Patents

Literature

257 results about "Shield tunnelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tunnelling shield is a protective structure used during the excavation of large, man-made tunnels. When excavating through ground that is soft, liquid, or otherwise unstable, there is a health and safety hazard to workers and the project itself from falling materials and/or a cave-in.

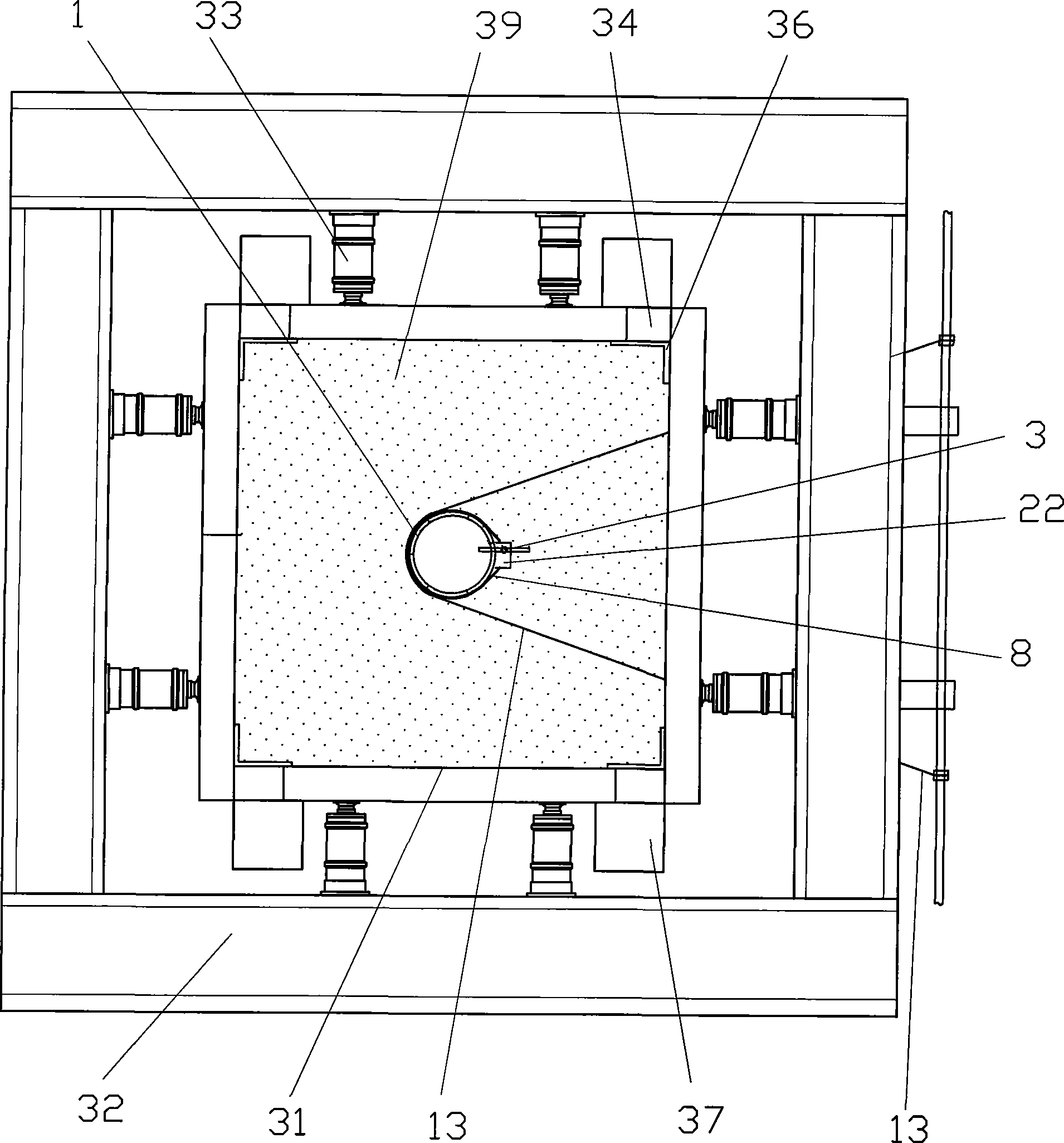

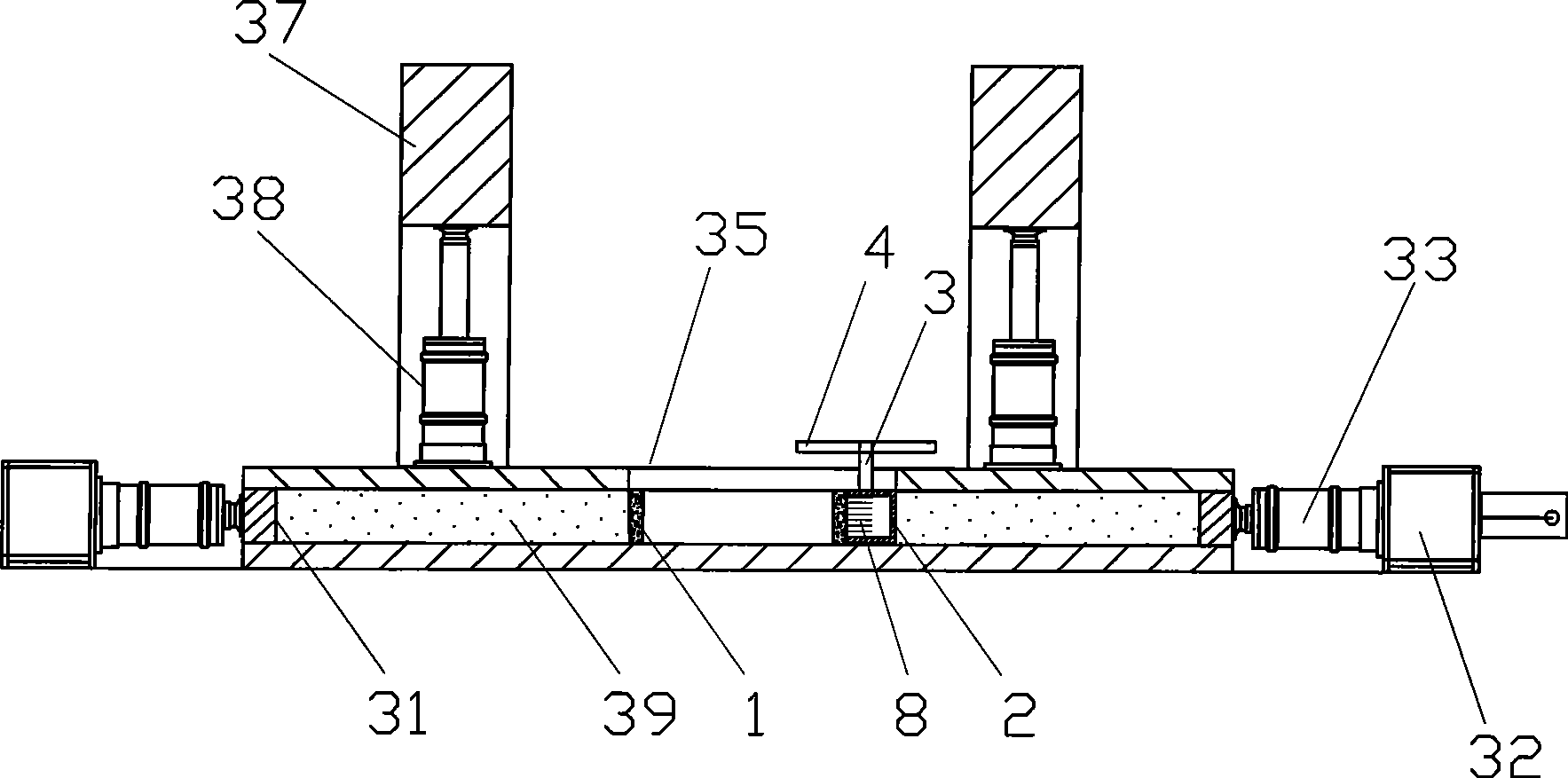

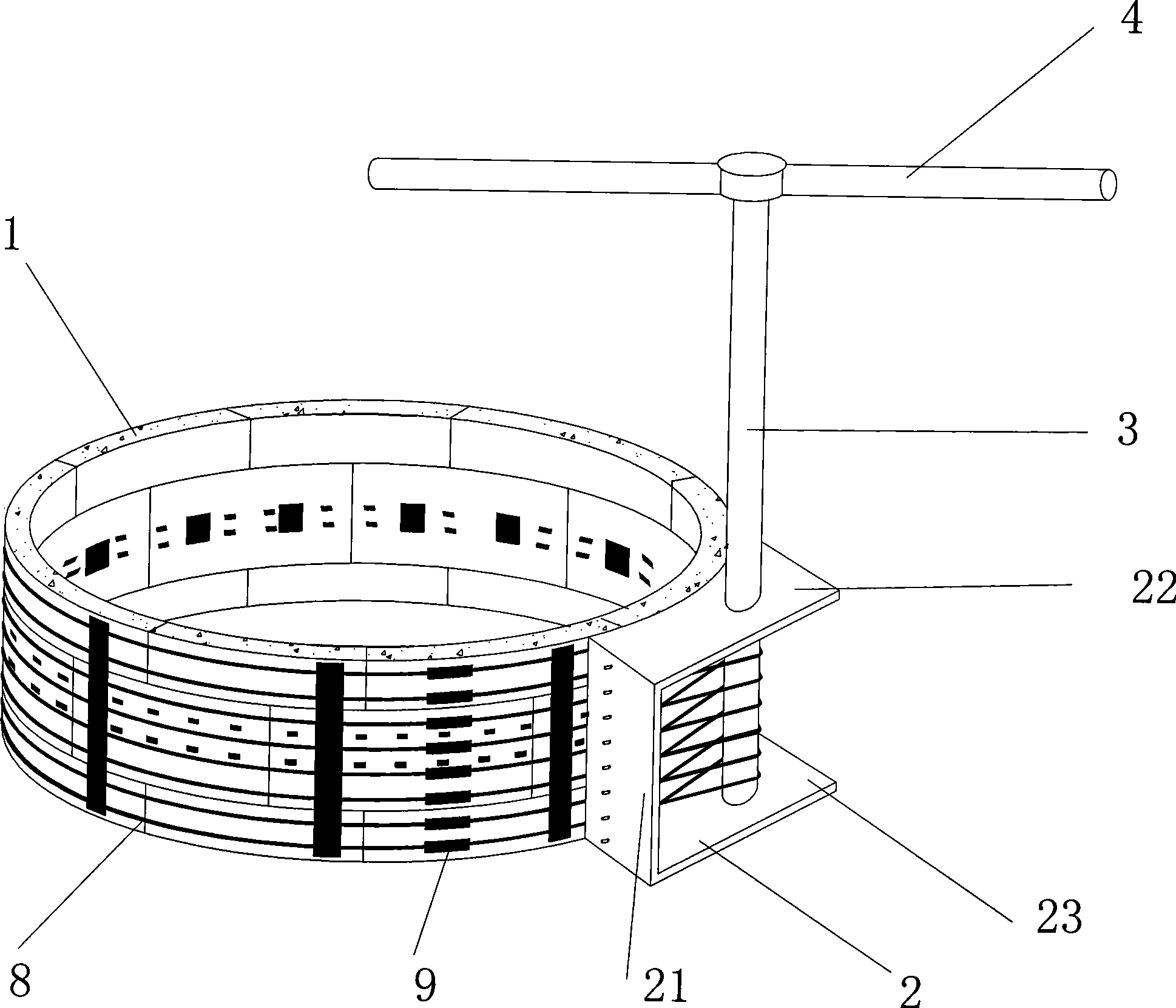

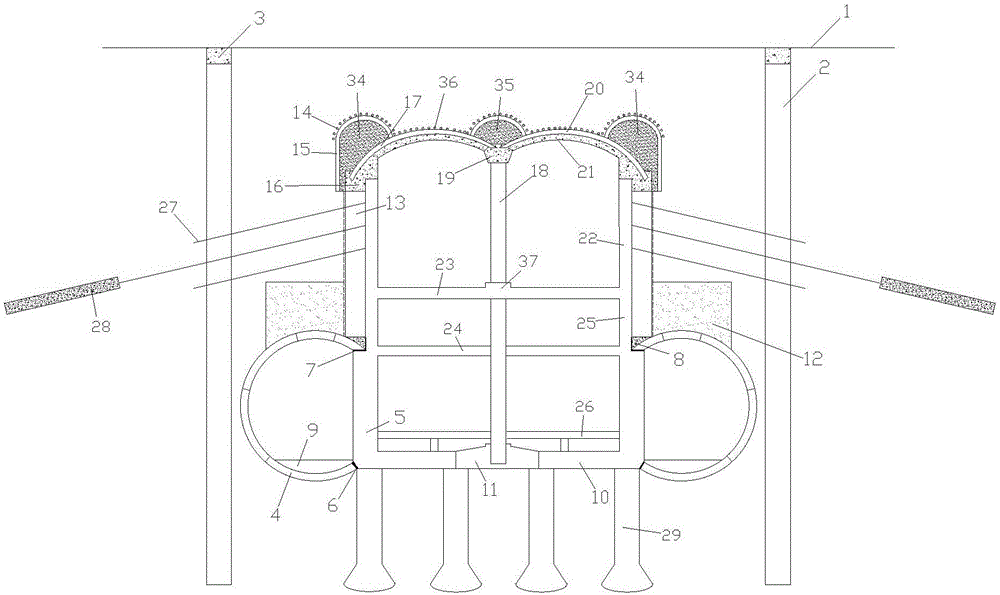

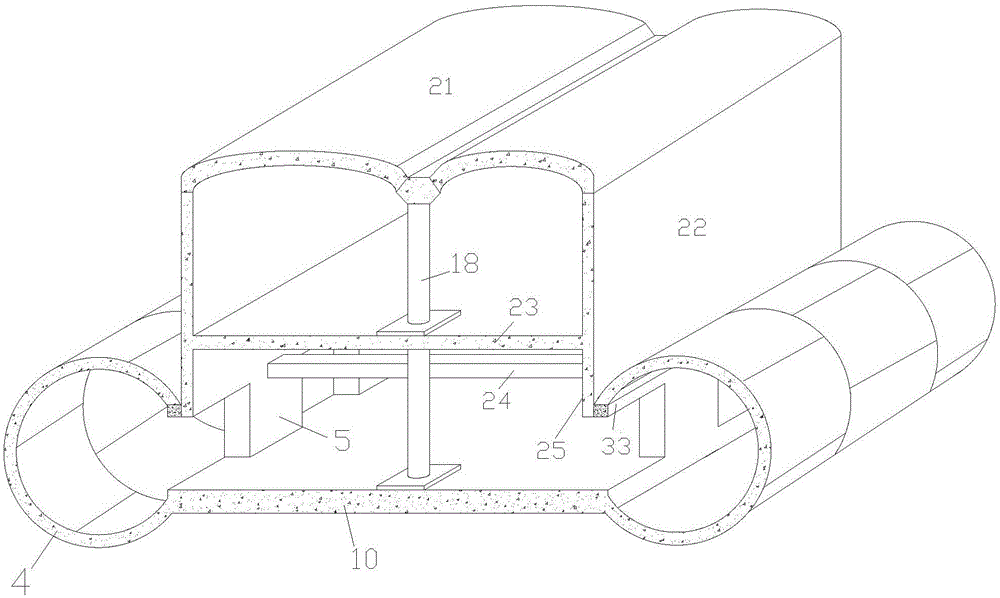

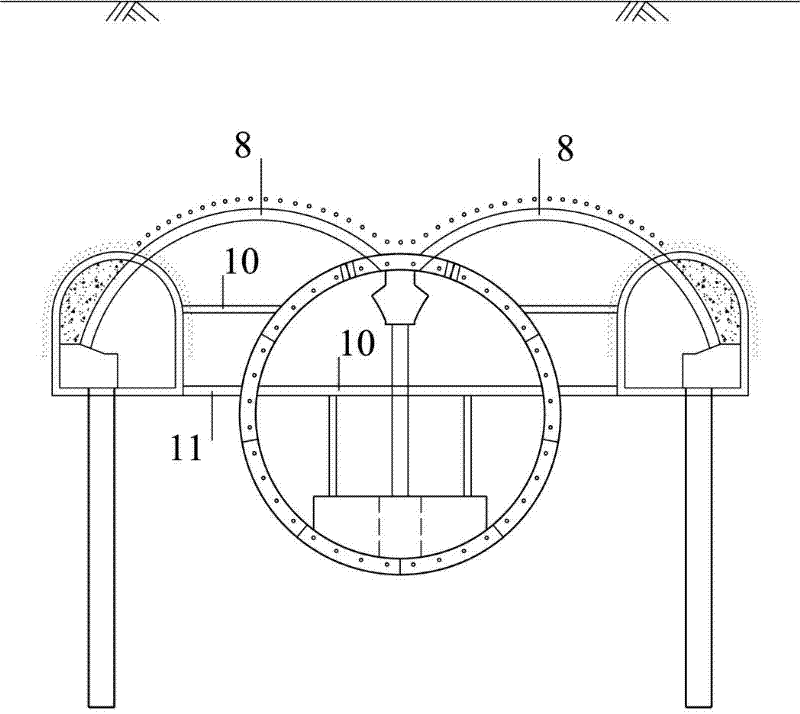

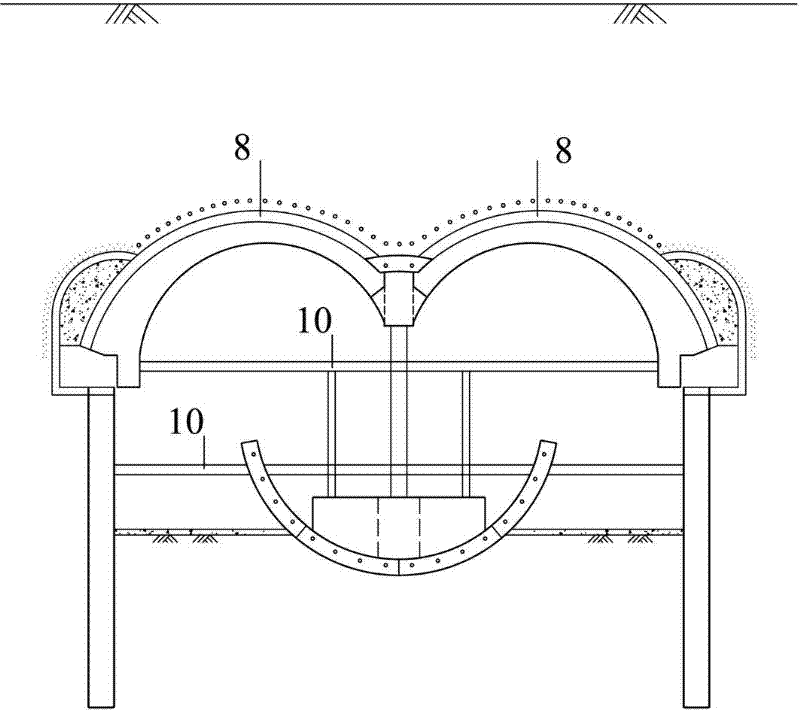

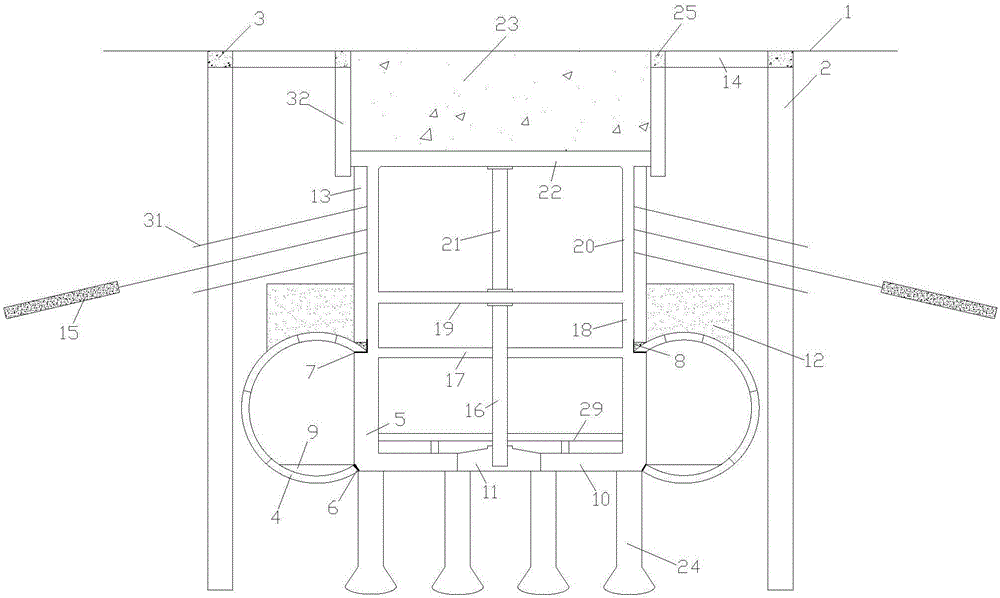

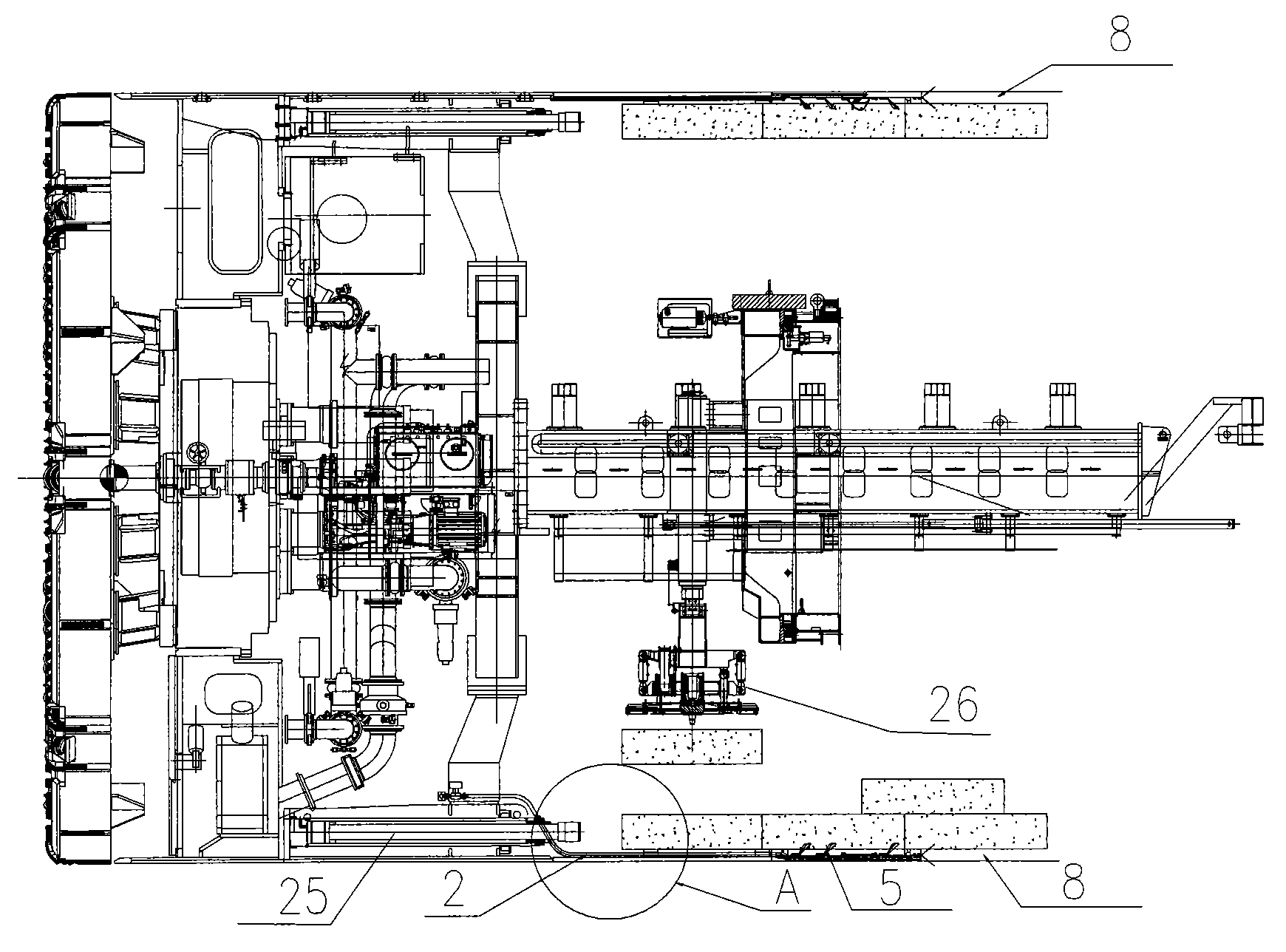

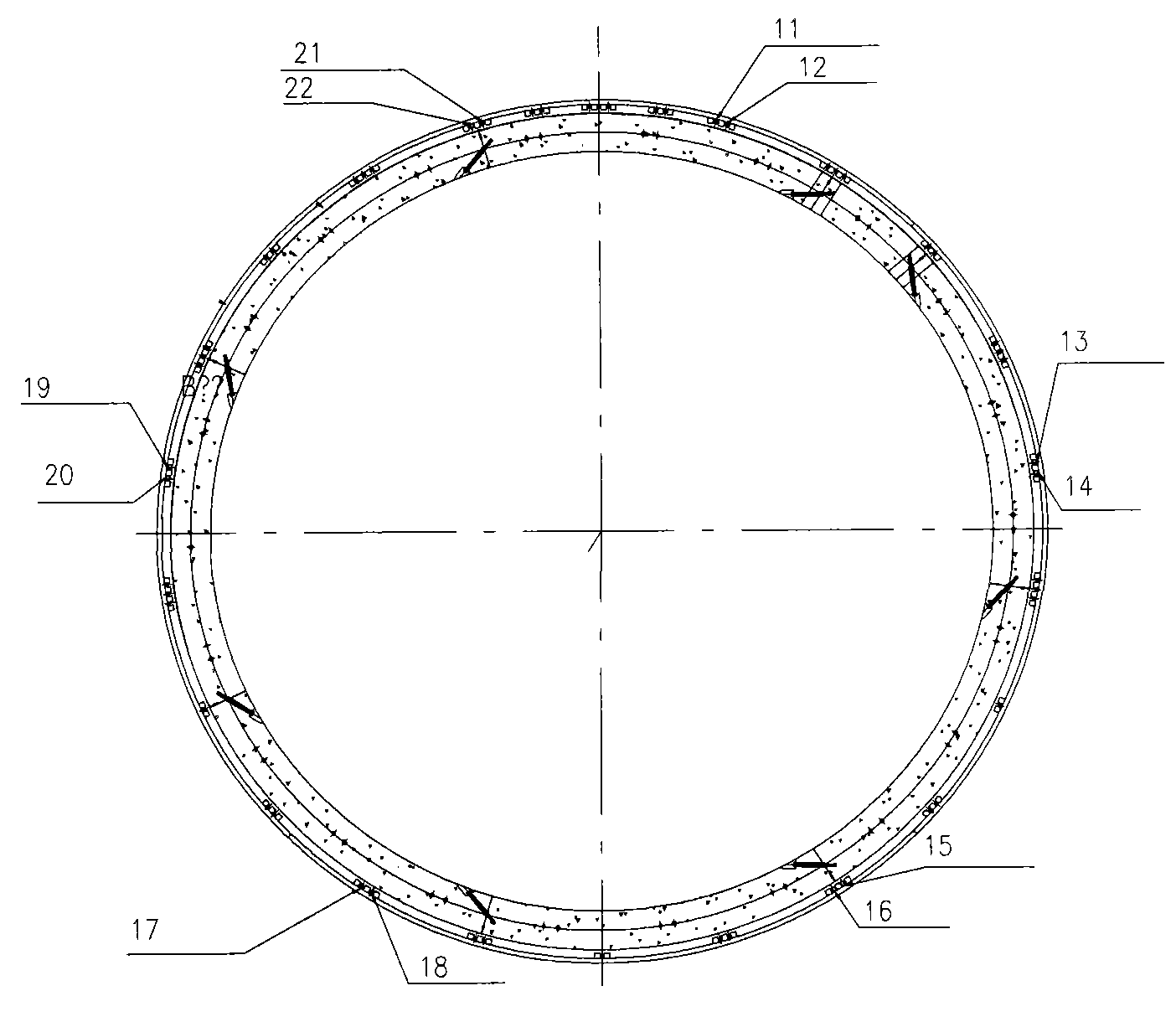

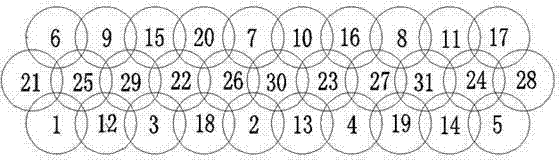

Comprehensive test system of shield tunnel construction model

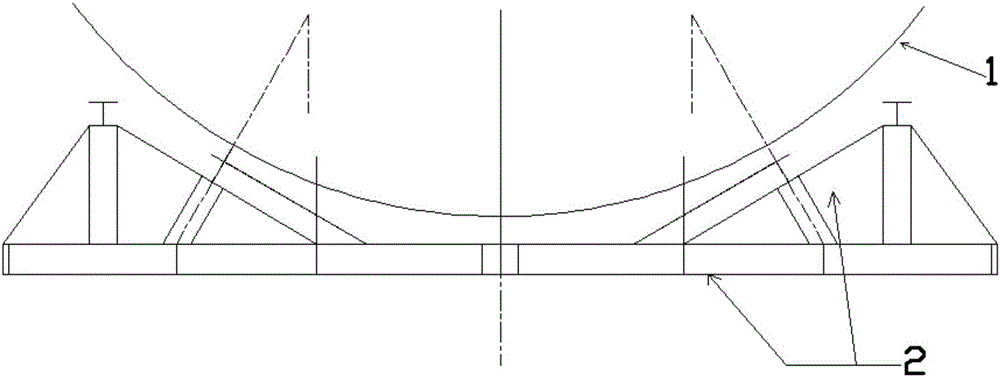

InactiveCN101435746ARealistic simulation of formation pressureThe test data is accurateForce measurementStructural/machines measurementEngineeringShield tunnelling

