Patents

Literature

516 results about "Piezoelectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric Charge Constant. The piezoelectric charge constant, d, is the polarization generated per unit of mechanical stress (T) applied to a piezoelectric material or, alternatively, is the mechanical strain (S) experienced by a piezoelectric material per unit of electric field applied.

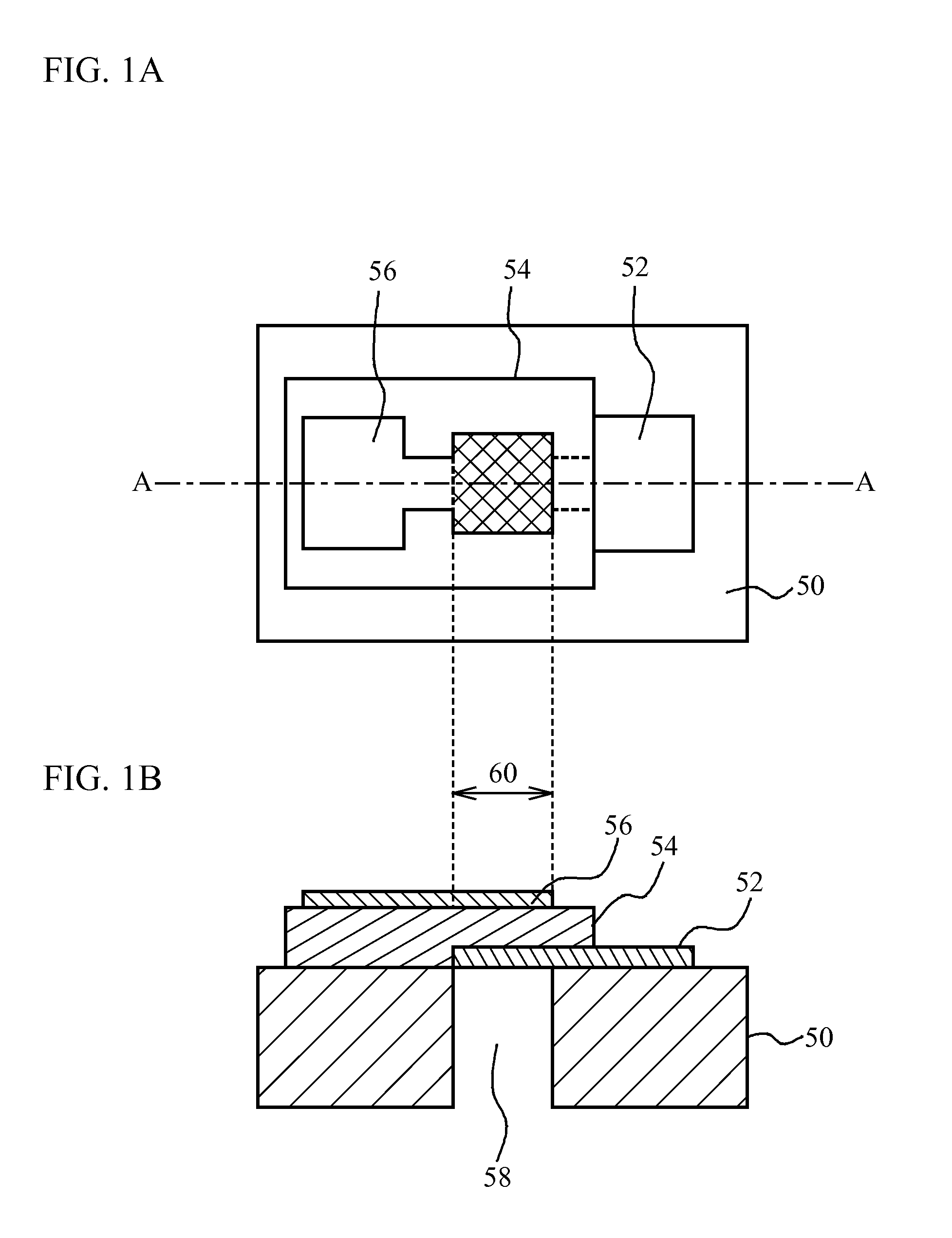

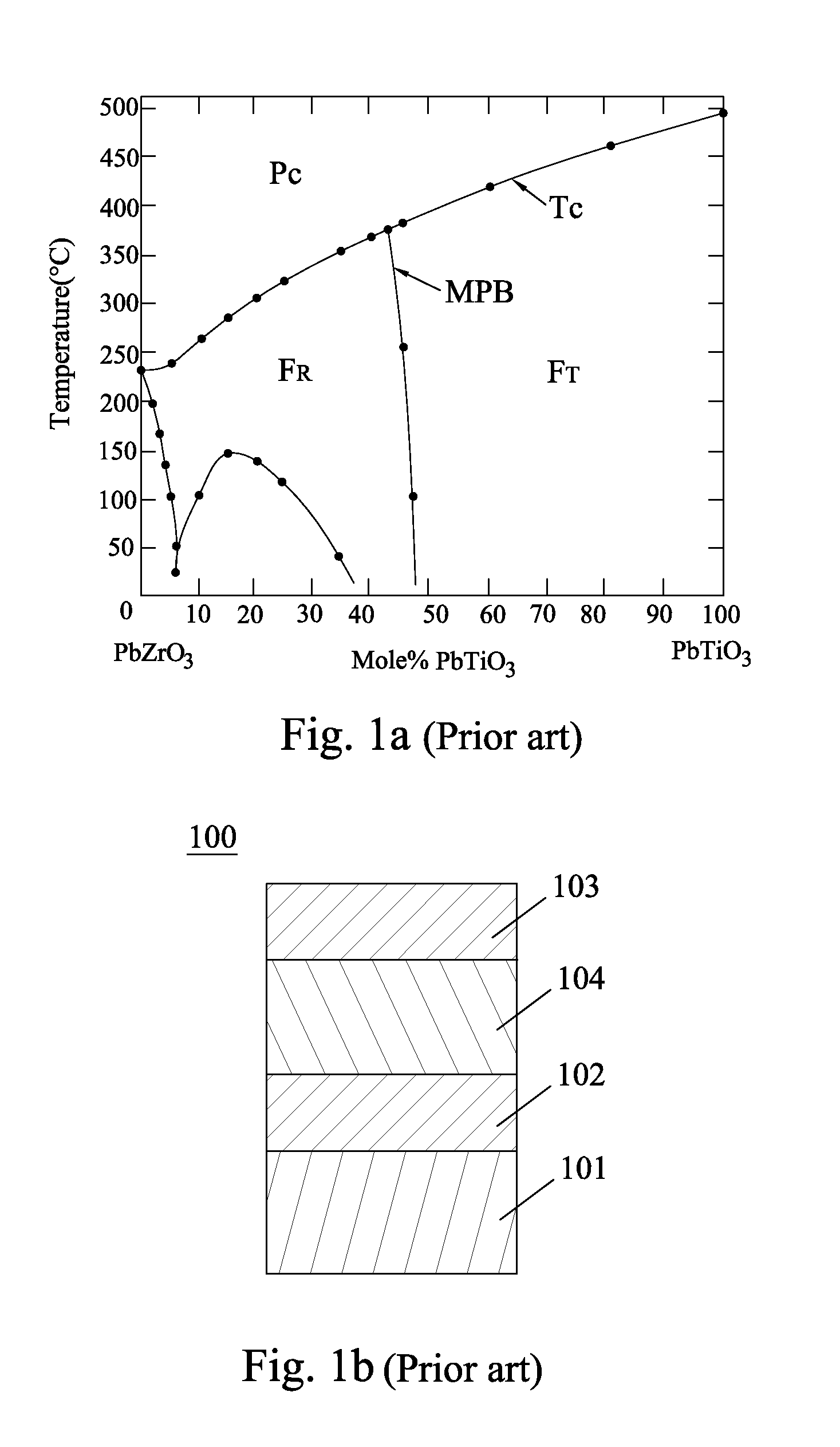

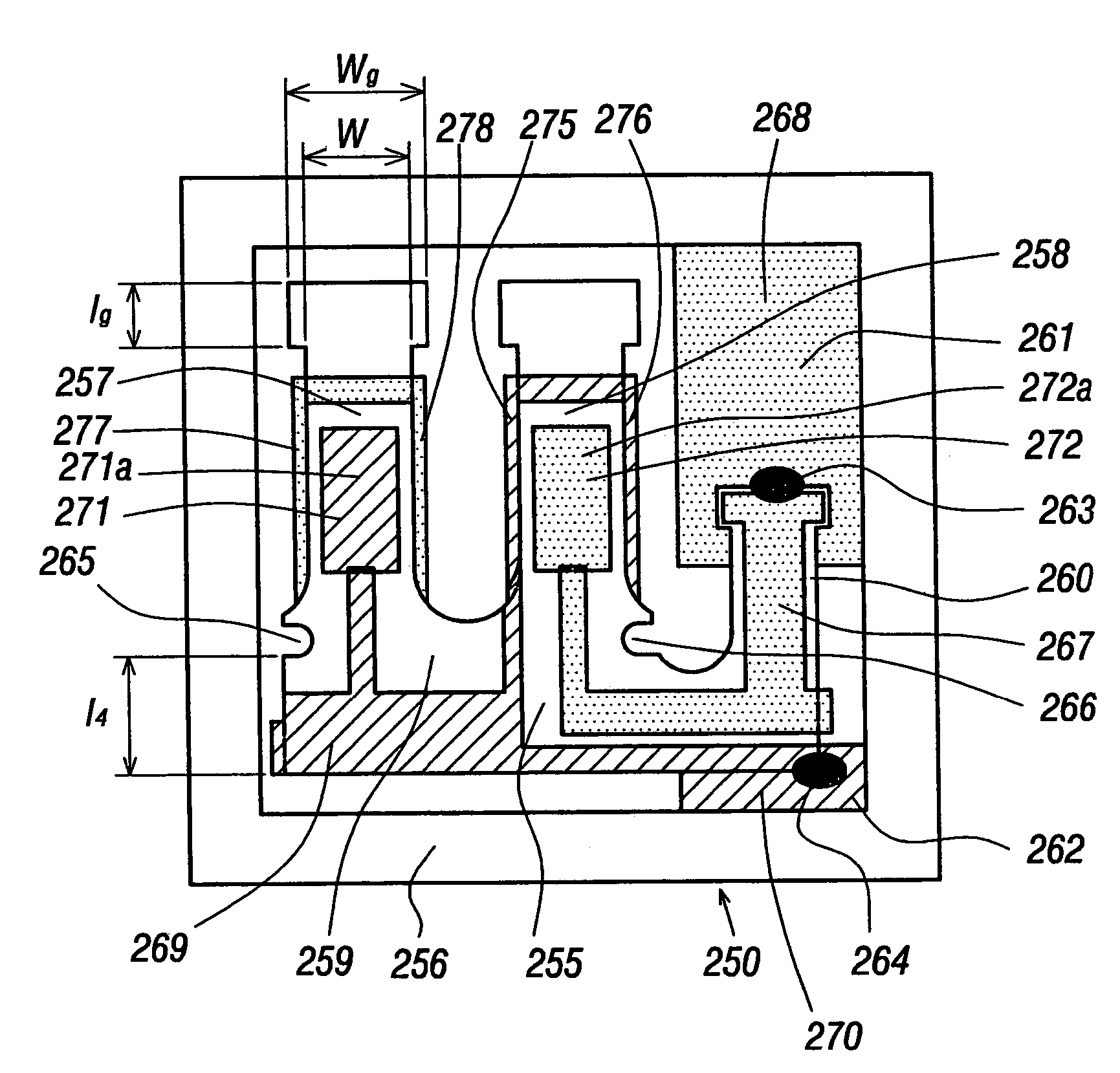

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

Ternary system sodium-bismuth titanate lead-free piezoelectric ceramics

InactiveCN101200370AExcellent piezoelectric propertiesPracticalDevice material selectionElectricityVolumetric Mass Density

The invention discloses a triple system (Na,Bi)TiO3-based lead-free piezoelectric ceramic material, the formula of the disclosed lead-free piezoelectric ceramic component is denoted with (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO3-yBi(Me)O3 and (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO-yBi(Me)O3+zM(a)O(b), in the formula x,y and z denote molar fractions, wherein x is bigger than or equal to 0 and smaller than or equal to 1.0, y is bigger than or equal to 0 and smaller than or equal to 0.2, z is bigger than or equal to 0 and smaller than or equal to 0.1, Me is trivalent metal element, M(a)O(b) is one or more oxides, wherein M is +1 to +6 valence and is an element that can be integrated with oxygen to form a solid oxide. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 180pC per N, Kp can reach above 0.36. The lead-free piezoelectric ceramic adopts traditional electronic ceramic preparation process, and has low sintering temperature, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

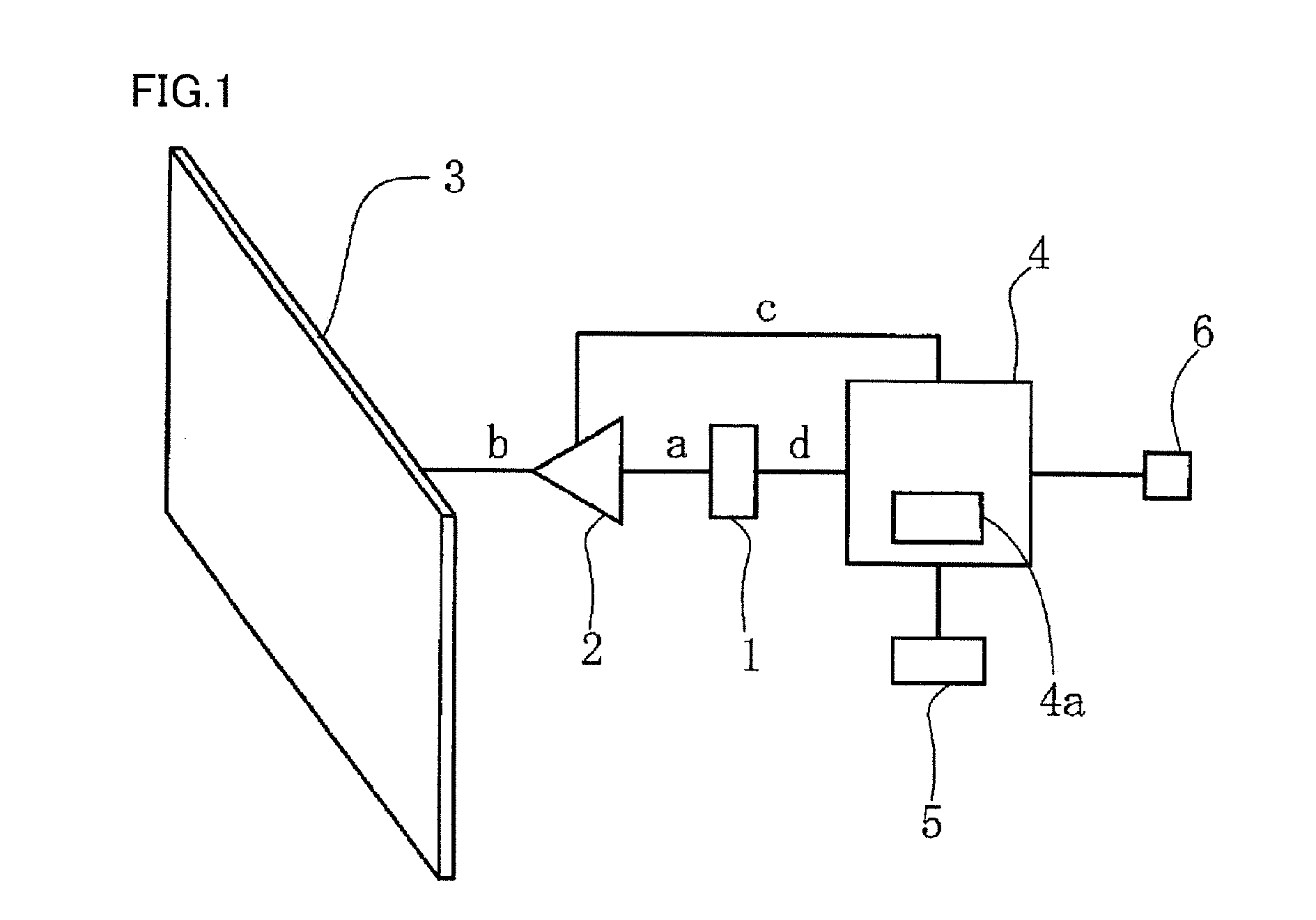

Piezoelectric device

ActiveUS20130108061A1Sound volume can be preventedAvoid volatilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersSound sourcesAudio power amplifier

A piezoelectric device is provided with a sound source IC, an amplifier for amplifying a sound source from the sound source IC, a piezoelectric speaker for generating sound based on a drive signal from amplifier, an MPU for performing a predetermined control process on the drive signal, a memory for storing temperature dependency information about the piezoelectric constant (d14) and Young's modulus E of the piezoelectric speaker, and a temperature sensor for detecting an ambient temperature. MPU has correcting unit, compares a detected result of the temperature sensor with the temperature dependency information, and performs temperature correction on the drive signal serving as an acoustic signal based on a compared result. The piezoelectric speaker outputs the acoustic signal temperature-corrected by correcting unit. Thus, it becomes possible to realize various piezoelectric devices, such as a piezoelectric speaker system, capable of preventing various input information from fluctuating even when there is a change in usage environmental temperature.

Owner:MURATA MFG CO LTD

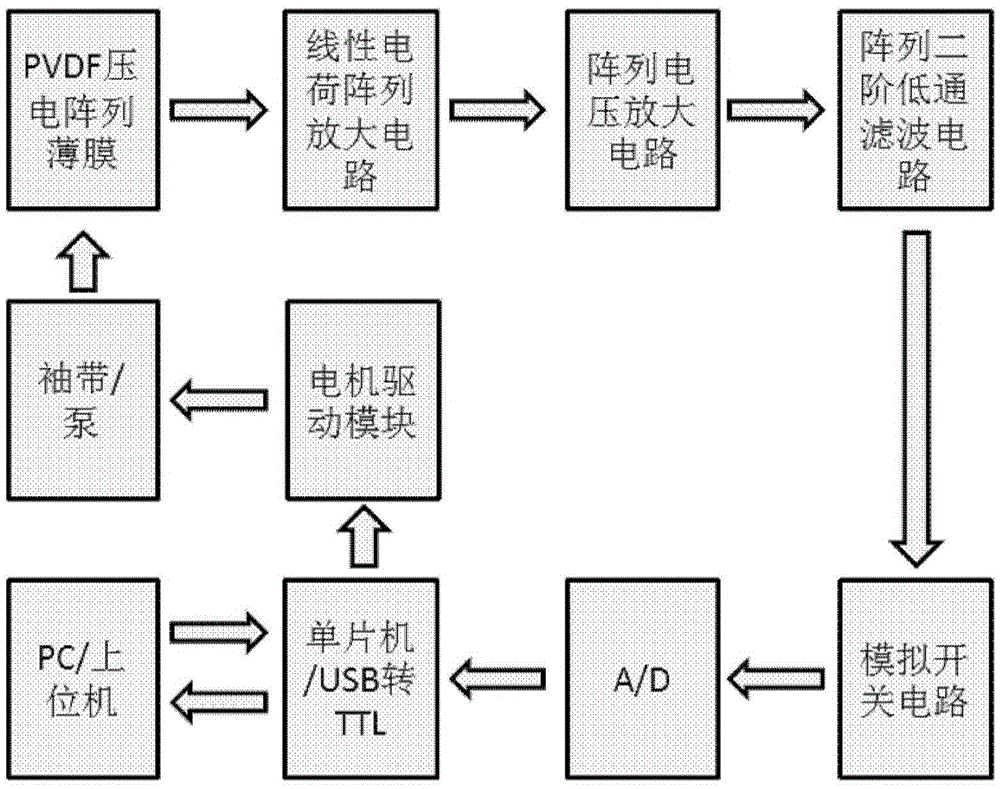

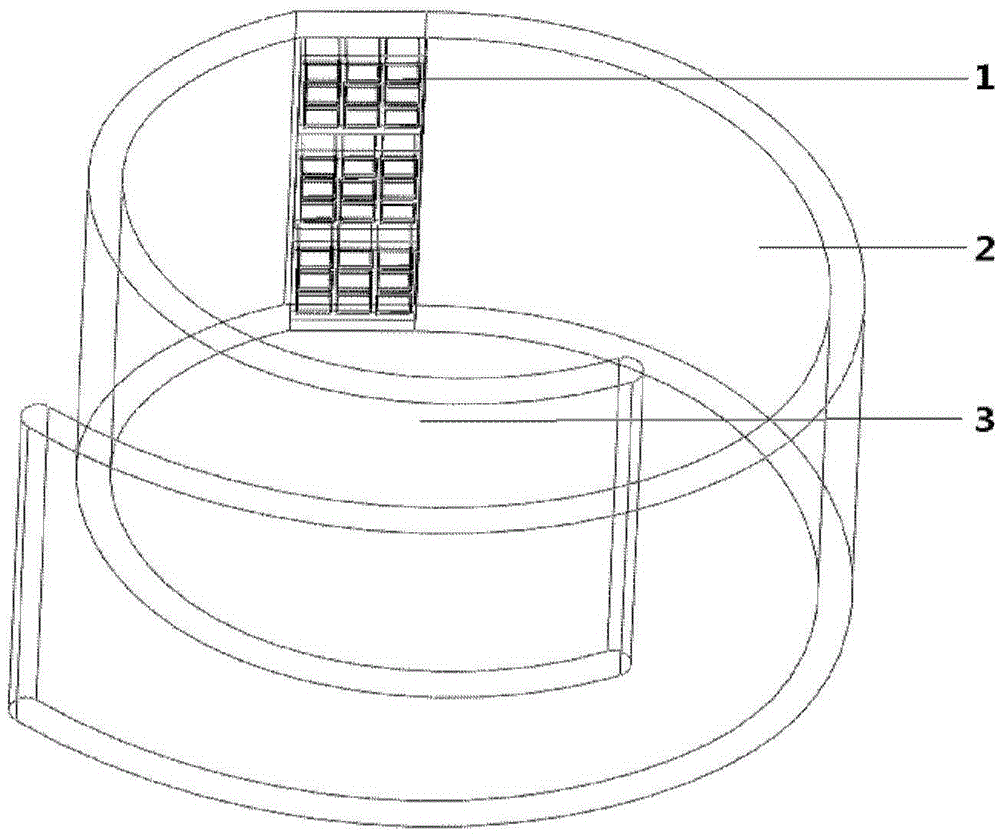

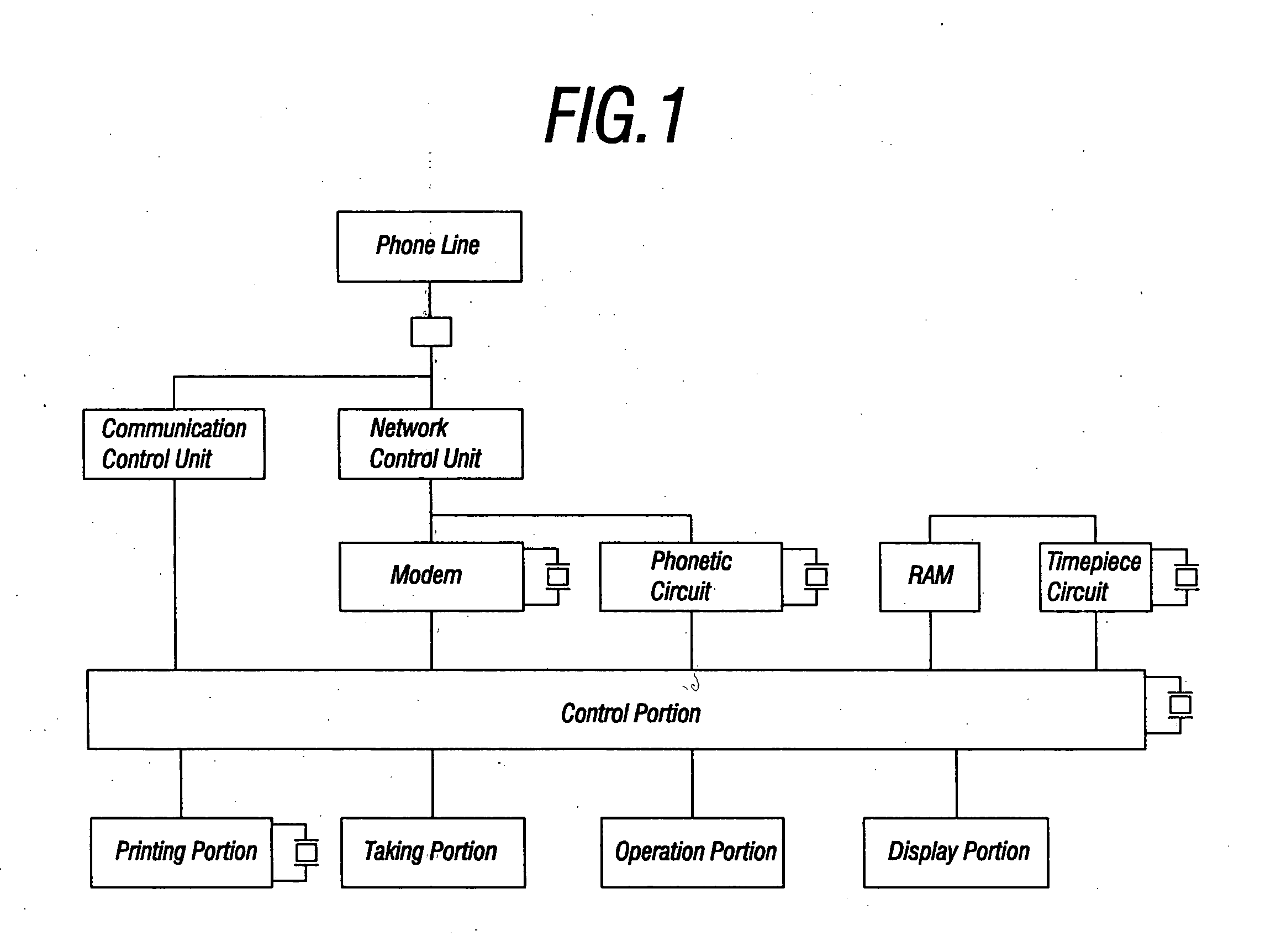

Pulse wave array sensor acquisition system and method

InactiveCN105640513AMeet the frequency characteristicsHigh piezoelectric constantCatheterDiagnostic recording/measuringResponse sensitivityWrist

The invention provides a pulse wave array sensor acquisition system and method. The acquisition system comprises multiple piezoelectric film sensors. The piezoelectric film sensors are PVDF film sensors arranged in an array mode and are used for converting pulse pressure signals into voltage signals. Array PVDF piezoelectric films are adopted in the acquisition system, the piezoelectric constant is large, variable force response sensitivity is high, the films are light and flexible, preparation is easy, impedance coupling with human tissue is good, mechanical quality factors are low, resistance is low, density is low, and the frequency characteristics of the pulse signals can be met. In addition, the acquisition system can guarantee that information of three positions of cun, guan and chi is completely acquired, more accurate positioning can be achieved, and artificial errors are eliminated. Gradual pressurized measurement can be conducted on wrist positions, and the problems that existing pulse sensors hardly conduct positioning and calibrate floating, centering and sinking are effectively solved. Circuits are simplified, and miniaturization of the circuits can be achieved.

