Three-electrode solid electrolyte electrochemical reactor

A solid electrolyte and solid electrolyte membrane technology, applied in the field of electrochemistry, can solve the problems of affecting the sealing performance and internal resistance of the reactor, and easy to influence each other, and achieve the effect of convenient use and maintenance, and stable monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

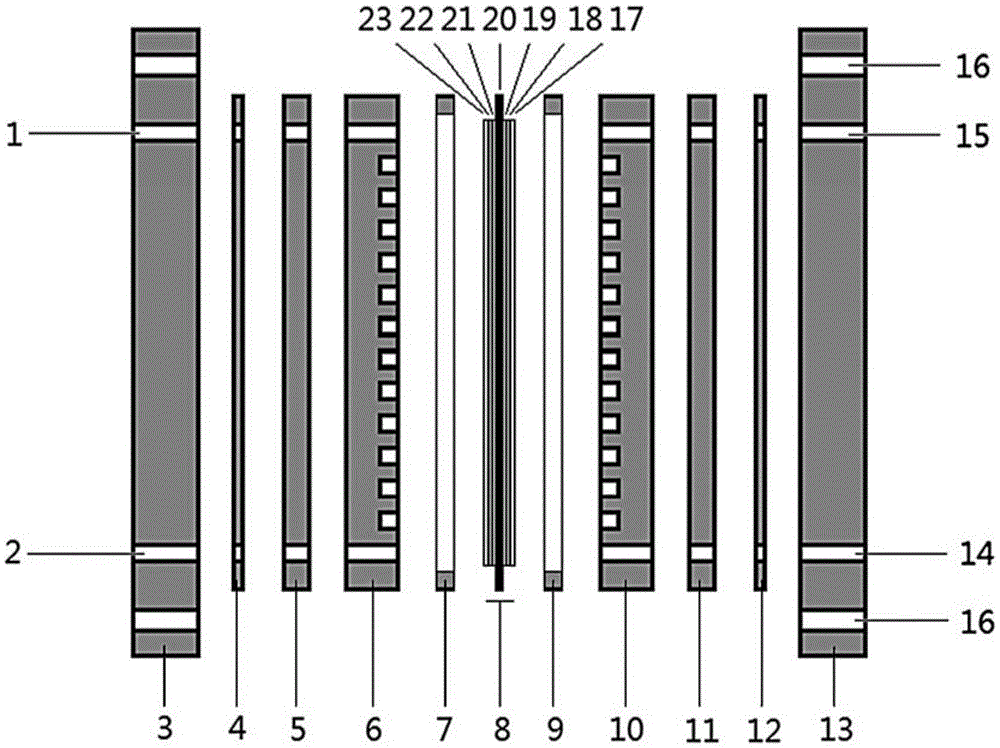

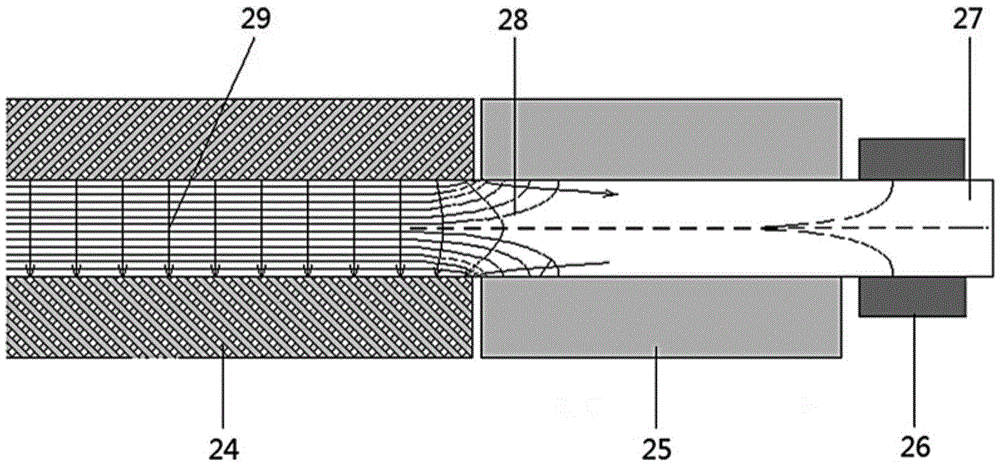

[0070] Such as figure 1 As shown, the monolithic solid electrolyte electrochemical reactor consists of basic structure and auxiliary structure. The basic structure includes cathode flow field plate 6 , membrane electrode assembly 8 and anode flow field plate 10 . In addition to the corresponding catalyst layers 21,19, the cathode surface and the anode surface on the membrane electrode assembly 8 can also have microporous layers 22,18, support layers 23,17, etc.; the catalyst layer 21 on the cathode surface of the membrane electrode assembly 8 , microporous layer 22, support layer 23, etc. and the cathode flow field plate 6 constitute the cathode, and the catalyst layer 19, microporous layer 18, support layer 17, etc. on the other side and the anode flow field plate 10 constitute the anode. Both the cathode and anode flow field plates 6 and 10 are made of inert electronically conductive material, and one side thereof has flow grooves to distribute the reactant fluid to the ent...

