Patents

Literature

194 results about "Phosphor bronze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphor bronze is an alloy of copper with 0.5–11% of tin and 0.01–0.35% phosphorus. The tin increases the corrosion resistance and strength of the alloy. The phosphorus increases the wear resistance and stiffness of the alloy.

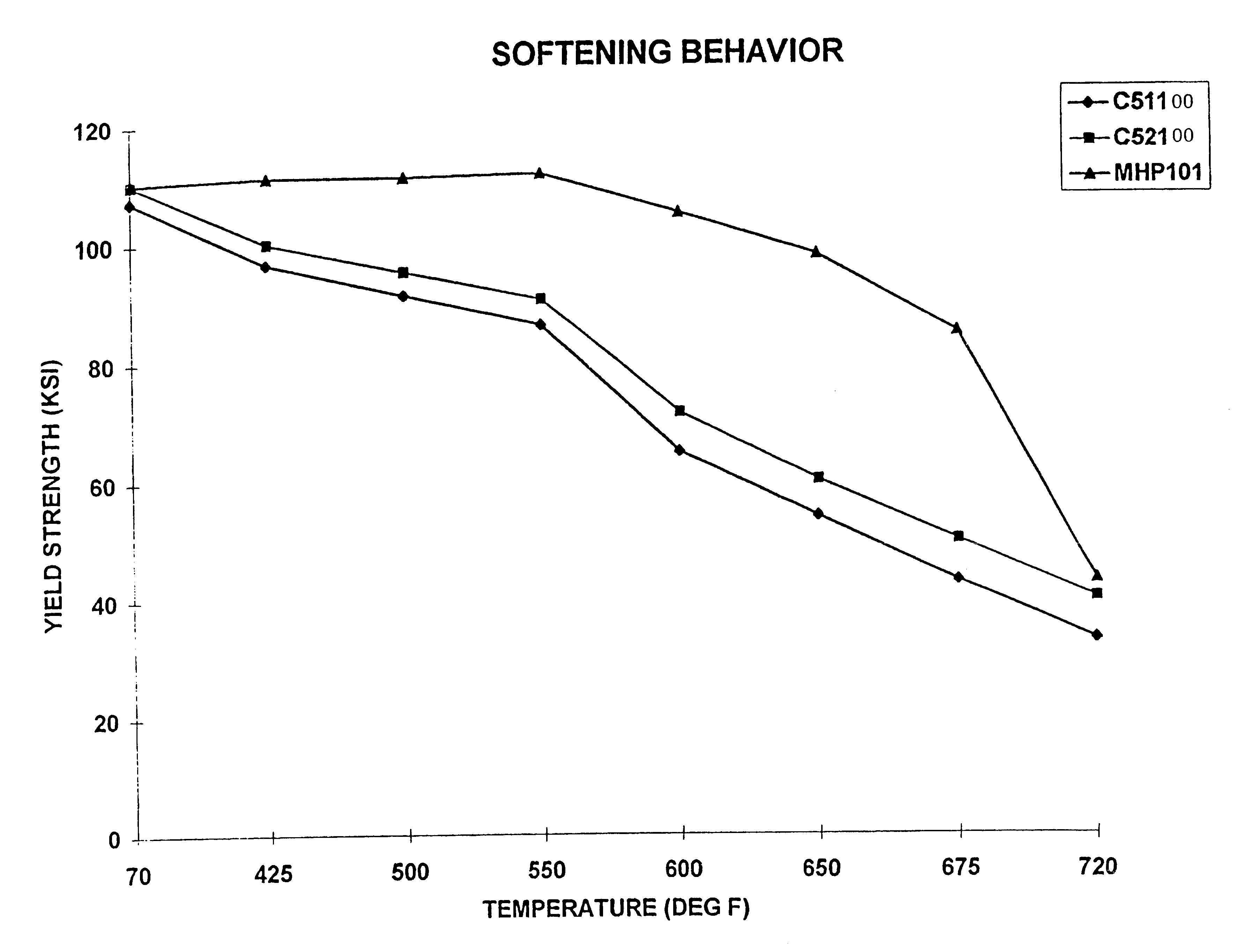

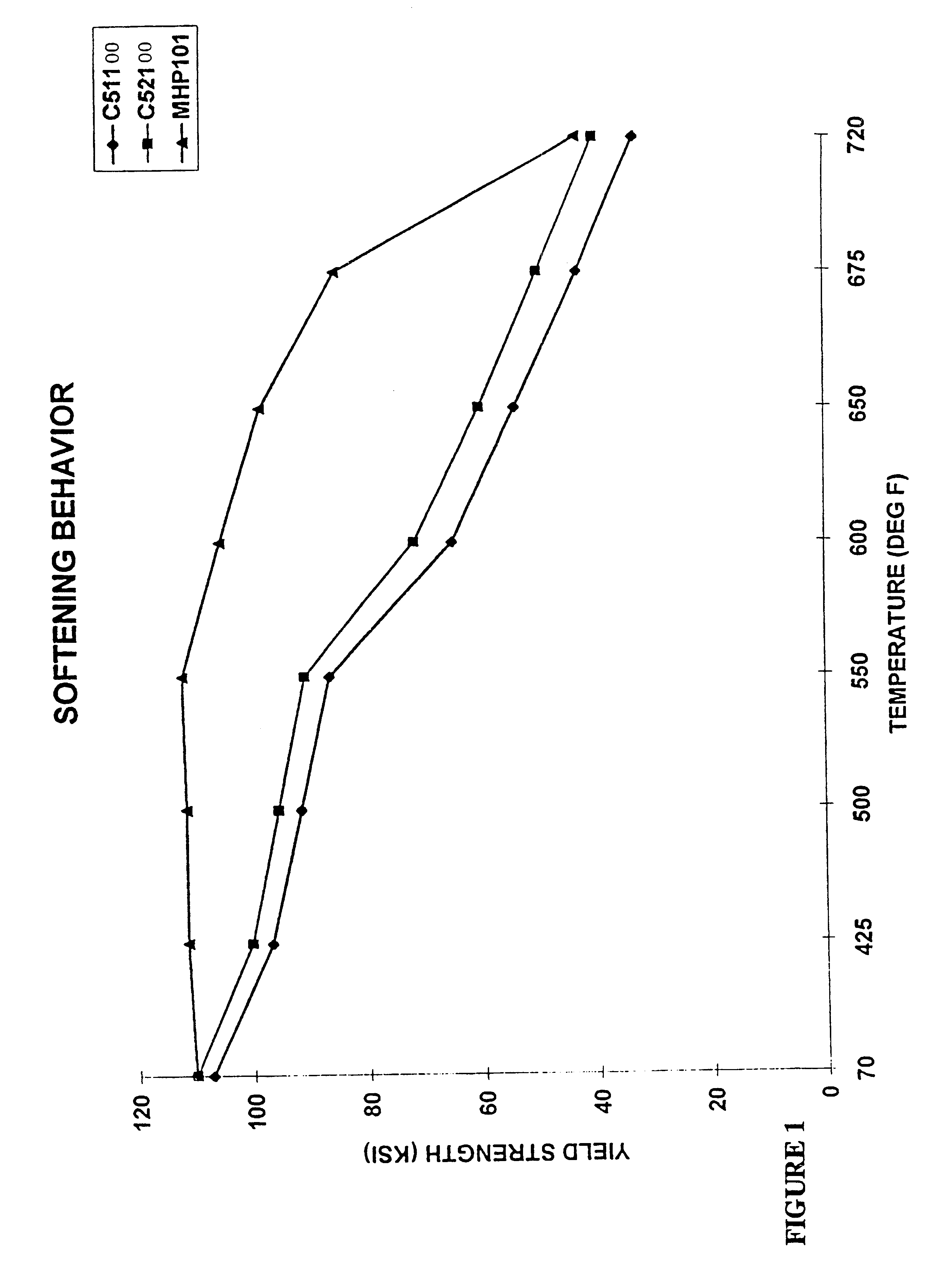

Copper based alloy featuring precipitation hardening and solid-solution hardening

InactiveUS6379478B1Good molding effectOptimal spring propertyCoupling contact membersPhosphor bronzeSolid solution

Owner:MILLER THE

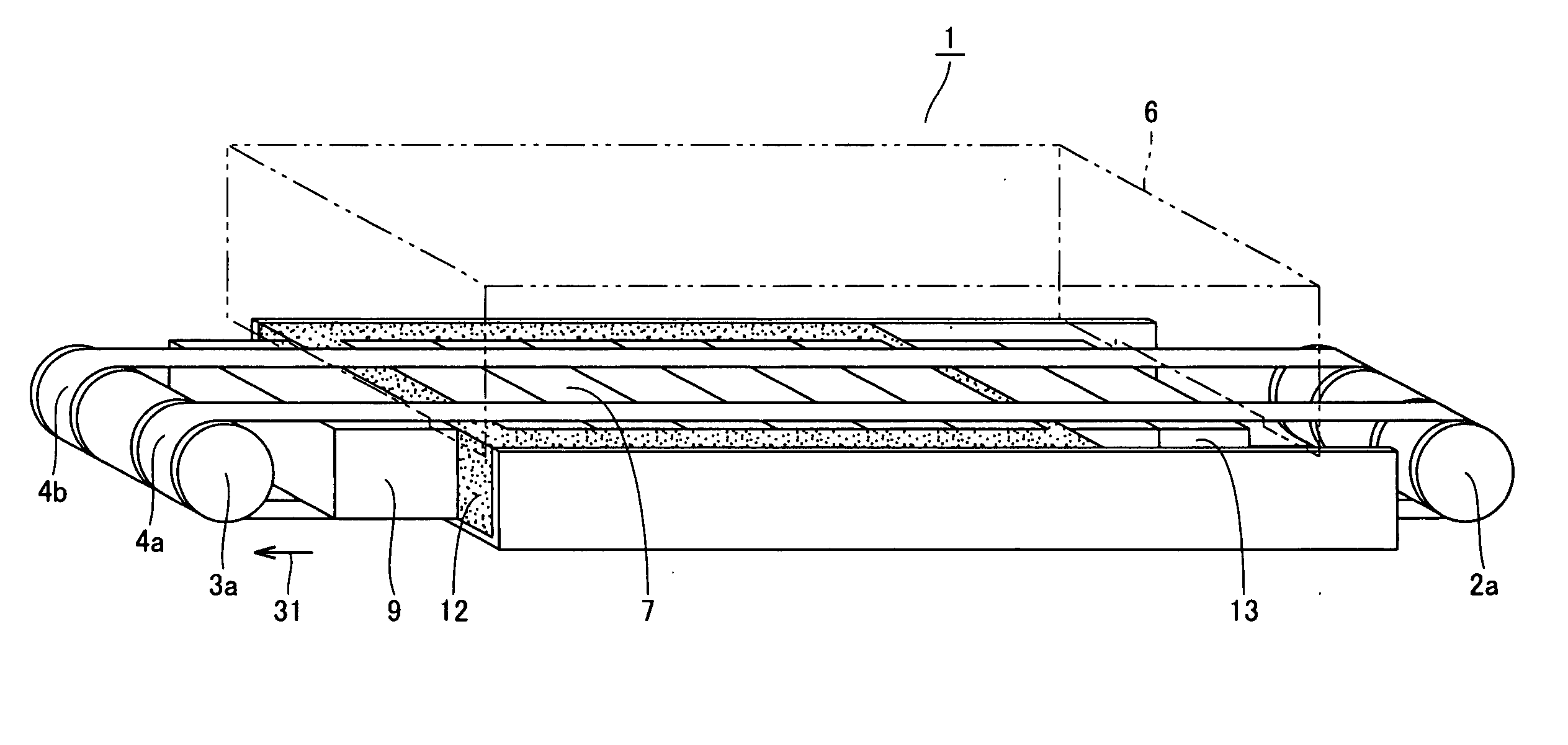

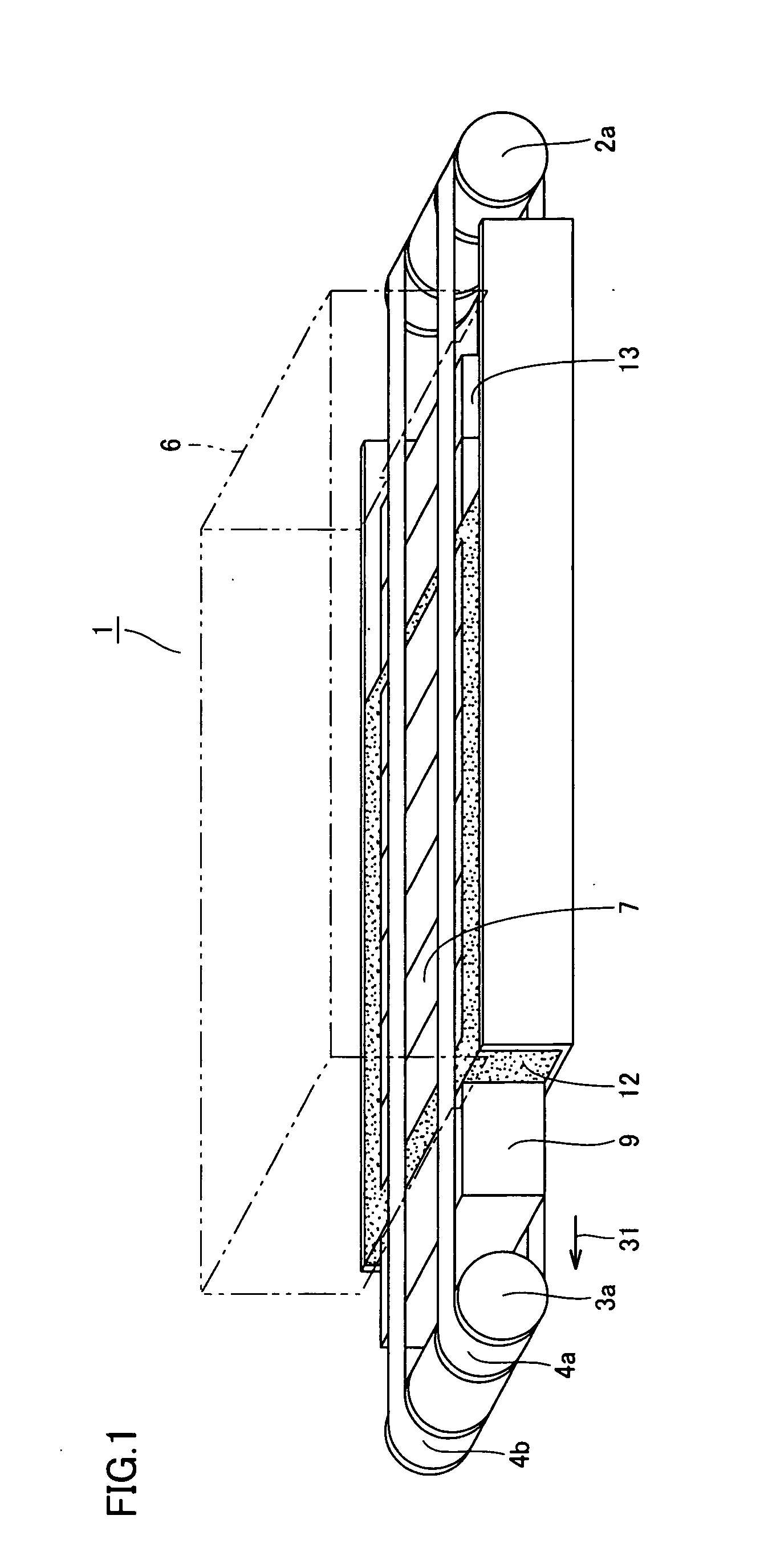

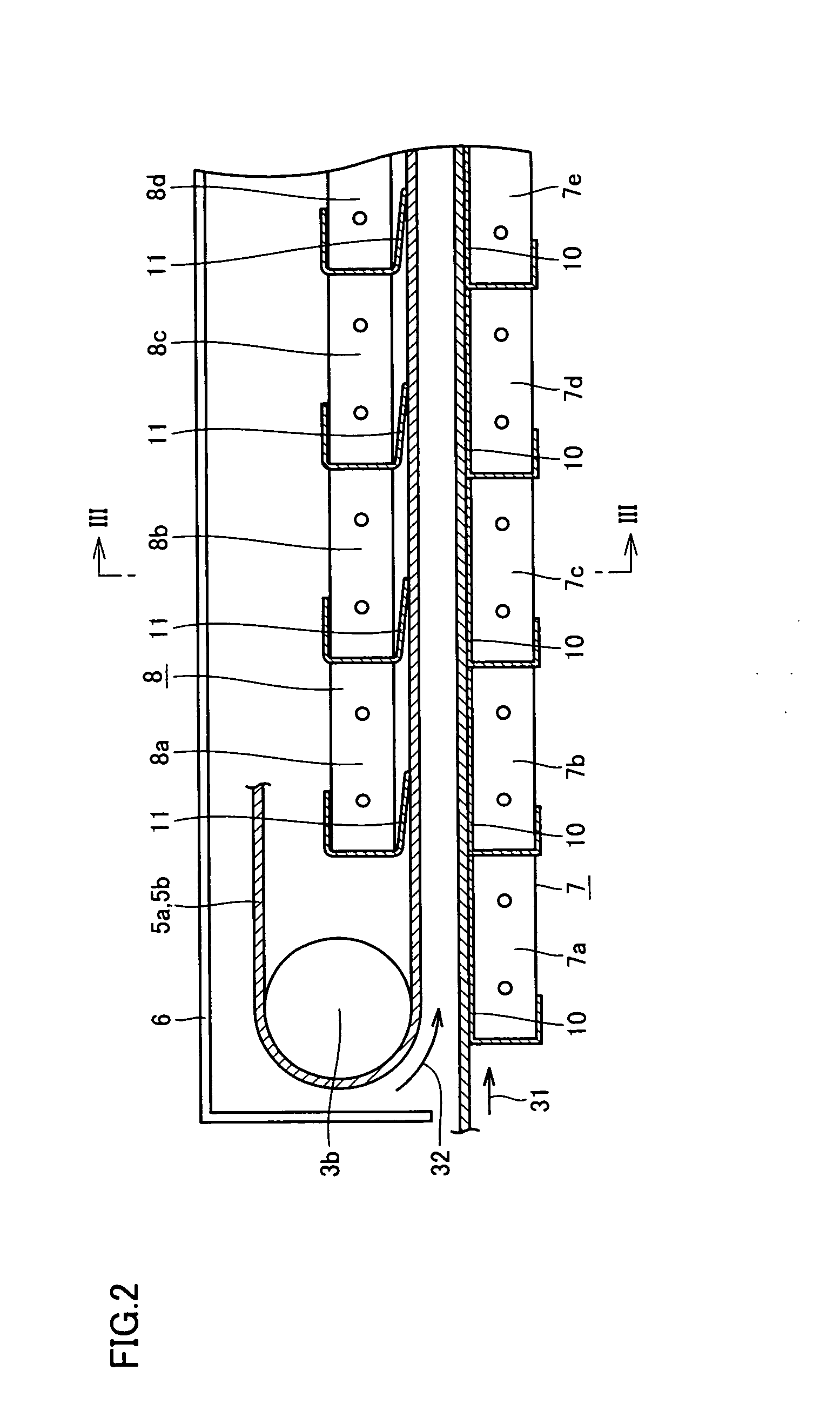

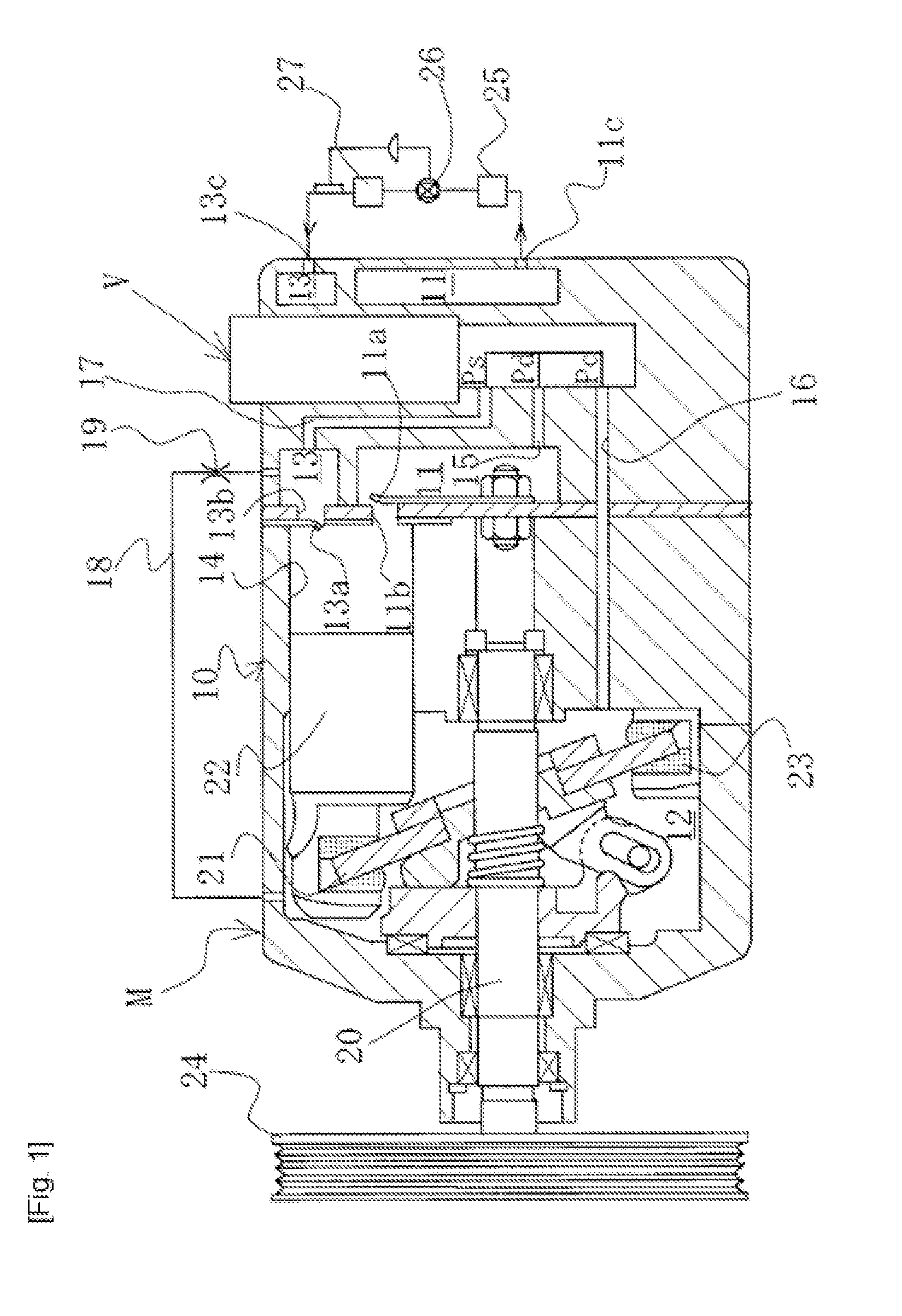

Solar Cell Fabrication Apparatus

InactiveUS20080061111A1Improvement of solar cell yieldReduce generationWelding/cutting auxillary devicesAuxillary welding devicesPhosphor bronzeElectrical battery

A solar cell fabrication apparatus includes a lower belt carrying a solar cell main body and tab lead to convey the same, and an upper belt pressing the same. A phosphor bronze plate is provided to apply an urging force against upper belts towards the lower belt. A plurality of lower heater blocks and upper heater blocks to heat a solar cell main body and tab lead from below and above, respectively, and a plurality of lower cooling blocks and upper cooling blocks to cool the same are provided. Lower heater blocks and upper heater blocks are surrounded by a heat insulator along the transportation direction.