Owner:北京中科芯健医疗科技有限公司

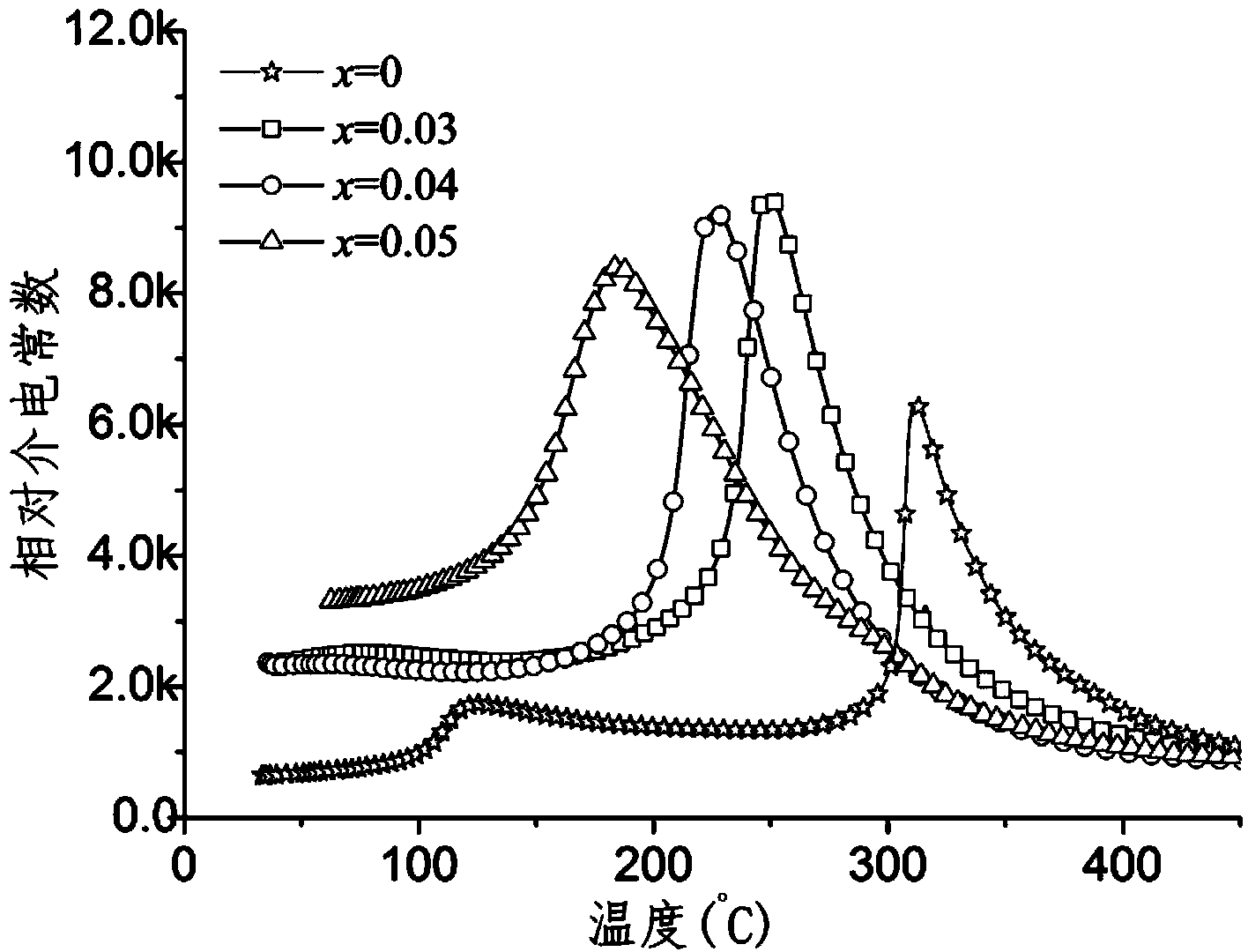

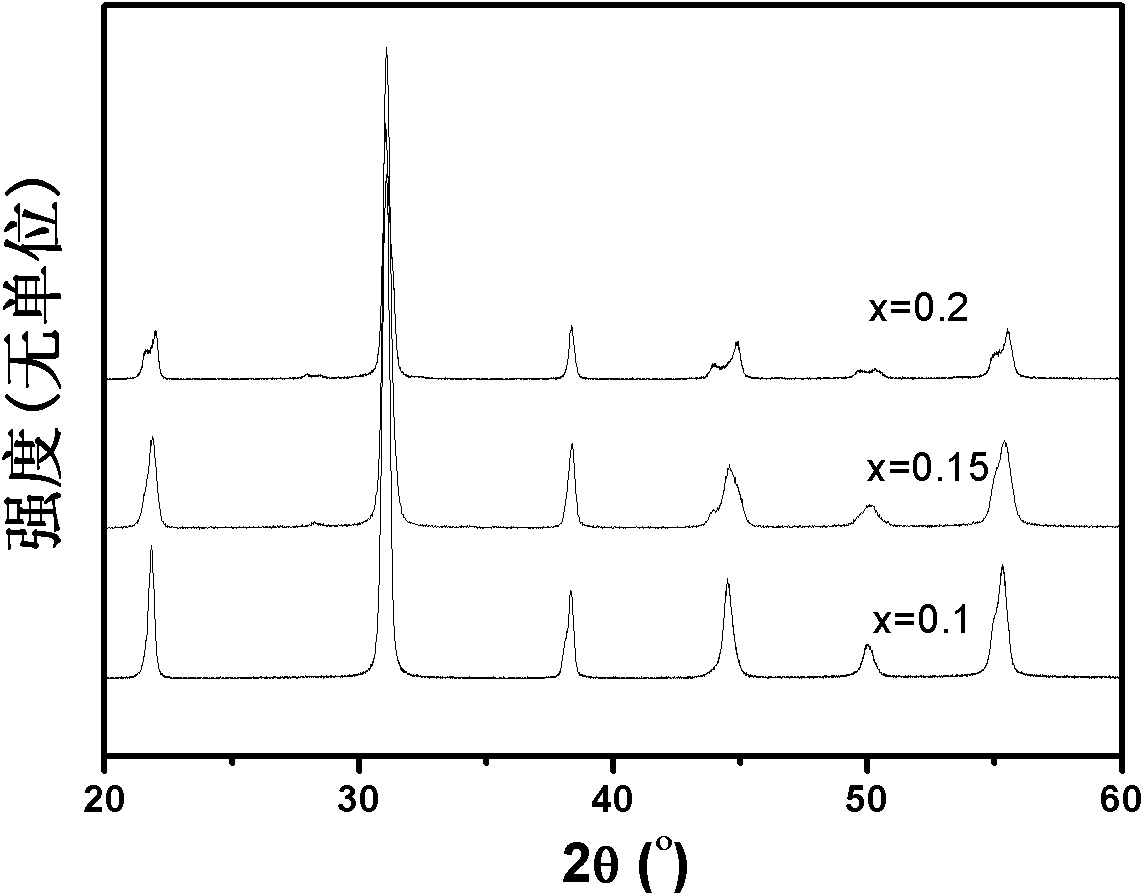

Titanium niobic zincic acid bismuth sodium system leadless piezo-electric ceramic and preparation method thereof

InactiveCN101200369AImprove performanceHigh densityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPiezo electric

The invention discloses a triple system (Na,Bi)TiO3-NiO3-ZiO3-based lead-free piezoelectric ceramic material and preparation method, the B digital ion in the (Na0.5Bi0.5)TiO3 of the ABO3 type perovstike structure is replaced partially by composite ion (Zn(one-third)Nb(two-third))4+ and the A digital ion (Na0.5Bi0.5)2+ is replaced by Ba2+ to form lead-free piezoelectric ceramic that can be denoted with the formula ((Na0.5Bi0.5)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b) and ((Na0.5Bi0.5)(1-y)Ba(y)Ti(1-x)(Zn(one-third)Nb(two-third))(x)O3)(+Z)M(a)O(b), wherein M(a)O(b) is one or more oxide. The piezoelectric ceramic adopts two-step synthetic method and is obtained by sintering. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 150pC per N, Kt can reach above 0.50, and Kp can be below 0.20. The lead-free piezoelectric has strong anisotropy, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with high piezoelectric constant and preparation method thereof

The invention relates to niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with a high piezoelectric constant and a preparation method thereof, which belong to the field of environmental coordinative piezoelectric ceramic of perovskite structures. The leadless piezoelectric ceramic with a general formula of (1-x) (K1-yNay) (Nb1-zSbz) O3 + xBi0.5 (Na1-uKu) 0.5ZrO3 is prepared by a traditional solid state sintering method, wherein in the formula, x is not smaller than 0 while not larger than 0.05, y is not smaller than 0.40 while not larger than 0.68, z is not smaller than 0.02 while not larger than 0.06, and u is not smaller than 0 while not larger than 1; the d33 of the leadless piezoelectric ceramic disclosed by the invention can be as high as 470 pC / N, kp can reach 47%, and Tc is as high as 313 DEG C. Devices prepared by the ceramic can work under high temperatures, so that the ceramic has a practical application value in high-temperature electronic equipment; since the ceramic contains no expensive tantalum element, the price of the used raw materials is low, so that the cost is saved.

Owner:SICHUAN UNIV

Novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate

InactiveCN102051685APolycrystalline material growthFrom melt solutionsCrystal rotationSingle crystal

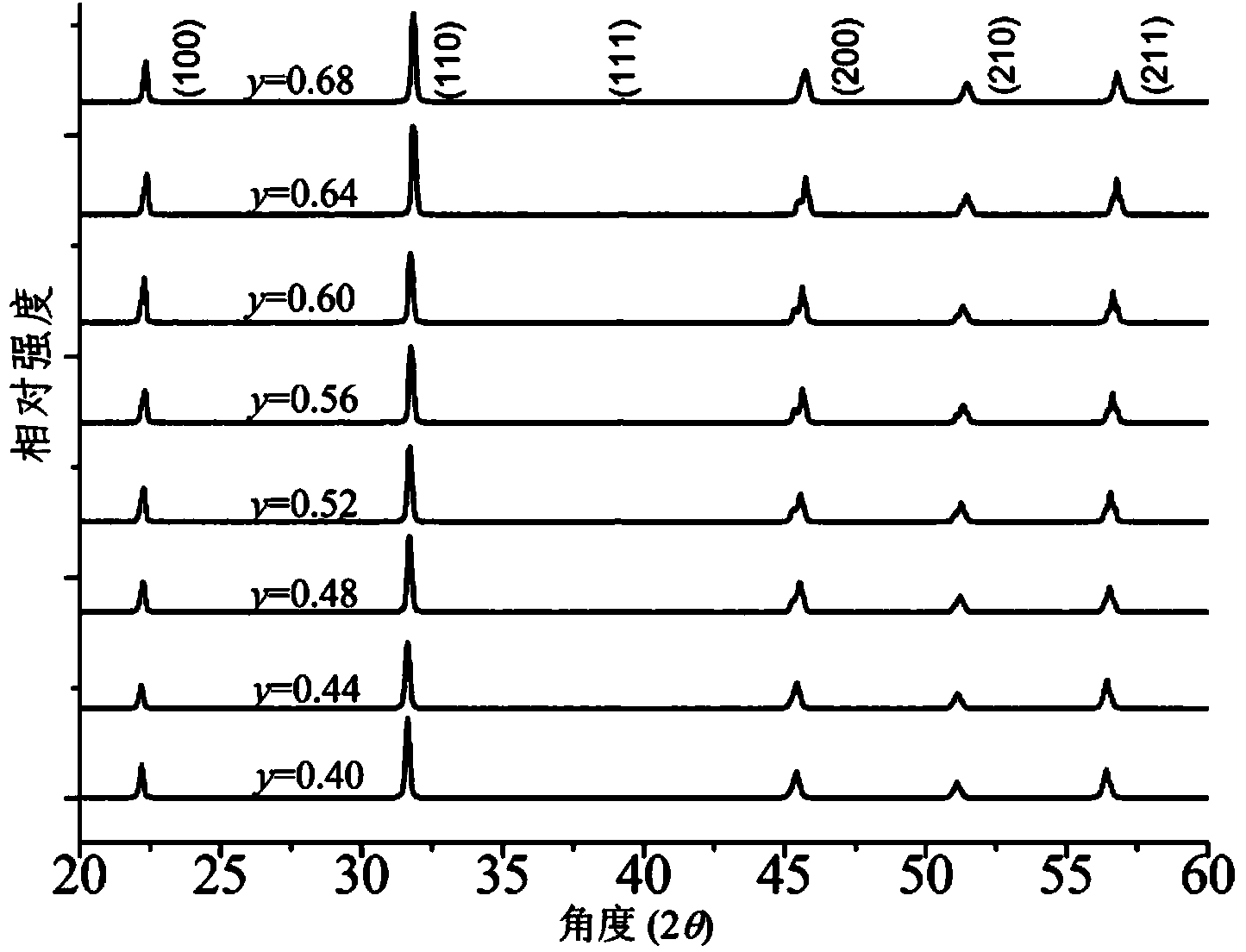

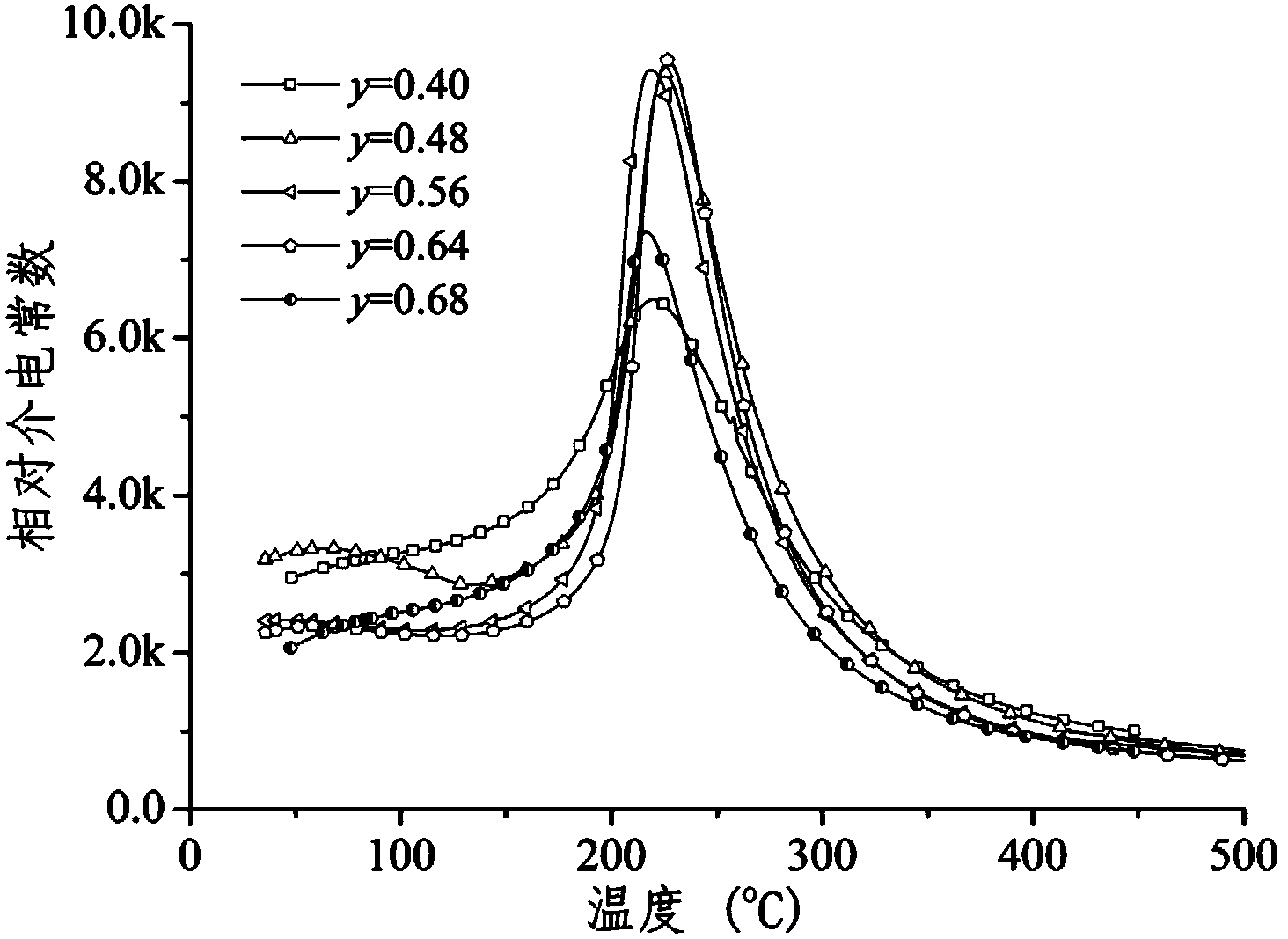

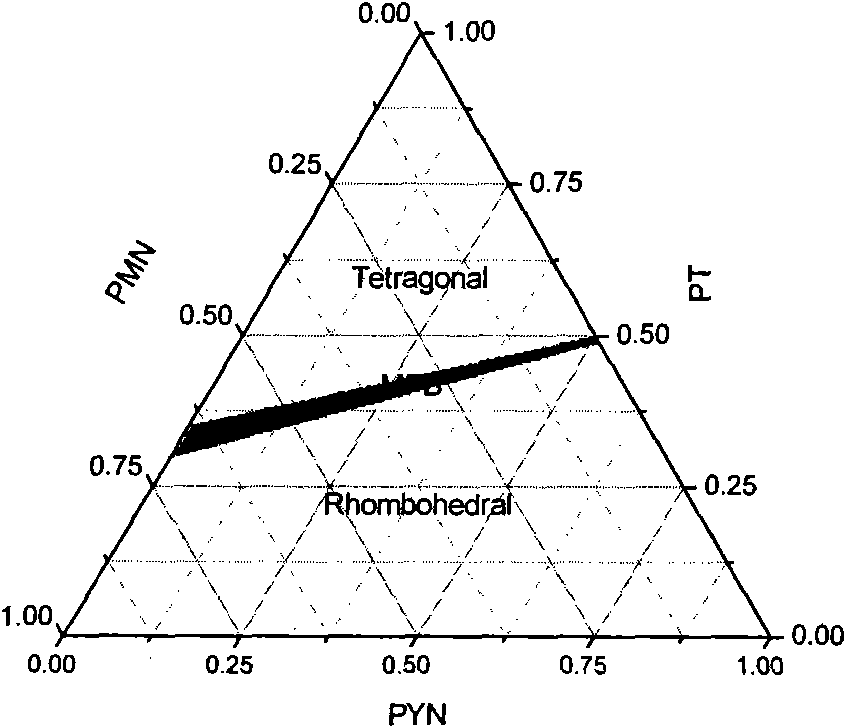

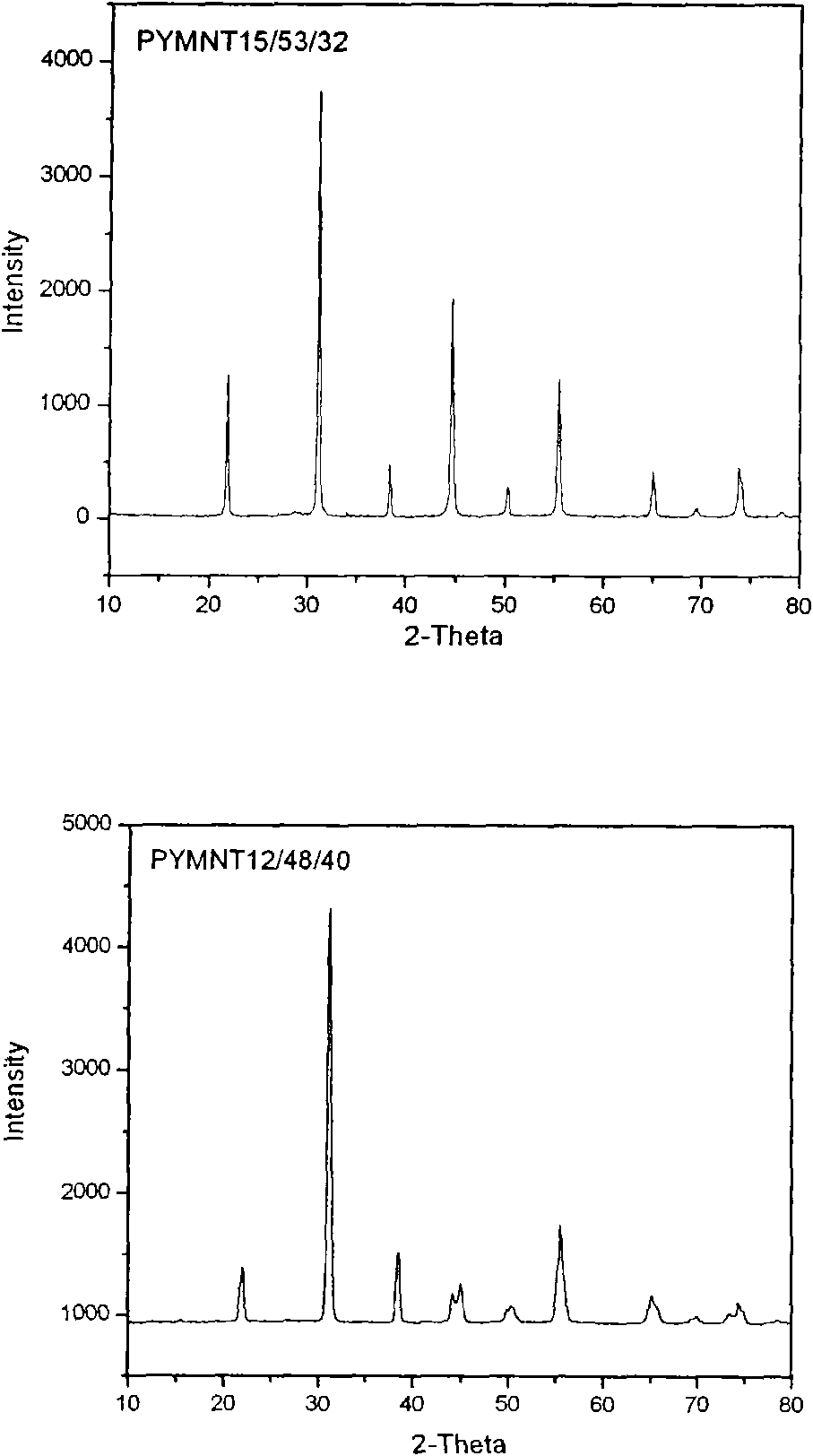

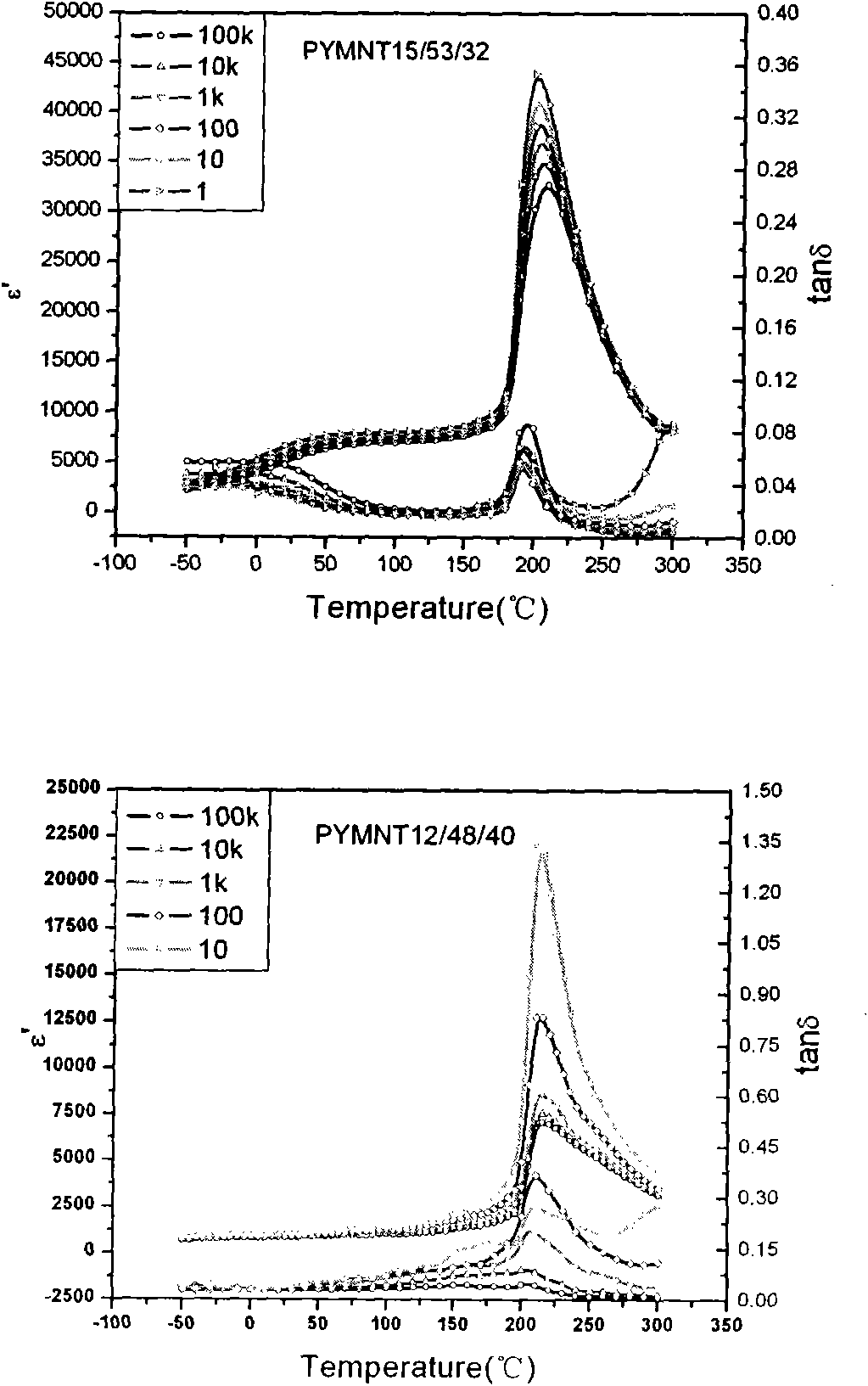

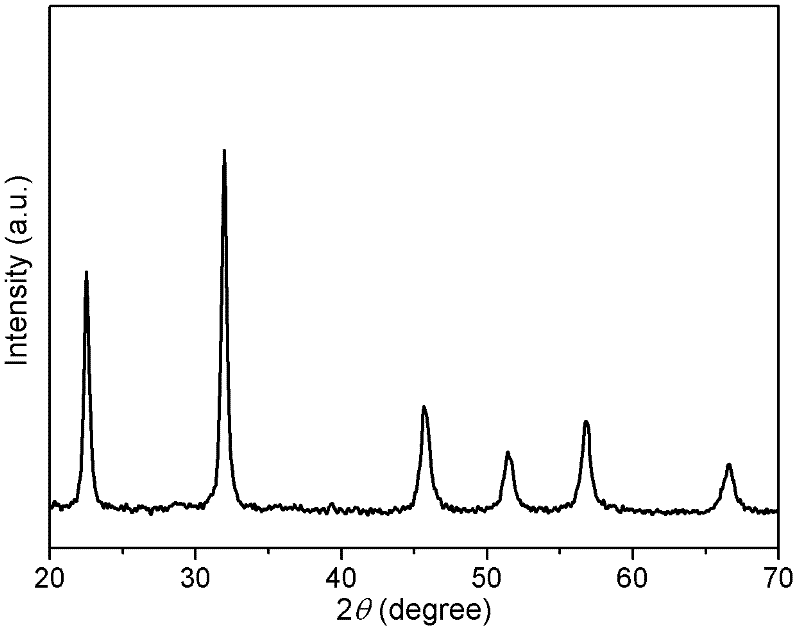

The invention relates to the growth, the structures and the properties of novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate. The crystal belongs to a perovskite structure, has an MPB region and has a chemical formula of (1-x-y)Pb(Yb1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3 which is short for PYMNT or PYN-PMN-PT. By adopting a top crystal-seeded method, the crystal with large size and high quality can grow under the conditions that the growth temperature of the crystal is 950-1100 DEG C, the crystal rotation speed is 5-30rpm, and the cooling speed is 0.2-5 DEG C / day, and the grown crystal exposes a 001 natural growth surface. Through X-ray powder diffraction, the system is confirmed as the perovskite structure; and through ferroelectric, dielectric and piezoelectric measurement, the ferroelectricity, the dielectric property and the piezoelectricity of the crystal are analyzed. The crystal has high Curie temperature and trigonal-tetragonal phase transition temperature, large piezoelectric constant and electromechanical coupling factor, high dielectric constant and low dielectric loss and better heat stability. The crystal can be widely applied to devices in the piezoelectric fields of ultrasonically medical imaging, sonar probes, actuators, ultrasonic motors, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

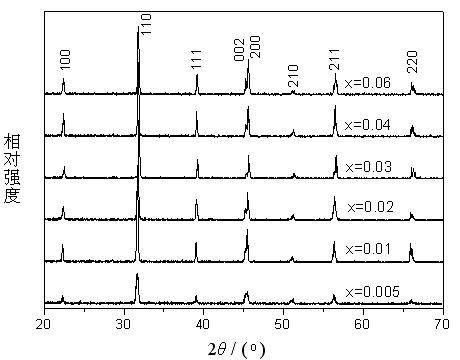

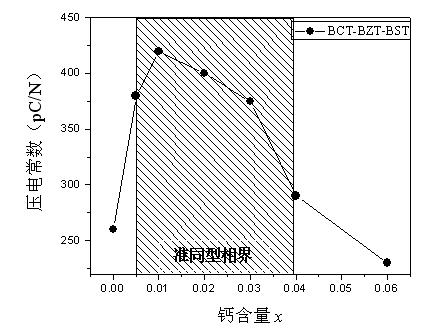

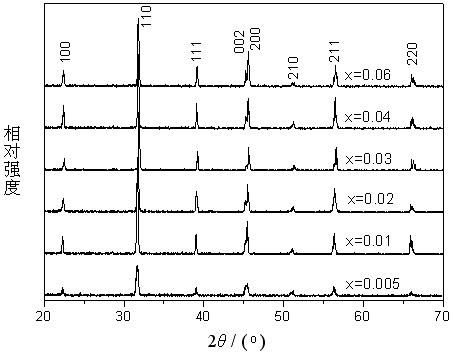

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

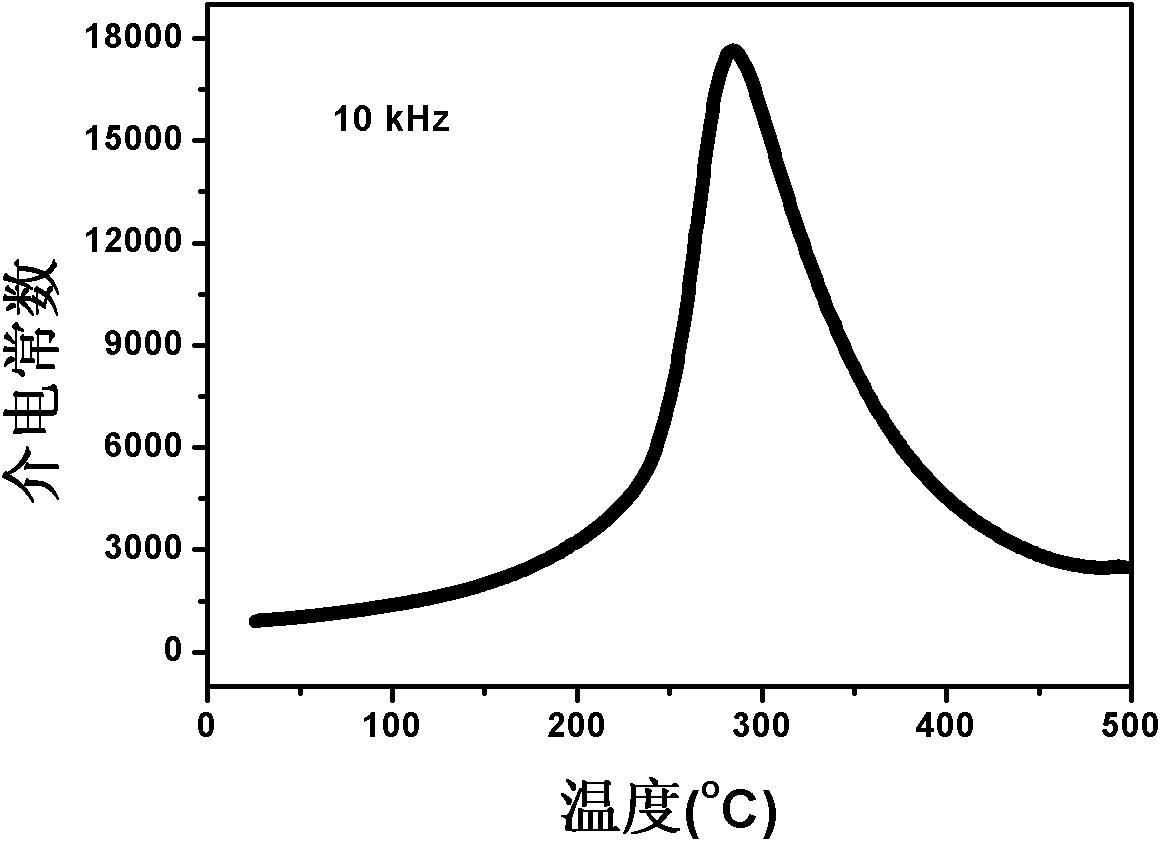

Bismuth ferrite-based leadless piezoelectric ceramic with high Curie temperature and preparation method thereof

The invention discloses a bismuth ferrite-based leadless piezoelectric ceramic with high Curie temperature and a preparation method thereof. The general formula for the piezoelectric ceramic is (1-x-y)(BizM1-z)t(FeuM'1-u)O3-xBaTiO3-yBiMnO3, wherein, M is a trivalent metallic element with large ionic radius, M' is a trivalent metallic element with small ionic radius, and x, y, u, t and z represent mole content in a ceramic system and satisfy the following relations: 0<=x<=1.0, 0<=y<=0.1, 0<z<1, 0.85<t<1.2, 0<u<1 and x+y<1. The piezoelectric ceramic is prepared by a conventional ceramic preparation method through selection of proper technological parameters. The piezoelectric constant d33 of the ceramic can reach 140 pC / N, Curie temperature can reach 490 DEG C, and Kt is more than 0.50. The preparation method has the advantages of a simple and stable process, and obtained leadless piezoelectric ceramic has excellent performance and is suitable for being used under high temperature.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Piezoelectric ceramic, piezoelectric element, ultrasonic motor, and dust removing device

ActiveUS20130278681A1High and stable constantHigh and stable mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDust controlOperating temperature

There is provided a lead-free piezoelectric ceramic having a high and stable piezoelectric constant and a high and stable mechanical quality factor in a wide operating temperature range. A method for manufacturing the lead-free piezoelectric ceramic is also provided. the general formula (1)(Ba1-xCax)a(Ti1-y-zSnyZrz)O3 (0.08≦x≦0.20, 0.01≦y≦0.04, 0≦z≦0.04) (1)A piezoelectric ceramic includes a main component containing a perovskite type metal oxide having the following general formula (1); and Mn as a first auxiliary component. The amount b (mol) of Mn per mole of the metal oxide is in the range of 0.0048≦b≦0.0400, and the value a of the general formula (1) or (2) is in the range of 0.9925+b≦a≦1.0025+b.

