Patents

Literature

75 results about "Piezoelectric voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

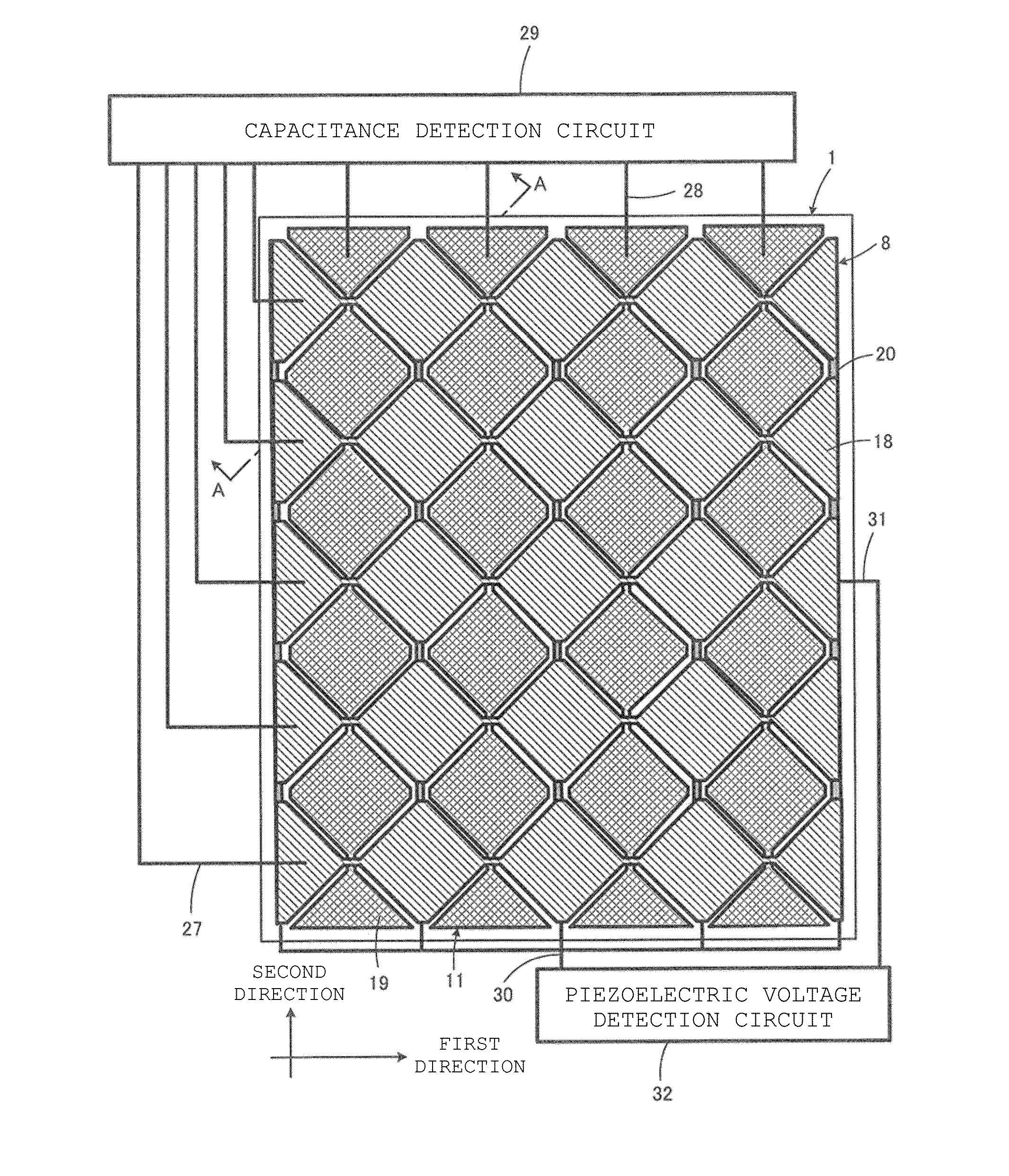

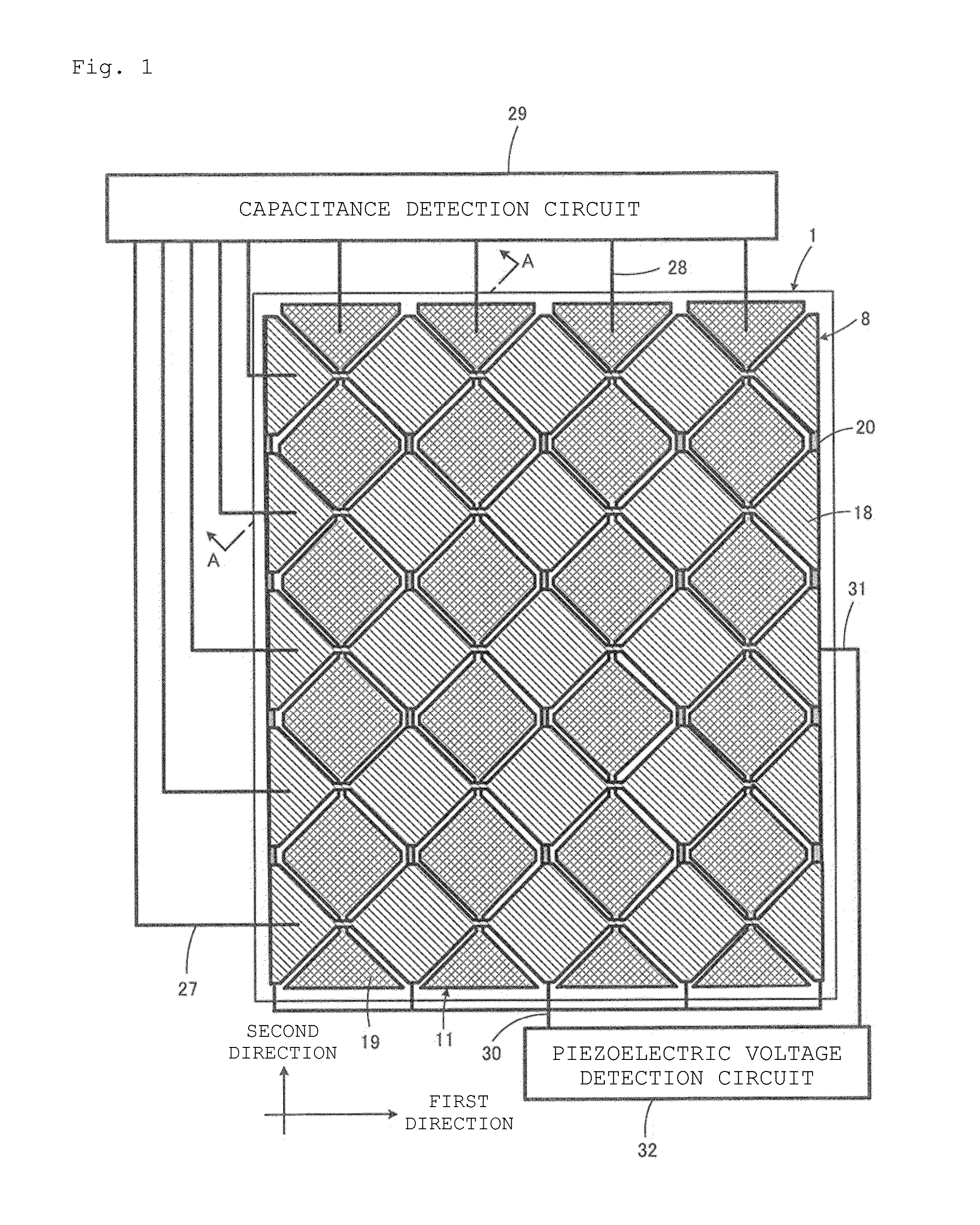

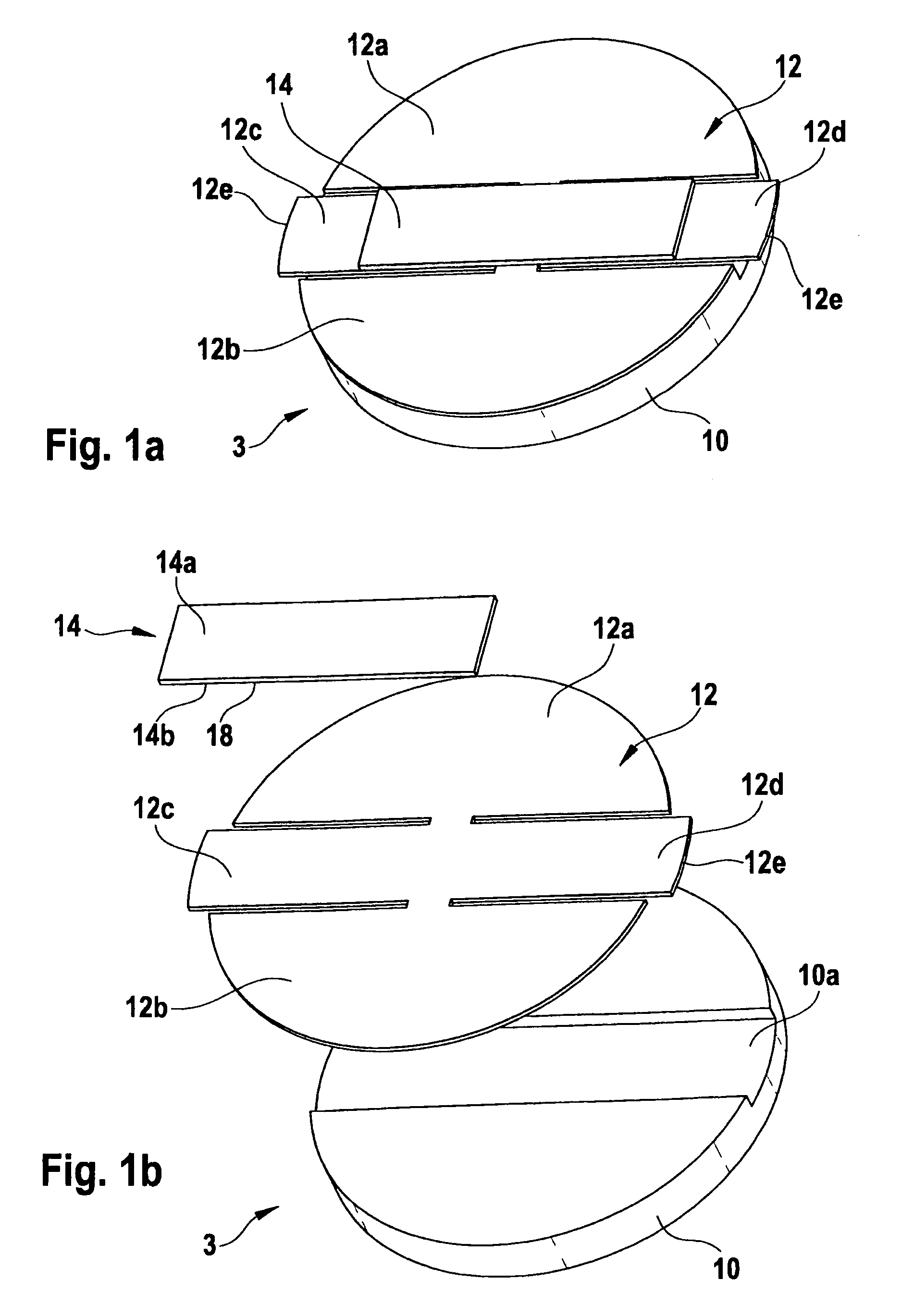

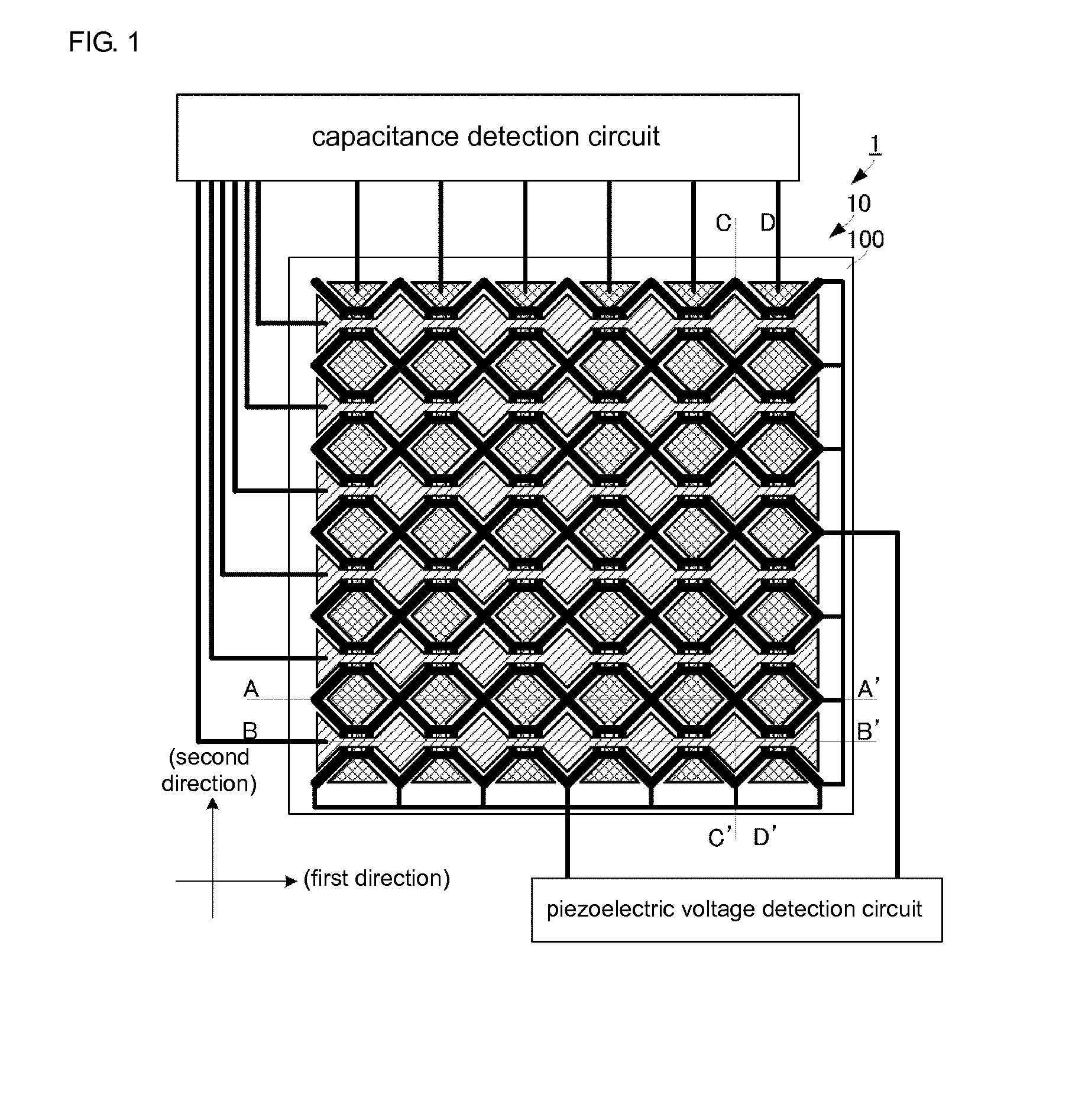

Touch panel

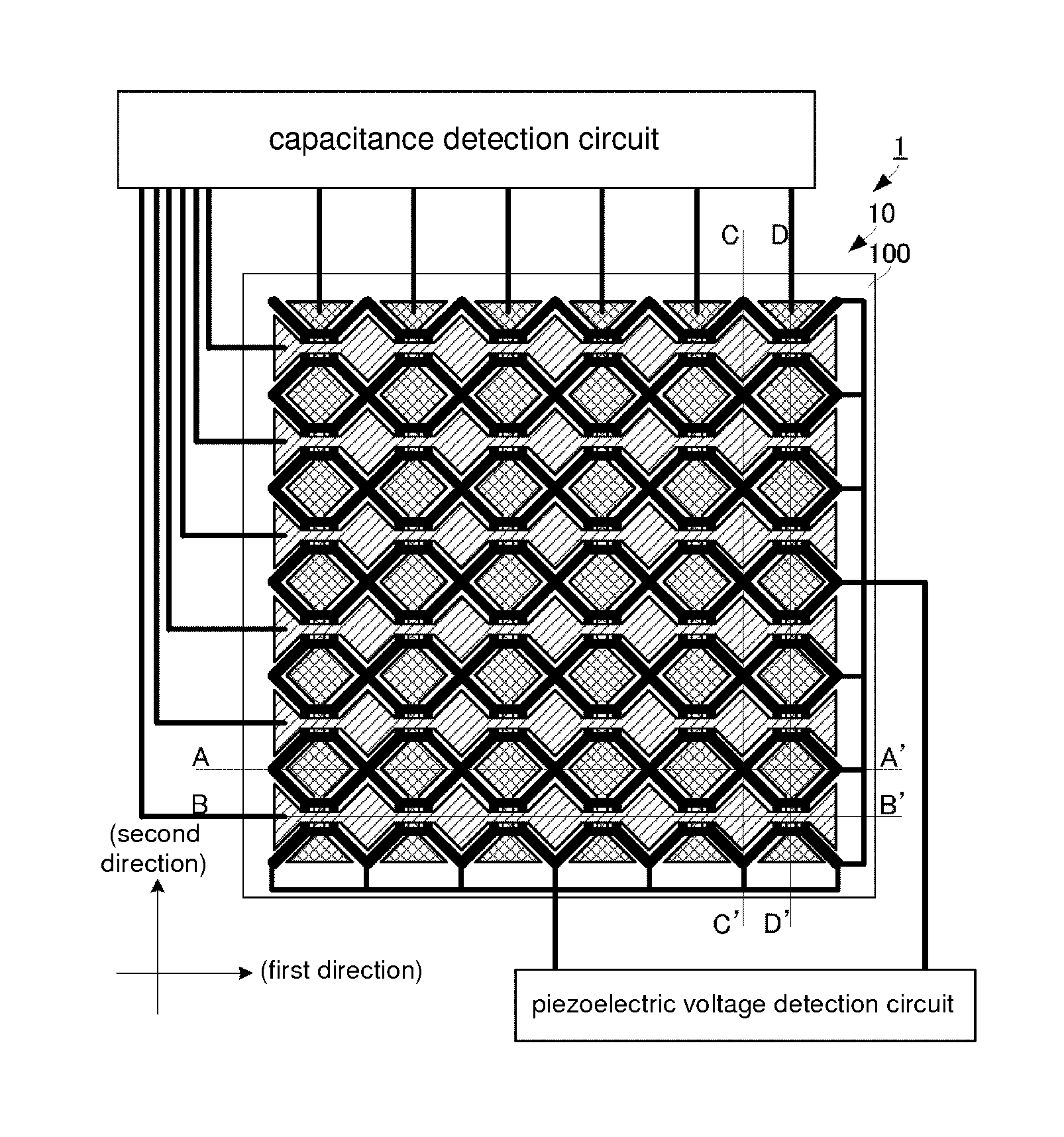

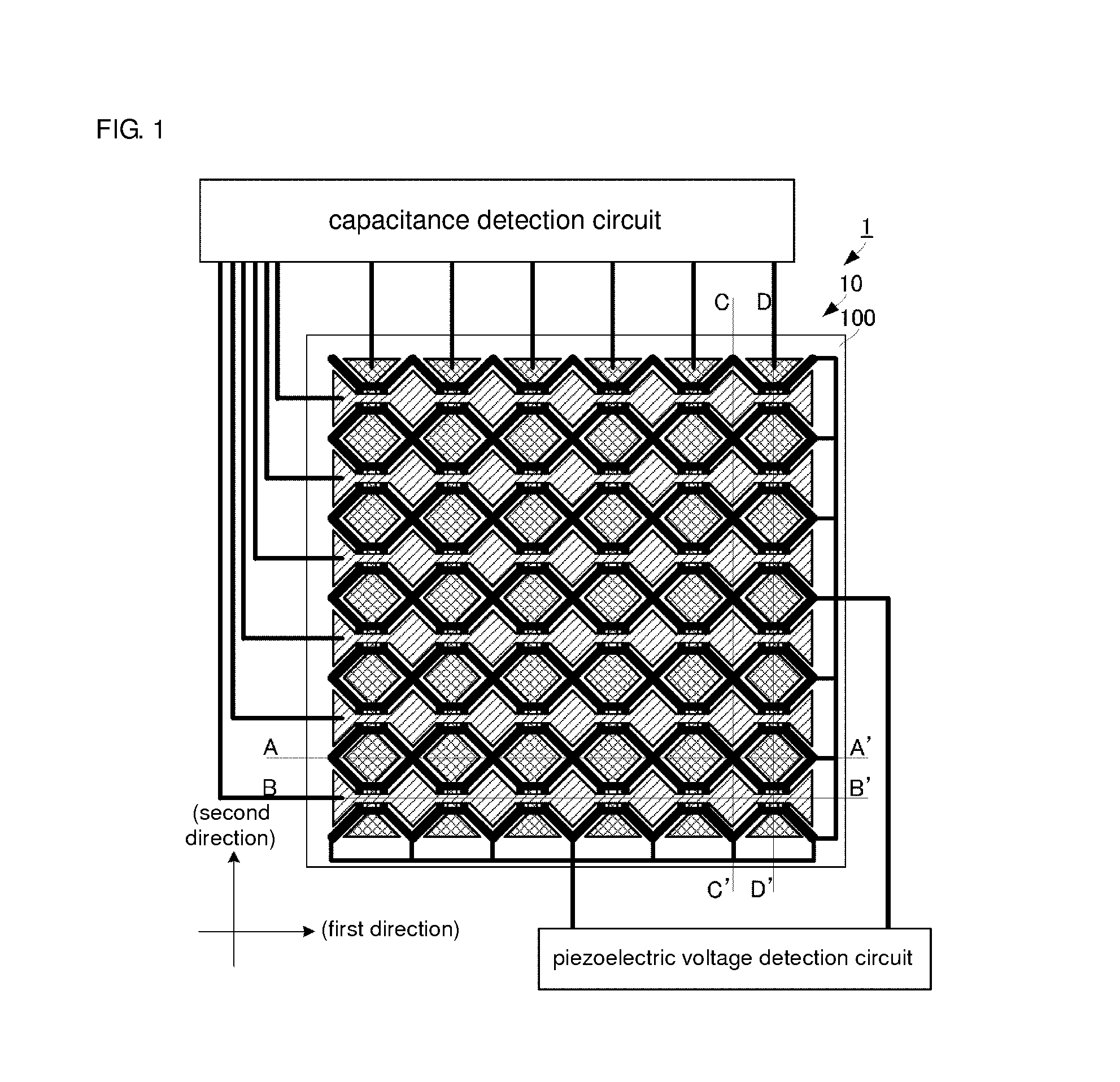

A touch panel that includes a flat membrane-like piezoelectric film provided with a first principal surface and a second principal surface which are opposed to each other. The touch panel includes first and second capacitance detection sub-electrodes on the first principal surface and the second principal surface of the piezoelectric film. The first and second capacitance detection sub-electrodes detect a touched position. The touch panel includes first and second piezoelectric voltage detection sub-electrodes on the first principal surface and the second principal surface of the piezoelectric film. The first and second piezoelectric voltage detection sub-electrodes detect a piezoelectric voltage according to an amount pressed into the piezoelectric film.

Owner:MURATA MFG CO LTD

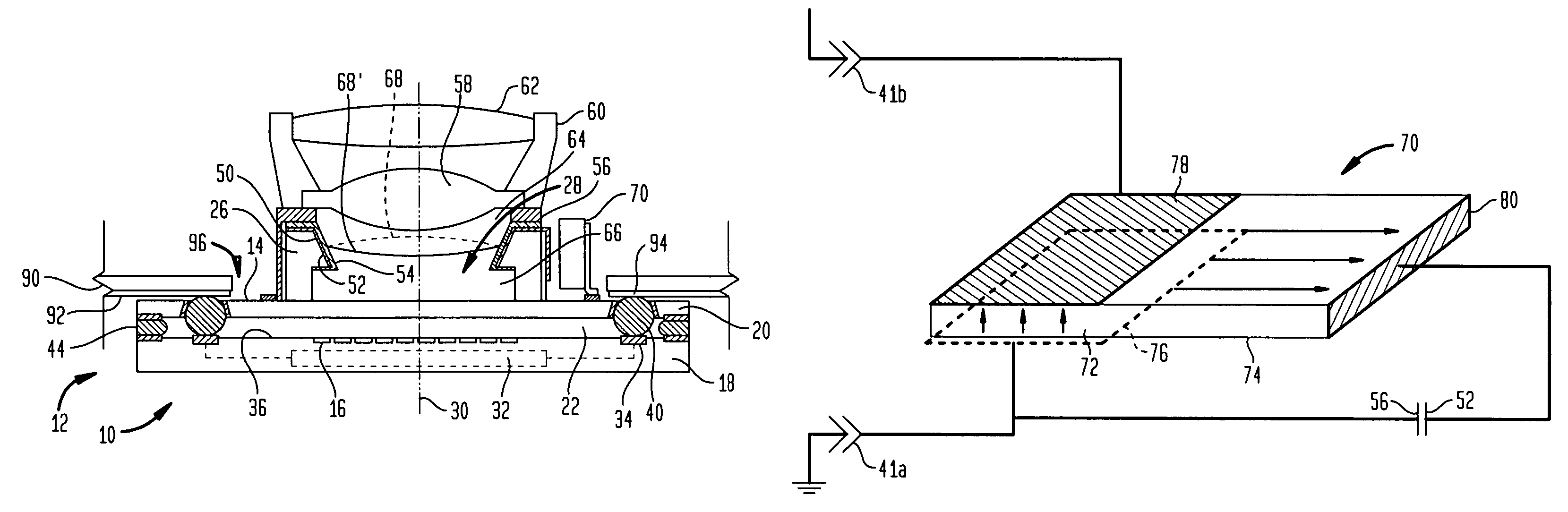

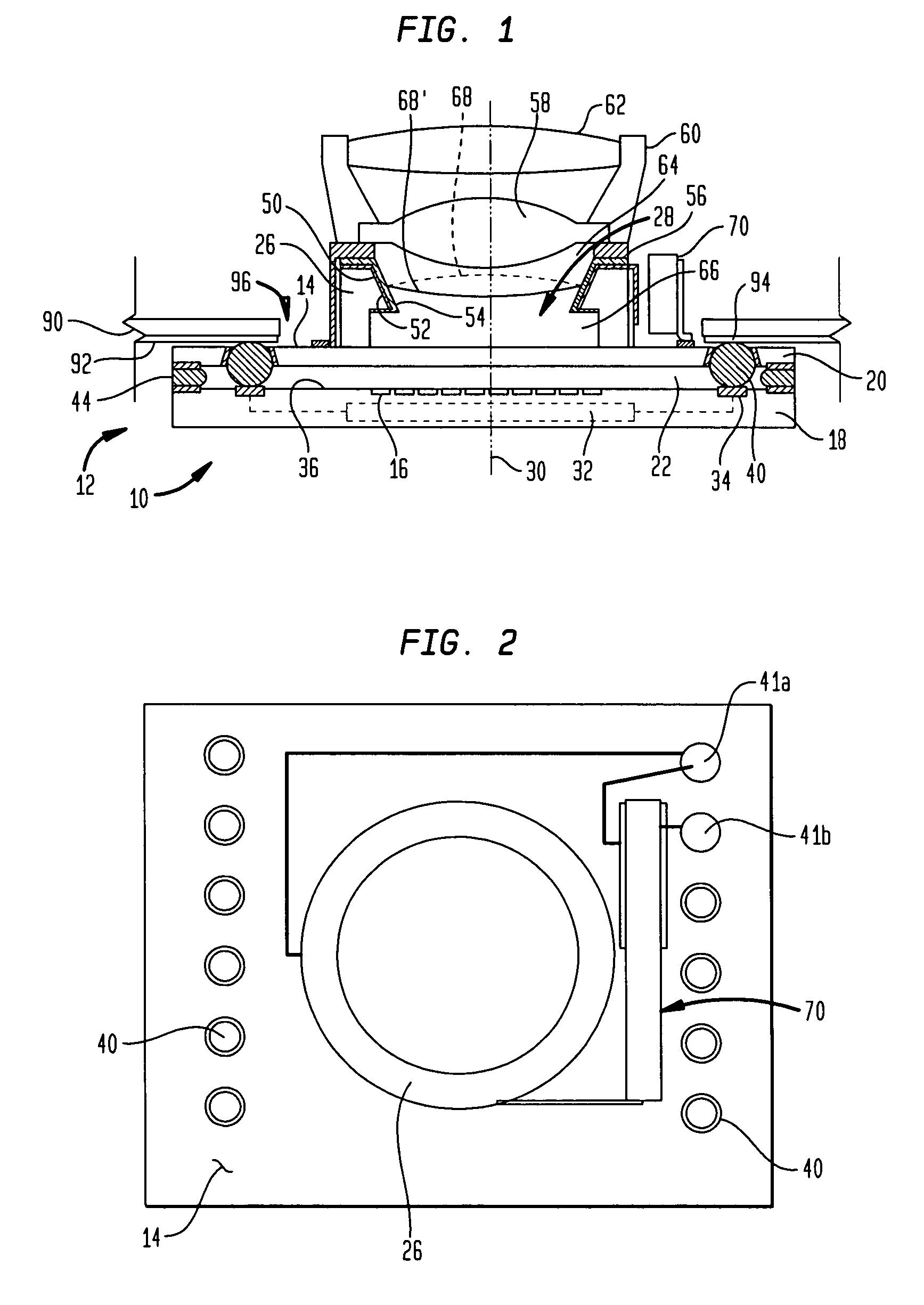

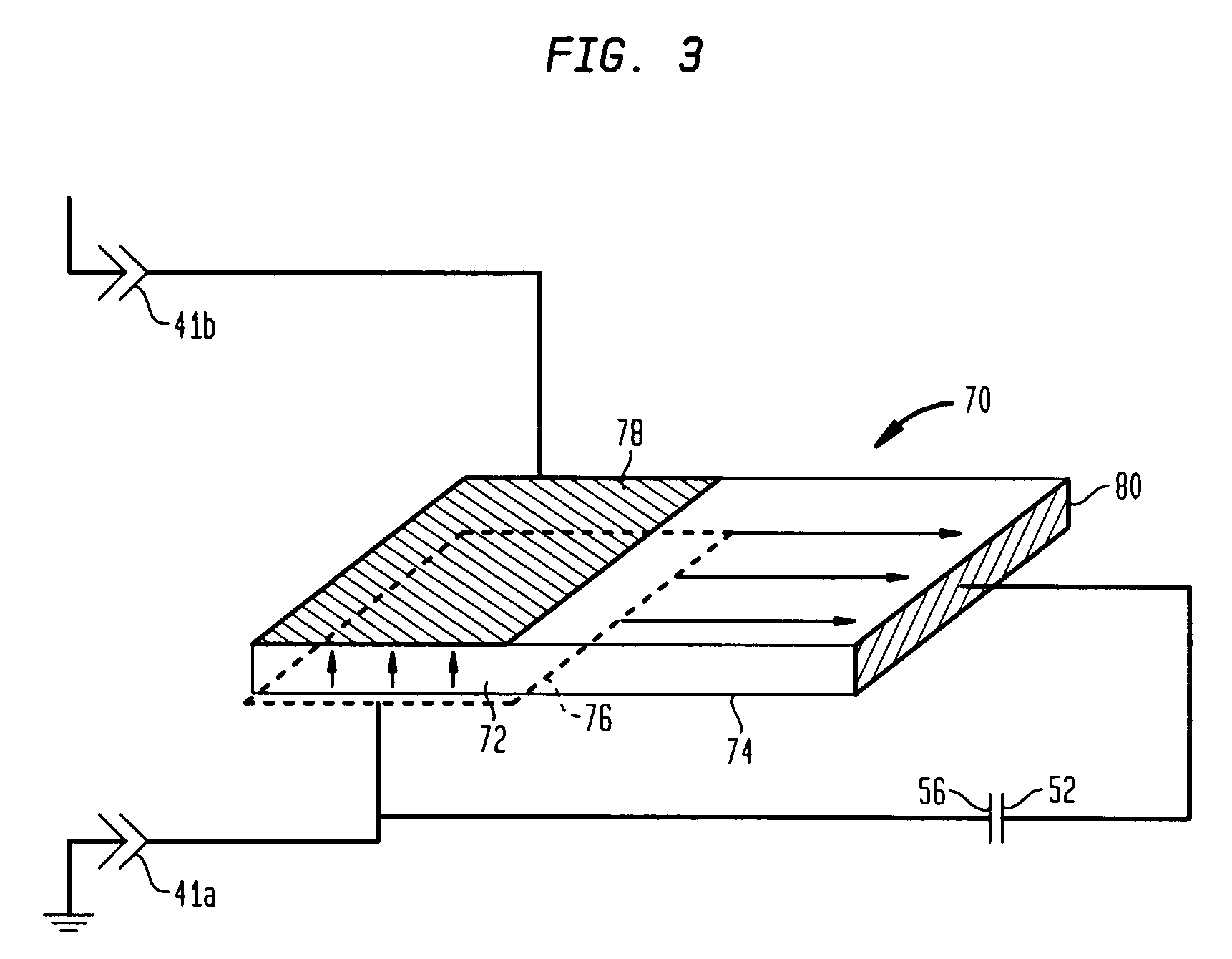

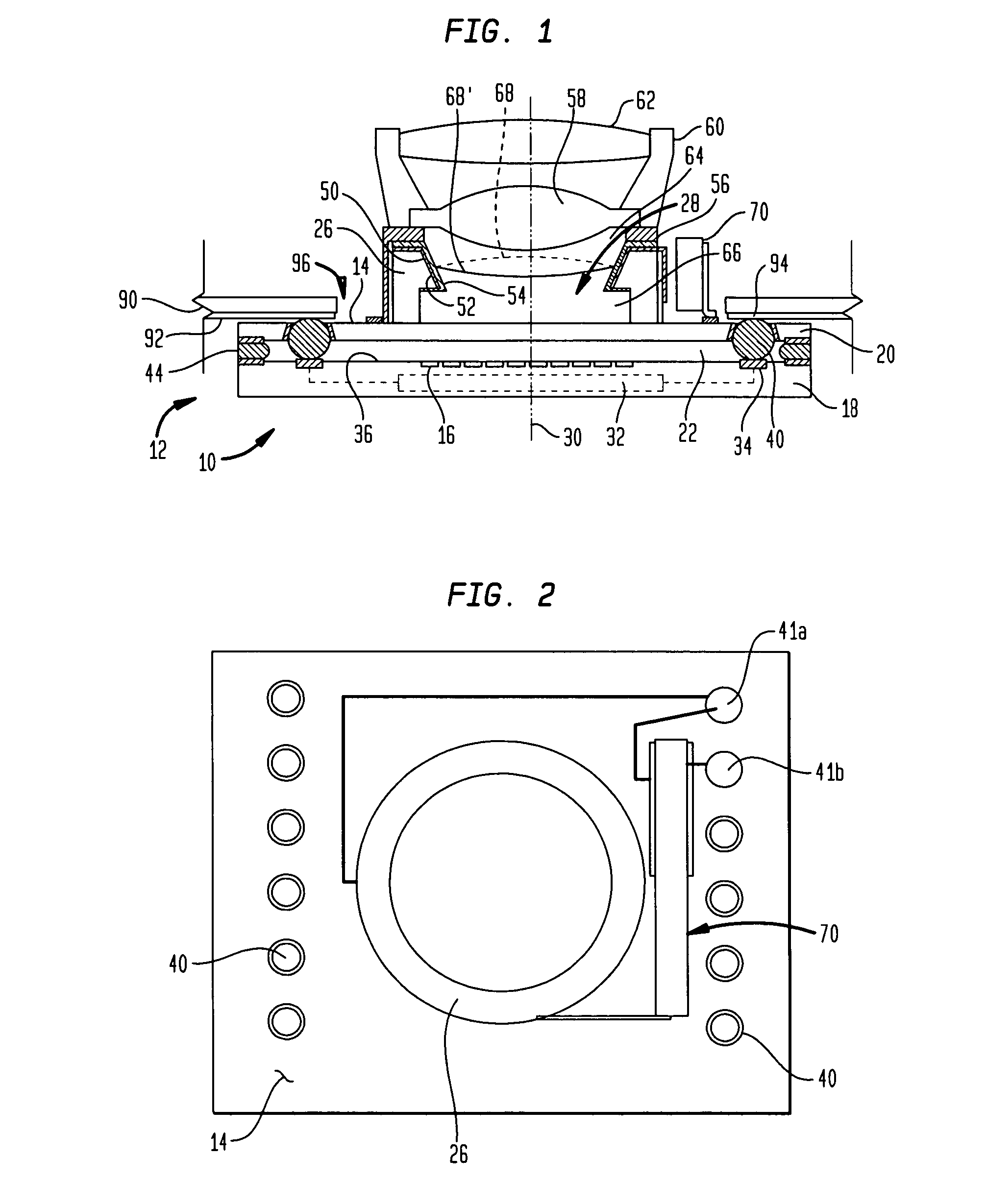

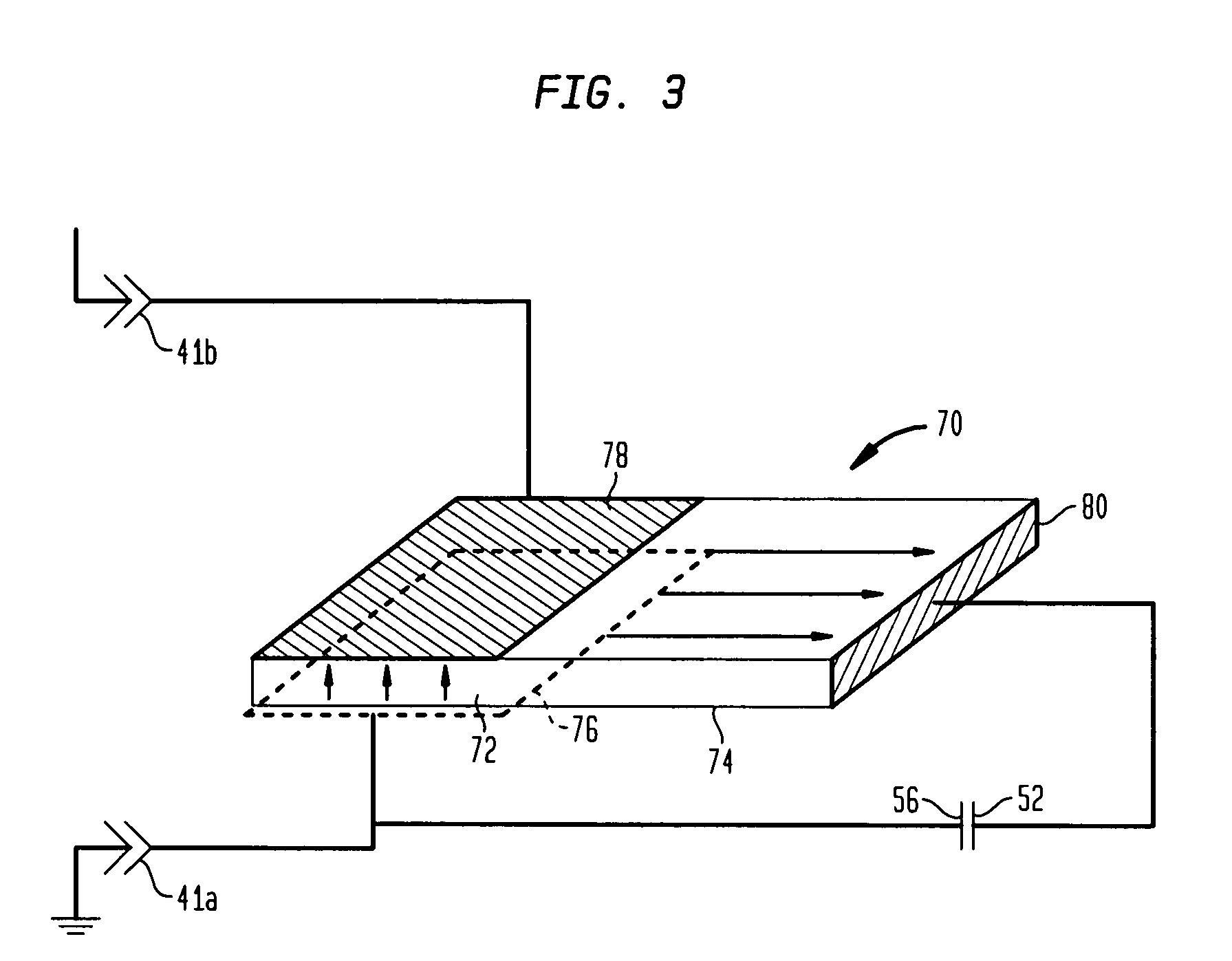

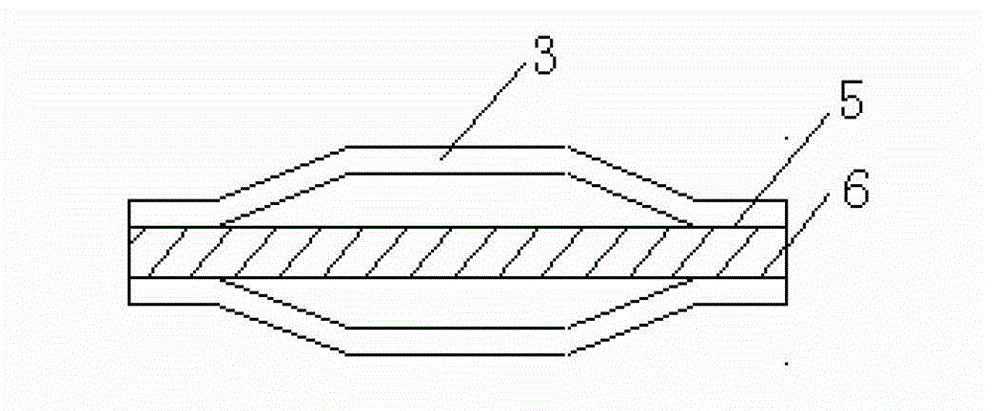

Liquid lens with piezoelectric voltage converter

InactiveUS7443597B2Easy to manufactureTelevision system detailsSolid-state devicesOptical propertyPiezoelectric voltage

An electronic camera module includes a lens or refractive element formed by a pair of immiscible liquids and having optical properties which can be varied by applying a voltage so as to deform the meniscus. One of the two liquids extends from the meniscus all the way to the front surface of the sensor, so that light passing through the meniscus does not encounter further changes in refractive index enroute to the sensor.

