System for creating microscopic digital montage images

a technology montage image, applied in the field can solve the problems of limited application of microscopic digital imaging, limited investigators looking at a single frame, and “subsampling” problem in all single frames, and achieve high throughput montage, high-quality montage, and accurate focus control of optical elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The following paragraphs describe the functionality of the inventive system and method for focus controlled, high throughput montage imaging of microscope slides using a standard microscope, camera, and a motorized mechanical stage.

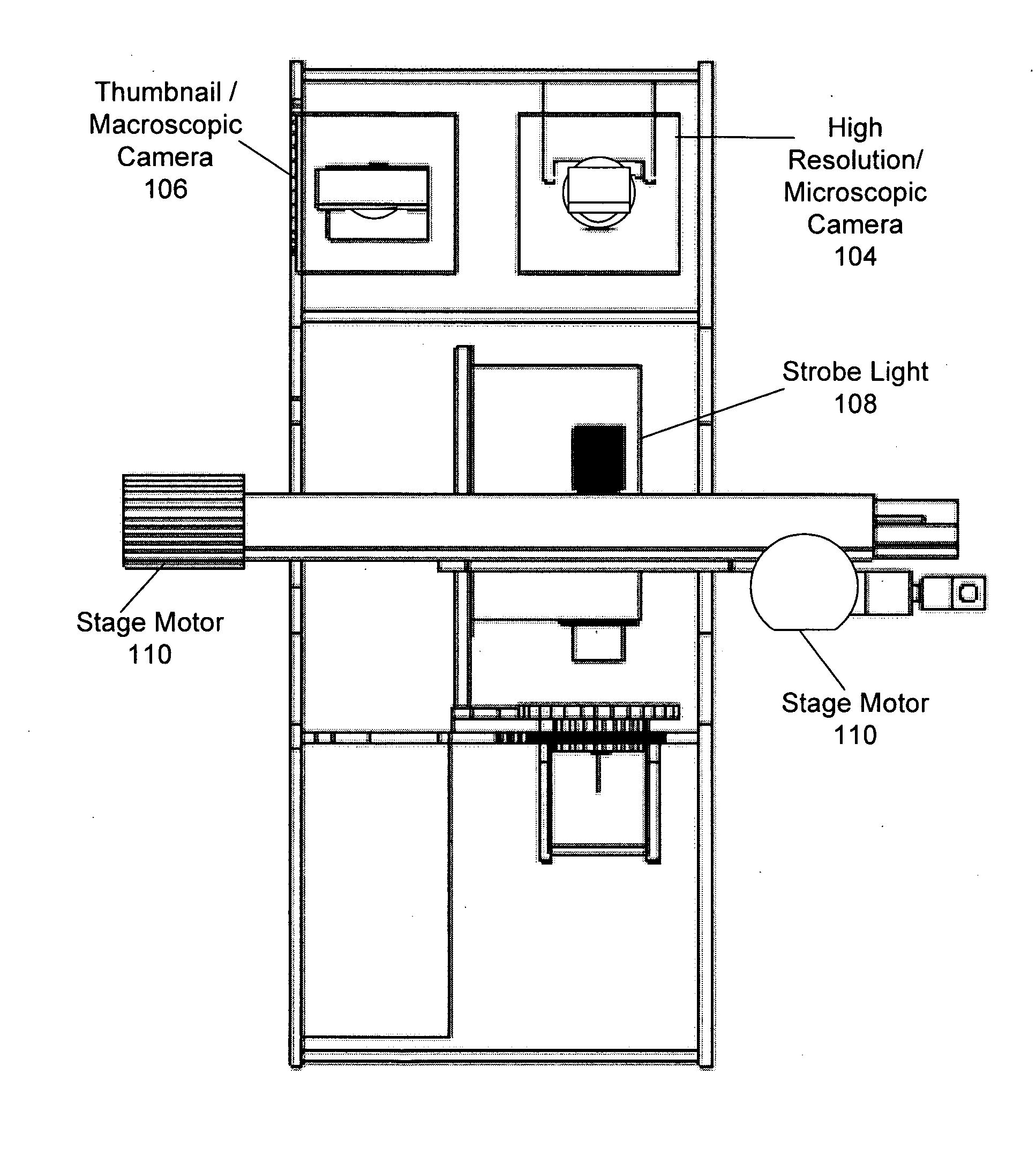

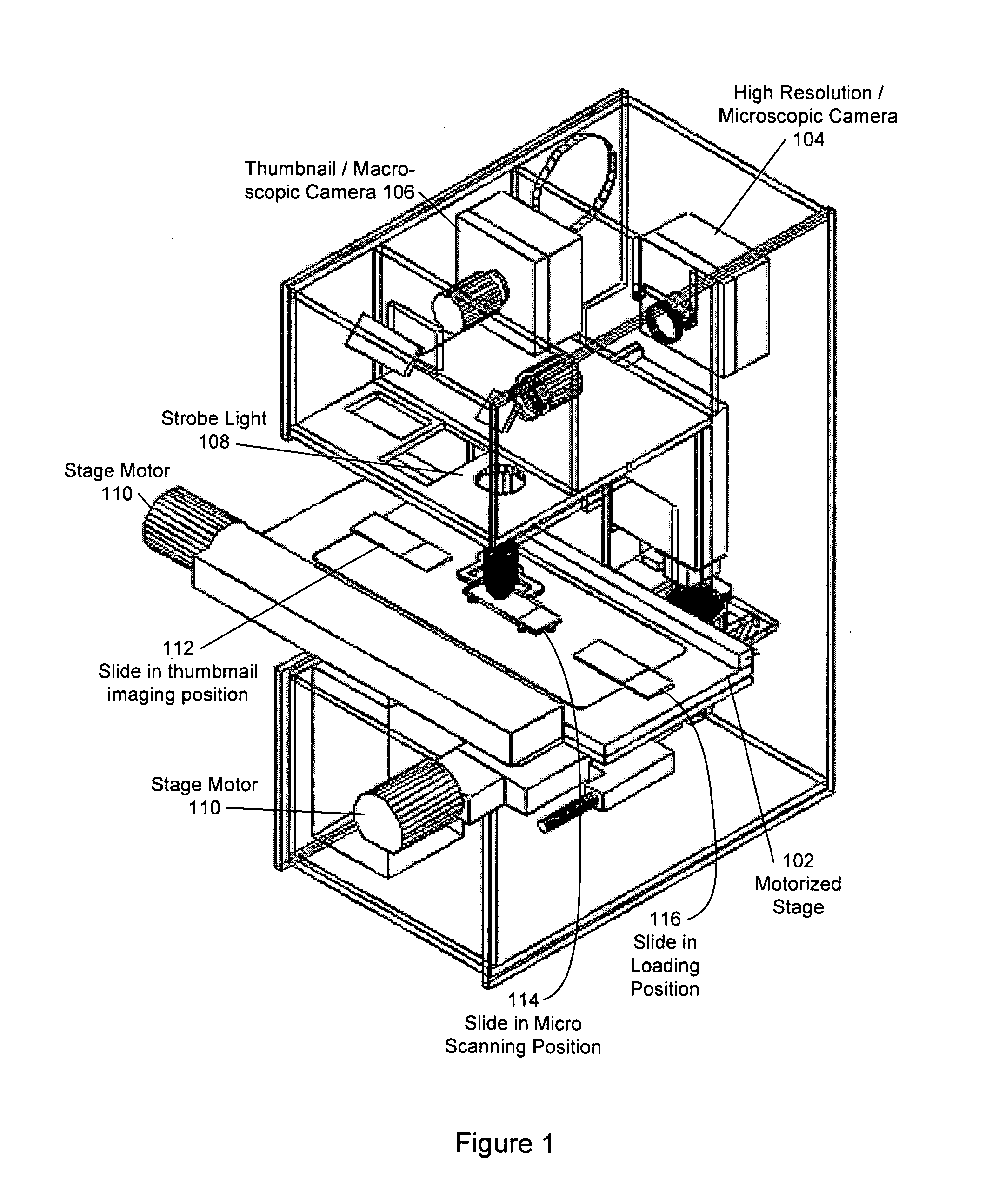

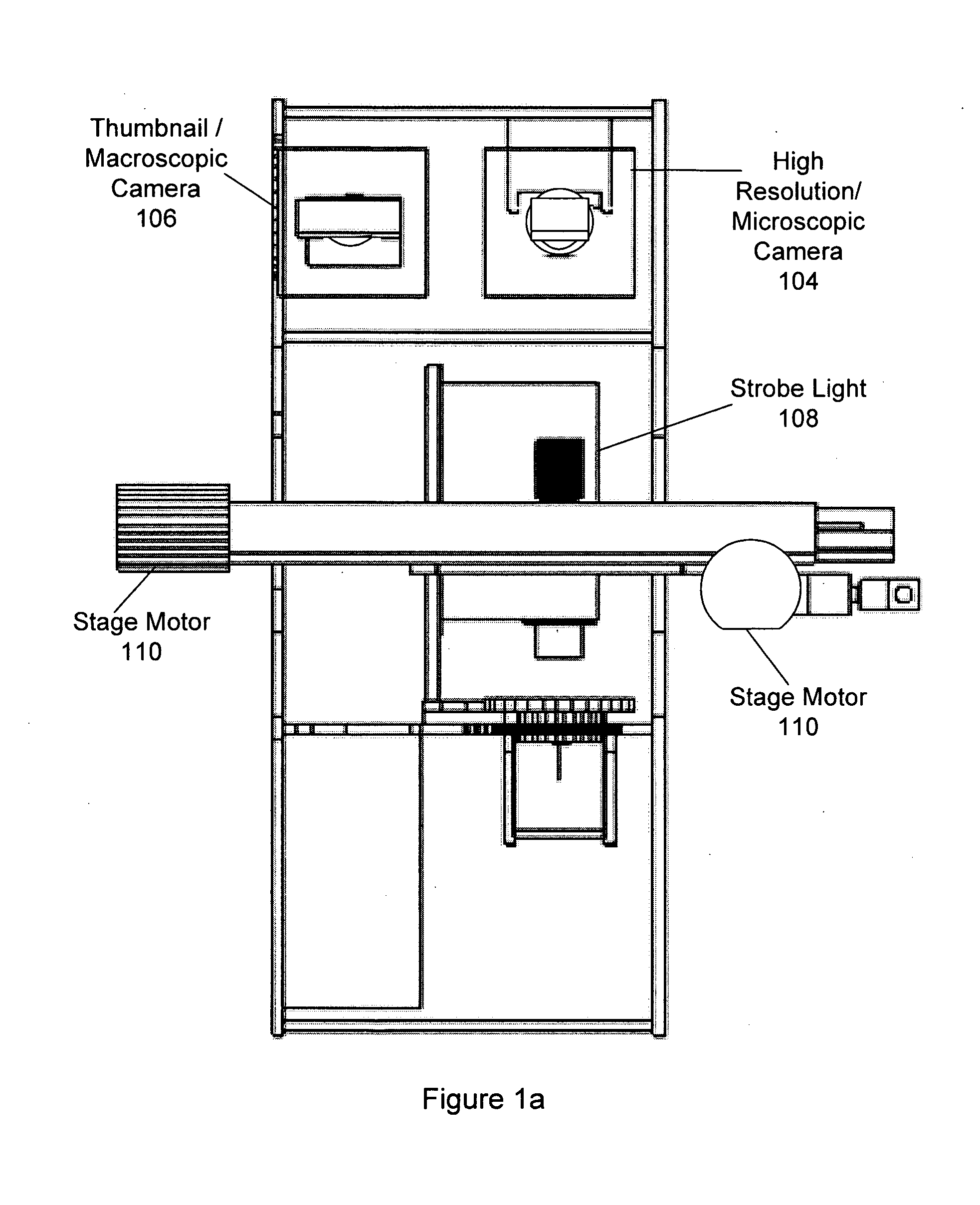

[0035]FIG. 1 illustrates a first embodiment of the imaging apparatus of the present invention. FIGS. 1a-1c illustrate front, side, and top views, respectively, of the imaging apparatus illustrated in FIG. 1. It should be noted that not all components that may be included in an imaging apparatus are illustrated in FIGS. 1-1c. For example, a stage support that attaches the stage to the imaging apparatus is not illustrated so as not to obstruct the view of other components. In this embodiment, a slide 112 to be imaged is placed on a thumbnail imaging position in a slide holder on a motorized stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com