A kind of piezoelectric ceramic material for high temperature piezoelectric sensor and preparation method thereof

A piezoelectric ceramic, high-temperature piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of affecting the temperature of high-temperature piezoelectric sensors Problems such as stability, unfavorable stability of high-temperature piezoelectric sensors, and decrease of Curie temperature achieve the effect of high-temperature DC resistivity, high-voltage electrical activity, and piezoelectricity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A piezoelectric ceramic material for high-temperature piezoelectric sensors with high Curie temperature, high-voltage electrical activity, high-temperature DC resistivity, and good temperature stability, and its preparation, characterized in that: the chemical composition of the ceramic material The ratio is: Ca 1-x-y-z (LM) x / 2 N y (NaBi) z / 2 Bi 2 Ta 2 O 9 ; Wherein L represents Li, Na, K; M represents lanthanide metal element or Bi; N represents Sr or +2 valence vacancy; x, y, z Represents the mole fraction of the corresponding element. Where 0 ≤ x + y + z ≤ 1, and 0 ≤ x ≤ 0.4, 0 ≤ y ≤ 0.1, 0 ≤ z ≤ 1; when z ≠ 0, the (LM) combination cannot be (NaBi). The preparation method includes the following steps:

[0028] (1) Calculate and weigh the required quality of each raw material according to the chemical ratio formula of the ceramic materials;

[0029] (2) Ball mill the weighed raw materials for 10-24 h;

[0030] (3) Bake the slurry after ball milling in step (2), pierce a ...

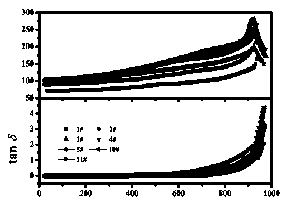

Embodiment 1

[0038] (1) Preparation of high Curie temperature piezoelectric ceramic powder by solid phase method

[0039] According to the general formula Ca 1-x (LiCe) x / 2 Bi 2 Ta 2 O 9 ( x = 0, 0.06) to calculate the formula, weigh and mix the raw materials in the stoichiometric ratio, put them in a polyurethane ball milling tank, use anhydrous ethanol as the dispersion medium, and use a planetary ball mill for 16 h at a speed of 180 rpm. Then discharge the material, bake it under a baking lamp until it is dried, and then continuously increase the temperature to 850 ℃ in a program-controlled temperature box furnace and keep it for 4 hours to obtain a high Curie temperature piezoelectric ceramic powder;

[0040] (2) Secondary ball milling

[0041] Put the prepared high Curie temperature piezoelectric ceramic powder in a polyurethane ball milling tank, use anhydrous ethanol as the dispersion medium, ball mill with a planetary ball mill for 12 hours, rotate at 180 rpm, and then discharge the mater...

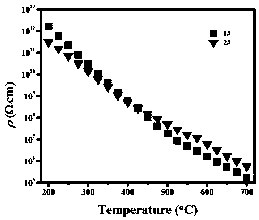

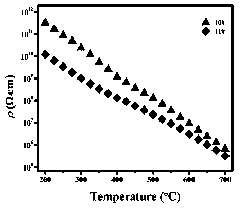

Embodiment 2

[0049] (1) Preparation of high Curie temperature piezoelectric ceramic powder by solid phase method

[0050] According to the general formula Ca 1-z (NaBi) z / 2 Bi 2 Ta 2 O 9 ( z = 0.10, 0.30, 0.50) to calculate the formula, weigh and mix the raw materials in the stoichiometric ratio, put them in a polyurethane ball mill tank, use anhydrous ethanol as the dispersion medium, and use a planetary ball mill for 16 h after ball milling at a speed of 180 rpm, followed by discharging, baking under a bake lamp until drying, and then continuously heating to 850 ℃ in a program-controlled temperature box furnace for 4 hours to obtain high Curie temperature piezoelectric ceramic powder;

[0051] (2) Secondary ball milling

[0052] Put the prepared high Curie temperature piezoelectric ceramic powder in a polyurethane ball milling tank, use anhydrous ethanol as the dispersion medium, ball mill with a planetary ball mill for 12 hours, rotate at 180 rpm, and then discharge the material and bake it un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com