The invention provides a comprehensive testing system for a shield tunnel structural model, which comprises a soil horizon simulating and soil pressure loading device and a tunnel structural model; the soil horizon simulating and soil pressure loading device is a simulated soil body cavity enclosed by steel plates; a horizontal reaction frame is arranged outside the soil body cavity; a horizontal soil pressure jack is connected between each edge of the reaction frame and the soil body cavity; the tunnel structural model is attached with a uniform water pressure loading device and a non-uniform water pressure loading device, and is axially and vertically arranged in the center of the soil body cavity; simulation testing soil is filled between the tunnel structural model and the soil body cavity; the upper part of the soil body cavity is covered by a steel cover board; a vertical reaction portal frame is arranged above the soil body cavity; and a vertical soil pressure jack is connected between the lower part of a girder of the vertical reaction portal frame and the steel cover board. The system can simulate interactions between tunnel structures in different forms of fractures with the stratum under different stratigraphic and hydrologic conditions, and more truly simulate the environment conditions of the tunnel structures with more accurate and reliable test data, thereby providing more reliable safeguard for shield tunnel constructions.

Owner:SOUTHWEST JIAOTONG UNIV

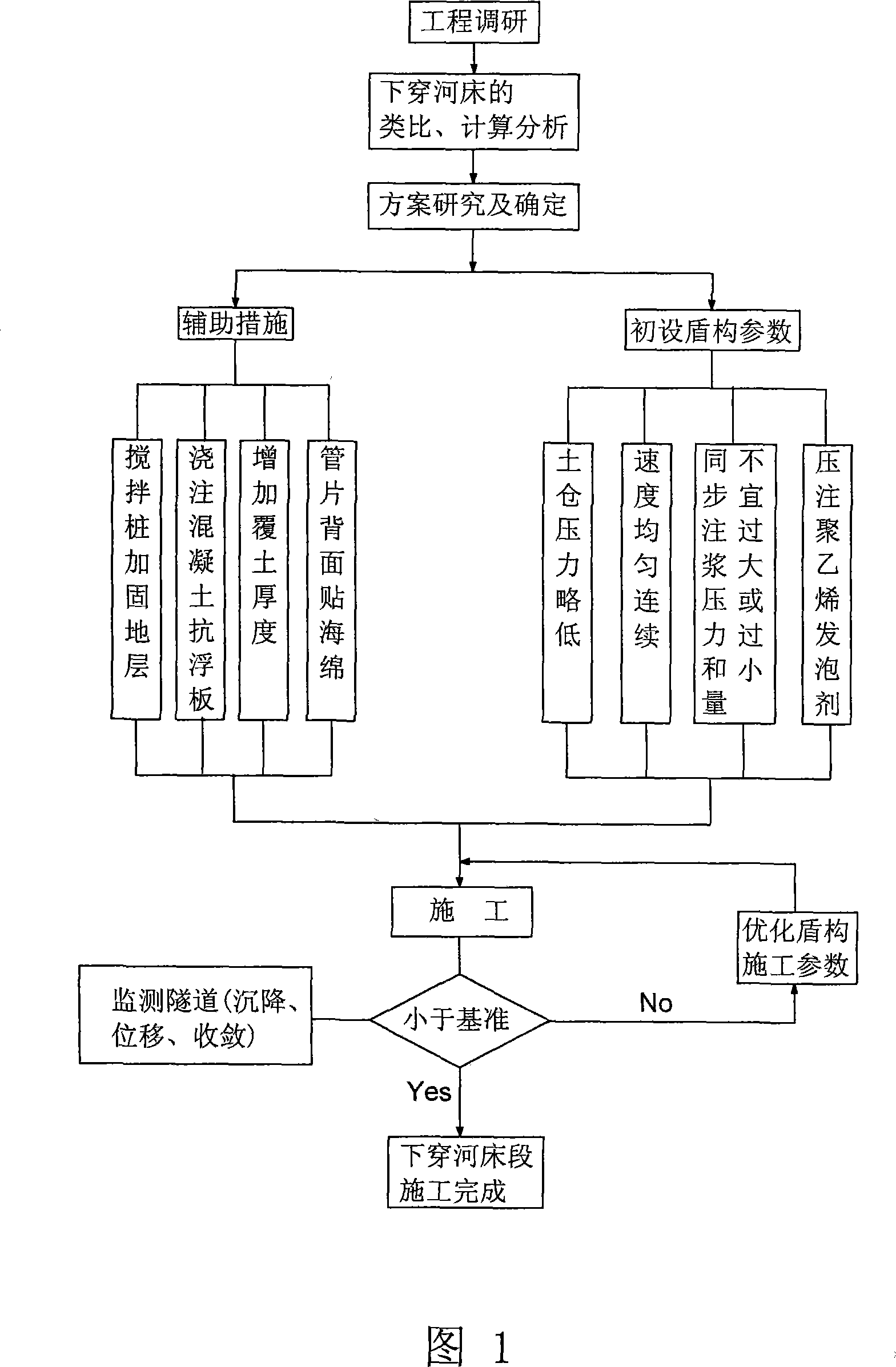

Construction method for shallow soil-covered river bed under shield tunnel

The construction process for shielded tunnel to penetrate through river bed with shallow covered soil layer includes the following steps: engineering investigation, river bed analogy, calculation and analysis, research and determination of technological scheme, determining auxiliary measures and setting the initial shielding parameters, river bed penetrating construction, etc. The auxiliary measures include foundation consolidation, setting anti-floating plate, surface blasting weight, etc. The initial shielding parameters include earth pressure, earth output amount, propulsion speed, grouting amount, etc. During the construction, one computerized real-time monitoring system is adopted for comprehensive monitoring on tunnel sedimentation, displacement and other conditions. The construction process can ensure safety and avoid water inrush, collapse and other accidents.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

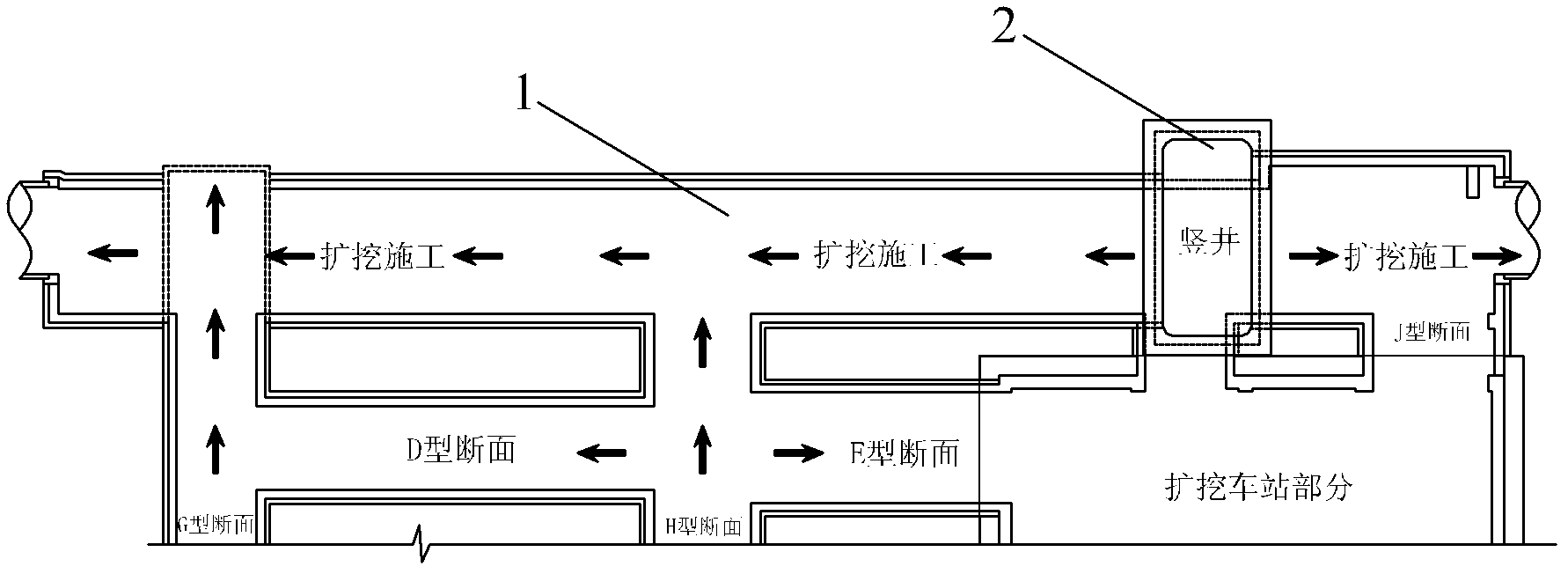

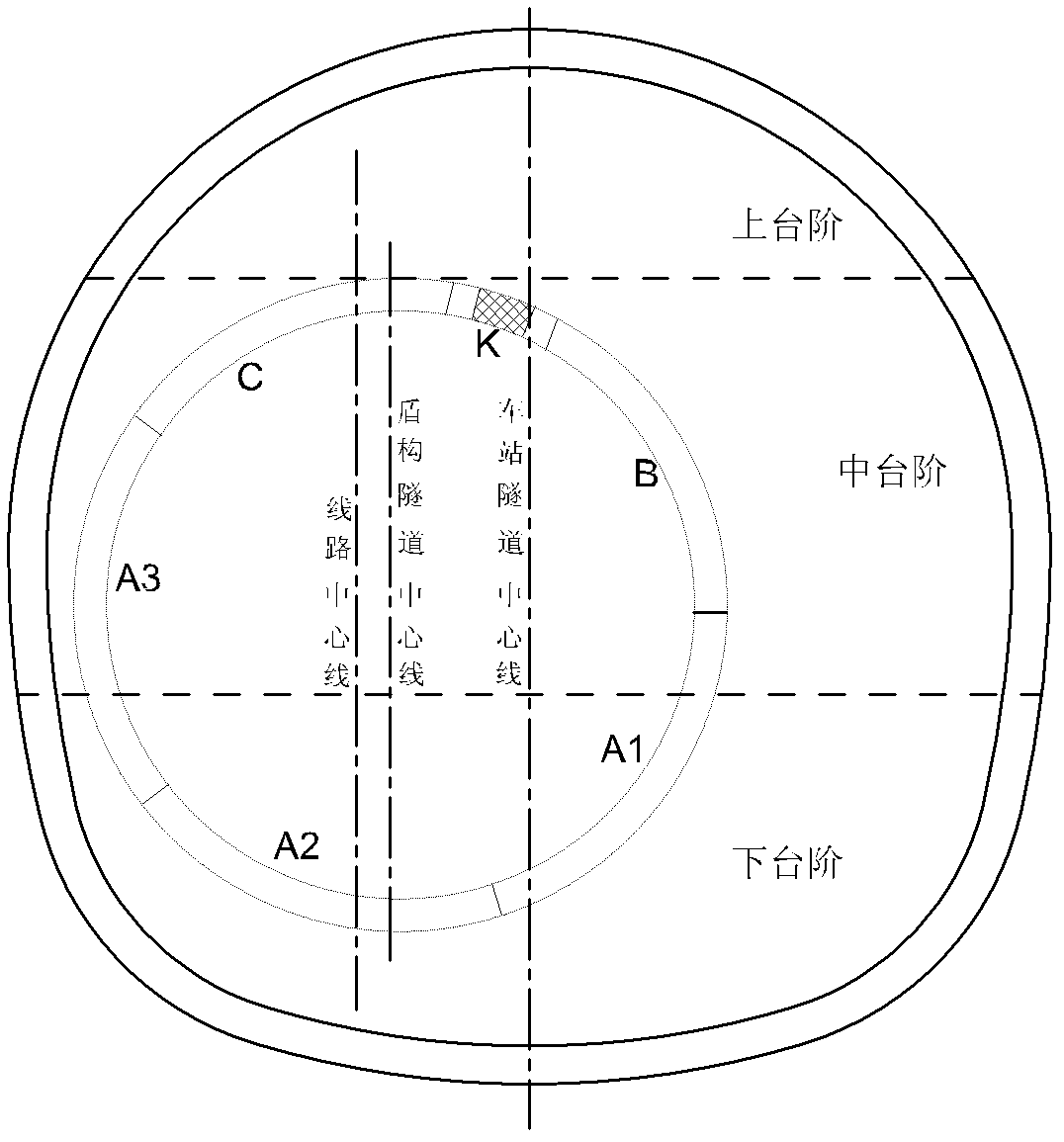

Underground excavation construction method for expanded excavation of station on basis of metro regional shield tunnel

InactiveCN105041349AReduce non-propulsion workImprove construction efficiencyUnderground chambersTunnel liningSlurry wallMetro station

The invention relates to an underground excavation construction method for expanded excavation of a station on the basis of a metro regional shield tunnel. The structural form of the station formed through expanded excavation is a simple support framework wall column type double-layer metro station; piles in a row and a water stop heavy curtain or an underground continuous wall are used for blocking soil and water, and the lateral deformation of soil bodies is resisted; soil bodies between openings of parallel shield tunnel duct pieces are excavated, and a transverse passage is constructed; uplift piles, wall columns, a bottom plate, a middle upright post foundation and transverse support beams arranged between the wall columns are constructed in the transverse passage; the bottom plate is connected with the bottom of each wall column; the soil body above the tunnel is subjected to grouting reinforcement; an underground excavation reverse operation method is adopted for constructing the station main body structure; the station main body can be entered through a vertical shaft or the transverse passage built at an entrance and exit; and a small guide holes and the station top structure are constructed. The problem of low use efficiency of shield equipment is solved. The method has the advantages that huge economic benefits, social benefits and environmental benefits are brought; and important engineering application values and development prospects are realized.

Owner:BEIJING UNIV OF TECH

Shield method tunnel synchronous grouting slurry applied to compound stratum with upper soft part and lower hard part

ActiveCN101654356AImprove consistencyNot easy to segregateSolid waste managementUnderground chambersSlurryEarth surface

The invention discloses shield method tunnel synchronous grouting slurry which belongs to the technical field of shield tunnel engineering. The shield method tunnel synchronous grouting slurry consists of mortar and water glass, wherein the weight ratio of the mortar to the water glass is 1:4, and the weigh ratio of various raw materials in the mortar of cement to sand to fly ash to swell soil towater is 1:4.8-5.71:2.93-3.31:0.25-0.27:3.13-3.30. The shield method tunnel synchronous grouting slurry has good consistency and insusceptible separation, can effectively prevent the phenomena of slurry separation and grouting pipe blockage, can timely and effectively fill a building gap between a digging surface and the periphery of a pipe piece and control the ground surface settlement within 5to 7mm.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Method for building subway station by expansively digging large-diameter shield tunnel

InactiveCN102392648AResolve time conflictsShorten the construction periodTunnelsArchitectural engineeringSubway station

The invention relates to a brand new method for building subway station by expansively digging large-diameter shield tunnel; namely, based on the large-diameter shield tunnel, the subway station is dug and built by shallow bedding and undercutting method. The invention mainly comprises the following steps: (1) assembling the large-diameter shield segments for the station in the range of the station; (2) building bottom girder, rectangular column and top girder in the shield tunnel, and establishing a temporary support; (3) symmetrically digging first supporting protection of the platform tunnel by the shallow bedding and undercutting method; (4) symmetrically removing the shield segments, the temporary support and other temporary structures; (5) constructing the second lining and platform panel of the platform tunnel. The invention gives full play of the advantages of the shield method and the shallow bedding and undercutting method, which can largely reduce the influence to the surrounding environment and adjacent building structures under complex construction environment of city; the construction period is shortened and the project cost is decreased.

Owner:BEIJING RAIL TRANSIT CONSTR MANAGEMENT +6

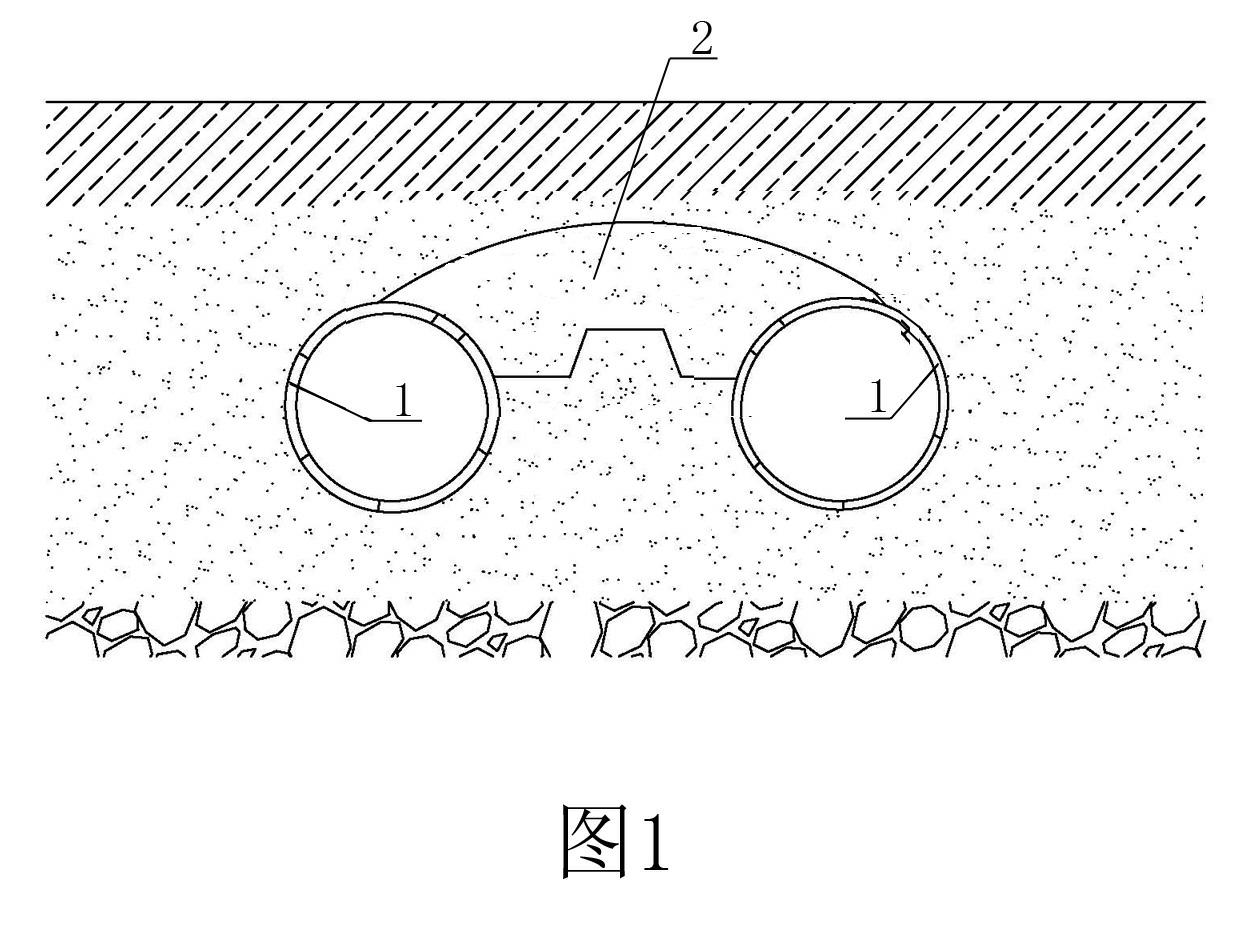

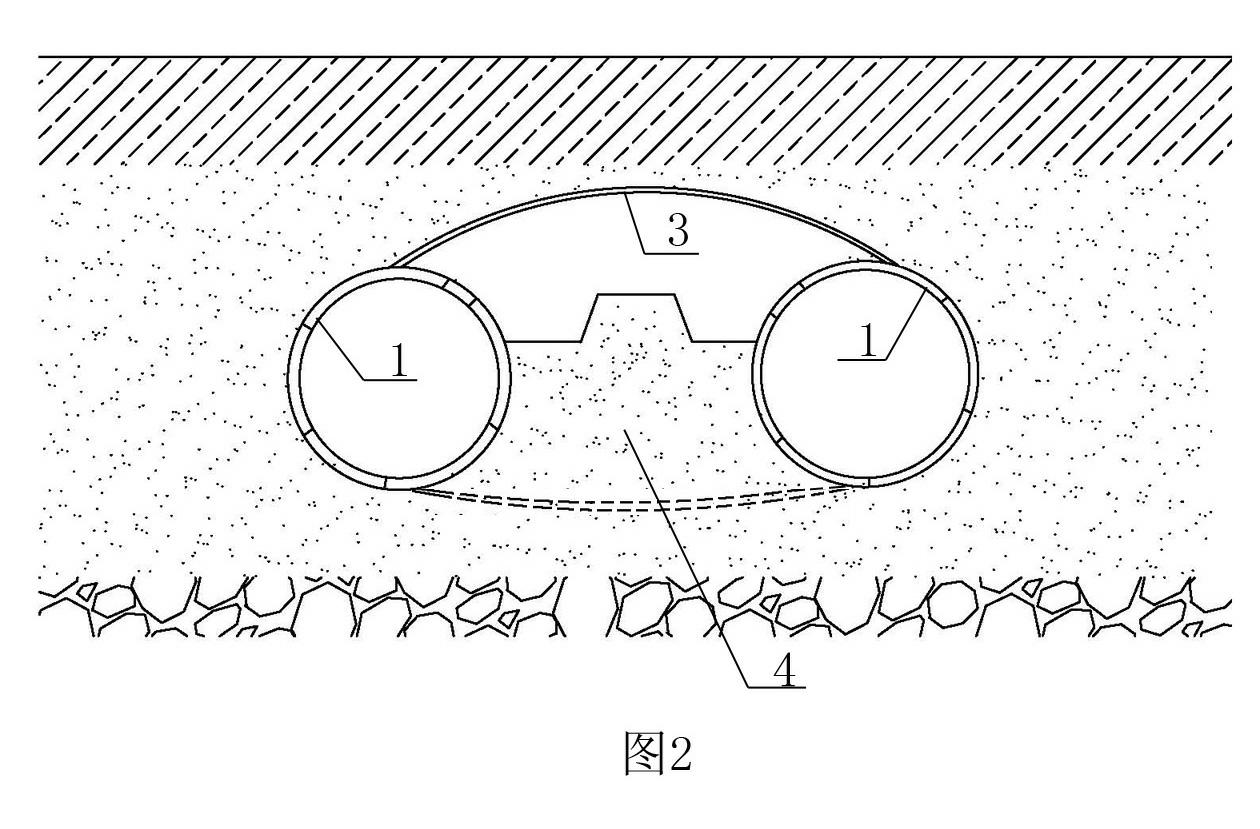

Method for constructing underground space by shield-shallow buried covered excavation composite method

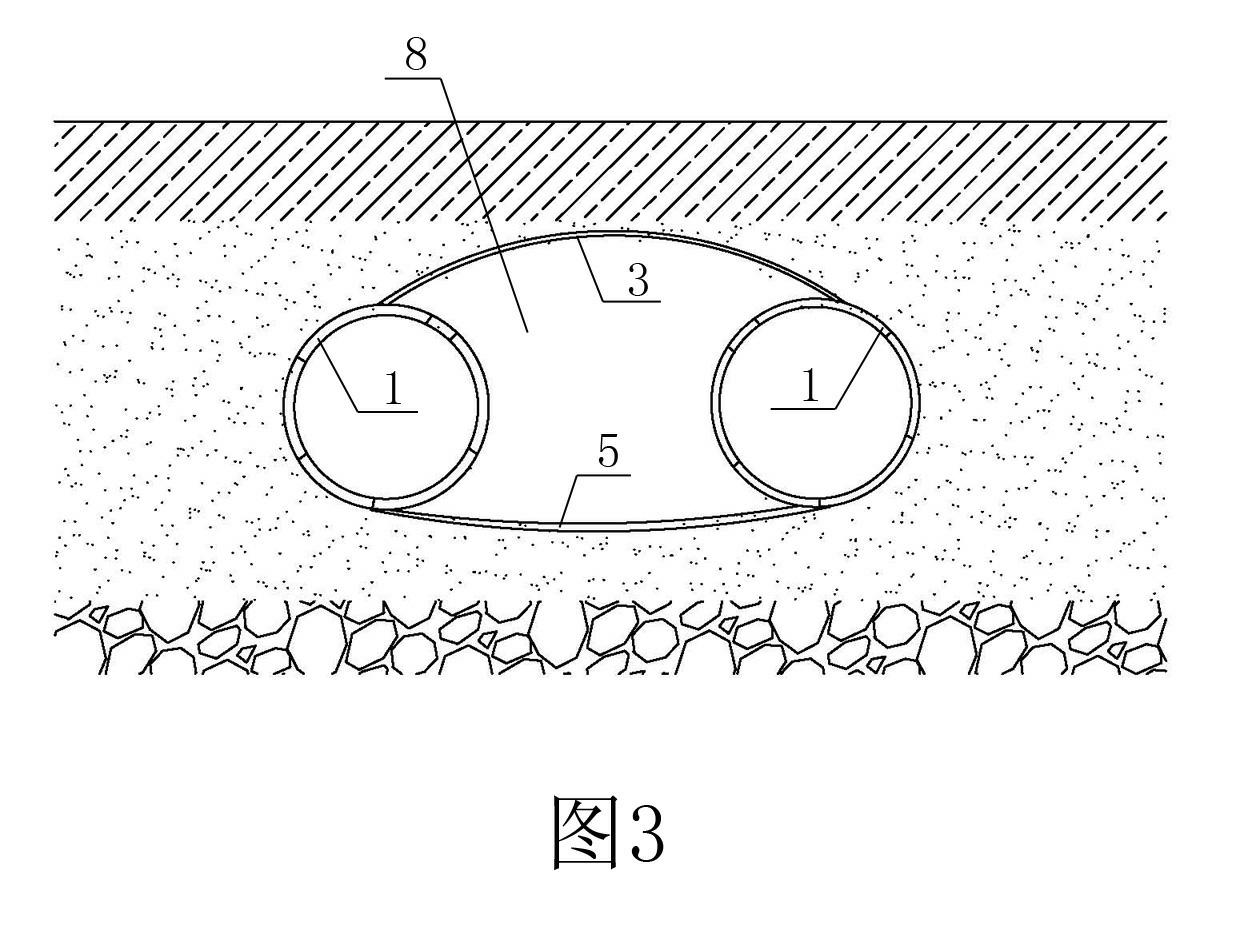

InactiveCN102094649AReduce disturbanceReduce construction riskUnderground chambersTunnel liningStructural engineeringShield tunnelling

The invention relates to a method for constructing an underground space by a shield-shallow buried covered excavation composite method, and belongs to the technical field of construction methods of the underground space. The construction method comprises the following steps of: constructing two or more shield tunnels in advance by a shield method; and excavating a soil body between the shield tunnels by a shallow buried covered excavation method. By the method, the construction of the underground space with a large cross section is safe and high-efficiency, a structure is definitely stressed, construction speed is high and construction cost is low. The method can be used for constructing large-scale underground spaces in various forms.

