Device and method for measuring spool displacement based on laser displacement sensor

A technology of laser displacement and valve core displacement, applied in measurement devices, optical devices, instruments, etc., can solve the problems of valve core resistance, high cost, valve performance impact, etc., to improve measurement accuracy, simple structure, and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

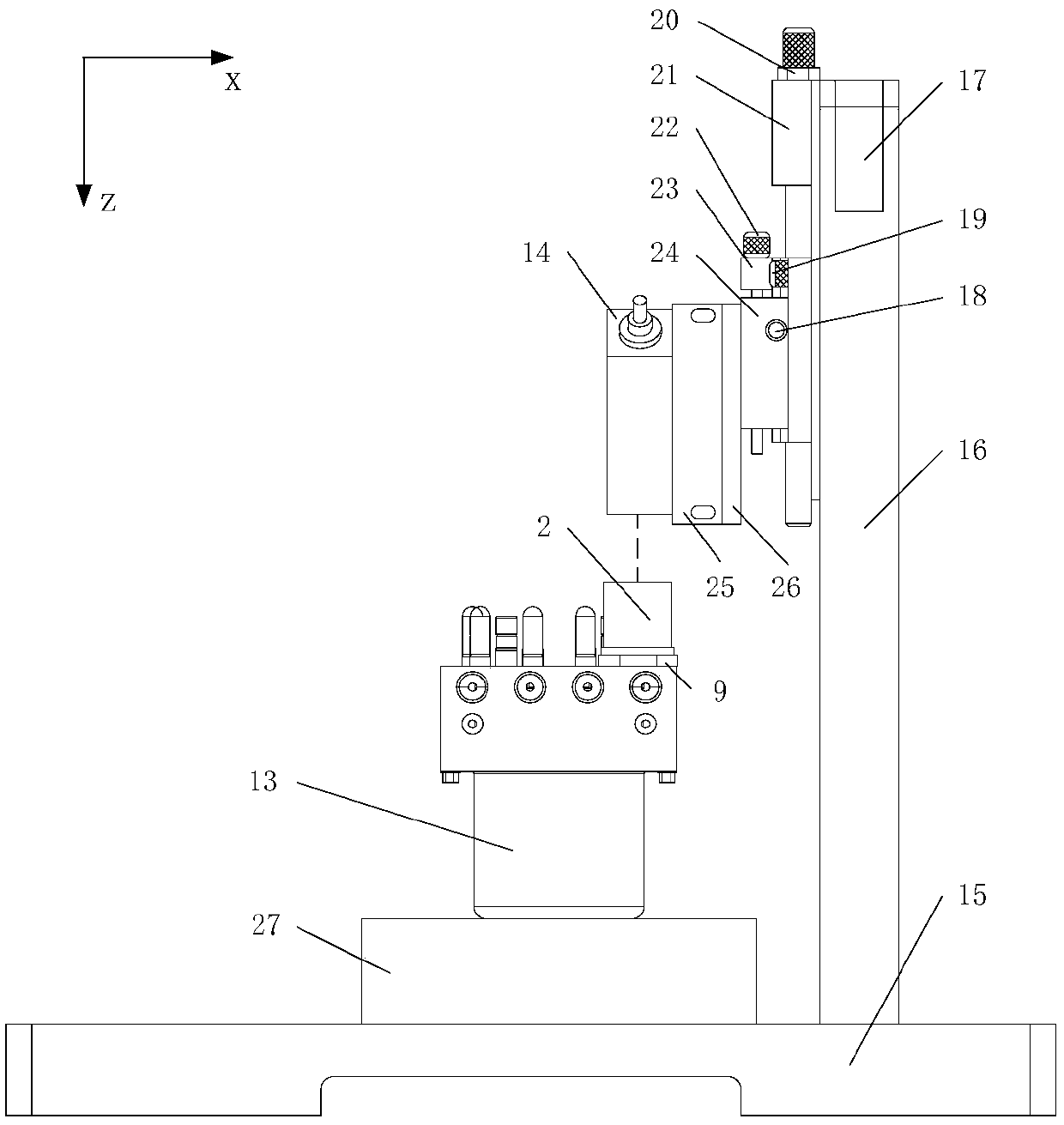

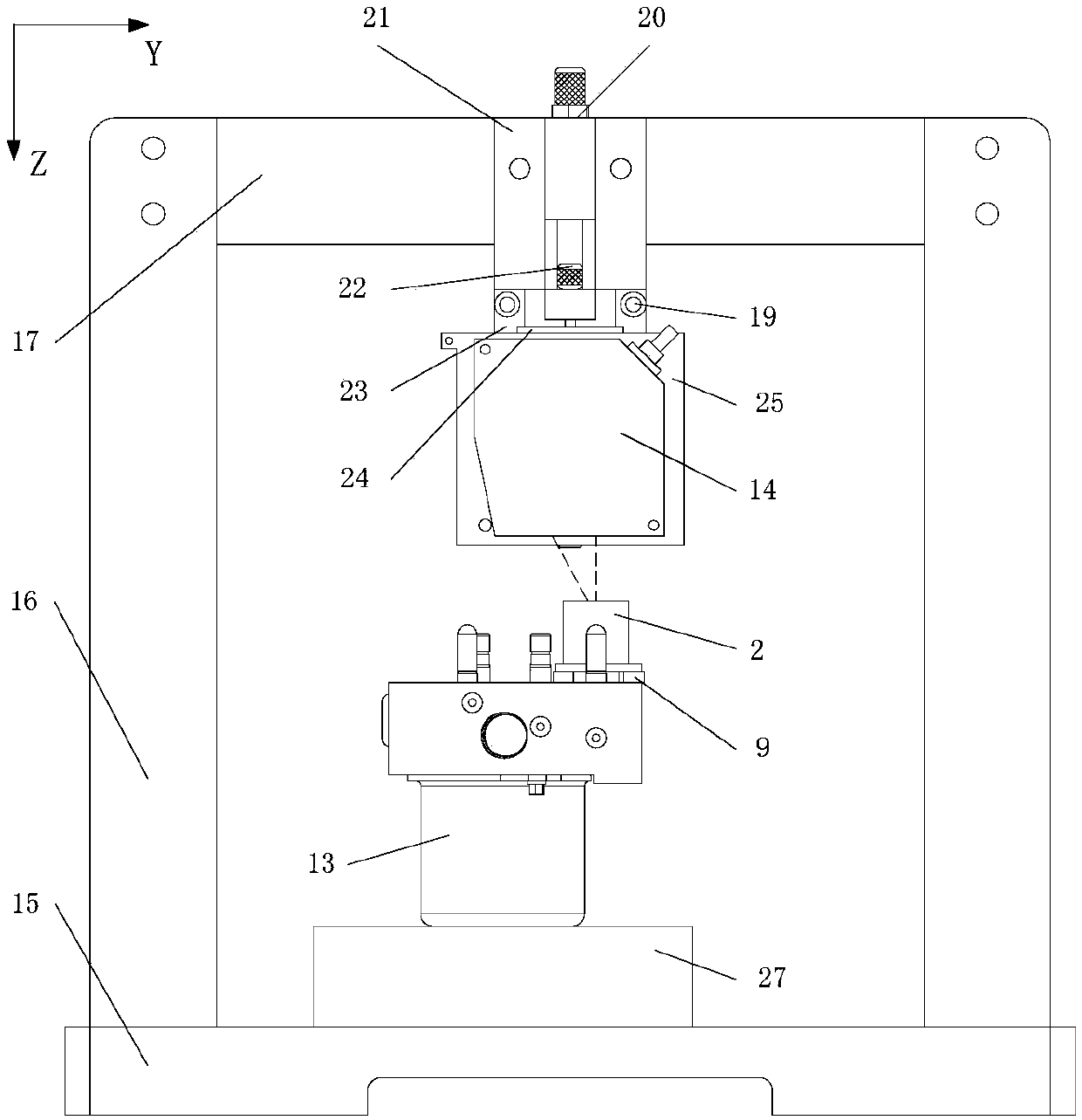

[0036] Attached below Figure 1-13 The present invention is described in detail.

