Patents

Literature

1585results about "Electric/magnetic position measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

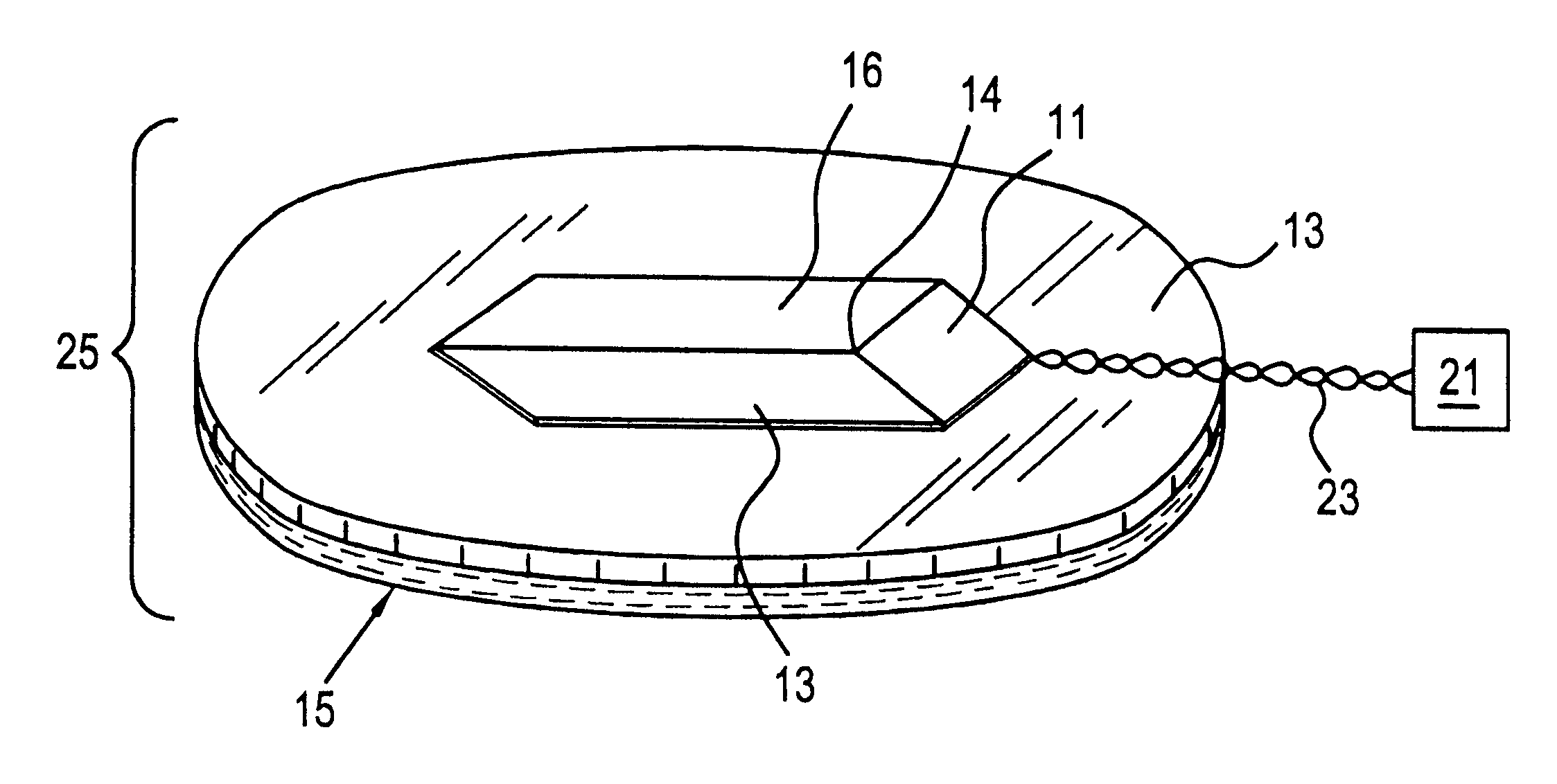

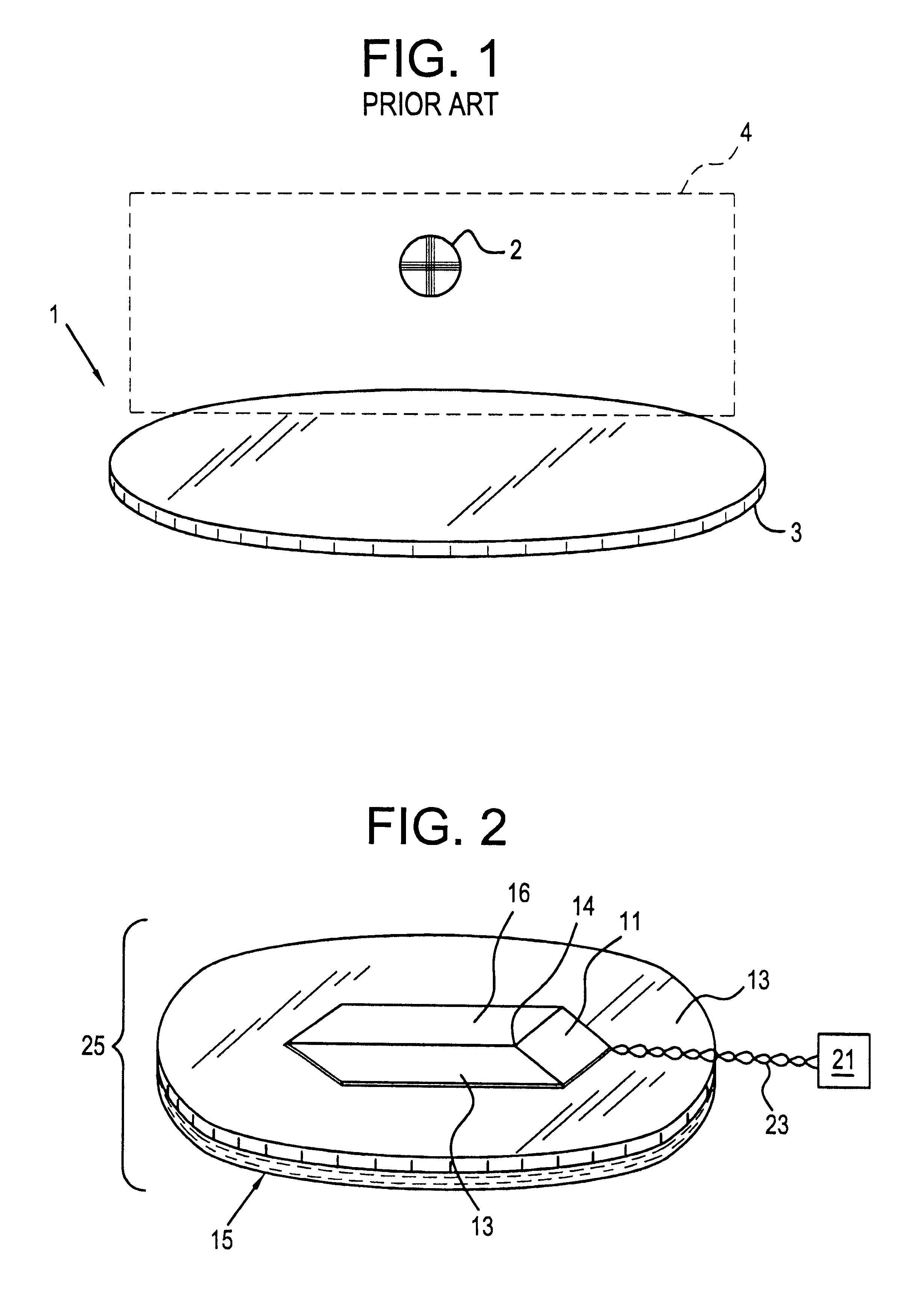

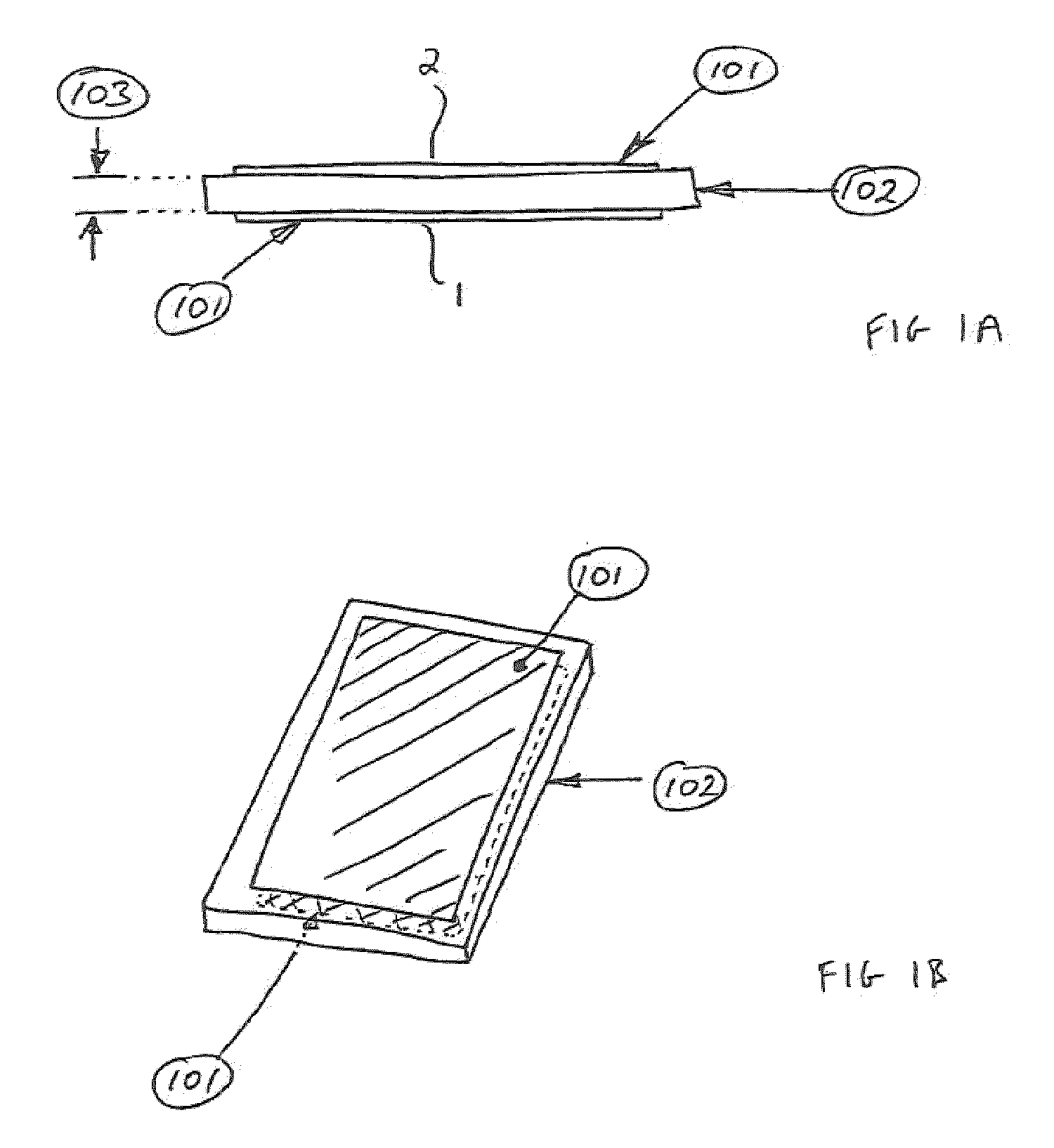

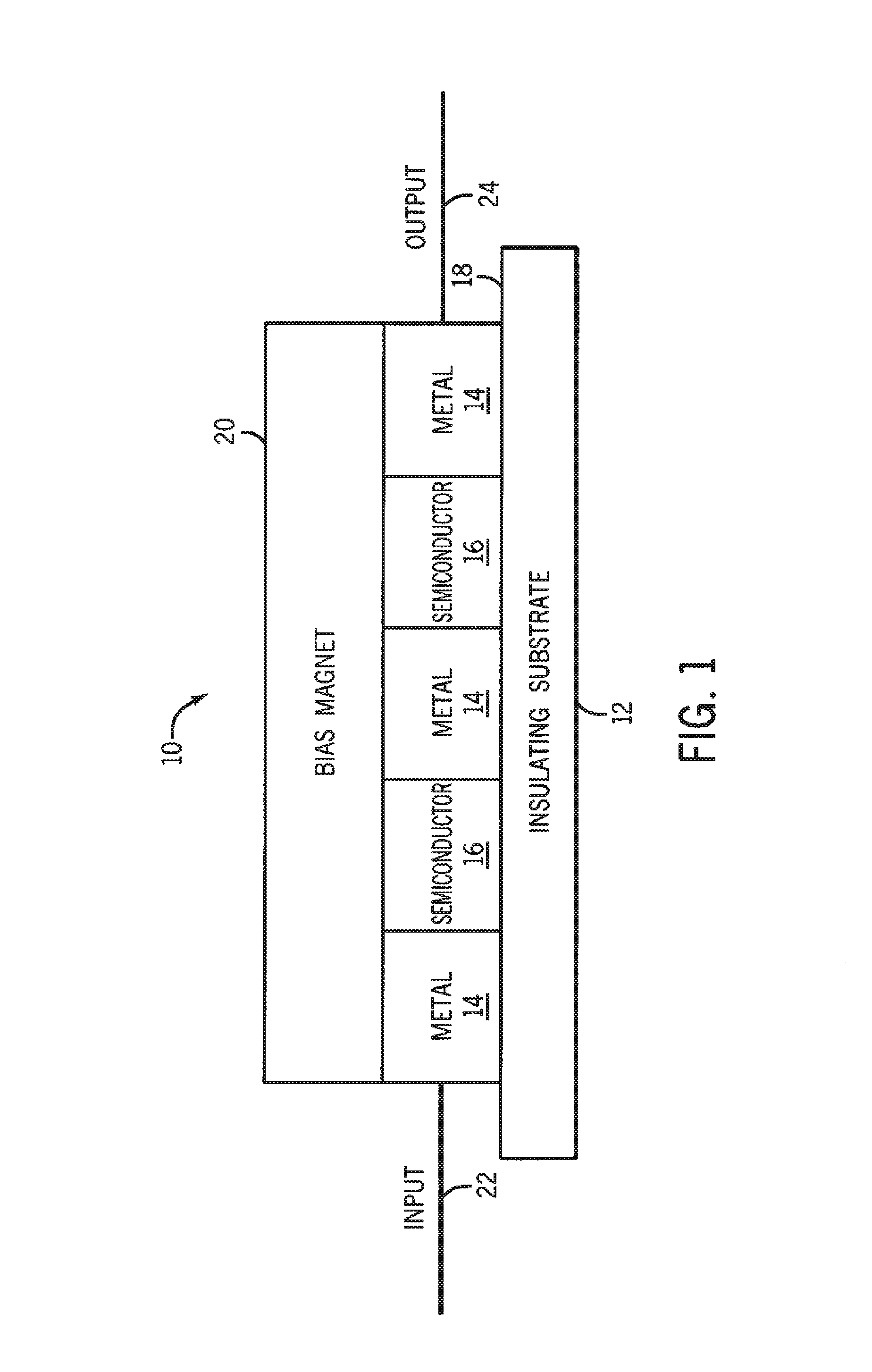

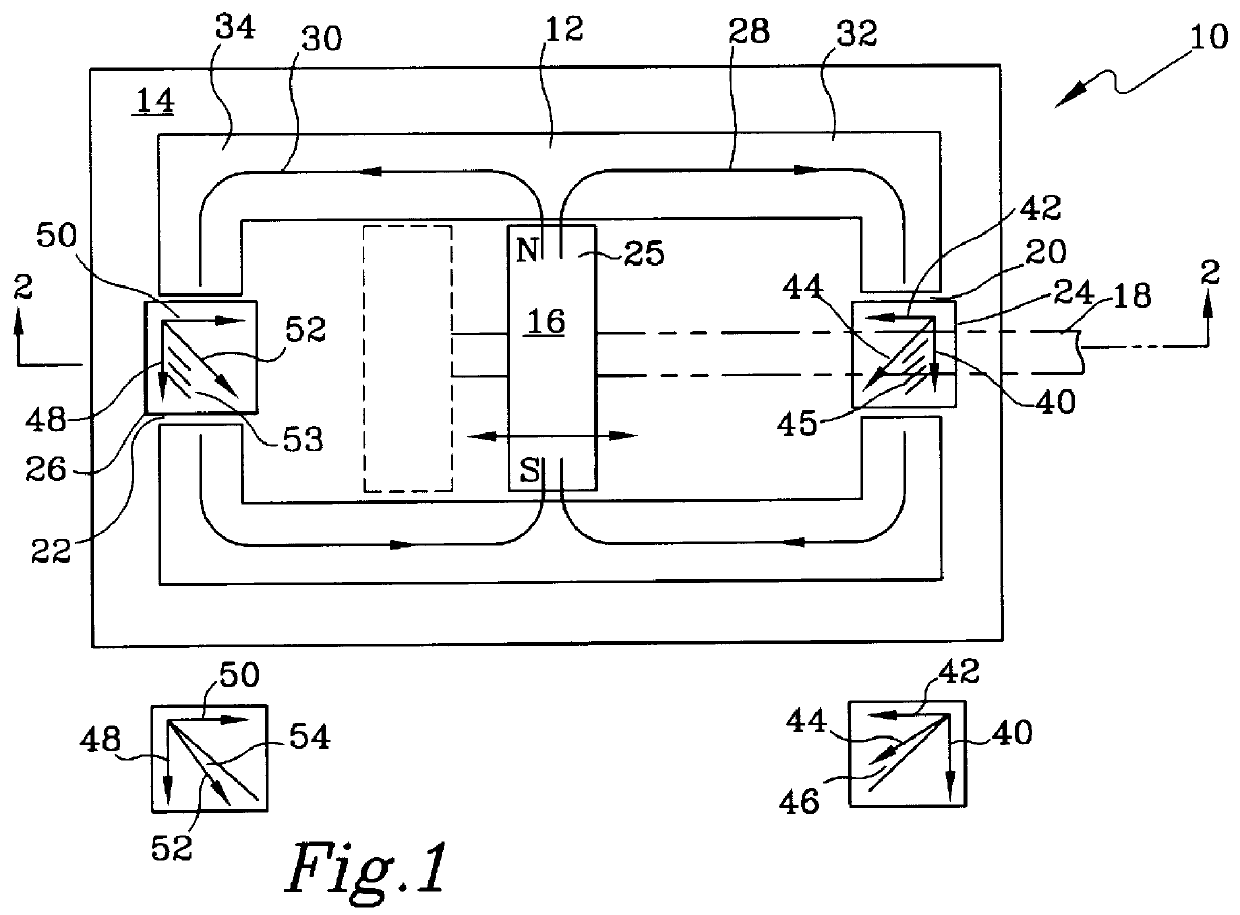

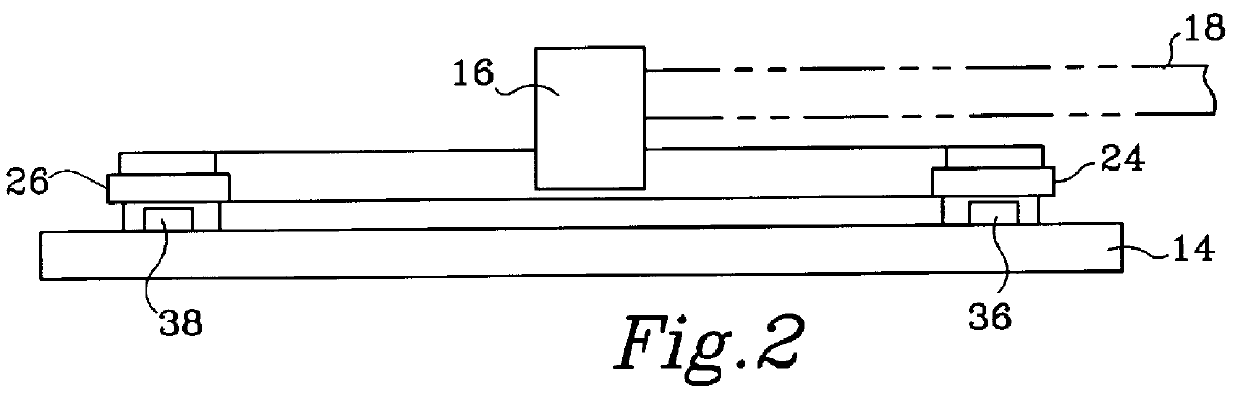

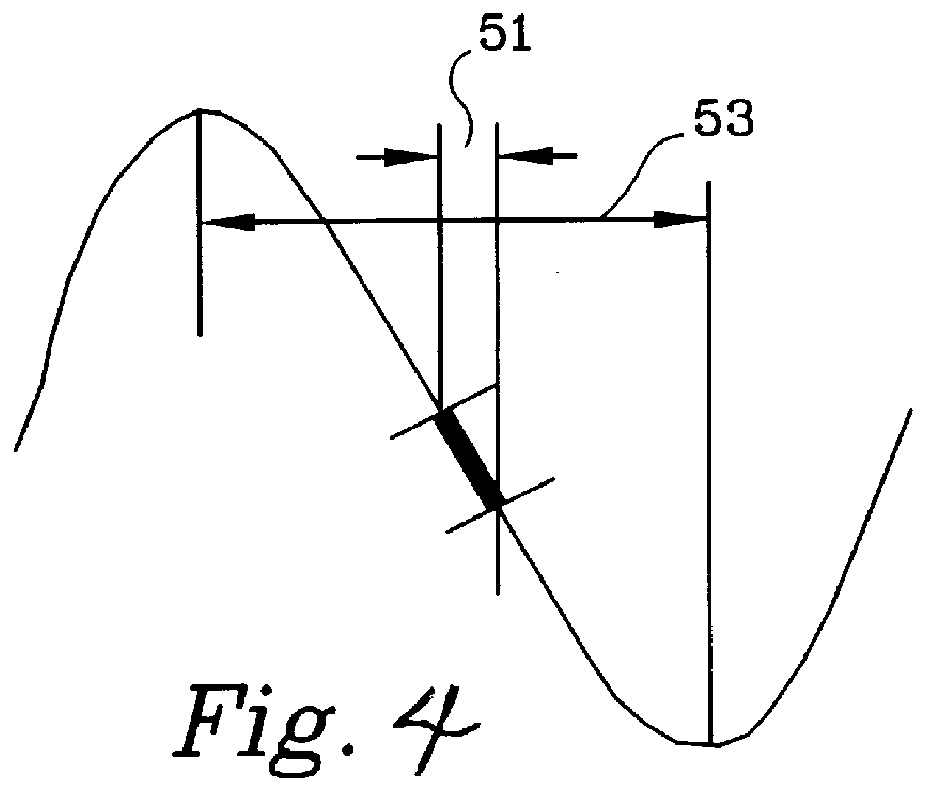

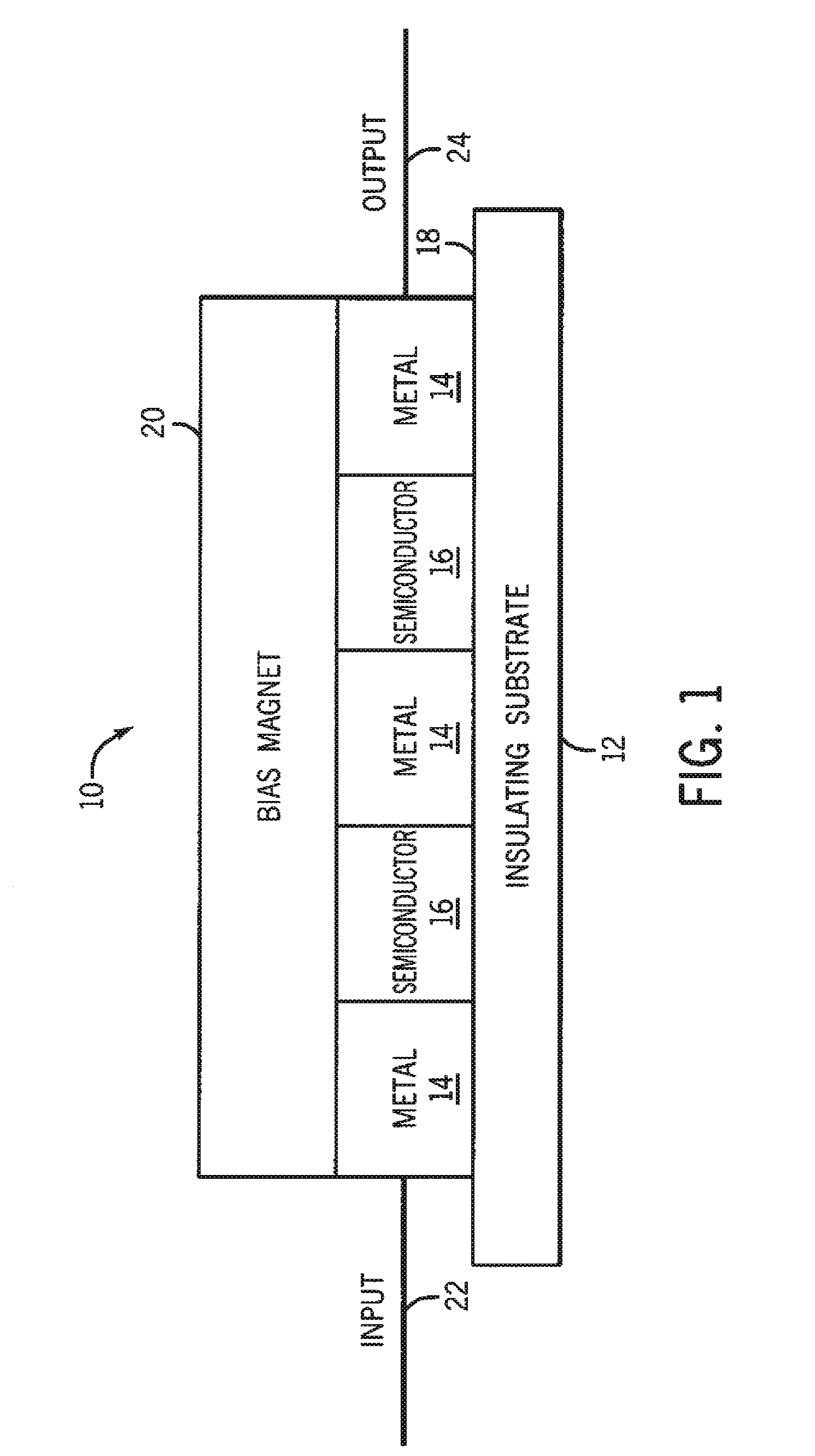

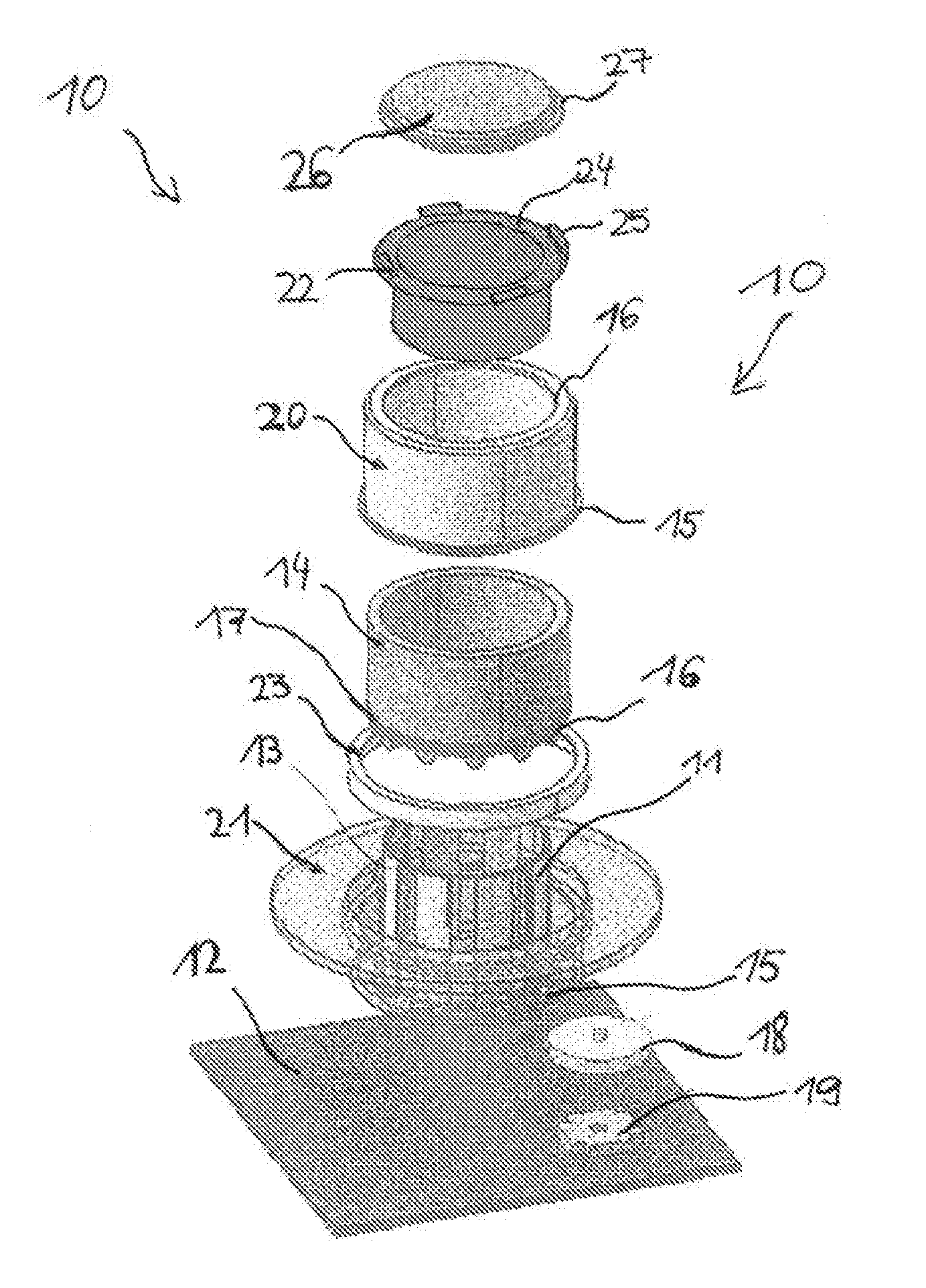

Magnetic field permeable barrier for magnetic position measurement system

InactiveUS6246231B1SurgeryElectric/magnetic position measurementsOrientation measurementMetallic Object

