Patents

Literature

3318 results about "Signal amplifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

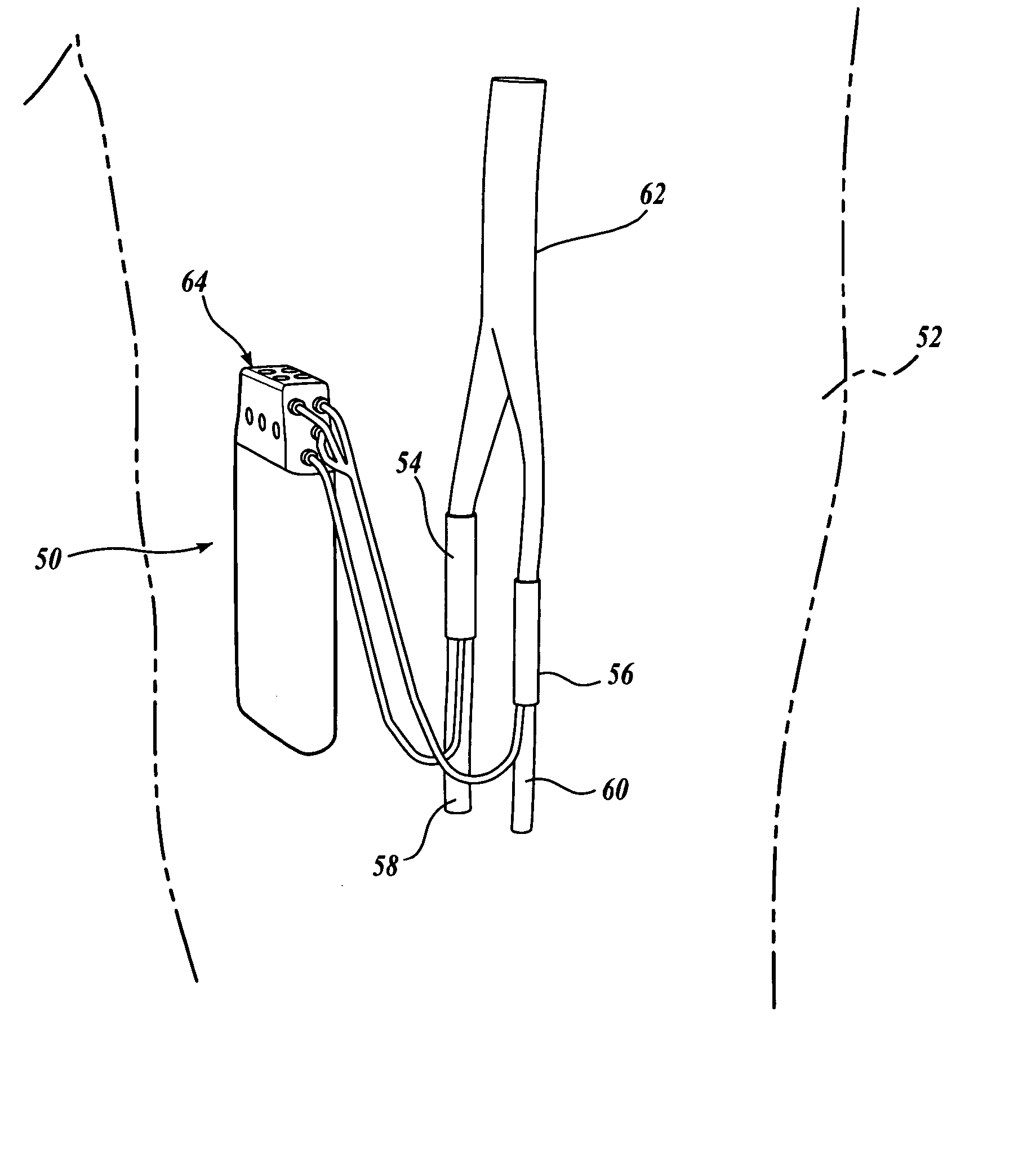

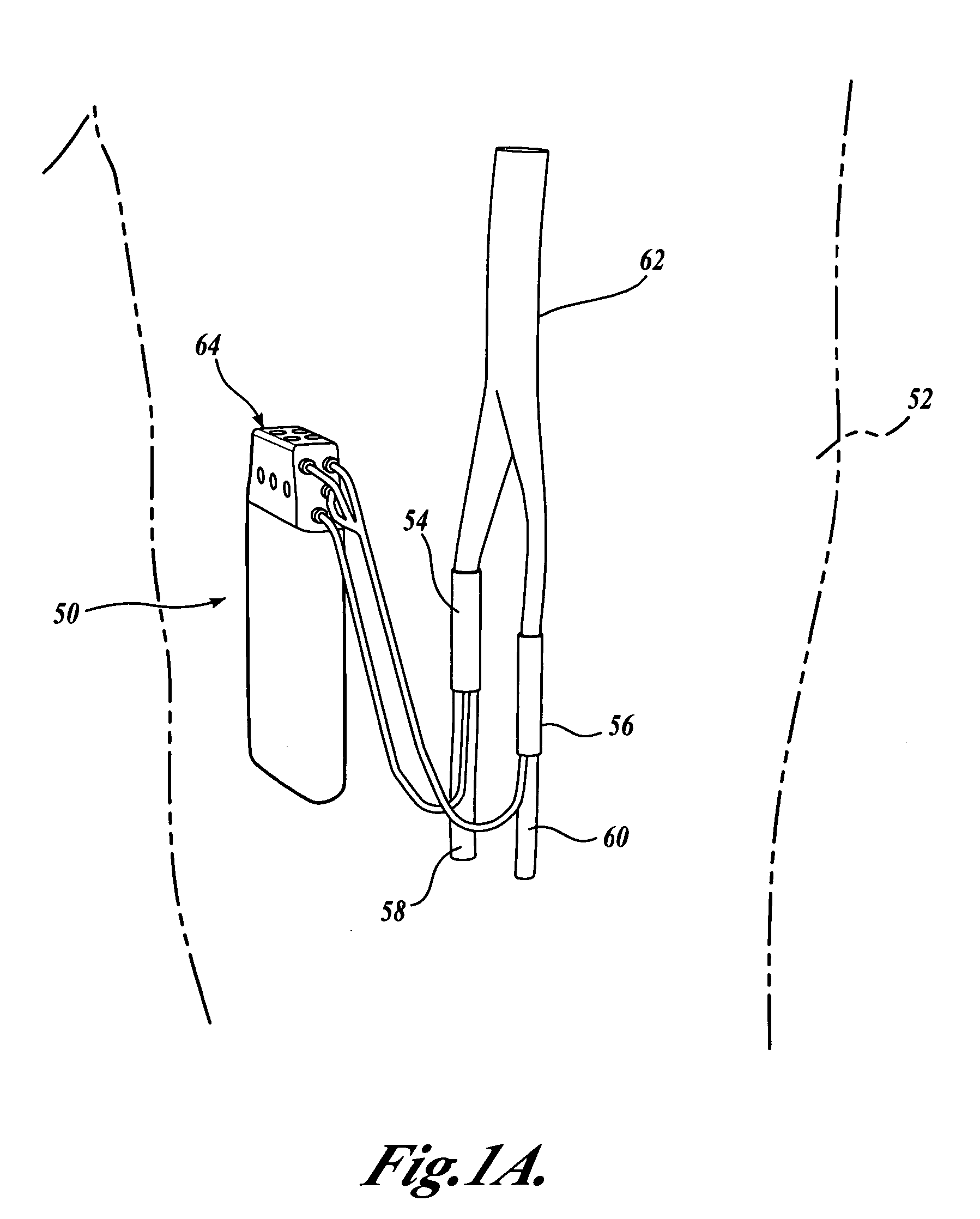

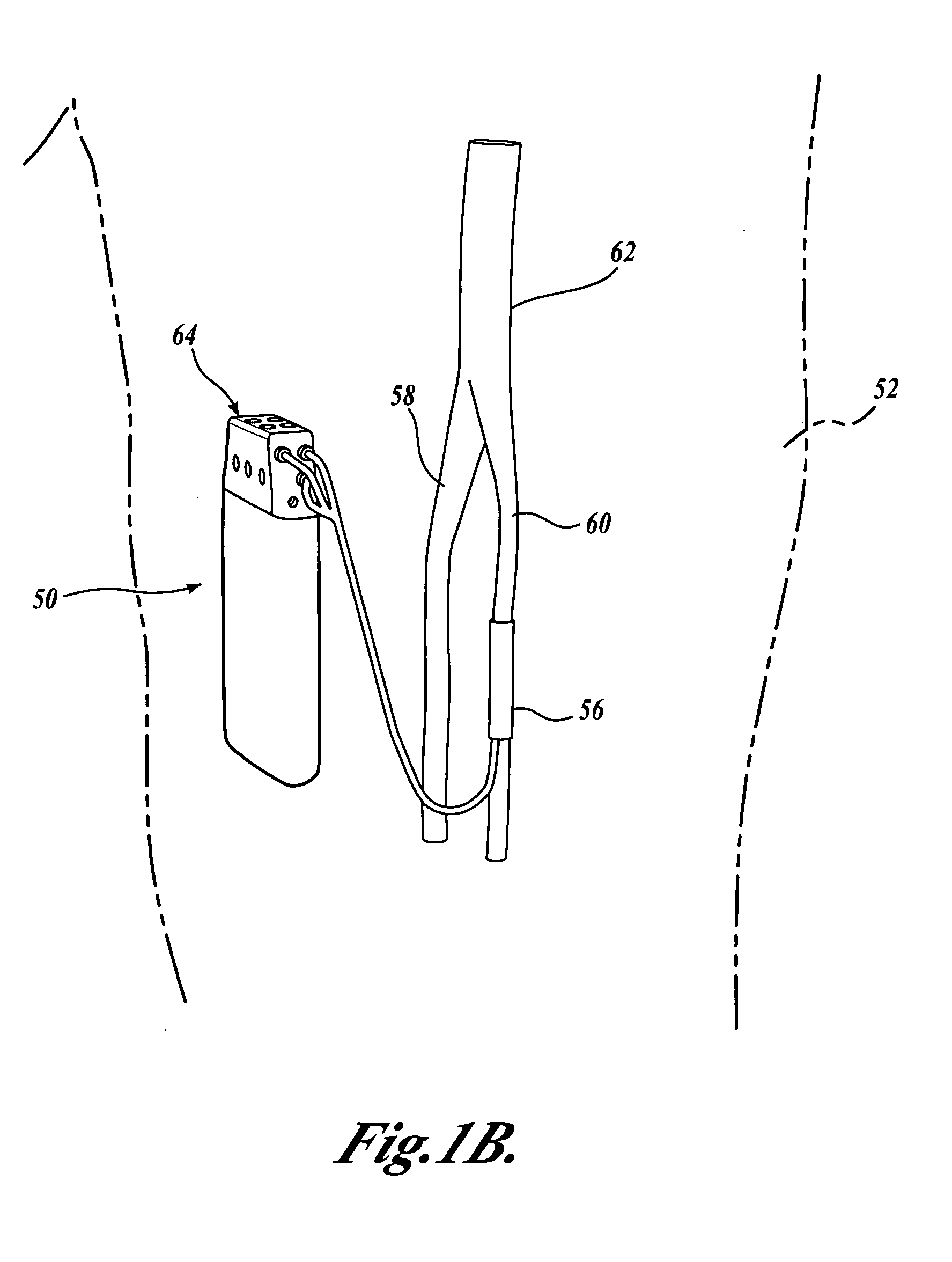

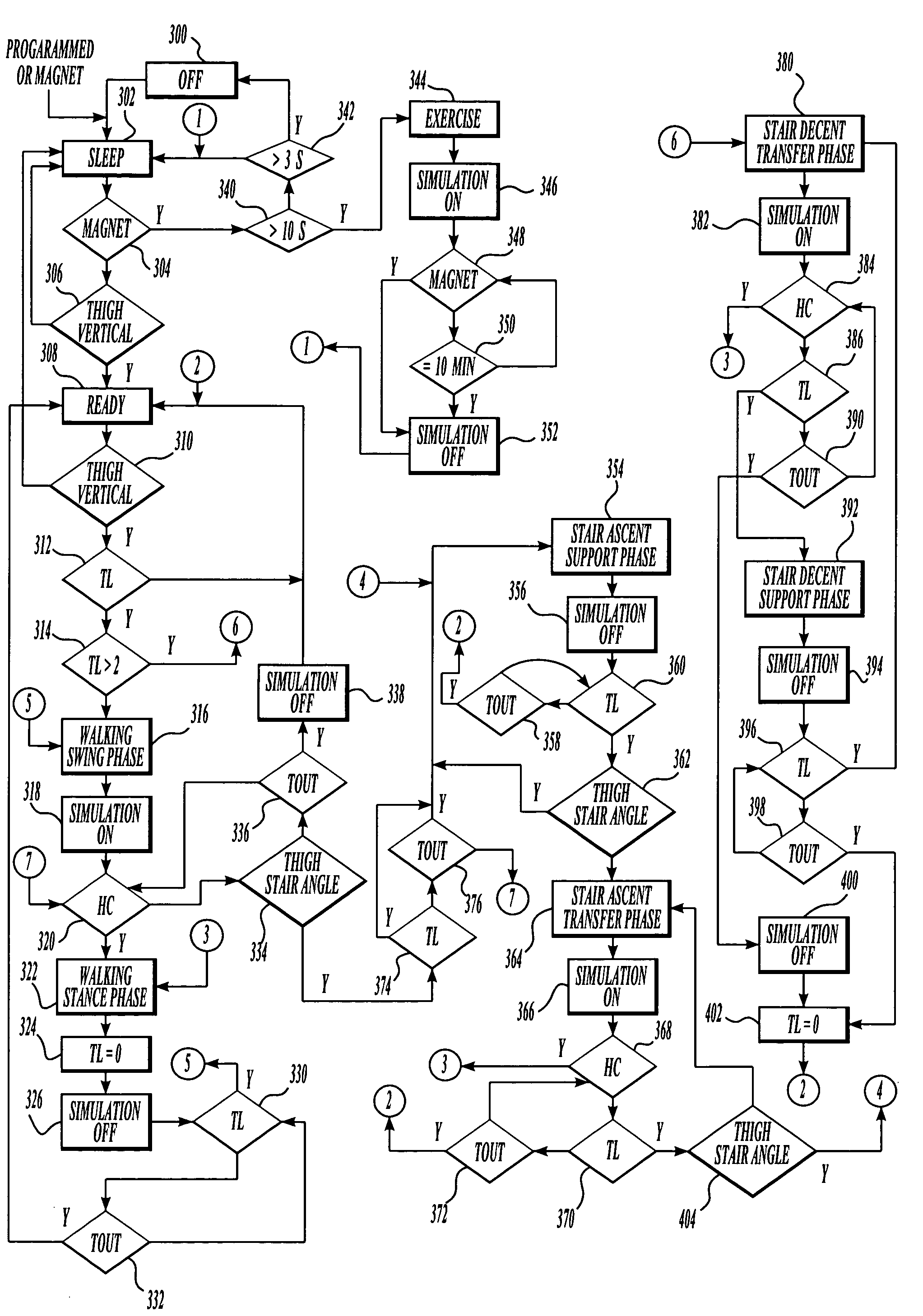

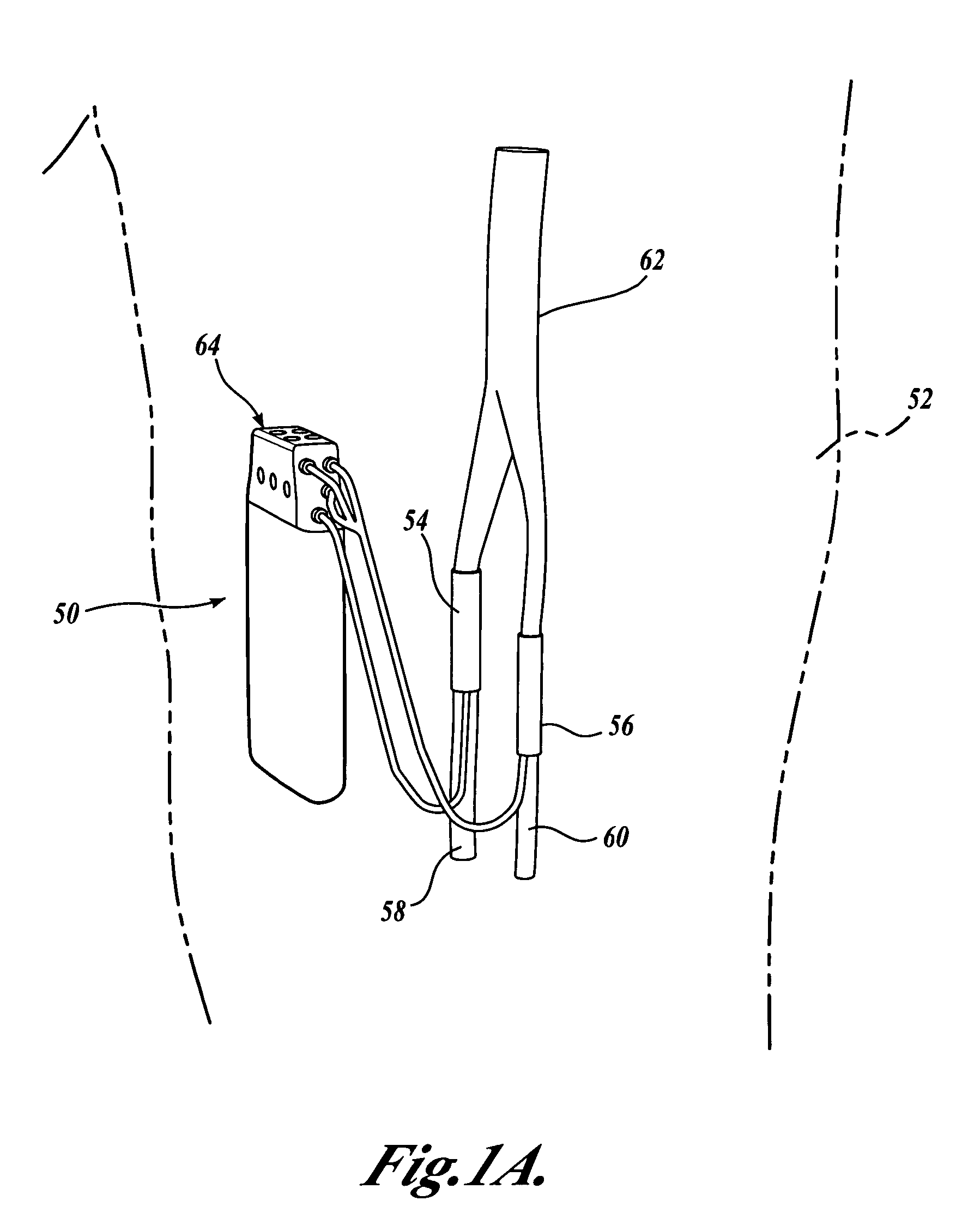

Fully implantable nerve signal sensing and stimulation device and method for treating foot drop and other neurological disorders

InactiveUS20050010265A1Minimizing battery power consumptionLengthen expected life of batterySpinal electrodesDiagnostic recording/measuringSignal amplifierPower component

A fully implantable nerve stimulation system includes an event-triggered, closed-loop control unit that detects physiological events from nerve signals and delivers stimulation pulses to a nerve to produce a desired physiological response. The stimulation system includes a low-noise, low-power nerve signal amplifier, accelerometers that detect position and a battery powered processor that selectively powers components in the system to detect physiological events and deliver stimulation pulses with a minimum of battery power.

Owner:4491343 CANADA

Fully implantable nerve signal sensing and stimulation device and method for treating foot drop and other neurological disorders

InactiveUS7636602B2Lengthen expected life of batteryMinimize consumptionSpinal electrodesDiagnostic recording/measuringLow noiseAccelerometer

Owner:4491343 CANADA

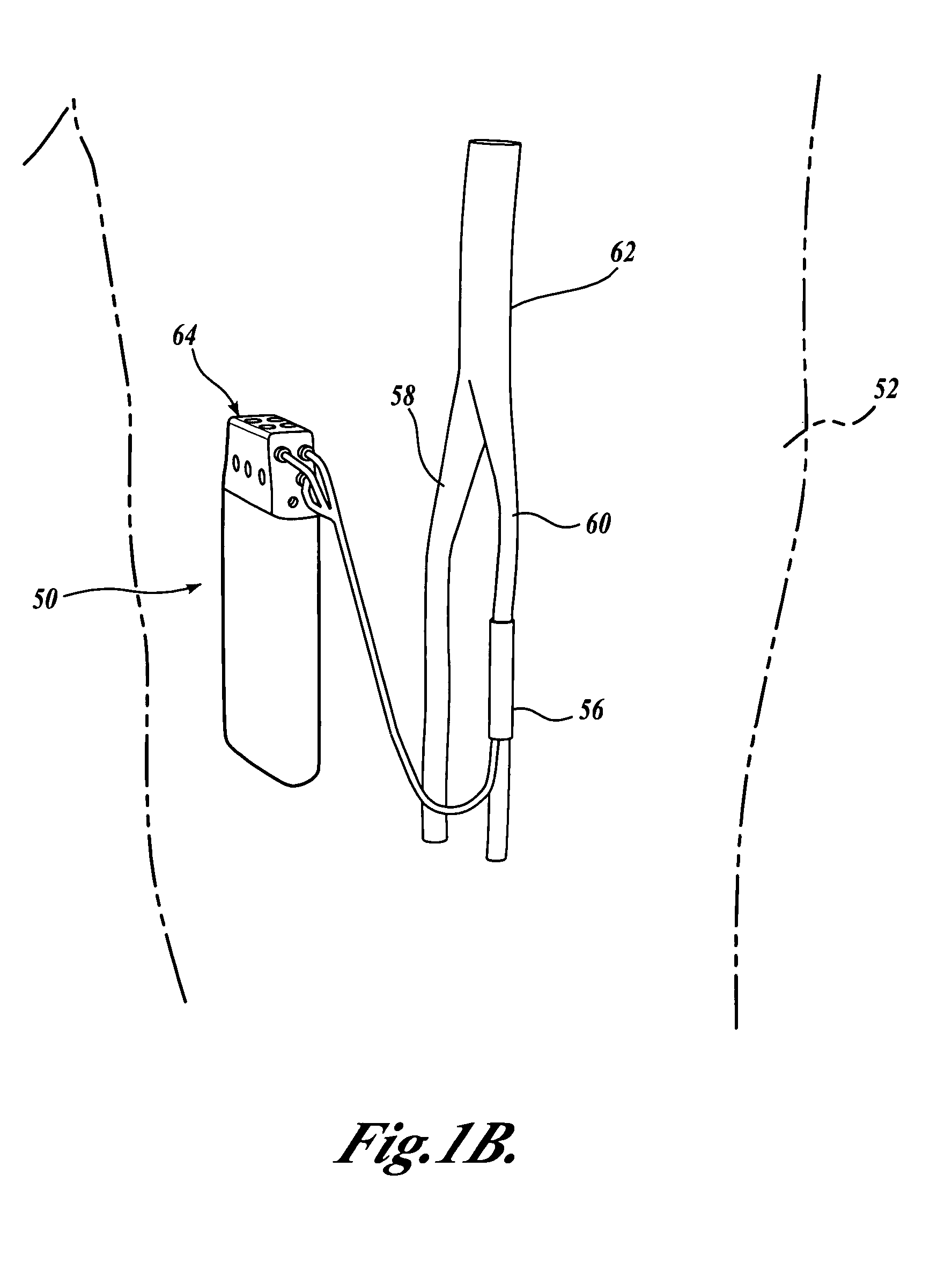

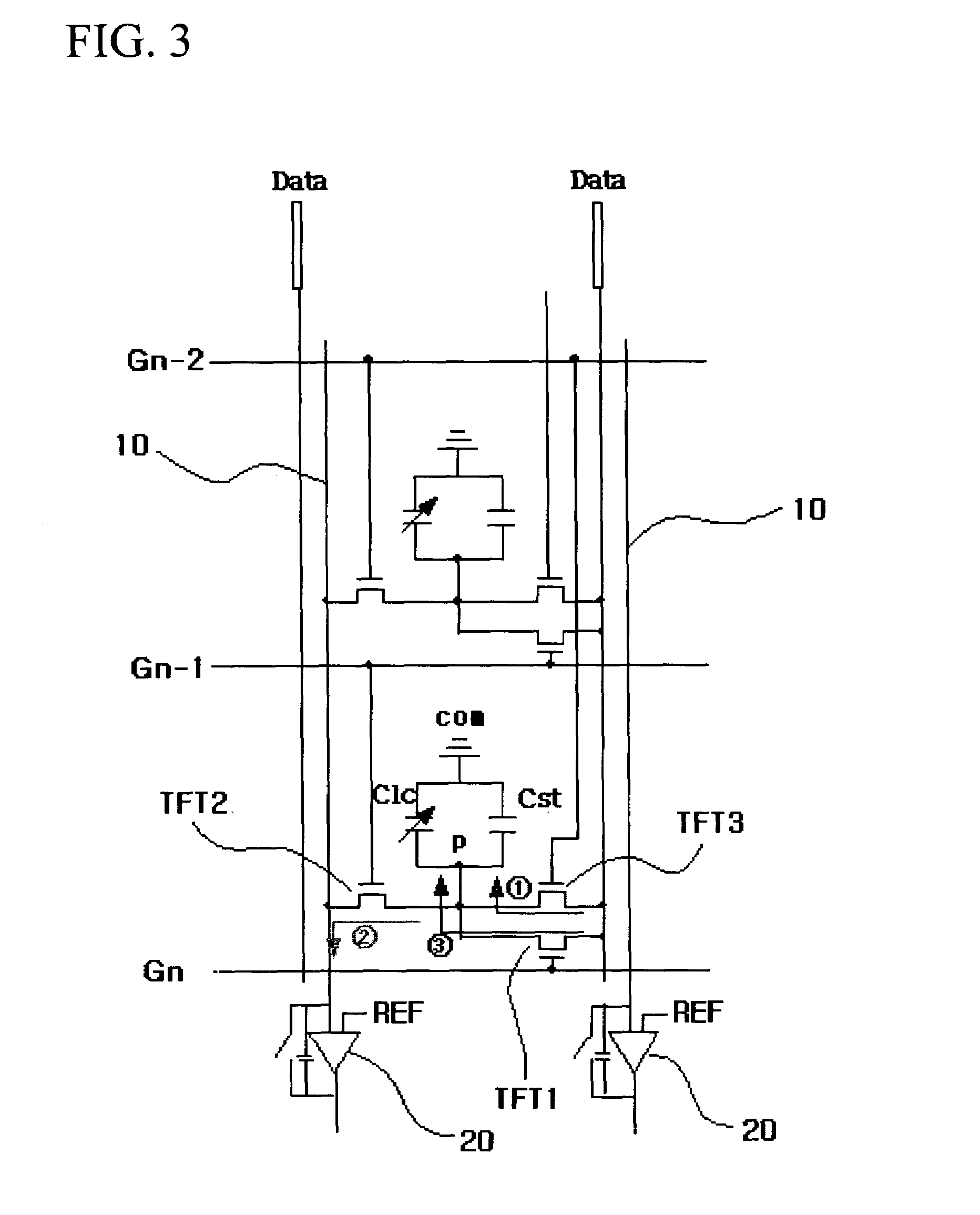

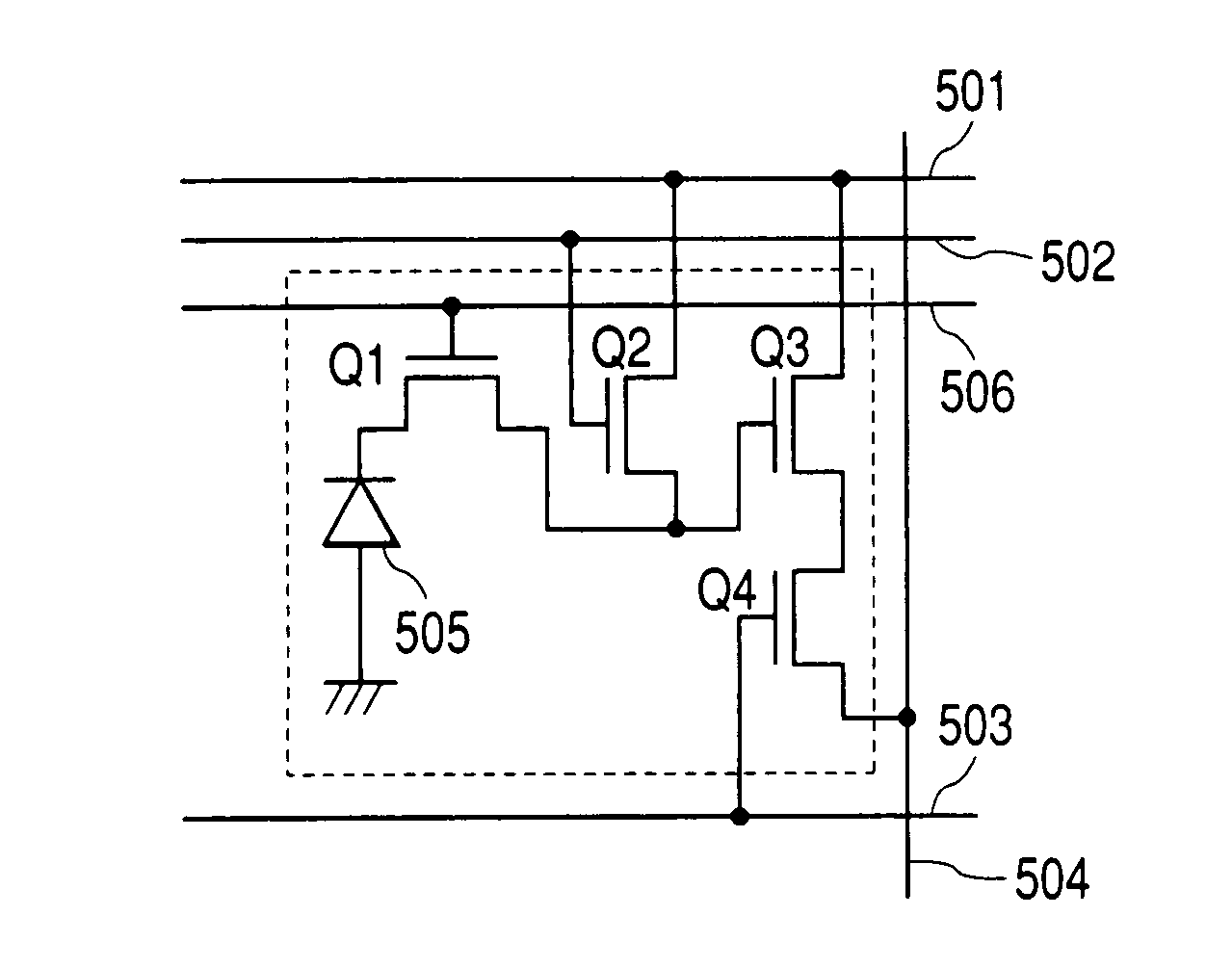

Liquid crystal display device having touch screen function and method of fabricating the same

The present invention relates to an LCD device having a touch screen function. The LCD device of the present invention includes a plurality of gate lines, a plurality of data lines intersecting the gate lines, and a plurality of signal lines that are insulated from and juxtaposed with the data lines. First to third switching elements are formed in each of a plurality of pixel regions in the form of a matrix, which are surrounded by the gate lines and the data lines. Here, a gate electrode of the first switching element is connected to a gate line Gn, a source electrode thereof is connected to the data line, and a drain electrode thereof is connected to a pixel electrode. Further, liquid crystal capacitance and storage capacitance are formed between the pixel electrode and a common electrode. At this time, the liquid crystal capacitance is changed due to variation in the liquid crystal cell gap. The second and third switching elements are designed to read variation in the liquid crystal capacitance. A source electrode of the second switching element is connected to the pixel electrode, a drain electrode thereof is connected to the signal line, and a gate electrode thereof is connected to a previous gate line Gn-1. Furthermore, a source electrode of the third switching element is connected to the data line, a drain electrode thereof is connected to the pixel electrode, and a gate electrode thereof is connected to a second previous gate line Gn-2. Each signal line is connected to each signal amplifier.

Owner:SAMSUNG DISPLAY CO LTD

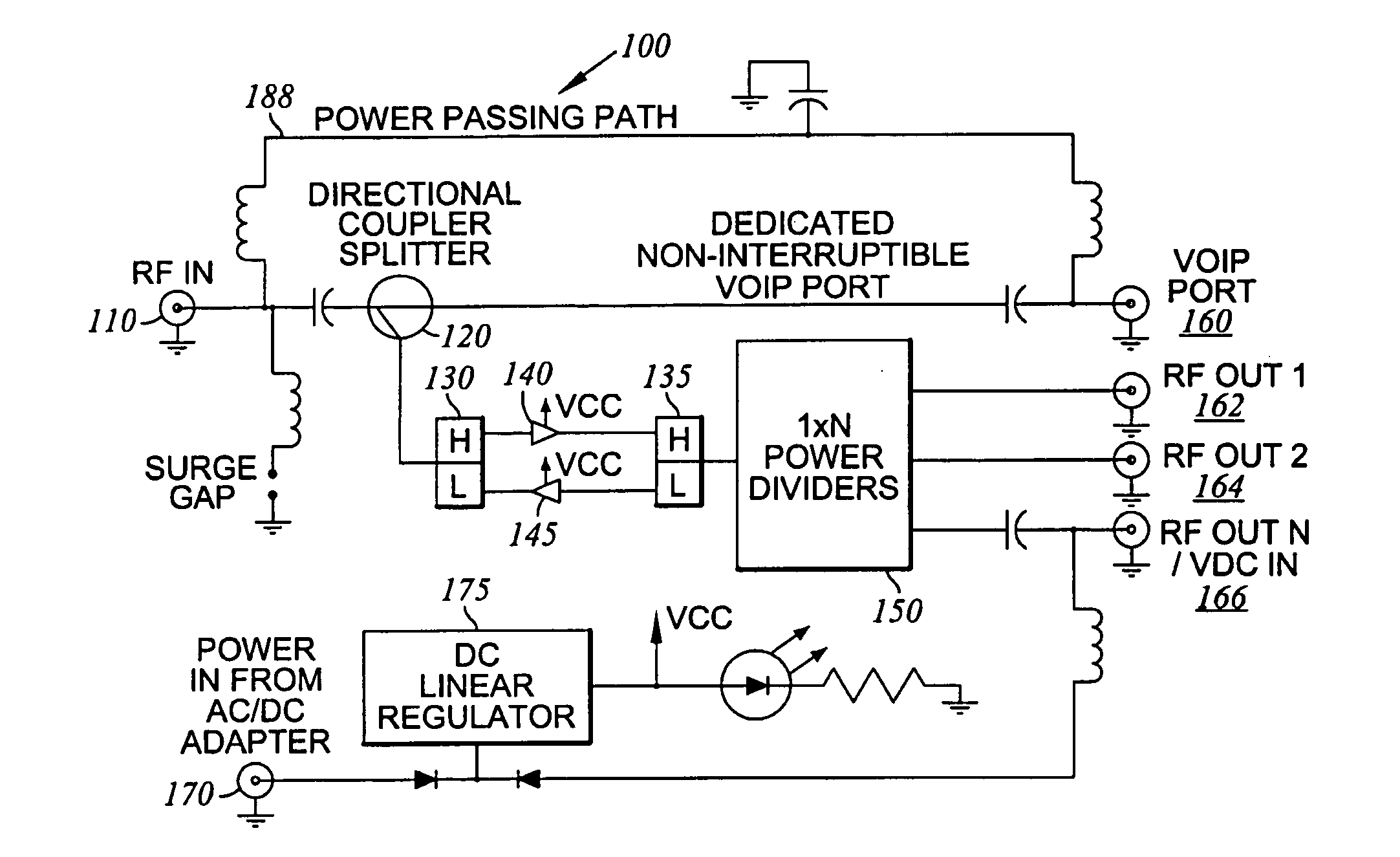

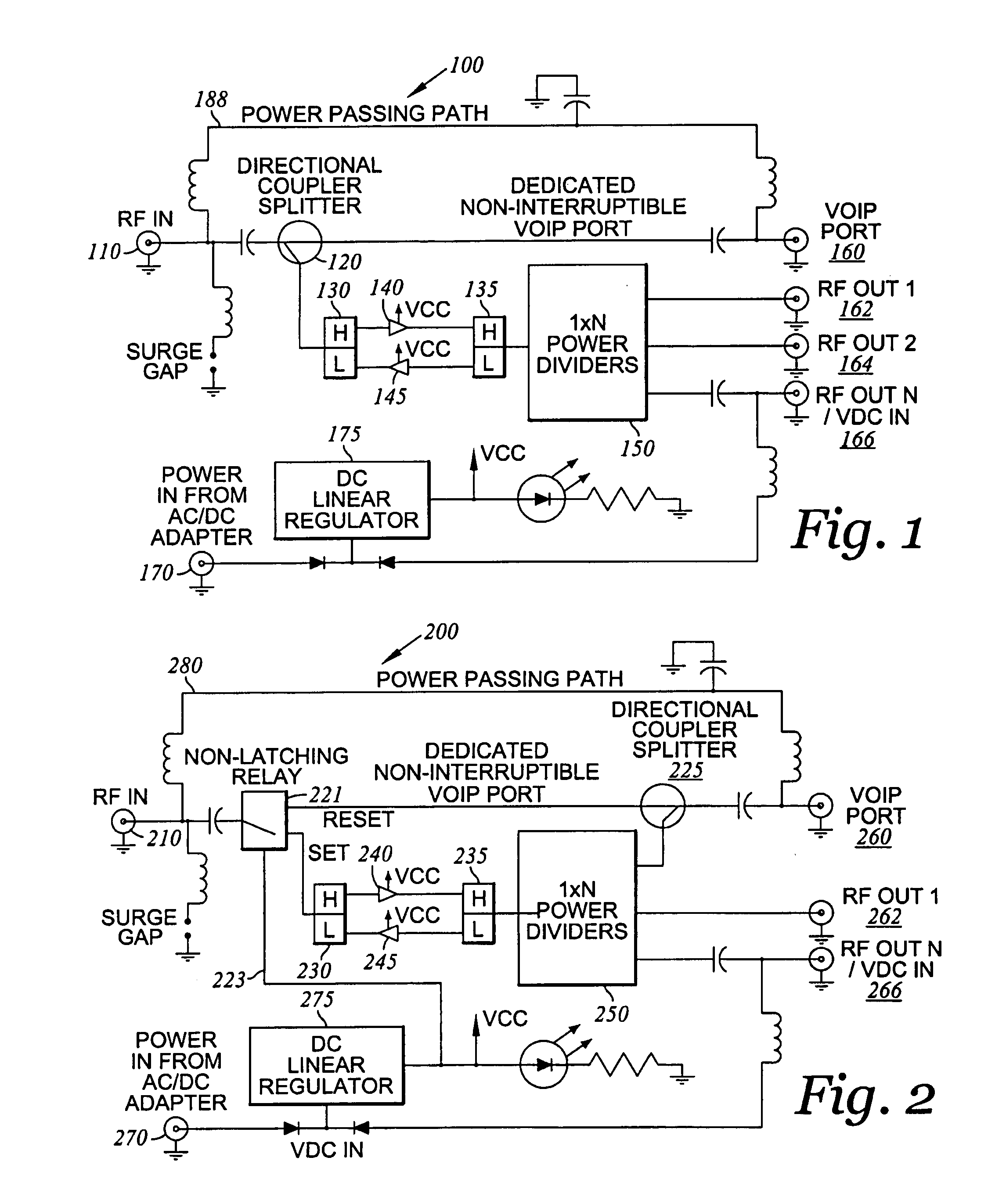

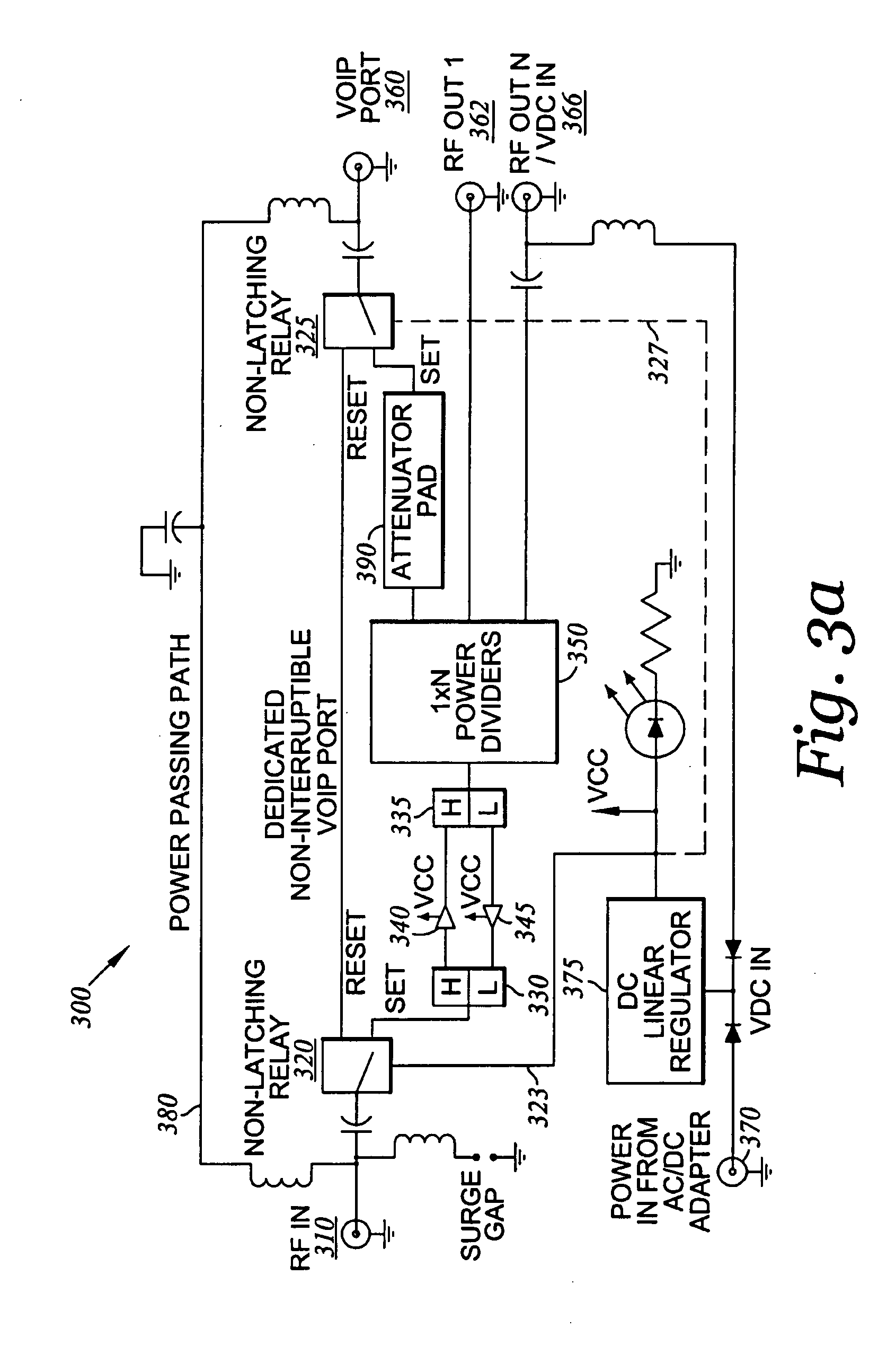

Bi-directional amplifier with non-interruptible port

InactiveUS20060205442A1Facilitate communicationGated amplifiersTwo-way amplifiersAudio power amplifierService provision

A bi-directional RF signal amplifier can be provided with a non-interruptible communication path for maintaining communication between an input and output port in the event of power failure. The amplifier may receive RF signals from a service provider or any other appropriate signal source through an input port. In residential applications, the amplifier may receive a composite RF signal comprising information for telephone, cable television (CATV), Internet, VoIP, and / or data communication from a service provider. The amplifier may increase the signal to a more useful level of approximately 20 dBmV / carrier and pass the amplified signal to one or more devices in communication with the amplifier through various output ports. In the event of power failure, a signal may still be passed through the non-interruptible communication path between the service provider and the communication device.

