Patents

Literature

250results about How to "Clearance adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

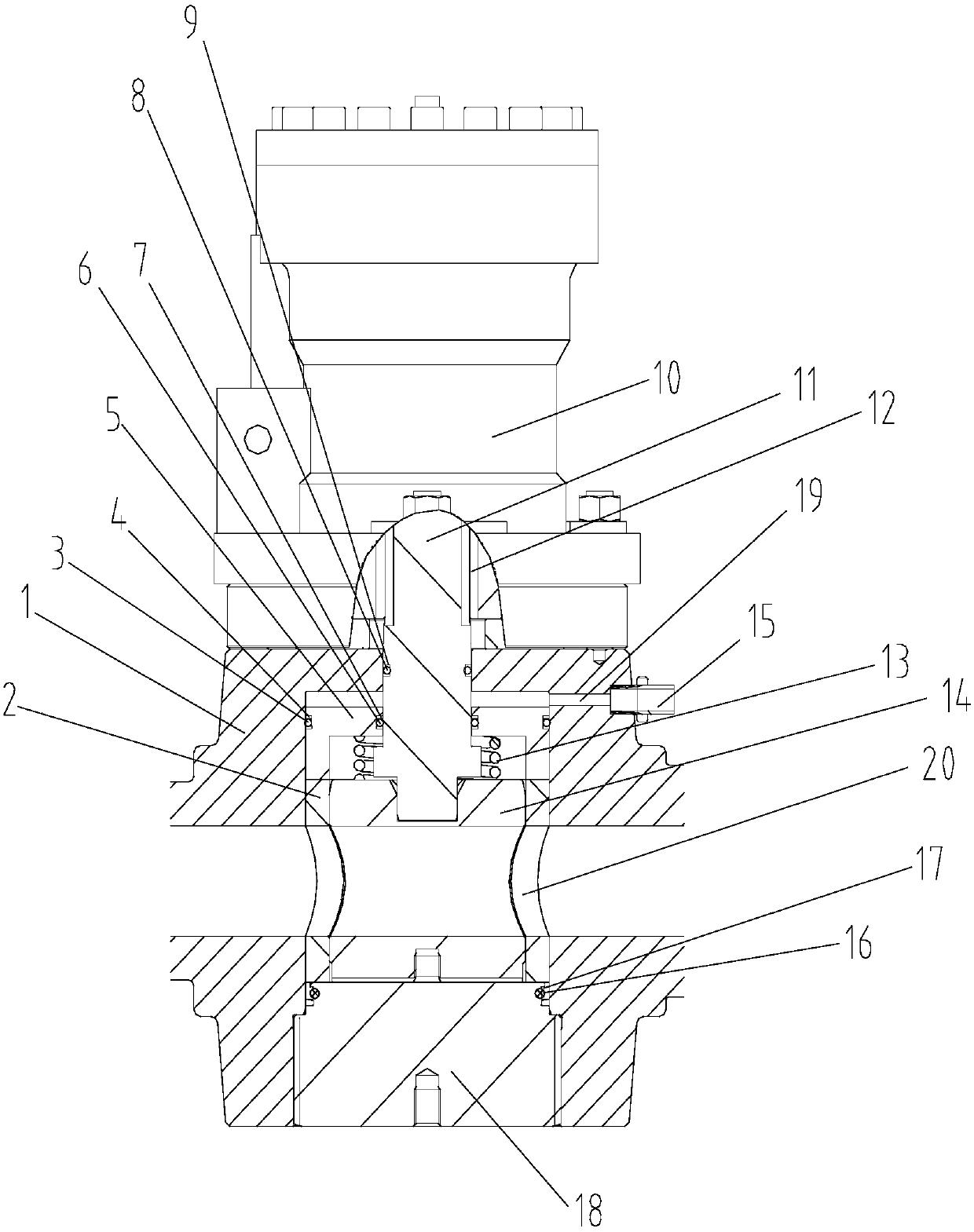

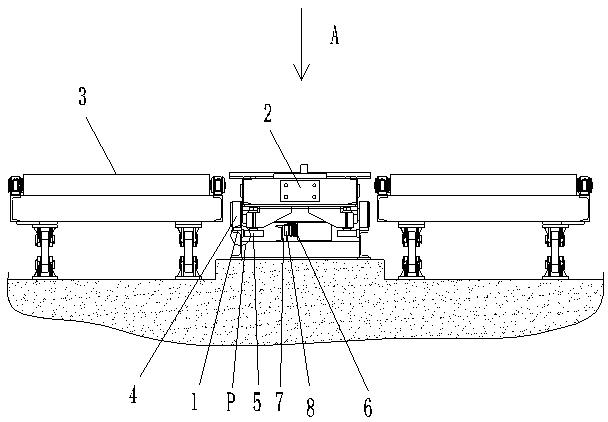

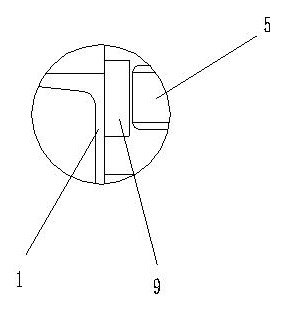

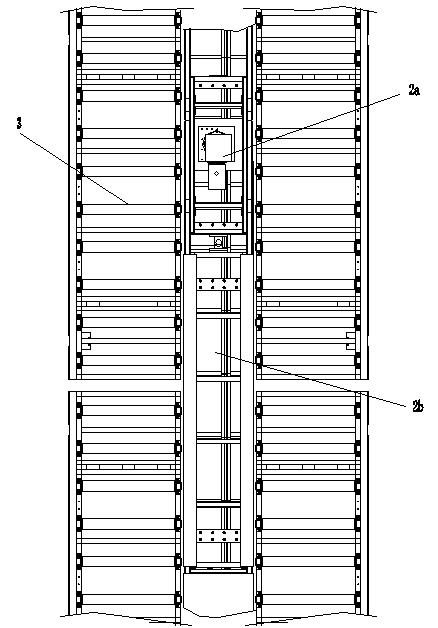

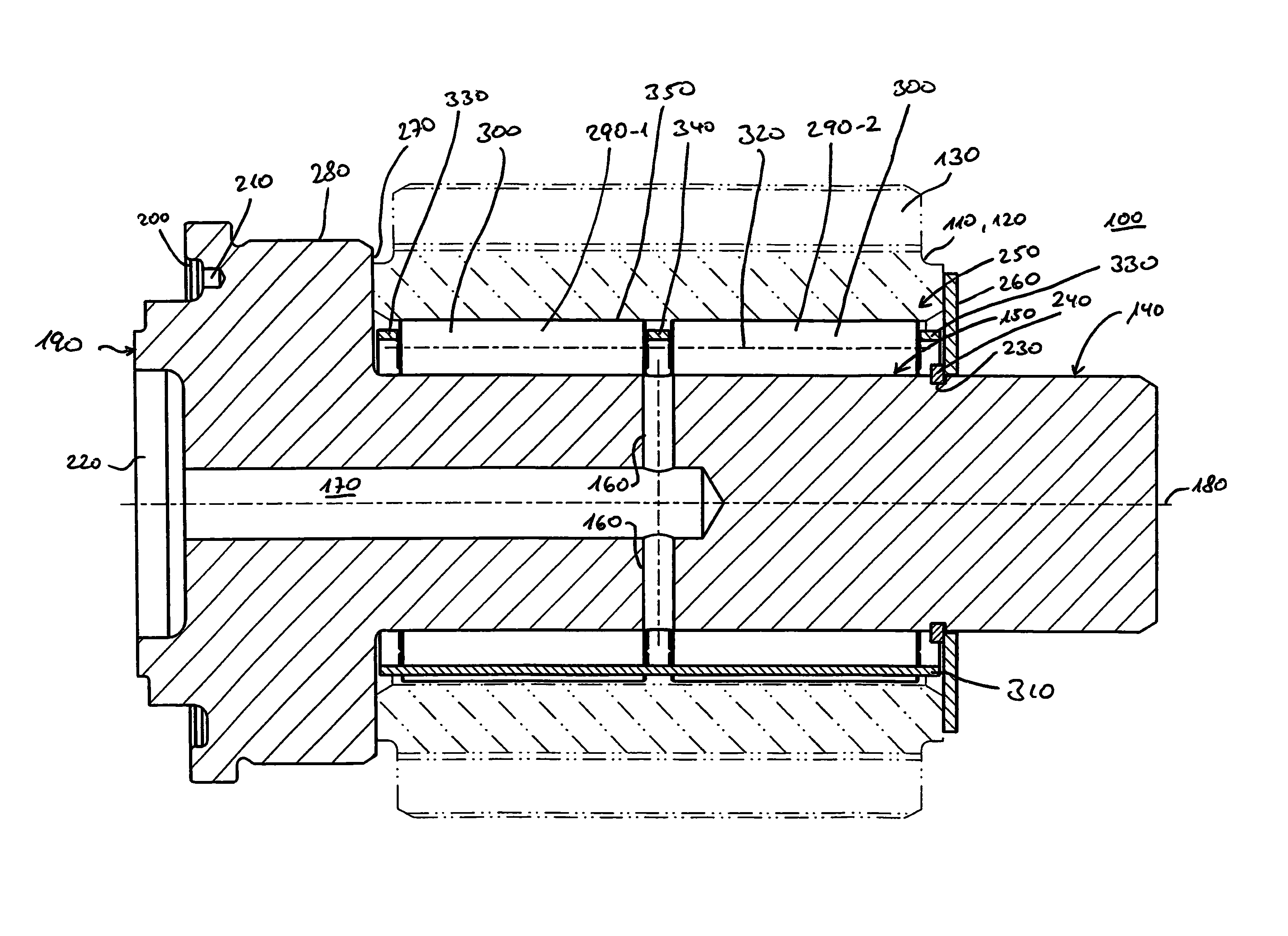

Anti-sand-accumulation plug valve

ActiveCN108036071AClearance adjustableGap noSpindle sealingsPlug valvesEngineeringMechanical engineering

The invention relates to the technical field of oil-gas field construction operation equipment, in particular to an anti-sand-accumulation plug valve which comprises a valve body, a valve cover and aplug rod arranged in the valve body. The valve body is connected with the valve cover; the lower end part of the plug rod is connected with a plug; a driver is arranged on the upper end part of the valve body and is connected with the valve body; the driver transmits a torque to the plug rod through a flat key; a sealing rubber core is arranged on the outer part of the plug; a piston is arranged on the upper part of the sealing rubber core; an annular seal cavity is formed among the plug, the plug rod and the piston; a spring is arranged in the seal cavity; the piston, the plug rod, the sealing rubber core and the plug are located in an inner core of the valve body; the inner core of the valve body communicates with an oil passage; and the oil passage is filled with hydraulic oil for driving the piston to move up and down. According to the anti-sand-accumulation plug valve provided by the invention, a gap between the sealing rubber core and the plug can be adjusted, and no gap exists among the plug, the sealing rubber core and the valve body during a pressure-bearing and fluid conveying process, so that sand is prevented from being accumulated.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

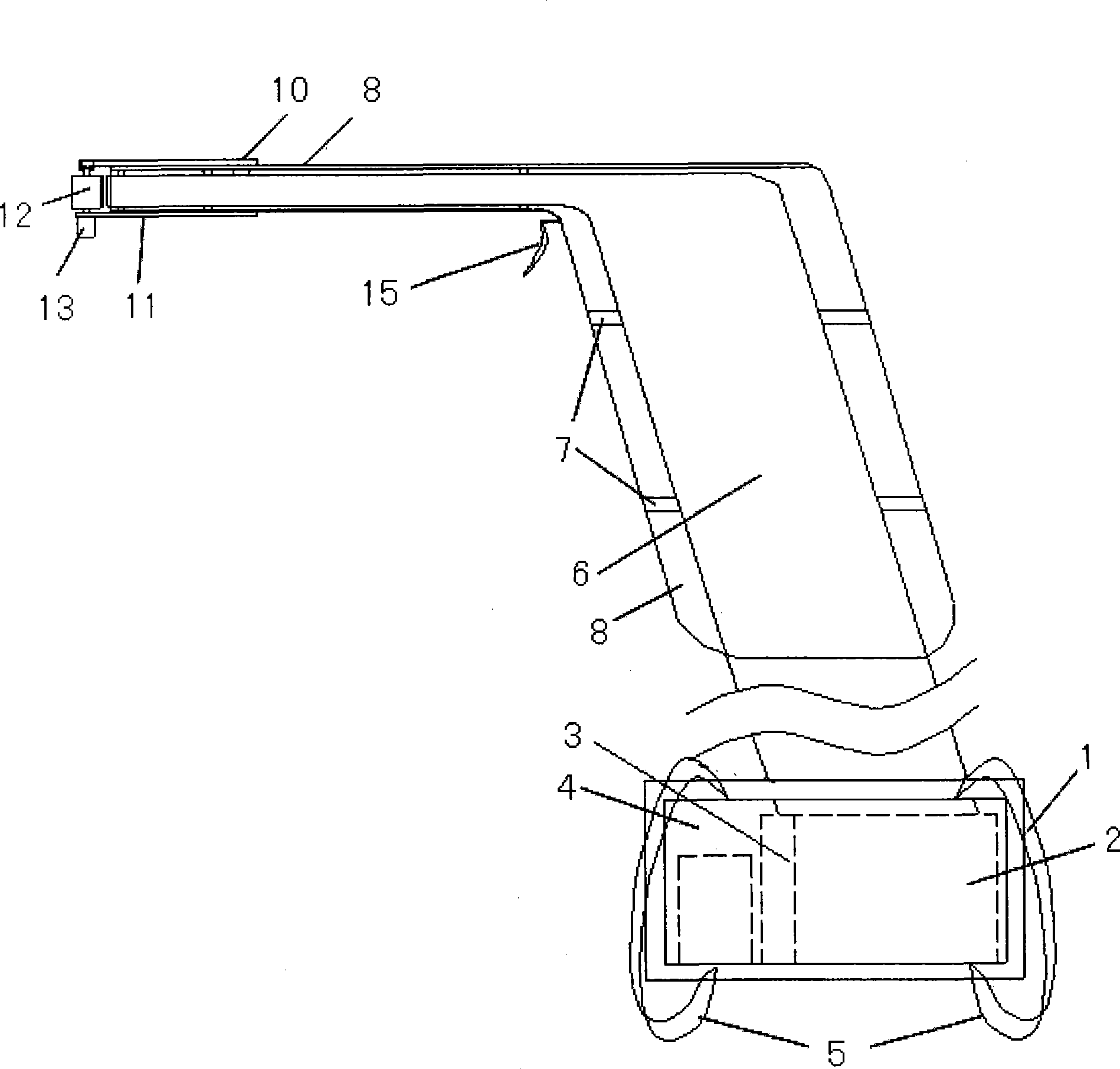

Backpack medlar-picking machine

The invention relates to a backpack medlar picking machine, and is characterized in that the picking machine comprises a backpack box, wherein a strap is tied up on the outside of the backpack box, and a fruit collecting box, an electric suction fan and a storage battery are arranged in the backpack box; the suction opening of the electric suction fan is communicated with the fruit collecting box, the inlet of the fruit collecting box is connected with a soft suction pipe, the periphery of other end of the soft suction pipe is connected with a handle, the upper part of the front end of the handle is provided with two upper fixing plates at intervals, and correspondingly, the lower part of the handle is provided with two lower fixing plates at intervals; a roller driven by a roller electric motor is arranged between each fixing plate and each lower fixing plate, soft brushes are arranged on the two rollers respectively, and a gap which faces the mouth of the soft suction pipe is kept between the two rollers. A manually operated switch is arranged at the handle and is connected with the electric suction fan, the roller electric motor and the storage battery. The backpack medlar picking machine utilizes an air suction pipeline and a roller structure to separate medlar fruits and fruit branches, so that damage to branches and leaves is reduced.

Owner:CHINA AGRI UNIV

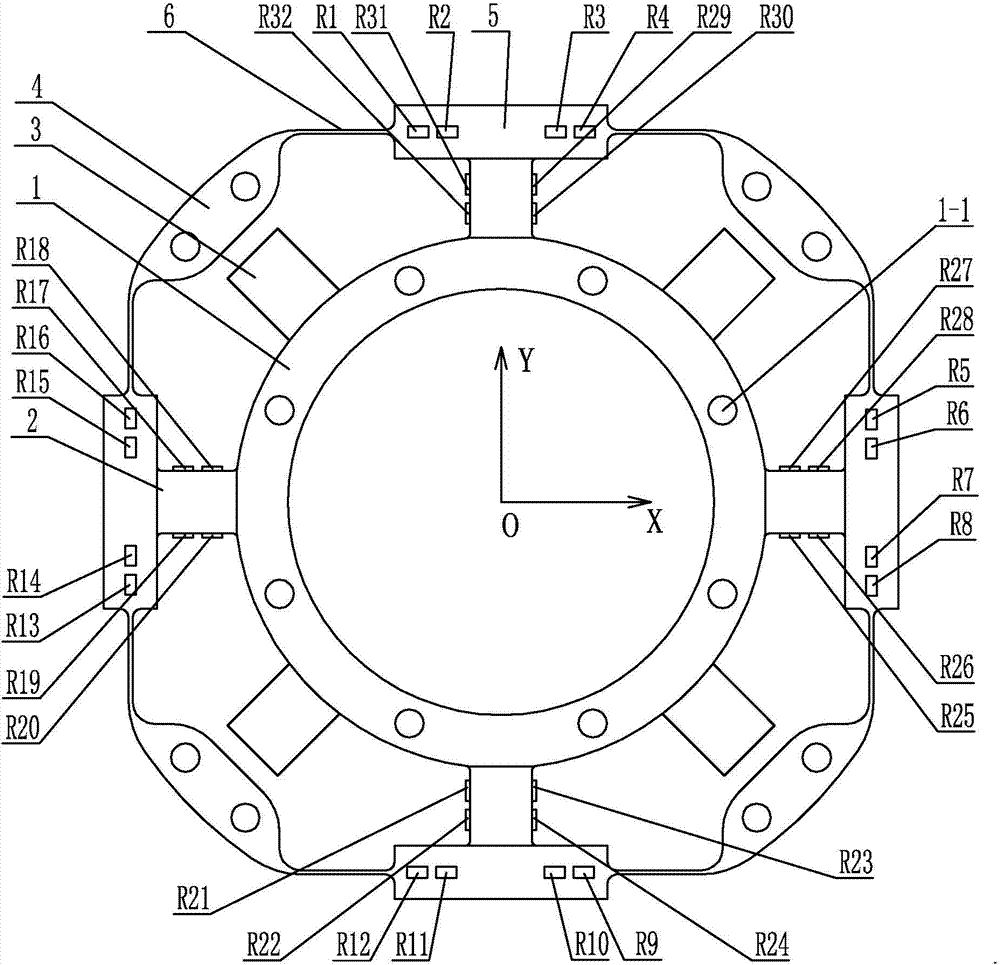

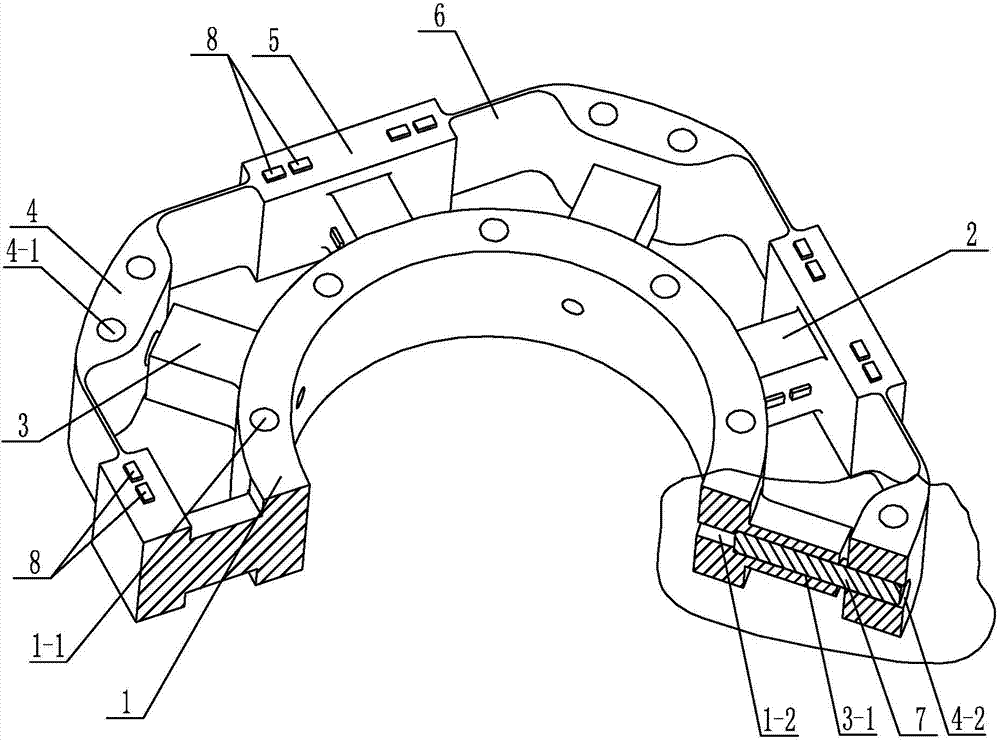

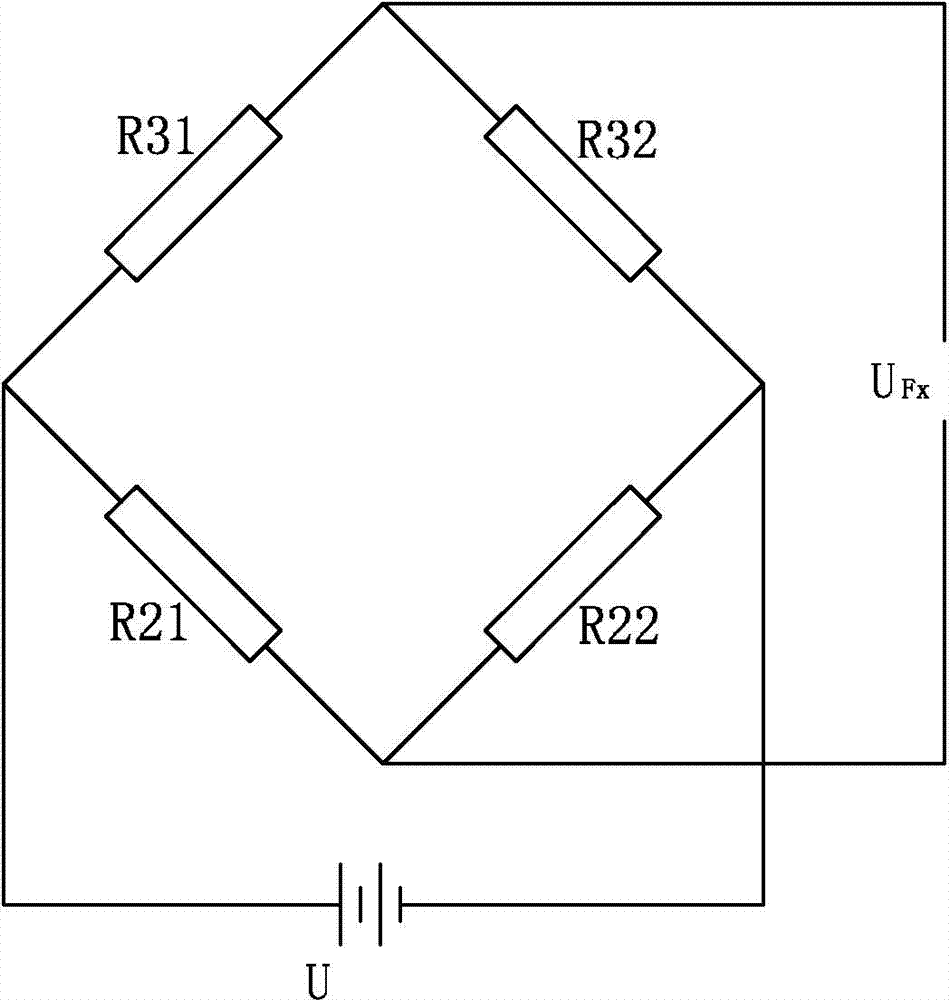

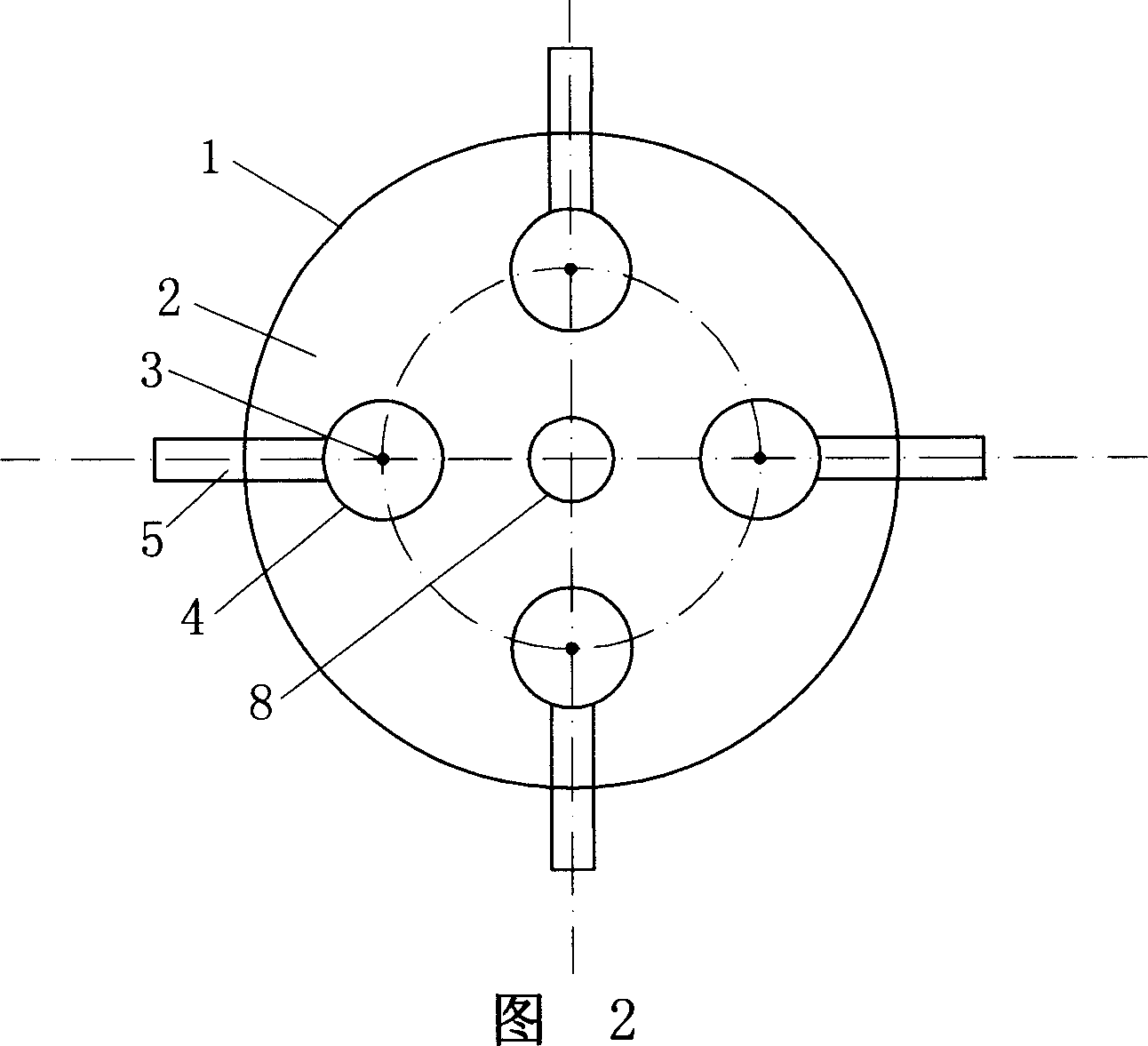

Cross-beam-type six-dimensional force sensor with overload protection function

ActiveCN103528726AIncrease stiffnessClearance adjustableForce measurementInterference fitElectrical resistance and conductance

The invention provides a cross-beam-type six-dimensional force sensor with an overload protection function, relates to a six-dimensional force sensor, and aims to solve the problems that the conventional six-dimensional force sensor adopts a bolt way for achieving overload protection, so that the gap precision and the strength and the rigidity of the whole sensor after overload are difficultly guaranteed. Four inner beams and four overload protection beams are uniformly arranged along the outer wall of an inner ring in a staggered way; four outer beams are arranged on the outer sides of the four inner beams; the four outer beams are in one-to-one correspondence with the four inner beams; an outer ring is correspondingly arranged on the outer side of each overload protection beam; one outer beam is arranged between each two adjacent outer rings; the two ends of each outer beam are fixedly connected with the outer rings through connecting plates respectively; protection pins are in interference fit with through holes of the overload protection beams; the protection pins are in clearance fit with technical through holes of the outer rings; two resistance strain gauges are adhered to each of the two side surface of each inner beam; two resistance strain gauges are adhered to each of the two sides of the upper end surface of each outer beam. The cross-beam-type six-dimensional force sensor with the overload protection function is applied to industrial automation, automobiles, ship building, military industry or robots.

