Patents

Literature

378results about How to "Avoid manual cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

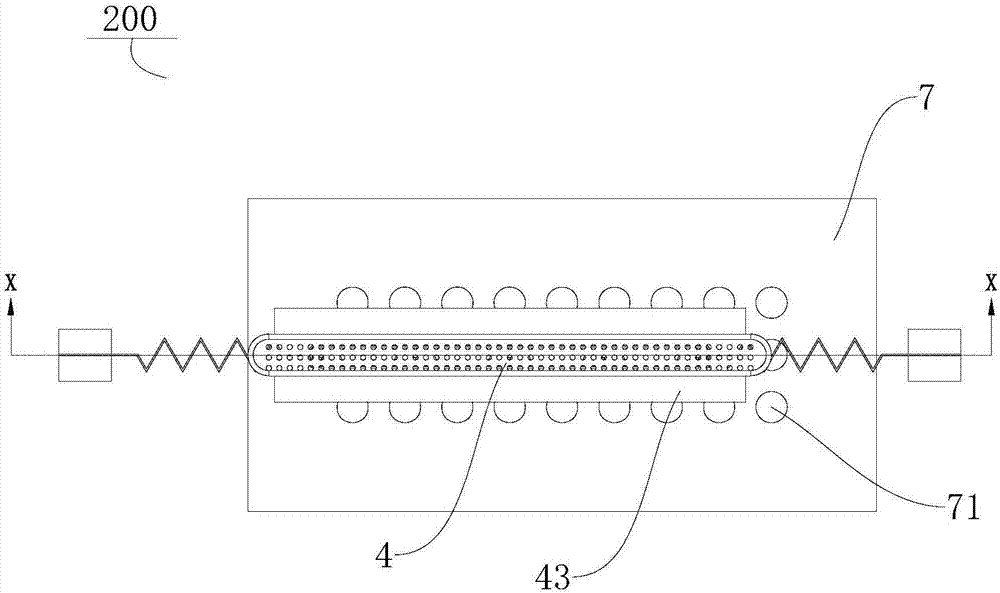

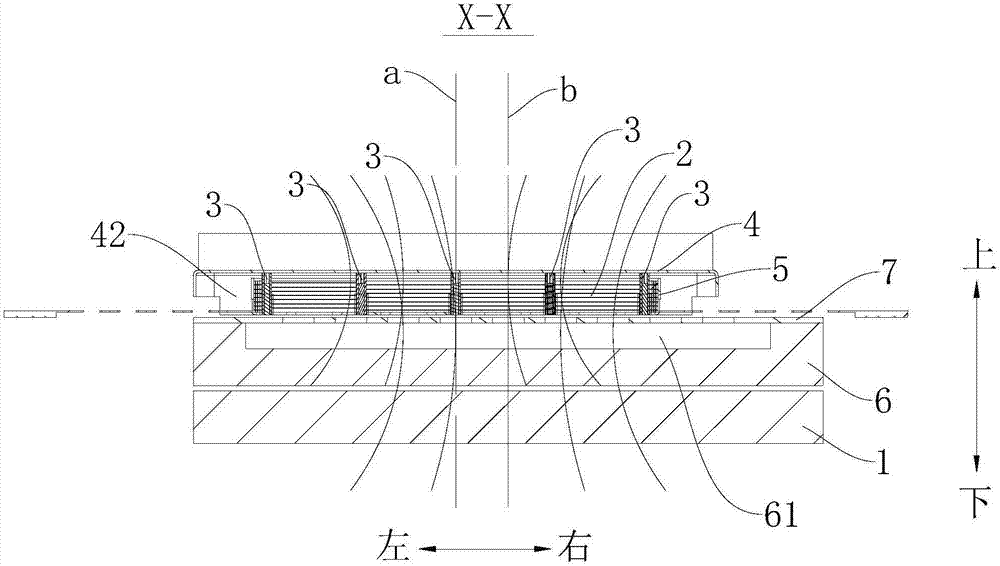

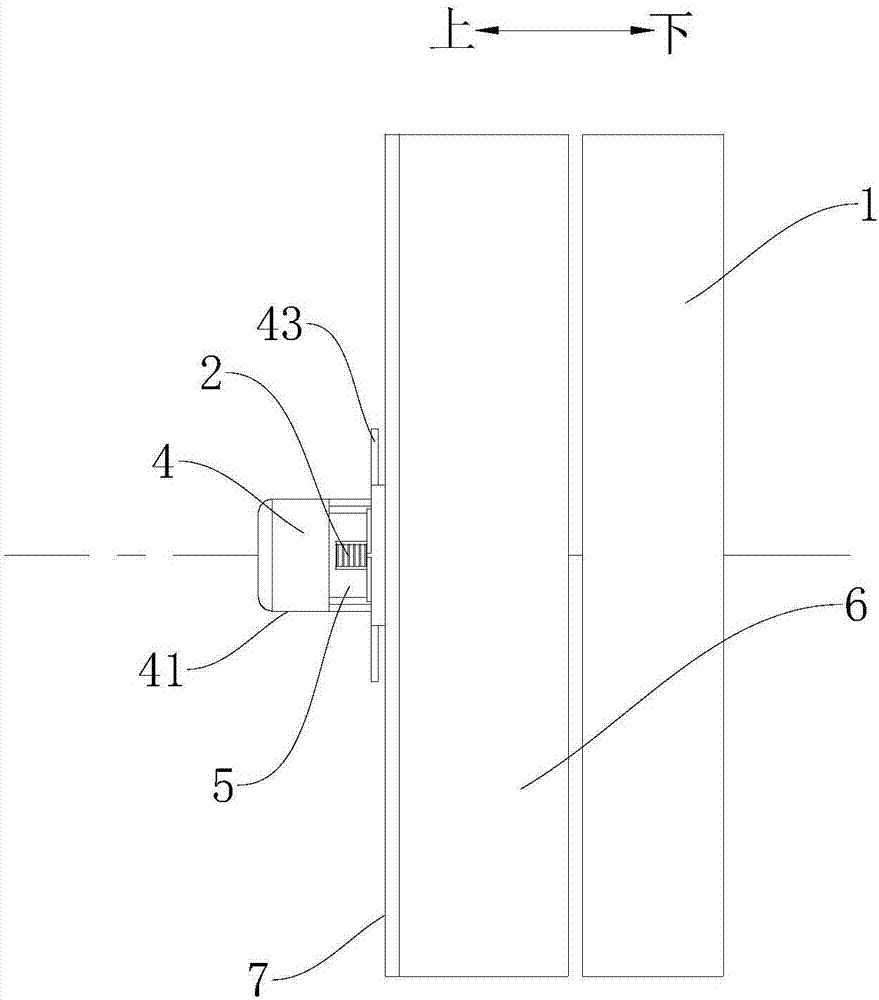

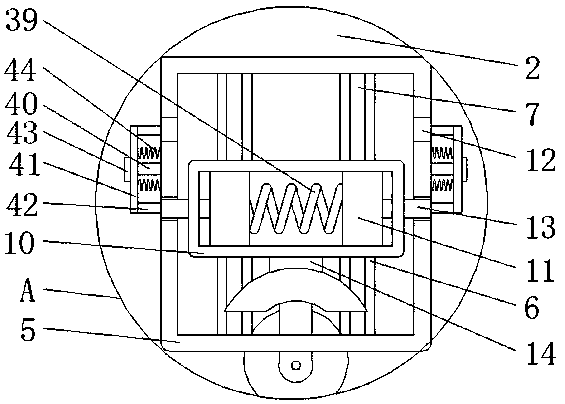

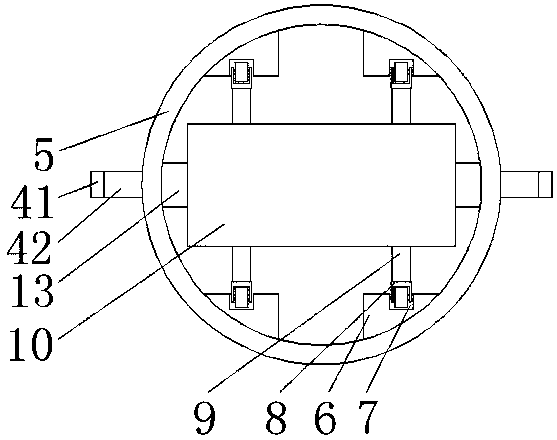

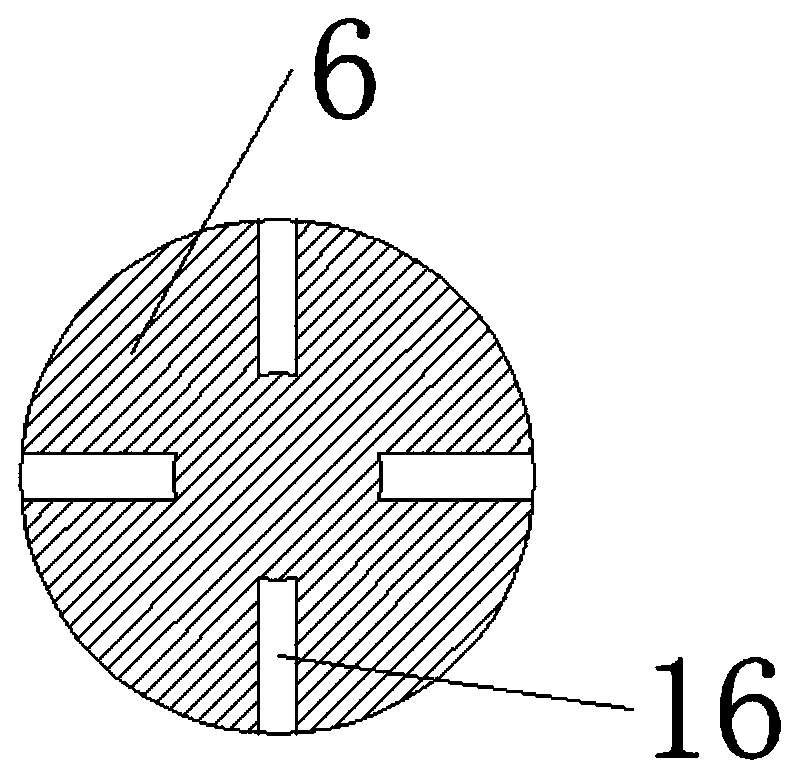

Dust screen assembly, electric acoustic assembly, housing assembly and electronic device

PendingCN107318072AWash thoroughlyAvoid manual cleaningElectrical transducersLoudspeakersElectric devicesMagnet

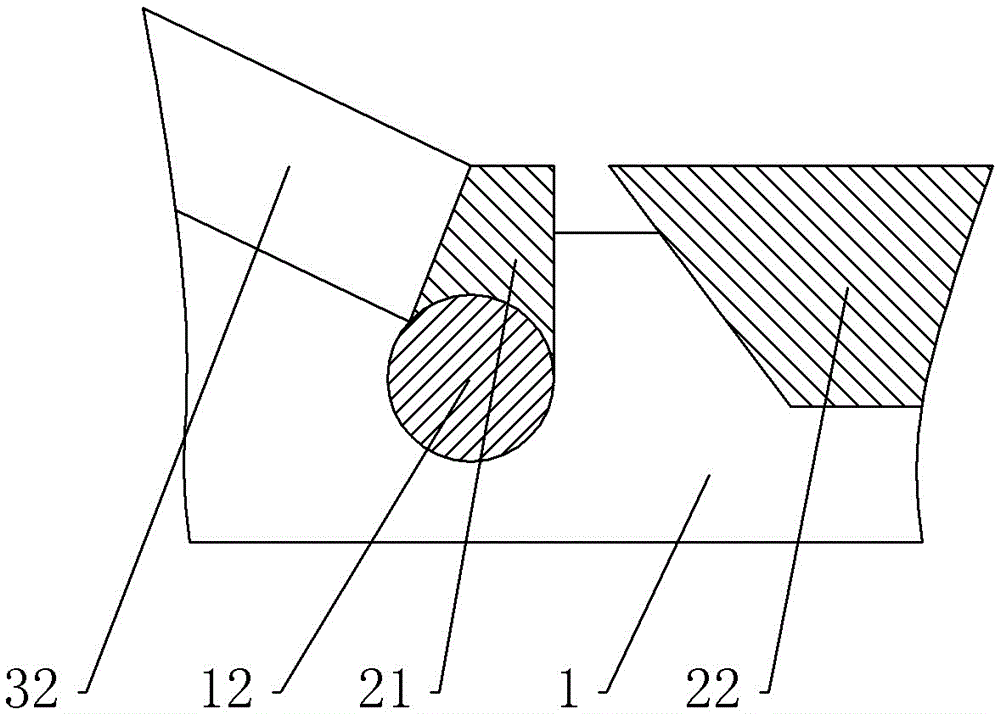

The invention discloses a dust screen assembly, an electric acoustic assembly, a housing assembly and an electronic device. The dust screen assembly comprises a magnet which has a first magnetic field, a coil which is located at one side of the magnet and is suitable for generating a second magnetic field, brush heads which are arranged in the coil and are connected with the coil, and a dust screen which is located at the side, far from the magnet, of the coil, wherein the end surface of the brush head goes beyond the end surface of the coil; when the direction of the second magnetic field and the direction of the first magnetic field are opposite, the coil moves towards the dust screen, the brush heads are suitable for making contact with the dust screen; and when the direction of the second magnetic field and the direction of the first magnetic field are identical, the coil moves towards the magnet. According to the dust screen assembly, the dust screen can be cleaned thoroughly, holes in the dust screen are not blocked, the quality of the electronic device is improved, the dust screen is not cleaned manually, and the after-sale expenditure is lowered.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

Fermentation bed used for ecological pig raising

InactiveCN102106262AEfficient recyclingSatisfy the habit of digging soil for foodAnimal housingFecesBrick

A fermentation bed used for ecological pig raising relates to the technical field of pig raising and is characterized in that a tunnel with the depth of 80 cm to 100 cm is dug underground; brick walls with the thickness of 24 cm are arranged at the periphery of the tunnel; padding is laid in the tunnel and comprises three lower layers, an intermediate layer, and an upper layer; each lower layer is 30 cm in thickness and is composed of 90% of corn straws and 10% of red earth, and a thin layer of livestock salt is spread on each lower layer; the intermediate layer is 20 cm in thickness and is composed of 90% of saw dust and 10% of red earth, and a thin layer of livestock salt is spread on the layer; and the upper layer is composed of native bacteria and nutrient fluid, wherein the native bacteria and the diluted nutrient fluid are 2 kilograms per square meter, and are uniformly sprayed into the padding by means of clean water until the humidity reaches 75%. The fermentation bed used for ecological pig raising has the benefits that cyclic utilization of forage resource can be developed effectively through ecological raising, so that the manufacturing cost is reduced; excrement of pigs can be degraded, and bad odors can be eliminated, so that the environment is prevented from being polluted; and environmental stress of pigs can be eliminated, and the habit that pigs rout about for food can be satisfied.

Owner:ANHUI FUKANG PIG COOP

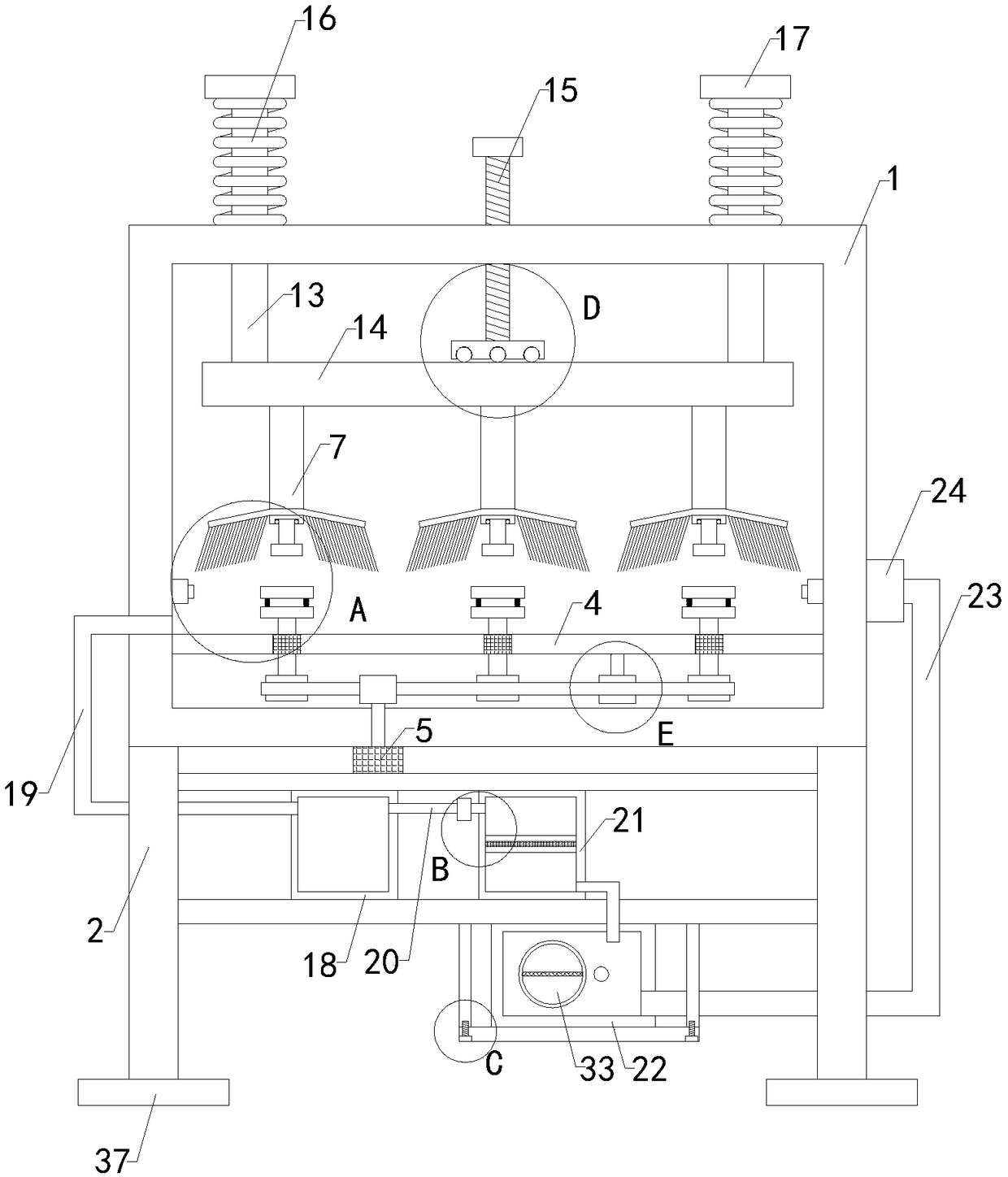

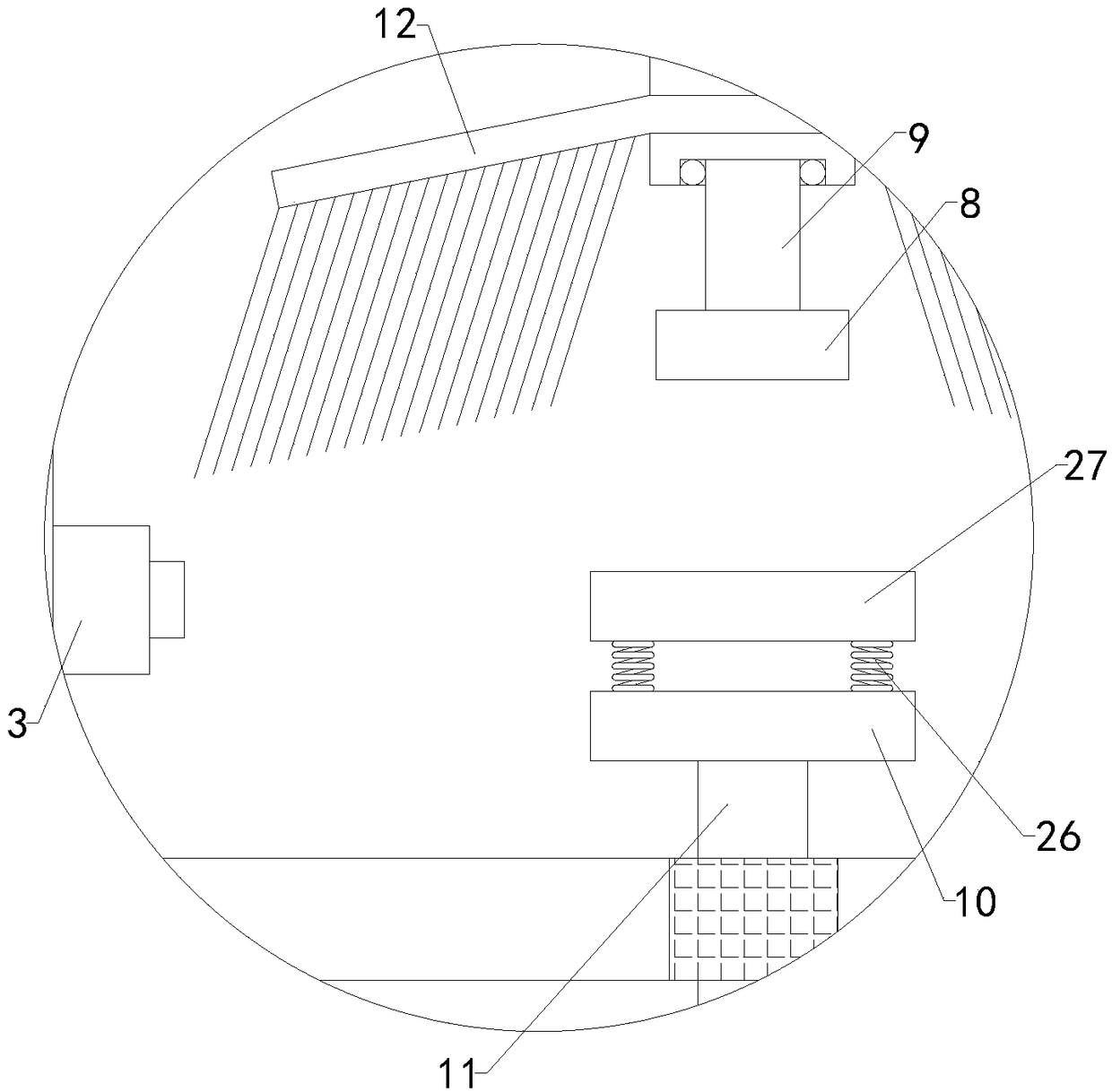

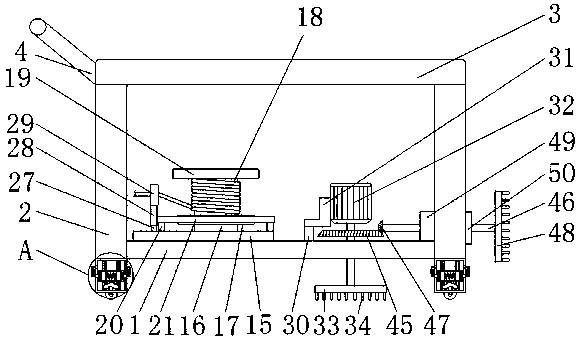

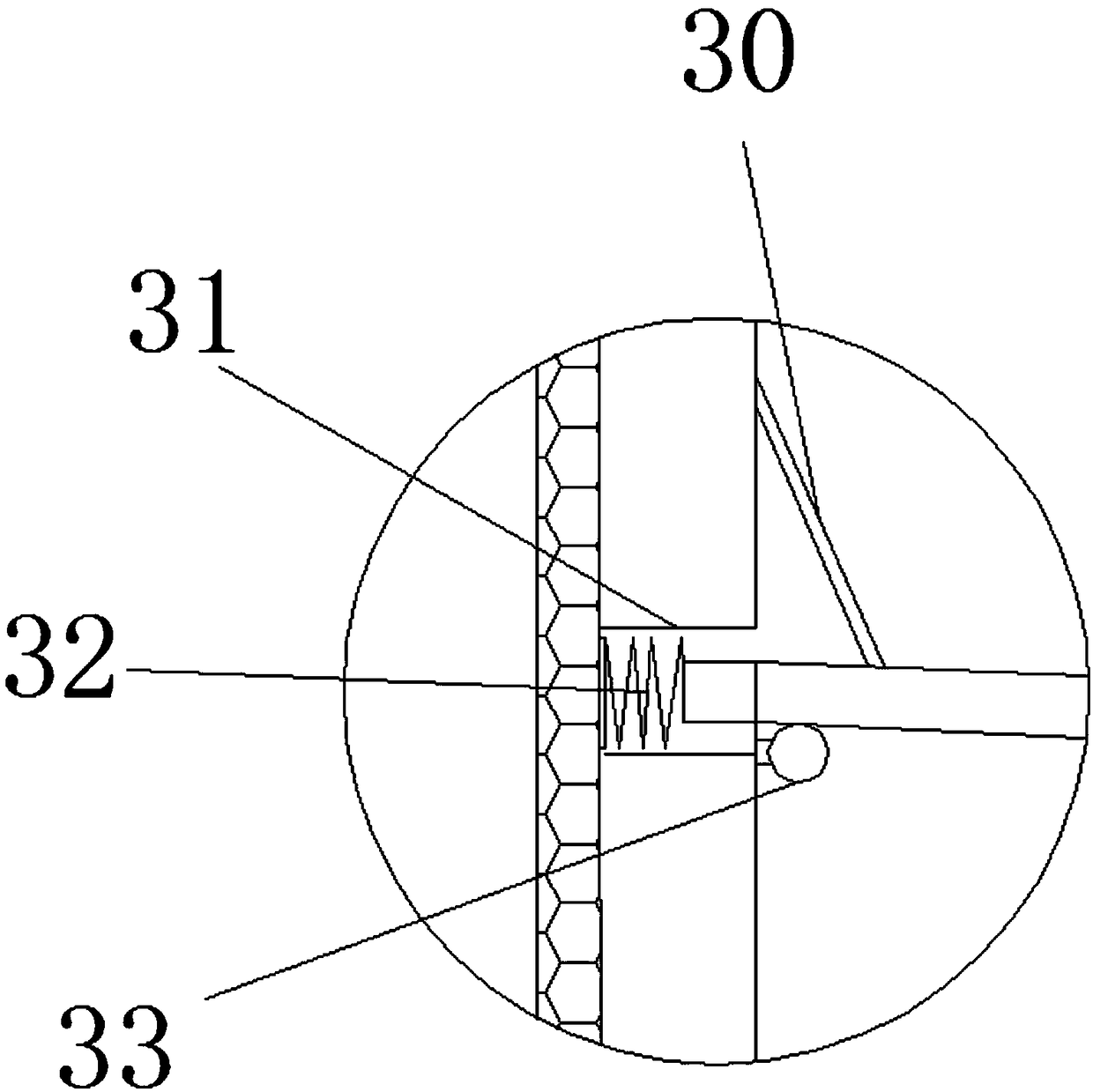

Cleaning device for automobile hub cover production

InactiveCN108971103APrevent fallingEasy to cleanCleaning using toolsCleaning using liquidsDrive shaftWater resources

The invention relates to the technical field of automobile hub cover production accessory devices, in particular to a cleaning device for automobile hub cover production. Manual cleaning is not needed, the cleaning effect is improved, the effect of cleaning of the interior of a groove in a hub cover is improved, meanwhile, batched cleaning can be conducted, the labor intensity is lowered, and theusage limitation is reduced. Waste water obtained after cleaning can be recycled, water resource waste is reduced, and practicability is improved. A cleaning box and four standing legs are included, and a first cleaning nozzle is arranged on the inner wall of the left end of the cleaning cavity. A partition plate, a drive motor, a chain, three support columns, three pressing plates, three rotationshafts, three first support plates, three transmission shafts, three cleaning covers, four limiting sliding columns, an adjusting plate, an adjusting bolt and four supporting springs are included. Asettling tank, a dirt discharging pipe, an overflow pipe, a filter box, a buffering box and a liquid return pipe are further included, a second cleaning nozzle is arranged on the inner wall of the right end of an upper cavity, and the overflow pipe is provided with an overflow valve in a communication manner.

