Enclosed flare stack and method of flaring waste gas

a technology of waste gas and stack, which is applied in the direction of combustion types, lighting and heating apparatus, incinerator apparatus, etc., can solve the problems of a taller external radiation fence, the loss of the ability to direct air flow at a given velocity, and the major cost of enclosed flares

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

[0038]While the following is described in conjunction with specific embodiments, it will be understood that this description is intended to illustrate and not limit the scope of the preceding description and the appended claims.

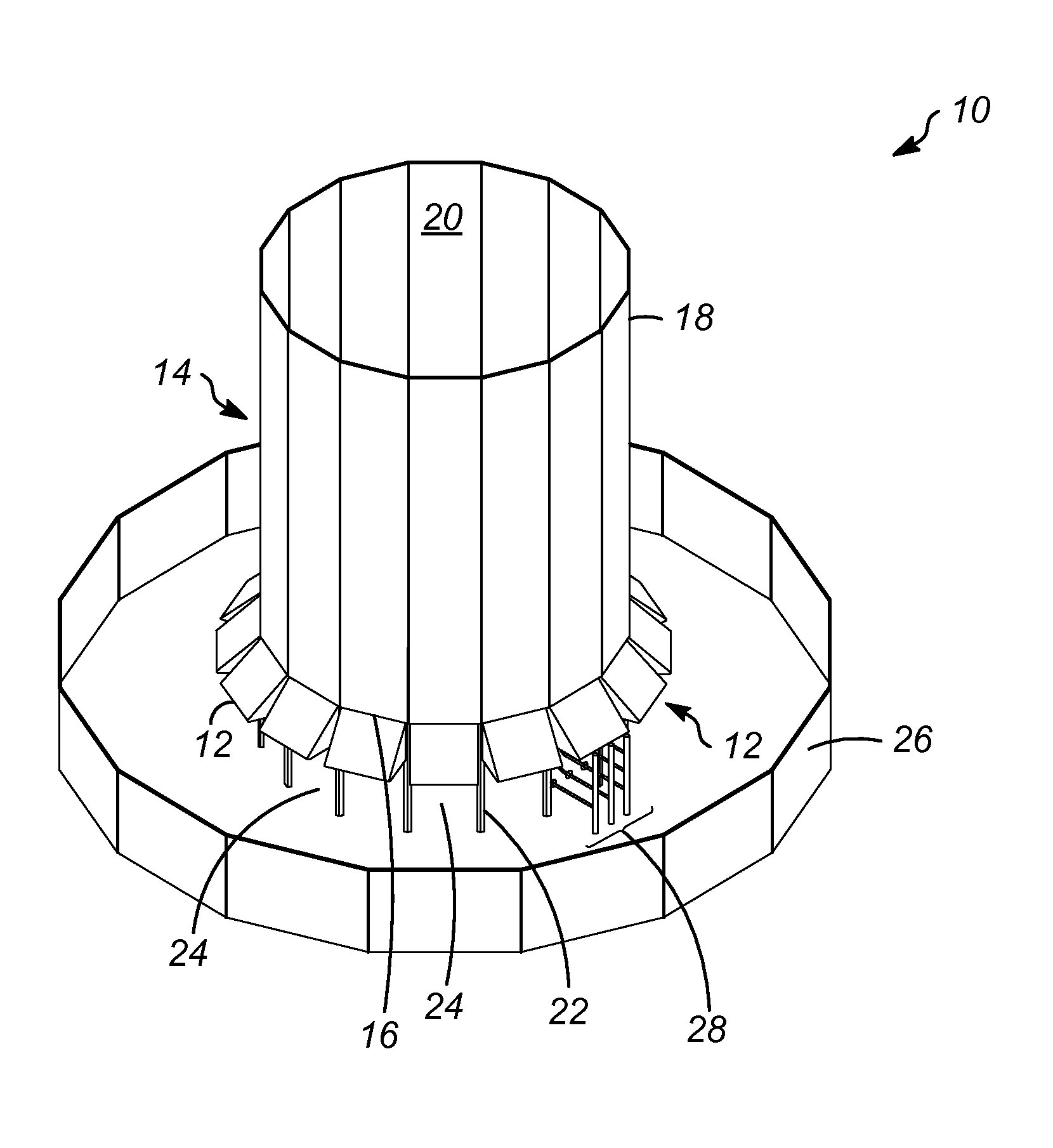

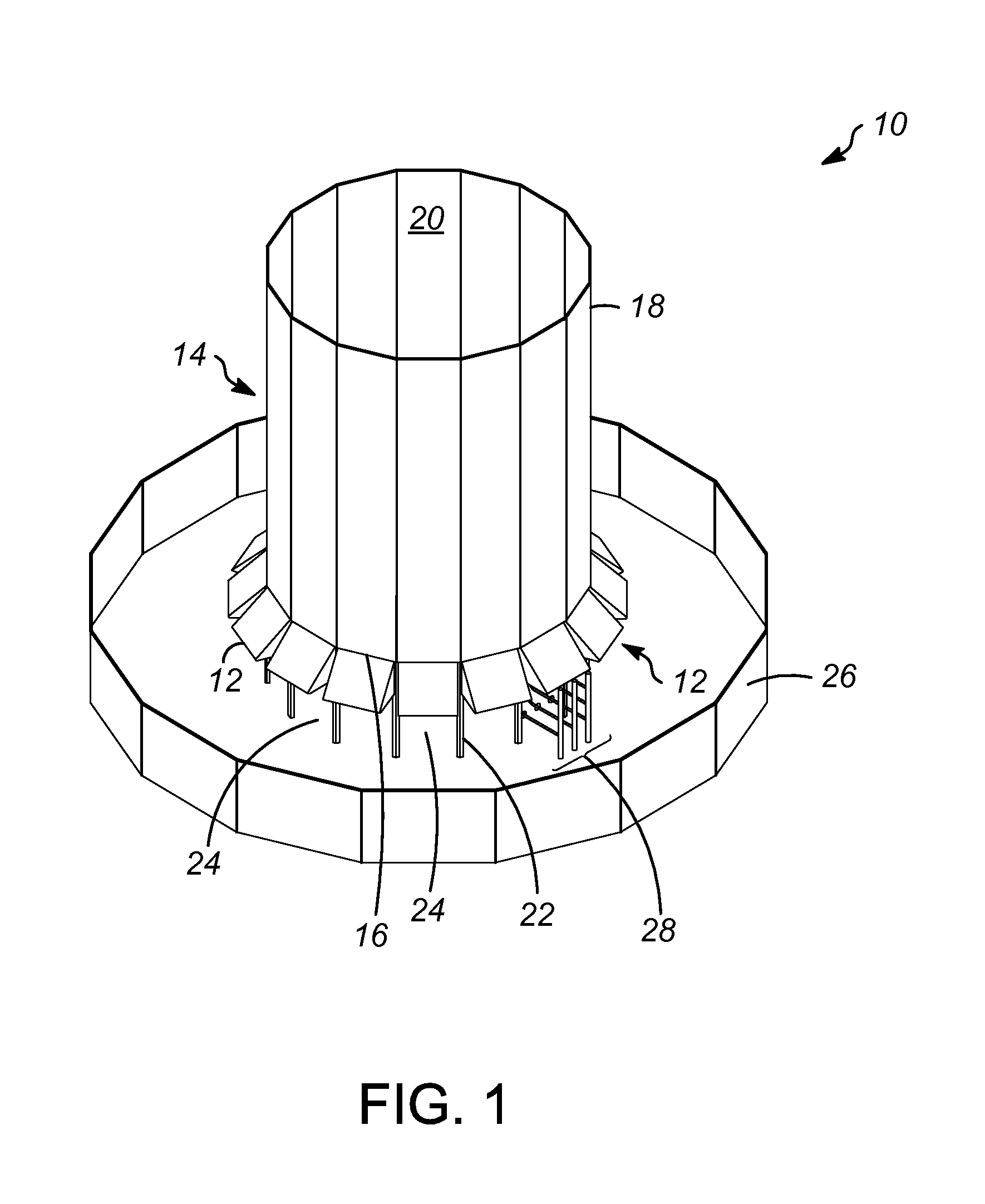

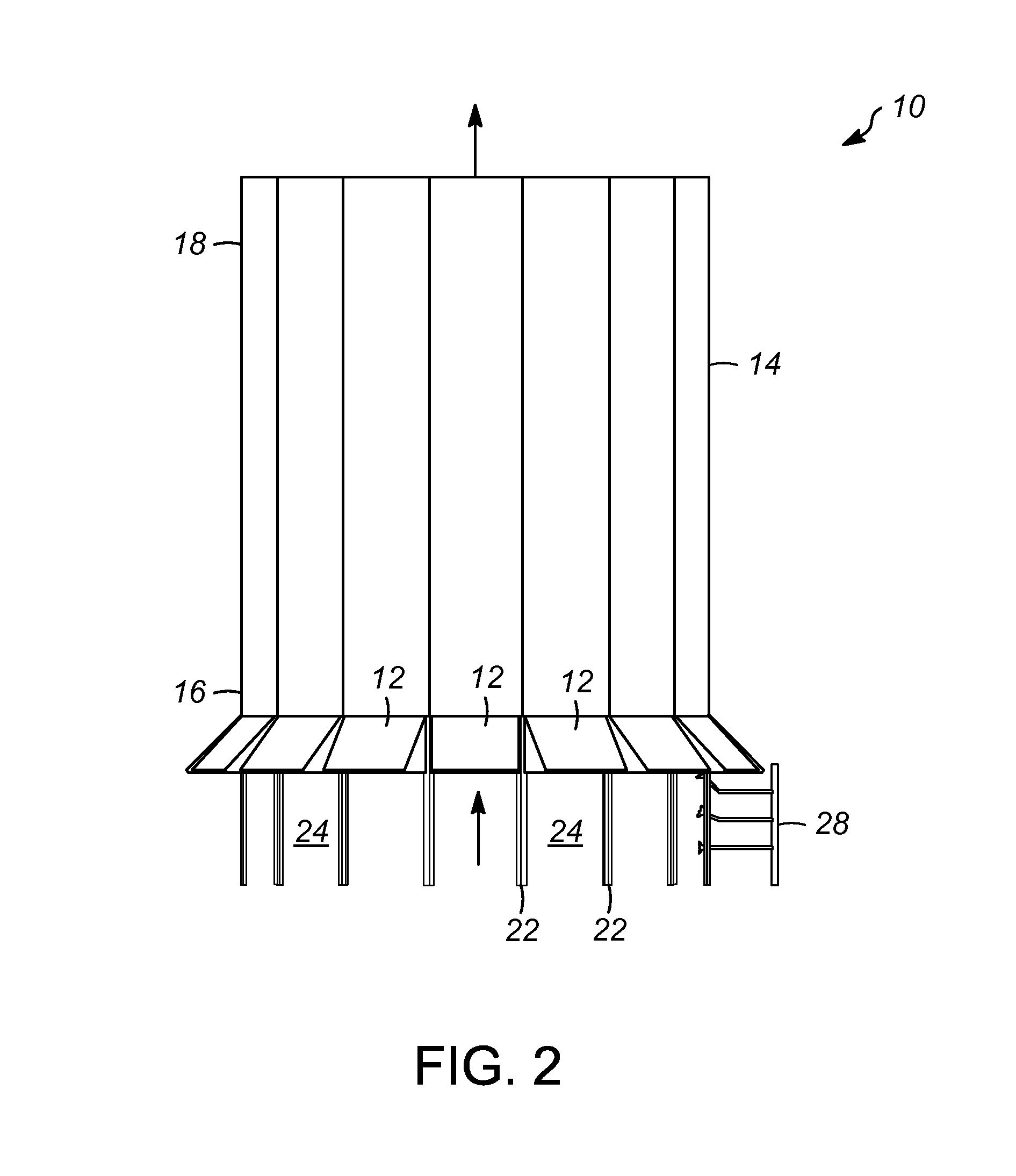

[0039]A first embodiment of the invention is an enclosed flare stack having a flow path for flaring waste gas, the stack comprising an enclosure assembly having a bottom portion with at least one expanded air entry and an upper portion through which the flared waste gas escapes, the expanded air entry comprising at least one upper panel having a predetermined angle with respect to the upper portion of the enclosure assembly; and a flare window adjacent to the expanded air entry of the enclosure assembly. An embodiment of the invention is one, any or all of prior embodiments in this paragraph up through the first embodiment in this paragraph further comprising a radiation fence that completely surrounds and circumnavigates the flare stack. An embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com