Owner:TESSERA INC

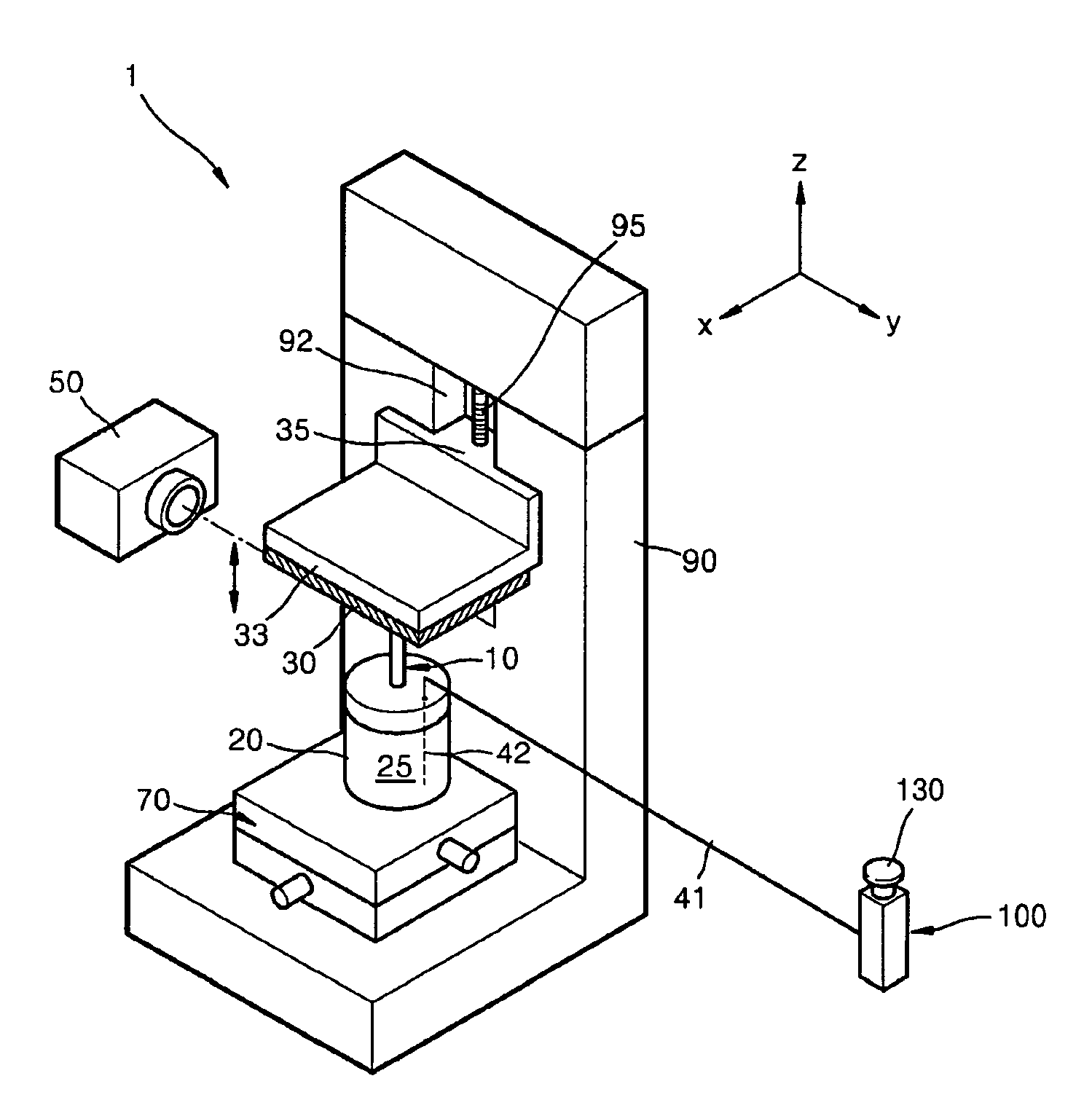

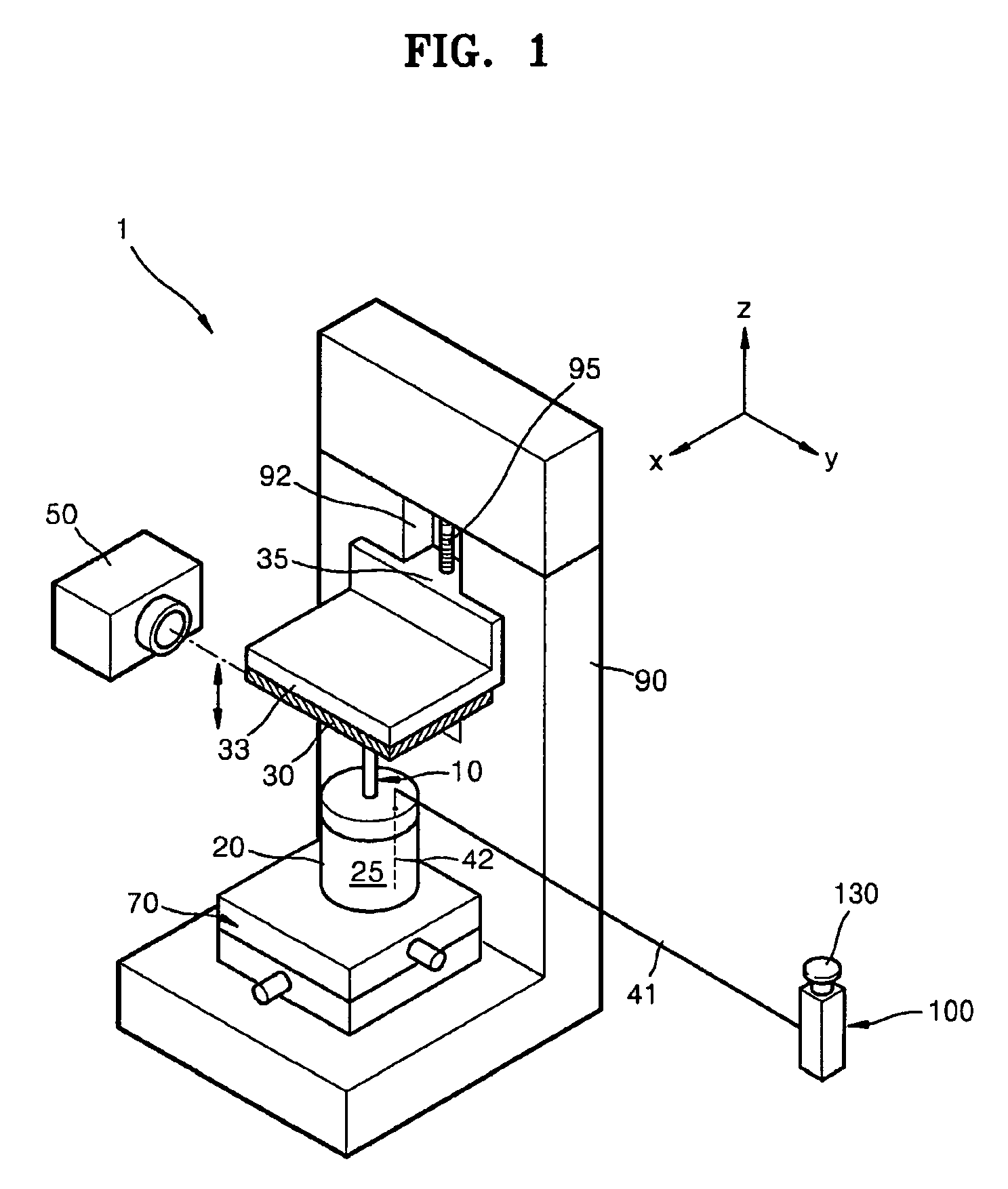

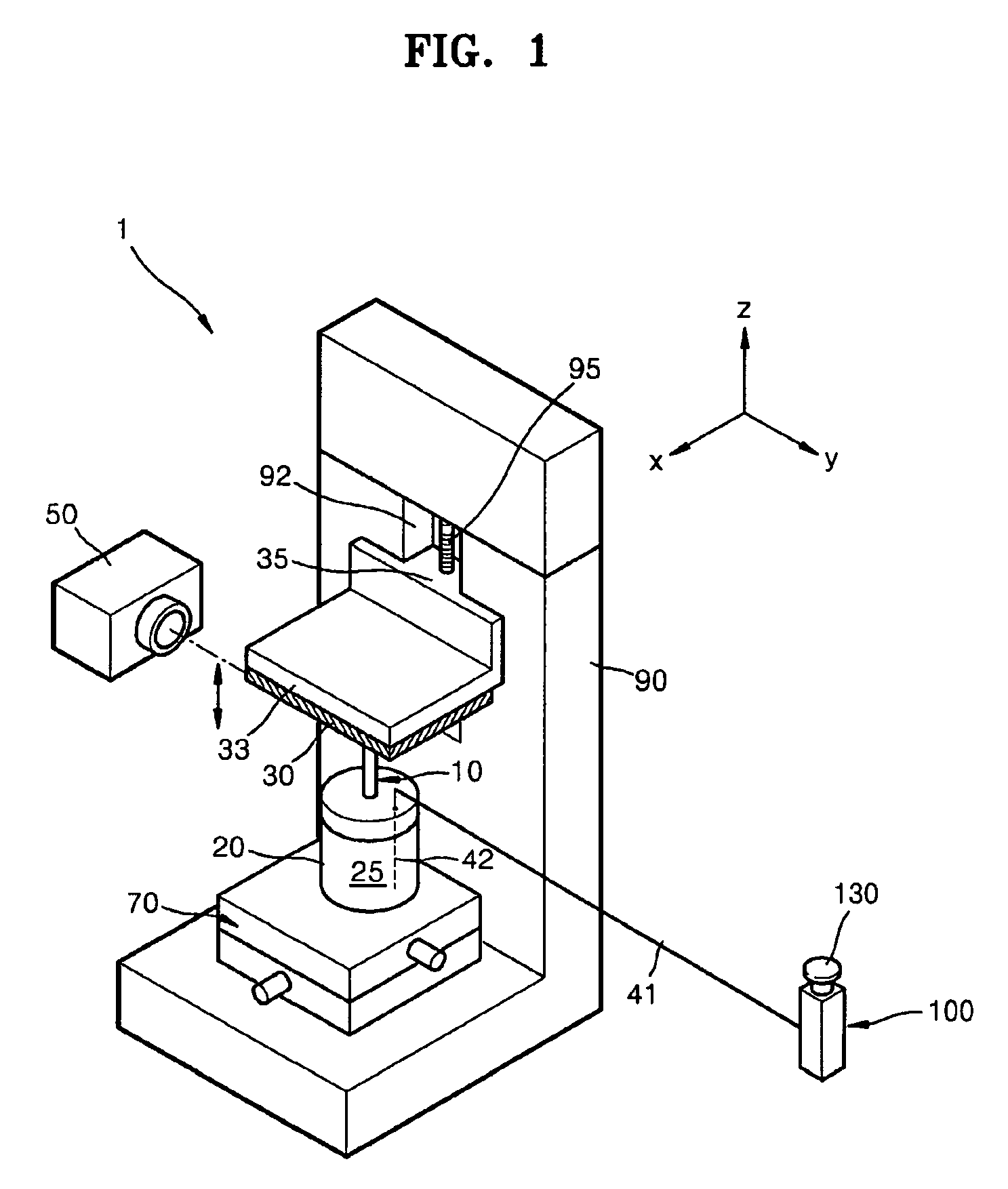

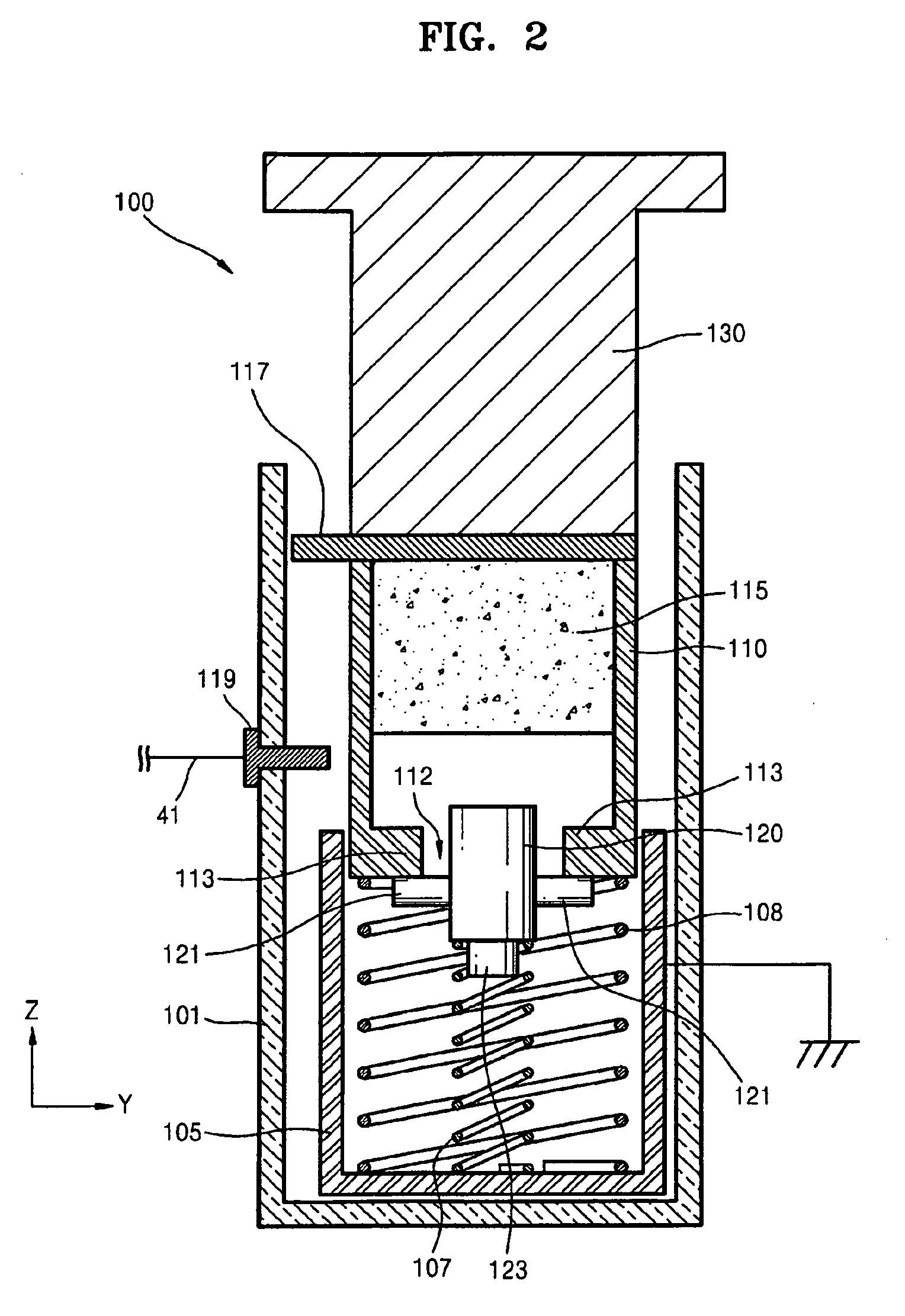

Droplet emitting apparatus having piezoelectric voltage generator and method of emitting a droplet using the same

ActiveUS8282894B2Reduce distanceIncrease distanceWithdrawing sample devicesLaboratory glasswaresVoltage generatorElectricity

Provided are a droplet emitting apparatus and a method of emitting droplets using the same. The apparatus includes a solution tank for containing a solution; a nozzle including an opening through which at least a droplet of the solution is emitted; and a voltage generator including a piezoelectric material for generating a voltage by instantaneous pressure application, wherein the voltage generated by the pressure to the piezoelectric material is applied to the solution in order for the at least a droplet of the solution to be emitted through the nozzle.

Owner:SAMSUNG ELECTRONICS CO LTD

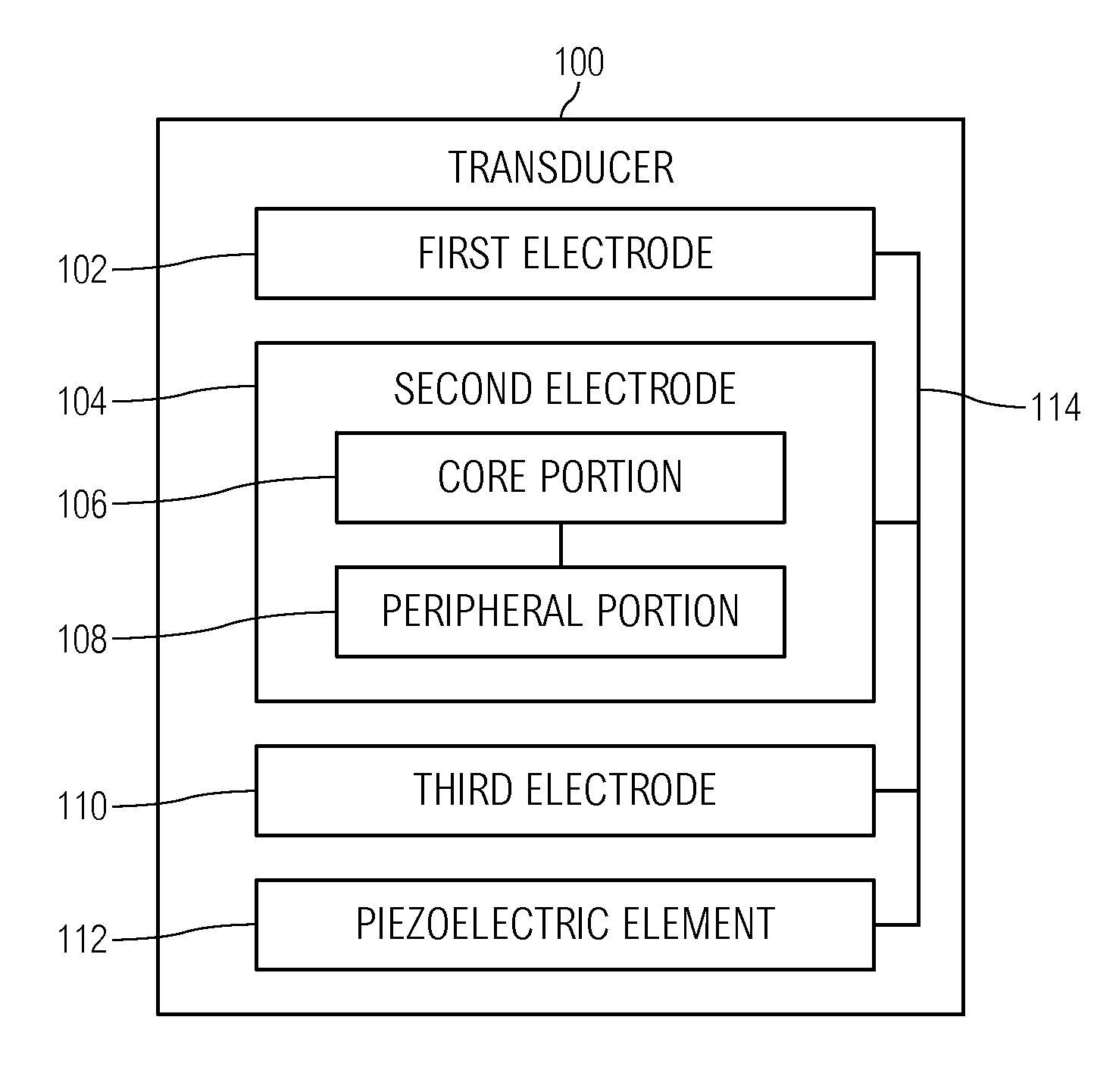

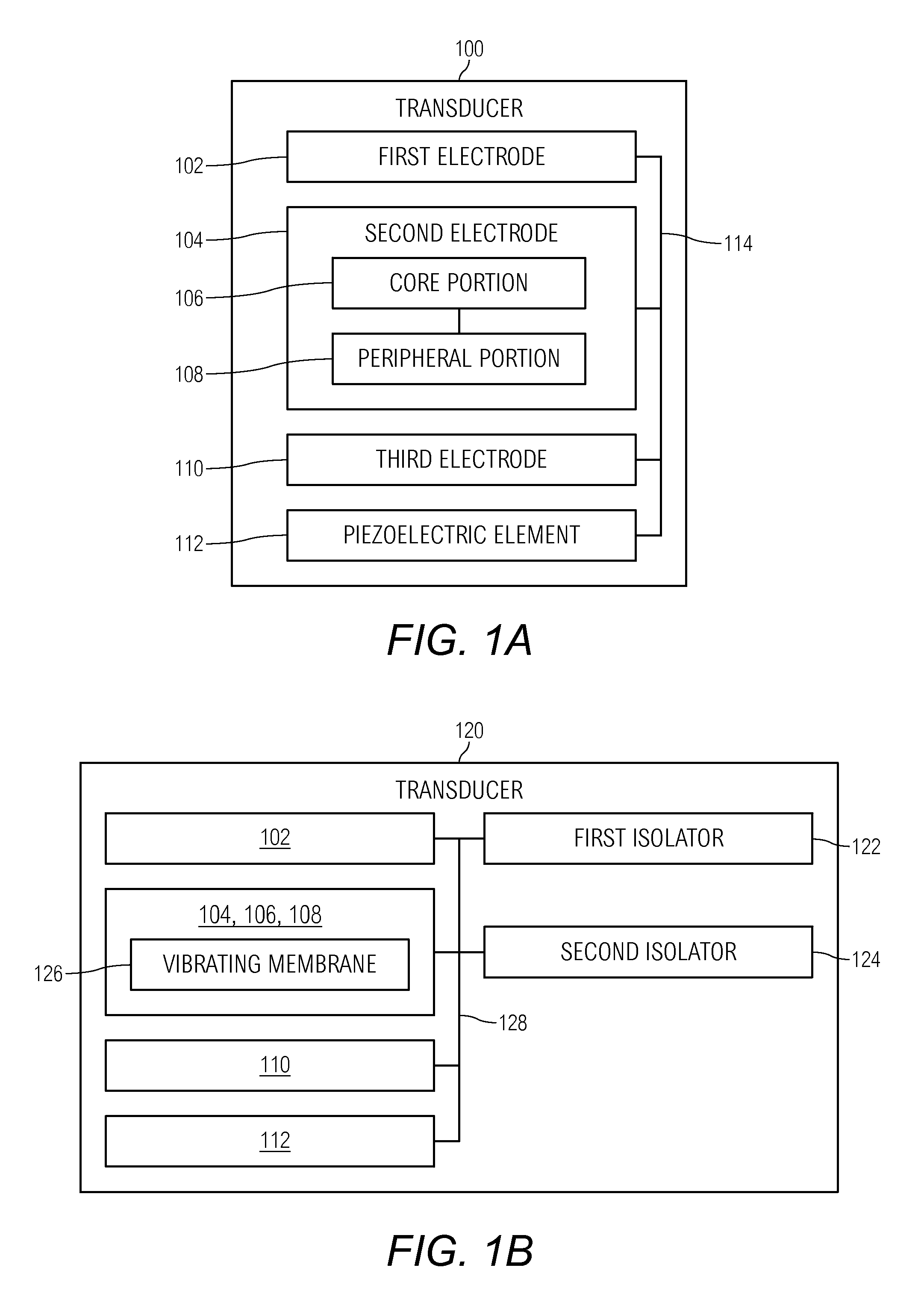

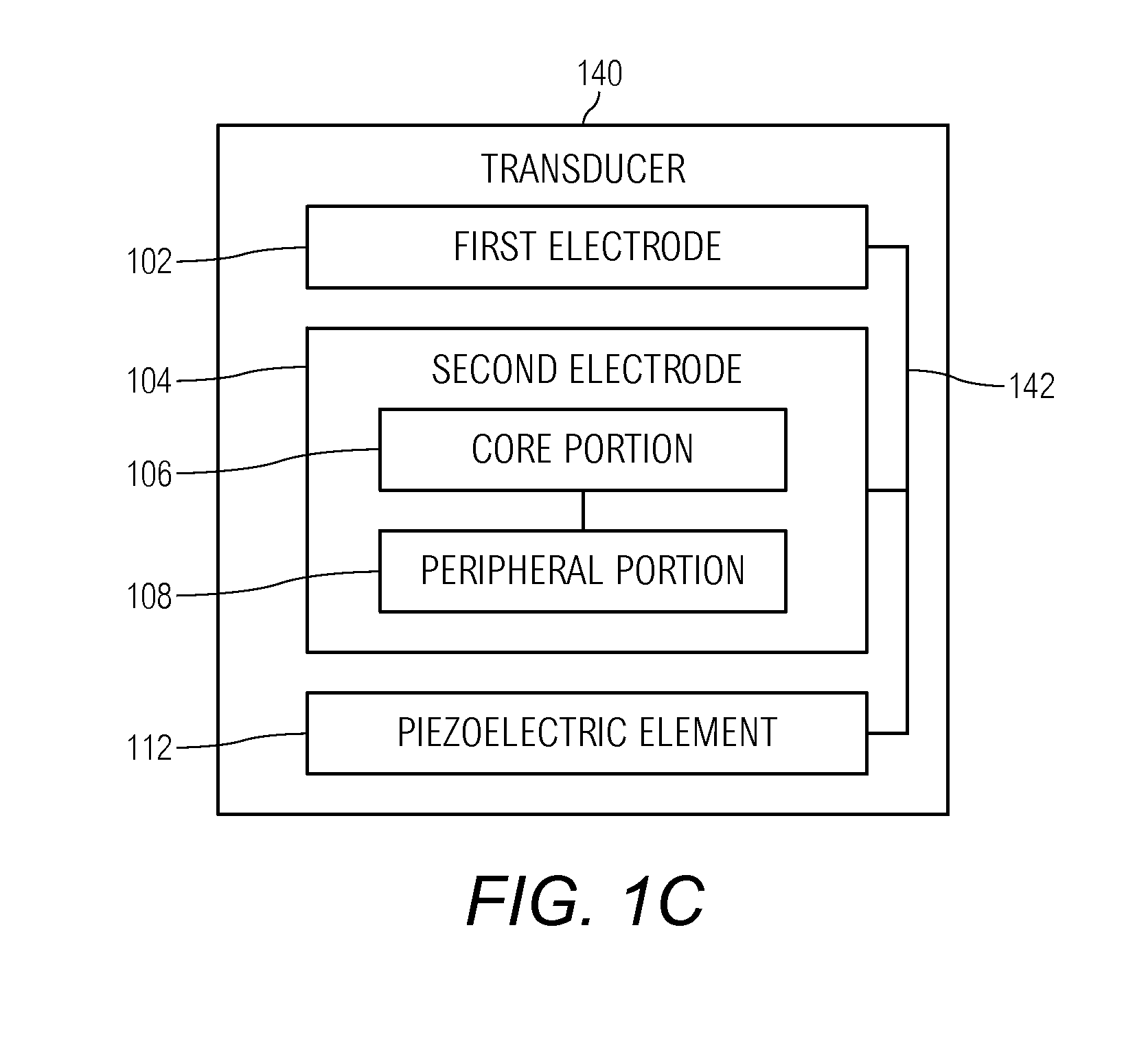

Transducer

InactiveUS20120104898A1Piezoelectric/electrostriction/magnetostriction machinesSemiconductor electrostatic transducersPiezoelectric voltageTransducer

According to embodiments of the present invention, a transducer is provided. The transducer includes a first electrode, a second electrode disposed over the first electrode such that the first electrode and the second electrode form respective capacitive electrodes of a capacitor, the second electrode comprising a core portion and a peripheral portion, a third electrode disposed relative to the second electrode such that the third electrode overlaps with the peripheral portion of the second electrode, and a piezoelectric element disposed between the peripheral portion of the second electrode and the third electrode, so as to tune a tensional force provided by the piezoelectric element onto the second electrode by varying a piezoelectric voltage applied between the second electrode and the third electrode.

Owner:AGENCY FOR SCI TECH & RES

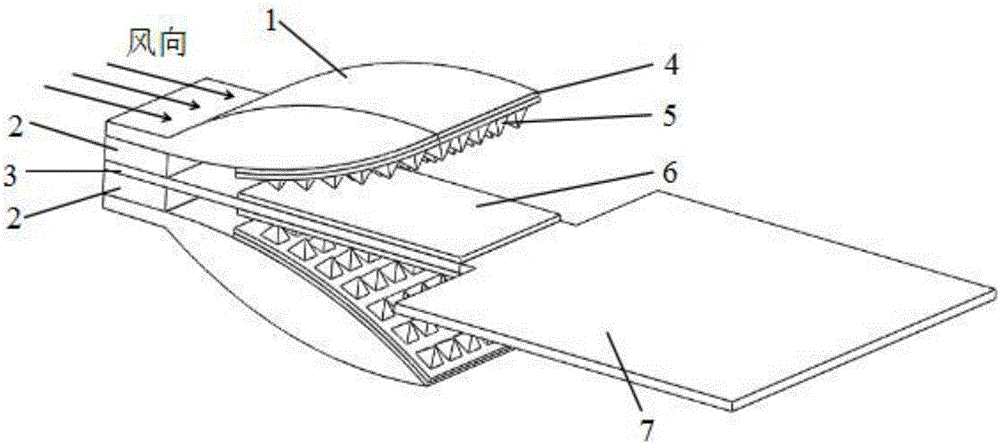

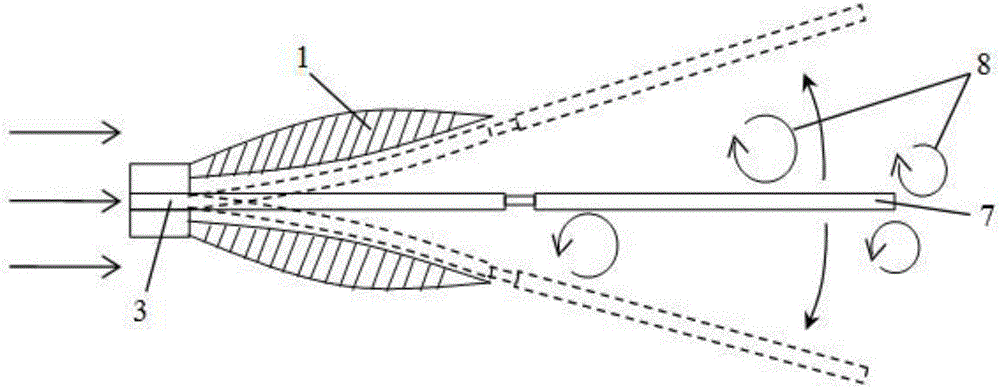

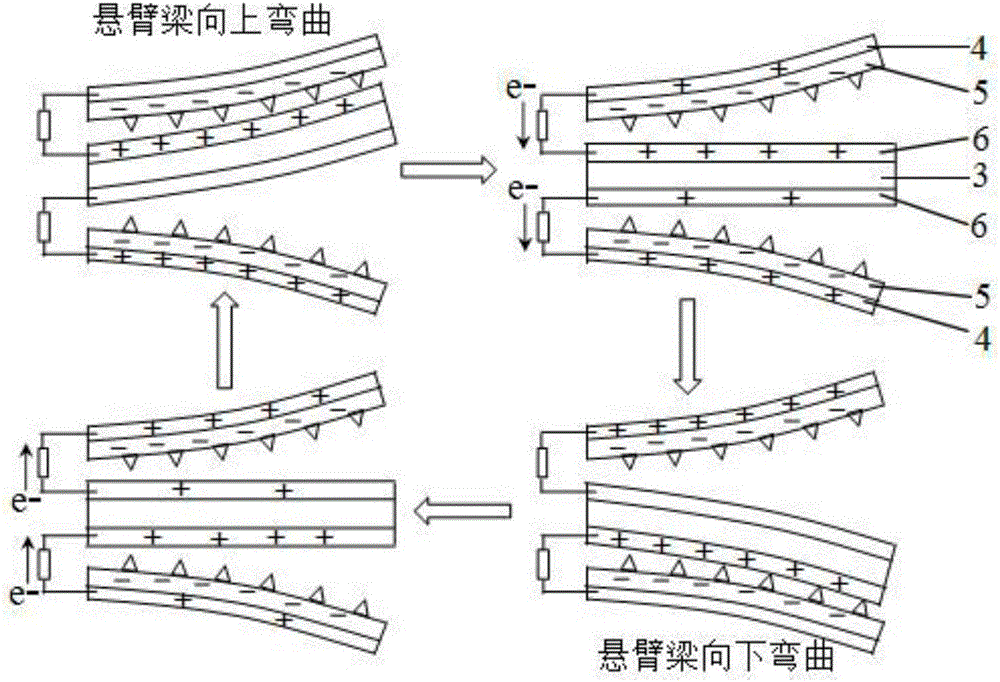

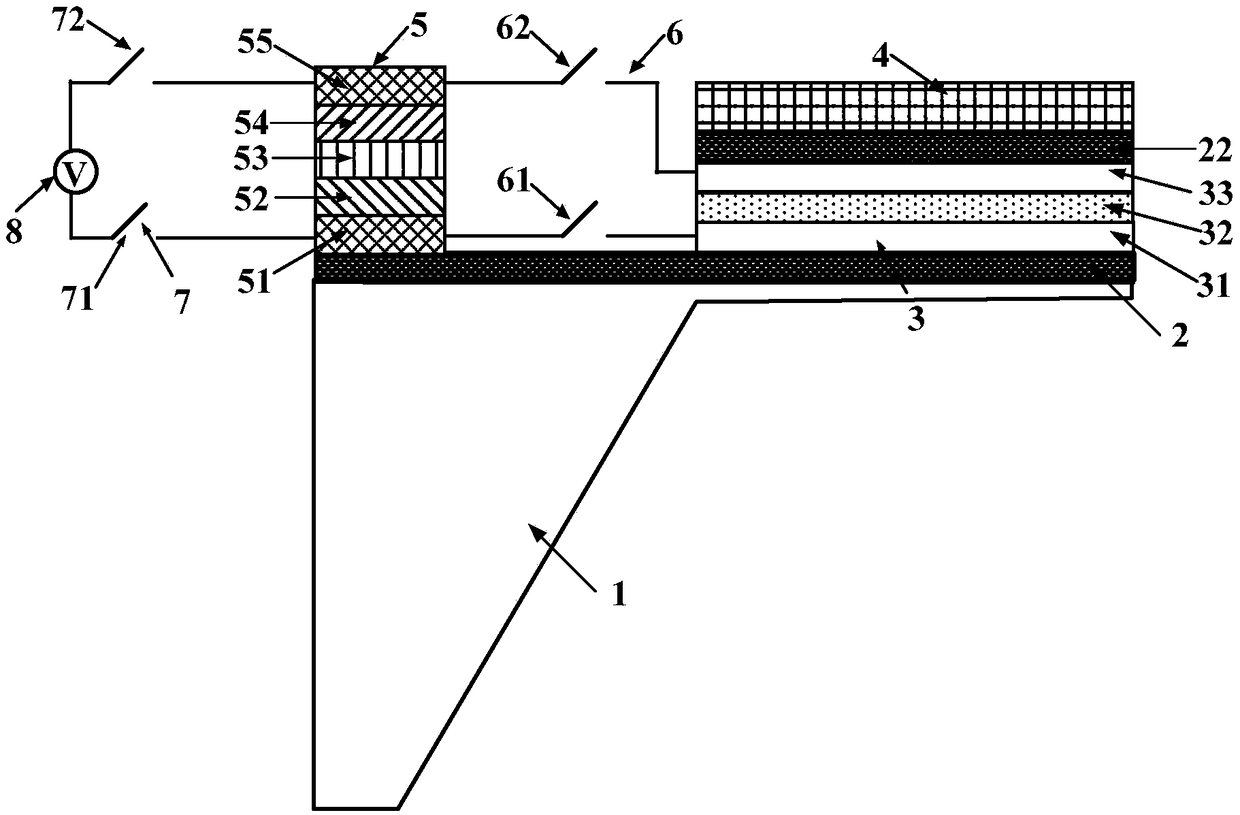

Blade-type composite pneumatic energy collector

ActiveCN105680717AEfficient conversionIncreased energy output densityPiezoelectric/electrostriction/magnetostriction machinesFriction generatorsPiezoelectric voltageElectricity

A blade-type composite pneumatic energy collector comprises a piezoelectric type energy collecting module and a friction type energy collecting module. The piezoelectric type energy collecting module comprises blades and a flexible piezoelectric cantilever. The blades are in parallel connection with the free end of the flexible piezoelectric cantilever. The blades can drive the flexible piezoelectric cantilever to vibrate periodically in a frame. The friction type energy collecting module comprises a moving friction layer pasted on the surface of the flexible piezoelectric cantilever and a fixed friction layer pasted on the surface of the frame. The moving friction layer and the fixed friction layer can relatively contact and separate periodically in the frame. The collector adopts two energy collecting modes: the friction type and the piezoelectric type, and the energy output density is increased. The blades at the tail end of the cantilever can response better to the disturbance of the wind flow, and the amplitude of the piezoelectric cantilever and the piezoelectric voltage output are increased. In addition, the double-arc-shaped flow choking structure of the frame can enlarge the contact area between the friction layers, and the friction voltage output is increased.