Owner:乐贵平 +1

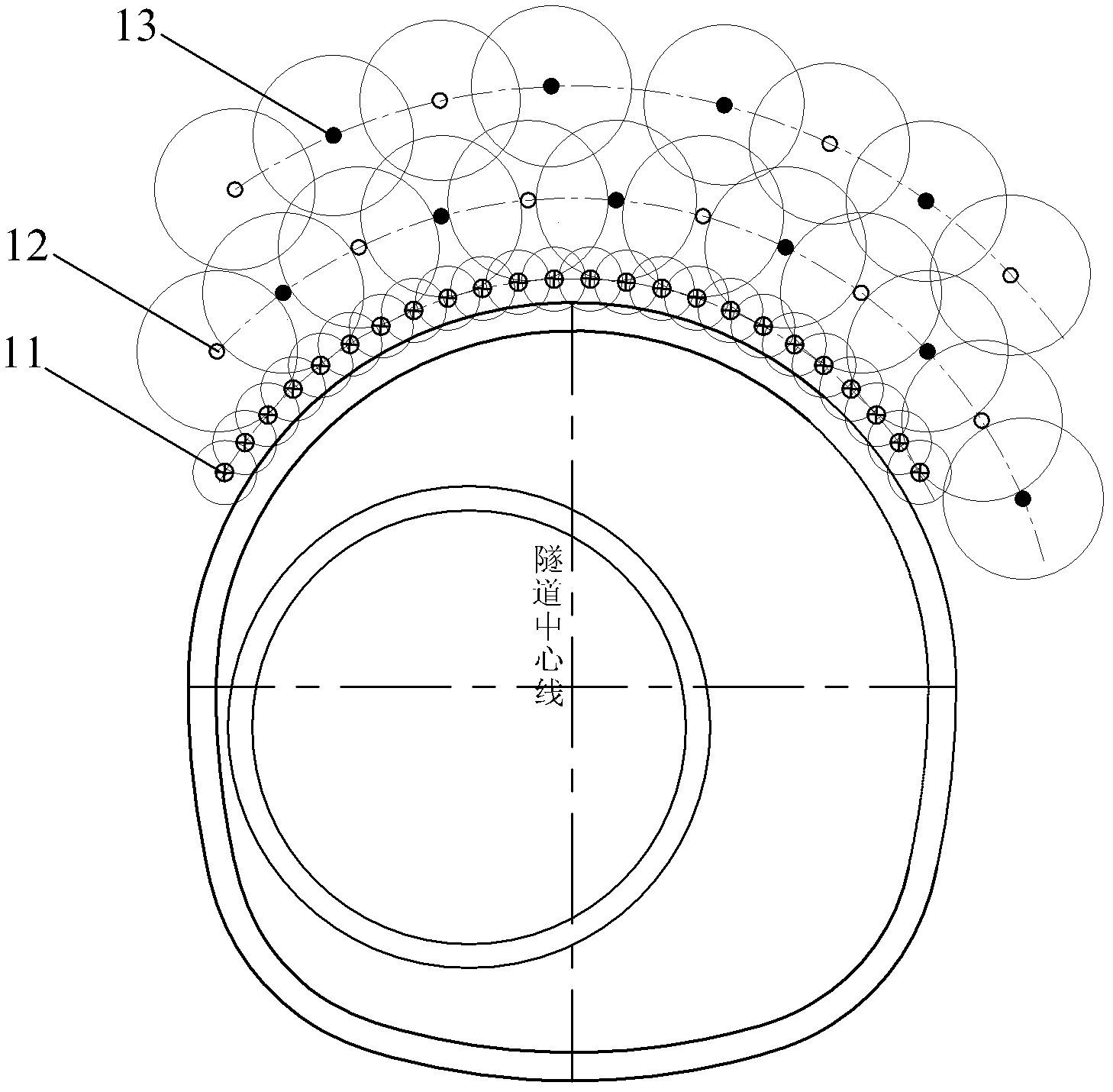

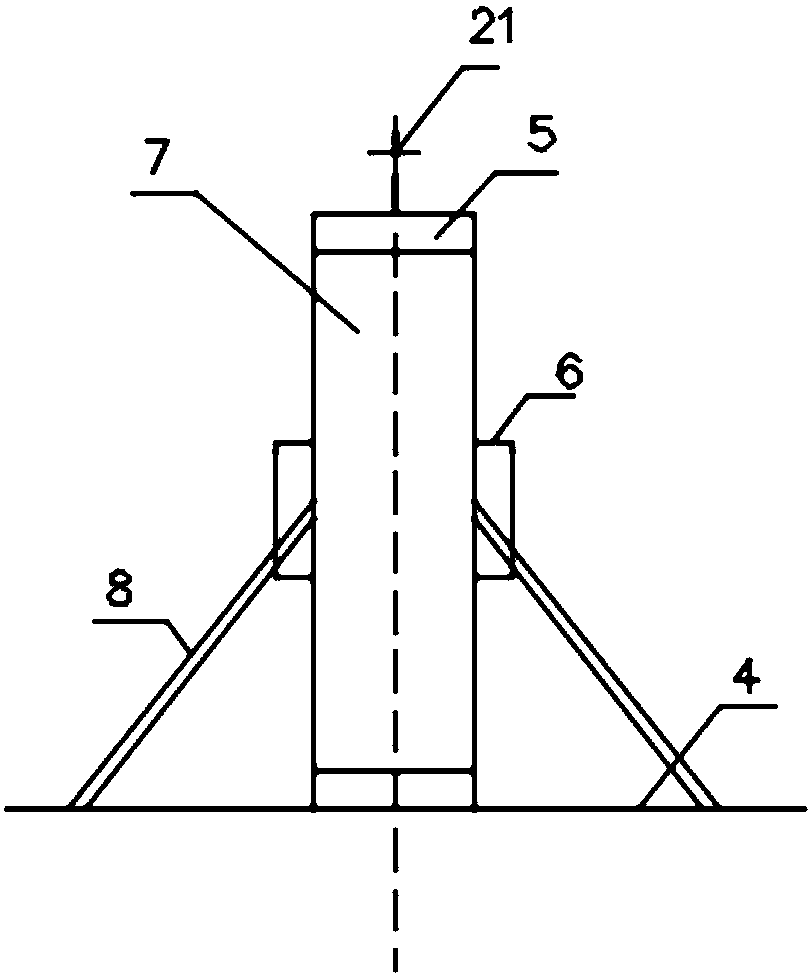

Construction structure and construction method for strengthening stratum at end of shield tunnel

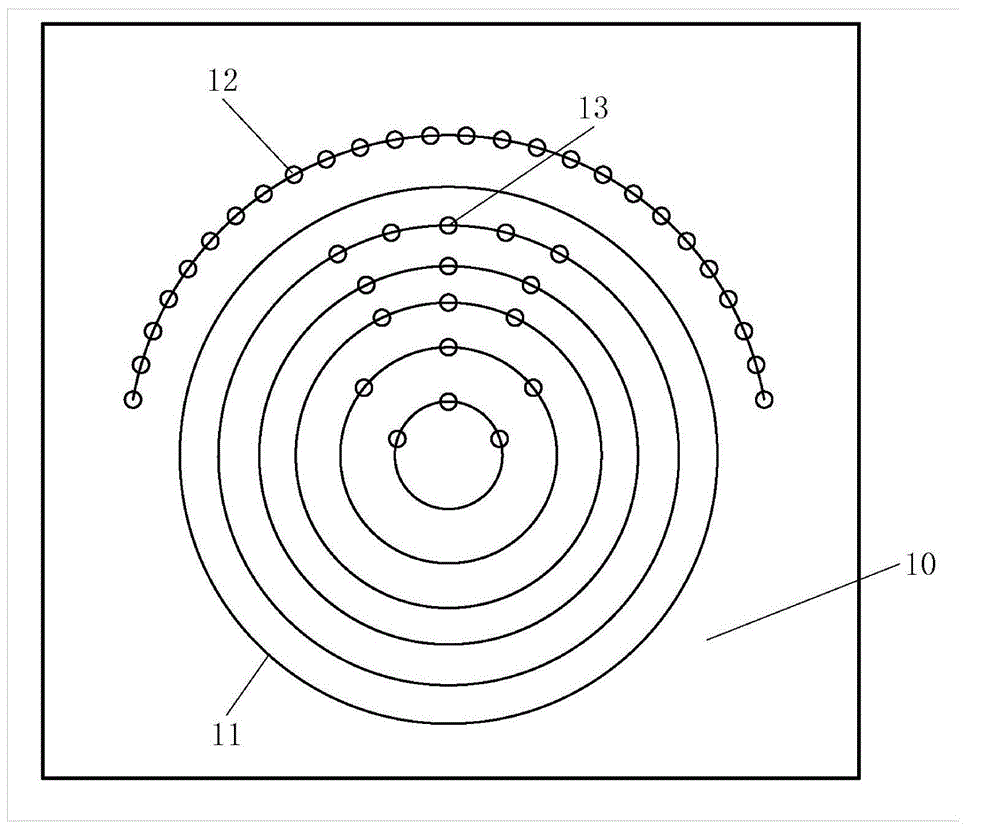

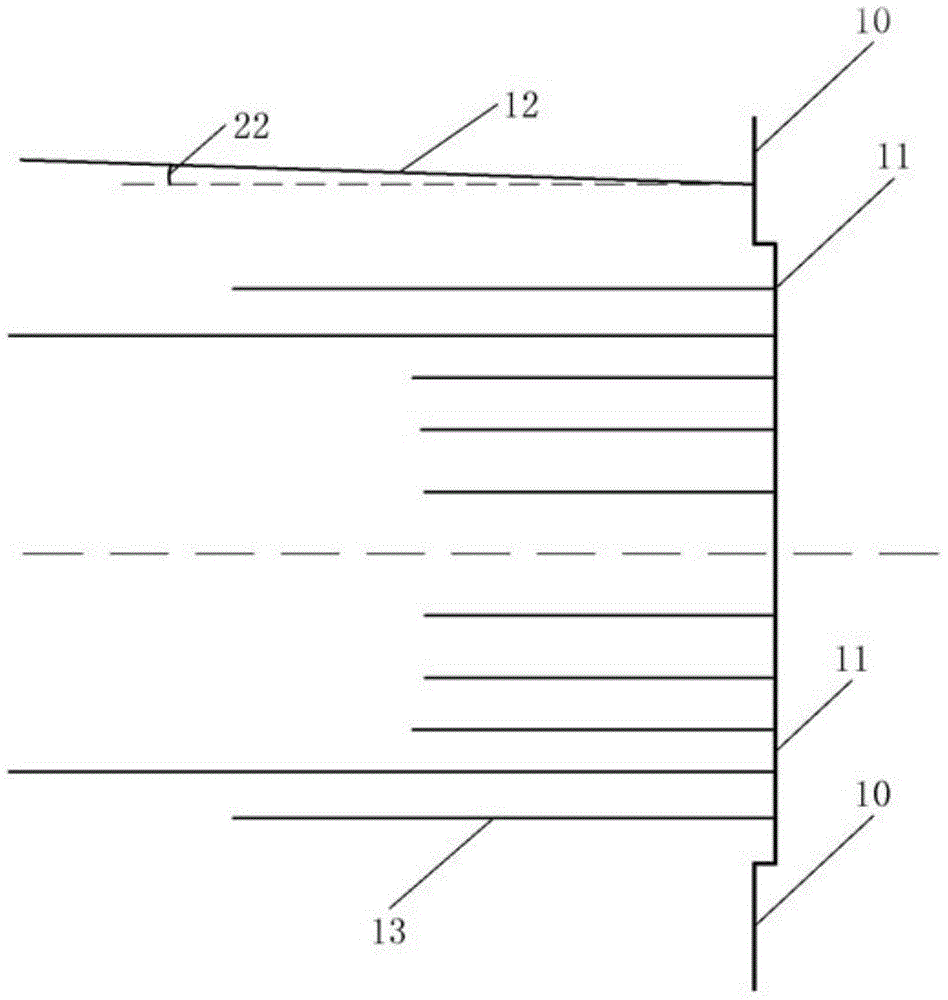

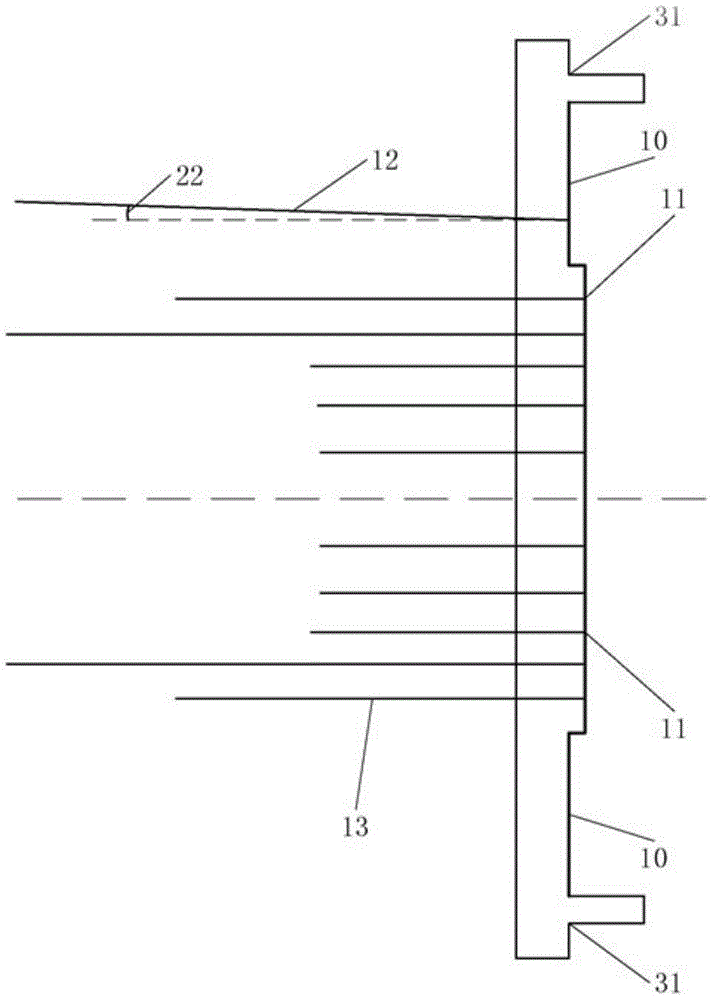

InactiveCN104405410ATo achieve reinforcementPrevent water and sand leakageUnderground chambersTunnel liningWater leakageSleeve valve

The invention provides a construction structure and a construction method for strengthening the stratum at an end of a shield tunnel. The construction structure comprises a working well face which comprises a to-be-shielded working well portal having the same radius with a shield machine, a plurality of pre-grouting long pipe-sheds arranged above the to-be-shielded working well portal perpendicularly to the to-be-shielded working well portal, and a plurality of horizontal grouting pipes arranged in the to-be-shielded working well portal perpendicularly to the to-be-shielded working well portal; a PVC sleeve valve pipe with a grouting hole is arranged in each horizontal grouting pipe. The plurality of pre-grouting long pipe-sheds and the plurality of horizontal grouting pipes are arranged above and inside the working well portal to form a cup shape together to strength and protect the soil above and inside the working area of the stratum at the end of the shield tunnel, and therefore, the case that the construction quality is affected by water leakage and sand leakage due to insecure soil above and inside the working area in the working process is prevented, and therefore, the shield is capable of going in and out the portal safely.

Owner:HAINAN UNIVERSITY

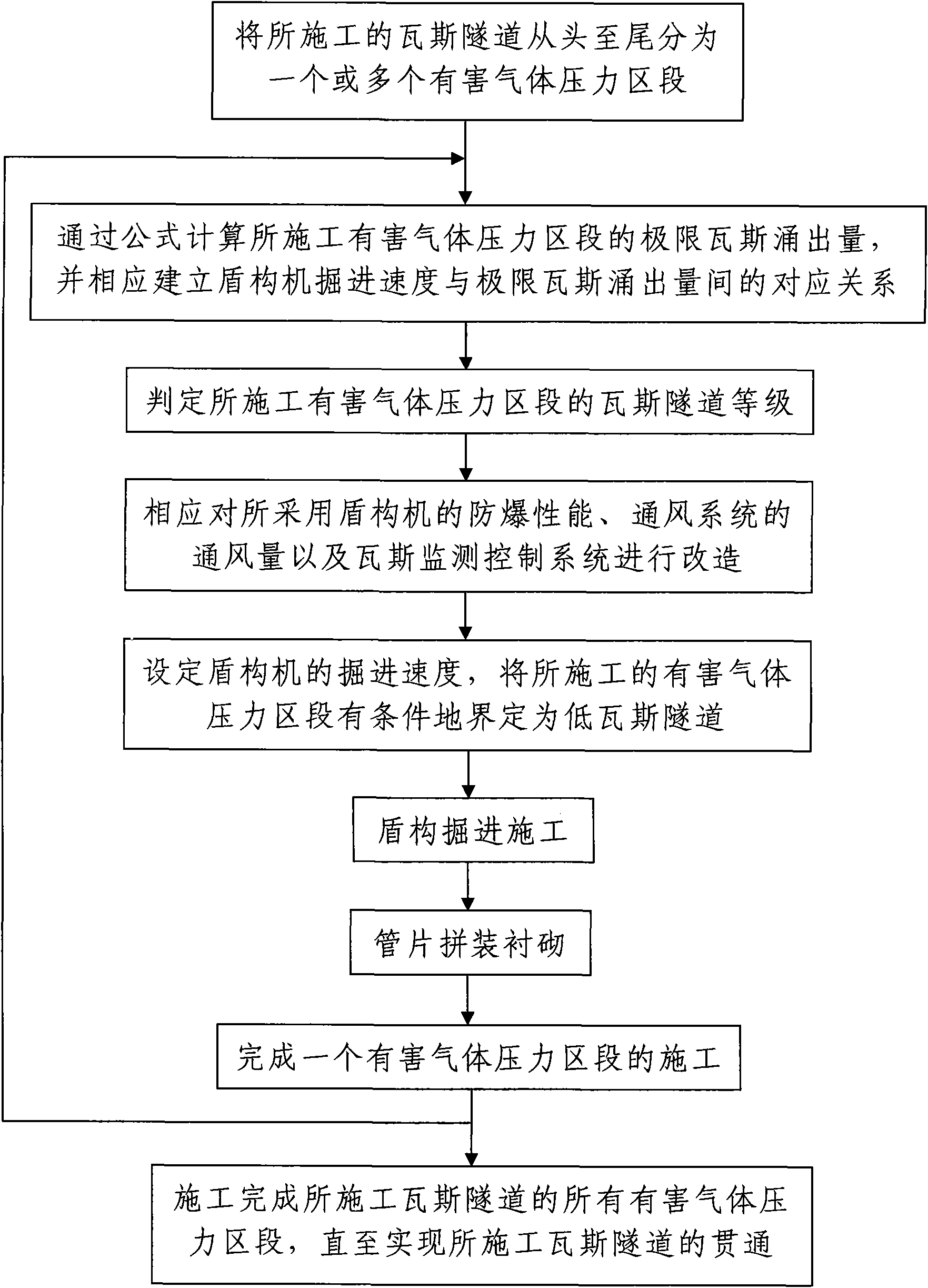

Subway shield gas tunnel construction method

ActiveCN101571044AIngenious designReasonable designMining devicesUnderground chambersExplosion protectionControl system

The invention discloses a subway shield gas tunnel construction method, which comprises the following steps: 1, dividing a gas tunnel to be constructed into one or more harmful gas pressure sections from end to end; 2, respectively constructing the harmful gas pressure sections in turn according to the construction work stages of the gas tunnel to be constructed, wherein construction processes of one harmful gas pressure section are as follows: calculating limit gas emission and correspondingly judging the level of the gas tunnel, and modifying the explosion protection performance of a shield machine, the ventilation quantity of a ventilation system and a gas monitoring control system; setting the driving speed of the shield machine; performing shield driving construction; and performing duct piece assembly and lining construction; and 3, completing constructing all the harmful gas pressure sections of the gas tunnel to be constructed until realizing the run-through of the gas tunnel to be constructed. The method has the advantages of skillful and reasonable design, convenient implementation, small construction difficulty and good construction effect, and can effectively solve the problem of safe construction for running through a shield tunnel of a gas reservoir, namely a subway shield gas tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD

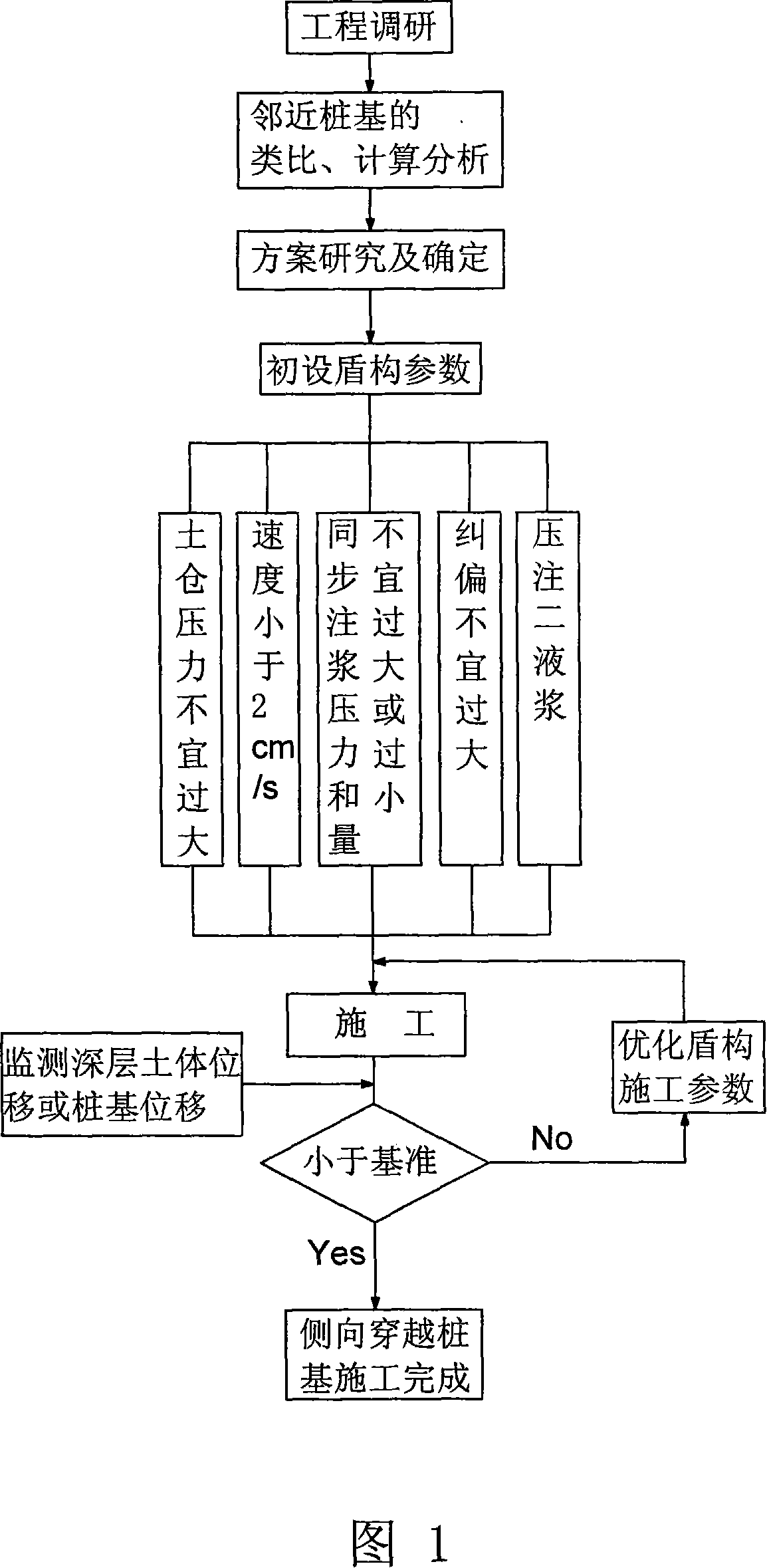

Shield tunnel lateral cross-over pile base construction method

ActiveCN101126319ASafe Approach ConstructionSmooth approach to constructionTunnelsShield tunnellingComputational analysis