Owner:COMMSCOPE INC

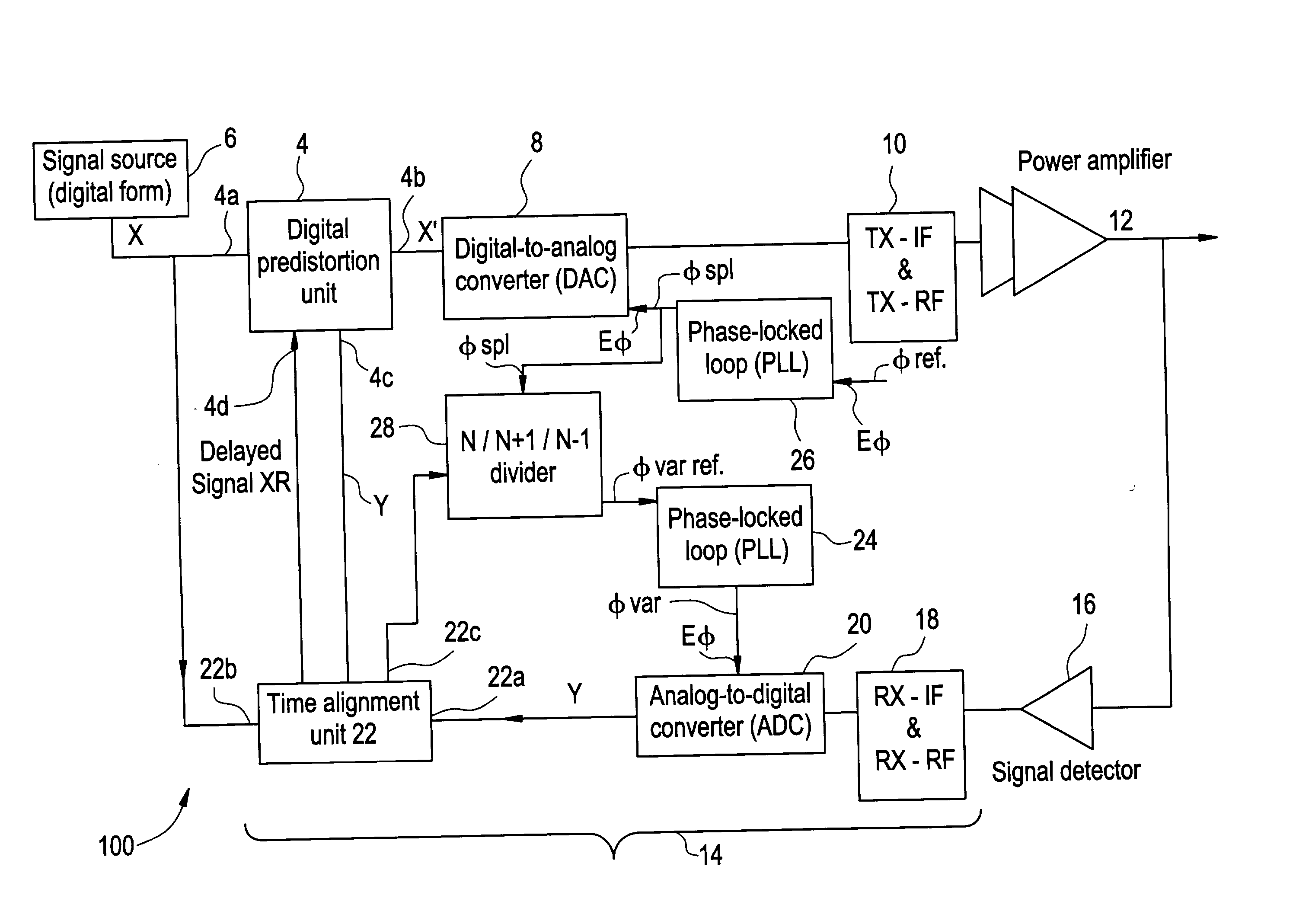

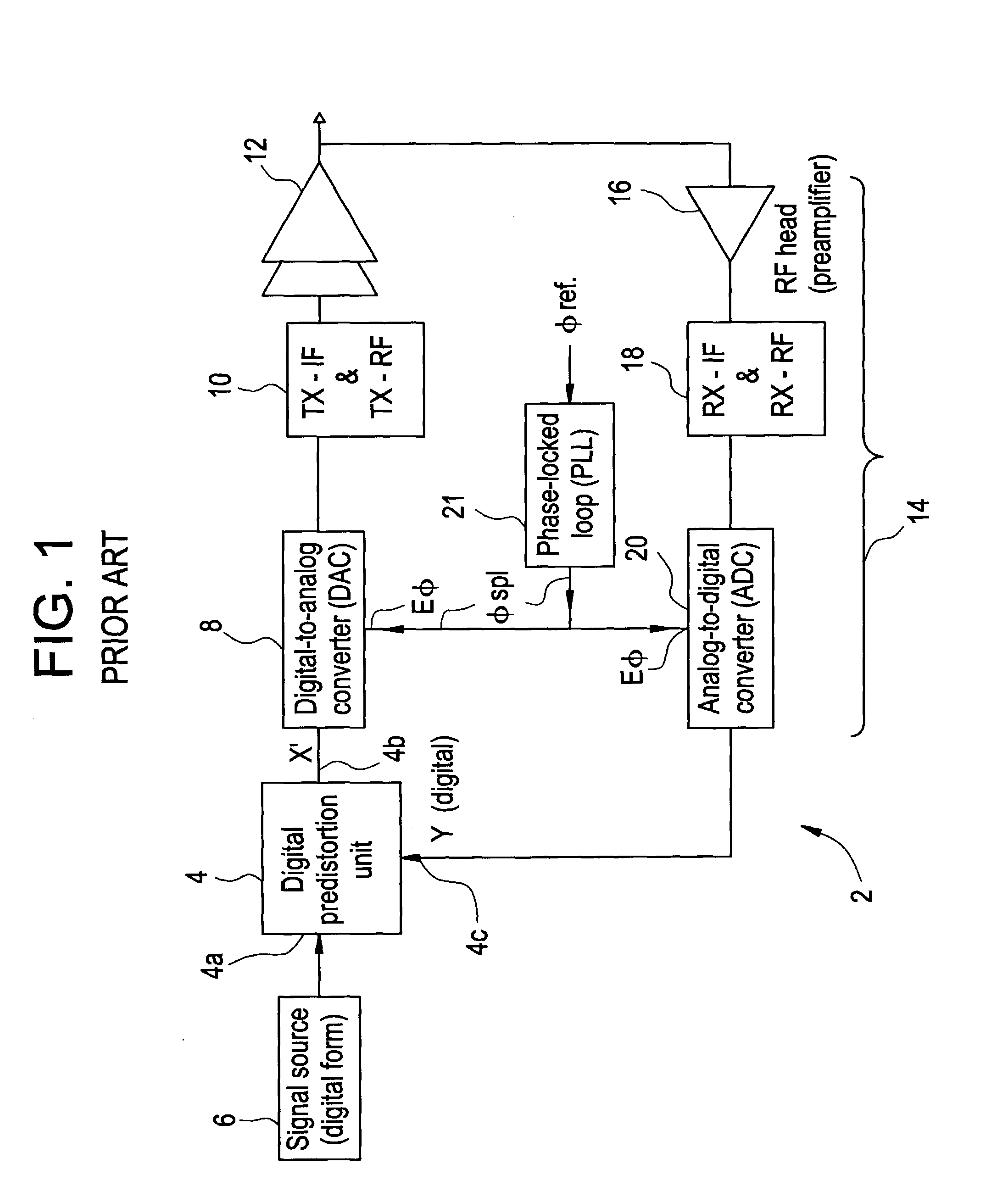

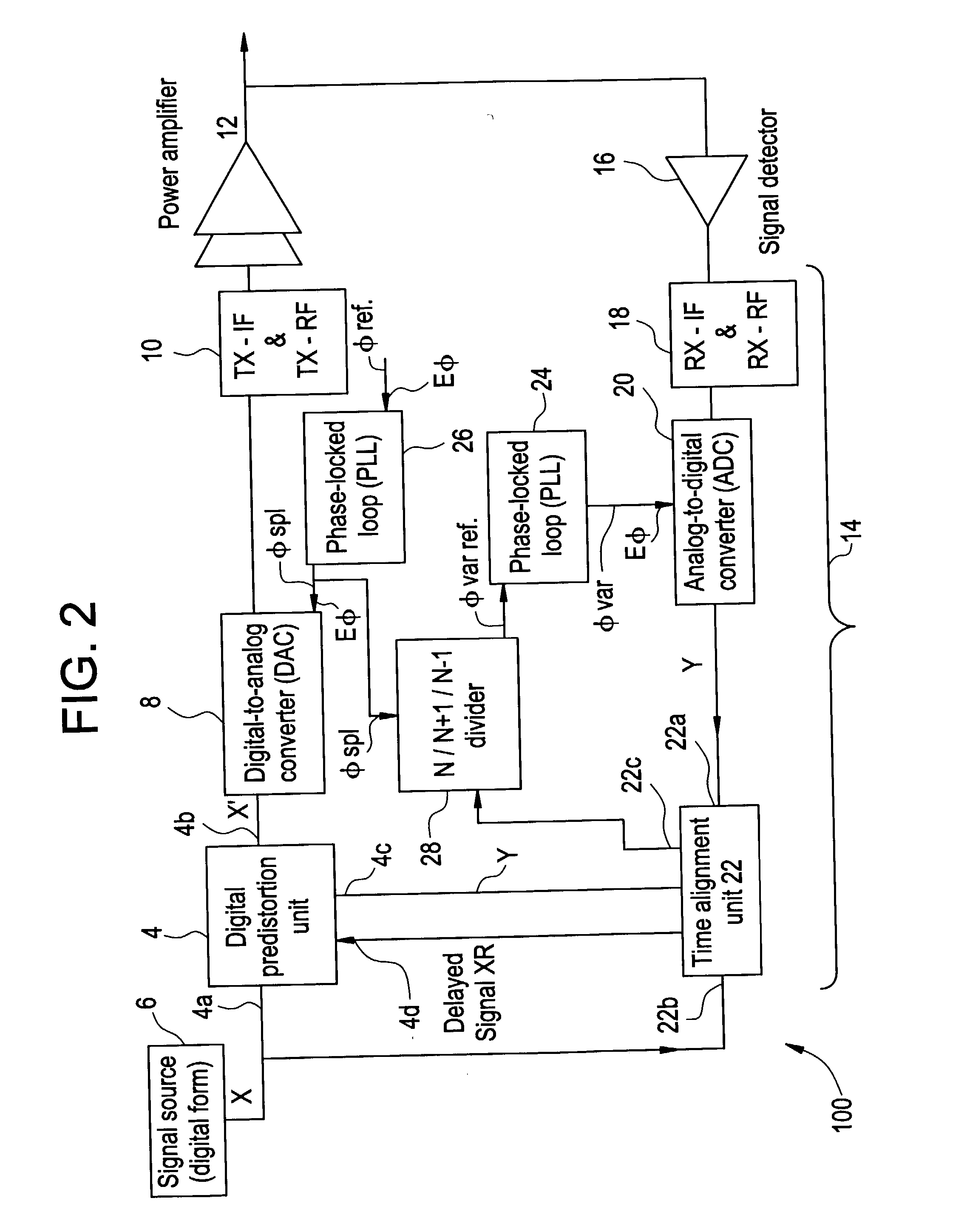

Method and apparatus for preparing signals to be compared to establish predistortion at the input of an amplifier

InactiveUS20030156658A1Improve electricity efficiencyImprove performance efficiencyAmplifier modifications to reduce non-linear distortionElectric signal transmission systemsAudio power amplifierUnit of time

The invention relates to a method of preparing signals (X and Y) to be compared to establish predistortion at the input of an amplifier (12), the signals comprising a signal (X) before amplification and a signal (Y) after amplification by said amplifier. Preparation includes time aligning (22) the signal before amplification (X) with the signal after amplification (Y) before using them to establish said predistortion. The invention preferably operates in two stages, namely a stage of coarse time alignment, in which the signal before amplification (X) is subjected to a time delay comprising an integer number of first time units, and a stage of fine time alignment, in which a delay or advance value of a fraction of the first time unit is determined.

Owner:EVOLIUM

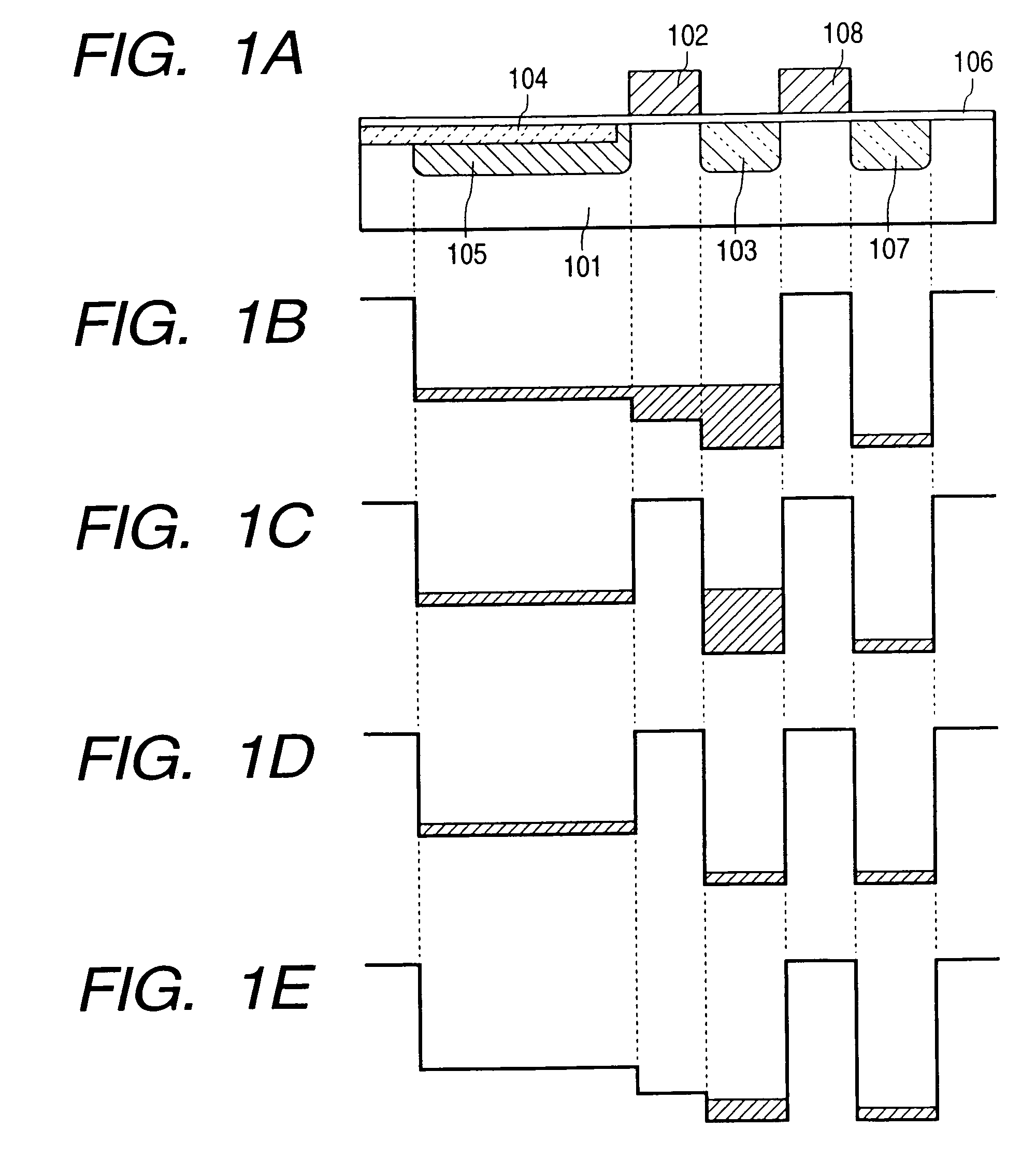

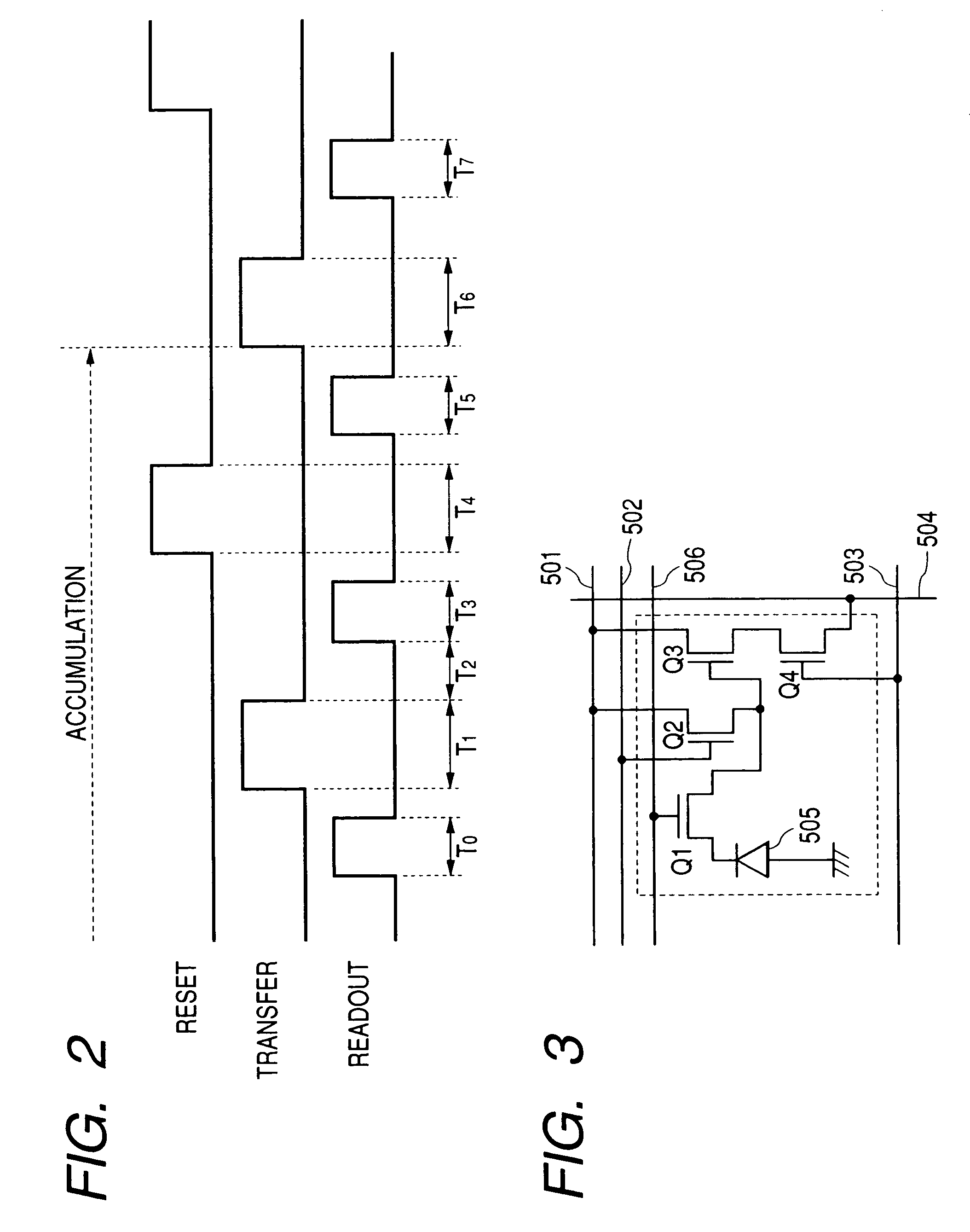

Solid image pickup device, image pickup system and method of driving solid image pickup device

InactiveUS7324144B1Less amount of noiseSolve the large power consumptionTelevision system detailsTelevision system scanning detailsAudio power amplifierPhotoelectric conversion

The solid image pickup device of the present invention comprises a photoelectric conversion part, a charge-voltage conversion part for converting electric charges from the photoelectric conversion part to voltage signals, a signal amplifier for amplifying the voltage signals generated in the charge-voltage conversion part, charge transfer means for transferring photo-electric charges from the photoelectric conversion part to the charge-voltage conversion part, and means for applying a certain voltage to a charge-voltage conversion part, wherein at least two readout operations for reading out the photo-electric charges accumulated during a period of accumulating photo-electric charges in the photoelectric conversion part via a signal amplifier.

Owner:CANON KK

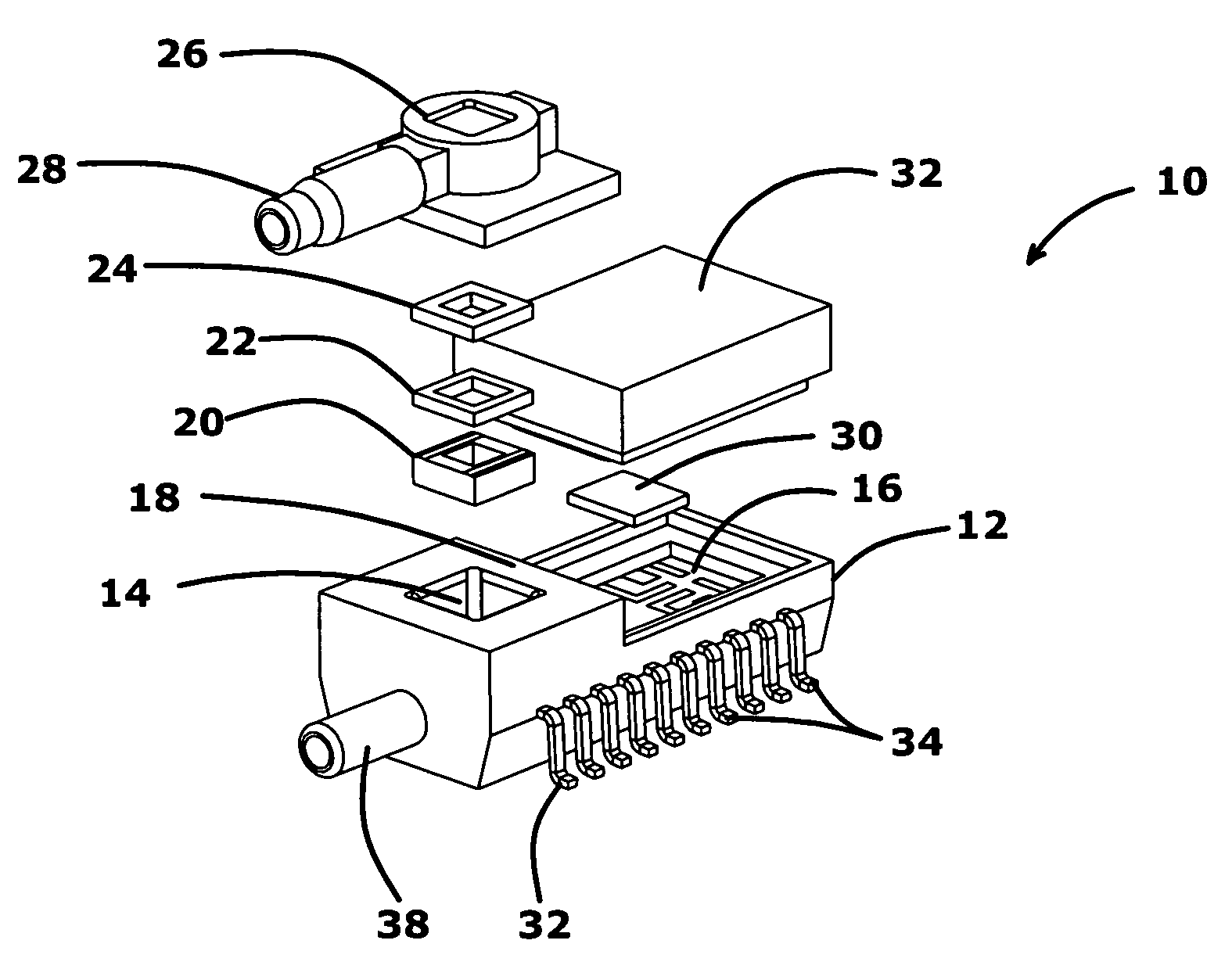

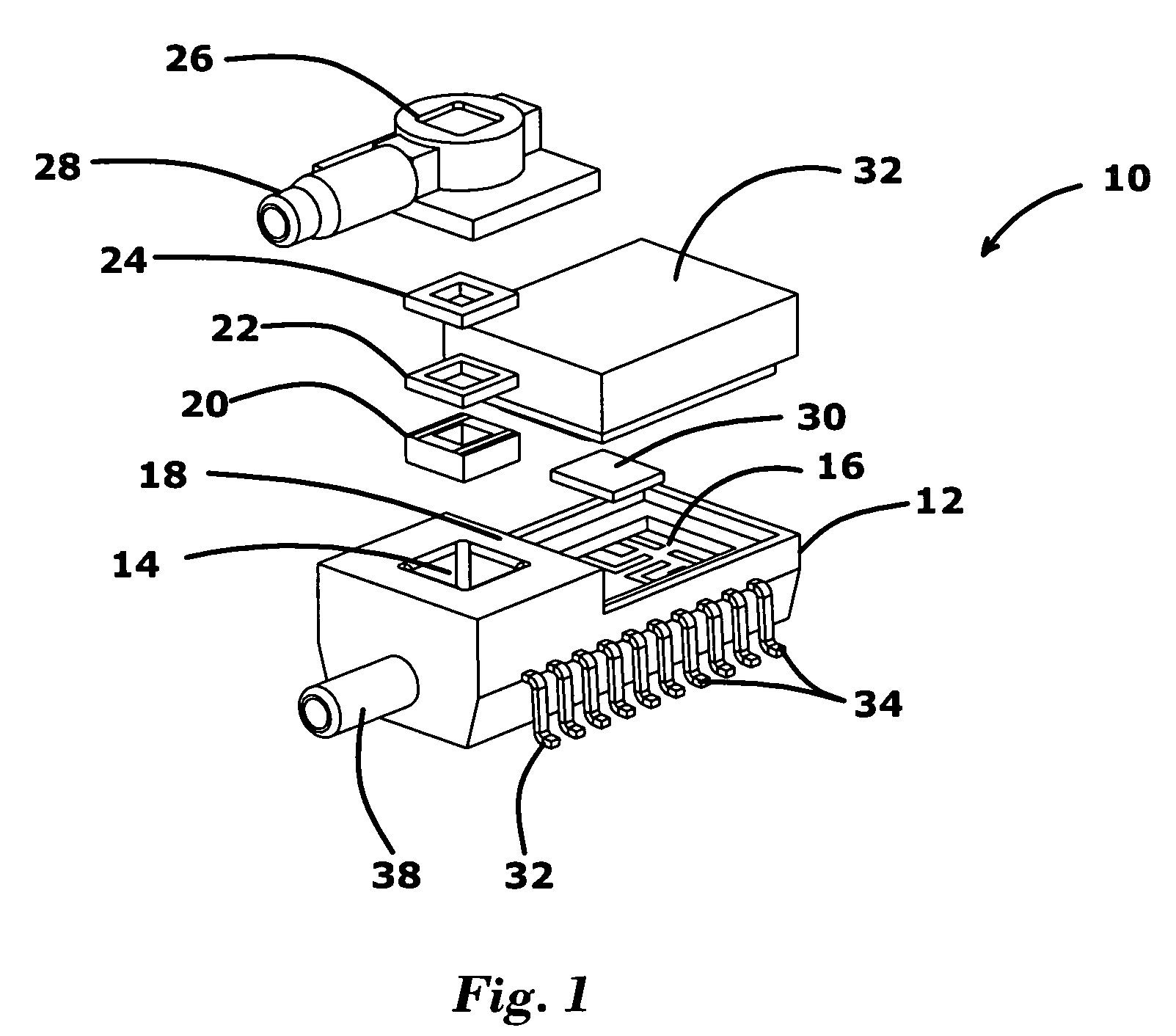

Design of a wet/wet amplified differential pressure sensor based on silicon piezoresistive technology

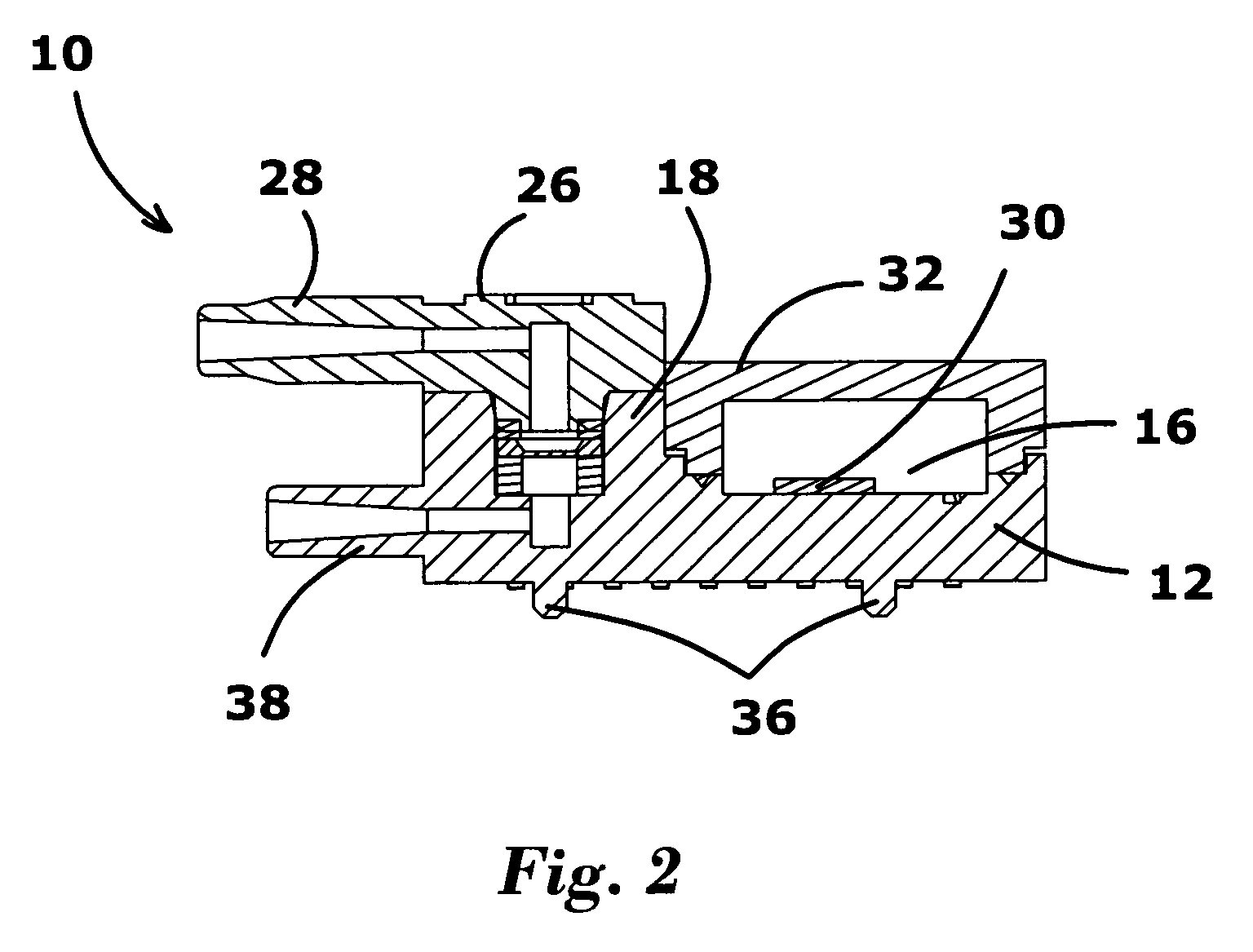

InactiveUS7162927B1Fluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsAudio power amplifierHermetic seal

The invention provides pressure sensors for use in wet environments. A pressure sensor package according to the invention has a housing having a pair of cavities separated by a wall member. Sequentially contained within one cavity is a conductive elastomeric seal pad, a pressure sensor and an elastomeric media seal. A pressure cap is attached to the housing such that the pressure cap and the housing together form a hermetic seal. The pressure cap has a port for admitting a gas under pressure into the first cavity. A signal amplifier is positioned within the second cavity and a cover encloses the signal amplifier within the second cavity. An electrical connector through the wall member forms an electrical connection between the pressure sensor and the signal amplifier. A lead frame extends through the housing and forms electrical connections with the pressure sensor and the signal amplifier.