Owner:TAICANG GATZ AUTOMOTIVE COMPONENTS CO LTD

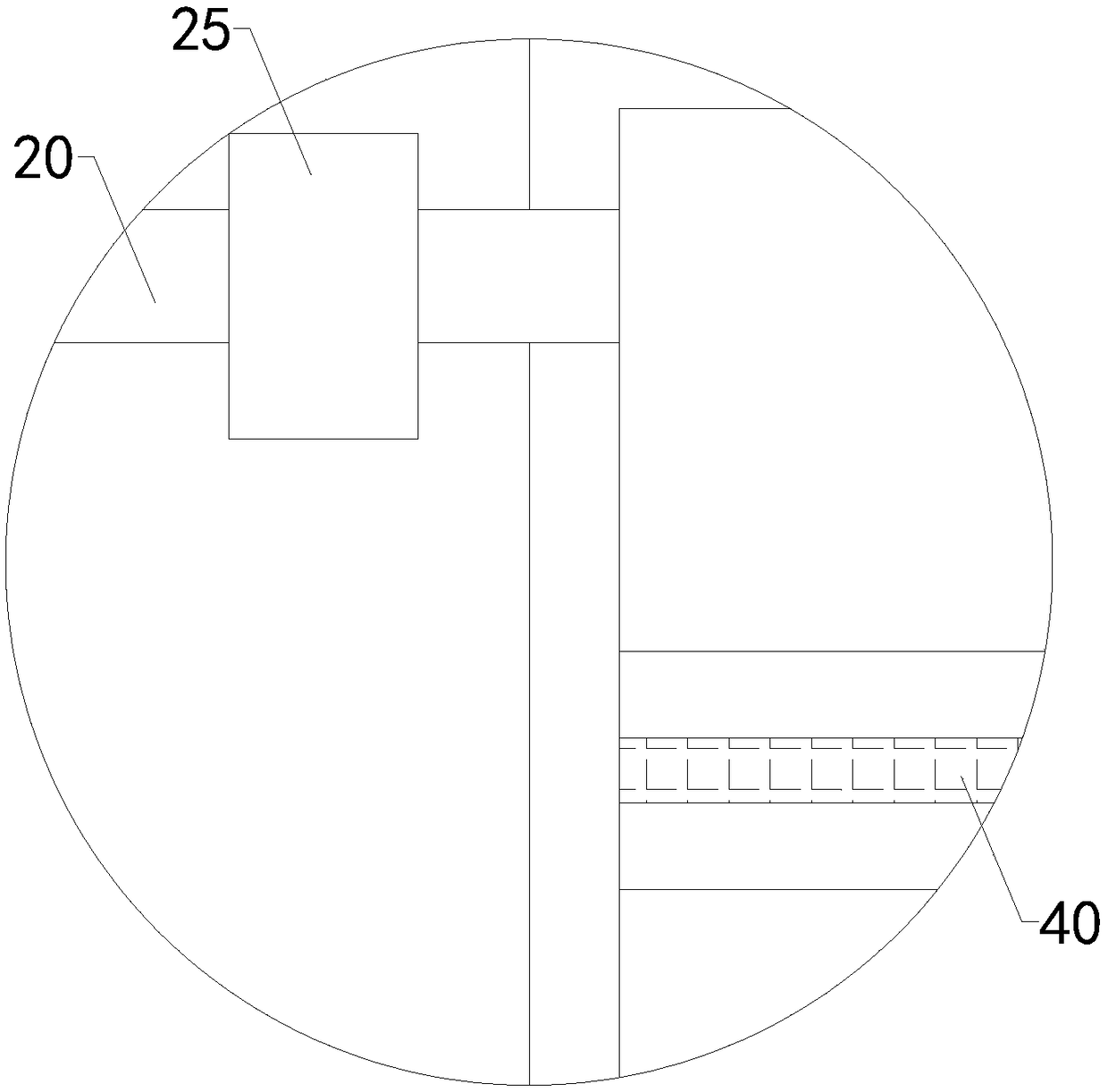

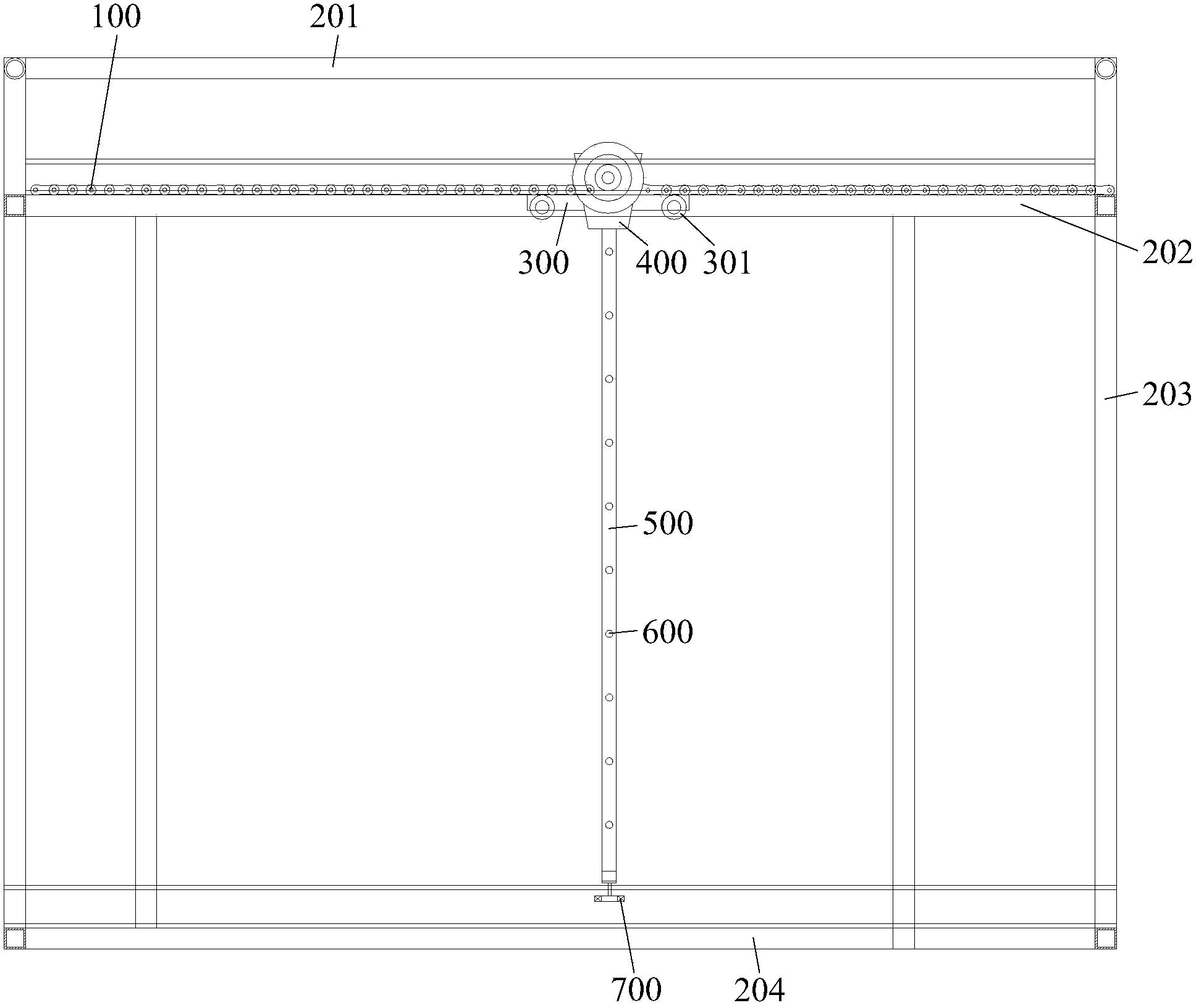

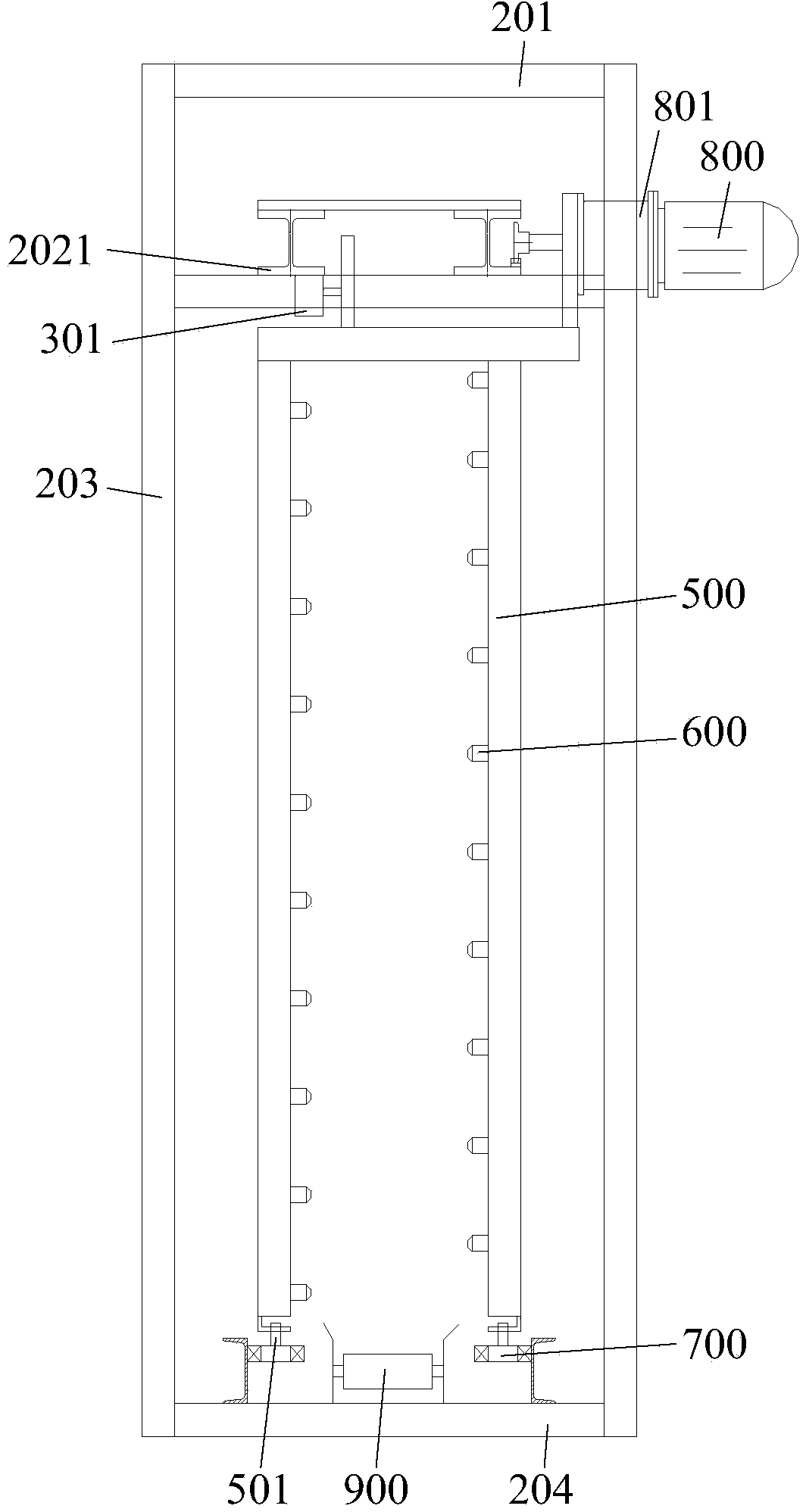

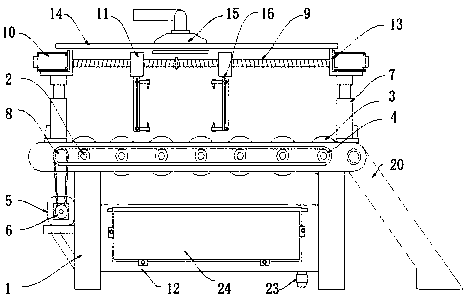

Screen printing plate cleaning device

InactiveCN103639140AShorten the timeImprove efficiencyCleaning using liquidsScreen printingSpray nozzle

The invention discloses a screen printing plate cleaning device. The screen printing plate cleaning device comprises a frame, spraying pipes and a reciprocating driving motor, wherein the frame comprises a bottom frame, a plurality of pillars fixedly connected with the bottom frame, a top frame fixedly connected with the pillars, and a cross beam with two ends connected with different pillars respectively; a chain is laid on the cross beam, and an up-going track is fixed on the cross beam; two spraying pipes are all vertically arranged; each spraying pipe is provided with a plurality of spray nozzles positioned on the spraying pipe and towards the other spraying pipe; end parts of the two spraying pipes are fixedly connected with a connection pipe; a connection piece with guide wheels is fixed on the connection pipe; the guide wheels are tightly propped against the up-going track; a chain wheel is fixed on the output shaft of the reciprocating driving motor, and is matched with the chain; the output shaft can be rotatably inserted into the connection piece. The screen printing plate cleaning device can clean two sides of a screen printing plate simultaneously, so that time can be saved, and efficiency is improved.

Owner:YUYUE HOME TEXTILE

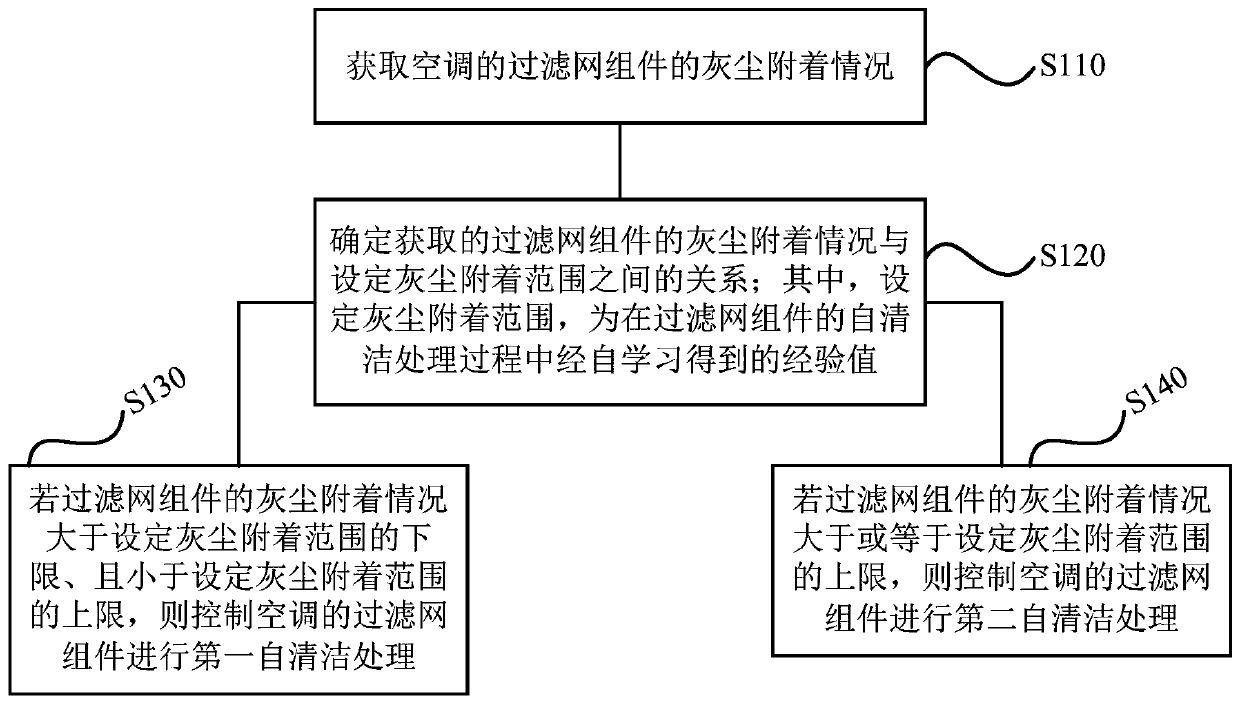

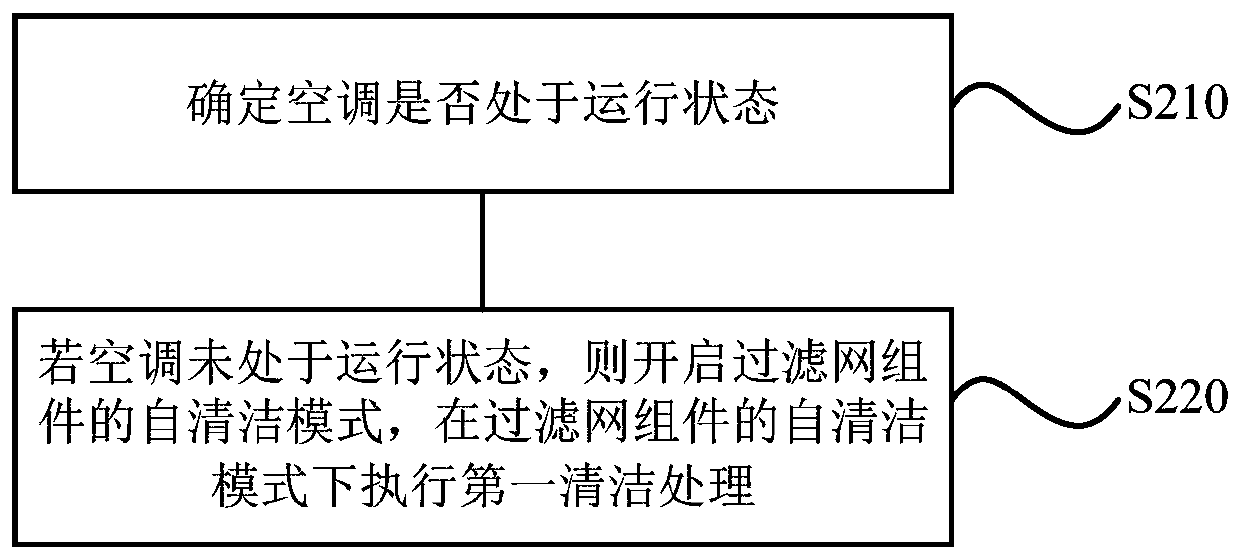

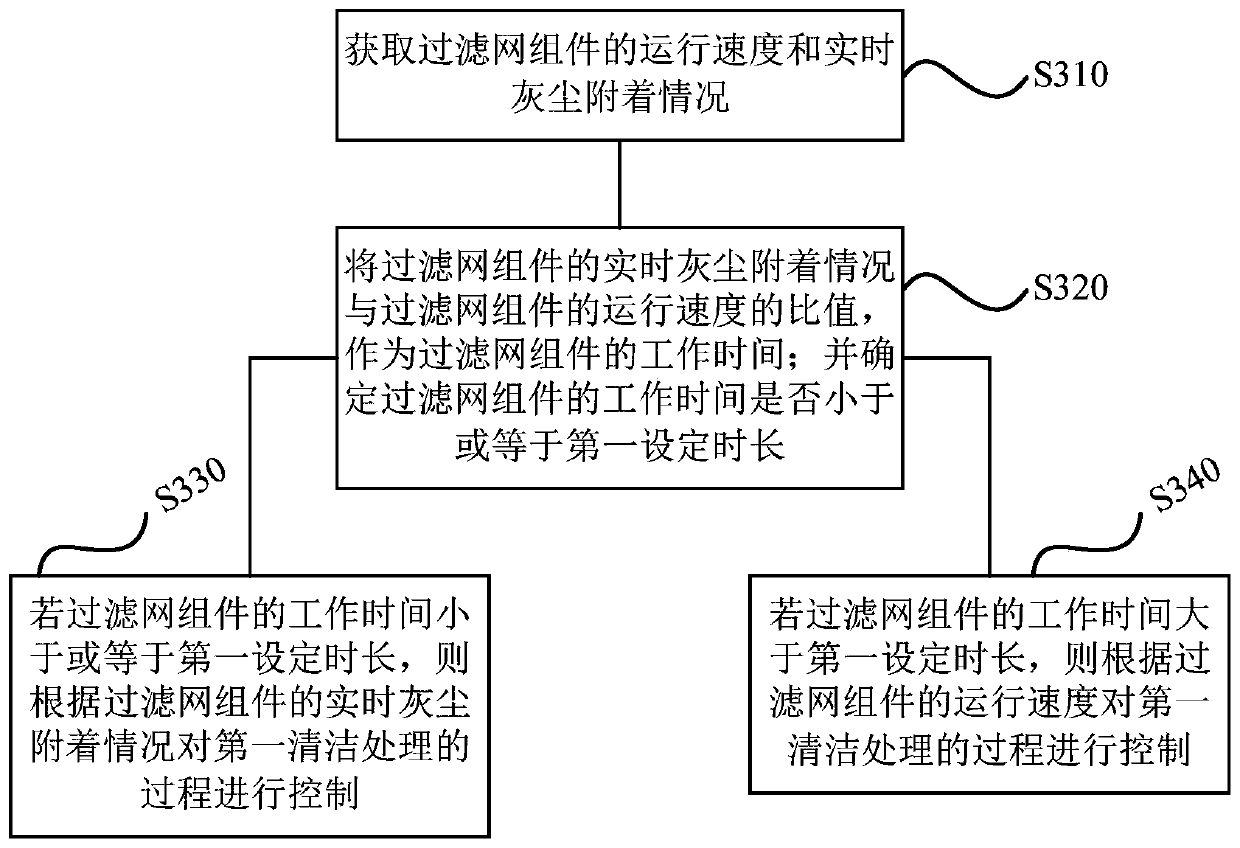

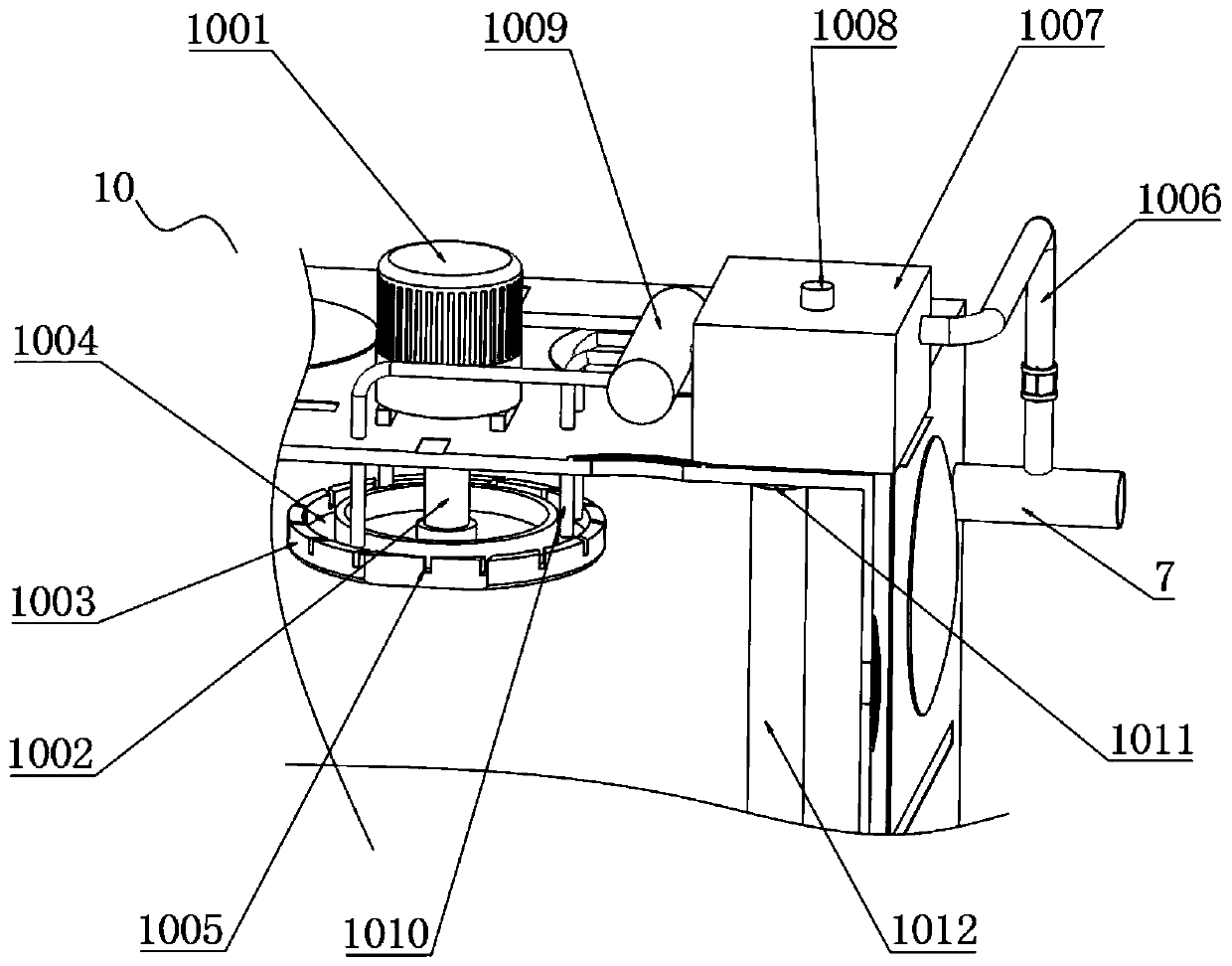

Air conditioner cleaning method and device, storage medium and air conditioner

ActiveCN111102684AAvoid manual cleaningImprove convenienceMechanical apparatusLighting and heating apparatusEnvironmental engineeringMechanical engineering

The invention discloses an air conditioner cleaning method and device, a storage medium and an air conditioner. The method comprises the steps that the dust attachment condition of a filter screen assembly of the air conditioner is obtained; a relationship between the acquired dust attachment condition of the filter screen assembly and a set dust attachment range is determined, wherein the dust attachment range is set to be an empirical value obtained through self-learning in a self-cleaning treatment process of the filter screen assembly; if the dust attachment condition of the filter screenassembly is larger than the lower limit of the set dust attachment range and smaller than the upper limit of the set dust attachment range, the filter screen assembly of the air conditioner is controlled to conduct first self-cleaning treatment; and if the dust attachment condition of the filter screen assembly is larger than or equal to the upper limit of the set dust attachment range, the filterscreen assembly of the air conditioner is controlled to conduct second self-cleaning treatment. According to the scheme, the problem that a filter screen of the air conditioner is inconvenient to clean can be solved, and the effect of improving the cleaning convenience of the filter screen of the air conditioner is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Anti-wire return swimming pool cleaning device

InactiveCN108035566AEasy to moveEasy to disassemble and replaceGymnasiumSwimming poolsMarine engineeringAxial symmetry

The invention relates to the technical field of swimming pool cleaning equipment and discloses an anti-wire return swimming pool cleaning device. The anti-wire return swimming pool cleaning device comprises a bottom plate, both sides of the bottom plate are fixedly connected with vertical plates which are in axial symmetry relative to the bottom plate, the tops of the two vertical plates are fixedly provided with a horizontal plate, the left of the horizontal plate is fixedly provided with a pushing handle, and the bottoms of the two vertical plates are fixedly provided with first barrels. According to the anti-wire return swimming pool cleaning device, through interaction of a support table and a rotating plate, a winding column can conveniently rotate to wind, take up and pay off power lines; under the action of a first spring, when a user pulls the power lines to drive the rotating plate to rotate, rotation of the rotating plate can be impeded with interaction of a stopping bar andan impeding bar; when the user does not pull the power lines, the rotating plate cannot rotate to avoid loosening and separation, to maintain winding regularity of the power lines and further to facilitate next usage of the power lines.

