Patents

Literature

630results about How to "Improve demoulding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

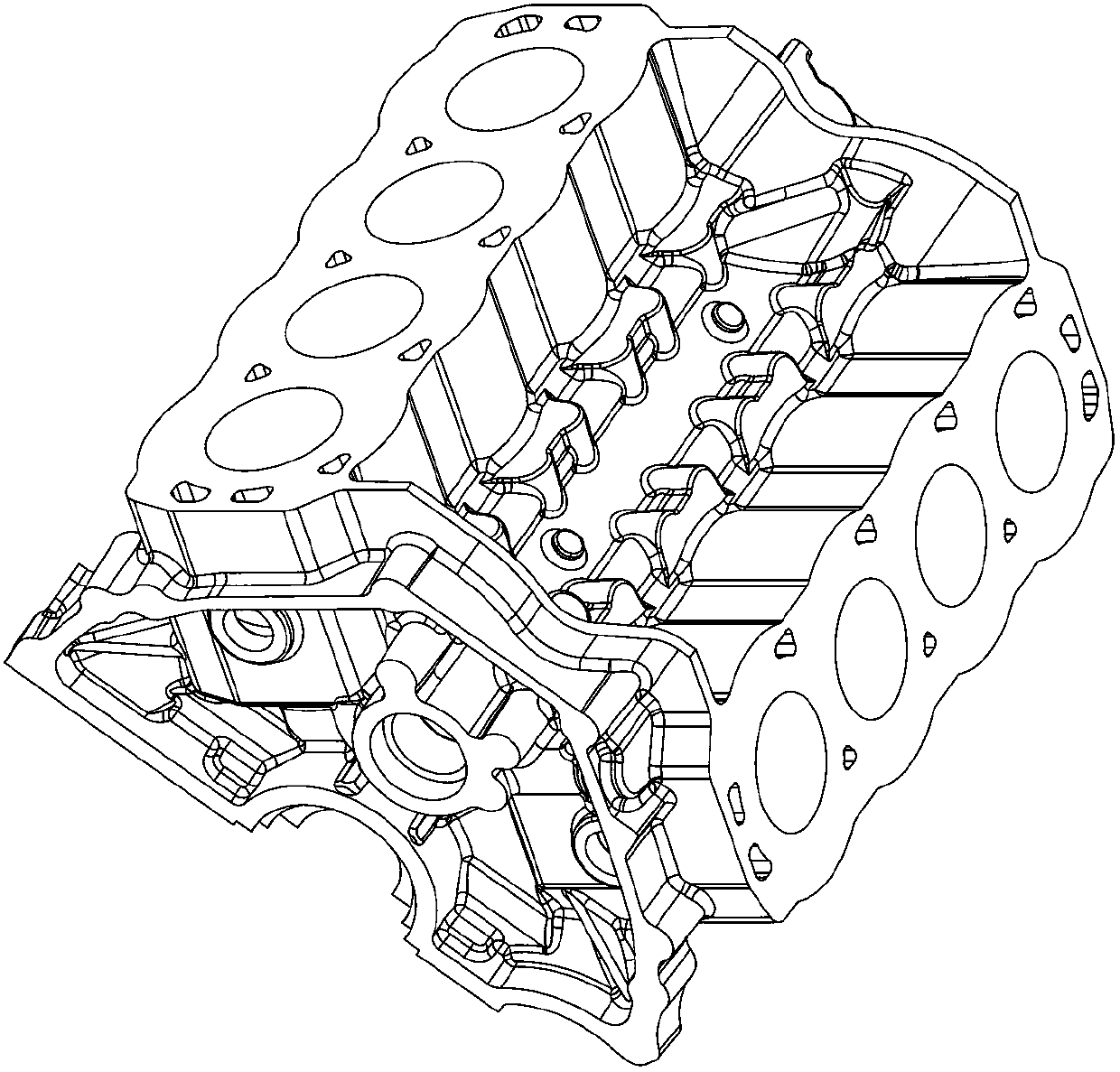

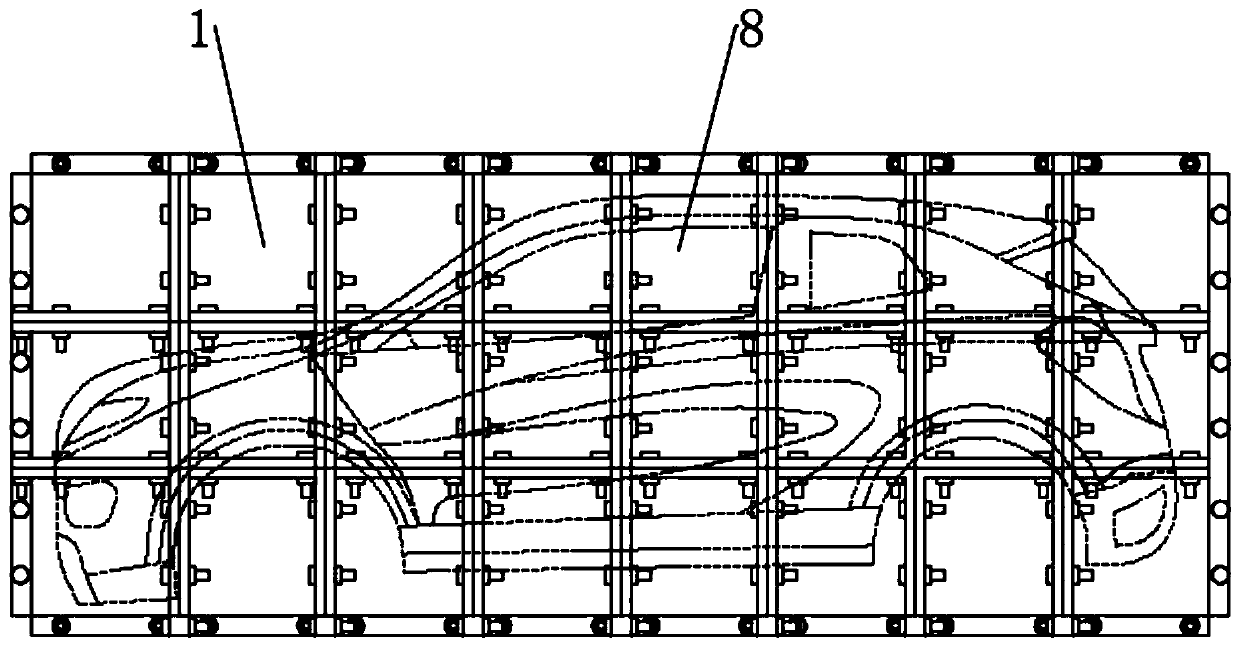

V8 type gray cast iron cylinder body casting pouring method

ActiveCN103121082AStable flow rateSmall structureFoundry mouldsFoundry coresAssembly structureMaterials science

The invention discloses a V8 type gray cast iron cylinder body casting pouring method which is carried out by adopting a core assembly pouring mode. The V8 type gray cast iron cylinder body casting pouring method comprises the following steps of: 1, setting a pouring position of a casting; 2, arranging a pouring system; 3, assembling a core assembly; and 4 pouring. Compared with the prior art, the V8 type gray cast iron cylinder body casting pouring method has the characteristics of relatively simple core assembly structure, high yield and low production cost.

