Tire pressure monitor system with side entry pressure port

A tire pressure monitoring, inlet hole technology, applied in tire measurement, tire parts, vehicle parts, etc., can solve the problem of permanent damage to sensor elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Description of the preferred embodiment

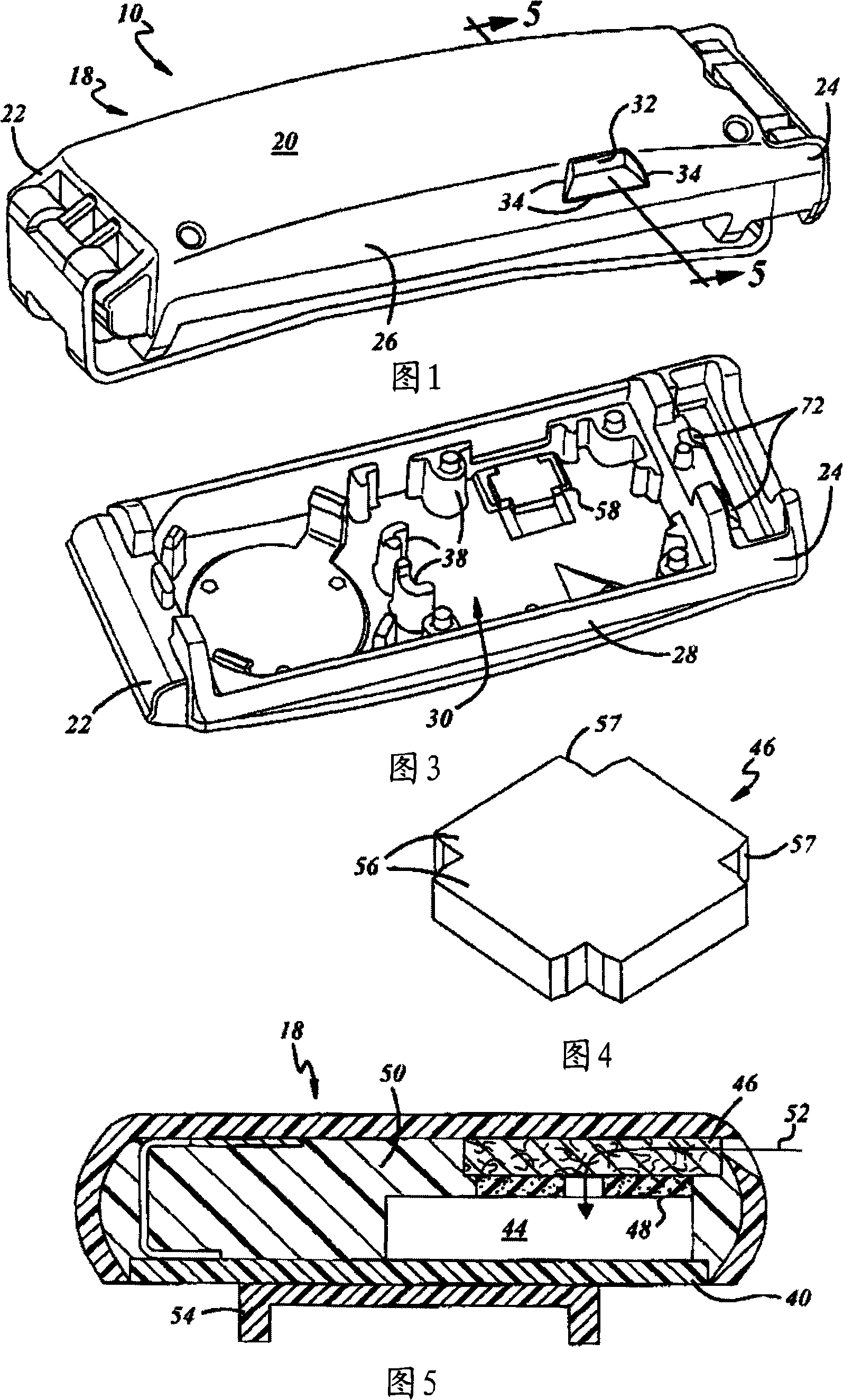

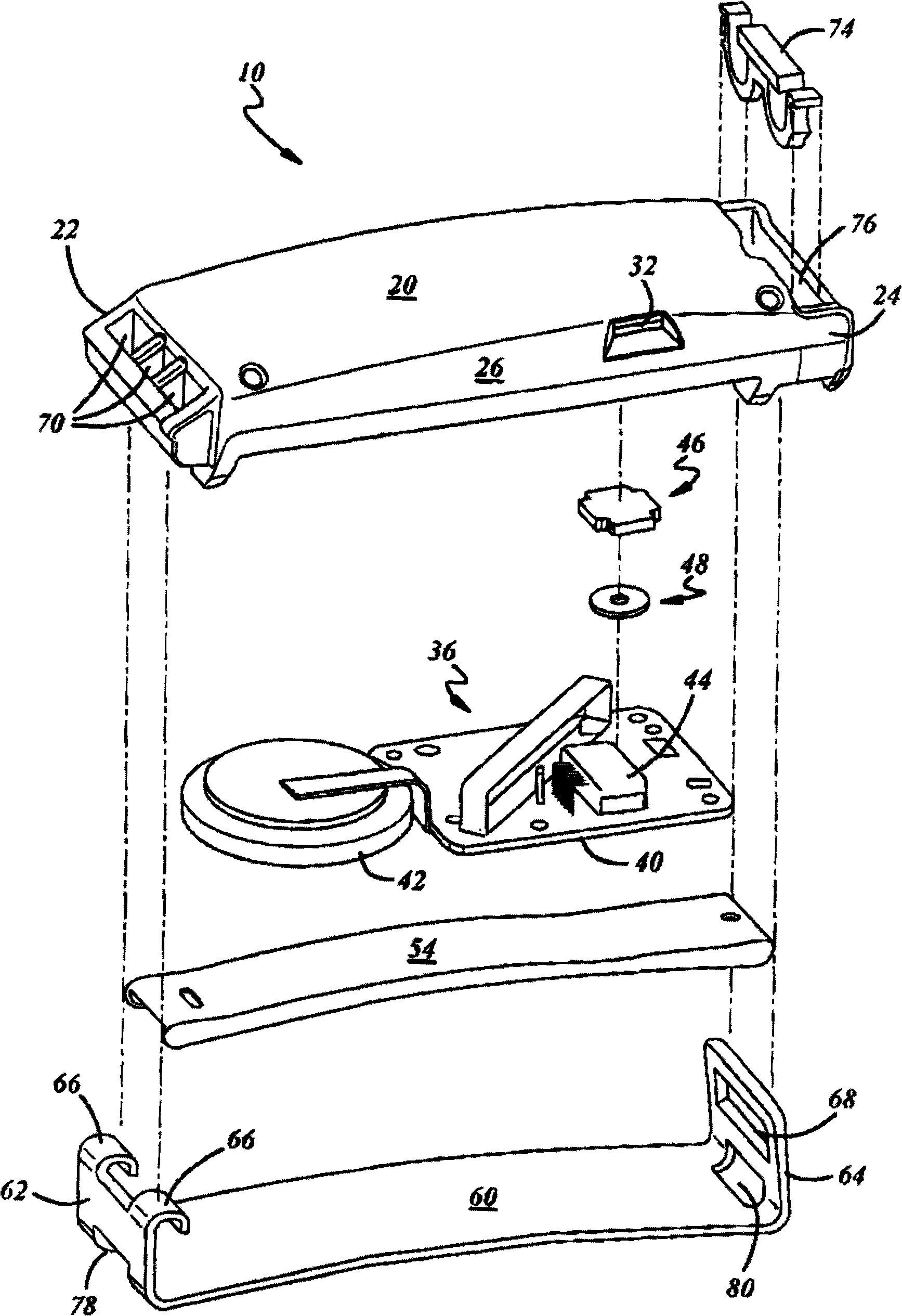

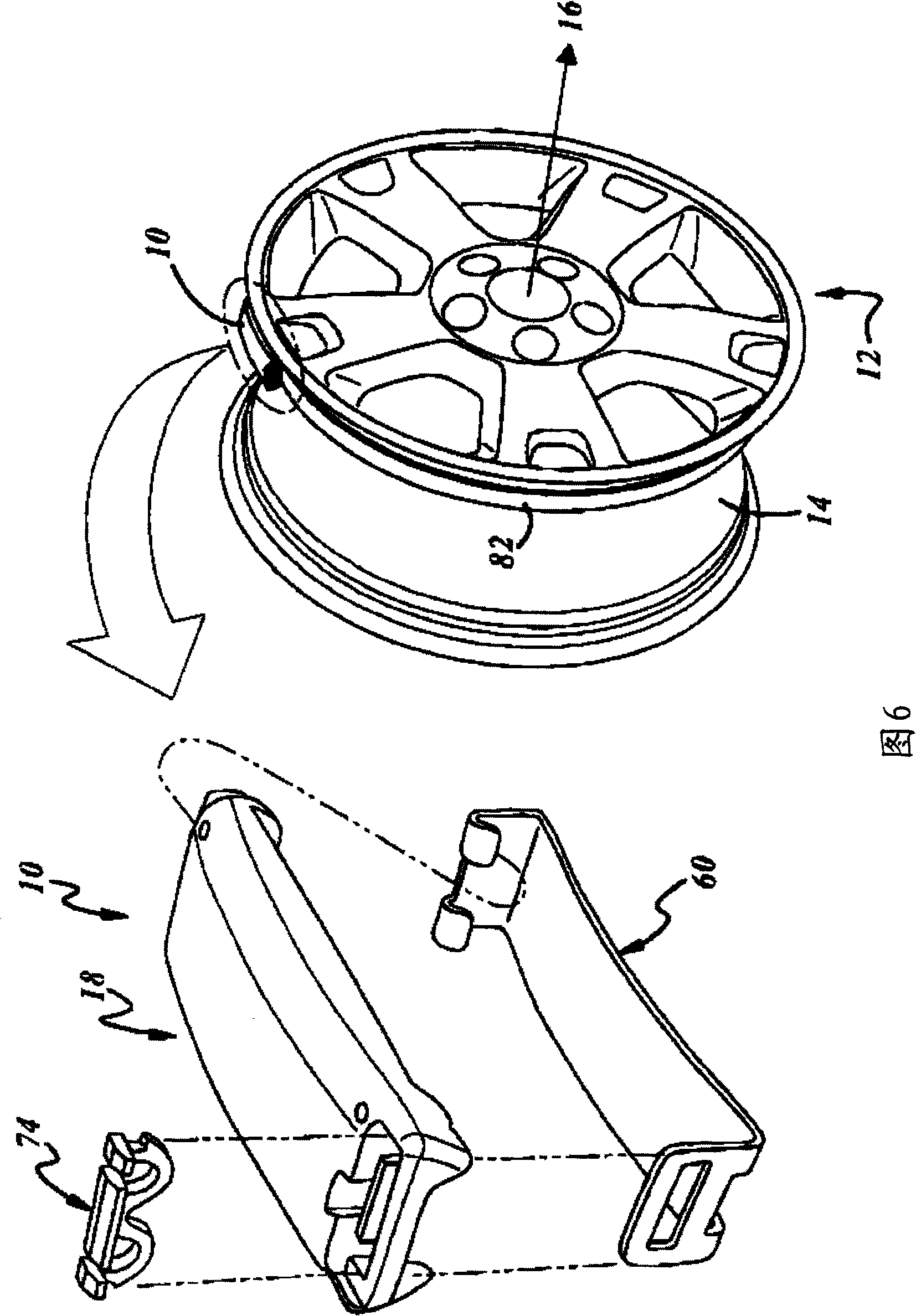

[0015] Referring now to Figure 1 and figure 2 , which is a diagram of a tire pressure monitoring system 10 according to the present invention. The tire pressure monitoring system 10 is envisioned for use with motor vehicles, although various tire-based applications may be apparent in light of this disclosure. The tire pressure monitoring system 10 is intended to be mounted within a rim 12 having a rim inner surface 14 and a rim axis of rotation 16 (see FIG. 6 ). Although a variety of processes may be used to mount the tire pressure monitoring system 10 to the rim 12, it is preferably contemplated that the system 10 may be mounted using a band attachment process.

[0016] The tire pressure monitoring system 10 includes a sensor housing 18 having an arcuate configuration adapted to engage the inner surface 14 of the rim. The sensor housing 18 is preferably molded to produce a housing upper surface 20 , a first housing end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com