Owner:MECH CORP

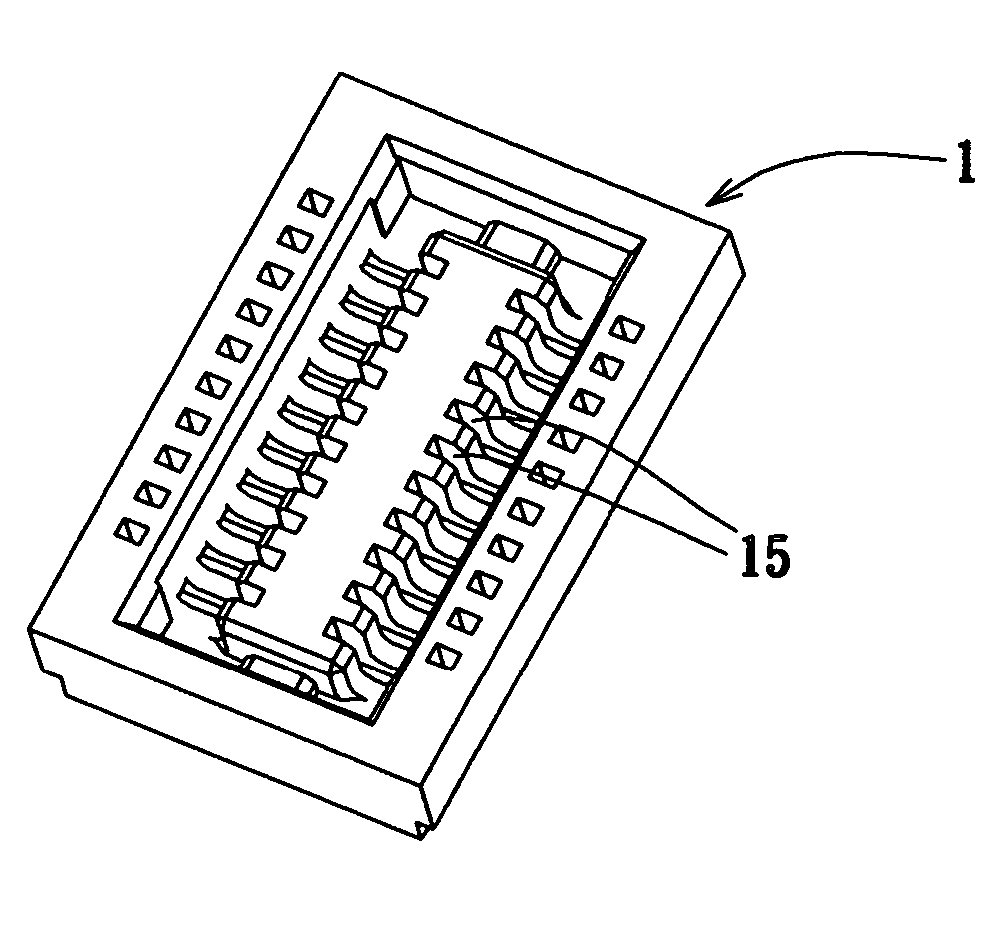

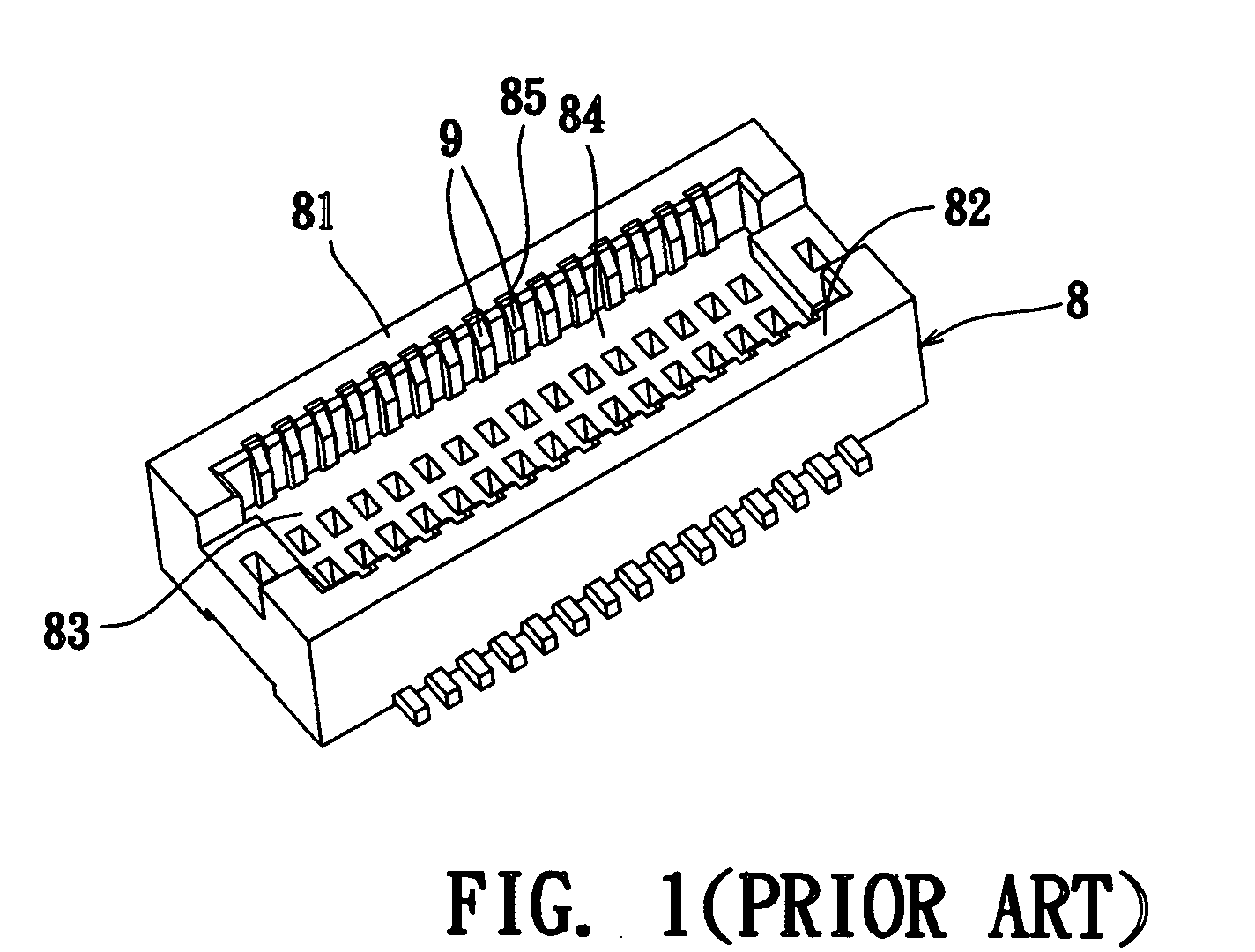

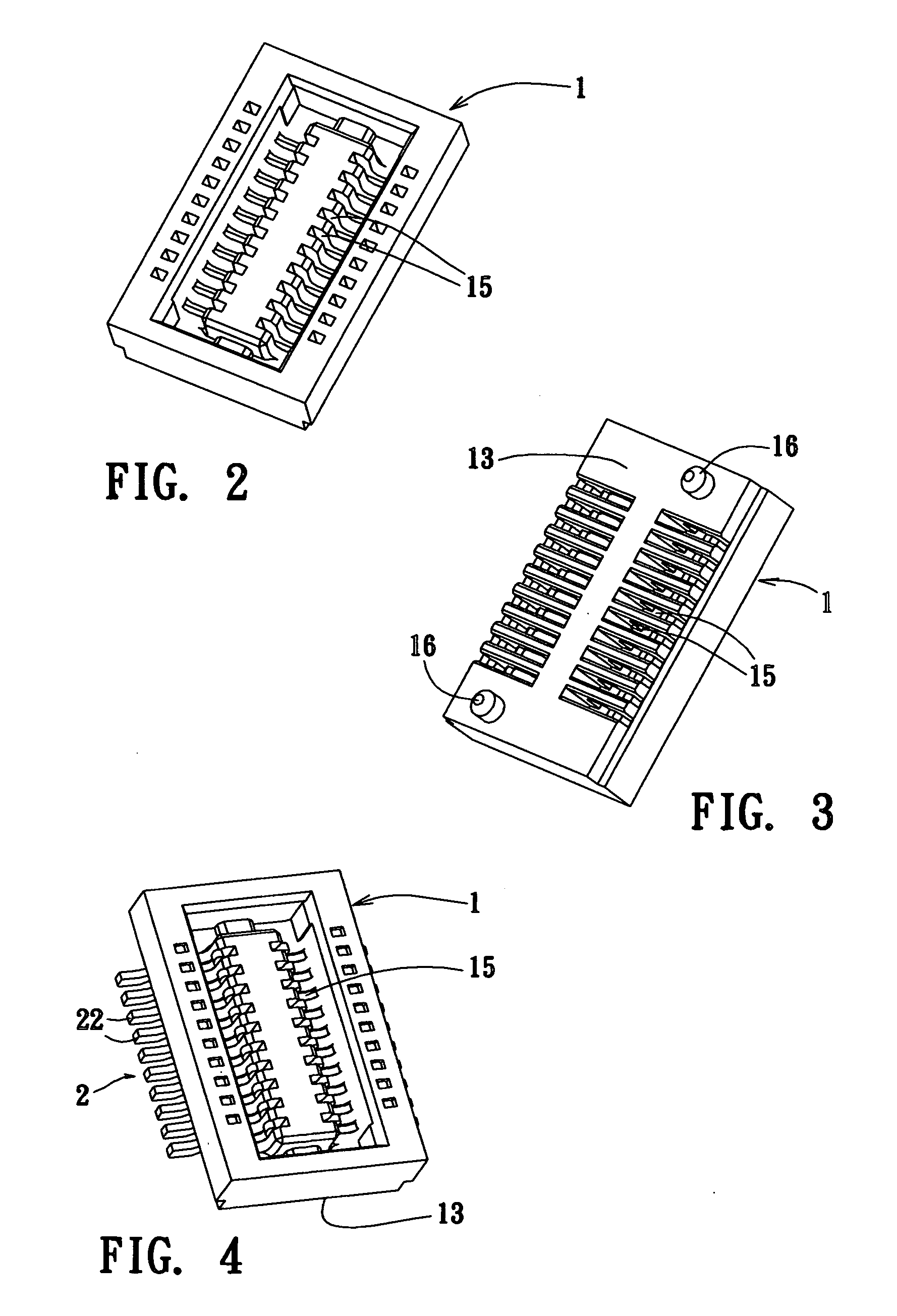

Electrical connector

InactiveUS20050191877A1Improve heat resistanceGood formabilityPrinted circuitsPhosphor bronzeSurface mounting

An electrical connector comprising a rectangular insulated body and a plurality of electrical pins has been described and claimed. The insulated body is made of a liquid crystal polymer (LCP) with good heat resistance and flow molding properties; the electrical pins are made of phosphor bronze with better elasticity. The insulated body has a bottom wall for contacting PCB, a plurality of pin containers passing through the bottom wall for containing the electrical pins, and a plurality of protruding pillars under the bottom wall, corresponding in position to holes on the PCB such that the insulated body can be positioned accurately on the PCB with the protruding pillars. A soldering section is on each electrical pin to be soldered onto the PCB using SMT (Surface Mount Technology).

Owner:NELTRON INDAL

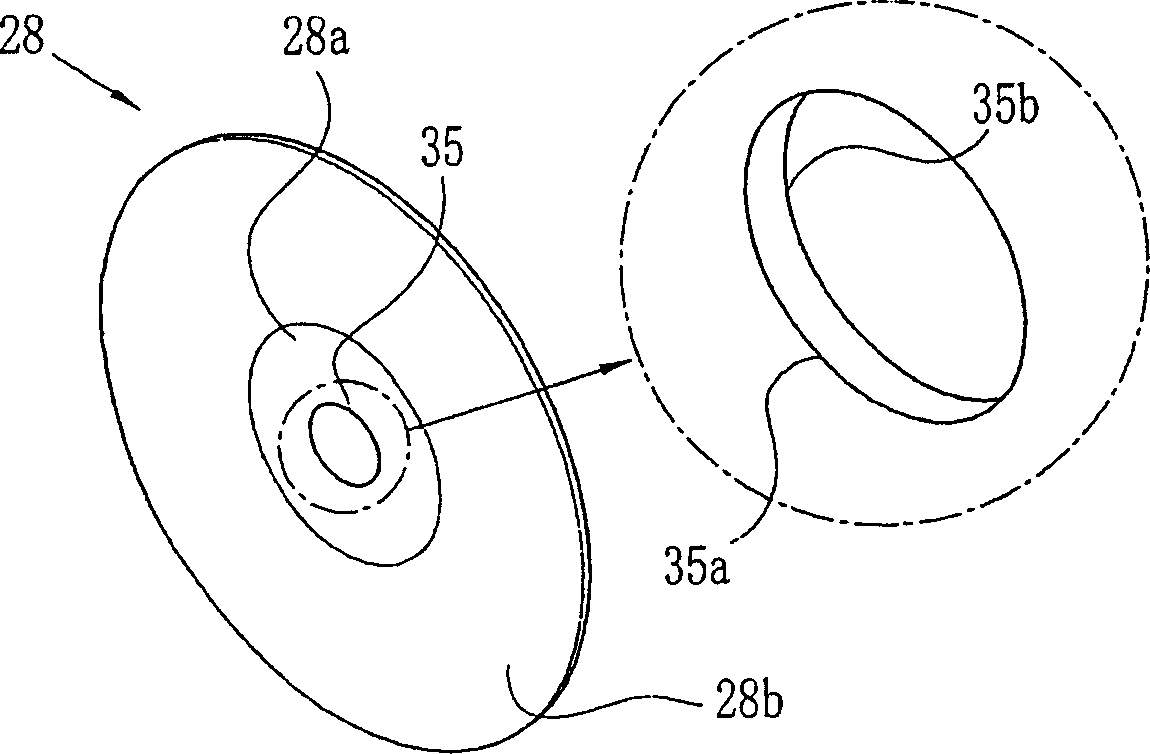

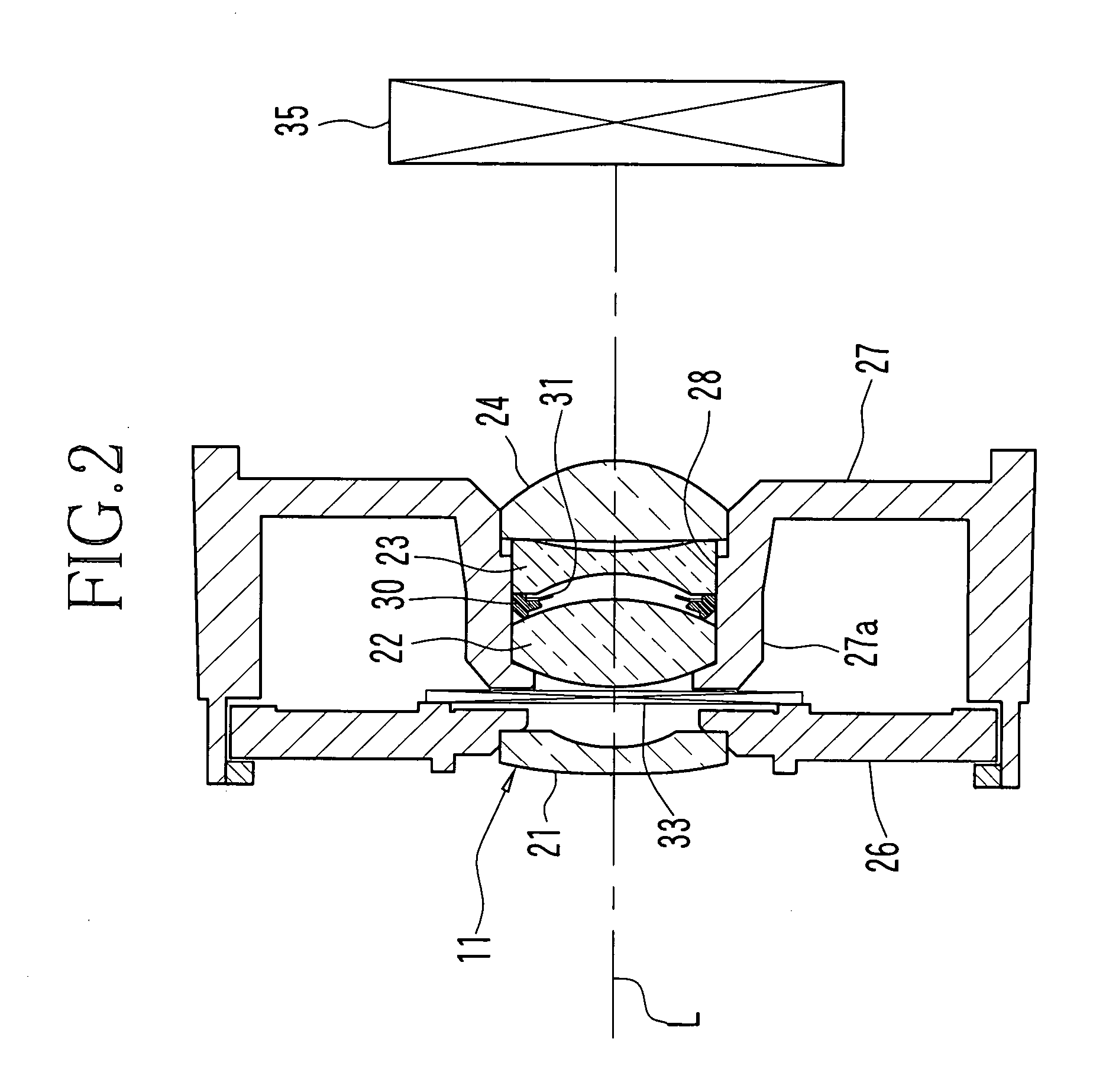

Aperture board

To provide a diaphragm plate which has sufficient strength and doesn't transmit light and suppresses the occurrence of flare and ghost. A diaphragm plate 28 is made of, for example, phosphor bronze or stainless steel. The diaphragm plate 28 comprises a first tabular portion 28a having a diaphragm aperture 35 formed therein and a second tabular portion 28b formed surrounding the periphery of the first tabular portion 28a. The first tabular portion 28a is made thinner than the second tabular portion 28b. An entrance peripheral portion 35d and an exit peripheral portion 25e are formed in an inner peripheral surface 35c of the diaphragm aperture 35. The entrance peripheral portion 35d and the exit peripheral portion 25e are formed circularly. Therefore, the diameter of the diaphragm aperture 35 is made gradually larger according as going toward an entrance 35a and an exit 35b. The inner peripheral surface 35c is coated with a paint preventing reflection of light.