Owner:宁波亿泰来模具有限公司

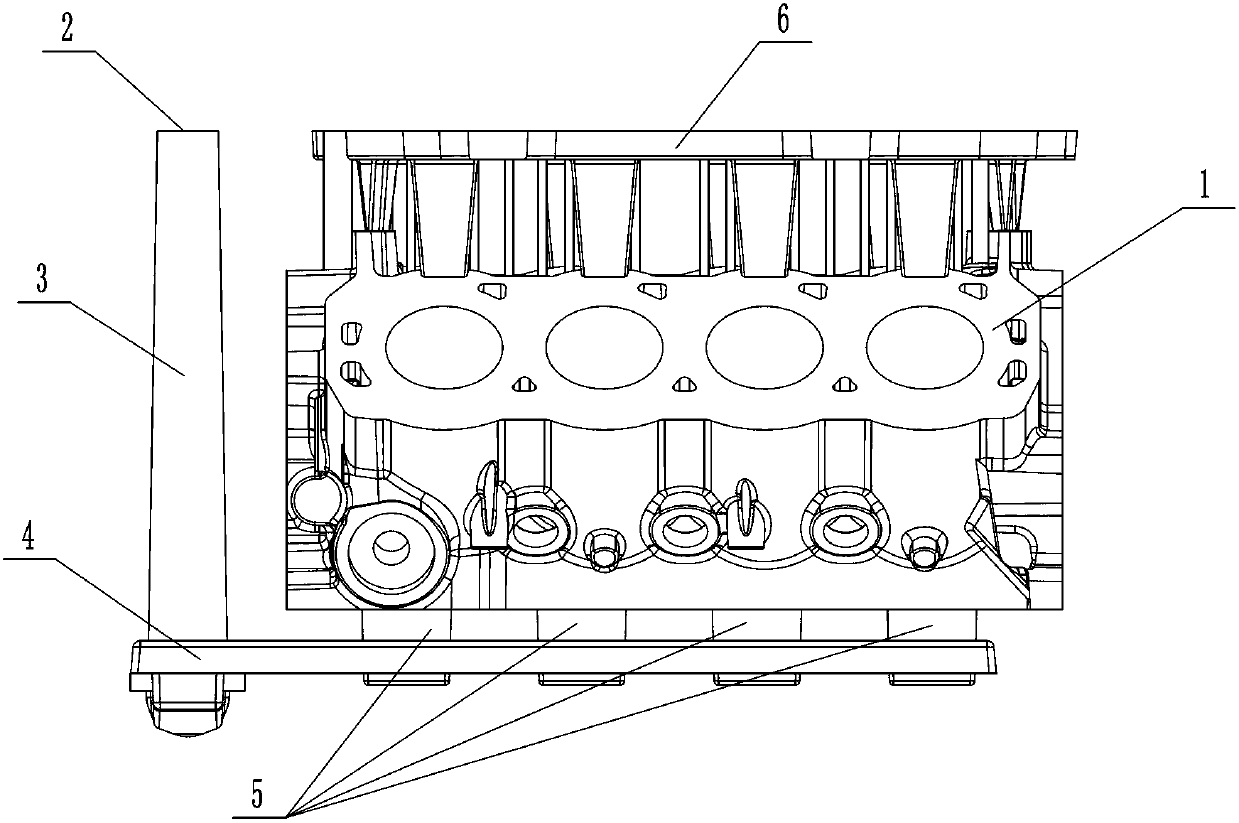

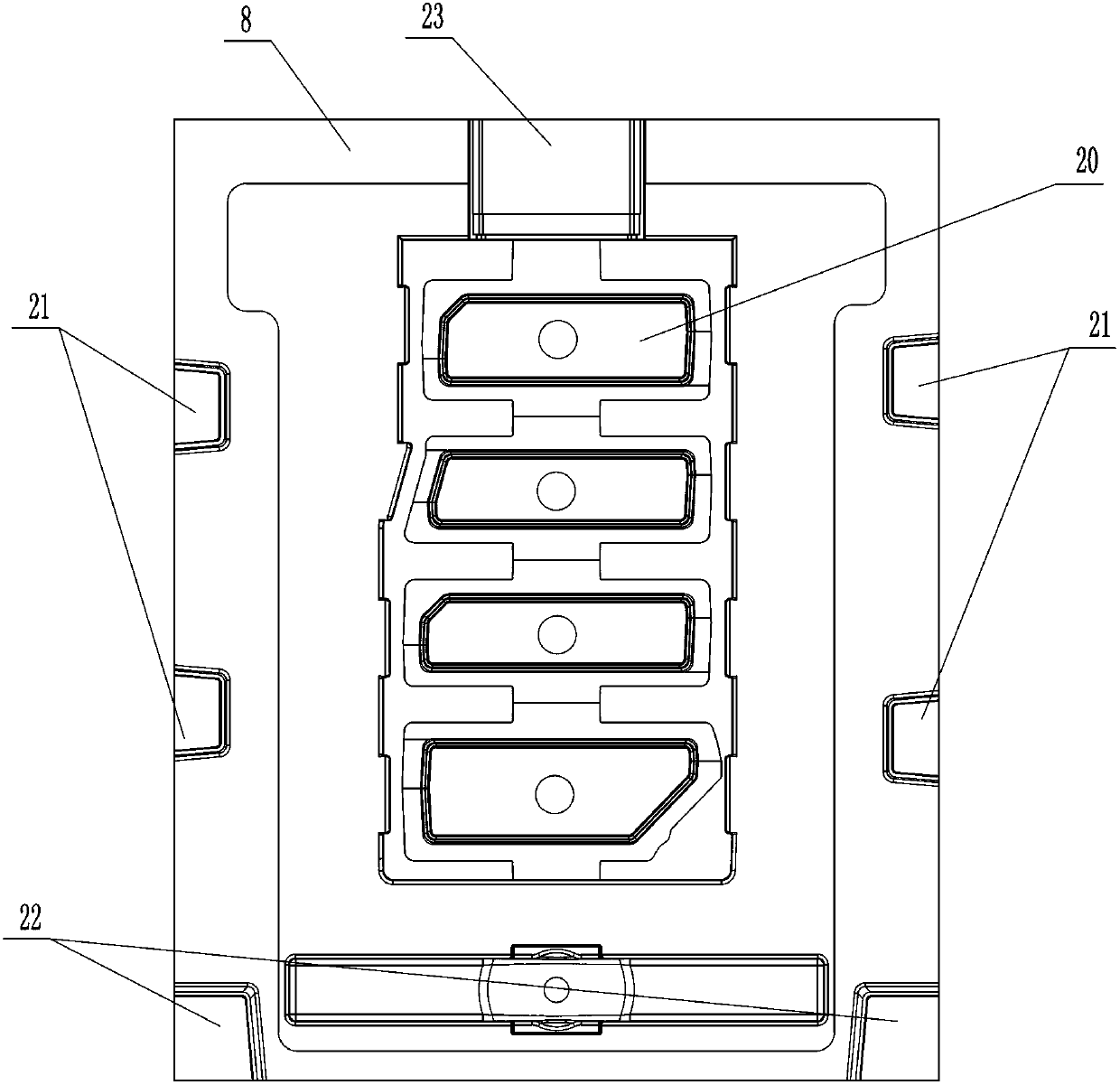

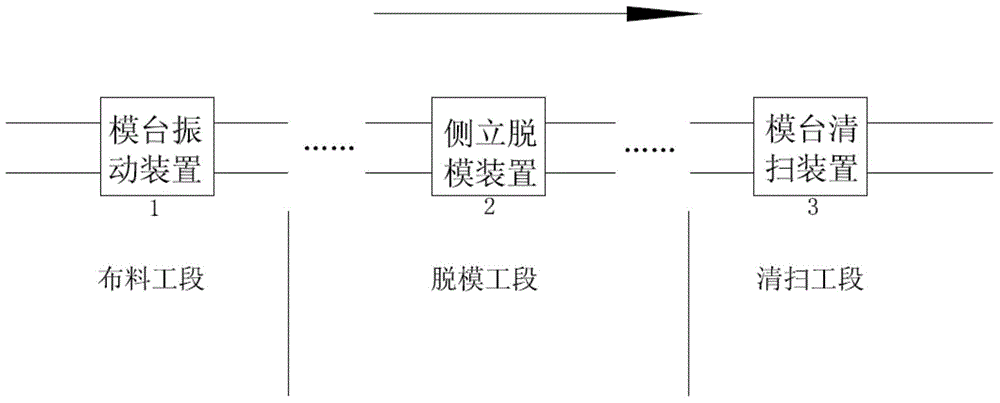

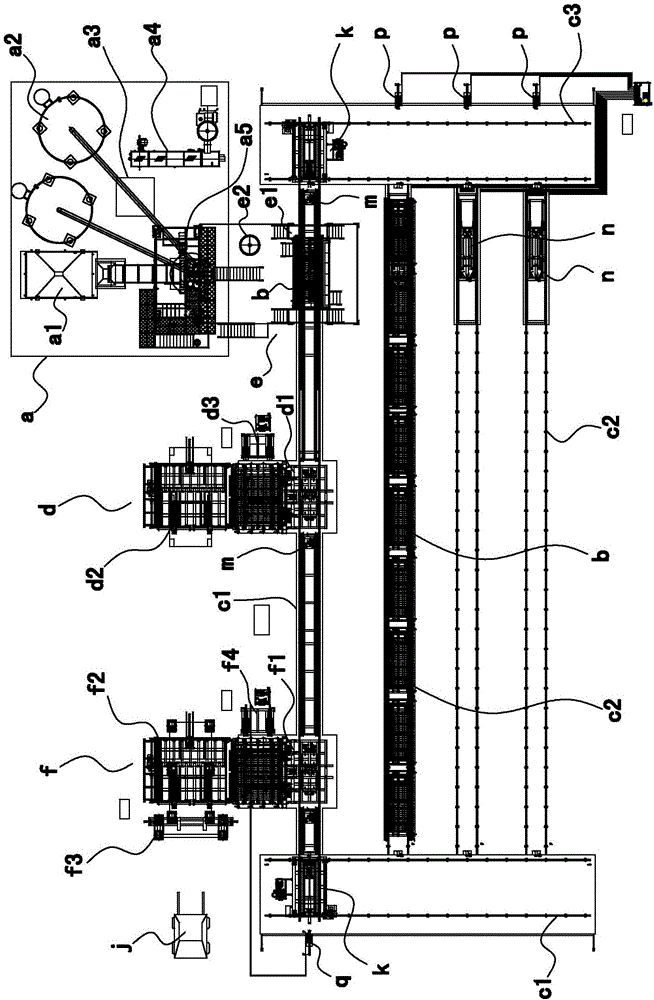

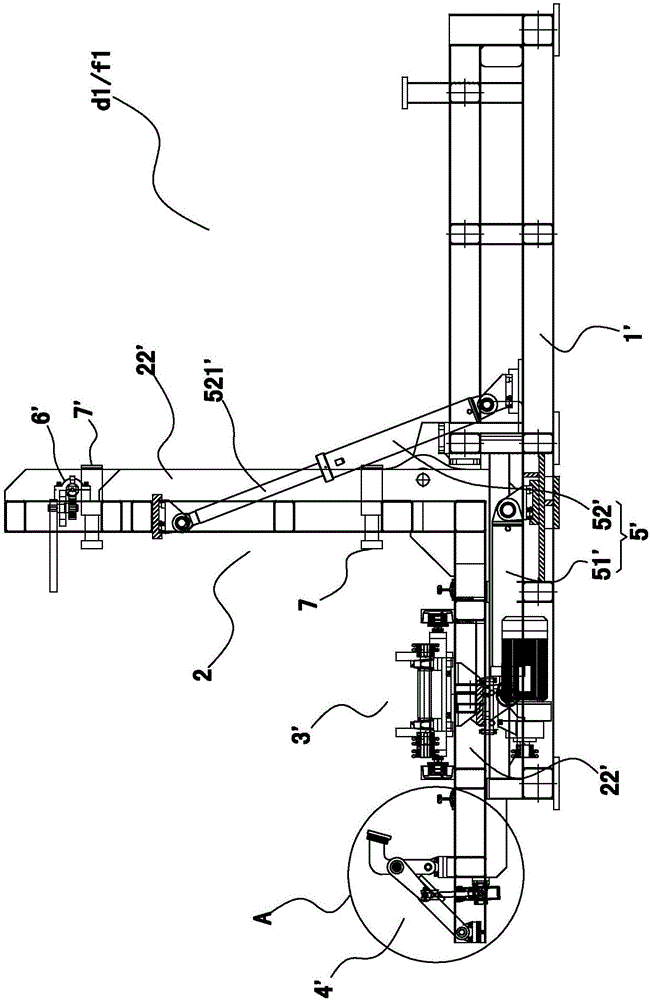

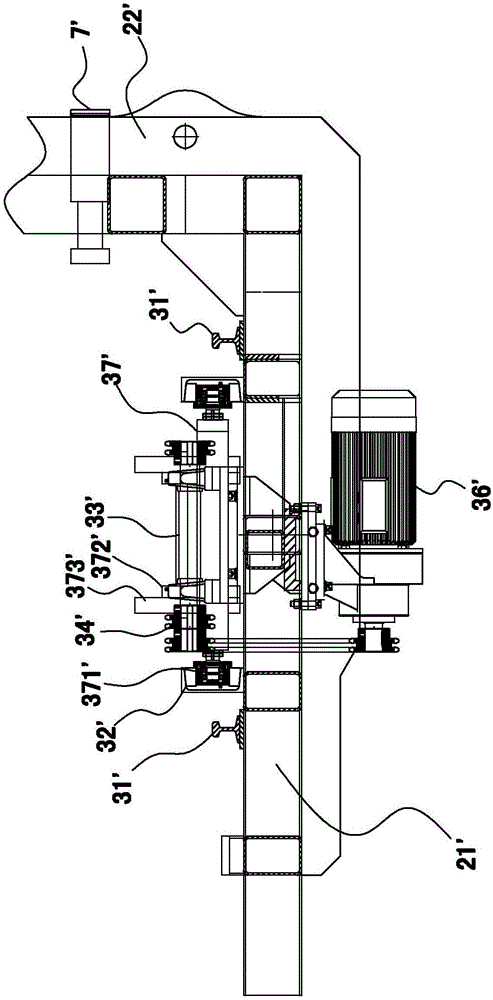

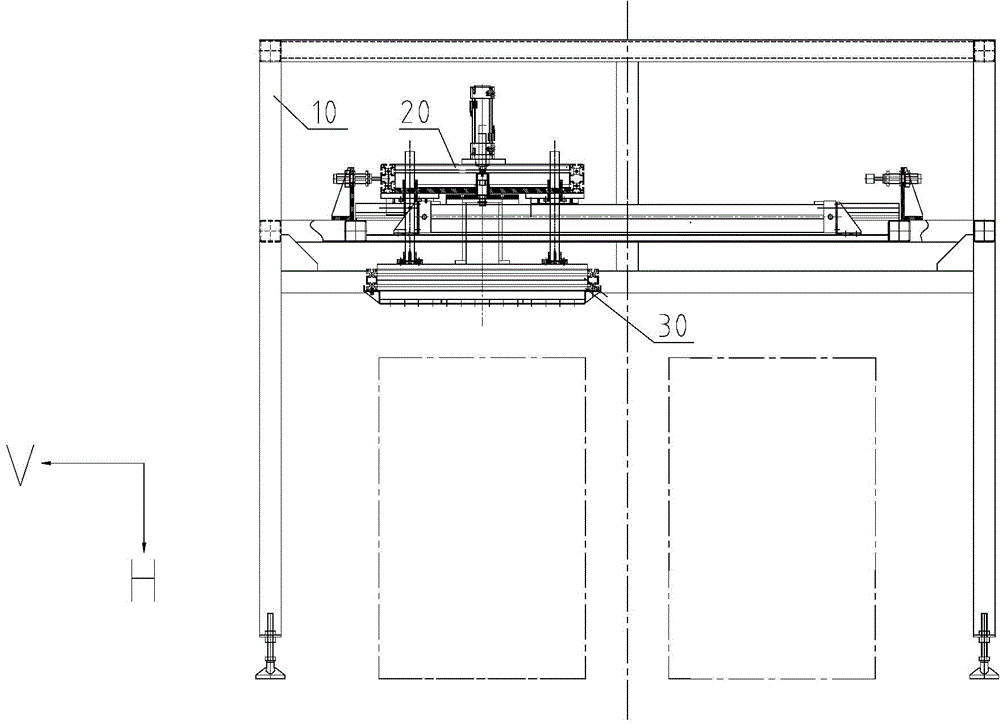

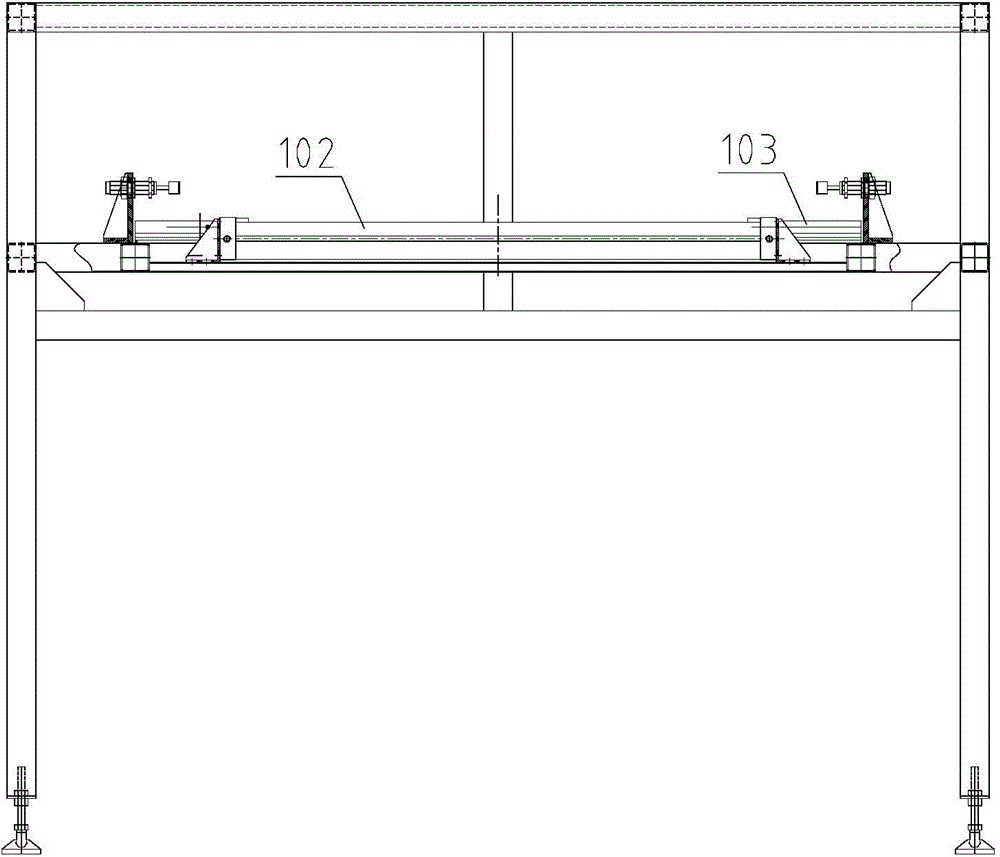

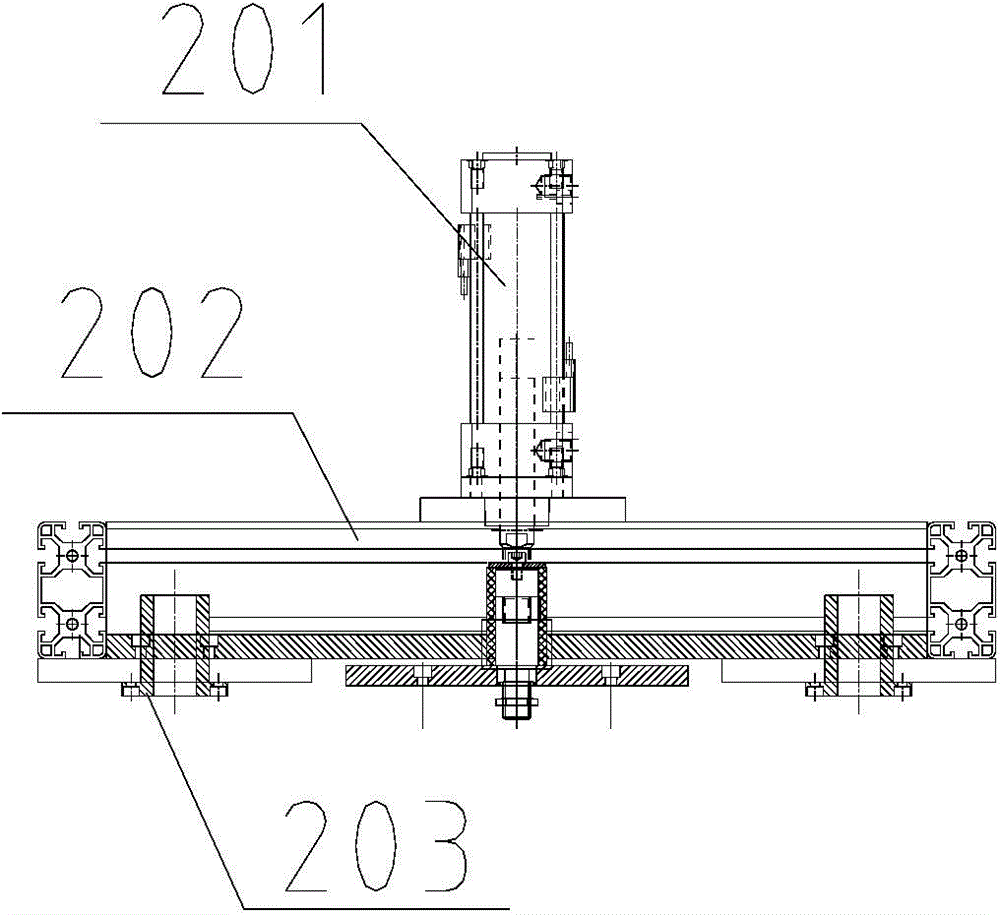

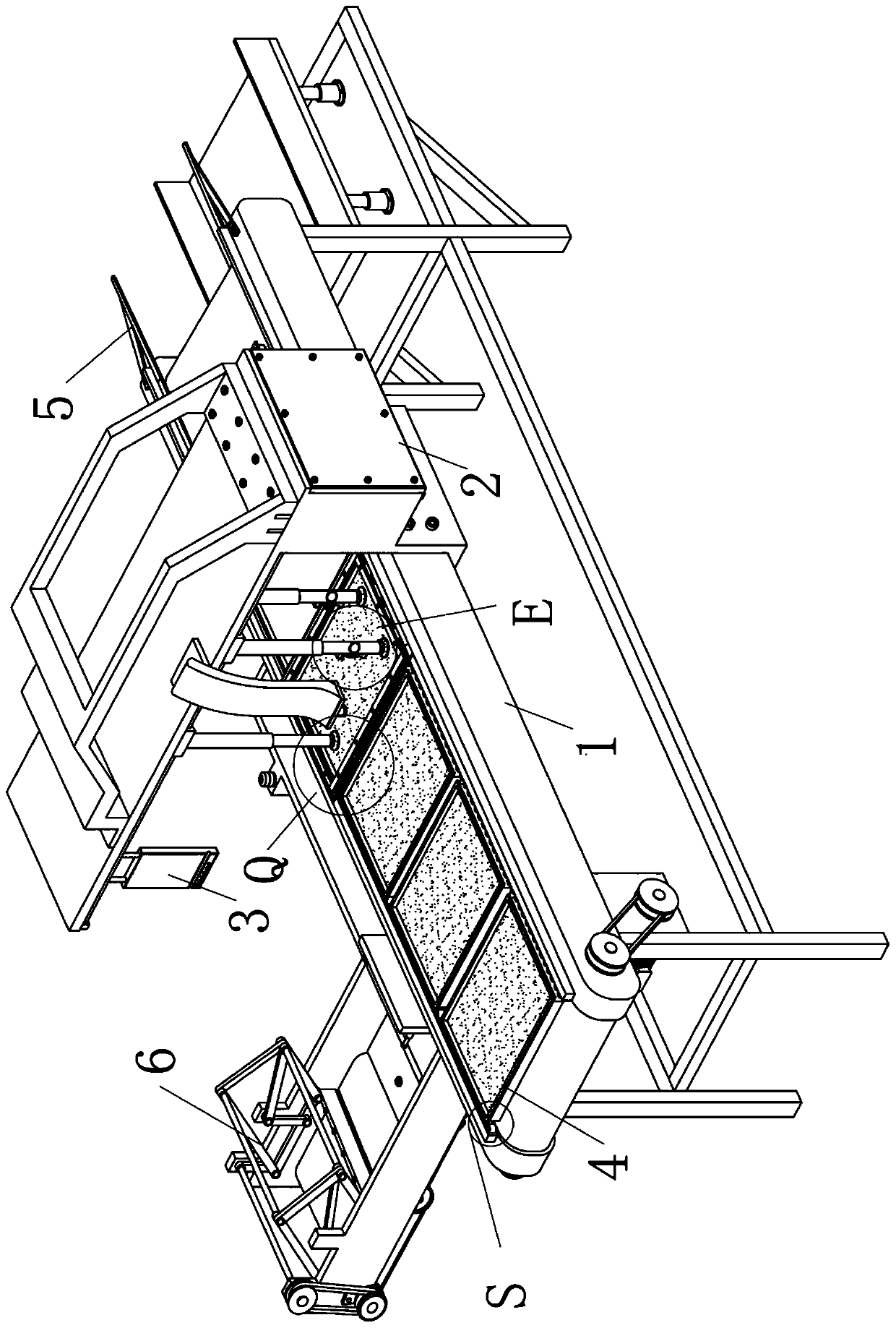

Novel production line of concrete precast plate

ActiveCN104476666AAvoids situations where the rollers of the travel system cannot be accurately dropped backSimple structureDischarging arrangementCeramic shaping plantsProduction lineIndustrial engineering

The invention discloses a novel production line of a concrete precast plate. The novel production line of the concrete precast plate comprises a material distributing section, a demoulding section, and a cleaning section, the material distributing section is provided with a platform vibration device, the demoulding section is provided with an edge-on demoulding device, the cleaning section is provided with a platform cleaning device, a lifting device of the platform vibration device is synchronously lifted by a lead screw elevator, the technology is mature and the reliability is high. In addition, a support lifting part is arranged at the lower part, a vibration holding positioning part is arranged at the upper part, and the middle part is connected by an elastic device, the parts are not intervened mutually, and the graduation is clear. The cleaning efficiency of the platform cleaning device is high, the platform vibration device and the platform cleaning device are provided with position detecting devices suitable for various layouts of the production line, and the practicability is strong. The edge-on demoulding device is provided with an assistant demoulding device, the positioning precision is high, and the demoulding efficiency is higher.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

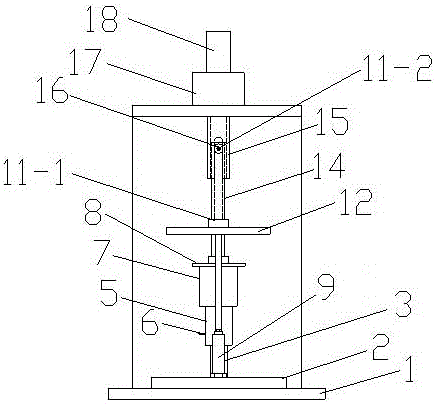

High-efficiency energy-saving reconstituted bamboo square stock automatic stripping machine and stripping method thereof

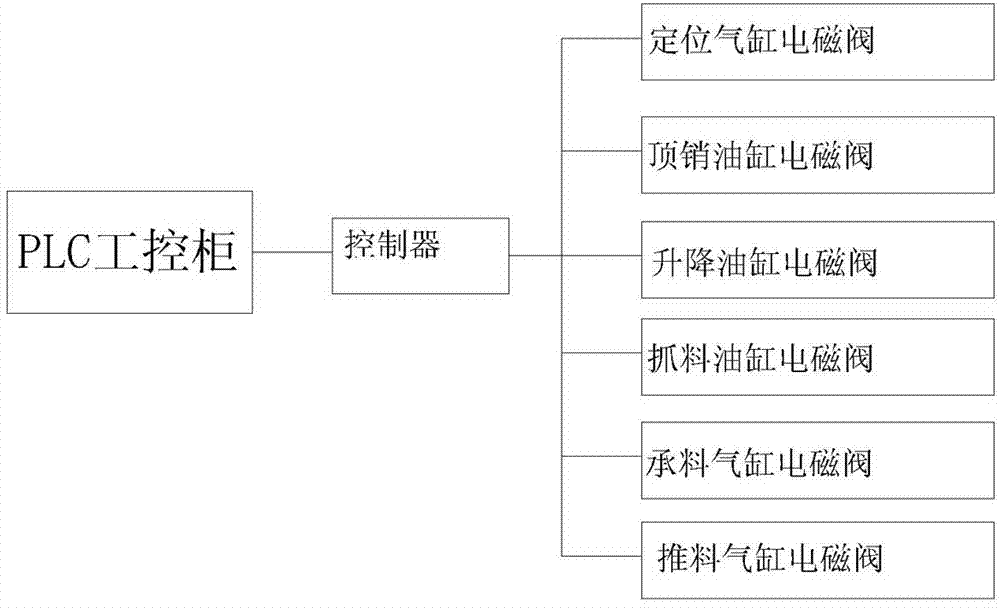

ActiveCN104493949AImprove demoulding efficiencyExtended service lifeWood working apparatusDomestic articlesProgrammable logic controllerControl system

The invention discloses a high-efficiency energy-saving reconstituted bamboo square stock automatic stripping machine. The machine comprises a host and a control system, wherein the host comprises a pedestal, a rack, a movable cross beam and a lifting oil cylinder; the rack is provided with a mold cavity for accommodating a mold; the bottom of the movable cross beam is provided with a press head which is abutted against the upper part of the mold; the rack is provided with a positioning cylinder for positioning the mold and a rear retaining rack which is matched with the positioning cylinder; a pin ejection oil cylinder and an ejection rod for ejecting a pin in the mold are also arranged on one side of the rack; the two ends of the movable cross beam are provided with a grabbing arm and a grabbing oil cylinder; the control system comprises an electric control system; the electric control system comprises a controller; an input end of the controller is connected with a PLC (Programmable Logic Controller) industrial control cabinet; an output end of the controller is in control connection with the positioning cylinder, the lifting oil cylinder, the pin ejection oil cylinder and the grabbing oil cylinder. By using the stripping machine, the reconstituted bamboo square stock stripping efficiency can be improved, and the service life of the mold is prolonged; the labor intensity of a worker is also reduced, the production efficiency is improved, and the production cost is reduced.

Owner:ANJI YUKANG MACHINERY

Gas barrier easy-demolding fully biodegradable beverage bottle production method

ActiveCN106366588AImprove oxygen resistanceHigh barrierBio-packagingBottlesPlasticizerBlowing bottles

The invention provides a gas barrier easy-demolding fully biodegradable beverage bottle production method which includes the steps: raw material modification: adding plastic additives into fully biodegradable materials, mixing the plastic additives and the fully biodegradable materials according to a certain proportion, and performing granulation for the mixture; processing plastic master batches: uniformly mixing the mixture, and processing the mixture into the plastic master batches; blowing bottles; performing surface treatment of the bottles. The plastic additives are at least one in chain extenders, nucleating agents, plasticizers and plastic expansion microspheres, the fully biodegradable materials include powder biodegradable materials which are at least four in PLA (polylactic acid), PBS (poly butylene succinate), PHA (polyhydroxyalkanoate), PBSA poly(butylene succinate adipate), PBAT (poly butylene adipate-co-terephthalate) and starch, and blowing bottles include blowing the bottles by extrusion and blowing the bottles by injection molding.

Owner:ZHEJIANG BILI PACKAGING

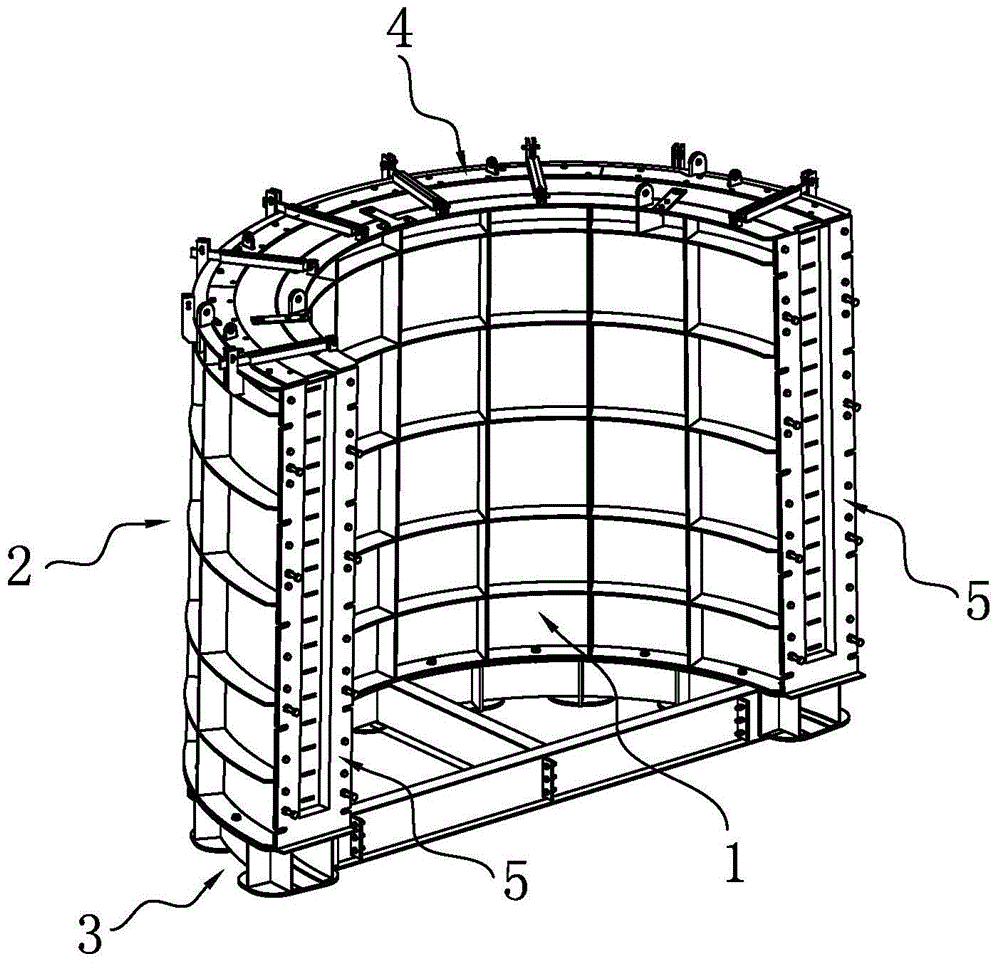

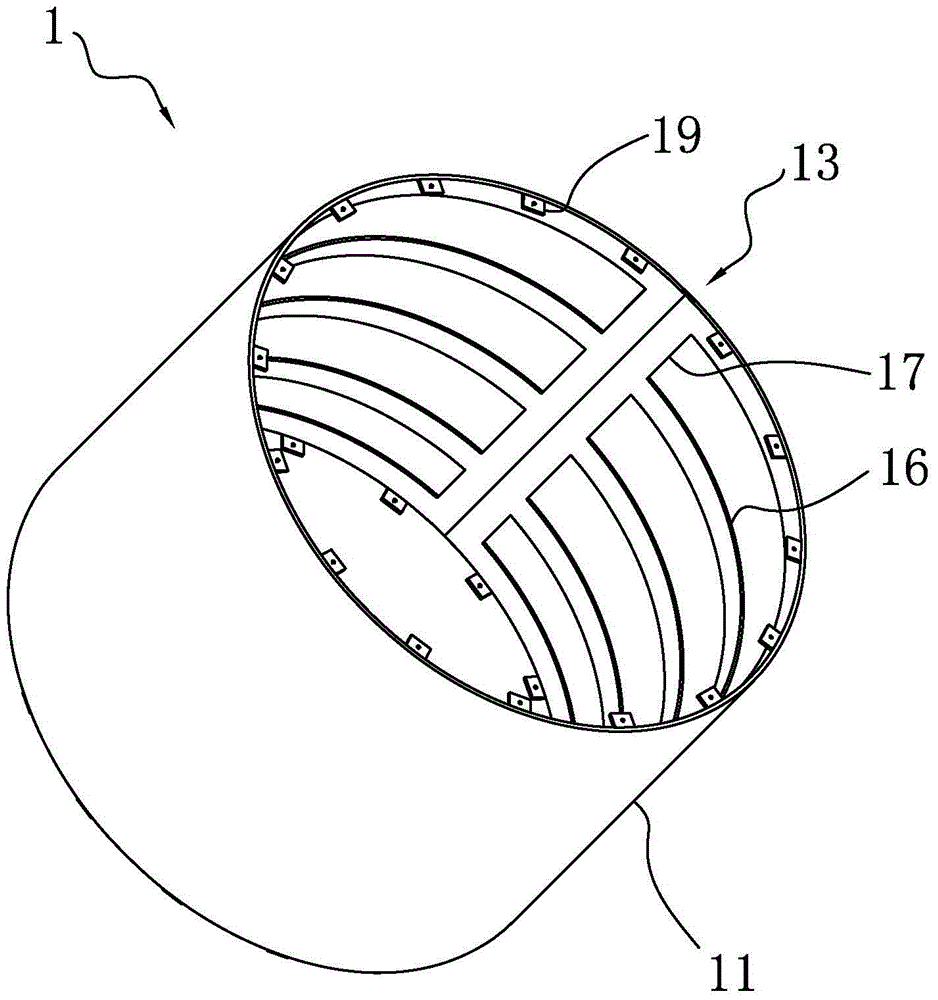

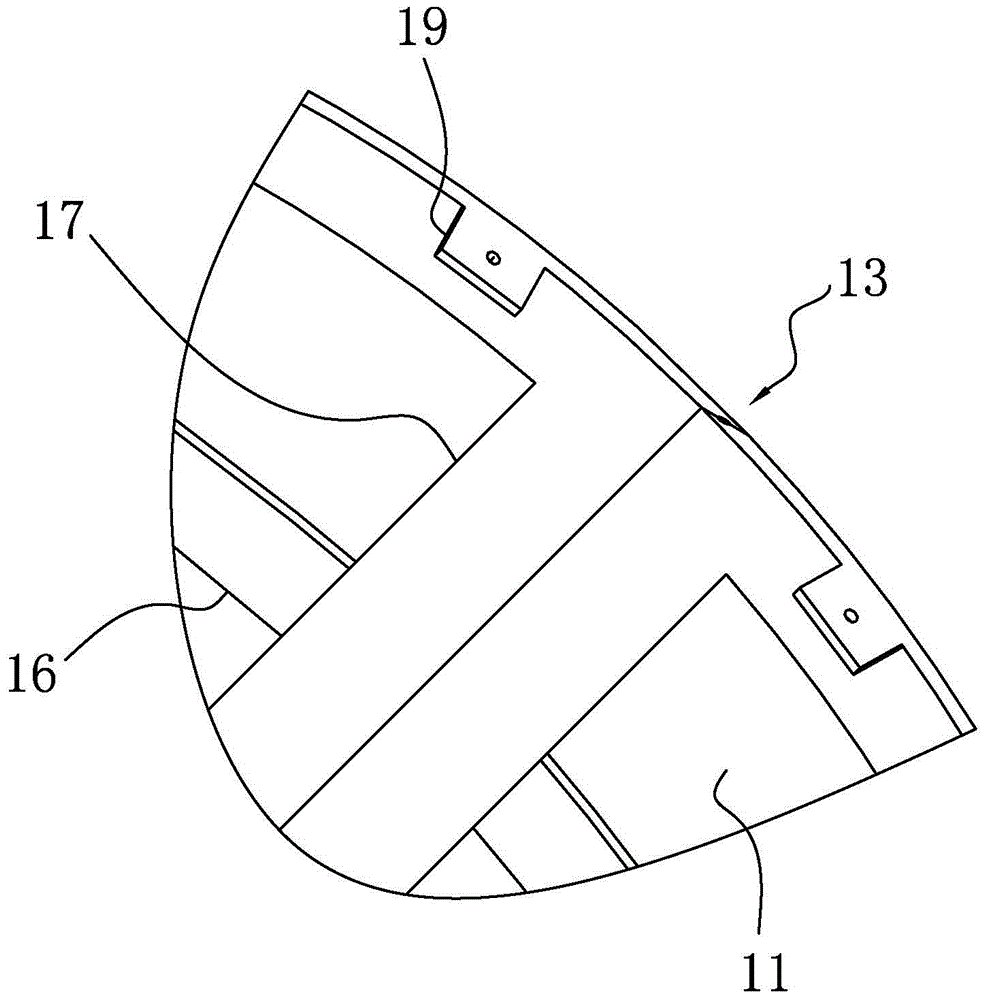

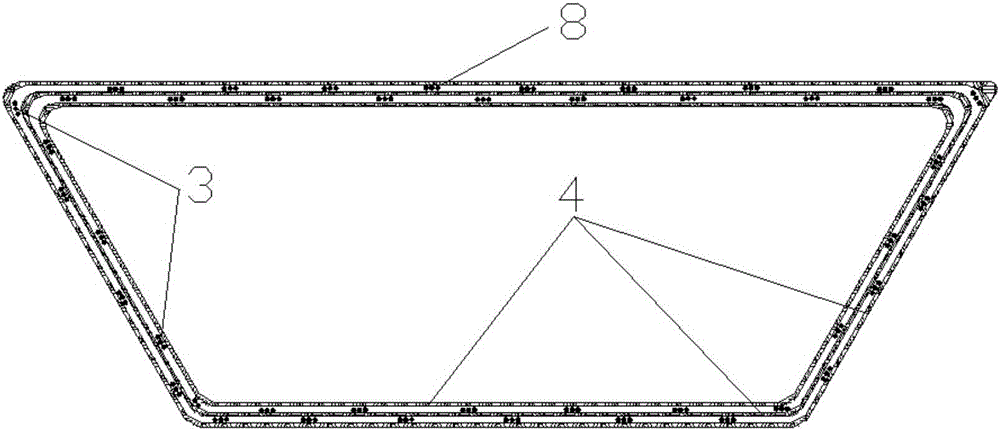

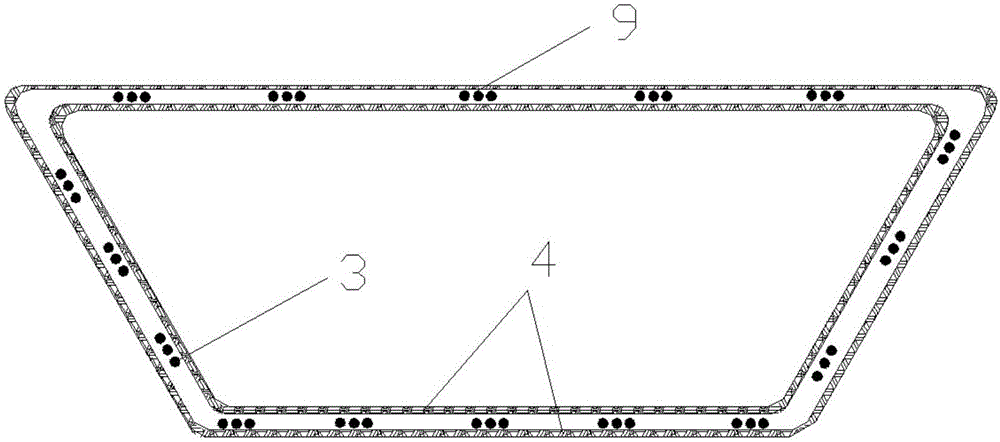

Internal mould, demoulding method thereof, mould for prefabricated concrete tower sections and production method

The invention provides an internal mould, a demoulding method thereof, a mould for prefabricated concrete tower sections and a production method. The internal mould provided by the invention comprises an internal formwork, both ends of the internal formwork are connected, so that the internal formwork is curved into the shape of a barrel, both ends of the internal formwork are provided with slopes, and the slopes of both ends of the internal formwork are matched with each other and form a demoulding opening. The demoulding method of the internal mould provided by the invention includes the following step: one end, which is located inside the demoulding opening, of the internal formwork is moved simultaneously along the radial direction and tangent direction of the internal mould to get close to the center of the internal mould and extend into the space in the internal formwork. The internal mould provided by the invention can be used for casting a whole ring, the overall elastic deformation of the internal formwork can be conveniently utilized to implement the demoulding and restoration of the internal mould, and a great deal of welding work can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

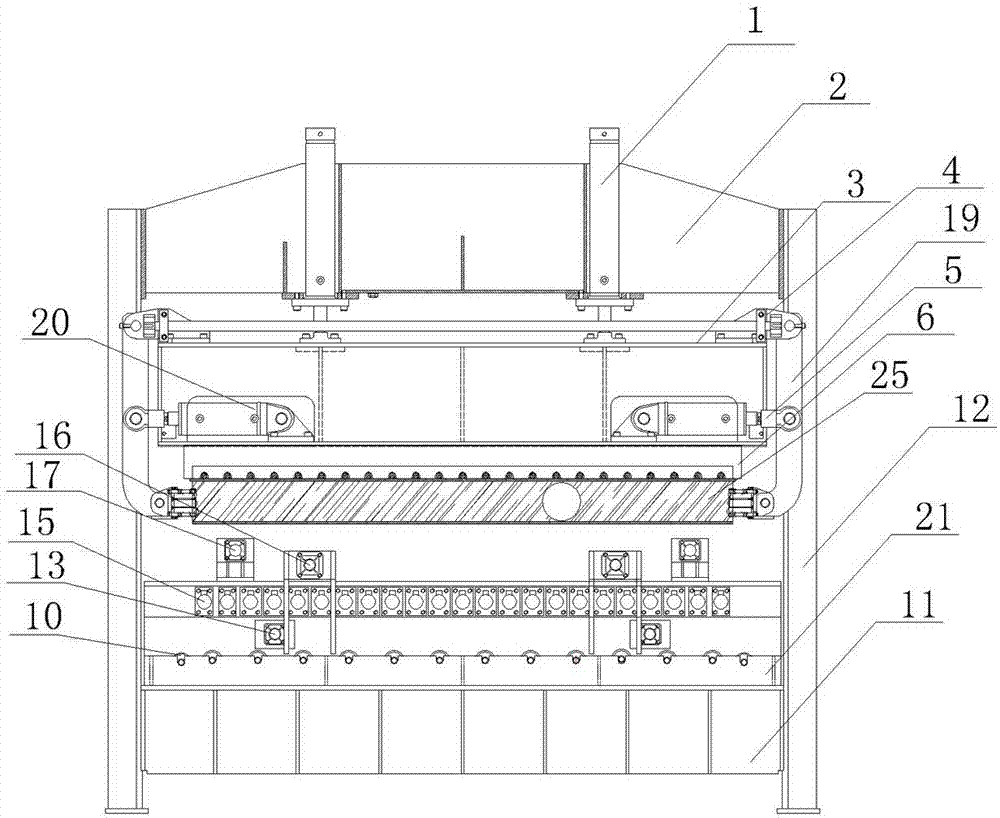

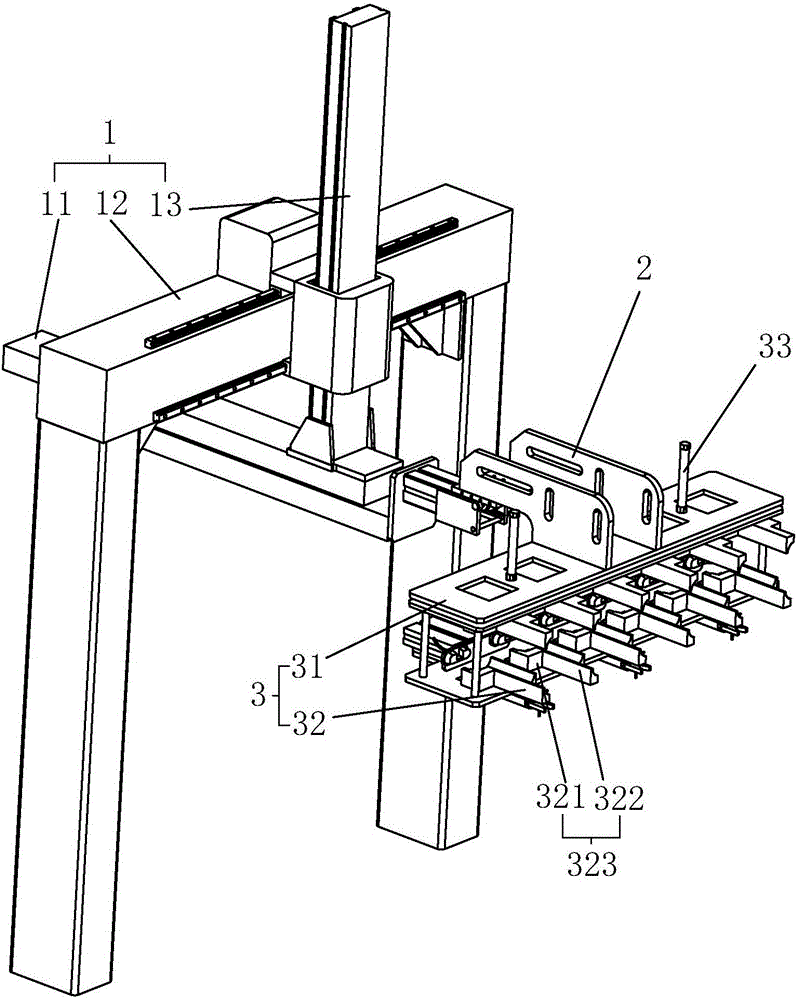

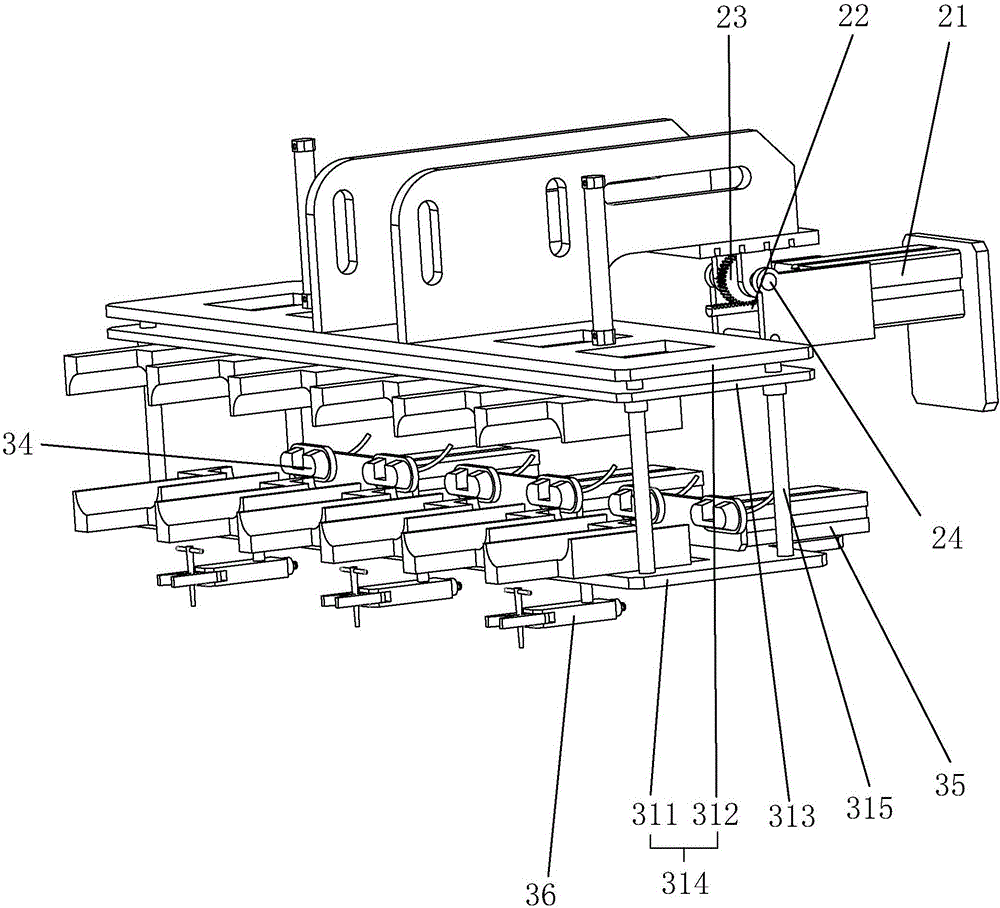

Wire harness seal sleeve demolding manipulator and production equipment with same

ActiveCN106827422ARealize fully automatic productionImprove demoulding efficiencyDomestic articlesSlide plateEngineering

The invention discloses a wire harness seal sleeve demolding manipulator. The wire harness seal sleeve demolding manipulator comprises a triaxial displacement table, a clamping assembly and connecting arms. The clamping assembly comprises a support and a demolding part. The demolding part comprises a demolding cavity. The demolding cavity comprises a clamping portion and a protection portion in sequence. The support comprises fixed plates and a sliding plate. The demolding part is divided into two portions which are fixed to one fixed plate and the sliding plate correspondingly. When the sliding plate moves towards one fixed plate to the limiting position, the two portions of the demolding part are combined and attached to each other to form the whole demolding cavity, a blowing portion communicating with an external air source is fixedly arranged on one fixed plate and located on the other side, opposite to the protection portion, of the clamping portion, and the connecting arms are fixedly connected with one fixed plate. Besides, the invention further discloses production equipment with the manipulator. By means of the wire harness seal sleeve demolding manipulator and the production equipment with the same, automatic production and automatic demolding of wire harness seal sleeves are achieved, the labor cost is reduced, and meanwhile, the production efficiency is improved.