Owner:HONEYWELL INT INC

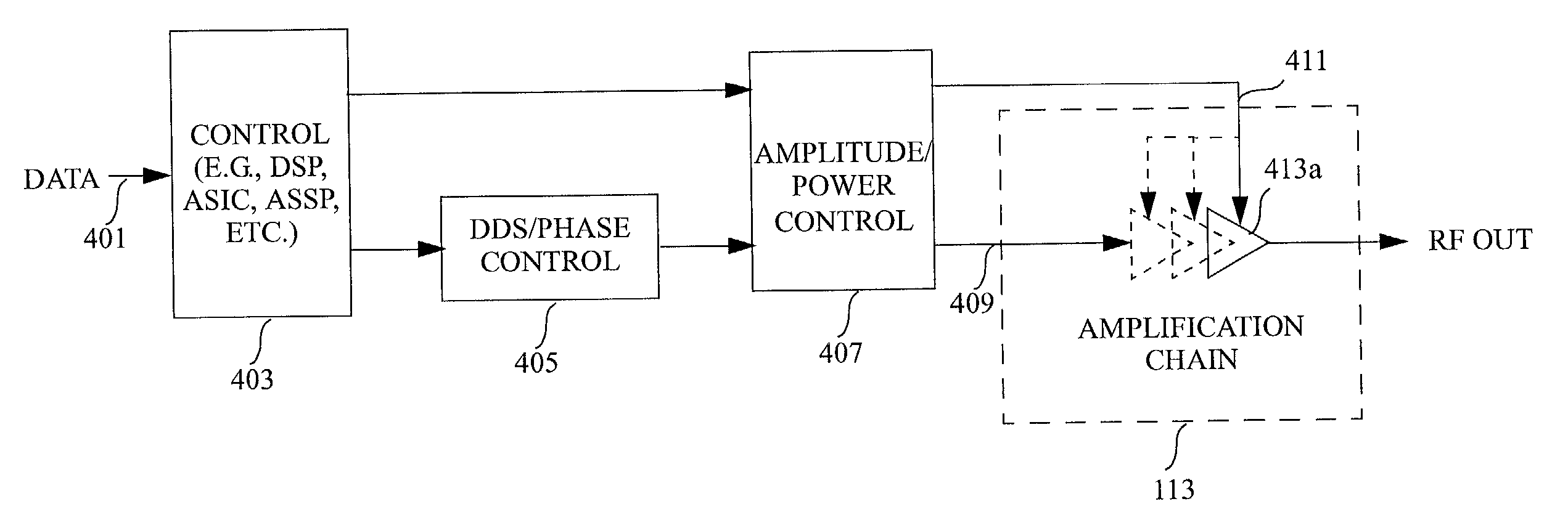

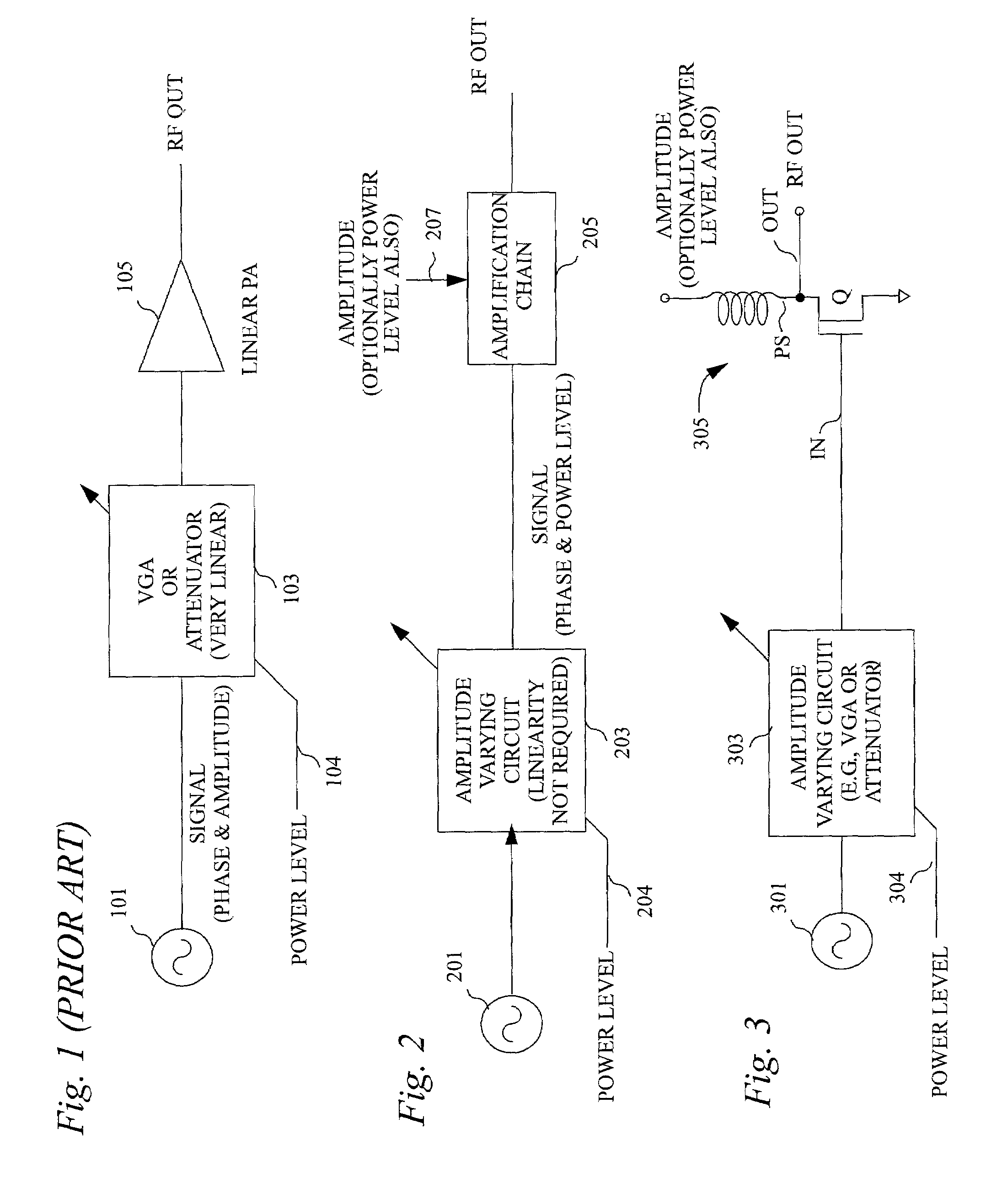

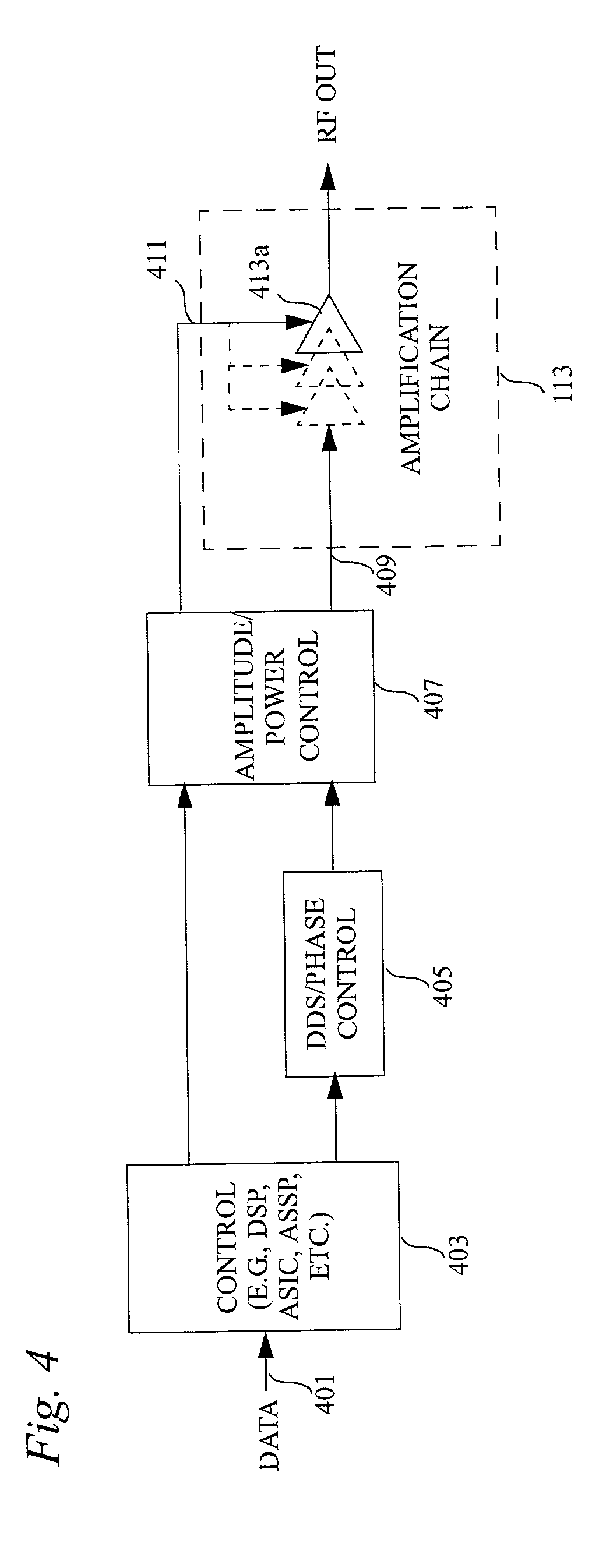

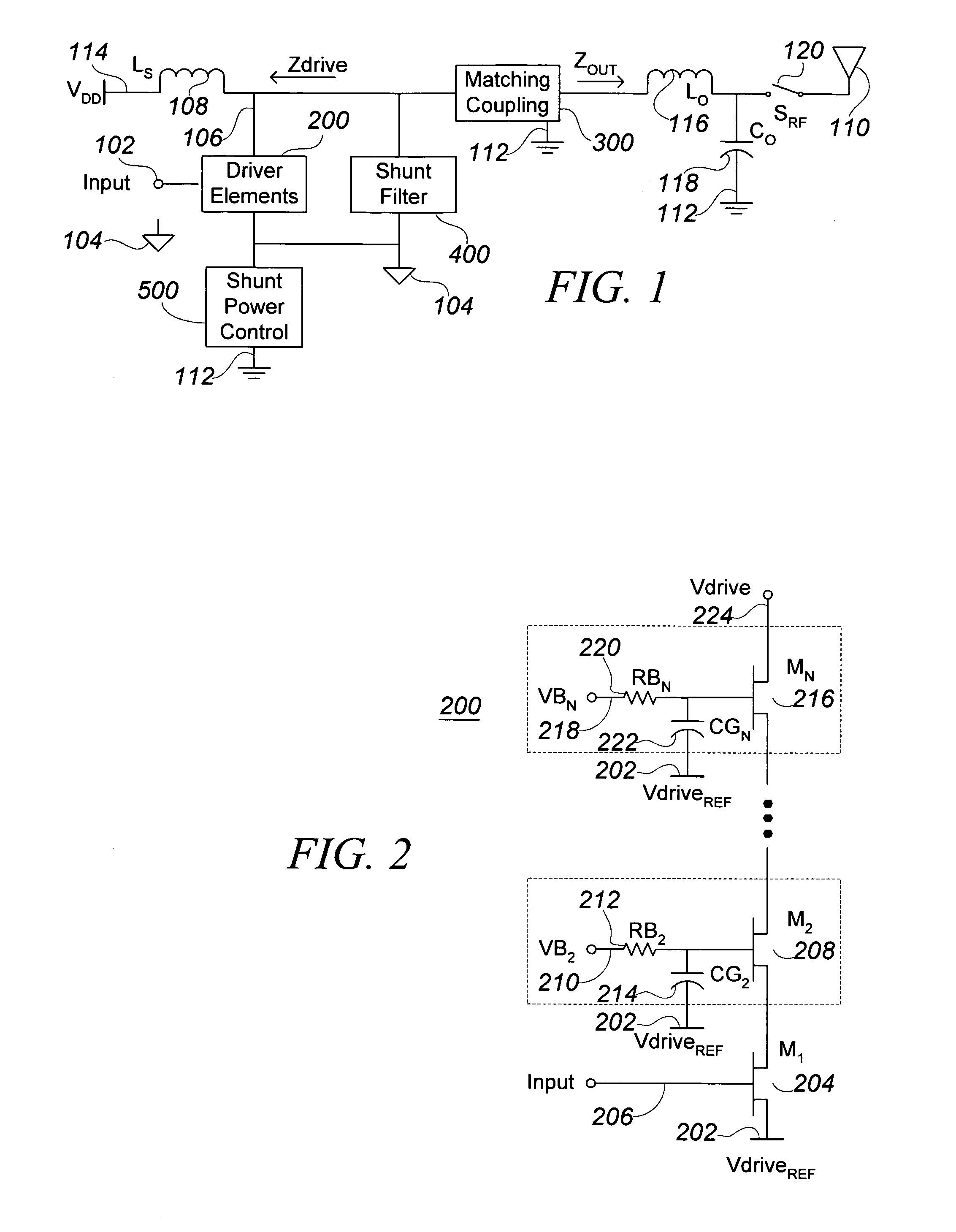

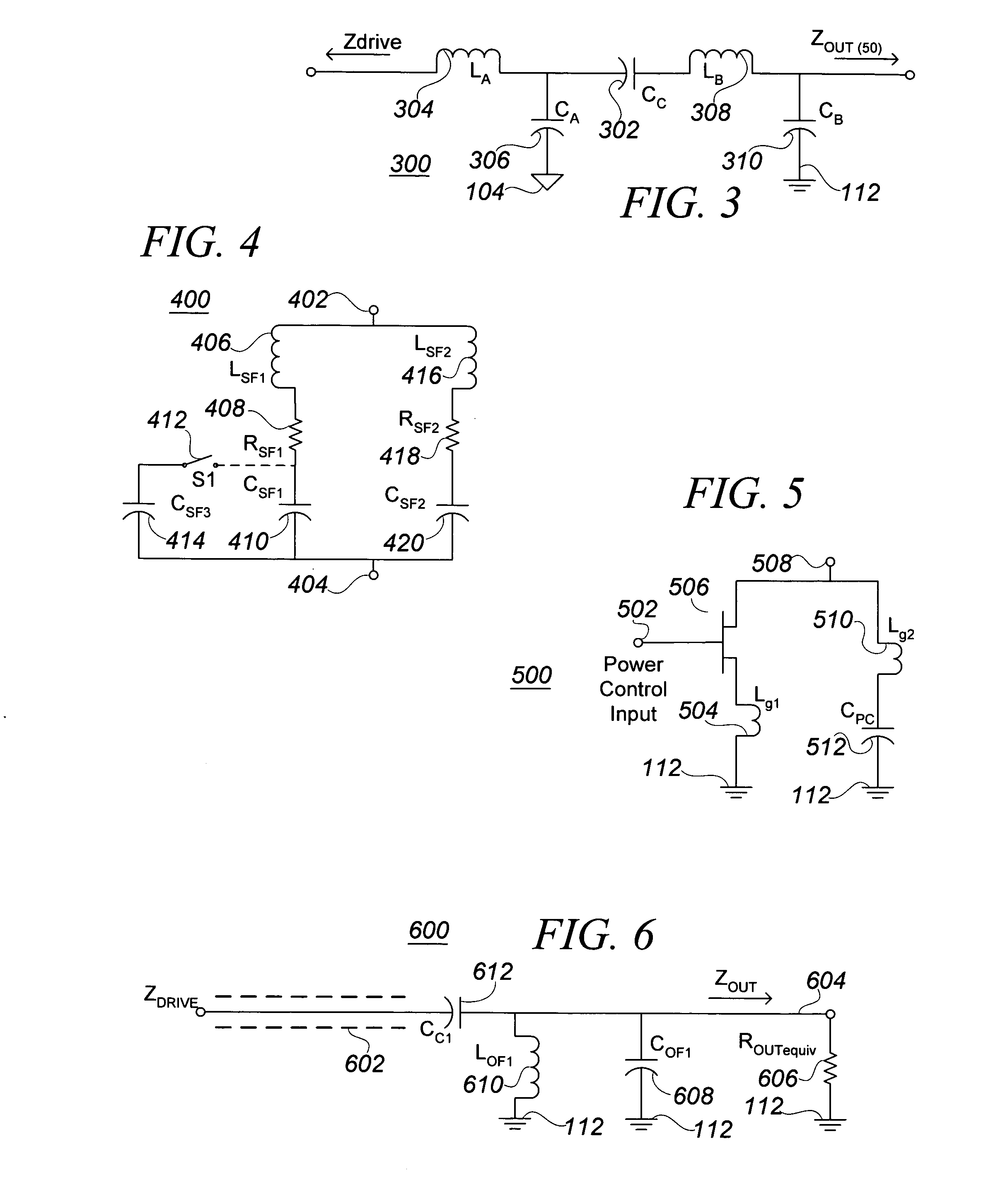

Communications signal amplifiers having independent power control and amplitude modulation

InactiveUS7010276B2Improve efficiencyResonant long antennasPower amplifiersAudio power amplifierCarrier signal

The present invention, generally speaking, provides methods and apparatus for producing an amplitude modulated communications signal, in which a constant-envelope carrier signal is modified in response to a power control signal to produce a modified constant-envelope carrier signal. The modified constant-envelope carrier signal is amplified in response to an amplitude modulation signal to produce a communications signal having amplitude modulation and having an average output power proportional to a signal level of the modified constant-envelope carrier signal. This manner of operation allows wide dynamic range of average output power to be achieved. Because amplitude modulation is applied after amplitude varying circuitry used to produce the modified constant-envelope carrier signal, the amplitude modulation is unaffected by possible non-linearities of such circuitry. In accordance with another aspect of the invention, operation in the foregoing manner at comparatively low average output power levels is combined with switch mode operation at comparatively high average output power levels, enabling high overall efficiency to be achieved. Hence, the disclosed modulator and amplifier combination, in addition to supporting very low power signals, also supports high power signals.

Owner:INTEL CORP

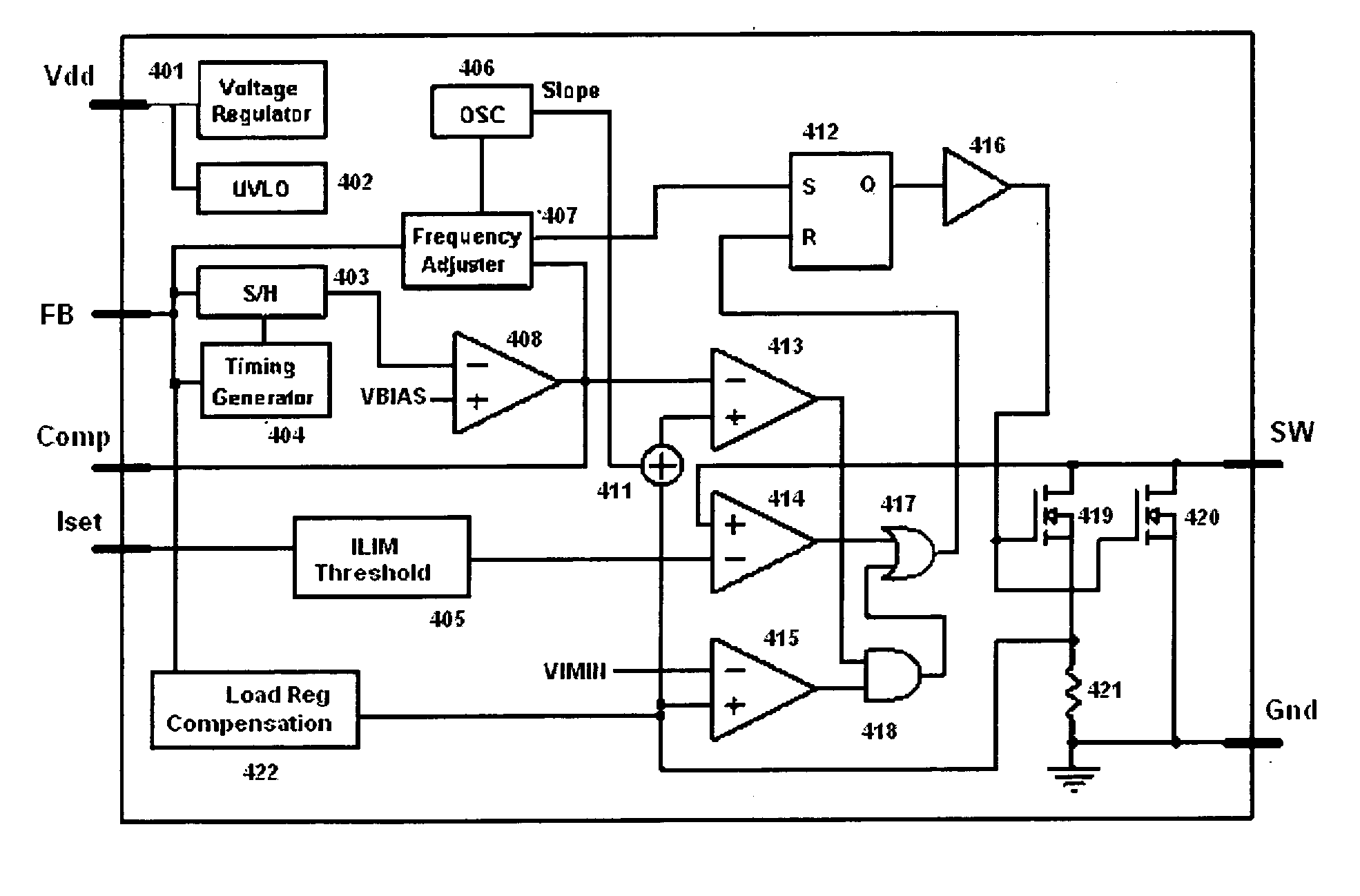

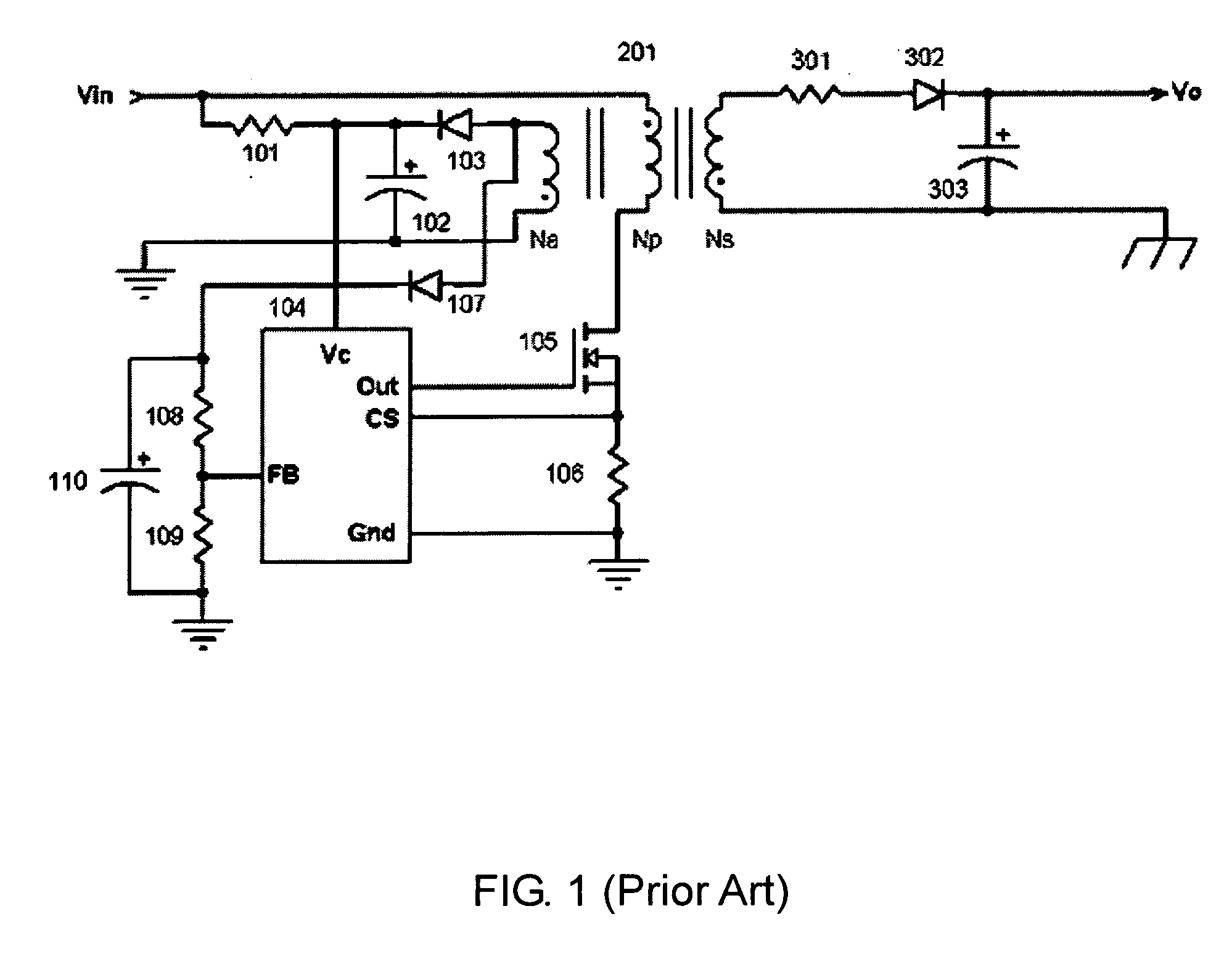

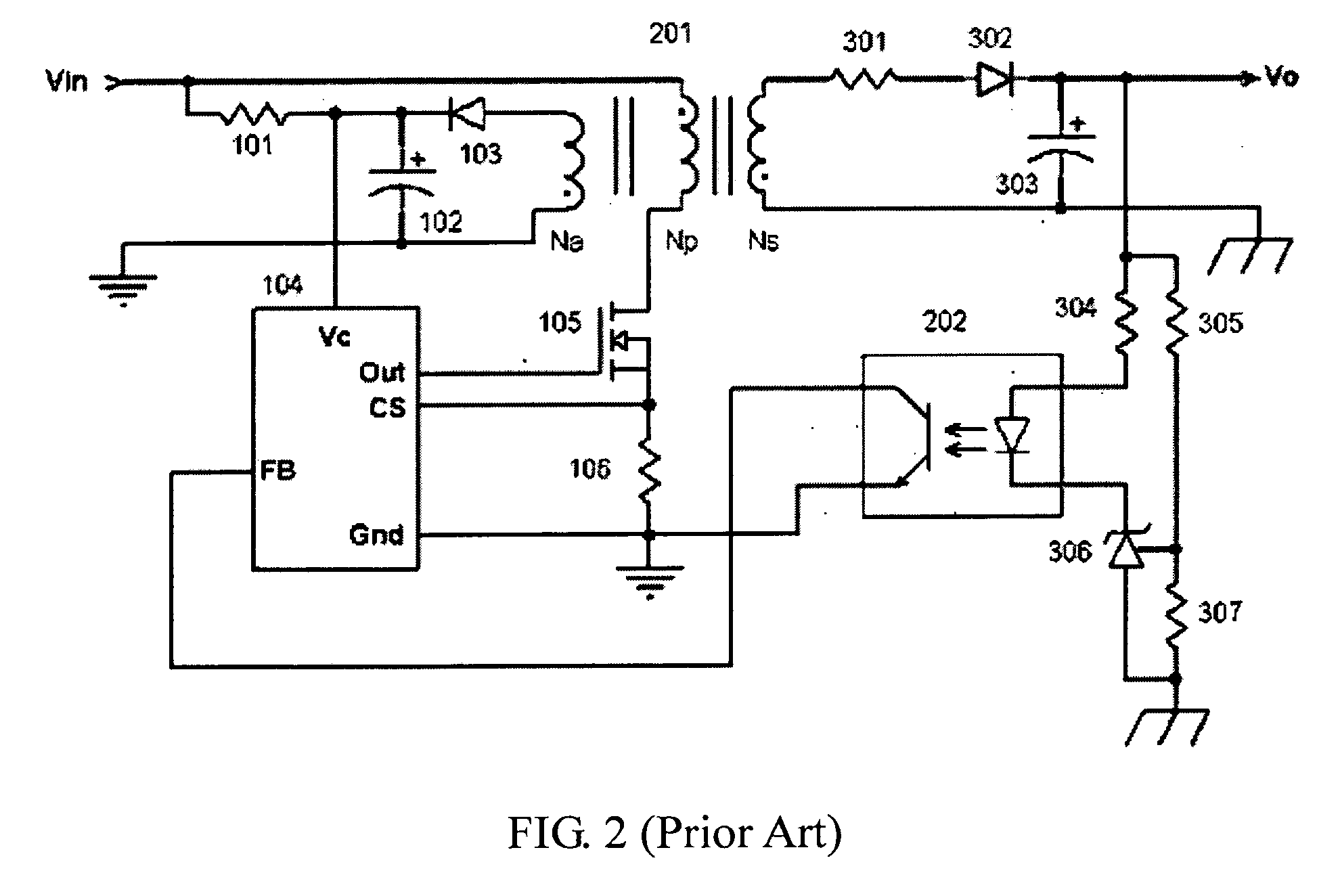

System and method for a primary feedback switched mode power supply

ActiveUS20070133234A1Reduce electromagnetic interference emissionReducing electromagnetic interference emissionDc-dc conversionElectric variable regulationAudio power amplifierControl power

A primary side controlled power converter having a voltage sensing means coupled to a transformer of the power converter and configured to provide a voltage feedback waveform representative of an output of the transformer is provided. A primary switching circuit operates to control energy storage of a primary side of the transformer. The primary switching circuit is operable during an on time and inoperable during an off time. The on and off time is switched at a system frequency. A feedback amplifier generates an error signal indicative of a difference between the voltage feedback waveform and a reference voltage. A sample and hold circuit samples the error signal at a periodic frequency during the off time. An error signal amplifier is configured to provide the sampled value to the primary switching circuit wherein the primary switching circuit controls the transformer and thereby regulates an output of the power converter.

Owner:ACTIVE SEMI

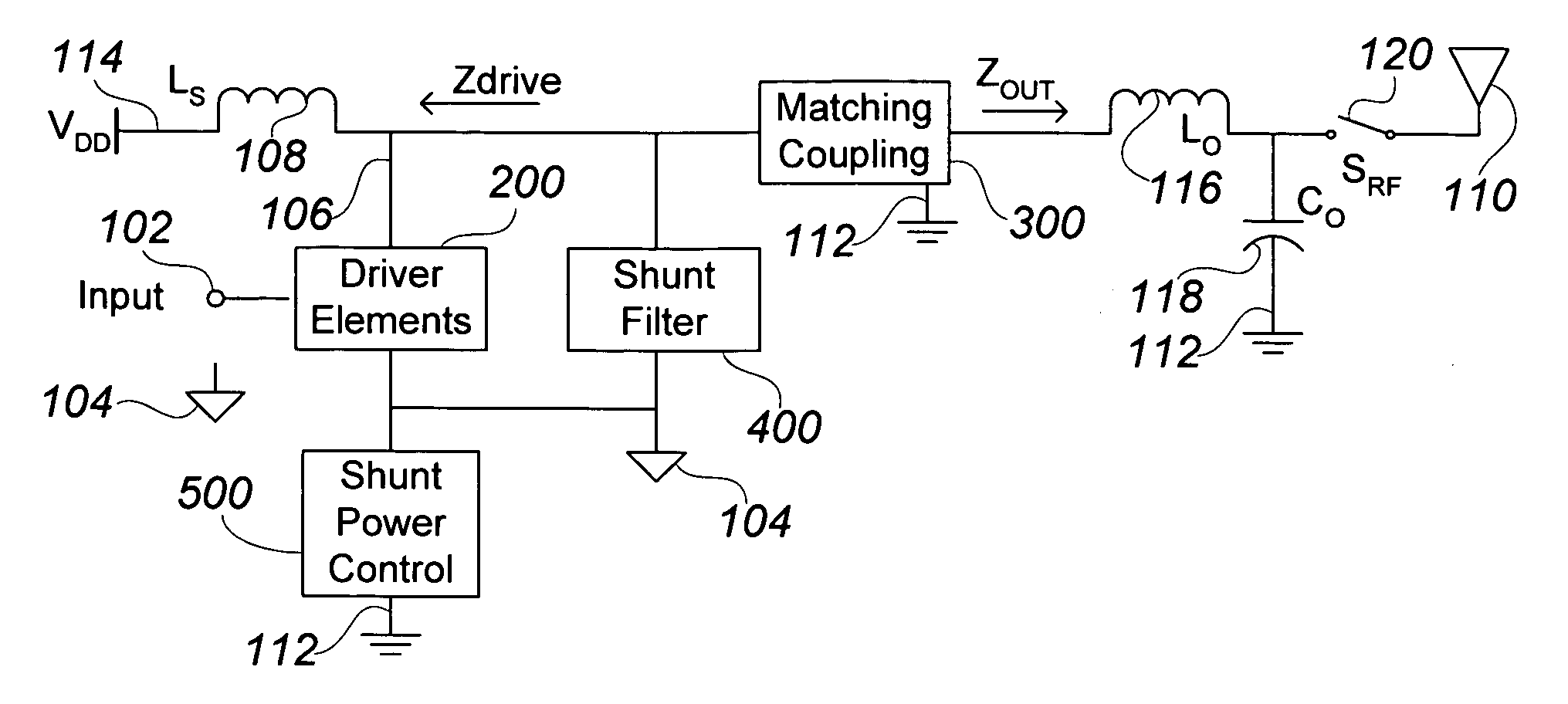

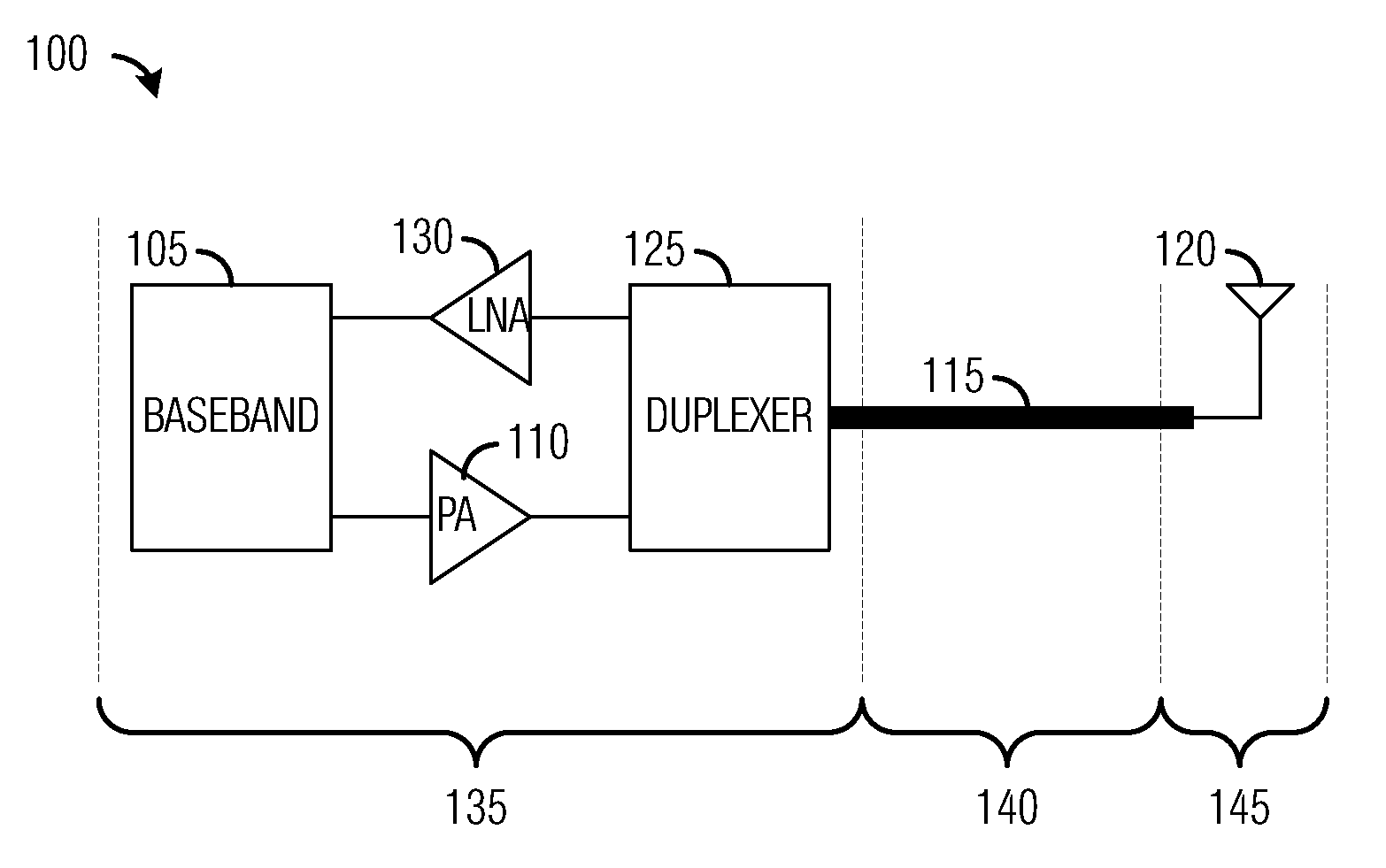

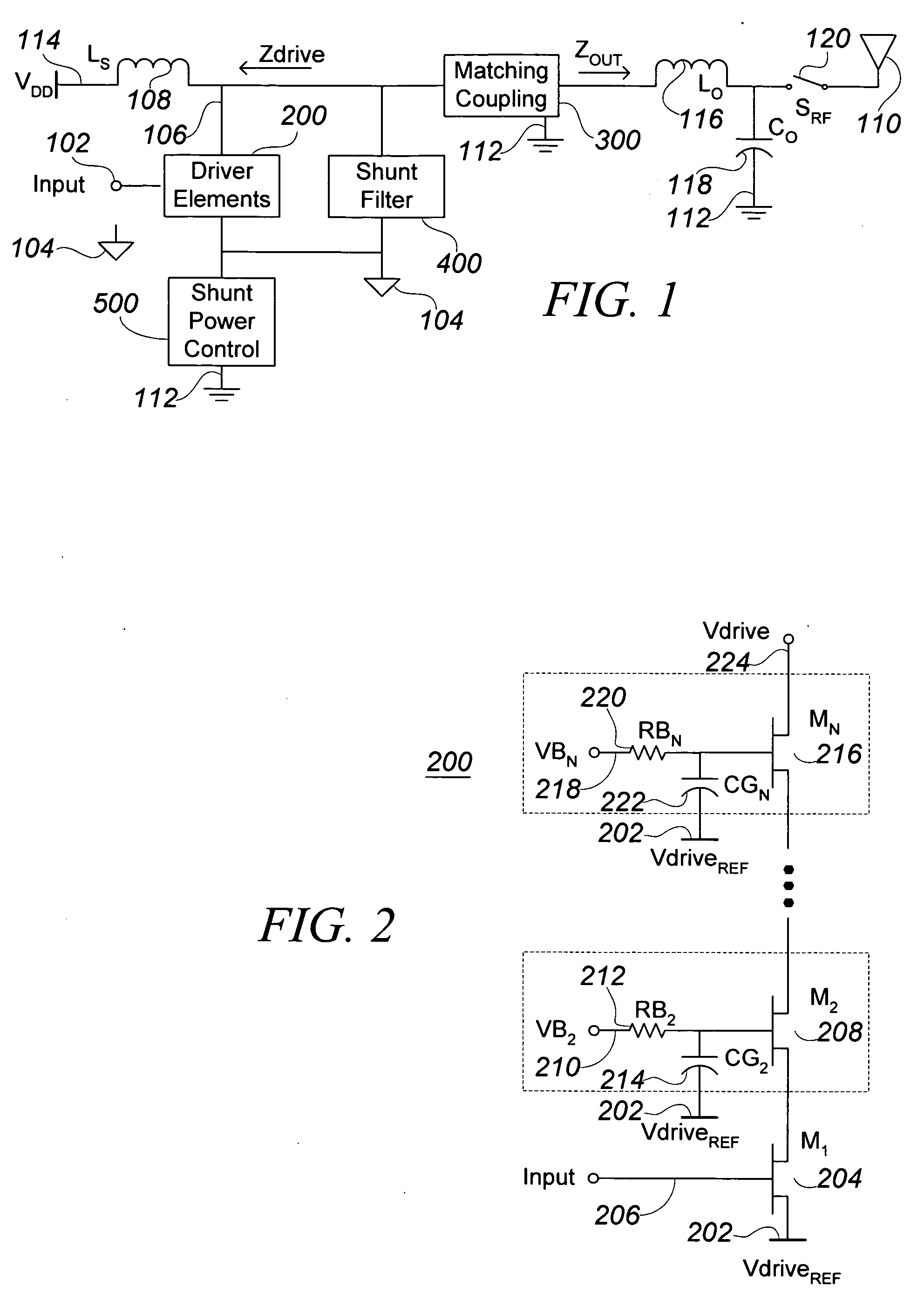

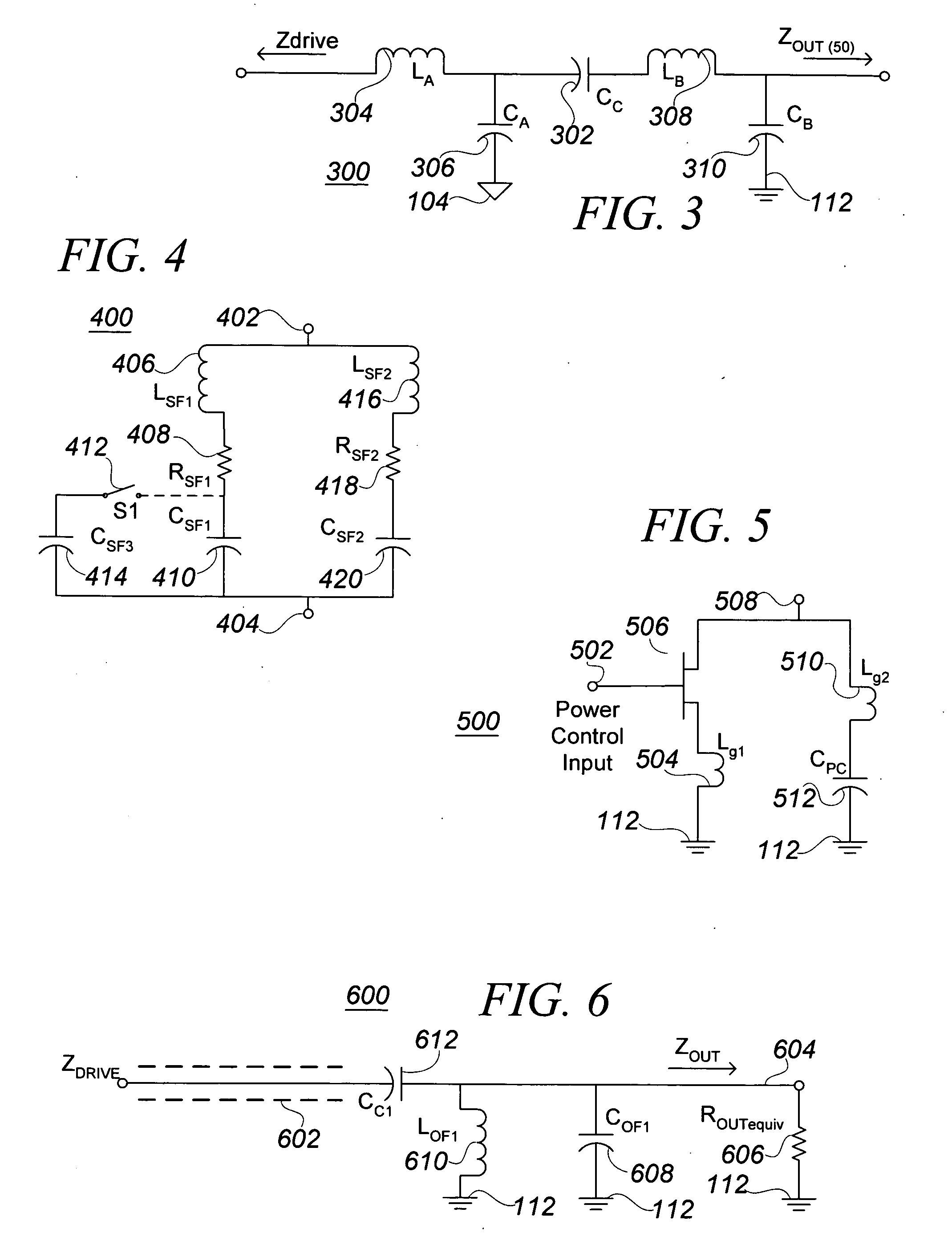

Integrated RF front end

ActiveUS7088971B2Effective protectionResonant long antennasHigh frequency amplifiersVoltage amplitudeTransceiver

A monolithic integrated circuit (IC), and method of manufacturing same, that includes all RF front end or transceiver elements for a portable communication device, including a power amplifier (PA), a matching, coupling and filtering network, and an antenna switch to couple the conditioned PA signal to an antenna. An output signal sensor senses at least a voltage amplitude of the signal switched by the antenna switch, and signals a PA control circuit to limit PA output power in response to excessive values of sensed output. Preferred fabrication techniques include stacking multiple FETs to form switching devices. An iClass PA architecture is described that dissipatively terminates unwanted harmonics of the PA output signal. A preferred embodiment of the RF transceiver IC includes two distinct PA circuits, two distinct receive signal amplifier circuits, and a four-way antenna switch to selectably couple a single antenna connection to any one of the four circuits.