Owner:鲁忠华

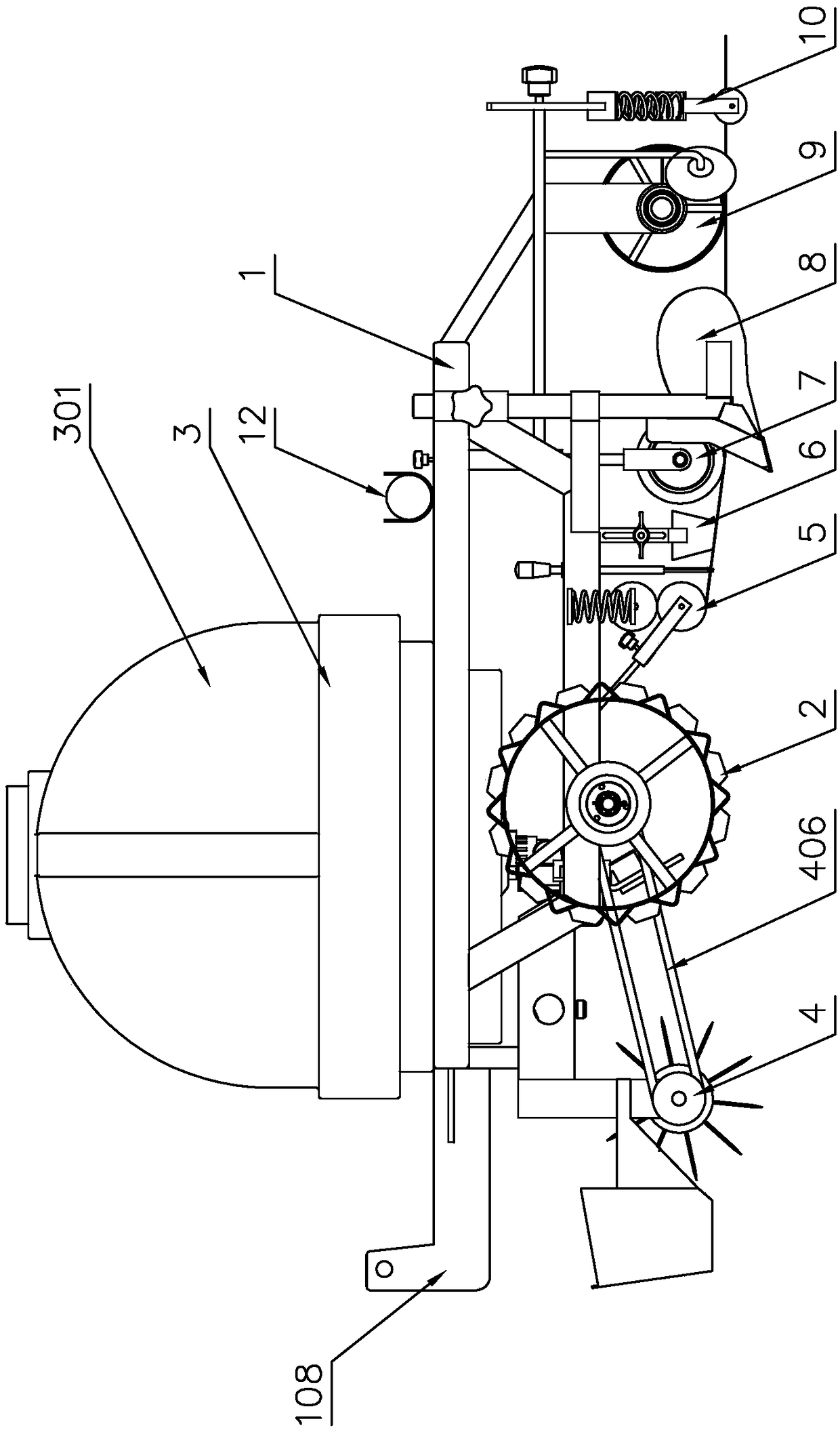

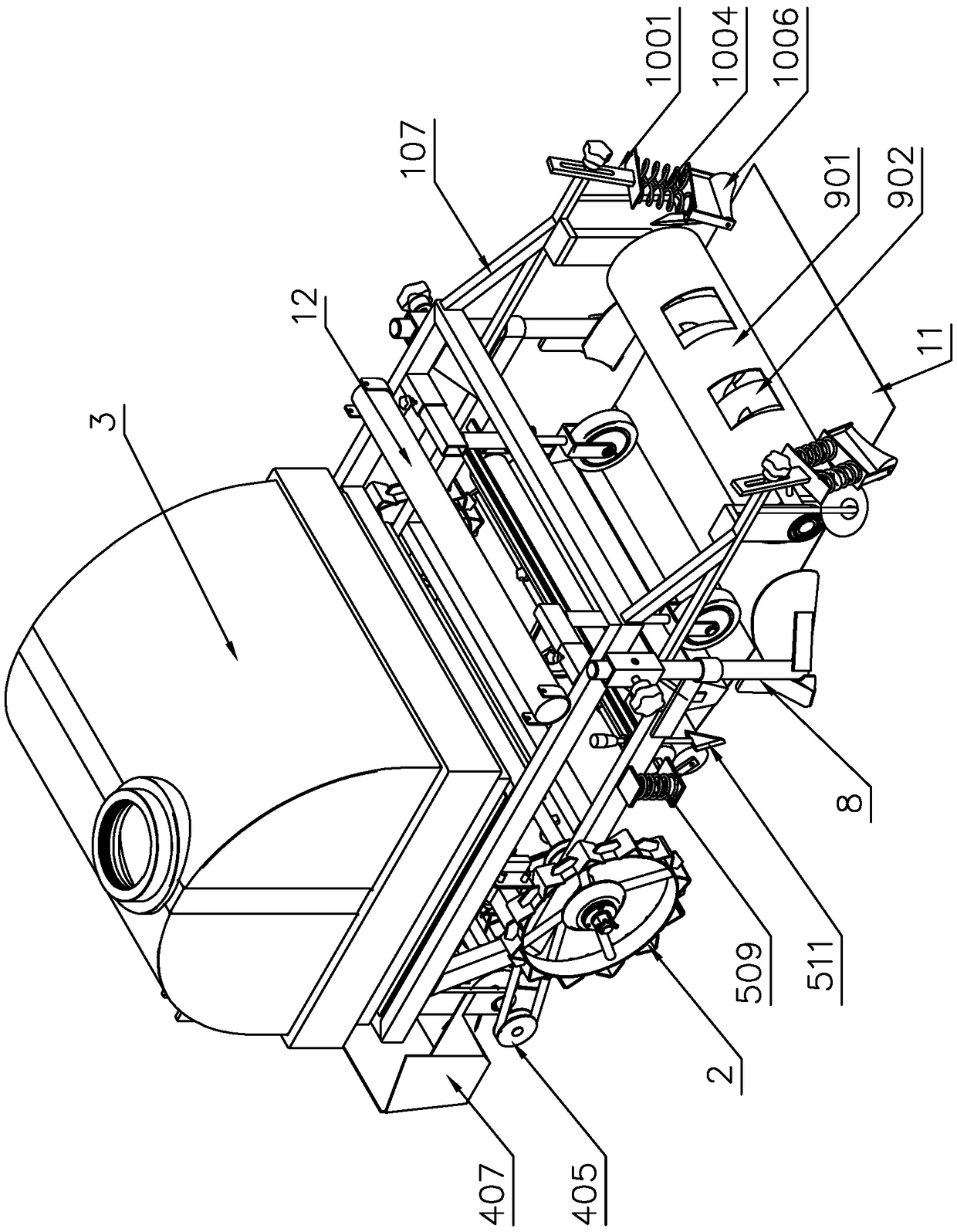

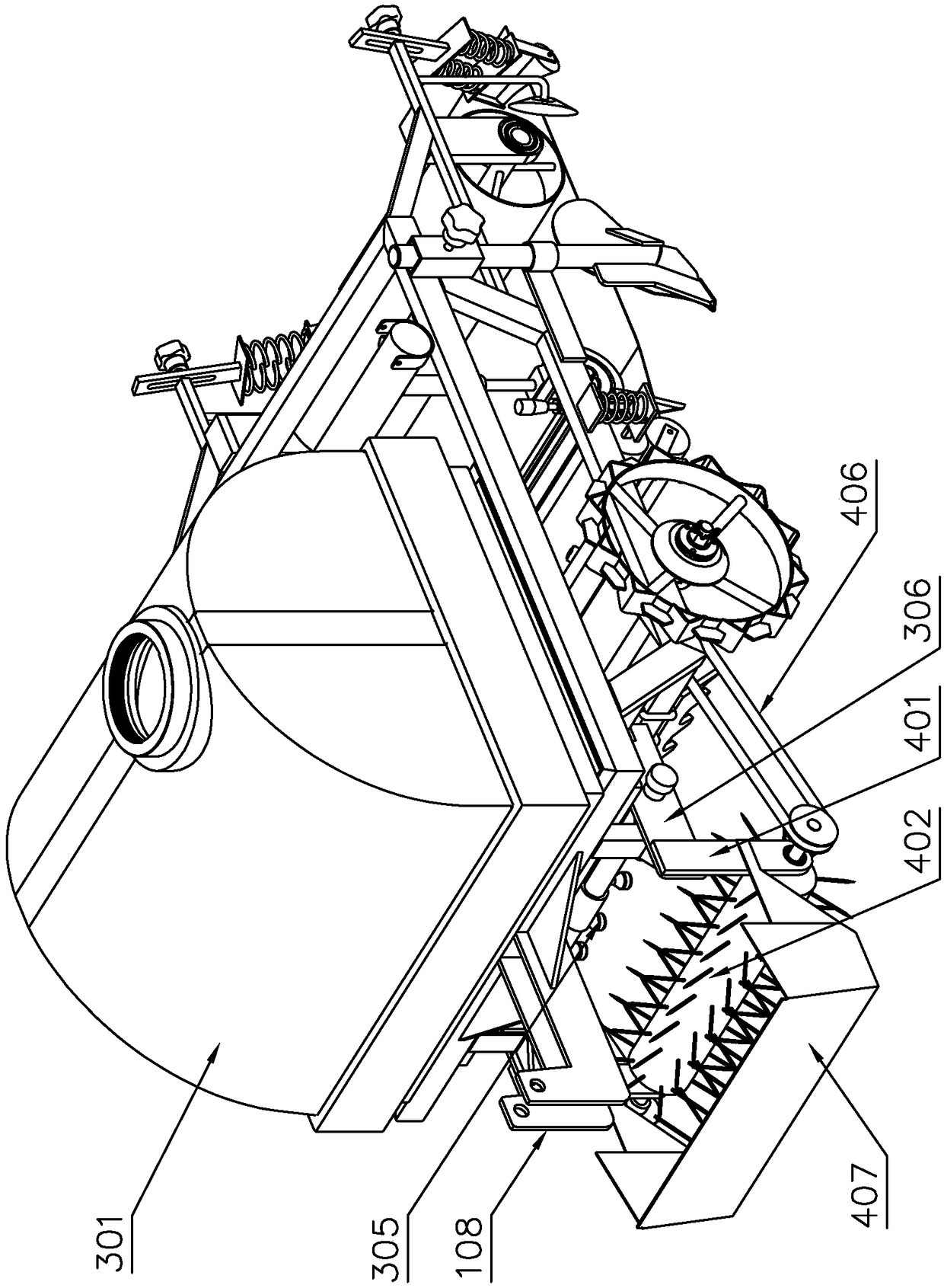

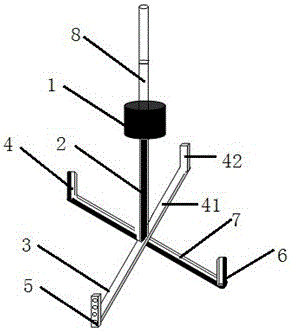

Agricultural ditch and ridge pesticide spraying and film laminating integrated device

ActiveCN109041603AGuaranteed effectImprove planting efficiencySpadesPloughsAgricultural engineeringUltimate tensile strength

The invention discloses an agricultural ditch and ridge pesticide spraying and film laminating integrated device which comprises a machine frame, wheels, a pesticide spraying device, a film pick-up device, a film put-down mechanism, a film pressing mechanism, a soil covering mechanism and a soil pressing mechanism. The pesticide spraying device is arranged on one side of the upper portion of the machine frame. The wheels are arranged on one side of the lower portion of the lower frame. The film pick-up device is arranged on one side of the wheels. The film put-down mechanism is arranged on oneside of the film pick-up device. The film pressing mechanism is arranged on one side of the film put-down mechanism. The soil covering mechanism is arranged on one side of the film pressing mechanism. The soil pressing mechanism is arranged on one side of the soil covering mechanism. By means of the integrated device, pesticide spraying and film laminating are integrated, pesticide spraying and film laminating can be completed at the same time through one time of operation, and the ditch and ridge film laminating planting efficiency is improved; by arranging the soil pressing mechanism, the film laminating effect is ensured; in addition, by arranging the film pick-up device, residual films on ditches and ridges are automatically picked up, and the labor intensity of farmers is relieved.

Owner:众智机械(临沂)有限公司

Environmental-protection equipment convenient to clear up smoke exhaust barrel

The invention discloses environmental-protection equipment convenient to clear up a smoke exhaust barrel. The environmental-protection equipment comprises a base, a door rotating shaft, a first motor,first shaft rods, pulleys, a horizontal plate, steel ropes, first hair brushes, ash scraping plates, a connecting rod, second hair brushes, a motor chassis, a second motor, an ash collecting box, a sliding door and the smoke exhaust barrel. According to the environmental-protection equipment convenient to clear up the smoke exhaust barrel disclosed by the invention, through arrangement of rotation of the ash scraping plate and motion of the ash scraping plate in the vertical direction, an inner wall of the smoke exhaust barrel is cleared up without needing person to enter into a chimney, so that the use of the environmental-protection equipment is flexible and convenient to use; through arrangement of the first hair brush, secondary cleaning on the smoke exhaust barrel is carried out, blocking of the smoke exhaust barrel is avoided, and the working efficiency of the smoke exhaust barrel is improved; and through arrangement of the second hair brushes, scraped dust is swept into the dust collecting box, so that the dust is collected preferably, the working strength of cleanup personnel is reduced, and the practicability of a cleanup device is improved.