Owner:HARBIN INST OF TECH

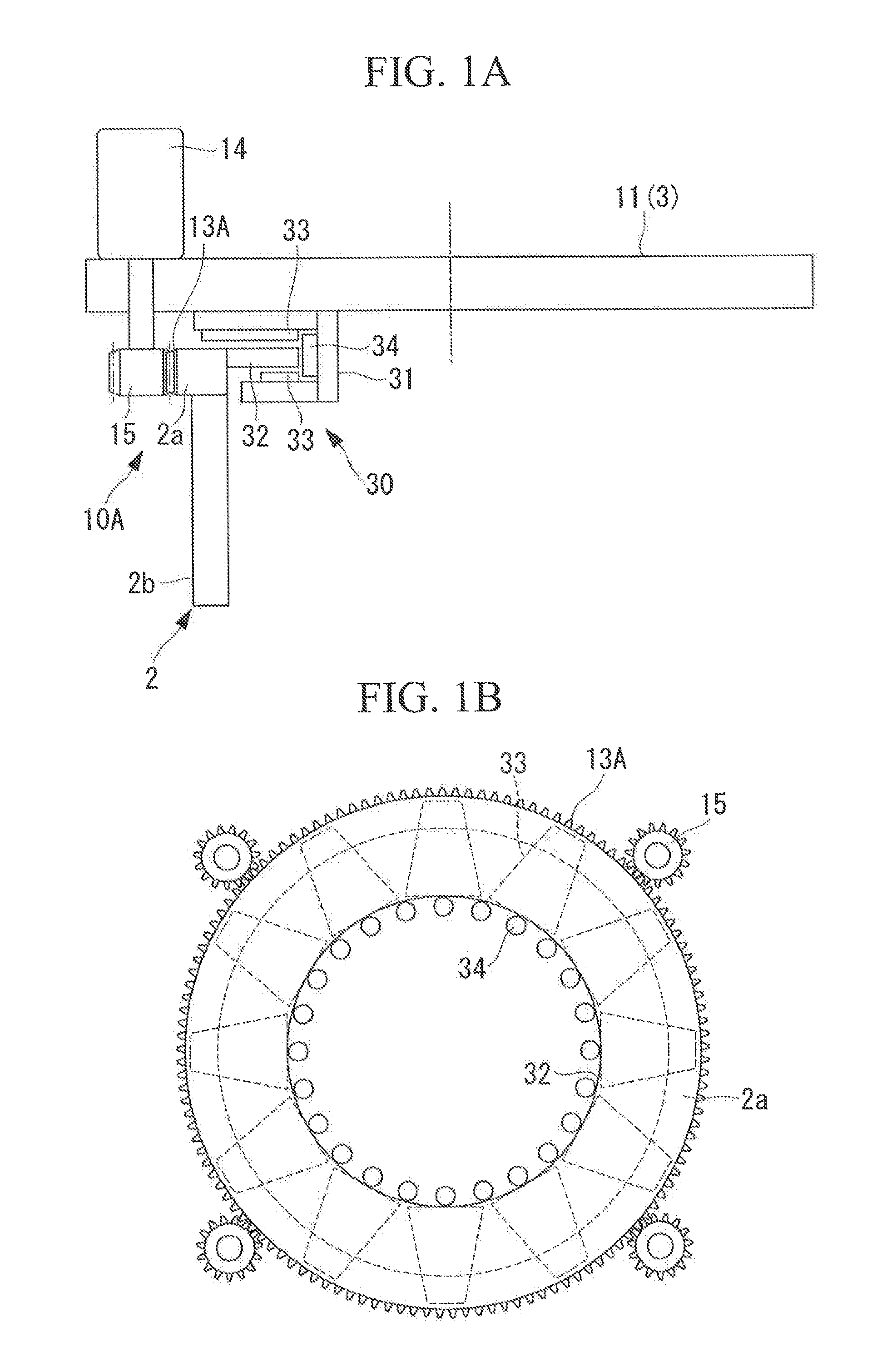

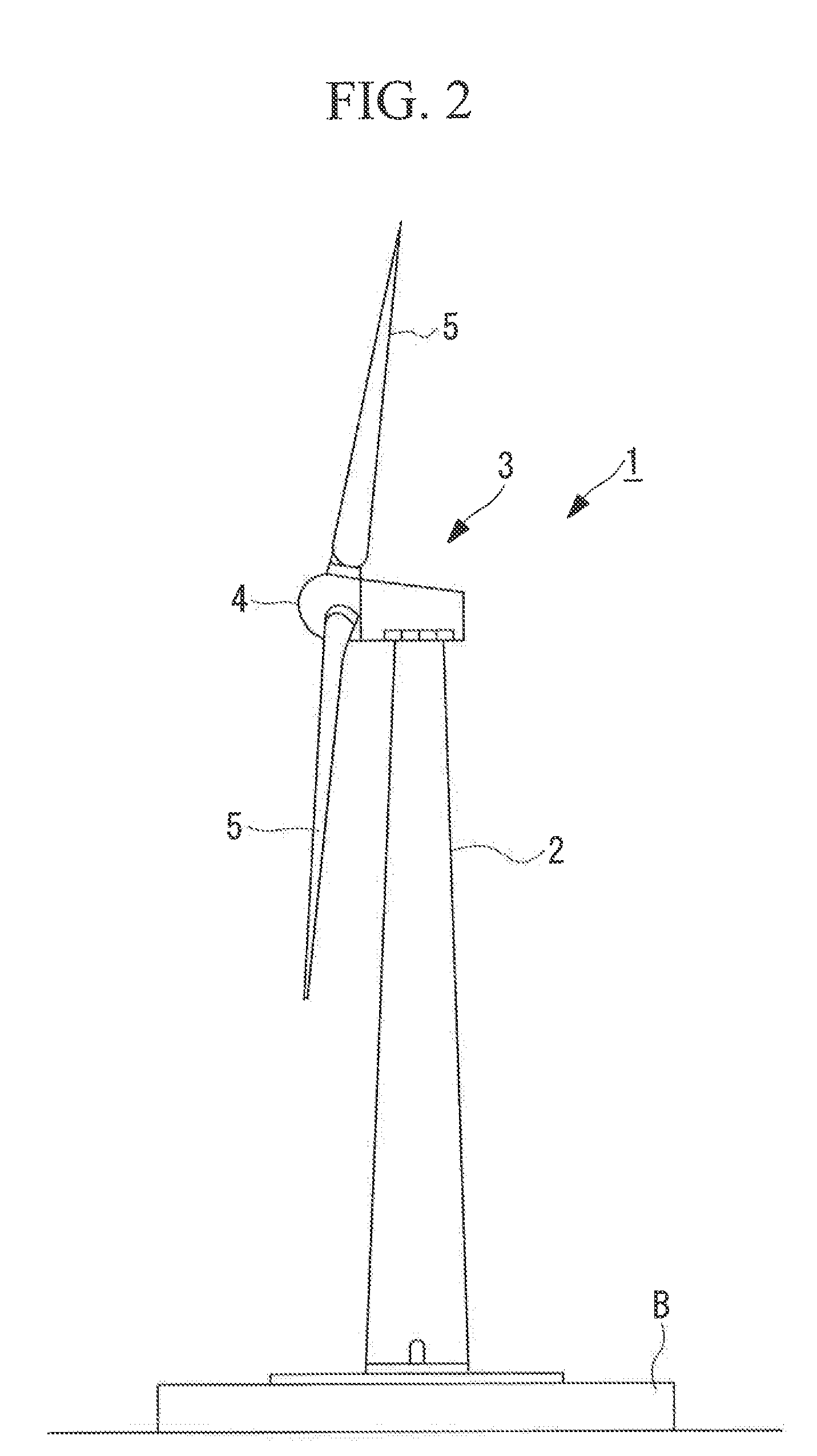

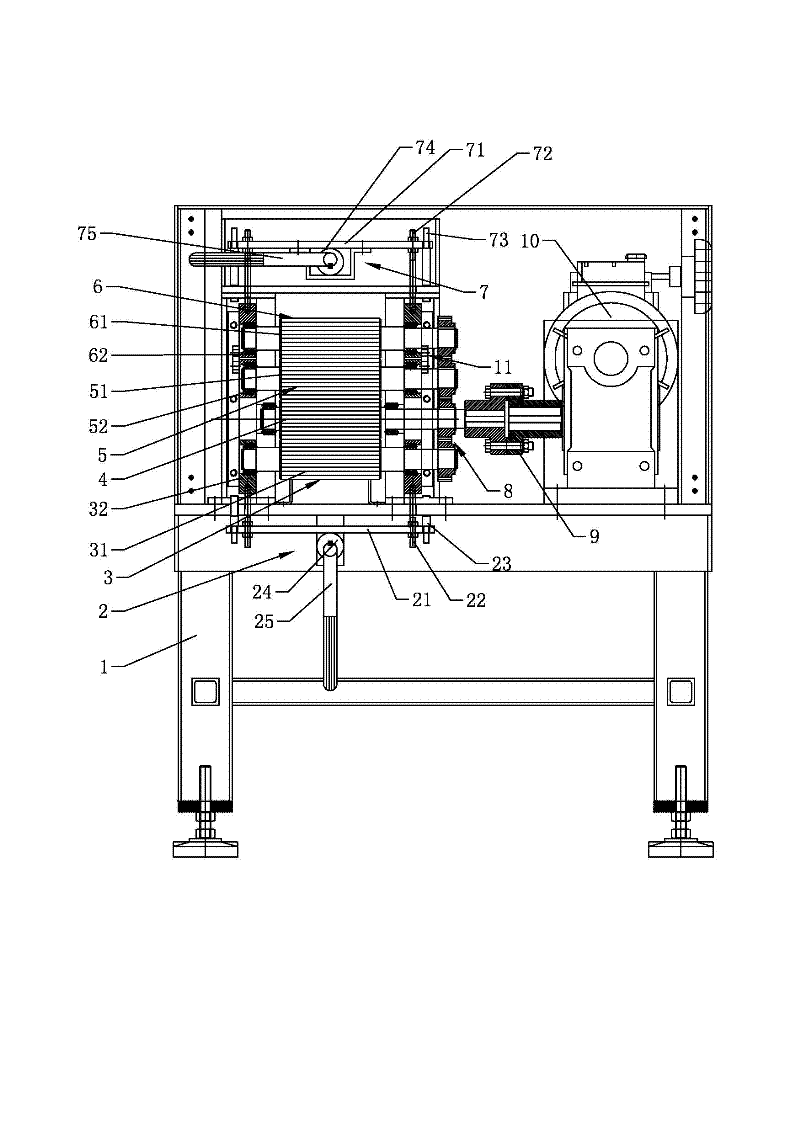

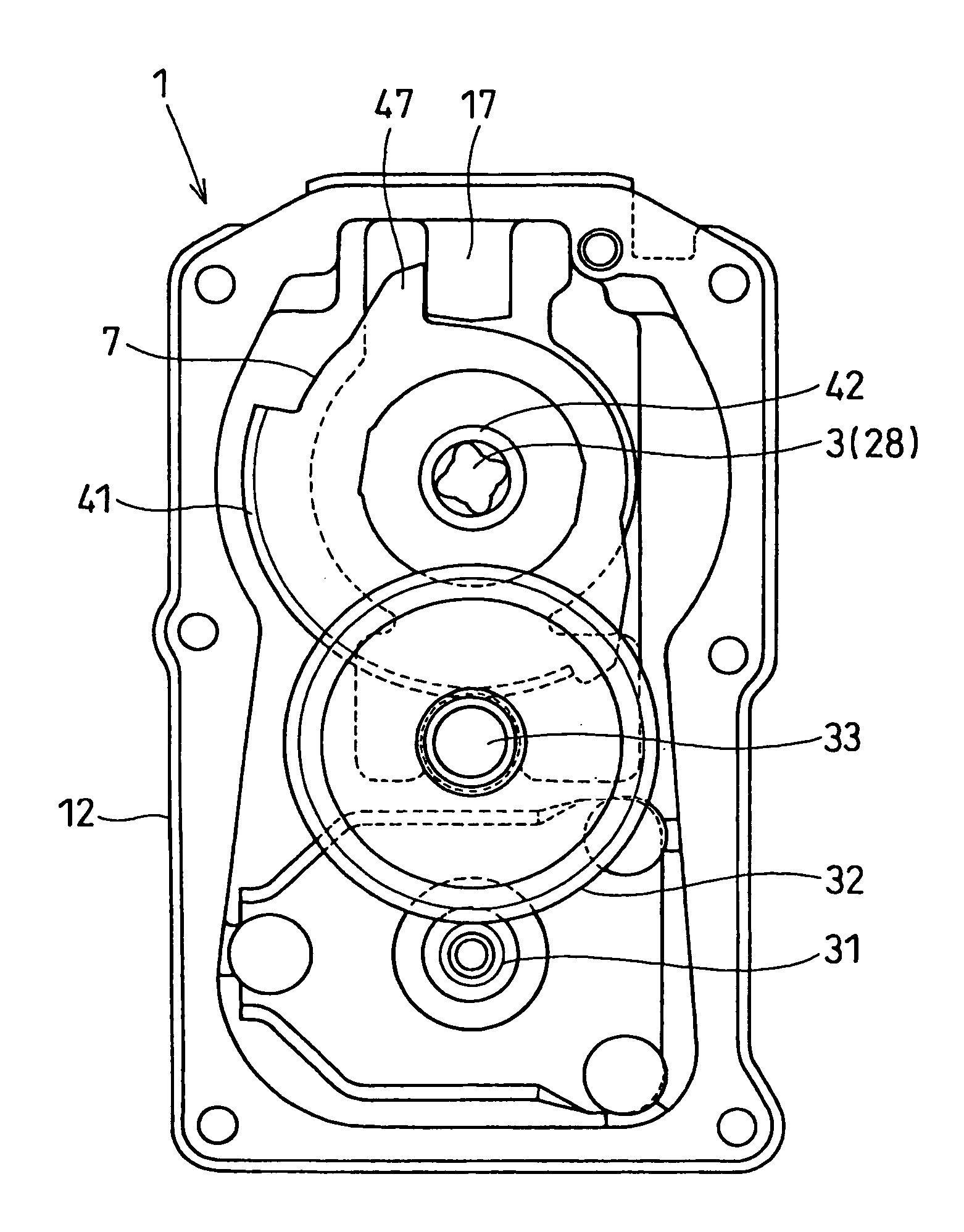

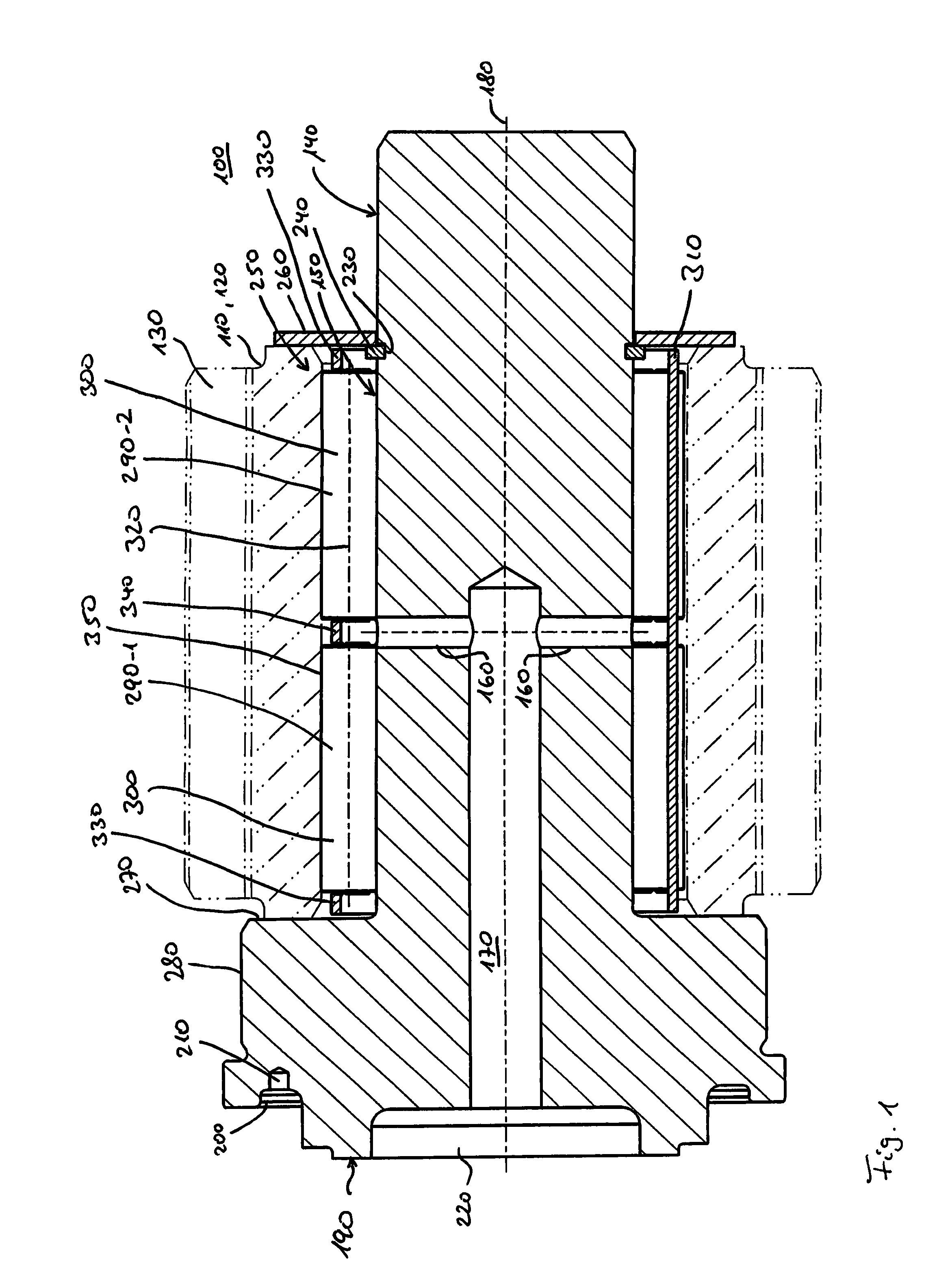

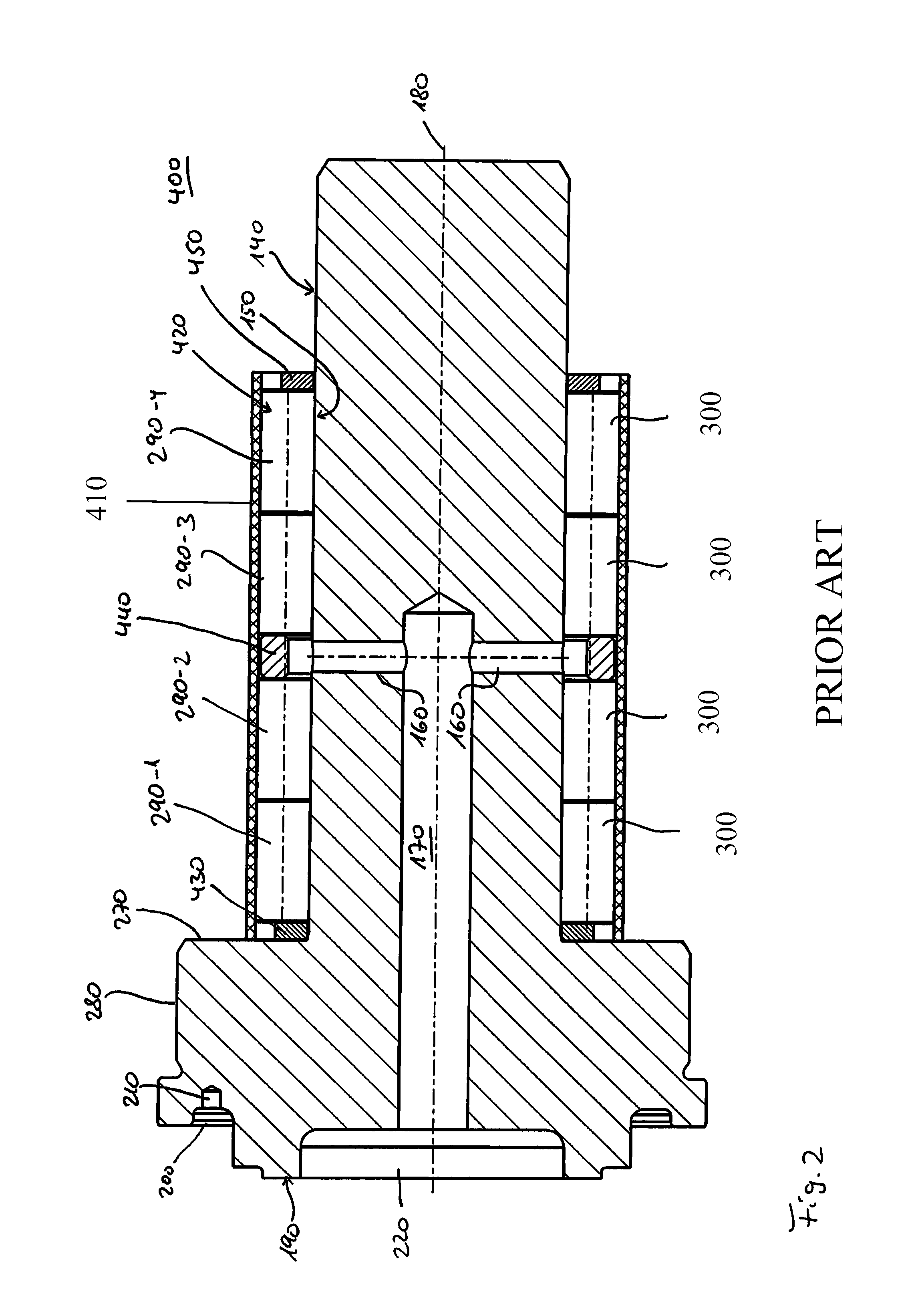

Wind turbine generator

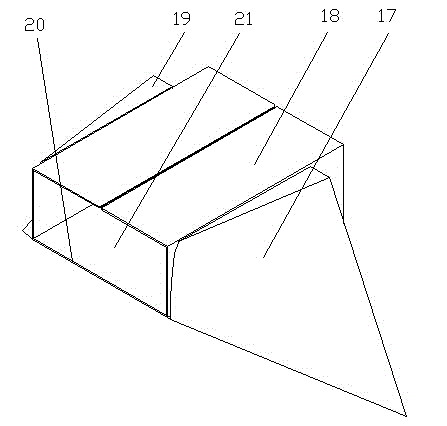

InactiveUS20110233939A1Easily adjust clearanceGuaranteed uptimeRotary combination bearingsRoller bearingsNacelleHearing perception

A wind turbine generator provided with a sliding bearing as a yawing ring bearing that can reduce shifting of an axial center by making radial-direction clearances small. In a wind turbine generator in which a nacelle installed at the top of a tower is turnably supported via a yawing sliding bearing, the yawing sliding bearing is provided with a sliding member 33 disposed between top and bottom support surfaces of a flange formed mainly at a stationary portion and a turning portion; and a rolling element disposed between the stationary portion of the yawing sliding hearing and the turning portion.

Owner:MITSUBISHI HEAVY IND LTD

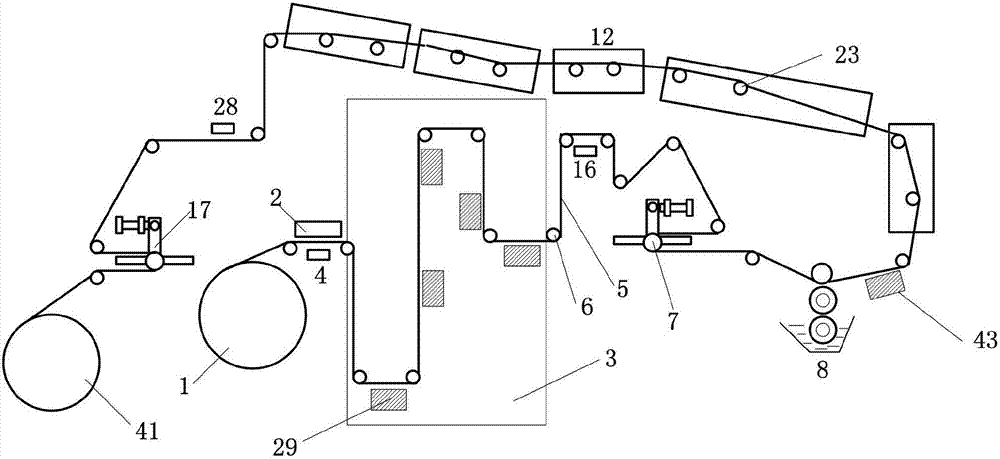

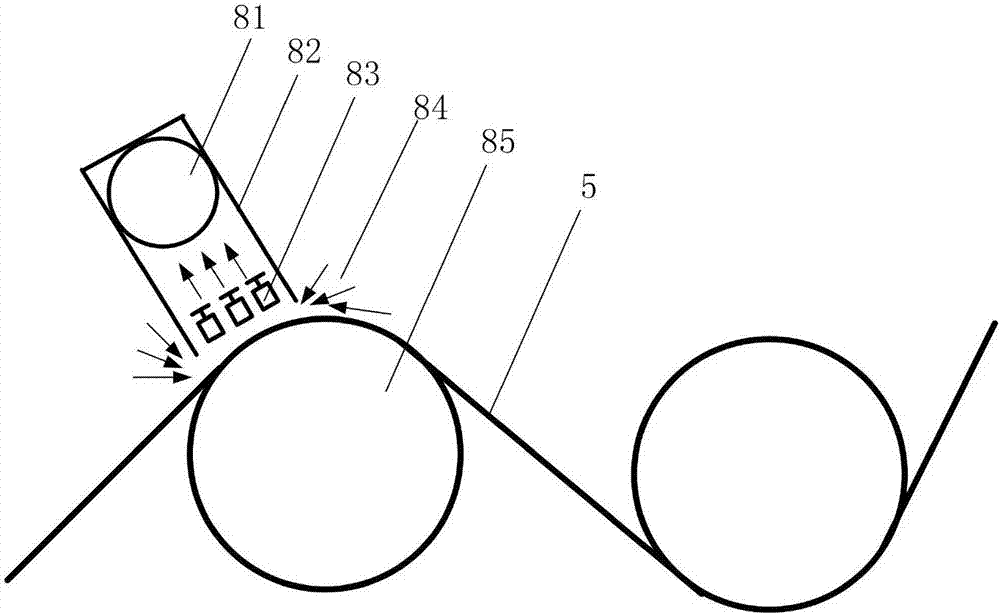

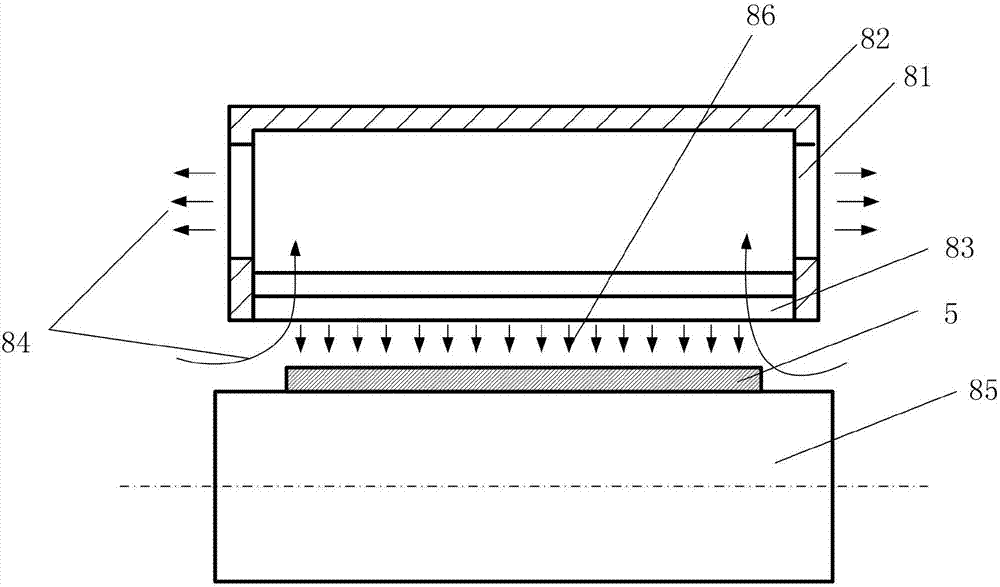

Device for coating graphene on surfaces of metal foils

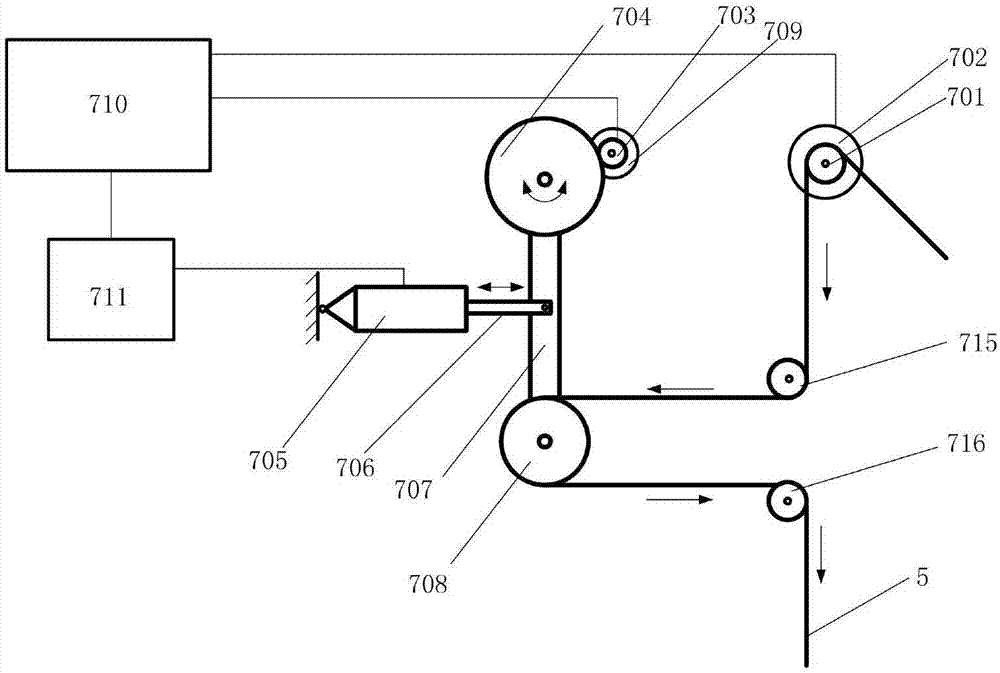

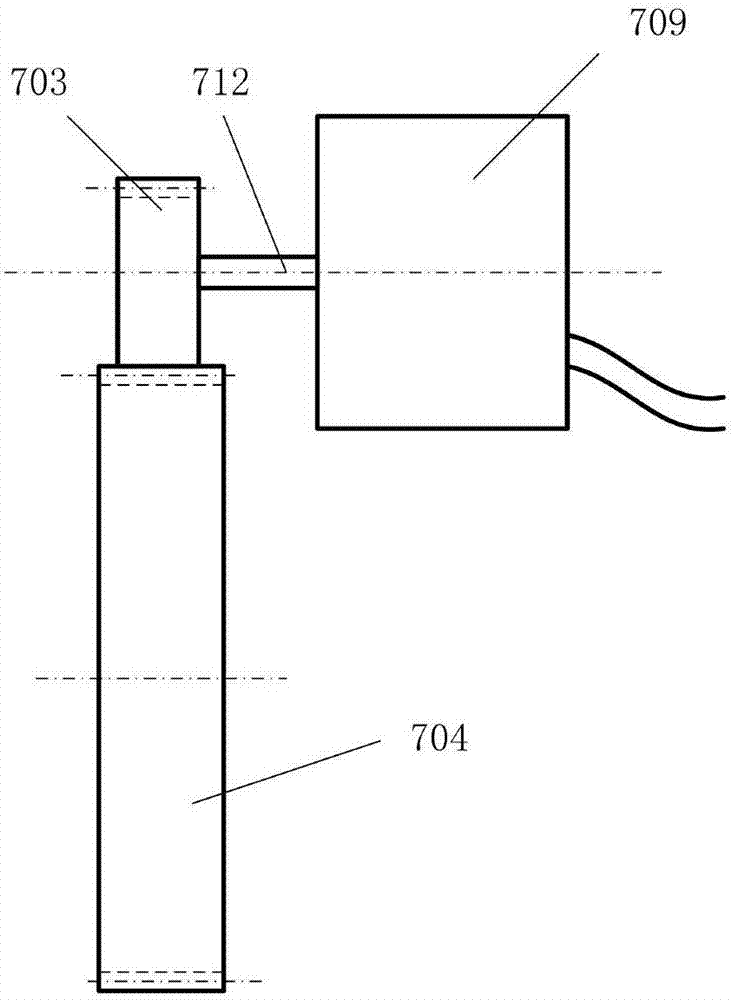

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

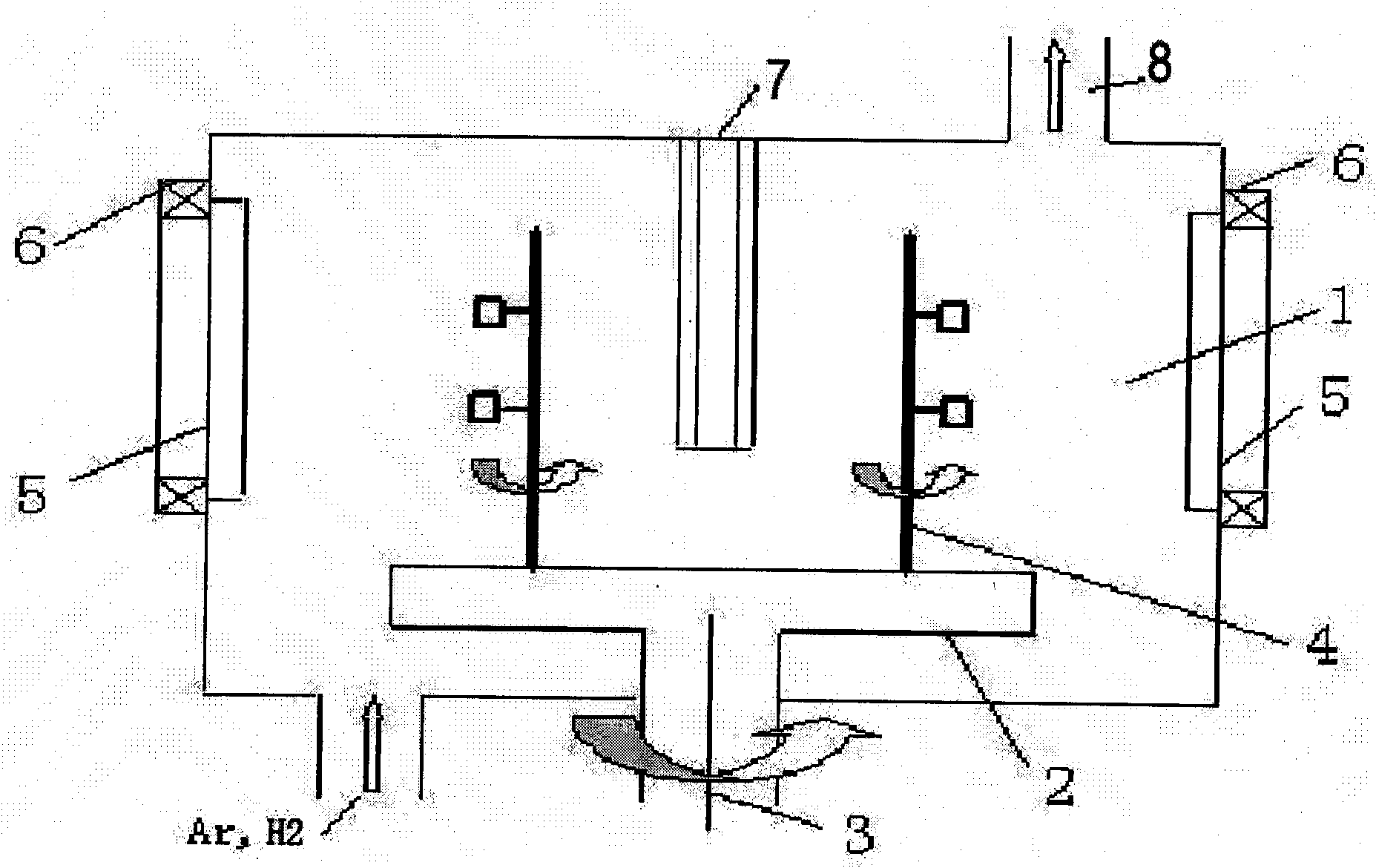

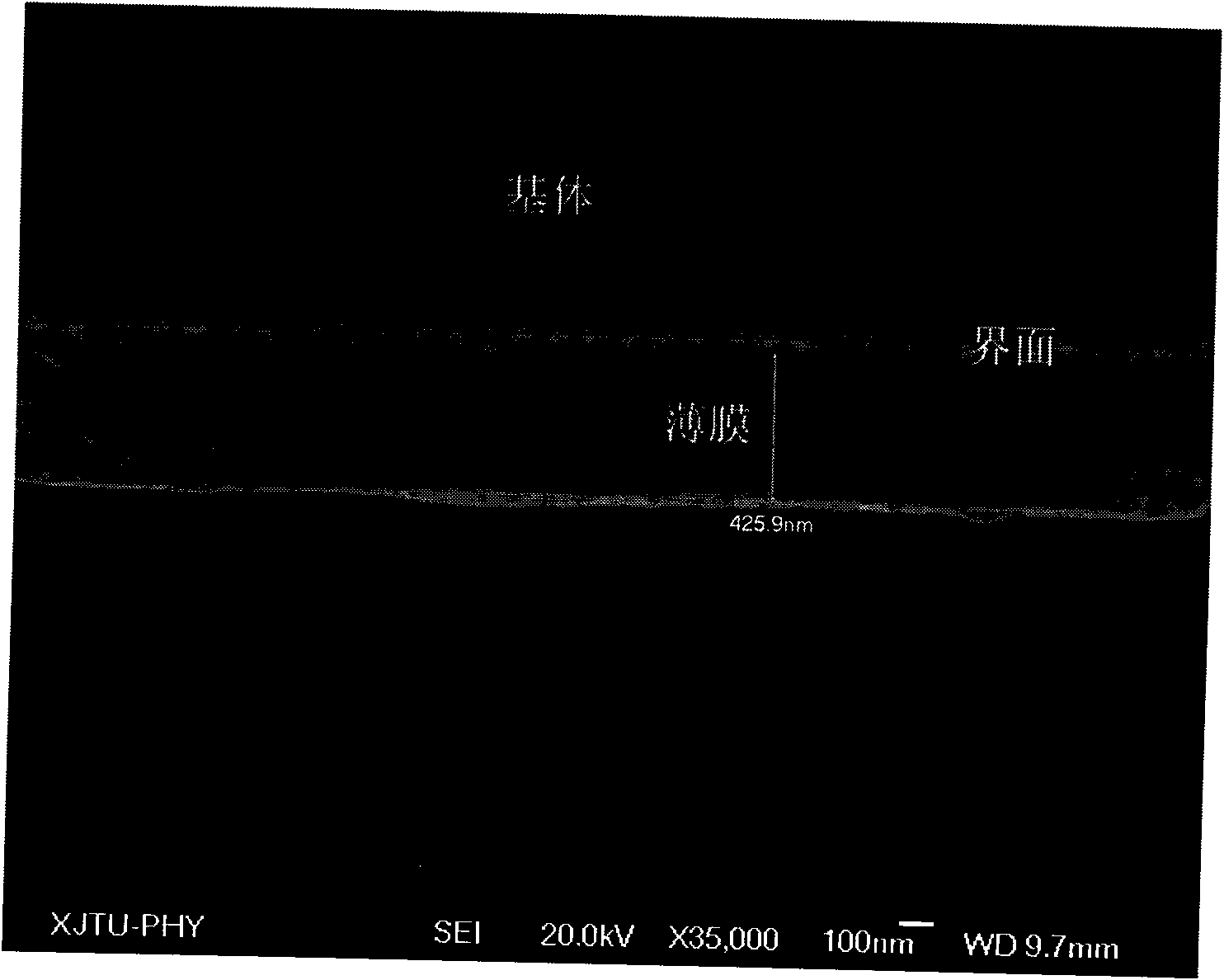

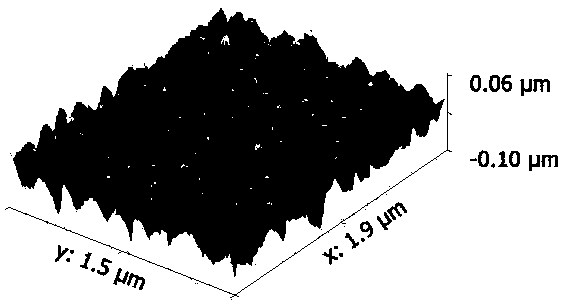

Method for preparing hydrogenated silicon film by utilizing magnetron sputtering

InactiveCN101660131AChange photoelectric propertiesFlat surfaceVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

