Grinding equipment for cement clinker production

A cement clinker and grinding technology, which is applied in the directions of sounding equipment, solid separation, sieve, etc., can solve the problems of cement coagulation and unusability, and achieve the effect of reducing damage, prolonging service life and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

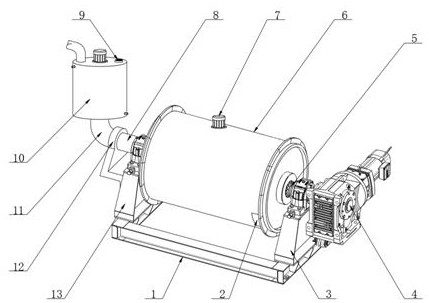

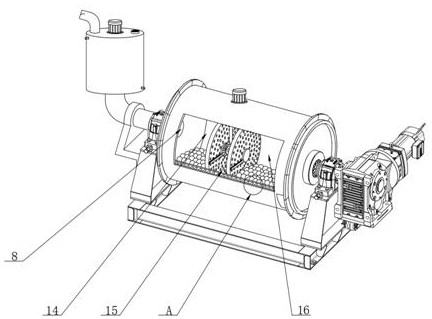

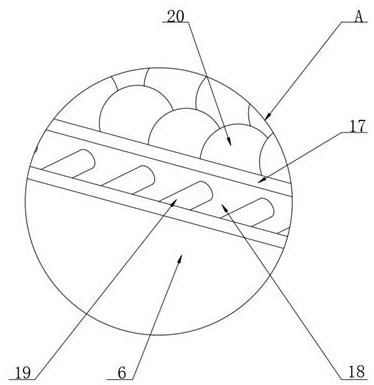

[0025] see Figure 1~5 , in the embodiment of the present invention, a grinding equipment for cement clinker production, including a base 1, the upper part of the base 1 is symmetrically fixed on both sides of the second bearing seat 13 and the first bearing seat 3, the second bearing seat 13 and the first bearing seat 3 are provided with a ball mill part, and the outside of the second bearing seat 13 is provided with a pretreatment part connected with the ball mill part, the pretreatment part includes a preliminary treatment cylinder 10, and the bottom of the preliminary treatment cylinder 10 is fixed There is a feed pipe 11 communicating with the feed pipe 8, and the feed pipe 11 is connected to the feed pipe 8 through a rotating connection seat 12. The inside of the preliminary treatment cylinder 10 is provided with a screening mechanism, and the top of the preliminary treatment cylinder 10 Embedded and fixed with a feeding pipe 21, the screening mechanism includes a filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com