A kind of preparation method of pure lead zirconate titanate nanofiber ceramic material

A technology of nanofibers and ceramic materials, applied in the field of piezoelectric ceramics, can solve the problems of unstable performance of PZT powder, hidden dangers of device performance and stability, and unstable doping ions, etc., and achieve excellent piezoelectric activity and reduced grain size. Small, to avoid the effect of impurity phase formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

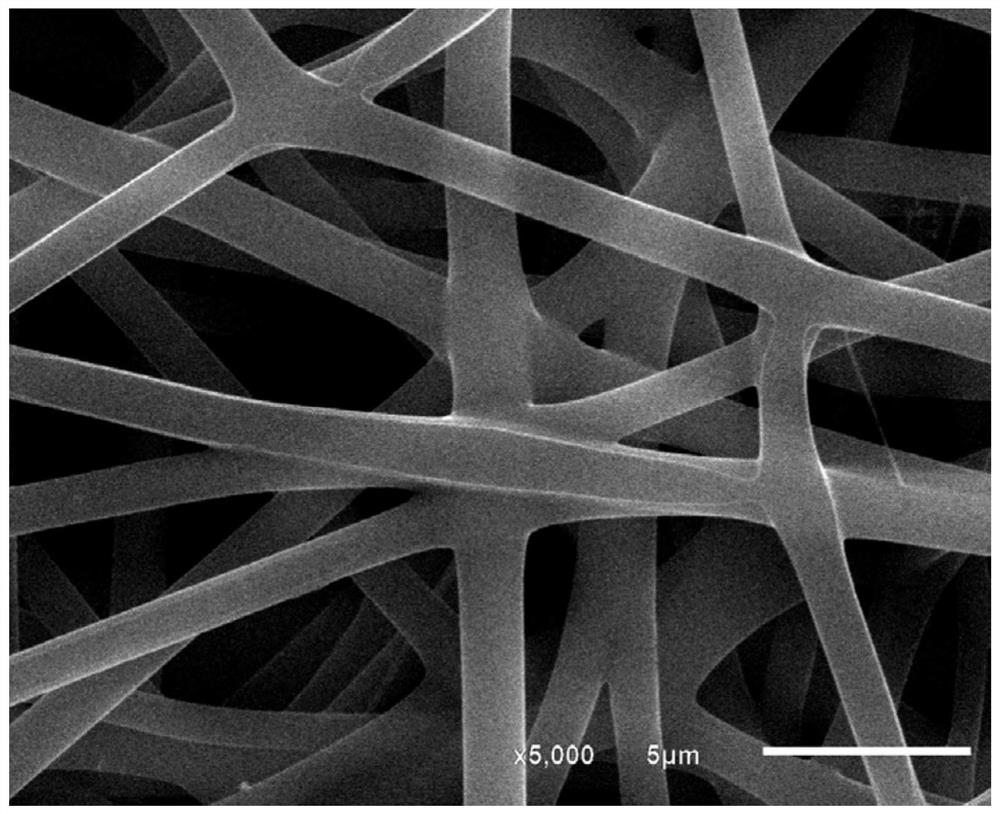

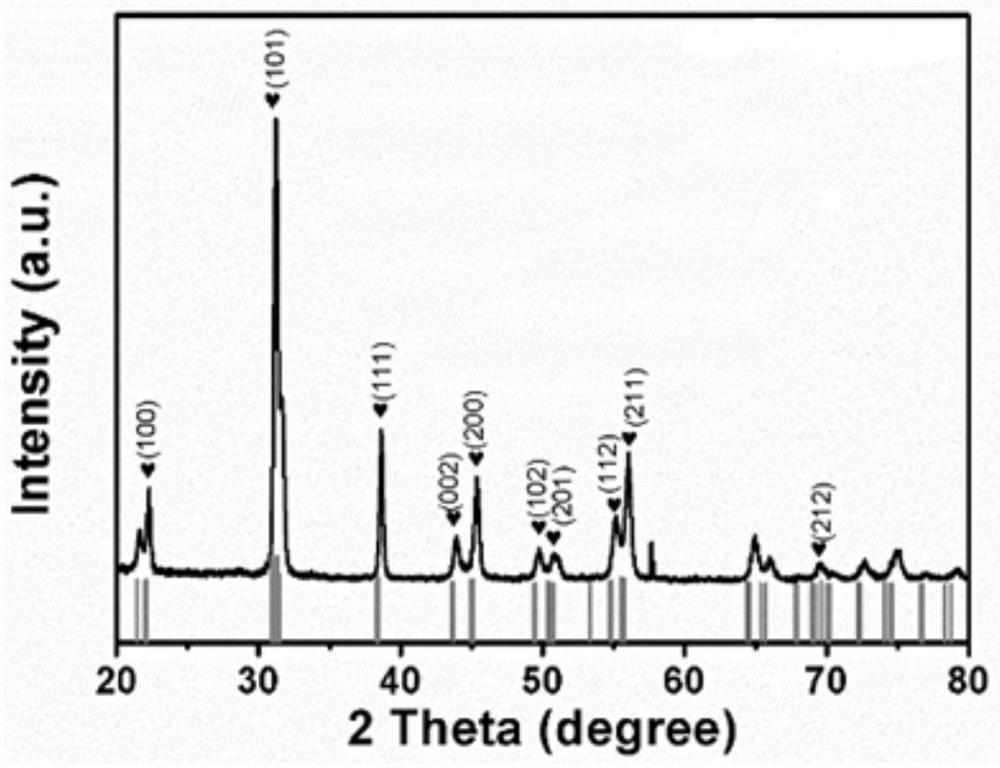

[0045] According to some embodiments provided by the present invention, the preparation method of the pure lead zirconate titanate nanofiber ceramic material includes:

[0046] S1: Dissolve lead salt in ethylene glycol to configure the first solution;

[0047] S2: Mix ethylene glycol, glacial acetic acid, and anhydrous ethanol to form a mixed solvent, and then add the first part of PVP, zirconium salt, and titanium salt to dissolve in sequence, and configure the second solution;

[0048] S3: mixing the first solution with the second solution, and then adding a second portion of PVP to dissolve to obtain a PZT precursor sol solution;

[0049] S4: electrospin the PZT precursor sol solution to obtain PZT precursor fibers;

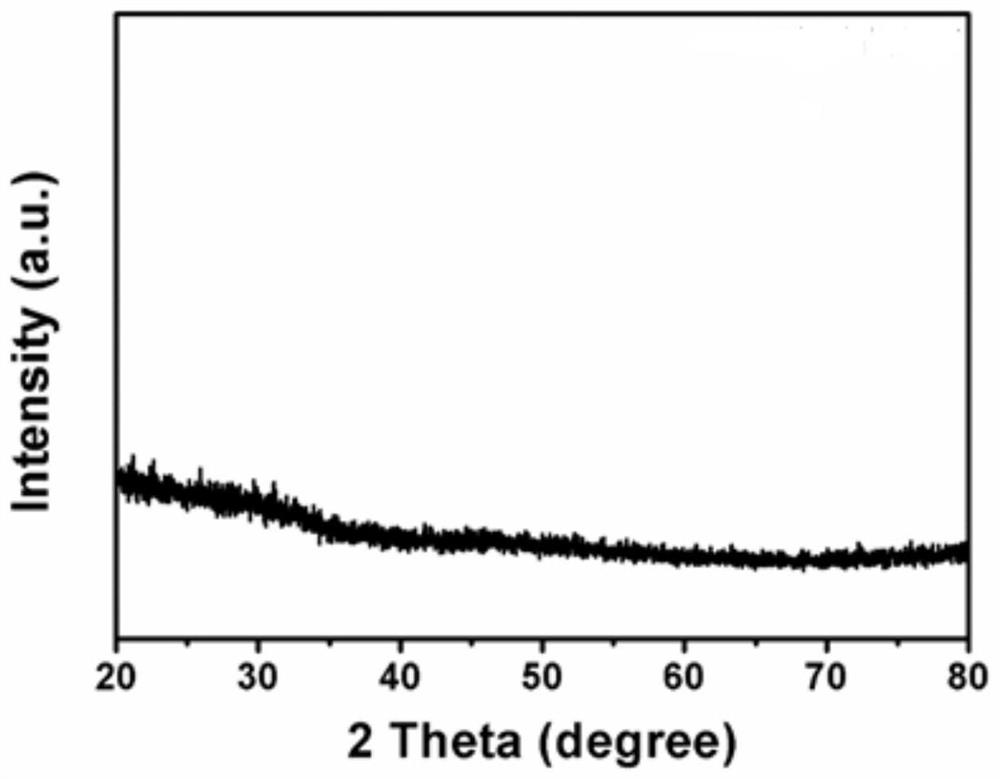

[0050] S5: heat treatment of the PZT precursor fiber to obtain a pure lead zirconate titanate nanofiber ceramic material.

[0051] According to some embodiments provided by the present invention, the preparation method of the pure lead zirconate titanate nan...

Embodiment 1

[0060] 1. PZT precursor sol solution configuration

[0061] First, weigh 2.0864g of lead acetate trihydrate and dissolve it in 5g of ethylene glycol solution, stir on a magnetic stirrer for 30 minutes, and configure the first solution; into 60g mixed solvent, add mass fraction of 1% PVP (based on the mass of the mixed solvent as 100%) and stir to dissolve, then weigh 0.6012g of zirconium oxynitrate and dissolve it in the mixed solvent, heat and stir properly until it is completely dissolved, and cool to 10 After ℃, 0.8168g of tetrabutyl titanate was added dropwise, and fully stirred on a magnetic stirrer to configure a second solution; the first solution was slowly added dropwise into the second solution, and stirred well, and then an appropriate amount of 7% PVP was added. (Based on the mass of the mixed solvent as 100%), stir to dissolve, and place in a 60° C. water bath to stir for 6 hours until the solution is clear and transparent.

[0062] 2. Electrospinning into PZT pr...

Embodiment 2

[0069] 1. PZT precursor sol solution configuration

[0070] First, weigh 2.0864g of lead acetate trihydrate and dissolve it in 5g of ethylene glycol solution, stir on a magnetic stirrer for 30 minutes, and configure the first solution; into 60g mixed solvent, add mass fraction 2% PVP (based on the mass of the mixed solvent as 100%) and stir to dissolve, then weigh 0.6012g of zirconium oxynitrate and dissolve it in the mixed solvent, heat and stir properly until it is completely dissolved, and cool to 10 After ℃, 0.8168g of tetrabutyl titanate was added dropwise, fully stirred on a magnetic stirrer, and configured into a second solution; the first solution was slowly added dropwise to the second solution, and fully stirred, and then an appropriate amount of 8% PVP was added. (Based on the mass of the mixed solvent as 100%), stir to dissolve, and place in a 60° C. water bath to stir for 6 hours until the solution is clear and transparent.

[0071] 2. Electrospinning into PZT pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com