Owner:浙江一番汽车配件科技有限公司

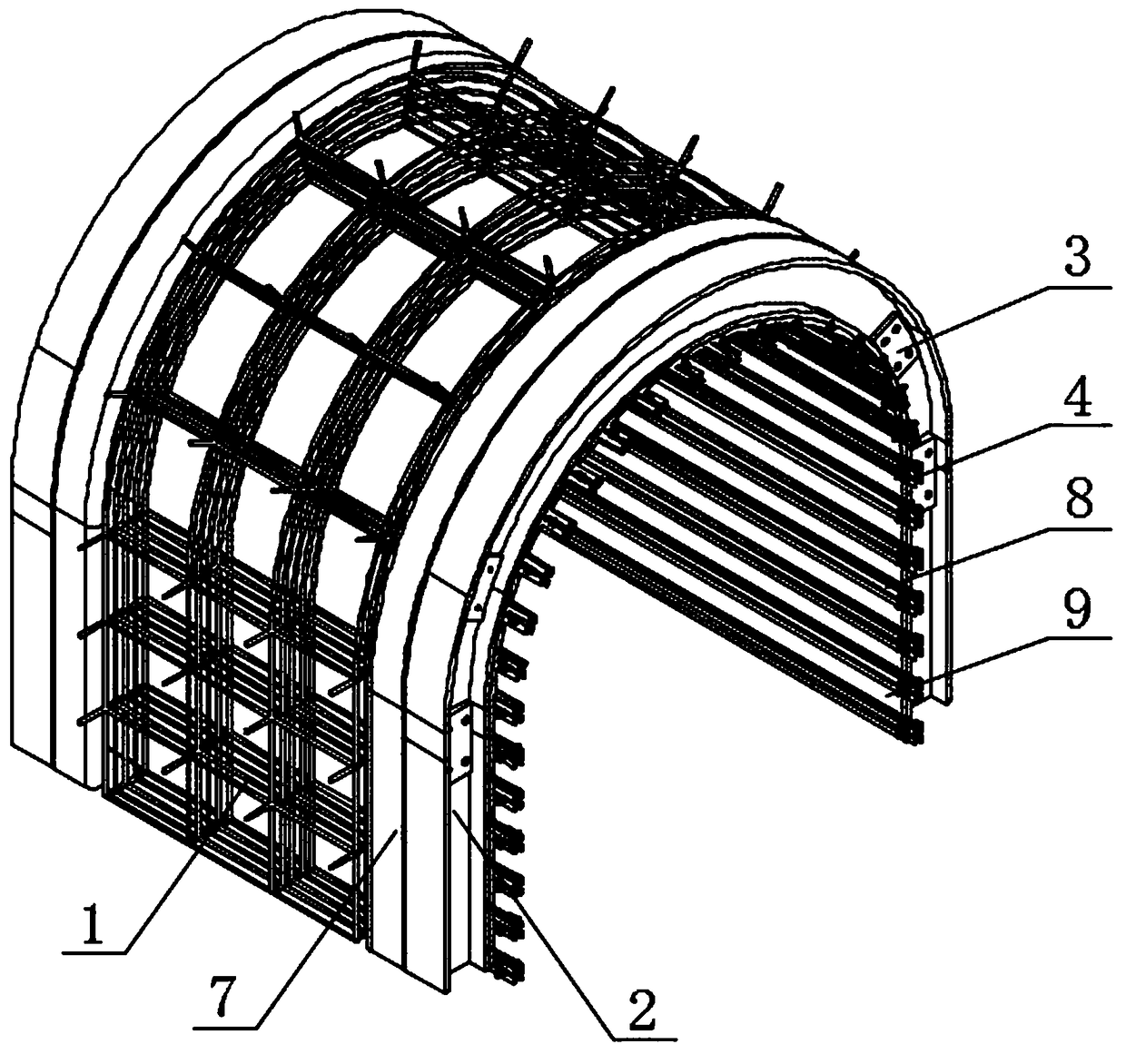

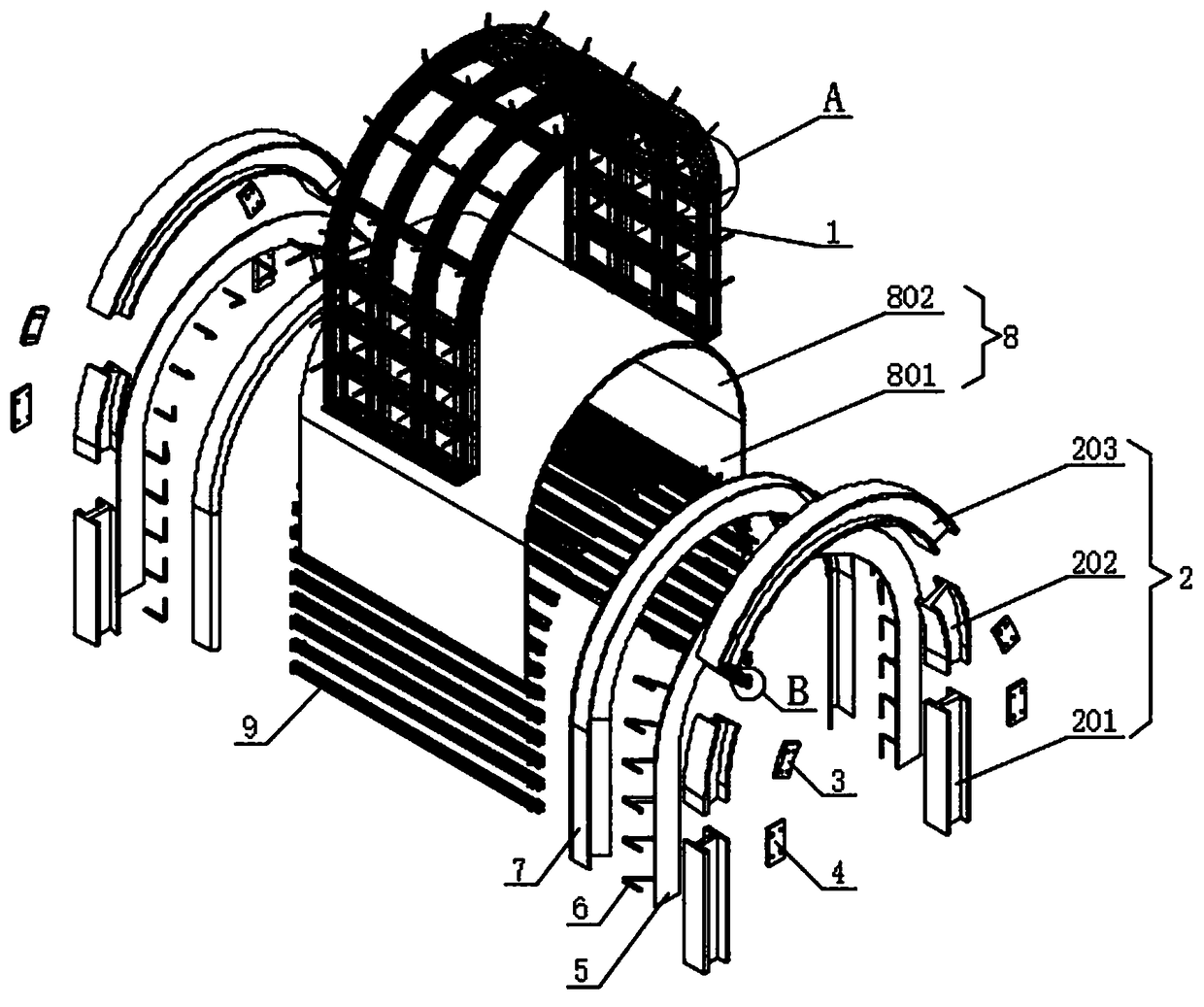

Existing tunnel lining reinforcement structure and reinforcement method

PendingCN109252875AEasy to removeReduce difficultyUnderground chambersTunnel liningStress conditionsEngineering

The invention discloses an existing tunnel lining reinforcement structure and a reinforcement method. The reinforcement structure is characterized in that arch lining steel frames serve as main supporting structures and are adopted for supporting formwork to form supporting units, a distance between the inner side of each supporting unit and an existing tunnel lining is smaller than 37.5cm to guarantee catenary safety and construction safety, concrete is poured to the inner side of the supporting formwork repeatedly, and the lining steel frames and the formwork are demounted after pouring is finished. According to the reinforcement method, the existing tunnel is equally segmented, segments are sequentially numbered, the supporting units are erected at intervals on odd segments, width of the supporting units is determined according to the segmenting conditions and stress conditions in a concrete pouring process, each supporting unit forms an independent concrete pouring cavity, concreteend faces of odd segments serve as end moulds of the even segments, and only inner side formwork supporting is needed; by segmented pouring, the lining steel frames can be demounted conveniently, influences on concrete service life due to pouring of the lining steel frames in concrete are avoided, and operating efficiency is greatly improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Mechanical part die with die releasing conveniently conducted

The invention discloses a mechanical part die with die releasing conveniently conducted. The mechanical part die comprises an outer cylinder body and a die body. A drive motor is fixedly connected tothe center position of the top of the inner surface wall of the bottom of the outer cylinder body, and the top of the drive motor is in drive connection with the die body through an output shaft. Multiple arc angle protruding blocks are welded to the outer side of the die body at equal angles around the circle center of the die body. According to the mechanical part die, the arc angle protruding blocks are arranged on the outer side of the die body, steel balls are arranged on the inner surface wall of the outer cylinder body, the drive motor is used for driving the die body to rotate so thatthe arc angle protruding blocks can collide with the steel balls intermittently, a knocking vibration effect is generated, and a blank part can be loosened from the die body through the knocking vibration effect. In addition, a certain centrifuging effect can be generated in the rotating process of the die body, and the blank part can be more easily loosened from the die body through the centrifugal force. Furthermore, due to the arrangement of an MYT3-23 hydraulic thruster and an electromagnetic plate, the blank part can be easily taken out, the working difficulty is lowered, and the die releasing efficiency is improved.

Owner:任大龙

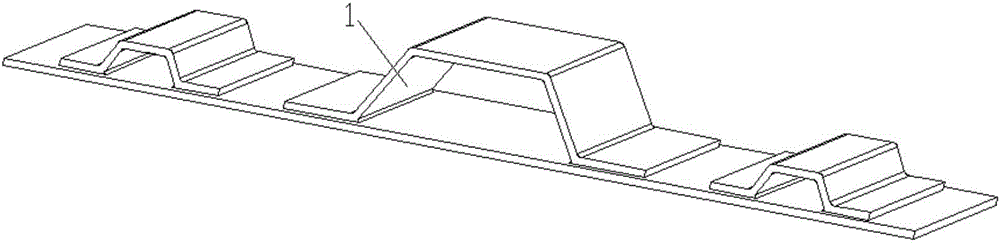

Method for preparing and using fiber-reinforced hat-shaped rib molding soft mold

The invention belongs to the composite molding technology, and relates to the improvement on the technology for preparing hat-shaped ribbed composite wall panel molding soft molds, in particular to a method for preparing and using a fiber-reinforced hat-shaped rib molding soft mold. A traditional pure rubber soft mold is improved, a unidirectional fiber reinforcement body is added in the soft mold in the rib length direction, and therefore the toughness, in the length direction, of the soft mold is increased, transmission of demolding tensile force is facilitated better, the problem of breakage of the fiber-reinforced hat-shaped rib molding soft mold in the demolding process is avoided, and the demolding efficiency is improved. The unidirectional fiber reinforcement body has a large limiting function on deformation, in the length direction, of the fiber-reinforced hat-shaped rib molding soft mold in the demolding process, the fiber-reinforced hat-shaped rib molding soft mold is not prone to being broken and damaged, restoring of deformation in the length direction is easy, the repeated use performance of the fiber-reinforced hat-shaped rib molding soft mold is improved, and the process cost is reduced.

Owner:AVIC BASIC TECH RES INST

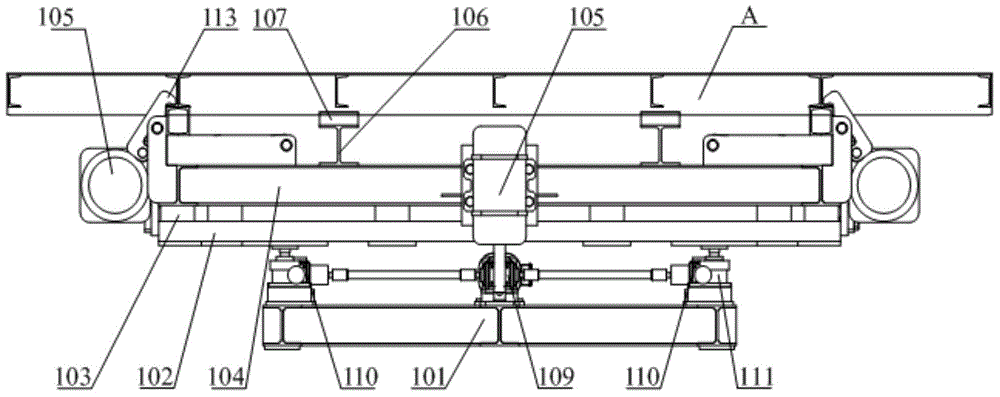

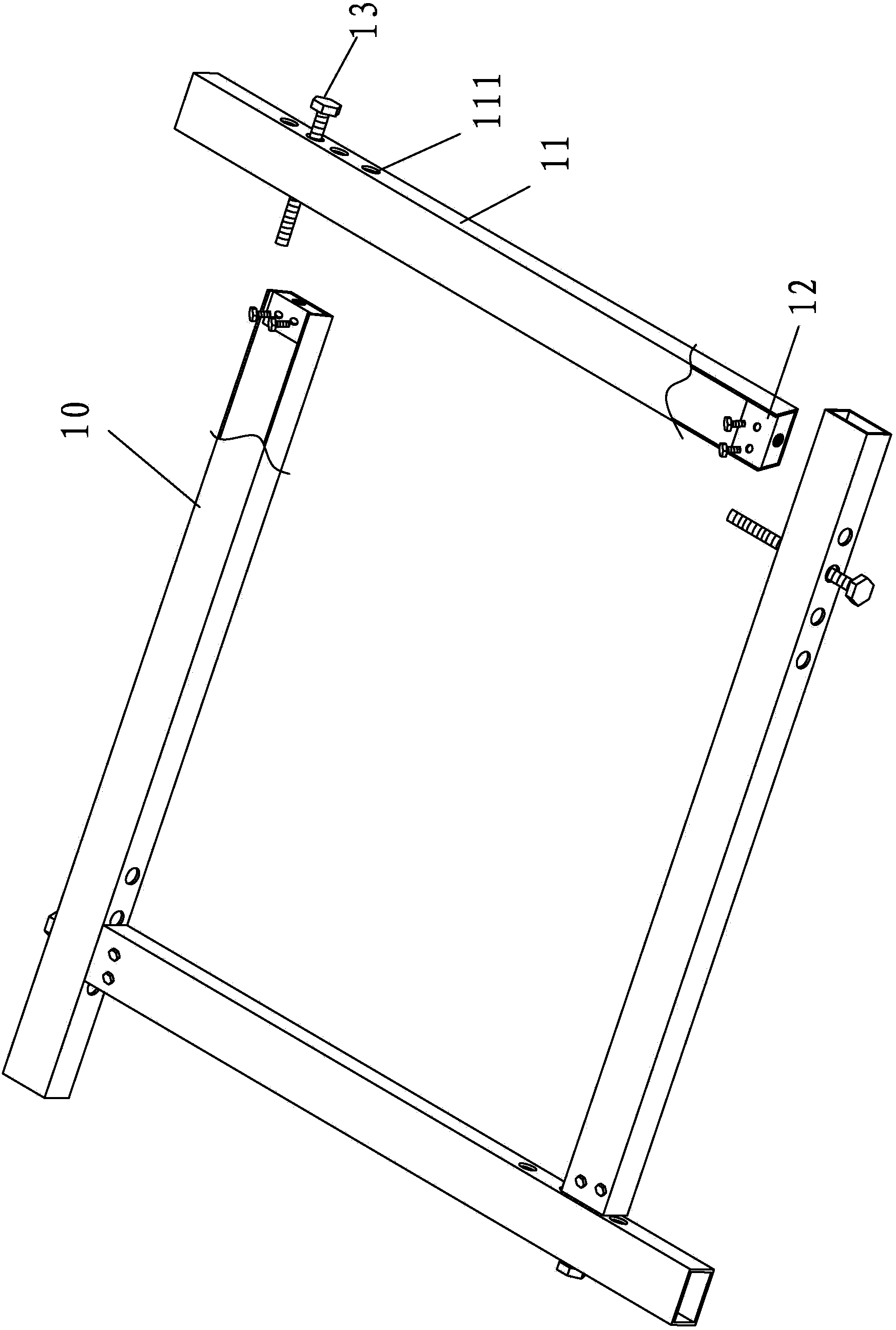

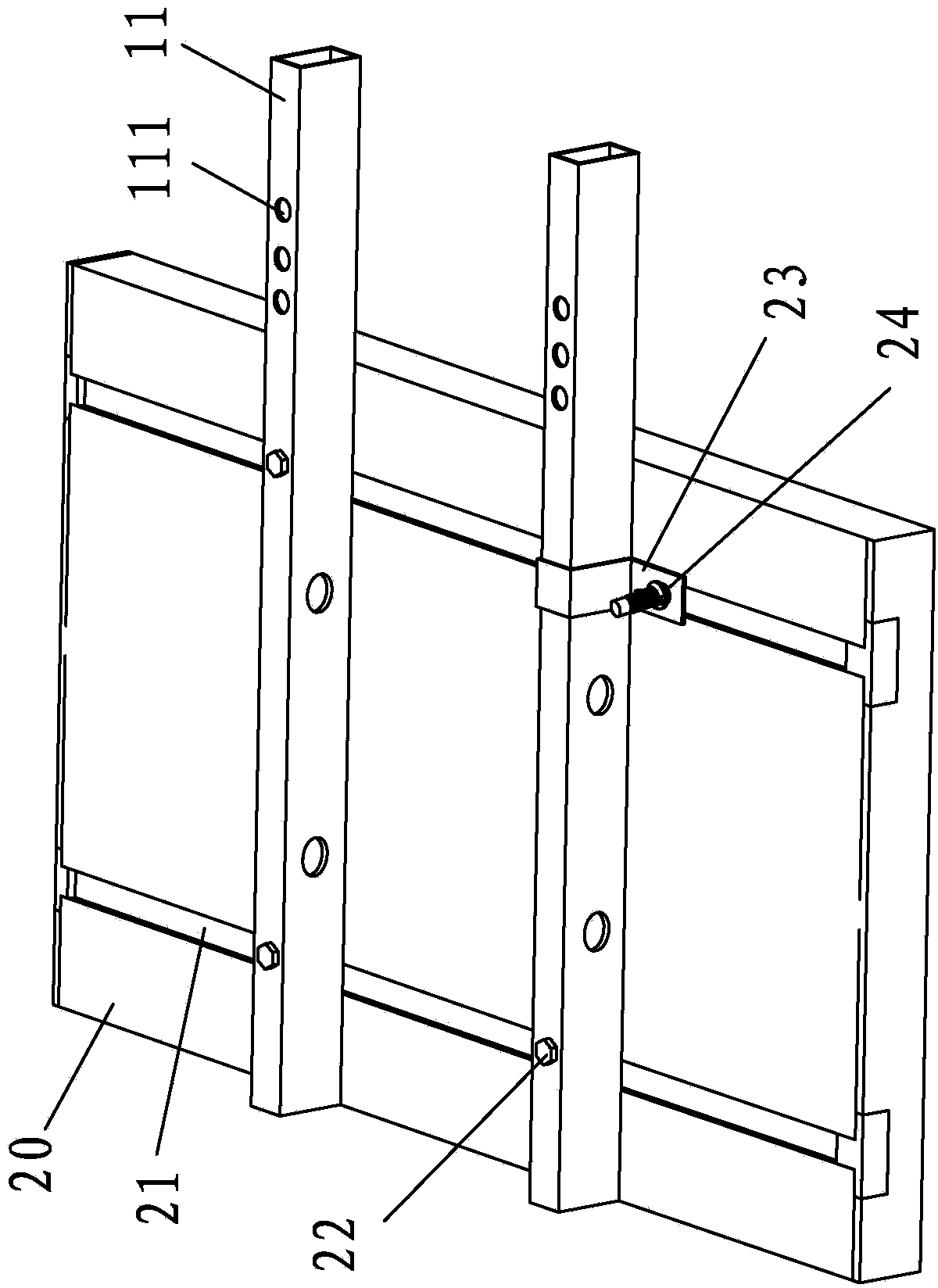

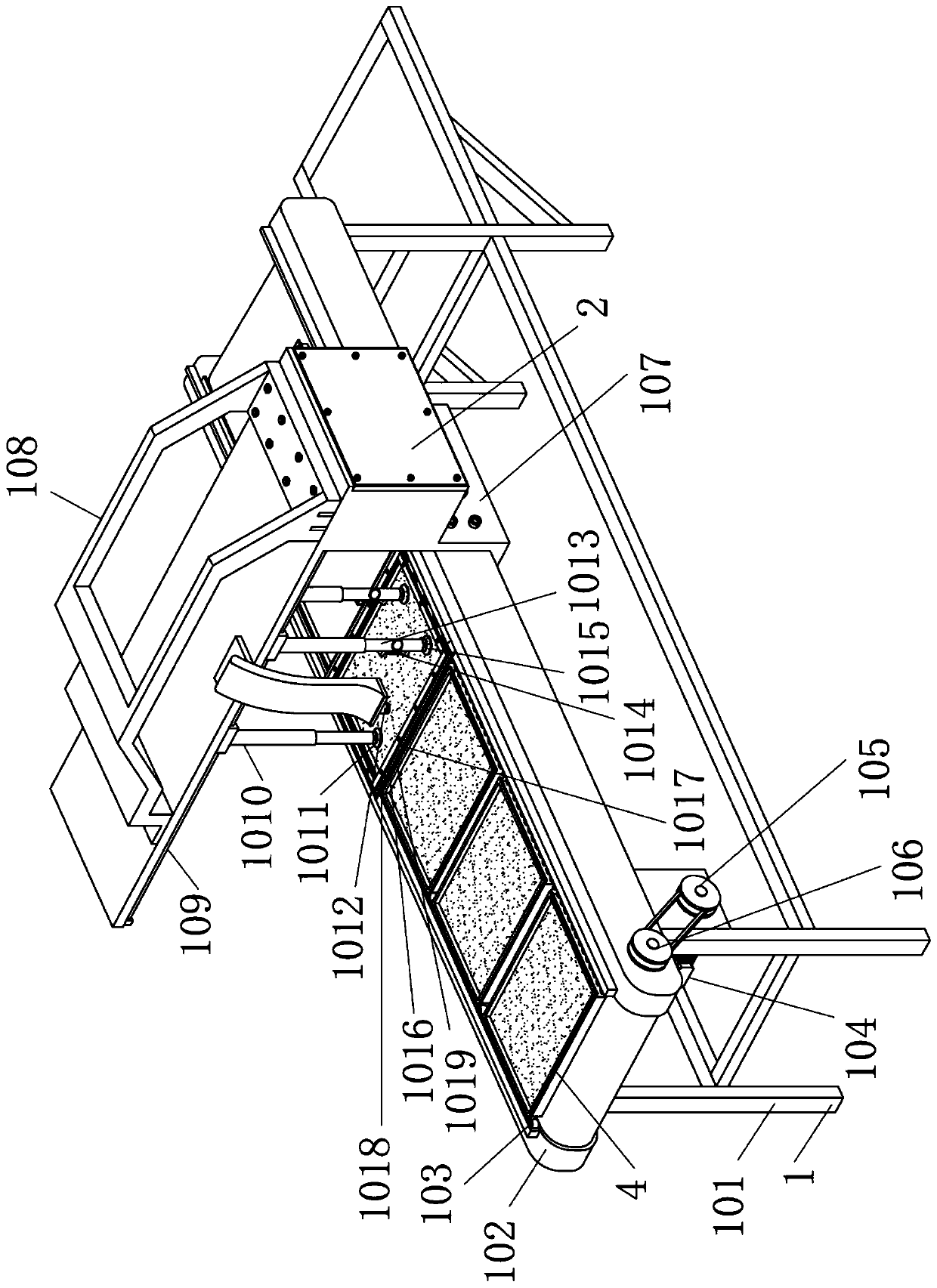

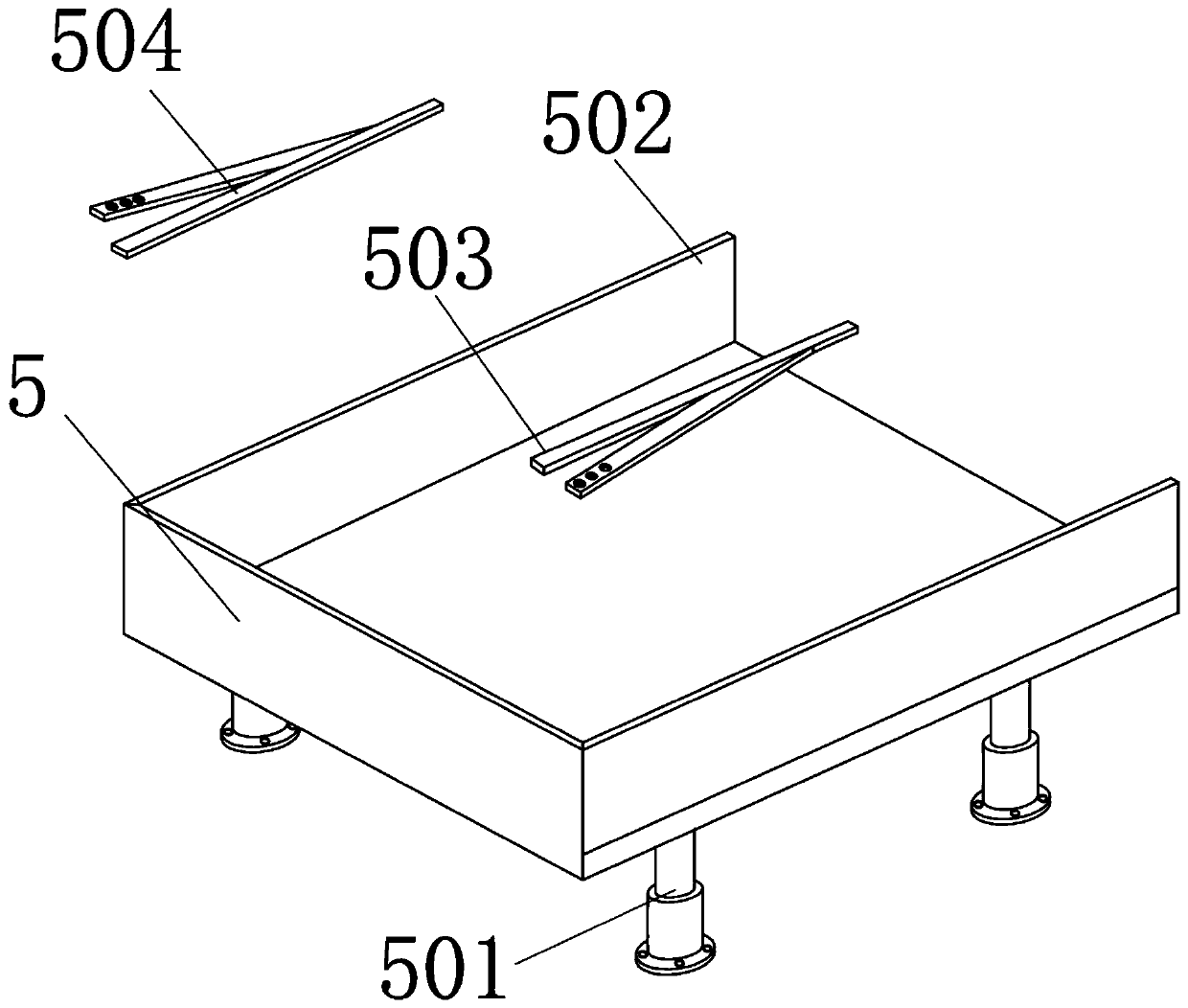

Light insulation wallboard production line

ActiveCN106272943AReduce investmentReduce labor intensityDischarging arrangementCeramic shaping plantsMaterials preparationProduction line

