Method for producing biogas through high-efficiency anaerobic fermentation of organic waste resource in intensive vegetable area

A technology for vegetable waste and organic waste, applied in the field of biogas, can solve the problems of long processing time, unrealized recycling of waste resources, slow efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Separate anaerobic fermentation of vegetable waste in intensive vegetable area.

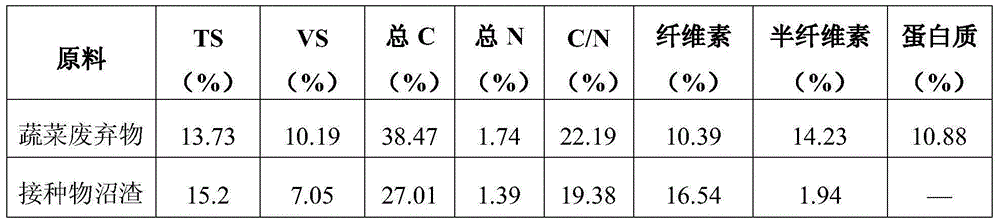

[0060] The characteristics of vegetable waste and inoculum are shown in Table 1.

[0061] Table 1 Characteristics of vegetable waste and inoculum

[0062]

[0063] A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0064] (1) The collected vegetable waste is pulverized to 1.5cm and set aside;

[0065] (2) Take 480 g of crushed vegetable waste, add 60 g of anti-acidification microbial preparation and mix, add water and stir evenly, adjust the C / N ratio after mixing to 25:1, and the water content is 88%, to obtain the mixed material;

[0066] The acidification-inhibiting microbial preparation is prepared by mixing and uniformly obtaining fermented liquid obtained from Bacillus subtilis, Bacillus megaterium, Pseudomonas fluorescens, Saccharomyces cerevisiae, and Pichia pas...

Embodiment 2

[0068] Example 2: Mixed anaerobic fermentation of vegetable waste in intensive vegetable area and cow manure.

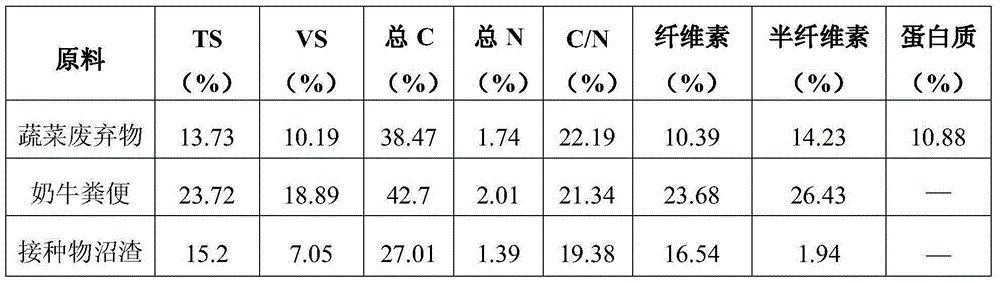

[0069] The characteristics of the vegetable waste, cow manure and inoculum are shown in Table 2.

[0070] Table 2 Characteristics of vegetable waste, cow manure and inoculum

[0071]

[0072] A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0073] (1) The collected vegetable waste is pulverized to 1.5cm and set aside;

[0074] (2) Take 300 g of crushed vegetable waste, add 100 g of fresh cow feces and mix, add water and stir evenly, adjust the C / N ratio after mixing to 25:1, and the water content is 88%, to obtain a mixed material;

[0075] (3) Add 700 g of inoculum to the mixed material of step (2), add water to adjust the material TS to 10.0%, and adjust the pH value to 7.8 to obtain the fermented material, which is anaerobically fermented at a temperatu...

Embodiment 3

[0076] Example 3: Mixed anaerobic fermentation of vegetable waste and corn stalks in intensive vegetable area.

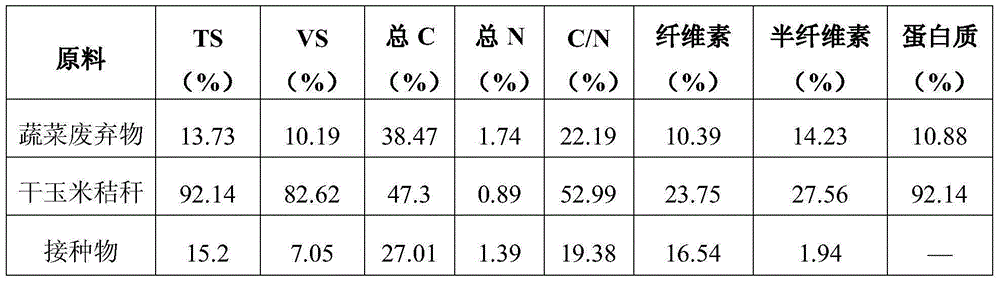

[0077] The characteristics of vegetable waste, corn stover and inoculum are shown in Table 3.

[0078] Table 3 Characteristics of vegetable waste, dairy manure and inoculum

[0079]

[0080]A method for efficient anaerobic fermentation of organic waste resources in an intensive vegetable area to produce biogas, comprising the following steps:

[0081] (1) The collected vegetable waste is pulverized to 2cm and set aside;

[0082] (2) Add fresh cow feces and stalks treated with bacterial agents to the crushed vegetable waste, mix them, add water and stir evenly, adjust the C / N ratio after mixing to 26:1, and the water content to 88%, to obtain a mixed material ; The mass ratio of fresh cow manure, straw pretreated by bacterial agents, and crushed vegetable waste is: 2:3:4;

[0083] The straw treated with the bacterial agent is obtained as follows: crush the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com