Owner:FUJI PHOTO OPTICAL CO LTD

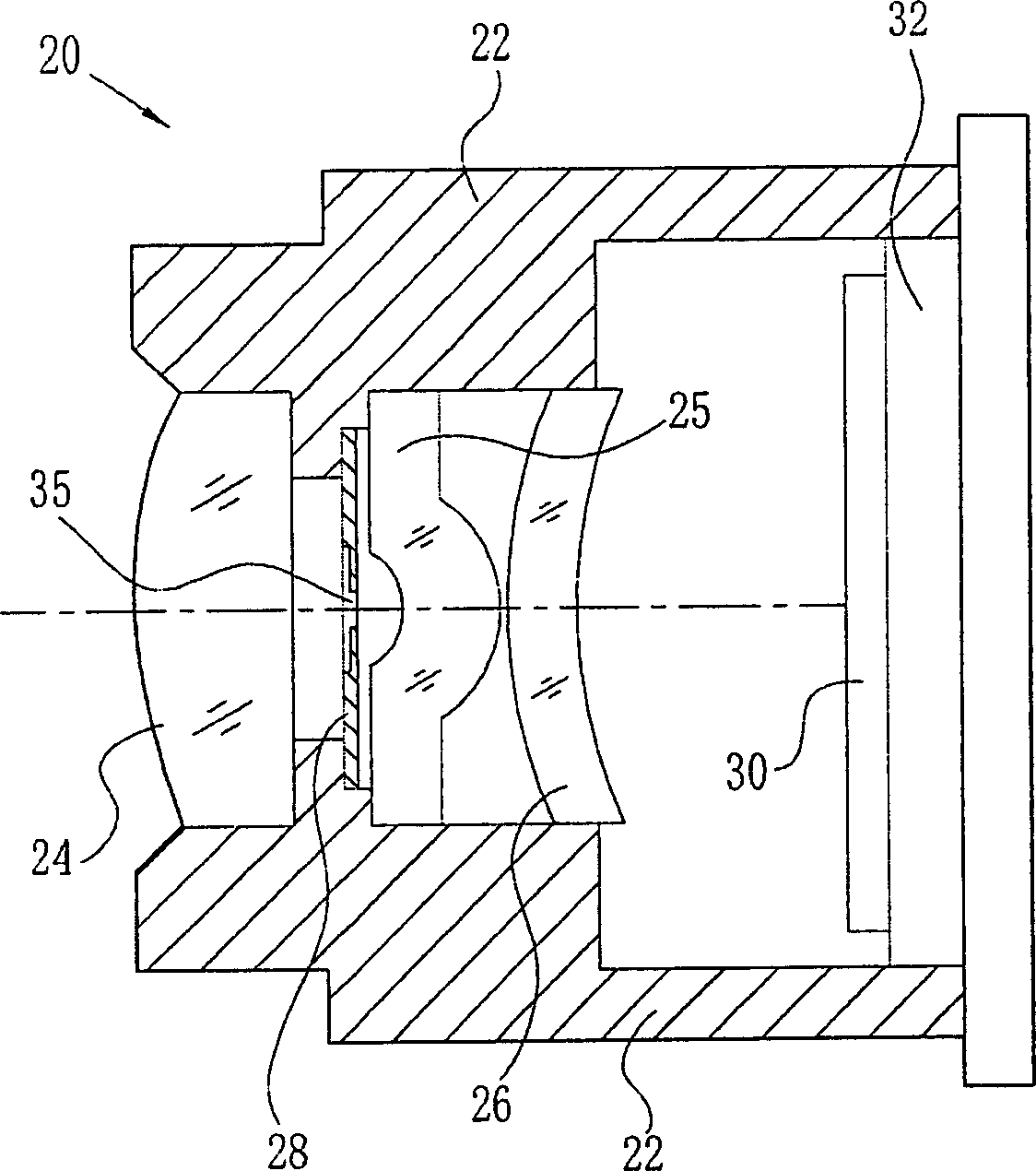

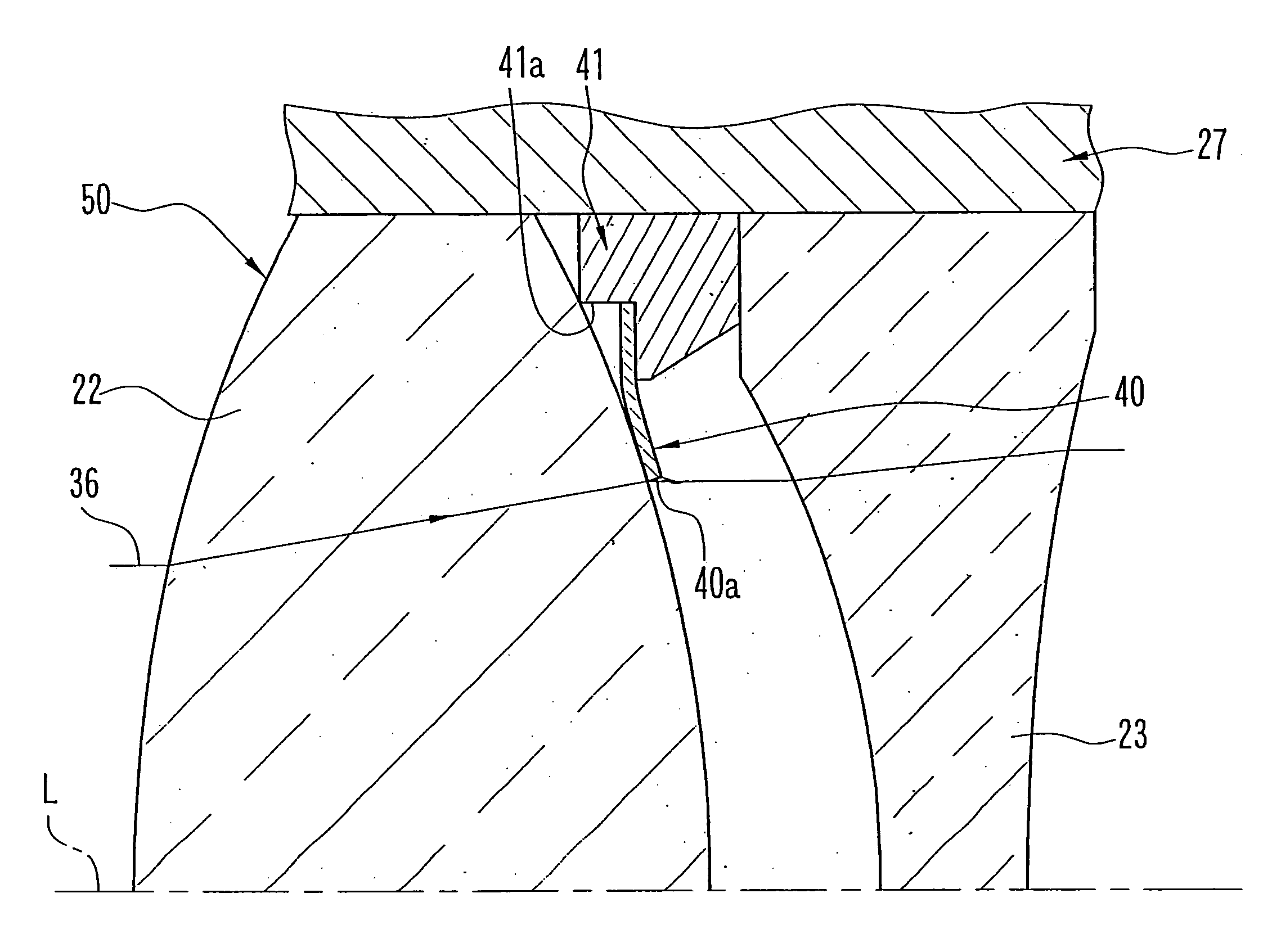

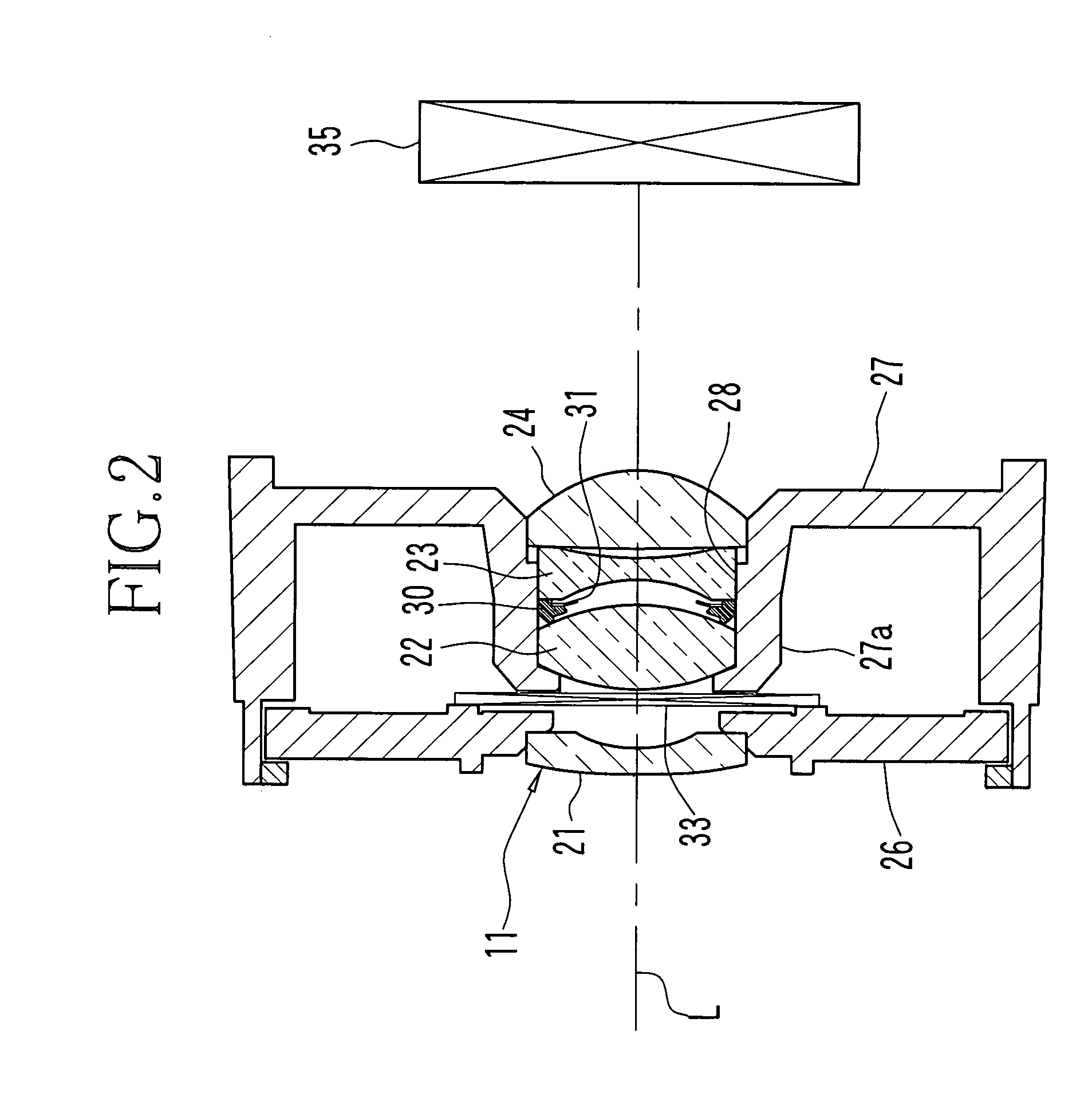

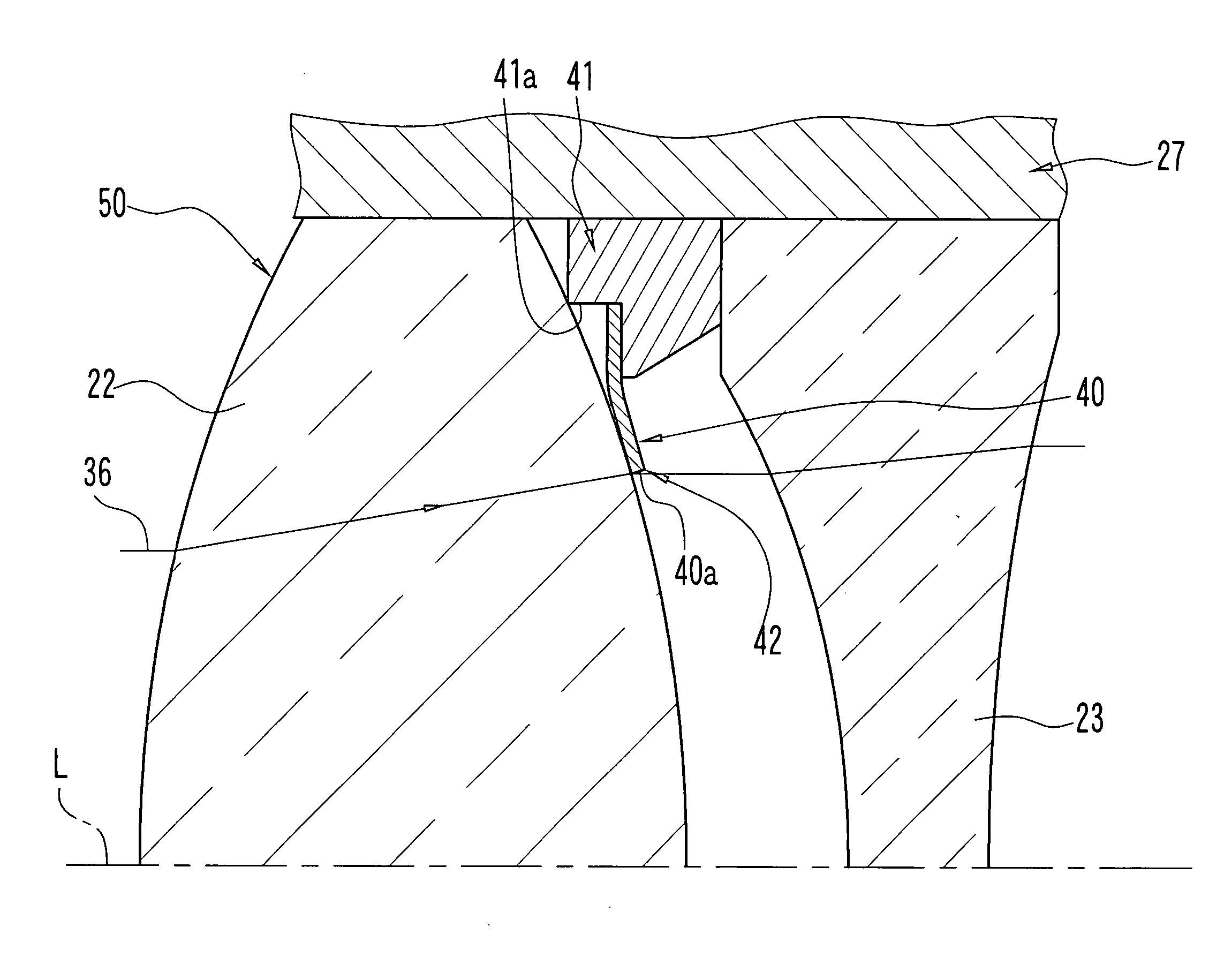

Flare stoppper and taking lens unit

InactiveUS7158318B2Reduce generationReduce occurrenceMicroscopesTelescopesCamera lensPhosphor bronze

A ring-shaped flare stopper is made of a phosphor bronze plate having a thickness of 0.03 mm by sheet metal stamping. An inner periphery for defining a circular opening is formed in the flare stopper. The inner periphery has the form of the side face of a circular truncated cone. The flare stopper is so installed in a lens barrel that the inner periphery is inclined with respect to an optical axis of a taking lens unit. Since incident light is not reflected by the inner periphery of the flare stopper, the occurrence of ghost and flare is prevented. To prevent the deformation and misalignment of the flare stopper, the flare stopper installed in the lens barrel is attached to a spacer.

Owner:FUJI PHOTO OPTICAL CO LTD

Flare stopper and taking lens unit

A ring-shaped flare stopper is made of a phosphor bronze plate having a thickness of 0.03 mm by sheet metal stamping. An inner periphery for defining a circular opening is formed in the flare stopper. The inner periphery has the form of the side face of a circular truncated cone. The flare stopper is so installed in a lens barrel that the inner periphery is inclined with respect to an optical axis of a taking lens unit. Since incident light is not reflected by the inner periphery of the flare stopper, the occurrence of ghost and flare is prevented. To prevent the deformation and misalignment of the flare stopper, the flare stopper installed in the lens barrel is attached to a spacer.

Owner:FUJI PHOTO OPTICAL CO LTD

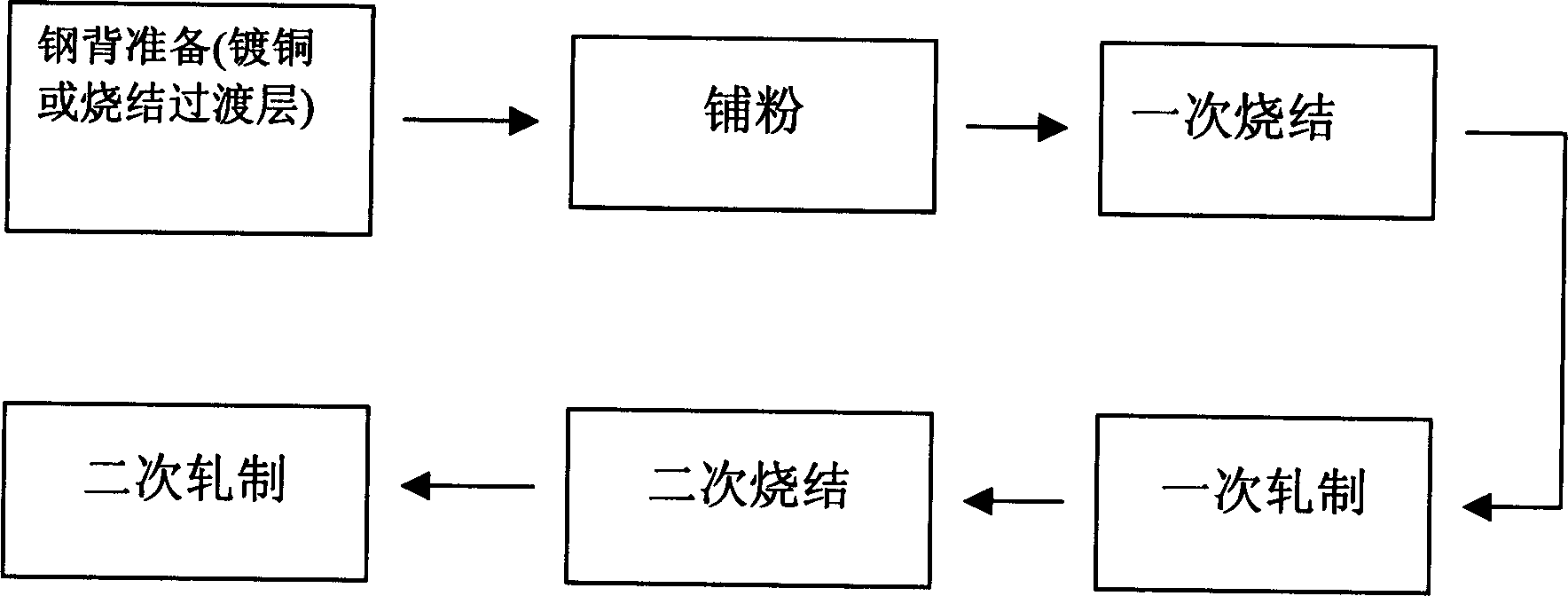

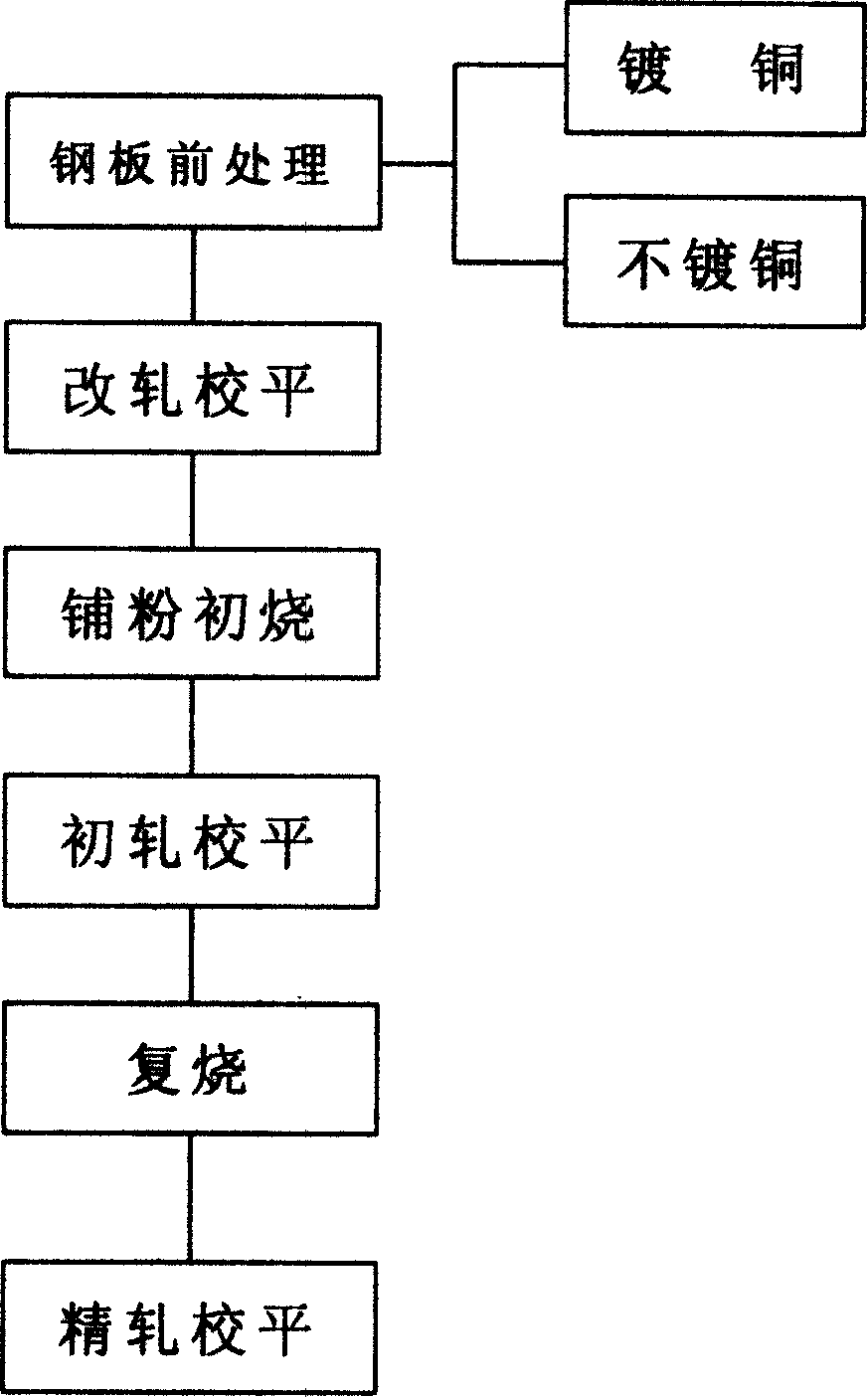

Process for manufacturing phosphor bronze-steel bimetal bearing material with phosphor content more than 0.1%

The present invention relates to a preparation process of phosphorus bronze-steel bimetallic bearing material in which the phosphorus content is greater than 0.1%. its preparation process includes the following steps: on the steel back of previously-prepared carbon constructional steel with required grade and thickness setting a metal or alloy transition layer with proper thickness, then uniformly spreading phosphorus bronze alloy powder with a certain phosphorus content on the steel back and making it have a certain thickness, then adopting first sintering step, first rolling step, secondary sintering step and secondary rolling step so as to obtain the invented product.