The invention discloses a construction method on the side-crossing pile foundation in the shield tunnel, the main procedures comprises: the investigation and research of the project, the analogy and the computational analysis on the side-crossing pile foundation, the study and decision of the construction plan, the preliminary shield parameters for the shield construction of the side-crossing pile foundation and so on; wherein, the preliminary shield parameters mainly comprises the earth pressure, the advancing speed, the injection amount of the mortar, the rectification amount and so on; during the shield construction process of the side-crossing pile foundation, a computer is adopted to realize the real-time monitoring on the displacement of the deep soil, the displacement of the pile foundation and so on. With the method provided by the invention, the construction of the crossing pile foundation can be finished safely and smoothly without any accessory method; also, the method has no distinct influence on the existing pile foundation at the near distance and the surrounding environment.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Method for constructing subway station by enlarging and digging shield tunnel by adopting mining method

InactiveCN102322027AFacilitate reasonable connectionAvoid mutual interferenceRefuge islandsUnderground chambersSleeve valveSubway station

The invention discloses a method for constructing a subway station by enlarging and digging a shield tunnel by adopting a mining method. The method comprises the following steps of: (1) firstly advancing a platform layer tunnel passing through a station by adopting a shield machine; (2) excavating a vertical well to elevation of the platform layer tunnel of the station at one end of the station; (3) constructing along with a tunnel vault and manufacturing a pipe shed, perforating by adopting a large pipe shed advance support and grouting; (4) constructing along with the tunnel vault and manufacturing a sleeve valve pipe, and grouting for complementing and reinforcing; (5) enlarging and digging in the platform layer tunnel by adopting the mining method; (6) dismounting and recovering pipe pieces; and (7) constructing and manufacturing a concrete structure comprising a secondary lining, a platform plate and a rail head wind channel. In the invention, the shield machine participates in construction of the subway station, a cave is firstly excavated, then an underground station is enlarged, excavated and constructed by adopting the mining method, respective advantages of the shield machine and the mining method are fully played, and waste of equipment and underground space resource caused by a special large-diameter shield machine is avoided.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

Water proof method of shield tunnel adaptable for large value stratum ununiform settling or diastrophism

InactiveCN1904316ASimple structureQuality improvementUnderground chambersTunnel liningEngineeringShield tunnelling

This invention relates to the tunnel, it is concretely relate to a kind of waterproof method which is fit for the shield structure tunnel that large amount of stratum subside unevenly or a move alternatively, the shield structure tunnel of this method set up liner big deformation ring in the location around the fissure, using synthetic waterproof system which has multiple line of defence to satisfy the request that the seam doesn't leak under the working condition of the big deformation.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

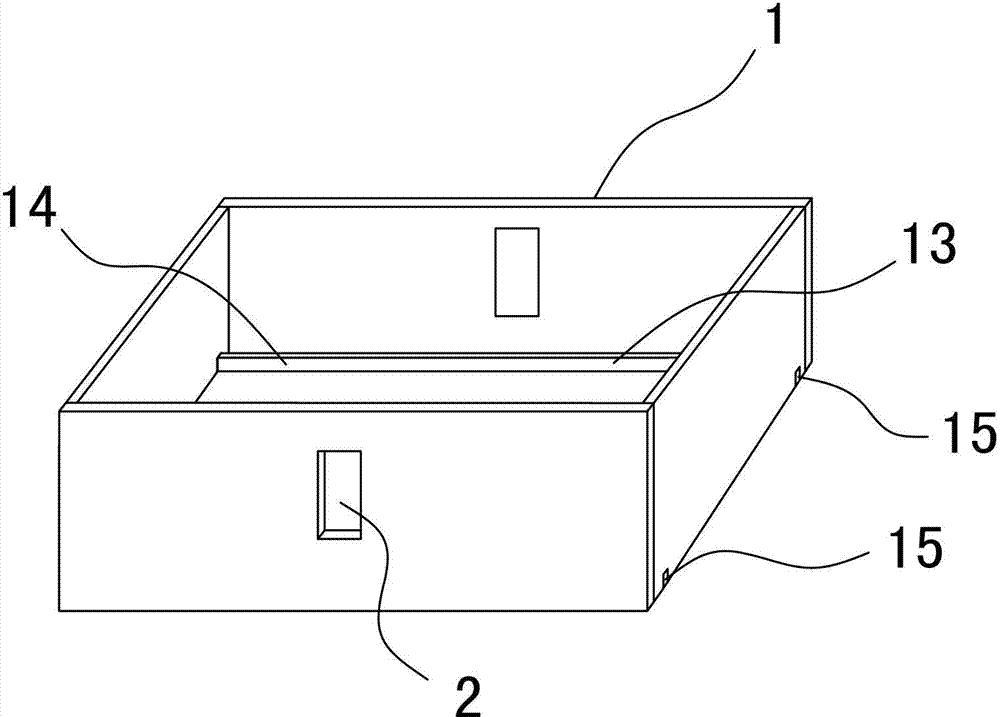

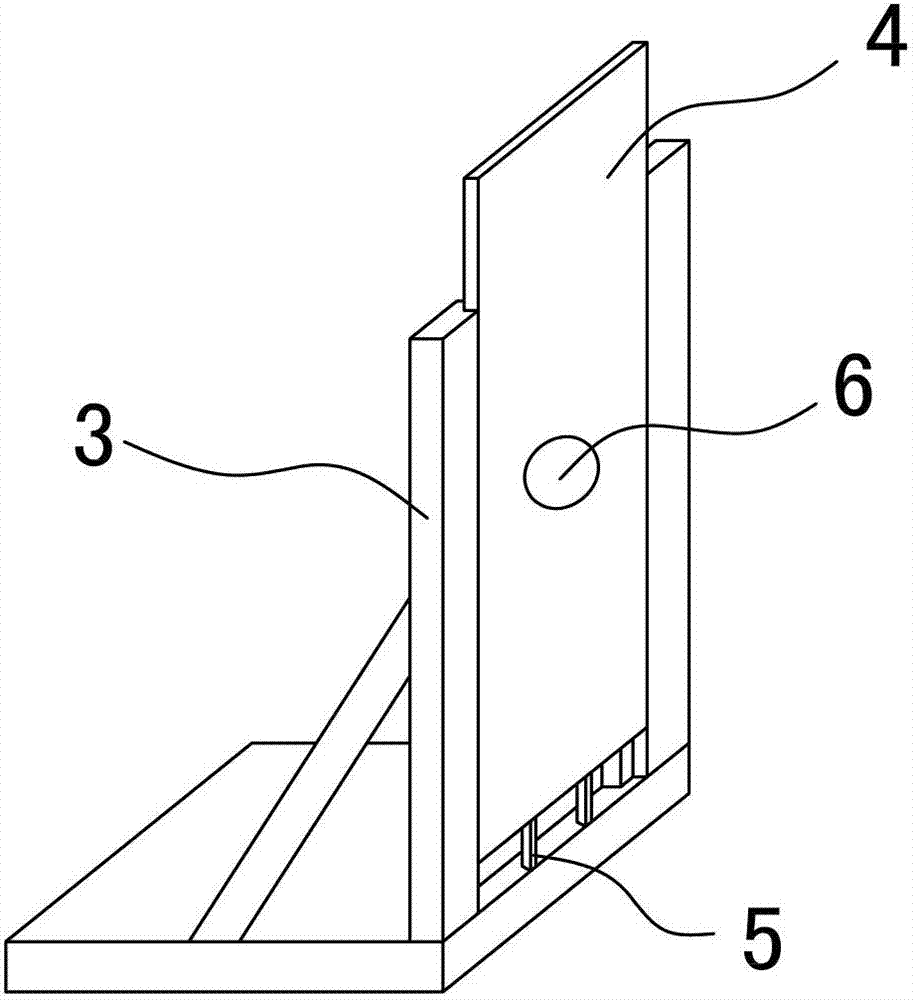

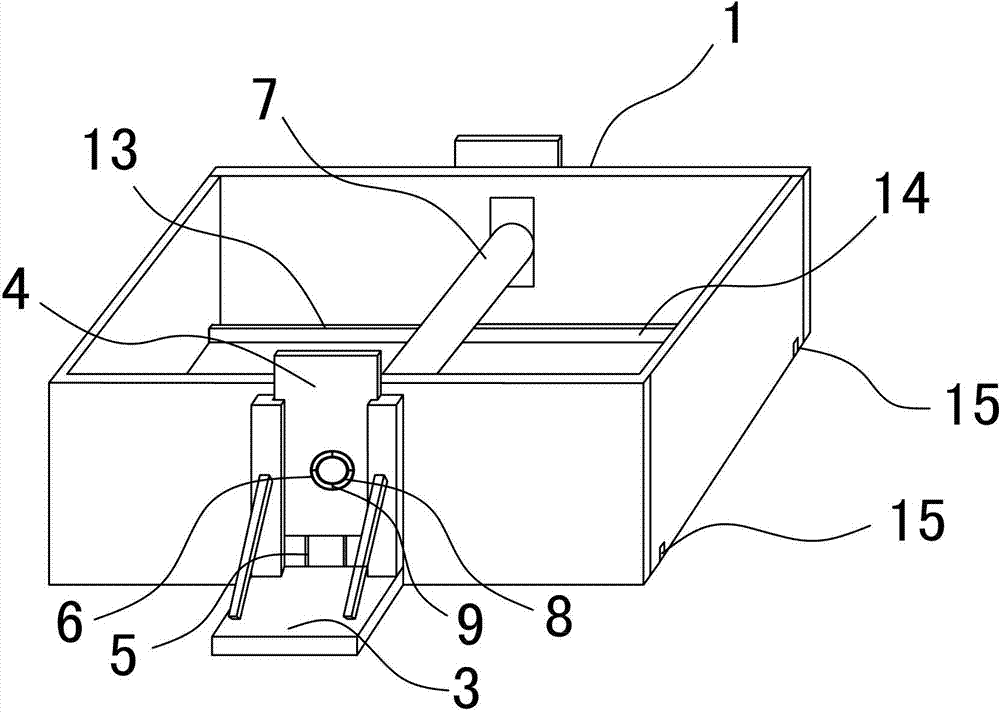

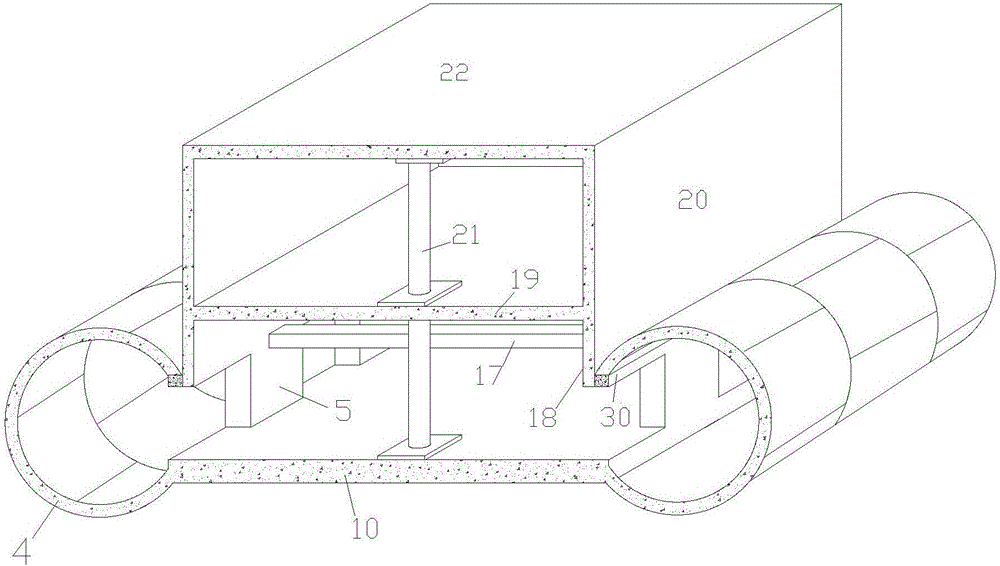

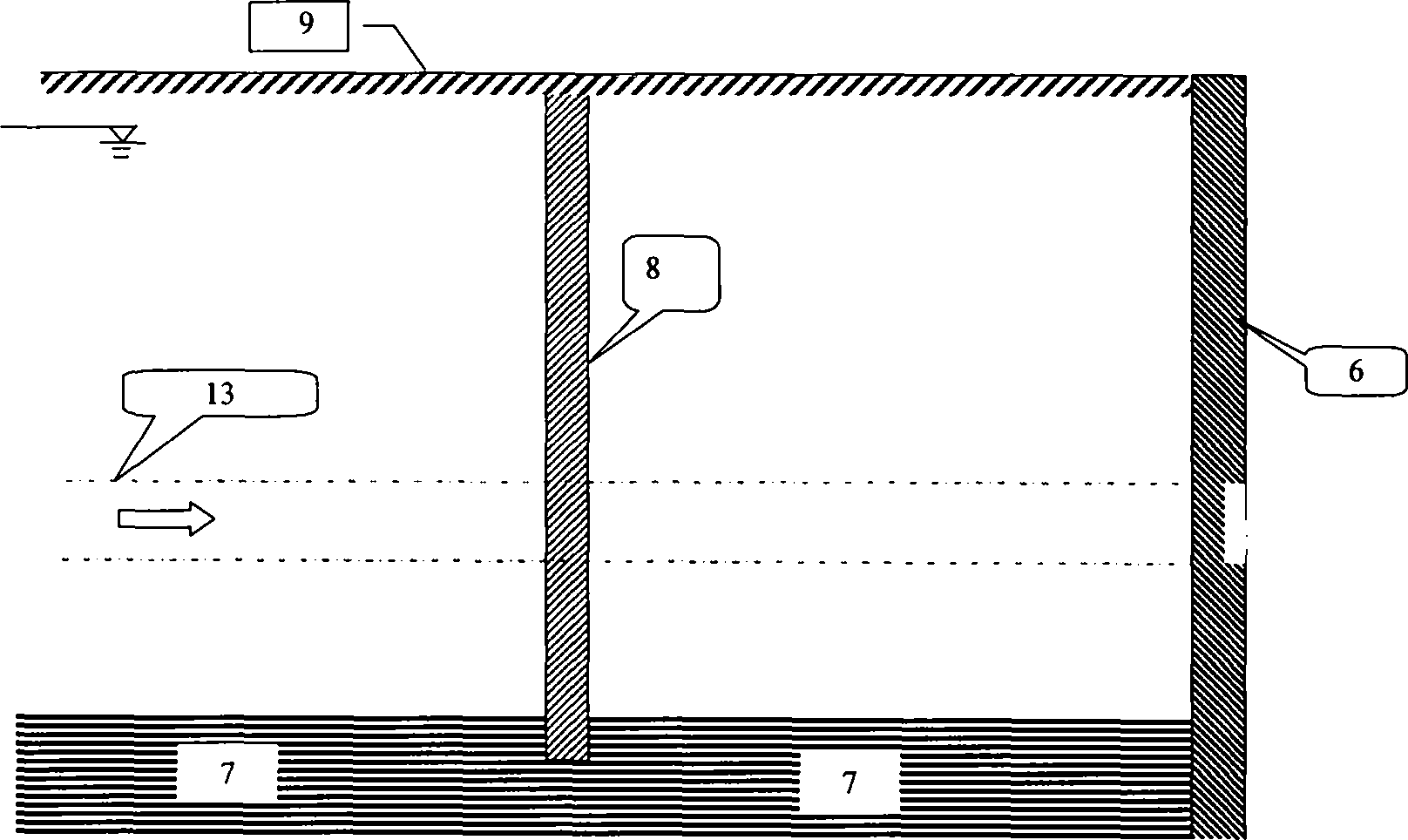

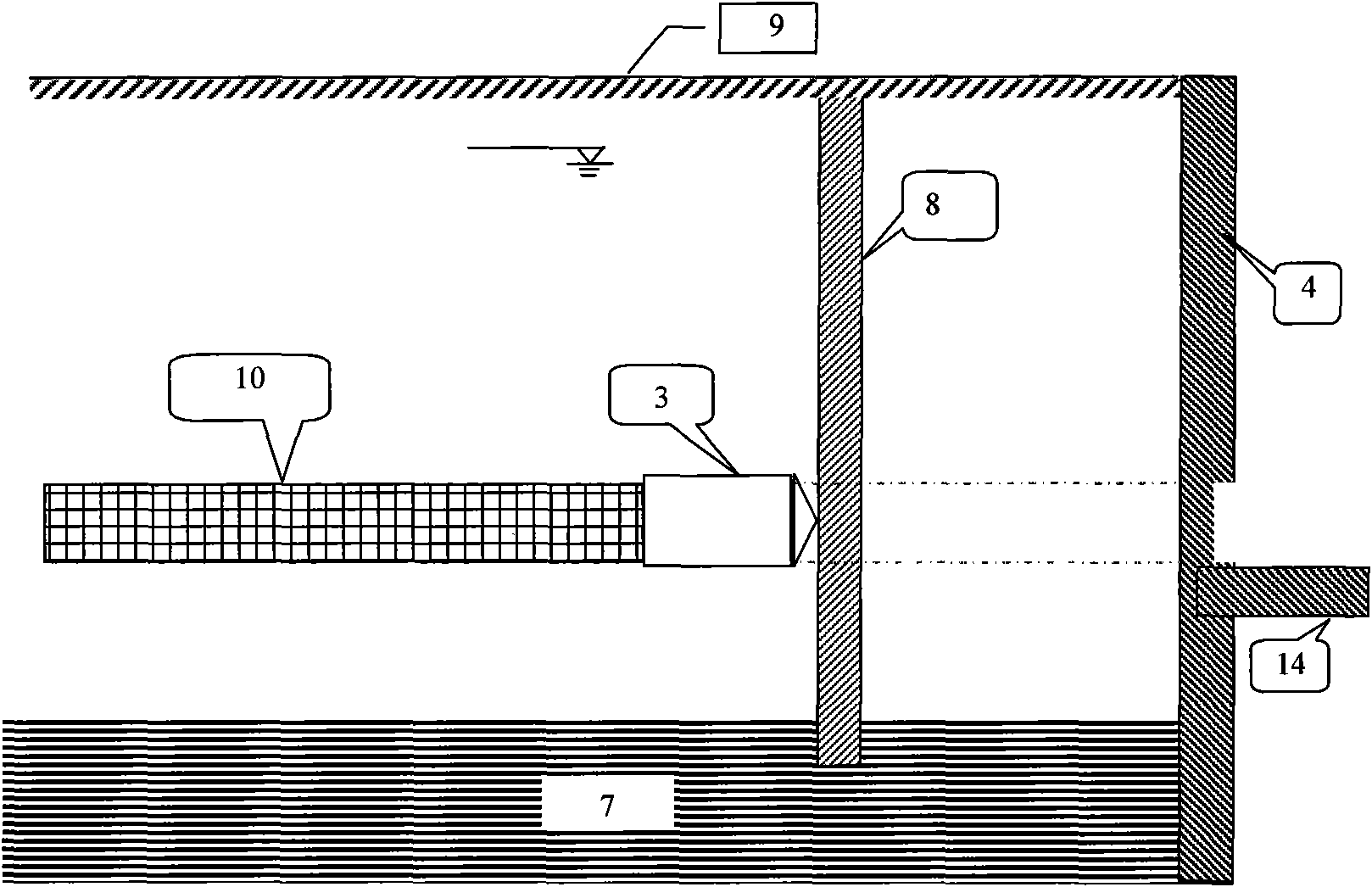

Experimental facility for simulating shield tunnel dynamically boring causing ground loss and surface subsidence

An experimental facility for simulating shield tunnel dynamically boring causing ground loss and surface subsidence includes a model case which is provided with a tunnel simulation mechanism and lifting regulating mechanisms. The model case is formed by splicing four lateral plates and a base plate, wherein through grooves are correspondingly formed on two lateral plates which are opposite to each other. The tunnel simulation mechanism is provided with a shield pipe and a tunnel pipe, the shield pipe is sleeved outside the tunnel pipe, and at least two sets of elastic support pieces are arranged between the shield pipe and the tunnel pipe in an axial direction of the pipes. Each of the through grooves is provided with a set of lifting regulating mechanism which includes lifting plates, wherein the lifting plates are attached firmly to the lateral plates of the model case on the positions of the through grooves and connected with a climbing mechanism or a lifting mechanism, through holes are formed on the position of the lifting plates, which is corresponding to the position of the shield pipe, and the tunnel simulation mechanism is arranged in the through holes and through grooves in a penetrating mode. The experimental facility for simulating shield tunnel dynamically boring causing ground loss and surface subsidence solves the problem in existing indoor physical modeling experiment method that the influence effect and influence rule of influence factors such as cutting depth and cutting diameter on ground displacement can not be considered.

