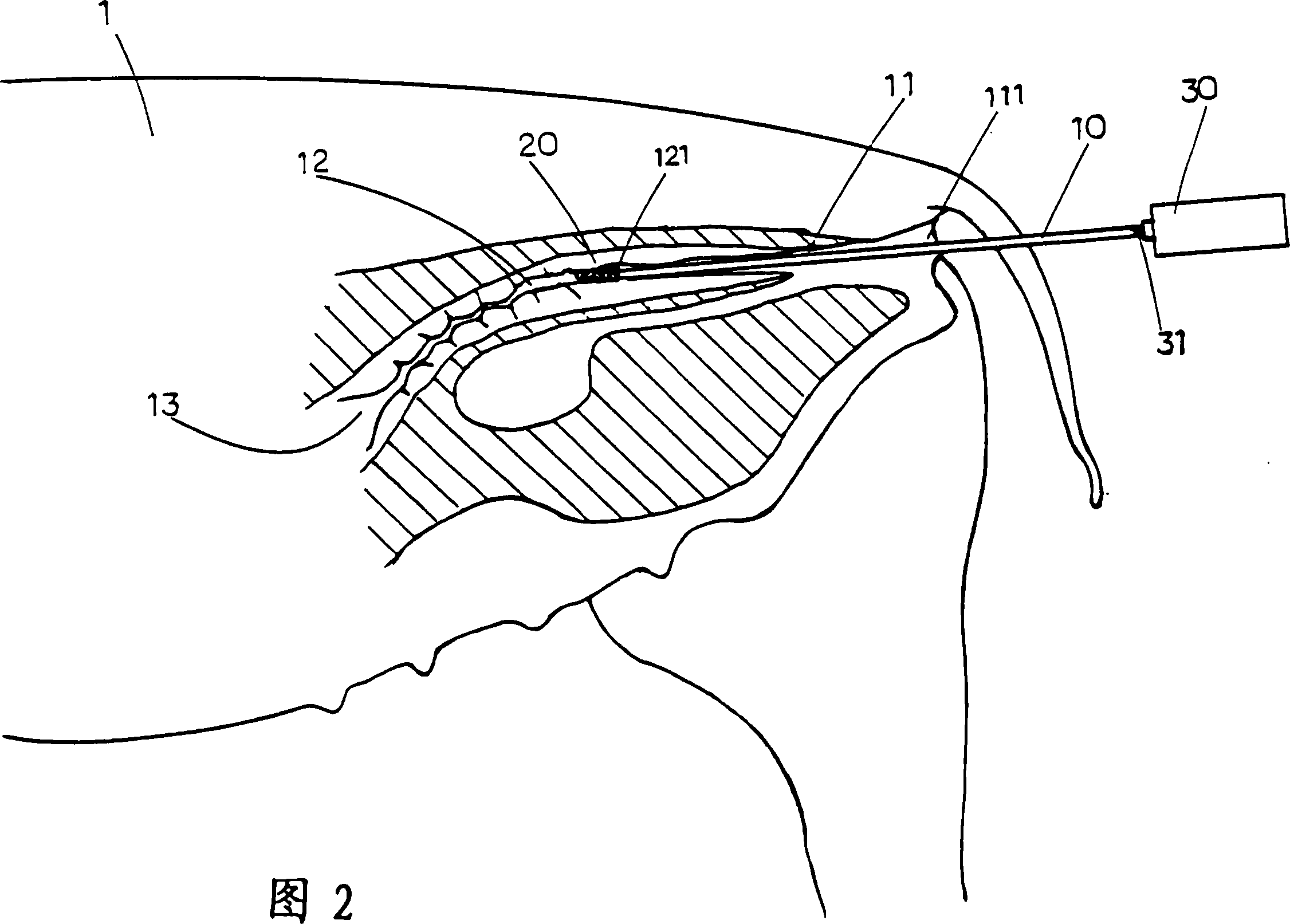

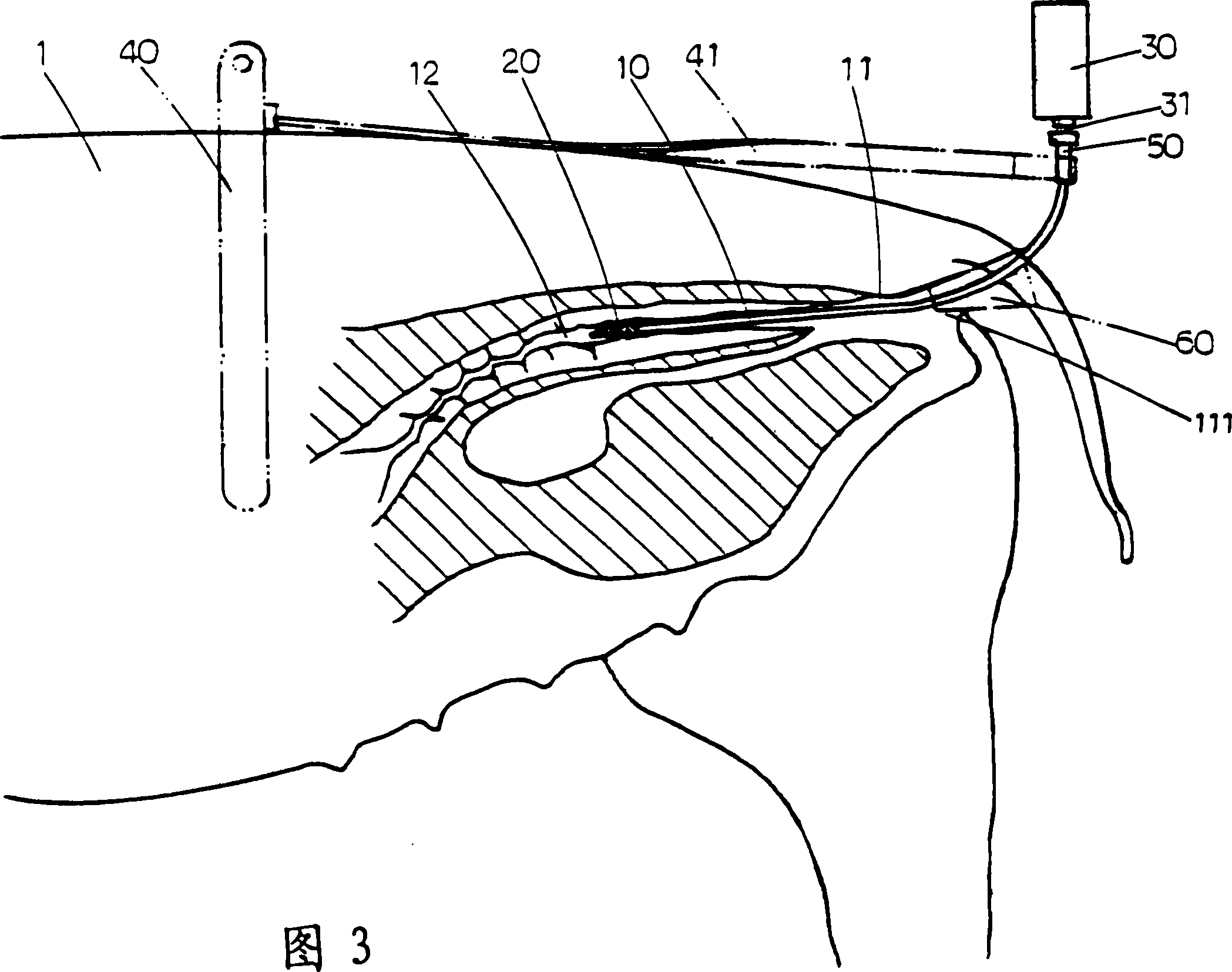

Artificial trace insemination device for animal

InactiveCN1879577ASmooth movementImprove the efficiency of artificial inseminationAnimal reproductionPosition uterusEngineering

The invention relates to artificial microscale semination machine used for animal. A elastic semination sleeve is set between injector passage and front end of conduit central pore in compressed condition, and the back end of said elastic semination sleeve is located on front end of injector. The invention is characterized in that: inserting injector into animal vaginal and making it in the first neck ring of uterine cervix, the extension part of elastic semination sleeve extending from injector front end by using entry pressure of semen from conduit back end, the extension part extending to uterus along uterine cervix, the entered semen entering into uterus or two passage in uterus corner through preset joint-cutting smoothly cooperated with contraction of animal uterus. The adverse current effect of semen is improved, and the economic benefit of micro-scale semination and artificial semination efficiency are increased.

Owner:陈生瑞

A hollow fiber membrane

ActiveUS20190247802A1High mechanical strengthGood anti-wetting propertyMembranesSeawater treatmentHollow fibreMembrane distillation

There is provided a hollow fiber membrane for vacuum membrane distillation having a maximum tensile strength of a ≥3.5 MPa and a liquid entry pressure (LEP) of ≥3.0 bar, wherein the hollow fiber membrane is a single layer hollow fiber membrane comprising a wall with a thickness of ≤150 μm and a cross-section comprising two open cell layers with an array of interconnected pores and a macrovoid layer between the two open cell layers. The hollow fiber has improved mechanical strength and vacuum membrane distillation flux.

Owner:NAT UNIV OF SINGAPORE

Turbo rotational frequency detection device

InactiveUS9804059B2Good effectLow costElectrical controlGas-turbine engine testingTurbochargerEngineering

Based on entry / exit pressures of a compressor detected by atmospheric / boost pressure sensors, a pressure ratio of compressor is calculated. Based on mass flow rate and entry temperature of intake air detected by intake air flow-rate / temperature sensors and entry pressure, a volumetric flow rate of intake air is calculated in environmental condition at a detection time using gas state equation, and is corrected into a volumetric flow rate under