The invention discloses a method for preparing a hydrogenated silicon film by utilizing magnetron sputtering. The method comprises the following steps, pretreating a substrate and placing the substrate in a magnetron sputtering filming device; utilizing a plane Si target as a source of Si element; adjusting the power of an intermediate frequency pulse power supply to control the sputtering rate ofthe Si target; utilizing high-purity Ar gas as main ionization gas, and ensuring the effective glow discharge process; and adopting high-purity H2 gas as reaction gas, ionizing the H2, and combiningthe H2 with the Si element, forming the hydrogenated silicon film on the surface of the substrate through deposition, and annealing the film at the temperature of 550 DEG C to 950 DEG C in vacuum to obtain the nano-crystalline / non-crystalline composite structure. The invention achieves regulation and control to microstructure of the hydrogenated silicon film by changing introduction proportion ofhydrogen so as to further change the photoelectric properties of the film. The preparation method is simple and reliable, and the prepared hydrogenated silicon film is hopeful to be applied to solar batteries.

Owner:XI AN JIAOTONG UNIV

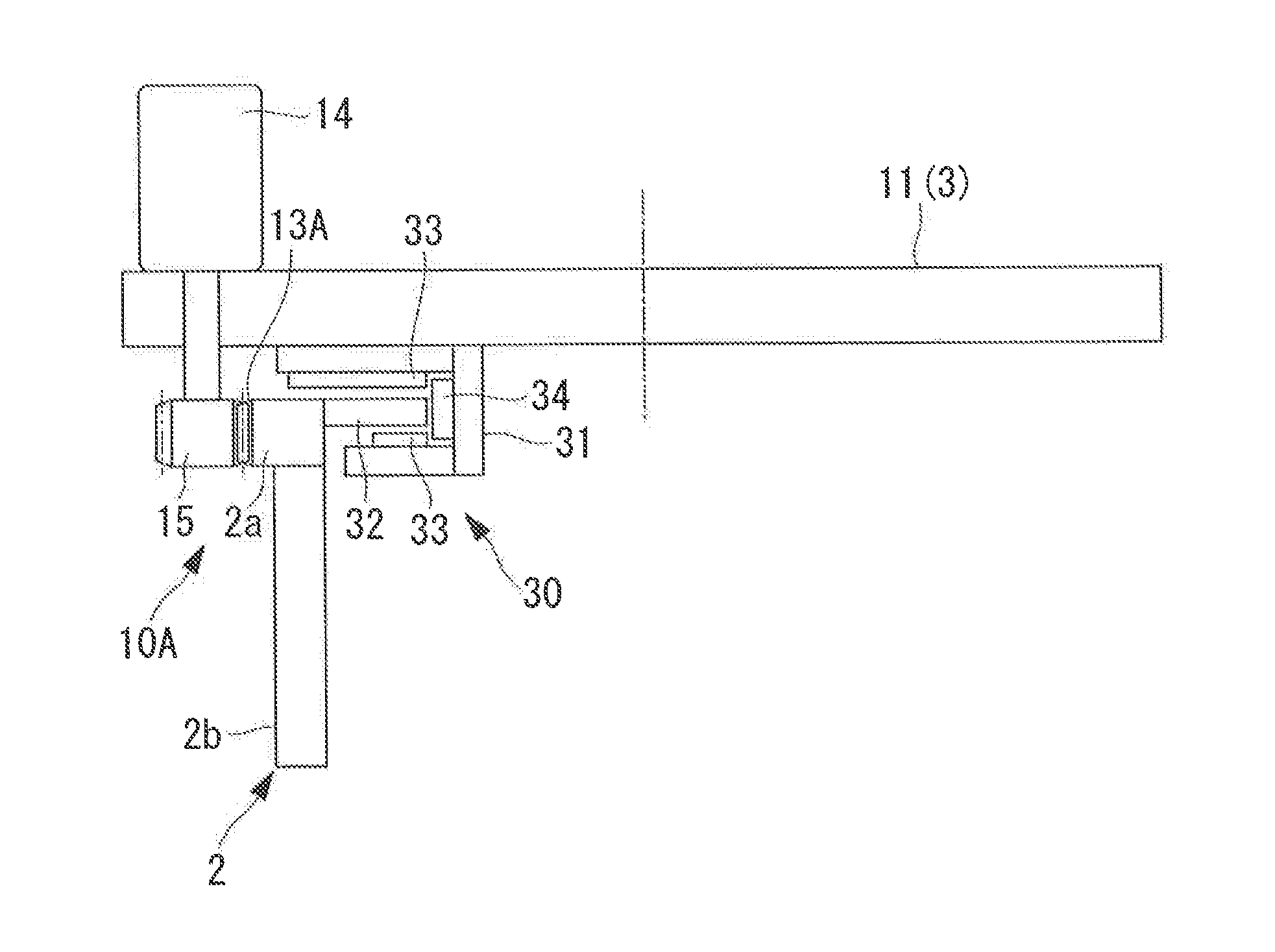

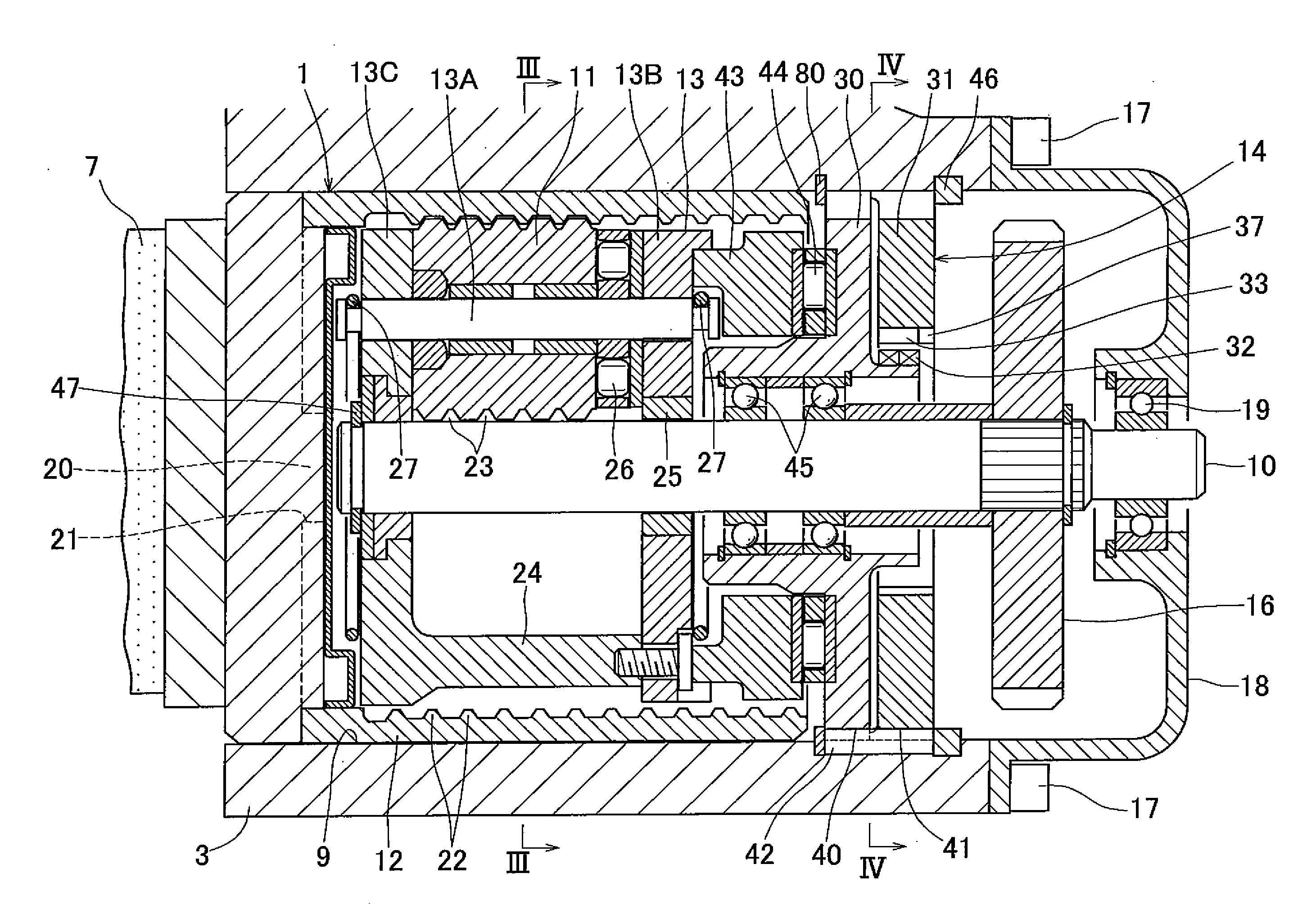

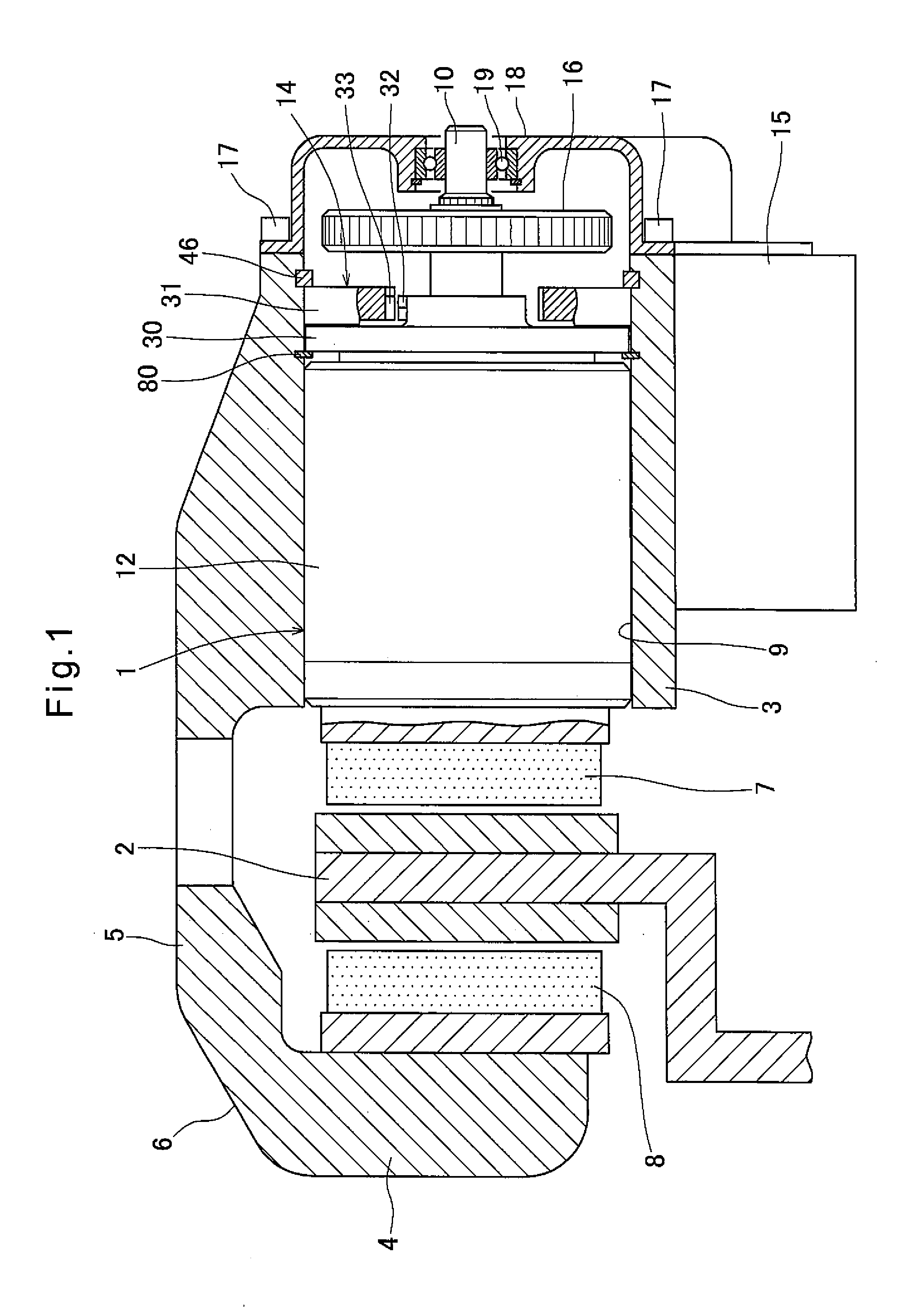

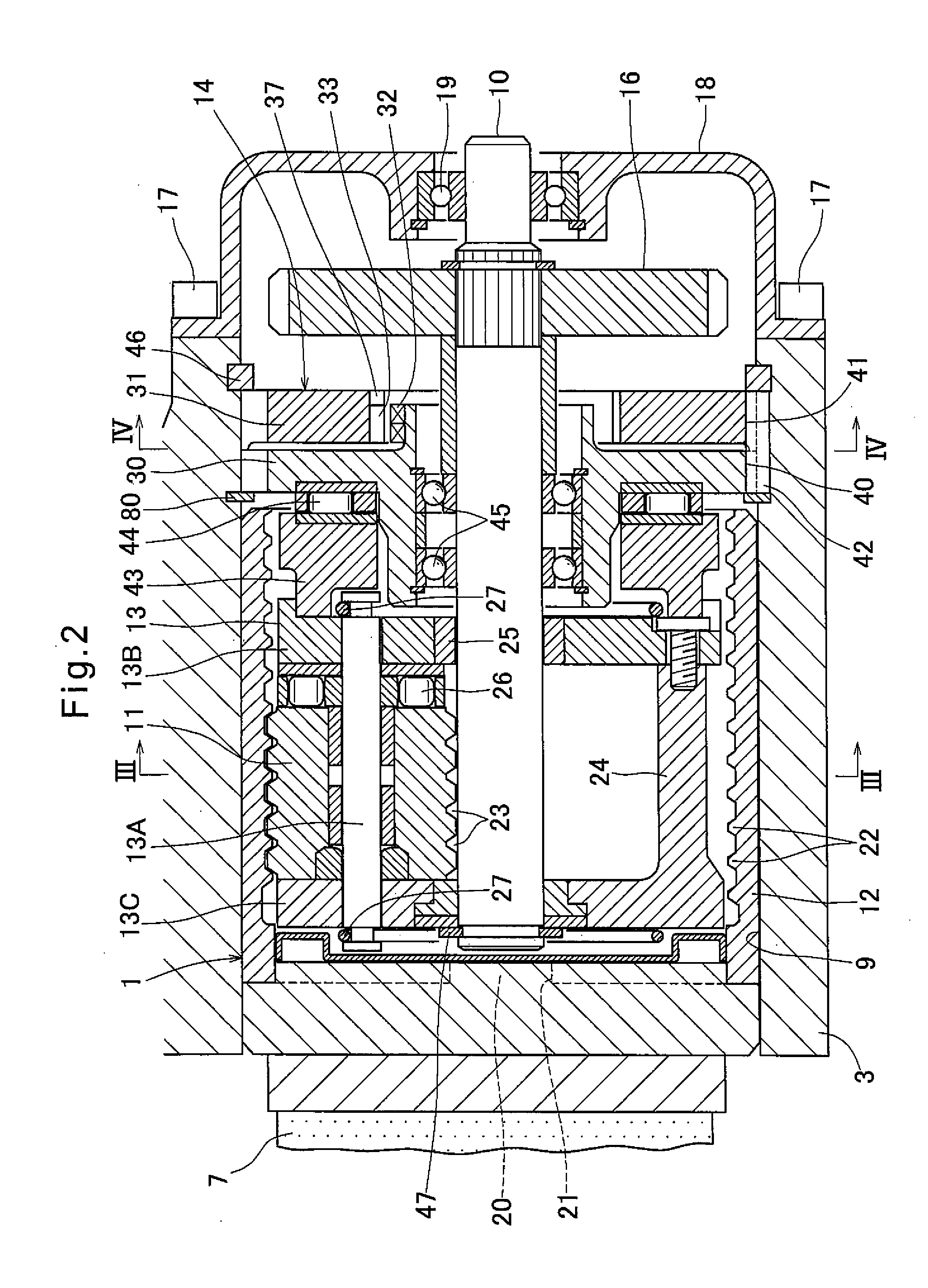

Electric linear motion actuator and electric brake system

ActiveUS20140262634A1Clearance adjustableSampled-variable control systemsComputer controlLinear motionActuator

An electric linear motion actuator is provided which can set the clearance during normal braking operation of an electric brake system. The linear motion actuator includes a load sensor for detecting the magnitude of the load with which a friction pad is pressed against the brake disk, a temperature sensor for compensating for the influence of temperature on the load sensor, and an electronic control unit. The electronic control unit is adapted to calculate a target rotational angle from the position of the electric motor corresponding to the magnitude of the load detected by the load sensor to the position of the electric motor where the clearance is at a predetermined value, and control the electric motor to rotate the electric motor by the target rotational angle.