Owner:洛阳高昌机电科技有限公司

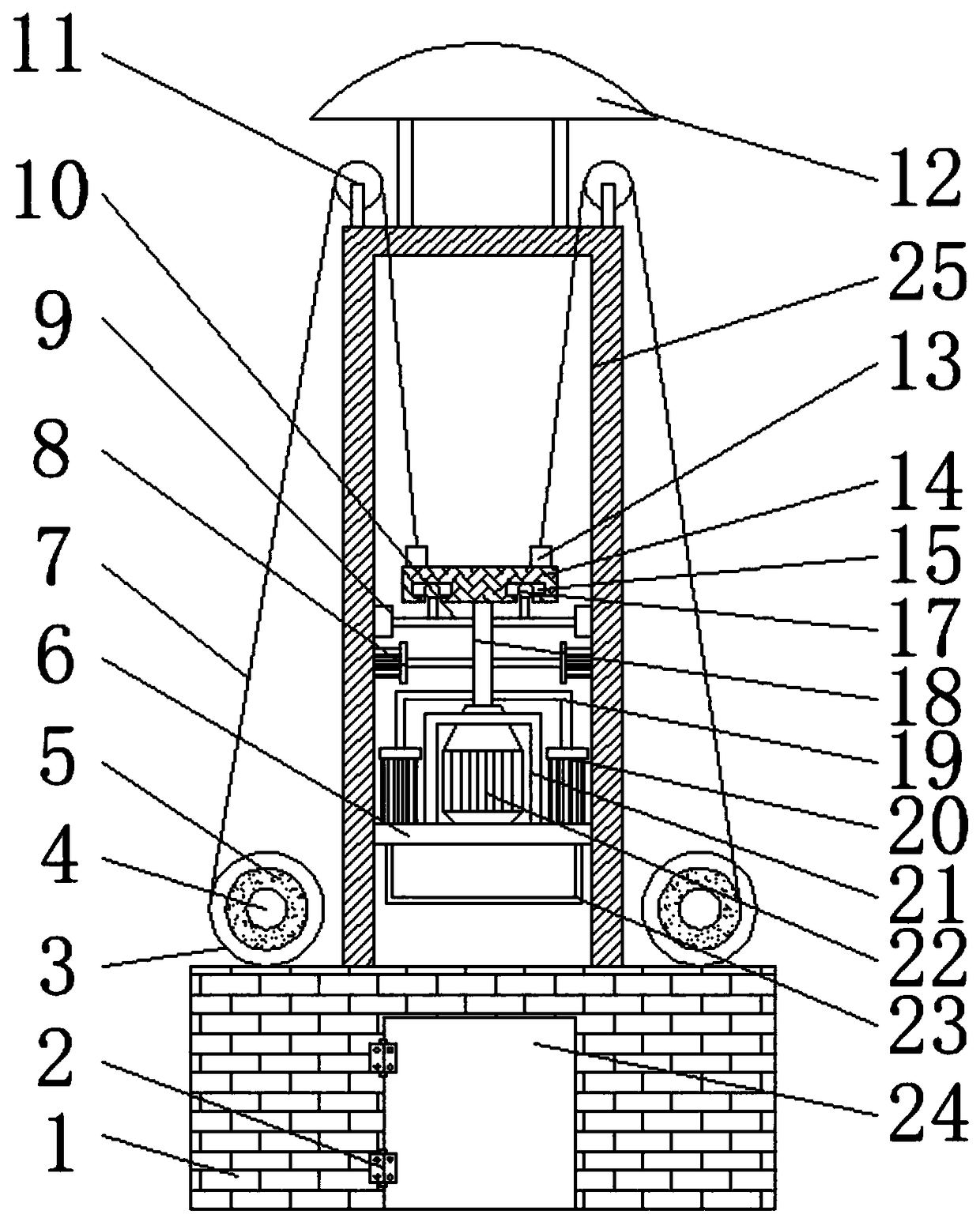

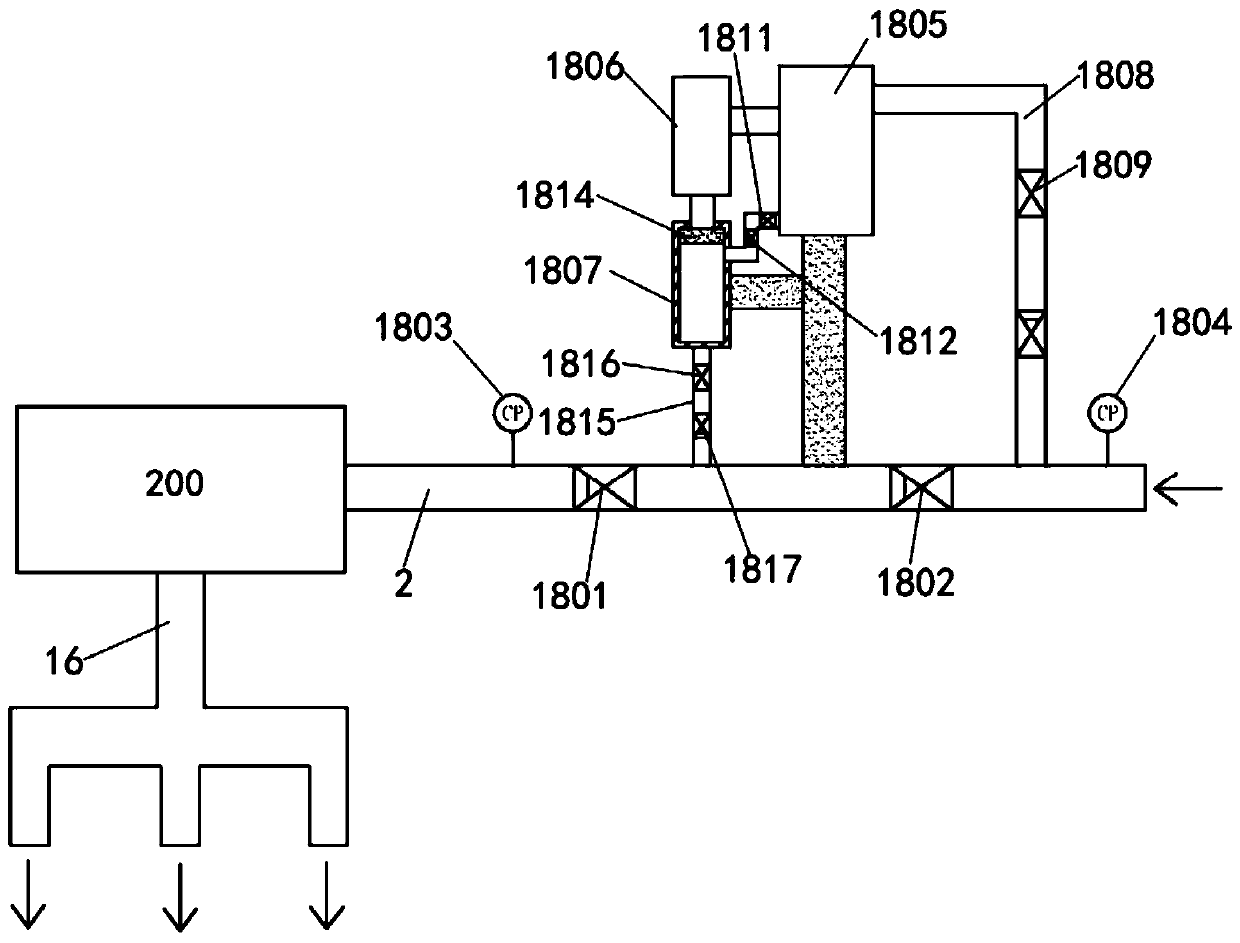

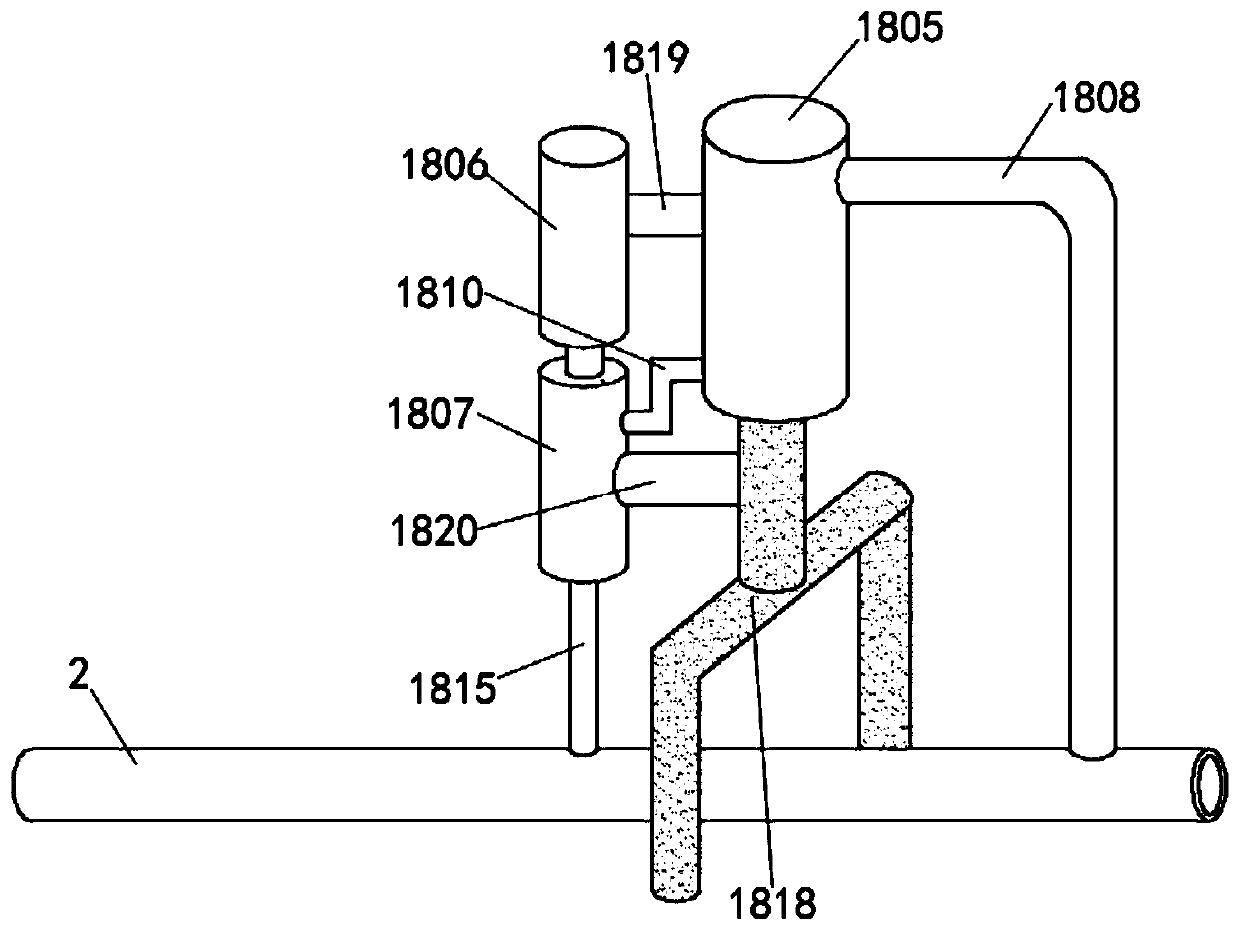

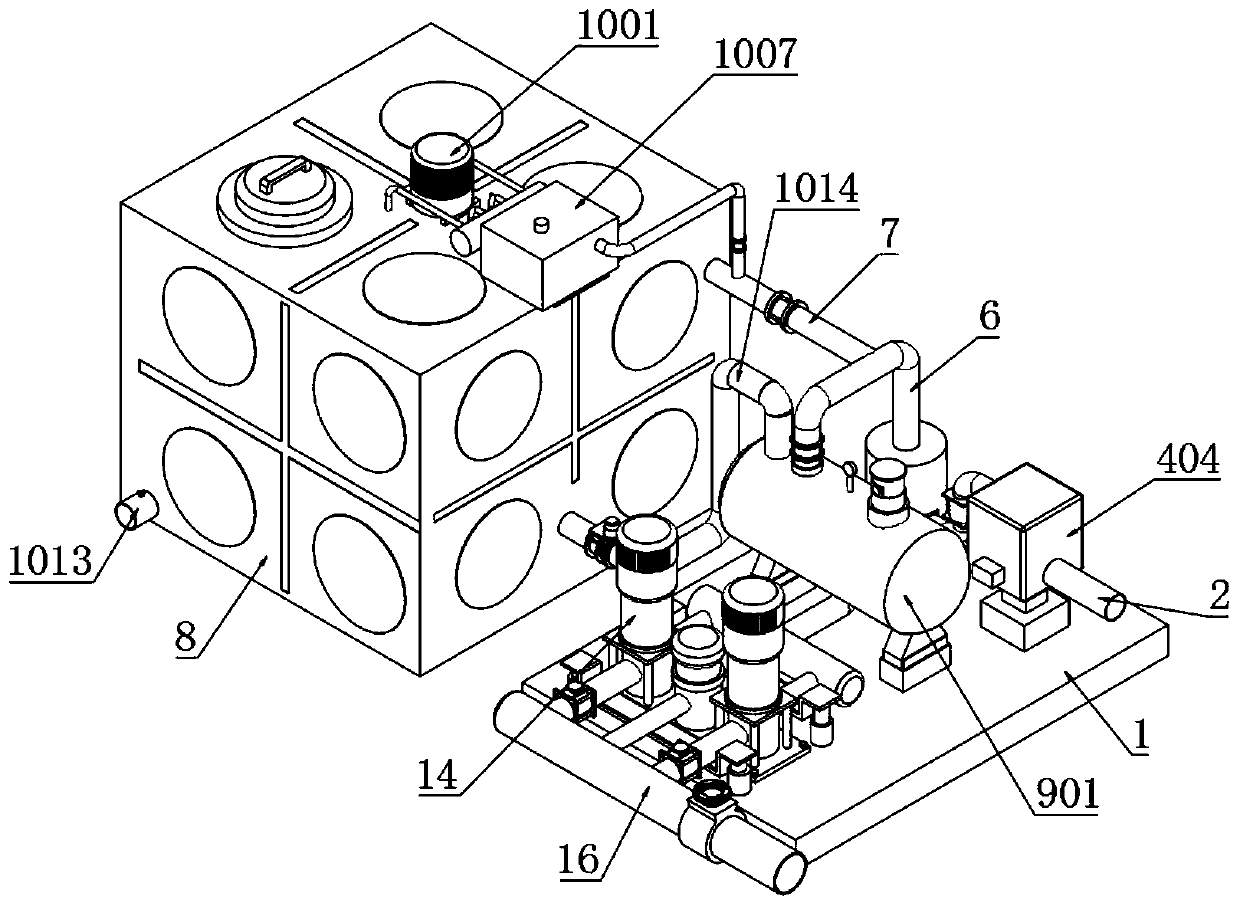

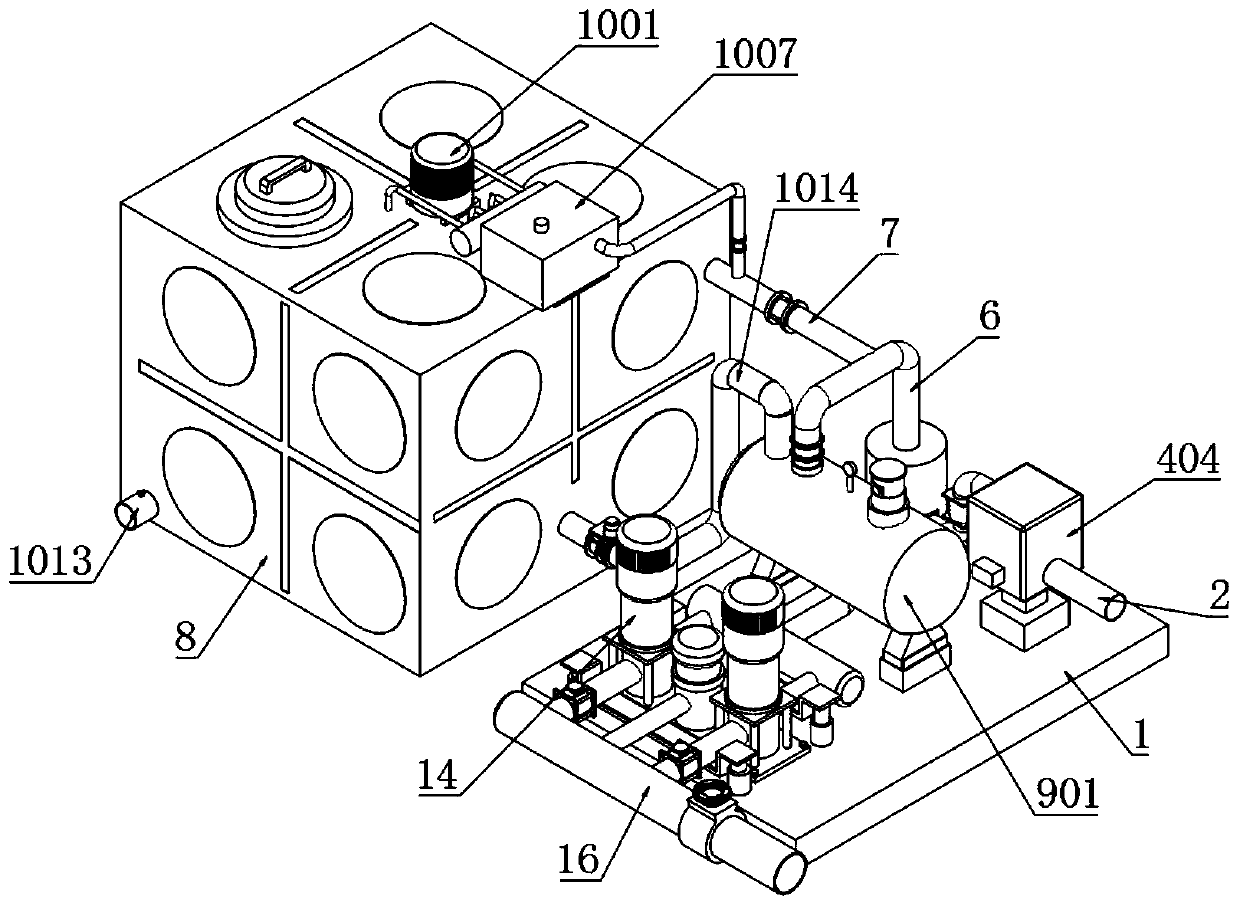

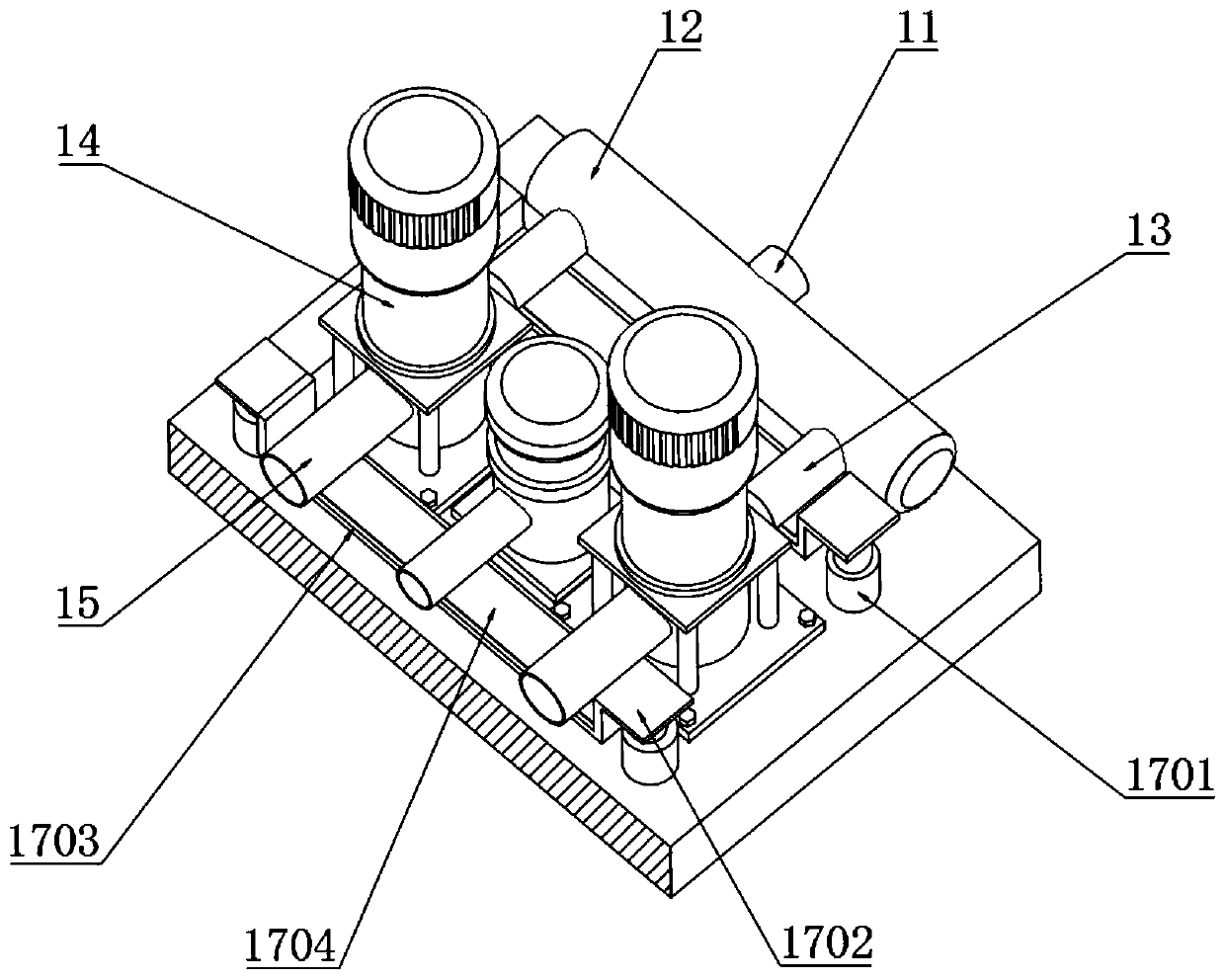

Pressure stabilizing type non-negative pressure water supply system

ActiveCN111561023AScientific and reasonable structureSafe to useWater/sewage treatment by irradiationGeneral water supply conservationWater supply networkPiston

The invention discloses a pressure stabilizing type non-negative pressure water supply system which comprises a water inlet pipe, a water inlet pipe pressure stabilizing device, a water supply power combination device and a water supply pipe. The water inlet pipe pressure stabilizing device is integrally arranged on the water inlet pipe communicated with a municipal tap water pipe, and the water inlet pipe is supplied to all users after being treated and pressurized by the water supply power combination device; the water inlet pipe pressure stabilizing equipment comprises a high-level water tank, a hydraulic cylinder and a pressurizing barrel, the high-level water tank is communicated with the water inlet pipe through an L-shaped pipe, a water replenishing valve is arranged on the L-shapedpipe, the bottom of the high-level water tank is communicated with the pressurizing barrel through a folding pipe, a first electromagnetic control valve and a third check valve are arranged on the folding pipe, and a liquid level sensor is arranged in the high-level water tank; and an output shaft of the hydraulic cylinder is fixedly connected with a piston in the pressurizing barrel, the bottomend of the pressurizing barrel is communicated with the water inlet pipe through a pressurizing pipe, and a second electromagnetic control valve and a fourth check valve are arranged on the pressurizing pipe.

Owner:安徽海沃特水务股份有限公司

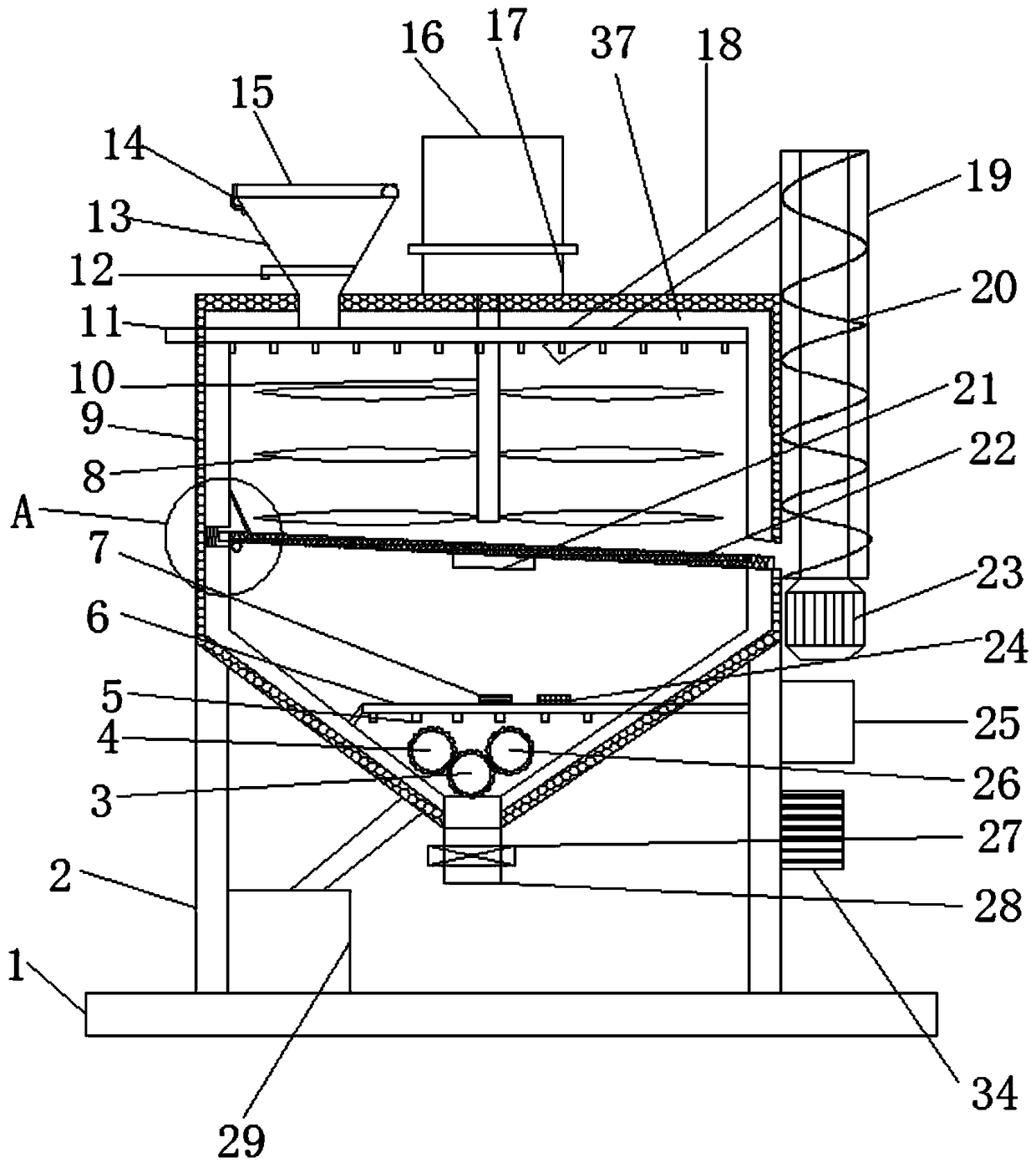

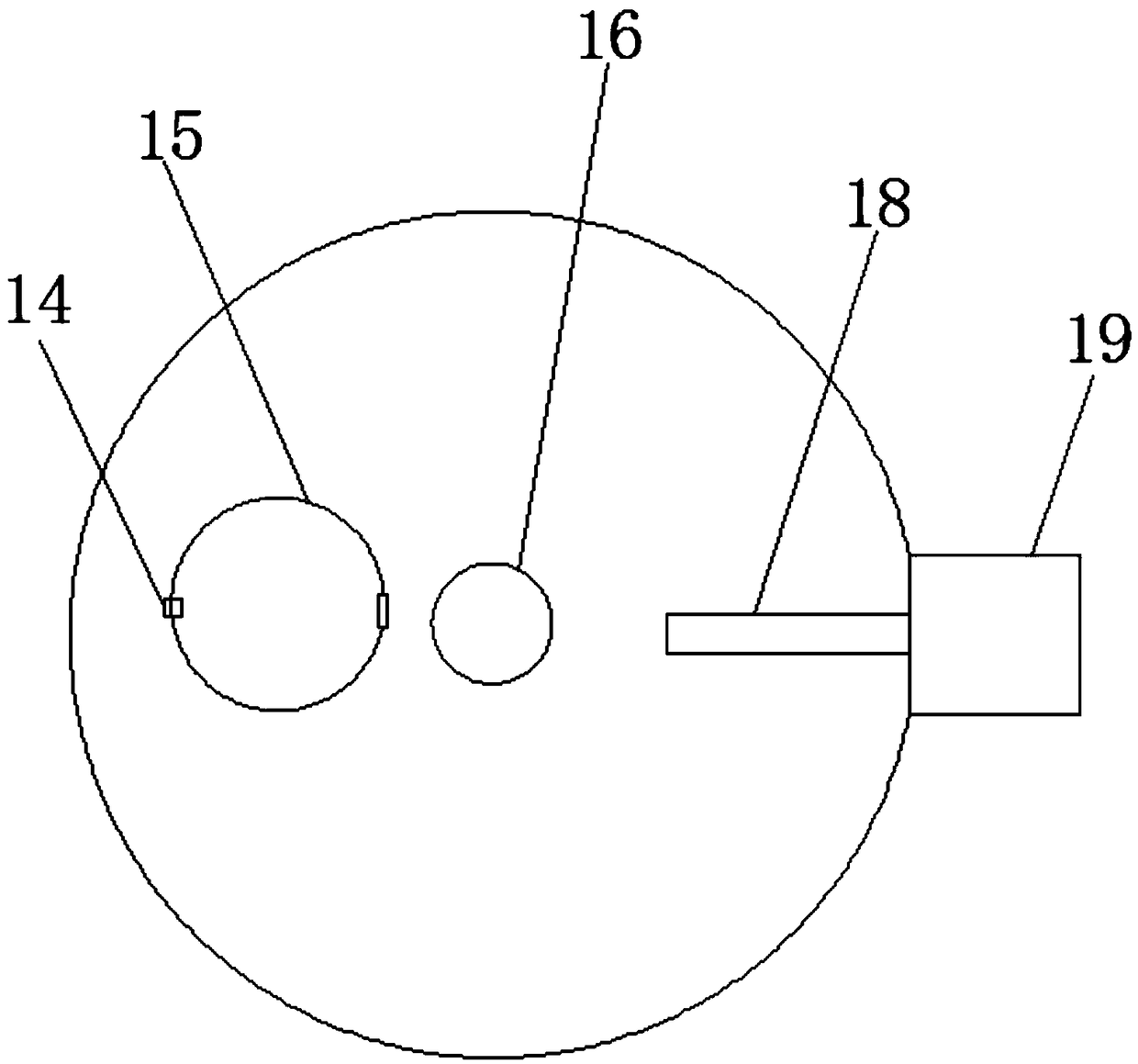

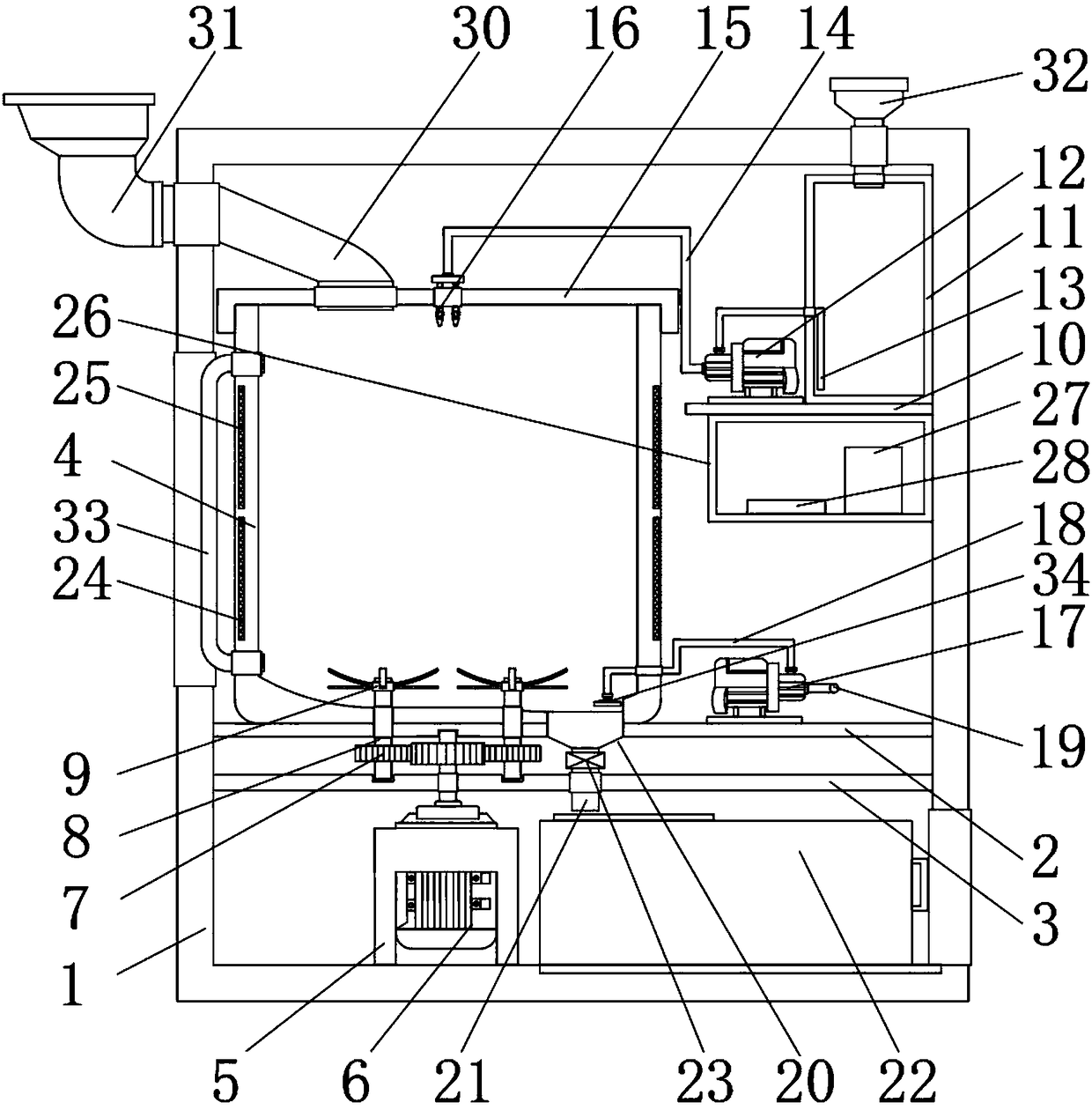

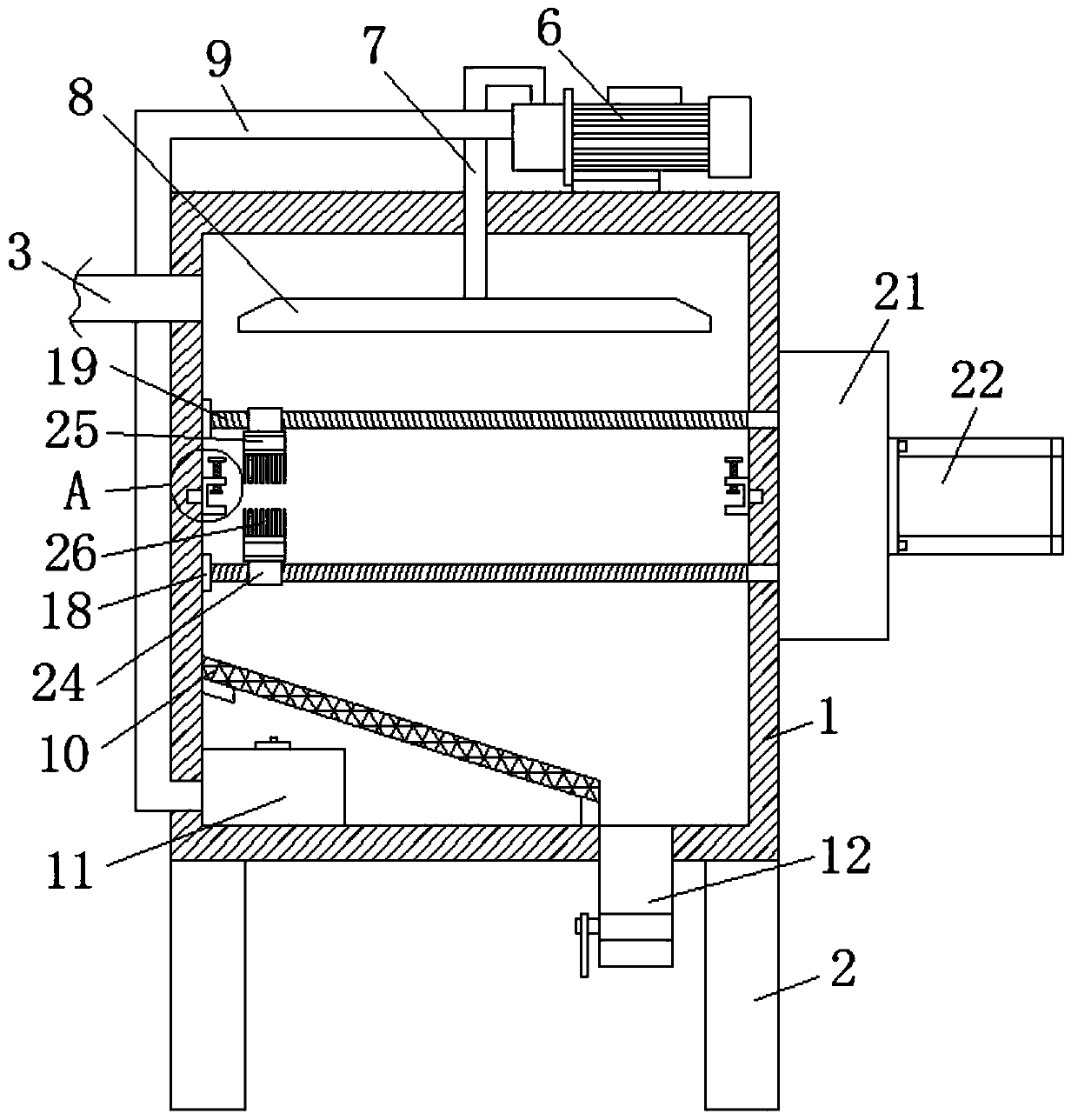

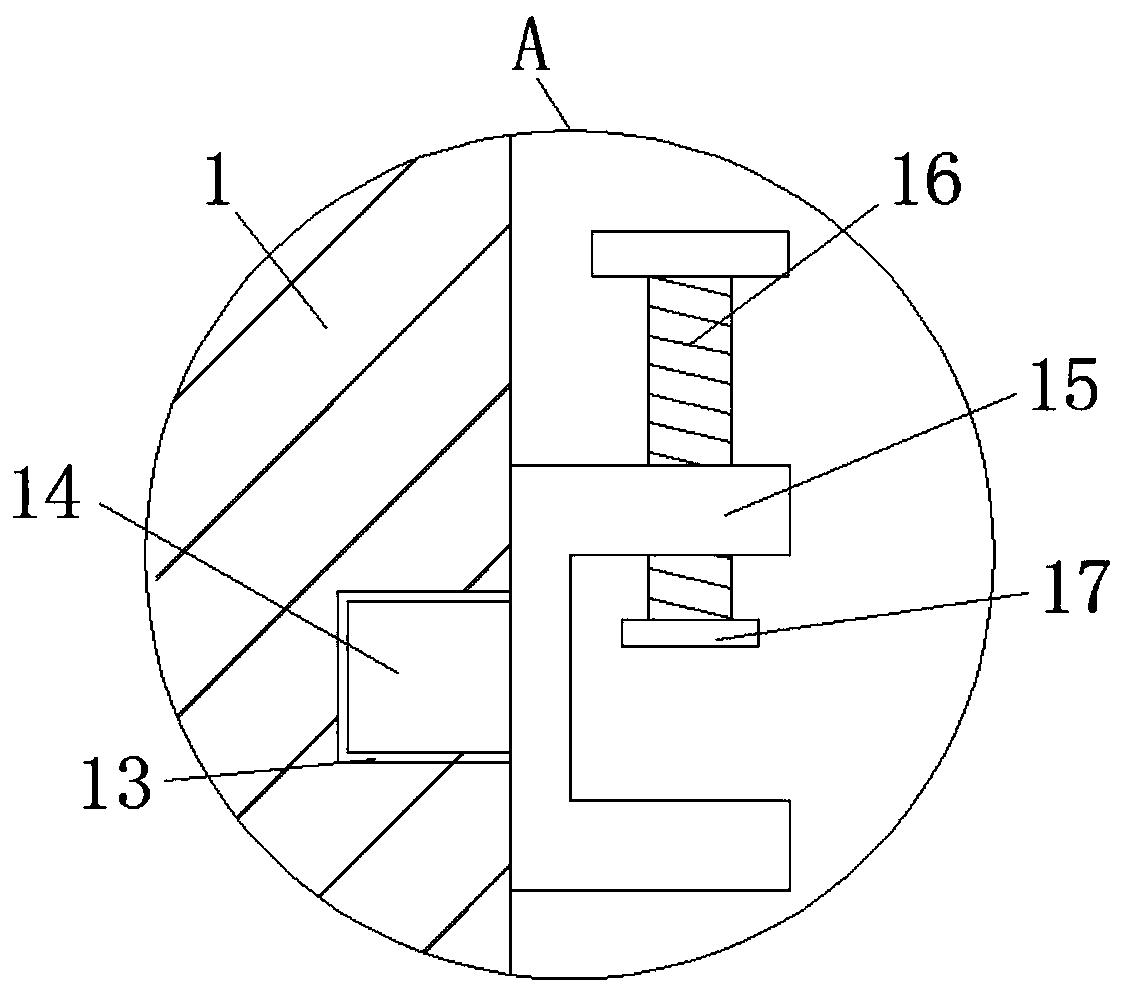

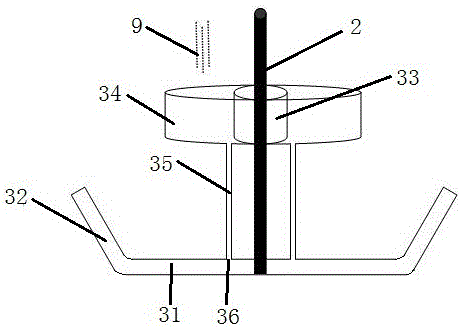

Efficient raw material crushing device for pharmaceutical production and processing

InactiveCN108940529AAvoid cloggingExtended service lifeHollow article cleaningDrying gas arrangementsWater pipeAir heater

The invention belongs to the technical field of pharmaceutical production equipment, and particularly relates to an efficient raw material crushing device for pharmaceutical production and processing.The following scheme is put forward aiming at the problems of incomplete crushing and inconvenient cleaning. The efficient raw material crushing device comprises a base, wherein the four corners of the top of the base are connected with supporting columns through bolts, the tops of the supporting columns are connected with a box body through bolts, a first through hole is formed in the top of thebox body, a feed hopper is welded in the first through hole, and a rectangular groove opening is formed in one side of the feed hopper. The efficient raw material crushing device is provided with a high pressure water inlet, a high pressure water pipe, a high pressure spray head and an air heater, after medicine making is finished, high pressure water can be pressed into the high pressure water pipe from the high pressure water pipe and sprayed out through the high pressure spray head and can flush the raw materials adhered to the inner wall of the box body, a stirring shaft has a better rotary cleaning effect, manual cleaning is avoided, a lot of labor is saved, a controller controls the air heater to blow hot air into the box body, the drying speed of the box body can be increased, andthe working efficiency is improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

High-efficiency drug-decocting apparatus for traditional Chinese medicine

InactiveCN108309800AIncrease contentGuaranteed effective contentHollow article cleaningPharmaceutical product form changeEngineeringChinese traditional medicine

The invention discloses a high-efficiency drug-decocting apparatus for traditional Chinese medicine. The high-efficiency drug-decocting apparatus comprises a box, wherein a frying pan is fixedly connected to one side of the top of a first supporting plate; third supporting plates are fixedly connected to two opposite sides of the inner wall of the box and positioned on one side of the frying pan;the tops of the third supporting plates are sequentially and fixedly connected with a cleaning water tank and a cleaning water pump; a cleaning nozzle is fixedly connected to the center of the bottomof a pot cover; a traditional Chinese medicine water pump is fixedly connected to one side of the top of the first supporting plate; a medicine suction tube is communicated with the water inlet end ofthe traditional Chinese medicine water pump; one end, which is far away from the traditional Chinese medicine water pump, of the medicine suction tube penetrates through the frying pan and extends tothe bottom of an inner wall of the frying pan; a medicine delivery tube is communicated with the water outlet end of the traditional Chinese medicine water pump; a drug residue funnel is communicatedwith one side of the bottom of the frying pan; a first heater and a second heater are sequentially and fixedly connected inside the walls of the frying pan. The invention relates to the technical field of drug decocting in traditional Chinese medicine. According to the high-efficiency drug-decocting apparatus for traditional Chinese medicine disclosed by the invention, the problem that manual labor is consumed during the traditional artificial decocting is solved, the decocting efficiency is improved, and the apparatus is convenient to use.