Owner:SUZHOU UNIV

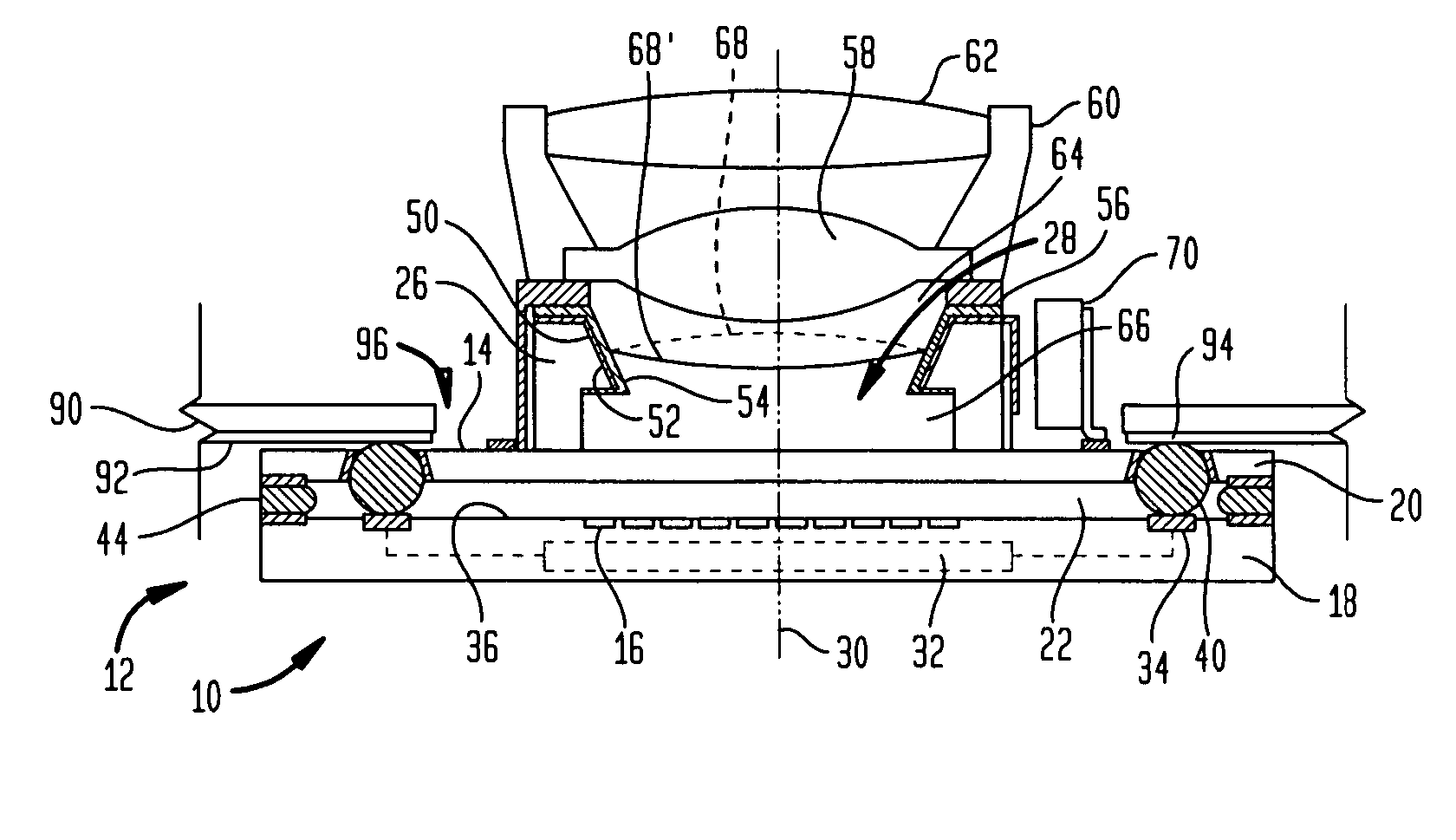

Liquid lens with piezoelectric voltage converter

InactiveUS20070146894A1Easy to manufactureTelevision system detailsSolid-state devicesOptical propertyPiezoelectric voltage

An electronic camera module includes a lens or refractive element formed by a pair of immiscible liquids and having optical properties which can be varied by applying a voltage so as to deform the meniscus. One of the two liquids extends from the meniscus all the way to the front surface of the sensor, so that light passing through the meniscus does not encounter further changes in refractive index enroute to the sensor.

Owner:TESSERA INC

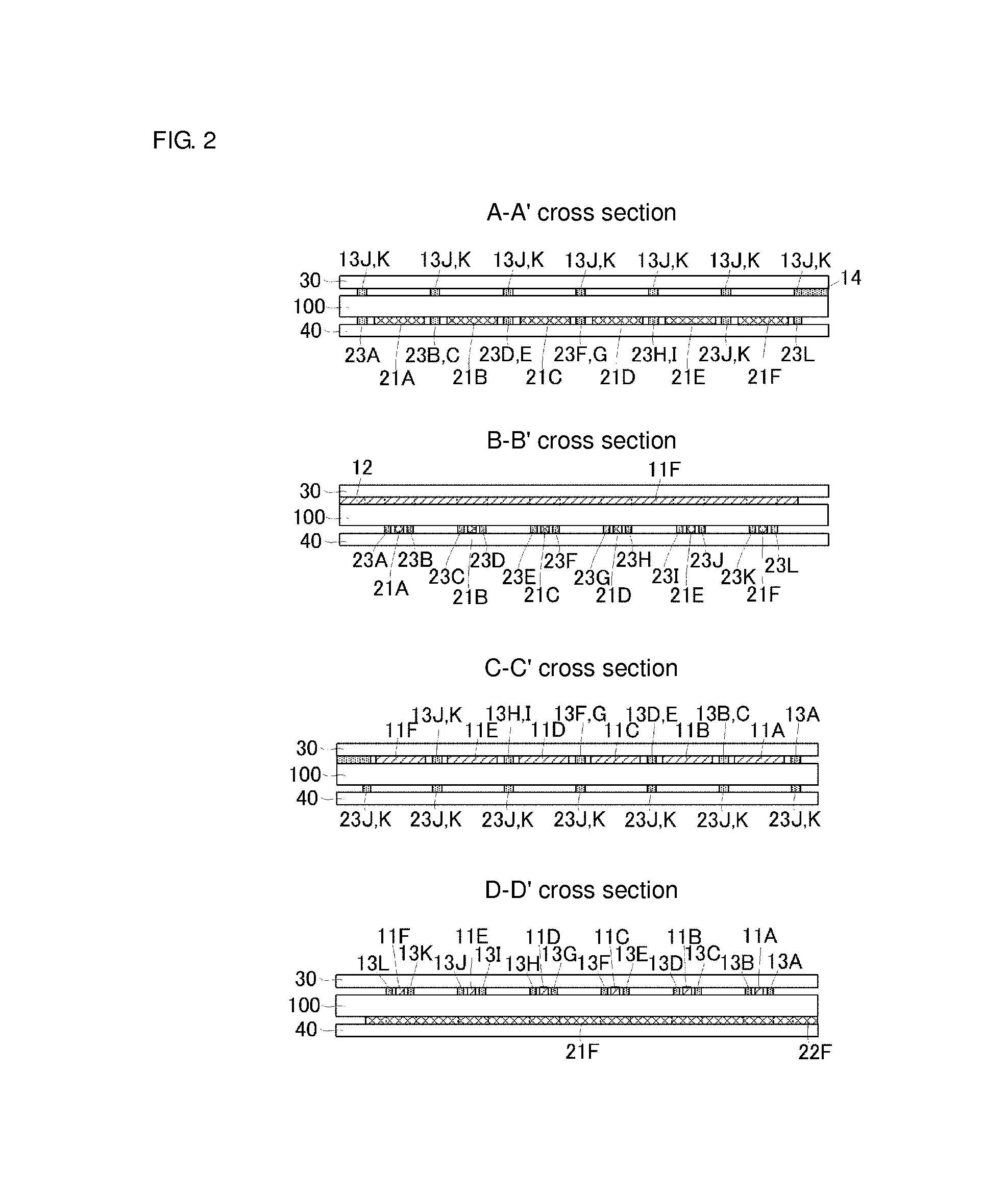

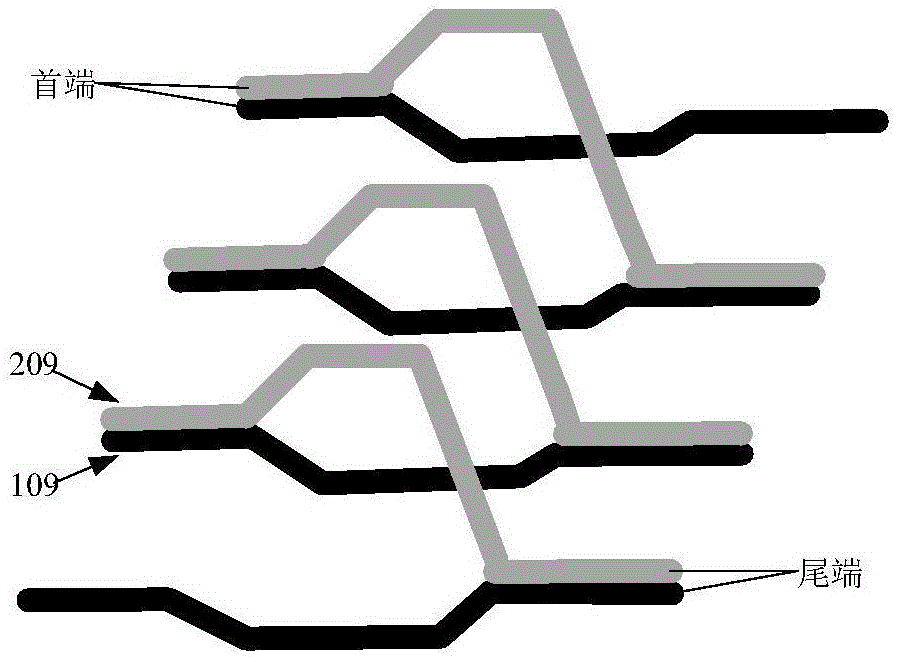

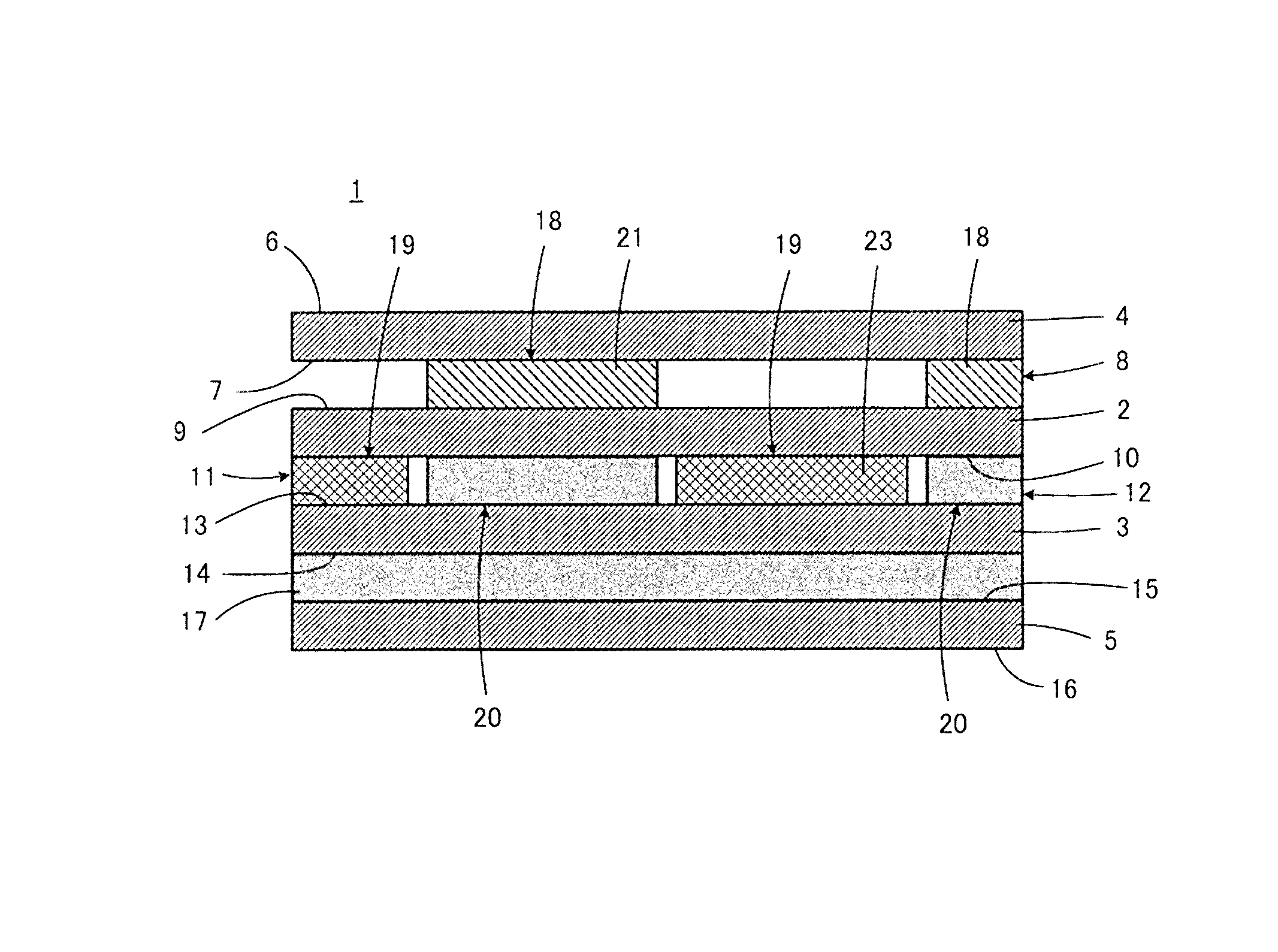

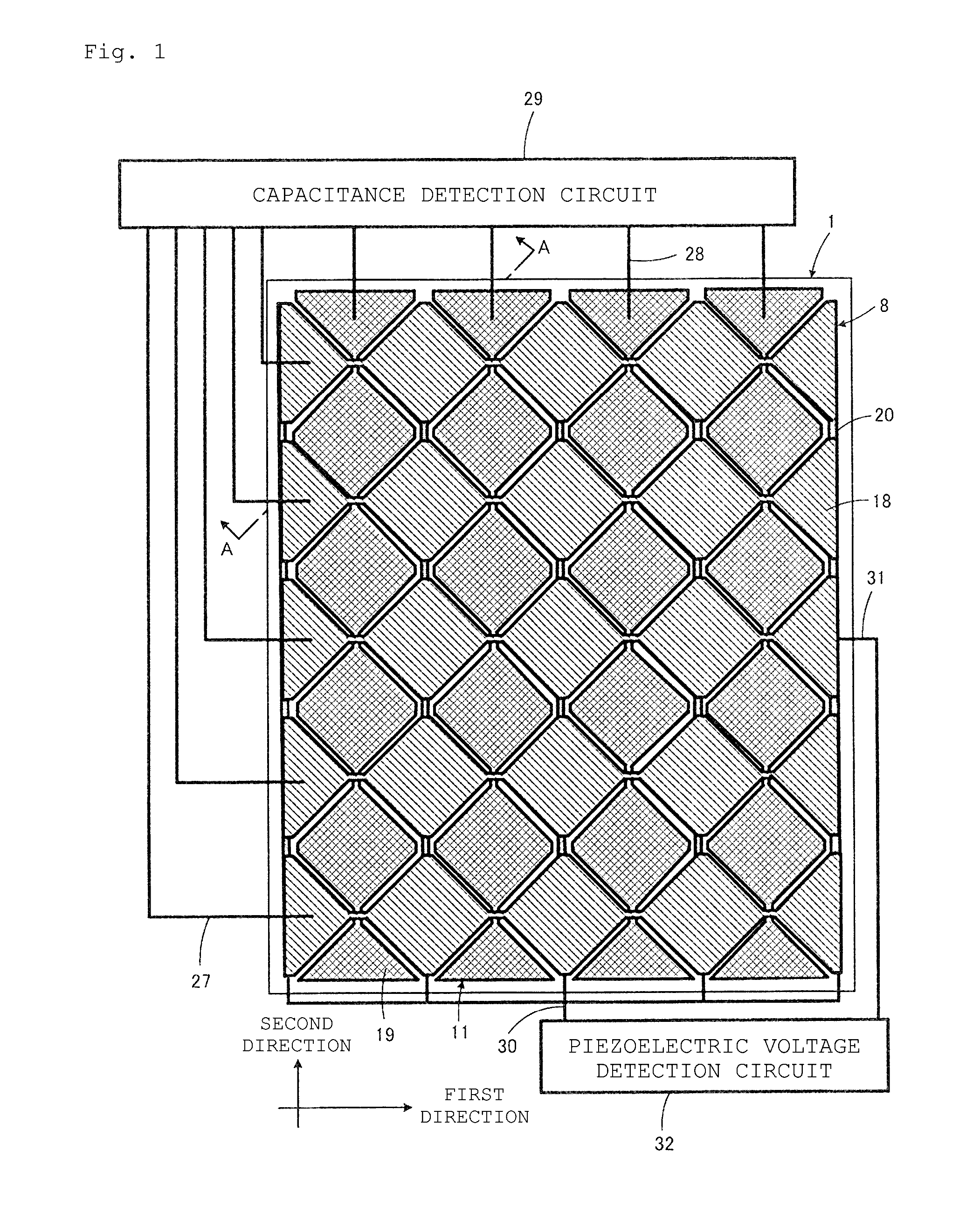

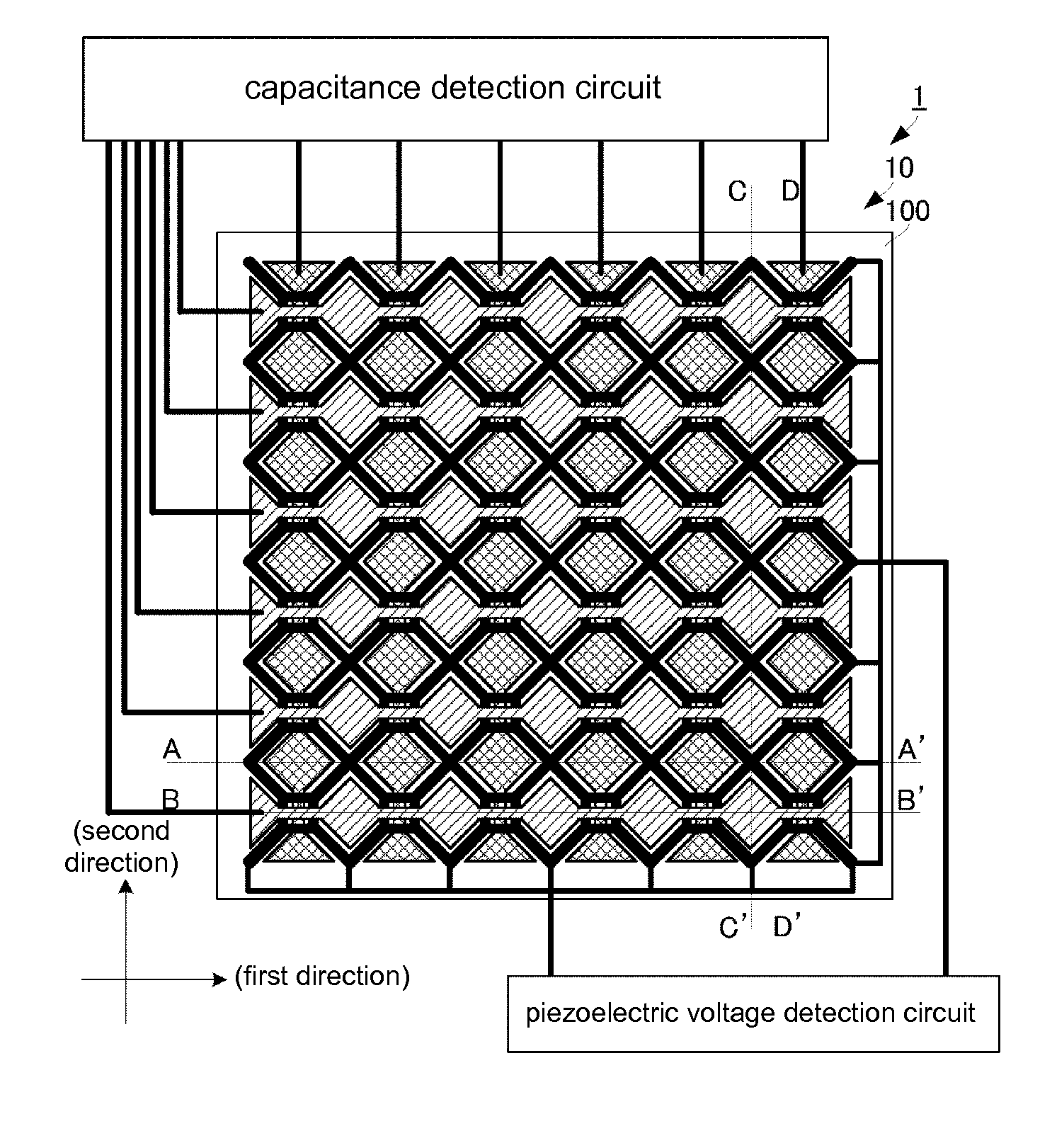

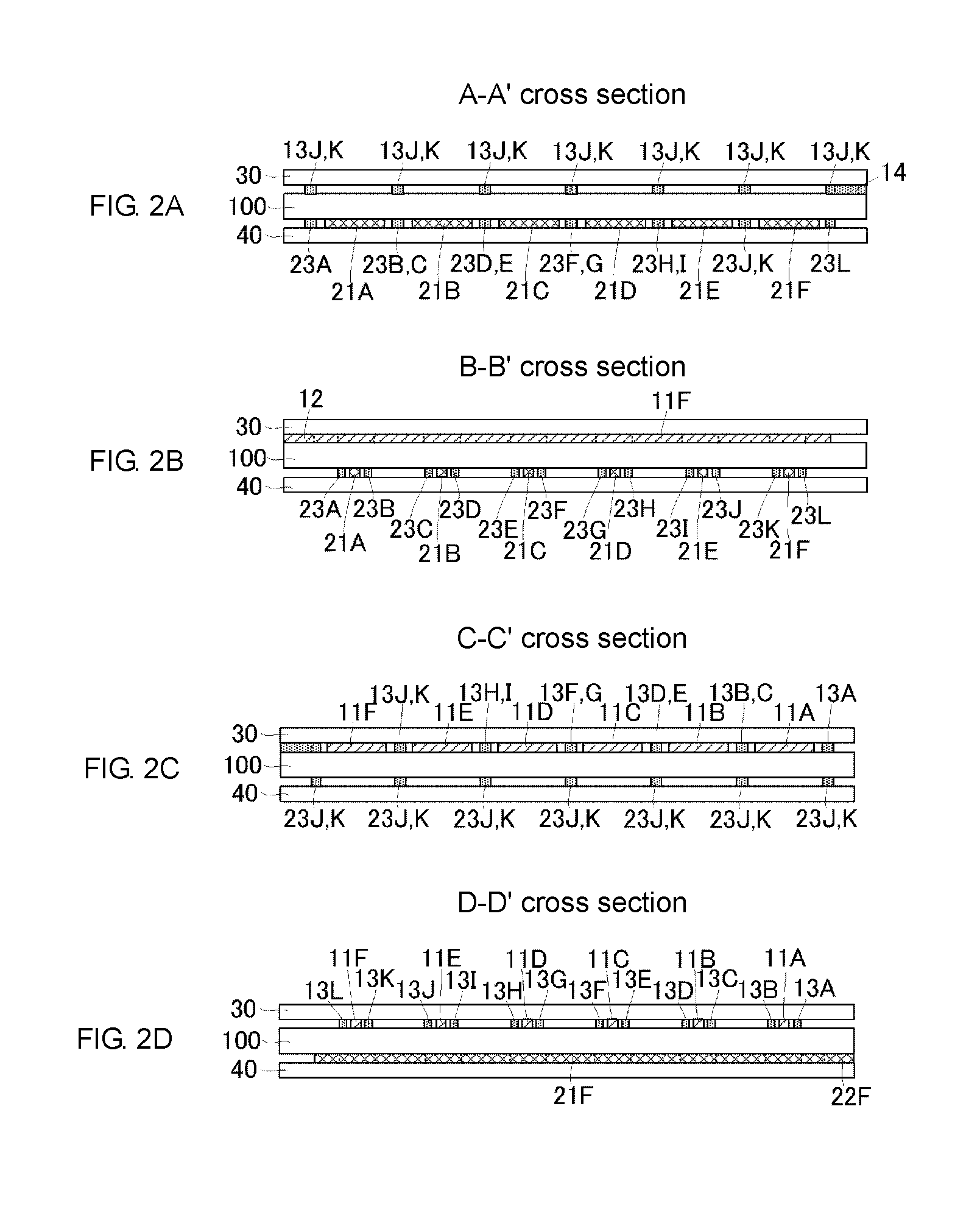

Touch panel

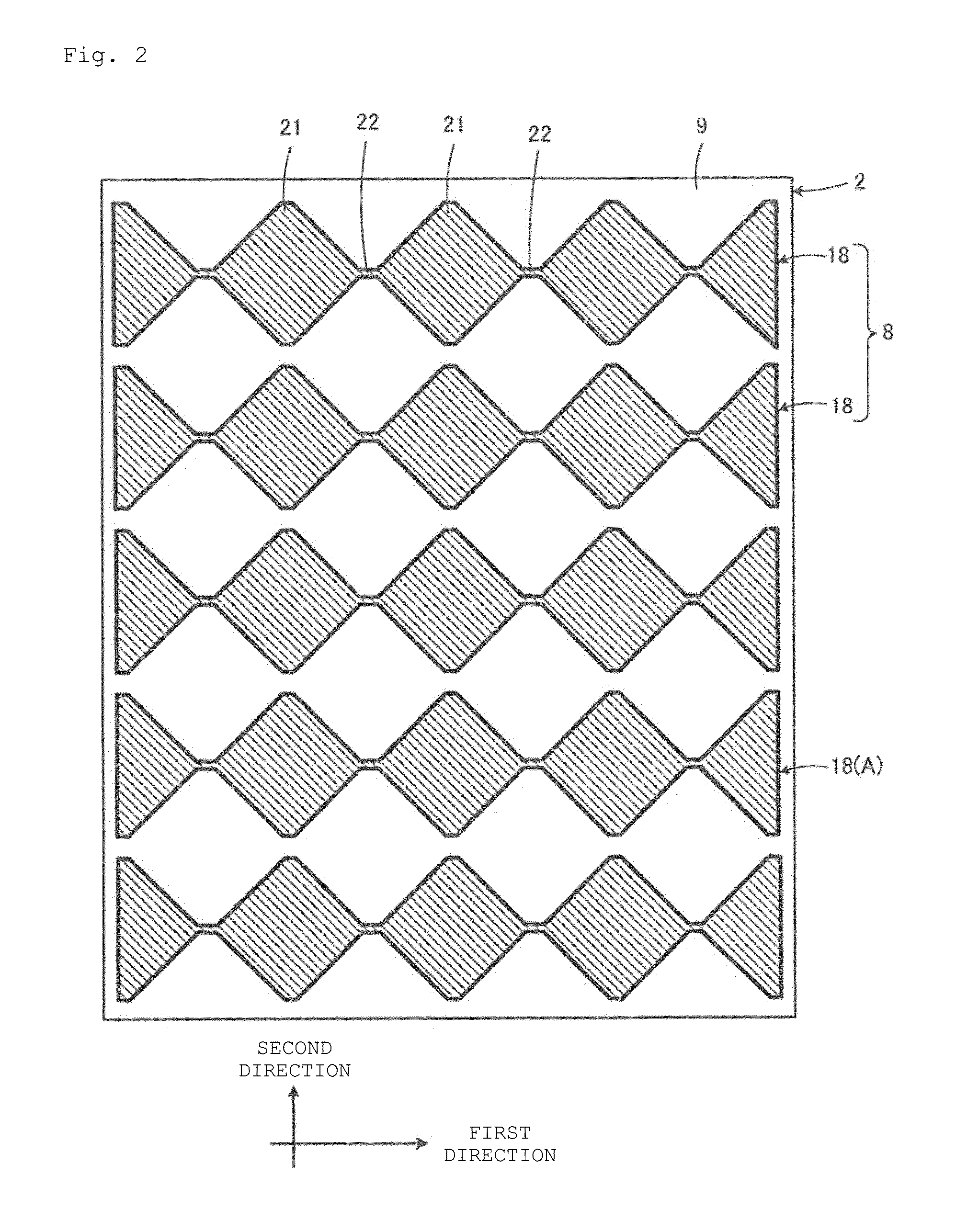

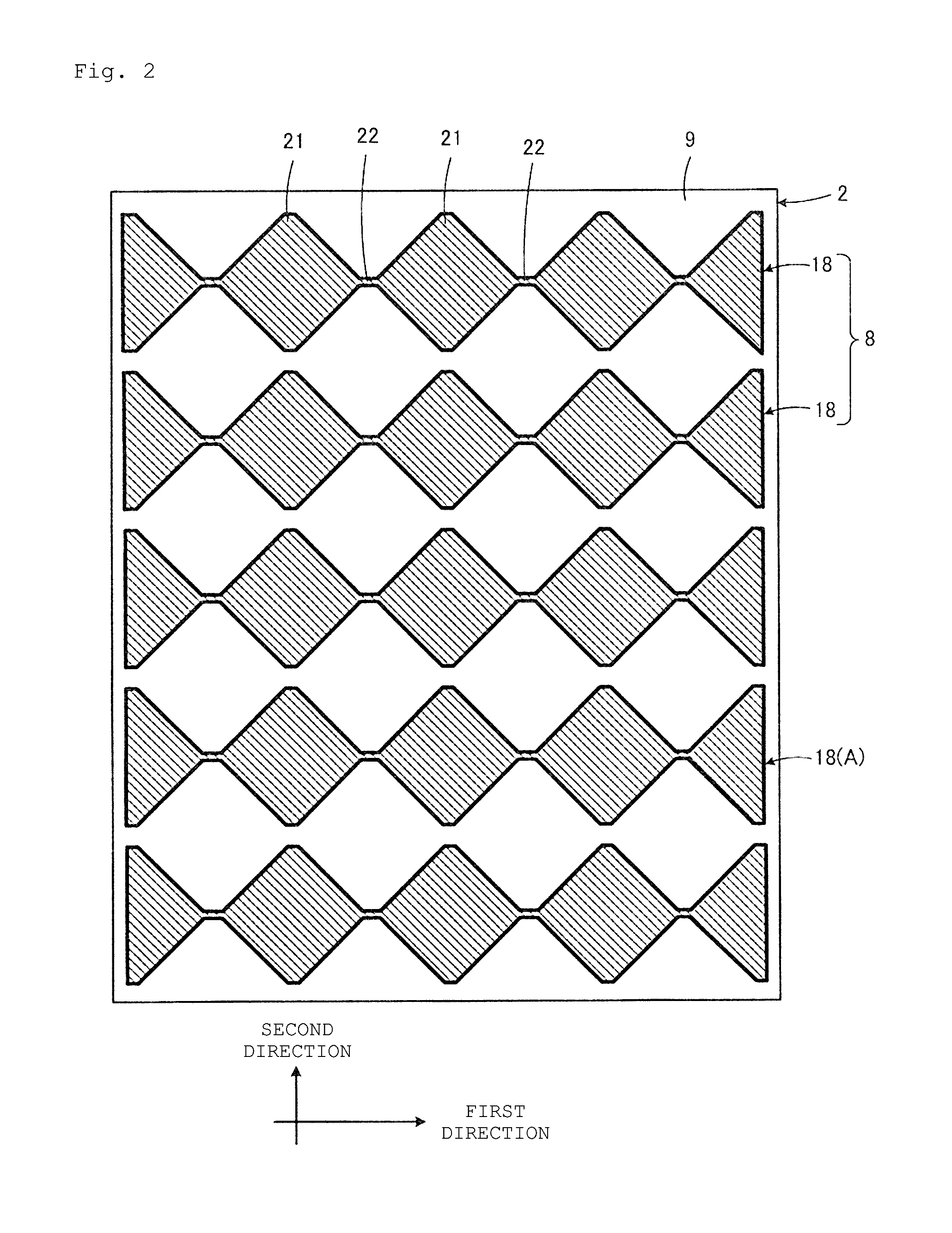

ActiveUS20150193055A1Efficient disposalReduce light transmittanceElectric/magnetic position measurementsUsing electrical meansCapacitanceDielectric

A touch panel that includes a dielectric film and a piezoelectric film. A first capacitance detection electrode is disposed on an upper main surface of the dielectric film, a second capacitance detection electrode and a first piezoelectric voltage detection electrode are disposed between a lower main surface of the dielectric film and an upper main surface of the piezoelectric film, and a second piezoelectric voltage detection electrode is disposed on a lower main surface of the piezoelectric film. The first capacitance detection electrode includes plural sub-electrodes extending in a first direction, the second capacitance detection electrode includes plural sub-electrodes extending in a second direction orthogonal to the first direction, and the first piezoelectric voltage detection electrode includes plural sub-electrodes disposed between the plural sub-electrodes.