Owner:SUZHOU UNIV OF SCI & TECH

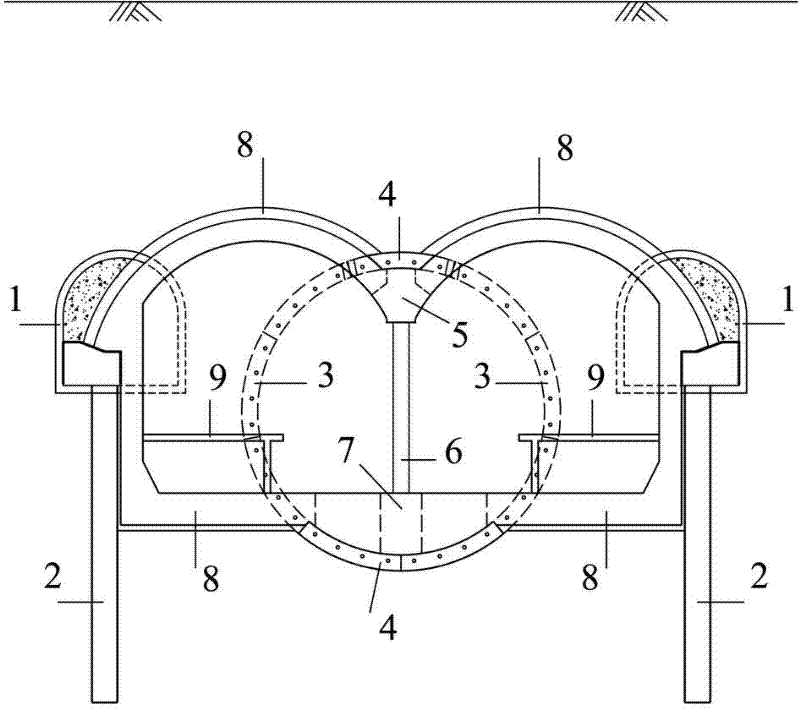

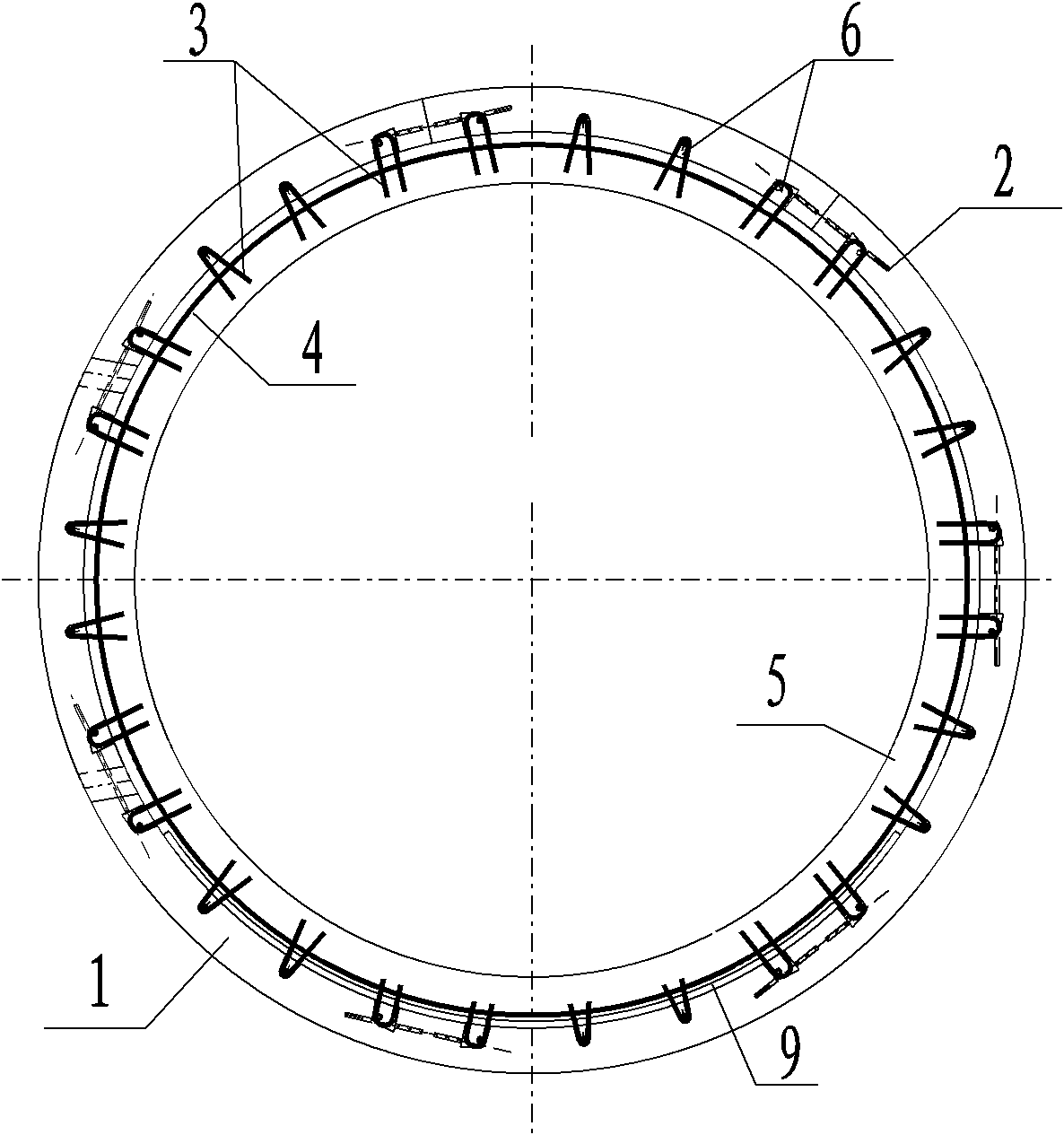

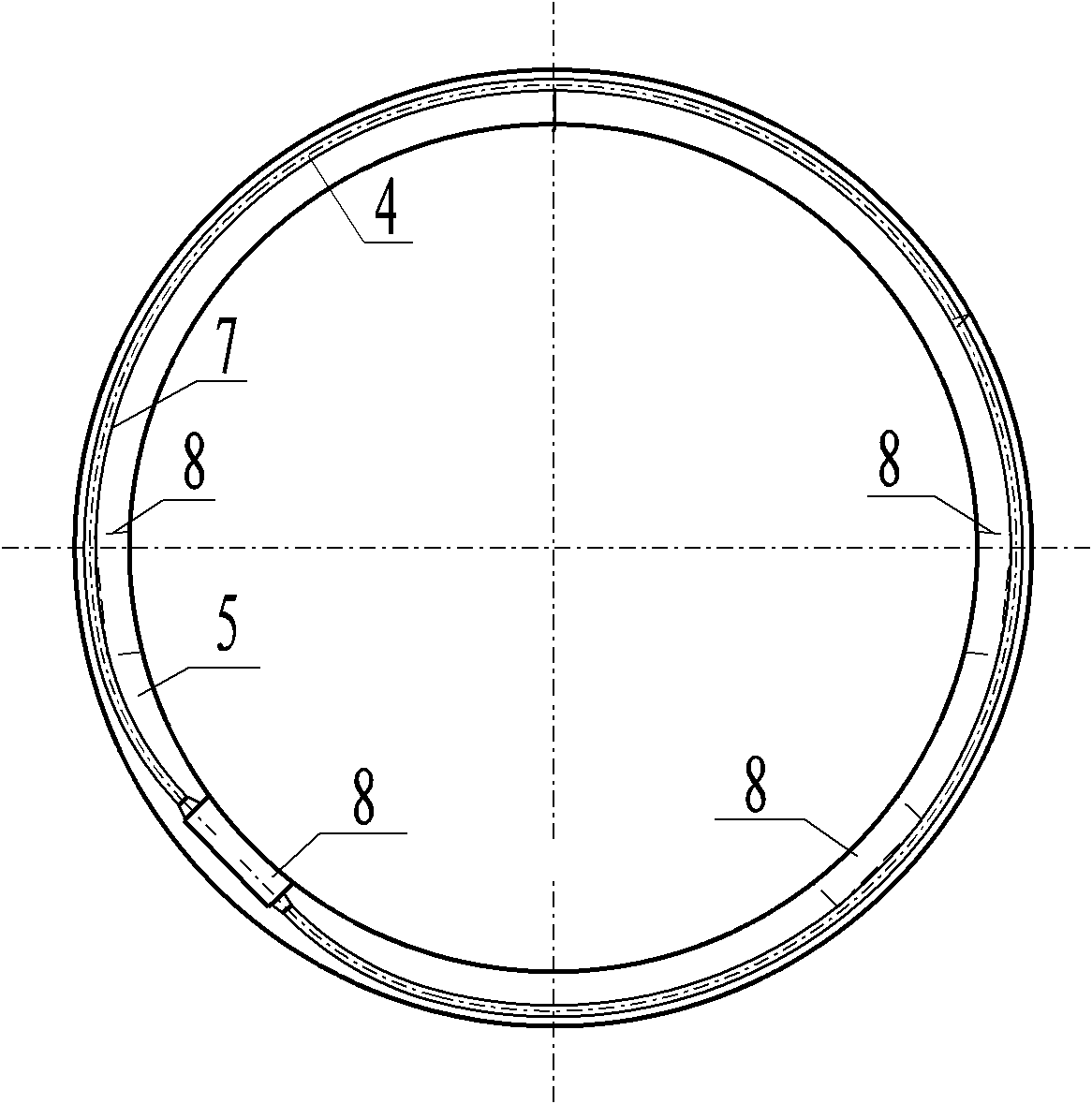

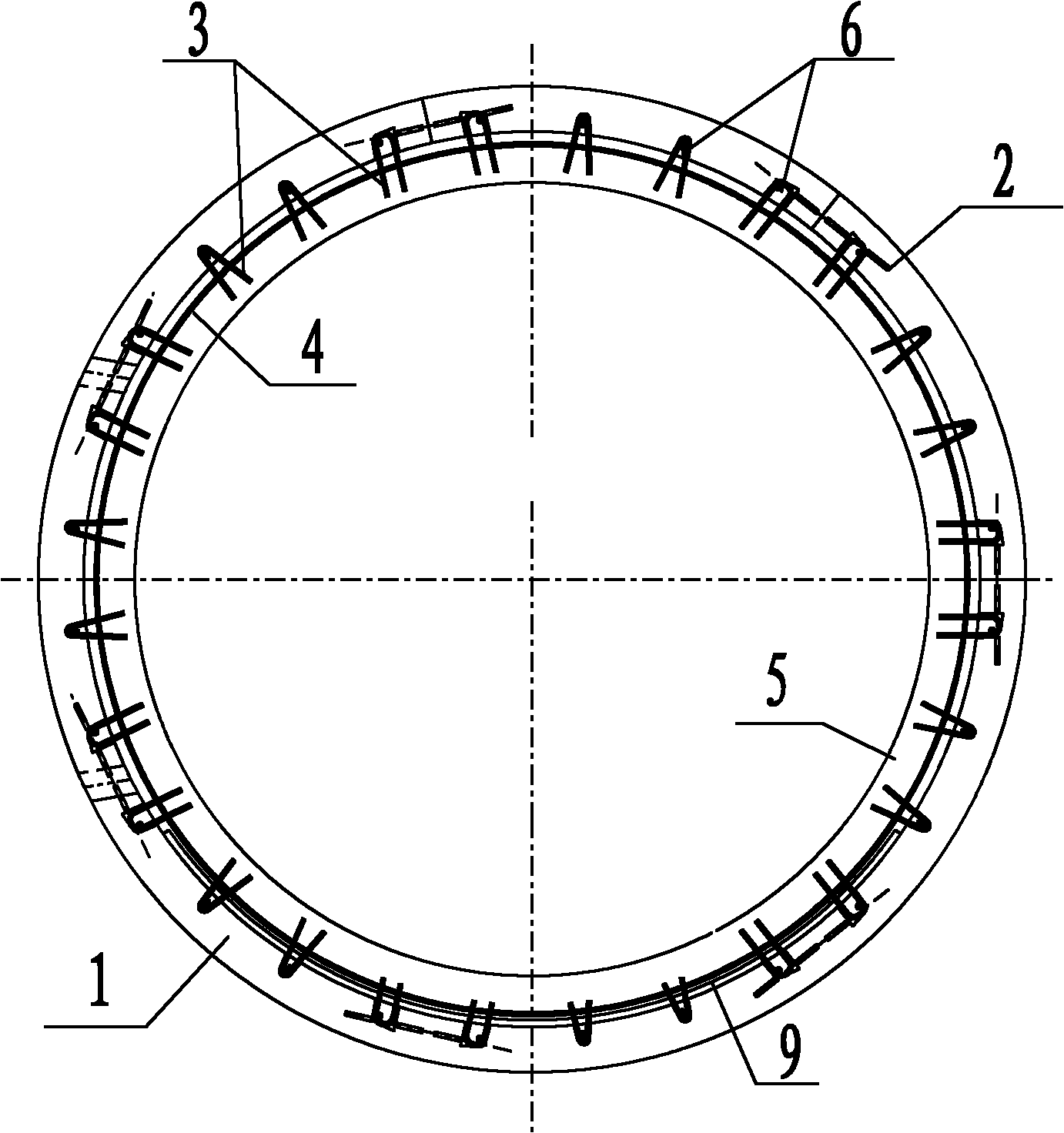

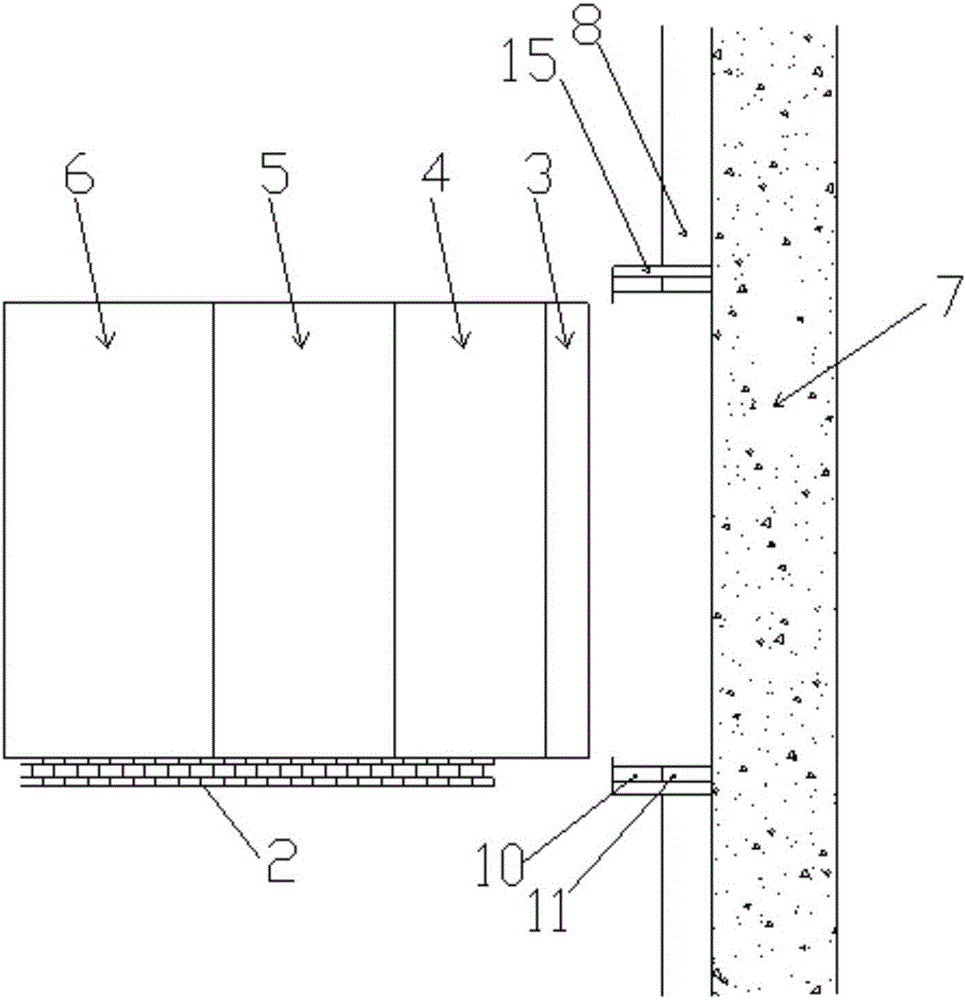

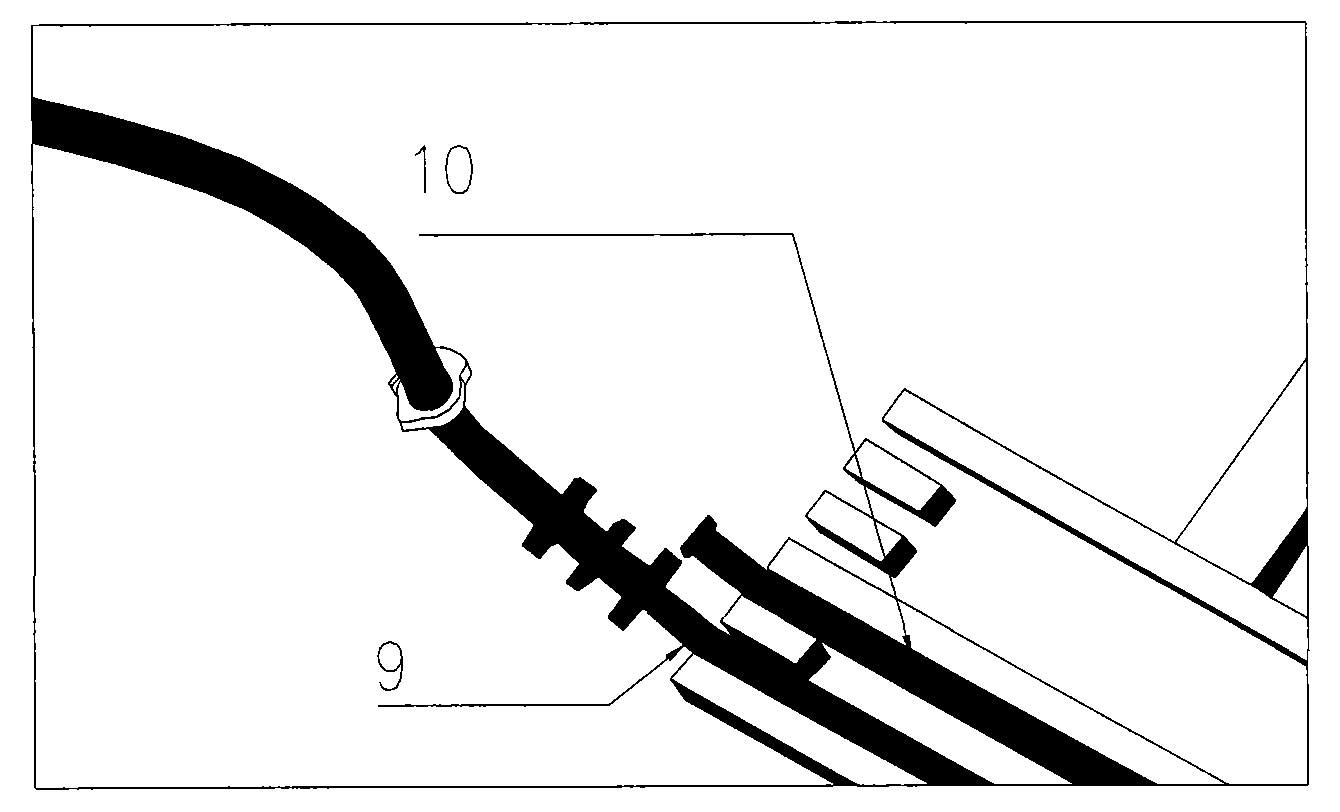

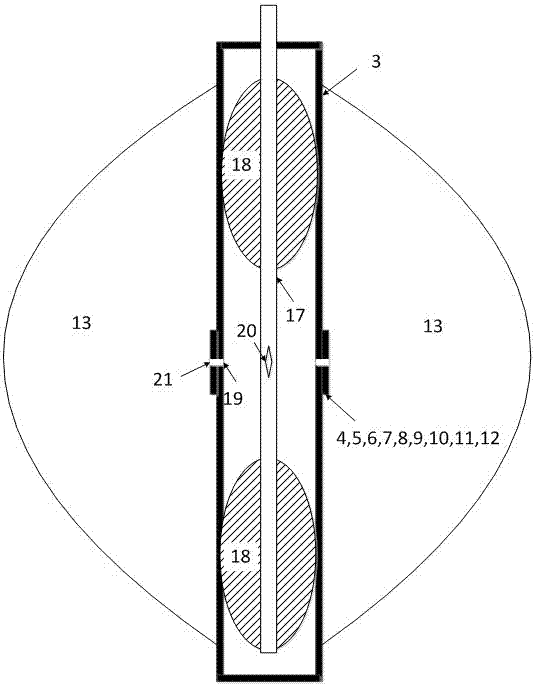

Water conveyance tunnel with prestressed composite lining for shield tunnelling

InactiveCN102191940AHigh degree of simulationLarge scale testUnderground chambersDrainageSocial benefitsReinforced concrete

The invention provides a water conveyance tunnel with a prestressed composite lining for shield tunnelling. The tunnel comprises an ordinary reinforced concrete outer lining (1) which is formed by shield construction and is an assembled segment ring, wherein segments on the same ring are connected by connecting bolts (2); dowel bars (3) are installed in hand holes on the assembled segment ring; concrete is directly poured on the outer lining (1) to form an inner lining (5); shear keys (6) are formed in such a manner that concrete is filled in the hand holes of the outer lining; and the inner lining (5) and the outer lining (1) are combined via the dowel bars (3) and the concrete shear keys (6) to form a composite lining structure. Thus, the defects of great construction difficulty, long construction period and higher investment caused by the separated pressure pipeline water conveyance scheme for shield tunnelling are overcome. The technical problems of high head, high flow, high load and possibility of endangering the tunnel safety due to seepage of underground water, which are encountered when the soft soil layer of the riverbed is tunnelled in the shield tunnelling construction of the Yellow River crossing tunnel, are solved. Besides, the invention reduces the project investment and has obvious social benefits.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

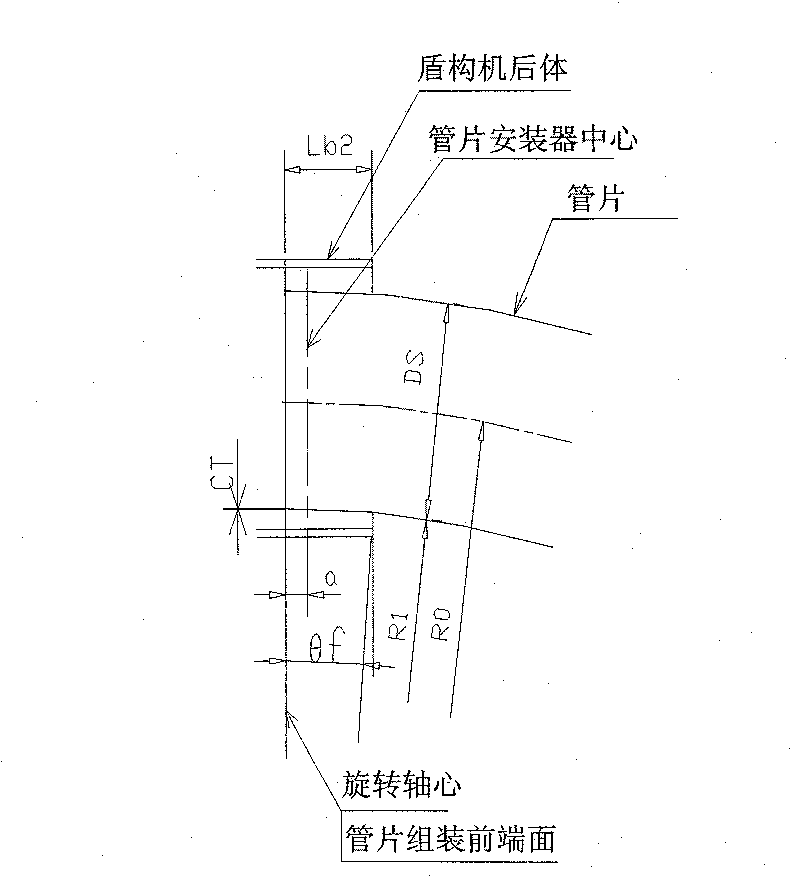

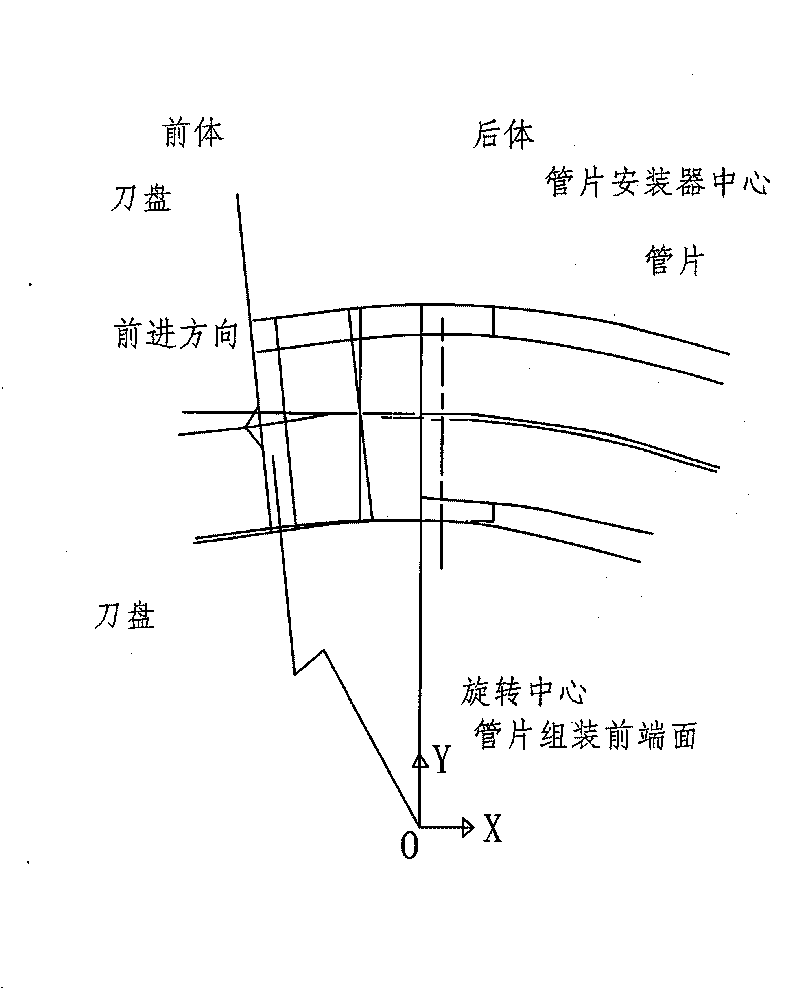

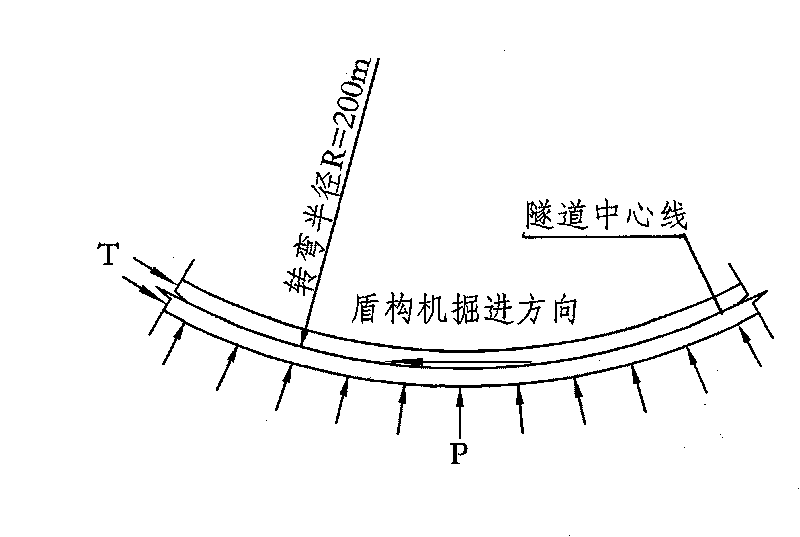

Small-radius shield tunnel construction technology

The invention introduces a shield excavation technology of a tunnel with a sharp curve on the basis of the analysis of easy occurred problems in shield construction of a metro tunnel with a sharp curve and the combination of an engineering example of a long-distance tunnel with an extremely sharp curve between districts in a Yangjiji zoo. The development of a city promotes the development of rail transit construction. Because the selection of a rail transit line is restricted by planning, buildings and structures, the shape of the rail transit line is more and more complicated. Although the line shape of the tunnel with the sharp curve is not excellent, the line shape is applied more and more frequently. Compared with the conventional shield construction technology, the shield construction technology of the tunnel with the sharp curve has certain particularity. The research on the shield construction technology of the tunnel with the sharp curve, in particular to the shield construction technology of the tunnel with the sharp curve in complex strata in Guangzhou, has a certain reference function for similar shield construction of the tunnel with the sharp curve in the future.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

Construction method for earth pressure balance shield construction pressure launching in subway tunnel engineering

InactiveCN105822312AGuaranteed tightnessEnsure construction safetyTunnelsArchitectural engineeringIncreased risk

The invention provides a construction method for earth pressure balance shield construction pressure launching in subway tunnel engineering. According to the method, a tunnel portal extending ring is matched with rubberized cord fabric, a folding pressure plate and a spring steel plate dual-sealing device to maintain pressure, and replacement is carried out on in-bin residue earth of a launching ring during trial boring launching. According to the method, pressure can be built quickly and normally to reach earth pressure balance tunneling requirements by replacing the in-bin residue earth of the launching ring when the launching ring excavates during the shield launching, water burst risk and sand burst risk generated by directly breaking a tunnel portal are avoided, the construction period is shortened and the construction cost is reduced. According to the shield tunnel construction pressure launching construction method, the risk increased by directly breaking the tunnel portal can be avoided, the leakproofness of the tunnel portal can be ensured, construction pressure excavation can be quickly realized, cost is saved, and the construction safety of the shield tunnel can be guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