Owner:张新慧

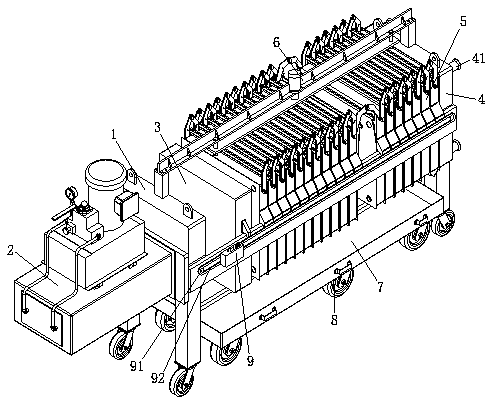

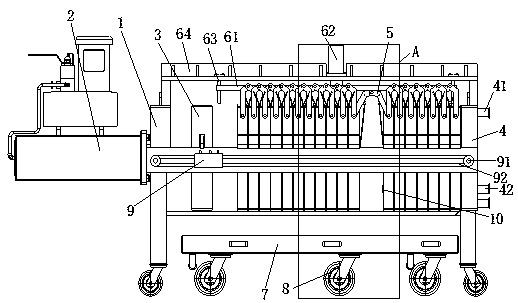

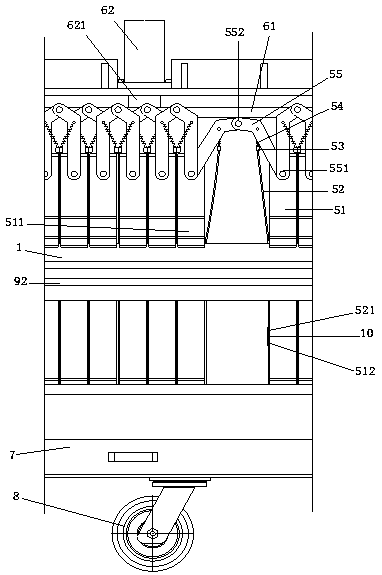

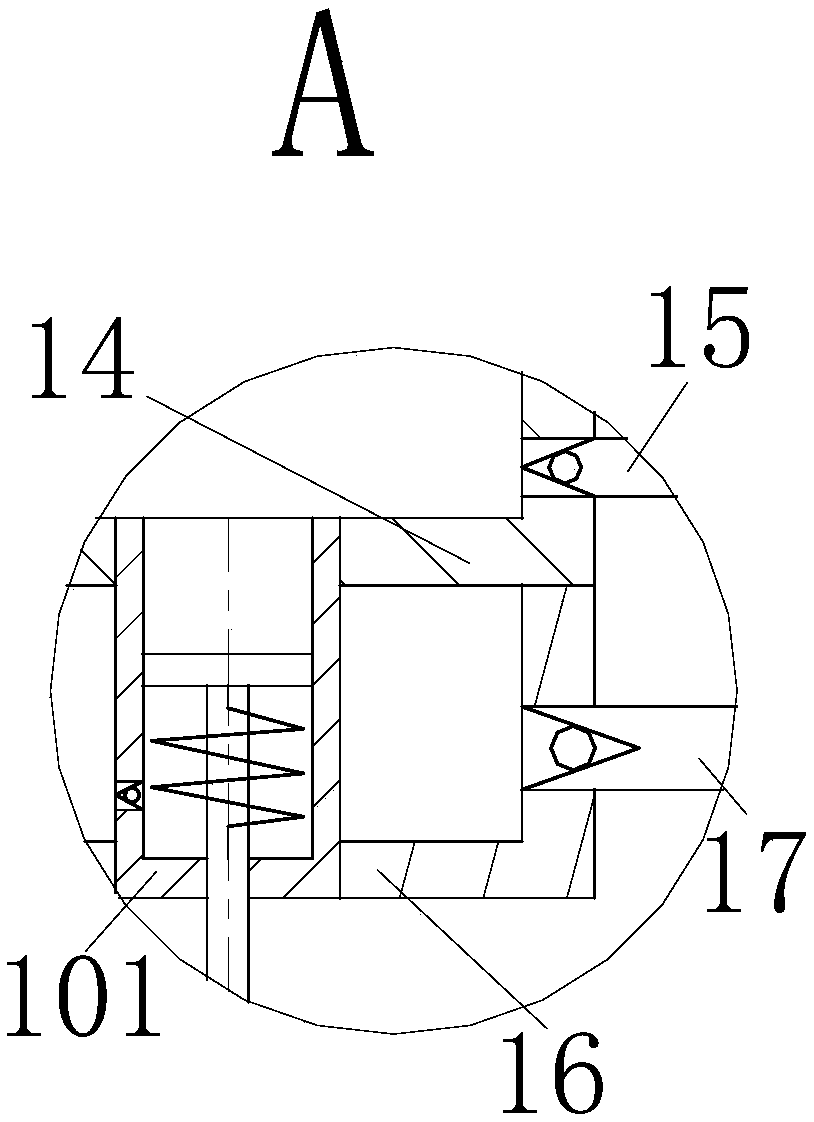

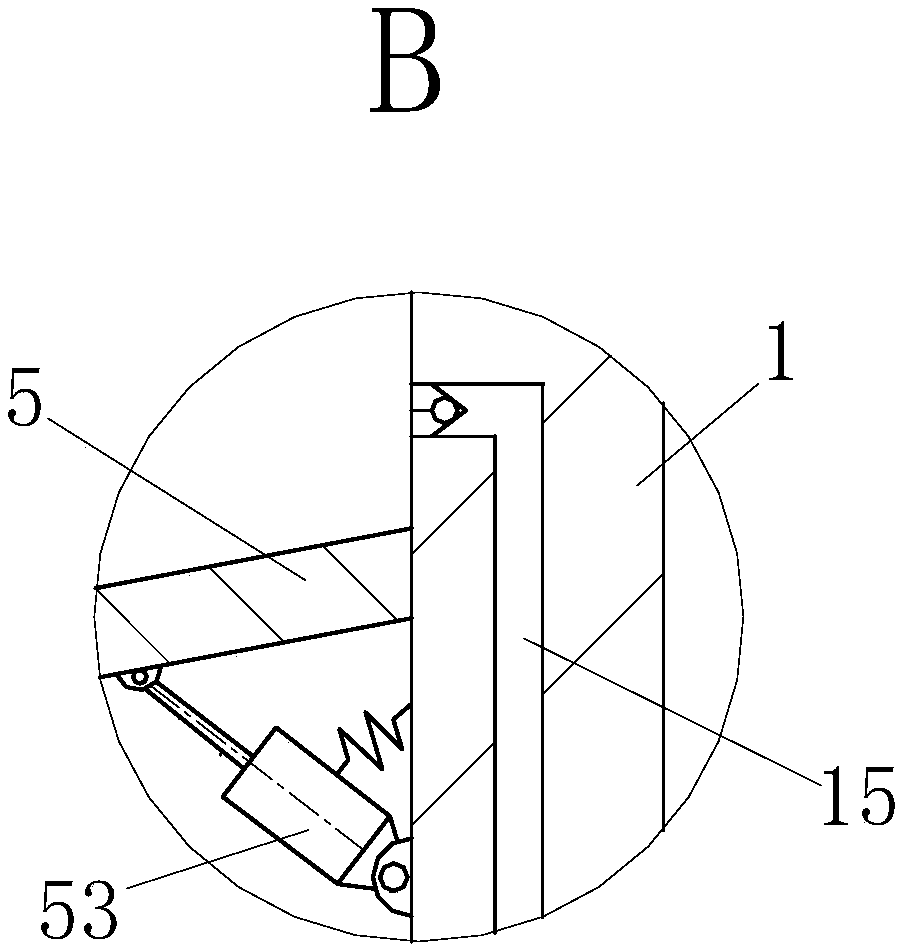

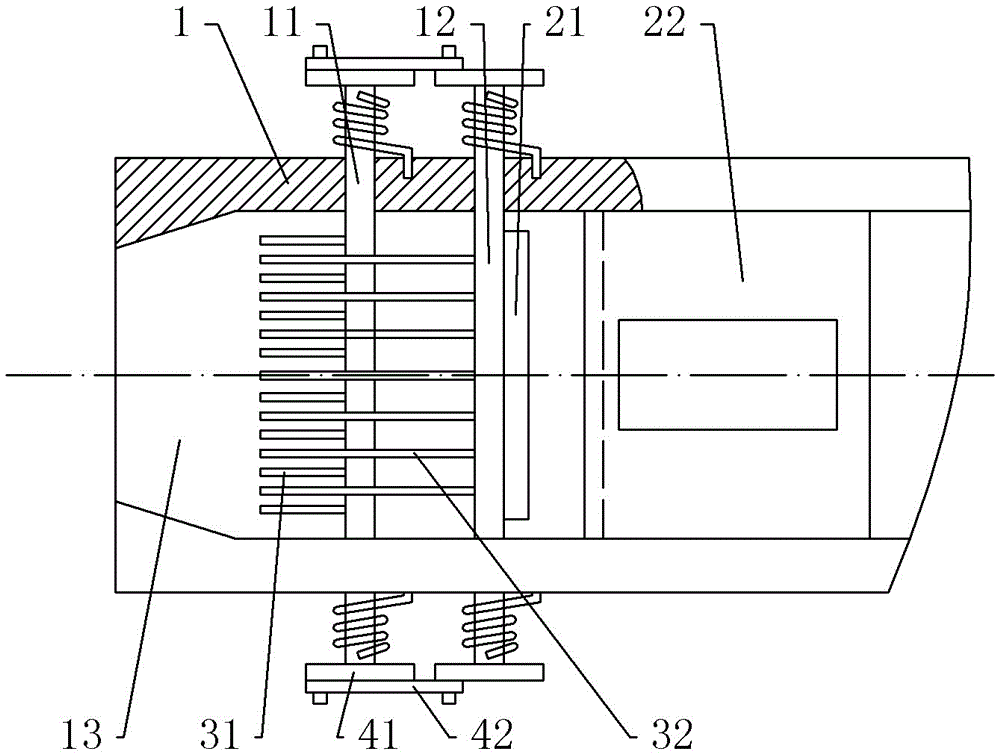

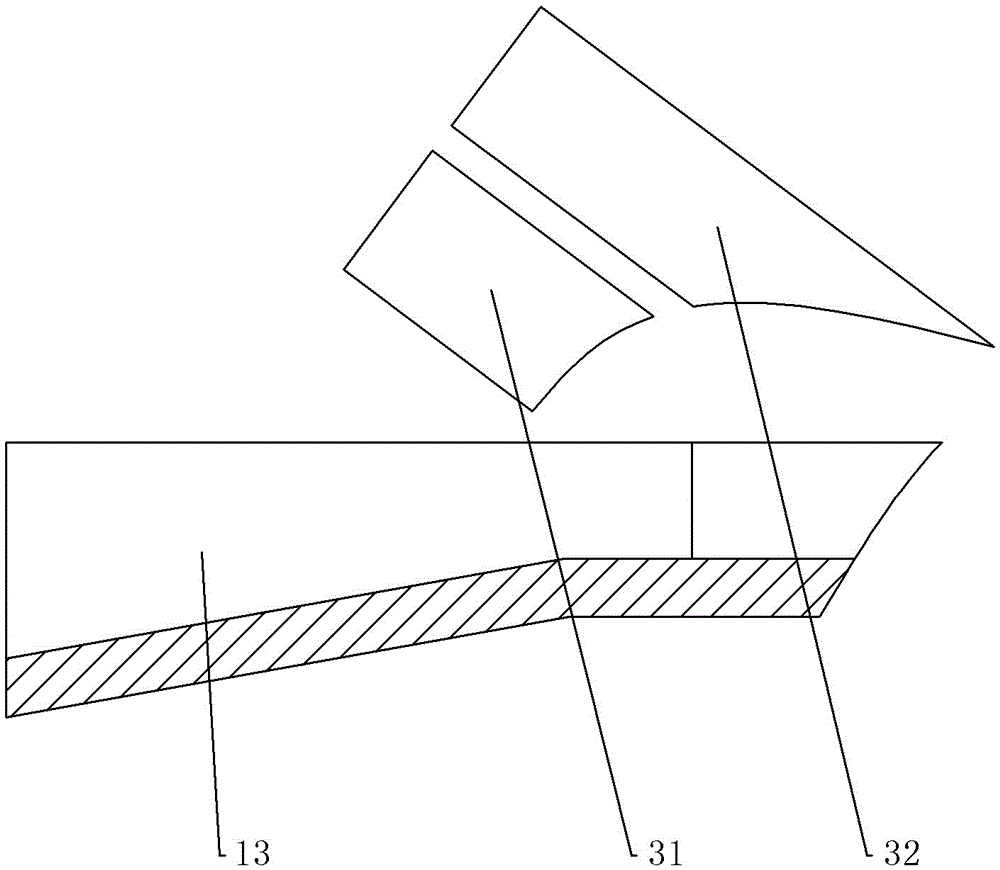

Van-type filter press for preventing mud cake from sticking to filter cloth and method for separating from mud cake

PendingCN110624289AGuaranteed filtering effectAvoid manual cleaningFiltration separationVibration amplitudePull force

The invention relates to the technical field of van filter press, in particular to a van-type filter press for preventing mud cake from sticking to filter cloth and a method for separating from mud cake. The press comprises a frame, the upper end of the filter cloth is fixed under the action of the force plate, the upper end of the filter cloth can be driven away from the filter plate through thestress plate, at the same time, under the mutual cooperating of the elastic force of the tension spring, the stress plate can be driven to vibrate, and the stress plate can drive the filter cloth to vibrate, so that the mud cake remaining on the filter cloth, which is difficult to fall off, can be vibrated and separated, and at the same time, the sludge remaining in the gap of the filter cloth canbe vibrated to fall off, so as to ensure the filtering effect of the filter cloth; under the action of the vibration pressing plate, the stress plate can be quickly pushed, so that the tension springgenerates vibration with larger amplitude, which is beneficial to improving the vibration amplitude of the filter cloth, thus ensuring that the residual mud cake on the filter cloth can fall down, thus reducing and avoiding manual cleaning of the mud cake, effectively reducing the manual workload, and increasing the efficiency of filtering sludge.

Owner:泉州绿拓智能环保设备有限公司

Anti-corrosion secondary water supply non-negative pressure equipment

InactiveCN111547929AScientific and reasonable structureEasy to useWater/sewage treatment by irradiationSpecific water treatment objectivesIon exchangeIon-exchange resin

The invention discloses anti-corrosion secondary water supply non-negative pressure equipment. One end of a water conveying pipe is connected with a treatment tank; a granular activated carbon filterscreen is fixedly mounted at the top of a treatment tank; an annular fixing frame is fixedly connected to a position, which is located below the granular activated carbon filter screen, in the treatment tank; an annular fixing groove is formed in the bottom end of the annular fixing frame; an ion exchange resin filter element is mounted in the middle of the treatment tank; and the top end of the ion exchange resin filter element is fixedly connected with an upper mounting block. The structure is scientific and reasonable, the equipment is safe and convenient to use, by using the ion exchange resin filter element, free anions and cations in the water are removed, the pH value of water is reduced, corrosion of water to the equipment is reduced, water in the equipment will not be polluted bythe rusts, chlorides in the water can be absorbed by using the granular activated carbon filter screen, and the probability that the equipment is corroded is further reduced.

Owner:罗显容

Rapid demolding device for wear-resistant casting

InactiveCN111451487AAdjust the vertical distanceVertical distance is easy to adjustCleaning using liquidsPull forceElectric machinery

The invention discloses a rapid demolding device for a wear-resistant casting. The rapid demolding device comprises a demolding machine table, wherein a rectangular through hole is formed in the uppersurface of a table plate of the demolding machine table, a rotating shaft is rotationally connected to the inner wall of the rectangular through hole, a rotating wheel fixedly sleeves the surface ofthe rotating shaft, the end, extending to the front face of the demolding machine table, of the rotating shaft is fixedly connected with a chain wheel, and a driving motor is mounted on the left sideof a supporting leg of the demolding machine table. According to the rapid demolding device for the wear-resistant casting, the vertical distance between two threaded clamping nails is convenient to adjust by arranging height adjusting bolts, so that the rapid demolding device is suitable for sand mold wooden templates of different sizes, and a demolding motor is arranged to drive a driving lead screw to rotate, so that two lead screw nut blocks move oppositely or relatively for generating relative pulling force, and shells of the sand mold wooden templates are separated; and meanwhile, the rotating shaft is further arranged to drive a transmission wheel to rotate, so that the sand mold templates are convenient to convey and concentrate, and manpower is saved.