Owner:CANON KK

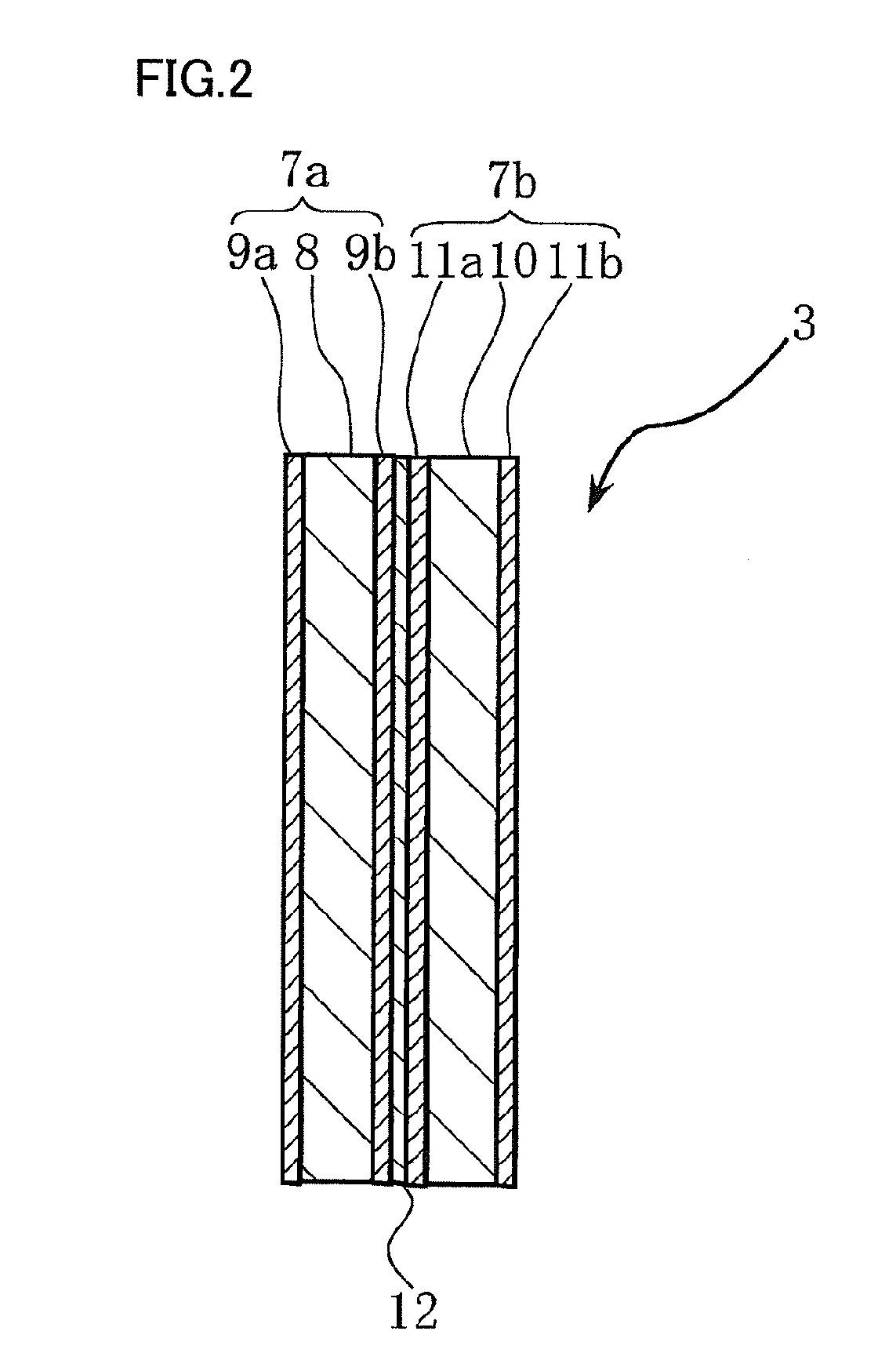

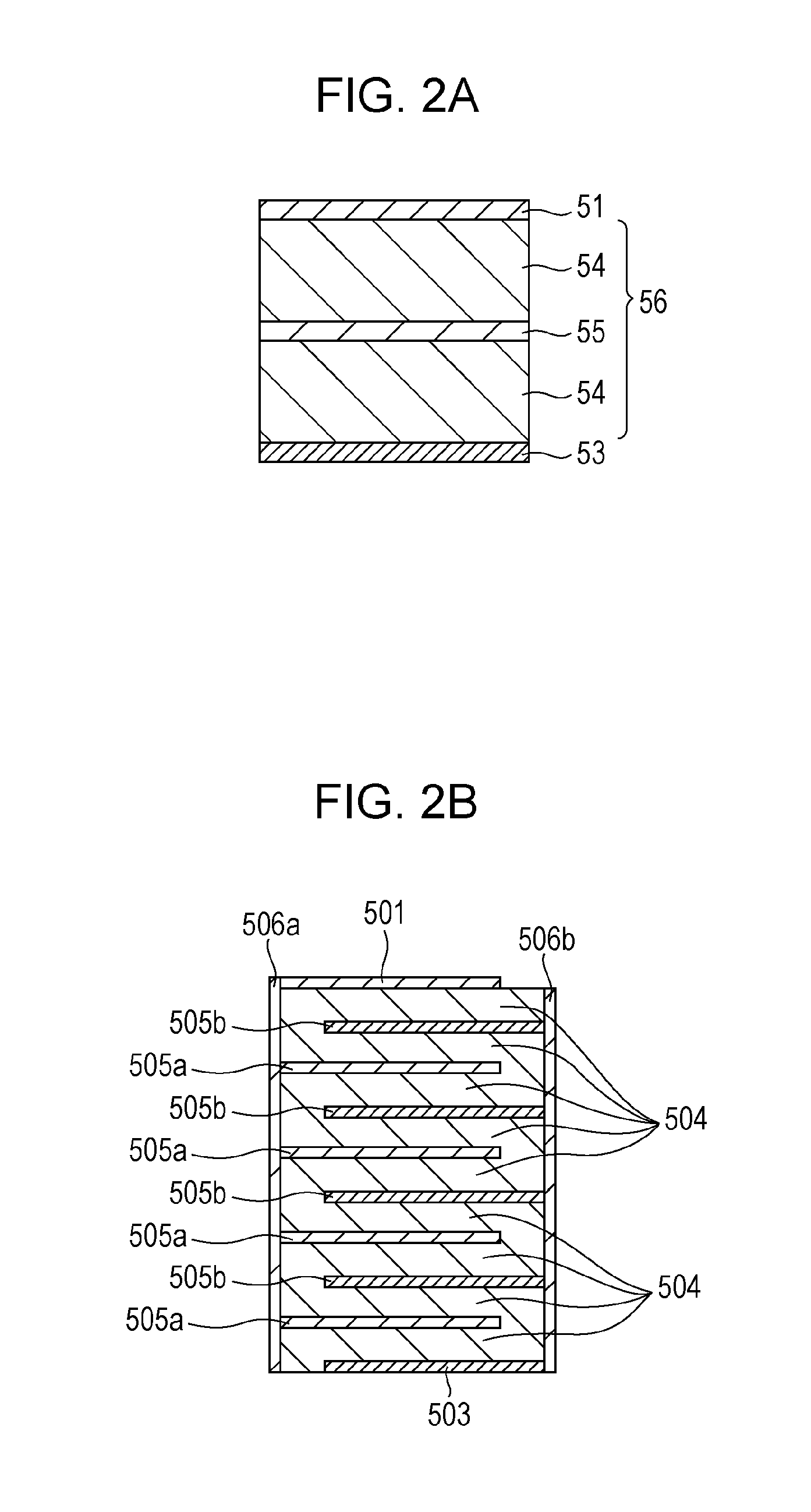

Acoustic wave device

ActiveUS20120104900A1Constant gainPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveAcoustics

An acoustic wave device includes: a first piezoelectric thin film resonator including a first lower electrode, a first upper electrode and a first piezoelectric film sandwiched between the first lower and upper electrodes; a decoupler film provided on the first upper electrode; and a second piezoelectric thin film resonator provided on the decoupler film and including a second lower electrode, a second upper electrode and a second piezoelectric film sandwiched between the second lower and upper electrodes, wherein the first piezoelectric film and the second piezoelectric film comprise aluminum nitride and include an element increasing a piezoelectric constant of the aluminum nitride.

Owner:TAIYO YUDEN KK

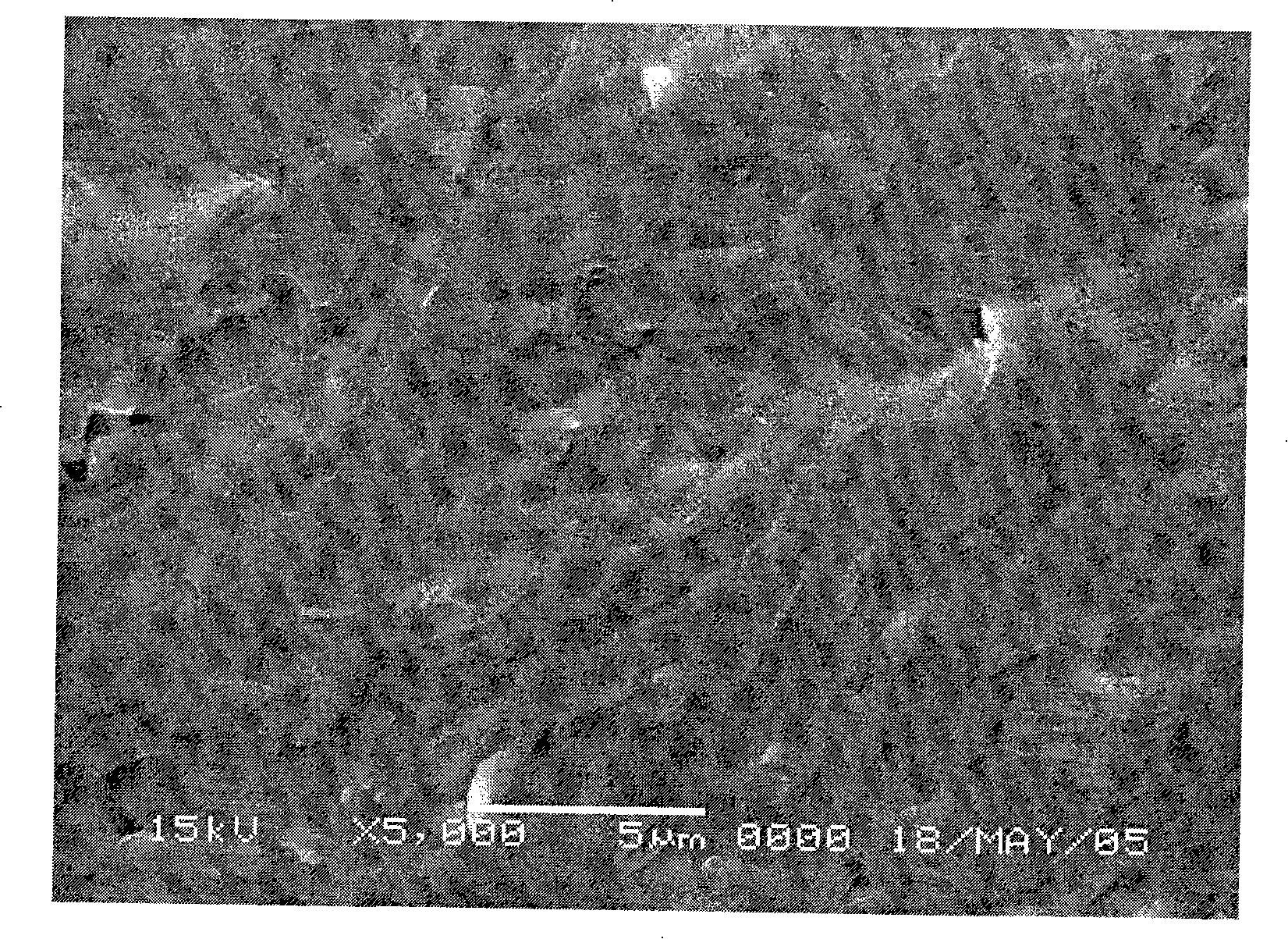

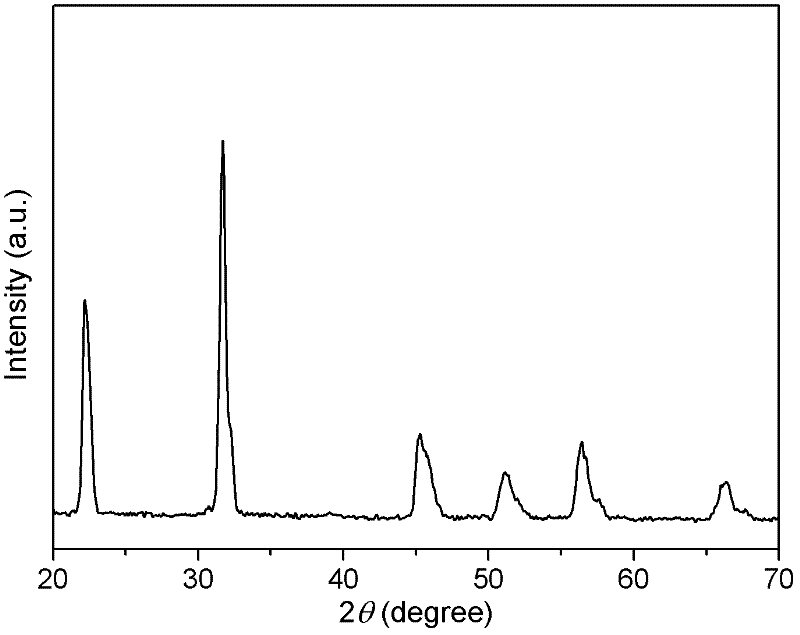

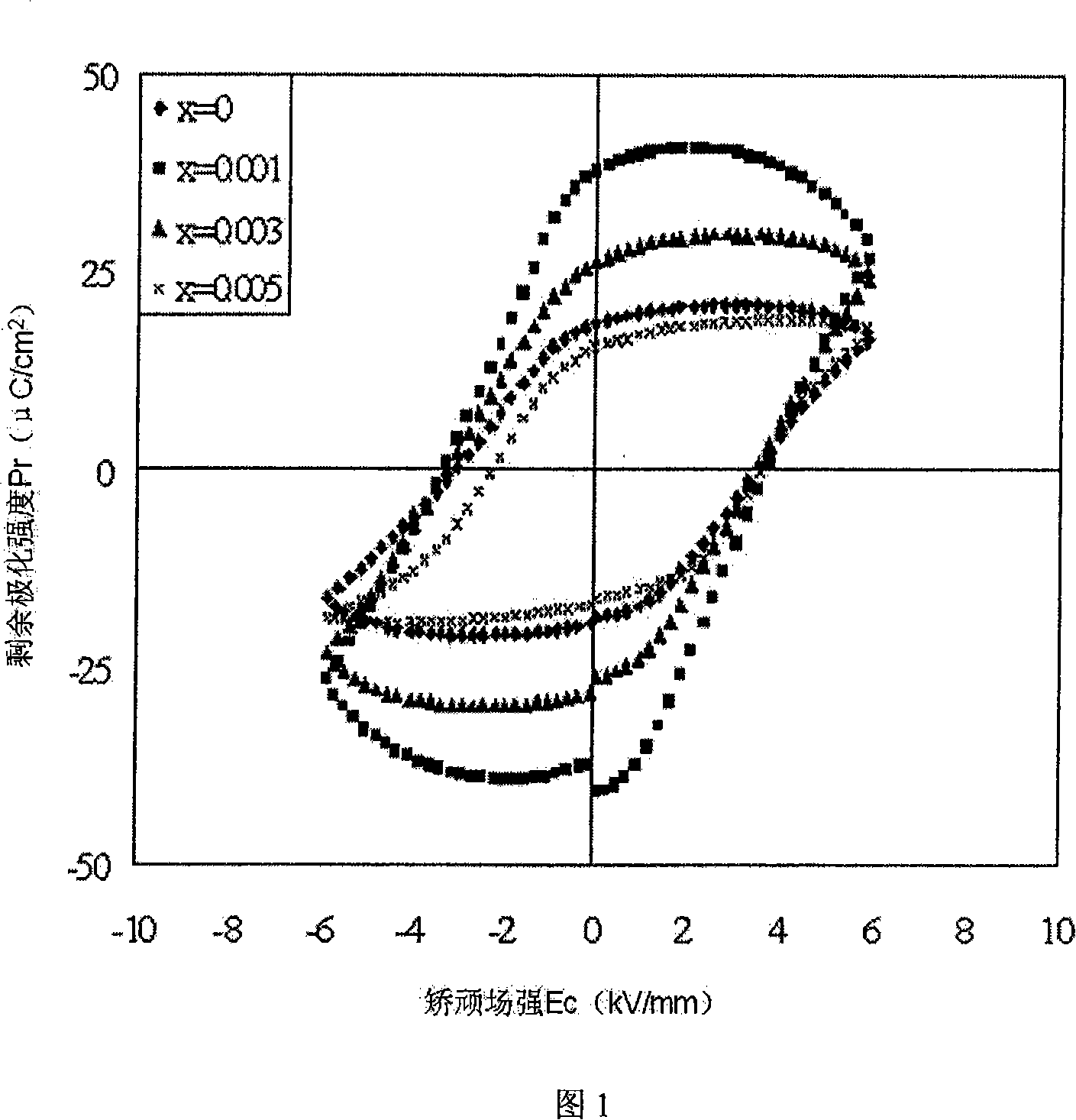

Preparation method of (K05Na05) NbO3 (KNN) lead-free piezoelectric ceramic material

Belonging to the lead-free piezoelectric material field, the invention specifically relates to a preparation method of KNN lead-free piezoelectric ceramic material via high-energy ball milling. With Na2CO3, K2CO3 and Nb2O5 as the raw materials, the method comprises the steps of: weighing raw material mass according to the chemical formula (KxNa1-x) NbO3 (x=0.42-0.58), mixing the raw materials uniformly and putting them in a high energy bowl mill for ball milling at a rotating speed of 200r / min for 8-32h, thus obtaining submicron powder of high activity, then synthesizing the powder at a low temperature and carrying out the second ball milling, and conducting dry-pressing and molding as well as sintering, thus obtaining the ceramic material. The preparation method of the invention substantially reduces the synthesis temperature of KNN powder in prior art, and improves sinterability of KNN ceramic material, as well as promotes the ferroelectric and piezoelectric performance improvement thereof, with the remanent polarization Pr and the piezoelectric constant d33 both enhanced by about 10% compared with traditional preparation technologies.

Owner:TONGJI UNIV

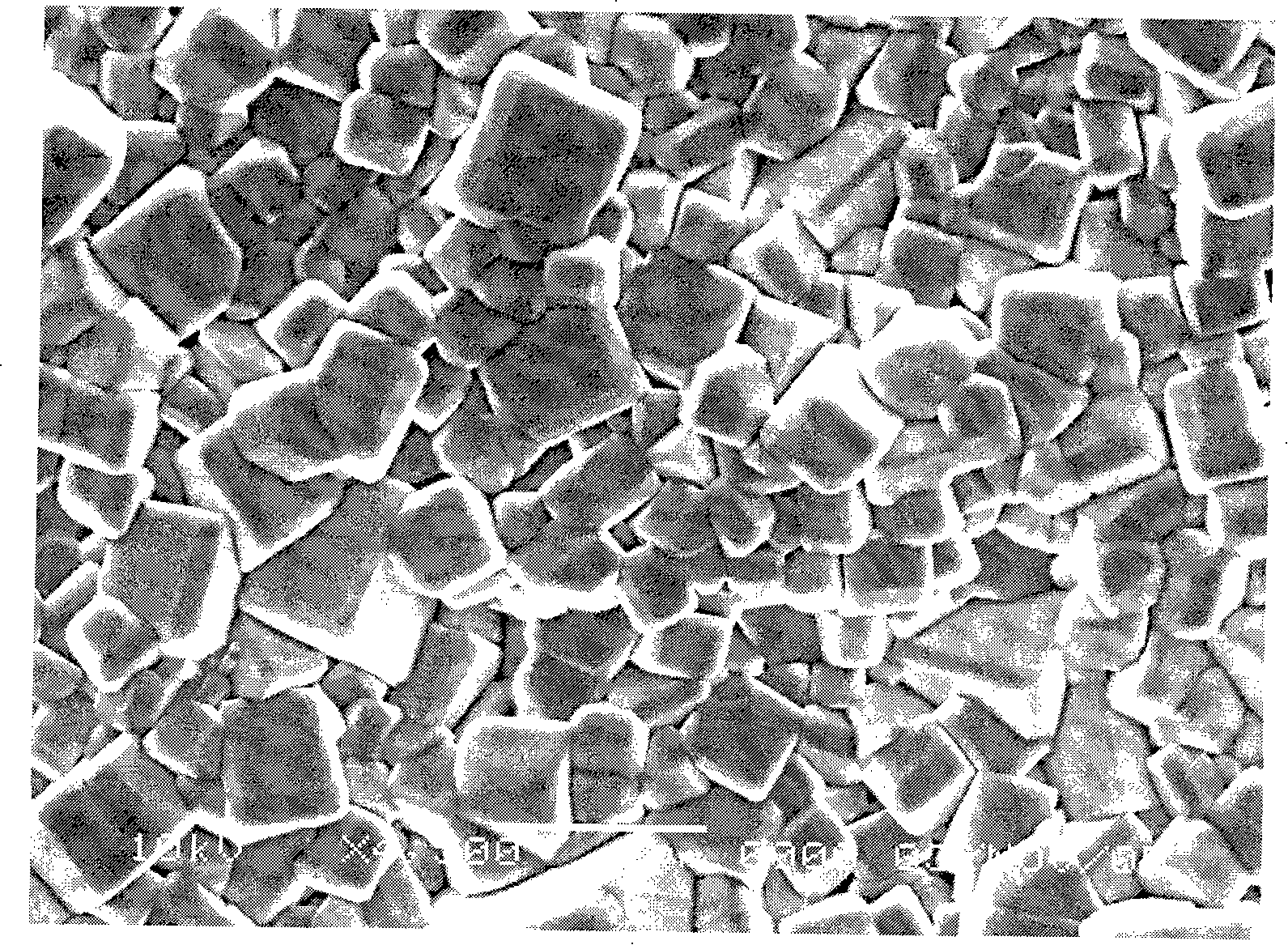

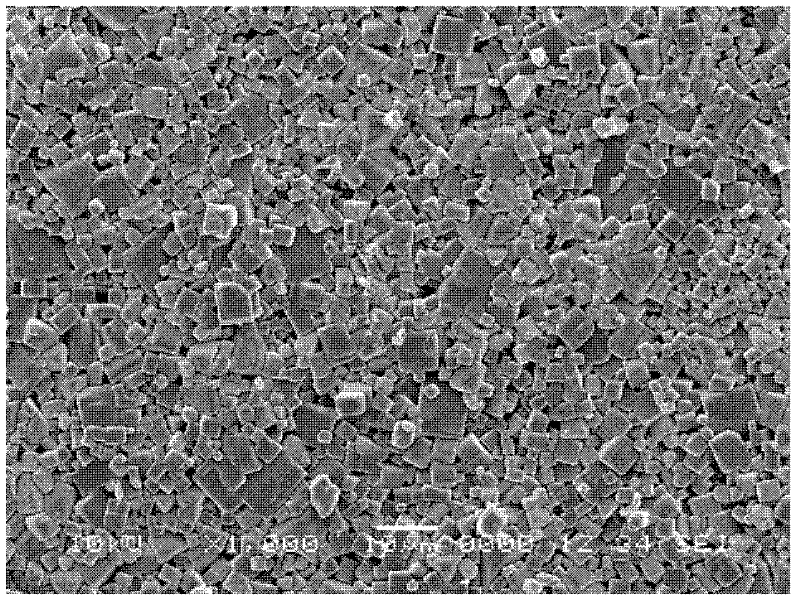

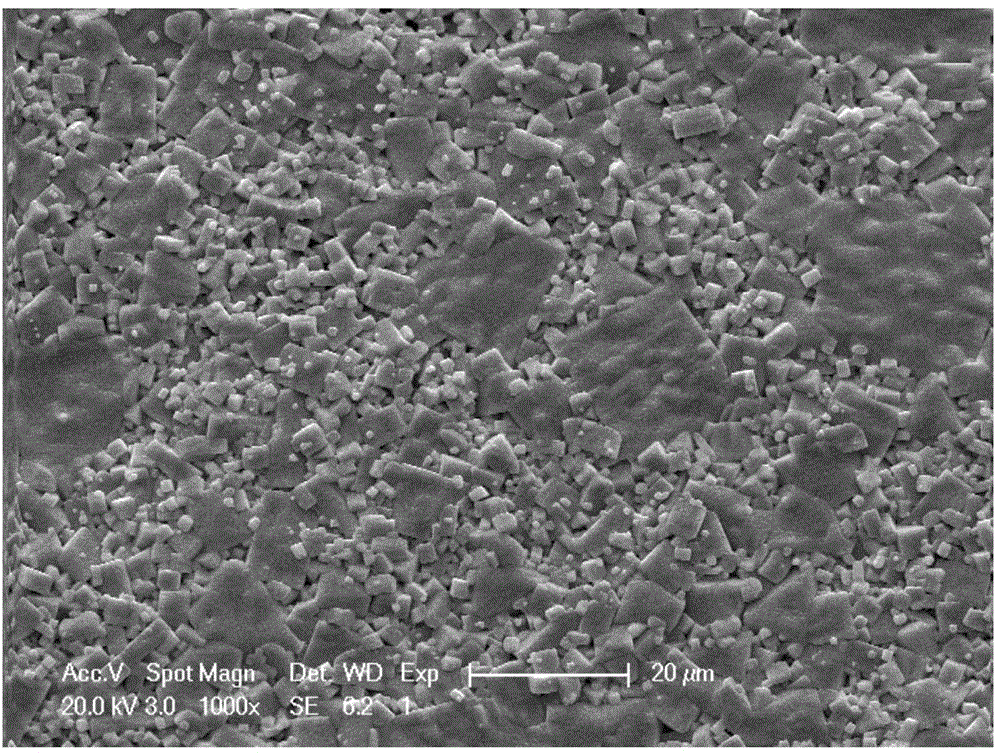

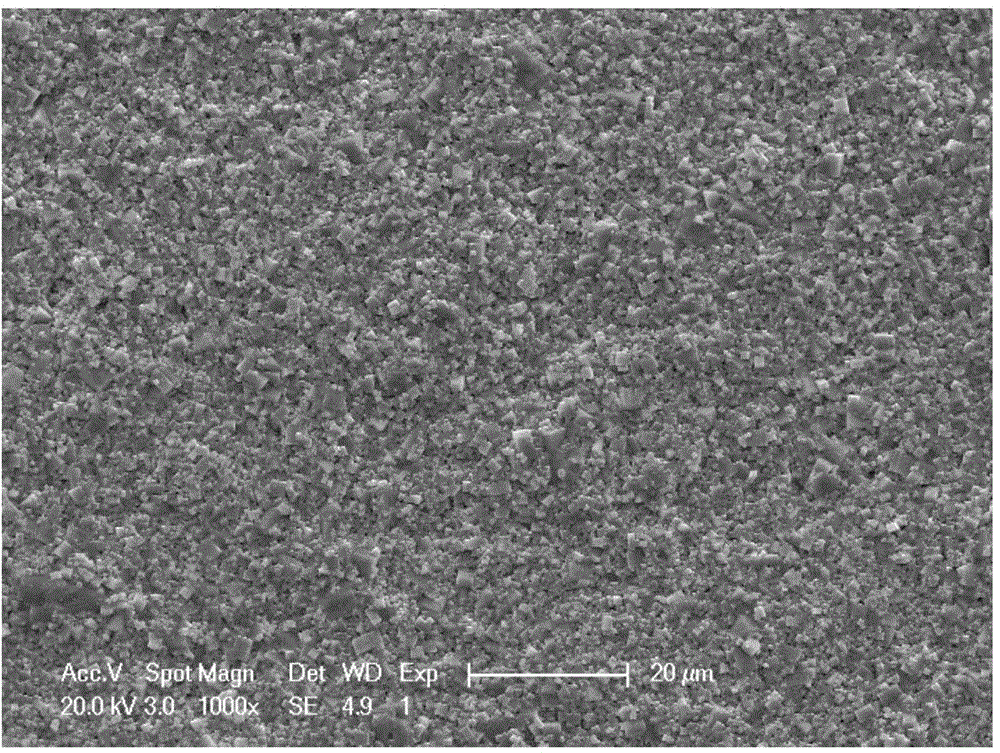

Barium titanate based piezoelectric ceramic materials as well as preparation method and uses thereof

InactiveCN101182203AReduce manufacturing costLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesUltrasonic sensorBarium titanate

The invention relates to a titanium acid barium based piezoelectric ceramic material which uses titanium dioxide and barium carbonate as initial raw materials to produce tetragonal barium carbonate based powder through milling and pre-sintering solid phase reaction. The particle average size of the powder is at submicron grade, and the crystal structure of the powder is tetragonal. Then the titanium acid barium based piezoelectric ceramic material is produced, which is provided with a microstructure, the average size of the middle grain particle diameter of which is 0.2-7.5 Mu m, and the piezoelectric performance index d33 value of which is larger than 225pC / N. the barium titanate based piezoelectric ceramic material of the invention has the characteristics of low production cost, large piezoelectric constant d33 value and high planar electromechanical coupling factor kp value, can be applied to various electronic components and devices of sensors, drivers, ultrasonic transducers, resonators, filters, buzzers, electronic igniters, etc. and can be used as lead-free piezoelectric ceramic to substitute lead bearing PZT piezoelectric ceramic material which is widely applied currently.

