Preparation method of piezoelectric ceramic/epoxy resin composite

A technology of piezoelectric ceramics and epoxy resin, which is applied in the field of preparation of piezoelectric ceramics/epoxy resin composite materials, can solve problems affecting material performance, unstable materials and performance, and difficult gas escape, and achieve high-voltage electric Constant, stable performance, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

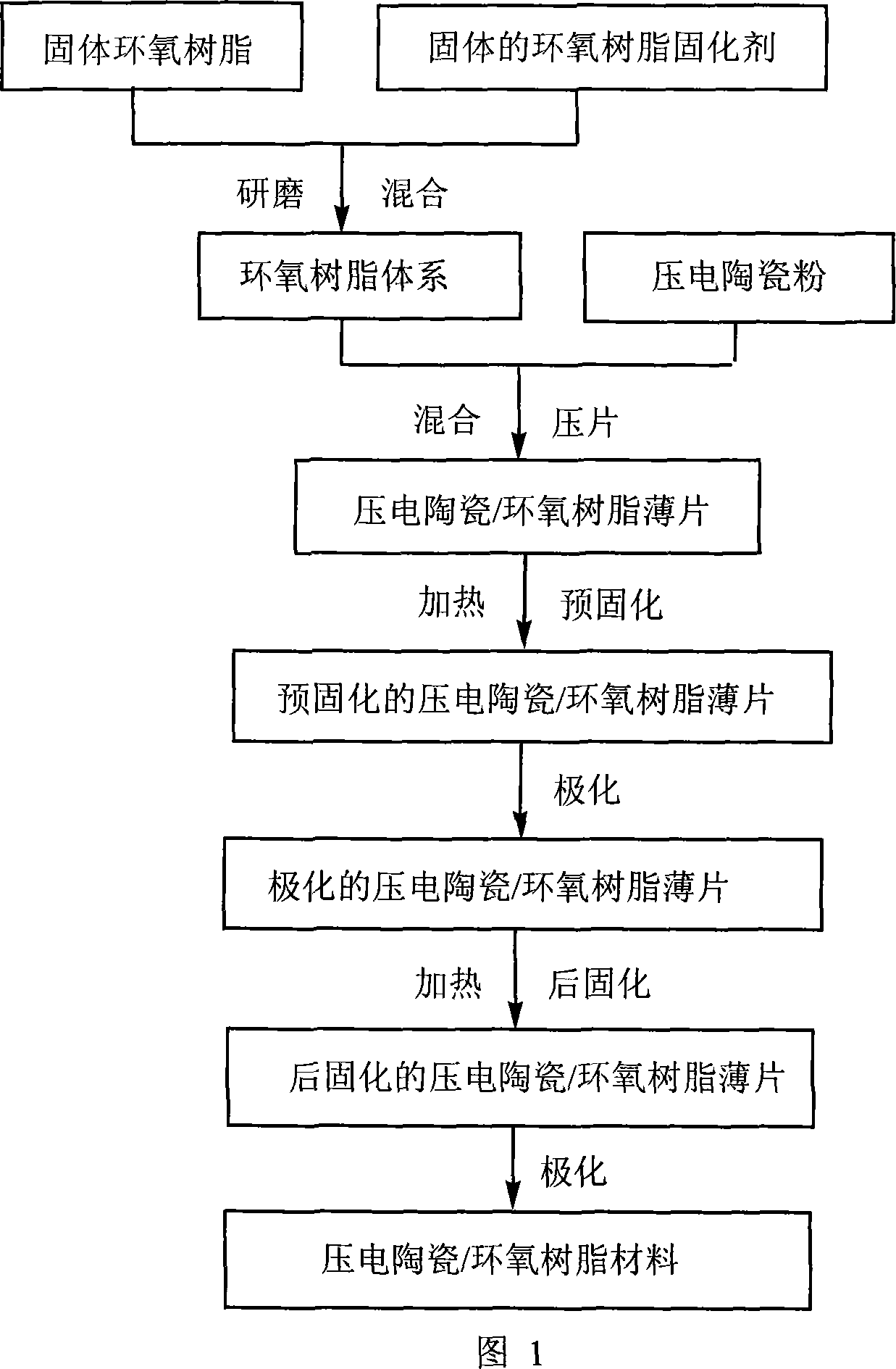

[0023] As shown in Figure 1, grind solid epoxy resin CYD017, solid epoxy resin curing agent phthalic anhydride, and piezoelectric ceramic PMN to 10-50 μm respectively, according to the ratio of CYD017: phthalic anhydride: PMN 1: 0.15: 5 parts by mass and mix evenly, then add polyvinyl alcohol adhesive accounting for 0.5% of the total weight of CYD017, phthalic anhydride and PMN, press it into a thin sheet under 30MPa pressure, and place it in an electric heater at 130°C Incubate in a constant temperature drying oven for 1 h and then cool to room temperature. Polish the slice, cover it with silver, polarize it at 100°C and 8KV for 20min, then keep it at 150°C for 2h, and then conduct the second polarization to prepare the piezoelectric ceramic / epoxy resin composite material. The piezoelectric voltage constant of the composite material is 16pC / N.

Embodiment 2

[0025] Grind solid epoxy resin, solid epoxy resin curing agent diaminodiphenylmethane, and piezoelectric ceramic PZT to 60-80 μm respectively, according to solid epoxy resin D.E.R.692: diaminodiphenylmethane: piezoelectric ceramic PZT The mass and number ratio is 1:0.30:10, mix evenly, then add PVA adhesive accounting for 1.5% of the total weight of solid epoxy resin D.E.R.692, diaminodiphenylmethane and piezoelectric ceramic PZT, and press under 50MPa pressure to form Thin slices were placed in an electric constant temperature drying oven at 90°C for 1 hour and then cooled to room temperature. Polish the slice, cover it with silver, polarize it at 80°C and 6KV for 15 minutes, then keep it at 120°C for 3 hours, and then conduct the second polarization to prepare the piezoelectric ceramic / epoxy resin composite material. The piezoelectric voltage constant of the composite material is 23pC / N.

Embodiment 3

[0027] As shown in Figure 1, a kind of preparation method of piezoelectric ceramic / epoxy resin composite material, it comprises the steps:

[0028] 1). The solid epoxy resin and the solid epoxy resin curing agent are pulverized and ground to a particle size of 5 μm respectively, and then mixed evenly in parts by mass of solid epoxy resin: solid epoxy resin curing agent=1: 0.08, Obtain an epoxy resin system for subsequent use; the solid epoxy resin is CYD019, and the epoxy resin curing agent is phthalic anhydride.

[0029] 2). Grinding and ball milling the piezoelectric ceramic sheet to a particle size of 5 μm to obtain the piezoelectric ceramic powder; the epoxy resin system and the piezoelectric ceramic are selected according to the mass-number ratio of the epoxy resin system and the piezoelectric ceramic powder at 1:3 Piezoelectric ceramic powder is added to the epoxy resin system and mixed evenly to obtain piezoelectric ceramic / epoxy resin powder; the piezoelectric ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com