Owner:MURATA MFG CO LTD

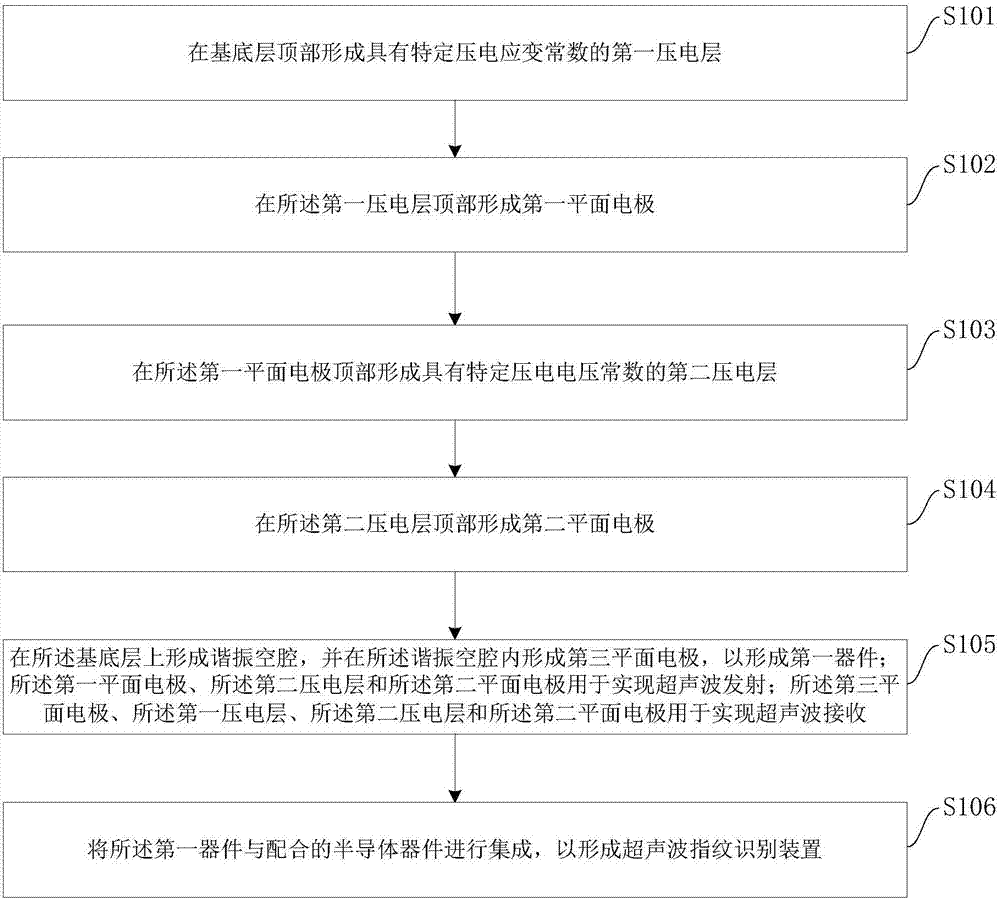

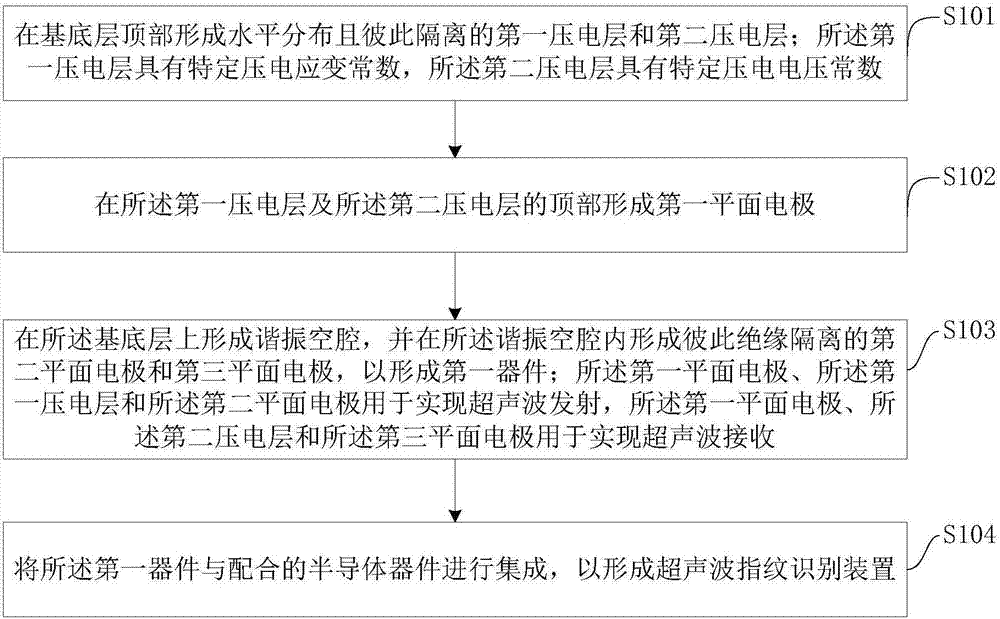

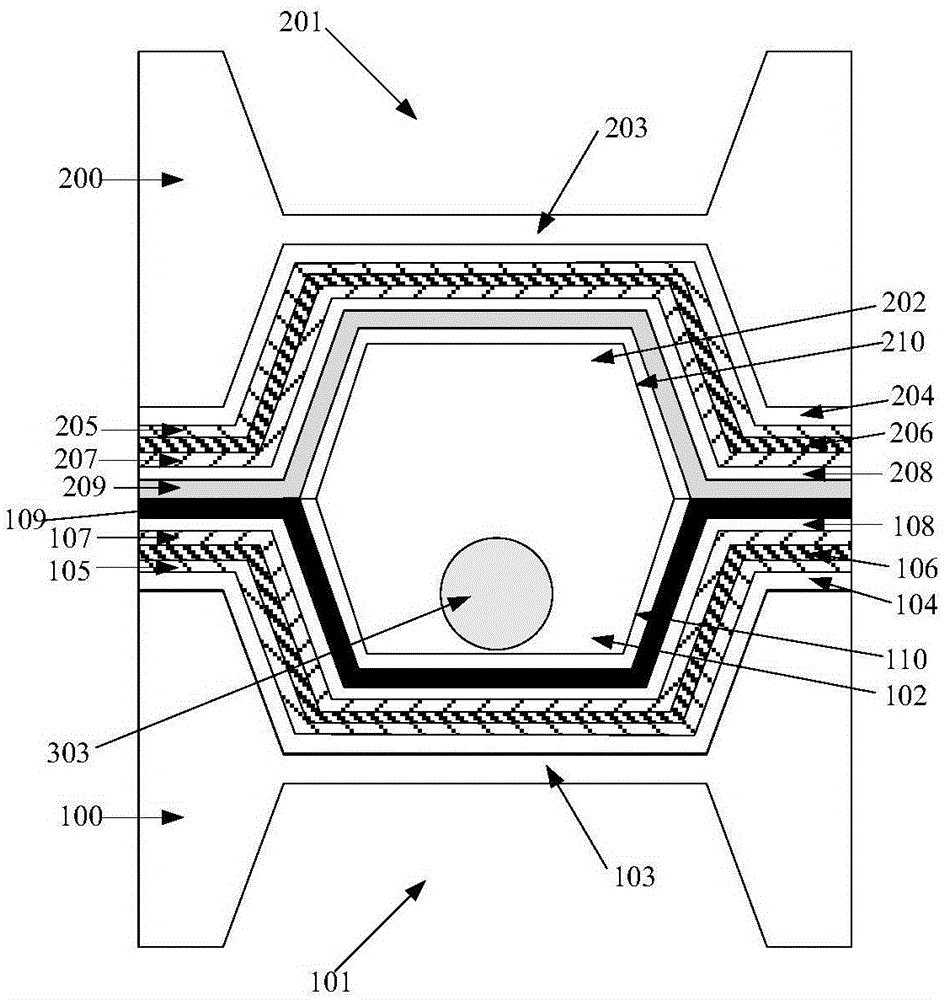

Electronic apparatus, ultrasonic fingerprint recognizing apparatus and manufacturing method thereof

ActiveCN107229909AHigh loop efficiencyHigh sensitivityIndividual entry/exit registersPrint image acquisitionPlanar electrodeResonant cavity

The embodiment of the application provides an electronic apparatus, an ultrasonic fingerprint recognizing apparatus and a manufacturing method thereof. The method comprises: a first piezoelectric layer having a specific piezoelectric strain constant is formed at the top of a substrate layer; a first planar electrode is formed at the top of the first piezoelectric layer; a second piezoelectric layer having a specific piezoelectric voltage constant is formed at the top of the first planar electrode; a second planar electrode is formed at the top of the second piezoelectric layer; a resonant cavity is formed at the substrate layer and a third planar electrode is formed in the resonant cavity to form a first device, wherein the first planar electrode, the second piezoelectric layer, and the second planar electrode are used for realizing ultrasonic wave transmitting and the third planar electrode, the first piezoelectric layer, the second piezoelectric layer, and the second planar electrode are used for realizing ultrasonic wave receiving; and the first device and a cooperative semiconductor device are integrated to form an ultrasonic fingerprint recognizing apparatus. Therefore, the loop efficiency and the recognition sensitivity of the ultrasonic fingerprint recognizing apparatus are improved.

Owner:SILEAD

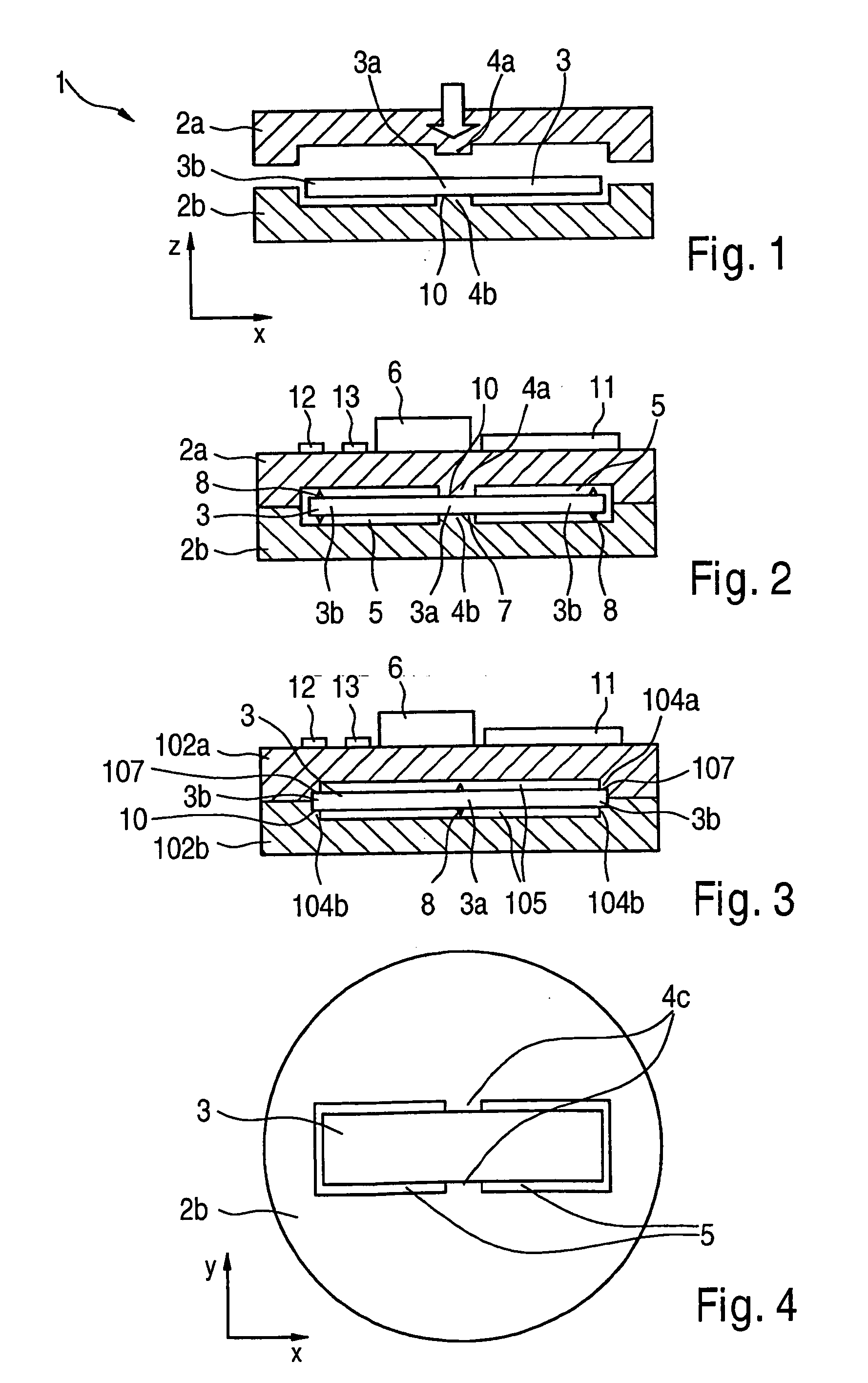

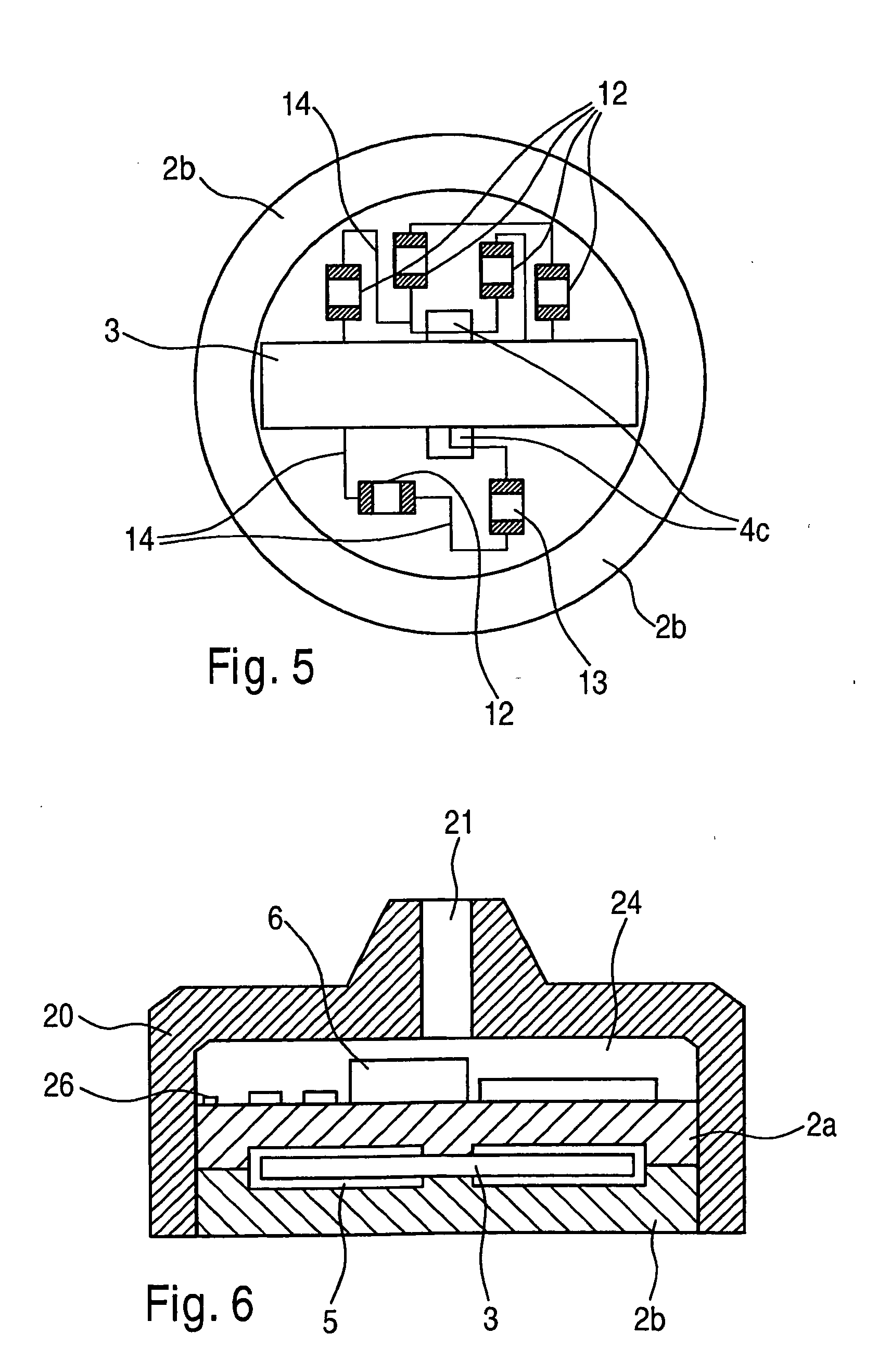

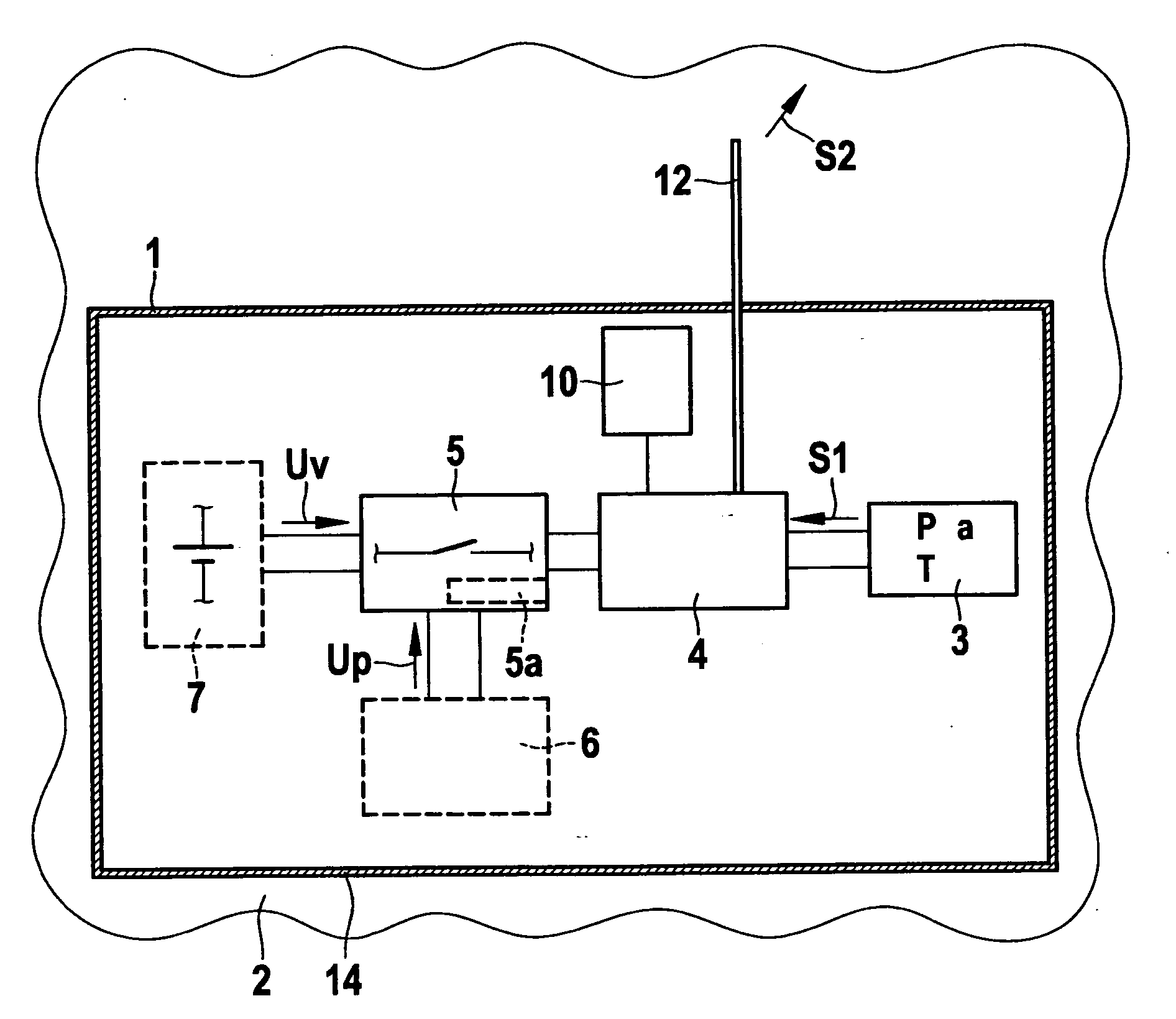

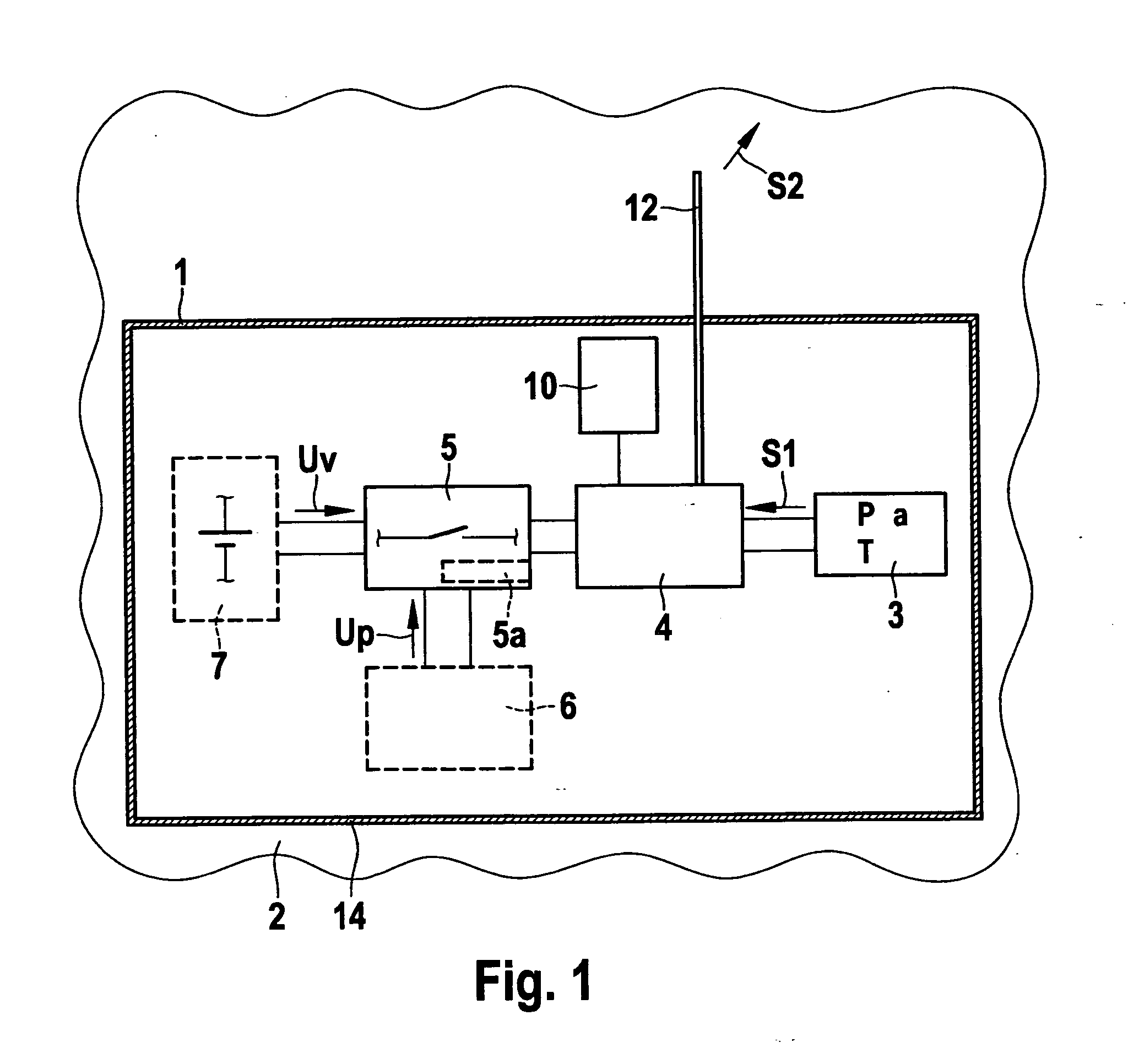

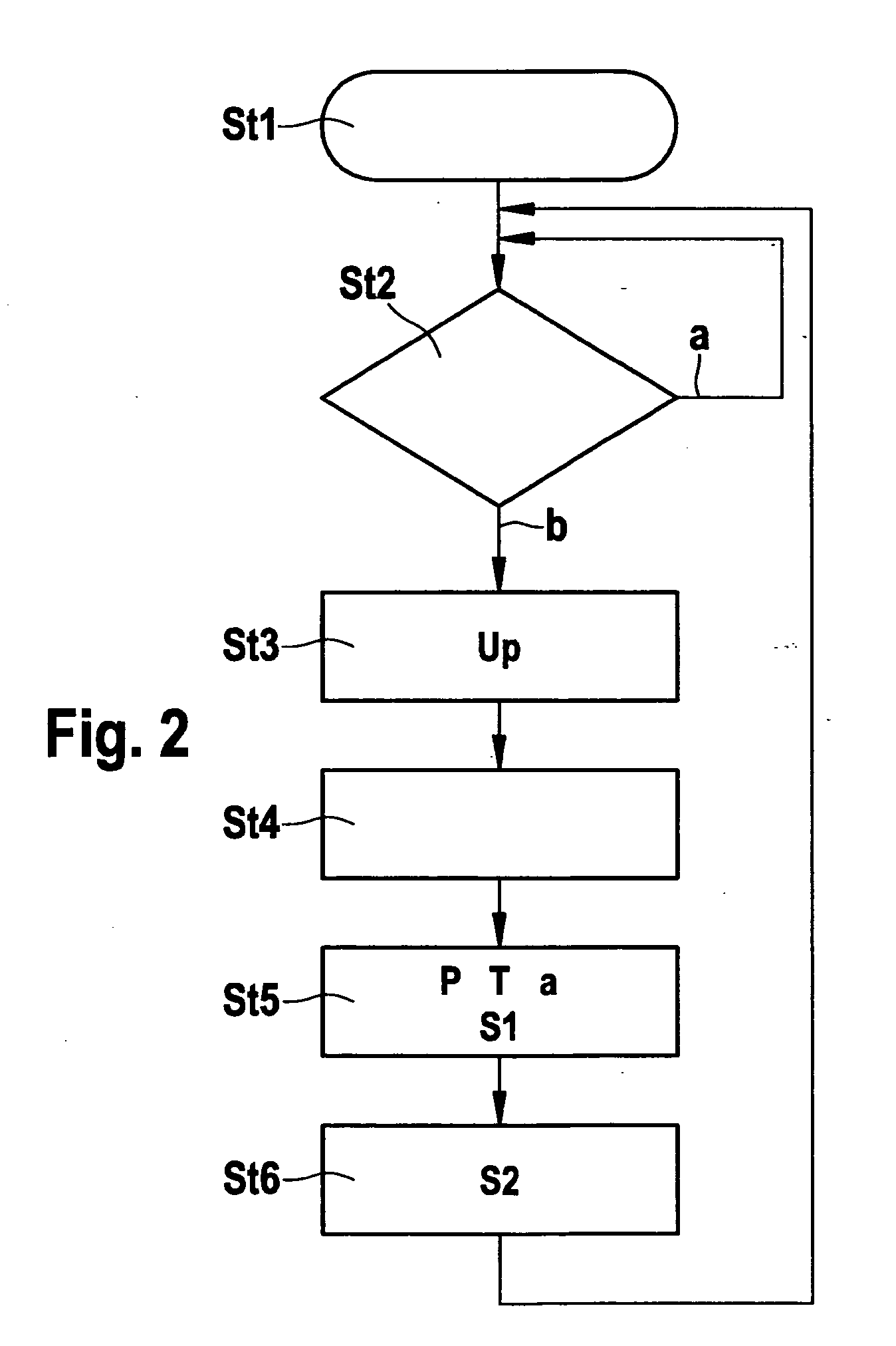

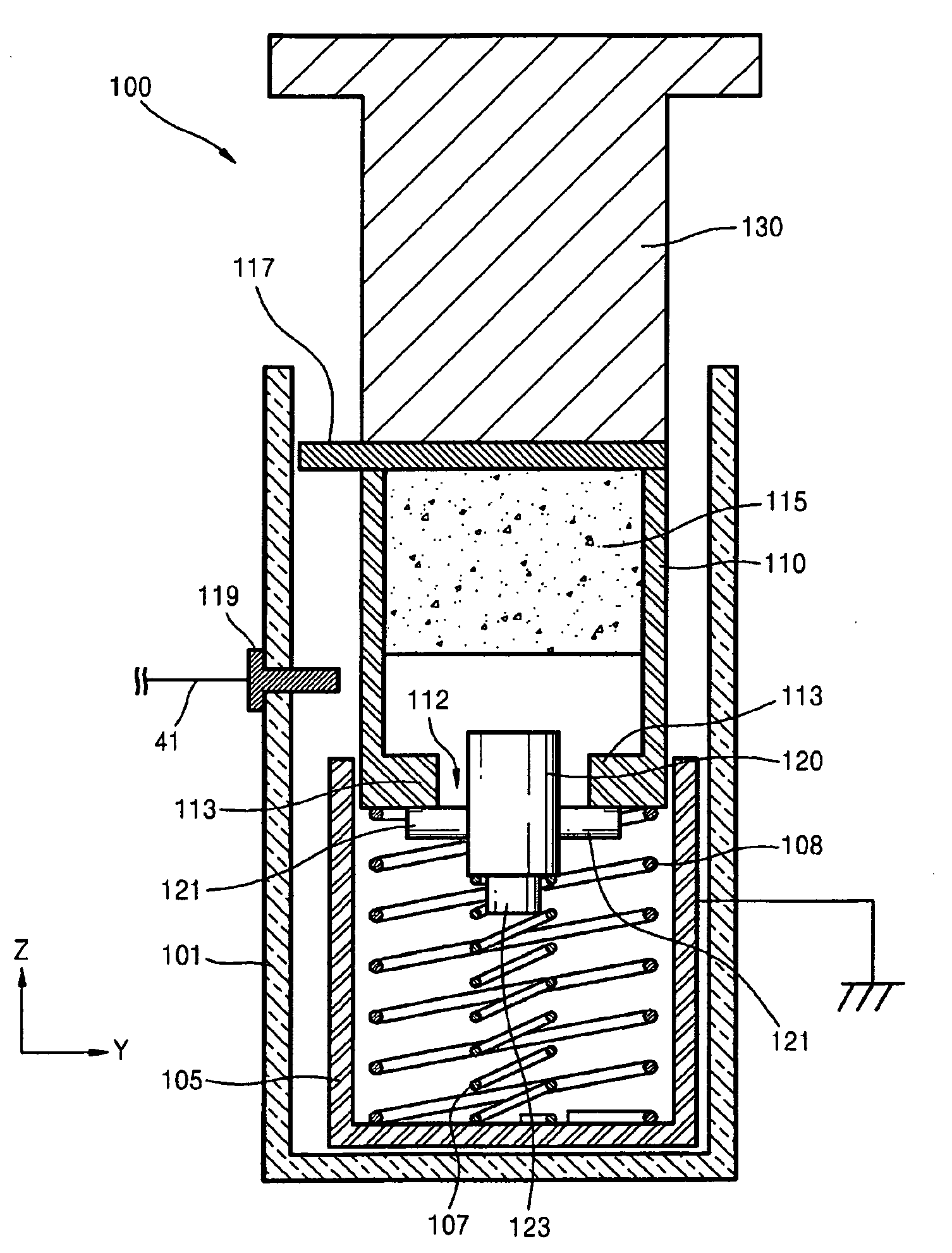

Circuit Module

InactiveUS20090206703A1Piezoelectric/electrostriction/magnetostriction machinesFluid pressure measurement by mechanical elementsPiezoelectric voltageComputer module