Owner:SHANDONG UNIV

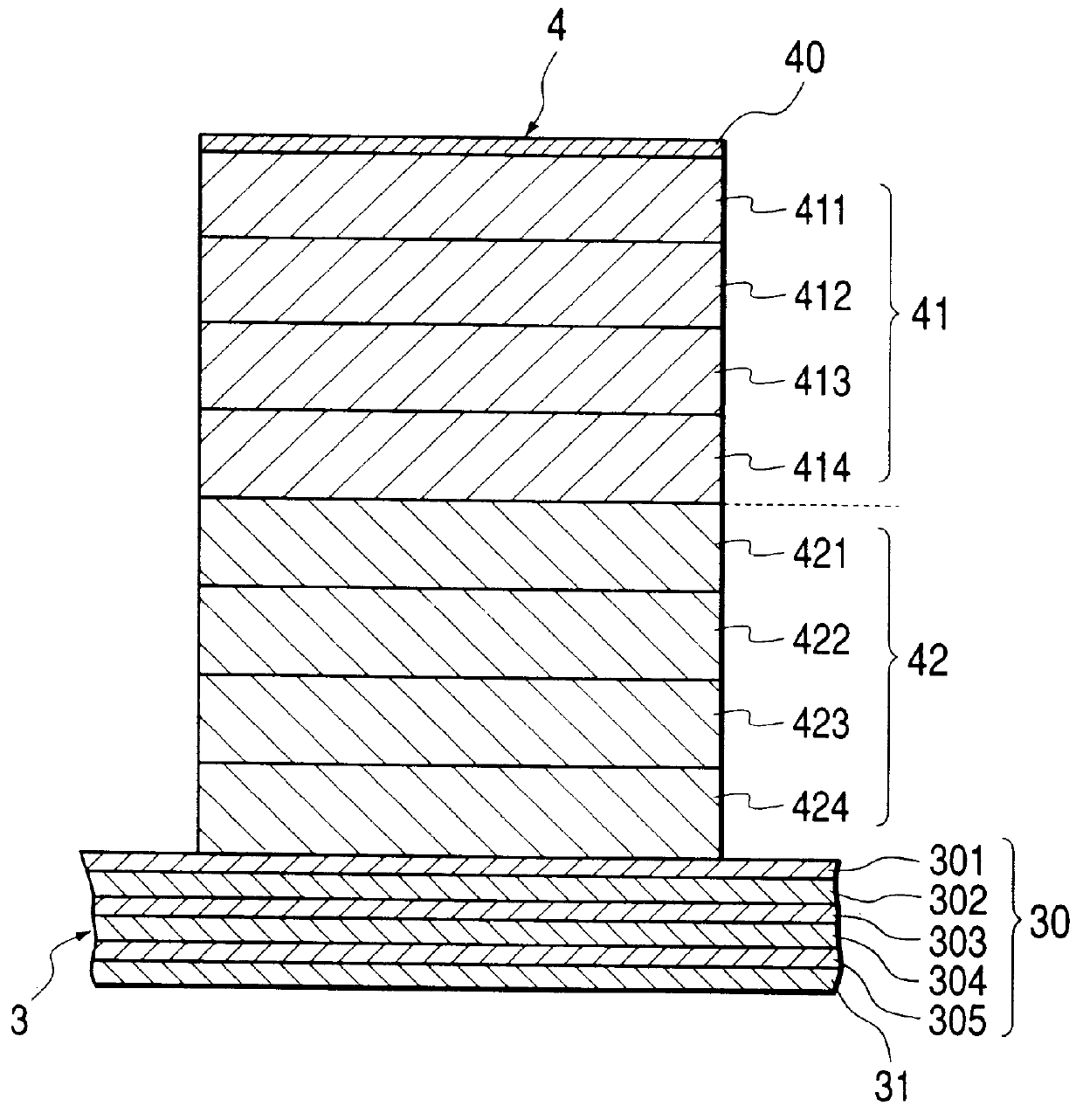

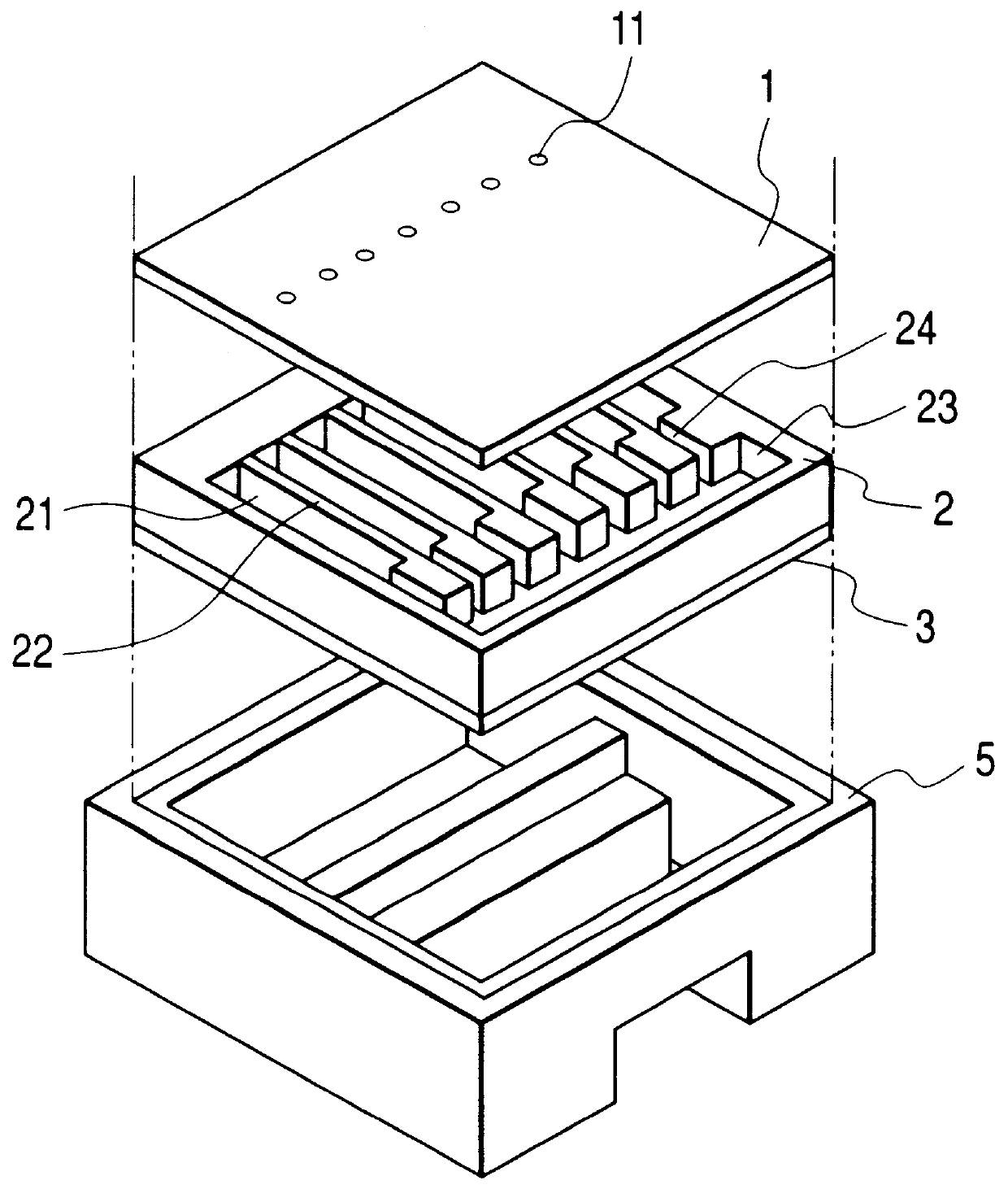

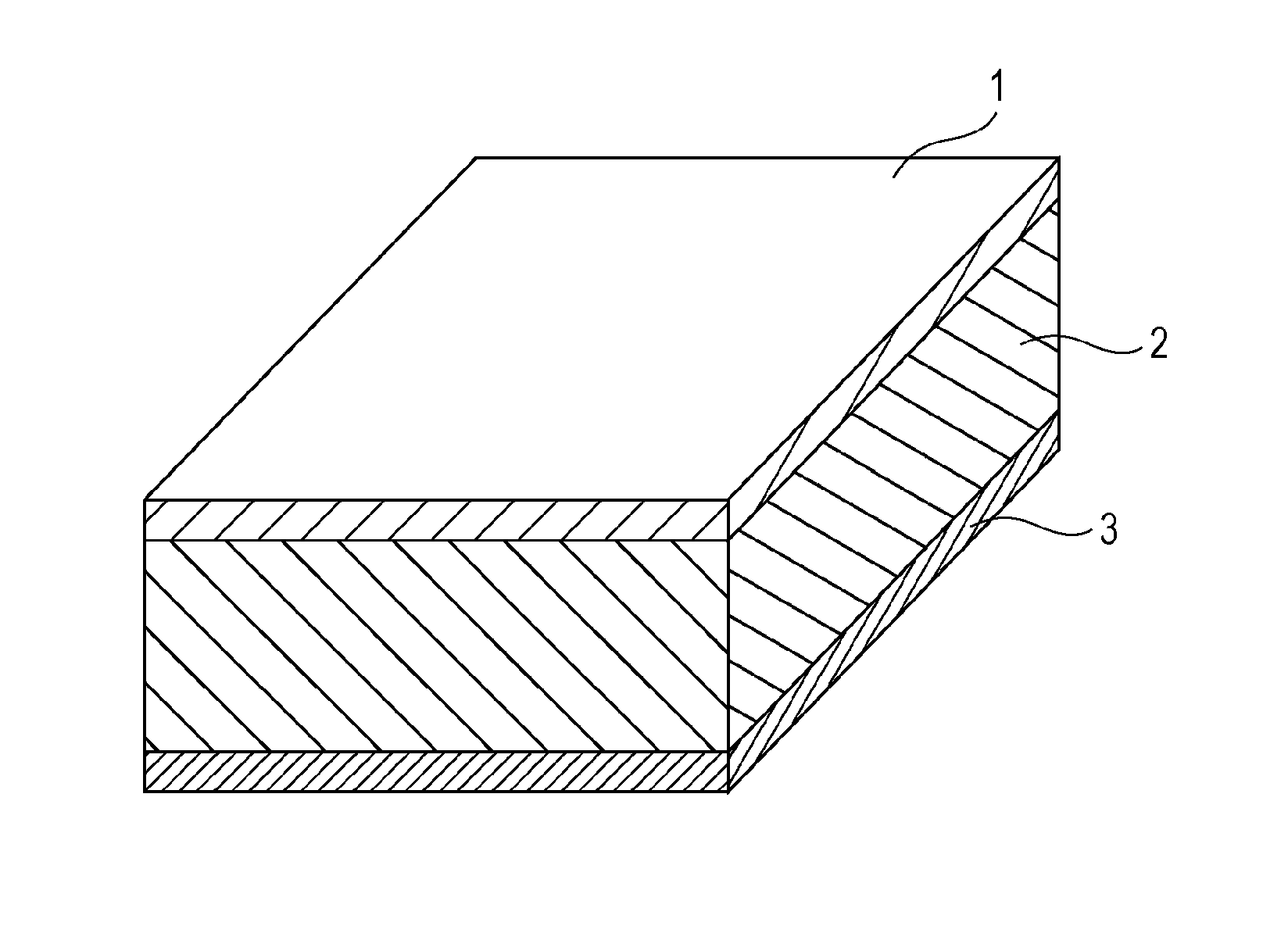

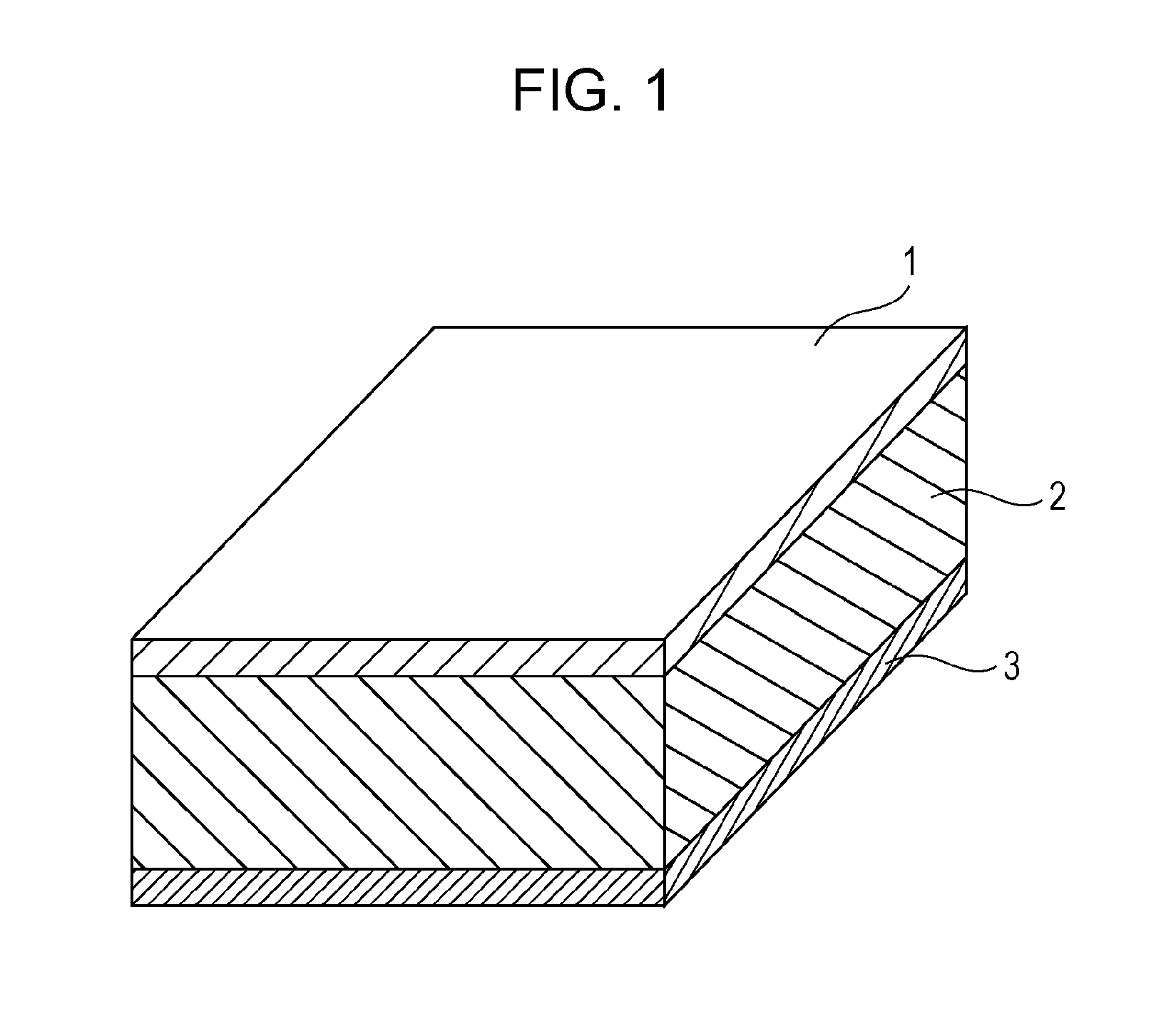

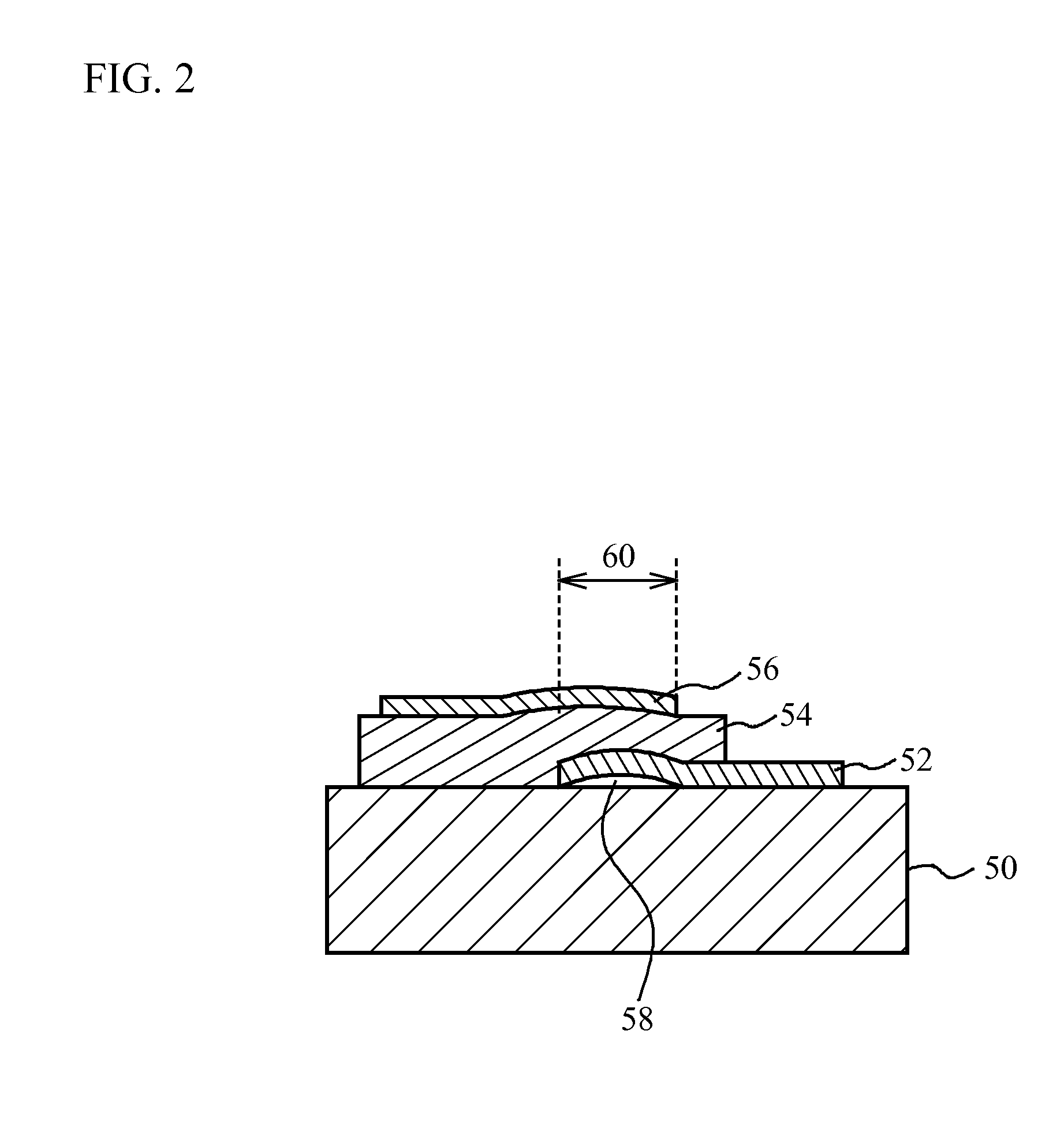

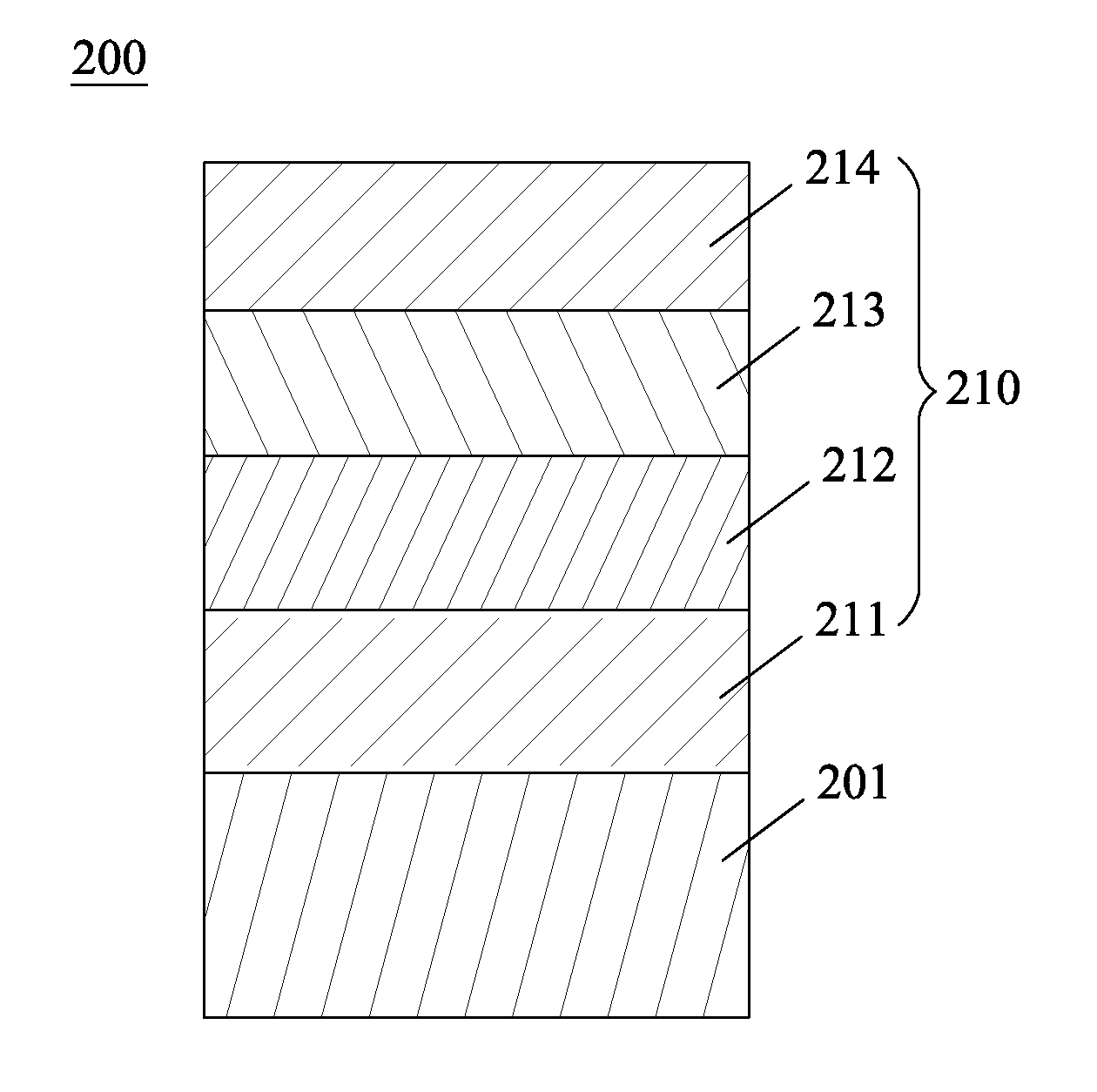

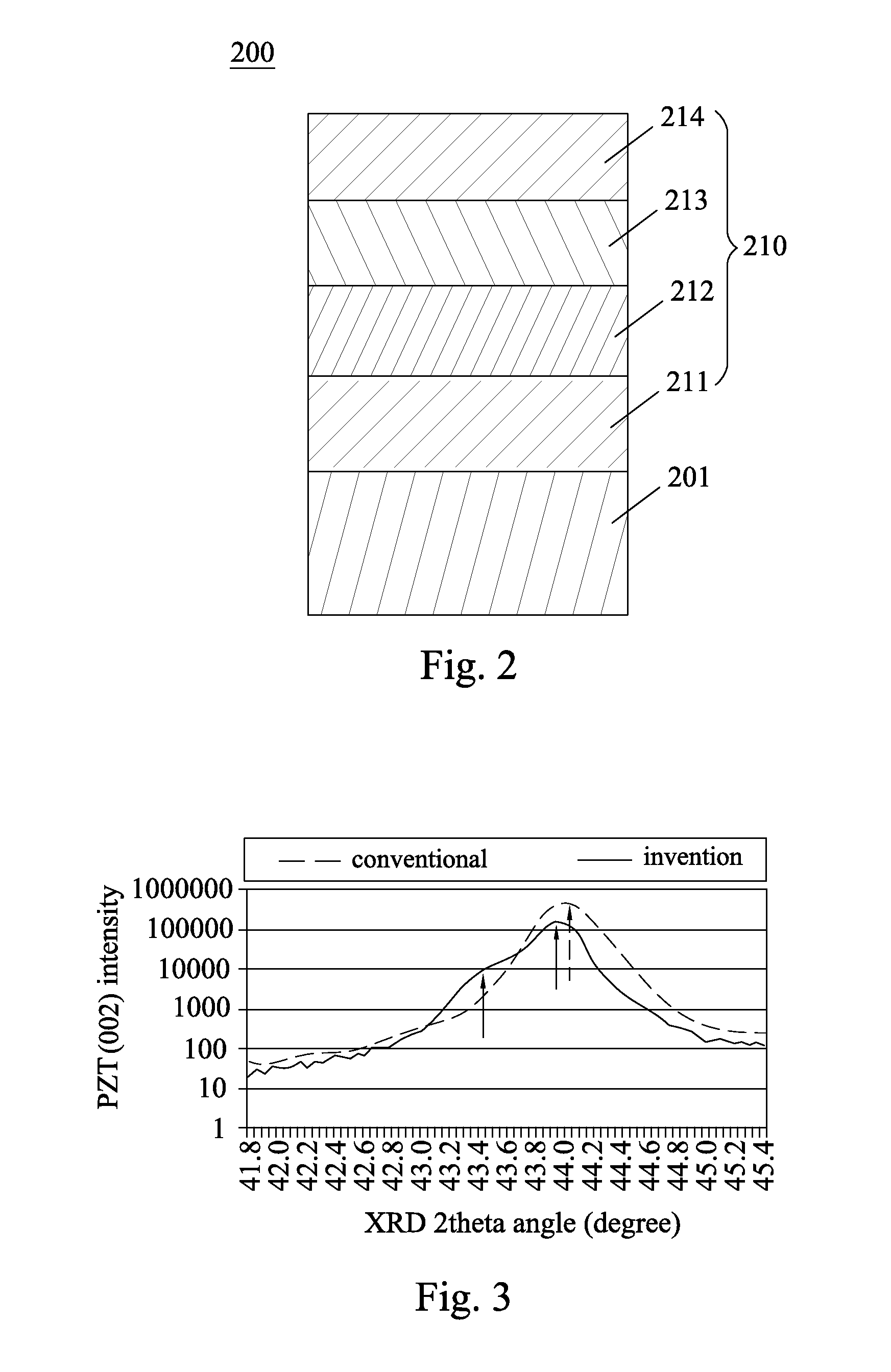

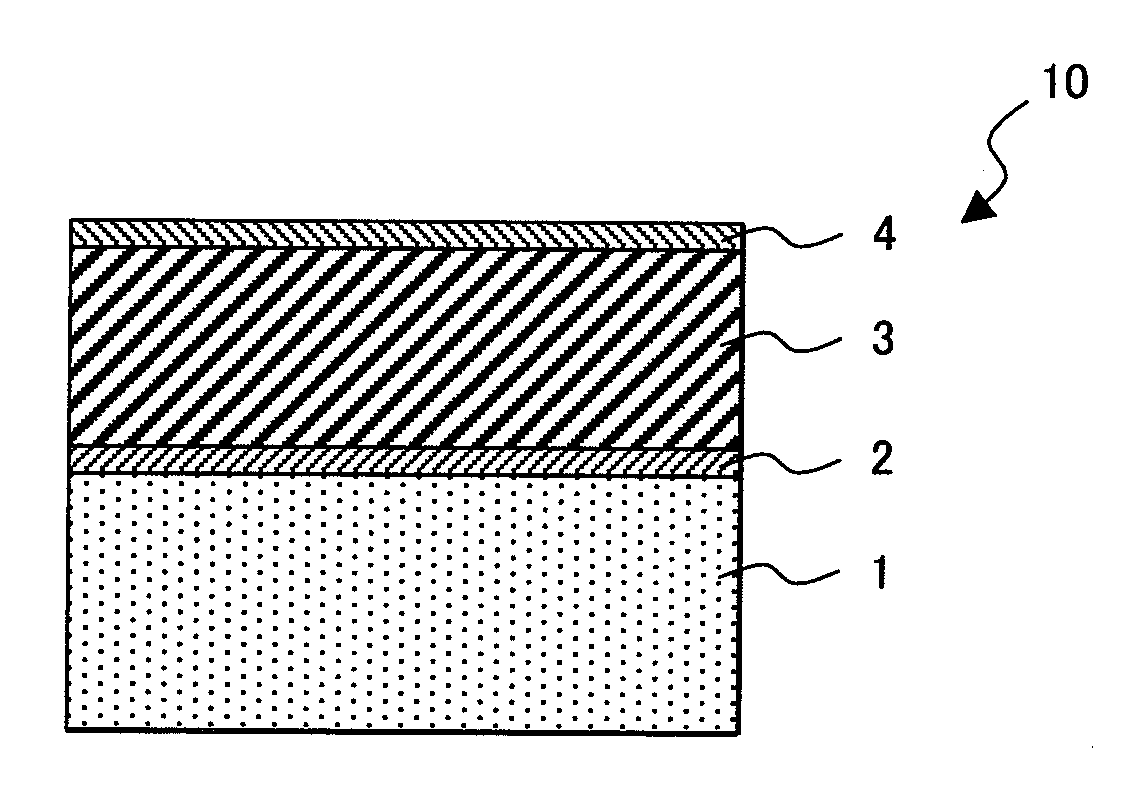

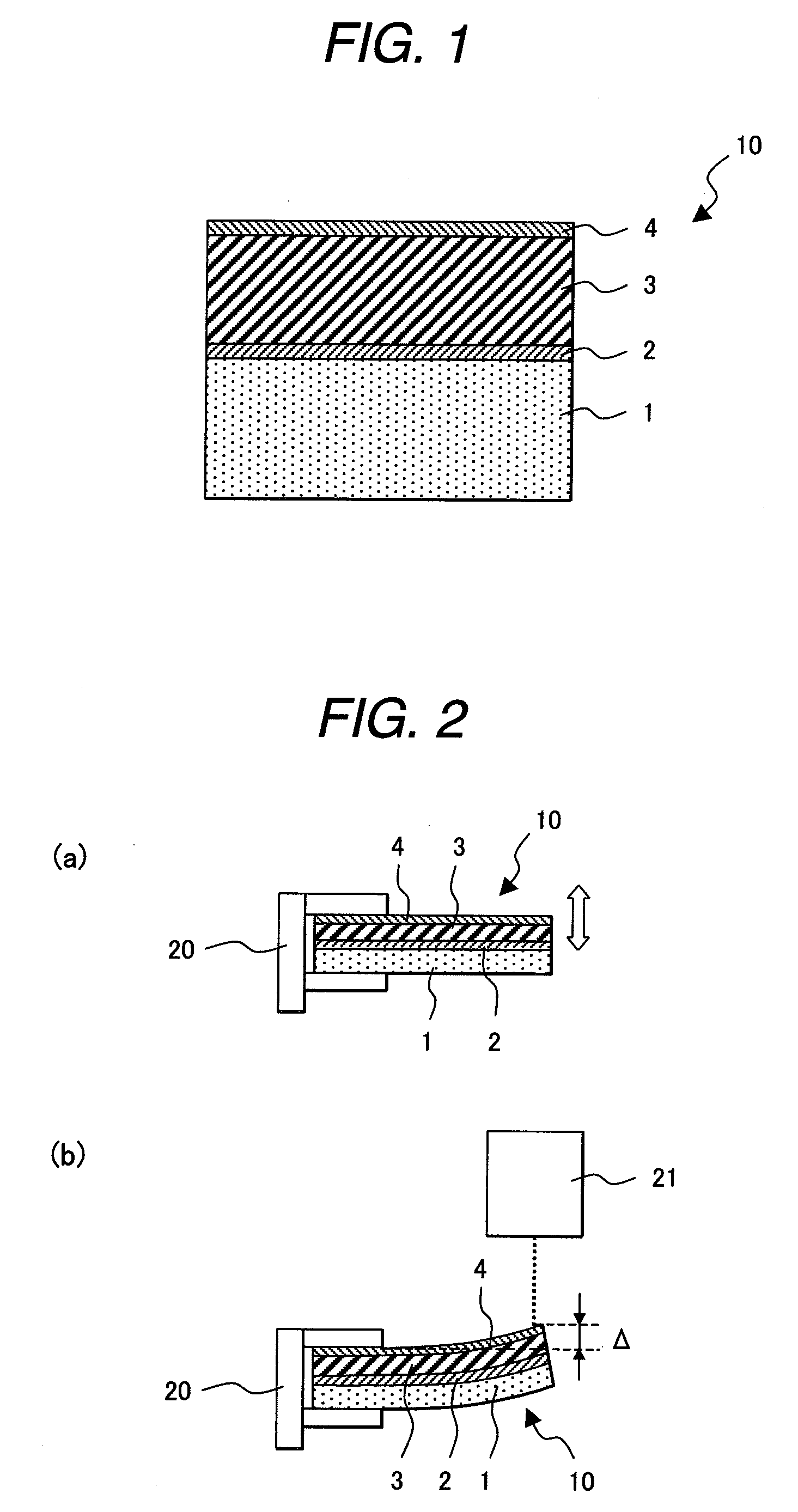

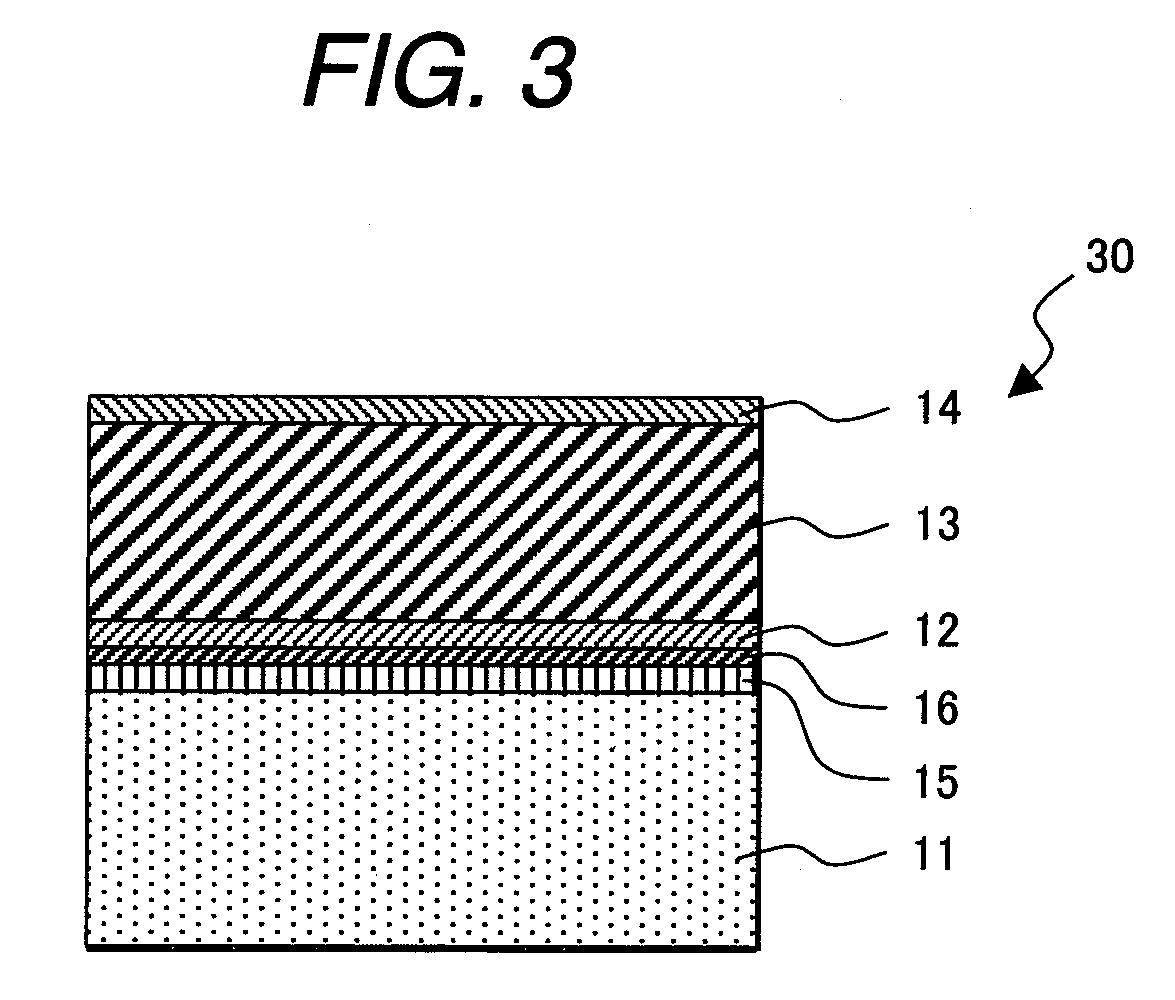

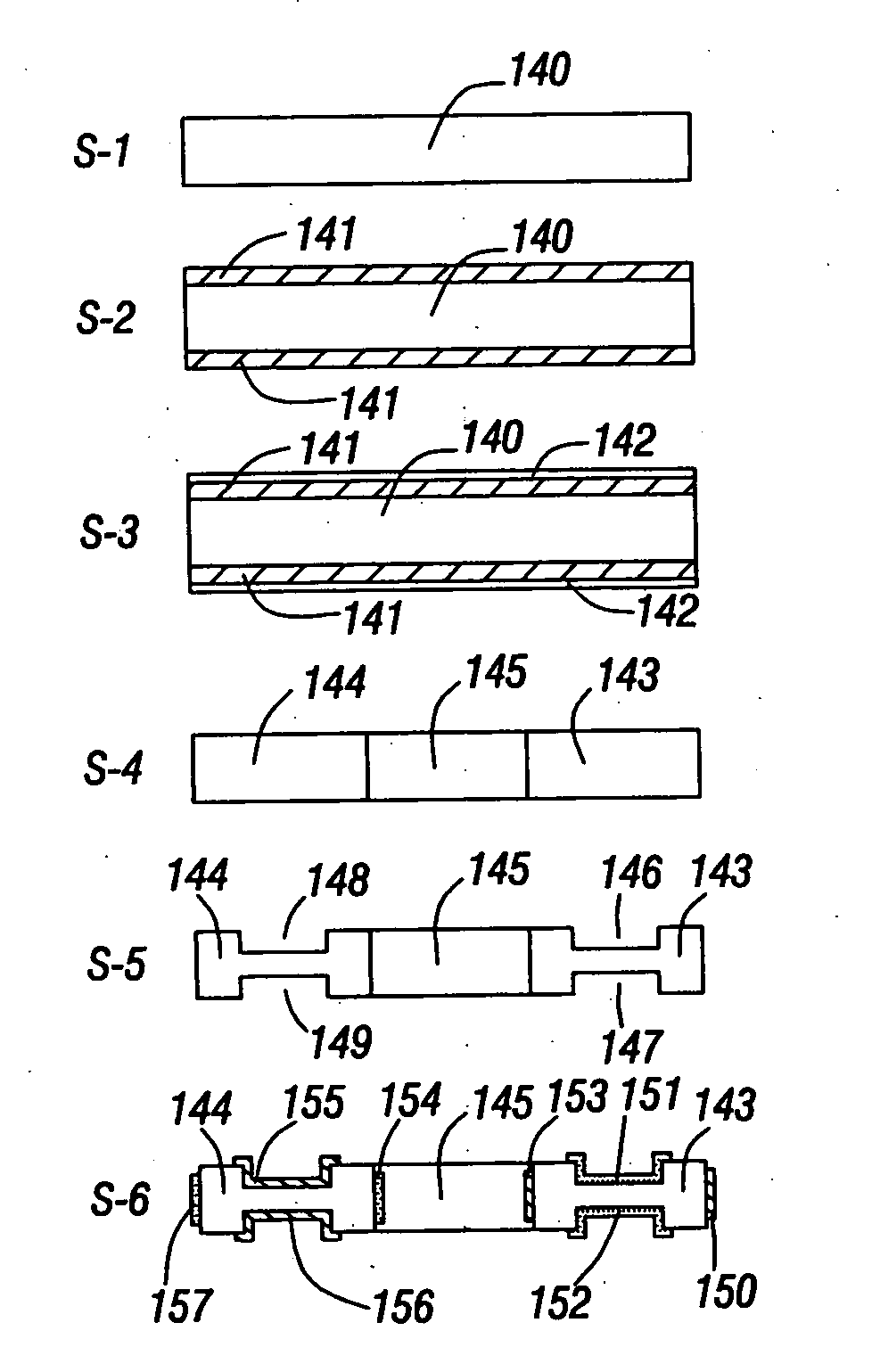

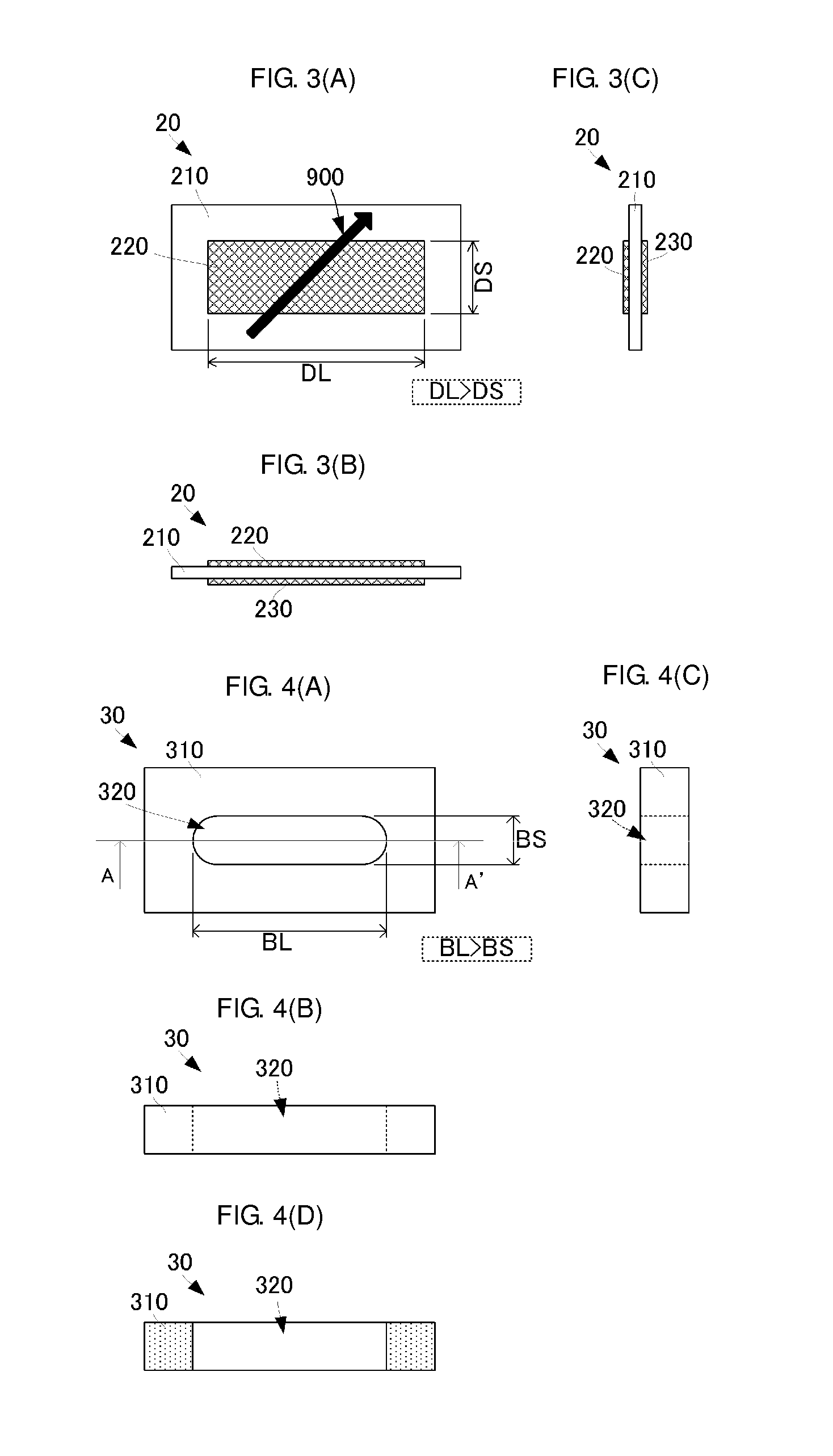

Thin film piezoelectric element and manufacturing method thereof, micro-actuator, head gimbal assembly and disk drive unit with the same

ActiveUS20130279042A1High constantHigh strengthPiezoelectric/electrostriction/magnetostriction machinesRecord information storageThin membraneActuator

A thin film piezoelectric element of the present invention includes a substrate and a piezoelectric thin film stack formed on the substrate. The piezoelectric thin film stack includes a top electrode layer, a bottom electrode layer and a piezoelectric layer sandwiched between the top electrode layer and the bottom electrode layer, wherein the piezoelectric layer includes a first piezoelectric layer and a second piezoelectric layer whose compositions have different phase structures. The present invention can obtain high piezoelectric constants, enhanced coercive field strength and good thermal stability, thereby enabling larger applied field strength without depolarization and achieving a large stroke for its applied device.

Owner:SAE MAGNETICS (HK) LTD

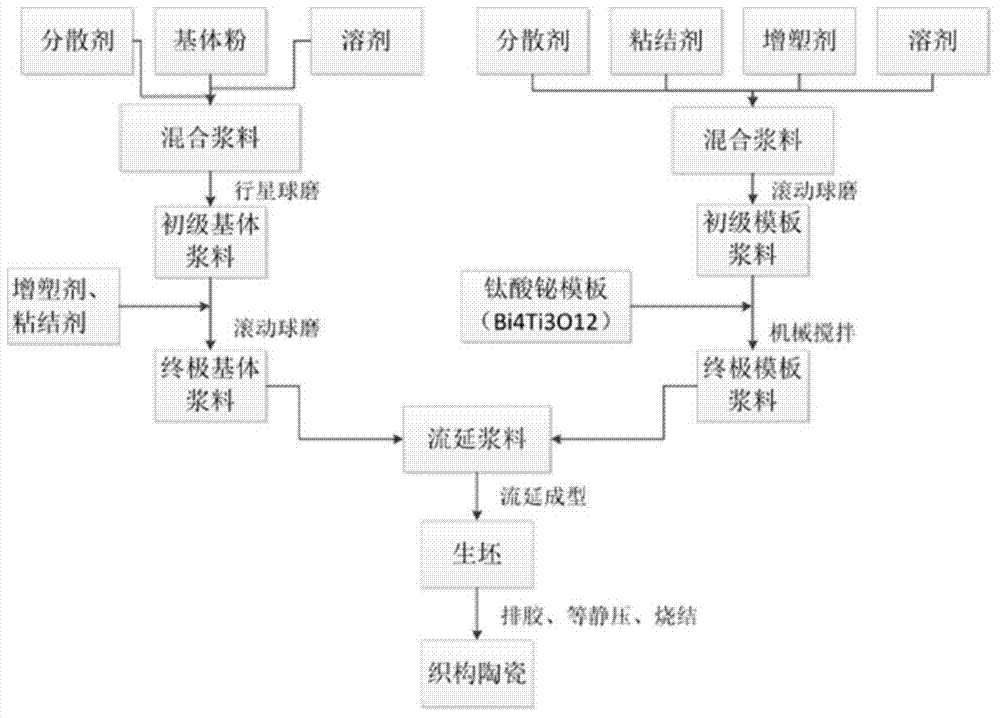

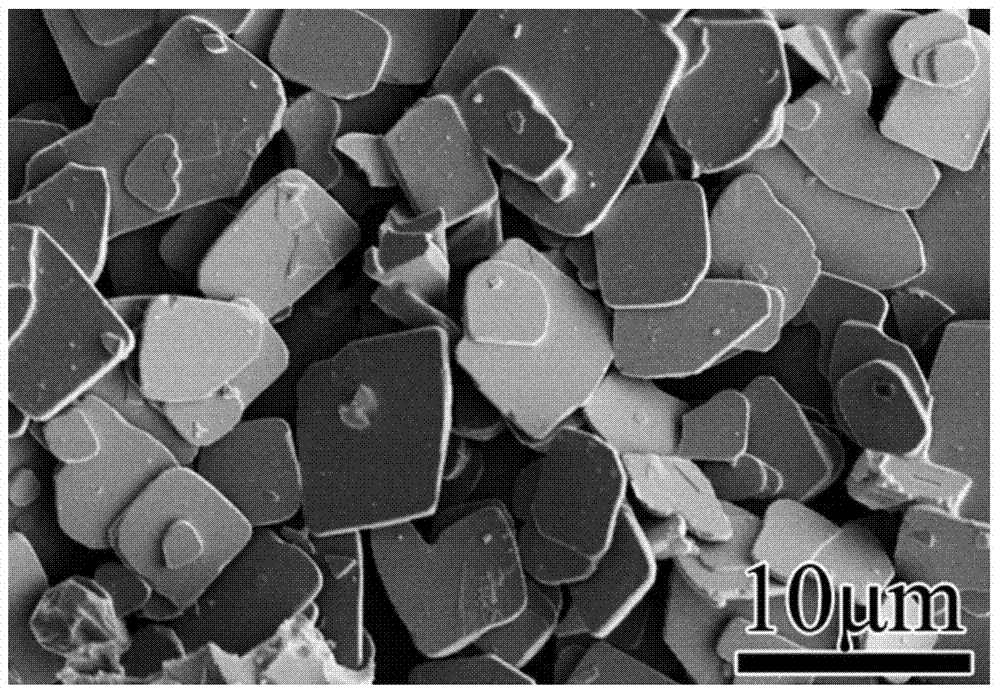

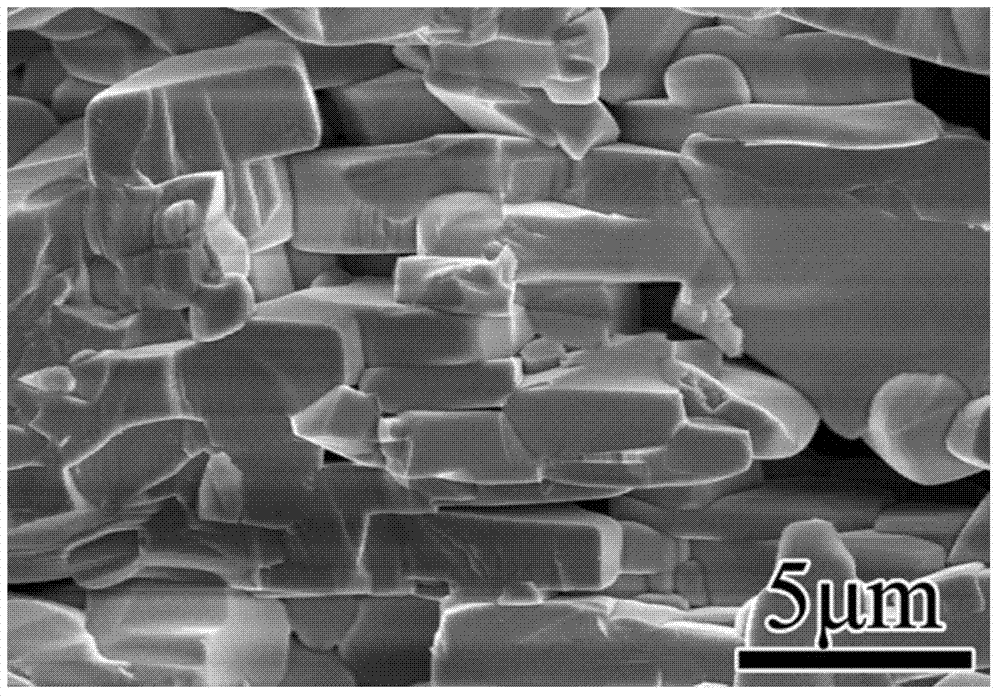

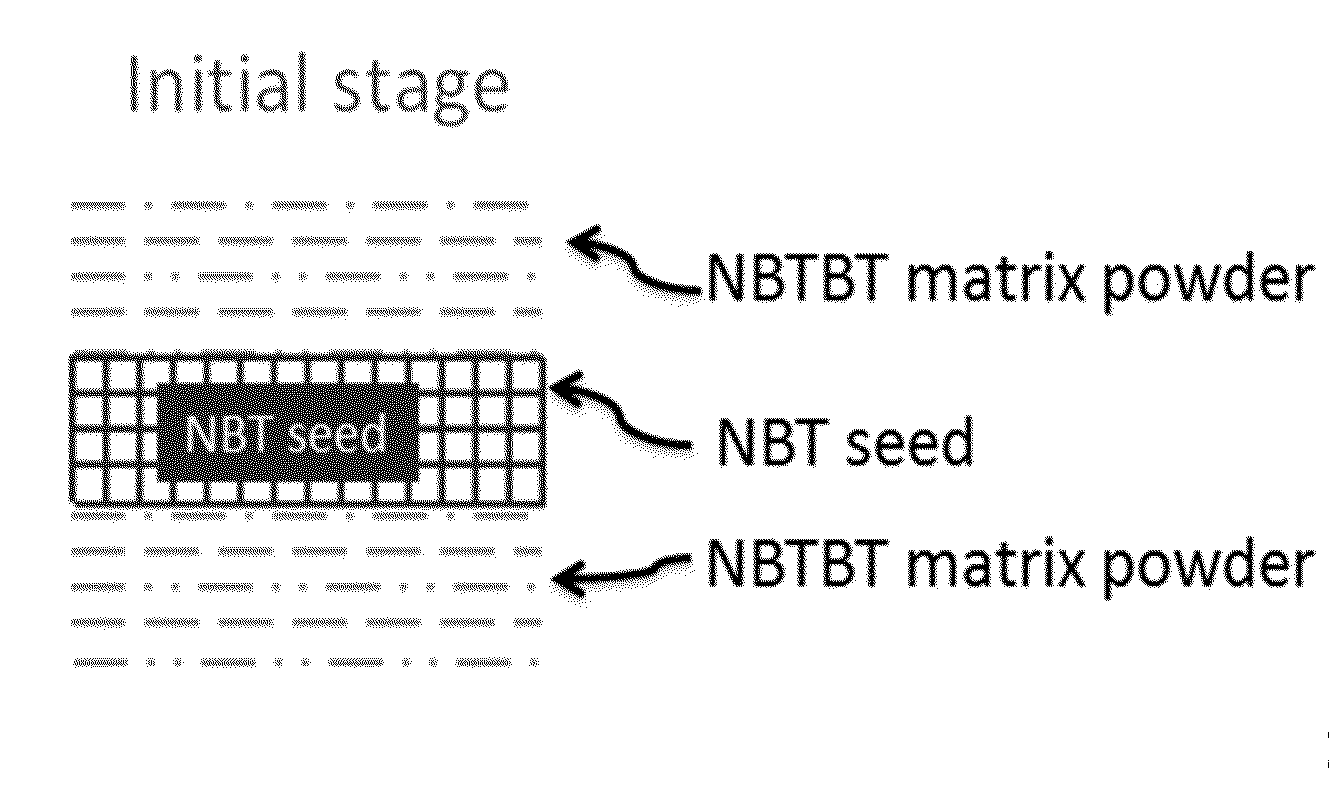

Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

InactiveCN103613382AExcellent piezoelectric propertiesThe original composition does not changeBarium titanatePotassium