The invention discloses a light insulation wallboard production line. The light insulation wallboard production line comprises a control system for controlling mechanical automation, a material preparation system, a wallboard forming machine, a rail net for operating the wallboard forming machine, mold mounting equipment for mounting a template and a mold frame on the wallboard forming machine, a grouting platform for grouting, and wallboard demolding equipment; the rail net includes a first rail, a curing input rail, a curing rail and a curing output rail; the mold mounting equipment, the grouting platform and the demolding equipment are spaced on the first rail to divide the first rail into multiple sections; the mold mounting equipment is arranged between the demolding equipment and the grouting platform, and includes a first forming machine overturning car, a plate and mold mounting machine and an auxiliary mold mounting machine; and the demolding equipment includes a second forming machine overturning car, a demolding stacking machine, a separator and an auxiliary demolding machine. All parts form a mechanical automatic production line capable of continuously and circularly operating and producing, so that the problems of high labor intensity and low efficiency caused by manual operation in the prior art are solved.

Owner:QUANZHOU S L MACHINERY MFG

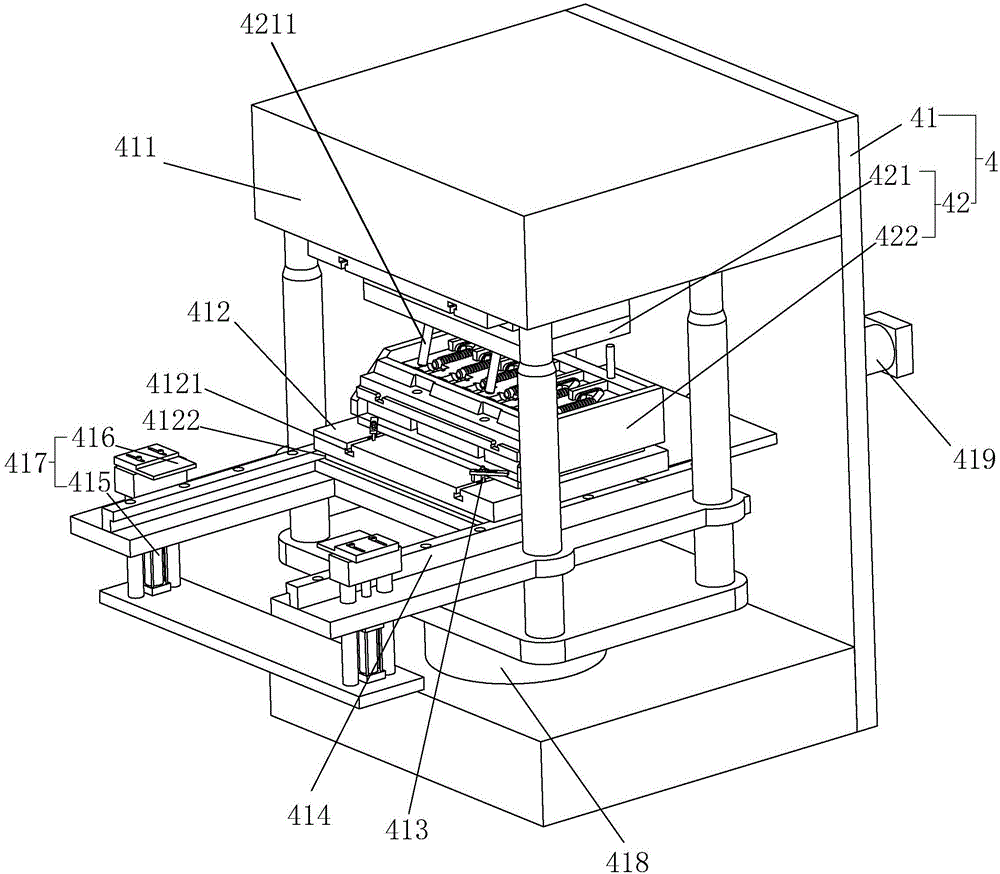

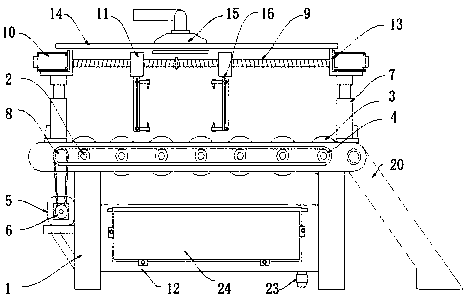

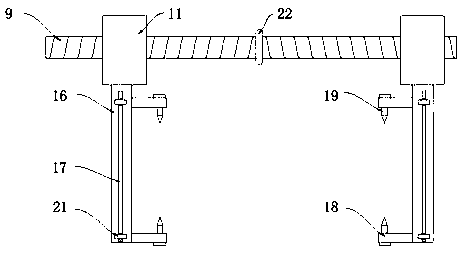

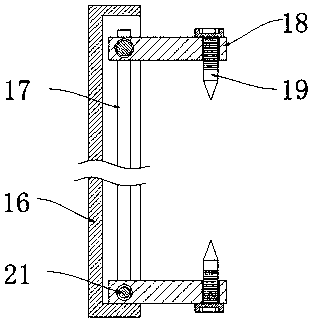

Needle piercing type stripping device

ActiveCN104146016AAvoid pollutionAvoid the problem of food deformationBaking ovenBiomedical engineeringPower output

The invention discloses a needle piercing type stripping device comprising a rack, a movement component and a translation driving mechanism. The movement component comprises a lifting driving mechanism and a needle piercing mechanism, the needle piercing mechanism comprises a shell and needle piercing mounting racks, lifting cylinders are mounted on the shell, the needle piercing mounting racks are connected on power output parts of the lifting cylinders and can be driven by the lifting cylinders to move up and down relative to the shell, piercing needles are arranged on the needle piercing mounting racks which are located above the bottom of the shell, and the bottom of the shell is provided with guide slots allowing the piercing needles to penetrate. By the aid of the translation driving mechanism and the lifting driving mechanism, the needle piercing mechanism can be driven to move, the piercing needles of the needle piercing mechanism are used for taking food by means of piercing, artificial stripping can be replaced, stripping efficiency can be improved, and food safety is improved beneficially.

