High piezoelectric strain constant d31, low piezoelectric strain constant g31 piezoelectric ceramic material and preparation thereof

A technology of strain constant and voltage constant, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems that restrict the performance of dual-chip actuating components, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

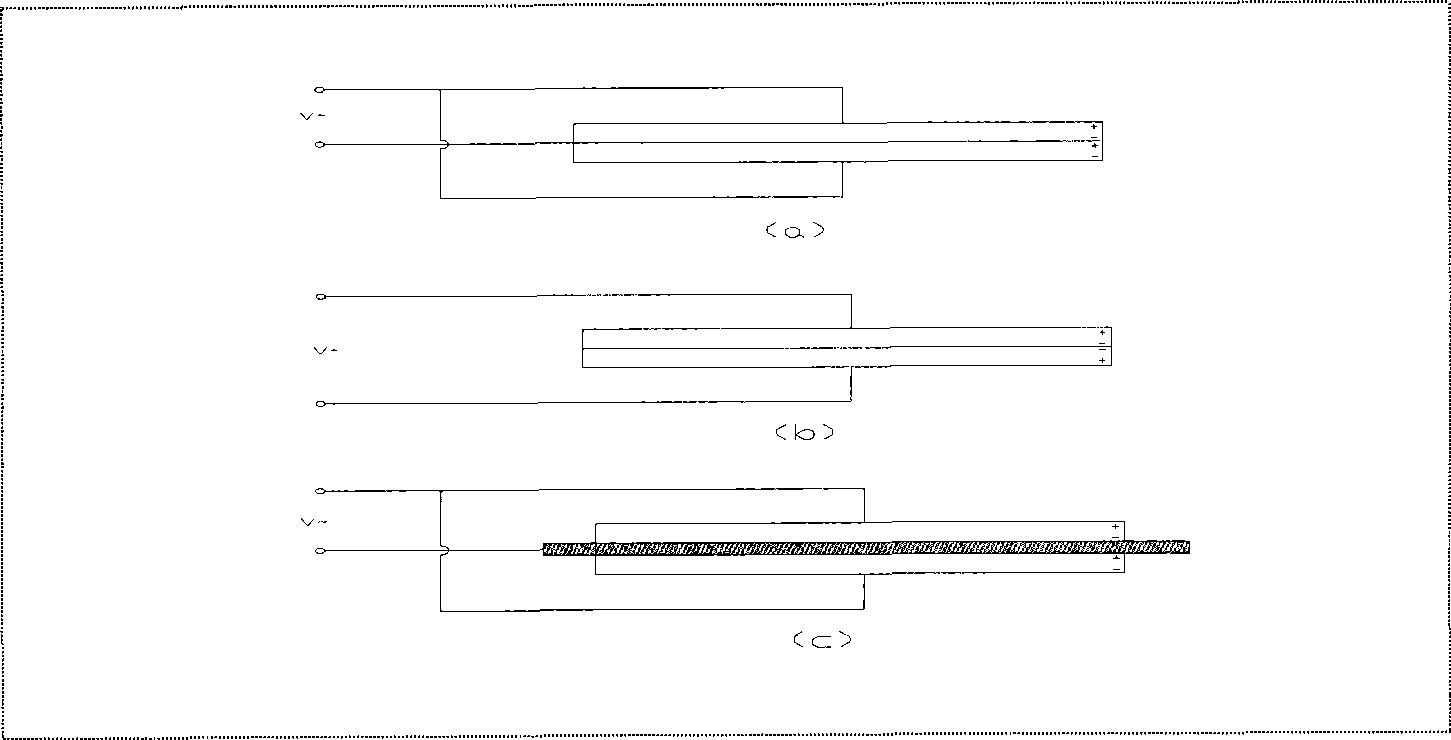

Image

Examples

Embodiment 1

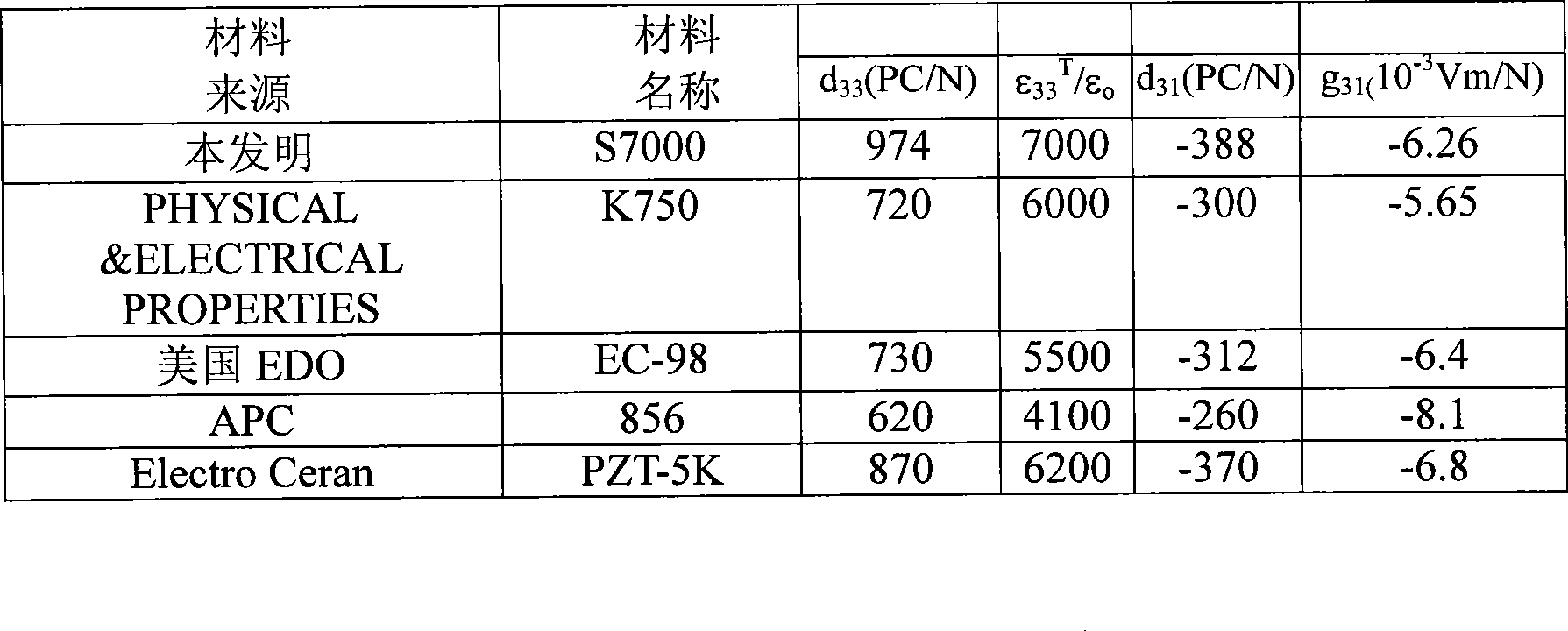

[0020] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), BaCO 3 (industrial pure), Nb 2 o 5 (industrial pure), La 2 o 3 (chemically pure), MgCO 3 (industrial pure), Sb 2 o 3 (industrial pure), SiO 2 (chemically pure) as raw material, according to 0.3715PbZrO 3 +0.2885PbTiO 3 +0.25Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +0.04SrTiO 3 +0.03BaTiO 3 +0.02LaTiO 3 +0.05wt.% SiO 2 +0.02wt.%Nb 2 o 5 +0.04wt.%Sb 2 o 3Stoichiometric weighing, with deionized water and agate balls as the medium, after barrel milling for 8 hours, after discharging and drying, perform the first stage of briquette synthesis at 650°C / 2h, and then carry out the second stage at 850°C / 2h Synthesis, after pulverization, barrel milling for 24 hours, discharge drying, adding binder, granulation molding (molding pressure is 150MPa), plastic discharge (800℃ / 1h), oxygen sintering (1280℃ / 2), cold processing , ultrasonic cleaning, upper electrode, polariza...