The invention provides sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing a template with organic additives such as matrix powder, an organic solvent and a binder to obtain slurry by taking a Bi4Ti3O12 crystal as the template; preparing the slurry into a film sheet with thickness of 30 mu m-60 mu m through a curtain coating process; and sintering the film sheet after laminating, cutting, rubber exhausting and isostatic cool pressing to prepare a BNBK texture ceramic material with high oriented growth, wherein original components of the materials are not changed due to precise control in the process. The prepared sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic constitutes a (1-x-y)Na0.5Bi0.5TiO3-xBaTiO3-Yk0.5Bi0.5TiO3 ternary system, has good crystalline grain orientation effect, excellent performances in the lead-free piezoelectric field, a piezoelectric constant of over 210 pC / N and a Curie temperature of over 320 DEG C.

Owner:TIANJIN UNIV

Method for preparing potassium sodium niobate base leadless piezoelectric ceramic

InactiveCN101186502AExcellent piezoelectric ferroelectric propertiesHigh piezoelectric constantRoom temperatureChemical constituents

The invention discloses potassium-solium niobate leadless piezoelectric ceramics and a preparation method thereof, and pertains to the functional material field. A chemical constituent of the material is (1-x) (Li0.06Na0.52K0.42)NbO3+xRO, wherein, x is more than or equal to 0 and less than or equal to 0.02, and the RO is metallic oxide. The invention adopts two steps sintering method to produce the potassium-solium niobate leadless piezoelectric ceramics under strictly controlling sinter temperature and the speed of raising temperature; the first step is that temperature raises to 850 - 950 DEG C at a speed of 30 DEG C per minute; the second step is that the temperature is raised to between 1050 and 1150 DEG C at a speed of 10 DEG C per minute and 2 to 10 minutes for insulation; the temperature lowers to 950 - 1050 DEG C at a speed of 20 DEG C per minute and 10 to 20 hours for insulation, and then the temperature is lowered to room temperature; after the steps, the novel piezoelectric ceramics is finally made; compared with the traditional sintering technique, the piezoelectric constant d33 is raised by 10 to 20 percent.