Owner:PSEMI CORP

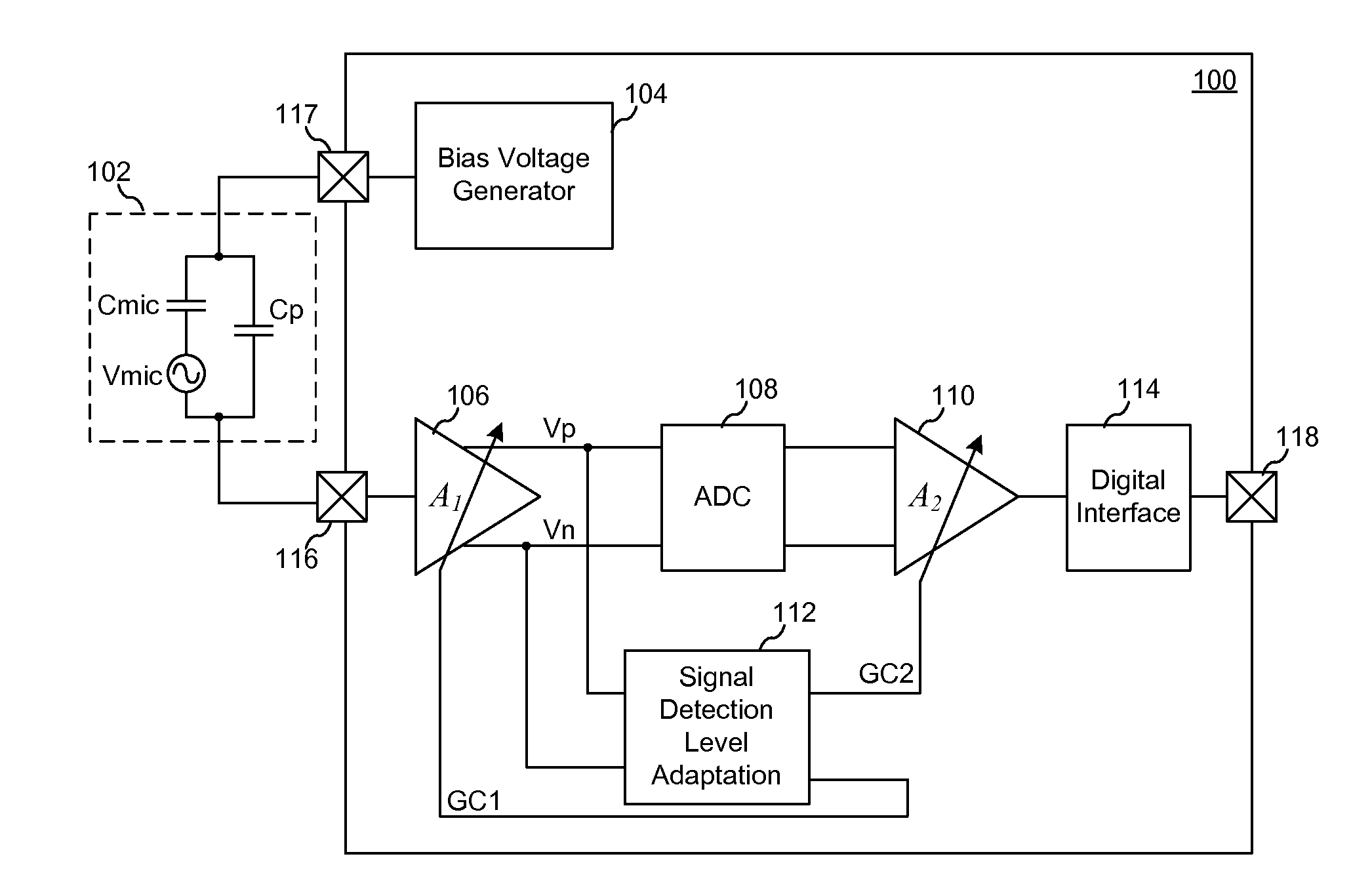

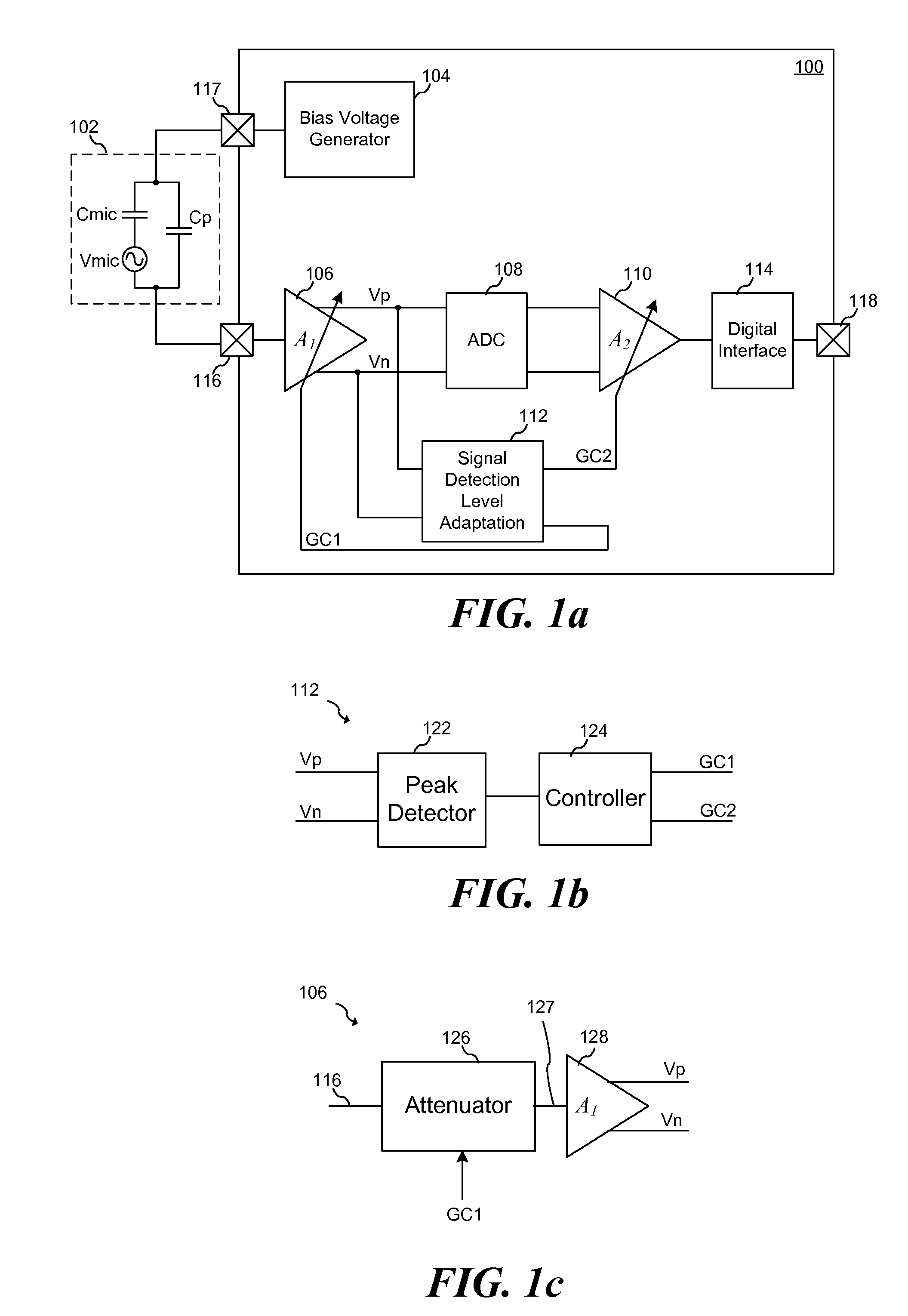

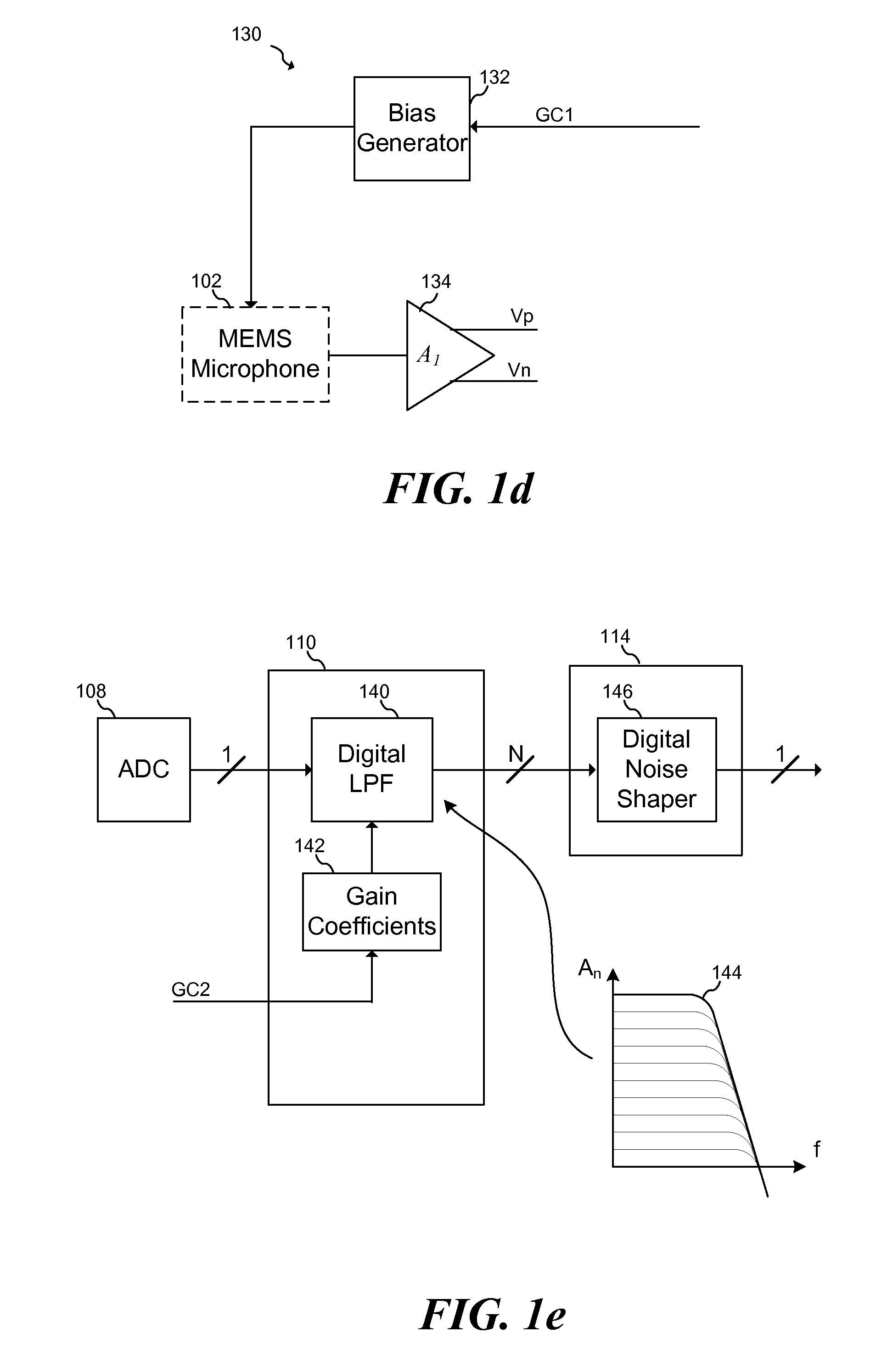

System and Method for High Input Capacitive Signal Amplifier

ActiveUS20130271307A1Electric signal transmission systemsVolume compression/expansion having semiconductor devicesCapacitanceAudio power amplifier

In accordance with an embodiment, a method includes determining an amplitude of an input signal provided by a capacitive signal source, compressing the input signal in an analog domain to form a compressed analog signal based on the determined amplitude, converting the compressed analog signal to a compressed digital signal, and decompressing the digital signal in a digital domain to form a decompressed digital signal. In an embodiment, compressing the analog signal includes adjusting a first gain of an amplifier coupled to the capacitive signal source, and decompressing the digital signal comprises adjusting a second gain of a digital processing block.

Owner:INFINEON TECH AG

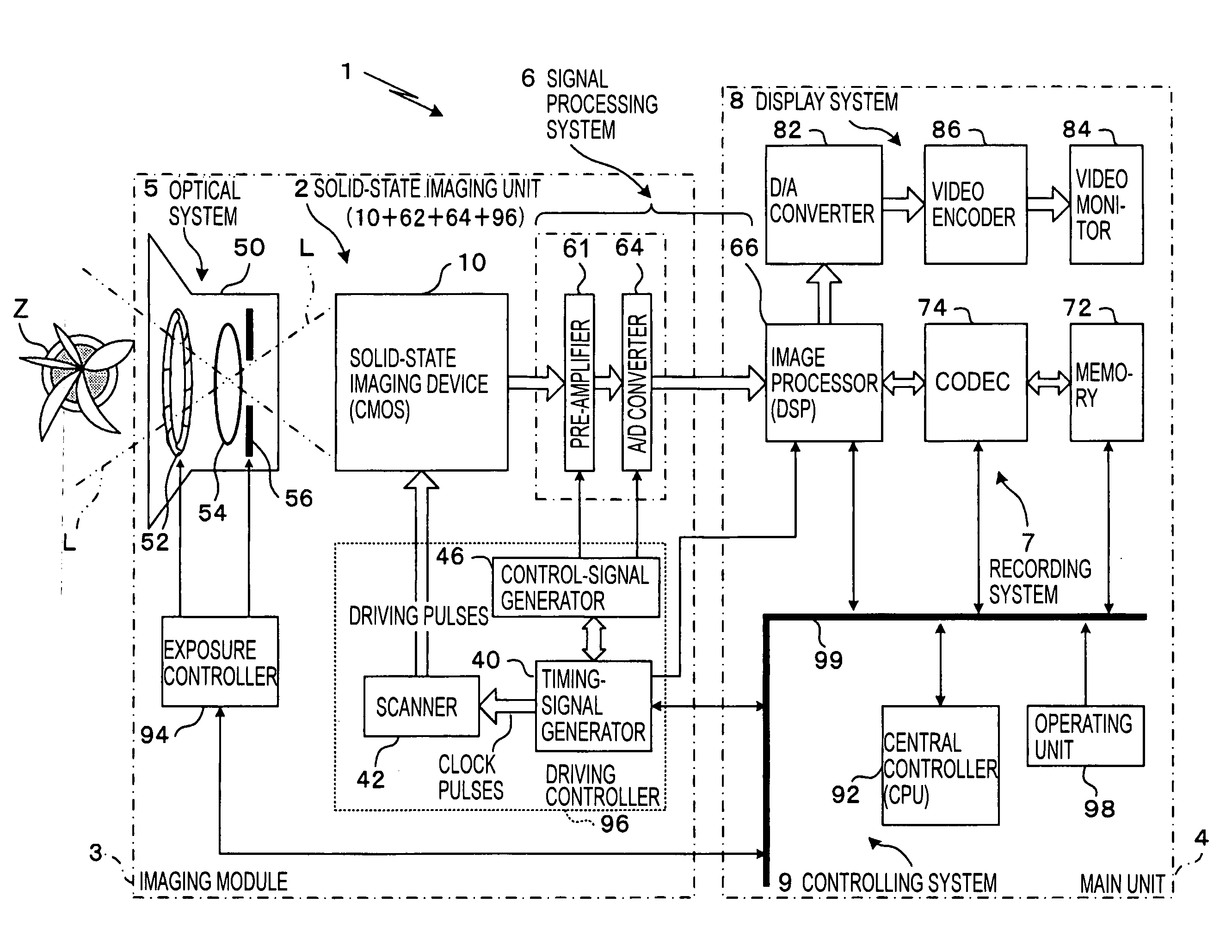

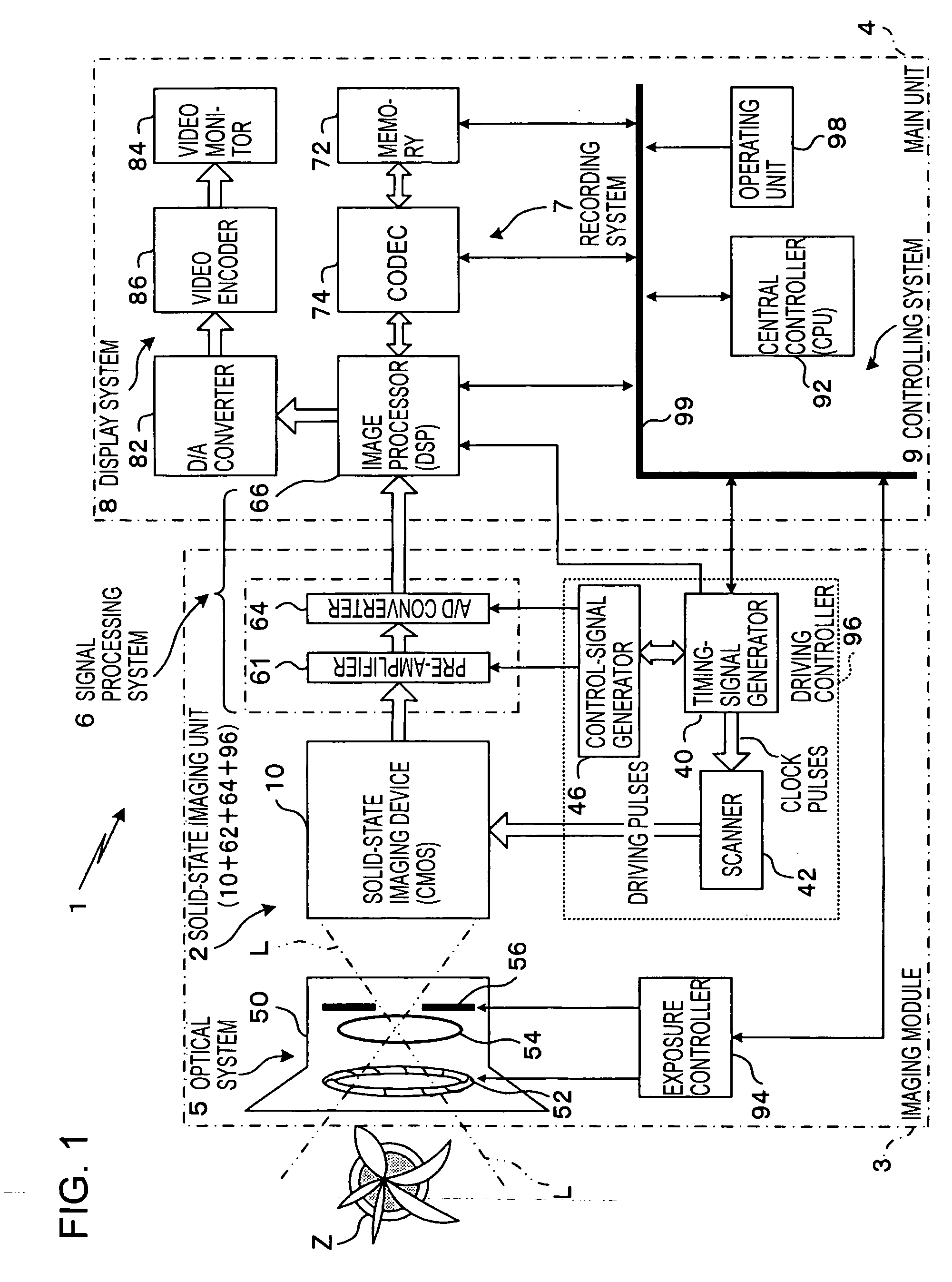

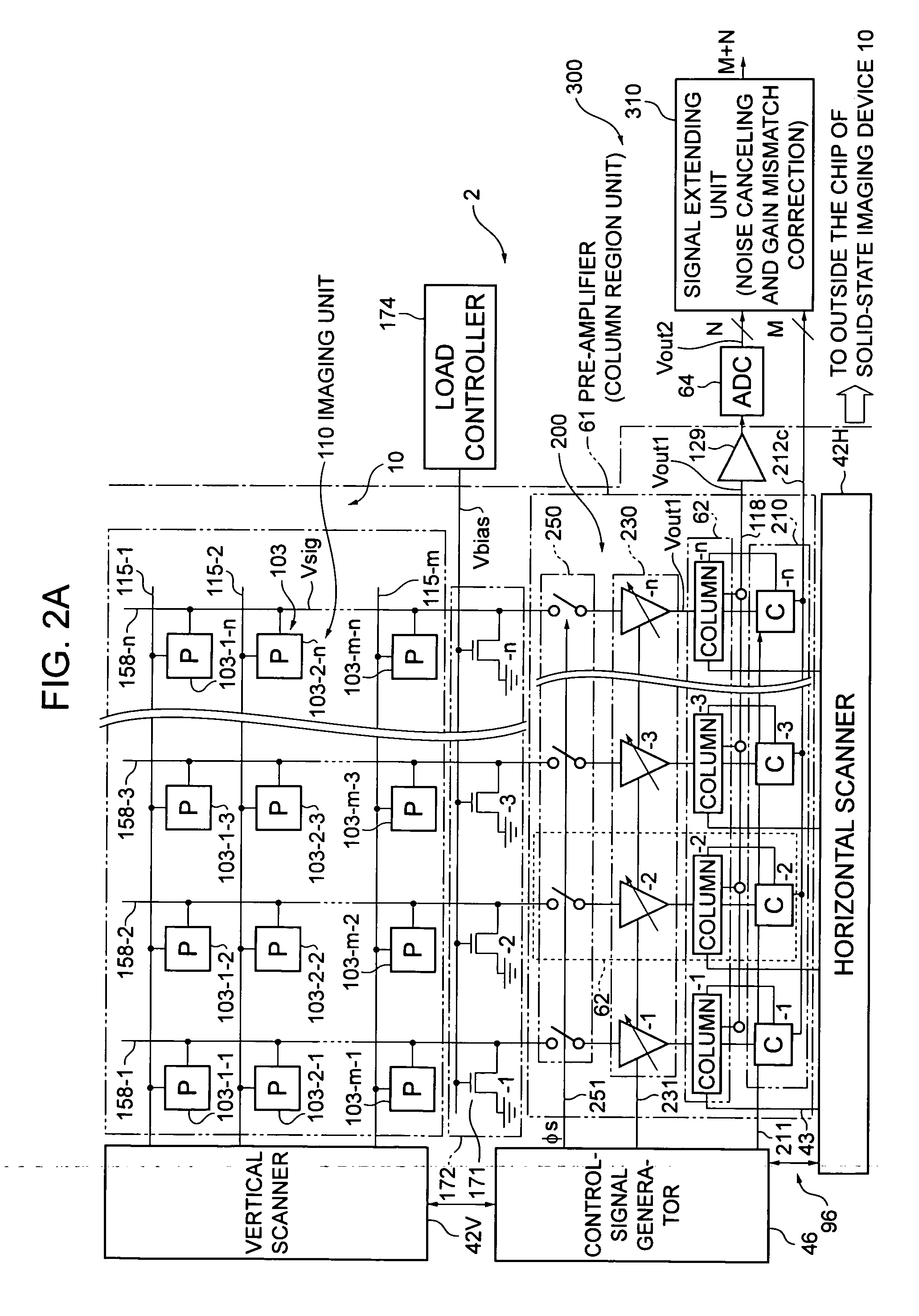

Method of controlling semiconductor device, signal processing method, semicondcutor device, and electronic apparatus

InactiveUS20050168602A1Improve signal-to-noise ratioImprove dynamic rangeTelevision system detailsTelevision system scanning detailsDevice materialEngineering

A pre-amplifier (column region unit) of a solid-state imaging device includes a pixel-signal controller. The pixel-signal controller, for each vertical signal line, detects the level of each pixel signal independently by a pixel-signal detector on the output side of a pixel-signal amplifier, and sets a gain independently to the pixel-signal amplifier according to the level of the signal. At a subsequent stage of the solid-state imaging device, an analog-to-digital (A / D) converter and a signal extending unit are provided. The A / D converter digitizes a pixel signal, and the digitized pixel signal is corrected by a gain set to the pixel-signal amplifier with reference to a classification signal from the pixel-signal detector, so that the dynamic range of signals of one screen is extended.

Owner:SONY CORP

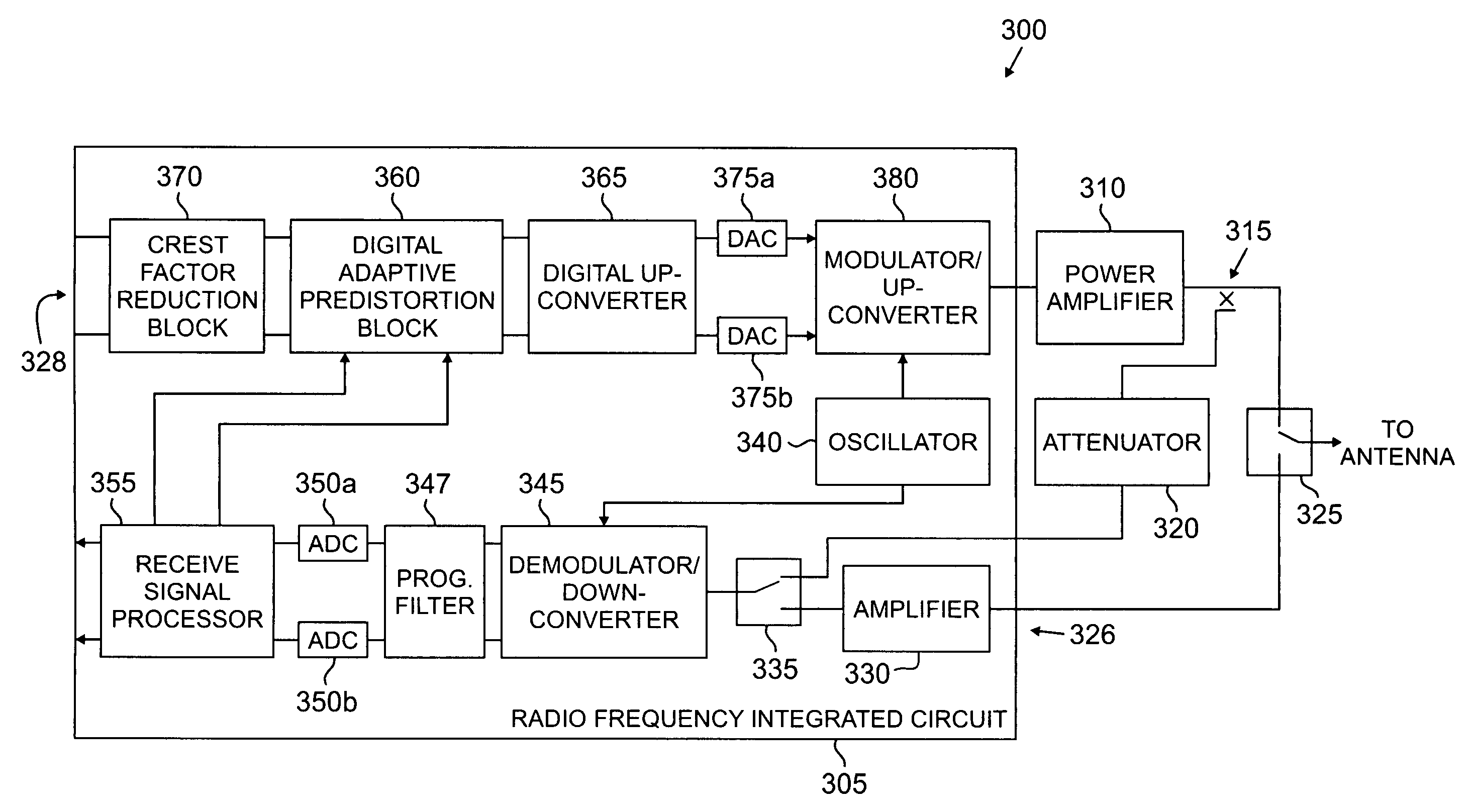

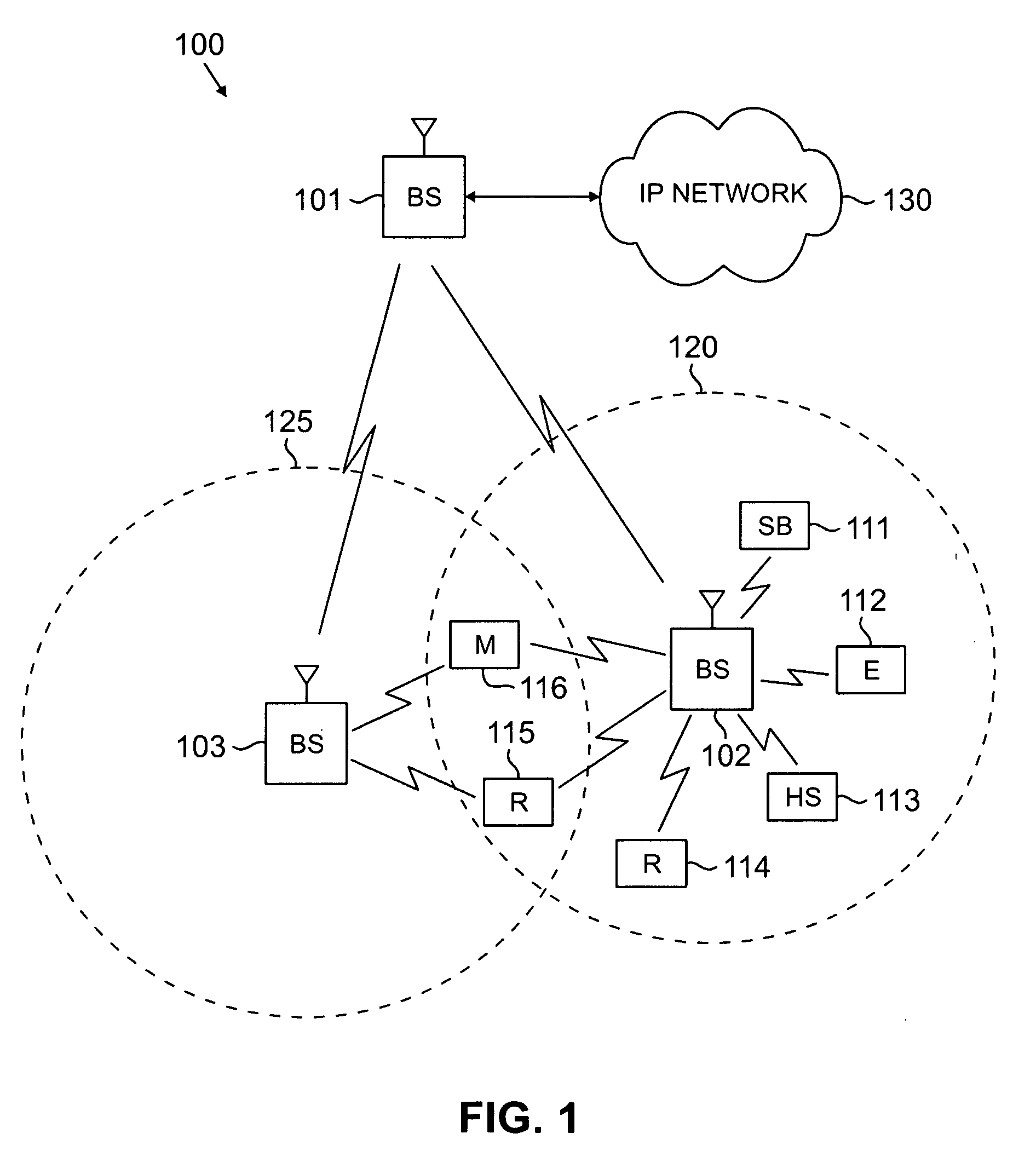

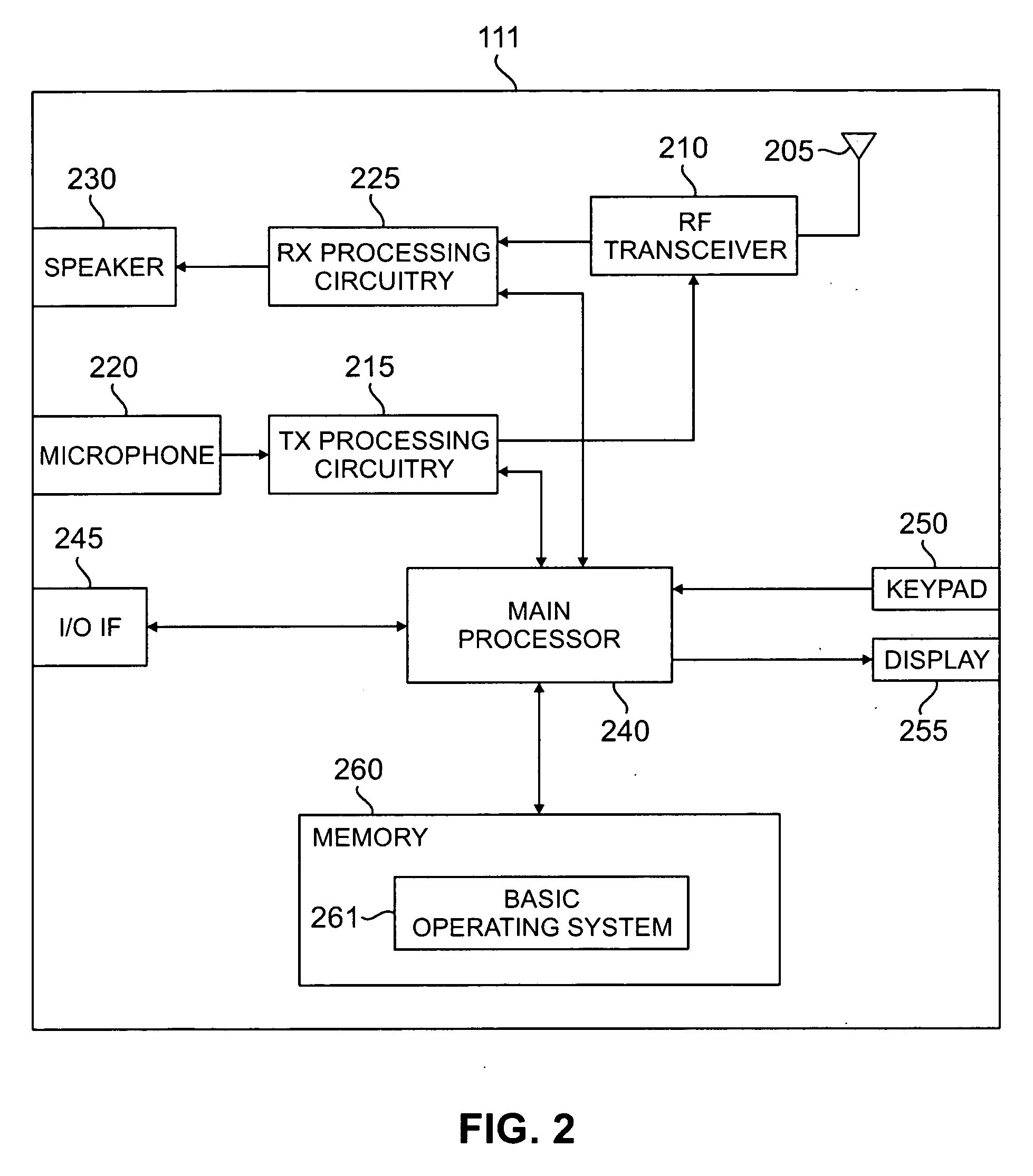

Method and system for providing digital adaptive predistortion in a subscriber station

A method for providing digital adaptive predistortion in a subscriber station is provided that includes applying predistortion, based on a set of predistortion characteristics, to a transmit signal to generate a predistorted signal. An amplifier input signal is generated based on the predistorted signal. The amplifier input signal is amplified to generate an amplified signal. The amplified signal is sampled to generate a sampled signal. The sampled signal is processed through a receive channel of the subscriber station to generate a processed signal. A determination is made regarding whether to adjust the set of predistortion characteristics based on the processed signal.

Owner:SAMSUNG ELECTRONICS CO LTD

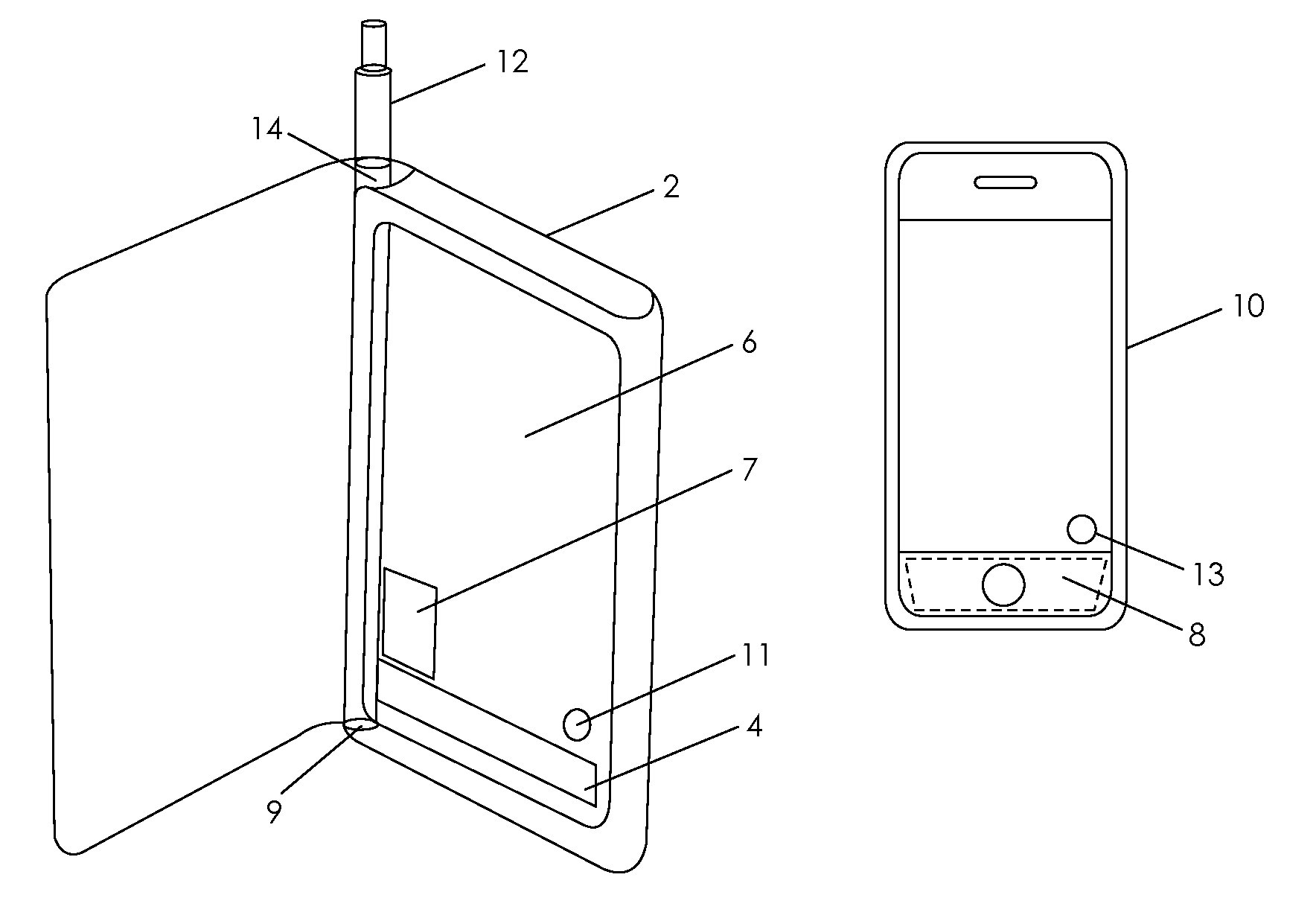

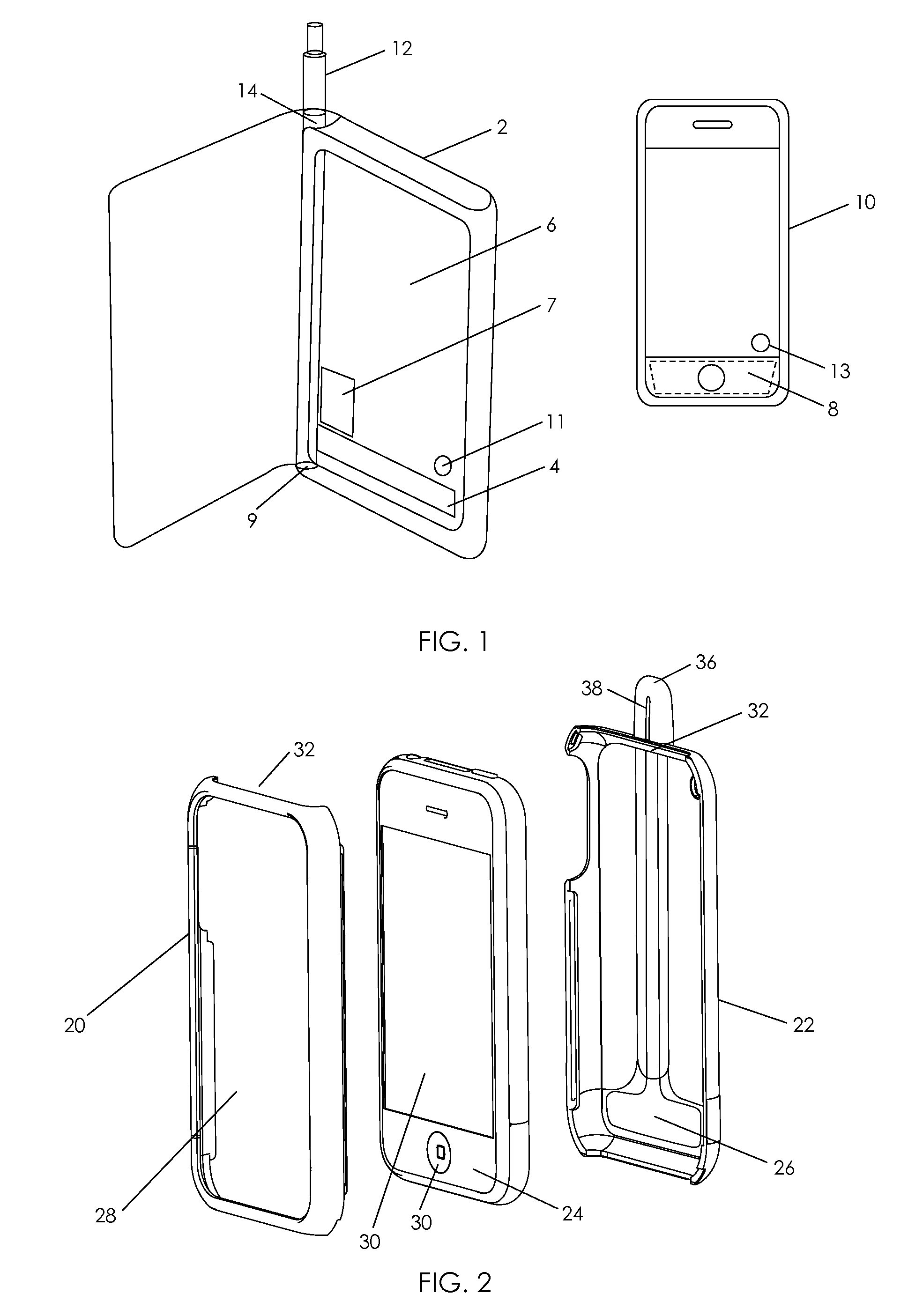

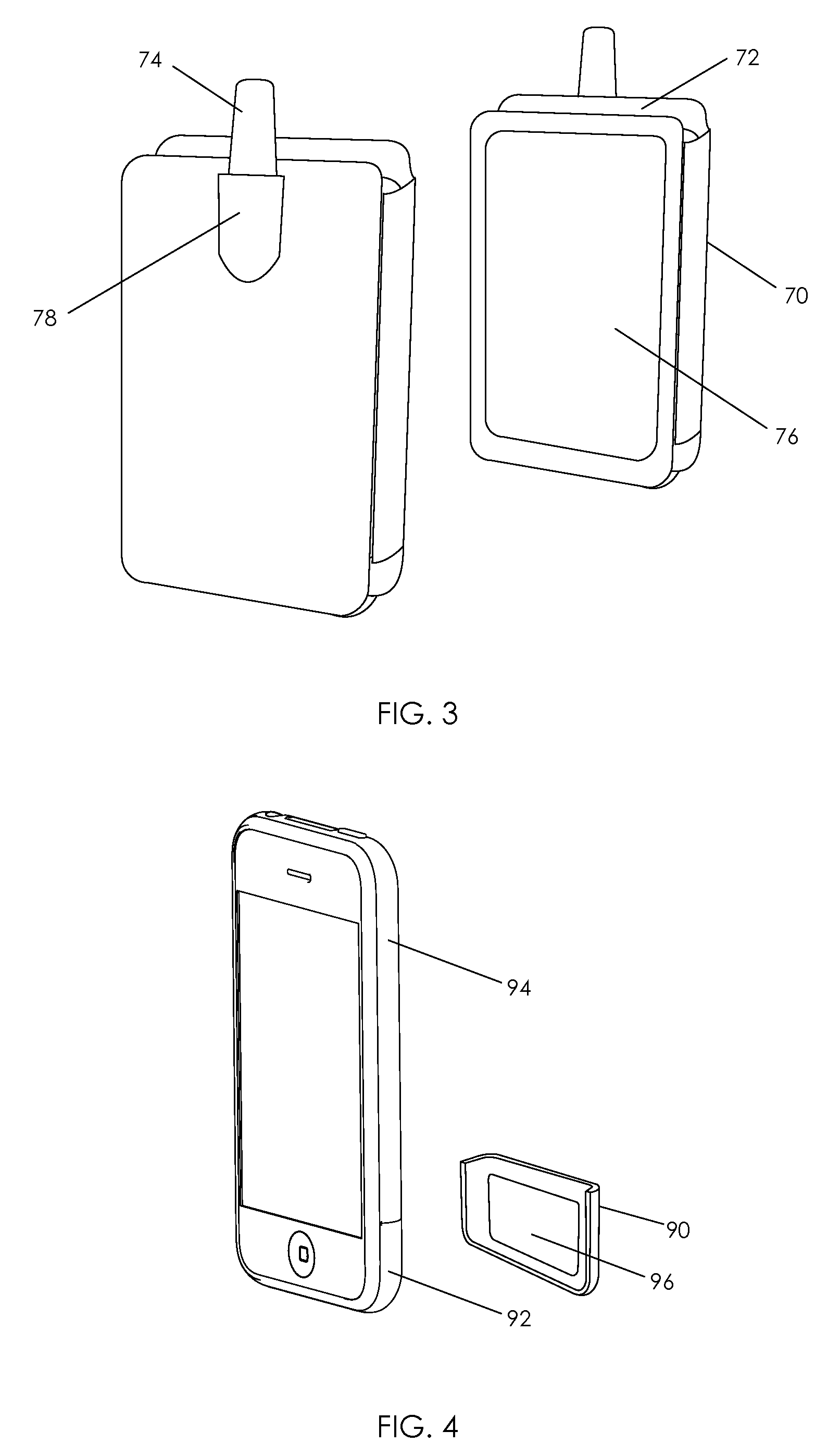

Reception Boosting Accessory

InactiveUS20090181735A1Easy to receiveEnhanced signalSubstation equipmentAntenna detailsAudio power amplifierCoupling

A carrying case for a portable electronic device includes a coupling element that couples to an antenna of the device without establishing a direct electrical connection. The coupling element increases the reception of the device by increasing the effective size of the antenna. The coupling element is designed to correspond to the reception capabilities of the device for which the case is designed. Preferably, the coupling element is a copper foil that is positioned in the case such that it is adjacent the antenna of the device when the device is held within the case. The copper foil is shaped to correspond to a profile of the device. An antenna and signal amplifier can be used in connection with the coupling element to further boost the device's reception capability.