standard environmental condition thorough multiplication by a corrective coefficient based on entry temperature of intake air. Based on the corrected value and the calculated pressure ratio, a rotational frequency of compressor under standard environmental condition is read out in light of operating characteristic diagram for the compressor. Read-out rotational frequency is corrected into actual rotational frequency of the compressor through multiplication by a corrective coefficient based on entry temperature of intake air, which is determined as rotational frequency of turbocharger.

Owner:HINO MOTORS LTD

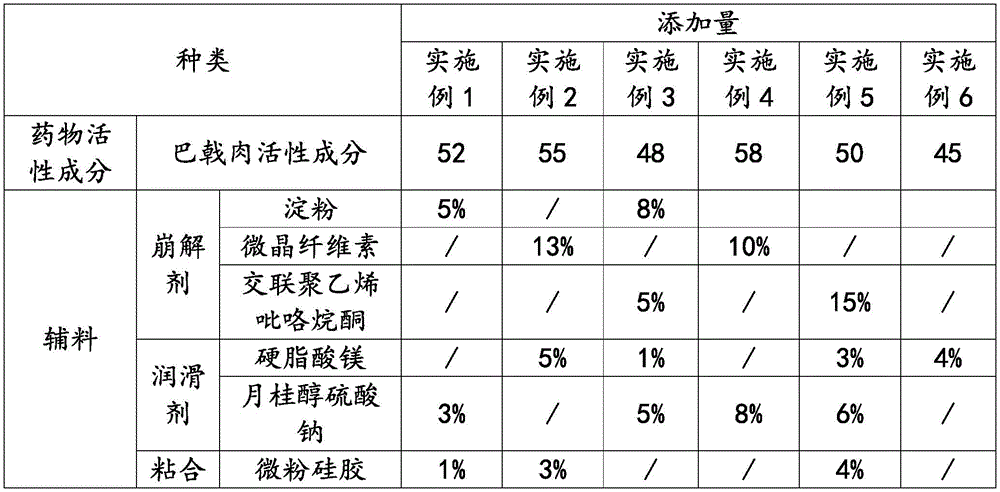

Morinda officinalis pure powder ultrafine decoction pieces and preparation method thereof

The invention discloses a preparation method of ultrafine decoction pieces of Morinda officinalis pure powder and the prepared product. Preparation method: after washing the fresh Morinda officinalis meat, dry it by freeze-drying technology, then crush the active ingredients of the dried Morinda officinalis meat to a particle size of less than 300 microns, and then ultrafinely pulverize it in an airflow mill to obtain the Morinda officinalis officinale The ultrafine decoction pieces of halberd meat pure powder, the conditions of ultrafine pulverization are: pulverization temperature 15-22°C, pressure when entering the ultrafine pulverizer is 1-2Mpa, pulverization pressure 2-6Mpa, air velocity 200-285m / s, the crushing time is 1‑3h. The oral preparation prepared by the preparation process has good drug effect, good dissolution property, good stability, high bioavailability, and improved odor and mouthfeel.

Owner:磐安县道地磐药中药研究所

Waste magnetic suspension liquid processing method and device

InactiveCN100372788CEasy to handleSolve the emission problemWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater qualityLiquid tank

The invention discloses a waste magnetic suspension liquid processing method and device, wherein the method comprises four steps of coagulation, pre-filming, filtering and backwashing. The device comprises a raw liquid tank, a coagulating bath in conduct connection with the raw liquid tank through a sewage water pump and valves, a pre-filming tank in conduct connection with the coagulating bath through valves, a filter in conduct connection with the pre-filming bath through clean pumps and valves, and a pressure control apparatus for controlling the pressure difference between the entry pressure and outlet pressure of the filter.