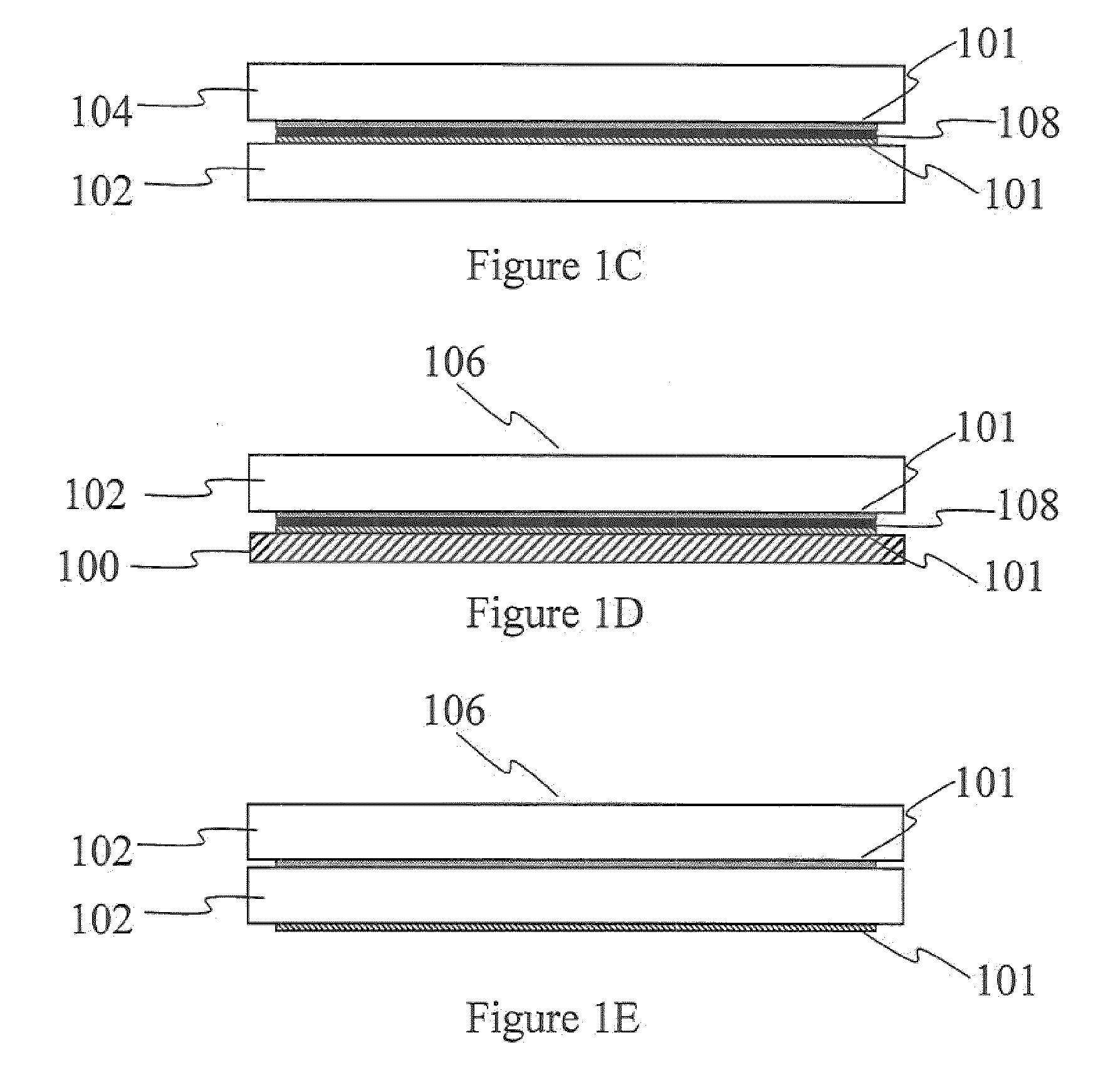

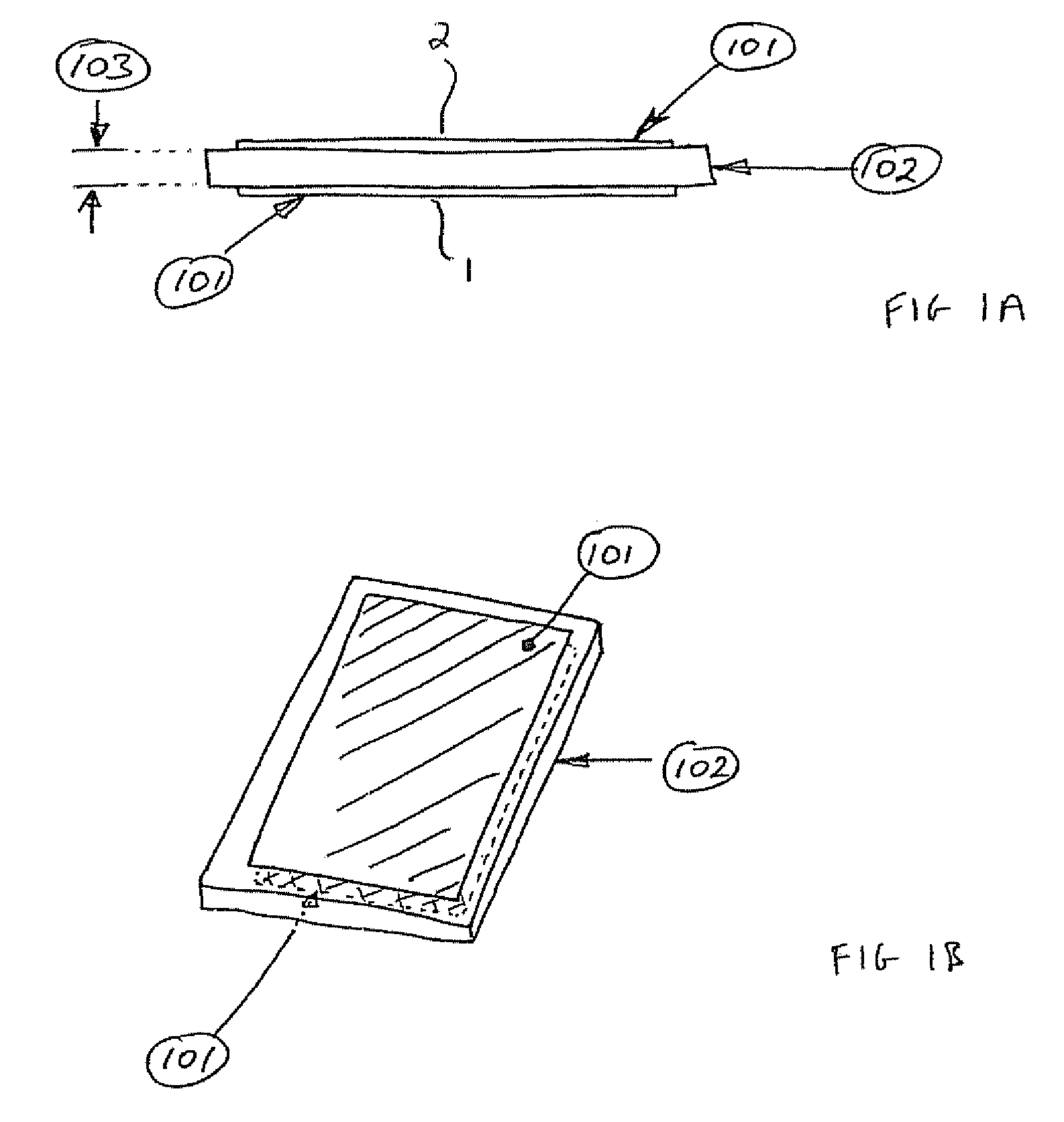

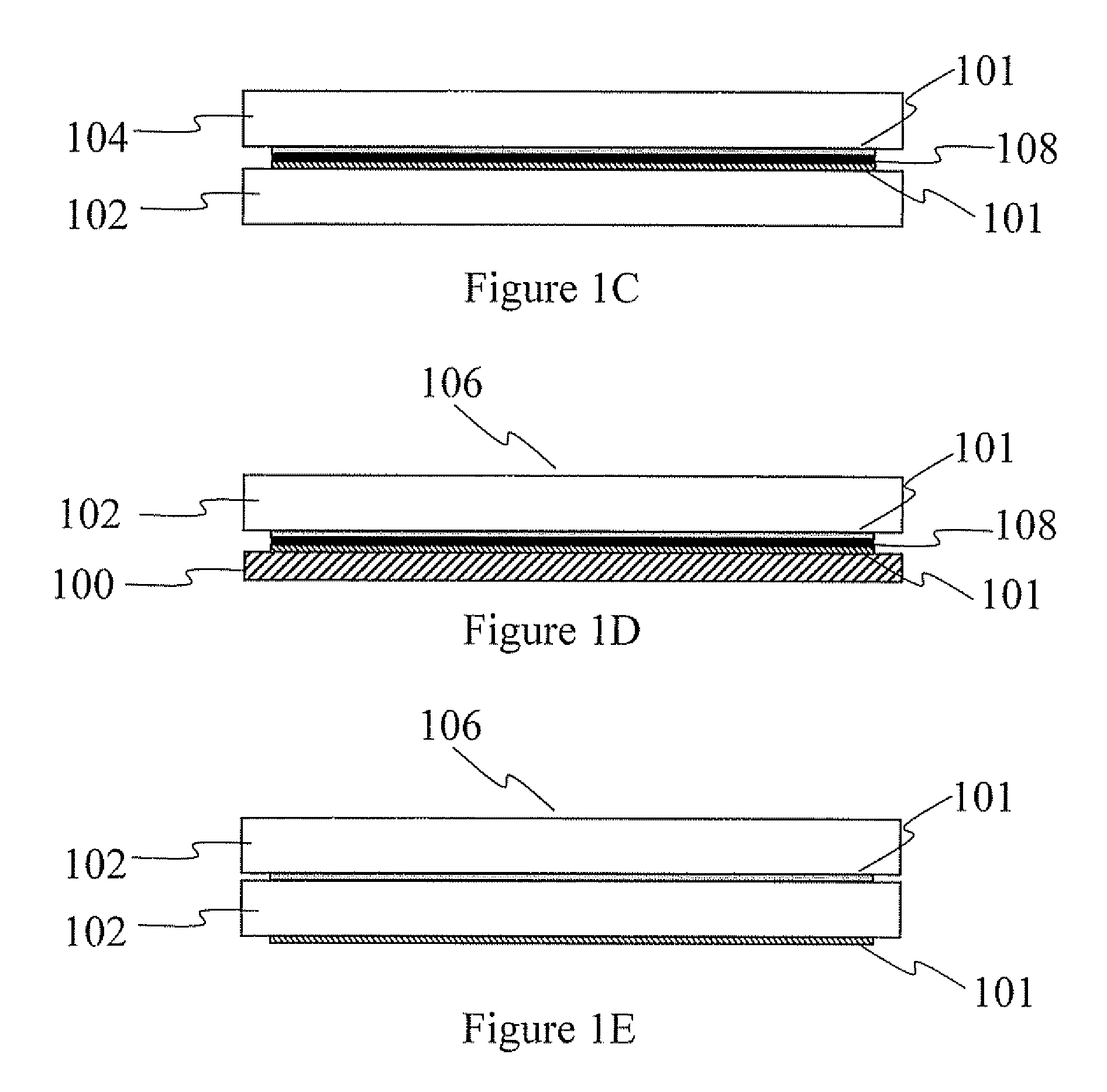

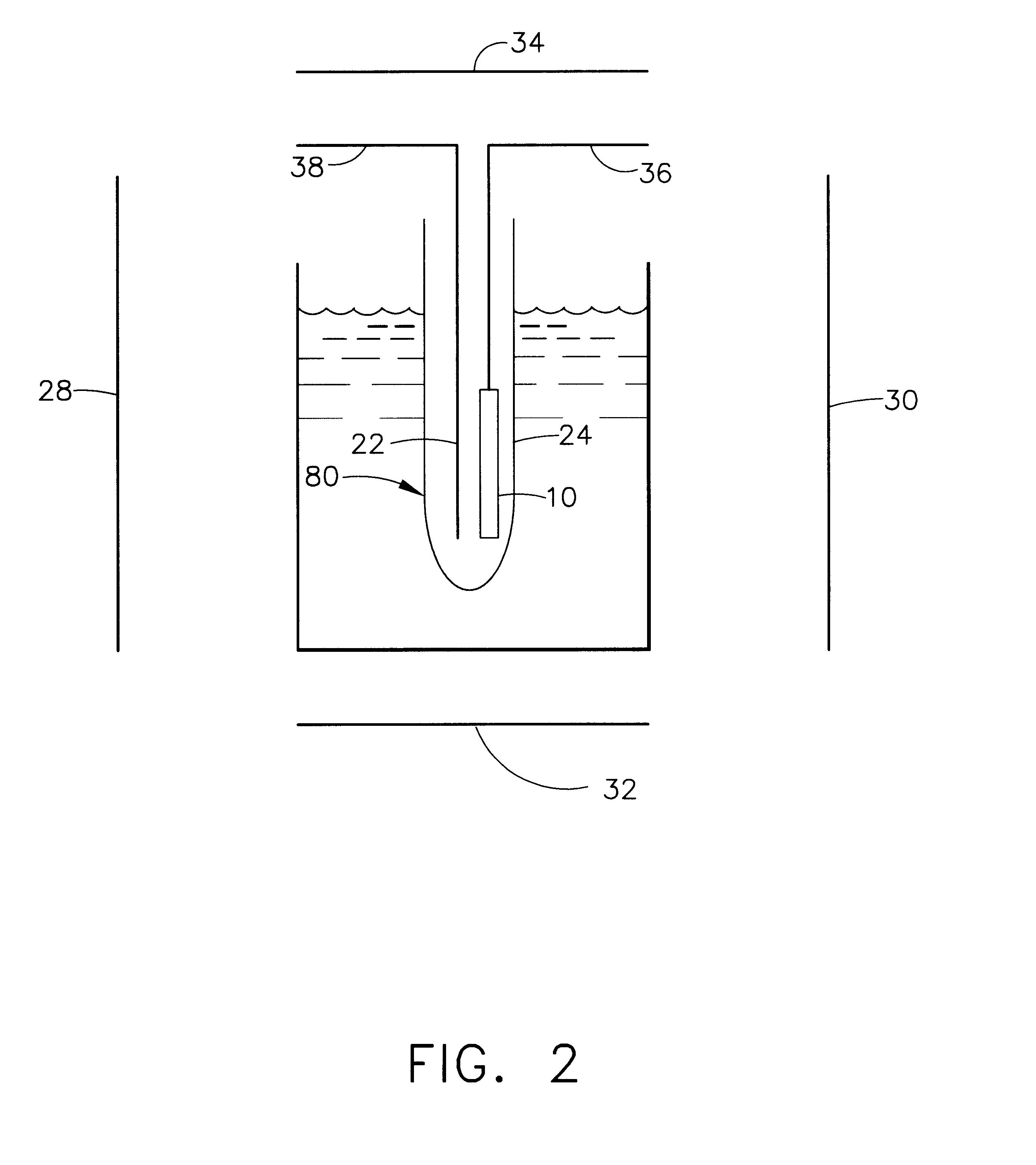

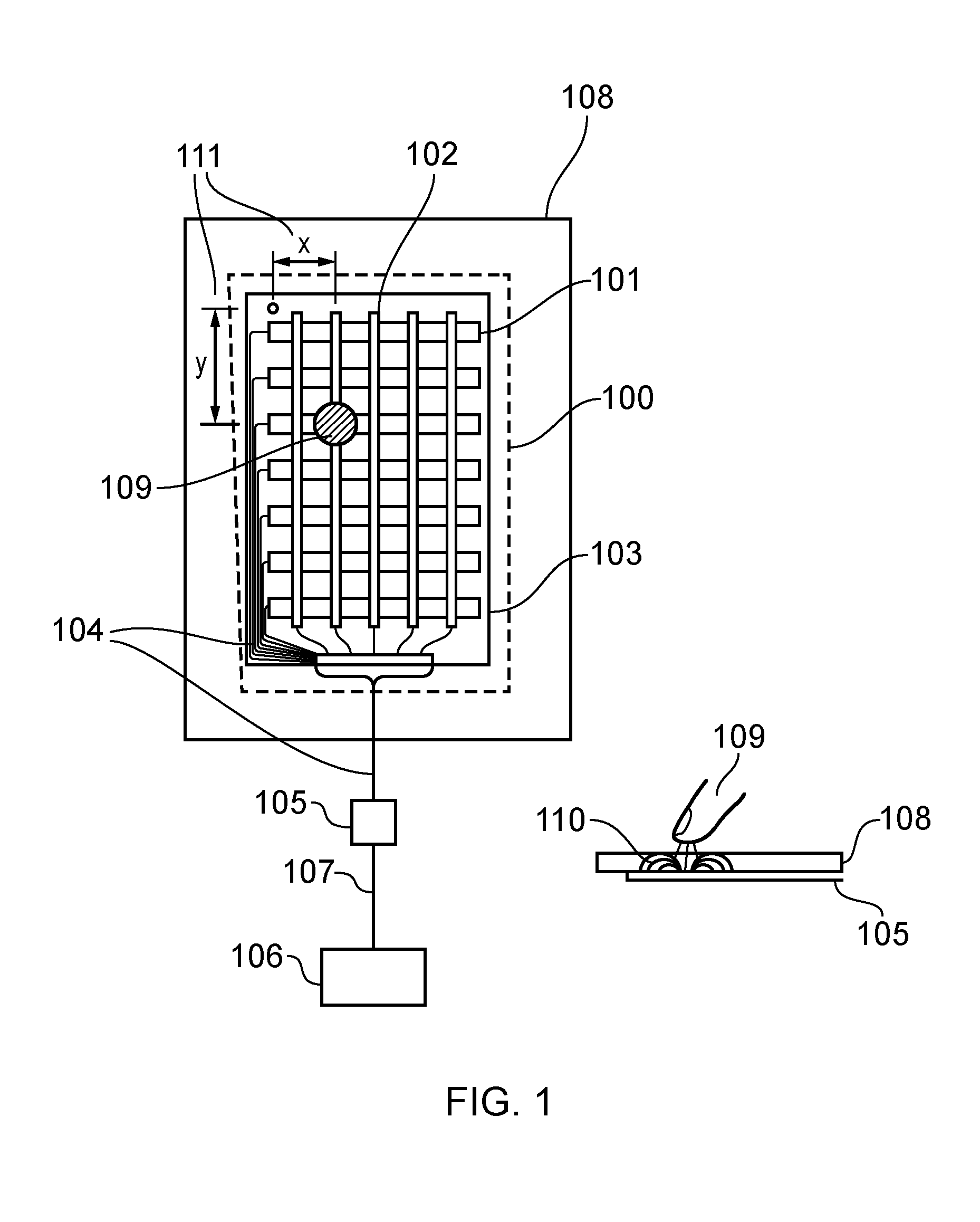

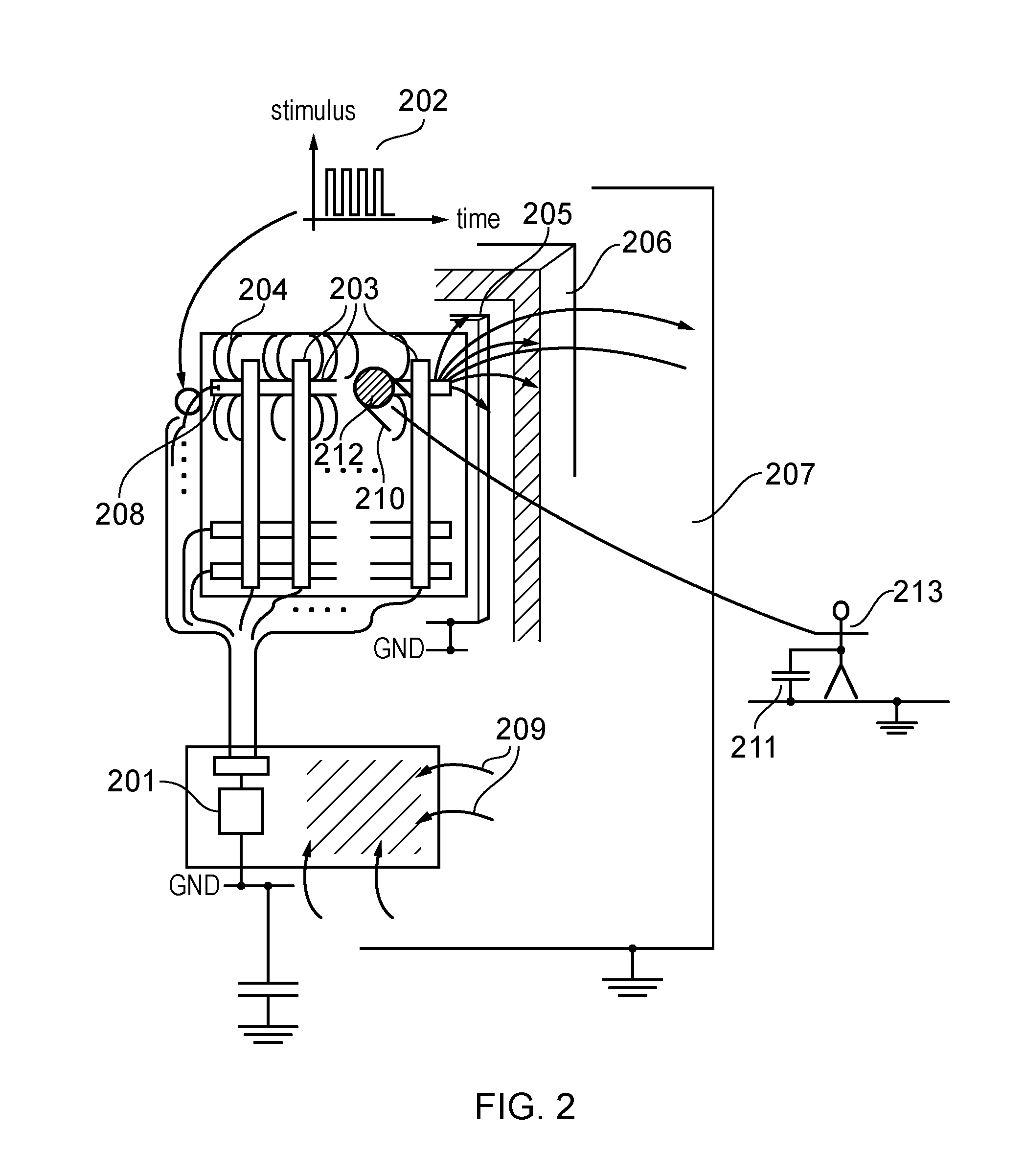

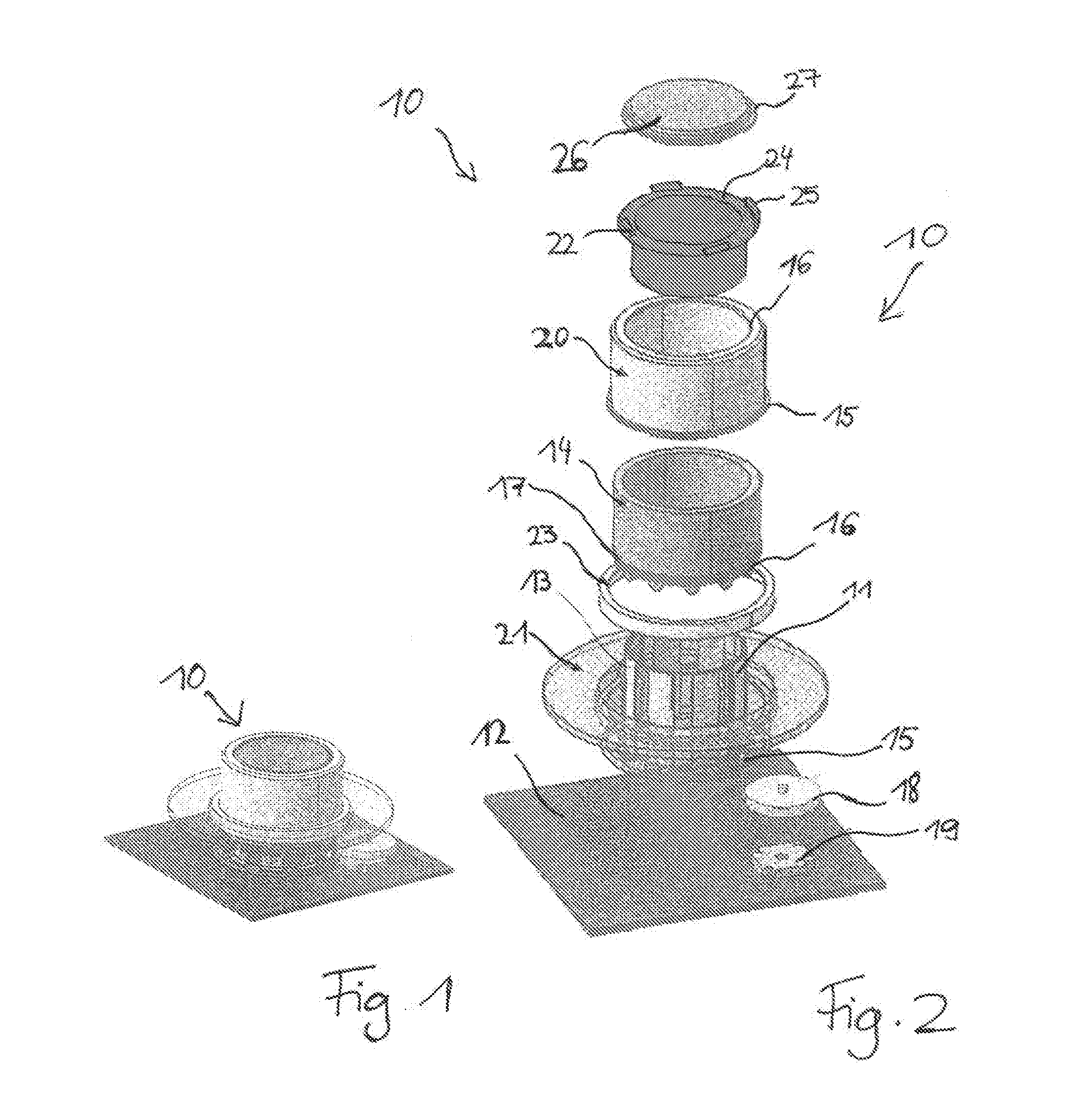

A magnetic field position and orientation measurement system contains, confines and re-directs the magnetic field from one or more transmitters such that the fields are attenuated in areas outside of the operating volume in areas where metallic objects are commonly found. A thin barrier made of a highly permeable material such as ferrite or mumetal is placed on top of a conductive plate. The thickness of the permeable layer is from 0.01 inches to 0.25 inches while the conductive plate, preferably made of an aluminum alloy, may preferably be from {fraction (3 / 16)} of an inch to ¼ inch in thickness. On top of the permeable barrier, a rhombic three axis transmitter is placed. In the preferred embodiment, the transmitter consists of a PC board carrying the transmitter. PC boards having thicknesses varying from 0.03125-0.125 inches may be employed. Thus, the entire "stack" including the transmitter, the permeable barrier and the conductive plate may only be from ½ inch to ⅝ of an inch in thickness. The permeable barrier may have a flat, planar configuration. Alternatively, it may be made to resemble, in cross-section, a cake pan having a flat central region with uplifted peripheral edges. Alternatively, the permeable barrier may have a generally flat configuration with peripheral edges that taper outwardly from the top surface thereof to the bottom surface thereof with the taper making an angle with the bottom surface in the range of, preferably, 30° to 85°.

Owner:ASCENSION TECH

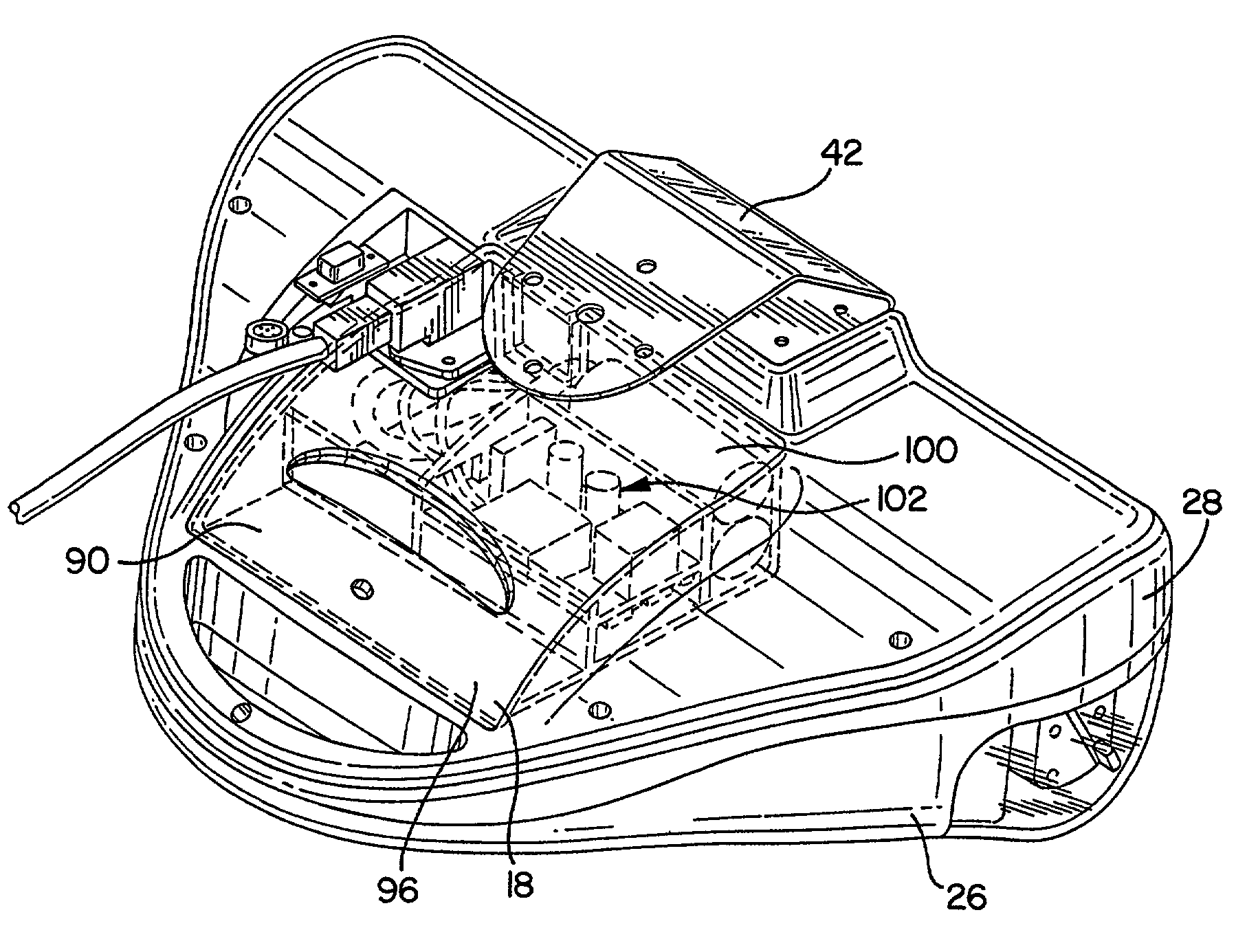

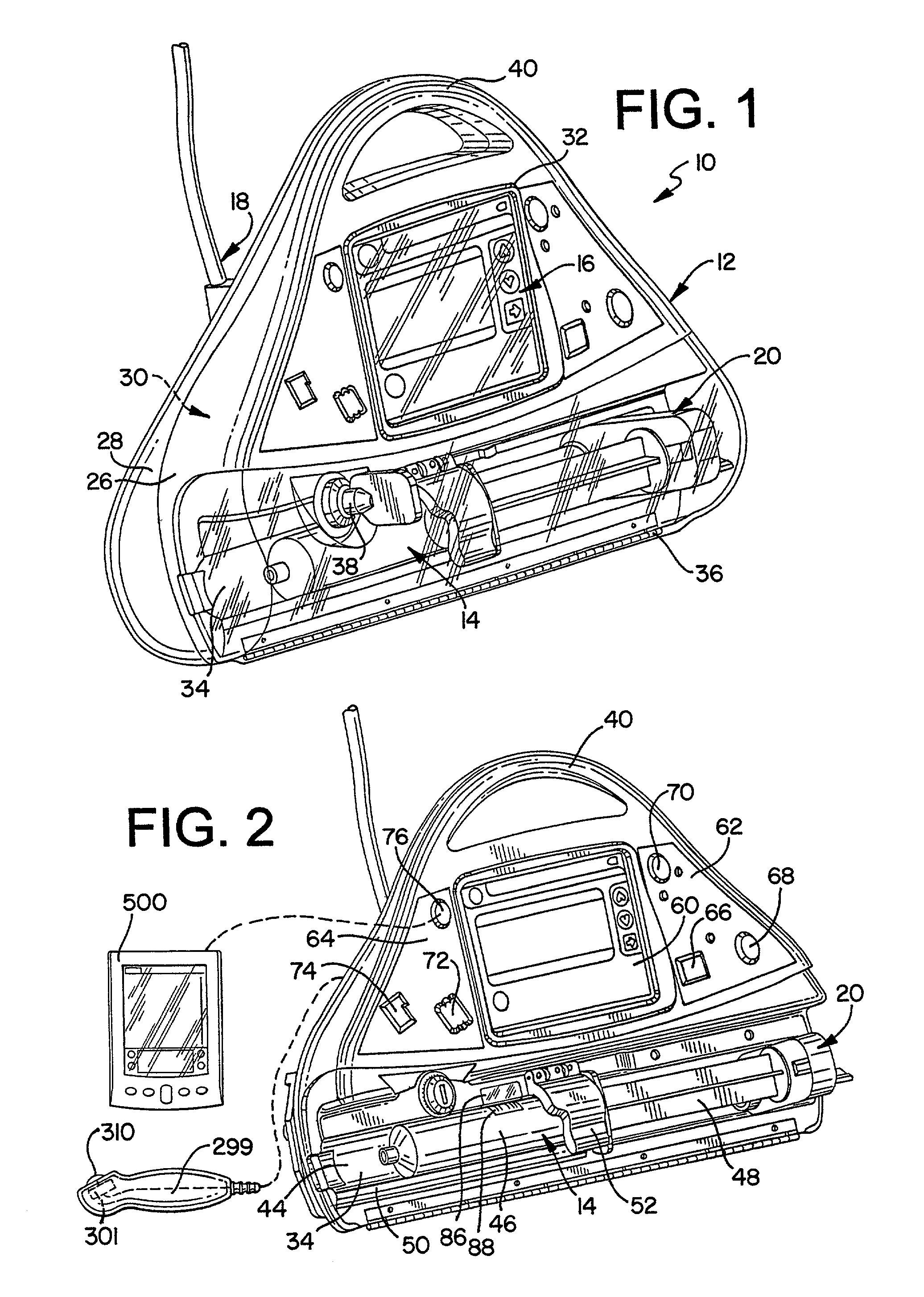

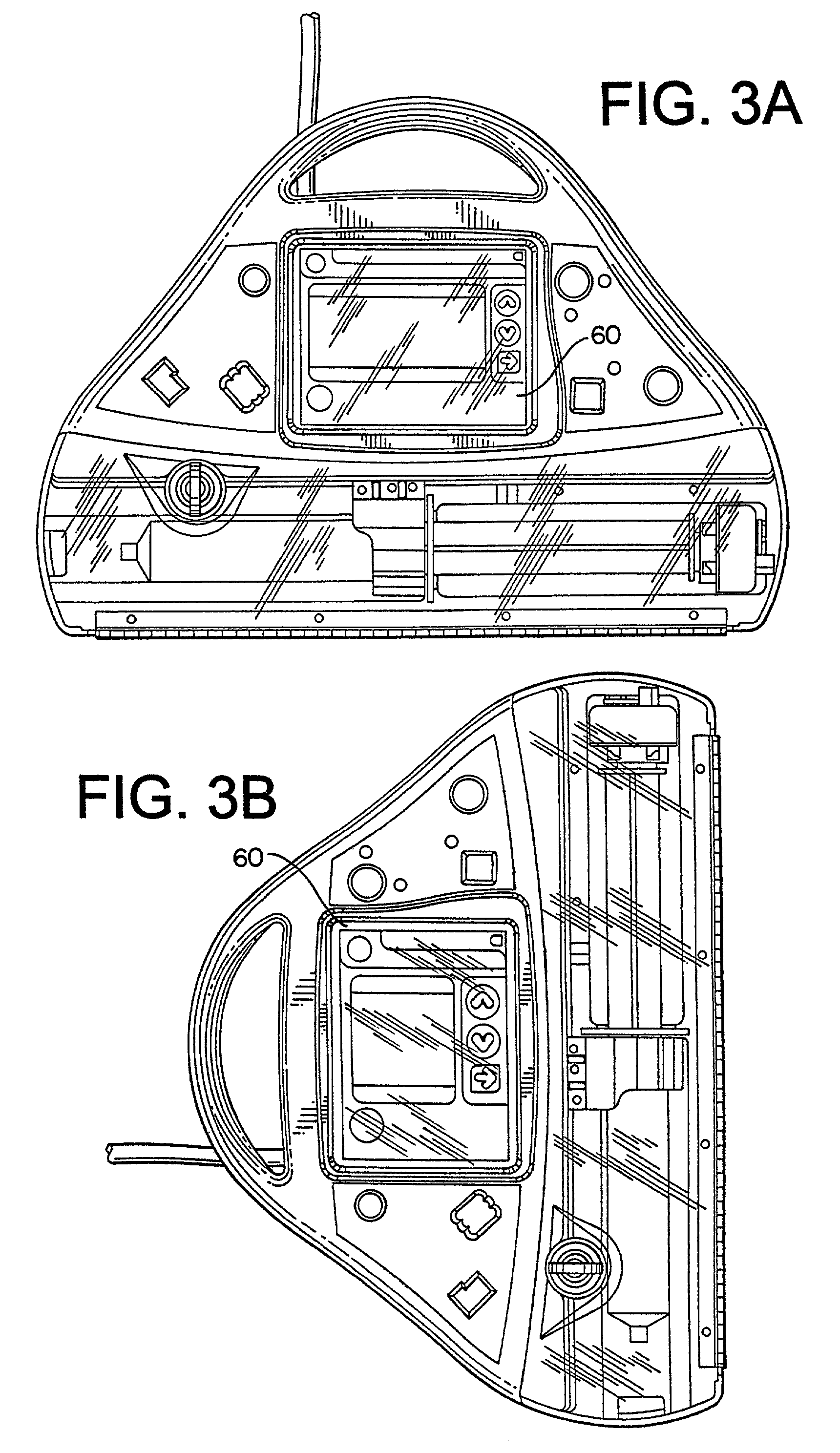

Infusion pump

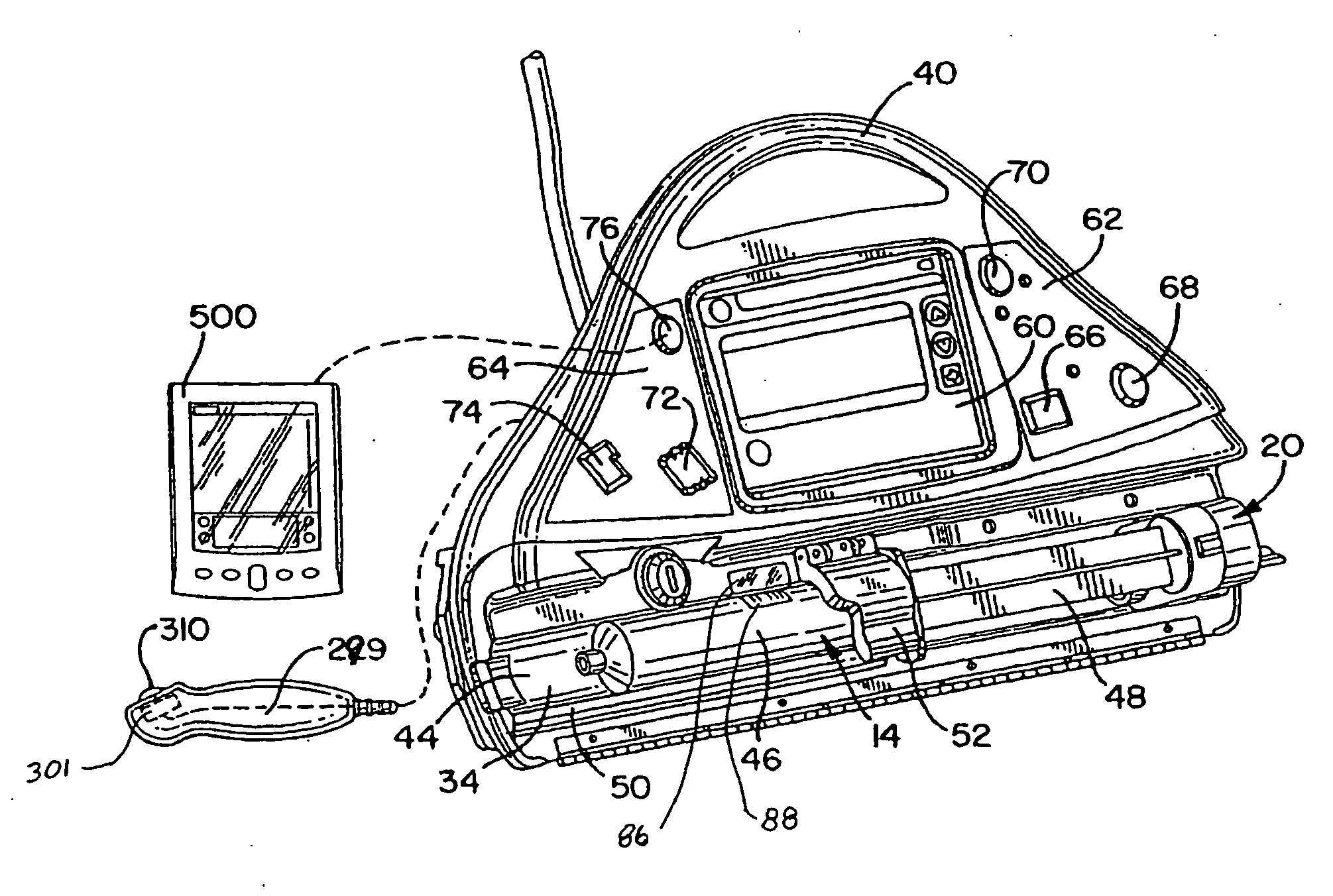

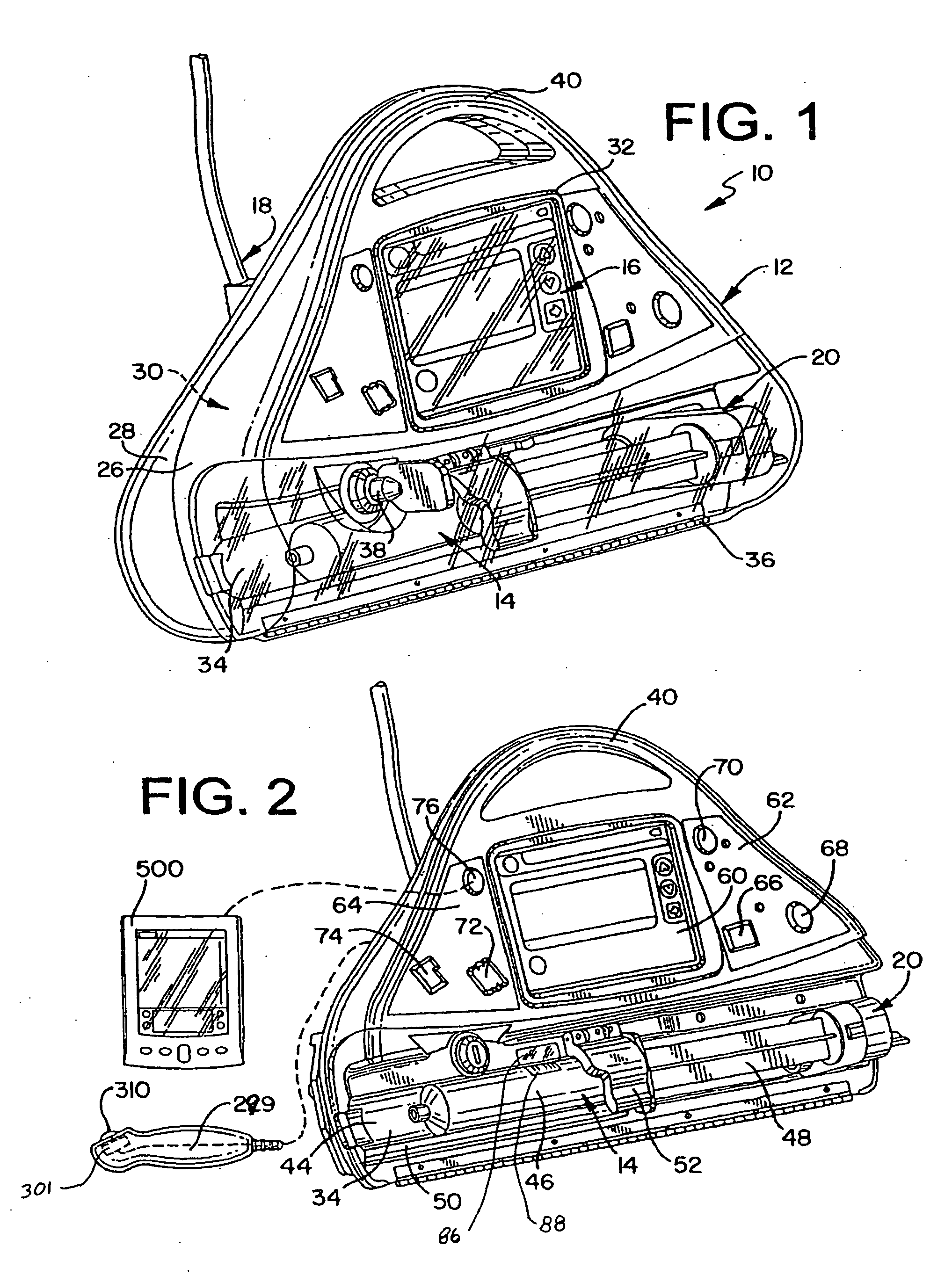

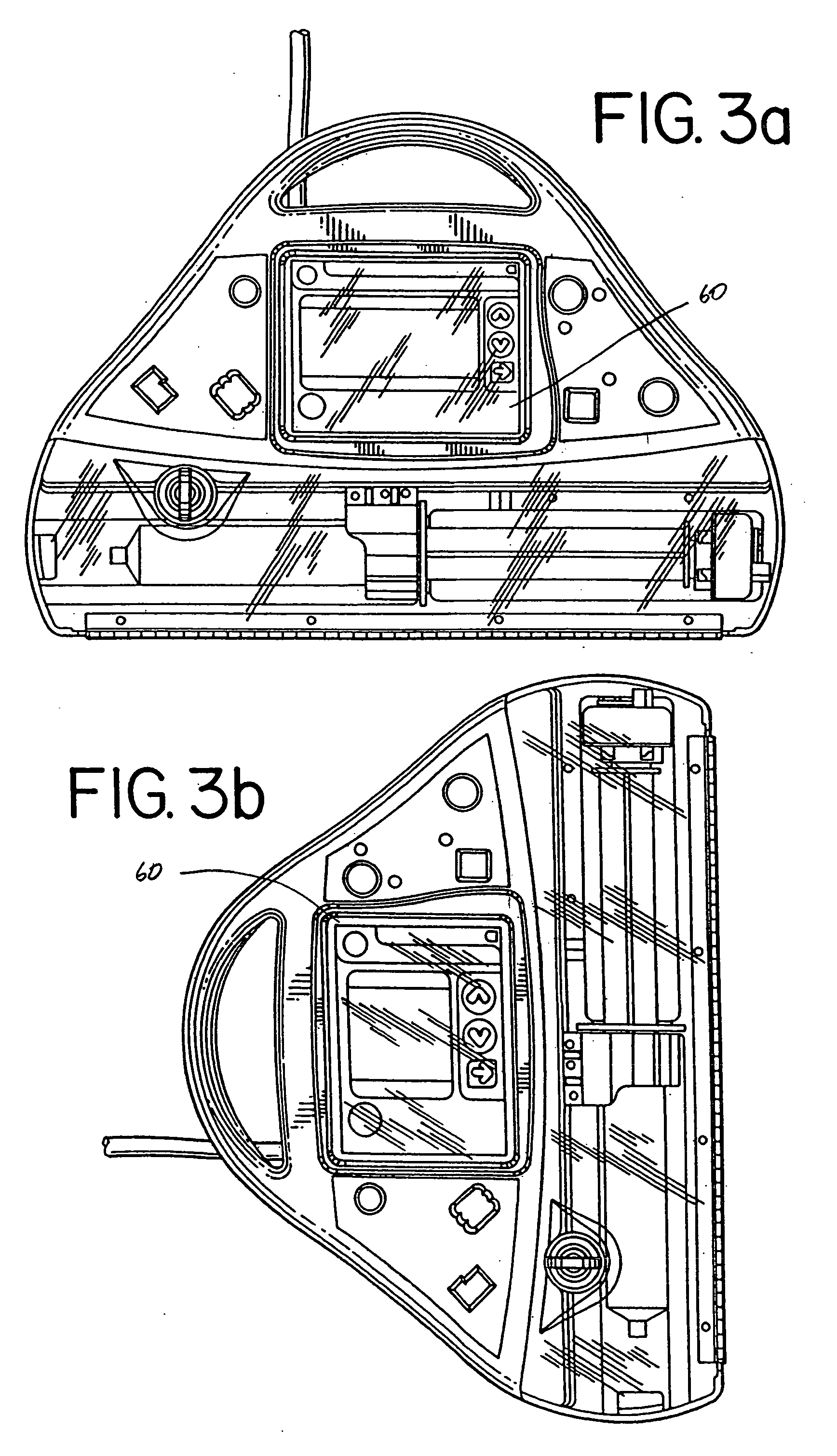

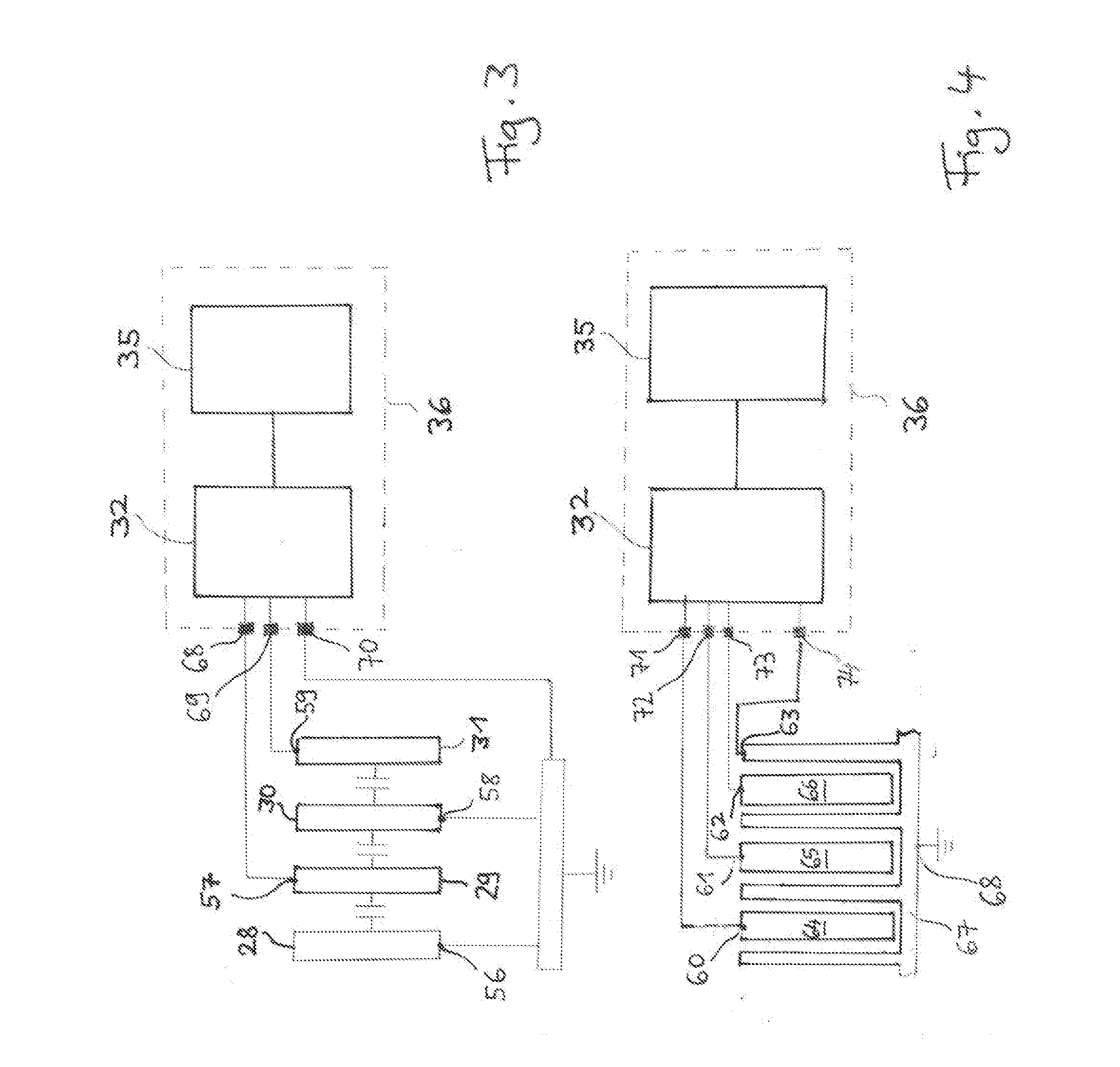

InactiveUS7018361B2Improve communication performanceGeometric image transformationDrug and medicationsRechargeable cellEngineering

An infusion pump (10) is configured to be powered by either a disposable battery source or a rechargeable battery source. The infusion pump (10) has a housing (12) having a recess (33). A motor is positioned within the housing (12) and is operably connected to an electrical contact (94) disposed in the recess (33). The motor powers the pump (10). The recess (33) receives one of a rechargeable battery unit (90) having an electrical contact (98) that contacts the recess electrical contact (94), and a disposable battery unit (92) having an electrical contact (144) that contacts the recess electrical contact (94).