Owner:UNIV OF SCI & TECH BEIJING

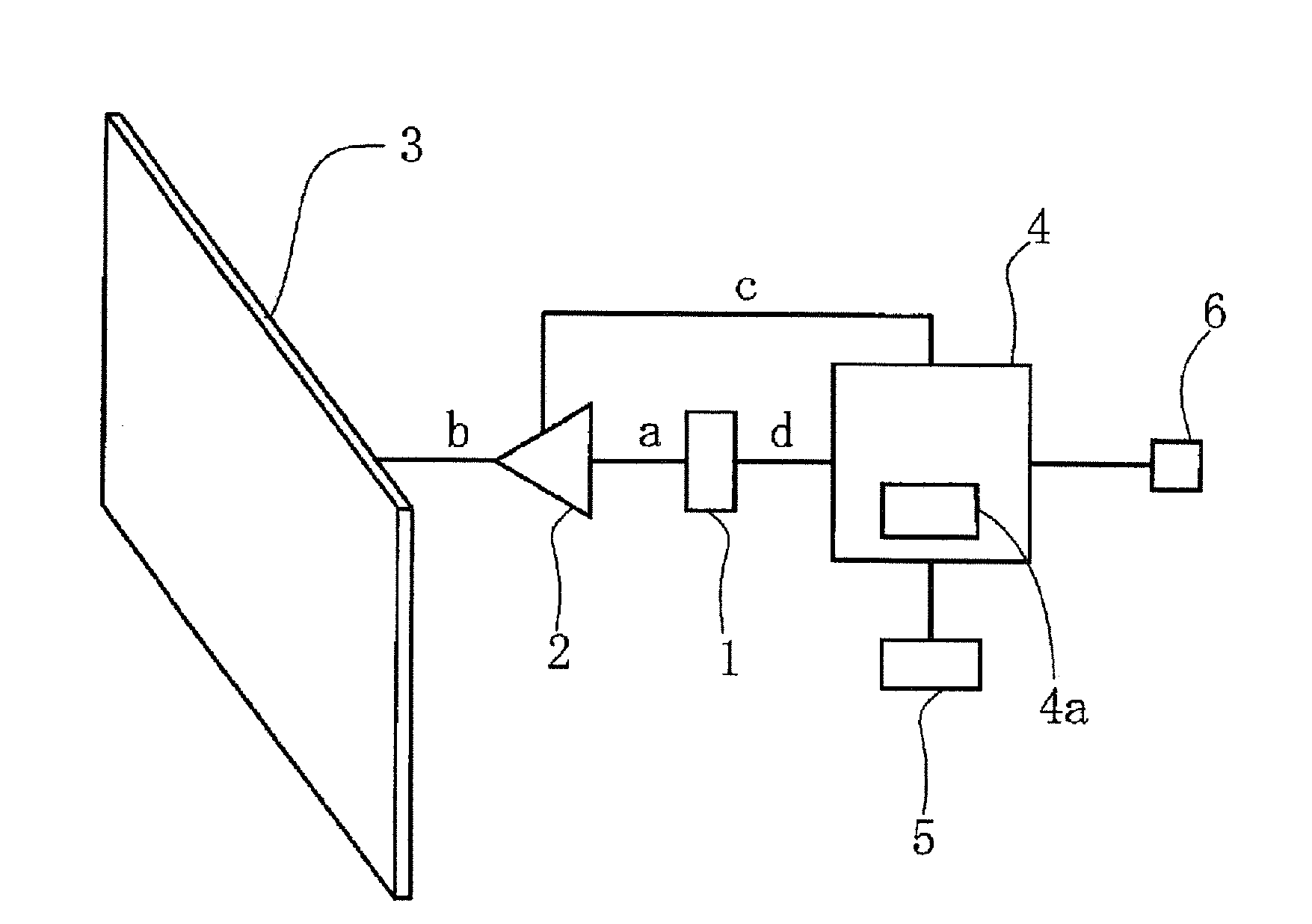

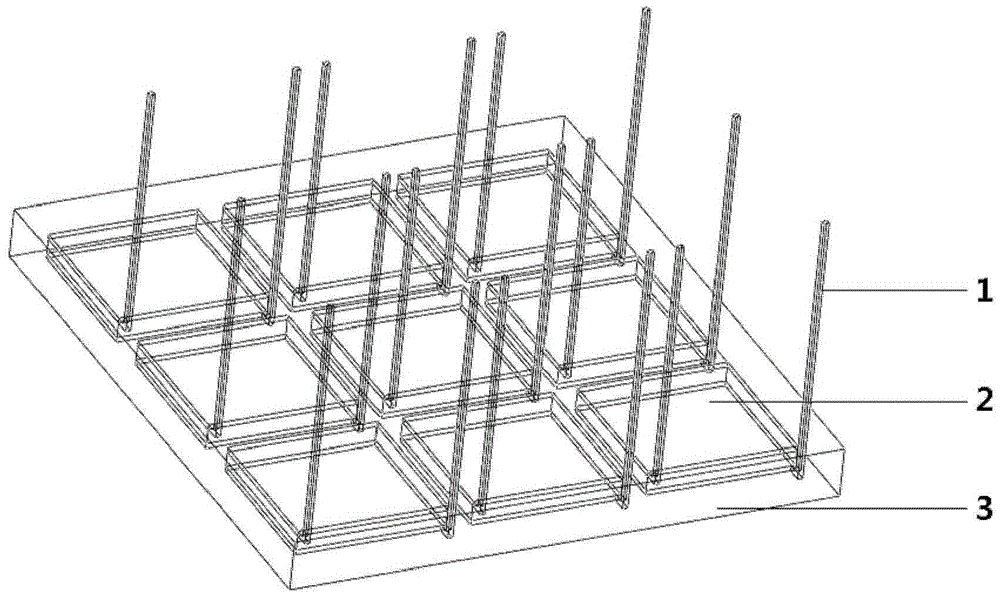

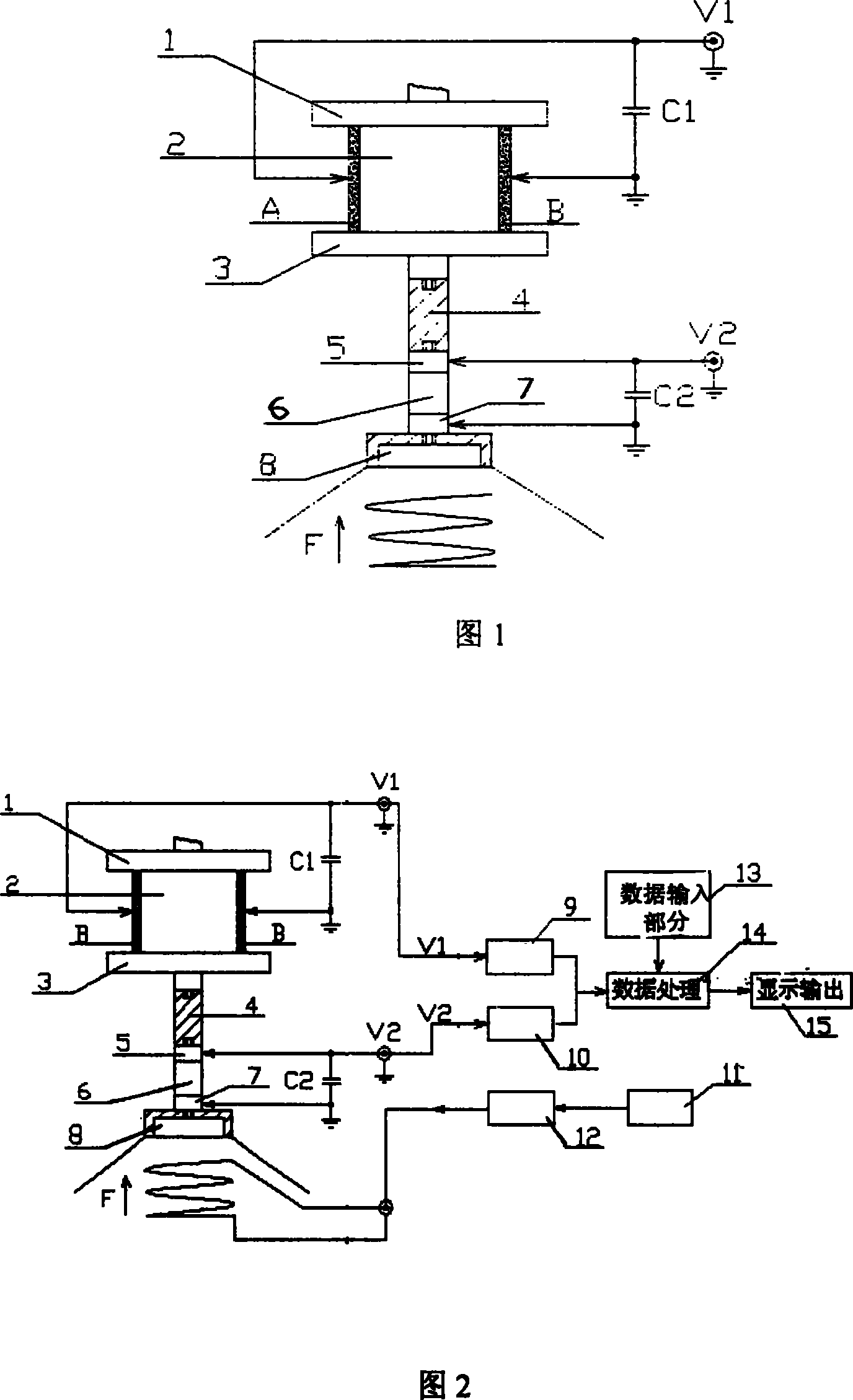

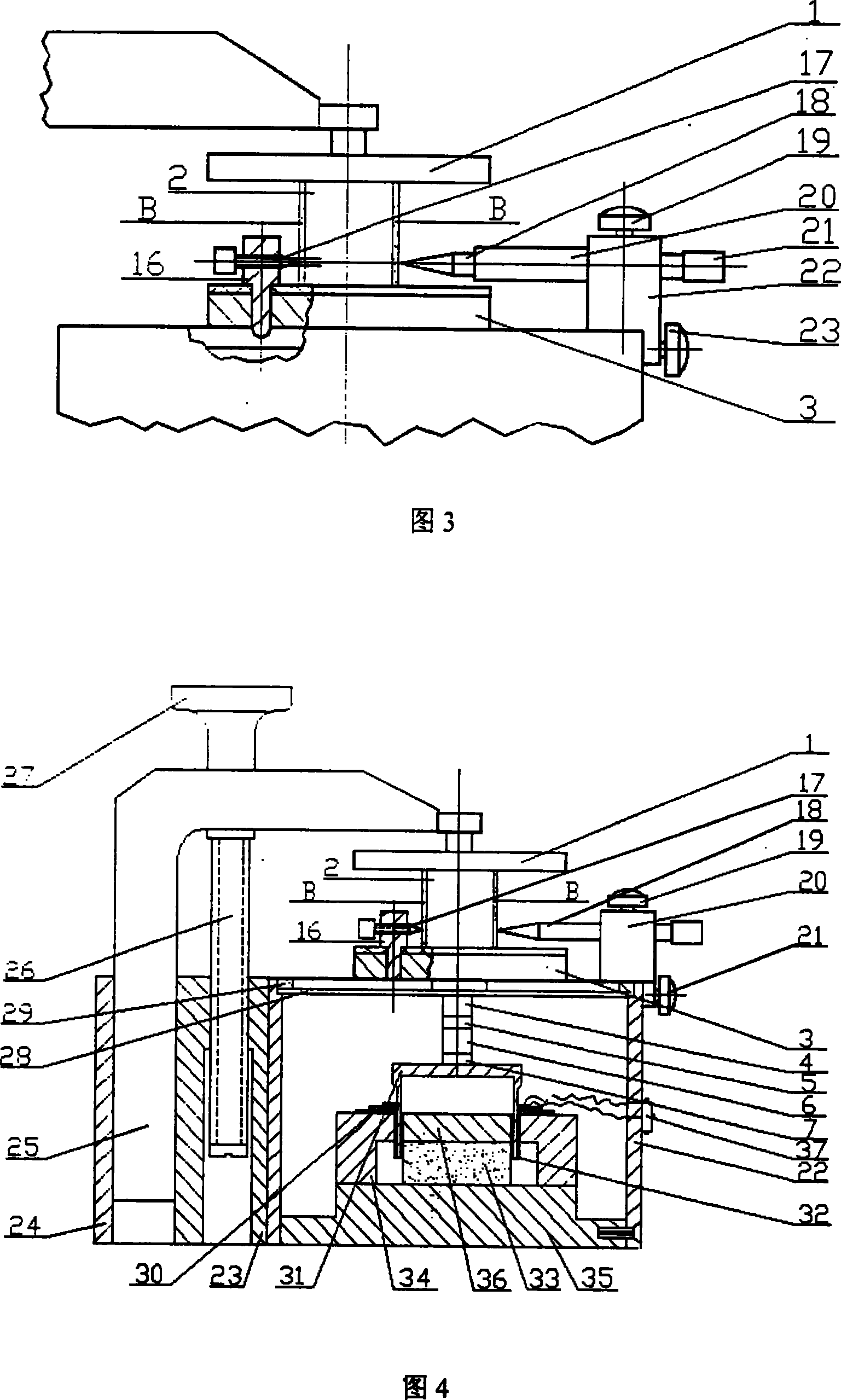

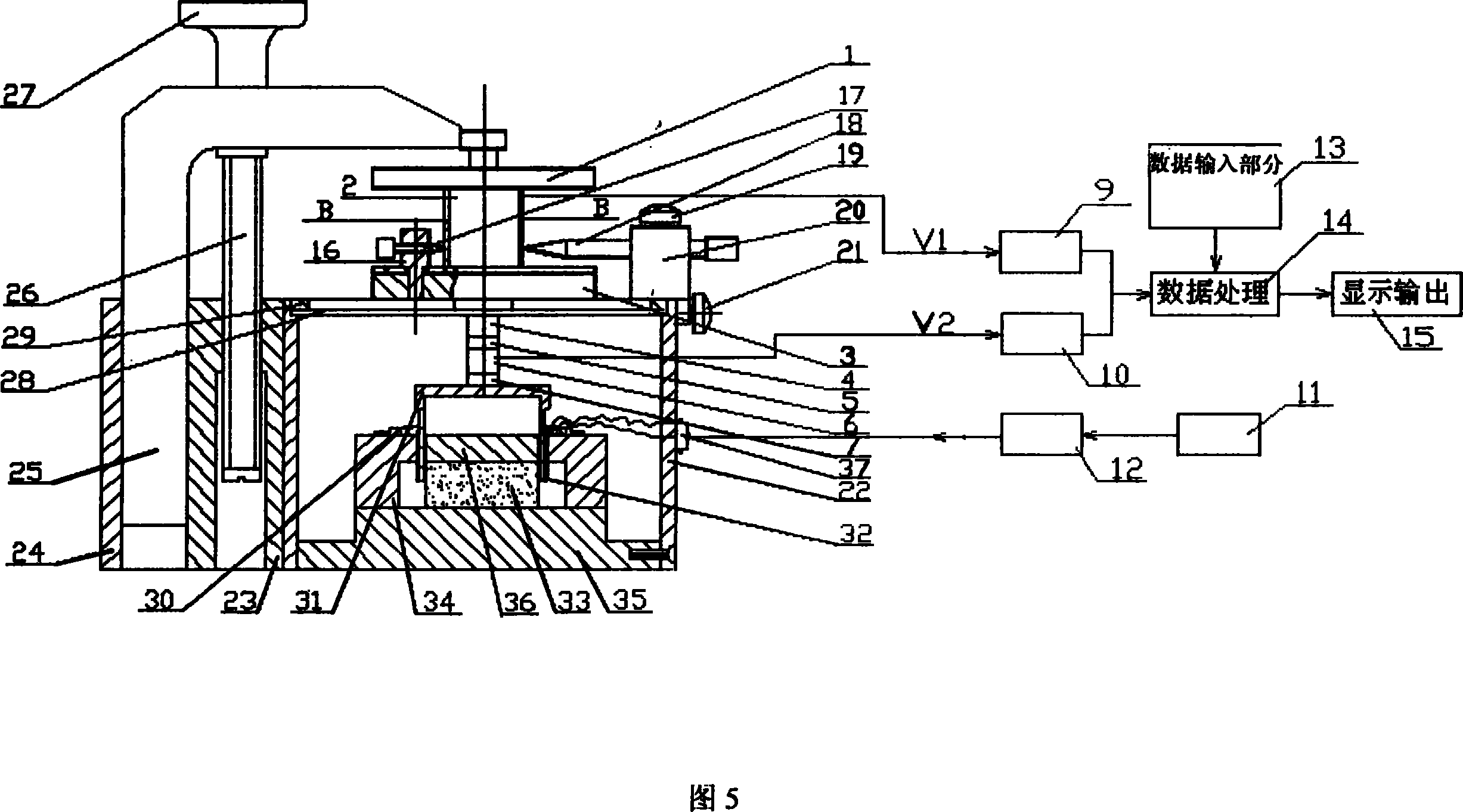

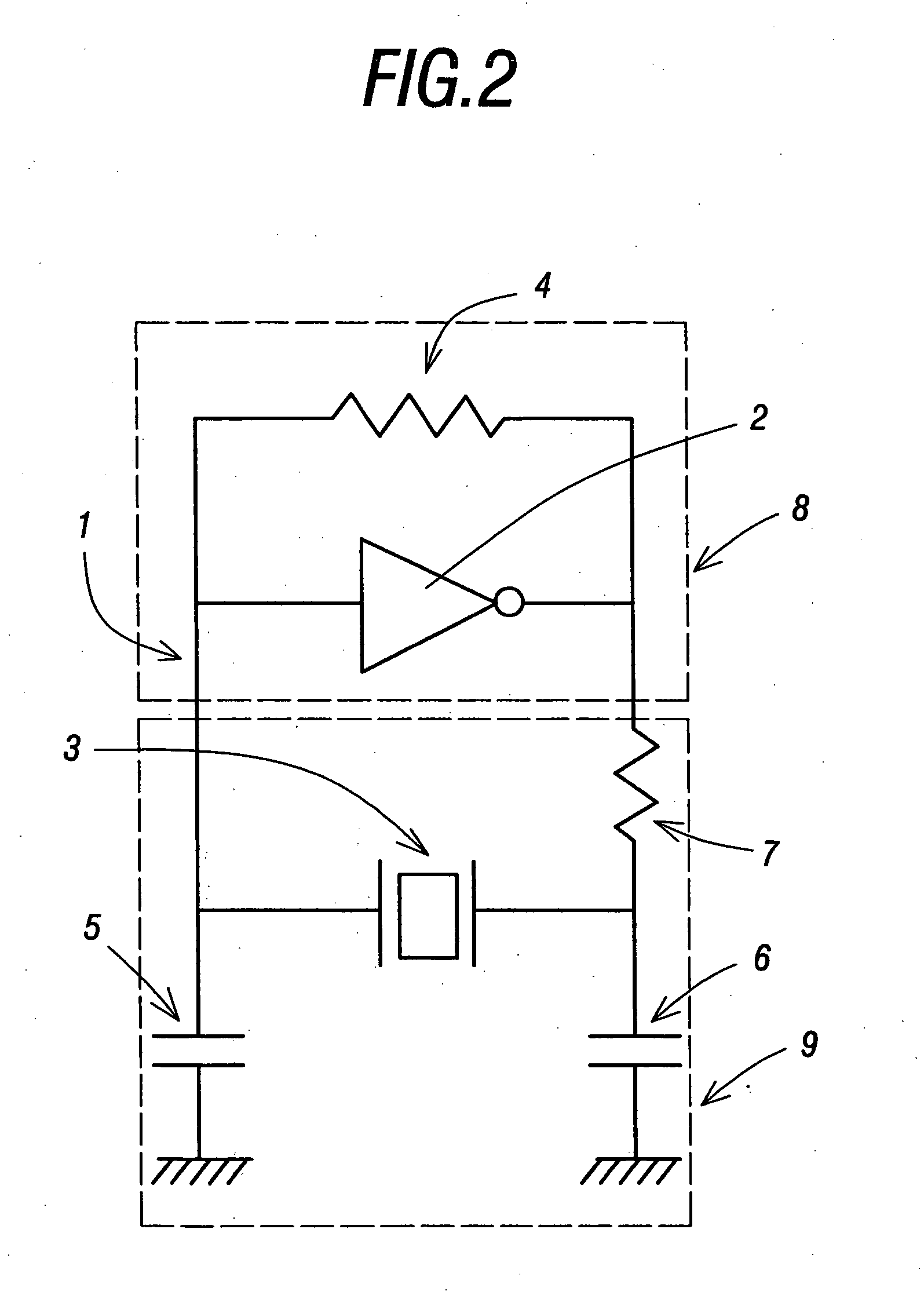

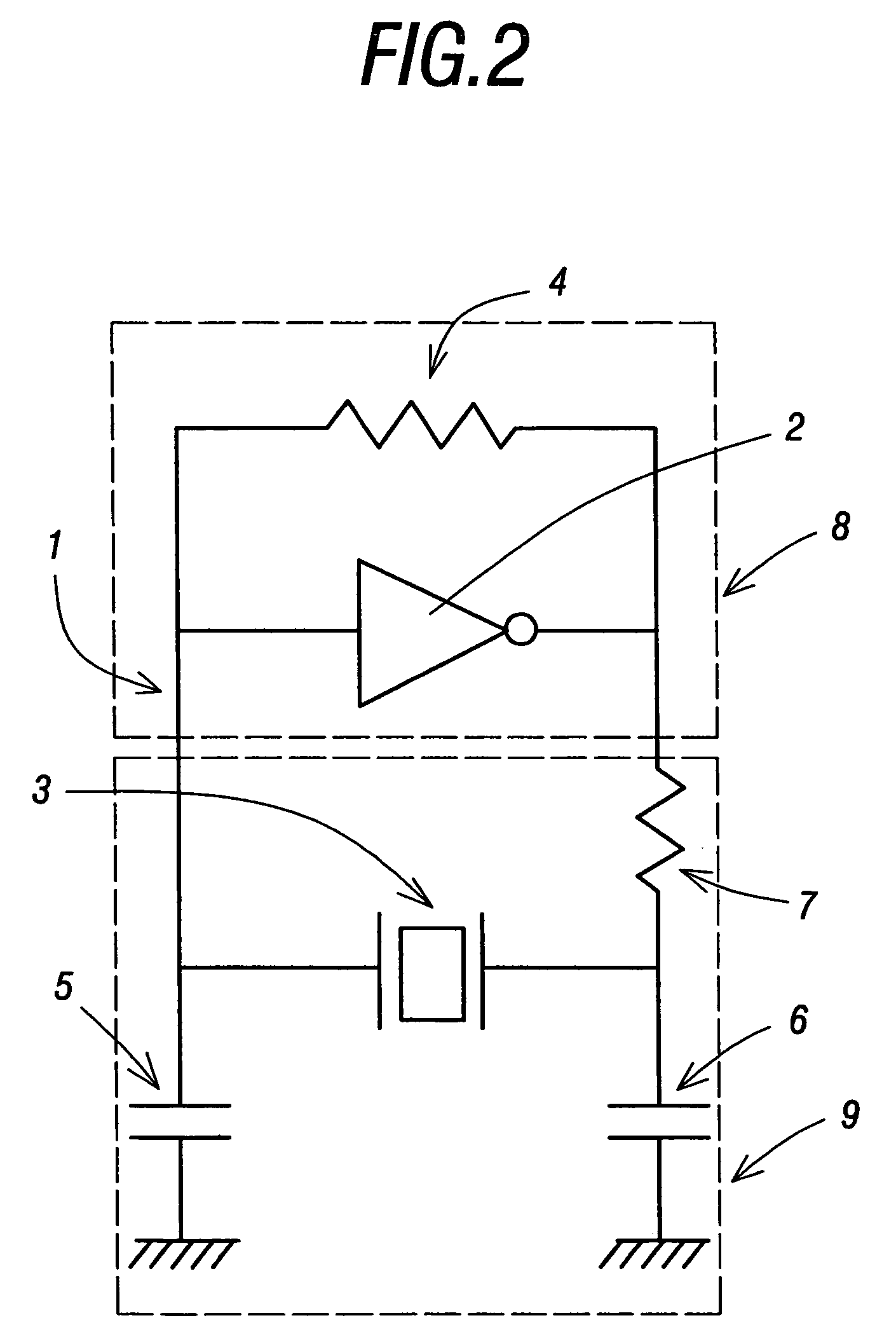

Transverse piezoelectric strain constant measuring method by piezoelectric material quasistatic method and system thereof

The invention relates to a measuring method and system for d31 piezoelectric constant that adopts quasi-static method to testing d21 piezoelectric. The system is made up of energizing equipment and circuit equipment. The energizing equipment supplies acting force to testing sample by special stressing accessory. Circuit equipment supplies electric driving signal and taking amplifying and processing to low frequency alternating voltage signal, and display d31 piezoelectric constant. It has the advantages of easy to operate, rapid and accurate.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Piezoelectric ceramic composition

ActiveUS20080237531A1Constant gainIncrease valuePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionSolid solutionCrystal base

A piezoelectric ceramic composition having a large piezoelectric constant (d) and as well having a large Qm value is to be provided. The piezoelectric ceramic composition aimed at has a composition corresponding to a solid solution containing a first compound possessing a rhombohedral crystal-based perovskite structure, a second compound possessing a tetragonal crystal-based perovskite structure, and a third compound. The third compound is a compound oxide containing Bi as a first component element, Mn as a second component element, and a tetravalent metallic element or a pentavalent metallic element as a third component element. The tetravalent metallic element is at least one member selected from the group consisting of Ti, Zr, Hf, and Sn. The pentavalent metallic element is at least one member selected from the group consisting of Nb, Ta, and Sb.

Owner:TDK CORPARATION

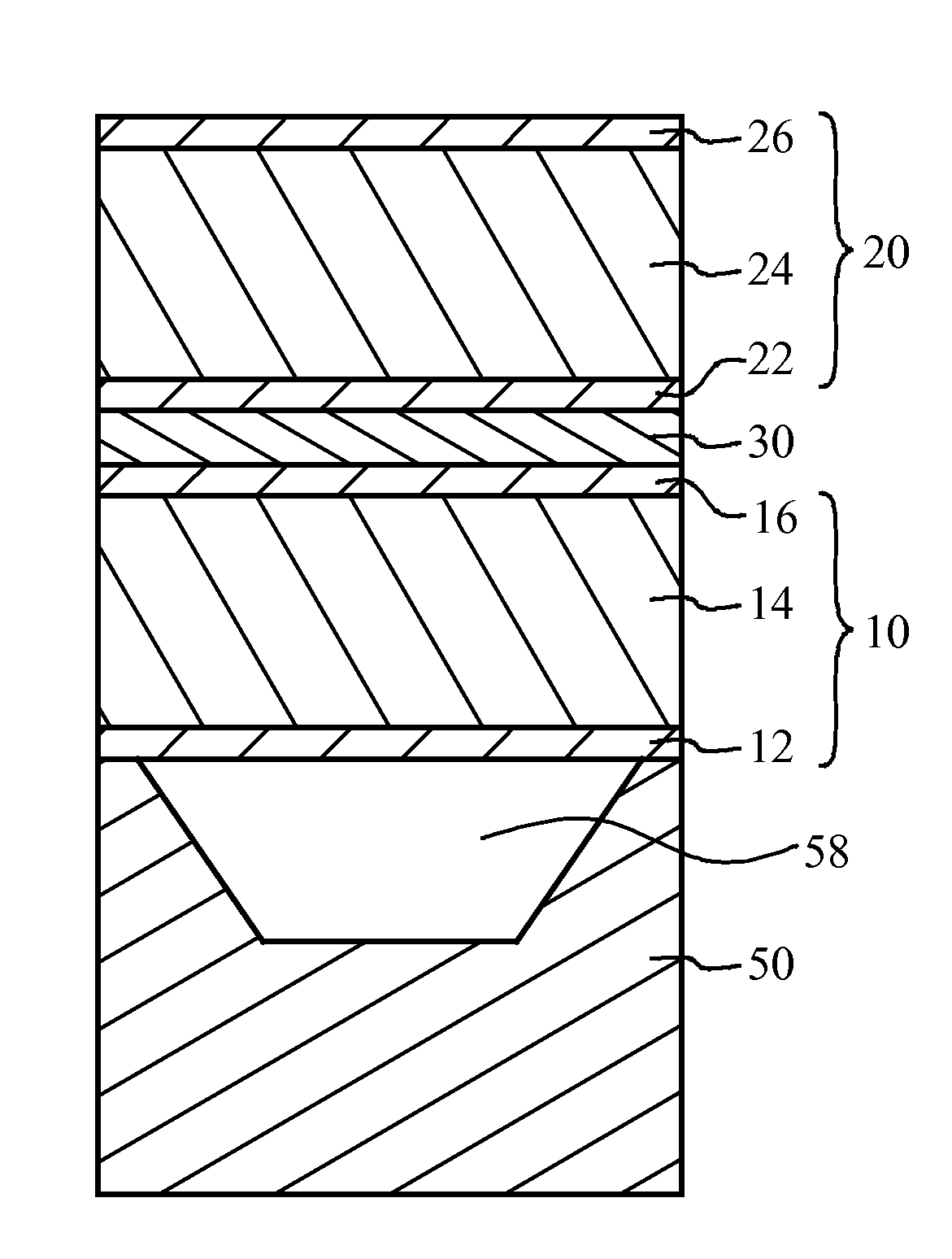

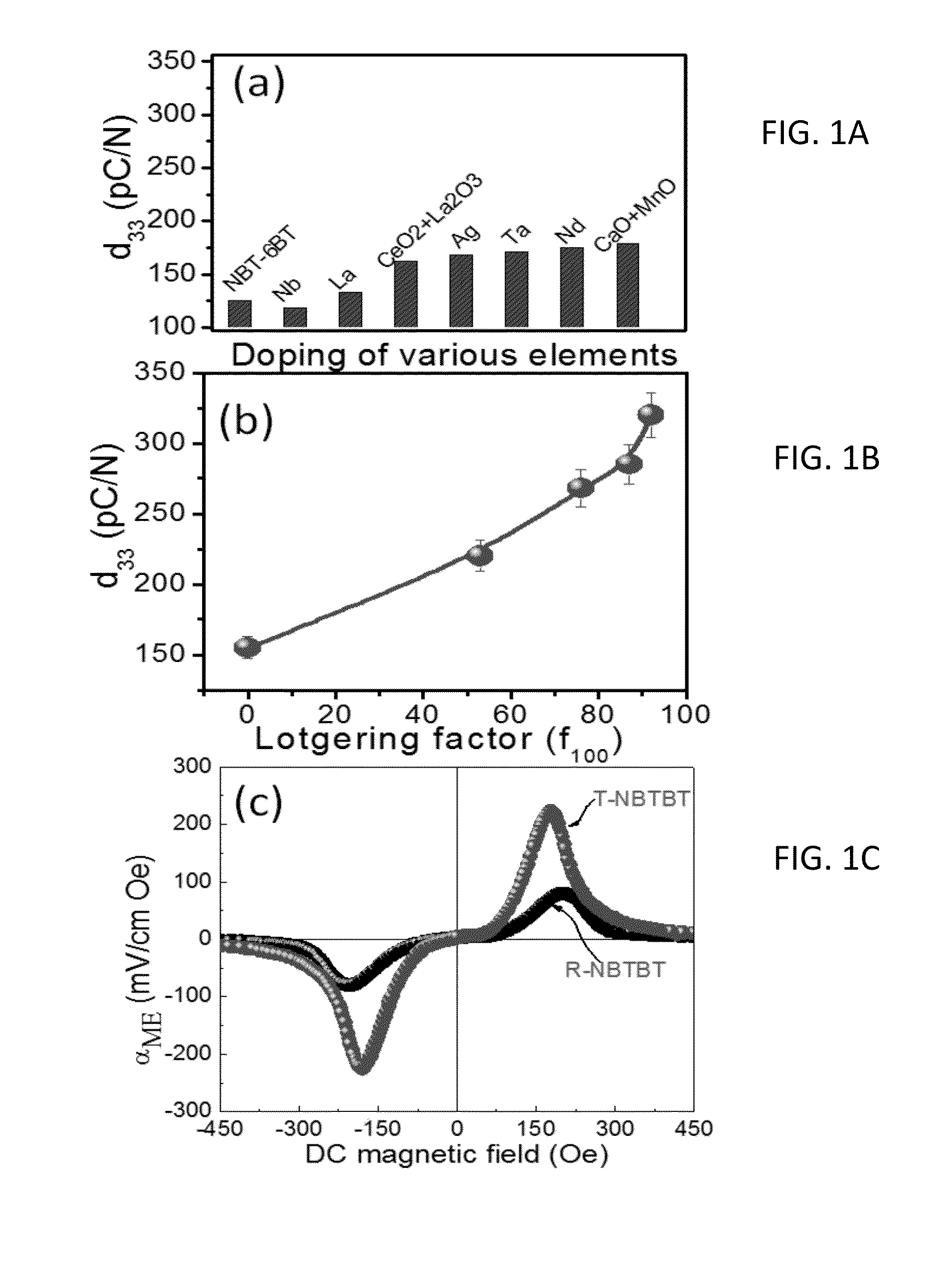

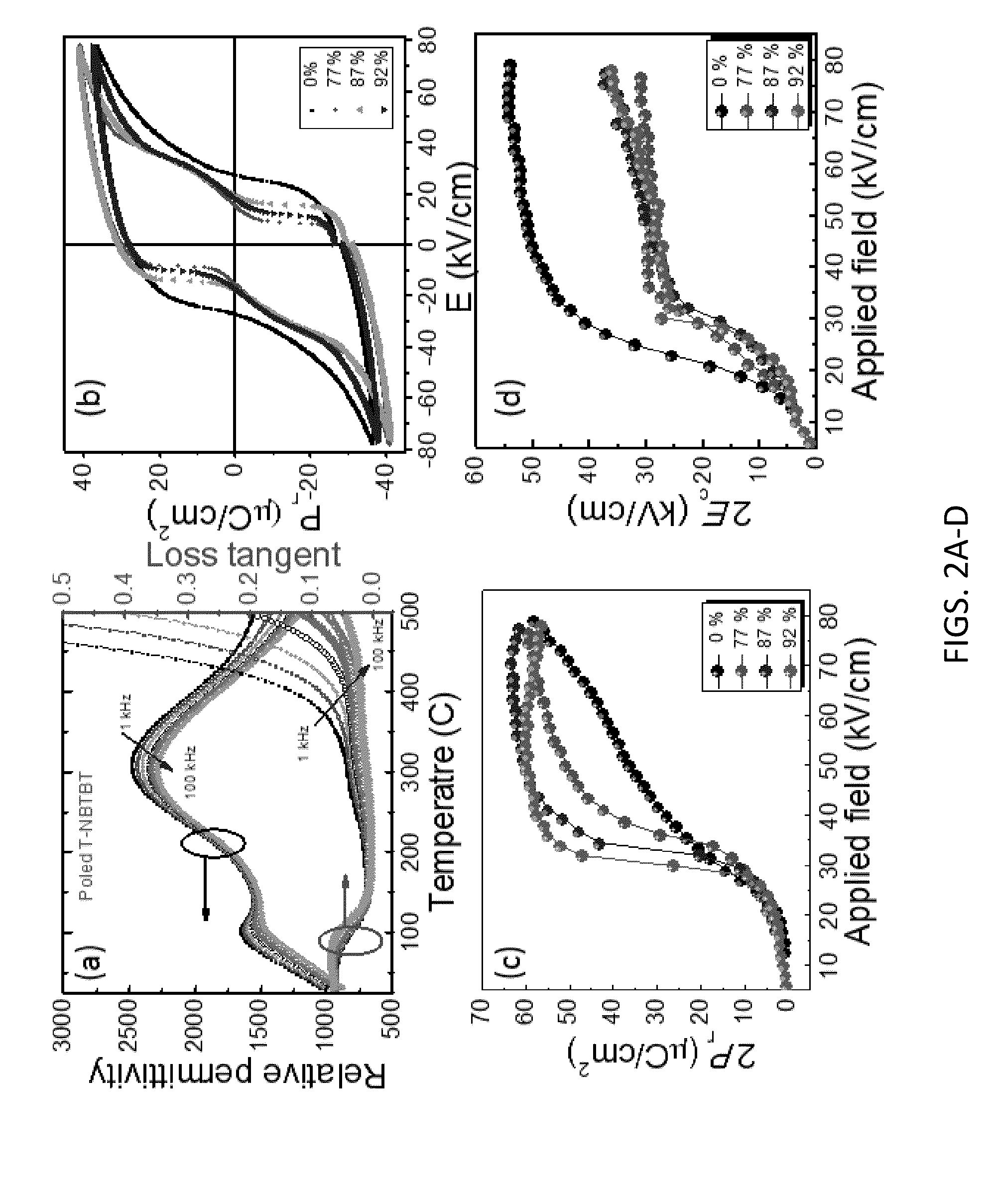

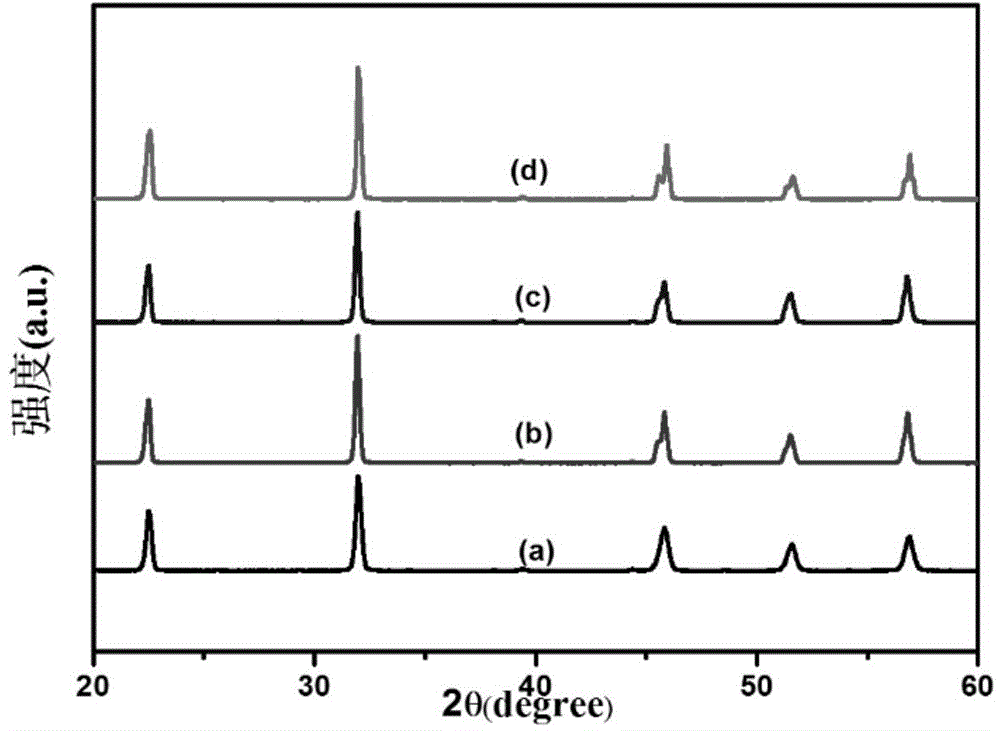

NEW PROCESSING METHOD FOR GRAIN-ORIENTED LEAD-FREE PIEZOELECTRIC Na0.5Bi0.5TiO3-BaTiO3 CERAMICS EXHIBITING GIANT PERFORMANCE