Owner:安徽省安工机械制造有限公司

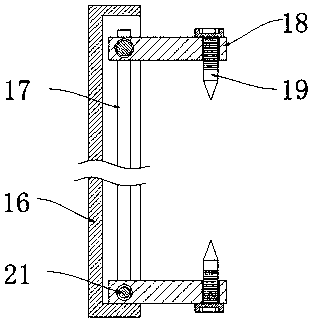

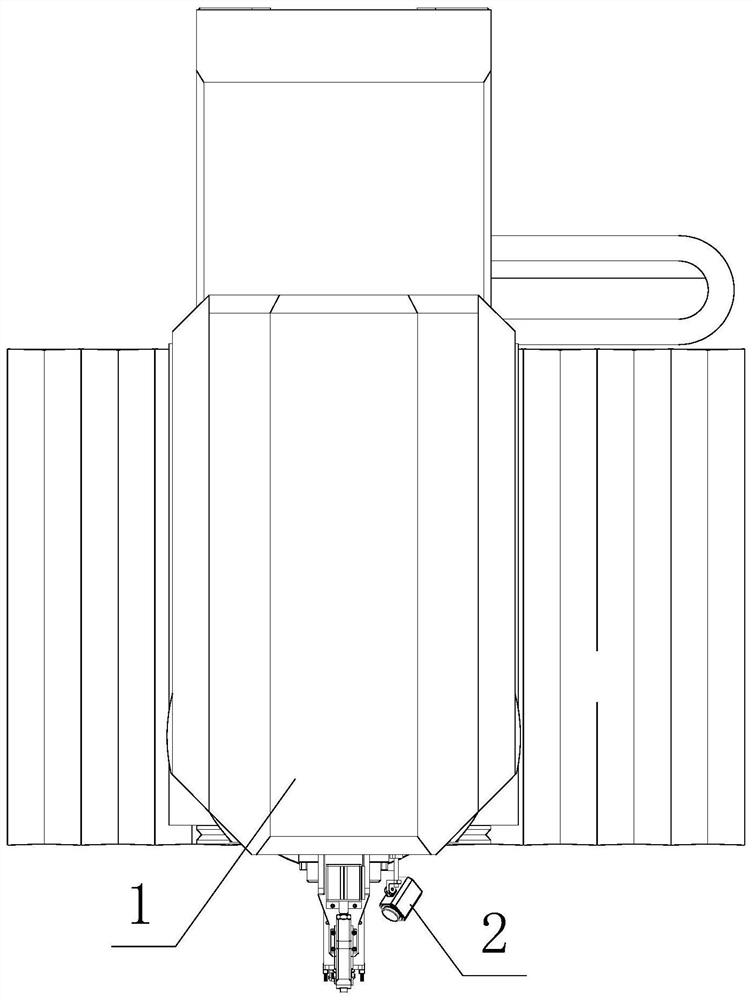

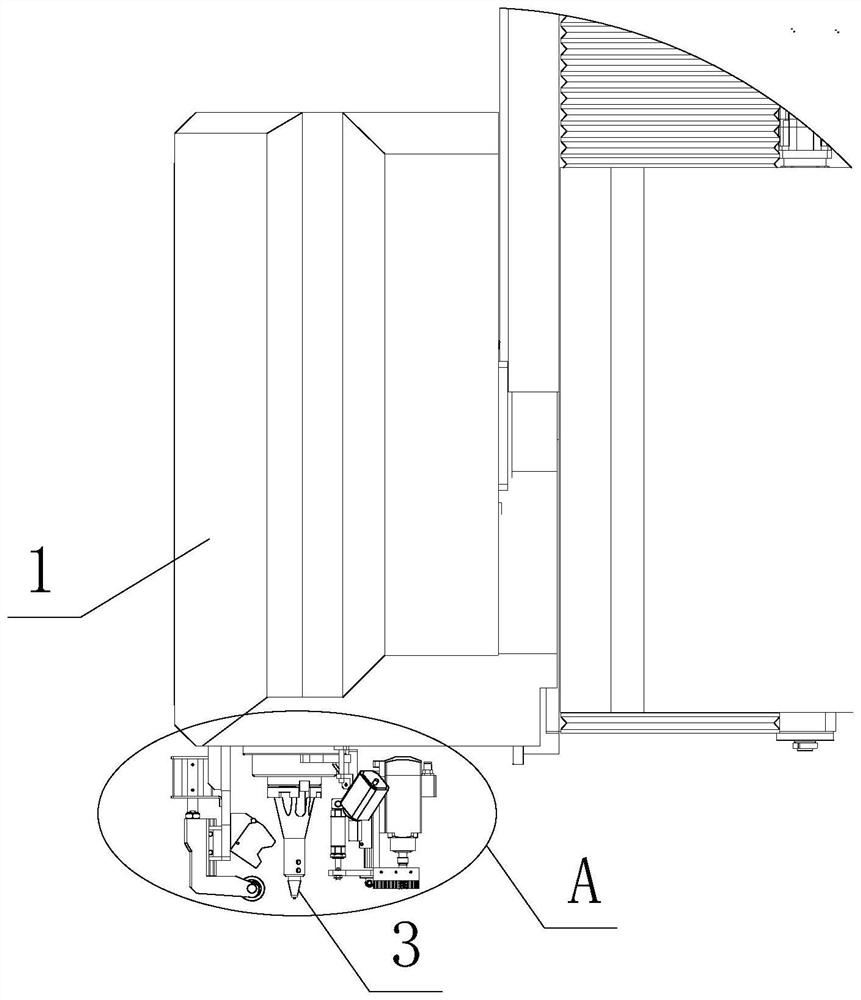

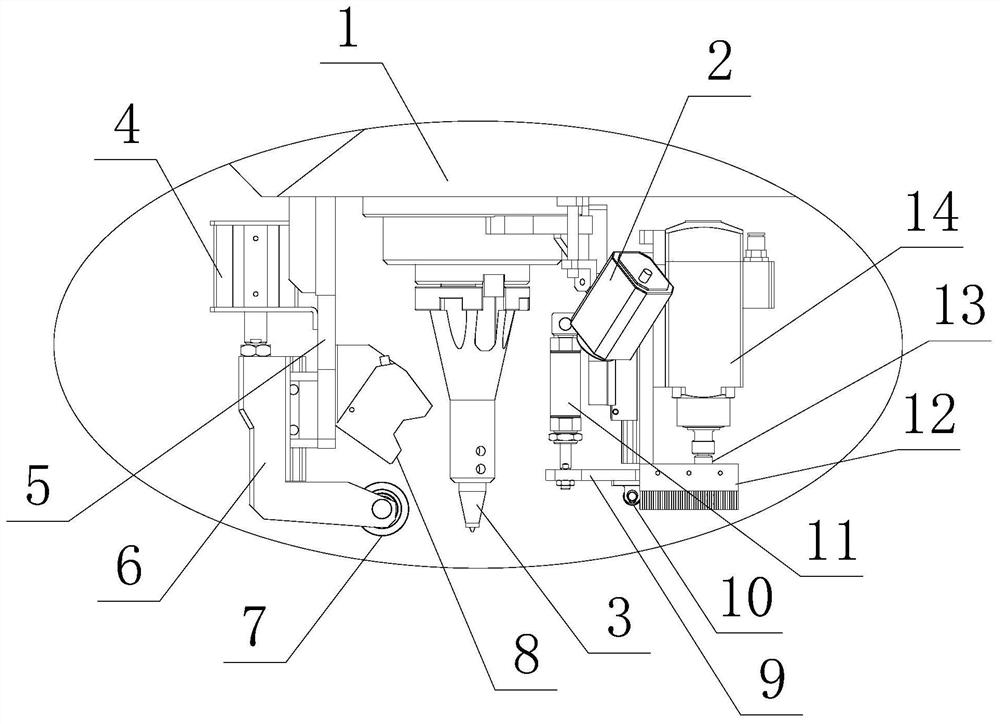

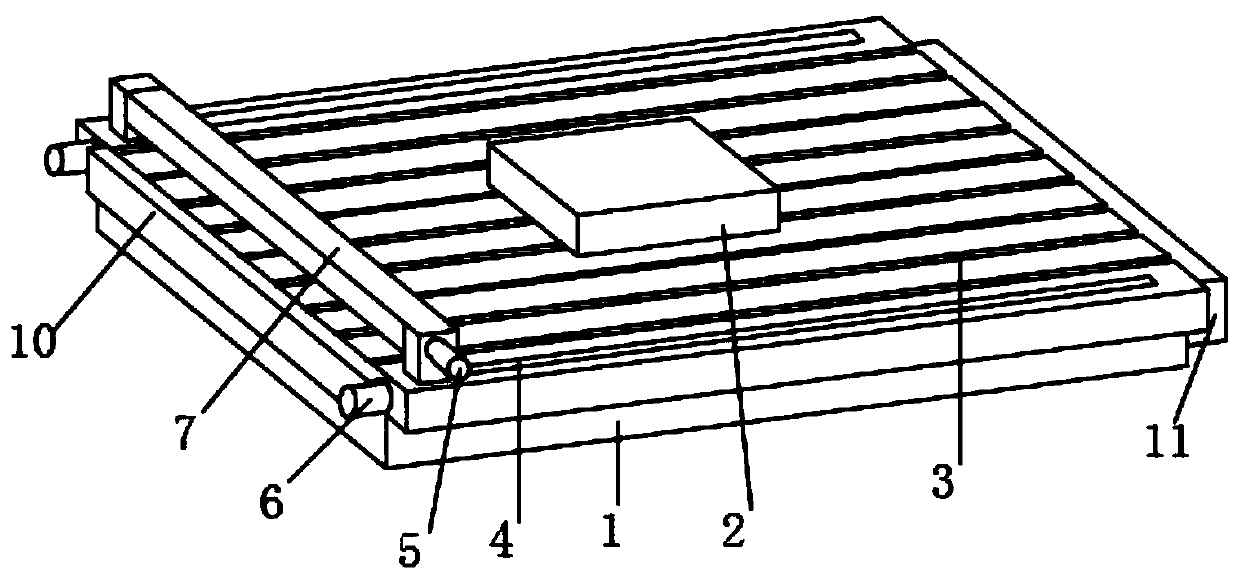

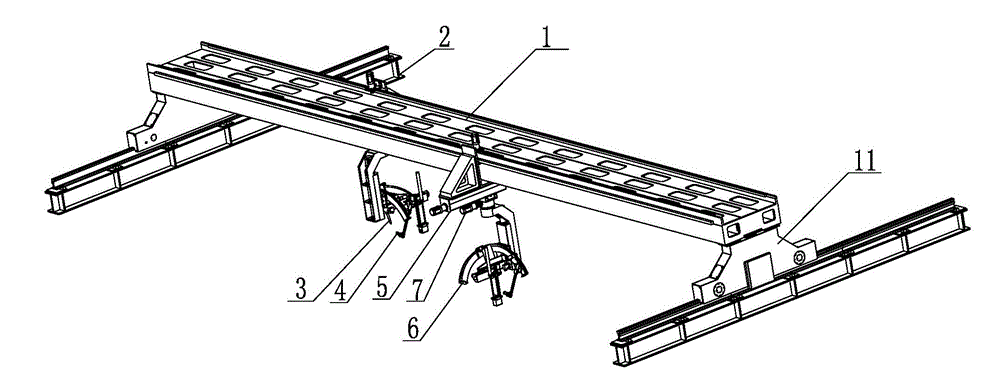

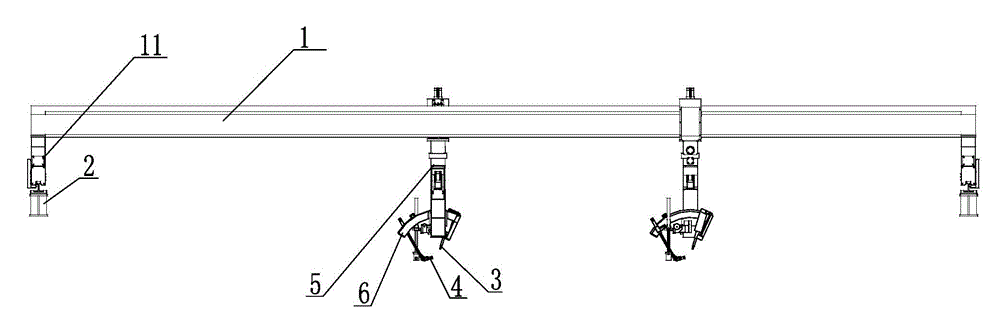

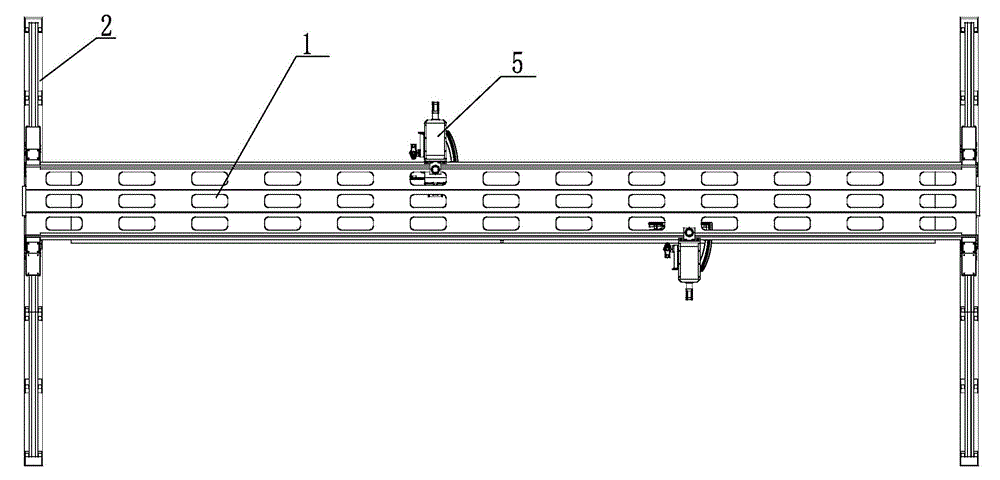

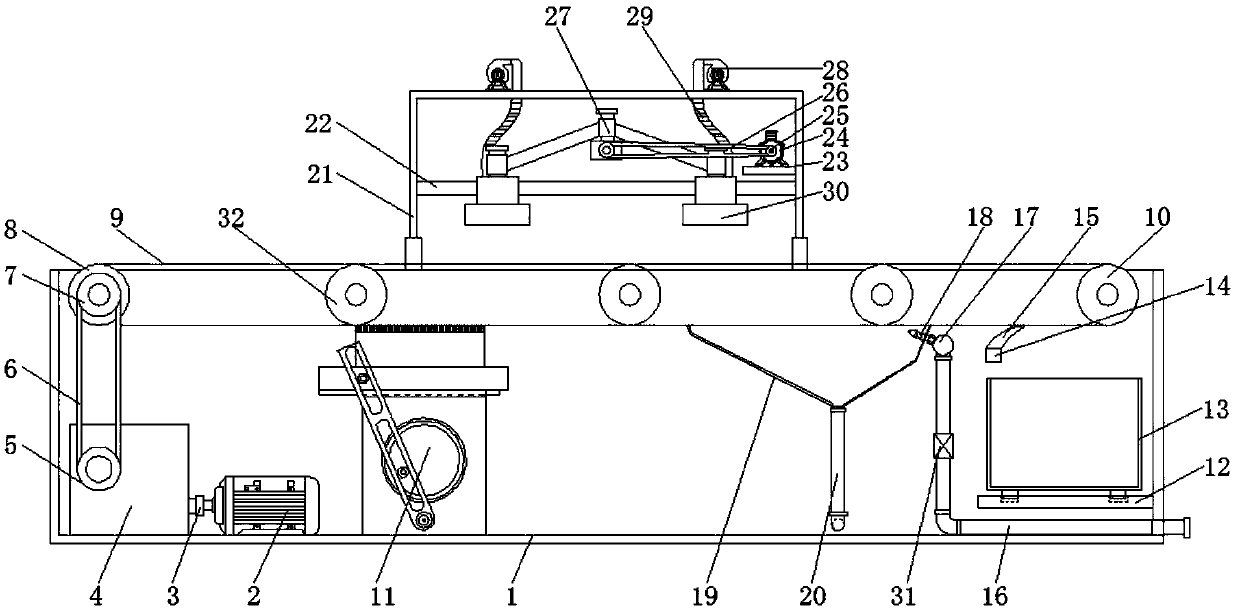

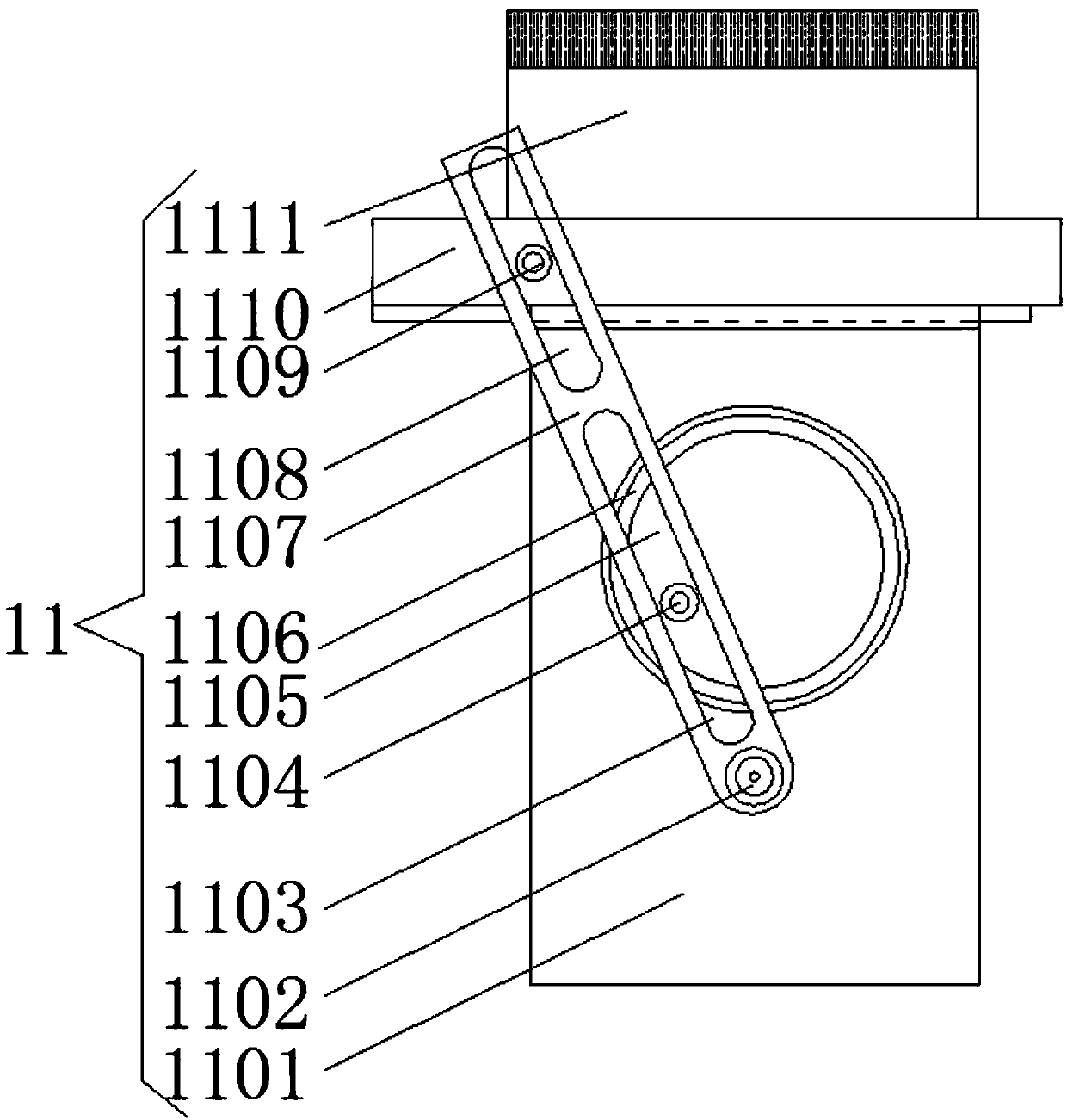

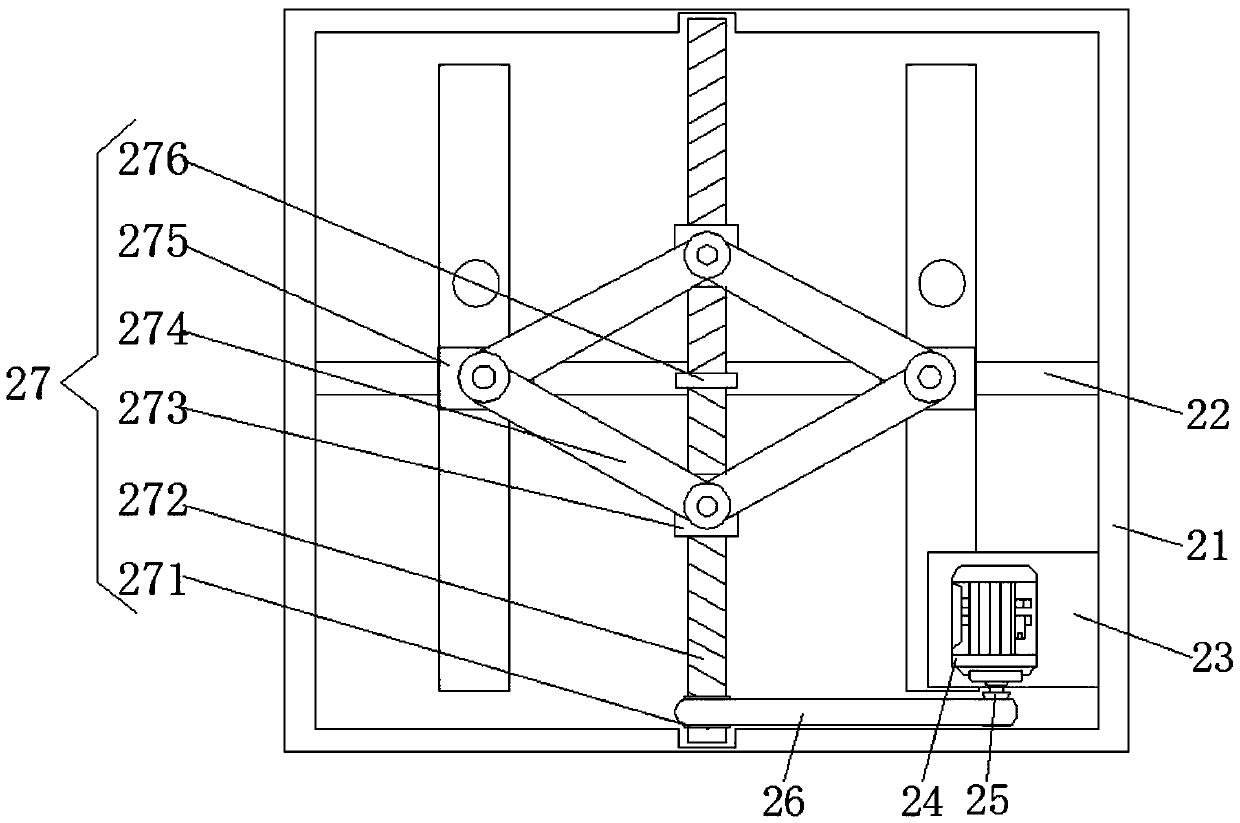

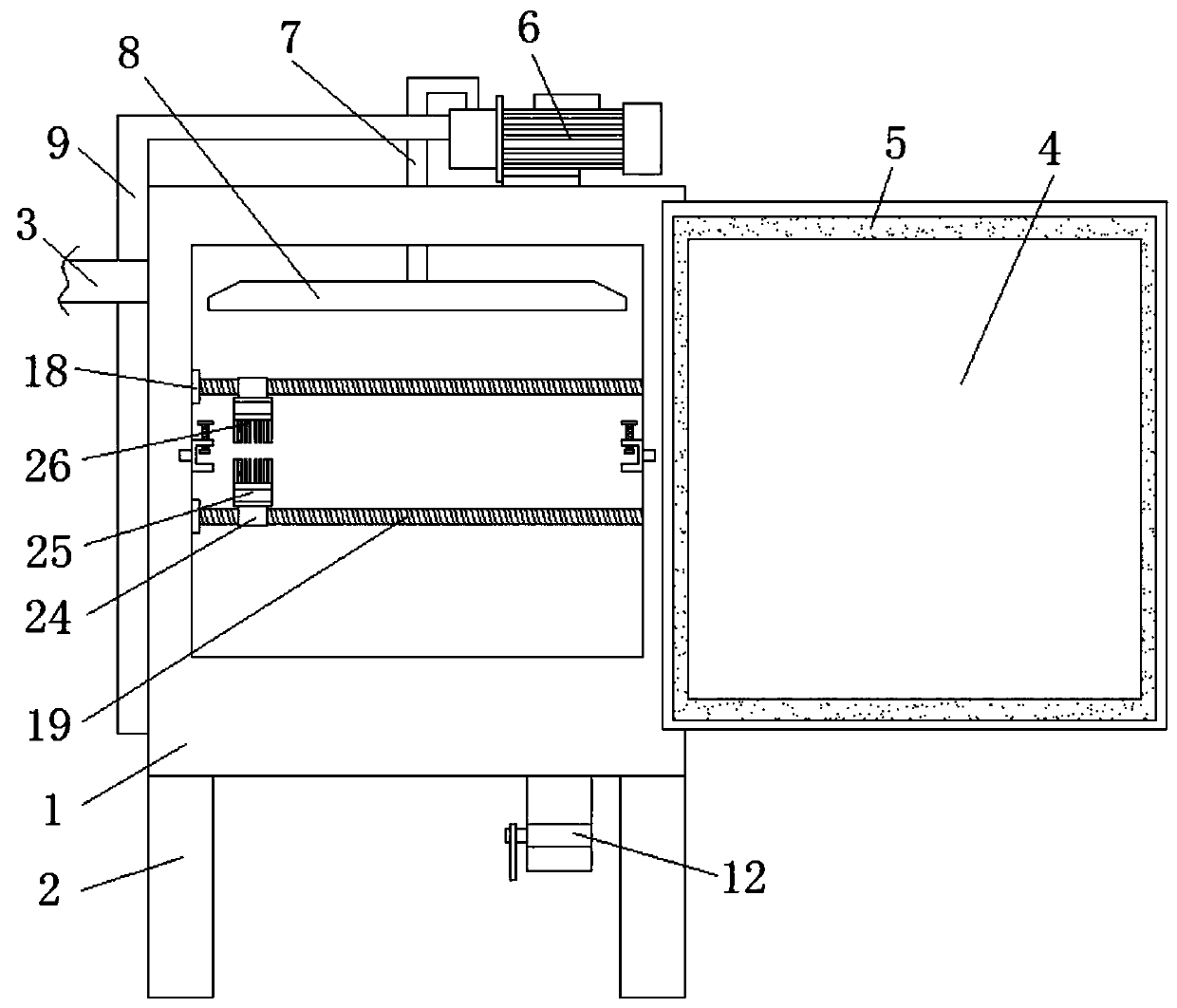

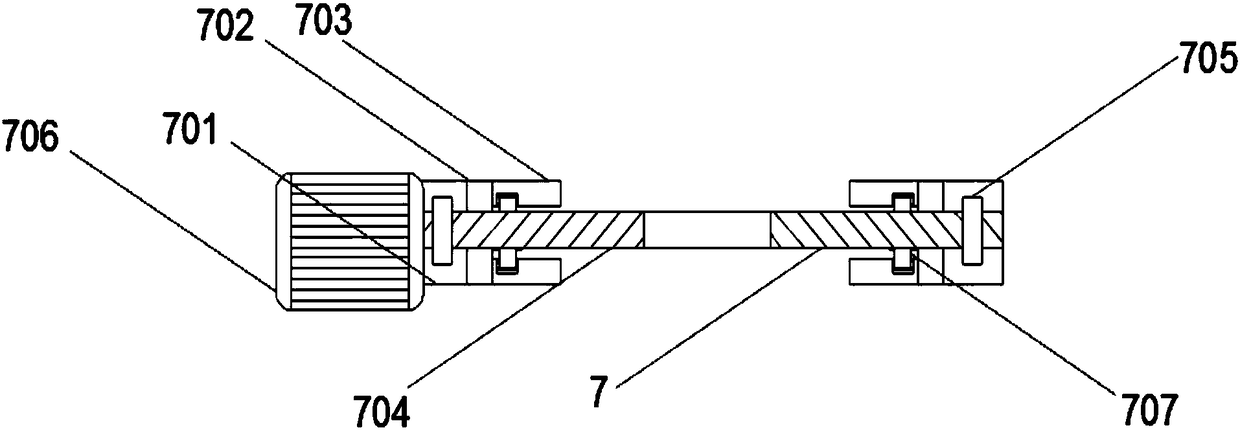

Multifunctional composite movable gantry friction stir welding device

PendingCN112192016AAchieve levelingAvoid warpingOther manufacturing equipments/toolsNon-electric welding apparatusMilling cutterEngineering

The invention relates to a multifunctional composite movable gantry friction stir welding device, and belongs to the technical field of machine tool equipment. The multifunctional composite movable gantry friction stir welding device comprises a machine head, wherein a friction stir welding tool is arranged on the machine head; a follow-up welding pressing system and a weld joint flash milling system are further arranged on the machine head; the follow-up welding pressing system comprises a first follow-up compression roller device positioned in front of the friction stir welding tool and a second follow-up compression roller device positioned behind the friction stir welding tool; and the weld joint flash milling system comprises a milling cutter positioned behind the second follow-up compression roller device and a milling driving device connected with the milling cutter. The multifunctional composite movable gantry friction stir welding device realizes online flattening, polishing and grinding of workpieces before and after welding, and improves the welding quality and the welding production efficiency.

Owner:CHONGQING MACHINE TOOL GROUP

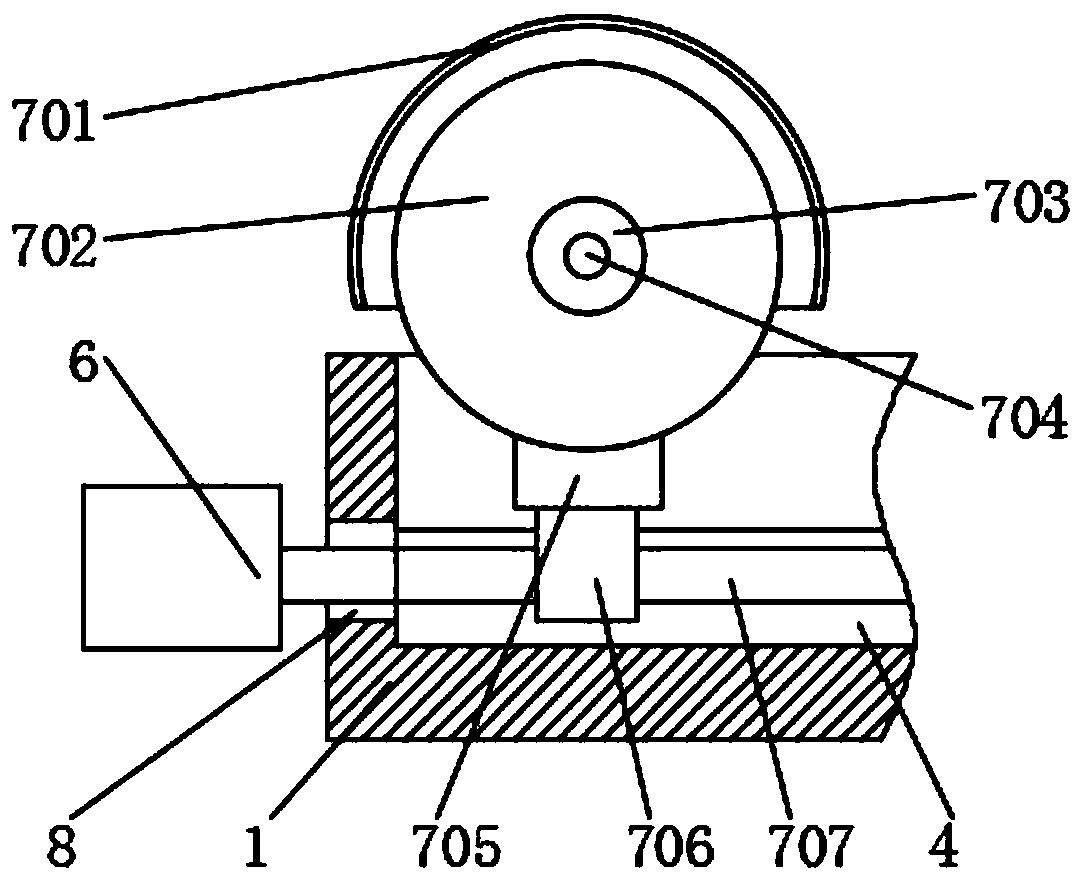

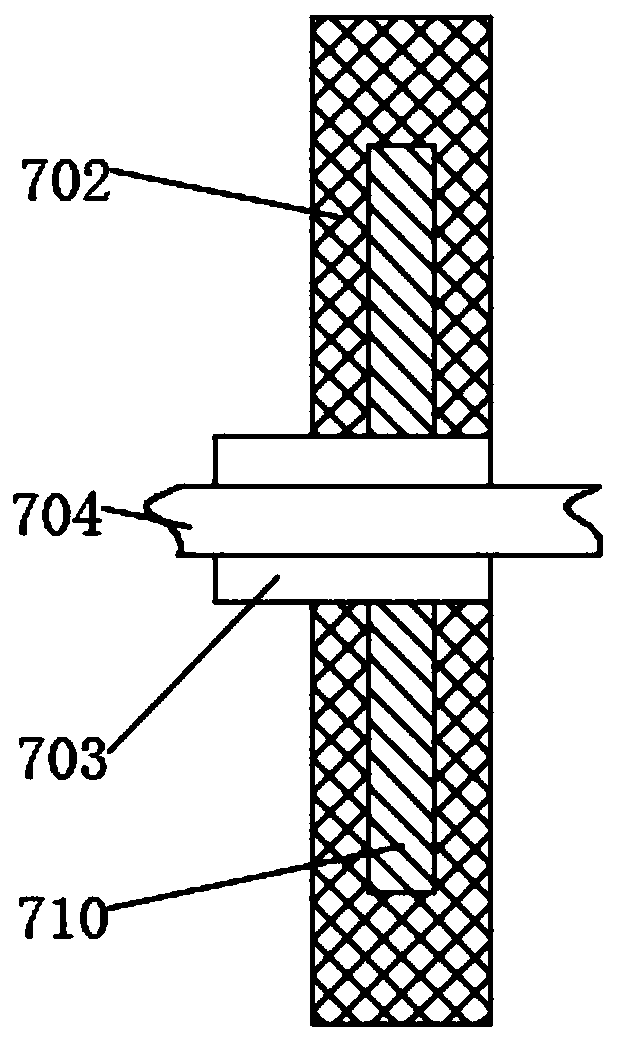

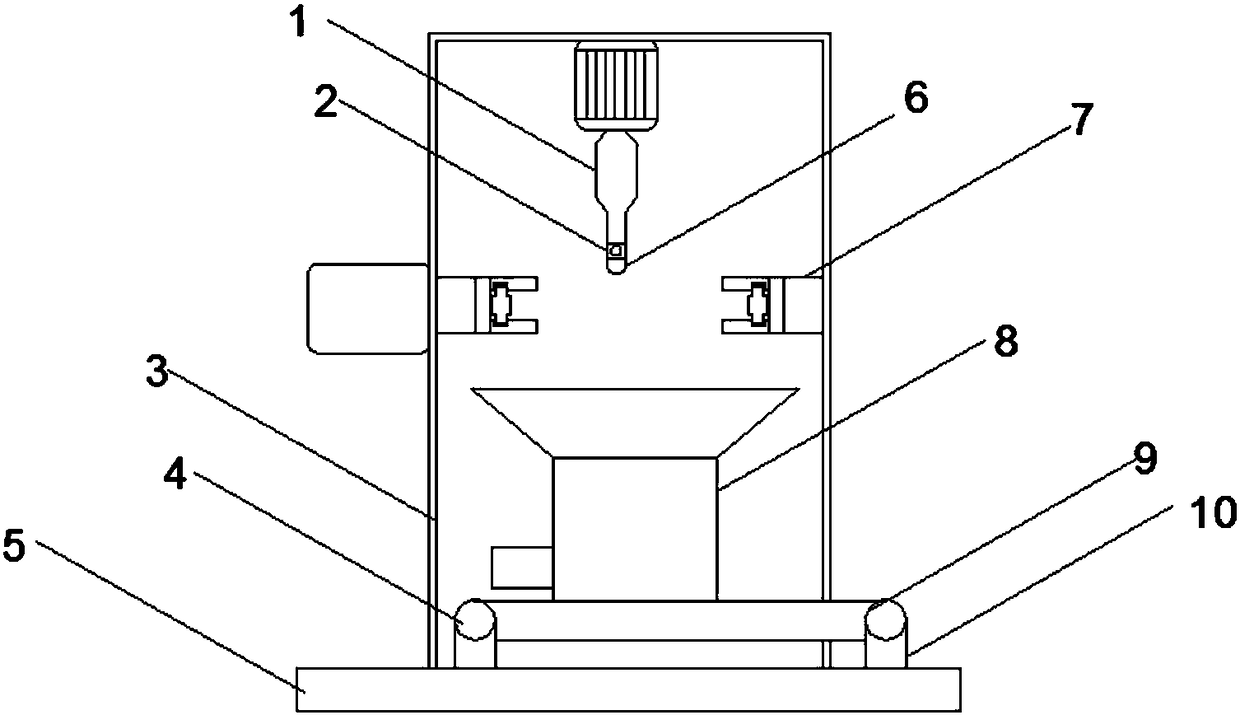

Grinding device for building materials

InactiveCN108098512AEasy to cleanAvoid manual cleaningGrinding machinesGrinding work supportsArchitectural engineeringWater pipe

The invention discloses a grinding device for building materials in the technical field of grinding. The grinding device comprises a grinding device box. A grinding motor is mounted at the top of thegrinding device box. A grinding tool is mounted at the bottom of the grinding motor. A cleaning device is mounted at the top of an inner cavity of the grinding device box. An air cylinder is mounted at the center of the bottom of the inner cavity of the grinding device box. A push rod is mounted at the top of the air cylinder. A clamp is mounted at the top of the push rod. A water box is mounted at the bottom of the grinding device box. A rotating barrel is mounted at the bottom of an inner cavity of the water box. The cleaning device is mounted in the inner cavity of the grinding device, spray heads on a cleaning water pipe are used for cleaning the inner cavity of the grinding device, manual cleaning is avoided, and manpower is saved. The rotating barrel is mounted in the inner cavity ofthe water box, mixed liquid is filtered in an inner cavity of the rotating barrel and can be reutilized, and resources are saved. The clamp is arranged on a workbench, the situation that the grindingdevice is replaced with different grinding devices due to different building materials is avoided, and the work efficiency is improved.