Owner:GUANGZHOU FUYA MACHINERY

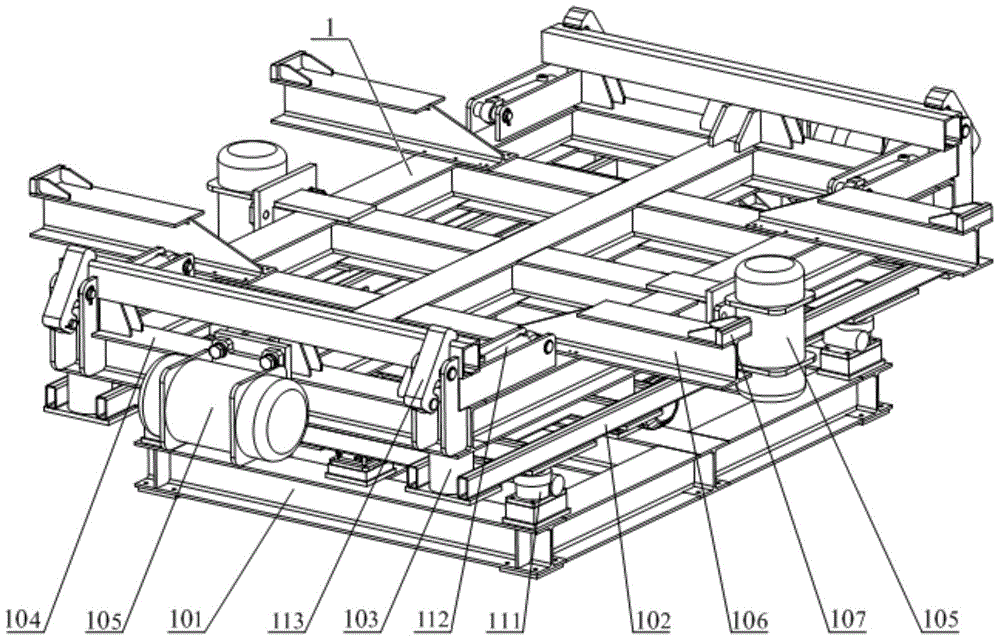

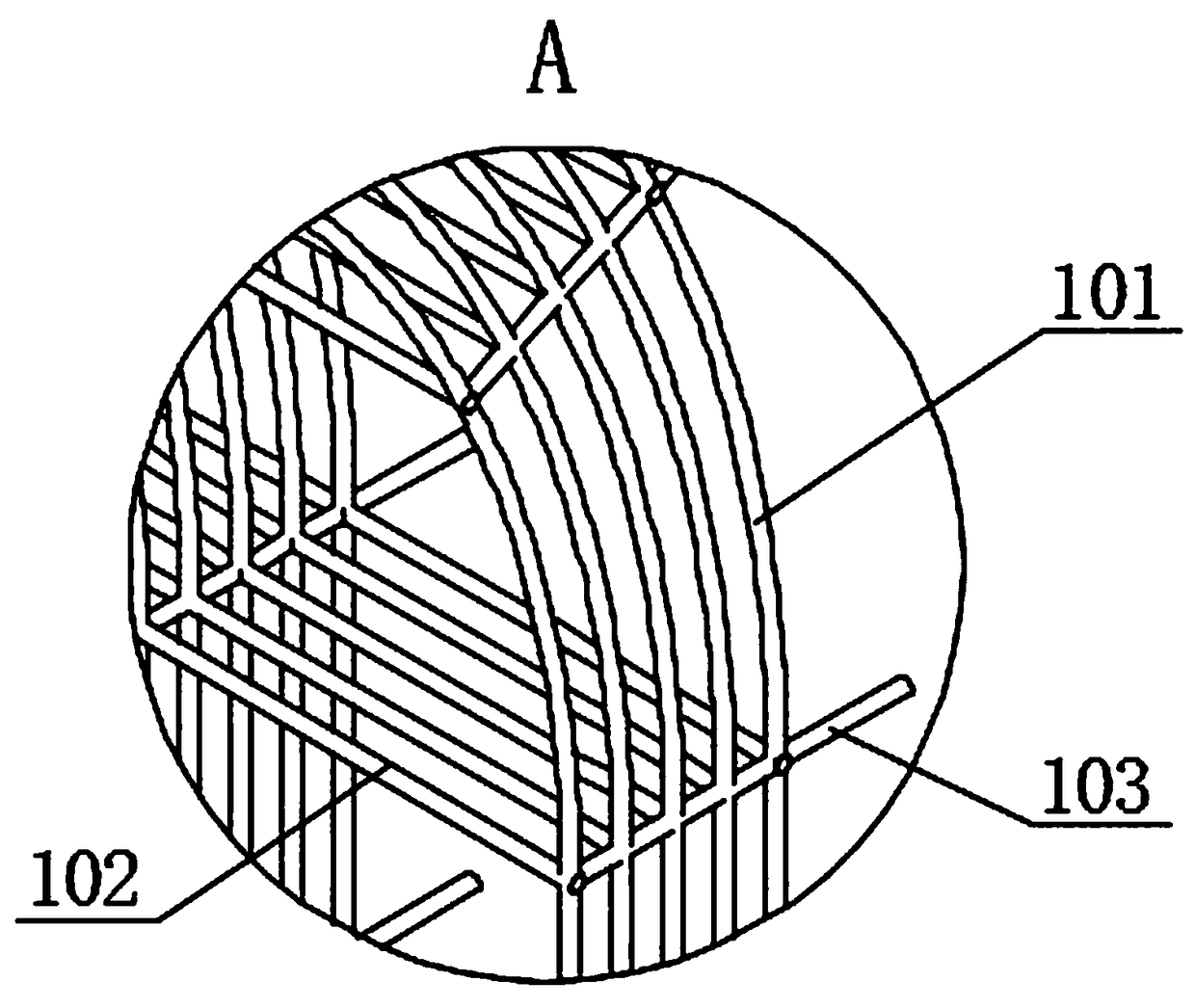

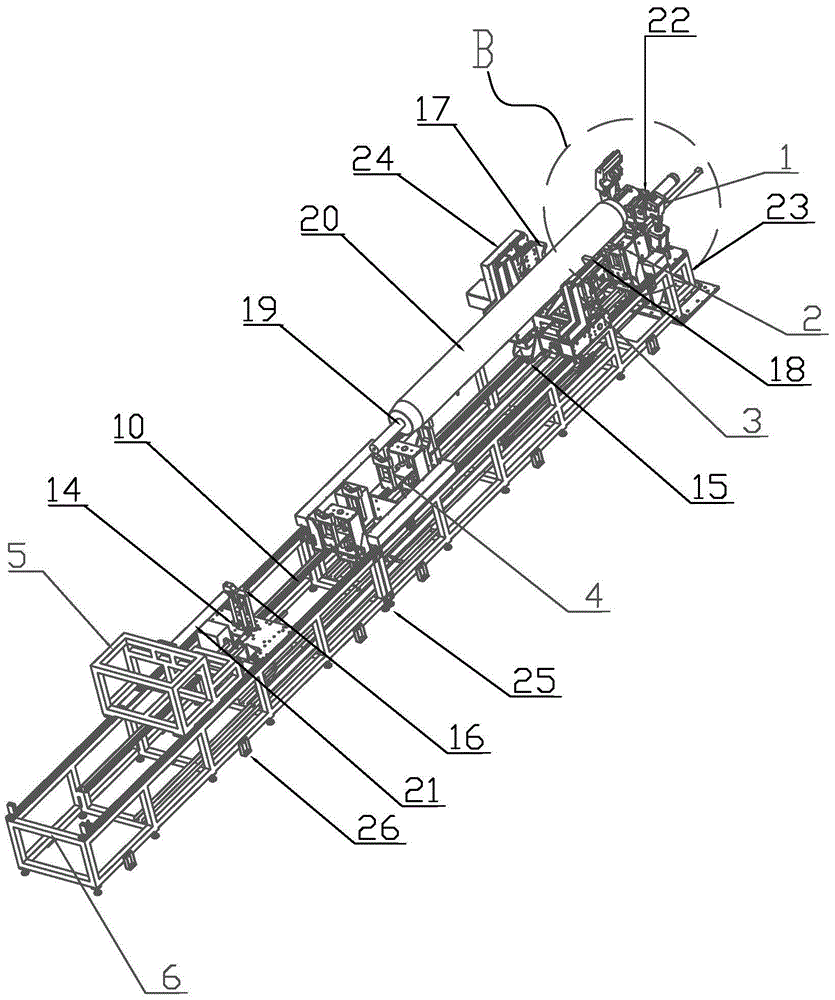

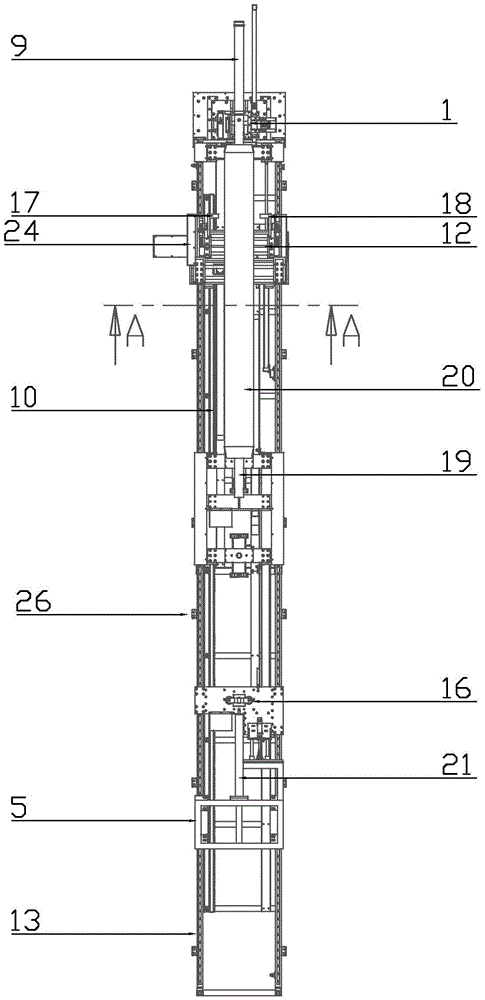

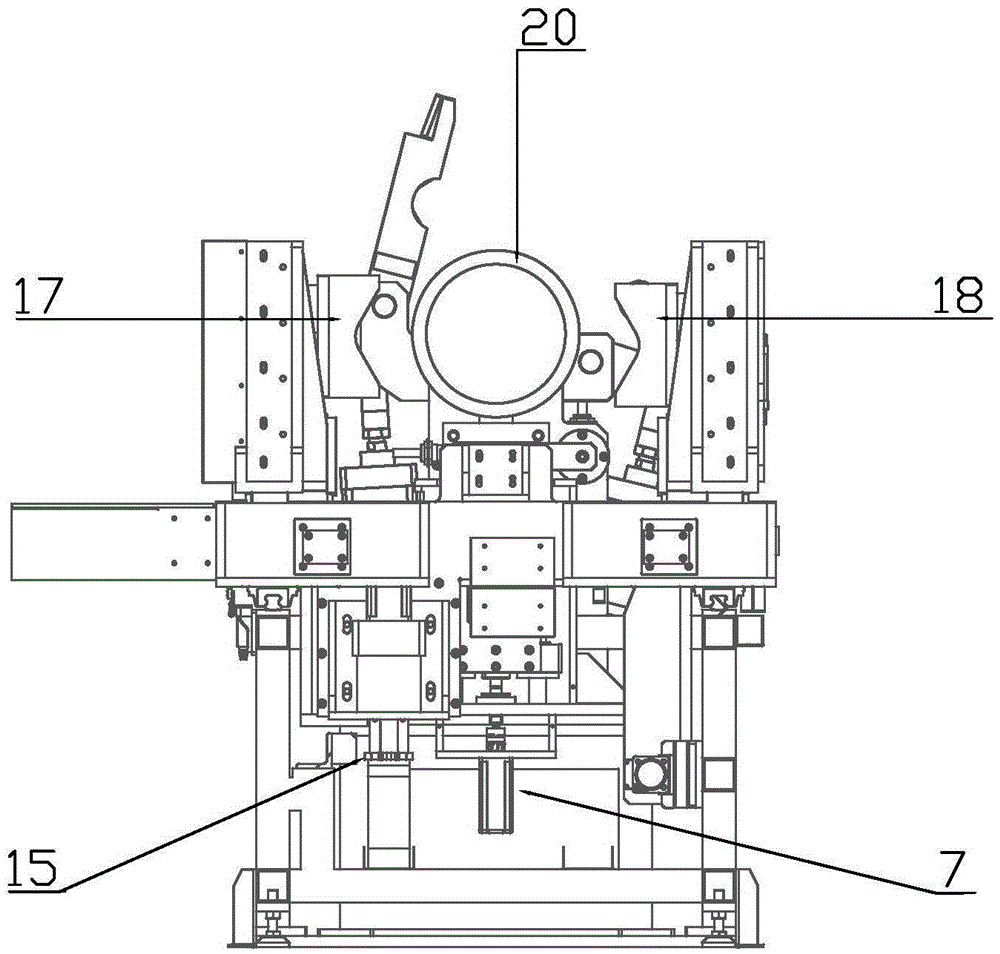

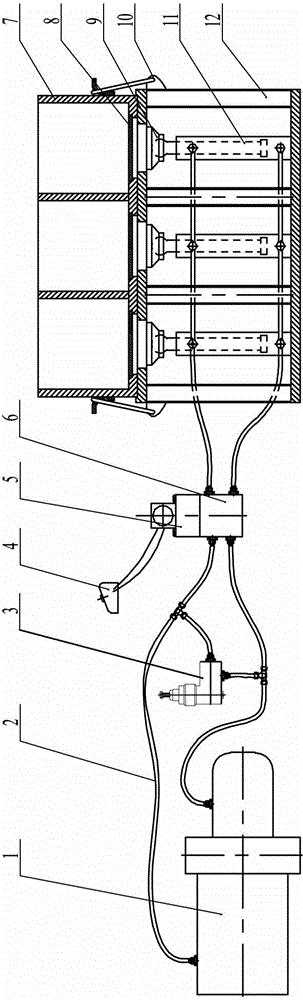

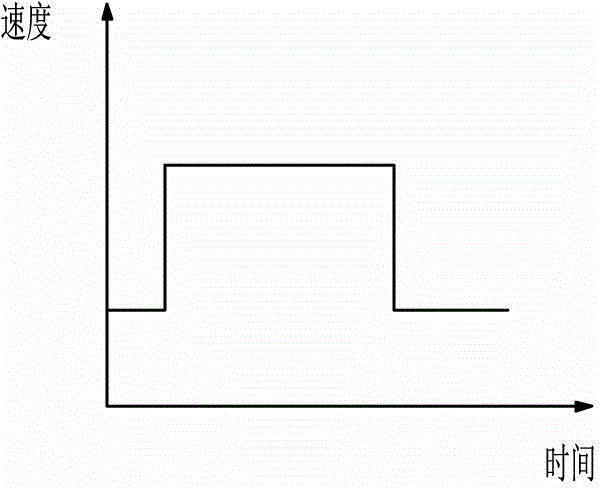

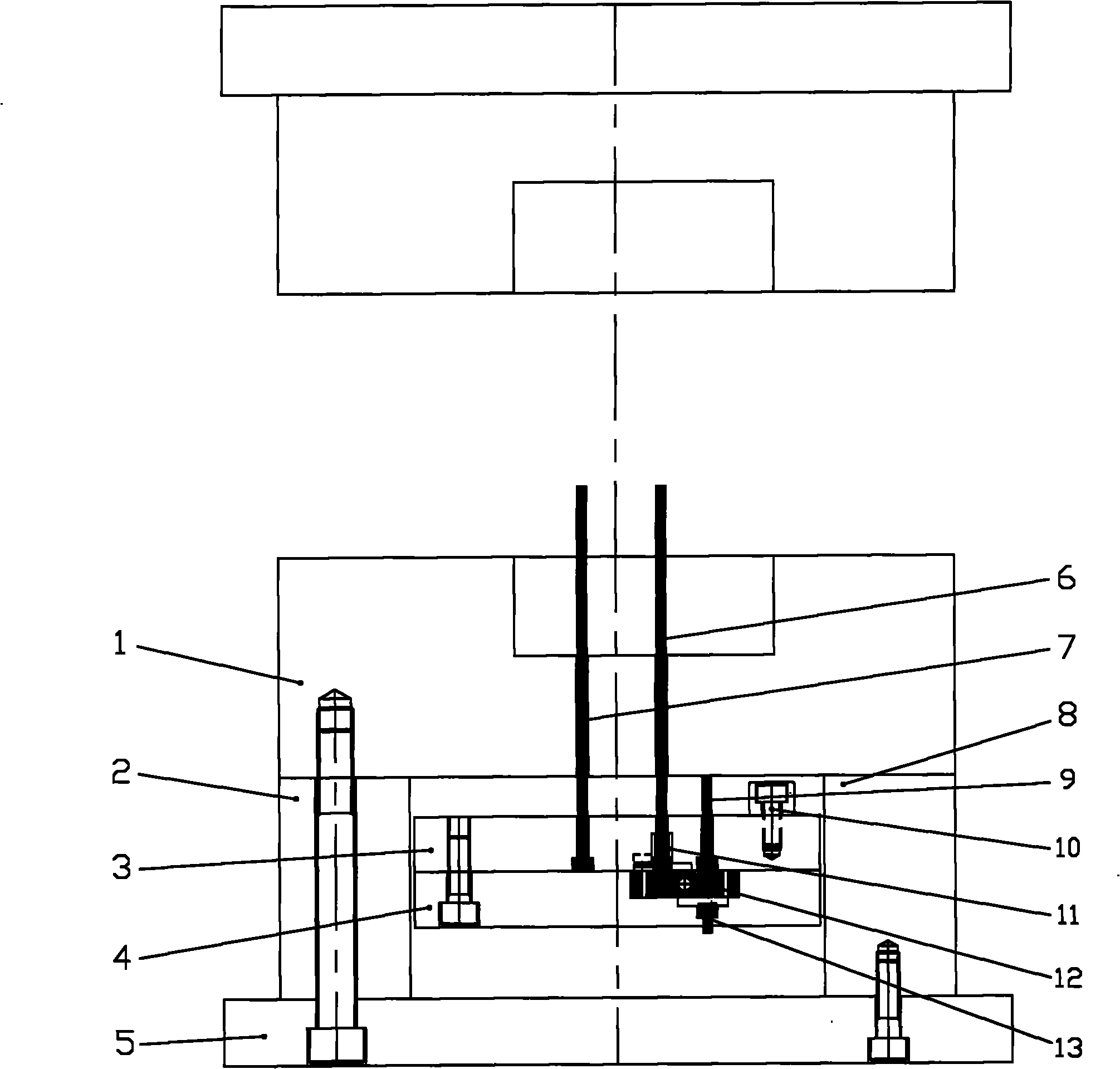

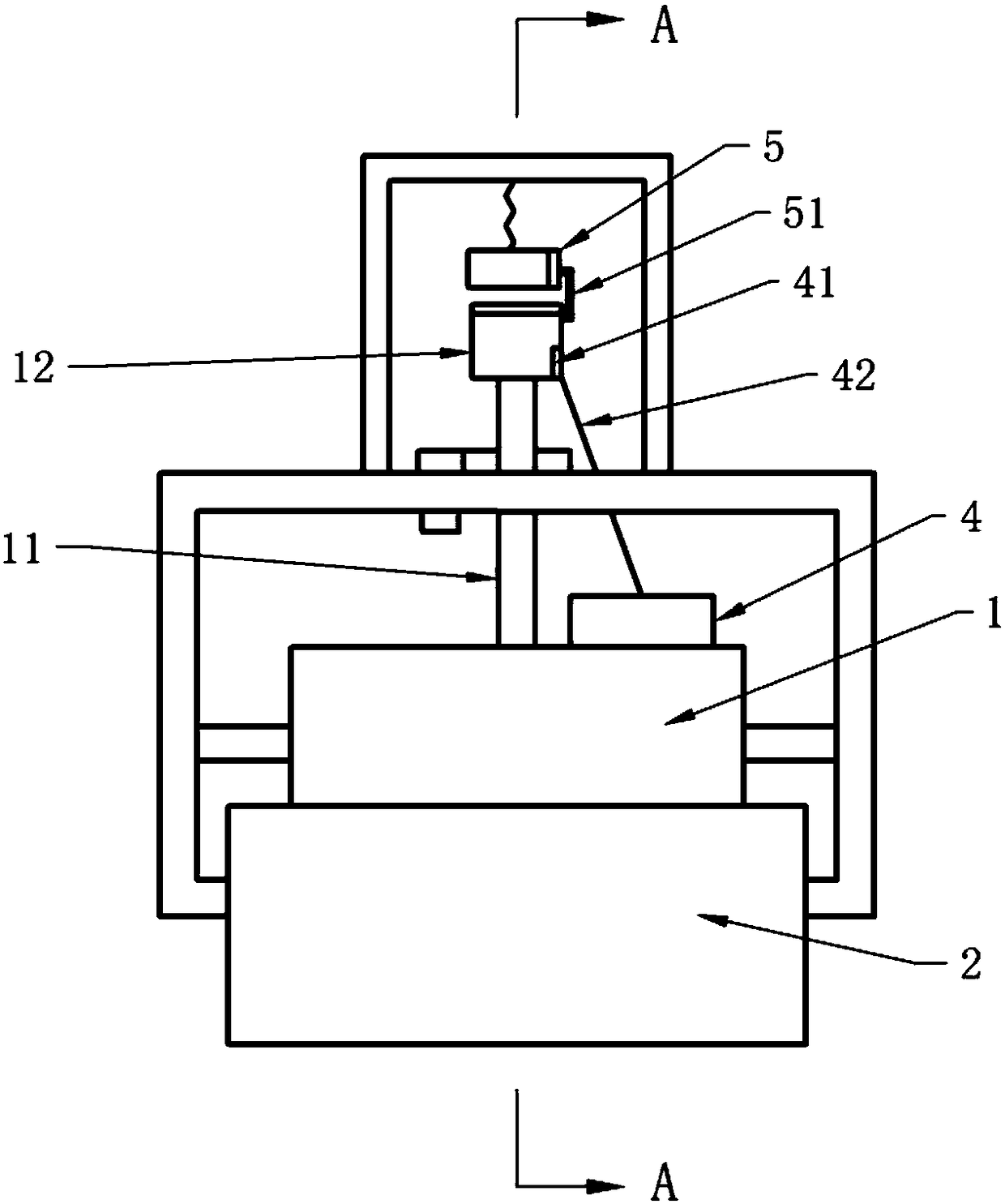

Winding demoulding machine of winding glass steel tube demoulding machine

The invention discloses a winding demoulding machine of a winding glass steel tube demoulding machine. The winding demoulding machine comprises core mould clamping mechanisms, a front supporting rack, a clamping demoulding mechanism, a movable support, a core mould tail rack, a demoulding machine framework, a rack, a lead screw, a linear sliding rail, a tail supporting rack and a controller. A clamping frame, a clamping base and the front supporting rack are arranged at the front end of the demoulding machine framework, and the core mould clamping mechanisms are arranged on the two sides of the clamping base. The linear sliding rail is disposed on the side edge of the demoulding machine framework, and the rack is arranged on the inner side face of the demoulding machine framework. The clamping demoulding mechanism, the movable support, the tail supporting rack and the core mould tail rack are sequentially arranged on the linear sliding rail. A gear, a servo motor and a displacement sensor are disposed below the clamping demoulding mechanism, the movable support, the tail supporting rack and the core mould tail rack respectively. The controller is arranged on the clamping demoulding mechanism, and a control program is set in the controller. Automatic demoulding is achieved, demoulding efficiency is high, demoulding speed is high, and the winding demoulding machine is suitable for large-scale demoulding, good in demoulding quality and wide in application range.

Owner:SUZHOU KUAIJIE AUTOMATION EQUIP CO LTD

Auxiliary concrete prefabricated mold safety demolding device

ActiveCN110696173AStable jobStable working conditionDischarging arrangementArchitectural engineeringStructural engineering

The invention discloses an auxiliary concrete prefabricated mold safety demolding device. The auxiliary concrete prefabricated mold safety demolding device comprises a lower support plate, a hydraulicdevice, a first electric telescopic rod and a second electric telescopic rod, wherein the hydraulic device and a lower supporting rod are fixed to the upper side of the lower supporting plate, an upper supporting plate is connected to the upper end of the hydraulic device and the upper end of the lower supporting rod, an upper supporting rod is fixed to the upper side of the upper supporting plate, a fixing base is fixed to the upper end of the upper supporting rod, a reinforcing ring is fixed to the outer side of the fixing base, the first electric telescopic rod is connected inside the reinforcing ring, a stabilizing rod is arranged on the outer side of the reinforcing ring, and a movable plate is connected to the outer side of the stabilizing rod. The auxiliary concrete prefabricated mold safety demolding device is provided with a control shell and a knocking hammer, so that demolding work can be assisted, the side edges of the mold are blown through a high-pressure air nozzle, theseparation and demolding work of concrete products in the mold can be accelerated, and the demolding efficiency is effectively increased.

Owner:上海民航新时代机场设计研究院有限公司

Concrete briquette automatic demoulding device and demoulding method

The invention relates to a demoulding device and a demoulding method, in particular to a concrete briquette automatic demoulding device and a demoulding method. The device comprises a forming test mould, a demoulding support base, three hydraulic oil cylinders and a hydraulic power device, wherein the forming test mould is a three-connection mould, test mould support boards are arranged in the centers of the baseboards of the forming test mould, sealing rings are arranged around the test mould support boards, a positioning groove is formed in the upper surface of the demoulding support base, the side wall of the groove is provided with a hinged buckle which tightly clamps the three-connection mould, a basket-like nut is arranged in the middle part of the hinged buckle, the three hydraulic oil cylinders are arranged in parallel, top blocks are hinged to the upper ends of the hydraulic oil cylinders, the lower ends of the hydraulic oil cylinders are fixed with a demoulding support, an electromagnetic reversing valve pinboard and a direct-acting overflow valve are respectively connected onto the oil inlet and the oil outlet of the hydraulic power unit, the electromagnetic reversing valve pinboard is connected with the three hydraulic oil cylinders in parallel, an electromagnetic reversing valve is installed on the electromagnetic reversing valve pinboard, and the electromagnetic reversing valve and the hydraulic power unit are electrically connected with an electrically controlled box. The concrete briquette automatic demoulding device is simple in mould and high in forming precision, the automatic demoulding does not be damaged easily.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Ejection mechanism for injection mould

Owner:SHENGMEI PRECISION INDAL KUSN

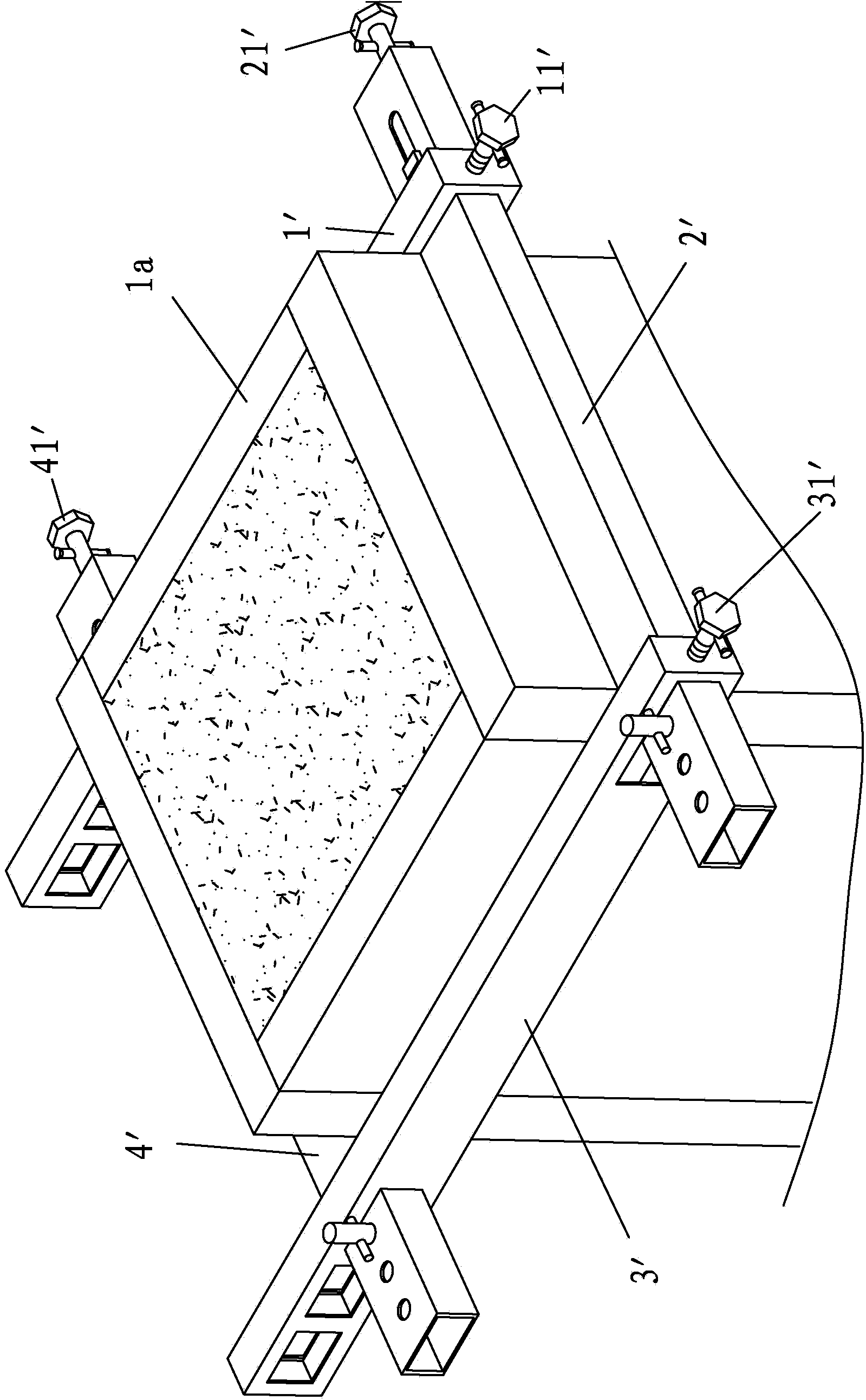

Construction method for column mold composed of concrete formworks

InactiveCN103963146AImprove demoulding efficiencyImprove assembly accuracyMould separation apparatusAuxillary shaping apparatusBuilding construction

The invention discloses a construction method for a column mold composed of concrete formworks. The construction method comprises the following steps of preparing parts, wherein the concrete formworks and square pipes are provided, each concrete formwork comprises opposite pouring surfaces and opposite installation surfaces, one end of each square pipe is the nut end, each nut end is provided with a pipe nut, the other end of each square pipe is the bolt end, and each bolt end is provided with a through hole; prefabricating column mold plates, wherein the square pipes are arranged on the installation surfaces, the nut ends are located in the mode that the nut ends extend out of the outer edges of the concrete formworks by the thickness of one concrete formwork, the bolt ends extend out of the concrete formworks, and the column mold plates are prefabricated; splicing the column mold plates, wherein the multiple column mold plates are spliced to form a column pouring mold cavity, and a pipe bolt penetrates the through hole in each square pipe and then is arranged inside a pipe nut of another square pipe in a screwed mode. According to the construction method for the column mold composed of the concrete formworks, the square pipes do not need to be removed from or installed on the concrete formworks one by one, so that the column mold assembly efficiency and the demolding efficiency are improved on a construction site. Besides, the column mold plates can be prefabricated in advance on the ground, so that assembly is convenient, the altitude effect is avoided, the work difficulty is greatly lowered, and assembly precision can be improved.

Owner:FUYUAN FUJIAN ENVIRONMENTAL PROTECTION TEMPLATE

Forced demolding device used after injection mold product forming

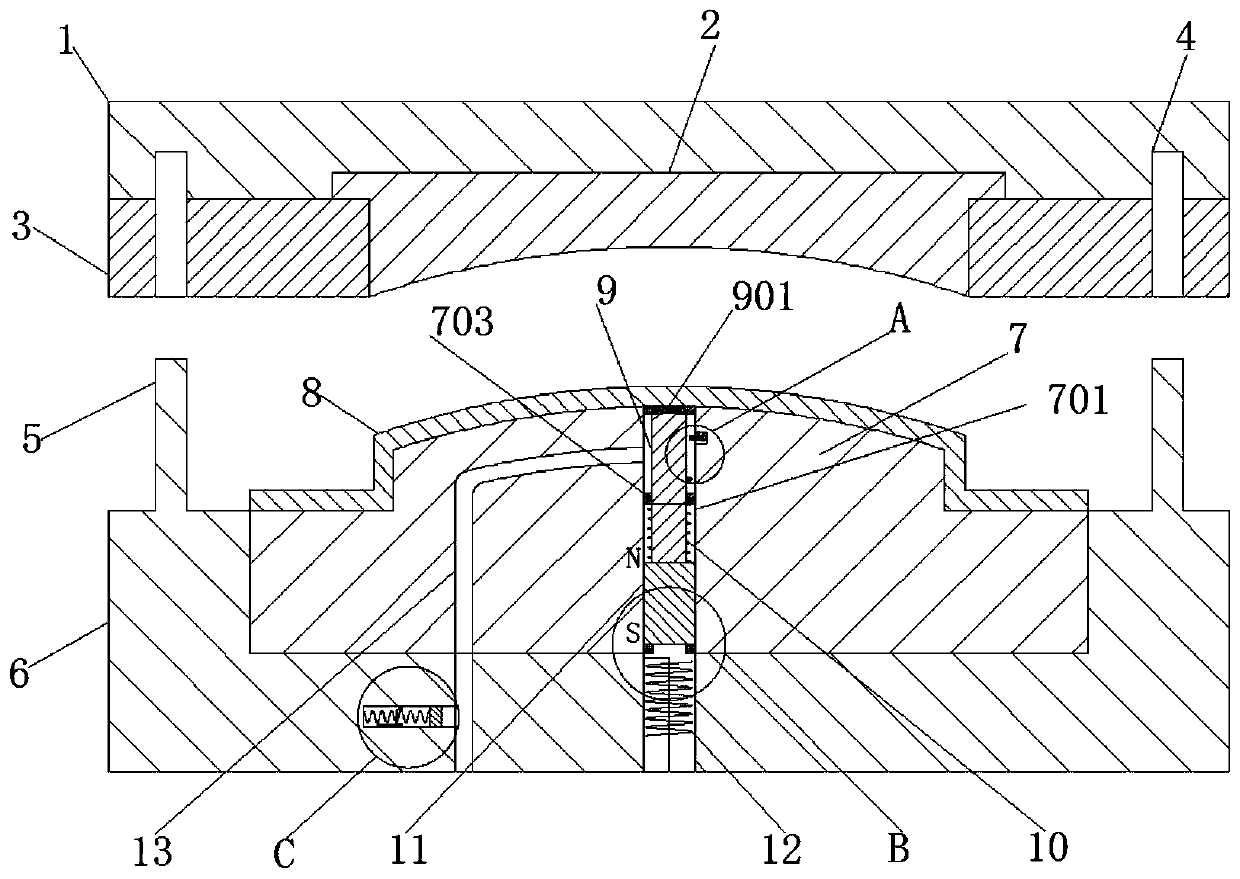

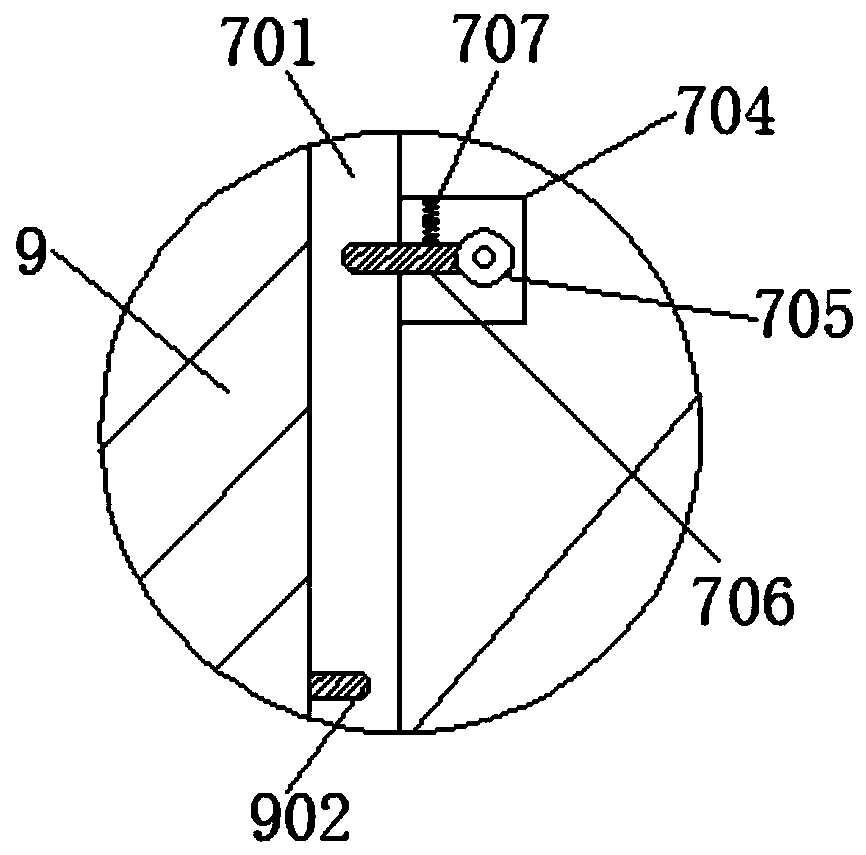

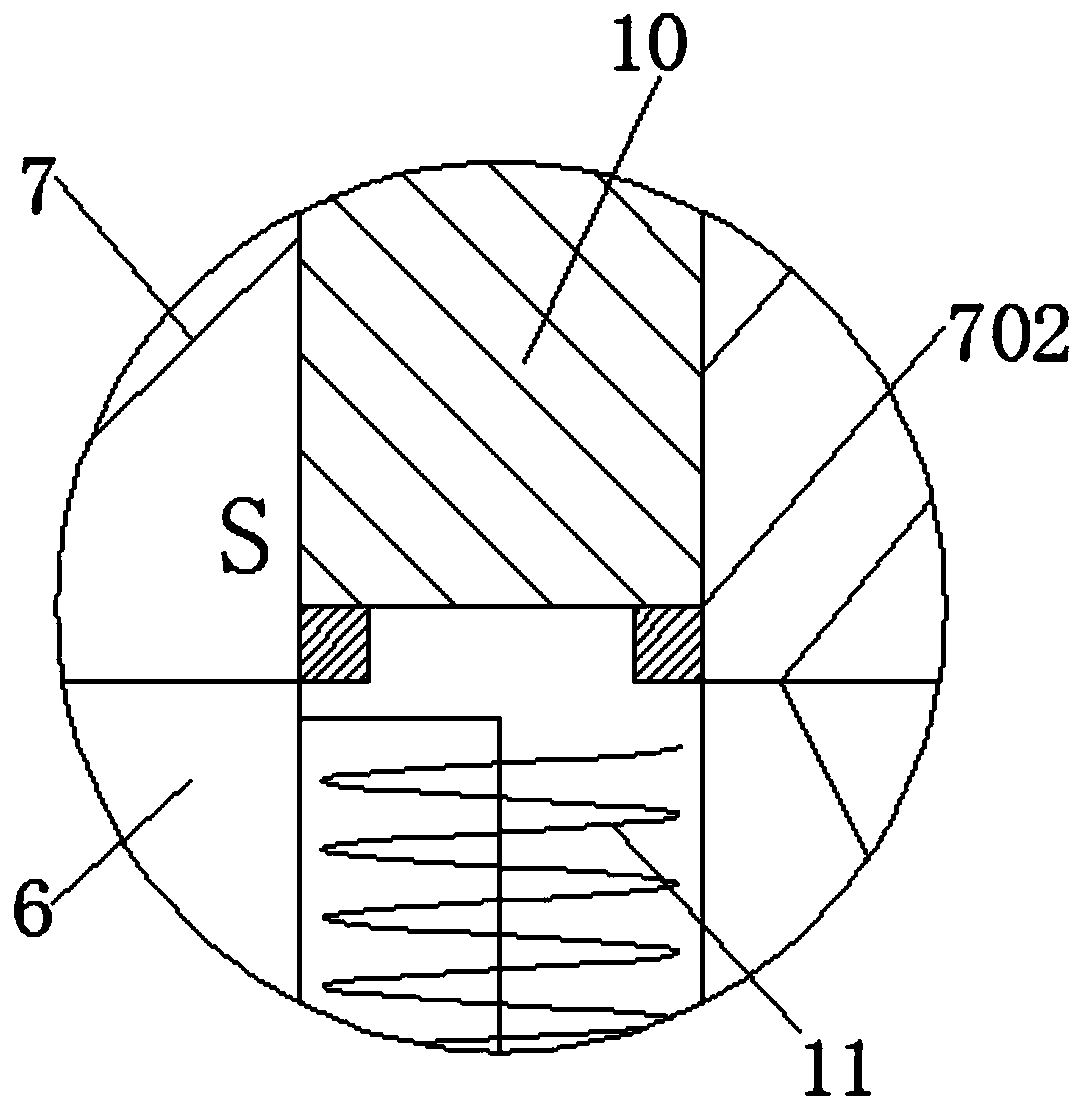

The invention relates to the technical field of injection molds, and discloses a forced demolding device used after injection mold product forming. The forced demolding device comprises a fixed mold holder, the inner middle of a mold core is connected with a sliding column, the outer side of the lower end of the sliding column is connected with a first spring, a permanent magnet is arranged underthe sliding column, an electromagnetic induction coil is arranged under the permanent magnet, and the interior of a movable mold holder and the interior of the mold core are connected with a gas feedpipe. A magnetic field generated by the electromagnetic induction coil drives the sliding column to vibrate a workpiece, after the workpiece is loosened, a second metal column make contact with a first metal column, gas of the gas feed pipe blows the workpiece, meanwhile air pressure pushes a sliding block to compress a second spring to drive a metal ball to slide on a variable resistor, the output power of an air supply device is adjusted, and large impact of stable and constant power on the workpiece is prevented. Because of the structure, not only can the workpiece be forced out of the moldcore, but also the workpiece can also be cooled, and the occurrence of scald incidents of workers is reduced.

Owner:南通思泽塑业有限公司

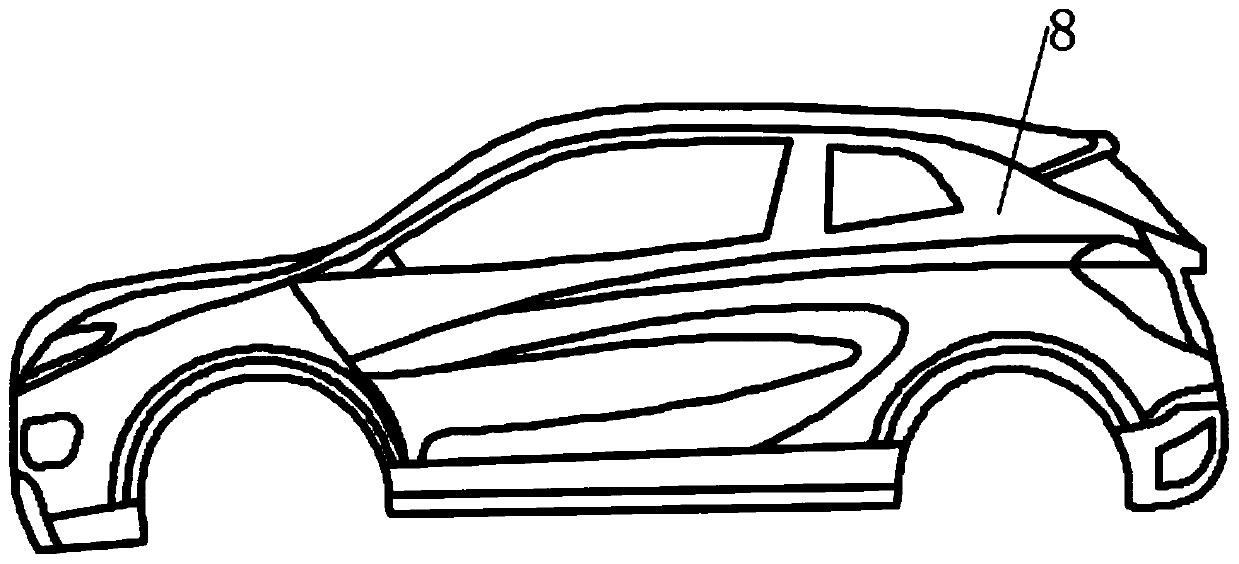

Rotational molding mould and processing technology thereof

ActiveCN110561671AExtended service lifeReduce difficultyDomestic articlesCoatingsGlass fiberGlobal temperature

The invention discloses a rotational molding mould and a processing technology thereof. A material-structure-process coupling design system can be developed, an all-plastic vehicle body mould is divided into three-dimensional units through preparation of glass fiber reinforced polyethylene resin and auxiliary materials and by a large complicated aluminum alloy mould unit segmenting, combining andmolding method, aluminum alloy micro-elements are manufactured by an aluminum alloy casting molding technology, the shape-responsible all-plastic vehicle body mould can be divided into different parts, thus, the integral processing difficulty of the vehicle body mould is reduced, the service life of the mould is prolonged, the apparent quality of the product is ensured, a novel temperature controlmethod for directional heating is introduced in the process, under the micro-control of ensuring the global temperature uniformity of the mould, directional heating of some key areas can be realized,high-quality products with uniform wall thicknesses can be produced, local areas can even be thickened, the mechanical strength of the product is improved, and the service life of the product is prolonged.