Owner:BAXTER INT INC

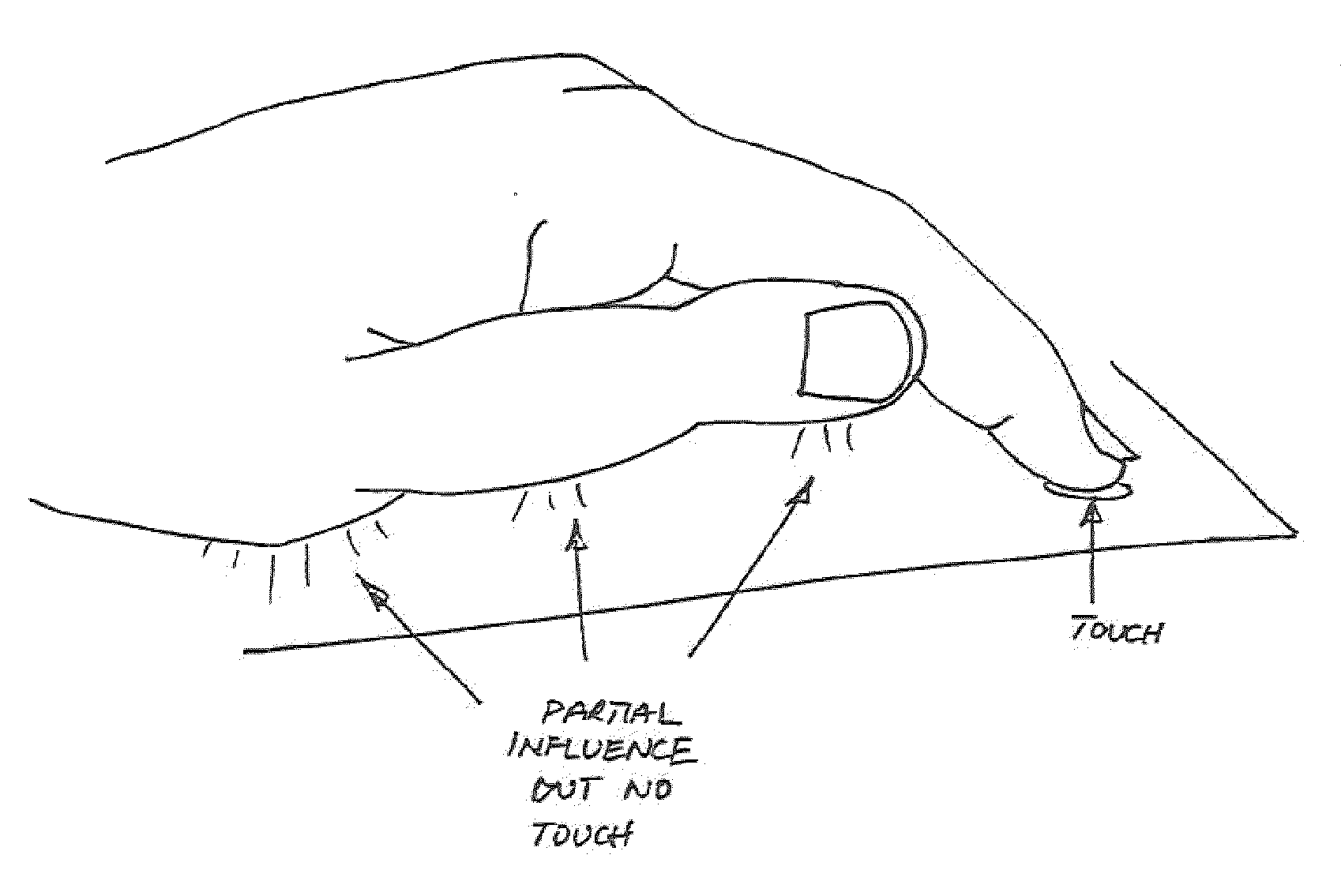

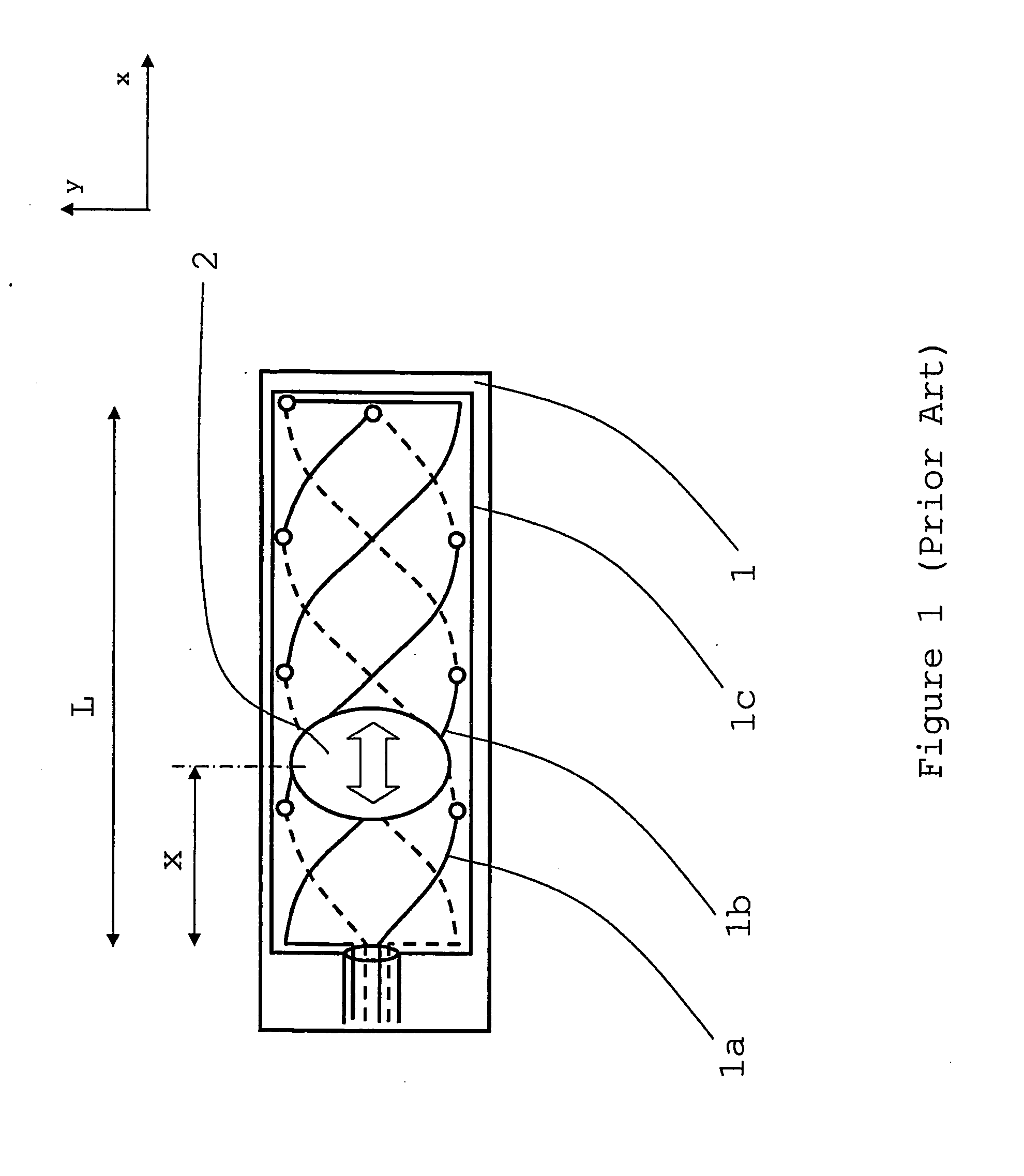

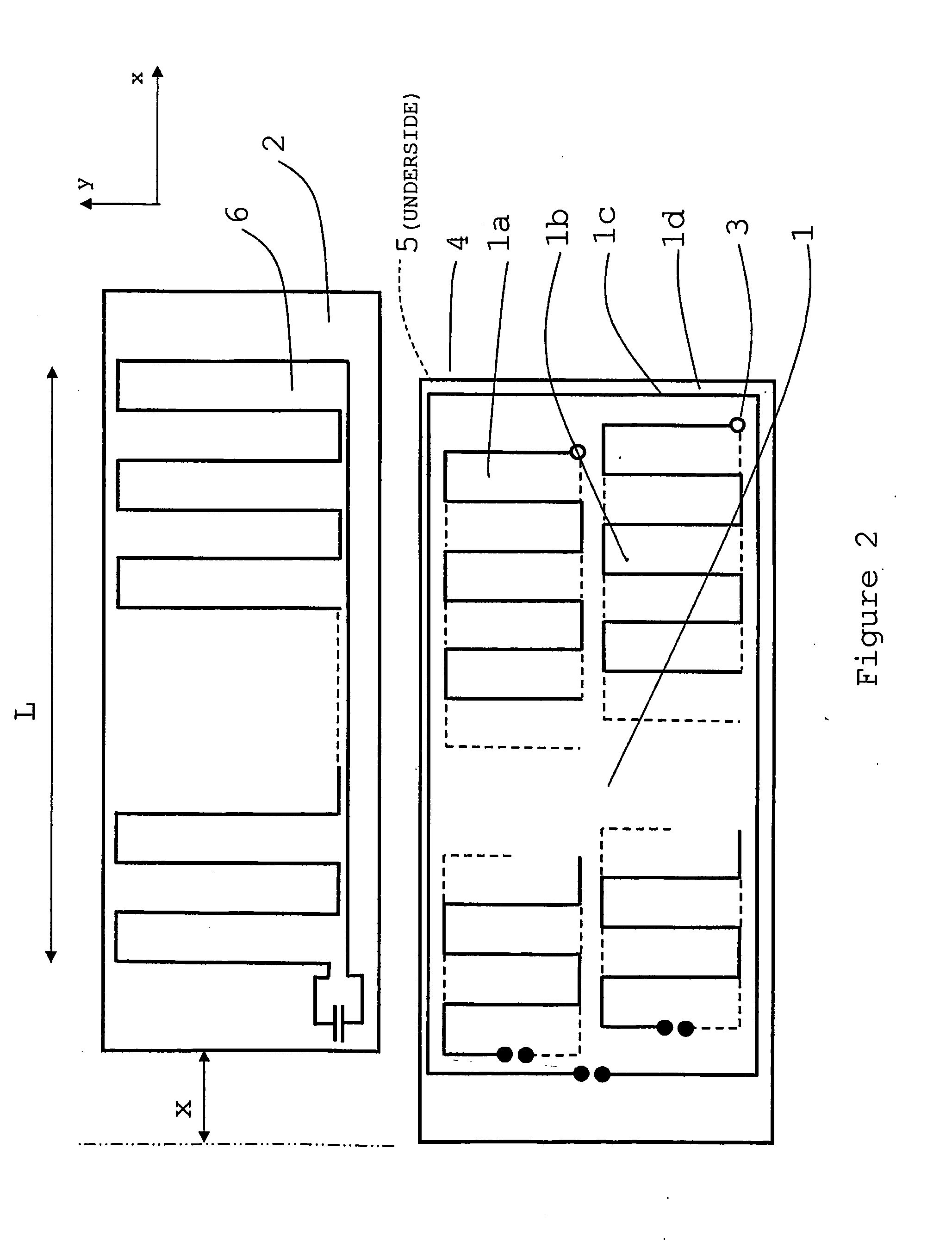

Capacitive Position Sensor

ActiveUS20100045632A1Increase the number ofGood light transmissionTransmission systemsDigital data processing detailsCapacitanceCapacitive coupling

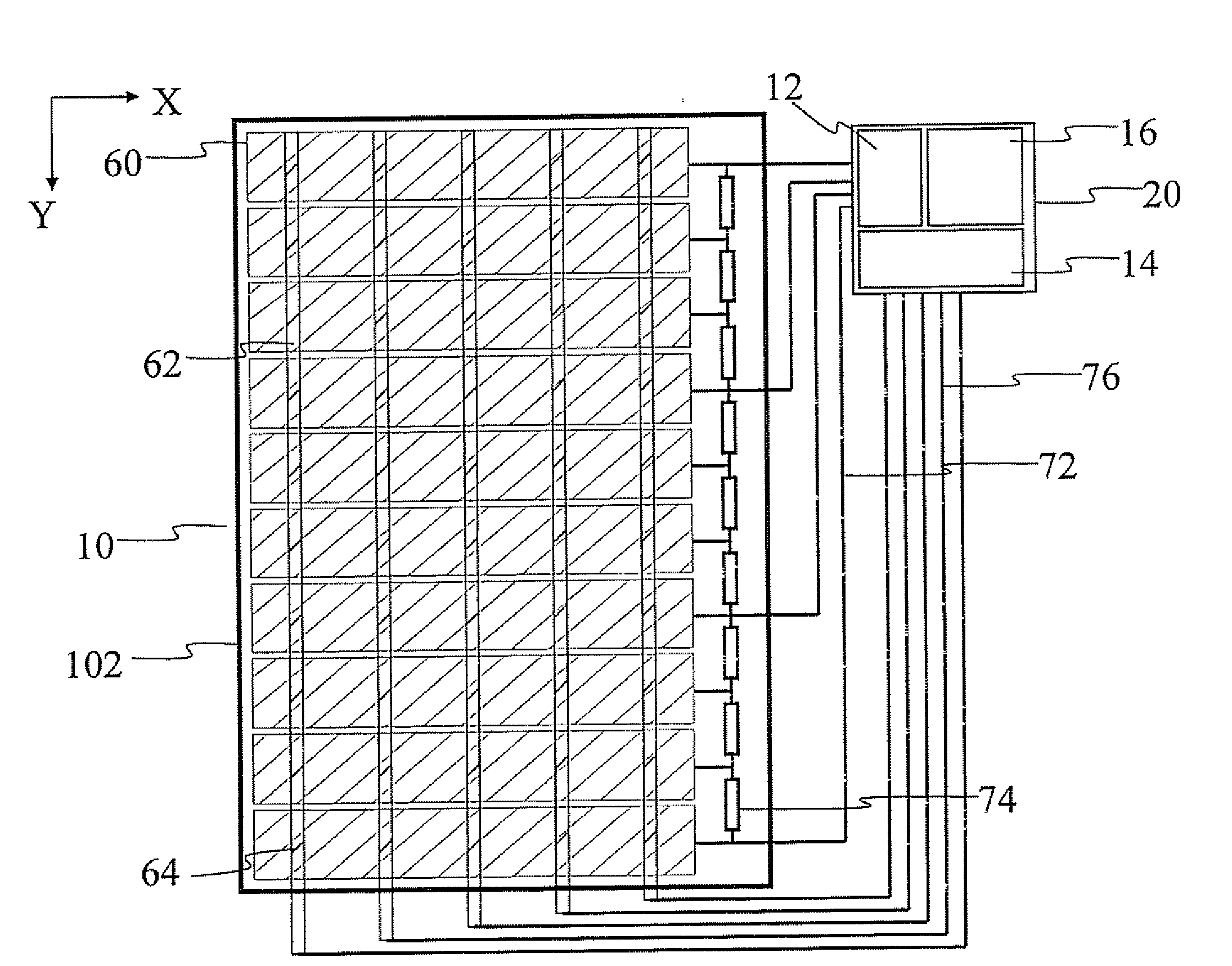

A capacitive position sensor has a two-layer electrode structure. Drive electrodes extending in a first direction on a first plane on one side of a substrate. Sense electrodes extend in a second direction on a second plane on the other side of the substrate so that the sense electrodes cross the drive electrodes at a plurality of intersections which collectively form a position sensing array. The sense electrodes are provided with branches extending in the first direction part of the way towards each adjacent sense electrode so that end portions of the branches of adjacent sense electrodes co-extend with each other in the first direction separated by a distance sufficiently small that capacitive coupling to the drive electrode adjacent to the co-extending portion is reduced. Providing sense electrode branches allow a sensor to be made which has a greater extent in the first direction for a given number of sense channels, since the co-extending portions provide an interpolating effect. The number of sense electrode branches per drive electrode can be increased which allows a sensor to be made which has ever greater extent in the first direction without having to increase the number of sense channels.

Owner:NEODRON LTD +1

Capacitive Touch Screen with Noise Suppression

ActiveUS20100044122A1Reduce sensitivityImprove linearityTransmission systemsDigital data processing detailsDisplay deviceNoise suppression

A capacitive touch sensor wherein the touch sensitive panel has drive electrodes arranged on the lower side of a substrate and sense electrodes arranged on the upper side. The drive electrodes are shaped and dimensioned to substantially entirely cover the touch sensitive area with individual drive electrodes being separated from each other by small gaps, the gaps being so small as to be practically invisible. The near blanket coverage by the drive electrodes also serves to screen out interference from noise sources below the drive electrode layer, such as drive signals for an underlying display, thereby suppressing noise pick-up by the sense electrodes that are positioned above the drive electrodes.

Owner:NEODRON LTD +1

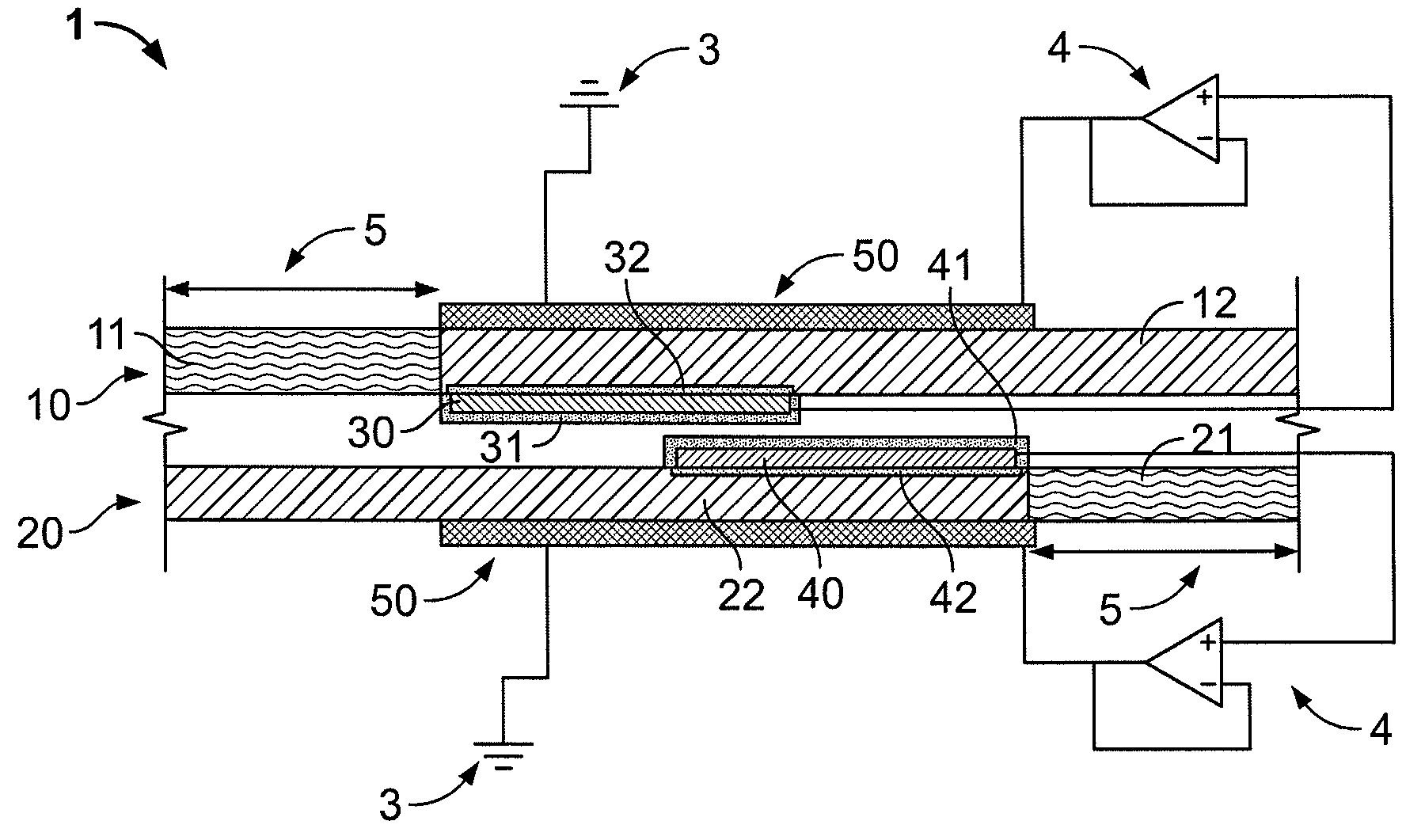

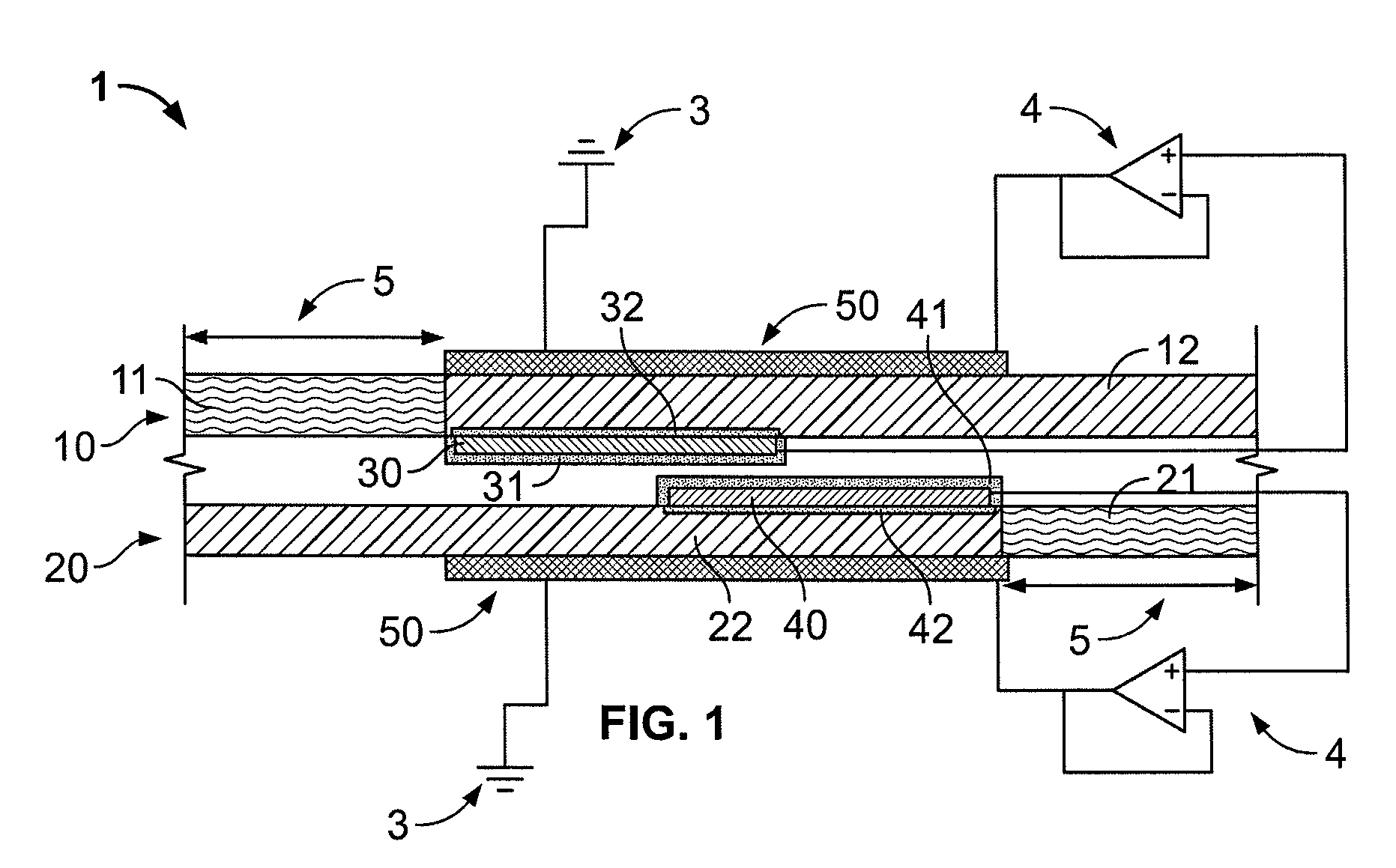

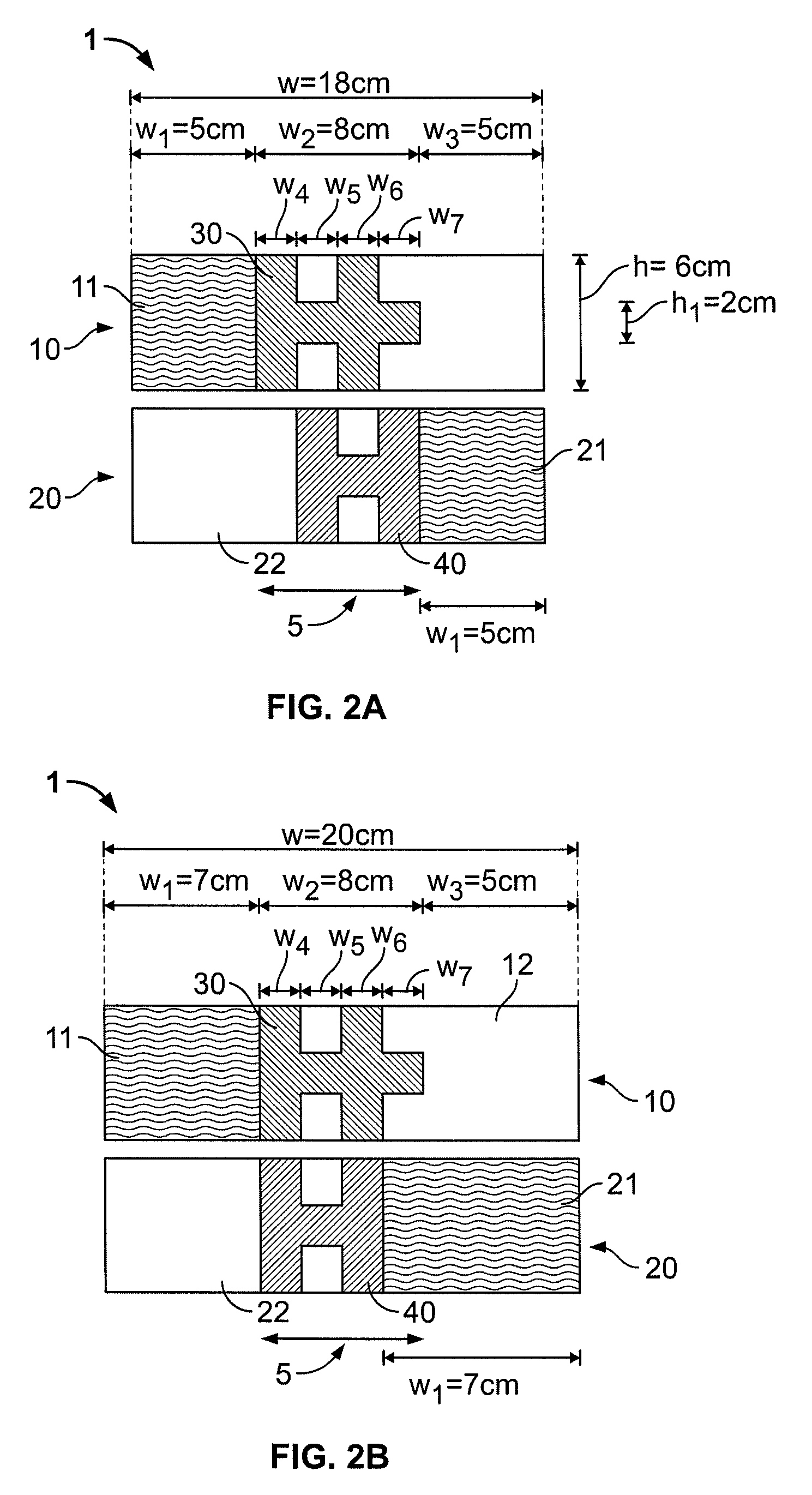

Sensor device for real-time monitoring or relative movement using capacitive fabric sensors

InactiveUS7712373B2Accurately and precisely measuring respiratory functionForce measurementElectric/magnetic position measurementsParallel plateRelative motion

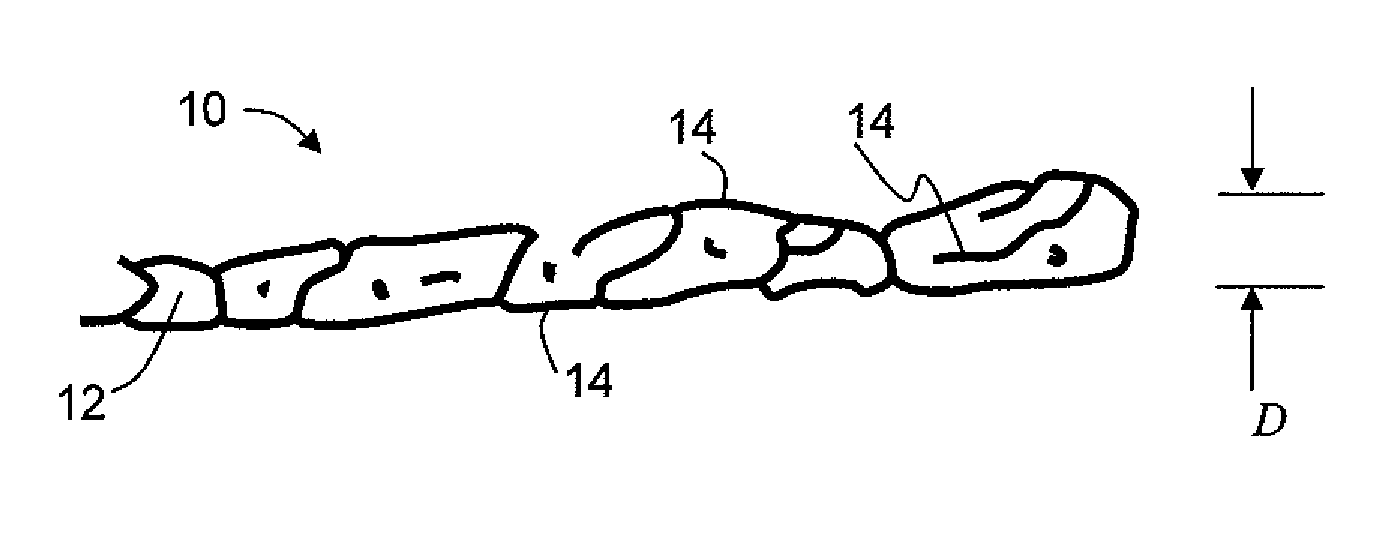

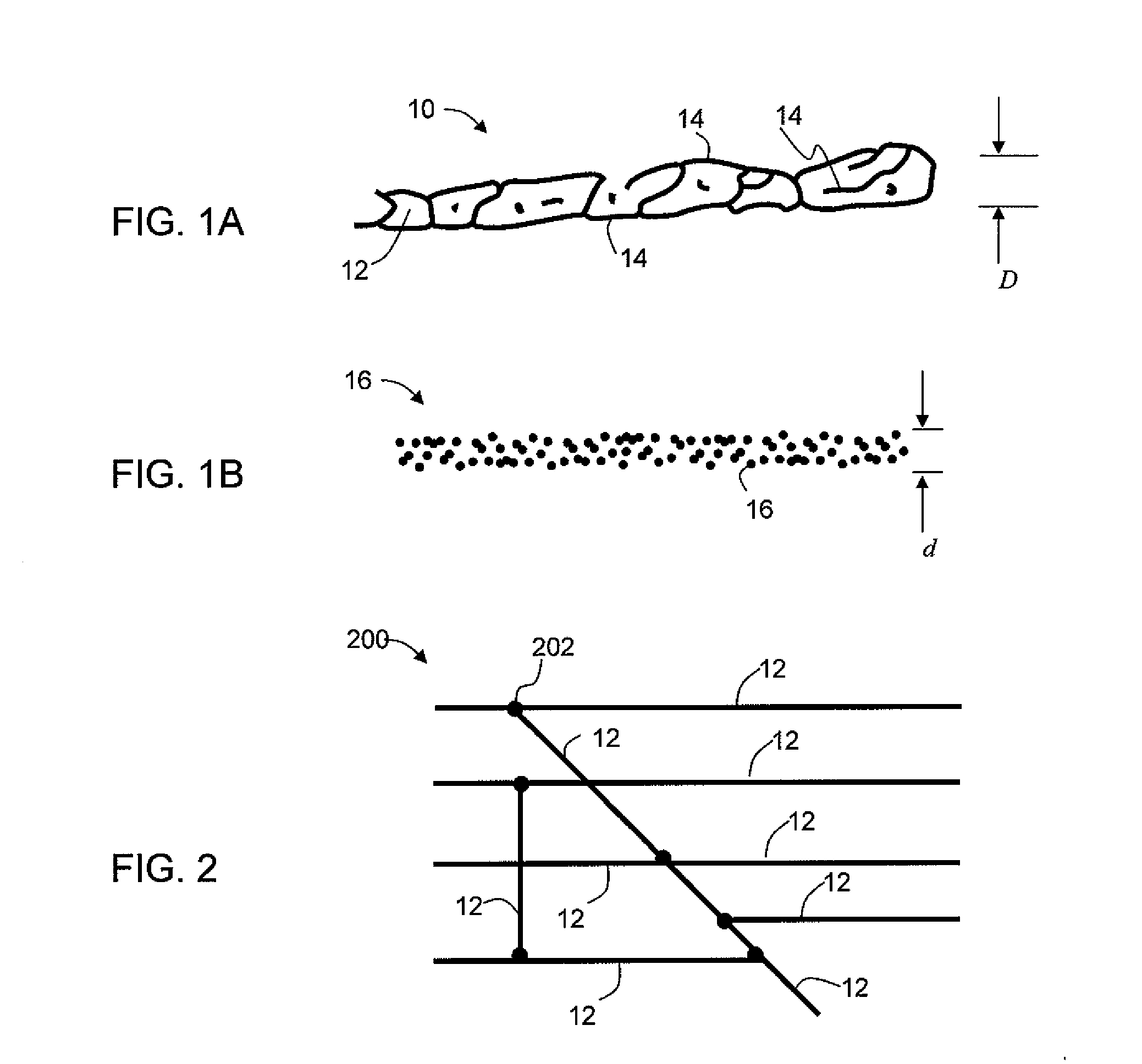

A capacitive sensor device, including electrode materials carried by fabric substrates, is provided for monitoring relative movement of an expanding and / or contracting structure, such as the mammalian chest and / or torso, corresponding to a performance parameter related, for example, to respiratory function. Some embodiments include non-woven fabric substrates comprising compliant portions configured to stretch only in a selected direction and non-compliant portions upon which electrode materials are disposed. In some embodiments, layers of fabric substrates, carrying corresponding first and second electrode materials, are configured to cooperate to form a parallel plate capacitive sensor having a variable capacitance corresponding to a relative motion of the fabric substrates.