Owner:VINCI BRANDS LLC

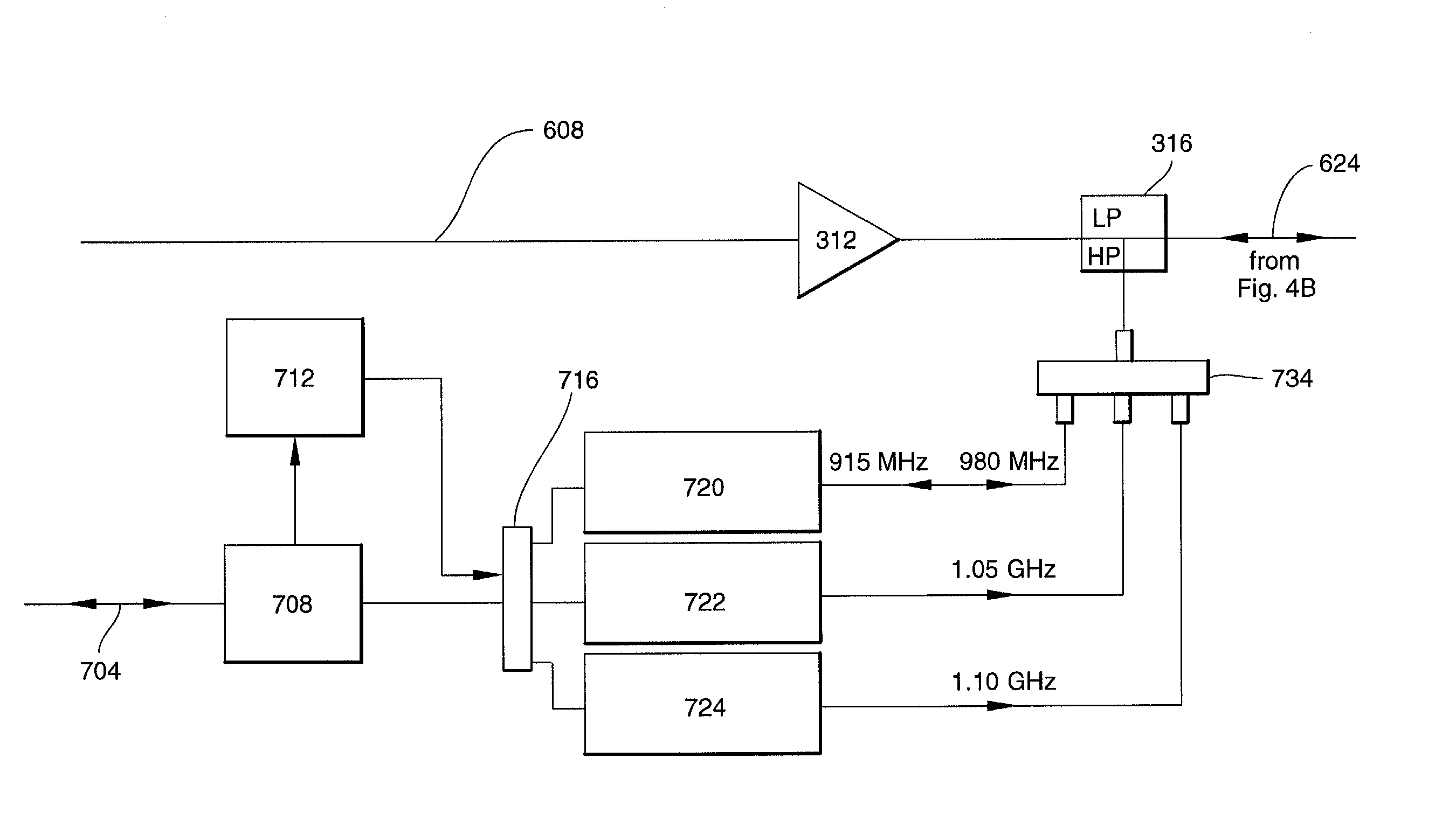

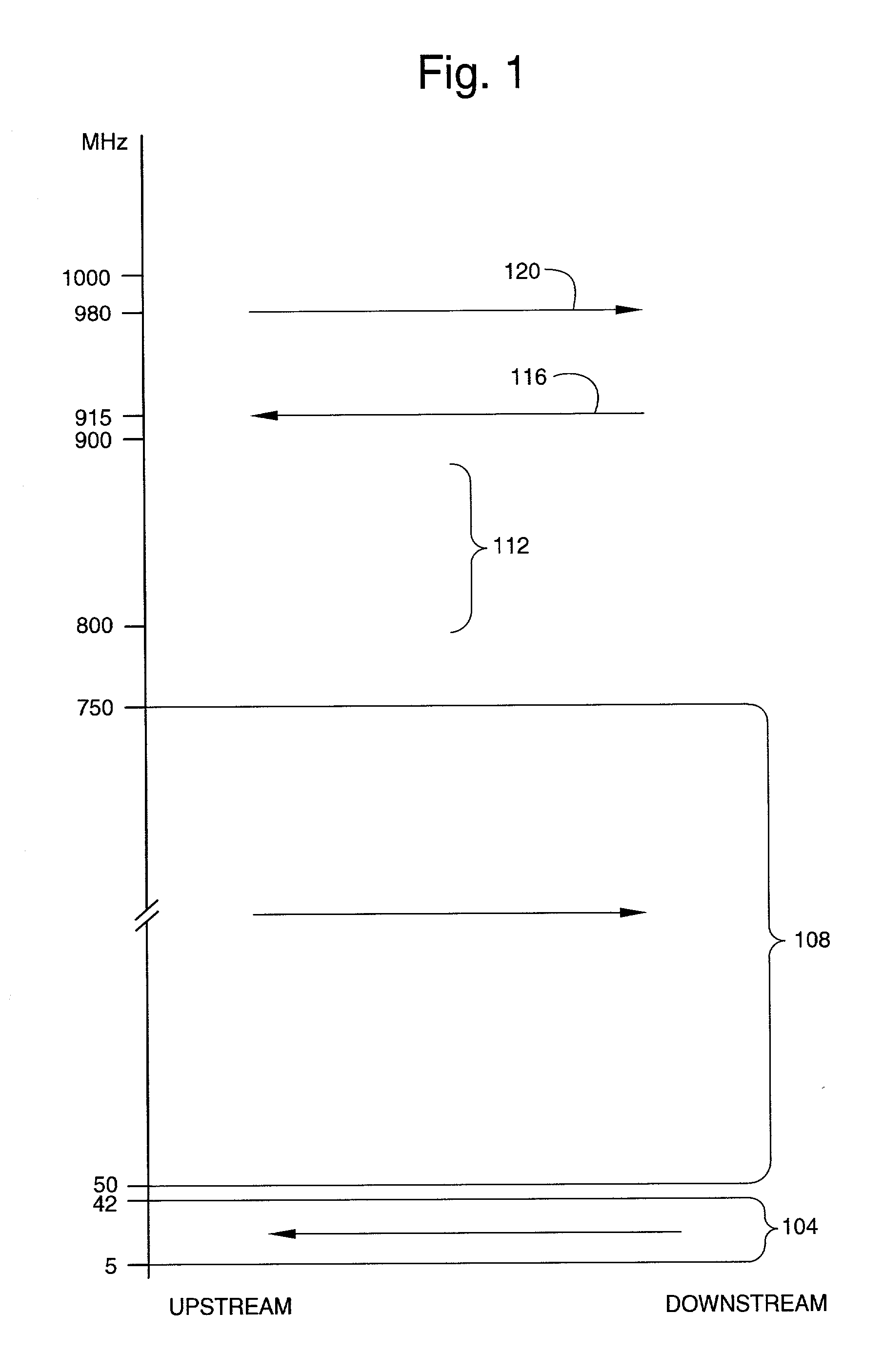

Multi-band coax extender for in-building digital communication systems

InactiveUS20020116720A1Increase data capacityError prevention/detection by using return channelBroadband local area networksMulti bandModem device

A method and system to expand digital transmission capacity in a "tree and branch" coax distribution system employing distributed TV signal amplifiers. Specifically, a number of separate bands are used in a main feeder cable that are frequency shifted and applied to a number of local coax distribution networks. In the preferred embodiment each of the local coax distribution networks use the same pair of upstream and downstream frequencies. Using identical pairs of upstream and downstream frequencies allows the use of a single standardized non-tuning end-user data interface (client modem), that can be connected to any of the local coax distribution networks. This abstract is provided as a tool for those searching for patents, and not as a limitation on the scope of the claims.

Owner:COAXMEDIA

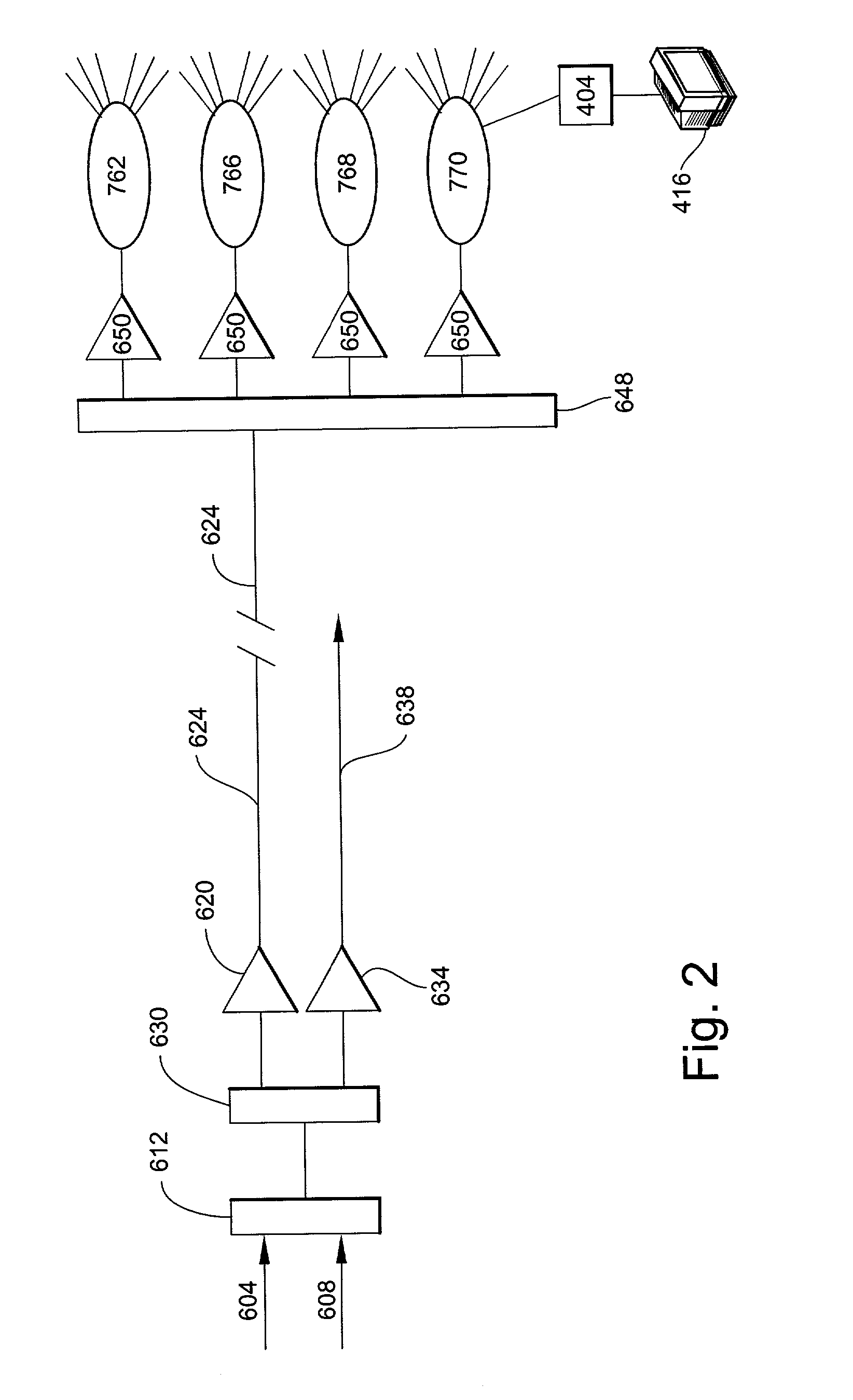

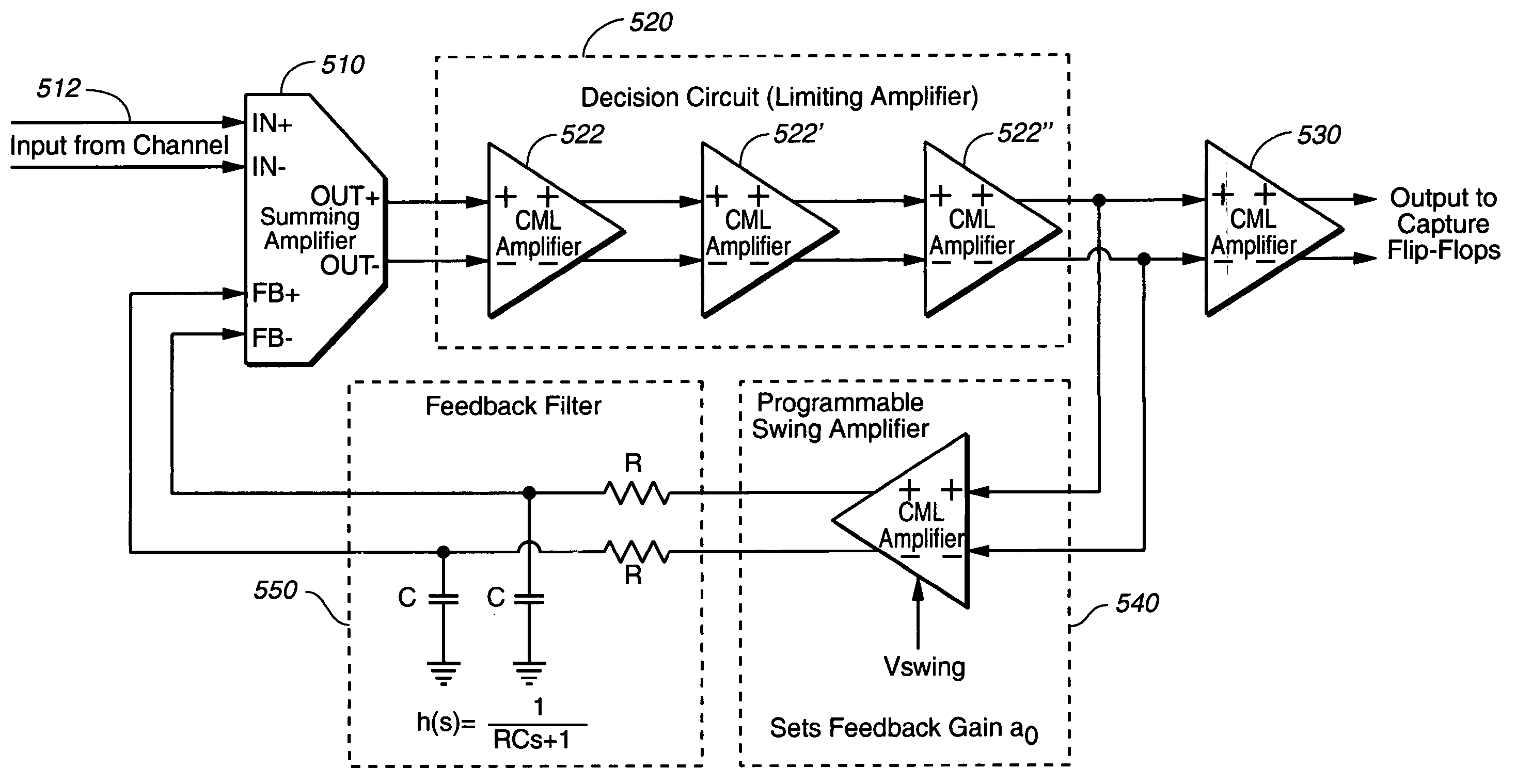

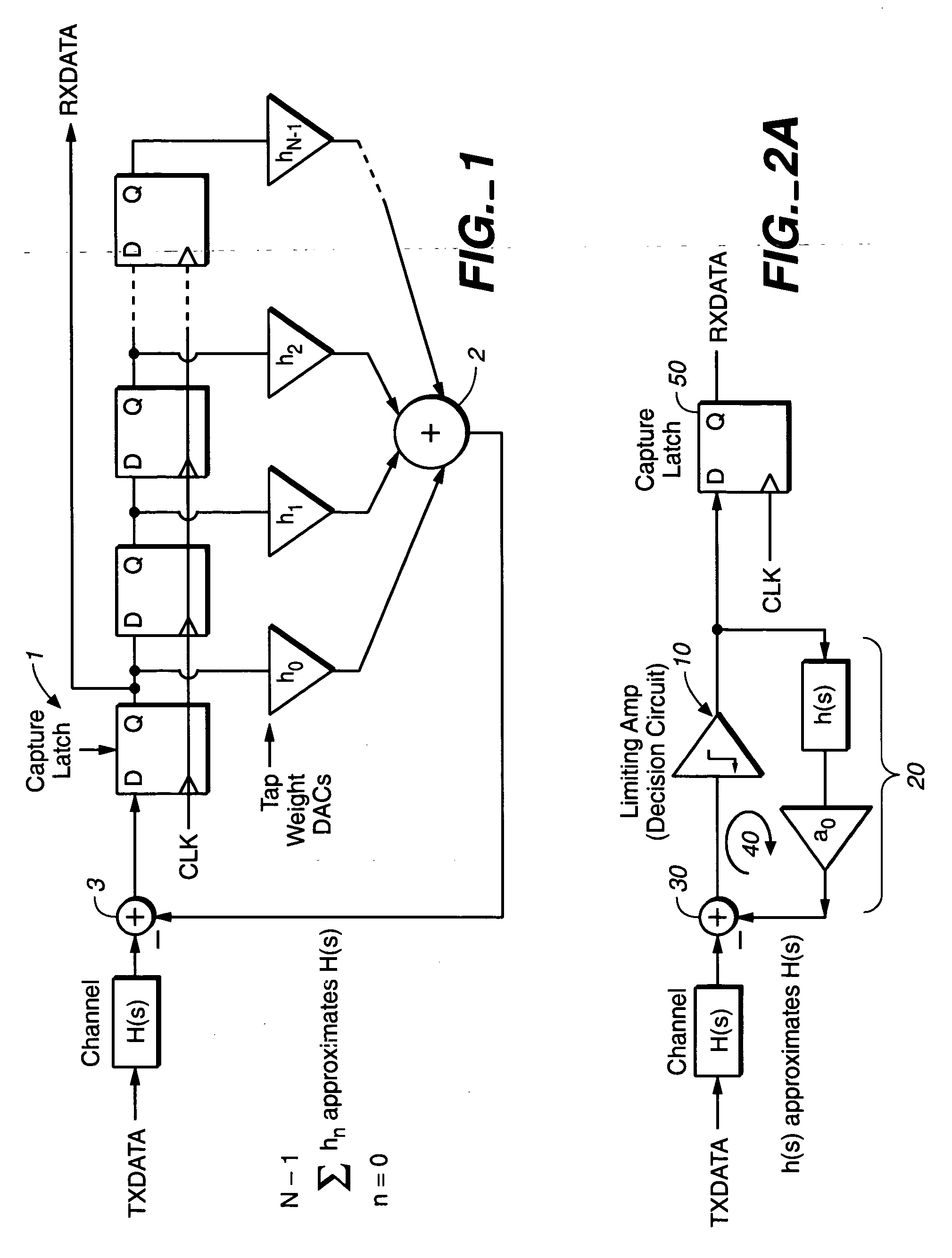

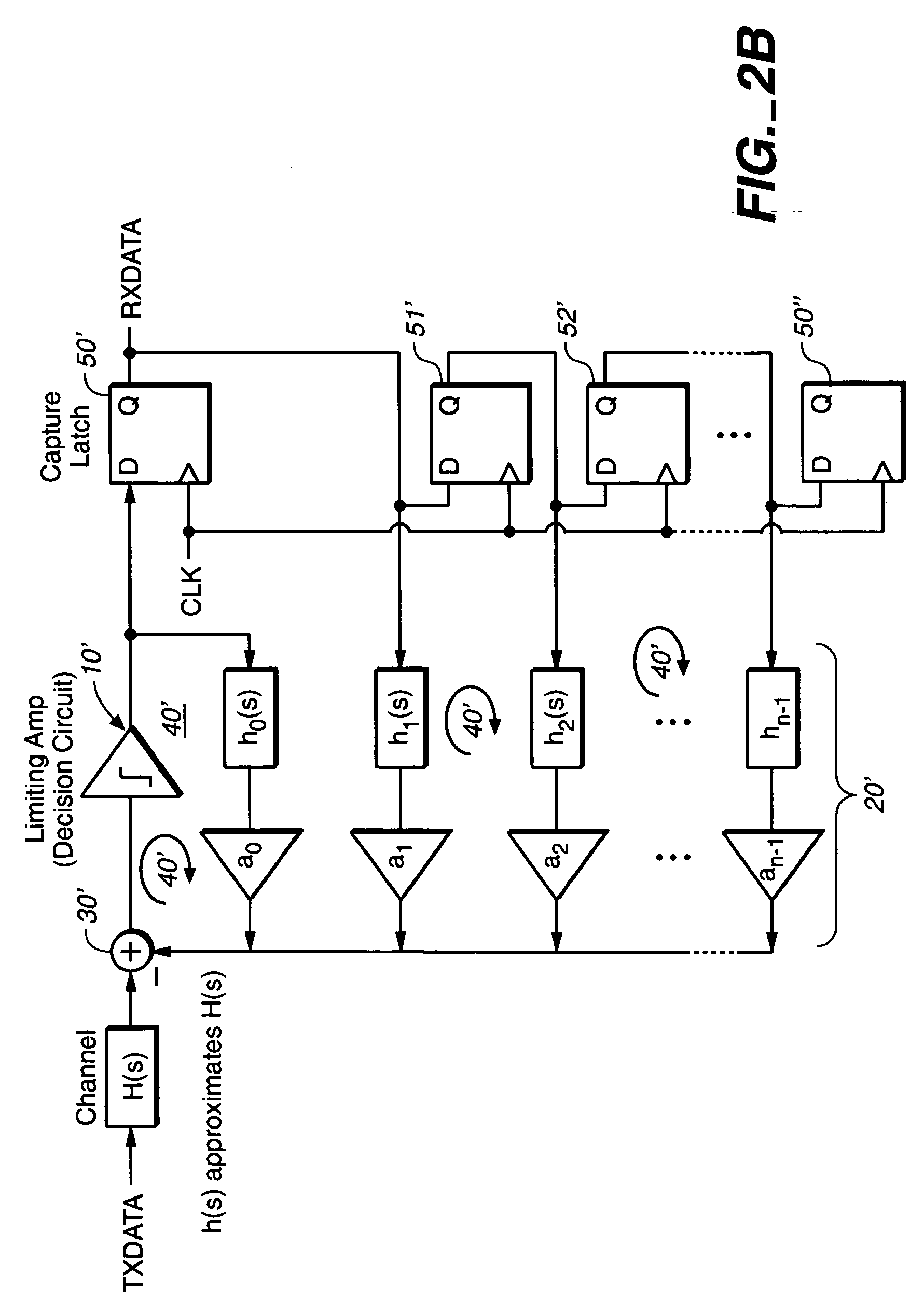

Continuous-time decision feedback equalizer

ActiveUS20060239341A1Low costSimple circuitMultiple-port networksDelay line applicationsNegative feedbackDecision circuit

A continuous-time domain Decision Feedback Equalizer (DFE) for use in a serial communication channel comprises in one embodiment a summer, a decision circuit, a capture flip-flop (FF) and an N-th order active filter. The DFE and its active filter operate in continuous time to give improved performance over a discrete-time DFE. In one embodiment involving a first-order active filter, the capture FF is outside the continuous-time negative feedback loop of the DFE and involves a differential signal amplifier. In another embodiment, the capture flip-flop is inside the DFE loop, and in a third embodiment the decision circuit comprises a comparator.

Owner:AVAGO TECH INT SALES PTE LTD

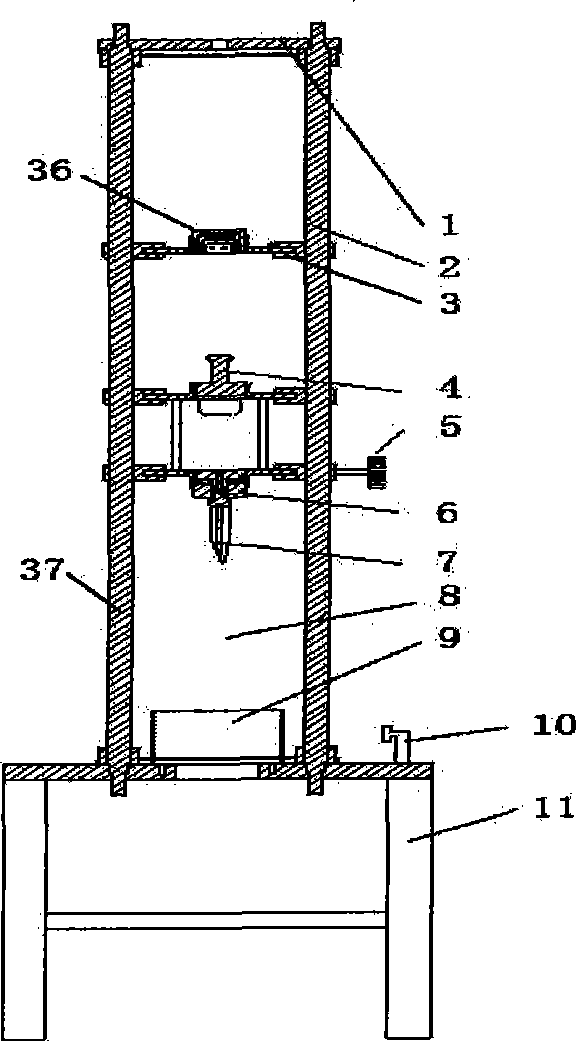

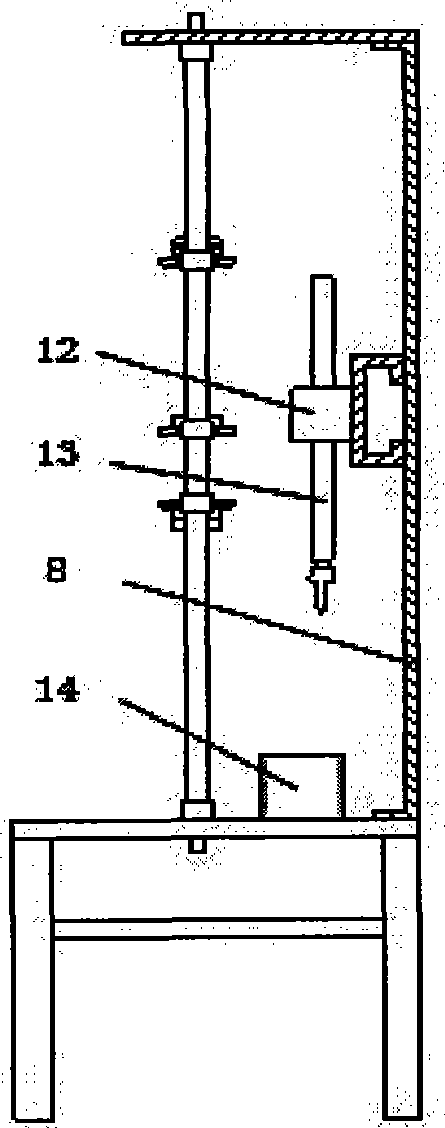

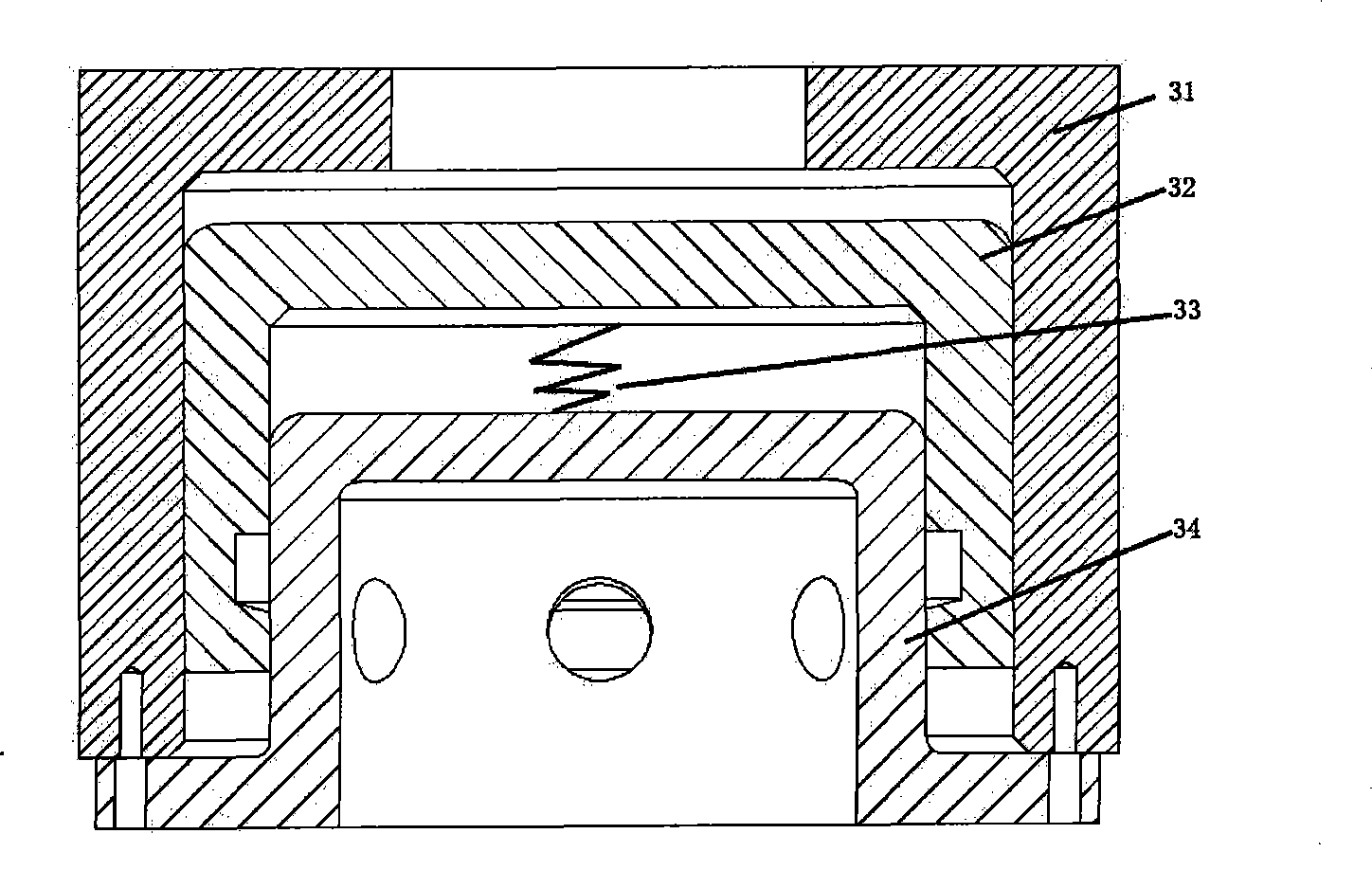

Multifunction flexible composite material impact test apparatus

The invention discloses a falling multifunctional measuring device for an impact test of soft composite materials, comprising an impact test unit. The device is also provided with a transient force and displacement testing unit which comprises a sensor supporting sleeve, a piezoelectric force sensor, a grating bar, a photoelectric sensor, a stabilized voltage supply, a charge amplifier and a signal amplifier. The testing unit can be arranged in the impact test unit in a detachable way; the piezoelectric force transducer is positioned in the sensor supporting sleeve, and the input end thereof is connected with the charge amplifier; the sensor supporting sleeve is arranged at the upper end of a hammer head; the grating bar and the sensor supporting sleeve are positioned at the same horizontal line; the grating bar can move synchronously with the hammer head and a base thereof is provided with the photoelectric sensor; the photoelectric sensor is positioned below the grating bar and the excitation voltage thereof is provided by the stabilized voltage supply; and the signal output end of the photoelectric sensor is connected with the signal amplifier. The device has simple structure, high integration level and low cost, and can provide testing data of composite materials in a small energy test.

Owner:NANJING UNIV OF SCI & TECH

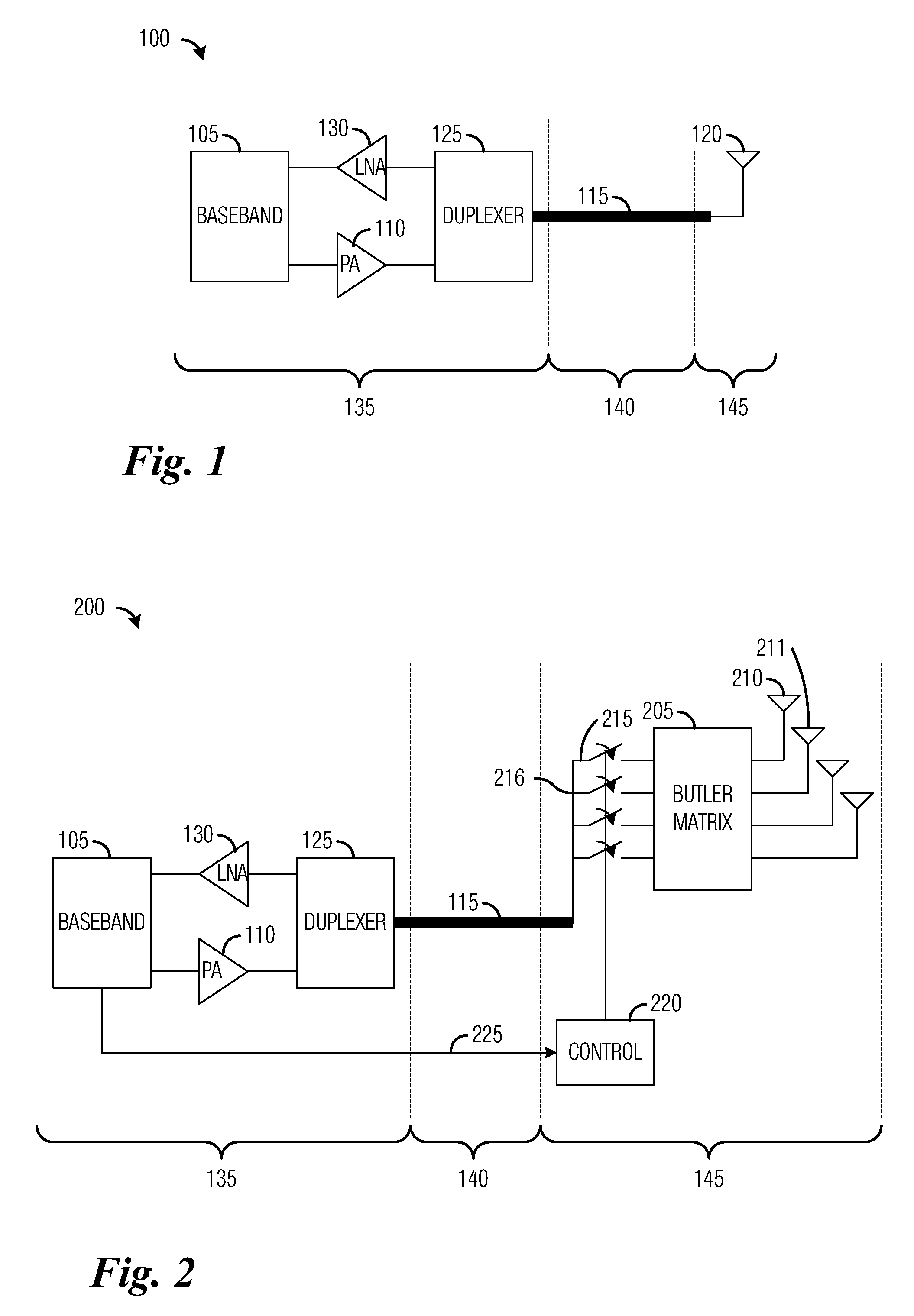

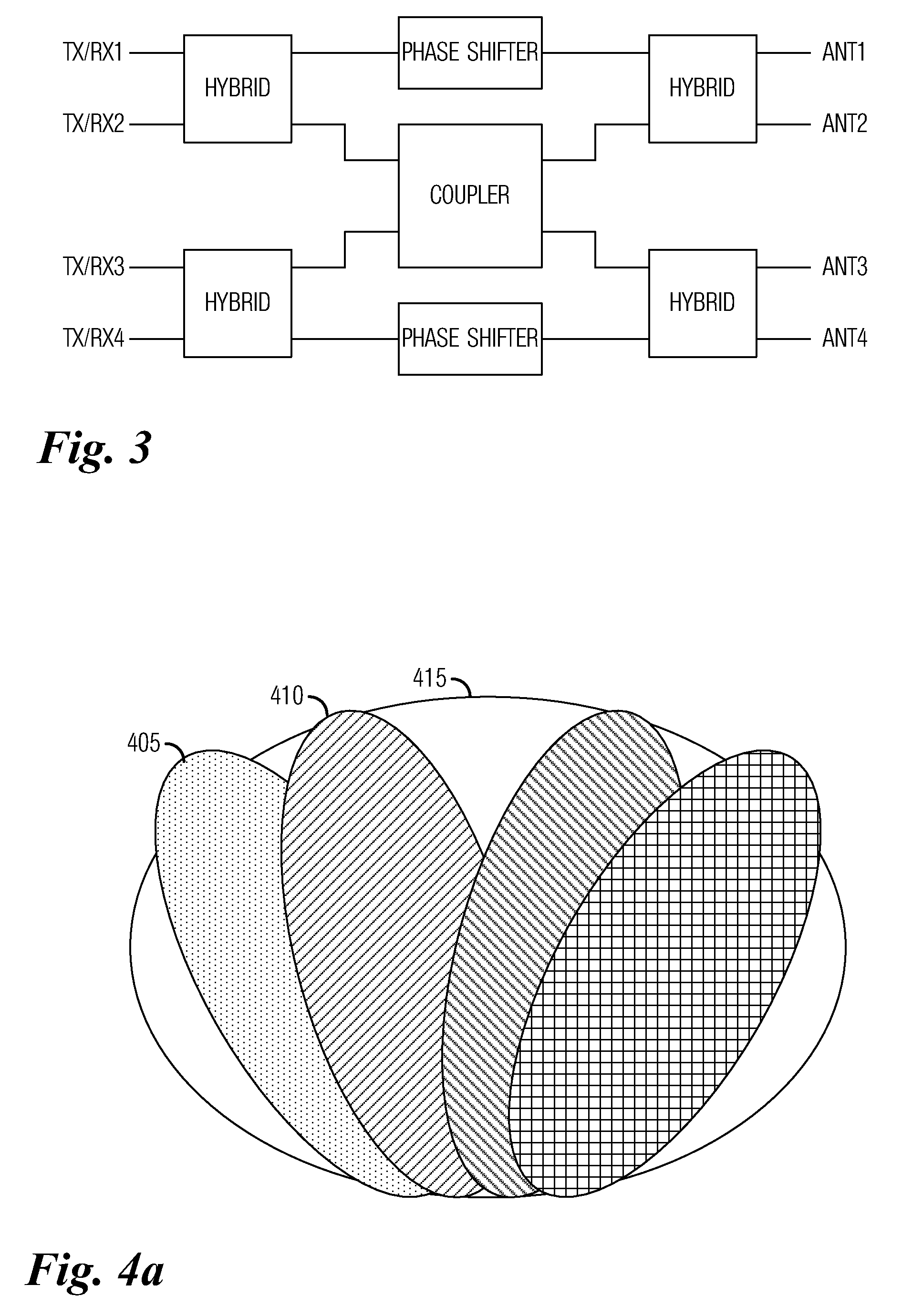

System and Method for Wireless Communications

ActiveUS20090253387A1Improve performanceLow implementation costPolarisation/directional diversitySubstation equipmentCommunications systemAudio power amplifier

A system and method for wirelessly communicating using beamswitching is provided. A communications system includes a high-power signal cable coupled to a signal amplifier, a radio frequency circuit coupled to the high-power signal cable, and a control unit coupled to the radio frequency circuit. The high-power signal cable conveys a transmission signal produced by the signal amplifier. The radio frequency circuit includes a plurality of antennas, a passive network having a plurality of output ports and a plurality of input ports, each output port coupled to an antenna of the plurality of antennas, and a plurality of switches coupled to the high-power signal cable, each switch coupled to an input port in the plurality of input ports. The control unit produces the control signal based on a specified coupling of the high-power signal cable to the passive network.