Owner:BAOSHAN IRON & STEEL CO LTD

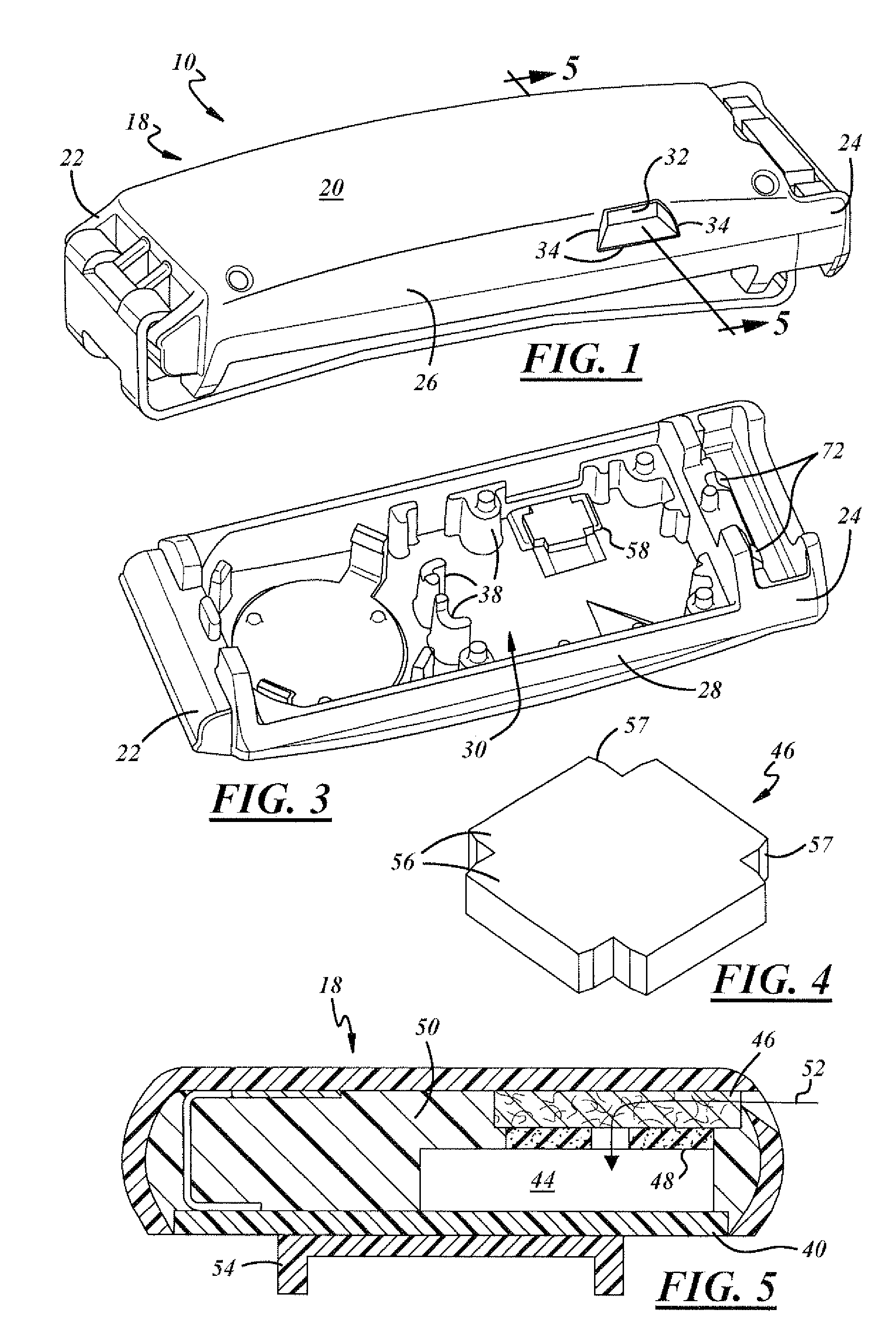

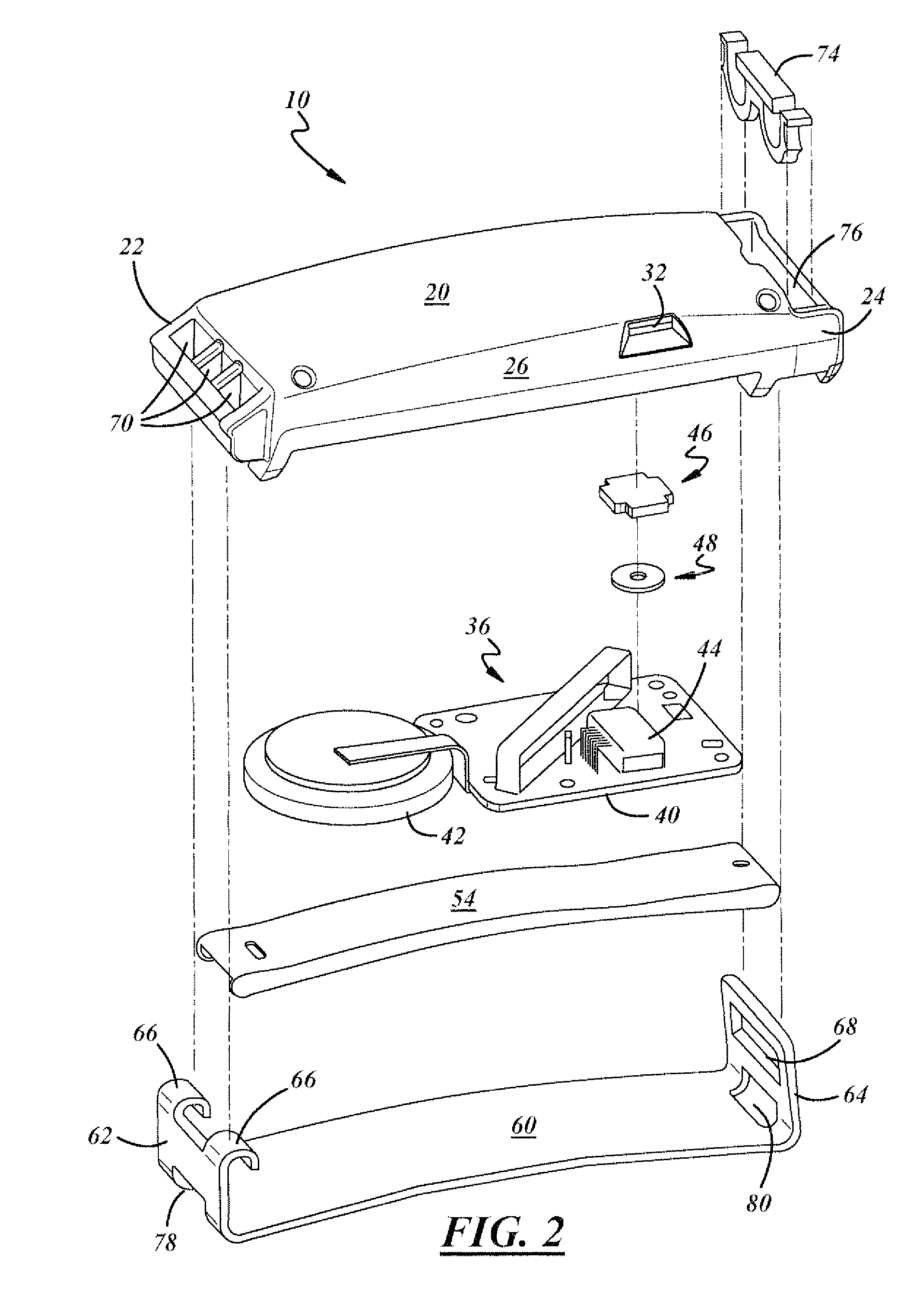

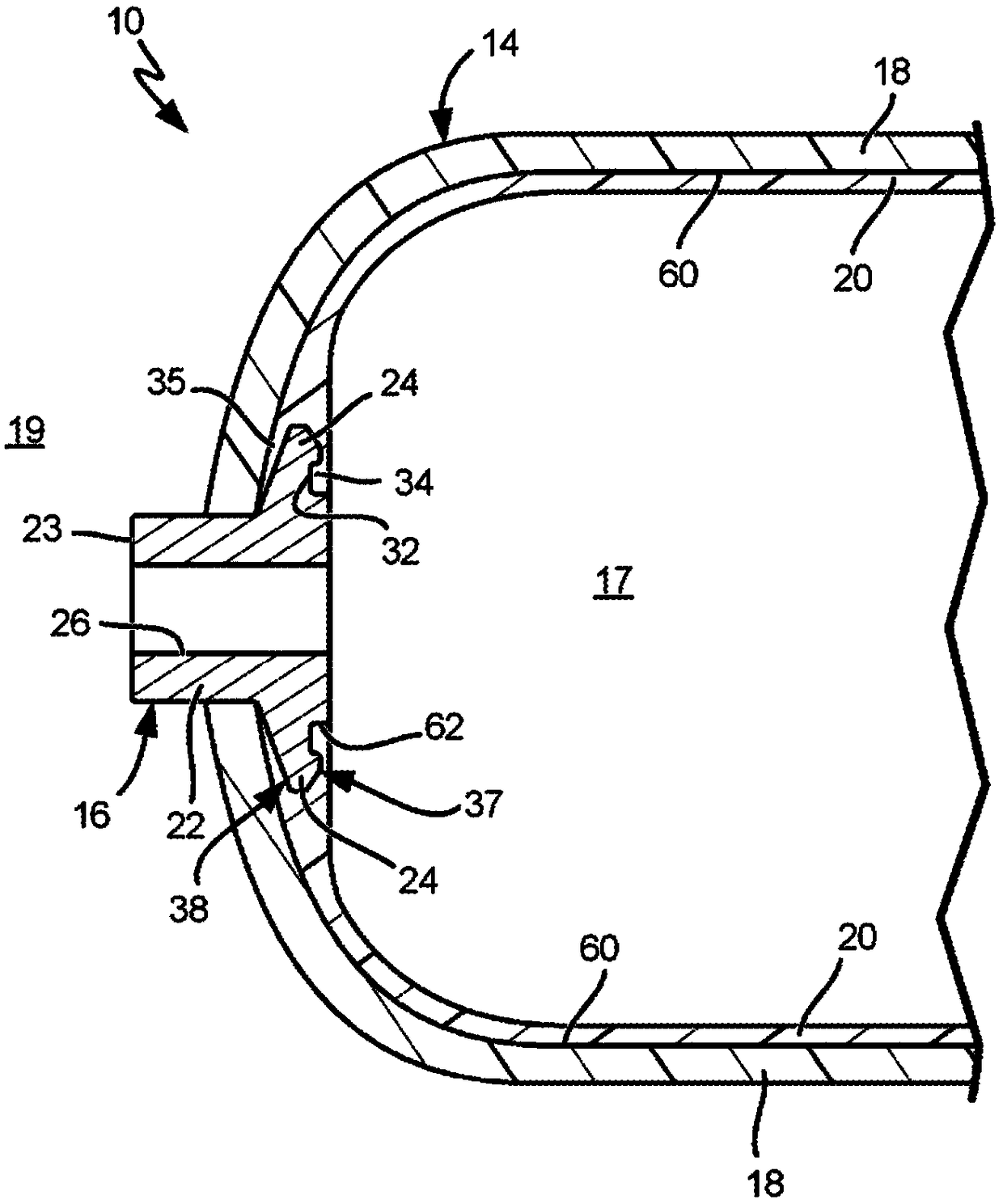

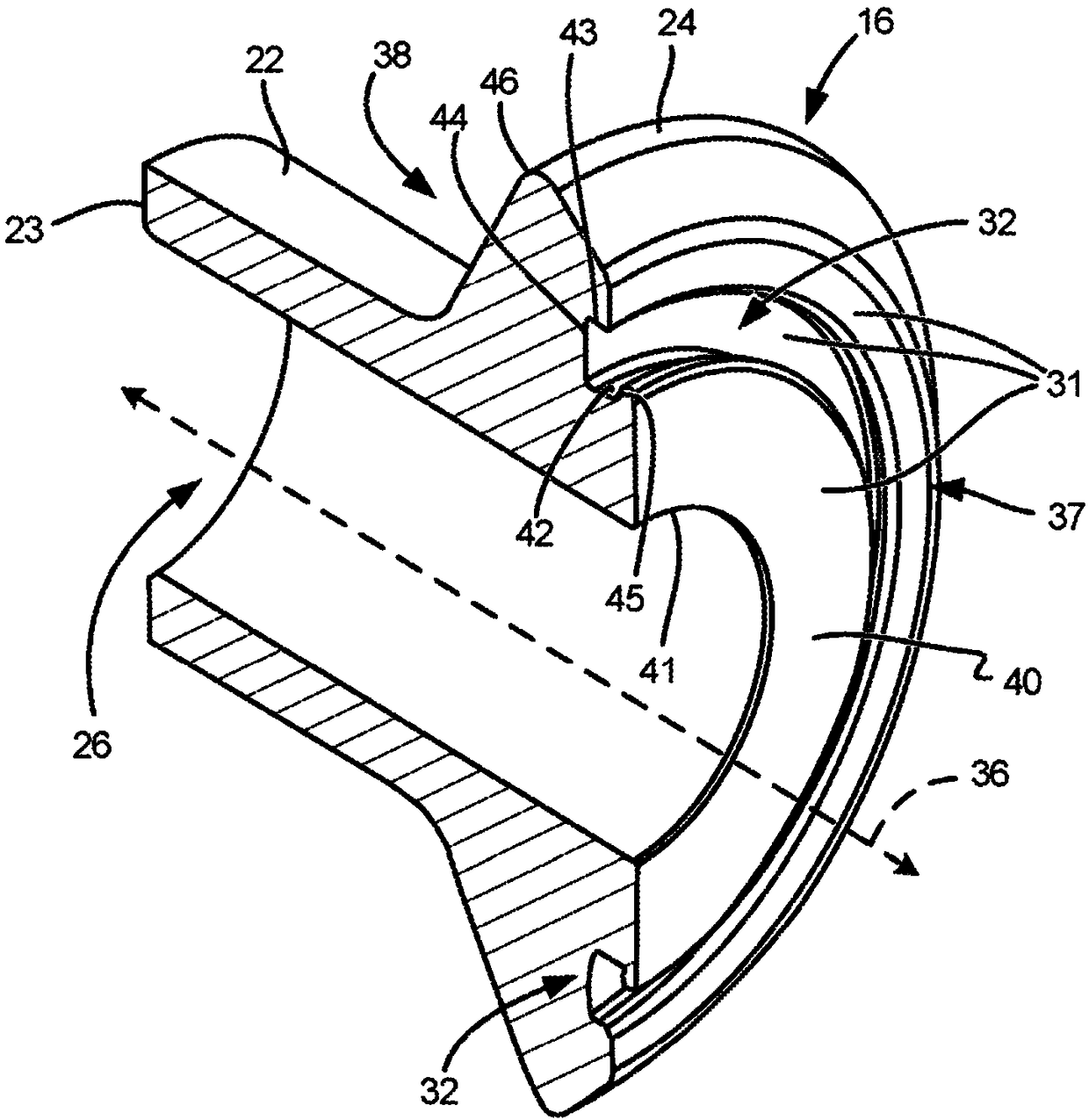

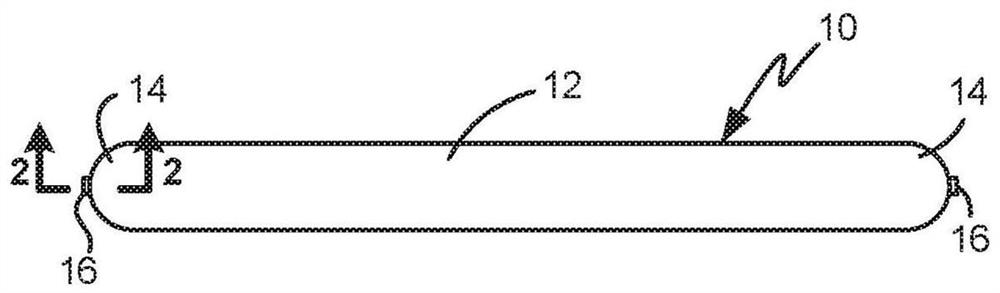

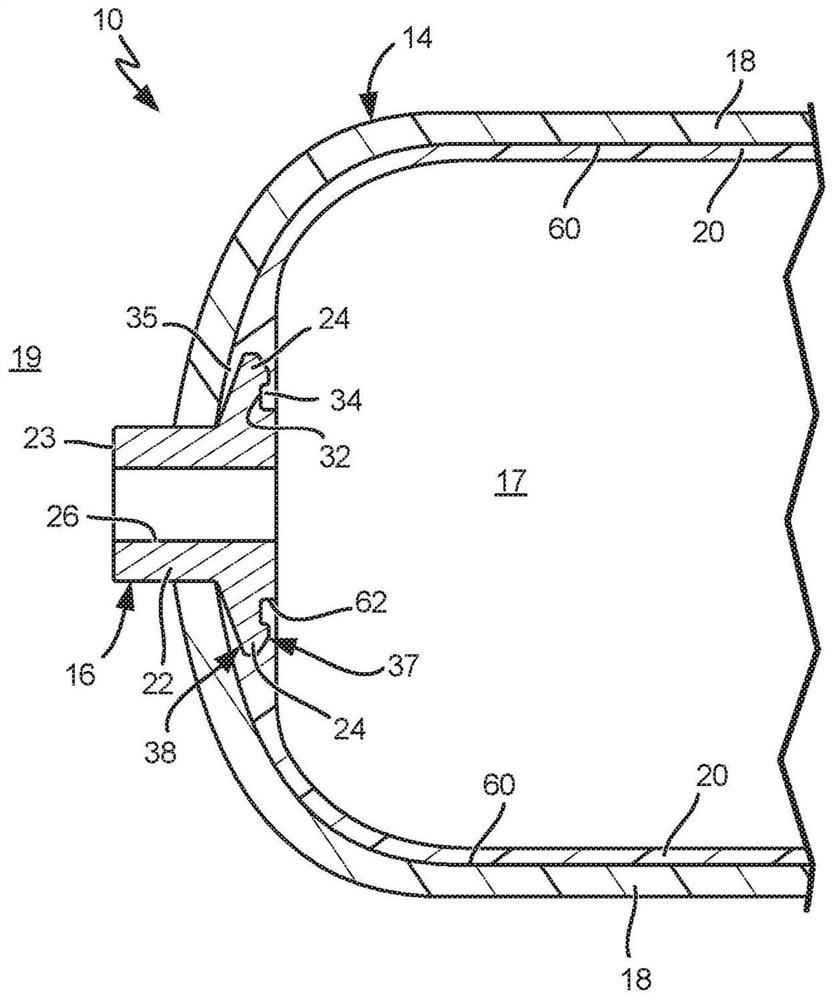

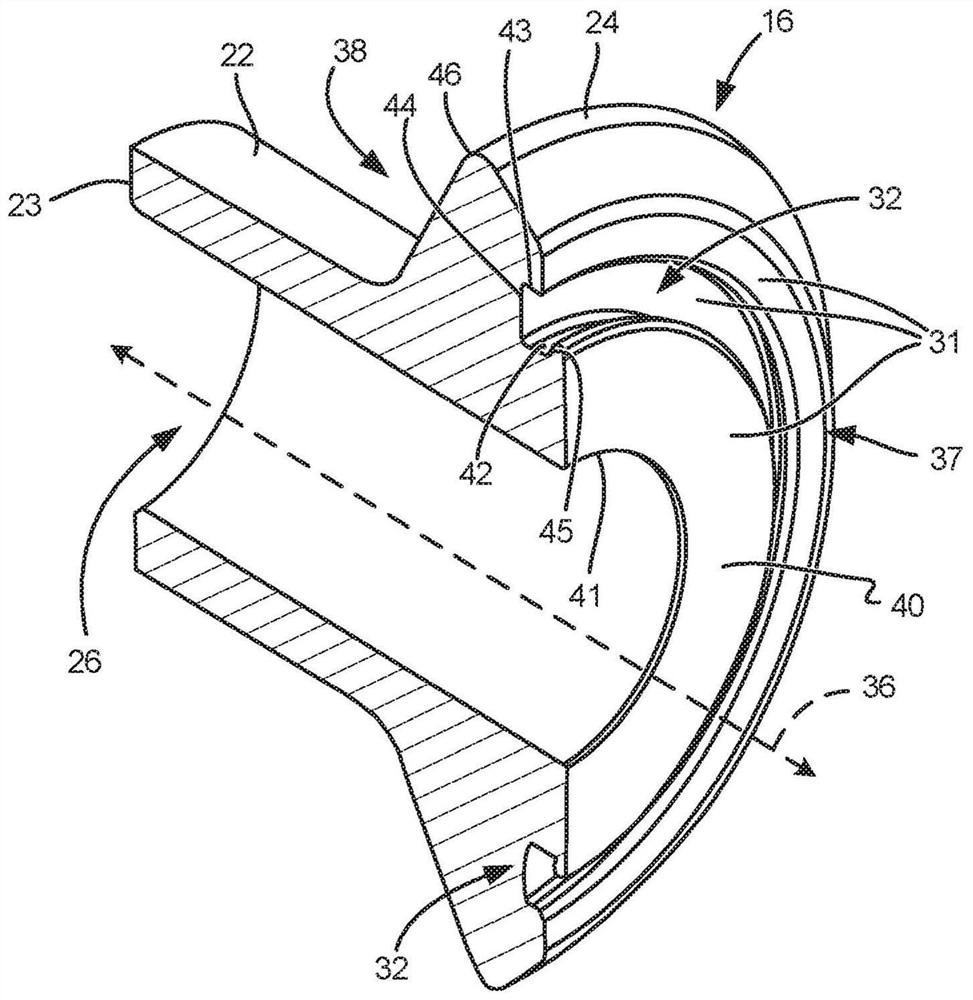

