Subway tunnel shield end reinforcing body and reinforcing method

A technology of tunnel shield and reinforcement, which is applied in tunnels, earthwork drilling, infrastructure engineering, etc., can solve problems such as excessive surface deformation, collapse, safety accidents, etc., and achieve safety, uniform strength, and short construction period for breaking the door. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

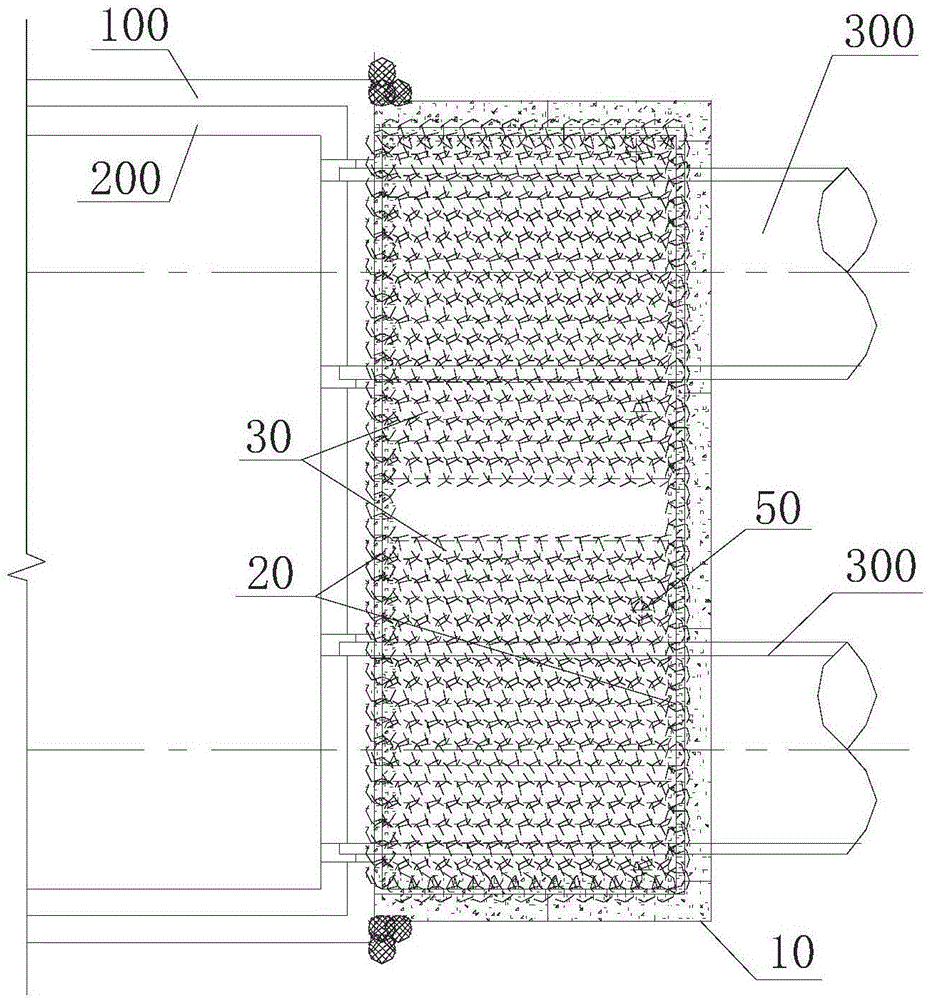

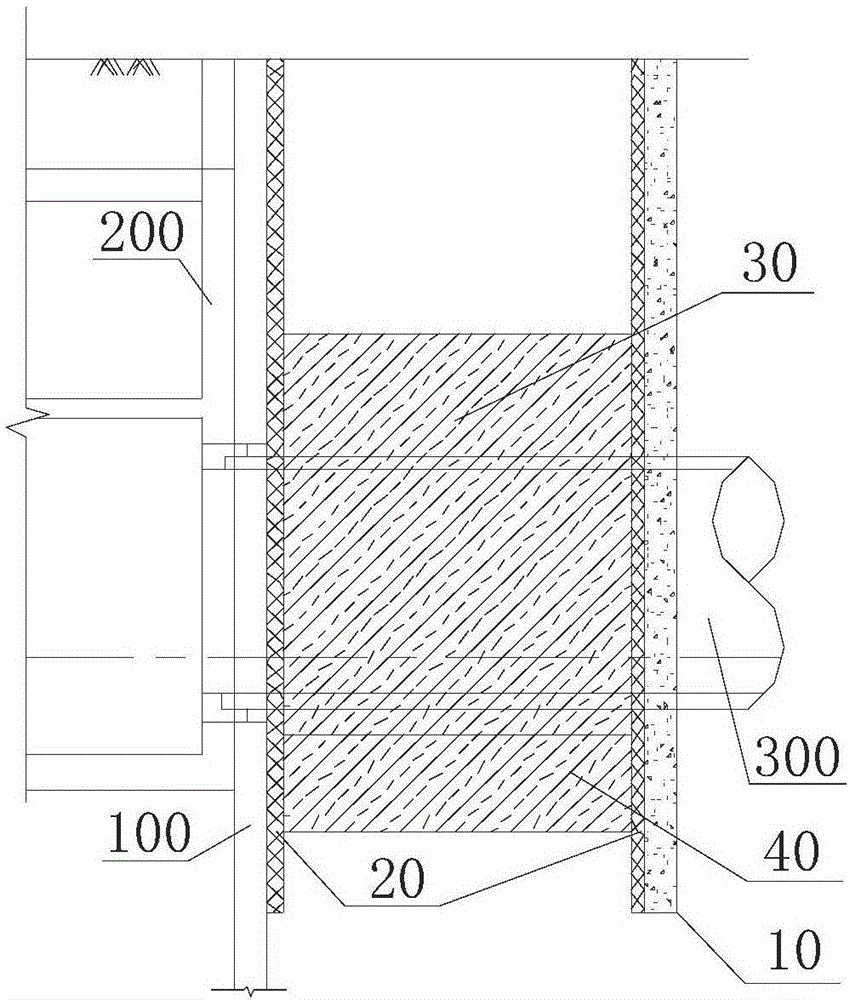

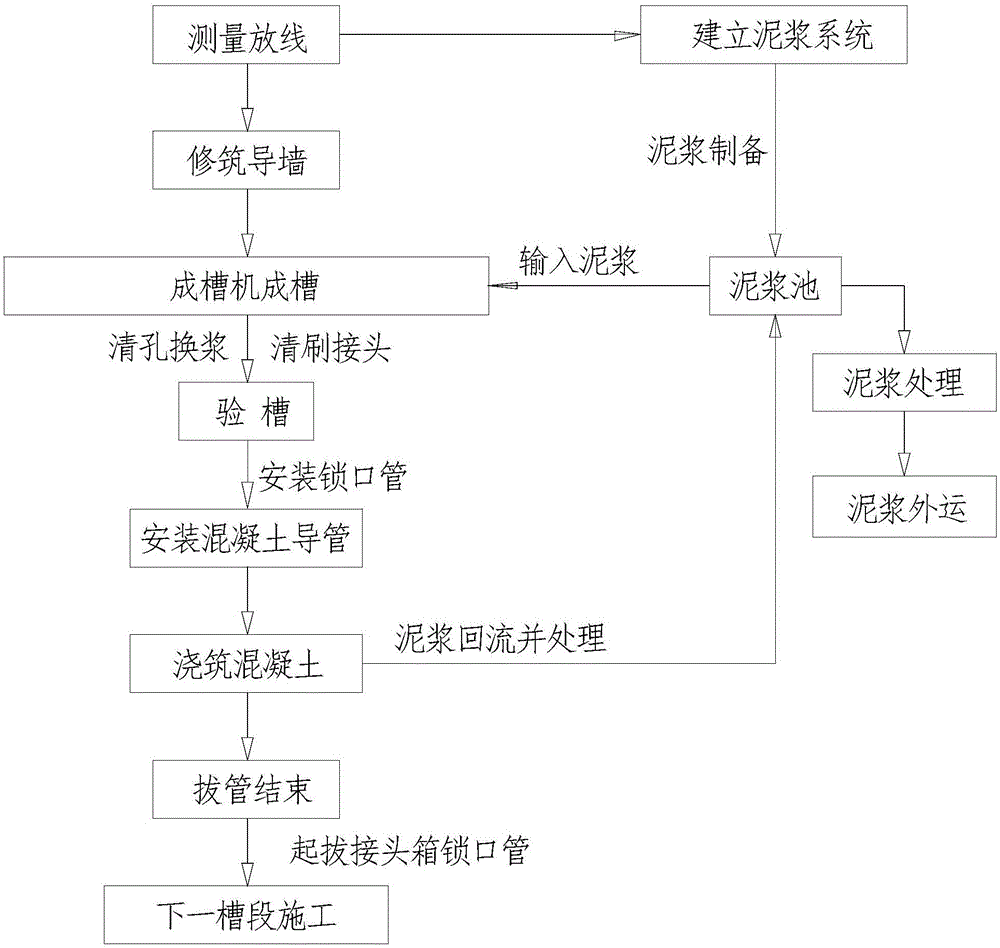

[0048] see figure 1 and figure 2 , the reinforced body at the end of the subway tunnel shield is arranged at the rear end of the enclosure structure 100 of the subway tunnel. The reinforced body includes a concave ground connection wall 10 on the outside and a three-axis stirring pile located inside the ground connection wall 10 Reinforcement structure 30, ground connection wall 10 and three-axis mixing pile reinforcement structure 30, and three-axis mixing pile reinforcement structure 30 and enclosure structure 100 are lapped by high-pressure rotary grouting piles 20, 0.5 meters below the bottom of shield tunnel 300 to Sleeve valve pipe grouting reinforcement 40 is used within 3 meters; the ground connection wall 10 is a C20 plain concrete wall with a total height of 20.845 meters and a depth of 5m below the bottom of the shield tunnel 300; the width of the three-axis mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com