Improved porous membrane

A technology of water inlet and extrudate, applied in the field of porous membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

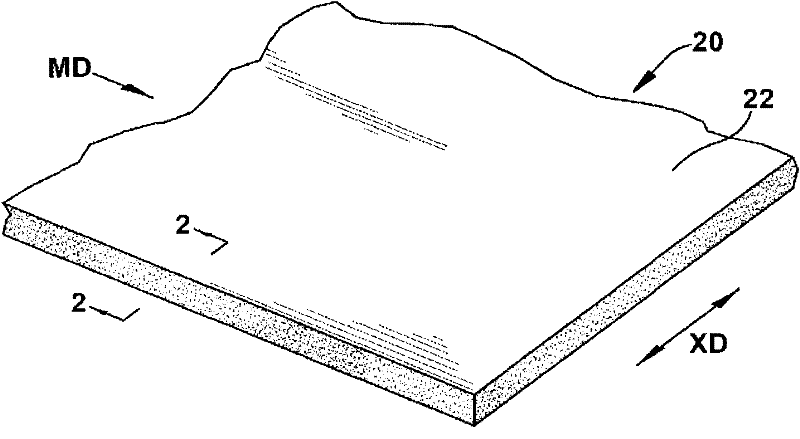

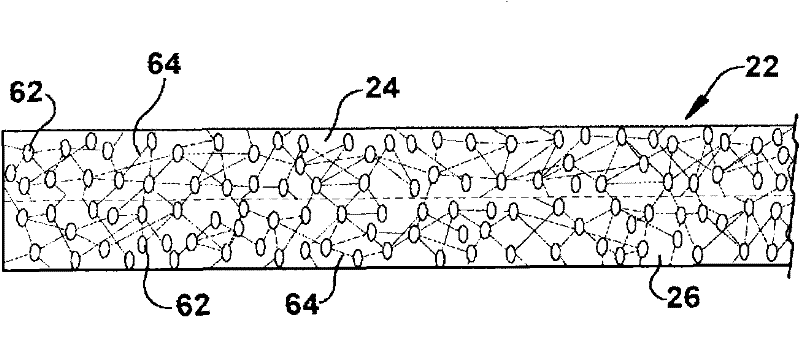

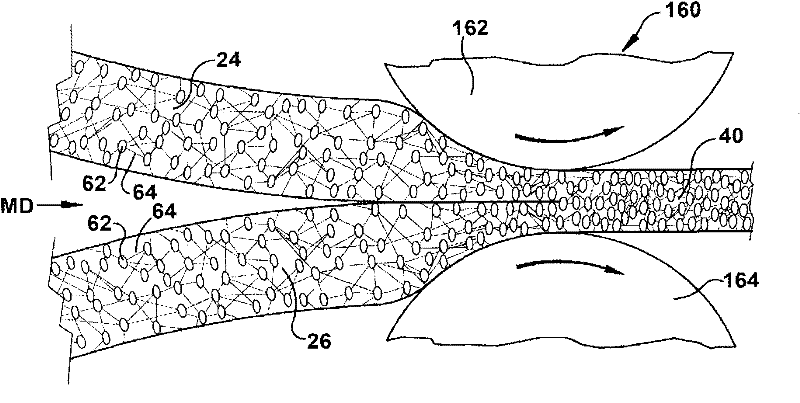

[0032] An improved membrane 20 made according to one aspect of the present invention ( figure 1 ) in the form of a sheet 22. slice 22 ( figure 2 ) combines at least two identical layers or components. The parts are in the form of extrudates 24, 26 made by a slurry extrusion process. The extrudates 24, 26 form an integral belt structure 40 ( image 3 and Figure 4 ). The unitary belt structure 40 is then biaxially stretched to form the sheet 22 of film 20 .

[0033] The resulting sheet 22 of membrane 20 is porous, and preferably microporous, with a three-dimensional matrix or lattice type structure of a plurality of nodes 62 linked by a plurality of fibrils 64 . The material from which sheet 22 of membrane 20 is made is made of expanded polytetrafluoroethylene (ePTFE) which may or may not be sintered.

[0034] The surfaces of nodes 62 and fibrils 64 define a plurality of interconnected pores that extend completely through sheet 22 of membrane 20 along tortuous paths bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com