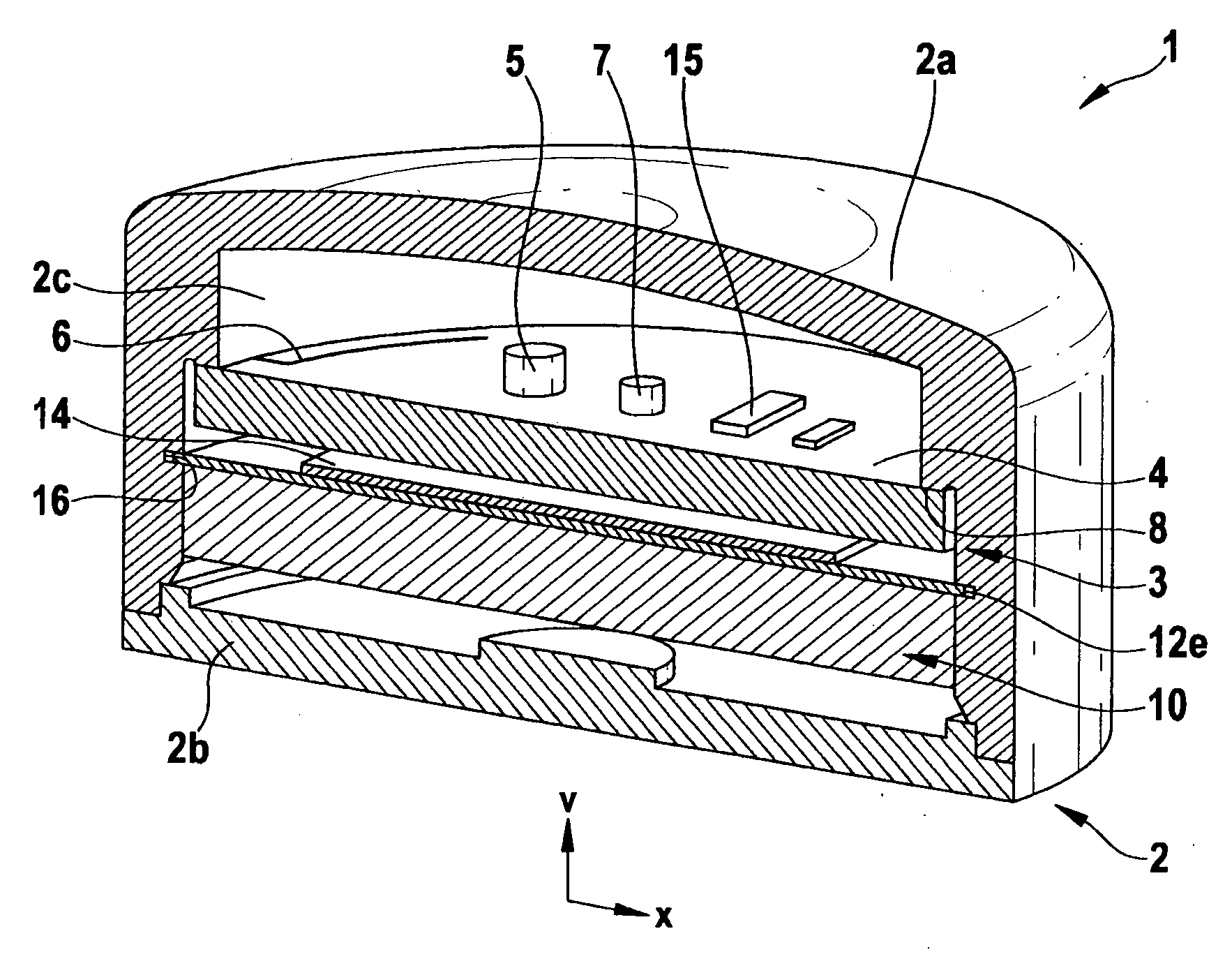

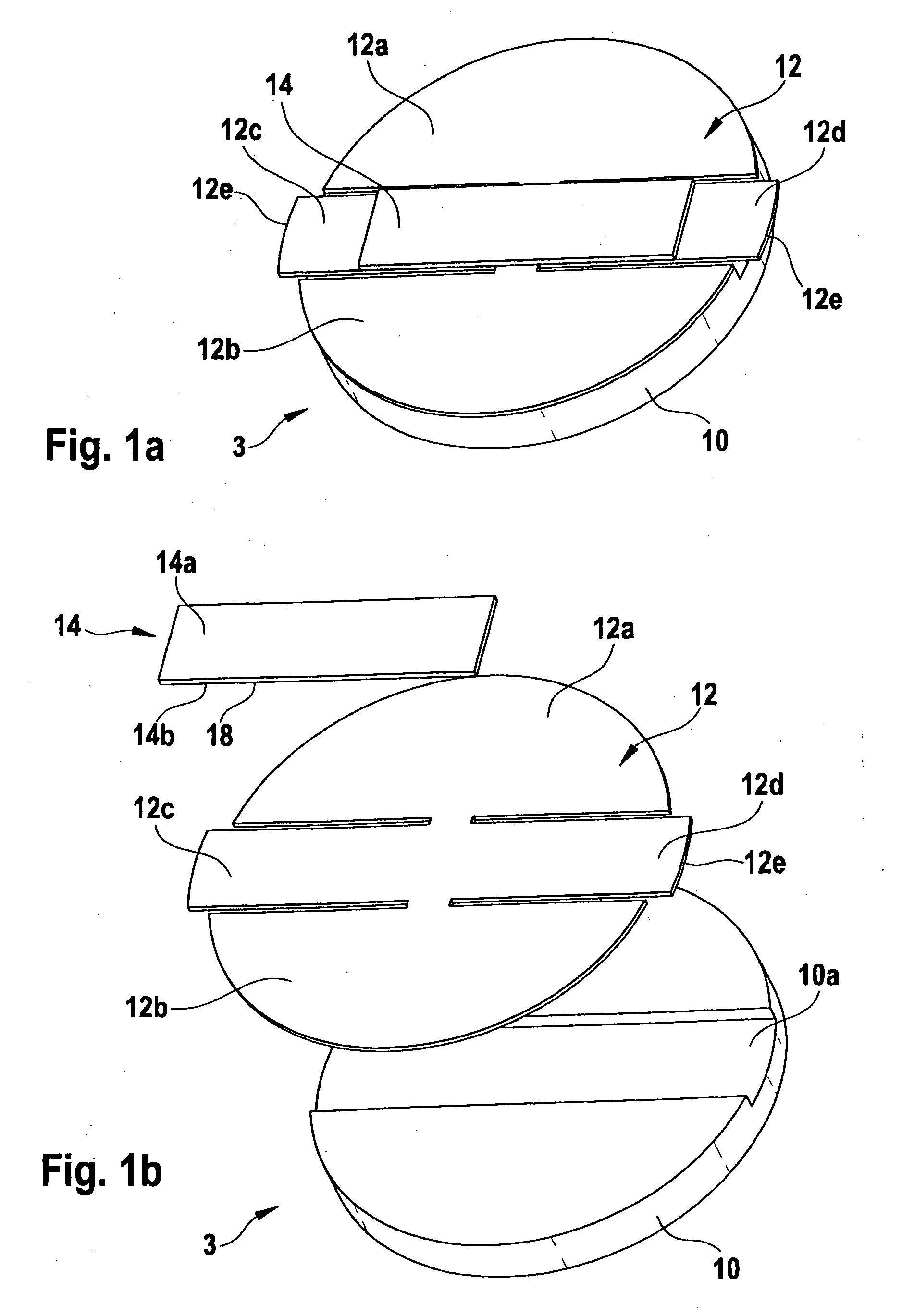

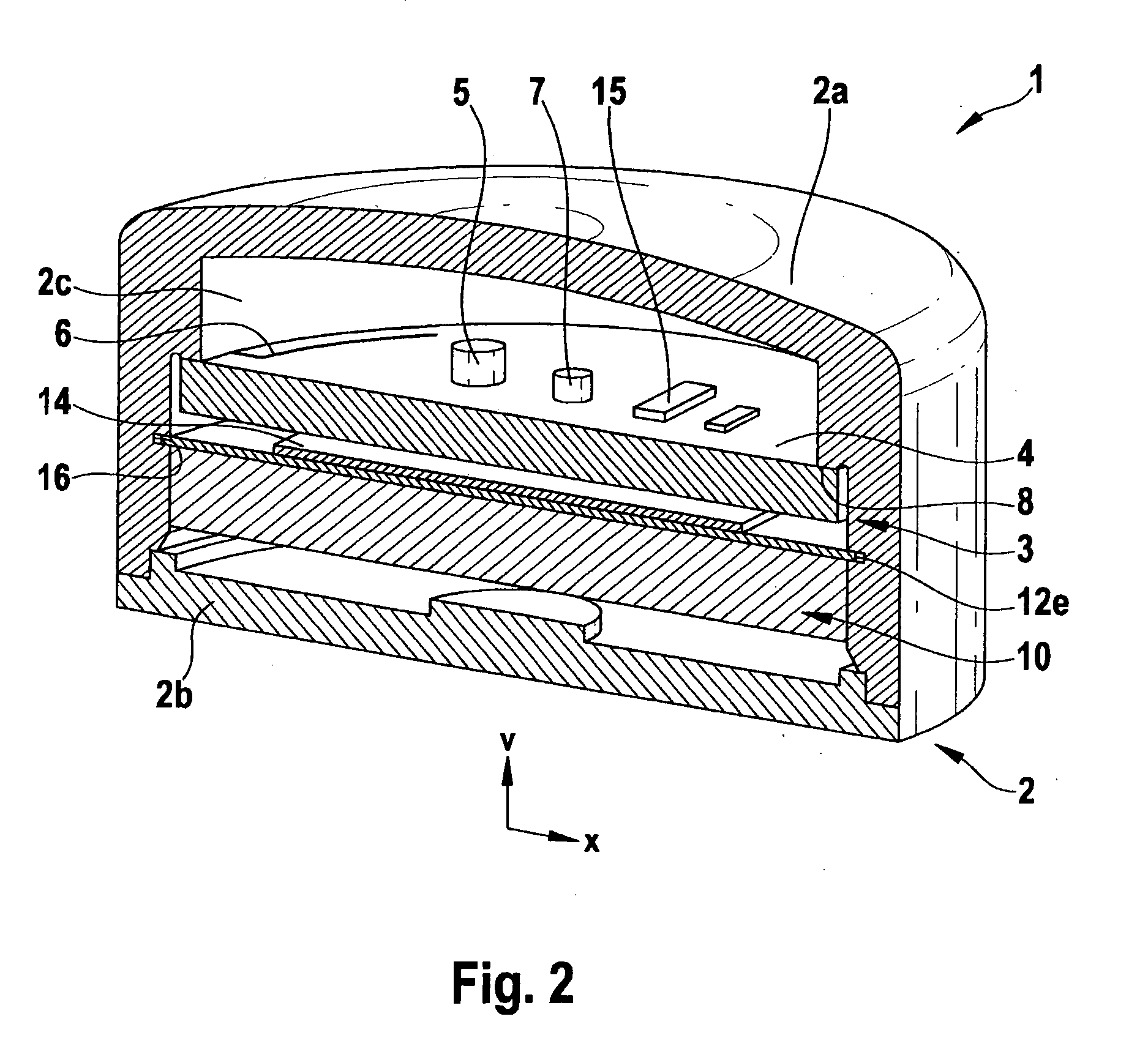

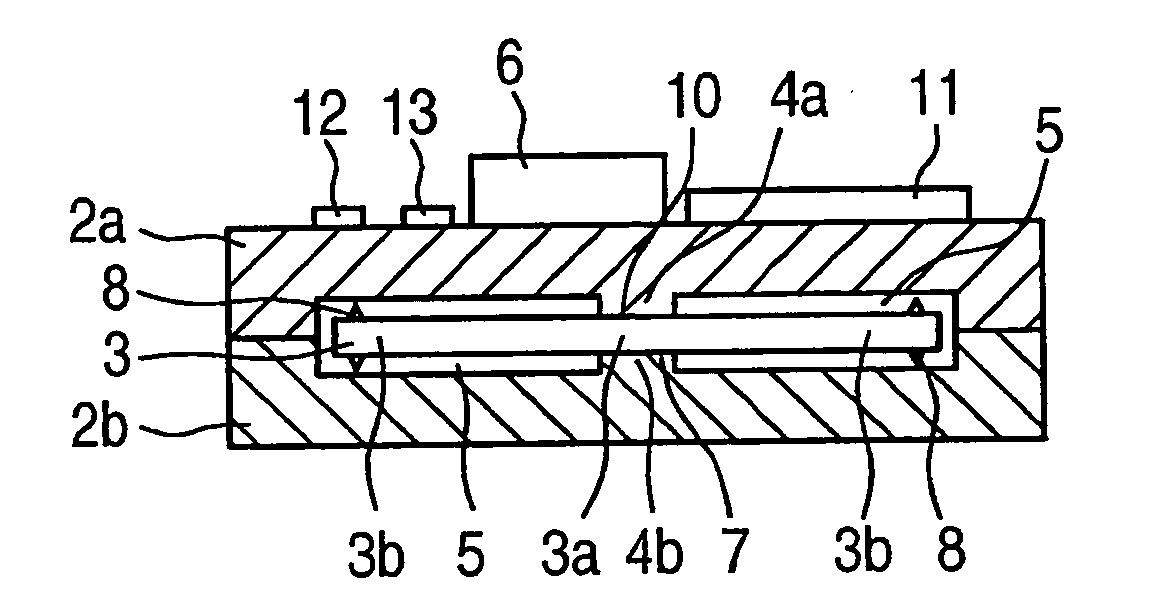

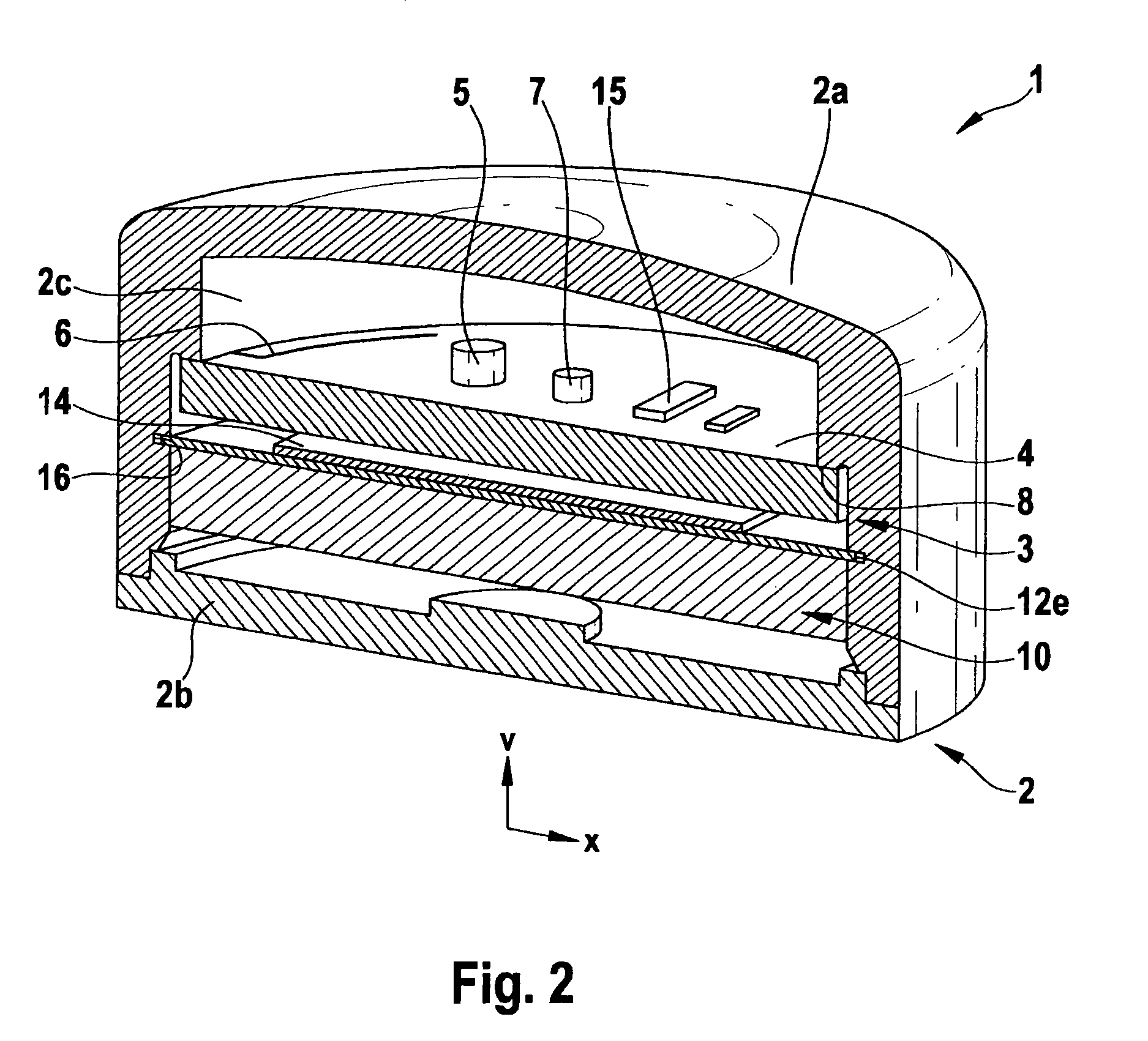

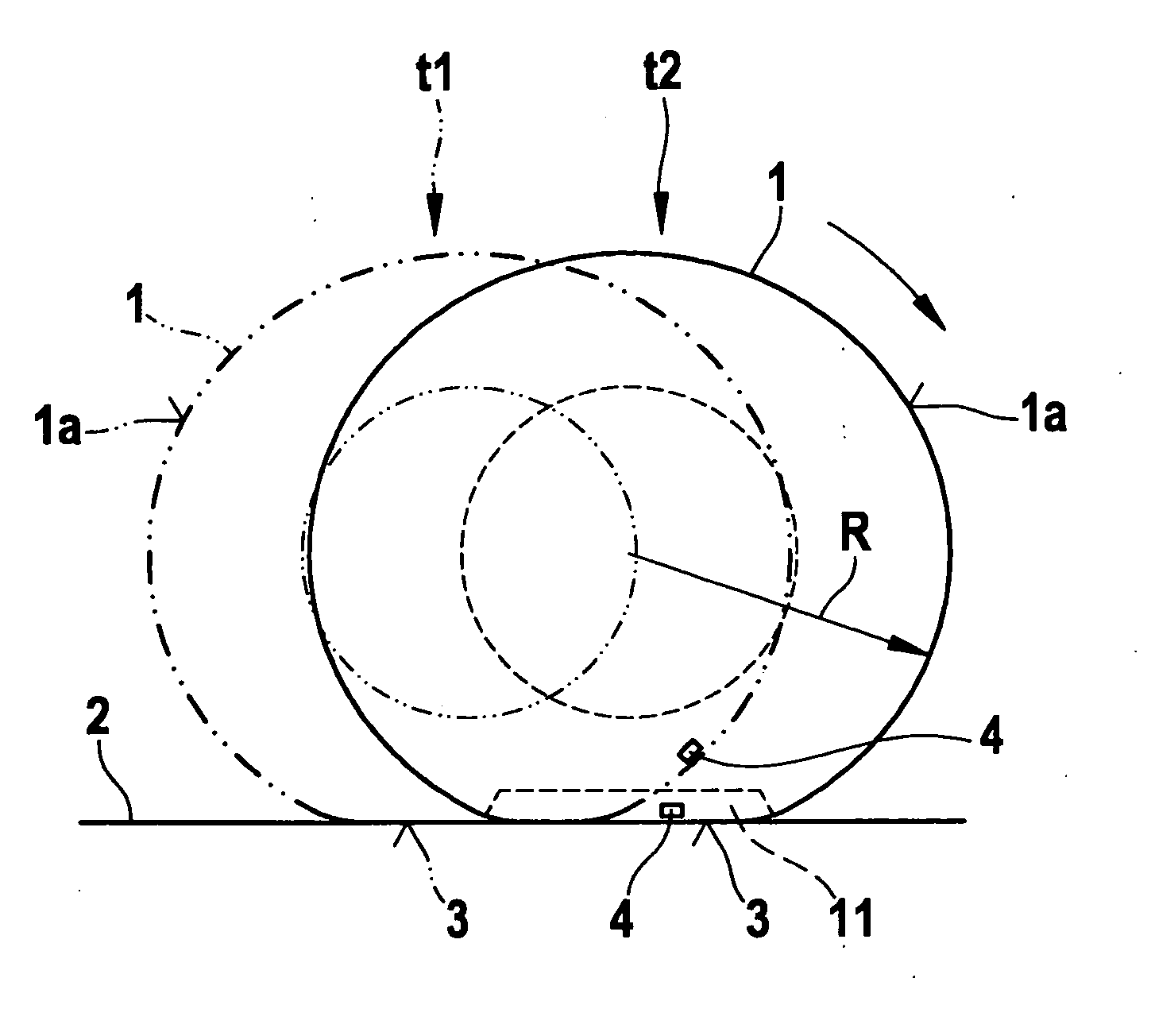

A circuit module, in particular for use in a vehicle tire, having at least: a housing (2), a piezoelectric generator (3), which has a mass element (10) that is movable within the housing (2) and a spring device (12, 14), which has at least one piezoelectric element (14), the mass element (10) and the spring device (12, 14) forming an oscillatory system, and the piezoelectric element (14) being elastically deformable in response to the oscillation of the oscillatory system (10, 12, 14); and a current-supply circuit (5) for receiving a piezoelectric voltage output by the piezoelectric element (14) in response to the mechanical deformation thereof and for supplying power to the circuit module (1).

Owner:ROBERT BOSCH GMBH

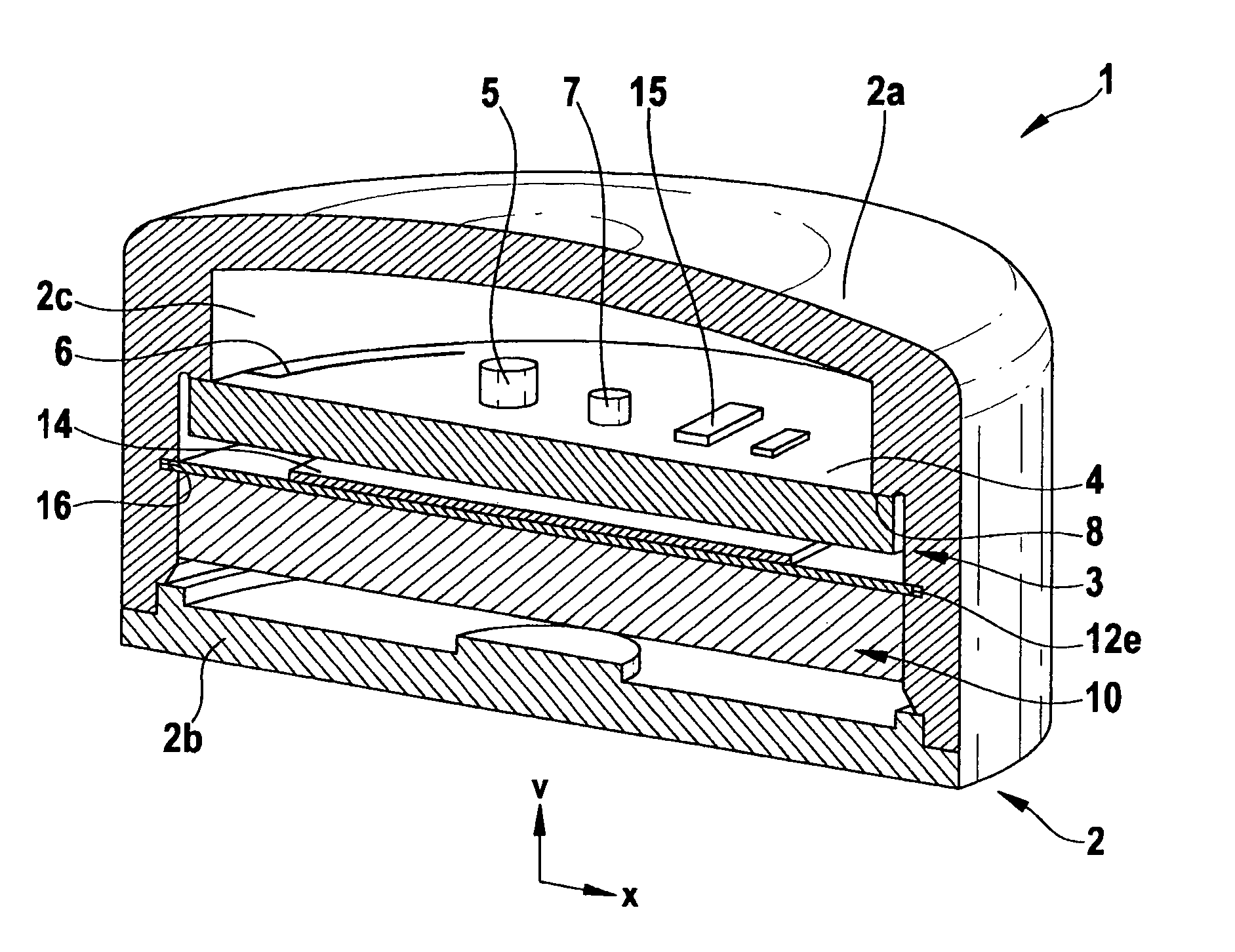

Circuit Module

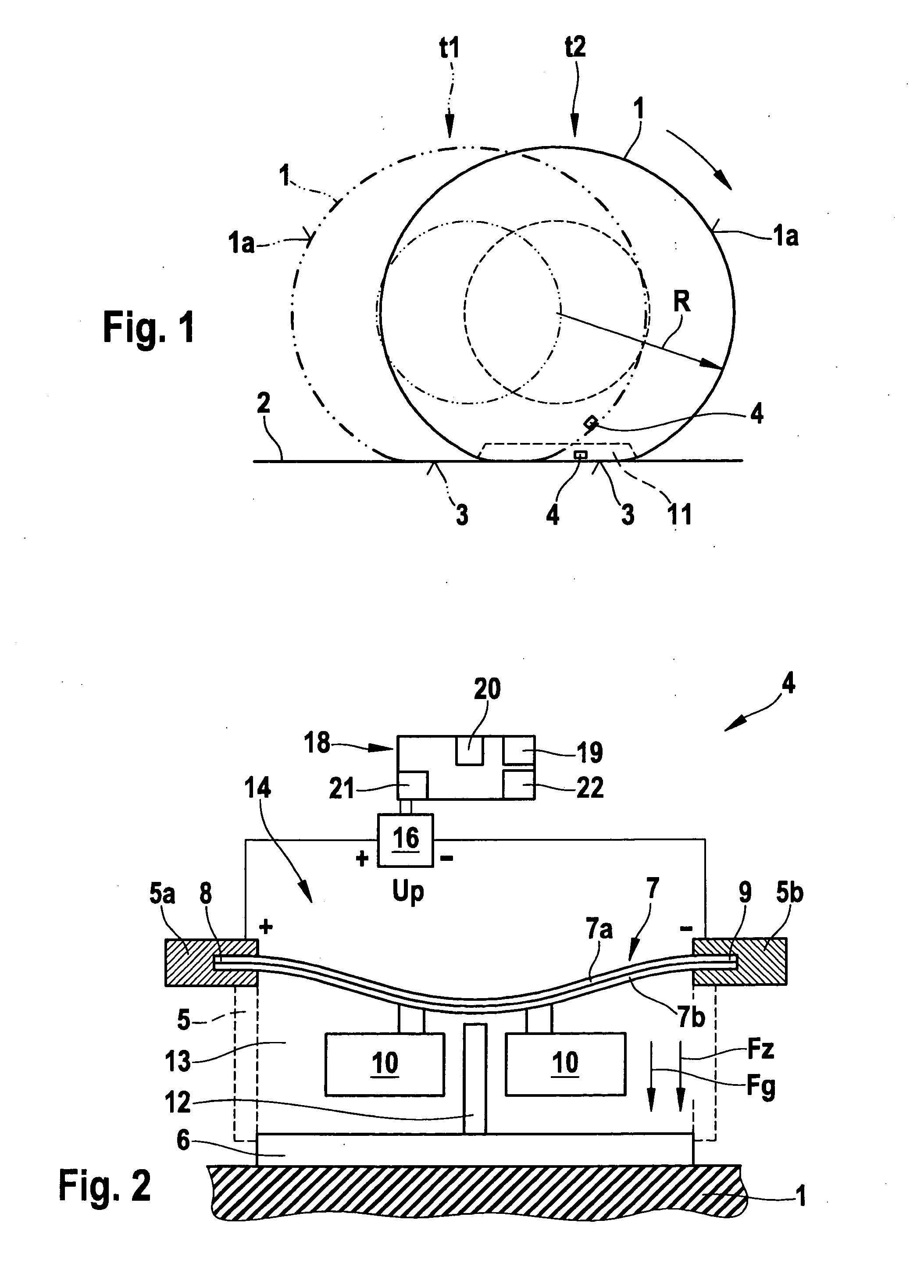

ActiveUS20090205435A1Good environmental compatibilitySimple processPiezoelectric/electrostriction/magnetostriction machinesFluid pressure measurement by electric/magnetic elementsPiezoelectric voltageComputer module

A circuit module, in particular a tire sensor module, which at least includes: a substrate, on or in which at least one component is mounted, a piezoelement, which has at least one clamping region and at least one oscillatory region, the piezoelement being clamped in its clamping region on the substrate or on an arrangement secured to the substrate, and its oscillatory region being accommodated in a manner that permits oscillation, contacts provided on the piezoelement for tapping off a piezoelectric voltage, and a current-supply circuit, which receives the piezoelectric voltage generated by the piezoelement, being used as a voltage source for supplying power to the circuit module. The piezoelement is preferably clamped between at least two substrate elements, at least one cavity being formed within which the at least one oscillatory region of the piezoelement is accommodated in a manner that permits deflection, and is limited in its oscillation displacement.

Owner:ROBERT BOSCH GMBH

Circuit module

InactiveUS7919907B2Piezoelectric/electrostriction/magnetostriction machinesTyre measurementsPiezoelectric voltageDevice form

A circuit module, e.g., for use in a vehicle tire, includes a housing, a piezoelectric generator, which has a mass element that is movable within the housing and a spring device, which has at least one piezoelectric element, the mass element and the spring device forming an oscillatory system, and the piezoelectric element being elastically deformable in response to the oscillation of the oscillatory system. A current supply circuit is provided for receiving a piezoelectric voltage output by the piezoelectric element in response to the mechanical deformation thereof and for supplying power to the circuit module.

Owner:ROBERT BOSCH GMBH

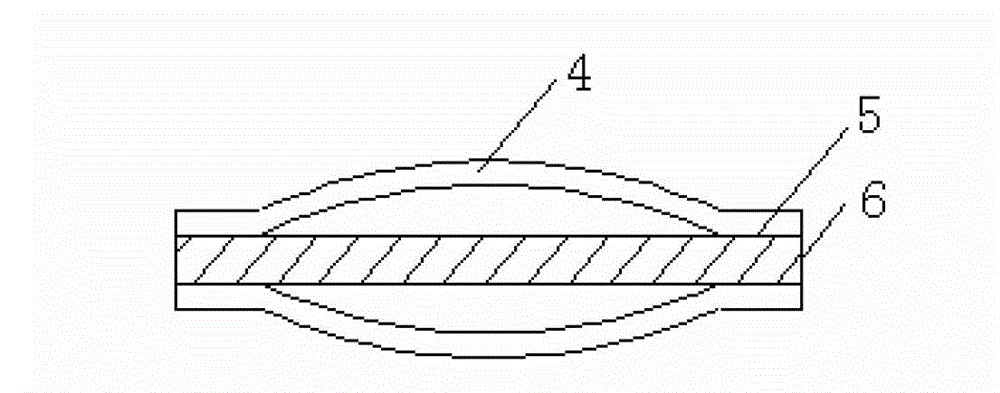

Power-generating unit for a tire sensor module

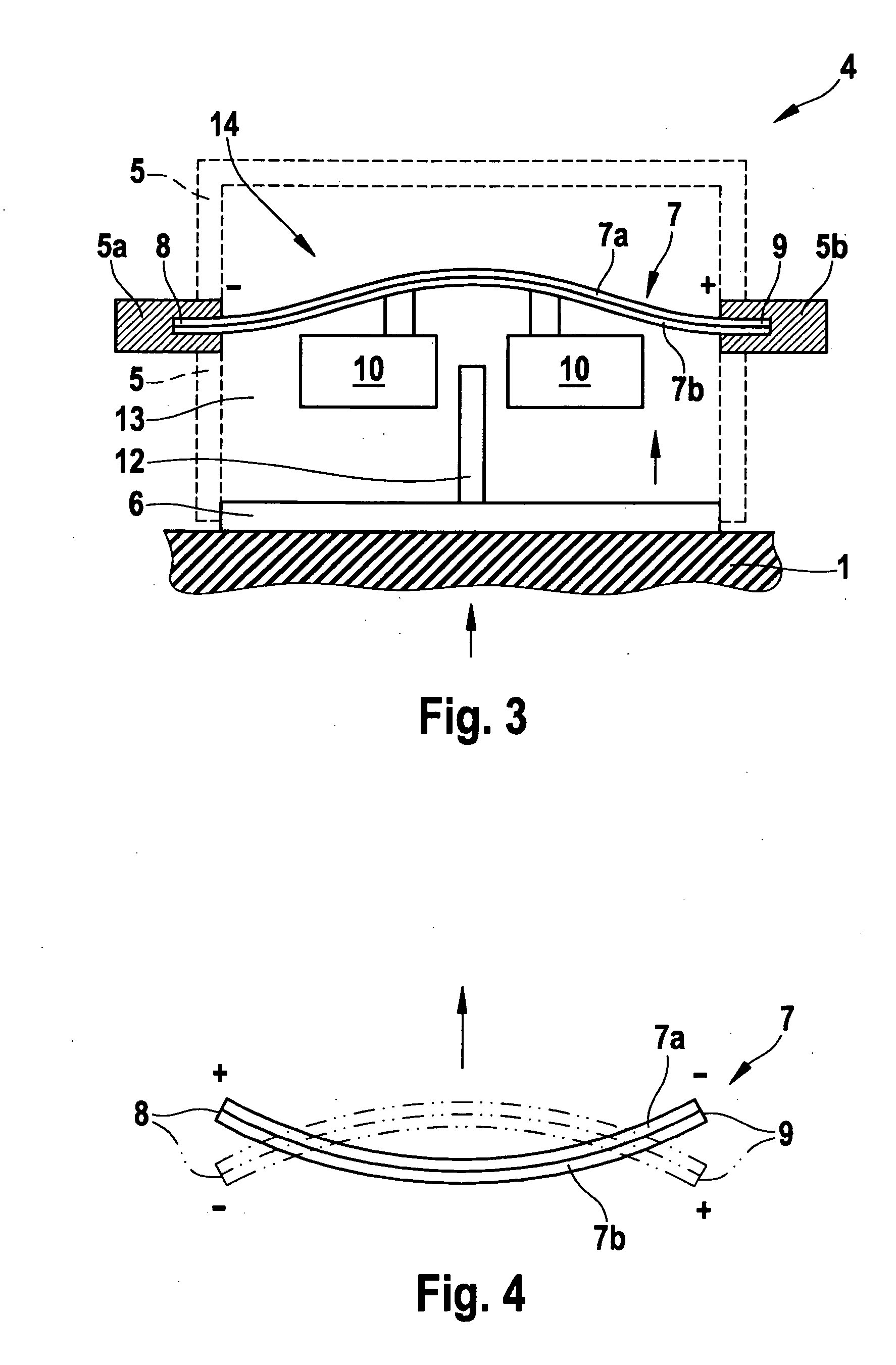

InactiveUS20100295655A1Easy to fixAchieve movementPiezoelectric/electrostriction/magnetostriction machinesElectric testing/monitoringPiezoelectric voltageComputer module

A power-generating unit for a tire sensor module of a vehicle tire has: a piezoelectric element, which is displaceable between a first stable bent position and a second stable bent position and outputs a piezoelectric voltage upon the displacement between the stable bent positions, and a restoring unit for the mechanical displacement of the piezoelectric element from the first stable bent position into the second stable bent position, the restoring unit being activatable by a deformation acting on the power-generating unit, e.g., in a deformed tire area of the vehicle tire above its tire contact patch. The piezoelectric element is clamped in receptacles at its end areas and has two oppositely arched stable bent positions having unstable intermediate states.

Owner:ROBERT BOSCH GMBH

Tire sensor module

InactiveUS20100141417A1Low costSmall sizeTyre measurementsRoads maintainenceElectricityElectrical battery

A tire sensor module for use in a vehicle tire including at least one sensor device for measuring at least one measured variable and for outputting at least one measuring signal, a control device, e.g., an analyzer ASIC for receiving the measuring signal and for outputting at least one transmitted signal to a wireless interface for emitting the transmitted signal to a receiver in or on the vehicle, and an energy accumulator, in particular a battery, for supplying power to at least the control device. A switching device is provided between the energy accumulator and the control device which interrupts or closes the power supply of the control device by the energy accumulator as a function of a control signal, and an electromechanical energy transducer which, under the effect of a deformation, a motion and / or a pressure change, outputs the control signal, in particular a piezoelectric voltage, to the switching device for closing the power supply.

Owner:ROBERT BOSCH GMBH

Electronic equipment, ultrasonic fingerprint identification device and manufacturing method thereof

ActiveCN107194345AHigh loop efficiencyHigh sensitivityPrint image acquisitionPiezoelectric voltageElectric equipment

An embodiment of the invention provides electronic equipment, an ultrasonic fingerprint identification device and a manufacturing method thereof. The method comprises the following steps of forming a first piezoelectric layer and a second piezoelectric layer which are horizontally distributed and are isolated to each other on a substrate layer top, wherein the first piezoelectric layer possesses a specific piezoelectric strain constant and the second piezoelectric layer possesses a specific piezoelectric voltage constant; forming first plane electrodes on tops of the first piezoelectric layer and the second piezoelectric layer; forming a resonant cavity on a substrate layer, and forming a second plane electrode and a third plane electrode which are insulated and isolated to each other in the resonant cavity so as to form a first device, wherein the first plane electrode, the first piezoelectric layer and the second plane electrode are used for realizing ultrasonic emission, and the first plane electrode, the second piezoelectric layer and the third plane electrode are used for realizing ultrasonic receiving; and integrating the first device and a cooperated semiconductor device so as to form the ultrasonic fingerprint identification device. In the embodiment of the invention, loop efficiency and identification sensitivity of the ultrasonic fingerprint identification device can be increased.

Owner:SILEAD

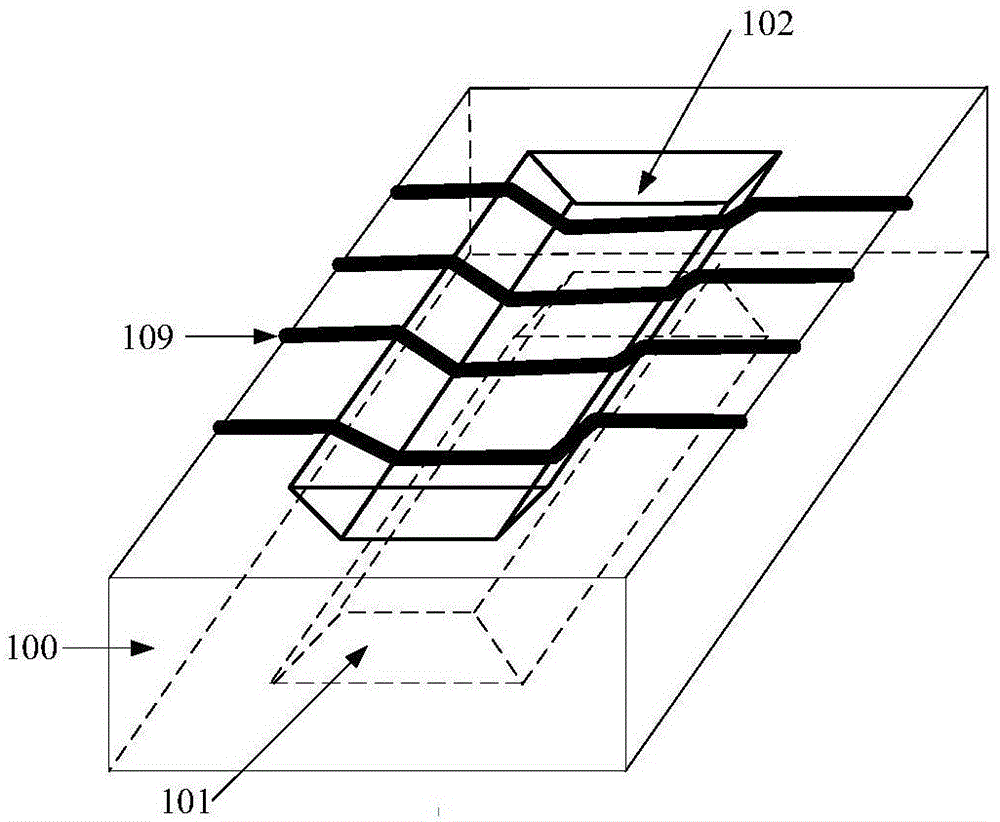

Piezoelectric-electromagnetic hybrid MEMS vibration energy collector and preparation method thereof

ActiveCN105006994AIncrease the output voltageIncrease output currentPiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsElectricityPiezoelectric voltage

The present invention discloses a piezoelectric-electromagnetic hybrid MEMS vibration energy collector and a preparation method thereof. A movable permanent magnet is used as a pick-up structure. Under the effect of a vibration environment, the movable permanent magnet moves in a cavity, thus the magnetic flux in a spiral inductance coil is changed, induction current is generated in a closed loop formed by the spiral inductance coil and an external load, and the conversion of vibrational energy into electrical energy through an electromagnetic induction mode is realized. In addition, when the movable permanent magnet moves in the cavity, the generated pressure or impact causes the bending deformation of a first square film or a second square film, the deformation of a piezoelectric layer is caused to generate piezoelectric voltage, the conversion of the vibrational energy into the electrical energy through a piezoelectric effect is realized, and the piezoelectric electrode of the piezoelectric layer is connected to supply power to the load. According to the piezoelectric-electromagnetic hybrid MEMS vibration energy collector and the preparation method, the modes of electromagnetic induction and piezoelectric effect are combined to convert the vibrational energy into the electrical energy, and the electromagnetic induction and the piezoelectric effect are superimposed to supply power to the load.