Owner:东莞秋元精密塑胶模具有限公司

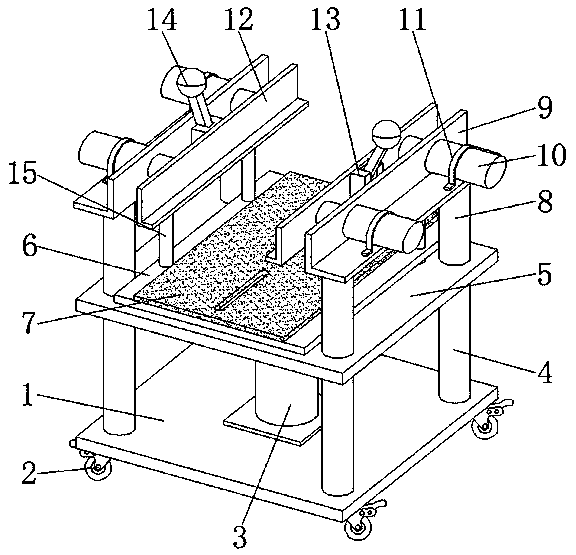

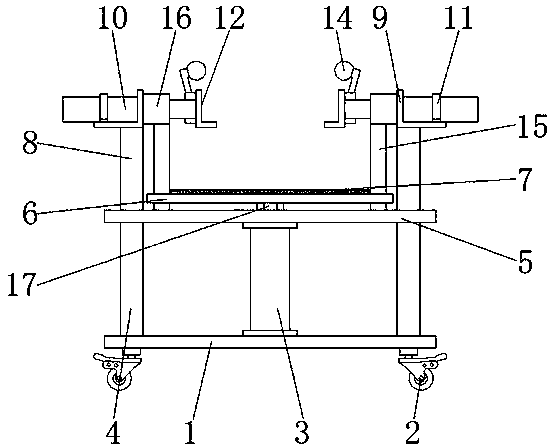

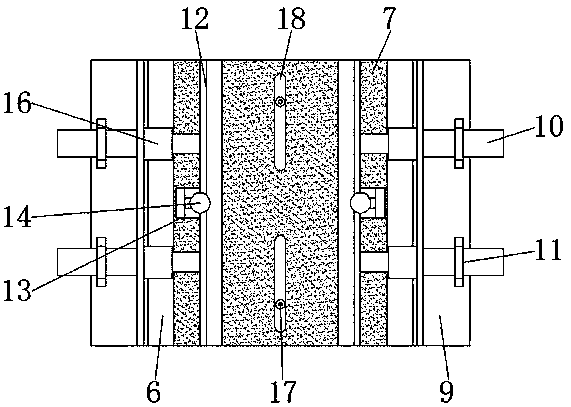

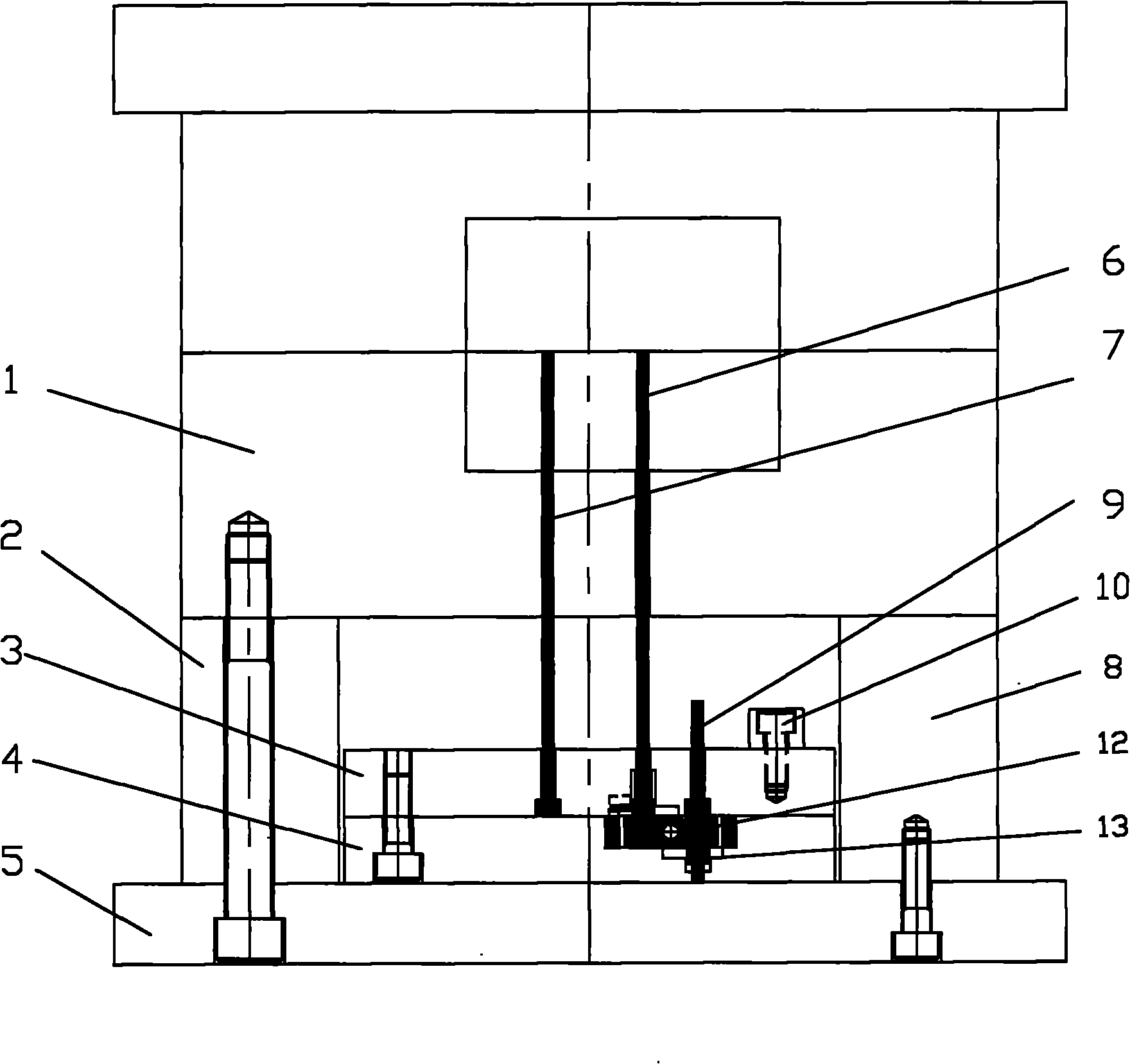

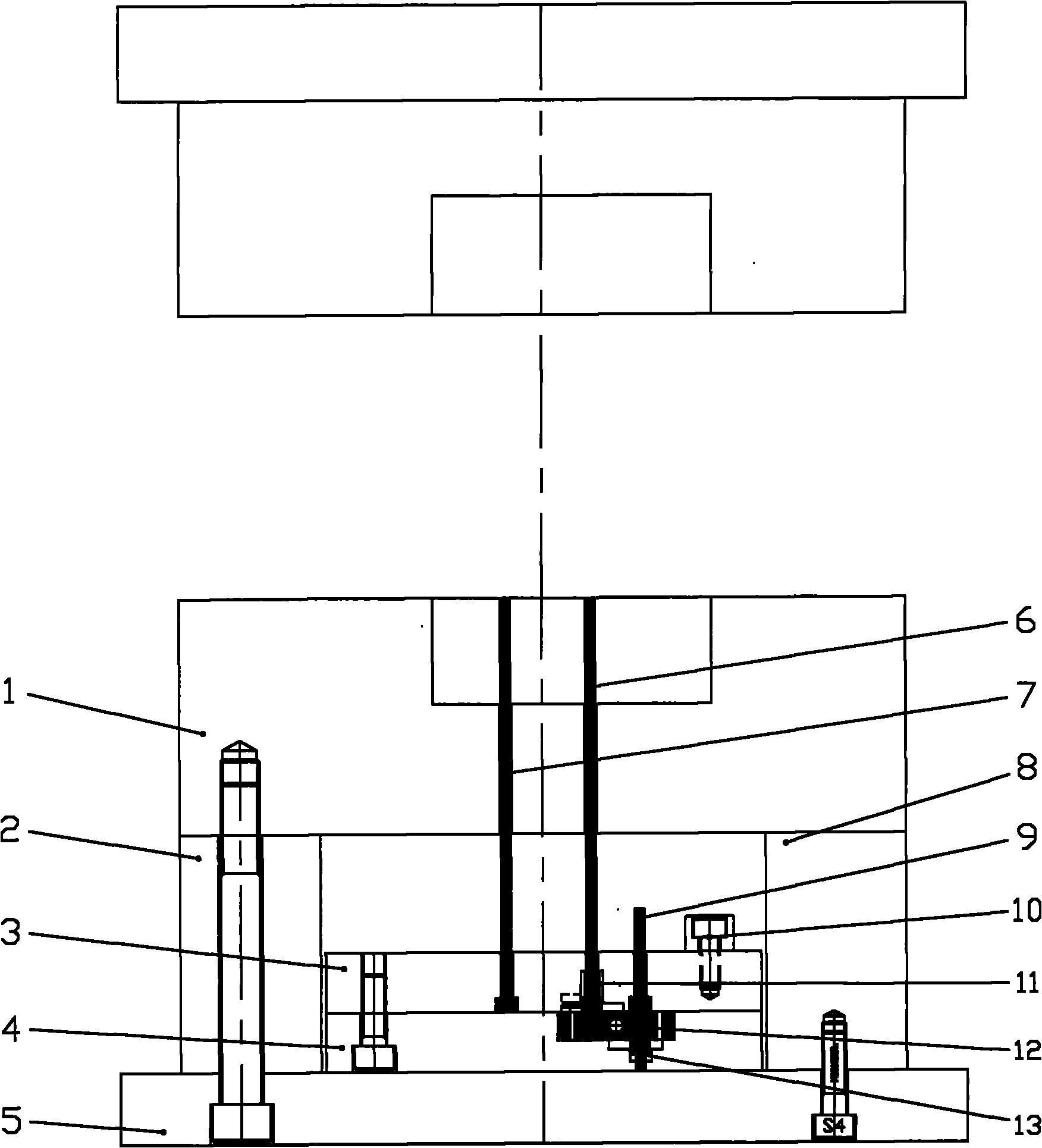

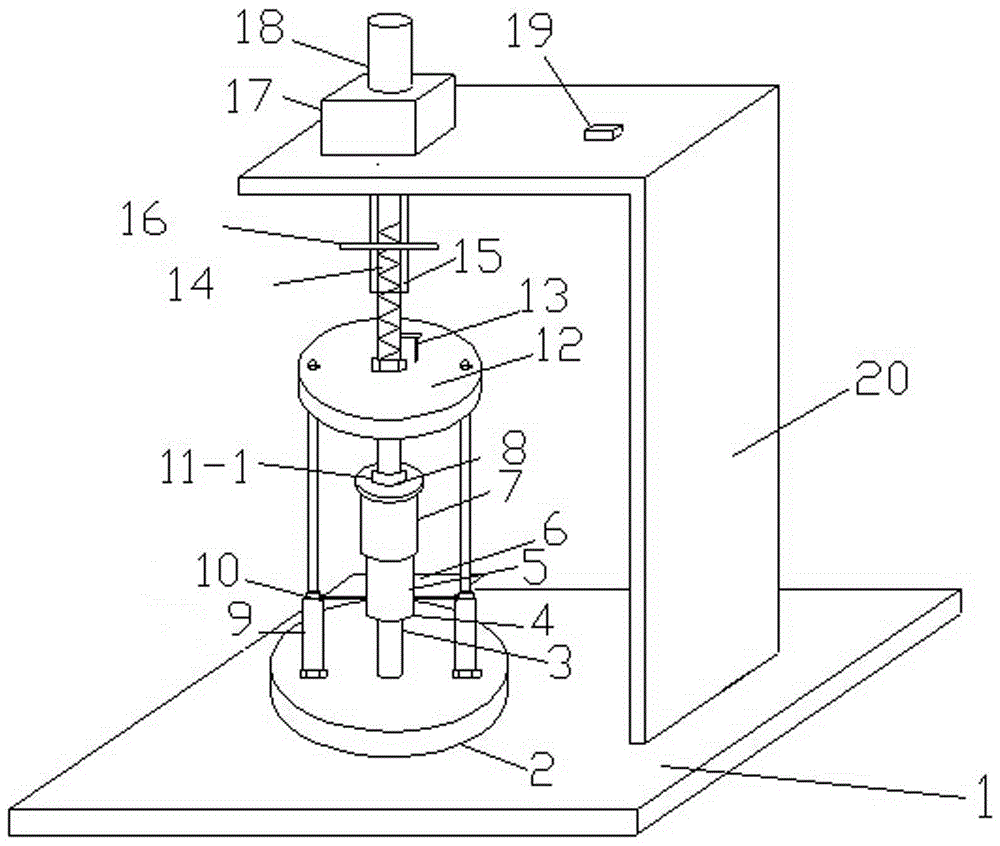

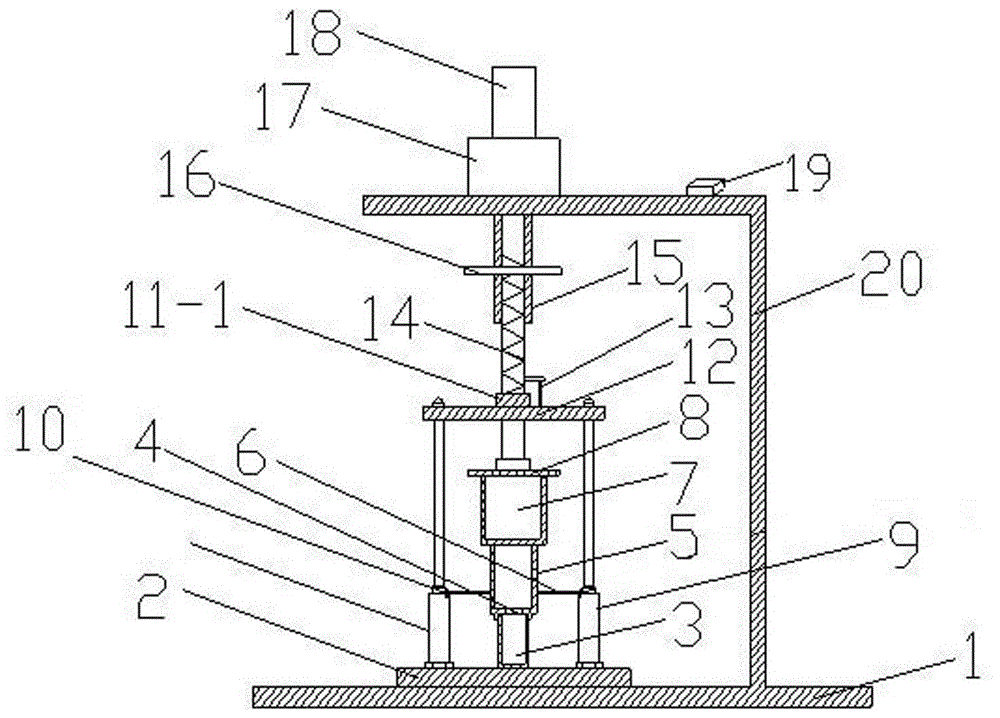

Test piece mold release device for civil engineering tests

InactiveCN105784449AImprove demoulding efficiencySimple structural designPreparing sample for investigationConstruction engineeringStructural engineering

A test piece mold release device for civil engineering tests comprises a base, a bottom plate and a support.The bottom plate is arranged on the base.A mold release device body is installed in the space between the bottom plate and the support and comprises a test piece cylinder positioning mechanism and a screw propelling mechanism.A test piece cylinder to be released from a mold is installed and positioned through the test piece cylinder positioning mechanism, deviation of a placing position of the test piece cylinder is eliminated, and the integrity of a test piece after mold releasing is ensured.The screw propelling mechanism rotationally propels a loading screw, and the test piece in the test piece cylinder is ejected out of the test piece cylinder.According to the test piece mold release device, electric operation and manual operation are integrated, physical strength consumption can be relieved, the mold releasing efficiency can be improved, and manual mold releasing can be adopted when outage occurs or a power source is not available; the ejecting travel of the loading screw is large, ascending and descending operation is consecutive, and the mold releasing efficiency is high; the whole device is simple in structure, convenient to operate, low in manufacturing cost and convenient to manufacture and maintain.