Owner:苏州智吉兴敏电子科技有限公司

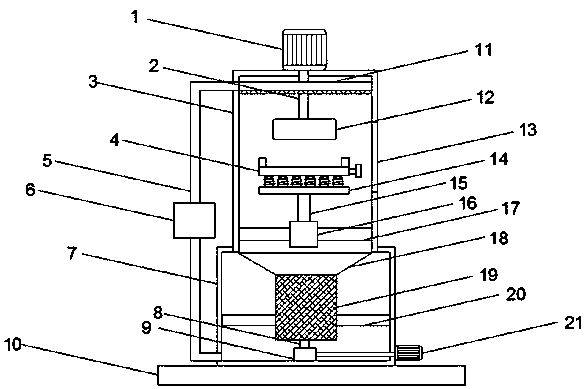

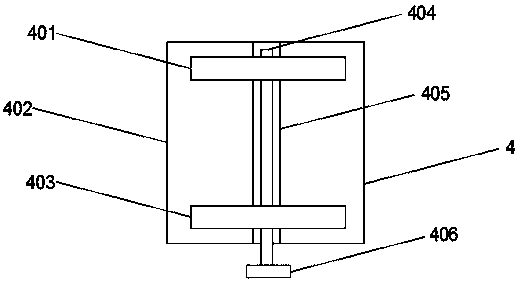

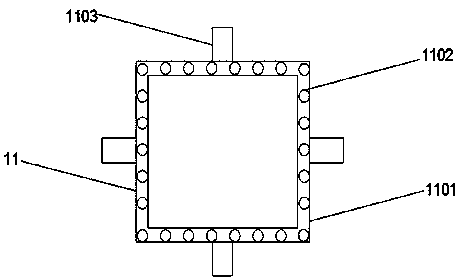

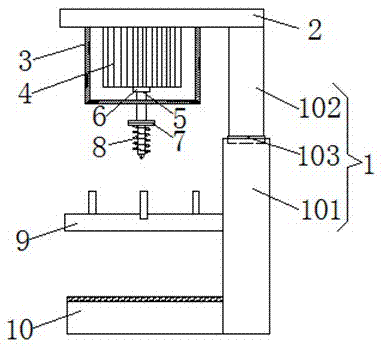

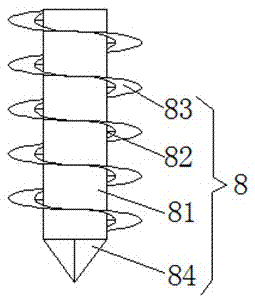

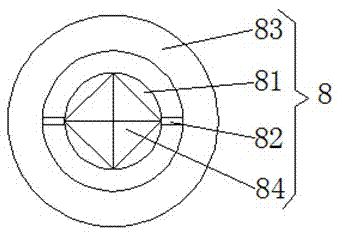

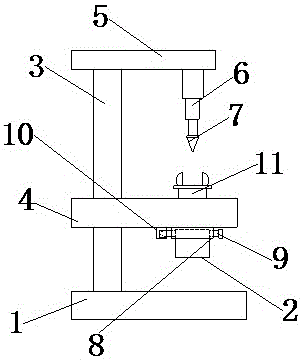

Drilling machine

InactiveCN105436933ASimple structureReasonable designDriving apparatusPositioning apparatusElectric machineryEngineering

The invention discloses a drilling machine. The drilling machine comprises a driving device; a dust collection box is movably mounted at the bottom of one side of the driving device; one side of the driving device is also fixedly connected with a worktable; the worktable comprises a worktable body and a positioning block; one side of the top of the driving device is also fixedly connected with a motor bracket through a connecting plate; a servo motor is mounted inside the motor bracket; the bottom of the servo motor is movably connected with the top end of a rotating shaft; the top of the rotating shaft is also fixedly connected with a differential speed changer; the bottom end of the rotating shaft is fixedly connected with a drill bit component through a flange. The drilling machine is simple in structure and reasonable in design, and has the advantages of preventing damages of a drill bit by regulating the rotating shaft to drive the rotating speed of the drill bit component, collecting scraps generated during a drilling process, saving the labor, preventing influences caused to the work progress by deviation, caused by position offset, of a drilling position of a pre-drilled work piece, increasing the cutting speed of the drill bit and improving the work efficiency of the drilling machine.

Owner:WUXI FUMEI LIGHT ALLOY TECH

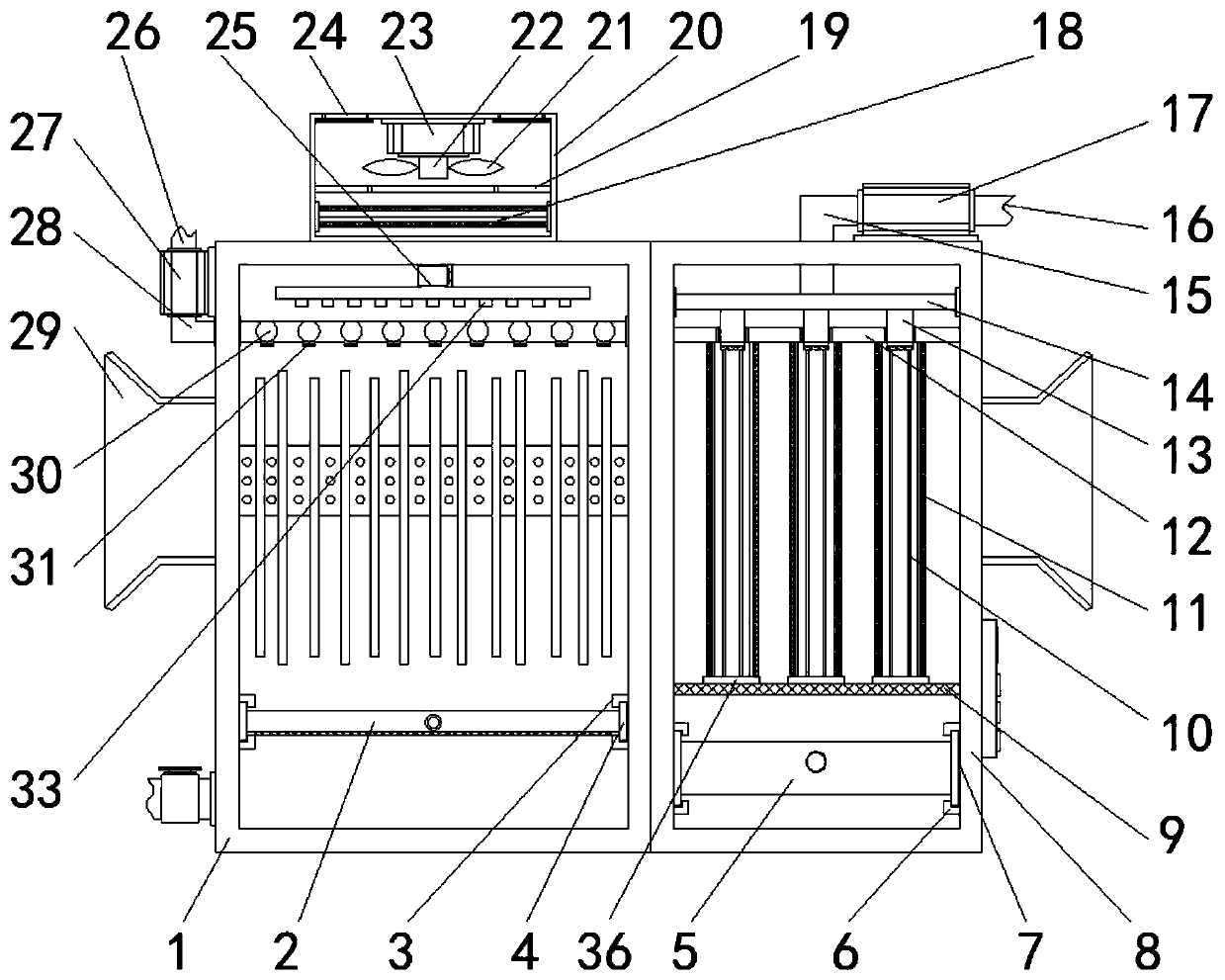

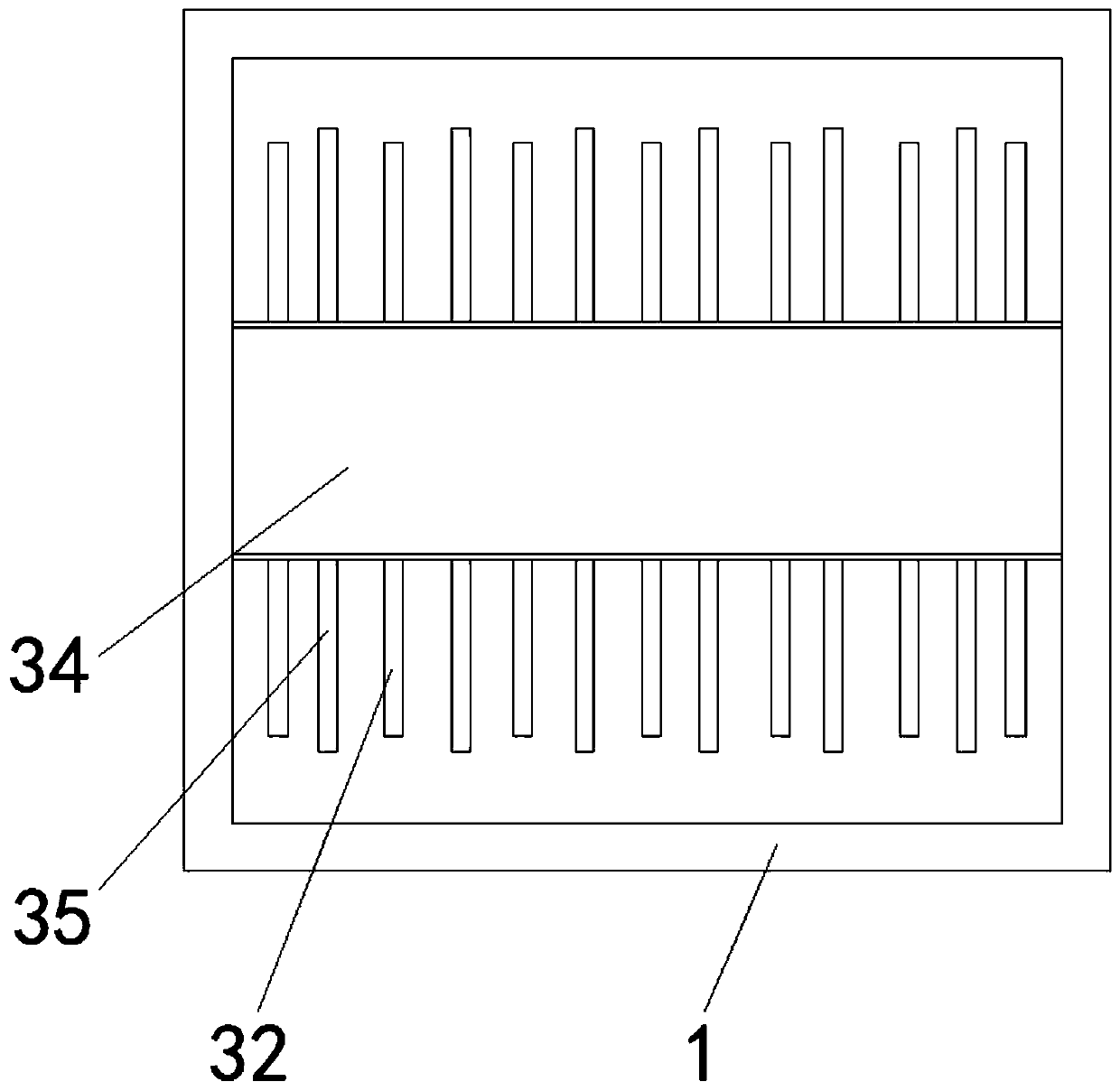

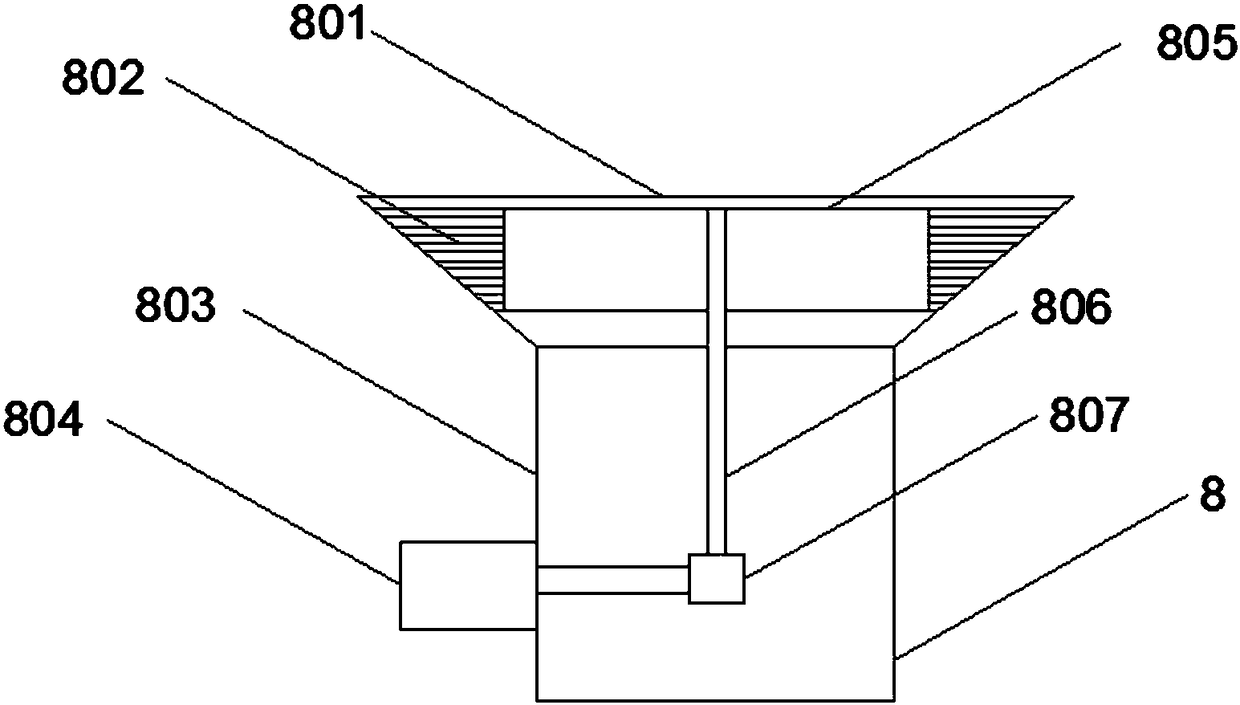

Full-automatic high-efficiency electrostatic dust removal device

ActiveCN110681490AImprove dust removal effectQuick releaseCombination devicesDispersed particle filtrationElectric machineDust control

The invention relates to the technical field of dust removal devices, and discloses a full-automatic high-efficiency electrostatic dust removal device comprising a first processing bin.A hot air bin is fixedly connected on the top of the first processing bin. The top of the hot air bin is provided with two air inlet holes. The inner top wall of the hot air bin is fixedly provided with a rotating motor located between the two air inlet holes.The output shaft of the rotating motor is fixedly connected with a rotating rod. Fan blades are fixedly connected on the left and right sides of the rotating rod. According to the full-automatic high-efficiency electrostatic dust removal device,the air enters into the circulation pipe through a first circulation through hole through the air inlet holesand then enters the first processing bin through the air outlet holes on the front and back of the circulation pipe so that the air is enabled to pass through the discharge pile and the air moleculesare ionized to generate positive and negative ions, then the positive and negative ions collide with dust and are adsorbed on the dust surface and charged dust moves to the dust collection stage underthe action of an electric field and is collected by the dust collection stage.

Owner:扬州博林环保机械有限公司

Cleaning device for sculpt artware inner walls

ActiveCN108580480AEasy to cleanAvoid shakingHollow article cleaningEngineeringMechanical engineering

Owner:江西祈福工艺品有限公司

Urban solid waste treatment device

ActiveCN109092861AEnsure normal dischargeWon't blockSolid waste disposalEngineeringWaste treatment technologies

The invention belongs to the technical field of waste treatment, and particularly relates to an urban solid waste treatment device. The urban solid waste treatment device comprises a box, a motor, a connecting shaft, smashing rods, a partition plate, a first slideway, a high-temperature disinfection module, a second slideway, a first filtering net and an extruding module. The motor is fixed to theupper left portion of the box, and the connecting shaft is located in the box. The connecting shaft and an output shaft of the motor are connected, and the smashing rods are evenly mounted on the connecting shaft. The partition plate is mounted in the box and located below the smashing rods. A second filtering net is arranged in the middle of the partition plate, and the first slideway is fixed into the box. The high-temperature disinfection module is located below the first slideway and makes contact with the bottom of the first slideway. The second slideway is located in the box and locatedbelow the first slideway. The first filtering net is located in the box, mounted on the lower portion of the second slideway, and connected with the second slideway. The extruding module is located between the first filtering net and the high-temperature disinfection module.

Owner:深鹏环保工程有限公司

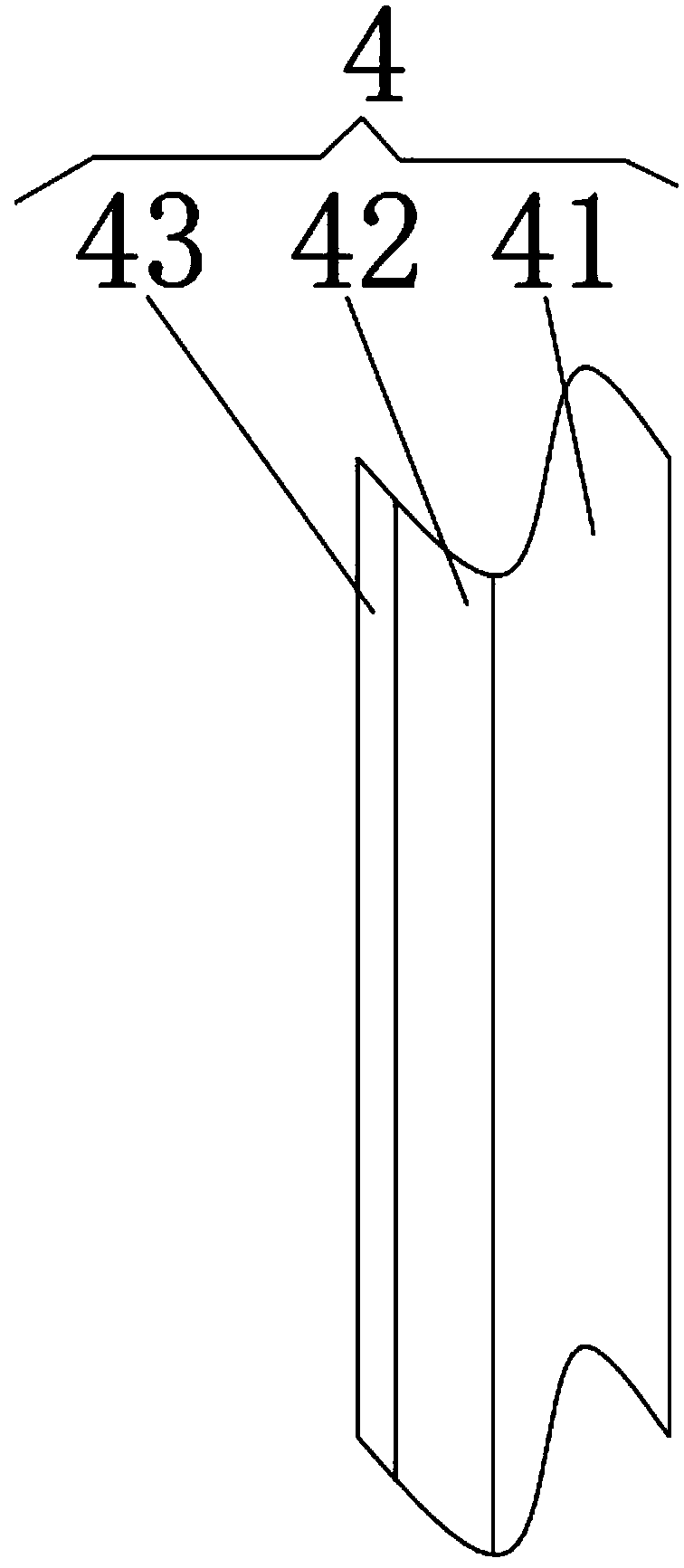

Rhizome crude medicine slicing device

The invention discloses a rhizome crude medicine slicing device and relates to a cutting device. The rhizome crude medicine slicing device comprises a machine frame, the front end of the machine frame is provided with a discharging groove, the machine frame is rotatably connected with a first rotating shaft and a second rotating shaft, and the first rotating shaft and the second rotating shaft are sequentially arranged at the rear of the discharging groove. Torsional springs are arranged at the two ends of the second rotating shaft, a first blade group is fixed to the first rotating shaft, a second blade group is fixed to the second rotating shaft, and the first blade group and the second blade group each are composed of a plurality of blades. The blades of the first blade group and the second blade group are staggered, the lower portions of the rear ends of the blades of the second blade group are provided with arc notches. Linkage wheels are fixed to the first rotating shaft and the second rotating shaft, rotating shafts are eccentrically arranged on the linkage wheels, and the linkage wheels are provided with connecting rods to be connected with the rotating shafts, so that the linkage wheels, the connecting rods and the machine frame form a parallelogram mechanism. The machine frame is further provided with a driving mechanism. When the device is used for crude medicine slicing, crude medicine slices are not blocked between gaps of the blades.

Owner:CHONGQING KANGZE SCI & TECH DEV CO LTD

Grinding equipment for cement clinker production

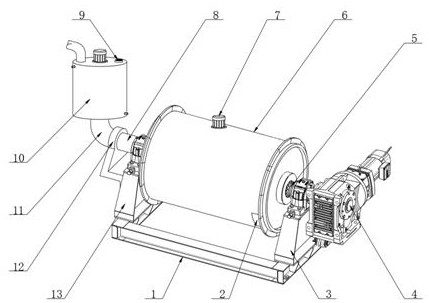

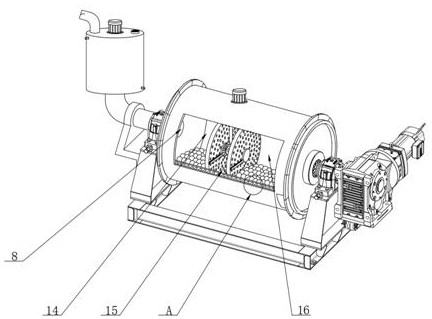

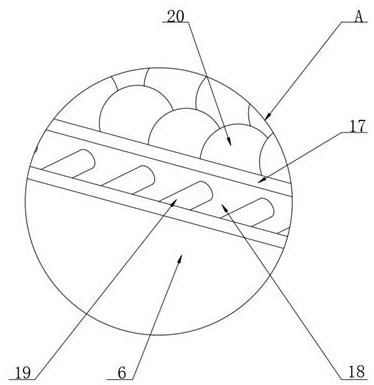

ActiveCN112619803AEnsure particle sizeReduce surface temperatureSievingNon-rotating vibration suppressionProcess engineeringClinker (cement)

The invention relates to the technical field of cement production, in particular to grinding equipment for cement clinker production. A second bearing seat and a first bearing seat are symmetrically fixed to the two sides of the upper portion of a base, a ball milling part is arranged between the second bearing seat and the first bearing seat, and a pretreatment part communicated with the ball milling part is arranged on the outer side of the second bearing seat. The grinding equipment is novel in design and simple in structure. Clinker just entering the equipment can be screened and cooled through the pretreatment part, on one hand, the particle size of the clinker is ensured, and on the other hand, the surface temperature of the clinker can be reduced to avoid the problem of low cement quality caused by too high temperature or too large particle size difference. A cleaning mechanism can clean holes in the surfaces of filter plates, manual cleaning is not needed, the maintenance cost is reduced, the problem that the passing rate of powder is affected due to blockage of the filter plates is solved, and the working efficiency is effectively improved.

Owner:辽宁银盛水泥集团有限公司

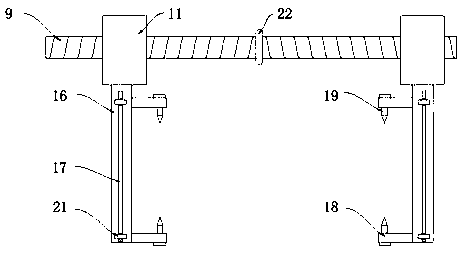

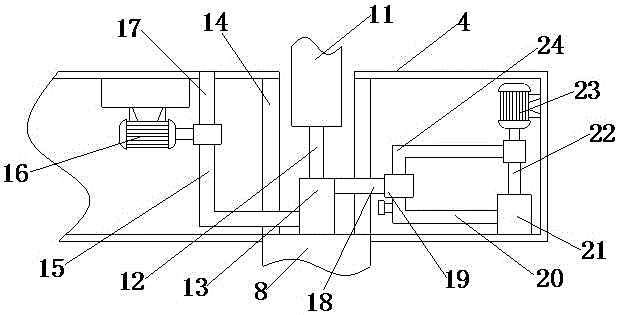

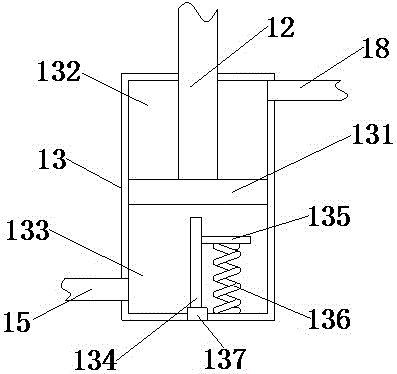

Cleaning device of numerical control machine tool

InactiveCN110722393AAvoid manual cleaningAvoid hard-to-clean situationsMaintainance and safety accessoriesNumerical controlElectric machinery

The invention discloses a cleaning device of a numerical control machine tool. The cleaning device comprises a workbench, wherein a T-shaped groove is formed in the upper surface of the workbench; a moving groove is formed in the position, positioned on the edge of the workbench, of the upper surface of the workbench; second motors are arranged at the positions, corresponding to the moving groove,of one end of the workbench; a sweeping device is arranged above the workbench; a first motor is arranged at one end of the sweeping device; an air blowing structure is arranged at the position, positioned at one end of the T-shaped groove, between the second motors; and a collecting structure is arranged at the position, positioned at the other end of the T-shaped groove, of the workbench. According to the cleaning device of the numerical control machine tool, the T-shaped groove can be swept through the sweeping device, scrap iron in the T-shaped groove is prevented from being manually swept, the distance of each cleaning brush can be adjusted according to the distance of the T-shaped groove, the scrap iron in the T-shaped groove can be collected through the collecting structure, cutting fluid in the scrap iron can be drained, and the situation that fine scrap iron or chippings are difficult to clean during cleaning is avoided.