Owner:MERRITT CAREY +5

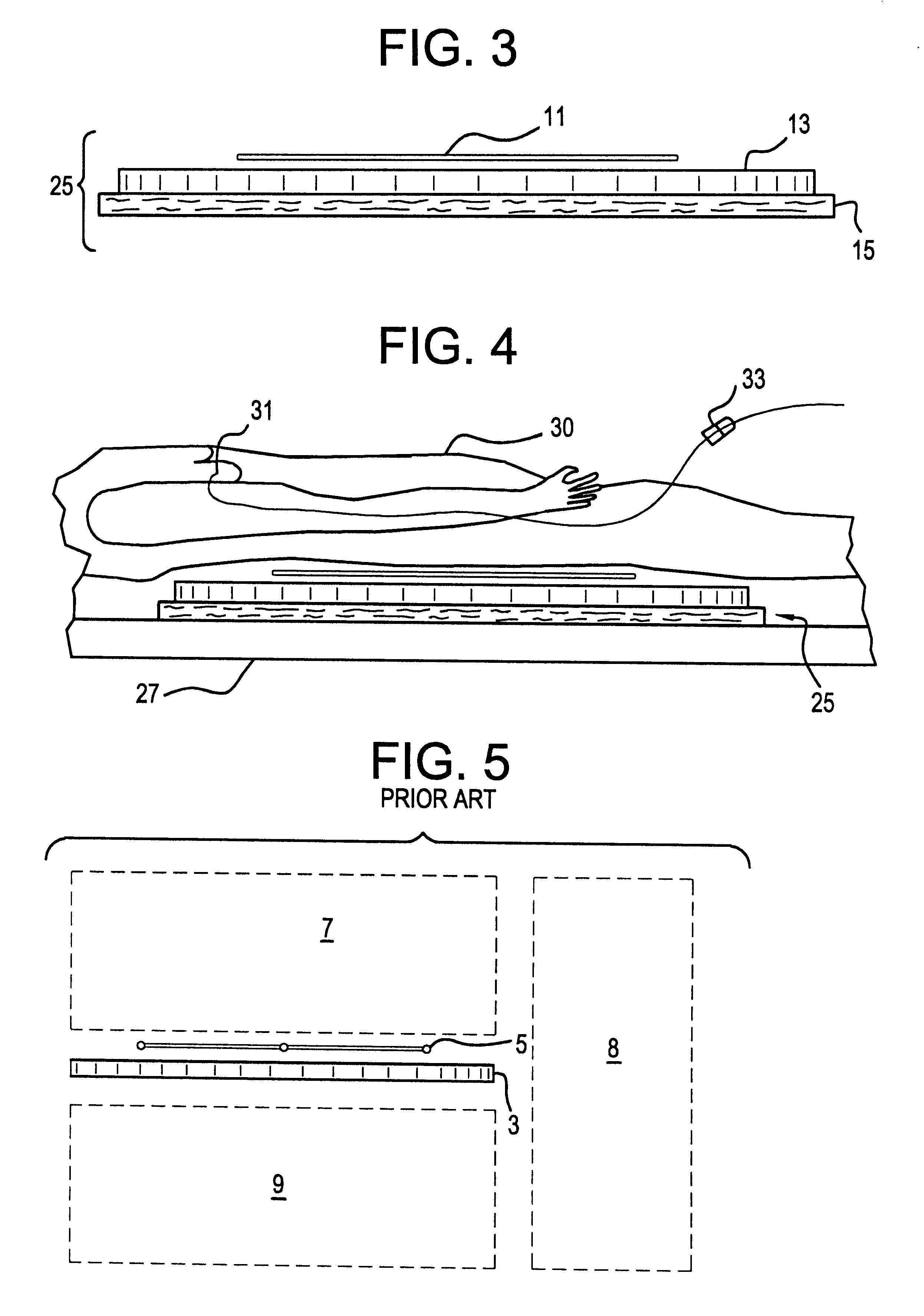

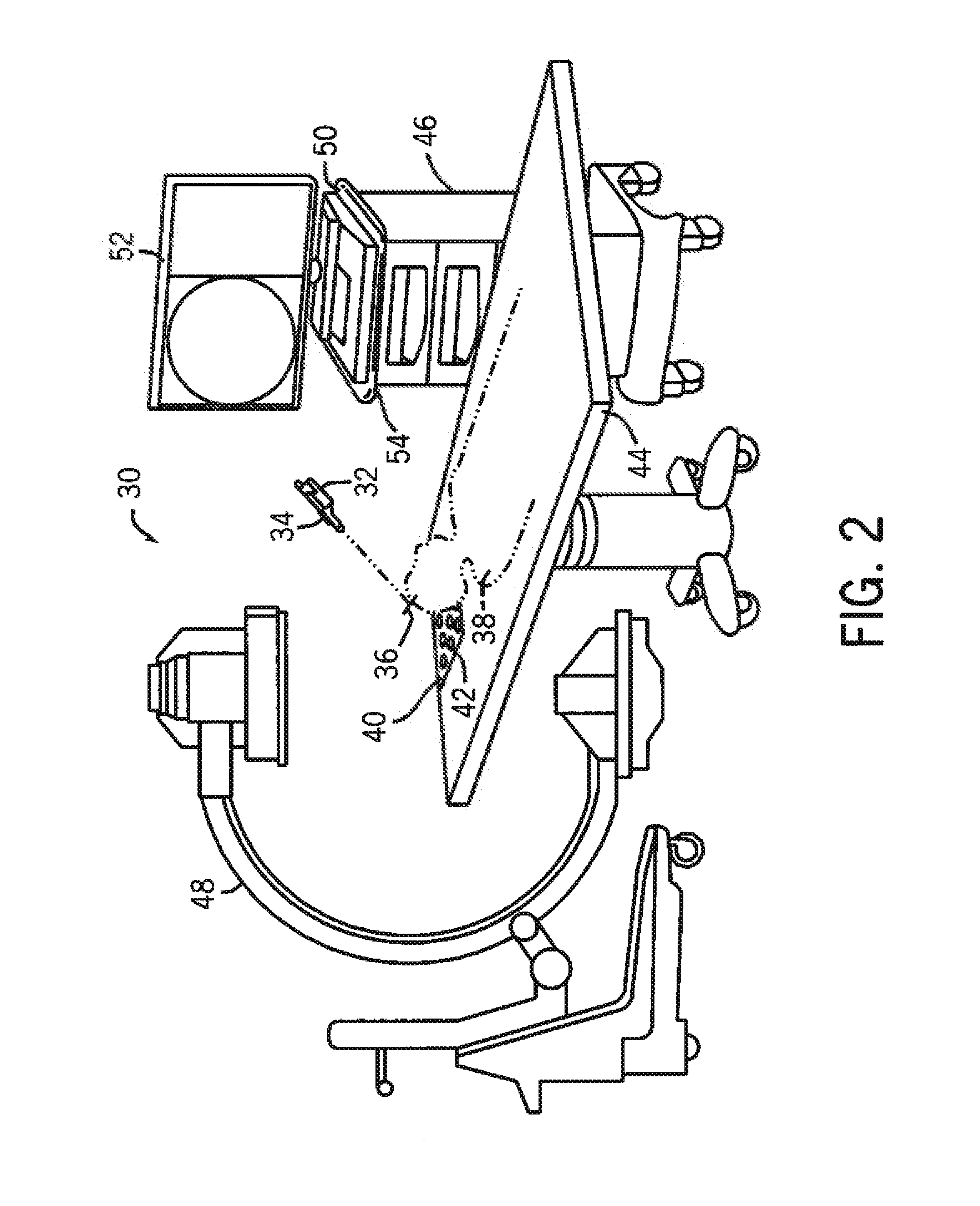

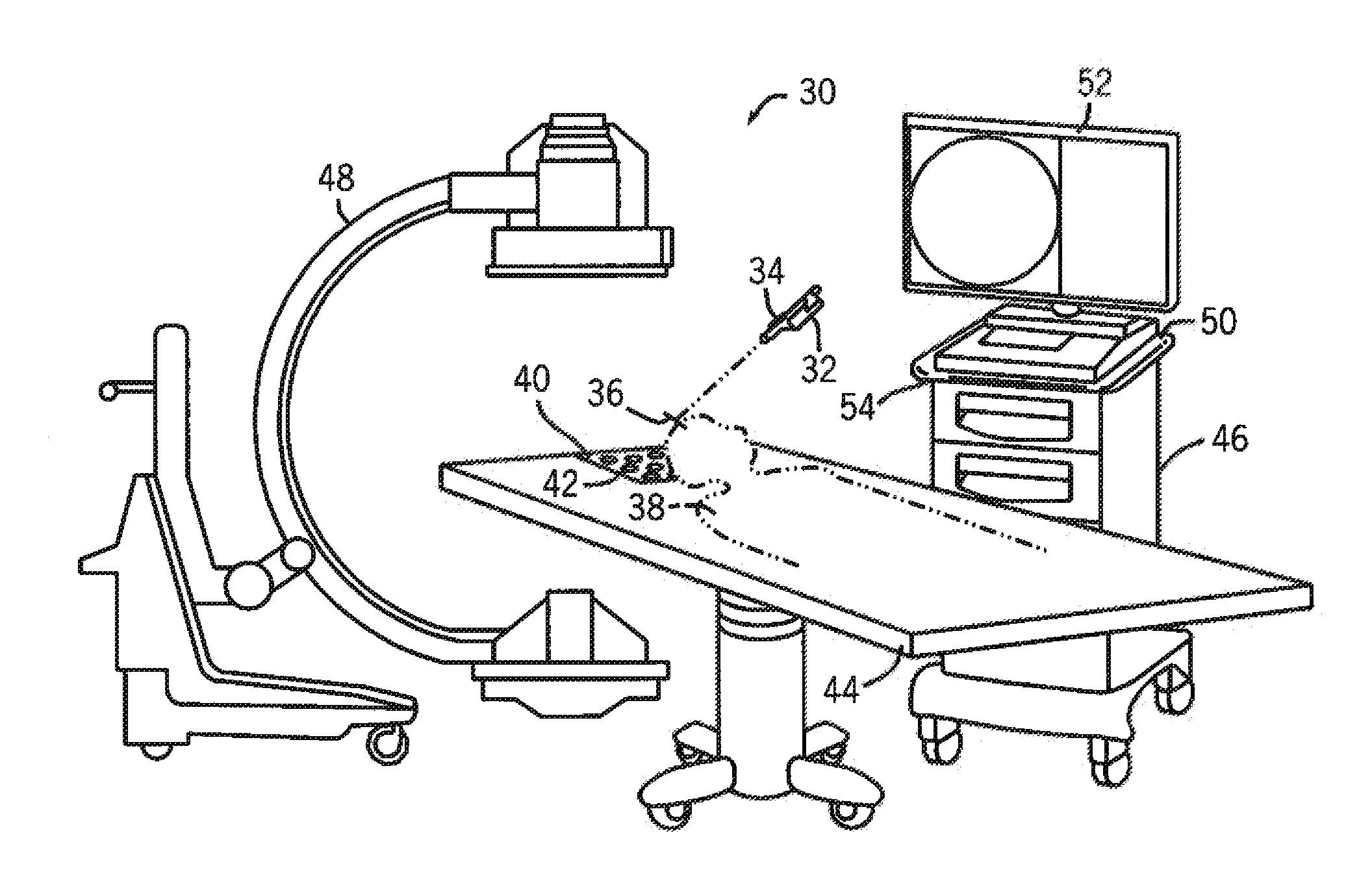

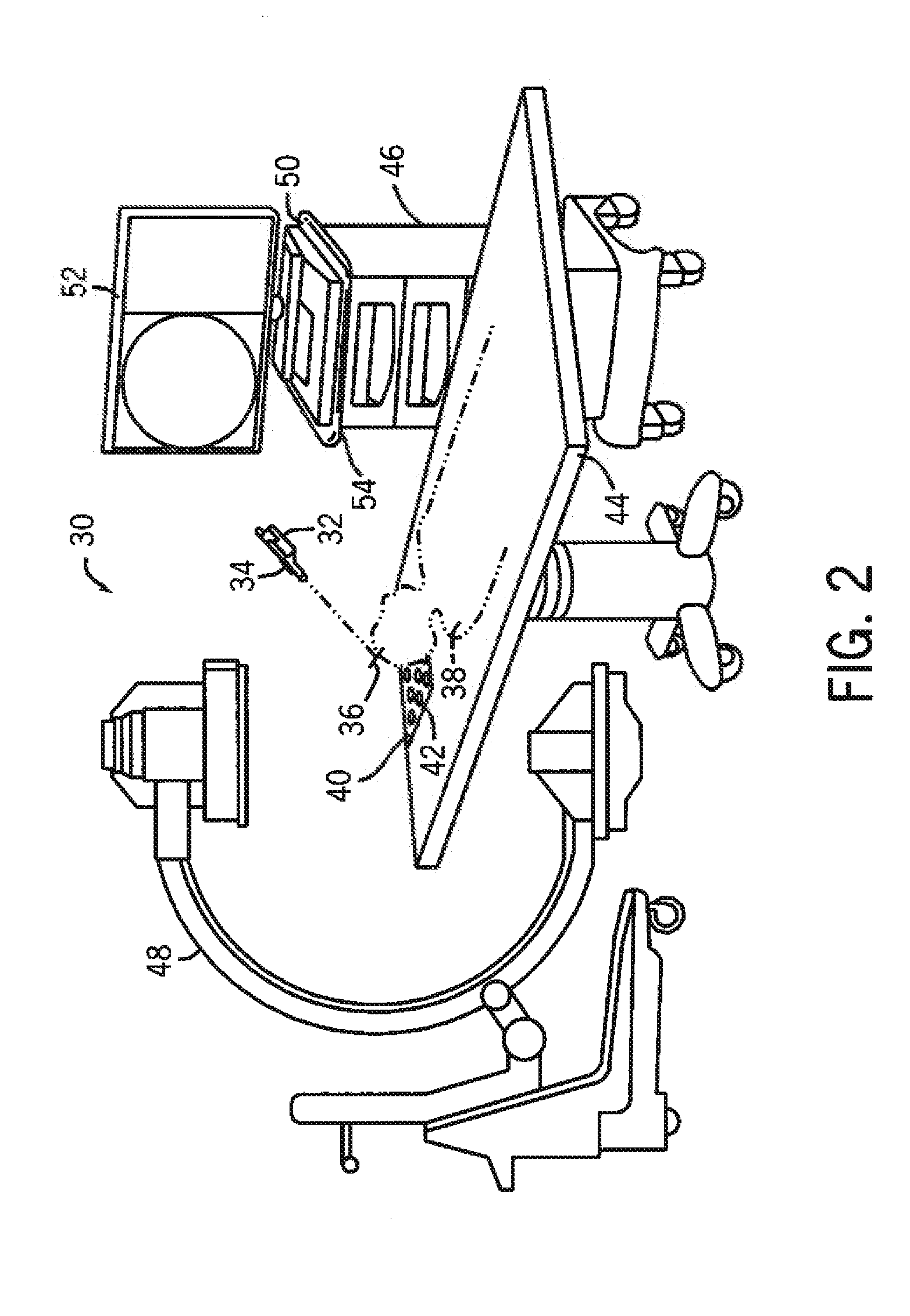

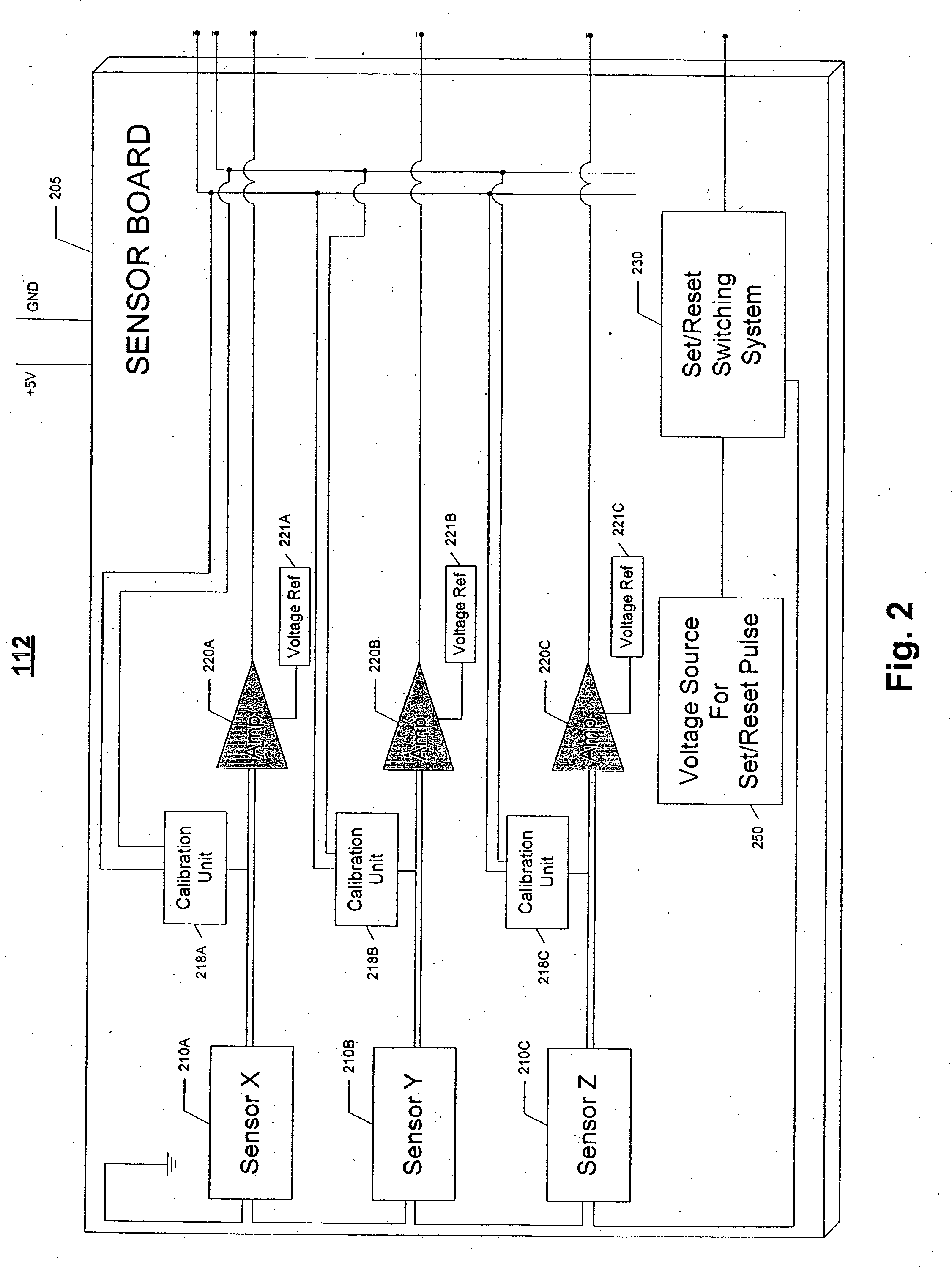

Surgical navigation enabled imaging table environment

A system for integrating radiolucent tracking sensors in a medical table, table mat, or surgical drape of a surgical navigation system, allowing the surgical navigation system to be less obtrusive in a surgery environment. A plurality of radiolucent magnetoresistance sensors are integrated into a table, table mat, or surgical draping of a surgical navigation system for improving surgical navigation workflow and eliminating image artifacts from intraoperative images. The plurality of radiolucent magnetoresistance sensors may be located within a table or adjacent to a table surface.

Owner:STRYKER EURO OPERATIONS HLDG LLC

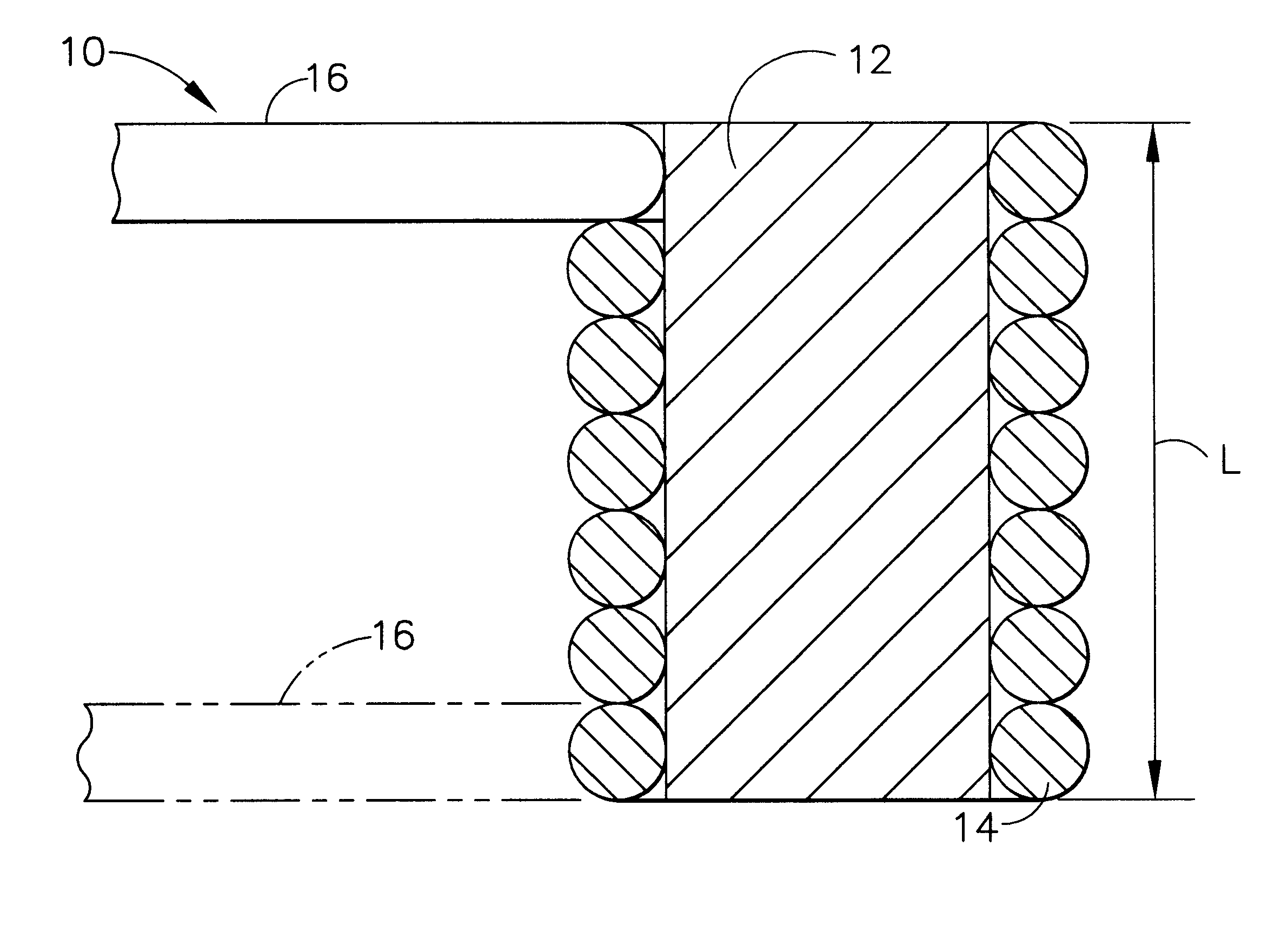

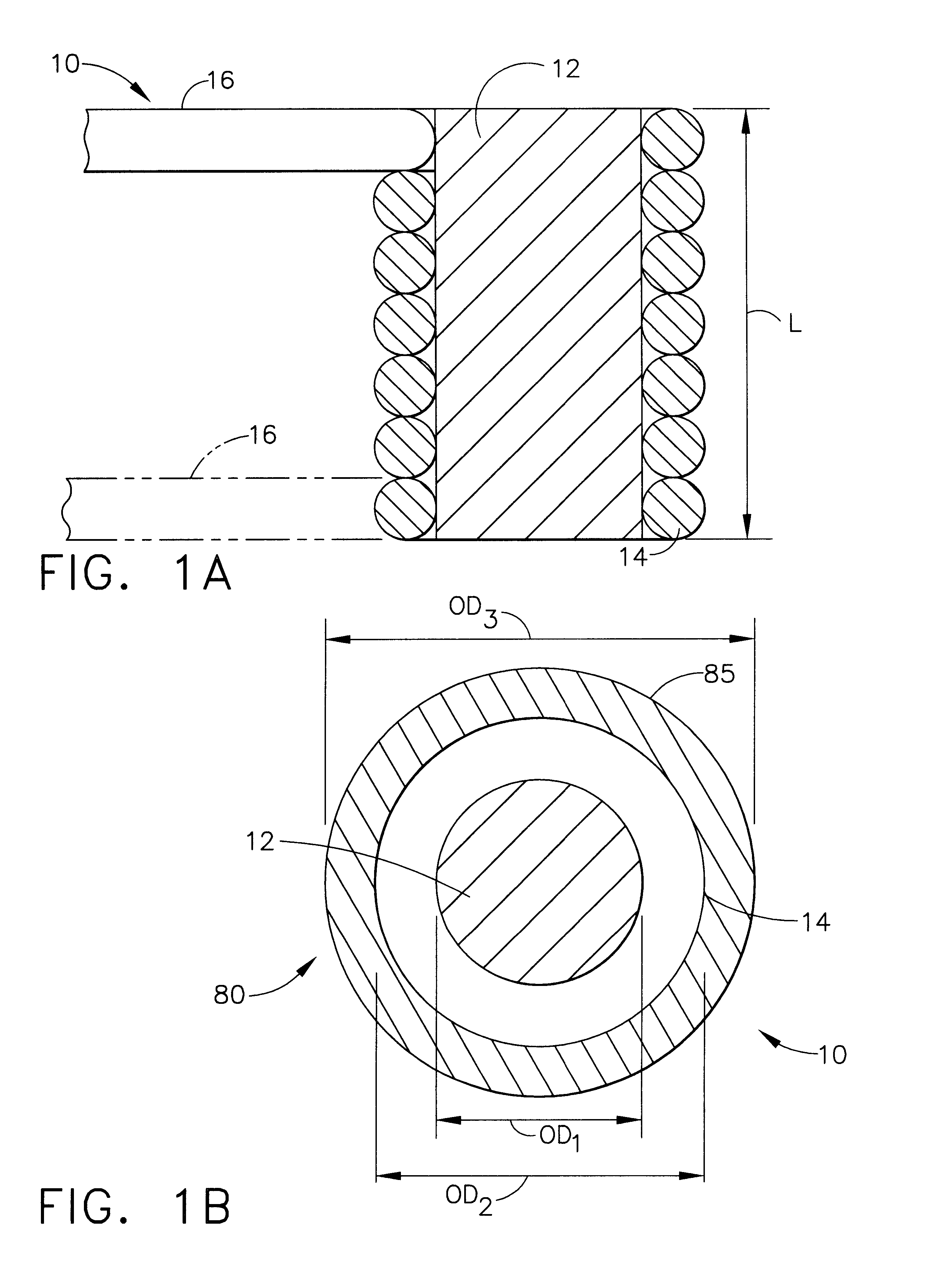

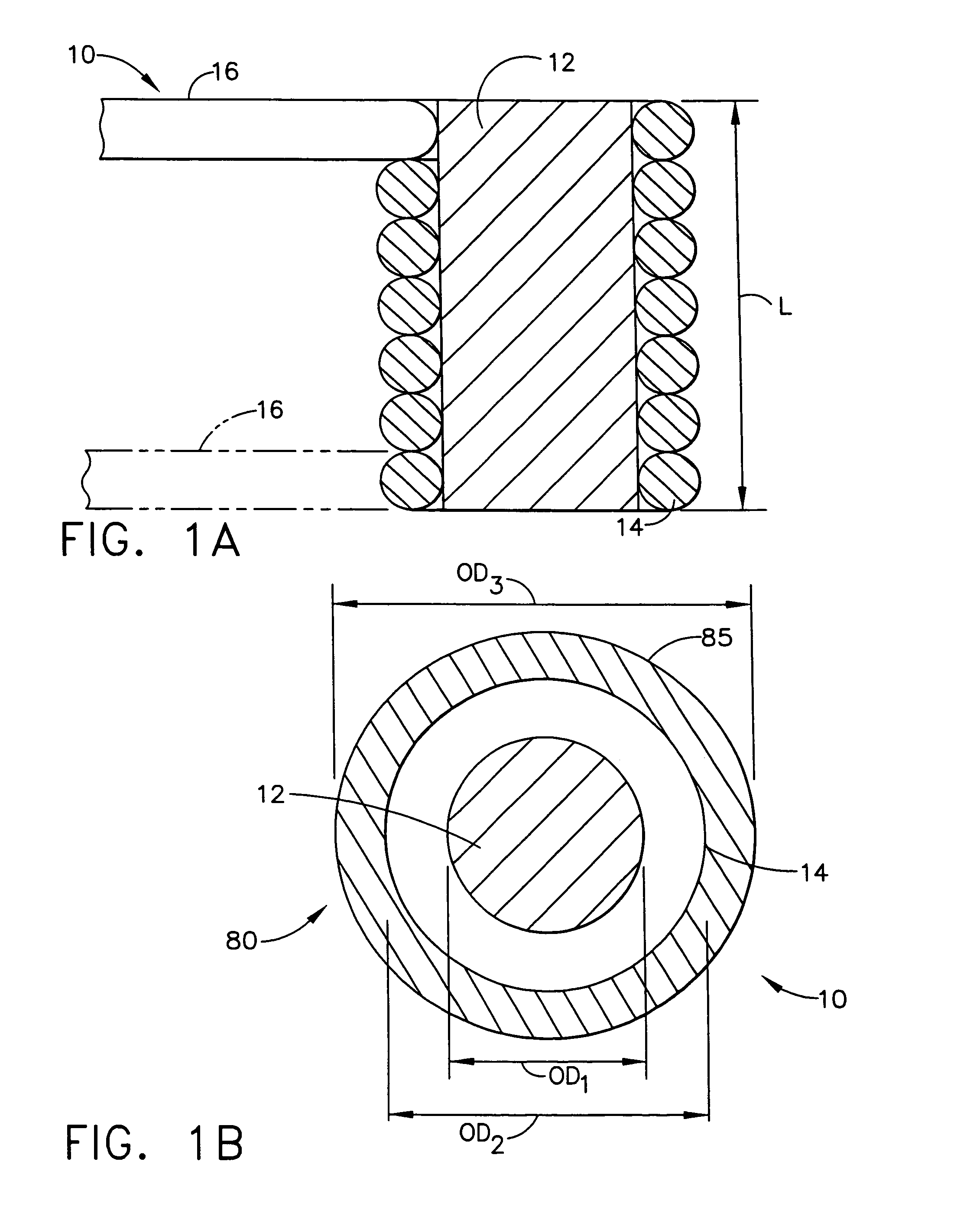

Medical device with position sensor having accuracy at high temperatures

ActiveUS7286868B2Maintain accuracySurgeryElectric/magnetic position measurementsCobaltMedical device

A medical device and position sensor combination for use in medical applications comprises a position sensor having a core made of a high permeable material The core material is made of a Wiegand effect material comprising a mixture of cobalt, vanadium, and iron. The position sensor has an outer diameter of approximately 0.4 mm and is used in a medical device having an outer diameter of approximately 0.67 mm.

Owner:BIOSENSE

Infusion pump

InactiveUS20060184123A1Improve communication performanceGeometric image transformationDrug and medicationsEngineeringInfusion pump

A drive mechanism for an infusion pump linearly moves a syringe plunger within a syringe barrel supported by the pump and includes: (i) a motor; (ii) a lead screw rotatably connected to the motor; (iii) a slide assembly having a threaded member supported thereon, the threaded member being associated with the lead screw; (iv) an arm having one end connected to the slide assembly and one end adapted to be engaged with the syringe plunger, and (v) the threaded member being rotatably biased in engagement with the lead screw, wherein upon rotation of the lead screw by the motor, the slide assembly linearly moves the arm wherein the arm is adapted to move the syringe plunger within the syringe barrel.

Owner:BAXTER INT INC

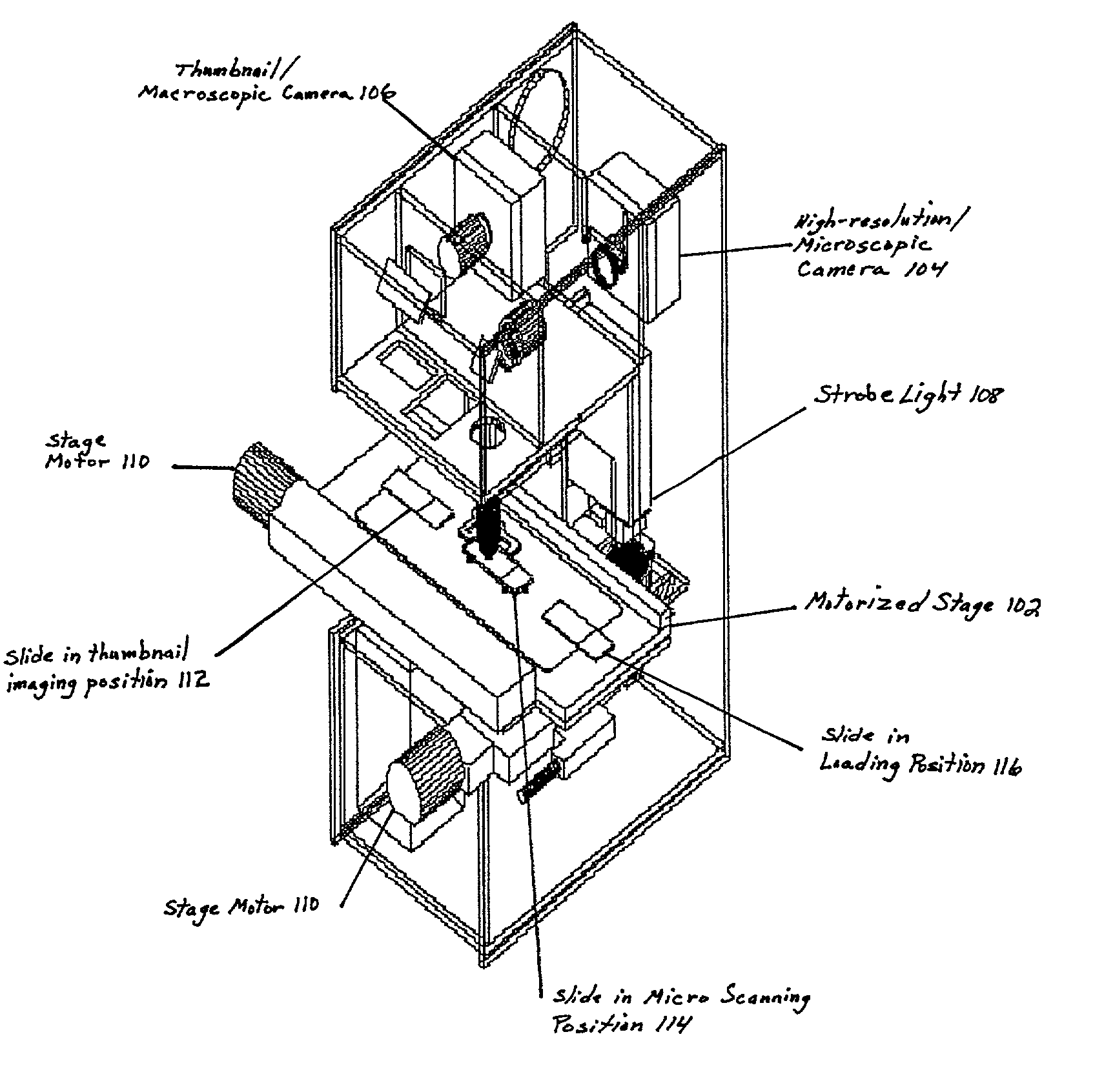

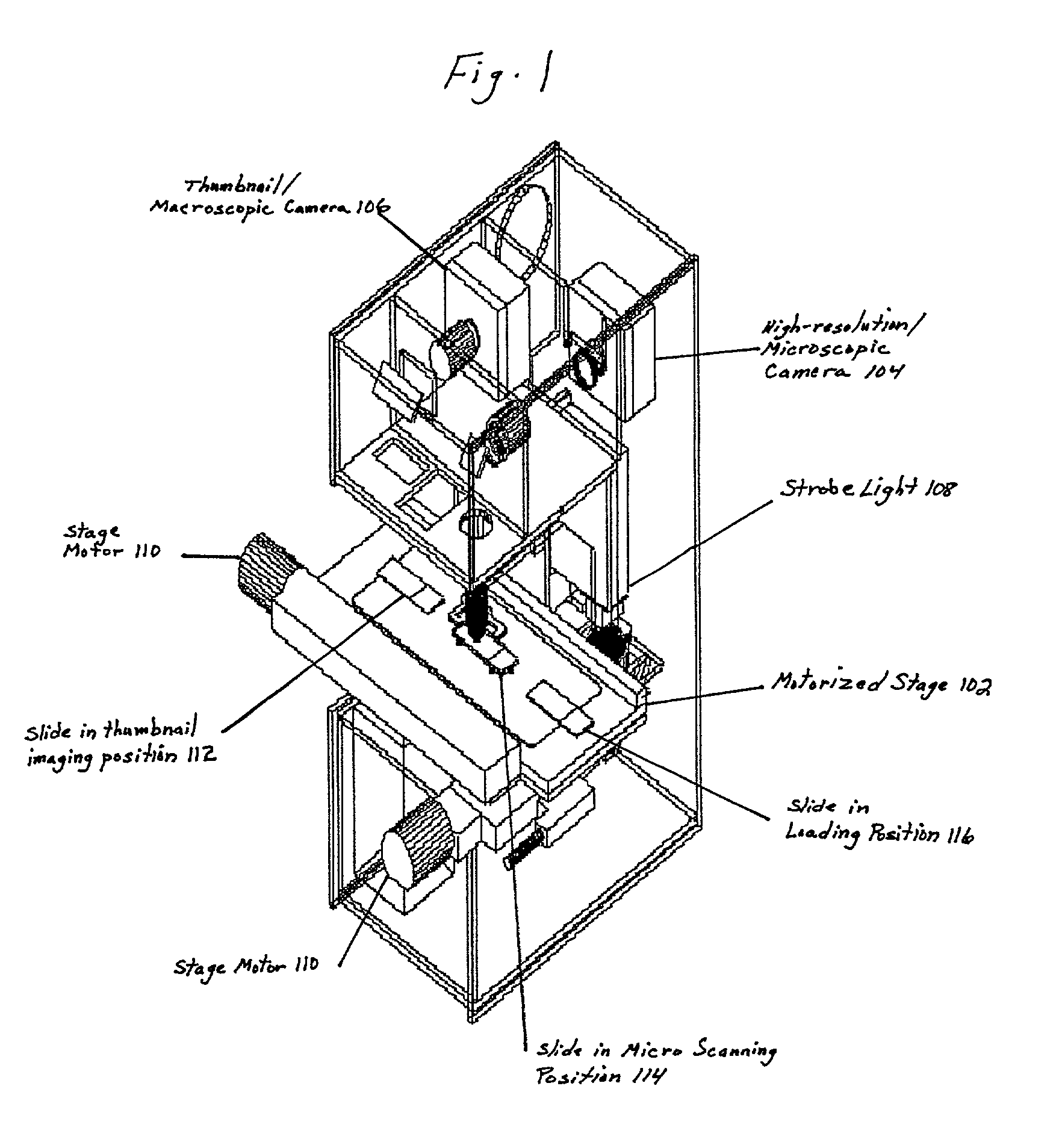

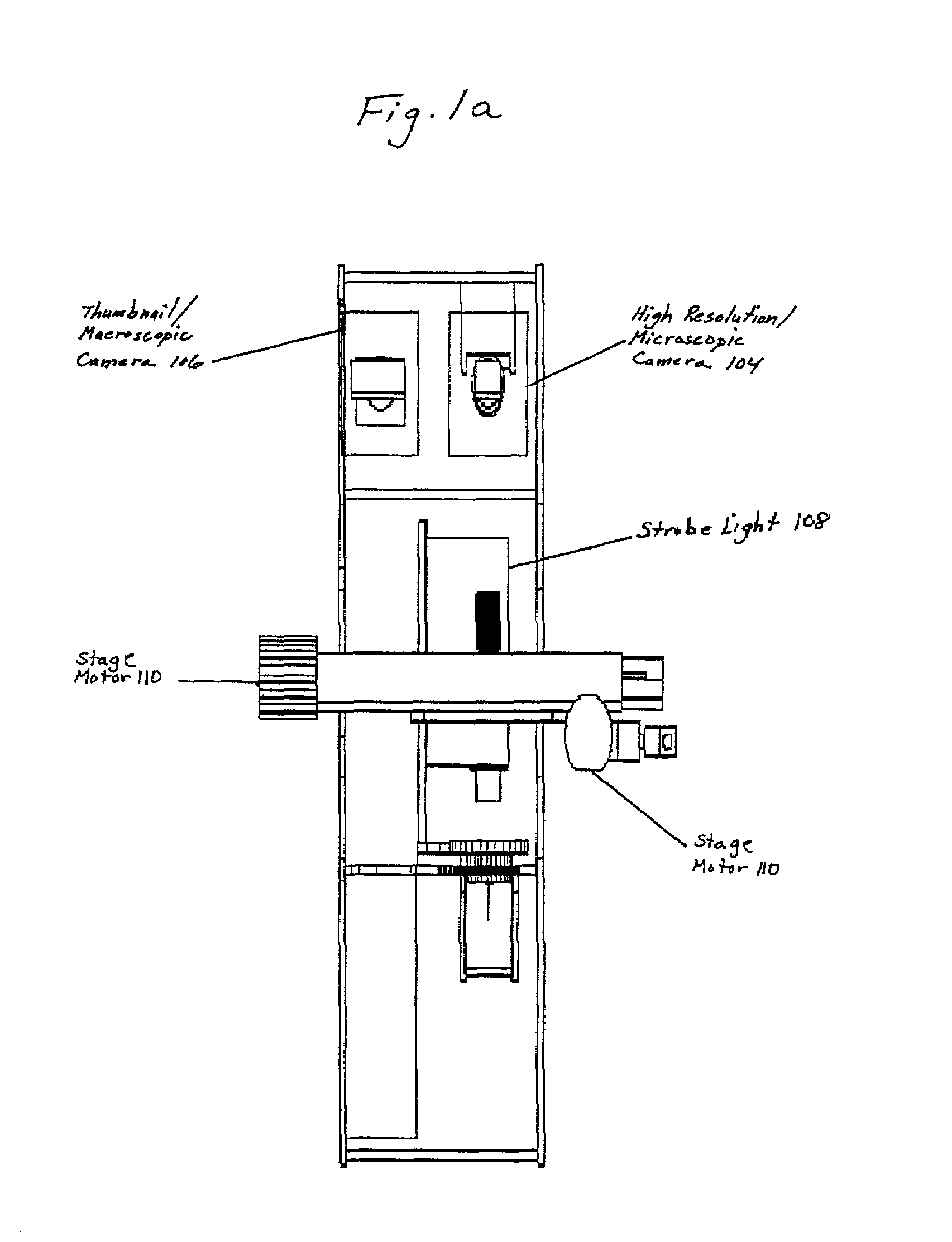

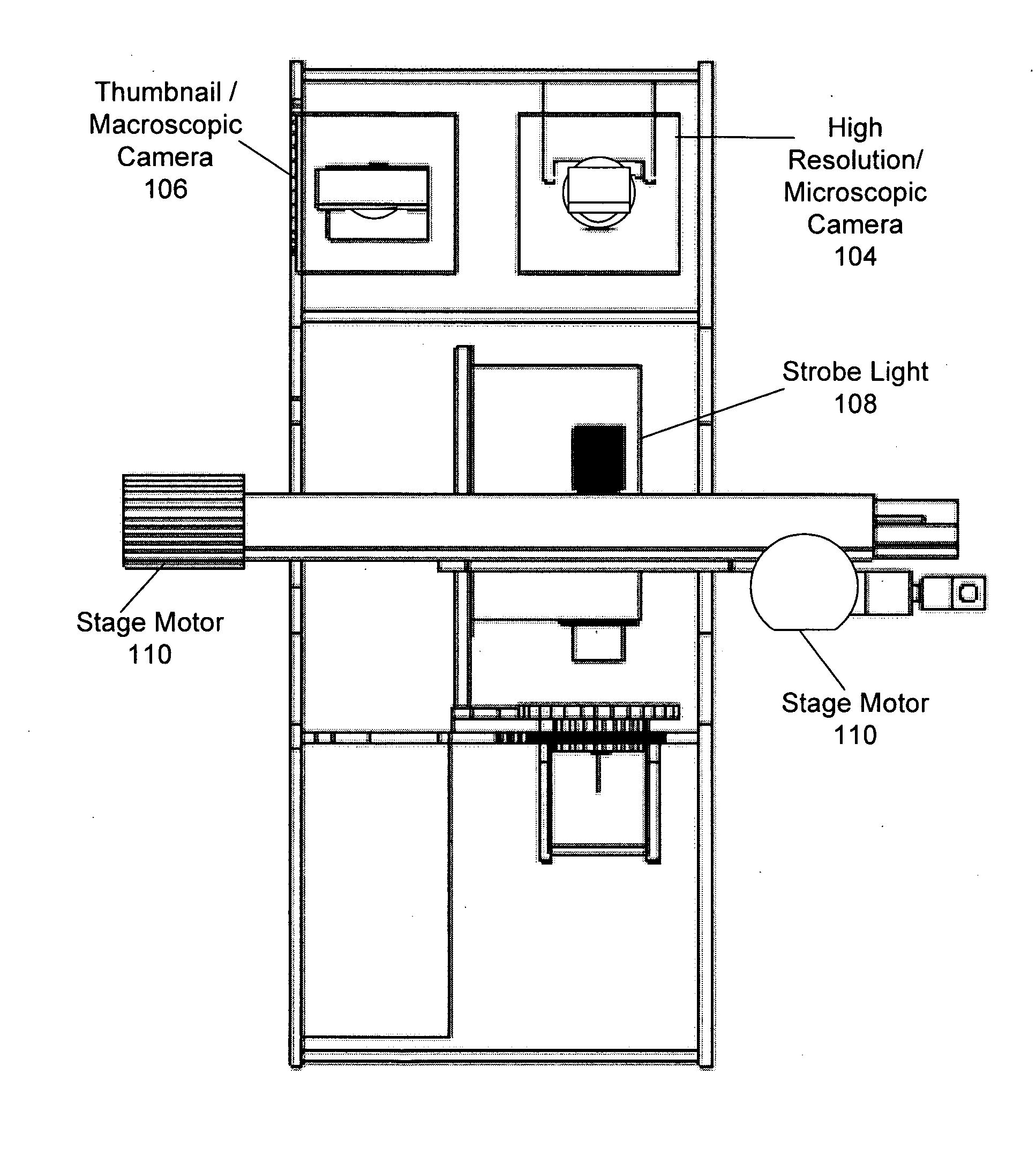

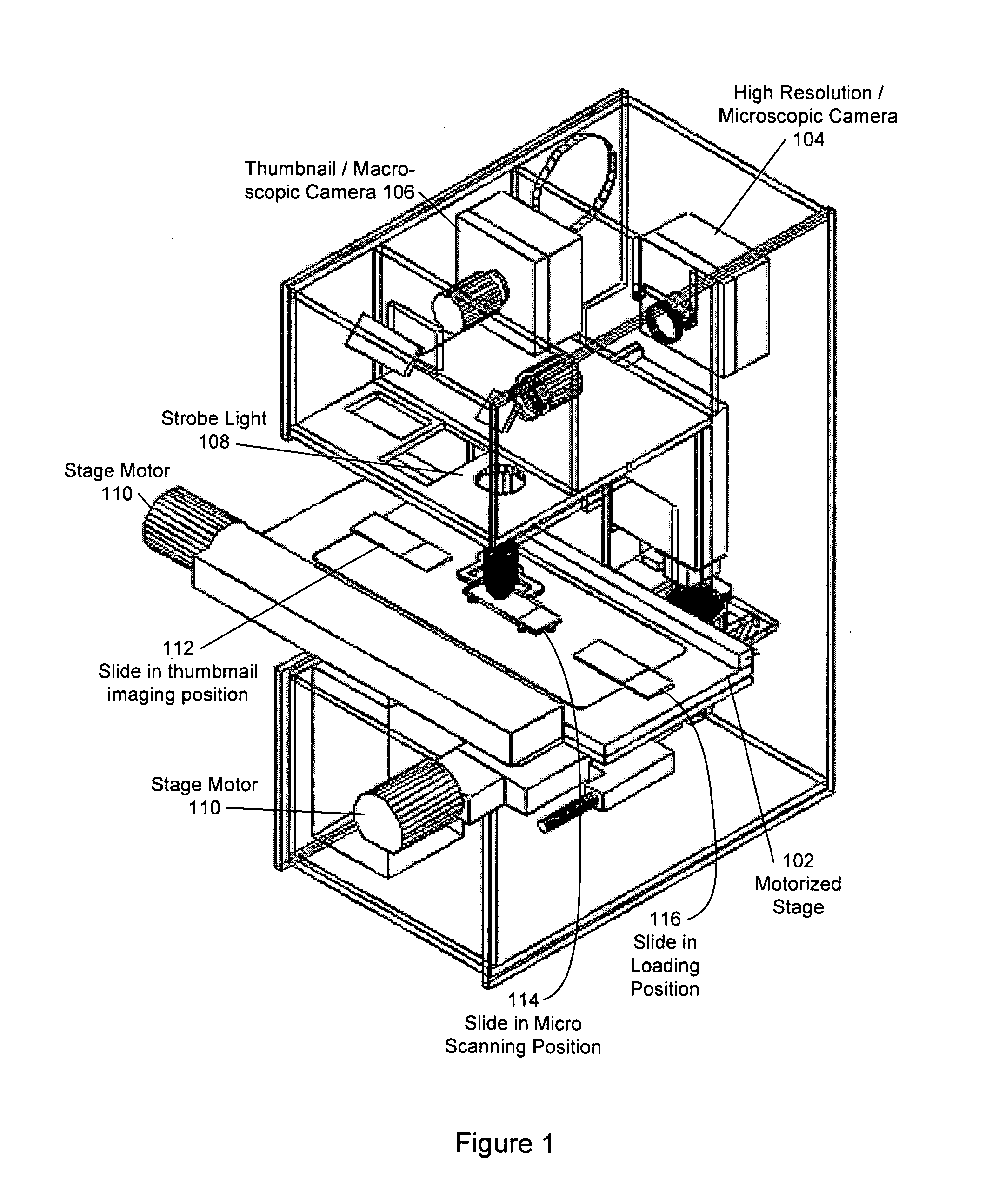

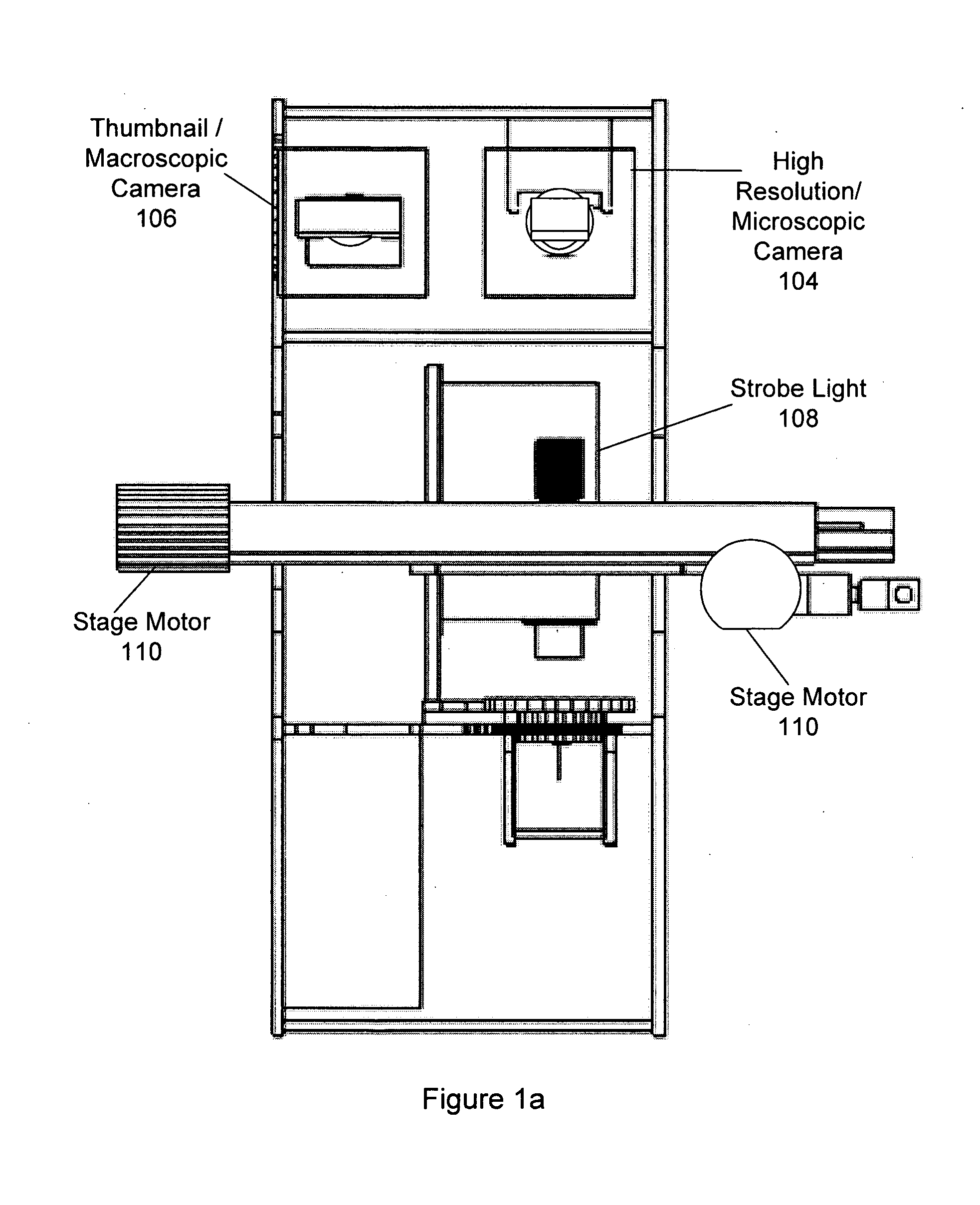

System for creating microscopic digital montage images

InactiveUS7155049B2Precise alignmentDecreasing expense and precisionImage analysisElectric/magnetic position measurementsImage conversionImaging equipment