Owner:HENAN UNIV OF SCI & TECH

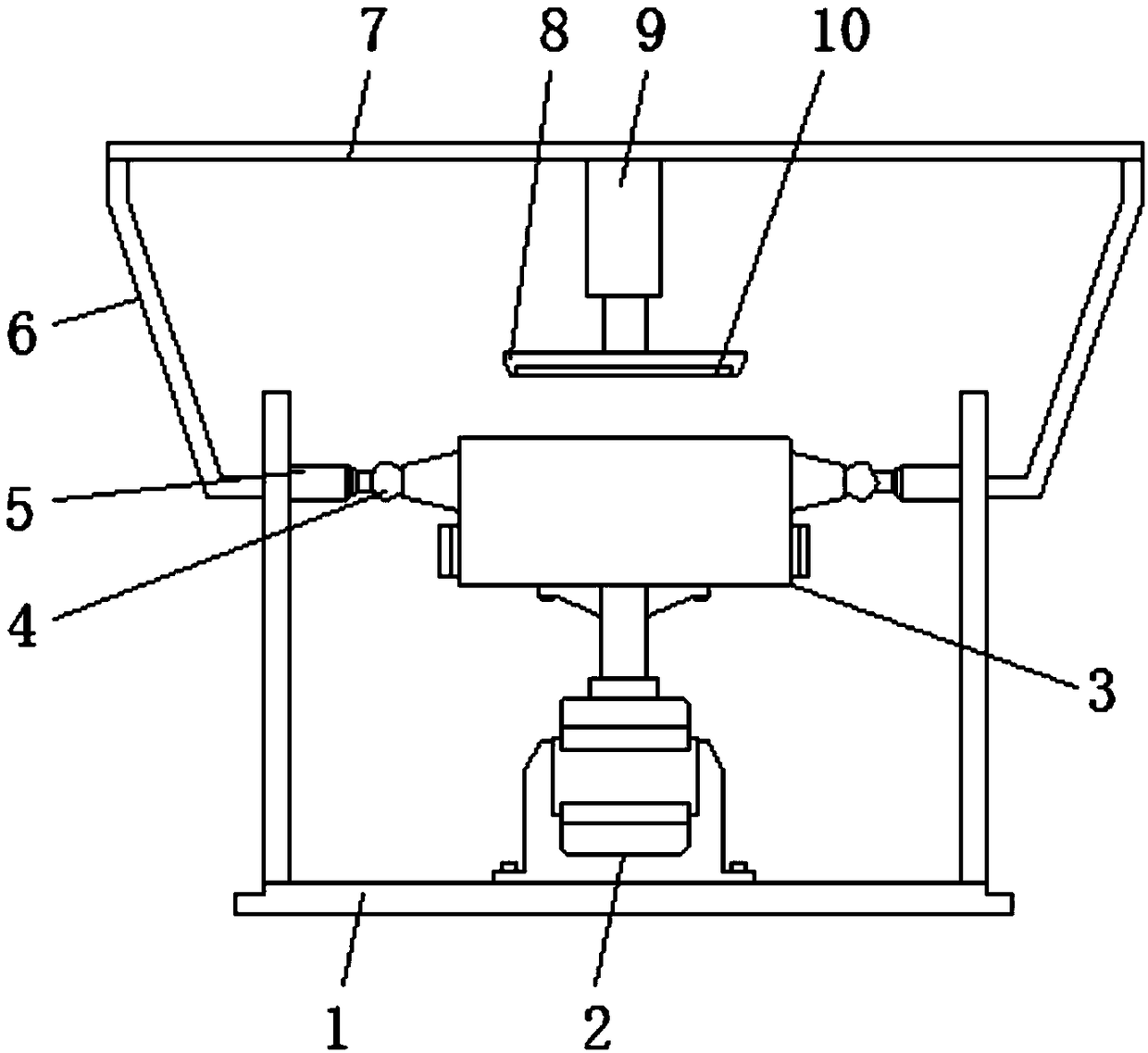

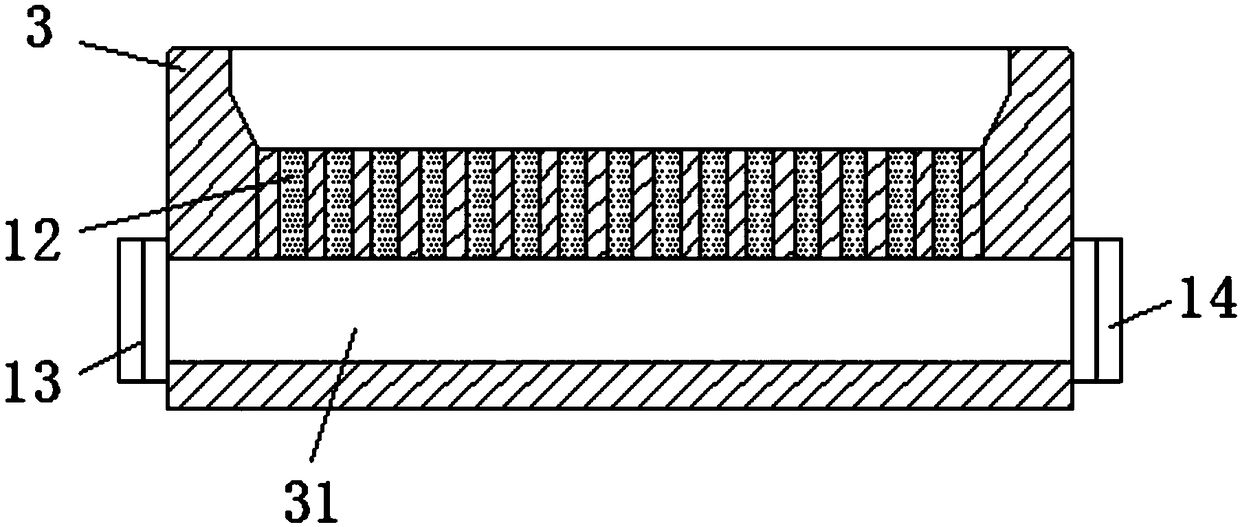

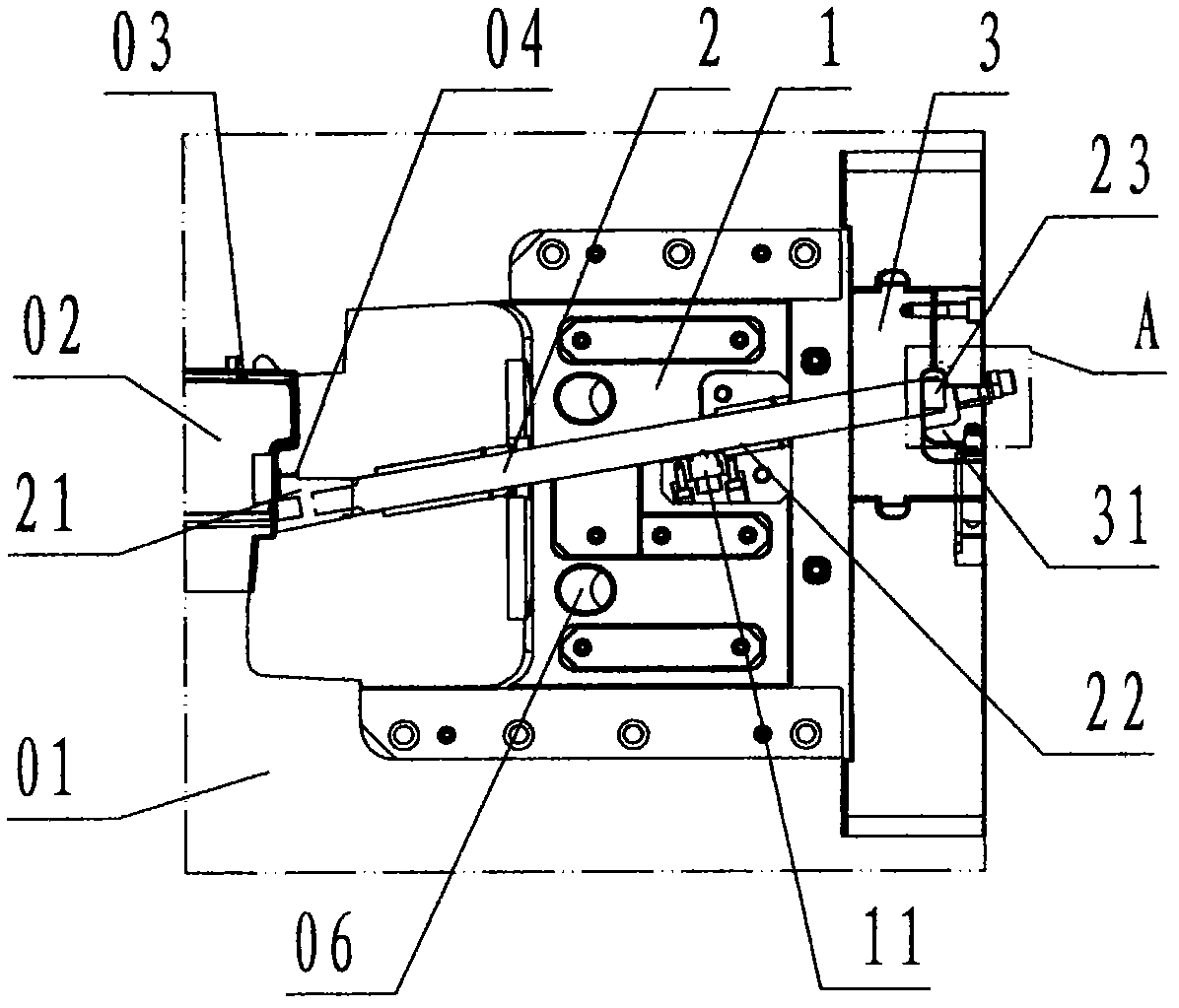

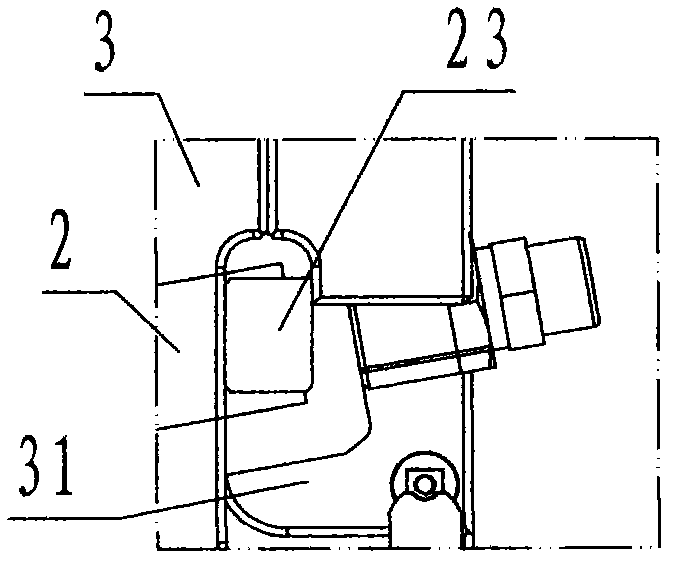

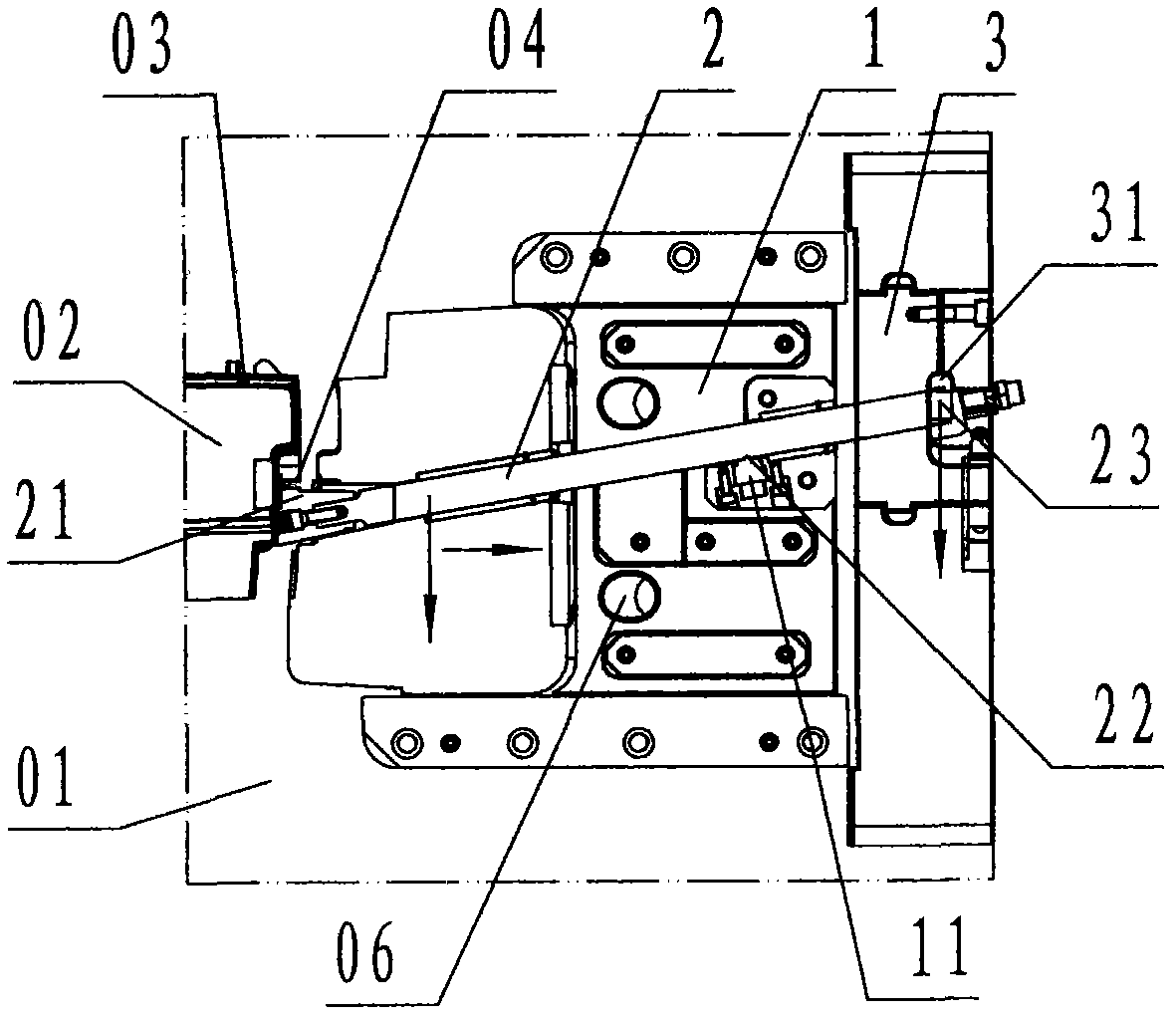

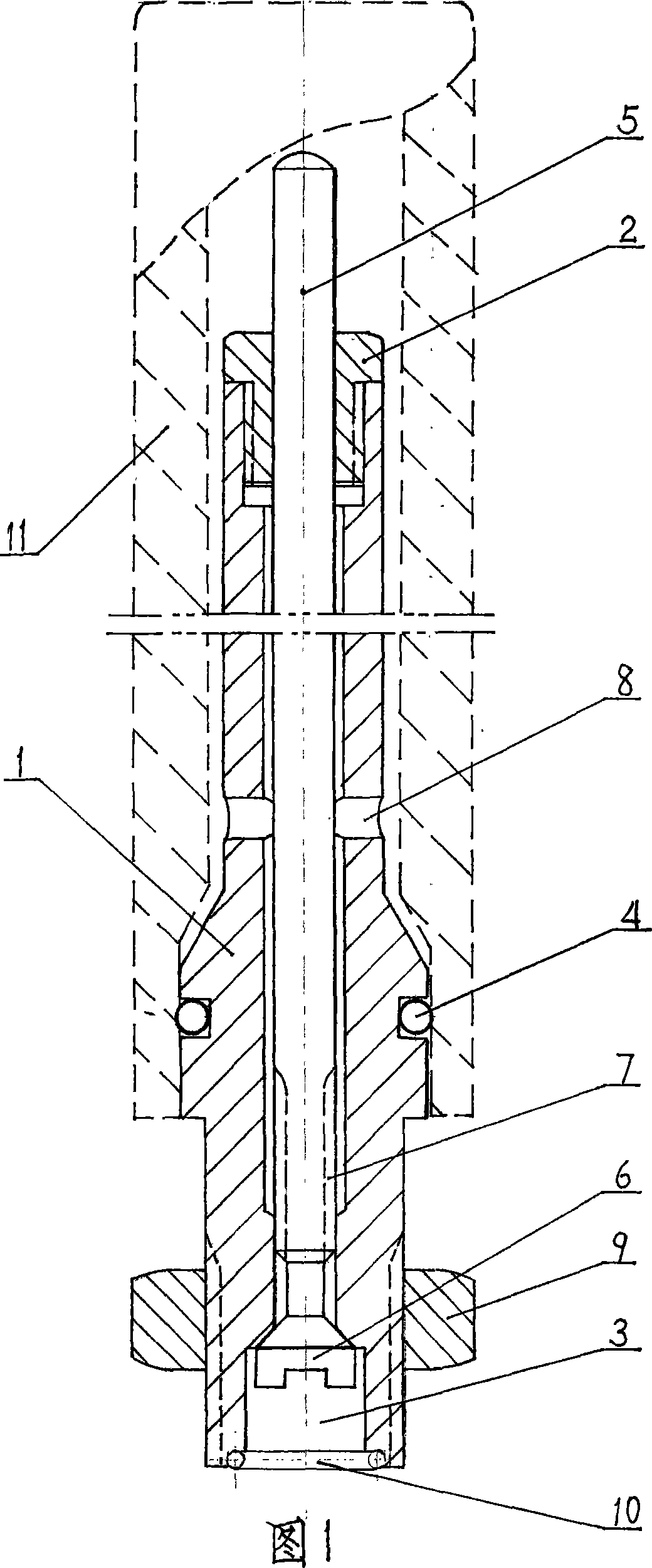

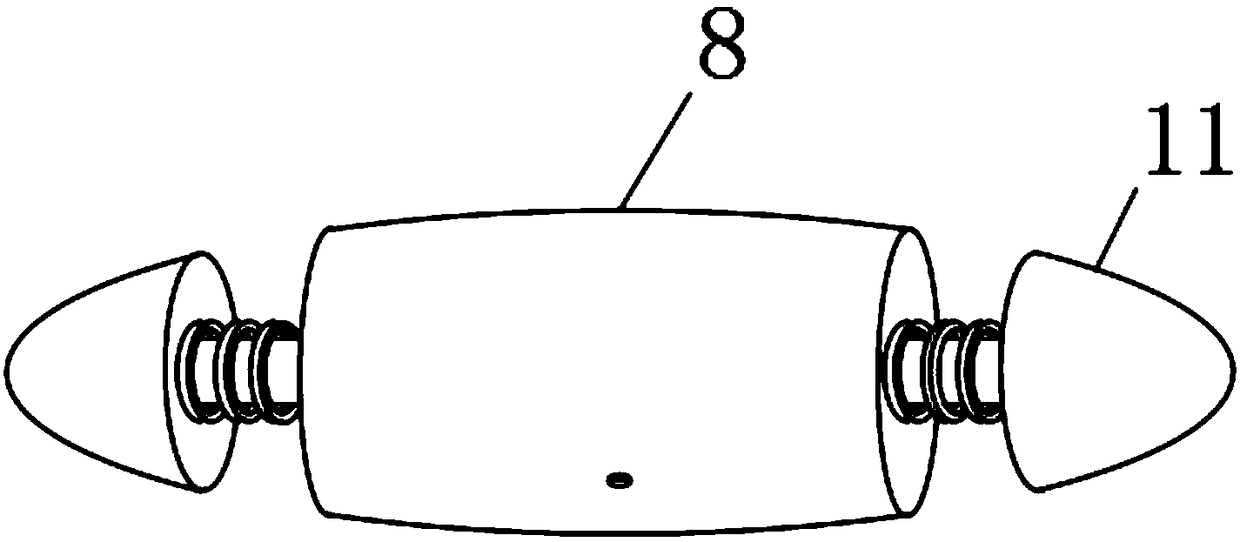

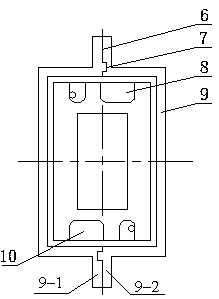

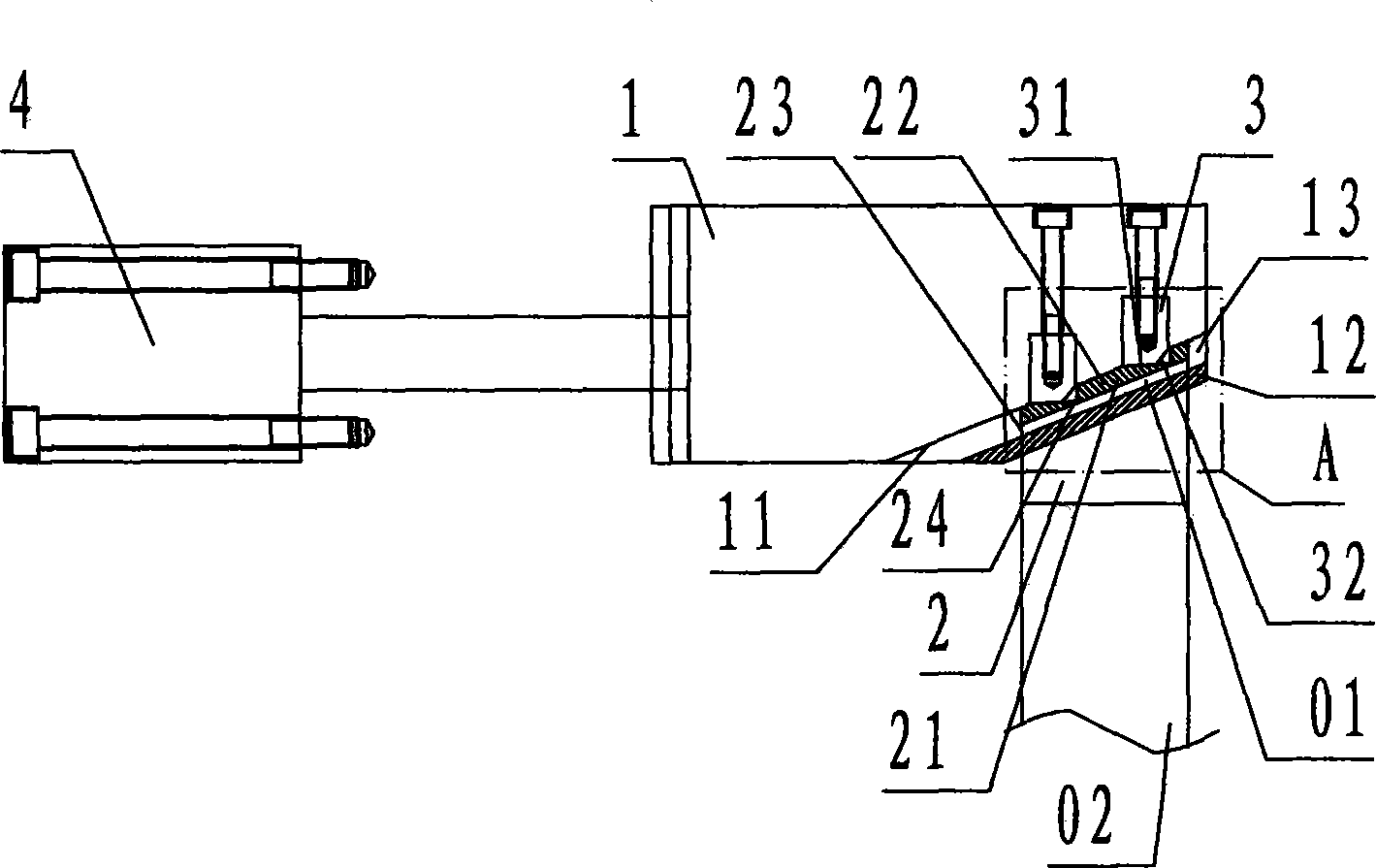

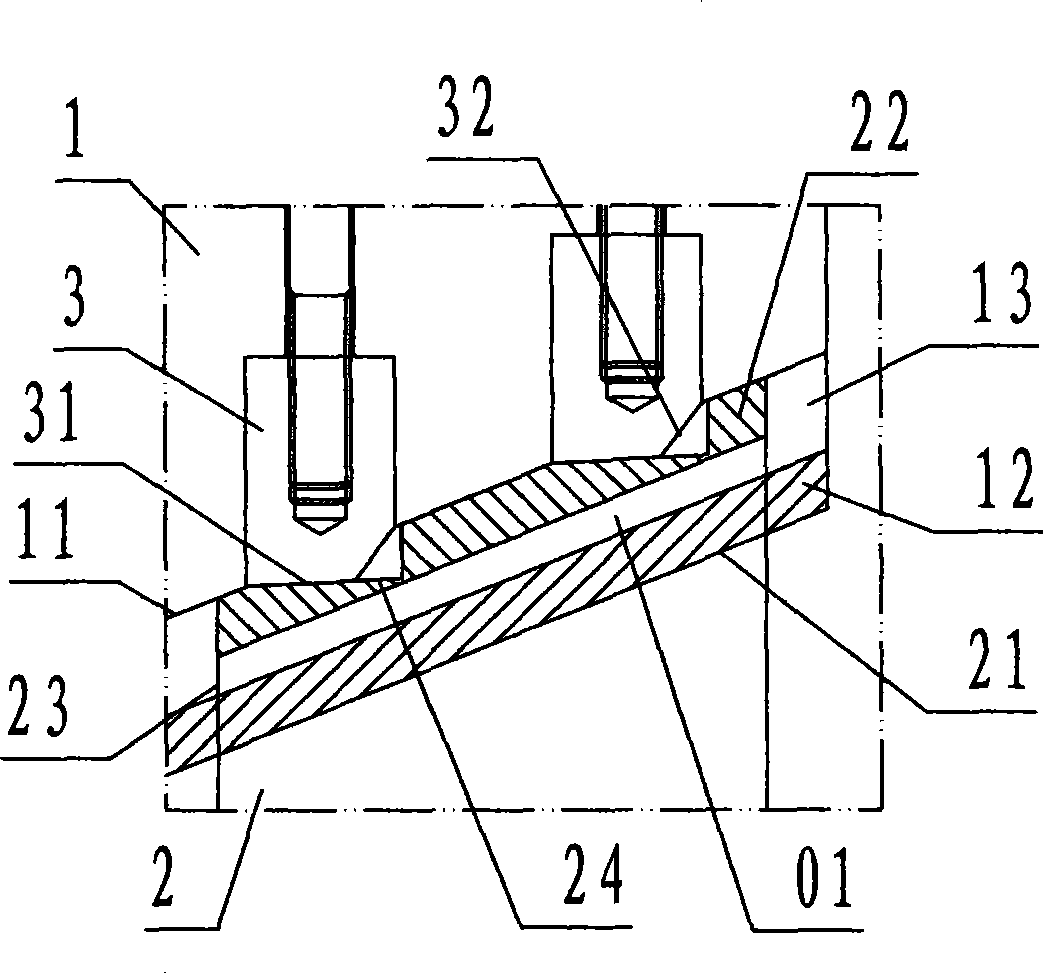

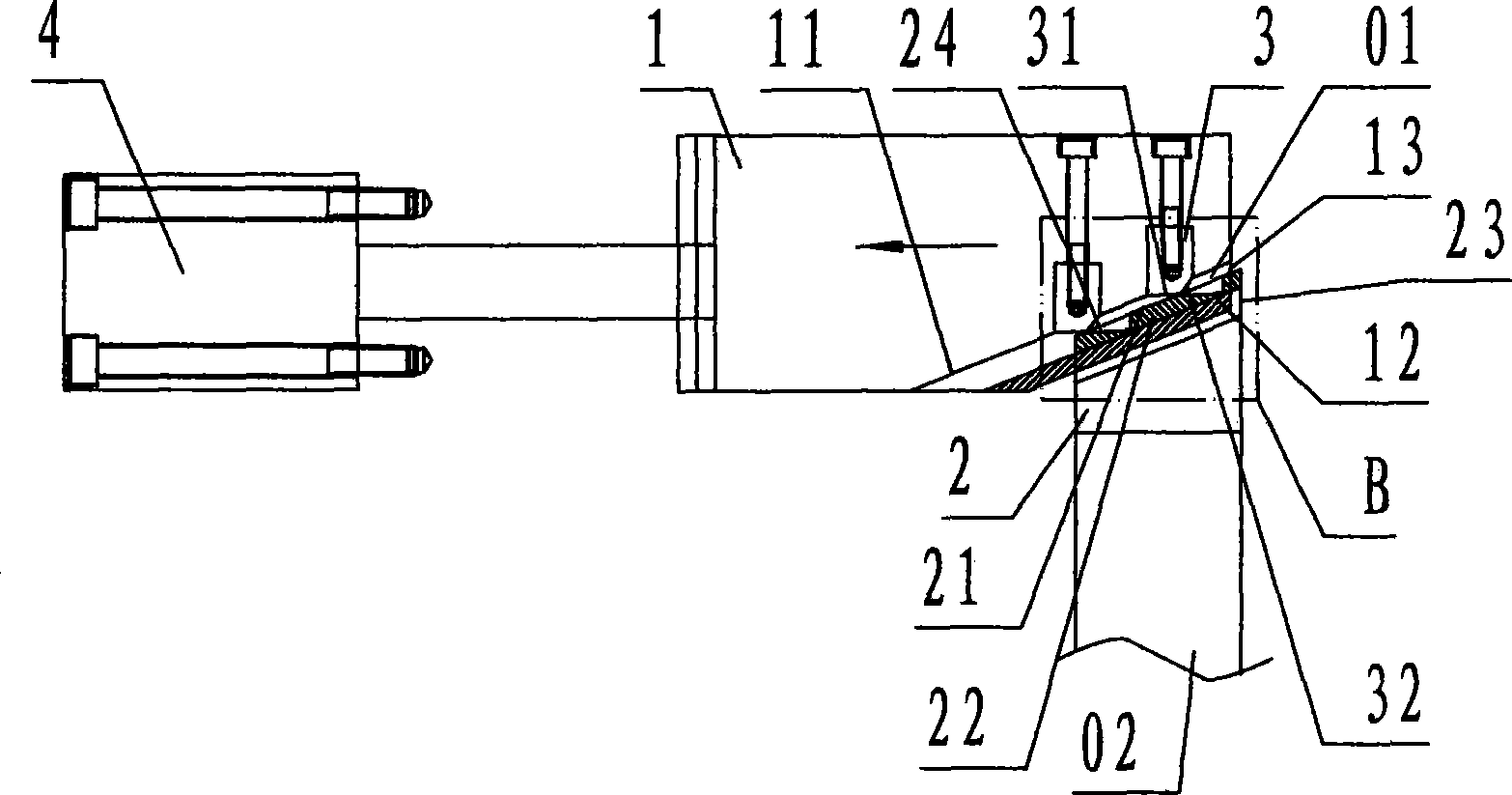

Lateral inclined-knockout core-loosening device arranged in lateral sliding block

ActiveCN102632592AOvercoming structural complexityOvercoming structural costsEngineeringCanis lupus familiaris

The invention discloses a lateral inclined-knockout core-loosening device arranged in a lateral sliding block. The technical scheme adopted by the invention is as follows: the device comprises a lateral sliding block (1), a ball pin (11), an inclined knockout rod (2), a back-off pellet (21), a pin hole (22), a stop dog (23), an inclined knockout base (3) and a restraining slot (31). The lateral inclined knockout core-loosening device arranged in the lateral sliding block is characterized in that the inclined knockout rod and the back-off pellet are arranged in the lateral sliding block; and during die sinking, the inclined knockout rod and the back-off pellet aslant slide to extend out of the lateral sliding block under the restriction of the stop dog while an inclined guide post drives the lateral sliding block to carry out lateral demoulding, so that the back-off pellet is laterally skew to loosen the core and demould in a back-off mode from a product along the direction orthogonal with the demoulding direction of the lateral sliding block, and therefore the problems and defects of complex structure, high cost, low efficiency and high possibility of generating wastes in the prior art are overcome. The inclined knockout mechanism is arranged in the lateral sliding block, so that the structure of the injection molding mould for laterally skewing to loosen the core and demould in a back-off mode for the product is simplified, the cost is lowered, the demoulding efficiency is improved, and wastes are avoided.

Owner:NINGBO FANGZHENG TOOL

Rapid demolding device for wear-resistant casting

InactiveCN111451487AAdjust the vertical distanceVertical distance is easy to adjustCleaning using liquidsPull forceElectric machinery

The invention discloses a rapid demolding device for a wear-resistant casting. The rapid demolding device comprises a demolding machine table, wherein a rectangular through hole is formed in the uppersurface of a table plate of the demolding machine table, a rotating shaft is rotationally connected to the inner wall of the rectangular through hole, a rotating wheel fixedly sleeves the surface ofthe rotating shaft, the end, extending to the front face of the demolding machine table, of the rotating shaft is fixedly connected with a chain wheel, and a driving motor is mounted on the left sideof a supporting leg of the demolding machine table. According to the rapid demolding device for the wear-resistant casting, the vertical distance between two threaded clamping nails is convenient to adjust by arranging height adjusting bolts, so that the rapid demolding device is suitable for sand mold wooden templates of different sizes, and a demolding motor is arranged to drive a driving lead screw to rotate, so that two lead screw nut blocks move oppositely or relatively for generating relative pulling force, and shells of the sand mold wooden templates are separated; and meanwhile, the rotating shaft is further arranged to drive a transmission wheel to rotate, so that the sand mold templates are convenient to convey and concentrate, and manpower is saved.

Owner:安徽省安工机械制造有限公司

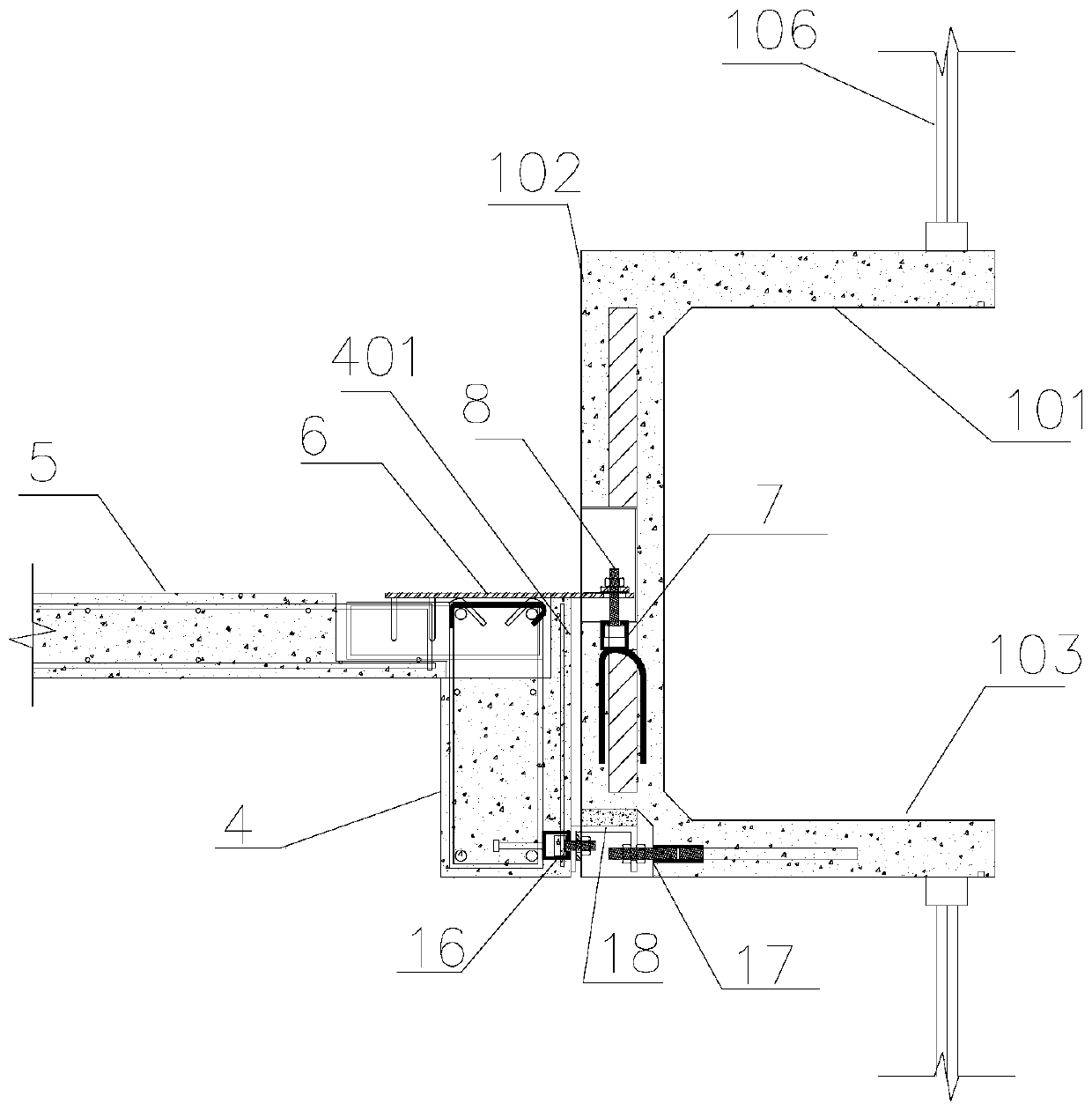

Connection structure for prefabricated integral bay window, and assembling method thereof

The invention provides a connection structure for a prefabricated integral bay window. The connection structure comprises a prefabricated integral bay window and a superposed beam and is characterizedin that the prefabricated integral bay window is integrally poured into a C-similar shape and comprises a top plate, a side wall and a bottom plate; the superposed beam comprises a prefabricated partand a cast-in-place part; the bottom surface of the bottom plate and the bottom surface of the prefabricated part are positioned on the same horizontal plane; the indoor side of the side wall is fixedly connected with the cast-in-place part through an upper connecting component; and the bottom plate is fixedly connected with the prefabricated part through a lower connecting component. When the connection structure for the prefabricated integral bay window in the scheme is produced and manufactured, no reinforcing steel bars extend out of the edge part of the prefabricated integral bay window,a production module is simple, demoulding efficiency is high, and a mould turnover frequency is improved. In a transportation stage, a loading rate can be improved; wet operations in an assembling field are few, form erection is avoided, field construction efficiency is improved, and construction cost is lowered; an error-tolerant rate of field assembling is high, the position of the prefabricated integral bay window can be regulated in field through ways, including gaskets, bolts, mortar, bed mortar and the like, and the connection structure disclosed by the invention is convenient for fieldinstallation and regulation.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

