Rapid demolding device for wear-resistant casting

A demolding device and demolding technology, applied in the field of wear-resistant castings, can solve the problems of inconvenient reuse, low efficiency, damage to the outer plate, etc., and achieve the effects of avoiding manual cleaning, facilitating the concentration of conveying, and improving the demoulding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

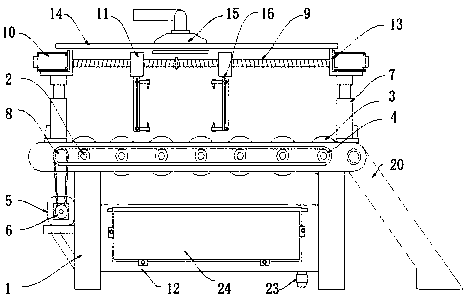

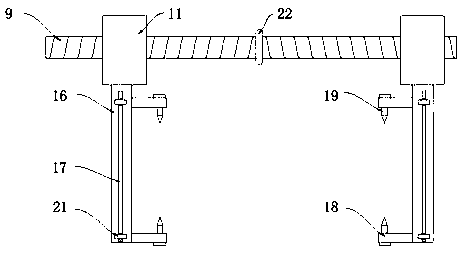

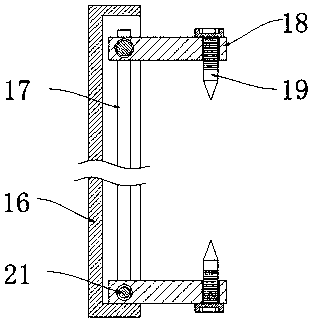

[0024] refer to Figure 1-4 , a fast demoulding device for wear-resistant castings, comprising a demoulding machine 1, a rectangular through hole is opened on the upper surface of the platen of the demoulding machine 1, the inner wall of the rectangular through hole is rotatably connected with a rotating shaft 2, and the surface of the rotating shaft 2 is fixed The rotating wheel 3 is sleeved, and the number of rotating shafts 2 is multiple, and the gap between the plurality of rotating wheels 3 fixedly sleeved on the surface of the rotating shaft 2 is 2-10 cm, and the rotating shaft 2 extends to the front of the demoulding machine 1. One end is fixedly connected with a sprocket 4, the left side of the support leg of the demoulding machine 1 is installed with a driving motor 5, the output shaft of the driving motor 5 is connected with a transmission wheel 6, and the front of the demoulding machine 1 is rotatably connected with an engaging wheel 8 , the connecting wheel 8 is co...

Embodiment 2

[0028] refer to figure 1 The difference from Example 1 is that the lower surface of the demoulding machine 1 is provided with a collection frame 12 for collecting foundry sand, the right end of the demoulding machine 1 is provided with a rotating connecting plate 20, and the lower surface of the cross bar 14 is installed with a High-pressure nozzle 15, the water inlet pipe of high-pressure nozzle 15 is connected with the output end of water pump, the lower surface of collection frame 12 is provided with drainage pipe 23, and the front of collection frame 12 is provided with rotary sealing door 24.

[0029] In this embodiment, by setting up the high-pressure nozzle 15, after the sand mold template is separated, the high-pressure water delivered by the high-pressure nozzle 15 is used to wash the foundry sand with high intensity, and the washed sand flows into the collection frame 12, so that the casting The foundry sand on the surface is cleaned, which avoids manual cleaning and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com