Blade-type composite pneumatic energy collector

An energy harvester and blade-type technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as high operating frequency, small amplitude, and complex structure , to achieve the effect of increasing the frictional voltage output, increasing the piezoelectric voltage output, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the prior art, wind energy harvesters that can achieve high output are usually large in size and complex in structure. Although the existing wind energy harvester with cantilever beam structure is simple in structure and small in size, its high operating frequency and small amplitude lead to low voltage output and it is difficult to obtain ideal power output.

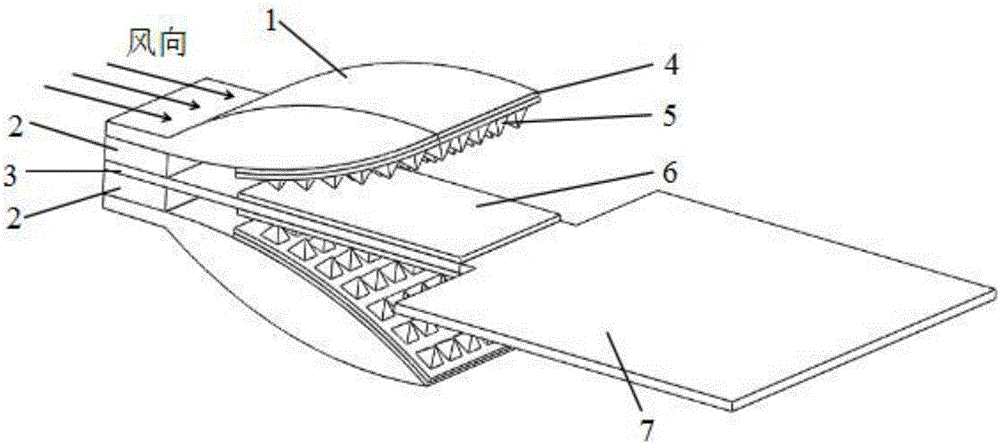

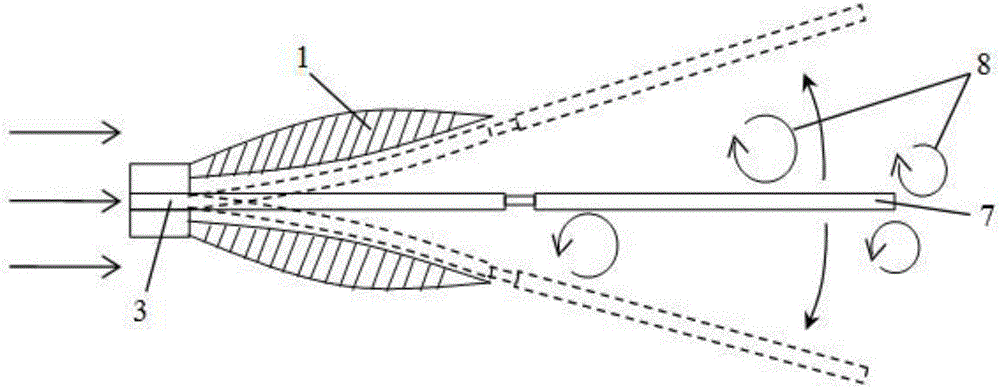

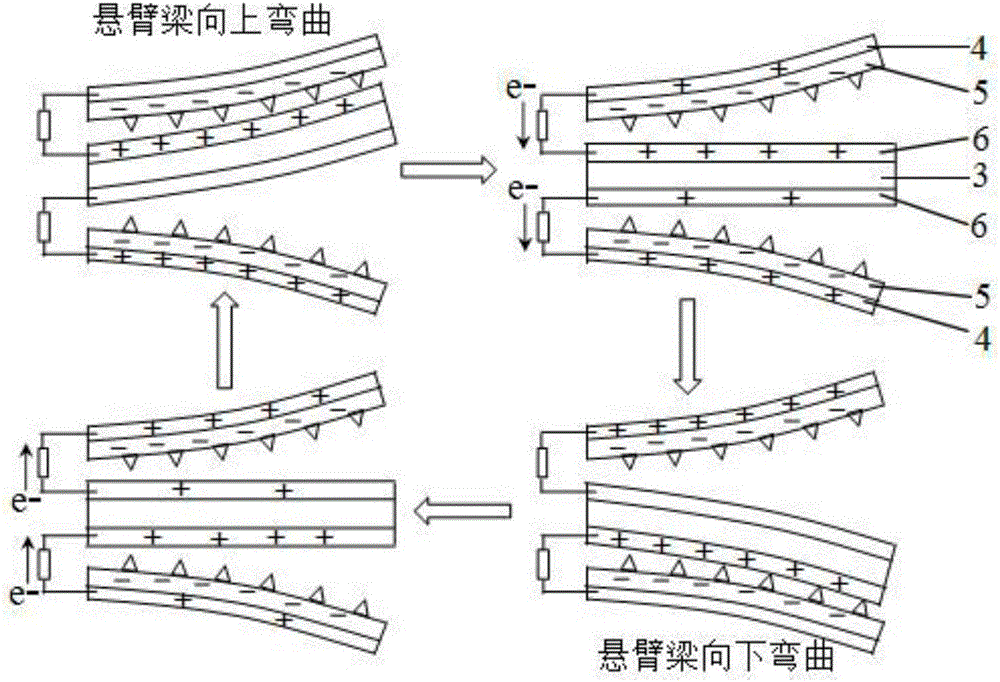

[0026] Aiming at the deficiencies of the prior art, the present invention provides a wind energy collector capable of efficiently converting wind energy into electric energy at low wind speeds and featuring high amplitude and high output. A blade-type composite wind energy harvester has two voltage output modes that cooperate with each other, a piezoelectric type and a friction type, and includes a piezoelectric energy harvesting module and a frictional energy harvesting module.

[0027] The piezoelectric energy harvesting module includes blades and flexible piezoelectric cantilever arms, the blades are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com