Owner:NTN CORP

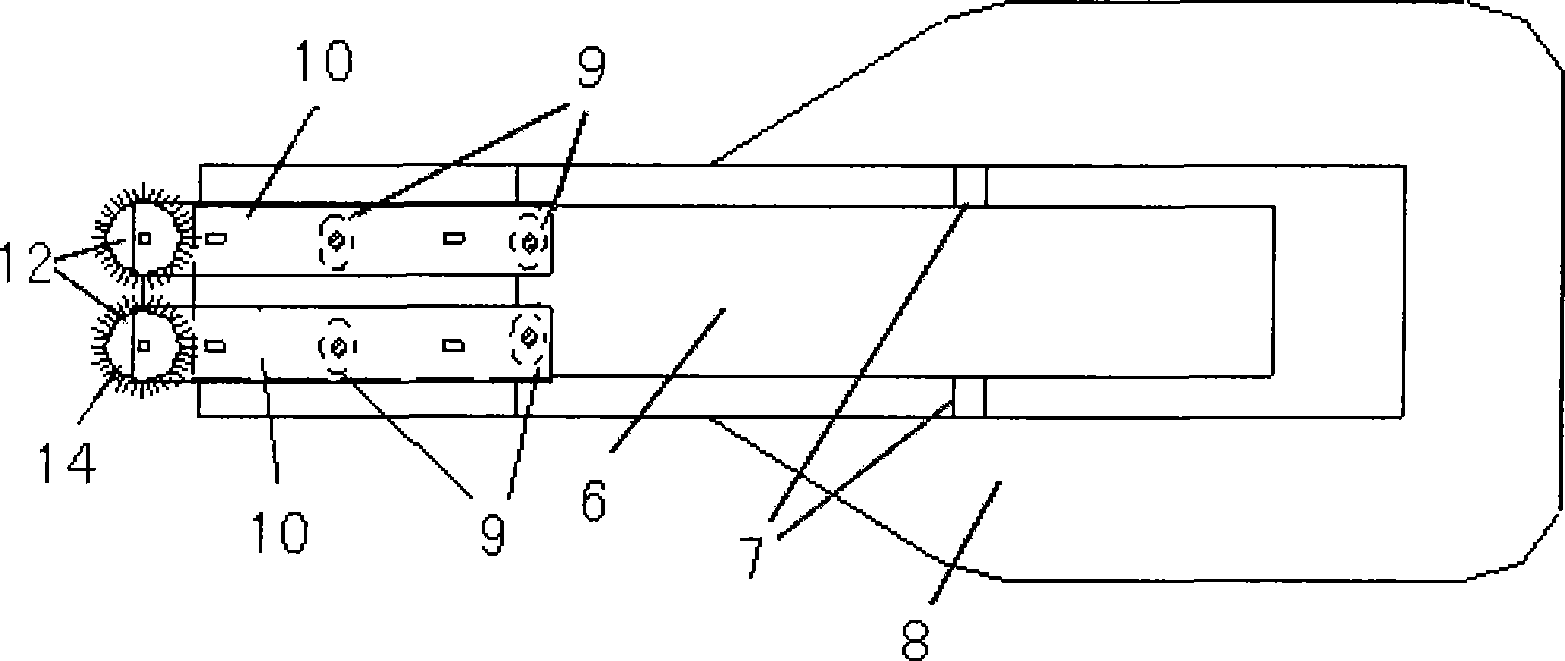

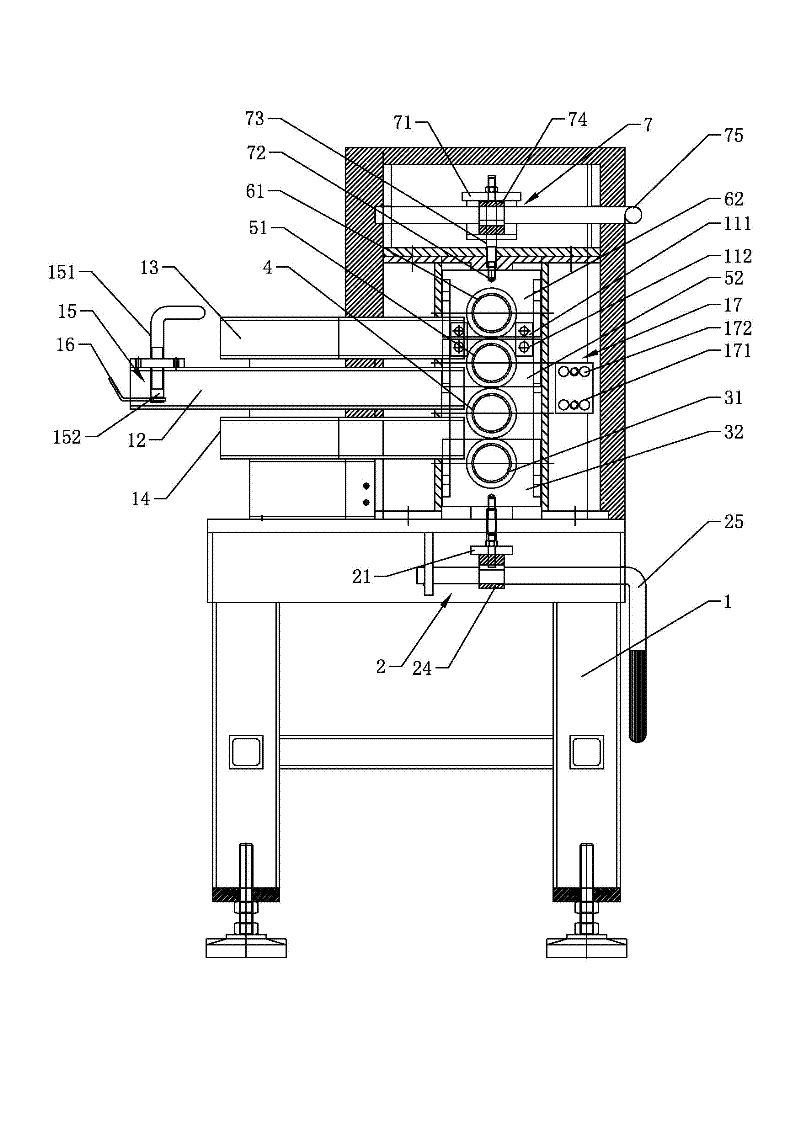

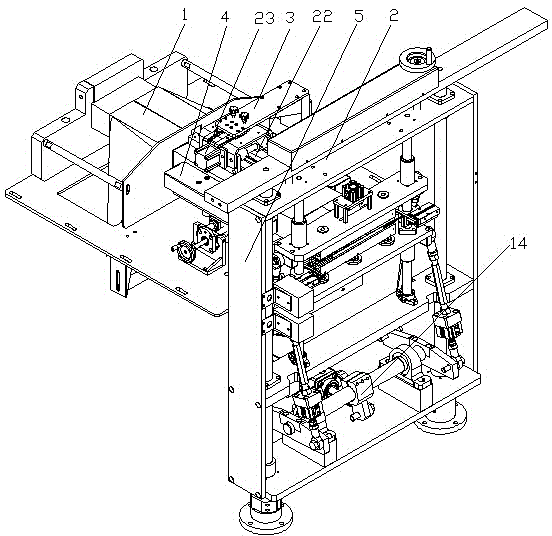

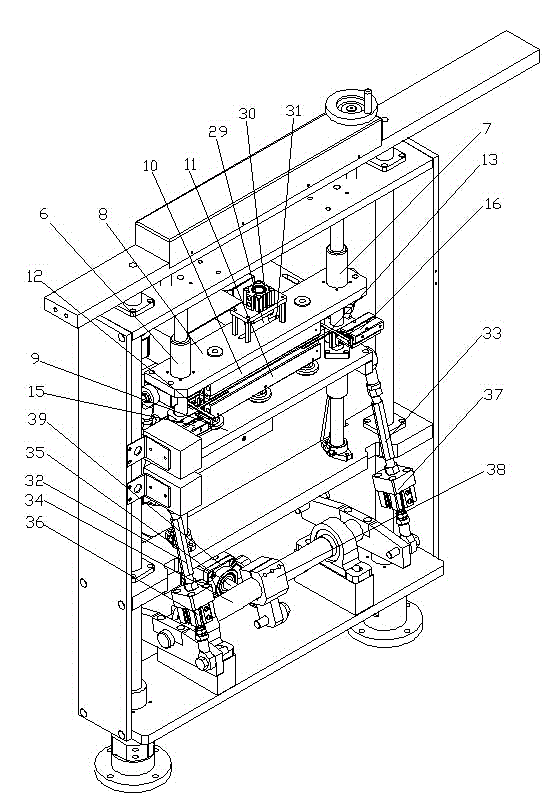

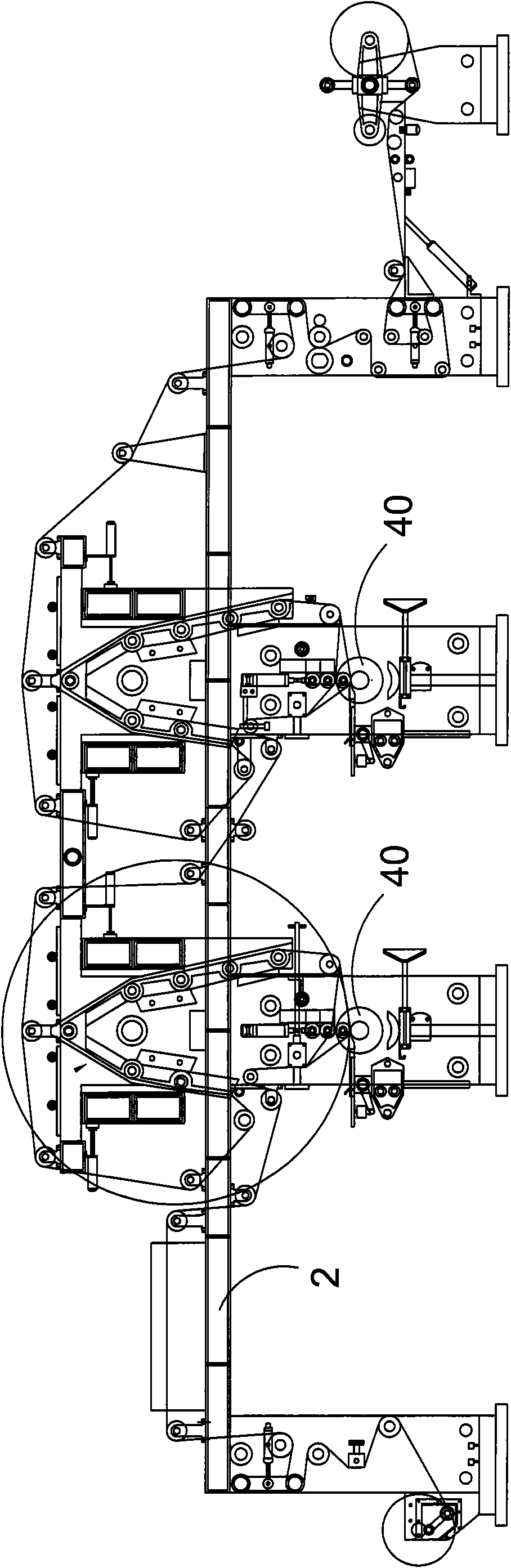

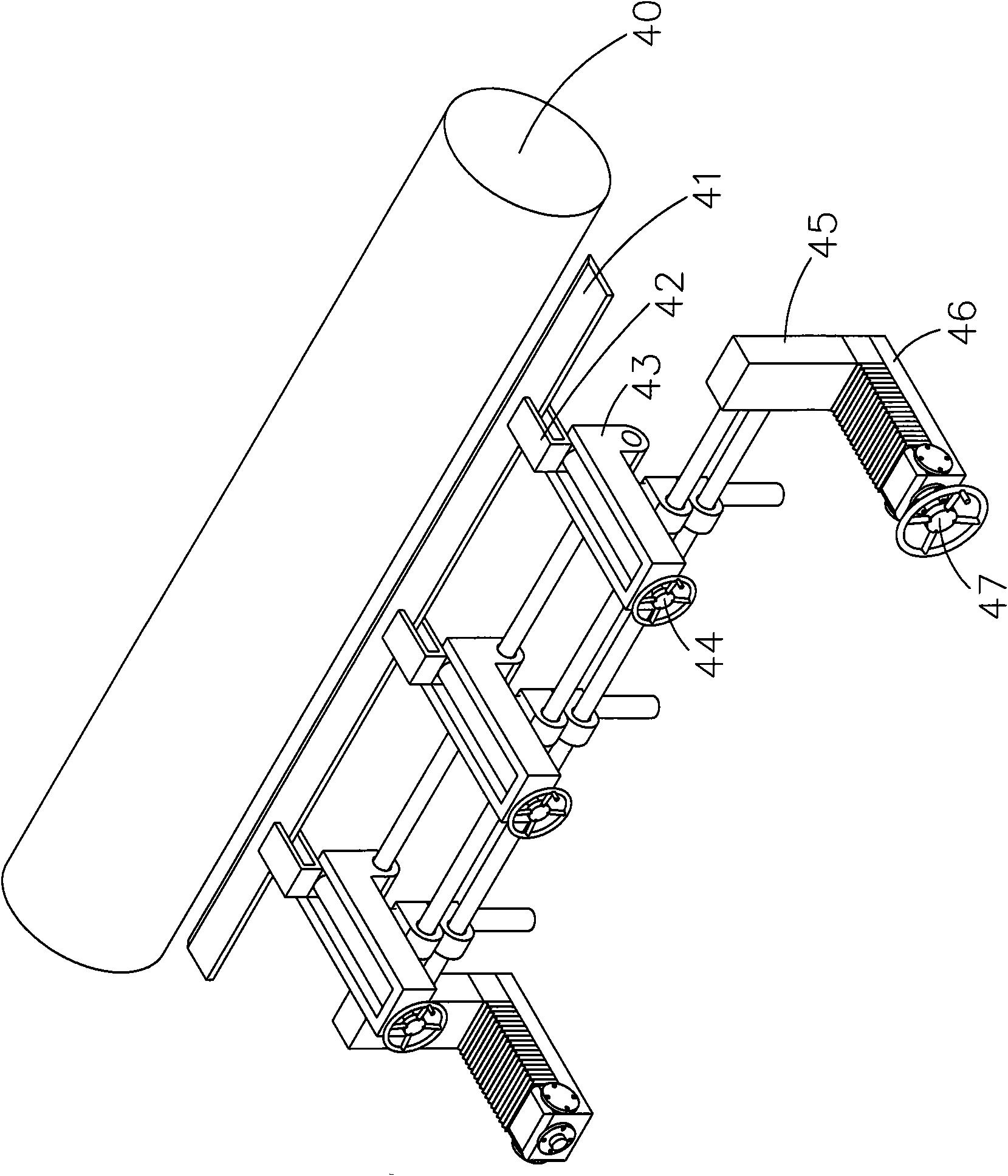

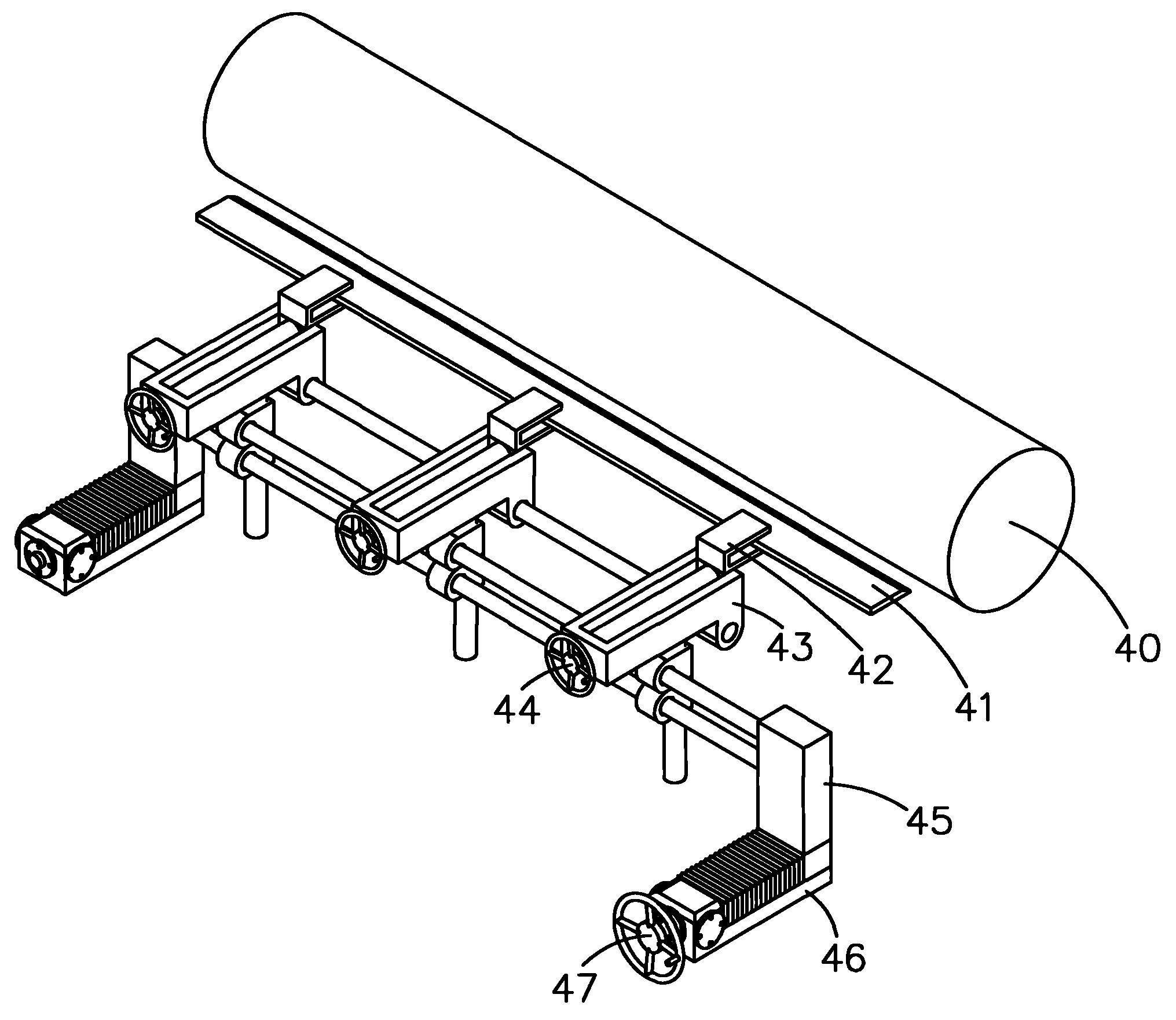

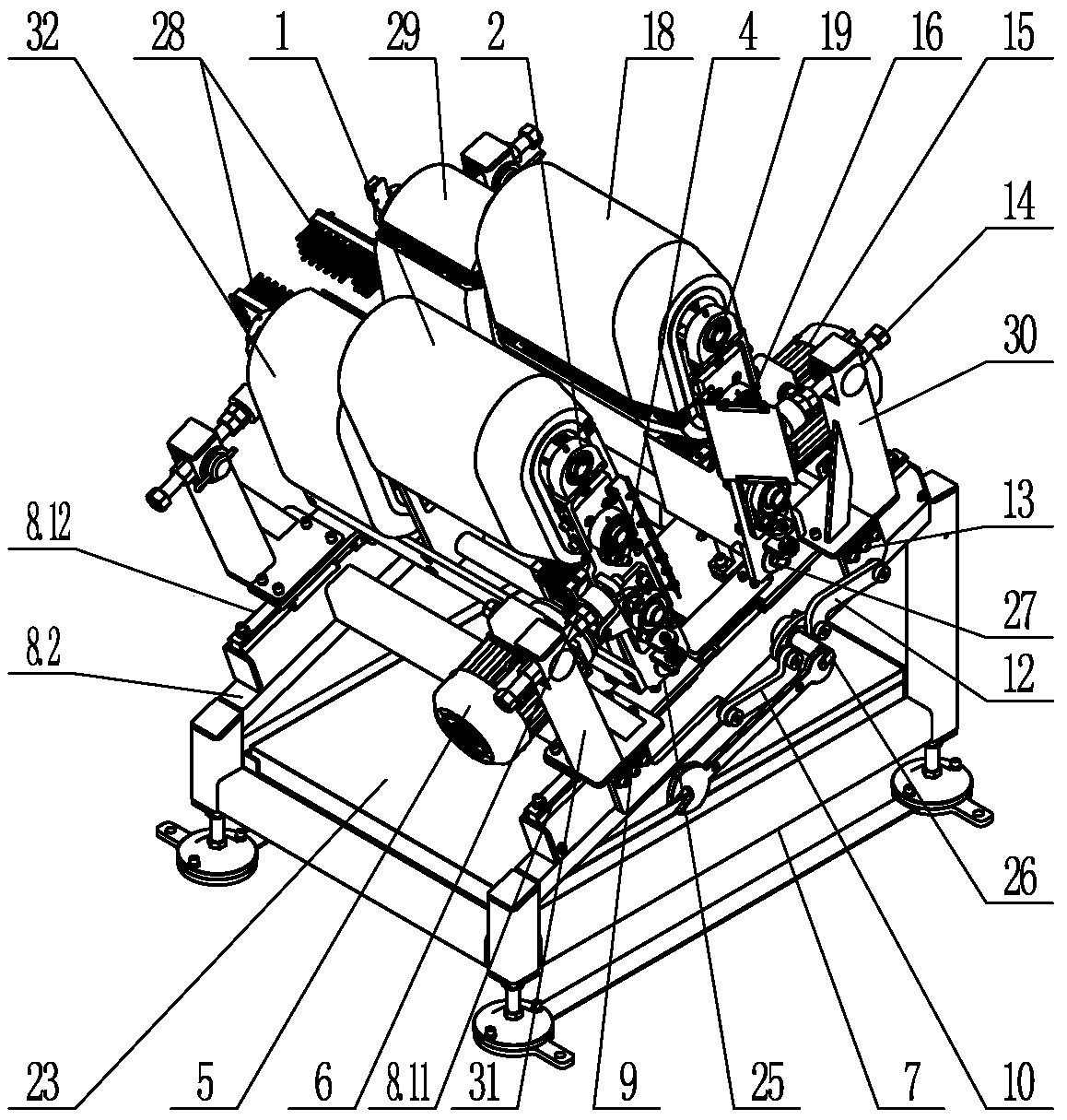

Stripping machine for metal and plastic composite plate

The invention discloses a stripping machine for a metal and plastic composite plate. The stripping machine comprises a stand, a stripping device, a tight supporting operation and control mechanism and a tight pressing operation and control mechanism, wherein the stripping device comprises four stripping rollers which are sequentially overlaid on the stand from bottom to top, the axial lines of the four stripping rollers are parallel and positioned on a same vertical plane, the four stripping rollers are sequentially connected in a transmission way, the first stripping roller and the fourth stripping roller are both vertically and slidably arranged on the stand, and the second stripping roller or the third stripping roller is connected with a power plant; the tight supporting operation and control mechanism is arranged between the first stripping roller and the stand; and the tight pressing operation and control mechanism is arranged between the fourth stripping roller and the stand. According to the stripping machine disclosed by the invention, the four stripping rollers are pairwise mutually matched to press and clamp an upper metal layer, a lower metal layer and a sandwich-layer plastic plate, and can be used for stripping metal and plastic fast and efficiently.

Owner:佰顿新材料科技江苏有限公司

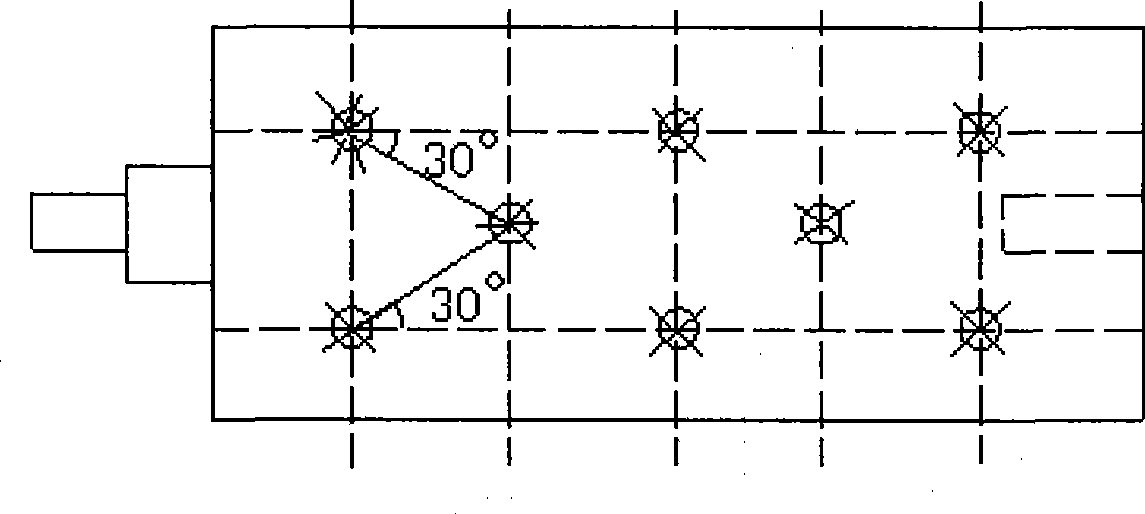

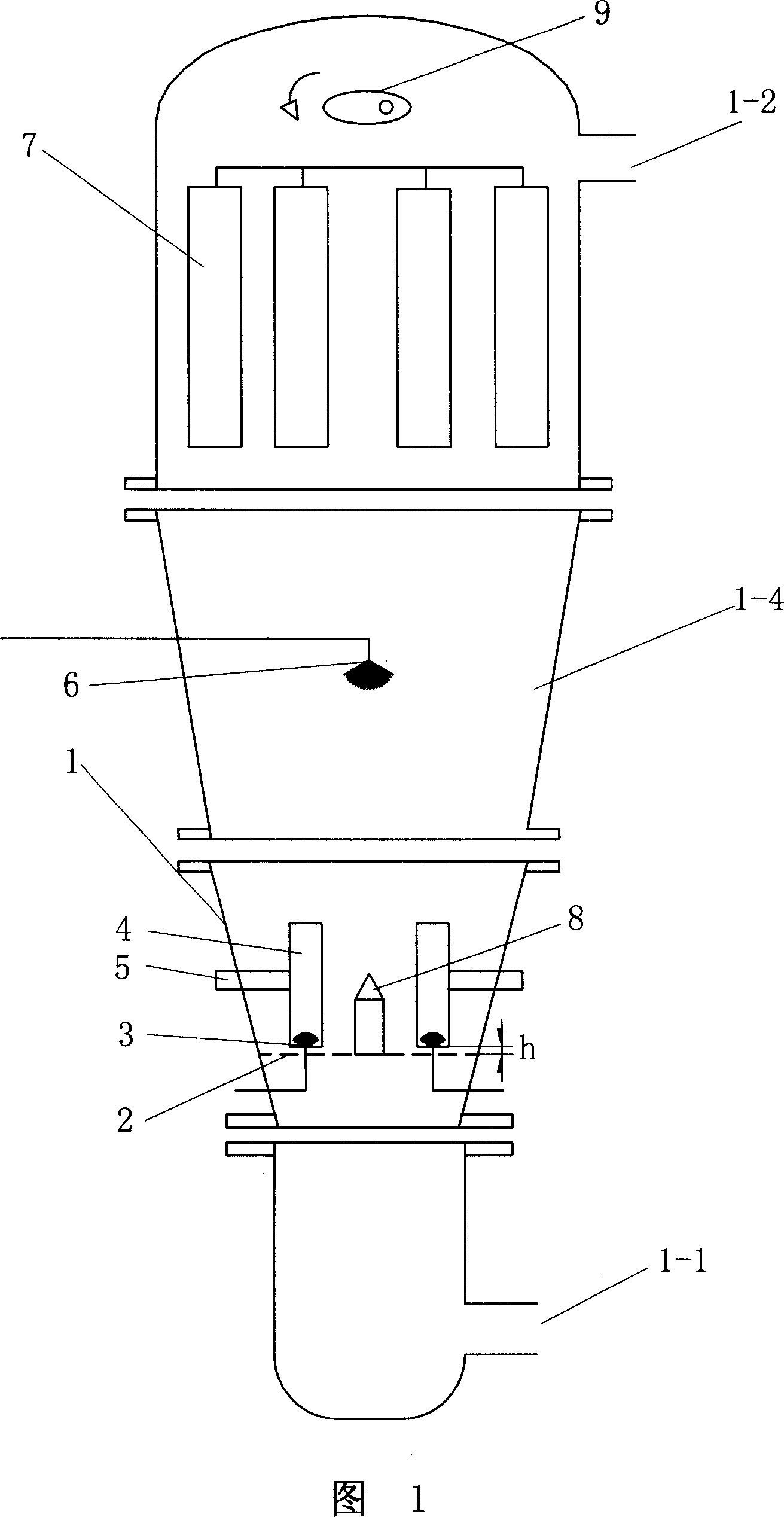

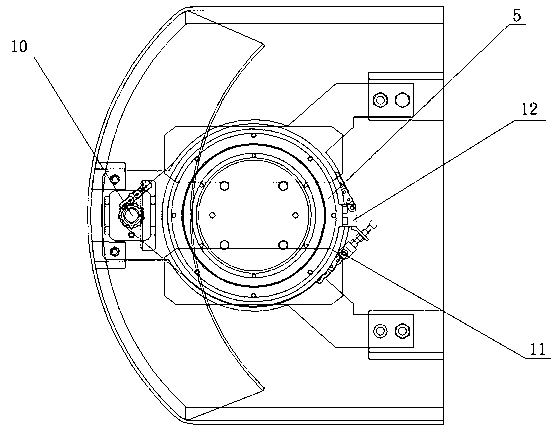

Fluidized-bed coating machine

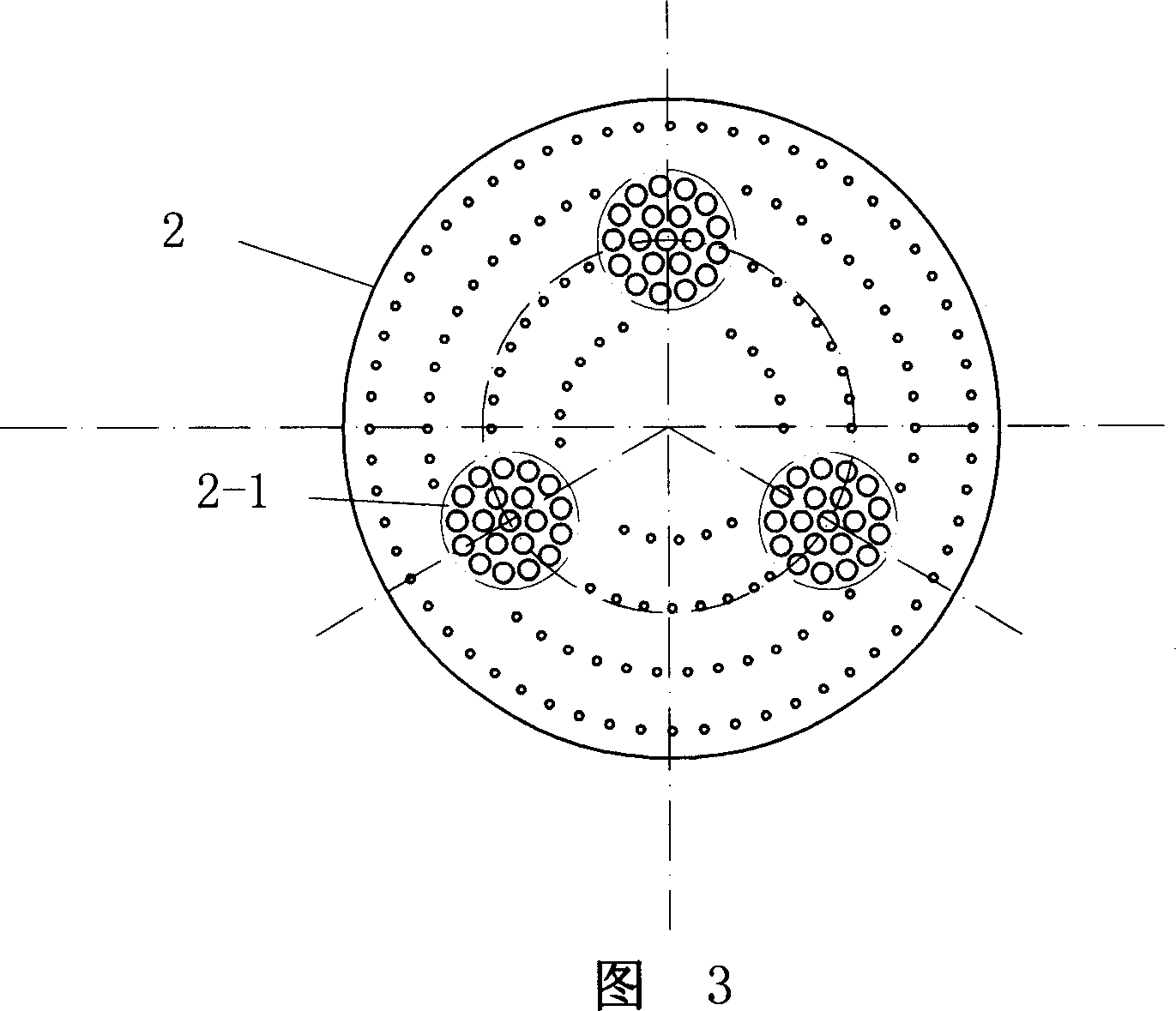

InactiveCN101061988AIncrease productionGood sustained releasePharmaceutical product form changeMaterial granulationFluidized bedSpray nozzle

The invention discloses a fluid bed tablet-coating machine, which is characterized by the following: possessing dry air inlet and tank of ventilating port; arranging air flow distribution plate and filter in the tank; arranging at least two big hole area on the same angular of even dispersing on the air flow dispersing plate; setting the perforated ratio of the big hole area at 65%; arranging guide barrel on the upper of the air flow dispersing plate; heading on each big hole area; possessing gap between the floor of the guide barrel and the air flow dispersing plate; arranging a dressing injector; corresponding to each guide barrel; projecting the dressing injector from the central hole of the big hole area of the air flow dispersing plate. This invention possesses high output, which can be fit for big scale industrial production.