Owner:CARL ZEISS MICROSCOPY GMBH

Multi-sensor distortion detection method and system

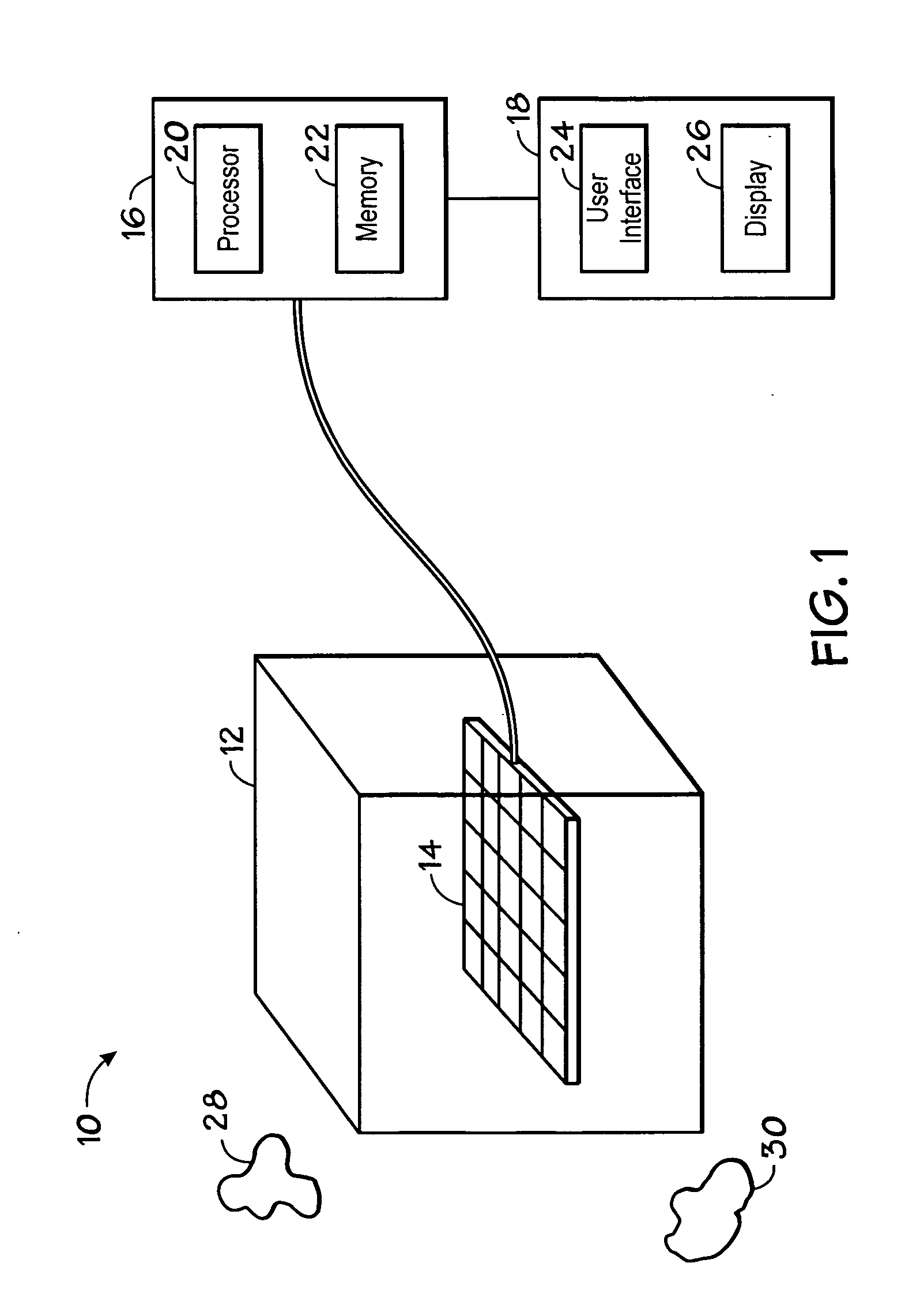

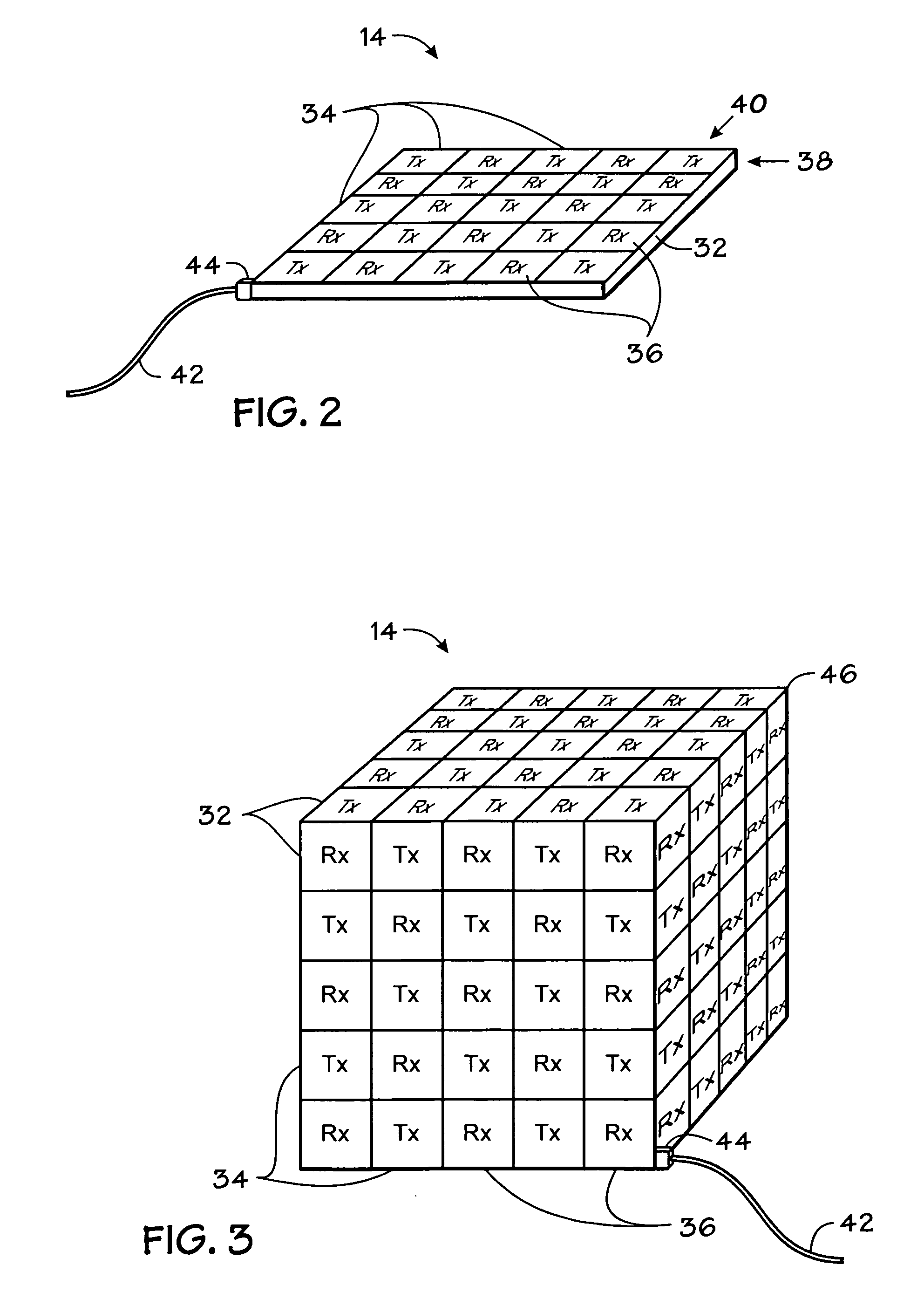

InactiveUS20080183064A1Electric/magnetic position measurementsUsing electrical meansEngineeringFixed position

A method for detecting EM field distorting includes sampling a sensor assembly positioned within a volume of interest to acquire measurements of EM fields within the volume of interest, and monitoring the measurements to detect EM field distortion within the volume of interest. The sensor assembly includes a set of EM transmitters and a set of EM receivers fixed thereon. A system for detecting EM field distorting includes a sensor assembly for positioning within a volume of interest, wherein the EM sensor assembly comprises a set of EM receivers, and a set of EM transmitters, wherein the EM receivers and the EM transmitters are disposed at fixed locations on the sensor assembly. The system further includes a tracker configured to sample the sensor assembly to acquire measurements of EM fields generated by the EM transmitters, and monitor the measurements to detect EM field distortion within the volume of interest.

Owner:GENERAL ELECTRIC CO

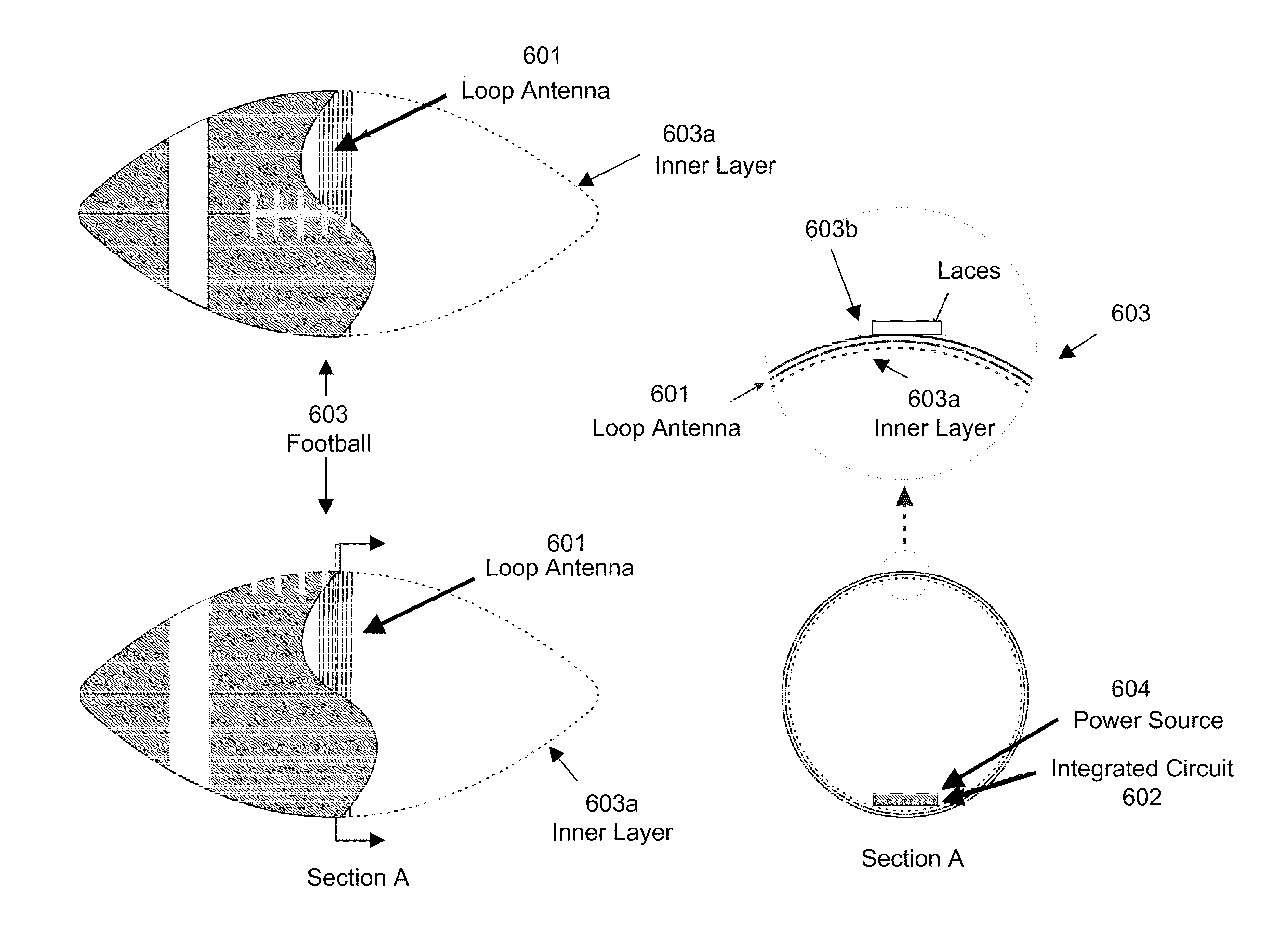

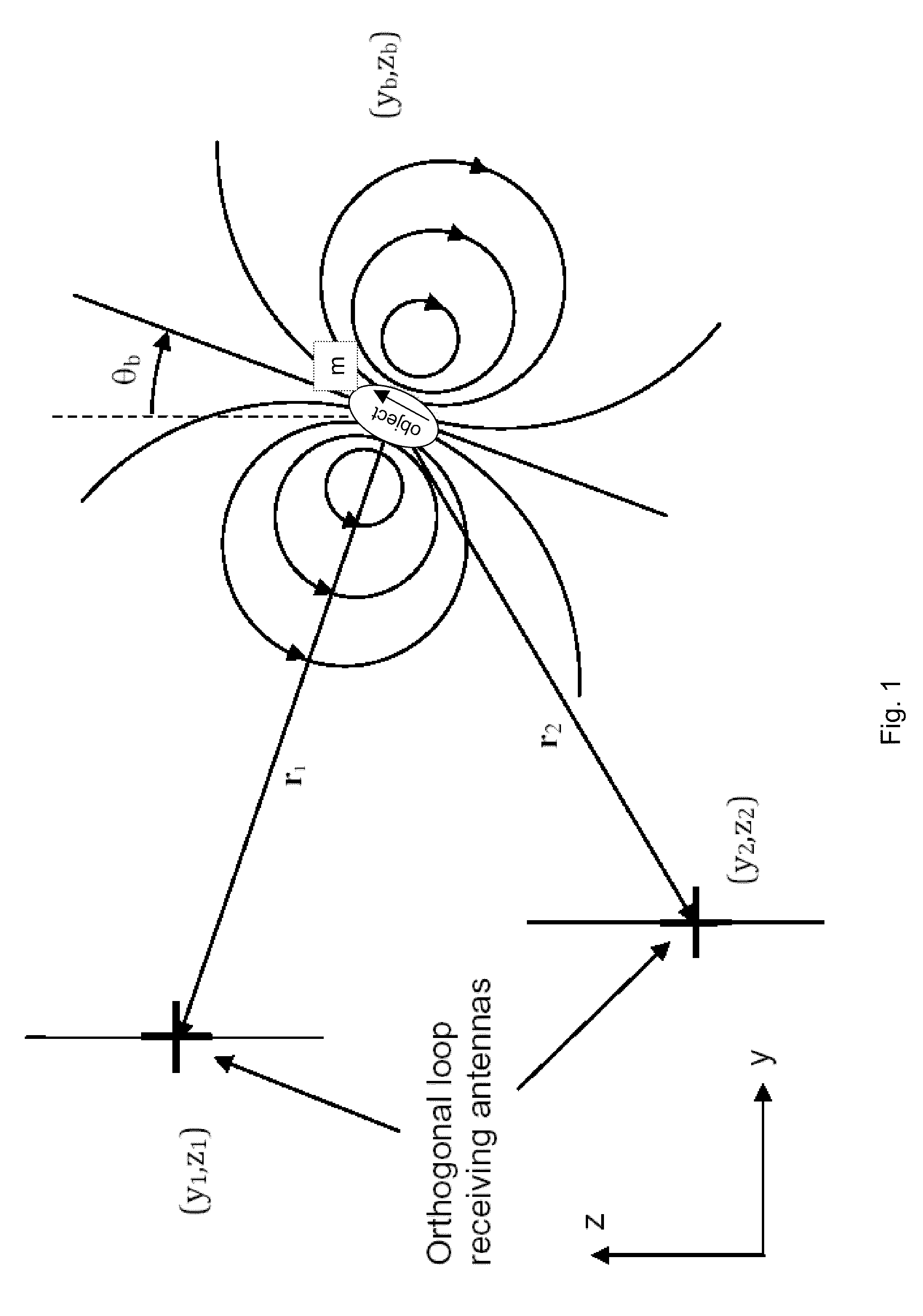

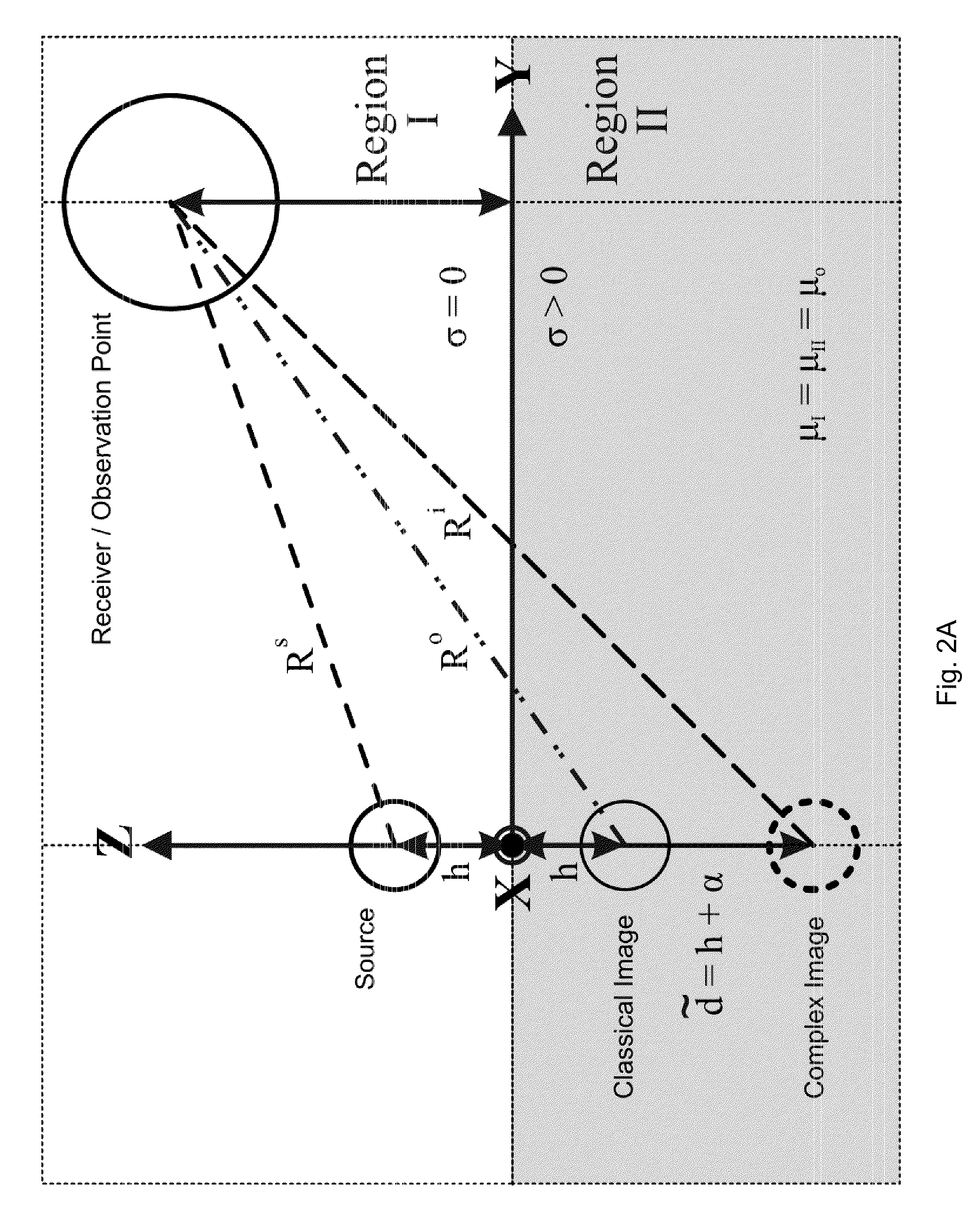

Systems and Methods for Position Tracking Using Magnetoquasistatic Fields

InactiveUS20110316529A1Gymnastic exercisingElectric/magnetic position measurementsLocation trackingNatural state

Embodiments of the invention broadly contemplate systems, methods, apparatuses and program products that provide position tracking using a simple, low frequency oscillator that is attached to an object to be tracked, and one or more receiving stations that are placed around the area in which the object moves. Embodiments of the invention enable position tracking of the object using light weight equipment which minimally impacts the object's natural state.

Owner:DISNEY ENTERPRISES INC +1

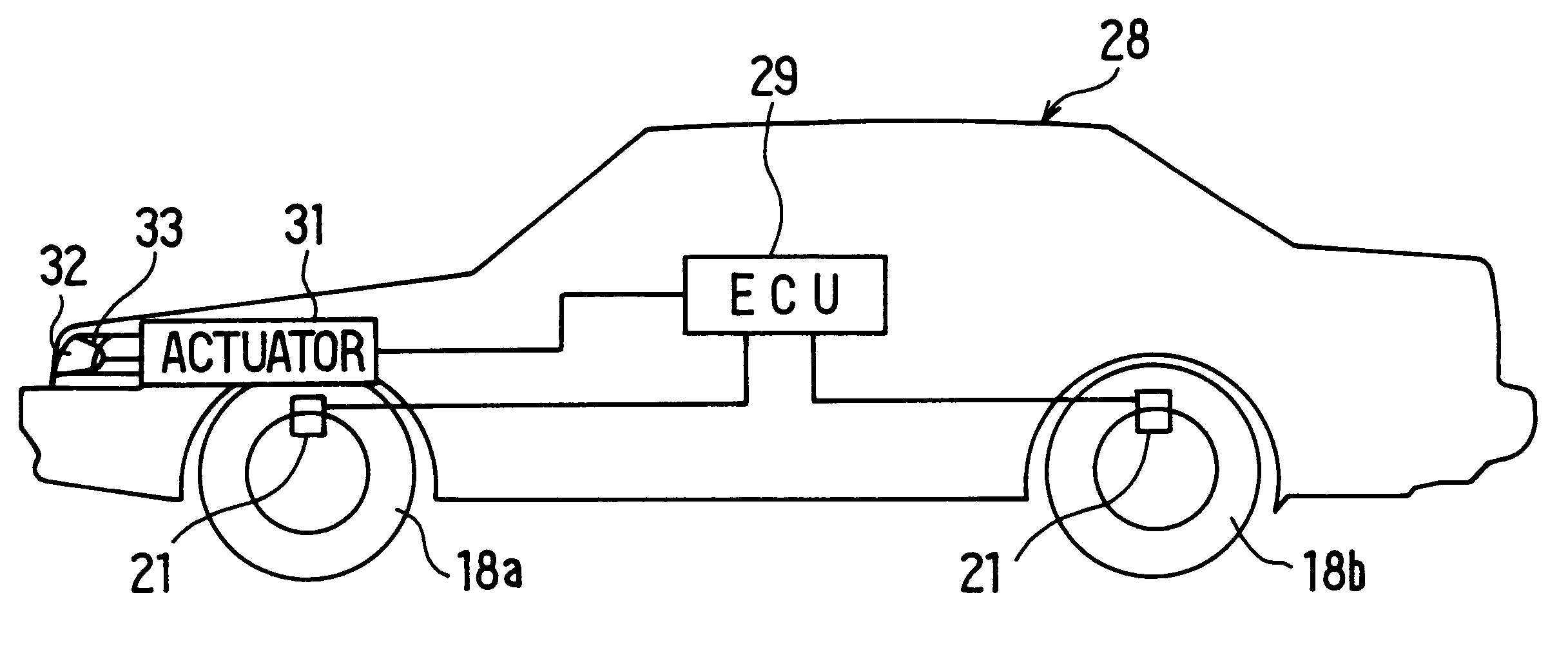

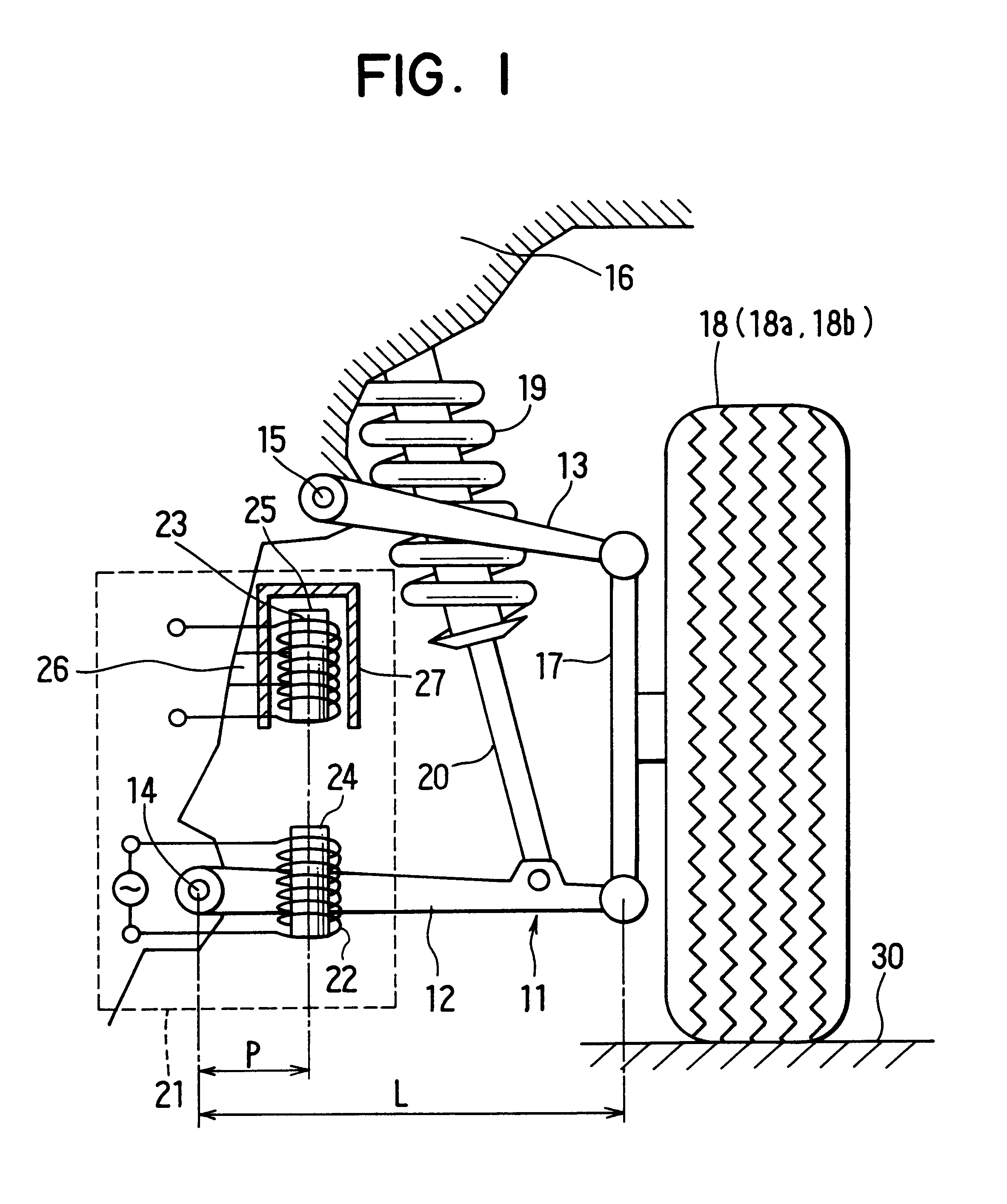

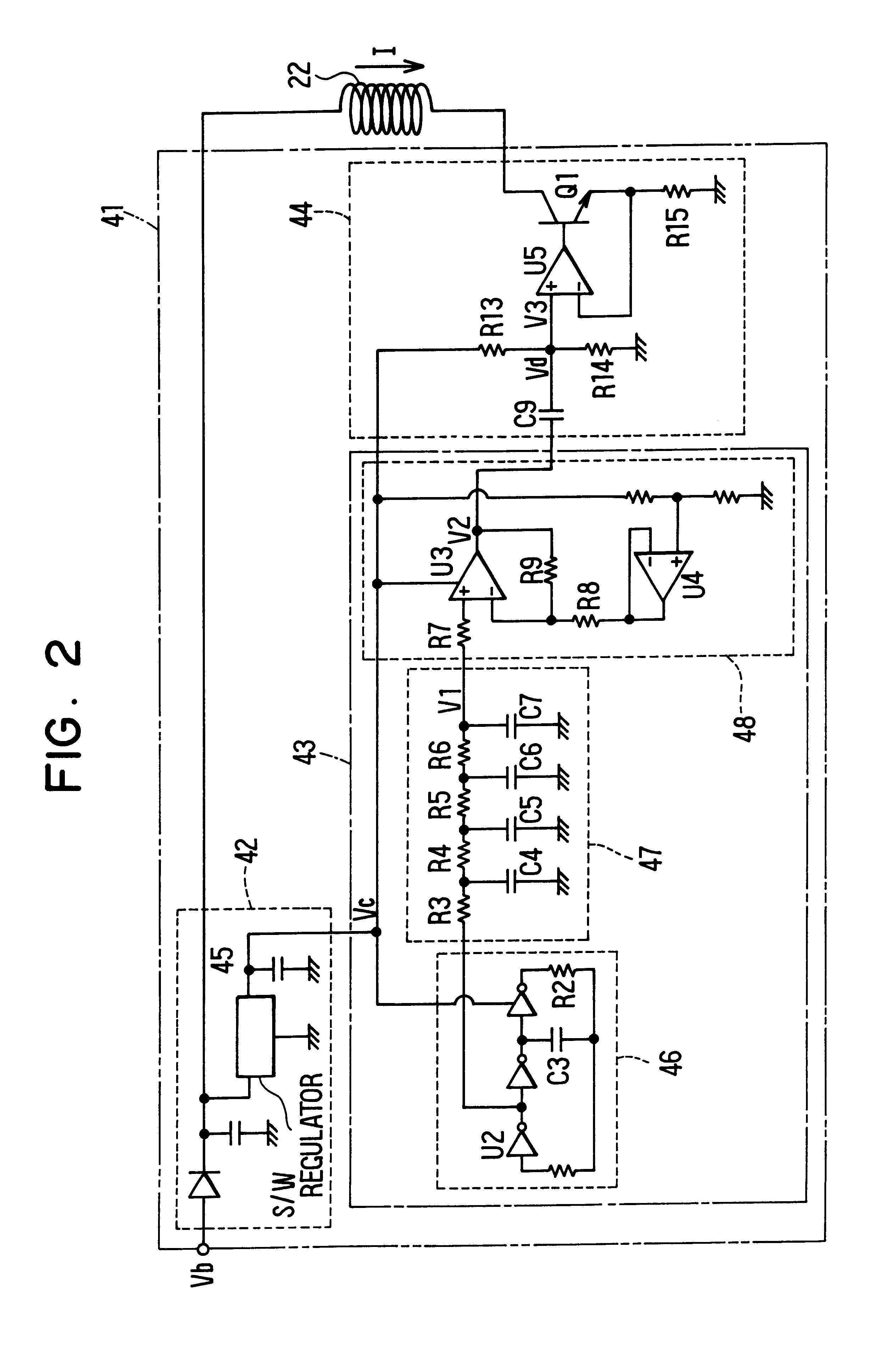

Height sensor and vehicular headlight beam axis leveling apparatus

InactiveUS6234654B1Low costSmall sizePoint-like light sourcePortable electric lightingEngineeringVoltage

A height sensor has an exciting coil for generating an alternating magnetic field and a pickup coil for detecting the magnetic field. The exciting coil is fixed to a suspension arm and the pickup coil is fixed to a body so as to face each other. Distance between these coils is determined by a voltage outputted from the pickup coil, and a height of the vehicle is calculated from the distance between these coils by taking the mounting position of the pickup coil on the suspension arm into account. The height sensor is readily fixed and a detection accuracy is improved by setting the mounting position of the pickup coil in a range of {fraction (1 / 10)} to ½ of a length of the suspension arm from a connecting portion between the suspension arm and the body.

Owner:DENSO CORP

Non-contact position sensor

InactiveUS6160395AMagnetic-field-controlled resistorsElectric/magnetic position measurementsEngineeringContact position

A core of semi-permeable material forms a magnetic circuit having air gaps. A movable magnet provides flux in a first portion and a second portion of the magnetic circuit with the location of the magnet determining the portion. Magnetoresistive sensors in the air gaps provide signals related to the position of the magnet.