InactiveUS20140239774A1High aspect ratioImprove propertiesPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionElectricityCoupling

Textured ceramic compositions having improved piezoelectric characteristics as compared with their random counterparts are provided. Methods of making the compositions and devices using them are also included. More particularly, compositions comprising textured ceramic Na0.5Bi0.5TiO3—BaTiO3(NBT-BT) materials synthesized from high aspect ratio NBT seeds exhibit improved characteristics, including an increased longitudinal piezoelectric constant (d33) and magnetoelectric coupling coefficient over randomly oriented NBT-BT. Additionally provided are compositions comprising of nanostructured Na0.5B0.5TiO3—BaTiO3 ferroelectric whiskers having a high aspect ratio. Nanostructured whiskers can be used to improve the piezoelectric properties of the bulk ceramics. The inventive materials are useful in microelectronic devices, with some finding particular application as multilayer actuators and transducers.

Owner:VIRGINIA TECH INTPROP INC

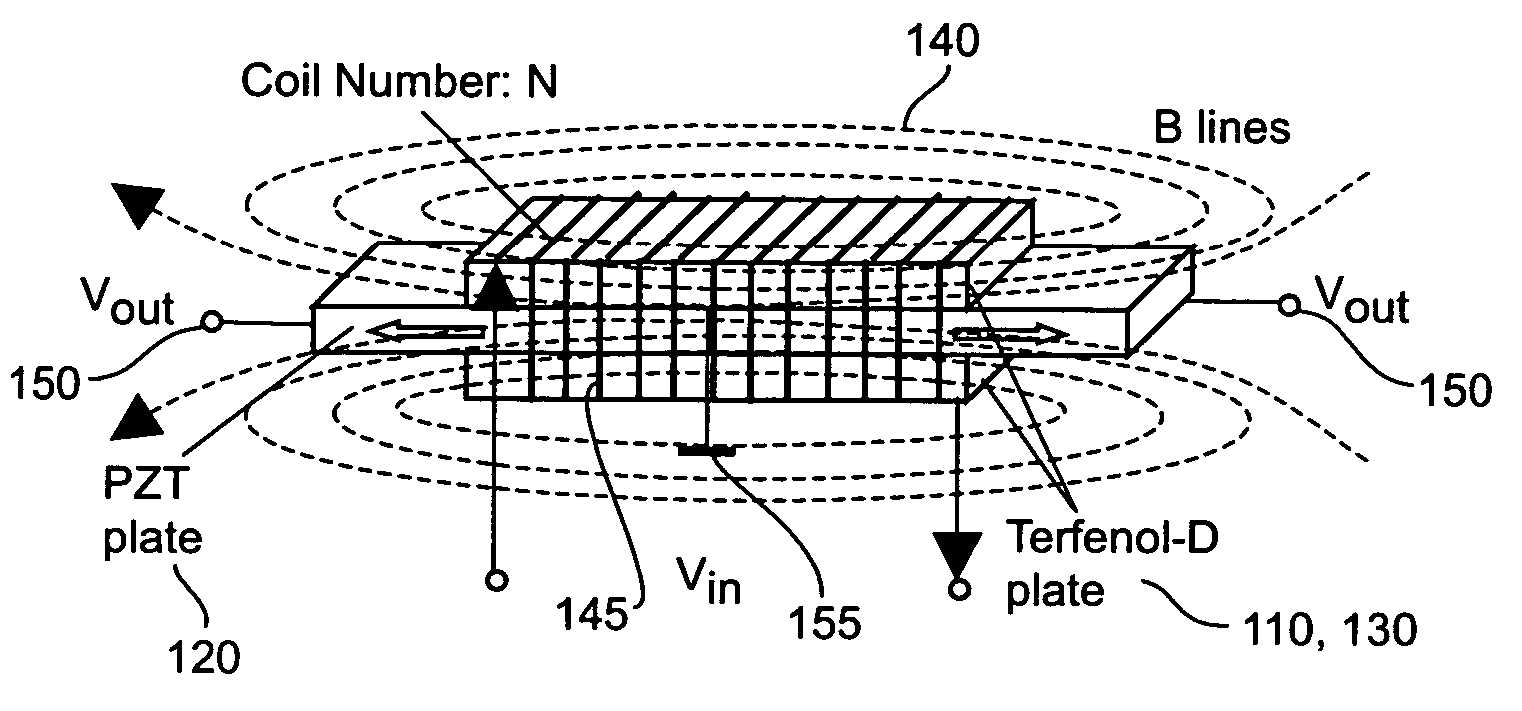

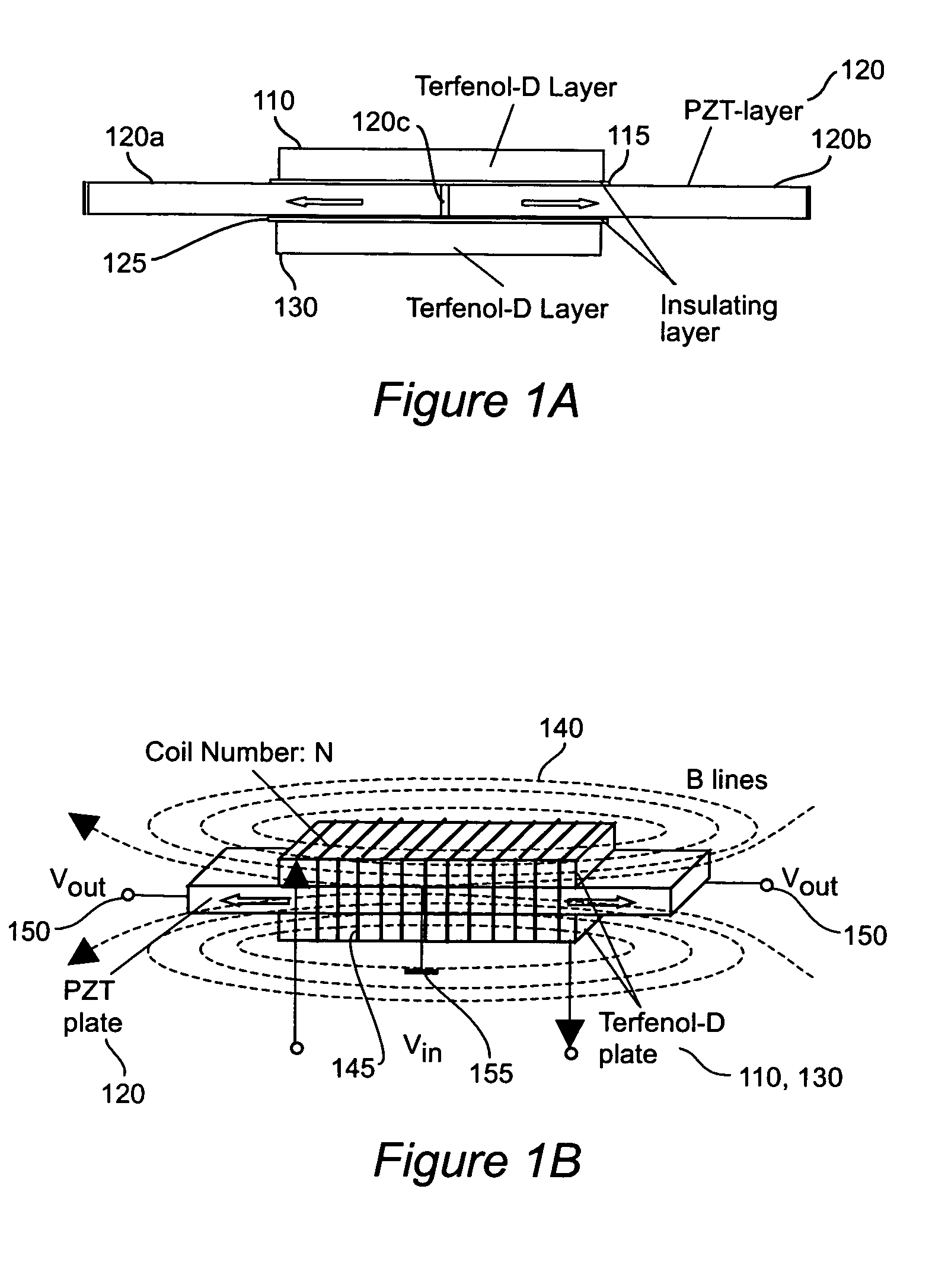

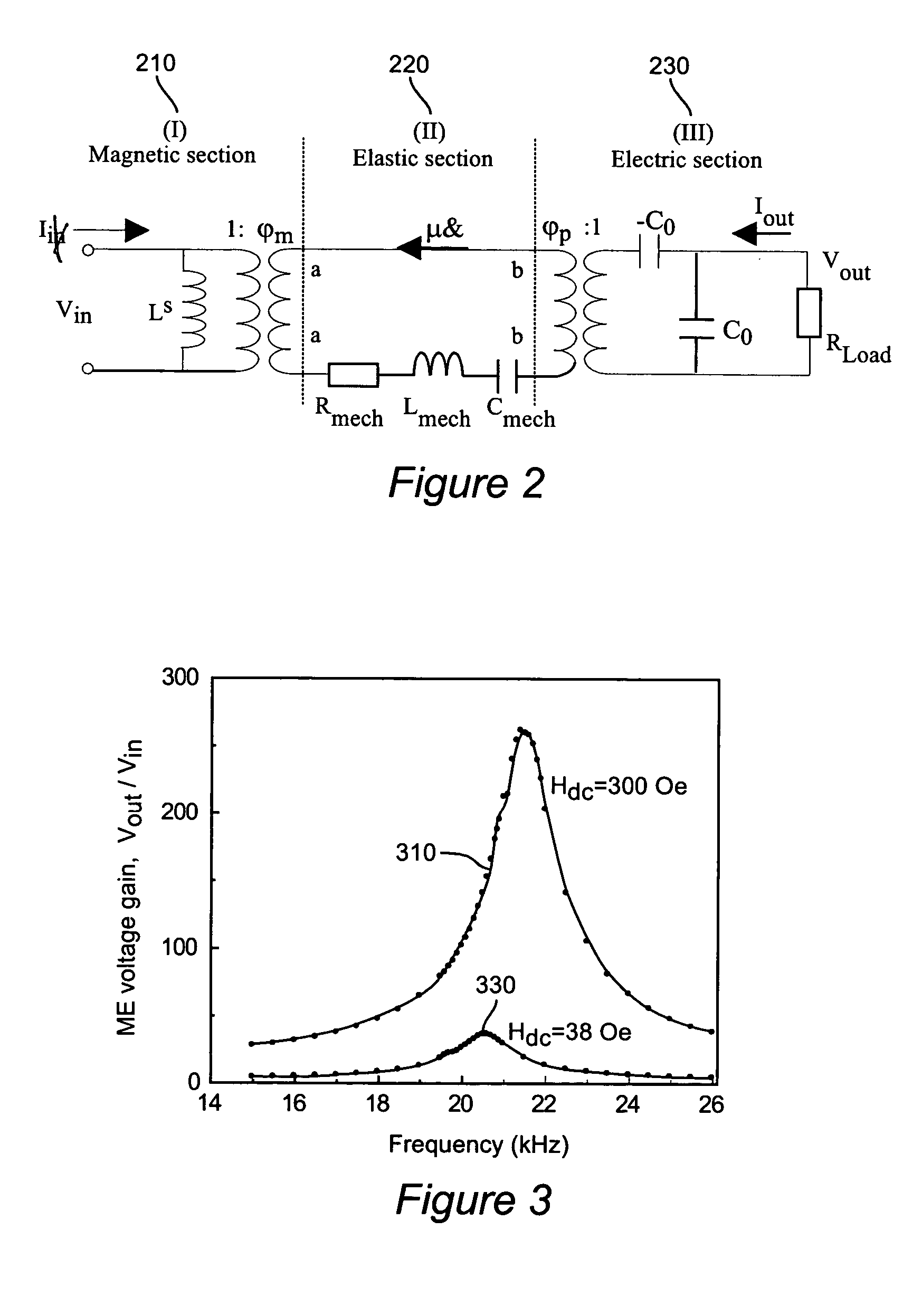

Method and apparatus for high voltage gain using a magnetostrictive-piezoelectric composite

InactiveUS7256532B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesHarmonicMechanical resonance

A method and apparatus attains high voltage gain by using a composite structure of an elastic section of piezoelectric layers bonded between magnetic and electric sections of magnetostrictive layers, with a harmonic magnetic field being applied along the layers at a mechanical resonance frequency of the composite structure, through coils around the laminate carrying current, such as to produce a continuity of both magnetic and electric flux lines, and achieving a high voltage output.

Owner:VIRGINIA TECH INTPROP INC

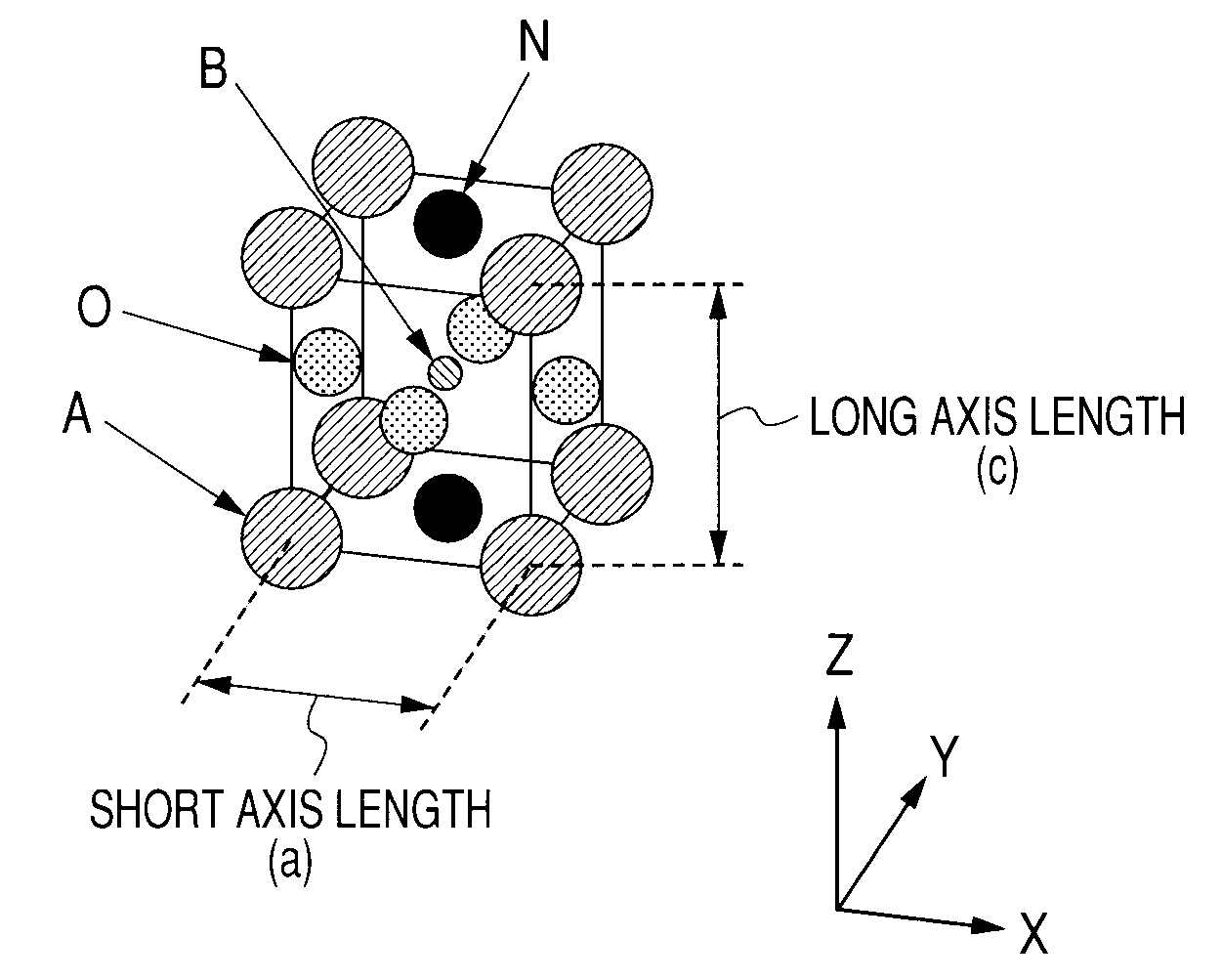

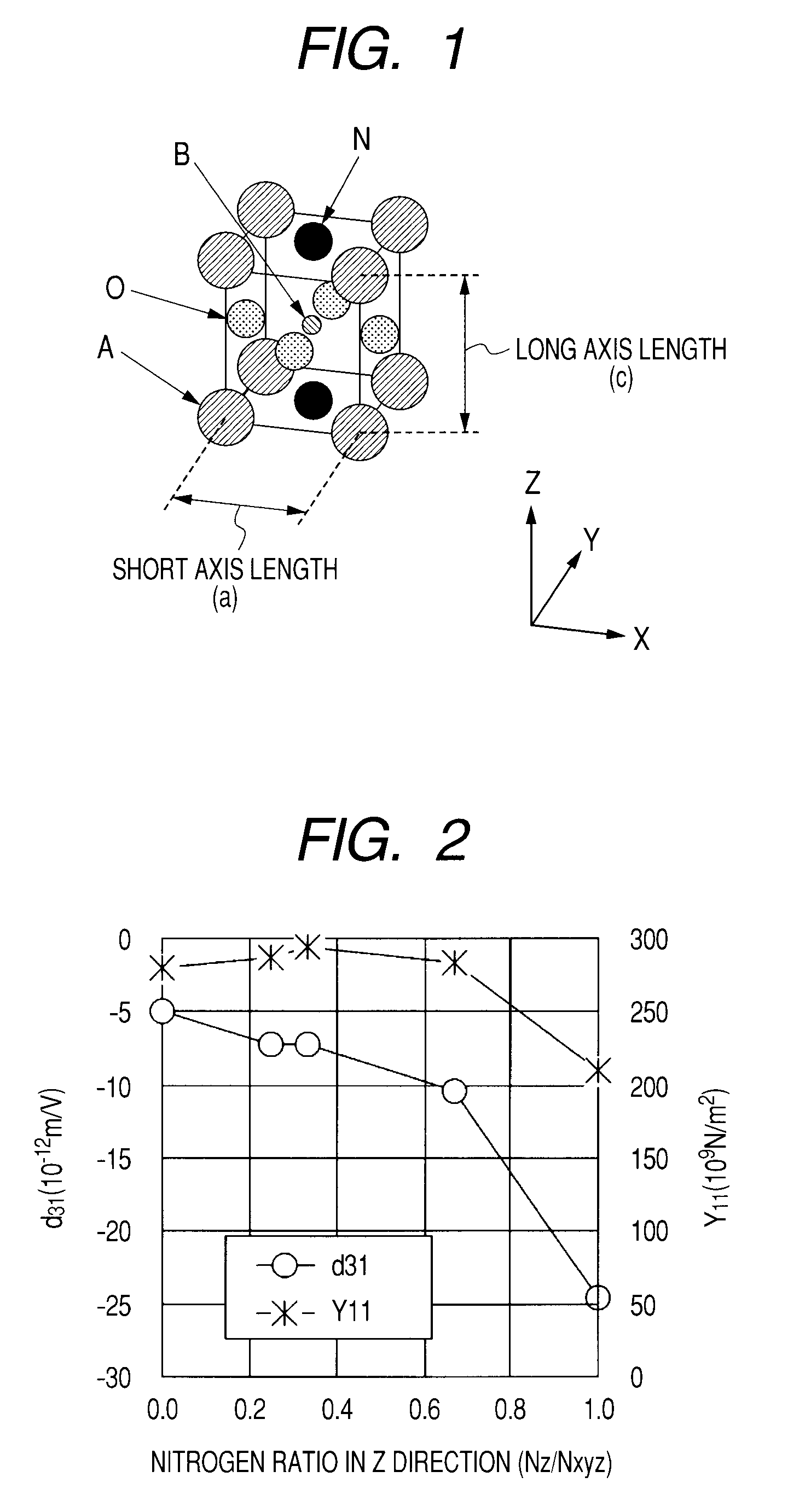

Piezoelectric material

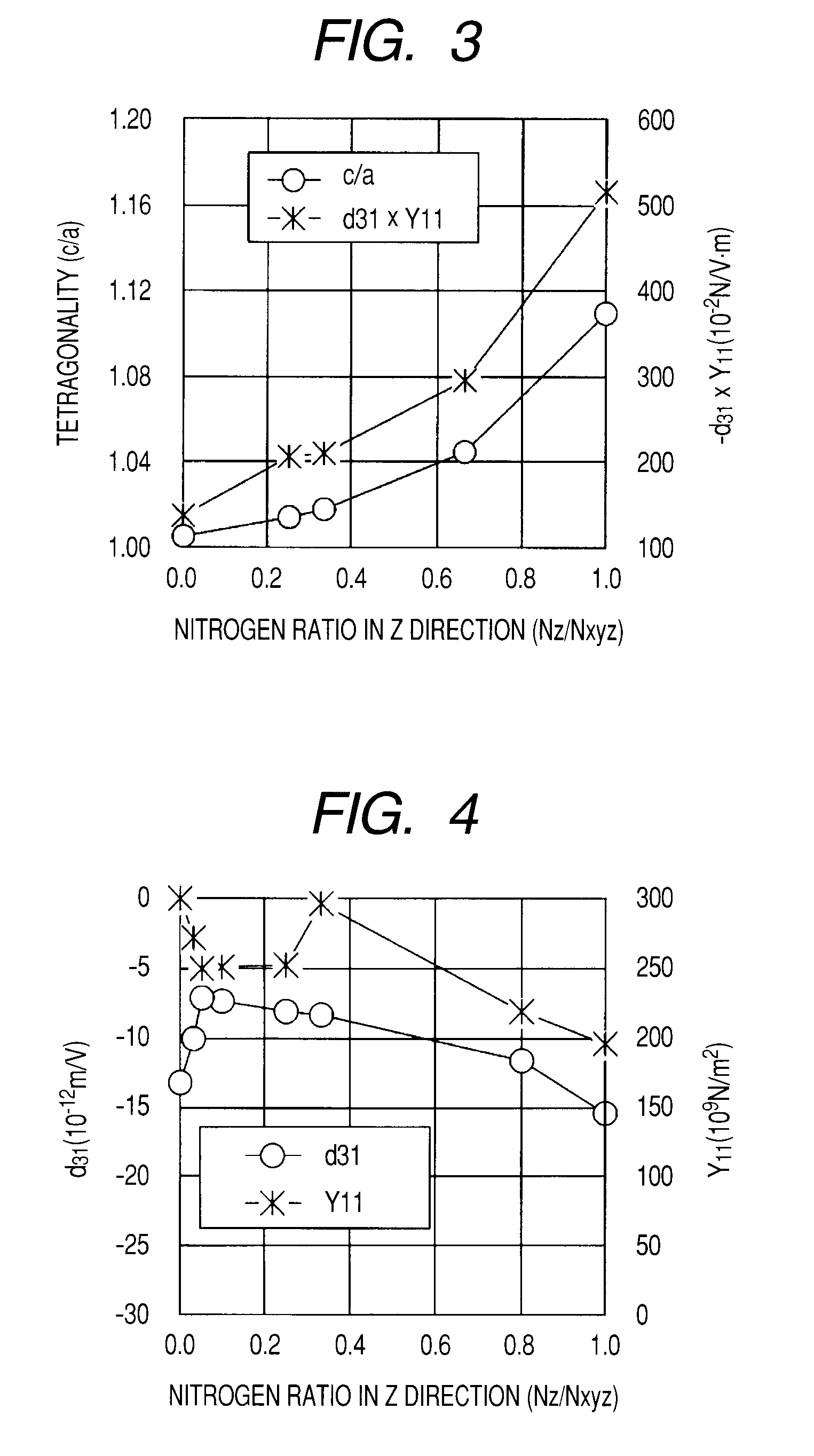

InactiveUS20100155646A1Excellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblySolid-state devicesLong axisNitrogen

Provided is a piezoelectric material in which the product of the piezoelectric constant and the Young's modulus is large to give excellent piezoelectricity without using lead. A piezoelectric material including a perovskite type crystal represented by a compositional formula of ABO2N wherein A represents a trivalent cation, and B represents a tetravalent cation provided that A and B are each other than lead, wherein when the number of nitrogen N atoms contained in the piezoelectric material is represented by Nxyz and the number of nitrogen atoms each disposed at a face-centered position in the crystal and in a long axis direction of the crystal, out of the nitrogen atoms the number of which is Nxyz, is represented by Nz, an expression of Nz / Nxyz>1 / 3 is satisfied. It is preferred that A and B are La and Ti, respectively.

