Method for preparing zinc oxide nanometer film carbon fiber piezoelectric material with core-shell structure and application thereof

A zinc oxide nano, core-shell structure technology, applied in the material selection of piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, the selection of device materials, etc., can solve the problems that cannot be solved by Used to drive practical equipment, low output and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

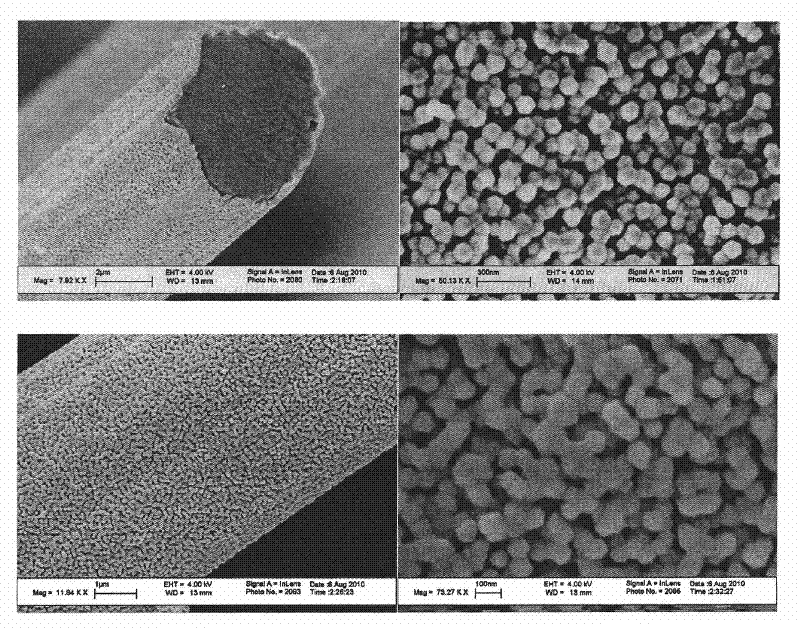

[0023] Cut three 10cm-long domestic carbon fiber CCF300 tows, remove the sizing agent according to the method in Appendix A of GJ B1982-94, and dry at 50 °C. Mix 1 gram of zinc oxide powder with a purity of 99.9% and 2 grams of activated carbon powder, coarsely grind it for 15 minutes, and then finely grind agate for 30 minutes to make it microscopically mixed. Slowly pour 3 grams of ground mixed zinc oxide carbon powder into the bottom of the quartz tube with one end closed, and add the dried and pretreated carbon fiber tow on the inner wall of the quartz tube; the installed quartz tube is placed in the middle of the vacuum tube furnace. Adjust the air valve of the vacuum pump to slowly evacuate until the vacuum degree is less than 5 millitorr, slowly introduce oxygen with a flow rate of 10ccm and argon gas with a flow rate of 30ccm, and adjust the vacuum degree to 2 Torr; Heat to 850°C, keep it warm for 10 minutes, then raise the temperature to 960°C at a rate of 10°C / min, a...

specific Embodiment approach 2

[0026] Cut two 4cm-long domestic carbon fiber CCF500 tows, remove the sizing agent according to the method in Appendix A of GJB1982-94, and dry at 50°C. Mix 2 grams of zinc oxide powder with a purity of 99.9% and 2 grams of activated carbon powder, and finely grind agate for 20 minutes to make it microscopically mixed. Slowly pour 0.5 g of ground mixed zinc oxide carbon powder into the bottom of the quartz tube with one end closed, and add the dried and pretreated carbon fiber tow on the inner wall of the quartz tube; the installed quartz tube is placed in the middle of the vacuum tube furnace. Adjust the air valve of the vacuum pump to slowly evacuate until the vacuum degree is less than 15 millitorr, slowly introduce oxygen with a flow rate of 8ccm and argon gas with a flow rate of 32ccm, and adjust the vacuum degree to 2..4 Torr; min, heated to 850°C, then raised to 960°C at a rate of 10°C / min, and kept for 45 minutes.