Owner:FUTUREWEI TECH INC

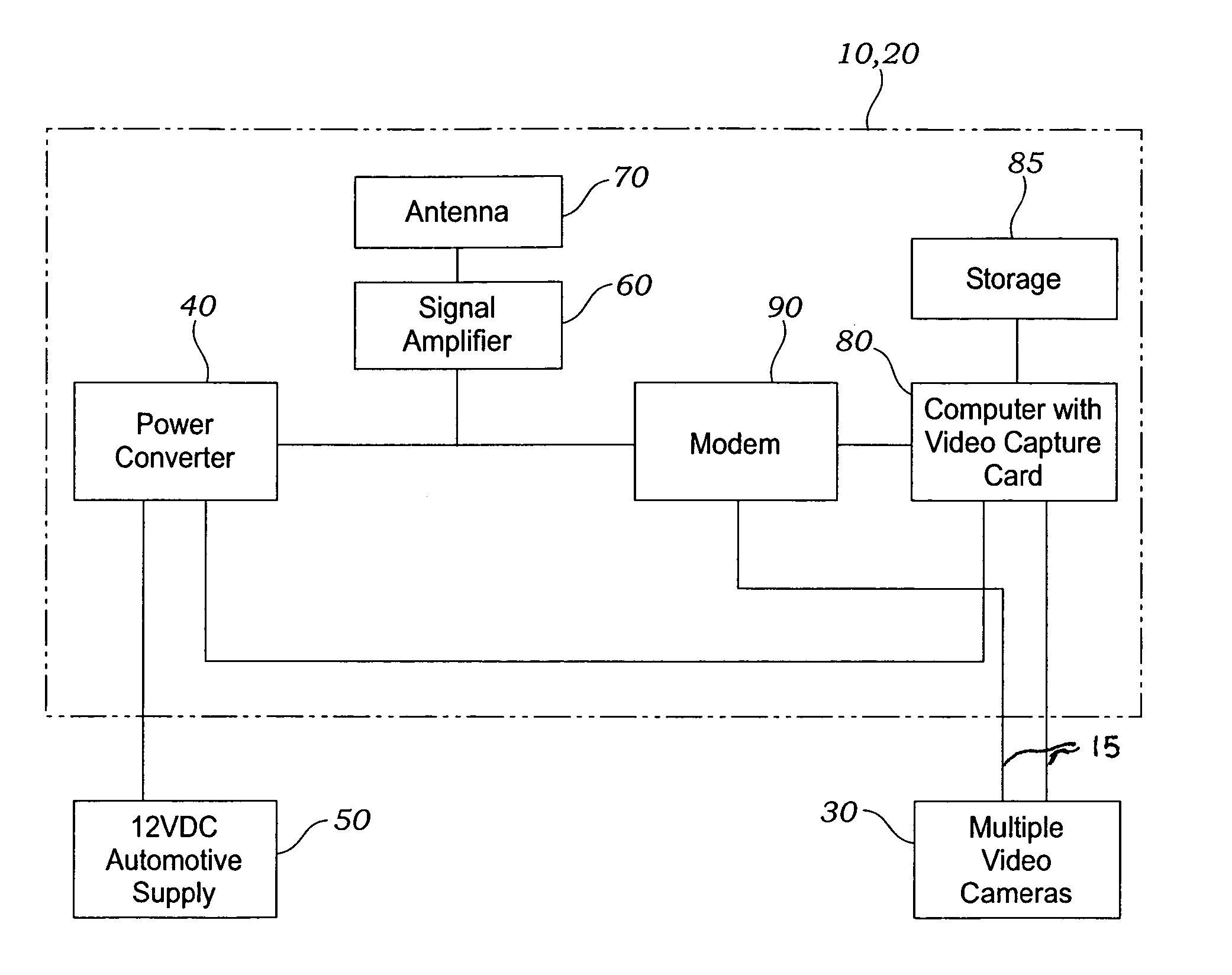

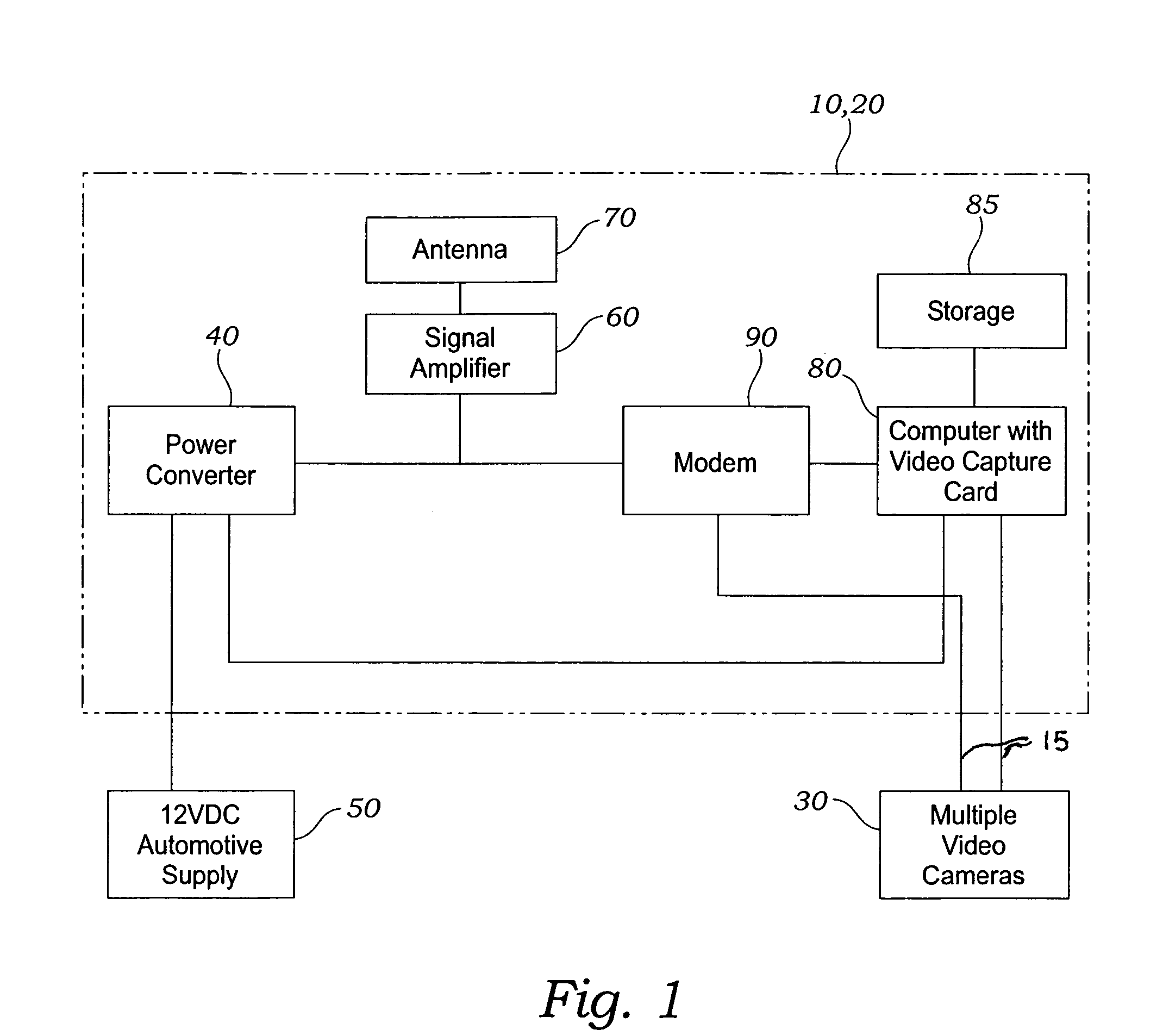

Integrated mobile surveillance system

InactiveUS20060259933A1Closed circuit television systemsTwo-way working systemsVideo monitoringAudio power amplifier

A mobile video surveillance apparatus comprises a single equipment chassis and enclosure within a motor vehicle, and plural video cameras mounted on the motor vehicle; the chassis incorporating a power converter interconnected for operation from a battery source, an embedded computer including a cellular wireless network device, a video capture circuit interconnected with multiple video cameras for receiving transmitting and recording video signals therefrom, storage capability, a signal amplifier whereby the video signals are able to be transmitted via the public cellular network via Internet to selected remote locations and remote viewers are able to select each of the plural video camera feeds for viewing via the Internet.

Owner:FISHEL ALAN +2

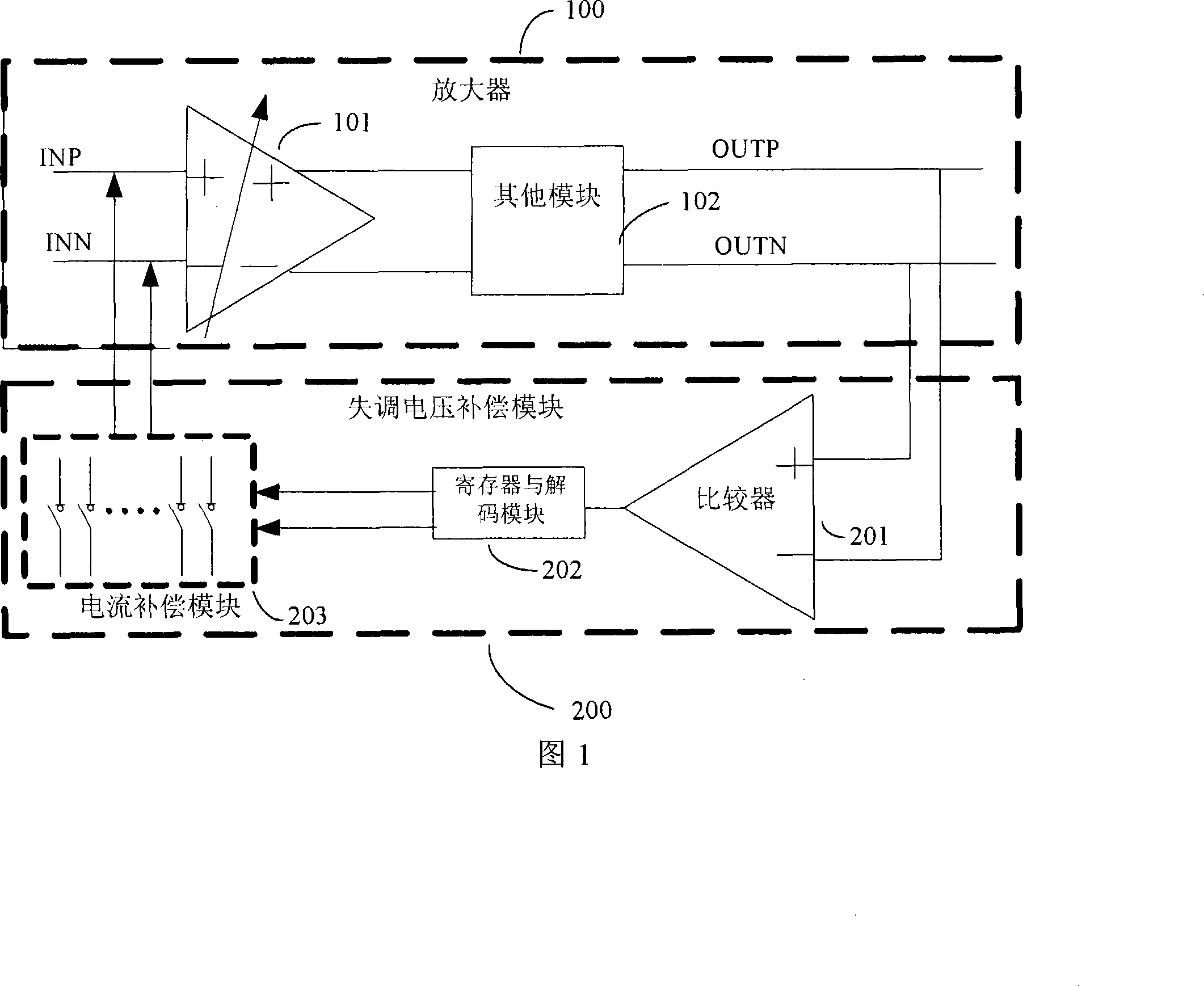

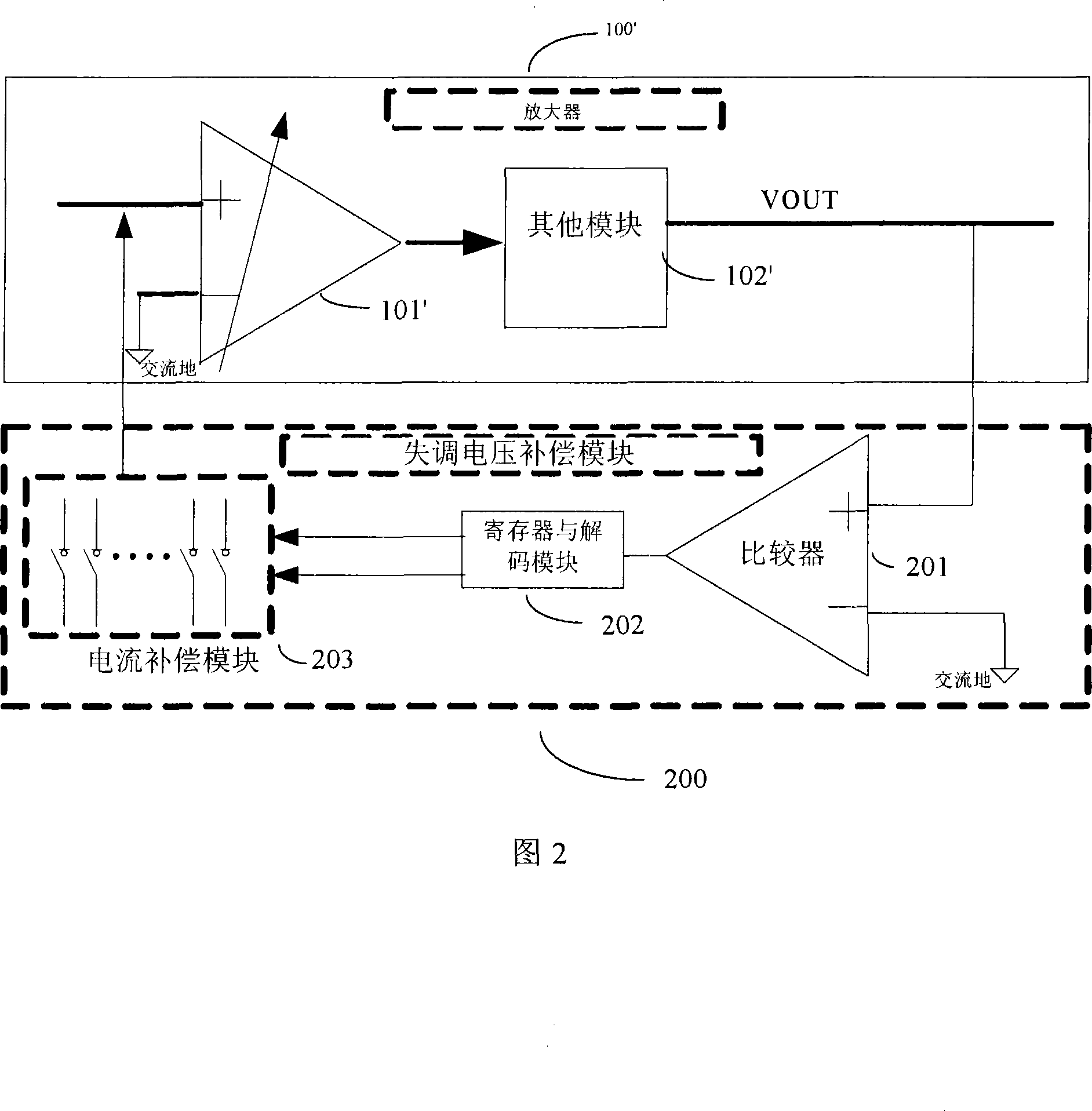

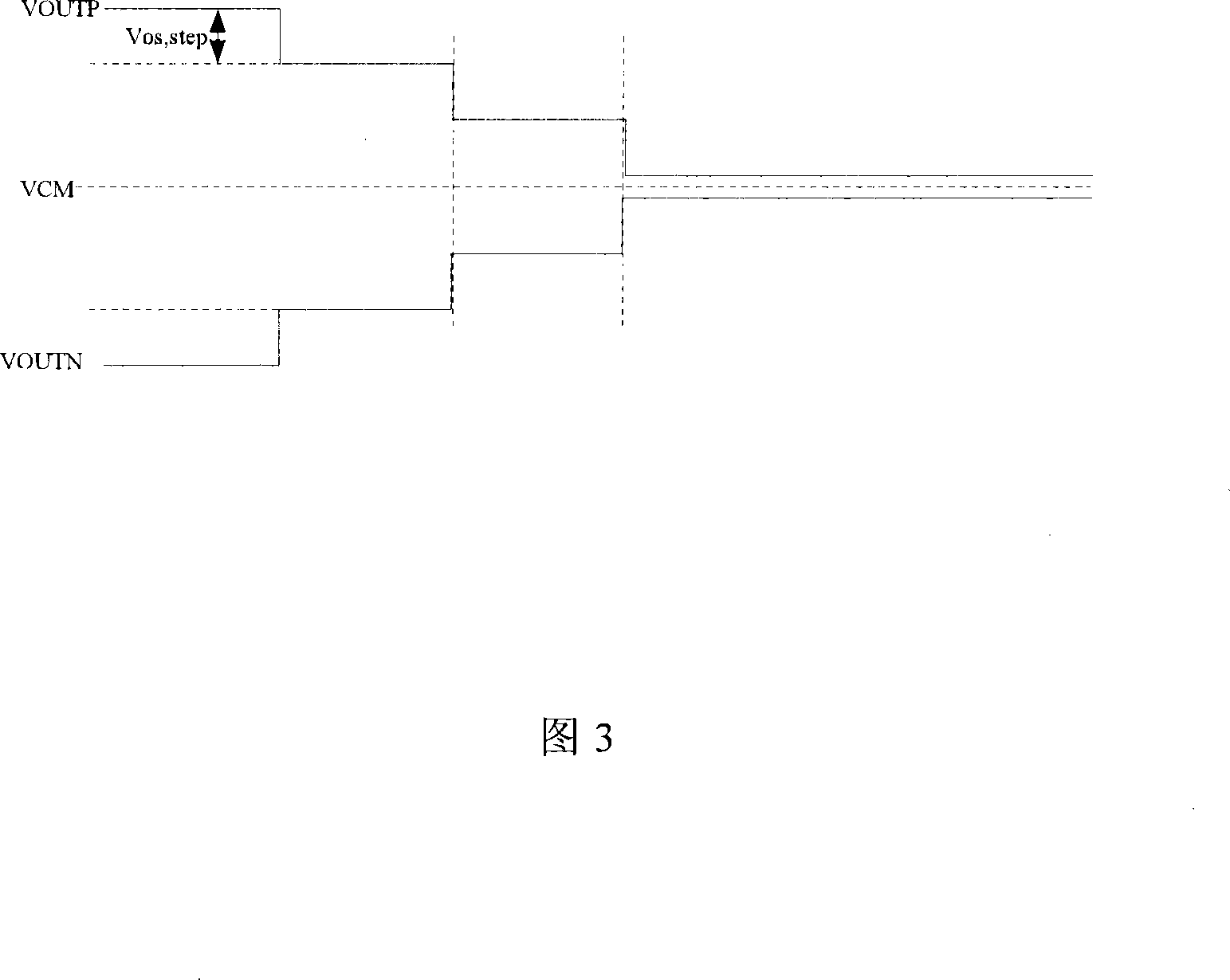

A compensatory method and device for DC offset voltage of amplifier

InactiveCN101217263ASmall scaleSimple structureDifferential amplifiersDc-amplifiers with dc-coupled stagesAudio power amplifierSwitching frequency

The invention provides a compensating method of the switching frequency of a amplifier which comprises the following steps: two output end polarities is compared in the state in which the amplifier has no signal outputting; the inputting end current of the amplifier is adjusted according to the electrode; repeated circle is carried out until achieving the requirement of stopping the cycle. The invention also provides a compensating device of the DC offset voltage of the amplifier which comprises a comparator, a register, a decoding module and a current compensation module. The invention has the advantages of simple structure, low cost, small power-consumption. Meanwhile, the invention is used both for a signal amplifier and an amplifier system, which can limit the imbalance voltage to be in small scope.

Owner:APEXONE MICROELECTRONICS

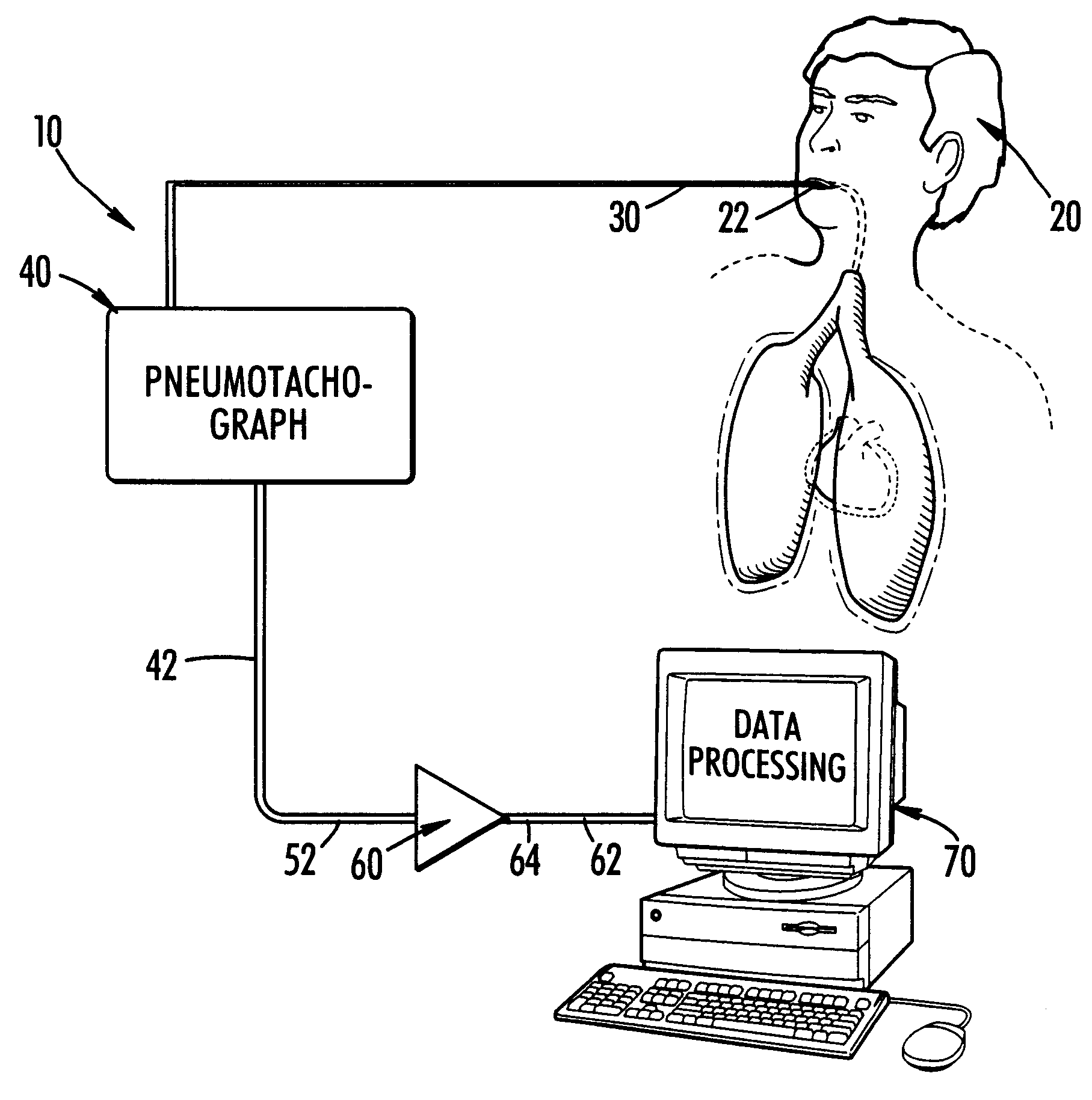

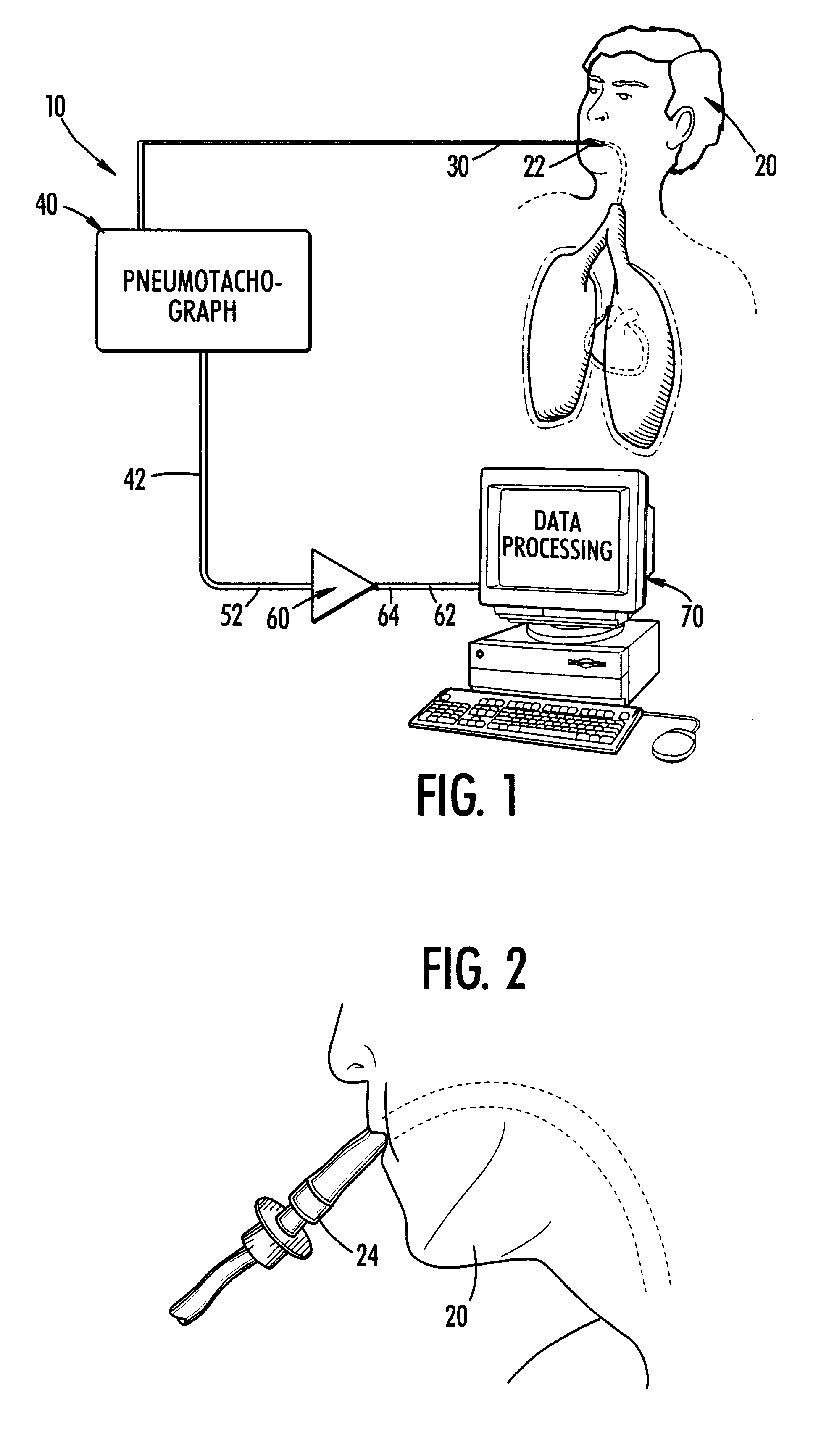

Method and system for continuously monitoring cardiac output

InactiveUS6186956B1Easily moved to patient and transportedLight weightCatheterRespiratory organ evaluationDigital dataAir volume

The present invention is a method and system for continuously monitoring cardiac output. In a preferred embodiment, the method and system of the present invention comprises a pneumotachograph, differential pressure transducer, and a signal amplifier / conditioner interconnected to a programmed digital computer. A patient, preferably, inserts the pneumotachograph in his mouth or, alternatively, the pneumotachograph is connected to a patient's tracheal cannula. As the patient exhales and inhales the differential pressure transducer measures the drop in pressure as air flows through the pneumotachograph thereby producing a weak electrical signal non-linearly proportional to flow. Next, the weak signal is directed through the amplifier / signal conditioner which increases the amplitude and removes some of the noise contained in the transducer output. A digital computer is then utilized to convert the analog time varying electrical signal into a stream of digital data, store it on disk, display it in real time and processes the signal using an experimentally determined correlation factor and mathematical equations relating the fluctuations in air flow with stroke volume to obtain the cardiac output.

Owner:UNIVERSITY OF SOUTH CAROLINA

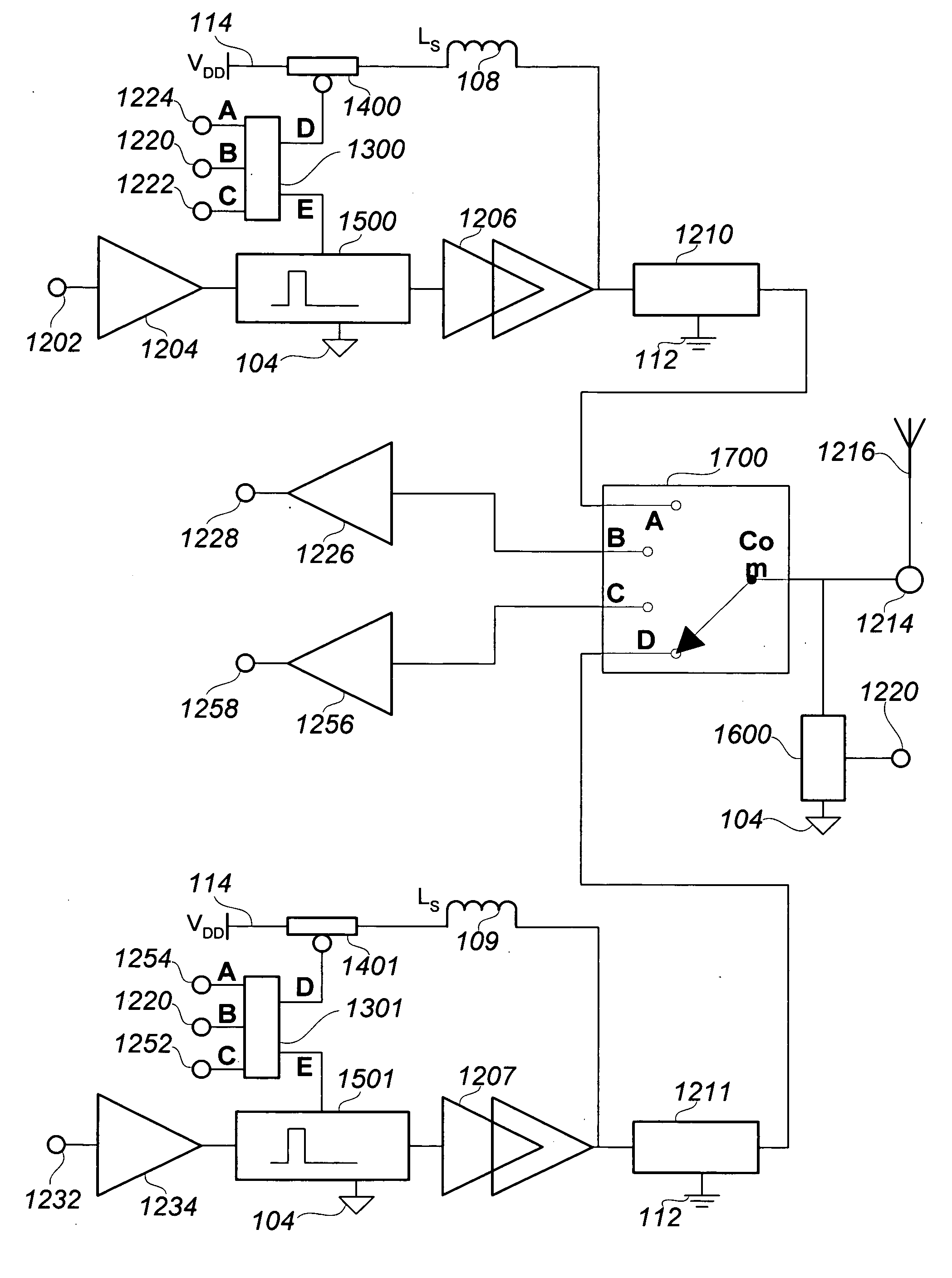

Integrated RF front end

ActiveUS20050287976A1Reduce the required powerEffective protectionResonant long antennasHigh frequency amplifiersVoltage amplitudeManufacturing technology

A monolithic integrated circuit (IC), and method of manufacturing same, that includes all RF front end or transceiver elements for a portable communication device, including a power amplifier (PA), a matching, coupling and filtering network, and an antenna switch to couple the conditioned PA signal to an antenna. An output signal sensor senses at least a voltage amplitude of the signal switched by the antenna switch, and signals a PA control circuit to limit PA output power in response to excessive values of sensed output. Preferred fabrication techniques include stacking multiple FETs to form switching devices. An iClass PA architecture is described that dissipatively terminates unwanted harmonics of the PA output signal. A preferred embodiment of the RF transceiver IC includes two distinct PA circuits, two distinct receive signal amplifier circuits, and a four-way antenna switch to selectably couple a single antenna connection to any one of the four circuits.

Owner:PSEMI CORP

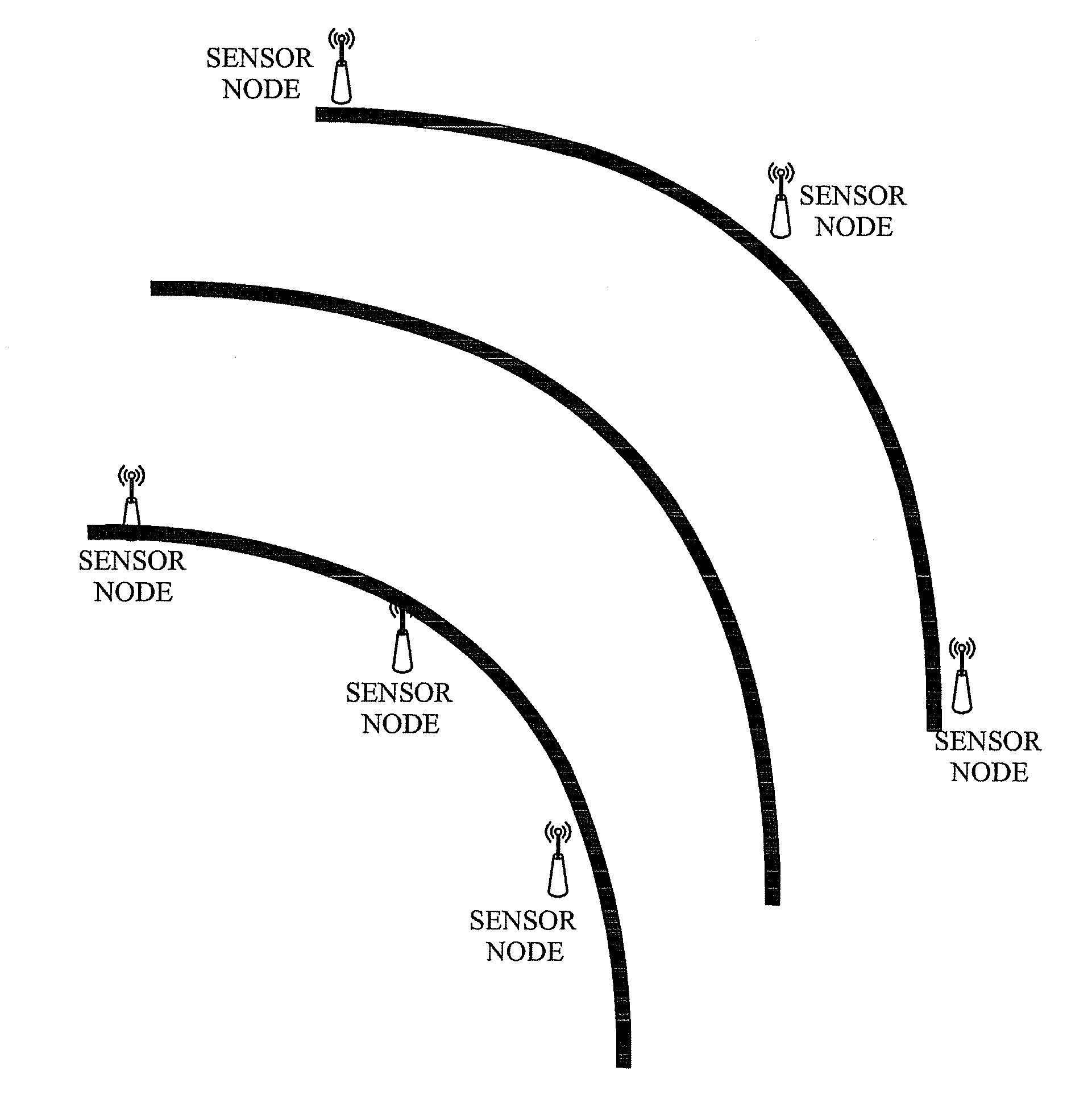

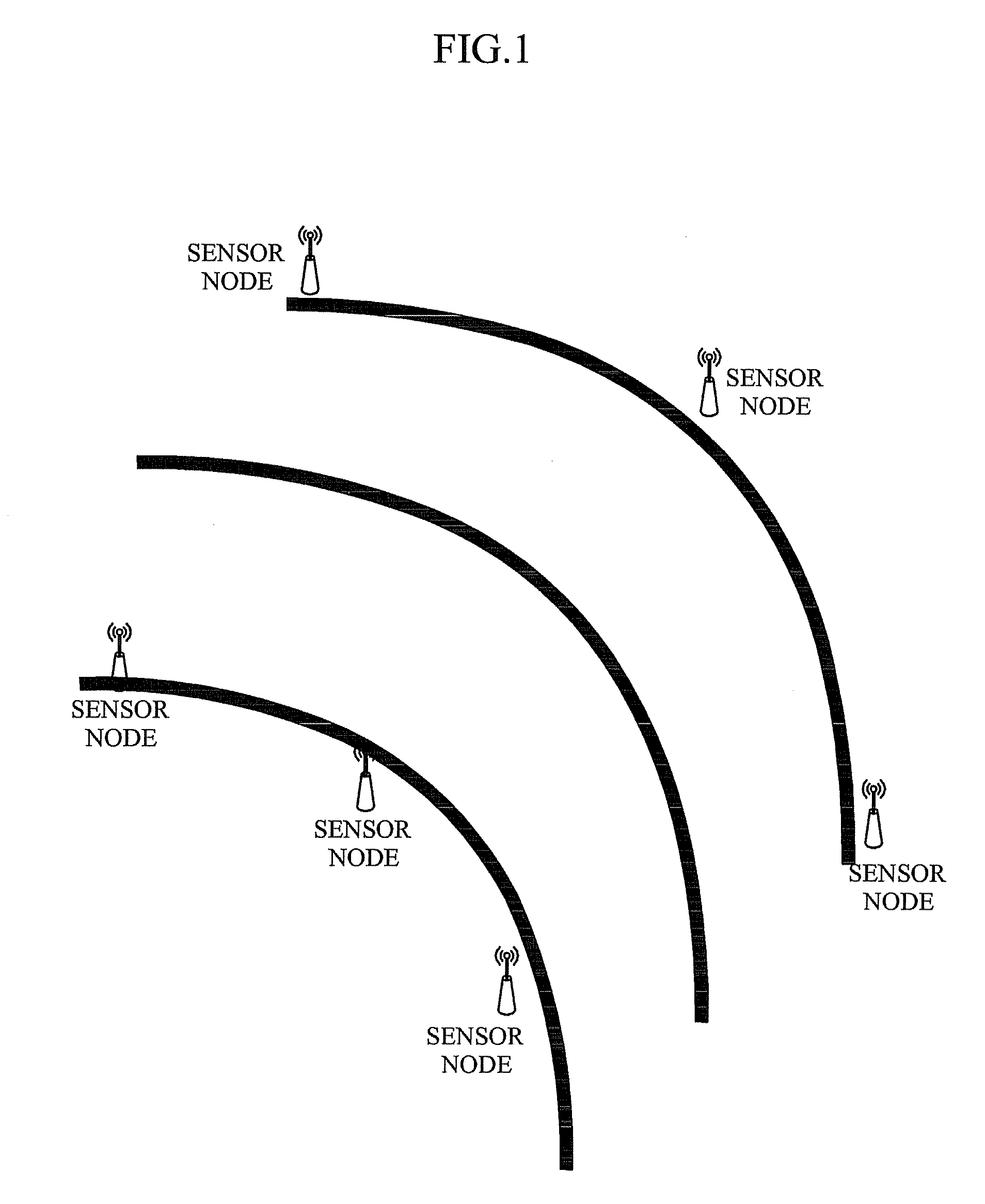

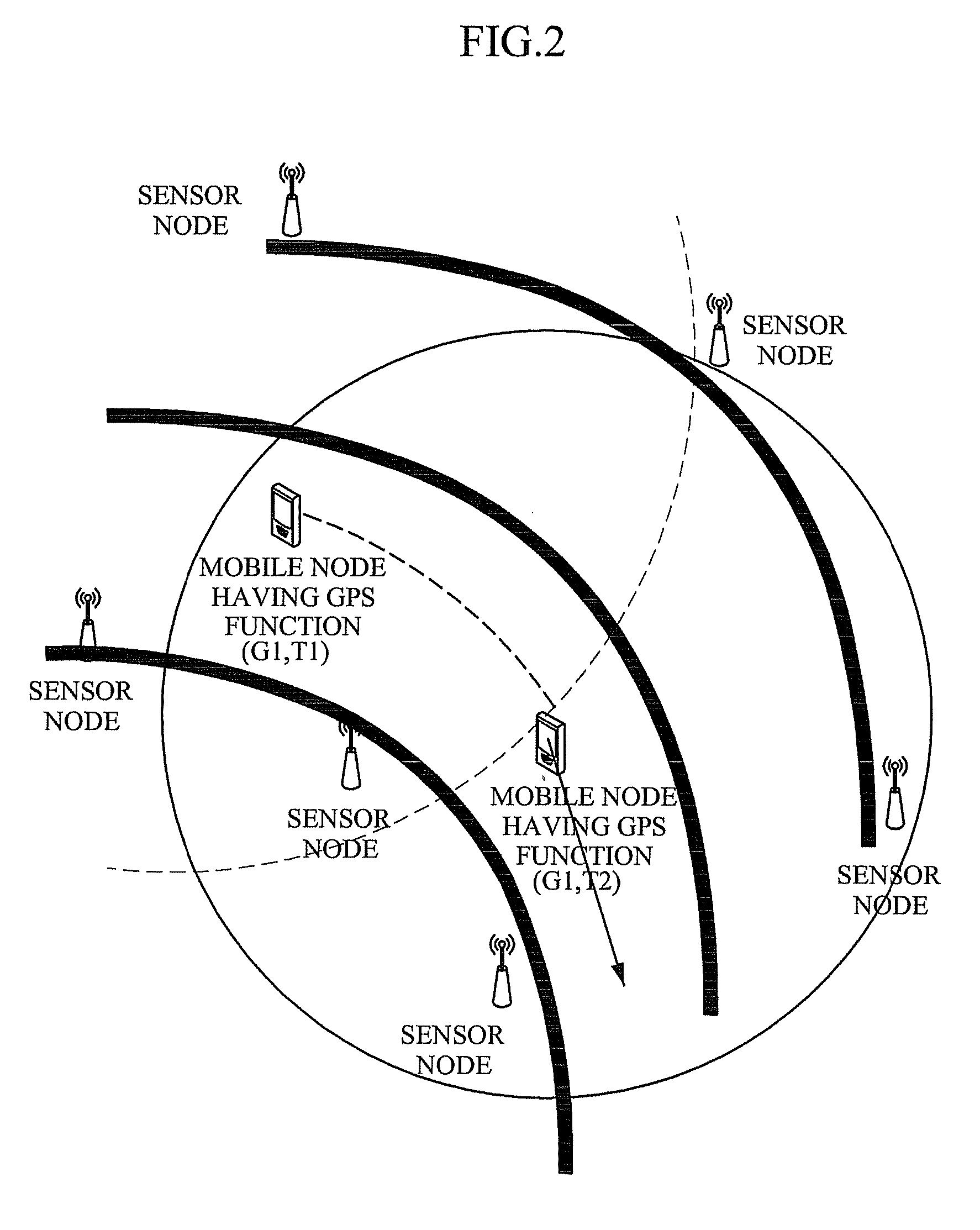

Sensor node having self localization function and self localization method thereof

InactiveUS20100150070A1Low additional costReduce power consumptionPosition fixationWireless commuication servicesTransceiverAudio power amplifier

Disclosed are a sensor node having a self localization function and a self localization method of the sensor node. The sensor node calculates a location thereof by receiving location information measured at each of two mobile nodes at different times and using four location information of the received location information. Additional cost and power consumption required for installing additional equipment such as an anchor node, a ultrasonic transceiver and a signal amplifier are reduced.