Owner:SHANGHAI HEWEI IND +1

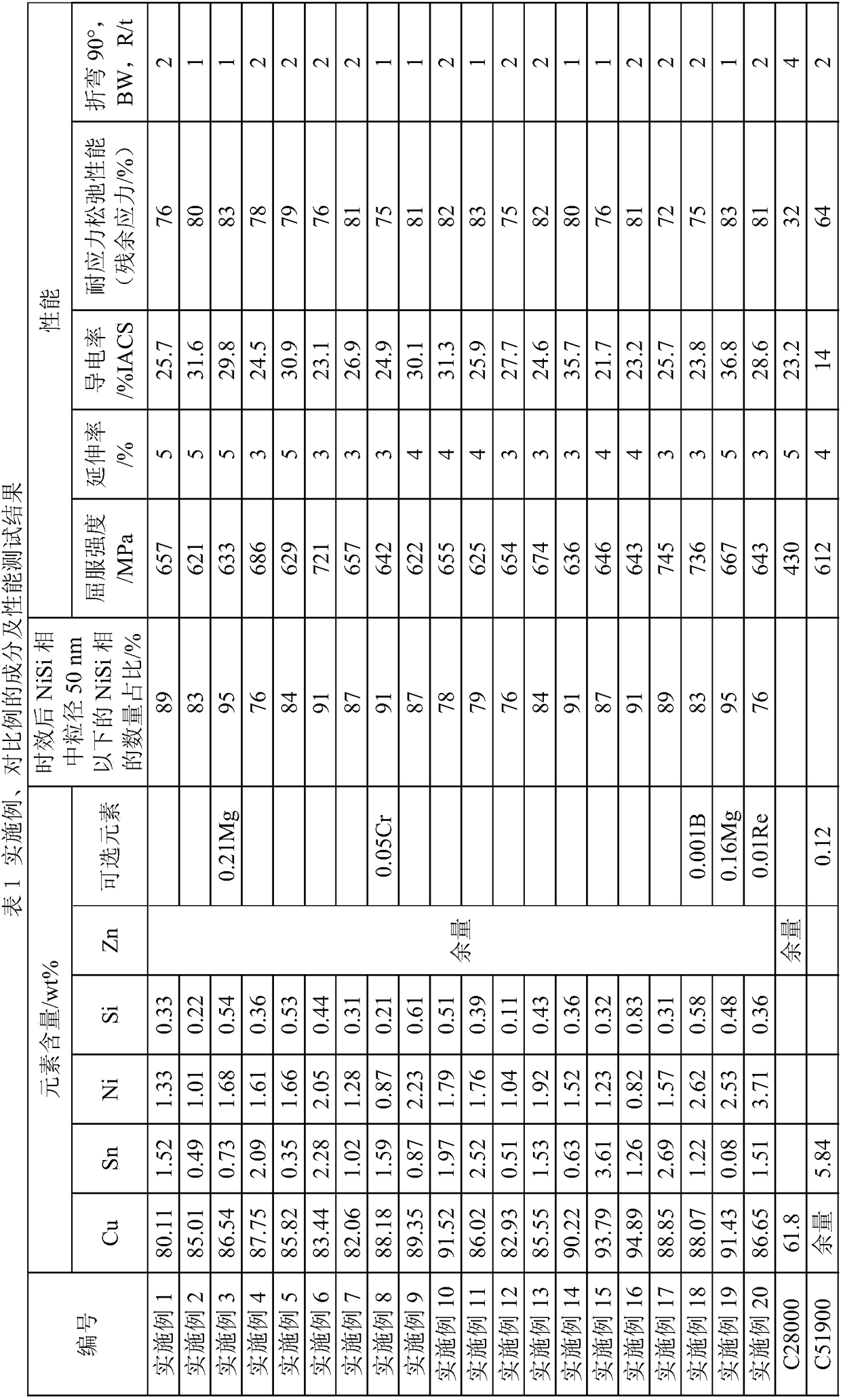

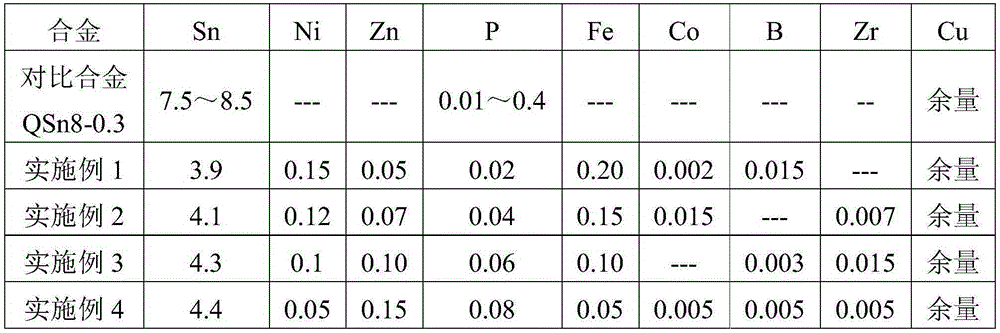

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

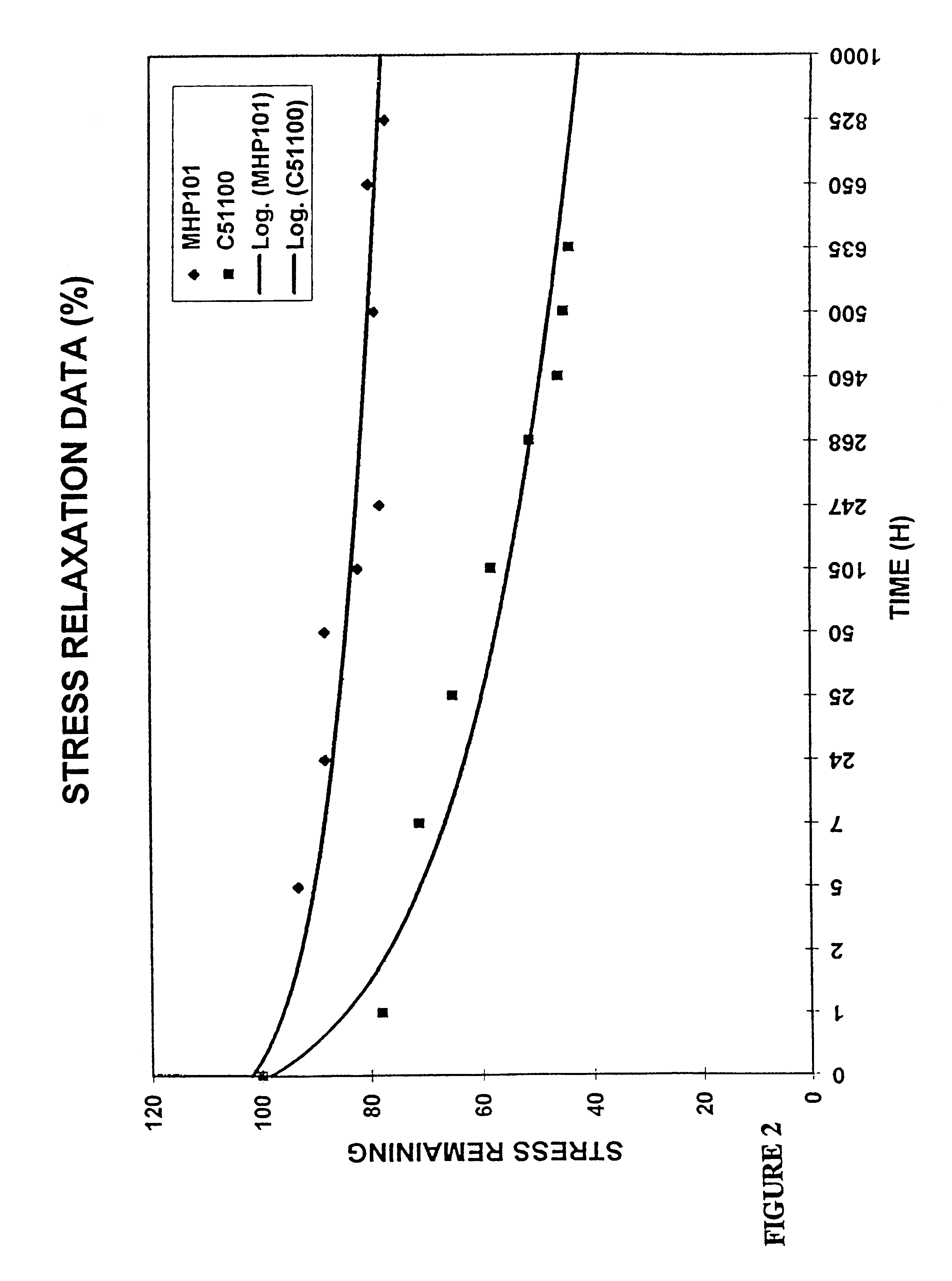

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

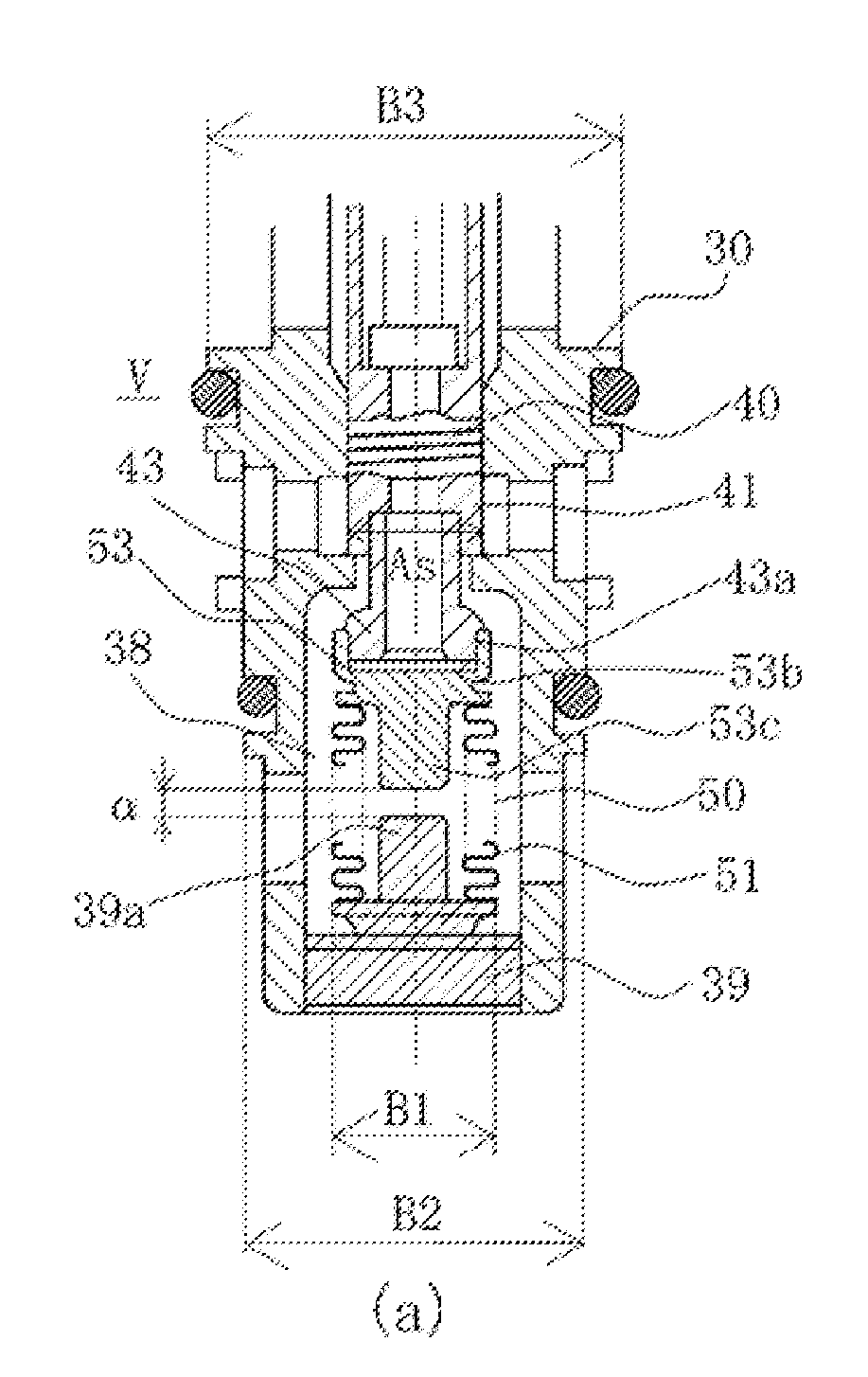

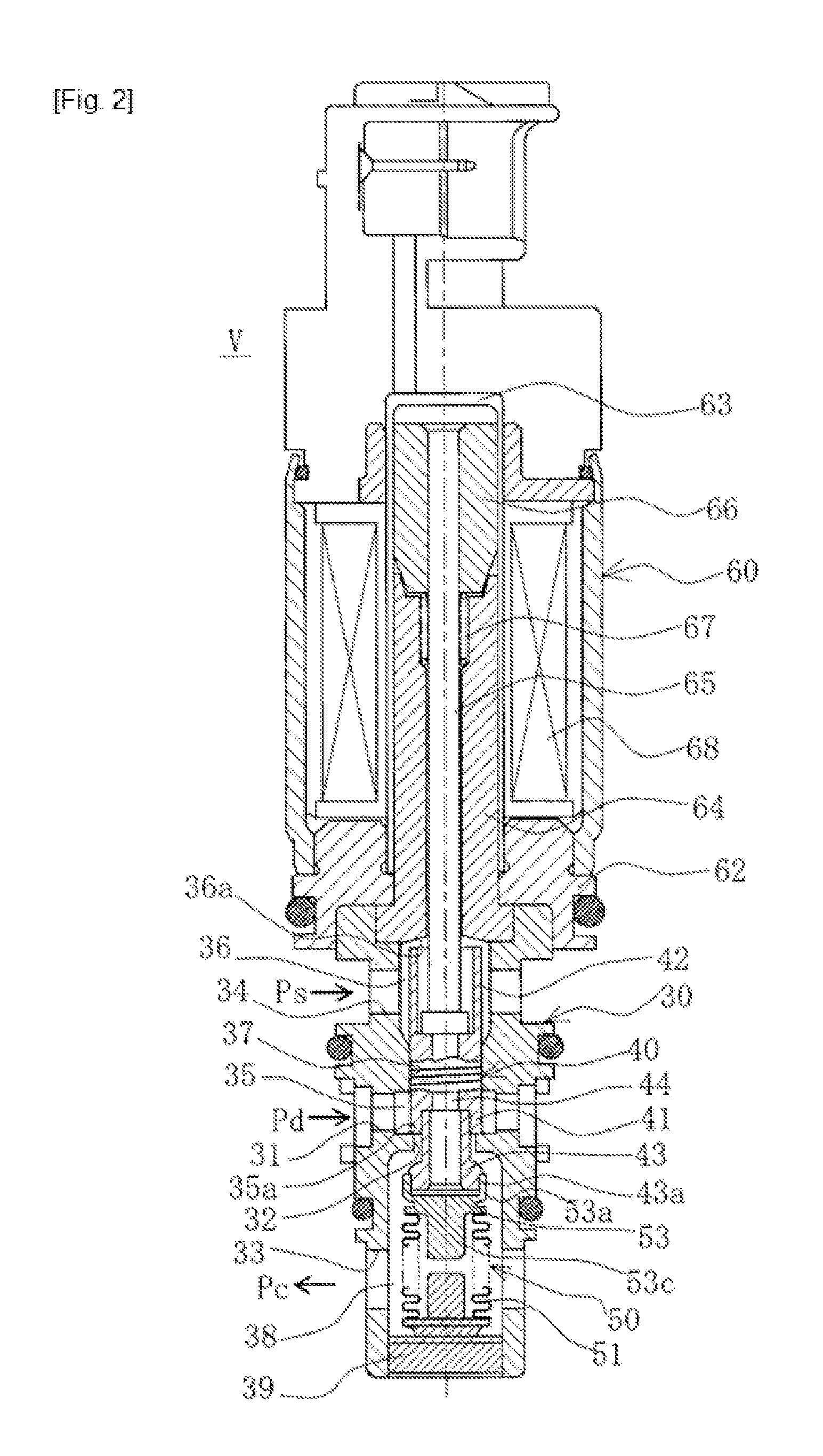

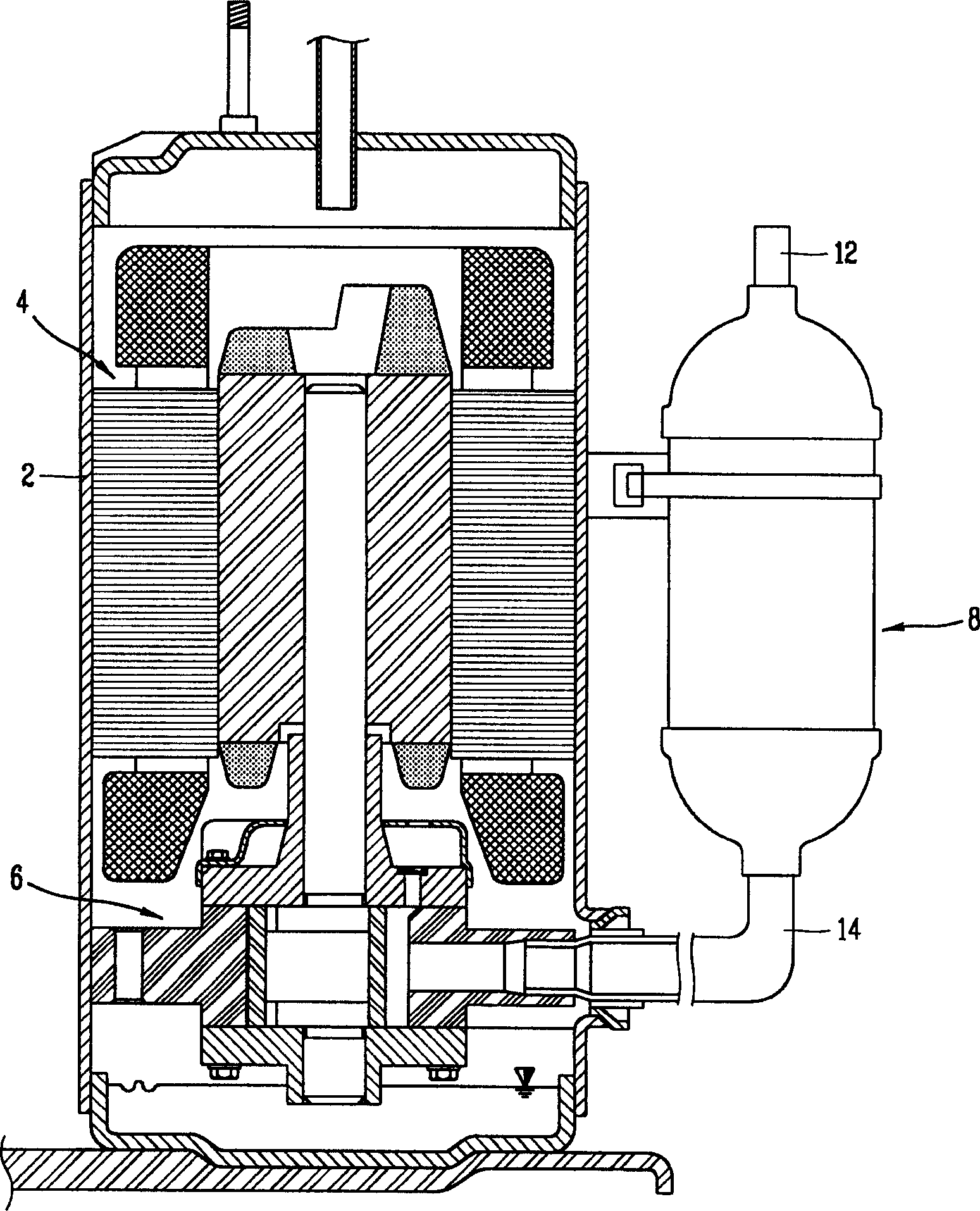

Capacity control valve

InactiveUS20150068628A1Good effectGreat yield stressOperating means/releasing devices for valvesMultiple way valvesPhosphor bronzeEngineering

In an embodiment, a capacity control valve includes: a pressure-sensitive body 50 positioned in a third valve chamber 38; an adapter 53 provided on the free end of the pressure-sensitive body 50 having a circular seating surface; a third valve part 43 that moves integrally with a valve element 40 in the third valve chamber 38 and has a circular engagement surface that opens / closes intake-side passages 34 by engaging with and separating from the seating surface of the adapter 53; and a solenoid 60 that applies an electromagnetic drive force to the valve element 40 in the direction of closing a first valve part 41, wherein the pressure-sensitive body 50 is formed by a formed bellows made of material having greater yield stress than phosphor bronze, and the formed bellows has its diameter set smaller and its stroke longer than the diameter and stroke of a phosphor bronze bellows.

Owner:EAGLE INDS

High-strength brass alloy

The invention relates to a high-intensity brass alloy, which is characterized in that the compositions of the weight percentage are that Zn is 15-30 percent, Al is 3.0-5.0 percent, Ni is 0.2-2.0 percent, Cr is 0-0.50 percent, Zr is 0-0.50 percent, the other content is Cu and inevitable impurity. The performance of the invention is higher or equivalent to phosphor bronze, the cost is low, and the invention is capable of replacing the phosphor bronze and partial beryllium bronze to prepare various elements. The invention guarantees the reliability, stability and long life of computers, aerospace and household appliance elements.