Owner:HONEYWELL INC

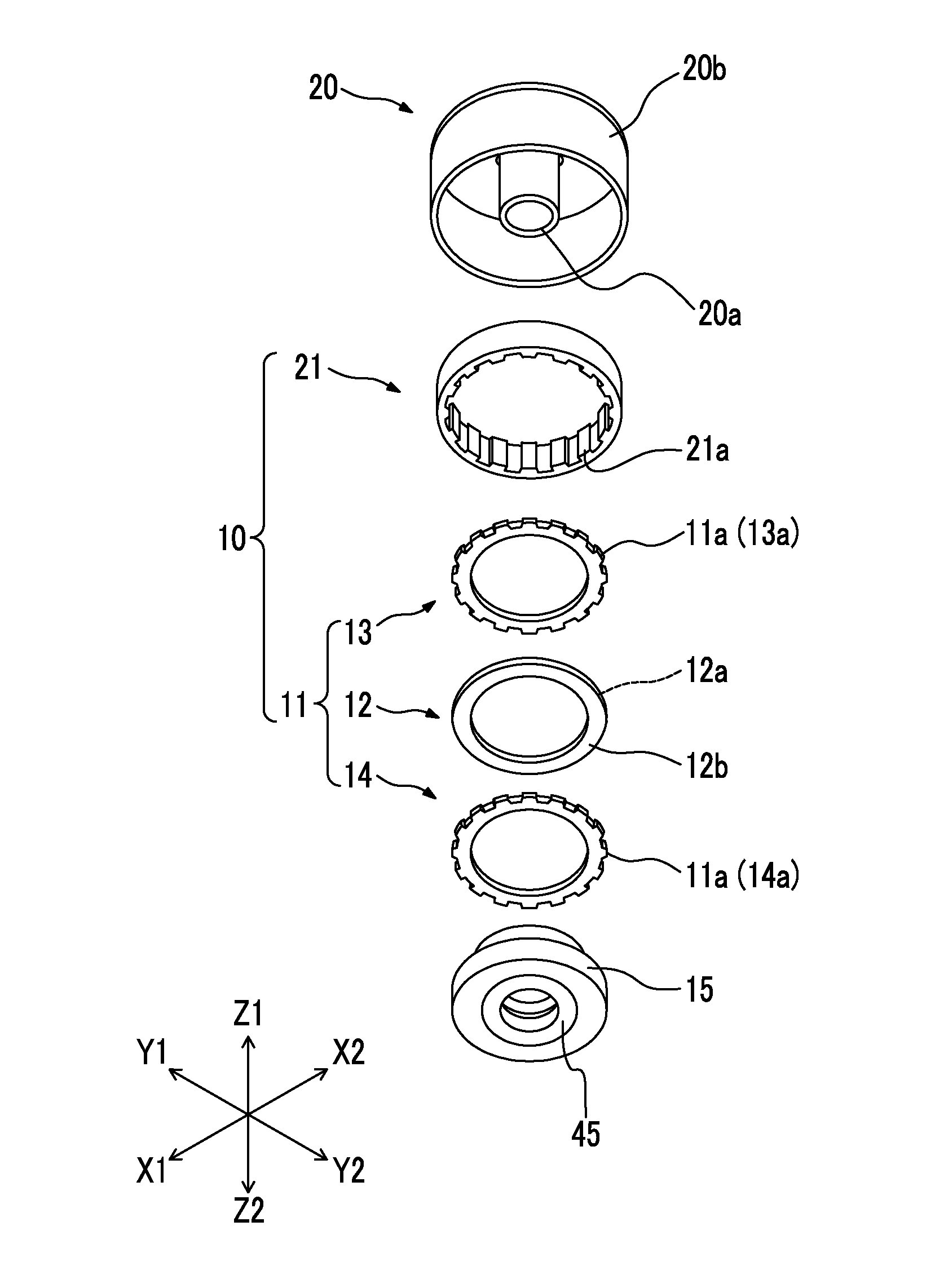

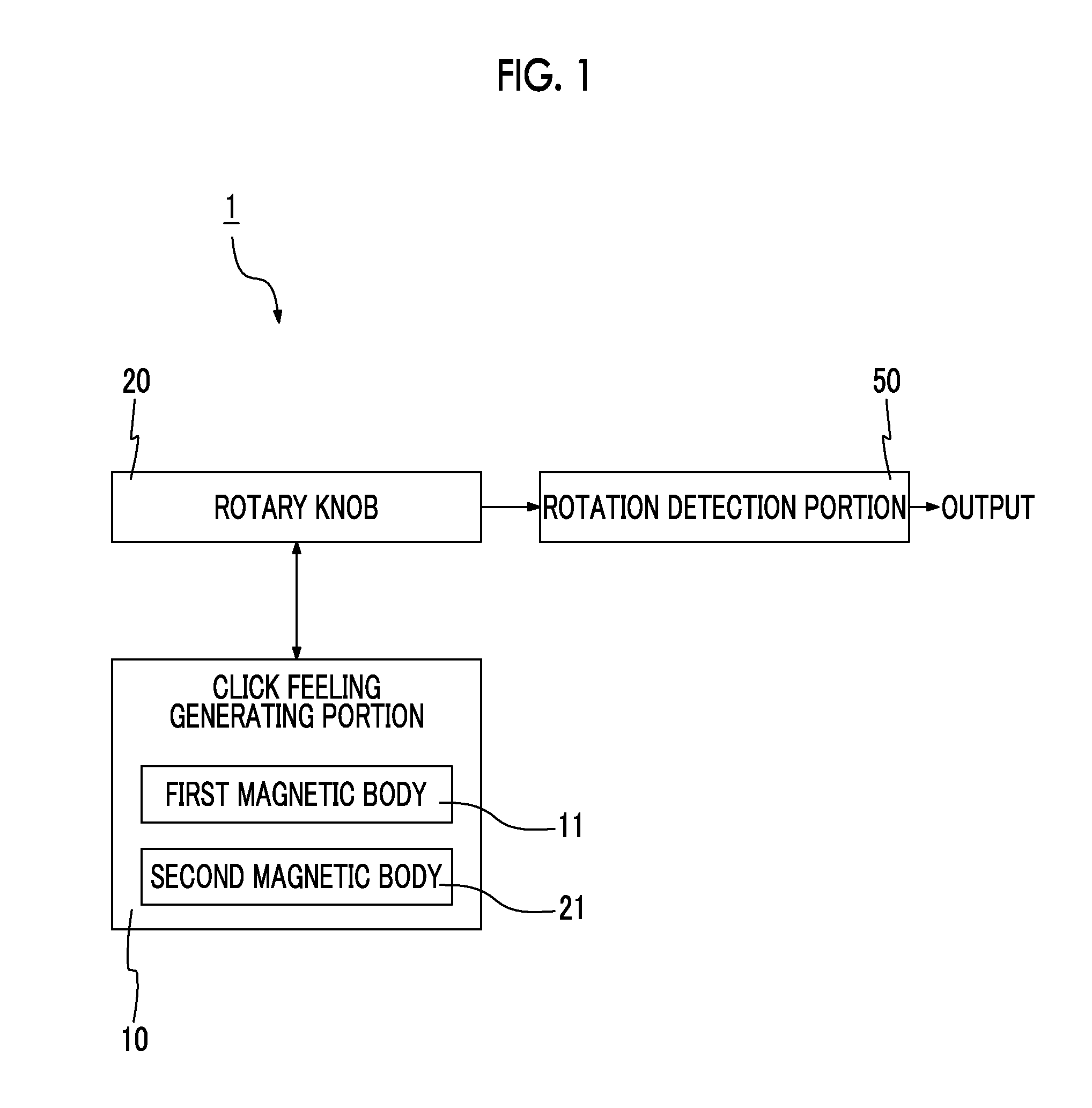

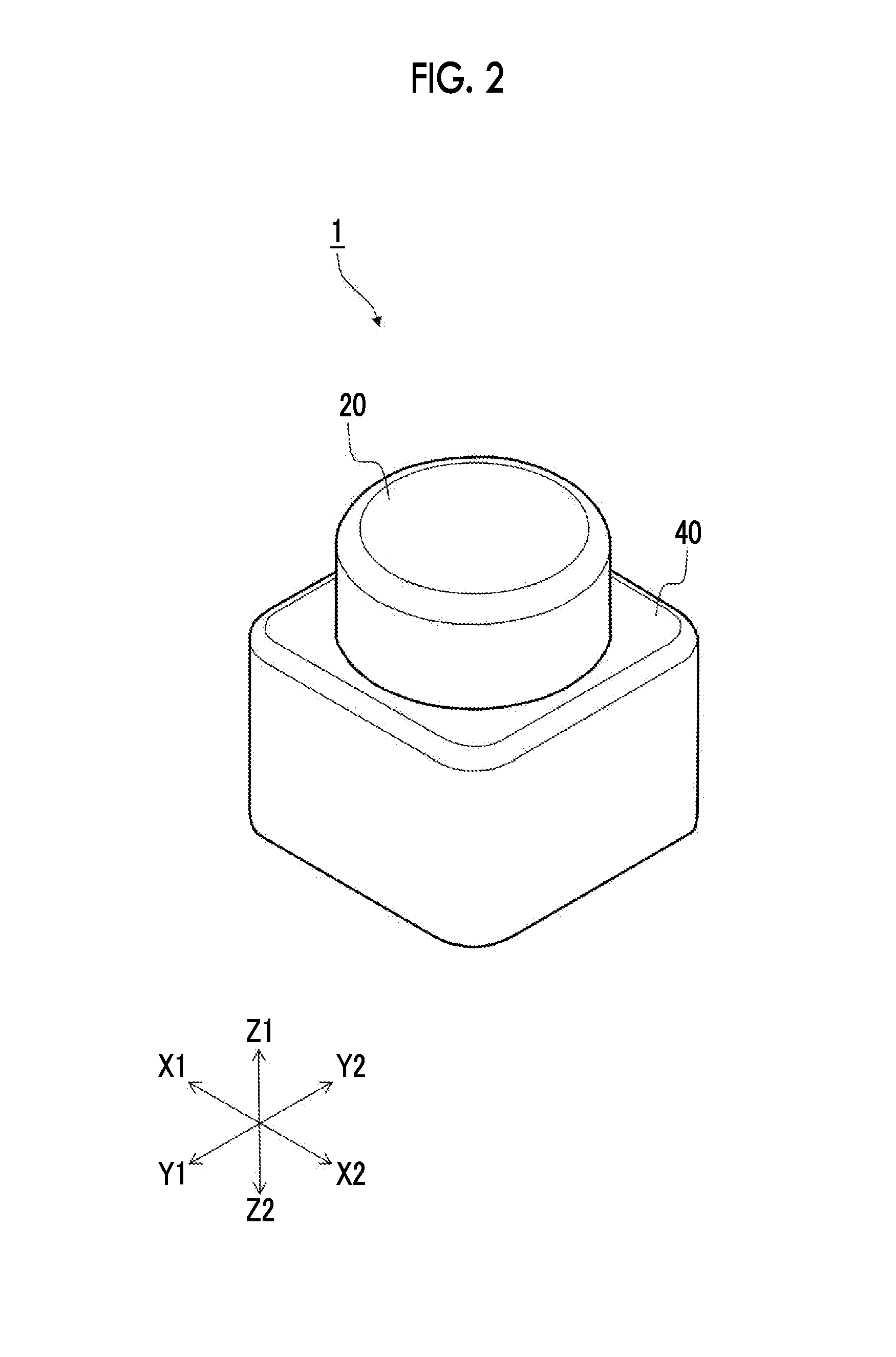

Rotary input device

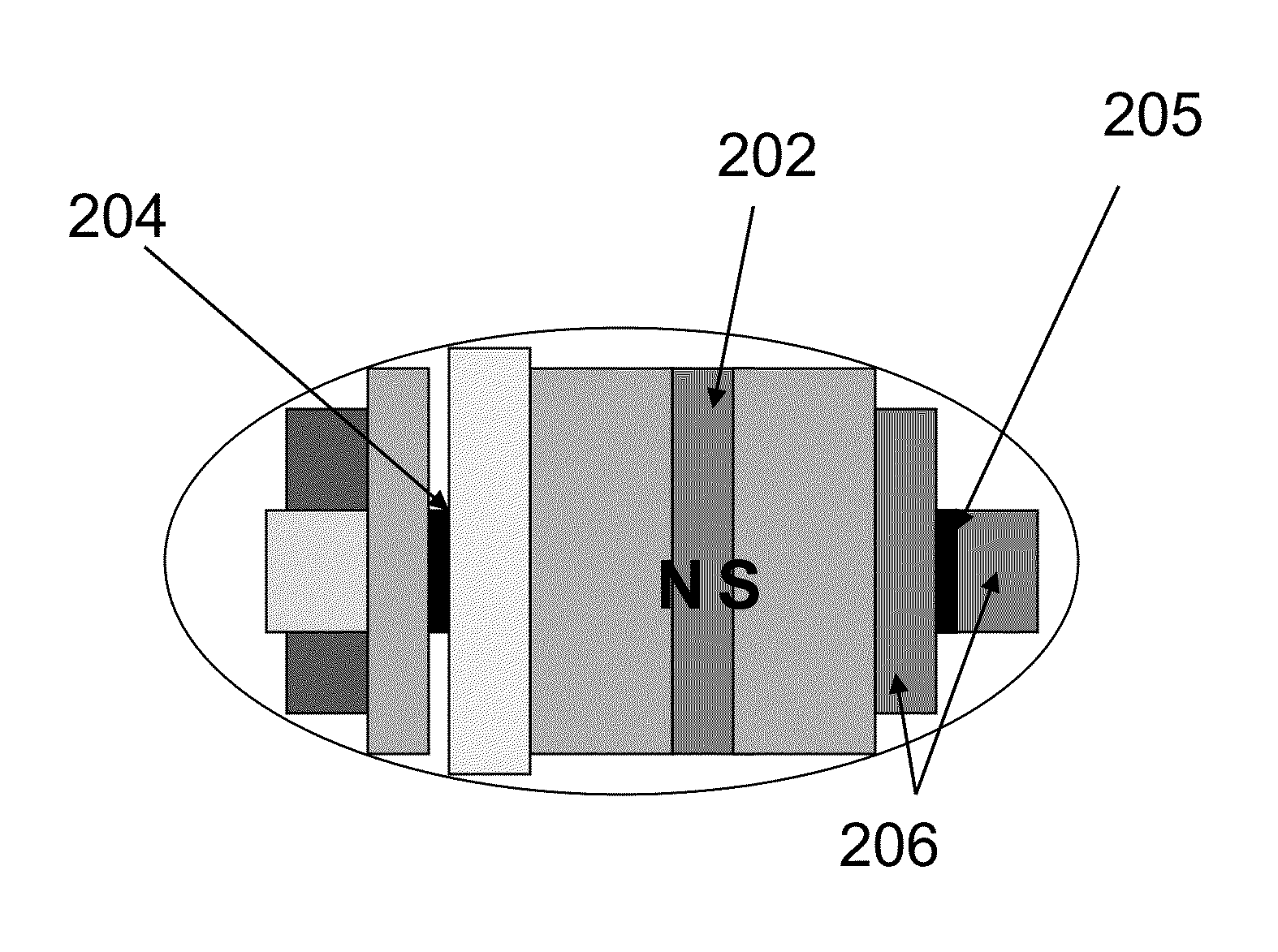

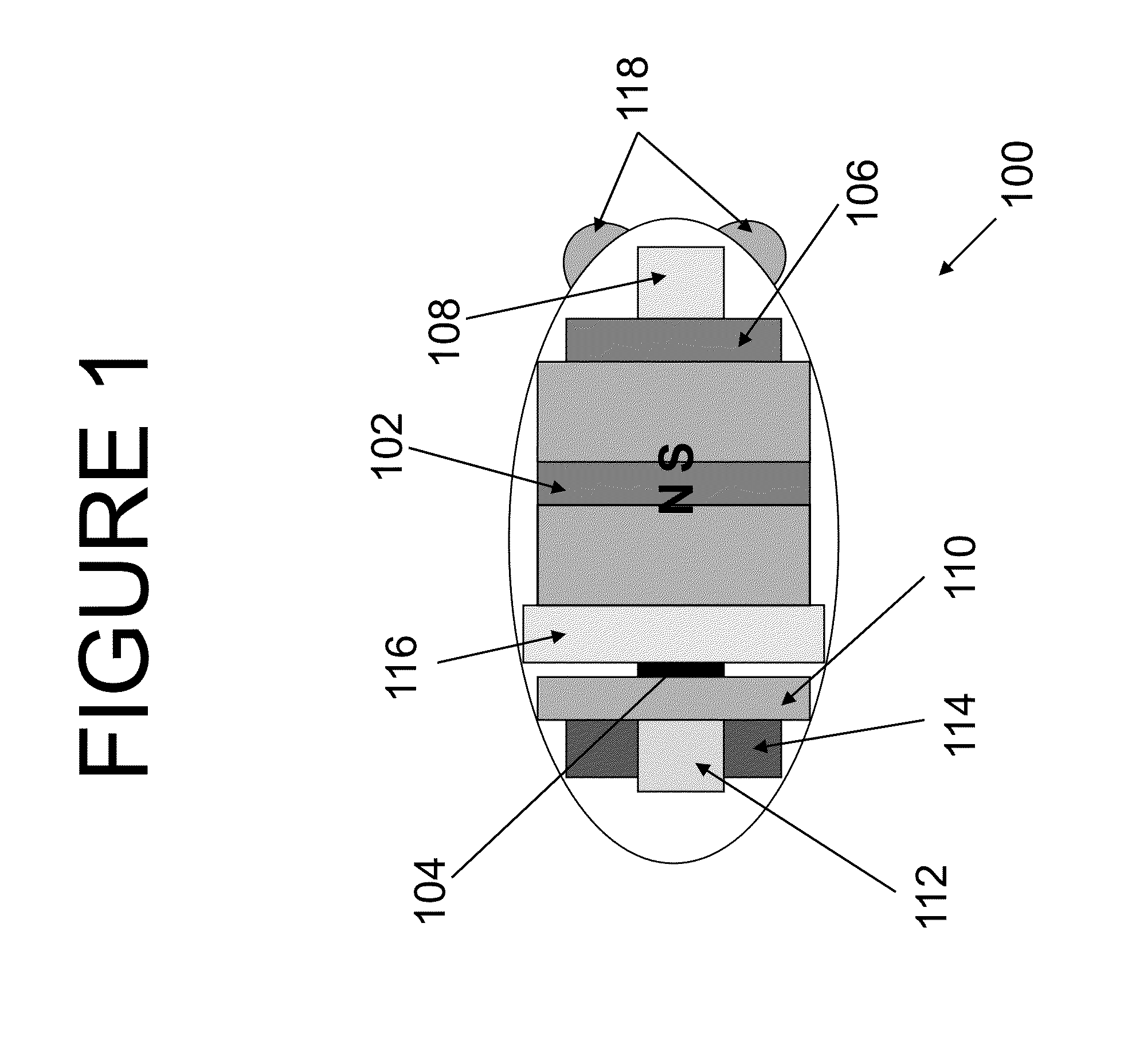

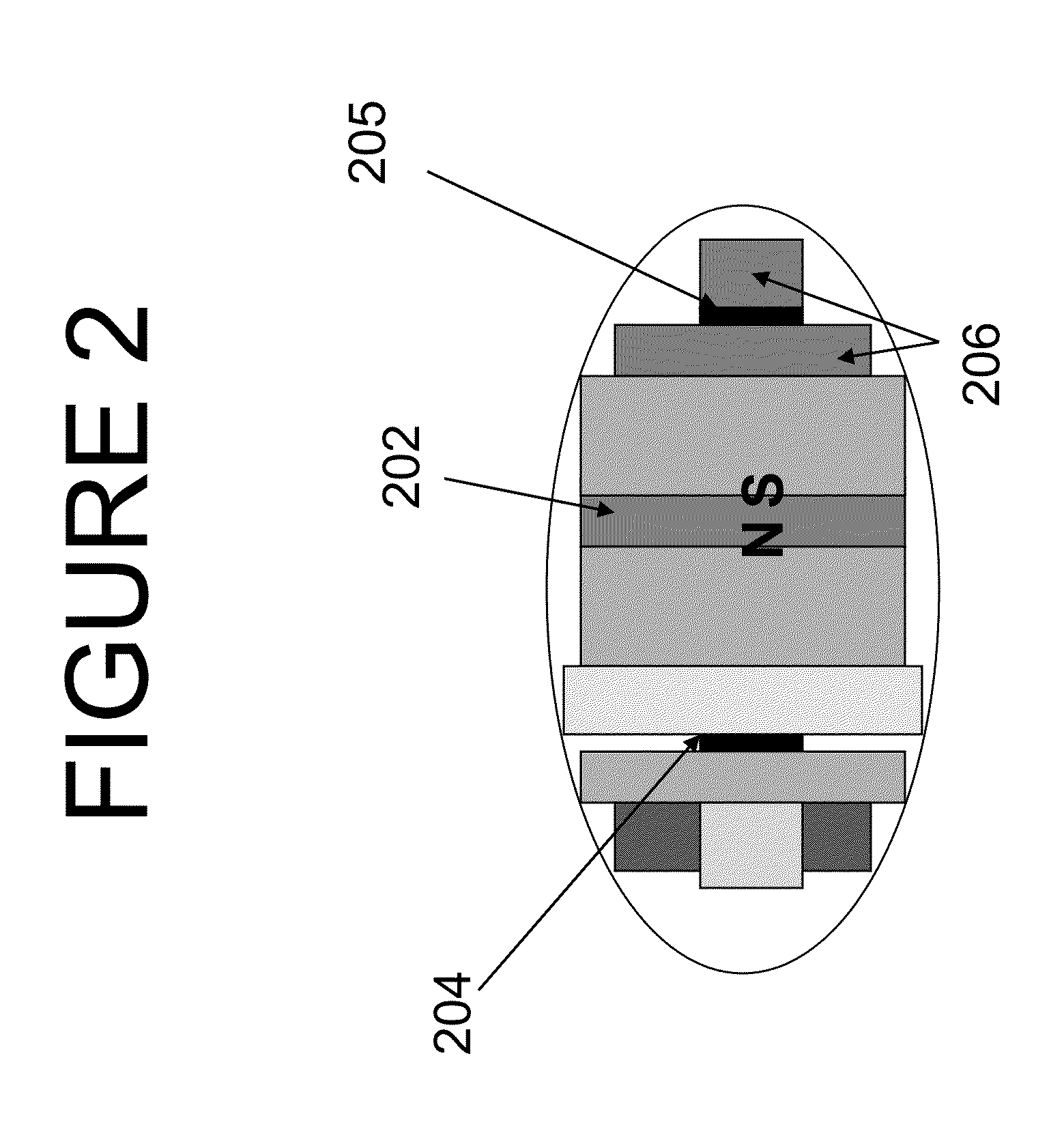

ActiveUS9437357B2Low costFeel goodManual control with multiple controlled membersControlling membersLower poleMagnet

A rotary input device includes a first annular magnetic body in which a plurality of outward protrusions protruding toward an outside in a radial direction are disposed along a circumferential direction, a second annular magnetic body in which a plurality of inward protrusions formed to oppose the outward protrusions of the first magnetic body are disposed along a circumferential direction, and a rotary knob configured to relatively rotate the first magnetic body and the second magnetic body. The first magnetic body includes a magnet in which opposing surfaces facing each other are vertically disposed and which is magnetized to two poles of an upper pole and a lower pole including the opposing surfaces, a pair of yokes that interposes the opposing surfaces of the magnet vertically, and the outward protrusion formed on the pair of yokes.

Owner:ALPS ALPINE CO LTD

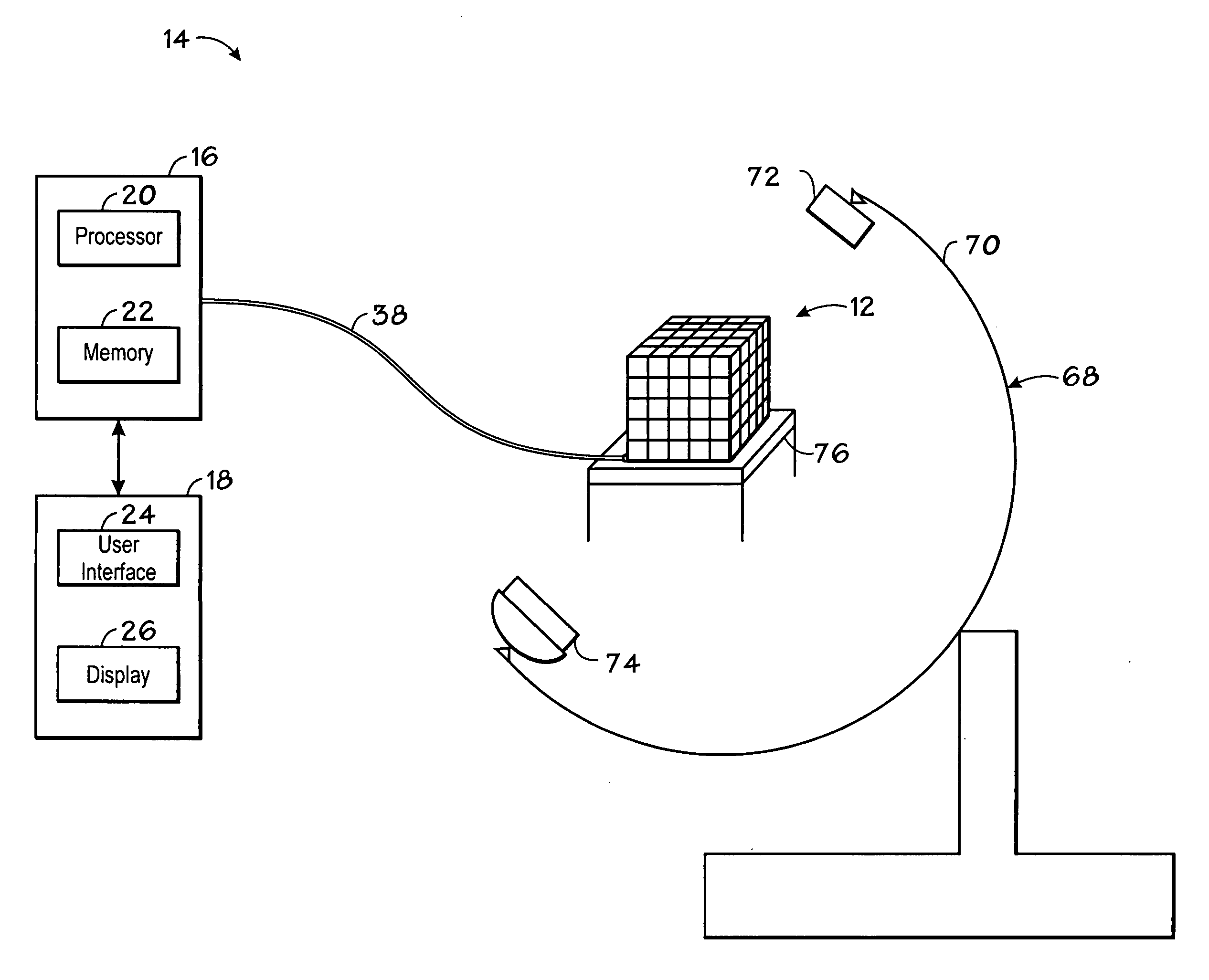

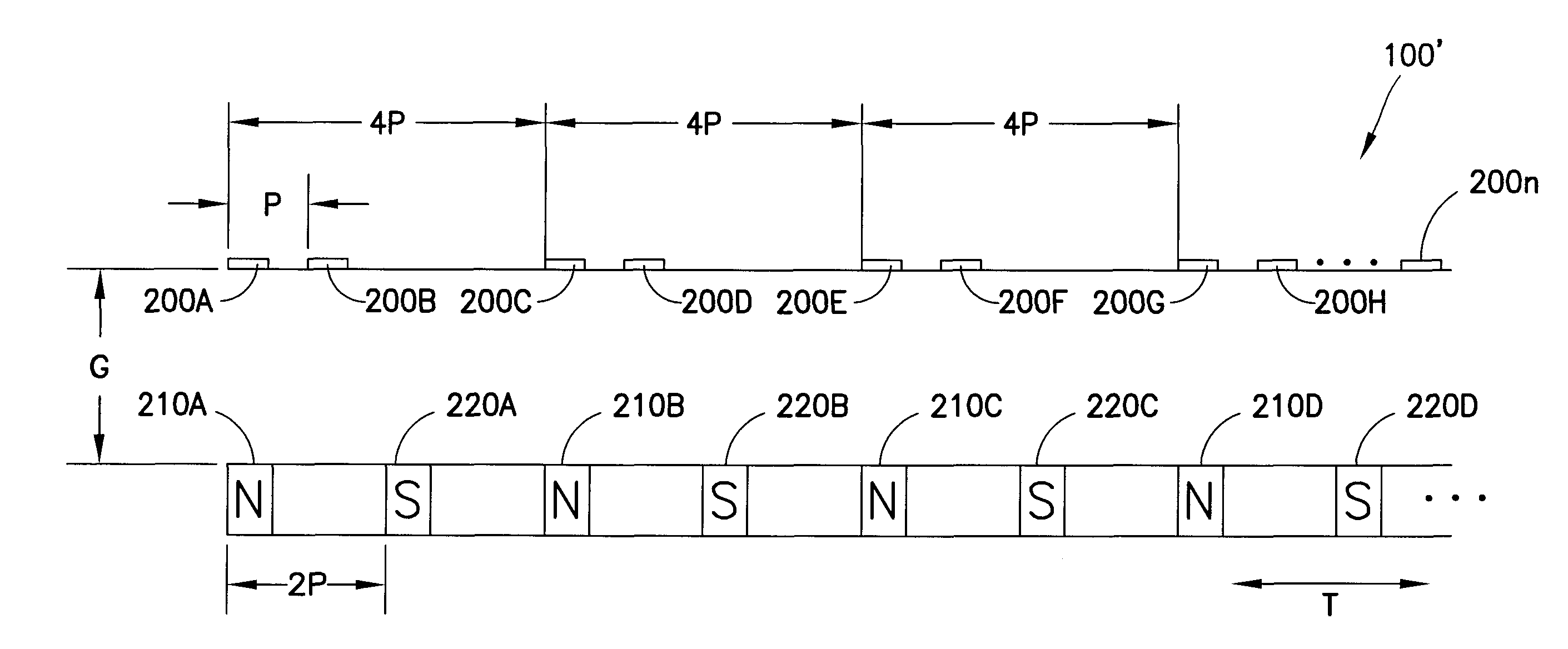

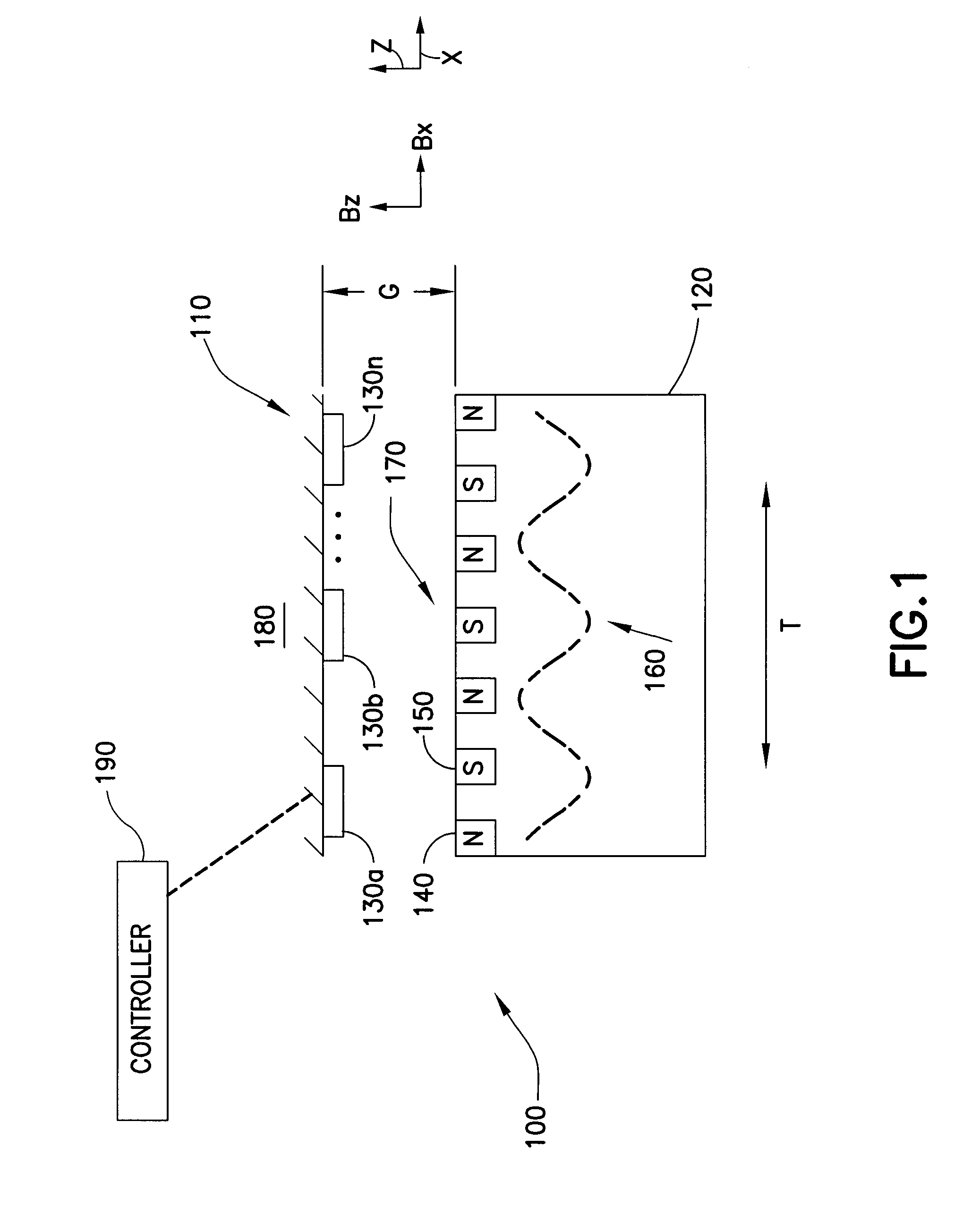

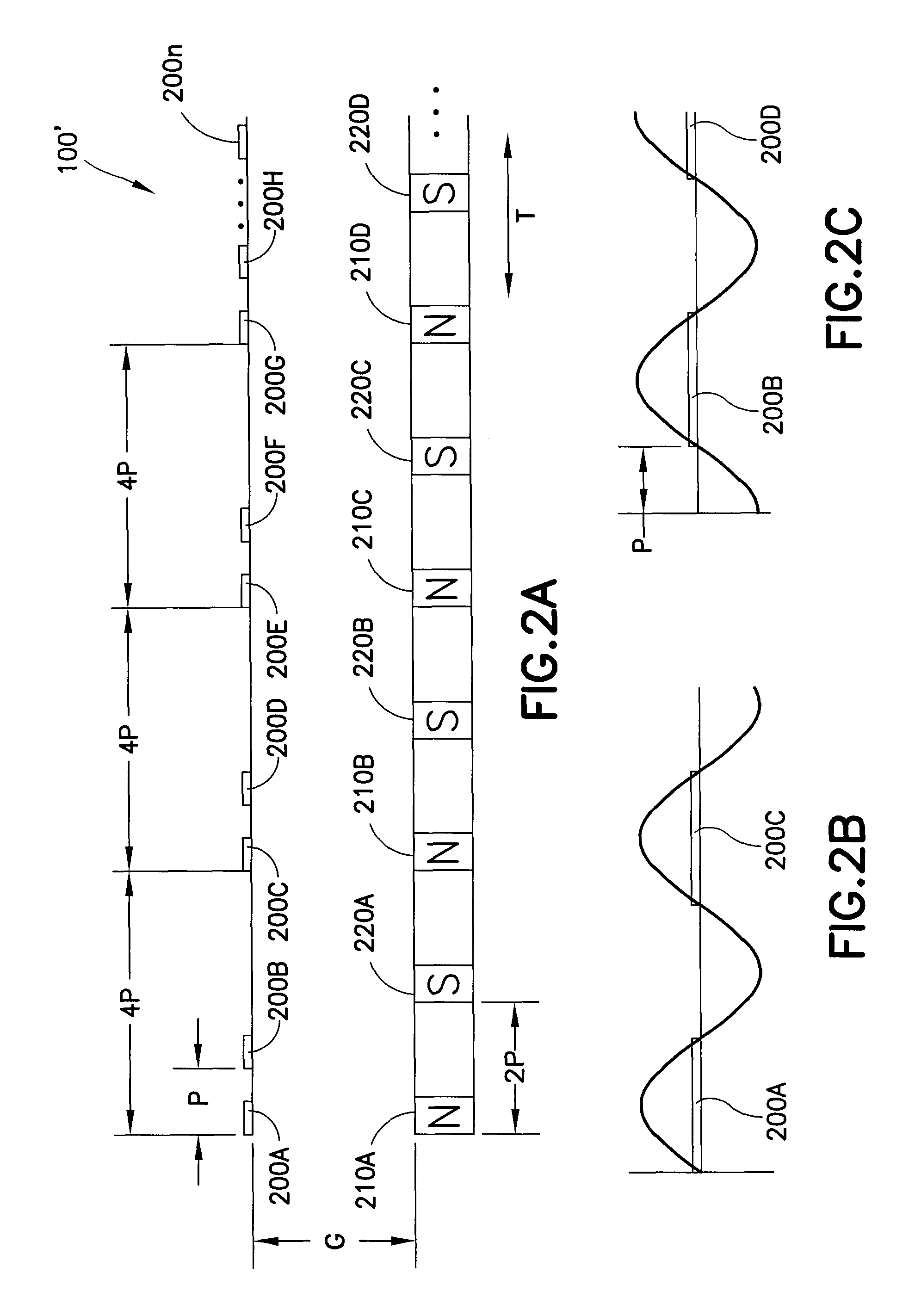

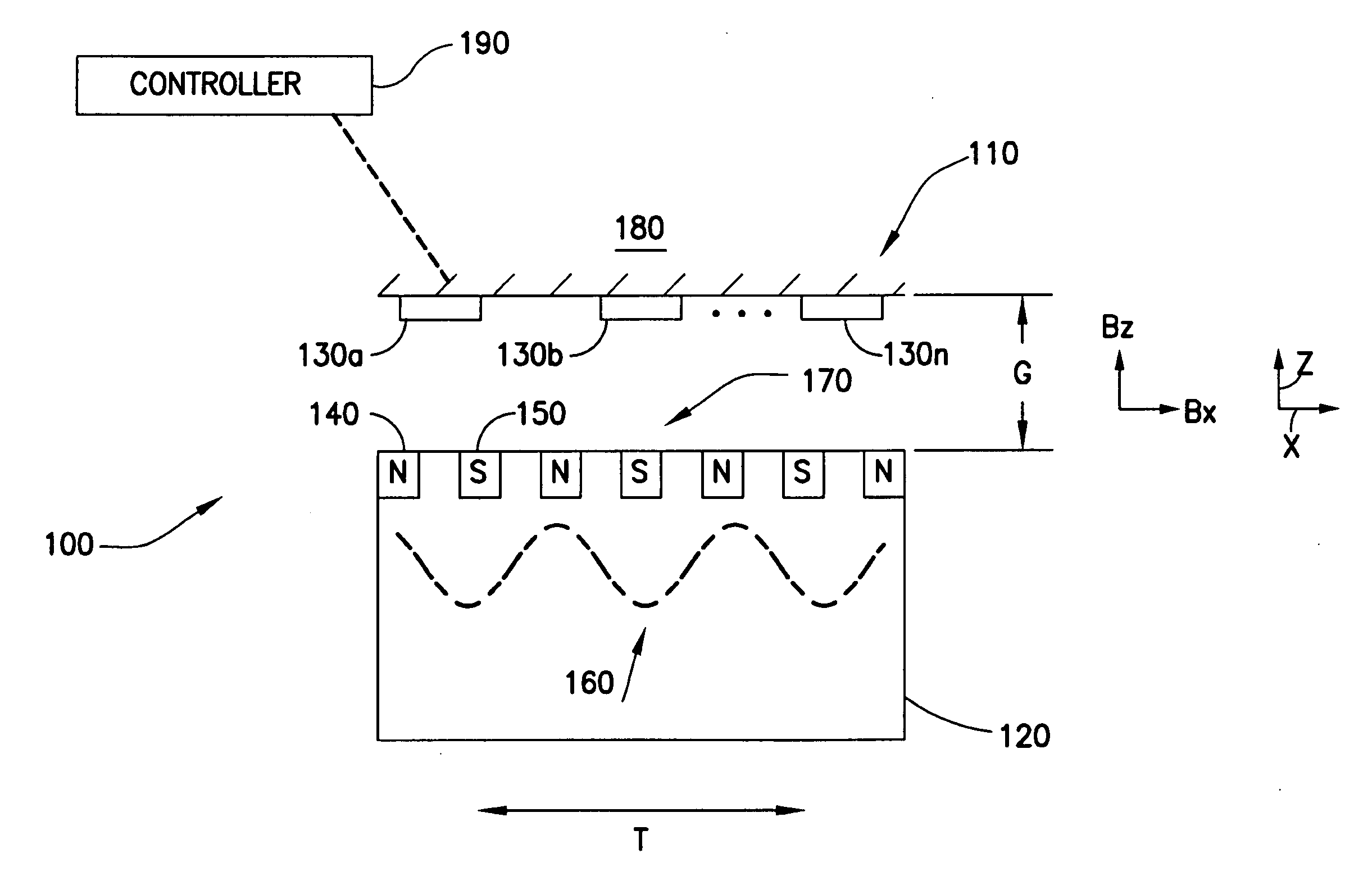

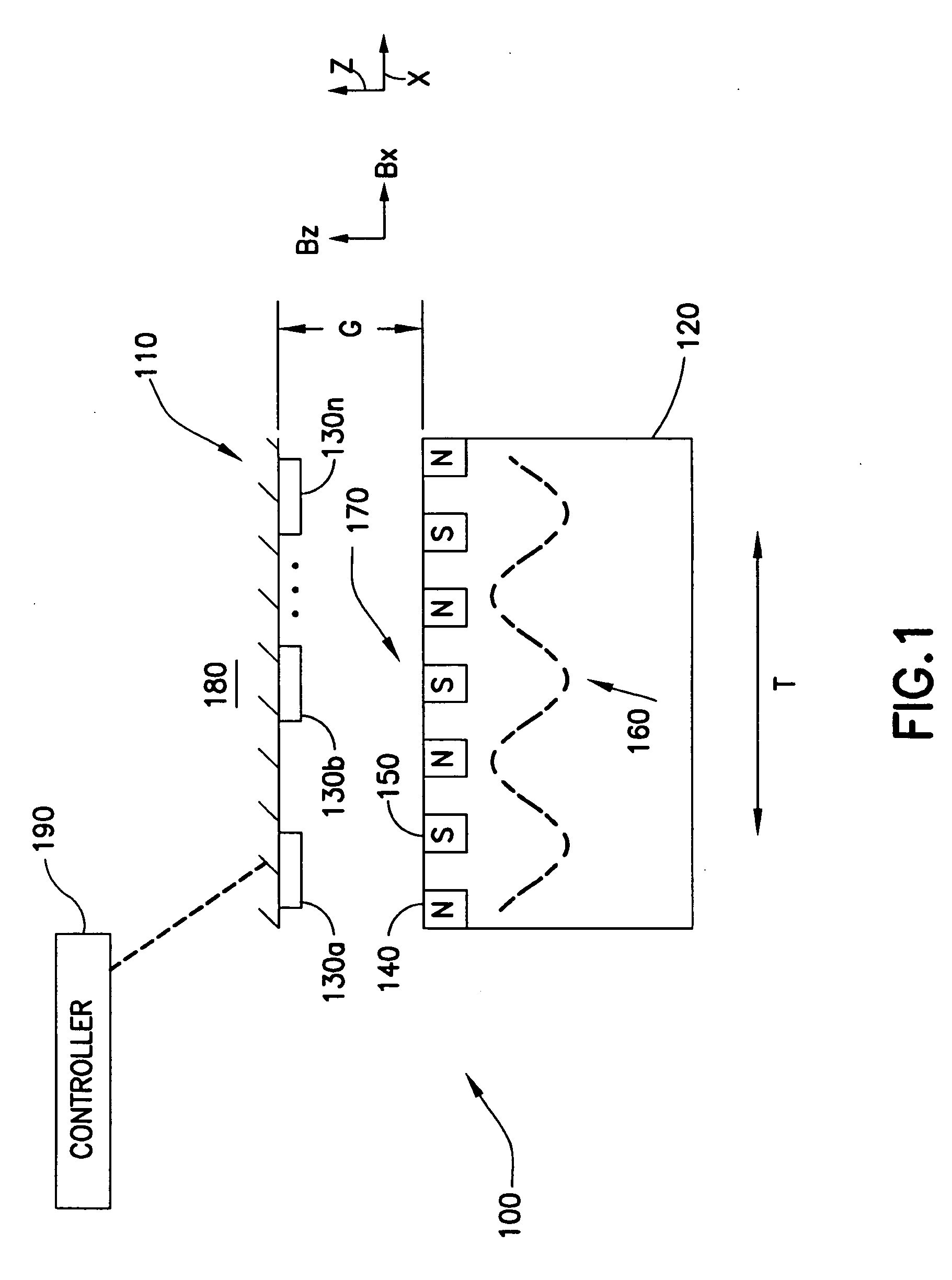

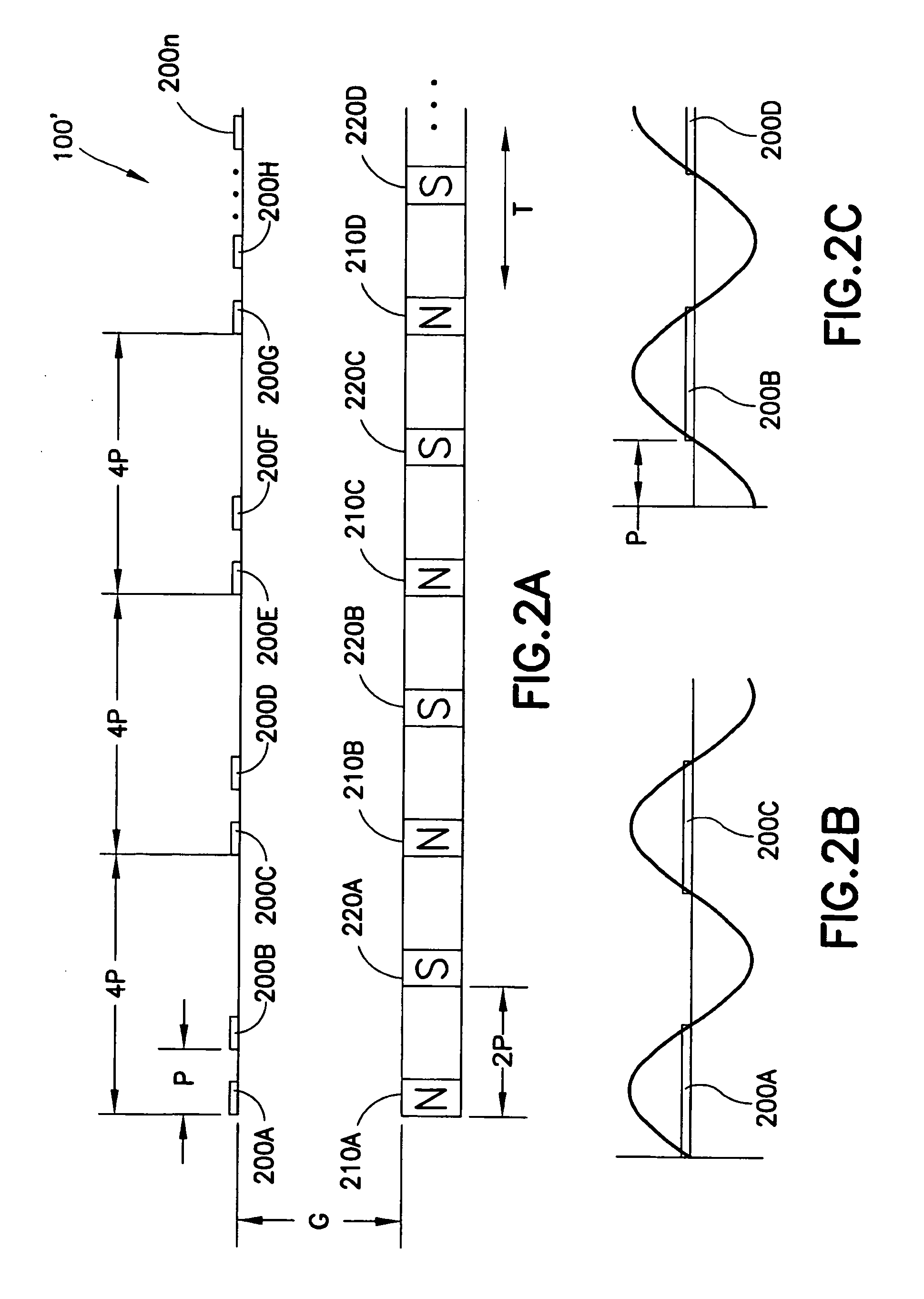

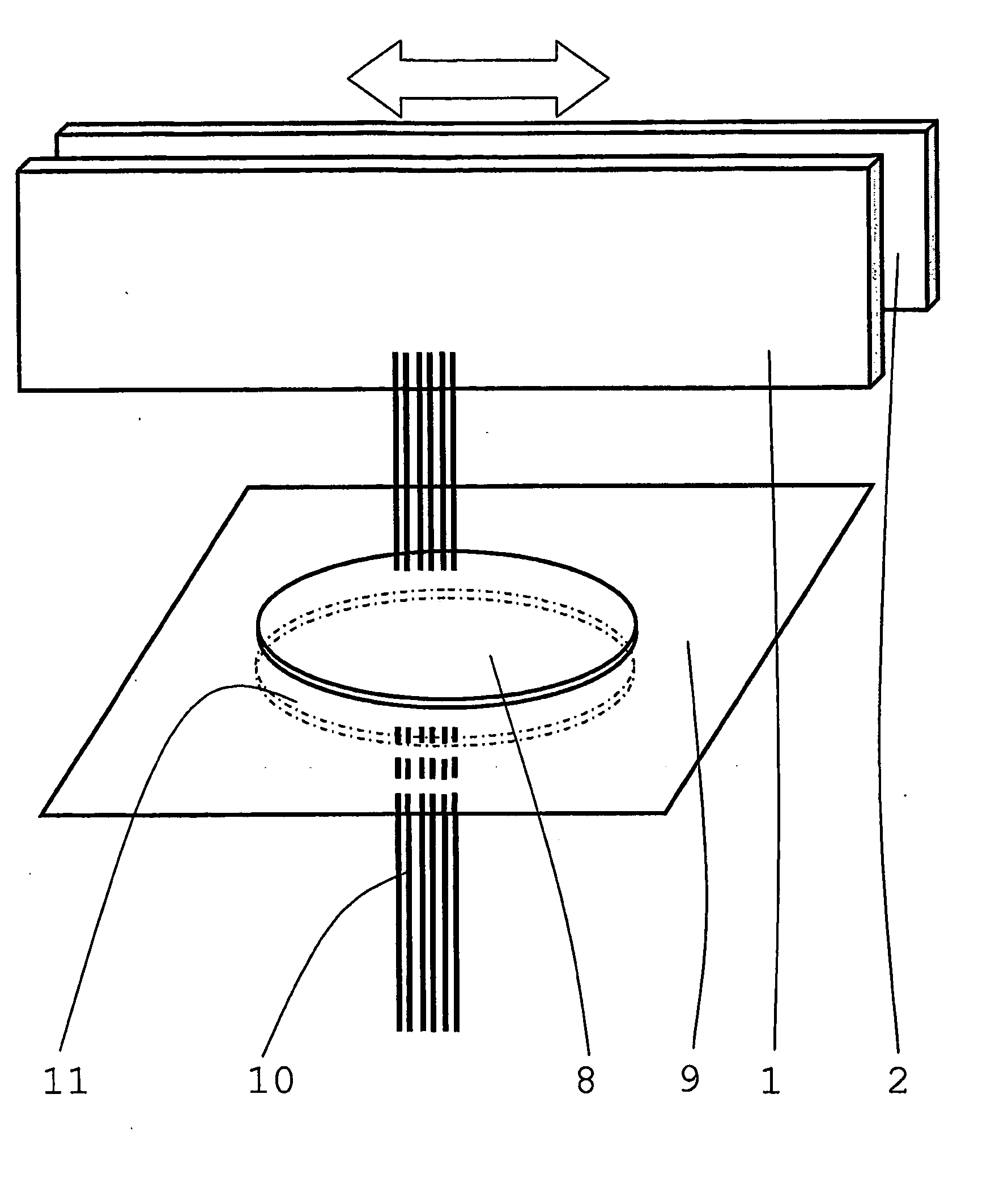

Multiple dimension position sensor

ActiveUS8129984B2Electric/magnetic position measurementsSolid-state devicesMeasurement deviceEngineering

An apparatus including a controller, a workpiece transport in communication with the controller having a movable portion and a transport path, and a multi-dimensional position measurement device including at least one field generating platen attached to the movable portion and at least one sensor group positioned along the transport path and in communication with the controller, the field generating platen is configured for position measurement and propelling the movable portion, each sensor in the at least one sensor group is configured to provide but one output signal along a single axis corresponding to a sensed field generated by the at least one field generating platen and the controller is configured calculate a multi-dimensional position of the movable portion based on the but one output signal of at least one of the sensors in the at least one sensor group, the multi-dimensional position including a planar position and a gap measurement.

Owner:BOOKS AUTOMATION US LLC

System for creating microscopic digital montage images

InactiveUS20060204072A1High throughput montageAccurate focus controlImage analysisElectric/magnetic position measurementsImaging equipmentComputer science

Owner:CARL ZEISS MICROIMAGING AIS

Multiple dimension position sensor

ActiveUS20090224750A1Solid-state devicesElectric/magnetic position measurementsMeasurement deviceEngineering

An apparatus including a controller, a workpiece transport in communication with the controller having a movable portion and a transport path, and a multi-dimensional position measurement device including at least one field generating platen attached to the movable portion and at least one sensor group positioned along the transport path and in communication with the controller, the field generating platen is configured for position measurement and propelling the movable portion, each sensor in the at least one sensor group is configured to provide but one output signal along a single axis corresponding to a sensed field generated by the at least one field generating platen and the controller is configured calculate a multi-dimensional position of the movable portion based on the but one output signal of at least one of the sensors in the at least one sensor group, the multi-dimensional position including a planar position and a gap measurement.

Owner:BOOKS AUTOMATION US LLC

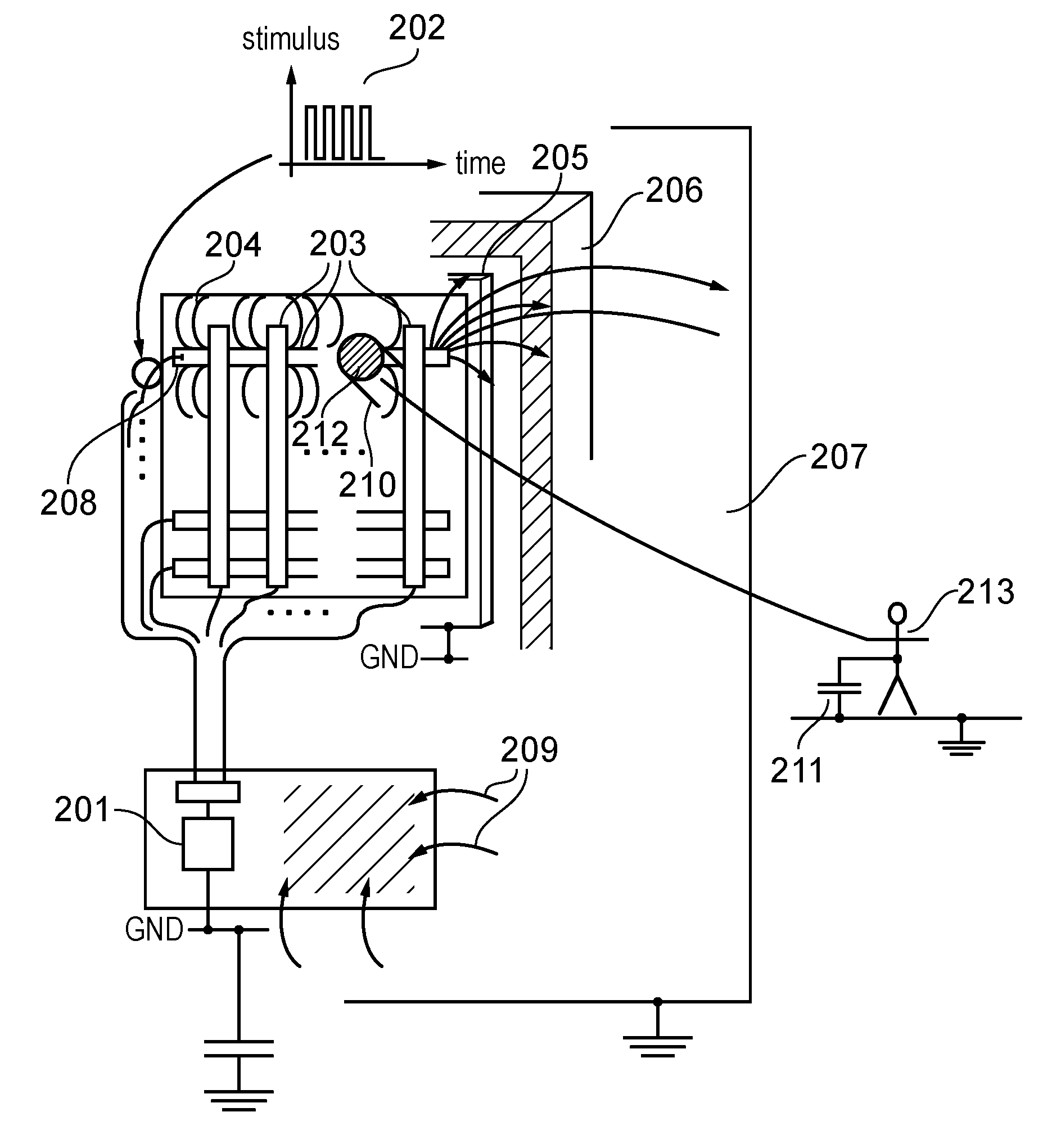

System and Method for Orientation and Movement of Remote Objects

InactiveUS20130267788A1RobustnessReduced Power RequirementsImage enhancementImage analysisExternal rotationClassical mechanics

The disclosed invention provides apparatus, systems, and methods for moving an object in an enclosed area using a magnetic dipole deployed in the enclosed area and thereafter applying an external rotating magnetic field for applying a rotational force to the dipole along one or more selected axis. The external magnetic field is moved to manipulate object in the desired direction(s) of movement.