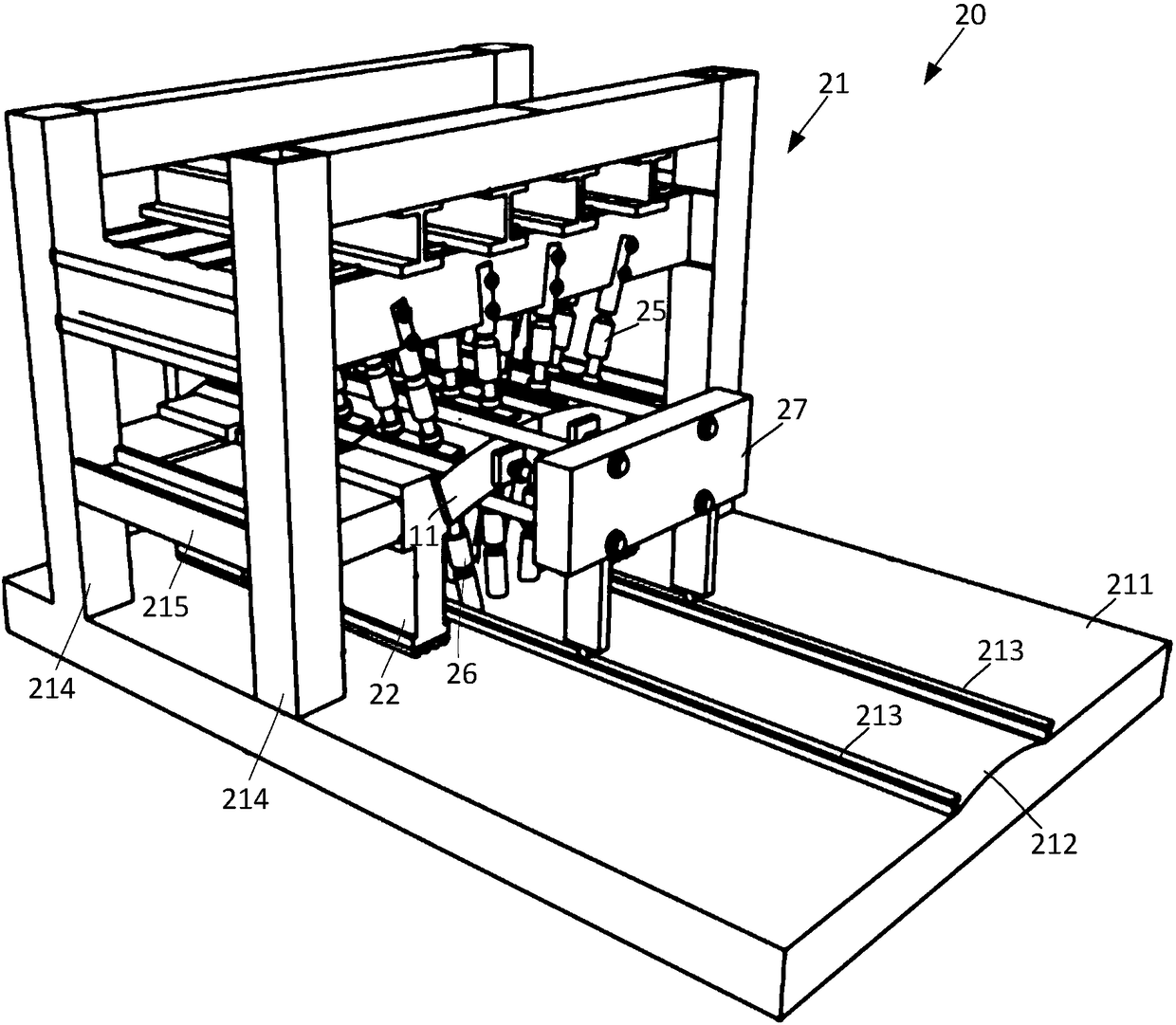

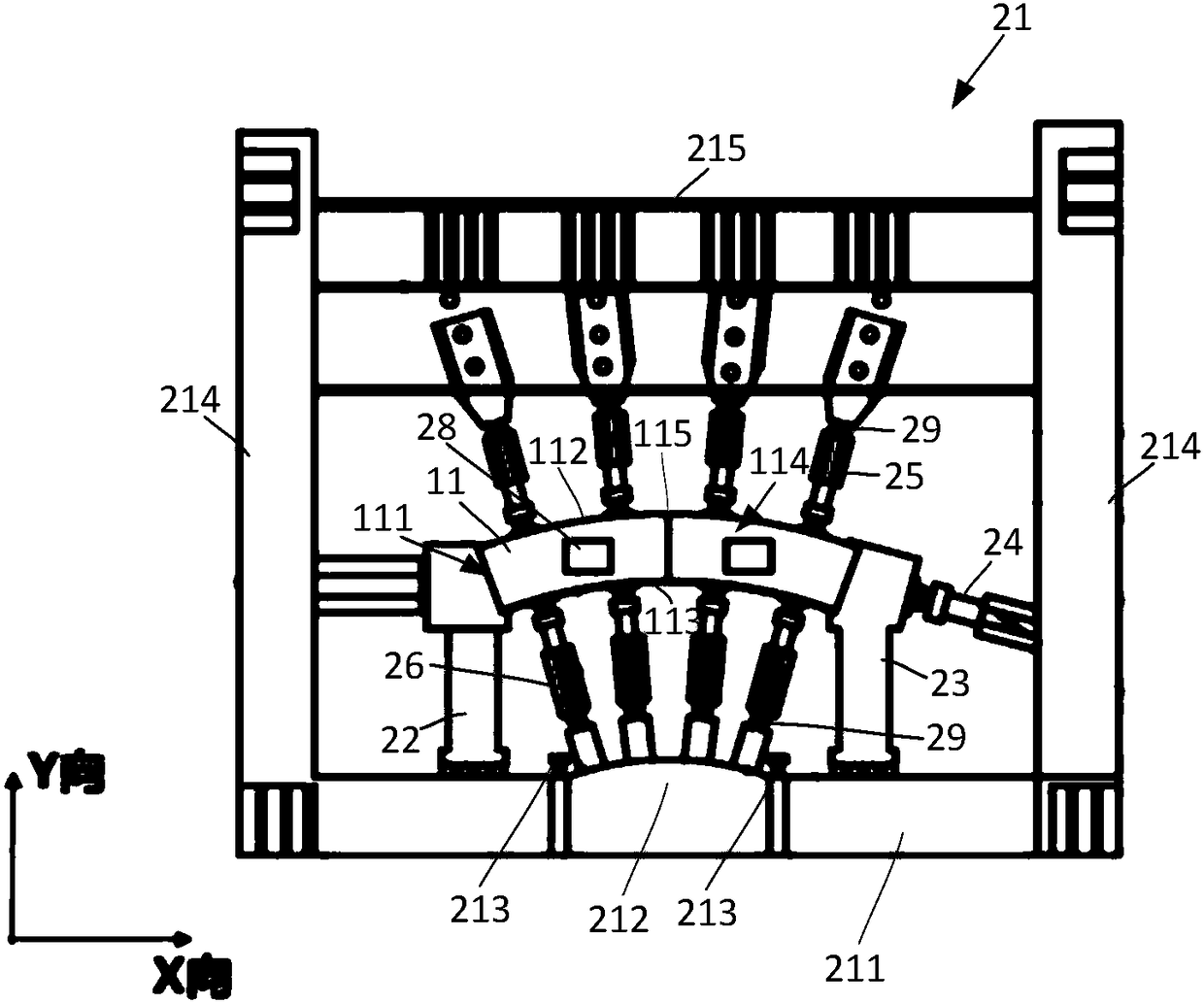

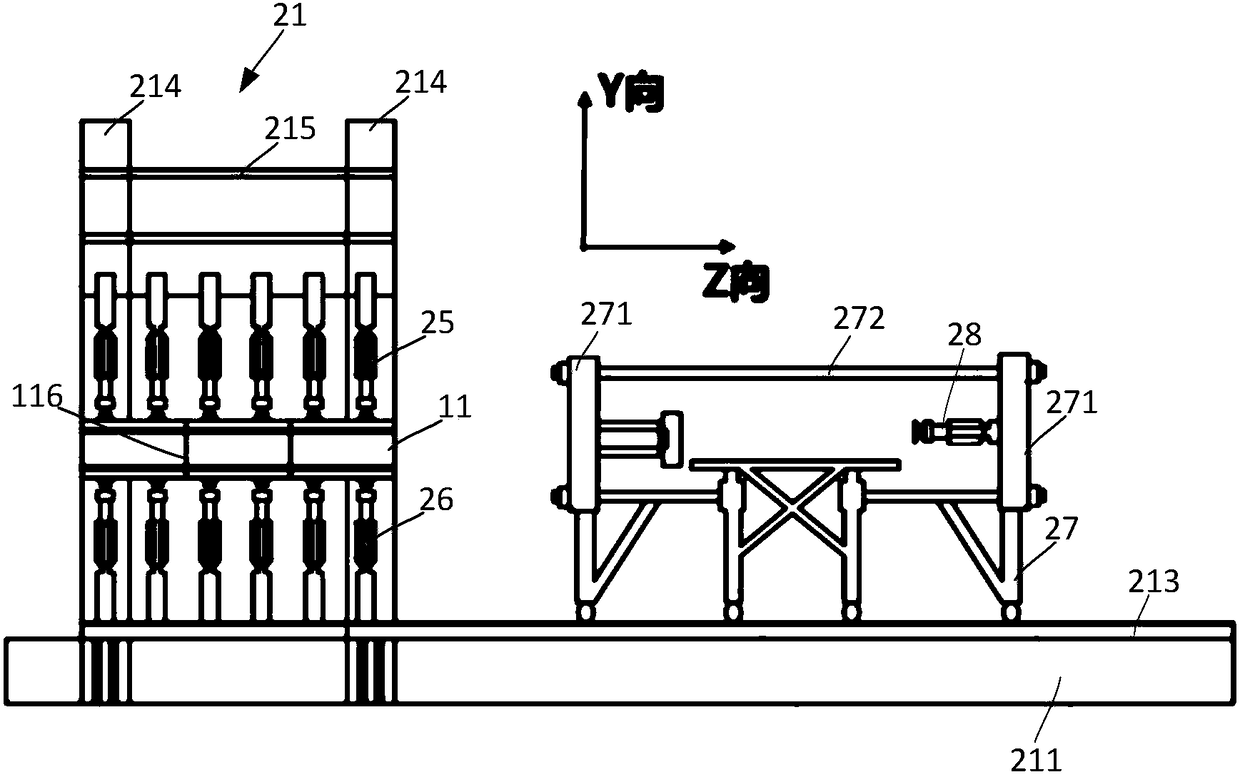

Multifunctional testing device for mechanical property of shield tunnel segment joint

The invention relates to a multifunctional testing device for mechanical properties of shield tunnel segment joints. The multifunctional testing device comprises a frame structure, a first support base, a second support base, an X-direction loading actuator, a Y-direction outer-side loading actuator and a Y-direction inner-side loading actuator, wherein the first support base is fixedly arranged on the frame structure; the second support base is opposite to the first support base and can be moved; the X-direction loading actuator is in support connection with the second support base and the frame structure; the X-direction loading actuator is used for pushing the second support base to be matched with the first support base to tightly clamp a tunnel segment to be tested, and is used for exerting an X-direction loading force perpendicular to the cross section of the tunnel segment to be tested; the Y-direction outer-side loading actuator is mounted at the top of the frame structure andis used for exerting a Y-direction outer-side loading force perpendicular to the outer side surface of the tunnel segment to be tested; and the Y-direction inner-side loading actuator is mounted at the bottom of the frame structure and is used for exerting a Y-direction inner-side loading force perpendicular to the inner side surface of the tunnel segment to be tested. By adopting the testing device provided by the invention, mechanical testing on three modes of longitudinal joint bending, longitudinal joint shearing and annular joint shearing can be achieved, and relatively high utilization efficiency is also achieved.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

Construction method of tunnel to cross airport runway by shield method

ActiveCN102080548AMeet the requirements of non-stop operationGuaranteed normal operationUnderground chambersTunnel liningSlurryPhase control

The invention relates to a construction method of a tunnel to cross an airport runway by a shield method, which comprises the following steps of: 1, design optimization, which comprises optimizing an axis line of the tunnel, unifying sedimentation control standards, designing special lining rings and optimizing lining waterproof performance; 2, optimization of shield equipment, which comprises optimizing synchronous grouting slurry and grouting equipment, optimizing synchronous grouting holes, and tapping a shield machine; 3, construction monitoring, which comprises measuring water level manually, automatically monitoring surface sedimentation of the runway and automatically monitoring sedimentation of shoulder of a road; 4, crossing airport runway by a shield, which comprises dividing phase control regions, setting an earth pressure, controlling advancing volume of excavated earth, improving soil body, controlling advance rate, grouting synchronously, assembling tunnel lining duct pieces, and grouting secondarily after shield crossing. The method not only realizes construction of crossing the airport runway by the shield method, but also guarantees the normal operation of the airport.

Owner:SHANGHAI TUNNEL ENG CO LTD

Reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways

InactiveCN105003272AImprove construction efficiencyGuaranteed stabilityUnderground chambersTunnel liningSlurry wallSoil nailing

The invention discloses a reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways. The expanded and excavated stations are simply supported frame wall column type double-layer subway stations in structural forms. The reversed construction method includes retaining soil and water by the aid of piles in rows and waterproof curtains or underground diaphragm walls, and resisting lateral deformation of soil mass; excavating the soil mass between openings of parallel shield tunnel segments and constructing cross passages; grouting and reinforcing the soil mass above tunnels, building foundation pit excavation supporting structures and short supporting piles of station bodies and connecting the tops of the foundation pit excavation supporting structures and the short supporting piles with the outer piles in the rows or the outer underground diaphragm walls by connecting beams; constructing the structures of the station bodies by the aid of cover and excavation top down processes, filling the station bodies with the soil mass and recovering road surfaces. Foundation pit slopes can be supported by the aid of composite soil nailing supporting technologies in excavation procedures. The reversed construction method has the advantages that the reversed construction method is reasonable and feasible, is high in operability and has important engineering application value and an important development prospect, and huge economic, social and environmental benefits can be brought by application of the reversed construction method.

Owner:BEIJING UNIV OF TECH

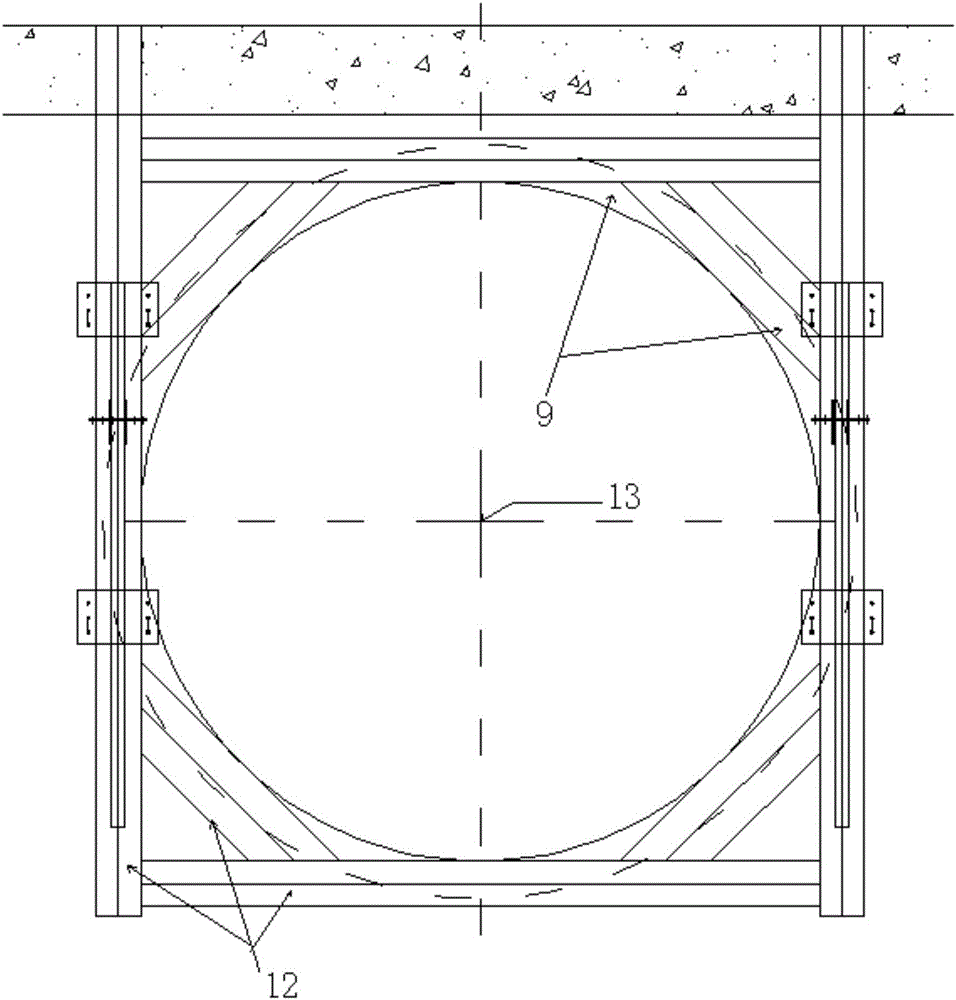

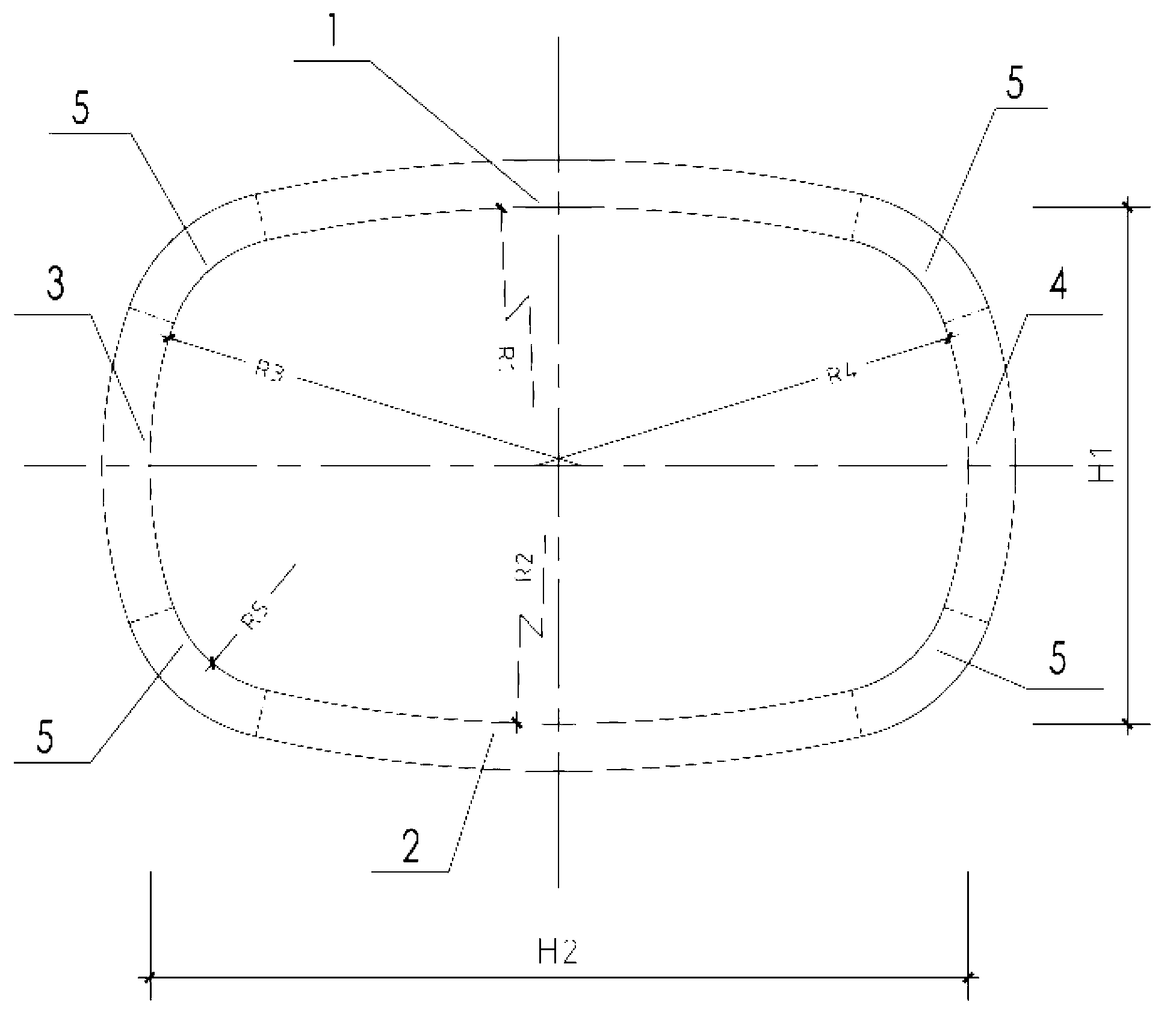

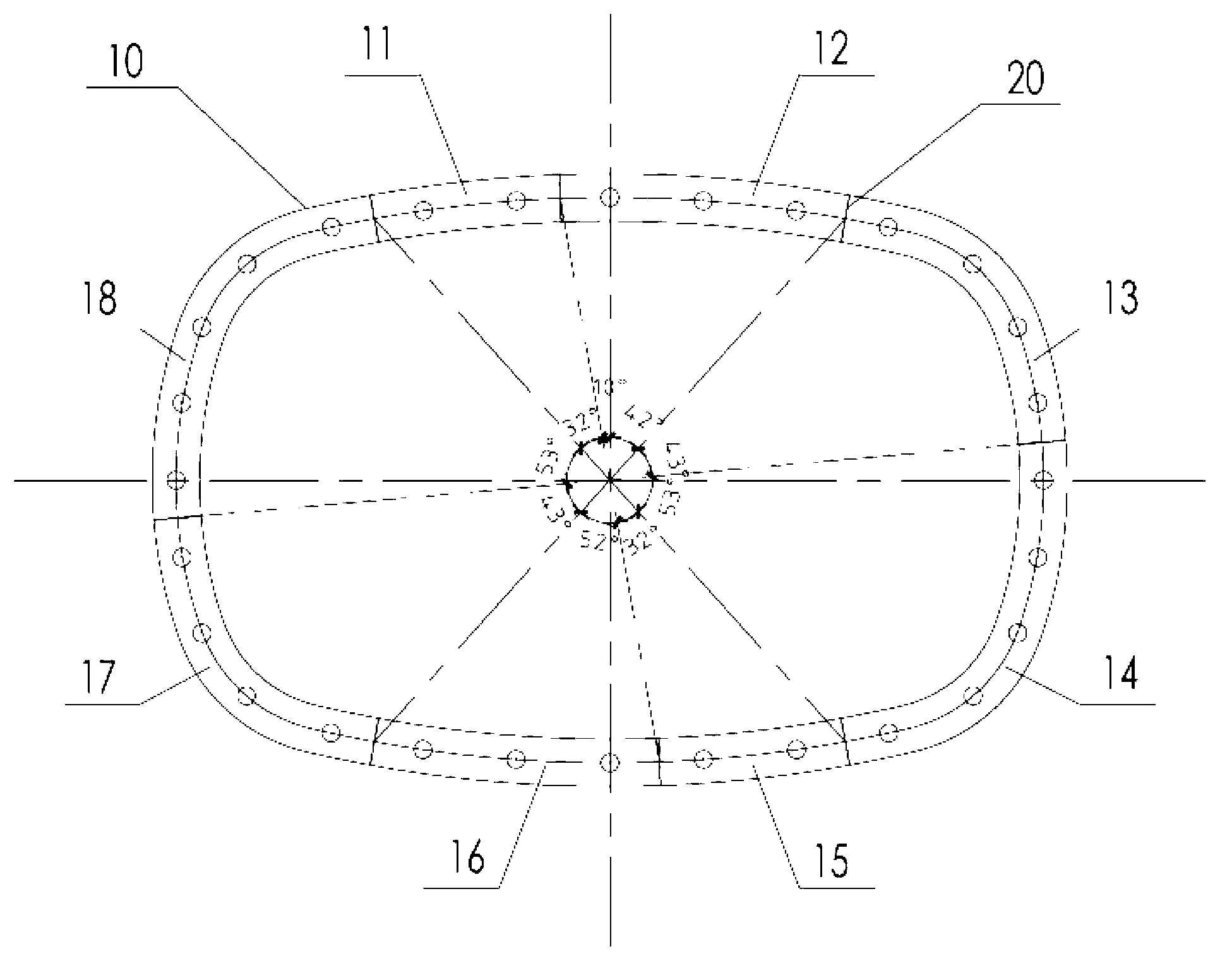

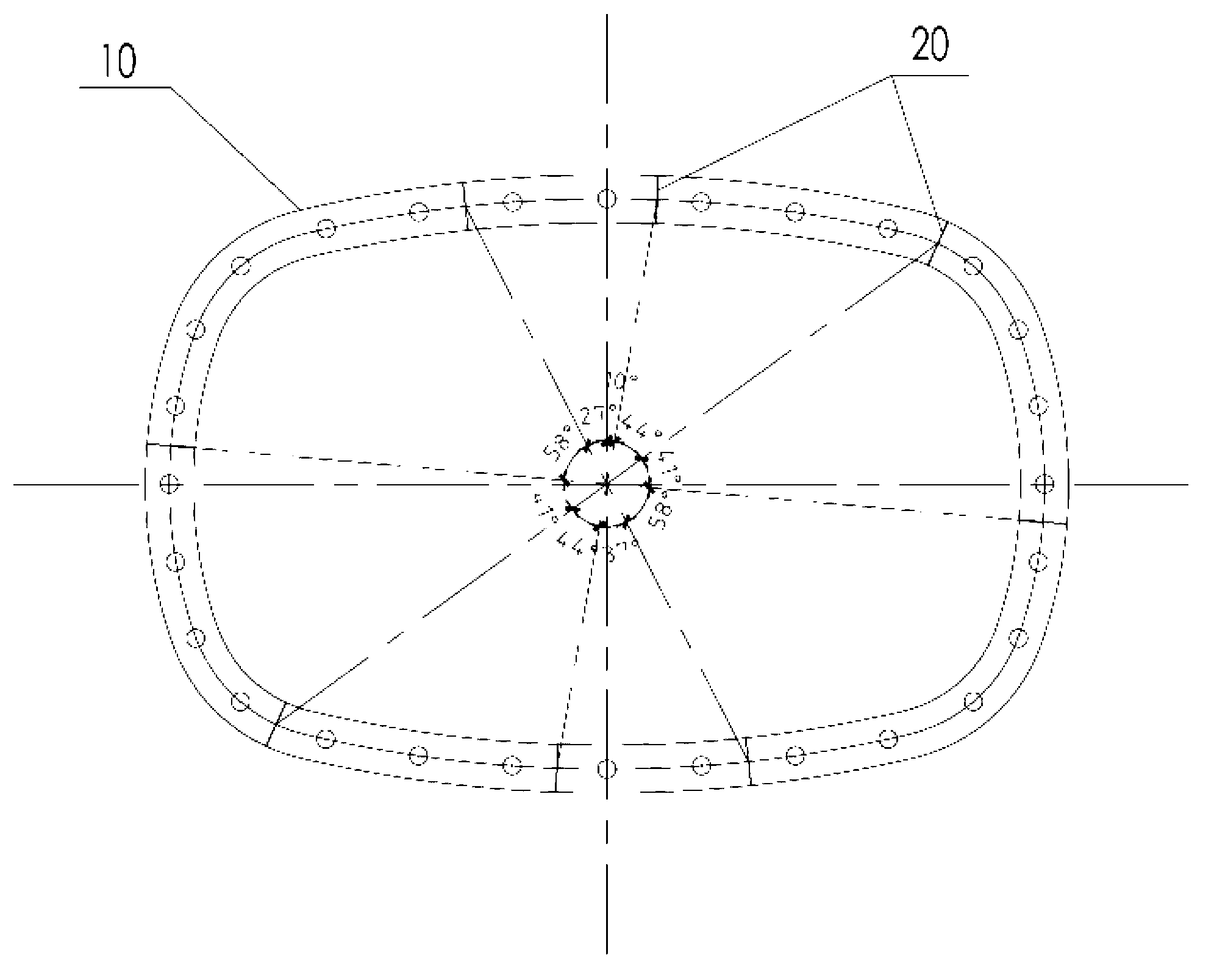

Shield segment structure and shield tunnel

InactiveCN103306685AIncrease usageReduce the cross-sectional areaTunnelsShield tunnellingInternal forces

The invention discloses a shield segment structure and a shield tunnel. The shield segment structure comprises a plurality of segments, wherein the segments are defined and spliced to form an integral ring; a cross section of the integral ring is a centrosymmetric and axisymmetric special-shaped face; the special-shaped face is formed by defining eight inferior arcs; the eight inferior arcs are a top inverted arch and a bottom inverted arch which are arranged vertically, oppositely and symmetrically, a left arch and a right arch which are arranged horizontally, oppositely and symmetrically, and four corners respectively; the segments are centrosymmetrically distributed on the integral ring; spliced seams, located on the cross section, of the adjacent segments are staggered with maximum internal force parts of the corners, and symmetry axes; a plurality of shield segment structures are butted to form the shield tunnel; and the spliced seams of the segments of the adjacent shield segment structures are arranged in a staggered manner. The shield segment structure and the shield tunnel can well integrate factors such as transverse internal force distribution of the shield tunnel, and connection of the longitudinal segments, so that the shield segment structure and the shield tunnel have good integrity, high efficiency and implementability.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Method and device for synchronously grouting shield tunnel pipe sheet

InactiveCN101672186APrevent floatingAvoid waterUnderground chambersTunnel liningSlurryShield tunnelling

The invention discloses a method and a device for synchronously grouting shield tunnel pipe sheet, solving the problem that the grouting effect in enriched water stratum is poor in the existing grouting method. The method for synchronously grouting shield tunnel pipe sheet provided by the invention comprises the following steps: A, horizontally and synchronously pouring mortar from the back of theliner building of the pipe sheet in the process of shield excavating; and B, pouring quick congealing mixture liquid to the back of the liner building of the pipe sheet while synchronously pouring the mortar. In the method and the device for synchronously grouting shield tunnel pipe sheet, the quick congealing mixture liquid and the mortar can be mixed and congealed rapidly, thereby efficiently preventing the pipe sheet from floating upwards, ensuring the initial stability of the liner building of the pipe sheet, preventing the water from flowing to the tail of the shield while opening a cabin to replace cutter in the hard rock construction for a long distance, and ensuring the construction effect.

