Power battery cover plate

A technology of power battery and cover plate, which is applied in the direction of battery cover/end cover, battery pack parts, battery box/coating, etc., to achieve the effects of enhancing safety, increasing riveting airtightness, and increasing detent torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

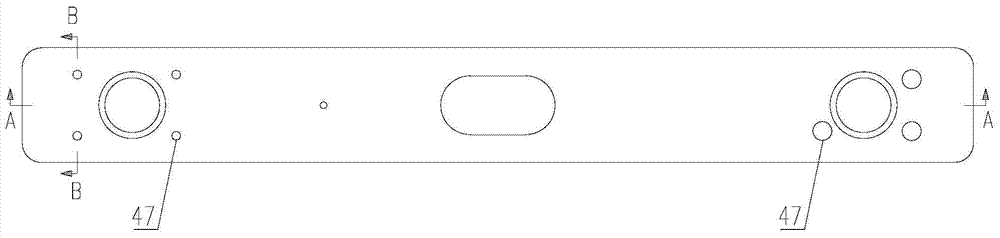

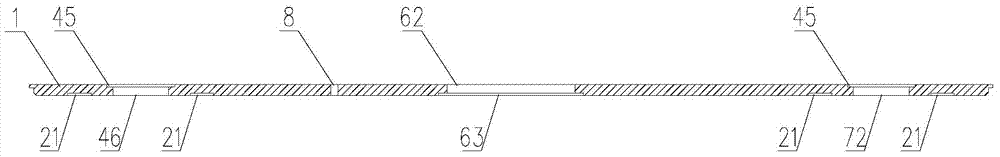

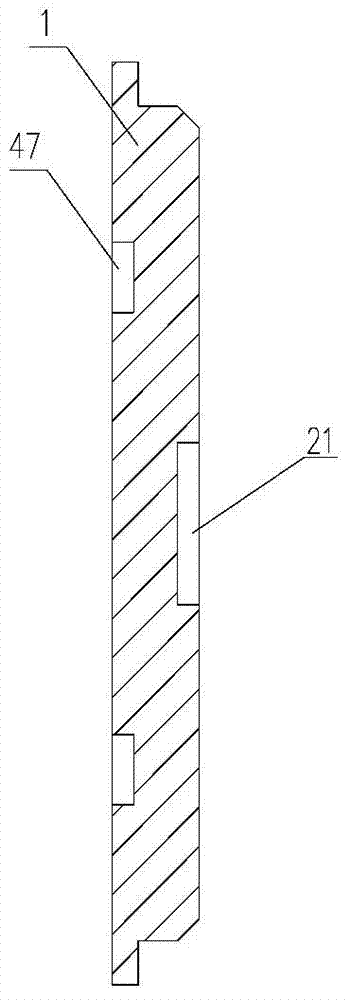

[0023] A power battery cover plate of this embodiment, please refer to Figure 1 to Figure 6 , a power battery cover plate, including a base plate 1, a positive pole 4 and a negative pole 7, the base plate 1 is provided with two pole holes 46 and 72 for respectively passing through the positive pole 4 and the negative pole 7, The ends of the positive pole 4 or the negative pole 7 passing through the substrate 1 are respectively riveted on one end of the positive riveting block 41 or the negative riveting block 71; the other end of the positive riveting block 41 is provided with a positive connecting bolt 43. The other end of the negative electrode riveting block 71 is provided with a negative electrode connecting bolt 73. In this example. The positive column 4 is machined from aluminum, and the negative column 7 is mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com