Owner:ANKON MEDICAL TECH (SHANGHAI) CO LTD

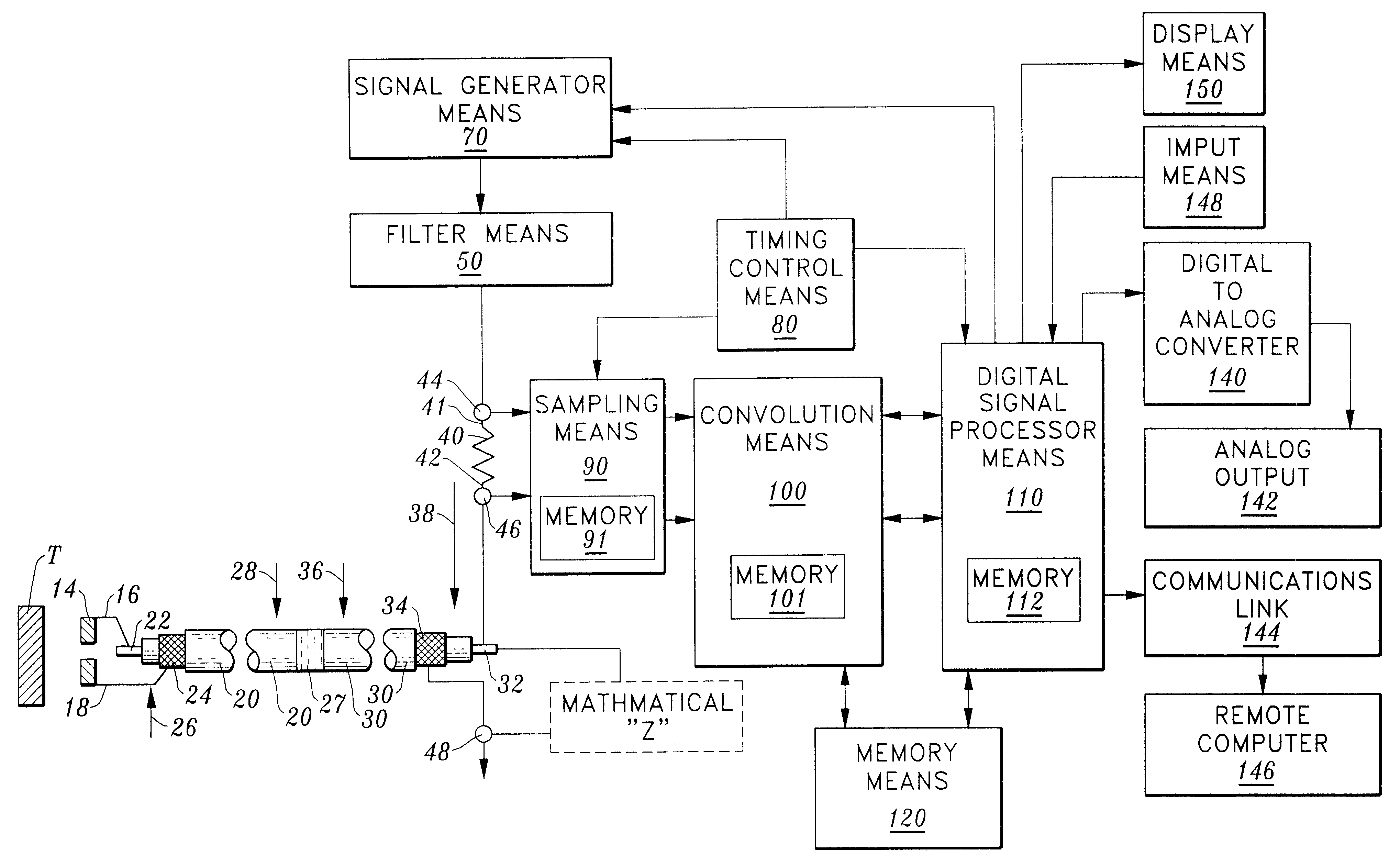

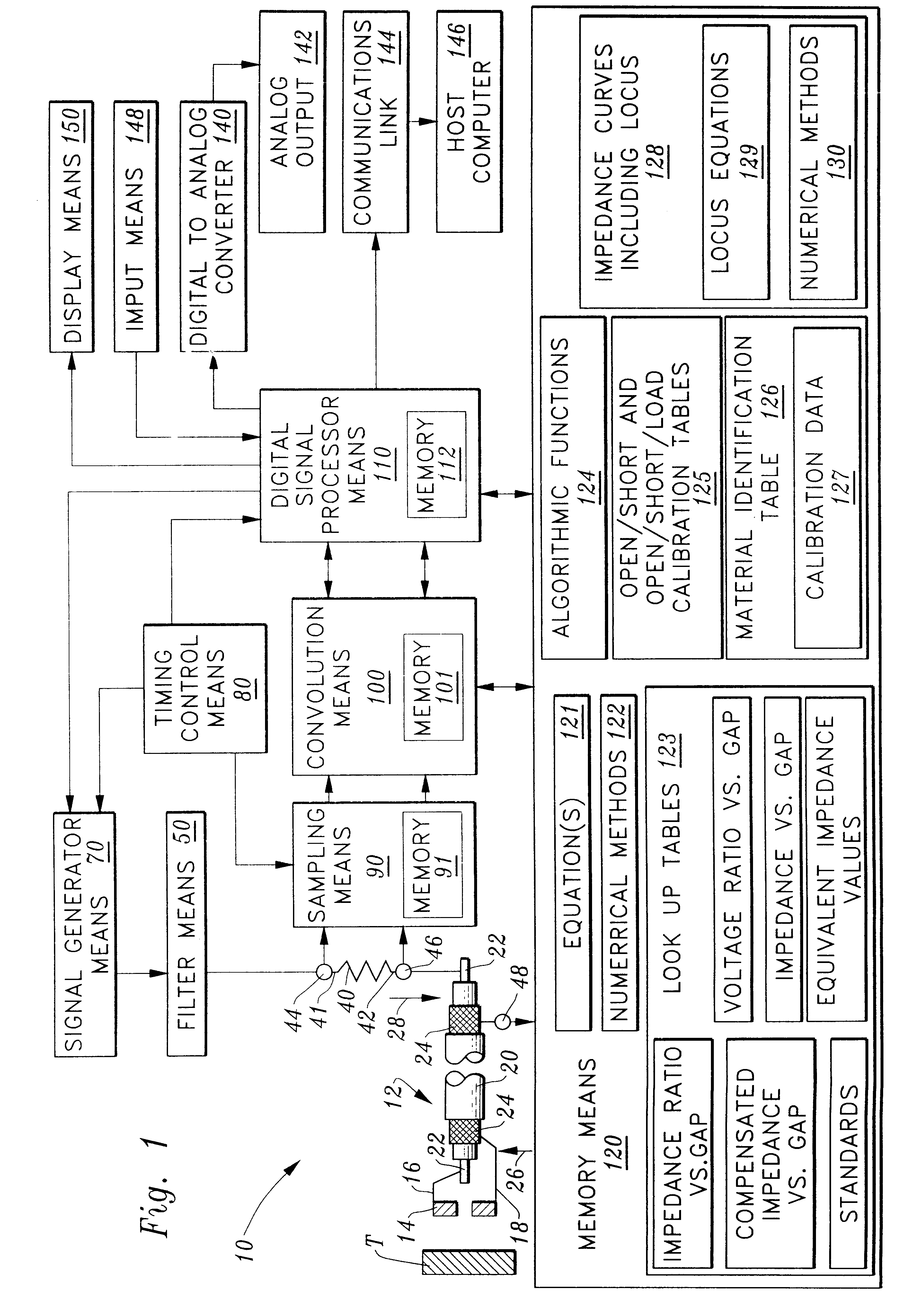

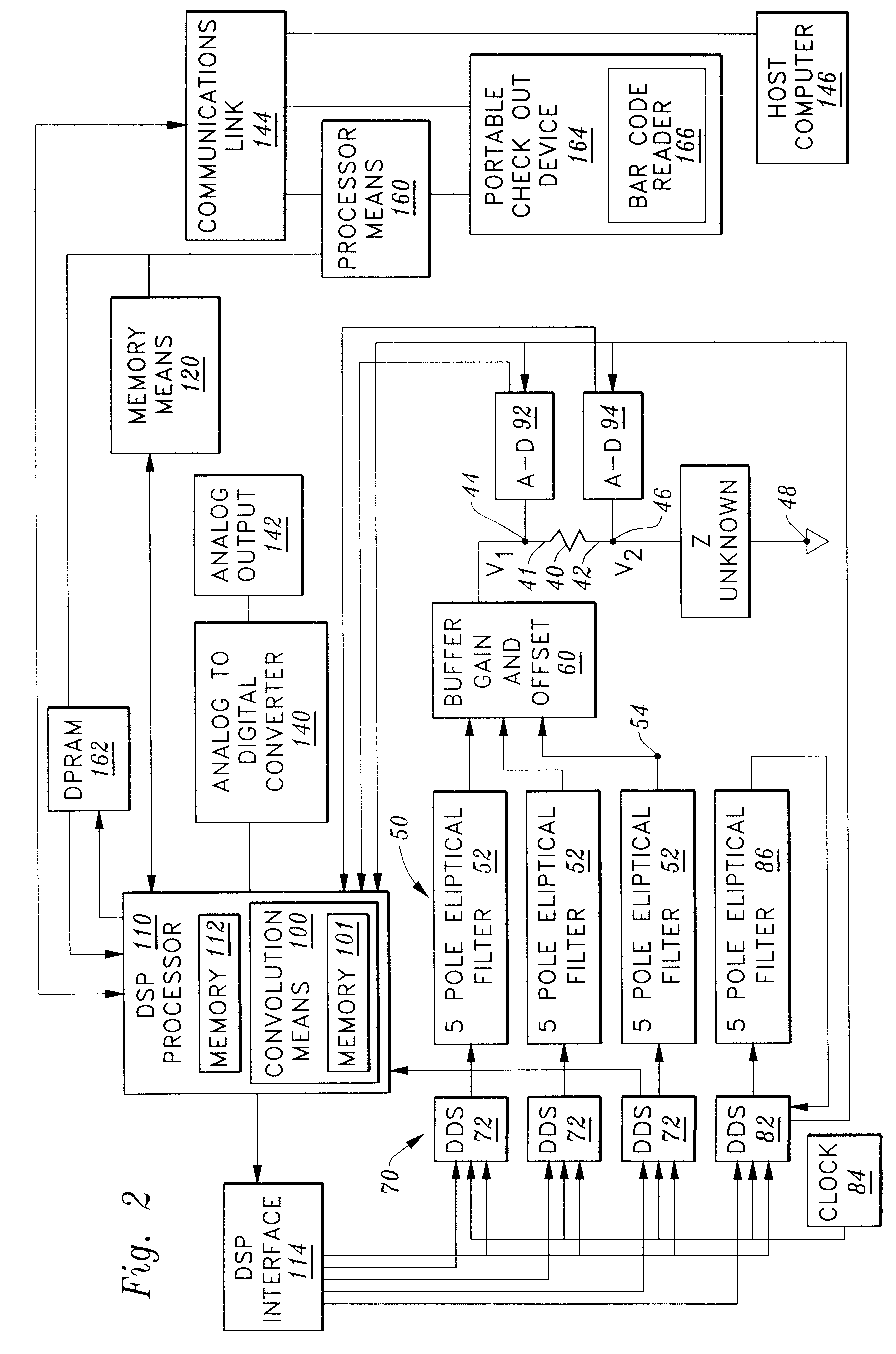

Digital eddy current proximity system: apparatus and method

InactiveUS6346807B1Magnetic measurementsResistance/reactance/impedencePosition dependentRatio method

A digital eddy current proximity system including a digital impedance measuring device for digitally measuring the proximity probes impedance correlative to displacement motion and position of a metallic target object being monitored. The system further including a cable-length calibration method, an automatic material identification and calibration method, a material insensitive method, an inductive ratio method and advanced sensing characteristics.

Owner:BENTLY NEVADA INC

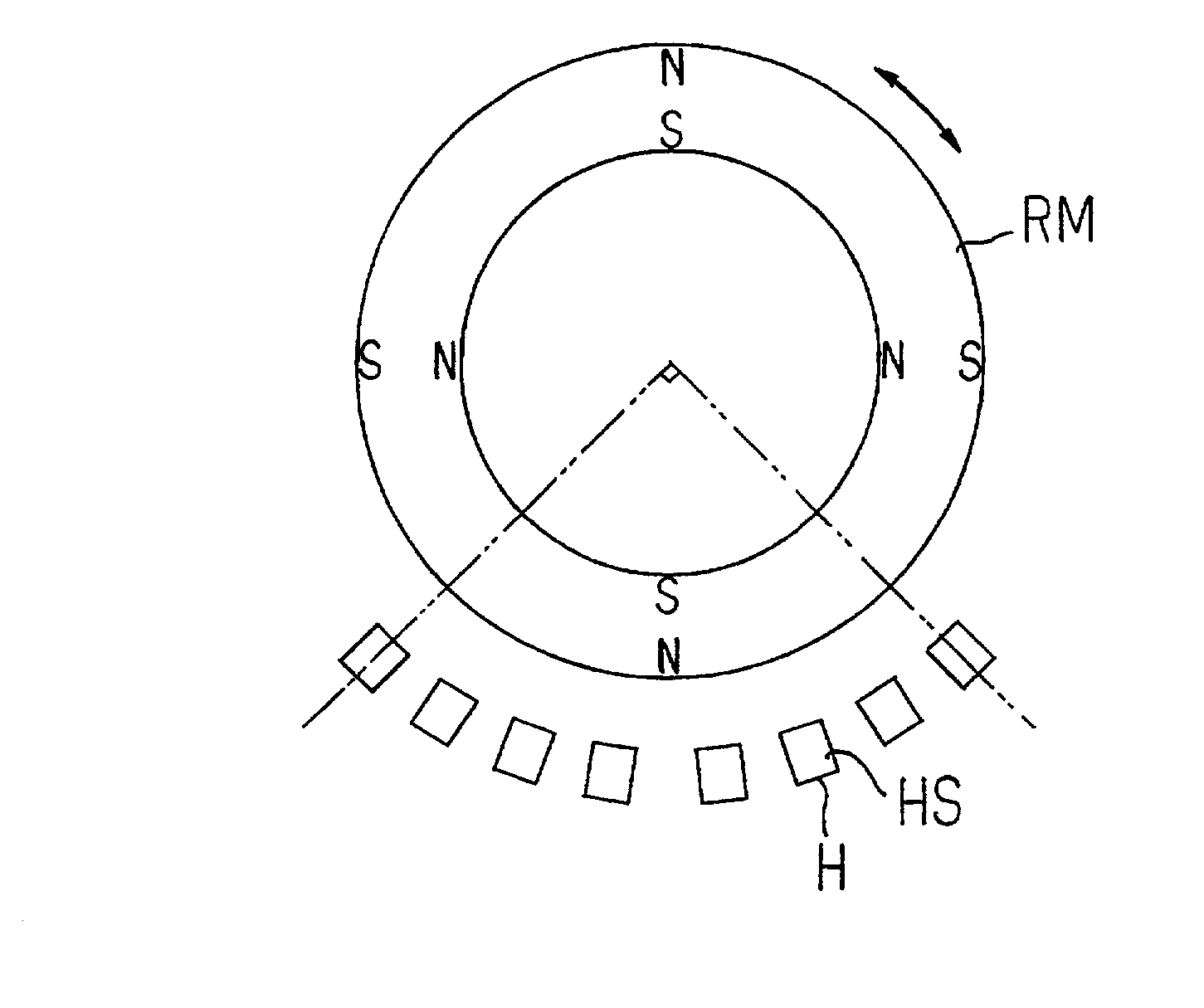

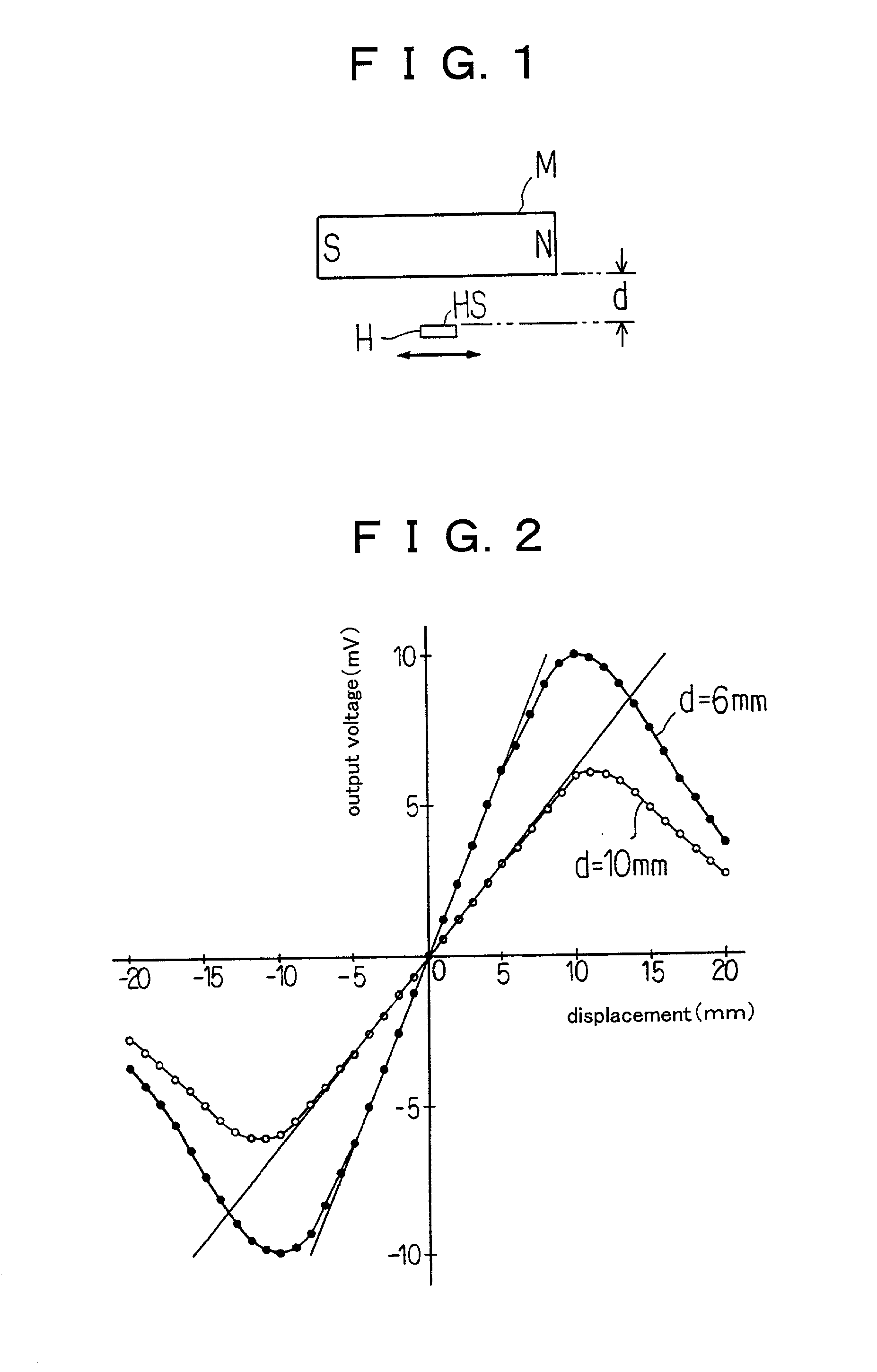

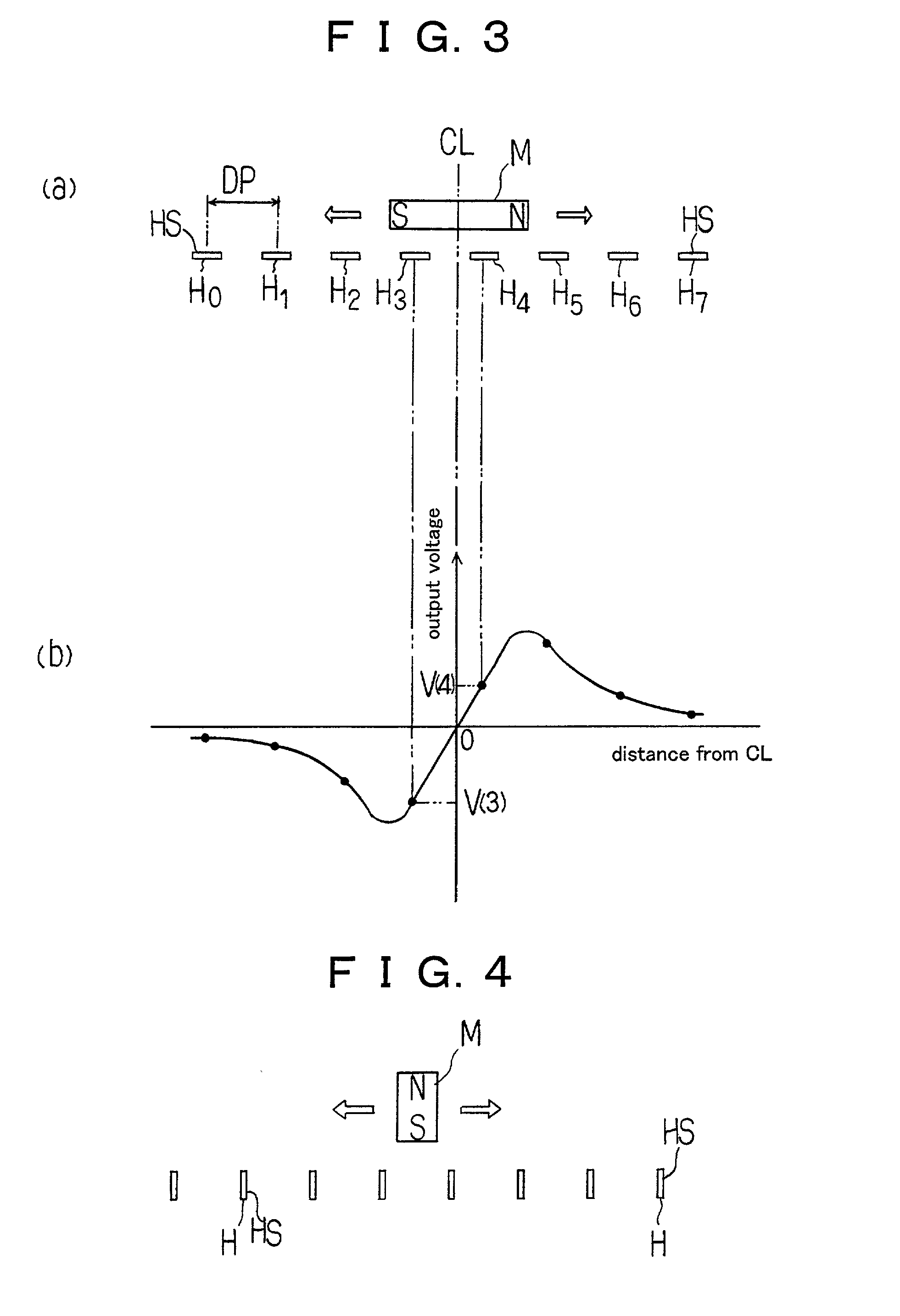

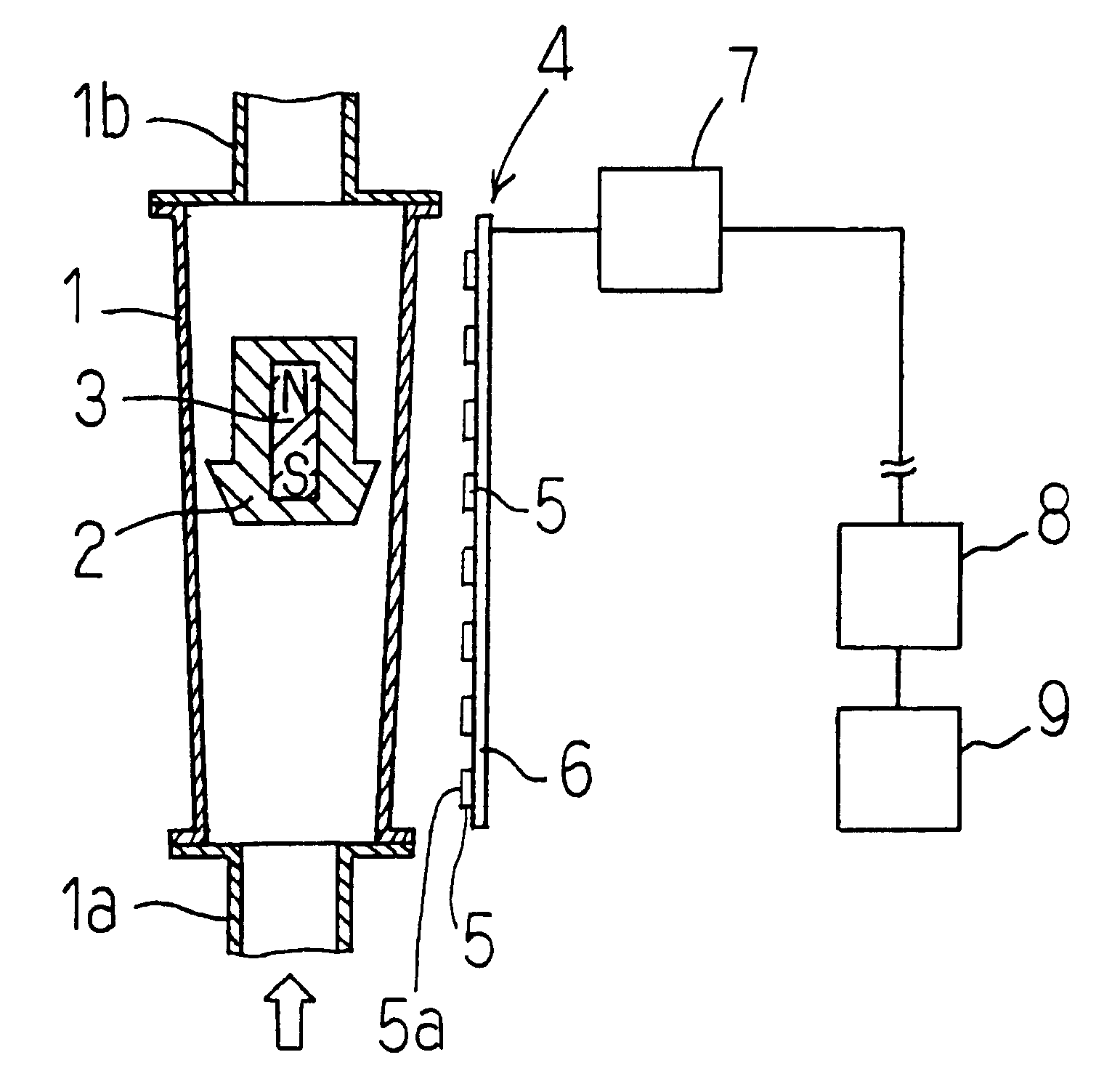

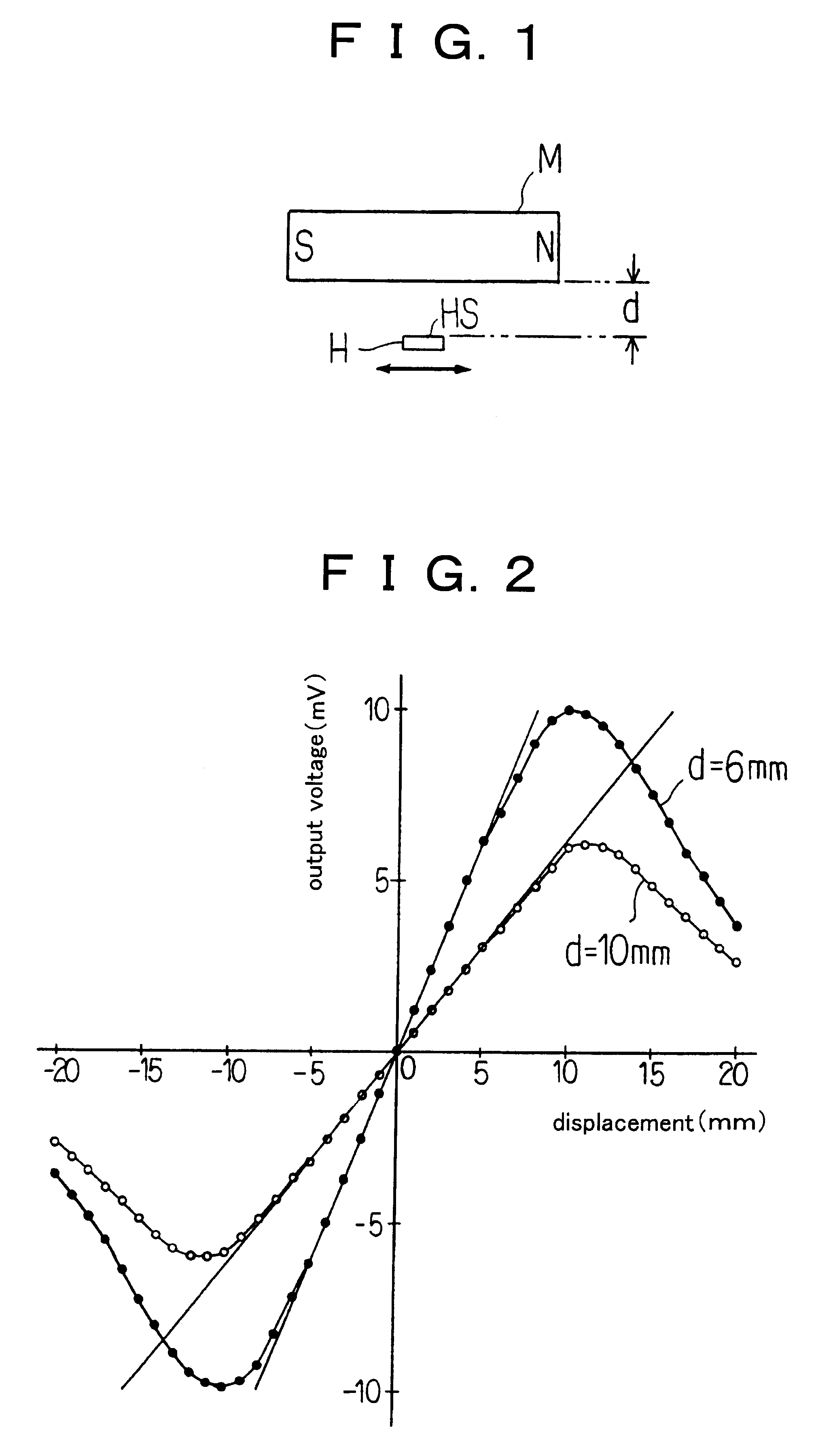

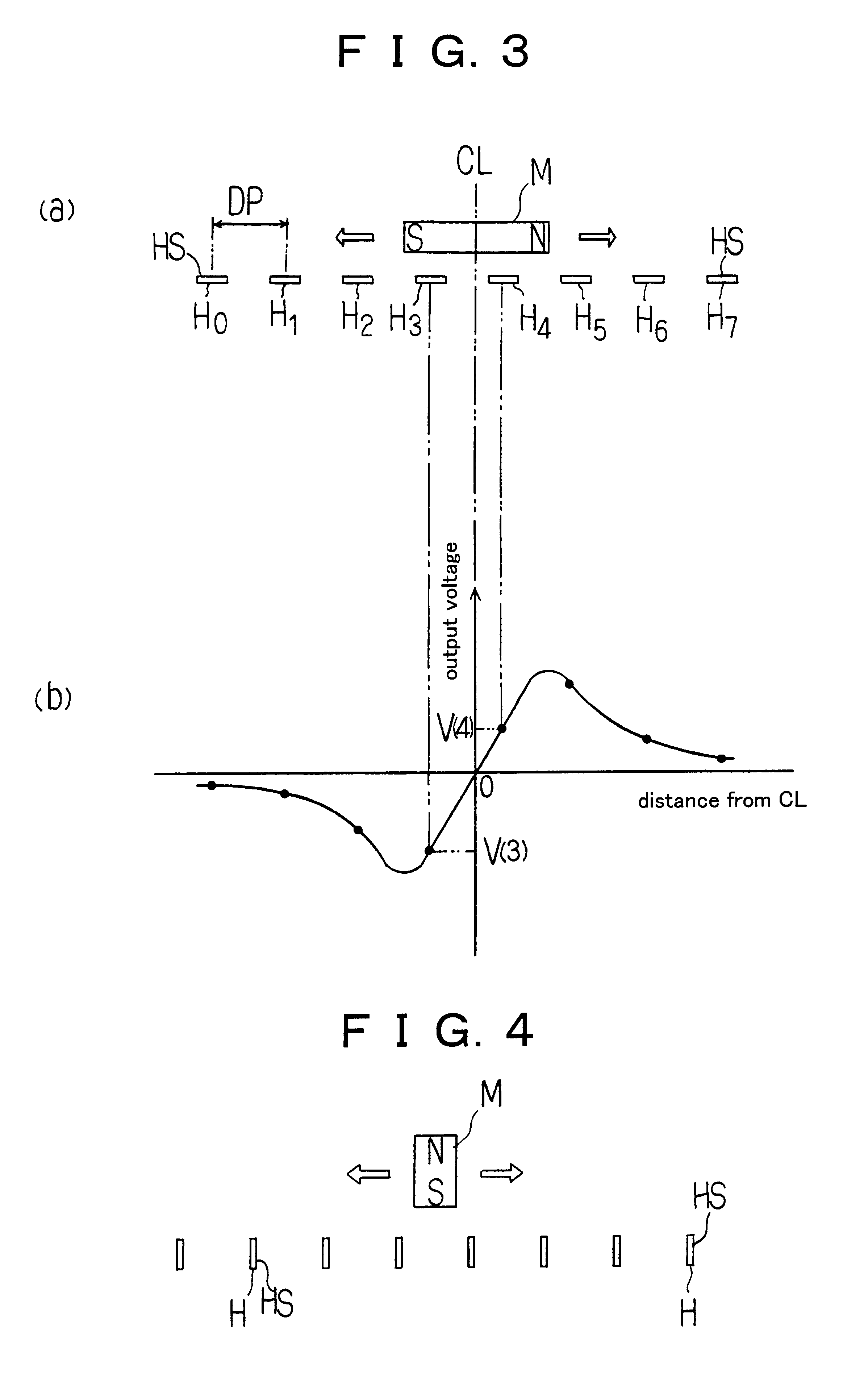

Apparatus and method for detecting the displacement

InactiveUS20020005715A1Level indicator with buoyant probesSolid-state devicesElectrical polarityMagnetic poles

An apparatus for detecting the displacement of a magnet is to be provided. The errors on the detected value due to the variation of temperature or that with time are hardly caused in the apparatus. The apparatus can detect the displacement in high resolution and precision. The apparatus is simple in its structure, and it can be expected that the apparatus can be manufactured in low cost. The apparatus is not limited in its application by the range of the displacement of the magnet. Further, a method for detecting the displacement of a magnet will be provided. An apparatus for detecting the displacement of a magnet M, the apparatus being characterized in that it further comprises a plurality of hall devices H0-H7 disposed in a predetermined spacing DP along a displacing path of the magnet in parallel thereto, wherein each of said hall devices includes a magnetically sensitive surface HS through which a magnetic flux from said magnet M permeate to generate an output the polarity and the voltage of which are depend on the direction and the density of the magnetic flux, and said magnetically sensitive surface HS of each hall device is disposed in a predetermined distance from the displacing path of the magnet M in parallel with the direction defined by the magnetic poles, and wherein two adjacent hall devices inverted in the polarity of their output voltages are detected to determine the general position of the magnet, and the precise position of the magnet between these two hall devices is determined on the basis of the output voltages.

Owner:TOKYO KEISO

Inductive position sensor

InactiveUS20100001718A1High resolutionElectric/magnetic position measurementsUsing electrical meansElectricityInductor

Owner:HOWARD MARK ANTHONY +1

Touch sensor for non-uniform panels

ActiveUS20150028894A1Reduce and substantially eliminate variation in overlap areaStop capacitance variationResistance/reactance/impedenceElectric/magnetic position measurementsSystematic variationEngineering

A two-dimensional capacitive touch sensor having a cover layer of varying thickness arranged on top of its electrode structure. An array of sensing nodes is formed between edge portions of the receiver electrodes and adjacent portions of the transmitter electrodes. To compensate for the varying thickness of the cover layer, the length of the edge portions per sensing node is varied to equalize node sensitivity across the sensor and thus suppress the systematic variation in node sensitivity which would otherwise arise as a result of the varying thickness of the cover layer.