Owner:CHINA RAILWAY TUNNEL

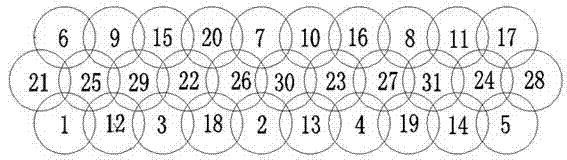

Shield construction method for clearing obstacles by punching rock stratum section

InactiveCN102654056AFast constructionQuality improvementUnderground chambersTunnel liningPunchingEnvironment effect

The invention relates to a shield construction method for clearing obstacles by punching a rock stratum section, comprising the following steps of: at first, determining a punching obstacle-clearing construction area as full-section punching construction; lapping at a pile hole position, wherein a bottom elevation of a pile is lower than a bottom elevation of a shield tunnel; determining a last-stage punching pile width range according to a probing result; carrying out punching obstacle-clearing construction by using a drilling construction process of a punching and filling pile; and directly injecting rapid-rigid slurry to fill an underground guide pipe after clearing the obstacles by punching. The obstacle-clearing construction method of a punching pile machine provided by the invention has the advantages of simple equipment, low manufacturing price, high security, rapid construction, smaller environment influence and the like, provides a novel treatment means for meeting the obstacles in underground engineering, such as shield, pipe-jacking and the like, and has a wide application prospect.

Owner:SHANGHAI FOUND ENG GRP

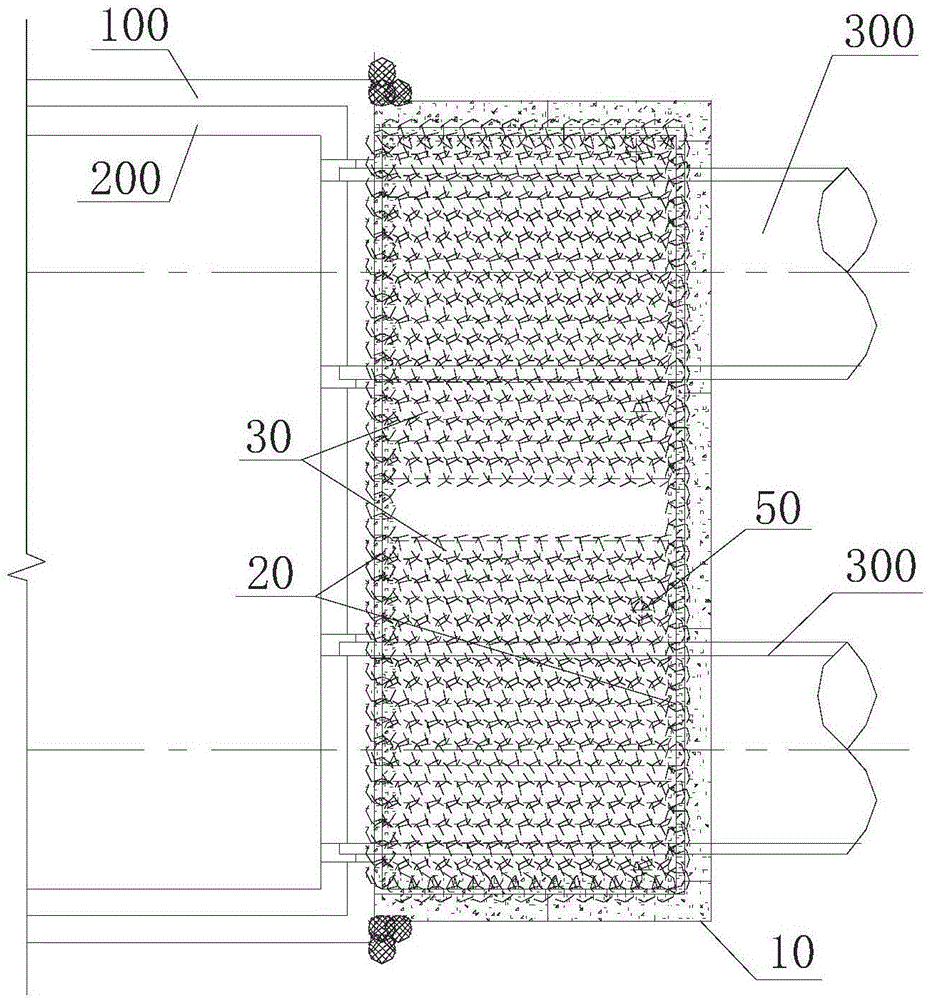

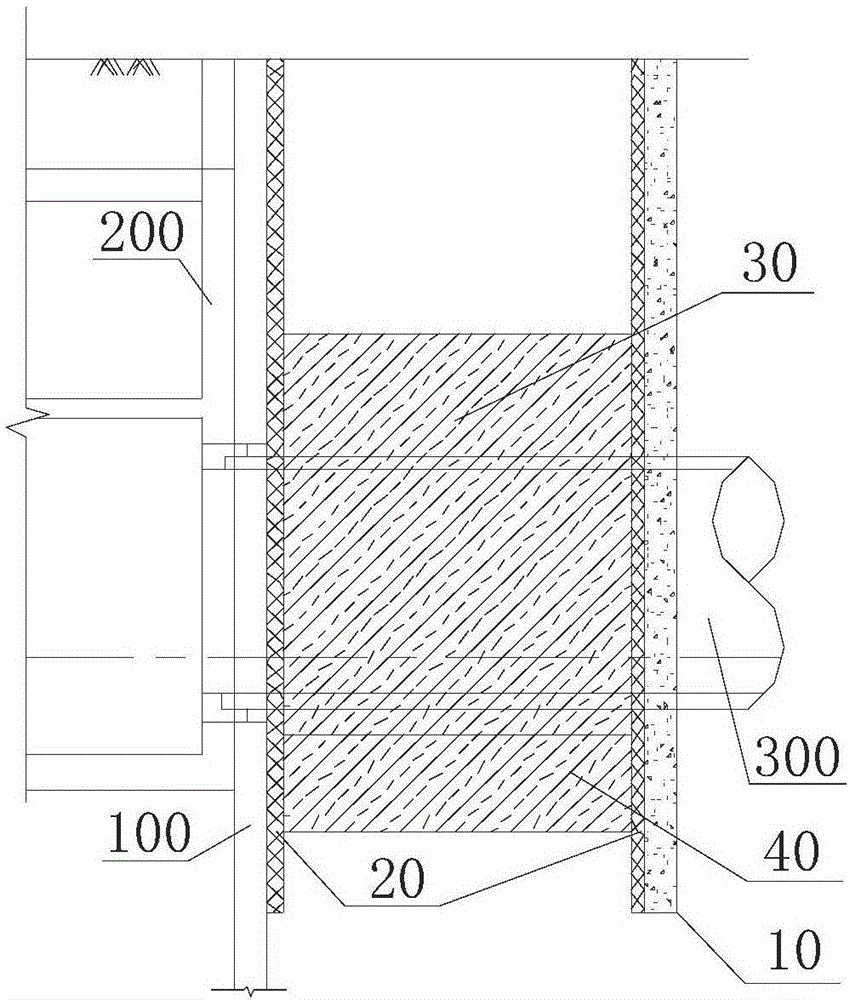

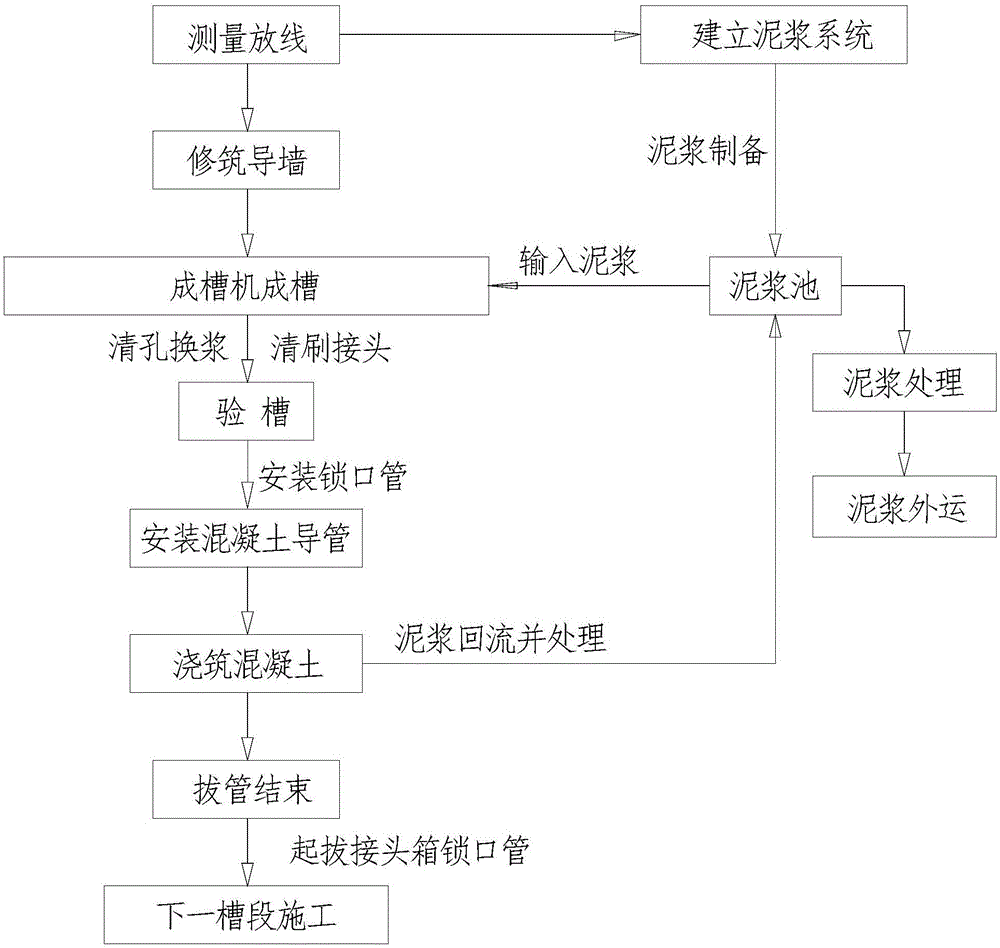

Subway tunnel shield end reinforcing body and reinforcing method

ActiveCN106545005AImprove waterproof performanceGood self-stabilityTunnelsBulkheads/pilesSleeve valveStructural engineering

The invention discloses a subway tunnel shield end reinforcing body and a reinforcing method. The reinforcing body comprises a ground continuous wall with a concavely surrounded outer side, and a three-shaft stirring pile reinforcing structure positioned in the ground continuous wall; the ground continuous wall and the three-shaft stirring pile reinforcing structure, and the three-shaft stirring pile reinforcing structure and the surrounded structure are joined by high-pressure jet grouting piles; and a sleeve valve pipe is used for grouting reinforcement below the bottom of a shield tunnel in a range of 0.5-3 m. The reinforcing method comprises the following steps: firstly, the ground continuous wall is constructed; then, a three-shaft stirring pile is reinforced, and the sleeve valve pipe is used for grouting reinforcement; and finally, the high-pressure jet grouting piles are joined. The invention discloses a subway tunnel shield end reinforcing structure. The reinforcing body and the reinforcing method enable reinforced soil to achieve excellent uniformity, independence and water resistance.

Owner:CCCC THIRD HARBOR ENG +2

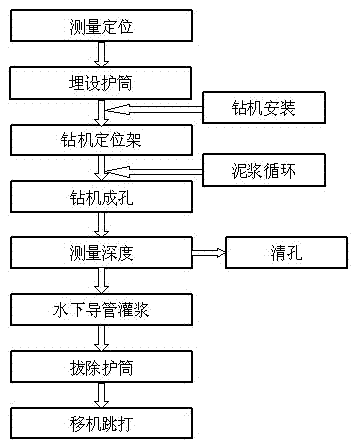

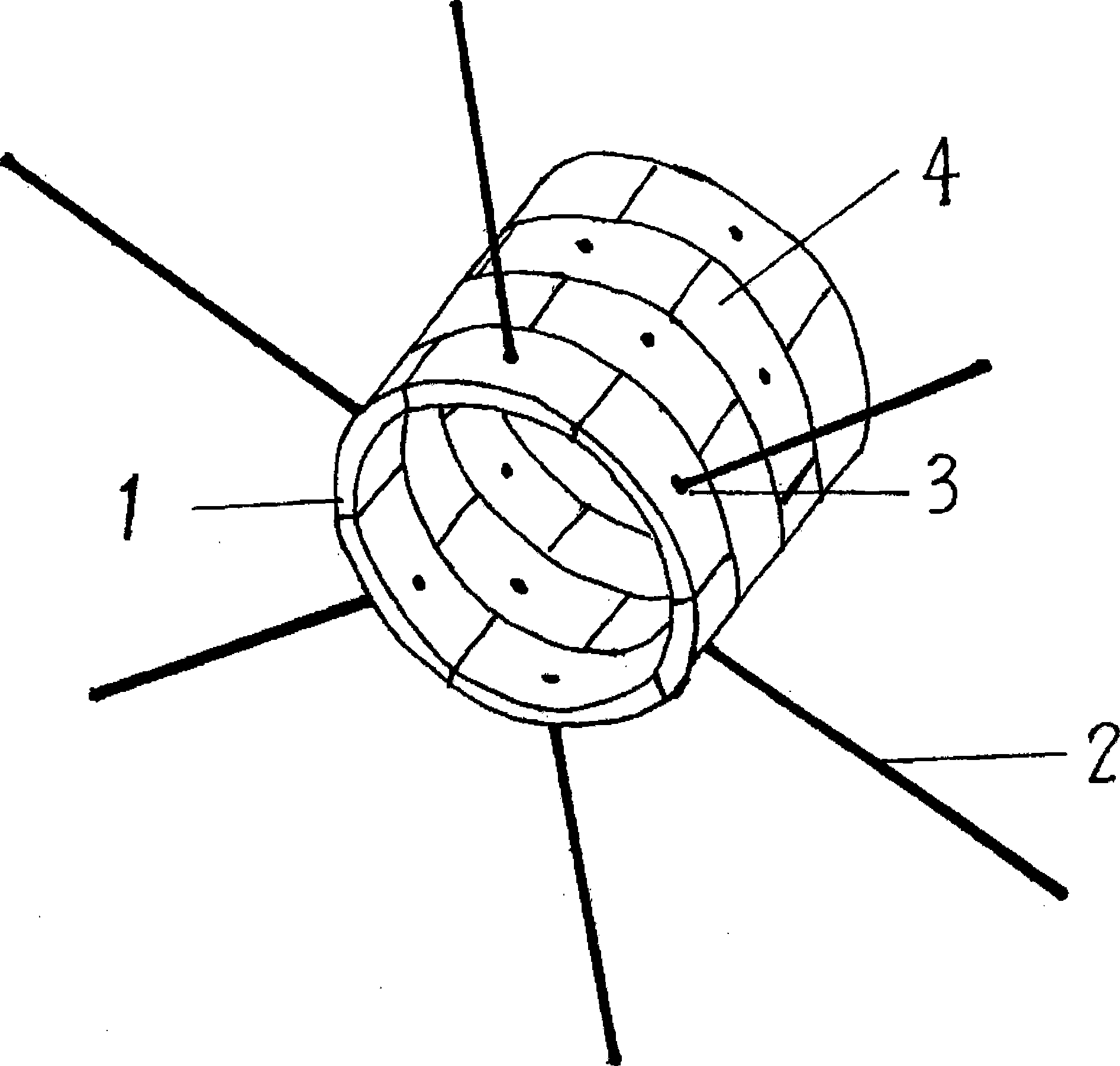

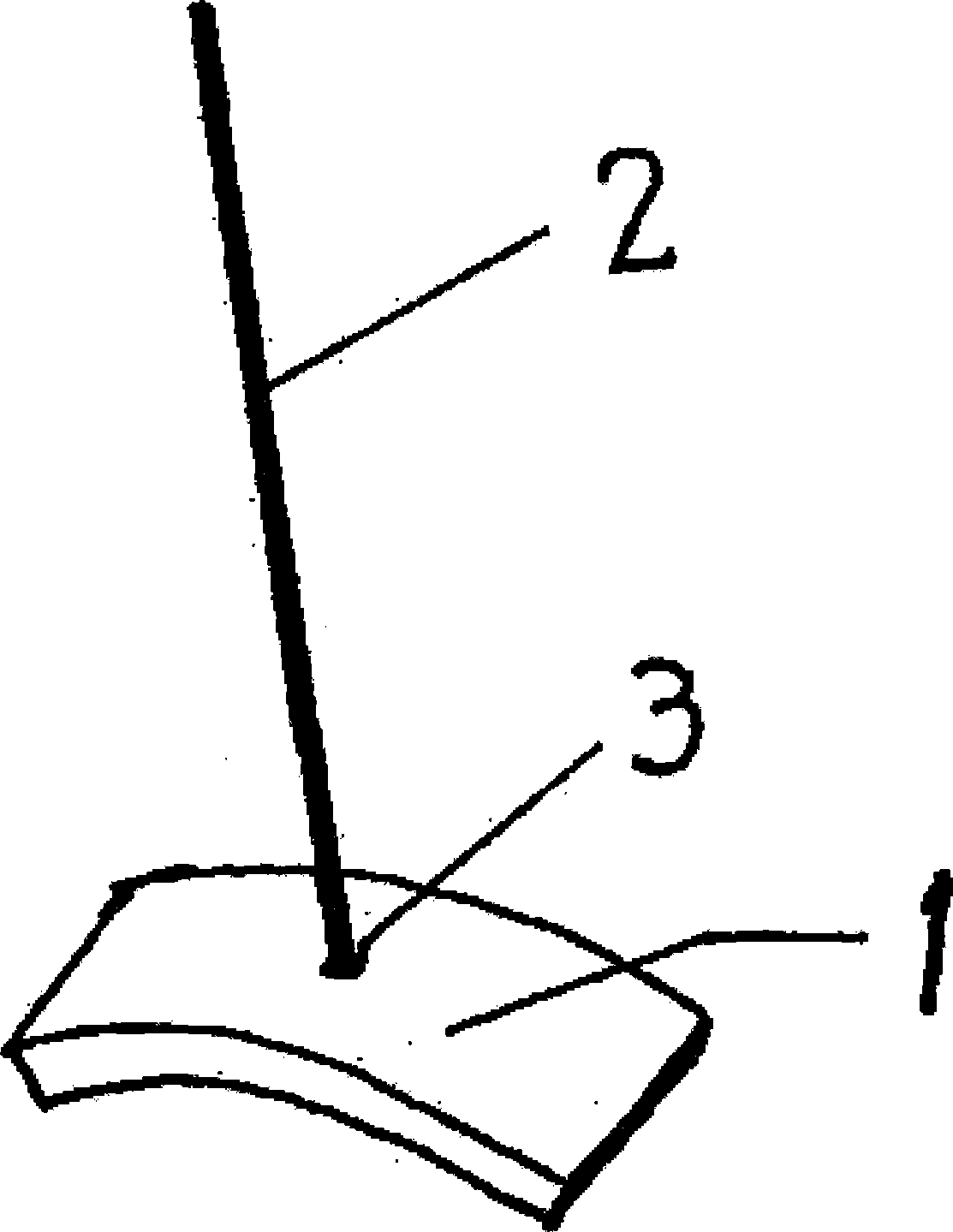

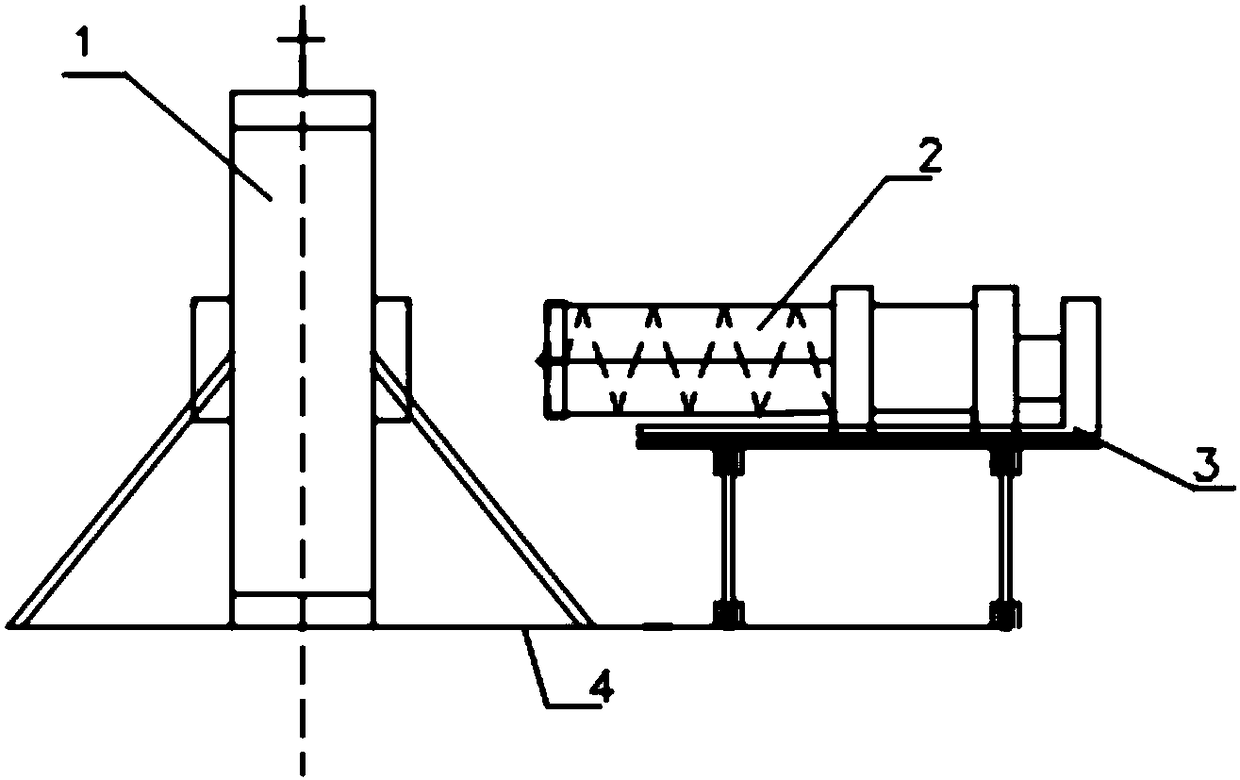

Mechanical shaft-forming method of shield cutterhead maintenance shaft in tunnel and underground construction