Owner:NINGBO POWERWAY ALLOY MATERIAL

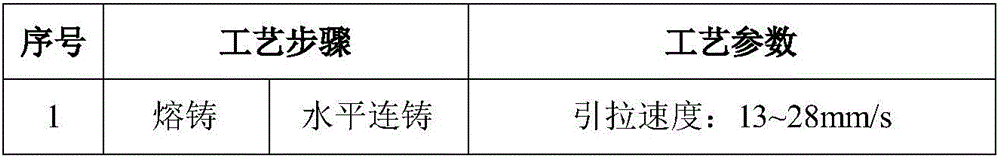

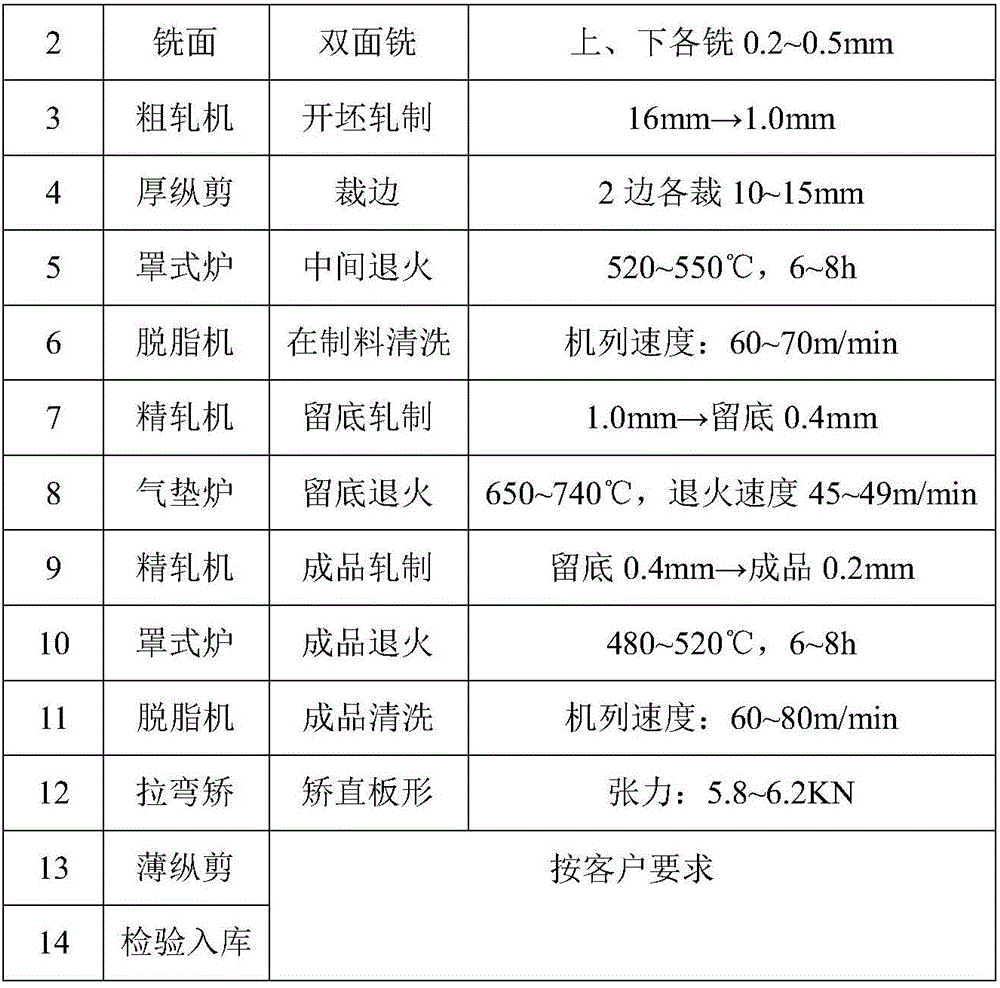

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

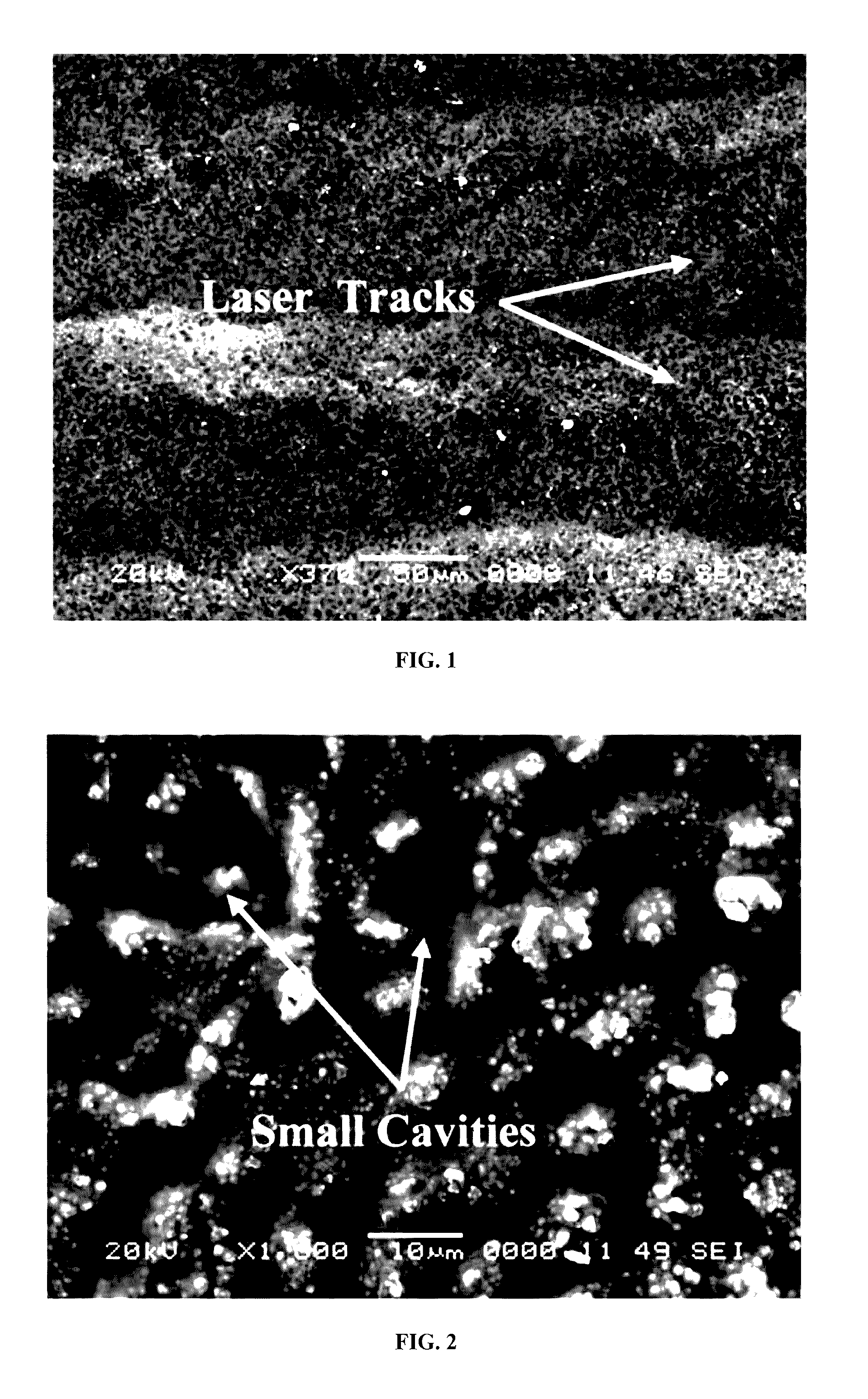

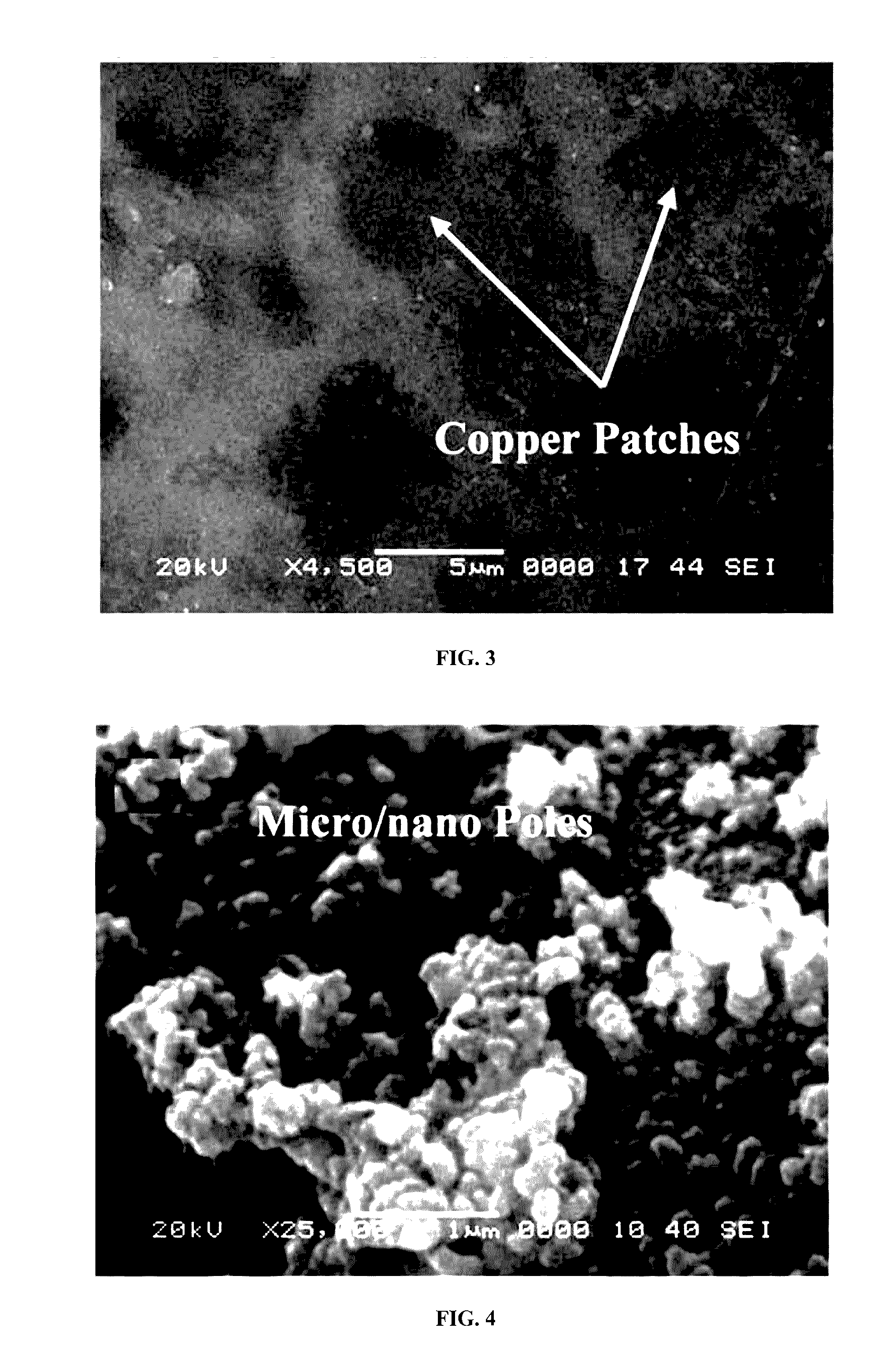

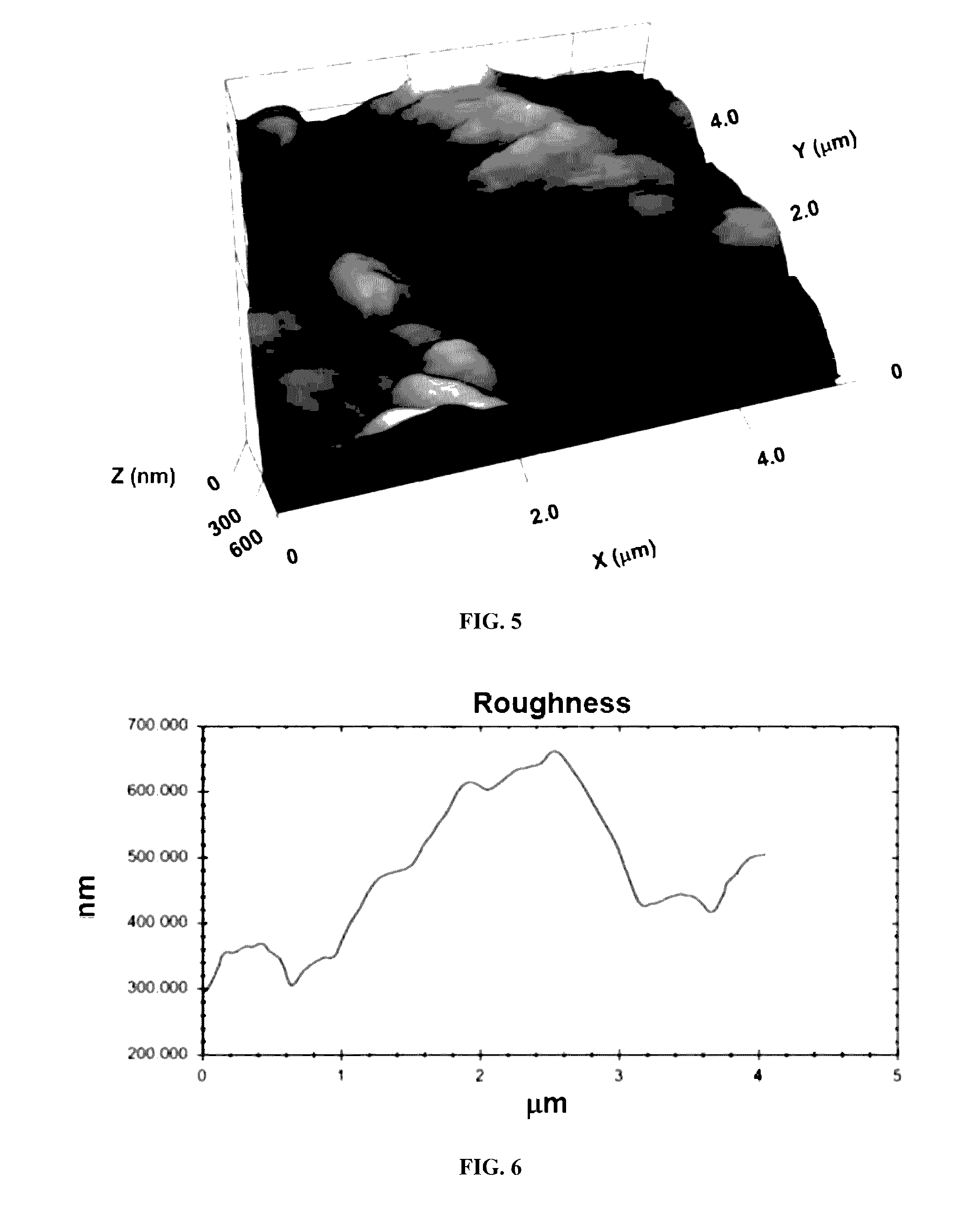

Laser ablation method for treating a copper alloy containing metallic surface and increasing hydrophobicity

InactiveUS20170014946A1Improve fracture toughnessImprove surface hydrophobicityWelding/soldering/cutting articlesLaser beam welding apparatusPhosphor bronzeHigh surface

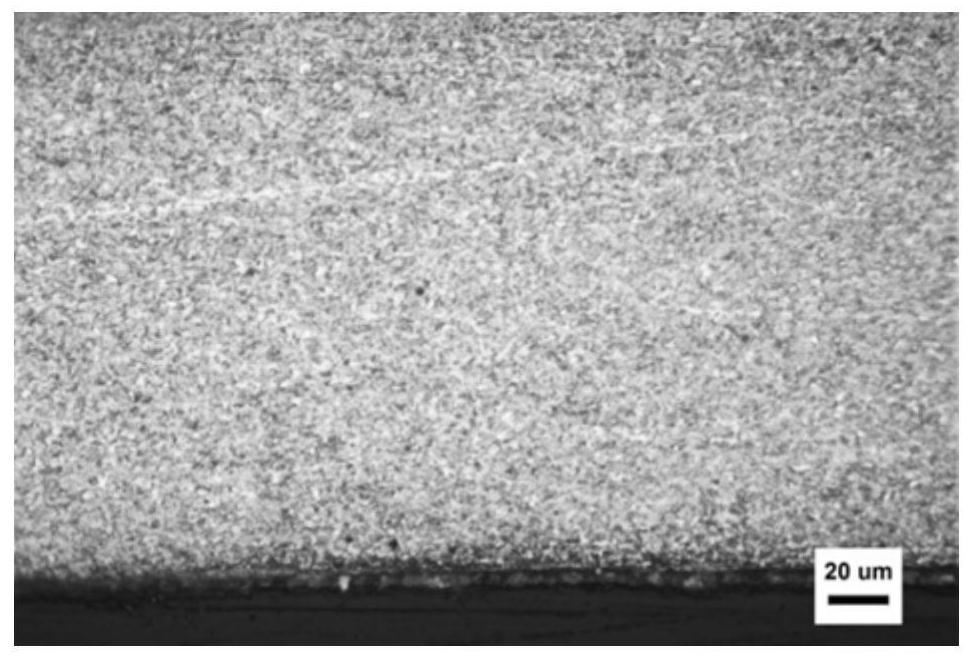

A method of treating a metallic surface comprising a copper alloy, such as phosphor bronze, whereby the metallic surface is ablated by directing a laser beam with a diameter of 200-400 μm produced by a CO2 laser with a pulse frequency of 1200-1800 HZ onto the metallic surface, and a N2 assist gas is concurrently applied with a pressure of 550-650 KPa co-axially with the laser beam to form an ablated metallic surface comprising microgrooves with Cu3N present on a surface of the microgrooves, wherein the ablated metallic surface has a higher surface hydrophobicity than the metallic surface prior to the ablating.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

High-elasticity and high-conductivity copper alloy and production method thereof

The invention relates to a high-elasticity and high-conductivity copper alloy which comprises the following components in percentage by mass: 0.1-1% of Fe, 0.05-0.3% of P, 0.1-1.0% of Sn, 0.1-1.0% of Ni, 13-20% of Zn, 0.005-0.05% of B and the balance of Cu and inevitable impurity. The production process flow comprises the following steps: smelting, performing pull casting, performing hot rolling, performing face milling, performing rough rolling, annealing, washing with acid, performing intermediate rolling, performing solution treatment, performing precision rolling, performing aging treatment, performing shear dividing, and packaging finished products. Temperature tests, weight hanging tests, 5000-time plugging / unplugging tests and plug unplugging required maximum force tests show that the high-elasticity copper alloy prepared through the production process flow has fine stress relaxation resistance. The copper alloy produced from the components through the method has high elasticity and high conductivity, is low in cost and can be used as an elastic electric connector material instead of a tin-phosphor bronze alloy.

Owner:JINTIAN COPPER GROUP CORP NINGBO

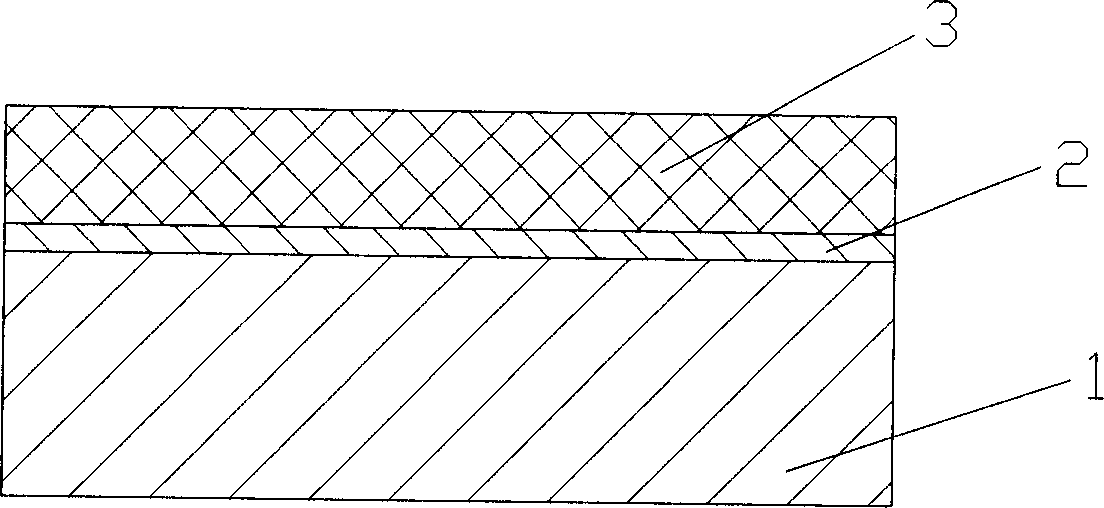

Phosphor bronze bimetal plate for making bush and process for making same

The invention discloses a phos-bronze bimetal sheet used to make brass. The surface of steel sheet is adglutinated with alloying layer, of which component comprises 5.5`7wt% of tin, 0.1~0.4wt% of phosphor, 0.05~0.8wt% of 0.05~0.8wt% of zine and 91.3~94wt% of copper. Flow process comprises steel sheet degreasing derusting and coppering or preprocessing without coppering (roller leveling, bedding alloy powder, first clinkering(800~900 Deg. C), roll flattening, second clinkering (840~920 Deg. C)and finish roll flattening). Phos-bronze bimetal sheet used to make brass has properties of high-intensity and fine abradability to meet the need of automobile engine of high power and high speed. Further more, the invention in faver of environmental conservation and improving the operation quality of car.

Owner:HUNAN FLYDISC NEW MATERIAL

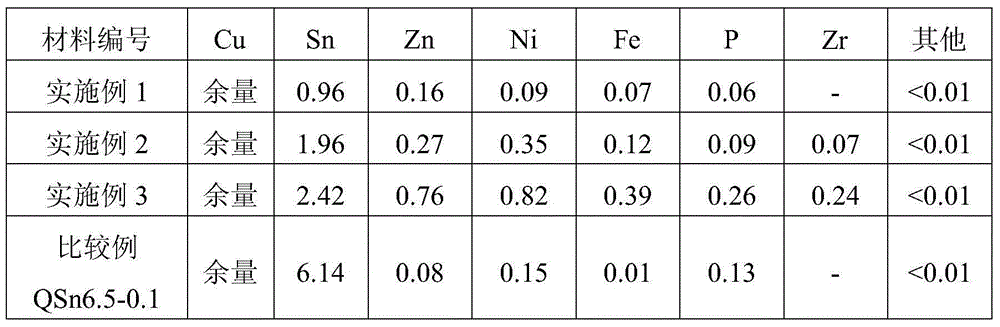

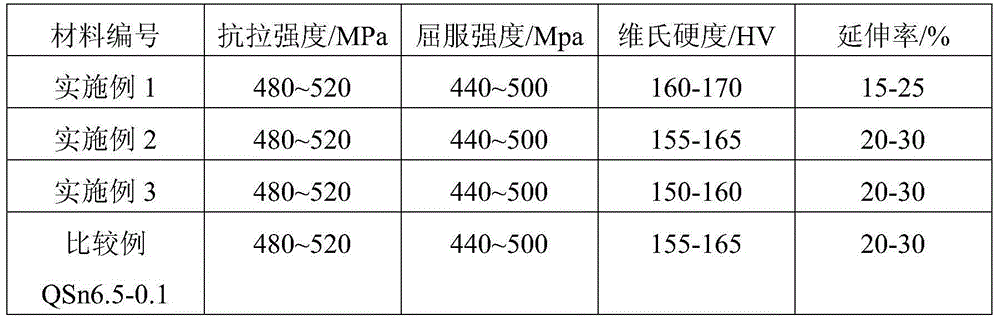

High-elasticity low-cost tin-phosphor bronze alloy belt and preparation method thereof

The invention discloses a high-elasticity low-cost tin-phosphor bronze alloy belt and a preparation method thereof. The high-elasticity low-cost tin-phosphor bronze alloy belt comprises, by weight, 0.5%-2.5% of tin, 0-1.0% of nickel, 0-1.0% of zinc, 0.05%-0.5% of iron, 0.05%-0.5% of phosphorus, 95%-99% of copper and 0-0.10% of inevitable impurities. The high-elasticity low-cost tin-phosphor bronze alloy belt meets the following grain orientation relation of I{420} / I0{420}>2, wherein I{420} is the diffracted intensity of an X ray of a {420} crystallization face on the surface of the bronze alloy belt, and I0{420} is the diffracted intensity of an X ray of a {420} crystallization face on the surface of pure copper powder. According to the high-elasticity low-cost tin-phosphor bronze alloy belt and the preparation method thereof, the component and rate of the alloy material are optimized, the content of the tin is decreased to be 0.5%-2.5% on the basis of keeping the alloy performance, scarce resources are effectively protected, and meanwhile the alloy elements such as the Sn, the P and the Zr are added; the large rolling machining rate larger than or equal to 70% is adopted during preparing, rolling passes can be decreased, and the production cost is reduced; the prepared tin-phosphor bronze alloy belt is good in elasticity and machining performance and stable in high-temperature stress-relaxation-resistance performance; and the elasticity modulus of the tin-phosphor bronze alloy belt is almost the same as that of an existing C5191 product.

Owner:JINTIAN COPPER GROUP CORP NINGBO

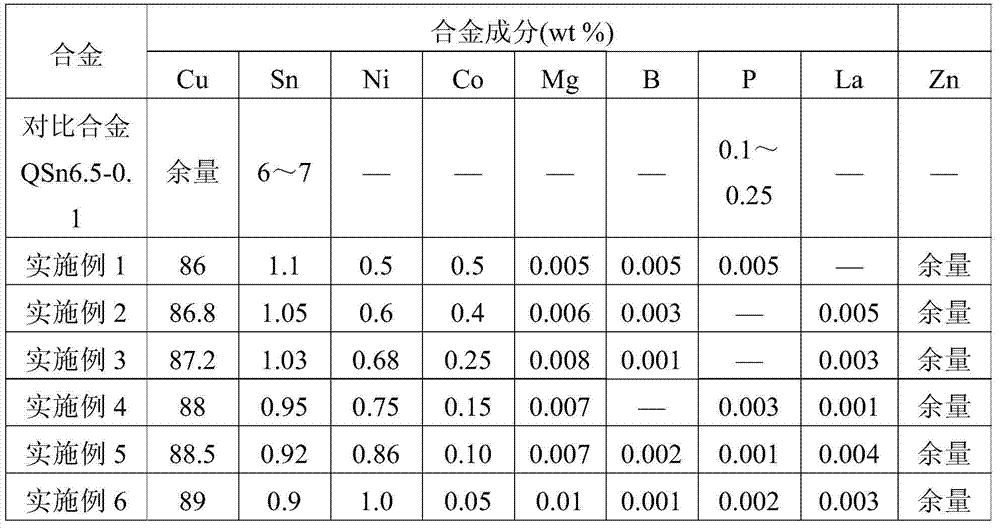

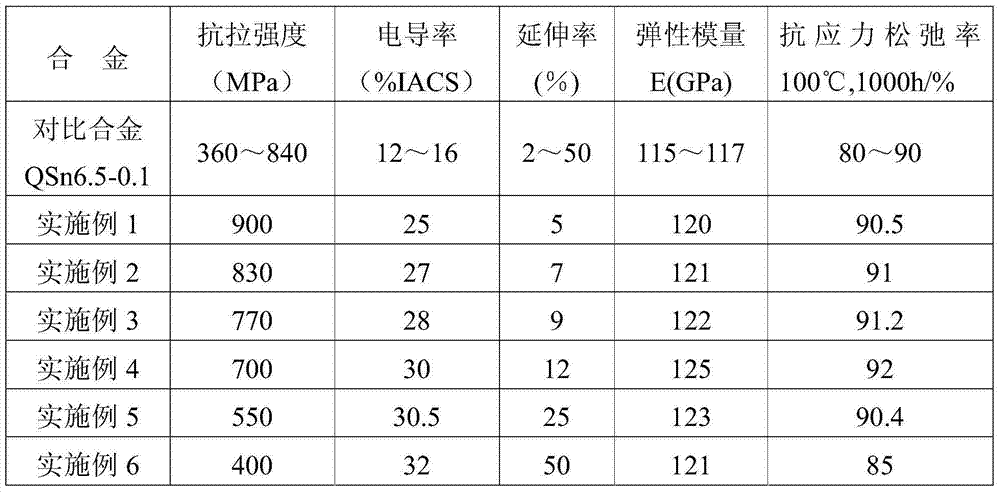

Elastic tin brass alloy material and preparation processing method for the same

The invention relates to elastic tin brass alloy material and a preparation processing method for the same and belongs to the nonferrous metal processing field. The elastic tin brass alloy material is composed of 86-89% of Cu, 0.9-1.1% of Sn, 0.5-1% of Ni, 0.05-0.5% of Co, 0.005-0.01% of Mg and rest of Zn by weight. The preparation processing method includes that a, preparing materials according to the mass percent, adding materials, smelting and casting; b, hot rolling; c, performing primary cold rolling; d, performing intermediate annealing; e, milling; f, performing secondary cold rolling; g, performing low temperature annealing. The tensile strength sigma b of the copper alloy is 400 to 900 MPa, the plastic elongation delta is 5-45%, the conductivity is 25-32% IACS, and the elasticity modulus is 120 to 125 GPa. The elastic tin brass alloy material is capable of substituting the existing tin-phosphor bronze to be broadly used for different fields, such as spring contact pieces, electric contacts, spot welding poles, relays, electrical contact components and plug-in components.