Owner:CANON KK

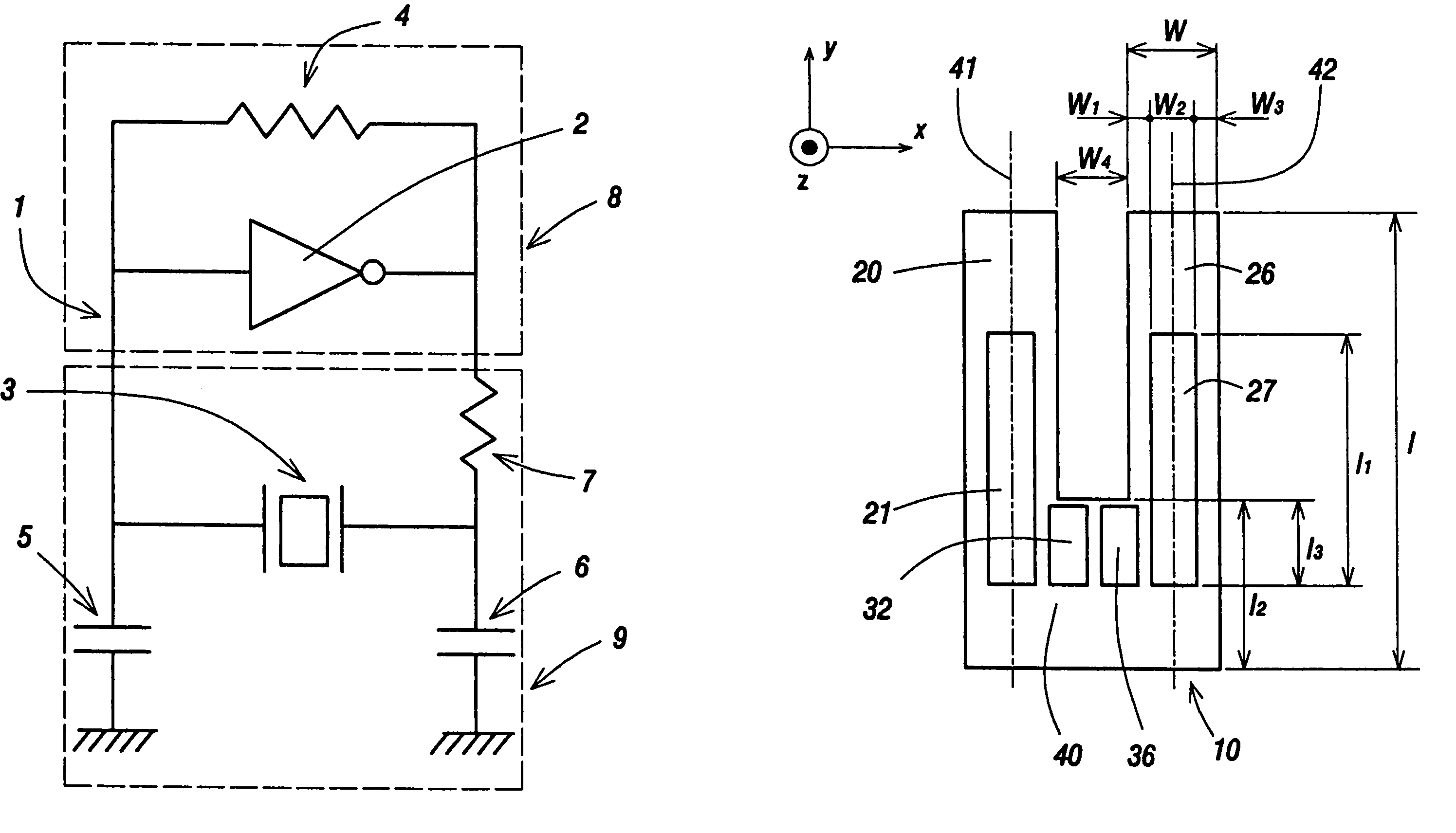

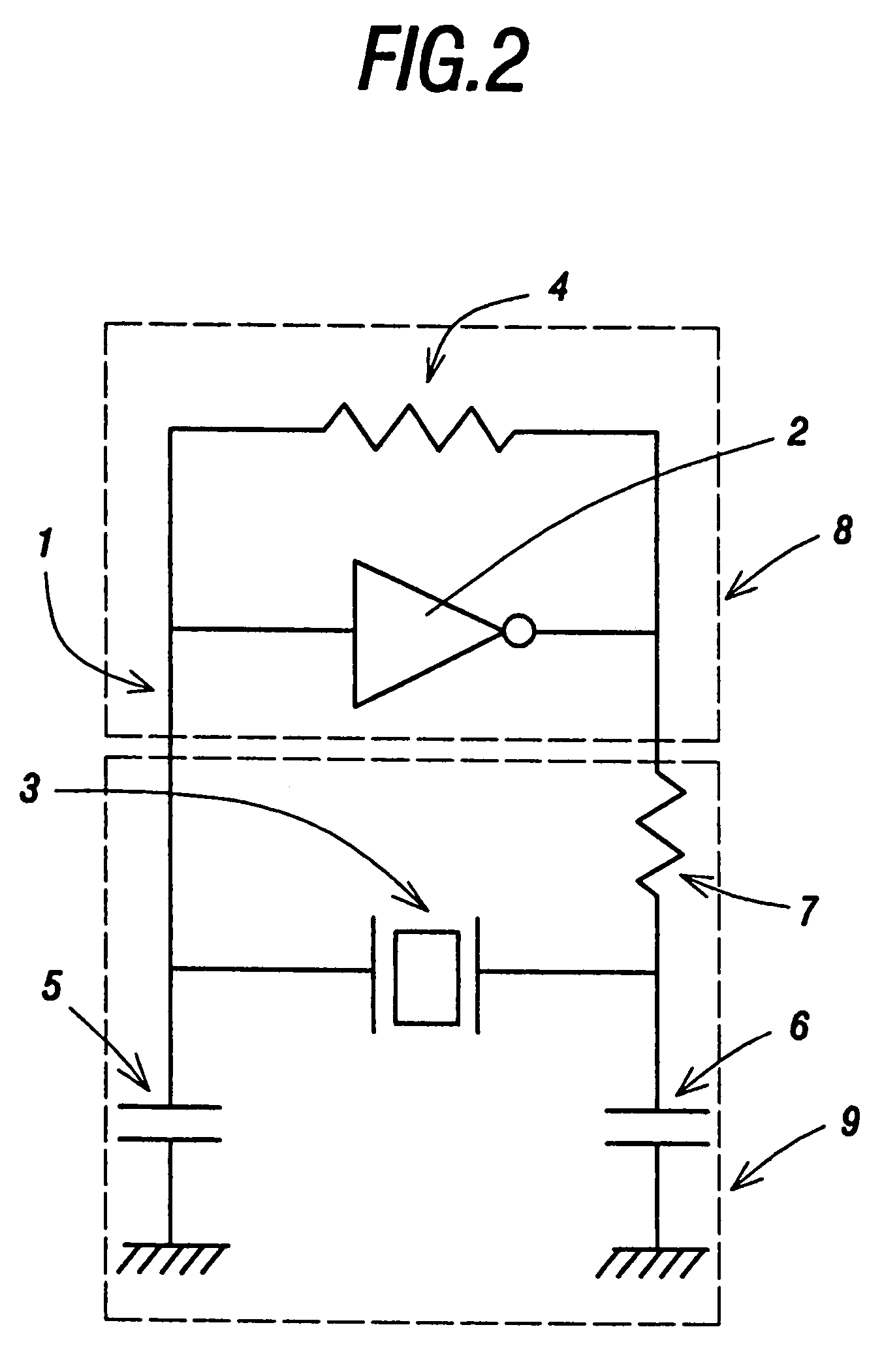

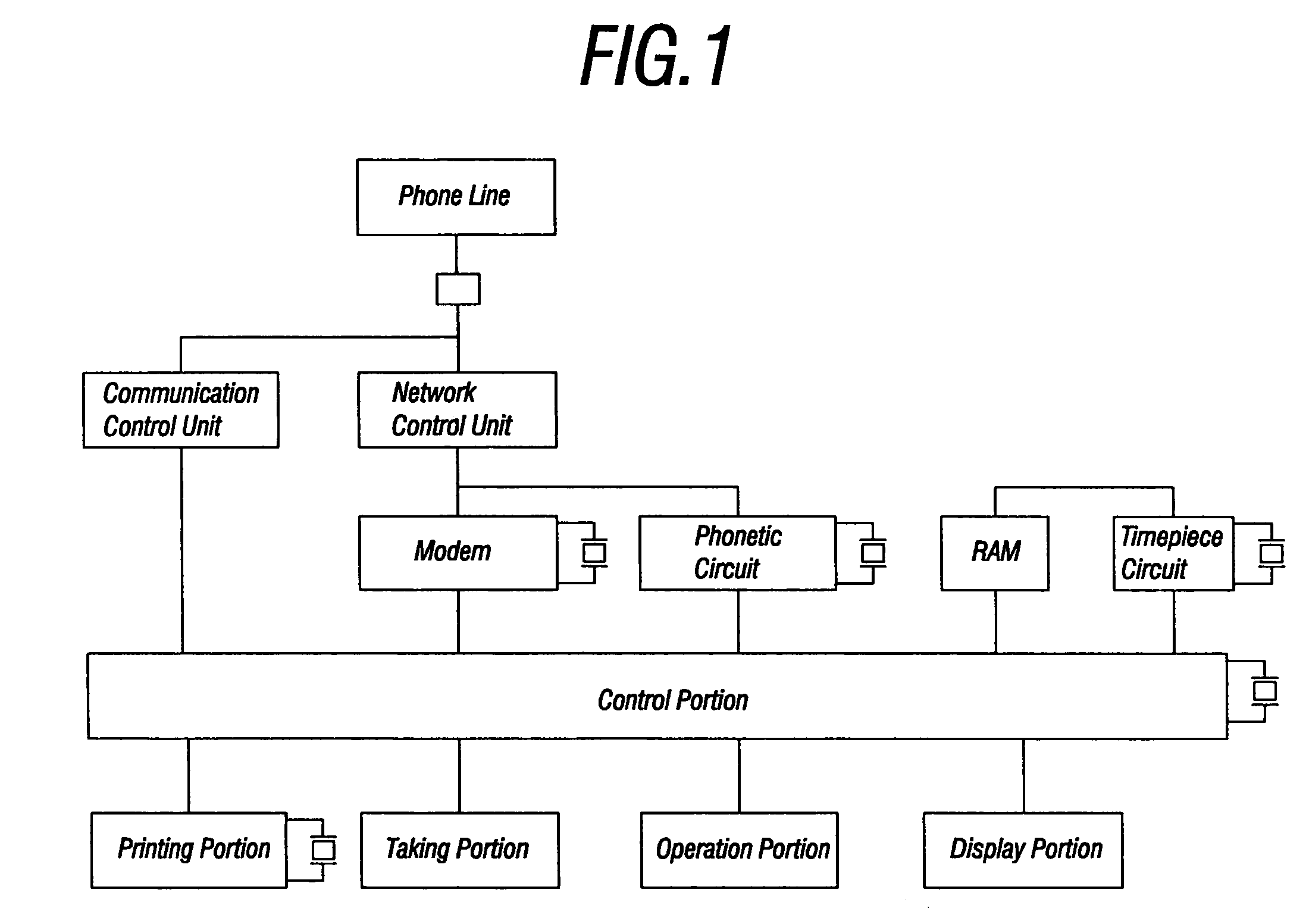

Quartz crystal resonator, unit having resonator, oscillator having unit, electronic apparatus having oscillator, and method for manufacturing electronic apparatus

InactiveUS7071794B2High-frequency stabilityHigh time accuracyImpedence networksPiezoelectric/electrostriction/magnetostriction machinesQuartz crystal resonatorCapacitance

A quartz crystal resonator has a quartz crystal tuning fork base and quartz crystal tuning fork tines connected to the quartz crystal tuning fork base. Each of the quartz crystal tuning fork tines has opposite main surfaces, a groove formed in at least one of the main surfaces, and an electrode disposed in the groove formed in at least one of the main surfaces so that a merit value M1 of a fundamental mode of vibration of the quartz crystal tuning fork resonator is greater than a merit value M2 of a second overtone mode of vibration thereof. The merit values M1 and M2 are defined by the ratios Q1 / r1 and Q2 / r2, respectively, where Q1 and Q2 represent a quality factor of the fundamental mode of vibration and the second overtone mode of vibration, respectively, of the quartz crystal tuning fork resonator and r1 and r2 represent a capacitance ratio of the fundamental mode of vibration and the second overtone mode of vibration, respectively, of the quartz crystal tuning fork resonator. A piezoelectric constant e12 of the the quartz crystal tuning fork resonator is within a range of 0.095 C / m2 to 0.19 C / m2 in the absolute value.

Owner:PIEDEK TECHN LAB

Piezoelectric Thin Film Device

ActiveUS20090189482A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsNiobium oxide

A piezoelectric thin film device according to the present invention comprises a lower electrode, a piezoelectric thin film and an upper electrode, in which the piezoelectric thin film is formed of an alkali niobium oxide-based perovskite material expressed by (K1-xNax)NbO3 (0<x<1), and in which dependency of the piezoelectric constant d31 of the piezoelectric thin film on applied electric field [=|(d31 under 70 kV / cm)−(d31 under 7 kV / cm)| / |d31 under 70 kV / cm|] is 0. 20 or less.

Owner:SUMITOMO CHEM CO LTD

Method for manufacturing quartz crystal unit and electronic apparatus having quartz crystal unit

InactiveUS20060090328A1High-frequency stabilitySmall series resistancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTuning forkElectrical polarity

In a method for manufacturing a quartz crystal unit and an electronic apparatus having the quartz crystal unit, each of the quartz crystal unit and the electronic apparatus having the quartz crystal unit, comprising the steps of forming a quartz crystal tuning fork resonator capable of vibrating in a flexural mode of an inverse phase, and having first and second quartz crystal tuning fork tines by etching a quartz crystal wafer; disposing an electrode on each of two of side surfaces of each of the first and second quartz crystal tuning fork tines so that the electrodes on the side surfaces of the first quartz crystal tuning fork tine have an electrical polarity opposite to an electrical polarity of the electrodes on the side surfaces of the second quartz crystal tuning fork tine; mounting the quartz crystal tuning fork resonator on a mounting portion of a case; and connecting a lid to the case to cover an open end thereof, the quartz crystal unit comprising the quartz crystal tuning fork resonator with a piezoelectric constant e′12 within a range of 0.12 C / m2 to 0.19 C / m2 in the absolute value.

Owner:PIEDEK TECHN LAB

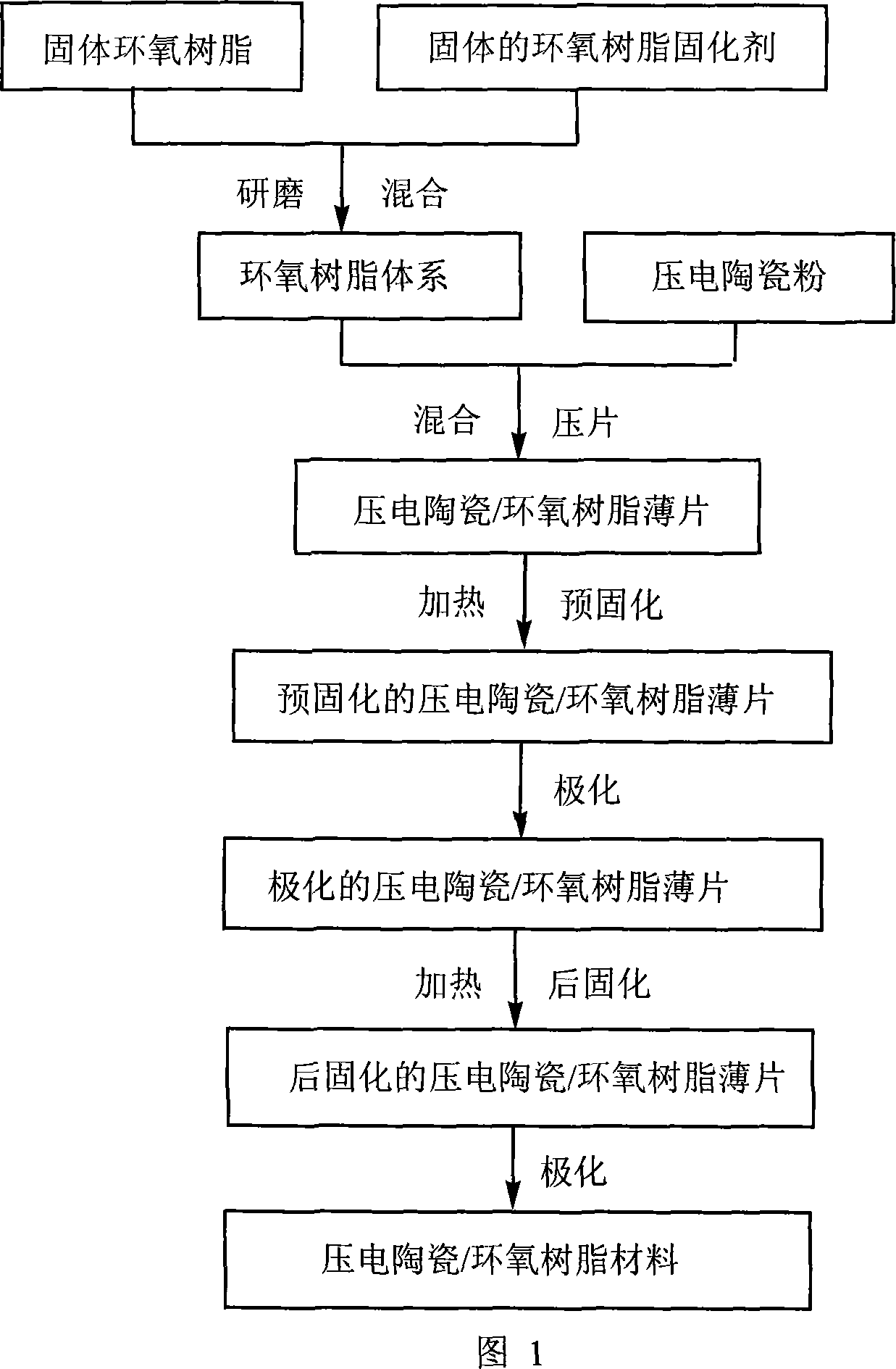

Preparation method of piezoelectric ceramic/epoxy resin composite

This invention relates to preparation method of a kind of piezoelectric ceramics / ethoxyline resin composite material. It first shatter and grind solid ethoxyline resin, solid epoxy resin curing agent, piezoelectric ceramics go as far as 5 to 100 mu m particle size, misce bene according to mixture ratio, then add adhesive agent, quench to flake by sheeter; flake takes thermal insulation 1 to 2 hours under resin system curing temperature, then natural cooling to room temperature, through polish / spread electrode / polarize, then takes thermal insulation 1 to 10 hours under resin system postcure temperature, another time polarize, then gain piezoelectric ceramics / ethoxyline resin composite material.

Owner:WUHAN UNIV OF TECH

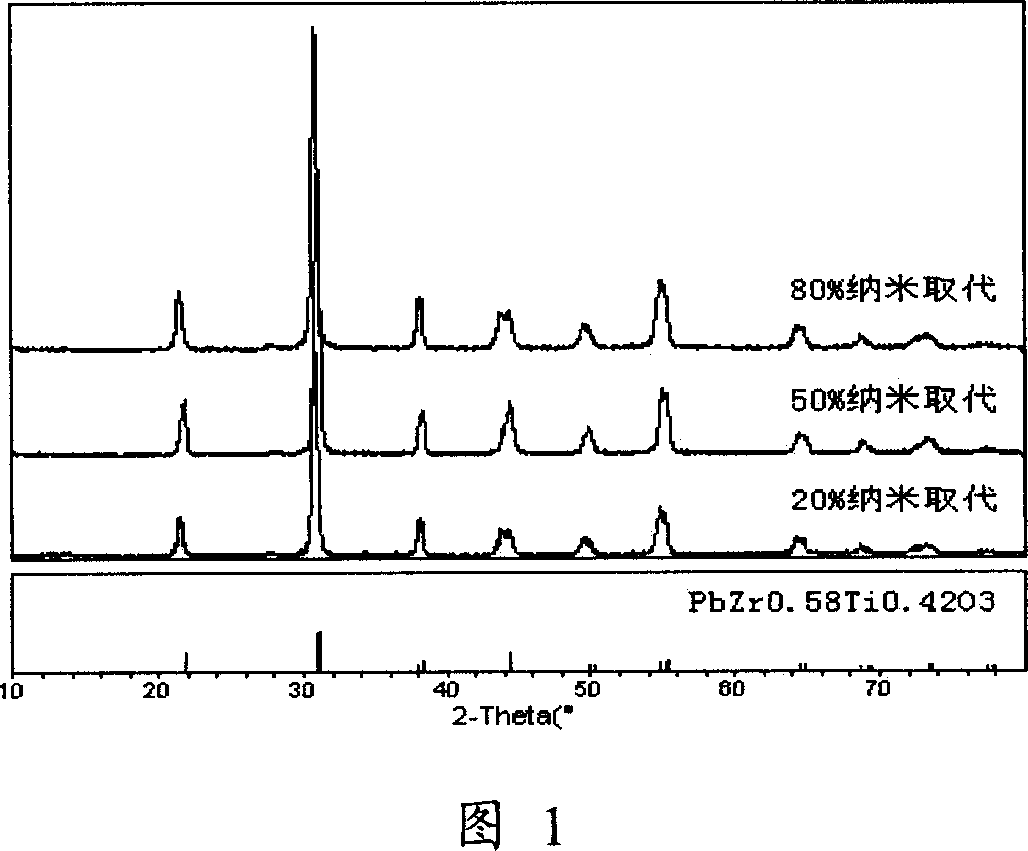

Modified PZT piezoelectric ceramics with Nano powder being added directly, and preparation method

ActiveCN1958509AProcess stabilityExcellent dielectric propertiesPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateNanometre

This invention relates to a method for preparing nanopowder-modified lead zirconate titanate piezoelectric ceramic. The method directly adds nanopowder as a substitute for micropowder into the mixed raw materials, which can reduce pre-sintering temperature by 50-200 deg.C and final-sintering temperature by 50-100 deg.C, and can adjust the crystalline and properties of pre-sintered sample as well as the electrical properties of the sintered piezoelectric ceramic. Nanopowder-modified piezoelectric ceramic sintered at 1200 deg.C has a Curie point increased by 50-100 deg.C. Besides, the piezoelectric ceramic has excellent impact stability (TC = 350-400 deg.C; epsiv = 350-800; KP = 0.48-0.60), adjustable piezoelectric constant, stable process and good repeatability. The piezoelectric ceramic can be used to produce ceramic frequency discriminator and ceramic filter.

Owner:ZHEJIANG JIAKANG ELECTRONICS CO LTD +1

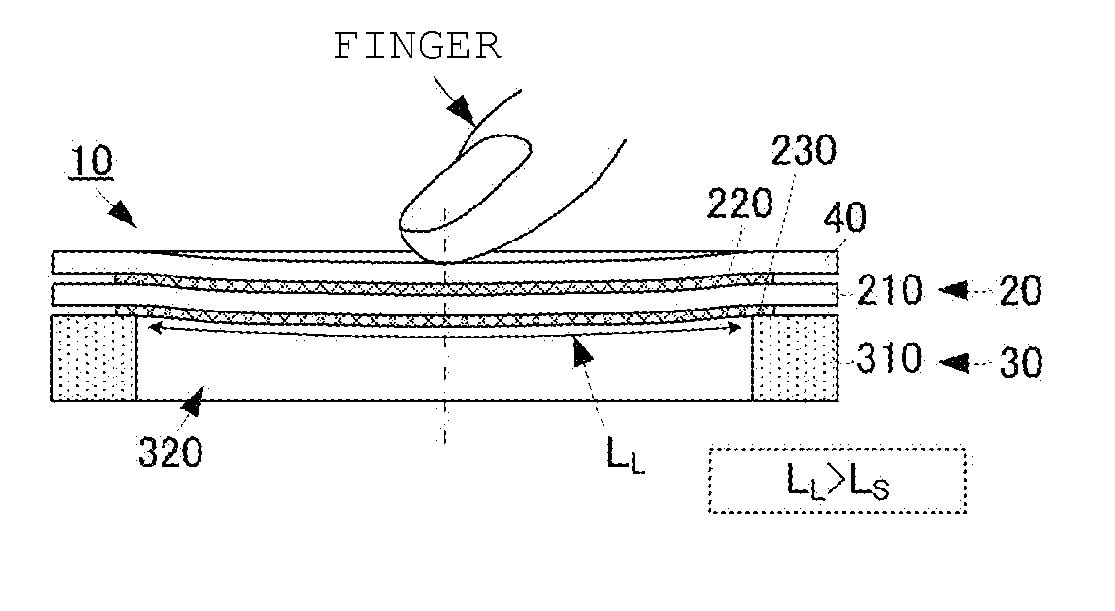

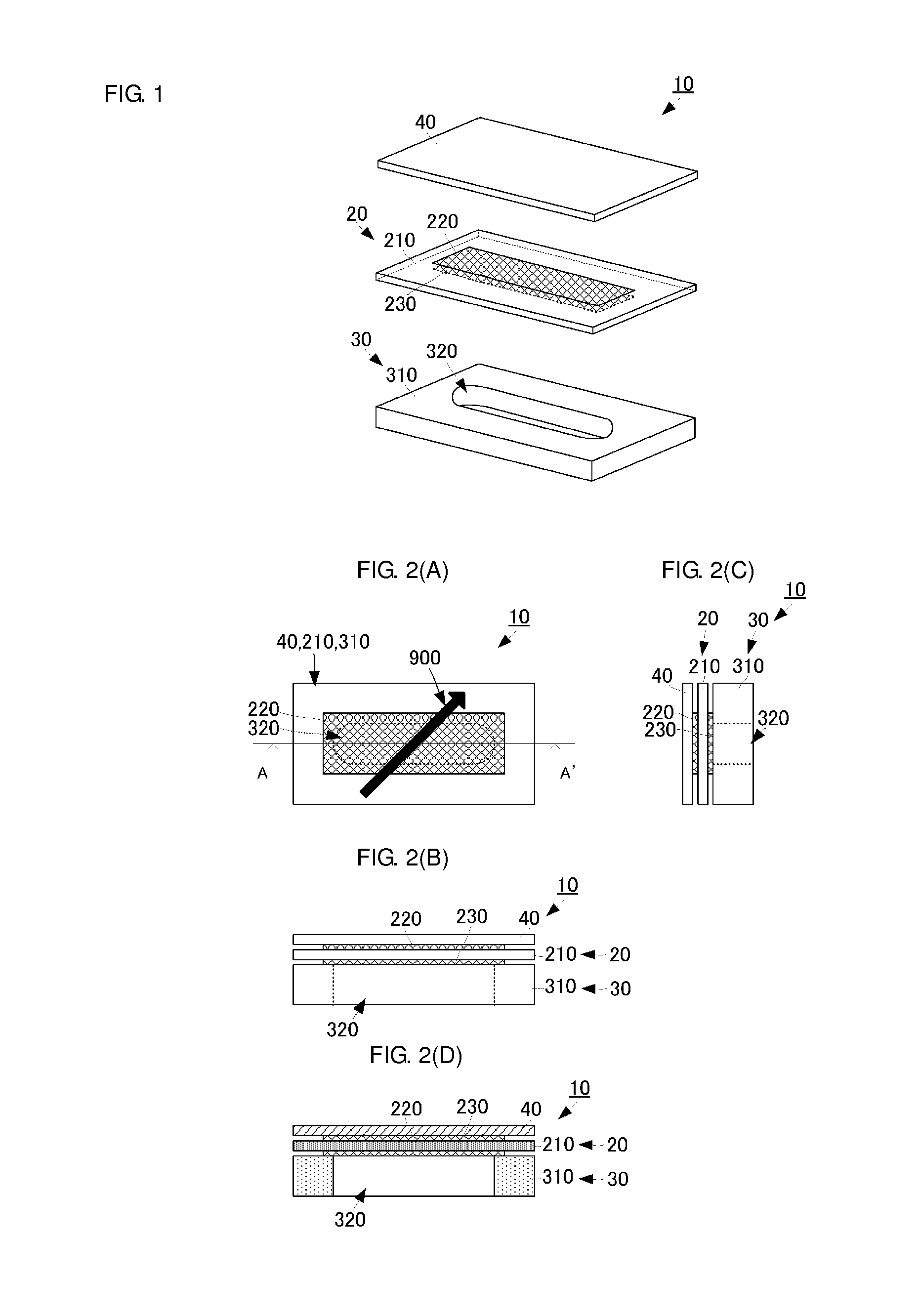

Pressing Force Sensor

ActiveUS20150035411A1Reliably detect operationReliable detectionPiezoelectric/electrostriction/magnetostriction machinesForce measurement using piezo-electric devicesEngineeringForce sensor

A pressing force sensor that includes a flat membrane piezoelectric element and a support. The flat membrane piezoelectric element includes a piezoelectric sheet having a piezoelectric constant d14. A first electrode is formed on a first main surface of the piezoelectric sheet and a second electrode is formed on a second main surface thereof. Long directions of the first electrode and the second electrode and a uniaxial stretching direction of the piezoelectric sheet form an angle of 45°. An opening portion having an elliptical section is formed on the support. The flat membrane piezoelectric element abuts the opening portion of the support. The support and the flat membrane piezoelectric element are disposed such that the opening portion is included within an area of the second electrode.

Owner:MURATA MFG CO LTD

High-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics and preparation method thereof

InactiveCN104876567AReduce volatilityShorten the time of high temperature sinteringElectricityUltrasonic sensor

The invention relates to high-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics and a preparation method thereof. The raw material composition of the high-piezoelectric coefficient potassium-sodium niobate based leadless piezoelectric ceramics is (1-a)(K0.5Na0.5)-.95Li0.05Nb0.93Sb0.07-aMZrO3, wherein M is Ca, Sr or Ba, and a is within the range of 0.01 to 0.06; the following three-step sintering solid-phase synthesis preparation method is adopted: in the first step, the sintering temperature is within the range of 1100-1120 DEG C and the heat preservation time is 0 minute; in the second step, the sintering temperature is within the range of 1160-1210 DEG C and the heat preservation time is 0-5 minutes; in the third step, the sintering temperature is within the range of 1000-1100 DEG C and the heat preservation time is 2-20 minutes; consequently, a novel leadless piezoelectric ceramic material can be obtained, and the maximum piezoelectric coefficient d33 of the material is 410pC / N, wherein d*33 is 450. The leadless piezoelectric ceramic material is applied to a plurality of fields such as ultrasonic transducers, piezoelectric buzzers, drivers and resonators.

Owner:TONGJI UNIV

Bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic and preparation method thereof

The invention discloses a bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic and a preparation method thereof. The bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic has a general formula: (1-n)[(1-u-v)Pb(Zr1-zTiz)O3+uBi(CxDy)O3+v(Bi0.5E0.5)TiO3]+nM. The ceramic has a morphotropic phase boundary of a rhombic ferroelectricity phase and a tetragonal ferroelectricity phase, has the advantages of excellent piezoelectric constants, higher Curie temperature, lowered lead content and practicability, can replace parts of traditional lead-containing piezoelectric ceramic and can be prepared from industrial raw materials by adopting the traditional preparation technology of the piezoelectric ceramic.

Owner:HEFEI UNIV OF TECH

Method for manufacturing quartz crystal unit and electronic apparatus having quartz crystal unit

InactiveUS7412764B2High-frequency stabilityHigh quality factorPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksTuning forkElectrical polarity

In a method for manufacturing a quartz crystal unit, a quartz crystal tuning fork resonator is formed by etching a quartz crystal wafer to form a quartz crystal tuning fork base and first and second quartz crystal tuning fork tines connected to the quartz crystal tuning fork base. The quartz crystal tuning fork resonator has a piezoelectric constant e′12 within a range of 0.12 C / m2 to 0.19 C / m2 in the absolute value to drive the quartz crystal tuning fork resonator. An electrode is disposed on each of two of side surfaces of each of the first and second quartz crystal tuning fork tines so that the electrodes disposed on the side surfaces of the first quartz crystal tuning fork tine have an electrical polarity opposite to an electrical polarity of the electrodes disposed on the side surfaces of the second quartz crystal tuning fork tine. The quartz crystal tuning fork resonator is mounted on a mounting portion of a case.

Owner:PIEDEK TECHN LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com