Owner:ELECTRONICS & TELECOMM RES INST

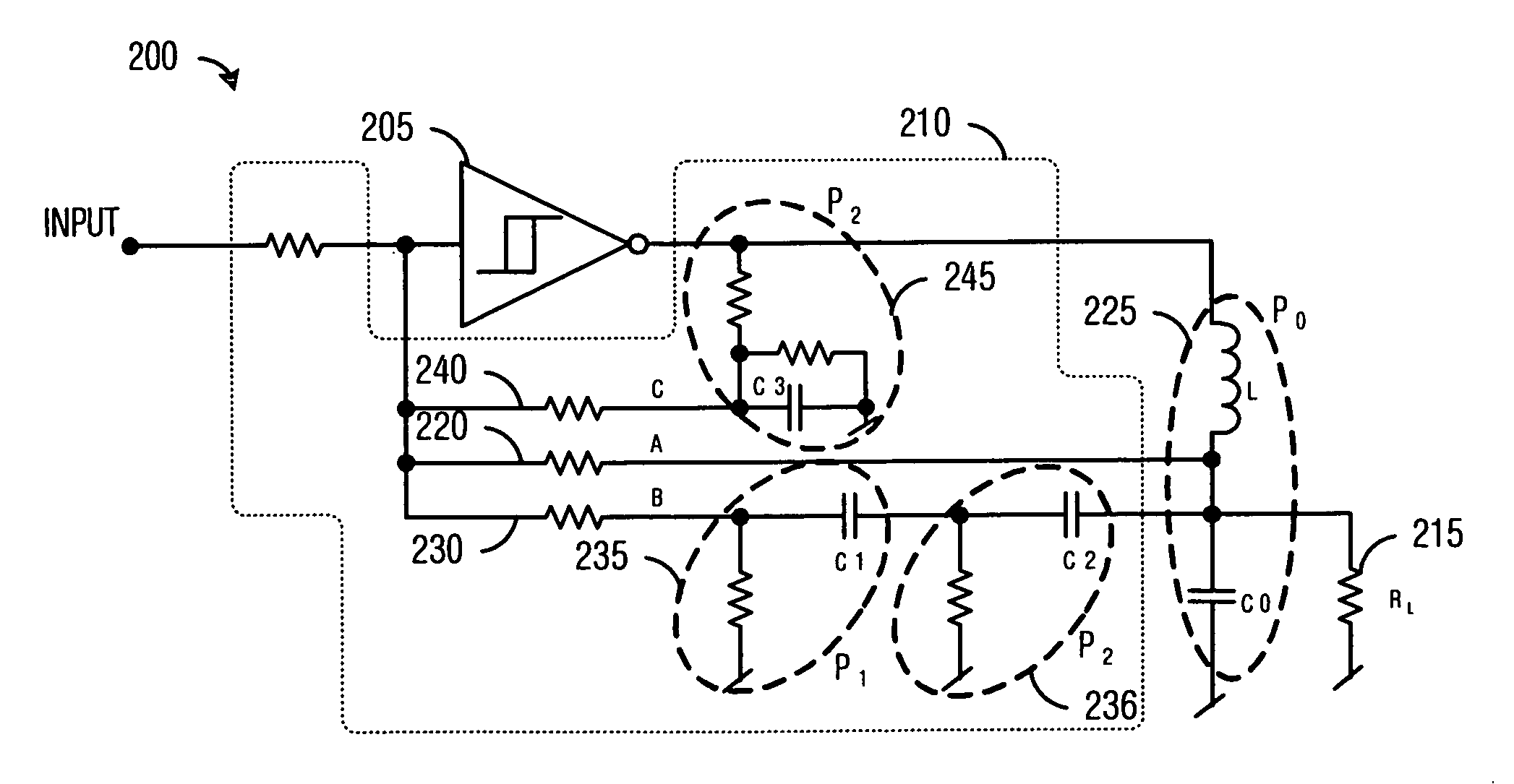

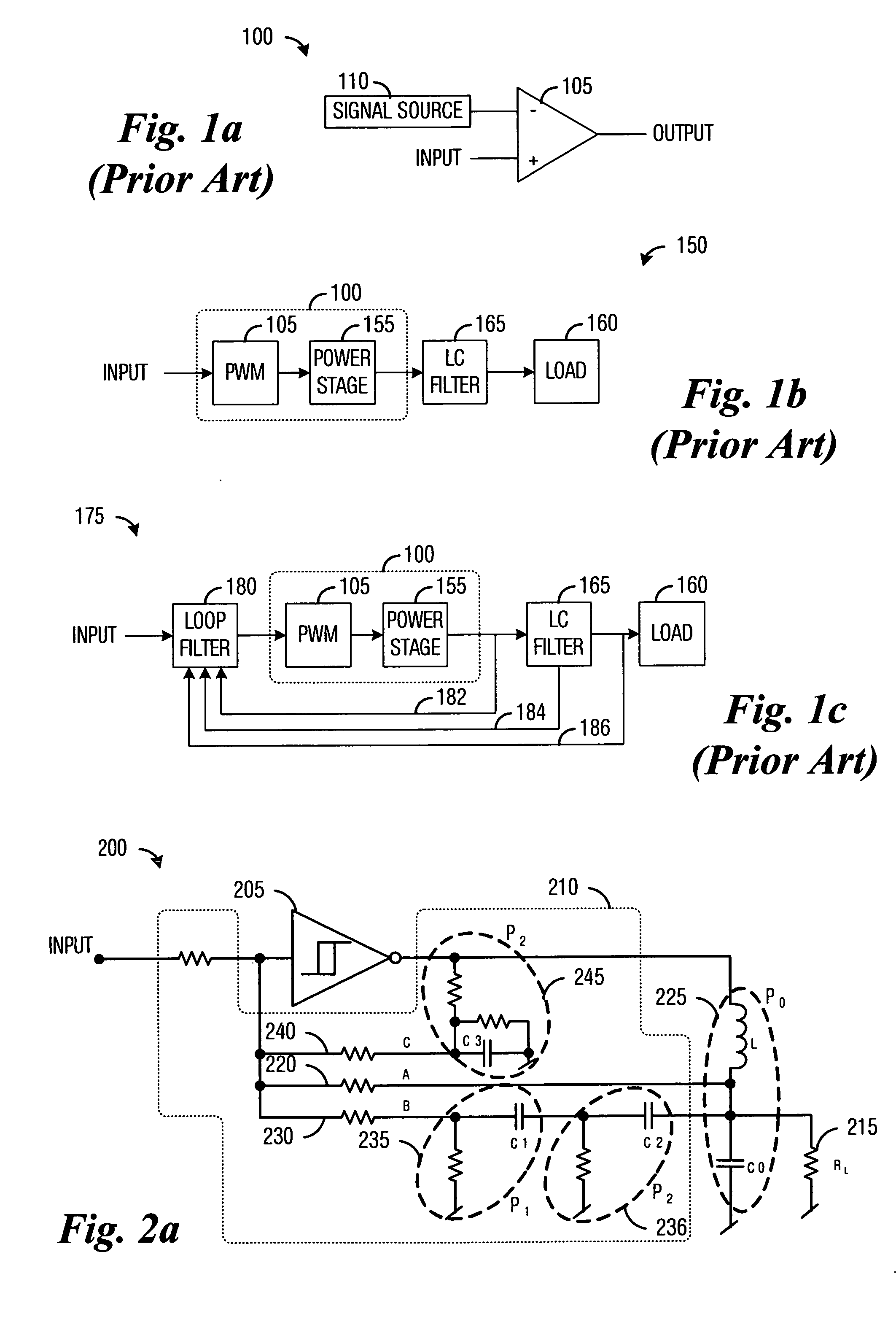

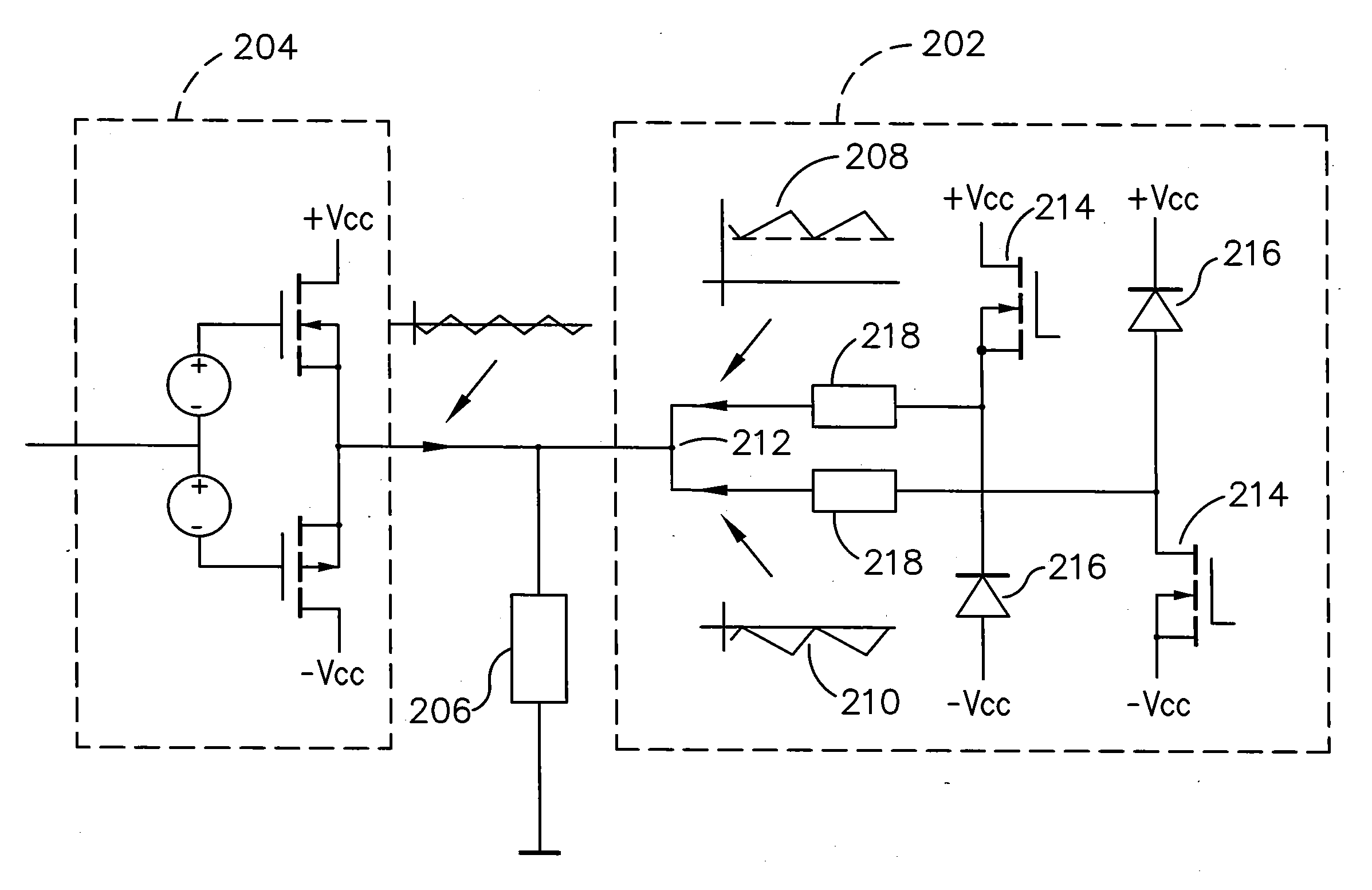

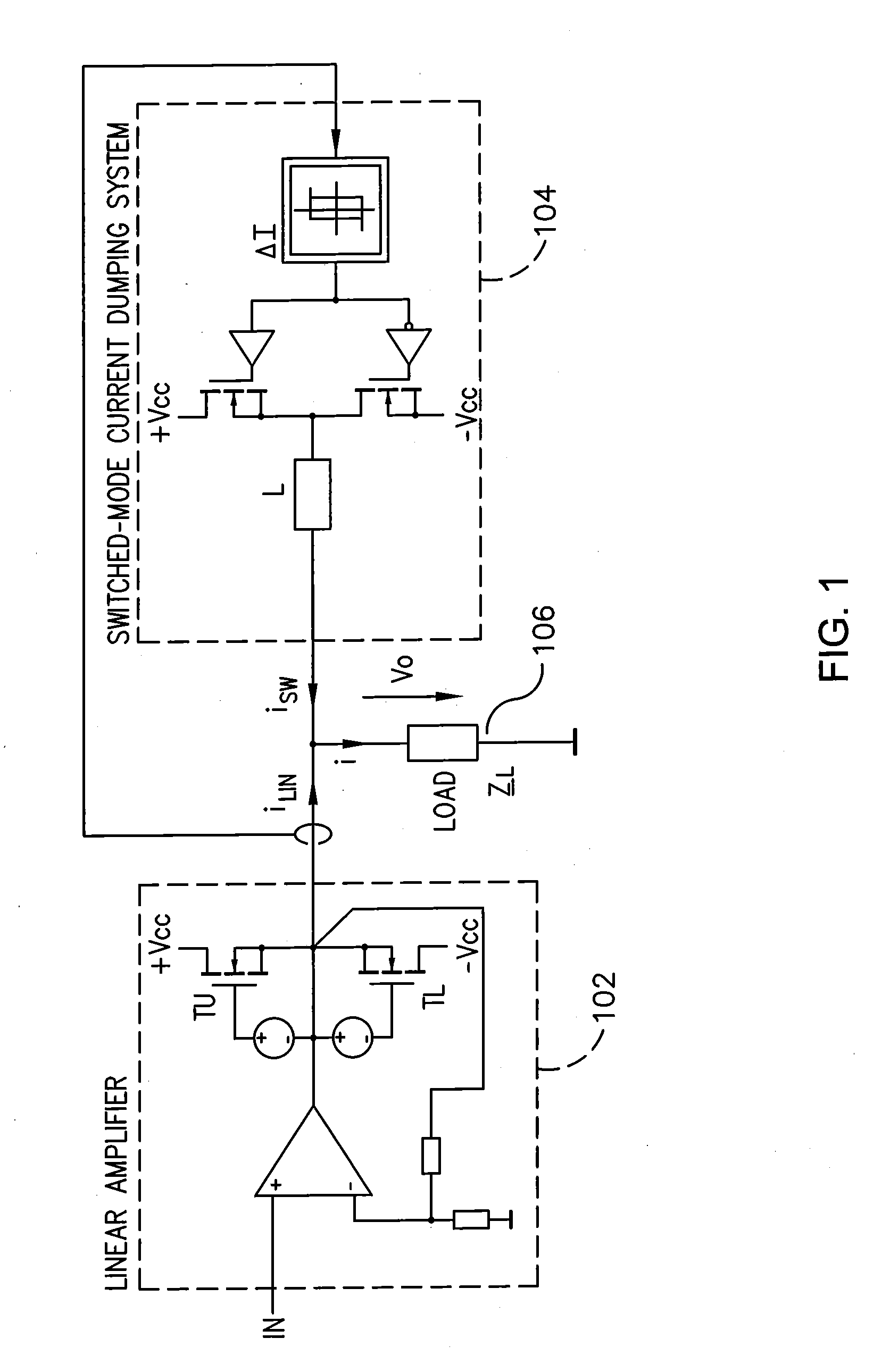

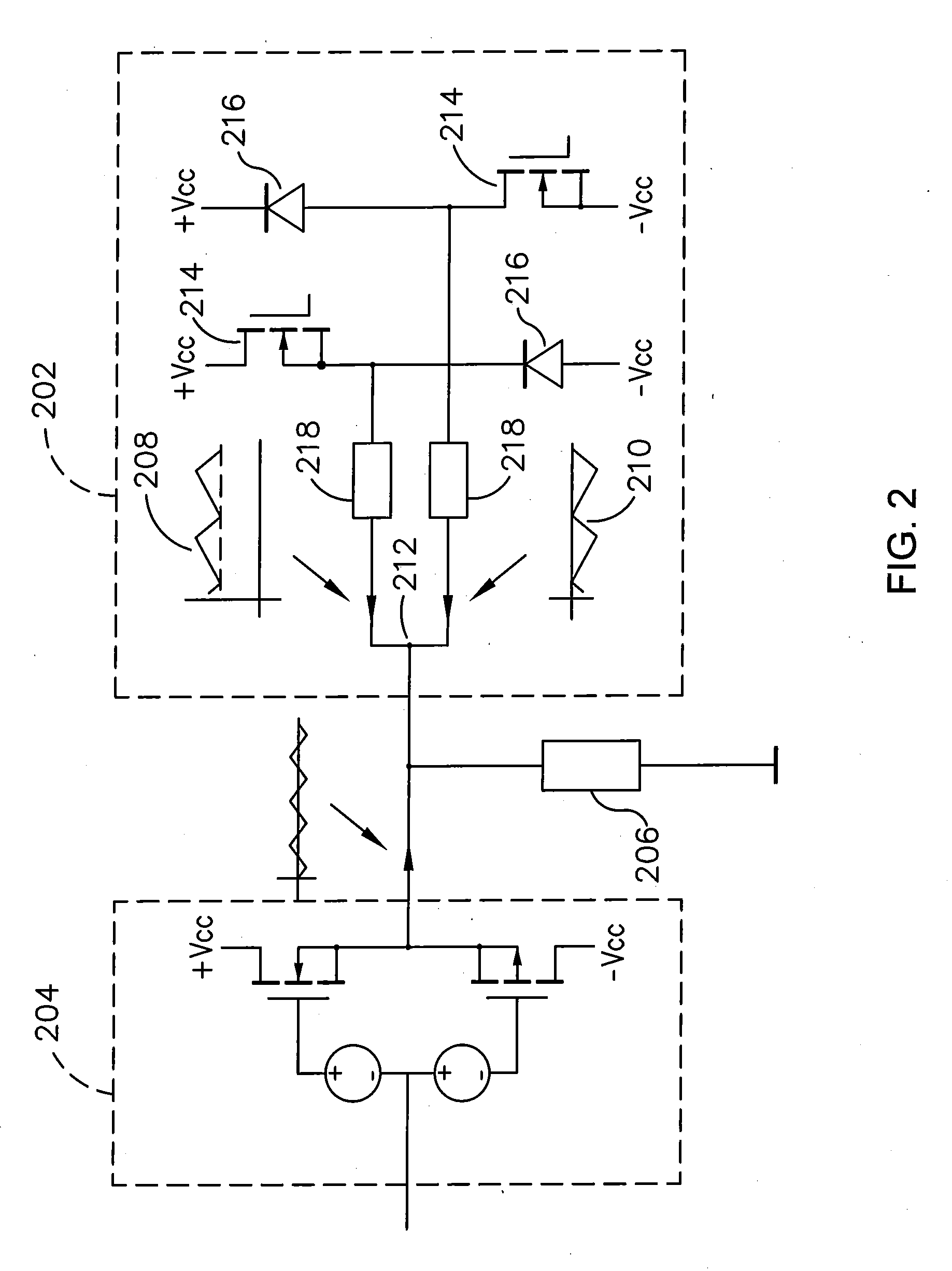

System for amplifiers with low distortion and low output impedance

InactiveUS20070057721A1Minimum errorLow output impedanceAmplifier modifications to reduce non-linear distortionNegative-feedback-circuit arrangementsLoop filterLow distortion

System for pulse-width-modulated class D audio amplifiers. In one preferred embodiment an adder is described to generate a difference signal responsive to an input signal and a feedback signal, a pulse-width-modulator coupled to the adder to compare the difference signal to a reference signal and produce a pulse-width-modulated signal based on the comparing, a filter coupled to an output of the pulse-width-modulator, and a loop filter having a first input coupled to the output of the filter and a second input coupled to the input of the filter, the loop filter to generate a feedback signal by applying transfer functions to signals at its inputs. The loop transfer function of the amplifier is minimum aliasing error transfer function. The minimum aliasing error properties provide low distortion and taking the feedback from the output of the filter reduces high frequency output impedance.

Owner:TEXAS INSTR INC

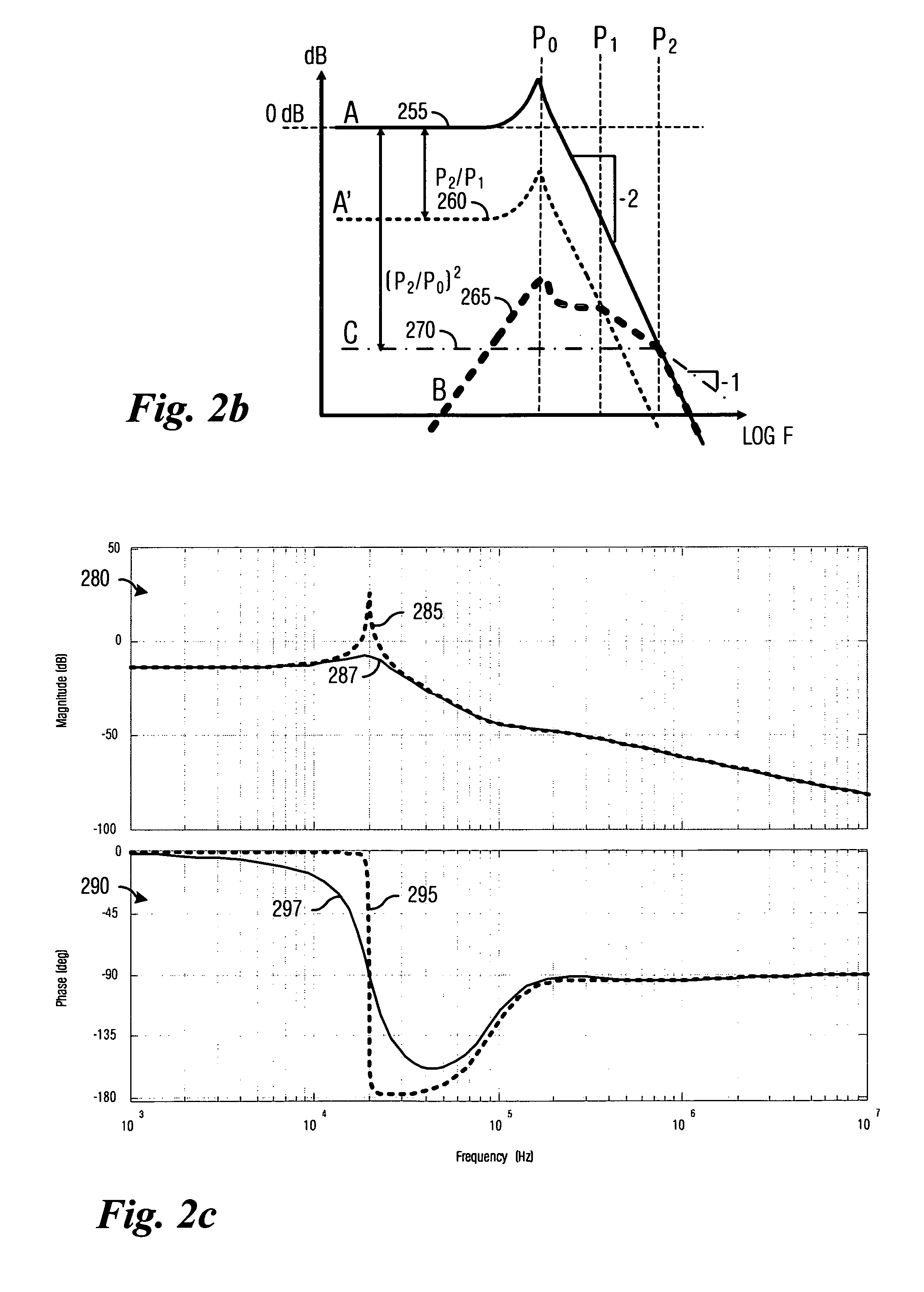

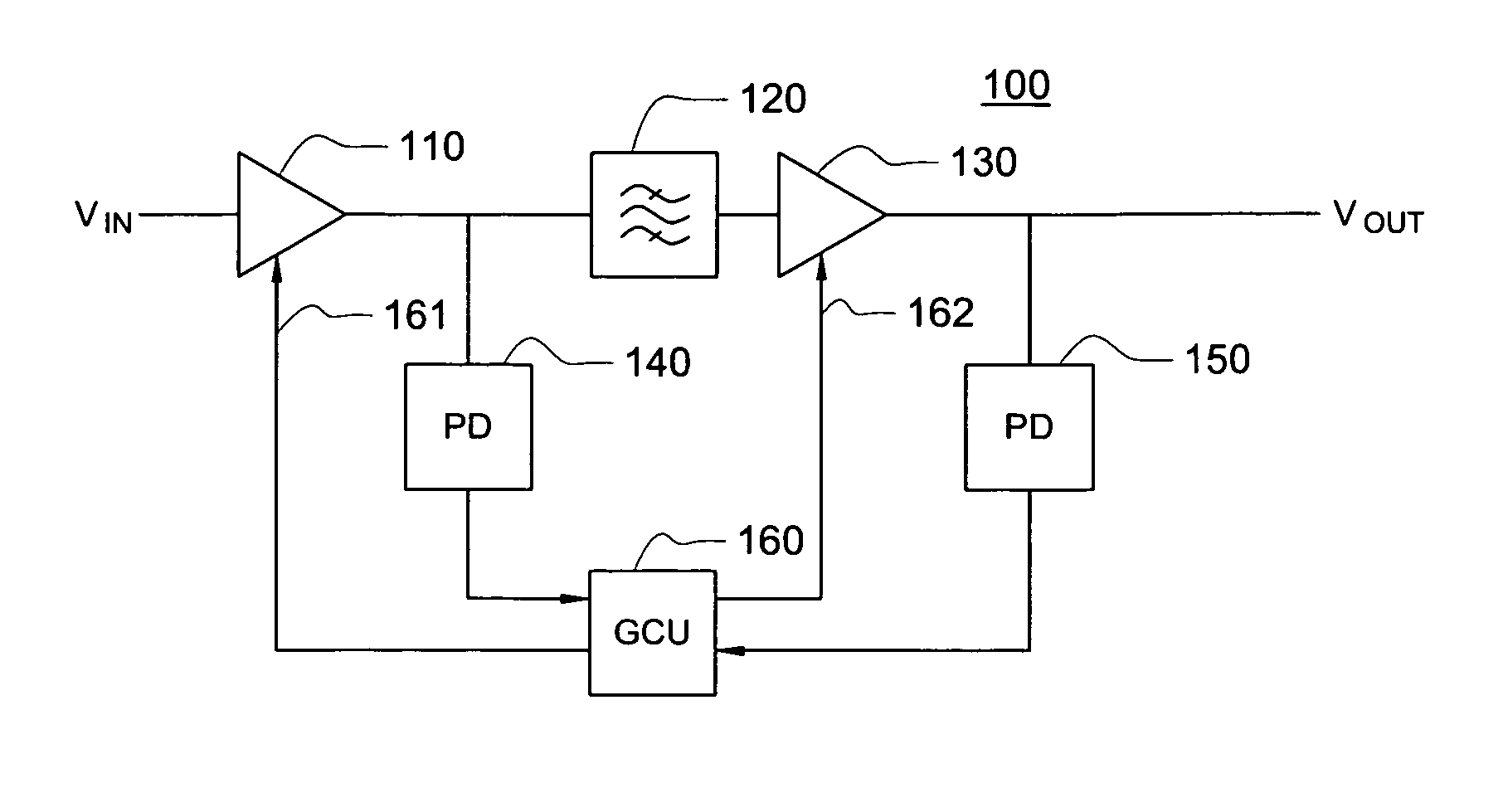

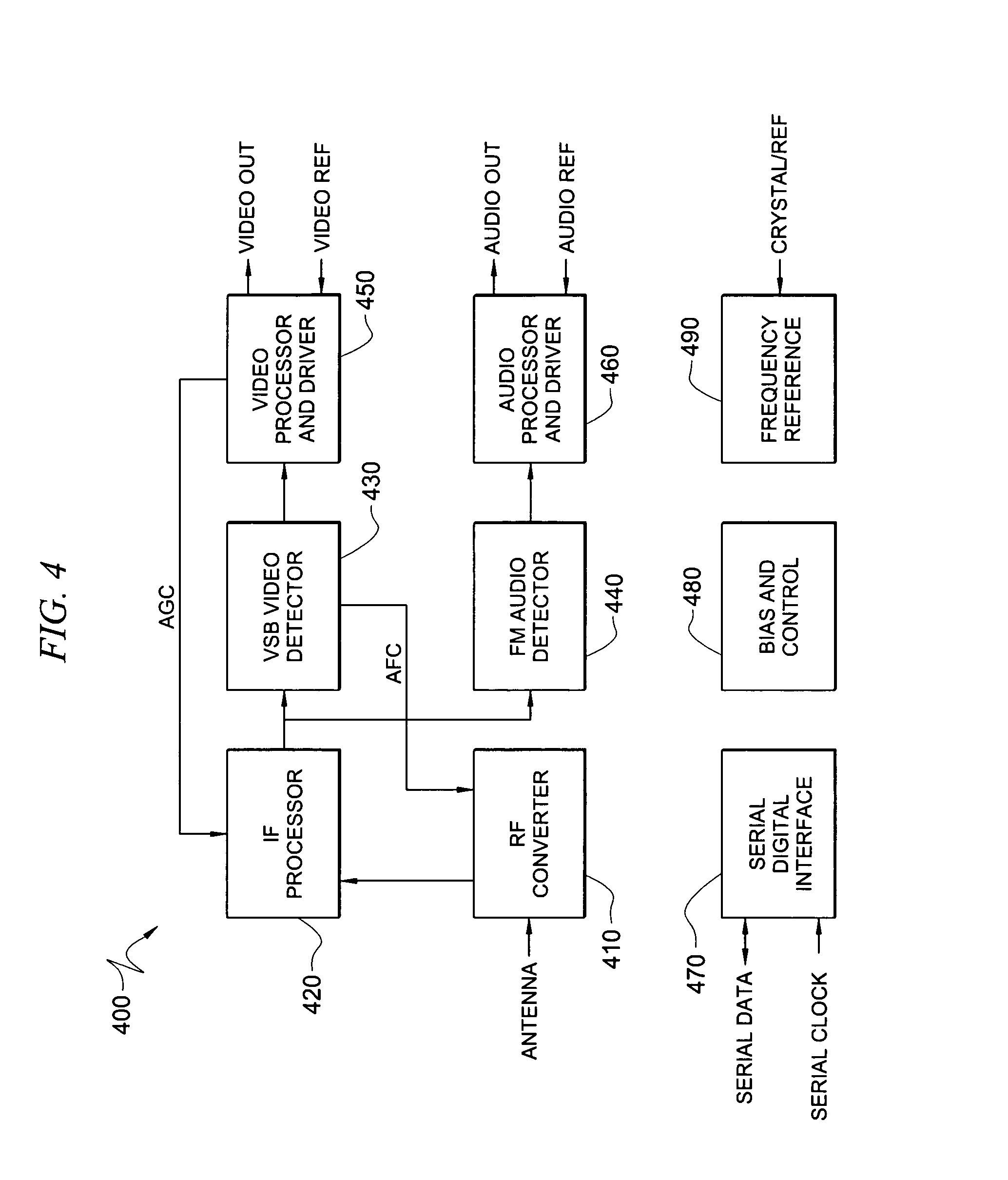

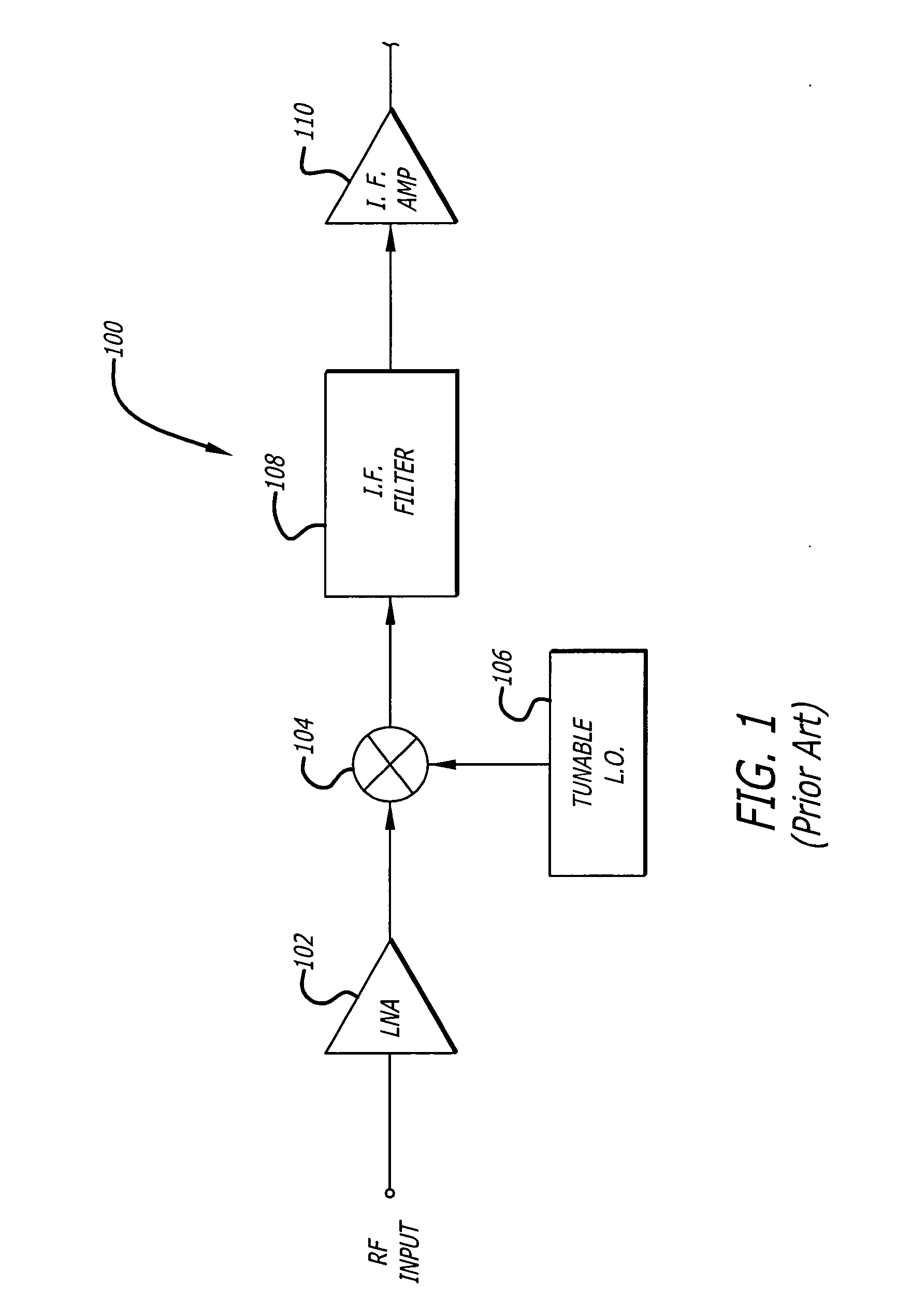

Dynamic performance control of broadband tuner

ActiveUS7783272B2Reduce signalingMinimum level of performanceTelevision system detailsResonant long antennasAudio power amplifierControl signal

A broadband signal amplifier includes one of more broadband amplifier circuits, each dynamically controlled in response to a total power level of signals applied thereto to reduce linearity in response to a reduction of input signal strength. A filter may couple the output of the broadband amplifier circuits to each other to form a tandem arrangement. Power detectors are connected to detect and provide outputs indicative of the total power levels of the signals applied to respective broadband amplifiers. A control unit is connected to and receives the output from the power detectors and, in response, provides a control signals to the broadband amplifier circuit so as to operate each over portions of their operating characteristic curves that provide only that degree of linearity necessary to limit distortion to a predetermined or dynamically adjustable maximum acceptable level.

Owner:CSR TECH INC

High efficiency balanced output amplifier system

ActiveUS20110304400A1Improve efficiencyAmplifier modifications to reduce noise influenceAmplifier combinationsAudio power amplifierSoftware engineering

A high efficiency amplifier system may include multiple output stages cooperatively operating to produce an amplified output signal. The amplifier system may be used in an audio system. The amplifier system may include a non-switchmode amplifier stage cooperatively operating with a switchmode amplifier stage to generate the amplifier output signal. The non-switchmode amplifier stage may selectively enable and disable the switchmode amplifier stage to optimize efficient operation. In addition, the switchmode amplifier stage may include multiple switching stages operated with interleave. The switching stages may be controlled to balance current output of the respective switching stages based on a measured current flow in at least one of the switching stages.