Owner:SOUTHEAST UNIV

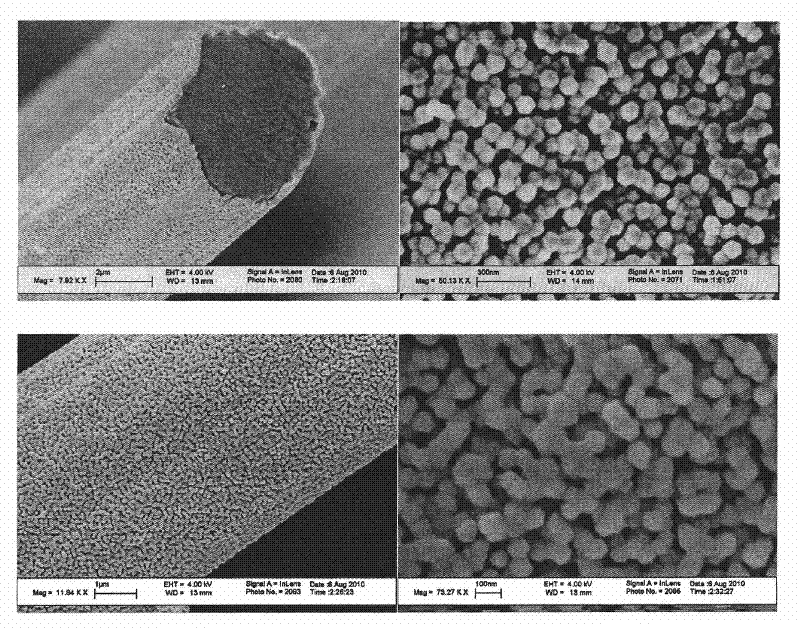

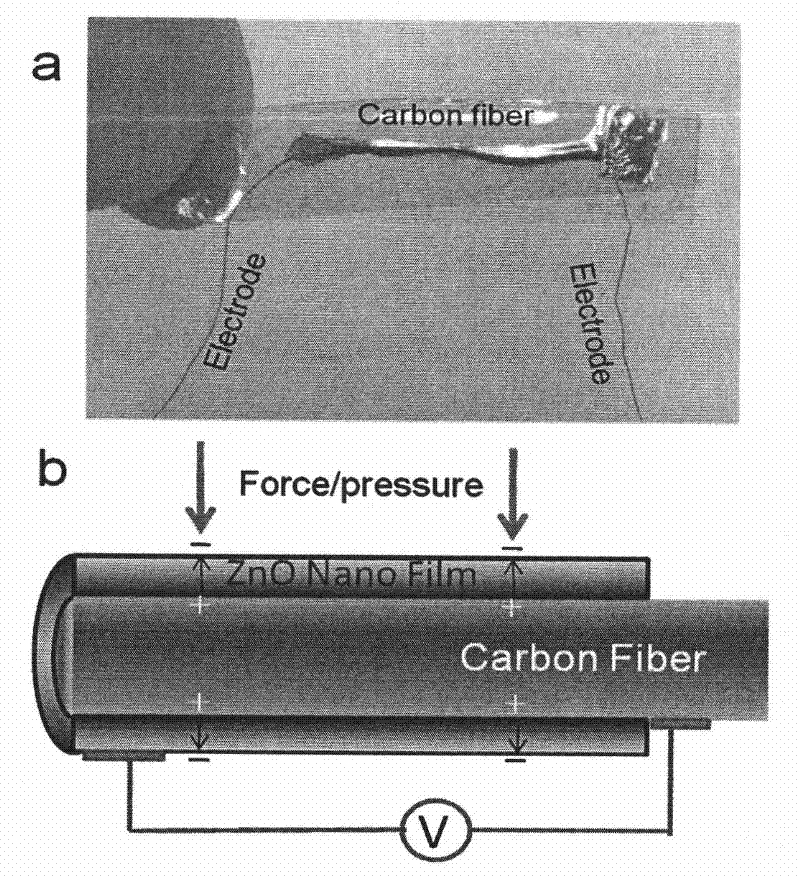

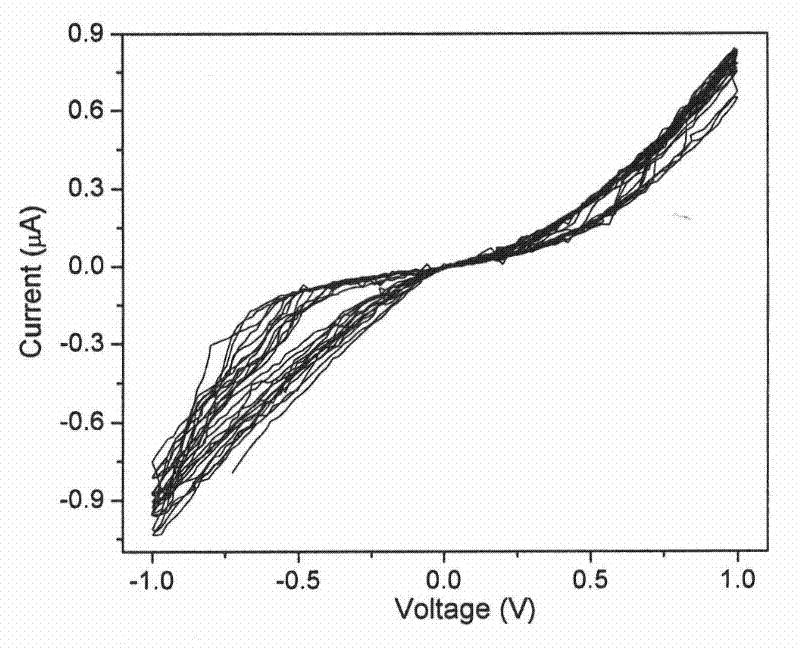

Method for preparing zinc oxide nanometer film carbon fiber piezoelectric material with core-shell structure and application thereof

InactiveCN102315381AUniform transfer of stressUniform stressPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiberPower sensor

The invention relates to a method for preparing a textured zinc oxide nanowire film, with a core-shell structure, growing on the surface of carbon fiber. The preparing method comprises the following steps of: removing a sizing agent on the surface of the carbon fiber or carbon fiber fabric, mixing zinc oxide powder and active carbon to obtain mixed zinc powder, feeding the mixed zinc powder as a growth source to a sealed tube type furnace, slowly vacuumizing, slowly introducing argon and oxygen mixed gas, heating to 850 DEG C, preserving the heat for 10min, then heating to 960 DEG C and preserving the heat for 30min, and then cooling, wherein the piezoelectric voltage of the zinc oxide film is educed through an electrode between the carbon fiber and the top of the zinc oxide, and the connection between the surface of the zinc oxide film and the electrode is of schottky connection. A device disclosed by the invention can be used as a gas pressure sensor or a pneumatic pressure nano engine of automobile / aircraft tyres. Besides, the device disclosed by the invention can also be used as a self-powered sensor for continuously monitoring pulse condition characteristic regions, such as pulse vibration frequency, pulse amplitude, and the like through a piezoelectric current change curve and provides a support for quantification representation of modern human body internet of things of traditional Chinese medicine.

Owner:李泽唐 +1

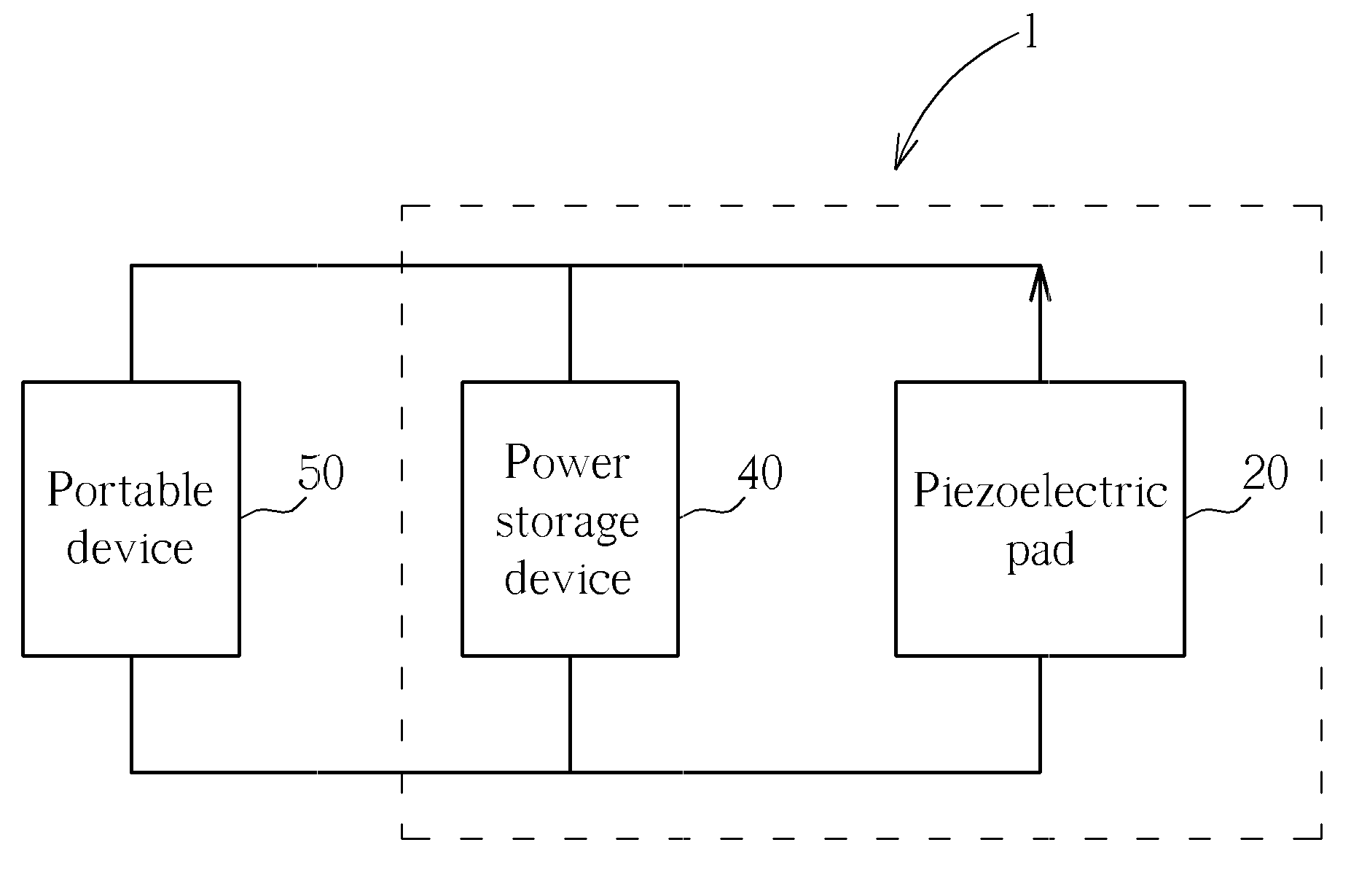

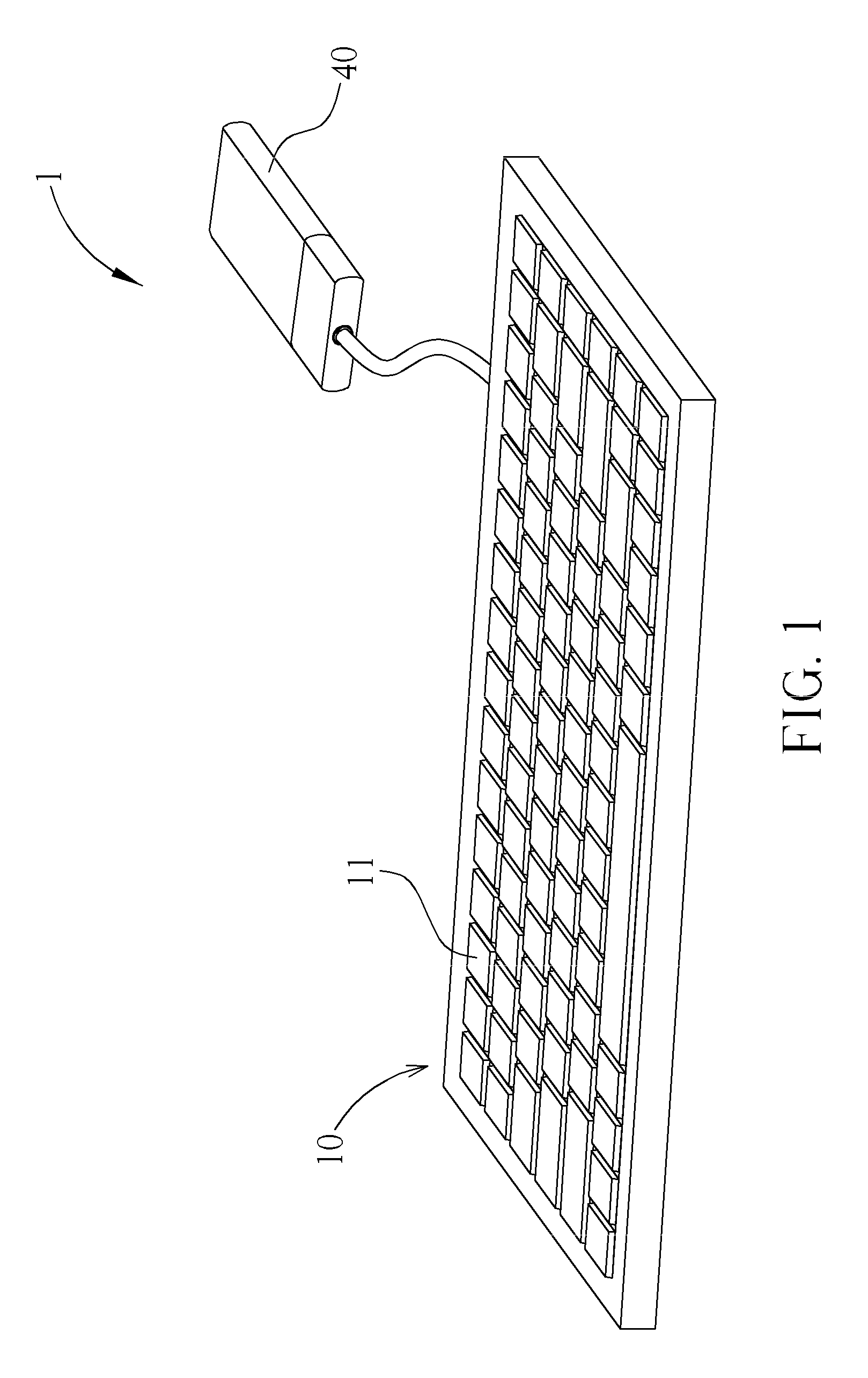

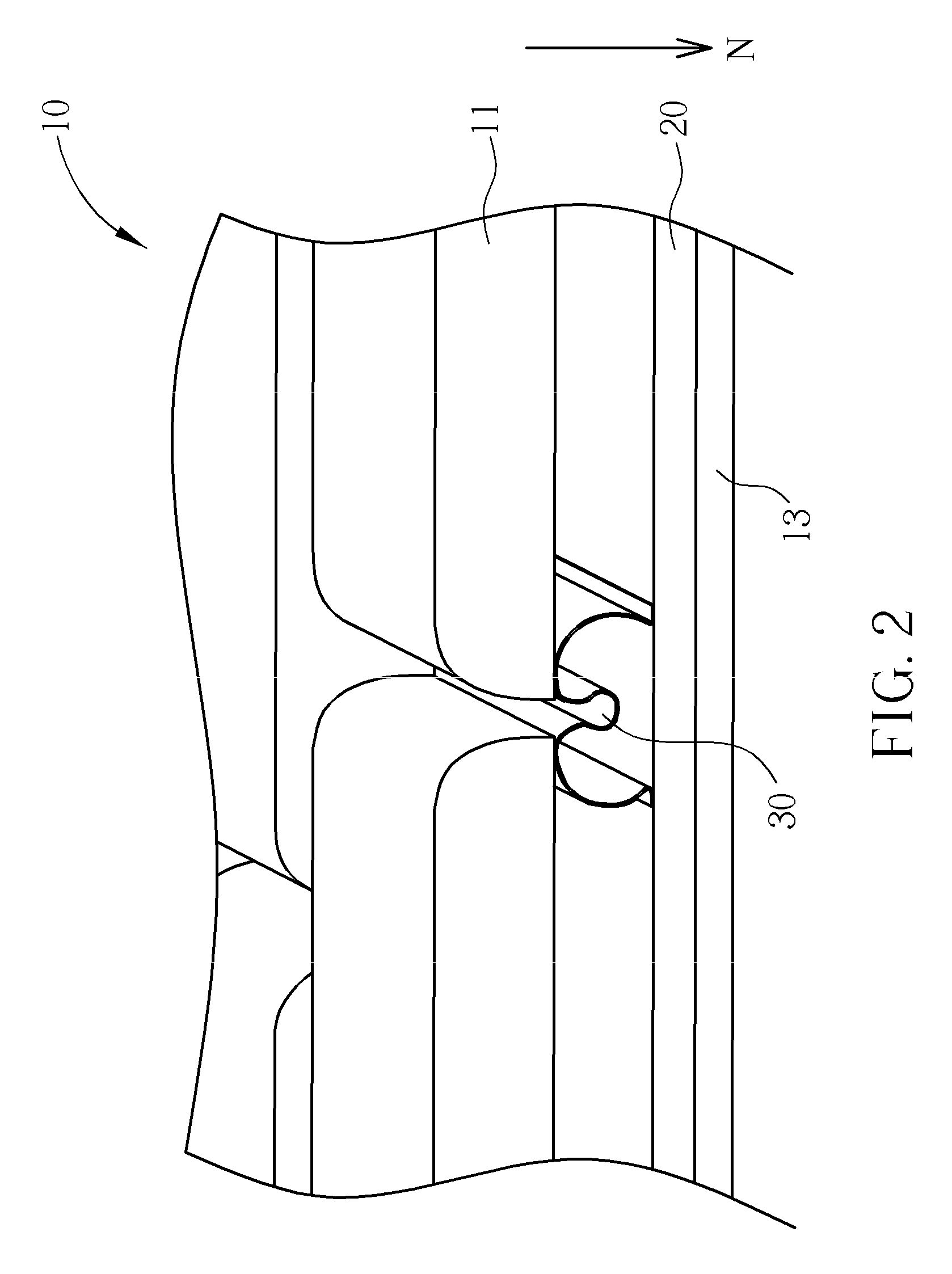

Input module having piezoelectric pad

InactiveUS20100253632A1Input/output for user-computer interactionPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric voltage

One or more piezoelectric pads are disposed into a keyboard and electrically connecting to a rechargeable battery of an electronic device or a portable electronic device. When one button of the keyboard is pressed, the movement of the button pushes and deforms the corresponding piezoelectric pad to generate a piezoelectric voltage for charging the battery. The electronic device or the portable electronic device can deal with power shortage during usage with the feature of transforming mechanical power into electrical power by using piezoelectric pads in the keyboard.

Owner:WISTRON CORP

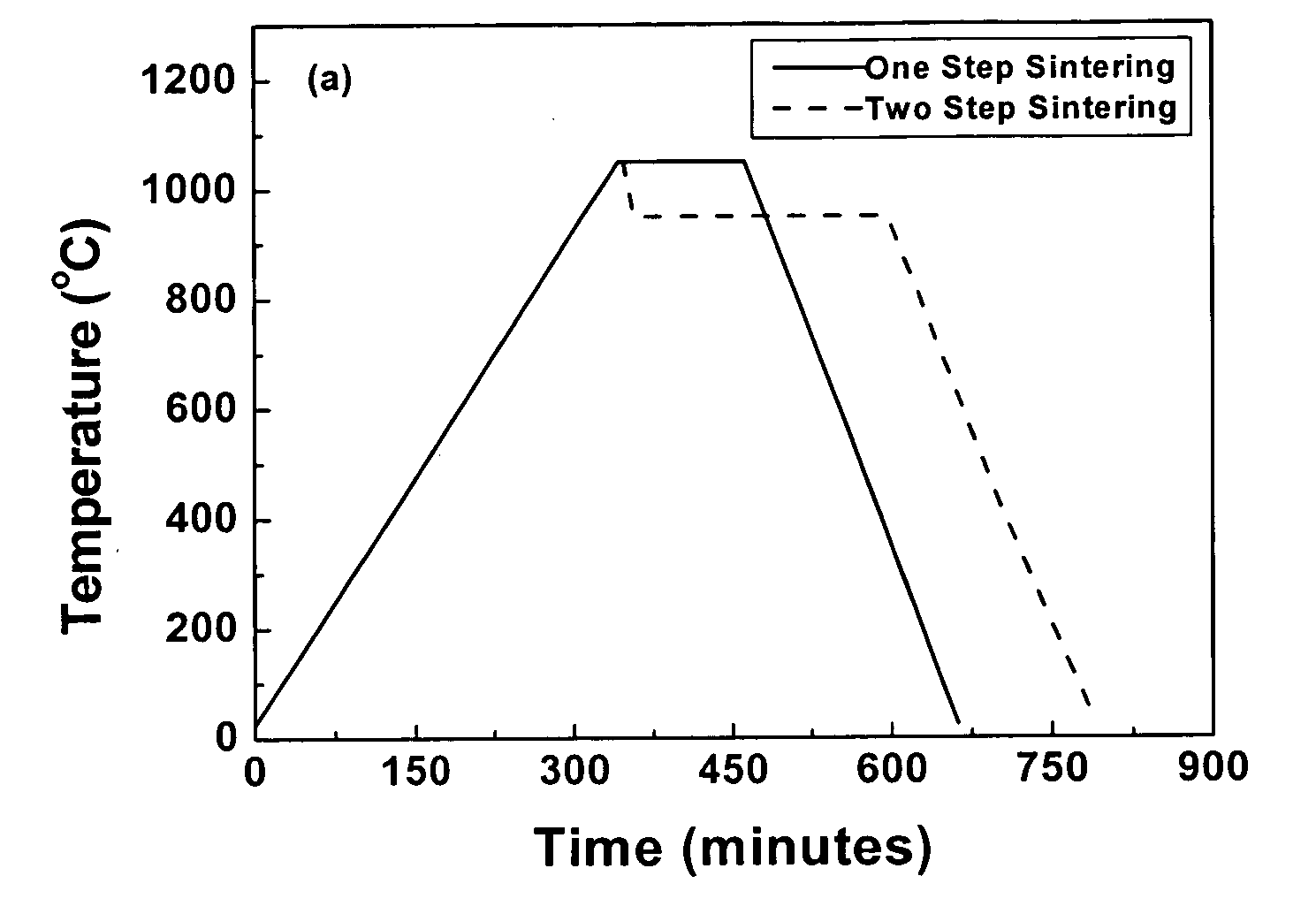

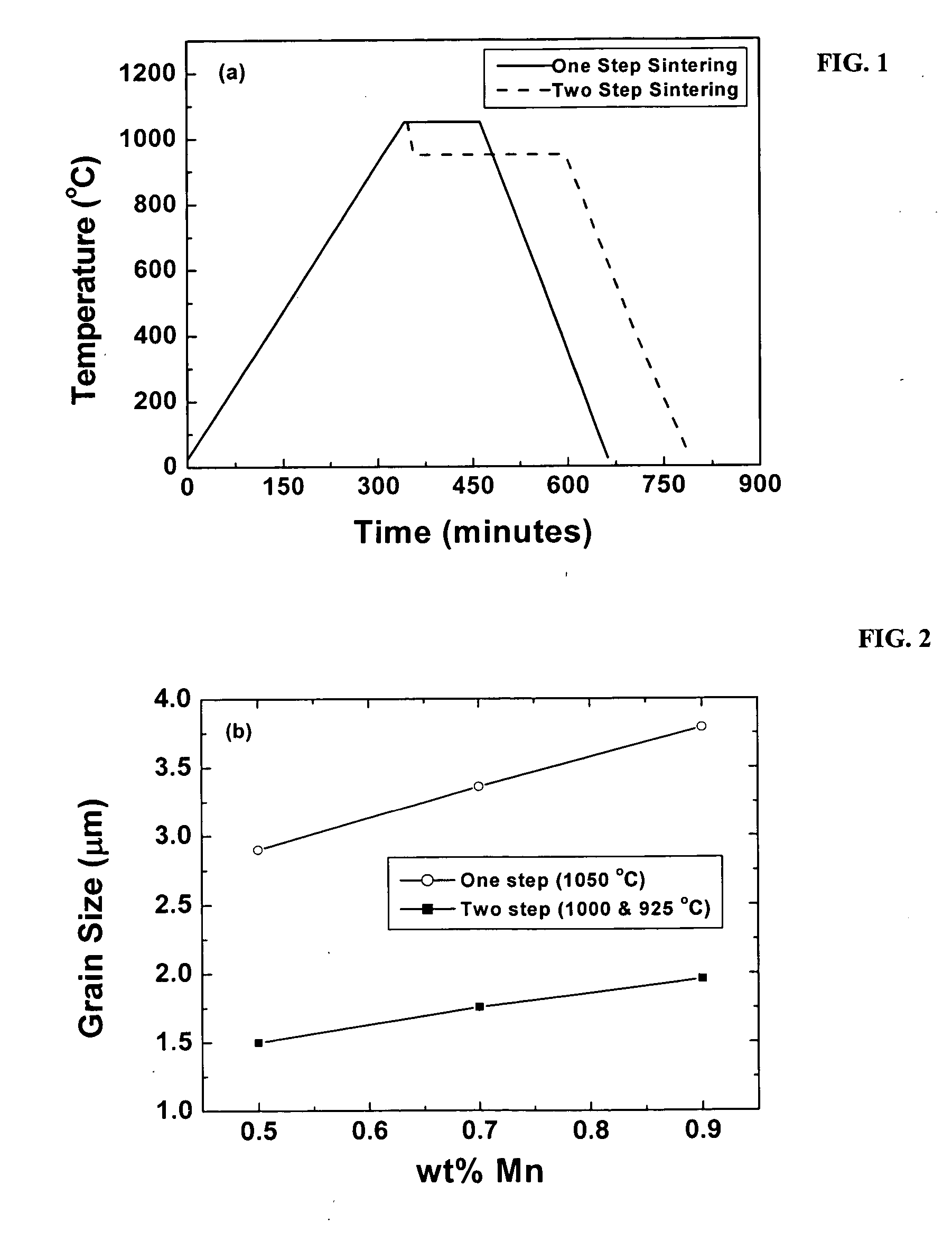

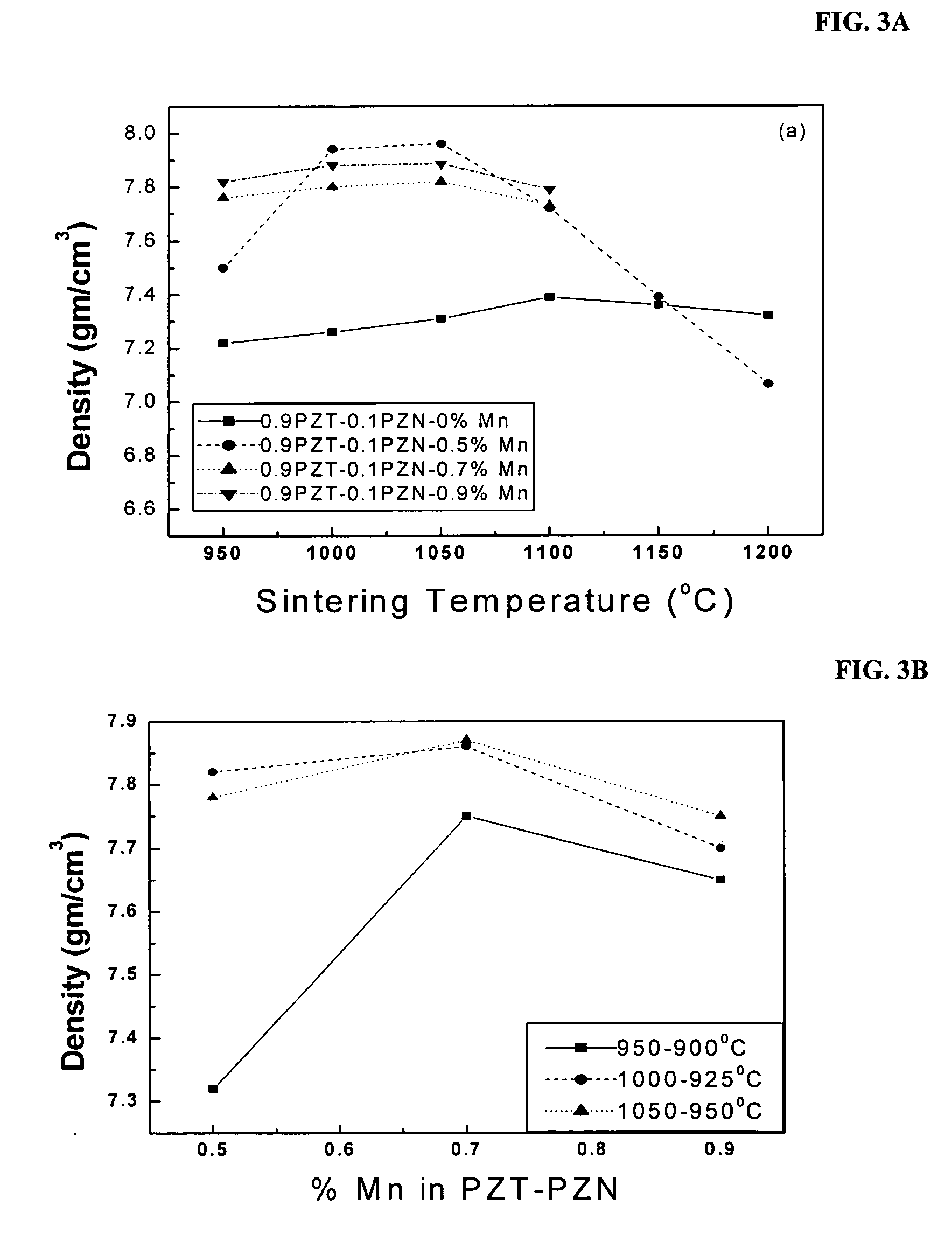

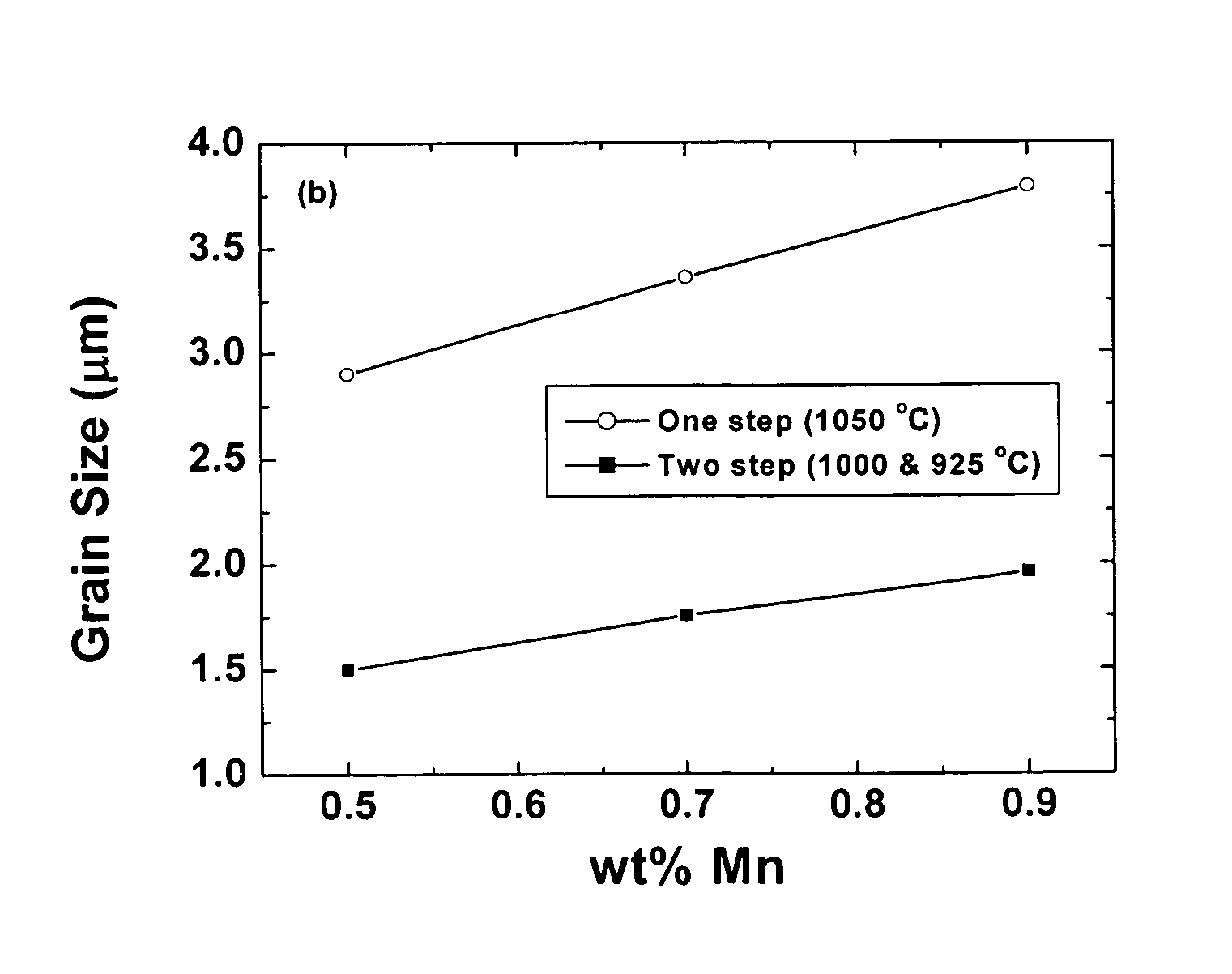

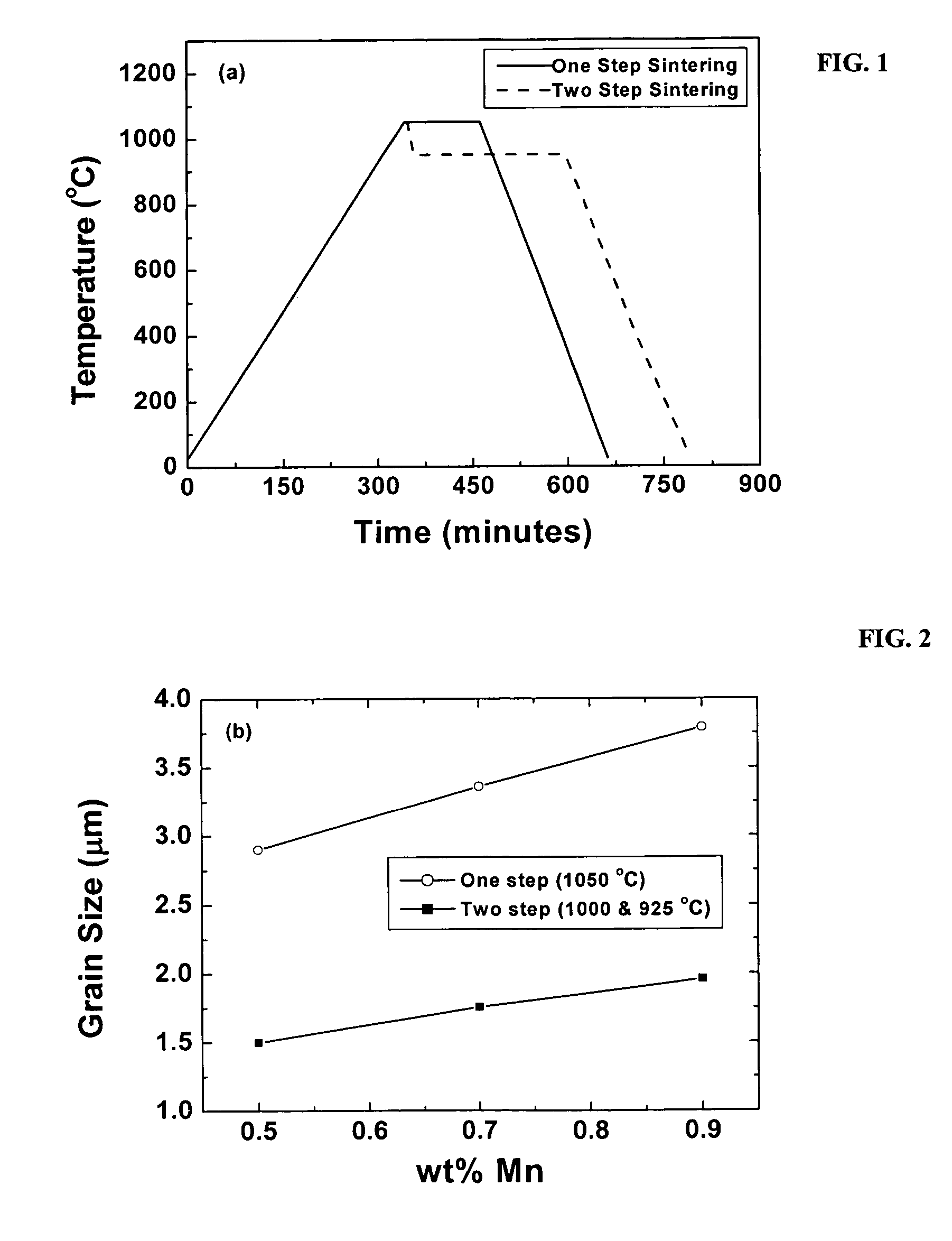

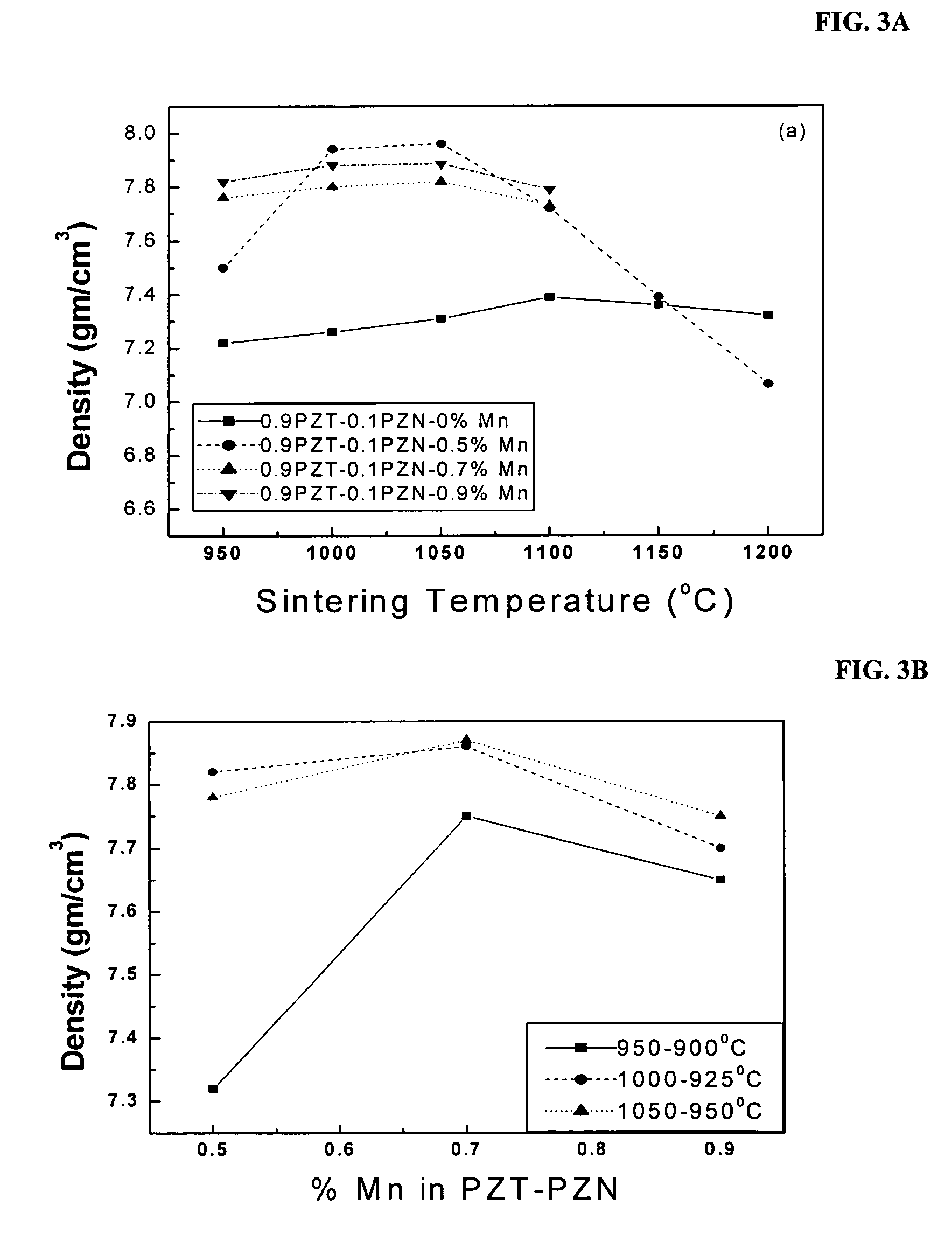

High energy density piezoelectric ceramic materials

InactiveUS20070087930A1Piezoelectric/electrostriction/magnetostriction machinesCeramic shaping apparatusHigh energyPiezoelectric voltage

The present invention includes methods, devices, and compositions having improved piezoelectric characteristics with high energy density. Compositions of the present invention are ceramic materials of the formula: Pb[(Zr0.52Ti0.48)O3]1−x[(Zn1 / 3Nb2 / 3)O3]x+Mn, where x is 0.05 to 0.20 and Mn is manganese in a form that is present from about 0.1 to 1.5 wt %. Suitable manganese forms include MnCO3, MnO2, MnO, and Mn3O4. The compositions exhibit a high product of piezoelectric voltage constant and piezoelectric stress constant. The compositions are polycrystalline or textured with a dense microstructure and small grain. The piezoelectric voltage constant and piezoelectric stress constant obtained from such compositions are superior to those of conventional hard or soft ceramics and yield a magnitude product of the piezoelectric voltage constant and piezoelectric stress constant that is significantly higher than those reported in the literature or in available with commercial or conventional ceramic compositions.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

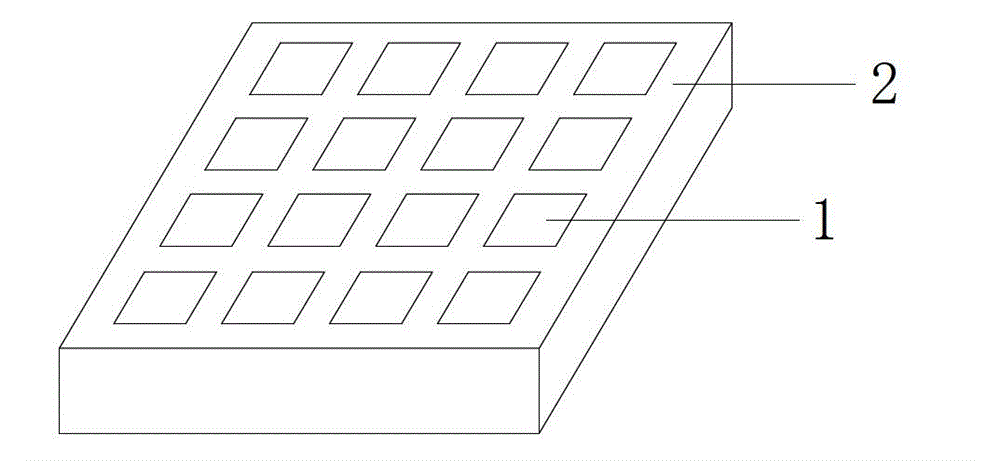

Touch panel

A touch panel that includes a dielectric film and a piezoelectric film. A first capacitance detection electrode is disposed on an upper main surface of the dielectric film, a second capacitance detection electrode and a first piezoelectric voltage detection electrode are disposed between a lower main surface of the dielectric film and an upper main surface of the piezoelectric film, and a second piezoelectric voltage detection electrode is disposed on a lower main surface of the piezoelectric film. The first capacitance detection electrode includes plural sub-electrodes extending in a first direction, the second capacitance detection electrode includes plural sub-electrodes extending in a second direction orthogonal to the first direction, and the first piezoelectric voltage detection electrode includes plural sub-electrodes disposed between the plural sub-electrodes.