Embodiment 2

[0022] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), BaCO 3 (industrial pure), MgCO 3 (industrial pure), Nb 2 o 5 (industrial pure), La 2 o 3 (chemically pure), SiO 2 (chemically pure) is raw material, and preparation technology is with embodiment 1, according to 0.3715PbZrO 3 +0.2685PbTiO 3 +0.25Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +0.05SrTiO 3 +0.04BaTiO 3 +0.02LaTiO 3 +0.02wt.% SiO 2 +0.04wt.%La 2 o 3 +0.03wt.%Nb 2 o 5 chemical formulations for preparation. The main performance of the obtained material standard sheet is d 33 =943pC / N,:d 31 =-377pC / N, ε 33 T / ε o =6720,g 31 =-6.33,k 31 =0.41;

Embodiment 3

[0024] with Pb 3 o 4 (industrial pure), ZrO 2 (industrial pure), TiO 2 (industrial pure), SrCO 3 (industrial pure), BaCO 3 (industrial pure), MgCO 3 (industrial pure), Nb 2 o 5 (industrial pure), SiO 2 (chemically pure) is raw material, and preparation technology is with embodiment 1, according to 0.372PbZrO 3 +0.258PbTiO 3 +0.25Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +0.10SrTiO 3 +0.02BaTiO 3 +0.03wt.% SiO 2 +0.04wt.%Nb 2 o 5 chemical formulations for preparation. The main properties of material standard sheets are: d 33 =974pC / N,d 31 =-388pC / N, ε 33 T / ε o =7000, g 31 =-6.26,k 31 =0.42;

[0025] Table 1 The present invention compares with prior art

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com