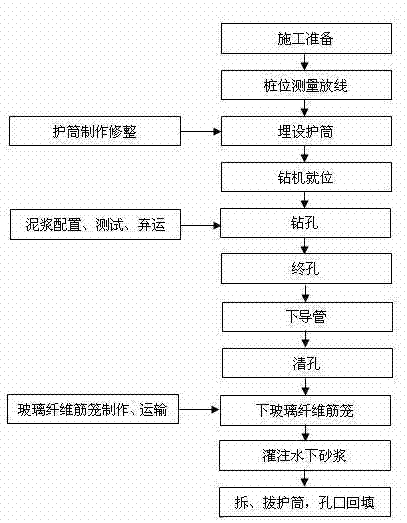

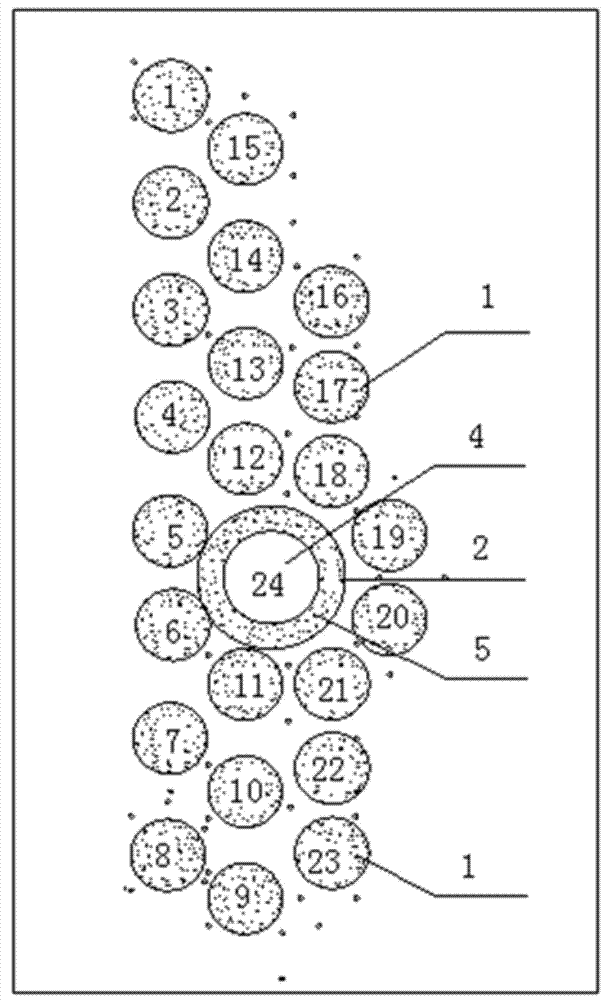

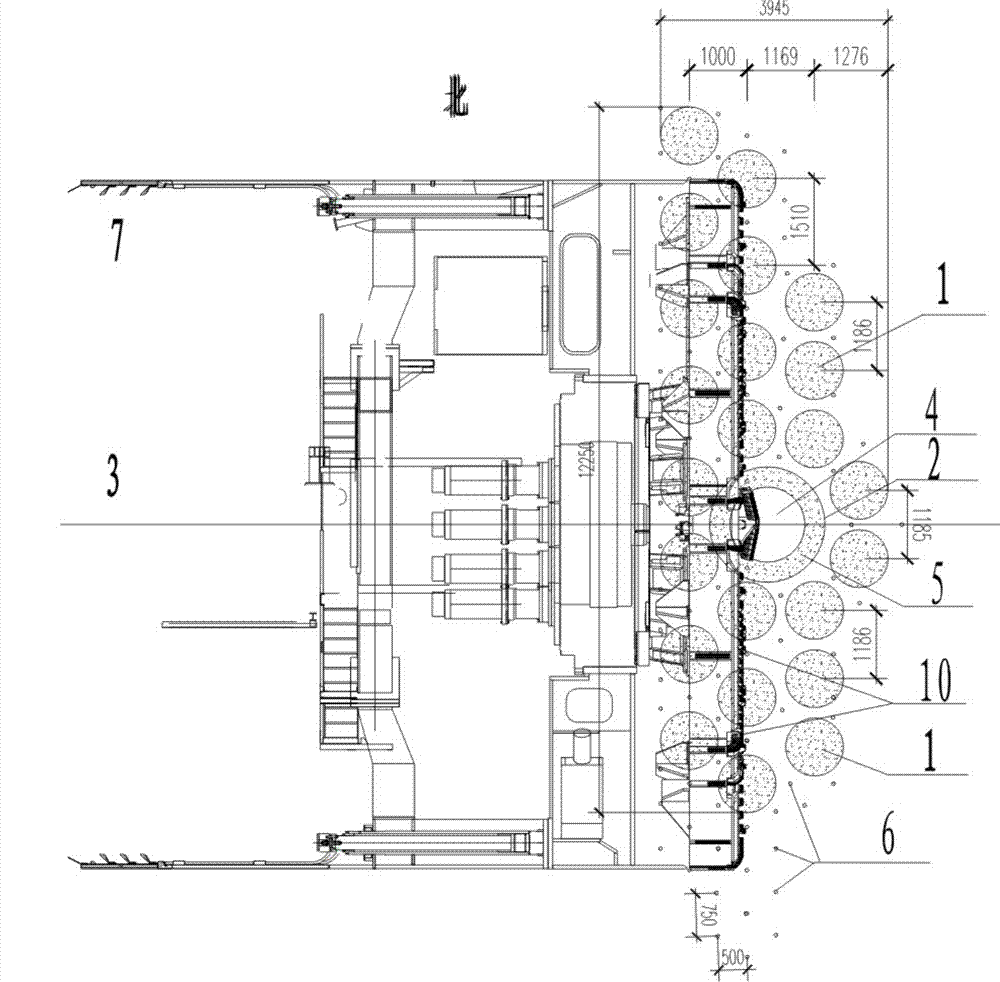

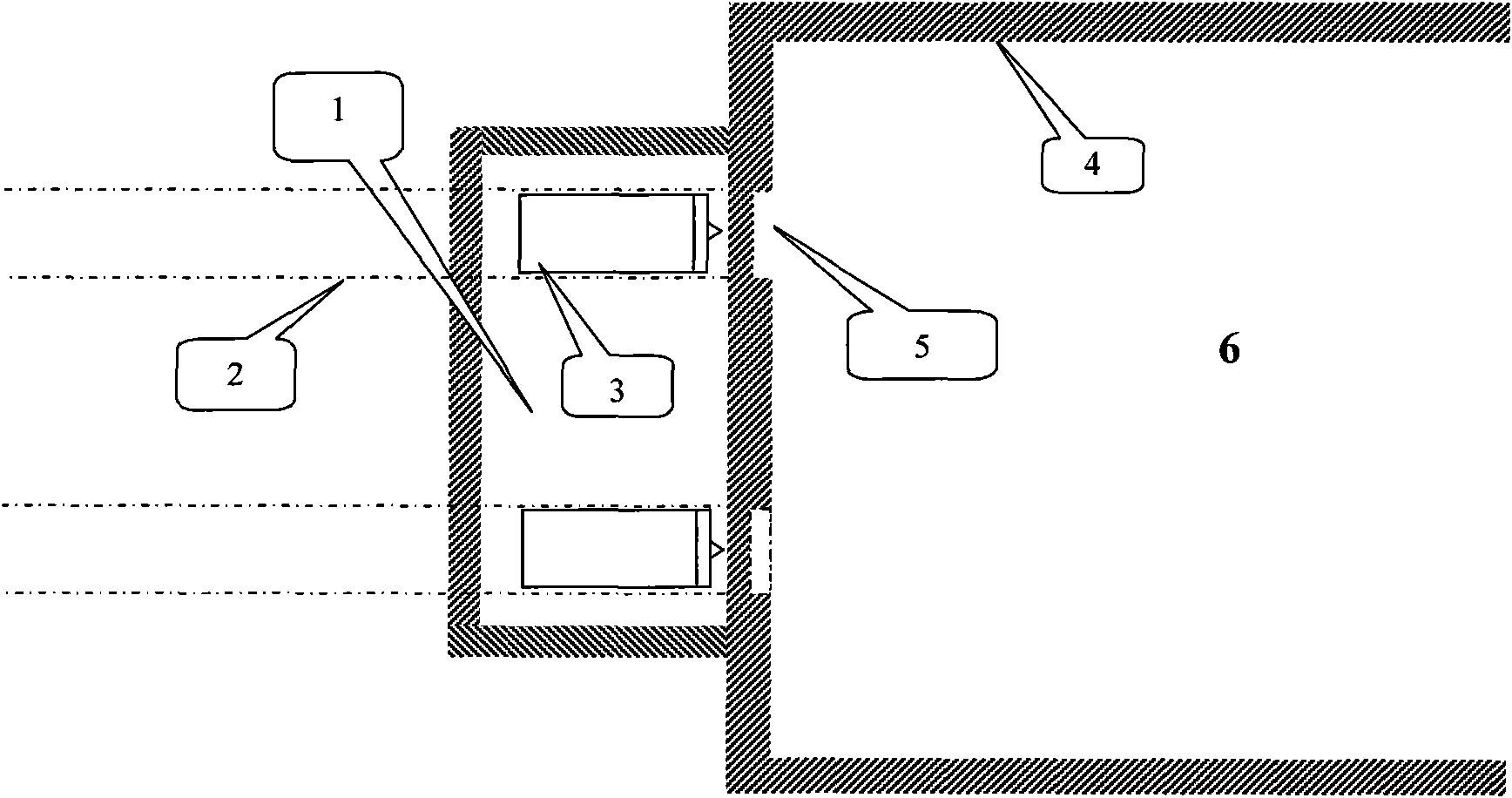

ActiveCN103161476AReduce in quantityShorten the construction periodUnderground chambersTunnel liningGlass fiberShield tunnelling

The invention relates to the technical field of shaft construction, and discloses a mechanical shaft-forming method of a shield cutterhead maintenance shaft in a tunnel and an underground construction. First, a position where a cutterhead needs maintenance in a shield tunnel is marked, and grouting reinforcement is conducted in a reinforcing range of bored cast-in place piles; then glass fiber cast-in-place piles (1) are adopted on a reinforcing range of the shield tunnel with the position of a pre-stop machine as the center; a cast-in-place pile (2) is constructed between pile groups on the tunnel axis (3) of a shield (6), then the shield cutterhead maintenance shaft (8) is formed by drilling of a hollow hole (4) in the middle of the cast-in-place pile (2) by a rotary-drill, and a steel pile casing is pre-buried at the mouth of the shield cutterhead maintenance shaft; then compensation grouting is conducted on a soil body stratum between the pile groups, finally a covered beam (9) is constructed on the top of the cast-in-place pile, and all the piles are connected in an integrated mode. The mechanical shaft-forming method of the shield cutterhead maintenance shaft in the tunnel and the underground construction is convenient to construct, rapid, safe, and capable of greatly reducing the number of excavation constructions, shortening a construction period and reducing construction cost and construction risks, and achieves the purpose that operation space is provided for shield cutterheads and shield cutters.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Double-well type reinforcement method of shield arrival or starting end and double-well type shield arrival method

ActiveCN101781991ASolve the huge risk of water and sand inrushLow costUnderground chambersTunnel liningEngineeringShield tunnelling

The invention belongs to the technical field of shield arrival methods in shield tunnel construction engineering, in particular to a double-well type reinforcement method of a shield arrival or starting end and a double-well type shield arrival method, solving the problems of larger risks and high cost of the traditional shield arrival methods. The double-well type reinforcement method of the shield arrival or starting end is characterized in that an advance well is arranged outside a final arrival well or a station of the shield arrival or starting end. The invention has the advantages that water is blocked outside the advance well in advance by utilizing the advance well so as to ensure that a shield machine carries out arrival construction under the geological condition of no water, thereby radically changing an original geological condition, breaking up the huge risk of the shield arrival into parts, radically avoiding the huge risk of water and sand jetting during shield arrival in an area of a water and sand rich layer and reducing the hazard rate by more than 50 percent at least; and moreover, expenses generated by large-area full section reinforcement are saved to a certain extent. The invention has simple process method, convenient construction, low manufacturing cost and convenient popularization.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Subsequent project and shield driving parallel construction method for long-distance railway tunnel

The invention relates to the technical field of shield tunnel construction, in particular to a subsequent project and shield driving parallel construction method for a long-distance railway tunnel. The method solves the technical problems that conventional railway shield tunnel driving cannot be constructed in parallel with subsequent projects of secondary linings, tunnel bottom longitudinal beams, cable grooves, communication passages and the like and has long construction period and high cost and the like. The method comprises the following steps of: performing shielded supporting facility and construction transport battery truck rail optimization during shield tunnel driving and extension of various pipelines in shield construction; and meanwhile, performing tunnel bottom longitudinal beam construction and secondary lining construction of a soft rock section, performing groove construction when the tunnel bottom and the secondary lining are not casted, detaching a sleeper during changing a tool, spreading a rail at the tunnel bottom, and performing next cycle. The method can be used for communication passage construction, caulking construction and contact net chute construction, and has the advantages of simplicity in process, short construction period, low construction cost, good popularization prospect and the like; and proved by practice, the method gains good economic benefit and social benefit.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Shield tunnel segment lining-anchor rod structure system

InactiveCN101392654AEnhanced longitudinal deformation resistanceReduce sinkingUnderground chambersTunnel liningEngineeringShield tunnelling

The invention discloses a shield tunnel segment lining-anchor rod structural system. Anchor rods are driven around a shield tunnel segment lining, and the effective connection between the anchor rods and the segment lining is established through steel bolts. The shield tunnel segment lining-anchor rod structural system introduces the anchorage function of the anchor rods into a shield tunnel segment lining structure, which can reduce the settlement or the floatation of tunnels, lighten the influence of recessive characters of surrounding soil bodies, strengthen the rigidity of adverse positions such as corners of the tunnels, stratum catastrophe positions and so on, and improve the whole and local stability of tunnel structures.

Owner:SHANGHAI UNIV

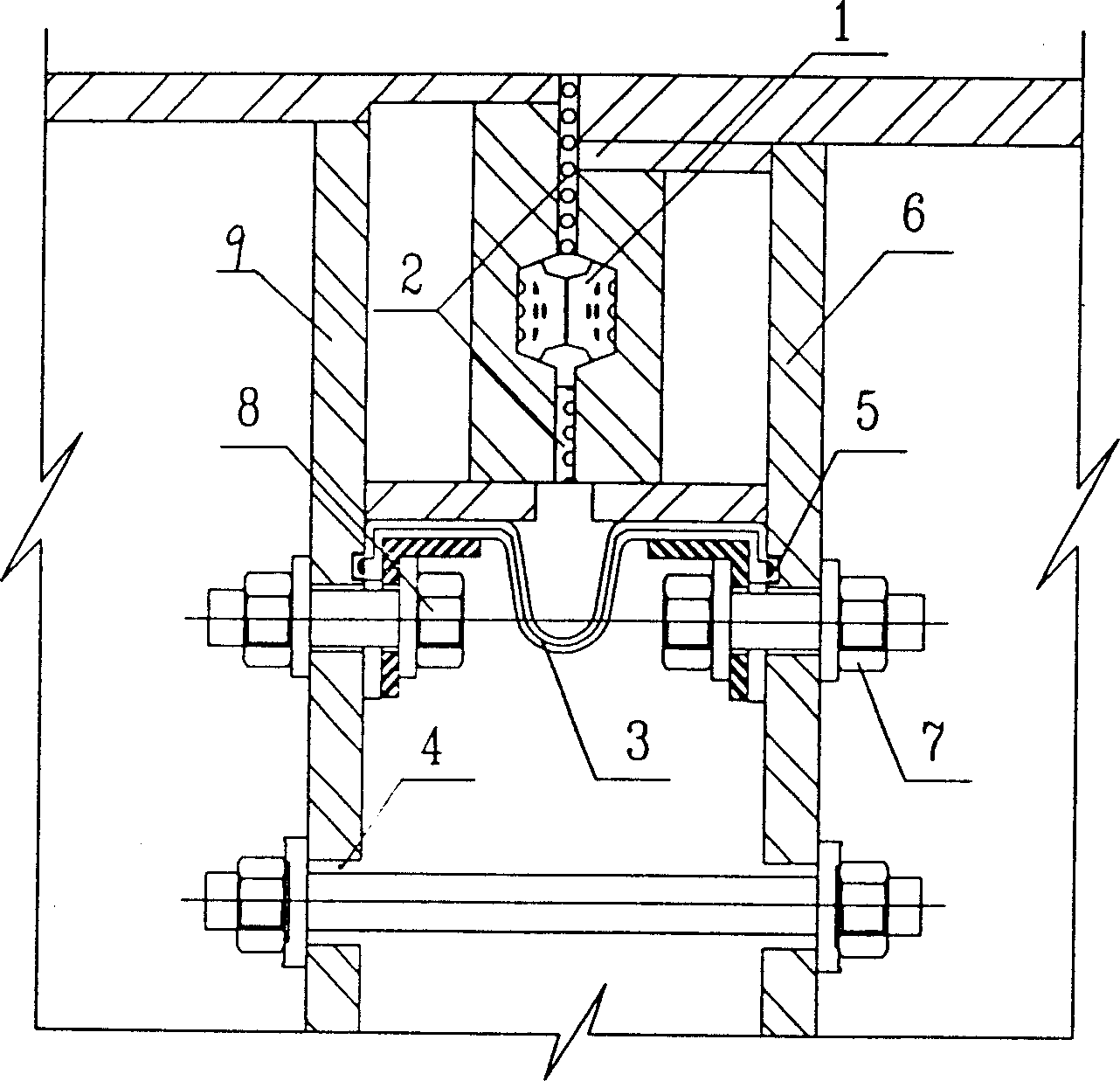

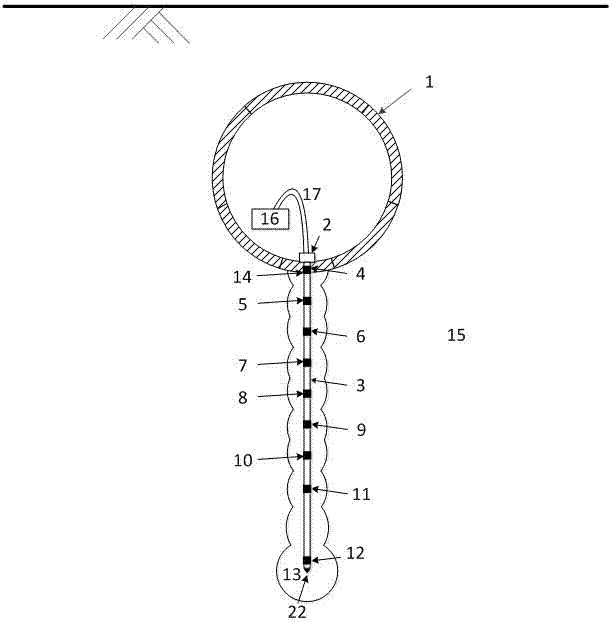

Steel sleeve grouting reinforcement device for settlement control over shield tunnel of soft foundation

ActiveCN103573274AThe purpose of controlling subsidenceUnderground chambersTunnel liningEngineeringShield tunnelling

The invention discloses a steel sleeve grouting reinforcement device for settlement control over a shield tunnel of a soft foundation. A duct piece of the shield tunnel is buried in the soil, a grouting device is arranged in the duct piece of the shield tunnel, one end of a steel sleeve formed by connecting a plurality of TAM units in series is perpendicularly buried in the soil, a pile toe is installed at the bottom end of the steel sleeve, the upper end of the steel sleeve penetrates through a grouting hole in the duct piece of the shield tunnel and is connected with an adapting piece, the adapting piece is fixed to the inner wall of the duct piece of the shield tunnel, one end of a grouting pipe is connected with the grouting device, and the other end of the grouting pipe is inserted into the steel sleeve. The steel sleeve is pressed into the soil below the tunnel through the grouting hole in the duct piece of the shield tunnel, grouting can be carried out on the surrounding soil at any burial depth through the TAM units on the steel sleeve, then a grouting area is formed around the steel sleeve, the steel sleeve and the grouting area can be treated as one mini-type pile at the moment, the mini-type pile is connected with the duct piece of the shield tunnel through the adapting pieces, and the aims of reinforcing the shield tunnel and controlling the settlement of the duct piece of the shield tunnel are achieved.

Owner:ZHEJIANG UNIV

Testing device and method for simulating shield tunnel excavation of karst region

PendingCN108489894ASolve the problem of difficult monitoring work and incomplete measurement itemsComprehensive research impactUsing mechanical meansMaterial analysisMechanical modelsKarst

The invention discloses a testing device and method for simulating shield tunnel excavation of a karst region. The testing device comprises a testing box, a shield excavation device, a supporting frame and a measurement system, wherein the supporting frame is connected with the testing box through a bottom plate; holes are pre-formed in two opposite wall surfaces of the testing box; the shield excavation device comprises a cutterhead, a shield machine body, a fixed motor and an outer pipe; the supporting frame comprises a counter-force support, a worktable and a thread steel column; the measurement system comprises a sedimentation rod, a displacement sensor and a pressure box. According to the testing device and method, disclosed by the invention, the problems in actual engineering that the monitoring work is difficult and measurement projects are not comprehensive are solved. More data foundations are provided for establishing mechanical models for tunnel excavation under different working conditions, and comprehensively researching influences of the shield tunnel excavation of the karst region on a soil body and a surrounding soil body deformation mechanism. A test design is carried out based on a similarity principle so that an obtained testing result has certain reference meaning on predication of actual surrounding soil body deformation of the karst region and stratum displacement.

Owner:DALIAN JIAOTONG UNIVERSITY

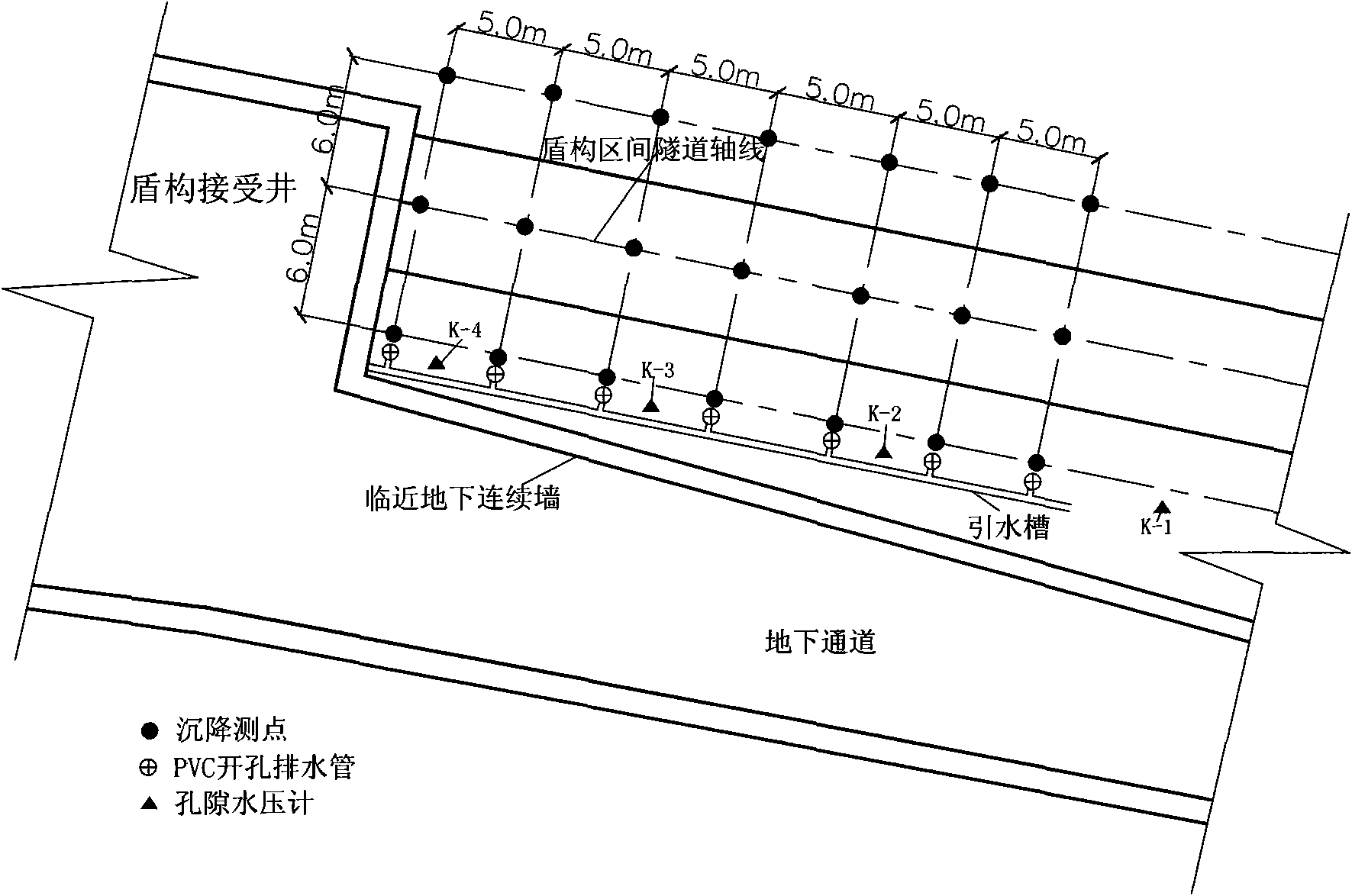

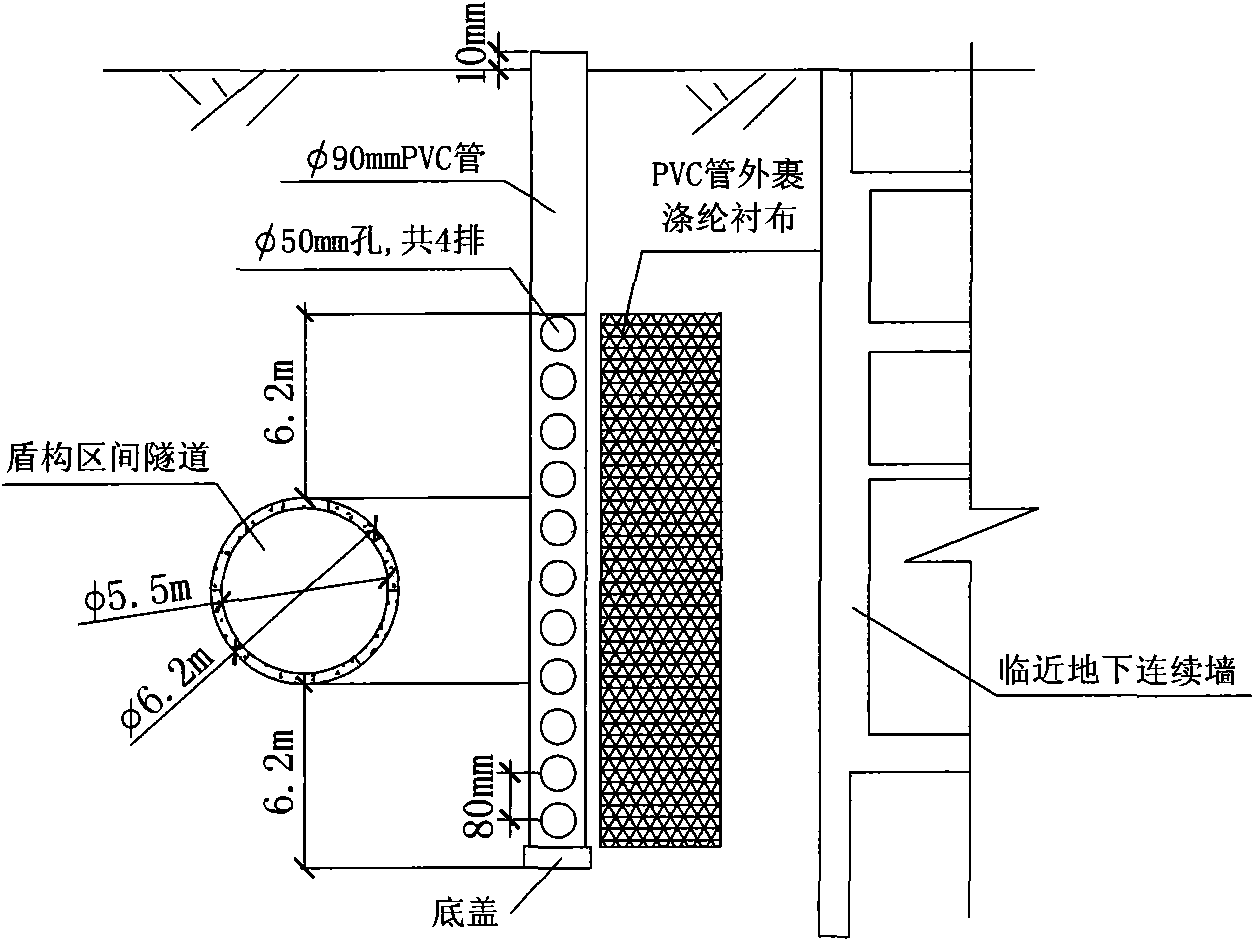

Control method for shield tunnel axis having underground structure on adjacent side

InactiveCN101598023AAddressing the impact of controlsEasy to useUnderground chambersTunnel liningElement modelQuality control

The invention relates to a control method for a shield tunnel axis having an underground structure on an adjacent side, comprising the following steps: using a three-dimensional finite element model to numerically stimulate the shield, setting a range L1 in which the underground structure starts influencing on near pass-through of the shield and a length L2 of the segment in which priority needs to be given to the tunnel axis; regarding a segment that is 20 meters away from the focused protection segment L2 as an experimental advancing section of the shield; installing a PVC pipe having the diameter of d1 and an opening on the side thereof in the soils between the shield tunnel and the adjacent underground structure in the range L2 determined by step (1), increasing channels from which pore water is drained and decreasing aggregation of pressure of the pore water; accurately measuring indicators that control the quality of the tunnel axis; and monitoring and real-time regulating. The invention solves the problem that the control of the shield tunnel axis is influenced by the existence of the underground structure, guarantees normal usage of the underground structure and quality control of the shield tunnel axis, and is suitable for similar working conditions.

Owner:SHANGHAI JIAO TONG UNIV

Method for blasting closed rock of shield tunnel in complex strata

The invention discloses a method for blasting closed rock of a shield tunnel in complex strata, comprising the following steps: (1) designing and arranging holes; (2) drilling holes directly on the ground or water surface; (3) checking the holes; (4) charging explosive; and (5) blasting the closed rock. The holes are directly drilled on the ground or water surface, and the explosive explodes in the closed rock in underground shield tunnel to blast the closed rock, wherein the particle size of the blasted rock meets the boring and deslagging requirements of a slag shield tunnel boring machine so that the slag shield tunnel boring machine can bore normally, the strata around the shield tunnel can not be damaged, and the medium around the shield tunnel can be kept intact and stable. The technology ensures convenience in construction, saves time, construction period and cost, is safe, efficient and environment-friendly and can be widely used for blasting the closed rock of the shield tunnel in the complex strata.

Owner:GUANGDONG BLASTING ENG +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com