Owner:MURATA MFG CO LTD

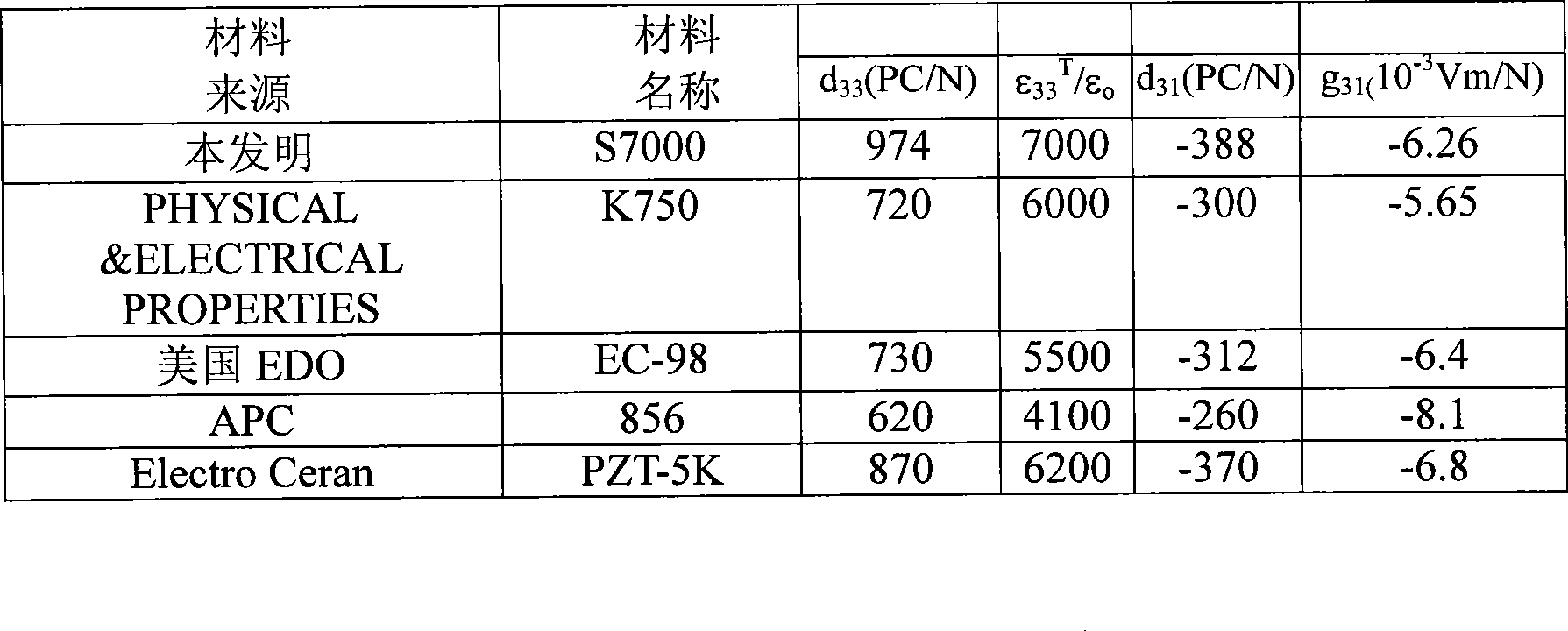

High piezoelectric strain constant d31, low piezoelectric strain constant g31 piezoelectric ceramic material and preparation thereof

ActiveCN101475373APiezoelectric/electrostrictive/magnetostrictive devicesElectricityPiezoelectric voltage

The invention relates to a piezoelectric ceramic material with a high-pressure electric strain constant d31 and a low-pressure electric strain constant g31 and a preparation method thereof, and belongs to the filed of ceramic composition and preparation. The chemical general formula of the piezoelectric ceramic material is xPbZrO3+yPbTiO3+zPb(Mg1 / 3Nb2 / 3)O3+mSrTiO3+nBaTiO3+pLaTiO3+awt.percent SiO2+bwt.percent La2O3+cwt.percent Nb2O5+dwt.percent Sb2O3, wherein x is between0.2 and 0.5, y is between0.2 and 0.5, z is between 0.1 and 0.4, m is between 0.0 and 0.10, n is between 0.0 and 0.10, p is between 0.0 and 0.10, a is between 0 and 0.5, b is between0 and 0.5, c is between 0 and 0.5, and d is between 0 and 0.5. The piezoelectric ceramic material is prepared through improvement on the basis of the prior piezoelectric ceramic technology. The main properties of a standard material plate are as follows: d33 is equal to 974pC / N, d31 is equal to -388pC / N, epsilon33 / epsilon o is equal to 7,000, g31 is equal to -6.26, and k31 is equal to 0.42. The material has high piezoelectric strain constant d31 and low piezoelectric voltage constant g31, and is a piezoelectric ceramic double-wafer driving material with superior properties. A piezoelectric ceramic double-wafer actuating element prepared from the material is provided to the China Braille Publishing House and used for manufacturing a Braille electronic display; double-wafer endpoints have large displacement, strong strength and good stability, and the blind has obvious hand feeling; and the Braille electronic display completely replaces imported products of the same type.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

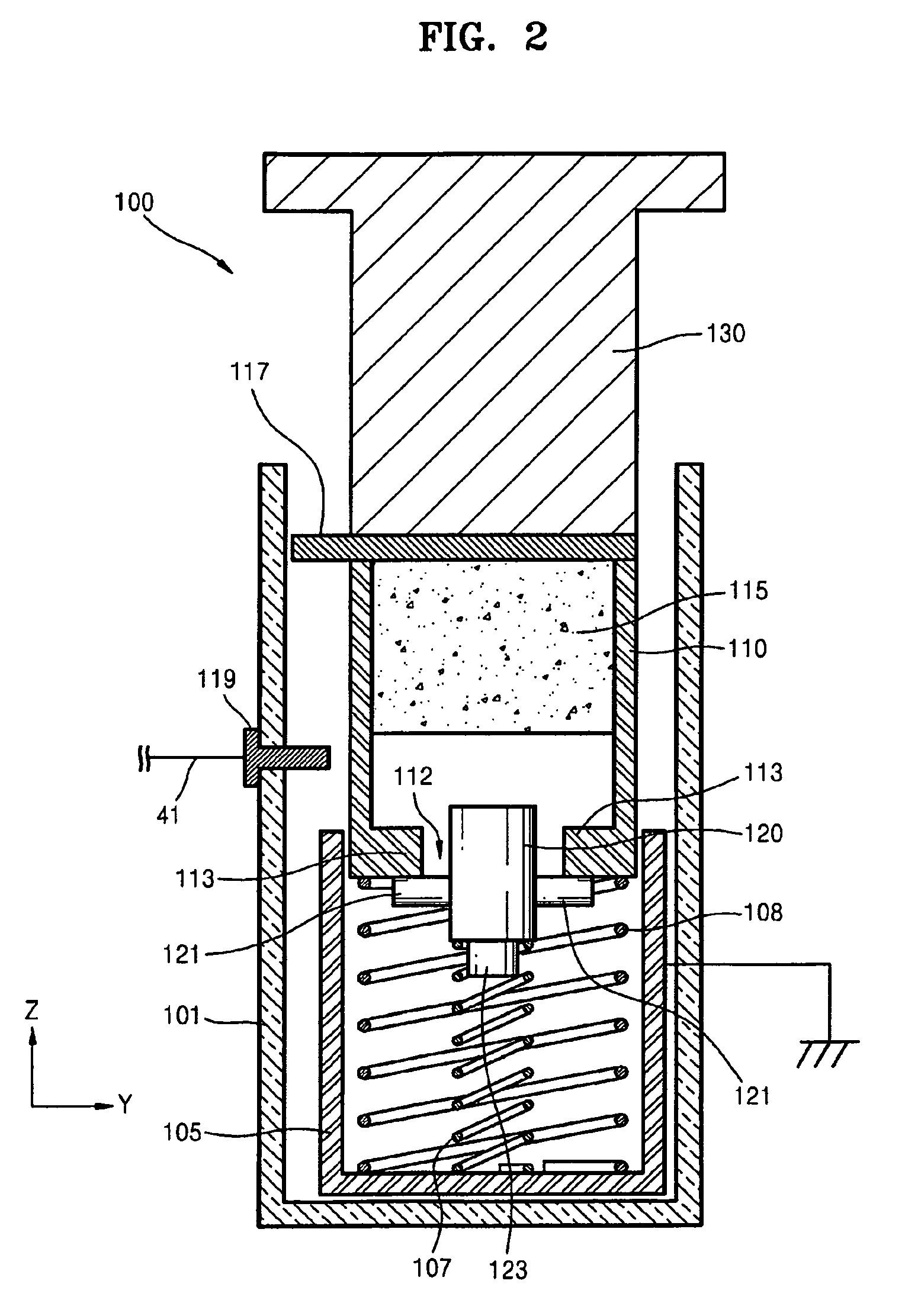

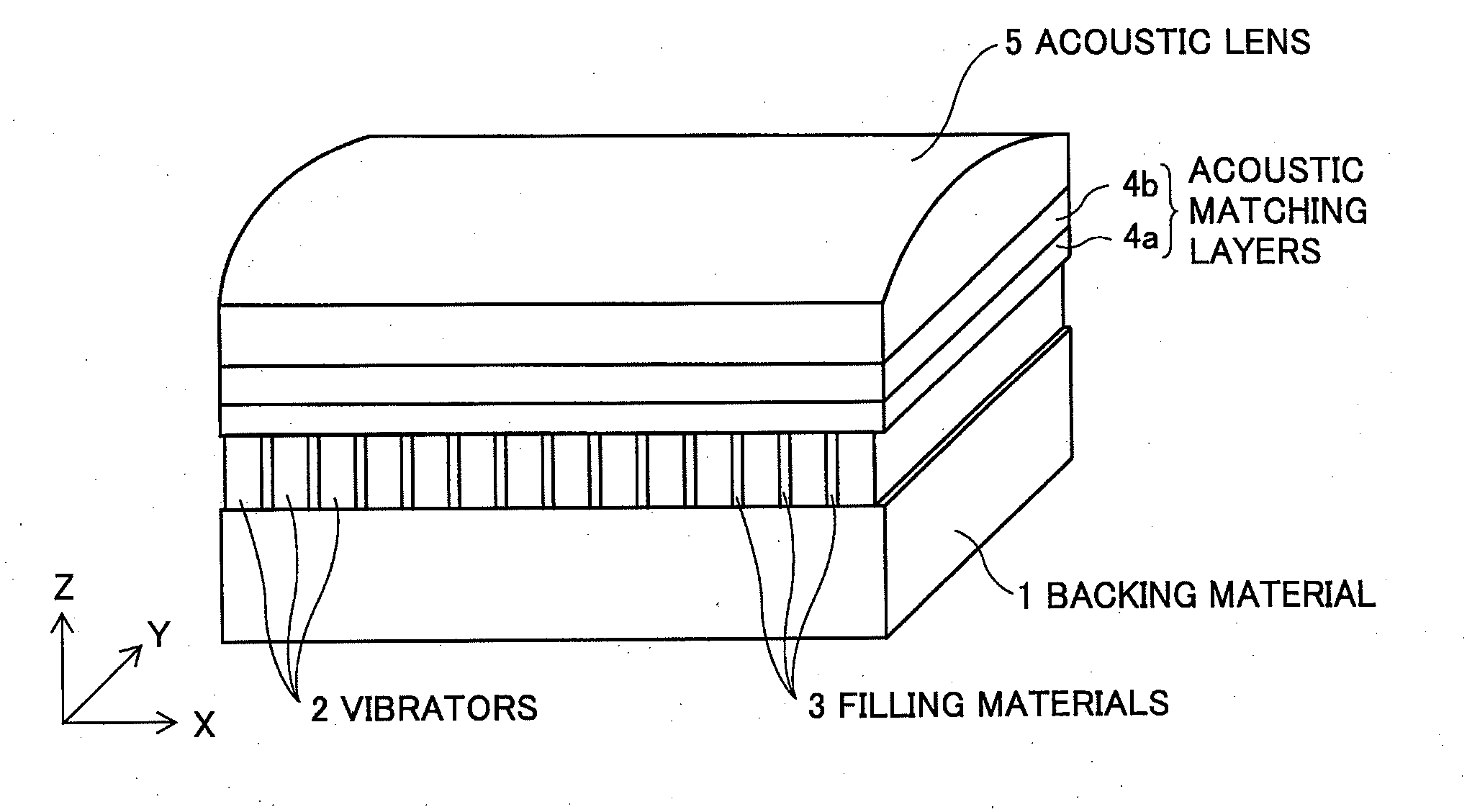

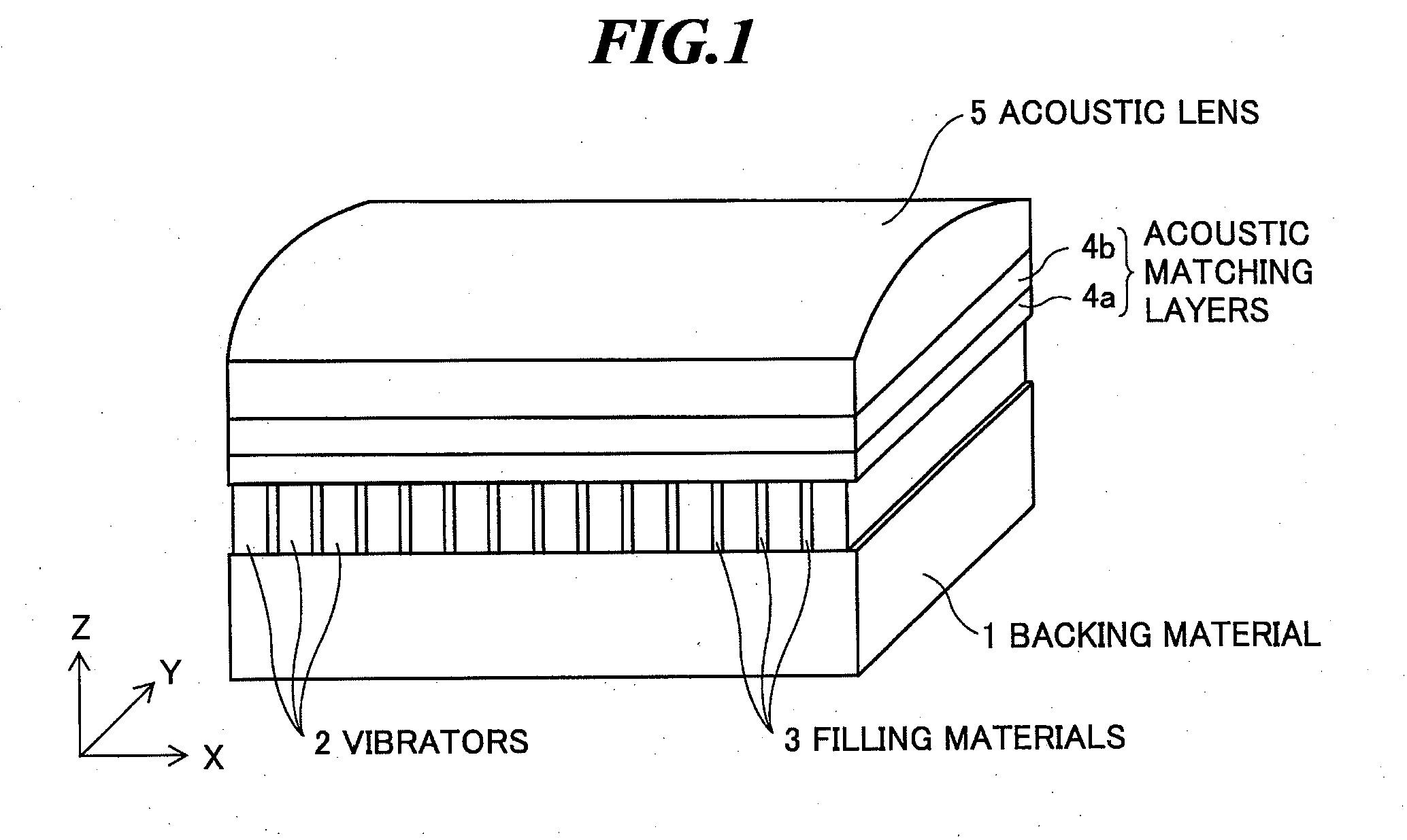

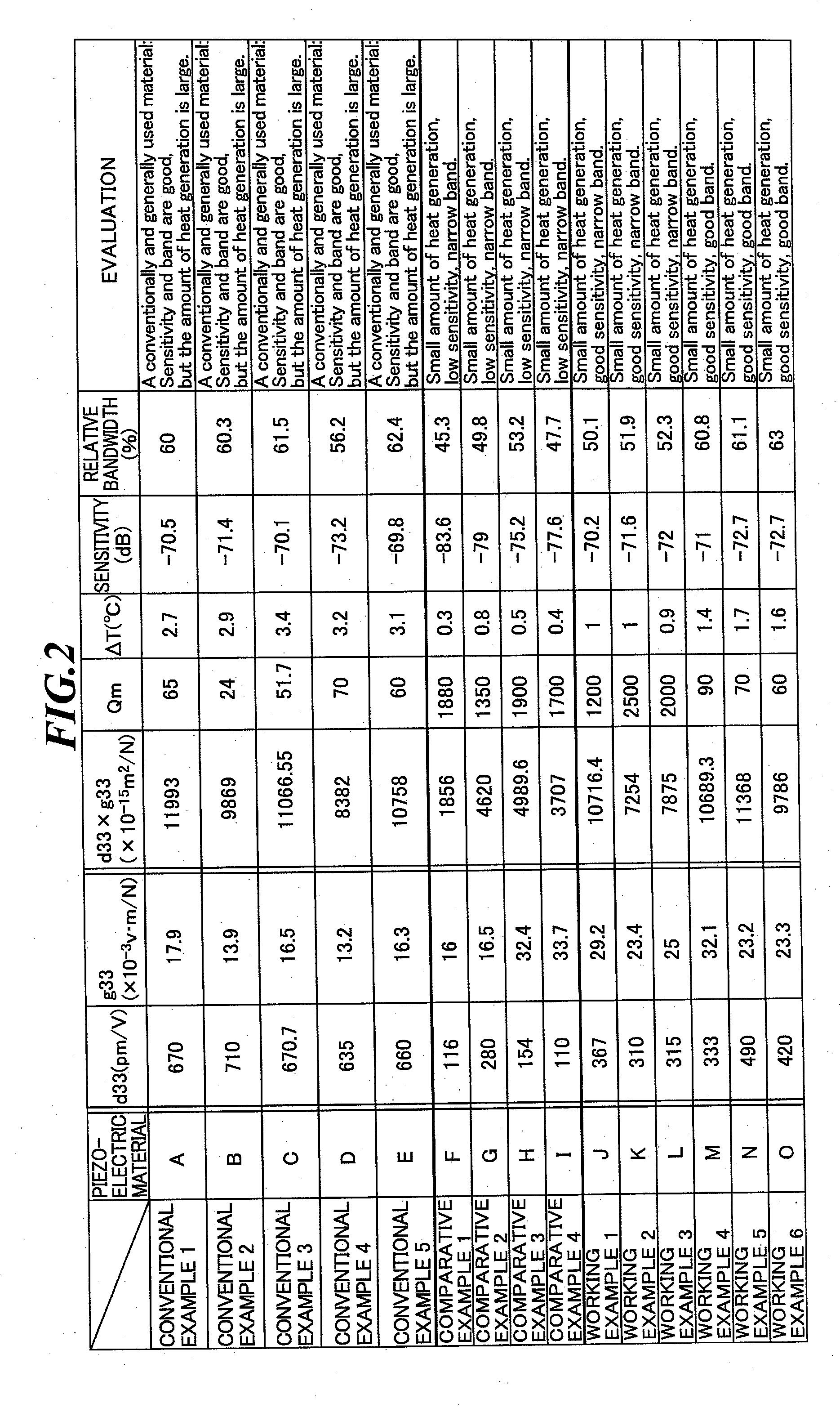

Ultrasonic probe, ultrasonic diagnostic apparatus and ultrasonic endoscopic apparatus

InactiveUS20090287086A1Suppress feverSuppressing of bandwidthUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric voltageUltrasonic Endoscopy

An ultrasonic probe in which a balance between basic performance and suppression of heat generation is achieved by suppressing heat generation of the ultrasonic probe without degrading sensitivity and relative bandwidth of the ultrasonic probe in transmission and reception of ultrasonic waves. The ultrasonic probe includes at least one vibrator for transmitting and receiving ultrasonic waves, the at least one vibrator including a piezoelectric material in which a piezoelectric strain constant d33 is equal to or less than 500 pm / V and a product of the piezoelectric strain constant d33 and a piezoelectric voltage constant g33 is equal to or more than 7000×10−15 m2 / N, at least one acoustic matching layer provided on a first surface of the at least one vibrator, and a backing material provided on a second surface opposite to the first surface of the at least one vibrator.

Owner:FUJIFILM CORP

High energy density piezoelectric ceramic materials

InactiveUS7686974B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric voltageHigh energy

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

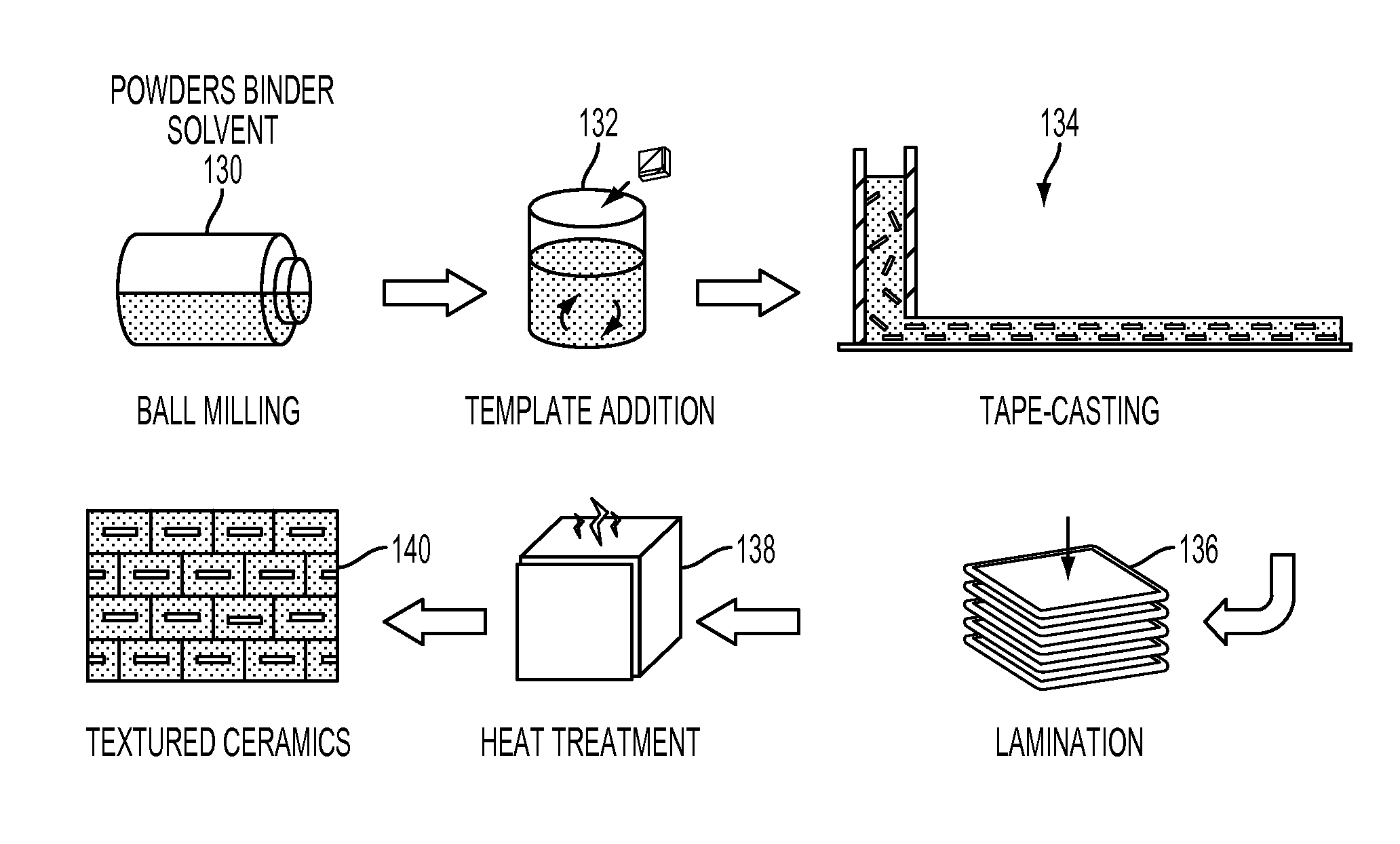

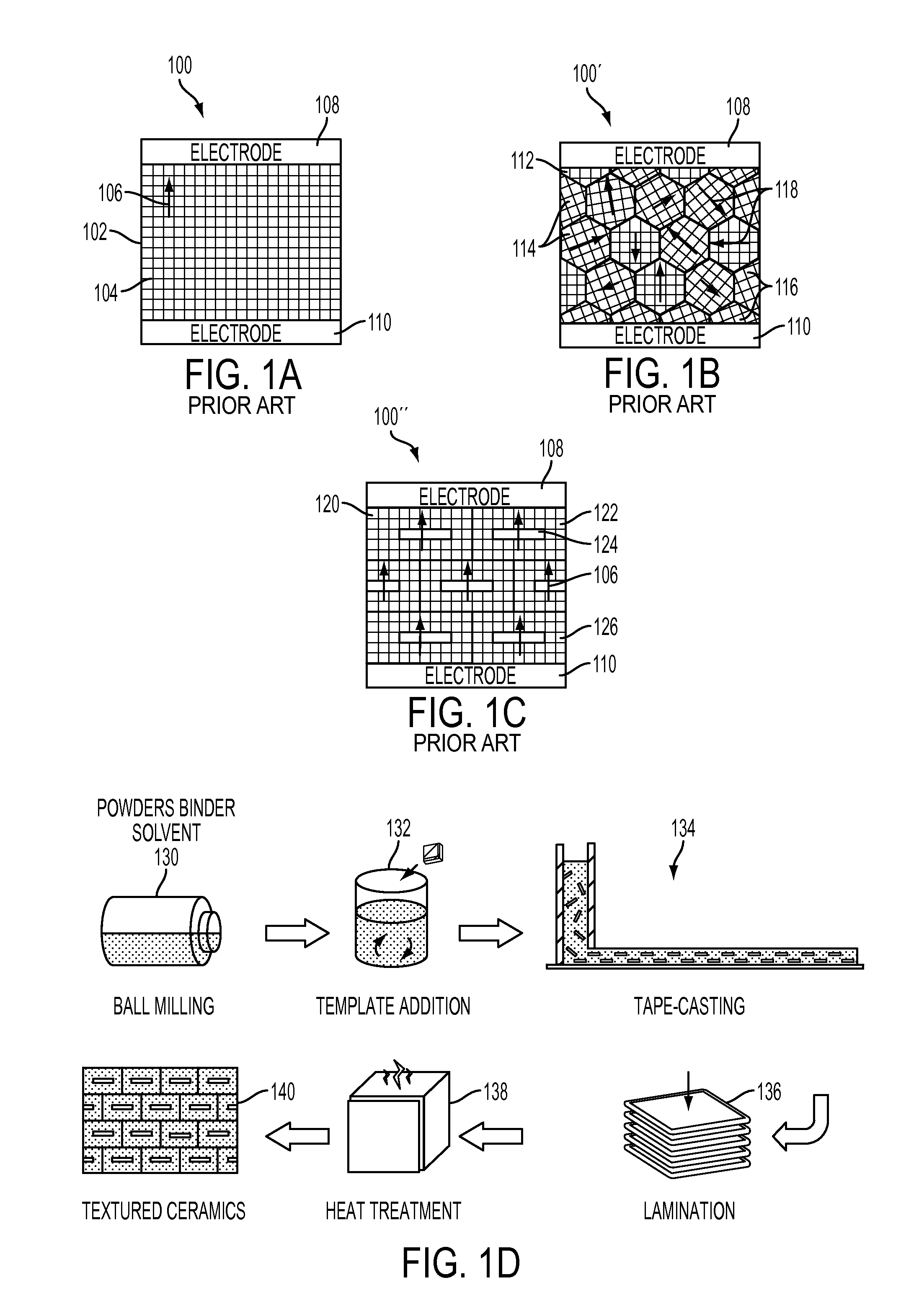

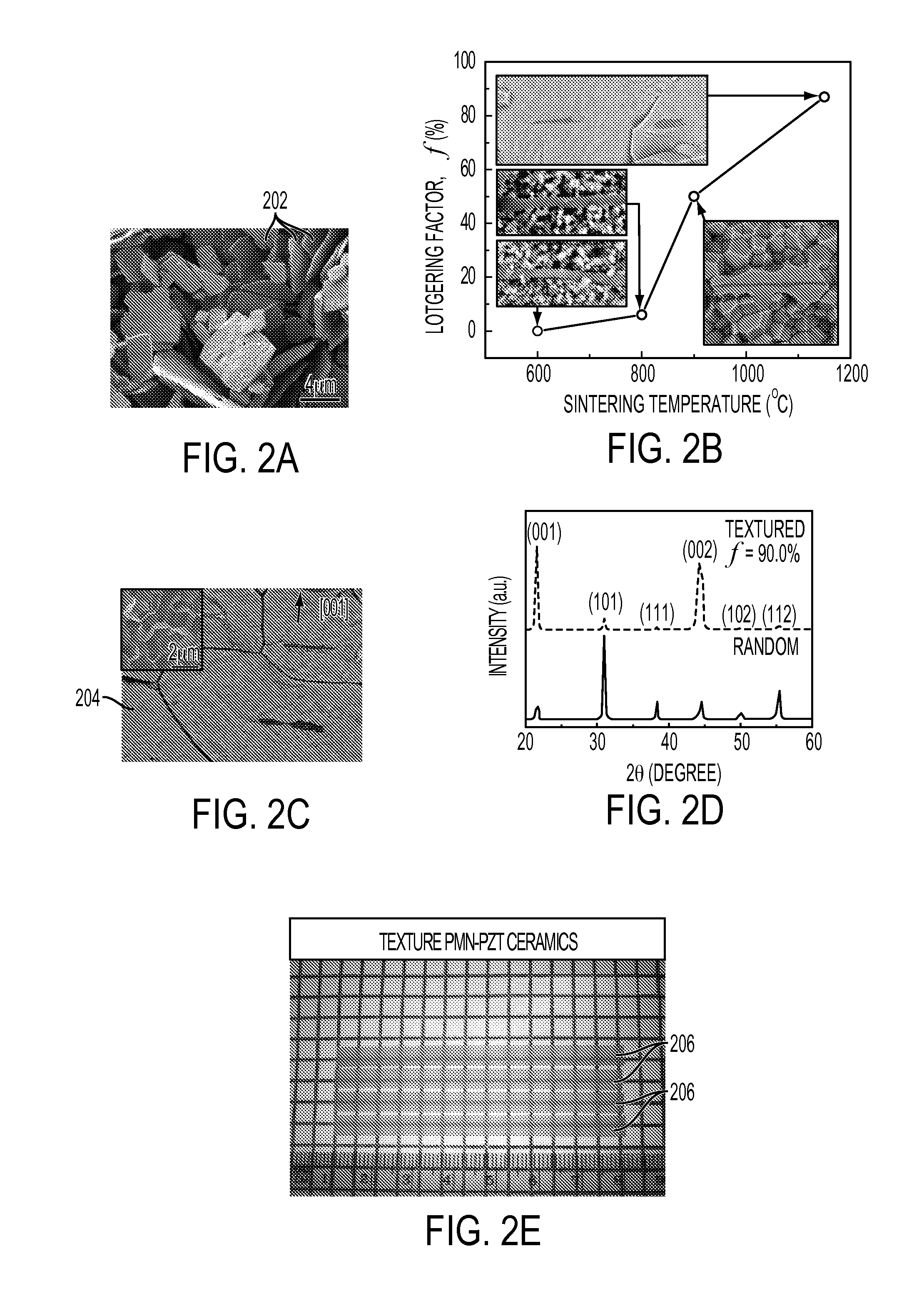

High performance textured piezoelectric ceramics and method for manufacturing same

InactiveUS20140295138A1Increase volume fractionEffect piezoelectric responseFrom gel statePolycrystalline material growthPiezoelectric voltageCeramic capacitor

A textured PMN-PZT ceramic is created using templated grain growth to align seed crystals in a ceramic matrix powder by tape-casting process. Heat treatment then results in the nucleation and growth of matrix crystals on aligned templates. The resulting textured PMN-PZT ceramic has high longitudinal piezoelectric coefficient and a high piezoelectric voltage coefficient. In another embodiment, a textured PMN-PT ceramic has a volume fraction of the templates no greater than 1%. The utility of this invention includes both its exceptional piezoelectric properties as well as the utilization of an economical manufacturing process that is widely used in the multi-layer ceramic capacitor industry.