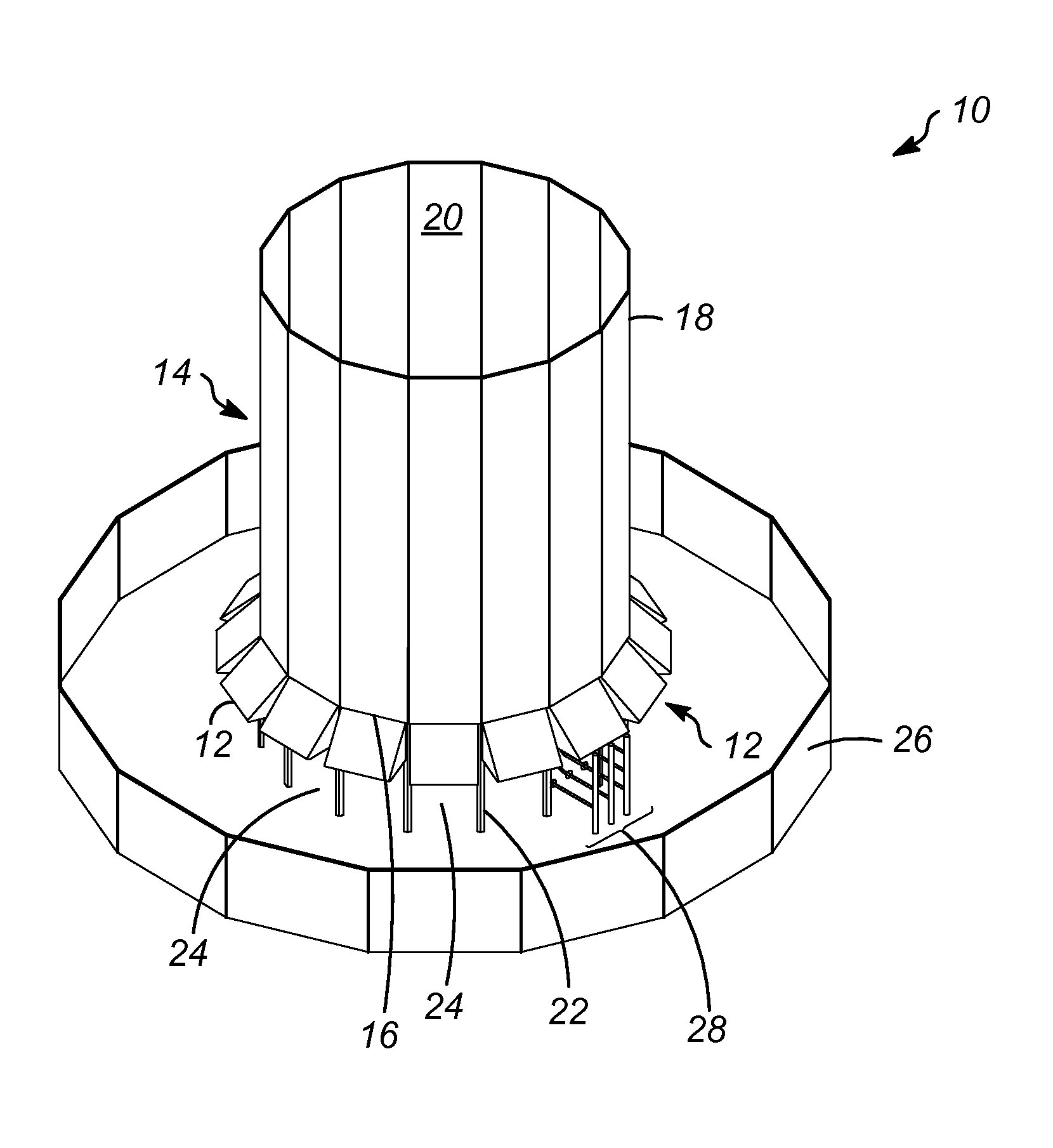

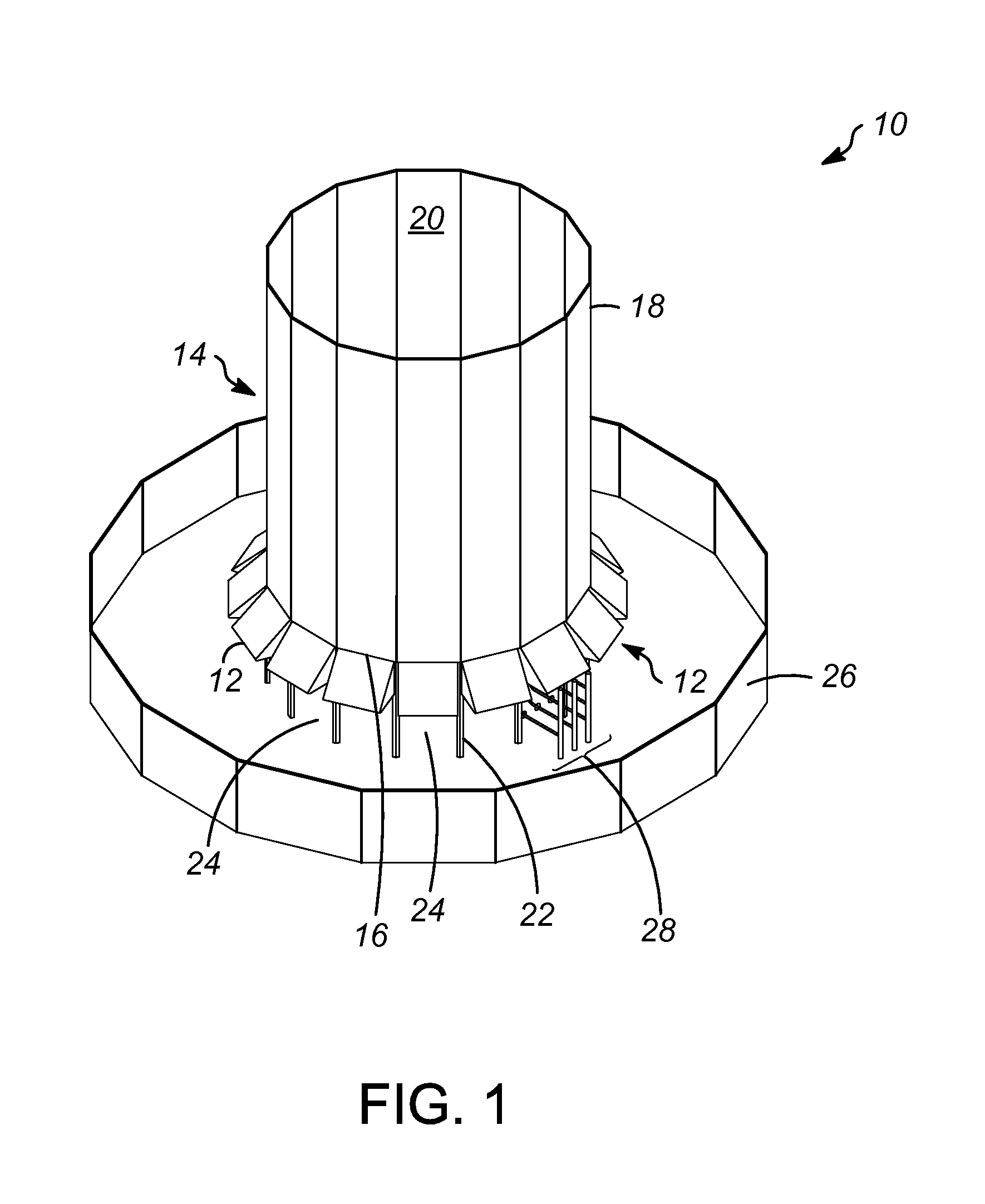

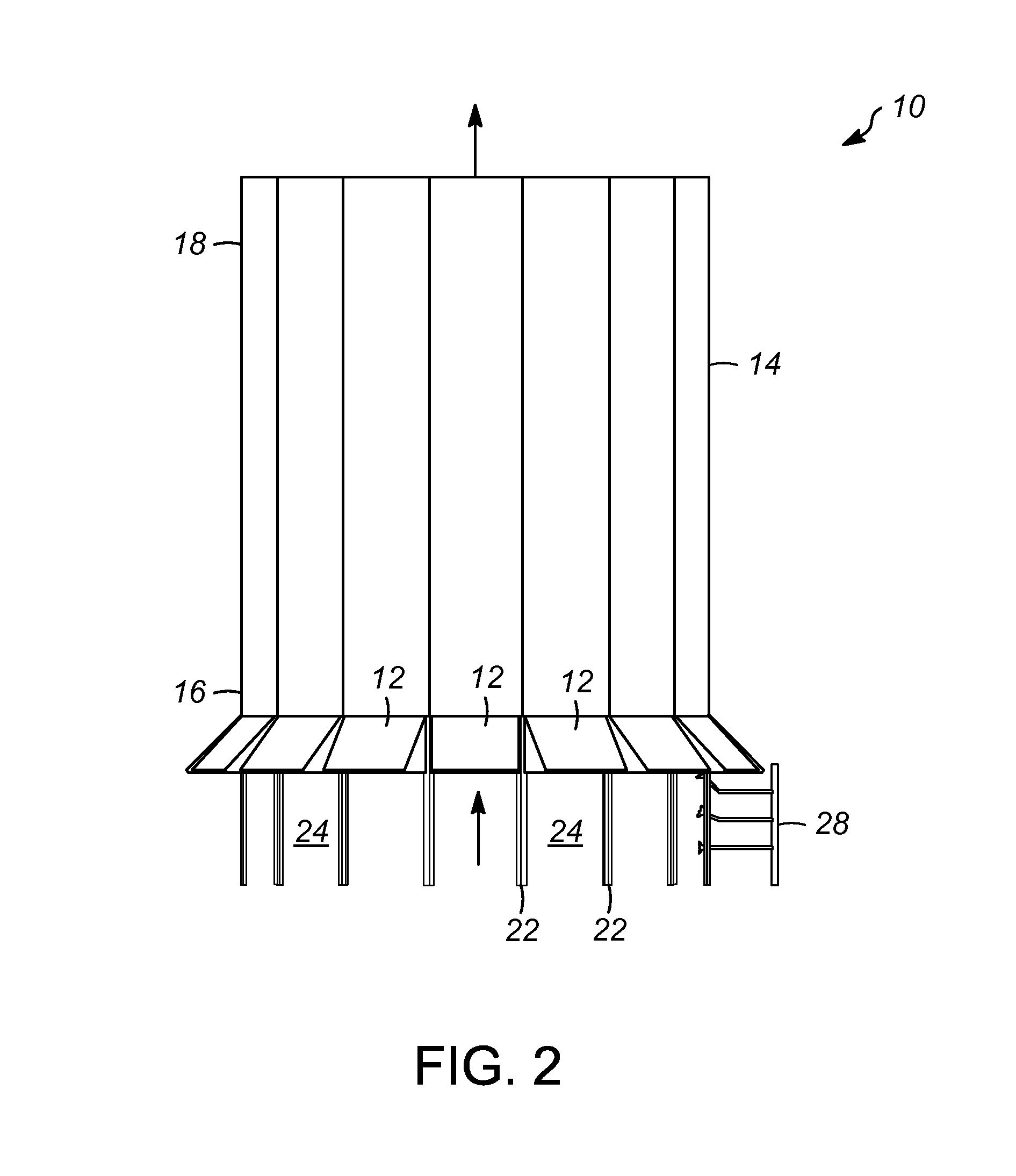

Pressure vessel vented boss with sintered metal plug

A pressure vessel (10) includes a shell (18), a liner (20), and a boss (16). The liner (20) is positioned within the shell (18) and defines the interior environment (17). The boss (16) is located at afirst interface (60) between the shell (18) and the liner (20). The boss (16) includes a cavity (27) and a venting structure (28) located in the cavity (27). The cavity (27) is located at a second interface (62) between the liner (20) and the boss (16), and the cavity (27) is located at an interior surface (31) of the boss (16) in communication with the interior environment (17). A gas vent path(54) is defined from the first interface (60), through the venting structure (28), and into the interior environment (17) of the pressure vessel (10). The disclosure also describes a boss (16) for a pressure vessel (10) and a method of manufacturing the boss (16). The boss (16) includes a port (26), a flange (24), a cavity (27) and a gas venting structure (28). The cavity (27) and gas venting structure (28) are located on an interior (37) of the flange (24).