Owner:NINGBO XINGYE SHENGTAI GROUP

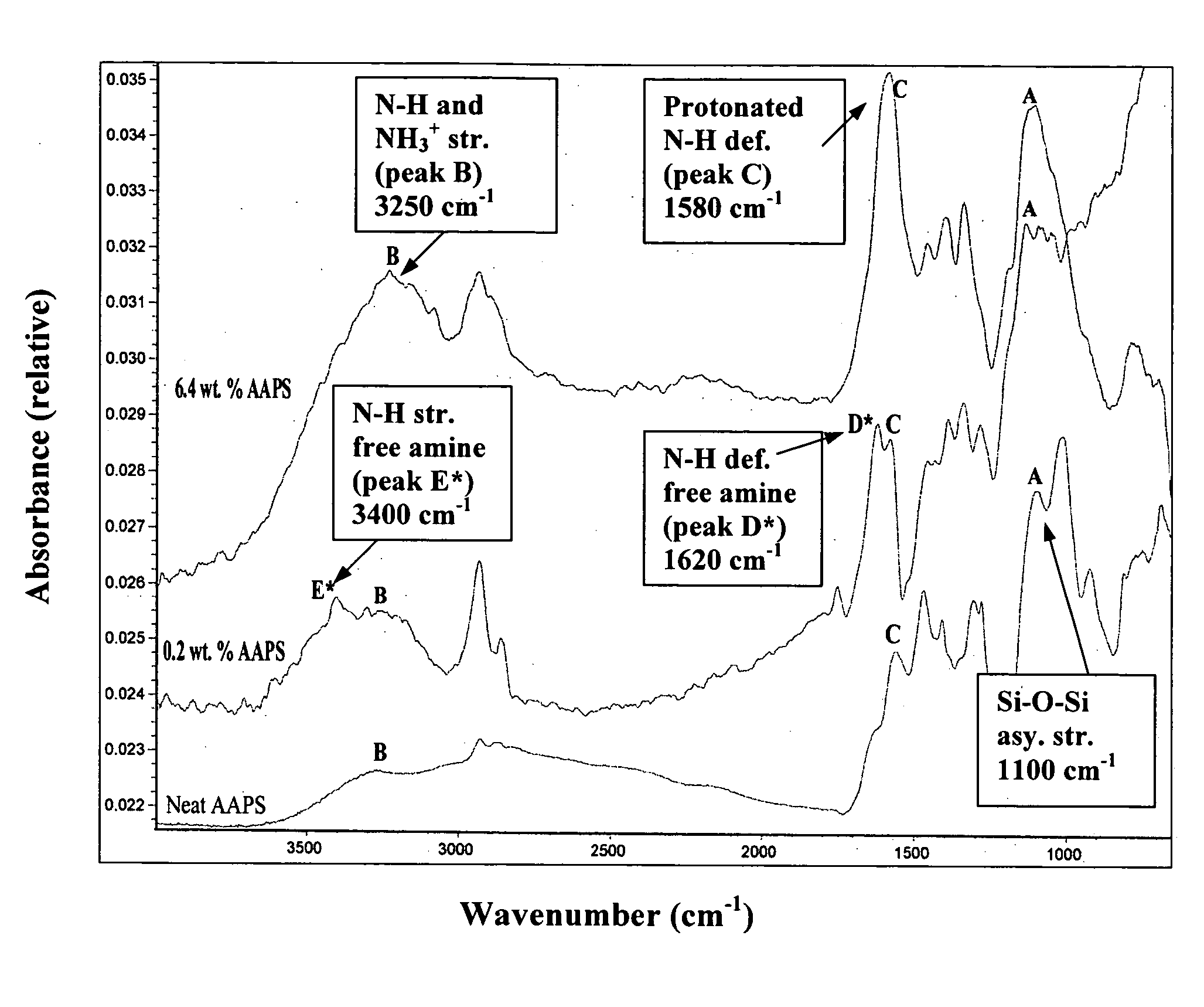

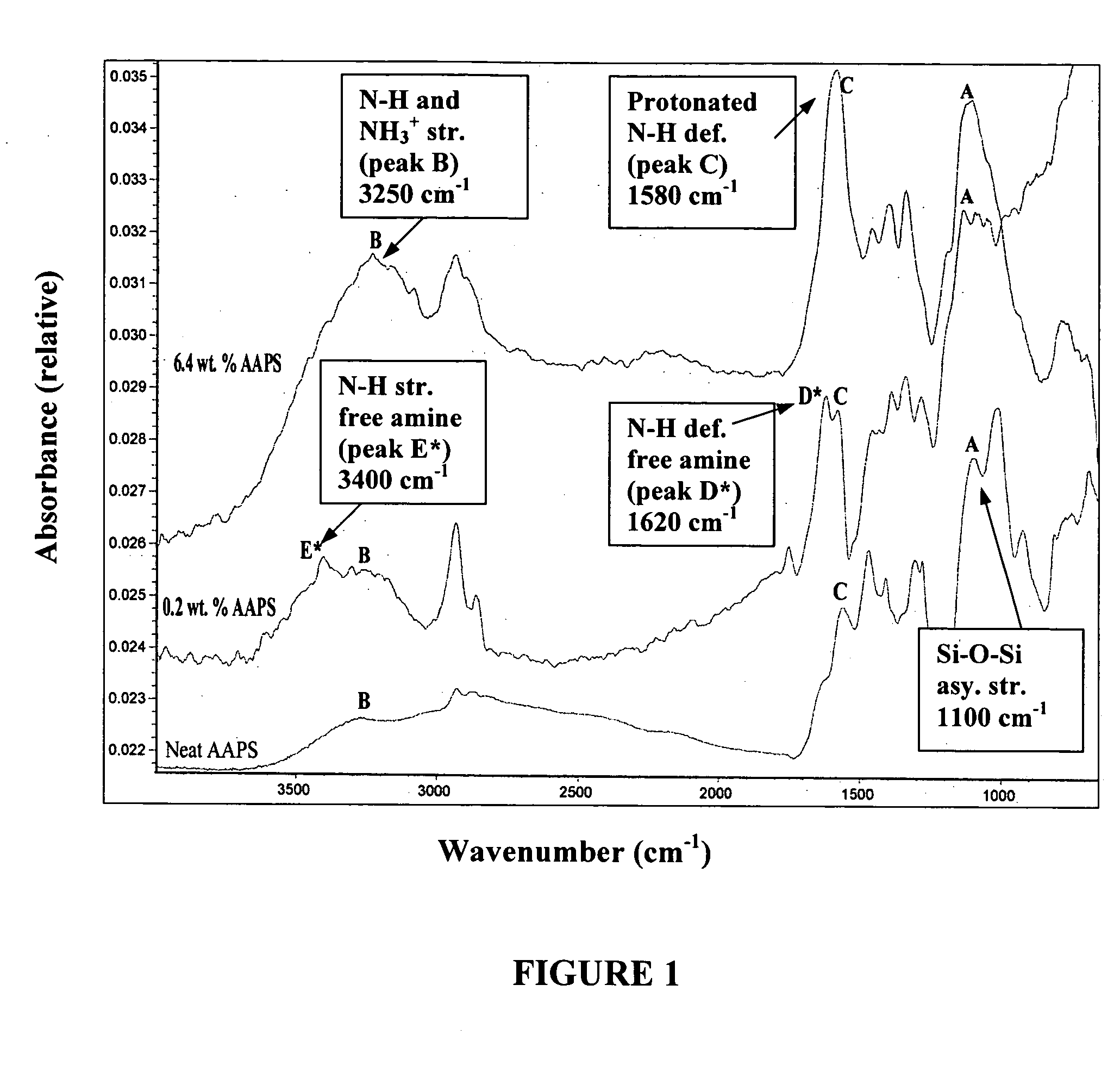

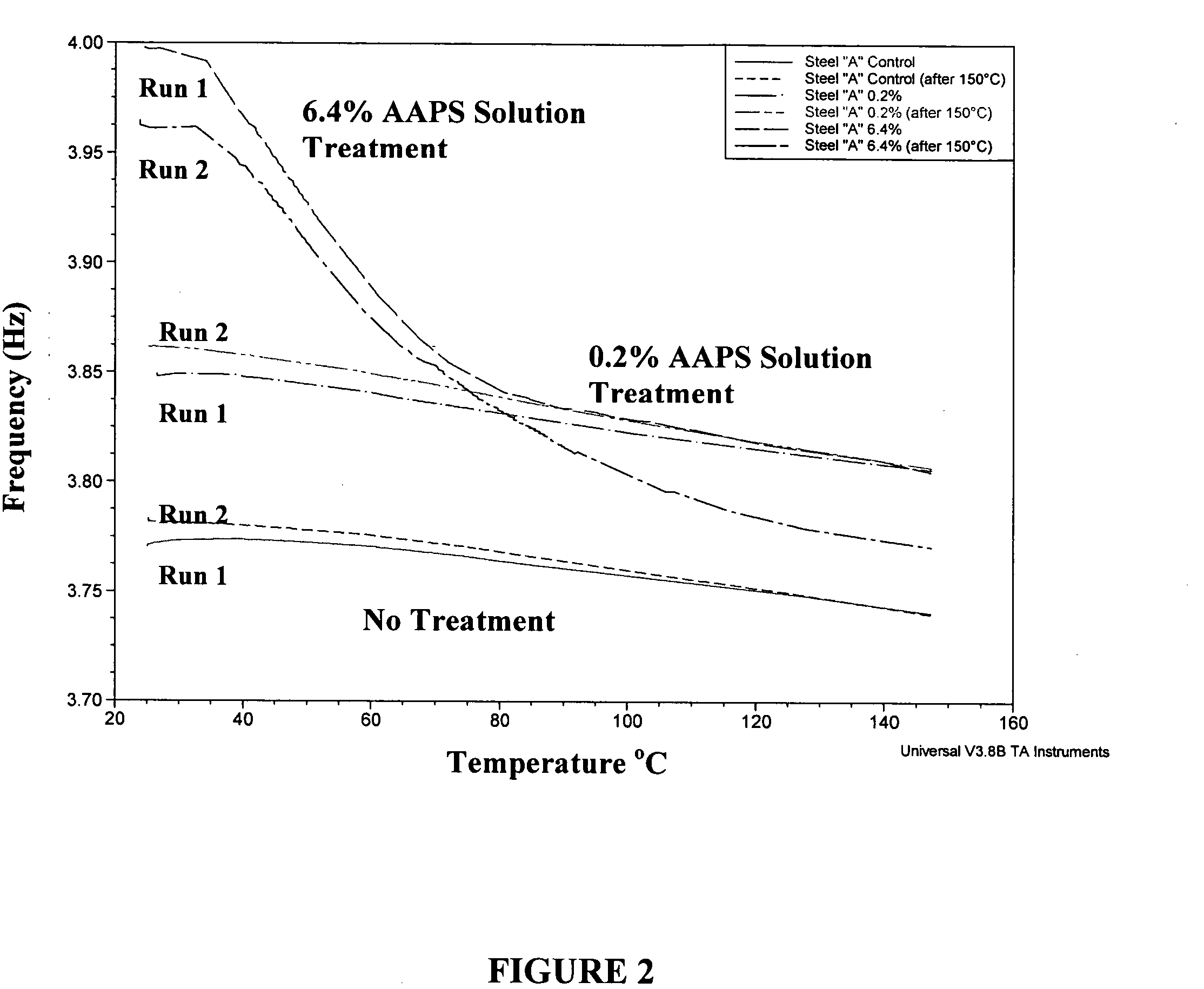

Organosilane surface treated musical instrument strings and method for making the same

ActiveUS20050241454A1Bonded firmlyOptimum corrosion protectionElectrophonic musical instrumentsStringed musical instrumentsPhosphor bronzeBronze

An improved musical instrument string combines the attributes of superior corrosion resistance, low stiffness, and long life during storage and end use. Superior corrosion resistance is achieved through surface treatment of wound strings with an organosilane compound, where the preferred winding is a copper alloy such as phosphor bronze, and the preferred organosilane surface treatment comprises an aminotrialkoxysilane such as N-2-aminoethyl-3-aminopropyltrimethoxysilane.

Owner:DREADNOUGHT INC

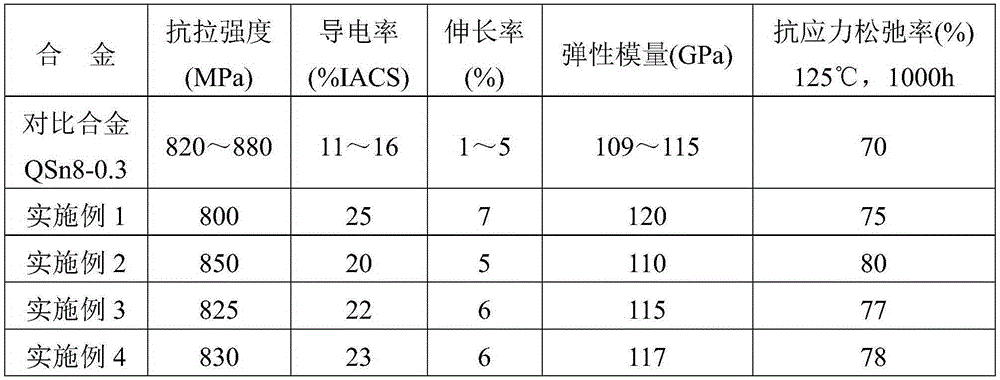

High-performance complex multi-element phosphor bronze alloy material and preparation method thereof

The invention relates to a high-performance complex multi-element phosphor bronze alloy material and a preparation method thereof, and belongs to the field of processing of nonferrous metal. The alloy material comprises the following components in percentage by weight: 3.9-4.4% of Sn, 0.05-0.1% of Ni, 0.05-0.2% of Zn, 0.05-0.2% of Fe, 0.02-0.08% of P, and the balance of Cu. In addition, the alloy further comprises two or more elements of Co, B and Zr. The material is obtained through such processes as smelting and casting, rough rolling, primary intermediate annealing, acid washing, intermediate rolling, secondary intermediate annealing, acid washing, finish rolling and low-temperature annealing. The method can omit a high-temperature and long-time uniform annealing process, the alloy production efficiency is improved, and the alloy production cost is greatly reduced. The alloy can replace a classic tin-phosphor bronze QSn8-0.3 alloy, and is applied to the manufacturing of such elements as contact pieces and connectors for electronic electric appliances and vehicles.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

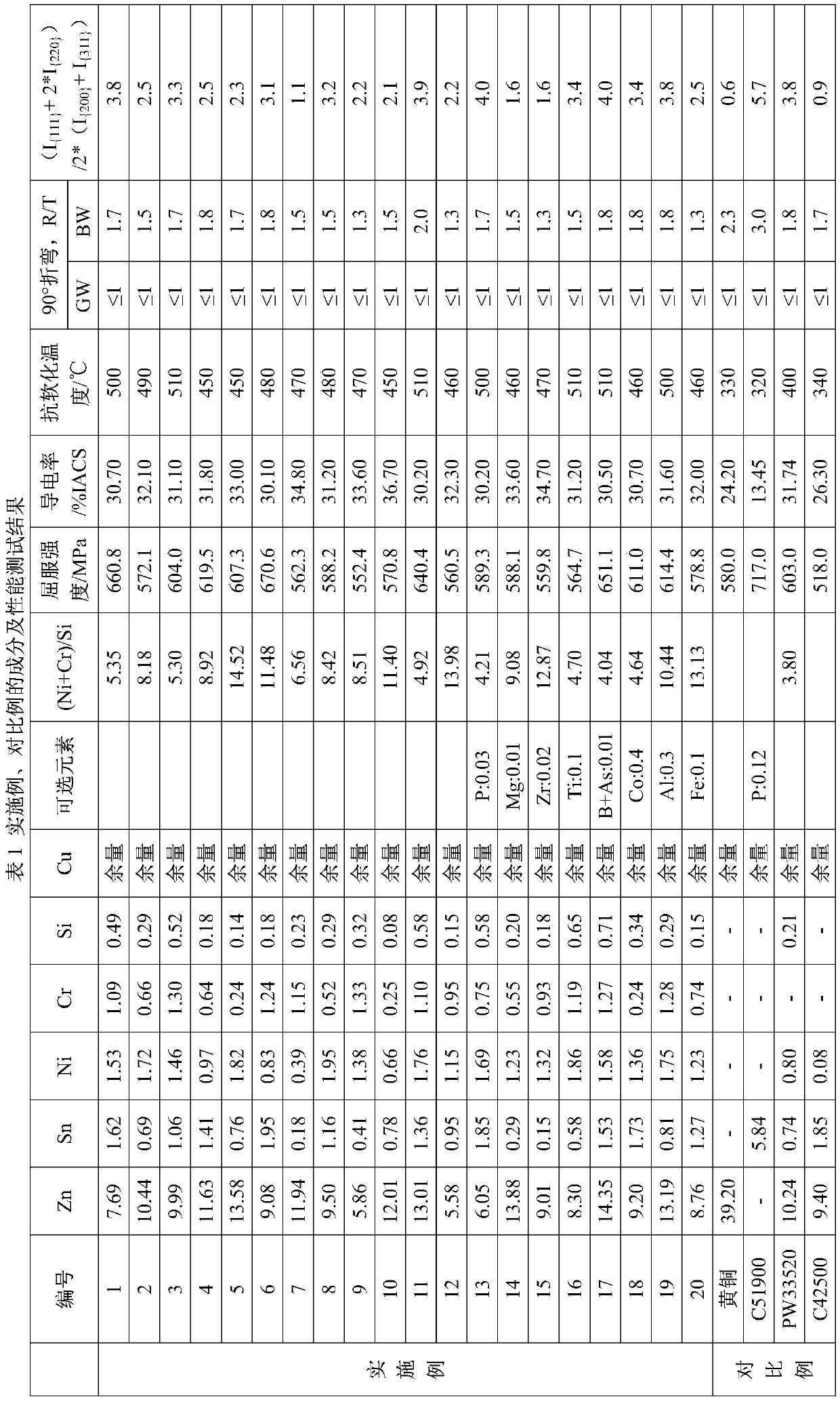

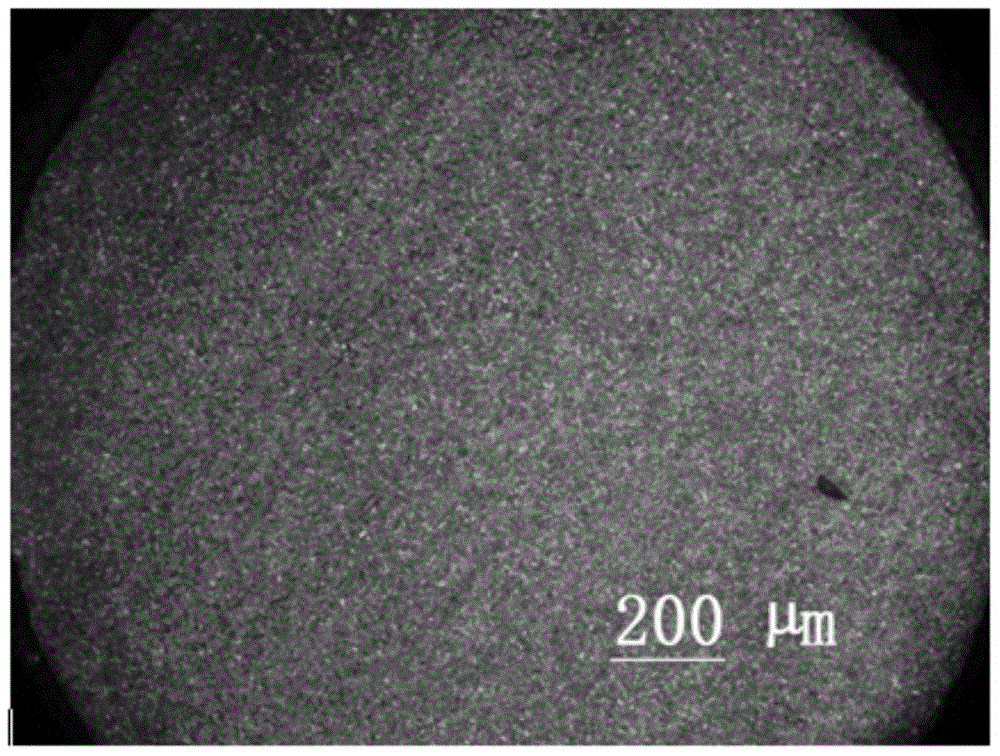

Copper alloy with softening resistance and preparation method and application thereof

ActiveCN110157945AImprove conductivityHigh strengthConductive materialMetal/alloy conductorsTin platingSolid solution strengthening

The invention discloses a copper alloy with softening resistance. The copper alloy comprises, by weight, 5.01%-15.0% of Zn, 0.1%-2.0% of Sn, 0.01%-2.0% of Ni, 0.01%-1.0% of Si, 0.001%-1.5% of Cr, andthe balance Cu and inevitable impurities. Using Cu-Zn-Sn as a matrix and adding the Ni, the Si, the Cr and other elements, the copper alloy with yield strength greater than or equal to 550 MPa, conductivity greater than or equal to 30% IACS, excellent bending processing performance and high temperature resistance softening temperature greater than or equal to 450 DEG C is obtained by combining solid solution strengthening and aging strengthening, so that the needs of the alloy in a developing electrical and electronic industry are met. The copper alloy with softening resistance and a preparation method and application thereof can solve various waste utilization problems, including tin plating waste such as tin-phosphorus bronze, a Cu-Ni-Si alloy and brass, so that the reducing of the environmental burden, the reducing of the alloy preparation cost and the promoting of the recycling of the waste are facilitated.

Owner:宁波博威新材料有限公司

High-performance tin-phosphor bronze wire and production method thereof

The invention discloses a high-performance tin-phosphor bronze wire and a production method thereof. The high-performance tin-phosphor bronze wire comprises the following elements in percentage by weight: 4.3-5.0 percent of Sn, 0.06-0.12 percent of P, 0-0.03 percent of Zn, 0-0.005 percent of Fe, less than 0.0.3 percent of Si, 0-0.05 percent of Ni, 0-0.005 percent of Cd, 0-0.02 percent of total impurities, and Cu in balancing amount. The materials are smelted and drawn to cast a rod blank with the diameter of 12 mm, and then the rod blank is subjected to five-pass processing. The required optimal grain size is achieved by controlling the contents of minor elements like Fe in the tin-phosphor bronze wire and adjusting the annealing temperature, heat preservation time and processing rate in the processing process, therefore, that the material performance is uniform is ensured, and the produced tin-phosphor bronze wire has uniform performance and a smooth surface, and can meet the use requirements of customers in the high-end electronic connector assembly industry.

Owner:安徽鑫科铜业有限公司

Elastic alloy brass with high strength

The invention provides elastic alloy brass with high strength, relating to the field of copper alloys. The elastic alloy brass with the high strength is characterized in that the strength and elasticity of the alloy are improved through adding elements of tin and phosphorus on the basis of a copper-zinc binary alloy; the alloy brass comprises the following components in percentage by weight: 59.0-65.0 % of copper, 0.2-1.5 % of tin and 0.015-0.15 % of phosphorus as well as the balance of zinc and not more than 0.05 % of inevitable impurities; and the alloy is prepared by smelting and rolling. The elastic alloy brass with the high strength, provided by the invention, has the advantages of reasonable mixing ratio design and higher performance cost; compared with the copper content of 93.0 % in the tin-phosphorus brass, the copper content in the alloy brass is reduced by 28.0 % and domestic scarce resource copper metal is saved. The elastic alloy brass with the high strength, provided by the invention, is mainly used for manufacturing electronic appliance connectors, springs, connectors, switches, contacts and the like as well as various copper alloy parts used under the marine environment; hardness and elastic modulus which are equivalent to those of the tin-phosphorus brass are obtained; and good dezincification corrosion resistance is also obtained; and the tin-phosphorus brass can be partially replaced with the elastic alloy brass.

Owner:菏泽广源铜带有限公司

High-performance phosphor bronze belt and preparing method thereof

ActiveCN107604202AExcellent bending performanceExcellent stress relaxation resistanceChemical compositionPhosphor bronze

Owner:NINGBO XINGYE SHENGTAI GROUP

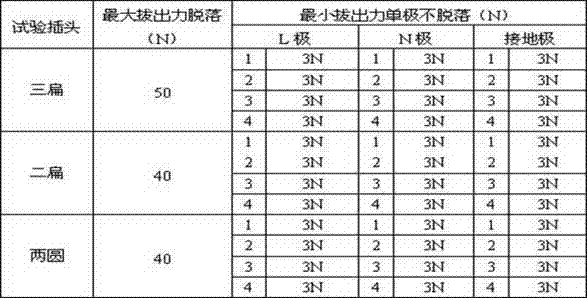

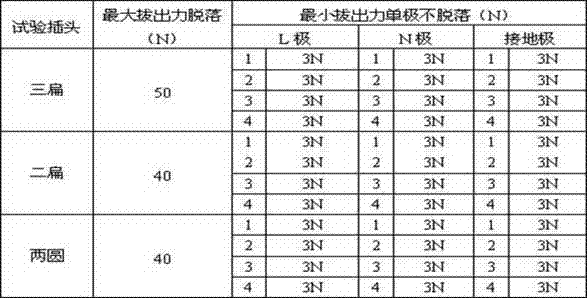

Low-cost elastic brass alloy

The invention discloses a low-cost elastic brass alloy. The alloy is characterized by comprising the following components by weight percent: 69-72% of copper, 23-26% of zinc, 3.3-3.6% of aluminum, 0.1-1.0% of nickel, 0.12-0.53% of manganese and the balance inevitable impurities. The low-cost elastic brass has the same hardness, elastic modulus and elongation rate as phosphor bronze; and the strength is higher than that of phosphor bronze in the Y2 state. The product is used to prepare connectors and conduct tests such as insert and extract and monopole lifting, and the obtained parameters all conform to the national standards. Meanwhile, the preparation process of the alloy is easy, the processing method is simple and the alloy is suitable for industrialized production. The elastic brass has the similar performances to phosphor bronze and the raw material cost is only 75%-80% of that of phosphor bronze, thus the elastic brass alloy can be used in the connector field to replace the phosphor bronze alloy.

Owner:JINTIAN COPPER GROUP CORP NINGBO

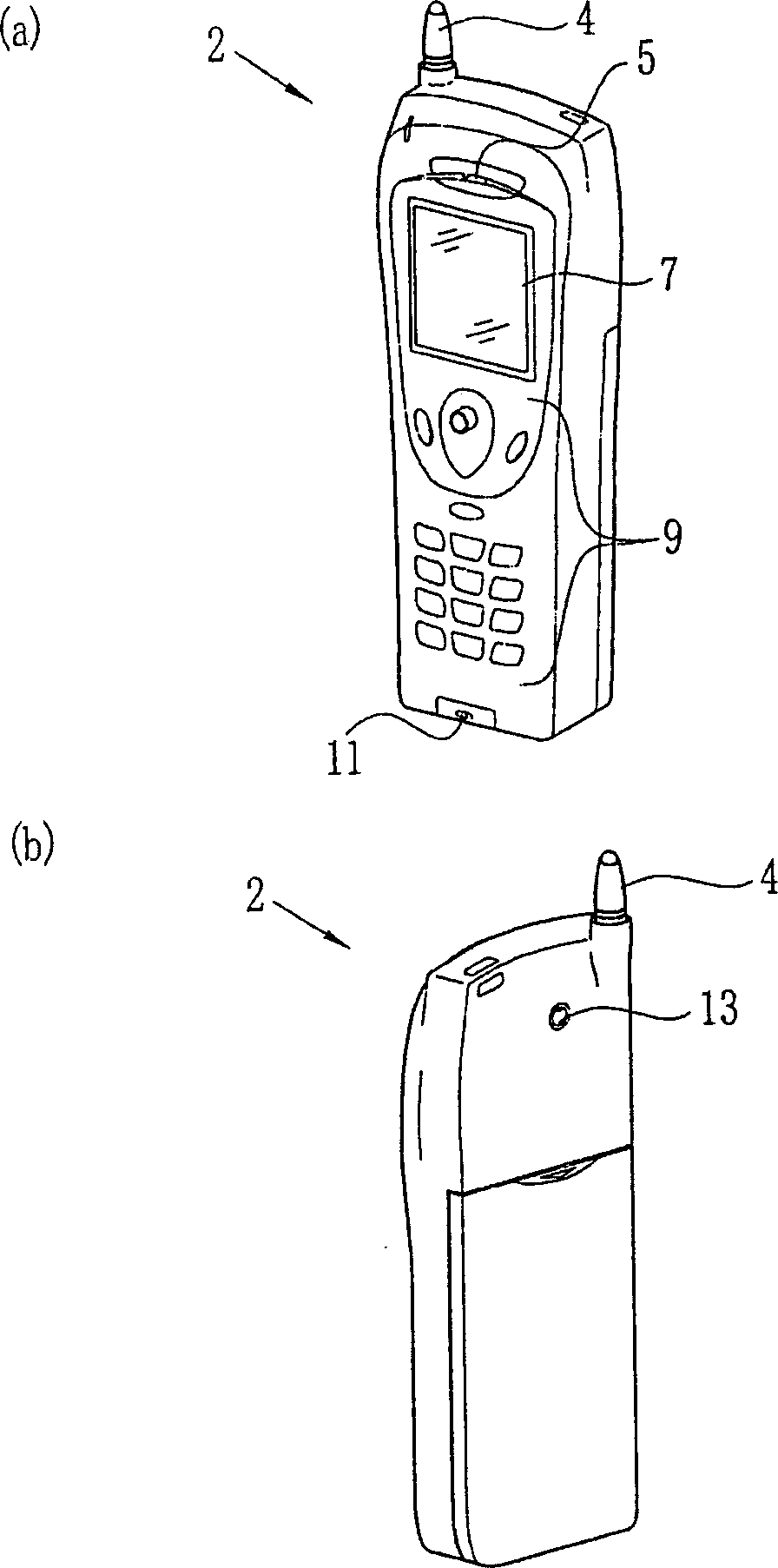

Connection structure

InactiveUS20090291587A1Firmly connectedCoupling device connectionsLighting support devicesElectrical conductorPhosphor bronze