Embodiment 2

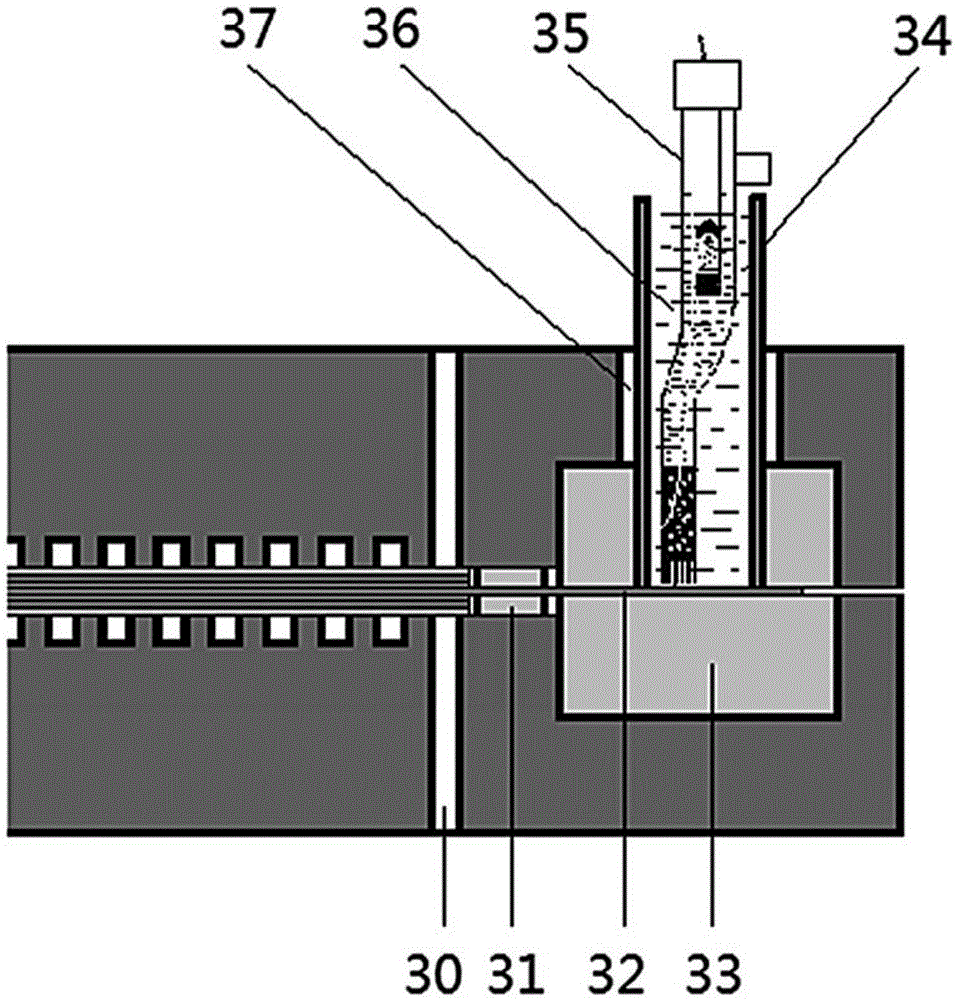

[0076] Such as Figure 8 As shown, when the flow field plate is not thick enough, for example, less than 4mm, the reference electrode sealing gasket 33 can be placed by using part of the thickness of the current collector plate 5 or even the splint 3 . Other structures are with embodiment 1. In order to show the connection of the reference electrode 35 more clearly, a part of the reactor is omitted in the figure, the same below.

Embodiment 3

[0078] Sometimes in order to reduce the expansion of the electrochemical reactor, it may be necessary to use a thinner reference electrode tube 34 or a reference electrode installation hole 37 , so that the reference electrode 35 cannot be directly inserted into the reference electrode tube 34 . In this case, the ionic connection of the electrolyte membrane to the reference electrode 35 can be achieved by means of a salt bridge 39, such as Figure 9 shown. Other structures are with embodiment 2 or embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com