Owner:HARMAN INT IND INC

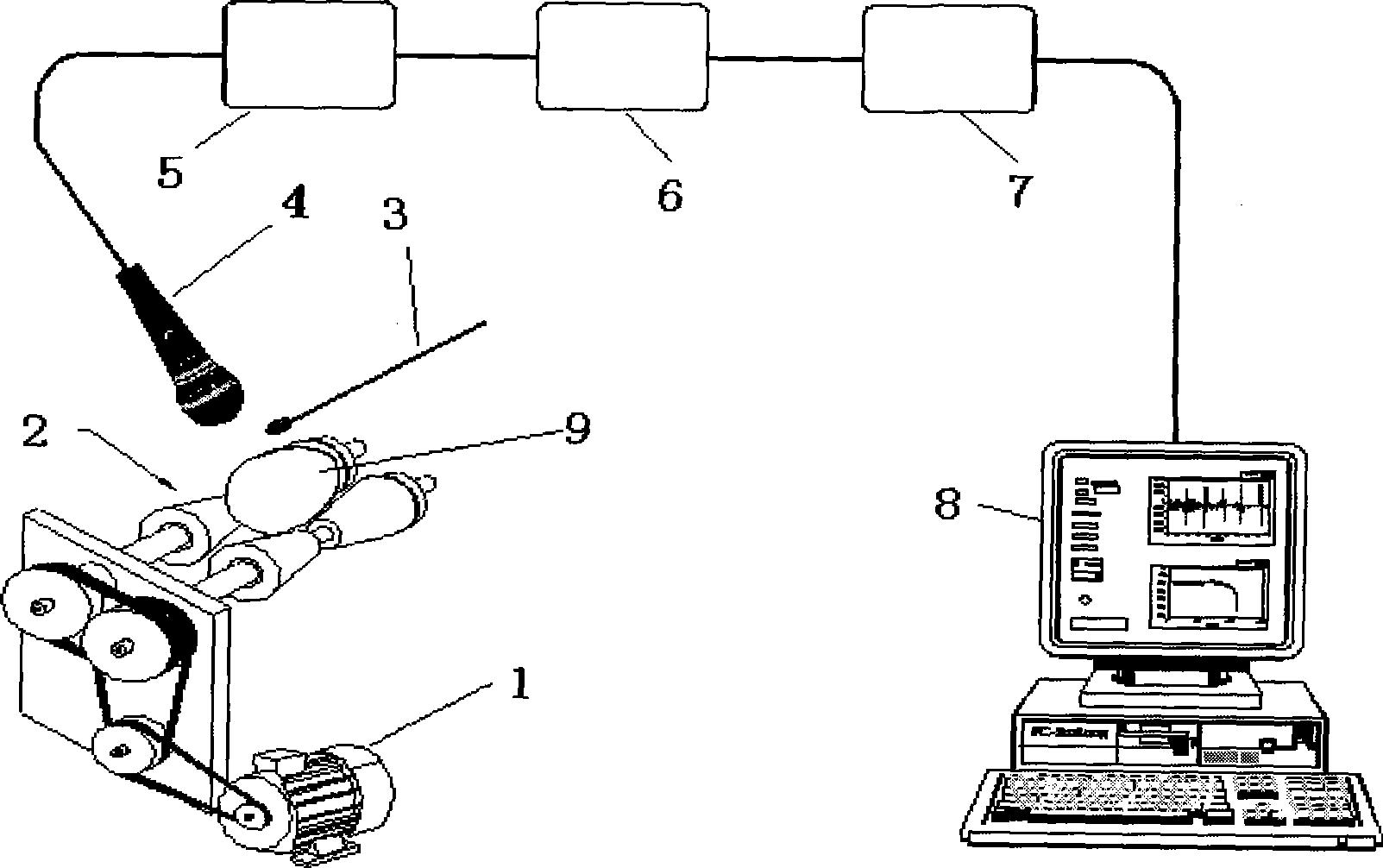

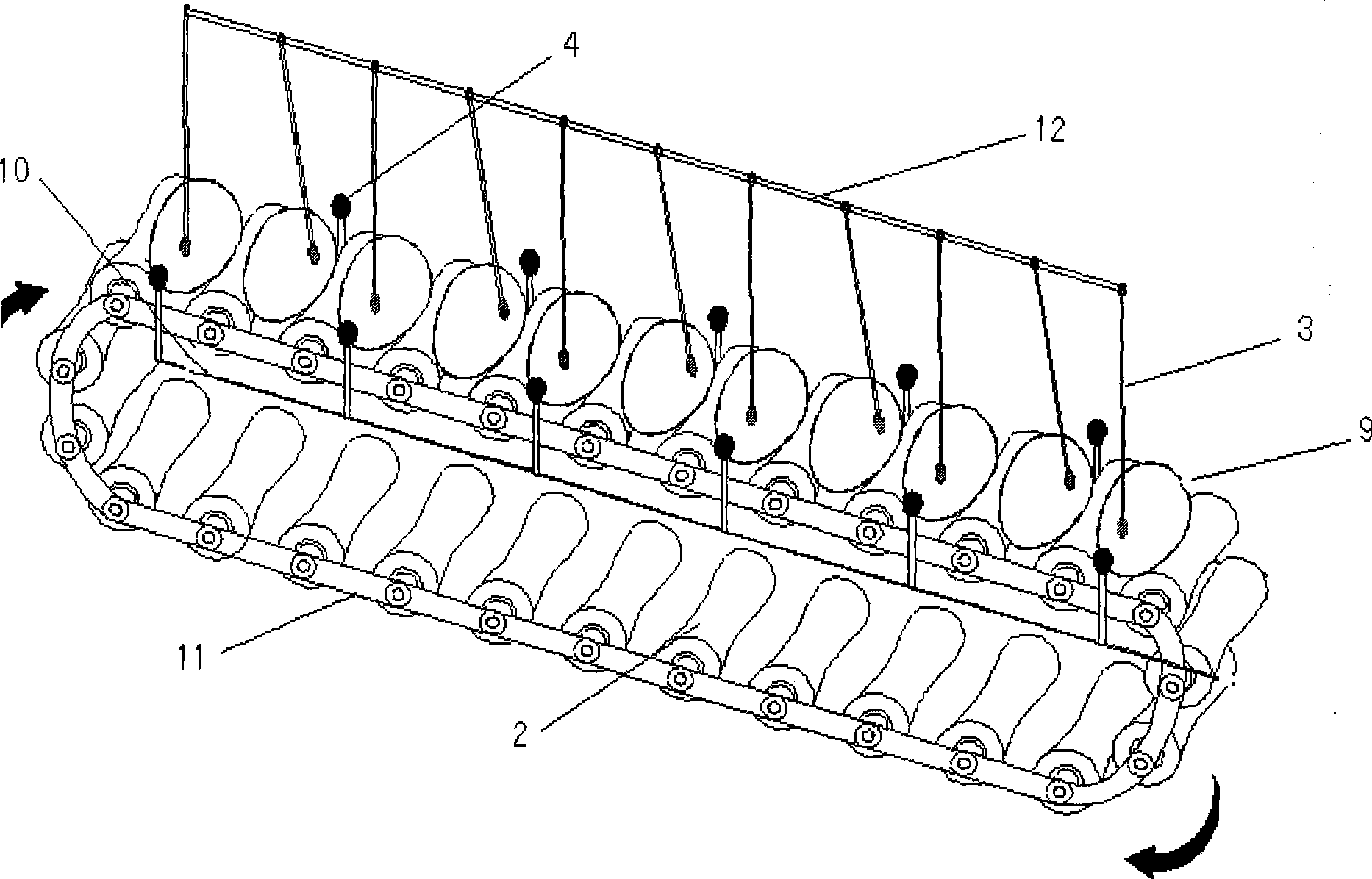

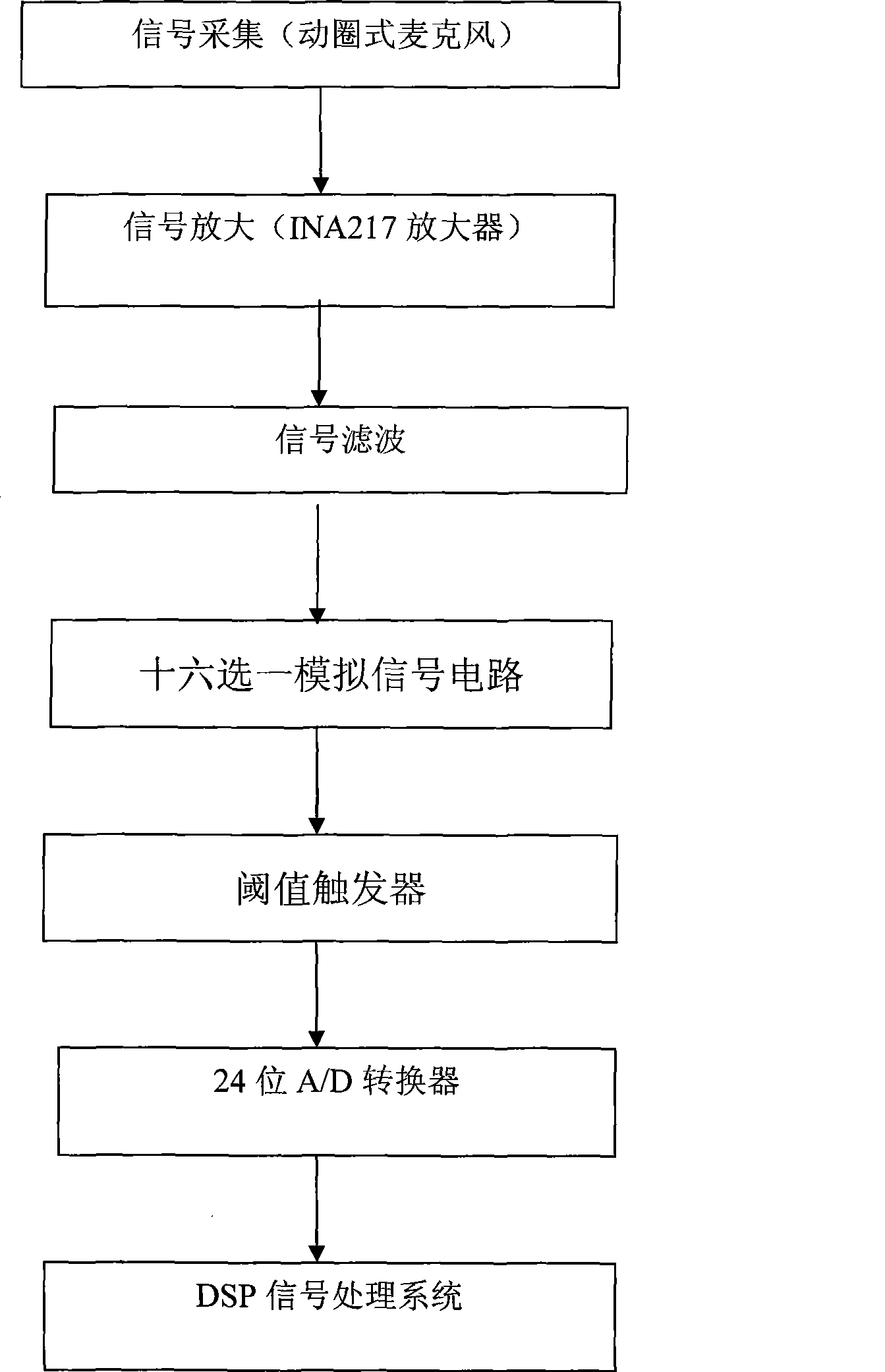

Fowl egg crack rapid on-line nondestructive detection device and method based on acoustic characteristic

InactiveCN101413928AQuality assuranceRealize automated detectionTesting eggsUltrasonic/sonic/infrasonic wave generationFowlAudio power amplifier

The invention discloses a device used for quick online nondestructive detection on cracks of poultry eggs on the basis of acoustic characteristic and a method thereof; the poultry egg is arranged on a supporting idler wheel; a stepping motor is connected with the supporting idler wheel and drives the supporting idler wheel; a microphone which is arranged beside the poultry egg is sequentially connected with a computer by a signal amplifier, a filter and an A / D converter; when the poultry egg rolls on a chain, different parts of the poultry egg are mechanically knocked at multi-point by a knocking rod; sound signals collected by the microphone are amplified by the signal amplifier, filtrated by the filter and converted by the A / D converter and subsequently input to the computer, thus comprehensively judging the cracking situation of the poultry eggs. The device and the method can adapt to poultry eggs with different types and different sizes, realize the classification and automatic detection of the poultry eggs during the production processing and circulation process, and can be popularized and applied to the nondestructive detection on the hardness and the maturity of agricultural products such as fruits, vegetables, and the like.

Owner:JIANGSU UNIV

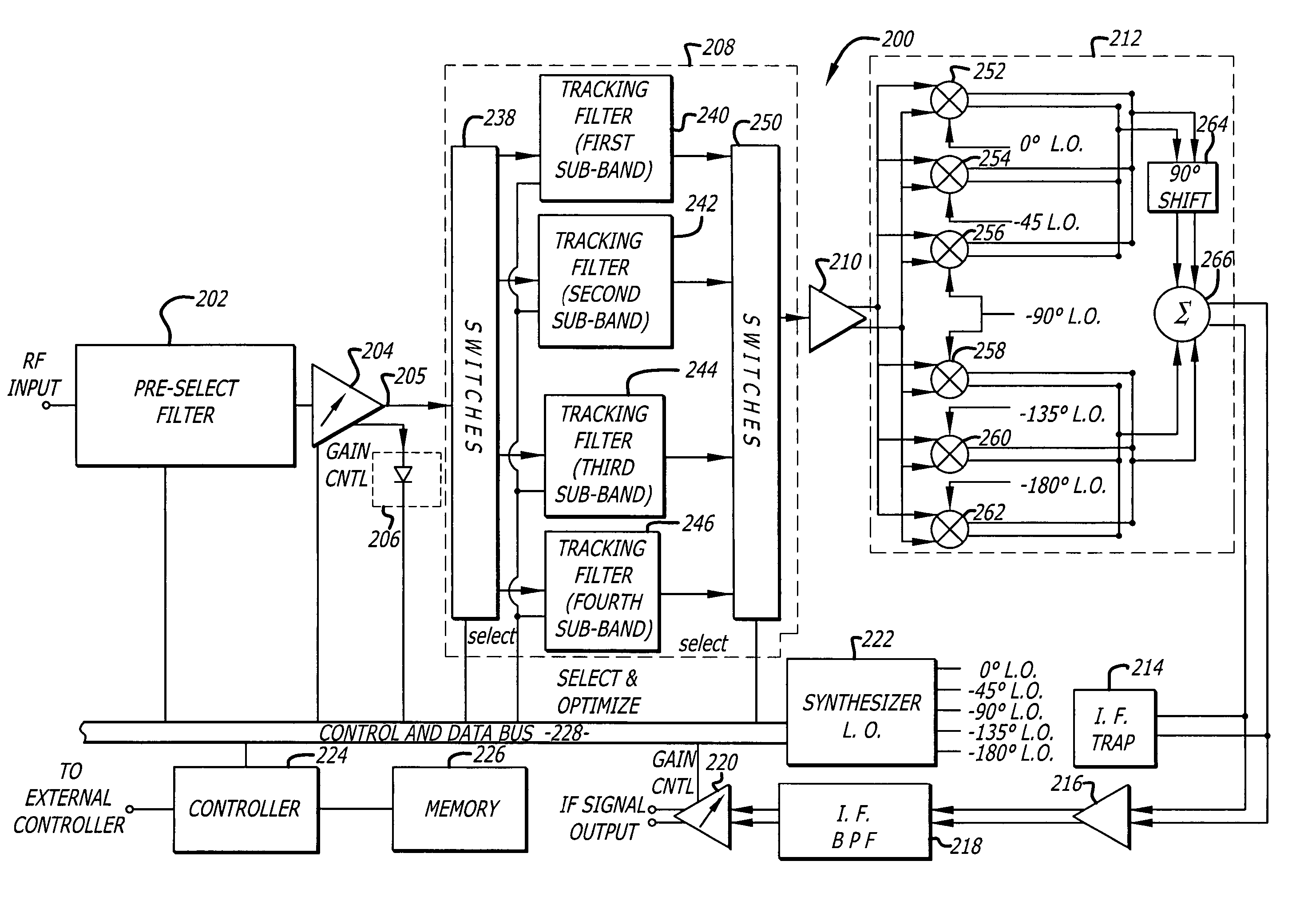

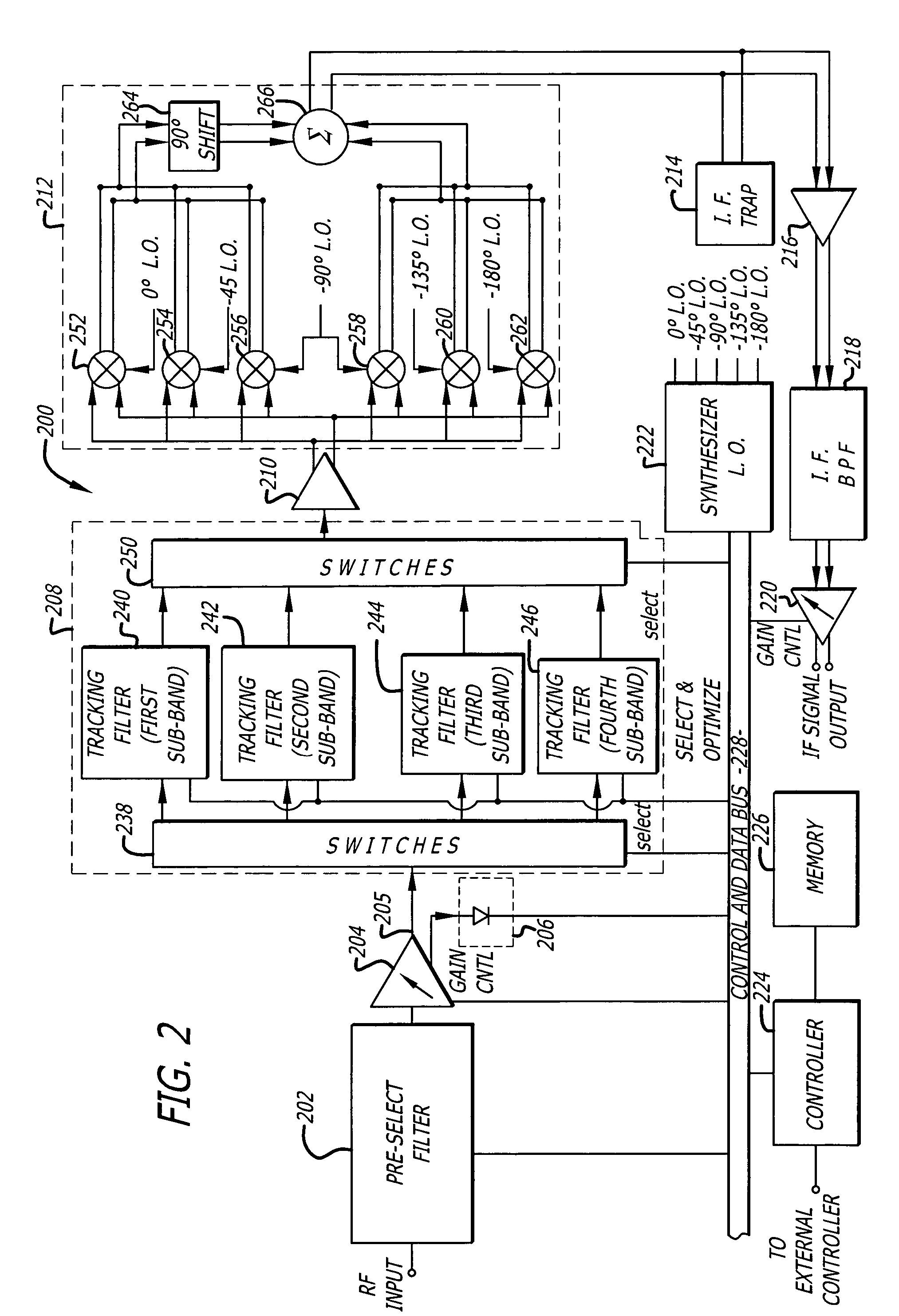

Broadband single conversion tuner integrated circuits

ActiveUS20050024544A1Television system detailsGHz frequency transmissionEngineeringSignal transition

A tunable receiver is disclosed including a plurality of select filters to perform an initial band selection, a variable-gain low noise amplifier (LNA) whose gain is controlled to prevent its output power level to exceed a pre-determined power threshold, a plurality of digitally-tunable tracking filters to pass signals within a selected channel and to reject signals in a corresponding image band, a second LNA to further amplify the received RF signal and to generate differential signal outputs, a down converting stage which converts the received RF signal to an IF signal while rejecting signals in the image band, an IF trap to further reject undesired signals present at the output of the down converting stage, an IF amplifier to amplify the IF signal to compensate for losses, an IF filter to provide channel select and reject undesirable signals, and a variable-gain IF amplifier to amplify the IF signal and maintain its power level within specification.

Owner:MAXIM INTEGRATED PROD INC

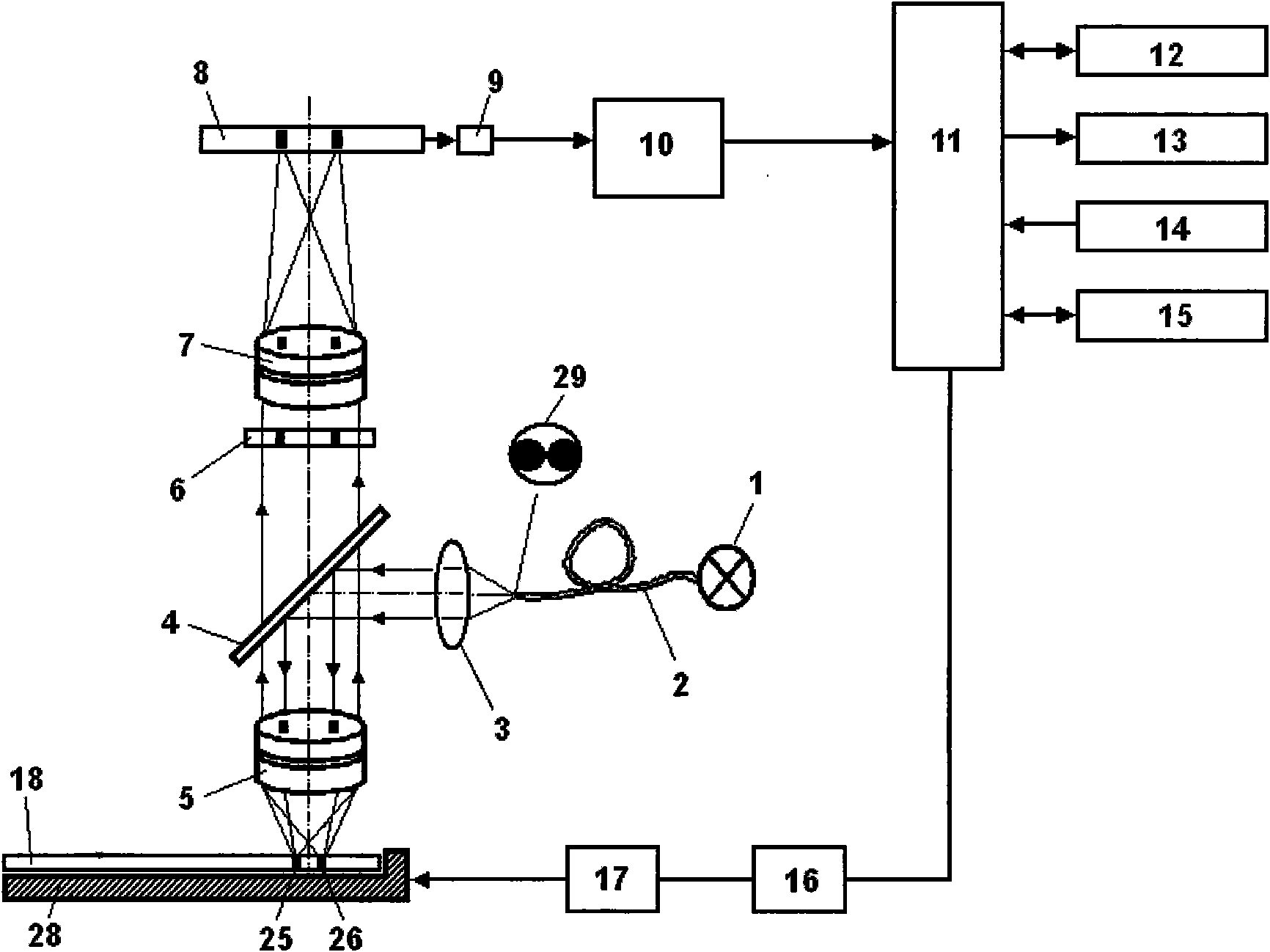

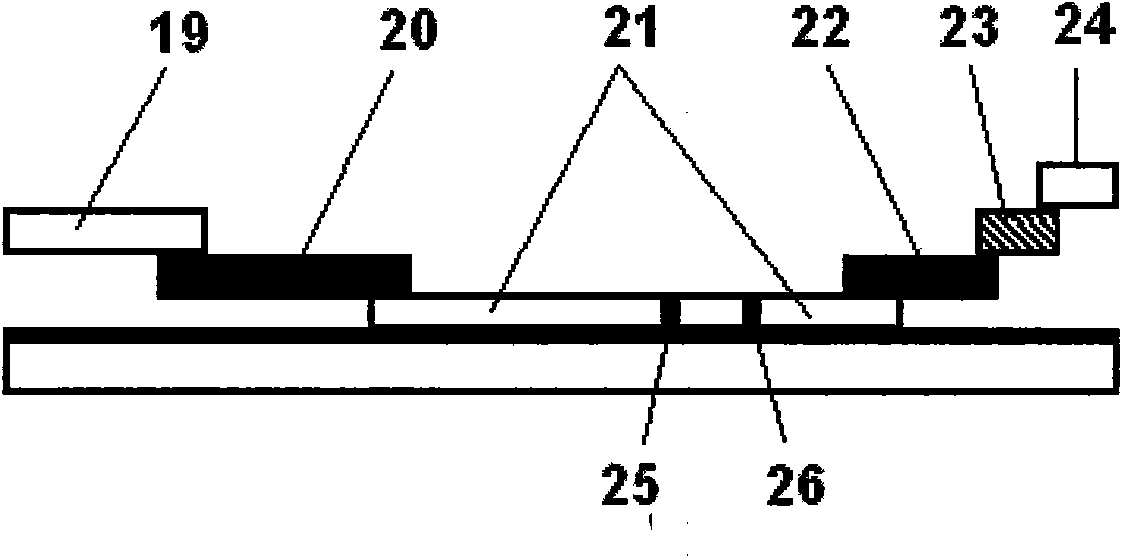

System and method for quantitative detection of test strips on basis of continuous fluorescent-substance markers

ActiveCN101592659AEmitting characteristic wavelengths with high fluorescence brightnessHigh fluorescence brightnessBiological testingFluorescence/phosphorescenceAcquired characteristicFluorescence

The invention belongs to the field of bio-medical instruments, and in particular relates to a system and a method for quantitative detection of test strips on the basis of continuous fluorescent-substance markers. The system comprises a continuous fluorescent-substance marker test strip, a test strip frame, a lighting system, an imaging system, a fluorescent image receiver, a signal amplifier, an analog / digital converter, a data processing-controlling system, an output display device, a printer, a keyboard and an IC card matched with the test strip. The data processing-controlling system reads parameters of the IC card and then controls the test strip frame to move so as to ensure that the light emitted by the lighting system is reflected via a dichroic mirror and then automatically scans the test strip; acquired characteristic wavelength reflection fluorescence is transmitted to the data processing-controlling system for optical density identification and concentration calculation via the fluorescent image receiver, the signal amplifier and the analog / digital converter; and the output display device displays results. The invention can quickly and accurately realize the quantitative or qualitative detection of single-component and multi-component samples. The system has the characteristics of high detection sensitivity, objective results, flexible use and the like.

Owner:马义才

Apparatus and method for monitoring the output of a warning or indicator light

ActiveUS20060001547A1Increase signal strengthAudible signalsPhotometry using reference valueMicrocontrollerAudio power amplifier

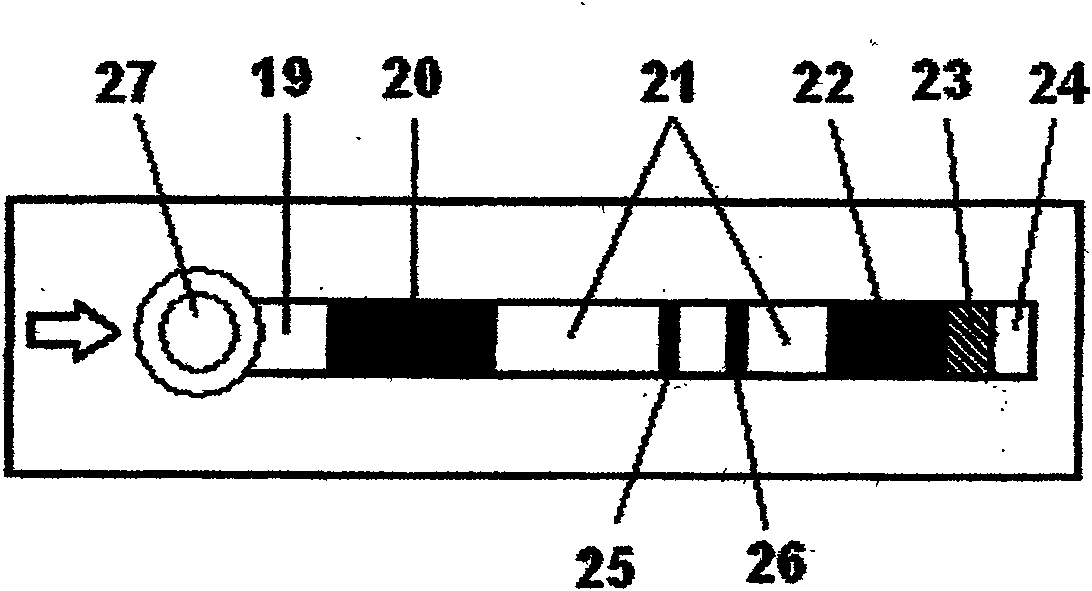

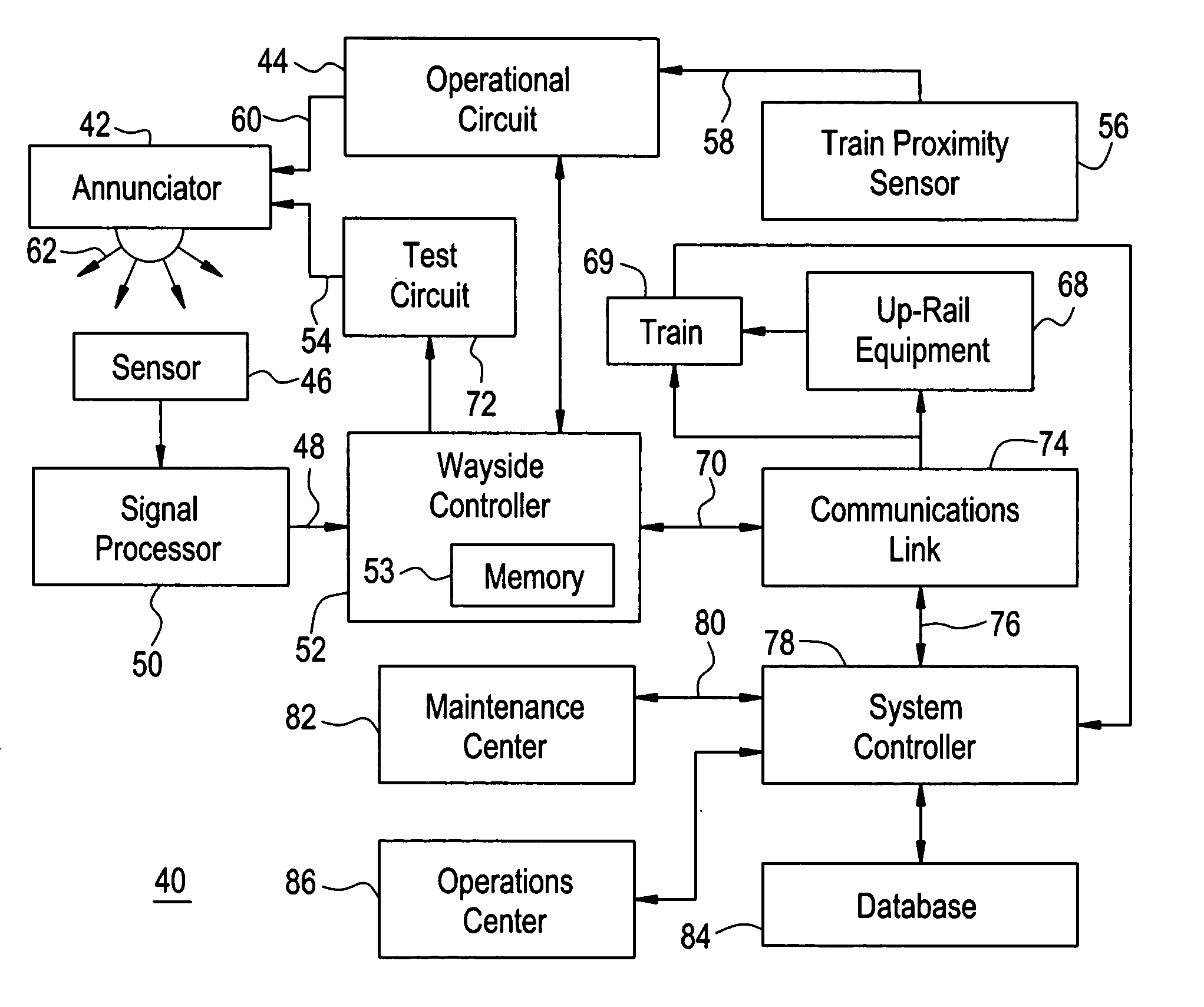

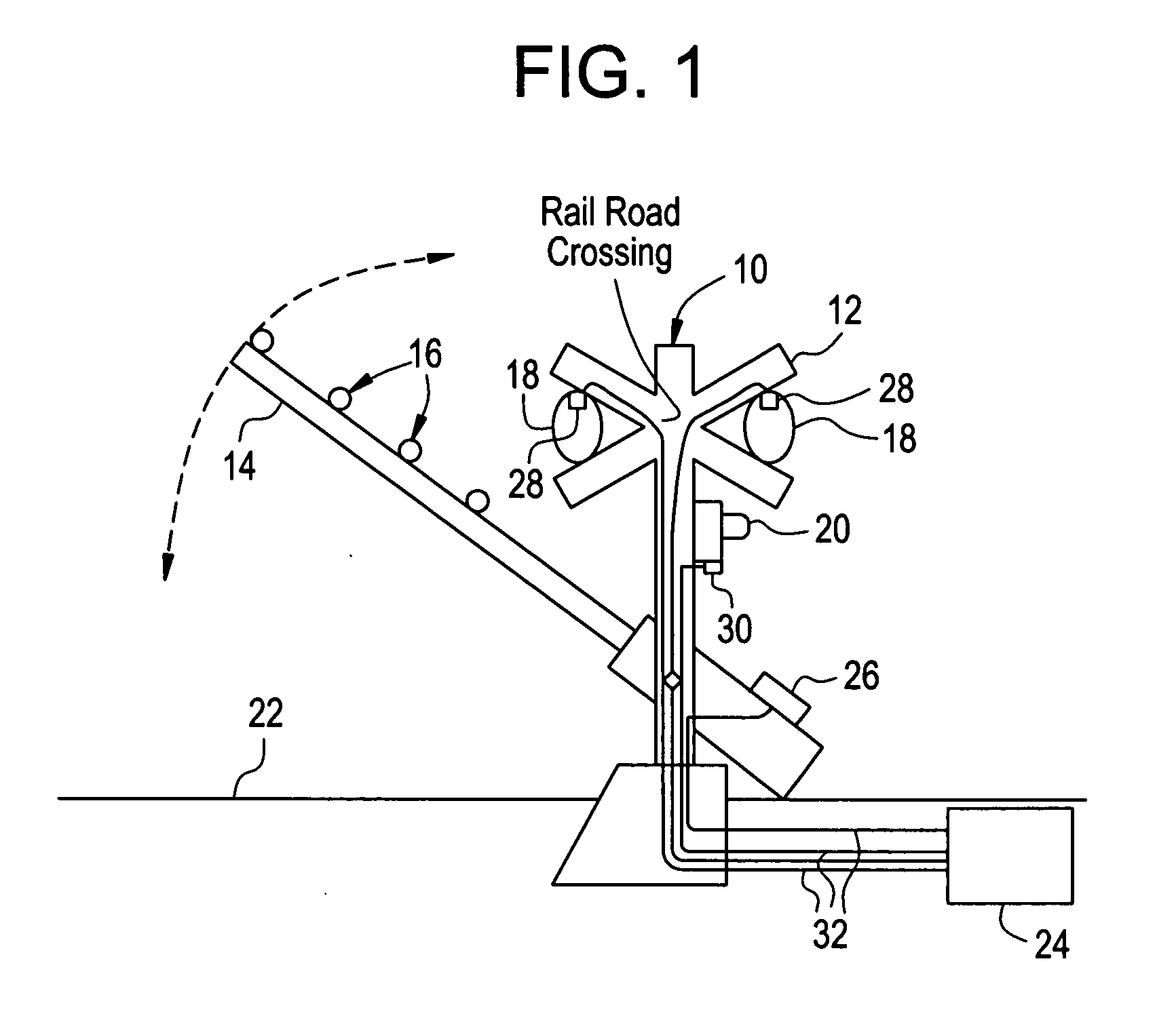

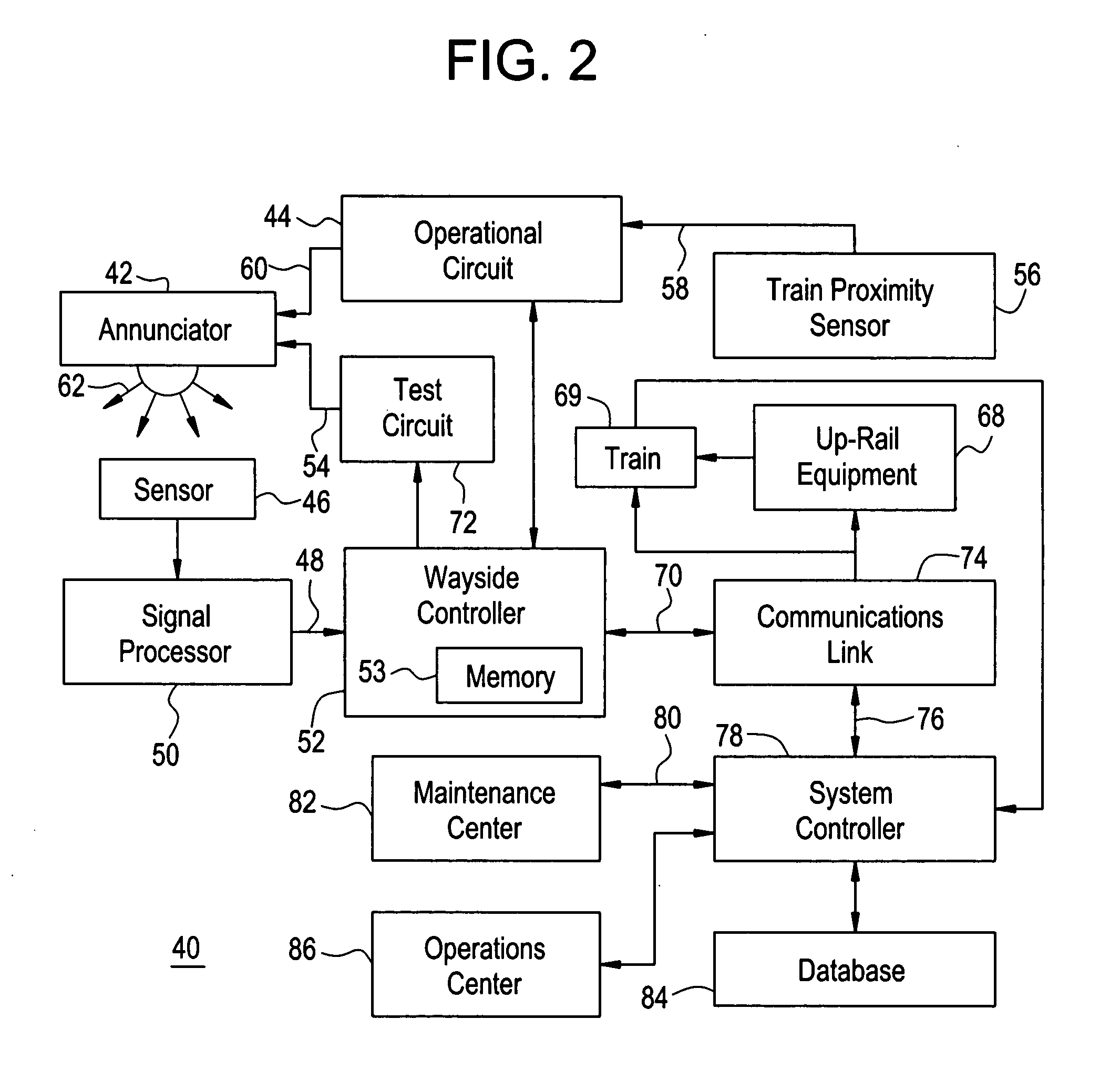

An operational status detection system for a railroad warning device having a warning light, comprising: a photodiode configured to generate a signal corresponding to a light output of the warning light of the railroad warning device; an amplifier for increasing a signal strength of the signal and providing an output corresponding to the signal; a filter for receiving the output, the filter being configured to only allow portions of the output corresponding to the light output of the warning light to be presented as an output signal of the warning light; and a microcontroller receptive to the output signal and for comparing the output signal to a threshold value, the threshold value corresponding to an acceptable light output of the warning light.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com