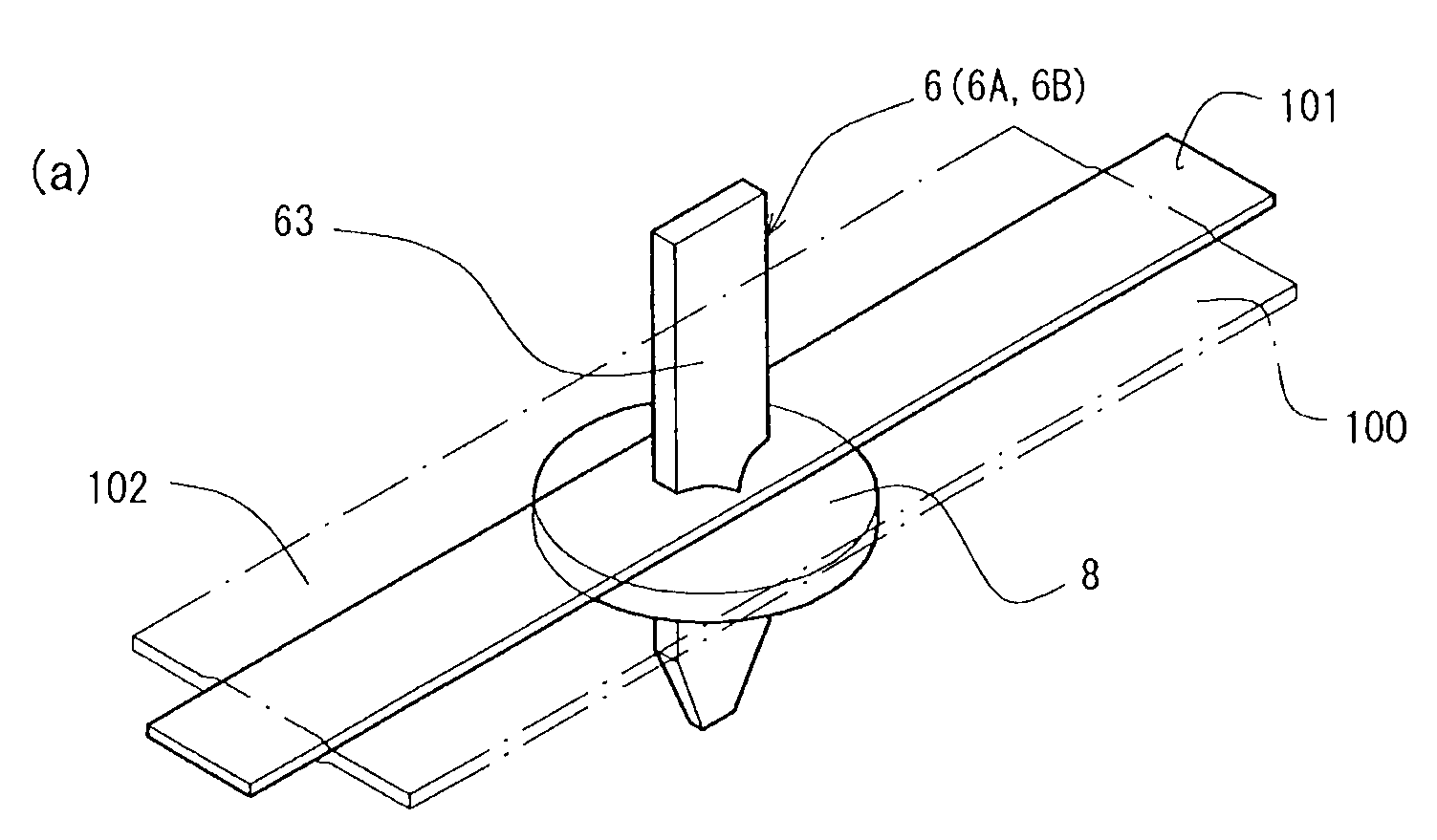

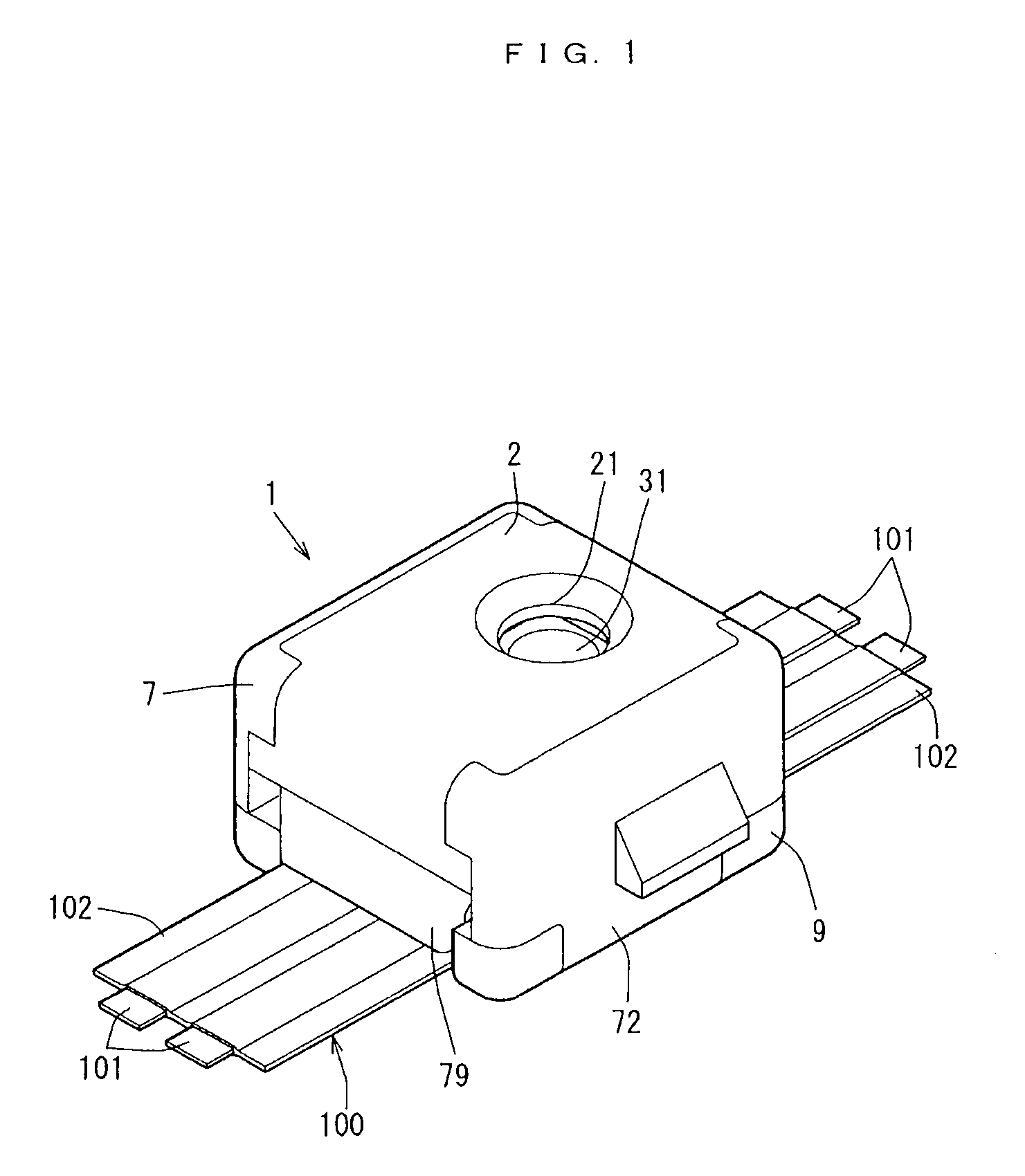

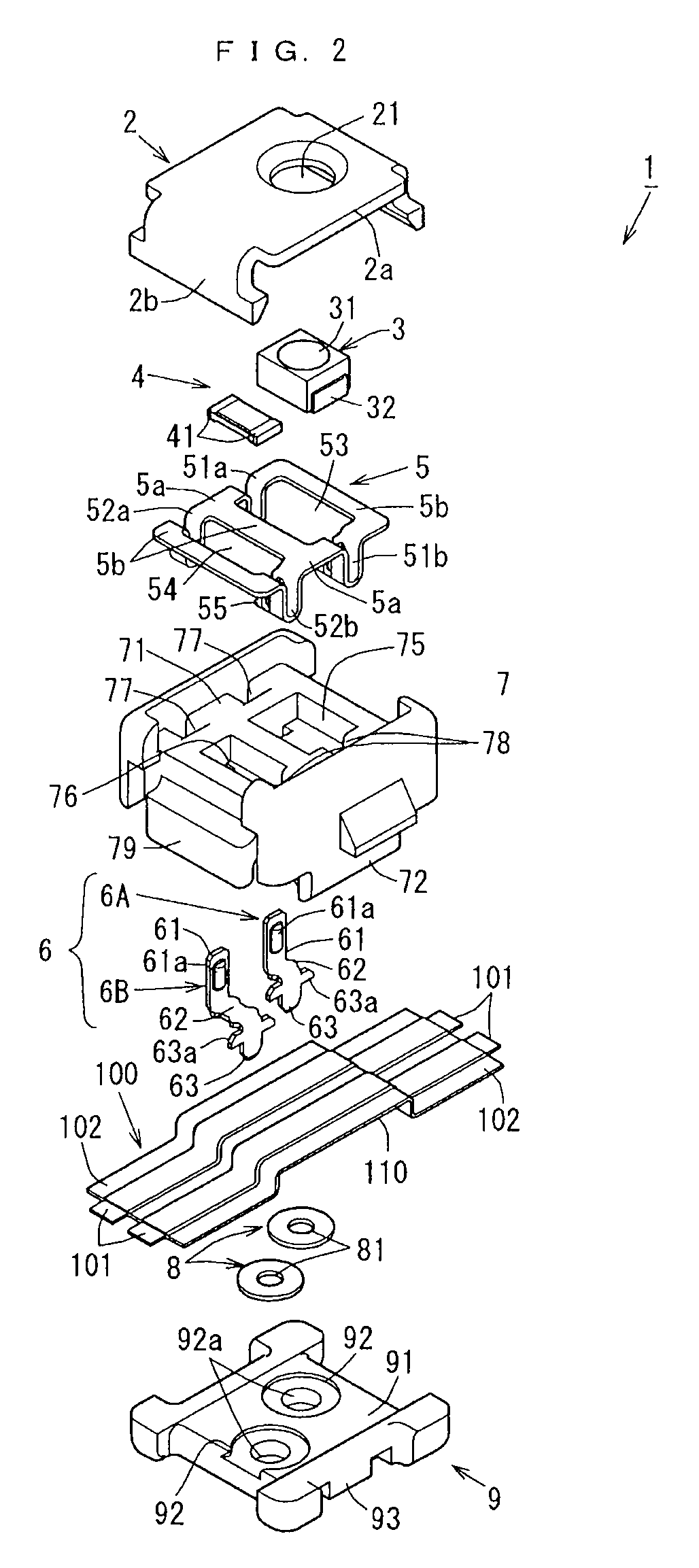

The present invention has an object of providing a connection structure capable of easily connecting an LED component to a flat cable. An LED unit 1 includes an upper case 7, a pierce terminal 6, a lower case 9 and an intermediate terminal 5. An LED chip 3 is pressed to the pierce terminal 6 by a convexed spring 51 to electrically connect the LED chip 3 to the flat cable 100. Conductors 101 included in the flat cable 100 are formed of phosphor bronze formed of tin (Sn), phosphorus (P), copper (Cu) and unavoidable impurities and having a tensile strength of 480 to 550 MPa, whereas a pierce plate 63 of the pierce terminal 6 piercing through the conductor 101 is formed of a copper alloy, which is a high strength conductive member having a higher strength than that of the conductor 101 and having conductivity.

Owner:TOYOTA BOSHOKU KK +2

Tin phosphorus bronze band and preparation method thereof

ActiveCN113088756AControl ratioSolve crackingFurnace typesHeat treatment furnacesPhosphor bronzeBronze

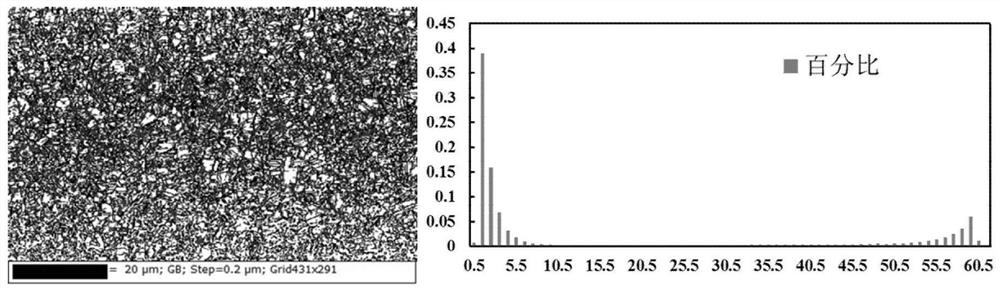

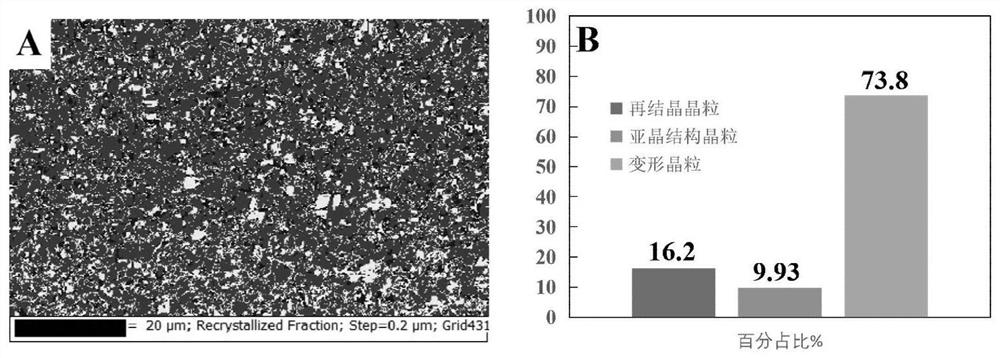

The invention discloses a tin phosphorus bronze band which is characterized in that the tin phosphorus bronze comprises the components in percentage by mass: 6.0-8.0 wt% of Sn, 0.08-0.12wt% of P, less than or equal to 0.1wt% of Fe, 0.1-0.2wt% of Ni and the balance Cu and inevitable impurities. According to the tin phosphorus bronze band, the volume percentage of small-angle grain boundaries is marked as L, the volume percentage of large-angle grain boundaries is marked as H, the ratio of L to H meets the condition that L / H is larger than or equal to 2.0, and the high-temperature softening resistance temperature of the tin phosphorus bronze band is larger than or equal to 370 DEG C; and the high-temperature softening resistant temperature of the band is larger than or equal to 370 DEG C and higher than that of a common phosphorus bronze band, other alloy elements do not need to be additionally added, the production cost is reduced, the electric conductivity of the band is larger than or equal to 14% IACS, the tensile strength is larger than or equal to 700 MPa, and cracking is avoided when the band is bent by 180 degrees and R / t is larger than or equal to 2.5.

Owner:JINTIAN COPPER GROUP CORP NINGBO

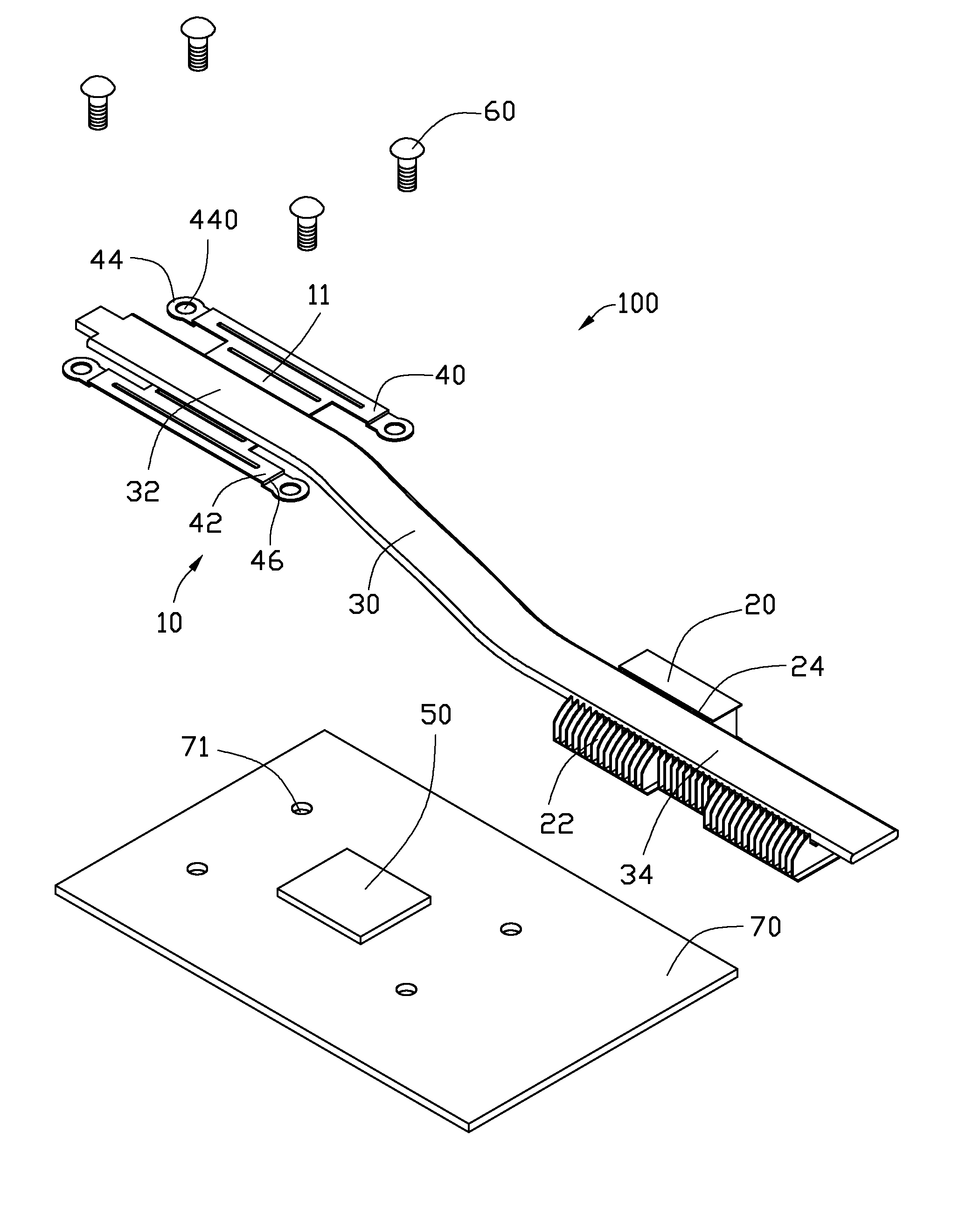

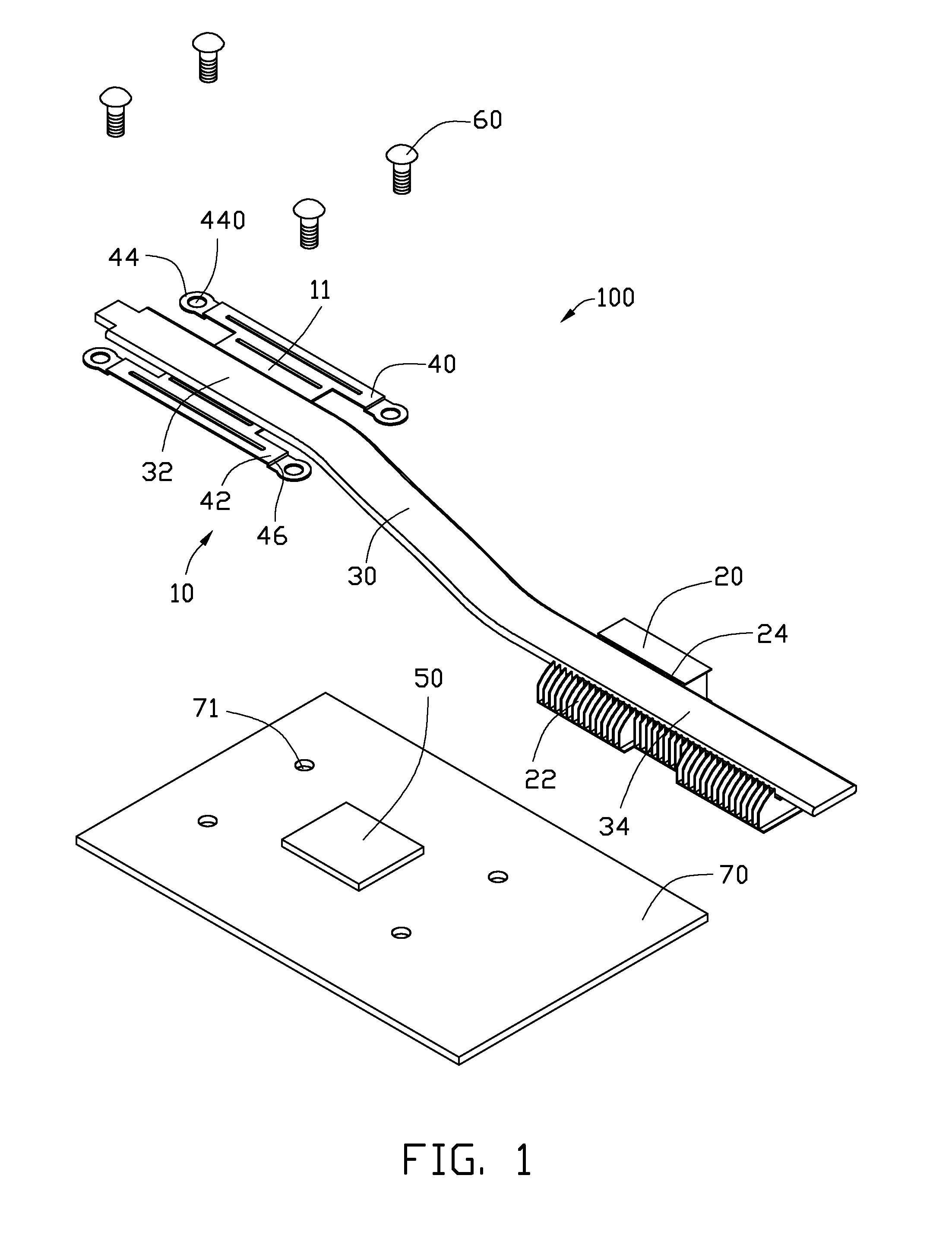

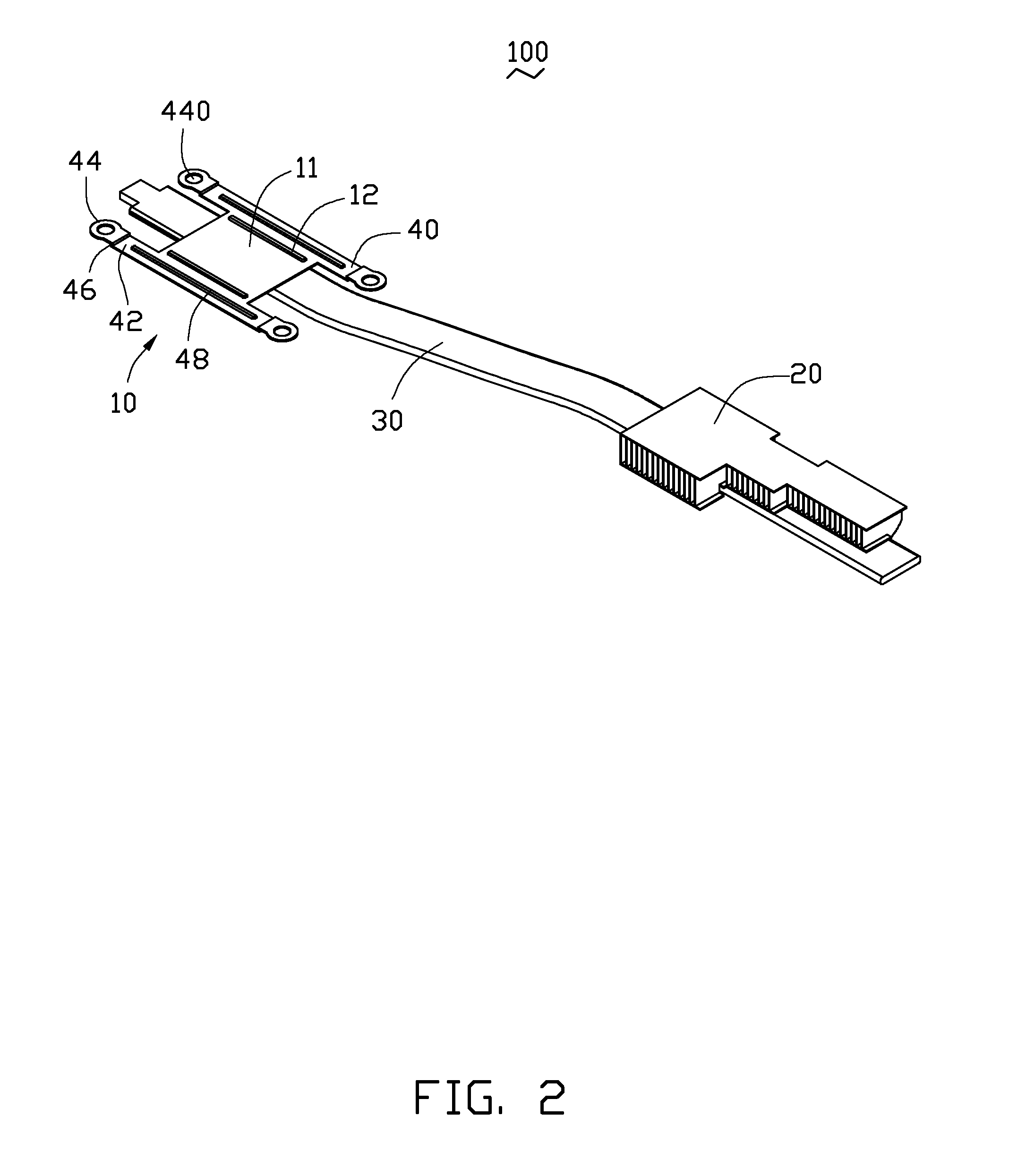

Heat dissipation module

InactiveUS20130070418A1Semiconductor/solid-state device detailsSolid-state devicesPhosphor bronzeSilicon alloy

An electronic device includes printed circuit board having an electronic component and a heat dissipation module mounted the printed circuit board. The heat dissipation module includes a base with a heat absorbing plate and two elastic pieces extending from the heat absorbing plate. The heat absorbing plate thermally engages on the electronic component. The elastic pieces are fixed on the printed circuit board. The base is made of one of copper-nickel-silicon alloy, beryllium copper, a titanium copper or phosphor bronze.