Owner:邹龙贵

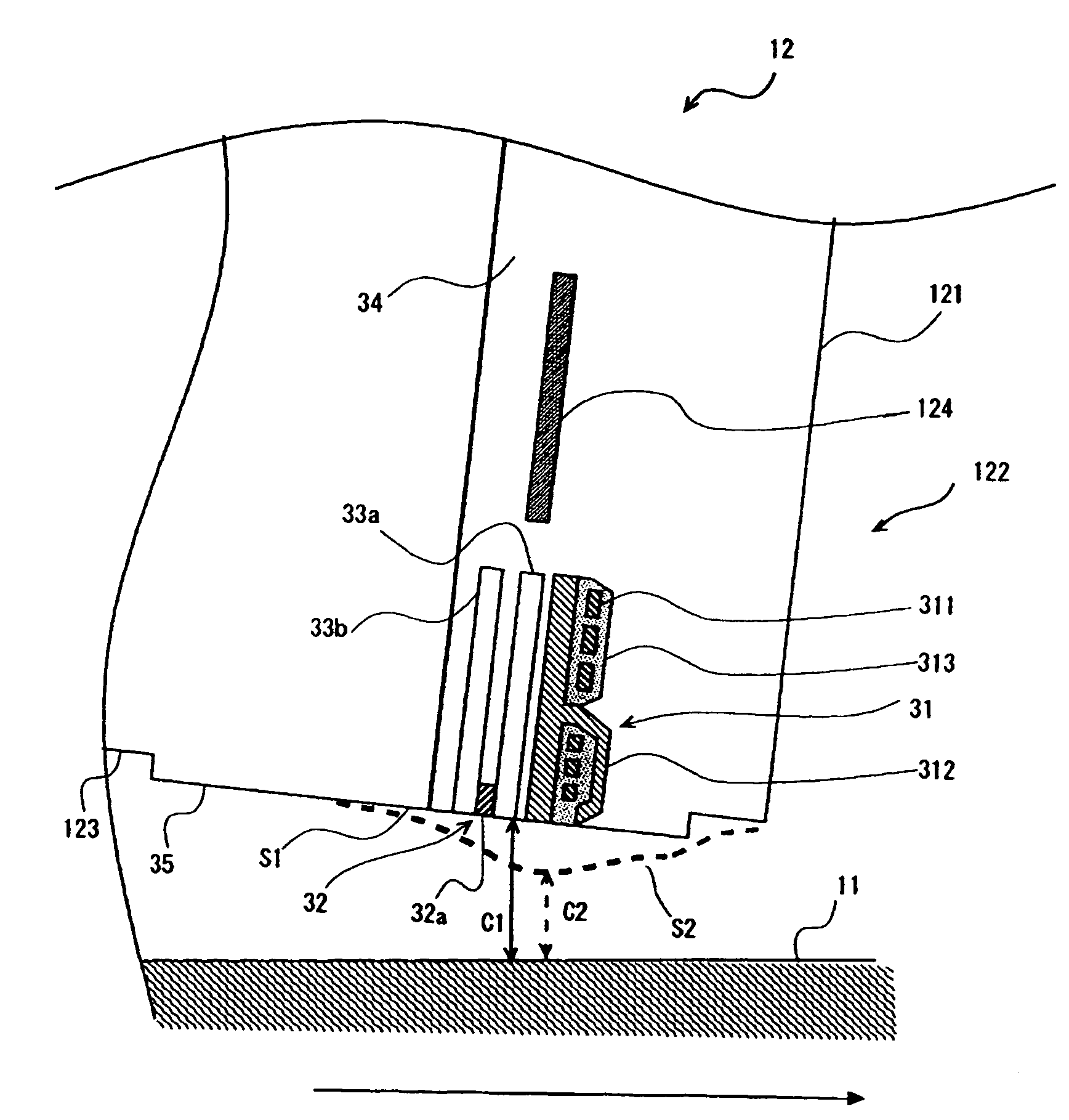

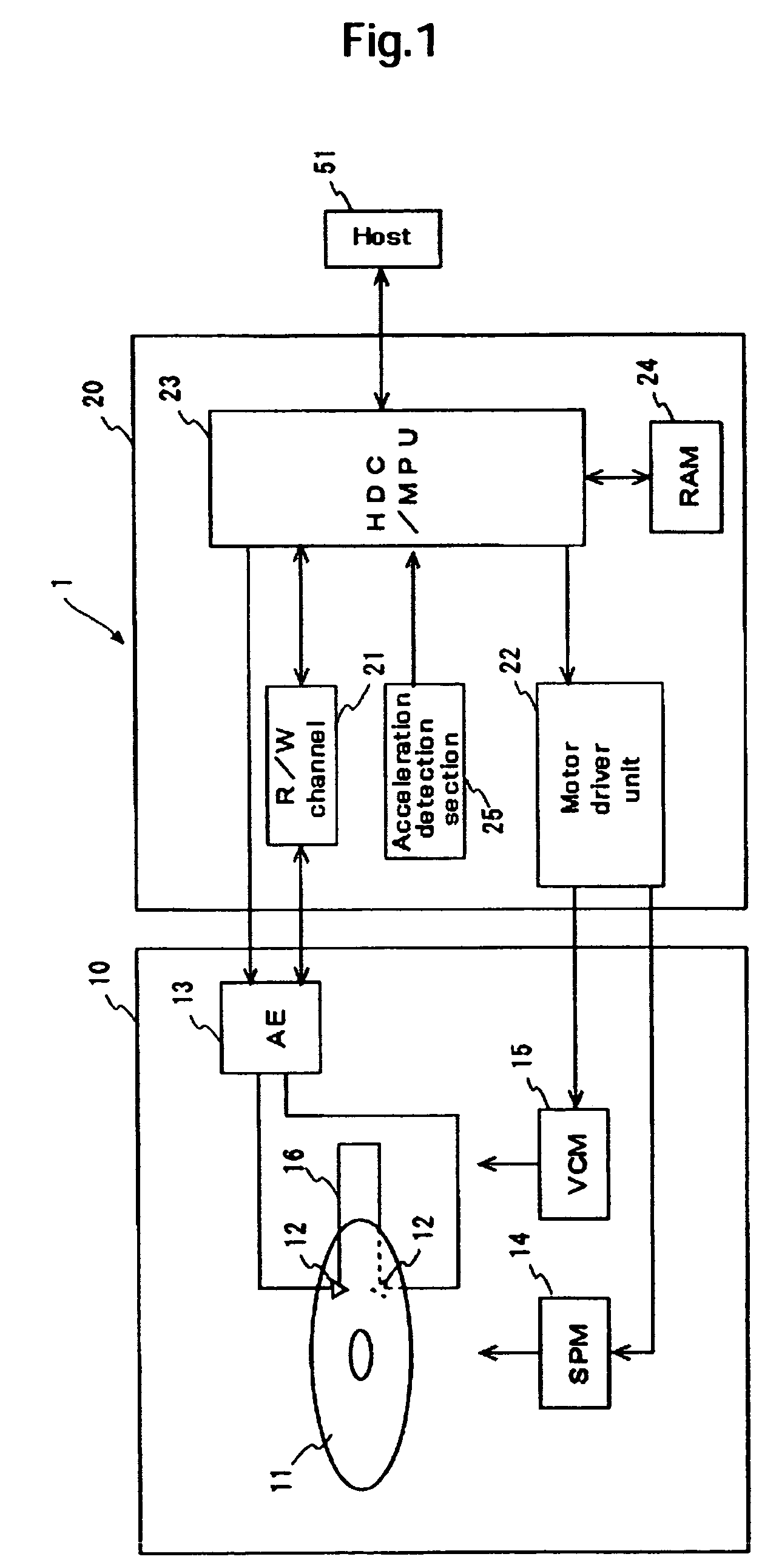

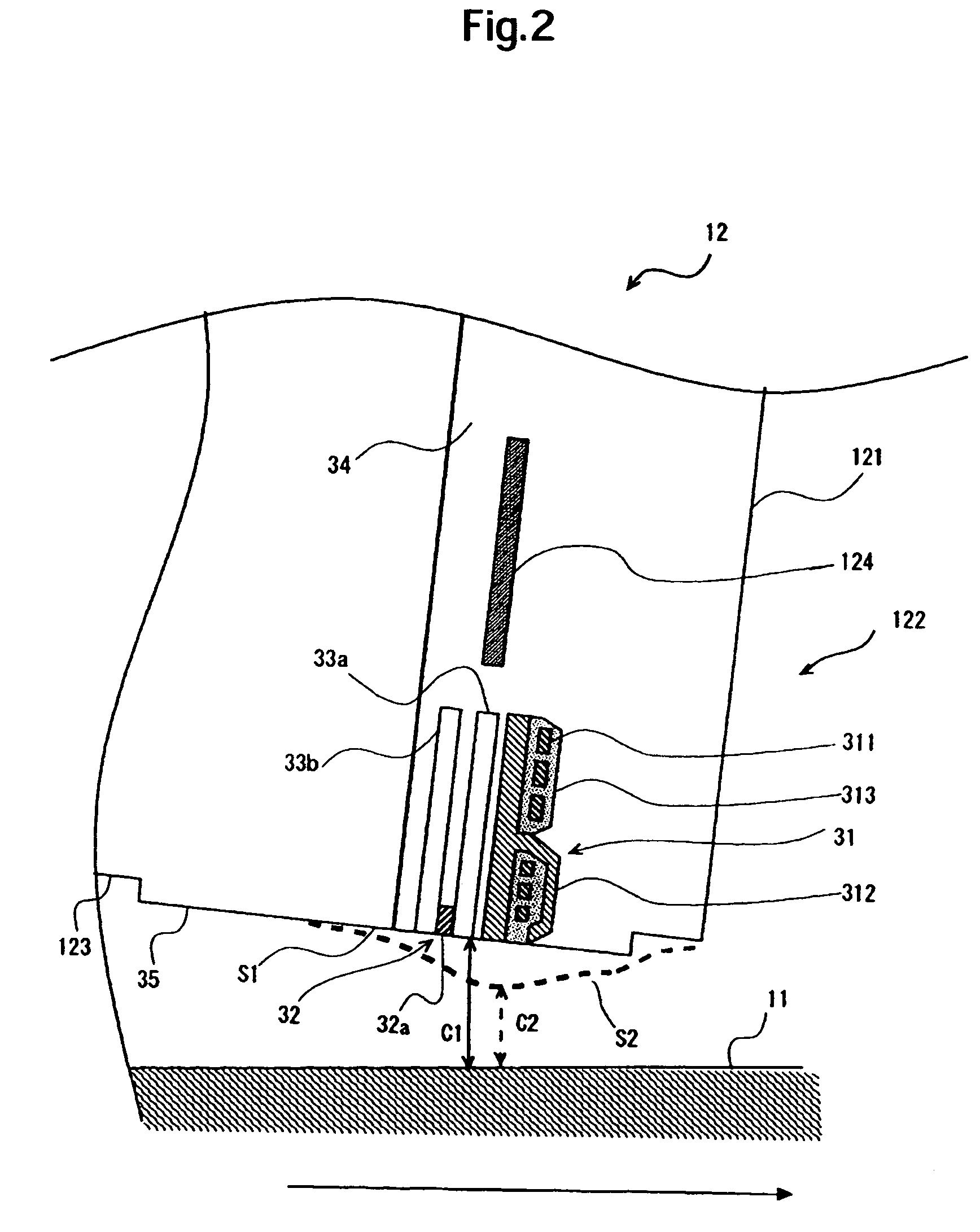

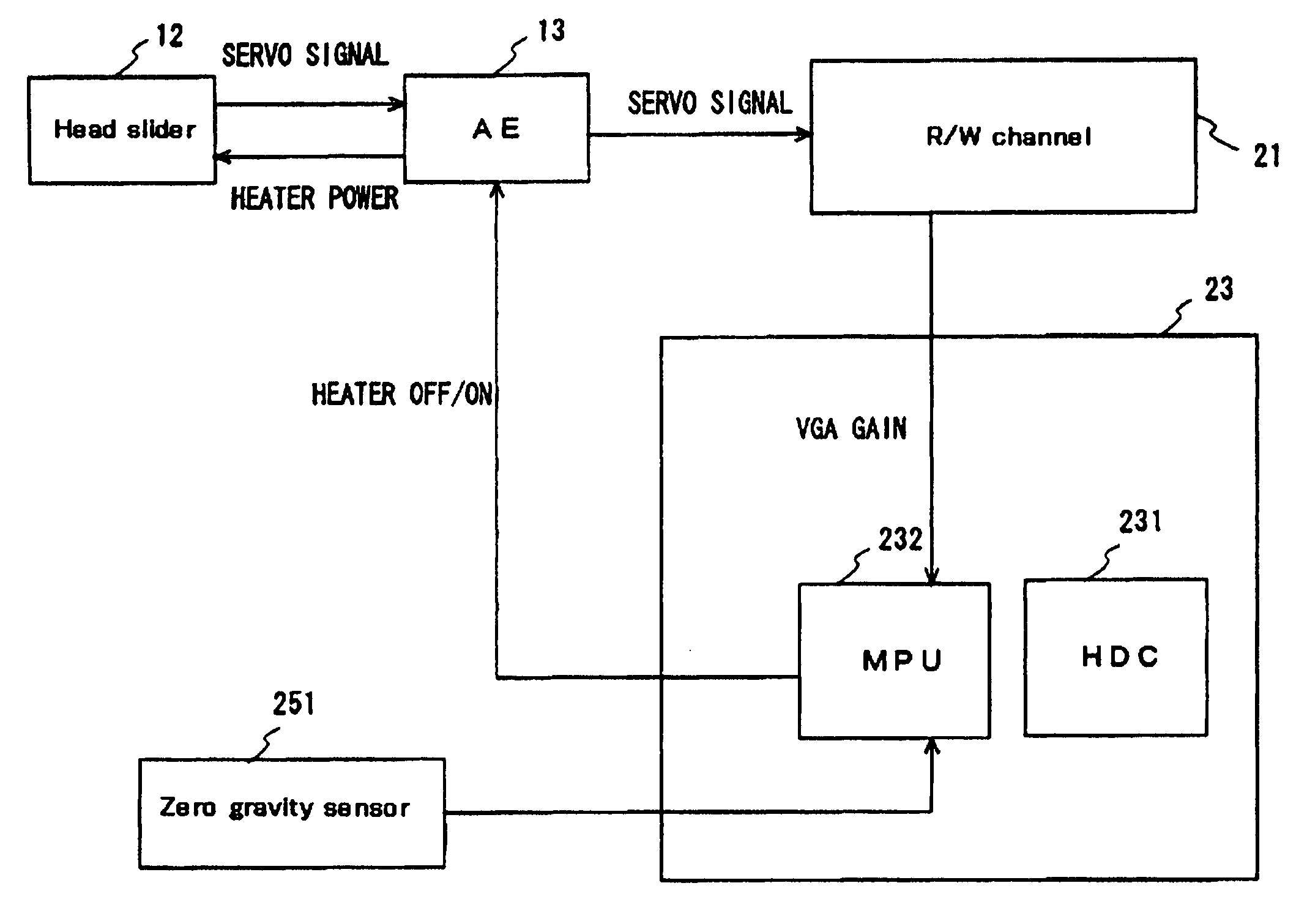

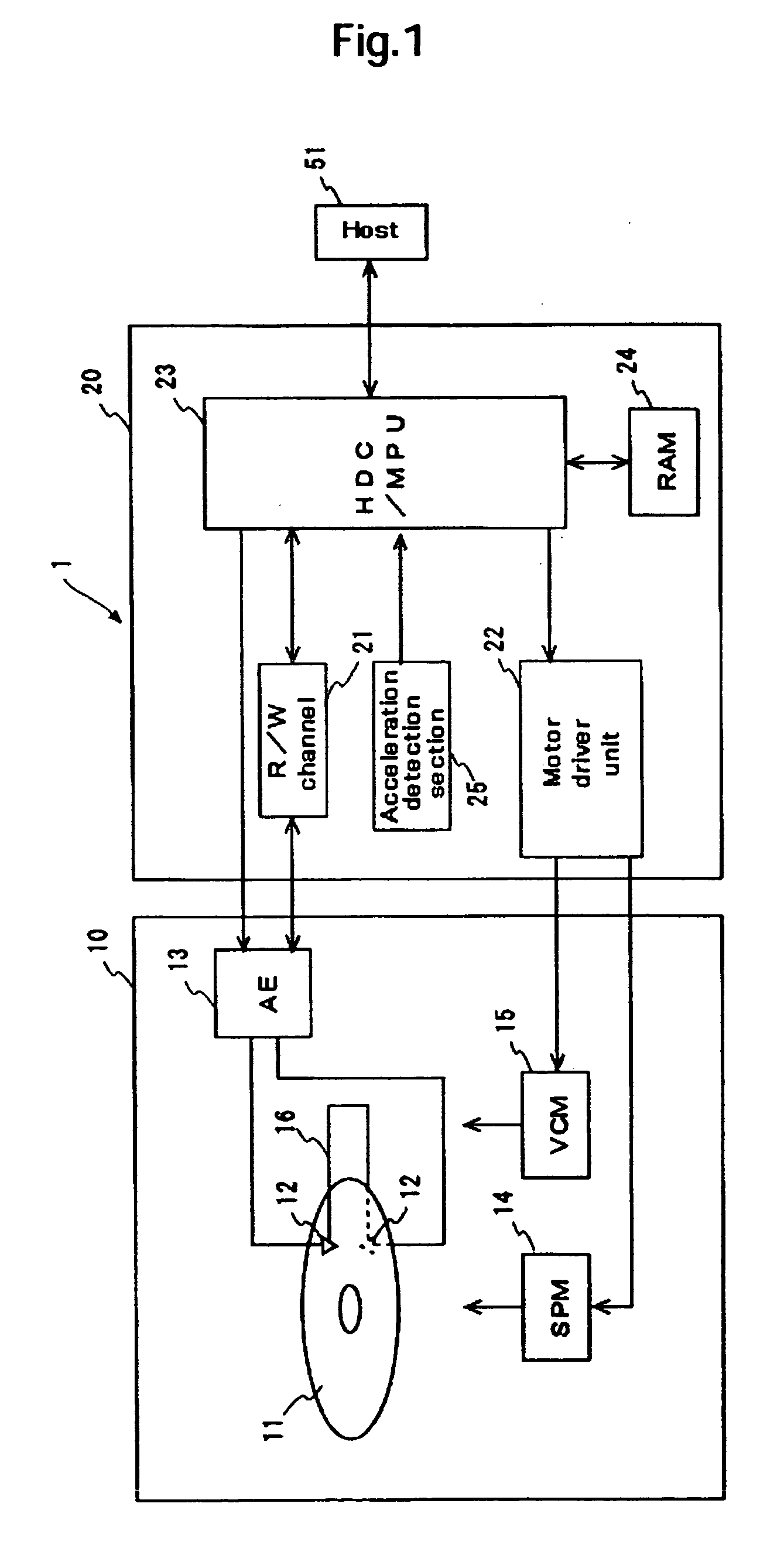

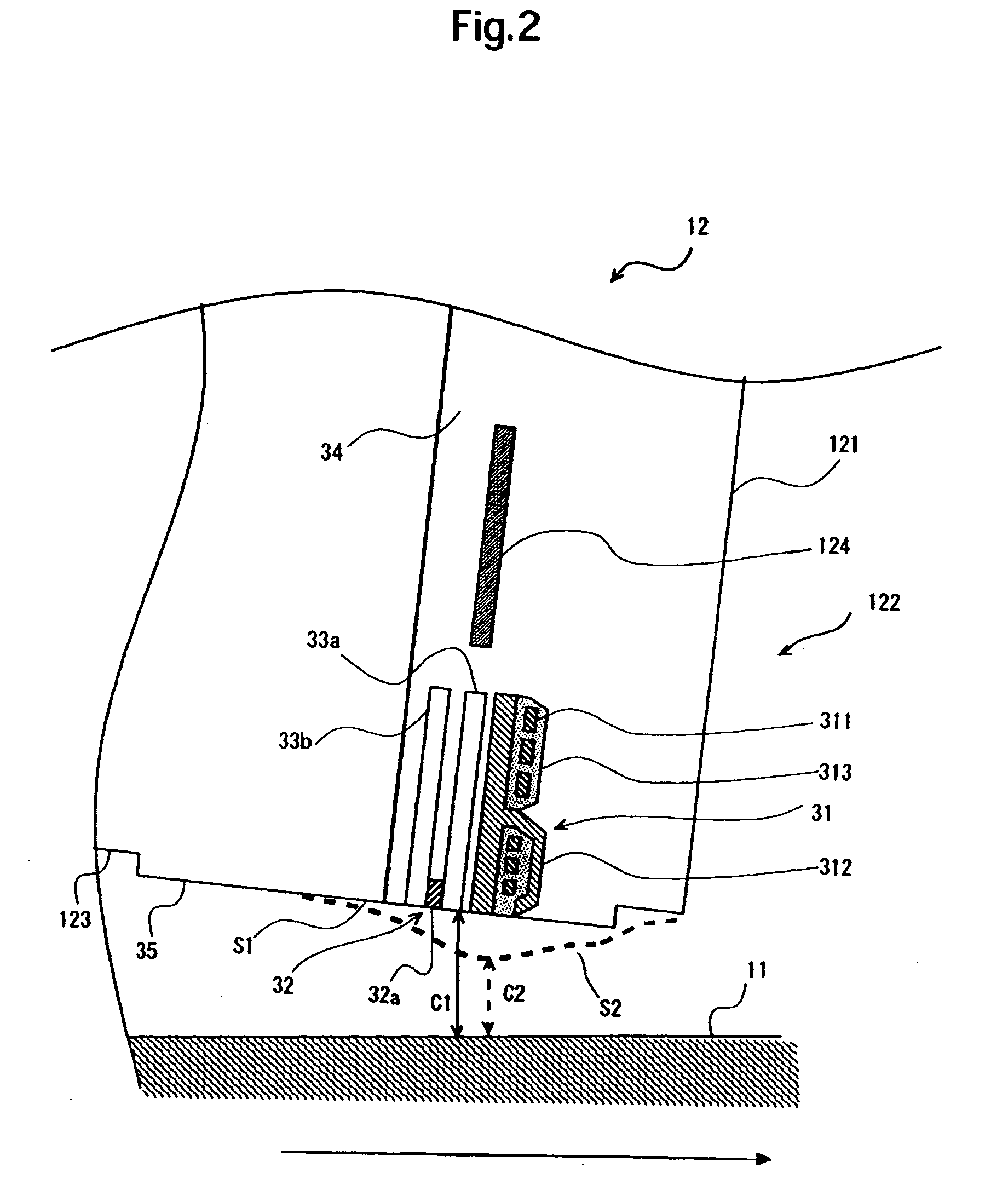

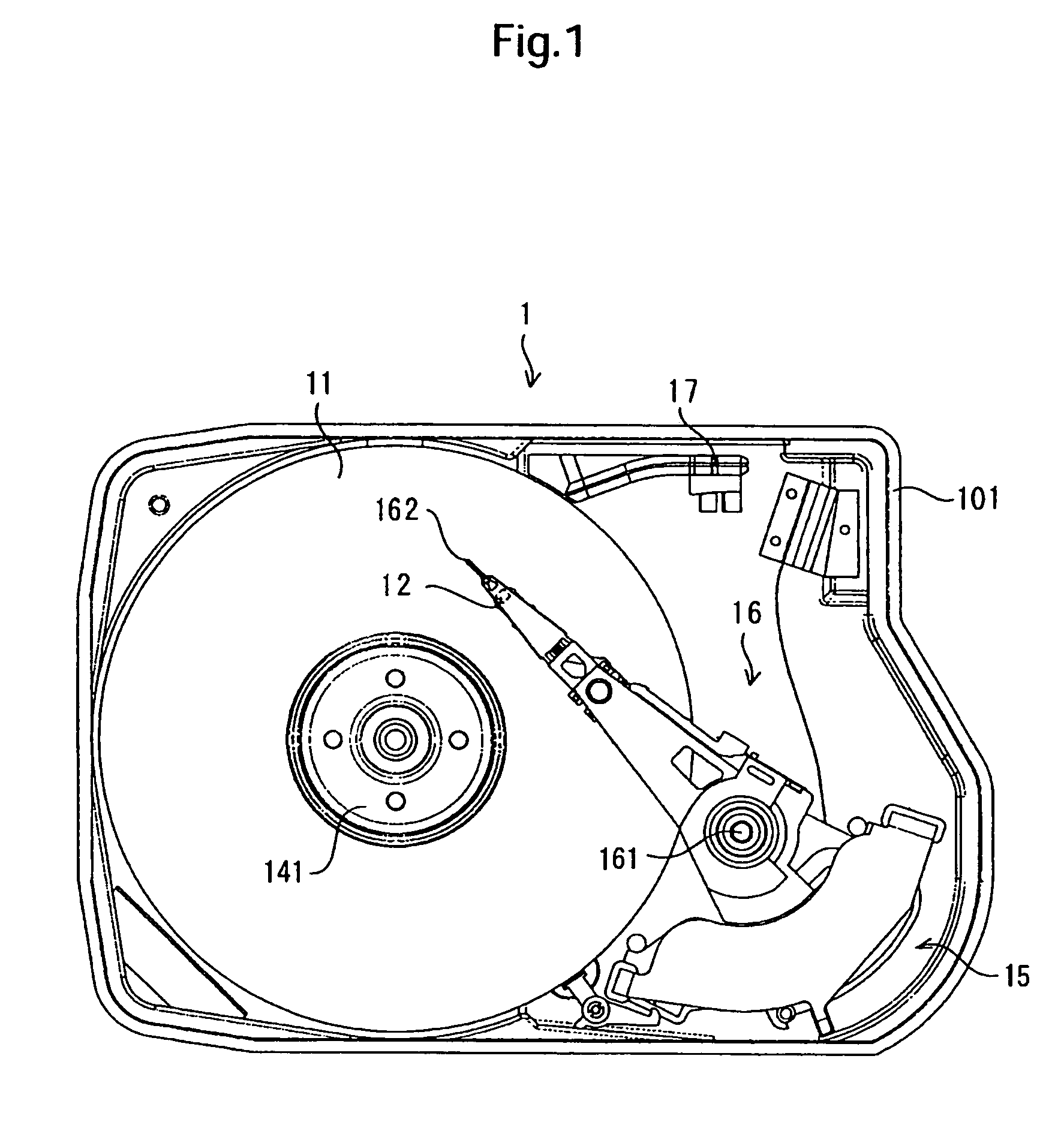

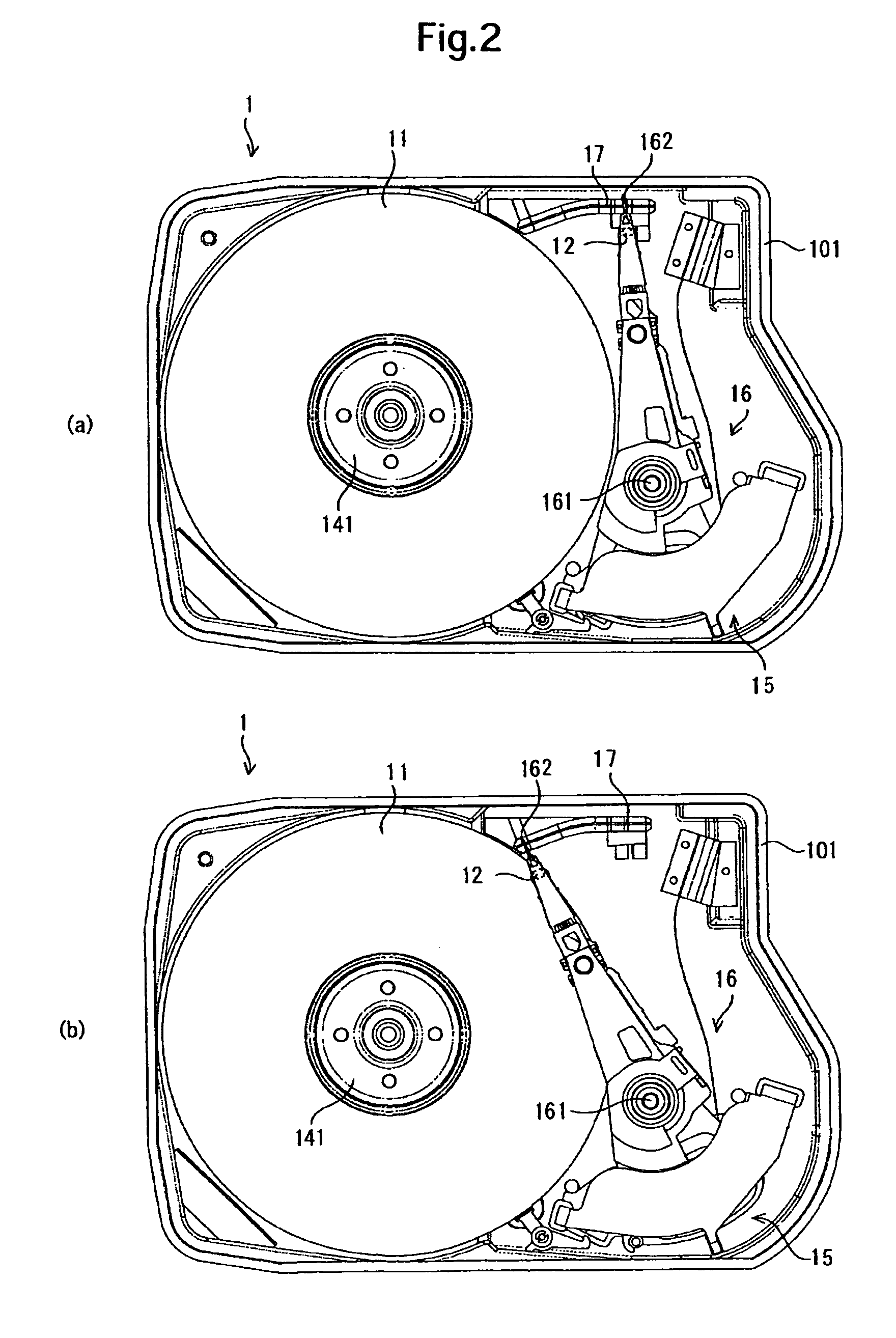

Disk drive and disk drive control method

InactiveUS7616397B2Avoid collisionReduce the probability of collisionDisposition/mounting of recording headsDriving/moving recording headsHard disc driveResidual vibration

Embodiments in accordance with the present invention improve the head characteristic and avoid collisions between a head element section and a recording disk. A hard disk drive according to an embodiment of the present invention performs TFC (Thermal Fly height Control) to adjust the clearance between the head element section and recording disk by means of thermal expansion. A head slider includes a TFC heater. The hard disk drive detects its acceleration and controls the TFC heater in accordance with the detected acceleration, thereby reducing the probability of collision between the head element section and recording disk. Further, the hard disk drive detects residual vibration prevailing after impact application. The heater turns back ON when the residual vibration becomes lower than a reference level.

Owner:WESTERN DIGITAL TECH INC

Disk drive and disk drive control method

InactiveUS20080019032A1Avoid collisionReduce the probability of collisionDisposition/mounting of recording headsDriving/moving recording headsHard disc driveResidual vibration

Embodiments in accordance with the present invention improve the head characteristic and avoid collisions between a head element section and a recording disk. A hard disk drive according to an embodiment of the present invention performs TFC (Thermal Fly height Control) to adjust the clearance between the head element section and recording disk by means of thermal expansion. A head slider includes a TFC heater. The hard disk drive detects its acceleration and controls the TFC heater in accordance with the detected acceleration, thereby reducing the probability of collision between the head element section and recording disk. Further, the hard disk drive detects residual vibration prevailing after impact application. The heater turns back ON when the residual vibration becomes lower than a reference level.

Owner:WESTERN DIGITAL TECH INC

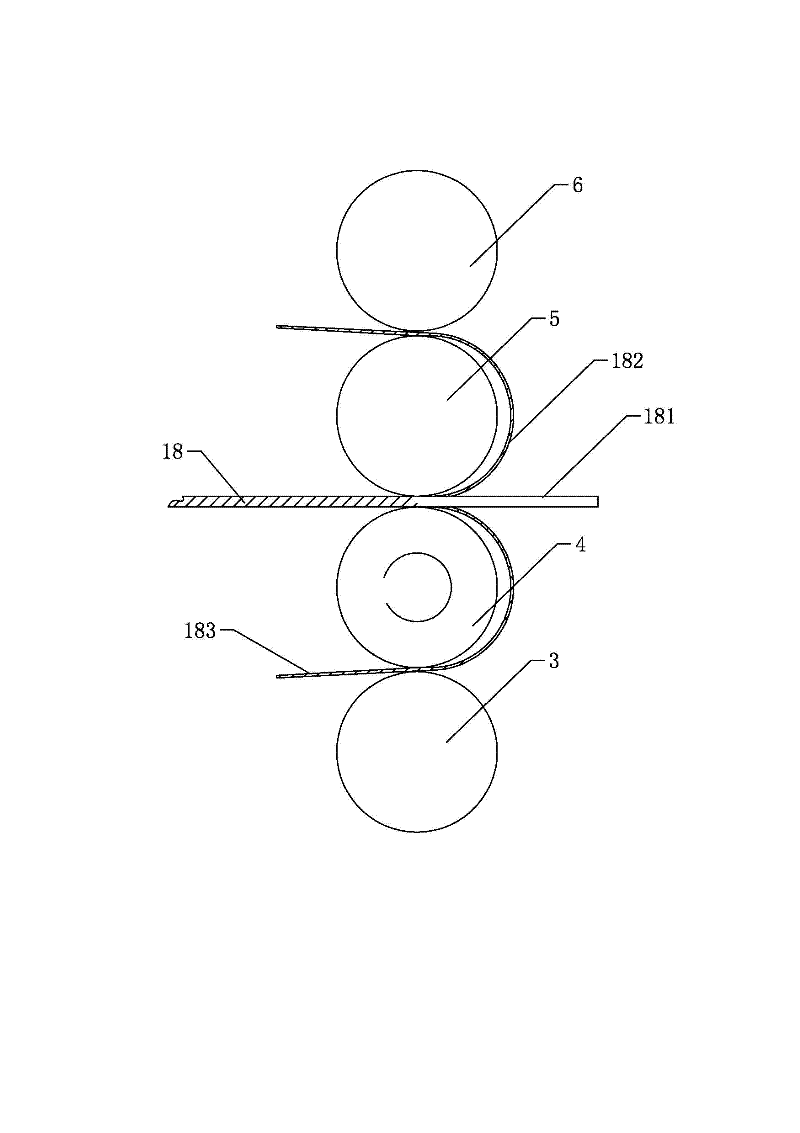

Three-roller coating printing unit for continuously coating surface of base material with viscous material

ActiveCN107350121AThin and uniform glue layerReduce usageLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a three-roller coating printing unit for continuously coating the surface of a base material with a viscous material. The unit comprises a pressing roller, a driving silica gel roller and a driving steel roller which are stacked from top to bottom. The driving silica gel roller and the driving steel roller rotate in opposite directions, and a micron order gap is kept; the driving steel roller is soaked with a colloid pond containing the viscous material, the base material is arranged between the pressing roller and the driving silica gel roller, and the base material is supported on the supporting roller and moves in the centrifugal force direction of the top vertex of the driving silica gel roller under power traction. Under the effect that the viscous material is extruded, stretched and extended through rotating rollers with the two different rotating speeds and the opposite directions, a rubber layer of the certain thickness is formed on the surface of the rubber covered roller, the material is transferred to the surface of the continuously running base material by means of the pressing roller, the thin and uniform coating is formed, and materials of the micro order and submicron order thickness and thinner materials can be uniformly sprayed to the surface of the base material.

Owner:陕西浩合机械有限责任公司

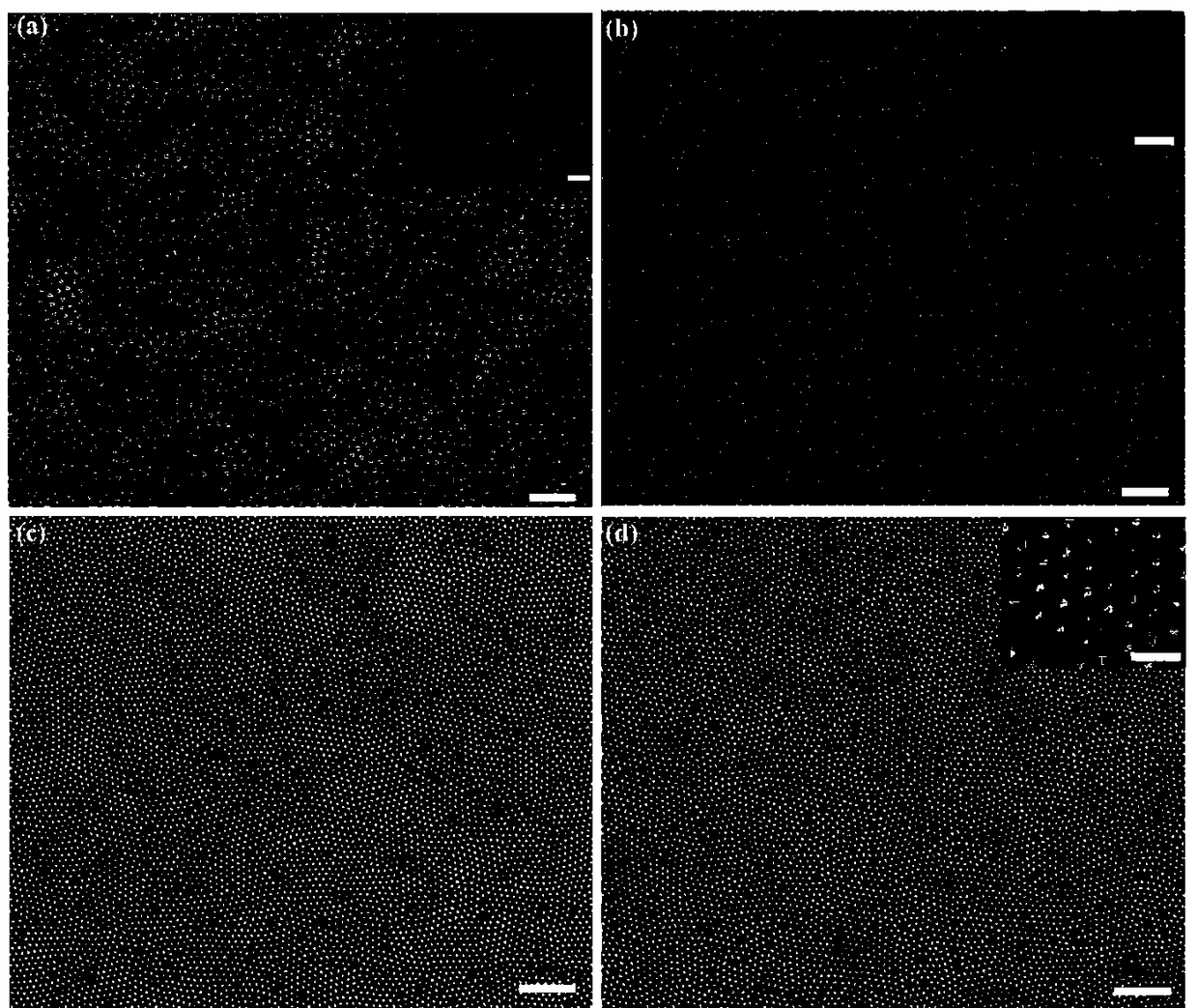

Preparation method of non-close packed inverse opal photonic crystal

ActiveCN102345167AComplete arrangementClosely arrangedPolycrystalline material growthSingle crystal growth detailsPhotonic crystalPhysical chemistry

A preparation method of non-close packed inverse opal photonic crystals comprises the following steps: preparing SiO2 spherical particles with ethyl orthosilicate as a raw material, performing ultrasonic treatment and vertical deposition of small-size SiO2 spherical particles and large-size organic particles to obtain a dual-size colloidal crystal structure, calcining the obtained heterogeneous dual-size colloidal crystal structure at a combustion decomposition temperature of the organic particles to remove organic matter so as to obtain non-close packed inverse opal photonic crystals; the method of the invention has simple equipment, simple operations, a short preparation period, and high yield.