Owner:VIRGINIA TECH INTPROP INC

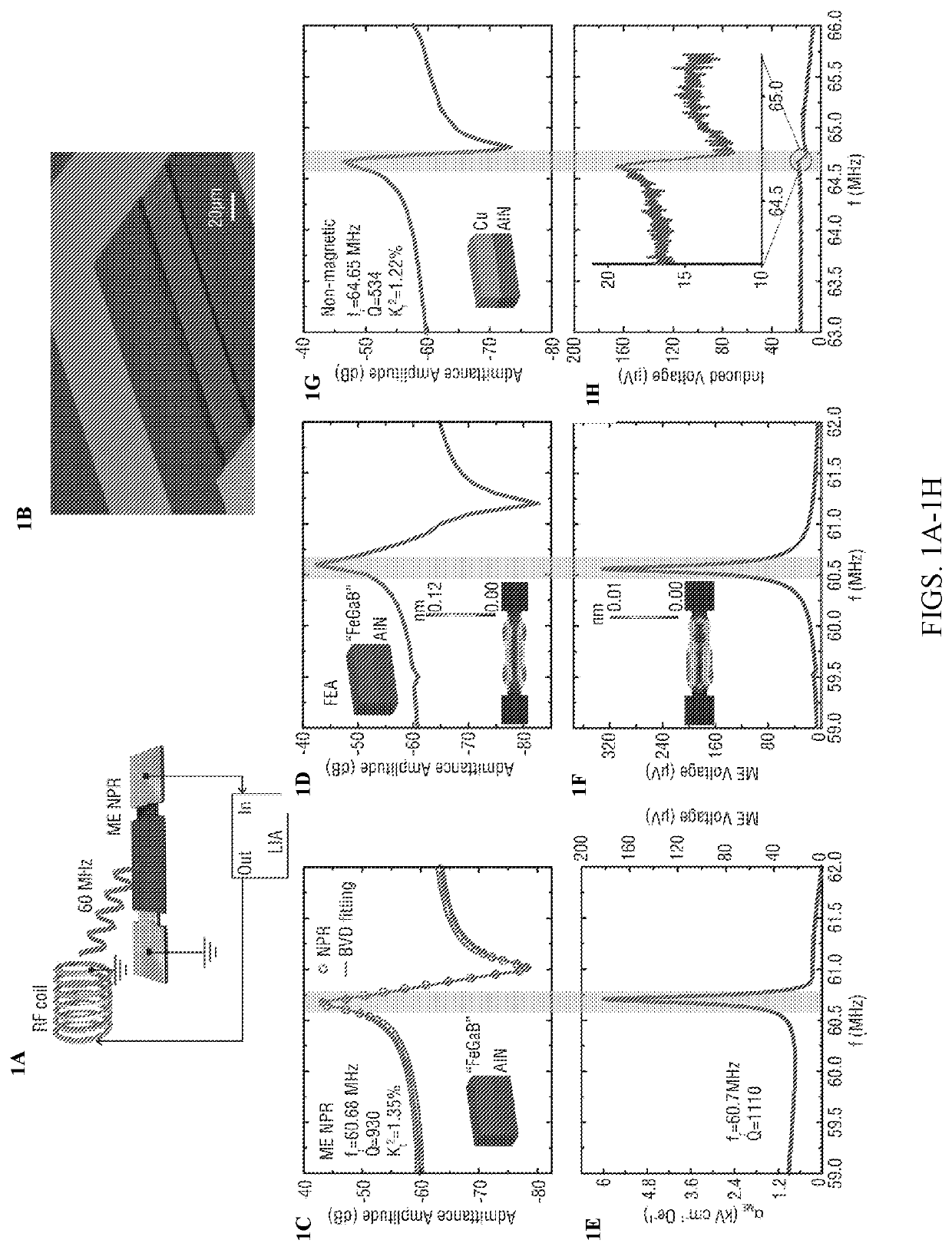

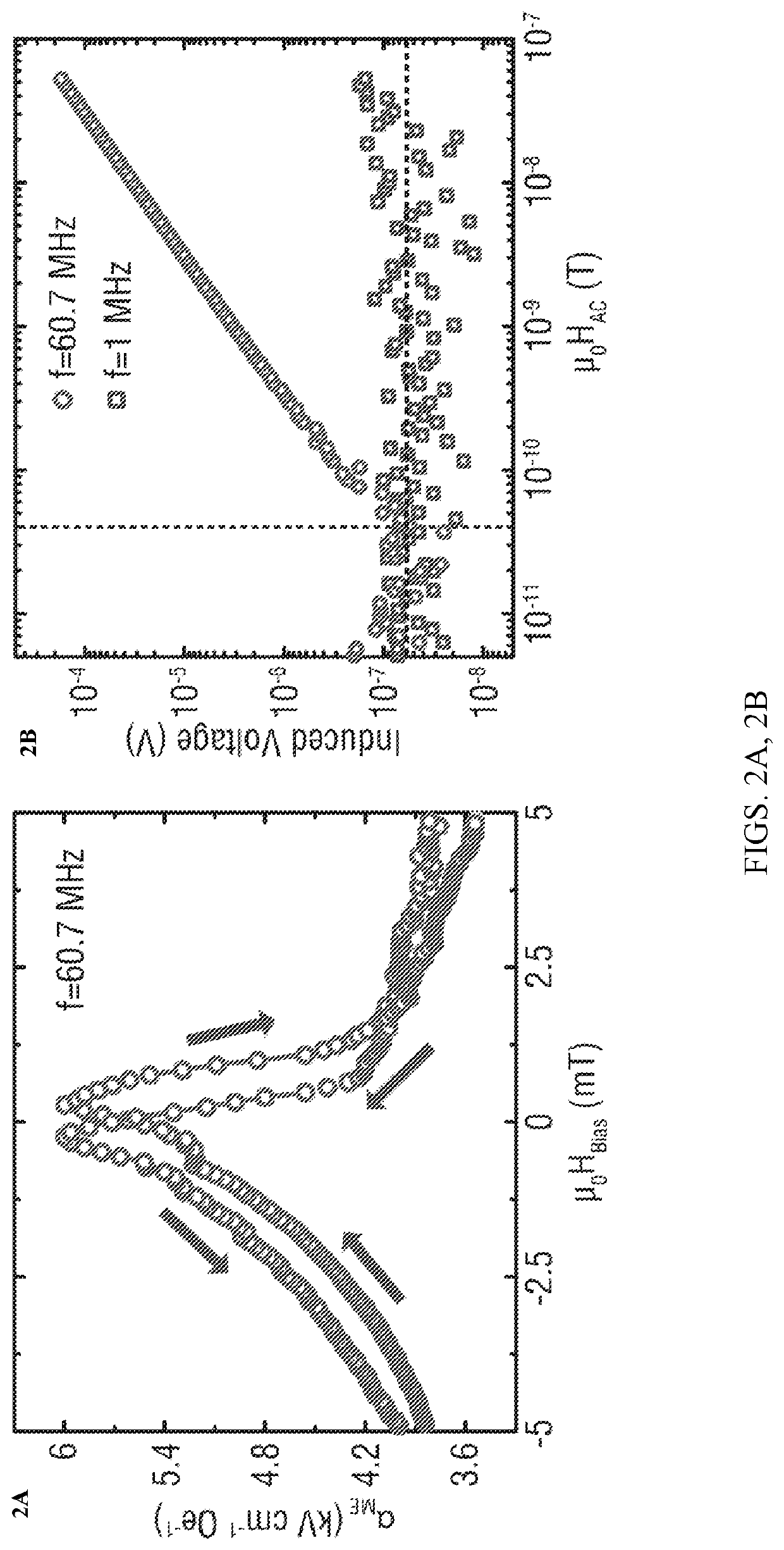

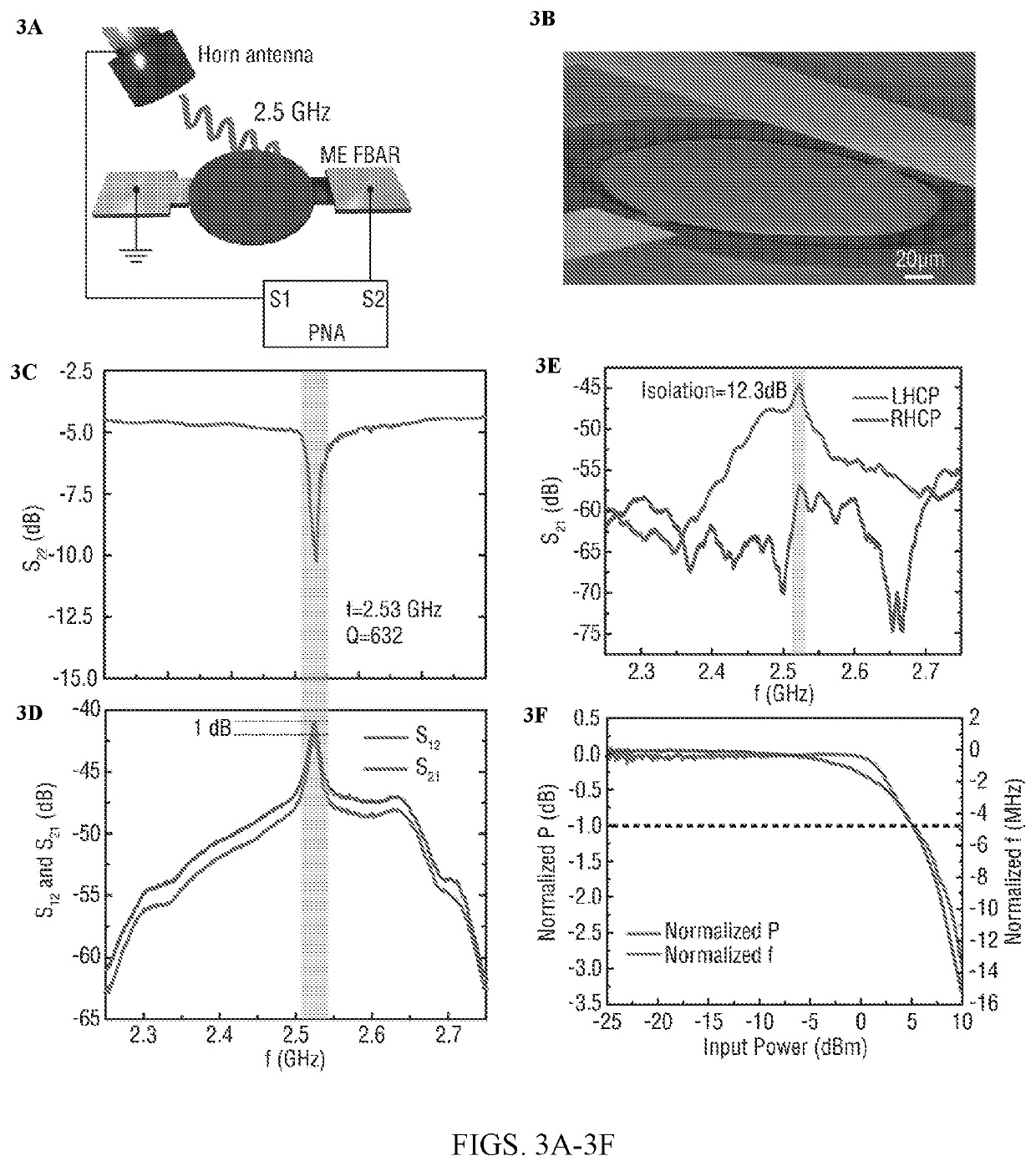

Nanoscale Radio Frequency Magnetoelectric Antenna

ActiveUS20200321512A1Small sizeRadiating elements structural formsPiezoelectric/electrostrictive device material selectionMagnetic currentHeterojunction

A nanomechanical magnetoelectric antenna includes a thin film heterostructure that has a magnetic element and a piezoelectric element. The heterostructure is suspended on a substrate and is capable of resonating at acoustic resonance frequencies. In the transmission mode of the antenna, oscillating mechanical strain produced by voltage-induced acoustic waves is transferred to the thin film heterostructure through strain mediated magnetoelectric coupling. This gives rise to magnetization oscillation or magnetic current that radiates electromagnetic waves at the acoustic resonance frequencies. In the receiving mode, the heterostructure senses magnetic components of electromagnetic waves arriving at the antenna, converting these into a piezoelectric voltage output.

Owner:NORTHEASTERN UNIV

Droplet emitting apparatus having piezoelectric voltage generator and method of emitting a droplet using the same

ActiveUS20090189932A1Reduce distanceIncrease distanceWithdrawing sample devicesLaboratory glasswaresVoltage generatorPiezoelectric voltage

Provided are a droplet emitting apparatus and a method of emitting droplets using the same. The apparatus includes a solution tank for containing a solution; a nozzle including an opening through which at least a droplet of the solution is emitted; and a voltage generator including a piezoelectric material for generating a voltage by instantaneous pressure application, wherein the voltage generated by the pressure to the piezoelectric material is applied to the solution in order for the at least a droplet of the solution to be emitted through the nozzle

Owner:SAMSUNG ELECTRONICS CO LTD

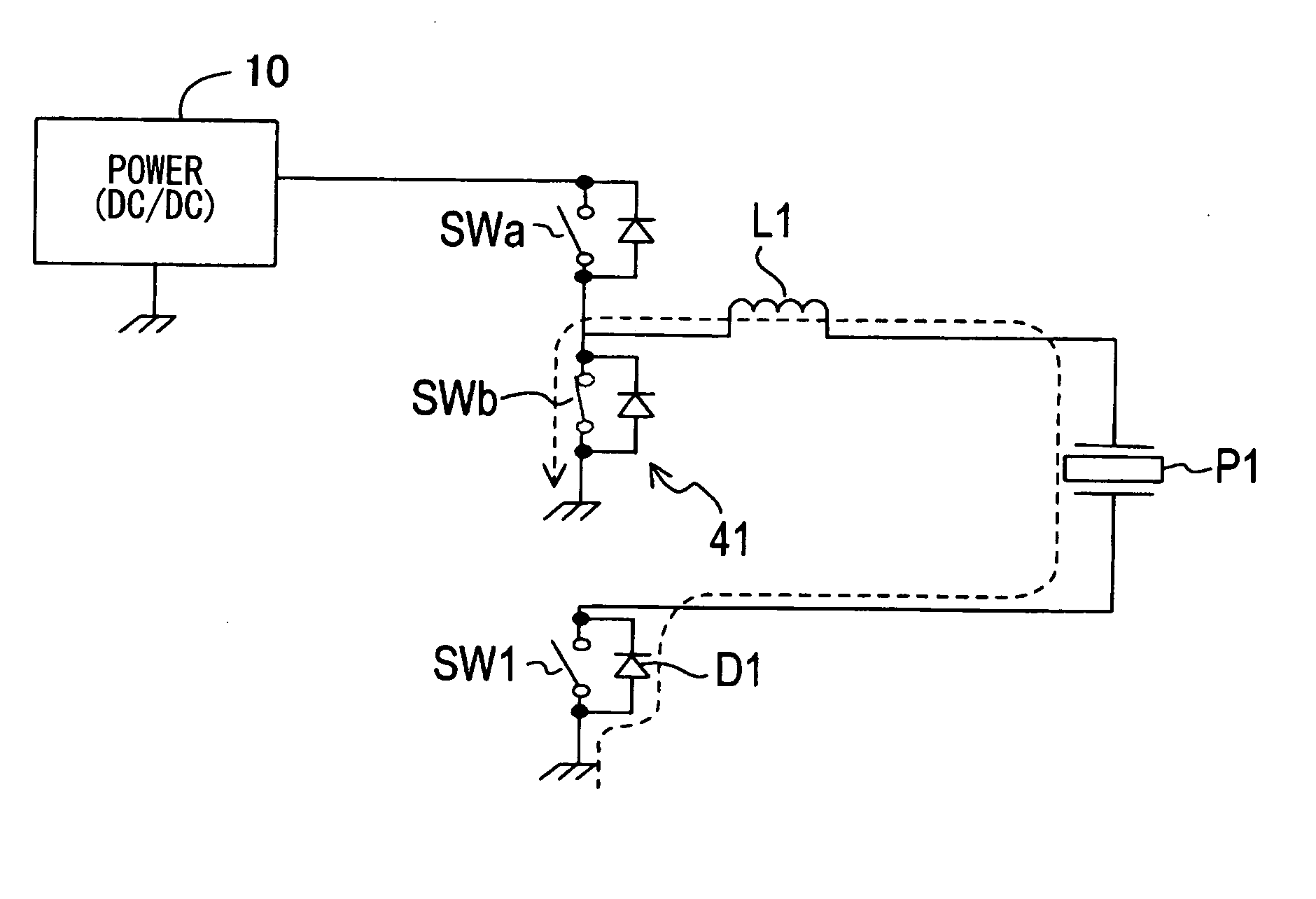

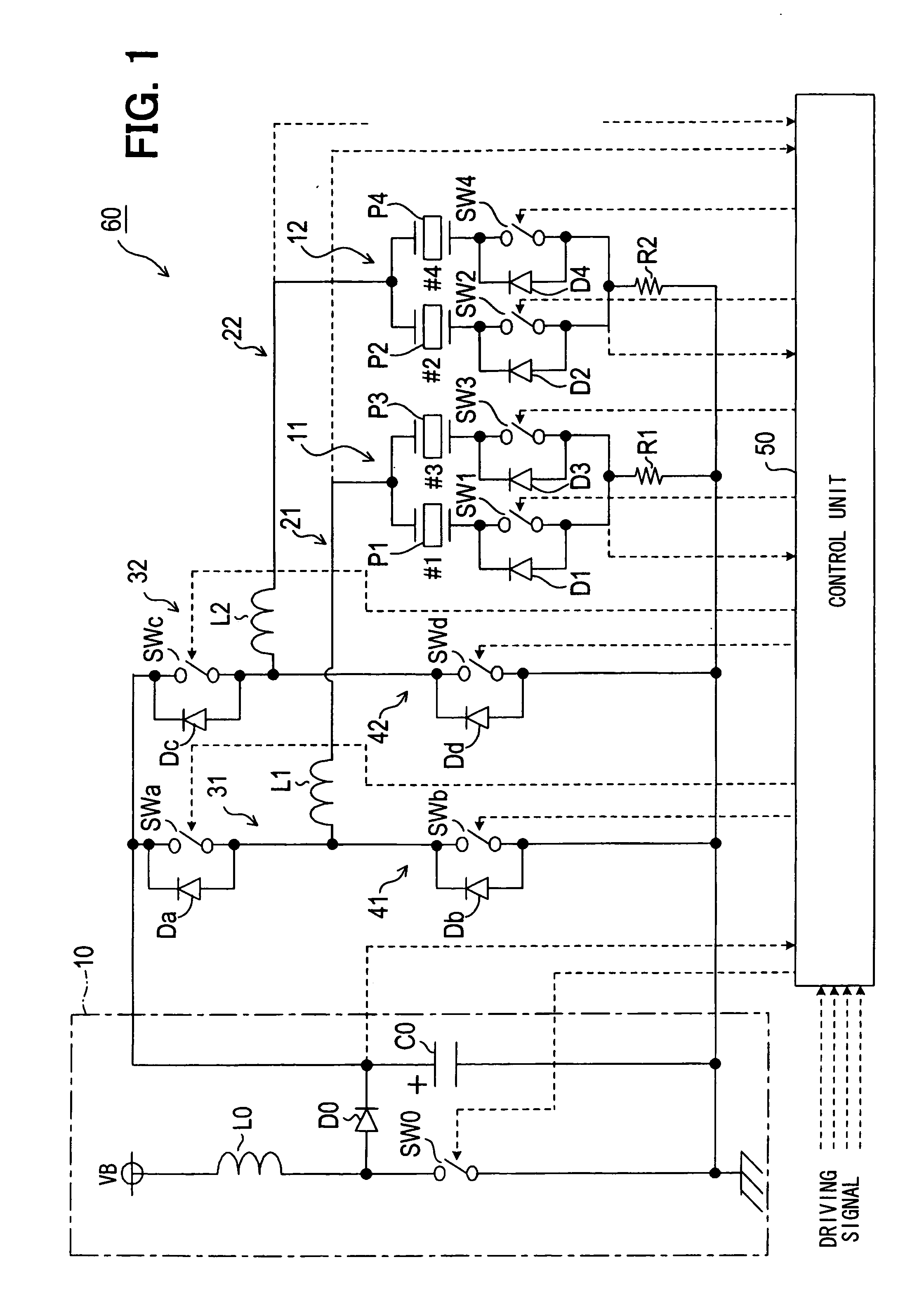

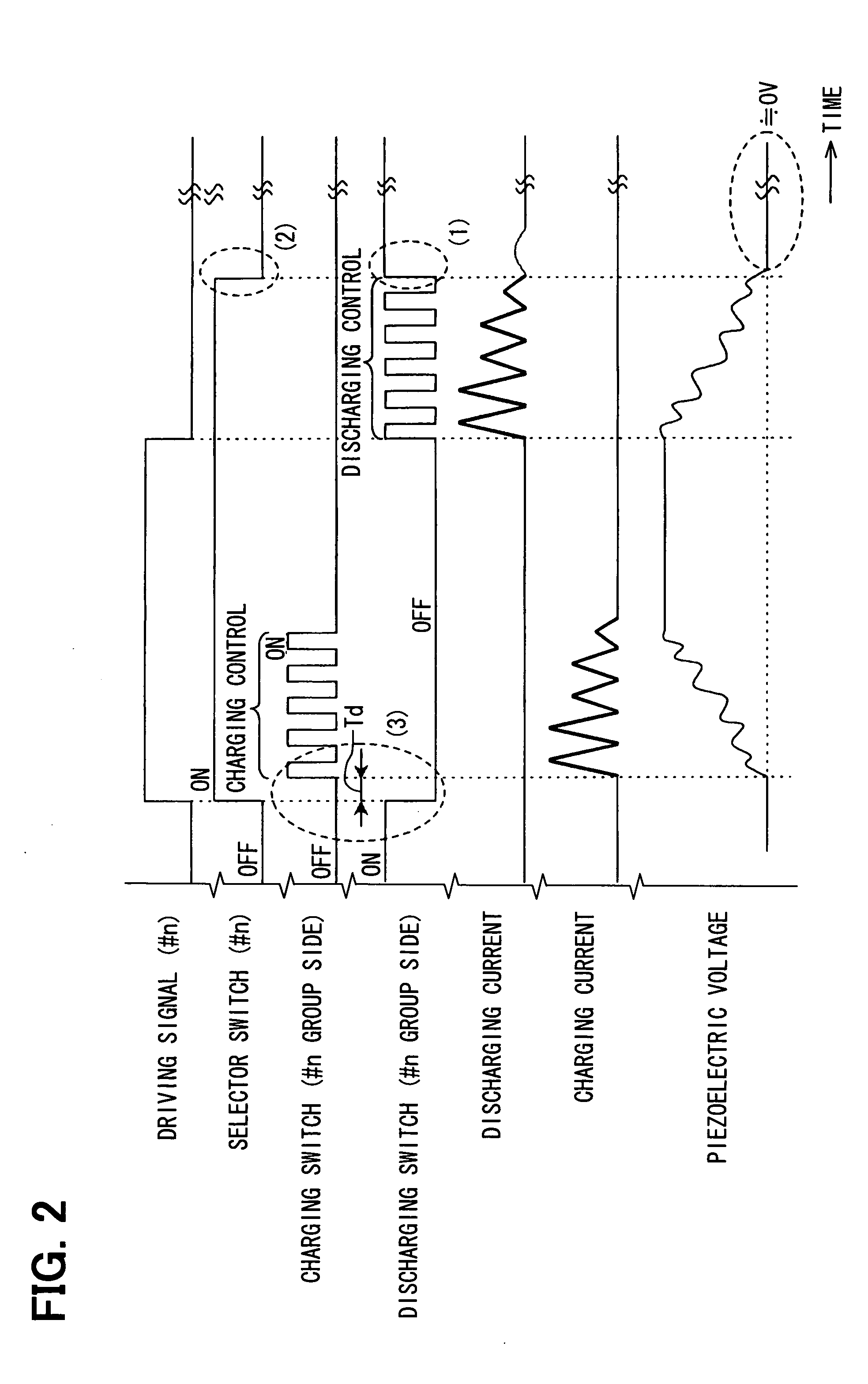

Piezoelectric actuator driving device and method

ActiveUS20080316671A1Improve accuracyElectrical controlElectrostatic/electro-adhesion relaysPiezoelectric voltagePiezoelectric actuators

A driving device for a piezoelectric actuator supplies charges and discharges the piezoelectric actuator through a charging switch and a discharging switch, respectively. The charging switch is repeatedly turned on and off thereby to charge and expand the piezoelectric actuator. The discharging switch is repeatedly turned on and off thereby to discharge and contract the piezoelectric actuator. The discharging switch is kept ON especially during a period from when the discharging switching control is terminated to when the charging switching control is started next. Thus, the piezoelectric voltage at the start of the next driving can be made substantially 0V.

Owner:DENSO CORP

Touch panel

A touch panel that includes a piezoelectric film having a first principal surface and a second principal surface that are opposed to each other, a capacitance detection electrode arranged on one side of the first principal surface of the piezoelectric film and configured to detect a touched position, and a piezoelectric voltage detection electrode arranged on one side of each of the first principal surface and the second principal surface of the piezoelectric film and configured to detect a piezoelectric voltage in accordance with an amount pressed into the piezoelectric film.

Owner:MURATA MFG CO LTD

Bridge shadow type bituminous pavement energy gathering device

ActiveCN103066883AImprove energy conversion efficiencyEnhanced couplingElectrical storage systemPiezoelectric/electrostriction/magnetostriction machinesPhosphor bronzePiezoelectric voltage

The invention relates to a new energy gathering and transforming device, in particular to an energy gathering device used for bituminous concrete pavement and provides a bridge shadow type bituminous pavement energy gathering device which comprises a packaging layer and a plurality of bridge shadow type piezoelectric transducers. The bridge shadow type piezoelectric transducers are arranged in the packaging layer. The bridge shadow type piezoelectric transducers comprise piezoelectric ceramic piece bodies. Upper surface end cap metal sheets and lower surface end cap metal sheets are respectively coated on the upper surfaces and the lower surfaces of the piezoelectric ceramic piece bodies. The upper surface end cap metal sheets and lower surface end cap metal sheets are matched with the belonging piezoelectric ceramic piece bodies in shape. The end cap metal sheets adopt a bridge shadow type structure and phosphor bronze materials, and enable the piezoelectric transducers to bear impact of ordinary driving vehicle loading without being damaged. The piezoelectric materials adopt piezoelectric transducer (PZT)-5H piezoelectric ceramics which has a high piezoelectric strain constant and piezoelectric voltage constant, and enables the bridge shadow type bituminous pavement energy gathering device to have high energy exchange efficiency.

Owner:TONGJI UNIV

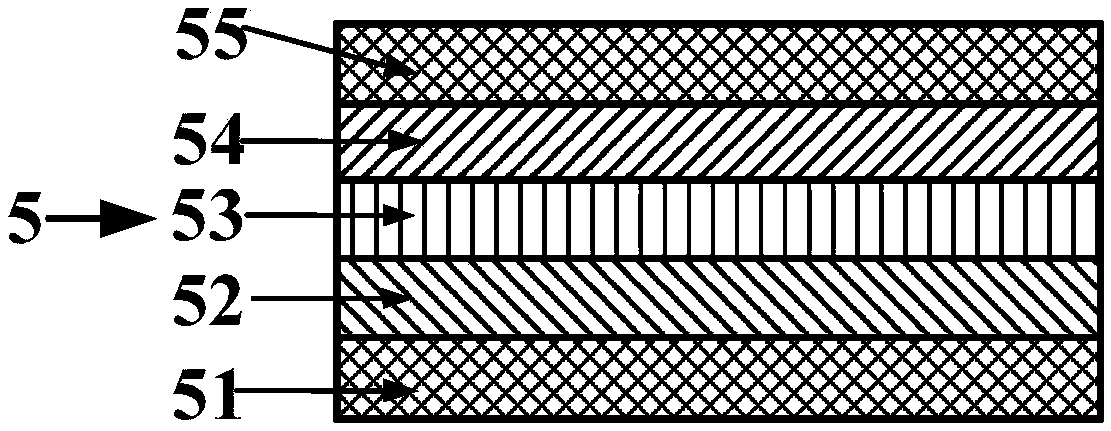

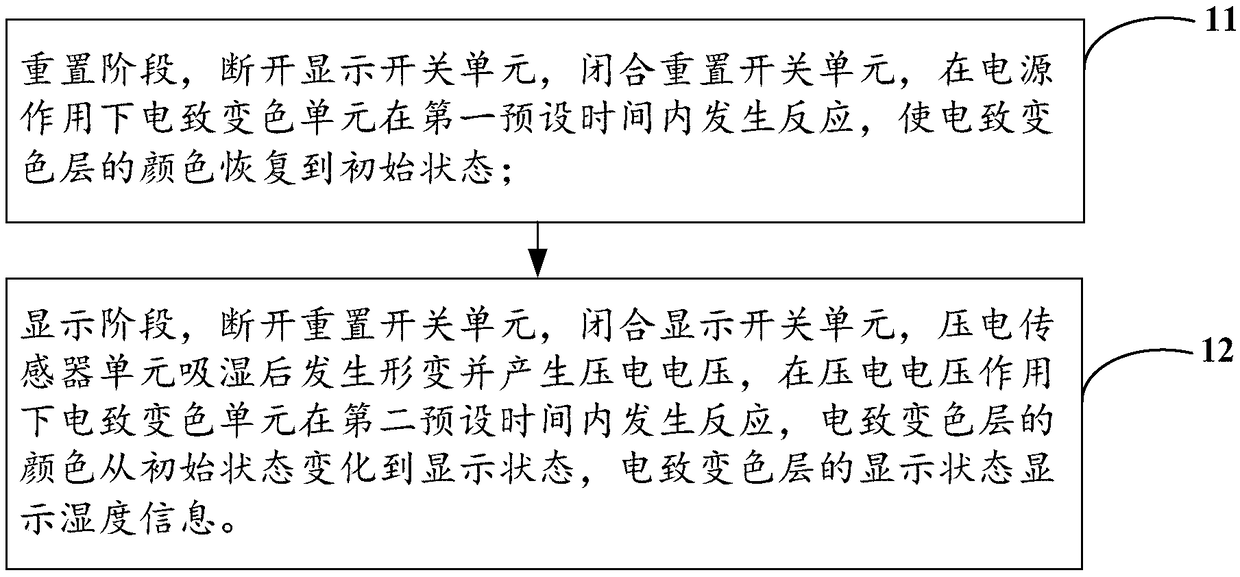

MEMS humidity sensor and operation method thereof

InactiveCN109283224ASimple designEasy to makeMaterial analysis by electric/magnetic meansElectricityPiezoelectric voltage

The invention relates to the technical field of sensors, and discloses an MEMS humidity sensor and an operation method thereof. The humidity sensor comprises a substrate, a first insulating layer located above the substrate, and a piezoelectric sensor unit and an electrochromic unit which are located above the first insulating layer and arranged at intervals; the piezoelectric sensor unit is connected with one side of the electrochromic unit through a display switch unit; a reset switch unit is arranged on the other side of the electrochromic unit; and when the display switch unit is switchedon and the reset switch unit is switched off, the piezoelectric sensor unit is deformed after absorbing moisture and generates a piezoelectric voltage, and the electrochromic unit generates a reactionunder the action of the piezoelectric voltage so as to display humidity information through color change. According to the MEMS humidity sensor, a complex interface circuit does not need to be additionally arranged, and the humidity information of a current environment can be obtained directly and quickly through human eyes; and the sensor has the advantages of being simple to design and manufacture, low in cost, small in size, low in power consumption and the like.

Owner:SOUTHEAST UNIV

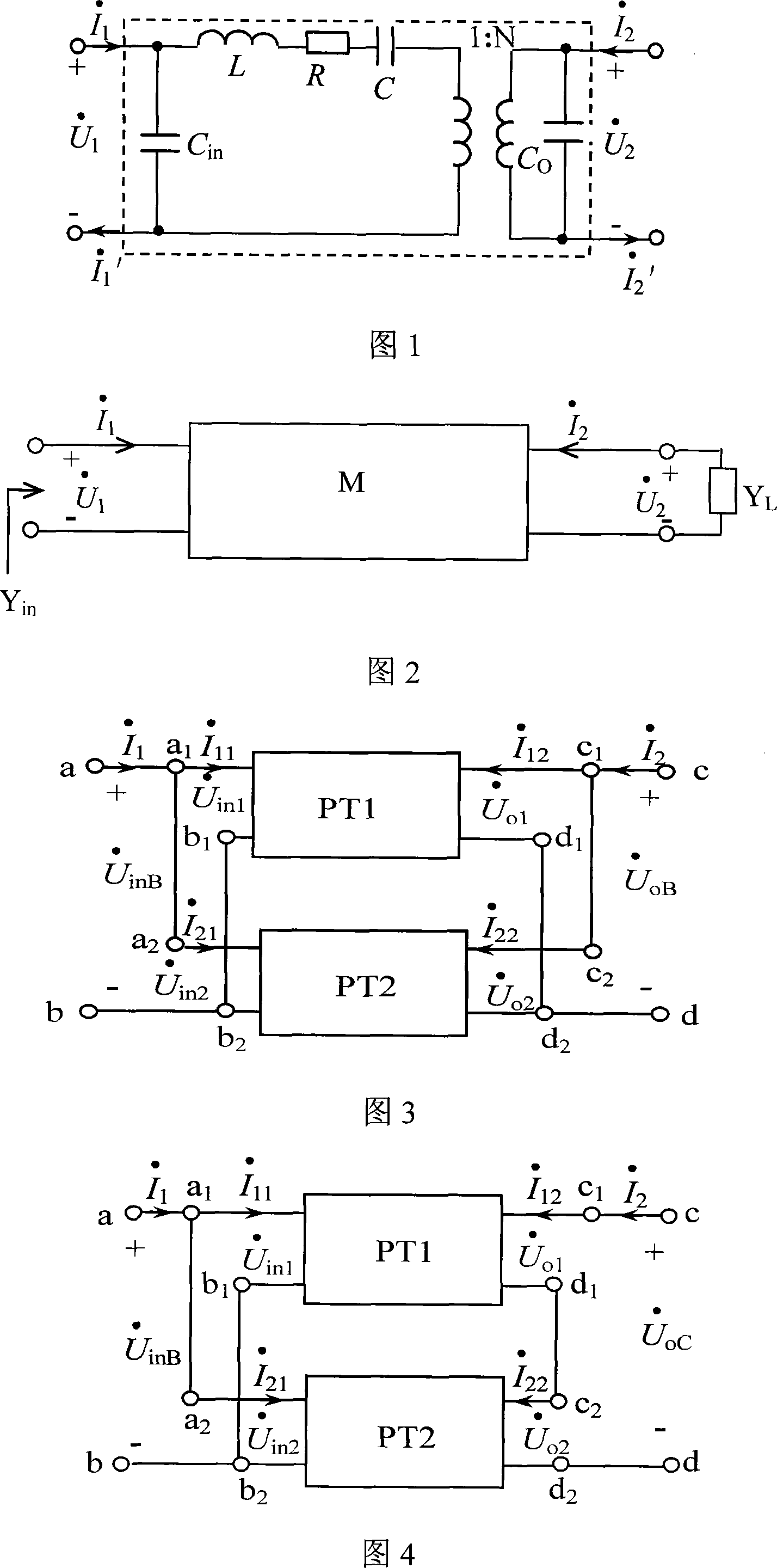

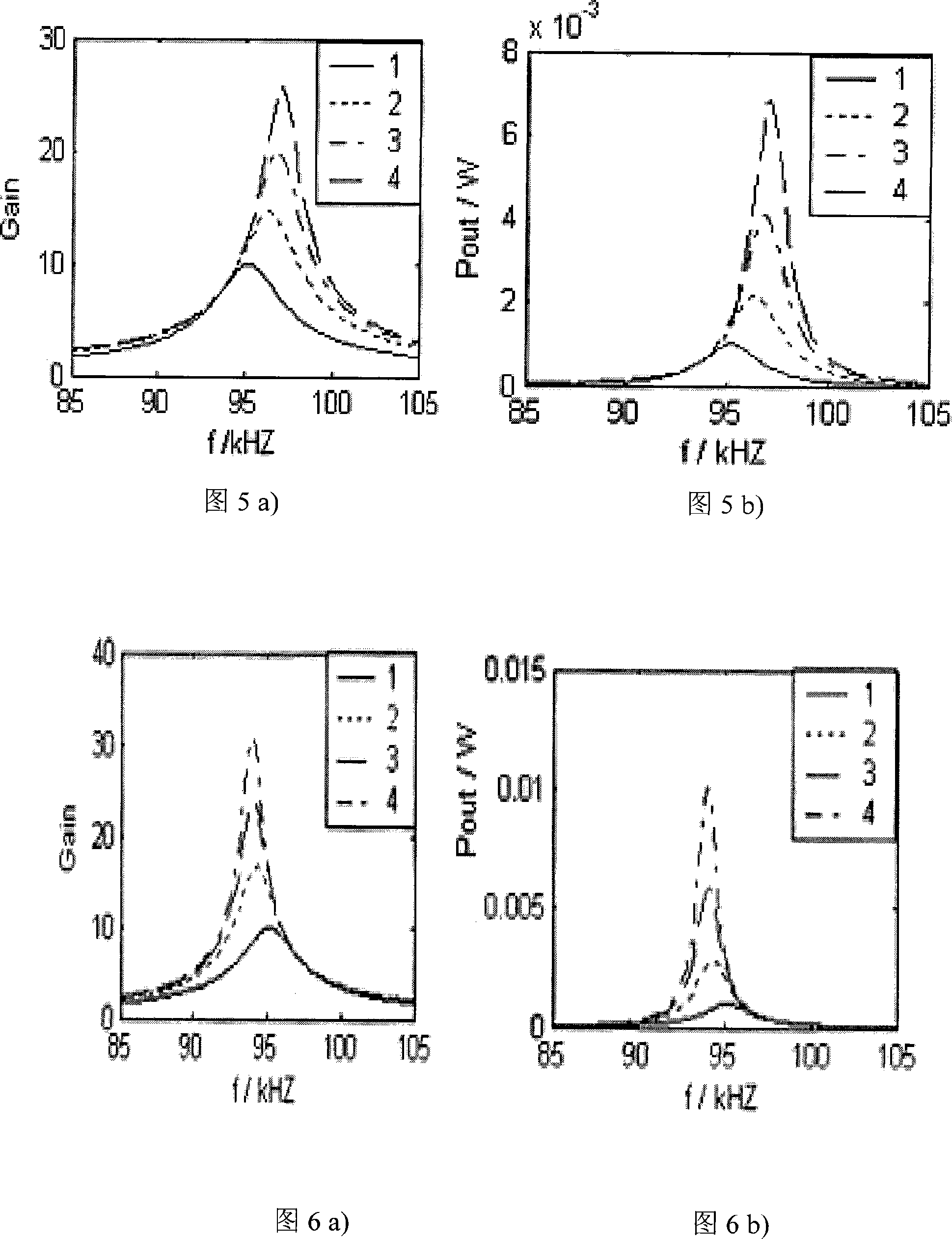

Analysis method for electrical characteristic of parallel connection and parallel-serial connected piezoelectric voltage transformer

InactiveCN101135707AIncrease output powerHigh voltage gainElectric devicesCurrent/voltage measurementPiezoelectric voltageEngineering

The method comprises: using the traditional lumped parameter equivalent-circuit model of the piezoelectric transformer, and using the admittance matrix Y to express the voltage gain, output power and correlated relation between the transmission efficiency specification and the piezoelectric transformer connection numbers (n) of the piezoelectric transformer.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com