Owner:HON HAI PRECISION IND CO LTD

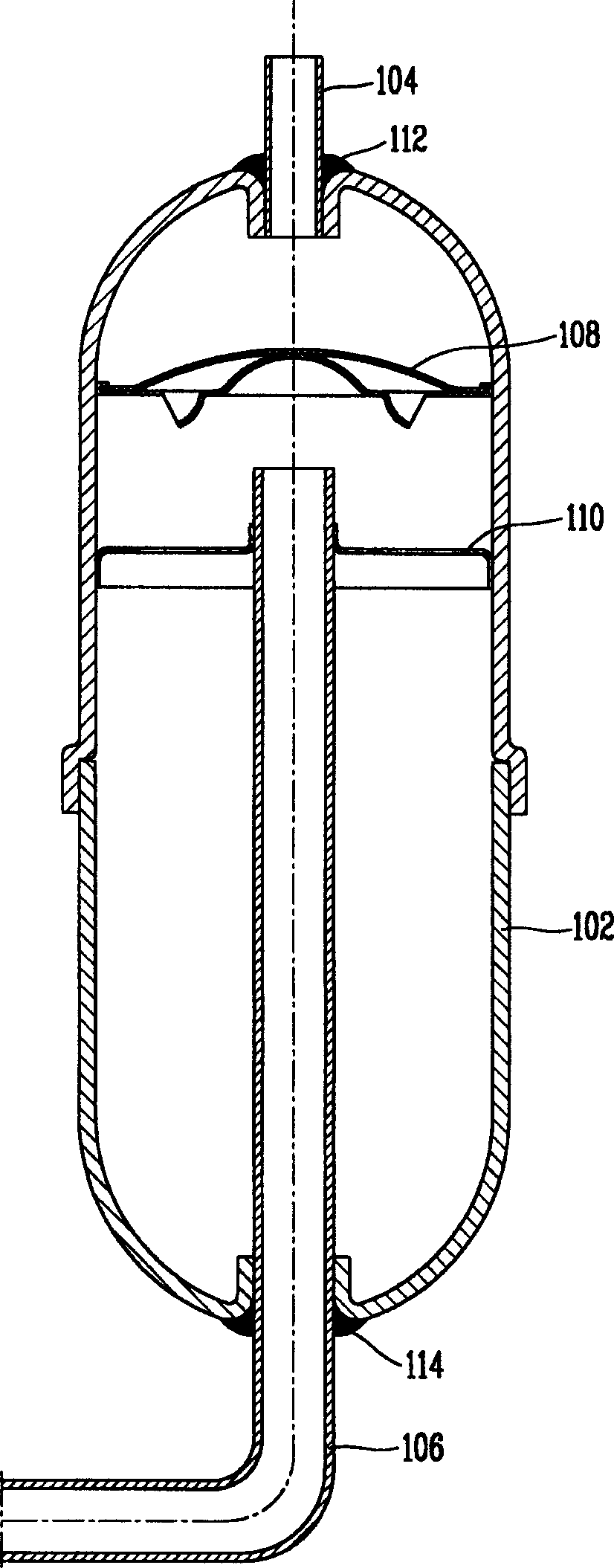

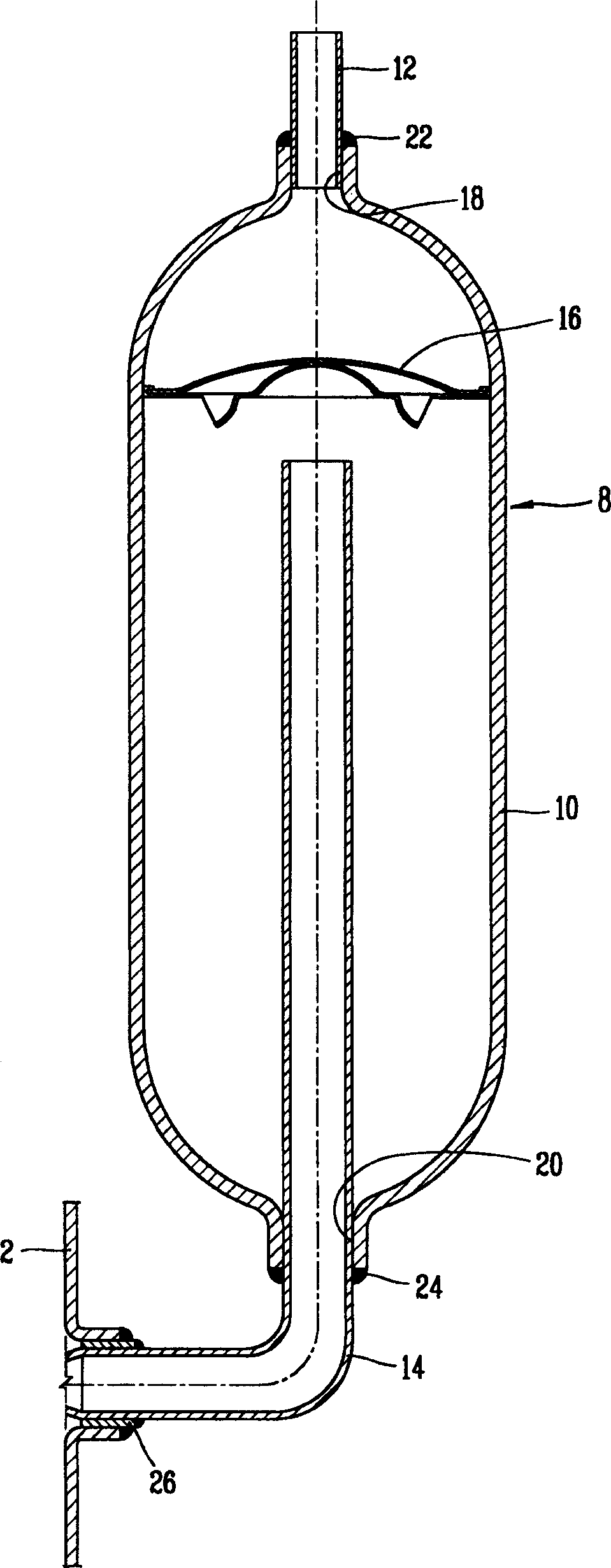

Gas-liquid separator for sealing compressor

InactiveCN1527009AAvoid damagePrevent leakagePositive displacement pump componentsRotary piston pumpsVapor–liquid separatorPhosphor bronze

An accumulator of an enclosed compressor comprises a case having a predetermined space; a suction pipe welded to the upper part of the case, to suck a refrigerant into the case; and a discharge pipe welded to the lower part of the case and connected to a compressor casing. At least one of a weld portion of the suction pipe and the upper part of the case and a weld portion of the discharge pipe and the lower part of the case is welded with phosphor bronze.

Owner:LG ELECTRONICS INC

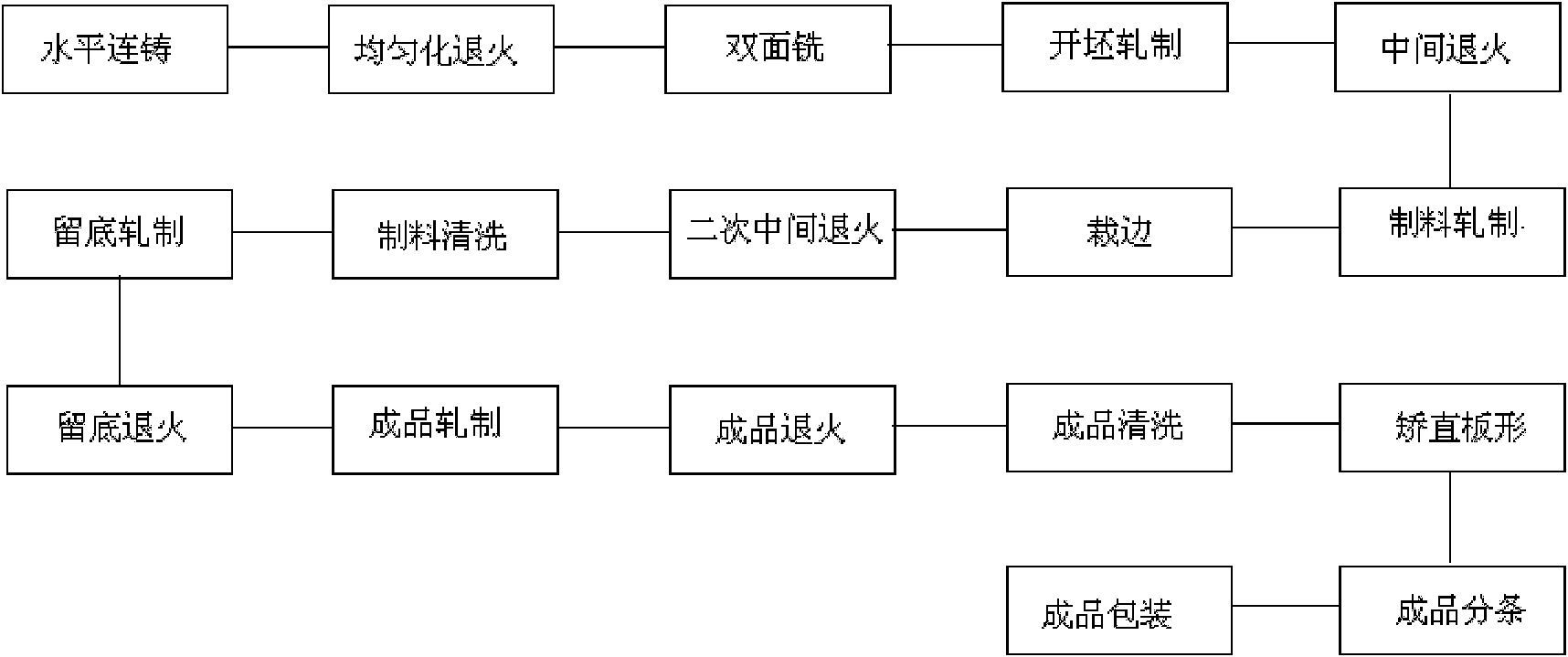

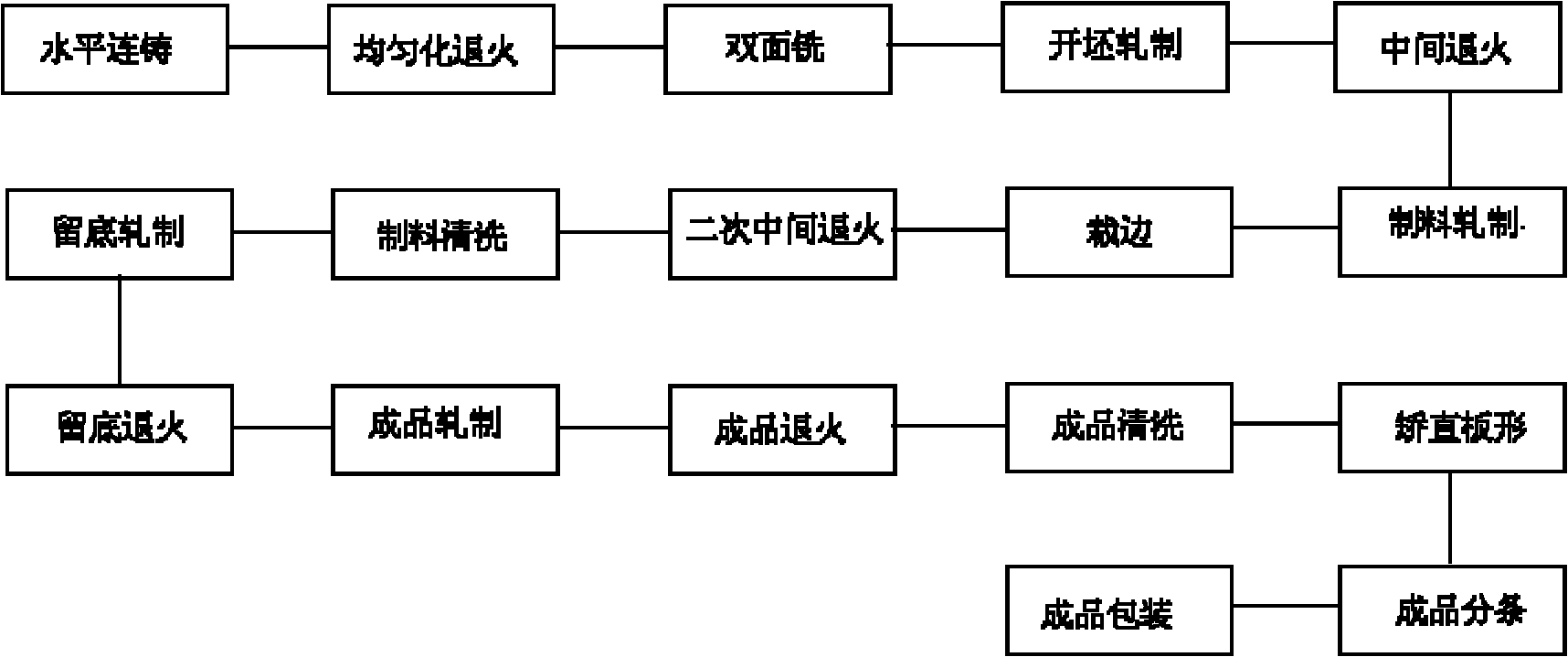

Production technology of phosphor bronze belt material

InactiveCN102021507AHigh yield strengthImprove fatigue resistancePhosphor bronzeManufactured material

The invention discloses a production technology of a phosphor bronze belt material, comprising the following steps: a) horizontally continuous casting; b) evenly annealing; c) double-sided milling; d) cogging and rolling; e) middle annealing; f) rolling manufactured materials; g) cutting edges; h) secondary middle annealing; i) cleaning the manufactured materials; j) rolling leftover; k) annealing the leftover; l) rolling a finished product; m) annealing the finished product; n) cleaning the finished product; and o) straightening the strip shape, wherein, in the step I) of rolling a finished product, the press force of a hydraulic press cylinder of a finishing mill is 100-120 ton; and in the step m) of annealing the finished product, the temperature in the furnace is 180-200 DEG C, and the annealing time in the furnace is 3-5 hours. Because of adopting the above structure, the invention has the advantage of improving the yield strength of bronze so as to improve the material fatigue durability. The yield strength of the original annealing technology is 534, and the yield ratio is 0.85; and after the technology is improved, the yield strength is 594, and the yield ratio is 0.95 which is improved by 12%.

Owner:ANHUI XINKE NEW MATERIALS

High-uniformity tin-phosphor bronze strip preparation process

The invention belongs to the technical field of bronze strip manufacturing, and particularly relates to a high-uniformity tin-phosphor bronze strip preparation process. The high-uniformity tin-phosphor bronze strip preparation process comprises the following steps of S1, smelting, S2, casting, S3, milling, S4, homogenizing heat treatment, S5, cold rough rolling, S6, intermediate annealing, S7, cold intermediate rolling, S8, cold finish rolling, and S9, finished product annealing. According to the technical scheme, the smelting process can improve the component and structure uniformity of a casting blank, the gas content in melt can be effectively reduced, meanwhile, the components in a smelting furnace are uniformly distributed, and the burnout rate of alloy elements is low; and in the subsequent processing process, microsegregation forms such as intragranular segregation and grain boundary segregation can be eliminated by promoting the high-temperature diffusion process, a recrystallization structure is controlled and residual stress is reduced through a combined deformation heat treatment process, the microsegregation and stress distribution uniformity of the alloy is further improved, so that a tin-phosphor bronze strip with good structure and performance uniformity is obtained.

Owner:中铜华中铜业有限公司

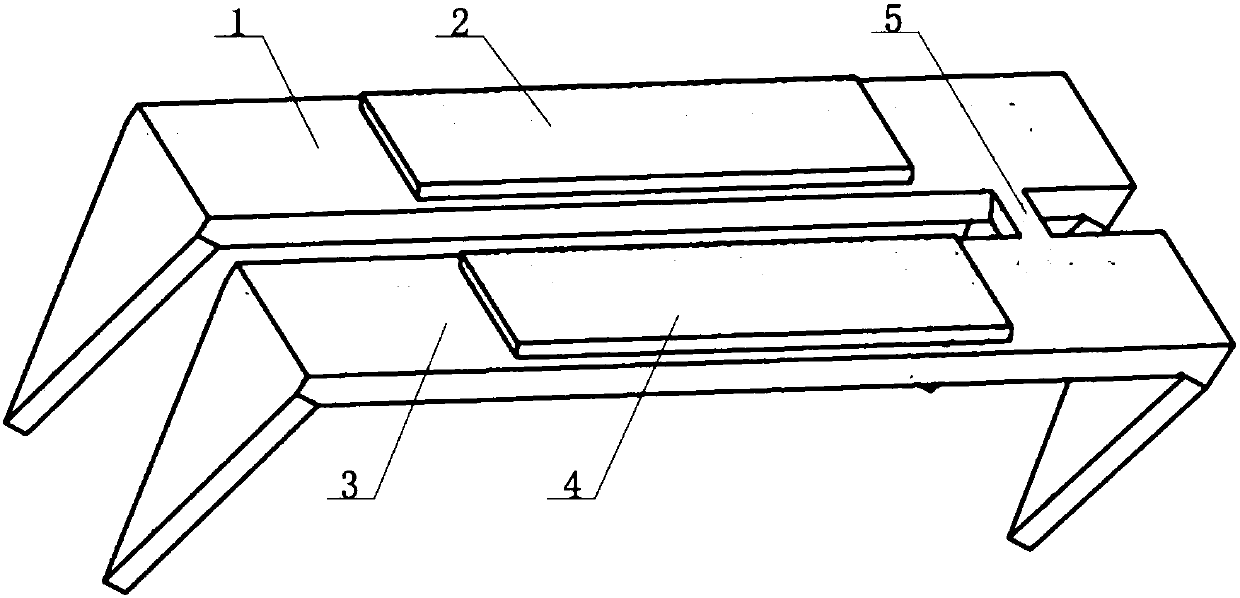

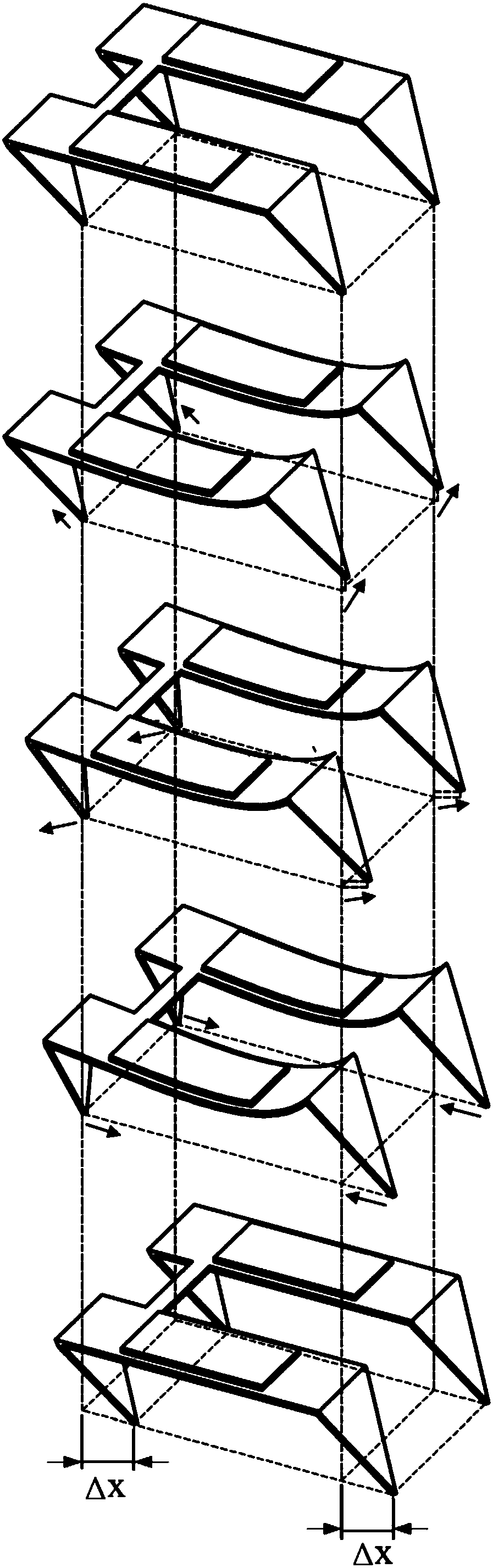

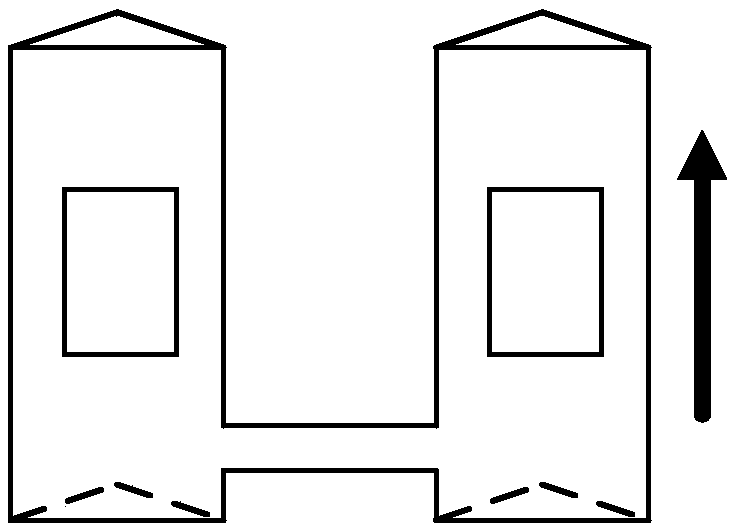

Piezoelectric driving-based crawling actuator and working method thereof

PendingCN107834897ASimple structureSmall sizePiezoelectric/electrostriction/magnetostriction machinesPhosphor bronzeReaction speed

The present invention discloses a piezoelectric driving-based crawling actuator and a working method thereof, and relates to the ultrasonic, MEMS and piezoelectric technology fields. According to thepresent invention, the actuator can simultaneously satisfy the characteristics of being small in size, fast in reaction speed and large in load, and being able to turn. The piezoelectric driving-basedcrawling actuator of the present invention comprises a first phosphor bronze matrix, a first piezoelectric ceramic piece, a second phosphor bronze matrix, a second piezoelectric ceramic piece and a connecting rod. By utilizing the inverse piezoelectric effects of the two piezoelectric ceramic pieces under the effect of a sinusoidal voltage respectively, and the 60-degree included angles formed bycontacting the respective two edges of the two feet of the matrixes with the ground, the two edges of the two feet generate the different vibration displacements under the driving of the piezoelectric ceramics, and the two feet of the matrixes generate the motion modes towards a same direction. By controlling and adjusting the input sinusoidal voltage values of the two feet, the different turningradiuses of the actuator are realized, and the preset advancing paths are finished.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com