Owner:JIANGSU GUOJIAO CHEM TECH

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

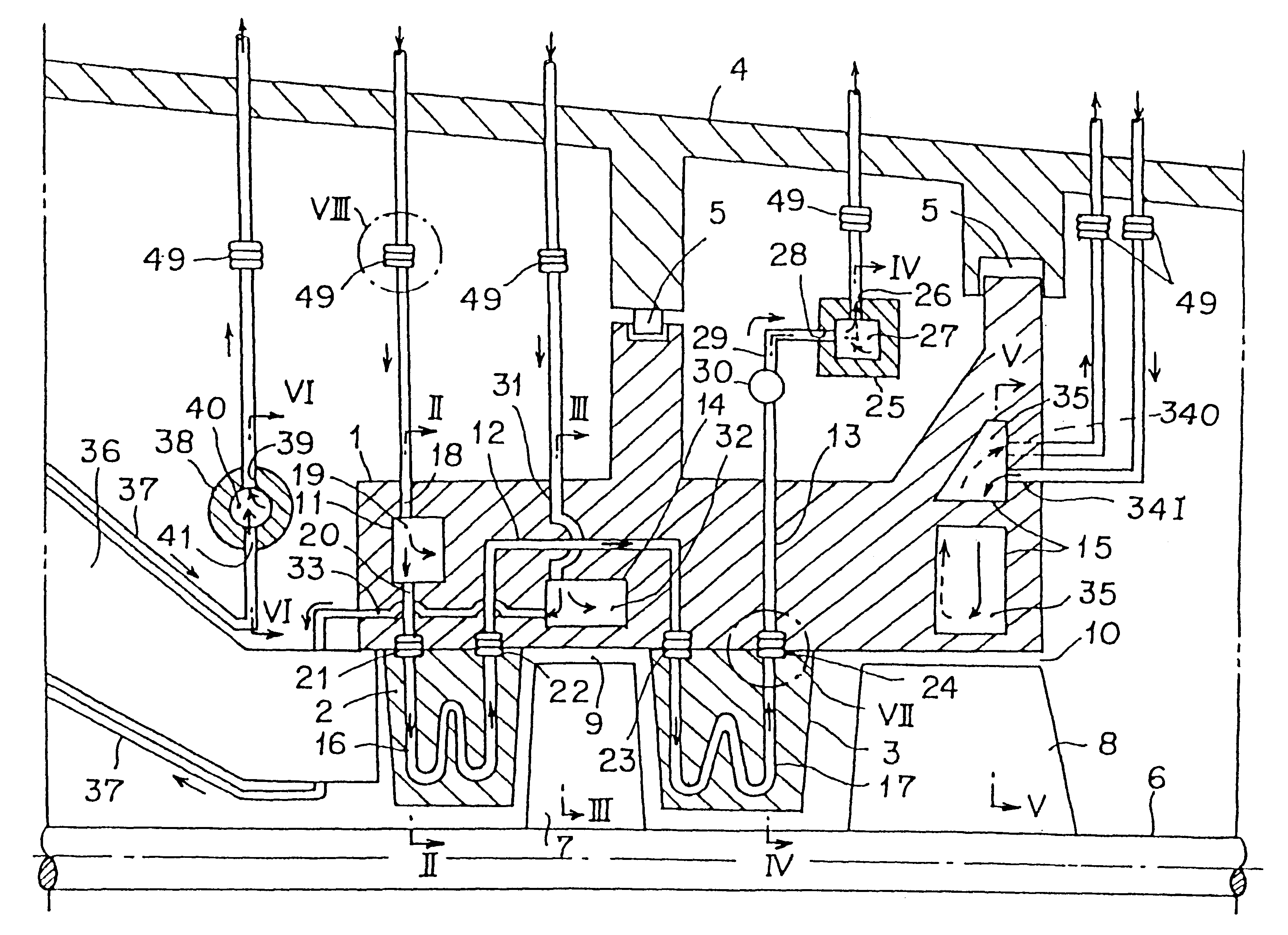

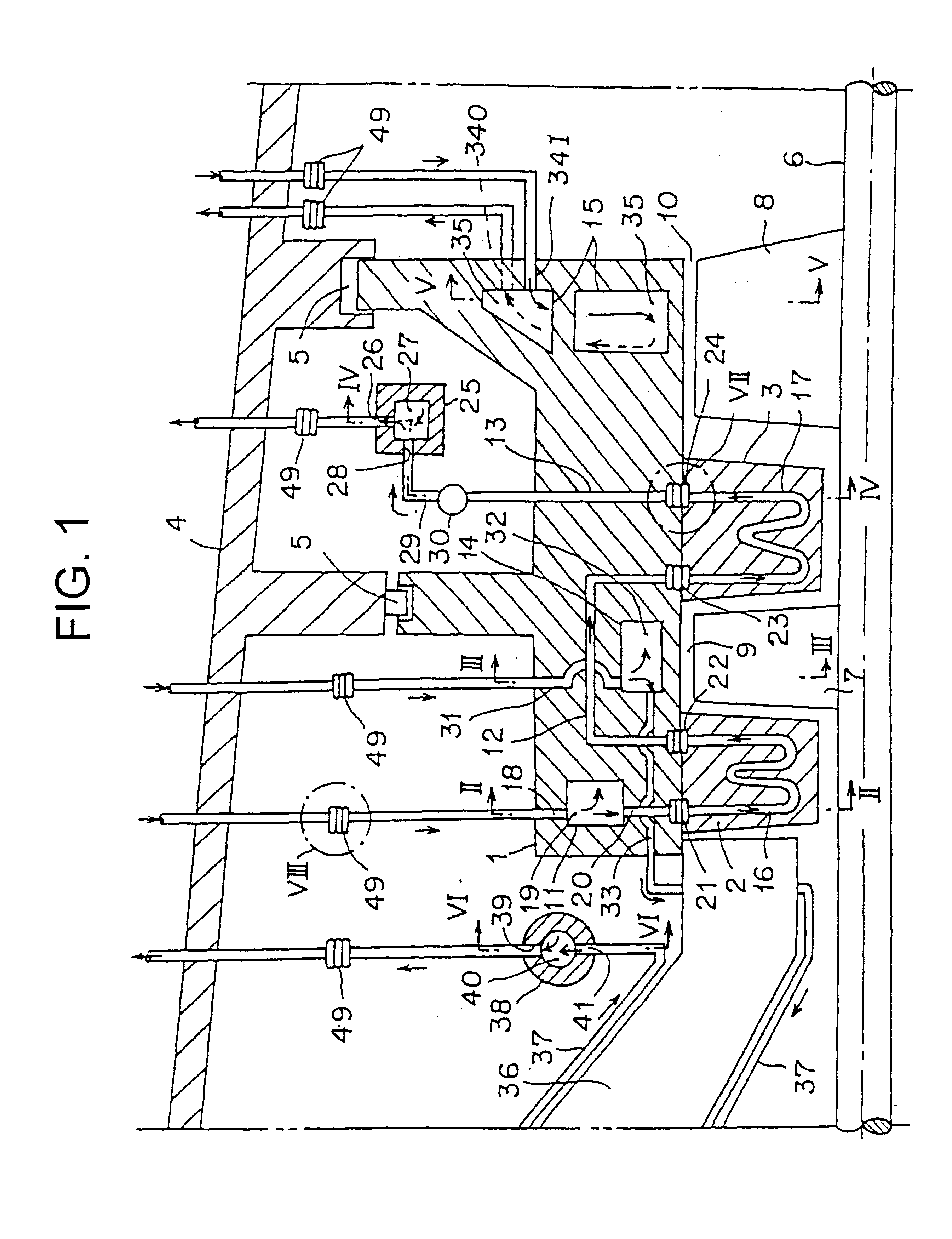

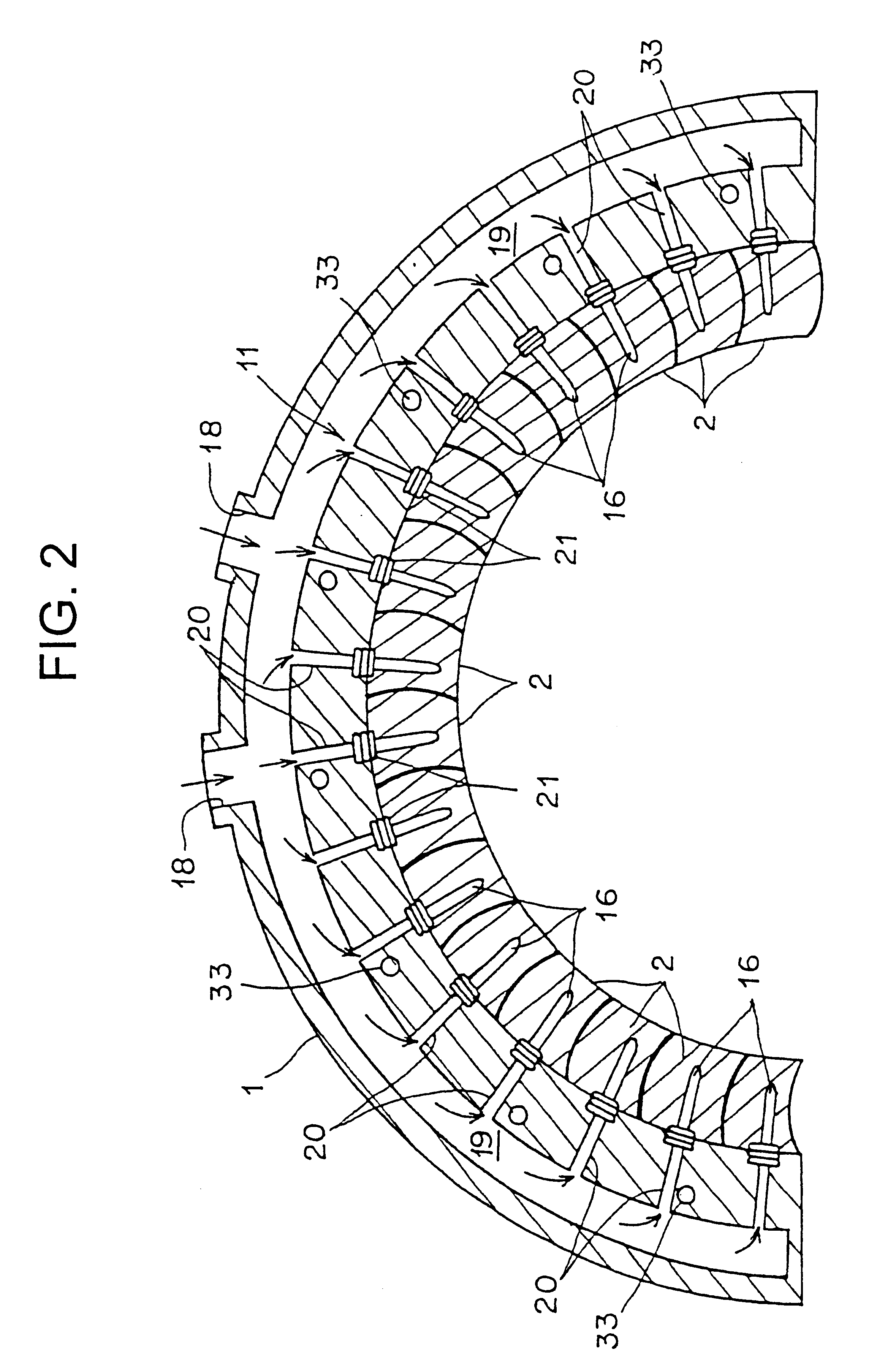

Steam-cooling-type turbine

InactiveUS6872047B2Clearance adjustablePump componentsEngine fuctionsThermal deformationTemperature difference

The steam-cooling-type gas turbine is provided with communication passages in number equal to that of the front-stage stator blades and the rear-stage stator blades. Many communication passages are placed in the blade ring densely. As a result, in the blade ring, the temperature difference between the portion having the communication passages and the portion without the communication passages becomes smaller. This makes it possible to minimize the thermal deformation of the blade ring, thereby making it possible to provide uniform clearance between the fixed side such as the blade ring and the rotary side members.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

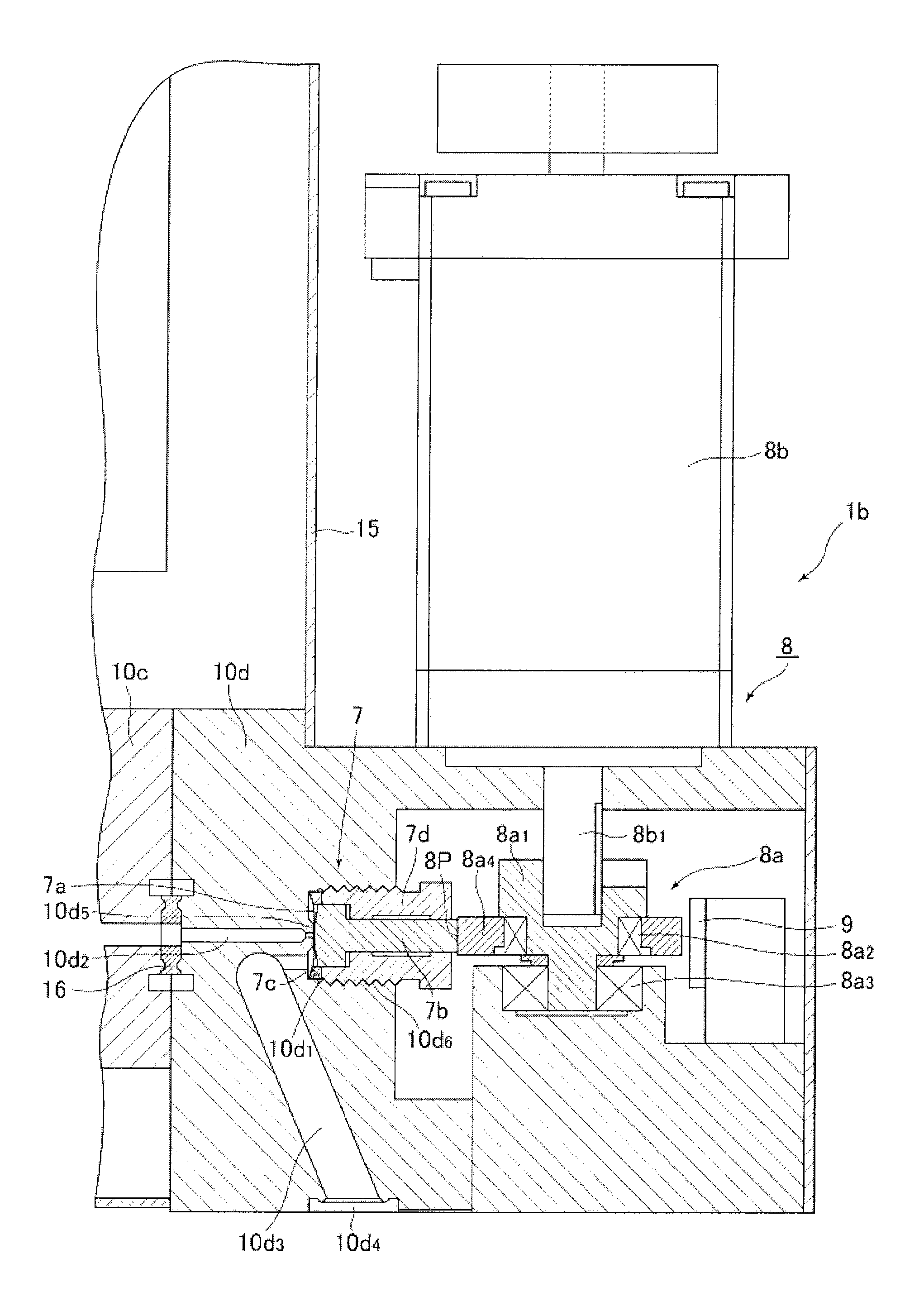

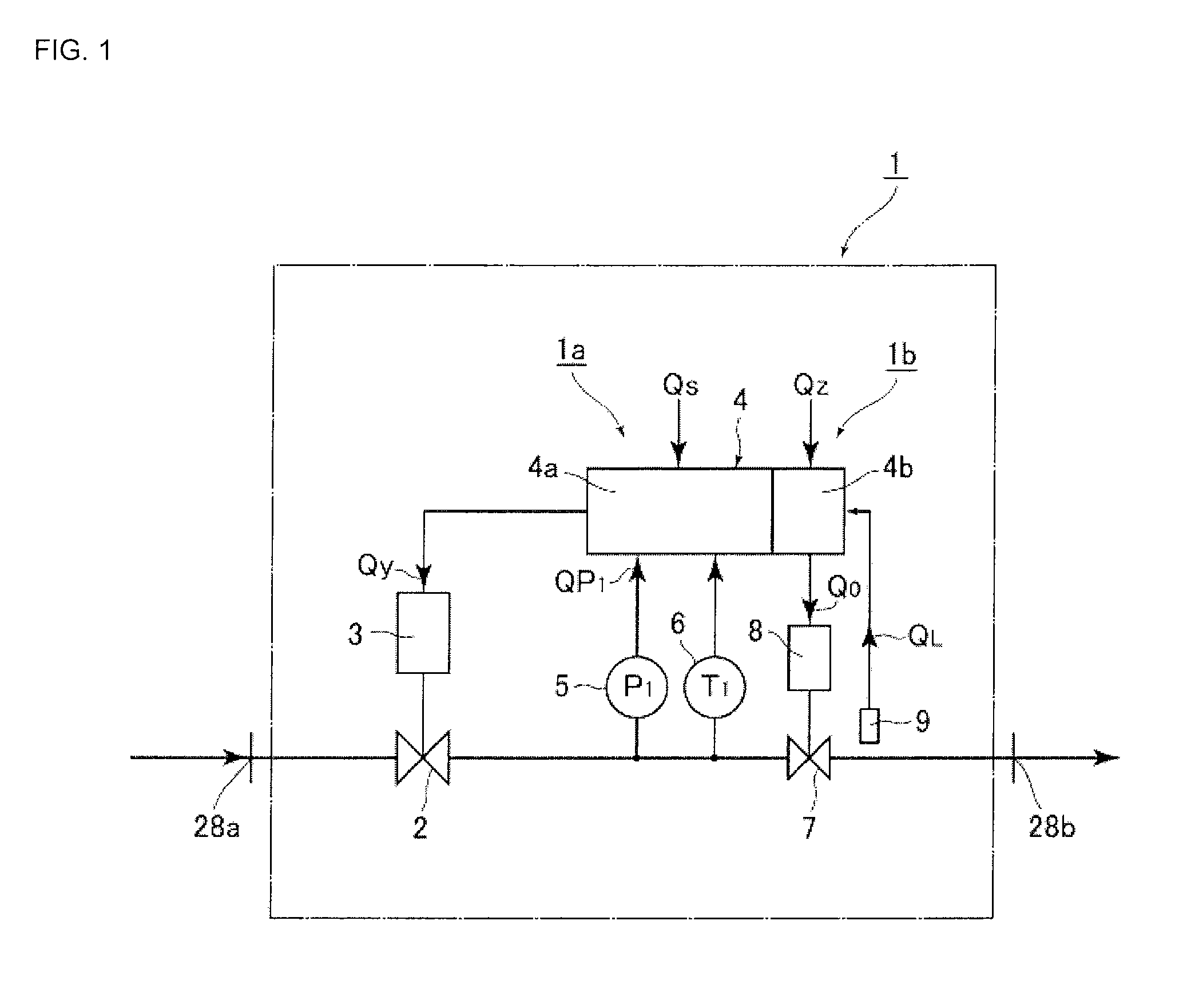

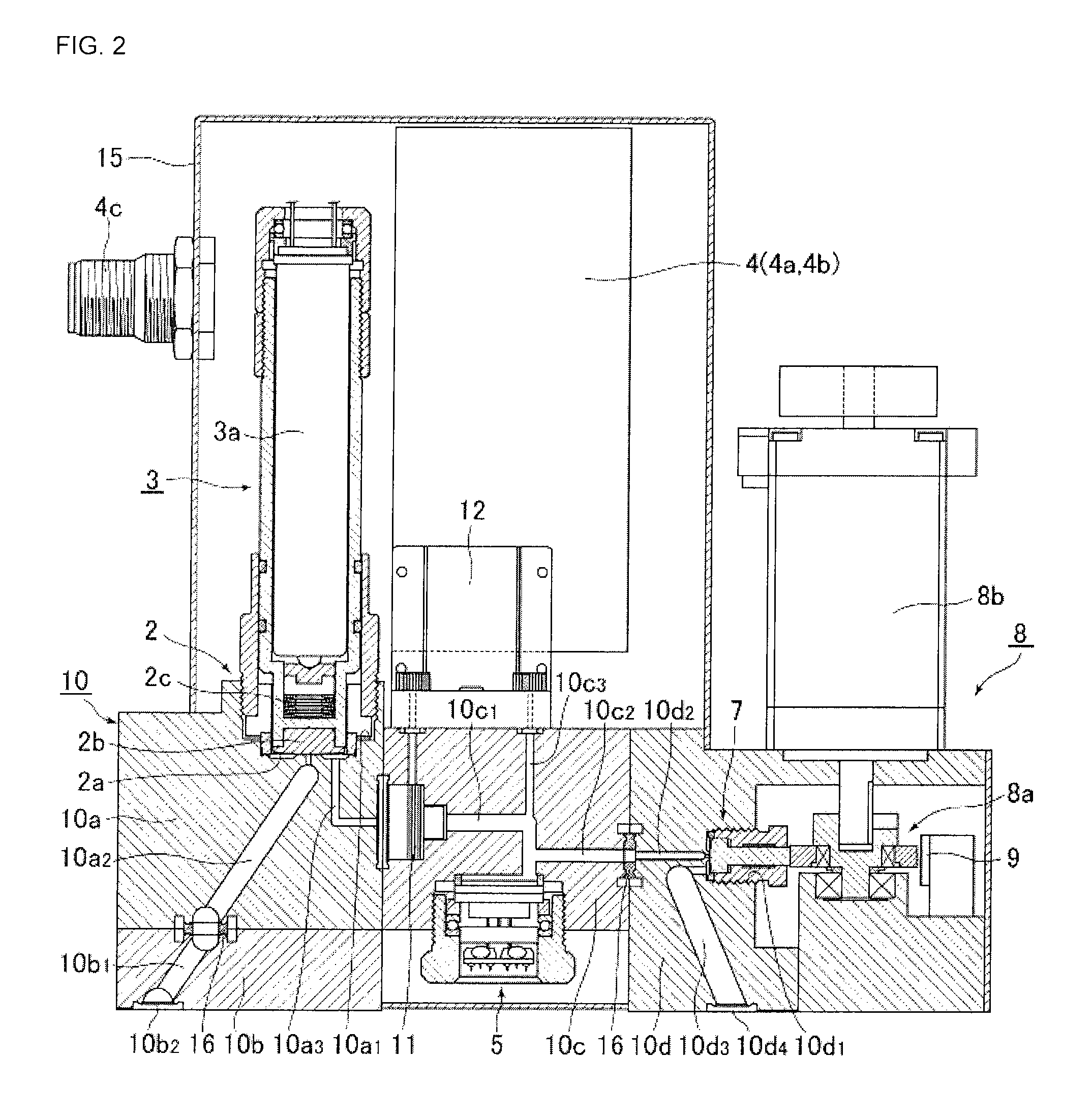

Variable orifice type pressure-controlled flow controller

ActiveUS9507352B2Clearance adjustableEasy to adjustDiaphragm valvesOperating means/releasing devices for valvesPressure controlled ventilationStreamflow

In a variable orifice type pressure-controlled flow controller that includes a pressure control unit and a variable orifice unit, computes a flow rate of a fluid distributed through an orifice of the variable orifice unit as QP1=KP1 (P1 is an orifice upstream side pressure and K is a constant), and switches a flow control range and performs flow control in the flow control range by changing a set flow rate signal Qs for a flow rate arithmetic and control unit of the pressure control unit and an orifice opening degree setting signal Qz for an orifice opening degree arithmetic and control unit of the variable orifice unit, the variable orifice unit includes the orifice opening degree arithmetic and control unit.

Owner:FUJIKIN INC

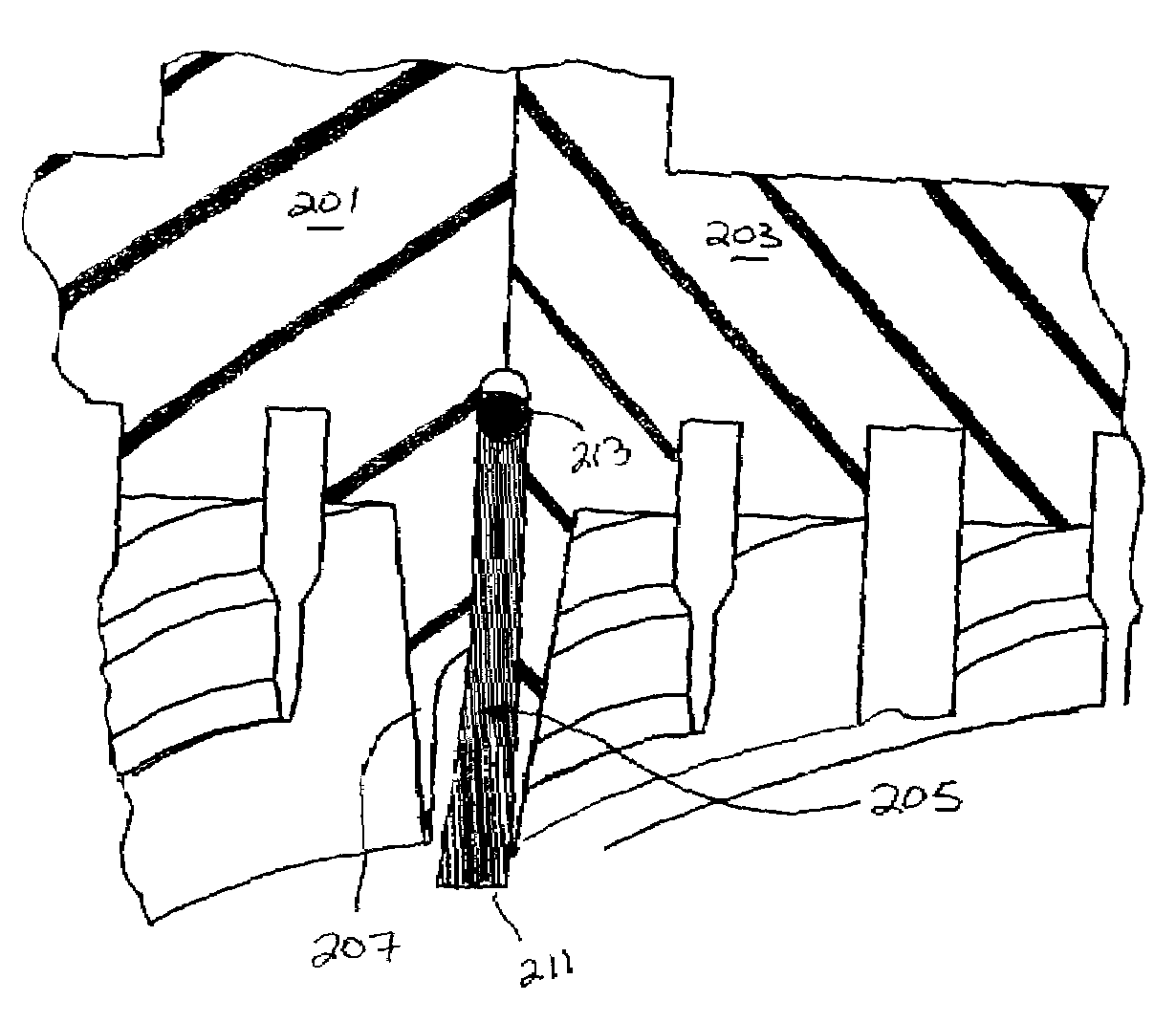

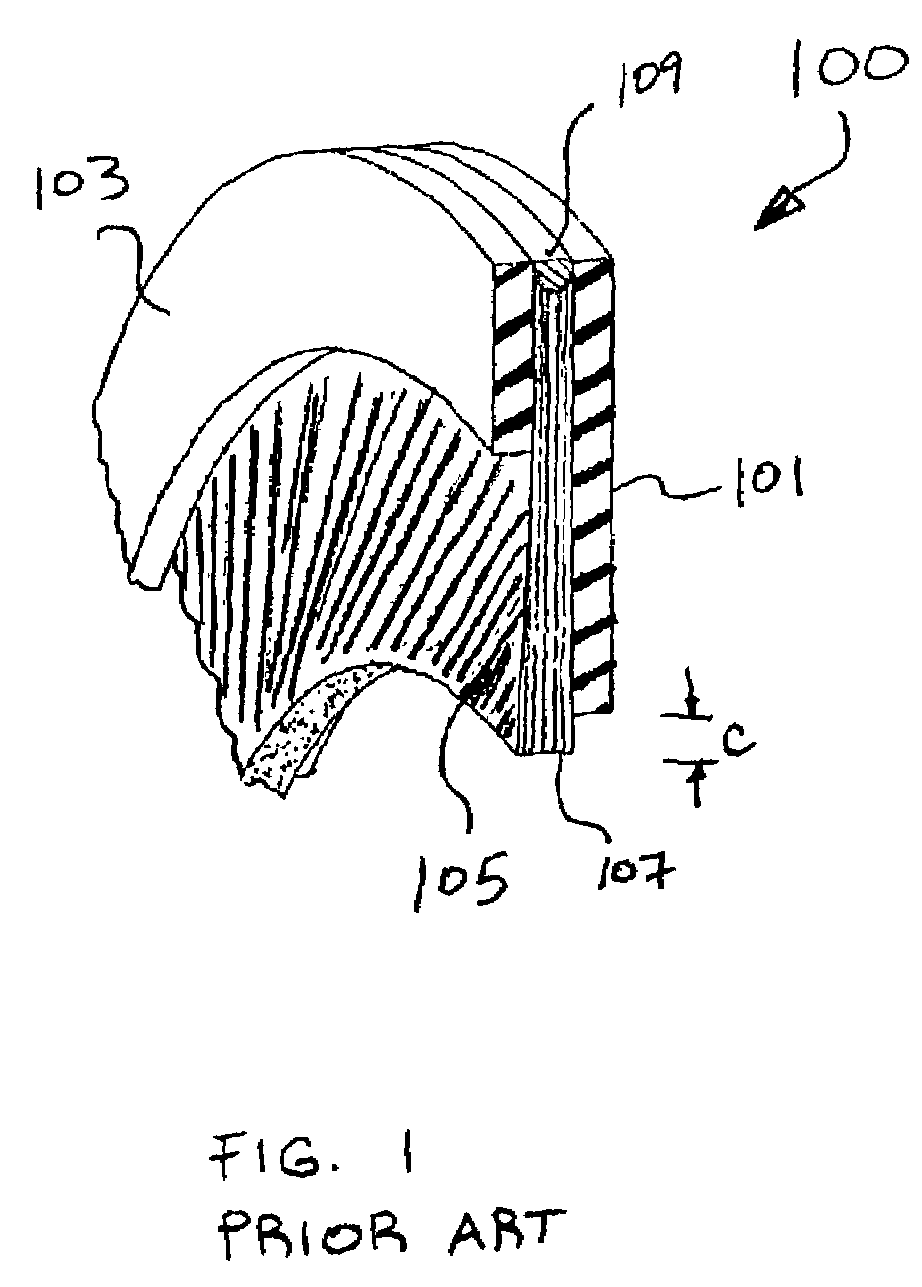

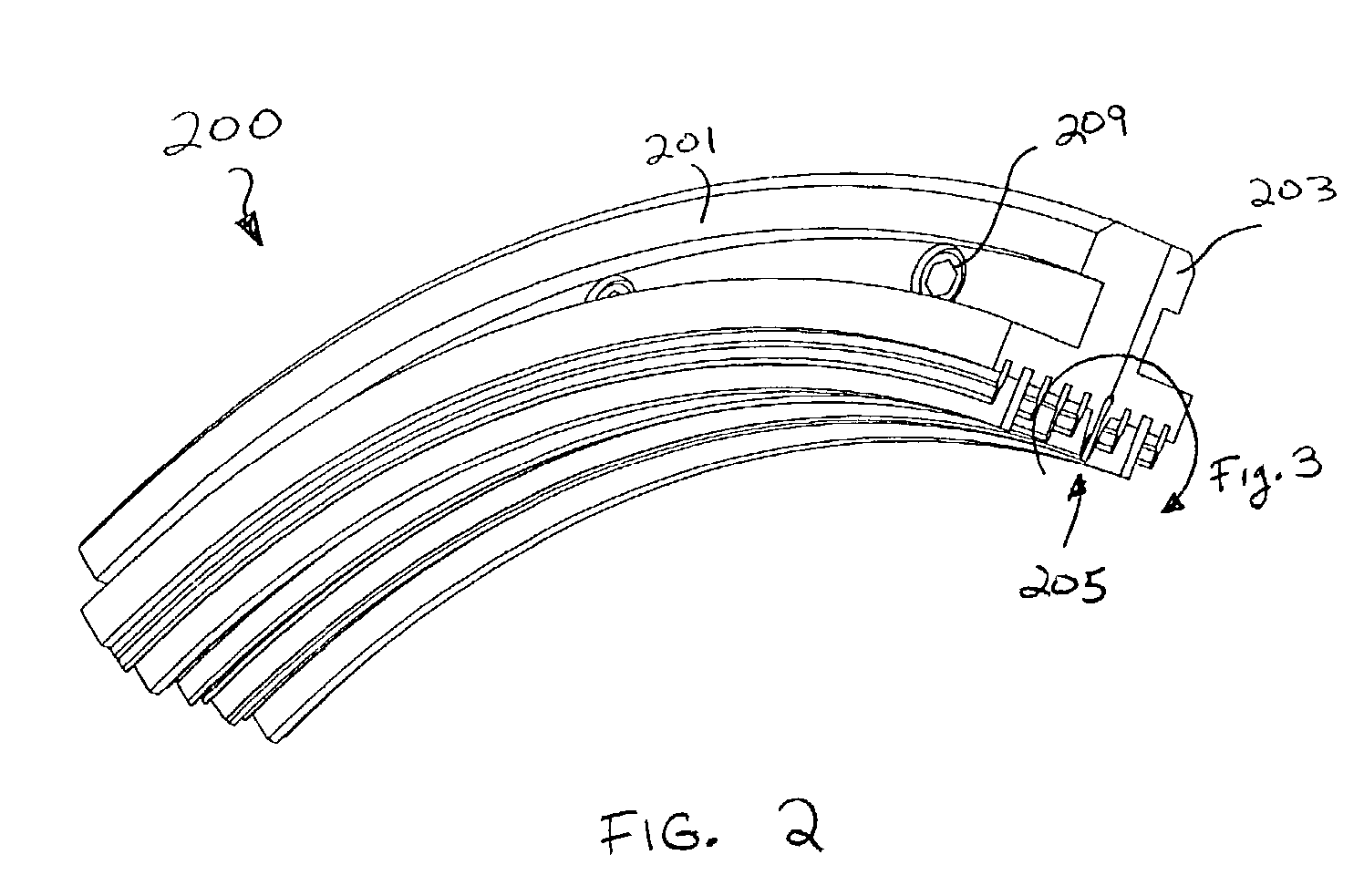

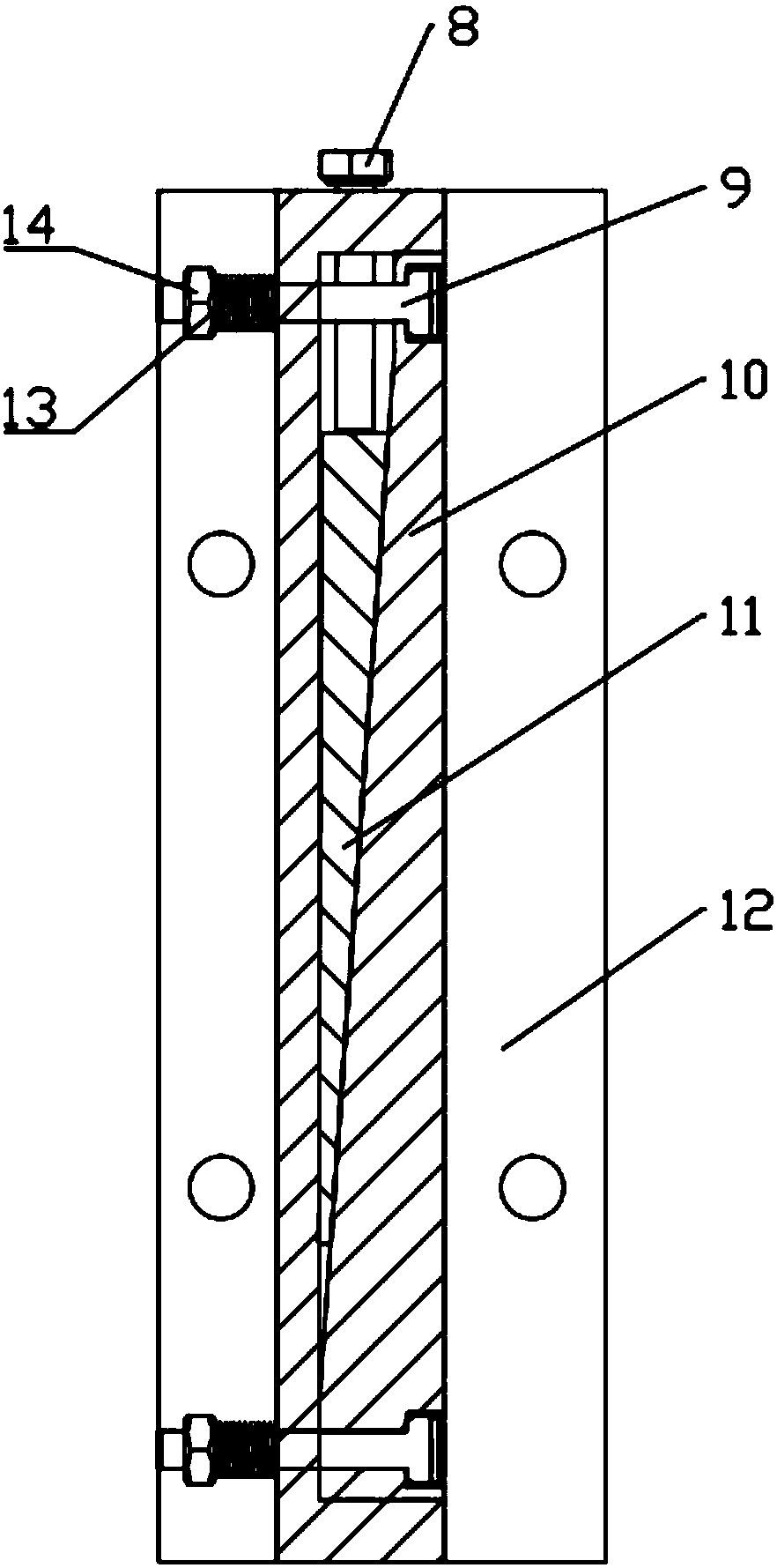

Brush seal with adjustable clearance

InactiveUS7270333B2Prevent movementClearance adjustableEngine sealsPump componentsEngineeringMechanical engineering

A brush seal, comprising: a bristle arrangement having a retention section; a pair of plates flanking the bristle arrangement and having a clamping section to frictionally engage the retention section. The clamping section allows movement of the retention section before the plates are secured together, to place the bristle arrangement at a desired position between the plates, and prevents movement of the retention section after the plates are secured together.