Owner:TOUCHNETIX

Nanowires, method of fabrication the same and uses thereof

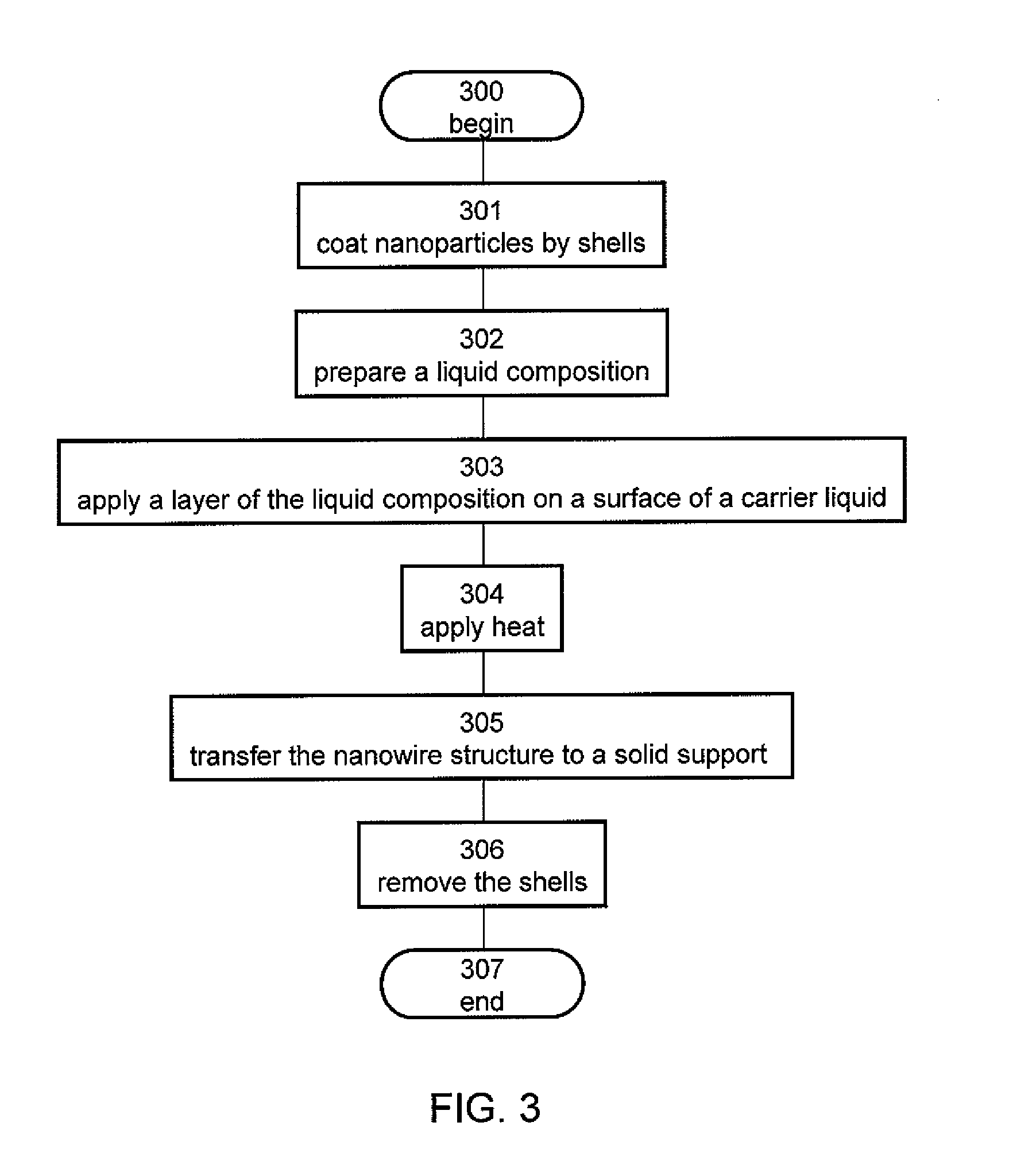

A method of forming a nanowire structure is disclosed. The method comprises applying on a surface of carrier liquid a layer of a liquid composition which comprises a surfactant and a plurality of nanostructures each having a core and a shell, and heating at least one of the carrier liquid and the liquid composition to a temperature selected such that the nanostructures are segregated from the surfactant and assemble into a nanowire structure on the surface.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

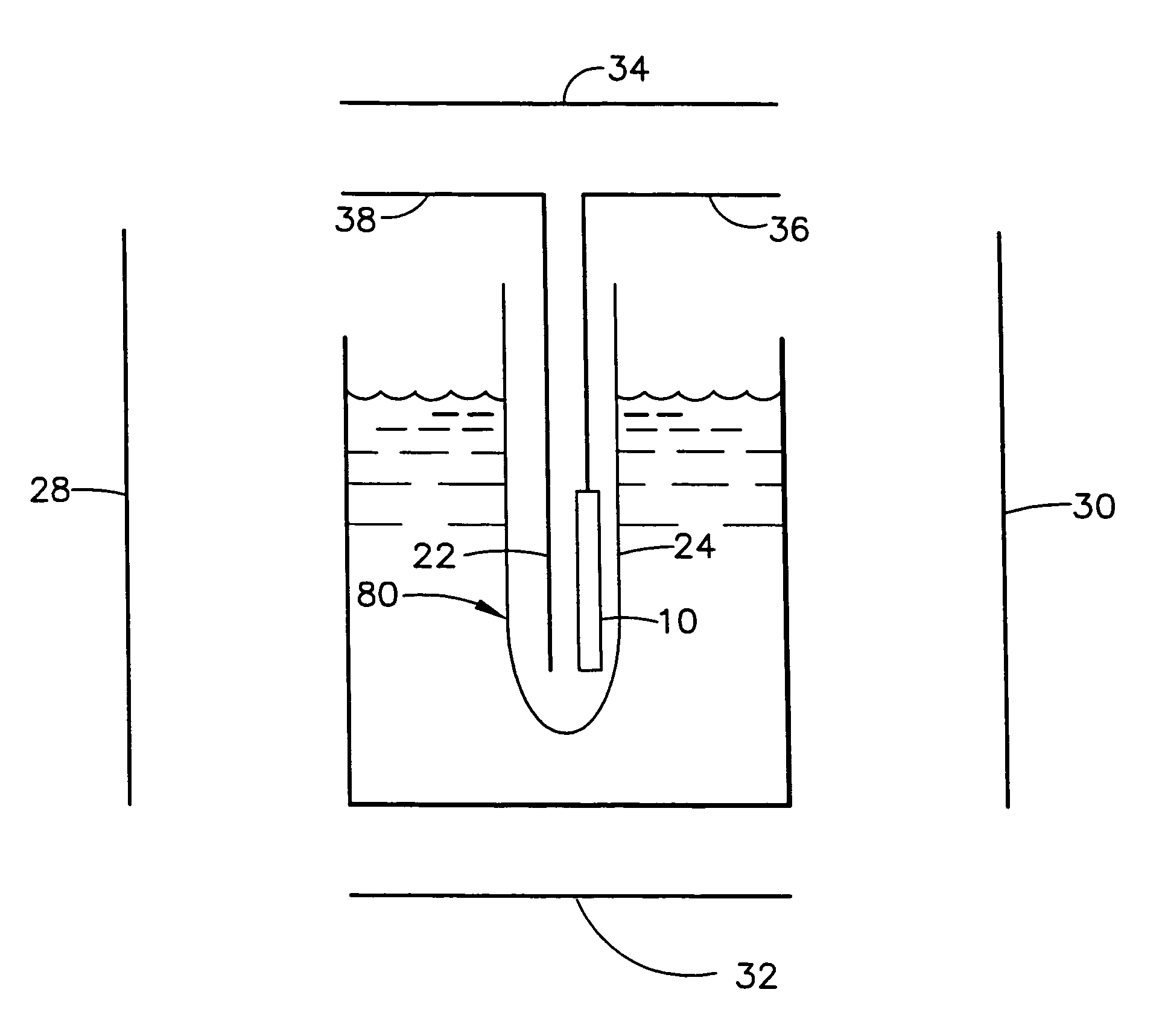

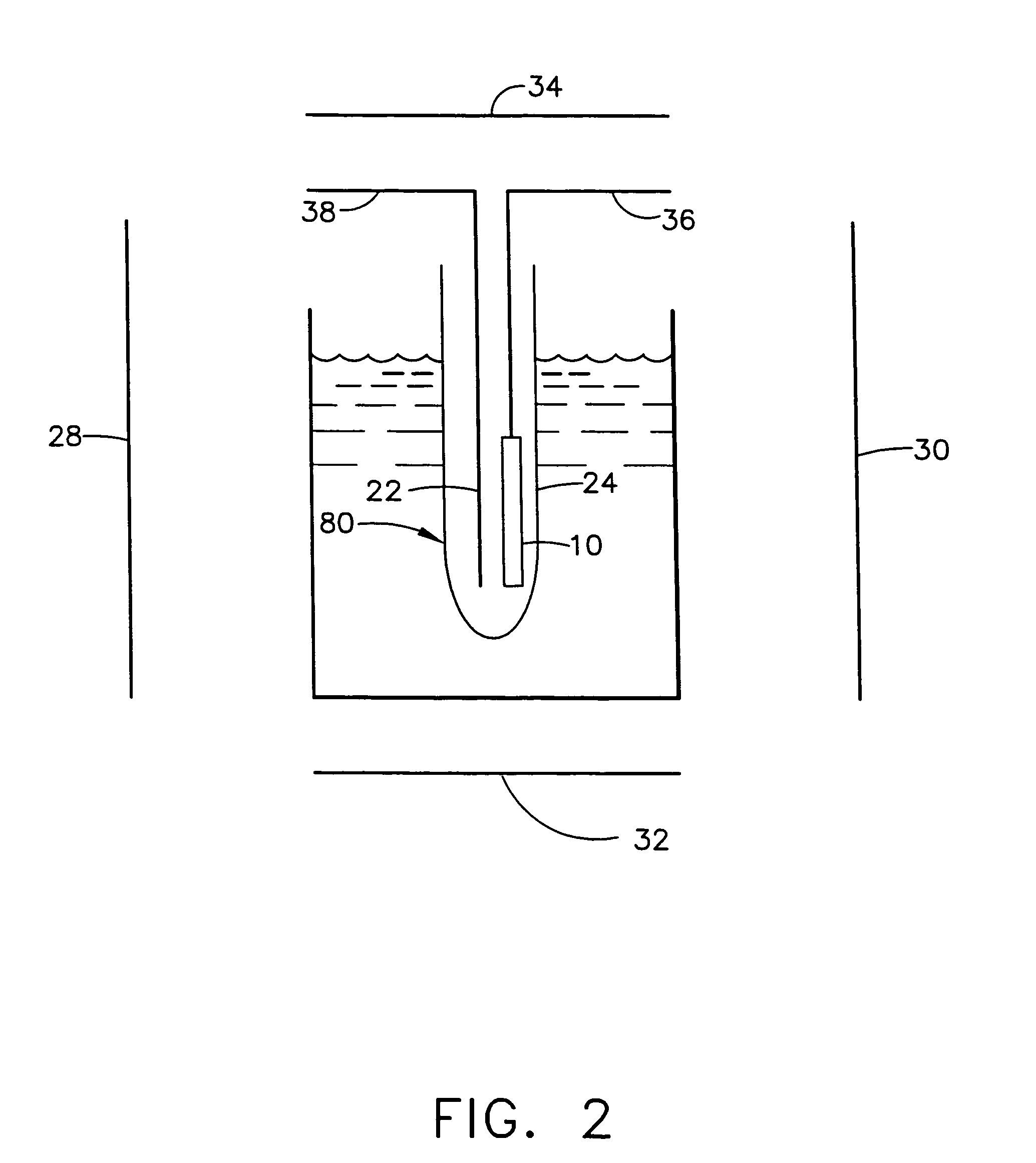

Medical device with position sensor having core with high permeability material for determining location coordinates of a portion of the medical device

InactiveUS6992477B2Maintain accuracySurgeryElectric/magnetic position measurementsConductor CoilMedical device

A medical location system includes a medical device having a body and a position sensor at a portion of the body. The position sensor has a core made of a Wiegand effect material and a winding circumferentially positioned around the core. The position sensor provides signals that are used to determine temperature at the position sensor and location information of the portion of the body of the medical device. A signal processor is coupled to receive the signals from the position sensor and the signal processor determines the temperature at the position sensor and location information of the portion of the body of the medical device based on the signals received from the position sensor.

Owner:BIOSENSE

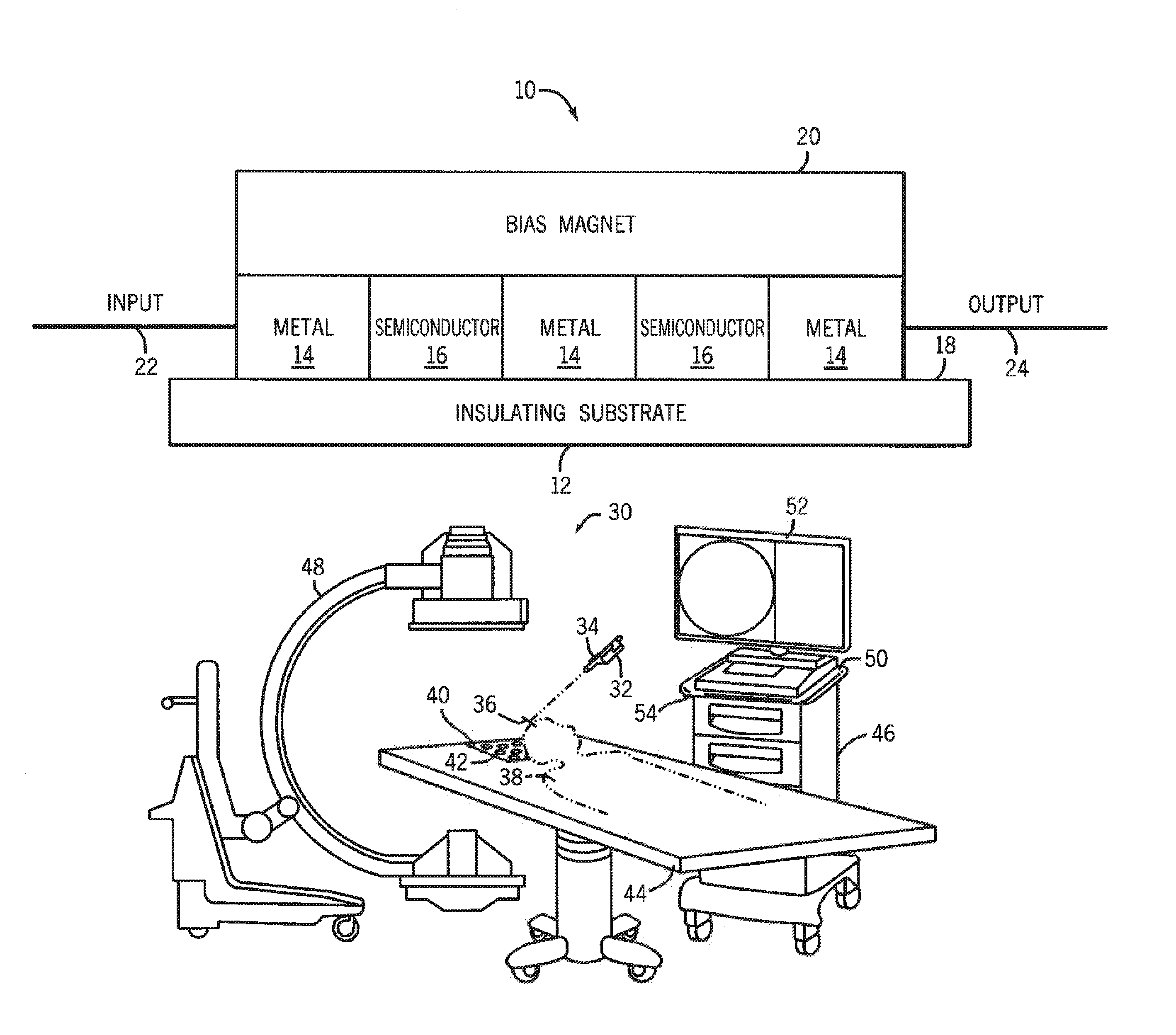

Surgical Navigation Enabled Imaging Table Environment

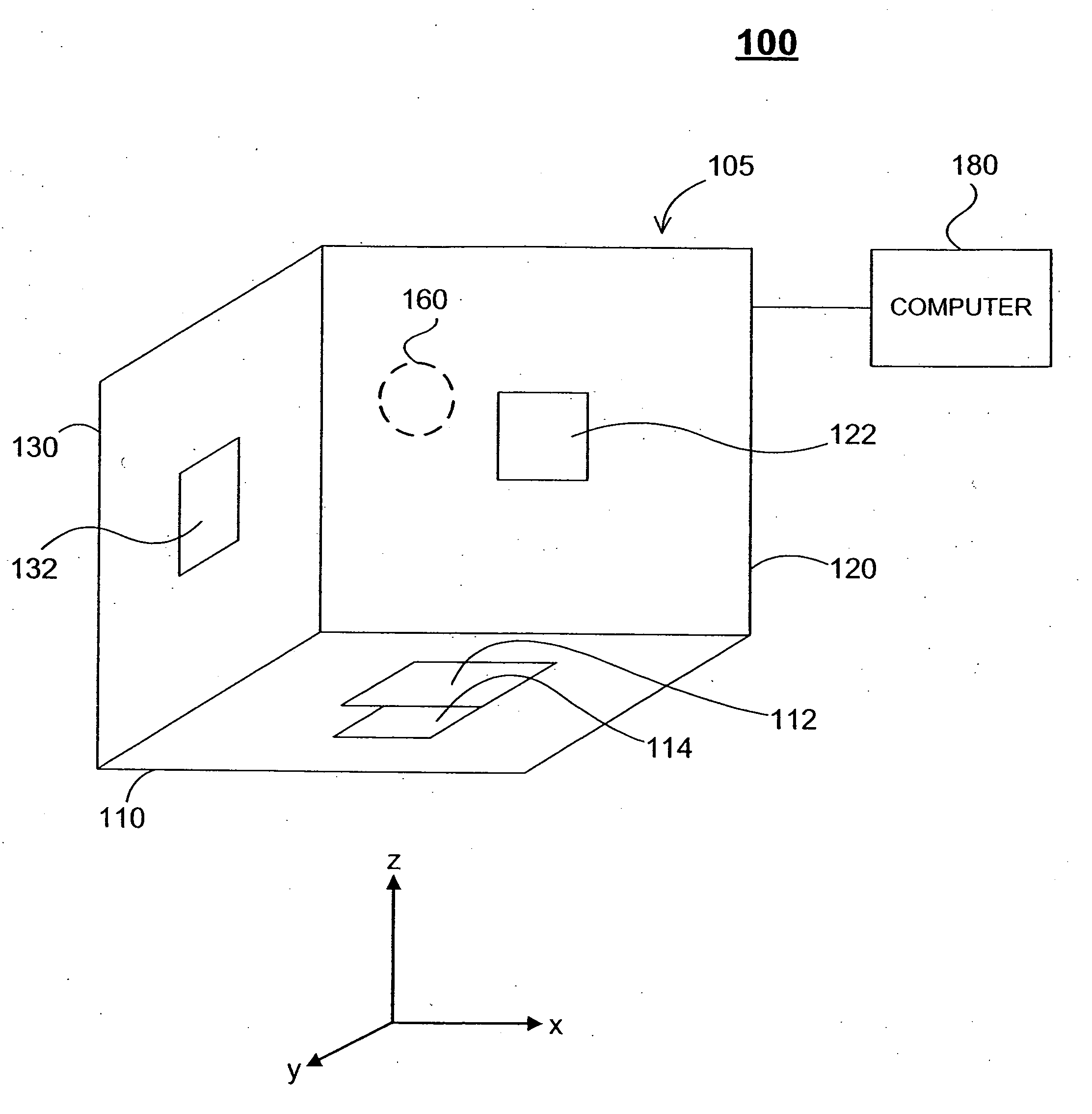

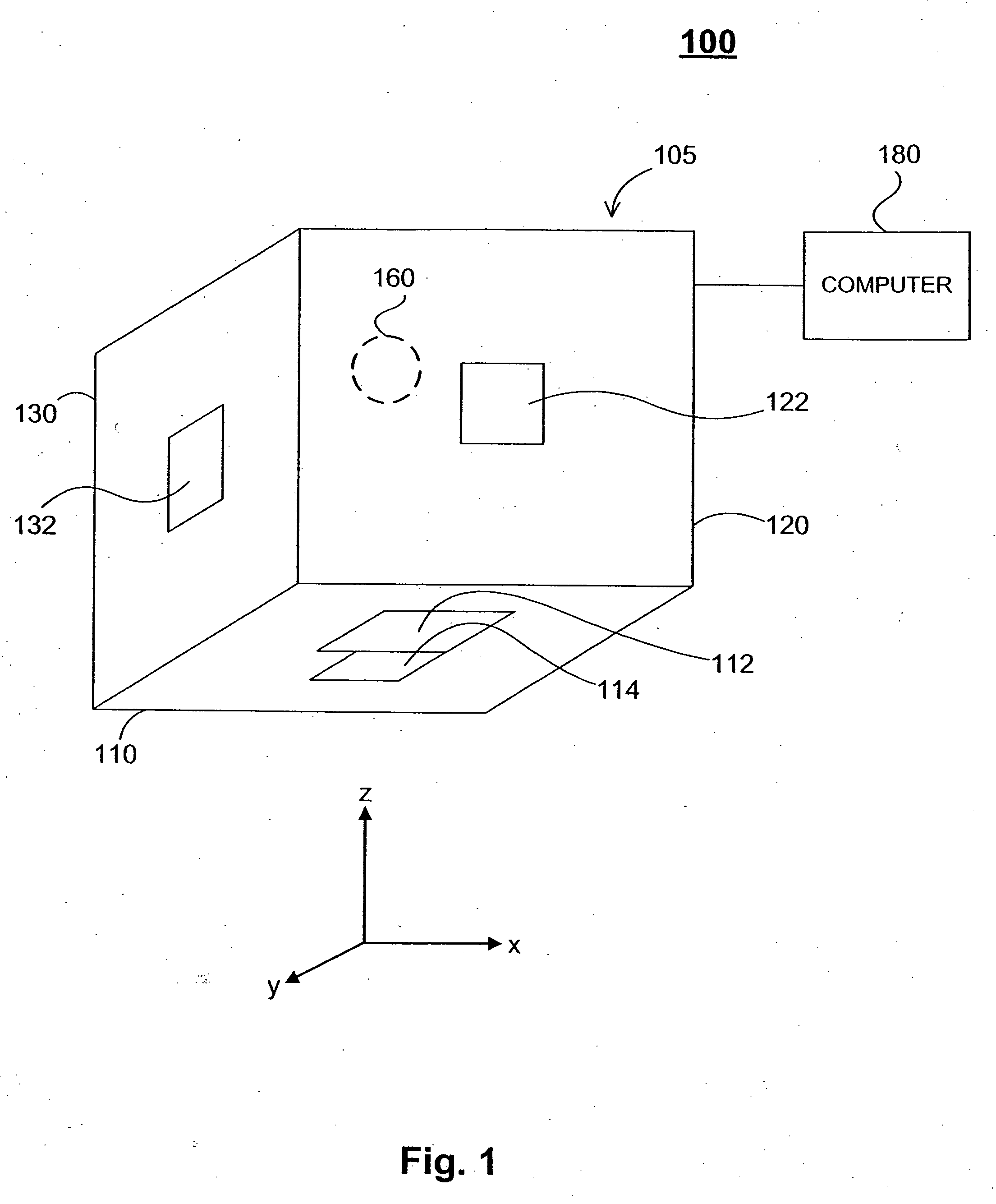

ActiveUS20100138183A1Operating tablesElectric/magnetic position measurementsNavigation systemSurgical Drape

A system for integrating radiolucent tracking sensors in a medical table, table mat, or surgical drape of a surgical navigation system, allowing the surgical navigation system to be less obtrusive in a surgery environment. A plurality of radiolucent magnetoresistance sensors are integrated into a table, table mat, or surgical draping of a surgical navigation system for improving surgical navigation workflow and eliminating image artifacts from intraoperative images. The plurality of radiolucent magnetoresistance sensors may be located within a table or adjacent to a table surface.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Capacitive sensing node integration to a surface of a mechanical part

ActiveUS20150241195A1Easy to carryHaptic feedback can be providedResistance/reactance/impedenceMouldsCapacitancePlastic materials

A motion detecting device has a stationary plastic sensor carrier. The stationary plastic sensor carrier has two sensor carrier sections and an insulation section. The carrier section has a first plastic material and the insulation section has a second plastic material. The insulation section extends between two adjacent sensor carrier sections. The sensor carrier sections and the at least one insulation section are integrally formed by a plastic molding process. Plated metal sensing surfaces are provided on the surfaces of the sensor carrier sections. Surface electrode contacts connect the plated metal sensing surface electrodes with a PCB and define at least one capacitive area between at the plated metal sensing surface electrodes. A plastic knob element is movably arranged on the plastic sensor carrier, such that the insulating plastic separator sections and the plated metal sensing surface electrodes are at least partly covered by the knob element.

Owner:CONTINENTAL AUTOMOTIVE GMBH

System and method for using magnetic sensors to track the position of an object

InactiveUS20060061354A1Testing/calibration apparatusElectric/magnetic position measurementsSemiconductorMagnet

A method is provided for tracking an object's position. One or more semiconductor-based sensors obtain measurements of an energy field associated with the object. A processor applies an algorithm to the measurements to generate one or more values representing a position of the object in a coordinate system. The energy field may comprise a magnetic field, for example. The object may comprise a magnet, for example.

Owner:WALLANCE DANIEL I +2

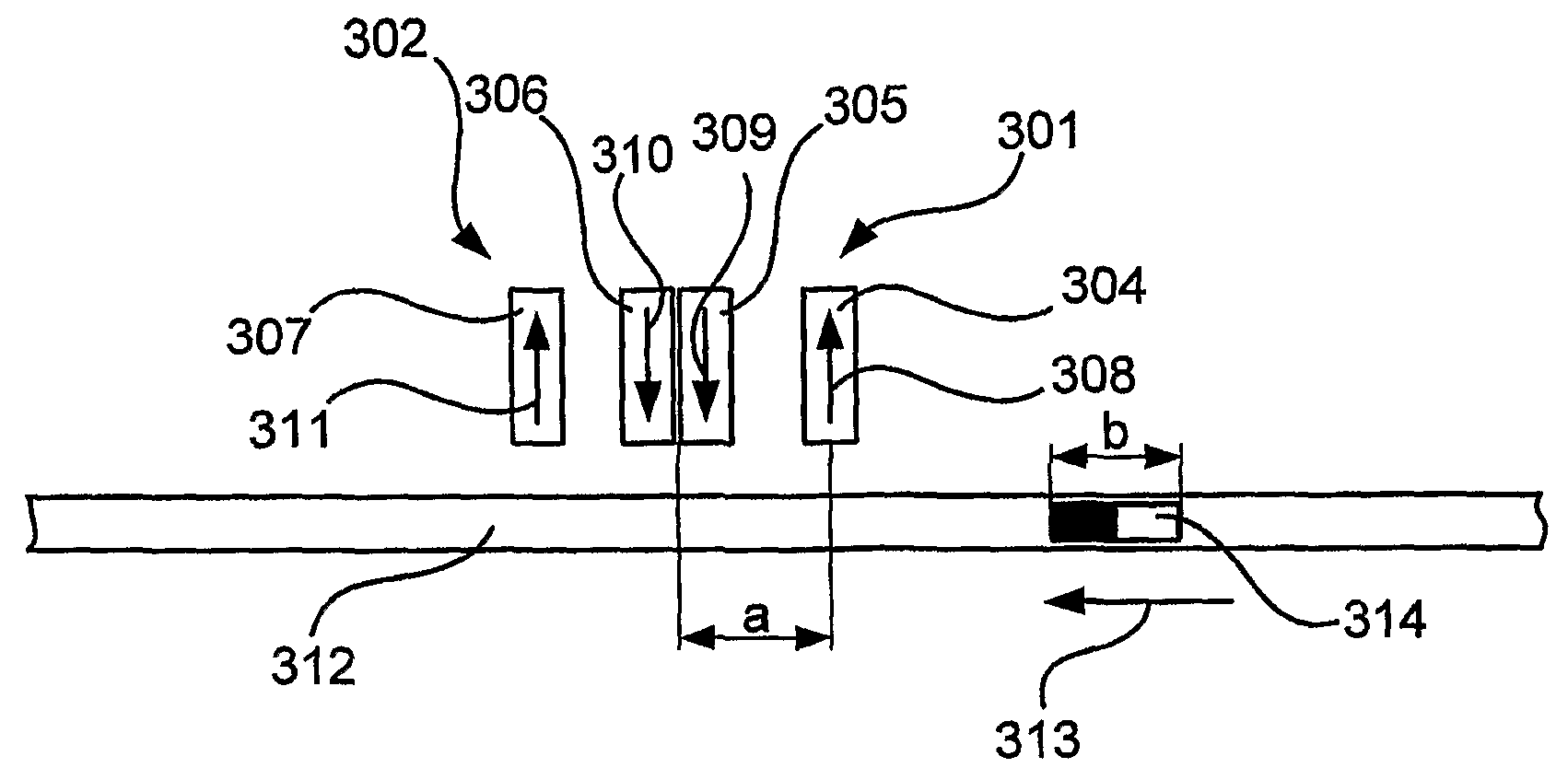

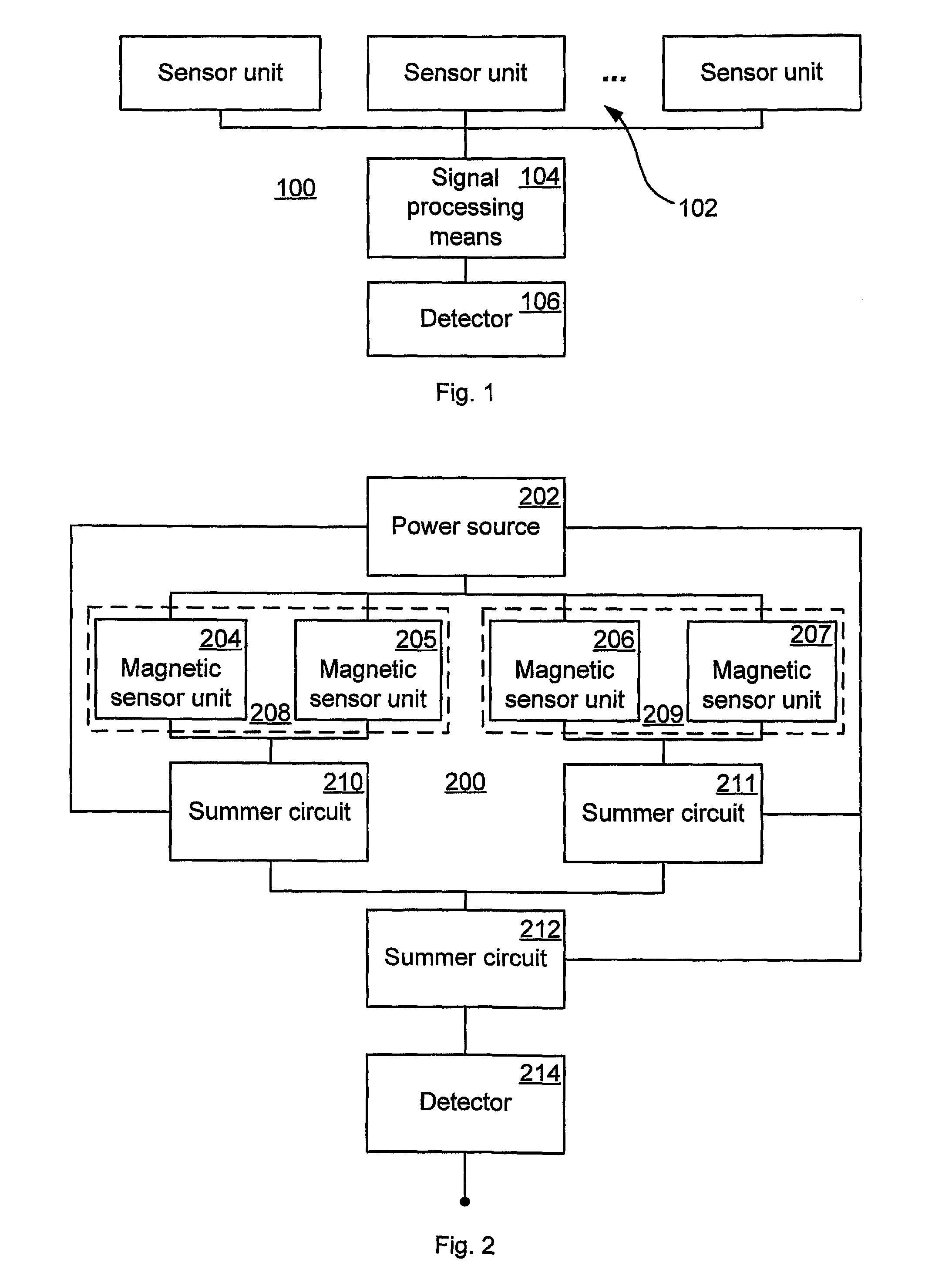

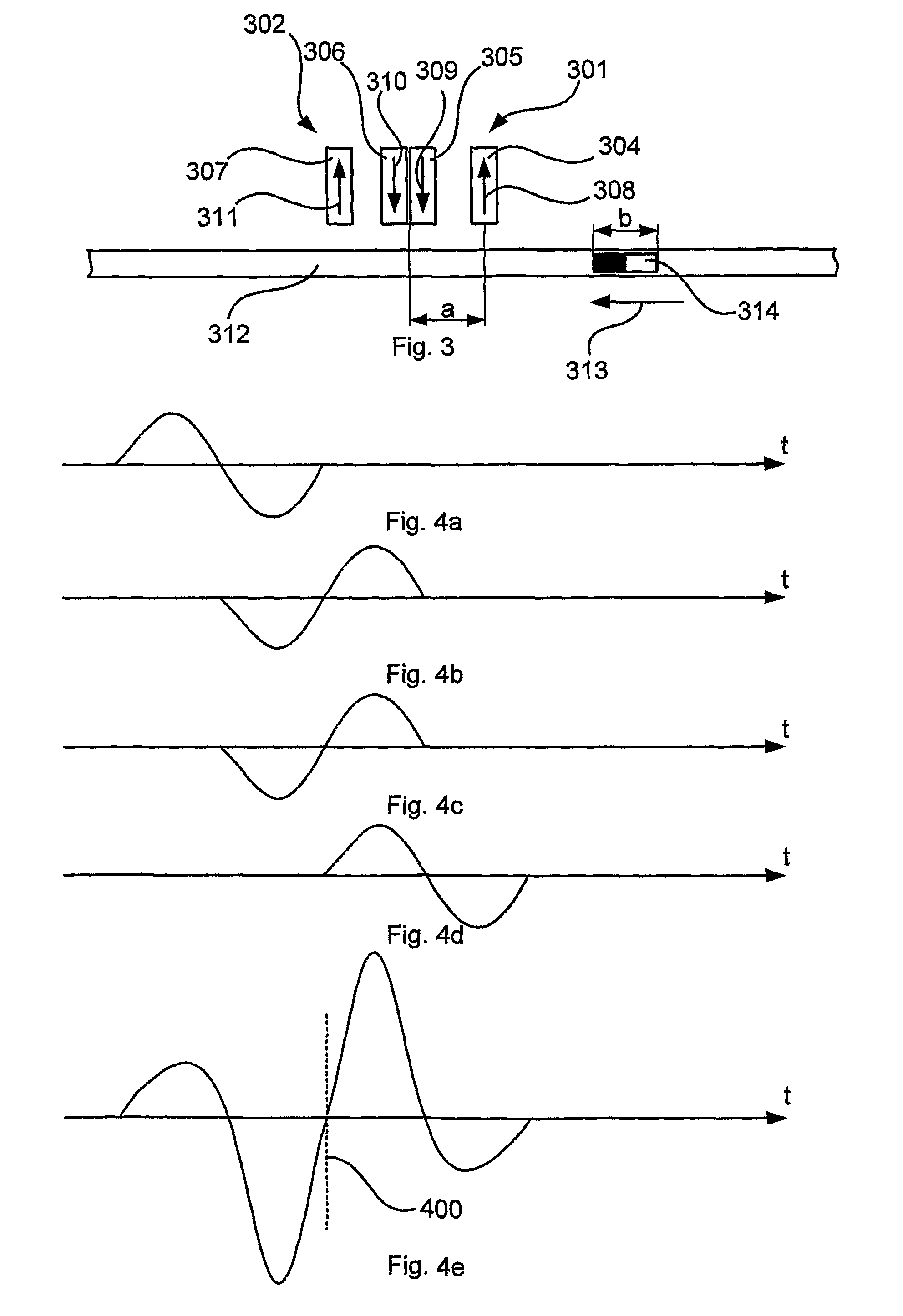

Position Detector and Method for Detecting a Position of a Packaging Material with Magnetic Marking

InactiveUS20080309327A1Robust positioningSimple signal processingMagnetic-field-controlled resistorsElectric/magnetic position measurementsMagnetic markerPack material

A position detector arrangement for detecting a position of a packaging material with magnetic marking comprises a sensor assembly comprising a plurality of magnetic sensor units each comprising an output providing an output signal. The magnetic sensor units are arranged in at least two sensor unit pairs, with the sensor units of each pair arranged with opposite sensitivity directions, and with the sensor units arranged to sense magnetic markings of the packaging material. A signal processing assembly is connected to the outputs of the magnetic sensors and comprises a combiner arranged to aggregate the output signals of the sensors to an aggregated signal; and a detector arranged to determine the position of the packaging material from the aggregated signal. Further, a method for detecting a position of a packaging material with magnetic markings is disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

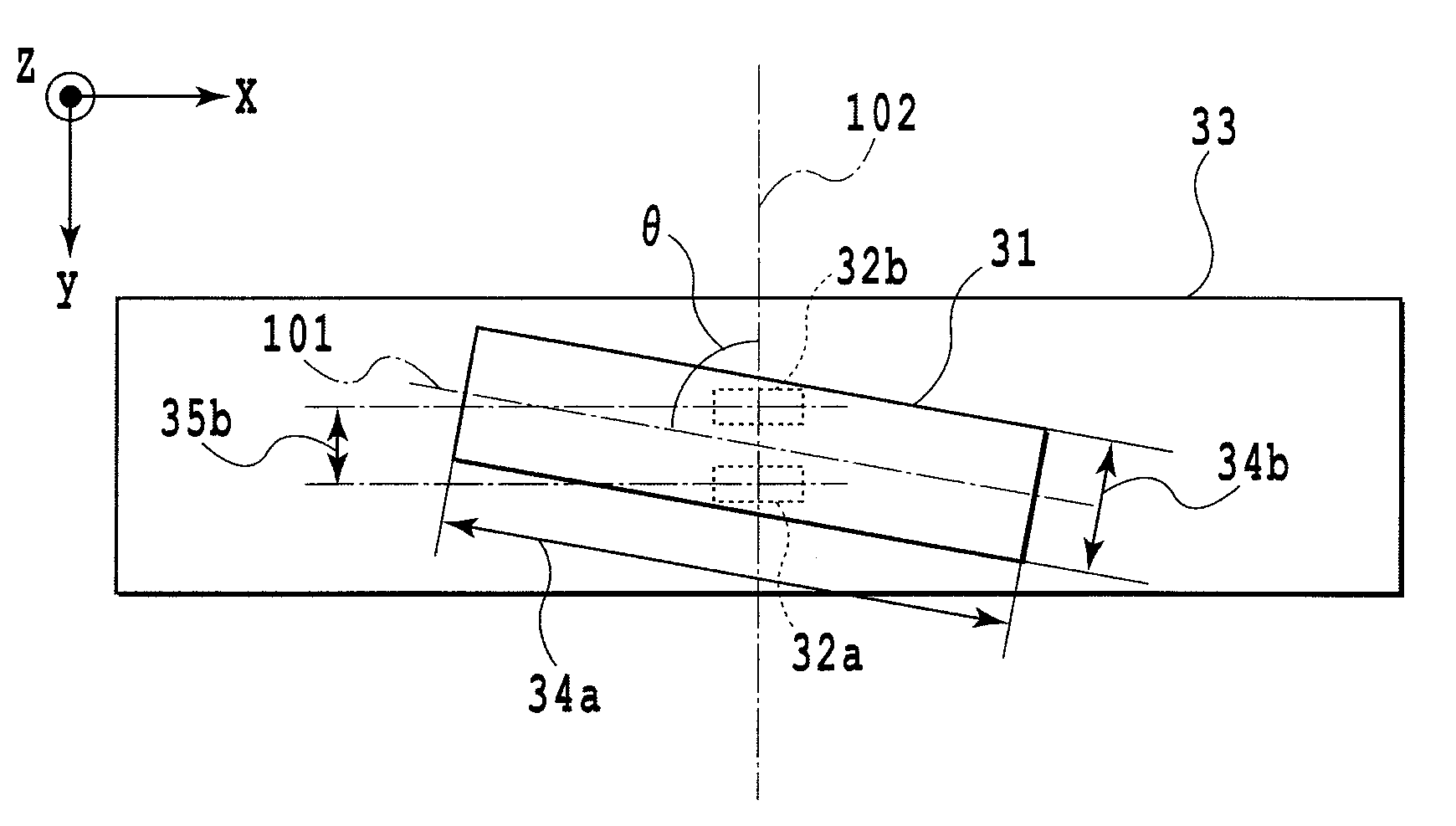

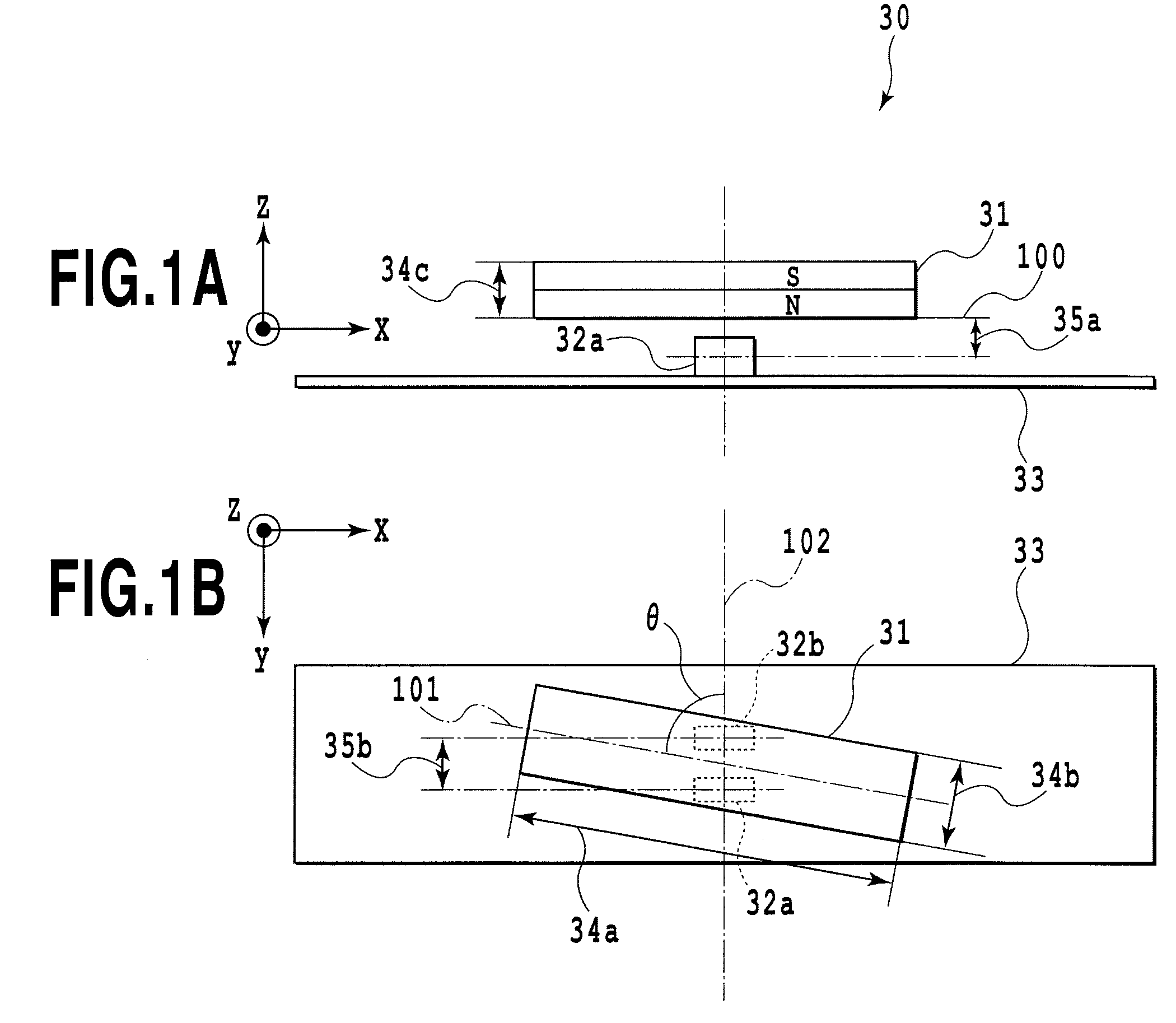

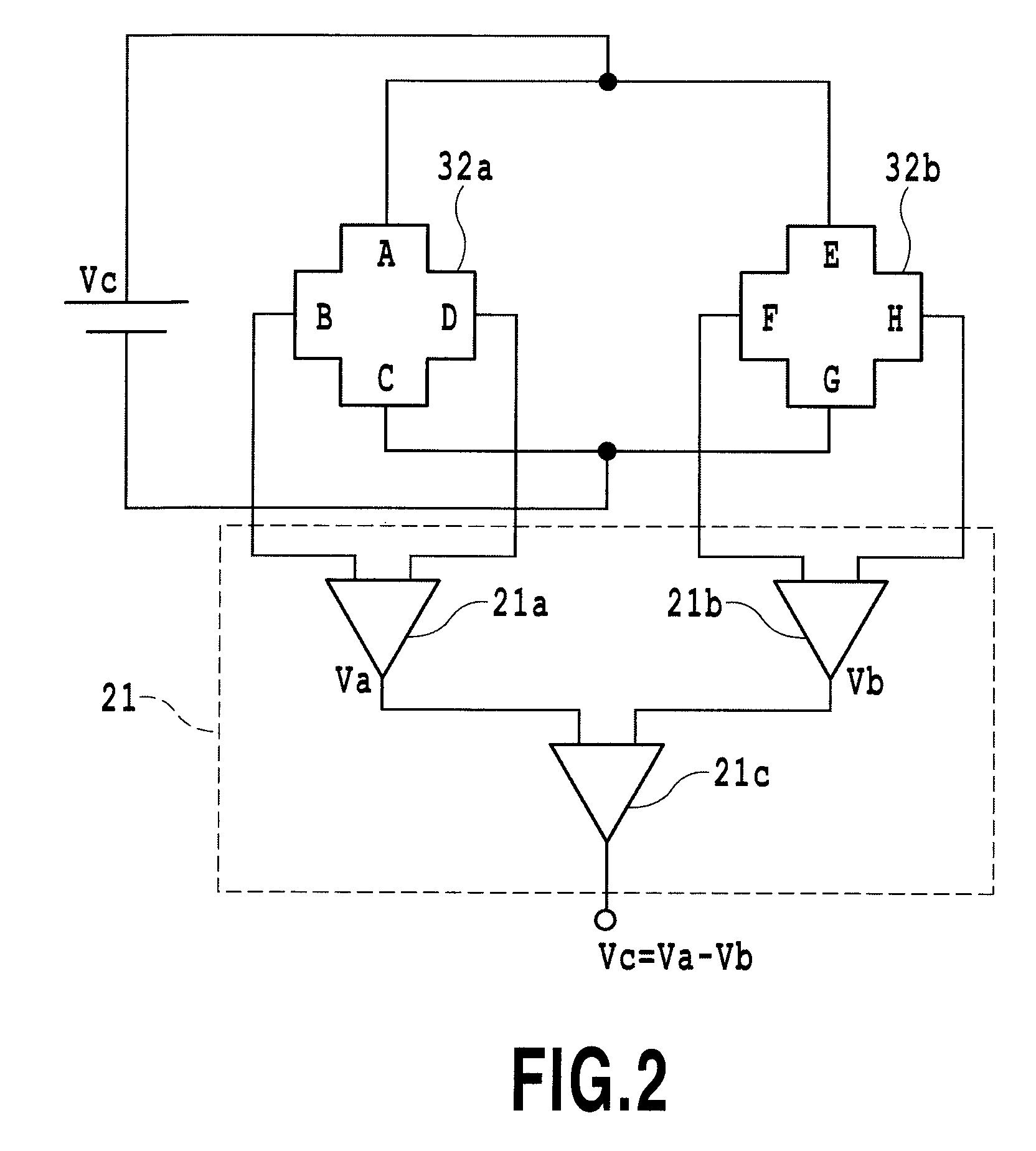

Position detection apparatus

ActiveUS20090045807A1Suppress effect detectionSimple circuit configurationMagnetic-field-controlled resistorsSolid-state devicesLocation detectionMagnetic flux

A magnetic flux detection unit and a rectangular solid magnet are provided. The magnetic flux detection unit includes one or more pairs of Hall sensors, each pair having two Hall sensors arranged on a substrate. The solid magnet is arranged movably in a direction in a plane parallel to the substrate. Each pair of two Hall sensors is arranged on the substrate so that a line connecting the centers of magnetism sensing sections of each pair of two Hall sensors is orthogonal to a movement direction of the magnet. A tetragon has a long side and a short side and the long side has a inclination angle to the line connecting the centers of magnetism sensing sections of the each pair of two Hall sensors. The magnet has one N-pole and one S-pole separately magnetized in orthogonal to the substrate on which the Hall sensors are arranged.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com