Owner:HEXAGON TECHNOLOGY AS

An automatic measuring device for radial support key assembly clearance

ActiveCN103925884BAvoid the pitfalls of manual measurementUsing optical meansMeasurement devicePressurized water reactor

The invention belongs to the technical field of the design of a nuclear reactor of a pressurized water reactor nuclear power plant, and particularly relates to an automatic measuring device for the assembly clearance of a radial support key. The automatic measuring device for the assembly clearance of the radial support key comprises a probe, a camera, a horizontal telescopic support, a vertical telescopic support and an installation platform. The camera is installed on one side of the probe. The other side of the probe is connected with the front end of the horizontal telescopic support. The rear end of the horizontal telescopic support is connected with the upper end of the vertical telescopic support. The lower end of the vertical telescopic support is connected with the installation platform. The automatic measuring device for the assembly clearance of the radial support key has the advantages of automatic measurement and high precision. A data acquisition device is controlled outside a pressure container so that the probe can be moved to measure the assembly clearance between different positions of the radial support key and a reactor core support block and the assembly clearance between the different positions of the radial support key and an insert of the radial support key; in this way, defects of manual measurement conducted by operation personnel in the prior art are overcome, and the limitation that the operation personnel must enter the pressure container to conduct measurement is avoided.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

A detection method for the pressure distribution of the oil cavity of the hydrostatic guide rail

ActiveCN106563970BQuick measurementAccurate measurementMeasurement/indication equipmentsInlet channelHydrostatic pressure

The invention discloses a method for detecting the pressure distribution in an oil cavity of a hydrostatic guideway. The method comprises the following steps: 1, hydraulic oil is sent by a hydraulic station into each oil cavity through an oil inlet channel and a throttling device, so that a guideway moving part can be floated; 2, the guideway moving part is moved to an oil cavity pressure measuring station, pressure oil in the oil cavity enters a pressure measuring channel, a pressure sensor takes a signal pressure signal as the input and begins to read the pressure value at a certain positon in the oil cavity, and the signal processing and the real-time display are performed; 3, after that, the oil cavity pressure of a corresponding position is recorded each time after the guideway moving part is moved by a small displacement, so that a curve of the pressure distribution in the oil cavity of the hydrostatic guideway can be obtained; and 4, according to the obtained curve of the pressure distribution, the impact of the pressure distribution in the oil cavity on the performance of the hydrostatic guideway is researched. According to the method disclosed by the invention, an oil cavity pressure testing point is arranged on the hydrostatic guideway, thereby effectively solving the problem about how to detect the pressure distribution in the oil cavity of the hydrostatic guideway.

Owner:HARBIN INST OF TECH

Pressure Vessel Vent Boss with Sintered Metal Plug

A pressure vessel (10) includes a shell (18), a liner (20) and a boss (16). A liner (20) is positioned within the shell (18) and defines an interior environment (17). The boss (16) is located at a first interface (60) between the shell (18) and the liner (20). The boss (16) includes a cavity (27) and a vent structure (28) located in the cavity (27). The cavity (27) is located at the second interface (62) between the liner (20) and the boss (16), and the cavity (27) is located on the inner surface (31) of the boss (16), and the inner environment (17) connected. A gas discharge path (54) is defined from the first interface (60), through the vent structure (28), and into the interior environment (17) of the pressure vessel (10). The present disclosure also describes a boss (16) for a pressure vessel (10) and a method of making the boss (16). Boss (16) includes port (26), flange (24), chamber (27) and gas vent structure (28). The cavity (27) and gas vent structure (28) are located on the interior (37) of the flange (24).

Owner:HEXAGON TECHNOLOGY AS

A single barrel capillary rheometer

InactiveCN105675443BEliminate pressure dropHigh precisionDirect flow property measurementEngineeringShear flow

The invention discloses a single-feed-cylinder capillary rheometer. A feed cylinder of the capillary rheometer is a single feed cylinder; the front end of the feed cylinder is provided with a plunger, the rear end of the feed cylinder is provided with a traveling nut, an electric heater is arranged around the feed cylinder, a long capillary die, a support part and a zero-length capillary die / short capillary die are arranged in the feed cylinder, and the outer diameter of the long capillary die, the outer diameter of the zero-length capillary die / short capillary die and the outer diameter of the support part all are matched with the inner diameter of the feed cylinder. The single-feed-cylinder capillary rheometer can be used for measuring extensional flow and shear flow parameters of polymer melt simultaneously, can eliminate entry pressure drop well, has the same function as a double-feed-cylinder capillary rheometer, and also has the advantages of saving raw materials, facilitating dismounting, purging easily, reducing artificial influences, realizing higher precision, and the like.

Owner:TAIYUAN INST OF TECH

The method of replacing the main drive seal in muddy water shield in complex formation

The invention provides a method for replacing the main drive seal of a slurry shield in a complex stratum. The method comprises the following steps: arranging a plurality of reinforced MJS (Metro Jet System) piles on the propelling axis of a shield tunnel to form a reinforced area; propelling a cutter head of a shield machine into the reinforced area; setting the storehouse entry pressure as the underground head pressure; replacing the main drive seal under the storehouse entry pressure. By adopting the method, the problem of lack of replacement of the main drive seal in the complex stratum in the existing technical scheme is solved, the replacement risk of the main drive seal is lowered greatly, and the safety and efficiency of main drive seal replacement construction are improved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Enclosed flare stack and method of flaring waste gas

An enclosed flare stack having expanded air entries for flaring waste gas. The flare stack includes an enclosure assembly having a bottom portion with expanded air entries and an upper portion through which the flared waste gas escapes. The enlarged air entries at the bottom end of the stack to reduce entry pressure loss and to increase entrained air flow when flaring waste gas. The enclosed flare stack and method of flaring waste gas also greatly reduce the height of the stack enclosure without greatly increasing the size of the flare windows.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com