Owner:RAYTHEON TECH CORP

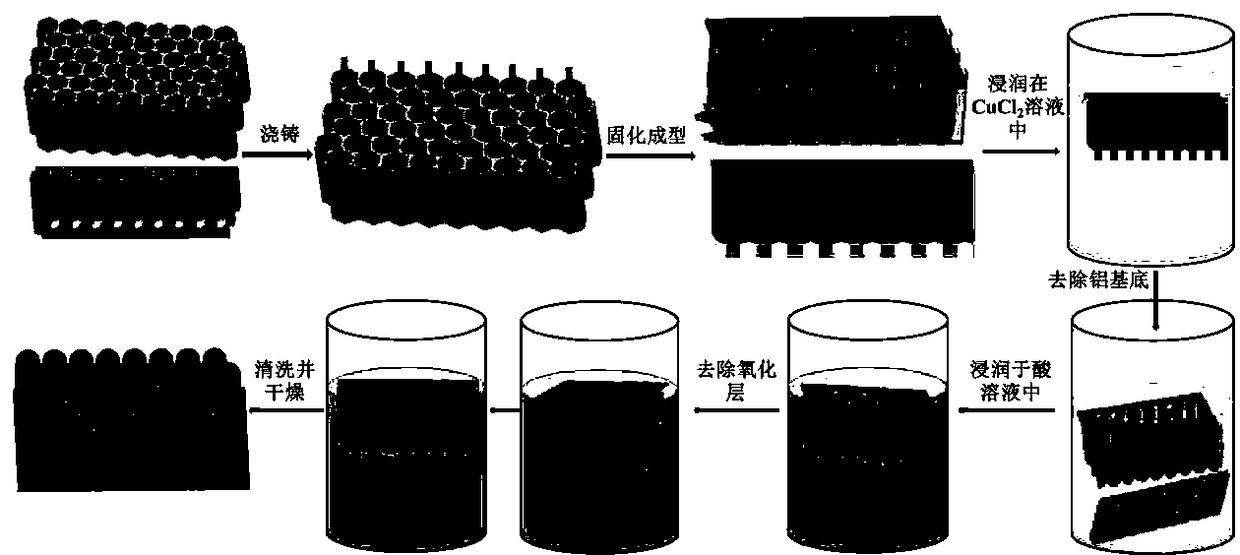

Flexible nanometer column array with top end coated with precious metal and preparation method and application thereof

InactiveCN108344725AGood repeatabilitySimple and fast operationVacuum evaporation coatingSputtering coatingSputteringEvaporation

The invention discloses a flexible nanometer column array with the top end coated with precious metal and a preparation method and application thereof. The preparation method comprises: pouring a polymer solution in a duct of a single-pass aluminium oxide template; enabling the polymer solution to be cured and formed in the duct of the template; placing the aluminium oxide template after a pouredpolymer is formed in chloride solution of which the activity is lower than that of aluminium to soak for 5 to 10min, and removing an aluminium layer on the back of the template; placing the template after a polymer nanocolumn is placed in a pore and the aluminium layer on the back is removed into acid solution to etch off the aluminium oxide template so as to prepare a size-controllable flexible transparent nanocolumn array thin film; placing precious metal particles on one surface of a flexible transparent nanocolumn array in a mode of electron beam evaporation or magnetron sputtering so as to prepare the flexible nanocolumn array with the top end coated with precious metal. The flexible nanocolumn array and the preparation method are simple and convenient to operate and good in effect.

Owner:NANTONG UNIVERSITY

Preparation method for non-close-packed SiO2 photonic crystals

ActiveCN102417309ALess prone to damageSimple production processPhotonic crystal structureCrystal structure

The invention relates to a preparation method for non-close-packed SiO2 photonic crystals. The preparation method comprises the following steps: taking tetraethoxysilane as a raw material, thereby preparing SiO2 nanometer and submicron sphere grains; ultrasonically and automatically assembling two SiO2 sphere grains at a certain particle size ratio, thereby obtaining a double-size photonic crystal structure; and roasting, etching and cleaning the double-size photonic crystal structure, thereby obtaining the non-close-packed SiO2 photonic crystals. The preparation method provided by the invention is short in preparation period and simple in processing equipment.

Owner:江苏优耐机械制造有限公司

Feeding conveyer for machining of large workpiece

The invention discloses a feeding conveyer for the machining of a large workpiece, which comprises a track and a driving vehicle, wherein the driving vehicle is used for bearing and driving the workpiece to move along the track and is arranged on the track by moving to and fro along the track. The feeding conveyer for the machining of the large workpiece has no relative sliding between the workpiece and the driving vehicle and can not cause damage to the surface of the workpiece by conveying the workpiece through the driving vehicle moving along the track, and also has a high feeding precision and a simple structure, has no complex transmission mechanism, has a few vulnerable components, a low failure rate during running and a low manufacturing cost and is convenient to maintain; non-powered roll tables on two sides of the driving vehicle make the workpiece be more stable in the running process and overcome the defect of inconsistent linear speed of live rollers on a powered roll table; the non-powered roll tables and the workpiece have no relative sliding therebetween, so no damage on the workpiece can be caused; the positive pressure between the workpiece and the driving vehicle, and between the workpiece and the roll tables can be regulated by regulating the height of the non-powered roll tables, so that the driving vehicle can work under the optimal working condition, the sliding of the workpiece is avoided and the stable feeding is ensured.

Owner:CHONGQING UNIV

Scraper mechanism of transfer printing machine

The invention relates to a scraper mechanism of a transfer printing machine, comprising a scraper. The scraper is arranged on a stand and can scrape redundant ink on a printing roller, and a scraper position adjusting mechanism is arranged between the scraper and the stand. The scraper mechanism of the transfer printing machine can adjust a gap between the scraper and the printing roller and is convenient to use.

Owner:SUZHOU BAODELONG IND

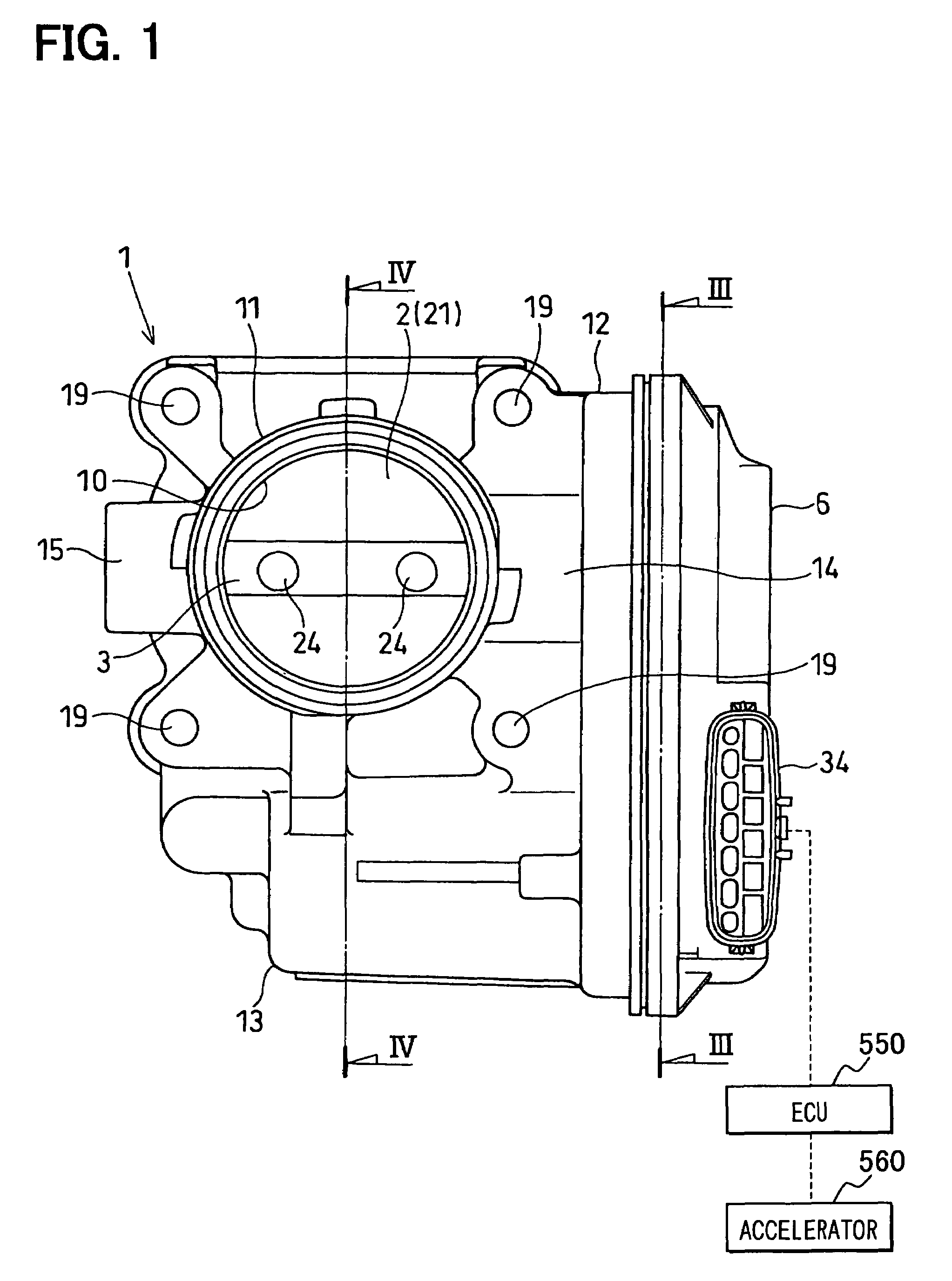

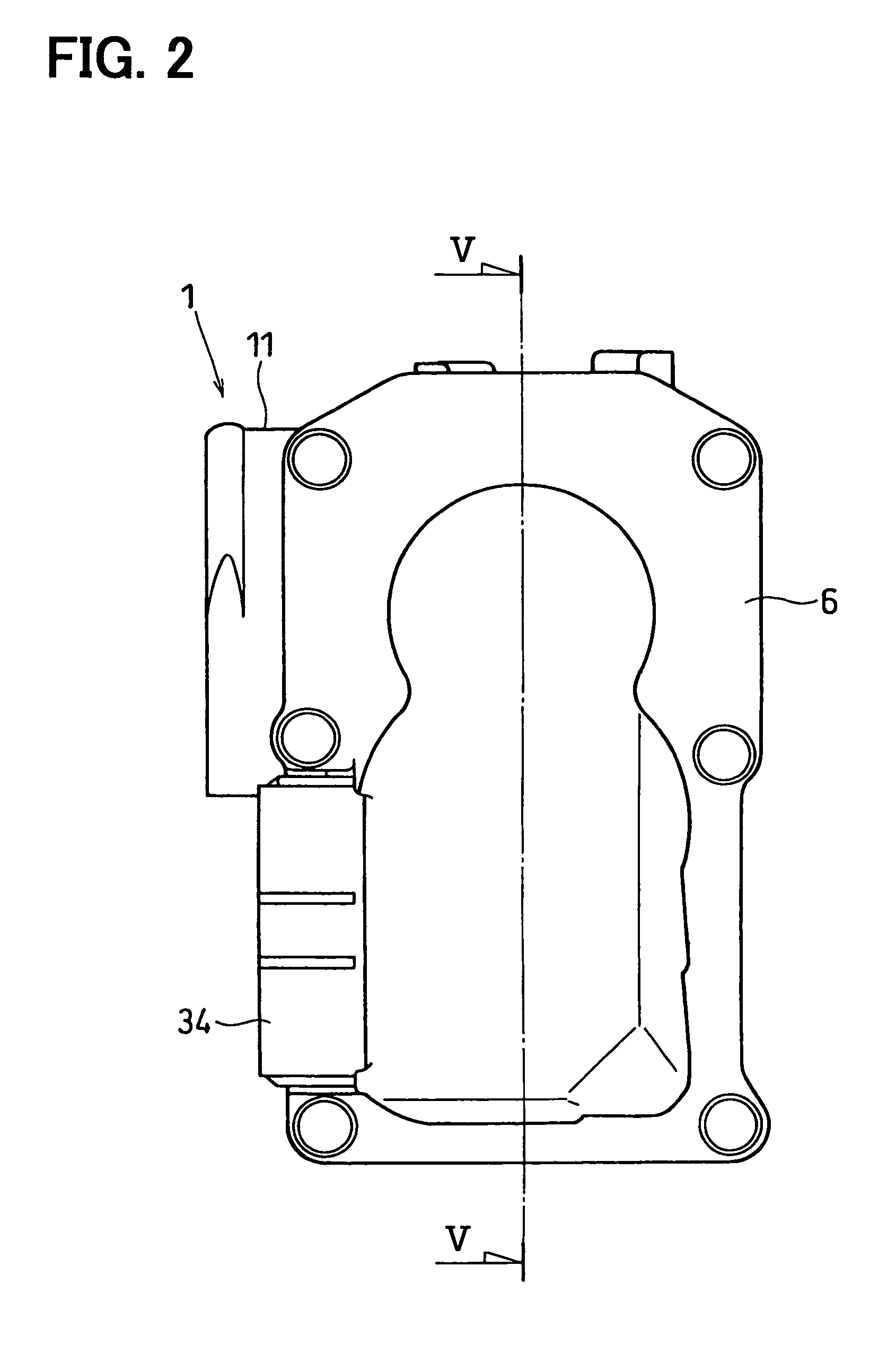

Intake control device for internal combustion engine

ActiveUS7080628B2Reduce outputReduce positioningEngine controllersMachines/enginesExternal combustion engineCoupling

Owner:DENSO CORP

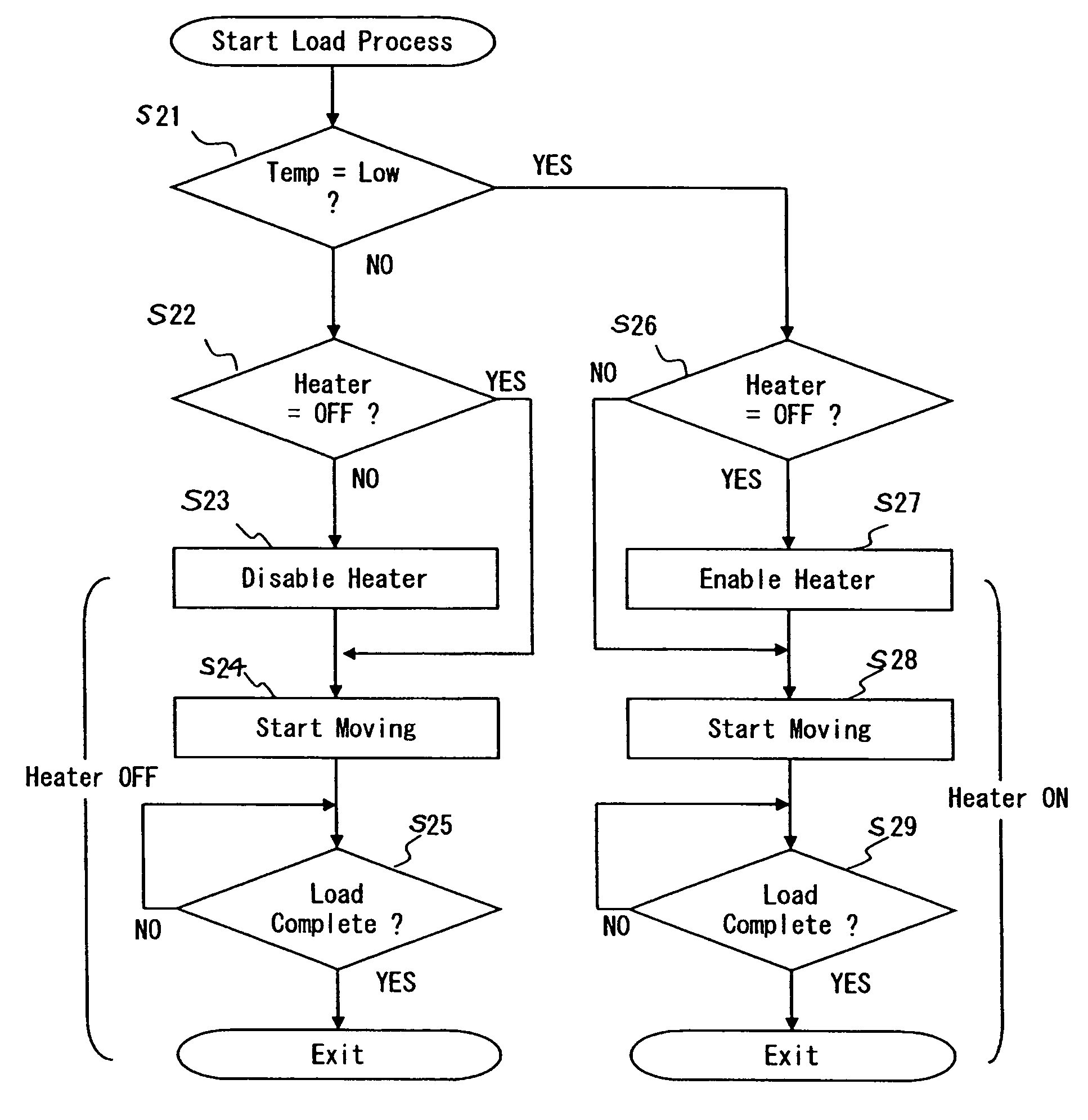

Disk drive with heater for slider and control method thereof

InactiveUS7426089B2Reduce the possibilityReduce the likelihood of a collisionDisposition/mounting of recording headsDriving/moving recording headsEngineeringActuator

Embodiments of the invention allow a heater to reduce the clearance between a head element section and the magnetic section while reducing the risk of collision between the head element section and the magnetic disk during load / unload. In one embodiment, an HDD judges whether a heater is ON or OFF after the load process is started. If the heater is found set to ON, the HDD sets the heater to OFF. With the heater kept OFF, the HDD starts the actuator pivoting. If the heater is found set to OFF, the HDD moves the actuator from the parking position to the magnetic disk with the heater kept OFF. Upon completion of the load process, the HDD goes to the subsequent process. Since the heater is OFF during load, the risk of collision between the head element section and the magnetic disk is reduced.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

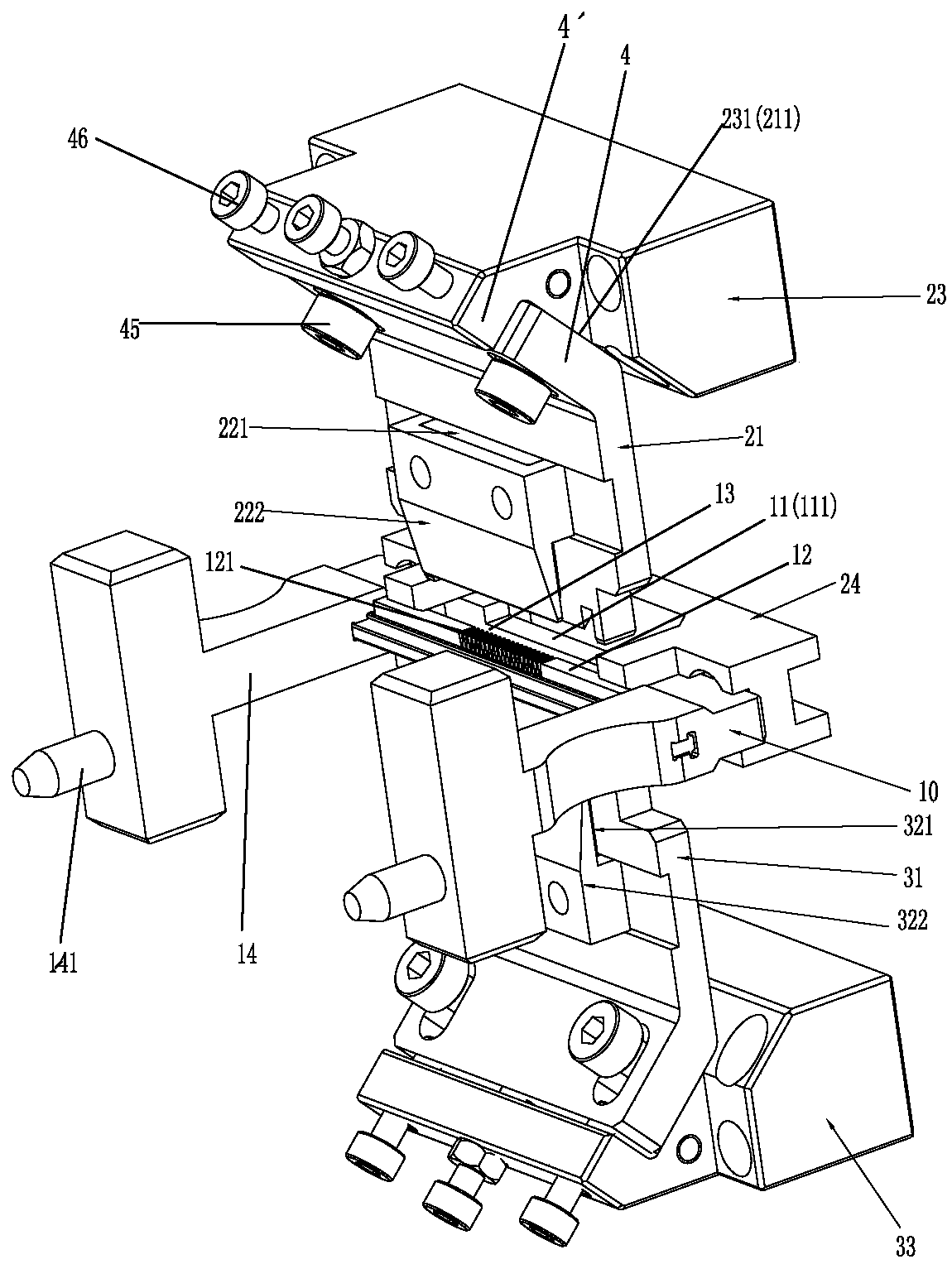

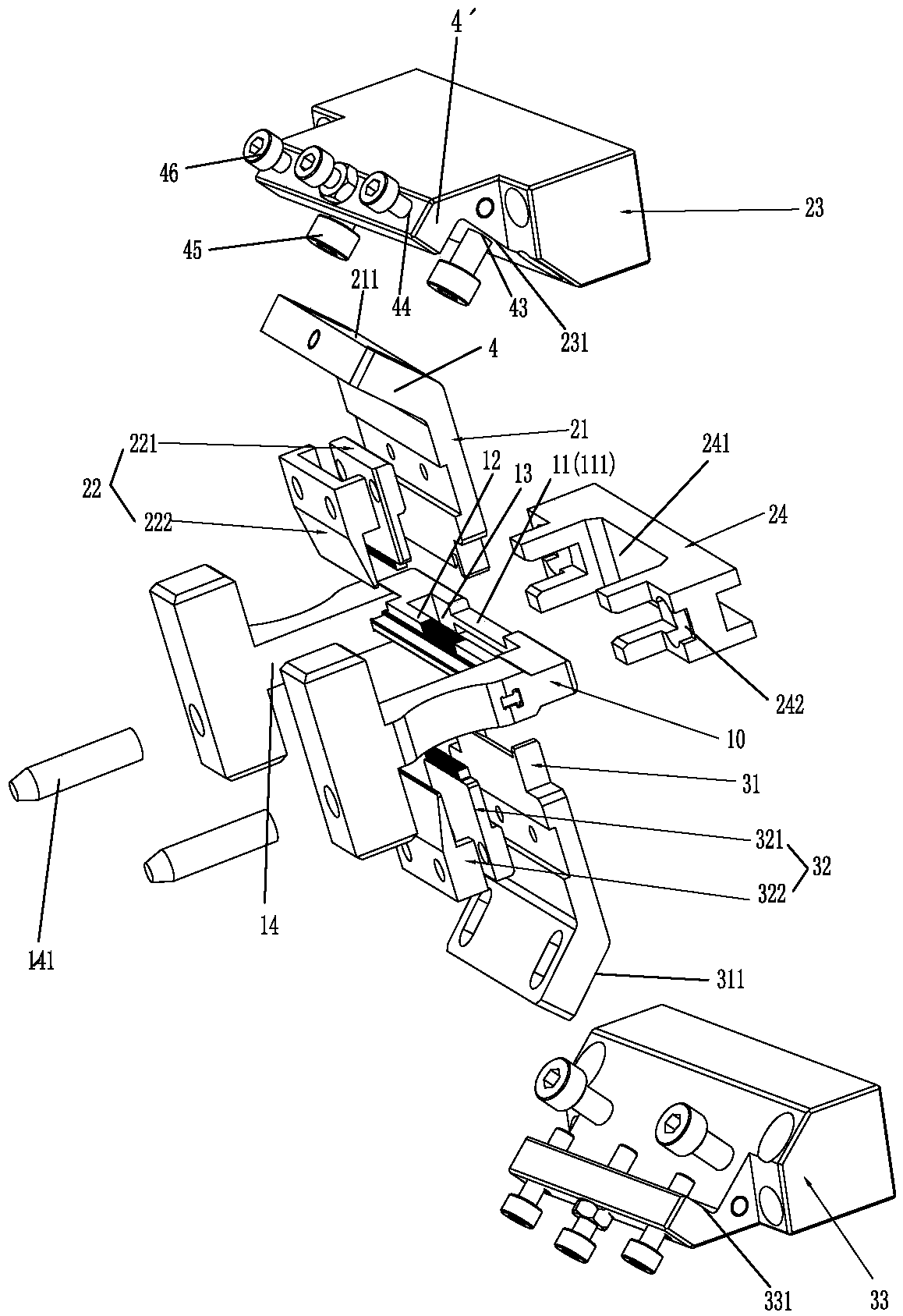

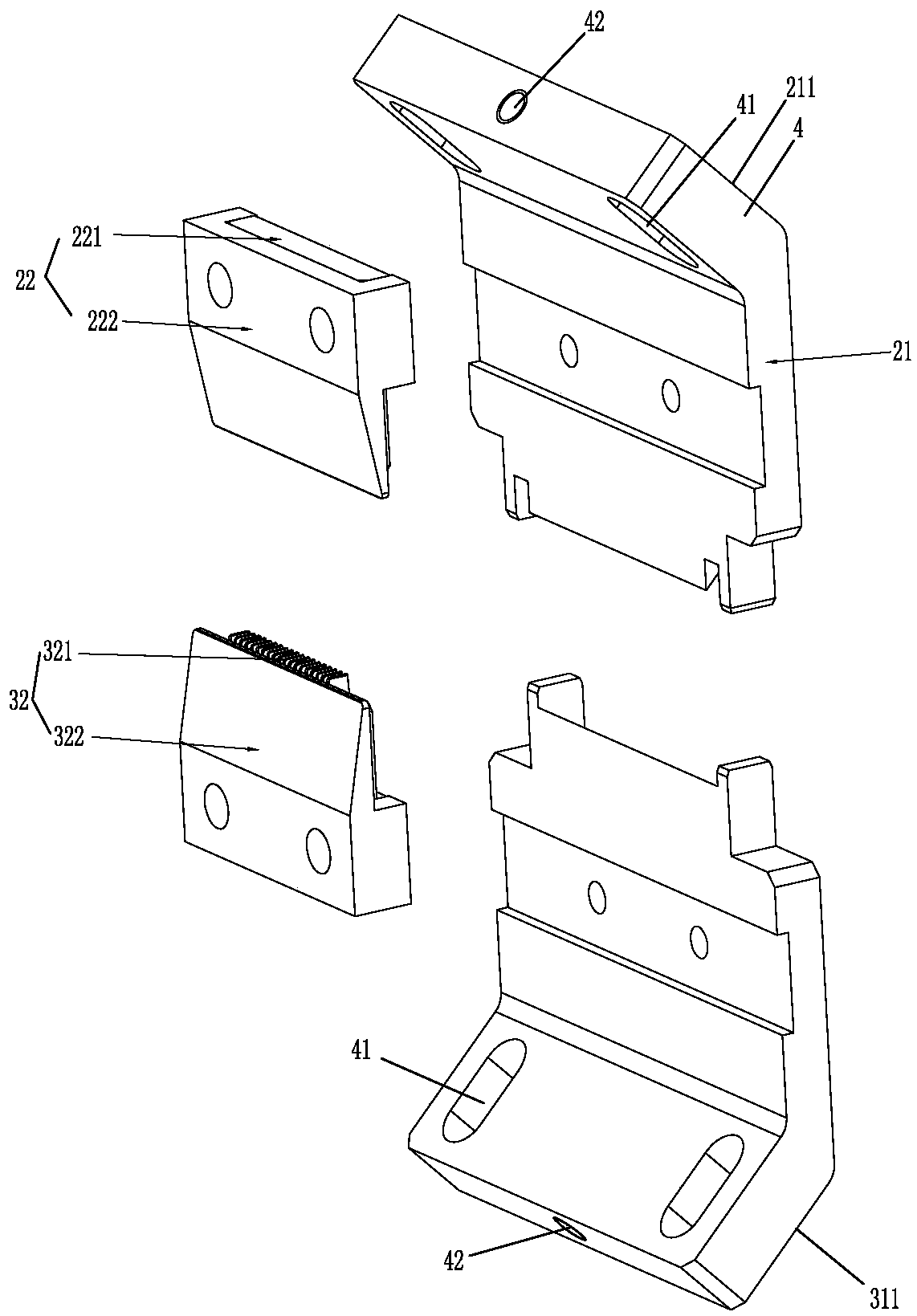

Shaping and cutting module

The invention discloses a shaping and cutting module. The shaping and cutting module comprises an upper shaping and cutting tool assembly, a middle line sorting tool and a lower shaping and cutting tool assembly. The upper shaping and cutting tool assembly and the lower shaping and cutting tool assembly selectively move close to or away from the middle line sorting tool. The upper shaping and cutting tool assembly comprises an upper cutting tool and an upper shaping tool arranged on the rear side of the upper cutting tool. The lower shaping and cutting tool assembly comprises a lower cutting tool and a lower shaping tool arranged on the rear side of the lower cutting tool. The middle line sorting tool is provided with a front line positioning part, a rear line positioning part and a receding through grove located between the front line positioning part and the rear line positioning part. The upper cutting tool and the upper shaping tool selectively and synchronously stretch downwards into the receding through groove. The lower cutting tool and the lower shaping tool selectively and synchronously stretch upwards into the receding through groove. In this way, synchronous shaping andcutting are achieved, the processing efficiency is greatly improved, and the manufacturing cost is reduced.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

Two-degree-of-freedom inchworm type micro-nano positioning platform

ActiveCN107705821AReduce distanceImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesInstrumental componentsMicro nanoImage resolution