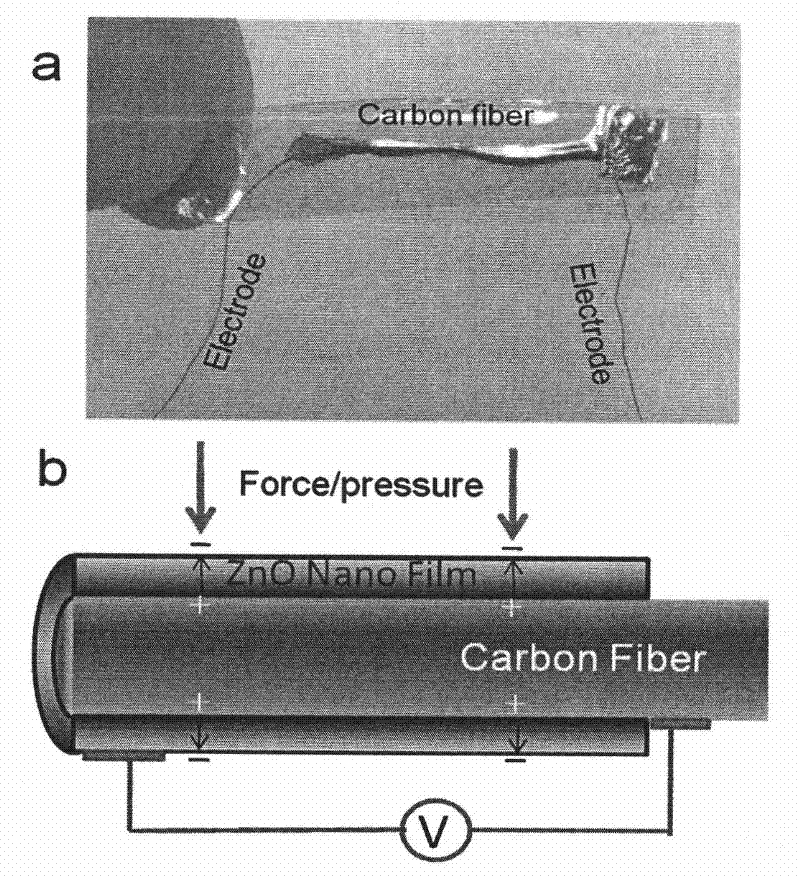

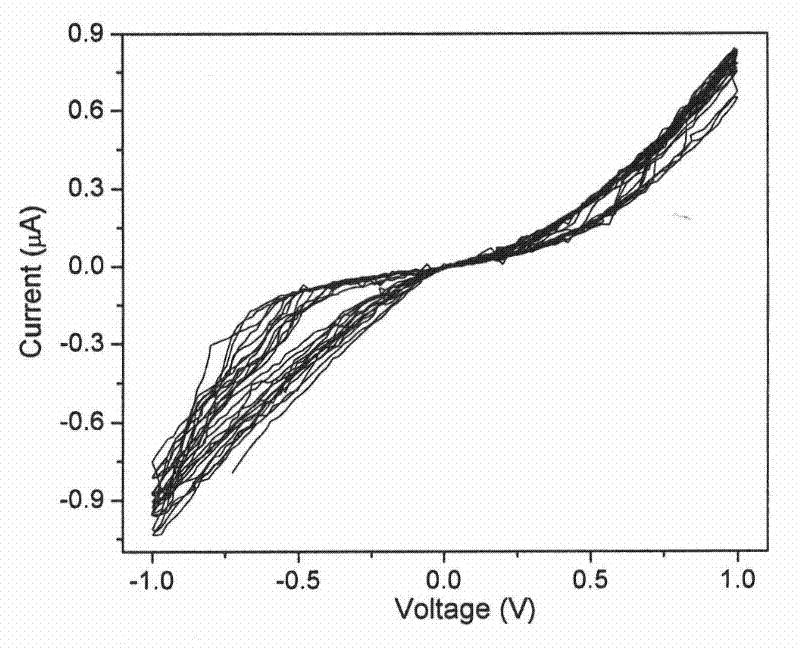

[0027]Making nano piezoelectric devices: Take out th...

specific Embodiment approach 3

[0028] Cut a 5cm-long domestic carbon fiber CCF400 tow, remove the sizing agent according to the method in Appendix A of GJB1982-94, and dry it at 50°C. 5 grams of zinc oxide powder with a purity of 99.9% and 3 grams of activated carbon powder were mixed, and ball milled for 30 minutes to make them microscopically mixed evenly. Slowly pour 1 gram of ground mixed zinc oxide carbon powder into the bottom of the quartz tube with one end closed, and add the dried and pretreated carbon fiber tow on the inner wall of the quartz tube; the installed quartz tube is placed on the left side of the vacuum tube furnace 2cm position. Adjust the air valve of the vacuum pump to slowly evacuate until the vacuum degree is less than 10 mtorr, slowly introduce oxygen with a flow rate of 10ccm and argon gas with a flow rate of 20ccm, and adjust the vacuum degree to 2.2 torr; to 800°C, then raised to 960°C at a rate of 10°C / min, and kept for 30 minutes.

[0029] Production of nano piezoelectric T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com