An adjustable cleaning sieve and a combine harvester with the cleaning sieve

A cleaning screen and adjustable technology, applied in the field of cleaning screen, can solve the problems that the uniformity and accuracy are difficult to be guaranteed, increase the complexity of equipment structure, increase the cost of equipment manufacturing, etc., to achieve reduced losses, simple operation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

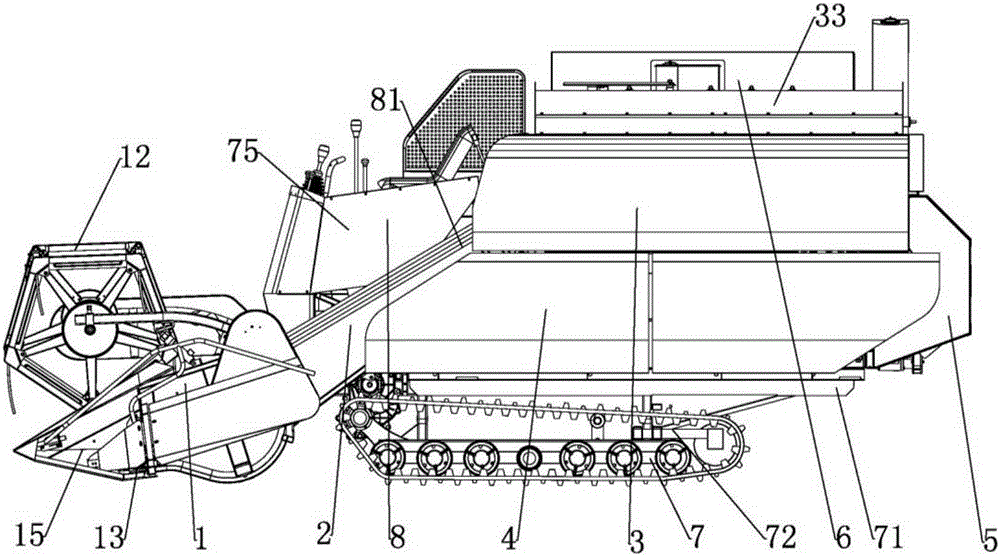

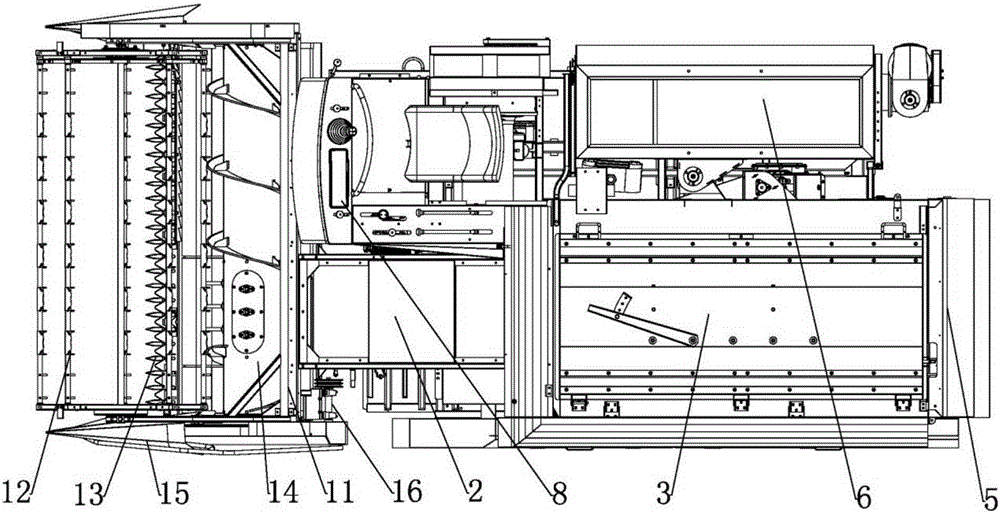

[0027] See attached figure 1 , 2 The combine harvester as a whole can be divided into header 1, feeding and conveying device 2, threshing and separating device 3, grain cleaning device 4, crushing and discharging device 5, grain collecting and unloading device 6, walking device 7 and other auxiliary devices 8 .

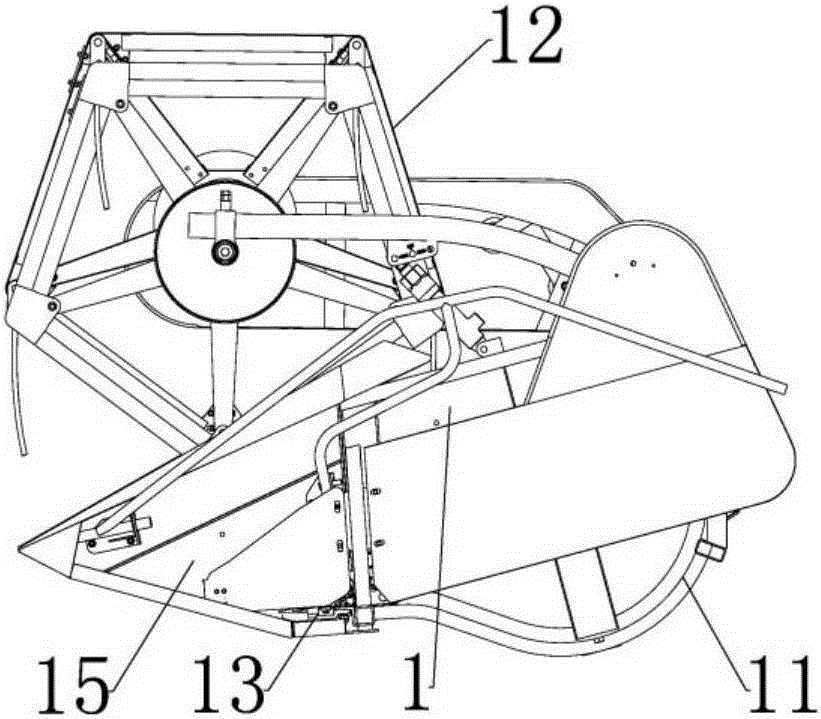

[0028] See attached figure 2 , 3 , the header 1 is used to move crops such as rice and large (small) wheat, and cut off the bottom of the stalk, so that the cut crops are poured into the combine harvester, gathered and transported to the feeding port, which mainly includes the header Frame 11, grain reel 12, cutter 13, header auger 14, crop divider 15 and header drive 16, the header frame is used as the main frame of the header to support the various functional components of the entire header, and consists of left and right walls Plate, header floor, knife beam, upper and lower beams, the reel moves rice, barley (small) wheat and other crops to the header, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com