Owner:SHANDONG UNIV

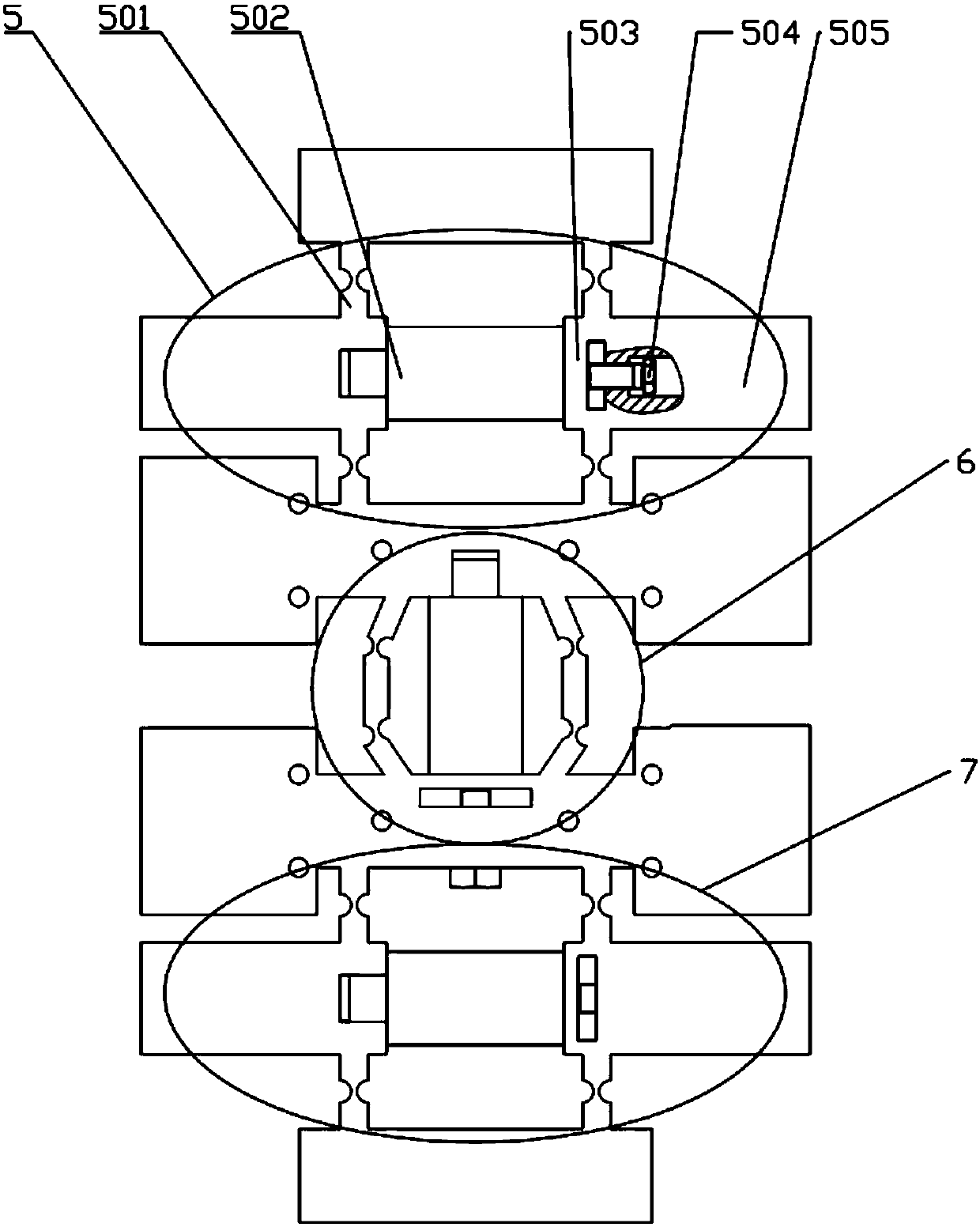

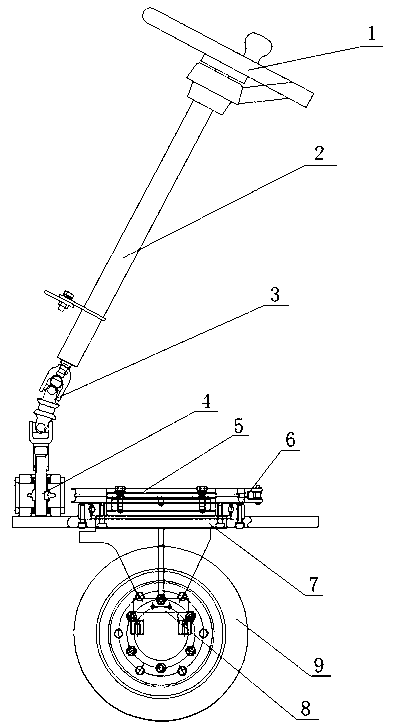

Electric fork-lift truck steering device

InactiveCN102975760AClearance adjustableSmall self-vibrationMechanical steering gearsHand wheelsSteering columnVehicle frame

The invention discloses an electric fork-lift truck steering device which comprises a steering wheel, a steering column, a cardan joint, a steering actuating device, a carframe and a shift wheel, wherein the steering column is arranged below the steering wheel and is connected with the steering wheel. The cardan joint is arranged below the steering column and is connected with the steering column. The steering actuating device is connected with the cardan joint. The carframe is connected with the steering actuating device. The shift wheel is arranged on the carframe. The steering actuating device comprises a chain wheel mechanism and the steering wheel, wherein the horizontally arranged steering is connected with the cardan joint through the chain whell mechanism. The carframe comprises a vertical part and a horizontal part, wherein the horizontal part is connected with the bottom end of the vertical part. The top end of the vertical part of the carframe is fixedly connected with the end face of the steering wheel. The horizontal part of the carframe is provided with the shift wheel. The electric fork-lift truck steering device has the advantages of being simple in structure, convenient to operate and low in cost. In the process of steering, a driver can adjust angles of the shift wheel by constantly steering the steering wheel according to factors such as road surface bending changes and speed changes to maintain steering tracks which a driver wants to reach, and therefore the electric fork-lift truck steering device is reliable in steering, and low in stoppage rate and the like.

Owner:ANHUI HECHA FORKELEVATOR

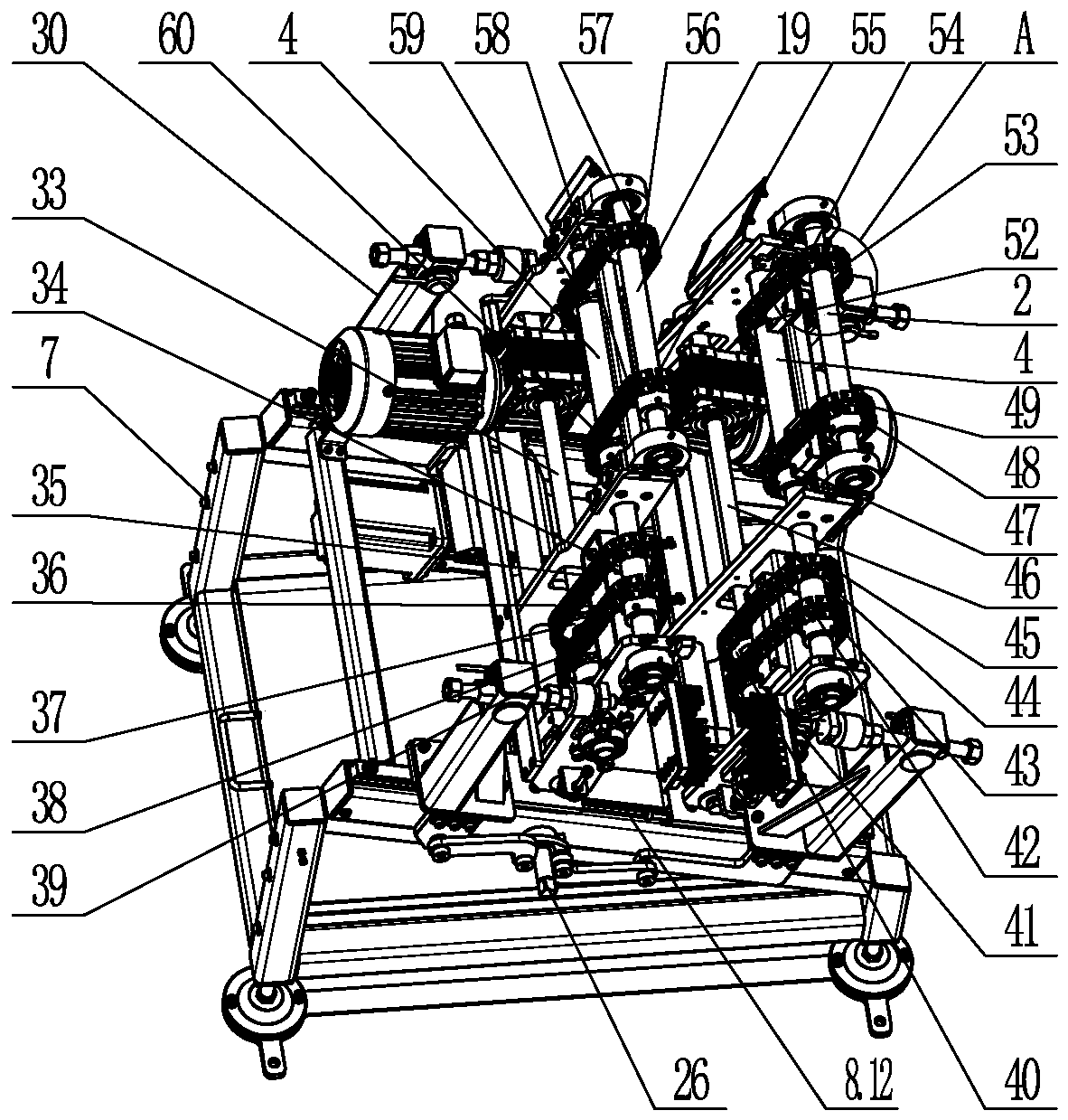

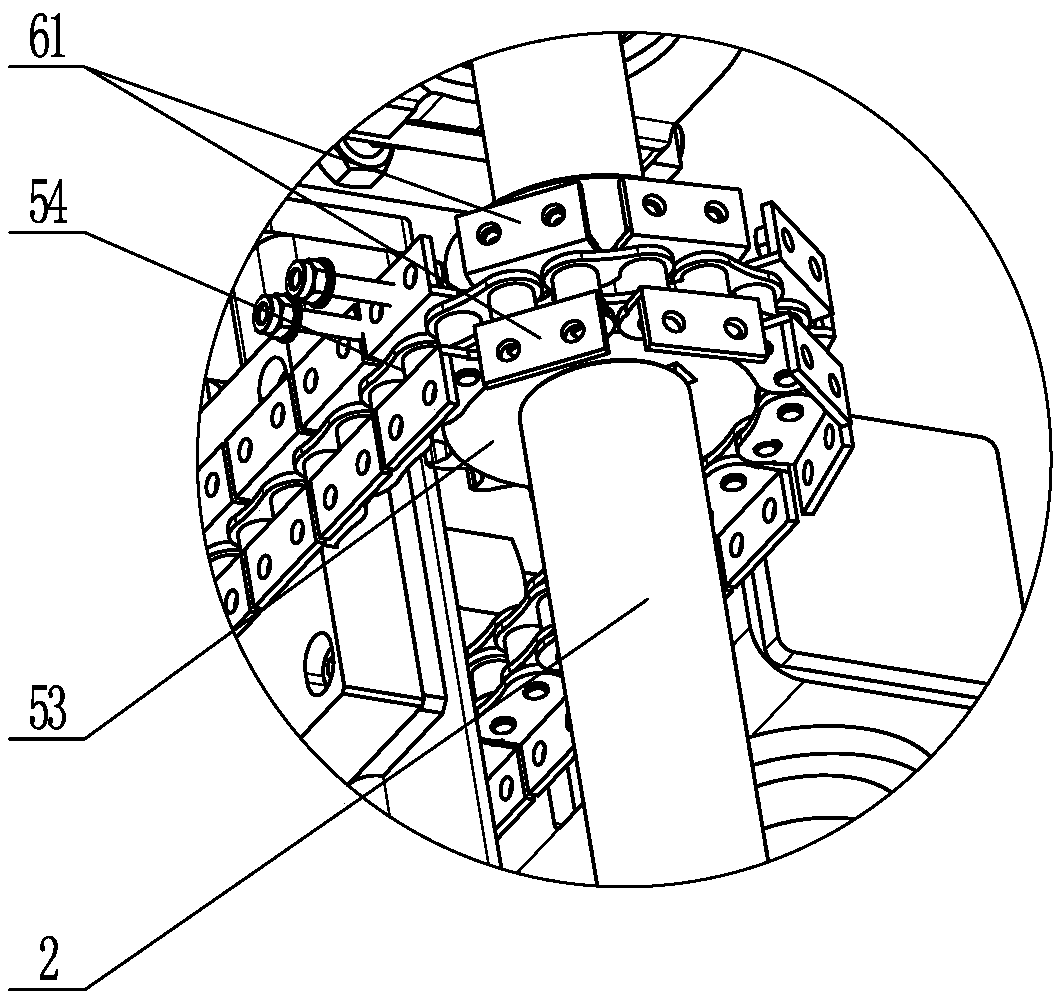

Full-automatic non-demoulded glove cleaning machine

PendingCN109774037AImprove release strengthImprove demoulding efficiencyDomestic articlesCoatingsEngineeringMechanical engineering

The invention discloses a full-automatic non-demoulded glove cleaning machine, and belongs to the field of glove demoulding equipment. The full-automatic non-demoulded glove cleaning machine is characterized in that a base, a sliding track device, a high-position demoulding assembly, a low-position demoulding assembly and a sliding driving assembly are included; the sliding track device is arranged on the base, the high-position demoulding assembly and the low-position demoulding assembly are arranged on the sliding track device, and each of the high-position demoulding assembly and the low-position demoulding assembly comprises at least one brush function set; the sliding driving assembly can drive the high-position demoulding assembly and the low-position demoulding assembly to get closeto each other, and the brush function sets of the high-position demoulding assembly and the low-position demoulding assembly can conduct opposite clamping and rotating for stripping of a glove on a hand die. According to the full-automatic non-demoulded glove cleaning machine, a plate brush type demoulding plane is arranged, high demoulding strength is provided by increasing the contact area, brushes are fixed to a chain through a plate structure, the density of the brushes on the glove contact face is guaranteed, and the demoulding strength is effectively improved. Equipment can adapt to thehalf demoulding work and can also be applicable to the non-demoulding work, and the demoulding efficiency is higher.

Owner:ZIBO REEBOW AUTOMATION EQUIP CO LTD

Pin for guiding a gear wheel, and planetary transmission containing the same

InactiveUS20140080658A1Compact designClearance adjustableRotary combination bearingsNeedle bearingsGear wheelRetaining ring

A pin for guiding a gear has a substantially cylindrical outer surface section, wherein the outer surface section comprises a substantially cylindrical rolling surface section, which is aligned and formed so as to make possible the guiding of the gear. The outer surface section further has a groove, which is formed so as to accommodate a retaining ring, wherein the groove is disposed with respect to the rolling surface section so as to make possible a guiding, directly or indirectly via the retaining ring, of a rolling-element assembly along the axial direction of the pin. In this way it is possible to provide a guiding of a gear wherein a small tolerance chain is implemented with respect to the axial position.

Owner:AB SKF

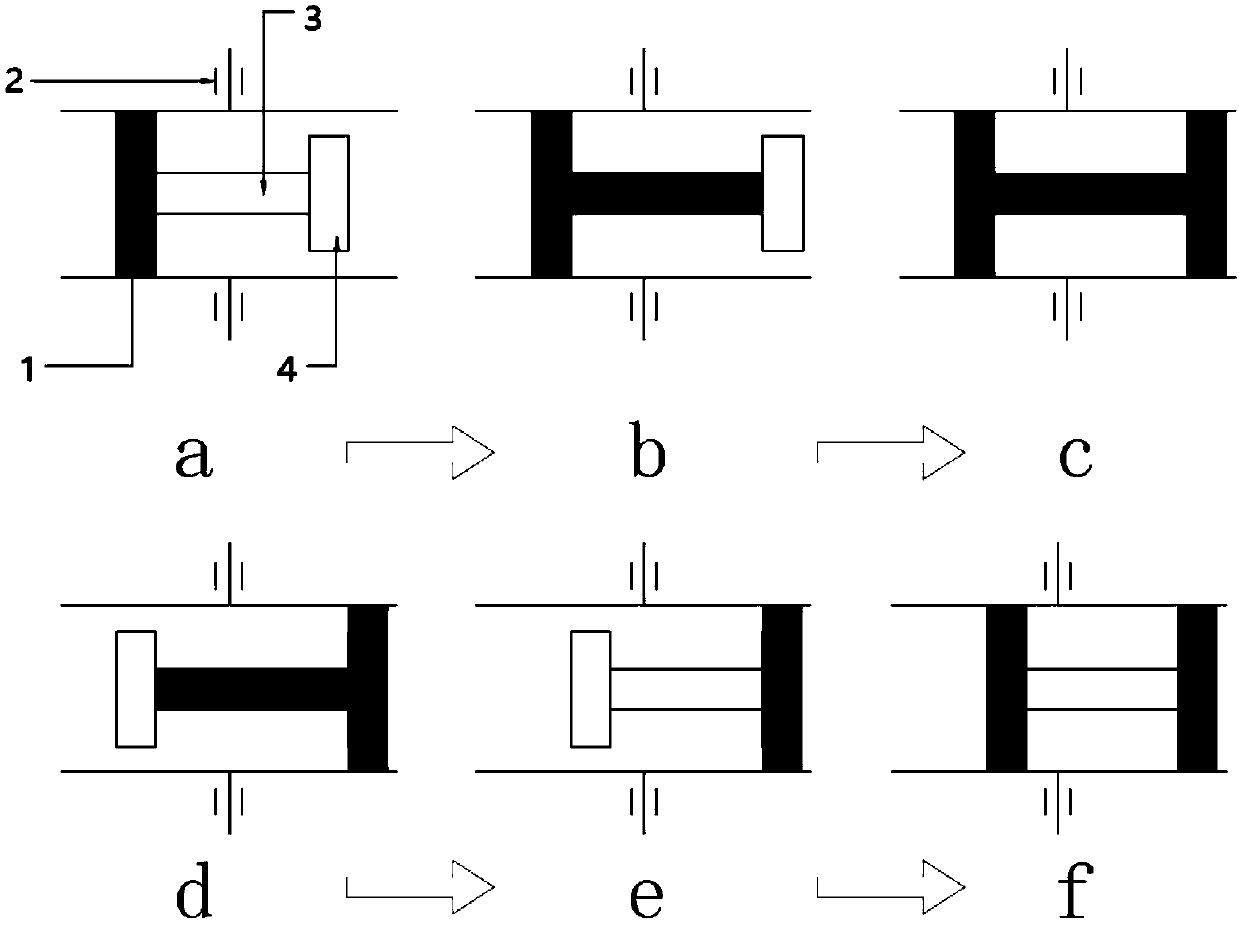

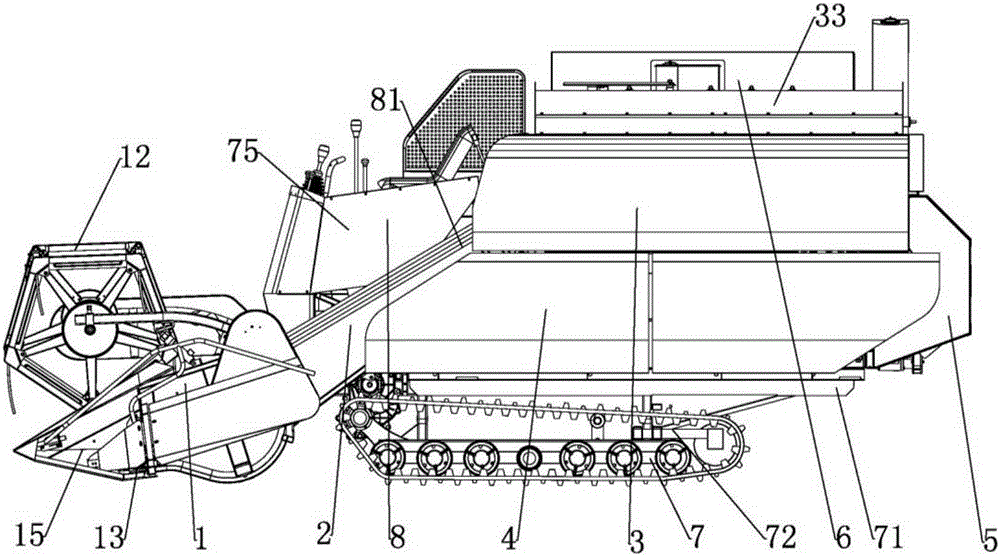

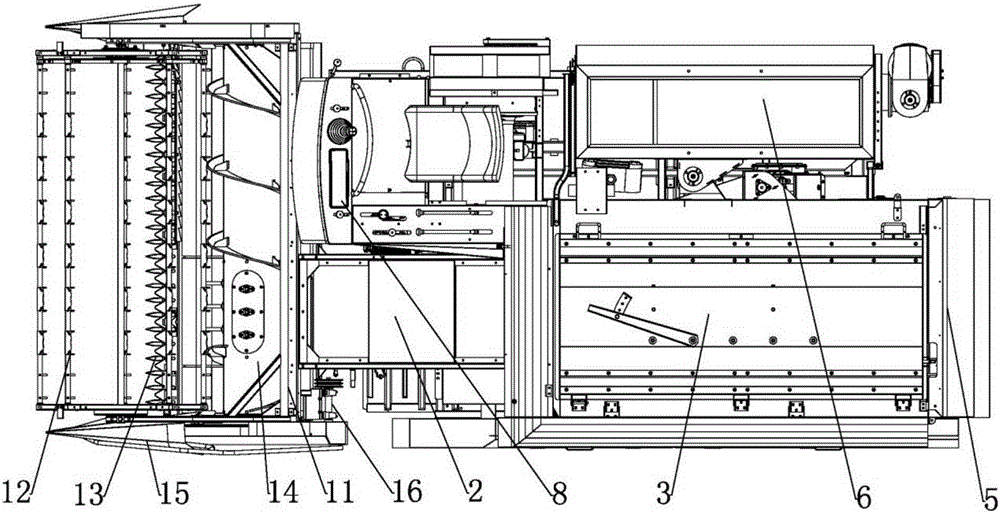

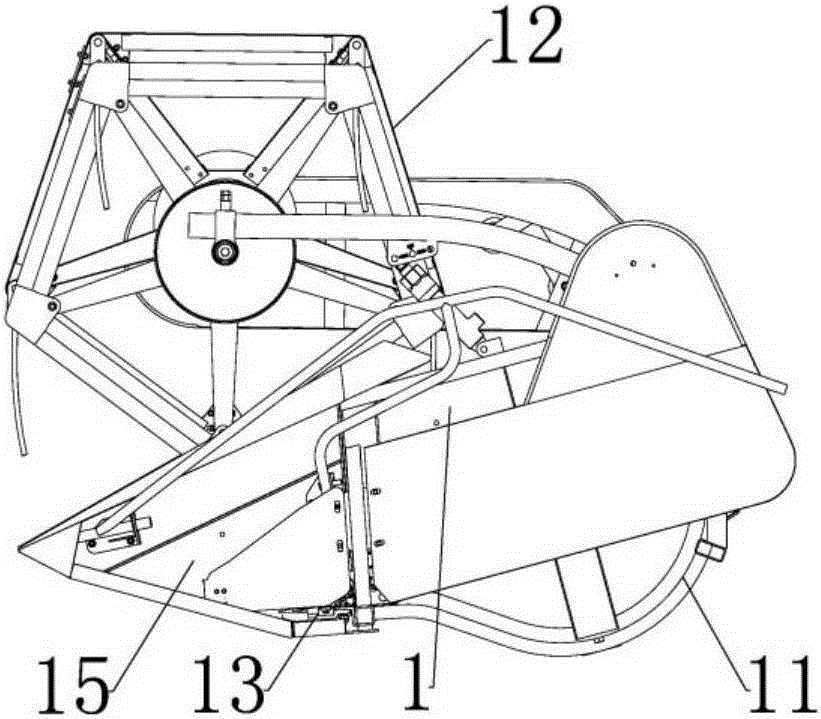

An adjustable cleaning sieve and a combine harvester with the cleaning sieve

The invention relates to an adjustable type cleaning sieve. A sieve sheet group (422) of the cleaning sieve (42) consists of a sieve sheet fixing strip (422a), a fixing sieve strip (422b), a movable sieve strip (422c), a sieve sheet movable strip (422d) and the like. The invention also relates to a combine harvester with the cleaning sieve. The cleaning sieve has the advantages that the additional adjusting mechanism is not needed, and then the opening degree of the cleaning sieve plate can be accurately adjusted; the structure is simple, the operation is convenient, and the cleaning efficiency is improved.

Owner:XINGGUANG AGRI MACHINERY

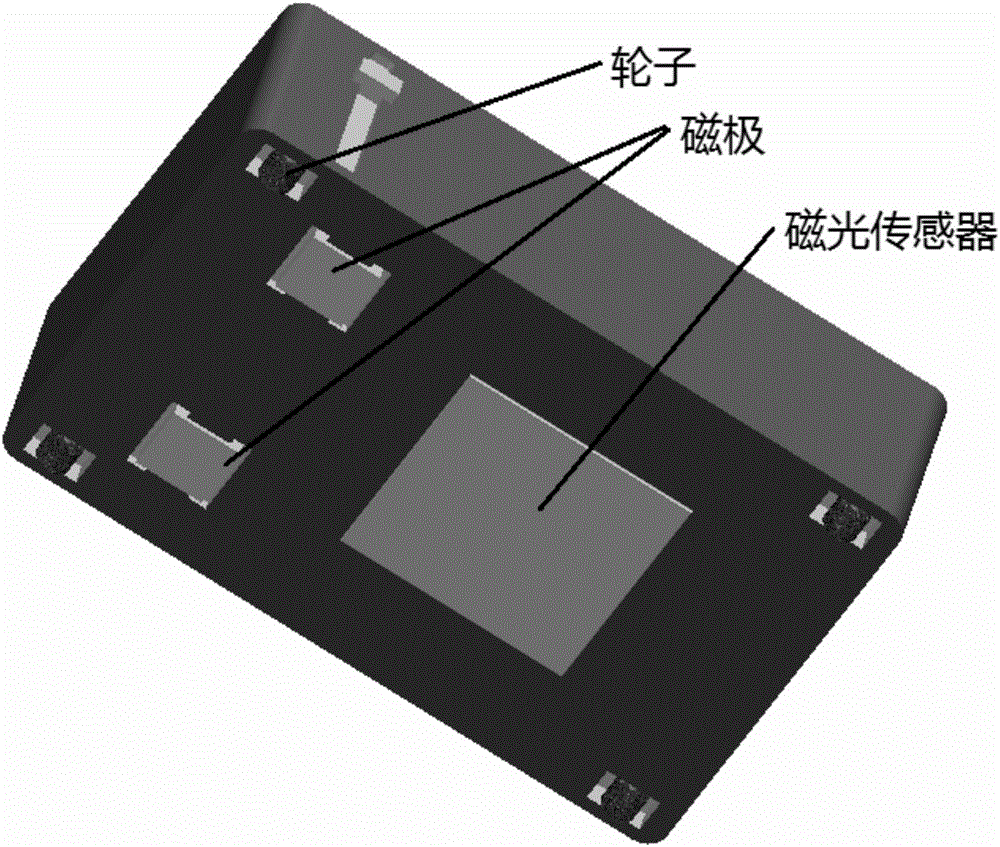

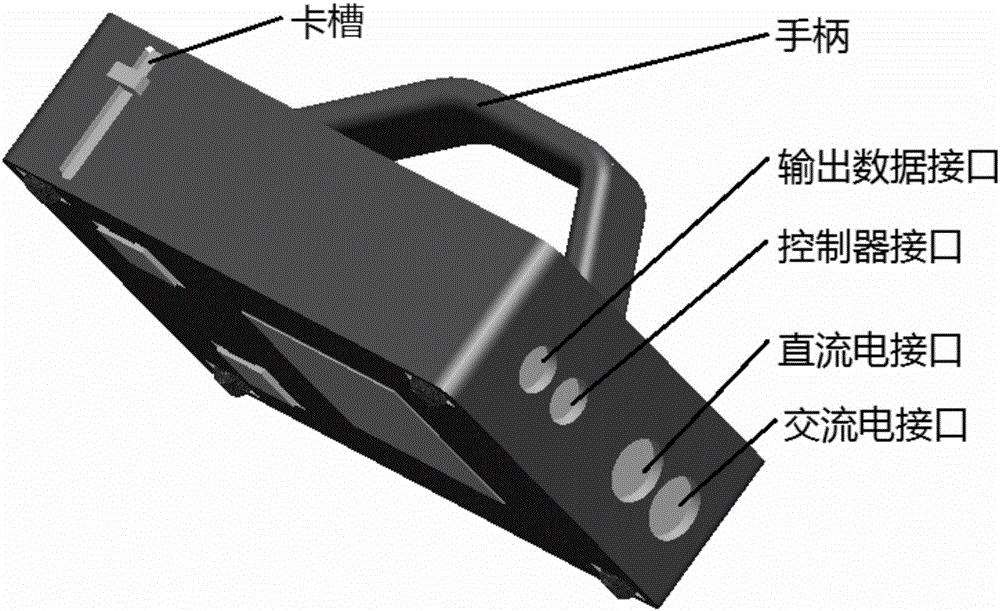

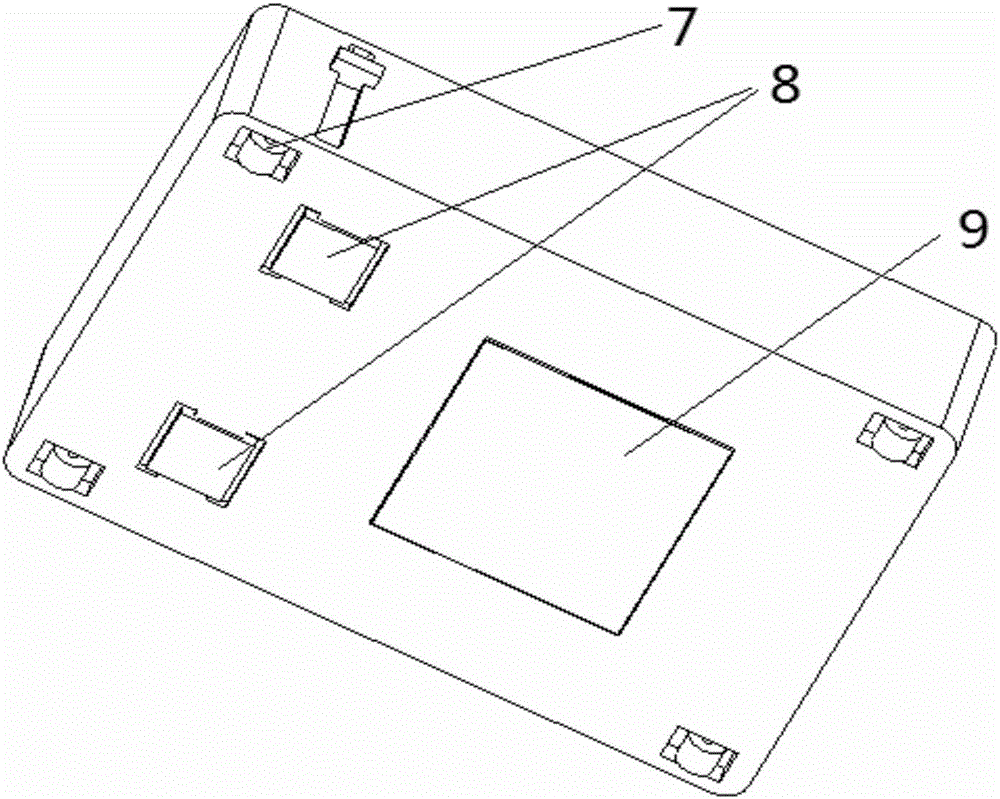

Magneto-optic imaging nondestructive testing device

PendingCN106770628AAchieve integrationReduce volumeOptically investigating flaws/contaminationMaterial magnetic variablesElectricityControl signal

The invention discloses a magneto-optic imaging nondestructive testing device. The device can be used for detecting defects of a workpiece, such as, detecting the quality of a mold casting and the working state of the casting in use. The device comprises a direct current port, an alternating current port, a controller, a magnetic field generator, a magneto-optic imaging sensor and a computer, wherein the magnetic field generator is electrically connected with the direct current port and the alternating current port through the controller; the direct current port is used for accessing direct current to the magnetic field generator; the alternating current port is used for accessing alternating current to the magnetic field generator; the magnetic field generator is used for supplying excitation to the workpiece according to a control signal of the controller; the magneto-optic imaging sensor is used for collecting a magneto-optic image of the workpiece and sending to the computer; and a distance between a magnetic pole of the magnetic field generator and the workpiece is adjusted through a blocking slot.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com