Owner:浙江海空机械配件有限公司

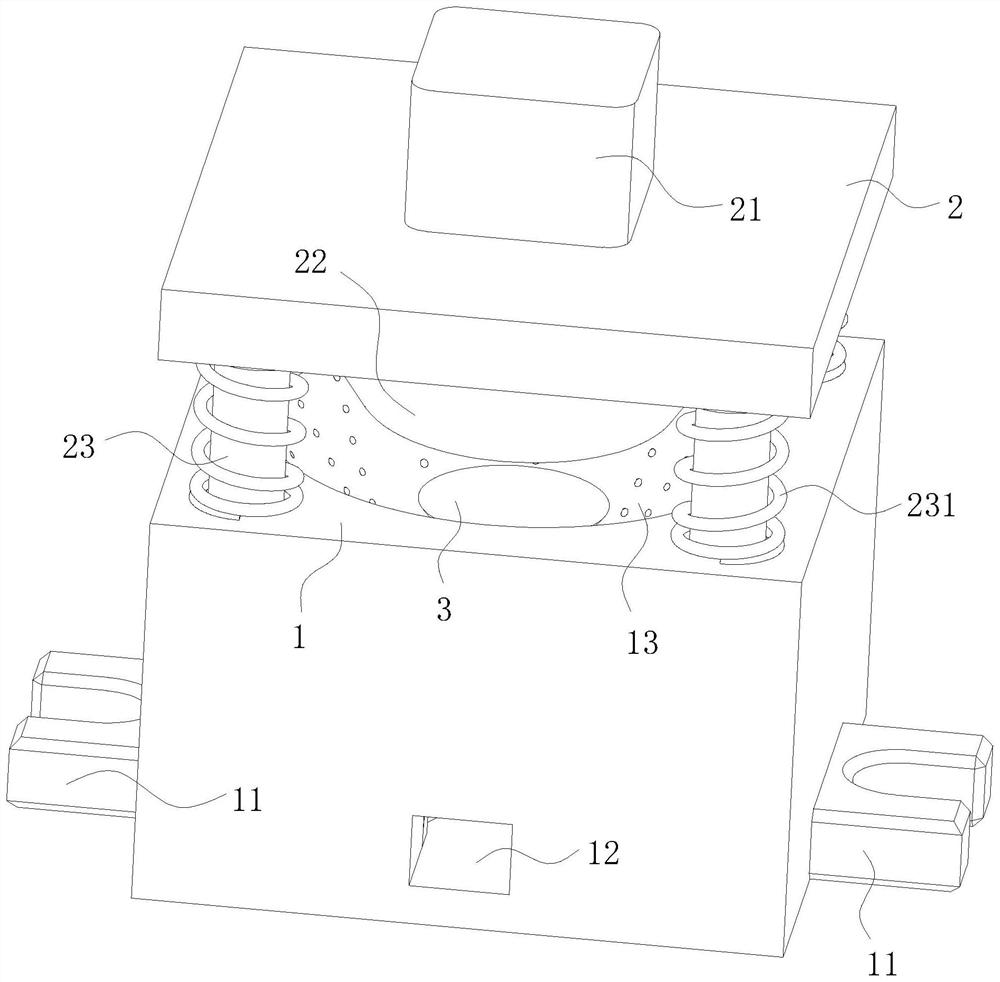

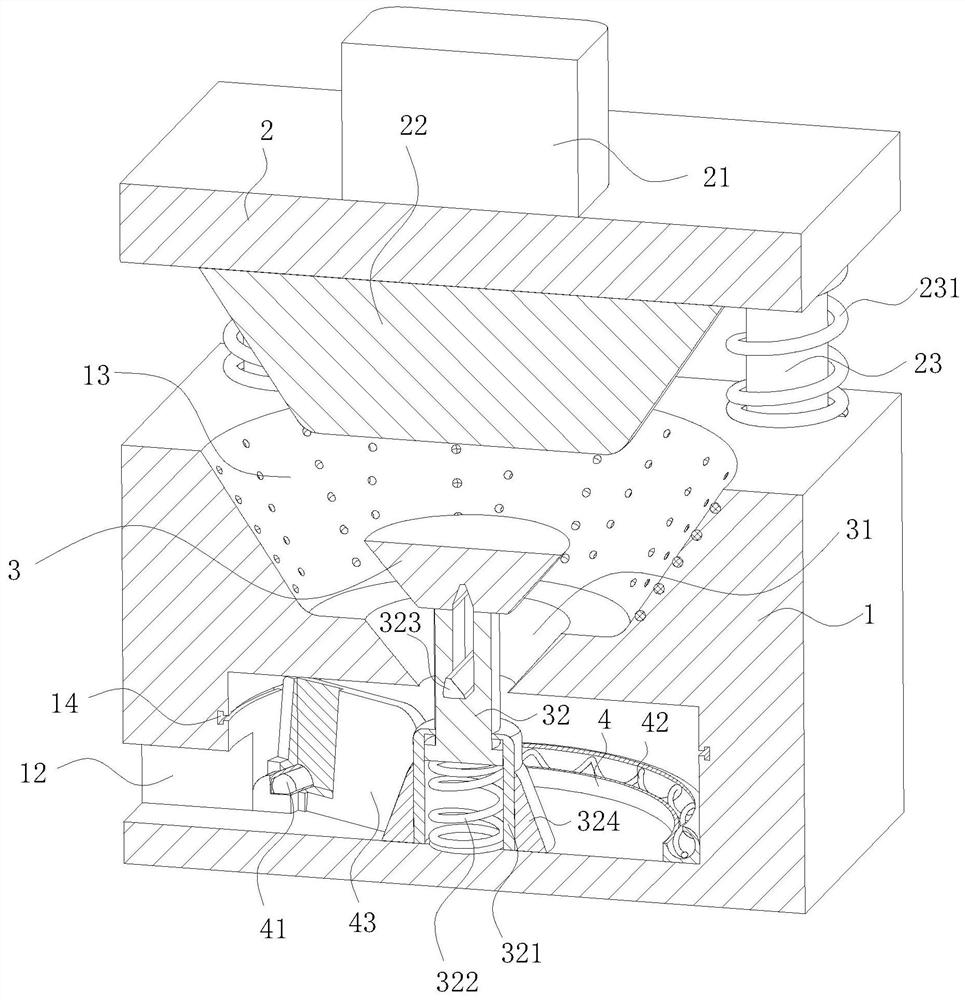

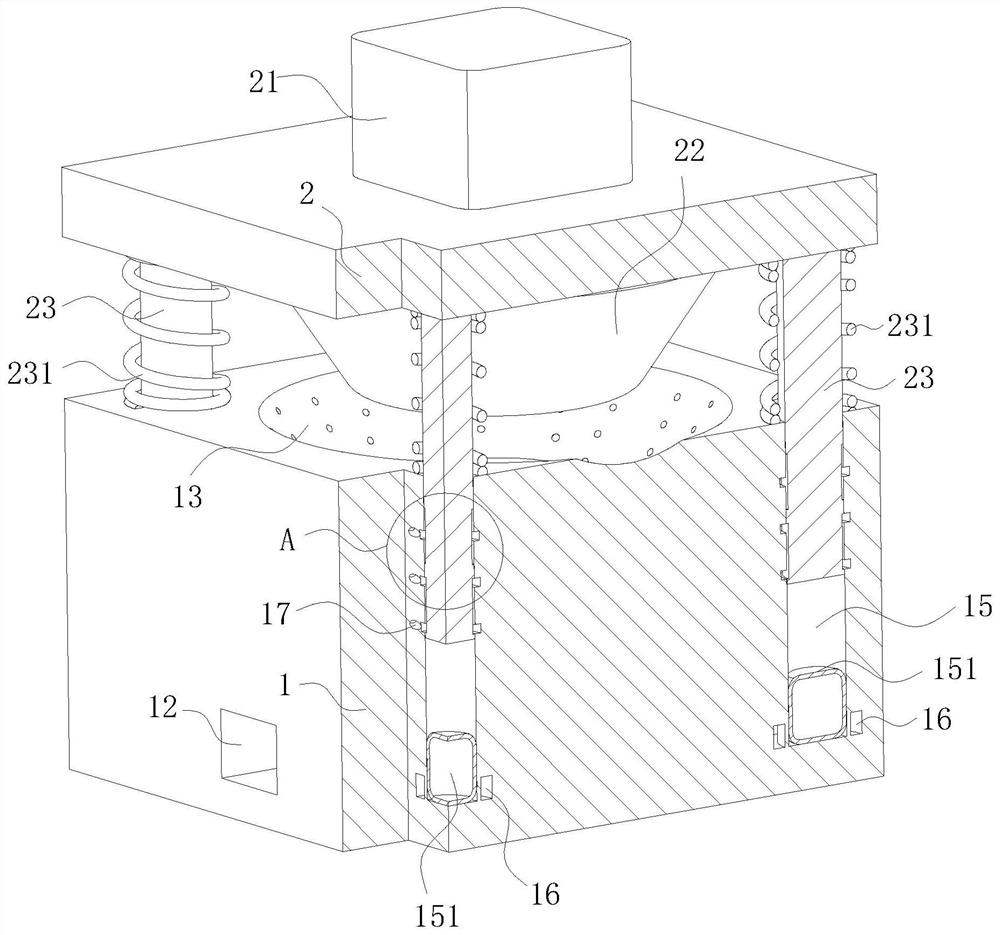

Stamping mold

InactiveCN112207190AShorten speedImprove processing qualityShaping toolsDirt cleaningEngineeringWaste material

The invention belongs to the technical field of molds, and particularly relates to a stamping mold. The stamping mold comprises a lower mold and an upper mold base, wherein a fixed pin is mounted on the lower mold, and a concave mold cavity is arranged in the lower mold; a fixed clamping block is mounted on the upper mold base; a convex mold is mounted on the upper mold base; a collecting cavity is formed in the lower mold; a blanking hole which communicates with the interior of the collecting cavity is formed in the concave mold cavity; a mounting seat in which a cavity I is formed is mountedin the collecting cavity; an extension column and a spring II are mounted in the cavity I; a conical block is mounted at the upper end of the extension column; a fixed cross rod penetrating through arectangular through hole in the extension column is mounted in the blanking hole; rolling balls are uniformly mounted on the side wall of the blanking hole; a micropore I is formed in the surface ofthe conical block; the micropore I communicates with the cavity I; and a chip removal opening which communicates with the collecting cavity is formed in the side surface of the lower mold. The stamping mold can automatically clear scraps to avoid waste accumulation, so that manual labor is reduced, and work efficiency and product quality are improved.

Owner:王红

Defect fusing and removing equipment for continuous casting slab

The invention provides defect fusing and removing equipment for a continuous casting slab. The defect fusing and removing equipment comprises a crossbeam, a pair of oppositely-arranged track foundations and a machine head. The machine head comprises an ignition gun, a purge gun and a tri-axial arm. The ignition gun and the purge gun are slidably arranged on a purge angle-tilting structure which is connected with the tri-axial arm. The purge angle-tilting structure is connected with a first ultrasonic sensor. A rotary servo motor is arranged on the tri-axial arm. The lower end of the tri-axial arm is connected with a second ultrasonic sensor. The defect fusing and removing equipment for the continuous casting slab has following beneficial effects: the technique requirement for working staff is lowered; purge quality is improved; damage to physical health of workers is reduced; and labor cost is decreased.

Owner:MCC BAOSTEEL TECH SERVICE

Drilling machine used for hardware machining and having waste recovery function

ActiveCN106077761ATo achieve the purpose of collection and recyclingReduce labor intensityBoring/drilling componentsMaintainance and safety accessoriesPulp and paper industryDrilling machines

The invention discloses a drilling machine used for hardware machining and having a waste recovery function. The machine comprises a lower base and a storage tank, wherein the top of the lower base is fixedly connected with one end of a fixing rod; the other end of the fixing rod penetrates through a stabilizing table and extends out of the stabilizing table to be fixedly connected with the bottom of an upper base; an electric telescopic rod is arranged at the bottom of the upper base; a drill bit is arranged at the bottom of the electric telescopic rod; a mounting block is arranged at the bottom of the stabilizing table; the storage tank is fixedly connected with the mounting block through a clamping bolt; through holes fit with the clamping bolt are formed in both the storage tank and the mounting block. With the adoption of the drilling machine used for hardware machining and having the waste recovery function, waste is collected and recovered, manual cleaning is avoided, a large quantity of manpower and time are saved, the labor intensity of operators is reduced, the working efficiency is improved, and the machine is simple in structure, convenient to operate, relatively low in cost and suitable for popularization and use.

Owner:南通观銮不锈钢制品有限公司

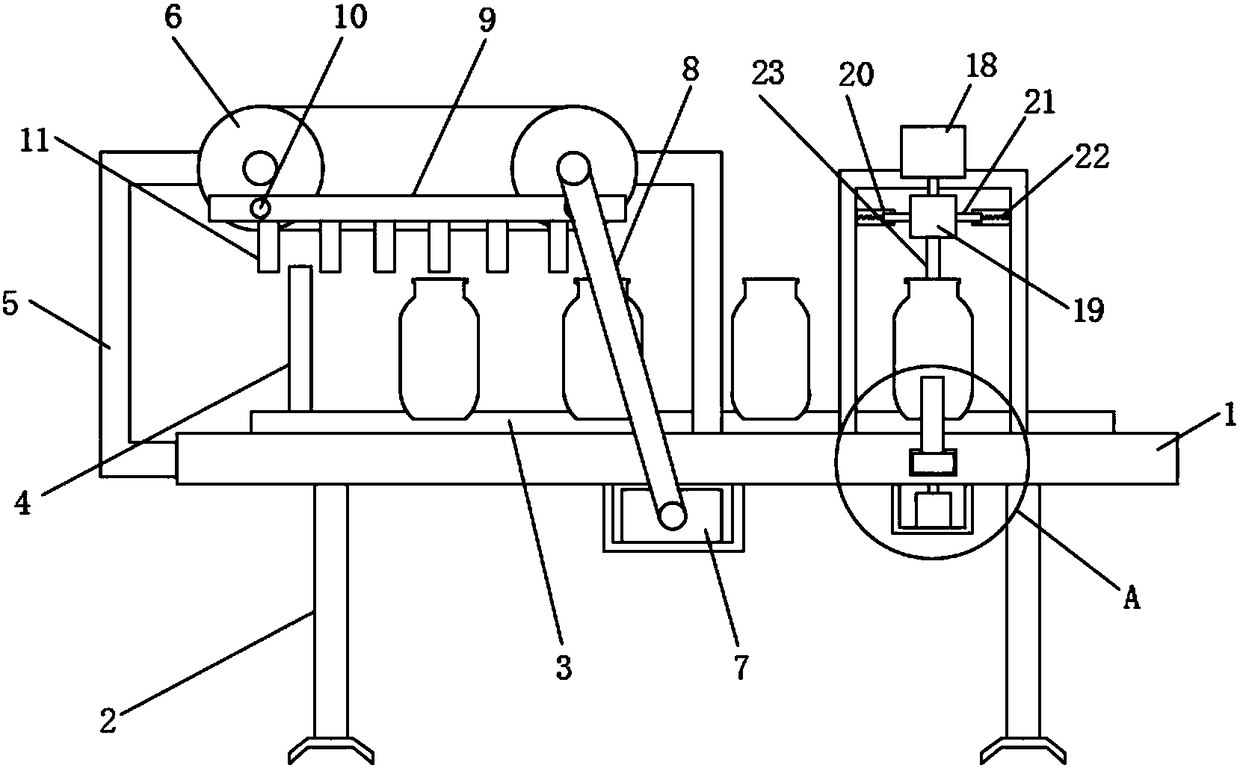

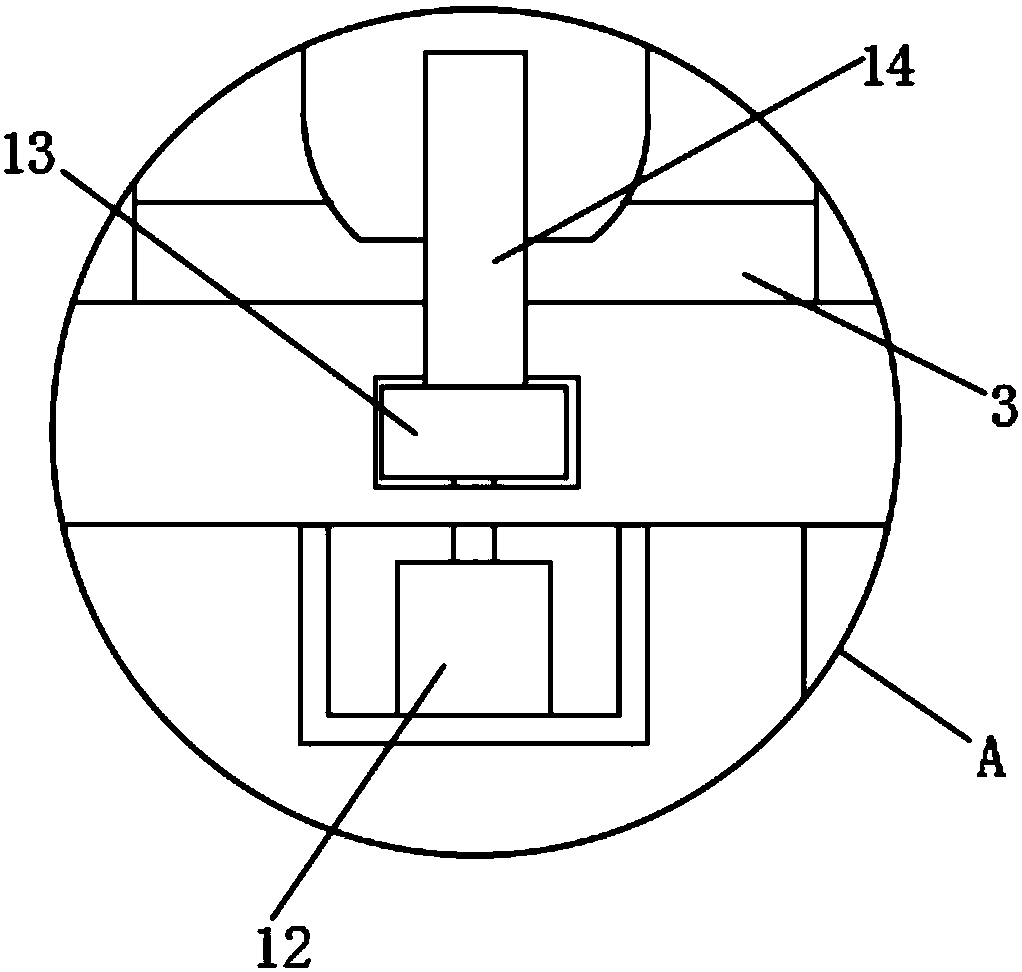

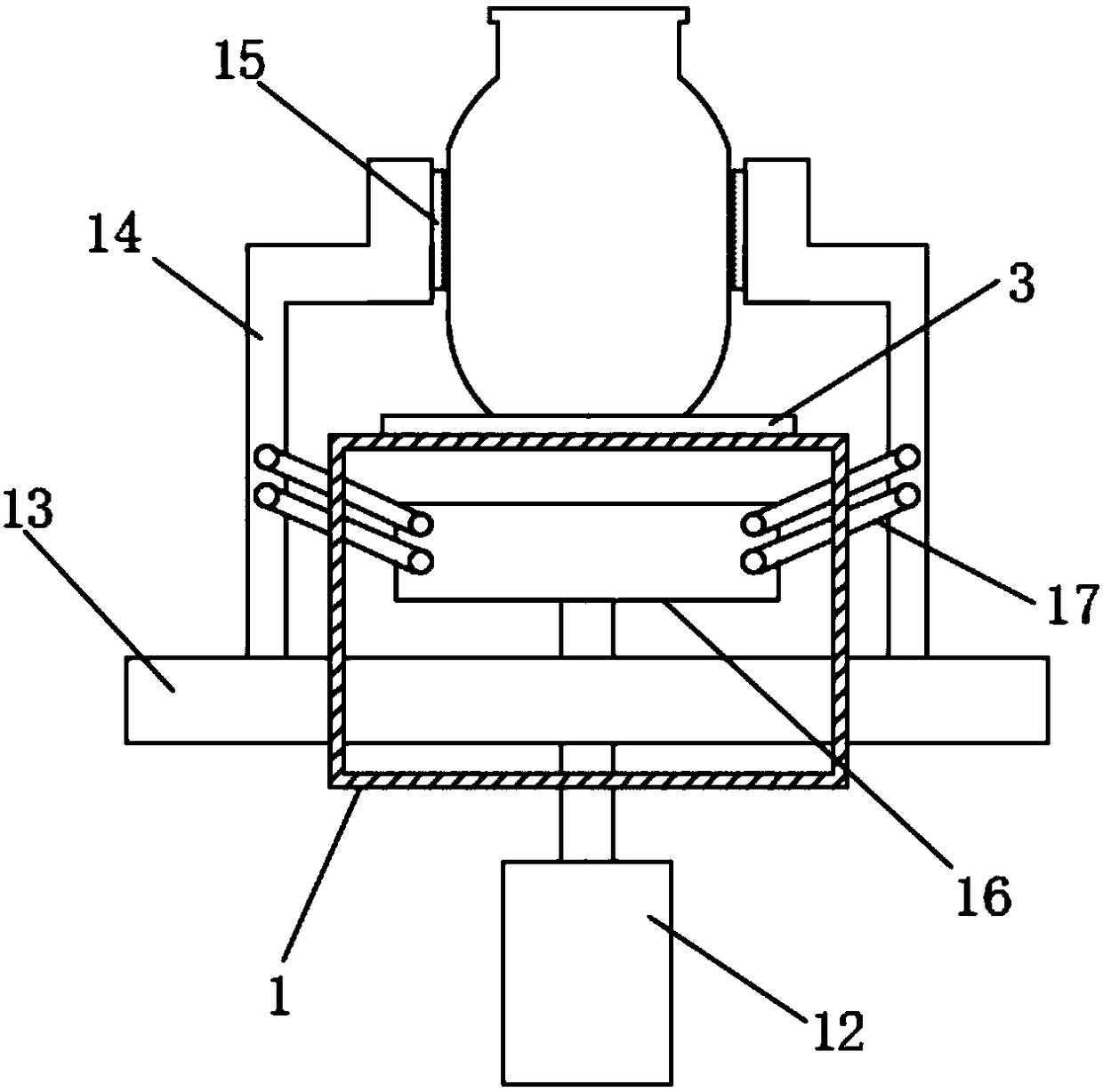

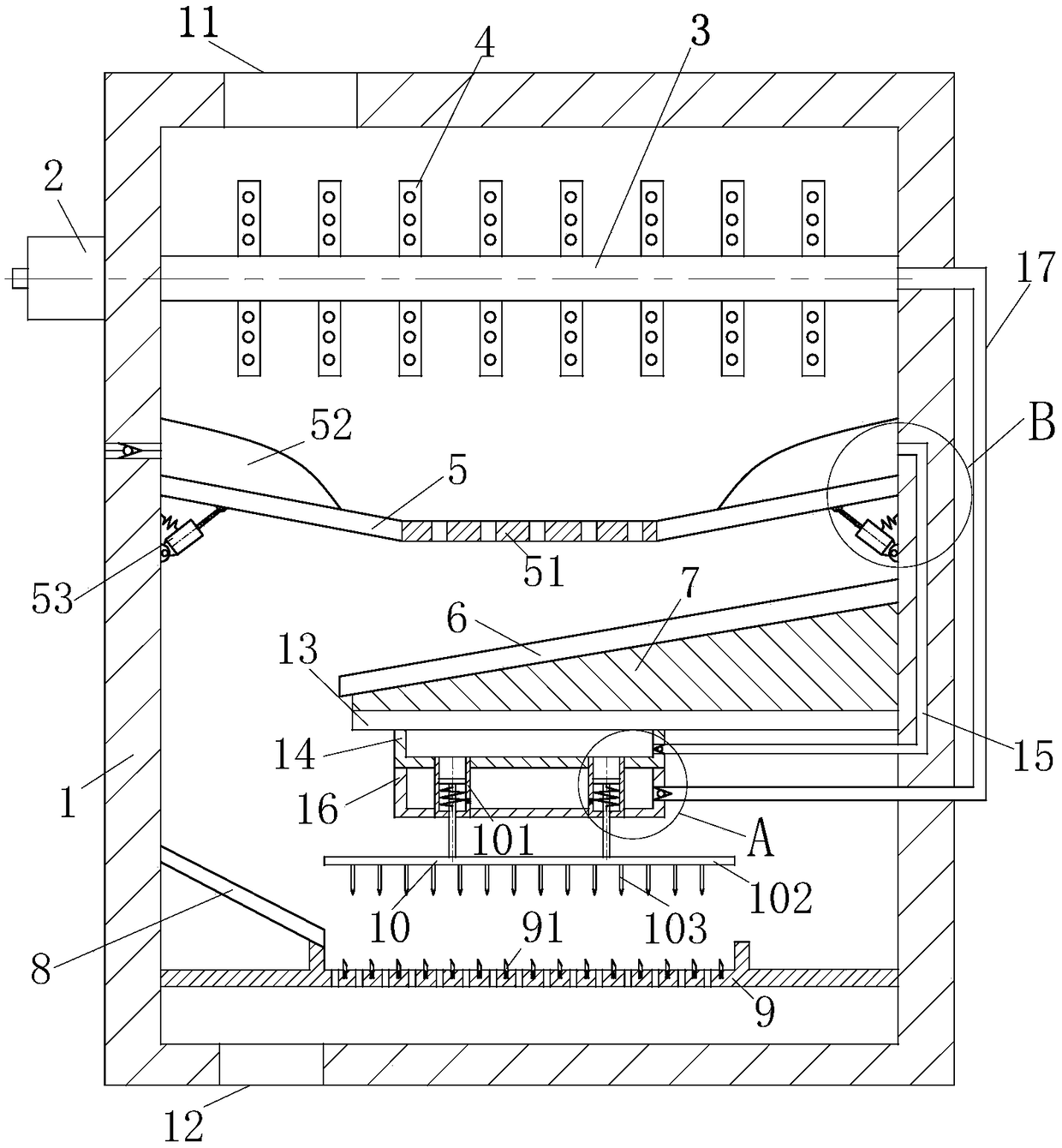

Conveying device with cleaning function for fermented grains

ActiveCN107600968AWith cleaning functionRealize deliveryCleaningAlcoholic beverage preparationSprayerEngineering

The invention discloses a conveying device with a cleaning function for fermented grains. The conveying device comprises a box body, wherein a first motor is fixedly connected to the left side of theinner wall bottom of the box body; the output shaft end of the first motor is in transmission connection with a first running roller through a transmission and a belt; the surface of the first runningroller is in transmission connection with a second running roller through a first conveyor belt; a water scraping device is fixedly connected to the inner wall bottom of the box body; a storage box is connected to the right side of the inner wall of the box body in a sliding manner through a fixing plate; a water inlet pipe is fixedly connected to the inner wall bottom of the box body; one end ofthe water inlet pipe communicates with a sprayer through a water pipe; water stop plates are fixedly connected to two opposite sides of the inner wall of the box body; a water outlet pipe communicates with the bottoms of the water stop plates; and cooling equipment is fixedly connected to the top of the box body. The conveying device relates to the technical field of conveying equipment. According to the conveying device with the cleaning function for the fermented grain, the problem of repeated cleaning of a traditional fermented grain conveying device is solved, the labor intensity is reduced, and the fermented grain cooling rate is improved.

Owner:河北邯郸丛台酒业股份有限公司

Filter screen cleaning device for petroleum filtering processing

InactiveCN110898506AEffectively fixedAvoid shakingRefining by filtrationStationary filtering element filtersMechanical engineeringPetroleum engineering

The invention discloses a filter screen cleaning device for petroleum filtering processing. The filter screen cleaning device comprises a box body, wherein supporting columns are fixedly connected with and arranged at four corners of the lower surface of the box body; a box door is hinged on the box body; a sealing gasket is fixedly connected with and arranged on the box door; a water inlet pipe is fixedly connected with and arranged above one side of the box body, and communicates with the interior of the box body; the upper surface of the box body is fixedly connected with a water pump; thewater outlet end of the water pump is fixedly connected with a water outlet pipe which longitudinally penetrates through the box body and is fixedly connected with a spraying head; the water inlet endof the water pump is fixedly connected with the water inlet pipe; the other end of the water inlet pipe is fixedly connected with one side of the bottom end of the box body, and the interior of the water inlet pipe is communicated with the interior of the box body; a U-shaped placement seat is respectively arranged at two sides of the inner cavity of the box body; and two rotating seats are symmetrically and fixedly connected with and arranged at the upper part and the lower part of one side, corresponding to the U-shaped placement seats, of the inner cavity of the box body. The filter screencleaning device provided by the invention avoids manual cleaning, improves the washing speed and the working efficiency, reduces the labor intensity of personnel and is simple in structure and convenient in use.

Owner:安徽省睿斯达石油有限公司

Plastic product toughness detecting device and method

PendingCN108303331AReduce clamping forceAvoid affecting test resultsHollow article cleaningStrength propertiesPunchingThreaded pipe

The invention discloses a plastic product toughness detecting device in the technical field of detecting. The plastic product toughness detecting device comprises a detecting device box body; a collecting device is arranged in the inner cavity of the detecting device box body; an electric hydraulic pushing rod is mounted at the bottom of the inner cavity of the detecting device box body; a punching head is mounted at the bottom of the electric hydraulic pushing rod; stretching clamping devices are arranged in the centre of the inner cavity of the detecting device body; according to the detecting device, buffering devices are arranged on clamps, and the clamping force of the clamps is reduced through the buffering devices, so that the influence on a detecting result caused by the damage ofan object to be detected because of excessive clamping force is avoided; the collecting device is arranged in the inner cavity, so that damaged objects are convenient to collect; a hairbrush is arranged in the collecting device, and the hairbrush is driven to clean the collecting barrel through a motor, so that conventional manual cleaning is avoided and manpower is saved; the clamp perform a stretching action through the matching of a threaded rod and an inner threaded pipe, so that conventional dual-cylinder driving is avoided, and the operating difficulty is reduced.

Owner:胡昌奎

Automatic washing device for cookware

InactiveCN106377215AAvoid manual cleaningEasy to cleanKitchenware cleanersCleaning equipmentDrive shaftWater source

The invention relates to domestic cleaning products, and particularly relates to an automatic washing device for cookware. The automatic washing device for the cookware comprises a motor, a transmission shaft, a water injection sheet and a washing sheet, wherein the upper end of the transmission shaft is connected with the motor; the lower end of the transmission shaft is connected with the washing sheet and the water injection sheet; the interior of the water injection sheet is hollow; the surface of the water injection sheet is provided with a water injection hole; the root of the water injection sheet is provided with an open hole; the open hole is communicated with a water source; the washing sheet comprises a rubber scraping strip and a scraping strip rack for fixing the rubber scraping strip; the motor is arranged to drive the washing sheet and the water injection sheet to rotate through the transmission shaft; the water injection sheet uniformly sprays water and a washing agent on the surface of a pot; the rubber scraping strip of the washing sheet scrapes off oil stain in the pot; the manual washing is avoided; the washing effect is good; obstinate oil stain and dirty stain can be removed; a hermetic ultrasonic generating device can be also arranged inside the washing sheet; the washing is carried out by utilizing an ultrasonic cavatition effect; the washing effect is better.

Owner:NANJING LEIMING MEDICAL INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com