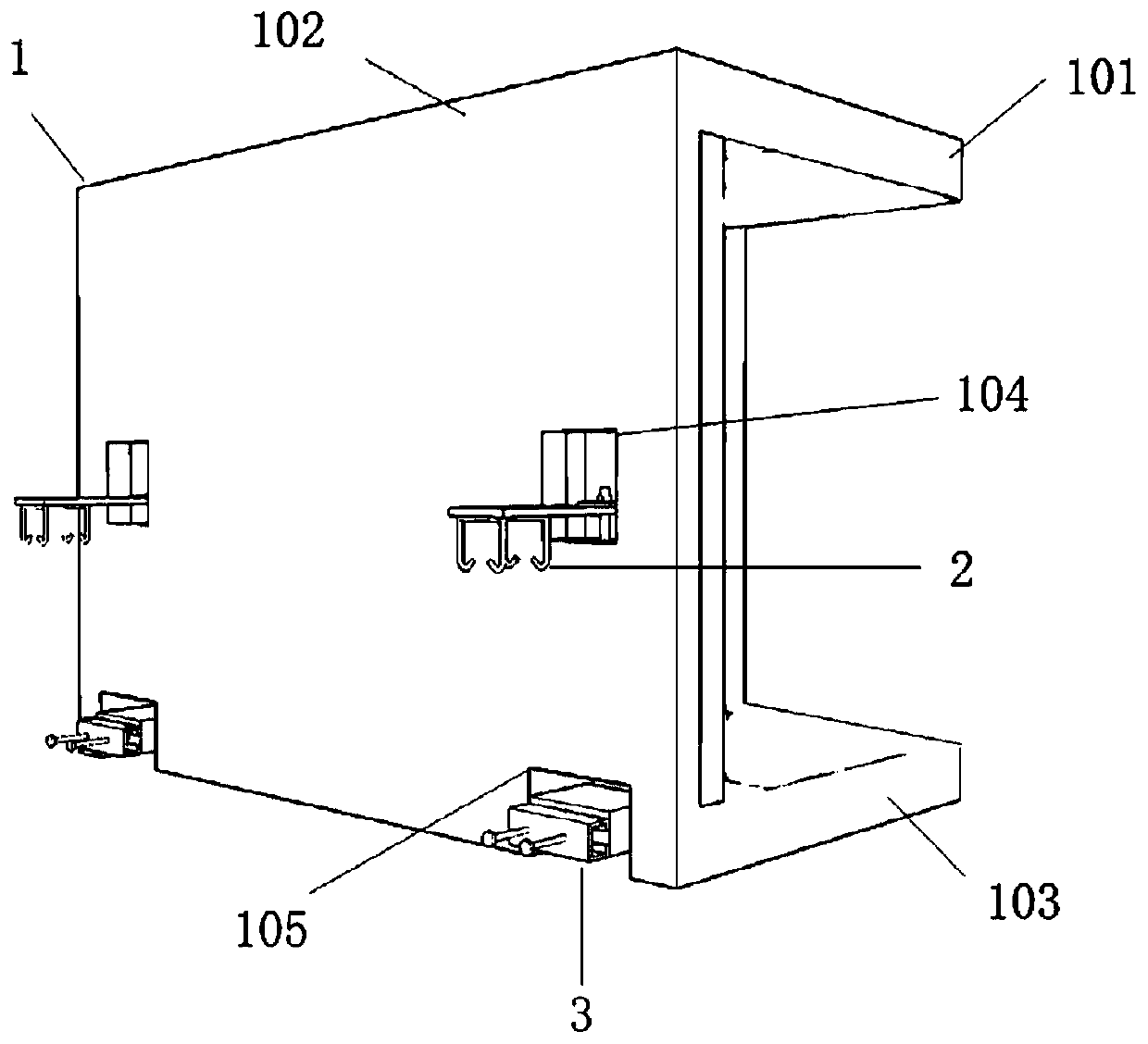

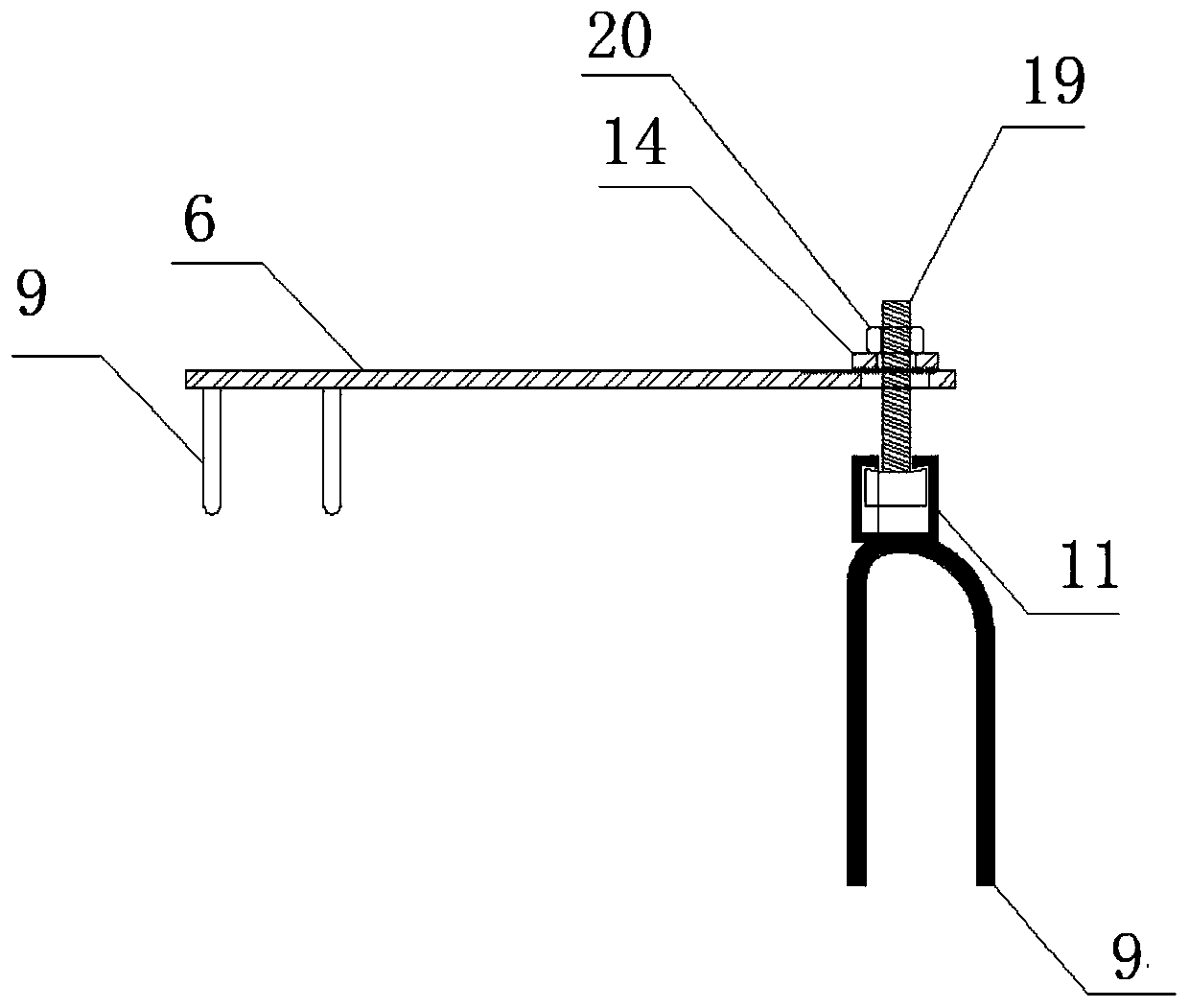

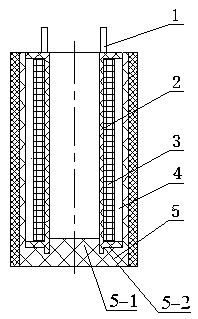

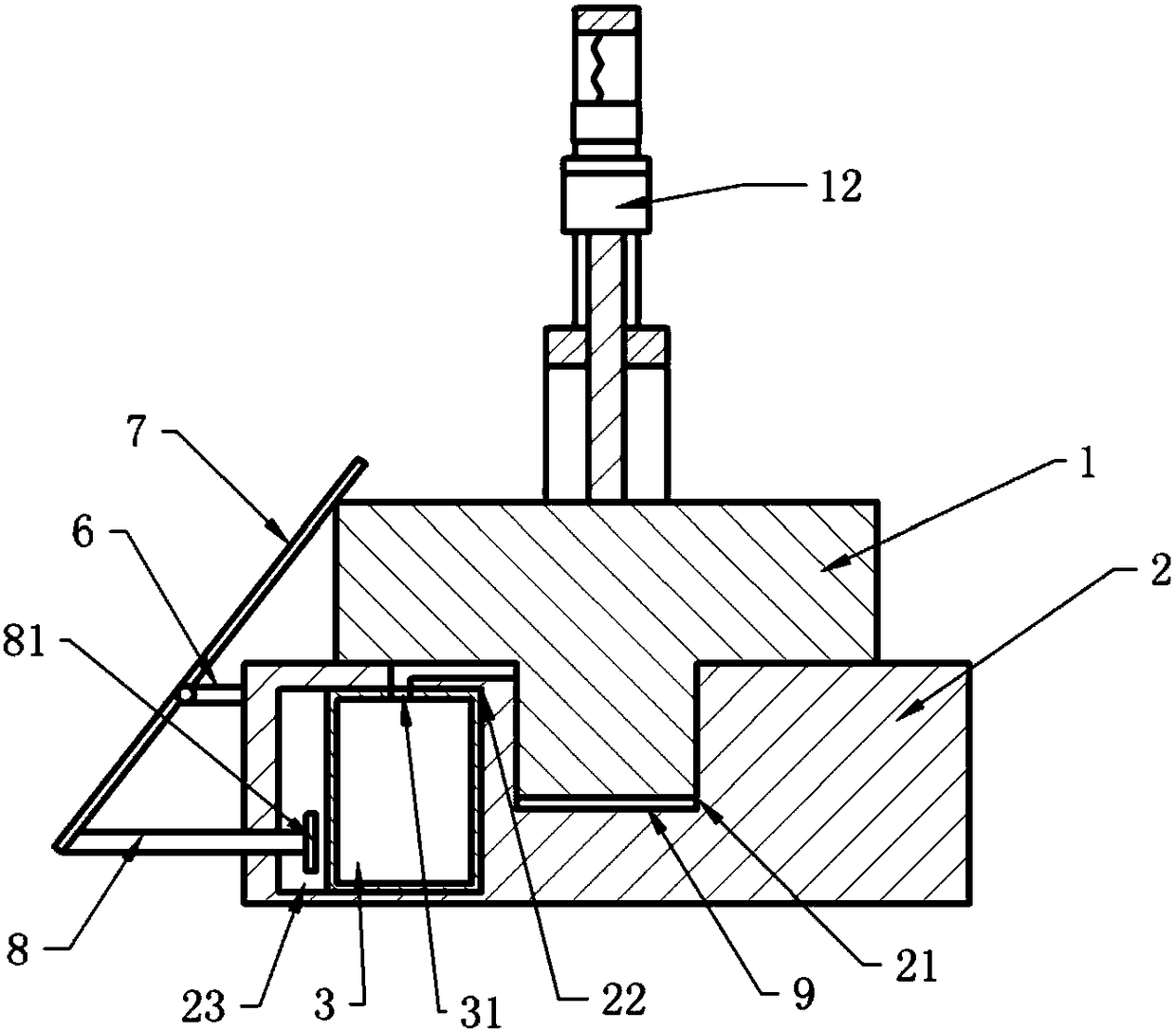

Sleeper embedded bushing positioning device, and positioning and demouding method

ActiveCN101085537APrecise positioningAvoid damageDischarging arrangementEngineeringHigh pressure water

The track collar sleeve tube positioning and mold fall off method comprises the tube with tubular cavity with one end installed of fixed core nut, the other connected to the interface, valve core inside the tubular cavity with one end going through by the fixed core nut, the other connected to the valve with tapering side, holes on the tube connecting the tube cavity with the outside, seal ring and fixed nut at the outside wall of the tube. It grinds the mold, installs steel rib and sleeve tube, connecting the its positioning device with the vacuum pump on the vibrating table, turning on the vacuum pump, pouring concrete, using high pressure water stripping the mold. It not only ensures the precise positioning of the sleeve tube, but also ejects the hydraulic pressure with improved stripping efficiency, reduced damage of inertia stripping to track concrete.

Owner:CHINA RAILWAY FIRST GRP CO LTD

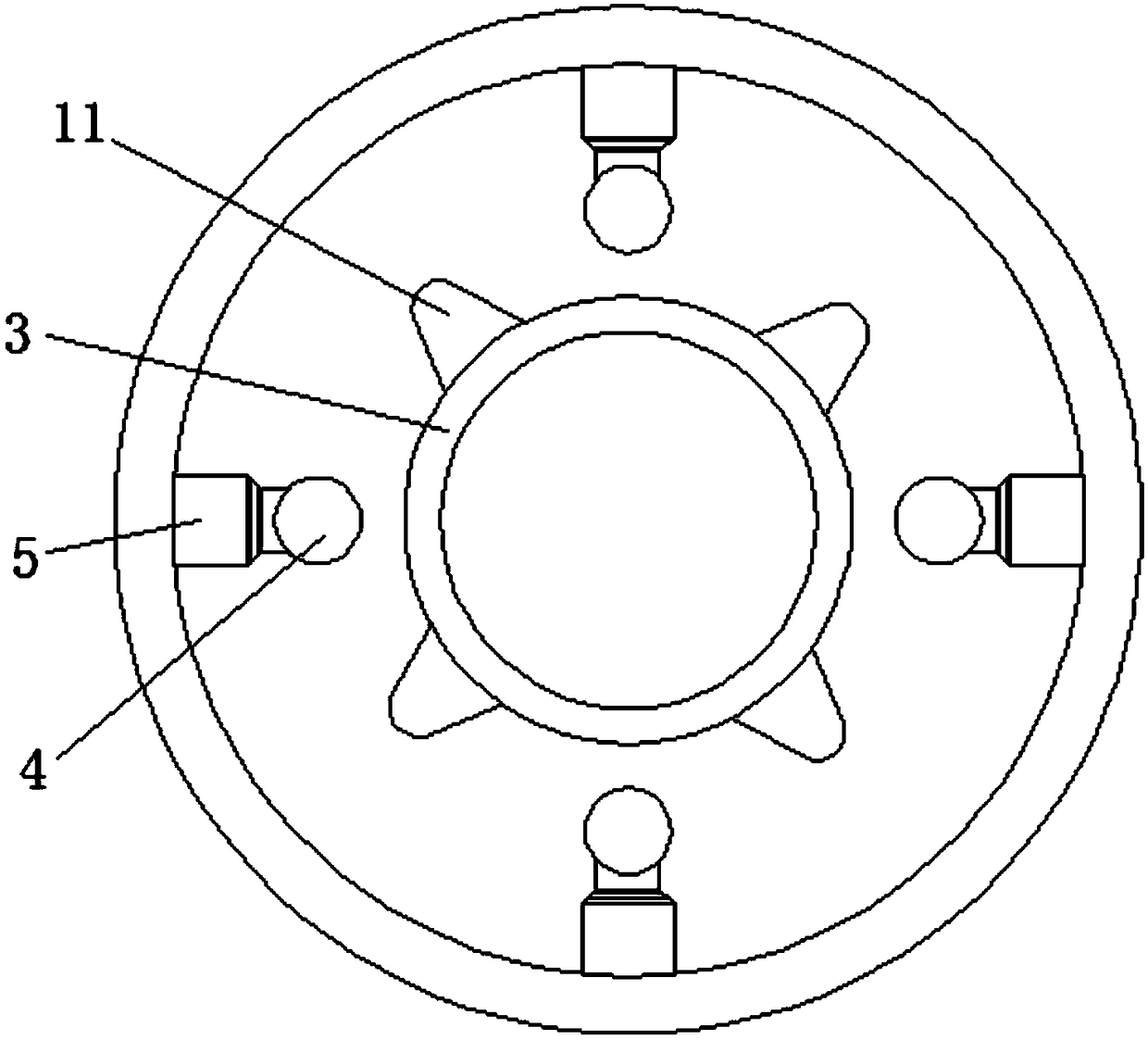

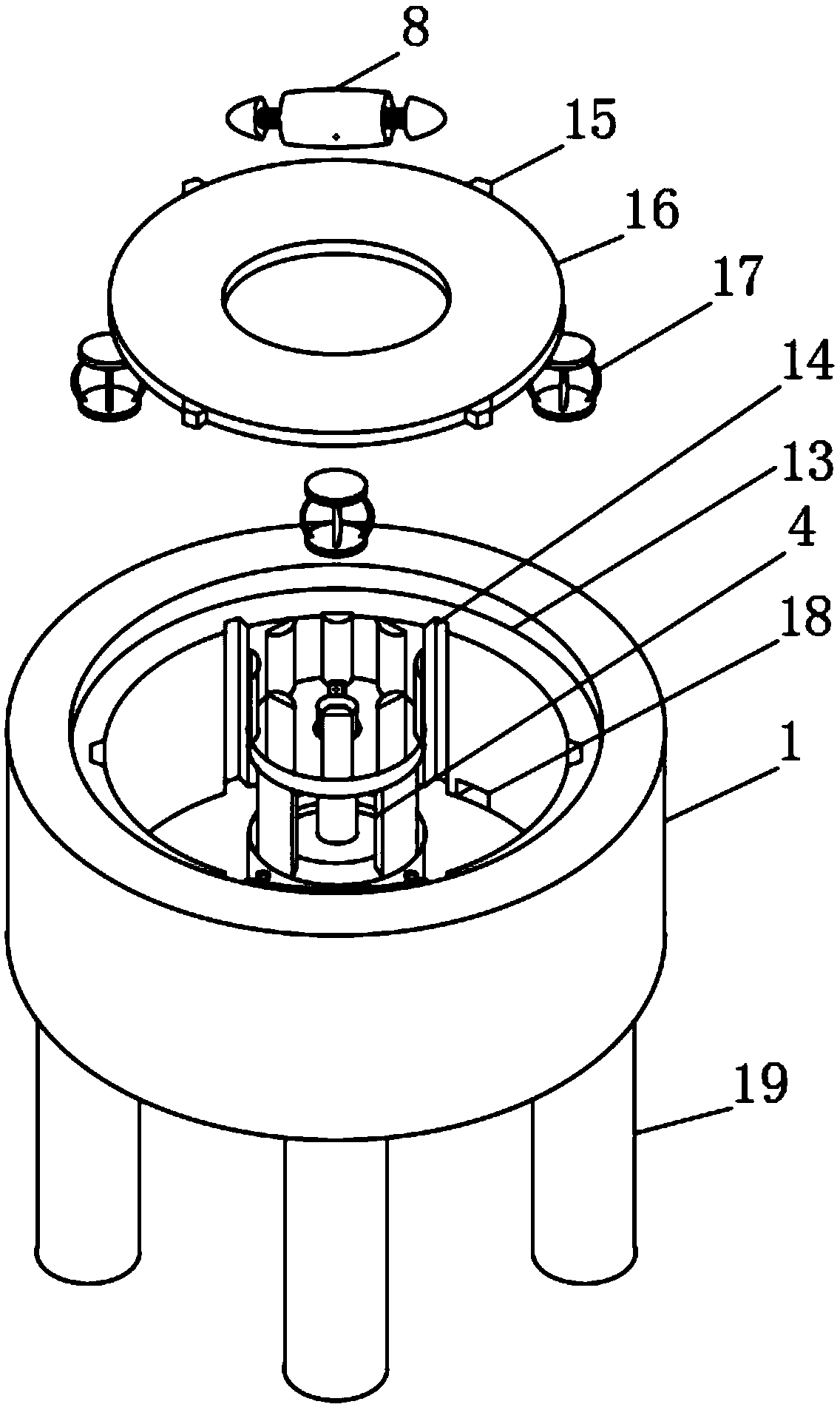

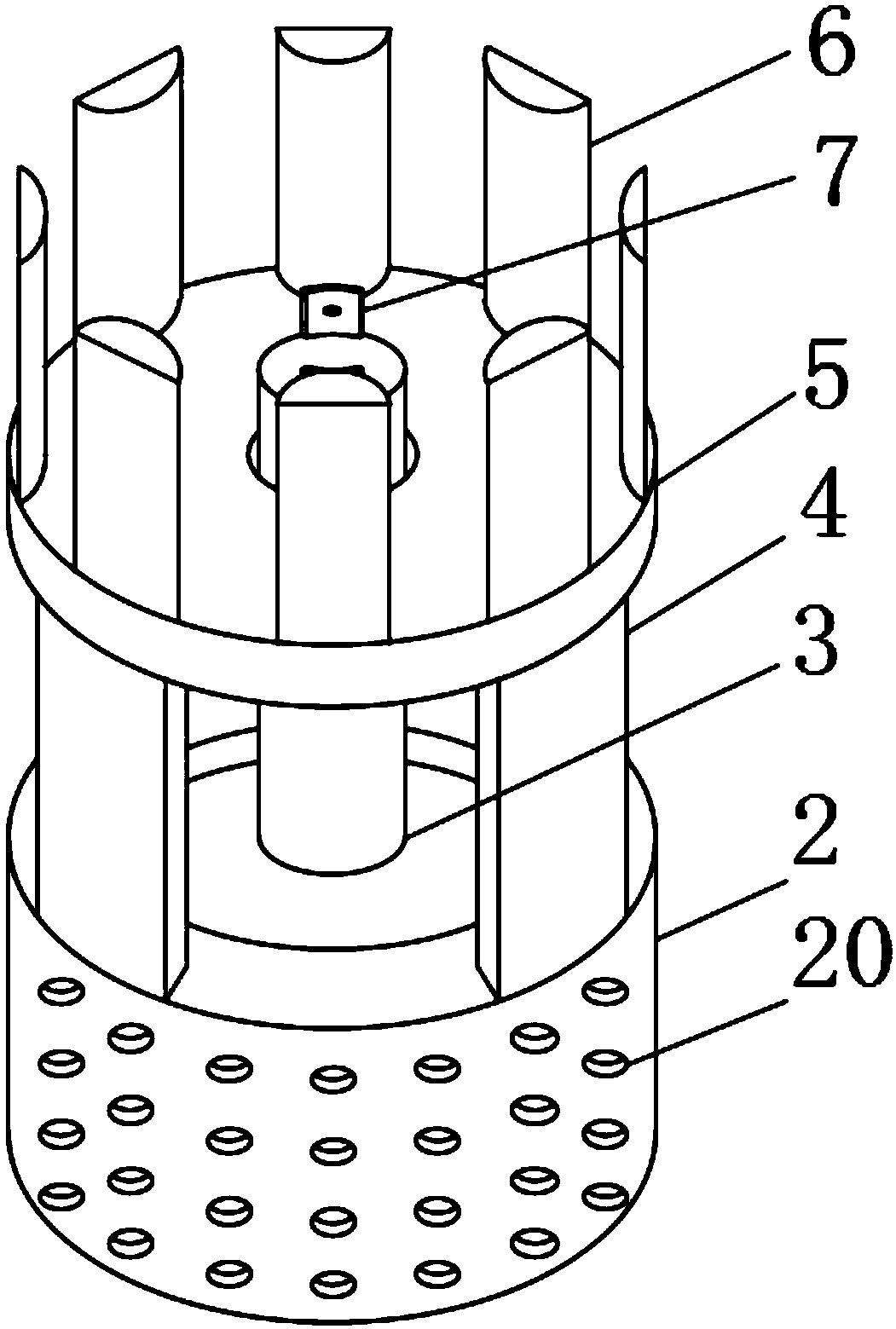

Annular column structure concrete prefabricated part demolding device

ActiveCN109382903AImprove demoulding efficiencyAvoid breakingDischarging arrangementDrive shaftEngineering

The invention discloses an annular column structure concrete prefabricated part demolding device. The device comprises a demolding device body, a motor frame is fixedly connected to the bottom face ofthe inner side of the demoulding device body, and a motor is fixedly connected to the interior of the motor frame; the top face of the motor frame is fixedly connected with an enclosure board, and the top end of the enclosure board is fixedly connected to the bottom face of a partition board; a limiting plate is fixedly connected to the plate surface of the partition plate, and a driving shaft ofthe motor penetrates through the partition plate; two buckling plates are fixedly connected to the end face of the driving shaft of the motor, and a rotating piece is connected between the two buckling plates in a buckling mode; the two end faces of the rotating piece are both provided with a telescopic inserting groove. According to the demoulding device, the rotating piece is driven by the motor to rotate, in the rotating process of the rotating piece, a rubber striking head is separated from the surface of the limiting plate, and then the outer wall of a mold is struck, so that a concreteprefabricated part of the annular column structure in the mold is vibrated down, and the demoulding efficiency of the concrete prefabricated part is improved.

Owner:日照新东港农业开发有限公司

Automatic demolding device for prefabricated part

ActiveCN111195982APromote repairImprove demoulding efficiencyDischarging arrangementStructural engineeringMechanical engineering

Owner:DONGTAI XINFUDA MACHINERY

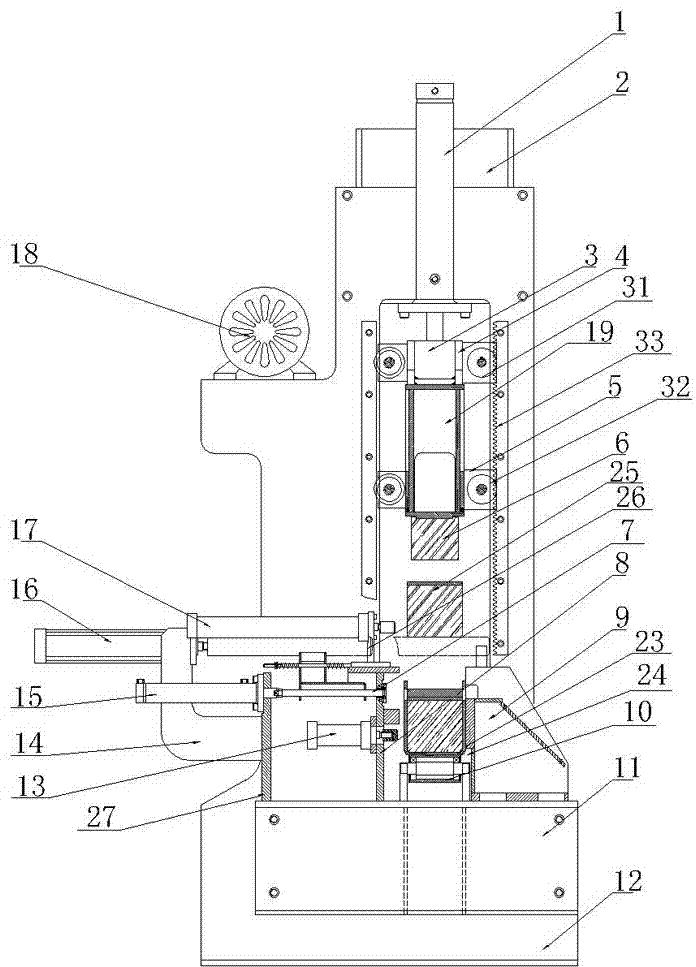

Epoxy resin pouring tooling and pouring process for skeleton coil

InactiveCN110739149ASimple structureReduce labor intensityCoils manufactureFirming agentMechanical engineering

The invention discloses an epoxy resin pouring tooling for a skeleton coil. The epoxy resin pouring tooling is characterized by comprising a rubber sleeve arranged outside the skeleton wound with thecoil, and a space to be filled with epoxy resin is arranged between the coil and the rubber sleeve. The bottom boss of the rubber sleeve is matched with the inner surface of the skeleton. The two endsof the setting and fixing shell a and the setting and fixing shell b of a setting and fixing device are provided with fixing stops, and the fixing strips of the outer side of the stops are clamped and fixed by dovetail clamps. The pouring process comprises the following steps: preheating and mixing the epoxy resin and the curing agent, vacuum inhaling the epoxy resin and the curing agent with anautomatic potting machine and vacuum defoaming; and pouring is performed from the pouring ports a and b on the skeleton; and placing on a curing platform for curing and demoulding after completion ofpoursing. The advantages are that demoulding saves time and labor, greatly improves demoulding efficiency and effectively avoids mold sticking during demoulding; the tooling can be reused so as to reduce the use cost; and the pouring process is simple, easy to operate, good in pouring effect and high in efficiency.

Owner:JIANGSU JINGJIANG INSTR TRANSFORMER FACTORY

Polyester slices for manufacturing vacuum blood collection tube and preparation method of polyester slices

InactiveCN104017338AImprove mobilityImprove demoulding efficiencyBulk chemical productionPolyesterChemistry

The invention relates to polyester slices for manufacturing a vacuum blood collection tube. The polyester slices are characterized by containing stearate and polyethylene wax, wherein stearate is selected from sodium stearate, potassium stearate, ammonium stearate or zinc stearate; the weight percent of stearate in the polyester slices is 0.1%-5%; the weight percent of the polyethylene wax in the polyester slices is 0.1%-1%, and the number-average molecular weight of the polyethylene wax is 500-10,000. The invention further relates to a preparation method of the polyester slices for manufacturing the vacuum blood collection tube. The polyester slices have the advantages of high flowability, high stability and quickness in demoulding.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD +1

Die for car interior part

ActiveCN108188274ARealize automatic demouldingImprove demoulding efficiencyShaping toolsEngineeringMechanical engineering

The invention belongs to the technical field of die for car parts processing, and discloses a die for a car interior part. The die for the car interior part comprises an upper male die and a lower female die; the lower female die is provided with a support formed by a cross plate and two vertical plates; the upper male die is provided with an electromagnet and a sliding rod penetrating through thecross plate; the cross plate is provided with a drive piece; the top portion of a sliding rod is provided with a support block; the lower portion of the side wall of the support block is provided with a conducting strip; an electric lead is arranged between the conducting strip and the electromagnet; the cross plate is provided with a support frame; a communicating block is arranged between the support frame and the cross plate; an elastic piece is arranged between the top potion of the communicating block and the bottom of the support frame; the communicating block is provided with a power source; the power source is provided with a conductive needle; one end, away from the power source, of the conductive needle is connected with the side wall provided with the conducting strip of the support frame in a sliding mode; the lower female die is internally provided with a cavity; and the cavity is internally connected with an iron block in a sliding mode. The die for the car interior partsolves the problem that the interior parts are tightly attached with the lower die after impact molding to the interior parts in the prior art, leading to the difficulty of removing the car interiorparts.

Owner:CHONGQING YINSHENG MOLD

Shell preparation method for investment casting

ActiveCN108746496AEffective identification of stress concentration locationsEffectively identify the easy-to-deform position of the investment patternFoundry mouldsFoundry coresInvestment castingMold filling

The invention relates to a shell preparation method for investment casting. The shell preparation method comprises the steps of stiffener determining, reinforced investment pattern module preparation,shell preparation, stiffener removal, investment pattern removal and shell roasting. According to a casting piece structure, the investment pattern stress situation and mold filling solidification process computer simulation, the position of a stiffener is determined, and the investment pattern and the shell are prevented from deformation advantageously and are supported. By removing the stiffener, a hole channel and a demolding opening are formed in the investment pattern, the shell can be separated from the investment pattern without being turned over, and the surface quality of an inner cavity of the shell is improved.

Owner:BAIMTEC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com