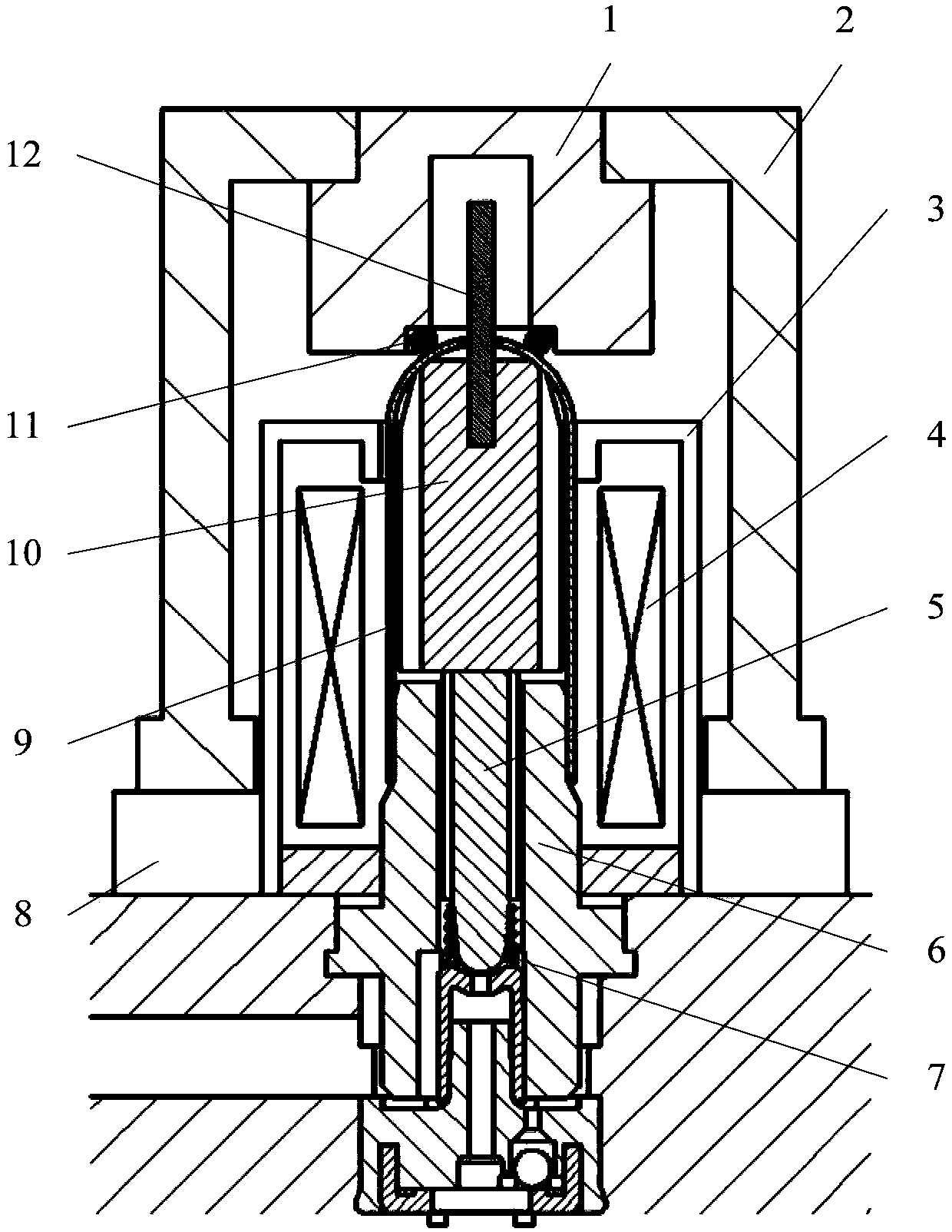

[0037] Such as image 3 and Figure 4 As shown, the detection object of the present invention is the high-speed on-off valve in the hydraulic control unit. To illustrate the structure of the on-off valve, one should first understand the HCU13, the spool displacement transmission device and the valve sealing device.

[0038] Wherein: HCU13 is the important part of automobile, and it comprises valve body, booster valve, decompression valve etc., introduces the present invention in detail with booster valve as example below, booster valve mainly comprises shell 3, coil 4, spool 5, Valve seat 6, spring 7, magnetic isolation tube 9 and moving iron 10; the external environment supplies power to the coil 4, thereby generating a magnetic field, and the moving iron 10 generates axial movement under the action of electromagnetic force, etc., because the spring 7 has a pre-tightening force , so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com